Page 1

20 BIN SORTER

(MINI)

(Machine Code: A423)

Page 2

12 February 1992 SPECIFICATIONS

1. SPECIFICATIONS

Paper Size for Bins: Maximum A3, 11" x 17"

Minimum A5, 5

Paper Weight: 52 to 90 grams (14 to 24 lb)

Number of Bins: 20 bins + proof tray

1/2

" x 8

1/2

"

Bin Capacity: Sort Mode: 30 sheets/A4 (8

15 sheets/B4 (8

" x 11")

1/2

" x 14")

1/2

10 sheets/A3 (11" x 17")

Stack Mode 30 sheets/A4 (8

10 sheets/B4 (8

" x 11")

1/2

" x 14")

1/2

10 sheets/A3 (11" x 17")

Proof Tray Capacity: 100 sheets (all sizes)

Power Source: 100 V, 50/60 Hz, 0.6 A (from copier)

Power Consumption: 60 W

Dimensions:

(W x D x H)

346 mm x 474 mm x 338 mm

13.6" x 18.7" x 13.3"

Weight: 12.7 kg (28.3 lb)

(MINI)

20 Bin Sorter

1

Page 3

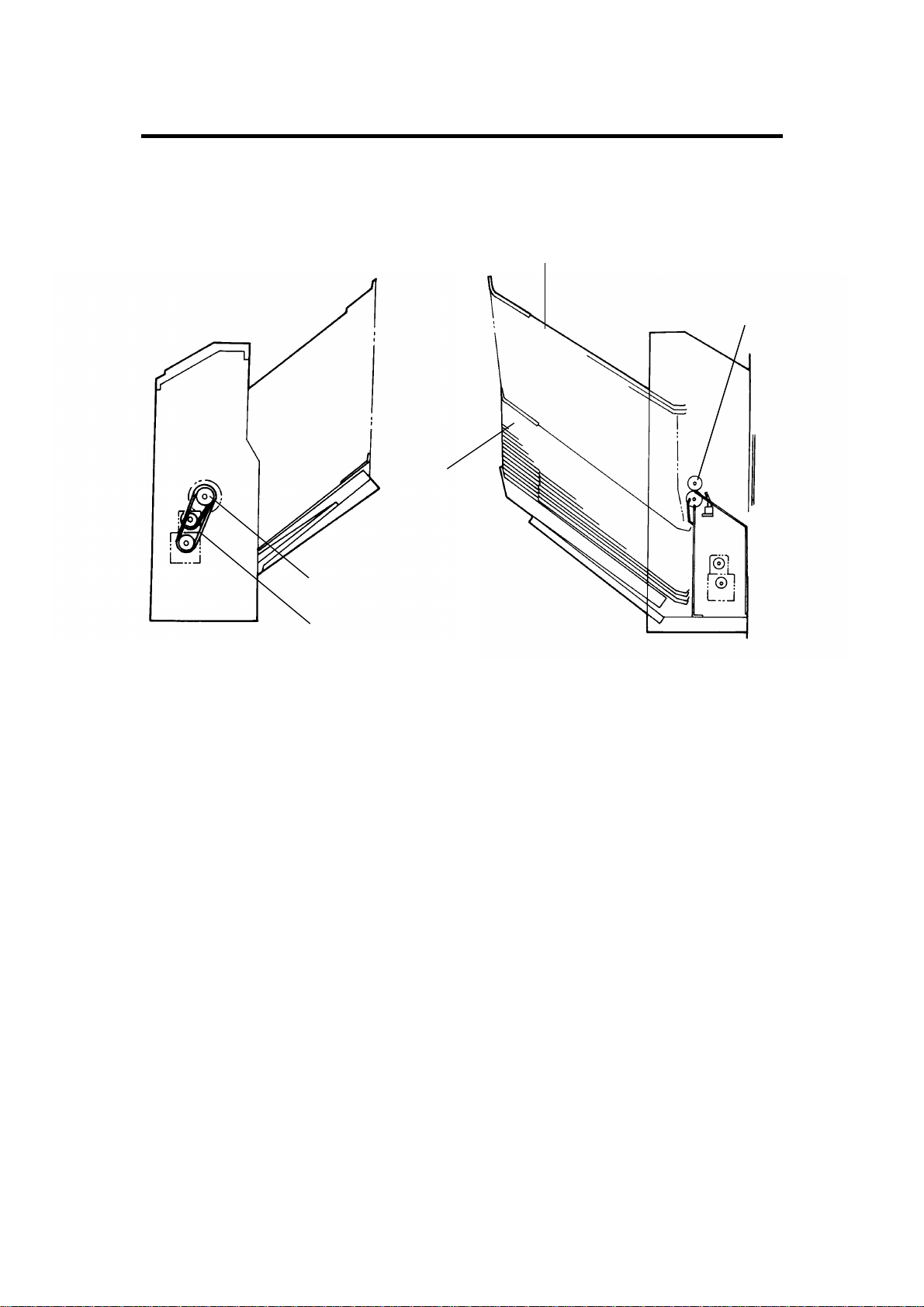

MECHANICAL COMPONENT LAYOUT 12 February 1992

2. MECHANICAL COMPONENT LAYOUT

3

1

4

2

5

1. Exit Rollers

2. Bin Drive Wheel

3. Proof Tray

4. Bins

5. Roller Drive Belt

2

Page 4

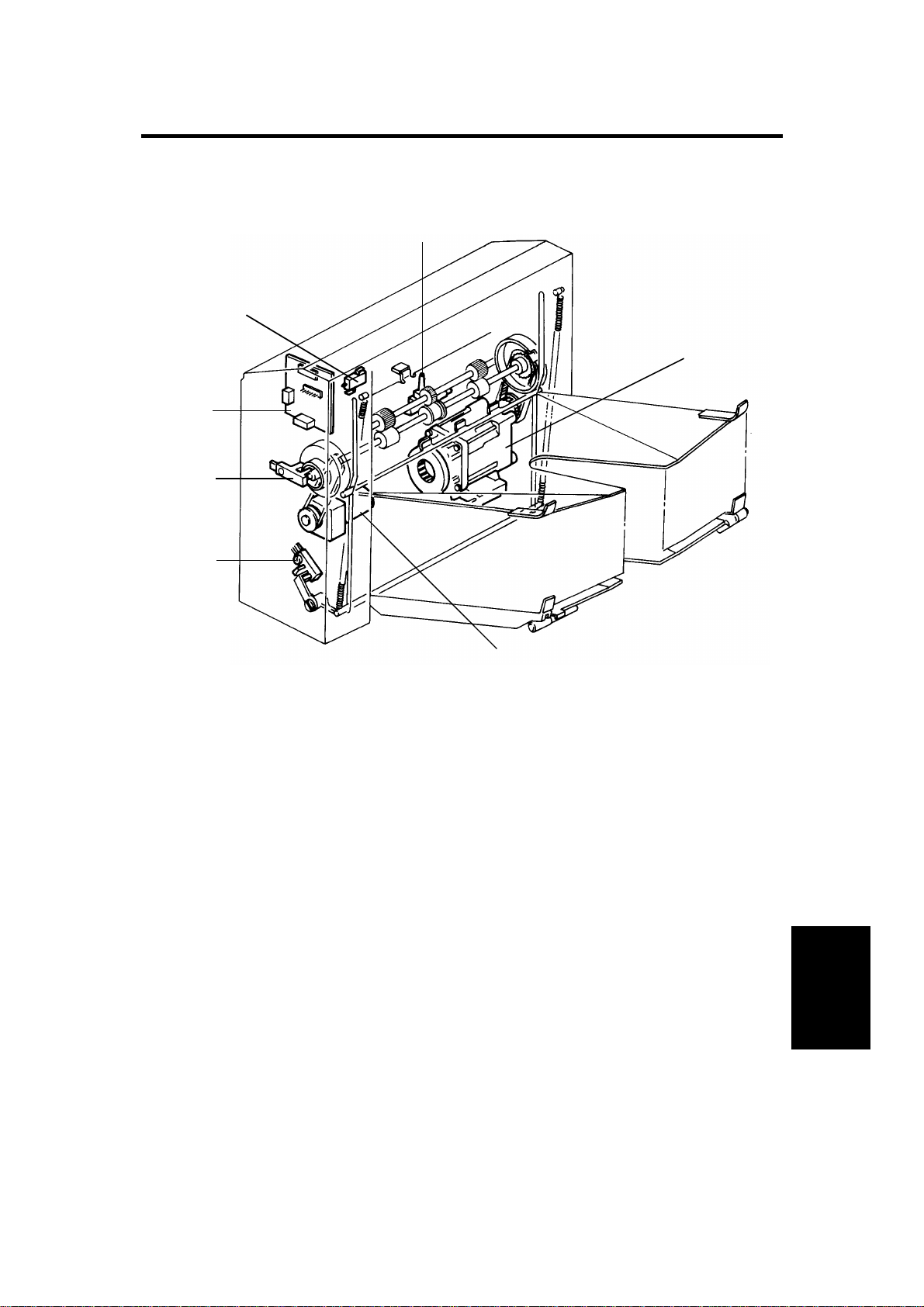

12 February 1992 ELECTRICAL COMPONENT LAYOUT

3. ELECTRICAL COMPONENT LAYOUT

1

7

2

6

5

4

3

1. Paper Sensor (S1)

2. Wheel Drive Motor (M1)

3. Roller Drive Motor (M2)

4. Bin Home Position Sensor (S2)

5. Wheel Sensor (S3)

6. Sorter Board (PCB1)

7. Cover Safety Switch (SW1)

(MINI)

20 Bin Sorter

3

Page 5

ELECTRICAL COMPONENT DESCRIPTIONS 12 February 1992

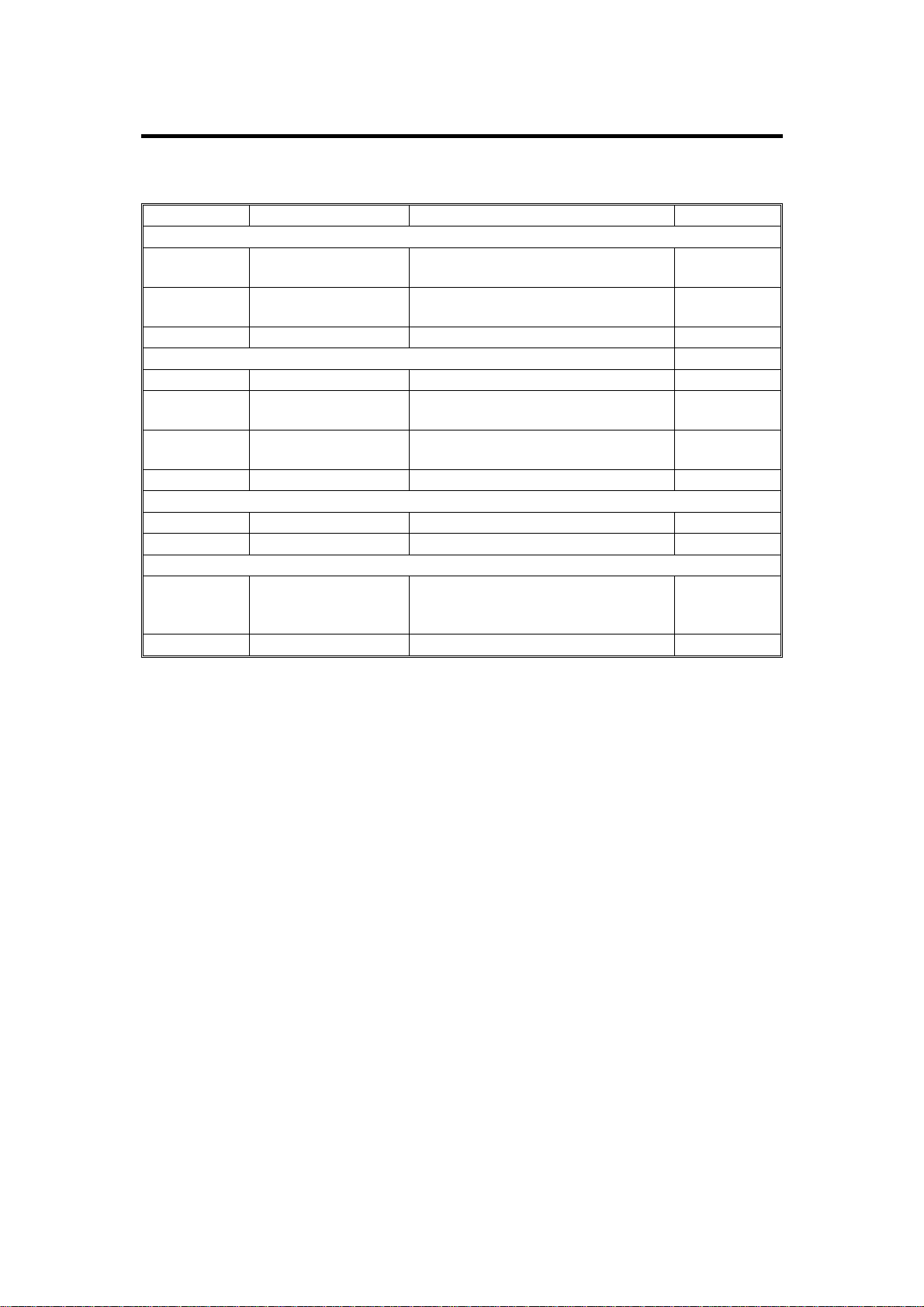

4.ELECTRICAL COMPONENT DESCRIPTIONS

Index No. Name Function Symbol

Motors

2

3

Sensors

1 Paper Sensor Misfeed detection for the sorter S1

4

5

Switch

7 Cover Safety Switch Detects when sorter cover is opened SW1

Wheel Drive Motor Drives the wheel that changes the

bin positions

Roller Drive Motor Drives all rollers in the sorter paper

path

Bin Home Position

Sensor

Wheel Sensor Detects each 1/2 turn of the wheel (1

Detects when all bins are in the

down position (home)

bin changed for each 1/2 turn)

M1

M2

S2

S3

Printed Circuit Board

Sorter Board Controls all sorter functions.

6

Communicates with I/O control PCB

through the interface PCB

PCB1

4

Page 6

12 February 1992 BASIC OPERATION

5.BASIC OPERATION

5.1CLEAR MODE

When the main switch of the copier is turned on, the sorter automatically

assumes a clear mode condition. It also changes to a clear mode condition if

the sort or stack mode is recalled or if the interrupt key is pressed. In a clear

mode condition, all copies are stacked on the proof tray.

Sorter operation starts when a sheet of copy paper activates the copier exit

sensor. At this time the roller drive motor energizes. The

roller drive motor de-energizes when the paper exits the copier and the paper

sensor is deactivated. The paper senso r signa l is sent to the copie r through an

interface board to check for paper misfeed. The wheel drive motor does not

turn on when in the clear mode.

5.2SORT MODE

After the sort mode is selected by pr e ssing the Sorter key, the wheel drive

motor turns on to move the proof tray up. When the first sheet of paper

activates the copier exit sensor, the roller drive motor turns on. Shortly after

the paper sensor turns off (420 ms later), the wheel drive motor turns and

advances the bins one step. When t he whee l senso r is acti vat ed , th e whe el

drive motor turns off.

5.3STACK MODE

As in the sort mode, the roller drive motor turns on when the first sheet of

paper actuates the copier exit sensor. All copies of the copy run are then fed

to the first bin. When the final copy passes the paper sensor, the wheel drive

motor turns on and advances the bins one step.

There are no limits on the number of copies that can be entered up to the full

999 copy limit of the copier. However, the physical capacity of the bins is a

good deal less. (See "Bin Capacity" in the specifications.)

When all 20 bins have been used, the wheel drive motor turns on until all the

bins have been lowered (including the proof tray).

(MINI)

20 Bin Sorter

5

Page 7

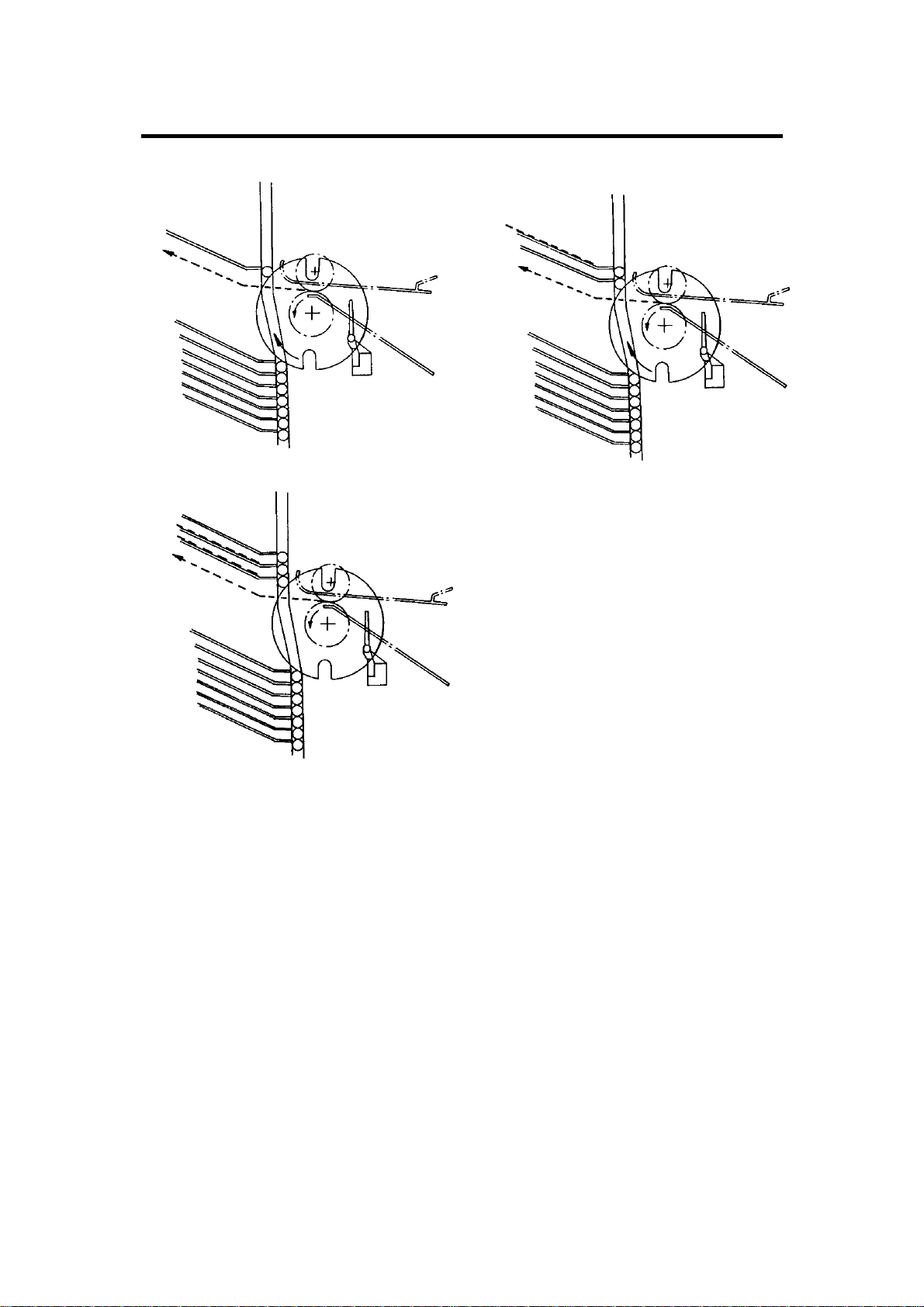

EXAMPLE OF SORT MODE OPERATION 12 February 1992

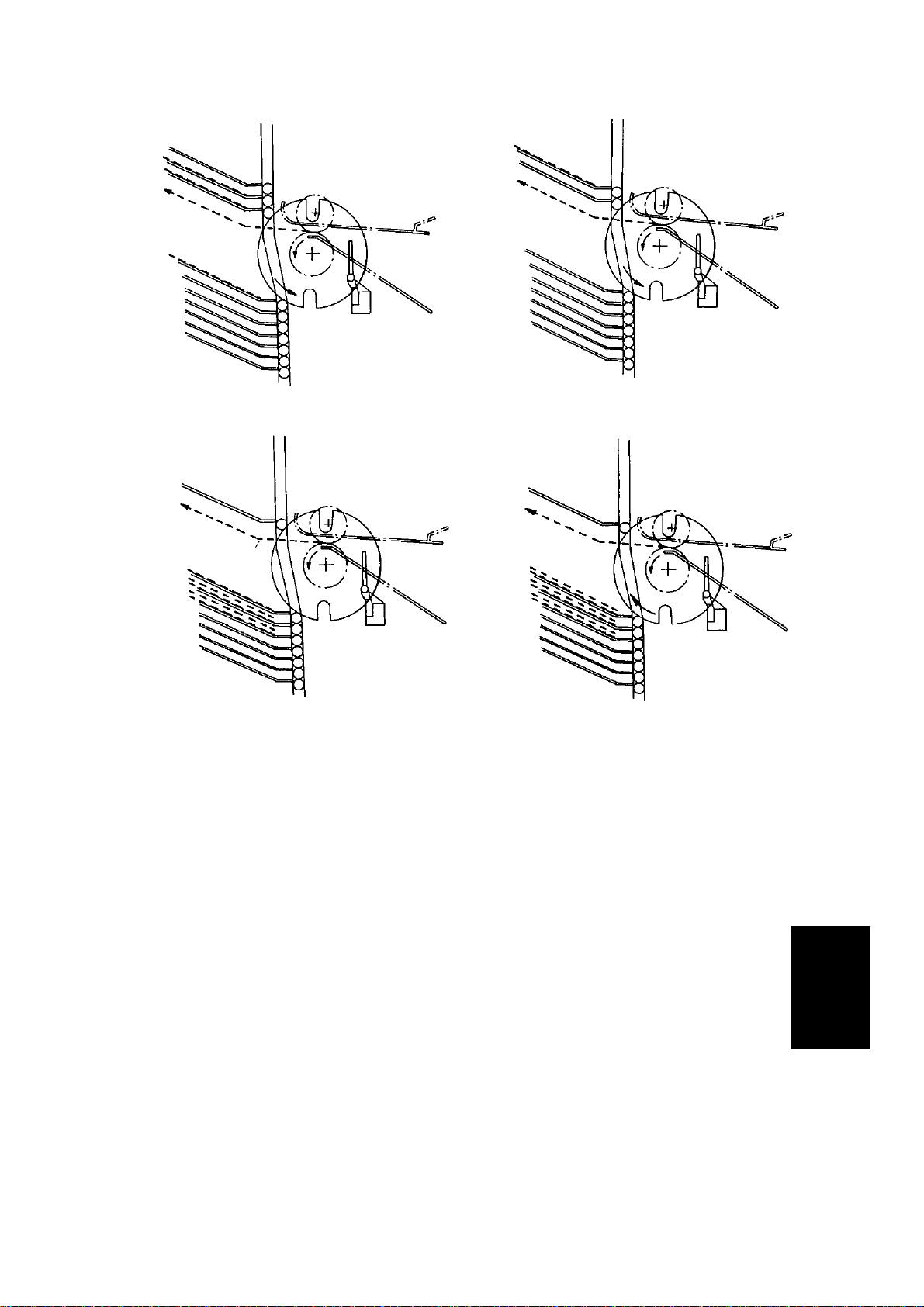

6. EXAMPLE OF SORT MODE OPERATION

1) 2)

3)

"3" copies entered/Start key pressed 3 times.

- Start Key ON -

1) The first copy feeds to the first bin. After the paper sensor turns off, the

wheel drive motor turns on and moves the first bin up.

2) The same action as #1.

3) The third copy feeds to the third bin . The whee l dr ive mot or do es no t tu r n

on after the paper sensor turns off. (The sorter will stay at this position

until auto-reset or until copying resumes.)

6

Page 8

12 February 1992 EXAMPLE OF SORT MODE OPERATION

4) 5)

6)

7)

- Start Key ON -

4) The first copy is fed to the third bi n. After the paper sensor turns off, the

wheel drive motor turns on and moves the second bin down.

5) The same as #4.

6) The third copy is fed to the first bin. The wheel drive motor does not turn

on after the paper sensor turns off.

- Start Key ON -

7) The first sequence (1, 2, and 3) is repeated.

7

(MINI)

20 Bin Sorter

Page 9

BIN DRIVE MECHANISM 12 February 1992

7. BIN DRIVE MECHANISM

[A]

[G]

[C]

[D]

[I]

[H]

[B]

[F]

[E]

The bin drive mechanism moves the bins [A] up an d do wn to re ceive copie s

under the direction of the copie r CPU. The ma in comp onents in this

mechanism are the wheel drive motor [B], the two transfer wheels [C], the

wheel sensor [D], and the bins themselves.

Pins on either side of each bin are inserted into slots in the sorter side frame.

The pins slide up and down in these slots. The bins r est on ea ch ot her with

the lower one resting on the lift bar [E ]. The spr ings [F], on either end of the

lift bar, lift it up forcing the bin pins against the transfer wheels. Plastic

spacers [G] on both ends of the bin keep the bins separated.

To move the bins up, the bin drive motor turns clockwise (as viewed from the

front). A timing belt [H] turns the transfer wheels [I].

8

Page 10

12 February 1992 BIN DRIVE MECHANISM

[A]

[B]

[C]

[E]

[D]

The transfer wheels have two slots in them 18 0 de gr e es ap ar t . As th e

transfer wheels turn, these slots en gage the pins of the bins and lift them up.

Each time the transfer wheels tu r n 18 0 de gr e es, the y ra ise on e bin .

The CPU counts the bins using the wheel sen sor . A cylindr ica l ac tu at or on

the front transfer wheel turns the wheel sensor on and off. This actuator has

two notches that are 180 de grees apart. The wheel sensor turns on each

time one of the slots passes through the sensor.

To move the bins down, the CPU reverses the bin drive motor and the above

process reverses.

The home position sensor [A] is locat ed at th e lowe r re ar en d of the sor te r .

When all the bins are lowered, the lift bar [B] presses down on the actuator

[C], actuating the sensor. The CPU checks the sensor whenever the power is

turned on. At this time, if the bins are not in the home position, the home

position sensor is deactuated the CPU will return the sorter bins to the home

position.

The mounting position is about 18.5 degrees off between the front tran sfe r

wheel [D], and the rear transfer wheel [E]. Therefore, the front and rear of the

bins do not rise simultaneously thus avoiding unusual noises and also

reducing load.

(MINI)

20 Bin Sorter

9

Page 11

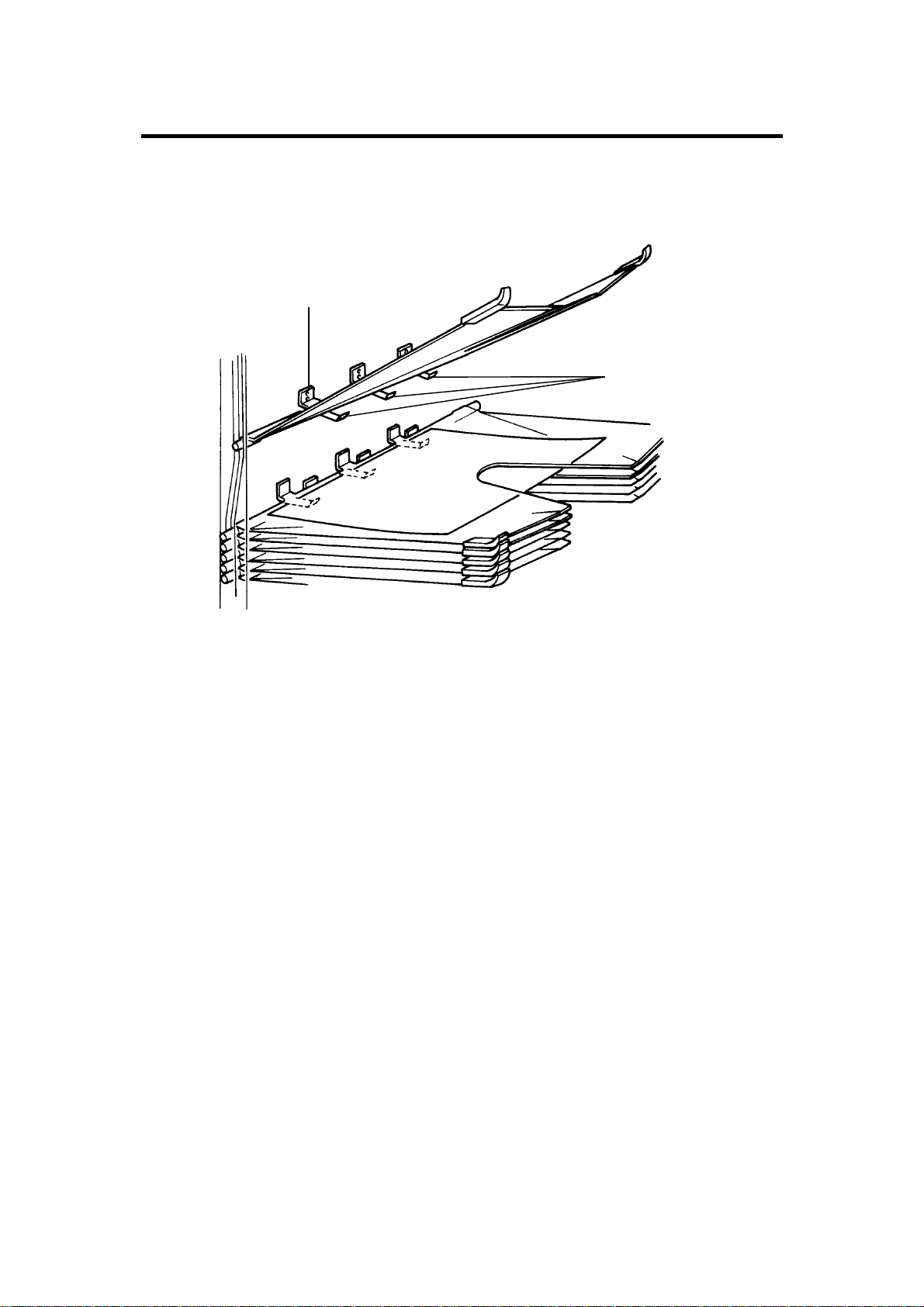

BINS 12 February 1992

8. BINS

[A]

[B]

The proof tray and the twenty bins are all basically the same. Formed out of

thin flexible steel plate, they ha ve spa cer s on the left end to hold them apart

and pins at the front and rear of the right end, which are inserted in guide

slots in the sorter frame.

On the right edge, the bins have stoppers [A] which prevent copies from

sliding back into the sorter after they have been fed out. The pattern of these

stoppers is different for even and odd numbered bins.

Three leaf springs [B] on the underside of each bin hold the copies flat in the

underlying bin.

10

Page 12

12 February 1992 EXIT ROLLERS

9. EXIT ROLLERS

[A]

The exit roller shaft is hollow and is mounted on the transfer wheel shaft [A]

(coaxial). When the copy actuates the copier’s exit sensor, the CPU sends a

signal to the sorter to turn on the roller drive motor. The roller drive motor

turns off at the same time as the copier main motor.

(MINI)

20 Bin Sorter

11

Page 13

ELECTRICAL TIMING 12 February 1992

10.ELECTRICAL TIMING

Fusing Exit Sensor

(Copier)

Paper Sensor

Roller Drive Motor

Wheel Drive Motor

Wheel Sensor

T1

1.76

1.57

JAM

T2

0.42

JAM

0.75

T3 T4

1.76

1.57

T1:When a sheet of copy paper activates the fusing exit sensor,

the roller drive motor starts rotating.

T2:1.57 seconds after turning on the fusing exit sensor, the paper

sensor turns ON.

0.42

T5

T3:0.42 second after the paper sensor turns OFF, the wheel drive

motor starts rotating and shifts the bin.

T4:When the wheel sensor is actuated, the wheel drive motor

turns OFF.

T5:0.42 second after the paper sensor turns OFF, the roller drive

motor stops.

12

Page 14

12 February 1992 INSTALLATION

11.INSTALLATION (FT4227/5233 SERIES)

11.1ACCESSORY CHECK

Check the quantity and conditio n of the accesso r ies in th e box according to

the following list:

1. Installation Procedure......................................................................1

2. New Equipment Condition Report

(–17, –27 machines only)................................................................1

3. Envelope for NECR

(–17 machine only)..........................................................................1

4. Thumb Screw..................................................................................1

5. Grounding Screw............................................................................1

6. Star Washer...... ...............................................................................1

7. Multilingual Decal

(–25, –26, –27 machines only)........................................................1

13

(MINI)

20 Bin Sorter

Page 15

INSTALLATION 12 February 1992

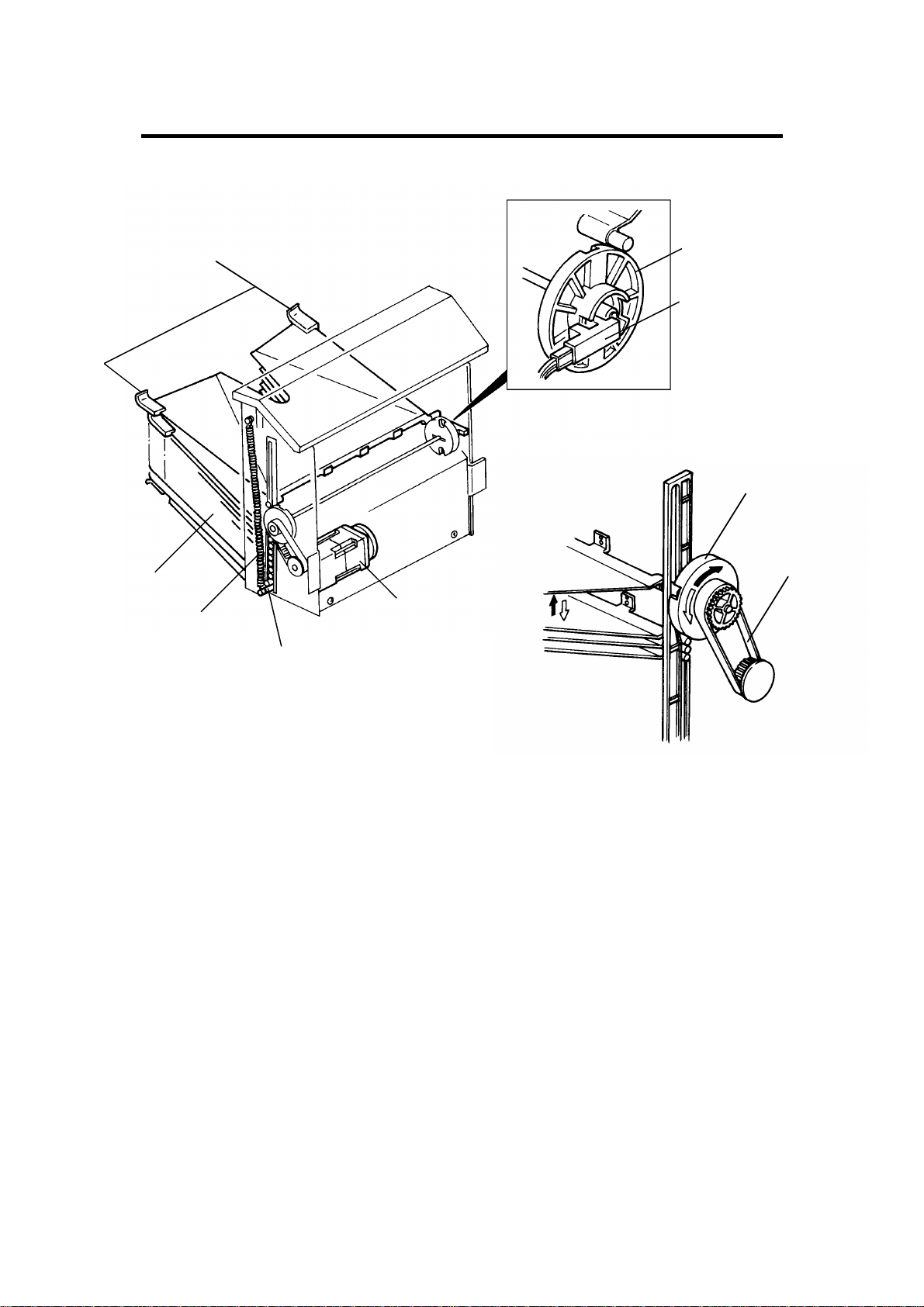

11.2 INSTALLATION PROCEDURE

[A]

[A]

[E]

[A]

[D]

[B]

[F]

CAUTION: Unplug the copier power cord before starting the following

procedure.

NOTE: •

The sorter adapter (A328) should be installed before the sorter is

installed.

[G][C]

1. Remove the strips of tape [A].

2. Remove the front sorter cover [B] (2 screws) and rear sorter cover [C] (4

screws).

3. Remove the cover plates [D] with cutting pliers and the plastic cap [E].

4. Mount the sorter on the copier. Insert the two mounting studs into the

docking holes, and pass the harness [F] through the access hole.

5. Attach the sorter unit to the copier with the two thumb screws [G].

14

Page 16

12 February 1992 INSTALLATION

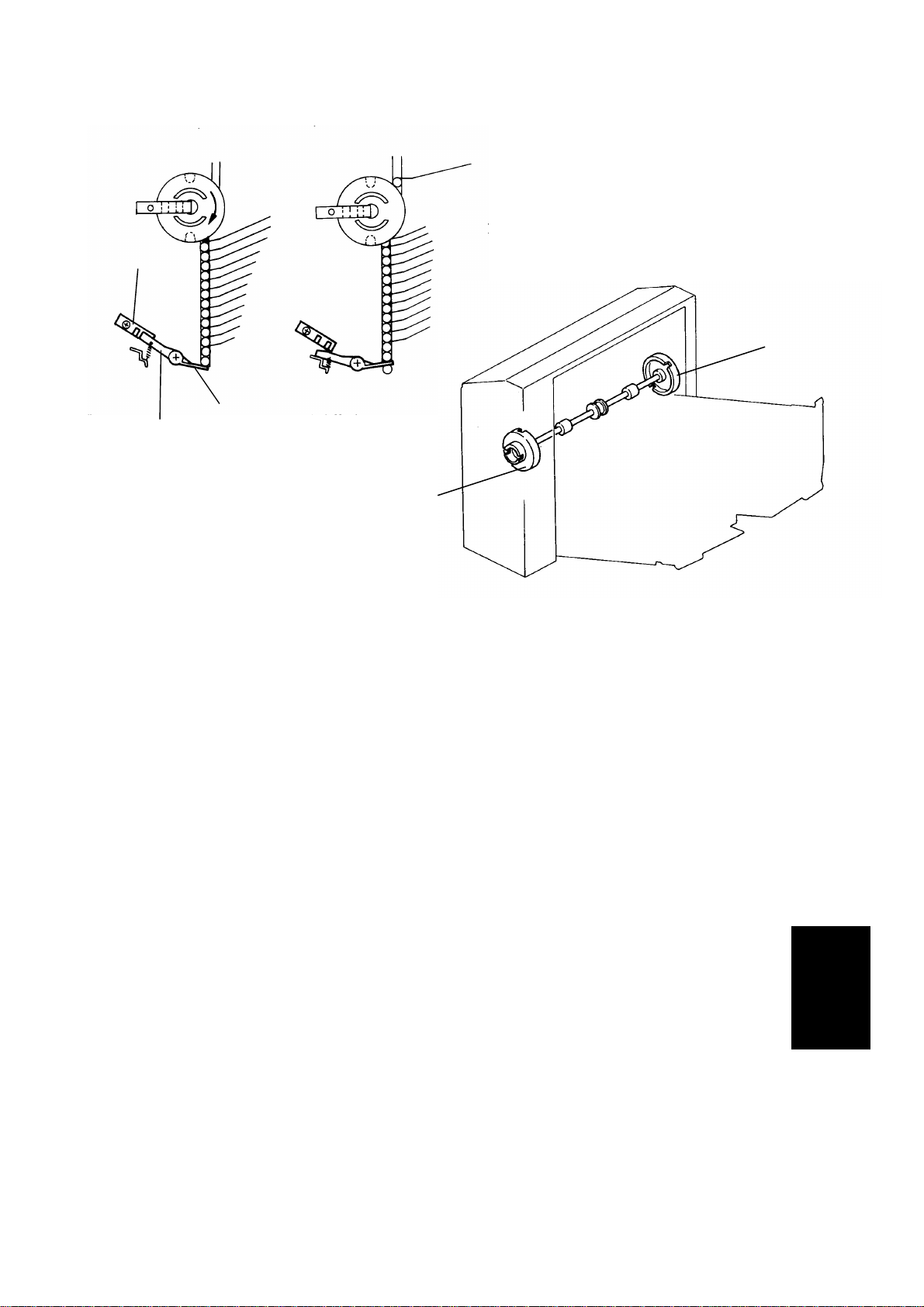

[A]

[B]

6. Secure the sorter protective earth wire [A] (1 screw and toothed washer).

7. Connect the three connectors [B] as follows:

2P red to 2P red free

4P white to 4P white free

11P white to 11P white free

(MINI)

20 Bin Sorter

15

Page 17

INSTALLATION 12 February 1992

[B]

[A]

8. Reinstall all the covers.

9. Plug in the copier power cord.

10. While pressing both 1 and 3 on the ope r at ion pan el nu mbe r keys, tu r n on

the main switch in order to access the SP mode.

NOTE:

Release the number keys after conf ir m ing tha t th e call ser vice

indicator and the copy coun ter number "0" are blinking.

11. Enter 71 using the number keys and then press the enter key.

12. Enter 2 using the number keys and then press the enter key.

13. Turn off the main switch.

14. Remove the left plastic cover [A] on the operation panel and install the

sorter key top and cover [B] instead.

NOTE:

The sorter key top and cover are provided as an accessory for

the copier.

15. Turn on the main switch and check the sort er ’s op er a tio n.

16

Page 18

28 February 1989

12. ACCESSORY CHECK (FT4460)

Check the quantity and condition of the accessories in the box according to

the following list:

1. Installation Procedure

(115V - English only / 220V - Five Languages)

2. New Equipment Condition Report . . . . . . . . . . . . . . . . . . . . . . . . 1

3. Envelope for NECR (115V only)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

1

1

4. Thumb Screw

5. Grounding Screw

7. Multilingual Decal (220/240V only) . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

1

8-13

Page 19

28 February 1989

13. INSTALLATION PROCEDURE (FT4460)

NOTE:

1.

2

.

.

3

4.

.

5

.

6

7.

Install the sorter unit after the optional date printer and the

document feeder have been installed.

Turn off the main switch and unplug the power supply cord of the copier.

Remove the strips of shipping tape [A].

Remove the receiving tray [B] and rear cover [C] of the copier (4 screws).

Remove the 5 plastic caps [D].

Remove the front sorter cover [E] (2 screws) and rear sorter cover [F] (4

screws).

Mount the sorter on the copier. Insert the two mounting studs into the

docking holes, and pass the harness through the access hole.

Attach the sorter unit to the copier with the two thumb screws [G].

8-14

Page 20

28 February 1989

8. Connect the sorter ac harness [A] (free red 2P connector).

9. Connect the sorter dc harness [B] (white 4P connector).

10. Connect the sorter harness [C] (CN2, white 11P connector).

11. Secure the sorter ground wire [D] (1 screw and star washer).

12. Mount the sorter covers and copier rear cover.

13. Remove the sheet [E] on the left end of the operational panel, and insert

the sorter key top [F] into the key hole. Then, stick on the sorter panel

sheet [G].

NOTE:

The sorter panel sheet and sorter key top are copier accessories.

8-15

Page 21

28 February 1989

14. Remove the key cover [A] (1 screw).

15. Plug in the power cord of the copier and turn on the main switch.

16. Turn on DIP SW 1-4 under the operation panel.

17. Enter “71” in the copy counter using number keys, then press the “#” key.

18. Enter “1” in the magnification ratio indicator using number keys, then

press the “#” key.

19. Turn off DIP SW 1-4 under the operation panel.

20. Install the key cover.

21. Check the sorter’s operation and fill out the New Equipment Condition

Report.

8-16

Page 22

1 January 1990

12. ACCESSORY CHECK (NC100)

Check the quantity and condition of the accessories in the box according to

the following list:

1. Installation Procedure..............................................1

2. New Equipment Condition Report...........................1

(17 and 27 machines)

3. Envelope for NECR (17 machine only). .. .. .. .. .. .. .... ..1

4. Thumb Screw..........................................................2

5. Grounding Screw.....................................................1

6. Star Washer.............................................................1

7. Multilingual Decal (16, 25, 26 and 27 machines)....1

8. Transport Mylar (for A030)...... .. .. .... .. .. .. .. .. .. .... .. .. .. ..1

8-14

Page 23

1 January 1990

12.1 INSTALLATION PROCEDURE (for Machine Code: A030)

[A]

[C]

[A]

[E]

[D]

[F]

1.Turn off the main switch and unplug the power supply cord of the copier.

2.Remove the strips of shipping ta pe [A].

3.Remove the receiving tray [B], ton er colle ction bottle cover [C] (2 screws)

and rear cover of the copier [D] (5 screws).

4. Remove the 5 plastic caps [E].

5. Stick the transport mylar [F] to the sorter as sho wn.

8-15

Page 24

1 January 1990

[A]

[B]

[C]

[D]

6.Remove the fusing exhaust fan [A] (2 screws ,1 connector).

7. Remove the front sorter cover [B] (2 screws) and rear so rte r cover [C] (4

screws).

8. Mount the sorter on the copier. Insert th e two moun tin g stu ds int o th e

docking holes, and pass the harness th rou gh the access ho le.

9. Fix the sorter unit to the copier with the two thumb screws [D].

8-16

Page 25

[G]

[A]

[B]

[C]

1 January 1990

[D]

[F]

[H]

[E]

10.Connect the sorter AC harness [A] (free red 2P connector), DC harness

[B] (white 4P connector) and harne ss [C] (CN2, white 11P connector).

11.Secure the sorter ground wire [D] (1 screw and sta r wa she r).

12.Remove the bracket [E] (1 screw).

13.Mount the sorter covers, fusin g fan exhaust and copier covers.

14.Remove the sheet [F] on the le ft end of th e op era tional panel, and insert

the sorter key top [G] int o the key hole. Then, stick on the sorte r pan el

sheet [H].

NOTE: The sorter panel sheet and sorter key top are copier accessories.

15.Enter SP mode. Then, enter sorte r mo de as follo ws:

7

16.Leave SP mode by pressing the Clear Modes key.

1

#

1

8-17

#

Page 26

ACCESSORY CHECK 20 December 1991

12.ACCESSORY CHECK (NC305)

Check the quantity and condition of the accessories in the box according to

the following list:

1. Installation Procedure........................................................................1

2. New Equipment Condition Report.....................................................1

(17 and 27 machines)

3. Envelope for NECR (17 machine only). .. .. .. .. .. .. .... .. .. .. .. .. .. .... .. .. .. .. .. ..1

4. Thumb Screw....................................................................................2

5. Grounding Screw...............................................................................1

6. Star Washer.......................................................................................1

7. Multilingual Decal (16, 25, 26 and 27 machines)..............................1

8. Transport Mylar (for A030/A072). .. .... .. .. .. .. .. .. .... .. .. .. .. .. .. .... .. .. .. .. .. .. ....1

14

Page 27

[D]

[B]

20 December 1991 ACCESSORY CHECK

12.1 INSTALLATION PROCEDURE (for Machine Code: A072)

[A]

[A]

[A]

[E]

[D]

[C]

1. Turn off the main switch an d un plu g the power supply cord of the copier.

2. Remove the strips of shipping tape [A].

3. Remove the receiving tray [B] , and op en the rear cove r [ C] (2 screws).

4. Remove the five plastic caps [D].

5. Stick the transport mylar [E] to the sort er as shown.

15

Page 28

[C]

ACCESSORY CHECK 20 December 1991

[A]

[B]

[G]

[F]

[E]

[D]

[H]

6. Remove the front sorter cove r [A] (2 screws) a nd re ar sort er cove r [ B] (4

screws).

7. Mount the sorter on the copie r. Insert the two mounting stud s into the

docking holes, and pass the ha rness through the access hole .

8. Fix the sorter unit to the copier with the two thumb screws [C].

9. Connect the sorter AC harness [D] (free red 2P connector), DC harness

[E] (white 4P connector) and harn ess [F] (CN2 , whit e 11 P con ne cto r).

10. Secure the sorter ground wire [G] (1 screw and star wa she r).

11. Remove the bracket [H] (1 screw).

12. Mount the sorter covers and copie r co ver.

16

Page 29

20 December 1991 ACCESSORY CHECK

13. Enter SP mode. Then, enter sorter mode as follows:

71

14. Leave SP mode by pressing the Clear Modes Key.

R/#

1

R/#

17

Page 30

12 February 1992 REPLACEMENT AND ADJUSTMENT

12. REPLACEMENT AND ADJUSTMENT

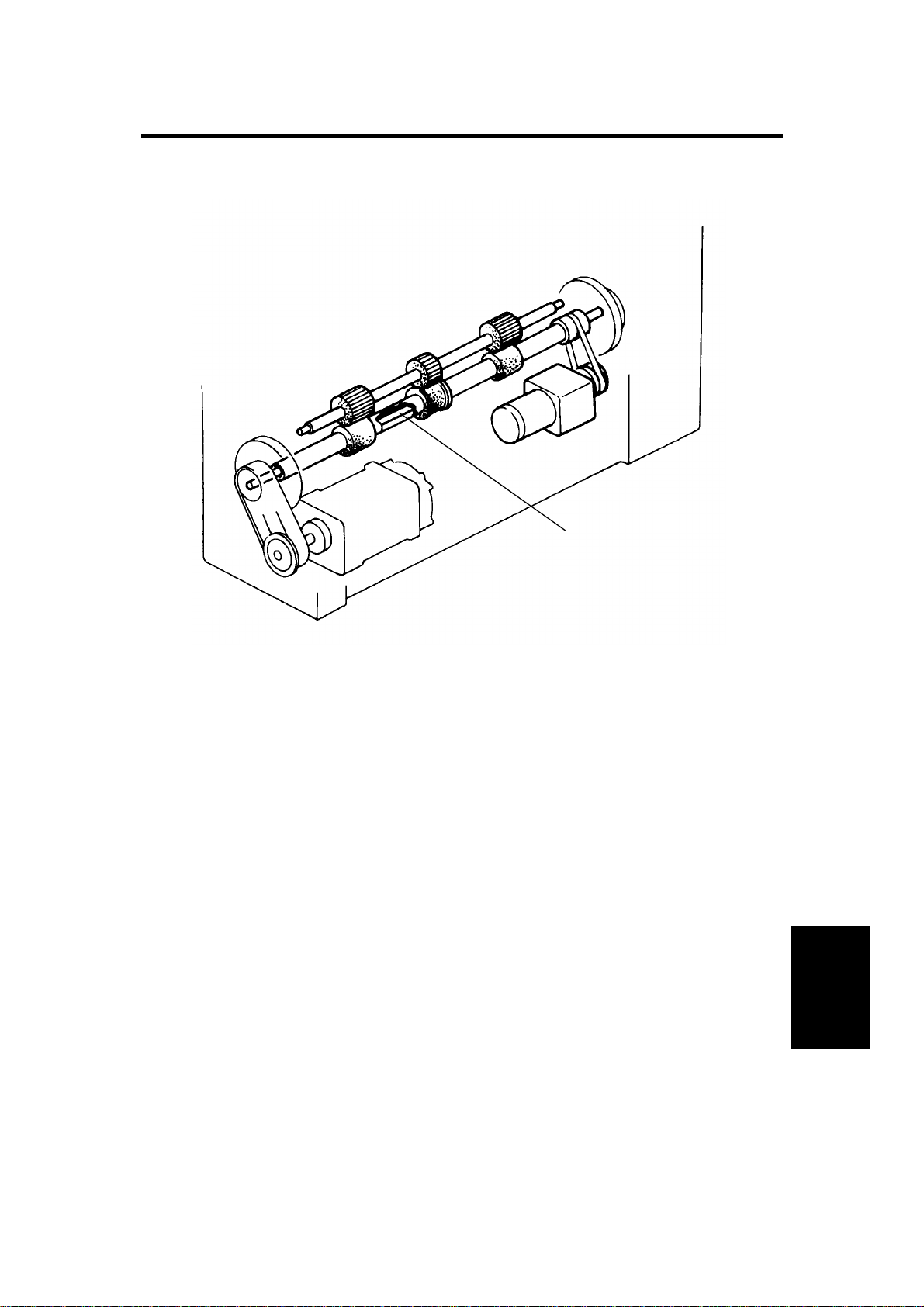

12.1 EXIT ROLLER AND O-RING REPLACEMENT

[A]

[E] [B]

[B]

[C]

[D]

1. Remove the sorter from the copier.

2. Remove the front and rear covers (2 screws each).

3. Remove the ground wire [A] of the upper guide plate [B] (1 screw).

4. Swing the guide plate up, then remove it by carefully pulling it up.

5. Remove the inner cover [C] (4 screws).

6. Unhook the front [D] and rea r [E] pr essu r e spri n gs.

(MINI)

20 Bin Sorter

17

Page 31

REPLACEMENT AND ADJUSTMENT 12 February 1992

CAUTION: Do not damage the paper sensor [K] when removing the

exit roller.

[A]

[B]

[C]

[K]

[J]

[D]

[H]

[G]

[I]

[F]

[E]

7. Remove the wheel sensor assembly [A] (1 screw).

8. Remove the rear transfer wheel [B] (1 E-ring).

NOTE:

Be sure not to lose the pin [C] for the wheel.

9. Remove the pin and bushing [D].

10. Loosen the four mounting screws [E] of the wheel drive motor [F].

11. Lift the wheel drive motor and slip off the timing belt [G].

12. Slide off the wheel drive shaft [H] and remove the exit roller [I]

and O-ring [J].

13. Replace the exit roller and O- ri n g, the n rea ssem b le.

NOTE:

a) When reinstalling the wheel sensor assembly, be sure that the

sensor does not touch the wheel.

b) When remounting the wheel drive mo to r , ad just the ti m ing belt

tension. (See Timing Belt Tension Adjustment.)

18

Page 32

12 February 1992 REPLACEMENT AND ADJUSTMENT

12.2 PAPER SENSOR REPLACEMENT

CAUTION: To avoid damaging the sensor, do not over-tighten the

sensor mounting screw.

[A]

[C]

[B]

1. Remove the sorter from the copier.

2. Swing up the guide plate [A].

3. Remove the inner cover [B] (4 screws).

4. Replace the paper sensor [C] (1 screw and 1 connector) and reassemble.

19

(MINI)

20 Bin Sorter

Page 33

REPLACEMENT AND ADJUSTMENT 12 February 1992

12.3 TIMING BELT TENSION ADJUSTMENT

200g (0.44 lb)

[C]

[D]

[A]

2 mm

0.080

[B]

+3

mm

−0

+0.12

−0

ADJUSTMENT STANDARD:

2 mm

+3

mm; 0.080

−0

+0.12

−0

inches

(deflection at 200 g (0.44 lb) pressure)

1. Remove the front cover.

2. Loosen the four mounting screws [A] of the wheel drive moto r [B].

3. Press the timing belt [C] with a tension gauge [D] as shown in the figure

and adjust the tension by repositioning the wheel drive motor.

20

Page 34

28 February 1989

13. ELECTRICAL CONTROL (FT4460)

The copier I/O control PCB controls all the functions of the sorter through the

interface board.

The copier supplies 100 volts ac to the wheel drive motor and the SSRs. SSR

101 turns the wheel drive motor to move the bins up and SSR 102 is for the

down operation.

The copier supplies two dc power levels, +5 volts and +24 volts, for the dc

components.

Signals from the sensors and the safety switch are sent to the copier I/O con-

trol PCB through the interface board. The copier I/O control PCB operates

motors and SSRs.

8-12

Page 35

13. ELECTRICAL CONTROL (NC100)

1 January 1990

Copier

Main PCB

BIN UP

BIN DOWN

ROLLER

PAPER

WHEEL

H.P.

COVER

100 Vac

100 Vac

Sorter Interface

PCB

24V

5V

GND

Sorter Control Board

SSR 101

24V

5V

SSR 102

100 Vac

Up

Down

Wheel

Drive

Motor

Roller

Drive

Motor

Paper

Sensor

Wheel

Sensor

H.P.

Sensor

Cover

Safety

The copier supplies 100 volts ac to the wheel drive motor and the SSRs. SSR

101 turns the wheel drive motor to move the bins u p and SSR 102 is for the

down operation.

The copier supplies two dc power levels, +5 volts and +24 volts, for the dc

components.

Signals from the sensors and the safety switch are sent to the copier main

PCB. The copier main PCB controls motors and SSRs.

8-13

Page 36

20 December 1991 ELECTRICAL CONTROL

13.ELECTRICAL CONTROL (NC305)

Copier

Main PCB

BIN UP

BIN DOWN

ROLLER

PAPER

WHEEL

H.P.

COVER

100 Vac

100 Vac

Sorter Interface

PCB

24V

5V

GND

Sorter Control Board

SSR 101

24V

SSR 102

5V

100 Vac

Up

Down

Wheel

Drive

Motor

Roller

Drive

Motor

Paper

Sensor

Wheel

Sensor

H.P.

Sensor

Cover

Safety

The copier supplies 100 volts ac to the wheel drive motor and the SSRs. SSR

101 turns the wheel drive motor to move the bins u p and SSR 102 is for the

down operation.

The copier supplies two dc power levels, +5 volts and +24 volts, for the dc

components.

Signals from the sensors and the safety switch are sent to the copier main

PCB. The copier main PCB controls motors and SSRs.

13

Page 37

4. SORTER

4. SORTER

Index No.

1.

2.

3.

4.

5.

6.

7.

8

9.

10.

11.

12.

13.

14.

15.

CN. No.

CN101

CN103

CN

104

T1

T2

CN116

CN117

CN115

CN113

CN111

CN114

CN102

CN2

CN902

CN3

Component

Sorter Board

Sorter Board

Sorter Board

Cover Safety Switch

Cover Safety Switch

Paper Sensor

Wheel Drive Motor

Roller Drive Motor

H.P. Sensor

Wheel Sensor

(Relay Drive Motor)

Sorter Board

Sorter Interface Harness

Sorter DC Harness

Sorter

AC Harness

--

Type

__

2P/W

12P/R

15P/W

P/W

3P/w

3P/W

3P/W

3P/W

3P/W

2P/W

3P/W

11P/W

4P/W

2P/R

--

--_-

H-7

G-617

H-6

H-7

H-7

P

to

H-8

H-7

ti-8

ti-9

H-8

ti-8

HH-7

G-6/7

F

-6

H-6

P

Loading...

Loading...