Page 1

FOUR-BIN MAILBOX

(Machine Code: G696)

Page 2

20 March 1998 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Number of Trays 4

2

Tray Capacity: 125 sheets (80 g/m

, 20lb)

Paper Size for Trays:

Maximum: A3 or 11" x 17"

Minimum: A5 (LEF) or 11" x 8

1/2

"

Executive SEF (7.25" x 10.5") can be used

Paper Weight: 60 ~ 90 g/m

2

, 16 ~ 24 lb

Power Consumption: 20 W or less (average)

Power Source: DC24 V, 5 V (from the printer)

Dimensions (W x D x H): 465 x 490 x 370 mm (18.3" x 19.3" x 14.6")

Weight: 7 kg , 15.4 lb

•

Specifications are subject t o change without notice.

G696-1

Options

Page 3

COMPONENT LAYOUT 20 March 1998

1.2 COMPONENT LAYOUT

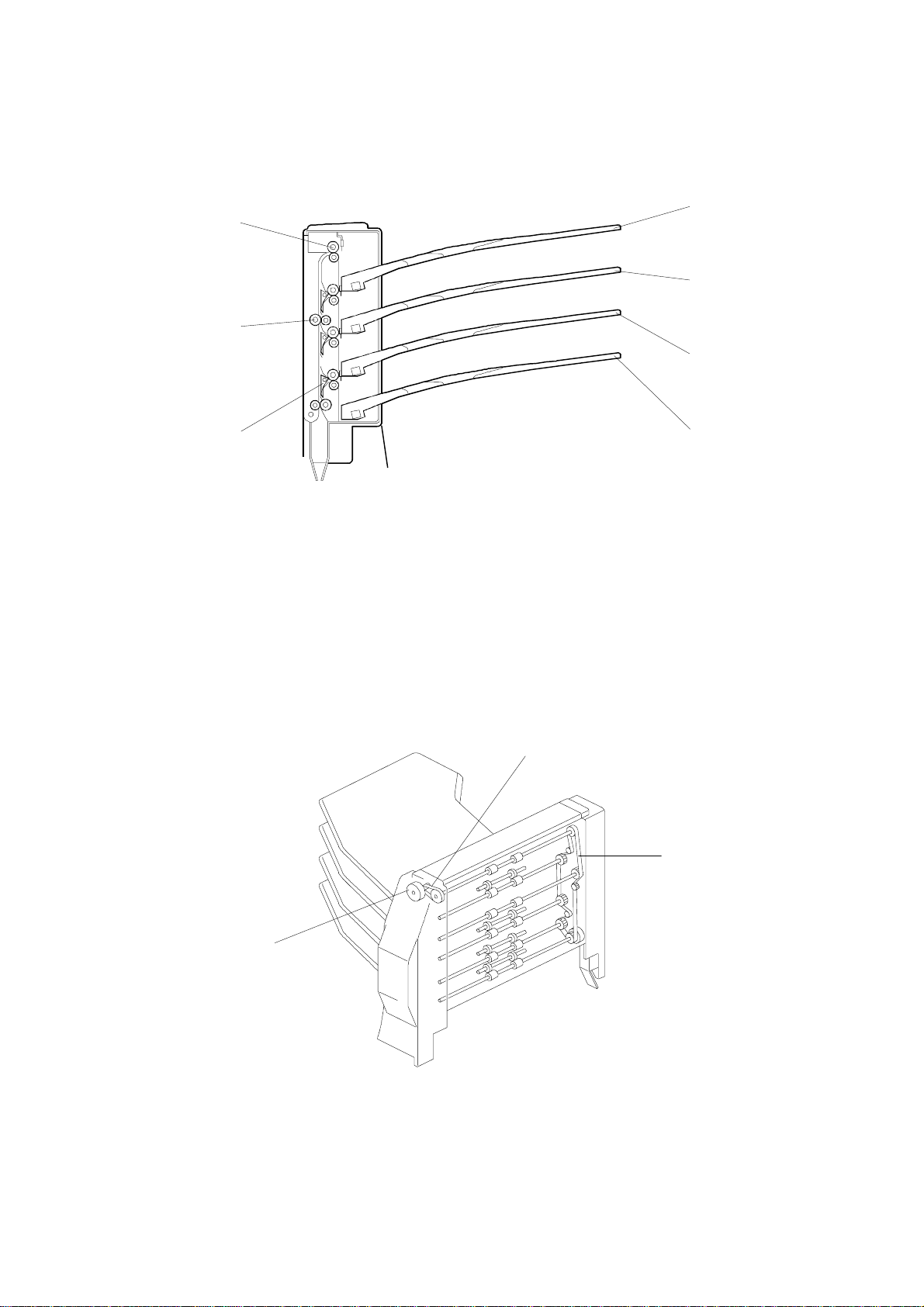

1.2.1 MECHANICAL COMPONENT LAYOUT

1

7

2

6

3

5

1. 5th Tray

2. 4th Tray

3. 3rd Tray

4. 2nd Tray

1.2.2 DRIVE LAYOUT

4

G696V500.WMF

5. Turn Gate

6. Vertical Transport Roller

7. Tray Feed Out Roller

3

1

1. Timing Belt

2. Main Mot o r

2

G696V501.WMF

3. Main Mot o r Timing Belt

G696-2

Page 4

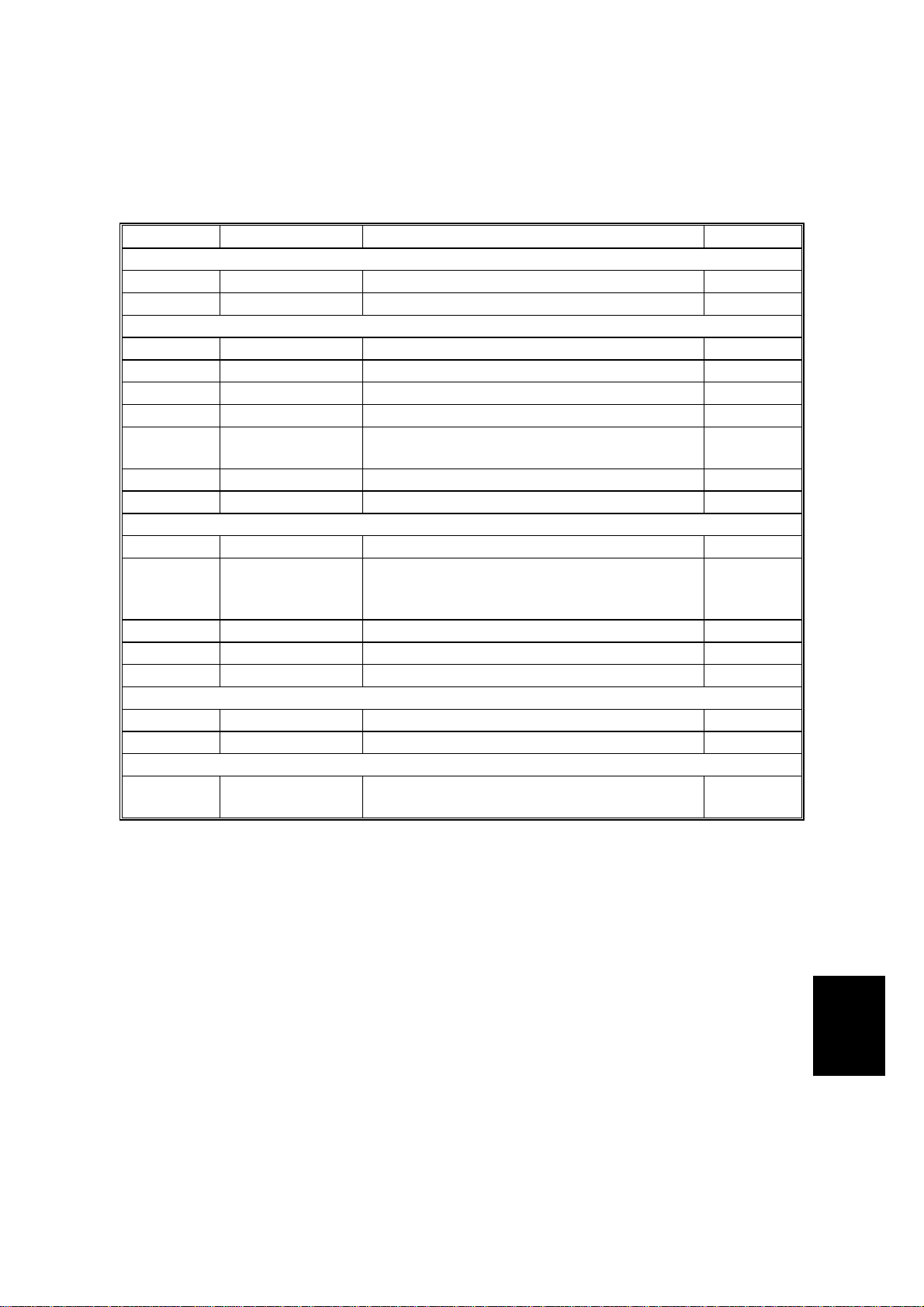

20 March 1998 ELECTRICAL COMPONENT DESCRIPTIONS

1.3 ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout and the point-to-point diagram on the

waterproof paper in the pocket for symbols and index numbers.

Symbols Name Function Index No.

Motors

M1 Main Drives all the mailbox rollers. 12

Sensors

S1 Tray 5 Paper Detects if there is paper in the 5th tray. 2

S2 Tray 4 Paper Detects if there is paper in the 4th tray. 3

S3 Upper Transport Detects misfeeds. 4

S4 Tray 3 Paper Detects if there is paper in the 3rd tray. 5

S5

S6 Tray 2 Paper Detects if there is paper in the 2nd tray. 7

Solenoids

SOL1 2nd Tray Opens and closes the 2nd tray gate. 8

SOL2

SOL3 3rd Tray Opens and closes the 3rd tray gate. 11

SOL4 4th Tray Opens and closes the 4th tray gate. 13

Lower Transport Detects misfeeds, and controls the 3rd

and 4th tray solenoid on/off timing.

Turn Gate Opens and closes the turn gate to direct

paper into either the 1st tray (the base

machine’s output tray) or to the mailbox.

6

9

PCBs

PCB1 Main Control Controls all sorter functions 10

Switches

SW1

Door Safety

Cuts the dc power line when the transport

cover is opened.

1

Options

G696-3

Page 5

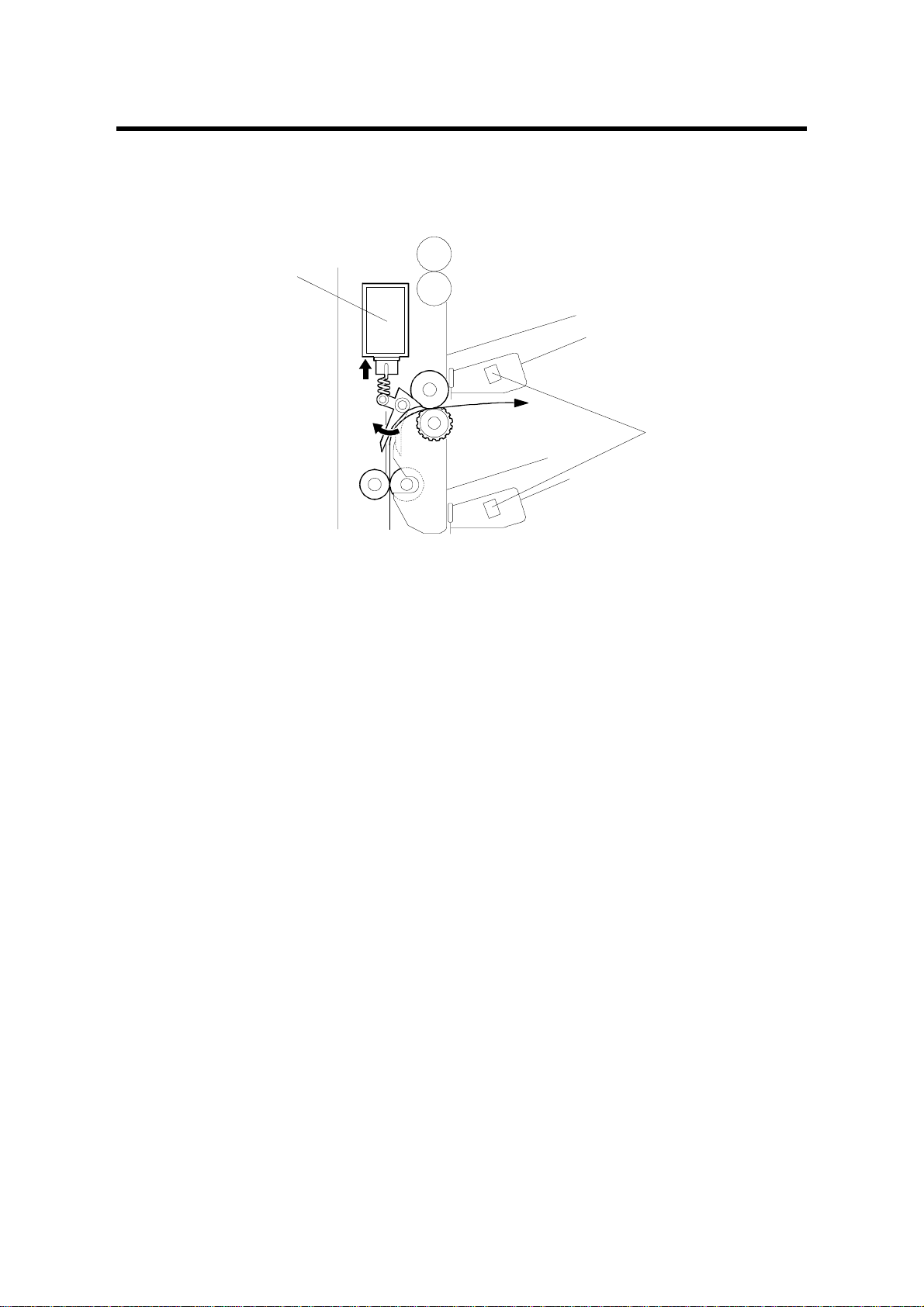

BASIC OPERATION 20 March 1998

2. DETAILED DESCRIPTIONS

2.1 BASIC OPERATION

[A]

[B]

G696D504.WMF

The four-bin mailbox is electrically connected to the base printer by an eight-pin

connector. One of these pins acts as a connection det ection mechanism.

Feed

When the mailbox is selected as the output tray and the lower exit sens or of the

base printer is actuated by the leading edge of the paper, the mailbox main motor

turns on, turning the transport rollers.

Soon after the main motor starts, t he turn gate solenoid energizes to direct the

paper to the four-bin mailbox. (If the standard output tray is selected, the turn gate

solenoid does not energize.) Then the selected tray solenoid [A] energizes, to

direct the paper to that tray. (If the 5th tray is selected, no solenoid turns on.)

When the last printout passes the transport s ensor and feeds out, the t ray sol enoi d

and the main motor turn off.

Normally, the paper transport speed is 180 mm/s. This speed is reduced to 114

mm/s when a large paper size is used (such as DLT or A3), to synchronize feed

speed with the fusing unit while part of the paper is still left in the fusing unit.

G696-4

Page 6

20 March 1998 BASIC OPERATION

Jam Detection

Two transport sensors, lower and upper, detect misfeeds within the unit. When the

2nd or 3rd tray is selected, the lower transport sensor (located just before the feedout section of the 2nd tray) monitors misfeeds. When the 4th or 5th tray is selected,

both sensors monitor misfeeds. Only the lower transport sensor is used to control

the on/off timing of the tray solenoids for prin ts that are fed out to the 3rd and 4th

trays. (For details, refer to the timing charts.)

Paper Sensors

Each tray has a paper sensor [B] to detect paper i n the t r ay. E ach tray is monitored

to ensure that the tray does not contain more than 125 prints. If a print job of more

than 125 sheets is executed, the base printer will do up to 125 prints, then an error

message will appear in the printer display panel and the printing job is stopped.

Once the output stack is removed, the printing job automatically continues.

G696-5

Options

Page 7

TIMING CHART AND MISFEED DETECTION 20 March 1998

2.2 TIMING CHART AND MISFEED DETECTION

2ND TRAY

Mailbox ON/OFF

Interface

Paper Feed-out

Signal (Printer)

Lower Transport Sensor

Upper Transport Sensor

Paper Feed-out Signal

(Mailbox)

Main Motor

Turn Gate Sol.

2nd Tray Sol.

3rd Tray Sol.

4th Tray Sol.

0

ON OFF

ON

0.86

0.4

@

12345

0.3

2nd tray feed-out

(1)

@

(2)

(seconds)

G696D500.WMF

NOTE:

1) Print size: LT (LE F )

2) Number of prints: 2

@

(1): Checks whether the lower transport sensor is actuated with i n 4.09 sec onds

after the paper feed-out signal from the printer.

@

(2): Checks whether the paper has passed through the lower transport sensor

2.92 seconds after it has been actuated.

G696-6

Page 8

20 March 1998 TIMING CHART AND MISFEED DETECTION

3RD TRAY

Mailbox ON/OFF

Interface

Paper Feed-out

Signal (Printer)

Lower Transport Sensor

Upper Transport Sensor

Paper Feed-out Signal

(Mailbox)

Main Motor

Turn Gate Sol.

2nd Tray Sol.

3rd Tray Sol.

4th Tray Sol.

0

ON OFF

ON

0.86

@

12345

0.7

3rd tray feed-out

(1)

@

(2)

(seconds)

G696D501.WMF

NOTE:

1) Print size: LT (LE F )

2) Number of prints: 2

@

(1): Checks whether the lower transport sensor is actuated with i n 4.09 sec onds

after the paper feed-out signal from the printer.

@

(2): Checks whether the paper has passed through the lower transport sensor

2.92 seconds after it has been actuated.

Options

G696-7

Page 9

TIMING CHART AND MISFEED DETECTION 20 March 1998

4TH TRAY

Mailbox ON/OFF

Interface

Paper Feed-out

Signal (Printer)

Lower Transport Sensor

Upper Transport Sensor

Paper Feed-out Signal

(Mailbox)

Main Motor

Turn Gate Sol.

2nd Tray Sol.

3rd Tray Sol.

4th Tray Sol.

0

ON OFF

ON

@

12345

0.5

(1)

@

(2)

@

(3)

(4)

@

(seconds)

0.3

4th tray feed-out

G696D502.WMF

NOTE:

1) Print size: LT (LE F )

2) Number of prints: 2

@

(1): Checks whether the lower transport sensor is actuated with i n 4.09 sec onds

after the paper feed-out signal from the printer.

@

(2): Checks whether the upper transport sensor is actuated withi n 1.06 sec onds

after the lower transport sensor is act uated.

@

(3): Checks whether the paper has passed through the lower transport sensor

2.92 seconds after it has been actuated.

@

(4): Checks whether the paper has passed through the upper transport sensor

2.92 seconds after it has been actuated.

G696-8

Page 10

20 March 1998 TIMING CHART AND MISFEED DETECTION

5TH TRAY

Mailbox ON/OFF

Interface

Paper Feed-out

Signal (Printer)

Lower Transport Sensor

Upper Transport Sensor

Paper Feed-out Signal

(Mailbox)

Main Motor

Turn Gate Sol.

2nd Tray Sol.

3rd Tray Sol.

4th Tray Sol.

0

ON OFF

ON

@

12345

(1)

(2)

@

(3)

@

(4)

@

(seconds)

0.7

5th tray feed-out

G696D503.WMF

NOTE:

1) Print size: LT (LE F )

2) Number of prints: 2

@

(1): Checks whether the lower transport sensor is actuated with i n 4.09 sec onds

after the paper feed-out signal from the printer.

@

(2): Checks whether the upper transport sensor is actuated withi n 1.06 sec onds

after the lower transport sensor is act uated.

@

(3): Checks whether the paper has passed through the lower transport sensor

2.92 seconds after it has been actuated.

@

(4): Checks whether the paper has passed through the upper transport sensor

2.92 seconds after it has been actuated.

Options

G696-9

Page 11

MAILBOX REMOVAL 20 March 1998

3. REPLACEMENT AND ADJUSTMENT

3.1 MAILBOX REMOVAL

[B]

[A]

G696R503.WMF

1. Turn off the main switch and unplug the power cord.

2. Remove the two knob screws [A] securing the mailbox [B].

3. Remove the mailbox as shown.

G696-10

Page 12

20 March 1998 EXTERIOR COVER REMOVAL

3.2 EXTERIOR COVER REMOVAL

[C]

[E]

[F]

[A]

[D]

[B]

G696R500.WMF

Tray Removal

1. Remove the trays [A].

Vertical Transport Cover

1. Open the vertical transport cover [B] and remove it (1 screw [C]).

Front/Rear/Top Cover

1. Remove the mailbox. (See Mailbox Removal.)

2. Remove the front cover [D] (1 screw).

3. Remove the rear cover [E] (2 screws).

4. Remove the top cover [F].

Options

G696-11

Page 13

TRAY PAPER SENSOR AND TRANSPORT SENSOR REPLACEMENT 20 March 1998

3.3 TRAY PAPER SENSOR AND TRANSPORT SENSOR

REPLACEMENT

[A]

[B]

[C]

G696R504.WMF

[E]

1. Turn off the main switch and unplug the printer.

2. Remove the mailbox from the printer. (See Mailbox Remo val .)

[F]

[D]

G696R505.WMF

3. Remove the rear cover. (See Exterior Cover Rem oval. )

Tray Paper Sensor

4. Remove the paper sensor cover [A] (3 snap fits).

5. Remove the tray paper sensor bracket [B] (1 sc rew and 1 connector).

6. Replace the tray paper sensor [C] (1 screw).

Transport Sensor

4. Free the tray feed-out cover [D] (1 screw).

5. Replace the transport sensor [E] (1 snap fit and 1 connector).

NOTE:

When reinstalling the tray feed-out cover, make sure that the transport

sensor actuator rests above the verti cal transport roller shaft [F], as shown.

G696-12

Page 14

20 March 1998 TURN GATE SOLENOID REPLACEMENT

3.4 TURN GATE SOLENOID REPLACEMENT

[B]

[C]

[A]

G696R501.WMF

1. Turn off the main switch and unplug the printer.

2. Remove the mailbox from the printer. (See Mailbox Remo val .)

3. Remove the rear cover. (See Exterior Cover Rem oval. )

4. Remove the turn gate solenoid with the bracket [A] (3 screws and 1 connect o r).

NOTE:

Remove the main control board [B] (4 screws and al l th e connect ors) if

the turn gate solenoid bracket can not be removed smoothly.

5. Replace the turn gate solenoid [C] (2 screws).

NOTE:

Make sure the solenoid’s plunger pin is installed in the cutout in the

frame.

Options

G696-13

Page 15

MAIN MOTOR AND TRAY SOLENOID REPLACEMENT 20 March 1998

3.5 MAIN MOTOR AND TRAY SOLENOID RE PLACEMENT

[D]

[B]

[C]

G696R502.WMF

1. Turn off the main switch and unplug the printer.

2. Remove the mailbox from the printer. (See Mailbox Remo val .)

3. Remove the rear cover. (See Exterior Cover Rem oval. )

4. Remove the main control board [A] (4 screws and all the connectors).

Mai n Mo t or

5. Remove the main motor bracket [B] (2 screws and a timing belt).

6. Replace the main motor [C] (2 screws).

Tray Solenoid

5. Replace the desired tray solenoid [D] (2 screws).

NOTE:

Make sure the solenoid’s plunger pin is installed in the cutout in the

frame.

[A]

G696-14

Page 16

4 BIN MAILBOX (G696) ELECTRICAL COMPONENT LAYOUT

12

11

10

13

1

2

3

4

5

6

7

9

Description Index No. P-to-P Location

Door Safety Switch (SW1) 1 D2

Tray 5 Paper Sensor (S1) 2 F2

Tray 4 Paper Sensor (S2) 3 J2

Upper Transport Sensor (S3) 4 K2

Tray 3 Paper Sensor (S4) 5 E2

Lower Transport Sensor (S5) 6 I2

Tray 2 Paper Sensor (S6) 7 H2

2nd Tray Solenoid (SOL1) 8 G16

Turn Gate Solenoid (SOL2) 9 E16

Main Control Board (PCB1) 10 K12

3rd Tray Solenoid (SOL3) 11 H16

Main Motor (M1) 12 B16

4th Tray Solenoid (SOL4) 13 J16

8

G696S500.WMF

Page 17

MAIL BOX (G696) POINT TO POINT DIAGRAM

DATE: September 5th '97

1234567891011121314151617

A

B

C

DOOR SAFETY SW

D

E

TRAY 3

PAPER SENSOR

F

TRAY 5

PAPER SENSOR

G

TRAY 2

PAPER SENSOR

H

LOWER

TRANSPORT

I

SENSOR

TRAY 4

J

PAPER SENSOR

Symbol Table

AC Line

DC Line

Signal Direction

Active High

V

Active Low

W

Voltage

[ ]

S4

S1

S6

S5

S2

(SW1)

COVER SW

GND

5V

3 BIN SEN.

GND1

5V

5 BIN SEN.

GND1

5V

2 BIN SEN.

GND1

GND1

LO SEN.

5V

5V

4 BIN SEN.

GND1

CN210-2

CN210-1

CN220-3

CN220-2

CN220-1

CN230-3

CN230-2

CN230-1

CN240-3

CN240-2

CN240-1

CN250-3

CN250-2

CN250-1

CN260-3

CN260-2

CN260-1

HOST

INTERFACE

CONNECT

TXD

RXD

STOP

GND1

5V

GND2

24V

CN225-1

CN225-3

CN235-1

CN235-3

CN245-1

CN245-3

CN245-4

CN245-6

CN265-1

CN265-3

CN265-4

CN265-6

CN200-1

CN200-2

CN200-3

CN200-4

CN200-5

CN200-6

CN200-7

CN200-8

CN225-3

CN225-2CN225-2

CN225-1

CN235-3

CN235-2CN235-2

CN235-1

CN245-6

CN245-5CN245-2

CN245-4

CN245-3

CN245-2CN245-5

CN245-1

CN265-6

CN265-5CN265-2

CN265-4

CN265-3

CN265-2CN265-5

CN265-1

CONNECT

TXD

RXD

STOP

GND1

5V

GND2

24V

COVER SW

GND1

5V

3 BIN SEN.

GND1

5V

5 BIN SEN.

GND1

2 BIN SEN.

GND1

GND1

LO SEN.

5V

N.C.

5V

4 BIN SEN.

GND1

GND1

UP SEN.

5V

CN100-1

CN100-2

CN100-3

CN100-4

CN100-5

CN100-6

CN100-7

CN100-8

CN150-1

CN150-2

CN150-3

CN150-4

CN150-5

CN150-6

CN150-7

CN150-8

CN160-15V

CN160-2

CN160-3

CN160-4

CN160-5

CN160-6

CN160-7

CN160-8

CN160-9

CN160-10

CN160-11

CN160-12

CN160-13

[W 5]

[VW 5]

[VW 5]

[W 5]

[V 5]

[V 5]

[V 5]

[V 5]

[V 5]

[V 5]

[V 5]

[VW 24]

[VW 24]

[VW 24]

[VW 24]

[W 24]

[W 24]

[W 24]

[W 24]

24V

24V

N.C.

A

/A

B

/B

24V

24V

24V

SOL4

CN120-1

CN120-2

CN120-3

CN120-4

CN120-5

CN120-6

CN120-7

CN130-1

CN130-2SOL1

CN135-1

CN135-2SOL2

CN140-124V

CN160-2SOL3

CN145-1

CN145-2

MAIN MOTOR

M1

SOL2

SOL1

SOL3

SOL4

TURN GATE

SOLENOID

2nd TRAY

SOLENOID

3rd TRAY

SOLENOID

4th TRAY

SOLENOID

A

B

C

D

E

F

G

H

I

J

K

UPPER

TRANSPORT

SENSOR

S3

GND1

UP SEN.

5V

CN270-3

CN270-2

CN270-1

MAIN CONTROL BOARD

PCB1

L

1234567891011121314151617

K

L

Loading...

Loading...