Ricoh D392 Technical Training Manual

Slide 1

D392 Ring Binder Training

V-C3 TECHNICAL TRAINING

OPTIONAL RING BINDER (D392)

No additional notes

1

Slide 2

D392 Ring Binder Training

Overview

No additional notes

2

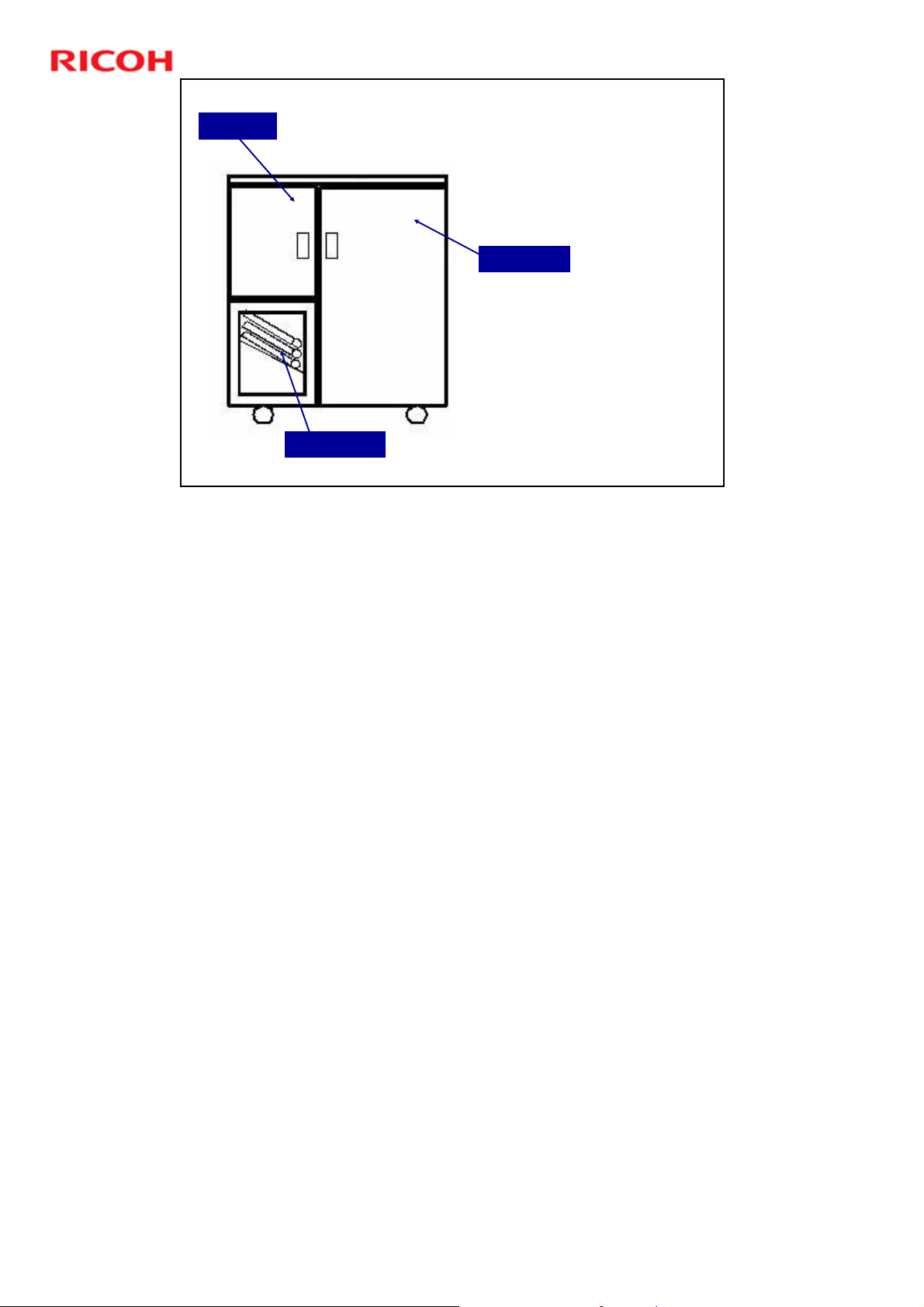

D392 Ring Binder Training

Left Door

Slide 3

External View

Do not use the empty

space below the output

tray as a storage area.

Right Door

Output Tray

D392 service manual, Details, Overview, Important Parts

3

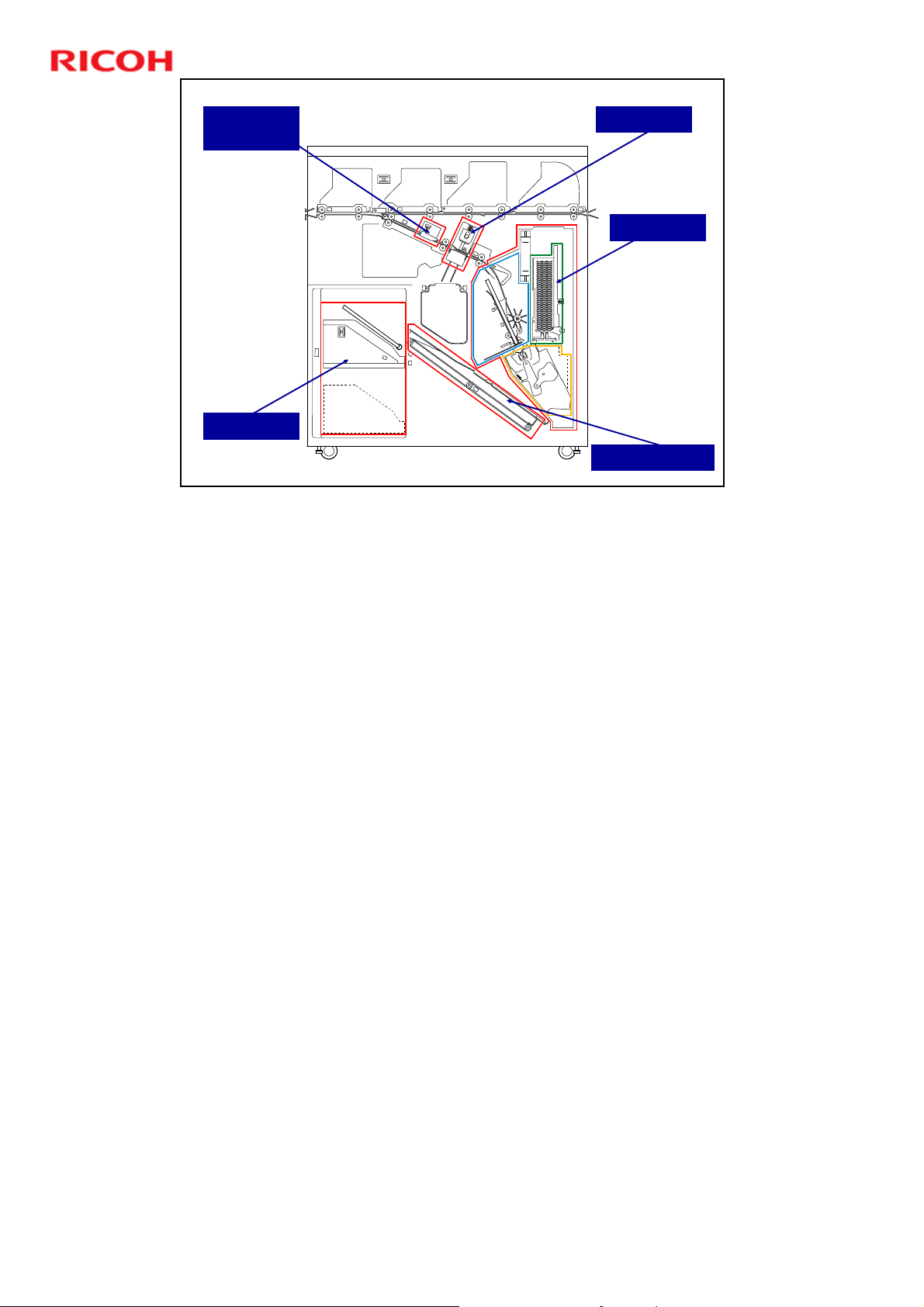

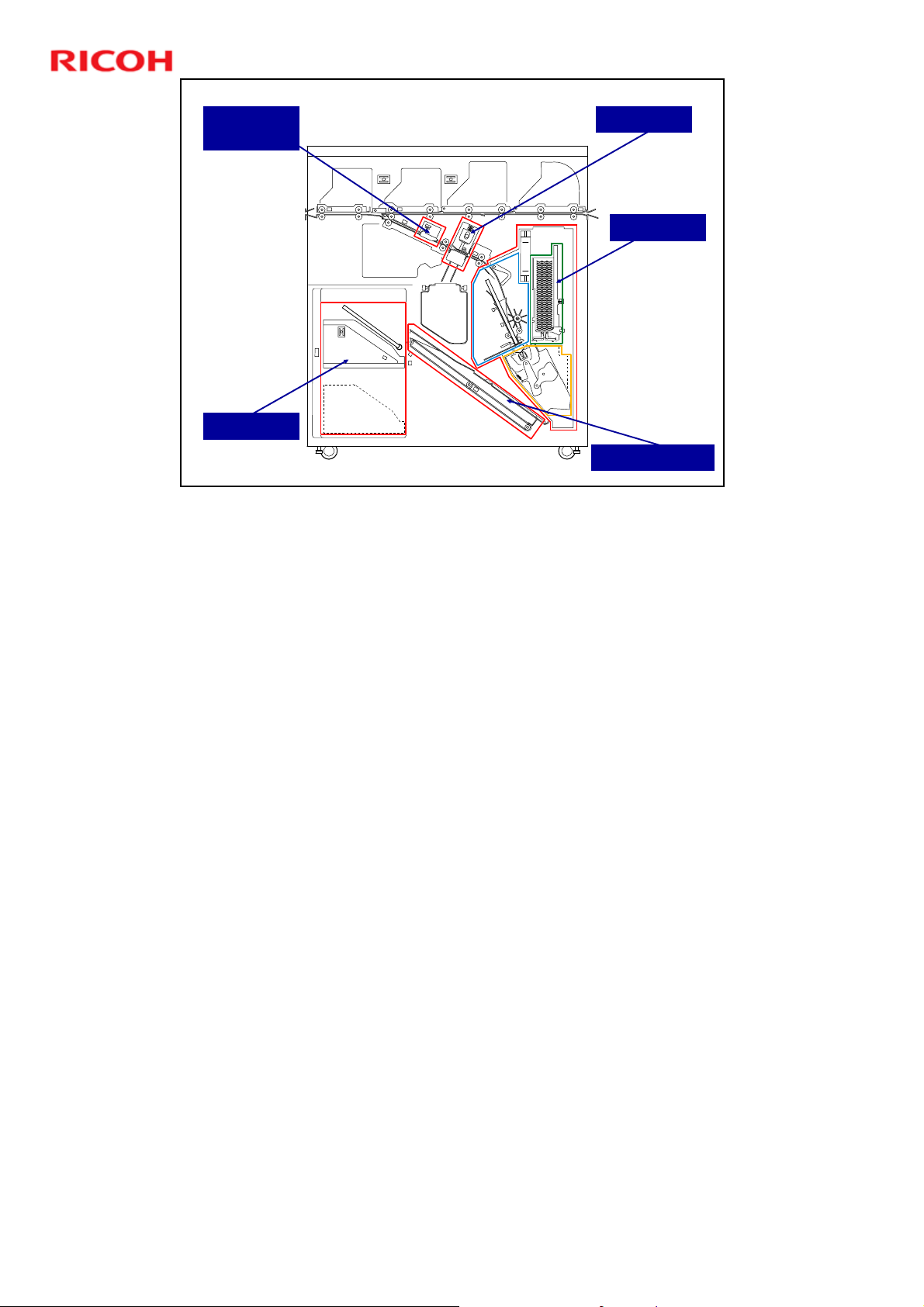

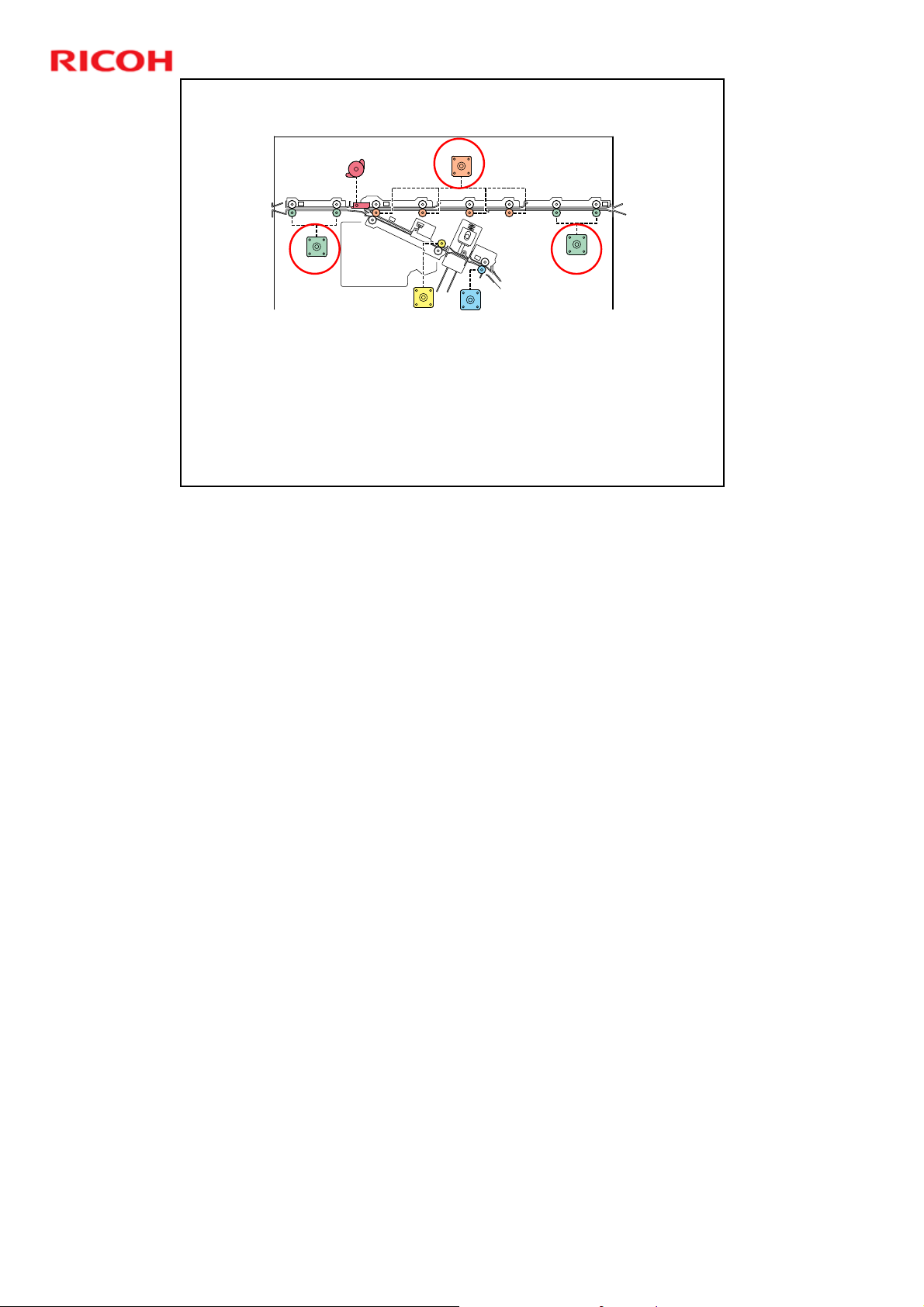

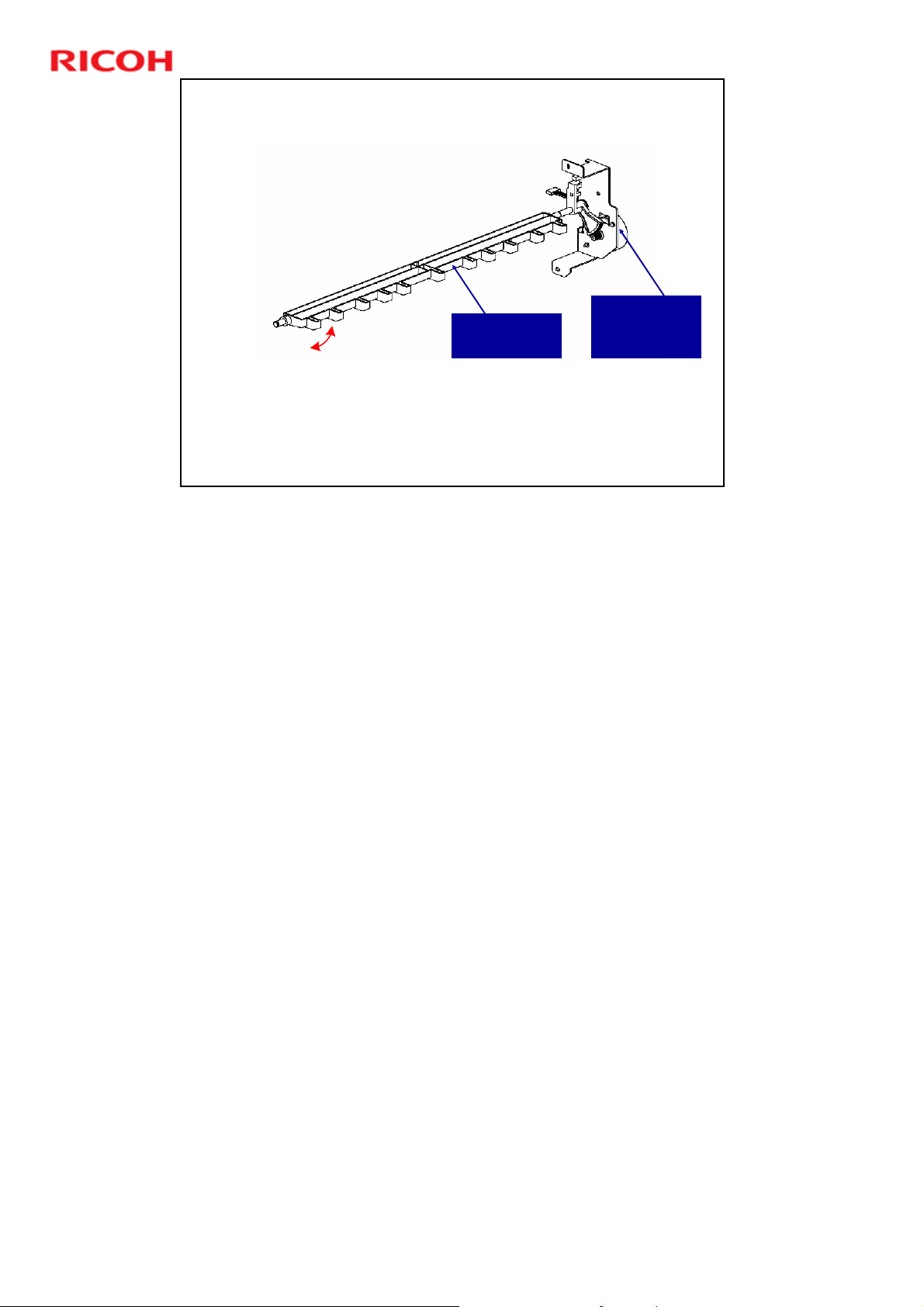

D392 Ring Binder Training

Pre-Punch

Jogger Unit

Stacker Unit

Slide 4

Main Units

Punch Unit

Binder Unit

Output Belt Unit

D392 service manual, Details, Overview, Important Parts

The binder unit contains the pre-bind jogger unit, ring supply unit, and clamp unit.

See the service manual for the locations of these within the binder unit.

4

Slide 5

D392 Ring Binder Training

Inform the Customers

The next few slides contain points to tell the customers after you finish the

installation.

5

Jams

Decals attached to the machine that provide

guidance for removing paper jams. Point out the

decal locations.

Detailed instructions on removing ring jams are

provided in the operating instructions under

"Removing Jammed Ring Combs".

Slide 6

D392 Ring Binder Training

No additional notes

6

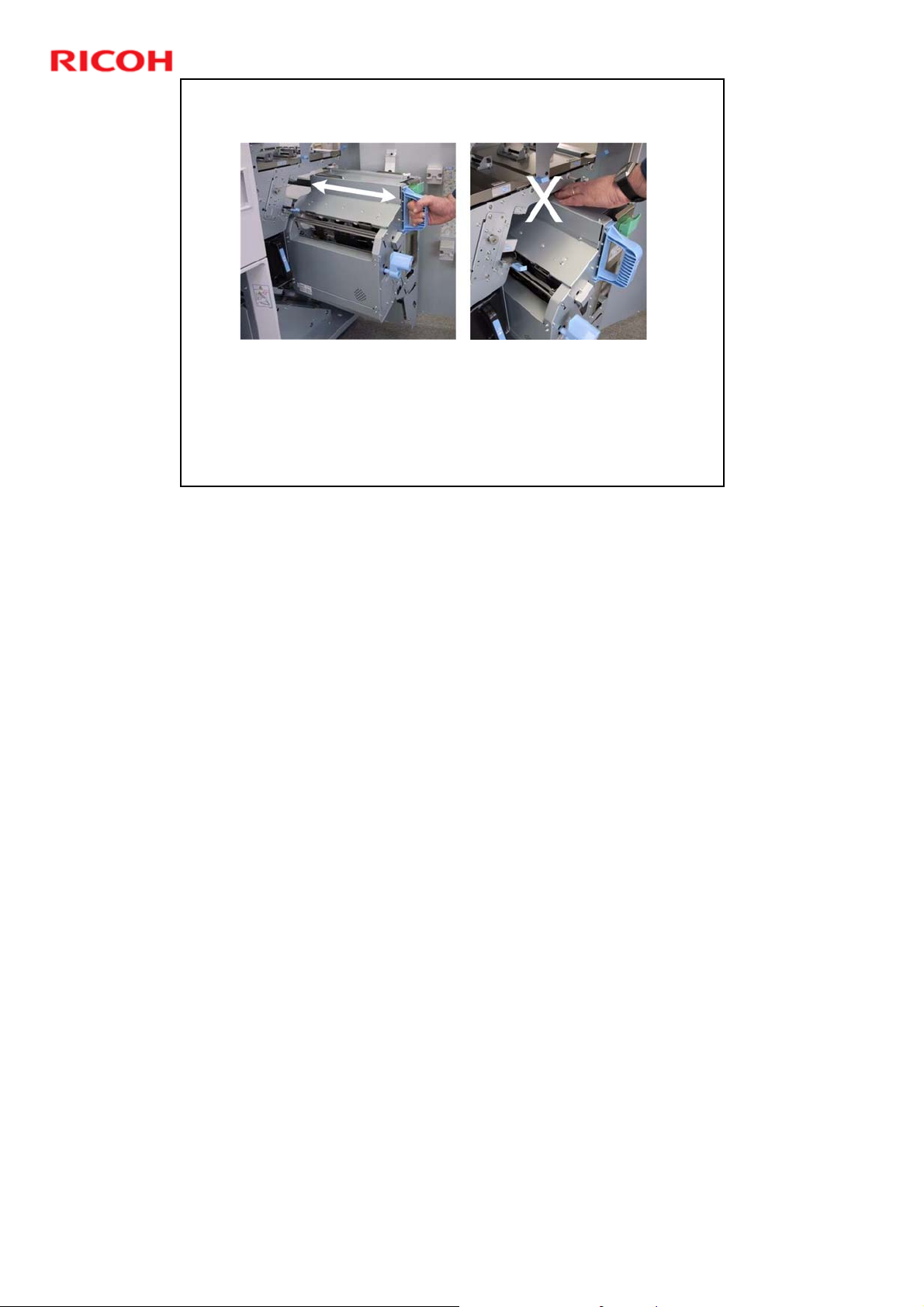

Pulling out/Pushing in the Binder Unit

Always grip handle Mc8 when pulling out or pushing in the binder

unit.

Never touch any other surface of the binder unit when it is

moving.

To avoid injury the fingers, never push on the top of the binder

unit to slide it back into the finisher.

Slide 7

D392 Ring Binder Training

No additional notes

7

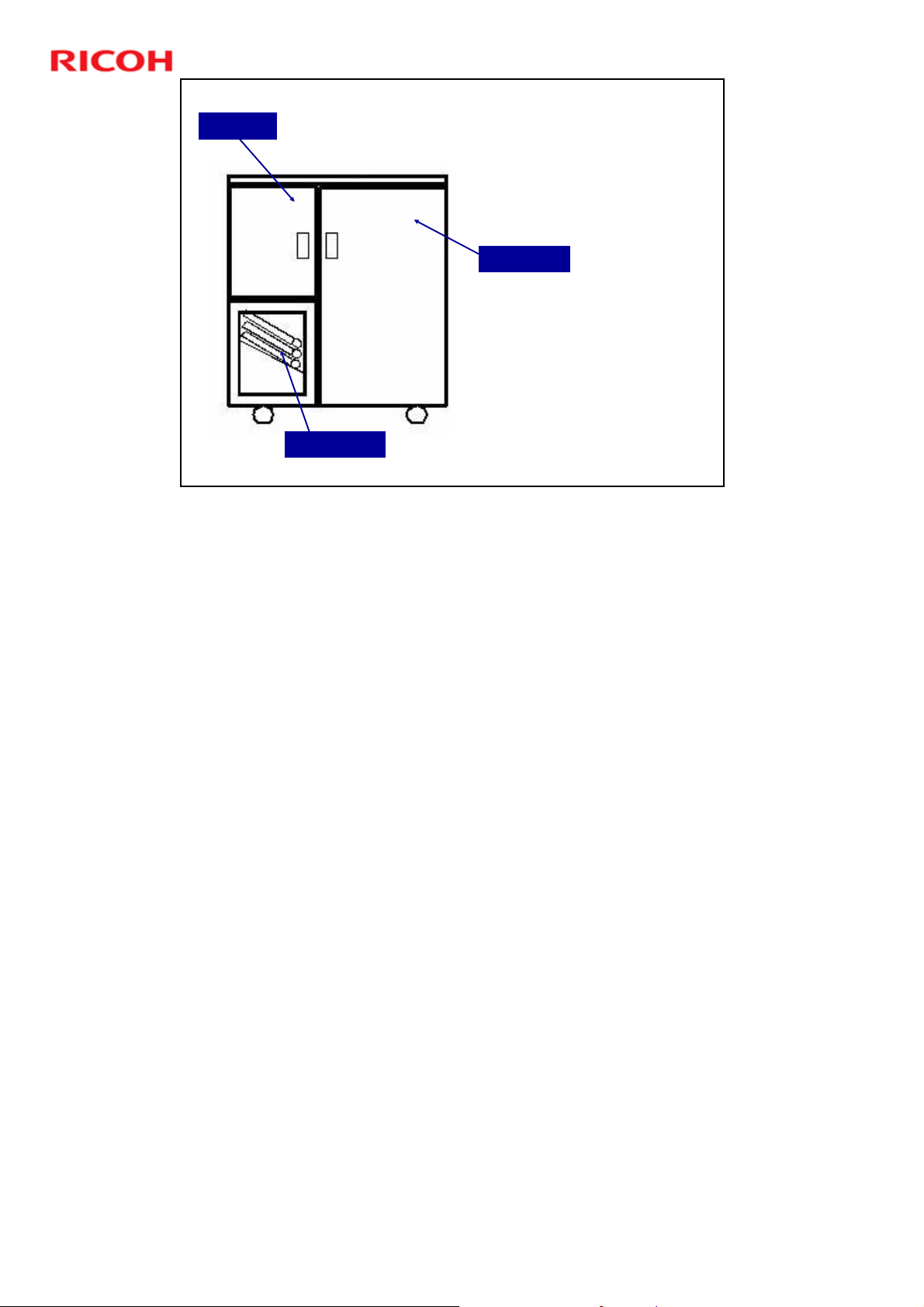

Left Door

Slide 8

D392 Ring Binder Training

Do not Store Things Below the

Output Tray

Do not use the empty

space below the output

tray as a storage area.

Right Door

Output Tray

D392 service manual, Details, Overview, Important Parts

Obstacles in this area (circled in the illustration) will interfere with the raising and

lowering of the tray and cause an error.

8

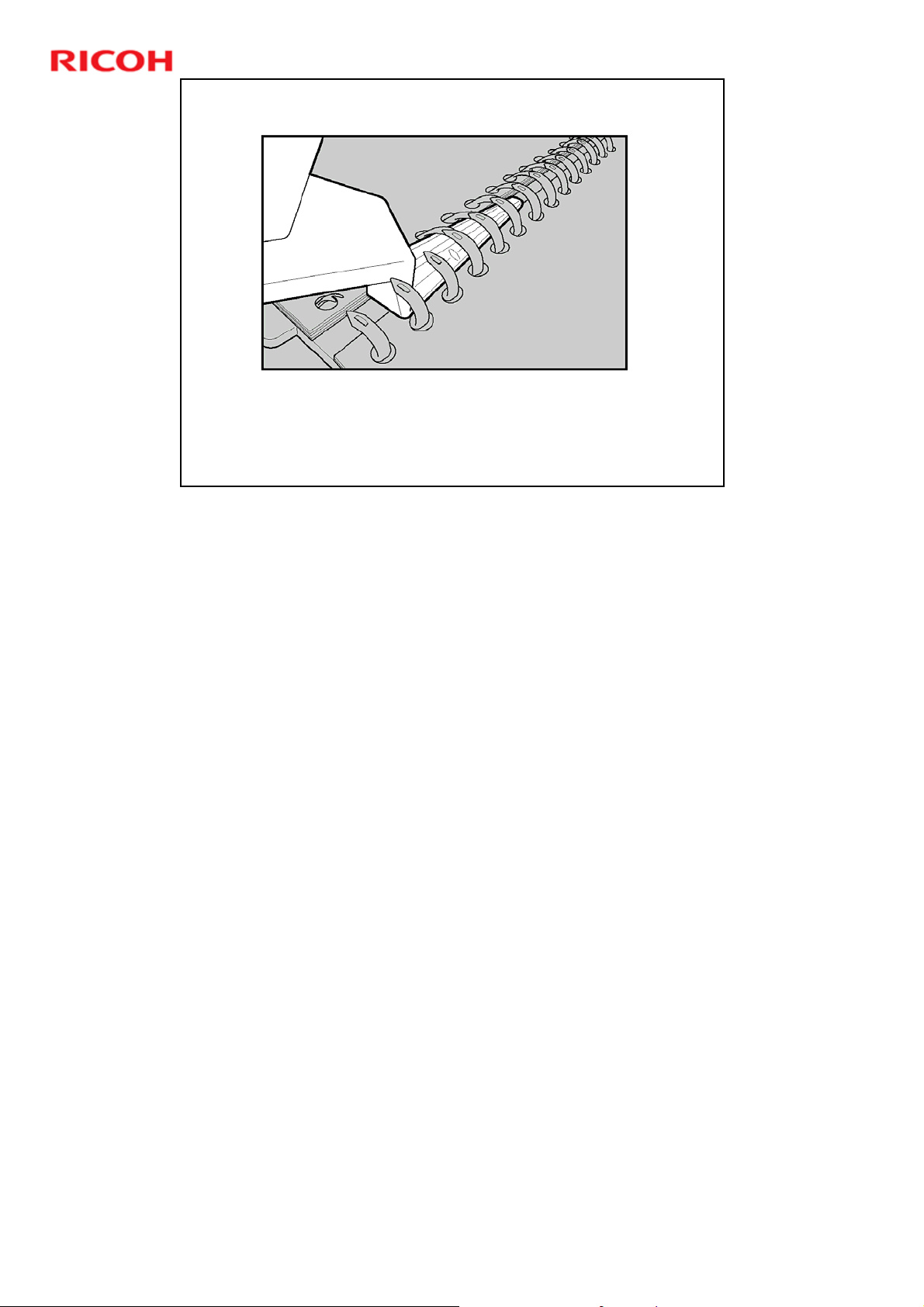

Ring Opener

The customer can use this to add pages to a document that

is already bound.

The additional pages must be printed with punching only

(no ring binding).

Slide 9

D392 Ring Binder Training

The ring binder is limited to 100 pages.

If the customer needs to bind a 120-page document:

First, do a run of 100 pages with ring binding enabled.

Then, do a 20-page run for the remaining pages, with punching only (no ring

binding).

Then, use the ring opener to open the ring and add the remaining pages to the

completed document.

For details about the ring opener, see the Operating Instructions for the ring

binder.

Troubleshooting, Inserting Pages into an Existing Ring Bound

Booklet

9

Slide 10

D392 Ring Binder Training

Machine Component Overview

No additional notes

10

D392 Ring Binder Training

Pre-Punch

Jogger Unit

Stacker Unit

Slide 11

Main Units

Punch Unit

Binder Unit

Output Belt Unit

D392 service manual, Details, Overview, Important Parts

This is a repeat of the slide that we saw at the start of the course, just to refresh

your memory after that arduous installation procedure.

The binder unit contains the pre-bind jogger unit, ring supply unit, and clamp unit.

See the service manual for the locations of these within the binder unit.

11

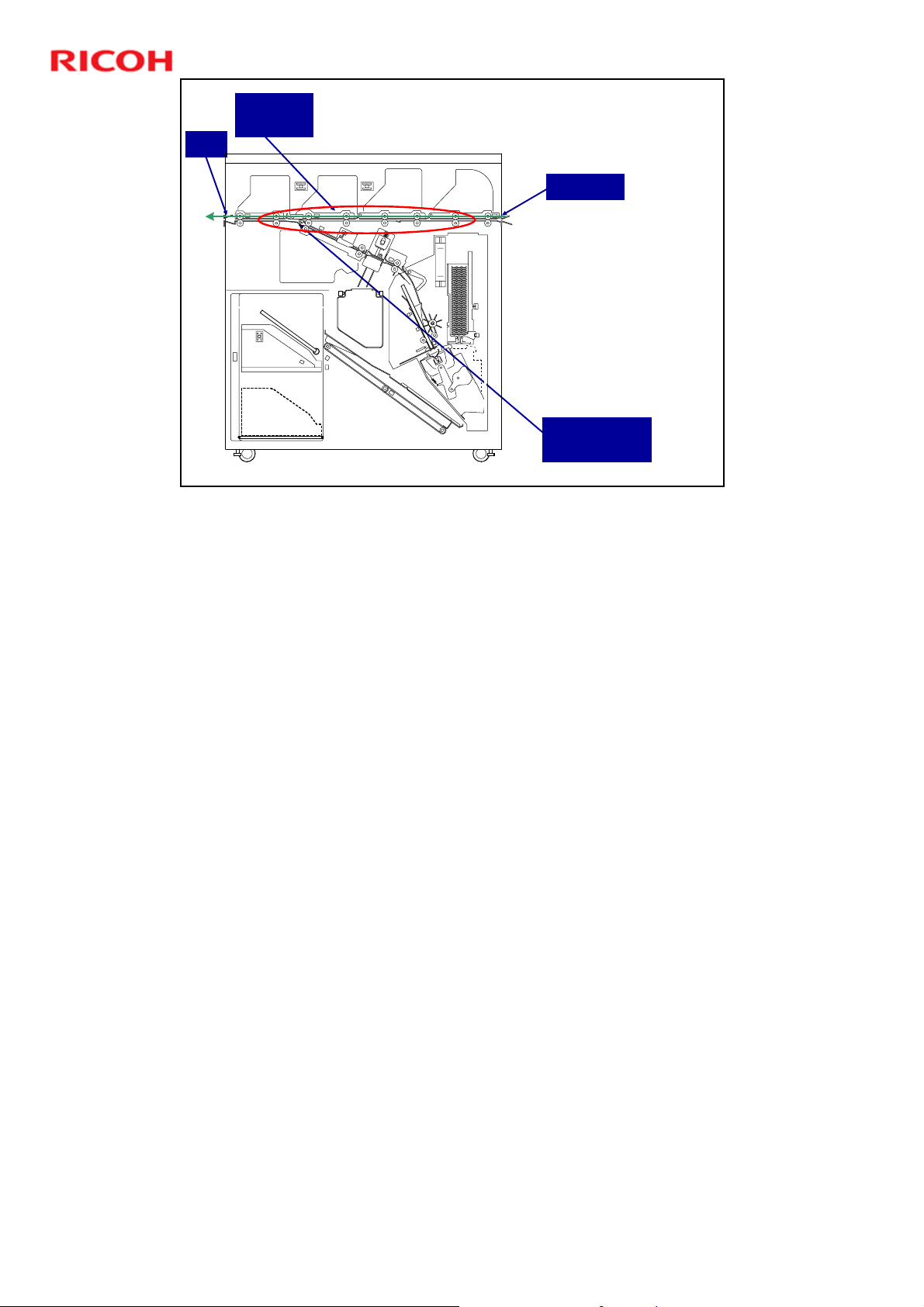

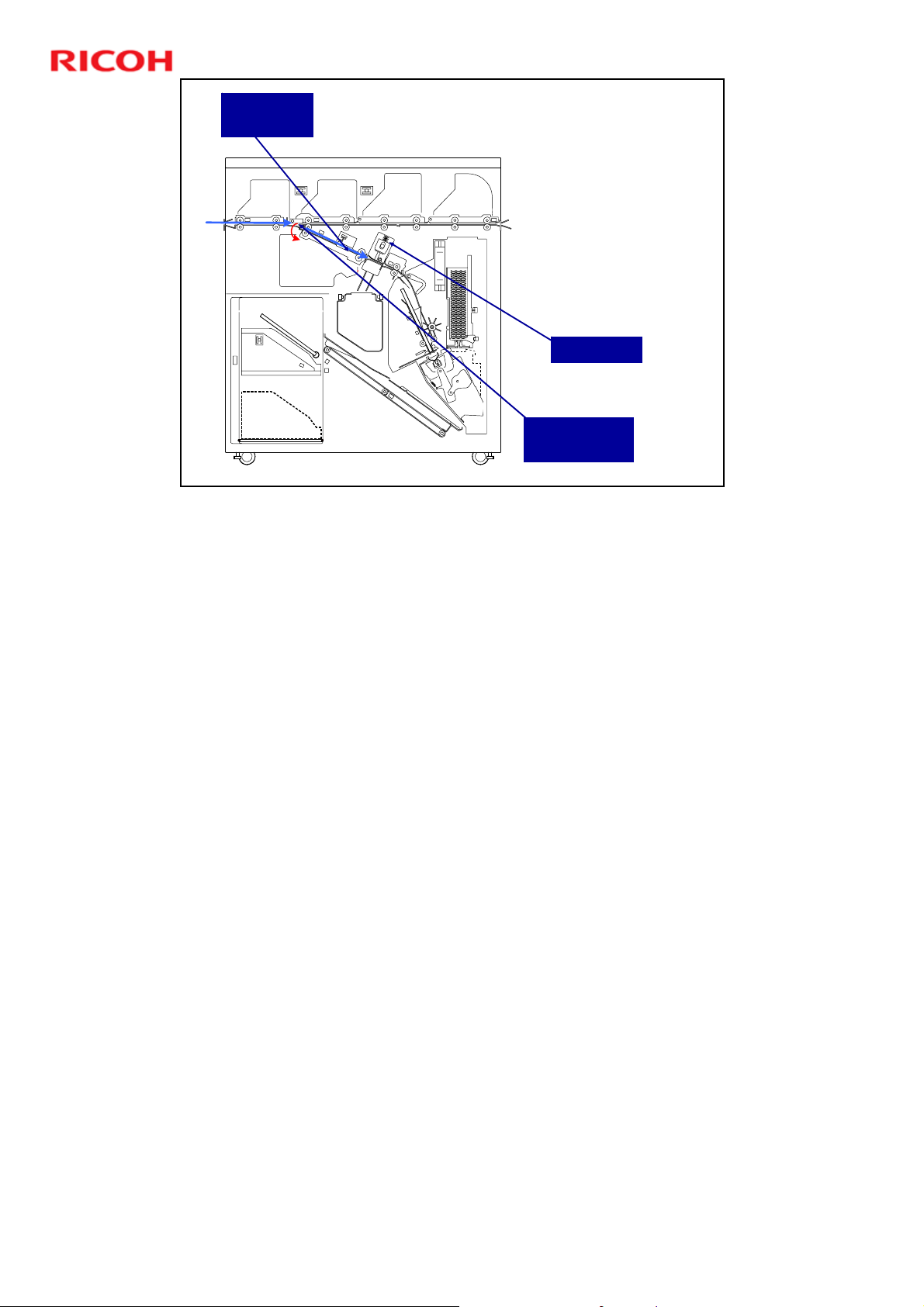

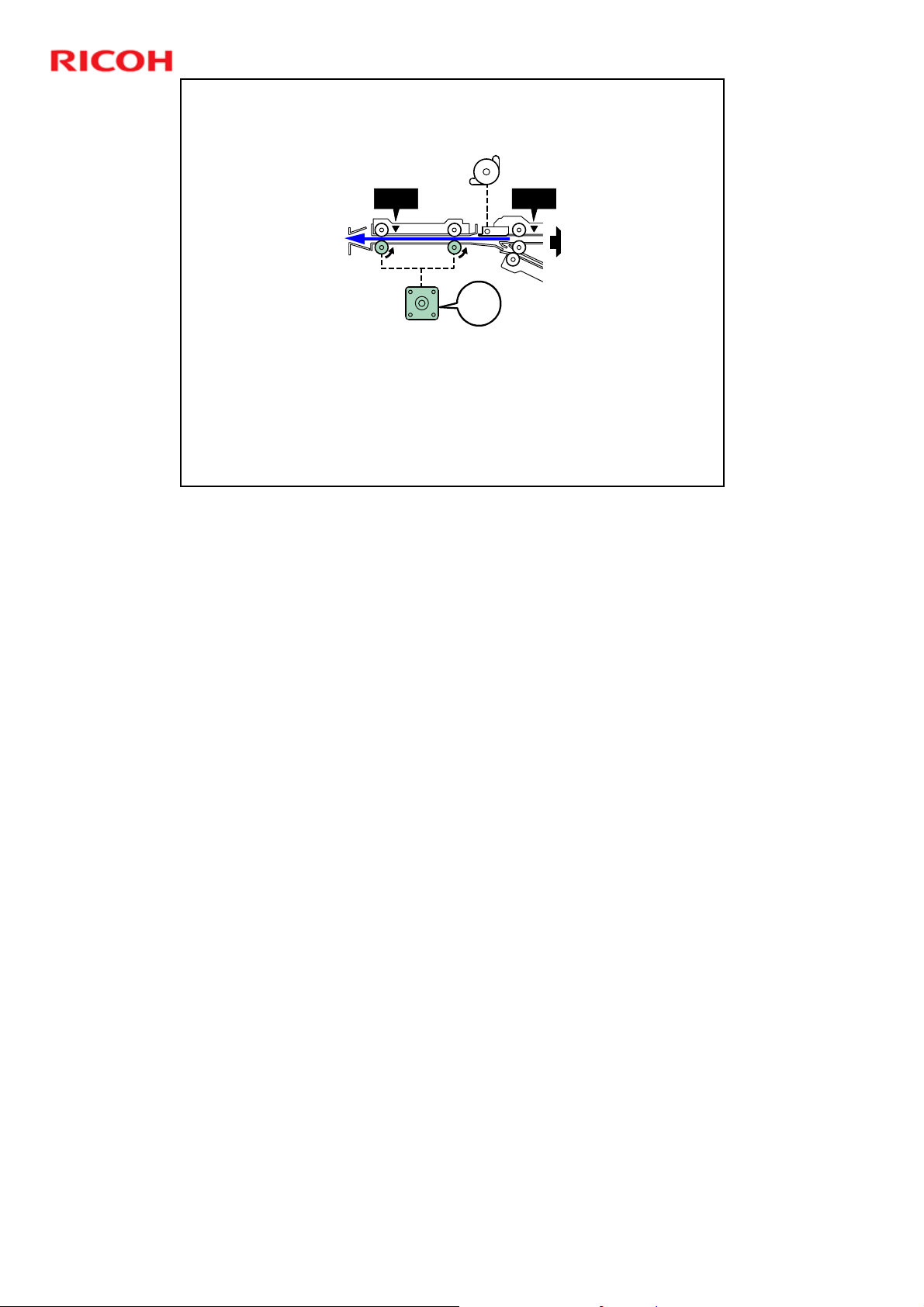

D392 Ring Binder Training

Exit

Slide 12

Transport

Rollers

Downstream Delivery

Paper Path

Entrance

The transport

rollers feed the

paper straight

through the top of

the machine.

The switchback

junction gate stays

in the ‘up’ position.

Switchback

Junction Gate

D392 service manual, Details, Overview, Paper Transport

This is how paper feeds through the finisher if ring binding is not selected for the

job.

12

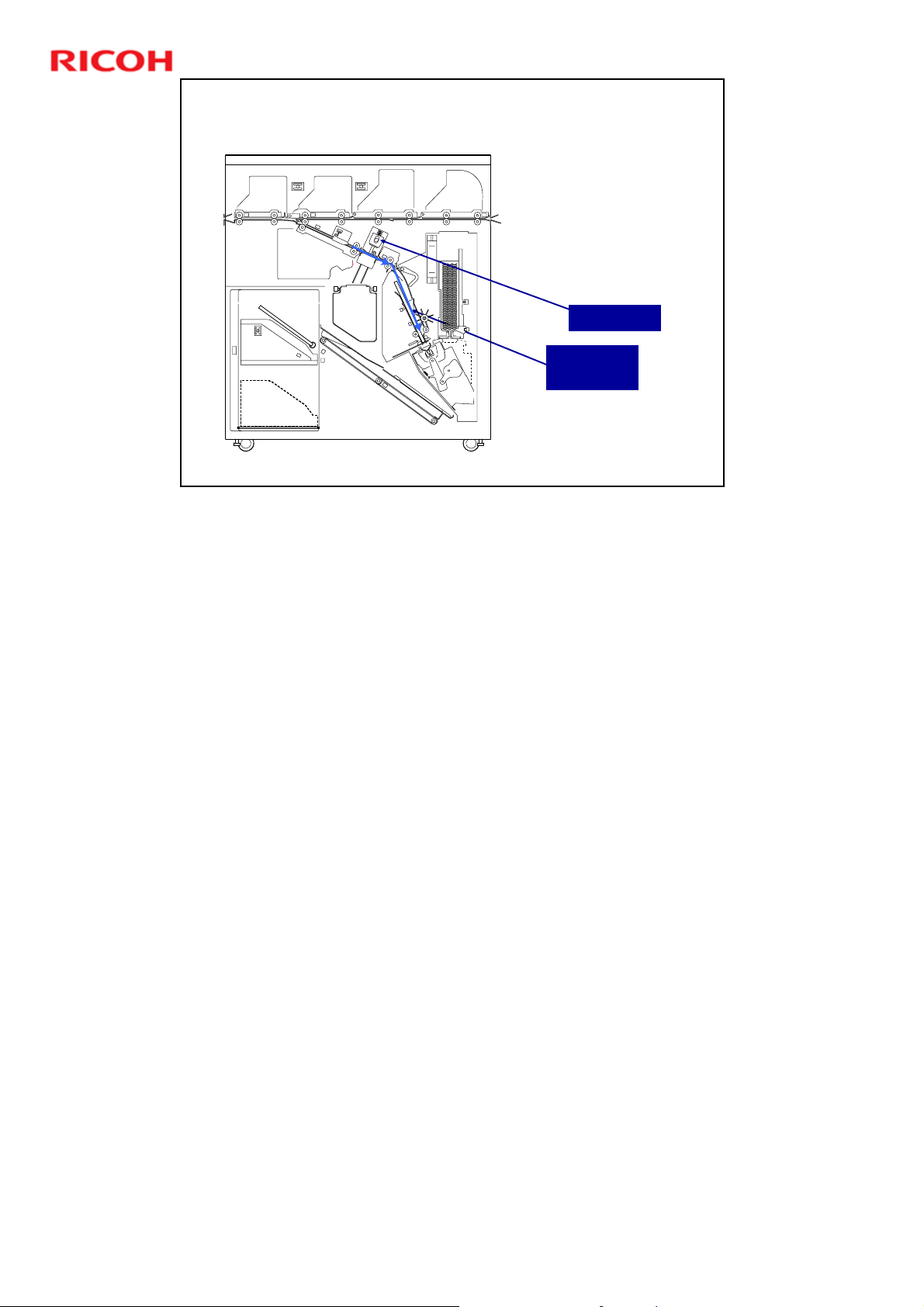

D392 Ring Binder Training

Transport

Rollers

Exit

Slide 13

Paper Path

Ring Binding - 1

The transport

rollers feed the

paper, until the

paper is part of the

way out of the exit.

Then, the exit

rollers stop, and the

switchback junction

gate lowers.

Switchback

Junction Gate

Exit Rollers

D392 service manual, Details, Overview, Paper Transport

The first phase is similar to downstream delivery, until the paper stops after the

leading portion of the paper is fed past the exit.

13

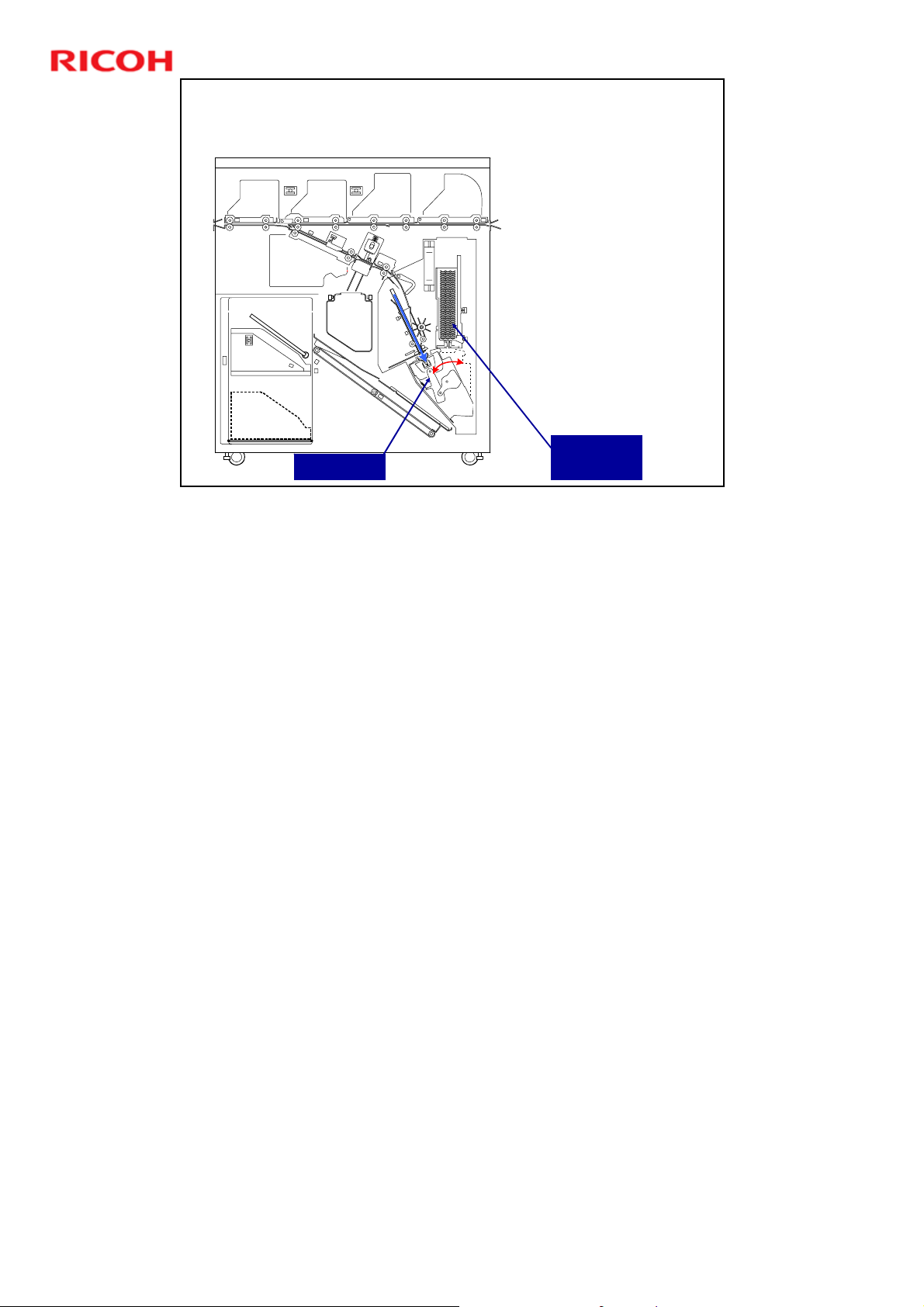

D392 Ring Binder Training

Pre-Punch

Jogger

Slide 14

Paper Path

Ring Binding - 2

D392 service manual, Details, Overview, Paper Transport

Now the paper is fed into the ring binder

The exit rollers feed

in reverse.

The switchback

junction gate sends

the paper to the prepunch jogger.

This aligns the

paper for

punching.

Punch Unit

Switchback

Junction Gate

14

Slide 15

D392 Ring Binder Training

Paper Path

Ring Binding - 3

The punch unit

punches the paper

and sends it to the

pre-bind jogger.

This aligns the

paper for binding.

Punch Unit

Pre-Bind

Jogger

D392 service manual, Details, Overview, Paper Transport

Now the paper is fed into the ring binder

15

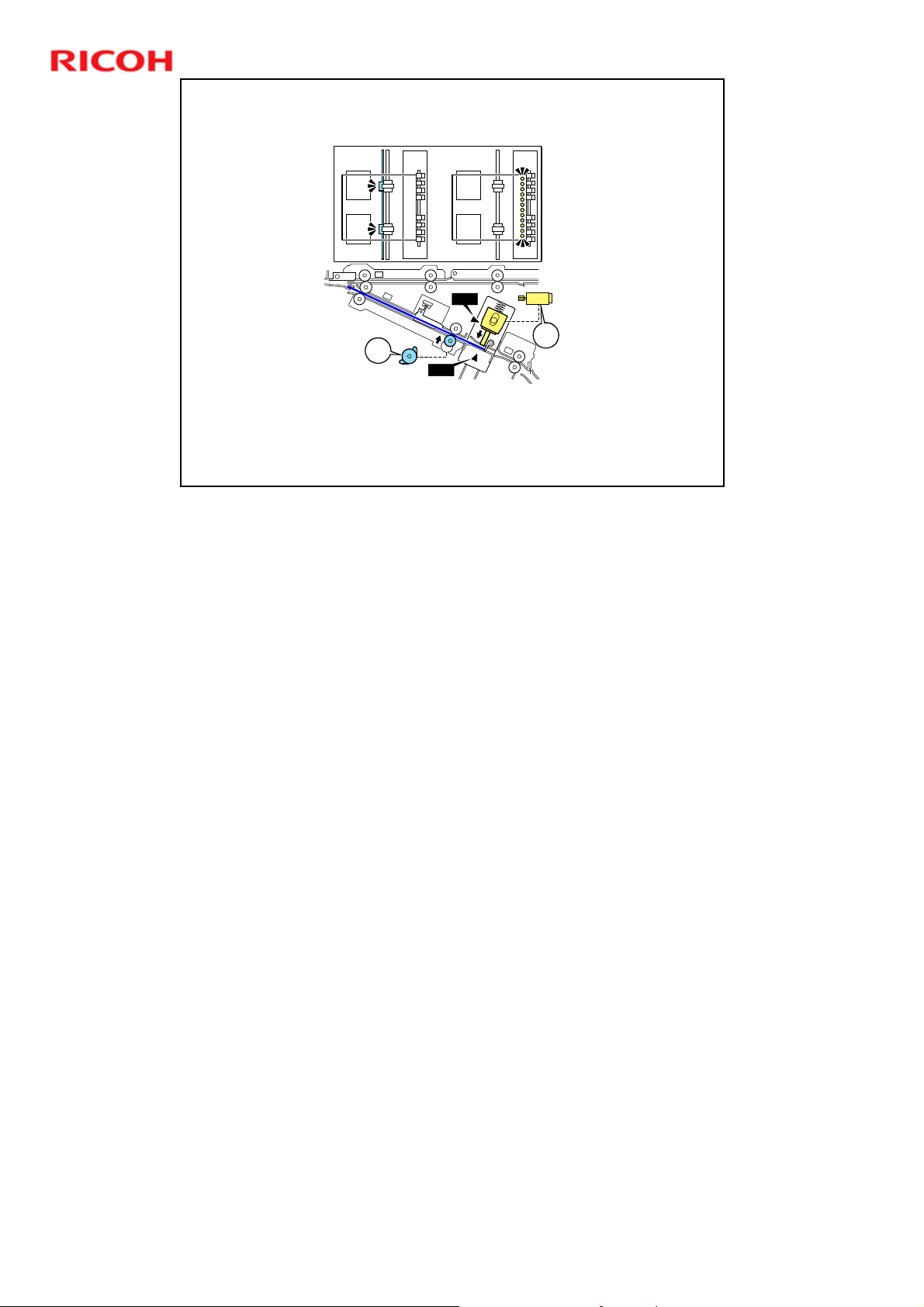

Slide 16

Ring Binding - 4

Clamp Unit

D392 Ring Binder Training

Paper Path

The binding unit

swings to the left to

catch the stack.

The stack feeds

forward a short

distance, so that the

leading edge enters

the top of the binder

unit.

In the binding unit, the

clamp unit takes one

ring from the cartridge

and clamps it through

the punched holes in

the stack.

Then the clamp unit

moves back to the

vertical position.

Ring

Cartridge

D392 service manual, Details, Overview, Paper Transport

Now the paper is fed into the ring binder.

The red arrow indicates the movement of the clamp unit in the binder unit.

16

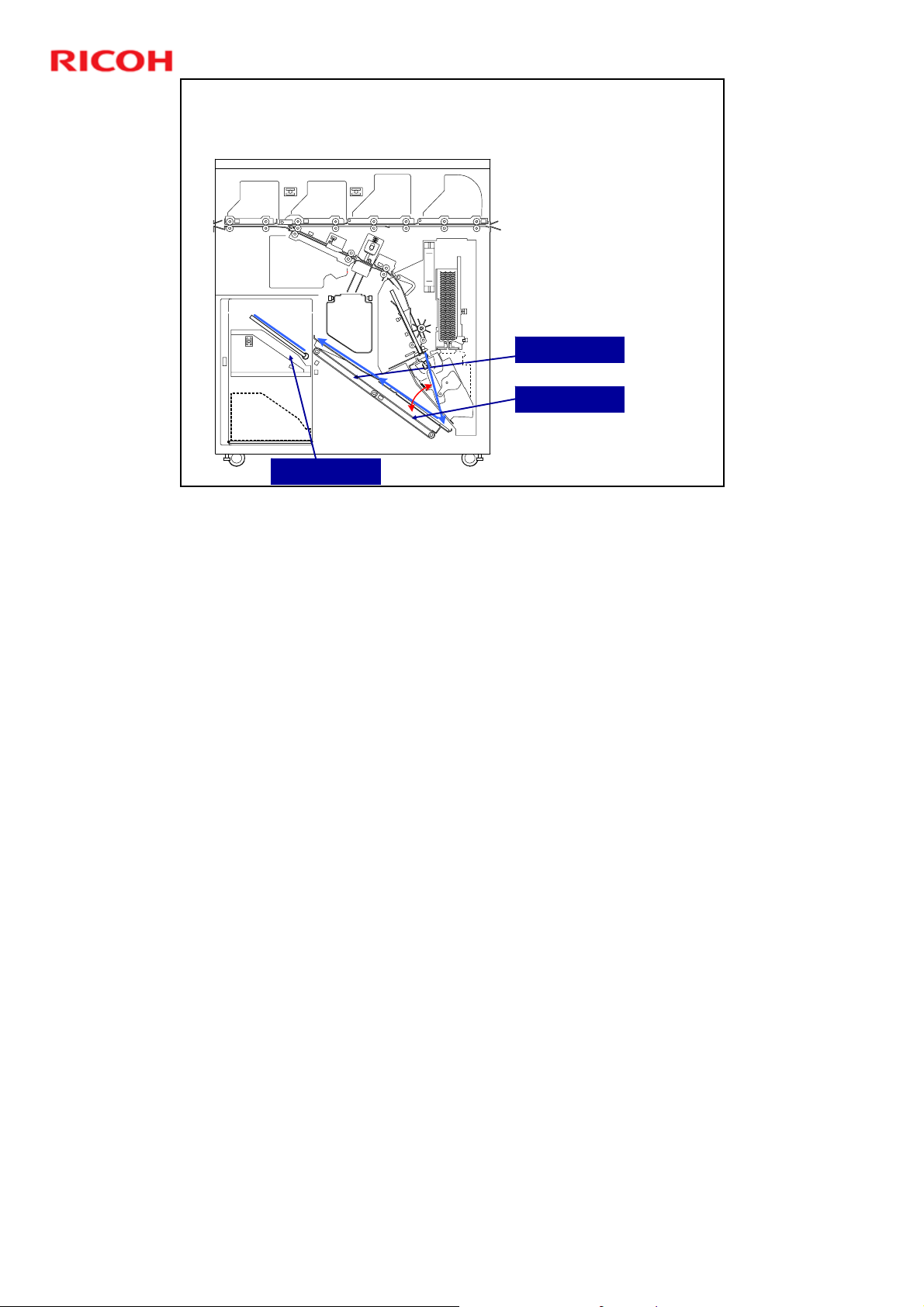

Paper Path

Ring Binding - 5

Output belt 1 moves

Output belts 1 and 2

Output Belt 2

Output Belt 1

D392 Ring Binder Training

up to catch the

bound stack. Then

it moves down to

the same level as

output belt 2.

then feed the stack

to the stacking unit.

Slide 17

Stacking Unit

D392 service manual, Details, Overview, Paper Transport

The red arrow indicates the movement of output belt 1 to catch the paper.

17

Slide 18

D392 Ring Binder Training

Paper Feed and Switchback

No additional notes

18

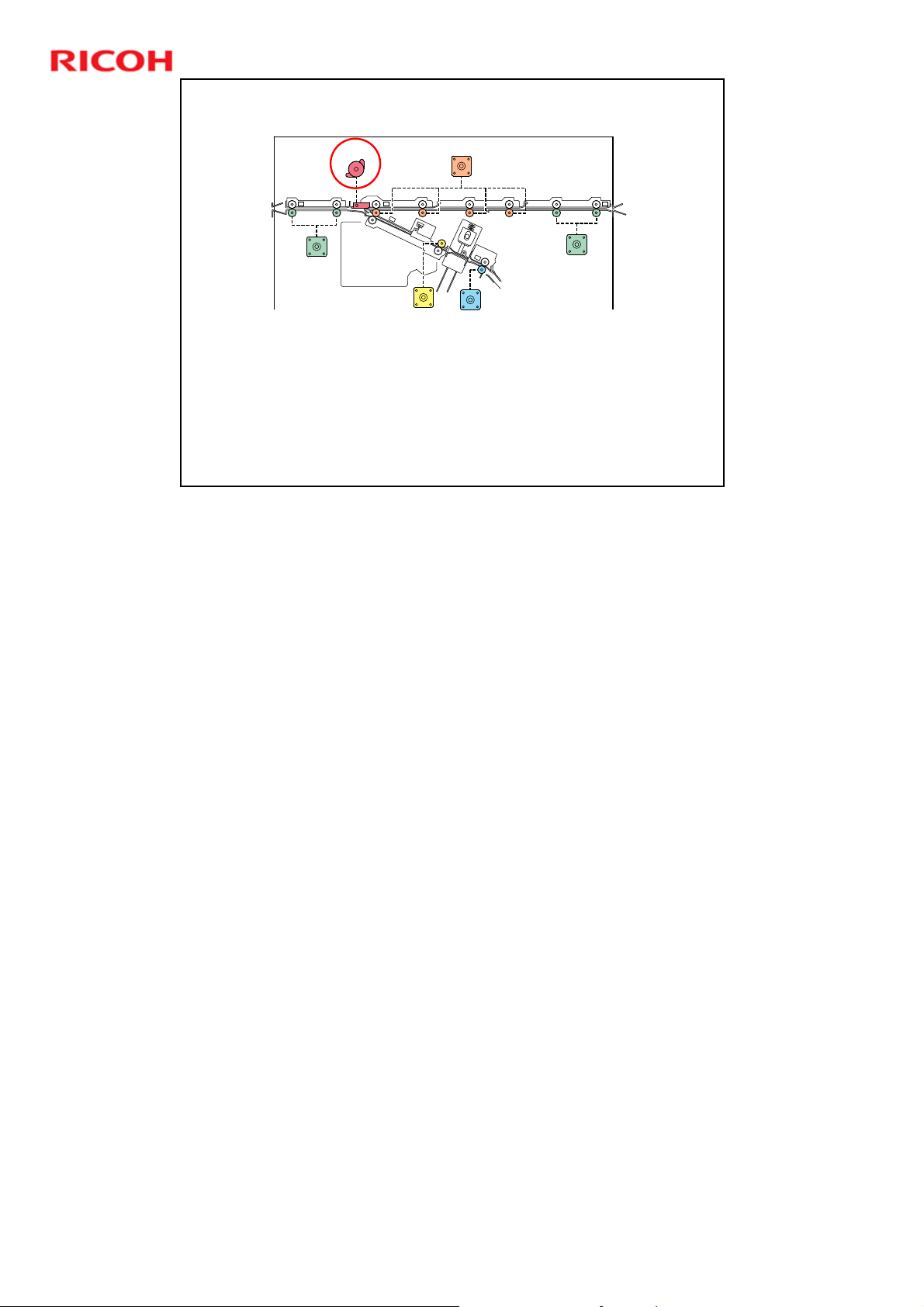

Paper Feed

M201

D392 Ring Binder Training

M102

M103

M301

M101 (Entrance motor): Drives the entrance roller and the 1st

transport roller

M102 (Transport motor): Drives the 2nd, 3rd, 4th, and 5th

transport rollers

M103 (Exit motor): Drives the 6th transport roller and the exit

roller.

Feeds in reverse to feed the paper back into the machine for ring

binding.

Slide 19

M303

M101

D392 service manual, Details, Overview, Paper Feed and

Switchback

19

Sensors

S103 S102

M103

S102 (Transport sensor) and S103 (Exit sensor) detect jams

in the feed path

Slide 20

D392 Ring Binder Training

No additional notes

20

Switchback

M201

D392 Ring Binder Training

M102

M103

M301

M303

M101

M201 (Path JG Motor): Controls the switchback junction

gate.

A spring normally keeps the gate open so that paper can

feed through for downstream delivery.

Slide 21

D392 service manual, Details, Overview, Paper Feed and

Switchback

21

Switchback Junction Gate

Switchback

Junction Gate

M201 (Path JG Motor): Controls the switchback junction

gate.

A spring normally keeps the gate open so that paper can

feed through for downstream delivery.

Slide 22

D392 Ring Binder Training

M201 (Path

Junction Gate

Motor)

No additional notes

22

Slide 23

D392 Ring Binder Training

Punching Holes in the Paper

No additional notes

23

Pre-punch Jogging - 1

M201

M102

D392 Ring Binder Training

M103

M301

M303

M101

M301 (Jog Roller Motor): Controls the roller that feeds the

paper into the pre-punch jogger.

Slide 24

D392 service manual, Details, Overview, Paper Feed and

Switchback

24

Slide 25

D392 Ring Binder Training

Pre-punch Jogging - 2

SOL302 (Top fence

solenoid): Controls the

stopper inside the punch

unit.

This stopper improves

the accuracy of hole

punching at the leading

edge of each sheet.

SOL

No additional notes

25

Pre-punch Jogging - 3

S302

D392 Ring Binder Training

M305 (Jog roller lift motor): Makes a gap between the two

rollers to allow the paper to be moved from side to side

during jogging.

Slide 26

No additional notes

M305

M304

S303

26

Loading...

Loading...