Ricoh df54 Service Manual

1. SPECIFICATIONS

Original Size and Weight: - Thin original mode -

Maximum A3 / 11" x 17"

Minimum B6 / 51/2" x 81/2"

Weight 41 to 128 g/m2 (11 to 34 lb)

- Thick original mode Maximum A3 / 11" x 17"

Minimum B6 / 51/2" x 81/2"

Weight 52 to 128 g/m2 (14 to 34 lb)

- Auto reverse mode Maximum A3 / 11" x 17"

Minimum B6 lengthwise /

51/2" x 81/2" lengthwise

Weight 64 to 105 g/m2 (17 to 28 lb)

Original Feed: Automatic feed — ADF mode

Manual feed one by one — SADF mode

1 January 1990

Original Table Capacity: 30 sheets / 80 g/m2 (20 lb)

Original Set: Face up. First sheet on top

Original Transport: One flat belt

Copy Speed: 12 copies/minute for A4 / 81/2" x 11" sideways

Power Consumption: 20 W

Dimensions (W x D x H): 670 x 460 x 103 mm (26.4" x 18.1" x 4.1")

Weight: Approximately 8.8 kg (19.4 lb)

7-1

1 January 1990

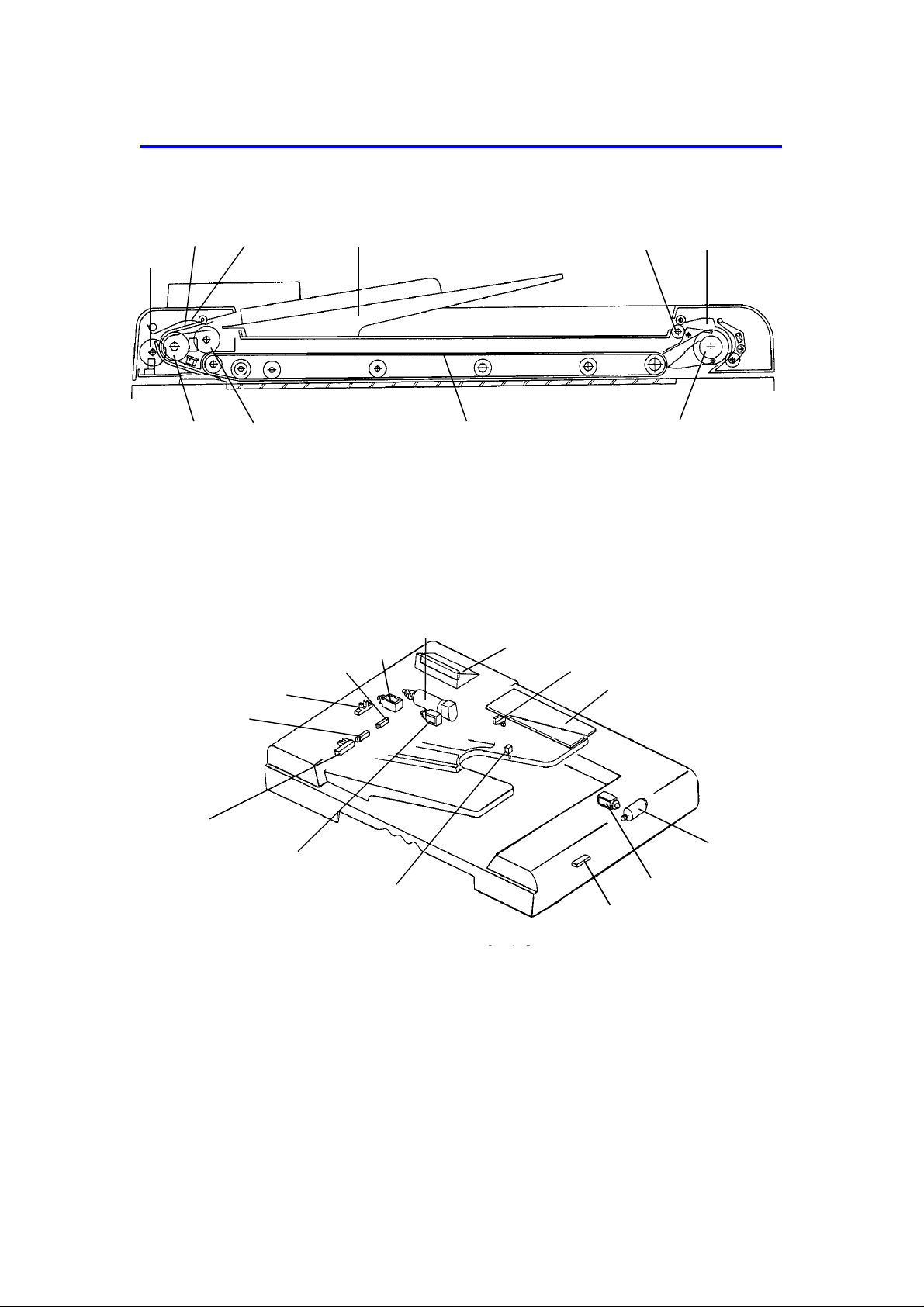

2. COMPONENT LAYOUT (NC100)

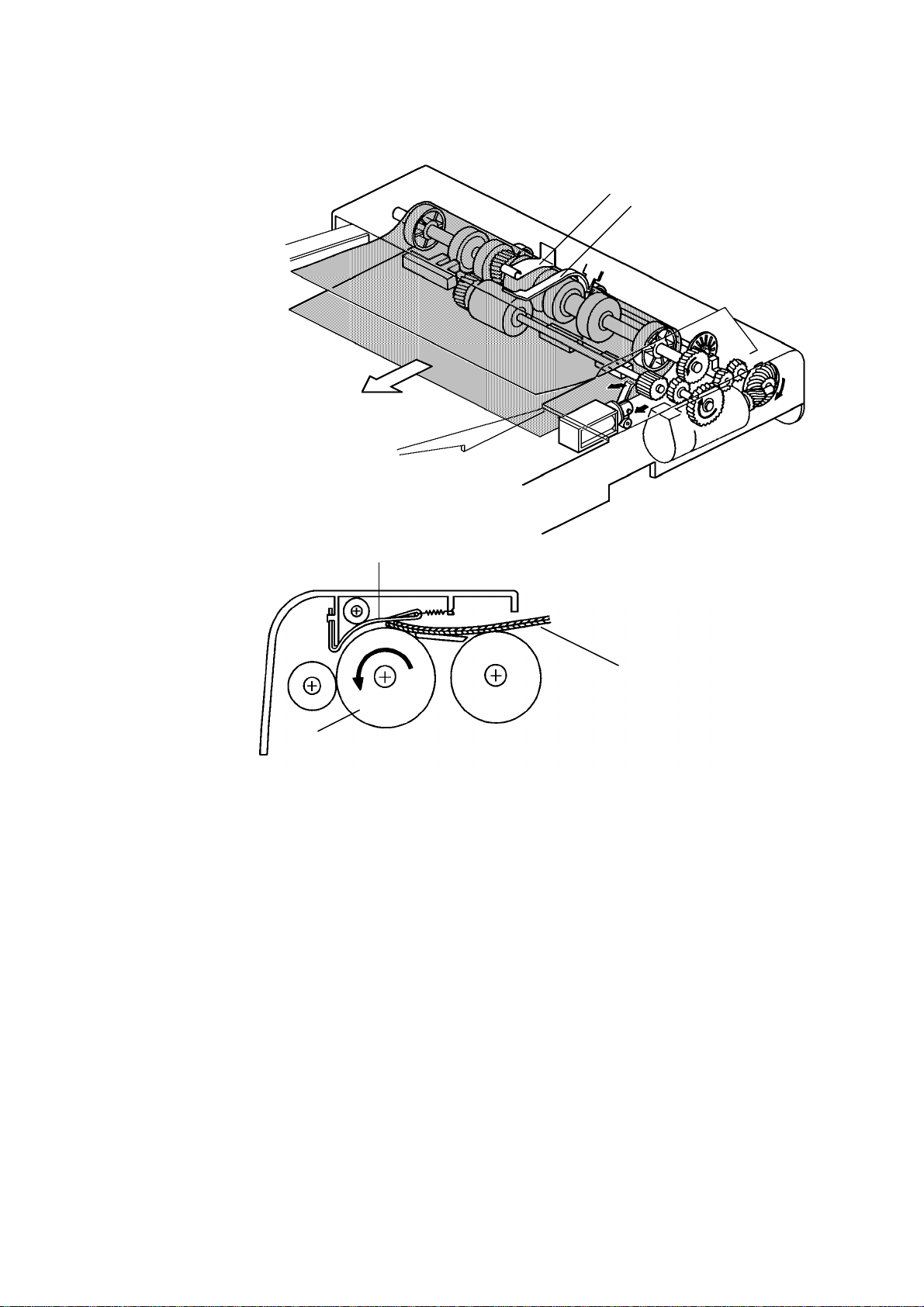

- Mechanical Components -

23

1

10

1. Pulse Generator Disk 6. Inverter Pawl

2. Friction Belt 7. Inverter Roller

3. Pick-up Lever 8. Transport Belt

4. Original Table 9. Pick-up Roller

5. Exit Roller 10. Feed Roller

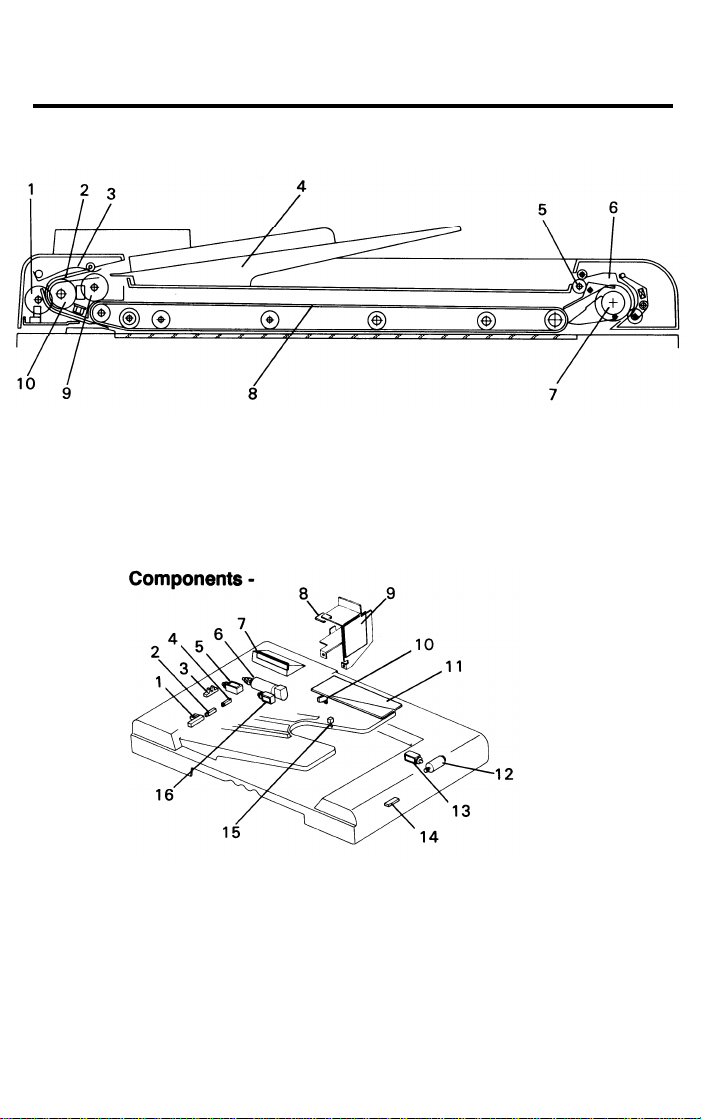

- Electrical Components -

3

2

4

4

5

89

6

7

8

5

9

6

7

1

14

1. Original Set Sensor

2. Registration Sensor

3. Pulse Generator Sensor

4. Original Width Sensor

5. Pick-up Solenoid

6. Belt Drive Motor

7. Indicator Panel

13

10

11

12

8. Lift Switch

9. DF Main Board

10. Feed-out Motor

11. Inverter Solenoid

12. Feed-out Sensor

13. Original Select Switch

14. Feed-in Solenoid

7-2

1 August 1988

2. COMPONENT LAYOUT (FT2260)

- Mechanical Components -

1. Pulse Generator Disk

2. Friction Belt

3. Pick-up Lever

4.

Original Table

5. Exit Roller

- Electrical

1. Original Set Sensor

2. Registration Sensor

3. Pulse Generator Sensor

4. Original Width Sensor

5. Pick-up Solenoid

6. Belt Drive Motor

7. Indicator Panel

8. Interface Board

6. Inverter Pawl

7.

Inverter Roller

8. Transport Belt

9. Pick-up Roller

10. Feed Roller

9. DF Power Supply Board

10. Lift Switch

11. DF Main Board

12. Feed-out Motor

13. Inverter Solenoid

14. Feed-out Sensor

15. Original Select Switch

16. Feed-in Solenoid

8-2

1 January 1990

3. ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Name Function Location

Motors

M1 Belt Drive Motor DC servomotor that drives to the transport

belt and feed-in system (pick-up roller, feed

roller, pull-out roller and relay roller).

M2 Feed-out Motor DC servomotor that drives the feed-out unit

of the DF.

Solenoids

SOL1 Pick-up Solenoid Energizes to press the pick-up lever against

the stack of originals in preparation for original feed-in.

SOL2 Feed-in Solenoid Turns on to engage the feed-in clutch so ro-

tation is transmitted to the feed roller, pullout rollers, and relay rollers.

SOL3 Inverter Solenoid Energizes to invert the original when copy-

ing two sided originals.

Switches

SW1 Lift Switch Informs the CPU when the DF is lifted and

also serves as the jam reset switch for the

DF.

SW2 Original Select

Switch

Selects thick original mode or thin original

mode.

6

10

5

14

11

8

13

Sensors

S1 Original Set Sen-

sor

S2 Registration Sen-

sor

S3 Original Width

Sensor

S4 Pulse Generator

Sensor

S5 Feed-out Sensor Checks for original misfeeds and sets origi-

Informs copier CPU that originals have

been placed and causes the Insert Original

indicator to go out.

Sets original stop timing and measures original length.

Determines the width of the originals. 4

Generates pulses used to measure the original length.

nal stop timing when in auto reverse mode.

7-3

1

2

3

12

1 January 1990

Symbol Name Function Location

Printed Circuit Boards

PCB1 DF Main Board Controls all DF functions. 9

PCB2 Indicator Panel

Board

Contains operator indicators. 7

7-4

1 January 1990

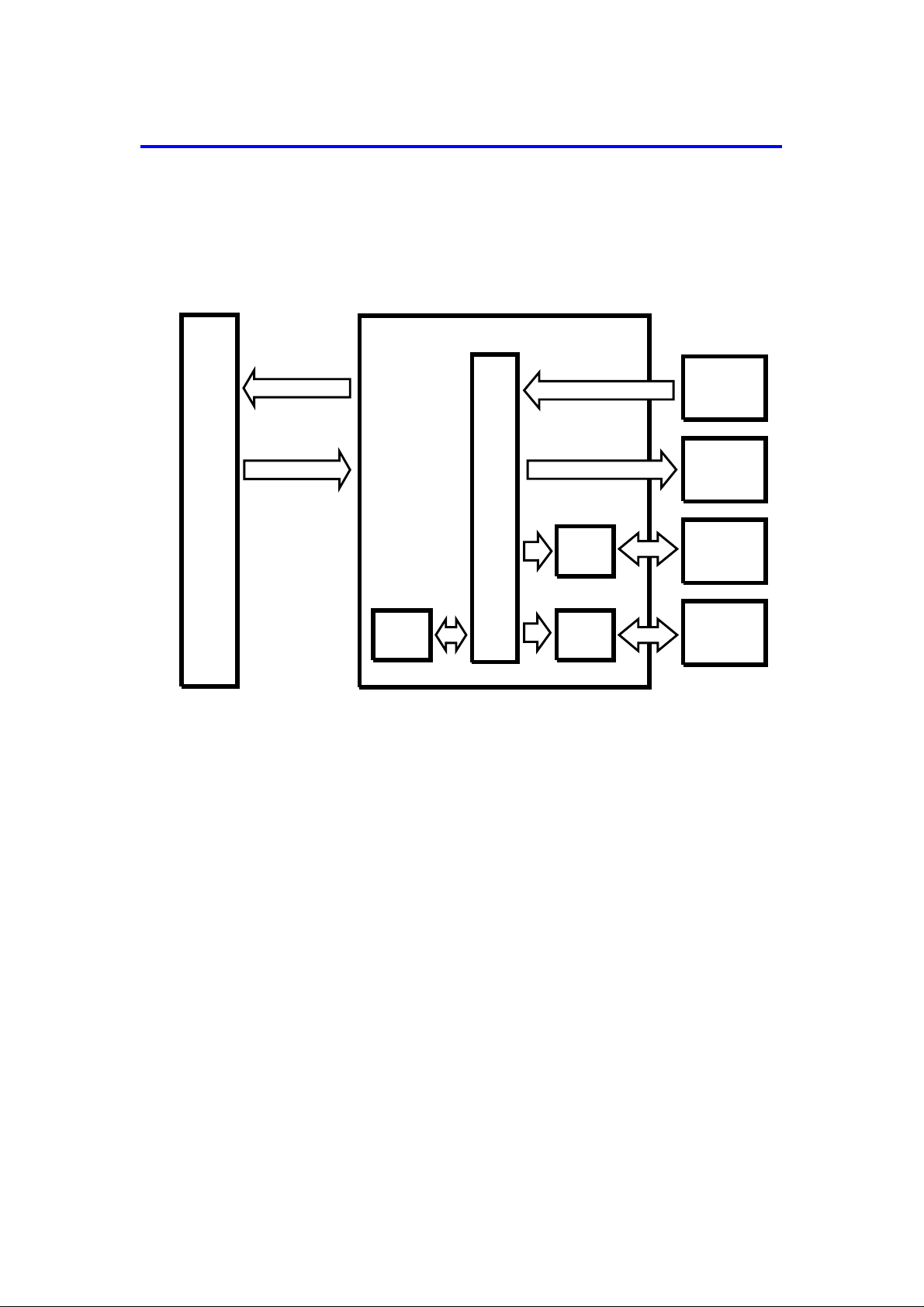

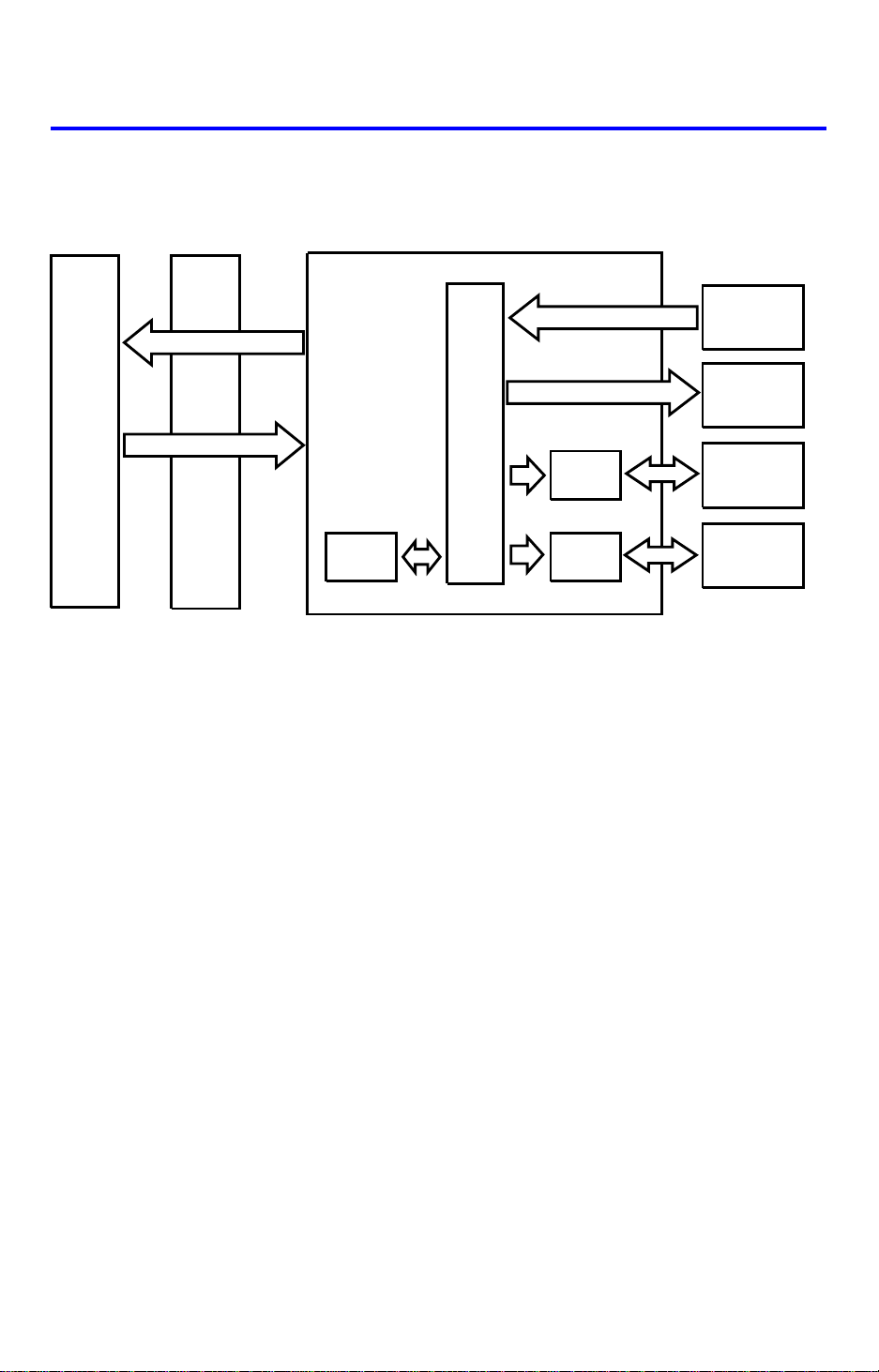

4. OVERALL MACHINE CONTROL (NC100)

Copier

Main PCB

DF Main Board

RXD

TXD

TXD

RXD

ROM

CPU

Driver

IC

Driver

IC

Sensors

Switches

Solenoids

Indicators

Belt Drive

Motor

Feed-out

Motor

The DF CPU monitors the input signals from the sensors and switch es, a nd

energizes the solenoids and the indicator LEDs directly. The belt drive motor

and the inverter motor are controlled by the DF CPU through their respective

driver ICs. The exchanged signals are shown in the tables on the next page.

7-5

1 August 1988

4. OVERALL MACHINE CONTROL (FT2260)

The DF CPU monitors the input signals from the sensors and switches, and

energizes the solenoids and the indicator LEDs directly. The belt drive motor

and the inverter motor are controlled by the DF CPU through their respective

driver ICs.

Also, the DF CPU communicates with the copier using a serial interface. The

exchanged signals are shown in the tables on the next page.

8-5

1 June 1990

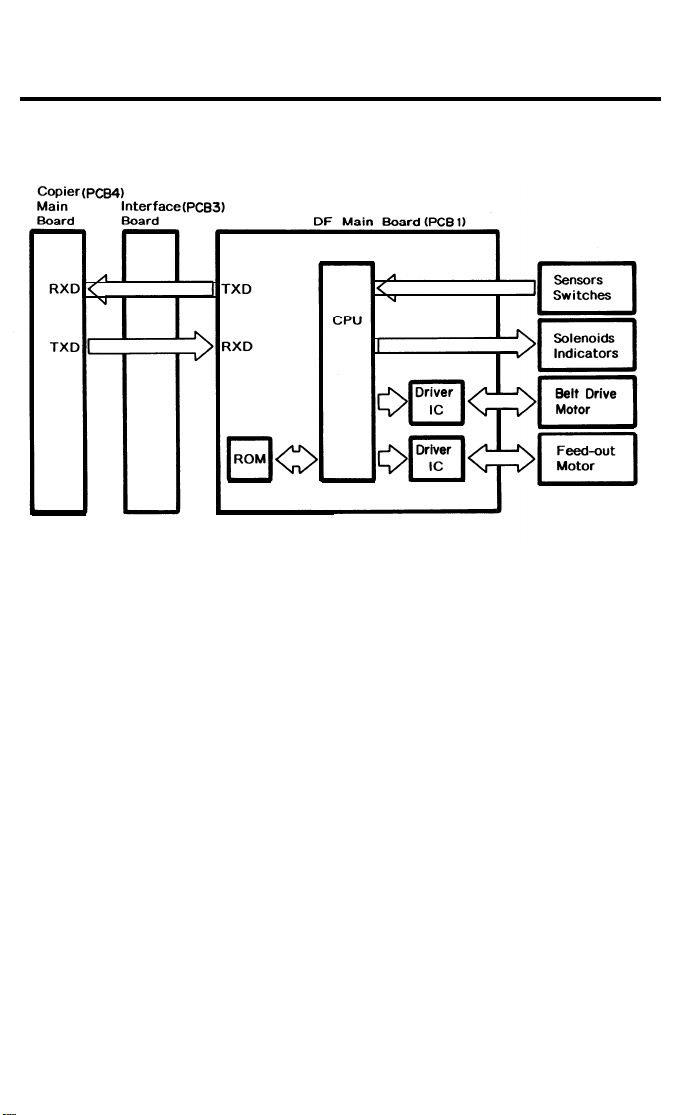

4. OVERALL MACHINE CONTROL (FT4418)

Copier (PCB1)

Main Board

RXD

TXD

Interface (PCB6)

Board

TXD

RXD

DF Main Board (PCB1)

ROM

CPU

Driver

IC

Driver

IC

Sensors

Switches

Solenoids

Indicators

Belt Drive

Motor

Feed-out

Motor

The DF CPU monitors the input signals from the sensors and switch es, a nd

energizes the solenoids and the indicator LEDs directly. The belt drive motor

and the inverter motor are controlled by the DF CPU through their respective

driver ICs. The exchanged signals are shown in the tables on the next page.

8-4

1 January 1990

1. DF → Copier

No. Signal Name Definition

1 Original Set Originals are set on the original table

2 Copy Start Allows the copier to start copy sequence

3 Lift Up The DF is lifted

4 DF Misfeed Misfeed occurs in the DF

2. Copier → DF

No. Signal Name Definition

1 Feed-in Reque sts th e DF to feed -in th e original

2 Feed-out Requests the DF to feed-ou t the original

3 Invert Original Requests the DF to invert the orig ina l

4 Auto Feed Shifts the DF to the auto feed mode

5 Original Stay

Attempt to use DF but the origina l from th e

previous copy run remains on th e exposure glass

7-6

1 January 1990

5. BASIC OPERATION

1. One-sided Original Feed

When an original is inserted face up into the DF, the Inse rt Orig inal indicator

light goes out and the DF informs the copier CPU that originals have been set.

When the Start key is pressed, the copier CPU moves the scanner 100 mm

away from the left scale an d sen ds the feed-in signal to the DF. On rece ipt of

this signal, the DF energizes the pick-up solenoid, the feed-in solenoid, and

the belt drive motor in order to feed-in the bottom sheet of the original sta ck

onto the exposure gla ss. The pick-up solenoid and the fee d-in solenoid

remain energized until the original leading edge rea che s the DF reg istra tio n

sensor. The belt drive motor turns off sho rtly af te r the origin al’s tra iling edge

passes the DF registration sen sor.

While feeding the original, the DF registra tio n sen sor and the paper width

sensor check the origina l size.

Just when the origina l trailing edge has passed the DF registra tion sensor,

the DF CPU sends the copy start signa l t o th e cop ier. On receipt of the

signal, the copier CPU carries out the origin al ID mea surement while

returning the scan ne r to the home position and starts th e copy cycle.

When the scanner reaches the return position, the copier CPU sends the

feed-out and the feed-in signals to the DF CPU in order to exchange the

original with the next original. At this time, the scanner be gin s retu rnin g to the

home position, but stays 100 mm away from th e lef t scale until the next

original is on the exposure gla ss. At this time the original ID measurement is

taken.

When the scanner comes to th e ret urn position after scanning the last

original, the copier CP U only sen ds the feed-out signal in ord er to feed-out

the last original.

7-7

1 January 1990

2. Two-sided Original Fee d

Unlike one-sided original feed, the back side of the original must be copied

first to keep the originals and copies in the correct order.

During original feed-in, the sequence is the same as fo r one-side d feed ;

however, the DF CPU also energizes the in vert er mot or an d th e inverter

solenoid a short time af te r t he origin al trailing edge has passed the DF

registration senso r. The be lt drive motor continues to fee d th e original until

the original leading ed ge passe s the fee d-o ut sensor. At this point th e

inverter mechanism inverts the origin al, in prep aration for copying the ba ck

side. Then the belt drive motor reverses and the original is fed towa rds th e

left scale and is aligned against the scale. The DF CPU sen ds th e copy st art

signal a short time afte r the origin al trailing edge has passed th e fe ed -out

sensor.

When the scanner reaches the return position, the copier CPU sends the

invert original signal to the DF CPU in order to make a copy of the front sid e.

The original is inverted in the same way as for back side copying.

3. Semi-automatic Document Feed

If a single original is inserte d int o the original table and cop ied, the DF shifts

to the semi-automatic feed mode and light s the Auto Fee d ind icat or. The

Auto Feed indicator remains on for five secon ds after the copier main motor

stops. If another origina l is inserted within that five-secon d period, it is

automatically fed and copied.

7-8

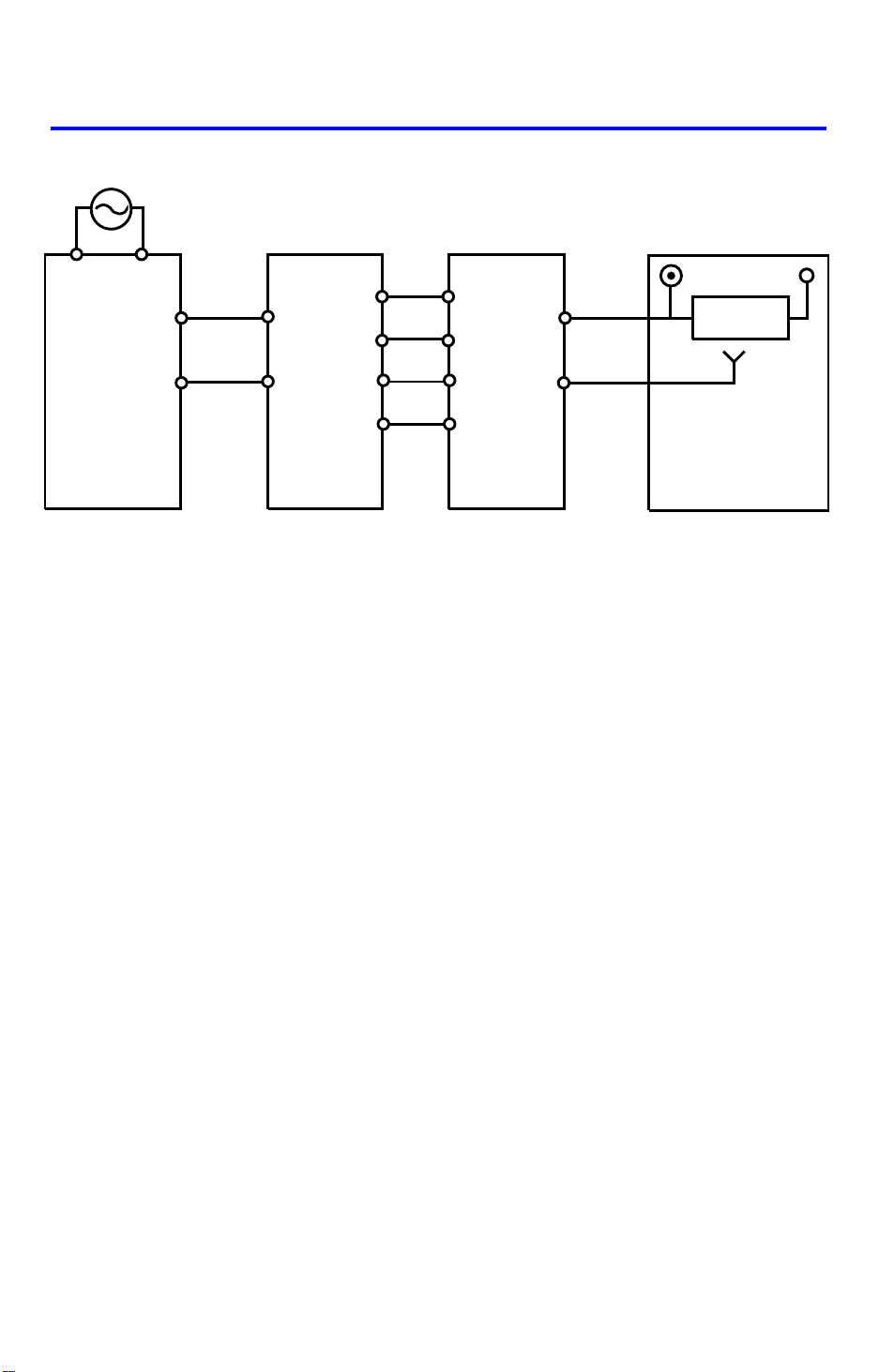

6. POWER DISTRIBUTION (NC100)

DF Main Board

CN808

1 January 1990

Copier

DC Power

PCB

CN101-3

+5V

+12V

Regulator

IC

The DF uses three DC power levels: +24 volts, +12 V, and +5 V.

The AC power from the wall outlet is supplied to t he DC power PCB o f th e

copier. The DC power PCB generates two DC voltages: +24V, +5V, and it

supplies power to the DF main board.

The regulator IC on the DF main board further steps down the +24V to +12V.

CN101-2

CN101-1

CN101-4

-4

-2

-1

-3

CN302-9

-10

304-8

301-14

GND

GND

[5]

[24]

~

7-9

6. POWER DISTRIBUTION (FT2260)

1 August 1988

The DF uses three dc power levels: +24 volts, +12 volts, and +5 volts.

The line voltage is applied to the DF power supply board where it is stepped

down and rectified to +24 volts and +5 volts. Then, those two dc voltages

are supplied to the DF main board.

The regulator IC on the DF main board further steps down the +24 volts to

+12 volts.

8-9

1 June 1990

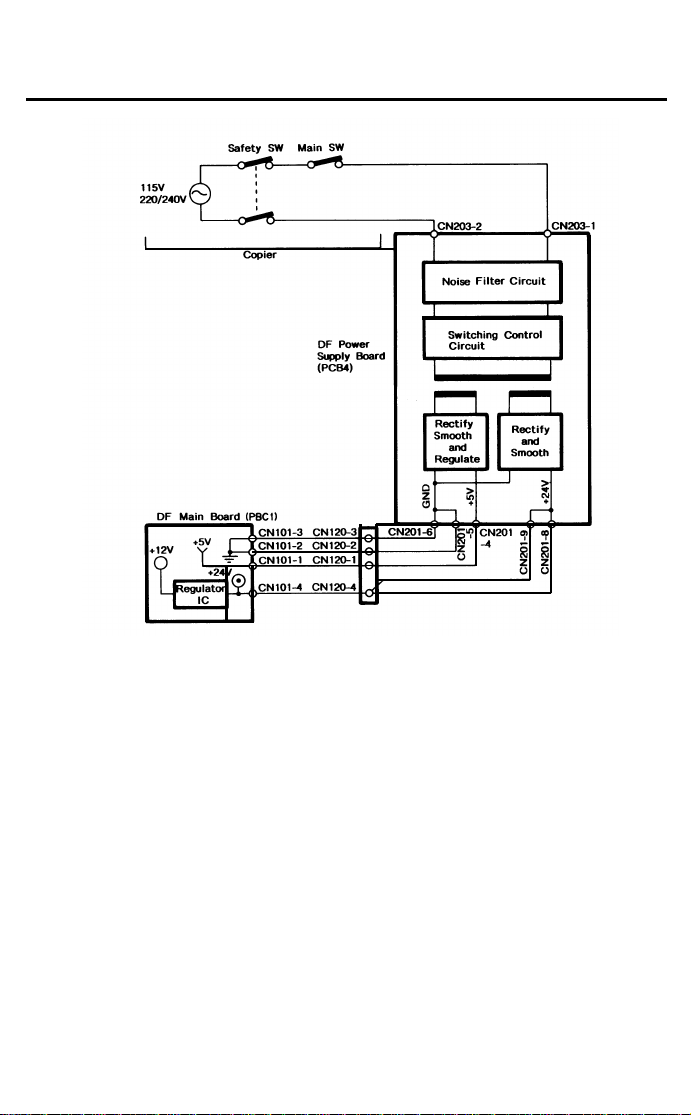

6. POWER DIST RIBUTION (FT4418)

AC Drive Board

(PCB2)

115Vac

220/240Vac

Optional

Transformer

(TR2)

26Vac

10Vac

Optional

DC Power

Supply Board

(PCB5)

+24V (VA)

+5V (VC)

+12V+24V

Regulator

IC

5V

DF Main Board

(PCB1)

The DF uses three DC power levels: +24 volts, +12 V, and +5 V.

When the main switch is turned on, the optional transformer receives the wall

outlet ac power through the ac drive board and outputs 10 volts ac and 26

volts ac to the optional dc power supply board. The optional dc power supply

board then converts the 10 volts ac input to +5 volts dc and the 26 volts ac

input to +24 volts. Then, thoes two dc voltsges are supplied to the DF main

board.

The regulator IC on the DF main board further steps down the +24V to +12V.

8-8

1 August 1988

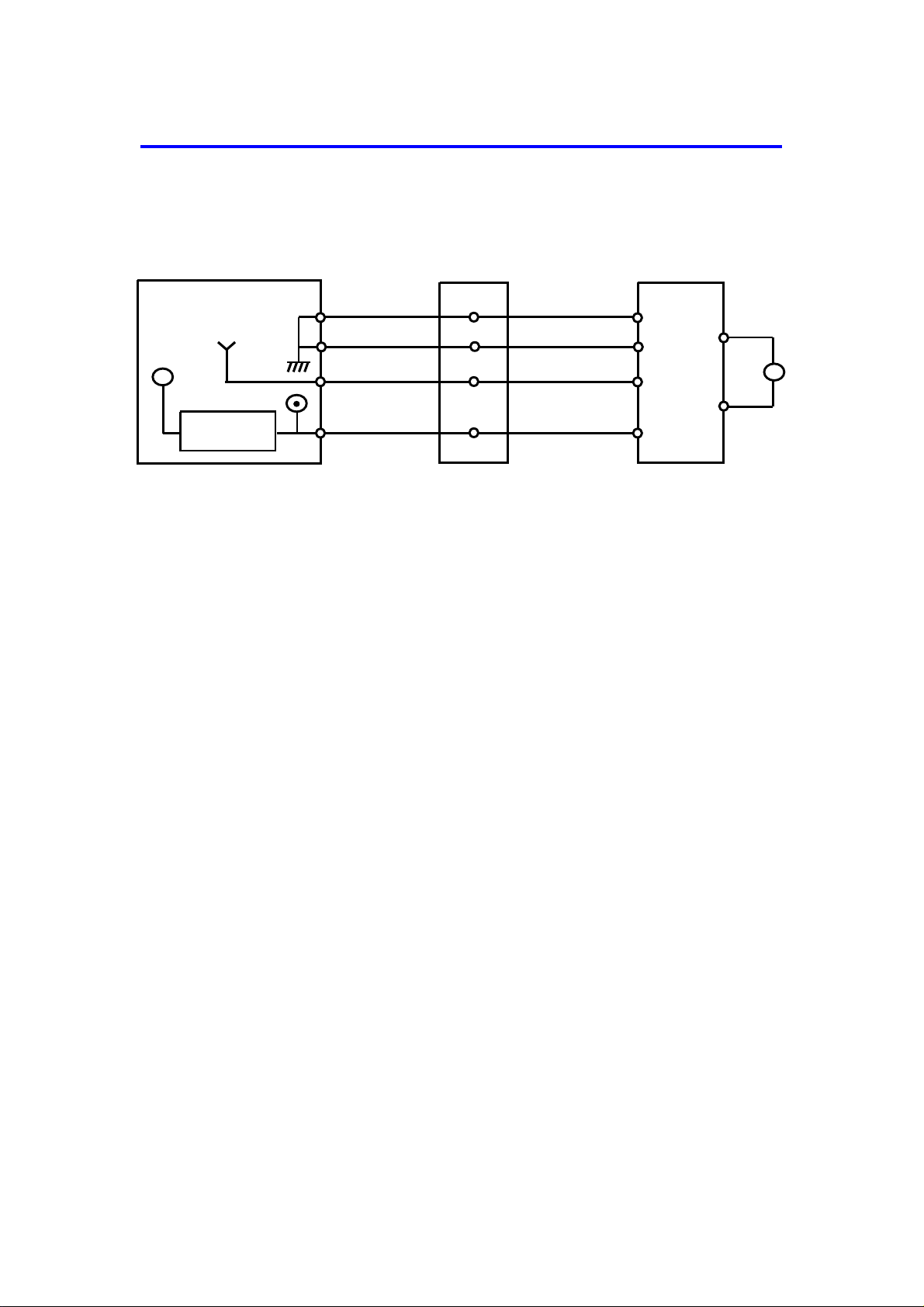

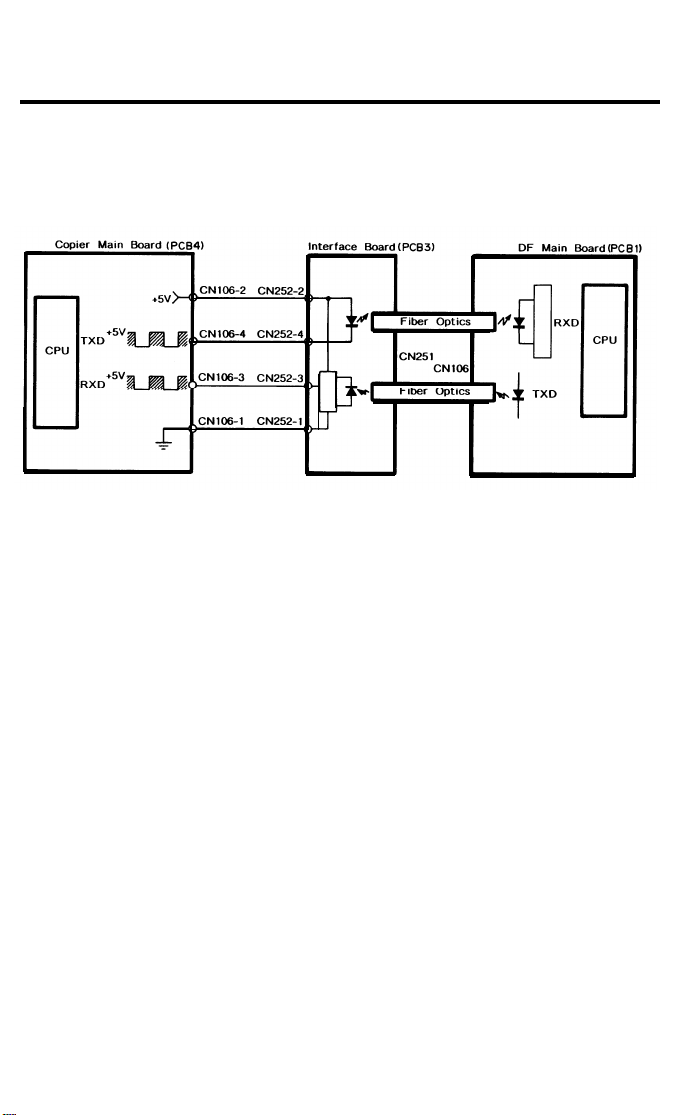

7. INTERFACE CIRCUIT (FT2260)

The Copier CPU and the DF CPU communicate via the interface board and

fiber optics. The interface board changes the optical signals to electrical signals (only vice versa).

8-10

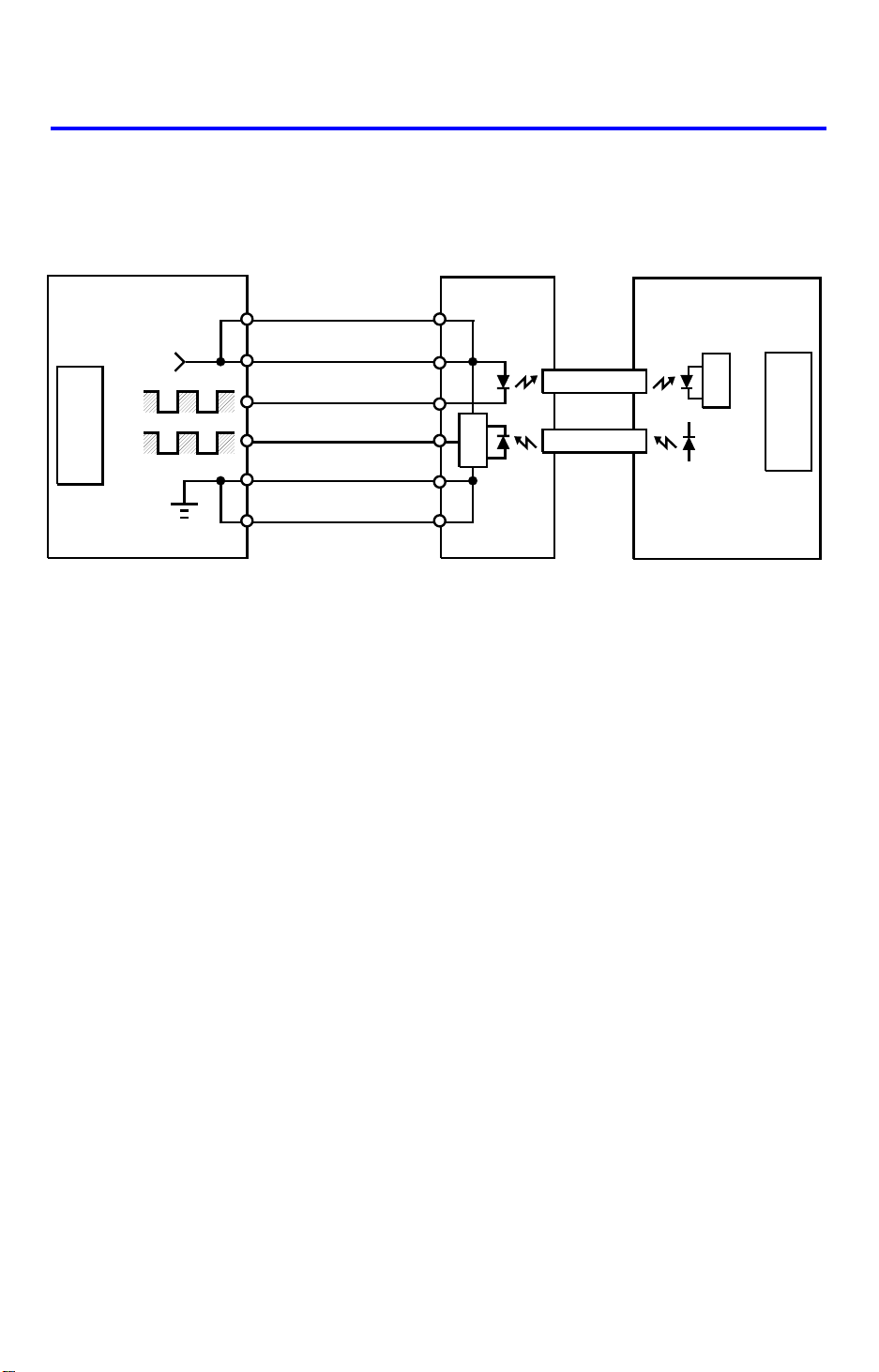

7. INTERFACE CIRCUIT (FT4418)

1 June 1990

Copier Main Board (PCB1)

+5V CN206

+5V

TXD

CPU

+5V

RXD

CN133-A14

CN133-B14

CN106-4

CN106-3

CN133-A1

CN133-B1

Interface Board (PCB6) DF Main Board (PCB1)

CN201-A14

CN201-B14

CN201-A3

CN201-B3

CN201-A1

CN201-B1

Fiber Optics

Fiber Optics

CN106

TXD

RXD

The copier CPU and the DF CPU communicate via the interface b oa rd and

fiber optics. The interface board changes the optical signals to electrical

signals (and vice versa).

CPU

8-9

1 January 1990

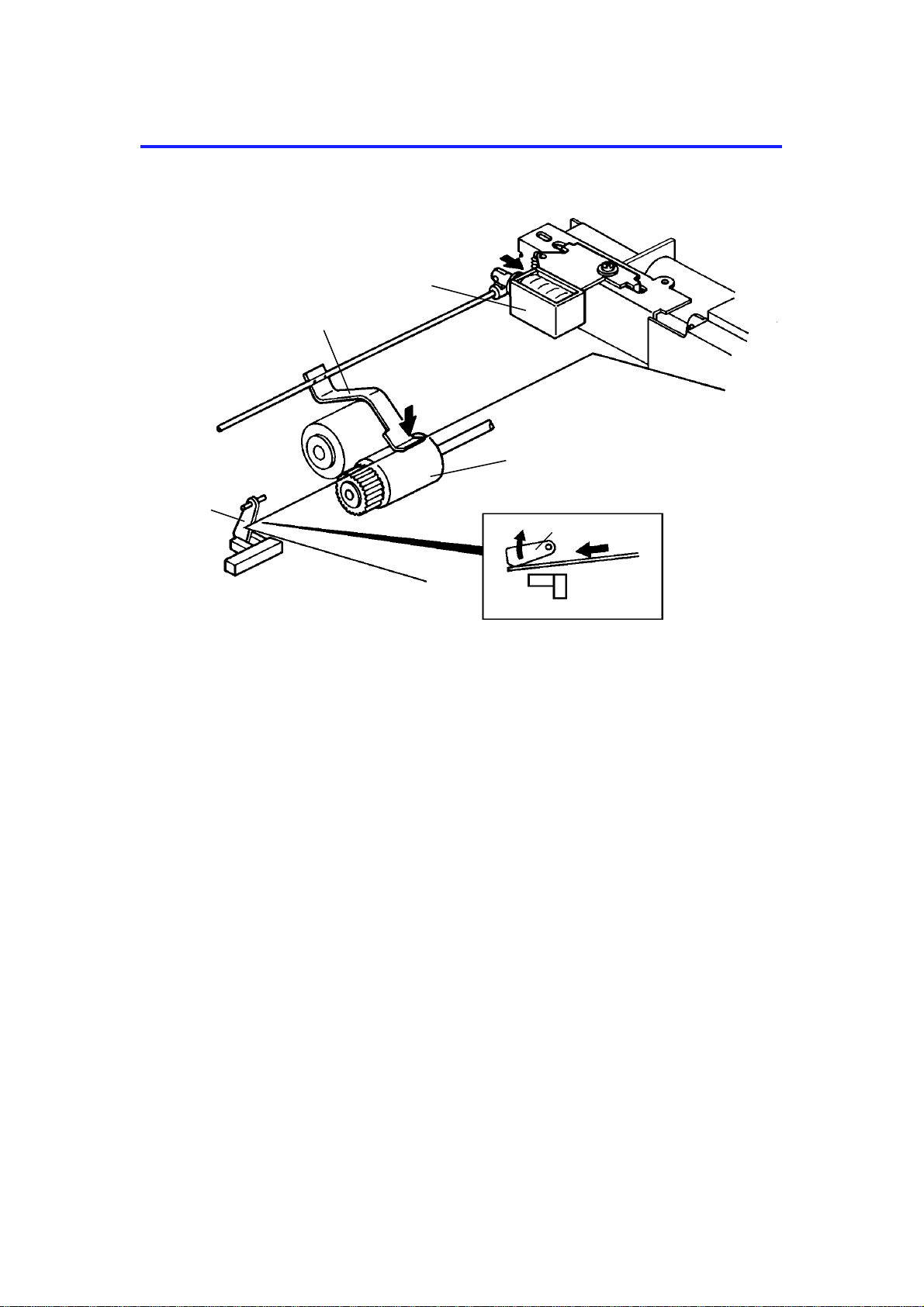

7. ORIGINAL FEED

7.1 ORIGINAL PICK-UP

[C]

[A]

[B]

[D]

[A]

After setting the origina ls on th e orig ina l tab le, the origin als con ta ct th e feeler

[A] of the original se t sen sor an d cau se the feeler to move out of th e sensor.

The DF then sends the orig ina l set signal to the copier CPU to inf orm it th at

the DF will be used. When the Start key is presse d, the pick-up solenoid [B]

is energized. The original sta ck is then presse d between the pick-up lever [C]

and pick-up roller [D]. The rotation of the pick-up roller advances th e bo tt om

original.

7-10

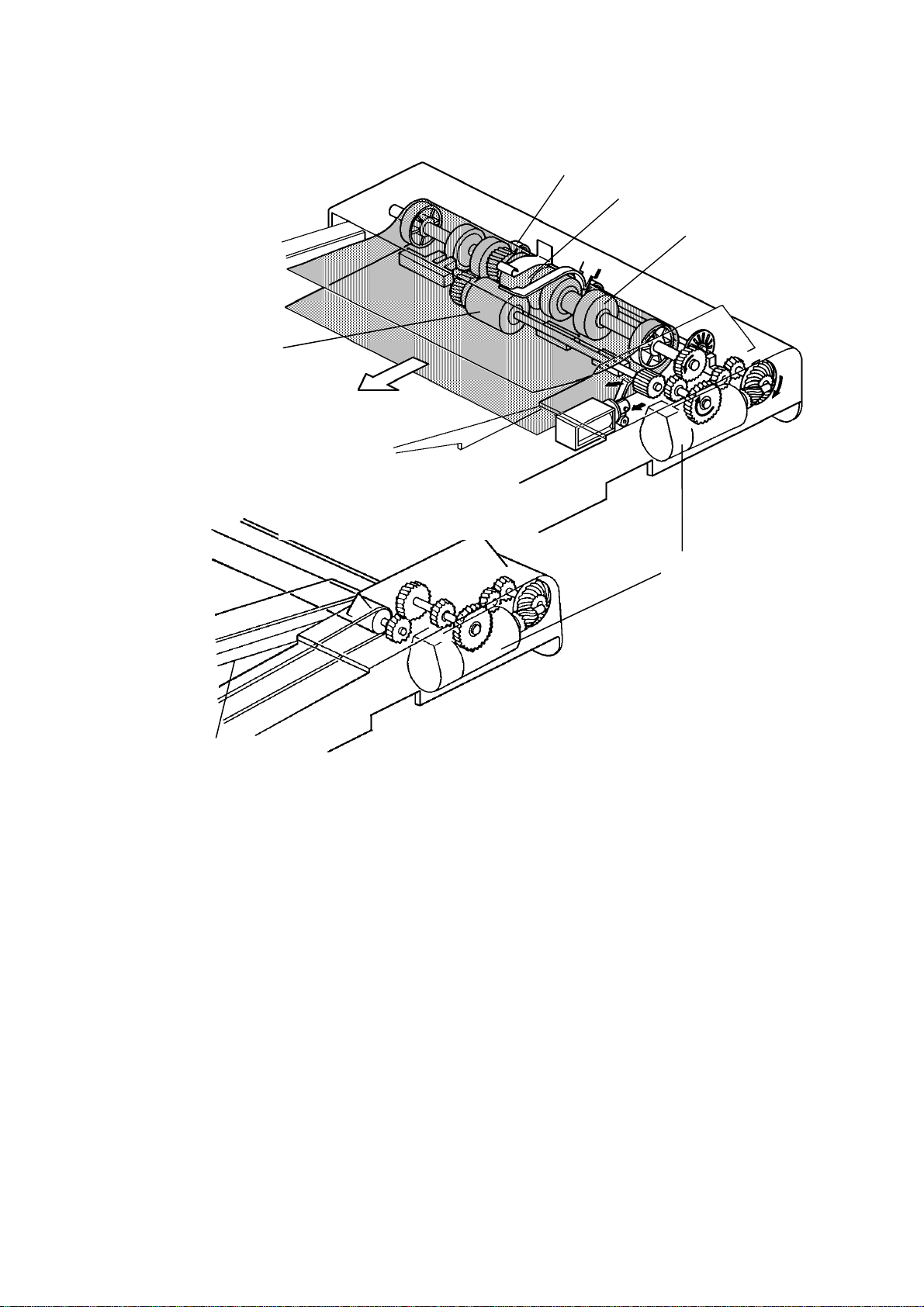

7.2 ORIGINAL SEPARATION

[B]

1 January 1990

[A]

[B]

[C]

[A]

The feed roller [A] and the friction belt [B] are use d to fee d-in and sepa rat e

the originals [C]. Only the bottom orig inal is fed because the friction belt

prevents any other origin als fro m f eeding.

Original feed starts when the feed roller starts turning and advances the

bottom original of the stack. The fee d roller mo ves th e original past the

friction belt because the driving force of the feed roller is great er than the

resistance of the frict ion belt . Th e frict ion belt prevents multiple feeds

because the resistance of the frict ion belt is great er th an the frictio n be twe en

original sheets.

7-11

1 January 1990

7.3 ORIGINAL FEED-IN MECHANISM

[B]

[E]

[C]

[D]

[A]

[F]

The belt drive motor [A] drives the pick-up roller [B], the feed ro ller [C] , the

pull out roller [D], the relay roller [E], and tra nsp ort belt [F] via a feed clutch

and a gear train.

The pick-up and feed-in soleno ids are ene rgize d 10 0 milliseco nd s aft er th e

Start key of the copier is pressed. Then 100 milliseconds afte r t he solen oids

are energized, the belt drive motor starts turning. The pulse gene rat or disc

[G] always turns when the belt drive motor is on.

Slightly after the original trailing edge passes the reg istra tio n sen sor, the

relay rollers and the transport belt sto p turnin g.

7-12

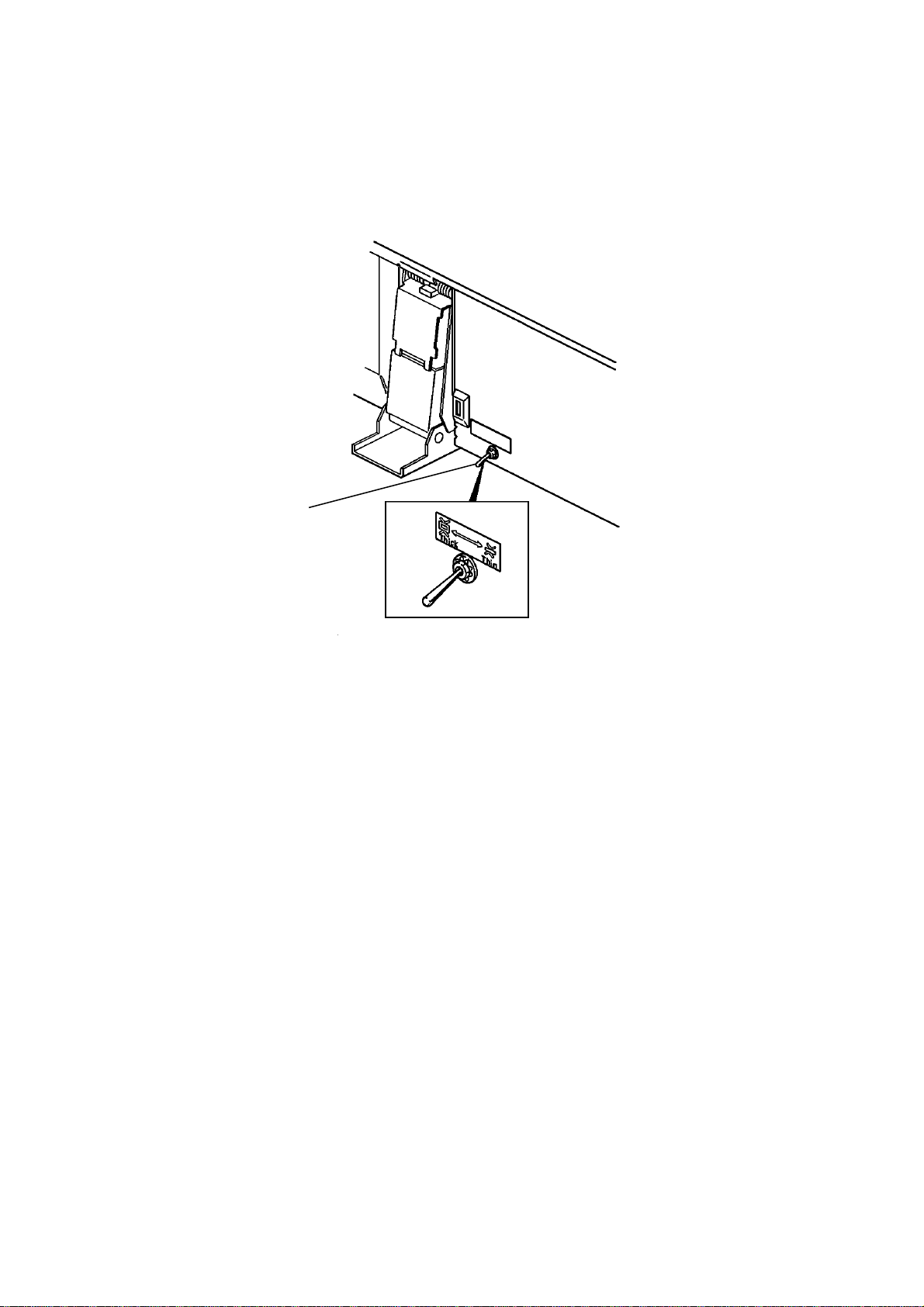

1 January 1990

This document feed er ha s two dif ferent ways of stopping originals at the

correct position on the exposu re gla ss. They are called the "thin original

mode" and the "thick original mode". The mode used is dete rmine d by the

original select switch [A].

[A]

- Original Select Switch -

1. Thin Original Mode

The original is stopped at th e correct position on the exposure glass based

on encoder pulse count. The belt drive mo to r stop s short ly a ft er th e original

trailing edge passes the DF registra tio n sensor. (Exact timing depends on

registration adjustme nt.) Thin original mode is selected at the fact ory.

2. Thick Original Mode

When thick original mode is selecte d, the belt drive mot or rema ins en erg ized

for an additional 30 encod er pu lses as comp ared to thin original mode. Then,

the belt drive motor pauses and reverse s f or 21 pulse s. This f orce s the

original against the left scale and thu s align s the edge of the origin al with the

scale.

After the exposu re cycle is completed, the copier send s the fee d-out signal to

the DF CPU and the belt drive and feed out motors start turning. At this time ,

the copied original f ee ds out an d the next original feeds in.

7-13

1 January 1990

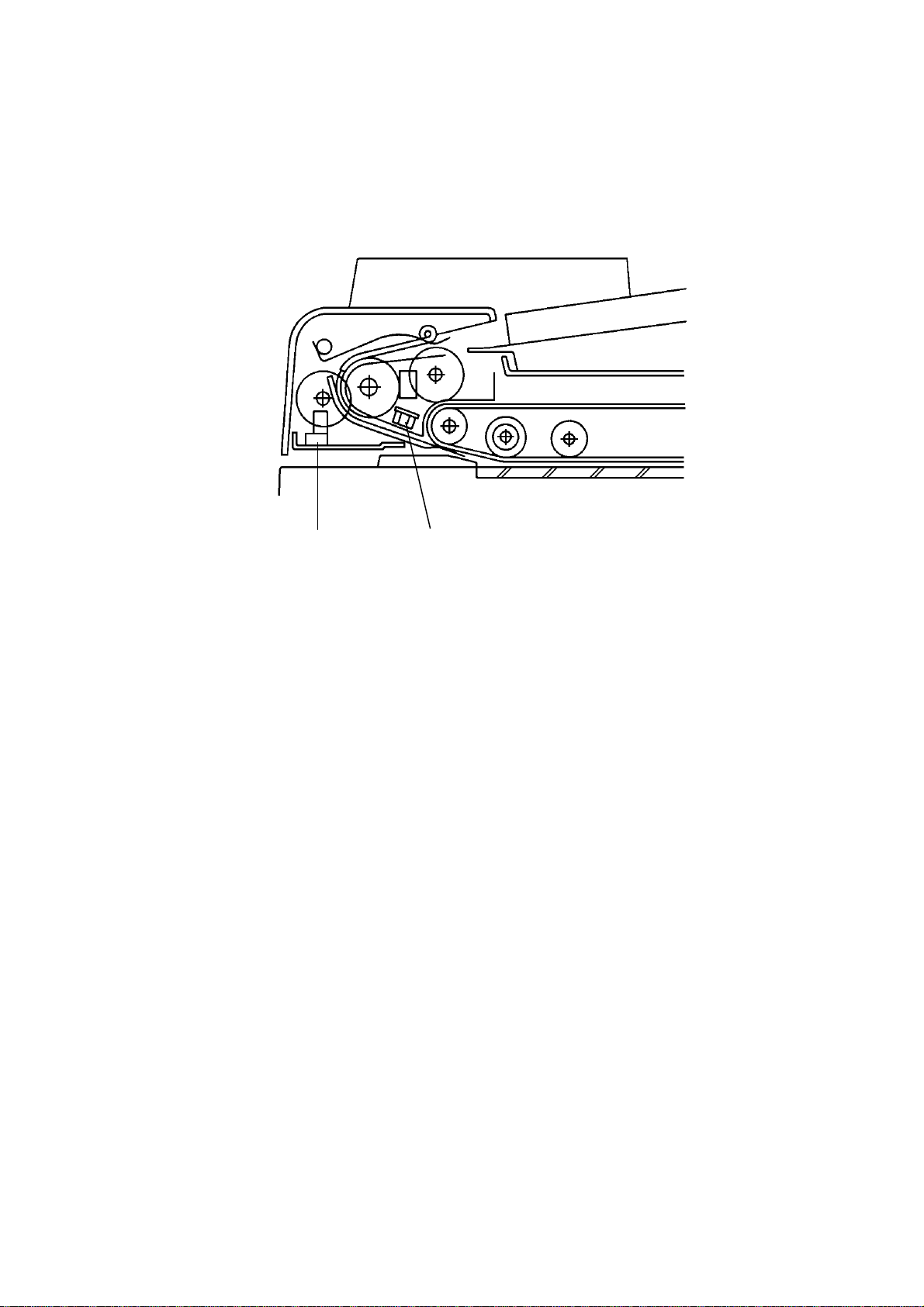

7.4 ORIGINAL SIZE DETECTI O N

[B]

[A]

The DF determines original size (bot h widt h and len gt h) th rou gh the use of

the original width sensor [A], registration sensor, and pulse gene rat or sen sor

[B]. The original’s length is calculated by countin g the numbe r of pulses fro m

the pulse generator while th e reg istration sensor is on.

Original size detection is necessary for the feed-in /feed-out timing of the DF.

7-14

Loading...

Loading...