Ricoh D096 Service Manual

D096

SERVICE MANUAL

005627MIU

D096

SERVICE MANUAL

D096

SERVICE MANUAL

005627MIU

It is the reader's responsibility when discussing the information contained

within this document to maintain a level of confidentiality that is in the best

interest of Ricoh Americas Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

F ASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH AMERICAS CORPORATION.

All product names, domain names or product illustrations, including

desktop images, used in this document are trademarks, registered

trademarks or the property of their respective companies.

They are used throughout this book in an informational or editorial fashion

only and for the benefit of such companies. No such use, or the use of

any trade name, or web site is intended to convey endorsement or other

affiliation with Ricoh products.

© 2010 RICOH Americas Corporation. All rights reserved.

The Service Manual contains information

regarding service techniques, procedures,

processes and spare parts of office equipment

distributed by Ricoh Americas Corporation.

Users of this manual should be either service

trained or certified by successfully completing a

Ricoh Technical Training Program.

Untrained and uncertified users utilizing

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property or loss of warranty

protection.

Ricoh Americas Corporation

WARNING

LEGEND

PRODUCT

CODE

COMPANY

GESTETNER LANIER RICOH SAVIN

D096 MP 1900 LD319 MP 1900 N/A

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

*

04/2010 Original Printing

SM i D096

D096

TABLE OF CONTENTS

PRODUCT INFORMATION

1. PRODUCT INFORMATION ...........................................................1-1

1.1SPECIFICATIONS ..................................................................................... 1-1

1.2MACHINE CONFIGURATION ................................................................... 1-2

1.3GUIDANCE FOR THOSE WHO ARE FAMILIAR WITH PREDECESSOR

PRODUCTS ..................................................................................................... 1-3

1.4OVERVIEW ................................................................................................ 1-4

1.4.1 COMPONENT LAYOUT ................................................................... 1-4

1.4.2 PAPER PATH ................................................................................... 1-6

1.4.3 DRIVE LAYOUT ................................................................................ 1-7

INSTALLATION

2. INSTALLATION ............................................................................2-1

2.1INSTALLATION REQUIREMENTS ............................................................ 2-1

2.1.1 ENVIRONMENT ............................................................................... 2-1

2.1.2 MACHINE LEVEL ............................................................................. 2-2

2.1.3 MINIMUM SPACE REQUIREMENTS ............................................... 2-3

2.1.4 POWER REQUIREMENTS ............................................................... 2-3

2.2COPIER INSTALLATION ........................................................................... 2-4

2.2.1 POWER SOCKETS FOR PERIPHERALS ........................................ 2-4

2.2.2 ACCESSORY CHECK ...................................................................... 2-4

2.2.3 INSTALLATION PROCEDURE ......................................................... 2-5

2.3PLATEN COVER INSTALLATION ............................................................. 2-9

2.3.1 ACCESSORY CHECK ...................................................................... 2-9

2.3.2 INSTALLATION PROCEDURE ......................................................... 2-9

2.4ADF INSTALLATION ............................................................................... 2-10

2.4.1 ACCESSORY CHECK .................................................................... 2-10

2.4.2 INSTALLATION PROCEDURE ....................................................... 2-11

2.5ANTI-CONDENSATION HEATER INSTALLATION ................................. 2-14

2.6TRAY HEATER ........................................................................................ 2-15

D096 ii SM

2.6.1 TRAY HEATER ............................................................................... 2-15

2.7ACCESSIBILITY HANDLE INSTALLATION ............................................ 2-17

PREVENTIVE MAINTENANCE

3. PREVENTIVE MAINTENANCE ....................................................3-1

3.1PM TABLES ............................................................................................... 3-1

3.2HOW TO RESET THE PM COUNTER ...................................................... 3-2

REPLACEMENT AND ADJUSTMENT

4. REPLACEMENT AND ADJUSTMENT .........................................4-1

4.1GENERAL CAUTIONS .............................................................................. 4-1

4.1.1 PCU (PHOTOCONDUCTOR UNIT) .................................................. 4-1

4.1.2 TRANSFER ROLLER ....................................................................... 4-1

4.1.3 SCANNER UNIT ............................................................................... 4-1

4.1.4 LASER UNIT ..................................................................................... 4-2

4.1.5 FUSING UNIT ................................................................................... 4-2

4.1.6 PAPER FEED ................................................................................... 4-2

4.2SPECIAL TOOLS AND LUBRICANTS ....................................................... 4-3

4.3EXTERIOR COVERS & OPERATION PANEL .......................................... 4-4

4.3.1 REAR COVER .................................................................................. 4-4

4.3.2 COPY TRAY ..................................................................................... 4-4

4.3.3 UPPER COVERS ............................................................................. 4-5

4.3.4 LEFT COVER ................................................................................... 4-5

4.3.5 FRONT COVER ................................................................................ 4-6

4.3.6 FRONT RIGHT COVER .................................................................... 4-6

4.3.7 RIGHT REAR COVER ...................................................................... 4-7

4.3.8 RIGHT DOOR ................................................................................... 4-7

4.3.9 BY-PASS TRAY ................................................................................ 4-8

4.3.10 PLATEN COVER SENSOR .......................................................... 4-9

4.4SCANNER UNIT ...................................................................................... 4-10

4.4.1 EXPOSURE GLASS/DF EXPOSURE GLASS ................................ 4-10

4.4.2 LENS BLOCK ................................................................................. 4-11

4.4.3 LAMP STABILIZER BOARD AND EXPOSURE LAMP ................... 4-12

4.4.4 SCANNER MOTOR ........................................................................ 4-13

4.4.5 SCANNER HOME POSITION SENSOR......................................... 4-14

SM iii D096

4.4.6 ADJUSTING SCANNER POSITIONS ............................................. 4-15

4.5LASER UNIT ............................................................................................ 4-19

4.5.1 LOCATION OF CAUTION DECAL .................................................. 4-19

4.5.2 TONER SHIELD GLASS ................................................................. 4-20

4.5.3 LASER UNIT ................................................................................... 4-21

4.5.4 LD UNIT .......................................................................................... 4-22

4.5.5 POLYGONAL MIRROR MOTOR .................................................... 4-23

4.5.6 LASER UNIT ALIGNMENT ADJUSTMENT .................................... 4-24

4.6PCU SECTION......................................................................................... 4-26

4.6.1 PCU ................................................................................................ 4-26

4.6.2 TONER SUPPLY MOTOR .............................................................. 4-27

4.6.3 PICK-OFF PAWLS AND TONER DENSITY SENSOR ................... 4-28

4.6.4 OPC DRUM .................................................................................... 4-29

4.6.5 CHARGE ROLLER AND CLEANING BRUSH ................................ 4-30

4.6.6 CLEANING BLADE ......................................................................... 4-31

4.6.7 DEVELOPER .................................................................................. 4-32

4.6.8 AFTER REPLACEMENT OR ADJUSTMENT ................................. 4-33

4.7PAPER FEED SECTION ......................................................................... 4-34

4.7.1 PAPER FEED ROLLER .................................................................. 4-34

4.7.2 FRICTION PAD ............................................................................... 4-35

4.7.3 PAPER END SENSOR ................................................................... 4-35

4.7.4 EXIT SENSOR ................................................................................ 4-36

4.7.5 BY-PASS FEED ROLLER AND PAPER END SENSOR ................ 4-37

4.7.6 REGISTRATION ROLLER .............................................................. 4-38

4.7.7 BY-PASS PAPER SIZE SWITCH ................................................... 4-39

4.7.8 REGISTRATION CLUTCH .............................................................. 4-40

4.7.9 REGISTRATION SENSOR ............................................................. 4-40

4.7.10 PAPER FEED CLUTCH AND BY-PASS FEED CLUTCH ........... 4-41

4.7.11 PAPER SIZE SWITCH ................................................................ 4-42

4.8IMAGE TRANSFER ................................................................................. 4-43

4.8.1 IMAGE TRANSFER ROLLER ......................................................... 4-43

4.8.2 IMAGE DENSITY SENSOR ............................................................ 4-44

4.9FUSING ................................................................................................... 4-45

4.9.1 FUSING UNIT ................................................................................. 4-45

4.9.2 THERMISTOR ................................................................................ 4-45

4.9.3 FUSING LAMPS ............................................................................. 4-46

D096 iv SM

4.9.4 HOT ROLLER STRIPPER PAWLS ................................................. 4-47

4.9.5 HOT ROLLER ................................................................................. 4-47

4.9.6 THERMOSTAT ............................................................................... 4-48

4.9.7 PRESSURE ROLLER AND BUSHINGS ......................................... 4-49

4.9.8 NIP BAND WIDTH ADJUSTMENT ................................................. 4-50

4.9.9 CLEANING ROLLER ...................................................................... 4-51

4.10 OTHER REPLACEMENTS ................................................................. 4-52

4.10.1 QUENCHING LAMP ................................................................... 4-52

4.10.2 HIGH-VOLTAGE POWER SUPPLY BOARD ............................. 4-52

4.10.3 BICU (BASE-ENGINE IMAGE CONTROL UNIT) ....................... 4-53

4.10.4 MAIN MOTOR............................................................................. 4-53

4.10.5 LEFT EXHAUST FAN ................................................................. 4-54

4.10.6 PSU (POWER SUPPLY UNIT) ................................................... 4-54

4.10.7 GEARBOX .................................................................................. 4-55

4.11 COPY ADJUSTMENTS PRINTING/SCANNING ................................ 4-58

4.11.1 PRINTING ................................................................................... 4-59

4.11.2 SCANNING ................................................................................. 4-60

4.11.3 ADF IMAGE ADJUSTMENT ....................................................... 4-63

SERVICE TABLES

5. SERVICE TABLES........................................................................5-1

5.1SERVICE PROGRAM MODE .................................................................... 5-1

5.1.1 SP TABLES ...................................................................................... 5-1

5.1.2 HOW TO ENTER THE SP MODE .................................................... 5-1

5.2USING SP MODES .................................................................................... 5-3

5.2.1 ADJUSTING REGISTRATION AND MAGNIFICATION .................... 5-3

5.2.2 ID SENSOR ERROR ANALYSIS (SP 2221) ..................................... 5-4

5.2.3 MEMORY CLEAR ............................................................................. 5-5

5.2.4 INPUT CHECK (SP 5803) ................................................................. 5-7

5.2.5 OUTPUT CHECK (SP 5804) ........................................................... 5-12

5.2.6 SERIAL NUMBER INPUT (SP 5811) .............................................. 5-14

5.2.7 NVRAM DATA UPLOAD/DOWNLOAD (SP 5824/5825) ................. 5-15

5.2.8 FIRMWARE UPDATE PROCEDURE ............................................. 5-17

5.2.9 TEST PATTERN PRINT (SP 5902 1) ............................................. 5-19

5.2.10 PAPER JAM COUNTERS (SP 7504) ......................................... 5-21

SM v D096

5.2.11 SMC PRINT (SP 5990) ............................................................... 5-22

5.2.12 ORIGINAL JAM HISTORY DISPLAY (SP 7508)......................... 5-22

5.2.13 JAM HISTORY CODES .............................................................. 5-22

5.2.14 ADF APS SENSOR OUTPUT DISPLAY (SP 6901) .................... 5-23

TROUBLESHOOTING

6. TROUBLESHOOTING ..................................................................6-1

6.1SERVICE CALL CONDITIONS .................................................................. 6-1

6.2ELECTRICAL COMPONENT DEFECTS ................................................... 6-2

6.2.1 SENSORS ........................................................................................ 6-2

6.2.2 SWITCHES ....................................................................................... 6-4

6.3BLOWN FUSE CONDITIONS .................................................................... 6-5

6.4LED DISPLAY ............................................................................................ 6-6

6.4.1 BICU ................................................................................................. 6-6

ENERGY SAVING

7. ENERGY SAVING .........................................................................7-1

7.1ENERGY SAVE ......................................................................................... 7-1

7.1.1 ENERGY SAVER MODES ................................................................ 7-1

Timer Settings ...................................................................................... 7-2

Return to Stand-by Mode ..................................................................... 7-2

Recommendation ................................................................................. 7-2

7.1.2 ENERGY SAVE EFFECTIVENESS .................................................. 7-3

D096 SERVICE MANUAL APPENDICES

SEE D096 SERVICE MANUAL APPENDICES SECTION FOR DETAILED TABLE OF

CONTENTS

DF 2000 (B813)

SEE SECTION B813 FOR DETAILED TABLE OF CONTENTS

PRODUCT INFORMATION

APPENDIX: SPECIFICATIONS

B813 DOCUMENT FEEDER DF2000

INSTALLATION

APPENDIX: PREVENTIVE MAINTENANCE

PREVENTIVE MAINTENANCE

APPENDIX: TROUBLESHOOTING GUIDE

REPLACEMENT AND ADJUSTMENT

APPENDIX: SP MODE TABLES

SERVICE TABLES

TROUBLESHOOTING

ENERGY SAVING

TAB

POSITION 2

TAB

POSITION 1

TAB

POSITION 3

TAB

POSITION 4

TAB

POSITION 6

TAB

POSITION 5

TAB

POSITION 8

TAB

POSITION 7

Read This First

Safety Notices

Important Safety Notices

Prevention of Physical Injury

1. Before disassembling or assembling parts of the copier and peripherals, make sure

that the power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are supplied with

electrical voltage even if the main power switch is turned off.

4. If a job has started before the copier completes the warm-up or initializing period, keep

hands away from the mechanical and electrical components because the starts

making copies as soon as the warm-up period is completed.

5. The inside and the metal parts of the fusing unit become extremely hot while the copier

is operating. Be careful to avoid touching those components with your bare hands.

Health Safety Conditions

Toner and d eveloper are non-toxic, but if you get either of them in your eyes by accident, it

may cause temporary eye discomfort. Try to remove with eye drops or flush with water as

first aid. If unsuccessful, get medical attention.

Observance of Electrical Safety Standards

The copier and its peripherals must be installed and maintained by a customer service

representative who has completed the training course on those models.

Safety and Ecological Notes for Disposal

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly when

exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in accordance with

local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

Handling Toner

Work carefully when removing paper jams or replacing toner bottles or cartridges to

avoid spilling toner on clothing or the hands.

If toner is inhaled, immediately gargle with large amounts of cold water and move to a

well ventilated location. If there are signs of irritation or other problems, seek medical

attention.

If toner gets on the skin, wash immediately with soap and cold running water.

If toner gets into the eyes, flush the eyes with cold running water or eye wash. If there

are signs of irritation or other problems, seek medical attention.

If toner is swallowed, drink a large amount of cold water to dilute the ingested toner. If

there are signs of any problem, seek medical attention.

If toner spills on clothing, wash the affected area immediately with soap and cold water.

Never use hot water! Hot water can cause toner to set and permanently stain fabric.

Always store toner and developer supplies such as toner and developer packages,

cartridges, and bottles (including used toner and empty bottles and cartridges) out of

the reach of children.

Always store fresh toner supplies or empty bottles or cartridges in a cool, dry location

that is not exposed to direct sunlight.

Laser Safety

The Center for Devices and Radiological Health (CDRH) prohibits the repair of laser-based

optical units in the field. The optical housing unit can only be repaired in a factory or at a

location with the requisite equipment. The laser subsystem is replaceable in the field by a

qualified Customer Engineer. The laser chassis is not repairable in the field. Customer

engineers are therefore directed to return all chassis and laser subsystems to the factory or

service depot when replacement of the optical subsystem is required.

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

WARNING FOR LASER UNIT

WARNING: Turn off the main switch before attempting any of the procedures in the

Laser Unit section. Laser beams can seriously damage your eyes.

CAUTION MARKING:

Symbols and Abbreviations

This manual uses several symbols and abbreviations. The meaning of those symbols and

abbreviations are as follows:

See or Refer to

Clip ring

Screw

Connector

Clamp

SEF Short Edge Feed

LEF Long Edge Feed

PRODUCT INFORMATION

REVISION HISTORY

Page Date Added/Updated/New

None

Specifications

SM 1-1 D096

Product

Information

1. PRODUCT INFORMATION

1.1 SPECIFICATIONS

See "Appendices" for the following information:

General Specifications

Supported Paper Size

Optional Equipment

Machine Configuration

D096 1-2 SM

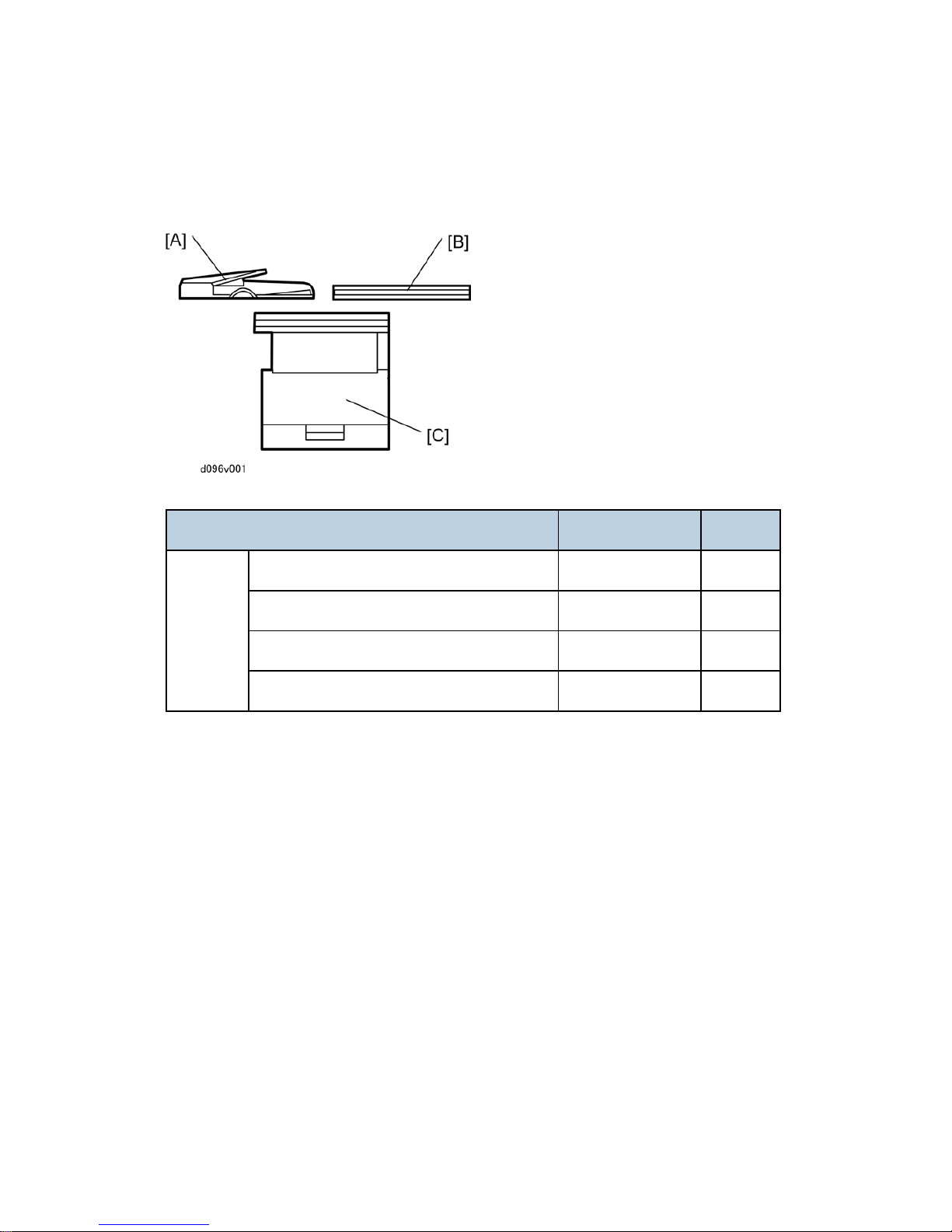

1.2 MACHINE CONFIGURATION

Unit/Component Machine Code Diagram

Copier

Copier (1-tray non-duplex model) D096 [D]

Platen cover (optional) B406 [B]

ADF (optional) B813 [A]

Accessibility Handle Type A (optional) B272 -

Guidance for Those Who are Familiar with Predecessor Products

SM 1-3 D096

Product

Information

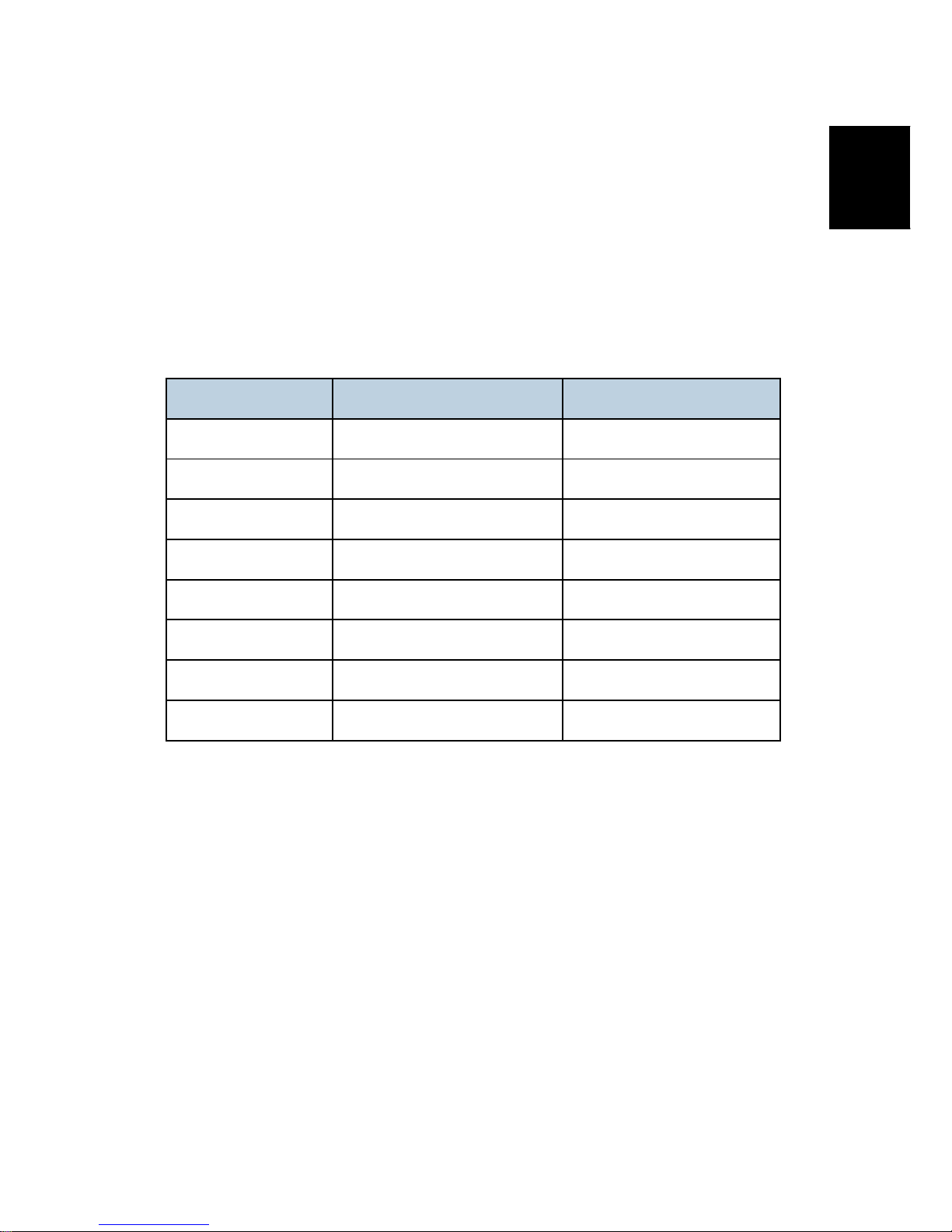

1.3 GUIDANCE FOR THOSE WHO ARE FAMILIAR

WITH PREDECESSOR PRODUCTS

The D096 model is successor models to the B245 model. If you have experience with the

predecessor products, the following information will be of help when you read this manual.

Different Points from Predecessor Products

D096 B245

Duplex Not available Not available

Paper Tray One tray One tray

Printer/ Scanner Not available Not available

Fax Not available Not available

GDI Controller Not available Not available

GW Controller Not available Not available

APS (Mainframe) Not available Available

Copy Speed 19 cpm 15cpm

Overview

D096 1-4 SM

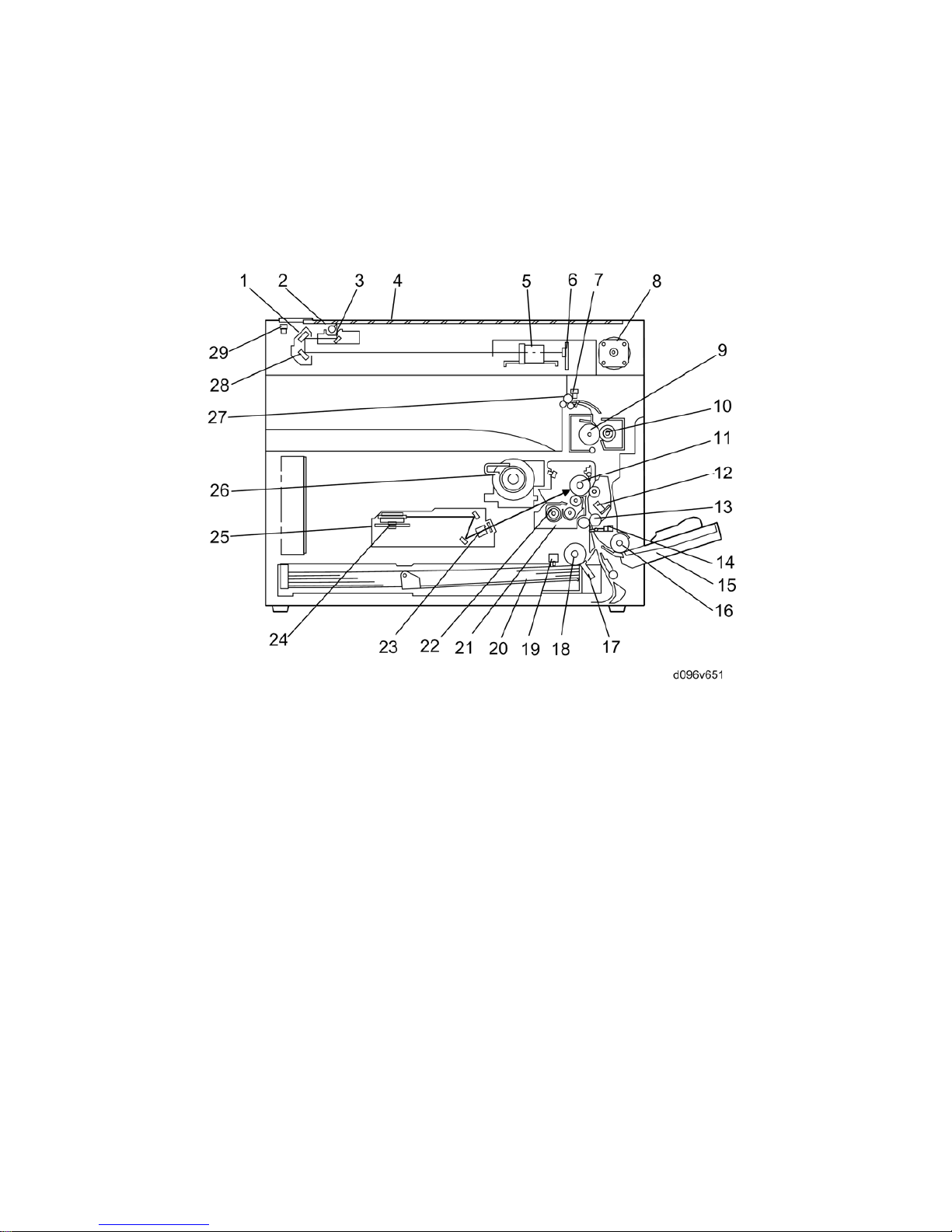

1.4 OVERVIEW

1.4.1 COMPONENT LAYOUT

Loading...

Loading...