Page 1

FOUR-BIN MAILBOX

(Machine Code: G518)

Page 2

1 October, 1999 SPECIFICATIONS

1 OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Number of Trays 4

Tray Capacity: 125 sheets (80 g/m2, 20 lb)

Paper Size for Trays: Maximum: A3 or 11" x 17"

Minimum: A5 (LEF) or 11" x 8

Executive SEF (7.25” x 10.5") can be used

Paper Weight: 60 ~ 105 g/m2, 16 ~ 28 lb

Power Consumption: 17 W or less (average)

Power Source: DC 24 V, 5 V (from the printer)

1/2

"

Dimensions (W x D x H)

Weight:

440 x 520 x 370 mm (17.3 x 20.5 x 14.6")

7 kg, 15.4 lb

G518-1

Options

Page 3

COMPONENT LAYOUT 1 October, 1999

1.2 COMPONENT LAYOUT

1.2.1 MECHANICAL COMPONENT LAYOUT

7

1

2

6

3

4

1. 4th Tray

2. 3rd Tray

3. 2nd Tray

4. 1st Tray

1.2.2 DRIVE LAYOUT

1

5

G518D101.WMF

5. Turn Gate

6. Vertical Transport Roller

7. Tray Feed Out Roller

3

2

1. Timing Belt

2. Main Motor

3. Main Motor Timing Belt

G518D103.WMF

G518-2

Page 4

1 October, 1999 ELECTRICAL COMPONENT DESCRIPTIONS

1.3 ELECTRICAL COMPONENT DESCRIPTIONS

14

15

13

1

12

11

2

3

4

5

6

7

8

9

10

G518D102.WMF

See the next page for the component description table.

Options

G518-3

Page 5

ELECTRICAL COMPONENT DESCRIPTIONS 1 October, 1999

Symbols Name Function Index No.

Motors

M1 Main Drives all the mailbox rollers. 2

Sensors

S1 Tray 4 Paper Detects if there is paper in the 4th tray. 6

S2 Tray 3 Paper Detects if there is paper in the 3rd tray. 13

S3 Vertical

Transport

Detects misfeeds (between the 1st and

2nd trays)

9

S4 Tray 2 Paper Detects if there is paper in the 2nd tray. 12

S5 Tray 1 Paper Detects if there is paper in the 1st tray. 11

S6 Tray 1 Paper

Detects paper overflow in the 1st tray. 10

Overflow

S7

Tray 2 Paper

Detects paper overflow in the 2nd tray. 8

Overflow

S8 Tray 3 Paper

Detects paper overflow in the 3rd Tray. 7

Overflow

S9 Tray 4 Paper

Detects paper overflow in the 4th tray. 5

Overflow

Solenoids

SOL1 Turn Gate

Solenoid 1

SOL2

Turn Gate

Solenoid 2

SOL3 Turn Gate

Solenoid 3

Opens and closes the junction gate to

direct paper into the 1st tray.

Opens and closes the junction gate to

direct paper into the 2nd tray.

Opens and closes the junction gate to

direct paper into the 3rd tray gate.

PCBs

PCB1 Main Control Controls all mailbox functions 1

Switches

SW1 Door Safety

Cuts the dc power line when the transport

cover is opened.

14

15

3

4

G518-4

Page 6

1 October, 1999 BASIC OPERATION

2. DETAILED DESCRIPTIONS

2.1 BASIC OPERATION

[A]

[B]

G518D104.WMF

G518D105.WMF

The mailbox is connected to the main unit by a 10-pin connector.

When the leading edge of the paper acti vates the exit sensor on the interchange

unit, the mailbox main motor turns on and the mailbox rollers begin to turn. The

paper is then fed out to the tray that has been selected.

Solenoids [B] open and close junction gates as shown, to direct the paper to the

selected tray. When the top tray (tray 4) is selected, none of the solenoids are

activated. As the last sheet is fed out, it turns off the vertical transport sensor, and

both the mailbox motor and the junction gate solenoid of the selected bin turn off.

The mailbox normally feeds paper at 121 mm/s. For the G038 printer, this is about

equal to the speed of the printer itself (actual transport speeds are: 121.6 mm/s

and 120.6 mm/s, respectively) .

G518-5

Options

Page 7

PAPER OVERFLOW DETECTION 1 October, 1999

2.2 PAPER OVERFLOW DETECTION

2.2.1 OVERVIEW

The overflow sensors are installed on each tray. They monitor the trays so that the

amount of paper present does not exceed the tray capacity. If a printing job is done

that exceeds the capacity of one or more of the trays, the main unit recognizes the

overload, displays an error message and stops the printing job. However, if the

excess paper is removed from the overloaded tray, the printing job will continue.

2.2.2 DETECTION TIMING

Between Sheets

T

Full

Not Full

(H)

(L)

Paper

Length

Paper

Length

Paper

Length

Full

G518D107.WMF

When the sensor output is high for longer than T (calculated by the equation

below), the machine determines that the tray is full.

The detection timing for a full tray is calculated by the equation below for each

paper size. For example, with a minimum ppm of 12 prints (for A3), the value of T

would be 15 seconds. Therefore, if the sensor continuously detects paper for 15 or

more seconds (as it would if the tray were actually full and a given sheet of paper

was stopped at the sensor), the machine stops the copy job, assuming that the tray

is full. The value of T will be different for each pap er size, since the value of ppm

will vary with size.

T (seconds) = (60/min. PPM) x 3 * PPM = prints per minute.

G518-6

Page 8

1 October, 1999 PAPER MISFEED DETECTION TIMING

2.3 PAPER MISFEED DETECTION TIMING

A4 sideways (longedge) paper to exit to the 1st bin tray

Main Motor

(Main frame)

J1

Exit Sensor

(Interchange Unit)

Main Motor

(Mailbox)

Turn Gate

Solenoid *1

*1: Time required for A4 longedge paper

*1

A4 sideways (longedge) paper to exit to the 2nd, 3rd, or 4th tray

Main Motor

(Main frame)

J1

Exit Sensor

(Interchange Unit)

Main Motor

(Mailbox)

Turn Gate

Solenoid *2

Vertical Transport

Sensor

*1: Time required for A4 longedge paper

*2: All solenoids stay off for feed to the 4th tray.

*1

J2

J3

*1

G518D108.WMF

Options

G518-7

Page 9

PAPER MISFEED DETECTION TIMING 1 October, 1999

J1 Timing:

J2 Timing:

J3 Timing:

After the leading edge of the paper activates the exit sensor of the

interchange unit, a misfeed is detected if this sensor does not turn off

within X + 0.52 s, where X is equal to the amount of time a given paper

size takes to pass the sensor (e.g. A4 - sideways = 1.74 s).

After the paper exit sensor of the interchange unit is activated, the

machine determines that the paper has not yet fed and detects a misfeed

if the vertical transport sensor does not activate within 1.94 s (in the case

of A4 paper).

After the vertical transport sensor is activated, a misfeed is detected if

this sensor does not turn off within X + 0.52 s (see above for an

explanation of X). For example, this value would be 2.26 s for A4

sideways.

G518-8

Page 10

1 October, 1999 EXTERIOR COVER REMOVAL

3. REPLACEMENT AND ADJUSTMENT

3.1 EXTERIOR COVER REMOVAL

[C]

[D]

[B]

[A]

G518R101.WMF

1. Turn the main switch off and remove the power cord from the outlet.

2. Take out each tray [A] (lift by the edges).

3. Remove the front cover [B] (1 screw).

4. Remove the rear cover [C] (1 screw).

5. Remove the upper cover [D].

G518-9

Options

Page 11

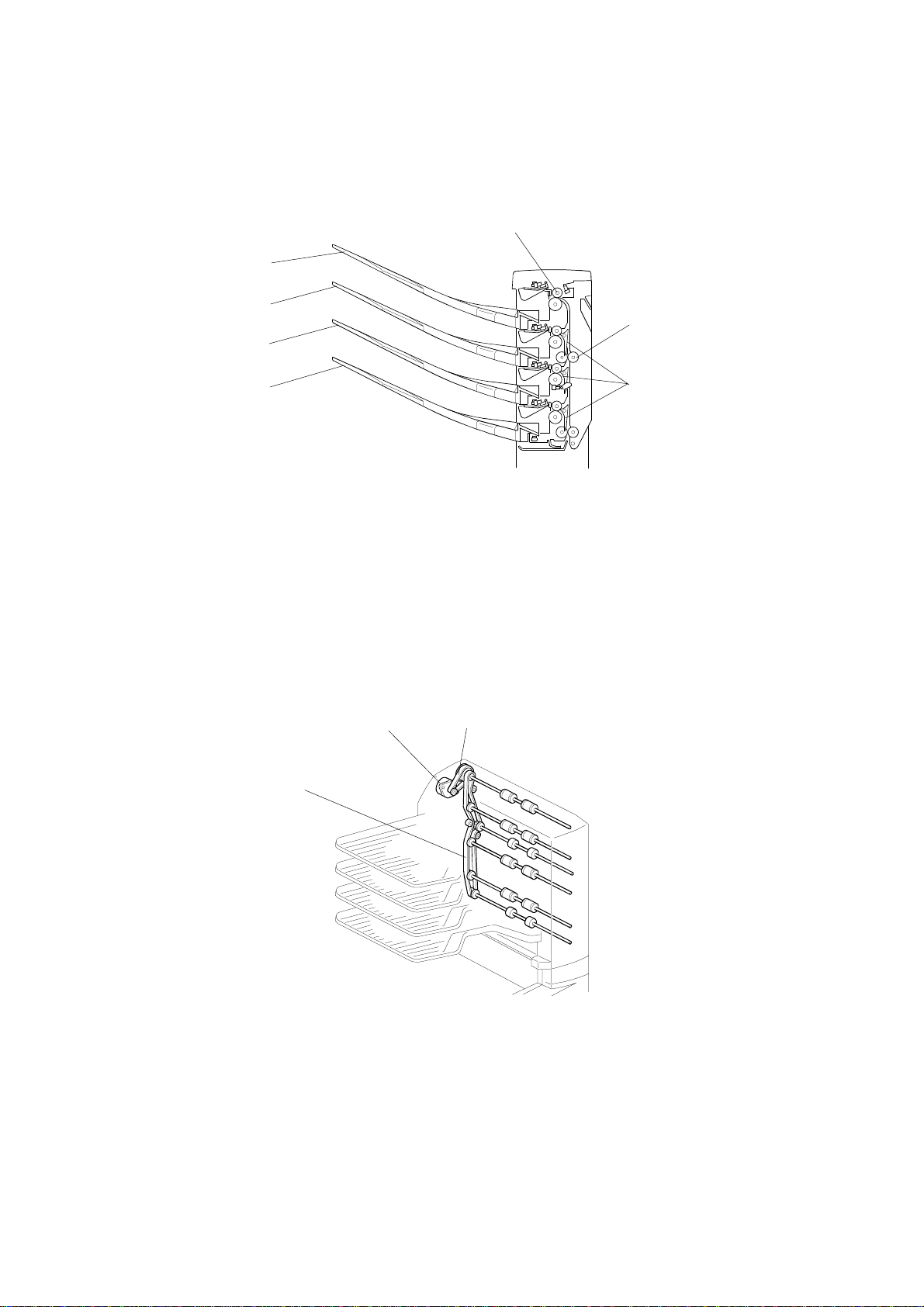

OVERFLOW AND VERTICAL TRANSPORT SENSOR 1 October, 1999

3.2 OVERFLOW AND VERTICAL TRANSPORT SENSOR

[A]

G518R103.WMF

[B]

[C]

1. Turn the main switch off and unplug the power cord.

2. Remove each tray.

3. Remove the bin covers [A].

4. Remove the connector of the tray sensor [B].

Remove the connector of the overflow sensor [C]

Remove the connector of the vertical transport sensor [D].

[D]

G518R104.WMF

5. Remove both the tray and overflow sensors as shown in the illustration.

For the vertical transport sensor, lift up the locking pawls (slightly).

Remove the sensor by rotating the bottom part upward.

G518-10

Page 12

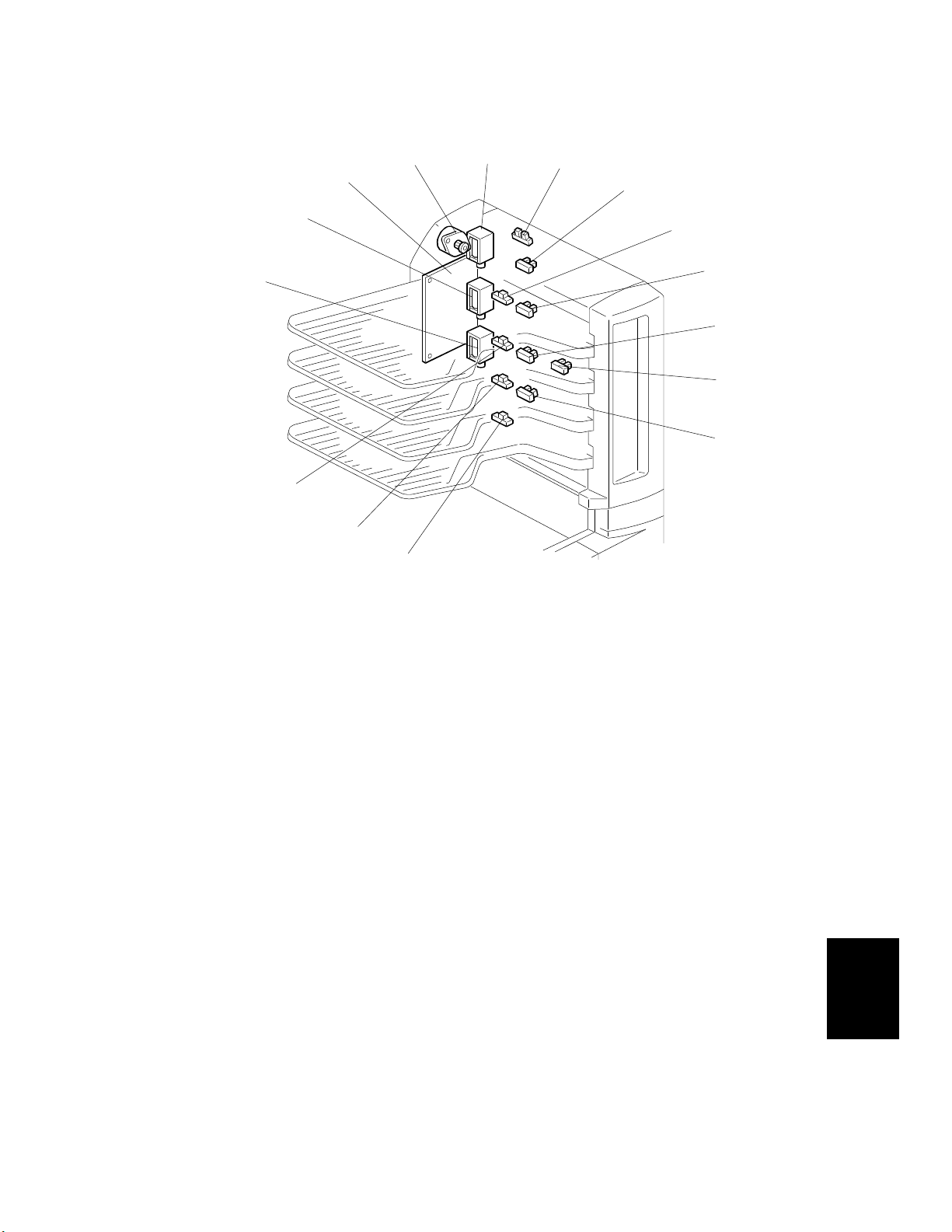

1 October, 1999 MAIN MOTOR REPLACEMENT

3.3 MAIN MOTOR REPLACEMENT

[B]

[C]

[D]

[A]

G518R102.WMF

1. Turn the main switch off and unplug the power cord.

2. Remove the rear cover.

3. Remove the control board [A] (2 screws, all connectors).

4. Remove the timing belt [B] (2 screws) and the main motor bracket [C].

5. Replace the main motor (2 screws) [D].

G518-11

Options

Loading...

Loading...