Page 1

Technical Bulletin No. RTB-011

SUBJECT: DF61 Dirty Mark on Back-side of Original DATE:July 31, ’96

PAGE: 1 of 3

PREPARED BY: S. Hizen

FROM: 1st Field Information Dept. QAC

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

MODEL:

Phoenix-series

(DF61)

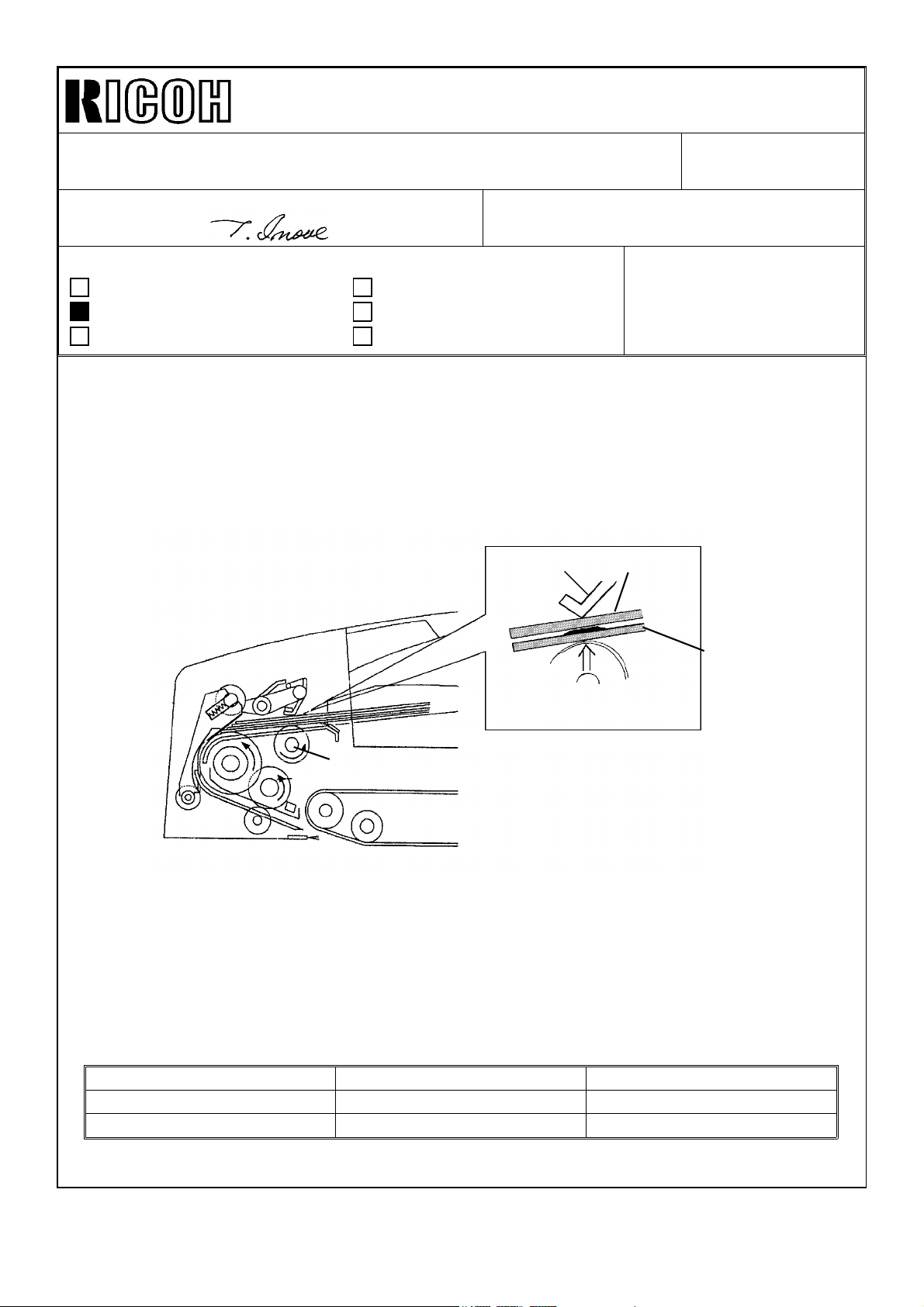

Problem: Three dirty marks on the back side of the original.

Cause: The toner on the first original is transferred to the back of the second

original due to the pressure applied by the pressure lever and the pick-up roller.

(See the illustration)

Pressure Lever

Second

Original

First Original

Pick-up Roller

Pick-up Roller

The dirty marks created are one of the limitations of the DF61. The degree to which

the marks appear varies depending on how completely the image on the first original

is fused, the type of image, and the type of paper used.

Countermeasure:

Due to this countermeasure for the DF61, the specifications listed in the service

manual have been changed as follows:

Specification Item Current DF Modified DF

Original Weight 52 to 128 g/m

2

Original Table Capacity 50 sheets at 80 g/m

2

35 sheets at 80 g/m

52 to 104 g/m

2

2

Page 2

Technical Bulletin No. RTB-011

SUBJECT: DF61 Dirty Mark on Back-side of Original DATE: July 31, ’96

PAGE: 2 of 3

The countermeasure for the dirty marks is designed to reduce the pressure applied

to the originals by replacing the entrance guide stopper spring with a new one. This

change also results in a decrease in the amount of force used to feed the original

and may create an original non-feed problem. Therefore, the separation bracket

has been modified to reduce the angle by 2 degrees.

Separation Bracket

Separation Bracket

2°

CURRENT

Modification Procedure:

1. Remove the three springs from the entrance guide stopper and install the new

spring (P/N:A548 9500) in the middle. If an original non-feed occurs, add the

outside springs (P/N:A548 9500) on both sides.

MODIFIED

Remove the spring

Remove the spring

Replace the spring with a

new one (weaker).

70g (current) → 40g (new)

Page 3

Technical Bulletin No. RTB-011

SUBJECT: DF61 Dirty Mark on Back-side of Original DATE: July 31, ’96

PAGE: 3 of 3

2. Remove the DF separation bracket. (1 snap ring)

3. Replace the separation bracket with A548 9502.

Plastic Plate

Mylar

Plastic

Plate

A548 1291

Current Type

4. Reassemble the parts.

Note: The spring (A548 9500), and the bracket (A548 9502) are available as

spare parts.

A548 9502

Modified Type

Mylar

Page 4

RICOH Technical Bulletin PAGE: 1/3

Bend

Angle

Model: DF61 (Phoenix series) Date: 15-Aug-97

No: 20

Subject: Bent Original Prepared by: S.Hizen

From: QAC 1st Field Information Dept.

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

SYMPTOM

There is a bend (wrapping) on the leading edge

of the original the same size as the width of the

separation belt. If the bend in the original is

large, dirty background may appear on the copy

in the area that corresponds with that bend.

Note: This phenomenon occurs more often if

the original has an upward curl. Originals

output from laser printers are particularly

susceptible.

CAUSE

The problem occurs as a result of the contact between the edge of the original and the

separation belt when the original is fed to the exposure glass. If the upward curl of the

original is large or the cut in the leading edge of the paper is not smooth, this problem is

more likely to occur.

The angle between the separation

belt and the originals, and the

symptoms caused by the angle.

Large: Good for separation, marginal

for original leading edge bending

Small: Good for original leading edge

bending, marginal for double-sheet

feeds.

The Separation Belt Tension also

affects the angle

Strong: If the tension is strong, the

angle is relatively large.

Separation bracket

Originals

Weak: If the tension is weak, the

angle is relatively small

Page 5

RICOH Technical Bulletin PAGE: 2/3

Model: DF61 (Phoenix series) Date: 15-Aug-97

No: 20

SOLUTION

This problem can be resolved by reducing the angle of the belt,

which will help original entrance, or by lowering the guide mylar

by 1 mm to reduce the resistance of the original.

Change the separation belt bracket (A5481291: #20 in the diagram

on the right) and the spring to reduce the angle between the

original and the belt and also decrease the force from the belt

on the edge of the original.

Replacement Part Number: A5489504

The chart below clarifies the modifications made to the separation bracket.

Separation bracket RTB-11

Mass-production. Bracket for the dirty mark

A548-1291 on the back side of original.

Bracket Spring: AA06-3503 A548-9502

Plastic Plate

Mylar

Mylar

Plastic Plate

RTB-20

Bracket for the leading edge

bend.

A548-9504

(This number is for the Bracket and the Spring)

24.5

Plastic Plate

Mylar

Page 6

RICOH Technical Bulletin PAGE: 3/3

Model: DF61 (Phoenix series) Date: 15-Aug-97

Note: If jams occur due to double-sheet feeds, please install the stronger pressure spring

packed with the machine. This measure is designed to facilitate the entrance of the

originals. However, if the friction between the originals is high, and the originals are large,

double-sheet feeds may occur if many originals are used at the same time.

If thin originals are used after the stronger pressure spring has been installed, they may

become creased. If so, please reinstall the original pressure spring and reduce the

number of originals used at one time.

The modified brackets shown above can also be used in the DF64.

No: 20

Loading...

Loading...