Page 1

D158/D159/D160/D161/D170

DETAILED DESCRIPTIONS

MANUAL

Page 2

D158/D159/D160/D161/D170

DETAILED DE SCRIPTIONS

TABLE OF CONTENTS

1. OVERVIEW .................................................................................... 1

1.1 COMPONENT LAYOUT ................................................................................... 1

1.1.1 D160/D161/D170: CIS SCANNER COMPONENT LAYOUT ................ 3

1.1.2 D158/D159: CCD SCANNER COMPONENT LAYOUT ........................ 3

1.2 PAPER PATH ................................................................................................... 4

1.3 DRIVE LAYOUT................................................................................................ 5

2. BOARD STRUCTURE .................................................................... 7

2.1 BLOCK DIAGRAM ............................................................................................ 7

BICU (Base Engine and Image Control Unit) ............................................ 8

2.2 SBU (SENSOR BOARD UNIT) ........................................................................ 8

3. COPY PROCESS OVERVIEW ....................................................... 9

4. SCANNING D158/D15 9 ................................................................ 11

4.1 OVERVIEW ..................................................................................................... 11

4.2 SCANNER DRIVE .......................................................................................... 12

4.3 ORIGINAL SIZE DETECTION IN PLATEN MODE ....................................... 13

4.4 ANTI-CONDENSATION HEATER ................................................................. 14

5. SCANNING D160/D16 1/D170 ...................................................... 15

5.1 OVERVIEW ..................................................................................................... 15

5.2 SCANNER DRIVE .......................................................................................... 16

6. LASER EXPOSURE ..................................................................... 18

6.1 OVERVIEW ..................................................................................................... 18

6.2 AUTO POWER CONTROL (APC) ................................................................. 19

6.3 LD SAFETY SWITCH ..................................................................................... 20

7. PHOTOCONDUCTOR UNIT (PCU) .............................................. 21

7.1 OVERVIEW ..................................................................................................... 21

7.2 DRIVE ............................................................................................................. 23

8. DRUM CHARGE .......................................................................... 24

8.1 OVERVIEW ..................................................................................................... 24

8.2 ID SENSOR PATTERN PRODUCTION TIMING .......................................... 25

8.3 DRUM CHARGE ROLLER CLEANING ......................................................... 26

9. DEVELOPMENT .......................................................................... 27

9.1 OVERVIEW ..................................................................................................... 27

9.2 DRIVE ............................................................................................................. 28

Detailed Descriptions i D158/D159/D160/D161/D170

Page 3

9.3

DEVELOPER MIXING .................................................................................... 29

9.4 DEVELOPMENT BIAS ................................................................................... 30

9.5 TONER SUPPLY ............................................................................................ 31

9.5.1 TONER BOTTLE REPLENISHMENT MECHANISM ........................... 31

9.6 TONER SUPPLY MECHANISM .................................................................... 32

9.7 TONER DENSITY CONTROL ....................................................................... 33

9.7.1 OVERVIEW ........................................................................................... 33

9.7.2 TONER DENSITY SENSOR INITIAL SETTING .................................. 35

9.7.3 TONER CONCENTRATION MEASUREMENT ................................... 35

9.7.4 VSP/VSG DETECTION......................................................................... 35

9.7.5 TONER SUPPLY REFERENCE VOLTAGE (VREF) DETERMINATION

36

9.7.6 TONER SUPPLY DETERMINATION ................................................... 36

9.7.7 TONER SUPPLY MOTOR ON TIME DETERMINATIONS ................. 36

9.8 TONER SUPPLY IN ABNORMAL SENSOR CONDITIONS......................... 38

9.8.1 ID SENSOR ........................................................................................... 38

9.8.2 TD SENSOR .......................................................................................... 38

9.9 TONER NEAR END/END DETECTION AND RECOVERY.......................... 38

9.9.1 TONER NEAR END DETECTION ........................................................ 38

9.9.2 TONER NEAR END RECOVERY ........................................................ 39

9.9.3 TONER END DETECTION ................................................................... 39

9.9.4 TONER END RECOVERY.................................................................... 39

10. DRUM CLEANING AND TONER RECYCLING............................ 40

10.1 DRUM CLEANING.................................................................................... 40

10.2 TONER RECYCLING ............................................................................... 41

11. PAPER FEED ............................................................................... 42

11.1 OVERVIEW ............................................................................................... 42

11.2 PAPER FEED DRIVE MECHANISM ....................................................... 43

11.3 PAPER FEED AND SEPARATION MECHANISM .................................. 44

11.4 PAPER LIFT MECHANIS M ...................................................................... 45

11.5 BY-PASS TRAY BOTTOM PLATE LIFT MECHANISM .......................... 46

11.6 PAPER END DETECTION ....................................................................... 47

11.7 PAPER SIZE DETECTION ...................................................................... 48

11.7.1 PAPER TRAY ................................................................................. 48

0: PUSHED, 1: NOT PUSHED .......................................................... 48

11.7.2 BY-PASS TRAY ............................................................................. 50

11.8 SIDE FENCES .......................................................................................... 51

11.9 PAPER REGISTRATION ......................................................................... 52

12. IMAGE TRANSFER AND PAPER SEPARATION ........................ 53

12.1 OVERVIEW ............................................................................................... 53

12.2 IMAGE TRANSFER CURRENT TIMING ................................................. 54

12.3 TRANSFER ROLLER CLEANING ........................................................... 55

12.4 PAPER SEPARATION MECHANISM...................................................... 56

13. IMAGE FUSING AND PAPER EXIT ............................................. 57

13.1 OVERVIEW ............................................................................................... 57

D158/D159/D160/D161/D170 ii Detailed Descriptions

Page 4

13.2 FUSING UNIT DRIVE AND RELEASE MECHANISM ............................ 58

13.2.1 FUSING UNIT DRIVE .................................................................... 58

13.2.2 DRIVE RELEASE MECHANISM ................................................... 58

13.2.3 CONTACT/RELEASE CONTROL ................................................. 59

13.2.4 DRIVE RELEASE SOLENOID ....................................................... 59

13.3 FUSING ENTRANCE GUIDE SHIFT ....................................................... 60

13.4 PRESSURE ROLLER .............................................................................. 60

13.5 FUSING TEMPERATURE CONTROL..................................................... 61

13.5.1 OVERVIEW .................................................................................... 61

13.5.2 TEMPERATURE CONTROL ......................................................... 62

13.6 OVERHEAT PROTECTION ..................................................................... 64

14. DUPLEX UNIT .............................................................................. 65

14.1 OVERALL.................................................................................................. 65

14.2 DRIVE MECHANISM ................................................................................ 66

14.3 BASIC OPERATION ................................................................................. 67

14.4 FEED IN AND EXIT MECHANISM .......................................................... 69

15. ENERGY SAVER MODES OF BASIC MACHINES ...................... 70

15.1 OVERVIEW ............................................................................................... 70

15.2 AOF ........................................................................................................... 71

15.3 TIMERS ..................................................................................................... 71

15.4 RECOVERY .............................................................................................. 71

16. ENERGY SAVER MODES OF GDI MACHINES .......................... 72

16.1 OVERVIEW ............................................................................................... 72

16.2 AOF ........................................................................................................... 73

16.3 TIMERS ..................................................................................................... 73

16.4 RECOVERY .............................................................................................. 73

17. OVERVIEW .................................................................................. 74

18. BOARDS ...................................................................................... 75

18.1 FCU ........................................................................................................... 75

19. SERVICE RAM ADDRESSES ...................................................... 77

20. VIDEO DATA PATH ..................................................................... 91

20.1 TRANSMISSION ...................................................................................... 91

20.1.1 MEMORY TRANSMISSION AND PARALLEL MEMORY

TRANSMISSION ............................................................................................ 91

20.1.2 IMMEDIATE TRANSMISSION ...................................................... 92

20.1.3 JBIG TRANSMISSION ................................................................... 92

20.1.4 ADJUSTMENTS ............................................................................. 92

20.2 RECEPTION ............................................................................................. 93

21. FAX COMMUNICATION FEATURES .......................................... 94

21.1 DOCUMENT SERVER ............................................................................. 94

21.2 INTERNET MAIL COMMUNICATION ..................................................... 95

21.2.1 MAIL TRANSMISSION .................................................................. 95

Detailed Descriptions iii D158/D159/D160/D161/D170

Page 5

21.2.2

MAIL RECEPTION ......................................................................... 98

21.2.3 HANDLING MAIL RECEPTION ERRORS .................................. 100

21.2.4 SECURE INTERNET RECEPTION ............................................. 101

21.2.5 TRANSFER REQUEST: REQUEST BY MAIL ............................ 101

21.2.6 E-MAIL OPTIONS (SUB TX MODE) ........................................... 102

22. IP-FAX ........................................................................................ 106

22.1 WHAT IS IP-FAX? .................................................................................. 106

22.2 T.38 PACKET FORMAT ......................................................................... 106

22.2.1 UDP RELATED SWITCHES ........................................................ 106

22.3 SETTINGS .............................................................................................. 106

D158/D159/D160/D161/D170 iv Detailed Descriptions

Page 6

1. OVERVIEW

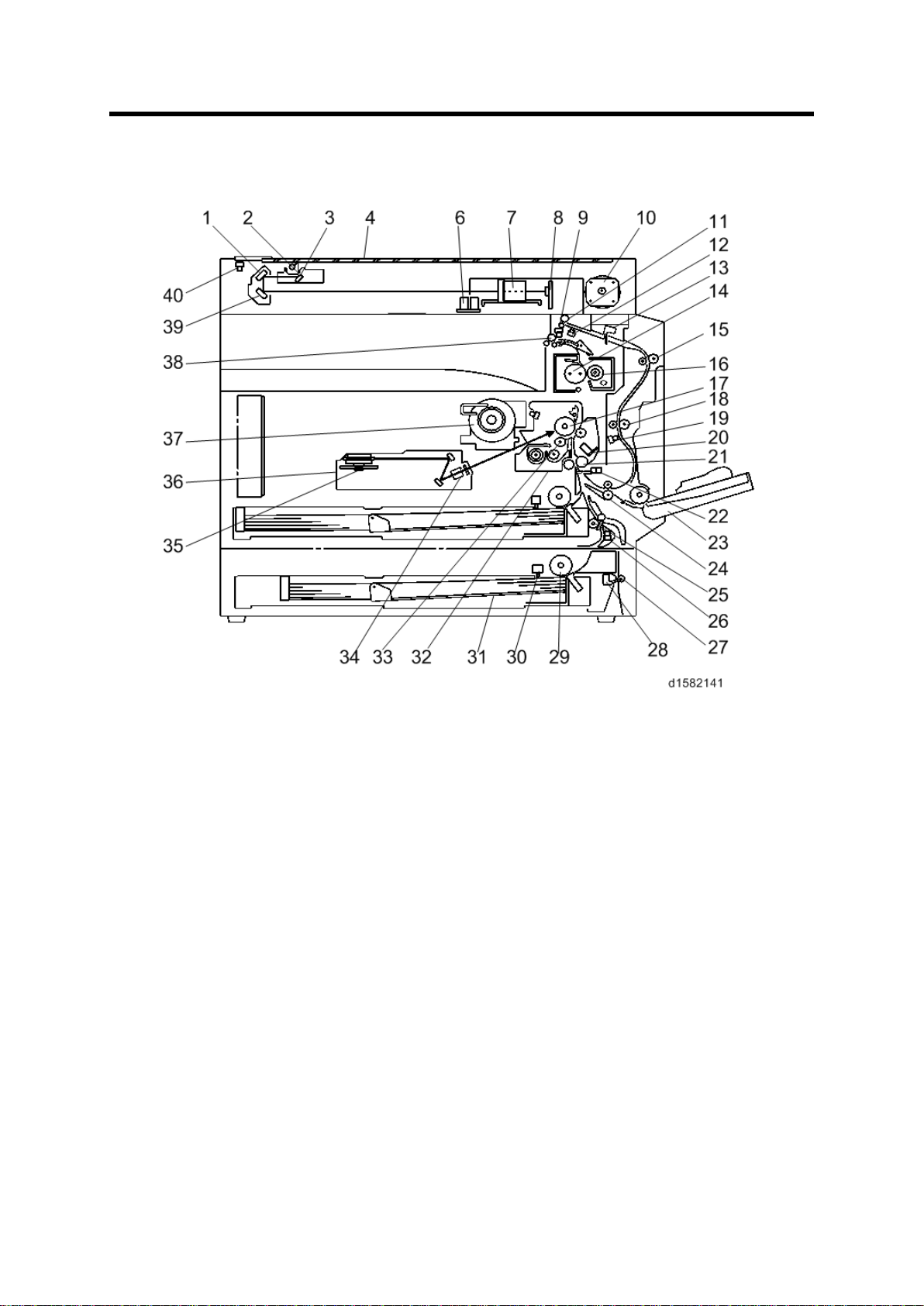

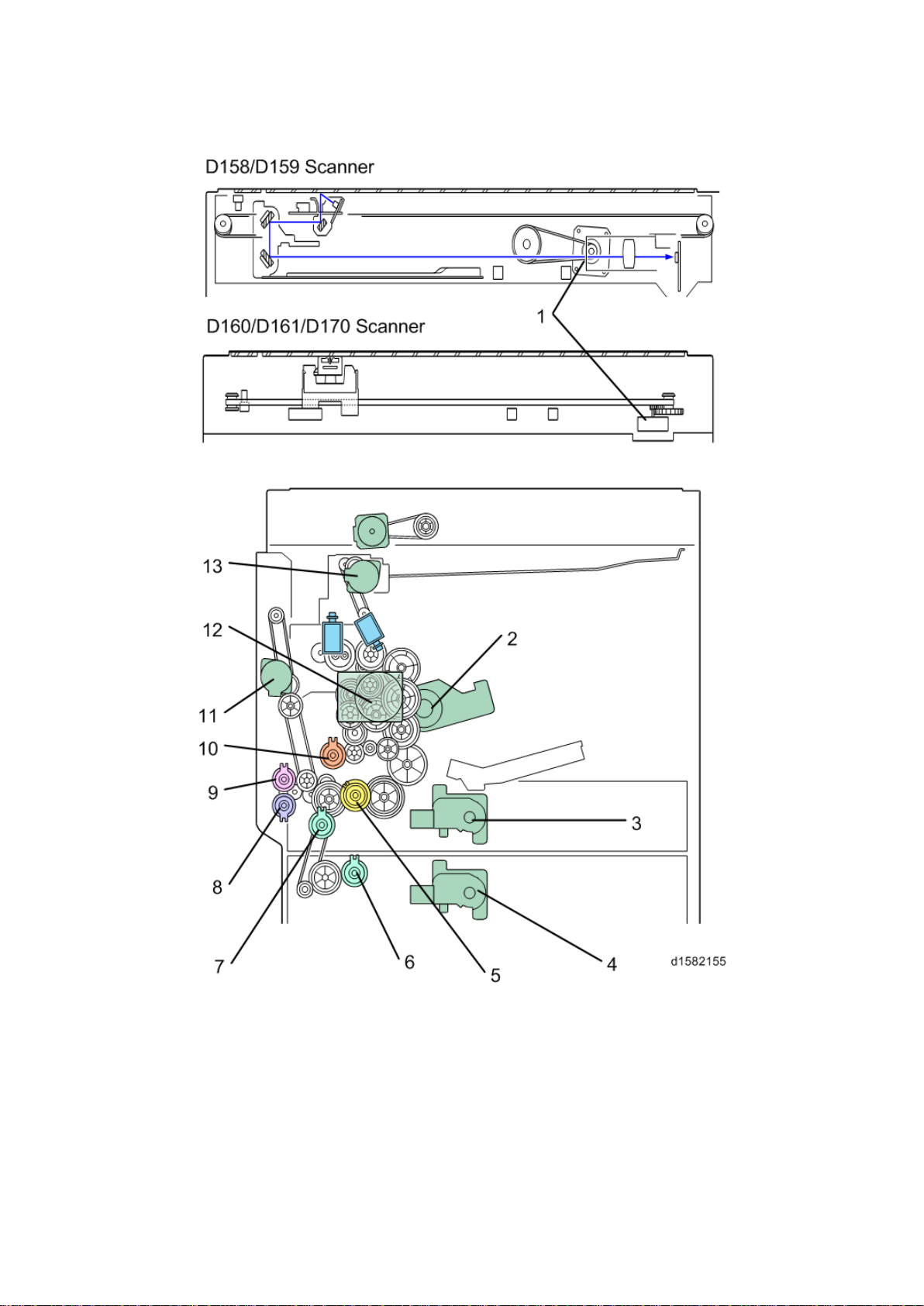

The ab ove il lu s tr ation is th e D158/D159 model.

1.1 COMPONENT LAYOUT

Component Layout

• D170: No duplex unit

• D158/D159: CCD scanner

• D160/D161/D170: C IS scan ner

Detailed Descriptions 1 D158/D159/D160/D161/D170

Page 7

Component Layout

1. 2nd Mirror

2. Exposure Lamp

3. 1st Mirror

4. Exposure Glass

6.

7. Lens Block

8. SBU

9. Exit Sensor

10. Scanner Motor

11. Inverter Roller

12. Duplex Invert er Sensor

13. Duple

14 . H ot R oll er

15. Upper Transport Roller

16. Pressure Roller

17. OPC Drum

18 . Middl e Transpor t R oller

19. Duplex Exit Sensor

20. Image Density S ensor

21 . R egist rat ion Roll er

22 . R egist rat ion Sen sor

23. By

24 . L ower Trans port Ro

25. Upper Relay Roller

26 . R elay Sen sor

27 . L ower Relay Roller

28. Vertical Transport Sensor

29 . Paper Feed Roller

30. Paper End Sensor

31. Bottom Pla te

32. PCU

33 . D evelopment Rol ler

34. WTL

35. Polygon Mirror Motor

36. Laser Unit

37. Toner Supply Bo

38. Ex it Ro ller

39. 3rd Mirror

40. Scanner HP Sensor

APS sensor (Length)

D158/D159/D160/D161/D170 2 Detailed Descriptions

x Entrance Sensor

-pass Tray

ller

tt le H older

Page 8

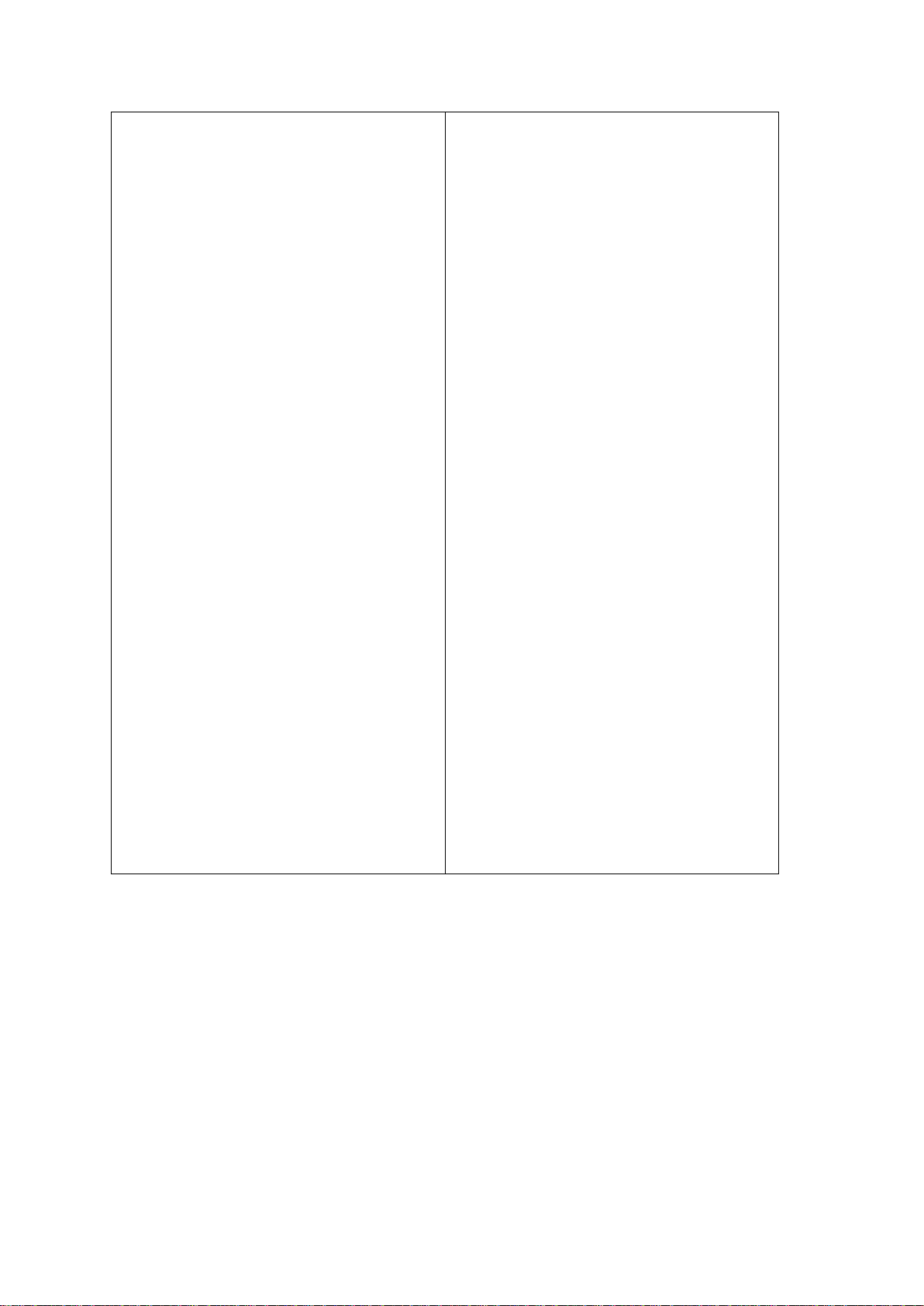

Component Layout

1.CIS Unit

2

3

4

5

6

7. DF

1. DF Exposure Glass

2.

3

4

5

6. SBU

7

8

9

10.3

11. Scanner HP Sensor

1.1.1 D160/D161/D170: CIS SCANNER COMPONENT LAYOUT

. APS Sensor (Width)

. Exposure Glass

. S canner HP Sen sor

. Scanner Motor

Exposure Glass

. APS Sensor (Length)

1.1.2 D158/D159: CCD SCANNER COMPONENT LAYOUT

2n d M irror

. Exposure Lamp

. Exposure Glass

. Scanner Motor

. APS Sensors

. Scanner Heater

. 1st Mirror

rd

Mirror

Detailed Descriptions 3 D158/D159/D160/D161/D170

Page 9

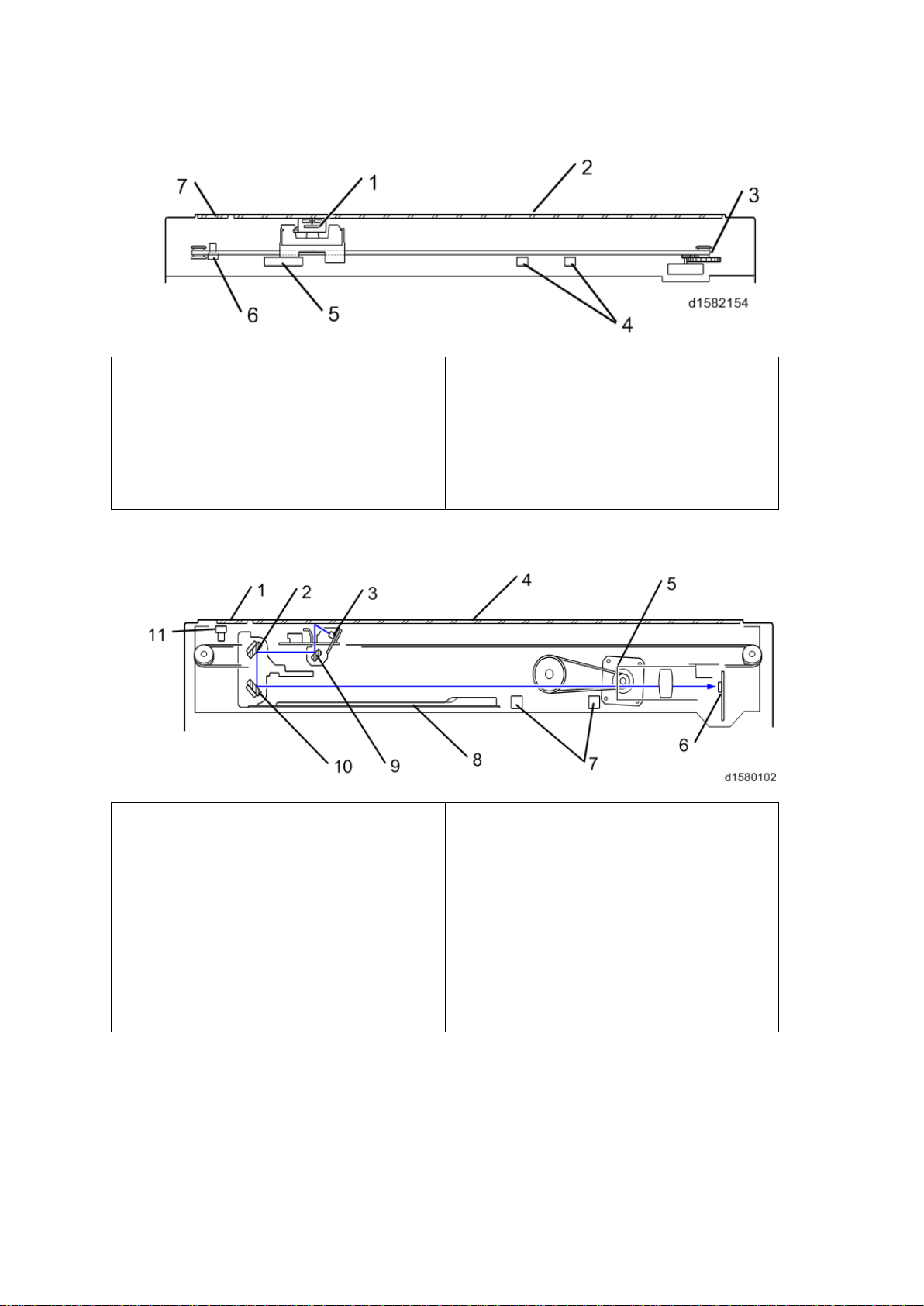

Paper Path

1.2 PAPER PATH

The D158, D159, D160, and D161 models have a duplex unit mounted on the right side of

the machine.

All models have a b y-p ass tr ay.

D158/D159/D160/D161/D170 4 Detailed Descriptions

Page 10

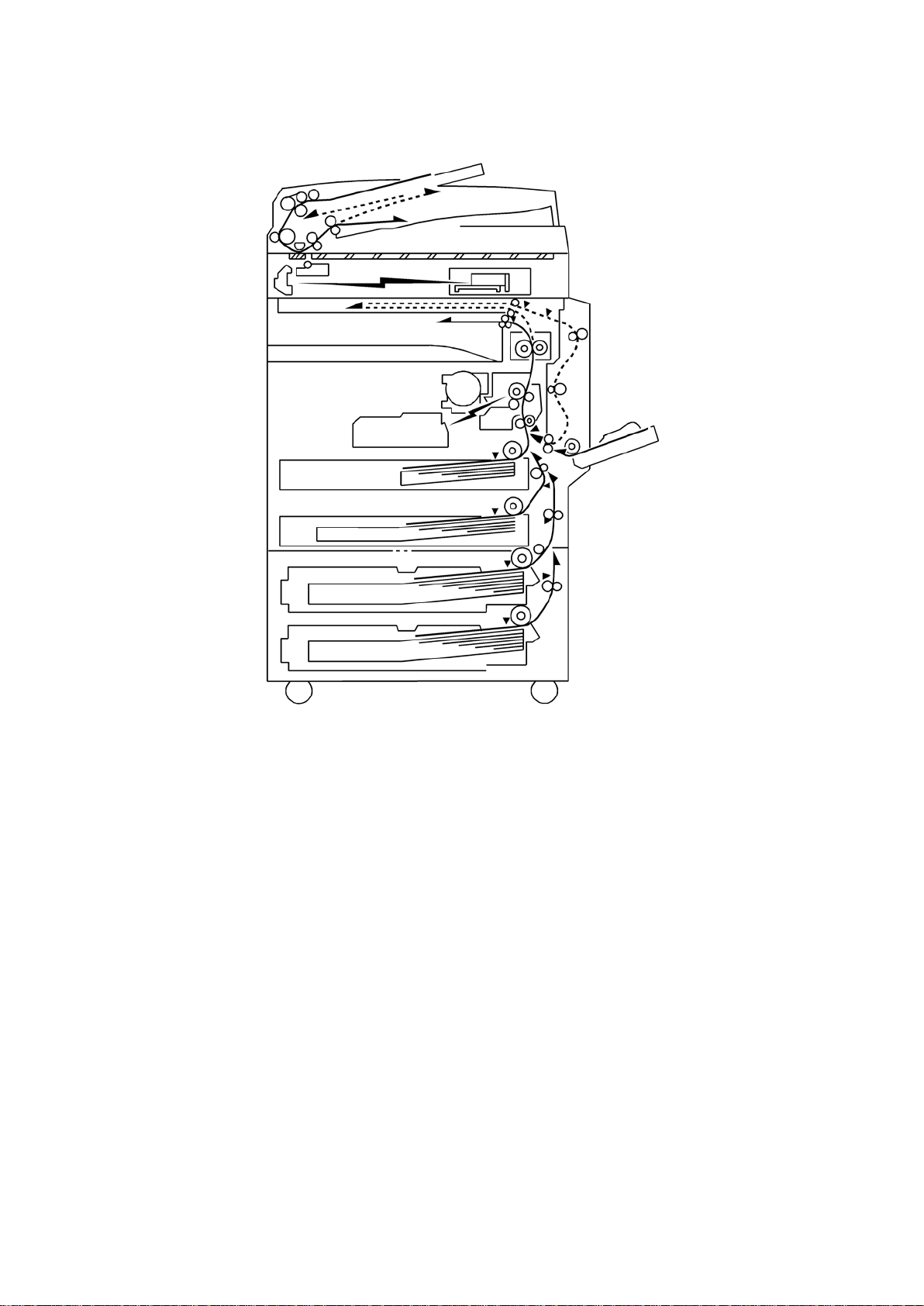

1.3 DRIVE LAYOUT

Dri ve L ayou t

Detailed Descriptions 5 D158/D159/D160/D161/D170

Page 11

Dri ve L ayou t

1. Scanner Motor

8. By-pas s P aper Feed C lu tch

2. Toner Su pply M otor

3. Tray 1 Lift M otor

4. Tray 2Lift Motor

5. Upper Paper Feed Clutch

6. L ower Paper Feed Clutch

7. R elay Clut ch

9. By-pass Tray Lift Clutc h

10. Registration Clutch

11. Duplex Motor

12 . Main M otor

13. Inver ter Motor

D158/D159/D160/D161/D170 6 Detailed Descriptions

Page 12

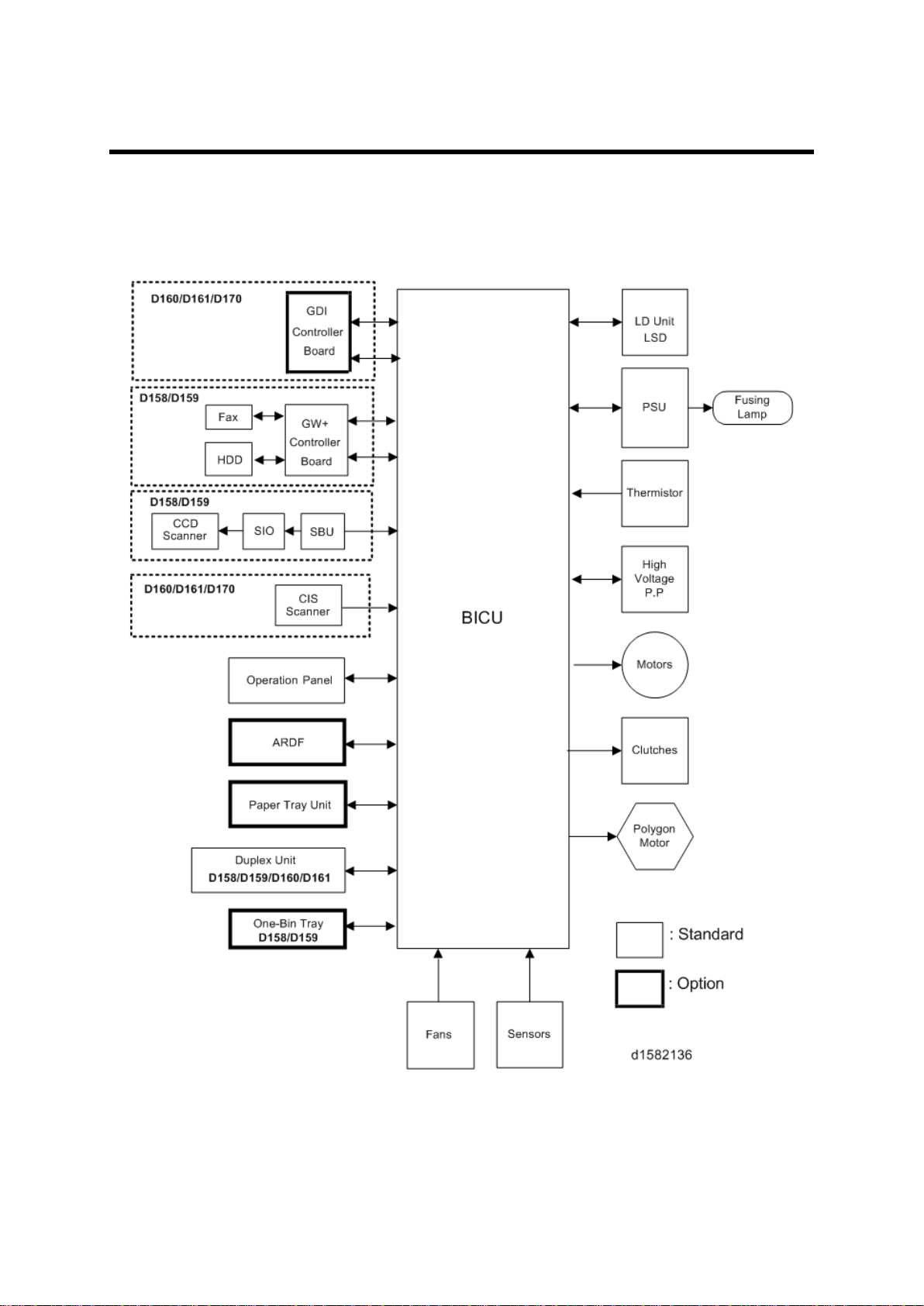

2. BOARD STRUCTURE

2.1 BLOCK DIAGRAM

Block Diagram

Detailed Descriptions 7 D158/D159/D160/D161/D170

Page 13

SBU (Sensor Board Unit)

BICU (Base Engine and Image Control Unit)

The main board con tr ols the following functions:

Engine sequence

Timing control for peripherals

Im age processing, v ideo control

Operati on c ont rol, syst em contr ol ( Basic m achine only)

Mach in e con trol

Dri ve c ont rol for the sens ors, m otor s, and clutches of t he print er and scanner

High voltage supply board control

Serial in terfac es with p eripherals

Fusing control

2.2 SBU (SENSOR BOARD UNIT)

The SBU d eals wit h the an alog signals from the CCD and con verts th em int o digi tal signals.

The SBU is attached to the CCD scanner (D158/D159).

D158/D159/D160/D161/D170 8 Detailed Descriptions

Page 14

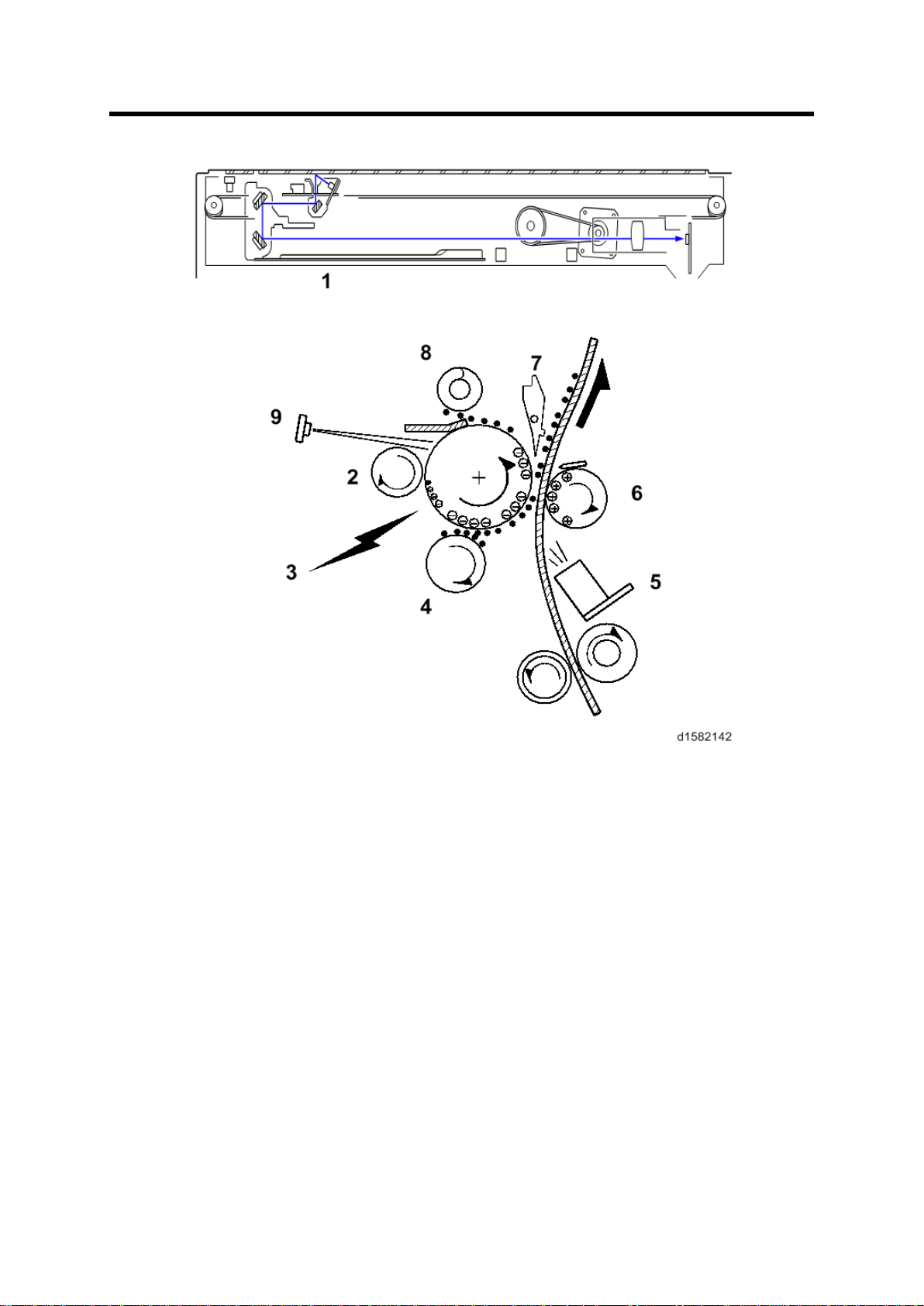

3. COPY PROCESS OVERVIEW

SBU (Sensor Board Unit)

1. Exposure

A xenon lamp exposes the origin al. Light reflec ted from the original passe s to th e CCD,

w here it is conver ted into an analog data signal. Thi s data i s c onver ted to a di gital signal,

processed and st ored in the memory. At the time of print in g, the dat a is ret rieved and

sent to the las er diode.

2. Drum Charge

In th e dark , the charge r oller gi ves a negati ve c harge to the organ ic phot o-conductive

(O PC ) drum. The c harge r emains on th e surface of the dru m because t he OP C layer has

a high elect rical resistance in th e dark .

3. Laser Exposure

The pr ocessed data scanned f rom th e origi nal is ret rieved from the memory and

trans ferred to the dru m b y a laser beam, which f orms an electrical latent image on th e

dr um surface. Th e amount of charge remainin g as a laten t image on th e drum depends

on the laser beam intensity, which is controlled by the BICU board.

Detailed Descriptions 9 D158/D159/D160/D161/D170

Page 15

SBU (Sensor Board Unit)

4. Development

The magnet ic dev elop er brus h on th e development r oll er comes in c ontac t w ith the latent

image on th e drum sur fac e. Toner par tic les are el ectrostaticall y attached t o t he areas of

the drum surface wh ere th e laser red uced the negative charge on t he drum.

5. ID Sensor

The laser for ms a sensor pat ter n on t he drum surface. The ID sens or measures th e

reflectivity of the pattern. The output signal is one o f the factors used for toner sup pl y

cont rol . Al so, the ID sensor measures t he reflectivity of t he dr um surface. The outpu t

si gnal i s us ed f or char ge roll er v oltage con tr ol.

6. Image Transfer

Paper is fed to the area between the drum surface and the tran sfer roller at the proper

ti me for ali gning t he copy paper and the developed image on th e drum surface. T hen, the

trans fer r oller applies a high positive charge t o th e rever se s ide of t he paper. T his

positi ve charge pull s the ton er partic les f rom the drum surf ace ont o the p aper. At th e

same time, the paper is electr ostatically attracted to the tr ansfer rolle r.

7. Paper Separation

Paper separates f rom the drum as a r esult of t he elect ros tati c attraction between the

paper and t he t ransf er r oller. Th e disc harge pl ate ( groun ded) helps s eparate the pap er

from the drum.

8. Cleaning

The c leanin g blade removes any toner remai ni ng on t he drum su rface after t he imag e

trans fers to the paper.

9. Quenching

The light from the quenc hing l amp electrically neutr ali zes the c harge on the drum

surface.

D158/D159/D160/D161/D170 10 Detailed Descriptions

Page 16

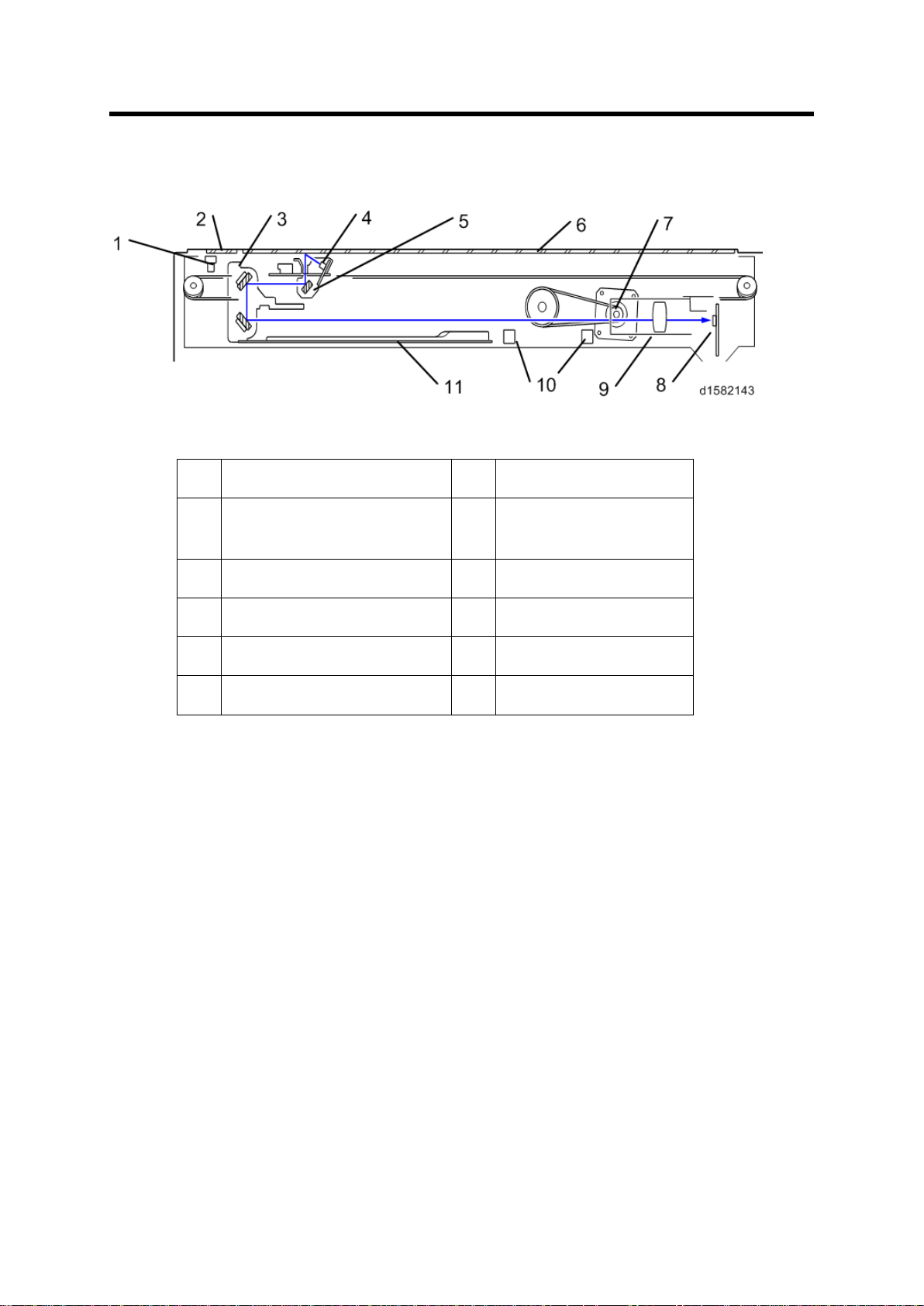

4. SCANNING D158/D159

1.

Scan ner HP s ensor

7.

Scan ner motor

2.

DF exposu re glass

8.

Sensor board unit

3.

2nd scanner (2nd carriage)

9.

Len s Block

4.

Scan ner lamp

10.

AP S s ensor

5.

1st s can ner (1s t carri age)

11.

Scanner Heater

6.

Exposure glass

4.1 OVERVIEW

Overview

(SBU)

The original on t he exp osure g la ss or ARDF exposure glass reflects the li ght emitted f rom

the scanner l amp. The reflected li ght goes t o th e CCD on the sensor b oard by way of the 1 st

and 2nd scanners. The sensor board converts th e CCD an alog sig nals into digital signals.

W hen the original is manually placed on the exposure glass, the scanner motor pulls the 1st

and 2nd scanners via mechanical linkage. The original is scanned from l eft to right.

Wh en th e origi nal is fed f rom th e optional A RDF, it is automat ical ly tr ansp orted ont o the

ARDF exposure glass, and to the original exit. The original does not stay on the glass; but

goes to the exit. T he 1st and 2nd scanners stay at their home positi ons.

Detailed Descriptions 11 D158/D159/D160/D161/D170

Page 17

Scanner Drive

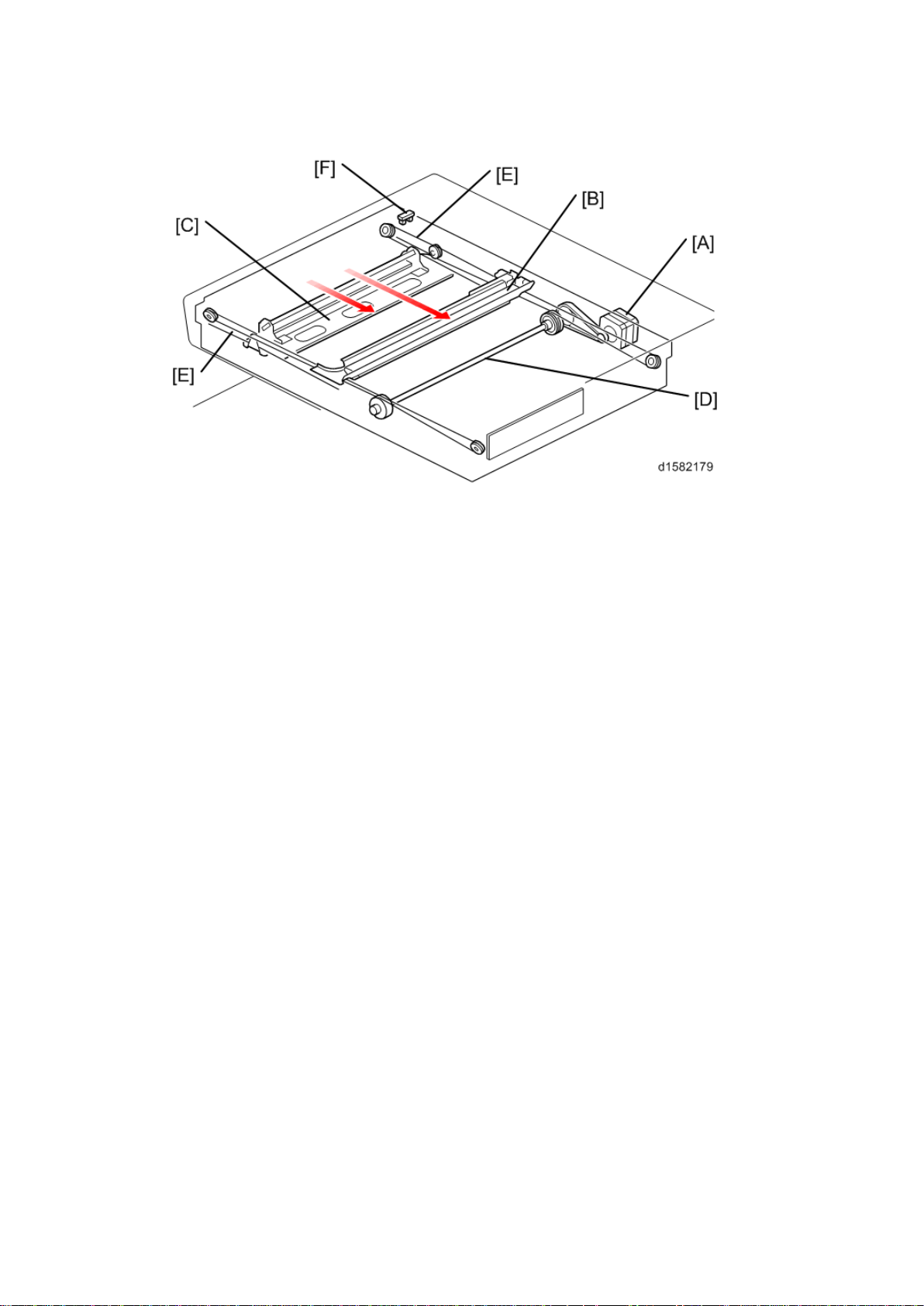

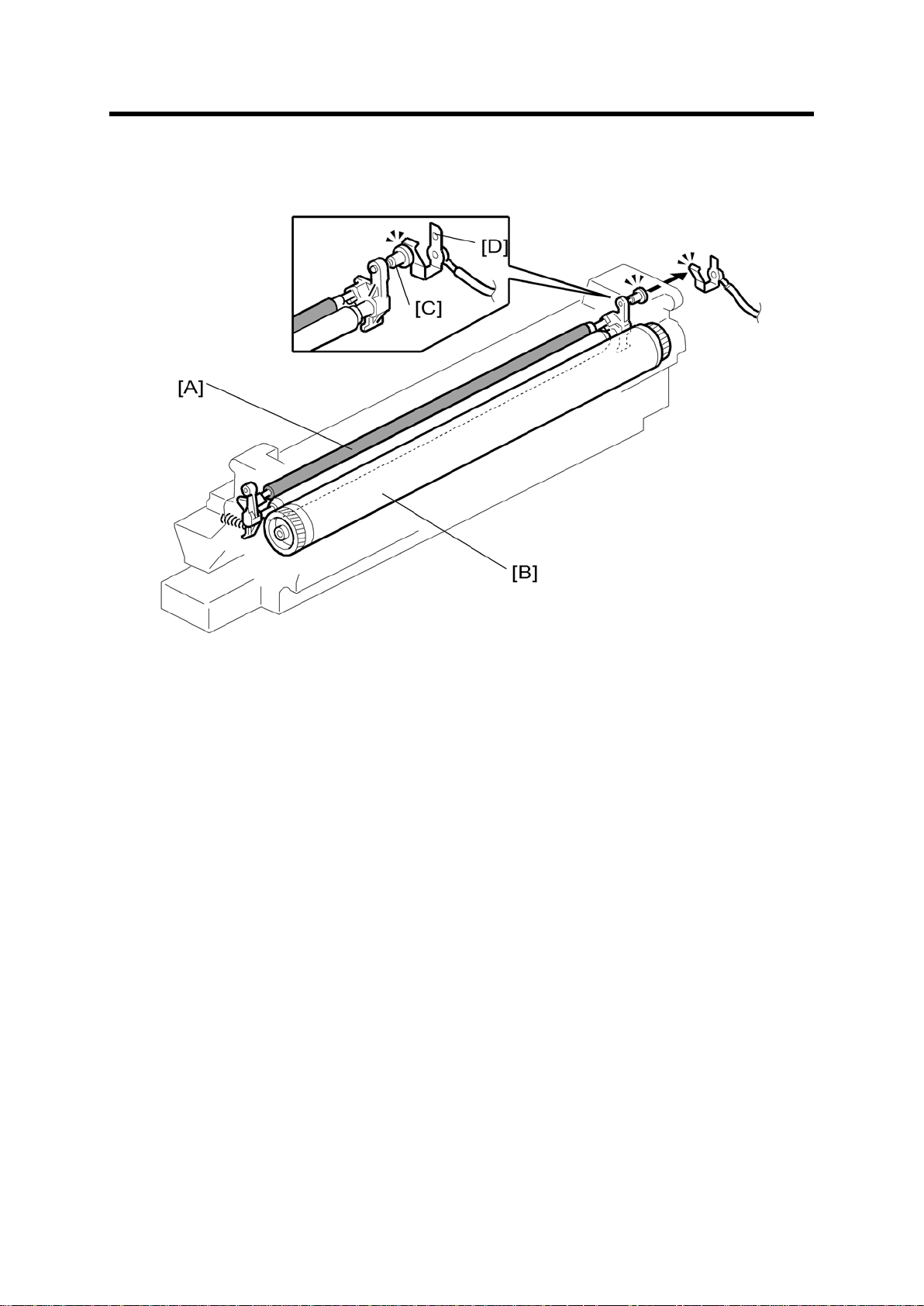

4.2 SCANNER DRIVE

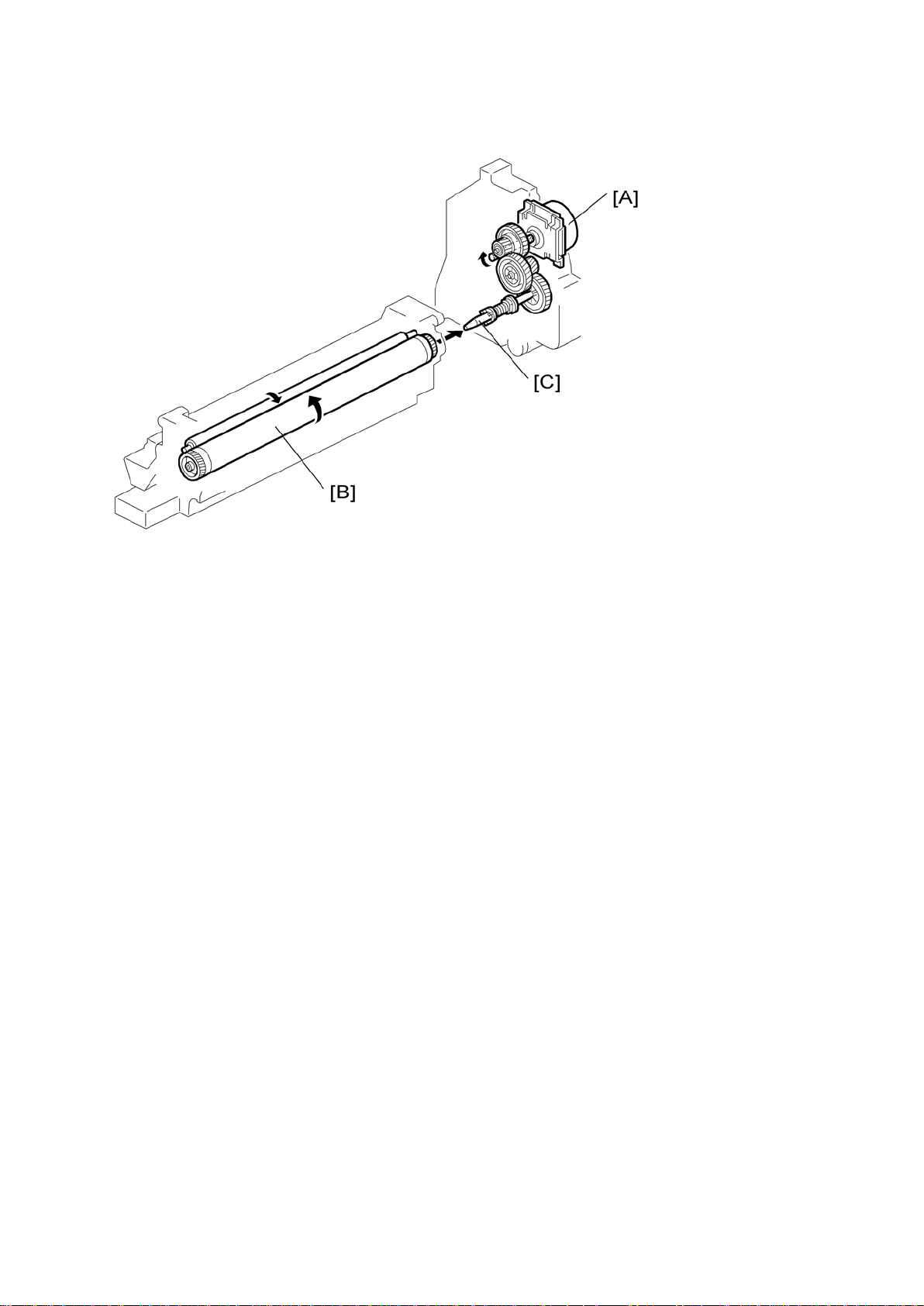

The scanner mot or [A] drives the 1st scanner [B] and the 2nd scanner [C] through the

scanner drive pull ey, scan ner drive shaft [D], and t wo s canner wires [ E].

Book mode -

The SBU board controls the scanner drive motor. The 2nd scanner speed is half that of the

1st scanner.

In reduction or enlargement mode, the scan ni ng s peed depends on th e magnificat ion rat io.

The returning speed is always the same, whether in full size or magnification mode. The

image length change in the sub scan direction is done by changing the scanner m otor

speed. In the main scan direction it is done by im age processing on the BICU board.

You can adjust the magnification in the sub-scan direction by changing the scanner motor

speed with SP4-008.

ARDF mode -

The scanners always st ay in t heir home positi on (th e s canner HP sensor [F] detects the 1st

scanner ) t o sc an t he original. The AR DF motor f eeds th e ori gi nal t hrough t he A RDF. I n

reduction/enlargement mode, the image length change in the sub-scan direction is done by

changing the ARDF motor speed. Magnification in the main scan direction is done in the

BICU board. This is the same as for book mode.

You can adjust magnific ation in the sub-scan direction by changing the ARDF motor speed

with SP6 -017.

D158/D159/D160/D161/D170 12 Detailed Descriptions

Page 18

Origi n al S iz e Detection in Pl at en M ode

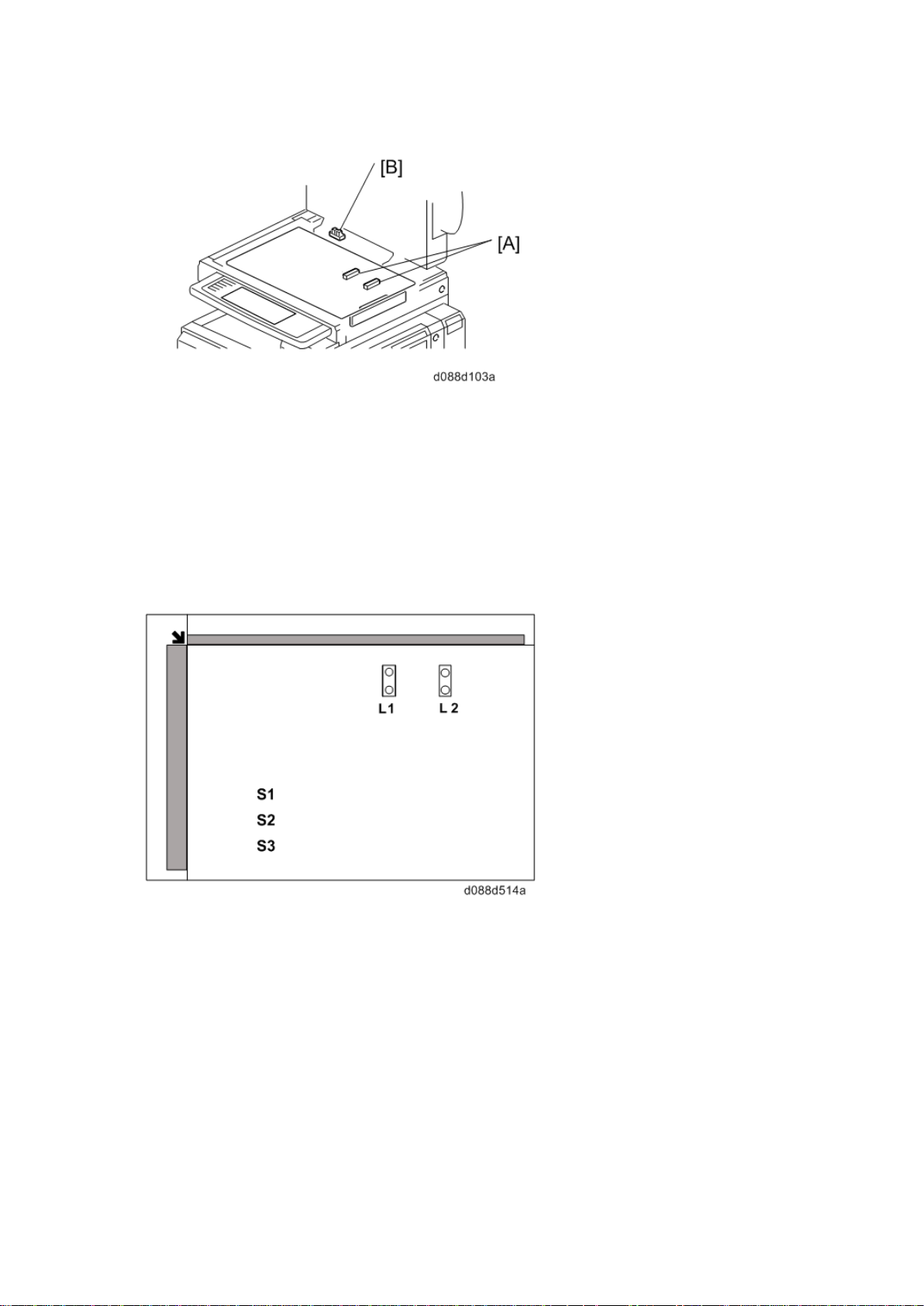

4.3 ORIGINAL SIZE DETECTION IN PLATEN MODE

Ther e are no APS s ensor ( width) in the scanner unit. However, the original width can be

detec ted by CCD . The A PS s ensor ( length) [A] det ects the original length.

The BIC U board ch eck s each s ensor status when the plat en c over s ensor [B] is

activated as it is closed. It det ects the or ig inal size by t he on/off s ignals it gets f rom each

sensor.

If the copy is mad e with t he platen cover f ul ly open, th e CPU det ermi nes the ori ginal size

from the sen sor outp ut s after t he S tar t key is pressed.

Detailed Descriptions 13 D158/D159/D160/D161/D170

Page 19

Anti-Cond ensati on Heat er

4.4 ANTI-CONDENSATION HEATER

The anti-condensati on heater is av ailable as an optional unit. The anti-condensation heater

pr even ts con densat ion on th e mirror s. Cond ensation can occu r wh en the s canner unit is, for

example, moved from a col d room to a warm r oom. Condensati on c an c ause abno rmal

images.

D158/D159/D160/D161/D170 14 Detailed Descriptions

Page 20

5. SCANNING D160/D161/D170

1. CIS unit (with carriage)

4. APS sensor (length)

2. Exposure Glass

5. APS sensor (widt h)

3. Scanner Motor

6. Scanner HP sensor

7. DF Exposure Glass

5.1 OVERVIEW

Overview

CIS unit

1-ch unity-magnifying contact im age sen sor (R GB_LED+SLA+C MOS

sensor)/capable of A3 color scanning

Bottom frame

Resin base

Upper frame

Composed of a resin base, exposure glass, and DF exposure glass

Sensor

1-ch CIS + integrated carriage + slide guide

Drive

Belt dr ive using a P M st epping motor

Exterior

The bottom fr ame (resin base) is integrated in to the exterior.

APS Sensor

2 width sensors and 2 length sensors (the sens or location depends on the country of

use)

Detailed Descriptions 15 D158/D159/D160/D161/D170

Page 21

Scanner Drive

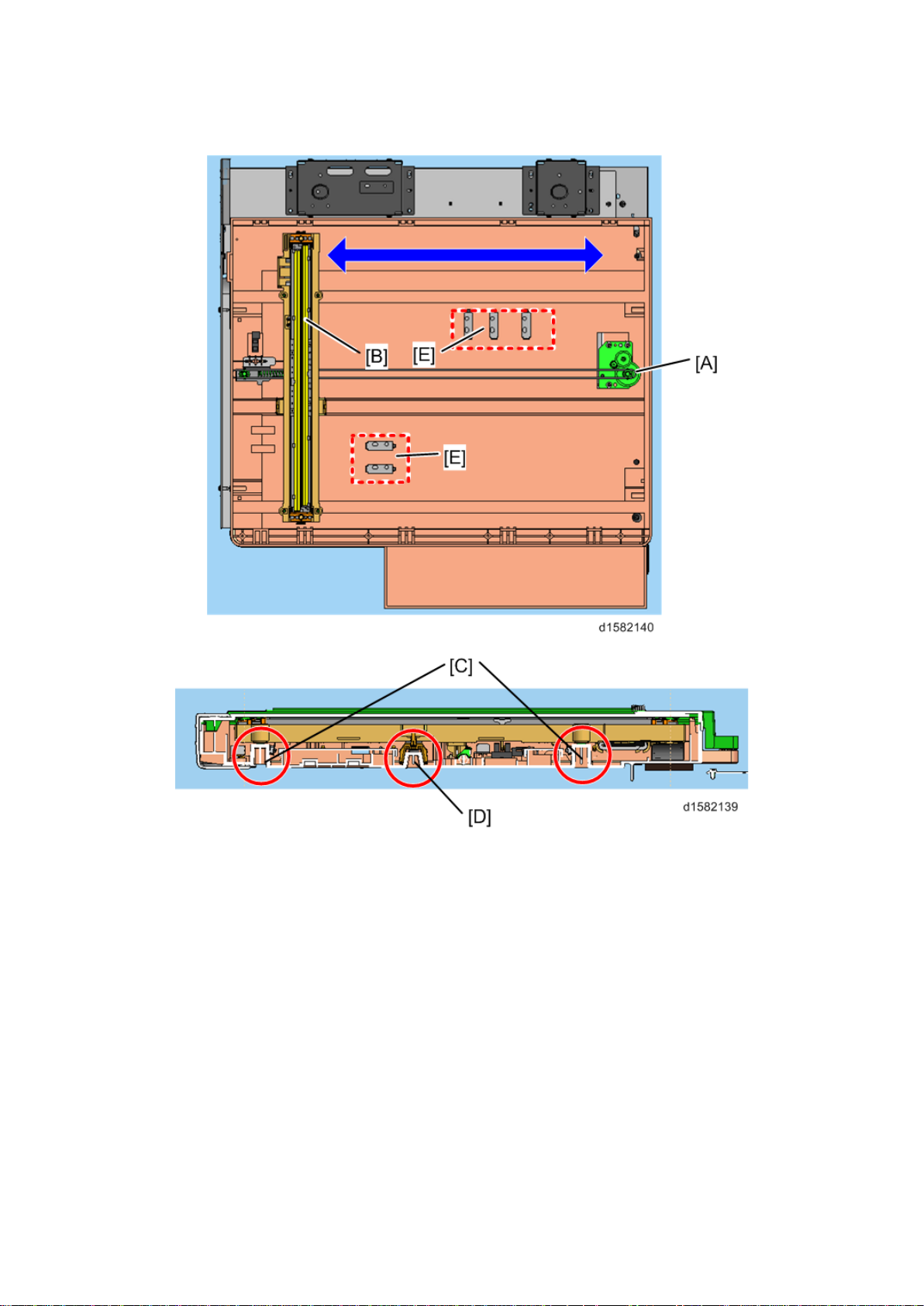

5.2 SCANNER DRIVE

Models D160, D161 and D170 are flat bed scanners using a CIS.

To s can an origi nal , the s canner motor (A ) moves the car riage on which the CIS (B ) is

mounted al ong th e car rier guide rail.

The CIS can be raised or lowered using the side guide rails (C) and adjusted relative to the

main scanning direction using the center guide rail (D). This is a factory adjustment; do not

do this in the field.

The size of th e original is detect ed by the AP S sen sor s (E) on t he bot tom fr ame.

D158/D159/D160/D161/D170 16 Detailed Descriptions

Page 22

[A]: All areas except China

[B]: China only

Scanner Drive

Detailed Descriptions 17 D158/D159/D160/D161/D170

Page 23

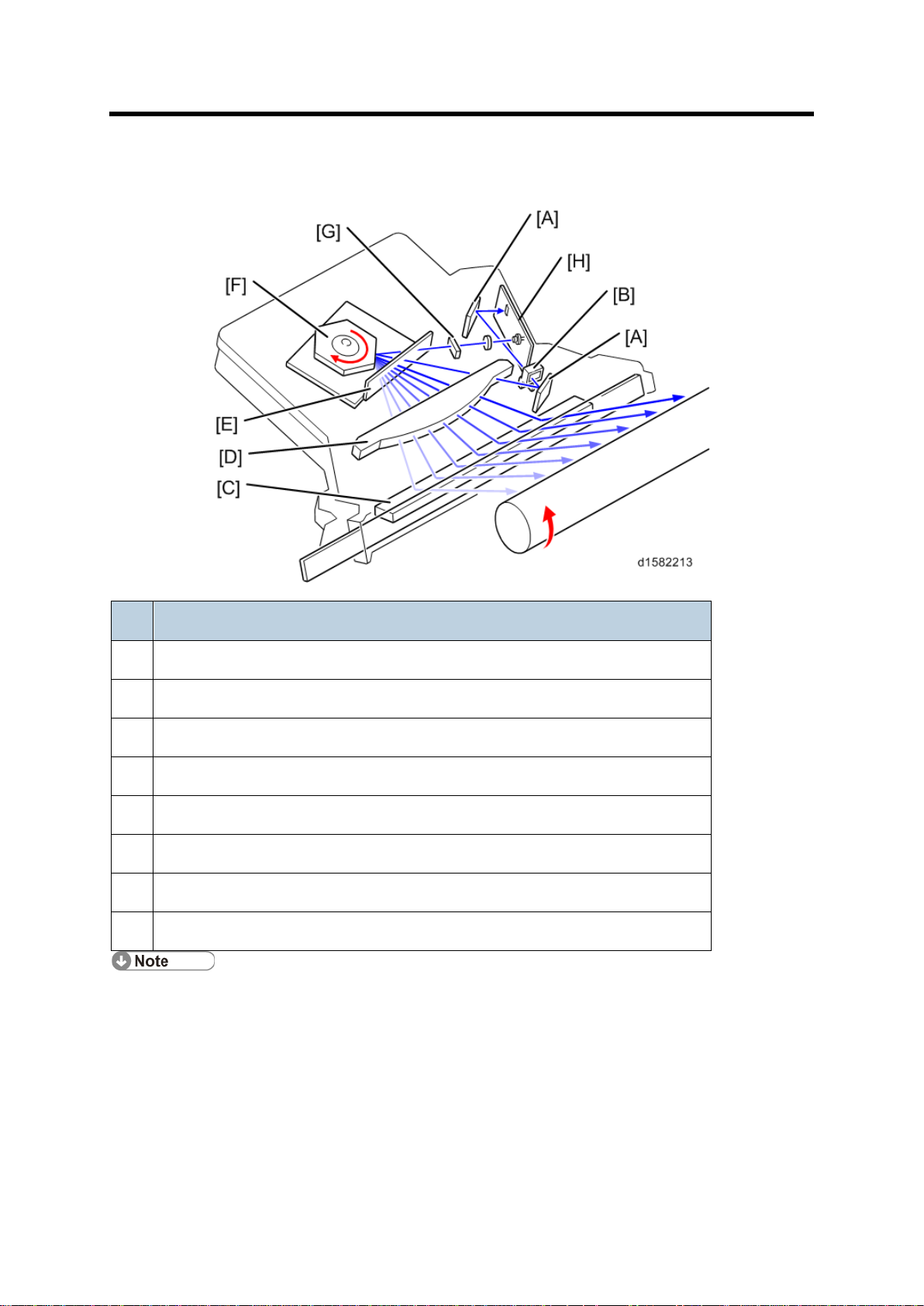

Overview

Name

A

Synchronization detect or mi rrors

B

Synchronization detect or lens

C

Mirror

D

F-thet a lens

E

Soundproof glass

F

Polygon Motor

G

Cylindrical lens

H

LD board

The LD drive board controls both the laser output and laser synchronization

mecha

The machine cuts off the power supply to the LD drive board if the front or right cover

is opened.

6. LASER EXPOSU RE

6.1 OVERVIEW

nism.

D158/D159/D160/D161/D170 18 Detailed Descriptions

Page 24

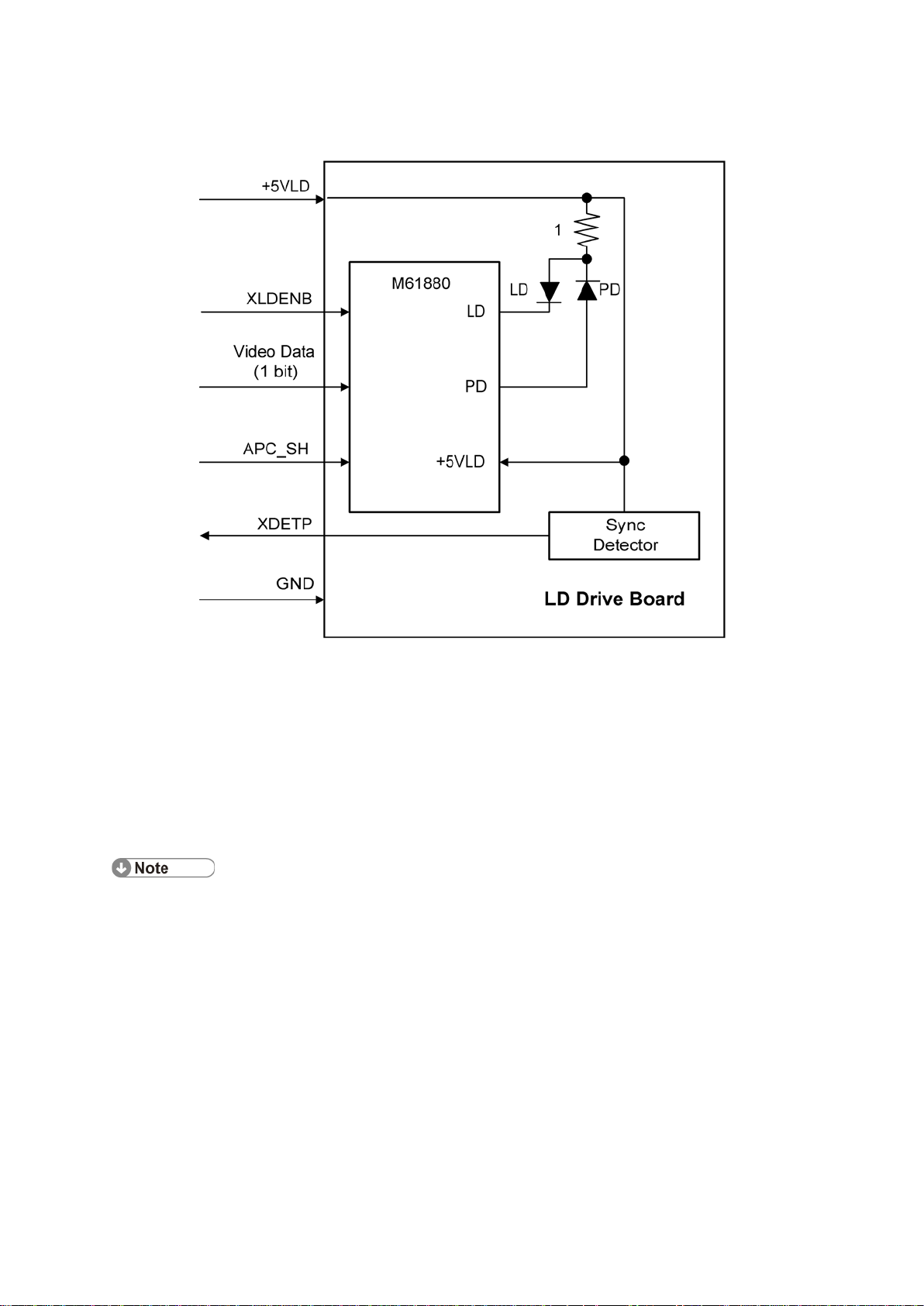

6.2 AUTO POWER CONT ROL (APC)

Do not touch the variable resistors on the LD unit in the field.

Auto Power Control (APC)

The LD driver IC drives the laser diode. To preven t the in ten sity of the laser b eam from

changing because of the temperature, the machine monitors the current passing through the

laser diode (LD). T he machine adjusts th e curr ent to the laser diode by compar in g i t with th e

re ference level from t he reference circuit.

This auto power c ont rol i s done jus t af ter th e machine i s turned on and during printing.

The laser diode power is adjus ted on the producti on lin e.

Detailed Descriptions 19 D158/D159/D160/D161/D170

Page 25

LD Safety Switch

6.3 LD SAFETY SWITCH

To ensure t echnician and us er s afety and to prevent the laser beam from inad ver tently

switching on during servicing, safety switc hes are located at the front and right covers. The

switches are installed on the +5VLD line through the BICU board.

Wh en th e f ront cover or th e ri ght cover is opened, th e power s upply t o th e laser diode is

interrupted.

D158/D159/D160/D161/D170 20 Detailed Descriptions

Page 26

7. PHOTOCONDUCTOR UNIT (PCU)

1. Cleaning Blade

6. Dev elopment Rol ler

7.1 OVERVIEW

Overview

The PCU c onsists of th e components shown in t he above ill ustration. An organic

photoconductor (OPC) drum (diameter: 30 mm) is used in this machine.

2. Toner Collection Coil

3. Pick-of f Pawl

4. OPC Drum

5. ID Sensor (see note)

7. Dev elopment Unit

8. Charg e Roll er

9. Charge Roller Cleaning Brush

10. Quenching Lamp (see note)

Detailed Descriptions 21 D158/D159/D160/D161/D170

Page 27

Overview

The ID sensor and quenching lamp are not included in the PCU.

The OPC drum's shutter [A] of

the previous model has been removed.

D158/D159/D160/D161/D170 22 Detailed Descriptions

Page 28

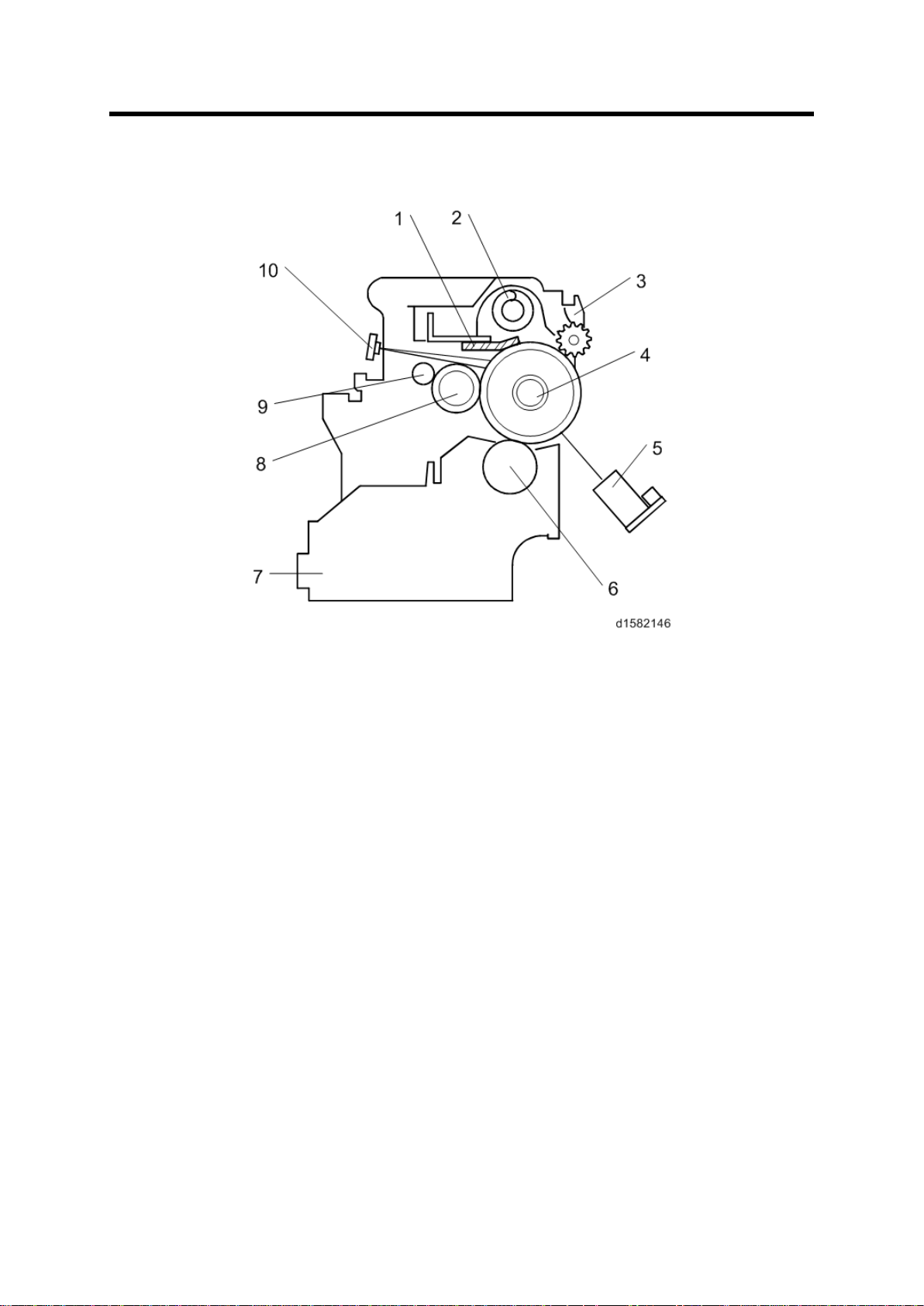

7.2 DRIVE

Drive

The main m otor [A] dr ives t he drum [B] through a s eries of ge ars and th e drum drive s haft

[C] . Th e mai n m otor ass embly inc lu des a d rive c ontr oller, which outputs a motor l ock s ig nal

w hen the rot ation sp eed is out of th e specified range.

Detailed Descriptions 23 D158/D159/D160/D161/D170

Page 29

Overview

8. DRUM CHARGE

8.1 OVERVIEW

This cop ier uses a drum ch arge roll er t o charge the drum. The drum c harge roller [A] alway s

cont acts th e surface of th e drum [B ] to gi v e it a negat ive c harge of –950 V.

The high voltage supply board gives a negat ive c harge of –1700 V t o the drum charge roller

through the screw [C] and terminal plate [D]. This voltage can be changed using SP2-001001 (Charge Roll er Bias Adjust Setting (Copying)).

D158/D159/D160/D161/D170 24 Detailed Descriptions

Page 30

ID Sensor Pattern Production Timing

8.2 ID SENSOR PATTERN PRODUCTION TIMING

The ID sen sor pattern is not made every page or every job.

It is only made in the following conditions:

During warm -u p at power on

W hen t he m ach in e st art s war ming up from energ y s aver mode and th e temper atu re

is less t han th e target temp erat ure as set w i th SP Mode.

When the machine start s war ming up from en ergy saver mode and t he machine

prints more than 100 prints after generating the p-pattern.

Detailed Descriptions 25 D158/D159/D160/D161/D170

Page 31

Drum Charge Roller Cleaning

8.3 DRUM CHARGE ROLLER CLEANING

Becau se th e dru m charge roller [A ] alway s c ont acts th e drum, it get s dirty easil y. So, t he

cleaning brus h [ B] also con tacts the drum char ge roller all th e time to c lean t he surface of

the drum charg e roller .

D158/D159/D160/D161/D170 26 Detailed Descriptions

Page 32

9. DEVELOPMENT

9.1 OVERVIEW

Overview

The develop ment unit c onsists of th e following part s.

1. Develop ment roller

2. Mixing auger 2

3. TD sen sor

4. Mixing auger 1

5. Doctor b lade

This machine uses a single-r oll er dev elopment s ystem. T wo mi xing augers mix the

developer. The toner densit y (TD) sen sor and imag e densit y (ID) sen sor (see the illustration

in the P CU section) are us ed t o con tr ol the i mage density on the copy.

Detailed Descriptions 27 D158/D159/D160/D161/D170

Page 33

Drive

9.2 DRIVE

The main motor [A] drives the development roller [B] and mixing augers [C] through a train of

gears and the development drive shaft [D]. When the PCU is pushed in, the developm ent

dr ive s haft engages th e dev elopment roller gear.

The develop ment drive gear s (except for t he gears in the development unit) are helic al

ge ars. T hes e gears are quieter than normal gears.

D158/D159/D160/D161/D170 28 Detailed Descriptions

Page 34

9.3 DEVELOPER MIXING

Devel op er Mi xi ng

The two m ixi ng augers , [A , B] k eep t he developer even ly mixed . Mixing auger 2 [A]

trans port s excess developer, s cr aped of f the development roller [ C] by t he doctor blade [D ],

towards th e f ront of the machin e. Mixing auger 1 [B] ret urns the exc ess dev elop er, along

w ith new ton er, to the rear of th e mixing assemb ly. Here t he developer is reapplied to the

develop ment roller.

Detailed Descriptions 29 D158/D159/D160/D161/D170

Page 35

Development Bias

9.4 DEVELOPMENT BIAS

This mach in e uses a negative-positive d evelopment s ystem, in which black areas of the

laten t image are at a low negat ive charg e (about –154 ± 50 V) and white areas are at a high

negative ch arge (abou t –950 V).

To attract negativel y c harged t oner to the black areas of the latent image on the drum, the

high voltage supply board applies a bias of –650 volts t o th e development rollers throughout

the imag e development p rocess. The bias is applied to the development r oller s haf t [A ]

through the drive sha ft [B].

The develop ment bias v oltage (–650 V) can be adjusted with SP 2201 1.

D158/D159/D160/D161/D170 30 Detailed Descriptions

Page 36

9.5 TONER SUPPLY

9.5.1 TONER BOTTLE REPLENISHMENT MECHANISM

Tone r Supply

W hen a toner bottle is placed in the bottle holder unit [A] and the unit is pushed in

completely, t oner sh ut ter [B] moves again st th e side [ C] of the PCU. When the toner bottle

holder lever [D] is put back in the original position, the cap [E] on the toner bottle is pulled

away and kept in place by the chuck [F].

The toner su pply mechanism trans port s t oner from the bottl e to the dev elop ment unit. Th e

toner bottle has a spiral groove [G] that helps move toner to the development unit.

To add a new t oner bottle, fir st lift th e ton er bottle hol der. When this is done, the c huc k

rele ases th e tone r bottl e cap in to it s pr oper pos iti on t o prev ent toner from scat ter in g.

Then, when t he bottle hol der unit is pull ed out to add a new toner bot tle, th e ton er shutter

shuts to block the opening as a result of pressure from a spring.

Detailed Descriptions 31 D158/D159/D160/D161/D170

Page 37

Tone r Supply Mechanism

9.6 TONER SUPPLY MECHANISM

The toner su pply motor [A] d ri v es t he ton er bot tle [ B] and th e mylar blades [C]. Firs t , t he

toner f all s down in to the ton er bottle hol der. The toner sup pl y mylar blades transfer th e toner

to the slit [D]. When the PCU is installed in the machi ne, the shutter [E] above the PCU is

op ened by th e toner bottle h older. Then t he t oner f all s down in to the dev elopmen t unit

through the slit and the shutter.

D158/D159/D160/D161/D170 32 Detailed Descriptions

Page 38

Toner Density Control

Mode

Sensor control 1 (SP 2921, “0”): Normally use this setti ng only

Toner supply

Comp are Vt with a r efe rence v oltage (Vt s or Vref )

Toner cont rol

Toner is supplied to the development unit when Vt is higher than

9.7 TONER DENSITY CONTROL

9.7.1 OVERVIEW

Ther e are four modes for cont rolling toner su pply as shown in t he following tables , whic h can

be changed with by SP 2921. The factory setting is s ensor contr ol 1 mode.

Basically, th e ton er concen tration i n t he developer is cont rolled using t he standard TD

sensor v oltage ( Vts), t oner s uppl y r eferen ce voltage (Vr ef) , actual TD sen sor output voltage

(Vt), and ID sensor output data (Vsp/Vsg).

The four-toner densit y c ont rol modes ar e as follows .

Se nsor c ontr ol 1

decision

process

the ref erenc e volt age (V ts or V ref) . This mode ke eps th e Vr ef

val ue for us e with t he next t oner dens ity con tr ol.

Vts i s us ed fo r t he firs t toner dens ity con tr ol aft er a new PC U

has been installed, until i t h as been c orrec ted with the I D sensor

output.

Vref is u sed after Vts has b een cor rected with the ID sens or

output voltage ( cor rected during th e f ir st ton er dens ity contr ol for

a new P CU).

Detailed Descriptions 33 D158/D159/D160/D161/D170

Page 39

Toner Density Control

Toner supply

Varies

Toner end detect ion

Performed

Sensor control 2 (SP 2921, “1”): For designer’s use only; do not

Toner supply

Comp are Vt with a r efe rence v oltage (Vt s)

Toner cont rol

This toner con tr ol p roces s is the s ame as s ensor control 1

Toner supply

Varies

Toner end detect ion

Performed

Fixed control 1 (SP 2921, “2”): For designer’s use only; do not

Toner supply

Comp are Vt with a r efe rence v oltage (Vt s or Vref)

Toner cont rol

This toner con tr ol p roces s is the s ame as s ensor control 1

Toner supply

Fixed (SP 2925)

Toner end detect ion

Performed

amount

Se nsor c ontr ol 2

Mode

decision

process

amount

Fixed control 1

Mode

decision

use in th e f ield

mode. However , the reference voltage used is always Vts.

use in th e f ield

process

mode.

amount

D158/D159/D160/D161/D170 34 Detailed Descriptions

Page 40

Fixed control 2

Fixed control 2 (SP 2921, “3”): Use t emp orarily if th e TD sensor

Toner supply

None

Toner cont rol

Toner is supplied every p rint ed page regar dless of Vt.

Toner supply

Fixed (SP 2925)

Toner end detect ion

Not performed

Toner Density Control

Mode

decision

process

amount

ne eds to be replaced

9.7.2 TONER DENSITY SENSOR INITIAL SETTING

The TD sen sor in itial setti ng (SP2-801-0 01 D eveloper In itializati on) pr ocedu re mu st be done

after replacing th e developer. During TD sens or initial setti ng, the T D s ensor is set s o that

the TD sensor output is the value of SP 2926 (default: 2.5V) . Thi s value will be us ed as the

standar d ref erenc e volt age (V ts) of the TD sens or.

9.7.3 TONER CONCENTRATION MEASUREMENT

The toner c oncentration in the d eveloper is detect ed once ev ery copy cycl e. The sen sor

output voltage (Vt) during the detection cycl e is compared with the stan dard ref erence

vol tage (Vt s) or th e toner s upply r eferen ce voltage (Vr ef ).

9.7.4 VSP/VSG DETECTION

The ID sen sor detects th e followi ng v oltages.

Vsg: The ID sensor output when checking the drum surface

Vsp: The ID sensor output when checking th e ID sensor pat ter n

In th is way, the r eflec tivit y of b oth th e drum surface and t he pat ter n on th e drum are

checked , com pensati ng f or any variation s in t he ref lectivit y of the pattern on th e drum or the

re f lect iv ity of th e drum surface.

The ID sen sor pattern is made on t he drum by the char ge roller and laser d iode.

Vsp/V sg is not d etected every pag e or job ; it i s detect ed at the fol lowi ng times to deci de V ref.

During warm-up at p ower on

If the machine starts warmi ng up when the fusing temperature is 30°C or less (default) after

entering night mode or low power mode (SP 2994 specifies the temperature setting).

Detailed Descriptions 35 D158/D159/D160/D161/D170

Page 41

Toner Density Control

Value of SP2-925

Motor On Time (t = 200 ms)

0 T 1

2t 2 4t 3 8t 4 12t 5 16t

6

Continuously

7

Not supplied

9.7.5 TONER SUPPLY REFERENCE VOLTAGE (VREF)

DETERMINATION

The toner su pply reference volt age (Vref ) i s us ed f or t oner s upply determinat ion (s ee below).

Vref is det erm i ned using the foll owi ng data:

ID sensor output (V sp/Vsg)

(Vts or the current Vref) - Vt

9.7.6 TONER SUPPLY DETERMINATION

The re feren ce vol tage ( Vts or Vref) is th e th reshold volt age for deter min in g whet her or not to

supply ton er. If Vt bec omes greater than th e ref erenc e volt age, the machine supplies

add itional toner.

This can be checked using SP 2220.

9.7.7 TONER SUPPLY MOTOR ON TIME DETERMINATIONS

For fixed control mode, the toner supply motor on time is specified by the setting of SP 2925,

and does not vary. The default setting is 200 ms for each copy. The toner supply motor on

ti me for eac h value of SP 2925 is as f ollows .

For sens or c ontrol modes 1 and 2, the toner supply motor on time is decided by the following

factors.

Vt

Vref or V ts

TD sensor sen sitivit y (coeffic ien t: S, value i s 0.4)

D158/D159/D160/D161/D170 36 Detailed Descriptions

Page 42

Toner Density Control

Level

Decision

Motor On Time (seconds)

1

(Vts or Vref) < Vt ≤ (Vts or Vref) + S/16

t (0.4)

2

(Vts or Vref) < Vt ≤ (Vts or Vref) + S/8

t x 2 (0.8)

3

(Vts or Vref) < Vt ≤ (Vts or Vref) + S/4

t x 4 (1.6)

4

(Vts or Vref) < Vt ≤ (Vts or Vref) + S/2

t x 8 (3.2)

5

(Vts or Vref) < Vt ≤ (Vts or Vref) + 4S/5

t x 16 (6.4)

6

Vt ≥ (Vts or Vref ) + 4S /1 6 (near-end)

T (30); see note 3

7

Vt ≥ (Vts or Vref ) + S ( ton er end)

T (30); see note 3

The value of “t” can be changed using SP 2922 (default: 0.4 second)

The value of “T” can be changed using SP 292

T (30) means that toner is supplied intermittently in a 1/3 duty cycl e (1 s on, 2 s off) for

30 seconds

Ther e are seven levels for toner supply motor on t i me as shown bel ow.

3 (default: 30 seconds)

Detailed Descriptions 37 D158/D159/D160/D161/D170

Page 43

Toner Supply in Abnormal Sensor Conditions

9.8 TONER SUPPLY IN ABNORM AL SENSOR

CONDITIONS

9.8.1 ID SENSOR

Re adings are ab normal if any of the f ollowing con ditions oc cu r:

Vsg ≤ 2.5V

Vsg < 3.5V when maximum power (979) is applied

Vsp ≥ 2.5V

(Vsg – Vsp) < 1.0V

Vt ≥ 4.5V or V t ≤ 0.2V

The above ID sensor values can be checked using SP 2221.

Wh en th is i s detec ted , the machine changes th e value of Vref to 2.5 V then does the toner

den sity cont rol proc ess ( in a s imil ar way to sen sor c ont rol mode 2 ).

No SC code is generat ed if t he I D sen sor is defective.

9.8.2 TD SENSOR

The TD sen sor outp ut is checked every copy. If t he readings from the TD sensor become

abnormal, the mach in e ch anges t he t oner dens ity contr ol mode to fixed s upply mode 2, and

the toner supply amount per page is always 200 m s, regardless of the value of SP 2925. If

the m ach in e det ects th e TD sensor error c ondition 10 t i mes con secu tively, an SC cod e is

generated (SC390) and the machine must be repaired.

9.9 TONER NEAR END/END DETECTION AND RECOVERY

The toner near end and end c onditions are detected using th e Vt and Vr ef values, i n a

si milar way to t oner densit y cont rol.

This is don e in all ton er supply m odes except for fixed mode 2, when toner end is not

detected.

9.9.1 TONER NEAR END DETECTION

If Vt is at level 6 (see the tab le on t he prev ious page) f ive t imes con sec ut iv ely, th e machi ne

enters the toner near end condition and the toner end indicator starts blinking. T hen the

mac hin e s uppl ies toner for a c ert ain time, w hich depends on t he s etti ng of SP 29 23 (see the

pr evious page).

D158/D159/D160/D161/D170 38 Detailed Descriptions

Page 44

Toner Near End/End Detection and Recovery

9.9.2 TONER NEAR END RECOVERY

If the mach in e det ects “Vt < (Vr ef or V ts ) + 4S/5” t wice consec utively in any of the following

situations, the machine clears the toner near end condition.

While i n t he t oner recovery cy cle (sup pl ying ton er on and off for 30 sec onds ) after t he

mac hin e has detec ted a toner near en d condition.

During copying in the toner near end condition.

If the fr ont c over is opened and c losed for more than 10 seconds while a toner near end

condition exists.

9.9.3 TONER END DETECTION

Ther e are two situati ons for enter in g t he t oner end con dition.

Wh en V t is level 7 th ree times c onsecu tively, t he m ach in e ent ers the ton er end c ondition.

W hen 50 copies have been made since entering the toner near end condition. The

number o f c opies bet ween toner near-end and toner end can be changed using SP

2213.

9.9.4 TONER END RECOVERY

While t urning on t he m ain switch, if the fron t cover is opened for 10 secon ds or more and

then closed while a T oner E nd con di tion exis ts (following ton er bottle replacement) , the

mac hin e clears th e Ton er E nd c ondition. Th e rec overy procedu re is the same as for toner

ne ar end. It takes about two mi nut es.

Detailed Descriptions 39 D158/D159/D160/D161/D170

Page 45

Drum Cleaning

10. DRUM CLEANING AND TONER RECYCLING

10.1 DRUM CLEANING

The c leanin g blade [ A] removes any toner remainin g on th e drum af ter the image is

trans ferred to the paper. T his model uses a count er blade system.

The cleaning blade scrapes off toner remaining on the drum . When toner builds up in the

clean ing uni t, ton er at the top of the pile is removed by the toner collection c oil [B].

To r emov e th e toner and other part icl es that are accumu lated at the edge o f t he c lean ing

blade, the dr um turns in r ever se for about 5 m m at th e end of every copy job.

D158/D159/D160/D161/D170 40 Detailed Descriptions

Page 46

10.2 TONER RECYCLING

Toner Recycling

Toner pi ck ed up by th e ton er c ollec tion coil [A], is t rans port ed t o the op eni ng [B] in t he side

of t he P CU. T hen, thi s t oner fal ls in to the dev elopment unit w i th new ton er c oming from th e

toner bottle and it is all mixed together by mixing auger 1 [C] and used again.

Detailed Descriptions 41 D158/D159/D160/D161/D170

Page 47

Overview

1. Tray H eater

6. By-pass Feed Roller

11. PAPER FEED

11.1 OVERVIEW

There are one or tw o paper trays, each of which can hold 250 sheets.

The paper tr ay feed stations us e a fr ict ion pad s ystem. To prevent paper f rom get ting

caught inside the machine when the tray is pu lled ou t, the paper fe ed roller an d shaft d o

not separate f rom the tray w hen th e tr ay is pulled out.

The two relay s ensor s are used for paper jam detect ion. The lower one d etec ts jams

when paper is fed up from the optional paper feed unit.

The c ompon ent s of th e paper feed station are as follows.

2. Paper End Sensor

3. Pap er Feed Roller

4. Regist rat ion Roll er

5. Regist rat ion Sen sor

7. Upper Relay Sensor

8. Lower Relay Sen sor

9. Friction Pad

10.Tray Lift Sensor

11. Paper S ize Switch

D158/D159/D160/D161/D170 42 Detailed Descriptions

Page 48

11.2 PAPER FEED DRIVE MECHANISM

Paper Feed Drive Mec h anism

The main m otor [A] dr ives t he pick-up and feed mechanism of both the first and second

paper tr ays . The paper feed clutches [ B ] transfer drive f rom this mot or t o the p aper fe ed

rollers [C ].

Wh en th e paper f eed clutch t urns on , the feed roller starts to feed th e paper. T he paper feed

clu t ch s tay s on u ntil shortl y after t he regist rati on sensor has been activated.

Detailed Descriptions 43 D158/D159/D160/D161/D170

Page 49

Paper Feed an d S eparati on M ec h anism

11.3 PAPER FEED AND SEPARA TION MECHANISM

The paper feed roller [A] dri ves the top sheet of paper from t he paper tray to the cop ier. The

frict ion pad [B] al lows only one sh eet to feed at a time. The fric tion pad appli es press ure t o

the fe ed roller wi th a sprin g [ C].

The friction pad pressure cannot be adjusted.

D158/D159/D160/D161/D170 44 Detailed Descriptions

Page 50

11.4 PAPER LIFT MECHANISM

[A] Botto m plate

[B

[C] Bottom plate lift gear

[D] Tr ay lif t mo tor

[E] Bottom plate lift HP sensor

] B ottom pl ate lift arm

Paper Lift Mechanism

The tray li f t mot or rotates the gear [ C] and th e gear makes th e rack [F] move.

The movement of the rack pull s the spring and thi s moves the bot tom plate li ft arm [B].

The arm li f ts the b ottom pl ate [A].

The pos ition of th e bottom p late is detect ed by the bottom pl ate lif t H P sen sor [E]. T his

mac hin e does not u se mot or control to detect the bottom plate position.

Detailed Descriptions 45 D158/D159/D160/D161/D170

Page 51

By-pass t r ay b ot t om pl ate lift mechanism

[A] By -pass tra y bottom plate

[B] Pressure spring

[C] By

[D] A ctu ato r

[E] By

[F] By

11.5 BY-PASS TRAY BOTTOM PLATE LIFT MECHANISM

-pass tr ay bot tom plat e lift c am HP sen sor

-pass tray bottom plate lifting up cam (Front and rear)

-pass tr ay bottom plate lifting up cam clutch

The paper tr ansp ort motor rotates th e by-p ass tray bottom plate lift cam clutch [F], and this

moves the by -pas s tray bot tom plate [A] up and dow n.

The pos ition of th e by-pa ss tray b ottom plat e li ft cams ( and bec ause of this, the by-pass tray

bott om plat e) is detect ed by the by -pas s t ray bott om plate lif t cam H P sen sor . [C].

D158/D159/D160/D161/D170 46 Detailed Descriptions

Page 52

Paper End Detection

11.6 PAPER END DETECTION

If there is an y pap er i n t he paper tray, the paper stac k lifts t he fe eler, t he paper en d sensor

[A ] is deactivated .

Wh en th e paper tray ru ns out of p aper, th e paper end fe eler d rops into the cuto ut [B] in th e

tray b ottom p late and t he pape r end s ensor is activated .

W hen the paper tray is drawn out with no paper in the tray, the shape of the paper end feeler

causes it to lif t up .

Detailed Descriptions 47 D158/D159/D160/D161/D170

Page 53

Paper Size Detection

Models

Switch Location

North America

Europe/Asia

SW4

SW3

SW2

DLT (A3) SEF*

1

A3 (DLT) SEF*

1

0 0 1

LG (B4) SEF*

2

B4 (L G) SEF *

2

0 0 0

A4 SEF

A4 SEF

1 1 0

LT SE F

LT SE F

1 1 1

B5 SEF

B5 SEF

0 1 1

LT (A4) LEF*

3

A4 (LT) LEF*

3

1 0 0

Exe (B5) LEF*

4

B5 (Exe) LEF*

4

0 1 0

A5 LEF

A5 LEF 1 0

1

11.7 PAPER SIZE DETECTION

11.7.1 PAPER TRAY

Ther e is no size swi t ch for tr ay 1. T he paper s ize is fix ed at either A4 or LT (LEF for b oth

sizes). You can change the size setting with SP5-181-1.

For tr ay 2, there are four paper size switches [ A ] w orking in combination. Switch 1 (right en d)

is for tray set detect ion. The oth er three swit ches detect t he paper size as shown in the table

below. The actu ator [B] i s moved by the end p late [C ].

0: Pushed, 1: Not pushed

D158/D159/D160/D161/D170 48 Detailed Descriptions

Page 54

Paper Size Detection

*1 : The machine detects eit her D LT SEF or A3 SEF, dependi ng on the set ting of

3.

*2: The machine detects either LG SEF or B4 SEF, depending on the setting of SP5

*3 : The machine detects eit her L T L EF or A4 LE F, depending on the setting of SP5

*4 : The machine detects eit her Exe LE F or B5 LEF, dependi ng on t he s

SP 5

SP5-181-

-181-4.

-181-2.

etting of SP5-181-5

-181-6 t o –19 doe s similar f uncti ons for t he opt ional paper trays.

The mac hi ne disables paper feed from a tray if the paper size cannot b e det ected (i f th e

paper size actuator is b rok en or no tray is inst all ed).

For non-standard paper sizes , if they are not visib le on th e user tool screen for select ing

paper sizes , then set SP5-112-001 (Non-St andard Paper Selection) to "1". If th e user s elects

on e of these s izes, auto paper size selection is disabled.

Detailed Descriptions 49 D158/D159/D160/D161/D170

Page 55

Paper Size Detection

CN No. (BICU)

11" x 17"

81/2" x 14"

51/2" x 81/2"

CN136-1

ON/OFF

OFF

OFF

OFF

OFF

CN136-2

OFF

OFF

OFF

ON

OFF

CN136-3 (GND)

OFF

OFF

OFF

OFF

OFF

CN136-4

OFF

ON

OFF

OFF

ON

CN136-5

ON

ON

OFF

OFF

OFF

CN No. (BICU)

A3

A4 SEF

8" x 13"

A5 SEF

CN136-1

ON/OFF

OFF

OFF

OFF

CN136-2

OFF

OFF

OFF

ON/OFF

CN136-3 (GND)

OFF

OFF

OFF

OFF

CN136-4

OFF

ON

ON

OFF

CN136-5

ON

ON

OFF

OFF

11.7.2 BY-PASS TRAY

The by-pass feed paper size switc h [ A] monitors the paper width. Th e s id e fen ce is

connected to the ter minal pl ate g ear. When the s ide fen ces move to mat ch th e paper width,

the c ircular ter minal pl ate r otates over the w irin g patterns on th e rectangular part of the

paper size switc h. The patterns for each paper width in the paper size switch are unique.

North Amer ica

Europe/Asia

D158/D159/D160/D161/D170 50 Detailed Descriptions

Page 56

Side Fences

11.8 SIDE FENCES

If the tray is full of paper and it is pushed in strongly, the fences may deform or bend. This

may cause t he paper to s kew or th e side-to-side reg istrati on t o be incorrect. To correc t this,

each side f ence ha s a stopper [A] att ach ed to it . Each side f enc e can be secured with a

screw, for custom ers who do not want to change the paper s ize.

Detailed Descriptions 51 D158/D159/D160/D161/D170

Page 57

Paper Registration

11.9 PAPER R E GI STRATION

The dr ive fr om the m ain motor [A] is tr ansmi tted to the regist rat ion r oller th rough the

reg istration clutch gear [B].

The reg istrati on s ensor [C] is u sed for correcting paper skew and for detecting paper

misfeeds.

The c leanin g mylar [D ] con tacts the registration roller. It r emoves paper du st from th e

registration roller so that this dust will not transfer into the development unit through the

drum-cleaning unit.

The amount of paper buc kle at the registration roller to correct sk ew can be adjust ed with

SP1-003 ( Pap er B uckle).

If jams frequent ly occur after regist ration, S P1-90 3 (Feed Cl Re-en ergize) can be used to

activate the relay clut ch so that the relay r oller assists the registration roller i n fe eding th e

paper along. When feeding from the by-pass tray, the by-pass fe ed clutch i s ac tivated,

turning the by-pass feed roller. This feature may be needed when feeding thick paper, and

cannot be used for the first paper feed tray.

D158/D159/D160/D161/D170 52 Detailed Descriptions

Page 58

Overview

12. IMAGE TRANSFER AND P APER SEPARATIO N

12.1 OVERVIEW

The transfer roller [A ] touches th e sur face of th e drum [B ] . The high volt age supply b oard

suppli es a posit ive c urrent to t he t rans fer roll er, whic h attracts t he t oner from the drum onto

the paper. Th e cu rrent depends on th e paper w id th, paper type, and paper feed tr ay.

The c urv atu re of the dr um and the d ischarg e pl ate [C] hel p th e paper to separate from t he

drum. The discharge plate is grounded.

Drive fr om the drum throu gh a gear [D] tu rns th e tr ansfer roll er.

Detailed Descriptions 53 D158/D159/D160/D161/D170

Page 59

Image Transfer Current Timing

Paper Tray/

By-pass Tray

A3/A4 LEF

11 µA

12 µA

13 µA

12 µA

17 µA

DLT

12 µA

18 µA

15 µA

18 µA

17 µA

B4 SEF

12 µA

12 µA

15 µA

12 µA

18 µA

LT SE F

17 µA

17 µA

15 µA

17 µA

24 µA

A4 SEF

21 µA

15 µA

28 µA

15 µA

24 µA

B5 SEF

22 µA

19 µA

28 µA

19 µA

22 µA

A5 SEF

22 µA

19 µA

28 µA

19 µA

28 µA

HLT SEF

22 µA

19 µA

28 µA

—

—

B6 SEF

22 µA

19 µA

28 µA

—

—

A6 SEF

22 µA

19 µA

34 µA

—

—

Post card/

12.2 IMAGE TRANSFER CURRENT TIMING

Ther e are two tran sf er cu rrent levels: low and high. The image transfer pr oced ure is as

follows:

6. When the CPU rec eives th e imag e writ in g start s ignal , the CPU i nstructs t he hi gh

voltage supply board to supply +10 microamperes (low transfer current level) to the

roller. T hi s pr event s any pos itively c harged t oner on the drum surf ace f rom

trans ferr in g t o th e tr ansfer roller .

7. At a certain time after t he low t ransf er c urrent has been s upplied to t he rolle r, high

trans fer current is appli ed t o th e rol ler t o tr ansf er t he t oner t o th e paper (see t he

tabl e below).

8. After th e tr ailing edge of the paper has passed through the roller, transfer current

turns off. In multipl e c opy mode, the t ransf er c urrent shift s ag ain to the low tr ansfer

current.

The high transfer current levels (default) are as shown in the followi ng table. With SP 2301,

the high transfer current level used for the paper feed trays, duplex tray, by-pas s t ray, and

cleaning an be adjusted.

By-pass Tray

(Thick/OHP)

By-pass Tray

(Normal)

(Special/

Envelope)

Duplex

(1st Side)

Duplex

(2nd Side)

Envelope

D158/D159/D160/D161/D170 54 Detailed Descriptions

22 µA 19 µA 34 µA — —

Page 60

Transfer Roller Cleaning

Be careful when increasing the transfer current. This may cause a ghosting effect, in which

par t o f the image at the top of the page is repe ated lower down the page at a lower dens ity.

In th e worst c ase, it may also damage th e OP C drum.

12.3 TRANSFER ROLLER CLEANING

If the pap er size is smaller than th e image, or if a paper jam occurs d uring printing, toner

may b e tr ansferred t o th e roller sur face. To prev ent the toner from transf erring to the b ack

side of the printouts, the transfer roller requires cleaning before the next printi ng run.

During transfer roller cleaning, the high voltage supply unit supplies a negati ve cleaning

voltage (about –1 k V) t o th e tr ansfer roller . Any neg atively ch arged toner on t he t rans fer

roller is then transferred back to the drum. Then a positive cleaning current (+10

microamperes) is appli ed t o th e tr ansf er r oller to push b ack to the drum any posit ively

charged tone r on th e tr ansfer roller .

The machine goes through the cleaning mode in the following conditi ons:

Before starting the printing j ob (only if enabled with SP 2996; note that the default

sett ing i s off).

Just af ter the power is swi t ched on.

After a copy jam has been cleared.

After 10 or more she ets of paper have b een cop ied and t he copy job has fin ished.

Also, the transfer roller cleaning current can be adjusted using SP 2301 4.

Detailed Descriptions 55 D158/D159/D160/D161/D170

Page 61

Paper Separation Mechanism

12.4 PAPER SEPARATION MEC HANISM

The discharge plate [ A] and t he dr um c urv atu re of th e drum help th e paper t o separate away

from the drum. The discharge plate is grounded.

D158/D159/D160/D161/D170 56 Detailed Descriptions

Page 62

13. IMAGE FUSING AND PAPER EX IT

1. Paper exit roller

6. Fusing lamps

13.1 OVERVIEW

Overview

2. Exit sensor

3. Hot roller s tr ippers

4. Pressure roller

5. Pressure spring

7. Thermistor

8. Thermostat

9. Hot roller

Detailed Descriptions 57 D158/D159/D160/D161/D170

Page 63

Fusing Unit Dri v e and Rel eas e M ec h ani sm

13.2 FUSING UNIT DRIVE AND RELEASE MECHANISM

13.2.1 FUSING UNIT DRIVE

The main motor [C] drives the fusing unit through a gear train, and drives the paper exit

rollers [A] through the timing belt [B].

13.2.2 DRIVE RELEASE MECHANISM

W hen the right door [I] is open, the spring [G] pushes the top end of the gear holder [F] to

the right. The drive gear is released from the fusing-unit drive gear [J]. When you close the

right door, the m echanical link [H] pushes the spring [G]. The gear holder turns

counter clockwi se by th e force of another s prin g [ D] , and engages wi t h the fusing-unit drive

gear.

D158/D159/D160/D161/D170 58 Detailed Descriptions

Page 64

Fusing Unit Drive and Release Mechanism

Fusing Temp.

Contact/Release

18°C or higher

Release

Less than 18°C

Contact

Solenoid

Drive gear

Off

Engaged

On

Released

13.2.3 CONTACT/RELEASE CONTROL

The drive power is not transmitted to the fusing unit during warming up when the fusing

temperature (at the start) is 18°C or higher. The drive power is transmitted when the fusing

temper atu re is less th an 18°C. Th is contact /r elease con trol is based on the followin g

conditions.

The hot roller [L ] takes a shorter t i me to bec ome hot enough if it is not turning during

w armin g up. W hen, however, the fusing t emper atu re (at th e start) is low , the temperat ure of

the hot-rol ler surface may bec ome uneven.

You can disable this control (SP1103 1).

13.2.4 DRIVE RELEASE SOLENOID

The fus in g dr iv e releas e solenoid [E] is on the rear end of the g ear holder. When th e

solenoid is off, the spring [D] pulls the gear holder, and the drive gear engages with the

fusing unit drive gear. When the solenoid is on, it pulls the top end of the gear hol der t o th e

right, and the gear holder turns clockwise. As a result, the drive gear is released from the

fusing unit drive gear.

The releas e solenoid comes on wh en you tu rn on t he m ain sw i tc h if th e f using t emp eratu re

is 18°C or higher. T he solenoid rel eases the drive gear from the fusing unit drive gear. The

fusing lamp s heat the h ot r oller [L] more ef fectively since the heat i s not conducted to the

pr ess ure r oller [K ]. When t he hot roller becomes hot enough, th e release so lenoi d tur ns of f ,

letting the drive gear engage with the fusing unit drive gear.

Detailed Descriptions 59 D158/D159/D160/D161/D170

Page 65

Fusing Entrance Guide Shift

13.3 FUSING ENTRANCE GUIDE SHIFT

The entrance guide [A] is adjustable for paper thickness to prevent creasing. The outer

screw h oles [B] on each side are used as the default setting.

If creasing occ urs frequently in the fusing unit, adjust the entrance guide to the right, by

securing it with t he i nner holes [C ]. This all ows more direct acc ess to t he gap bet ween the

hot roller and the press ure r oller.

13.4 PRESSURE ROLLER

The pressure springs [A] constantly apply pressure between the hot roller [B] and the

pressure roller [C]. Applied pressure can be changed by adjusting t he position of the

pressure springs. The spring is positioned at the end [D] as the default setting.

D158/D159/D160/D161/D170 60 Detailed Descriptions

Page 66

Fusing Temperature Control

13.5 FUSING TEMPERATURE CONTROL

13.5.1 OVERVIEW

Ther e are two fusing lamps ( not identical), t wo th ermis tor s, and f our t hermost ats .

The fusing temperatur e is controlled using the thermistors [A].

The CPU checks the output from the fusing thermistor once every 1.5 seconds. The CPU

decides how long the lam ps must be switched on during the next 1.5 seconds by comparing

the following t emp erat ures:

The cen ter th ermi st or t emper atu re and the tar get center temperature

The end thermi st or t emper atu re and the tar get en d temperature

The fusing lamp works to maintain a target fusing temperature of 160°C during copying.

Detailed Descriptions 61 D158/D159/D160/D161/D170

Page 67

Fusing Temperature Control

13.5.2 TEMPERATURE CONTROL

Acc ording t o th e operat ion mod e, the fus in g t emp erature i s c ont rolled. T he diagram

illustrates the transition of fusing temperature. After you turn the main switch on, the fusing

temper atu re rises f rom the room t emper atu re (t 0) to one of the spec ifi ed temperatures. Y ou

can adjust some of the temperatures.

A1: Regular Start Mode/A2: Cold Start Mode (SP1-105-001, 002)

Turning the fusing lamp on and off may affect t he voltage of the powe r source i n th e room,

causing the fluorescent lights in the room to flicker. To lighten this problem, you can reduce

the checking repetit i on to 20 times.

Wh en machine in itial ization end s, th e fus ing temperat ure is set t o one of the following

temperatures:

The Standby Temperature (T2: SP 1105 3-4) when there is no print job.

The First Print Temperature when the copier has received a print request during

machine initialization.

You cannot directly adjust the First Print Temperature. This temperature is 10°C higher (up

to 185°C) than the Copying Temperature (

Copy Adjustments Printing/Scanning).

D158/D159/D160/D161/D170 62 Detailed Descriptions

Page 68

Fusing Temperature Control

C: Copying Mode

Wh en th e cop ier is making copies, the f using t emperatu re is s et to one of the following

temperatures:

The Warm Up Temperature (SP 1105 1-2) to out put the first print af ter th e Low

Power Mode (

The Copying Temperature (T4: SP 1105 5-6) t o output the second print (and after the

second)

You c an raise t he Warm Up Temp erat ure t o make better the fusing quality of the f irst p rint.

While t he copier is adjusti ng th e f using t emper atu re to the Warm Up Temper atu re, the

message "Copy starts after war m up " is displ ayed.

c : Thick Paper Mode

Wh en th e machine is makin g cop ies on th ick paper, the fusing t emper atu re is set to the

Thick Paper Temperature (SP 1105 9-10). When thick paper reaches the registration sensor,

the c opi er c hecks the fusing temperature, and e xec utes one of the fol low ing proces sing:

Copy Adjustments Printing/Scanning)

Stops feeding the thick paper (and keeps it at the registration sensor) and waits for

the fusing temperature to reach the predefined temperature–the temperature 5°C

lower th an t he T hick Paper Temper atur e. ( Th e fusing t em perature keeps rising until it

re ach es th e Thick Paper Temp eratu re wh ile t he t hick pap er tr avels from the

registration sensor to the fusing unit. )

Continues feeding paper and executes the print job if the fusing temperature is high

enough.

Detailed Descriptions 63 D158/D159/D160/D161/D170

Page 69

Over h eat P r otec t i on

b1/b2: Standby Mode

Wh en th e cop ier is not makin g c opi es, the fusing temperature i s s et to t he S tan dby

Temperature (T2: SP 1105 3-4). You c an adju st th is t emper atu re. However , if you hav e

rais ed t hi s temperatu re, th e BICU may be u nable to gener ate a SC code in the event of

fusing lamp error.

While in the Stan dby Mode, the copier ch eck s t he fu sing temp erature e ver y 1.5 sec onds (G:

SP 1108 1). Turning on and off the fusing lamp may affect the voltage of the power source

(in the room), causing the fluorescent lights (in the room) to f li ck er. To l ig hten such trouble,

you can adjust t he control p eriod. H owever , if you elongate thi s per iod (t o two secon ds or

longer) , the BICU may be u nable to gene rate a SC cod e in the ev ent of a fusing lamp er ror .

e: Low Power Mode

When t he E nergy Saver Timer (

Timer) expir es, th e fus in g t emperatu re is set to the Low P ower Temp erature ( T1: SP 1 105 7-

8).

> System Setti ngs > Timer Settings > Energy Saver

13.6 OVERHE AT PROTECTION

This mach in e protect s its h ardware from overhe at by three featu res. Normally, the fi rst

featu re can fully protect th e hardware. T he s econd featu re wor ks a s t he f ail-sa fe featu re f or

the firs t one. The third feature wor k s as th e fail -safe f eat ure f or t he sec ond one.

First Feature:

If the fusing temperature reaches 230°C (or higher) and stays so for one second, the

controller turns the fusing lamp off. In a case like this, SC543 or SC553 shows.

Second Feature:

If the fusing feature reaches 250°C, the controller cuts off the 24V line. (The fusing lamps

ar e on th e 24V line.)

Third Feature:

Two thermost ats are attached on each li ne of the two fusing lamps. (four th ermostats in

total). One of the two thermostats cuts the power supply to the fusing lamp at 179°C, and the

other cuts the power supply at 180°C. (Note that the thermostat temperat ure is s omew hat

lower th an t he fu sing temperatu re.)

D158/D159/D160/D161/D170 64 Detailed Descriptions

Page 70

14. DUPLEX UNIT

1. Duplex Inverter Roll er

5. Duplex Exit Sensor

14.1 OVERALL

Overall

The printed page from t he fusing unit goes straight t hrough to the exit tray, or upward to the

inverter section, depending on the position of the junction gate.

If the us er s elect s duplex mode, th e page is directed to the in verter t ray, t hen rever sed

through the duplex unit, and back int o the machine for printing the second side.

2. Duplex Entrance Sensor

3. Upper Transpor t R oller

4. Mi ddle Tran sport Roll er

6. Lower Transpor t R oller

7. Junction Gate

8. Duplex Inverter Sen sor

Detailed Descriptions 65 D158/D159/D160/D161/D170

Page 71

Dri ve Mec hanism

1. Duplex Inverter Roll er

4. Duplex Transport Motor

14.2 DRIVE MECHANISM

2. Duplex Inverter Motor

3. Upper Transpor t R oller

5. Lower Transpor t R oller

6. Mi ddle Tran sport Roll er

D158/D159/D160/D161/D170 66 Detailed Descriptions

Page 72

Basic op er at i on

14.3 BASIC OPERATION

To incr ease the producti vit y of the duplex unit, copies are printed as follows.

- Larger than A4 Short-edge/LT Short-edge -

The paper fe ed pat h can h old only one she et of cop y paper at a time.

Example: 8 pag es. T he number [A] in th e il lu stration sh ows the order of pages . The n umb er

[B ] in t he i l lust rat ion s hows the order of sheet s of copy p aper ( if bl ack , this indi cates th e

second s ide).

Detailed Descriptions 67 D158/D159/D160/D161/D170

Page 73

B asi c o peration

- Up t o A4 Short-edge/LT Short-edge -

The paper feed path can hold two sheets of copy paper.

Example: 8 pag es. T he number [A] in th e il lu stration sh ows the order of pages. The n umb er

[B ] in t he i l lust rat ion s hows the order of sheet s of copy p aper ( if black, this indicates the

second s ide).

D158/D159/D160/D161/D170 68 Detailed Descriptions

Page 74

14.4 FEED IN AND EXIT MECHANISM

Feed In and Exit Mechanism

During duplex copying, the inverter gate solenoid [A] switches on and the junct i on gate [B]

swi t ches over to d irect the pap er t o the inver ter. When t he paper trai li ng edge re aches th e

du plex inverter sens or [C], th e inverter roll er [ D] reverses its r otation direction and th e paper

goes to the duplex unit. The paper is then sent to the mainframe registration rollers to print

the reve rs e side.

If there are two or more copies being made with A4/8

sheet waits at the registration sensor for the current sheet to exit the inverter.

Detailed Descriptions 69 D158/D159/D160/D161/D170

1

/2" x 11" SEF (or smaller), the next

Page 75

Overview

Op eration panel

Engine

Exhau st f an

Op erating Mode*

On

On

On

Low Pow er Mode

Off

On

Off

Night/Off Mode

Off

Off**

Off

15. ENERG Y SAVER MODES OF BASIC MACHINES

This sect ion il lu st rat es the energy saver modes of the basic machine (th e machine without

the optional con tr oller ). For th e energy saver modes of the GDI machin e (t he machine with

the optional con tr oller ), see the section of "En ergy Saver Modes of G DI M achines ".

15.1 OVERVIEW

The mac hi ne has two energy-saver modes: the Low Power Mode and the Night/Off Mode.

The tabl e li st s t he stat us of seve ral components. For the fus ing temperat ure, s ee the section

of "Fu sing Temp erat ure Con trol".

*

The "Operating Mode" here refers t o all the modes (and stat us) ot her th an th e Low

Power Mode and Night/Off Mode. Actual power consumption (during the Operating

Mode) depends on job status and environmental conditions.

**

The S RA M is ali ve and bac ks u p t he engine control ler.

D158/D159/D160/D161/D170 70 Detailed Descriptions

Page 76

AOF

Spec ified v alue

Low Pow er Mode

Night/Off Mode

Energy Sav er T imer > Auto O f f Timer

Can s tar t

Can s tart

Energy Sav er T imer = Auto O f f Timer

Can not star t

Can s tar t

Energy Sav er T imer < Auto O f f Timer

Can not star t

Can s tar t

15.2 AOF

Wh en A OF is off, the engine controller is unable to start the N ig ht /Off M ode. T he user s hould

keep AOF on (

> System S etti ngs > Key Operator T ool s > AO F).

15.3 TIMERS

The eng ine contr oller references the En ergy Saver Timer to s tar t the Low Power Mode, and

re ferences the Aut o Off Timer t o s tar t the Ni ght/Off M ode. The us er c an set these timer s

(

> System Settings > Timer Settings).

The Energy Saver Timer an d t he A ut o Off Timer start at th e same t i me (t

mac hin e ends all job s or when t he user ends all manu al operat ion s. Note that the Au to O ff

Timer d oes n ot wait for the En ergy Saver Timer . Ther efore, i f th e user specifies a s maller

val ue in the Energy Saver Timer , the Auto Of f Ti mer expires ea rl ier than the E nergy Saver

Timer. I n a cas e li ke t his, th e Low Power M ode is not acti vated. Inst ead, th e engin e

cont rol le r starts th e Ni ght/Of f Mode when the A uto Of f Timer expires.

) when the

0

15.4 RECOVERY

Any of the following operations brings the machine back to the Operating Mode:

The pow er switch is pres sed.

Originals are set on t he docu ment feede r.

The platen cove r (or document feeder) is opened .

Detailed Descriptions 71 D158/D159/D160/D161/D170

Page 77

Overview

Op eration panel

Engine

Exhaust fan

Op erating Mode*

On

On

On

Low Pow er Mode

Off

On

Off

Tr ansit Mode

Off

On

Off

Night/Off Mode

Off

Off**

Off

16. ENERG Y SAVER MODES OF GDI MACHINES

This sect ion il lu st rat es the energy saver modes of the GDI mac hin e (t he machine with the

opti onal controller ). For the ener gy saver modes of the bas ic m achine (the mac hine wi th out

the optional con tr oller ), see the section of "Ener gy Saver Modes of Basic Machines".

16.1 OVERVIEW

The mac hi ne has three energy -saver modes: the Low Power Mode, the Transit Mode, and

the Night /Off Mode. The Transit M ode continues for about two seconds (probably, the user

do es n ot r ecognize thi s mode when it occurs ). The tab le list s the st atu s of sever al

compon ent s. For th e fus in g t emperature, see the section of "F usi ng Temperature Control".

*

The "Operating Mode" here refers t o all the modes (or s tatus) oth er t han th e Low P ower

Mode and N ig ht /O ff Mode. Actual power c onsu mption (during the Operating Mode) depends

on job status and environmental conditions.

D158/D159/D160/D161/D170 72 Detailed Descriptions

Page 78

AOF

**

The SRA M is ali ve and bac ks u p t he engine control ler.

16.2 AOF

See "A OF " i n the section of "Energy Saver Modes of Basi c Mach in es".

16.3 TIMERS

The Energy Saver Timer an d A ut o Off Timer start at the s ame ti me (t 0) when the machin e

end s all job s, wh en the u ser ends all manual operat ions, or w hen th e cont roll er starts th e

default application program (the program specified by the user [

General Fe atu res > F unction Pr iority]). The defau lt applicat ion progr am starts when the

System Auto Reset Ti mer e xp ires (

Reset Timer).

For more information , see " Timers" in the section of "Ener gy Saver Modes of Basic

Machines".

> System Settings > Timer Settings > System Auto

> System Settin gs >

16.4 RECOVERY

Any of the fol lowi ng operati ons brings the machine back to the Operat ing Mode:

The pow er switch is pres sed.

Originals are set on th e doc umen t feeder.

The platen cove r (or document feeder) is opened .

The con tr oller receiv es a job ov er t he network or the t elephon e line.

An SC code is generated.

Detailed Descriptions 73 D158/D159/D160/D161/D170

Page 79

Recovery

17. OVERVIEW

The FCU contr ols all the fax communicati ons and fax f eat ures , in cooperation with the

controller board.

D158/D159/D160/D161/D170 74 Detailed Descriptions

Page 80