Page 1

10-BIN SORTER

(MICRO - α)

(Machine Code: A557)

Page 2

13th January 1995 SPECIFICATIONS

1. SPECIFICATIONS

Number of Bins: 10 bins

Paper Size for Bins: Sort/Stack Mode

Maximum - A3, 11" x 17"

Minimum - A5, 51/2" x 81/2"

Paper Weight: Sort/Stack Mode: 64 to 90 g/m2 (17 to 24 lb)

Non-Sort/Stack Mode: 52 to 162 g/m2 (14 to 43 lb)

Bin Capacity:

Sort/Stack Mode

(All Bins)

A4, 8

1/2" x 11"

or less

1/2" x 14" 15 100

B4, 8

A3, 11" x 17" 10 100

20 100

Non Sort/Stack Mode

(Top Bin)

Power Source: +5 volts and +24 volts from the copie r

Power Consumption: 15 W

Dimensions:

(W x D x H)

402 mm x 455 mm x 217 mm

(15.7" x 17.8" x 16.7")

Weight: 7.5 kg (16.5 lb)

)

α

(MICRO -

10-bin Sorter

1

Page 3

[2]

COMPONENT LAYOUT 13th January 1995

2. COMPONENT LAYOUT

— Mechanical Components —

[1]

1. Bins

2. Transfer Wheel

3. Exit Roller

4. Upper Paper Guide

5. Lower Paper Guide

6. Bin Guide

[3]

[6]

[4]

[5]

— Electrical Components —

[6]

[5]

1. Sorter Main Board 5. Bin Drive Motor

2. Wheel Switch 6. Sorter Switch

3. Roller Drive Motor 7. Bin Home Position Switch

4. Paper Sensor

[7]

[4]

[3]

[1]

[2]

2

Page 4

13th January 1995 ELECTRICAL COMPONENT DESCRIPTIONS

3. ELECTRICAL COMPONENT DESCRIPTIONS

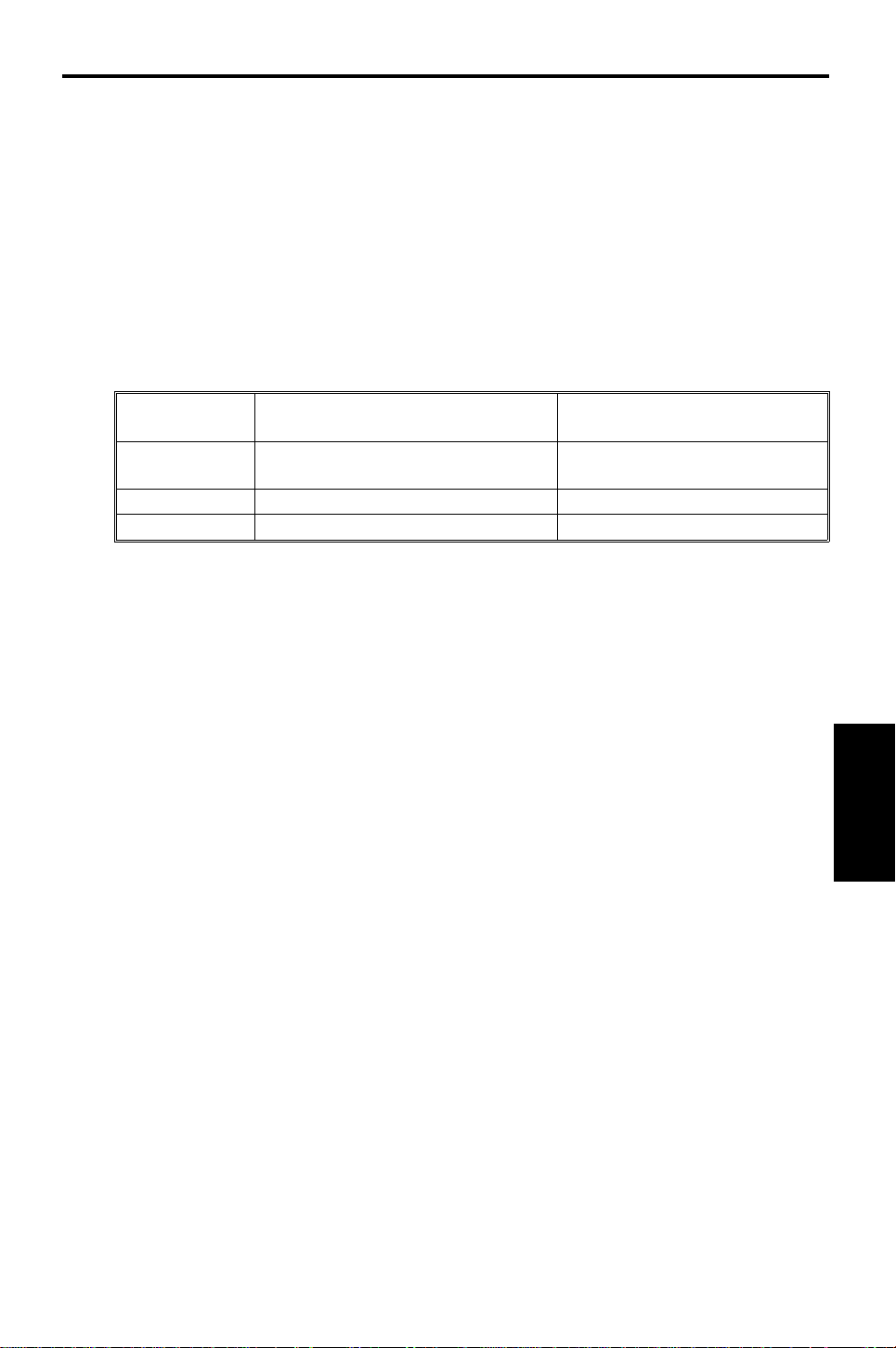

Symbol Name Function Index No.

Motors

M1 Roller Drive Motor This dc motor drives the lower exit rollers. 3

M2 Bin Drive Motor

Switches

SW1 Wheel Switch

SW2 Sorter Switch

SW3

Sensors

S1 Paper Sensor

Printed Circuit Boards

PCB1 Sorter Main Board

Bin Home Position

Switch

This reversible dc motor moves the bins up

or down.

Detects the rotation of the transfer wheel

and stops it in the correct position.

This reed switch becomes activated when

the sorter is in the proper position (aligned

next to the copier). It also works as a jam

reset switch for the sorter.

Informs the CPU that all the bins are

lowered.

Serves as the misfeed sensor for the sorter

and also sets exit roller and bin drive timing.

Serves as the communication board

between the copier main board and the

sorter.

5

2

6

7

4

1

)

α

(MICRO -

10-bin Sorter

3

Page 5

BASIC OPERATION 13th January 1995

4. BASIC OPERATION

- Clear Mode -

When the main switch of the copier is turned on, the sorter automatically

assumes clear mode. In this mode, all copie s are stacked in the first bin. The

sorter also assumes clear mode when int errupt mode is selected.

Sorter operation beg ins when the copier sends th e pape r f ee d sign al to the

selected paper feed statio n. At th is time, the roller drive motor energize s.

When the paper exits onto the sorter bin, the paper sen sor is d e-a ctiva te d

and the roller drive motor is then de-en erg ized. The copier main board

monitors the paper sensor through the sorter main board to che ck for pa per

misfeeds.

- Sort Mode -

In this mode, all copies of the first original are delivered to separate bins

starting from the top . The copies of the second original are delivered to the

same bins, but starting from th e bottom. The copies of the third origin al sta rt

from the top and so on. At 250 milliseconds after th e cop y has go ne thro ug h

the paper sensor, the bin drive motor turns on to advan ce th e bin one st ep.

- Stack Mode -

In this mode, all copies of the first original are delivered to the first bin, all

copies of the second origina l a re de livere d to the secon d bin, and so on. At

250 milliseconds after the last copy of the origin al ha s gone th rou gh the

paper sensor, the bin drive motor turns on to advan ce th e bin one step .

4

Page 6

[B]

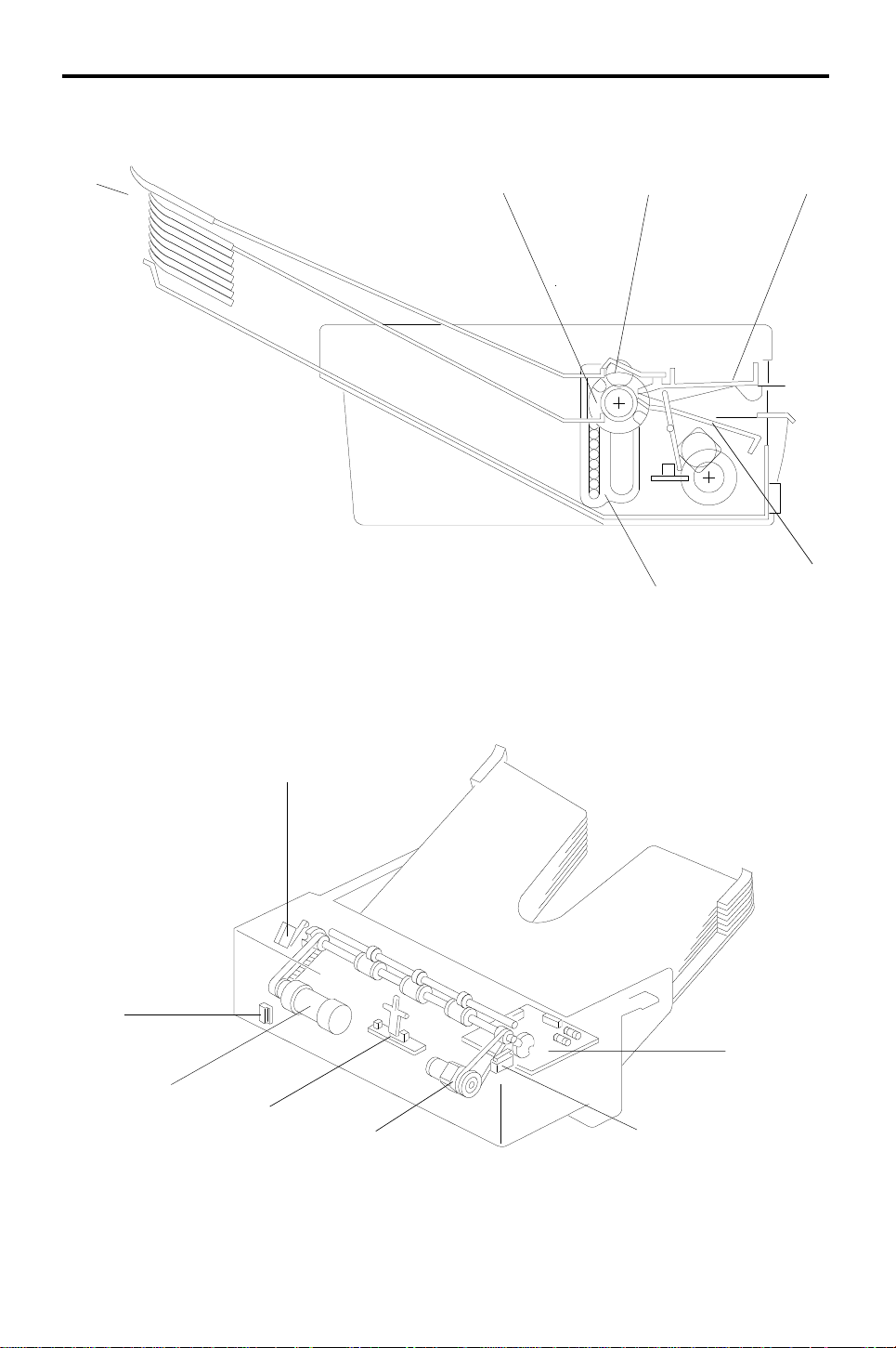

13th January 1995 EXIT ROLLER DRIVE MECHANISM

5. EXIT ROLLER DRIVE MECHANISM

[A]

[I]

[D]

[J]

[F]

[K]

[L]

[C]

[G]

[H]

[H]

F: Transfer Wheel

G: Bin Drive Belt

H: B in Drive Pulley

[E]

I: Exit Roller Pulley

J: Upper Paper Guide

[L]

K: Lower Paper Guide

L: Roller Drive Motor Pulley

The exit rollers [A] take over paper tran sport from the copier. When the cop ier

sends the paper feed sign al to the selected paper feed station, the exit rollers

start rotating. The exit rolle rs cont inu e to rota te for 250 milliseco nd s aft er th e

copy paper has gone throu gh the pap er sensor [B].

)

α

(MICRO -

10-bin Sorter

The roller drive motor [C] rotates the lower exit roller via the roller drive belt

[D]. The shaft of the lower exit roller is a cylindrical cavity type which rotates

around the transfer wheel shaft [E]. The pap er sensor is positioned just in

front of the exit rollers. The paper senso r det ects misfeeds in the sorter.

5

Page 7

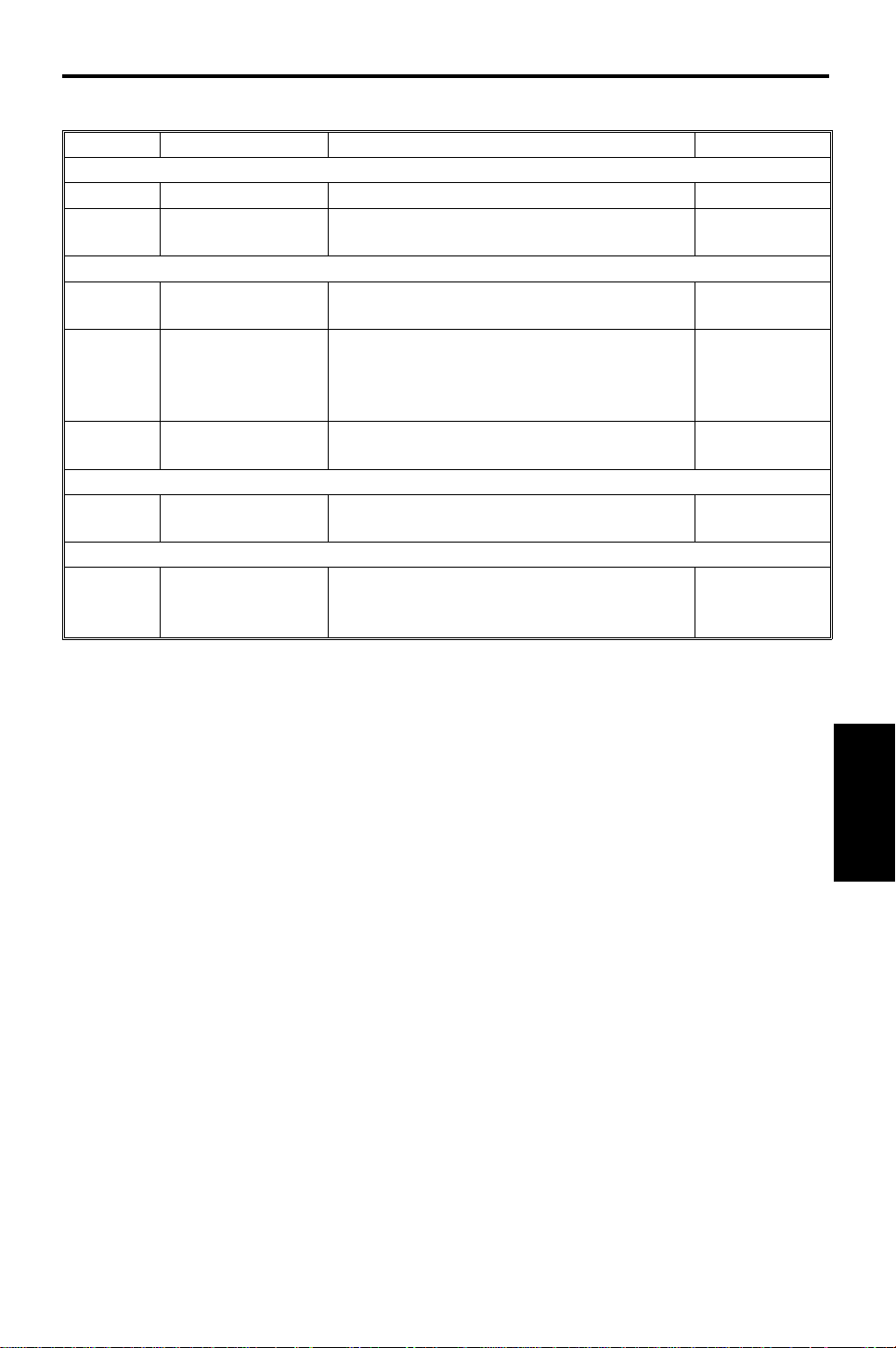

BIN DRIVE MECHANISM 13th January 1995

6. BIN DRIVE MECHANISM

[E]

[D]

[B]

G : Exit Roller

H : Upper Paper Guide

I : Lower Paper Guid e

[F]

[A]

[A]

[C]

[G]

[E]

[D’]

[B’]

[H]

The bin drive mechanism moves the bins up

and down to receive copies und er the

direction of the copier CPU. The main

components in this mechanism are the bin

drive motor [A], two transfer wheels [B,B’],

the wheel switch [C], and the bins

themselves.

Pins on either side of each bin are inserted

into slots called bin guides [D,D’]. The bins

slide up and down in the bin guides. The

bins sit on each other with the lower bin

resting on the 10th bin (th e 10 th bin is

permanently fixed in position). The upper

and lower paper guides pivot up an d do wn

depending on th e height of the bin to be

picked up or released.

[I]

[B]

6

Page 8

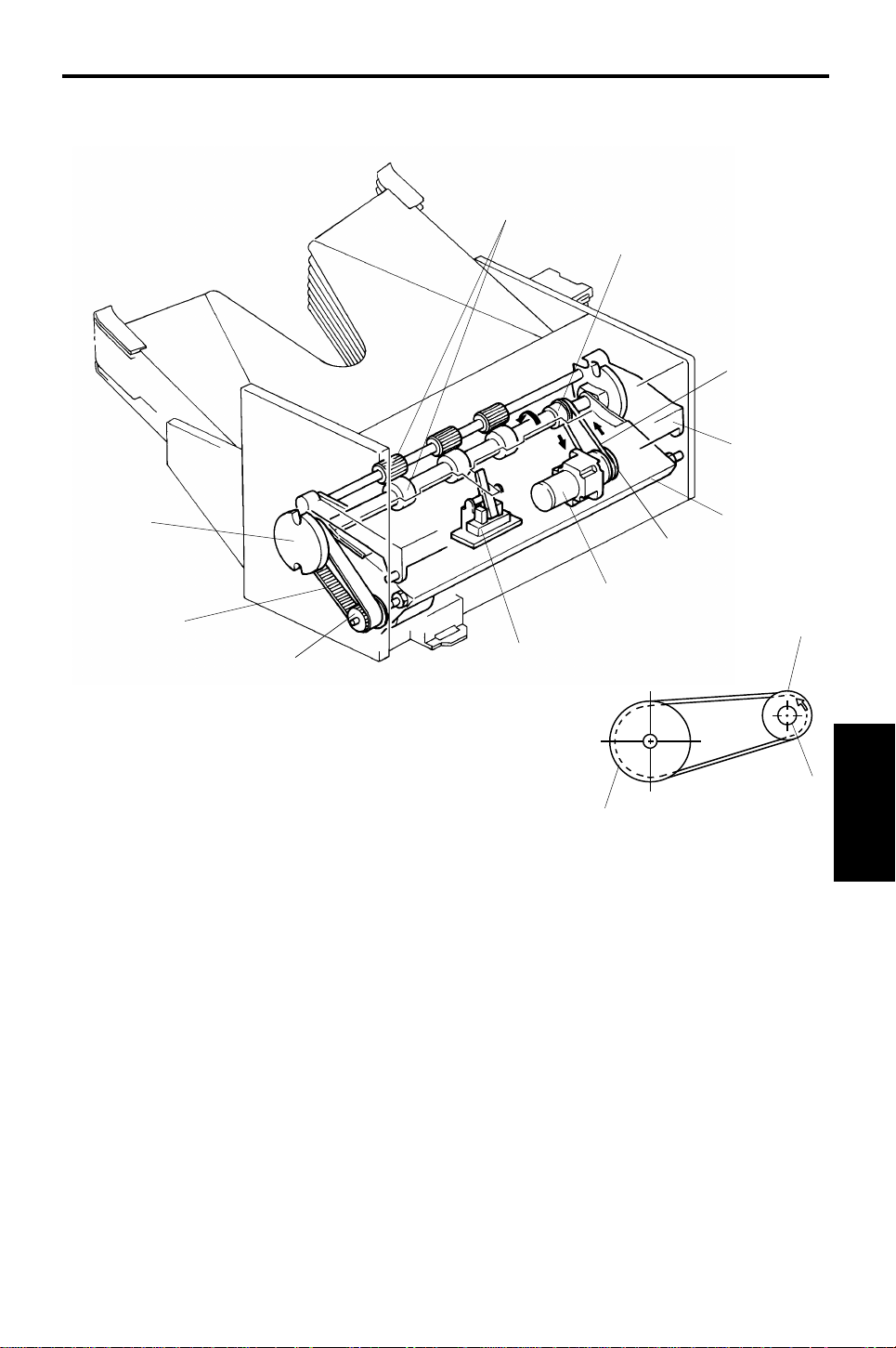

13th January 1995 BIN DRIVE MECHANISM

The bin home position switch [E] informs

the CPU when all the bins are lowered.

To move the bins up, the bin drive mot or

turns clockwise (as viewed from the

front). A timing belt [F] turns the tran sfe r

wheels.

The transfer wheels have two slots in

them 180 degrees apart . As th e transfer

wheels turn, these slots e ngag e th e bins

and lift them up. Each time the transf er

wheels turn 180 degrees, the y ra ise on e

bin.

To move the bins down, the CPU

reverses the bin drive motor and the

above processes reverses.

The CPU monitors the position of the

bins through pulses generated by the

wheel switch and the actuator cam [J].

The actuator cam has two flat side s tha t

are 180 degrees apart and is mounted

behind the rear transfer wheel. A pu lse

is generated each time one of the lobes

of the actuator cam passes th e wheel

switch.

[B]

[J]

[C]

)

α

(MICRO -

10-bin Sorter

7

Page 9

MISFEED DETECTION 13th January 1995

7. MISFEED DETECTION

In addition to being used for the exit roller drive timing, the paper sen sor

checks for misfeeds in the sorter.

J1 - Paper Sensor On Check: The copier CPU checks whether the paper

sensor is actuated within 942 pulses (3.8 seconds) after the registration

clutch turns on (at 2,000 pulses).

J2 - Paper Sensor Off Check: The copier CPU starts a timing cycle when

the paper sensor is actuated. Then, at 2.75 (A4 sidewa ys) o r 2.8 0 (Letter

sideways) seconds, the CPU checks whet he r the copy pa per has pa ssed

through the paper sensor.

In misfeed condition , th e "Check Paper Path" and "Misfe ed Loca tio n"

indicators light and copier operation is disabled. To recover the sorter from

the misfeed condition, the sorte r has to be slid away from th e cop ier, the

misfed paper removed, and the sorte r re tu rned to its original position.

8

Page 10

13th January 1995 INSTALLATION

8. INSTALLATION

8.1 ACCESSORY CHECK

Check the quantity and condition of the accessorie s in the box against the

following list:

1. Magnet Catch .................. .......... .......... .................. ........1

2. Sorter Holder Bracket .................................................. 1

3. Tapping Screw - M4 x 6................................. .......... ...... 3

4. Tapping Screw - M4 x 8................................. .......... ...... 2

5. Snap Ring...................................................................... 1

6. Installation Procedure.................................................... 1

7. New Equipment Condition Report....... .. .. .. .. .. .. .. ............1

)

α

(MICRO -

10-bin Sorter

9

Page 11

INSTALLATION 13th January 1995

8.2 INSTALLATION PROCEDURE

[C]

[A]

[F]

[B]

[D]

[E]

[D]

NOTE: (1) Keep the shipping retainers after in sta lling the machine. They will

be reused if the machine will be transported to an another

location in the future.

(2) Proper installatio n of the shipping retainers is require d in ord er to

avoid any transport damage.

(3) Do not grasp the sorter by the top cover and stay as shown by

[A]. Hold both sides of th e sort er as shown by [B]. This is to

prevent damage to th e an ti-st atic brush [C].

CAUTION

!

Unplug the copier power cord before starting the following procedure.

1. Remove the strips of tape [D] and styrofoam blocks [E].

2. Remove the copy tray [F] .

10

Page 12

[A]

13th January 1995 INSTALLATION

[B]

[C]

[D]

3. Remove the cover plat e [A ] (2 screws).

4. Cut the links in the cover plate [A] with nippers to remove th e smaller part

[B].

5. Remount the cover plate [A] (1 screw).

6. Mount the sorter holder bra cket [C] (3 tapping screws) on the cop ier

frame as shown.

7. Mount the magnetic catch [D] on the exit cove r (2 self-t ap pin g screws).

)

α

(MICRO -

10-bin Sorter

11

Page 13

[A]

INSTALLATION 13th January 1995

[B]

[D]

[C]

8. Install the sorter [ A] on th e sorter holder bracket [B] (1 snap ring) as

shown.

9. Connect the conne cto r [ C] to the socket [D] on the rear side of the cop ier.

10. Plug in the copier power cord and turn on th e main swit ch.

11. Press the following sequence of keys to enter SP mode.

→→→

NOTE:

(1) Hold the last key for more than 3 seconds.

(2) Upon entering SP mode, "1" blin ks in the 3rd dig it of the copy

counter, the Auto Im ag e Density indicator starts blin king and

the reduce/enlarg e ind icator turns off.

(3) The above procedure must be fin ished within 20 seconds.

12. Press the following sequence of keys to change th e "SP6-101" value t o "1".

→ → → → →

→ →

13. Turn the main switch off and on.

14. Check the sorter’s operation.

12

Page 14

13th January 1995 PREPARATION FOR TRANSPORTATION

9. PREPARATION FOR TRANSPORTATION

CAUTION

!

When removing and transporting the sorter, be careful not to carry it

in a vertical position as the bins wil l bec ome dislocated.

CAUTION

!

Refore moving the sorter, be sure to prepar e it for tra nspor tati on a s

follows. The sorter may be badly damage d if i t is mov ed wi thout

proper preparation.

1. If the bins are not at the home position, turn on the main switch of the

copier to move the bins to the home position.

2. Secure the bins with strips of tape as sho wn in th e illust ration.

3. Remove the sorter from the copier. (See the Insta llat ion Procedure.)

)

α

(MICRO -

10-bin Sorter

13

Page 15

[J]

[B]

ROLLER DRIVE BELT REPLACEMENT 13th January 1995

10. ROLLER DRIVE BELT REPLACEMENT

[M]

[N]

[K]

[L]

[I]

[D]

[F]

[H]

[E]

[G]

[A]

[C]

1. Remove the front cover [A] (1 screw).

2. Remove the rear cover [B] (1 screw) and the sorter hinge [C] (2 screws).

3. Remove the rear flat cover [D] (2 screws).

4. Lift off the to p cover [E].

5. Lift the upper paper guide [F] up and out of positio n (1 gro unding wire).

6. Remove the entrance guide bracket [G] (2 screws).

7. Lift the lower paper gu ide [H] out of position and turn it over to remove the

roller drive belt [I].

NOTE: Be careful not to damag e th e bin home position switch act ua to r

[J] when reassembling.

8. Remove the transfer spacer [K], wheel [L] , pin [M], and bushing [N] on

both sides of the shaft.

9. Slide the wheel shaft towa rds th e fro nt and repla ce th e rolle r drive be lt.

14

Page 16

13th January 1995 BIN GUIDE LUBRICATION

11. BIN GUIDE LUBRICATION

A

B

C

A

B

C

B

C

B

C

B

C

[B]

Grease 501

Grease 501

[B]

[A]

)

α

1. Remove the lower paper guide . (Se e Roller Drive Belt Replacement .)

2. Remove all bins [A] from the bin guid es [B ].

3. Apply Grease 501 to the grooves of the bin guides.

NOTE: There are three types of bins (types A, B, and C in the above

diagram). Therefore, when installing the bins, be sure that they

are installed in the correct ord er.

15

(MICRO -

10-bin Sorter

Page 17

Loading...

Loading...