Page 1

3-BIN SORTER

(Machine Code: A849)

Page 2

24 February, 1999 MECHANICAL COMPONENT LAYOUT

1. SPECIFICATIONS

Paper Size for Bins: Sort/Stack Modes:

Lengthwise: A6 to A3

5

1/2

Sideways: A5 to A4

5

1/2

Paper Weight for Bins: Face up:

1st bin: 52 ~ 160 g/m2 (14 ~ 42 lbs.)

2nd/3rd bins: 52 ~ 105 g/m2 (14 ~ 28 lbs.)

Face down:

All bins: 64 ~ 105 g/m2 (17 ~ 28 lbs.)

Bin Capacity: 1st bin:

A4, 8

B4, 8

2nd/3rd bins:

A4, 8

B4, 8

1/2

" x 8

" x 8

" x 11" or smaller:

1/2

" x 13" or larger:

1/2

" x 11": or smaller:

1/2

" x 13" or larger:

" (HTL) to 12" x 18"

1/2

" (HTL) to 8

1/2

" x 11" (LT)

1/2

500 copies (80 g/m2, 20lbs.)

250 copies (80 g/m2, 20 lbs.)

250 copies (80 g/m2, 20lbs.)

125 copies (80 g/m2, 20lbs.)

Number of Bins: 3 copy trays

1 inverter tray

Power Source: DC 24 V, 5 V (from the main machine)

Power Consumption: Average: Less than 30 W

Weight: 13 kg (28.7 lbs.)

Weight: 14 kg (30.9 lbs.)

Dimensions (W x D x H): 361 x 483 x 427 mm (14.3" x 19.1" x 16.9")

Options

A849-1

Page 3

MECHANICAL COMPONENT LAYOUT 24 February, 1999

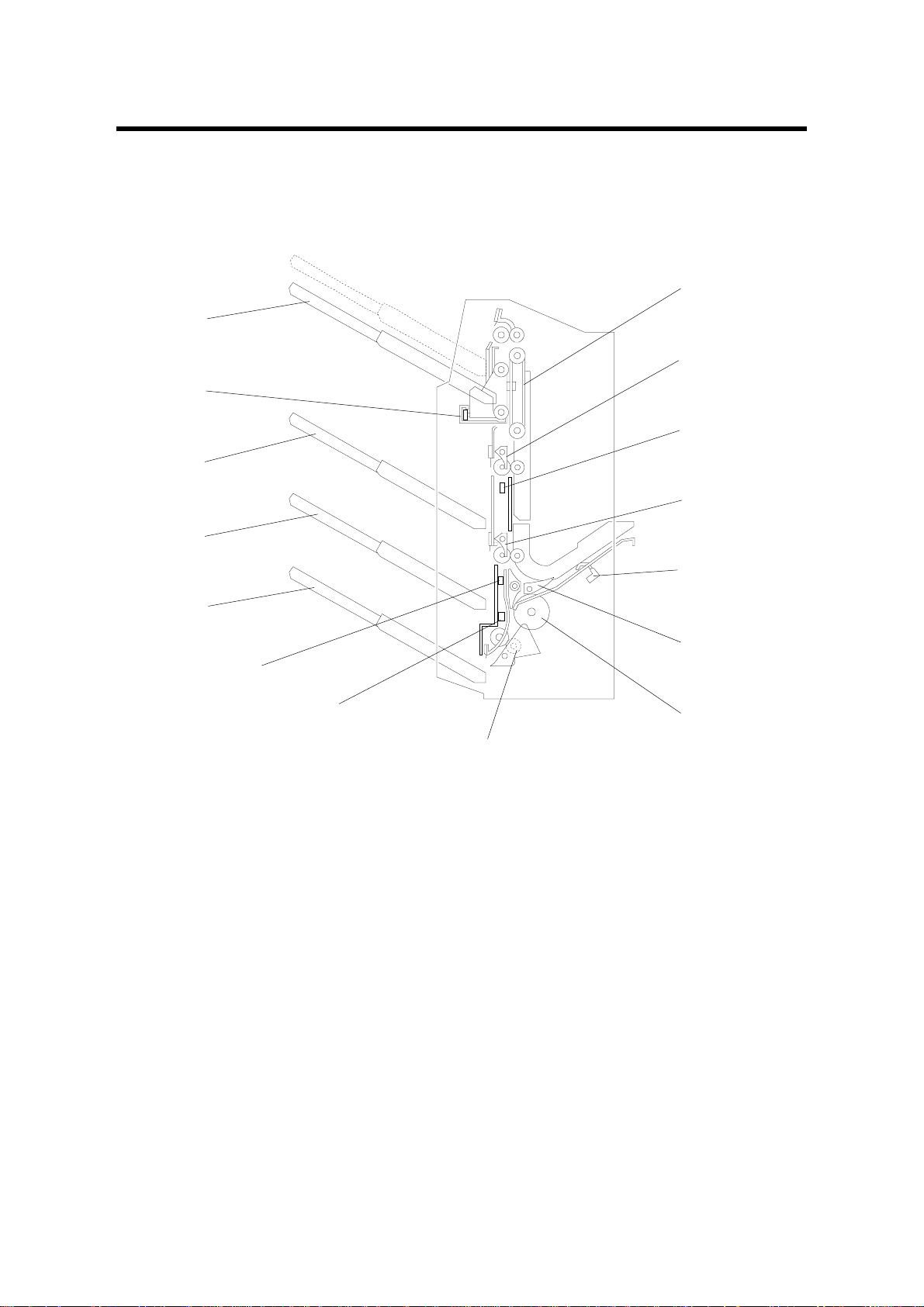

2. COMPONENT LAYOUT

2.1 MECHANICAL COMPONENT LAYOUT

1

15

2

14

3

13

4

12

11

10

1. Tray Lift Belt

2. 2nd Bin Gate

3. 2nd Exit Sensor

4. 3rd Bin Gate

5. Entry Sensor

6. Junction Gate

7. Feed Roller

5

6

9

8

9. Inverter Sensor

10. 3rd Exit Sensor

11. Inverter Bin

12. 3rd Bin

13. 2nd Bin

14. Tray Lower Limit Sensor

15. 1st Bin

A849V001.WMF

7

8. Return Pinch Roller

A849-2

Page 4

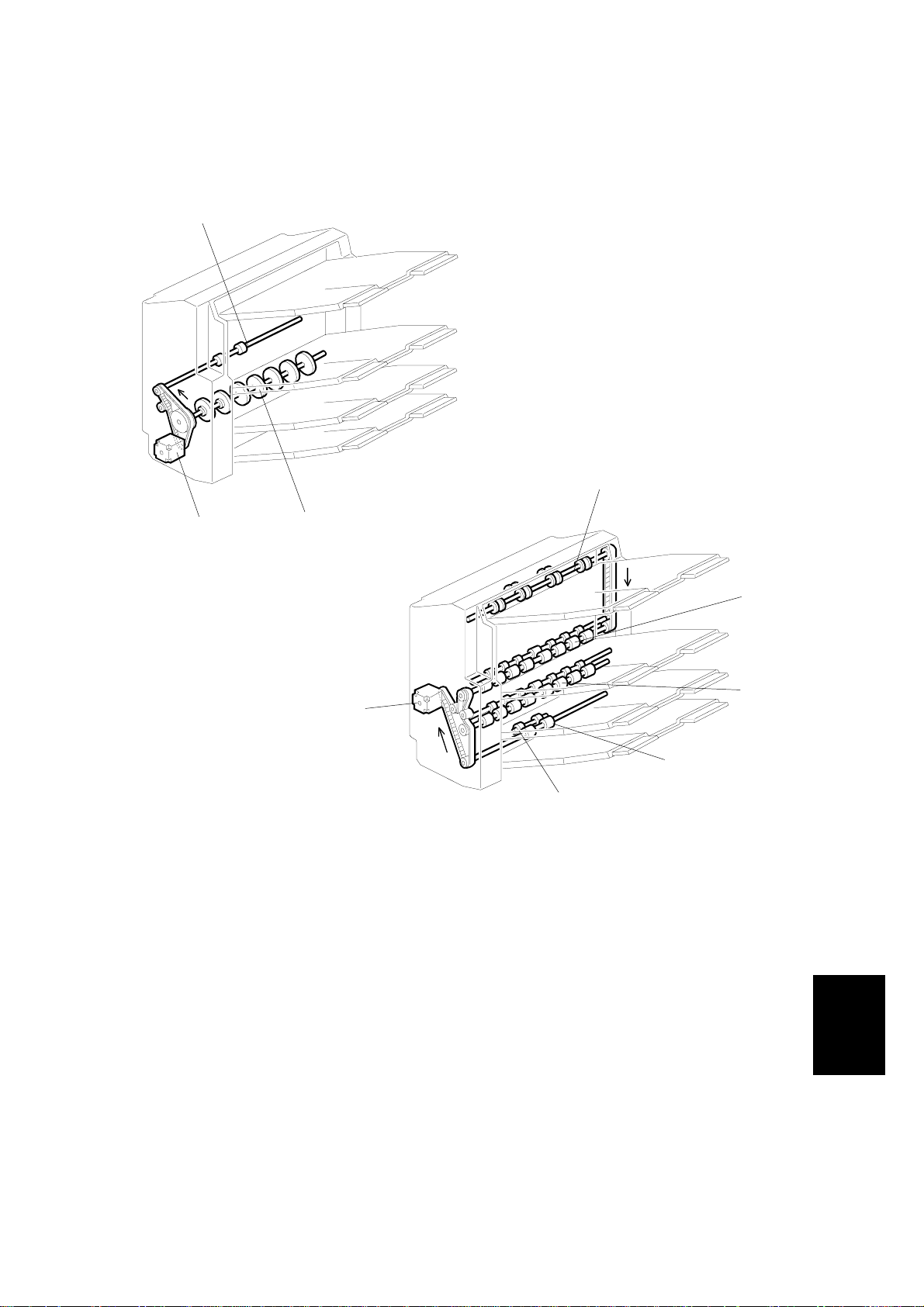

24 February, 1999 DRIVE LAYOUT

2.2 DRIVE LAYOUT

1

4

A849V002.WMF

3

1. Entry Roller

2. Feed Roller

3. Entrance Motor

2

5

6

9

7

8

A849V003.WMF

6. 3rd Exit Roller

7. Inverter Roller

8. Return Pinch Roller

4. 1st Exit Roller

5. 2nd Exit Roller

9. Exit Motor

Options

A849-3

Page 5

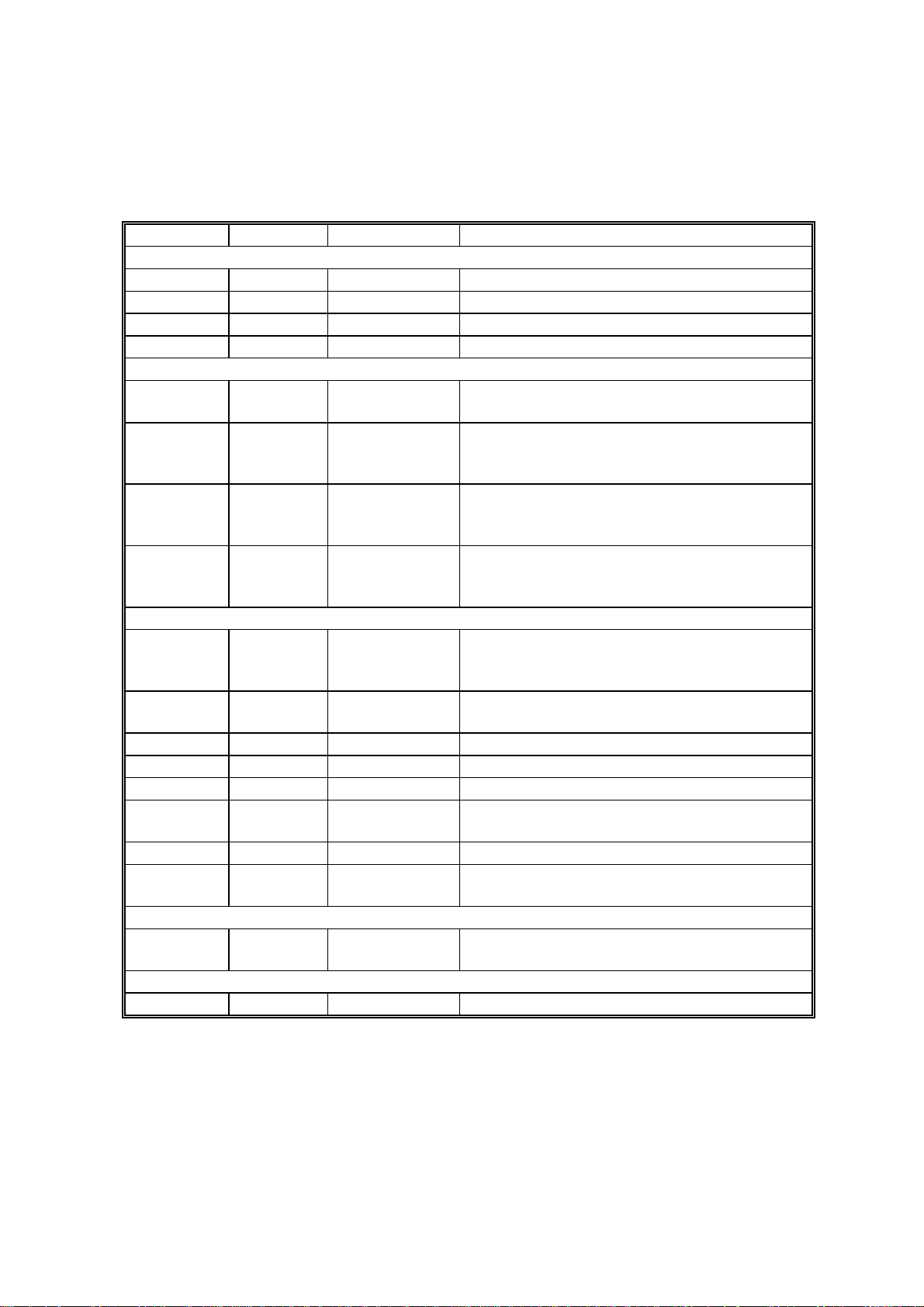

ELECTRICAL COMPONENT DESCRIPTION 24 February, 1999

2.3 ELECTRICAL COMPONENT DESCRIPTION

Refer to the electrical component layout on the reverse side of the point-to- point

diagram (on waterproof paper).

Symbol Index No. Description Note

Motors

M1 13 Entrance Drives the feed roller and the entry roller.

M2 14 Exit Drives the inverter roller and the exit rollers.

M3 18 Tray Shift Moves the 1st bin from side to side.

M4 16 Tray Lift Moves the 1st bin up or down.

Solenoids

SOL1 4 2nd Bin Gate Opens and closes the 2nd bin gate to direct

the copies into either the 2nd bin or 1st bin.

SOL2 5 3rd Bin Gate Opens and closes the 3rd bin gate to direct

the copies into either the 3rd bin or the other

bins.

SOL3 6 Junction Gate Opens and closes the junction gate to direct

copies into either the inverter area or other

exits.

SOL4 7 Pinch Roller In face down mode, contacts the return

pinch roller with the copy to deliver the copy

to bin 1, 2, or 3.

Sensors

S1 2 Stack Height

S2 17 Tray Half-turn

S3 1 1st Exit Detects paper jams at the 1st bin.

S4 8 2nd Exit Detects paper jams at the 2nd bin.

S5 9 3rd Exit Detects paper jams at the 3rd bin.

S6 10 Inverter Detects misfeeds and synchronizes the

S7 11 Entry Detects misfeeds and copy paper entry.

S8 15 Tray Lower

Limit

Switches

SW1 3 Sorter Set

Circuit Board

PCB1 12 Control Controls all sorter functions.

Detects when the copy paper stack is at the

correct height, and detects when the 1st bin

is at its upper limit position.

Detects complete side-to-side movement of

the 1st bin.

inverter gate.

Detects when the 1st bin is at its lower limit

position.

Detects when the sorter is attached to the

main machine.

A849-4

Page 6

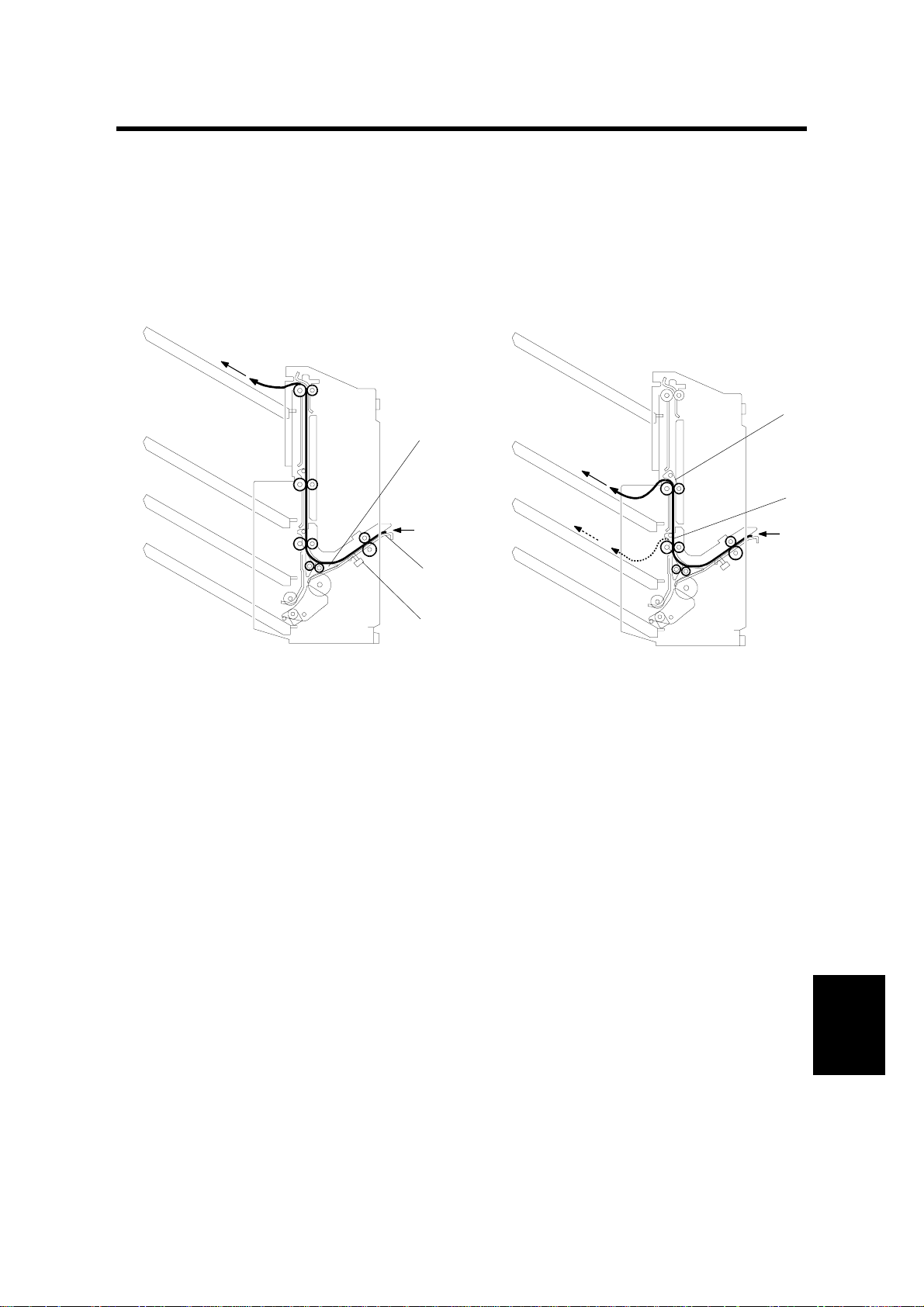

24 February, 1999 BASIC OPERATION

3. DETAILED SECTION DESCRIPTIONS

3.1 BASIC OPERATION

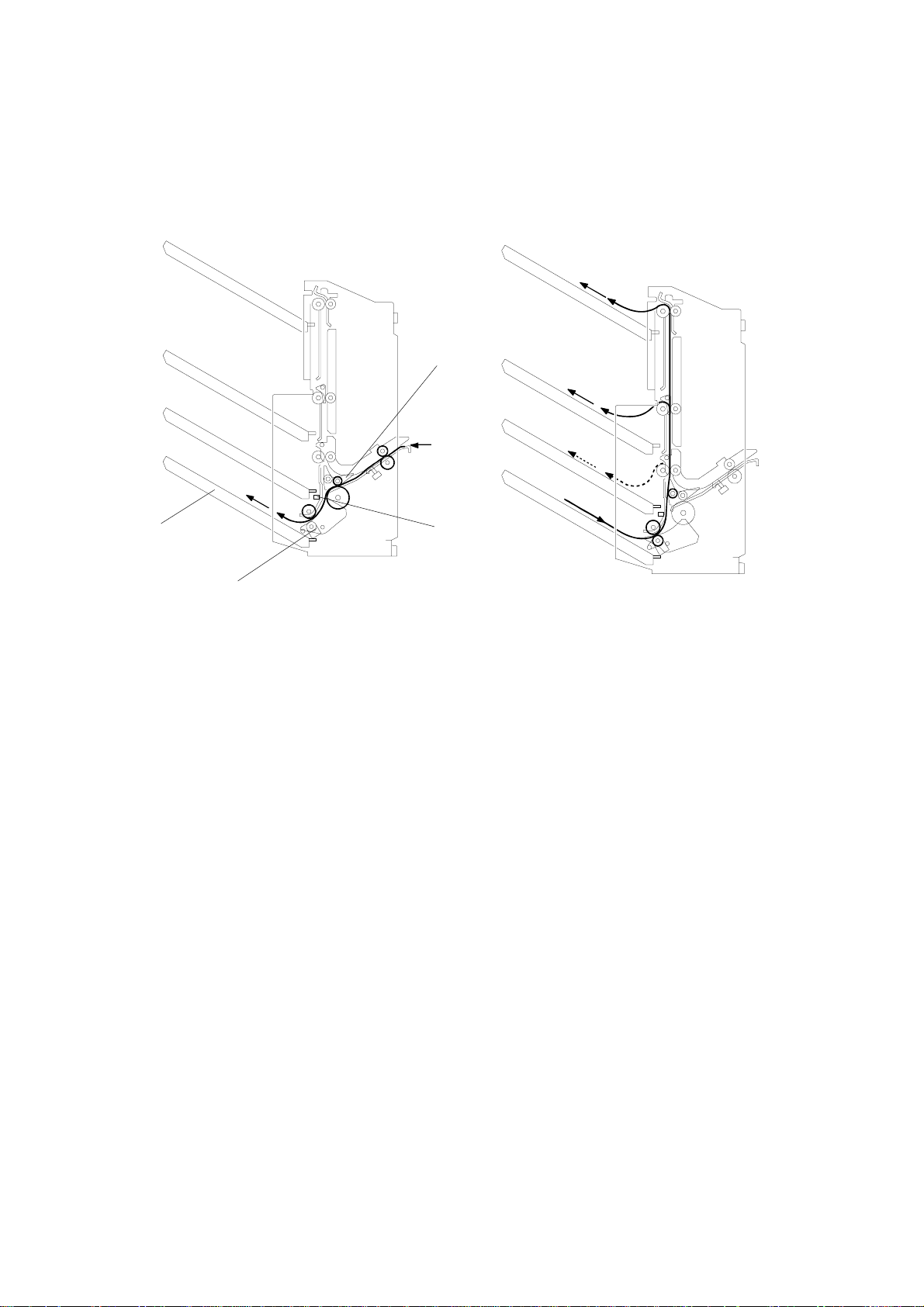

3.1.1 FACE-UP MODE

[D]

[C]

[E]

[A]

[B]

A849D001.WMF

A849D002.WMF

Copies exiting the copier pass through the entrance guide plate [A]. The entry roller

will send copies either to the inverter bin or to each bin, depending on the selected

mode.

When the sorter receives the feed-out s ignal from the main machine, th e entrance

motor and exit motor energize to rotate all the rollers in the sorter. During copying,

all rollers transport the paper at a speed that depends on the copier. When the

leading edge of the copy passes the entry sensor [B], the speed of the rollers

changes to 550 mm/s.

- 1st, 2nd and 3rd bins -

When the junction gate [C] is closed as sh own above, the copies pass through the

upper part of the junction gate. For 1st bin output mode, the copy goes straight up

from the junction gate directly to the bin. For the 2nd and 3rd bins, the copies from

the junction gate are delivered to these bins, as directed by the 2nd bin gate [D]

and 3rd bin gate [E].

Options

A849-5

Page 7

BASIC OPERATION 24 February, 1999

3.1.2 FACE-DOWN MODE

[A]

[B]

[D]

A849D003.WMF

[C]

A849D004.WMF

When the junction gate [A ] is opened, the copy goes to the inverter bin [B] through

the lower part of the junction. When the trailing edge of the copy passes through

the inverter sensor [C], the return pinch rollers [D] lower to contact the copy, then

the copy is fed back in by the rollers. The copy is fed out to any output bin and it

arrives face down.

A849-6

Page 8

24 February, 1999 1ST BIN UP/DOWN MECHANISM

3.2 1ST BIN UP/DOWN MECHANISM

[C]

[B]

[D]

[E]

[A]

A849D005.WMF

The tray lift motor (a dc motor) [A] controls the vertical position of the 1st bin [B]

through gears. When the main switch is turned on, the 1st bin is initialized at the

upper position. The bin's upper position is detected by the stack height sensor [C].

The 1st bin activates the stack height sensor, then the 1st bin lowers until it is at

the correct height to receive the copy. This initialization is performed before every

copy job.

During copying, when the stack of paper activates the stack height sensor, the 1st

bin lowers until the stack height sensor is deactivated.

When the 1st bin reaches its lower limit, actuator [D] enters the lower limit sensor

[E], and copying stops. After copying ends, the machine stops.

Options

A849-7

Page 9

1ST BIN SIDE-TO-SIDE SHIFT MECHANISM 24 February, 1999

3.3 1ST BIN SIDE-TO-SIDE SHIFT MECHANISM

[A]

[B]

[E]

A849D006.WMF

[B]

[E]

[G]

[F]

[C]

[D]

A849D007.WMF

In the sort/stack mode, the 1st bin [A] moves from side-to-side to s eparate the sets

of copies.

The tray shift motor (a DC motor) [B] and the shift cam [C] control the horizontal

position of the shift tray. After one set of copies is delivered to the bin, the tray shift

motor starts rotating, driving the shift cam through gears. The link [D] connected

between the shift cam and the tray shift plate [E] creates the side-to-side

movement required to separate the copy sets.

When the shift cam has rotated 180 degrees (when the tray is fully shifted across),

the tray half-turn sensor [F] is activated by the slot [G] in the actuator plate [H],

which is attached to the shift cam, and the tray shift motor stops. The next set of

copies is then delivered. The motor rotates, repeating the same process and

moving the bin back to the previous position.

A849-8

Page 10

24 February, 1999 PAPER FEED AND MISFEED DETECTION TIMING

3.4 PAPER FEED AND MISFEED DETECTION TIMING

— Normal Mode —

* 1

312 4560

(Sec.)

550 mm/s

J2

J1

J4

J4

J3

J3

300 mm/s 550 mm/s * 1

J3 J4

Normal Mode [A4 sideways, 3 pages, 40 CPM (200 mm/s)]

Feed Out Signal

Entrance Motor

Entry Sensor

*1: This speed depends on the copier.

Junction Gate Sol.

A849-9

3rd Exit Sensor

2nd Exit Sensor

1st Exit Sensor

A849D008.WMF

Exit Motor

Options

Page 11

PAPER FEED AND MISFEED DETECTION TIMING 24 February, 1999

— Inverter Mode —

* 1

312 4560

(Sec.)

550 mm/s

J7J6

J5

300 mm/s

J9

J9

J9

J8

J8

J8

550 mm/s

Inverter Mode [A4 sideways, 3 pages, 40 CPM (200 mm/s)]

Feed Out Signal

Entrance Motor

Entry Sensor

Junction Gate Sol.

*1: This speed depends on the copier.

Inverter Sensor

A849-10

Pinch Roller Sol.

1st Exit Sensor

Exit Motor

A849D009.WMF

2nd Exit Sensor

3rd Exit Sensor

Page 12

24 February, 1999 JAM DETECTION

3.5 JAM DETECTION

— Paper Jams —

J1: The entry sensor does not turn on within 2 s after the feed out signal has turned

on.

J2: The entry sensor does not turn off within 610 ms after the feed out signal has

turned off or the entry sensor stays on over 2.8 s.

J3: The following exit sensors do not turn on within the specified time after the entry

sensor has turned on.

1st exit sensor: 2.4 s

2nd exit sensor: 1.4 s

3rd exit sensor: 740 ms

J4: The following exit sensors do not turn off within the specified time after the entry

sensor has turned off.

1st exit sensor: 870 ms

2nd exit sensor: 500 ms

3rd exit sensor: 270 ms

J5: The inverter sensor does not turn off within 4.56 s after the inverter sensor has

turned on.

J6: The inverter sensor does not turn on again within 380 ms after the inverter

sensor has turned off.

J7: The inverter sensor does not turn off within 1.14 s after the inverter sensor has

turned on again.

J8: The following exit sensors do not turn on within the specified time after the

inverter sensor has turned on again.

1st exit sensor: 770 ms

2nd exit sensor: 430 ms

3rd exit sensor: 250 ms

J9: The following exit sensors do not turn off within the specified time after the

inverter sensor turned off again.

1st exit sensor: 770 ms

2nd exit sensor: 430 ms

3rd exit sensor: 250 ms

A849-11

Options

Page 13

EXTERIOR COVER AND BIN REMOVAL 24 February, 1999

4. REPLACEMENT AND ADJUSTMENT

4.1 EXTERIOR COVER AND BIN REMOVAL

[A]

[C]

[B]

[D]

1. Rear Cover [A] (3 screws)

2. Front Cover [B] (3 screws)

3. Top Cover [C] (2 screws)

4. Bins [D] (1st bin: 2 screws)

A849R006.WMF

A849-12

Page 14

24 February, 1999 TRAY LIFT/SHIFT MOTOR ASSEMBLY REMOVAL

4.2 TRAY LIFT/SHIFT MOTOR ASSEMBLY REMOVAL

[A]

[B]

A849R007.WMF

1. Remove the rear cover (see Exterior Cover and Bin Removal).

2. Remove the clip [A].

3. Remove the motor assembly [B] (3 screws, 3 connectors).

A849-13

Options

Page 15

ENTRANCE MOTOR REPLACEMENT 24 February, 1999

4.3 ENTRANCE MOTOR REPLACEMENT

[B]

[A]

A849R008.WMF

1. Remove the rear cover (see Exterior Cover and Bin Removal).

2. Remove the control board [A] (9 connectors, 4 clamps).

3. Remove the motor bracket [B] (2 screws).

4. Remove the exit motor [C] (2 screws).

[C]

A849R009.WMF

A849-14

Page 16

24 February, 1999 EXIT MOTOR REPLACEMENT

4.4 EXIT MOTOR REPLACEMENT

[B]

[A]

A849R010.WMF

1. Remove the rear cover (see Exterior Cover and Bin Removal).

2. Remove the motor bracket [A] (2 screws, 1 connector).

3. Remove the exit motor [B] (2 screws, 1 connector).

A849-15

Options

Page 17

STACK HEIGHT SENSOR AND 1ST EXIT SENSOR REPLACEMENT 24 February, 1999

4.5 STACK HEIGHT SENSOR AND 1ST EXIT SENSOR REPLACEMENT

[A]

A849R001.WMF

[C]

[B]

A849R002.WMF

1. Remove the front, rear, and top covers (see Exterior Cover and Bin Removal).

2. Remove all bins (see Exterior Cover and Bin Removal).

3. Remove the 3-bin sorter.

4. Remove the middle guide plate [A] (1 clip).

5. Remove the motor assembly [B] (see Tray Lift/Tray Shift Motor Assembly

Removal).

6. Remove the upper guide plate [C] (4 screws).

A849-16

Page 18

24 February, 1999 STACK HEIGHT SENSOR AND 1ST EXIT SENSOR REPLACEMENT

[D]

[E]

[F]

A849R003.WMF

7. Remove the middle shift guide plate [D] (3 screws).

8. Remove the stack height sensor [E] (1 connector).

9. Remove the 1st exit sensor [F] (1 screw, 1 connector).

A849-17

Options

Page 19

2ND / 3RD EXIT SENSOR AND INVERTER SENSOR REPLACEMENT24 February, 1999

4.6 2ND / 3RD EXIT SENSOR AND INVERTER SENSOR REPLACEMENT

[A]

[B]

[E]

[D]

[C]

A849R004.WMF

[G]

[F]

[H]

A849R005.WMF

1. Remove the front cover and rear cover (see Exterior Cover Removal).

2. Remove all bins.

3. Remove four tray brackets [A] (1 screw each).

4. Remove the upper exit cover [B] (2 screws).

5. Remove the lower exit cover [C] (2 screws).

6. Remove the sensor bracket [D] (1 screw) and replace the 2nd exit sensor [E] (1

screw, 1 connector).

7. Remove the sensor bracket [F] (1 screw) and replace the 3rd exit sensor [G] (1

screw, 1 connector).

8. Replace the inverter sensor [H] (1 screw, 1 connector).

A849-18

Page 20

млкйизжедмíìììëìêìéìèìç

$

кр%,1э6257(5эх$ейдфэ32,17э72э32,17э',$*5$0

&1êëí&1êêí

&1êéí

&1êìí

ðì

ðë

ðê

ðé

ðè

ðçðì

ðì

ðë

ðê

ðì

ðë

ðê

ðé

ðè

ðç

ðì

ðë

ðê

&1лднрл

ðê

ðë

ðì

ðê

ðë

ðì

ðê

ðë

ðì

ðì

ðë

ðê

ðì

ðë

ðê

ðì

&1ëèí&1ëèè&1ëçí&1ëçè&1ëæí&1ëæè&1ëåí&1ëåè

6ê

6ì

6é

6è

6ç

ìVWý([LWý6HQVRU

6WDFNý+HLJKW

6HQVRU

ëQGý([LWý6HQVRU

êUGý([LWý6HQVRU

,QYHUWHUý 6HQVRU

6RUWHUý6HWý6ZLWFK

6:ì

ðê

ðë

ðì

ðê

ðë

ðì

ðê

ðë

ðì

6ë

6å

6æ

7UD\ý +DOIð7XUQ

6HQVRU

7UD\ý/RZHUý/LPLW

6HQVRU

(QWU\ý6HQVRU

6<0%2/ý7$%/(

'&ý/LQH

3XOVHý6LJQDO

6LJQDOý'LUHFWLRQ

ýýýý ▼ $FWLYHý/RZ

эээээ▲ $FWLYHэ +LJK

ээ>эээээээ@ 9ROWDJH

0DLQý 0DFKLQH

%

>òèý9@

*1'

>òëéý9@

*1'

)ï*ï

î5;'ý>▼è@

î7;'ý>▼è@

7ì

&

(QWUDQFHý0RWRU

0ì

&1мннрм

&1ìèí

&1ìèí

&1мжнрм

'

ðæ

ðç

(

([LWý0RWRU

0ë

ðè

ðé

ðê

ðë

ðì

&1ëìí&1ëêè

ðì

ðë

ðê

ðé

ðè

ðç

ðæ

&1мднрм

ðë

ðê

ðé

ðë

ðê

ðé

ðè

ðç

ðæ

ðë

ðê

ðé

ðè

ðç

ðæ

>òèý9@

*1'

>òëéý9@

*1'

>▼è@ýî7;'

>▼è@ýî5;'

>òëéý9@

>òëéý9@

1&

>▼ëé@ý$

>▼ëé@ýî$

>▼ëé@ý%

>▼ëé@ýî%

>òëéý9@

>òëéý9@

1&

>▼ëé@ý$

>▼ëé@ýî$

>▼ëé@ý%

>▼ëé@ýî%

6WDFNý+HLJKWý>▲è@

&RQWUROý%RDUG

õ3&%ýìô

)

&1менрм

&1менрк

ðìí

>▼ëé@ýêUGý%LQý*DWH

ðë

>òëéý9@

>▼ëé@ý3LQFKý5ROOHU

ðé

>òëéý9@

ðè

1&

ðç

>▼ëé@ýëQGý%LQý*DWH

ðæ

>òëéý9@

ðå

1&

ðä

>òëéý9@

>▼ëé@ý-XQFWLRQý*DWH

7UD\ý+DOIð7XUQý>▲è@

7UD\ý/RZHUý/LPLWý>▲è@

&1ëêí&1ëêí&1ëëí

ðé

ðê

ðëðê

ðìðé

ðëðì

ðìðë

ðë

ðì

ðì

êUGý%LQý*DWHý6ROï

*

+

3LQFKý5ROOHUý6ROï

ëQGý%LQý*DWHý6ROï

-XQFWLRQý*DWHý6ROï

62/ë

62/é

62/ì

62/ê

ðë

ðì

ðë

,

ðë

7UD\ý6KLIWý0RWRU

-

7UD\ý/LIWý0RWRU

0ê

0é

ðì

ðë

ðì

&1ëéí

&1ëéè

ðë

ðì

ðë

ðì

&1мзнрм

&1мзнрк

>▲ëé@ý7UD\ý 6KLIWý 0RWRUýõòô

ðë

>í@ý 7UD\ý6KLIWý 0RWRUý õðô

>▲ëé@ý7UD\ý /LIWý 0RWRUýõòô

ðé

>▲ëé@ý7UD\ý /LIWý 0RWRUýõðô

>òèý9@

ìVWý([LWý>▲è@

*1'

>òèý9@

*1'

>òèý9@

ëQGý([LWý>▲è@

*1'

>òèý9@

êUGý([LWý>▲è@

*1'

>òèý9@

,QYHUWHUý>▲è@

*1'

*1'

6RUWHUý6HWý>▲è@

*1'

>òèý9@

*1'

>òèý9@

(QWU\ý>▼è@

*1'

>òèý9@

&1мкнрм

&1мкнрй

&1мкнрж

&1мйнрм

&1мйнрй

&1мйнрж

&1млнрм

1&

1&

ðìí

ðìì

ðç

ðè

ðë

ðé

ðê

ðê

ðë

ðè

ðç

ðê

ðë

ðå

ðì

ðä

ðç

ðë

ðè

ðê

ðé

ðê

ðè

ðë

ðç

ðì

ðå

ðë

ðê

ðé

ðè

ðç

ðæ

ðå

ðä

ðê

ðë

ðì

.

$

%

&

'

(

)

*

+

,

-

.

млкйизжедмíìììëìêìéìèìç

Page 21

3-BIN SORTER (A849) ELECTRICAL COMPONENTS

17

16

15

14

18

13

234

5

1

6

7

A849S001.WMF

8

101112

9

Index No. Description Symbol P-to-P

1 1st Exit S3 B13

2 Stack Height S1 B13

3 Sorter Set SW1 F13

4 2nd Bin Gate SOL1 H4

5 3rd Bin Gate SOL2 F4

6 Junction Gate SOL3 I4

7 Pinch Roller SOL4 G4

8 2nd Exit S4 C13

9 3rd Exit S5 E13

10 Inverter S6 E13

11 Entry S7 I13

12 Control PCB1 D9

13 Entrance M1 D4

14 Exit M2 E4

15 Tray Lower Limit S8 H13

16 Tray Lift M4 J4

17 Tray Half-Turn S2 H13

18 Tray Shift M3 J4

Loading...

Loading...