Page 1

Technical Bulletin No. RTB-005

[B]

SUBJECT: F400/F410 Dual Job Feeder separation belts

(manual correction)

PREPARED BY: S.MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

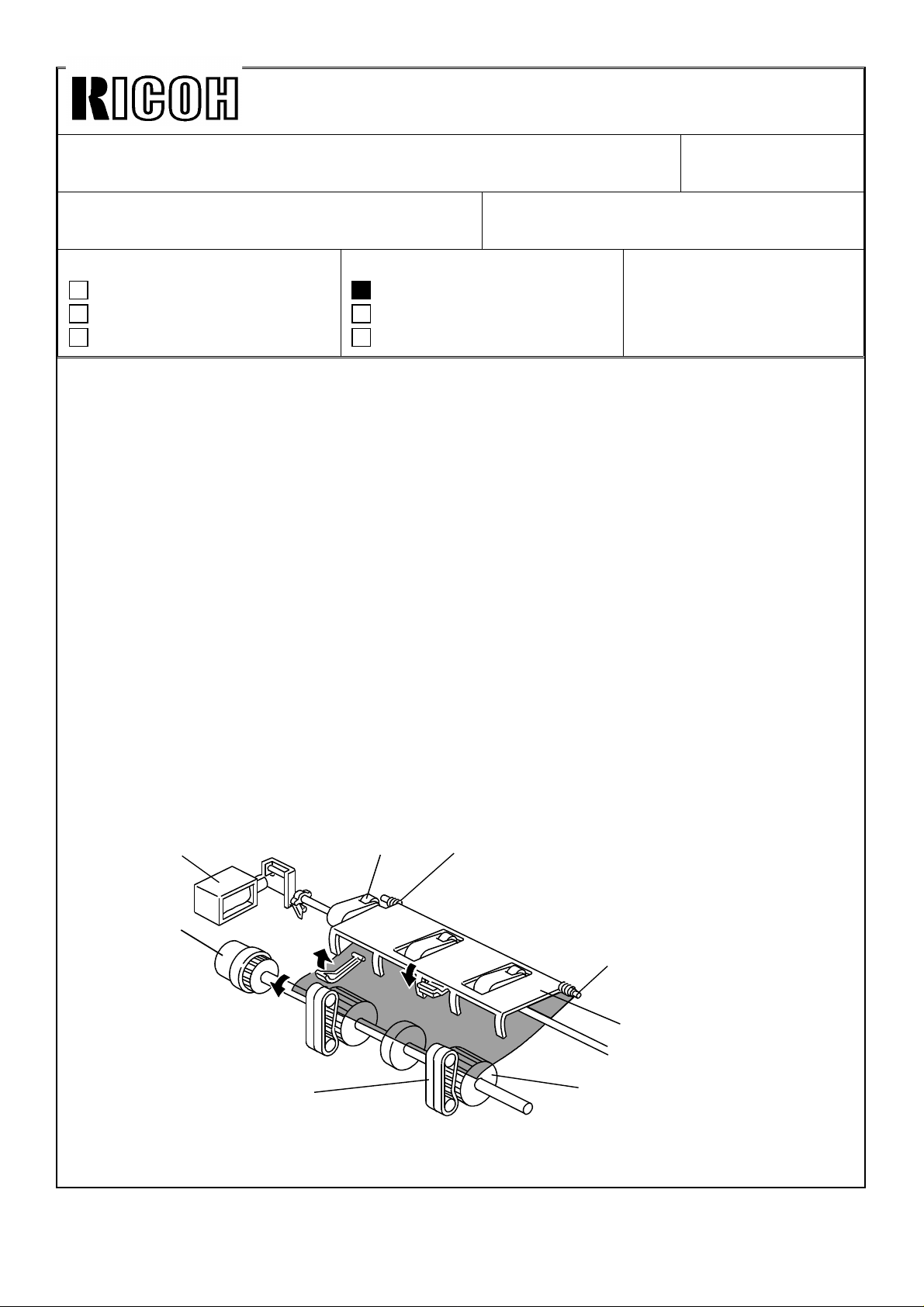

The quantity of the separation belt have been changed from two to four.

Reason of the modification:

On the original printed by the laser printer, the toner may not be fused sufficiently and the

image may smeared by the separation belts.

To prevent this, two more separation belts are added to widen the contacting area

between the separation belts and the original so that the separation pressure is not

concentrated to the narrow area.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Group

MODEL: F400/F410

DATE:SEP.15.’93

PAGE: 1 of 3

After this modification, these separation belts are still PM parts and the replacement

interval is 1PM (120k copies) as same as before this modification.

Because of this modification, the illustrations in page 7, 14, 15, 34 and 35 should be

changed. The quantity of the separation belts should be doubled. There is no correction

except illustrations.

Manual corrections:

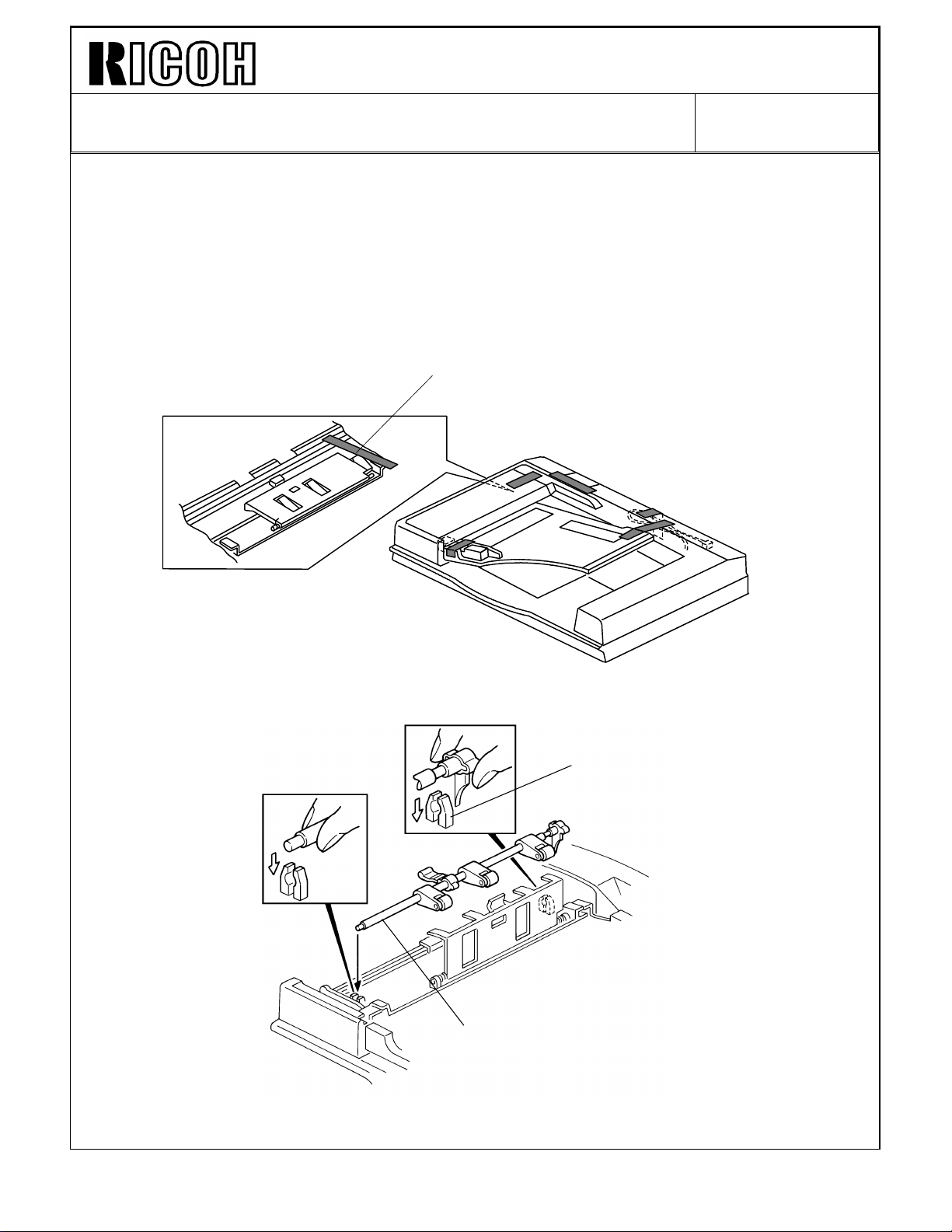

Page 7 - upper illustration

[C]

[A]

[E]

[D]

[F]

Page 2

Technical Bulletin No. RTB-005

[B]

[C]

SUBJECT: F400/F410 Dual Job Feeder separation belts

(manual correction)

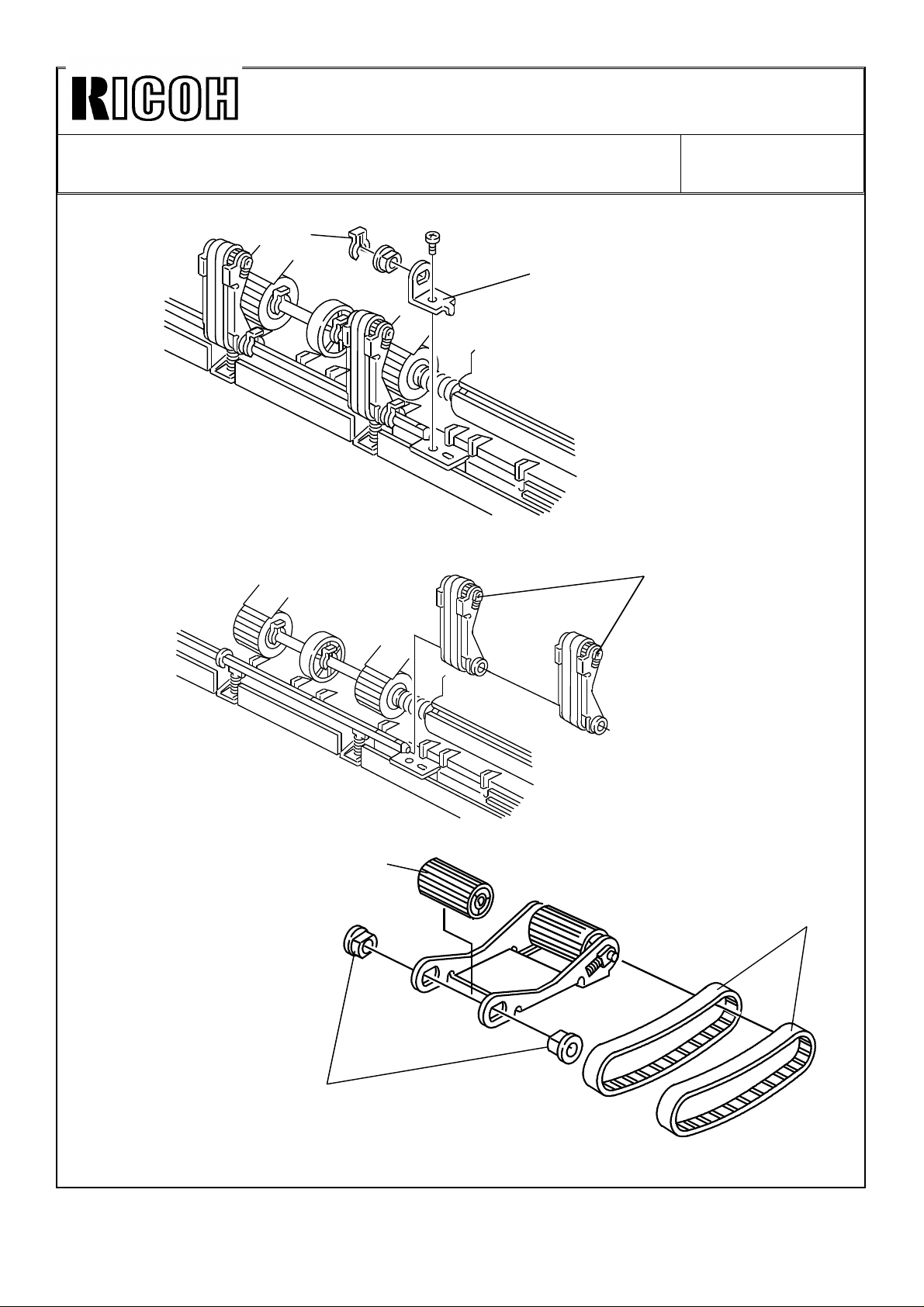

Page 14 lower illustration

[A]

[D]

[E]

Page 15 illustration

DATE:SEP.15.’93

PAGE: 2 of 3

[B]

[C]

[A]

[D]

Page 3

Technical Bulletin No. RTB-005

SUBJECT: F400/F410 Dual Job Feeder separation belts

(manual correction)

Page 34 lower illustration

[E]

[D]

Page 35 illustrations

DATE:SEP.15.’93

PAGE: 3 of 3

[A]

[B]

[C]

[D]

Page 4

Technical Bulletin No. RTB-006

SUBJECT: F400/F410 Troubleshooting DATE:Nov.30, ’93

PAGE: 7 of 10

9. DJF Original Skew

< Phenomenon>

If original skews occur as illustrated even if the DJF height is correctly adjusted, perform

the following adjustment.

Rear

Left scale

< Possible cause>

This skew is caused because the transport belt is faster than the feed-in motor speed,

even if both motor speeds are within the specification.

< Countermeasure>

1. Feed-in motor speed adjustment

Adjust the feed-in motor speed so that the motor speed becomes higher (within

specification).

1–1 Turn DIP SW 101-1, 2, 4 to "ON".

1–2 Turn DIP SW 102-1 to "ON".

1–3 Turn VR 103 towards "H" to turn LED 101 (Red) on.

1–4 Turn VR 103 towards "L" to turn LED 102 (Green) on.

2. Transport belt motor speed adjustment

Adjust the transport belt motor speed so that the motor speed becomes lower (within

specification).

1–1 Turn DIP SW 101-1, 2, 4 to "ON".

1–2 Turn DIP SW 102-2 to "ON".

1–3 Turn VR 104 towards "L" to turn LED 103 (Red) on.

1–4 Turn VR 104 towards "H" to turn LED 102 (Green) on.

Page 5

Technical Bulletin No. RTB-008

SUBJECT: DJF Multiple feeding DATE:Nov.30, ’93

PAGE: 1 of 2

PREPARED BY: S. MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

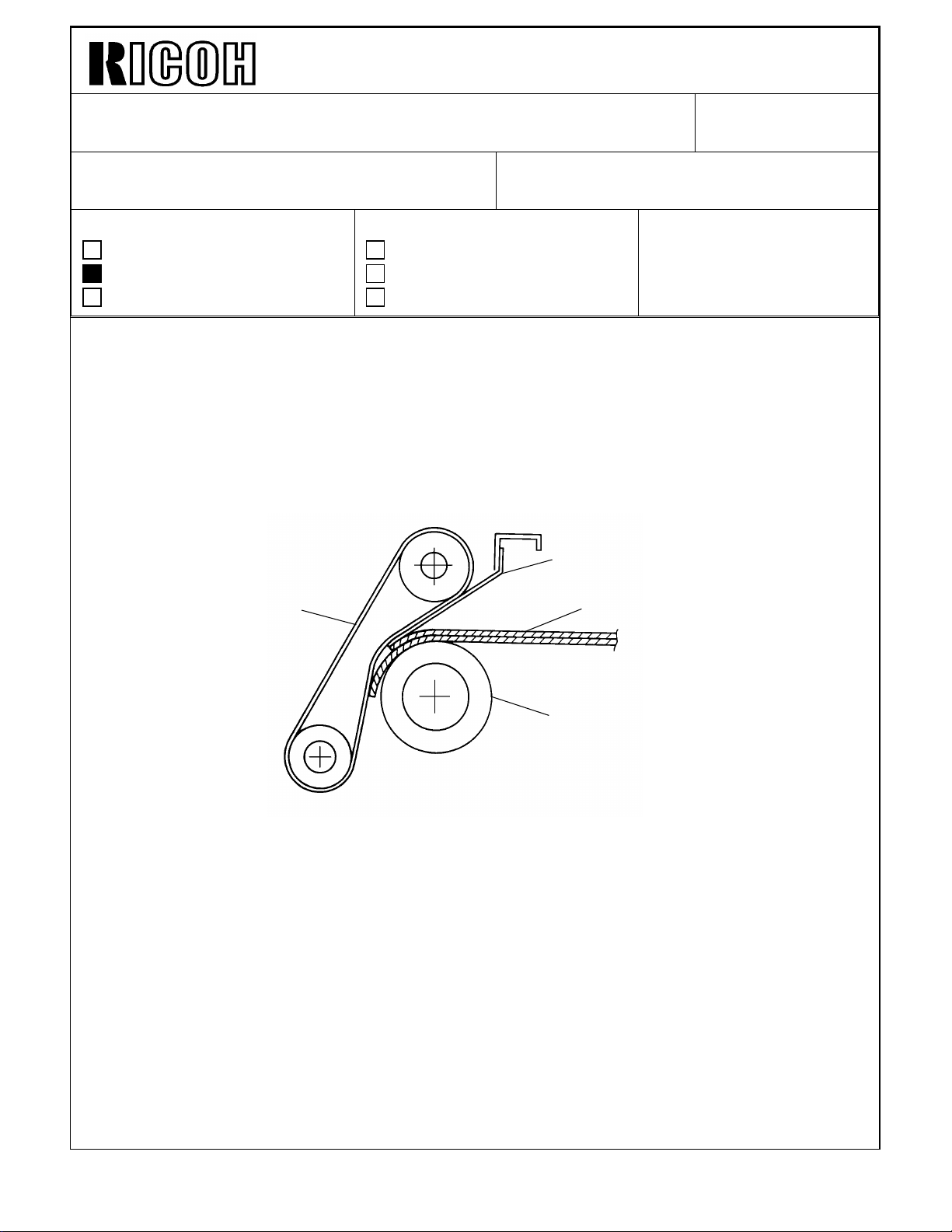

< Phenomenon >

Original multiple feeding occurs when there is high friction between the originals. This

tends to occur especially when the originals have staple holes, or computer forms with

rough edg es.

< Possible cause >

[C]

Revision of service manual

Information only

Other

FROM: Copier Technical Support Group

MODEL: F400/F410

[D]

[A]

[B]

When the originals [A] comes between the feed rollers [B] and the separation belts [C],

they meet the mylar [D] between them and the separation belts. This guide mylar

transports the originals smoothly to the gap between the feed rollers and the separation

belts. The mylar length determines the original separation force. If the mylar is longer, the

area where the originals touch the separation belt becomes narrower, therefore the

separation force become weaker. If the mylar is shorter, the separation force becomes

stronger. (If it is too short, too much separation force stops original feed)

As a result of our investigation, we found that making the mylar 2mm shorter is the best

condition (higher separation ability without feeding error).

Page 6

Technical Bulletin No. RTB-008

SUBJECT: DJF Multiple feeding DATE:Nov.30, ’93

PAGE: 2 of 2

< Countermeasure >

Replace the original guide mylars (2 mylars per machine). New part is the assembled part

of the mylar and the bracket. New part number is A3761254.

For the cut-in serial number, please refer to the modification bulletin which will be issued

soon.

Guide mylar ass’y : Part number A3761254

Page 7

Technical Bulletin No. RTB-009

SUBJECT: Installation procedure DATE:Nov.30, ’93

PAGE: 2 of 3

3. Caution for DJF shipping tape removal (dual job feeder service manual - installation

procedure page, 24)

When removing the tape [B] fixing the original press roller shaft [C], be careful to confirm

that the shaft is correctly in the holder [D]. It is possible that the shipping tape adheres

strongly to the shaft. The shaft migit be pulled out from the holder when the tape is

removed.

If the shaft is out of position, the original will not feed.

[B]

[C]

[D]

Page 8

Technical Bulletin No. RTB-010

SUBJECT: DJF feed roller assembly replacement DATE:Nov.30, ’93

PAGE: 1 of 3

PREPARED BY: S.MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

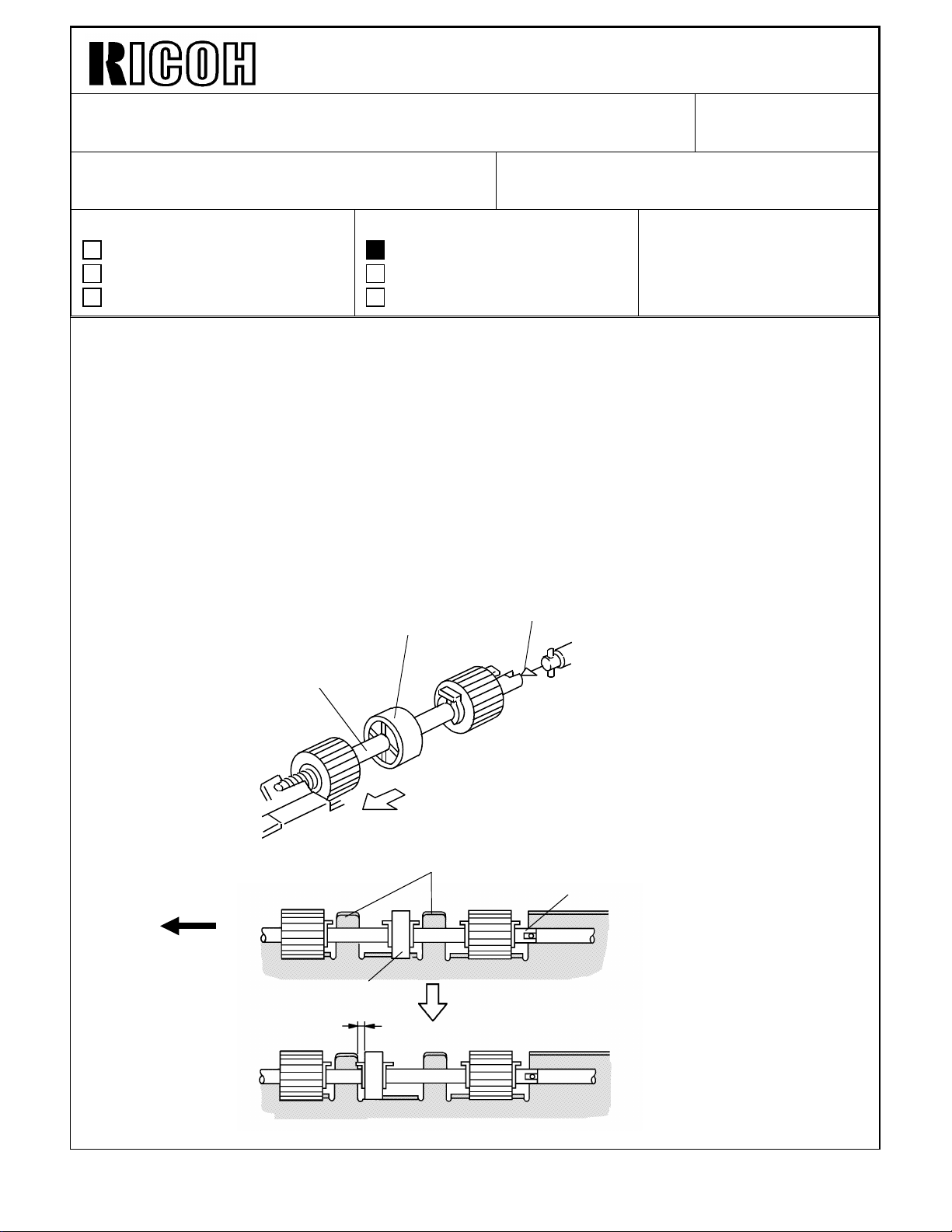

1. Manual correction

In the feed roller replacement procedure (page 32 to 33), there are steps asking to remove

the original table and original guide. Actually, this procedure is not necessary. Please skip

steps 2, 3, 4, and 5. You can directly access the feed roller.

2. Procedure change due to modification.

In the domestic market, we have experienced that the customer took off the feed roller

assembly [A] when removing a jammed original. When the jammed original is pulled to the

front, the feed rollers are pulled to the front and the joint part [B] comes out from the drive

shaft. To prevent this, The middle roller [C] position has been changed (to the rear) as

shown below.

Revision of service manual

Information only

Other

[C]

FROM: Copier Technical Support Group

MODEL: F400/F410

[B]

Front

[A]

Guide Plate

[B]

Old

[C]

New

Page 9

Technical Bulletin No. RTB-010

SUBJECT: DJF feed roller assembly replacement DATE:Nov.30, ’93

PAGE: 2 of 3

Before the modification, the middle roller could be shifted to the front when the feed roller

was pulled to the front. After the modification, when the feed roller is pulled to the front,

the middle roller hits the guide plate and it cannot be moved to the front. This prevents the

joint part from being separated by mistake.

To replace the feed roller assembly, the following procedure is necessary before

performing step 6 (slide the feed roller assembly to the front, then remove it).

* Remove the guide mylars

* Remove the snap ring.

* Hold the feed roller.

After the modification, procedure "14.2 feed roller replacement" is changed as shown in

next page.

Page 10

Technical Bulletin No. RTB-010

SUBJECT: DJF feed roller assembly replacement DATE:Nov.30, ’93

PAGE: 3 of 3

[B]

[A]

Rear

[E]

[F]

[C]

1. Turn off the main switch then open the feed cover [A].

2. Remove the guide mylars [B] ( 1 screw each ).

3. Remove the snap ring [C].

4. Slide the roller [D] to the rear.

[D]

Front

5. Hold the feed roller [E] then slide the shaft to the front, then remove the feed roller

assembly as shown.

6. Remove the four snap rings [F], then remove the feed rollers.

7. Install the new feed rollers, then re-assemble the machine.

Page 11

Technical Bulletin No. RTB-016

SUBJECT: DJF VERTICAL REGISTRATION ADJUSTMENT FOR TWO

SIDED ORIGINAL MODE

PREPARED BY: S. MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Dual job feeders with the following serial numbers have the possibility that the vertical

registration for two sided original mode is improper due to insufficiant inspection during

production.

Machine Code From To

A376-15 first production 4123110190

A376-17 A3383100001 A338310674

A376-22 5323100001 5323110149

A376-26 3D81030001 3D81130040

A376-27 A3383100921 A3383111103

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL:

F400/F410

DUAL JOB FEEDER

A376-10 No machine

DATE:Jan. 31, ’93

PAGE: 1 of 3

If necessary, please adjust the vertical registration (refer to page 46 of the DJF service

manual).

If the vertical registration adjustment cannot be carried out using the procedure on page 46

of the DJF service manual (by using SP adjustment mode), return the SP adjustment data

to "00".

Then adjust the vertical registration by turning VR102 on the DJF main board. The VR102

adjustment has a wider adjustable range than SP adjustment mode (adjustable range by

SP adjustment: -7.5 mm ∼ +7.5 mm, 0.5mm/step).

Page 12

Technical Bulletin No. RTB-016

[B]

VR102

SUBJECT: DJF VERTICAL REGISTRATION ADJUSTMENT FOR TWO

SIDED ORIGINAL MODE

Two Sided Original Mode

[A]

10 ± 2

[C]

DATE:Jan. 31, ’93

PAGE: 2 of 3

1. Remove the copier’s left scale [A] (2 screws).

2. Remove the small cover at the rear side on the upper DJF cover then turn on DIP SW

101-2, 101- 4, and 102- 1.

3. Set a sheet of A4 / 8 1/2" x 11" (53 ∼ 80 g/m2 / 14 ∼ 22 lb) paper sideways on the

original table.

4. Push SW 101 [B].

5. After the original stops on the exposure glass, gently raise the DJF (so that the original

does not move).

6. Confirm that the gap between the trailing edge of the paper and the left edge [C] of the

original rear scale is 10 ± 2 mm.

7. If the gap is not within specification, adjust the registration by using the copier SP mode

1

( SP Adjustment - PAGE 6).

NOTE: 1. Before setting the original on the original table again, open and close the

feed unit cover [C].

2. After completing the adjustment, return the DIP switches to their original

condition.

Page 13

Technical Bulletin No. RTB-016

SUBJECT: DJF VERTICAL REGISTRATION ADJUSTMENT FOR TWO

SIDED ORIGINAL MODE

8. If the registration cannot be adjusted even though the SP data is changed to the

maximum value, return the data to "00".

9. Adjust the vertical adjustment by turning VR102 on the DJF main board.

DATE:Jan. 31, ’93

PAGE: 3 of 3

Page 14

Technical Bulletin No. RTB-017

SUBJECT: MANUAL CORRECTIONS DATE: Jan. 31,’94

PAGE: 9 of 13

Page 6-19 1.15

• Incorrect

1.15 DUAL JOB FEEDER

Definition: [Level:B]

Encoder pulse is not detected by the DJF main board......

Possible causes

DJF feed motor defective

DJF transport motor defective

DJF feed out motor defective

DJF inverter motor defective

• Correct

1.15 DUAL JOB FEEDER/RECIRCULATING DOCUMENT HANDLER

Definition: [Level:B]

Encoder pulse is not detected by the DJF/RDH main board......

Possible causes

DJF/RDH feed motor defective

DJF/RDH transport motor defective

DJF/RDH feed out motor defective

RDH inverter motor defective

Page 11 of DJF Illustration

• Incorrect

In Fig.2, the left paper is expressed by a dotted line and the right paper is expressed by

solid line.

• Correct

In Fig.2, the left paper position is shown

by a solid line and the right paper position

is shown by a dotted line as shown.

Page 15

Technical Bulletin No. RTB-017

SUBJECT: MANUAL CORRECTIONS DATE: Jan. 31,’94

PAGE: 10 of 13

Page 12 of DJF 3rd line of [Figure 3] explanation

• Incorrect

A few pulses (0 ∼ 14 pulses: depends on the SP mode adjustment) ....

• Correct

A few pulses (0 ∼ 14 pulses: depends on the DIP switch adjustment) ....

Page 27 of DJF 3rd line of upper NOTE and Illustration

• Incorrect

..... loosen four truss head screws [D], and tighten.

[D]

• Correct

..... remove the cover [D] (4 screws), and loosen then tighten 4 screws [E].

[D]

[E]

Page 16

Technical Bulletin No. RTB-017

[C]

SUBJECT: MANUAL CORRECTIONS DATE: Jan. 31,’94

PAGE:11 of 13

Page 43 of DJF Illustration

• Incorrect

• Correct

[D]

[C]

Page 46 of DJF Step 6

• Incorrect

6. Confirm that the gap between the trailing edge of the paper and the left edge [C] of

the original rear scale is 10 ± 2mm.

• Correct

6. Confirm that the gap between the trailing edge of the paper and the right edge of the

original rear scale is 10 ± 2mm.

[E]

[E]

[D]

Page 17

Technical Bulletin No. RTB-020

SUBJECT: Manual Correction DATE:

February. 15, 1994

PAGE: 1 of 2

PREPARED BY: S. Mano

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MANUAL CORRECTION

Page 4-59 DUAL JOB FEEDER Preventive Maintenance Schedule

Incorrect

EM 120K 240K 360K NOTE

DUAL JOB FEEDER (for originals)

Transport Belt

Pick-up Roller

Feed Roller

Separation Belts

CRRR

CCCC

CRRR

CRRR

Belt cleaner. Replace if

necessary.

Alcohol. Replace if

necessary.

Alcohol. Replace if

necessary.

Alcohol. Replace if

necessary.

MODEL: F400 DJF

Correct

DUAL JOB FEEDER (for copies)

Transport Belt

Pick-up Roller

Feed Roller

Separation Belts

EM 120K 240K 360K NOTE

CRRR

CCCC

CRRR

CRRR

Belt cleaner. Replace if

necessary.

Alcohol. Replace if

necessary.

Alcohol. Replace if

necessary.

Alcohol. Replace if

necessary.

Page 18

Technical Bulletin No. RTB-020

SUBJECT: Manual correction DATE:

February 15, 1994

PAGE: 2 of 2

Each parts’s actual estimated life is 48K original feed times.

Since estimated average copies per one original is 2.5, we recommend to replace the

transport belt, separation belts and feed roller at the same time as the copier’s 120K PM.

(48,000 x 2.5 = 120, 000)

Because the F400/F410 series has an SP mode PM counter (indicates the original feed

time since the last PM), you can recognize how many times originals have been fed since

the last PM parts replacement. We recommend utilizing this function to manage the PM

parts replacement interval.

Therefore, if you utilize PM counter for original feed ( 9 PM COUNTER CLEAR PAGE4),

the PM table is as follows:

EM 48K 96K 144K NOTE

DUAL JOB FEEDER (for originals)

Transport Belt

Pick-up Roller

Feed Roller

Separation Belts

CRRR

CCCC

CRRR

CRRR

Belt cleaner. Replace if

necessary.

Alcohol. Replace if

necessary.

Alcohol. Replace if

necessary.

Alcohol. Replace if

necessary.

Concerning the RDH, the copy volume and original feed times are almost the same.

We just recommend to replacing PM parts at the same time as the copier’s 120K PM

(transport belt: replace at every copier’s 240K PM).

Page 19

Technical Bulletin No. RTB-025

[A]

SUBJECT: DJF ORIGINAL DOUBLE FEEDING DATE: Mar. 15 ’94

PAGE: 1 of 2

PREPARED BY: S. MANO

CHECKED BY: S. Hamano

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:DJF for F400

series

Phenomenon

Original double feeding (two originals are fed at a time) tends to occur when the

separation belts [A] become dirty with foreign matter which being transferred from the

original surface.

Cause

When the separation belt surface is covered with foreign matter, the friction between the

original and the separation belt decreases. This reduces the original separation ability.

[A]

Page 20

Technical Bulletin No. RTB-025

SUBJECT: DJF ORIGINAL DOUBLE FEEDING DATE: Mar. 15 ’94

PAGE: 2 of 2

Countermeasure

Clean the separation belt surface with alcohol to recover the separation ability. We

recommend to do this at every customer visit including at the installation to eliminate

further EM calls.

Note: If block original feeding (10~20 sheets of originals are fed at a time) occurs,

replace the original guide mylars [A] to the new parts (A3761254). Please refer to

RTB-008 for the details.

[A]

Page 21

Technical Bulletin No. RTB-033

SUBJECT: Irregular original stack in auto counting mode DATE: April 30, ’94

PAGE: 1 of 2

PREPARED BY: S. MANO

CHECKED BY: S. Hamano

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

<PHENOMENON>

During auto counting mode, the original delivery speed varies. The original stack alignment

become irregular, and in the worst case, the original order changes.

This probleme specially occurs when feeding letter (8 1/2" x 11") sideways originals.

<PHENOMENON>

When the original is delivered in auto counting mode, the original exit motor changes its

speed. Just before the trailing edge of the original passes through the exit roller, its speed

decreases to correct the original stack. Normally the original exit motor changes to the

quicker speed after completely feeding out the original. However, sometimes, the exit

motor returns to the quicker speed before the original trailing edge passes through the exit

roller. In this case, the original is pushed out quickly, resulting in the irregular original stack.

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL: F400 / F410

Page 22

Technical Bulletin No. RTB-033

SUBJECT: Irregular original stack in auto counting mode DATE: April 30, ’94

PAGE: 2 of 2

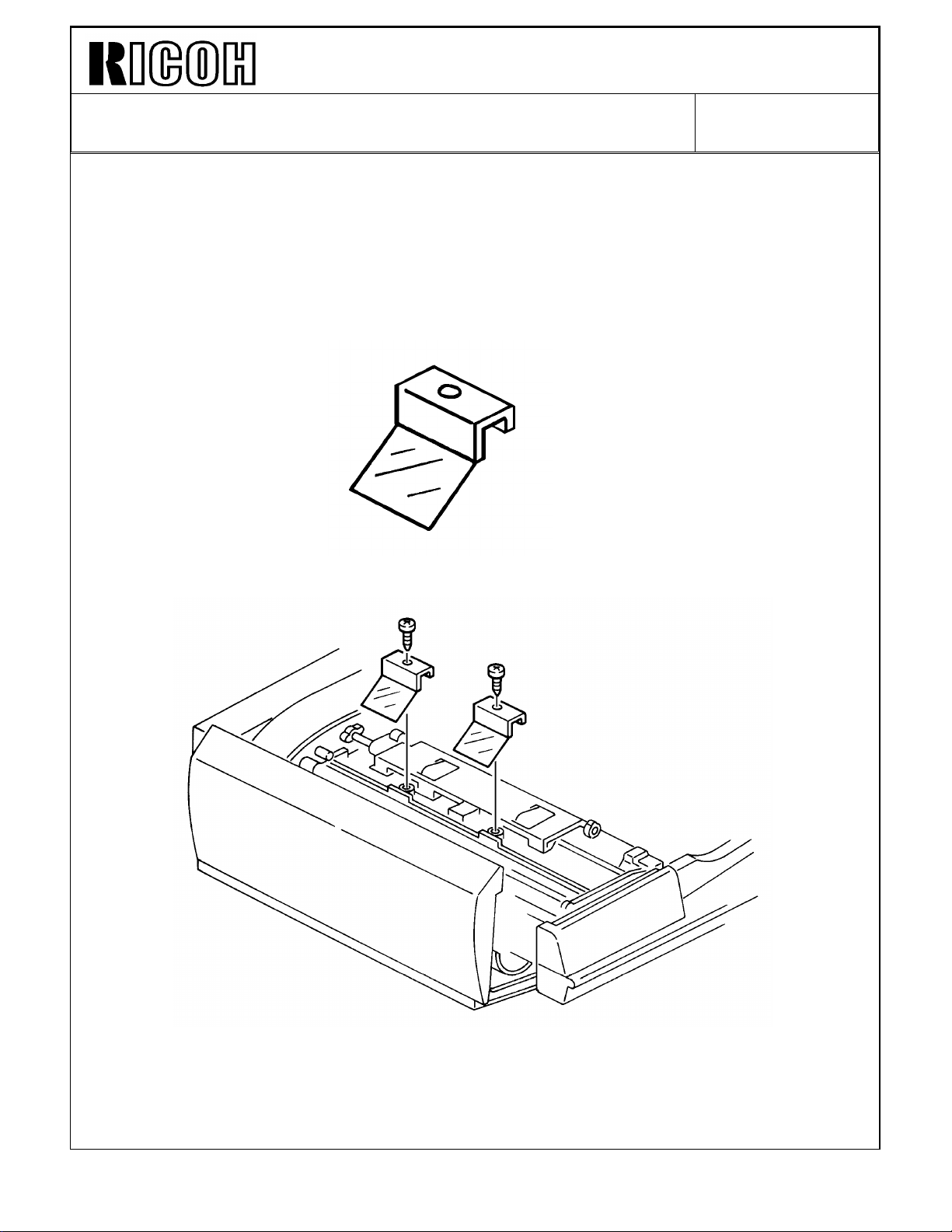

<COUNTERMEASURE>

The original stack guide mylar is added. This mylar is attached to the DJF as an

accessory. Please install the mylar at installation as shown in the illustration below.

Page 23

Technical Bulletin No. RTB-036

SUBJECT: ORIGINAL DOUBLE FEEDING DATE:June 30, ’94

PAGE: 1 of 2

PREPARED BY: S. MANO

CHECKED BY: S. Hamano

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

This is additional information of RTB-025 "DJF double feeding".

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:DUAL JOB

FEEDER FOR

F400/F4 10/F420

<PHENOMENON>

Original double feeding (two or more sheets of the originals are fed at a time)

<POSSIBLE CAUSE>

The separation belts become dirty with the toner, loosing the friction to separate the

originals.

This is especially true when the customer feeds lots of poorly fused originals such as laser

output or cotton paper.

Separation Belts

Page 24

Technical Bulletin No. RTB-036

SUBJECT: ORIGINAL DOUBLE FEEDING DATE: June 30, ’94

PAGE: 2 of 2

<FIELD COUNTERMEASURE>

Replace the separation belts with the new parts. The new part number is A3769502.

The material of the separation belts has been changed to the one which less toner

adheres to.

NOTE: Depending on the type of originals that the customer use, there is still a possibility

that the separation belts become dirty. For those cases, cleaning the belts at every

visits, which was introduced in the previous RTB, is recommended.

This modification is implemented from the following serial numbers.

A376-10: 537403xxxx

A376-15: 41 240300 01

A376-17: A33840 30001

A376-22: 53 240300 01

A376-26: 3D80340001

A376-27: A33840 30150

As explained in RTB-008 "DJF multiple feeding", if the block original feeding (10~20

sheets of originals are fed at a time) occur, replace the original guide mylars [A] with the

new parts (A3761254). Please refer to RTB-008.

This modification has been implemented from the November 1993 production (Please refer

to MB No.3 of DJF for the cut-in serial numbers).

To completely eliminate the original double/multiple feeding, replace both original guide

mylar (new part number A3761254) and separation belts.

Page 25

Technical Bulletin No. RTB- 046

SUBJECT: SOFTWARE MODIFICATION DATE:Dec. 31, ’94

PAGE: 1 of 7

PREPARED BY: S. Mano

CHECKED BY: S. Hamano

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL: F400/F410

1. "A" version ROMs

From the following serial numbers, the EPROMs (A0965151 and A0965153) on the main

board have been updated to version "A".

Code Serial Number

A095-10 5204480 001

A095-15 2644600 001

A095-17 A335446 0277

A095-22 5234050 106

A095-26 3D50540001

A095-27 A335405 0001

A095-29 A335405 0320

A096-10 5244470 002

A096-15 2844600 037

A096-17 A336446 0002

A096-22 5274050 001

A096-26 3D60540001

A096-27 A336405 0001

A096-29 A336405 0096

A097-all

From the first

production

The following are corrected by this software change:

1-1. Black shadow in ADF reduction mode

When the original is fed by the DJF while in reduction mode, sometimes (depending on the

reproduction ratio) a black line appears on the front edge because the shadow of the

original edge is erased incompletely.

Page 26

Technical Bulletin No. RTB-011

SUBJECT: Sorter/DJF Installation DATE: September 15, ’95

PAGE: 1 of 2

PREPARED BY: N. Kaiya

CHECKED BY: M. Iwasa

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

To comply with the CE mark, it is necessary to attach five ferrite cores when installing a

sorter on DFC - α. The ferrite cores have been enclosed in the screw bag of the DFC - α

from September production. Please refer to the following for the installation procedure of

the ferrite cores.

Additional procedure for sorter installation

Ferrite core P/N 16070418 4 pcs.

Ferrite core P/N 16070721 1 pc.

1. Turn off the main switch and unplug

the machine.

2. Remove the sorter top cover

(3 screws).

3. Remove the sorter rear cover

(4 screws).

4. Attach the ferrite core ( [A] P/N

16070721 ) to the DC harness as

shown.

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL:

DFC - α

[A]

[D]

[B]

5. Remove the harnesses for second

bin solenoid (CN100) and third bin

solenoid (CN101). Pass the both

harnesses through the ferrite core

( [B] P/N 16070418 ) and reconnect

them to the sorter main board.

6. Remove the harnesses for the fourth bin solenoid (CN102) and the fifth bin solenoid

(CN103). Pass the both harnesses through the ferrite core ( [C] P/N 16070418 ) and

reconnect them to the sorter main board.

7. Remove the harnesses for the encoder (CN150) and the entry sensor LED (CN170).

Pass the both harnesses through the ferrite core ( [D] P/N 16070418 ) and reconnect

them to the sorter main board.

8. Remove the harnesses for the entry sensor Phototransistor (CN160) and the inlet

sensor (CN165). Pass the both harnesses through the ferrite core ( [E] P/N 16070418)

and reconnect them to the sorter main board.

9. Reassemble the unit.

[E]

[C]

Page 27

Technical Bulletin No. RTB-011

SUBJECT: Sorter/DJF Installation DATE: September 15, ’95

PAGE: 2 of 2

Ferrite Cores Packed with DFC - α

For Sorter Installation

P/N 16070721

For DJF installation

P/N 16070418

P/N 16070638

P/N 16070623

Loading...

Loading...