Ricoh D104, D106 Product Support Manual

RICOH Americas Corporation

Content ID# rfg047077

Product Support Guide

Model D104/D106

Introduction

Model Type Color MFP

Launch Date 2/1/2011

S/N Configuration V97/V98

Product Code D104/D106

Brand/Model Name

Product Code Lanier Ricoh Savin Gestetner

D104 LD 620C MP C2051 C9120 MP C2051

D106 LD 625C MP C2551 C9125 MP C2551

Product Concept

The D104/D106 series is replacing the D037/D038/D041 series.

The D104/D106 will be launched to enhance our competitiveness, offering

higher productivity, more solutions, improved eco specifications and advanced

security features. The D104/D106 will allow us to keep our #1 color market share

position and further expand it.

Launch Objectives are to:

1 - Keep color MFP Market share, Replace competitor’s MIF and protect our

MIF.

2 - Maximize profitability of aftermarket sales, Increase color document

volume.

3 - Satisfy market demands for Eco friendly products In order to keep the #1

position and expand the color market share in Segment 1 and lower

Segment 2, Ricoh has developed D104/D106. In the lower segment market,

many users use inkjet printers or color laser printers for their color

documents. Model D104/D106 targets to obtain competitors’ TDV by

replacing competitors’ inkjet printers and color laser printers.

As a B2C strategic product, D104/D106 will replace monochrome MFPs in

Segment 1 and lower Segment 2, and start the B2C conversion of sub

devices in medium to large-sized companies, bringing color closer to the

customer. By capturing their color document volume, D104/D106 would be

more profitable than selling monochrome MFPs.

Ver.1.5 Page 1 of 43 12/9/2011

Subject to change without notice

Product Support Guide

Model D104/D106

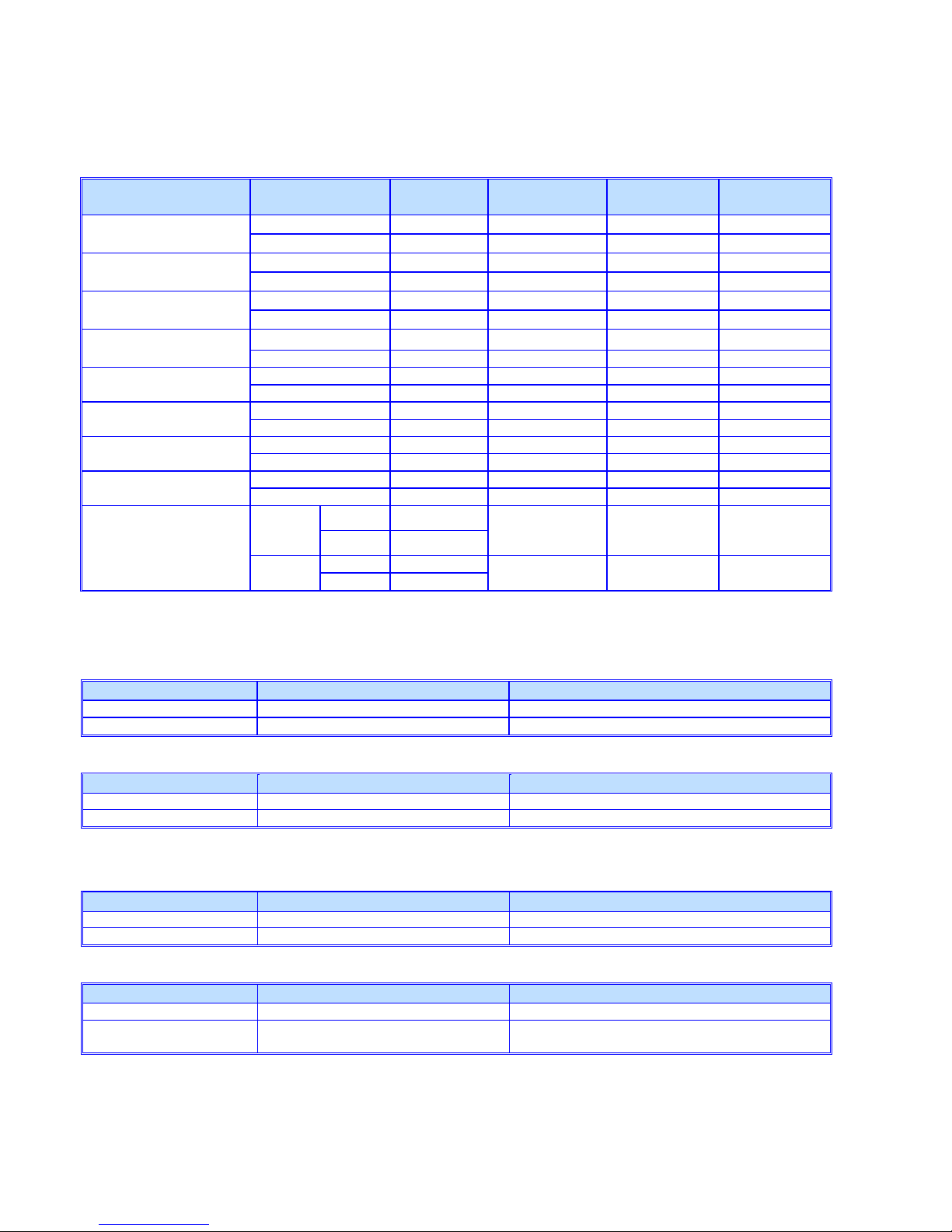

Order Number

Main Frame

Item Model Name EDP Code Notes

Lanier LD 620C

D104

D106

Note: Order Numbers are provided for reference purposes only. Please refer to your Pricing List for proper order numbers to

insure you receive the correct branding emblem.

Ricoh MP C 2051

Savin C9120

Lanier LD 625C

Ricoh MP C2551

Savin C9125

415511

415526

Includes Duplex, Bypass, ADF, Printer/ Scanner,160GB

HDD, 1.5GB Ram, VM Card, App2Me, Data Overwrite

Security, Encryption

Includes Duplex, Bypass,ADF,Printer/ Scanner,160GB

HDD, 1.5GB Ram, VM Card, App2Me, Data Overwrite

Security , Encryption

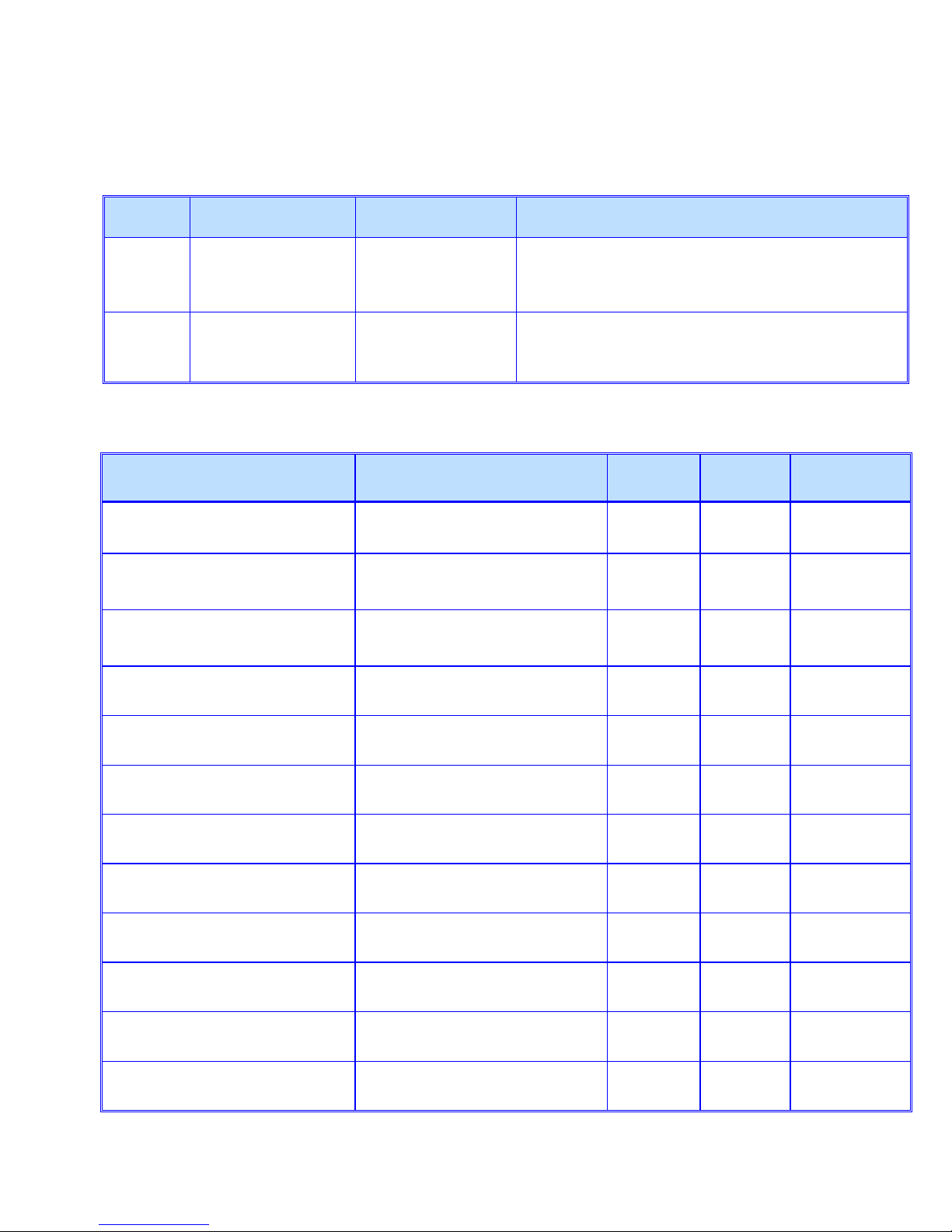

Options

Item Description EDP Code

Fax Option Fax Option Type C2551 415537 D555-01 ( U )

Envelope Feeder EF3010 Envelope Feeder EF3010 415562 D559-01

Postscript3 Unit Type C2551 Postscript3 Unit Type C2551 415543 D556-04 ( U )

USB Attachment Option USB2.0/SD Slot Type G 415672 D556-16 ( U )

Product

Code

Common /

Unique

( U ) Must set

SP5063-002 to

enable

Caster Table for PB3070 Caster Table Type B 414819 D448-03 ( C ) D038/D041

Inner 1 Bin Tray 1 Bin Tray BN3060 414617 D426-17

PictBridge

1 Tray Paper Bank (500 x 1) Paper Feed Unit PB3070 414616 D425-17

Side Tray Side Tray Type C2550 414618 D427-17

Internal Shift Tray Internal Shift Tray SH3030 414619 D428-17

Internal Finisher Internal Finisher Type C2550 414620 D429-17

Punch Unit NA 2/3 holes Punch Unit PU3010NA 414621 D390-17

Camera Direct Print Card Type I

415575 D546-21

( C ) D038/D041

(C) D086/D087

( C ) D038/D041

( C ) D038/D041

( C ) D038/D041

( C ) D038/D041

( C ) D038/D041

Ver.1.5 Page 2 of 43 12/9/2011

Subject to change without notice

Product Support Guide

Model D104/D106

Item Description EDP Code

Punch Unit EU 2 holes Punch Unit PU3010EU2 414622 D390-27

Punch Unit EU 4 holes Punch Unit PU3010EU4 414624 D390-67

Accessibility Handle ADF Handle Type B 414965 D366-10

Platen Platen Cover Type 3800C 412 551 G329-57

2 Tray Paper Bank (500x 2) Paper Feed Unit PB3030 413673 D331-01

SAF memory for Fax Memory Unit Type B 32MB N/A G578-17

IEEE1284 IEEE 1284 Interface Board Type A 411699 B679-17

IEEE 802.11a/g EU/AA IEEE 802.11a/g Interface Unit Type J 414009 D377-02

Product Common /

Code Unique

( C ) D038/D041

( C ) D038/D041

( C ) D038/D041

( C ) D038/D041

( C ) D038/D041

( C ) D038/D041

( C ) D038/D041

( C ) D038/D041

IEEE 802.11g Specified Countries IEEE 802.11g Interface Unit Type K 414186 D377-19

File Format Converter File Format Converter Type E 414007 D377-04

Key Counter Bracket Key Counter Bracket Type H 412552 A674-05

Optional Counter Interface Unit Type A Optional Counter Interface Unit Type

A

Unicode Font Package for SAP 1

License

Unicode Font Package for SAP 10

License

Unicode Font Package for SAP 100

License

Fax Stamp ink Marker Type 30 334049 H903-02

Hand Set for Fax Hand Set Type1018 410781 B433-01

IEEE 802.11a/g NA IEEE 802.11a/g Interface Unit Type J 414008 D377-01

Unicode Font Package for SAP 1

License

Unicode Font Package for SAP 10

License

Unicode Font Package for SAP 100

License

413012 B870-11

413009 B869-01

413010 B869-02

413011 B869-03

( C ) D038/D041

( C ) D038/D041

( C ) D038/D041

( C ) D038/D041

( C ) D038/D041

( C ) D038/D041

( C ) D038/D041

( C ) D038/D041

( C ) D038/D041

( C ) D038/D041

Data Overwrite Security Unit Data Overwrite Security Unit Type H 414002 D377-06 ( C ) D086/D087

Ver.1.5 Page 3 of 43 12/9/2011

Subject to change without notice

Product Support Guide

Model D104/D106

Item Description EDP Code

Card Reader Bracket Type C5501 Card Reader Bracket Type C5501

Gigabit Ethernet Gigabit Ethernet Type B 414204 D377-21 ( C ) D017/D009

Cabinet FAC43 Cabinet Stand 415016 --- ( C ) D038/D041

Blue Tooth TBA TBA TBA TBA

IPDS TBA TBA TBA TBA

USB Keyboard Optional USB Keyboard 100 266FNG --- ---

Bracket Optional USB Keyboard Bracket 100268FNG --- ---

Note: The Data Overwrite Security Unit is ISO 15408 is Certified. The Standard unit included with the machine is not certified

415495 D547-03 ( C ) D086/D087

Product Common /

Code Unique

Supplies/Yields

Item Name Order Code Target Yield Notes

Ricoh/Savin/Lanier

Black Toner

Y ellow Toner

Magenta Toner

Cyan Toner

Toner (Existing)

Black Toner

Cyan Toner

Magenta Toner

Y ellow Toner

Staple Set Cartridge Staple Type T 415009 5,000

Staple Refill

Cartridge

Marker 30 Marker Type 30 334049 12,000

Supply Yield Condition:

1) * 5% chart is used to measure the yield.

2) The condition is standard temperature and humidity.

3) This yield number may change depending on the circumstances and printing conditions.

4) The New Toner is Tri-branded and used in all models. (One EDP Code)

5) The new toner cartridge is a High Yield Cartridge

Print Cartridge Black Type MP

C2551/C9125/LD625C

Print Cartridge Yellow Type MP

C2551/C9125/LD625C

Print Cartridge Magenta Type

MP C2551/C9125/LD625C

Print Cartridge Cyan Type MP

C2551/C9125/LD625C

Print Cartridge Black Type MP

C2550/C9025/LD525C

Print Cartridge Cyan Type MP

C2550/C9025/LD525C

Print Cartridge Magenta Type

MP C2550/C9025/LD525C

Print Cartridge Yellow Type MP

C2550/C9025/LD525C

Refill Staple Ty pe T 415010 10,000

841500 10,000* Used in D104/D106 only

841501 9,500*

841502 9,500*

841503 9,500*

841280 10,000*

841281 5,500

841282 5,500

841283 5,500

Can be used in

D104/D106/D037/D038/D041

Can be used in

D104/D106/D037/D038/D041

Can be used in

D104/D106/D037/D038/D041

Used in D037/D038/D041

only

Can be used in

D104/D106/D037/D038/D041

Can be used in

D104/D106/D037/D038/D041

Can be used in

D104/D106/D037/D038/D041

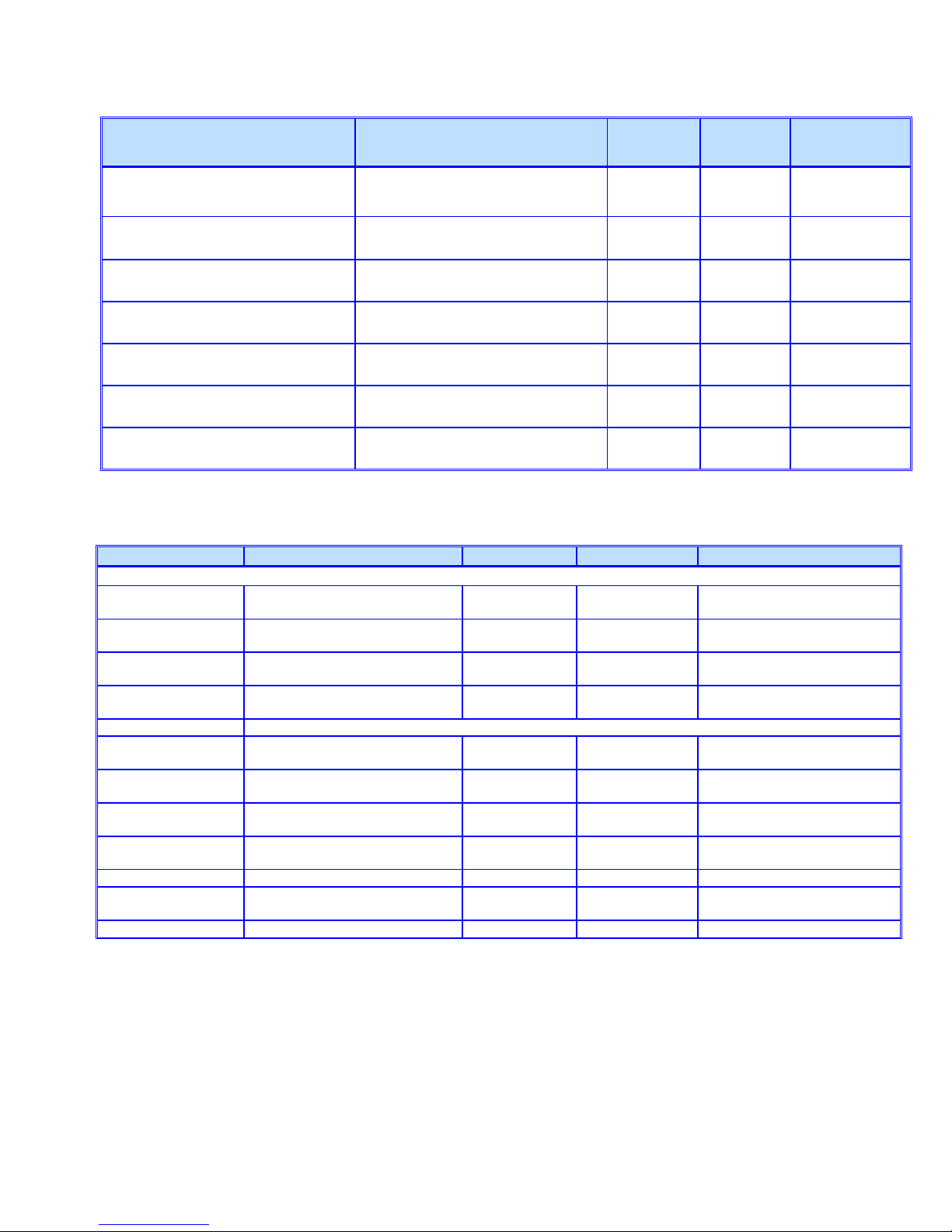

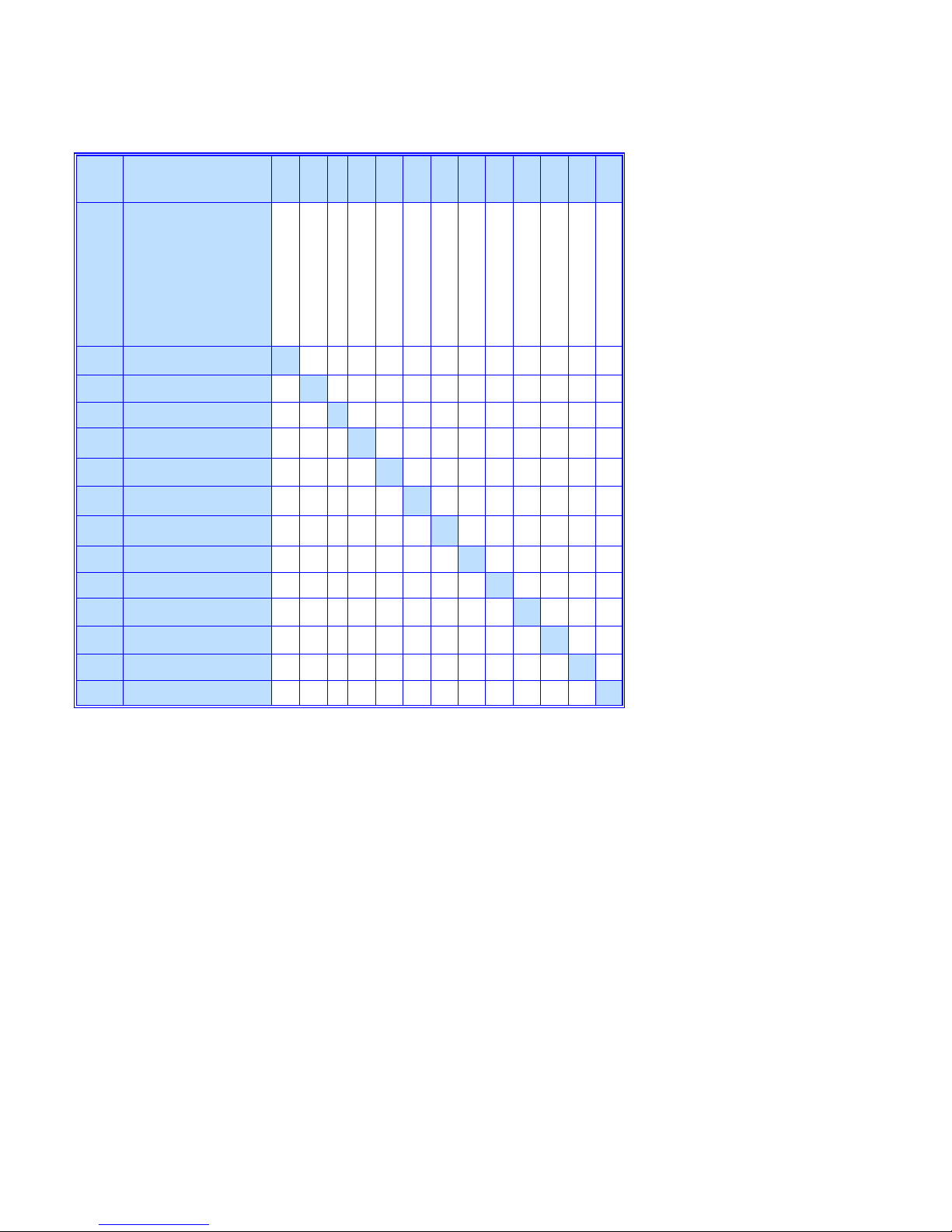

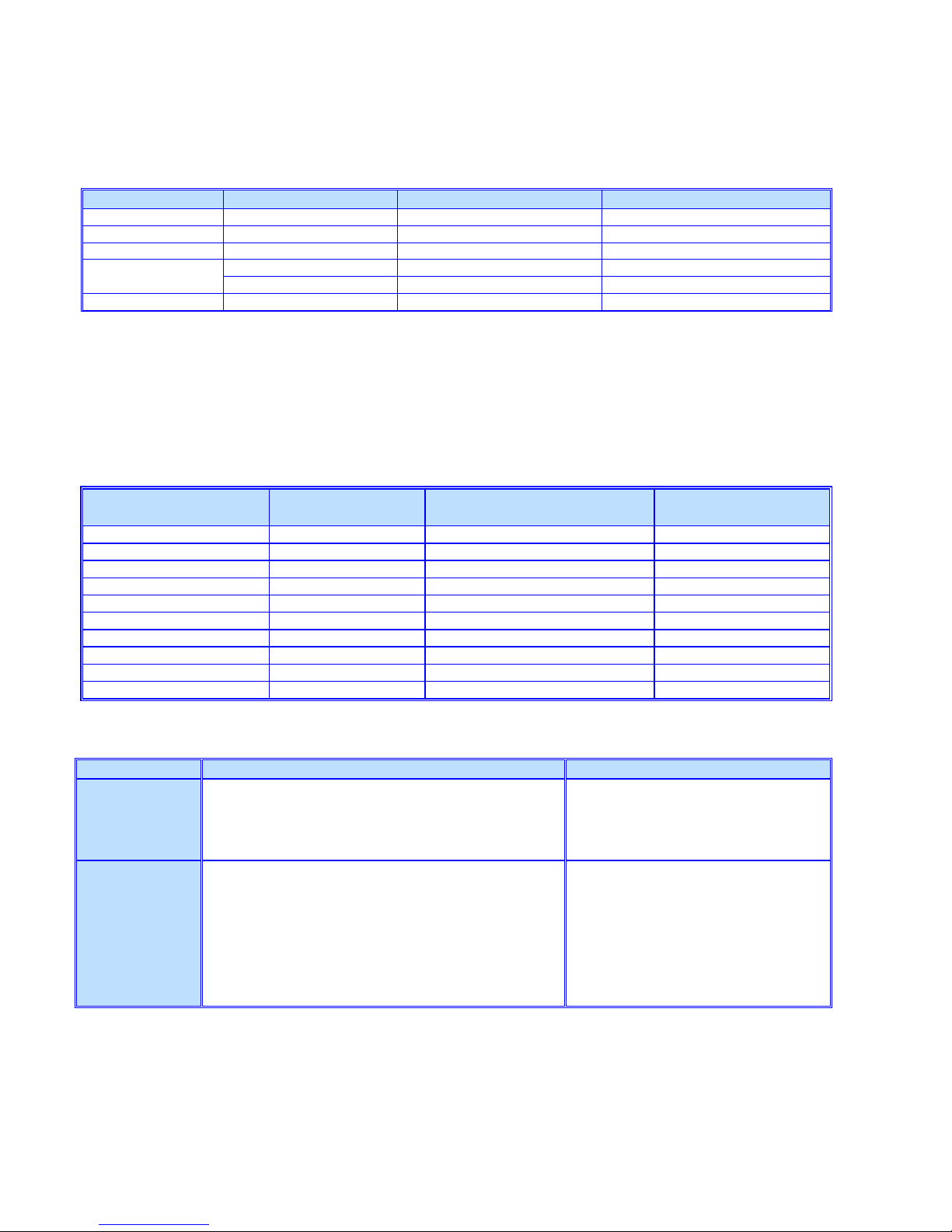

Option Compatibility

Ver.1.5 Page 4 of 43 12/9/2011

Subject to change without notice

Hardware options

interface

1

Platen

1 Platen

2 ARDF

3 Accessibility handle

4 1-Tray Paper bank

5 Caster table

6 2-Tray Paper Bank

7 1 Bin Tray

8 Shift Tray

9 Side Tray

10 Internal Finisher

Punch Unit (US

11

2/3)

12 Envelope Feeder

Key Counter

13

Bracket

Optional Counter

14

interface

15 Cabinet

N

N

Y: Must Install / N: Cannot Install

Controller options

Product Support Guide

Model D104/D106

2

3

4

5

6

7

8

9

10

11

ARDF

Accessibility handle

1-Tray Paper bank

Caster table

2-Tray Paper Bank

1 Bin Tray

Shift Tray

Side Tray

Internal Finisher

Punch Unit (US 2/3)

NN

Y

Y

Y N

Y N

N N

N N

N N

N N Y

N N Y

N N N

N

12

13

14

15

Envelope Feeder

Key Counter Bracket

Optional Counter

Cabinet

N

N

Ver.1.5 Page 5 of 43 12/9/2011

Subject to change without notice

1 Fax Option

2 SAF memory

3 Handset

4 Fax Stamp

5 PostScript3

6 PictBridge Option

6 IEEE 1284 Interface

7 IEEE802.11a/g

8 Gigabit Ethernet

9 HDD Data Overwrite

10 USB2.0/SD SLOT

11

File Format Converter

12 Card Reader Bracket

1

Fax Option

Y

Y

Y

Y: Must Install / N: Cannot Install

Product Support Guide

Model D104/D106

2

3

4

5

5

6

7

8

9

10

11

12

SAF memory

Handset

Fax Stamp

PostScript3

PictBridge Option

IEEE 1284 Interface

IEEE802.11a/g

Gigabit Ethernet

HDD Data Overwrite

USB2.0/SD SLOT

File Format Converter

Card Reader Bracket

Y Y Y

N N N

N N N

N N N

N N N

Ver.1.5 Page 6 of 43 12/9/2011

Subject to change without notice

Product Support Guide

Model D104/D106

Branding Information

Branding is required as the machines are shipped as a generic version.

Ricoh version machines: You must attach the model label (provided) to the front cover.

Savin/Lanier: You must attach the model label (provided) to the front cover and set the Plug and Play name with

SP 5-907.

Branding Plaques

Model Ricoh Lanier Savin

D104 D104-31 415517 D104-34 415520 D104-32 415518

D106 D106-31 415532 D106-34 415535 D106-32 415533

Product Code MIU Product Code MIU Product Code MIU

Configuration

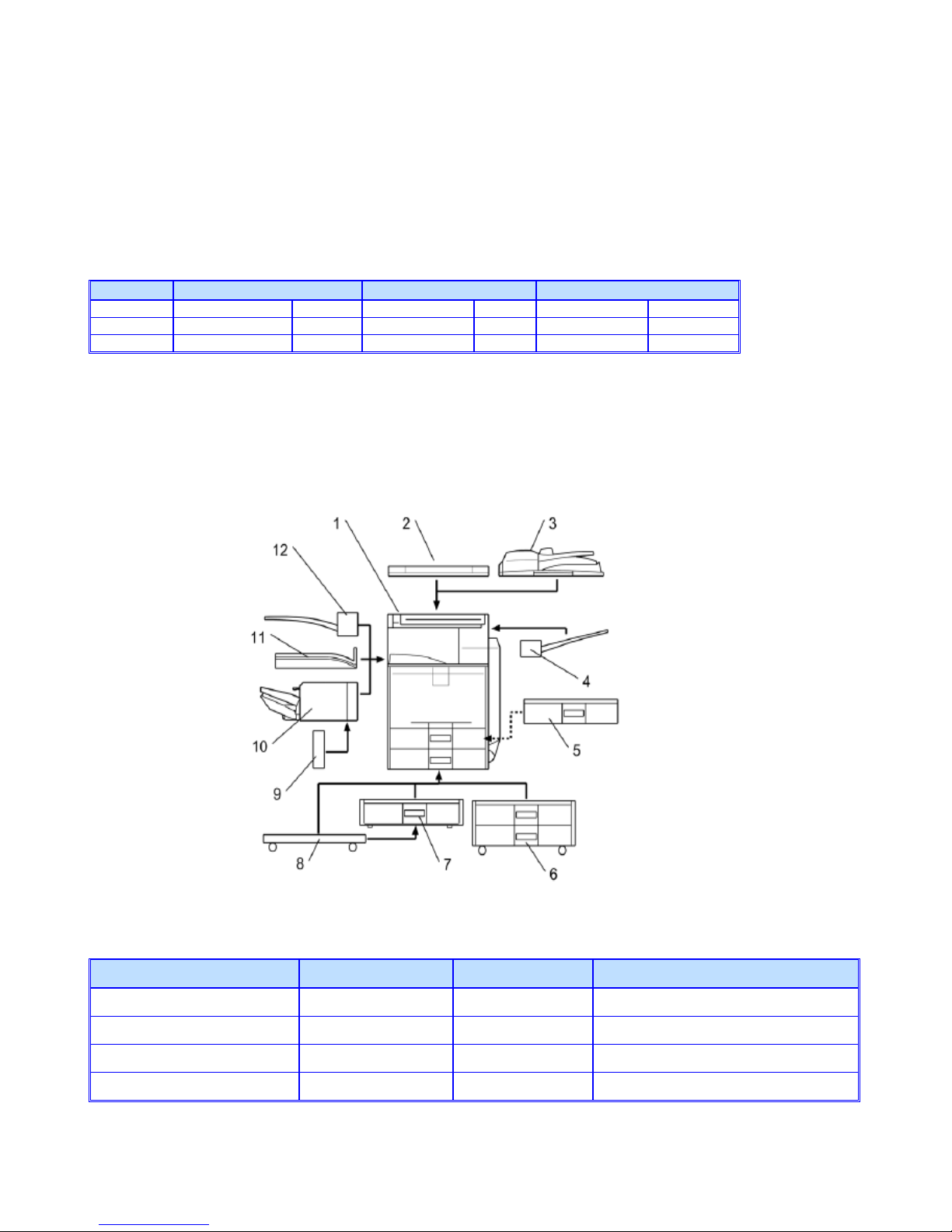

Main Frame Configuration

D104/D106

Item Machine Code Call Out Remarks

Mainframe D104/D106 [1] D104/D106

Platen Cover G329 [2]

ARDF D541 [3] Standard

Side Tray D427 [4]

Ver.1.5 Page 7 of 43 12/9/2011

Subject to change without notice

Product Support Guide

Model D104/D106

Item Machine Code Call Out Remarks

1-Bin Tray D426 [12]

Shift Tray D388 [11]

Internal Finisher D429 [10]

Punch unit: 2/3 holes D390-17 [9] Requires [10]

Punch unit: 2 holes D390-27 [9] Requires [10]

Punch unit: 4 holes D390-31 [9] Requires [10]

Two Tray Paper Feed unit D331 [6]

One Tray Paper Feed Unit D425 [7]

Caster Table D448 [8}

Envelope Feeder D559 [5}

One of the following 4 choices: [10]

only, [11] only, [12] only, or [11] and

[12]

One from [6], [7], and [8]

The one- Tray PFU [6] Requires [8]

If neither [6] nor [7] is installed, install

[8] if required by the customer

This option can only be installed in tray

1 of main frame

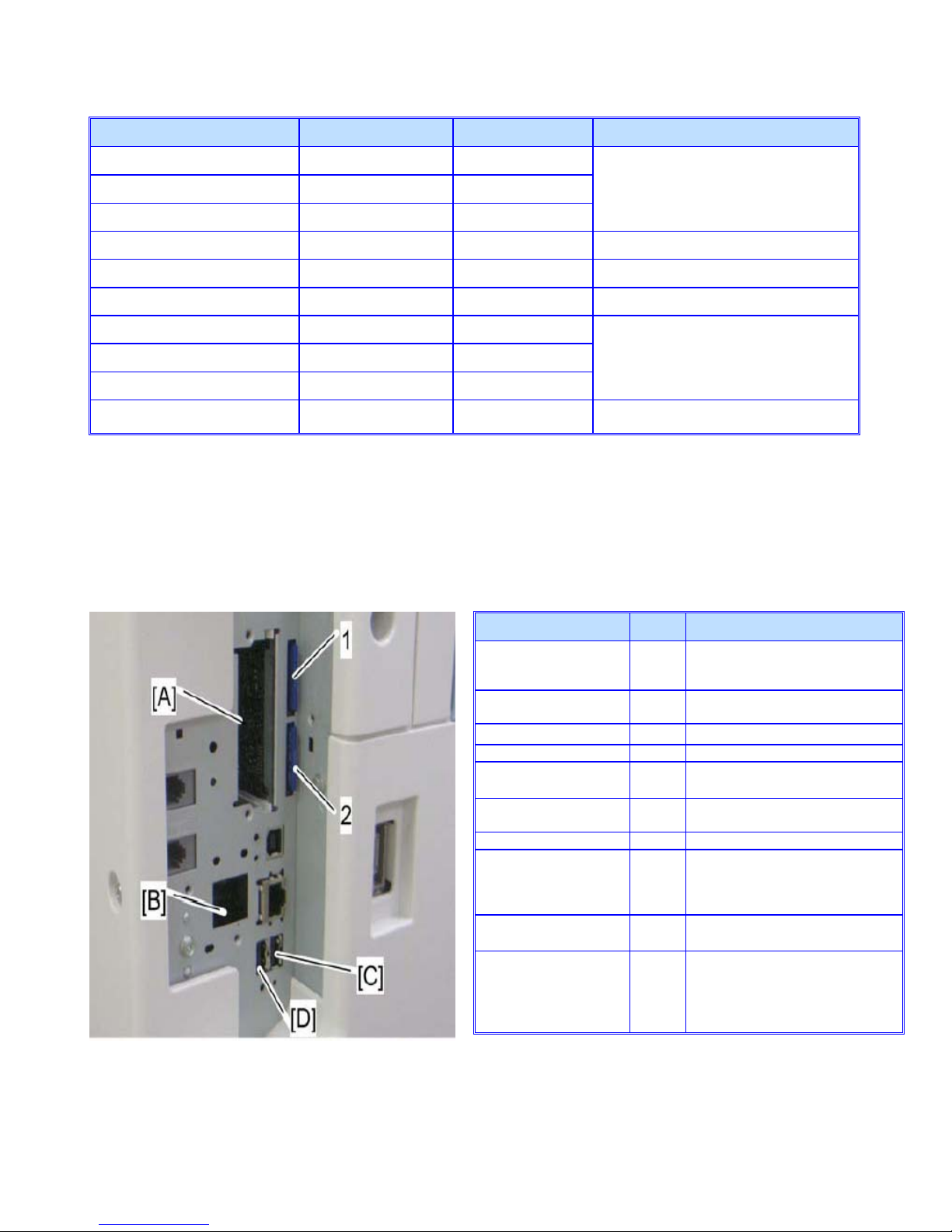

MFP Options

MFP Option Board Slot / SD Card Assignments

Option Slot Notes

Data Overwrite

Security/HDD

Encryption

PostScript 3 1

Picbridge 1 Must merge to PostScript

IPDS 1 TBA

Updating Firmware 2

VM Card 2

Gigabit Ethernet B Used for Gigabit Ethernet only

IEEE1284

IEEE802.11a/g

File Format Converter

Bluetooth

USB Slot for Digital

Camera

USB Slot for Optional

USB2.0/SD Card Slot

1

A

C

D

Standard

Pre-installed on a single SD

card in slot 1

Must merge Data Overwrite

Security/HDD Encryption

VM Card must be removed to

update firmware

Comes standard with machine

and must stay in slot 2

Only one option can be installed

in I/f Slot B

Bluetooth (TBA)

Camera must be Picbridge

compliant

Scan to and Print from

PostScript or PDF Direct Card

must be installed

PDF Direct Card supplied with

USB2.0/SD Card option

Ver.1.5 Page 8 of 43 12/9/2011

Subject to change without notice

Product Support Guide

3

Model D104/D106

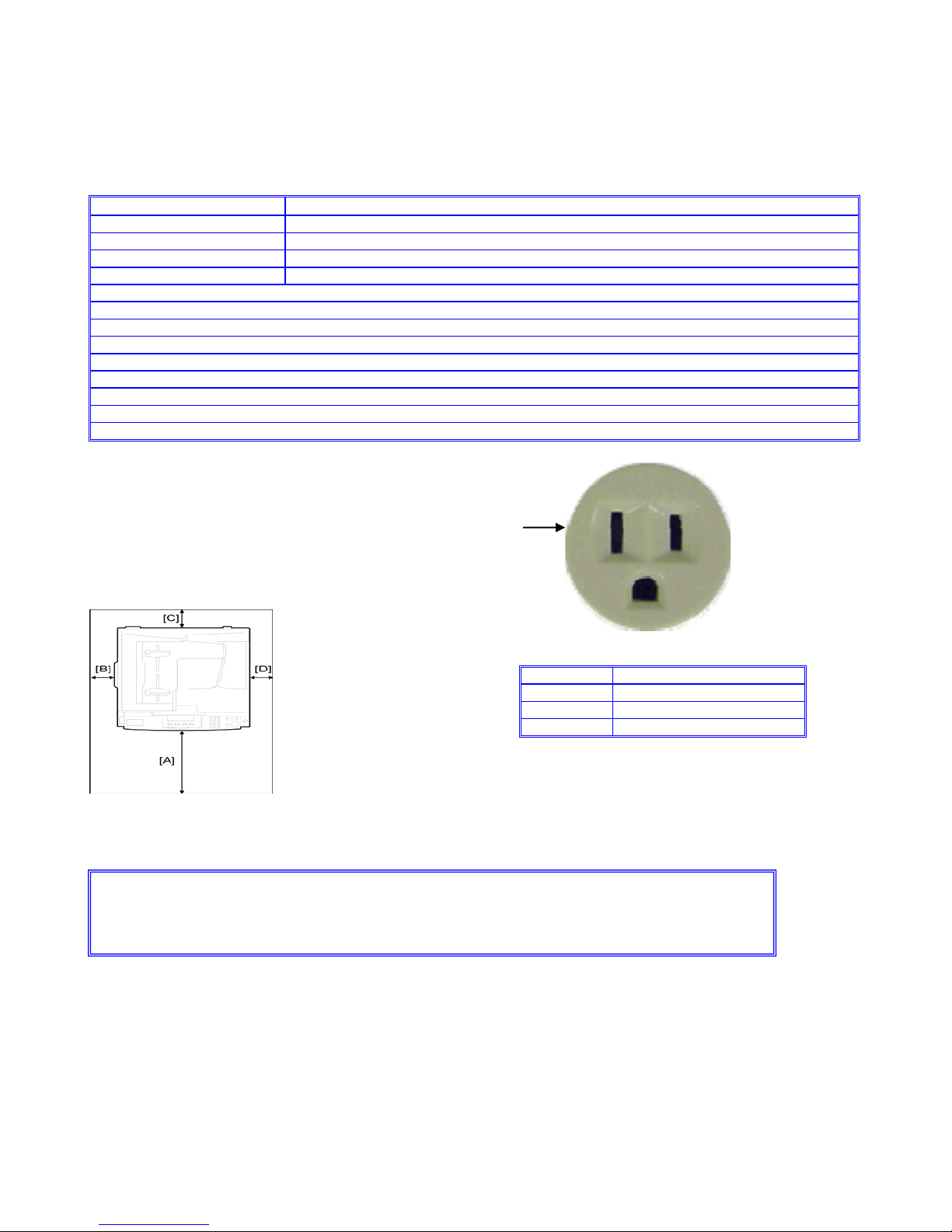

Installation

Installation Requirements

Temperature Range:

Humidity Range: 15% to 80% RH

Ambient Illumination: Less than 1,500 lux (do not expose to direct sunlight)

Ventilation: 3 times/hr/person

Ambient Dust: Less than 0.075 mg/m

Avoid areas exposed to sudden temperature changes:

Areas directly exposed to cool air from an air conditioner

Areas directly exposed to cool from a heater.

Do not place machine where it will be exposed to corrosive gas or vapor.

Do not install the machine at any location over 2,000m (6,500 ft.) above sea level.

Place the machine on a strong and level base. Inclination on any side should be no more than 5mm (0.2”)

Do not place the machine where it may be subject to strong vibrations.

Machine level Front to back: within 5mm (0.2”) of level

Machine level Right to left: within 5mm (0.2”) of level

Power Requirements

Input voltage level: 110 - 120 V, 60Hz: 12A

Do not place anything on power cord.

The required wall outlet is a NEMA 5-15R (receptacle)

Space

10° C to 32° C (50° F to 89.6° F)

(2.0 x 10-6oz/yd3)

A (Front) Over 100m(3.9”)

B (Left) Over 100m(3.9”)

C (Rear) Over 315m(12.4”)

D (Right) Over 400m(15.7”)

Foot Print

Di

mensions: W 587mm x D 655mm x H 725mm / 23.1”x25.8”x28.5” (w/o ARDF)

Dimensions: W 587mm x D 655mm x H 845mm / 23.1”x25.8 x33.3” (with ARDF)

NOTE: Measurement Conditions: Without F inisher installed and bypass table closed

Ver.1.5 Page 9 of 43 12/9/2011

Subject to change without notice

Product Support Guide

D104/D106

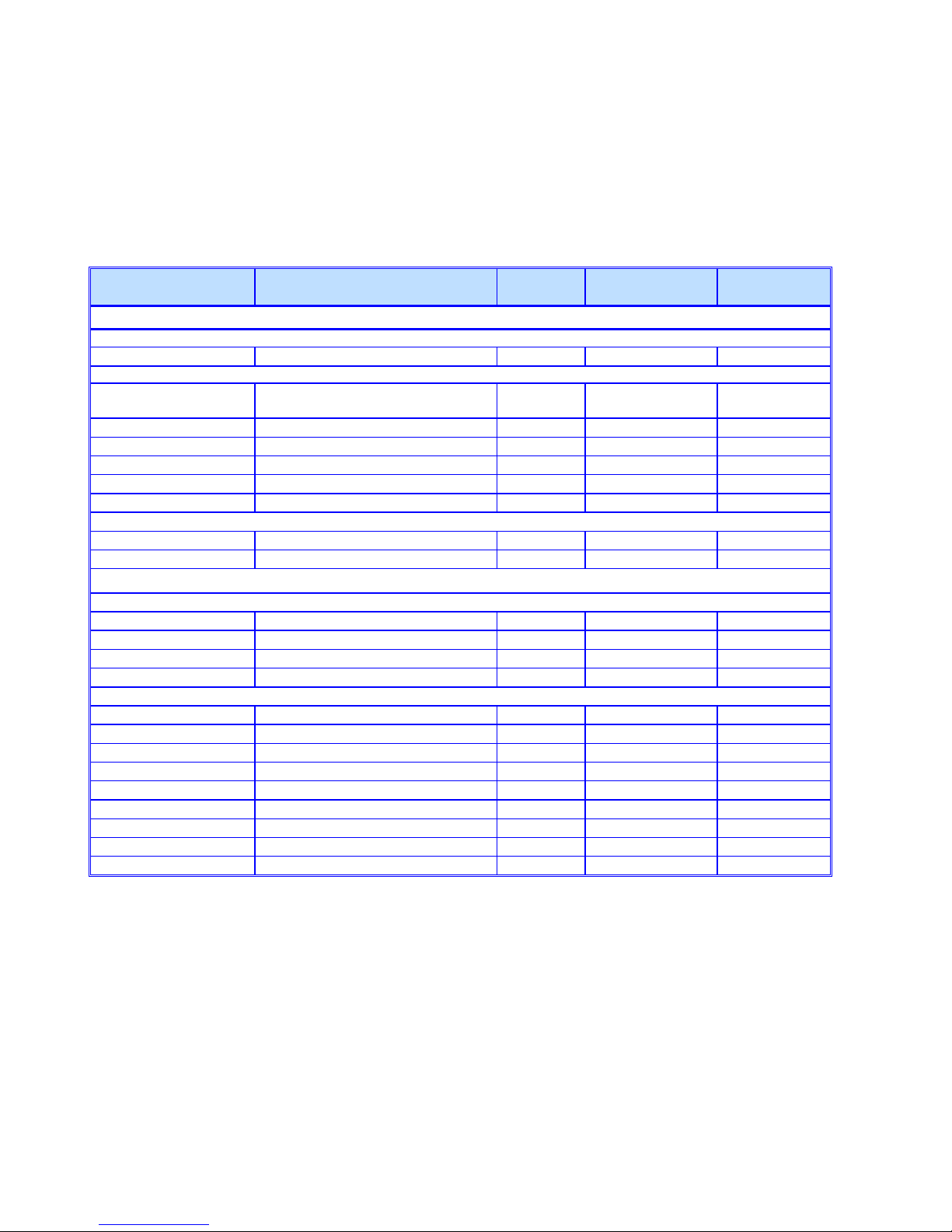

Power Consumption / Noise Emission

Power Consumption

US/EU Wattage Recovery Time

Shift Time BTU

Max Power

Operating Power

Ready Mode

Standby

Panel Off Timer

Panel Off level 2

Low Power

Sleep Mode

TEC (Typical Electricity

Consumption)

Note: Energy Star Qualified Version ES 1.2

D014

D106

US 1500 watts --EU 1680 watts --US 540 watts --EU 540watts --US 120 watts --EU 119 watts --US 250 watts --- --- 853.0

EU 250 watts --- --- 853.0

US 250 watts 7 Sec 1 min 853.0

EU 246 watts 7 Sec 1 min 839.38

US 204 watts 10 Sec 1 min 696.0

EU 210 watts 10 Sec 1 min 716.5

US 96.7 watts 18 sec 15 min 329.9

EU 106 watts 17 sec 16 min 361.6

US 1.0 watts 24 sec 45 min 3.4

EU 1.1 watts 24 sec 30 min 3.4

US 1.000 (kWh)

EU 1.000 (kWh)

US 1.274(kWh)

EU 1.200 (kWh)

---

---

---

---

---

---

---

--- -- ---

---

5118.2

5459.4

1842.5

1842.5

409.4

406.0

---

Sound Noise Level

Mainframe only/

Stand-by 40 dB 40 dB

Copying 64 dB 66 dB

Complete System (Data is a result of actual measurement)

Stand-by 44 dB 44 dB

Copying 68db 70 dB

Sound Pressure Level

Mainframe only

Stand-by 34 dB 34 dB

Copying 58 dB 60 dB

Complete System

Stand-by 38.0 dB 38.0 dB

Copying

Note: Power consumption data are actual data and may differ depending on the

condition and environment of the machine.

Monochrome : 61.0 dB

D104 D106

D104 D106

D104 D106

D104 D106

Monochrome : 62.8 dB

Color: 62.0 dB

Color: 63.5 dB

Ver.1.5 Page 10 of 43 12/9/2011

Subject to change without notice

Product Support Guide

D104/D106

Ozone/ Dust / Styrene / TVOC / Benzene Emission Level (Target)

*Please note these are targeted value only. Please refer to “Product Environment Information” for actual data.

Full Color (mg/ h) Monochrome (mg/h)

Ozone Emission Stand by + Copying 3.0 mg/h or less 1.5 mg/h or less

Dust Stand by + Copying 4.0 mg/h or less 4.0 mg/h or less

Styrene Emission Stand by + Copying 1.8 mg/h or less 1.0 mg/h or less

TVOC (*)

Benzene Stand by + Copying Less than 0.05 mg/h Less than 0.05mg/h

(*) TVOC: Total Volatile Organic Compounds

NOTE: The above measurements were made in accordance with ISO

7779. The measurements were taken from the normal position of

the operator.

Installation Times

Mainframe: 30 minutes

Peripherals:

Peripherals

ARDF* 15 PostScript3 5

1-Tray Paper Feed unit 10 PictBridge 5

2-Tray Paper Feed unit 10 IEEE802.11a/g 5

1 bin Tray 10 Gigabit Ethernet 5

Shift Tray 10 IEEE 1284 5

Side Tray 10 File Format Converter 10

Internal Finisher 15 Envelop Feeder 5

Punch Unit 30 Caster Table 5

FAX Option 15 Platen Cover 5

USB/SD Slot 10 Fax Hand Set 5

Storage/Transportation

Mainframe

Toner (*1)

NOTE: Do not store more than 12 hours under the temperature between 40 C and 500C(860F-1220F). Do not store more than a

month under the temperature between 35

not exceed 40

Stand by 2.0 mg/h or less 2.0 mg/h or less

Stand by + Copying 18.0 mg/h or less 10.0 mg/h or less

Installation Time

(Minutes)

Internal Options

Storage Transportation

Temperature/humidity

0

C 40oC(860F-104oF) Less than 85%RH

- 30

Storage Period:

Maximum 12 months from production

Temperature/humidity

0

C or less

50

(Do not leave under 36

one month or under 50

Avoid direct sunlight

15% ~ 80% RH

Storage Period

Storage period: Max 12 months

0

C (1040F) on continuance storage/transportation conditions.

0

C~ 400C(96.80F-1040F) over

0

C over 12 hours)

0

C and 400C(950F-1040F). Store in a dry, dark place where temperature does

Temperature/humidity:

-300C– 450,C (86o F-113o F)15% - 95%RH

Other condition is same as storage

0

Installation Time

(Minutes)

Ver.1.5 Page 11 of 43 12/9/2011

Subject to change without notice

Product Support Guide

r

D104/D106

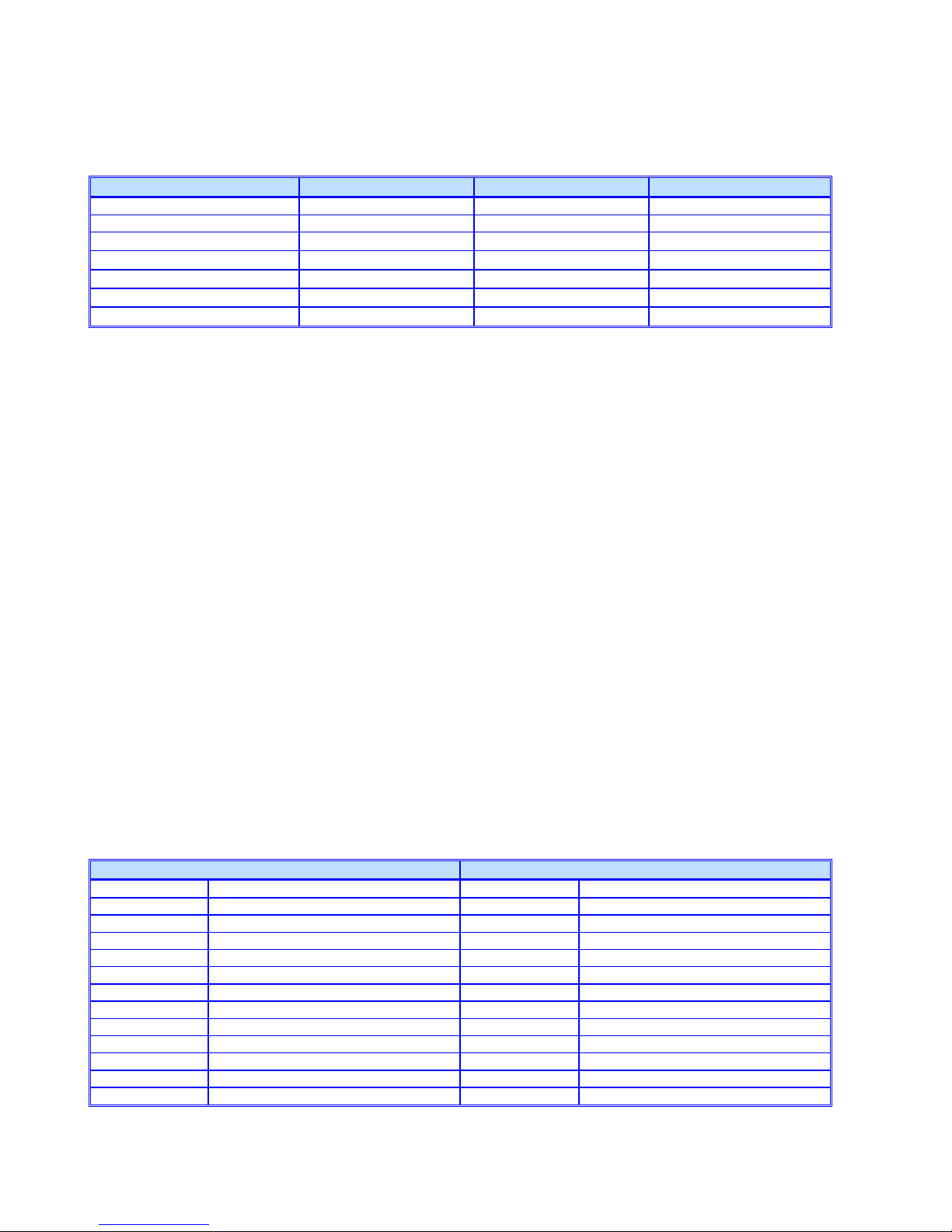

Parts / Special Tools / Maintenance

PM/EM Parts / Yields

Mainframe D106/D106

Unique/Common

U: Unique for this model

C: Common with listed model

Part Number Description

Q’ty/

Unit

PM Interval

PM Parts

PCU

D0392030 Drum Unit 1 60K ( C ) D038/D041

Transfer

D1056036 Intermediate transfer cleaning unit

with the waste toner tank

D0396029 Image Transfer Belt 1 240K ( C ) D038/D041

D0396210 PTR Unit 1 240K ( C ) D038/D0 41

Paper Feed

B1542722 Friction Pad 2 120K ( C ) D038/D041

AF031084 Feed Roller 2 120K ( C ) D038/D041

Other

D0396401 Drum Waste T oner Tank (Note 2, 3) 1 60K ( C ) D038/D041

AA010122 Dust Filter 1 150K ( C ) D038/D04 1

1 60K

(Note 1,3)

EM Parts (Replace as needed)

Developer Unit

D8303001 Devel op er Unit (Bk) Note:4,6 1 Note:4,6 U

D8093002 Developer Unit (C) Note:4,6 1 Note:4,6 ( C ) D038/D041

D8093003 Developer Unit (M) Note:4,6 1 Note:4,6 ( C ) D038/D041

D8093004 Developer Unit (Y) Note:4,6 1 Note:4,6 ( C ) D038/D041

PCDU

D8302000 PCDU-(BK) Note:4,6 1 Note:4 U

D8092001 PCDU-(C) Note:4,6 1 Note:4 ( C ) D038/D041

D8092002 PCDU-(M) Note:4,6 1 Note:4 ( C ) D038/D041

D8092003 PCDU-(Y) Note:4,6 1 Note:4 ( C ) D038/D041

Fusing

D1054050 Belt Unit Ass y Note:4 1 Note:4 U

AE020192 Pressure Roller Note:4 1 Note:4 U

D1064001 Fusing U nit (NA) Note:4,5 1 Note:4,5 U

D1064002 Fusing Unit (EU) Note:4,5 1 Note:4,5 U

NOTE 1: The yield of the Intermediate transfer cleaning unit (w/o waste toner tank) is 180k, but the waste toner tank yield is 60k.

NOTE 2: This item is also user-replaceable.

NOTE 3: The yield figures in the above table are based on the following conditions:

A4 (LT) long-edge feed, 5% image coverage ratio, Color ratio: 20%, 2 print/job

Note 4: Due to their durability and extended service life, the above parts are treated as EM parts.

Note 5: The fusing unit does have a target yield of 240k. However, the total copy/print volume made by the machine will not reach the

target yield of 240K within the machine’s targeted lifetime if the machine is used under the target usage conditions (ACV, color ratio, P/J,

and C/O).

Note 6: The PCDU consist of the entire Drum assembly with PCU, Developer Unit and Cleaning Unit, there is no set replacement interval.

For this reason, the fusing unit is not categorized as a PM part but as a yield part (EM part).

Ver.1.5 Page 12 of 43 12/9/2011

Subject to change without notice

Unique o

Common

( C ) D038/D041

Product Support Guide

r

D104/D106

Additional Yield Information

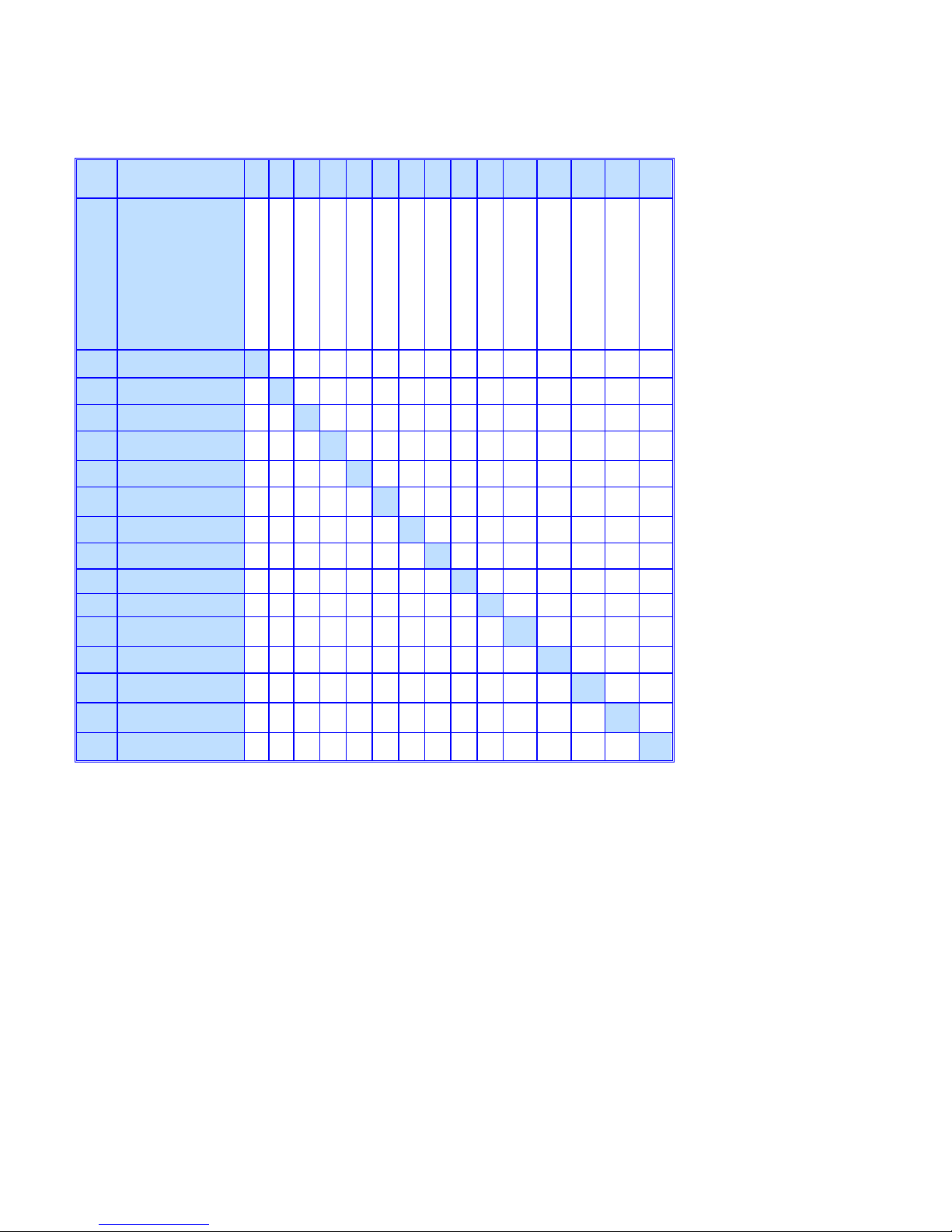

1P/J 2P/J (Target) 3p/j

PCU - K 37k (62%) 60k (100%) 60k (100%)

PCU – CMY 36k (60%) 60k (100%) 60k (100%)

Developer Unit – K 240k (71%) 240k (100%) 240k (100%)

Developer Unit – CMY 171k (71%) 240k (100%) 240k (100%)

ITB Unit 147k (61%) 240k (100%) 240k (100%)

PTR UNIT 147k (61%) 240k (100%) 240k (100%)

Fusing Unit 152k (63%) 240k (1 00%) 240k (100%)

Note: Image coverage ratio, color ratio and pages per job will impact the life expectancy of specific PM parts.

Managing the PM Cycle

The “No. of Days Remaining” Counter

The following SP modes display the estimated number of days left until a given PM part is expected to reach its target yield, either in

terms of pages or rotational distance. This estimation takes into account the current value of the page or rotational counter, as well as

the daily usage trends (number of pages, rotational distance) of the machine.

Checking this value is an easier and more accurate way of knowing how close a given PM part is to its target yield than simply

checking the PM counter.

Units to which these counters apply:

PCU (K/C/M/Y)

Development unit (K/C/M/Y)

ITB unit

ITB cleaning unit

Fusing unit

Paper transfer unit

IMPORTANT:

Since a highly accurate estimate cannot be produced based on the number of pages or rotational d istan ce alone, when confirming the

number of days remaining for a given part, please check both types of “No. Days Remaining” counters.

The number of days remaining is calculated as follows:

No. Days Remaining (pages) = [Target yield (Page) - Current Page counter] / Value of the “Ave. No. pages printed daily” counter

No. Days Remaining (rotational distance) = [Target yield (Rotation) - Current Rotation counter] / Ave. daily rotational distance

If the value of either of these counters is “10”, this means that the part is estimated to reach its target yield in approximately ten days.

If the value of either of these counters is “255”, this means that the part is estimated to reach its target yield in approximately 255 days

(or more). This value has been set as the maximum value displayed, in order to maximize the accuracy of the estimate.

If the value of either of these counters is “0”, this means that the part has already reached/surpassed its target yield

Remain day: Page counter Remain day: Rotation counter

SP Number Name: SP - Numbe

SP7951-01 Remain day: Page: PCU: Bk SP7951-31 Remain da y: Rotation: PCU: Bk

SP7951-02 Remain day: Page: PCU:C SP7951-32 Remain day: Rotation: PCU:C

SP7951-03 Remain day: Page: PCU: M SP7951-33 Remain day: Rotation: PCU:M

SP7951-04 Remain day: Page: PCU: Y SP7951-34 Remain day: Rotation: PCU:Y

SP7951-05 Remain day: Page: Dev unit: Bk SP7951-35 Remain day: Rotation: Dev unit: Bk

SP7951-06 Remain day: Page: Dev unit: C SP7951-36 Remain day: Rotation: Dev unit: C

SP7951-07 Remain day: Page: Dev unit: M SP7951-37 Remain day: Rotation: Dev unit: M

SP7951-08 Remain day: Page: Dev unit: Y SP7951-38 Remain day: Rotation: Dev unit: Y

SP7951-13 Remain day: Page: ITB SP7951-43 Remain day: Rotation: ITB

SP7951-14 Remain day: Page: Cleaning SP7951-44 Remain day: R otation: Cleaning

SP7951-15 Remain day: Page: Fusing unit SP7951-45 Remain day: R otation: Fusing unit

SP7951-18 Remain day: Page: Paper Transfer SP7951-48 Remain day: Rotation: Paper Transfer

Name:

Ver.1.5 Page 13 of 43 12/9/2011

Subject to change without notice

Loading...

Loading...