Ricoh D146, D147, D148, D149, D150 Service Manual

D146/D147/D148/D149/D150

SERVICE MANUAL

It is the reader's responsibility when discussing the information contained

within this document to maintain a level of confidentiality that is in the best

interest of Ricoh Americas Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN

ANY

FASHION AND DISTRIBUTED WITHOUT THE

PRIOR

PERMISSION OF RICOH AMERICAS

CORPORATION.

All product names, domain names or product illustrations, including

desktop images, used in this document are trademarks, registered

trademarks or the property of their respective companies.

They are used throughout this book in an informational or editorial fashion

only and for the benefit of such companies. No such use, or the use of

any trade name, or web site is intended to convey endorsement or other

affiliation with Ricoh products.

2013 RICOH Americas Corporation. All rights

reserved.

WARNING

The Service Manual contains information

regarding service techniques, procedures,

processes and spare parts of office equipment

distributed by Ricoh Americas Corporation.

Users of this manual should be either service

trained or certified by successfully completing a

Ricoh Technical Training Program.

Untrained and uncertified users utilizing

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property or loss of warranty

protection.

Ricoh Americas Corporation

INSTALLATION

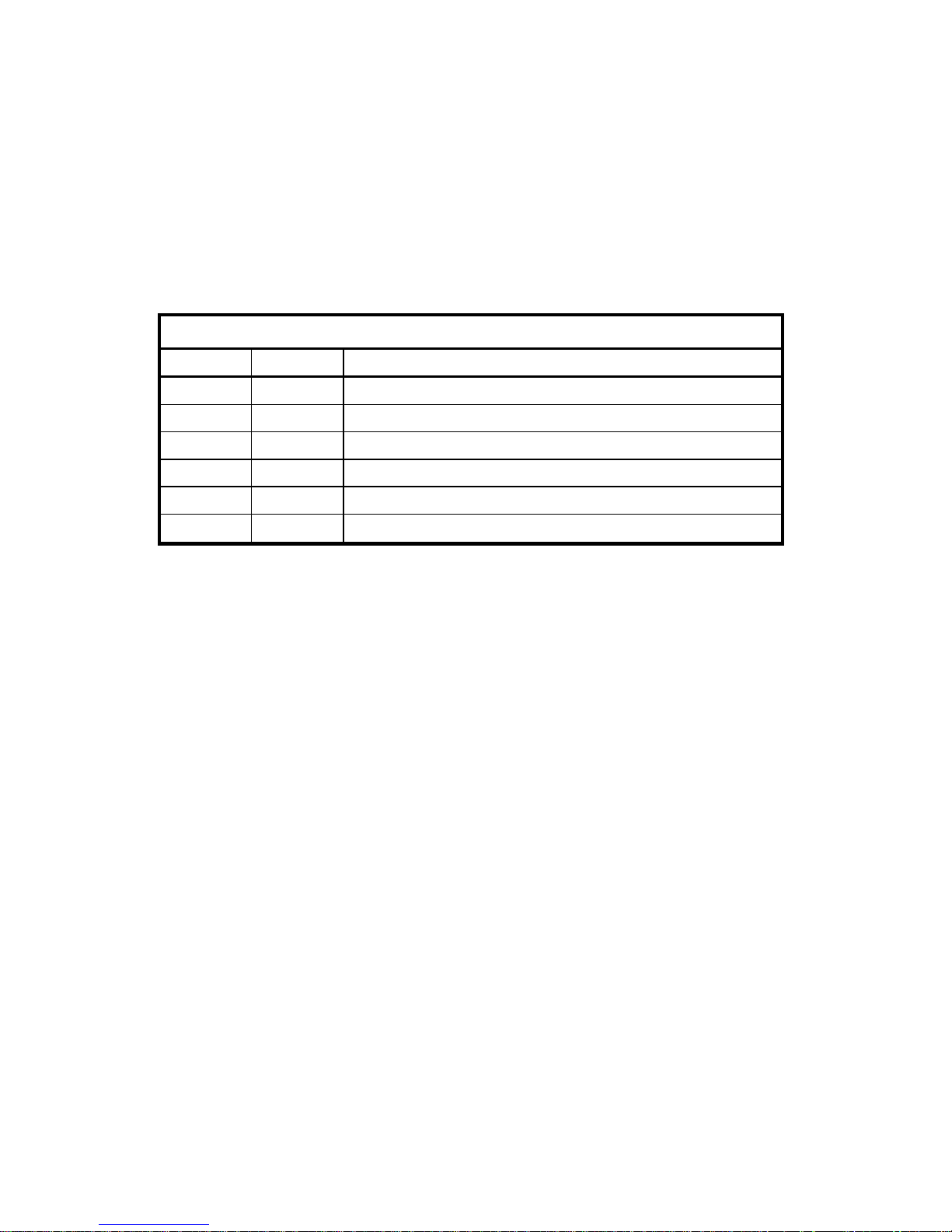

REVISION HIST OR Y

Pag e

Date

Add e d/ Upda ted/ Ne w

45 ~ 46

3/11/2014

Caster Table Type M3

81 ~ 82

12/23/2014

Internal shift tray

192 ∼ 197

10/08/2013

Added Smart Card Reader (D379) installation instructions.

198 ∼ 208

04/07/2014

Added Tray Heater sections

208

05/15/2014

Revised Step 12 of Paper Feed Unit PB3150

209 ~ 220

5/26/2015

Anti-Condensation Heater

Installation Requirements

SM

2-1

D146/D147/D148/D149/D150

Installation

2. INSTALLATION

2.1 INSTALLATION REQUIREMENTS

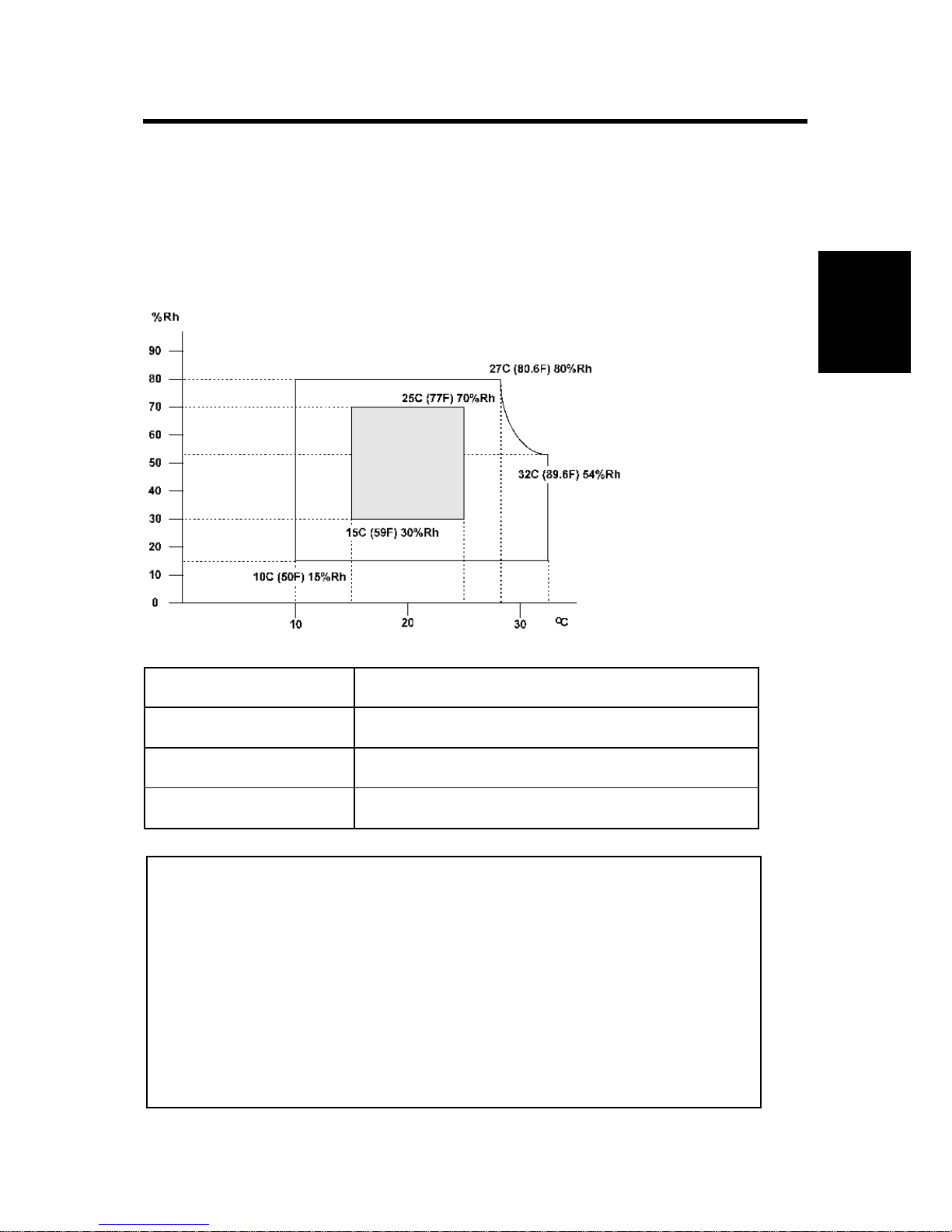

2.1.1 ENVIRONMENT

Temperature Range:

10°C to 32°C (50°F to 90°F)

Humidity Range:

15% to 80% RH

Ambient Illumination:

Less than 1,500 lux (do not expose to direct sunlight.)

Ventilation:

Room air should turn over at least 30 m3/hr/person

1. Avoid areas exposed to sudden temperature changes:

1) Areas directly exposed to cool air from an air conditioner.

2) Areas directly exposed to heat from a heater.

2. Do not place the machine where it will be exposed to corrosive gases.

3. Do not install the machine at any location over 2,000 m (6,500 ft.) above sea level.

(D135 for NA can be installed only up to 2,500m (8,202 ft.))

4. Place the main machine on a strong and level base. Inclination on any side should

be no more than 5 mm (0.2").

5. Do not place the machine where it may be subjected to strong vibrations.

Installation Requirements

D146/D147/D148/D149/D150

2-7

SM

2.1.2 MACHINE LEVEL

Front to back: Within 5 mm (0.2")

Right to left: Within 5 mm (0.2")

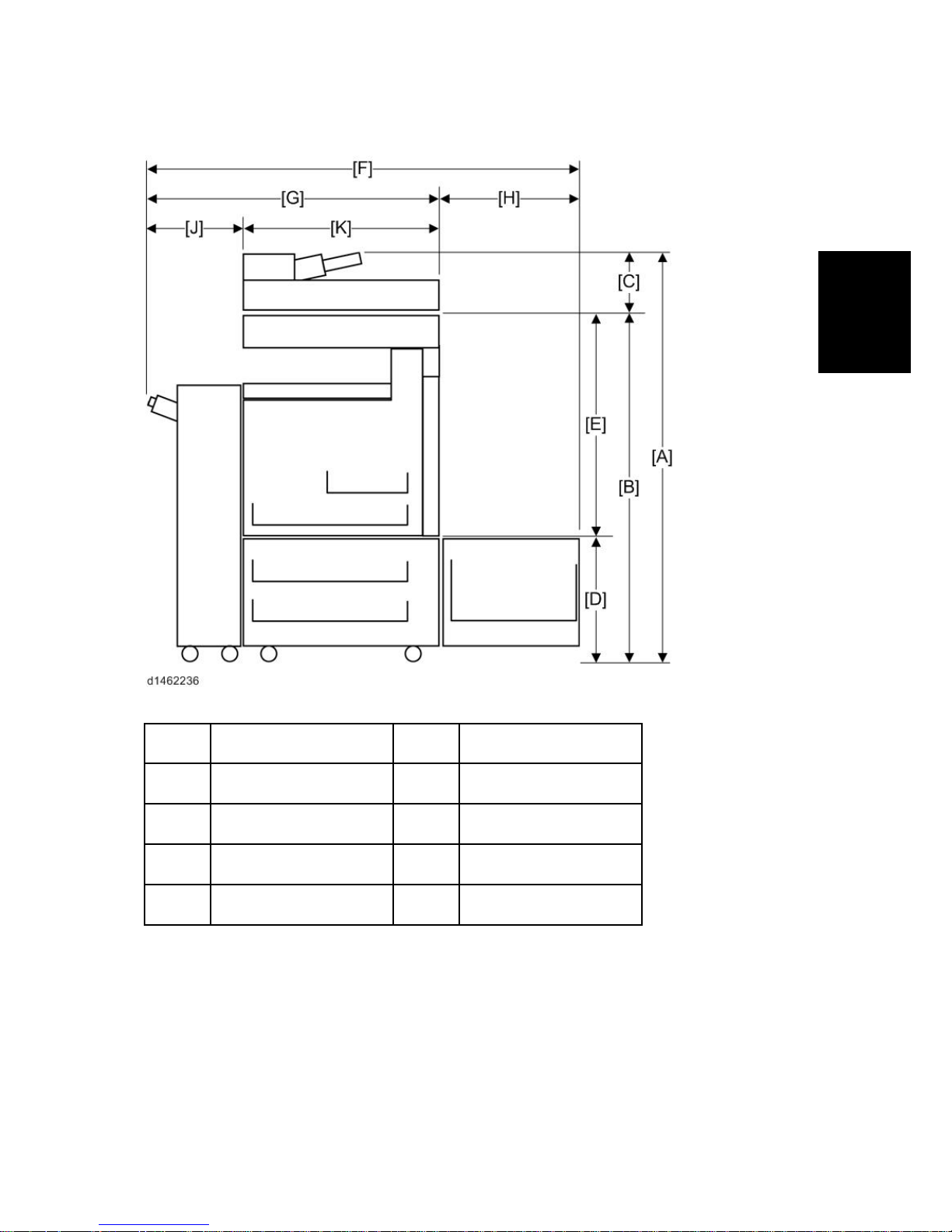

2.1.3 MACHINE SPACE REQUIREMENTS

[A]

Left Over 100 mm (3.9")

[B]

Rear

Over 100 mm (3.9")

[C]

Right

Over 100 mm (3.9")

[D]

Front

Over 750 mm (29.5")

Put the machine near the power source with the clearance shown above.

Installation Requirements

SM

2-3

D146/D147/D148/D149/D150

Installation

2.1.4 MACHINE DIMENSIONS

[A]

1210 mm

[F]

1589.5 mm

[B]

1030 mm

[G]

1249.5 mm

[C]

180 mm

[H]

340 mm

[D]

247 mm

[J]

662.5 mm

[E]

783 mm

[K]

587 mm

Installation Requirements

D146/D147/D148/D149/D150

2-4

SM

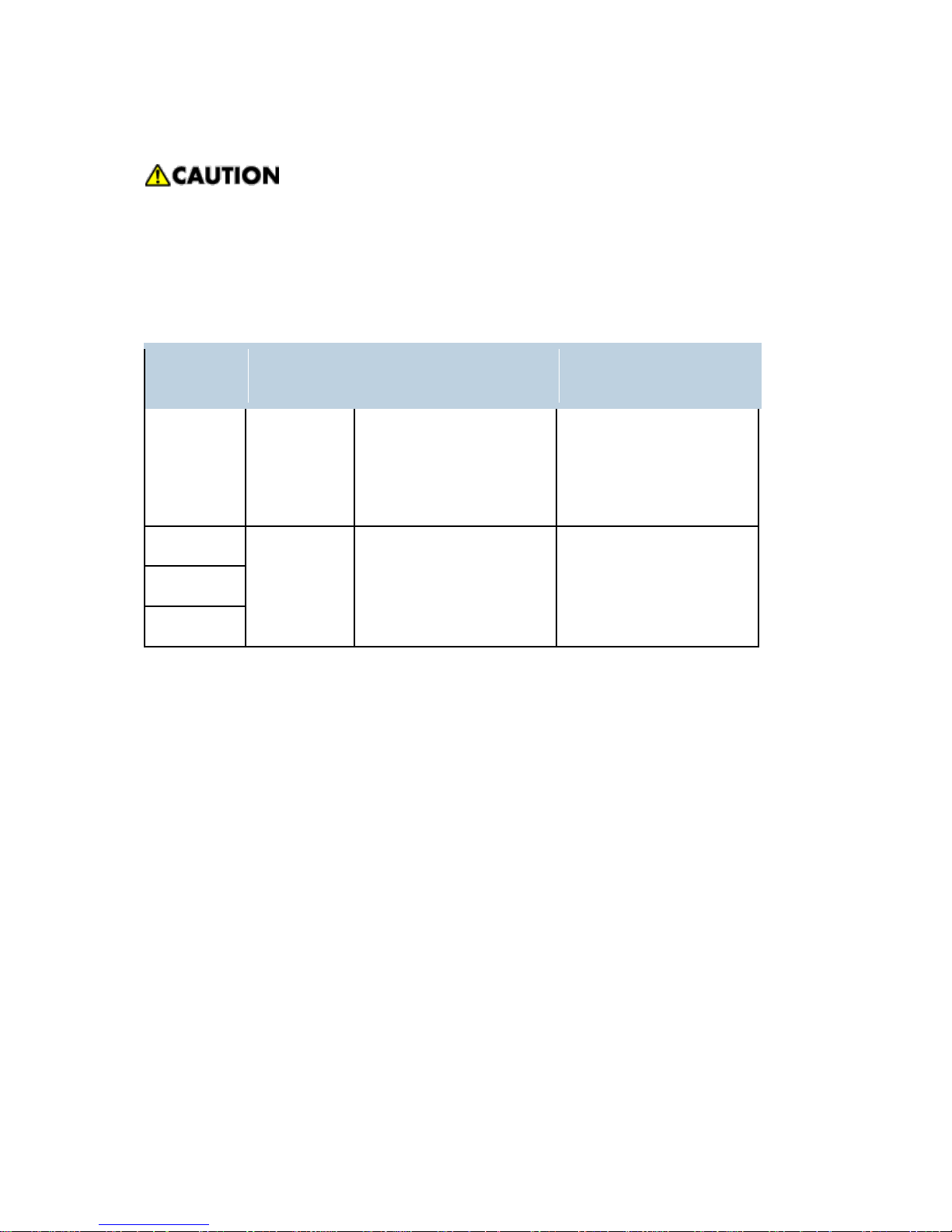

2.1.5 POWER REQUIREMENTS

·

Insert the plug firmly in the outlet.

·

Do not use an outlet extension plug or cord.

·

Ground the machine.

Input voltage level

Destination

Power supply

voltage

Rated current consumption

Permissible voltage

fluctuation

NA

120 to 127V

12A or more

Imaging: 108V(120V-10%)

to 138V(127V+8.66%)

Motions: 102V(120V-15%)

to 138V(127V+8.66%)

EU

220 to 240V

10A

Imaging: ±10%

Motions: ±15%

AP

CHN

SM

2-5

D146/D147/D148/D149/D150

Main Machine Installation

Installation

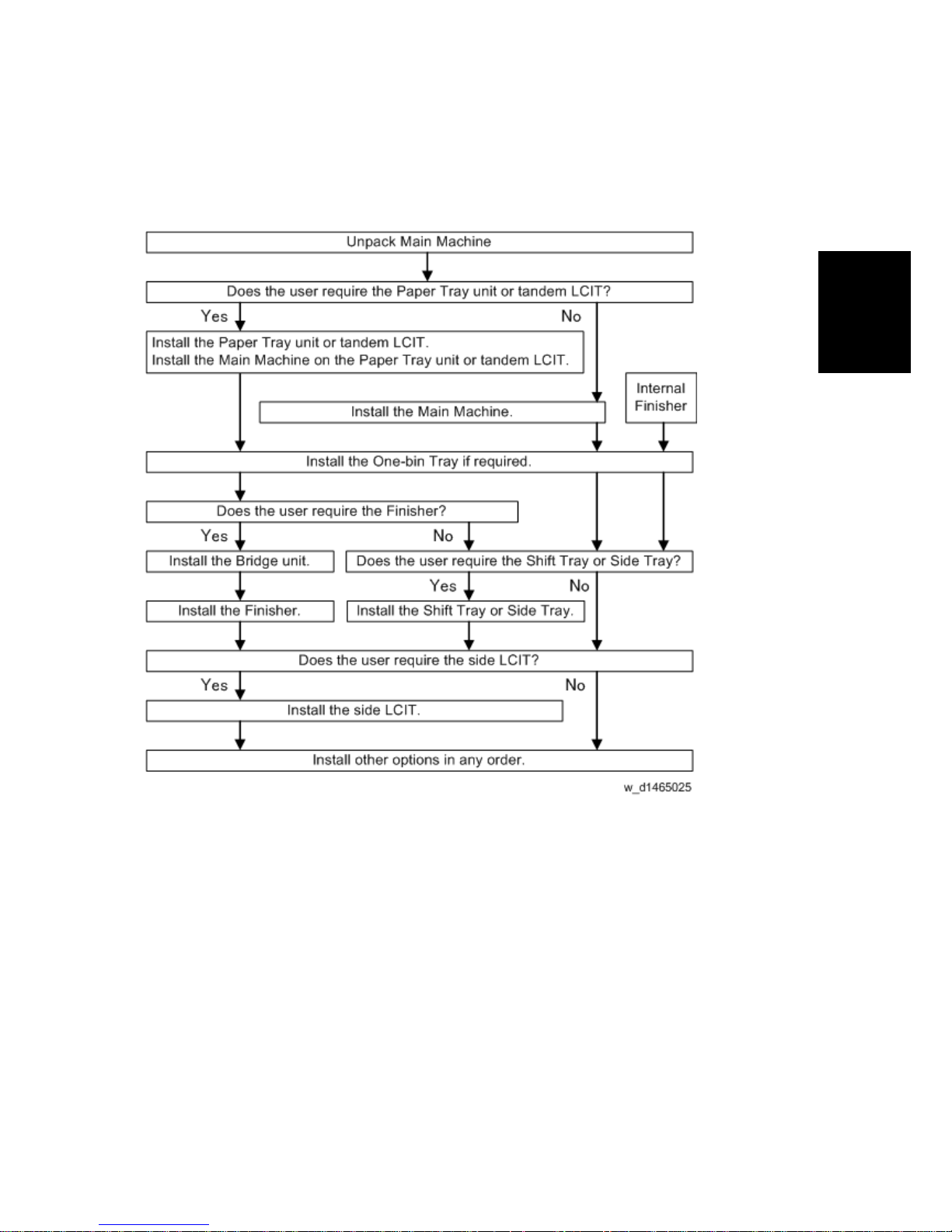

2.2 MAIN MACHINE INSTALLATION

2.2.1 INSTALLATION FLOW CHART

You need the optional paper tray unit or the tandem LCT if you want to install the finisher D686,

D687, D688 or D689) or side LCT (D696).

The punch unit is for 1000-sheet booklet finisher (D686), 1000-sheet finisher (D687),

2000-sheet booklet finisher (D688) and 3000-sheet finisher (D689).

D146/D147/D148/D149/D150

2-6

SM

Main Machine Installation

2.2.2 ACCESSORY CHECK

Description

Q’ty

D146/D147

D148/ D149/ D150

Power Supply Cord (NA)

1

1

Operation Instructions

4

4

CD-ROM - Driver (NA)

1

-

CD-ROM - Driver

- 1

CD-ROM - OI

1

1

Sheet - 20 Languages (CHN)

1

1

Seal - 20 Languages

1

1

Holder 1 1

PCU Cover

4 4

Image Transfer Cover

1

1

Sheet - Application : Multi Language :Blank

1

1

Sheet - Application : Multi Language (NA)

1

1

Decal - Paper Tray

1

1

Decal - Original Table

1

1

Decal - Caution : Original : Multi Language

1

1

Plate – Logo

1 1

End Fence

1

1

SM

2-7

D146/D147/D148/D149/D150

Main Machine Installation

Installation

2.2.3 INSTALLATION PROCEDURE

·

Remove the tape from the development units before you turn the main switch on. The

development units can be severely damaged if you do not remove the tape.

Put the machine on the paper tray unit or the LCT first if you install an optional paper tray unit or

the optional LCT at the same time. Then install the machine and other options.

·

Keep the shipping retainers after you install the machine. You may need them in the

future if you transport the machine to another location.

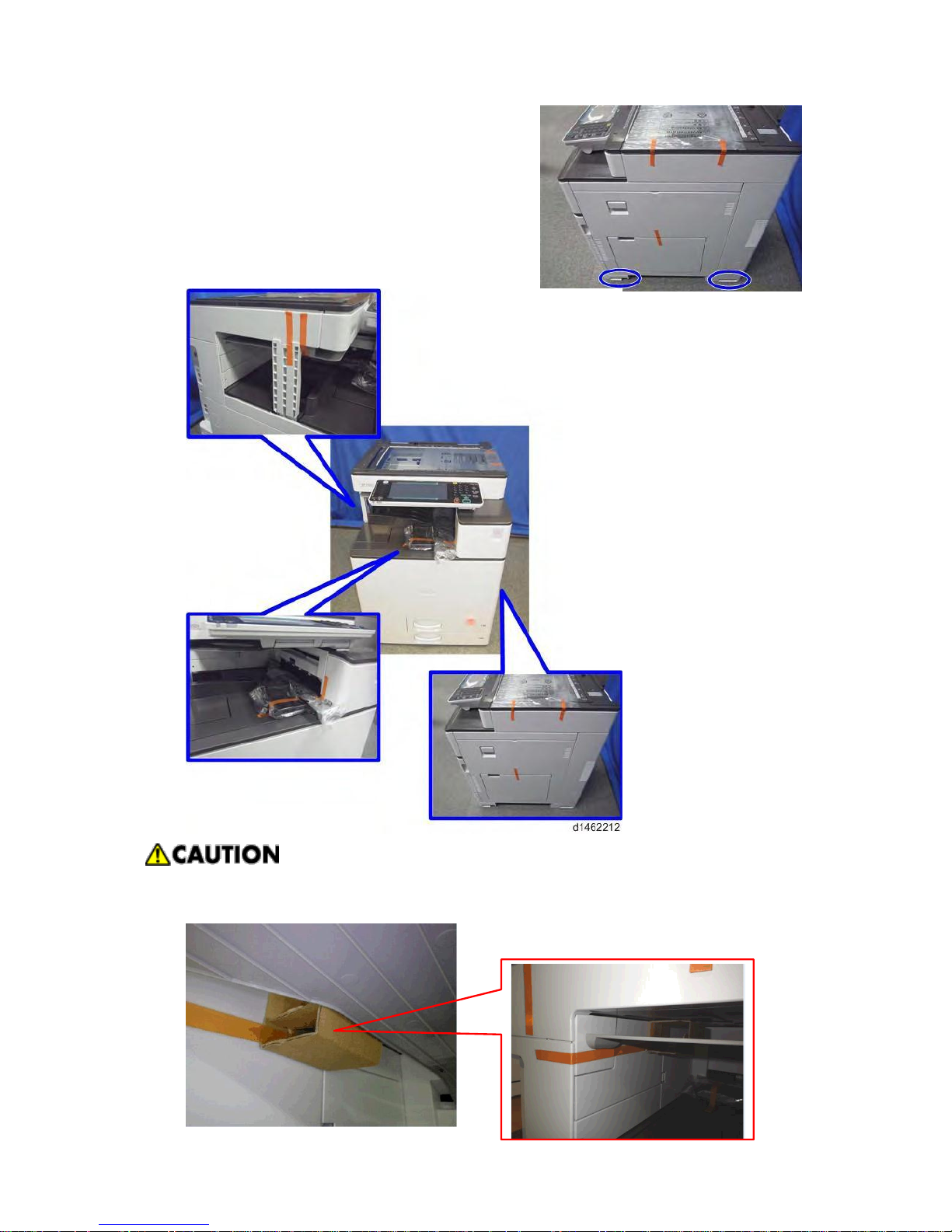

Removal of packing materials and shipping retainers / Removal of PCDU

seal

1. Remove the machine from the box, and check the items in the package.

·

Before lifting up the machine, as there are hidden handles, remove the retainers [A]

at the lower front right.

·

When you lift the machine, hold the correct parts, as shown in the diagram below.

·

Do not lift by holding the scanner unit, etc., because this might deform the machine

or break the exterior covers

D146/D147/D148/D149/D150

2-8

SM

Main Machine Installation

2. Remove the orange tape and retainers on the

outside.

For a machine with preinstalled SPDF,

remove the orange tape and retainers on the

SPDF.

Make sure to remove the cardboard stabilizer shown below. If you do not, JAM 27 or JAM

64 may occur when printing out onto B4, DLT, or SRA3 sized paper in duplex mode.

SM

2-9

D146/D147/D148/D149/D150

Main Machine Installation

Installation

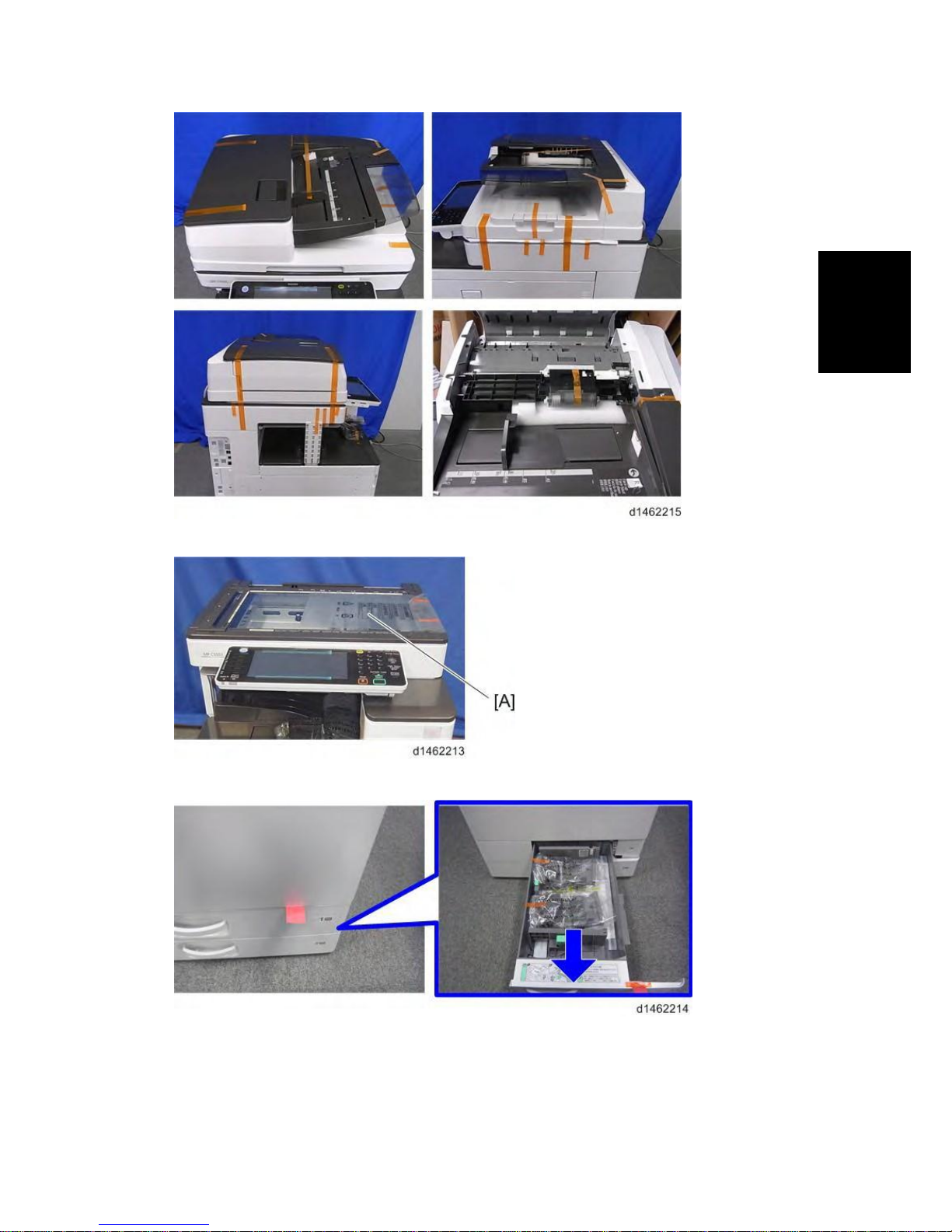

3. Remove the paper size decal [A] on the exposure glass.

4. Pull out the 1st paper feed tray, and remove the orange tape and retainers.

5. Pull out the 2nd paper feed tray, and remove the orange tape and retainers.

6. Remove the scanner support [A].

D146/D147/D148/D149/D150

2-

SM

Main Machine Installation

7. Open the front cover, and store the scanner support in the storage location [A].

·

The factory setting sheet is kept in the position [A].

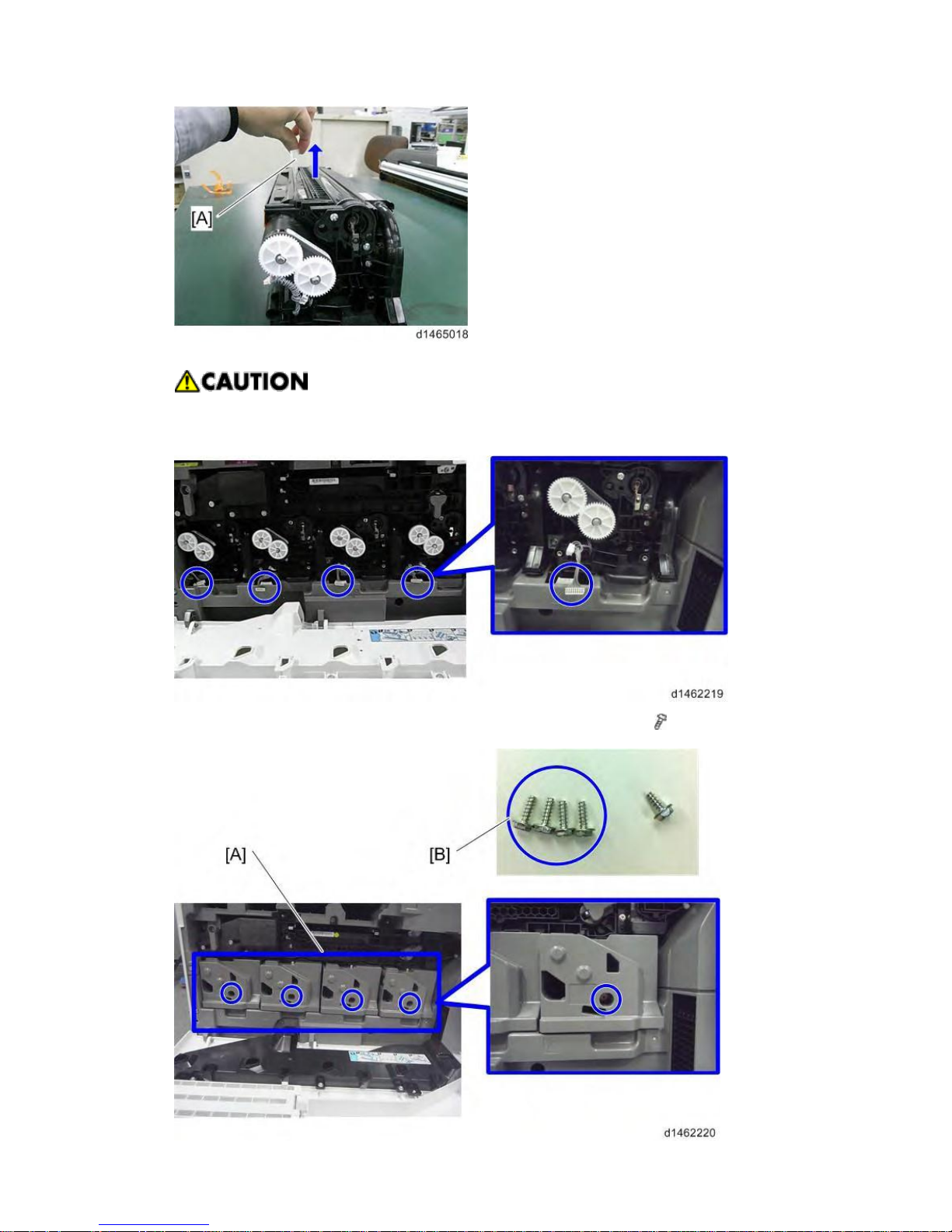

8. Remove the PCDU [A]. ( ×4, ×4)

SM

2-11

D146/D147/D148/D149/D150

Main Machine Installation

Installation

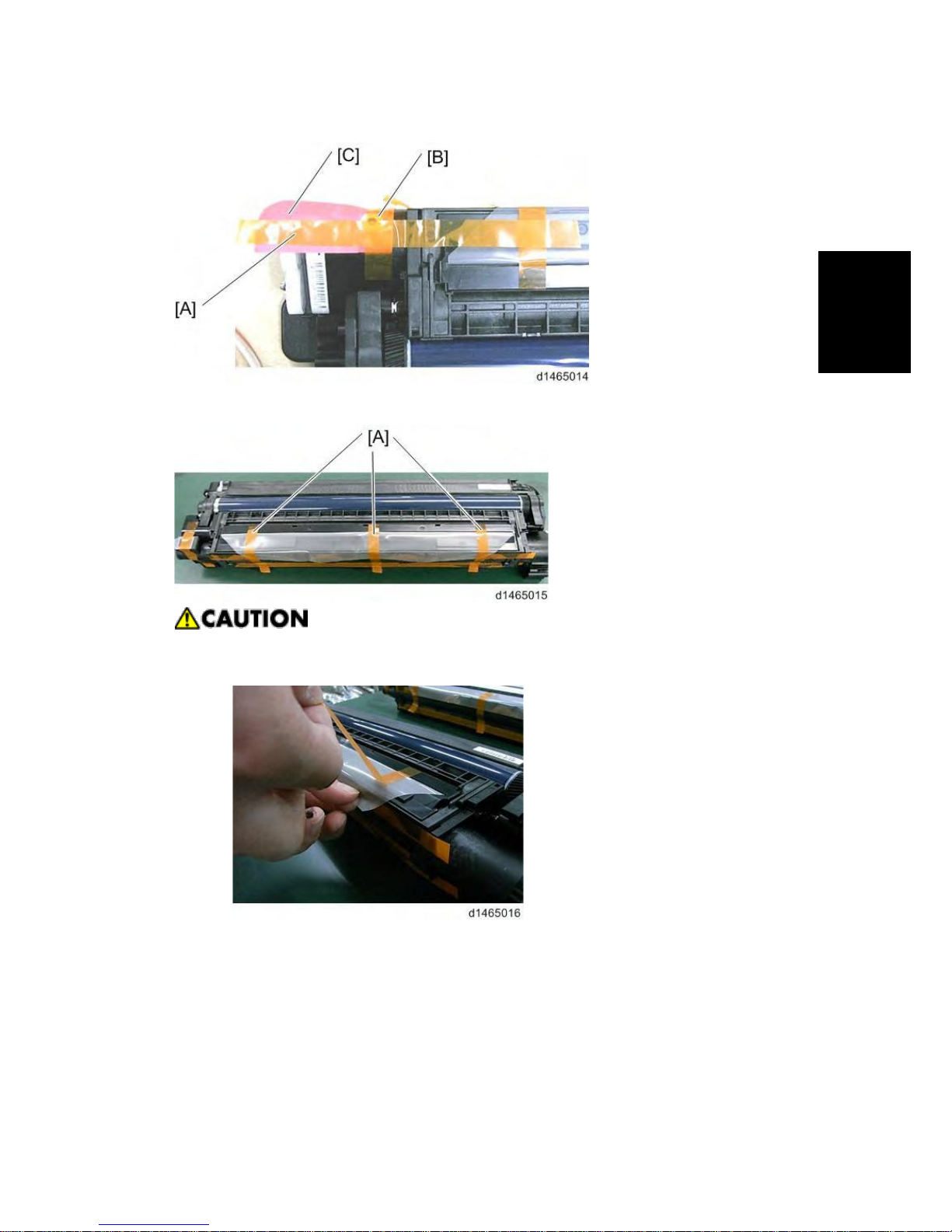

9. After removing the orange tape [A], remove the orange tape [B] and red tag [C].

10. Remove the orange tapes [A].

·

When removing the orange tapes, remove the orange tapes one by one without

removing the preset seal as shown below.

11. Remove the preset seal [A] in the direction of the blue arrow.

D146/D147/D148/D149/D150

2-

SM

Main Machine Installation

12. Return the PCDU to its original position, and connect the harnesses (4 for each unit).

·

When you return the PCDU to its original position, check the color (engraving), and

set each color unit in the right position.

13. Attach the PCDU front cover [A] with the screws provided (3×10) [B]. ( ×4)

SM

2-13

D146/D147/D148/D149/D150

Main Machine Installation

Installation

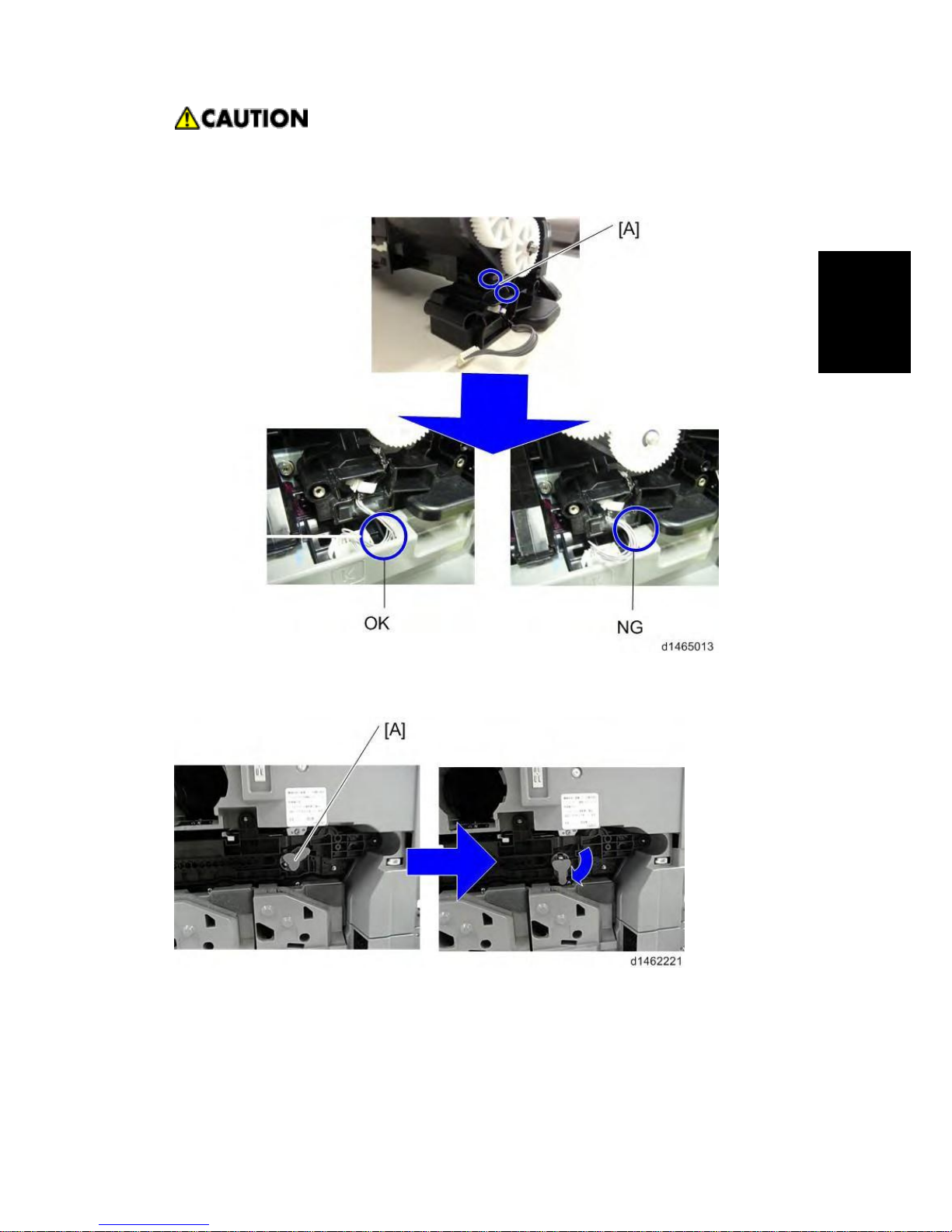

·

Be careful not to trap the harness with the PCDU front cover. Place the excess

portion of the harness on the inside of the inner cover. Also, hook the harness in two

places [A].

14. Rotate the ITB contact/separation lever [A] clockwise, and set it to the position in the following

picture.

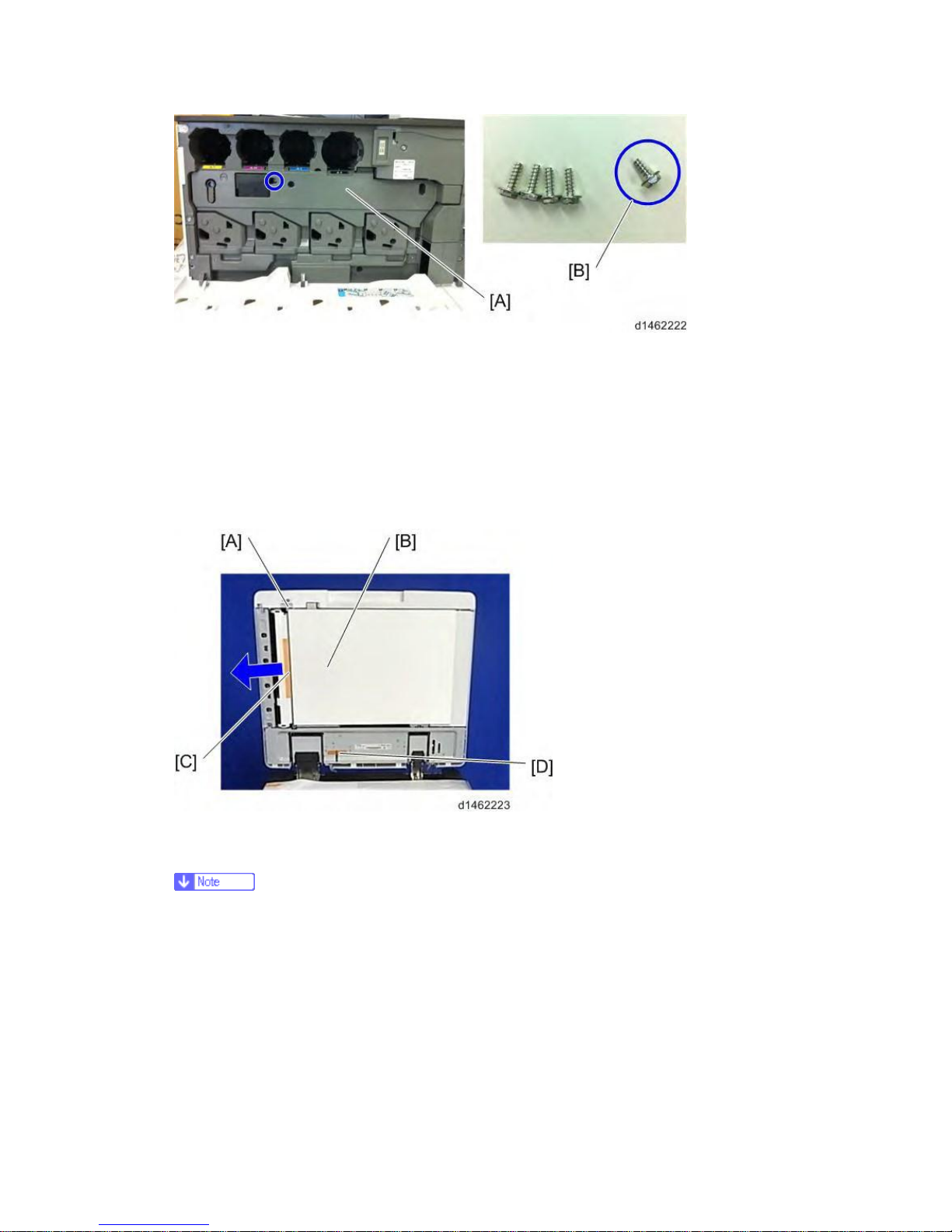

15. Attach the ITB unit front cover [A] with the screw provided (3×8) [B].

D146/D147/D148/D149/D150

2-

SM

Main Machine Installation

16. Close the front cover.

For machines with preinstalled SPDF: Removal of protective sheet

1. Open the SPDF.

2. Release the lever [A], open the pressure plate sheet [B], and pull out the protective sheet [C]

slowly.

At this time, remove the filament tape [D].

3. Close the pressure plate sheet.

4. Close the SPDF.

·

If the protective sheet remains in the SPDF, a paper jam will be detected.

Toner bottle installation

1. Open the front cover.

2. Shake the toner bottle (Bk) 5 to 6 times.

3. Remove the toner bottle protection cap [A].

SM

2-15

D146/D147/D148/D149/D150

Main Machine Installation

Installation

4. Push the toner bottle into the machine slowly.

5. Set the toner bottles (Y, M, C) in the same way.

6. Close the front cover.

·

When the power is turned on, it will fill up for the first time in about 5 minutes.

D146/D147/D148/D149/D150

2-

SM

Main Machine Installation

Attaching paper output tray parts

1. Attach the part [A] to the paper output tray.

First, insert and attach the front pin (inside the blue circle).

Attaching the decals

1. Attach the correct paper tray number and size decals to the paper trays.

·

Paper tray number and size decals are also used for the optional paper tray or the

optional LCT. Keep these decals for use with these optional units.

Connecting the power cord

·

Do not use any connectors other than the power cord provided. Also, do not use an

extension cord.

1. Connect the power cord to the machine.

SM

2-17

D146/D147/D148/D149/D150

Main Machine Installation

Installation

2.2.4 IMAGE QUALITY TEST / SETTINGS

Image quality test

When there are other options to be installed, install according to the procedure for each.

1. After checking that clamps, etc., have been removed, connect the power plug to the wall

socket.

2. Turn the main power supply switch ON.

3. Check that the operation panel shows the following display.

"Please supply the tray with paper."

4. The paper size is basically detected automatically.

1. Pull out the paper feed tray slowly until it stops.

2. While pressing the release lever, adjust the side fence to the paper size to be set.

3. Set the back fence.

Checking the copy image with the test chart

Check the copy image with the test chart.

Paper setting

1. Set some paper in the feed tray.

* SP5-181-001 to 017 (Size Adjust)

1. If necessary, adjust the registration for the paper feed tray.

* SP1-002-002 (Side-to-Side Registration Paper Tray 1)

* SP1-002-003 (Side-to-Side Registration Paper Tray 2)

Security Function Installation

The machine contains the Security functions (Data Overwrite Security and HDD Encryption unit)

built into the controller board.

If you are installing a new machine, it is recommended to activate the Data Overwrite Security and

HDD Encryption unit by selecting "Format All Data" from “System Settings” on the operation

panel.

D146/D147/D148/D149/D150

2-

SM

Main Machine Installation

·

This method is recommended because there is no user data on the hard drive yet

(Address Book data, image data, etc.).

If the customer wishes to activate the Data Overwrite Security and HDD Encryption unit on a

machine that is already running, it is recommended to activate the unit by selecting "All Data" from

“System Settings” on the operation panel.

·

Selecting "All Data" will preserve the data that has already been saved to the hard drive.

(If "Format All Data" is selected, all user data saved to the hard drive up to that point will

be erased).

Immediately after encryption is enabled, the encryption setting process will take several minutes

to complete before you can begin using the machine.

·

If encryption is enabled after data has been stored on the disk, or of the encryption key is

changed, this process can take up to three and a half hours or more.

The machine cannot be operated while data is being encrypted.

Once the encryption process begins, it cannot be stopped.

Make sure that the machine's main power is not turned off while the encryption process is in

progress.

If the machine's main power is turned off while the encryption process is in progress, the hard disk

will be damaged and all data on it will be unusable.

Print the encryption key and keep the encryption key (which is printed as a paper sheet).

Keep the encryption key in a safe place. If the encryption key is lost and is needed, the controller

board, hard disk and NVRAM must all be replaced at the same time.

·

"NVRAM" mentioned in he re means the NVRAM on the Controller Board.

·

"NVRAM" or EEPROM on the BCU has nothing to do with this.

Please use the following procedure when the Data Overwrite Security and HDD Encryption is

reinstalled.

Data Overwrite Security

Before You Begin the Procedure

1. Make sure that the following settings (1) to (3) are not at their factory default values.

(1) Supervisor login password

(2) Administrator login name

(3) Administrator login password

If any of these settings is at a factory default value, tell the customer these settings must be

changed before you do the installation procedure.

2. Make sure that “Admin. Authentication” is on.

[System Settings] -> [Administrator Tools] -> [Administrator Authentication Management] ->

SM

2-19

D146/D147/D148/D149/D150

Main Machine Installation

Installation

[Admin. Authen tication]

If this setting is off, tell the customer this setting must be on before you do the installation

procedure.

3. Make sure that “Administrator Tools” is enabled (selected).

[System Settings] -> [Administrator Tools] -> [Administrator Authentication Management] ->

[Available Settings]

If this setting is disabled (not selected), tell the customer this setting must be enabled

(selected) before you do the installation procedure.

Installation Procedure

1. Connect the network cable if it needs to be connected.

2. Turn on the main power switch.

3. Go into the SP mode and push “EXECUTE” in SP5-878-001.

4. Exit the SP mode and turn off the operation switch. Then turn off the main power switch.

5. Turn on the machine power.

6. Do SP5-990-005 (SP print mode Diagnostic Report).

7. Go into the User Tools mode, and select [System Settings] [Administrator Tools] [Auto

Erase Memory Setting] [On].

8. Exit the User Tools mode.

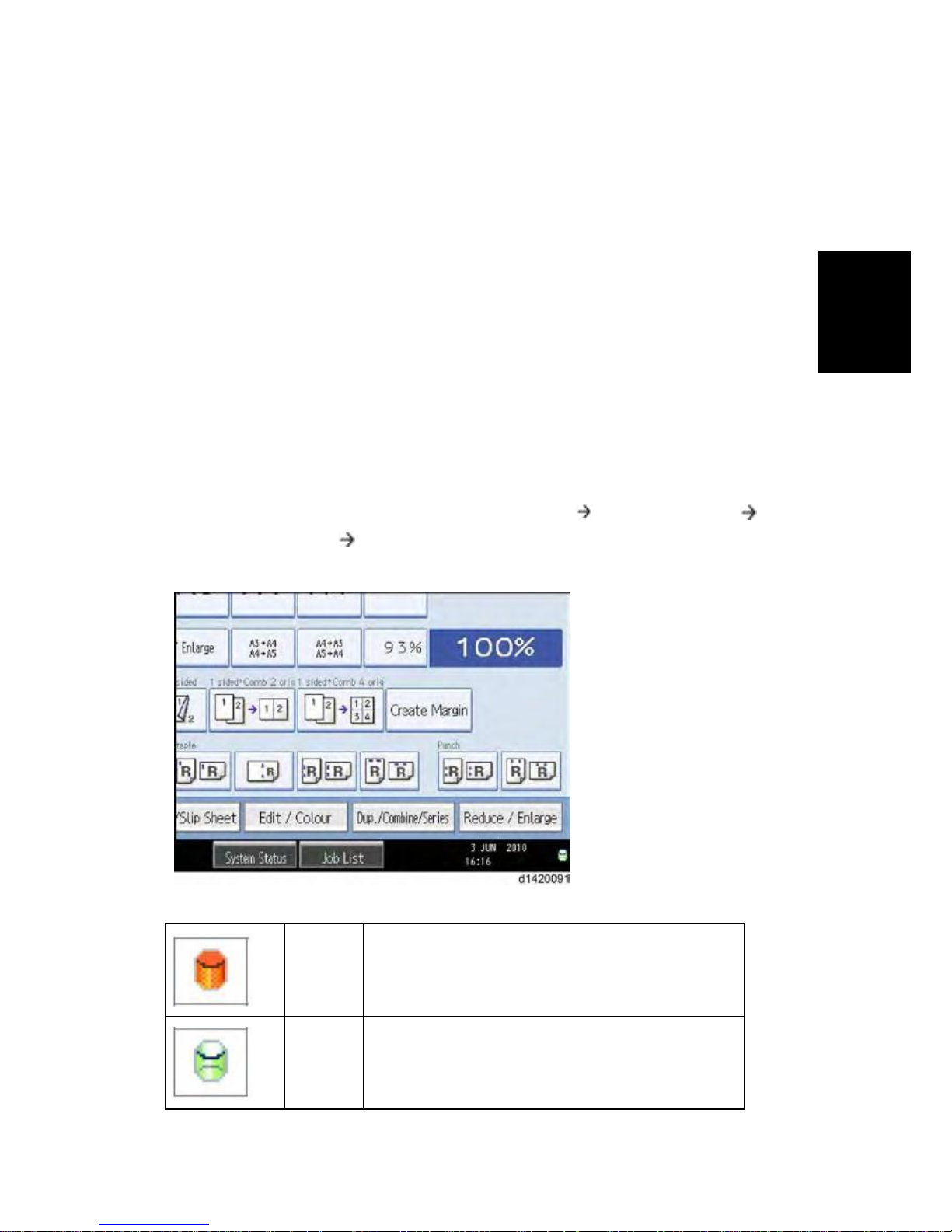

Icon [1]

This icon is lit when there is temporary data to be

overwritten, and blinks during overwriting.

Icon [2]

This icon is lit when there is no temporary data to be

overwritten.

D146/D147/D148/D149/D150

2-

SM

Main Machine Installation

9. Check the display and make sure that the overwrite erase icon appears.

10. Check the overwrite erase icon.

The icon [1] is lit when there is temporary data to be overwritten, and blinks during

overwriting.

The icon [2] is lit when there is no temporary data to be overwritten.

HDD Encryption

Before You Begin the Procedure:

1. Make sure that the following settings (1) to (3) are not at the factory default settings.

(1) Supervisor login password

(2) Administrator login name

(3) Administrator login password

These settings must be set up by the customer before the HDD Encryption unit can be

installed.

2. Confirm that "Admin. Authentication" is on: [User tools/Counter] key -> [System Settings] ->

[Administrator Tools] -> [Administrator Authentication Management] -> [Admin.

Authentication] -> [On]

If this setting is off, tell the customer that this setting must be on before you can do the

installation procedure.

3. Confirm that "Administrator Tools" is selected and enabled.

[User tools/Counter] key -> [System Settings] -> [Administrator Tools] -> [Administrator

Authentication Management] -> [Available Settings]

"Available Settings" is not displayed until step 2 is done.

If this setting is not selected, tell the customer that this setting must be selected before you

can do the installation procedure.

Installation Procedure:

1. Turn on the main power switch, and then enter the SP mode.

2. Select SP5878-002, and then press "Execute" on the LCD.

3. Exit the SP mode after "Completed" is displayed on the LCD.

4. Turn off the main power switch.

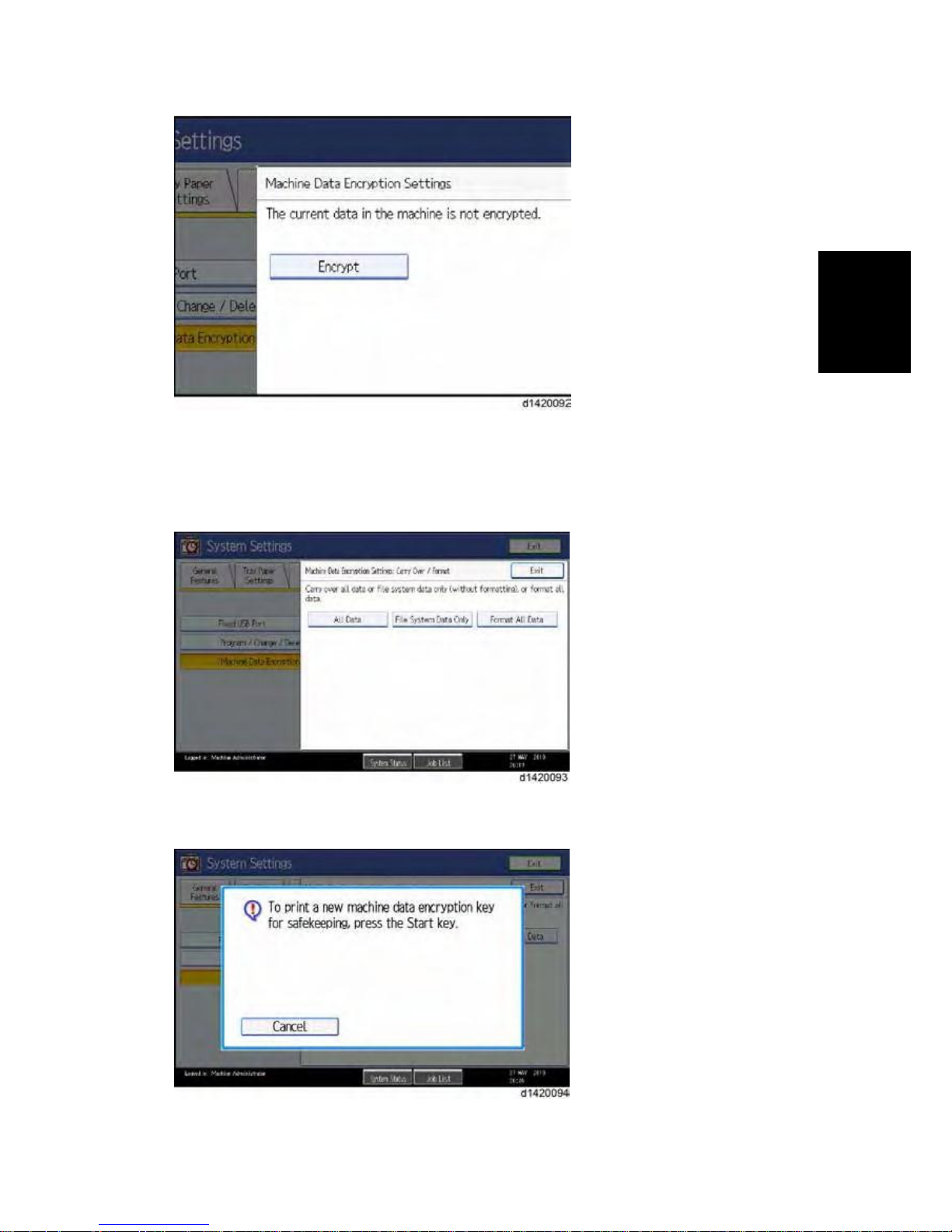

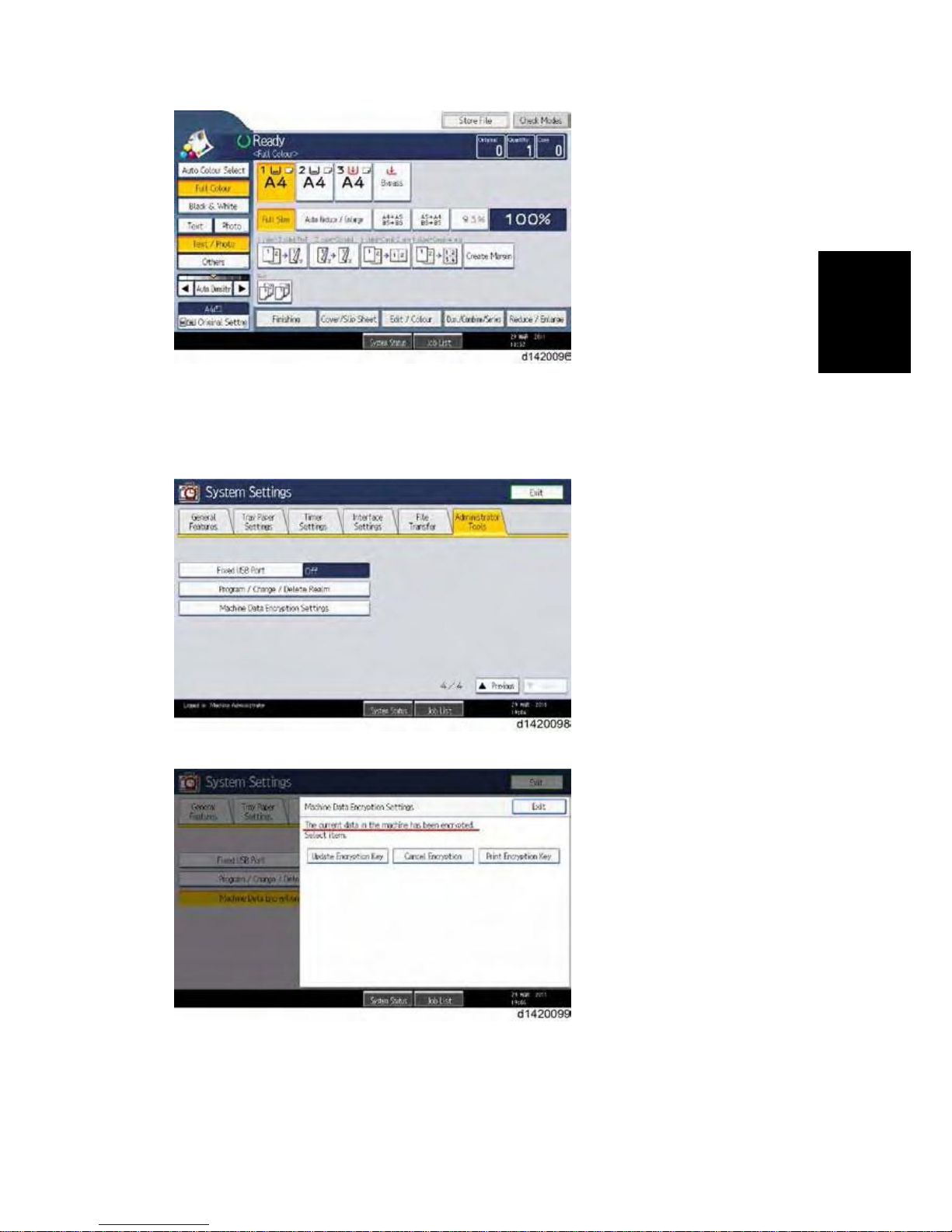

Enable Encryption Setting:

1. Press the [User tools/Counter] key.

2. Press [System Settings].

3. Press [Administrator Tools].

4. Press [Machine Data Encryption Settings].If this item is not visible, press [Next] to display

more settings.

5. Press [Encrypt].

SM

2-21

D146/D147/D148/D149/D150

Main Machine Installation

Installation

1. Select the data to be carried over to the hard disk and not be reset.

To carry all of the data over to the hard disk, select [All Data].

To carry over only the machine settings data, select [File System Data Only].

To reset all of the data, select [Format All Data].

2. The following message will be displayed. Press the [Start] key to print the encryption key for

safe keeping.

3. Press [Exit] to remove the following message.

D146/D147/D148/D149/D150

2-

SM

Main Machine Installation

4. Press [Exit] again.

5. Press the [User Tools/Counter] key.

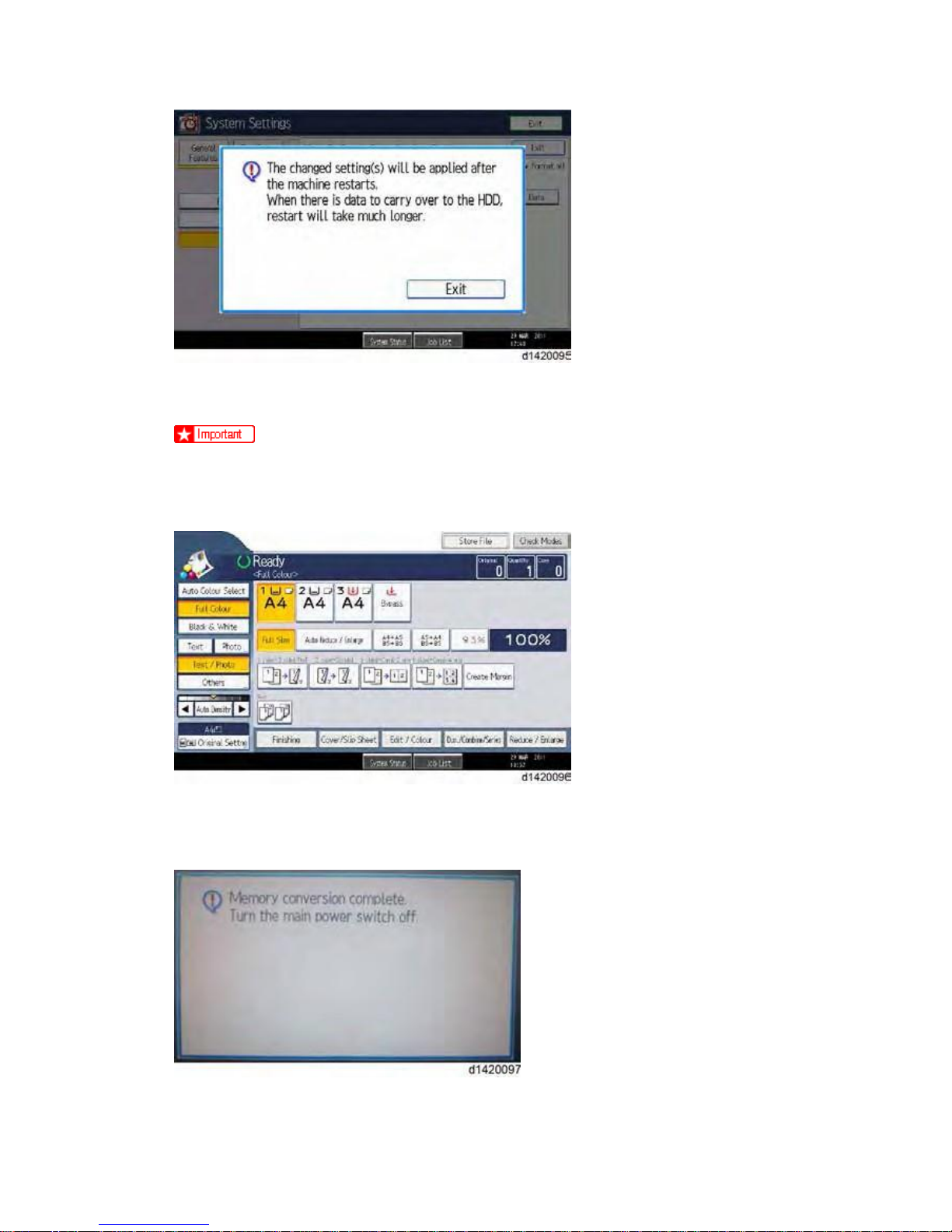

·

After step 10, the initial operation display appears as below. However, HDD data

encryption has not been completed at this moment. Step 11 and step 12 should be

performed in order to encrypt the HDD data.

6. Turn the main power switch off and on.

7. "Memory Conversion complete. Turn the main power switch off" is displayed as below. Then

turn the main power switch off and on.

8. Then initial operation display appears again. After this step, HDD data encryption has already

been completed.

SM

2-23

D146/D147/D148/D149/D150

Main Machine Installation

Installation

Check the Encryption Settings

1. Press the [User tools/Counter] key

2. Press [System Settings].

3. Press [Administrator Tools].

4. Press [Machine Data Encryption Settings].

5. Please confirm whether the encryption has been completed or not on this display.

D146/D147/D148/D149/D150

2-

SM

Main Machine Installation

Print the encryption key

Use the following procedure to print the key again if it has been lost or misplaced.

1. Press the [User tools/Counter] key.

2. Press [System Settings].

3. Press [Administrator Tools].

4. Press [Machine Data Encryption Settings].

If this item is not visible, press [Next] to display more settings.

1. Press [Print Encryption Key].

Encryption key sample

The encryption key is printed out as a sheet of paper like the example shown above.

Please instruct the customer to keep it in a safe place.

Loading...

Loading...