Page 1

AUTO REVERSE

DOCUMENT FEEDER

(Machine Code: A663)

Page 2

30 March, 1999 MECHANICAL COMPONENTS

1. SPECIFICATIONS

Original Size and Weight: Thick original mode (default mode)

Use this setting for normal paper types

Maximum A3, 11" x 17"

Minimum B6 (sideways), 5

Weight 52 ~ 128 g/m2 (14 ~ 34 lbs.)

Thin original mode

Maximum A3, 11" x 17"

Minimum B6, 5

1/2

" x 8

Weight 40 ~ 128 g/m2 (11 ~ 34 lbs.)

Auto reverse mode

Maximum A3, 11" x 17"

Minimum B5, 5

1/2

" x 8

Weight 52 ~ 105 (14 ~ 27 lbs.)

Original Feed: Automatic feed - ADF mode

Manual feed one by one - SADF mode

Auto Reverse Feed - ARDF mode

1/2

1/2

1/2

" x 8

1/2

"

"

"

Original Table Capacity: 50 sheets at 80 g/m2 (21 lbs.)

Original Placement: Face up, first sheet on top

Original Separation: Feed Roller and Friction Belt

Original Transport: One flat belt

Power Consumption: 45 W

Power Source:

24 V ± 10% from the copier, 1.8 A

Dimensions (W x D x H): 610 x 507 x 130 mm (24.0" x 20.0" x 5.1")

Weight: Approximately 10.5 kg (23.2 lbs.)

1 to 1 Copying Speed

Capability

40 cpm

(A4/LT sideways)

Original Transport Speed 555 mm/s

Time Needed for Original

Replacement (A4

sideways)

590 ms

(thin original mode)

690 ms

(thick original mode)

Peripherals

A663-1

Page 3

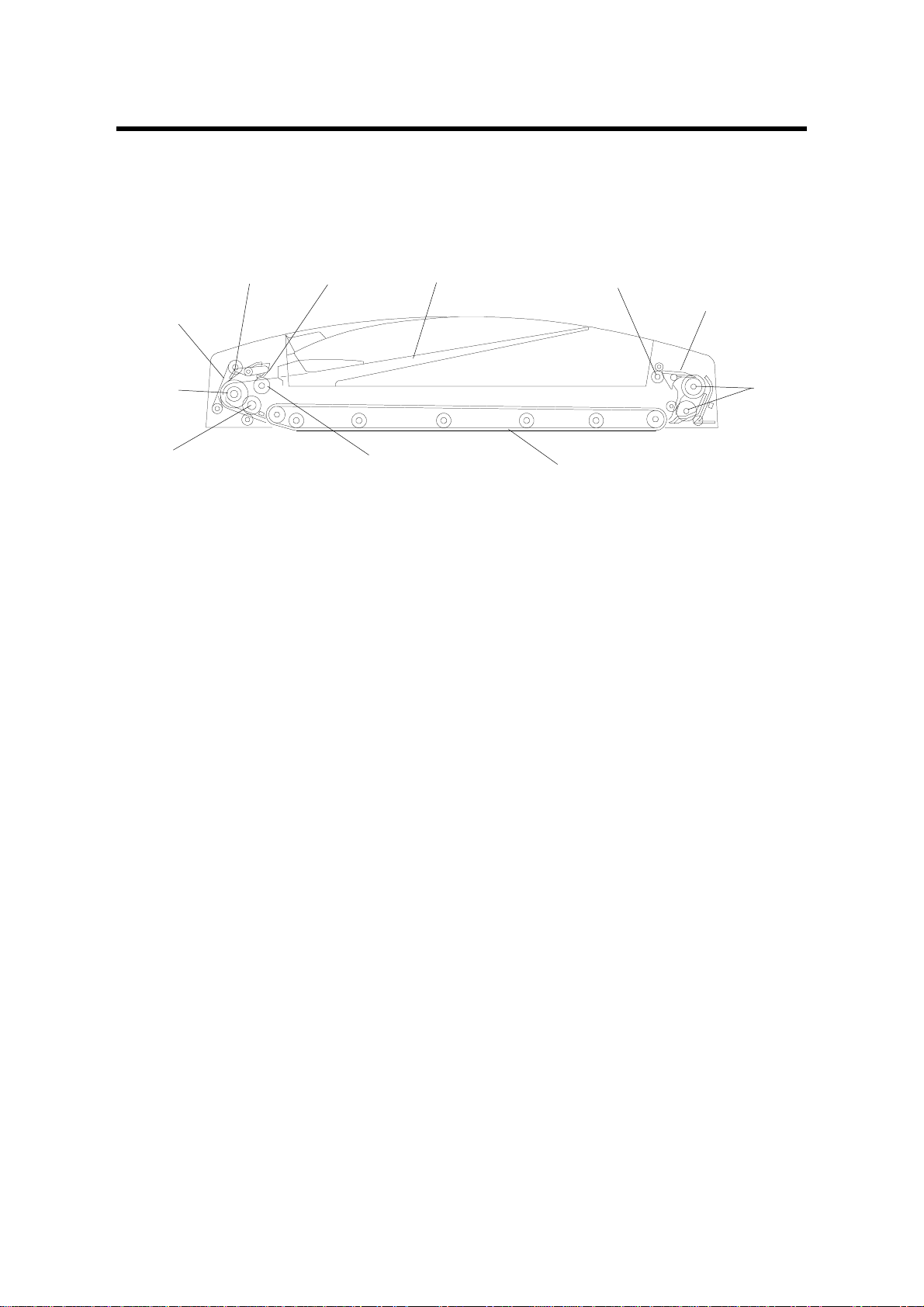

MECHANICAL COMPONENTS 30 March, 1999

2. COMPONENT LAYOUT

2.1 MECHANICAL COMPONENTS

12 3

11

10

9

1. Original Stopper

2. Press Lever

3. Original Table

4. Exit Rollers

5. Inverter Pawls

4

5

6

A663V502.WMF

8

7. Transport Belt

8. Pick-up Rollers

9. Pull-out Roller

10. Feed Roller

11. Friction Belt

7

6. Inverter Rollers

A663-2

Page 4

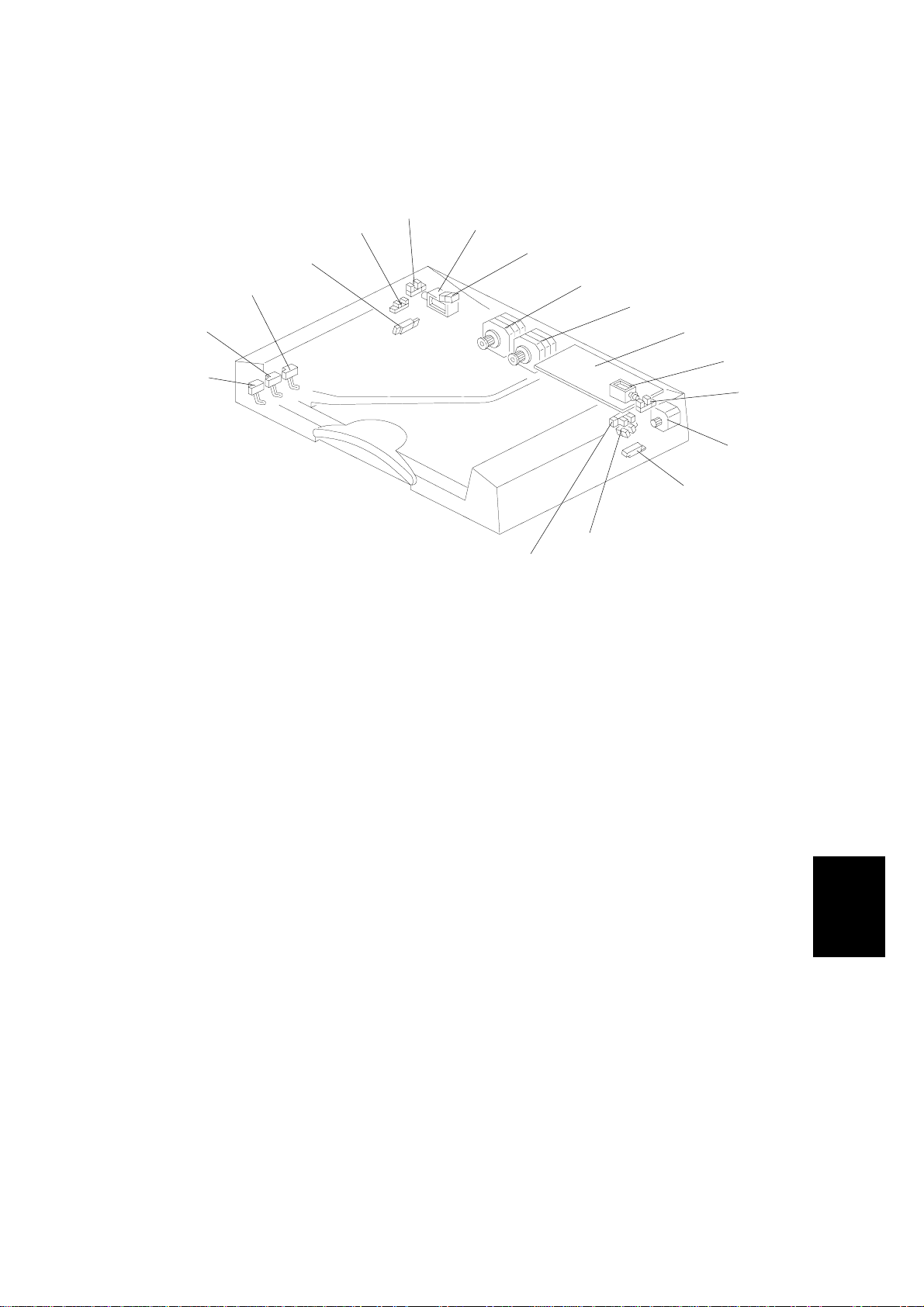

30 March, 1999 ELECTRICAL COMPONENTS

2.2 ELECTRICAL COMPONENTS

15

14

17

16

A663V503.WMF

2

1

3

4

5

6

7

8

9

10

11

12

13

1. Original set sensor

2. Feed –in Cover Open Sensor

3. Stopper Solenoid

4. Indicator Panel Lamps

5. Feed-in Motor

6. Belt Drive Motor

7. DF Main Board

8. Inverter Solenoid

9. Feed-out Cover Open Sensor

10. Feed-out Motor

11. Feed-out Sensor

12. APS Start Sensor

13. DF Position Sensor

14. Original width Sensor-1

15. Original width Sensor-2

16. Original Width Sensor-3

17. Registration Sensor

Peripherals

A663-3

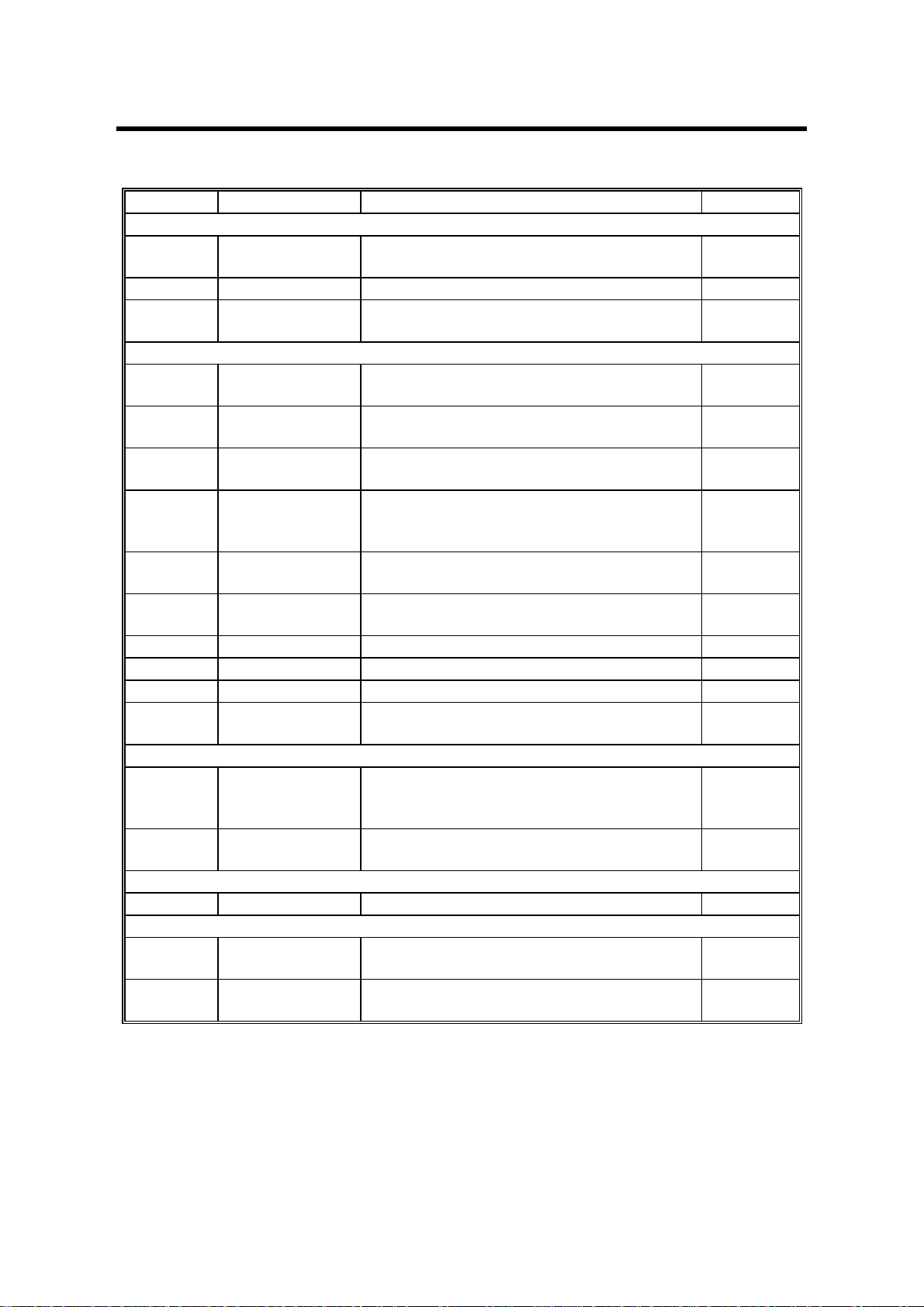

Page 5

ELECTRICAL COMPONENTS 30 March, 1999

3. ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function Index No.

Motors

M1 Feed-in

M2 Belt Drive Drives the transport belt 6

M3 Feed-out Drives the feed-out and the inverter

Sensors

S1 Original Set Detects whether originals have been

S2

S3 Feed-out Cover

S4 Feed-out

S5 APS Start Informs the CPU that it is time to detect

S6 DF Position

S7 Original Width-1 Detects the width of the original 14

S8 Original Width-2 Detects the width of the original 15

S9 Original Width-3 Detects the width of the original 16

S10 Registration Determines original stop timing and

Solenoids

SOL1 Stopper

SOL2 I nvert er Energizes to invert the original when

PCB

PCB1 DF Main Board Controls all DF functions 7

Indicators (Lamps)

L1 Ready

L2 Auto Informs the operator that the auto feed

Feed-in Cover

Open

Open

Drives the feed-in system (pick-up feed

and pull-out rollers separation belt)

system

placed on the original table

Informs whether the feed-in cover is open

or not

Informs whether the feed-out cover is

open or not

Checks for original misfeeds and

determines original stop timing when in

auto-reverse mode

the original size (in platen mode)

Informs the CPU whether the DF is in the

up or down position

measures the length of the original

Lifts the original stopper and lowers the

feed-in lever to feed the set of originals to

the feed roller

copying two-sided originals

Informs the operator that the DF is in the

down position.

mode is available.

5

10

1

2

9

11

12

13

17

3

8

4

4

A663-4

Page 6

30 March, 1999 ORIGINAL PICK-UP MECHANISM

4. DETAILED DESCRIPTIONS

4.1 ORIGINAL PICK-UP MECHANISM

[B]

[C]

[D]

[A]

[E]

A663D514.WMF

When an original is placed on the table, the leading edge is stopped by the stopper

[A], and the feeler activates the original set sensor [B]. The Insert Original indicator

light goes out and the DF informs the copier's CPU that the originals have been

set.

When the Print key is pressed, the stopper solenoid [C] activates to raise the

stopper to allow the originals to be fed in, and to lower the press lever [D] to press

the originals against the pick-up rollers [E].

An anti-static brush [F] is installed to eliminate static electricity caused during the

original pick-up process.

[F]

A663-5

Peripherals

Page 7

SEPARATION AND PAPER FEED MECHANISM 30 March, 1999

4.2 SEPARATION AND PAPER FEED MECHANISM

[D]

[A]

[E]

[B]

A663D515.WMF

[F]

[C]

[D]

[E]

[A]

A663D516.WMF

[B]

Originals are separated using the friction belt [A] and the feed roller [B]. When the

copier sends a signal to the DF to feed in the original, the feed-in motor [C] starts

rotating (clockwise) to drive the pick-up [D], feed and pull-out [E] rollers. A one-way

bearing stops the friction belt from rotating. Originals are separated and fed in one

by one because the resistance of the stationary friction belt is greater than the

friction between pages of the original.

When the registration sensor [F] detects the separated first original, the feed-in

motor reverses (counter clockwise), and the drive is transmitted only to the pull-out

rollers due to a one-way bearing. In this condition, the pull-out rollers are still

rotating in the same direction, and they feed the original to the exposure glass. The

motor turns off when the trailing edge of the 1st original has finished passing over

the sensor.

To prepare the next original, the feed-in motor turns clockwise to separate the

second original and the motor turns off when the registration sensor detects the

second original. When it is time for the second original to be fed to the exposure

glass, the feed-in motor turns counter clockwise.

A663-6

Page 8

30 March, 1999 FRICTION BELT DRIVE MECHANISM

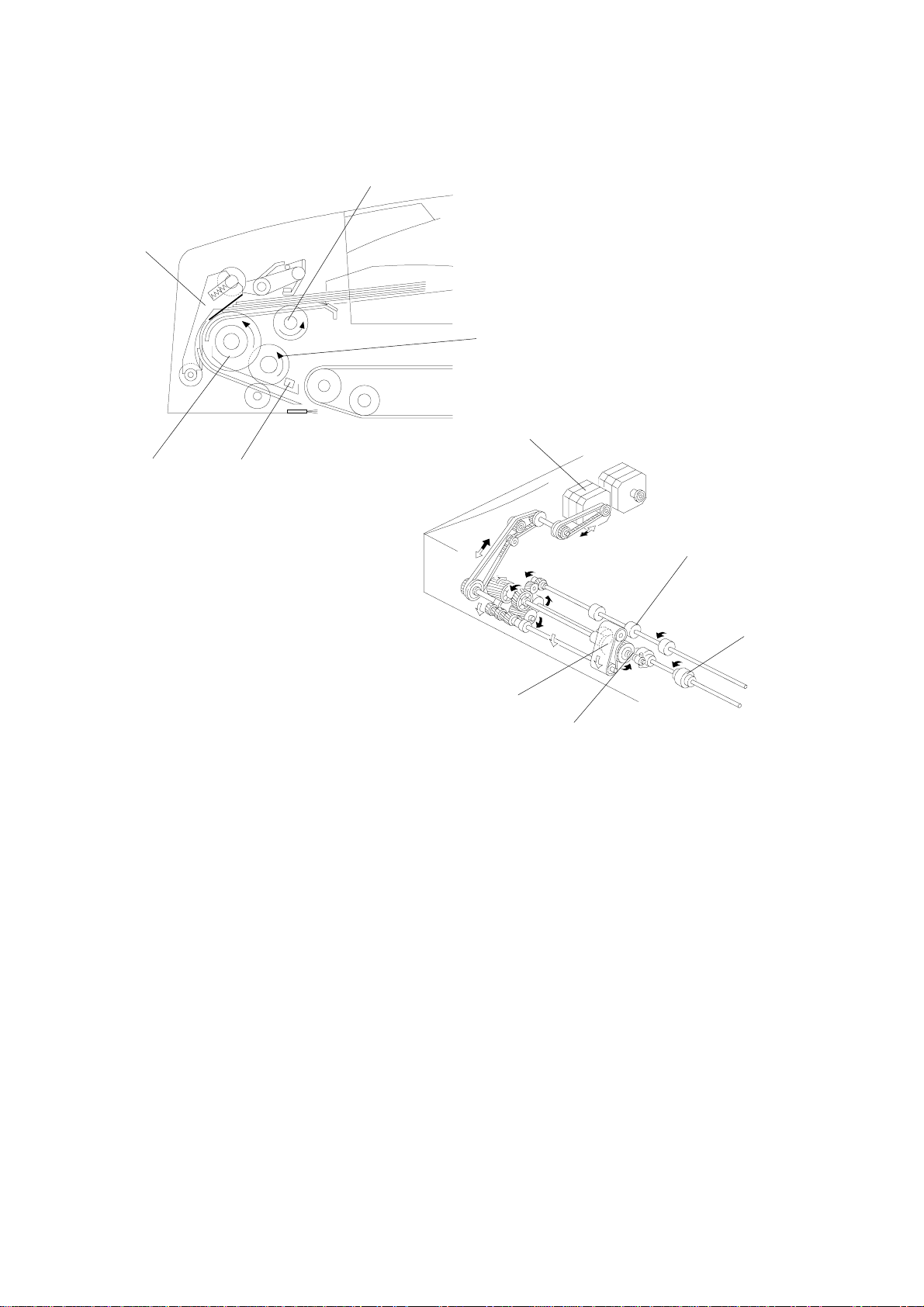

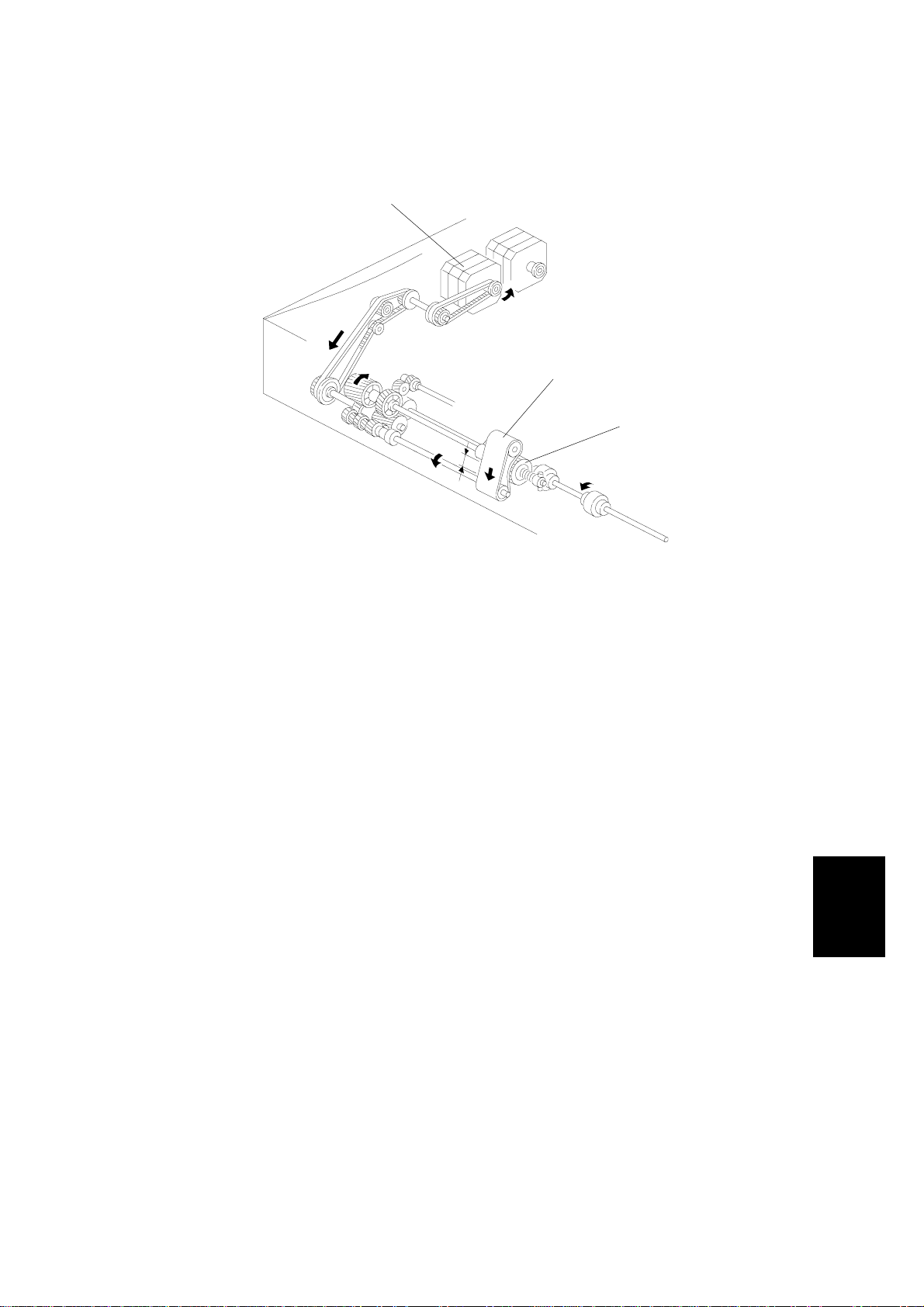

4.3 FRICTION BELT DRIVE MECHANISM

[A]

[B]

[C]

A663D517.WMF

The feed-in motor [A] drives the friction belt [B] through timing belts and gears. The

one-way bearing allows the belt to rotate in the direction shown only when the

feed-in motor is rotating counterclockwise. (The feed-in motor rotates

counterclockwise when the original is passing over the registration sensor, and

only the pull-out rollers are rotating to feed the paper to the exposure glass.)

As a result of this operation, the part of the friction belt that contacts the feed roller

[C] or the original changes. This prevents multiple feeding or causing originals to

become dirty.

The reverse movement of the friction belt will not affect the next original because

the pressure of the press lever holds the originals in place.

Peripherals

A663-7

Page 9

ORIGINAL SIZE DETECTION 30 March, 1999

4.4 ORIGINAL SIZE DETECTION

[C]

[B]

A663D518.WMF

[A]

The DF detects original width using three original width sensors-1 [A], -2 [B] and -3

[C]. It also detects the original length using the registration sensor.

The DF CPU counts the feed-in motor's drive pulses during the on timing of the

registration sensor. Based on this pulse count, the CPU determines the original

length.

The machine detects the original size by the total combination of all four sensors.

A663-8

Page 10

30 March, 1999 PAPER TRANSPORT MECHANISM

4.5 PAPER TRANSPORT MECHANISM

[A]

[C]

[B]

A663D519.WMF

Rear Scale

Left Scale

Original

3.5 mm

A663D520.WMF

An independent motor called the belt drive motor [A] (a dc stepper motor) drives

the transport belt [B]. The belt drive motor starts rotating soon after the copier

sends an original feed-in signal.

Inside the transport belt are four pressure roller shafts, which achieve the proper

amount of pressure between the belt and the original. The pressure roller shaft [C]

closest to the left original scale is made of rubber for the stronger pressure that is

required when in the thick original mode (this is the mode used for normal paper).

The other rollers are sponge rollers.

Since the copier's original alignment position is at the left rear corner (not in the

center), the originals fed from the DF must also be at this position. But if the

original was to be fed along the rear scale, unnecessary original skew, jam or

wrinkling may occur.

Peripherals

To prevent such problems, the original transfer position is set to 3.5 mm away from

the rear scale as shown. The correction for this 3.5 mm gap is compensated for by

the position of the lens unit. (Also see "Horizontal Lens Positioning" in the Optics

section of the manual for the copier main body.)

A663-9

Page 11

THICK/THIN ORIGINAL MODES 30 March, 1999

4.6 THICK/THIN ORIGINAL MODES

Fig. 1

[A]

Fig. 2

Fig. 3

A663D521.WMF

This document feeder has two different ways of stopping originals at the correct

position on the exposure glass. The technician can select one of these using a

copier SP mode. The user can also select the mode.

1. Thick Original Mode (Normal Paper Mode)

This mode is the factory set mode. The belt drive motor remains energized to

carry the original approximately 7 mm pass the left scale (Figures 1 and 2).

Then the motor pauses and reverses to feed the original back against the left

scale (Fig. 3). This forces the original to hit against the left original scale [A] and

thus aligns the trailing edge to minimize the original skew on the exposure

glass.

2. Thin Original Mode

To protect originals from being damaged by the movements of the transfer belt,

thin original mode can be selected. The belt drive motor stops shortly after the

original trailing edge passes the registration sensor. This stops the original at

the correct position on the exposure glass.

A663-10

Page 12

30 March, 1999 ORIGINAL FEED-OUT MECHANISM

4.7 ORIGINAL FEED-OUT MECHANISM

[A]

[B]

A663D522.WMF

[B]

A663D523.WMF

When the sca nner reaches the return position , the copier's CPU sends the feed-out

signal to the DF CPU. When the DF receives the fe ed-out signal, the belt drive and

feed-out motors [A] turn on.

The feed-out sensor [B] installed in the feed-out section counts the number of

pulses to calculate how long the feed-out motor must stay on to feed the original

out of the machine completel y .

Peripherals

A663-11

Page 13

TWO-SIDED ORIGINAL FEED MECHANISM 30 March, 1999

4.8 TWO-SIDED ORIGINAL FEED MECHANISM

[B]

[A]

[B]

A663D524.WMF

Unlike one-sided original feed, the backside of the original must be copied first to

keep the originals and copies in the correct order.

During original feed-in, the sequence is the same as for one-sided feed. However,

the belt drive motor continues rotating until the original reaches the inverter section.

The DF CPU also energizes the feed-out motor and the inverter solenoid [A] for a

short time to lift the inverter pawls [B].

After the inverter mechanism inverts the original, the belt drive motor reverses and

the original is fed towards the original scale. It is stopped at the correct position on

the exposure glass, and the DF CPU sends the copy start signal.

When the sca nner reaches the return position, the copier's CPU sends the invert

original signal to the DF CPU in order to make a copy of the front side. The original

is inverted in the same way as for copying the backside, as explained earlier on

this page.

A663-12

Page 14

30 March, 1999 A4 SIDEWAYS: 1 SIDED ORIGINAL

5. TIMING CHARTS

5.1 A4 SIDEWAYS: 1 SIDED ORIGINAL

A663-13

Peripherals

A663D525.WMF

Page 15

COMBINE 2 ORIGINAL MODE 30 March, 1999

5.2 COMBINE 2 ORIGINAL MODE

A663-14

A663D526.WMF

Page 16

30 March, 1999 A4 SIDEWAYS: DUPLEX

5.3 A4 SIDEWAYS: DUPLEX

A663-15

Peripherals

A663D527.WMF

Page 17

DIP SWITCHES 30 March, 1999

6. SERVICE TABLES

6.1 DIP SWITCHES

DPS 101 Function

1

0 0 0 0 Normal setting

1 0 0 0 One-sided thin original mode free run with paper

0100

1100

0 0 1 0 Two-sided mode free run with paper

1 0 1 0 Two-sided mode free run without paper

1 0 0 1 One-sided thin original mode free run with paper

0101

0 0 1 1 Two-sided mode free run with paper

1 0 1 1 Not used

234

^

One-sided thick original mode (normal mode) free

run with paper

One-sided thick original mode (normal mode) fee run

without paper

One-sided thick original mode (normal mode) free

run with paper

1 1 0 1 Solenoid test

0 1 1 0 Motor test

1 1 1 0 Combine two originals mode free run with paper

0 0 0 1 Not used

0 1 1 1 Not used

1 1 1 1 Indicators On

NOTE: 1) Paper will automatically feed after 3 seconds when the "with paper"

free run modes are selected.

2) To prevent the friction belt from wearing, open the feed-in cover when

performing the "without pap er " fre e run mod es.

To make a free run

1. Set up dip switches 1 to 4 for the required free run mode the test begins

automatically.

2. To stop the free run, put the dip switches back to 0.

A663-16

Page 18

30 March, 1999 VARIABLE RESISTORS

6.2 VARIABLE RESISTORS

VR No. Function

101 Adjusts the registration in one-sided thin original mode.

102 Adjusts the registration in two-sided original mode.

6.3 LED

LED No. Function

101 Monitors the communication with the copier.

6.4 FUSE

FUSE No. Function

101 Protects the 24 V line.

A663-17

Peripherals

Page 19

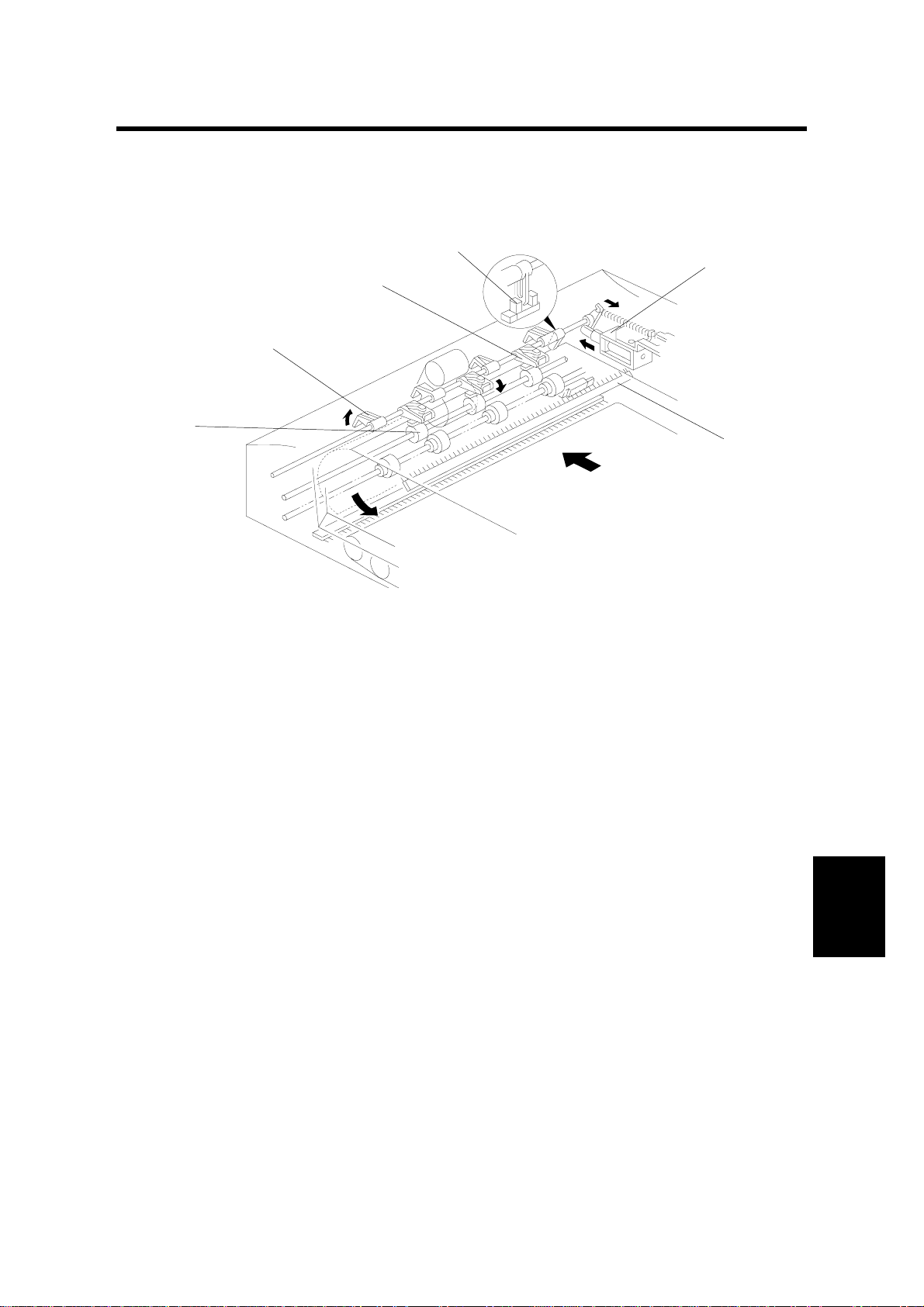

TRANSPORT BELT REPLACEMENT 30 March, 1999

7. REPLACEMENT AND ADJUSTMENT

7.1 TRANSPORT BELT REPLACEMENT

[A]

[B]

[C]

A663R510.WMF

[D]

[E]

A663R512.WMF

1. Turn off the main switch and lift up the DF.

A663R511.WMF

2. Remove the grip [A] (3 screws).

3. Remove the 6 screws securing the transport belt assembly [B].

NOTE: Remove the two lower screws [C] first.

1. Bend the transport belt assembly and pull out the transport belt [D] as shown.

NOTE: 1) When installing the transport belt, make sure that the belt runs unde r

the belt guide spacers [E].

2) When securing the transport belt assembly with the 6 screws, make

sure to secure the four upper screws first.

A663-18

Page 20

30 March, 1999 FEED ROLLER REPLACEMENT

7.2 FEED ROLLER REPLACEMENT

[B]

[D]

[C]

[A]

A663R513.WMF

1. Turn off the main switch and open the feed-in cover [A].

2. Remove the feed roller assembly [B] by pulling it towards the f ront.

3. Replace the feed roller.

NOTE: When installing the feed roller assembly, make sure the pins [C, D] on

both sides are fixed properly.

Peripherals

A663-19

Page 21

FRICTION BELT REPLACEMENT 30 March, 1999

7.3 FRICTION BELT REPLACEMENT

[B]

[A]

A663R514.WMF

[C]

A663R515.WMF

1. Turn off the main switch and open the feed-in cover [A].

2. Gently pull up the friction belt assembly [B] and remove it from the shaft.

3. Replace the friction belt [C].

A663-20

Page 22

30 March, 1999 ORIGINAL SET AND WIDTH SENSOR REPLACEMENT

7.4 ORIGINAL SET AND WIDTH SENSOR

REPLACEMENT

[A]

A663R516.WMF

[G]

[E]

1. Turn off the main switch.

2. Remove the upper cover [A] (7 screws).

[B]

[C]

[F]

[D]

A663R517.WMF

[H]

3. Remove the pick-up solenoid spring [B].

4. Remove the stopper/pressure lever shaft [C] (2 E-rings).

5. Remove both front [D] and rear [E] feed-in cover magnet catches (1 screw

each).

6. Remove the feed-in guide plate [F] (4 screws).

7. Remove the original set sensor assembly [G] (1 screw).

8. Remove the original width sensor assembly [H] (1 screw).

9. Replace the required sensor.

A663-21

Peripherals

Page 23

VERTICAL REGISTRATION ADJUSTMENT 30 March, 1999

7.5 VERTICAL REGISTRATION ADJUSTMENT

7.5.1 ONE SIDED THIN ORIGINAL MODE

NOTE: 1) After replacing the DF main board, always do the Rough Adjustment

using VR101 first. Then do the Fine Adjustment procedure.

2) At other times, just do the Fine Adjustment procedure.

3) After finishing the adjustment, be sure to turn off the dipswitch.

[B]

[C]

[A]

A663R518.WMF

- Rough Adjustment (Using VR101) -

1. Remove the small cover [A] at the rear of the DF upper cover (1 screw).

2. Turn on dipswitch 101-1 [B].

3. Place a sheet of A4/8

" x 11" sideways paper (64 g/m2, 17 lbs.s.) on the

1/2

original table. (The paper will feed automatically.)

4. After the original stops on the exposure glass, raise the DF carefully so that the

original does not move.

5. Check that the gap between the trailing edge of the paper and the left original

scale is 0 ± 2.5 mm.

6. If the gap is not within this specification, adjust the registration with VR101 [C].

(Turning VR101 counter-clockwise will increase the gap.)

- Fine Adjustment (Using a Copier SP Mode) -

1. Perform steps 1 through 5 of the rough adjustment procedure.

2. If the gap is larger than 2.5 mm, adjust the registration with the copier SP mode

for the DF Registration Adjustment in one-sided original mode. (Increasing the

setting will increase the gap.)

A663-22

Page 24

30 March, 1999 VERTICAL REGISTRATION ADJUSTMENT

7.5.2 TWO SIDED ORIGINAL MODE

NOTE: 1) After replacing the DF main board, always do the Rough Adjustment

using VR102 first. Then do the Fine Adjustment procedure.

2) At other times, just do the Fine Adjustment procedure.

3) After finishing the adjustment, be sure to turn off the dipswitch.

[C]

[B]

[A]

A663R518.WMF

- Rough Adjustment (Using VR102) -

1. Remove the copier's left original scale (2 screws).

2. Remove the small cover [A] at the rear of the DF upper cover (1 screw).

3. Turn on dip switch 101-3 [B].

4. Place a sheet of A4/8

" x 11" sideways paper (64 g/m2, 17 lbs.) on the

1/2

original table. (The paper will feed automatically.)

5. After the original stops on the exposure glass, raise the DF carefully so that the

original does not move.

6. Check that the gap between the trailing edge of the paper and the left edge of

the original rear scale is 10 ± 2 mm.

7. If the gap is not within this specification, adjust the registration with VR102 [C].

(Turning VR102 counter-clockwise will increase the gap.)

- Fine Adjustment (Using a Copier SP Mode) -

1. Perform steps 1 through 6 of the rough adjustment procedure.

2. If the gap is not within specification, adjust the registration with the copier SP

mode for the DF Registration Adjustment in two-sided original mode.

(Increasing the setting will increase the gap.)

A663-23

Peripherals

Page 25

SIDE-TO-SIDE REGISTRATION (DF POSITIO NI NG) ADJUST MENT 30 March, 1999

7.6 SIDE-TO-SIDE REGISTRATION (DF POSITIONING)

ADJUSTMENT

NOTE: 1) First, adjust the DF side-to-side registration using the copier SP mode

for this (see Replacement and Adjustment - Side-to-side Registration

Adjustment in the copier manual).C

2) Do the following adjustment only when the registration cannot be

brought within the specification (0 ± 2 mm) using the above menti on ed

SP mode.

SPECIFICATION (Original position from the rear scale)

Thick (Normal) Paper

Original Mode

Thin Original Mode

Two Sided Original Mode

1. Place a sheet of A4/8

1/2

3.5 ± 2 mm (3.5 ± 3 mm for B6 lengthwise)

3.5 ± 2 mm

3.5 ± 3 mm

" x 11"

sideways paper (64 g/m2, 17 lbs.) on

the original table and press the Print

key.

2. After the original stops on the exposure

glass, raise the DF carefully so that the

original does not move.

3. Check if the gap between the rear edge

of the paper and the rear original scale

is within the specification listed above.

4. If it is out of specification, reposition the

2 screws [A] securing the DF hinge to

the long screw hole as shown.

[A]

5. Repeat steps 1 to 3.

A663R519.WMF

6. Secure the DF unit at the position where the gap falls within specification.

7. Check the copy quality and adjust the ADF side-to-side registration with the

copier SP mode if it is not within the 0 ± 2 mm specification (see Replacement

and Adjustment - Side-to-side Registration Adjustment in the copier manual).

A663-24

Loading...

Loading...