Page 1

Mail Box CS4010

Machine Code:

D708

Field Service Manual

May, 2016

Page 2

Page 3

Safety, Conventions, Trademarks

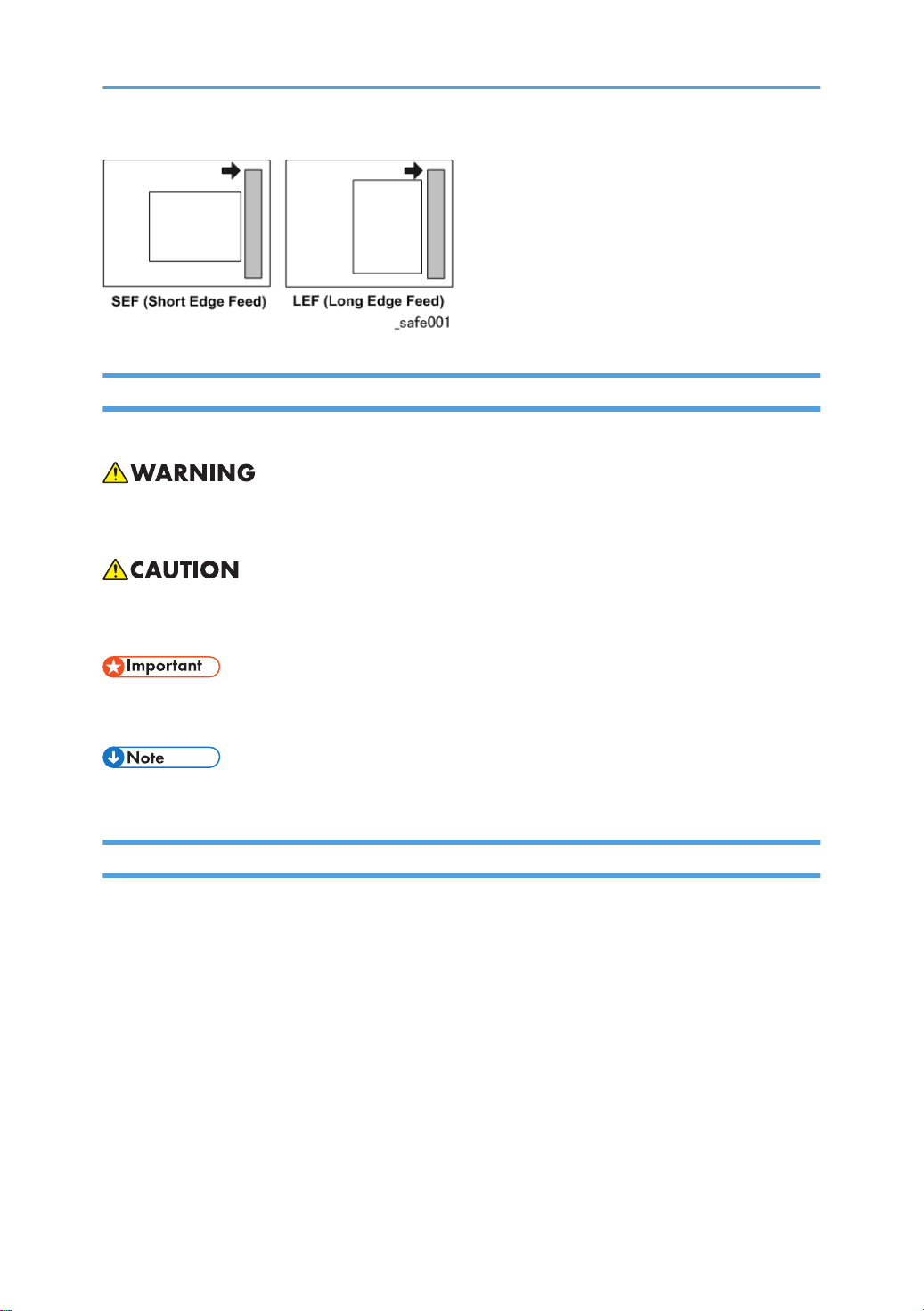

Conventions

Common Terms

This is a list of symbols and abbreviations used in this manual.

Symbol, Abbreviation Meaning

Blue screw

Bushing

C-ring

Connector

E-ring

Flexible film cable

Harness clamp

Hook

Screw

Spring

Timing belt

JG Junction Gate

LEF Long Edge Feed

SEF Short Edge Feed

TE Trailing Edge of paper

1

Page 4

Warnings, Cautions, Notes

In this manual, the following important symbols and notations are used.

• A Warning indicates a potentially hazardous situation. Failure to obey a Warning could result in

death or serious injury.

• A Caution indicates a potentially hazardous situation. Failure to obey a Caution could result in

minor or moderate injury or damage to the finisher or other property.

• Obey these guidelines to avoid problems such as misfeeds, damage to originals, loss of valuable

data and to prevent damage to the machine.

• This information provides tips and advice about how to best service the machine.

General Safety Instructions

For your safety, please read this manual carefully before you use this product. Keep this manual handy

for future reference.

Safety Information

Always obey the following safety precautions when using this product.

Safety During Operation

In this manual, the following important symbols and notations are used.

Switches and Symbols

Where symbols are used on or near switches on machines for Europe and other areas, the meaning of

each symbol conforms with IEC60417.

2

Page 5

Responsibilities of the Customer Engineer

Reference Material for Maintenance

• Maintenance shall be done using the special tools and procedures prescribed for maintenance of

the machine described in the reference materials (service manuals, technical bulletins, operating

instructions, and safety guidelines for customer engineers).

•

In regard to other safety issues not described in this document, all customer engineers shall strictly

obey procedures and recommendations described the “CE Safety Guide”.

• Use only consumable supplies and replacement parts designed for use of the machine.

Before Installation, Maintenance

Power

• Always disconnect the power plug before doing any maintenance procedure. After switching off

the machine, power is still supplied to the main machine and other devices. To prevent electrical

shock, switch the machine off, wait for a few seconds, then unplug the machine from the power

source.

•

Before you do any checks or adjustments after turning the machine off, work carefully to avoid

injury. After removing covers or opening the machine to do checks or adjustments, never touch

electrical components or moving parts (gears, timing belts, etc.).

• After turning the machine on with any cover removed, keep your hands away from electrical

components and moving parts. Never touch the cover of the fusing unit, gears, timing belts, etc.

3

Page 6

Installation, Disassembly, and Adjustments

• After installation, maintenance, or adjustment, always check the operation of the machine to make

sure that it is operating normally. This ensures that all shipping materials, protective materials, wires

and tags, metal brackets, etc., removed for installation, have been removed and that no tools

remain inside the machine. This also ensures that all release interlock switches have been restored

to normal operation.

Never use your fingers to check moving parts causing spurious noise. Never use your fingers to

•

lubricate moving parts while the machine is operating.

Special Tools

• Use only standard tools approved for machine maintenance.

For special adjustments, use only the special tools and lubricants described in the service manual.

•

Using tools incorrectly, or using tools that could damage parts, could damage the machine or

cause injuries.

During Maintenance

General

Safety Devices

4

• Before you begin a maintenance procedure: 1) Switch the machine off, 2) Disconnect the power

plug from the power source, 3) Allow the machine to cool for at least 10 minutes.

Avoid touching the components inside the machine that are labeled as hot surfaces.

•

• Never remove any safety device unless it requires replacement. Always replace safety devices

immediately.

Never do any procedure that defeats the function of any safety device. Modification or removal of

•

a safety device (fuse, switch, etc.) could lead to a fire and personal injury. Always test the

operation of the machine to ensure that it is operating normally and safely after removal and

replacement of any safety device.

Page 7

• For replacements use only the correct fuses or circuit breakers rated for use with the machine. Using

replacement devices not designed for use with the machine could lead to a fire and personal

injuries.

Organic Cleaners

• During preventive maintenance, never use any organic cleaners (alcohol, etc.) other than those

described in the service manual.

Make sure the room is well ventilated before using any organic cleaner. Use organic solvents in

•

small amounts to avoid breathing the fumes and becoming nauseous.

• Switch the machine off, unplug it, and allow it to cool before doing preventive maintenance. To

avoid fire or explosion, never use an organic cleaner near any part that generates heat.

• Wash your hands thoroughly after cleaning parts with an organic cleaner to contamination of

food, drinks, etc. which could cause illness.

• Clean the floor completely after accidental spillage of silicone oil or other materials to prevent

slippery surfaces that could cause accidents leading to hand or leg injuries. Use “My Ace” Silicone

Oil Remover (or dry rags) to soak up spills. For more details, please refer to Technical Bulletin

“Silicone Oil Removal” (A024-50).

Ozone Filters

• Always replace ozone filters as soon as their service life expires (as described in the service

manual).

An excessive amount of ozone can build up around machines that use ozone filters if they are not

•

replaced at the prescribed time. Excessive ozone could cause personnel working around the

machine to feel unwell.

Power Plug and Power Cord

• Before servicing the machine (especially when responding to a service call), always make sure that

the power plug has been inserted completely into the power source. A partially inserted plug could

lead to heat generation (due to a power surge caused by high resistance) and cause a fire or other

problems.

Always check the power plug and make sure that it is free of dust and lint. Clean it if necessary. A

•

dirty plug can generate heat which could cause a fire.

5

Page 8

• Inspect the length of the power cord for cuts or other damage. Replace the power cord if

necessary. A frayed or otherwise damaged power cord can cause a short circuit which could lead

to a fire or personal injury from electrical shock.

Check the length of the power cord between the machine and power supply. Make sure the power

•

cord is not coiled or wrapped around any object such as a table leg. Coiling the power cord can

cause excessive heat to build up and could cause a fire.

• Make sure that the area around the power source is free of obstacles so the power cord can be

removed quickly in case of an emergency.

• Make sure that the power cord is grounded (earthed) at the power source with the ground wire on

the plug.

• Connect the power cord directly into the power source. Never use an extension cord.

• When you disconnect the power plug from the power source, always pull on the plug, not the

cable.

After Installation, Servicing

Disposal of Used Items

• Always dispose of used items (developer, toner, toner cartridges, OPC drums, etc.) in accordance

with the local laws and regulations regarding the disposal of such items.

To protect the environment, never dispose of this product or any kind of waste from consumables at

•

a household waste collection point. Dispose of these items at one of our dealers or at an

authorized collection site.

Points to Confirm with Operators

At the end of installation or a service call, instruct the user about use of the machine. Emphasize the

following points.

Show operators how to remove jammed paper and troubleshoot other minor problems by

•

following the procedures described in the operating instructions.

• Point out the parts inside the machine that they should never touch or attempt to remove.

• Confirm that operators know how to store and dispose of consumables.

• Make sure that all operators have access to an operating instruction manual for the machine.

• Confirm that operators have read and understand all the safety instructions described in the

operating instructions.

6

Page 9

• Demonstrate how to turn off the power and disconnect the power plug (by pulling the plug, not the

cord) if any of the following events occur: 1) something has spilled into the product, 2) service or

repair of the product is necessary, 3) the product cover has been damaged.

Caution operators about removing paper fasteners around the machine. They should never allow

•

paper clips, staples, or any other small metallic objects to fall into the machine.

Safety Instructions for this Machine

1. The installation must be done by trained service technicians.

This machine weighs 92 kg. (202.9 lb.). At least four persons are required to remove the machine

2.

from its pallet and position it for installation.

3. To prevent fire hazards never use flammable solvents around the machine.

4. Never place any object on the machine.

5. If anything falls into the machine, turn off the main power switch on the right side of the machine,

then disconnect the power cord from the power source.

6. Locate the machine on a sturdy flat surface where it will not be exposed to excessive vibration.

7. To avoid fire hazard, confirm that the ventilation ports are not blocked, so air can flow freely.

8. Gas generated by the molten glue can irritate the eyes, throat, and nose. The machine should

always be used in a well ventilated room.

9. To avoid the dangers of fire and electrical shock, make sure that the machine is never exposed to:

• Excessive high temperatures and/or humidity

• Dust

• Water

• Direct sunlight

• Open flame

• Corrosive gases

Trademarks

• Microsoft®, Windows®, and MS-DOS® are registered trademarks of Microsoft Corporation in

the United States and /or other countries.

PostScript® is a registered trademark of Adobe Systems, Incorporated.

•

• PCL® is a registered trademark of Hewlett-Packard Company.

• Ethernet® is a registered trademark of Xerox Corporation.

• PowerPC® is a registered trademark of International Business Machines Corporation.

7

Page 10

• Other product names used herein are for identification purposes only and may be trademarks of

their respective companies. We disclaim any and all rights involved with those marks.

8

Page 11

TABLE OF CONTENTS

Safety, Conventions, Trademarks......................................................................................................................1

Conventions.................................................................................................................................................... 1

Common Terms...................................................................................................................................... 1

Warnings, Cautions, Notes...........................................................................................................................2

General Safety Instructions............................................................................................................................2

Responsibilities of the Customer Engineer.................................................................................................... 3

Reference Material for Maintenance...................................................................................................3

Before Installation, Maintenance..................................................................................................................3

Power......................................................................................................................................................3

Installation, Disassembly, and Adjustments.........................................................................................4

Special Tools..........................................................................................................................................4

During Maintenance...................................................................................................................................... 4

General.................................................................................................................................................. 4

Safety Devices........................................................................................................................................4

Organic Cleaners..................................................................................................................................5

Ozone Filters..........................................................................................................................................5

Power Plug and Power Cord................................................................................................................ 5

After Installation, Servicing............................................................................................................................6

Disposal of Used Items..........................................................................................................................6

Points to Confirm with Operators......................................................................................................... 6

Safety Instructions for this Machine...............................................................................................................7

Trademarks.............................................................................................................................................7

1. Replacement and Adjustment

Covers and Trays ............................................................................................................................................ 11

Sensors..............................................................................................................................................................12

Tray sensor, Tray overflow sensor, Vertical transport sensor...................................................................12

Main Motor and Control Board..................................................................................................................... 13

Main Motor..................................................................................................................................................13

Control Board...............................................................................................................................................13

2. Details

Overview.......................................................................................................................................................... 15

General Specifications................................................................................................................................ 15

Overview Layout..........................................................................................................................................16

9

Page 12

Drive Layout..................................................................................................................................................17

Electrical Components.................................................................................................................................

Mechanisms......................................................................................................................................................20

Basic Operation...........................................................................................................................................20

Paper Tray Full Detection............................................................................................................................ 21

Jam Detection...............................................................................................................................................23

18

10

Page 13

1. Replacement and Adjustment

Covers and Trays

1. Trays [A]

Grip each tray by the front and lift out.

2. Front cover [B] ( x 2)

3. Rear cover [C] ( x 3)

4. Top cover [D]

11

Page 14

1. Replacement and Adjustment

Sensors

Tray sensor, Tray overflow sensor, Vertical transport sensor

1. Switch the machine off and unplug the machine

Remove the tray.

2.

3. Bin cover [A]

12

4. Tray sensor ( x 1) [B]

Tray overflow sensor (

5.

Vertical transport sensor (

6.

Raise the pawl, then grip the bottom of the sensor to remove.

x 1) [C]

x 1) [D]

Page 15

Main Motor and Control Board

Main Motor

1. Rear cover page 11

Disconnect the harness of the main motor bracket. (

2.

x 2)

Main Motor and Control Board

3. Main motor bracket [A] ( x 3, timing belt x 1)

4. Main motor [A] ( x 2)

Control Board

1. Rear cover page 11

2.

Bracket [A] (

x4)

13

Page 16

1. Replacement and Adjustment

3. Control board ( x2, x15)

14

Page 17

2. Details

Overview

General Specifications

Number of Bins 9 bins

Paper Size A5. A4, A3

5

" x 8

1/2

Paper Weight 60 to 128g/m²

14 lb – 34 lb Bond

Dimensions (w x d x h) 540 x 600 x 660 mm (21.3 x 23.6 x 26 in.)

Weight Less than 15 kg (33 lb.)

1/2

", 8

" x11", 8

1/2

" x14", 11"x17"

1/2

Power Consumption Less than 48 W

Noise Less than 74 dB

Stack Capacity 100 sheets (each bin)

Power Source DC24V, 5V from main machine

Dimensions (w x d x h) 540 x 600 x 660 mm (21.3 x 23.6 x 26 in.)

Weight Less than 15 kg (33 lb.)

15

Page 18

2. Details

Overview Layout

16

No. Part

1 Exit Roller

2 Transport Roller

3 Junction Gate

4 1 Bin Tray

5 5 Bin Tray

6 9 Bin Tray

Page 19

Drive Layout

Overview

No. Part

1 Drive Belt

2 Driven Belt

3 Transport Motor

17

Page 20

2. Details

Electrical Components

18

No. Name Function

1 Main Motor Drives all the rollers in the unit

2 Tray Sensor (tray 1) to(Tray 9) Detects paper in tray 1 to 9

3 Vertical Transport Sensor 1 Detects misfeeds (located between trays 1 and 2)

4 Vertical Transport Sensor 2 Detects misfeeds (located between trays 3 and 4)

5 Vertical Transport Sensor 3 Detects misfeeds (located between trays 5 and 6)

6 Vertical Transport Sensor 4 Detects misfeeds (located between trays 7 and 8)

7 Vertical Transport Sensor 5 Detects misfeeds (located at the exit to tray 9)

Page 21

No. Name Function

Overview

8 Junction Gate Solenoid 1

Opens/closes the junction gate at the entrance to the

mailbox

9 Junction Gate Solenoids 2-9 Opens/closes the junction gates for trays 1-8.

10 Paper Tray Full Sensor 1 Detects paper full in tray 1.

11 Paper Tray Full Sensor 2-9 Detects paper full in trays 2 to 9. (cannot detect A5)

12 Controller Board Controls the unit.

19

Page 22

2. Details

Mechanisms

Basic Operation

This 9-pin mailbox connects electrically to the finisher with a 14-pin drawer connector. When a print job

starts, the main motor drives to rotate all rollers, and the specified bin receives the paper.

No. Part

1 9 Bin Tray

2 Exit Roller

3 Transport Roller

When the junction gate solenoid turns on, the gate switches and the tray receives the paper. When the

uppermost tray is selected, all solenoids stay off. When the last paper's trailing edge passes the overflow

sensor and the sensor turns off, the paper has gone to the tray, so the selected tray's junction gate

solenoid and the main motor turn off. Normally, the speed of paper transport in this unit is nearly the

same as in the finisher.

20

Page 23

No. Part

1 Junction Gate

Mechanisms

2 Junction Gate Solenoid

Paper Tray Full Detection

Each bin has a tray full sensor 1 (paper overflow sensor) that monitors each tray so it does not become

overloaded.

21

Page 24

2. Details

Paper Tray Full Detection Timing

When output from the paper overflow sensor is more than (T) seconds at the "High" level, full detection

will occur.

For example, at the lowest PPM (12 sheets / A3), when the sensor doesn't switch to "Low" by 40 sec

after the detection, the print job will be stopped.

The machine determines the following depending on the result of the detection and the machine state.

22

Page 25

Status Machine State Trigger

Output 8 sheets of paper in a

Full While receiving paper

row in the same tray while the

paper overflow sensor remains

ON.

Mechanisms

In all states other than receiving paper (with door

closed, no jam, and no remaining paper)

Not Full - The sensor turns OFF

The sensor stays on for more

than 1.5 sec.

Jam Detection

Jam is detected with the five sensors in the picture below;

23

Page 26

2. Details

24

No. Part

1 Finisher Exit Roller

2 Entrance Junction Gate (CS4010)

3 Vertical Transport Sensor

4 Vertical Transport Sensor 2

5 Vertical Transport Sensor 3

6 Vertical Transport Sensor 4

Page 27

No. Part

7 Vertical Transport Sensor 5

8 Open/Close Guide Plate

Jam Detection Details

Jam Name Detection Trigger Log Code

Even though paper moves "pulse x 1.5" (“distance

Transport Sensor 1 Late Jam

L”) from the finisher exit roller, the vertical transport

350

sensor 1 in the 9-bin mailbox doesn’t turn ON.

Transport Sensor 1 Lag Jam (No Change) 351

Transport Sensor 2 Late Jam (No Change) 352

Transport Sensor 2 Lag Jam (No Change) 353

Transport Sensor 3 Late Jam (No Change) 354

Mechanisms

Transport Sensor 3 Lag Jam (No Change) 355

Transport Sensor 4 Late Jam (No Change) 356

Transport Sensor 4 Lag Jam (No Change) 357

Transport Sensor 5 Late Jam (No Change) 358

Transport Sensor 5 Lag Jam (No Change) 359

Cannot continue to receive paper because the

Main Machine Ordering DataWrong Jam

ordering data from the main machine is wrong or

rebooting is demanded because paper reception

360

is unavailable.

25

Page 28

MEMO

26

Page 29

MEMO

27

Page 30

MEMO

28 EN

Loading...

Loading...