Page 1

ыэяью

Priport Controller

CPIF-26

Service Manual

Page 2

ø

ø

IMPORTANT SAFETY NOTICES

øø

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the printer and peripherals, make

sure that the power cord is unplugged.

2. The wall outlet should be near the controller and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off or

open while the main switch is turned on, keep hands away from electrified or

mechanically driven components.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

The controller must be installed and maintained by a customer service

representative who has completed the training course on those models.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

Dispose of replaced parts in accordance with local regulations.

i

Page 3

General Remarks

The following table shows the conversion of the model names for each

manufacturer:

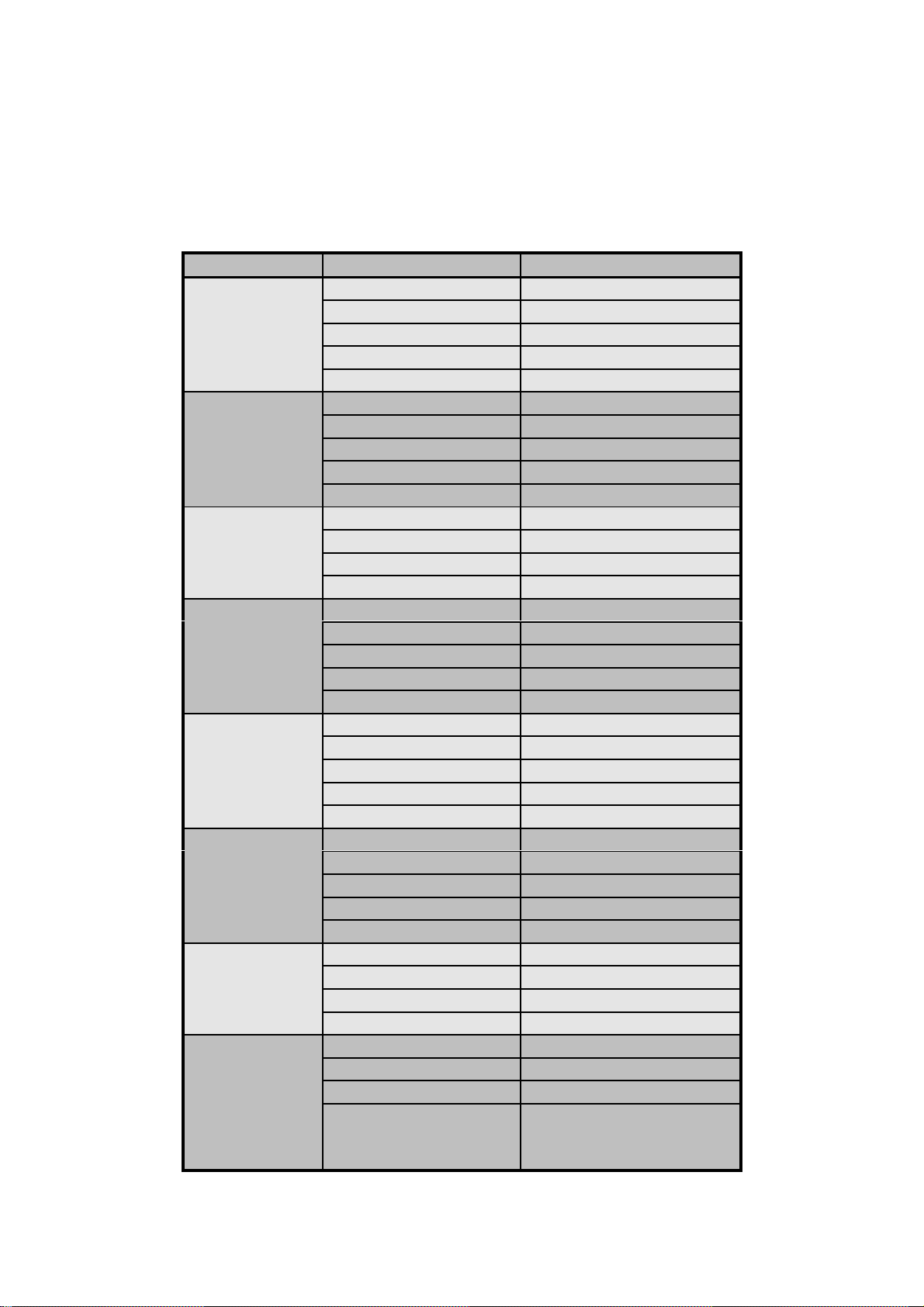

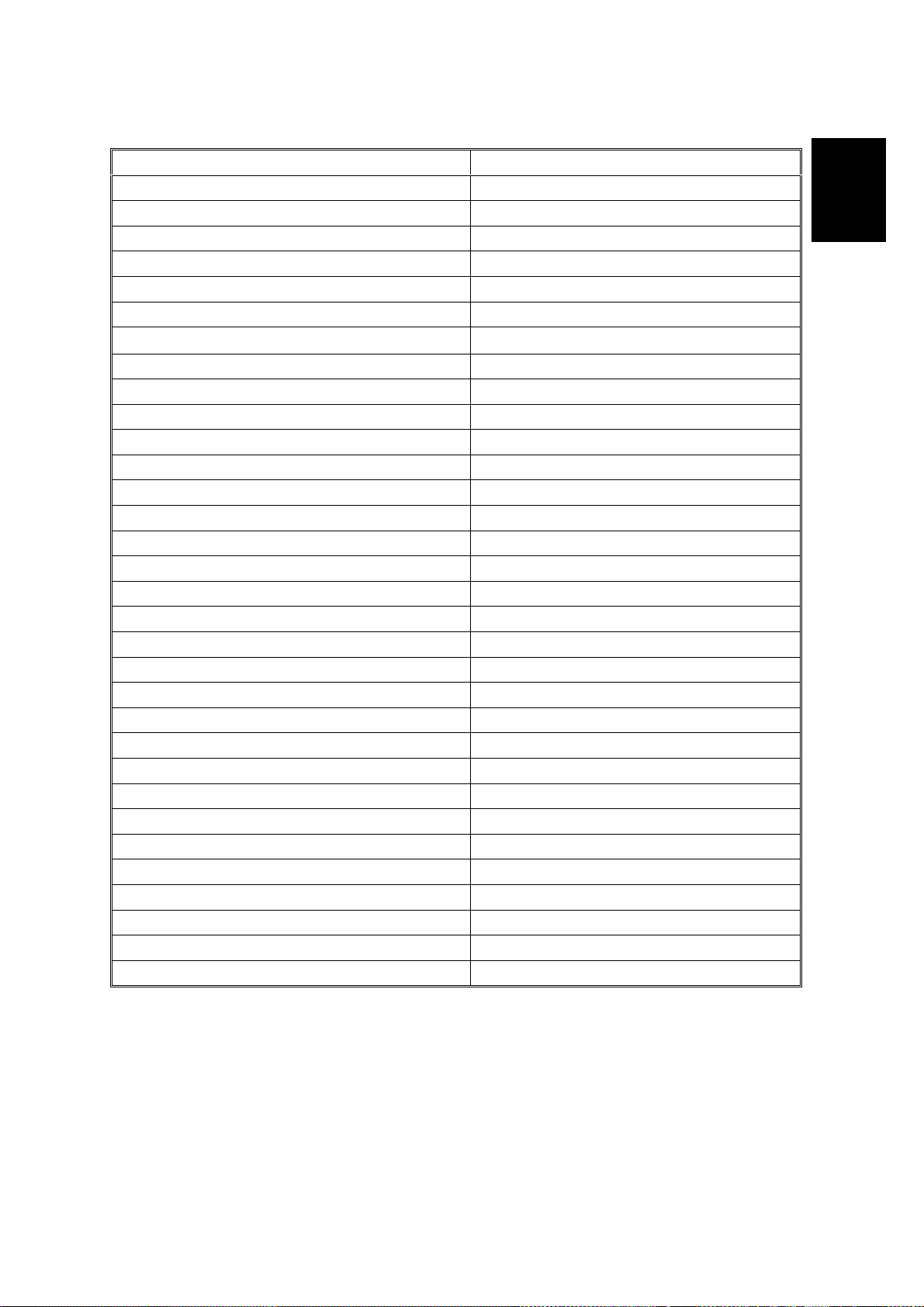

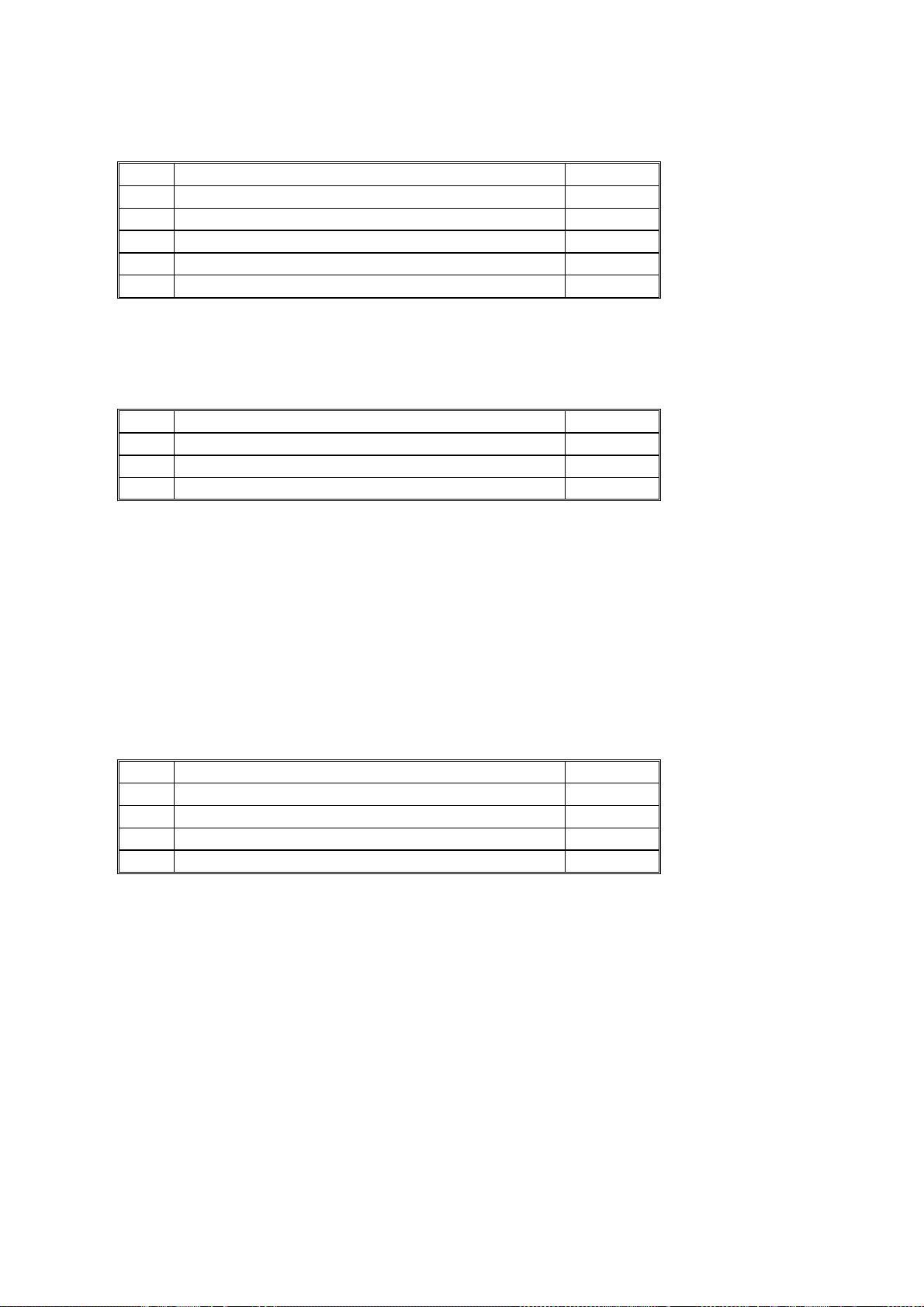

Model Code Company Model Name

C229

C231

C217

C225

C226

C224

C216

C211 Ricoh VT2100/VT2130/VT2150

Ricoh JP5000

Gestetner 5450

RexRotary 1560

Nashuatec CP450

Savin 3350DNP

Ricoh JP1010/1030/1045/1050

Gestetner 5306(L/b)/5000/5001

RexRotary 1224(B)

Nashuatec CP306(b)

Savin 3150DNP

Ricoh VT1730

Gestetner 5303

RexRotary 1220

Nashuatec CP303

Ricoh VT1800

Gestetner 5304

RexRotary 1222

Nashuatec CP304

Savin 3100DNP

Ricoh VT2250/VT2240

Gestetner 5329(L)

RexRotary 1254(L)

Nashuatec CP329(L)

Savin 3250DNP

Ricoh VT2200

Gestetner 5327

RexRotary 1252

Nashuatec CP327

Savin 3200DNP

Ricoh VT2105

Gestetner 5325

RexRotary 1250

Nashuatec CP325

Gestetner 5310/5315/5320

RexRotary 1240/1241/1242

Nashuatec CP310/CP315

ii

Page 4

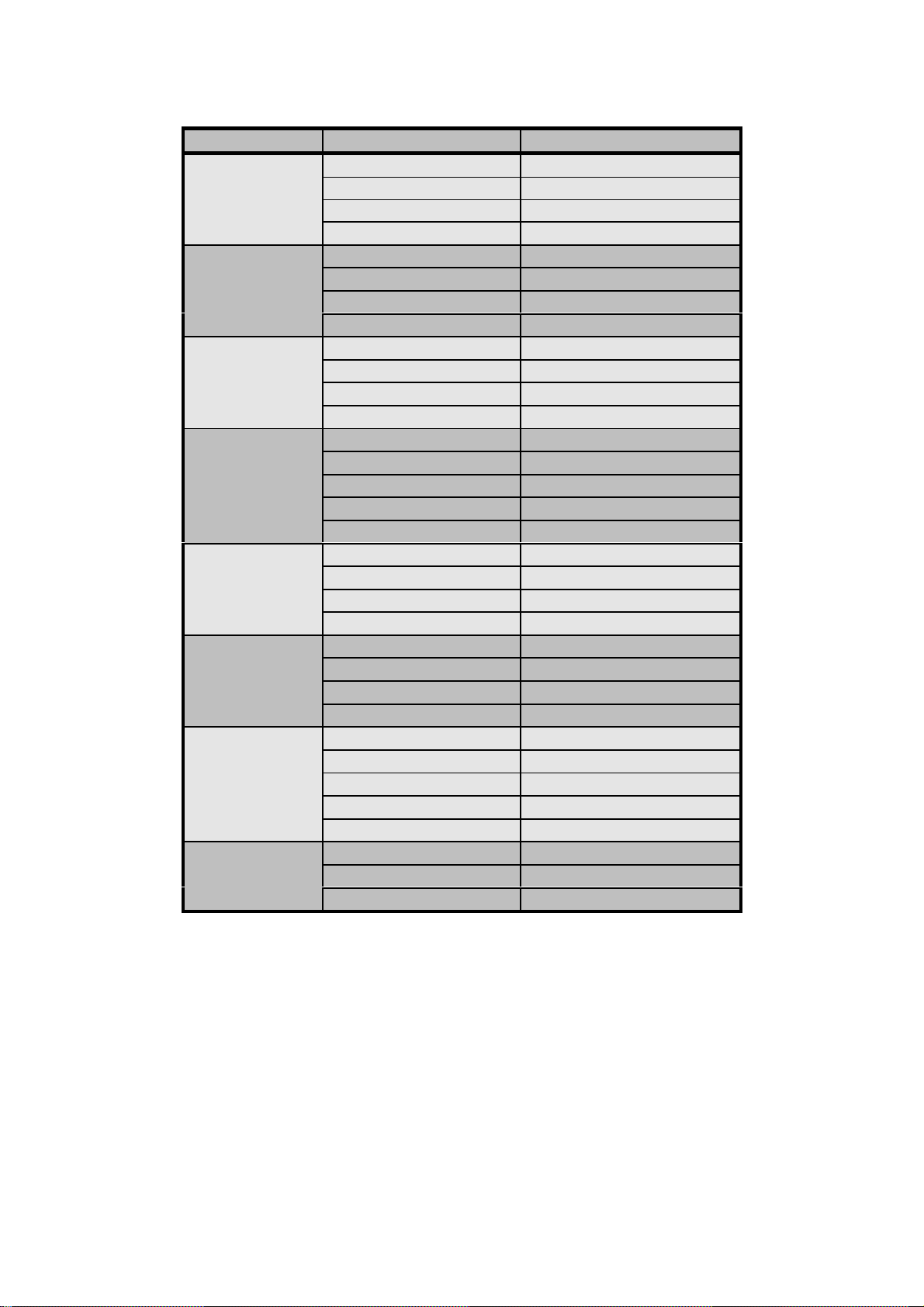

Model Code Company Model Name

C212

Ricoh VT2300

Gestetner 5330

RexRotary 1260

Nashuatec CP330

C210

Ricoh VT3500

Gestetner 5375

RexRotary 1280

Nashuatec CP375

C218

Ricoh VT3600

Gestetner 5380

RexRotary 1285

Nashuatec CP380

C223

Ricoh VT3800

Gestetner 5385

RexRotary 1290

Nashuatec CP385

Savin 3300DNP

C219

Ricoh VT2600/VT2630

Gestetner 5360

RexRotary 1270

Nashuatec CP360

C222

Ricoh VT2400

Gestetner 5340

RexRotary 1255

Nashuatec CP340

C228

Ricoh VT6000

Gestetner 5390

RexRotary 1295

Nashuatec CP390

Savin 3400DNP

C214

Gestetner 5305/5330

RexRotary 1230

Nashuatec CP305

iii

Page 5

Contents

1. OVERALL INFORMATION............................................................. 1

1.1 HOST SYSTEMS.........................................................................................1

1.2 BASIC SPECIFICATION..............................................................................1

1.3 RESIDENT FONT LIST................................................................................2

1.4 VIDEO INTERFACE KITS............................................................................5

2. BASIC FUNCTION......................................................................... 7

2.1 BASIC CONFIGURATION ...........................................................................7

2.2 SPECIFICATIONS AND CONFIGURATIONS OF I/O PORTS ....................9

3. VIDEO I/F INSTALLATION PROCEDURES ................................ 13

3.1 VIDEO I/F KIT TYPE-600 PARTS LIST .....................................................13

3.2 VIDEO I/F KIT TYPE-10 PARTS LIST.......................................................14

3.3 INSTALLATION PROCEDURES FOR INTERFACE KITS.........................15

4. OPERATION VERIFICATION....................................................... 27

4.1 TOOLS.......................................................................................................27

4.2 TESTS........................................................................................................28

5. TROUBLESHOOTING ................................................................. 31

5.1 BASIC STEPS FOR TROUBLESHOOTING..............................................31

5.2 TROUBLESHOOTING FLOW....................................................................33

5.3 PRIPORT/CONTROLLER FAILURE IDENTIFICATION............................34

5.4 SUBASSEMBLY TROUBLESHOOTING....................................................35

5.5 NIB FIRMWARE AND MEMORY UPGRADE TROUBLESHOOTING .......36

5.6 LED STATUS LIGHT SEQUENCE AND CONDITIONS ............................37

5.7 DIAGNOSTIC TEST PAGE CONTENTS...................................................43

5.8 CHECKING PRINTER DRIVER OPERATION...........................................44

5.9 COLLECTING INFORMATION FOR A PROBLEM REPORT....................45

6. DISASSEMBLY / ASSEMBLY..................................................... 47

6.1 REQUIRED TOOLS AND PRECAUTIONS................................................47

6.2 DISASSEMBLY PROCEDURES................................................................48

6.3 ASSEMBLY PROCEDURES ......................................................................53

6.4 UPGRADING CONT ROLLER FIRMWARE................................................56

6.5 UPGRADING CONTROLLER RAM...........................................................70

7. PARTS LIST................................................................................. 83

7.1 CPIF-26......................................................................................................83

7.2 PC CONTROLLER I/F KIT TYPE-600 .......................................................85

7.3 PC CONTROLLER I/F KIT TYPE-10 .........................................................87

Page 6

30 April 1999 HOST SYSTEMS

1. OVERALL INFORMATION

1.1 HOST SYSTEMS

Priport Controller CPIF-26 is external box type raster image processor for

PRIPORTs. By connecting the controller with PRIPORT, the computer data will be

printed in as well as printing from PRIPORT’s scanner. The following are the target

computer hosts for this controller.

Target Host Computer Systems

• IBM PC/AT compatible PC with Windows 95 with Internet Explorer 4.01 SP1,

Windows 98, or Windows NT4.0 with SP3 operating systems.

• Apple Macintosh with MAC OS 7.6.1, or later.

There are no minimum system hardware requirements, other than those imposed

by the operating systems.

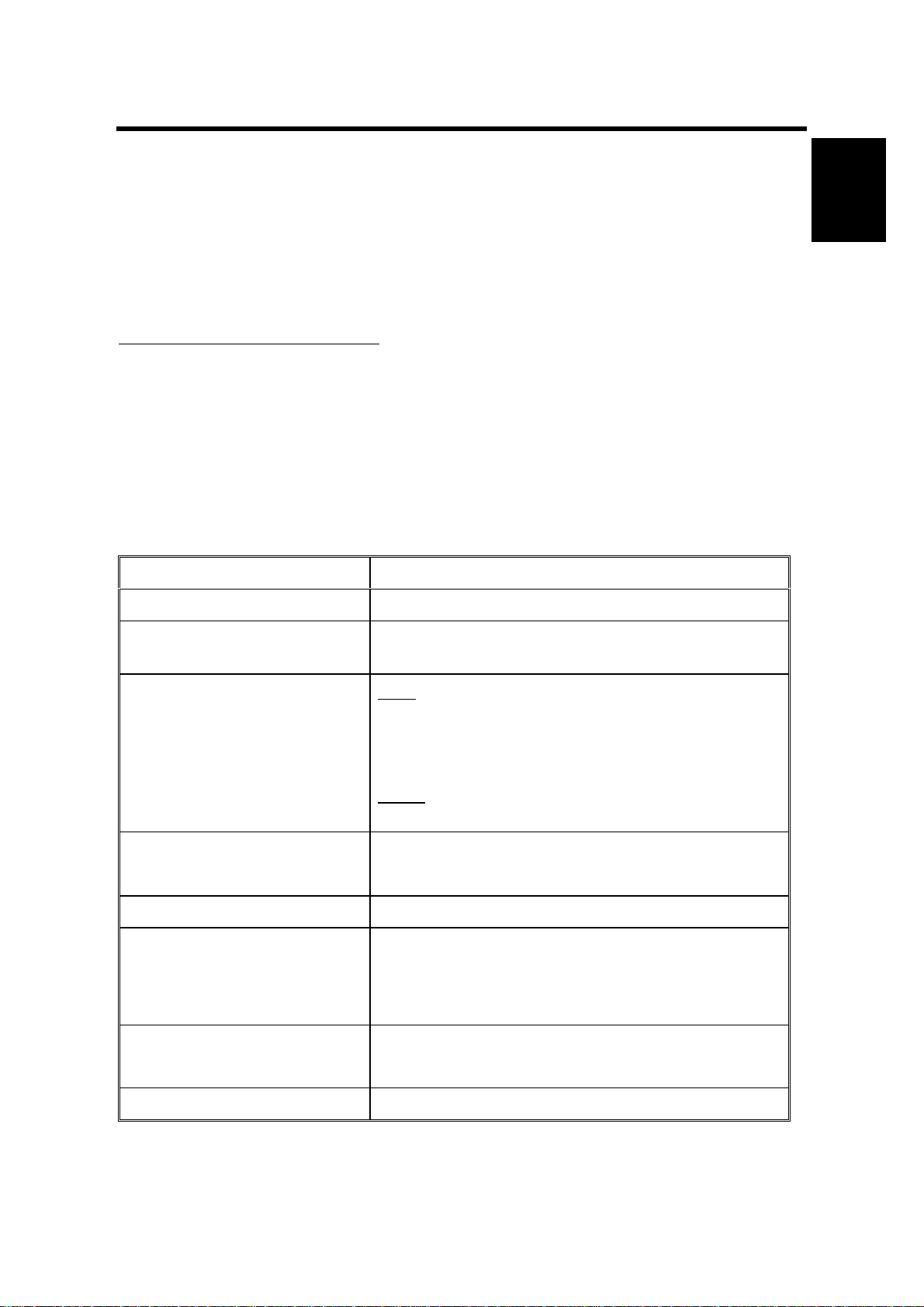

1.2 BASIC SPECIFICATION

Contents Description

Configuration External Box Type Controller Un it

Priport Models JP5000, JP1010, JP1030, JP1045, JP1050, and

VT6000

Overall

Information

I/O Interfaces Host

• Parallel I/F (ECP Bi-directional Centronics)

• LocalTalk (RS422)

• 10 BaseT (RJ45) Ethernet/EtherTalk

Video

• RSVI Interface

Page Description Language

Image Resolution 300 dpi, 400 dpi, 600 dpi

RAM Standard:32MB, Maximum: 256MB

Paper Size A3,A4,B4, B5,

Resident Fonts

PostScript3 Level 3

PCL-5e (HP LaserJet 4si compatible)

(72-pin 60ns EDO SIMM, non-parity, at 5 volts

with 2K maximum refresh rate)

• See Section 6.5 for more explanation.

US Letter, US Legal, US Tabloid

• See section 1.3 Resident Font List.

Table 1.2. Basic Controller Specifications.

1

Page 7

RESIDENT FONT LIST 30 April, 1999

1.3 RESIDENT FONT LIST

1.3.1 PS3 FONTS

Albertus ‡

Albertus Italic ‡ Courier

Albertus Light ‡ Courier Bold

AntiqueOlive Bold § Courier Bold Oblique

AntiqueOlive Compact § Courier Oblique

AntiqueOlive Italic § Eurostile **

AntiqueOlive Roman § Eurostile Bold **

Apple Chancery ˜ Eurostile Bold Extended Two **

Arial ‡ Eurostile Extended Two **

Arial Bold Italic ‡ Geneva

Arial Bold ‡ GillSans ‡

Arial Italic ‡ GillSans Bold ‡

ITC AvanteGarde Gothic Book ° GillSans Condensed Bold ‡

ITC AvanteGarde Gothic Book Oblique ° GillSans Bold Italic ‡

AvanteGarde Gothic Demi ° GillSans Condensed ‡

AvanteGarde Gothic Demi Oblique ° GillSans Extra Bold ‡

Bodoni GillSans Italic ‡

Bodoni Bold GillSans Light ‡

Bodoni Bold Italic GillSans Light Italic ‡

Bodoni Italic Goudy

Bodoni Poster Goudy Bold

Bodoni Poster Compressed Goudy Bold Italic

ITC Bookman Demi ° Goudy ExtraBold

ITC Bookman Demi Italic ° Goudy Oldstyle Italic

ITC Bookman Light ° Helvetica ✝

ITC Bookman Light Italic ° Helvetica Bold ✝

Carta •

Chicago ˜ Helvetica Condensed ✝

Clarendon ✝ Helvetica Condensed Bold ✝

Clarendon Bold ✝ Helvetica Condensed Bold Oblique ✝

Clarendon Light ✝ Helvetica Condensed Oblique ✝

CooperBlack Helvetica Narrow ✝

CooperBlack Italic Helvetica Narrow Bold ✝

Copperplate ThirtyThree Helvetica Narrow Bold Oblique ✝

Copperplate ThirtyTwo Helvetica Narrow Oblique ✝

Coronet Regular ••

Helvetica Bold Oblique ✝

2

Page 8

30 April 1999 RESIDENT FONT LIST

Helvetica Oblique ✝ Palatino Italic ✝

Hoefler Text Black ˜ Palatino Roman ✝

Hoefler Text Black Italic ˜ Stempel Garamond Bold ✝

Hoefler Text Italic ˜ Stempel Garamond Bold Italic ✝

Hoefler Text Ornaments ˜ Stempel Garamond Italic ✝

Hoefler Text ˜ Stempel Garamond Roman ✝

Joanna ‡ ITC Symbol °

Joanna Bold ‡

Tekton •

Joanna Bold Italic ‡ Times Bold ✝

Joanna Italic ‡ Times Bold Italic ✝

LetterGothic Times Italic ✝

LetterGothic Bold Times Roma n ✝

LetterGothic Bold Slanted Times New Roman Bold ‡

LetterGothic Slanted Times New Roman Bold Italic ‡

ITC Lubalin Graph Book ° Times New Roman Italic ‡

ITC Lubalin Graph Book Oblique ° Times New Roman ‡

ITC Lubalin Graph Demi ° Universe ✝

ITC Lubalin Graph Demi Oblique ° Universe Bold ✝

Marigold * Universe Bold Oblique ✝

ITC Mona Lisa Recut ° Universe Oblique ✝

Monaco ˜ Universe Light ✝

New Century Schoolbook Bold ✝ Universe Light Oblique ✝

New Century Schoolbook Bold Italic ✝ UniverseCondensed ✝

New Century Schoolbook Italic ✝ UniverseCondensed Bold ✝

New Century Schoolbook Roman ✝ UniverseCondensed Bold Oblique ✝

New York ˜ UniverseCondensed Oblique ✝

Optima ✝ UniverseExtended ✝

Optima Bold ✝ UniverseExtended Bold ✝

Optima Bold Italic ✝ UniverseExtended Bold Oblique ✝

Optima Italic ✝ UniverseExtended Oblique ✝

Oxford * Wingdings Regular °°

Palatino Bold ✝ ITC ZapfChancery Medium Italic °

Palatino Bold Italic ✝

ITC ZapfDingbats °

Overall

Information

Registered trademark of Adobe Incorporated, ∗∗ Trademark of Nebiolo,

•

✝

Registered trademark of International Typeface Corporation,

°

Hell AG and/or its subsidiaries, § Registered trademark of Marcel Olive,

Trademark of Alpha Omega Typography, ˜ Trademark of Apple Computer Inc.,

∗

Registered trademark of Ludlow type Foundry, °° Trademark of Microsoft Corporation, ‡

••

Trademark of Monotype Corporation

3

Trademark of Linotype-

#

Page 9

RESIDENT FONT LIST 30 April, 1999

1.3.2 PCL FONTS

Scalable Fonts: 35 Intellifont fonts

Albertus, Albertus Extrabold, Antique Olive, Antique Olive Italic, Antique Olive Bold,

Clarendon Condensed, Coronet, Courier, Courier Italic, Courier Bold, Courier Bold

Italic, Garmond Antiqua, Garamond Kursiv, Garamond Halbfett, Garamond Kursiv

Halbfett, Letter Gothic, Letter Gothic Italic, Letter Gothic Bold, Marigold, CG

Omega, CG Omega Italic, CG Omega Bold, CG Omega Bold Italic, CG Times, CG

Times Italic, CG Times Bold, CG Times Bold Italic, Univers Medium, Univers

Medium Italic, Univers Bold, Univers Bold Italic, Univers Medium Condensed,

Univers Medium Condensed Italic, Univers Bold Condensed, Univers Bold

Condensed Italic

Scalable Fonts: 10 TrueType fonts

Arial, Arial Italic, Arial Bold, Arial Bold Italic, Times New Roman, Times New

Roman Italic, Times New Roman Bold, Times New Roman Bold Italic, Wingdings

Fixed Pitch Fonts: 1 Intellifont font

Line Printer (8.5 pt 16.67 pitch)

4

Page 10

30 April 1999 VIDEO INTERFACE KITS

1.4 VIDEO INTERFACE KITS

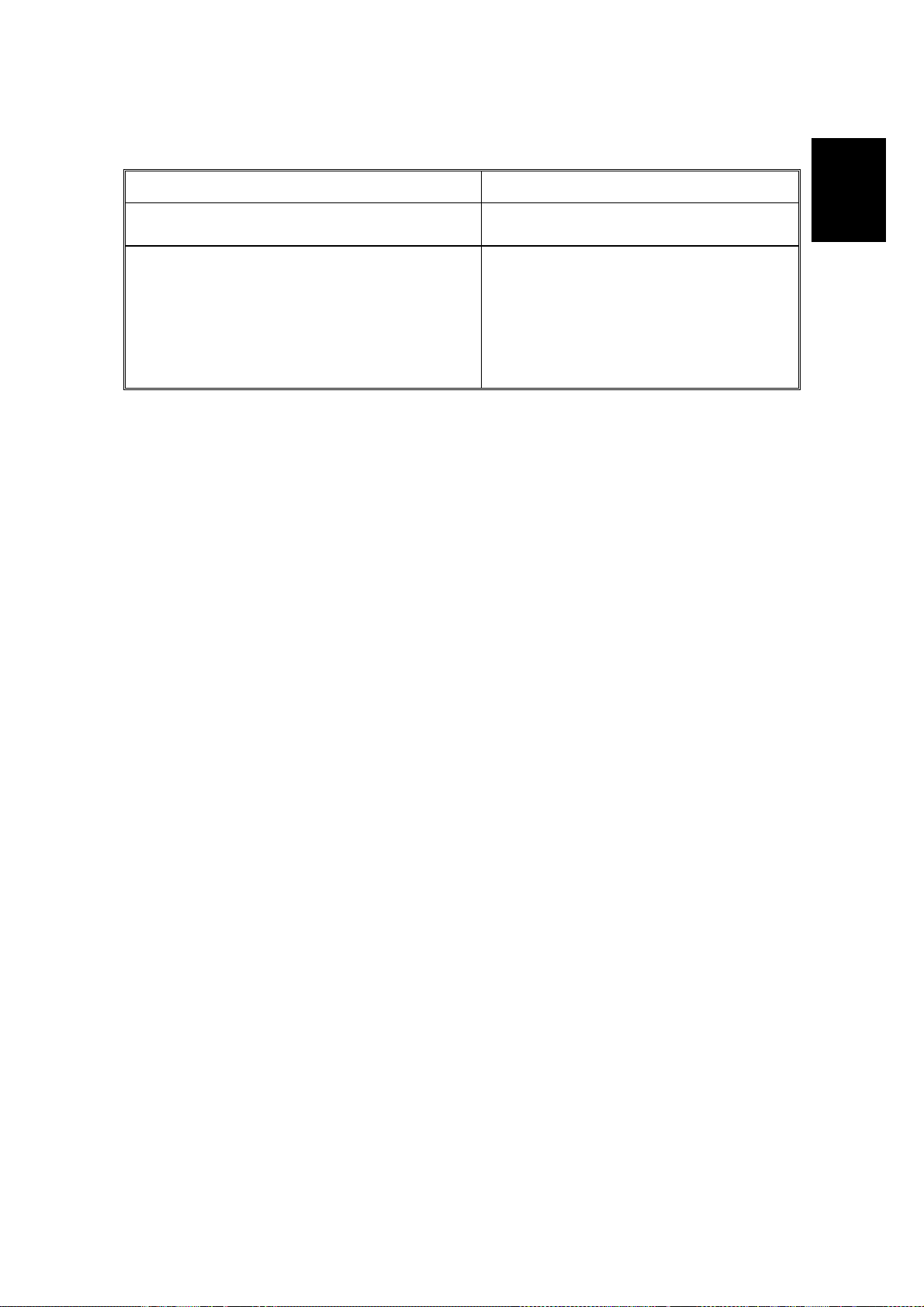

Description Contents

PC Controller I/F Kit Type-600 For the connection to VT6000

PC Controller I/F Kit Type-10 For the connection to JP1010,

JP1030, JP1045, JP1050, and

JP5000 (Asian version only)

* The interface kit is originally installed

for JP5000, except for the Asian

version machines.

Table 1.4. Interface Kits for use with the Controller.

Overall

Information

5

Page 11

30 April, 1999 BASIC CONFIGURATION

(

)

2. BASIC FUNCTION

2.1 BASIC CONFIGURATION

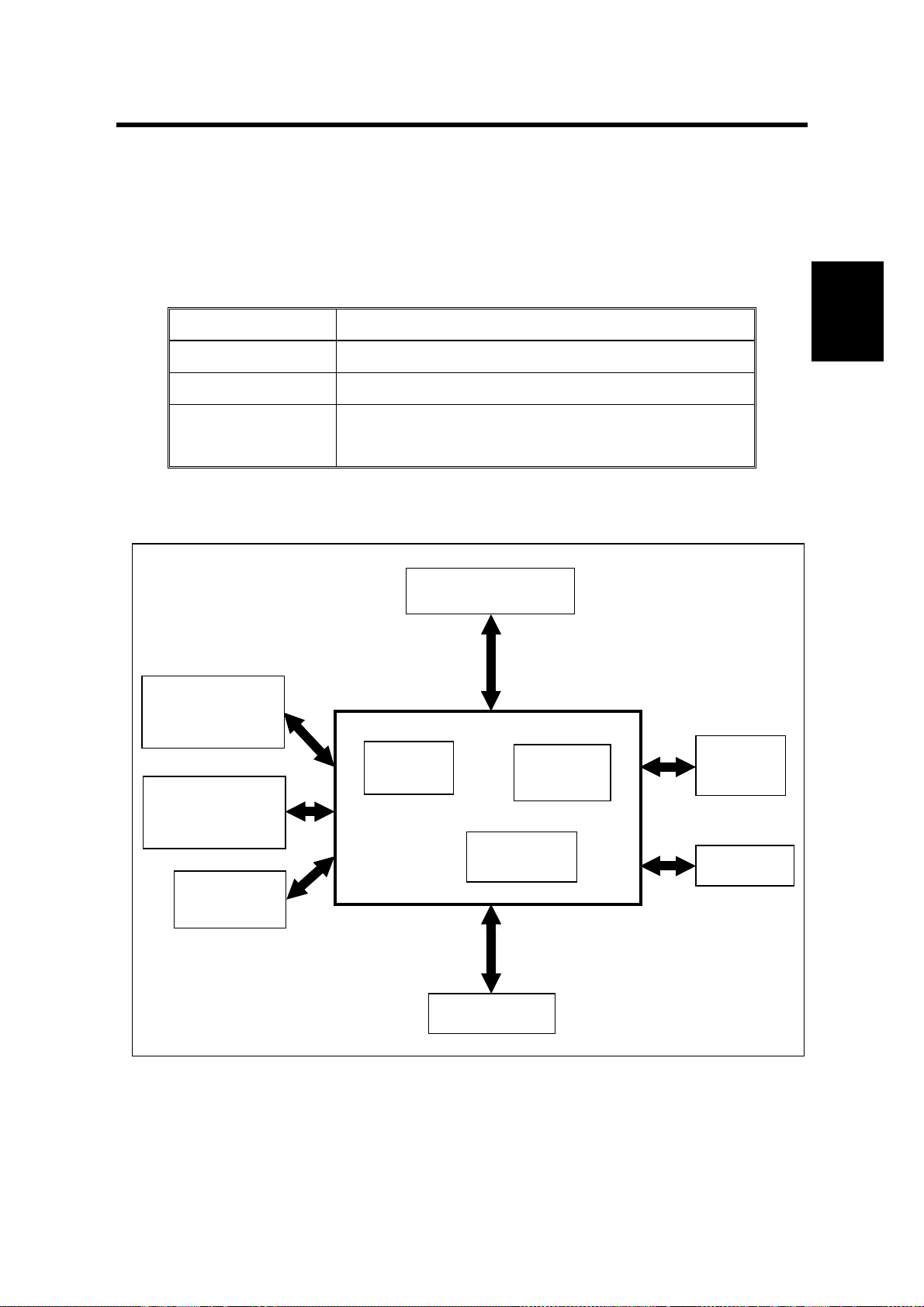

2.1.1 MAIN BOARD SPECIFICATIONS AND BLOCK DIAGRAM

Main Printed Circuit Board specifications are listed in the table below.

Description CPIF 26 Controller

CPU NEC VR4300 100MHz

DRAM 32MB (SIMM)

Flash ROM 8Mb on Main Board,

Block Diagram

Local Talk

(RS422)

Centronics I/F

1Mb Flash ROM SIMM (subject to change)

Table 2.1. Main Board Specifications.

CPU: VR4300

CPLD

Flash

ROM

ROM

SIMM

Basic

Function

(IEEE-1284)

10 Base T

RJ45

FPGA

Memory

Video I/F

Figure 2.1. Controller Block Diagram.

7

Page 12

BASIC CONFIGURATION 30 April, 1999

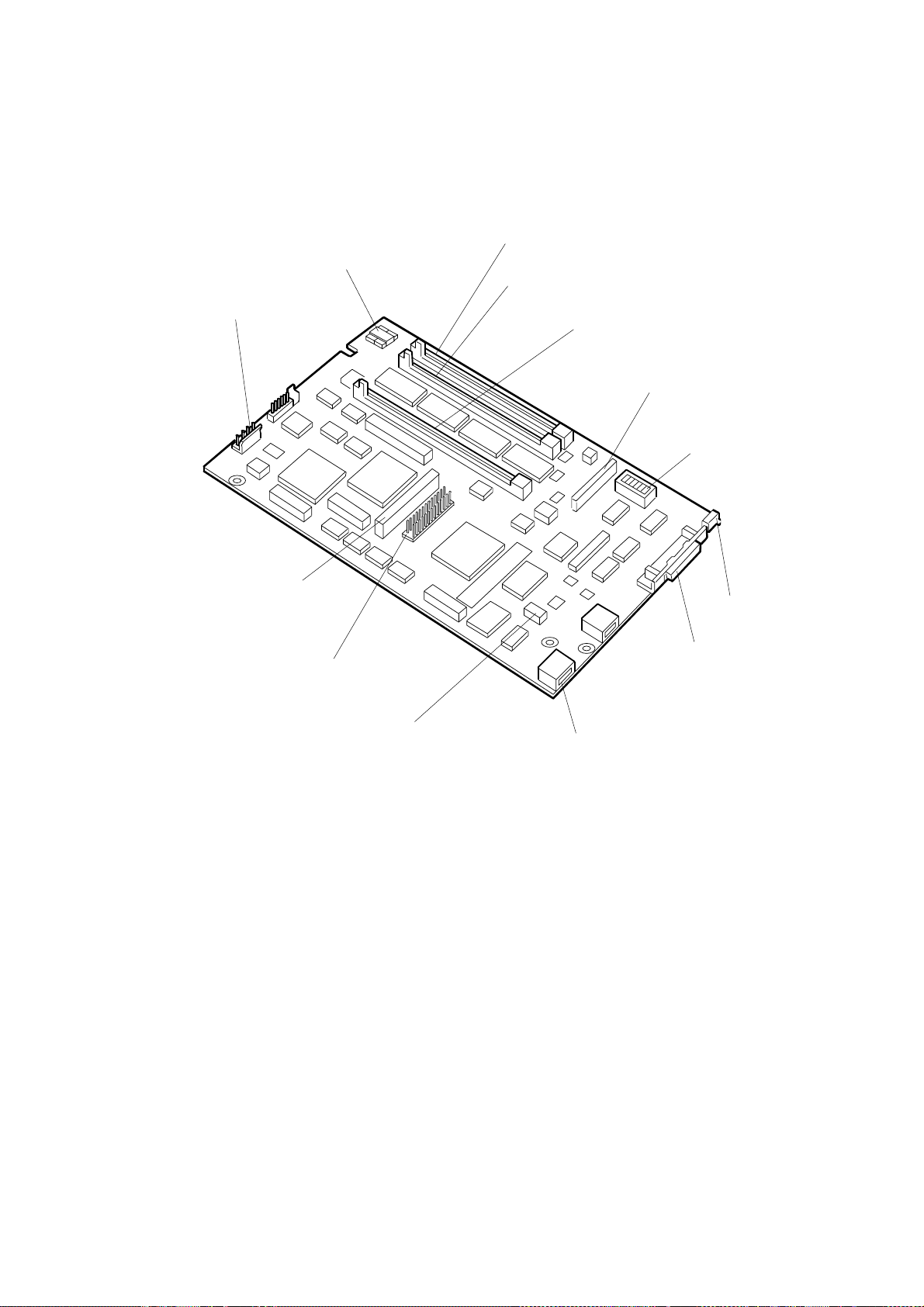

2.1.2 MAIN BOARD LAYOUT

RAM SIMM Slot 1

LED's

Power

Connector

– J12

Network I/F (NIB)

Connector – J8

26-pin Optional Printer

Port Connector – J9

Console Connector

Serial Port Header – JP2

RAM SIMM Slot 2

Flash ROM SIMM Slot

Duplicator Video I/F

Header – J2

Switch 1 – SW1

(4-pin switch)

Test Button

Parallel

AppleTalk

Figure 2.1.2. Main Board Layout

8

Page 13

30 April, 1999 SPECIFICATIONS AND CONFIGURATIONS OF I/O PORTS

2.2 SPECIFICATIONS AND CONFIGURATIONS OF I/O

PORTS

The CPIF 26 Controller supports connection to a computer for printing

from any of the following ports:

Parallel Port (IEEE 1284, ECP Bi-directional)

LocalTalk (Apple computers)

10-BaseT LAN Port

• Ethernet for IBM-compatible PCs (IPX and IP protocols)

• EtherTalk for Apple Macintosh PCs (AppleTalk and IP protocols)

2.2.1 PARALLEL MINI-CENTRONICS INPUT PORT

2.2.1.1 Description

The high-performance parallel input/output port on

the controller utilizes the

supporting hardware-enhanced, nibble-mode reversedirection data transfer, for high-speed communication

between the computer and controller. Be sure to use

a cable conforming to this design standard to realize the full data speed

benefit from this interface.

2.2.1.2 IEEE 1284 Parallel Port Characteristics

IEEE 1284 – 1994

design,

Basic

Function

Maximum data speed: 2 MBytes/sec.

Maximum cable length: 10 meters (30 feet).

Chassis connector type: IEEE 1284 Type C (Mini-Centronics).

Design standard: IEEE 1284 – 1994.

To use this interface, the parallel port (e.g., LPT1:) on the user’s

computer must be configured as an

For more information on the parallel port, point your Internet web

browser to:

http://www.fapo.com/ieee1284.htm

ECP

(not EPP)

9

Printer Port

.

Page 14

SPECIFICATIONS AND CONFIGURATIONS OF I/O PORTS 30 April, 1999

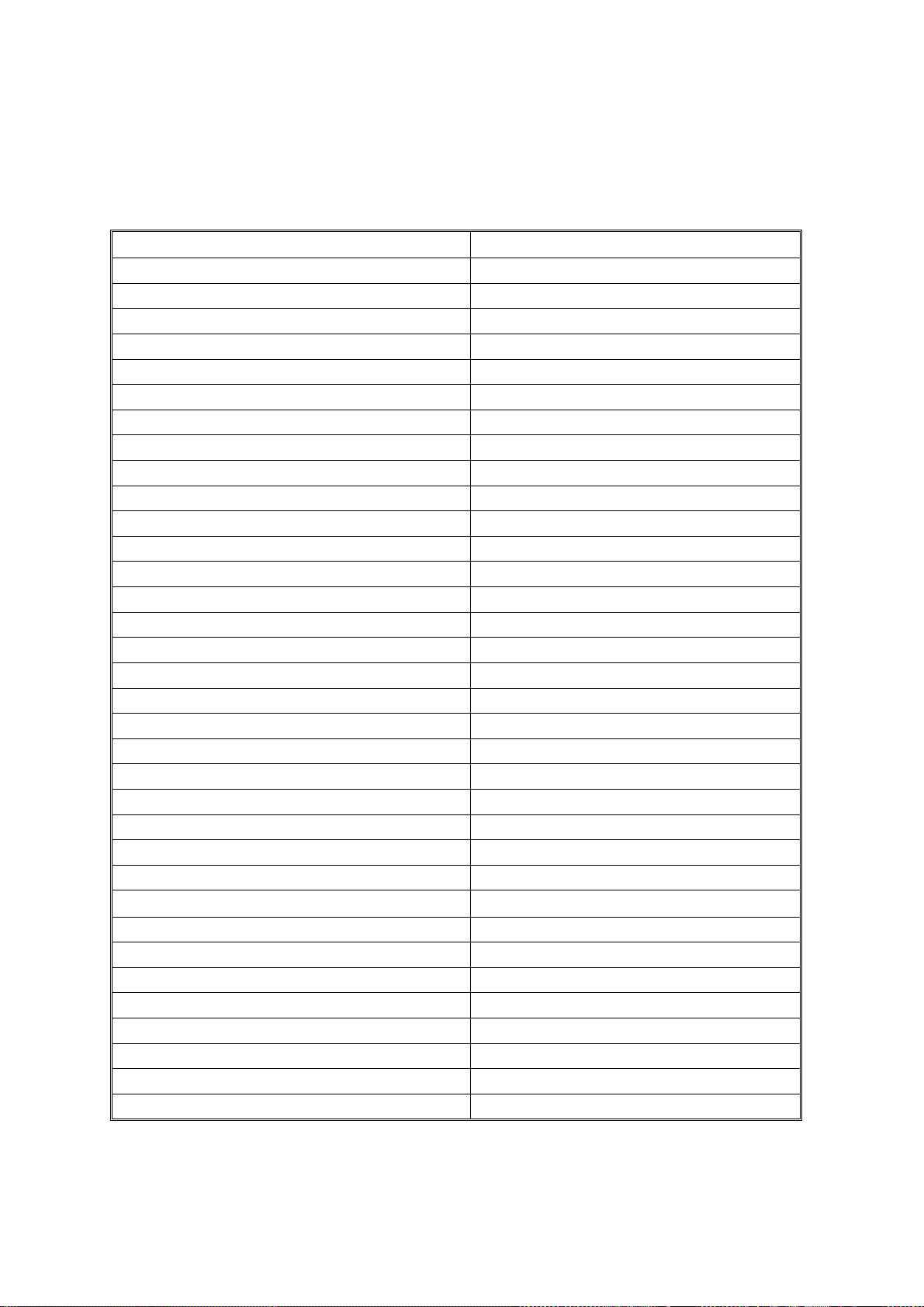

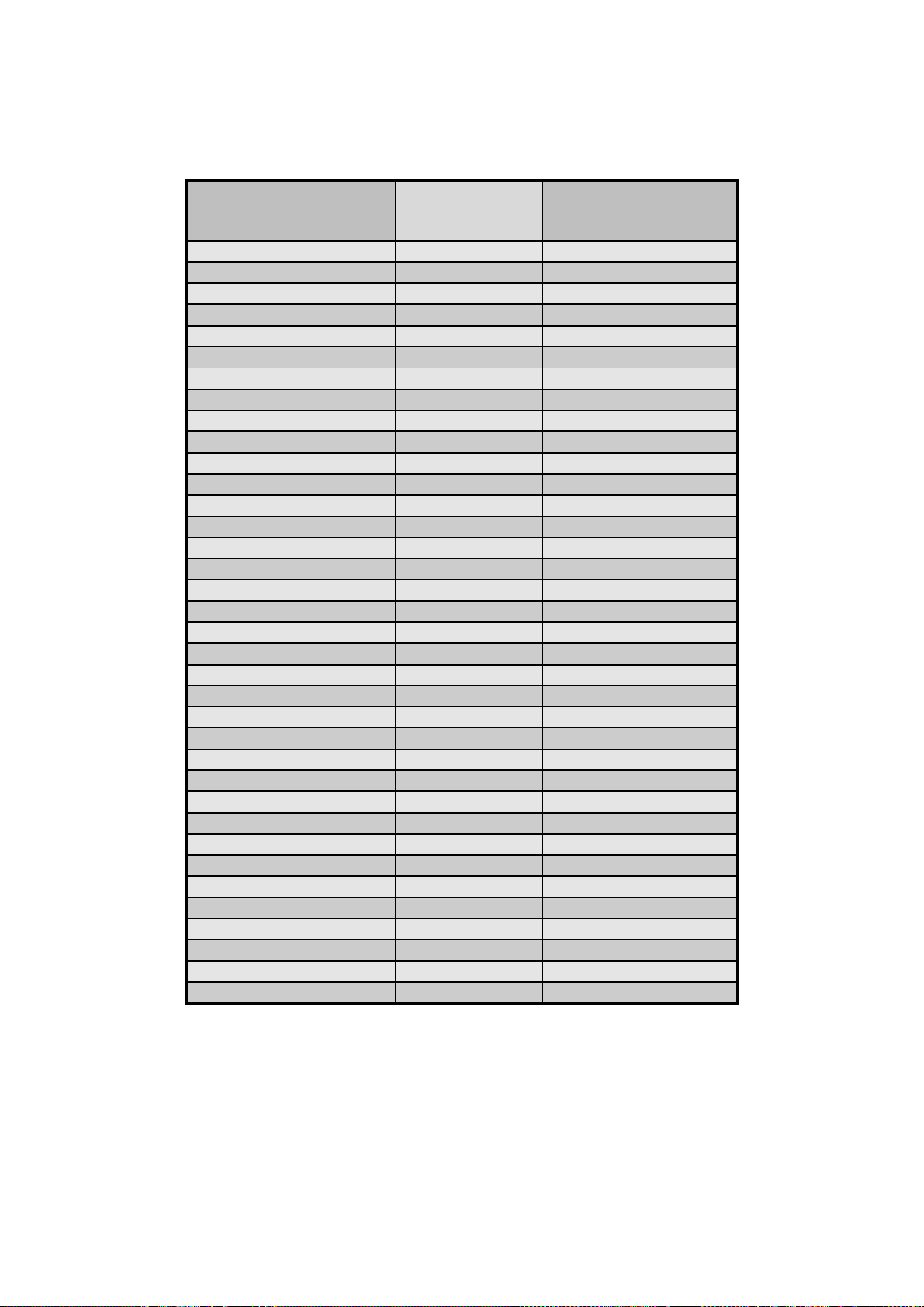

2.2.1.3 IEEE 1284 Parallel Port Pinout

Computer End Controller End

1284A Connector Pin

1 nStrobe 15

18 Rtn 33

2 Data_1 6

19 Rtn 24

3 Data_2 7

19 Rtn 25

4 Data_3 8

20 Rtn 26

5 Data_4 9

20 Rtn 27

6 Data_5 10

21 Rtn 28

7 Data_6 11

2 Rtn 29

8 Data_7 12

22 Rtn 30

9 Data_8 13

22 Rtn 31

10 nAck 3

24 Rtn 21

11 Busy 1

23 Rtn 19

12 PE 5

24 Rtn 23

13 Select 2

24 Rtn 20

14 nAutoFeed 17

25 Rtn 35

15 nFault 4

23 Rtn 22

16 nInit 14

25 Rtn 32

17 nSelectIn 16

25 Rtn 34

(nc) +5V/Host_Avail 18

(nc) Perph_Avail 36

Signal

1284C Connector Pin

Table 2.2.1.3. IEEE 1284 A-to-C Connector Contact Numbering

10

Page 15

30 April, 1999 SPECIFICATIONS AND CONFIGURATIONS OF I/O PORTS

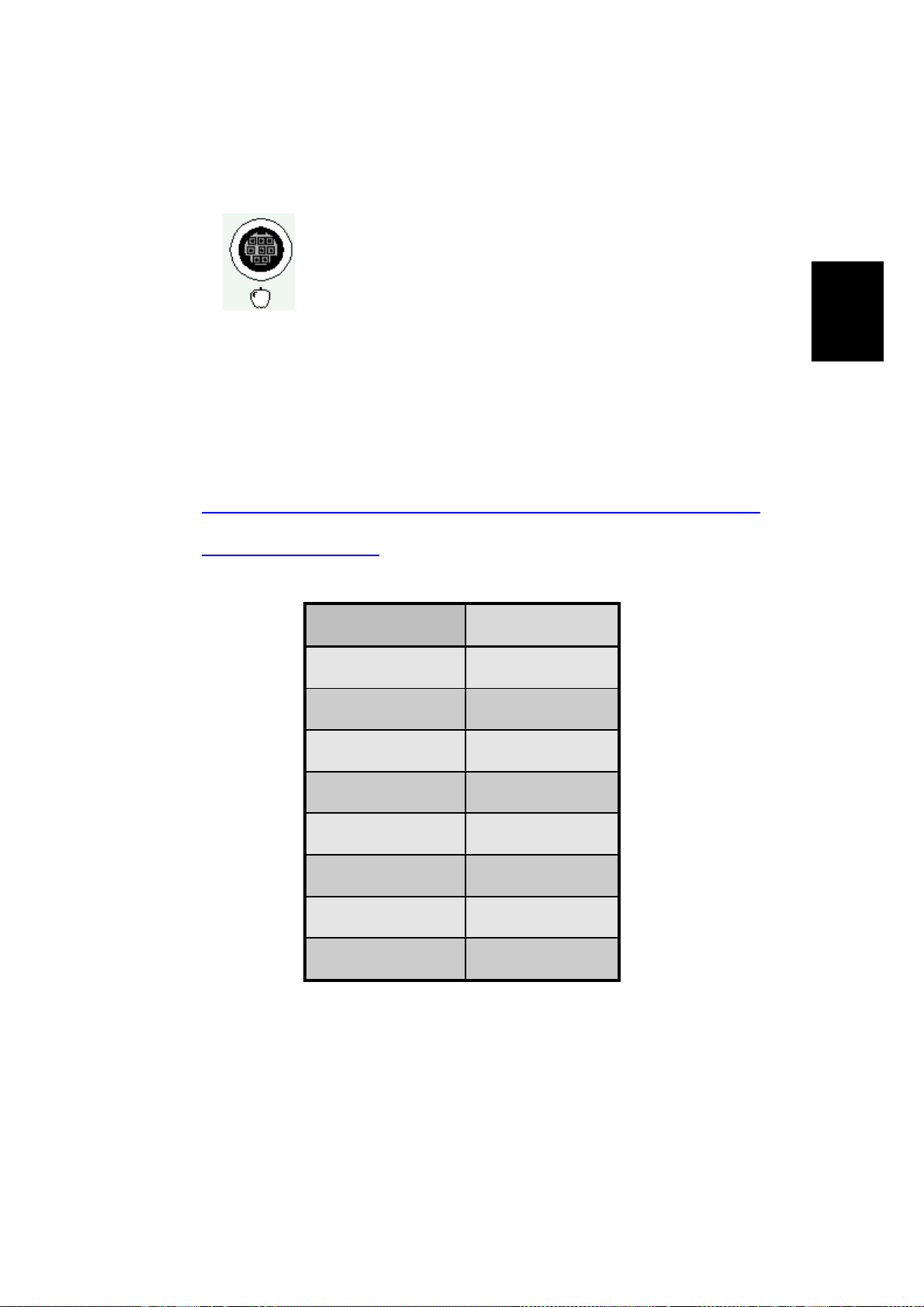

2.2.2 LOCALTALK CONNECTION

2.2.2.1 Description

The LocalTalk interface is used by the Macintosh series

of computers designed and built by Apple Computer, Inc.

It is a bi-directional port and supports the AppleTalk local

area network (LAN) protocol.

2.2.2.2 LocalTalk Port Characteristics

Maximum data speed: 230.4Kbs / 28.8KBytes/sec.

Maximum cable length: 300 meters (1000 feet).

Chassis connector type: 8-pin mini-DIN female.

Design standard: Apple proprietary.

For more information on AppleTalk and LocalTalk, point your Internet

web browser to:

http://www.cisco.com/univercd/cc/td/doc/cisintwk/ito_doc/55142.htm

http://www.apple.com

2.2.2.3 LocalT alk Port Pinout

Contact Number Signal Name

1 (not connected)

2 (not connected)

3 - Data Out

- or -

Basic

Function

4 Ground

5 - Data In

6 + Data Out

7 (not connected)

8 + Data In

Table 2.2.2.3. LocalTalk Connector Contact Numbering.

11

Page 16

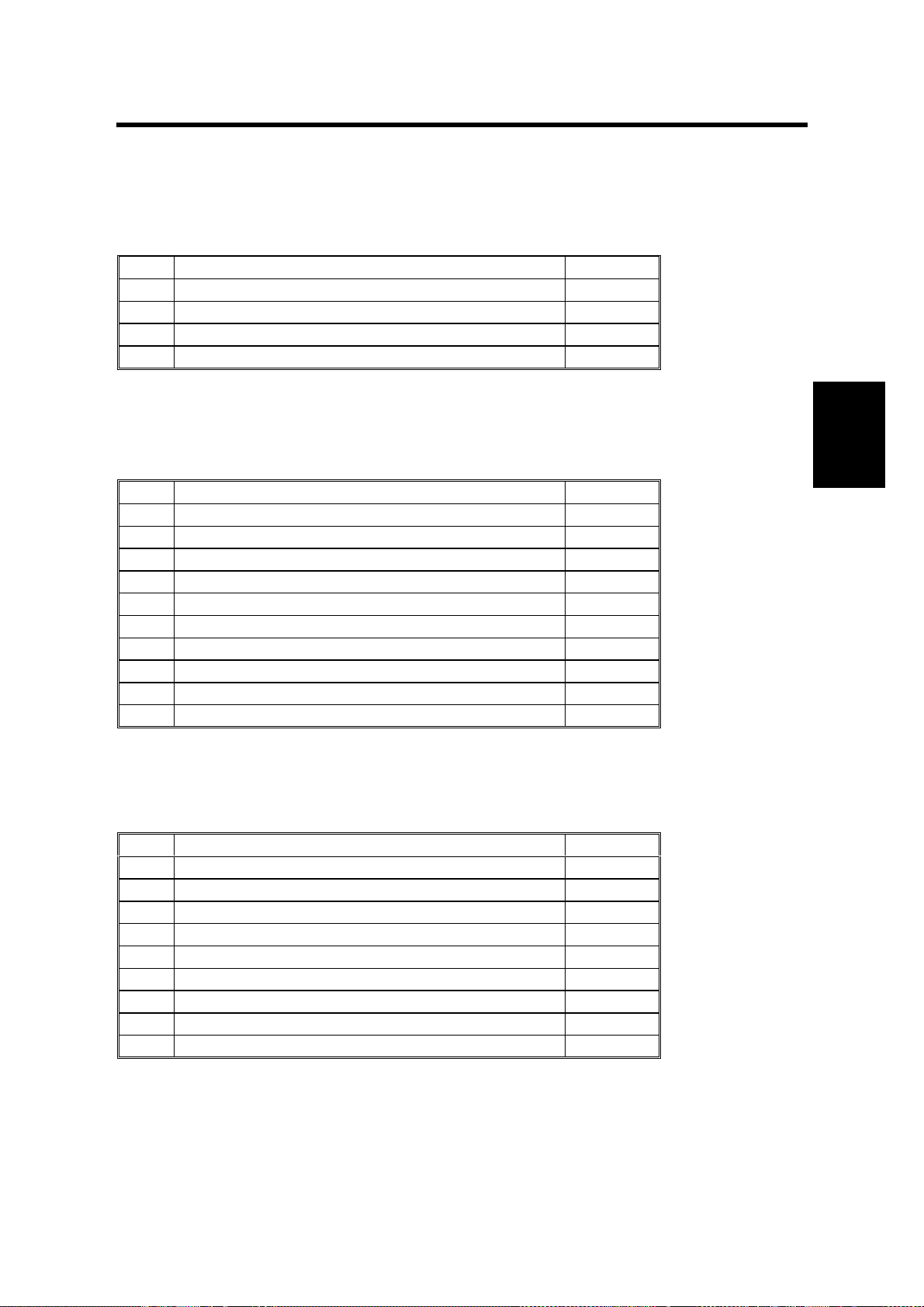

30 April, 1999 VIDEO I/F KIT TYPE-600 PARTS LIST

3. VIDEO I/F INSTALLATION PROCEDURES

3.1 VIDEO I/F KIT TYPE-600 PARTS LIST

3.1.1 COMMON ASSEMBLIES

No. Description Qty.

1 IC – Interface 1

2 Interface Board 1

3 Insulating sheet – 145 x 200 1

4 Interface Cable – Interface Board 1

Table 3.1.1. Common Assemblies.

3.1.2 SET FOR PART 1A

No. Description Qty.

5 Stud – 50mm 2

6 Spacer – 10mm 2

7 PCB Stud – 64mm 2

8 Harness Support Bracket 1

9 Philips Pan Head Screw – M3 x 35 1

10 Philips Flange Screw – M3 x 8 3

11 Philips Flange Screw – M4 x 8 3

12 Flat Cable – N810/NA33/NA3/NB2/RN925/N850 1

13 Wire Band 1

14 PCB Collar 1

Table 3.1.2. Set for Part 1A.

3.1.3 SET FOR PART 1B

No. Description Qty.

15 Flat Cable – NA2 1

16 Main Board Spacer 1

17 Stud – Bracket – Interface 2

18 Interface Board Bracket 1

19 Philips Screw with Flat Washer – M3 x 25 1

20 Stud – Main Board 1

21 Philips Screw with Flat Washer – M4 x 6 1

22 Philips Screw – M4 x 8 2

23 Philips Screw with Flat Washer – M3 x 6 2

Installation

Table 3.1.3. Set for Part 1B.

13

Page 17

VIDEO I/F KIT TYPE-10 PARTS LIST 30 April, 1999

3.1.4 SET FOR PART 1C

No. Description Qty.

24 Interface Board Stud 2

25 Main Board Stud – Long 4

26 Philips Screw – M4 x 8 2

27 Philips Screw with Flat Washer – M3 x 6 4

28 Flat Cable – N865 1

Table 3.1.4. Set for Part 1C.

3.1.5 PARTS FOR 1D

No. Description Qty.

29 Stud – 35mm 3

30 Philips Screw with flat Washer – M3 x 6 3

31 Philips Screw – M4 x 8 2

Table 3.1.5. Set for Part 1D.

3.2 VIDEO I/F KIT TYPE-10 PARTS LIST

No. Description Qty.

32 Interface Board 1

33 Relay Harness 1

34 Stepped Screw – M2.6 2

35 Tapping Screw – M3 x 6 2

Table 3.2.1. Video I/F kit Type-10.

14

Page 18

30 April, 1999 INSTALLATION PROCEDURES FOR INTERFACE KITS

3.3 INSTALLATION PROCEDURES FOR INTERFACE KITS

NOTE:

1) The CPIF26 Controller is designed for the JP1010/1030/1045/1050,

JP5000, and VT6000 models only. The installation procedures for the

other models are just for reference for the other controllers.

2) Numbers in parentheses ( ) in the installation procedures correspond to

the part numbers in Tables 3.1 through 3.2.

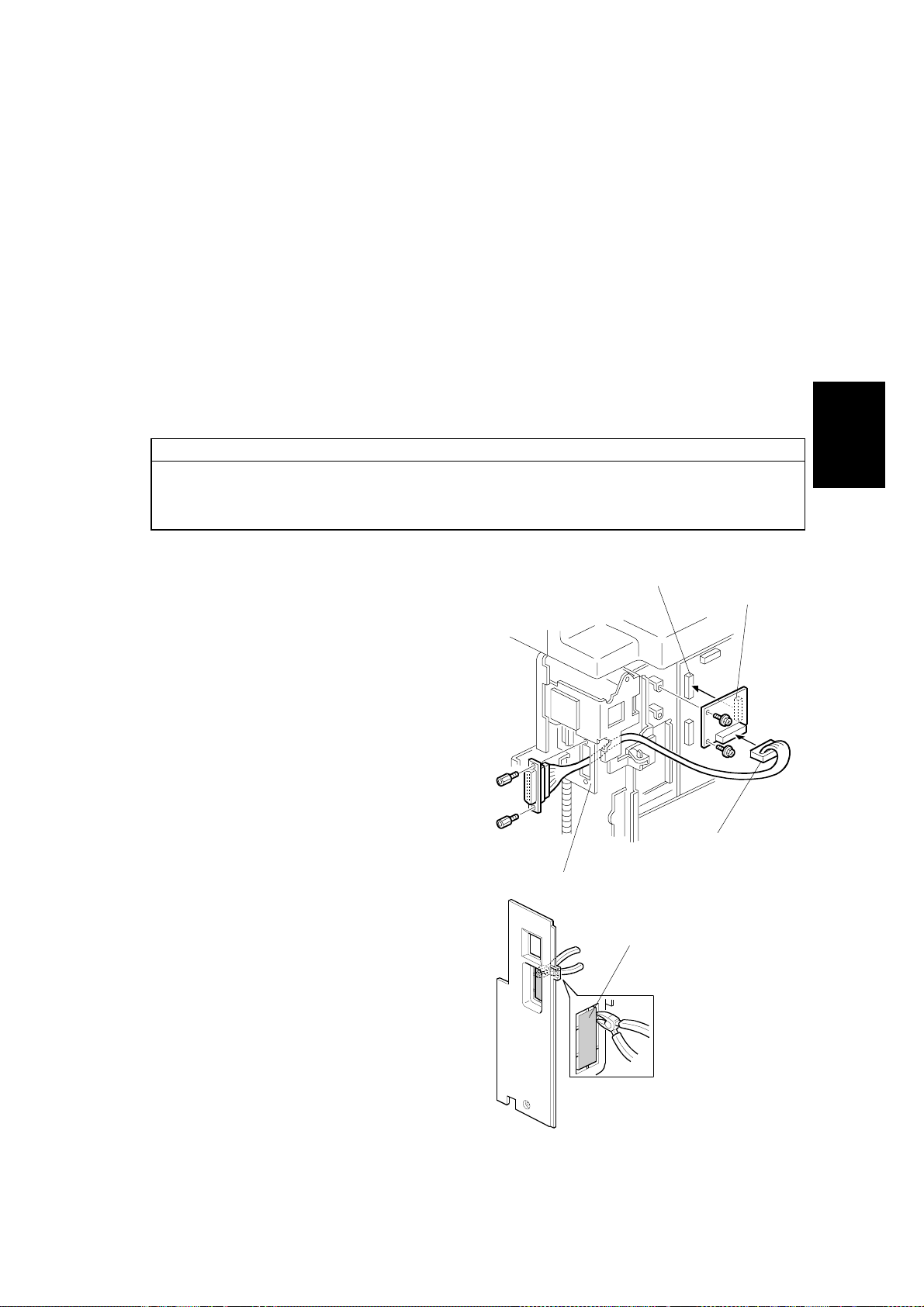

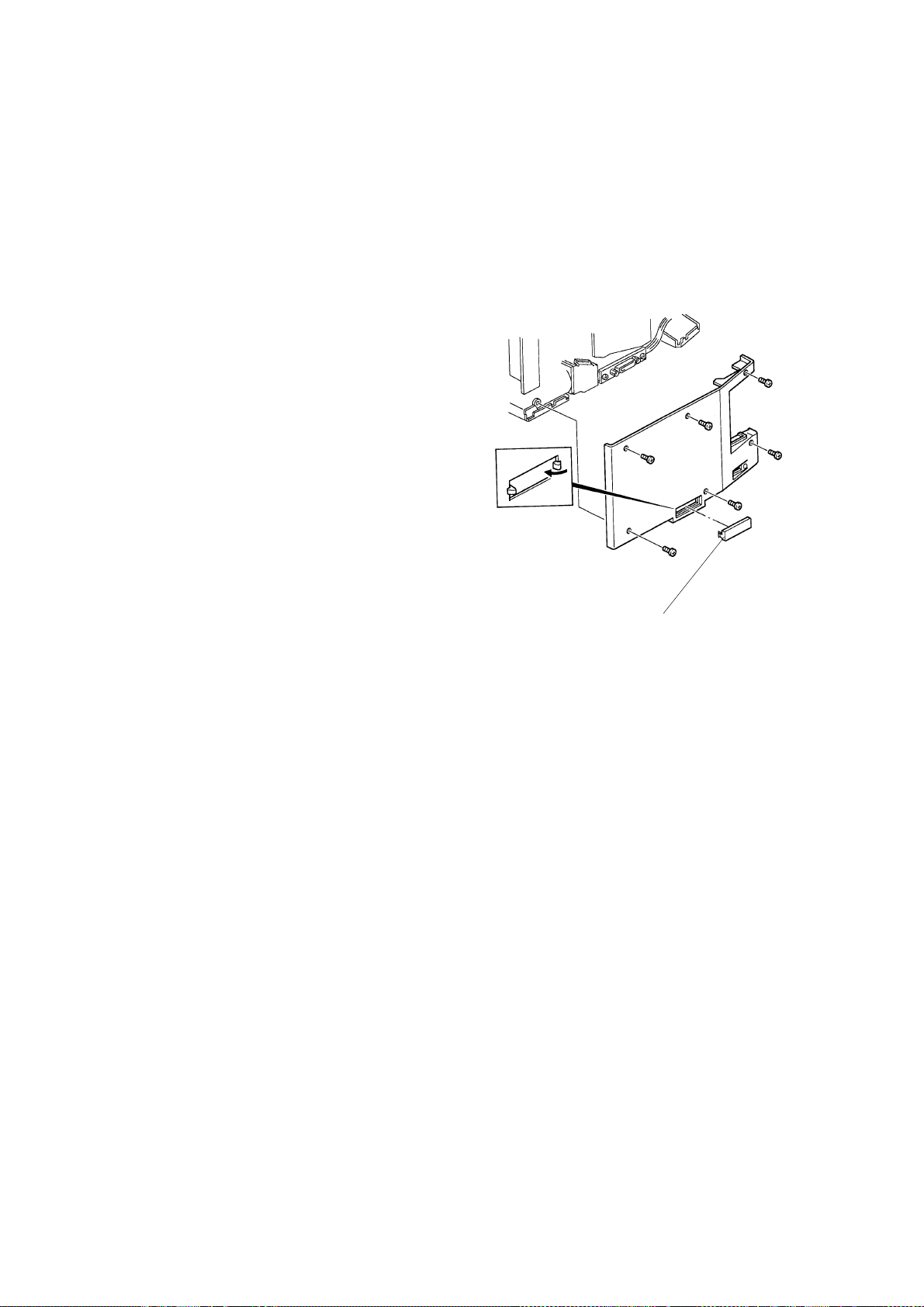

3.3.1 JP5000

NOTE:

The interface kit is originally installed for the JP5000, except for the Asian

version machines. You must perform step 3 only to connect the controller if

the kit is installed.

1. Remove the rear cover and right side

panel of the Priport.

2. Mount Printed Circuit Board (32) on

connector CN102 of the MPU board

using two M3x6 screws (35). Mount

the cable (33) on the Connector

Bracket using two stepped screws

(34).

CN102

Installation

Printed

Circuit

Board

3. Remove the blinding cover in the right

side panel.

NOTE:

If SP Mode 2-6 (PC Controller

Settings) is set at “AUTO” (i.e. the

default setting), the On-line key is

enabled automatically when the

controller and interface kit are

installed.

Harness

Connector Bracket

Blinding Cover

15

Page 19

INSTALLATION PROCEDURES FOR INTERFACE KITS 30 April, 1999

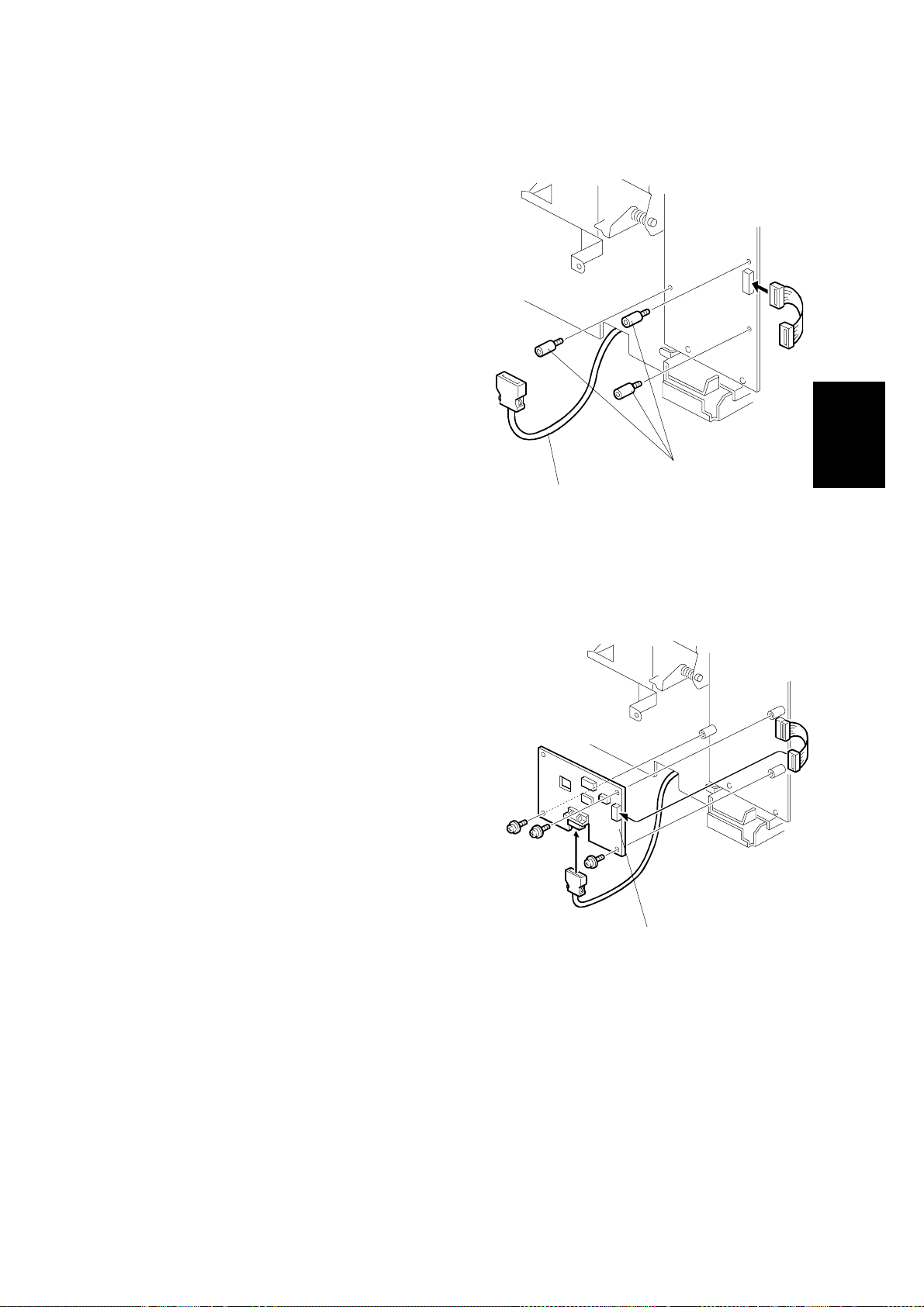

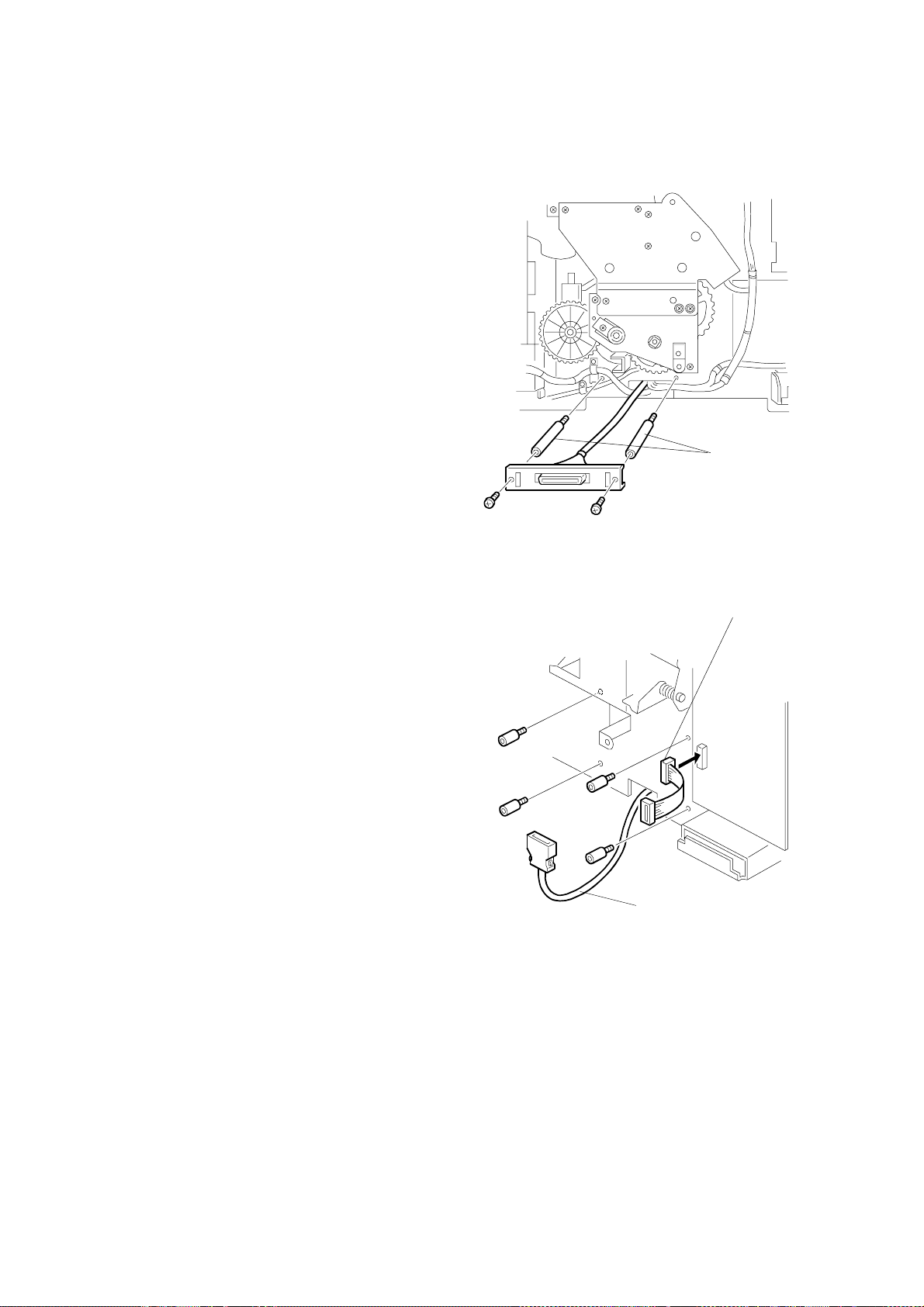

3.3.2 JP1010/1030/1045/1050

Harness

Printed Circuit Board

MPU

Connector Bracket

1. Turn off the main switch and unplug the power cord.

2. Remove the upper rear cover.

3. Remove the MPU cover.

4. Connect CN102 of the printed circuit board (32) to CN110 of the MPU board

and secure it using two screws (35).

5. Connect the harness (33) to CN101 of the printed circuit Board, and secure it to

the connector bracket using two stepped screws (34).

6. Remove the communications port cover plate (blinding cover) from the upper

rear cover.

7. Reinstall the MPU cover.

8. Reinstall the upper rear cover.

NOTE:

The On-line key on the operation panel is enabled automatically when the

controller and interface kit are installed.

16

Page 20

30 April, 1999 INSTALLATION PROCEDURES FOR INTERFACE KITS

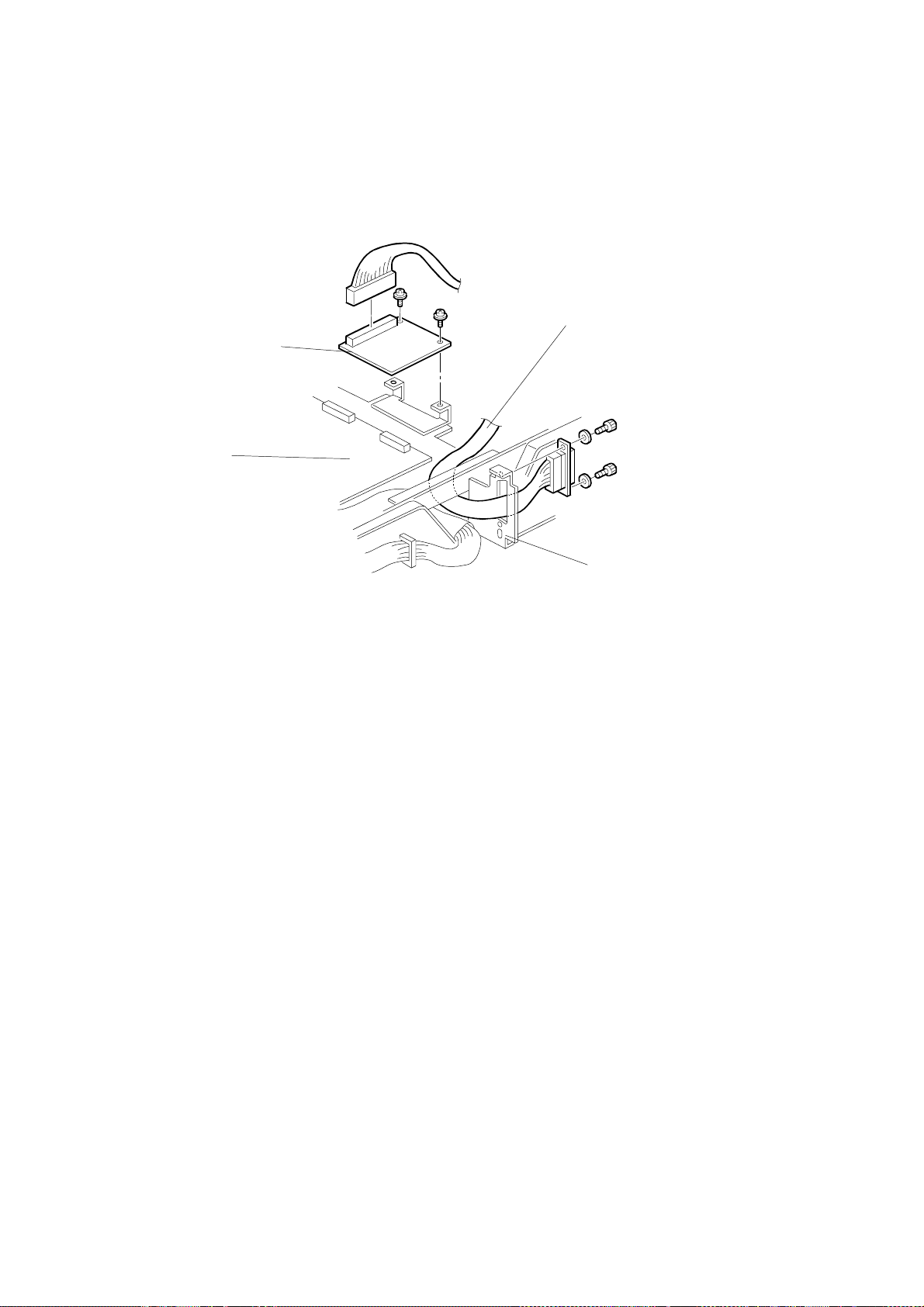

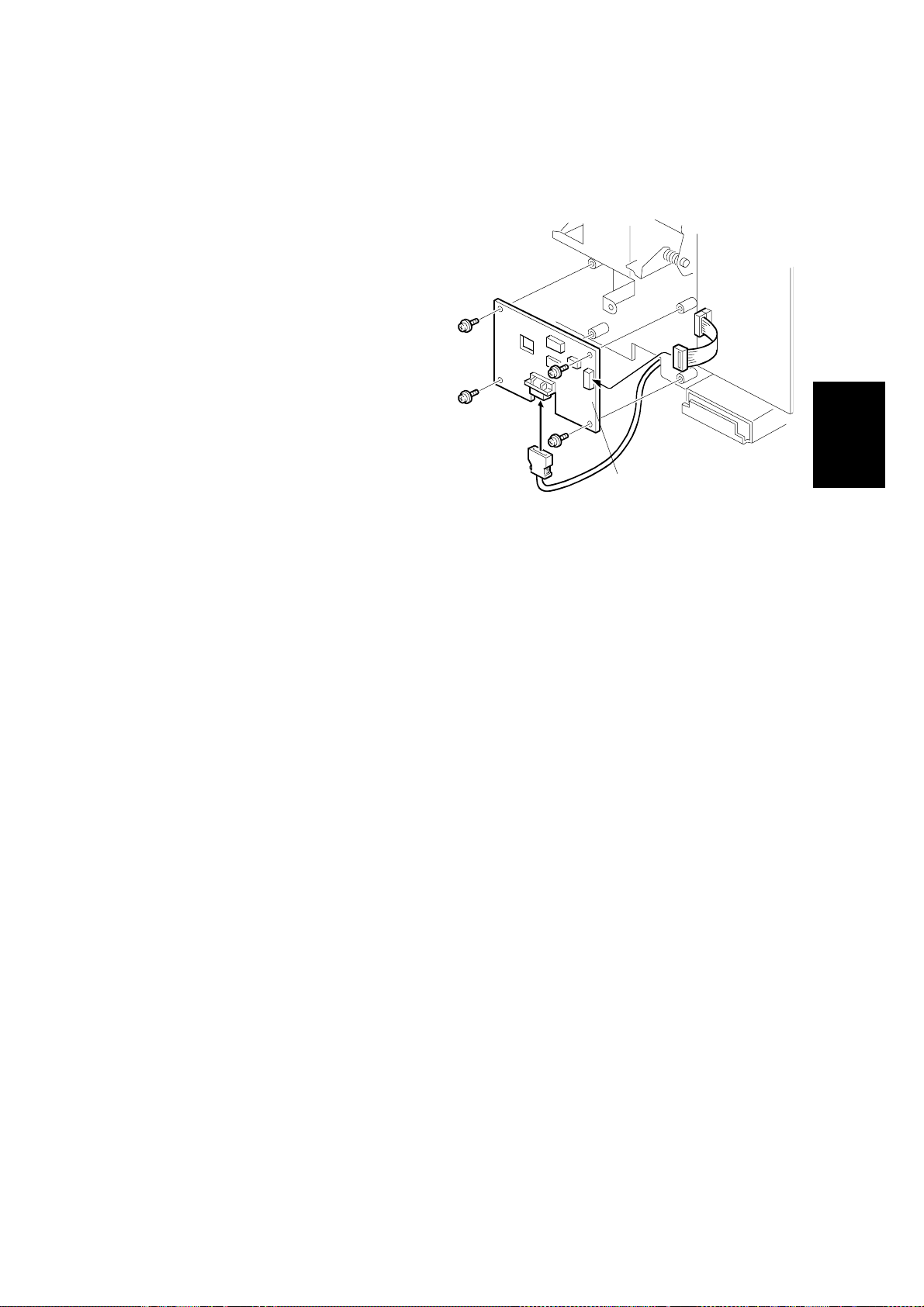

3.3.3 VT6000/3800/3600/3500/2600

1. Remove the rear cover and front side panel of the Priport.

2. Mount the Shielded Cable Interface (2).

a) Mount a Stud (17) on the rear chassis of the Priport.

b) Thread the Shielded Cable (4) from rear chassis to the front chassis

under the Priport body.

Note for the VT3600/3500/2600: first remove the bottom plate, then reattach it.

c) Attach the Shielded Cable (4) on the Stud (17) using two M4x8 Screws

(26).

NOTE:

Before mounting Printed Circuit Board Interface (2), attach one end of the

Ribbon Cable (12) to the IPU board ribbon cable connector.

Installation

3. Mount the Printed Circuit Board

Interface (2).

a) Mount a Stud (20) on the

Priport.

b) Mount the Bracket (18) on the

chassis using a M4x6 screw

and washer (21).

c) Attach the Printed Circuit Board

(2) using 2, M3x6 screws (27).

Attach the bottom of the right

hand side of the Printed Circuit

Board to the Spacer (16) using

a M3x25 screw (19).

d) Attach the connector of the

Printed Circuit Board (2) to the

Shielded Cable (4).

e) Attach free end of the Ribbon

Cable (21) to the Printed Circuit

f) Board Interface (2).

M4x6 Screw

Interface Board

M3x6 Screws

Stud

Bracket

M3x25 Screw

IPU board

Spacer

Ribbon

Cable

17

Page 21

INSTALLATION PROCEDURES FOR INTERFACE KITS 30 April, 1999

4. Set the Printed Circuit Board interface switches.

a) Set all switches on DIPSW 101 to OFF.

5. Re-attach the side cover panels

of the Priport.

a) Pop out the communication

port cover plate from the

lower center of the rear

cover panel.

b) Reinstall the rear and front

cover panels.

6. Connect the Priport and AC power to the Controller.

a) Connect a Video Cable between the Priport and the Controller.

b) Connect an AC cable to the Controller.

7. Set SP Mode 1 (for the Online Key On/Off) to ON.

Communication port cover

18

Page 22

30 April, 1999 INSTALLATION PROCEDURES FOR INTERFACE KITS

3.3.4 VT2400

1. Remove the rear cover and front side

panel of the Priport.

2. Mount Shielded Cable Interface (4).

3. Mount Printed Circuit Board Interface

(2).

a) Remove the three screws

attaching t he mainframe MPU

Board to the chassis (two

screws upper and lower side of

CN109, and one screw lower

side of the CN111).

b) Replace the screws removed in

a) above with Studs (29).

c) Connect one side of the Ribbon

Cable (12) to the connector of

Mainframe MPU Board.

d) Attach the Printed Circuit Board

Interface (2) to the Studs (29)

using M3x6 Screws (27).

e) Connect the free end of the

Ribbon Cable (12) to the CN102

connector of Printed Circuit

Board Interface (2).

f) Set all switches of DIPSW 101

on the Printed Circuit Board

Interface (2) to OFF.

Shielded Cable

Studs

Installation

4. Pop out the communication port cover

plate from the lower center of the rear

cover panel. Reinstall the rear and

front cover panels.

5. Set SP Mode 2-1 (Online Key On/Off)

to ON.

Printed Circuit Board Interface

19

Page 23

INSTALLATION PROCEDURES FOR INTERFACE KITS 30 April, 1999

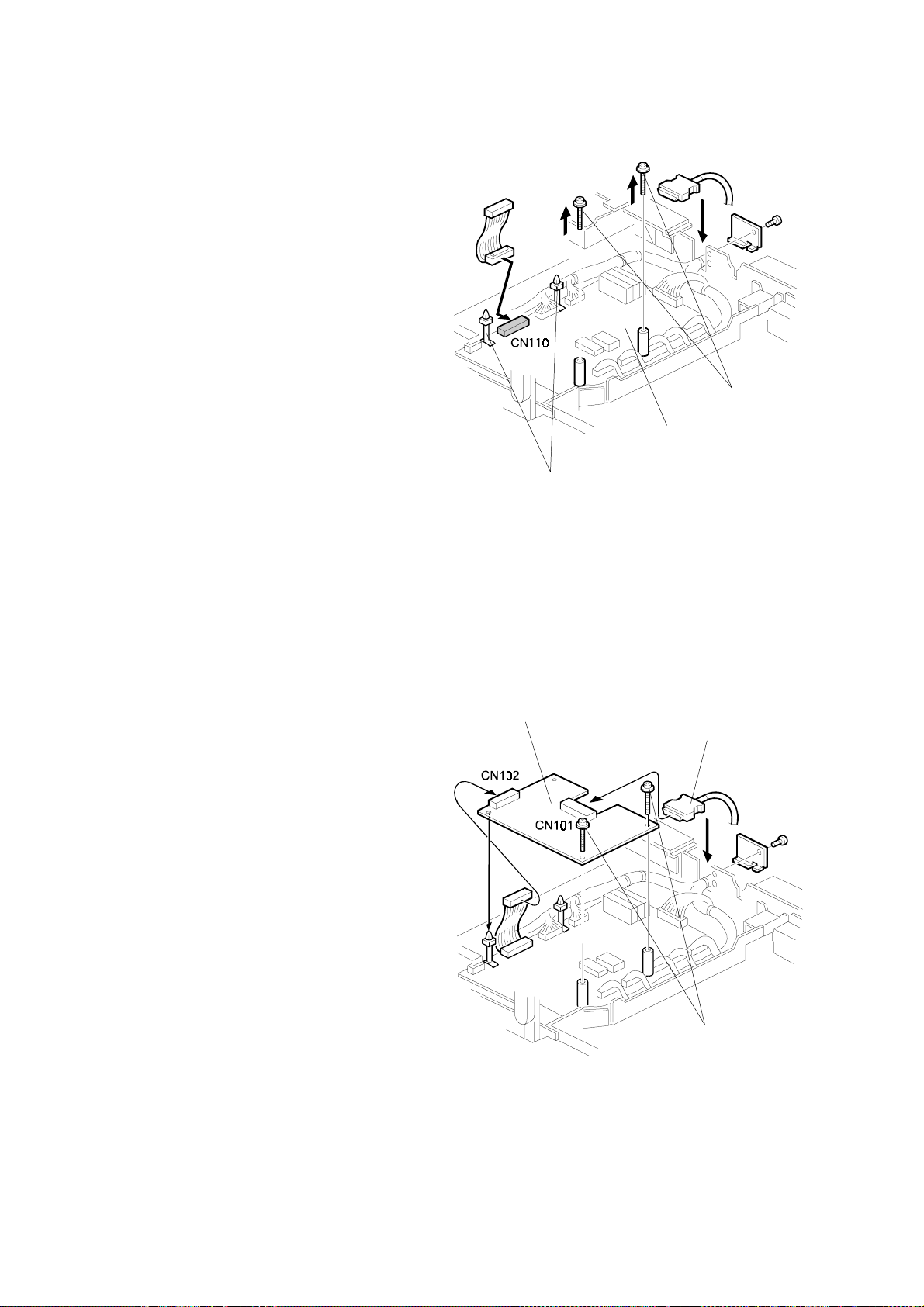

3.3.5 VT2240/VT2250

1. Remove the top cover of the

Mainframe MPU Board.

2. Remove screws attached to the

two studs on the top of MPU

Control Board.

3. Connect the free end of the

Ribbon Cable (12) to the

connector marked CN110

located at the left edge of the

MPU Control Board.

4. Position the MPU Control Board

and Printed Circuit Board

Interface (2) on the Studs.

5. Attach the Printed Circuit Board

Interface (2) to the MPU Control

Board, taking care to align the

left edge with the locking

spacers.

MPU Control Boar d

Locking Spacers

Screw

6. Attach the right side edge of the

Printed Circuit Board (2) to the

mounting Studs on the MPU

Control Board using three M3x6

screws.

7. Connect the free end of the

Ribbon Cable (12) to the

connector marked CN102 on the

Printed Circuit Board Interface

(2).

8. Attach the Shielded Cable to the

Printed Circuit Board Interface

(2).

Printed Circuit

Board Interface

Shielded Cable

Screws M3x6

20

Page 24

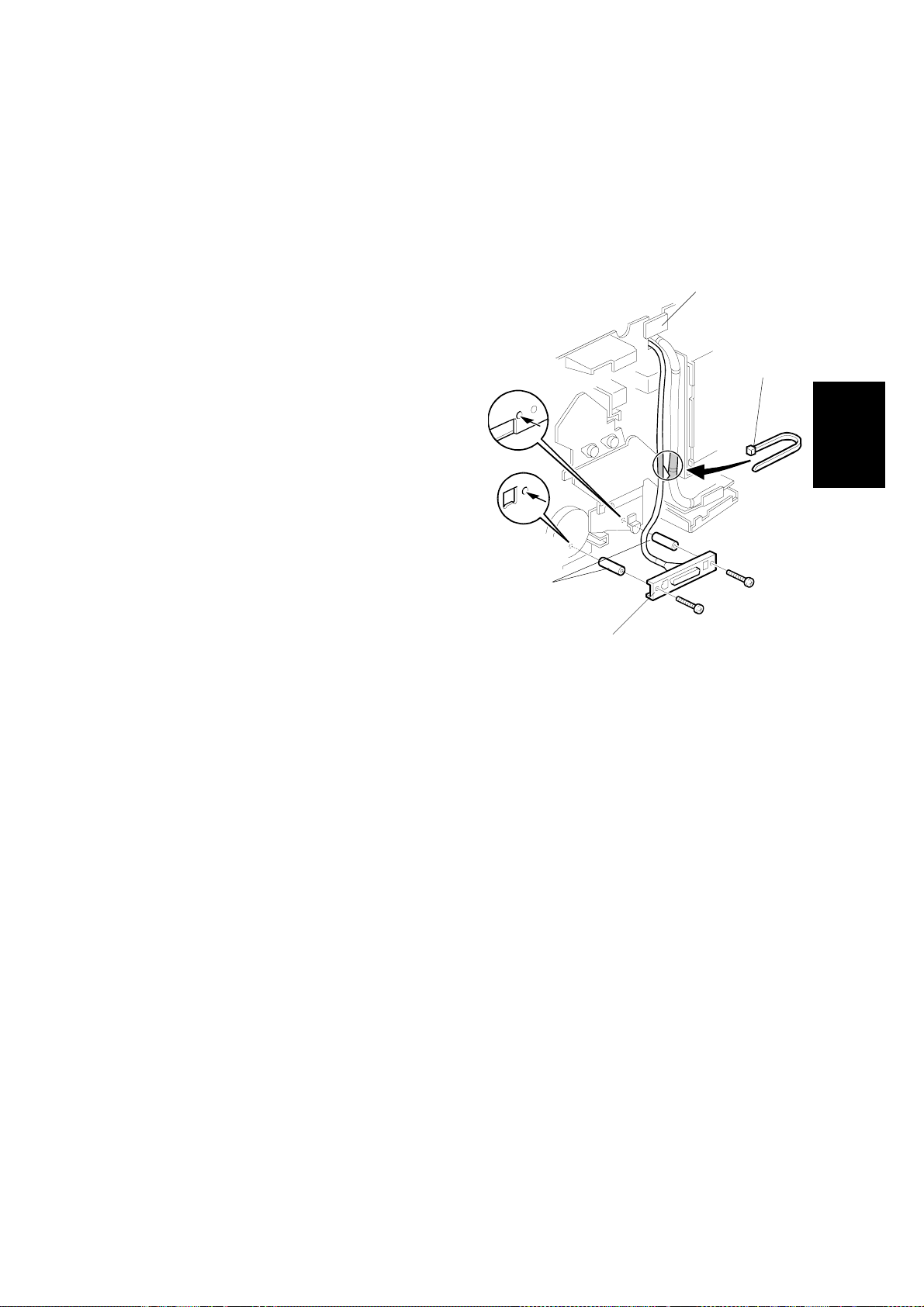

30 April, 1999 INSTALLATION PROCEDURES FOR INTERFACE KITS

9. Remove the rear cover panel of the Priport.

10. Remove the Plate attached to the channel for the Main Harness in the rear

upper of the Chassis.

11. Route the Shielded Cable (4)

along side the Main Harness.

12. Re-attach the Plate.

13. Mount the Studs (24) on the rear

chassis of the Priport.

14. Mount the Bracket end of the

Shielded Cable (4) onto the

Studs (24) using two M4x8

screws (26).

15. Tie the Shielded Cable (4) to

Main Harness using the Tie Band

(13).

16. Pop out the communication port

cover plate from the lower center

of the rear cover panel.

17. Reinstall the rear cover panel of

the Priport.

18. Set all switches on DIPSW 101 of

the Printed Circuit Board Interface (2) to OFF.

Plate

Tie Band

Installation

Studs

Bracket

19. Re-install the top cover of the Priport.

20. Set SP Mode 1 (Online Key On/Off) to ON.

21

Page 25

INSTALLATION PROCEDURES FOR INTERFACE KITS 30 April, 1999

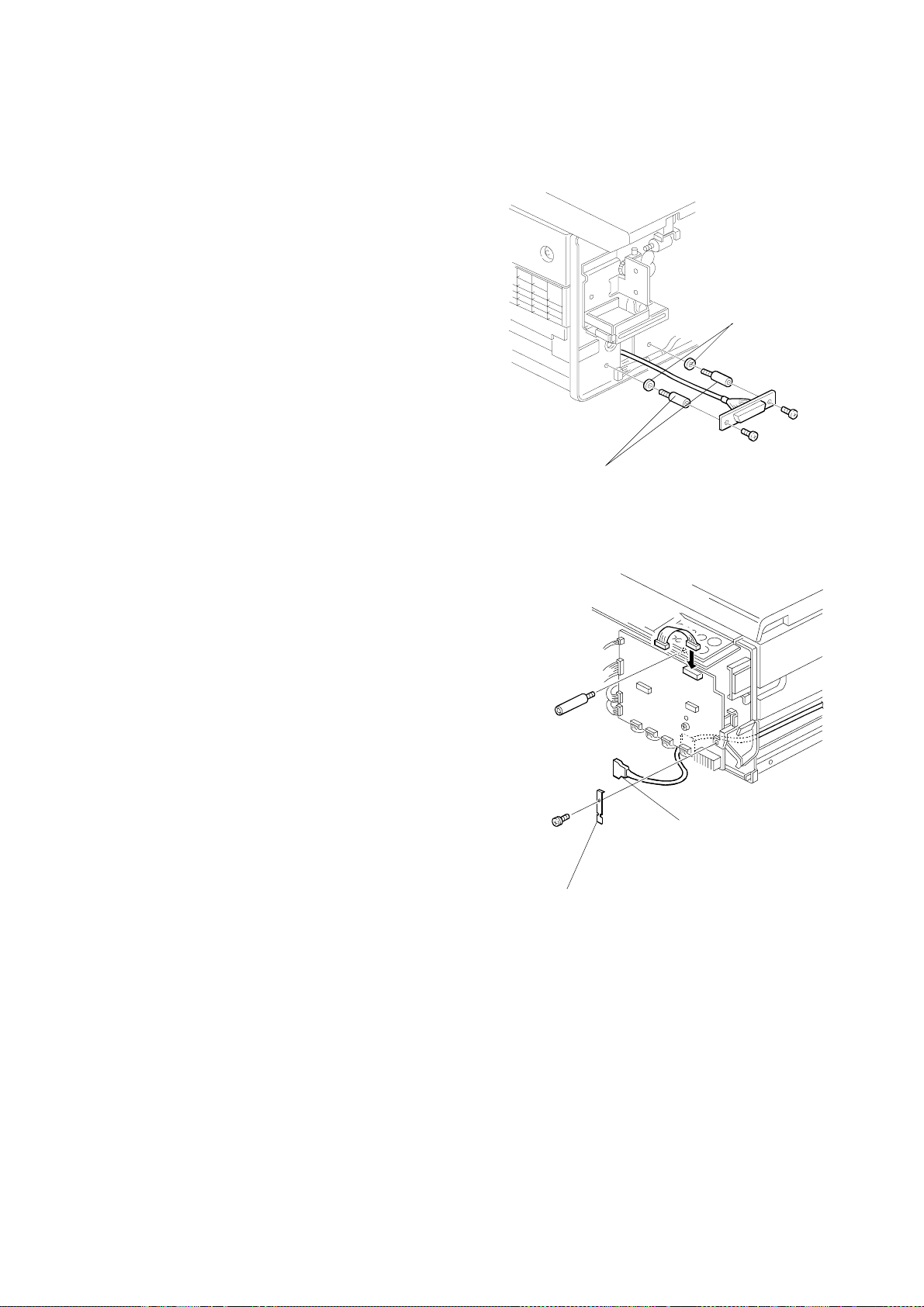

3.3.6 VT2200

1. Remove the rear and front covers

of the Priport.

2. Mount Shielded Cable Interface (4).

a) Mount two Studs (24) on the rear

chassis of the Priport.

b) Remove bottom plate of the

Priport.

c) Thread the Shielded Cable (4)

from the rear chassis to the front

chassis under the Priport body.

d) Reinstall the bottom plate.

e) Mount the Bracket of the

Shielded Cable (4) on the Studs

(8) using two Phillips Screws

M4x8 (26).

Stud

3. Mount Printed Circuit Board

Interface (2).

a) Mount four Studs (25) on the

front chassis of the Priport.

b) Connect the Ribbon Cable (12)

to the MPU board of the Priport.

Flat Cable

Shield Cable

22

Page 26

30 April, 1999 INSTALLATION PROCEDURES FOR INTERFACE KITS

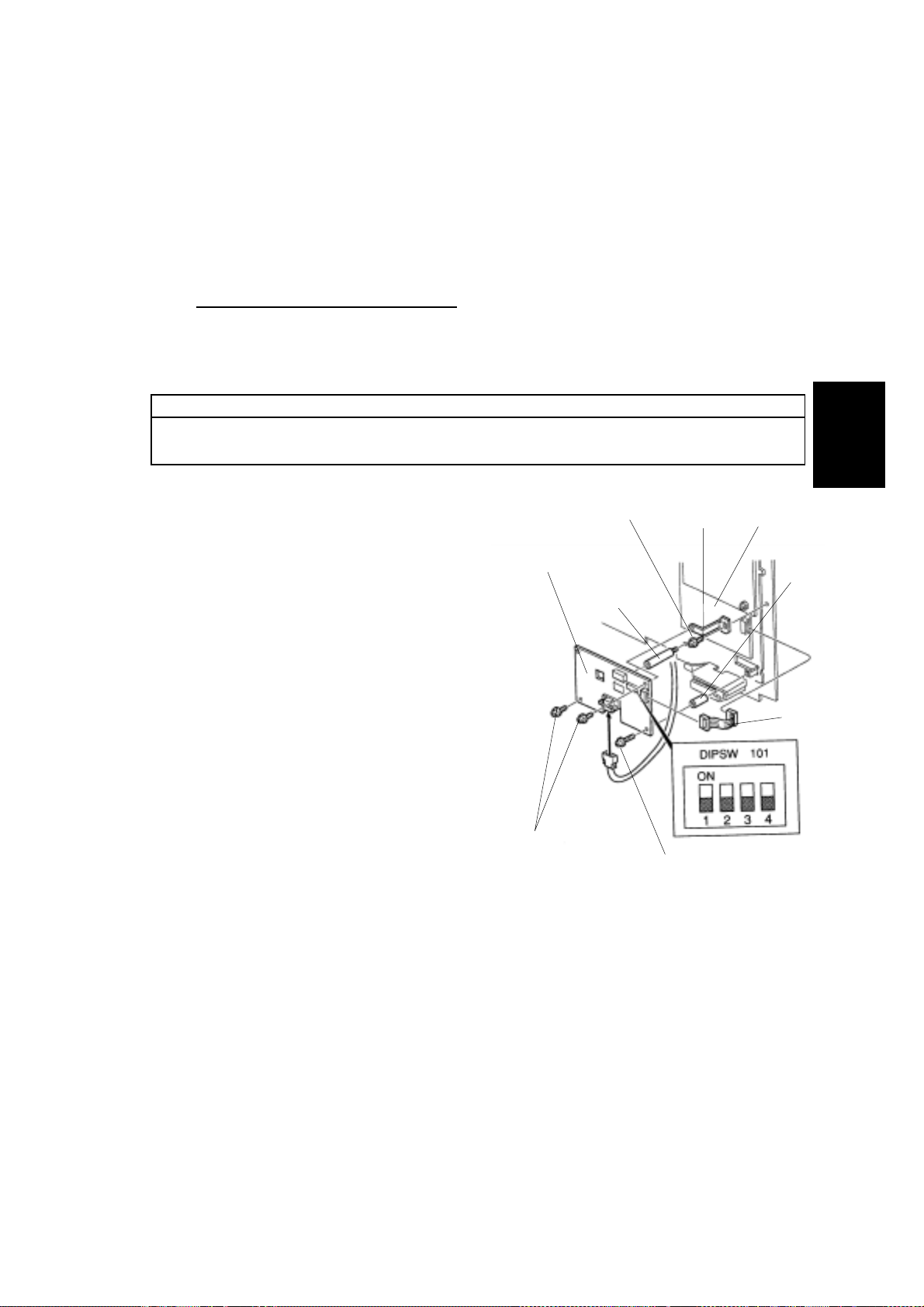

c) Attach the Printed Circuit

Board Interface (2) to the

Studs (25) using four M3x25

Screws (20).

d) Connect the free end of the

Ribbon Cable (27) to CN102

of the Printed Circuit Board

Interface (2).

e) Connect the Shielded Cable

(4) to CN101 of the Printed

Circuit Board Interface (2).

f) Set a ll switches on DIPSW

101 of the Printed Circuit

Printed Circuit Board

Board Interface (2) to OFF.

g) Set DIPSW 103-8 of the

Mainframe MPU Board

(Online On/Off) to ON.

Installation

4. Pop out the communication port cover plate from the lower center of the rear

cover panel.

5. Reinstall the rear and front cover panels of the Priport.

23

Page 27

INSTALLATION PROCEDURES FOR INTERFACE KITS 30 April, 1999

3.3.7 VT1730/1800

1. Remove the rear and front covers of

the Priport.

2. Mount Shielded Cable (4).

a) Mount two Studs (5) with Washers

(6) on the rear chassis of the

Priport.

b) Remove the cover panel under the

paper feed table.

c) Thread the Shielded Cable (4)

from the rear chassis to the front

chassis under the Priport body.

d) Reinstall the cover panel under the

paper feed table.

e) Mount the Bracket of the Shielded

Cable (4) onto the Studs (5) using

Phillips M4x8 screws (26).

f) Mount the Bracket (8) to the

bracket of the front chassis using

Phillips M4x6 screws (21).

g) Tie the Shielded Cable (4) to the

Bracket (21) using Tie Band.

Studs

Washer

24

Shielded Cable

Bracket

Page 28

30 April, 1999 INSTALLATION PROCEDURES FOR INTERFACE KITS

3. Mount the Printed Circuit Board

Interface (2).

a) Mount a Stud (7) on the front

chassis of the Priport.

b) Remove the left screw securing

DIP 103 to the Mainframe MPU.

c) Connect the Ribbon Cable (12) to

the MPU Board.

d) Attach Colored Spacer (14) to the

lower left corner of the Printed

Circuit Board Interface (2) using

one Phillips M3x35 screw (9).

Flat Cable

e) Mount the Printed Circuit Board

Interface (2) using three Phillips

Screws with Flat Washers (Black)

Colored Spacer

Printed Circuit Board

M3x6 (30).

f) Connect the free end of the Ribbon

Cable (12) to CN102 of the Printed

Phillips Screw M3x35

Circuit Board Interface (2).

g) Connect the Shielded Cable (4) to

CN101 of the Printed Circuit Board

Interface (2).

h) Set all switched of DIPSW 101 of

the Printed Circuit Board Interface

(2) to OFF.

Installation

NOTE:

The On-line key on the operation panel is enabled automatically when the

interface board is connected to the MPU at power on.

25

Page 29

30 April, 1999 TOOLS

4. OPERATION VERIFICATION

Operation verification of the Controller consists of using the Controller

with a computer and a PRIPORT to verify that all I/O ports function

properly.

Performing a successful operational verification provides a high degree

of confidence that the controller and PRIPORT to which it is attached are

operating normally.

4.1 TOOLS

The following items are needed to perform an operational verification of

the Controller. Items marked with (*) are included in the Service Kit

(see Section 5.1.2).

1) A PRIPORT.

2) A PRIPORT-to-Controller cable (*).

3) A PC with a LAN card installed running Windows 95 with IE4.01

SP1, or Windows 98. The PC must be set up to communicate via

IPX/SPX and TCP/IP protocols, and have the following programs

installed:

a) Controlle r utility software and drivers1,

b) Proper Priport printer drivers1,

c) IPX Redirector software

4) A MAC running OS 7.6.1 or later operating system.

5) The Installation CD (*).

6) A mini-centronics computer-to-Controller cable (*).

7) A cross-connect LAN cable (*).

8) An AppleTalk cable (*).

1

Operation

Verification

1

included on the Installation or Service CDs. (See Section 5.1.2 for the

Service CDs.)

27

Page 30

TESTS 30 April, 1999

4.2 TESTS

Verification of correct operation of all ports and status lights verifies that

the Controller is operating normally.

4.2.1 PRELIMINARY VERIFICATION OF PRIPORT AND VIDEO INTERFACE OPERATION

1) Verify that the following parts are properly connected:

a) I/F Board to the Priport Main Board (IPU Board),

b) Shielded Cable to the I/F Board,

c) All other parts of the I/F Kit.

2) Turn the Priport on and, while it is offline (i.e., Online OFF is

selected), verify that,

a) It can produce a good master from a scanned original, and

b) It can print from the master made of the scanned original.

3) Enable the “Online Mode” while the Priport is in the SP-MODE, and

verify that the

a) The Online LED illuminates when the Online Key is pressed, and

b) No error is displayed on LCD of Priport. If so, recover from the

error.

4.2.2 PROCEDURE TO VERIFY CONTROLLER POWER ON SEQUENCE AND PRIPORT INTERFACE

1) If not previously done, perform operation verification procedure 4.2.1.

2) Properly attach a video cable such as that supplied in the Service Kit

(see Section 5.1.2) between the Controller and Priport.

3) Power on the Priport.

4) Put the Priport ONLINE.

5) Set the Priport ready for master making and printing.

6) Wait while the Controller conducts its turn-on self-diagnostic test

(takes about thirty seconds.)

7) Check the Controller LED status lights:

a) The left red and right yellow lights flash alternately when the

power-on self-diagnostic test is in progress.

b) The Controller is ready for printing when the self-diagnostic test is

finished and the left light is green (the right light is dark).

NOTE:

A solid green left status light with the right status light off

verifies correct Controller power on process.

28

Page 31

30 April, 1999 TESTS

8) When the Contro ller is ready for printing, put paper int o the Priport

input tray and set Auto Cycle ON.

9) Press the Diagnostic Test Page button on the back of the controller.

The left green light will start to flash slowly, indicating the controller is

in the process of creating a Diagnostic Test Page.

10) Master making should begin when the right right light starts to flash

slowly.

11) Printing should begin when the left green and right green lights flash

alternately.

NOTE:

A correctly generated/printed Diagnostic Test Page verifies

correct operation of the Controller’s digital duplicator port.

4.2.3 PROCEDURE TO VERIFY THE CONTROLLER’S PARALLEL

AND LAN PORTS

1) If not previously done, perform operation verification procedures

4.2.1 and 4.2.2.

2) Connect a mini-centronics cable such as that supplied in Service Kit

(see Section 5.1.2) between the PC and the Controller.

3) If not previously done, install the Controller software and drivers onto

the PC. Make sure to install the printer drivers specific to the digital

duplicator (Priport) model with which you are working. Make sure the

port to which the printer is attached is LPT1:.

4) Select either the PCL or PS3 printer driver for the Priport and print

the Windows Test Page from the Printer Properties of the printer

driver:

a) Put paper into the input tray of the Priport and set Auto Cycle on,

b) In the Printers Folder, right-click on the Priport printer driver,

select Properties, then locate and click on Print Test Page,

NOTE:

A correct printout of the Windows Test Page verifies correct

operation of the Controller’s parallel port.

5) If not previously done, install the IPX Redirector program onto the PC

(located on the Installation or Service CDs: see Section 5.1.2 for the

Service CDs).

6) Connect a cross-connect LAN cable such as that supplied in the

Service Kit (see Section 5.1.2) between the PC and the Controller.

Operation

Verification

29

Page 32

TESTS 30 April, 1999

7) Select either the PCL or PS3 printer driver for the Priport and print the

Windows Test Page from the Printer Properties of the printer driver,

this time using the LAN port:

a) In the Printers Folder, right-click on the Priport printer driver,

select Properties, then click on Details.

b) Under ‘

belonging to the Controller as identified by

option)

c) Click on the

Page

NOTE:

Print to the following port:

, and click

General

,

A correct printout of the Windows Test Page verifies correct

operation of the Controller’s LAN port.

Apply

.

tab, then locate and click on

’, select the LAN port

(OTS Ethernet

Print Test

4.2.4 PROCEDURE TO VERIFY THE CONTROLLER’S LOCALTALK

PORT

1) If not previously done, perform operation verification procedures

4.2.1, 4.2.2, and 4.2.3.

2) Connect an AppleTalk cable such as that supplied in the Service Kit

(see Section 5.1.2) between the MAC and the Controller.

3) If not previously done, install the Controller software and drivers onto

the MAC. Make sure to install the printer drivers specific to the digital

duplicator (Priport) model with which you are working.

4) Select a graphic or text file and print it to the Controller/Priport.

NOTE:

A correct printout of the graphic or text file verifies correct operation of

the Controller’s AppleTalk port.

30

Page 33

30 April, 1999 BASIC STEPS FOR TROUBLESHOOTING

5. TROUBLESHOOTING

5.1 BASIC STEPS FOR TROUBLESHOOTING

5.1.1 CATEGORIZING PROBLEMS

When a problem is reported, it should be categorized according to the

data or information collected from the customer regarding its occurrence.

This data falls into three categories:

1) the steps required to generate the problem,

2) the conditions under which the problem occurs, and

3) the frequency of occurrence.

The process of categorization should proceed as follows:

Problem Hardware Malfunction of Priport Mainframe

I/F Board

Malfunction of Controller Mainframe

Memory

Limitation of the Hardware

Software Controller Software Bug Driver

Firmware

Limitation of the Controller

Trouble-

shooting

31

Page 34

BASIC STEPS FOR TROUBLESHOOTING 30 April, 1999

5.1.2 EQUIPMENT NECESSARY FOR TROUBLESHOOTING

The following items are needed, as well as a working Priport and

Win95/98 computer.

NOTE:

1) Cables for operational verification of the controller.

2) Set of all Installation CDROMs (all mfr Installation CDs and one

Companion CD) allowing setup of any PRIPORT and any controller

model number.

3) Cables for service/firmware updates.

4) Special software or tools for troubleshooting or updates.

The following items are available as the Service Kit. Refer to

section 7 for the part number.

a) 1, PRIPORT-to-controller video cable.

b) 1, computer-to-controller parallel cable.

c) 1, 5 meter AppleTalk cable.

d) 1, 5 meter normal LAN “patch” cable.

a) 1, serial ribbon cable: 10pin header to DB9F.

b) 1, 3 meter extension serial cable, DB9M to DB9F.

c) 1, 5 meter cross-over LAN cable for peer-to-peer connection

without a hub

a) 1, CDROM containing LAN Tools and service software.

5.1.3 INFORMATION NECESSARY FOR TROUBLESHOOTING

The following information should be collected before troubleshooting

begins:

• A Diagnostic Test Page from the controller,

• The name and version of the printer driver,

• A print sample showing the problem,

• The printer settings of the computer, and

• The name and version of the application software that generated the

page.

32

Page 35

30 April, 1999 TROUBLESHOOTING FLOW

5.2 TROUBLESHOOTING FLOW

5.2.1 TROUBLESHOOTING FLOWCHART

Problem

Priport works

normally

Controller LED

status is normal

Diagnostic page

is printed#normal

Is print test

result is normal?

No

No

No

Yes

Recover from

the error.

Recover from

the error.

- Main Board

- Program ROM

- Video Cable

Board

- I/F

- Shielded Cable

Limitation of Controller,

Printer Driver Setting ,

or Application Software

Setting.

Check the Priport - see

Section 5.3.

Check the Controller LED

status - see Section 5.6.

Check Controller

operation with the Priport

– see Section 5.3.

Check Controller operation

with a computer – see

Section 5.3.

Trouble-

shooting

No

Printed normal

with DOS

Printer Port of Computer

Printer Cable

Centronics I/F, LocalTalk

Yes

Windows Printer

Driver Fault

33

Check operation of the

printer driver – see

Section 5.8.

Page 36

PRIPORT/CONTROLLER FAILURE IDENTIFICATION 30 April, 1999

5.3 PRIPORT/CONTROLLER FAIL URE IDENTIFICATION

For each of the following failure modes, see the corresponding operation

verification procedure to assist with the troubleshooting process:

Apparent Failure Mode Operation Verification Procedure

Priport operation

the Controller.

Priport/Controller opera ti on

without a computer.

Priport/Controller opera ti on

with a computer.

Use the operation verification procedure indicated to help identify in

which component the problem lies.

without

Section 4.2.1

Section 4.2.2

For operation with a PC: Section 4.2.3.

For operation with a MAC: Section 4.2.4.

34

Page 37

30 April, 1999 SUBASSEMBLY TROUBLESHOOTING

5.4 SUBASSEMBLY TROUBLESHOOTING

Once you have positively identified a problem with the Controller, it will

be necessary to troubleshoot the problem to the assembly level, and

replace the faulty assembly.

5.4.1 IDENTIFYING THE FAULTY ASSEMBLY

A problem or fault must be traced to one of the subassemblies of the

Controller. As a general rule, it is best to chec k the sub assemblies in

order according to their respective expected failure rates, keeping in

mind the failure symptoms. Therefore it is generally recommended that

the boards be checked in the following order:

1) the PSU board,

2) one or more of the boards that plugs into the Main Board, or

3) the Main Board itself.

IMPORTANT:

The procedures to identify in which component the

problem lies may be used to verify the operation of the indicated

subassembly. If operation of any particular subassembly cannot be

verified, replace the entire subassembly – do not attempt componentlevel repair.

Trouble-

shooting

35

Page 38

NIB FIRMWARE AND MEMORY UPGRADE TROUBLESHOOTING 30 Apr il, 1999

5.5 NIB FIRMWARE AND MEMORY UPGRADE TROUBLESHOOTING

To solve any problems when updating NIB firmware, refer to sections 6.4.2.3

“Miscellaneous Support Procedures to the NIB Firmware Update” and 6.4.2.4 “NIB

Firmware Update FAQs”.

For the memory upgrade, refer to sections 6.5.2 “Testing a Memory upgrade” and

6.5.3 “Troubleshooting a Memory Upgrade”.

36

Page 39

30 April, 1999 LED STATUS LIGHT SEQUENCE AND CONDITIONS

5.6 LED STATUS LIGHT SEQUENCE AND CONDITIONS

5.6.1 EVENT: POWER ON

Status Contents Check Point

All LEDs are off. No power supply.

Yellow and red

LEDs are flashing

Self-diagnostic test

before ready.

alternately.

Left-green LED is

Ready.

on.

Left-green LED is

flashing.

Left-green LED is

Controller is

processing data.

Master making.

on and right-green

LED is flashing.

• No AC power, AC cord not

properly connected, or power

supply failure in the Controller.

• If this occurs for more than 60

seconds and network board

(NIB) lights are also flashing

yellow and green, check to see

if NIB jumper OP2 is set to OFF

instead of FACT.

• Check to see if there is a print

job in the print queue of the

network server, the print

manager, or the print spooler in

computer.

• Check to see if there is a print

job in the print queue of the

network server, the print

manager, or the print spooler in

computer.

Trouble-

shooting

Left-green and

right-green LEDs

are flashing

alternately.

Left-green and

right-green LEDs

are flashing

simultaneously.

Printing.

Proof printing.

• Check to see if the Diagnostic

Test Page button is stuck.

• Check to see that the PRIPORT

is making copies.

37

Page 40

LED STATUS LIGHT SEQUENCE AND CONDITIONS 30 April, 1999

Status Contents Check Point

Yellow LED is

flashing.

Red and yellow

LEDs are flashing

simultaneously.

No response from the

PRIPORT.

PRIPORT Error.

• Check that the PRIPORT is

turned on.

• Check that the Controller is

properly connected to the

PRIPORT with the provided

cable.

• Check that the switches on

DIPSW 101 of the Type600

Interface board are all set to the

OFF position.

• Check that the PRIPORT is OnLine (i.e., ON-LINE enabled).

• Check that the PRIPORT

Interface Card inside the

Controller is properly connected

to the Main Board at J2 through

the ribbon cable.

• Check for an error message

display on the PRIPORT control

panel.

• Check that the Controller is

properly connected to the

PRIPORT.

38

Page 41

30 April, 1999 LED STATUS LIGHT SEQUENCE AND CONDITIONS

Status Contents Check Point

The Red LED is

flashing, or is on

longer than 30

seconds, or the

Red and Yellow

LED’s stay flashing

alternately for

greater than one

minute.

Controller Error.

• Check that the Flash ROM

SIMM inside the Controller is

inserted properly into its socket.

• Check to see that only a single

RAM SIMM is installed into slot

1 nearest the edge of the Main

Board.

• Check that the dip switches of

SW1 on the Main Board are set

to defaults : 1 and 2 ON, 3 and 4

OFF.

• Check that the NIB has jumper

OP2 set OFF (not set to FACT).

• Check that JP3 on the Main

Board has jumpers 1-2 and 3-4

set to boot the on-board ROM.

Trouble-

shooting

39

Page 42

LED STATUS LIGHT SEQUENCE AND CONDITIONS 30 April, 1999

5.6.2 EVENT: PUSH THE DIAGNOSTIC TEST PAGE BUTTON

Status Contents Check Point

Left-green LED is

flashing.

Left-green LED is

on and right-green

LED is flashing.

Left-green and

right -green LEDs

are flashing

alternately.

Left-green and

right-green LEDs

are flashing

simultaneously.

Yellow LED is

flashing.

Data Processing.

Master making.

Printing.

Proof printing.

No response from the

PRIPORT.

• Check to see that the PRIPORT

is turned on.

• Check to see that the Controller

is properly connected to the

PRIPORT.

• Check to see that the switches

on DIPSW 101 are all set to the

OFF position.

Red and yellow

LEDs are flashing

simultaneously.

PRIPORT Error.

• Turn the PRIPORT on first,

then turn on the Controller.

• Check to see that the PRIPORT

is Online.

• Check to see that the PRIPORT

Card inside the Controller is

properly connected to the Main

Board at J2 through the ribbon

cable.

• Check for an error message on

the PRIPORT.

• Check to make sure the

Controller is properly connected

to the PRIPORT.

40

Page 43

30 April, 1999 LED STATUS LIGHT SEQUENCE AND CONDITIONS

5.6.3 EVENT: SEND A PRINT JOB

Status Contents Check Point

Left-green LED is

on.

Left-green LED is

flashing.

Left-green LED is

on and right-green

LED is flashing.

Left-green and

right -green LEDs

are flashing

alternately.

Left-green and

right-green LEDs

are flashing

simultaneously.

Yellow LED is

flashing.

Ready.

Controller is processing data.

Master making.

Printing.

Proof printing.

No response from the

PRIPORT.

• Check to see that the

computer is connected

Properly to the

controller.

• Verify that the

PRIPORT is printing

copies.

• Press Print on the

PRIPORT to continue

printing the requested

number of copies.

• Check to make sure

the PRIPORT is

powered on.

• Check to see that the

Controller is properly

connected to the

PRIPORT.

Trouble-

shooting

41

• Check to see that the

switched of DIPSW

101 are all in the OFF

position.

• Turn the PRIPORT on

first, then on the

Controller.

• Check to make sure

the Program ROM or

RAM SIMM sick inside

the Controller is

inserted properly into

its connector.

Page 44

LED STATUS LIGHT SEQUENCE AND CONDITIONS 30 April, 1999

Status Contents Check Point

Red and yellow

LEDs are flashing

simultaneously.

PRIPORT Error.

• Check for an error

message on the

PRIPORT.

• Check to make sure

the Controller is

properly connected to

the PRIPORT.

42

Page 45

30 April, 1999 DIAGNOSTIC TEST PAGE CONTENTS

5.7 DIAGNOSTIC TEST PAGE CONTENTS

Configuration and Settings:

Model Number: CPIF26 Installed RAM: 32MB Duplicator resolution 400 DPI

Model Brand Ricoh Standard Ports: Parallel AT Video I/F Version 4.0

Locale Setting Europe Additional Port: Network Default Paper Size: A4

PostScript Version: 3010.106 Ethernet Address: 00:40:af:79:XX.XX AutoCycle: ON

Post Script ROM Ver: 911000842 IP Address 0.0.0.0 PCL Symbol Set: PC-8

Flash ROM Version: 17.099.022 Ethertalk Name: Control l er RAM Font Cache 0MB

Controller Serial No. AU4YYMMXXXX IPX Printer Name OTS_ZZZZZZZ RAM Disk Size 384KB

CPU Board Serial No. Yyyyyy Network Serial No. ZZZZZZZ

Explanation of variables in fields above:

Controller Serial No.: AU4 YYMM XXXX

Prefix Production Year and Month

Serial Number

CPU Board Serial No.: Y yyyyy

Board Revision Level Serial Number

Network Serial No.: ZZZZZZ

SN# assigned at OEM vendor (saved in NIB NVRAM)

IPX Printer Name: OTS_ ZZZZZZ

Prefix Network Serial Number (saved in NIB NVRAM)

NOTE: The contents of “Configuration and Settings” shown above is subject

to change

.

Trouble-

shooting

43

Page 46

CHECKING PRINTER DRIVER OPERATION 30 April, 1999

5.8 CHECKING PRINTER DRIVER OPERATION

If the Windows Test Page does not print, or doesn’t look right, check

printer driver operation using the following steps.

1) Select the Details tab in the Properties Menu of the Printer Driver,

2) Change Port connection to “File :”,

3) Click on the Apply button, select the General Tab and click on the

Print Test Page button,

4) Set the file name (e.g., “test”), set the disk/directory location, and

save the file,

5) Click ‘YES’ when the message pops up asking whether the test

page printed correctly,

6) Open an MSDOS session (Start-Programs-MSDOS Prompt).

7) Check that the Priport and Controller are ready for printing, then

execute the following command at the MS DOS Prompt.

copy /b test.prn lpt1 ↵

NOTE:

a) Always input “/b” after “copy”.

b) The above example is if the file name saved in the step d) is

“test.prn”.

c) If the controller is connected to the second port of the computer,

replace “lpt1” with “lpt2.”

8) Input “exit ↵”and exit from MS DOS prompt.

9) If the image is printed correctly, reset the printer driver to print to the

printer port by doing the following:

a) select the Details tab in Properties Menu of the Printer Driver

b) change the Port back to the original setting (e.g., LPT1: or

LPT2:),

c) click Apply.

Failure to do this will result in subsequent print jobs using this

printer driver will be sent to a file on the hard drive instead of the

printer.

If the image did not print correctly, there is a problem with the printer

driver – it may be corrupt or out-of-date. Delete the printer driver and

replace with a version from the Installation CD. Then repeat this

process.

44

Page 47

30 April, 1999 COLLECTING INFORMATION FOR A PROBLEM REPORT

5.9 COLLECTING INFORMATION FOR A PROBLEM REPORT

The Problem Report should include the following items:

• A Diagnostic Test Page printed by the Controller.

• The name of computer manufacturer, and the model.

• The type of CPU, CPU speed and number of megabytes of RAM in

the computer.

• The model name and number of the PRIPORT.

• The name and version of the printer driver being used.

• The port to which the Printer Driver is connected (i.e., LPT1:, IPX,

etc.).

• The EPROM version of the PC Controller I/F Kit Printed Circuit Board

(for the JP series, the serial number of the Priport).

• The color and flashing pattern of both the Controller status lights at

time the problem is observed.

• The name and version of the application software (i.e., Microsoft

Word 97, Adobe PageMaker, etc.).

• The paper size and orientation selected in the application software’s

Print menu.

• A sample printout showing the problem.

Trouble-

shooting

45

Page 48

30 April, 1999 REQUIRED TOOLS AND PRECAUTIONS

6. DISASSEMBLY / ASSEMBLY

6.1 REQUIRED TOOLS AND PRECAUTIONS

• Anti-static wrist strap.

• #1 Phillips screwdriver.

• #2 Phillips screwdriver.

• 3/16" thin-wall nut driver or wrench.

DANGER

The Controller's power supply becomes hazardous with the chassis

opened. It exposes you to severe electrical shock if you do not

disconnect the power cord before opening.

CAUTION

The electronic components in this unit can be damaged by static

discharge. Please ensure that you are properly grounded before

touching any portion of the electronics. Also, touch the chassis with

your finger before connecting test cables, setting switches or

reattaching components.

47

/Assembly

Disassembly

Page 49

DISASSEMBLY PROCEDURES 30 April, 1999

6.2 DISASSEMBLY PROCEDURES

6.2.1 PREPARATION

1. Identify a static-safe area for storage of the electronic components

to be removed.

2. Disconnect the power cable.

6.2.2 REMOVI NG THE TOP COVER AND FRONT PANEL BEZEL

1. Turn the Controller over and lay it on its back.

2. Use the #1 Phillips screwdriver to remove the four 4-40 x ¼ " screws

in the feet to unfasten the lid. Set the screws and feet aside for later

re-assembly.

3. With the bottom facing you and the front facing up, grab both sides of

the controller and press the back against your knee. Gently slide the

top cover down off the back of the chassis.

4. Slide top cover away from front plastic bezel.

5. Remove the front plastic bezel by pressing in on one of the latch tabs

NOTE: Use caution not to break the latch tabs.

Latch Tabs

Top Cover

48

Page 50

30 April, 1999 DISASSEMBLY PROCEDURES

6.2.3 REMOVING THE PRIPORT INTERFACE.

1. Remove the top cover (see Section 6.2.2).

2. Remove the two 4-40 x ¼" x 4-40 jack screws (hex-shaped mounting

studs) securing the digital duplicator port DB25 connector to the

chassis rear panel, using the 3/16" nut driver or wrench.

3. Gently lift the interface card back to clear the upper lip on the chassis

rear panel, and rotate it to a vertical position.

4. Disconnect the ribbon cable at the end of the card connecting it to the

Main Board, and set the card aside in the static-free area.

6.2.4 REMOVI NG THE NETWORK BOARD OR OPTION CARD.

1. Remove the top cover (see Section 6.2.2).

2. Remove the two 4-40 x ¼ " screws securing the faceplate of the

network board (NIB) or the option (Local Printer Port) card to the

chassis rear panel, using the #1 Philips screwdriver.

3. Gently lift the card back to clear the upper lip on the chassis rear

panel, and rotate it to a vertical position.

4. Disconnect the ribbon cable at the end of the card connecting it to the

Main Board, and set it aside in the static-free area.

Network Board

Flat Cable

Interface Port

/Assembly

Disassembly

49

Page 51

DISASSEMBLY PROCEDURES 30 April, 1999

6.2.5 REMOVI NG THE CENTRONICS PORT AND MAIN BOARD.

1. Remove the top cover (see Section 6.2.2).

2. Remove the PRIPORT interface card (see Section 6.2.3).

3. Remove the network board (NIB) or option (Local Printer Port) card

(see Section 6.2.4).

4. Remove the digital duplicator port and NIB or option card ribbon

cables and set them aside with the top cover screws.

5. Remove the RAM and the Flash ROM SIMM sticks from the Main

Board, and place them in the static-safe area - see Section 6.4 for

instructions on removing SIMM’s from their respective carriers.

6. Remove the two M2.6 x 6 screws securing the mini-Centronics

connector of the Main Board to the chassis rear panel, using the #1

Philips screwdriver.

they are an odd size.

7. Remove three 6-32 x 7/16" screws attaching the Main Board to the

chassis, using the #2 Philips screwdriver.

IMPORTANT!

– do not lose these screws, as

8. Slide the Main Board slightly forward through the front slot.

Main Board

50

Page 52

30 April, 1999 DISASSEMBLY PROCEDURES

9. Lift the rear (connector end) of the board up and back

10. Disconnect the power harness at J2.

11. Lift the Main Board out, clear of the chassis, and place it into the

static-safe area.

6.2.6 REMOVING THE PSU

1. Remove the top cover (see Section 6.2.2).

2. Disconnect the AC power, Main Board, and fan cable assembles

from their respective headers on the PSU.

3. Note that the PSU is secured to the chassis with four 6-32 x ¼"

screws.

IMPORTANT!

stud nearest the ground stud DOES NOT have an integral lock

washer, as do the other three screws.

is an internal-tooth version and resides under the circuit board,

between the board and the mounting stud

safety requirements and must be re-assembled in the same fashion.

– note that the 6-32 x ¼ screw going into the mounting

The lock washer for this screw

. This is done to satisfy UL

4. Remove the three 6-32 x ¼" screws with external-tooth locking

washers and the plain 6-32 x ¼ screw attaching the PSU to the

chassis, using the #2 Philips screwdriver.

5. Lift up the PSU board and recover the 6-32 internal-tooth lock

washer described in 4 above. It may be stuck to the bottom of the

PSU circuit board, or sitting on top of the mounting stud.

6. Lift the PSU Board out of the chassis, and place in the static-free

area.

Location of UL

grounding screw

PSU Board

/Assembly

Disassembly

51

Page 53

DISASSEMBLY PROCEDURES 30 April, 1999

6.2.7 REPLACING THE AIR CIRCULATION FAN

1. Remove the top cover (see Section 6.2.2).

2. Remove the PSU (see Section 6.2.6).

3. Remove four 4-40 x ¾" screws securing the fan to chassis center

divider.

4. Remove the fan and connecting cable.

5. Install the new fan and cable, using the four screws removed in 3

above.

6. Reinstall the PSU (see Section 6.3.2).

7. Reinstall the top cover (see Section 6.3.5).

Fan

PSU

52

Page 54

30 April, 1999 ASSEMBLY PROCEDURES

6.3 ASSEMBLY PROCEDURES

Assembly procedures are essentially the reverse of disassembly.

6.3.1 INSTALLING THE PSU

1. Place the chassis on a flat, stable surface.

2. Place the special grounding 6-32 internal-tooth lock washer on the

PSU mounting stud nearest the chassis ground stud.

3. Orient the PSU board so that the fuse is located towards the back

panel of the chassis.

4. Gently place the PSU board on the chassis mounting studs, aligning

the four mounting holes with the holes in the studs, being careful not

to knock the special grounding lock washer off of its position

5. Place the 6-32 x ¼" screw without an integral lock washer through

the mounting hole of the PSU nearest the ground stud. DO NOT

TIGHTEN at this time.

6. Place the three 6-32 x ¼" screws with integral lock washers in the

other three PSU mounting holes.

7. Tighten all four mounting screws using the #2 Phillips screwdriver.

8. Inspect the UL grounding screw of the PSU to make sure the lock

washer underneath the board is securely in the proper position.

9. Attach the fan connector to header TB3, the Main Board connector to

header TB2, and AC connector to header TB1 on the PSU.

6.3.2 INSTALLING THE MAIN BOARD

1. Orient the Main Board so that the two status LEDs are at the leftfront section of the chassis (from the perspective of someone

looking at the front of the chassis).

2. Feed the front (status LED) edge of the Main Board through the slot

in the front chassis just enough so that the rear of the board clears

the lip on the rear chassis, allowing placement of the board onto the

chassis mounting studs.

3. Position the board back toward the rear of the chassis such that the

Diagnostic Test Page switch and the mini-centronics connector each

go through their respective access holes.

/Assembly

Disassembly

4. Place three 6-32 x 7/16" screws into the three chassis mounting

studs to locate the board into position. DO NOT TIGHTEN at this

time.

53

Page 55

ASSEMBLY PROCEDURES 30 April, 1999

5. Place two M2.6 x 6 screws on the holes that secure the minicentronics connector to the rear panel and tighten using the #1

Phillips screwdriver.

screw (e.g., M2.5 x 6) for the originals. Use only the proper screws

for this connector.

6. Tighten the three 6-32 x 7/16" screws that secure the Main Board to

the chassis mounting studs using the #2 Phillips screwdriver.

7. Attach the PSU connector to the header J12.

IMPORTANT!

– do not substitute a different size

Procedures 6.3.3 through 6.3.5 assume that the PSU and Main

Board have already been installed in the chassis – see Sections

6.3.1 and 6.3.2.

6.3.3 INSTALLING THE PRIPORT INTERFACE CARD

1. Position the DB25 connector (J1) of the card through the rear chassis

slot, aligning the threaded mounting holes with those in the rear

chassis.

2. Attach the DB25 connector (J1) to the rear chassis using two 4-40 x

¼" x 4-40 jack screws (hex-shaped mounting studs), with the 3/16

nut driver or wrench.

3. Attach the ribbon cable from J2 on the card to the DUPLICATOR

header J2 on the Main Board.

6.3.4 INSTALLING THE NIB OR OPTION CARD

1. Position the faceplate of the card into the rear chassis slot, aligning

the screw holes with those in the rear chassis.

2. Attach the faceplate to the rear chassis using the two 4-40 x ¼

mounting screws, with the #1 Phillips screwdriver.

3. Attach the ribbon cable to the card, then to the proper connector on

the Main Board (NIB connects to J8, Option to J9), taking care to not

twist the ribbon cable.

54

Page 56

30 April, 1999 ASSEMBLY PROCEDURES

6.3.5 INSTALLING THE TOP COVER AND FRONT PANEL BEZEL OF THE CONTROLLER

1. Carefully re-attach the front bezel, taking care to not break the

locking tabs.

2. Slide the cover back onto the chassis from the back of the Controller.

3. Gently use a small flat-blade screwdriver to pry the cover front lip

slightly up to clear the lip of the front chassis frame.

4. Using both hands, grab the sides and press the front against your

knee or torso. Be careful to not damage or scratch the front bezel if it

is attached. Repeat this process until there is no gap between the lid

and the front bezel. If completed correctly, the front bezel should be

snug against the front chassis panel and the top cover, and will not

rattle.

5. Turn the unit over and lay it on its back.

6. Attach four rubber feet with concentric 4-40 x ¼" screws through the

top cover holes to the four threaded mounting holes on the bottom of

the chassis, with the #1 Phillips screwdriver.

55

/Assembly

Disassembly

Page 57

UPGRADING CONTROLLER FIRMWARE 30 April, 1999

6.4 UPGRADING CONTROLLER FIRMWARE

6.4.1 MAIN BOARD FIRMW ARE UPDATE INSTRUCTIONS

Two (2) ROM images for CPIF26 can be updated:

1) The Adobe firmware (resides in an on-board FLASH ROM chip on the

Main Board).

2) The CPIF26 firmware (resides on a SIMM connected to the Main

Board).

The instructions below describe the procedures to perform either or both

or these updates.

6.4.1.1 Materials and Files

Obtain and have ready to use the following materials and equipment. All

items marked with a (*) are included in the Controller Service Kit (see

Section 5.1.2).

6.4.1.1.1 Hardware

• An

• A

• An

• A

• A

• A

6.4.1.1.2 Software

• The

• The

RS-232 ribbon cable adapter

end and a 10-pin header on the other.

2 meter or longer RS-232 extension serial cable

DB9 connector on one end and a female DB9 connector on the other.

IEEE 1284 Bi-directional mini-centronics cable

between your PC and the Controller unit.

PC with an IEEE 1284 Bi-directional interface port and an

available serial port running the Windows 95 with IE4.01 SP1, or

Windows 98 operating system.

PRIPORT-to-controller video cable

PRIPORT

ROM image file

area, the Elesys web site, or the Service CDs (see Section 5.1.2 for

the Service CDs), unZIPp’d if necessary, and stored in a local

directory on your computer:

parallel port download utility

Service CDs into

you stored the ROM images

download utility physically downloads the ROM image into the

CPIF26 Flash ROMs:

• As a reference, view or print “

locate connectors and jumpers.

(*) with a DB9F connector on one

(*) with a male

(*) that attaches

(*).

.

must be downloaded from your local support

(*) must be downloaded from the

the same working directory on your local PC where

. The PC DOS IEEE 1284 centronics

2.1.2 Main Board Layout Diagram

” to

56

Page 58

30 April, 1999 UPGRADING CONTROLLER FIRMWARE

6.4.1.2 Prepare the Controller and computer.

DANGER

The Controller's power supply becomes hazardous with the chassis

opened. It exposes you to severe electrical shock if you do not

disconnect the power cord before opening.

CAUTION

The electronic components in this unit can be damaged by static

discharge. Please ensure that you are properly grounded before

touching any portion of the electronics. Also, touch the chassis with

your finger before connecting test cables, setting switches or

reattaching components.

Prepare the controller for the ROM update process by doing the

following:

1. Turn off and unplug the power to the CPIF 26 unit. Remove all other

cables from the back panel.

2. Remove the top cover and front bezel using the procedure outlined in

Section 6.2.2.

3. Remove the network board (NIB) or option (Local Printer Port) card

using the procedure outlined in Secti on 6.2. 4.

4. Locate the Serial Port header JP2 towards the rear of the main board.

Attach the header end of the RS-232 ribbon cable to JP2. Make sure

pin 1 (with a red stripe or marked on the cable) is towards the front of

the Controller.

5. Attach the DB9 end of the cable to one end of the extension RS232

serial cable. Attach the other end of the extension cable to the

available serial COM port on your computer.

6. On the computer, start an MSDOS session and get into the working

directory where you downloaded the ROM image and centdown

files.

/Assembly

Disassembly

57

Page 59

UPGRADING CONTROLLER FIRMWARE 30 April, 1999

7. Configure or setup either the standard Windows Hyperterminal or a

substitute on your PC:

• Press

Start\Programs\Accessaries\Communications\Hyperterminal

• Choose “connect direct to COM1” or “COM2” as appropriate

• Set to 9600-8-N-1

• Locate DIP switch SW1 under PRIPORT interface adapter board.

• Set SW 8 ON (SW 4 on Production boards) to enter monitor

mode.

• Connect a parallel cable to unit.

IMPORTANT

: Make sure no

other devices (e.g., ZIP drives) are connected to the parallel port.

DANGER

To complete this process, you must reattach the power cable and

operate the unit with an exposed power supply. Use caution to

avoid touching any part of the power supply, as it contains exposed

high voltages capable of causing a lethal electrical shock.

• Re-connect the power cord to the controller and turn it on.

• In Hyperterm, press Enter a few times

• If you've set the baud rate correctly, you should get a single “>”

prompt:

r4300>

58

Page 60

30 April, 1999 UPGRADING CONTROLLER FIRMWARE

.4.1.3 CPIF26 Firmware SIMM Flash ROM update procedure

6

To update the CPIF26 SIMM flash ROM:

• Press ENTER to get the single prompt:

r4300>

• Type “z” and ENTER.

• Now you get a double “>>” prompt:

r4300>>

• Type “boot cent” .

• A message appears indicating it is waiting for the centronics port.

• Click on the MSDOS window and type:

centdown eleXXX.rom (where “eleXXX.rom” should be replaced by

the actual file name for the version of the CPIF26 ROM you are

downloading).

• Go to the Hyperterm window and answer “Y”.

• Click on the DOS window again to activate it.

• The download commences automatically. The monitor will first

indicate it is erasing Bank 1, the SIMM flash ROM. Then it will count

up by percentage complete. (The selection of which bank to

download into is done automatically for you.)

• W hen finished, it will show the CPU registry and say “buss error” ignore this error, since it is a normal part of the download process.

If you are updating only the CPIF26 Flash ROM, skip to section 6.4.1.5.

• Cycle power on the Controller.

/Assembly

Disassembly

59

Page 61

UPGRADING CONTROLLER FIRMWARE 30 April, 1999

6.4.1.4 Adobe Flash ROM update

To update in the Adobe on-board flash ROM:

• Press ENTER to find the single prompt:

r4300>

• Type “z” and ENTER.

• Now you get a double prompt:

r4300>>

• Type “boot cent” .

• A message appears indicating it's waiting on the centronics port.

• Now in a DOS window, type:

centdown adobe.rom (where “adobe.rom” should be replaced by the

actual file name for the new version of the Adobe ROM).

• Go to the Hyperterm window and answer “Y”.

• Click on the DOS window again to activate it.

• The download automatically. The monitor will first indicate it is erasing

Bank 0, which is the on-board flash ROM. Then it will count up by

percentage complete. (The selection of which bank to download into

is done automatically for you.)

• W hen finished, it will show the CPU registry and say “buss error” ignore this error, since it is a normal part of the download process.

• Cycle power to get the single prompt again.

60

Page 62

30 April, 1999 UPGRADING CONTROLLER FIRMWARE

6.4.1.5 Reset to factory default NVRAM settings.

• Set SW 7 (SW 3 on Production boards) to ON (SW 1-4 are OFF, SW

5-8 are all ON;

SW 1-4 are all ON on Production boards)

• Type: z

• Then type: boot ps

• Monitor output should say it is resetting factory defaults.

• Set SW 7 to OFF (SW 3 on Production boards)

• Cycle power and you'll get the single prompt again.

• Type: z

• Then type: boot ps

• It should say, among other things :

Flash ROM [SIMM] Version: 17.09X.XXX

Copyright 1998 Elesys, Inc. All rights reserved.

6.4.1.6 Check that the update procedure(s) worked.

• Set SW 8 to OFF on Beta main boards (SW 4 on Production main

boards) to enable autobooting again.

• Power down the unit and disconnect the serial and parallel cables leave power and PRIPORT cables connected.

• Reinstall the network board (NIB) or option (Local Printer Port) card

using the procedure outlined in Secti on 6.3. 4.

• Power on the unit again and print the Diagnostic Test Page by

pressing the test button on the back. Verify that the new firmware

revision has been updated as shown on the bottom of the Diagnostic

Test Page.

• Proceed with the next section when you are satisfied that the

Controller is operating properly.

6.4.1.7 Finish up.

• Disconnect the power and PRIPORT cables from the Controller.

• Replace the cover and front bezel (see Section 6.3.5).

61

/Assembly

Disassembly

Page 63

UPGRADING CONTROLLER FIRMWARE 30 April, 1999

6.4.2 NIB (NETWORK INTERFACE BOARD) FIRMWARE UPDATE INSTRUCTIONS.

The NIB firmware inside the CPIF 26 is contained in a flash ROM located

on the board. . It is updated using a ROM image file with a special FTP

download utility. These instructions describe how to perform an update

of this ROM.

6.4.2.1 Materials Required To Perform the NIB Firmware Update

Obtain and have ready to use the following materials and equipment. All

items marked with a (*) come in the Controlle r Service Kit (see Section

5.1.2).

6.4.2.1.1 Hardware

cross-connect LAN cable

• A

computer to the controller.

PC with a 10Base-T LAN card installed, running Windows 95

• A

(with IE4.01 SP1) or Windows 98 operating systems, and

known/demonstrated ability to communicate to another

computer via the IPX/SPX and TCP/IP protocols.

(*) of sufficient length to connect the

6.4.2.1.2 Additional Recommended Hardware

PRIPORT-to-controller video cable

• A

PRIPORT

• A

.

(*).

62

Page 64

30 April, 1999 UPGRADING CONTROLLER FIRMWARE

6.4.2.1.3 Software

• The

ROM image file

must be downloaded from your local support

entity, the Elesys web site, or the Service CDs (see Section 5.1.2 for