Page 1

1. SPECIFICATIONS

1 August 1988

Number of Bins:

Paper Size for Bins:

Paper Weight:

Bin Capacity:

Top Bin Capacity:

(Non-Sort/Stack Mode)

Power Source:

Power Consumption:

Dimensions:

(WxDxH)

Weight:

10 bins

Maximum

Minimum

A3, 11"x 17"

A6, 5½"

x 8½"

(Lengthwise)

64

to

90

g/m² (17 to 24 lb)

Sort/Stack

Mode 15 sheets/ B4,

20 sheets/ A4,

8½"

8½"

x11"

x 14"

10 sheets/ A3, 11" x 17"

100 sheets (all sizes)

+ 5 volts and +24 volts from the copier

7.7

W

440 mm x 391 mm x 367 mm

(1 7.3" x 15.4" x 14.4")

7.5 kg (16.5 lb).

9-1

Page 2

1 August 1988

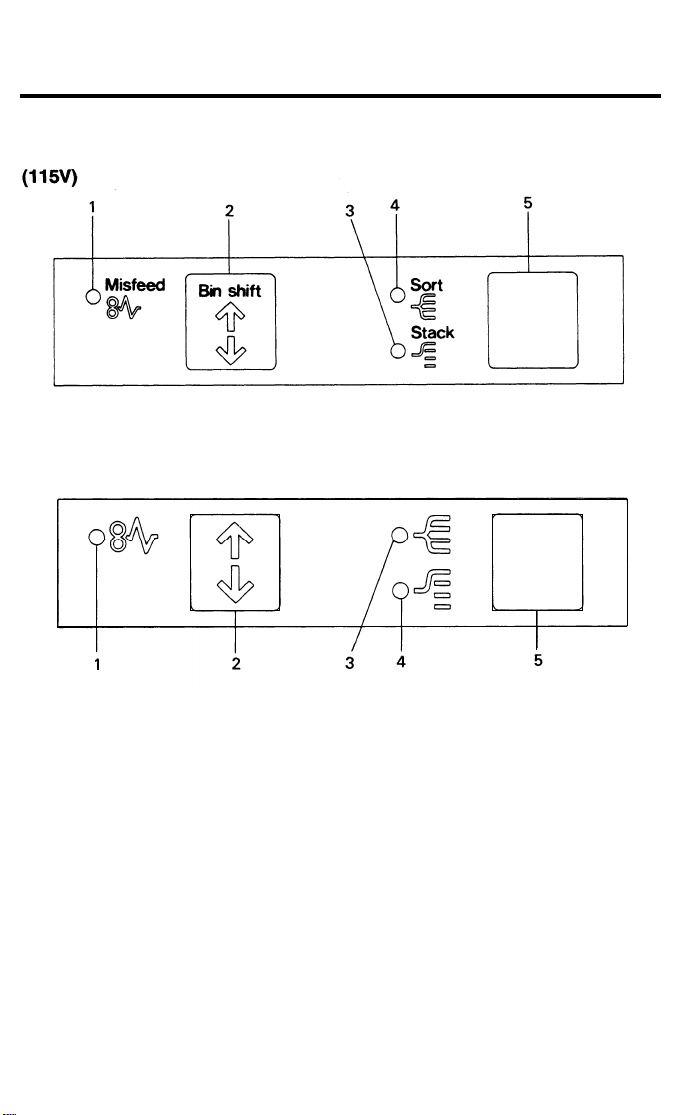

2. OPERATION PANEL

(220/240V)

1. Check Sorter Paper Path

Indicator

2. Bin Shift Key

3. Stack Indicator

4. Sort Indicator

5. Sorter Key

Lights when there is a paper misfeed in the

sorter.

Press to shift the bins. Use this key to

remove jammed paper.

Lights when copies from different copy runs

are to be grouped into individual stacks.

Lights when sets of copies are to be assembled in order.

Press to select sort and stack modes or to

turn off the sorter (clear mode).

9-2

Page 3

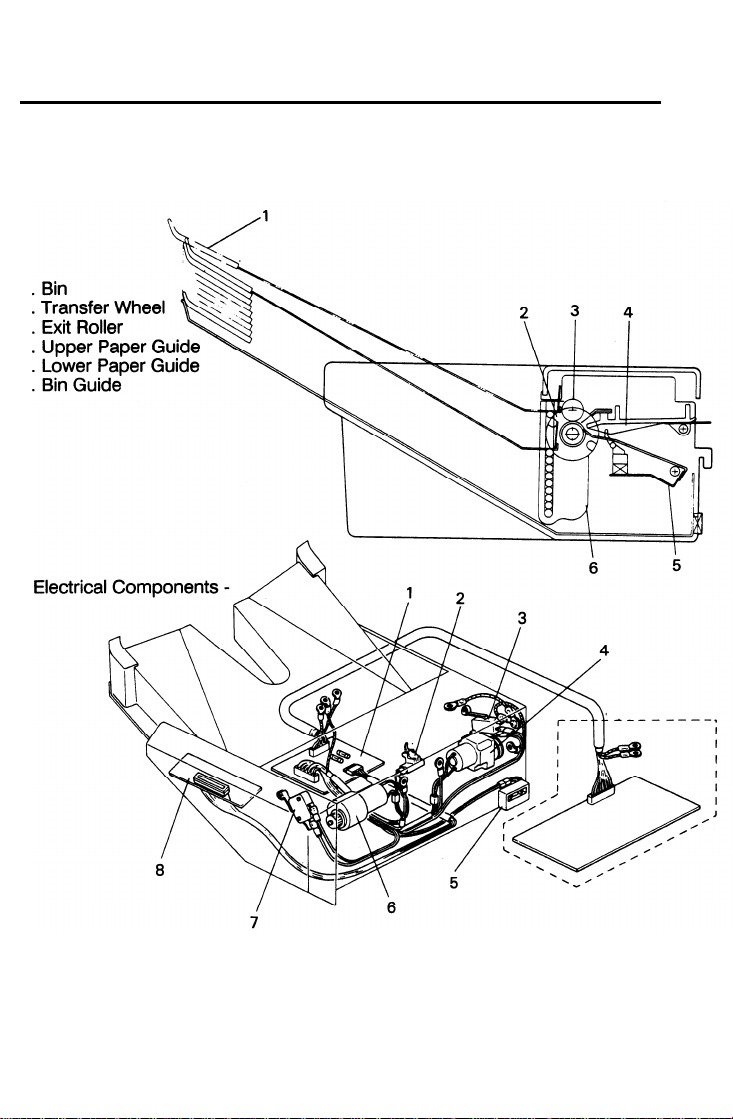

3. COMPONENT LAYOUT

- Mechanical Components -

1

2

3

4

5

6

1 August 1988

1. Sorter Main Board

2. Paper Sensor

3. Wheel Switch

4. Roller Drive Motor

5. Sorter Switch

6. Bin Drive Motor

7. Home Position Switch

8. Operation Panel Board

9-3

Page 4

1 August 1988

4. ELECTRICAL COMPONENT

Symbol Name

Motors

M1

M2 Bin Drive Motor

Roller Drive Motor

Switches

SW1

SW2

SW3

Wheel Switch

Sorter Switch

Home Position

Switch

Sensors

S1

Paper Sensor

Printed Circuit Boards

PCB1

PCB2

Sorter Main Board

Operation Panel

Board

DC motor that energizes to drive the lower

exit rollers.

Reversible DC motor that energizes to move

the bins up or down.

Detects the rotation of the transfer wheel

and steps it in the correct position.

Read switch that becomes activated when

the sorter is in the proper position (aligned

next to the copier). Also works as a jam

reset switch for the setter.

Informs the CPU that all the bins are

lowered.

Serves as the misfeed sensor for the sorter

and also sets exit roller and bin drive timing.

Serves as the communication board between the copier main board and the sorter.

Contains the Sorter key and Sorter Misfeed

indicators.

Function

DESCRIPTIONS

Location

4

6

3

5

7

2

1

8

9-4

Page 5

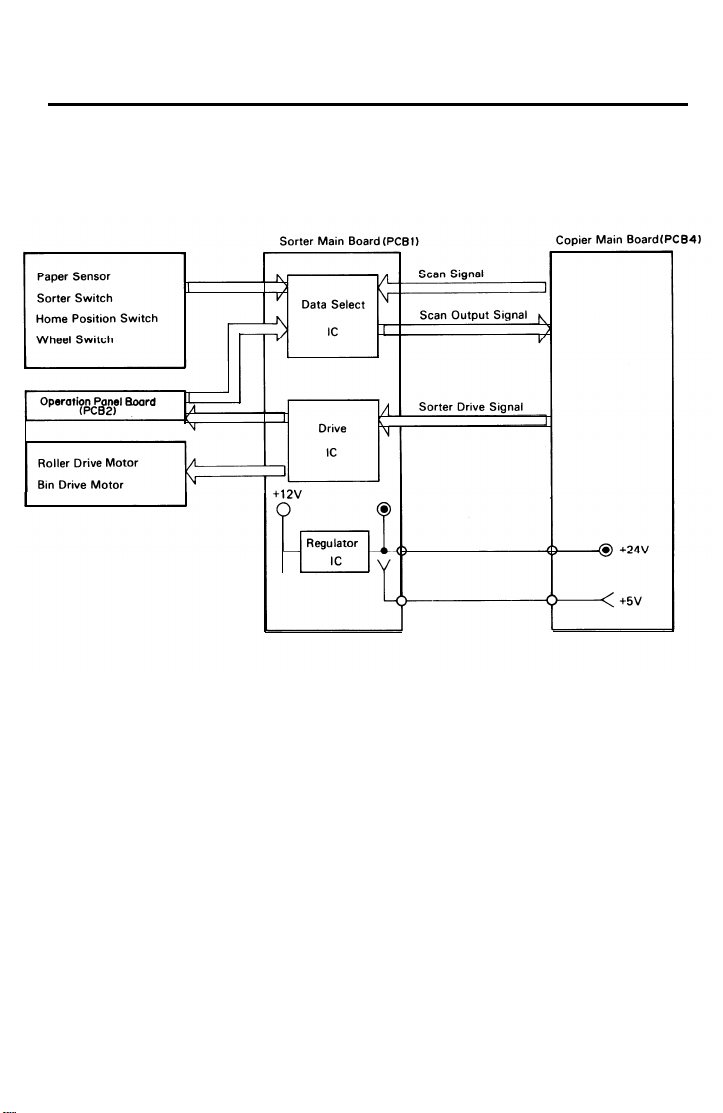

5. OVERALL MACHINE CONTROL

1 August 1988

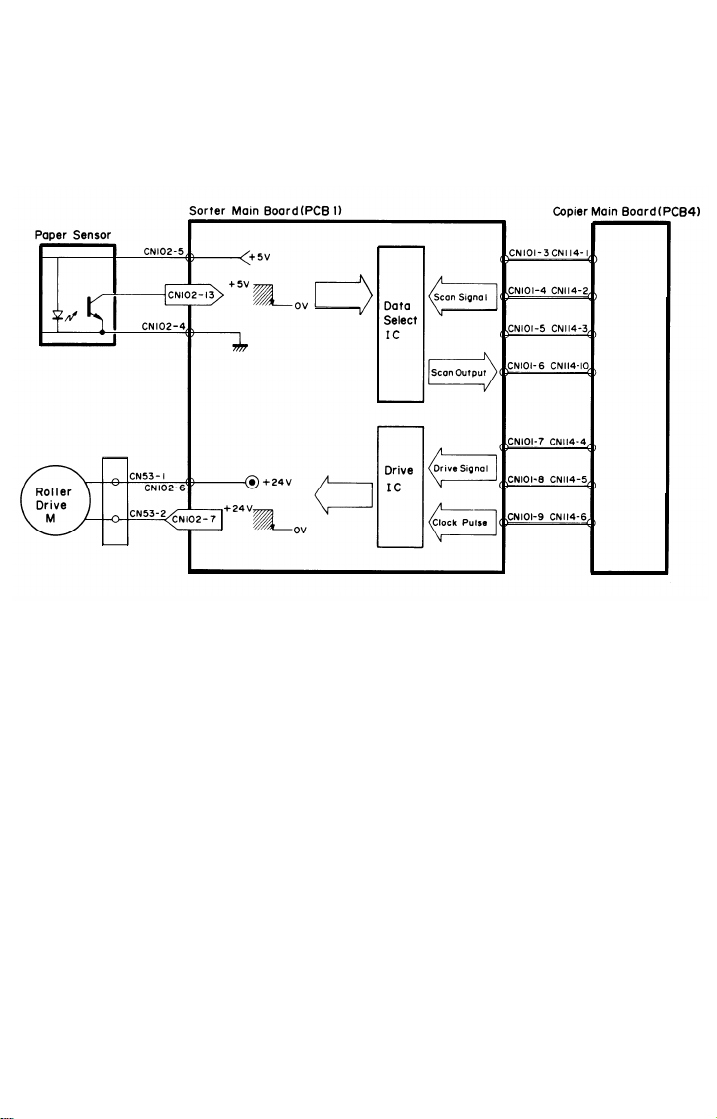

The copier main board provides the sorter main board with +24 volts and

+5 volts. +24 volts powers the roller drive motor and the indicator LEDs on

the operation panel board, and +5 volts powers all sensors and switches.

Also, +24 volts is changed to +12 volts by the regulator IC, which powers

the bin drive motor.

The copier main board controls the drive and checks the status of the sorter

via the sorter main board. The copier main board sends the scan signal to

the data select IC on the sorter main board. After receiving the scan signals,

the data select IC outputs the status of the sensor, switches, or keys as the

scan output signal.

The copier main board also sends the sorter drive signal. After receiving the

drive signals, the drive IC turns on the appropriate motors and operation

panel indicators.

9-5

Page 6

1 August 1988

6. BASIC OPERATION

- Clear Mode -

When the main switch of the copier is turned on, the sorter automatically as-

sumes the clear mode. In this mode, all copies are stacked on the first bin.

The sorter also assumes the clear mode when either the interrupt mode or

the manual feed mode is selected.

Sorter operation begins when a copy actuates the copier exit sensor. At this

time, the roller drive motor energizes. When the paper exits onto the sorter

bin, the paper sensor is de-activated and the roller drive motor is then de-

energized.

sorter main board to check for paper misfeeds.

- Sort Mode -

Pressing the Sorter key once shifts the copier to the sort mode. In this mode,

all copies of the first original are delivered to separate bins starting from the

top. The copies of the second original are delivered to the same bins, but

starting from the bottom. The copies of the third original start from the top

and so on. The bin drive motor turns on to advance the bin one step, 250

milliseconds after the copy has gone through the paper sensor. If the Copy

Quantity, Clear/Stop, Book Copy, or Sorter key is pressed during the sort

mode, all bins shift to the home position.

The copier main board monitors the paper sensor through the

- Stack Mode Pressing the Sorter key twice shifts the copier to the stack mode. In this

mode, all copies of the first original are delivered to the first bin, all copies of

the second original are delivered to the second bin, and so on. The bin drive

motor turns on to advance the bin one step, 250 milliseconds after the last

copy of the original has gone through the paper sensor. If the Sorter key is

pressed during stack mode, all bins shift to home position.

9-6

Page 7

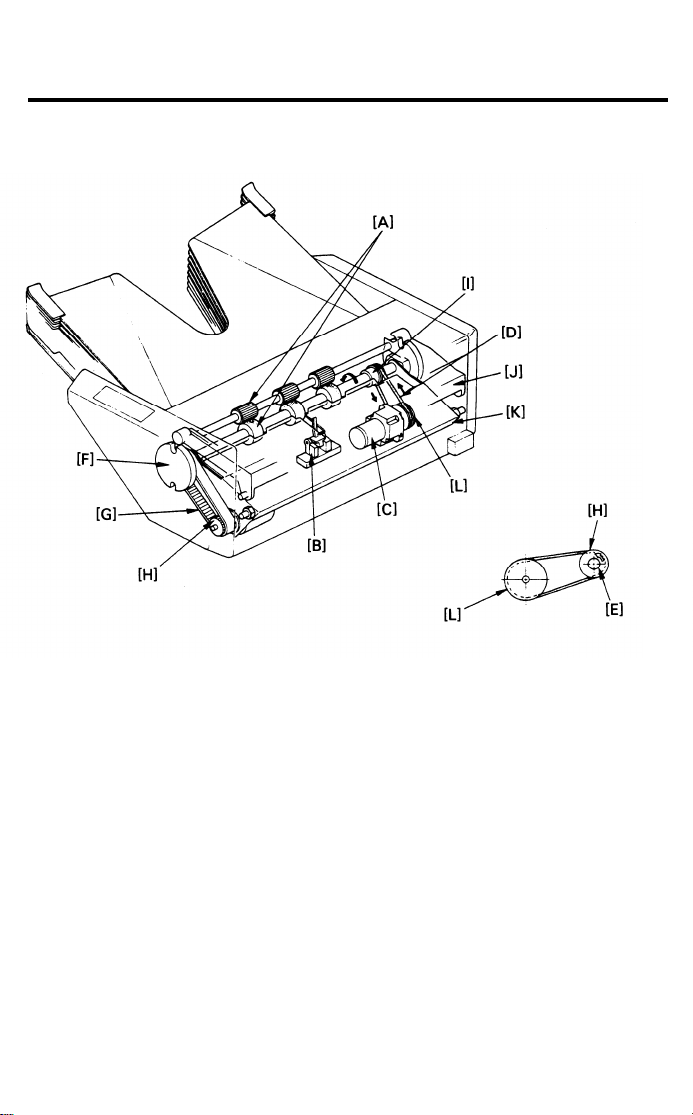

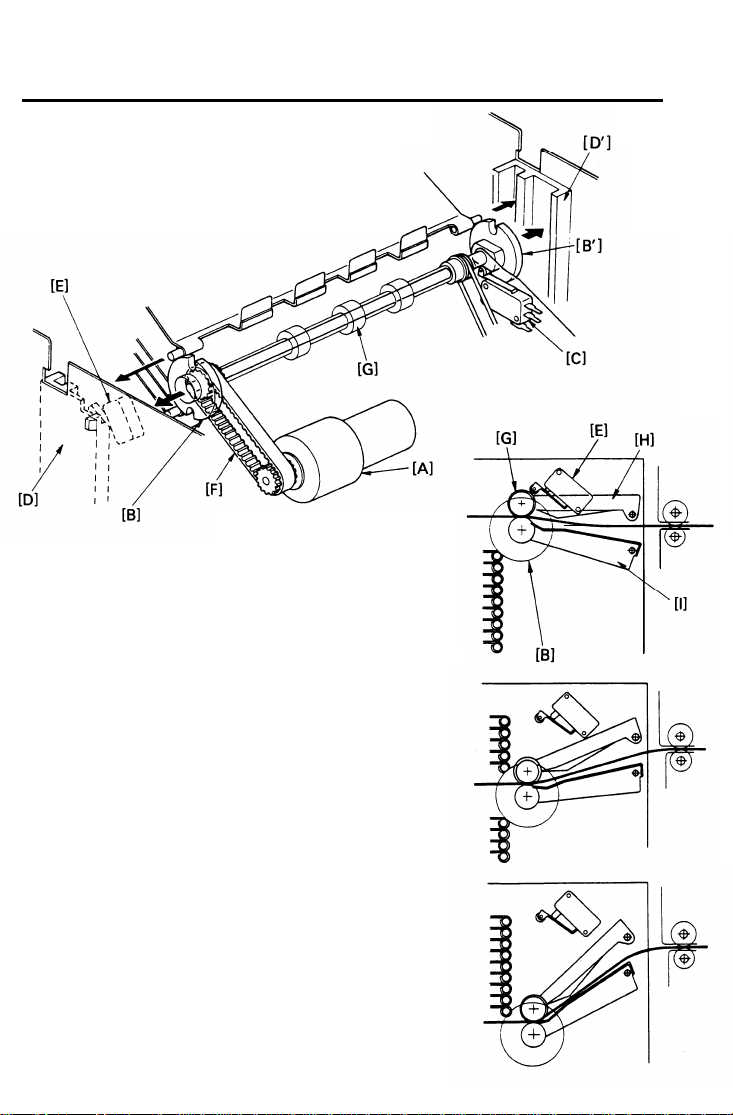

7. EXIT ROLLER DRIVE

7.1 Roller Drive Mechanism

1 August 1988

F:

G:

H:

I:

J:

K:

L:

The exit rollers [A] take over paper transport from the copier. When the copy

paper actuates the copier exit sensor, the exit rollers start rotating. The exit

rollers continue to rotate for 250 milliseconds after the copy paper has gone

through the paper sensor [B].

The roller drive motor [C] rotates the lower exit roller via the roller drive belt

[D]. The shaft of the lower exit roller is a cylindrical cavity type which rotates

around the transfer wheel shaft [E]. The paper sensor is positioned just in

front of the exit rollers. The paper sensor detects misfeeds in the sorter.

Transfer Wheel

Bin Drive Belt

Bin Drive Pulley

Exit Roller Pulley

Upper Paper Guide

Lower Paper Guide

Roller Drive Motor Pulley

9-7

Page 8

1 August 1988

7.2 Roller Drive Circuit

To turn on the roller drive motor, the copier main board sends a drive signal

to the drive IC on the sorter main board. After receiving the drive signal, the

drive IC drops CN102-7 from +24 to 0 volt to turn on the roller drive motor.

When the paper sensor is actuated, CN102-13 drops to LOW. The main

board outputs three scan signals to the data select IC. The status of the sensor changes the resulting scan output signal. Using the scan output signal,

the copier main board determines the status of the sensor. For safety

reasons, the CPU limits the operation time of the roller drive motor to 5

seconds.

9-8

Page 9

8. BIN DRIVE

8.1 Bin Drive Mechanism

1 August 1988

1

G:

H:

I:

Exit Roller

Upper Paper Guide

Lower Paper Guide

The bin drive mechanism moves

the bins up and down to receive

copies under the direction of the

copier CPU.

The main components in this mechanism are the

bin drive motor [A], two transfer

wheels [B,B’], the wheel switch

[C], and the bins themselves.

Pins on either side of each bin are

inserted into slots called bin guides

[D,D’].

The bins slide up and

down in the bin guides. The bins

sit on each other with the lower bin

resting on the permanentlymounted 10th bin. The upper and

lower paper guides pivot up and

down depending on the height of

the bin to be picked up or

released.

9-9

-

I

Page 10

1 August 1988

The home position switch [E] informs the CPU when all the bins

are lowered.

To move the bins up, the bin drive

motor turns clockwise (as viewed

from the front). A timing belt [F]

turns the transfer wheels.

The transfer wheels have two slots

in them 180 degrees apart. As the

transfer wheels turn, these slots

engage the bins and lift them up.

Each time the transfer wheels turn

180 degrees, they raise one bin.

To move the bins down, the CPU

reverses the bin drive motor and

the above processes reverses.

The CPU monitors the position of

the bins through pulses generated

by the wheel switch and the ac-

tuator cam [J]. The actuator cam

has two flat sides that are 180

degrees apart and is mounted behind the rear transfer wheel. A

pulse is generated each time one

of the lobes of the actuator cam

passes the wheel switch.

9-10

Page 11

8.2 Bin Drive Circuit

1 August 1988

To turn on the bin drive motor, the copier main board sends drive signals to

the drive IC on the sorter main board. After receiving the drive signals, the

drive IC either raises CN102-8 or CN102-9 to + 12 volts. This turns on the bin

drive motor which respectively moves a bin up or down. The main board

monitors the output of both sorter switches through the data select IC. When

either the home position switch or wheel switch is actuated, CN102-11 or

CN102-12 drops to LOW. The main board outputs three scan signals to the

data select IC. The status of the switches changes the resulting scan output

signal. Using the scan output signal, the copier main board determines the

status of the switch.

- Service Call Condition (EA1) The CPU monitors the on-time of the bin drive motor to detect a malfunction

of the bin drive motor. If the bin drive motor continues to rotate more than

twelve seconds, the CPU stops machine operation and displays EA1 on the

copier operation panel.

9-11

Page 12

1 August 1988

9. OPERATION PANEL CIRCUIT

As with the monitoring and the controlling of the switches and the motors, the

data select IC and the drive IC are respectively used to detect a pressed key

and to turn on the LEDs on the operation panel board.

When the Sorter key or the Bin Shift key is pressed, CN103-1 or CN103-4

drops to LOW respectively, informing the data select IC of the pressed key.

To turn on the Sort indicator LED, the Stack indicator LED, or the Check

Sorter Paper Path indicator LED, the drive IC drops either CN103-6, CN103-7,

or CN103-8 to LOW respectively.

9-12

Page 13

10. JAM DETECTION

Exit Sensor(Copier)

I

I

I

I

I

I

I

Paper Sensor

I

I

I

I

I

I

I

1

I

I

i

I

I

1

I

i

I

1 August 1988

In addition to being used for the exit roller and bin drive timing, the paper sensor checks for a misfeed in the sorter.

When the copier exit sensor is actuated by the copy paper, the CPU on the

copier main board starts a timing cycle. After 1,250 mini seconds, the CPU

checks whether or not the paper sensor is actuated. (J1: Paper Sensor ON

Check)

The CPU also starts a timing cycle when the paper sensor is actuated. Then

at 3.7 seconds, the CPU checks whether or not the copy paper has passed

the paper sensor. (J2: Paper Sensor OFF Check)

In misfeed condition, the “Check Sorter Paper Path” indicator on the sorter

operation panel lights and copier operation is inhibited. To recover the sorter

from the misfeed condition, the sorter has to be slid away from the copier,

then, after misfed paper removal, returned to its original position.

9-13

Page 14

1 August 1988

11 ● ACCESSORY CHECK

Check the accessories and their quantities according to the following list:

1. Mounting Base

2. Proof Tray

3. Anti-static Brush

4. Magnet

. . ..*..*..* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. Harness Bracket

6. Mounting Lock

7. Short Screw

. . . . . . . .... . . . . . ....... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . ......... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ..... . . . . . . . . . . . . . . .

. . ............. ........... . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . ..... . . . . . . . . . . . . . . ........ . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....... . . . . . . . . . . . . . .

(Incl. 1 Grounding Screw)

8. Stepped Screw

9. Bushing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ......

●

. . ......... . ....

10. Long Screw

11. Lower Guide Plate

12. Decal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13. Installation Procedure

14. N. E.C.R

. . . . . . ..... . . . . . . . ..... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . ........ . ........... . . . . . . . . . . . .

. . . . . . ...... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15. Envelope for N. E.C.R. (115V only) . . . . . . . . . . . . . . . . . . . . . . . 1

1 pc

1 pc

1 pc

1 pc

●

. ...

1 pc

2 pcs

3 pcs

1 pc

1 pc

2 pcs (not used)

1 pc

1 pc

1 pc

1 pc

PC

NOTE: To install the sorter on the FT2050 a sorter compatible main board

must be obtained. This is available as an options.

9-14

Page 15

12. INSTALLATION PROCEDURE

1. Install the copier on the

mounting base.

NOTE: Make sure that the legs

rest securely in the cutouts of the mounting

base.

2. Install the magnet on the left

cover as shown.

NOTE: Place the magnet in the

bottom right-hand corner

of the cutout.

3. Remove the two screws on the

exit cover.

1 August 1988

4. Install the anti-static brush.

NOTE:

Use one of the screws

removed in step 3 to

secure the left side, and

the stepped screw of the

accessories to secure the

right side.

9-15

Page 16

1 August 1988

5. Install the proof tray where the

copy tray normally fits.

(FT2050/2070 only)

6.

Replace the lower guide plate

with the accessory lower guide

plate (2 screws).

(FT2050/2070 only)

7. Insert the sorter hooks into the

vertical posts of the mounting

base, and then remove the

strips of tape from the sorter

bins.

8. Secure the sorter hooks by installing the mounting locks.

9-16

Page 17

1 August 1988

NOTE:

Separate installation procedures are needed to install the sorter on the

FT2050

and

FT2070/2260. Follow the

procedure from step 9

when installing the sorter

on the FT2050. Proceed

to step 22 when installing

the

sorter on

FT2070/2260.

Remove the rear cover (2

9.

screws).

Move the slider to the left by

10.

pressing the slider lock release

lever. Then, lower the front

cover and remove the right

cover

(4

screws).

the

the

Replace the copier main board

11.

with the sorter compatible

main board (3 screws and 8

connectors).

9-17

Page 18

1 August 1988

Remove the upper left cover (4

12.

screws).

13.

Remove the plastic cap from

the docking hole of the upper

left cover.

14. Install the harness bracket (2

screws).

15. Thread the sorter harness

through the docking hole and

the harness bracket.

9-18

Page 19

16.

The sorter harness has two

harness bands used as

markers. Place the bushing on

the sorter harness just behind

the first harness band from the

connector. Secure the bushing

in the harness bracket.

1 August 1988

17.

Secure both ground wires

the rear cover bracket

screw).

18.

Couple

the connector

CN114 on the main board.

19. Reassemble the copier.

20.

Slide the sorter to its normal

position.

to

(1

to

9-19

Page 20

1 August 1988

9-20

21. Replace the decal on the

sorter with the accessory

decal, and check the opera-

tion in all modes.

This completes the sorter in-

stallation on the FT2050.

22. Open the front cover.

23. (FT2070)

Move the slider to the center

and push down the release

lever to open the top unit.

(FT2260)

Push down the release lever to

open the top unit.

24. Remove the release lever (1 Ering).

Page 21

25. (FT2070)

Remove the inner cover (2

screws).

(FT2260)

Remove the inner cover (5

screws).

26. Lower the top unit.

1 August 1988

27. (FT2070)

Move the slider fully to the

right, then remove the upper

left cover (4 screws).

(FT2260)

Remove the upper left cover (4

screws).

28. Remove the rear cover (2

screws).

9-21

Page 22

1 August 1988

29.

Install the harness bracket on

the mounting bracket at the

rear of the copier (2 screws).

Remove the plastic cap from

30.

the docking hole of the upper

left cover.

Thread the sorter harness

31.

through the docking hole and

the harness bracket.

The sorter harness has two

32.

harness bands used as

markers. Place the bushing on

the sorter harness just behind

the second harness band from

the connector. Secure the

bushing in the harness brack-

et.

9-22

Page 23

Secure the sorter harness into

33.

the three wire clamps which

are mounted on the left underside of the optics unit.

(FT2070)

34.

Run the sorter harness above

the total counter bracket, and

couple

the connector to

CN114 on the main board.

(FT2260)

Run the sorter harness above

the operation panel bracket,

and couple the connector to

CN114 on the main board.

1 August 1988

35.

Secure the ground wire to the

front machine plate (1 screw).

Reassemble the copier.

36.

Slide the sorter to its normal

37.

position.

(FT2070)

38.

Replace the decal on the

sorter with the accessory

decal.

39

Check the operation in all

modes. Fill out the New Equipment Condition Report.

This completes the sorter in-

stallation on the FT2070/2260.

9-23

Page 24

1 August 1988

13.

PREPARATION FOR TRANSPORTATION

CAUTION: When removing and transporting the sorter, be careful not to

CAUTION: Before moving the sorter, be sure to prepare it for transportation

1. If the bins are not at the home position, turn on the main switch of the

copier to move the bins to the home position.

2. Secure the bins with strips of tape as shown in the illustration.

3. Remove the sorter from the copier. (See the Installation Procedure

[Sorter] section.)

carry it in a vertical position as the bins will become dislocated.

as follows. The sorter may be badly damaged if it is moved

without proper preparation.

9-24

Page 25

1 August 1988

14. ROLLER DRIVE BELT REPLACEMENT

1.

Remove the front cover [A] (1 screw, 1 connector) and rear cover [B] (1

screw).

Lift off the top cover [C].

2.

Remove the top stay [D].

3.

NOTE: Be sure that the short edge of the top stay is facing the exit side of

the sorter when reinstalling it.

4.

Lift the upper paper guide [E] up and out of position.

5. Lift the lower paper guide [F] out of position and turn it over to remove

the roller drive belt [G].

NOTE: Be careful not to damage the sorter home position switch actuator

[H] when reassembling.

6.

Remove the transfer wheel [I], spacer [J], pin [K] and bushing [L] (1 C-

ring).

7. Slide the wheel shaft [M] towards the front and remove the roller drive

.

belt

9-25

Page 26

1 August 1988

15. BIN GUIDE LUBRICATION

1.

Remove the lower paper guide. (See Roller Drive Belt Replacement sec-

tion.)

2.

Remove all bins [A] from the bin guides [B].

3.

Apply Grease 501 to the grooves of the bin guides.

NOTE: There are three kinds of bins. Therefore, when installing the bins, be

sure that they are installed in the correct order.

9-26

Page 27

Page 28

17. SORTER TIMING CHART

Exit Sensor (Copier)

Paper Sensor

Bin Up

Bin Drive Motor

Bin Down

Roller Drive Motor

August 1, 1988

2 COPIES/SORT MODE

Home Position Switch

Sorter Switch

Bin Shift Key

JAM CHECK

J1 : Paper Sensor

J2 : Paper Sensor

ON Check

OFF Check

A467

Page 29

ELECTRICAL COMPONENTS AND

CONNECTOR LAYOUT-SORTER

1 August 1988

1

2

11

6

5’

6

Index No.

1.

2.

3.

4.

5.

6.

7.

8.

Description

Sorter Main Board

Paper Sensor

Wheel Switch

Roller Drive Motor

Sorter Switch

Bin Drive Motor

Home Position Switch

Operation Panel Board

Symbol

PCB1

S1

SW 1

Ml

SW2

M2

SW3

PCB2

P to P

A5-B7

A5

A6

A5

A6

A5

A6

A6-A7

Index No

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

CN102

Sorter Main Board

CN101

Sorter Main Board

CN103

Sorter Main Board

T54

Wheel Switch

T53 Wheel Switch

CN54 Sorter Switch

CN53 Roller Drive Motor

CN51 Bin Drive Motor

T51 Home Position Switch

T52

Home Position Switch

CN52

Operation Panel Board

Symbol

PCB1

PCB1

PCB1

SW 1

SW 1

SW2

Ml

M2

SW3

SW3

PCB2

Type

13P/W

1 OP/W

10P/W

1 P/R

1 P/R

2P/W

2P/W

2P/W

1 P/R

1 P/R

8P/W

P to P

A5-A6

B5-B6

A6-A7

A6

A6

A6

A5

A5

A6

A6

A6-A7

A467

Loading...

Loading...