Ricoh df62 Service Manual

DUAL JOB FEEDER

(Machine Code: A610)

10 May 1996 SPECIFICATIONS

1. SPECIFICATIONS

Original Feed Mode: Automatic document feed mode

Automatic reverse document feed mode

Semi-automatic document feed mode

Combine 2 originals mode

Mixed sized mode

Preset mode

Original Size and Weight: Thick original mode (default mode)

Use this setting for normal paper types

Maximum: A3, 11" x 17"

Minimum: B6, 5

1/2

Weight: 52 ~ 128 g/m

Thin original mode

Maximum: A3, 11" x 17"

Minimum: B6, 5

1/2

Weight: 40 ~ 128 g/m

" x 8

" x 8

1/2

"

2

(14-34 lb)

1/2

"

2

(11-34 lb)

Auto reverse mode

Maximum: A3, 11" x 17"

Minimum: B6 (lengthwise)

Weight: 52 ~ 105 g/m

Combine two originals mode

Maximum: A4 (sideways), 8

Minimum: B5 (sideways), 5

Weight: 52 ~ 128 g/m

Mixed size Mode

Maximum: A3, 11" x 17"

Minimum: B5, 8

1/2

Weight: 52 ~ 80 g/m

Original Table Capacity: 50 sheets at 80 g/m

(or stack height of less than 5 mm)

Original Standard Position: Rear left

Original Separation: Feed and friction belt

" x 11"

2

(21 lb)

2

(14-28 lb)

1/2

" x 11" (sideways)

1/2

2

2

(14-21 lb)

" x 8

(14-34 lb)

1/2

" (sideways)

Feeder

Feeder

Dual Job

Dual Job

Original Transport: One flat belt

1

SPECIFICATIONS 10 May 1996

Power Source: DC24 V from the copier, 2.5 A (average)

Power Consumption: 70W

Dimensions (W x D x H): 680 x 522 x 133 mm

(26.8" x 20.0" x 4.6")

Weight: 14.5 kg (32.0 lb)

2

10 May 1996 COMPONENT LAYOUT

2. COMPONENT LAYOUT

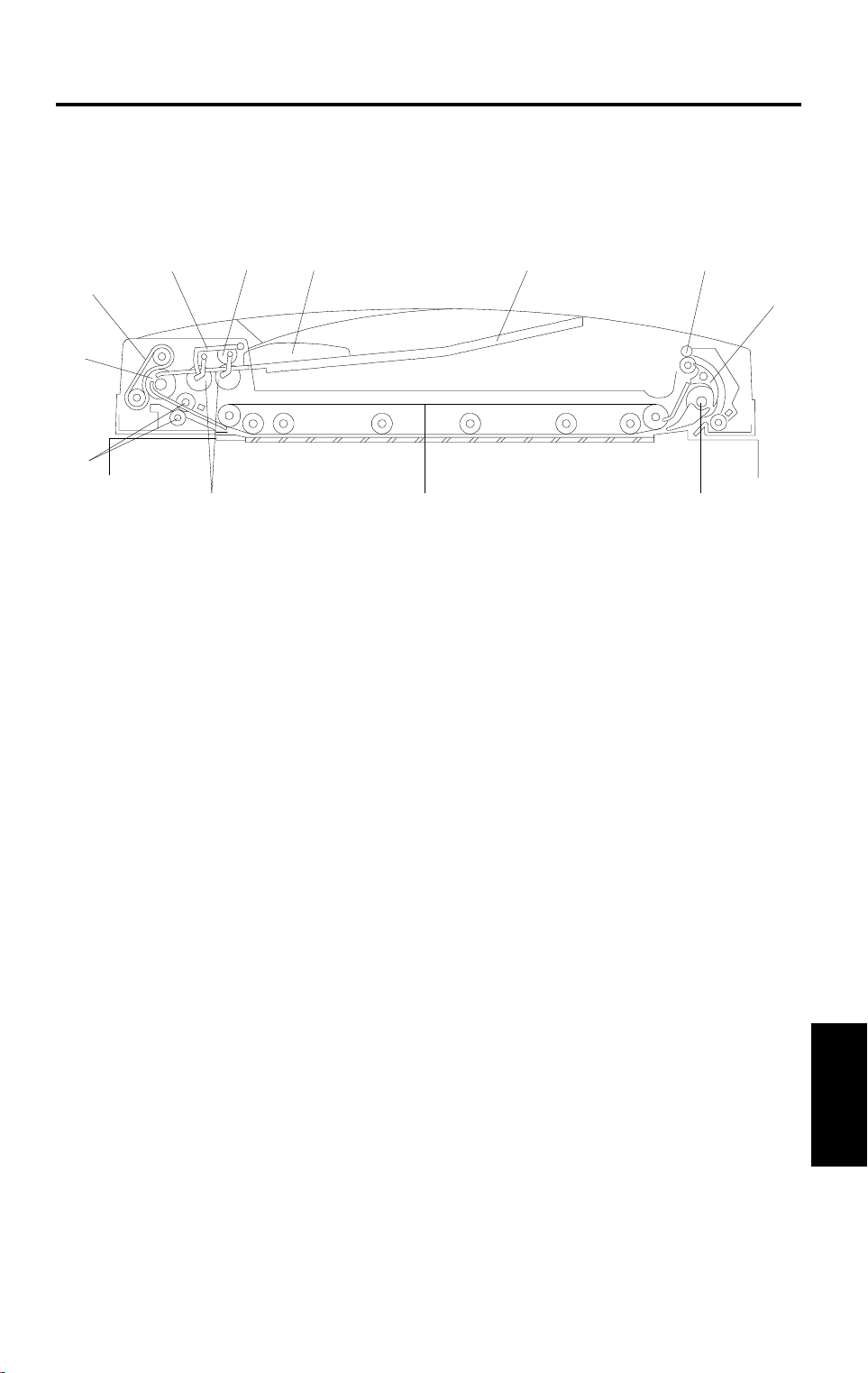

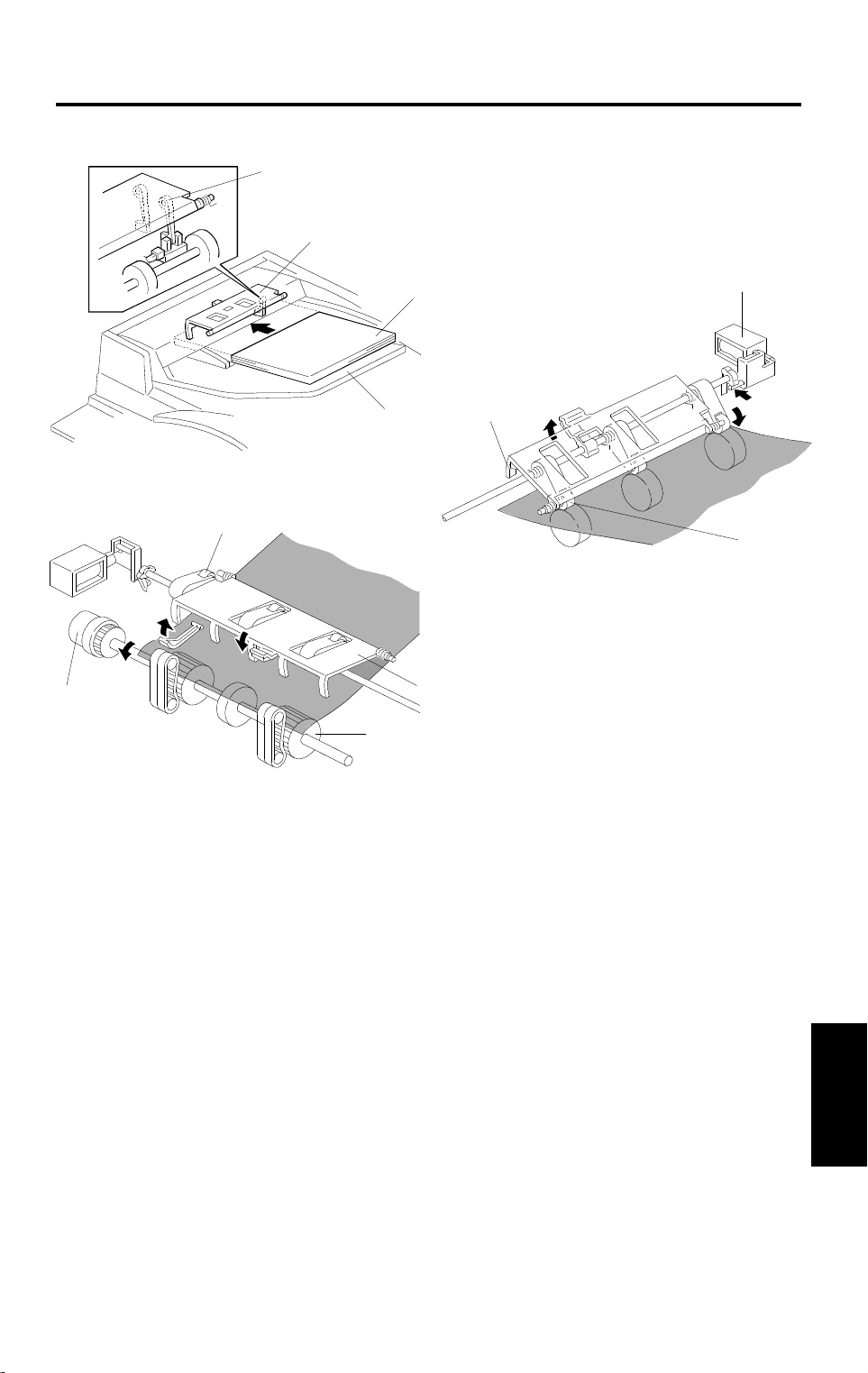

2.1 MECHANICAL COMPONENT LAYOUT

1

12

11

10

9

1. Original Stopper

2. Press Roller

3. Side Fence

2

35

4

6

8

7

A610V500.wmf

7. Inverter Roller

8. Transport Belt

9. Pick-up Rollers

4. Original Table

5. Exit Roller

6. Inverter Pawl

10. Pull-out Rollers

11. Feed Roller

12. Friction Belt

3

Feeder

Dual Job

COMPONENT LAYOUT 10 May 1996

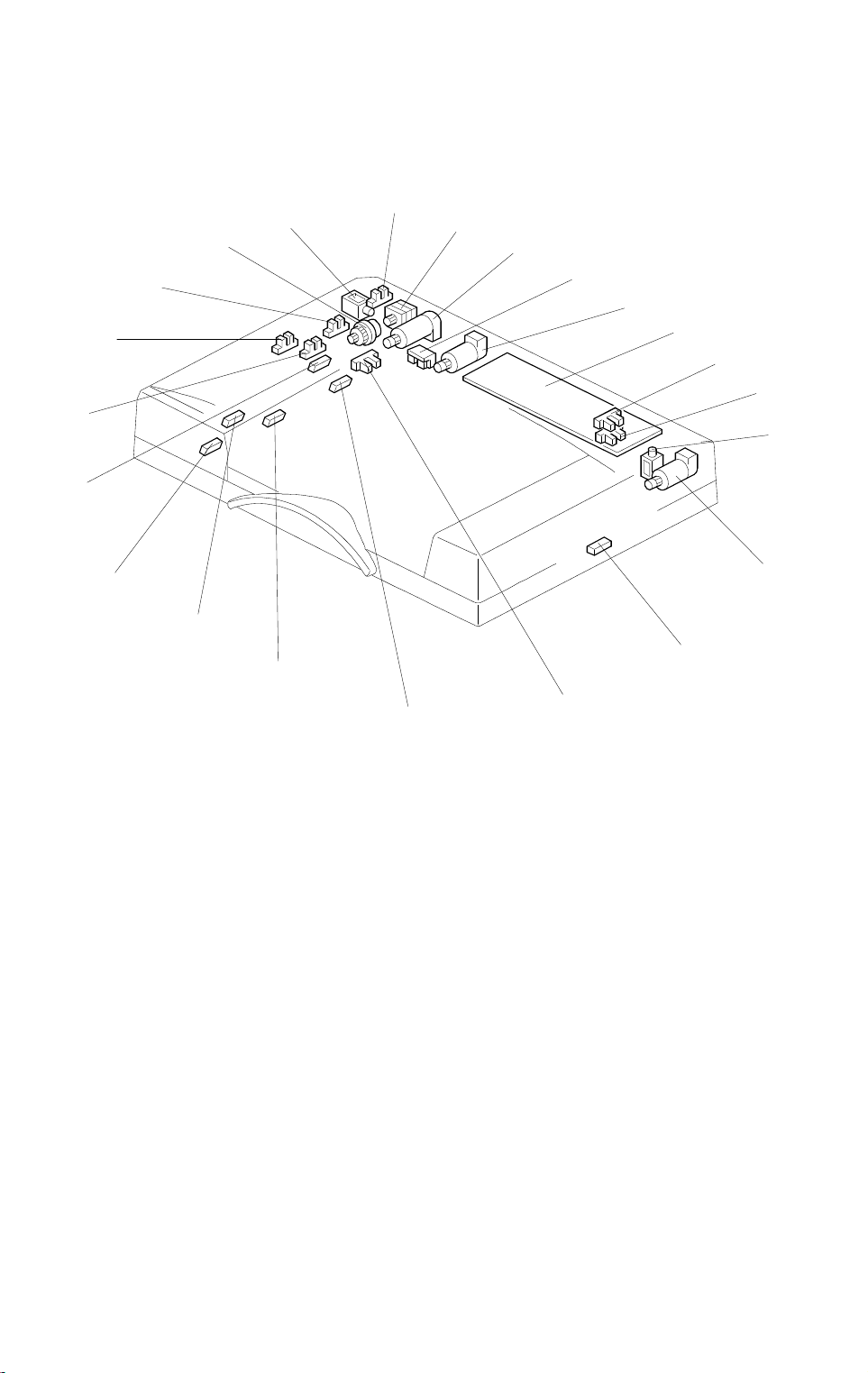

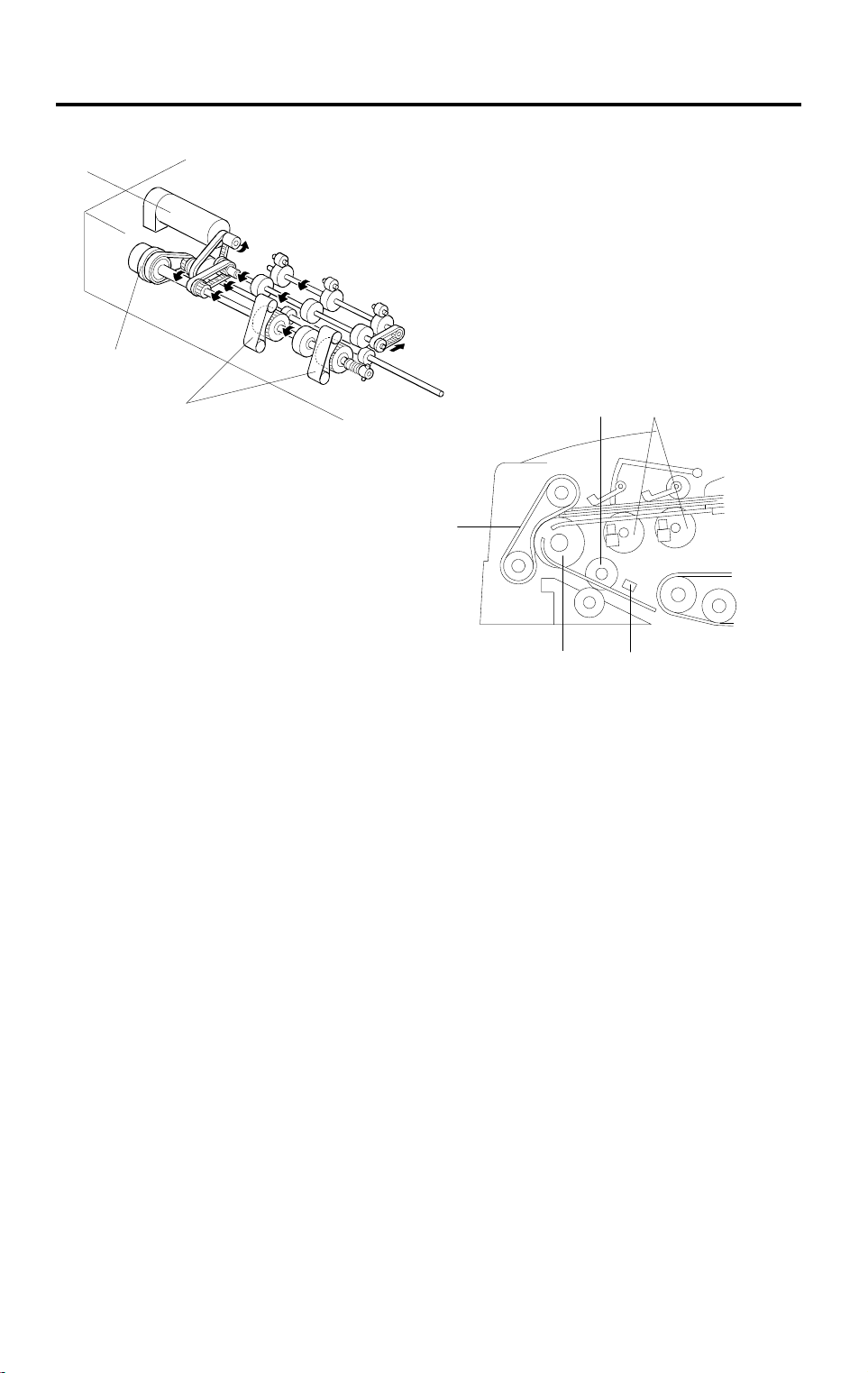

2.2 ELECTRICAL COMPONENT LAYOUT

18

17

19

16

20

15

21

14

22

1

13

2

3

4

5

6

7

8

9

10

11

12

1. Feed-in Cover Open Sensor

2. Friction Belt Motor

3. Feed-in Motor

4. Indicator Panel Lamps

5. Belt Drive Motor

6. DF Main Board

7. DF Position Sensor

8. APS Start Sensor

9. Inverter Solenoid

10. Feed-out Motor

11. Feed-out Sensor

A610V501.wmf

12. Pulse Count Sensor

13. Registration-2 Sensor

14. Original Width-1 Sensor

15. Original Width-2 Sensor

16. Original Width-3 Sensor

17. Registration-1 Sensor

18. Original Set Sensor

19. Original Feed Sensor

20. Friction Belt Turn Sensor

21. Feed-in Clutch

22. Stopper Solenoid

4

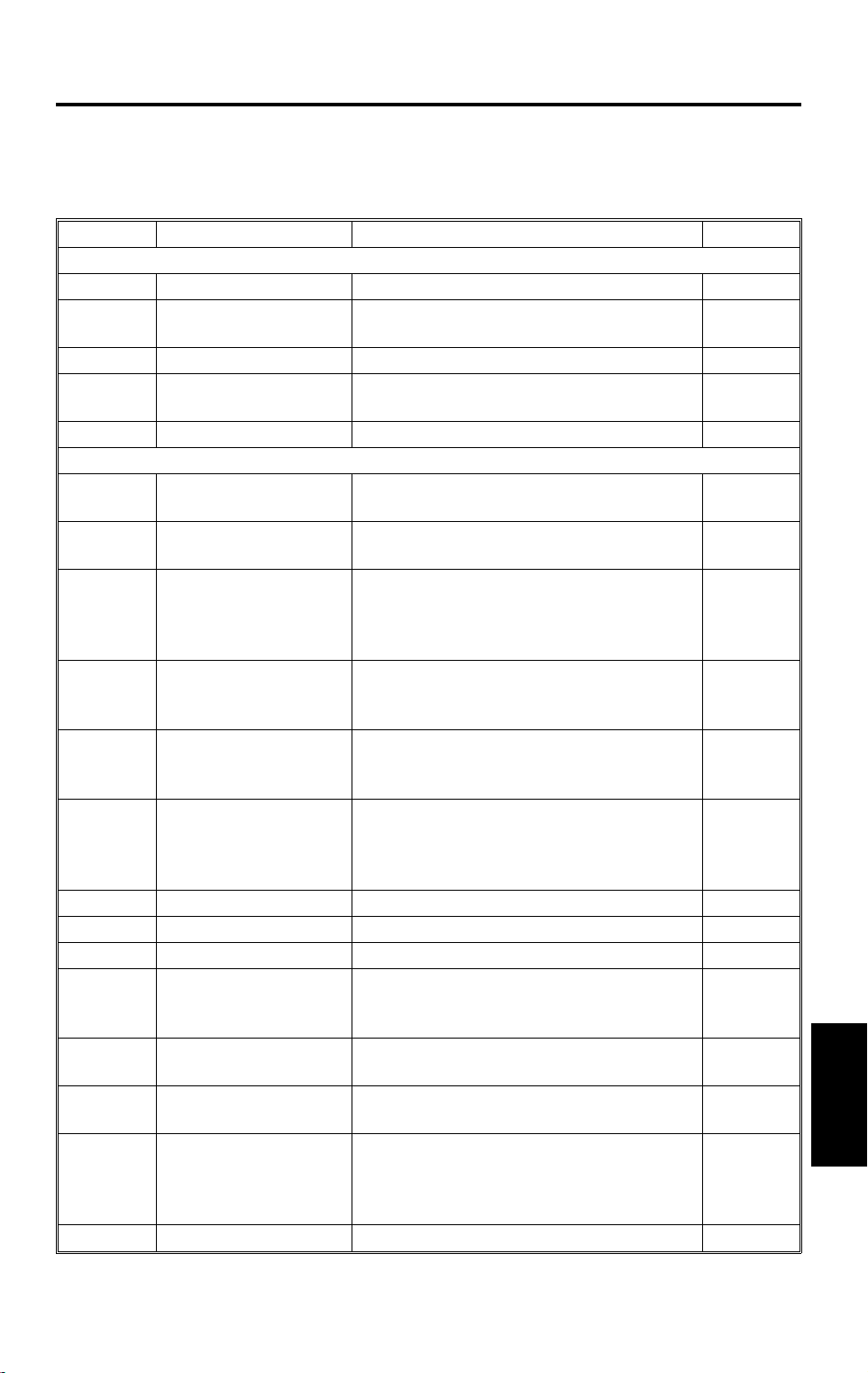

10 May 1996 ELECTRICAL COMPONENT DESCRIPTION

3. ELECTRICAL COMPONENT DESCRIPTION

Refer to the electrical component layout on the reverse side of the

point-to-point diagram for symbols and index numbers.

Symbol Name Function Index No.

Motors

M1 Friction Belt Drives the friction belt. 2

M2

M3 Belt Drive Drives the transport belt. 5

M4

Sensors

S1

S2

S3

S4

S5

S6

S7 Original Width- 1 Detects the original width. 14

S8 Original Width- 2 Detects the original width. 15

S9 Original Width- 3 Detects the original width. 16

S10

S11

S12

S13

Feed-in Drives the feed-in system (pick -u p, feed,

pull-out rollers)

Feed-out Drives the feed-out and the inverte r

system.

Feed-in Cover Open Detects whether or not the feed-in cover is

open.

DF Position Informs the CPU whether the DJF is in the

up or down position.

APS Start Informs the CPU when the DJF is being

closed so that the or i gi nal size sensor s in

the main body ca n check the original si ze

(in plat en mode).

Feed-out Checks for orig i nal misfeeds and set s

original stop timing when in auto- reverse

mode.

Pulse Count Counts the pulses generated by the pulse

generator disc t o det er mine the origi nal

length.

Registration -2 Detects the leadi ng edge of the original to

turn off the feed-i n cl utch and to chang e

the feed-in motor speed. Also detect s th e

original length.

Registration -1 Detects the original length and ori gi nal jam

by detecting the trailing edge of the

original.

Original Set Detects if originals have been placed on

the feed table.

Original Feed Detects if the originals have reached the

feed roller or not .

Friction Belt Turn Counts the pulses generated by the p ul se

generator disk t o m oni t or the friction bel t

motor.

3

10

1

7

8

11

12

13

17

18

19

20

Feeder

Dual Job

5

ELECTRICAL COMPONENT DESCRIPTION 10 May 1996

Symbol Name Function Index No.

Solenoids

SOL1

SOL2

PCBs

PCB1 DF Main Board Controls all DJF functions. 6

Magnetic Clutch

CL1

Indica t or Lamps

L1

Inverter Inverts the original when copying

two-sided originals.

Stopper Lifts the original stopper and lowers the

press roller to fe ed t he set of originals to

the feed roller.

Feed-in Transmits the feed-in motor drive to the

pick-up, feed, and pull-out rollers.

Ready Informs the oper at or that the DJF is in th e

down position.

Auto Informs the operator that the auto feed

mode is available.

9

22

21

4

6

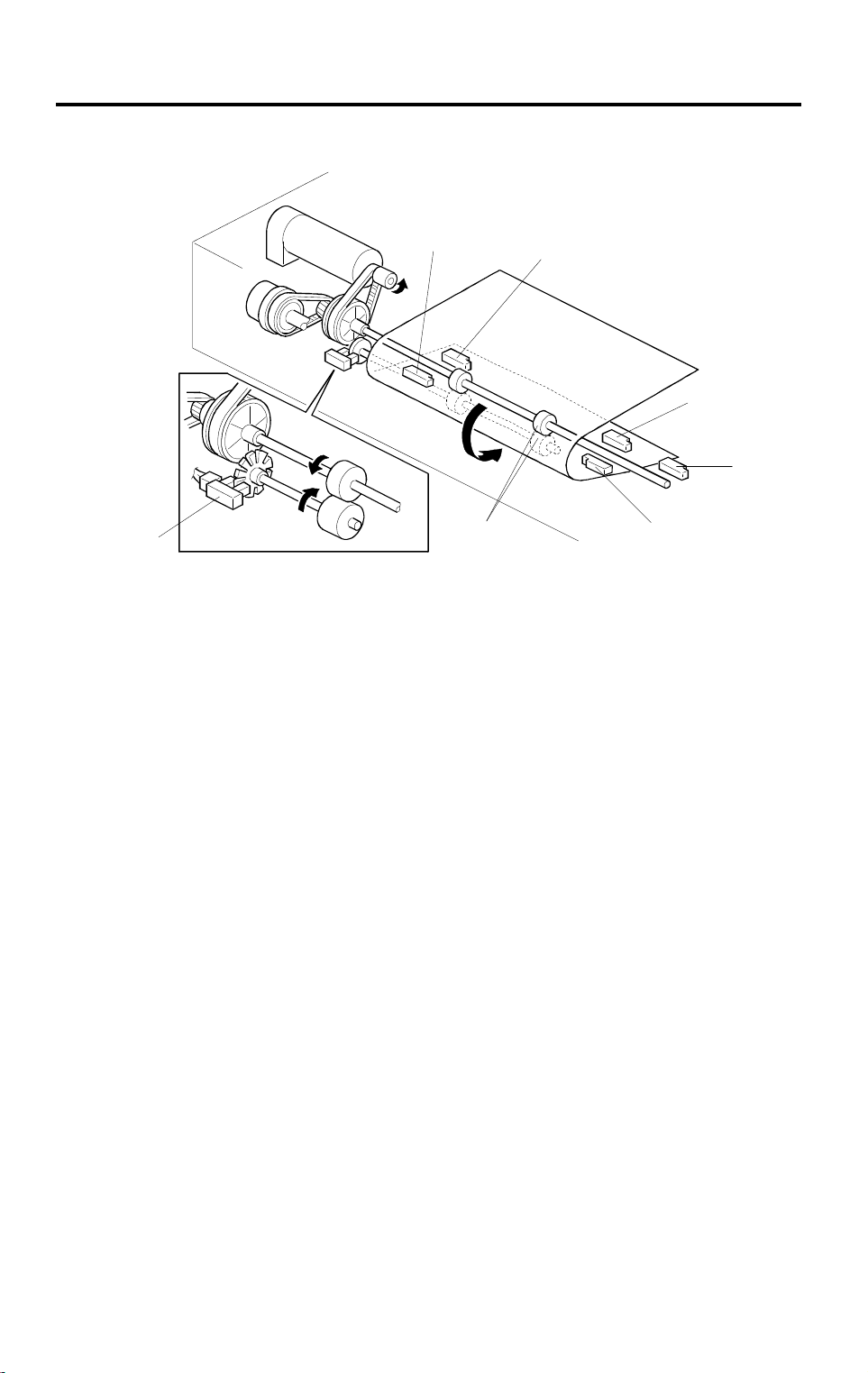

10 May 1996 ORIGINAL PICK-UP MECHANISM

4. ORIGINAL PICK-UP MECHANISM

[G]

[J]

[D]

[C]

A610D500.wmf

[B]

[E]

[A]

[C]

[F]

A610D501.wmf

[I]

[H]

A610D502.wmf

When an original [A] is placed on the original table [B], the leading edge is

stopped by the stopper [C], and the feeler [D] is pushed out of the original set

sensor. The Insert Original indicator light goes out and the DJF informs the

copier’s CPU that the originals have been placed on the original table.

When the Start key is pressed, the copier’s CPU sends the feed-in signal to

the DJF. On receipt of this signal, the stopper solenoid [E] activates to raise

the stopper, which allows the originals to be fed in, and to lower the press

rollers [F] to press the originals against the pick-up rollers, as shown.

The feed-in clutch [G] also activates when the DJF receives the feed-in

signal. 200 ms after the feed-in clutch activates, the feed-in motor feeds all

originals to the feed roller [H].

When the originals reach the feed roller, the stopper solenoid de-activates to

lower the original stopper [I] and to lift up the press rollers [J].

Feeder

Dual Job

7

SEPARATION AND FEED MECHANISM 10 May 1996

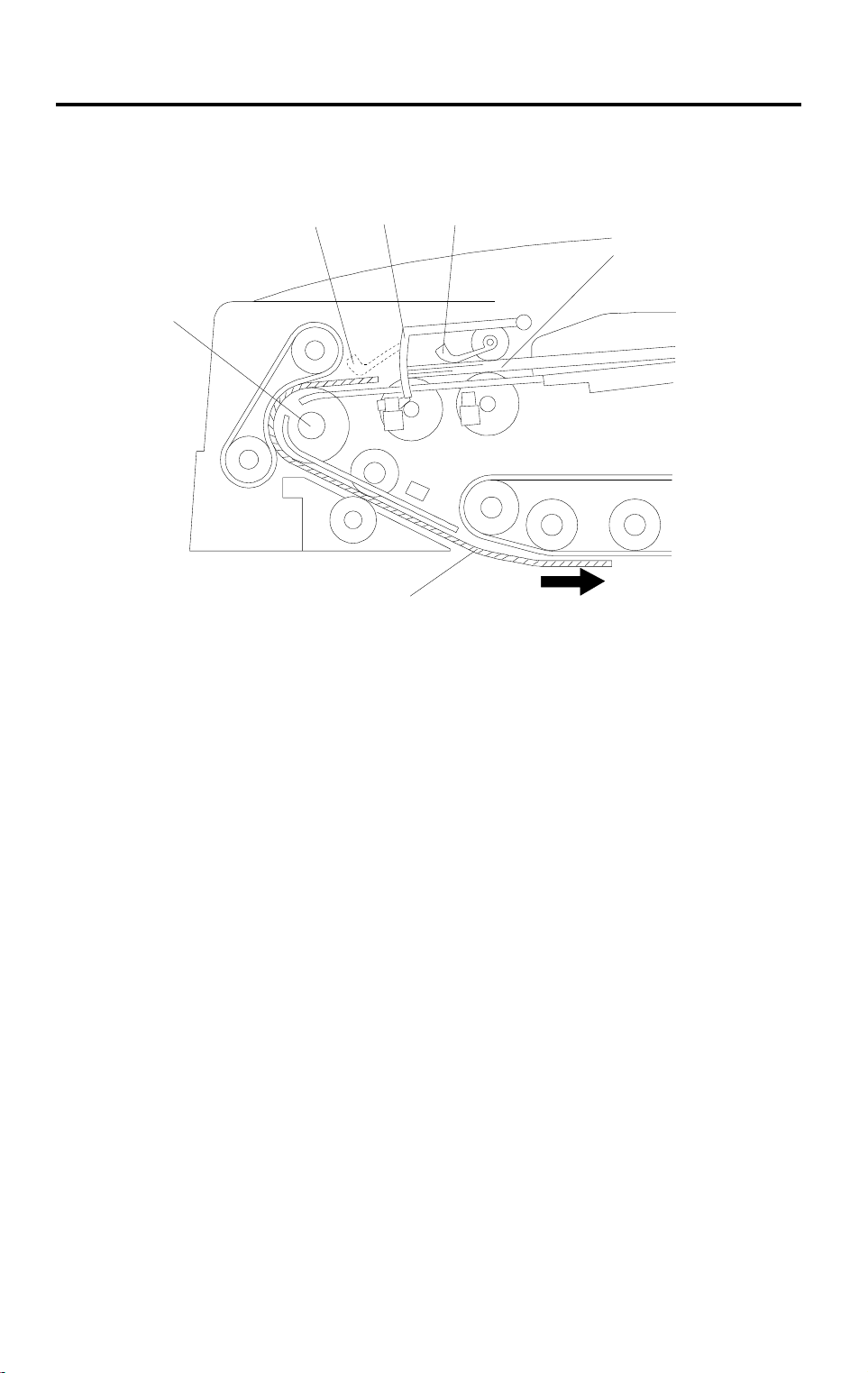

5. SEPARATION AND FEED MECHANISM

[A]

[E]

[F]

A610D505.wmf

[D] [B]

[F]

[C]

[G]

A610D504.wmf

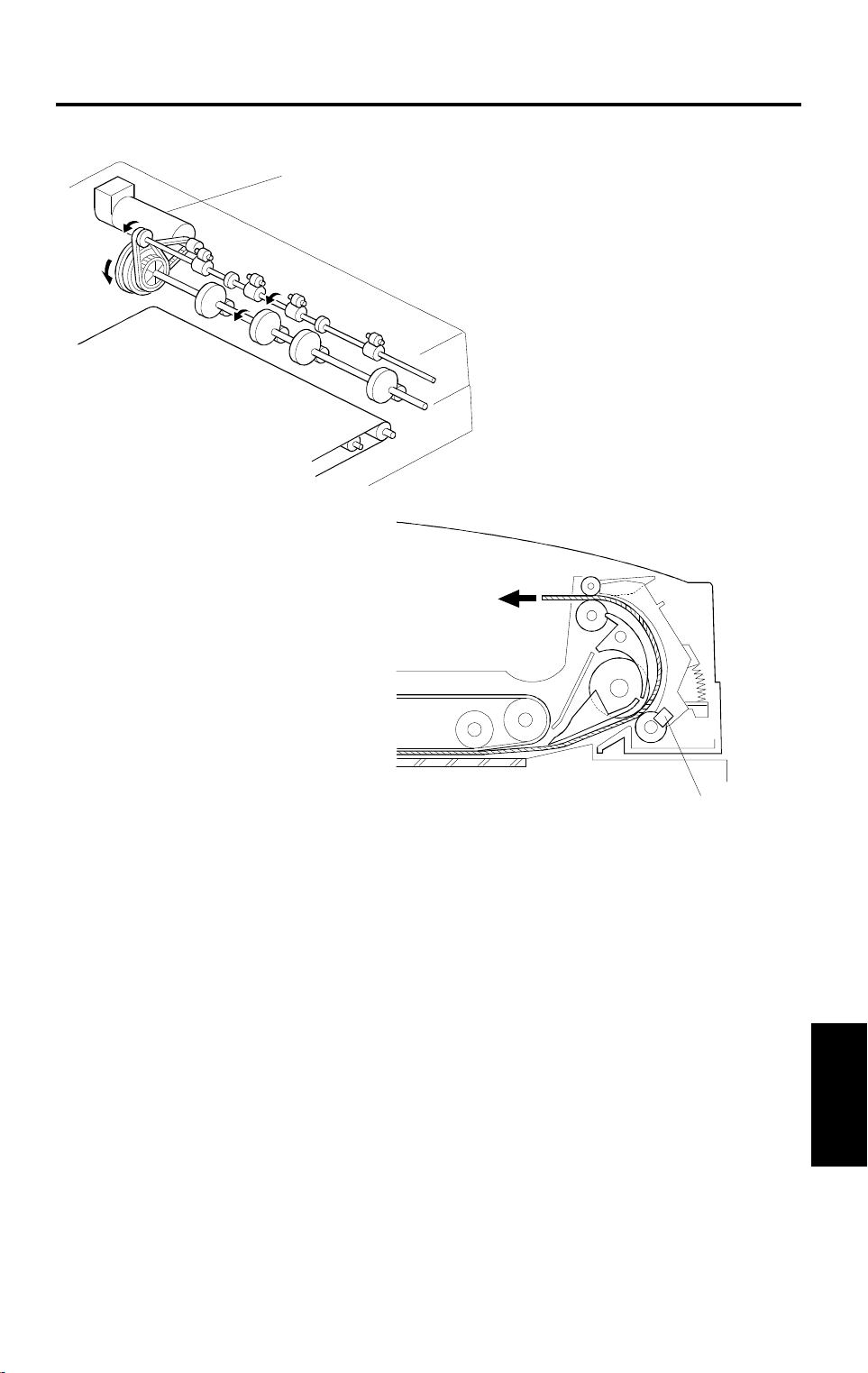

Drive from the feed-in motor [A] is transmitted to the pick-up [B], feed [C], and

pull-out rollers [D], through the feed-in clutch [E], as shown. The feed roller

and the friction belts [F] are used to feed and separate the originals.

Original feed starts when the feed roller starts turning to advance the bottom

original of the stack. The feed roller moves the original past the separation

belt because the driving force of the feed roller is greater than the resistance

of the friction belt. The friction belt prevents multiple feeds because the

resistance of the friction belt is greater than the friction between original

sheets. At this time, the feed-in motor rotates slowly to ensure proper feed

and separation of the original.

When the leading edge of the original activates registration sensor-2 [G], the

feed-in clutch turns off and the motor rotates more quickly. To reduce

mechanical load, only the pull-out rollers are driven to feed the original to the

exposure glass.

To prepare the next original, it is separated in the same manner as explained

above, and stopped when the leading edge is detected by the registration

sensor-2 [G]. When it is time to feed this sheet to the exposure glass, the

feed-in motor rotates at high speed.

8

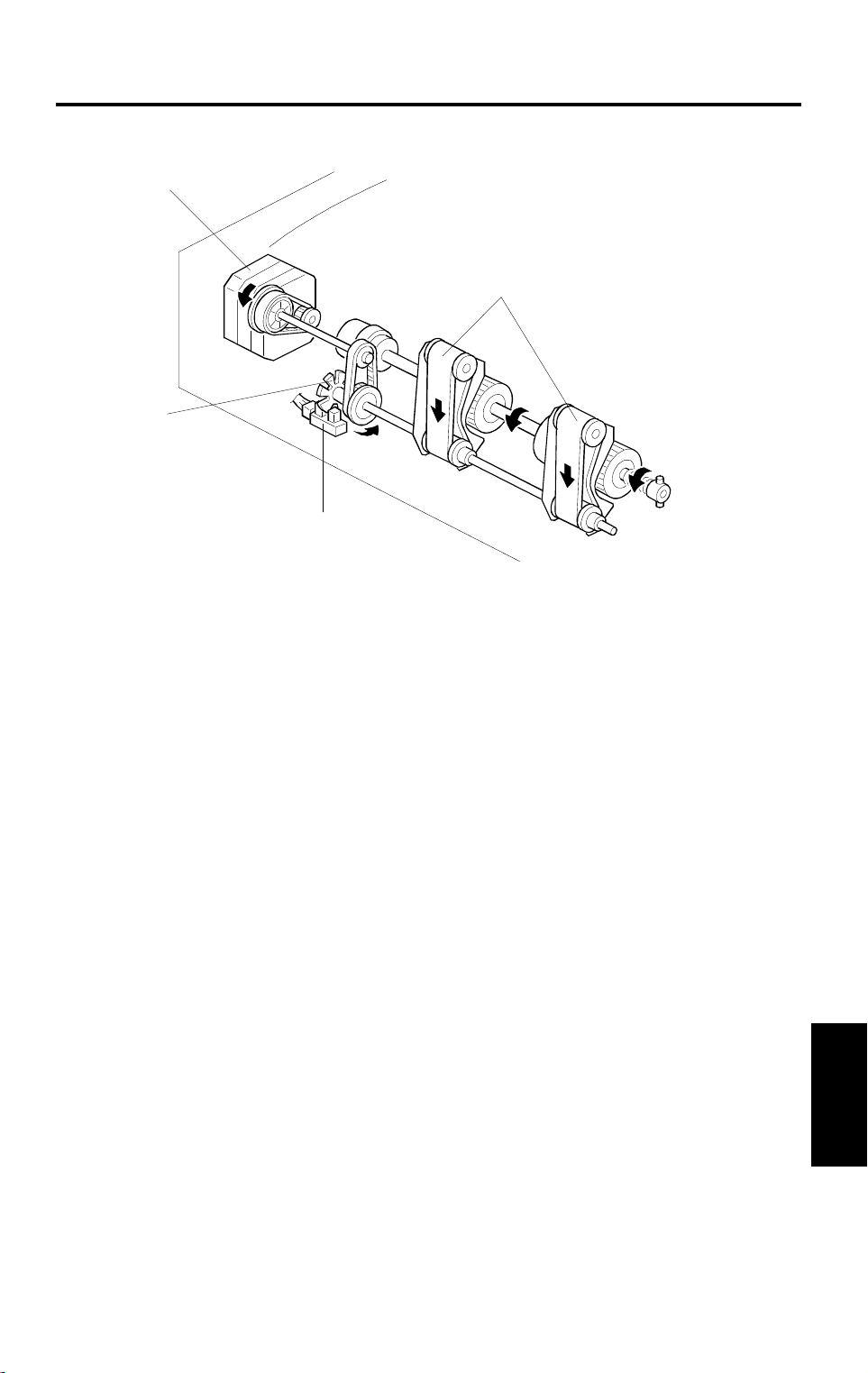

10 May 1996 FRICTION BELT DRIVE MECHANISM

6. FRICTION BELT DRIVE MECHANISM

[B]

[A]

[D]

[C]

A610D506.wmf

The friction belts [A] are driven by the friction belt drive motor [B] through

timing belts, as shown.

When the Start key is pressed, the friction belts are not rotated (the motor is

electrically ON but the motor does not turn as the voltage is too low; see the

timing chart in section 13.1). As the leading edge of the original activates the

registration sensor-2, the friction belts rotate in the reverse direction to

reverse out the next original from in between the friction belts and feed

rollers. This results in less of a chance for originals to be damaged or

become dirty. Also, the area of the friction belt that contacts the feed roller or

the original changes, to prevent multiple feeding.

The friction belt turn sensor [C] counts the pulses generated by the pulse

generator disk [D] on the friction belt shaft. The sensor detects friction belt

motor error conditions.

Feeder

Dual Job

9

ORIGINAL SIZE DETECTION 10 May 1996

7. ORIGINAL SIZE DETECTION

[D]

[E]

[A]

[C]

[F]

[G]

A610D507.wmf

[B]

The DJF detects original width through the on/off combination of the three

original width sensors-1 [A], -2 [B], -3 [C]. It also detects the original length

with the registration sensors-1 [D], -2 [E] and the pulse count sensor [F].

The DJF CPU counts the pulses between registration sensor-2 [E] on timing,

and registration sensor-1 [D] off timing. Based on this pulse count, the CPU

determines the original length.

The reasons for using two registration sensors are:

1) Registration sensor-2 [E] is used to stop the pre-fed original, which

waits until the previous original is fed out. For precise control, the

original stop position must be after the pull-out rollers [G]. Therefore,

registration sensor-2 is placed after the pull-out rollers.

2) Registration sensor-1 [D] checks the trailing edge of the original. This

check is used to place the original in the correct position on the

exposure glass. Because this is a fast feeding mechanism, some

distance is required between the sensor and the original scale. If

sensor-2 was used to detect the stop timing, there would not be

enough time to stop the original at the correct place. Therefore,

registration sensor-1 is used for this; it is placed 34.9 mm before

sensor-2.

(The diagram at the start of section 8-1 shows the position of the

sensors with respect to the rollers.)

10

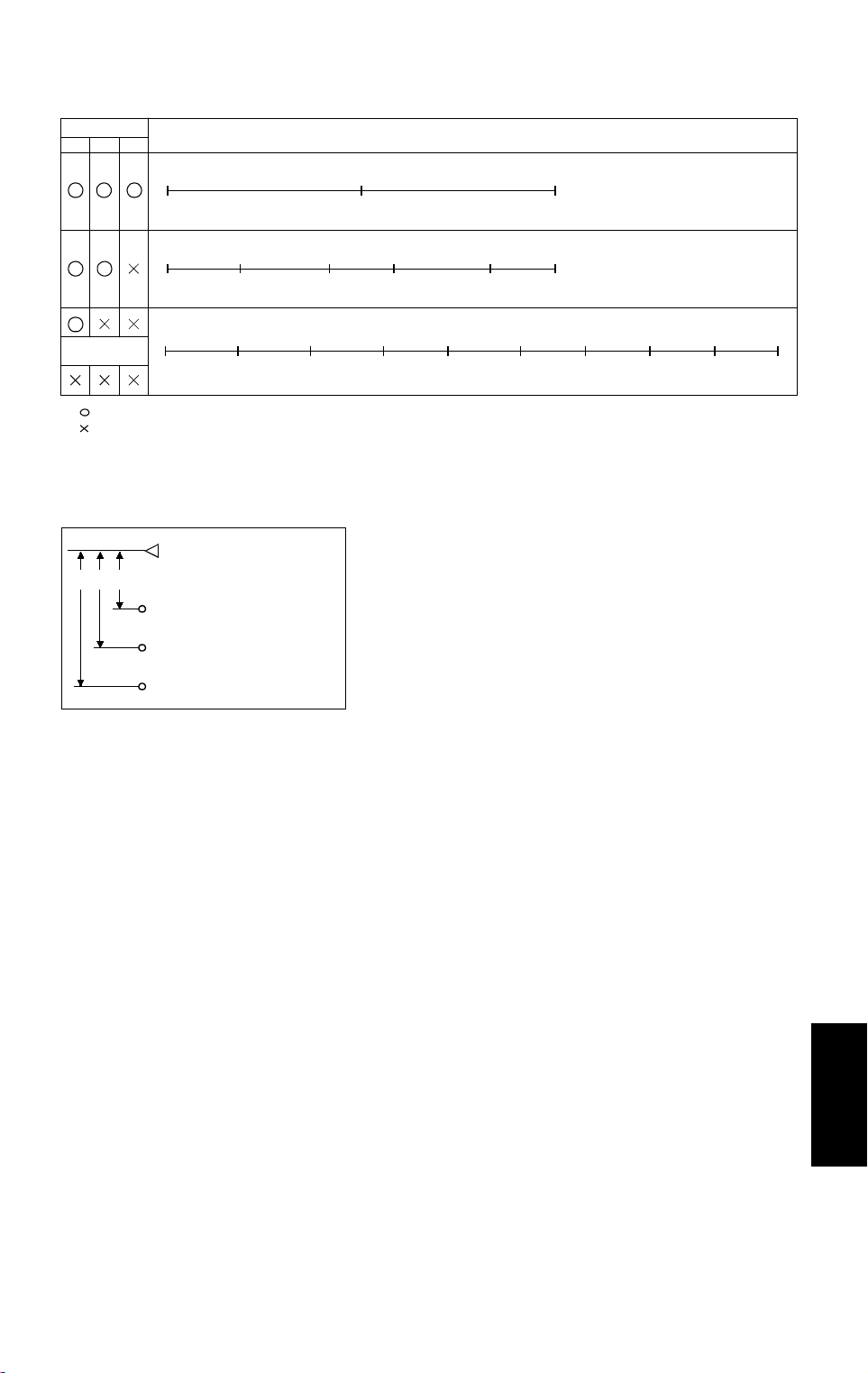

10 May 1996 ORIGINAL SIZE DETECTION

Width Sensor

123

or

: Paper Present

: No Paper

: Sideways

S

: Lengthwise

L

Width Sensor Position

Upper: Original Size

Lower: Threshold Level for Each Size (Pulse Count)

Original Alignment

ABC

Width Sensor 1: A = 210 mm

A4S A3

231 mm

(78)

B5 S LTS B4 11" x 15" A3

201 mm

(68)

B6S A5S B6 L A5 L B5 L

143 mm

(44)

236 mm

(80)

166 mm

(54)

377 mm

(136)

201 mm

(68)

231 mm

(78)

399 mm

(145)

271 mm

(95)

294 mm

(103)

316 mm

(115)

A3B4A4 LLT L

387 mm

(140)

A610D508.wmf

Width Sensor 2: B = 235 mm

Width Sensor 3: C = 284 mm

A610D509.wmf

The original size is determined by the combination of the detected original

width and length as shown above. Note that when only width sensor 1 detect

that paper is preset, or if all width sensors are off, the original size is detected

only by the pulse count sensor data.

Feeder

Dual Job

11

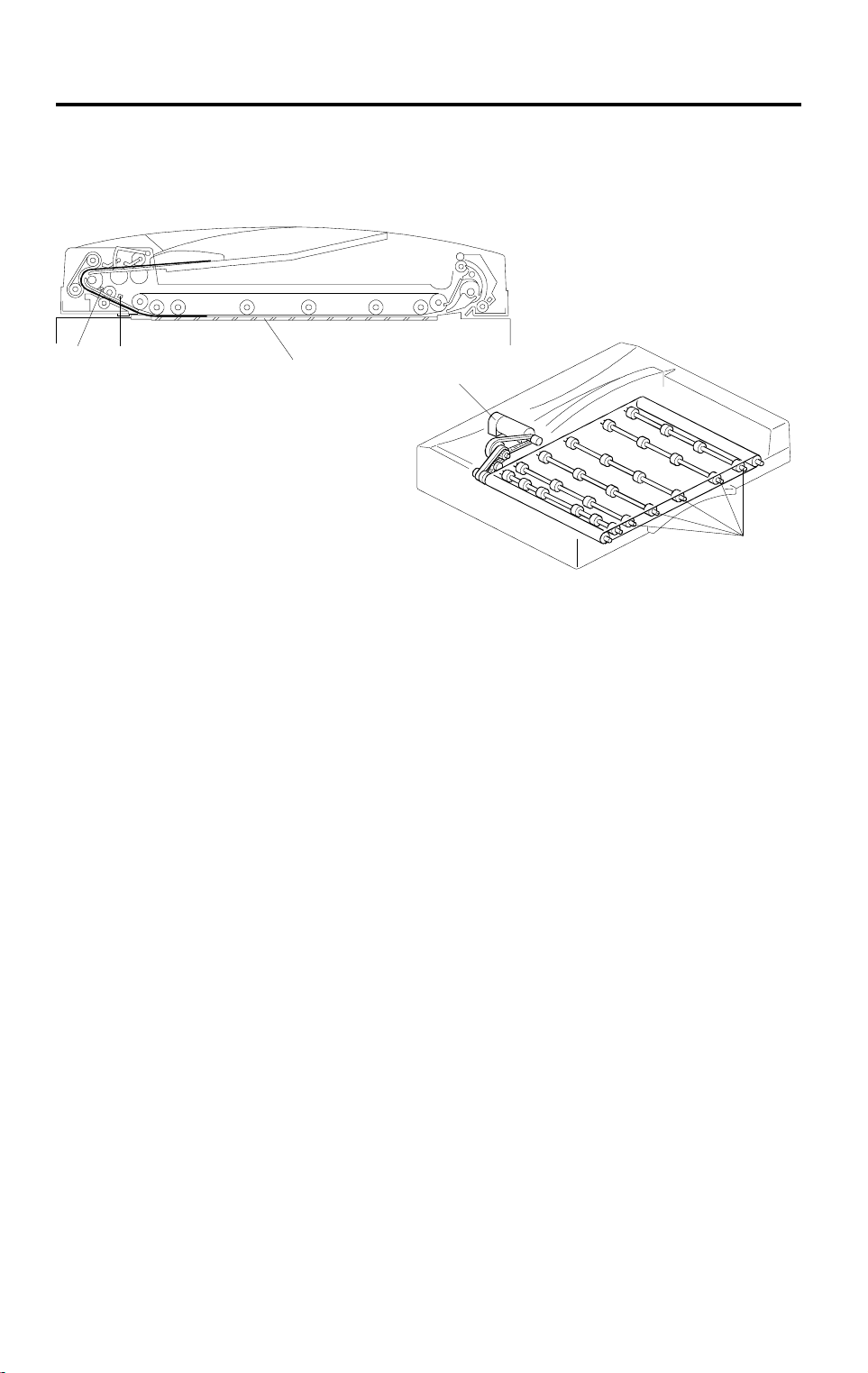

TRANSPORT MECHANISM 10 May 1996

8. TRANSPORT MECHANISM

8.1 BASIC OPERATION

[E]

[D]

A610D511.wmf

[A]

[B]

[C]

A610D512.wmf

The transport belt [A] is driven by an independent motor called the belt drive

motor [B]. The belt drive motor starts rotating soon after the copier sends an

original feed-in signal. Inside the transport belt are five pressure roller shafts

[C], which achieve the proper amount of pressure between the belt and the

original.

When the leading edge of the original reaches the exposure glass, the

original is transported by the transport belt (the belt drive motor turns on 200

ms after the start key is pressed).

When the trailing edge of the original passes through registration sensor-1

[D], the feed-in motor turns off. When the trailing edge of the original passes

through registration sensor-2 [E], the belt drive motor gradually decreases its

speed to stop the original at the proper place on the exposure glass.

100 ms after the belt drive motor turns off, the feed-in motor turns on until the

next original activates registration sensor-2 [E], the next original waits until

the first original copy job is complete. This operation reduces the original feed

in time.

When the scanner reaches the return position, the copier’s CPU sends the

feed-out and feed-in signals to the DJF CPU, and the feed-in motor is

activated again to change the original.

If the original is smaller than A4 sideways, the original just copied is

transported to the right side of the exposure glass then waits until the next

original copy job is completed. Then the previous original is delivered. This

operation also reduces the original feed-in time.

12

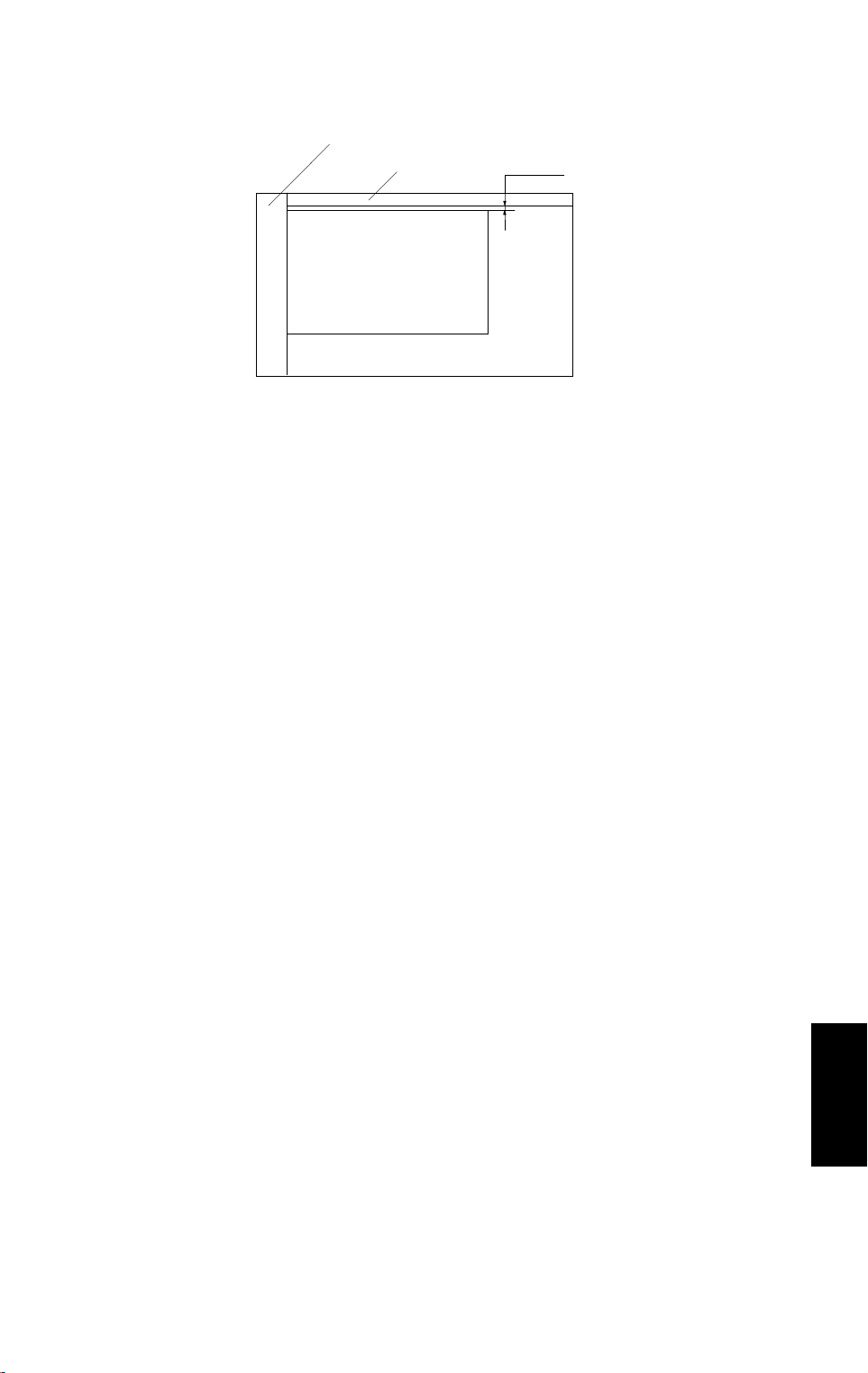

10 May 1996 TRANSPORT MECHANISM

Left Scale

Rear Scale

5.0 mm

Original

A610D513.wmf

Since the copier’s original alignment position is at the left rear corner (not in

the center), the originals fed from the DJF must also be at this position. But if

the original was to be fed along the rear scale, original skews, jams or

wrinkling, may occur.

To prevent such problems, the original transfer position is set to 5.0 mm

away from the rear scale as shown. The correction for this 5.0 mm gap is

compensated for by the base copier’s optics unit.

13

Feeder

Dual Job

TRANSPORT MECHANISM 10 May 1996

8.2 THIN/THICK ORIGINAL MODES

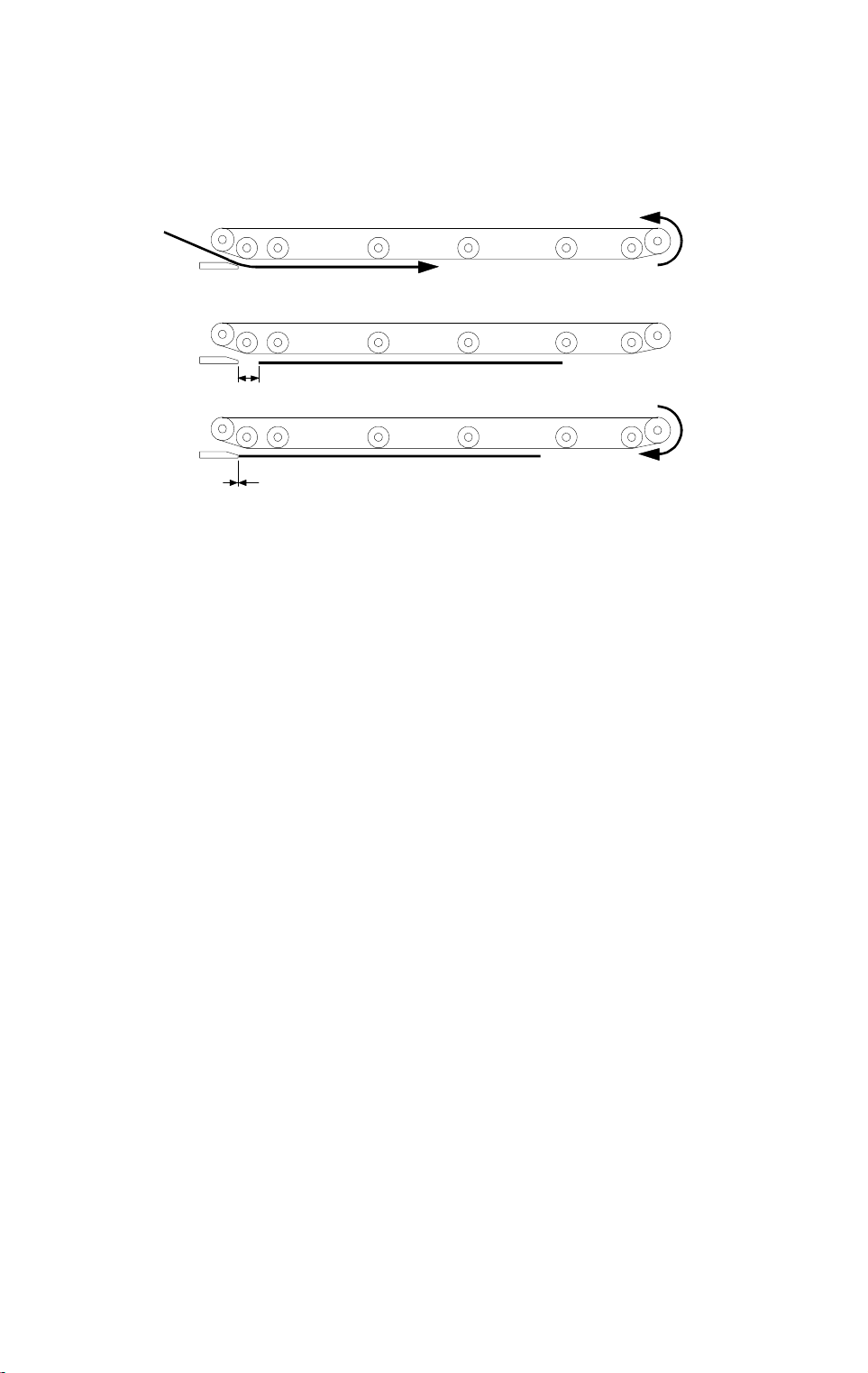

Fig. 1

10±2 mm

25 mm

Fig. 2

Fig. 3

A610D514.wmf

This document feeder has two different ways of stopping originals on the

exposure glass at the correct position. They are thin original mode and thick

original mode. The user can select the desired settings to match the type of

original being used.

1. Thick Original Mode

When thick original mode is selected, the belt drive motor remains

energized to carry the original approximately 10 mm past the left scale

(Figures 1 and 2). Then, the belt drive motor pauses and reverses to feed

the original back against the original scale for about 25 mm (Fig. 3). This

forces the original against the left scale and thus aligns the trailing edge

of the original with the scale.

Thick original mode is selected at the factory.

2. Thin Original Mode

To protect originals from being damaged by the movements of the

transfer belt, thin original mode can be selected. The original is stopped

at the correct position on the exposure glass based on an encoder pulse

count. The belt drive motor stops shortly after the original trailing edge

passes registration sensor-2. (Exact timing depends on registration

adjustment.)

The feed amount for both modes can be adjusted.

For more details, refer to the "Replacement and Adjustment" section.

14

10 May 1996 ORIGINAL FEED-OUT MECHANISM

9. ORIGINAL FEED-OUT MECHANISM

A610D516.wmf

[A]

[B]

A610D515.wmf

When the scanner reaches the return position, the copier’s CPU sends the

feed-out signal to the DJF CPU.

When the DJF receives the feed-out signal, the belt drive and feed-out

motors [A] turn on.

The feed-out sensor [B] installed in the feed-out section counts the number of

pulses to calculate how long the feed-out motor must stay on to feed the

original out of the machine properly. Also, the motor rotates at low speed for

the last 50 mm of the detected trailing edge to improve stacking efficiency.

15

Feeder

Dual Job

TRANSPORT BELT LEVELING MECHANISM 10 May 1996

10. TRANSPORT BELT LEVELING MECHANISM

[B]

[A]

[F]

[D]

A610D525.wmf

[F]

[E]

[C]

A610D526.wmf

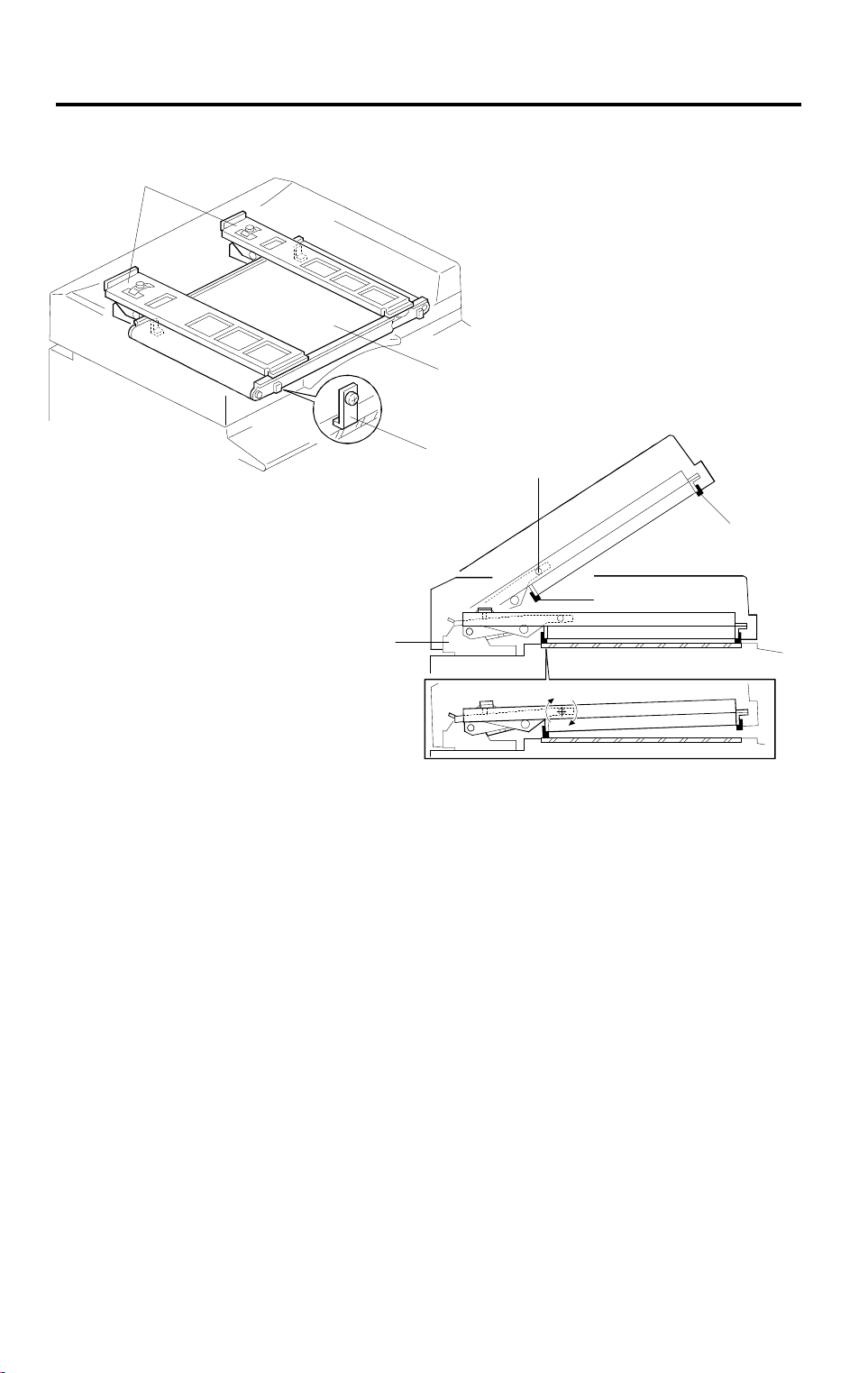

The transport belt [A] and the two support arms [B] are formed as one unit,

(made of aluminum). This results in a more flexible structure than the

monocoque type (in which the cover carries all of the stress), and the gap

between the transport belt and the original can easily be kept precise during

belt transport.

On the support arm linked with the DJF hinge [C], there is a fulcrum [D] to

support the DJF. When the DJF is being closed and the rear stopper [E]

contacts the base copier first, the DJF rotates about the fulcrum, rotates and

the front stopper [F] will also contact the base copier to level the belt with the

exposure glass.

16

10 May 1996 LIFT MECHANISM

11. LIFT MECHANISM

[A]

[C]

[B]

[E]

A610D527.img

➀

➂

➁

➂

➀

➁

A610D528.img

[D]

A610D533.wmf

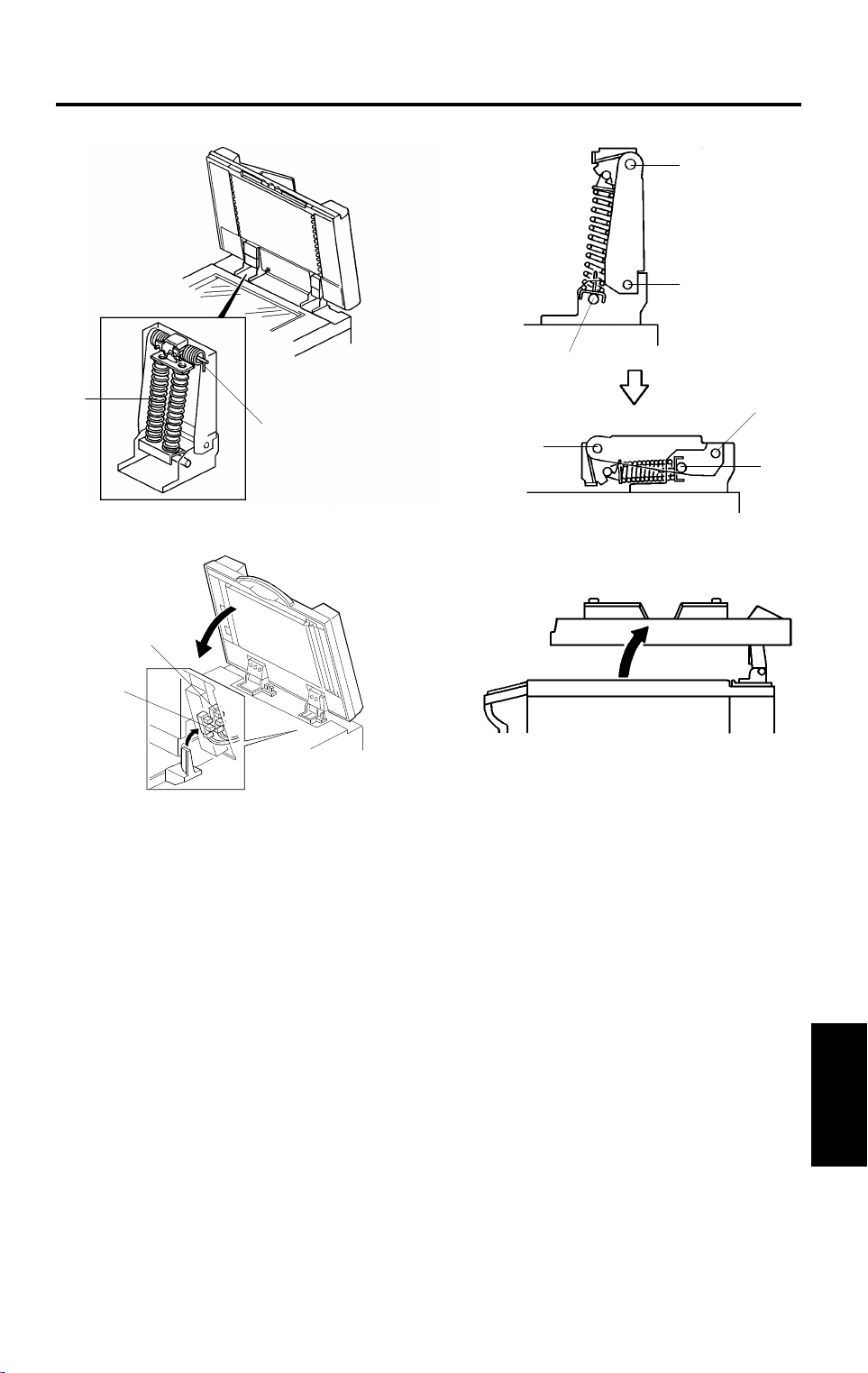

When the DJF is opened, the lift springs [A] provide enough force to ensure

that the DJF does not fall onto the exposure glass. When the DJF is closed,

", "➁", and "➂" are positioned as shown and no upward force is

points "

provided to the DJF.

The position sensor [B] is actuated when the DJF is closed. The copier then

shifts to the document feeder mode. The position sensor also serves as the

reset switch for DJF misfeeds.

After the cover is closed, the APS start sensor [C], which is below the DF

position sensor, informs the base copier CPU that original size sensors in the

main body can check the original size for the platen mode.

When a book or thick original (maximum thickness 60 mm) is copied, the DJF

acts as a cover for the original as shown in the diagram [D]. The position

sensor is turned off during this condition, so the DJF does not function. The

tension of spring [E] returns the DJF to the normal condition after copying a

thick original.

➀

A610D529.img

Feeder

Dual Job

17

SPECIAL FEATURES 10 May 1996

12. SPECIAL FEATURES

12.1 PRESET MODE

[C]

[E]

[B]

[D]

[F]

[A]

A610D510.wmf

Two sets of originals for independent copy jobs can be set on the original tray

at the same time.

While the first set of originals [A] remains on the original tray, both the original

set sensor feeler [B] and original feed sensor feeler [C] are lifted out of their

sensors. A second set of originals [D] can be placed in the feeder on top of

the first set, as far as the original stopper [E]. In this case, when the first set

of originals are all fed-in, the original set sensor feeler is still lifted out of the

sensor, but the original feed sensor has dropped into the sensor. Therefore,

the copier’s CPU recognizes that the first job is completed.

If the second job is already preset, the second set of originals is automatically

fed to the feed roller [F] and fed one-by-one into the machine in the same

manner as the first set of originals.

18

Loading...

Loading...