Page 1

Controller User’s Guide

Page 2

Customer Service

For a Printer Driver for your Digital

Duplicator, contact:

The nearest authorized supplier for your digital duplicator.

For Customer Support and Service, contact:

The nearest authorized supplier for your digital duplicator.

Page 3

Controller

User’s Guide

Part Number –UG026A40US

First Edition – January 1999

1999 Elesys, Inc. All rights reserved.

Page 4

Notice ELESYS MAKES NO WARRANTY OF

ANY KIND WITH REGARD TO THIS

MATERIAL INCLUDING, BUT NOT

LIMITED TO, THE IMPLIED

WARRANTIES OF

MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE.

Elesys shall not be liable for errors contained herein

or for incidental consequential damages in connection

with the furnishing, performance, or use of this

material.

1999 Elesys, Inc. All rights reserved.

Governmental rights to this product are restricted.

See license agreement.

This document contains proprietary information

which is protected by copyright. All rights are

reserved. No part of this document may be

photocopied, reproduced, or translated to another

language without the prior written consent of Elesys.

The information contained in this document is subject

to change without notice.

Printing History This manual was created using text formatting

software on personal computer. The body text is

printed in Times New Roman fonts, and chapter and

section heads are printed in Arial fonts.

First Edition – January 1999

Trademark Credits Elesys and Print Boss are registered trademarks of

Elesys, Inc. Adobe, the Adobe Logo, PageMaker,

PostScript, PostScript 3, the PostScript Logo, and

TIFF are trademarks of Adobe Systems Incorporated

which may be registered in certain jurisdictions. CG

Times is a product and Type Director is a U.S.

registered trademark of AGFA Corporation, Agfa

Division, Miles Inc. Macintosh computer, Apple

computer and LaserWriter are products of Apple

Computer, Inc. TrueType and AppleTalk are

trademarks of Apple Computer, Inc. Centronics is a

iv

Page 5

U.S. registered trademark of Centronics Data

Computer Corporation. WordPerfect is a product and

trademark of Corel Inc. Hewlett-Packard LaserJet is

a product and PCL-5e is a registered trademark of

the Hewlett-Packard Company, IBM by International

Business Machines Corp., Pentium, Pentium II, and

Intel by Intel Corp. Century Schoolbook is a U.S.

registered trademark of Kingsley-ATF Type

Corporation. Microsoft , MS-DOS, Windows and

Windows NT are either U.S. registered trademarks or

trademarks of Microsoft Corporation. Arial, Times

New Roman, and Monotype are registered trademarks

of The Monotype Corporation plc. Netscape and

Netscape Navigator are trademarks of Netscape

Communications Corporation. PANTONE is a

trademark of Pantone, Inc. UNIX is a registered

trademark in the United States and other countries.

Licensed exclusively through X/Open Company, Ltd.

Product names mentioned in the text of this document

may be trademarks and/or registered trademarks of

their respective companies.

All references to PostScript on the screen or in this

guide or manual are references either to the PostScript

interpreter or to the PostScript Language.

Conventions This manual uses the following conventions:

Bold indicates emphasis or a minor heading

Italic refers to a document title or is used for

emphasis.

COMPUTER type indicates text visible on a computer

screen

The cursive l is used in examples to distinguish the

letter l from the numeral 1 (one). The character • is

used in examples to distinguish the numeral 0 from

the letter O.

v

Page 6

Note Notes contain important information set off from the

text. Special note headings, such as Network Note,

indicate specific kinds of notes.

Caution Caution messages appear before procedures which, if

not observed, could result in loss of data or damage to

equipment.

Warning Warning messages alert you to a specific

procedure or practice which, if not followed

correctly, could cause serious personal

injury.

vi

Page 7

Table of Contents

1. Controller Features........................................................................ 1

Introduction................................................................................................. 1

Key Features............................................................................................... 2

System Requirements................................................................................. 3

Controller.................................................................................................... 4

2. Using Your Controller....................................................................7

Introduction................................................................................................. 7

Connection Components............................................................................. 8

Setting Up Your Controller........................................................................... 9

Installing a Printer Driver........................................................................... 24

Changing a Printer Driver.......................................................................... 28

Automatic I/O Switching ............................................................................ 30

Connecting to a Peer-to-Peer Ethernet Local Area Network....................... 32

Managing Paper ........................................................................................ 46

Shared Printer Environments..................................................................... 53

Managing Print Jobs.................................................................................. 57

3. Configuration Utility Features..................................................... 61

Introduction............................................................................................... 61

Configuration Utility Screen....................................................................... 62

4. User Administration.....................................................................69

Introduction............................................................................................... 69

Using the Configuration Utility to Set Up Your Network Controller.............. 71

Using a Web Browser to Perform Common Network Management Tasks .. 79

Network Environments and Special Utilities............................................... 83

5. Overlay Printing.......................................................................... 107

Introduction..............................................................................................107

6. Maintenance and Adjustments.................................................. 113

7. Troubleshooting......................................................................... 115

Introduction..............................................................................................115

Incorrect/Unexpected Digital Duplicator Output.........................................116

Controller, Digital Duplicator, and Computer Error Messages....................117

Frequently Asked Questions....................................................................119

Appendix A: Diagnostic Test Page............................................... 125

Generating a Test Page ...........................................................................125

Appendix B: Controller Status Lights .......................................... 129

Message Tables.......................................................................................129

vii

Page 8

Appendix C: Controller/Digital Duplicator Compatibility............ 133

Guidelines................................................................................................133

Appendix D: Service, Support, and Warranty Information ......... 135

Introduction..............................................................................................135

Assistance Sources..................................................................................135

Warranty..................................................................................................136

Appendix E: Environmental Specifications................................. 137

Location Requirements.............................................................................137

Controller Specifications...........................................................................138

FCC Regulations......................................................................................139

VDE.........................................................................................................139

Glossary.......................................................................................... 141

Index................................................................................................ 153

viii

Page 9

List of Figures

Figure 1-1.4. Controller (front and right side view).......................................4

Figure 1-1.5. Controller (rear view)...............................................................5

Figure 2-2.1. Major Components ..................................................................8

Figure 2-3.1. Items contained in the shipping box. ......................................10

Figure 2-3.2.1. Controller Ventilation Requirements...................................11

Figure 2-3.2.2. Connecting the Controller to the Controller-Digital

Figure 2-3.2.3. Connecting the Digital Duplicator to the Controller-Digital

Figure 2-3.3.1. Connect Power to the Controller .........................................14

Figure 2-3.3.2. Power On the Digital Duplicator.........................................15

Figure 2-3.3.3. Power On the Controller......................................................15

Figure 2-3.3.4. Push the ONLINE button on the Digital Duplicator.............16

Figure 2-3.4.1. Controller Green Light Status..............................................17

Duplicator Cable ................................................................... 12

Duplicator Cable ................................................................... 13

Figure 2-3.4.2. Push the Diagnostic Test Page Button.................................18

Figure 2-3.4.3. Diagnostic Test Page (sample) ............................................19

Figure 2-3.5.1. Connect your computer to the controller’s parallel port........20

Figure 2-3.6. Load the CDROM into your computer...................................21

Figure 2-3.7. Configuration Utility installation............................................22

Figure 2-4.3. Starting the CDROM installation program. ............................26

Figure 2-4.4. Model and serial number label. ..............................................27

Figure 2-5.1.1. Locate your software’s Print screen (example is Microsoft

Word 97)..............................................................................28

Figure 2-5.1.2. Selecting a different printer driver.......................................29

Figure 2-6.1. Automatic I/O Switching Ports ..............................................30

Figure 2-7.1. Connecting to a LAN.............................................................33

Figure 2-7.2. IPX/SPX protocol installation................................................34

Figure 2-7.3. IPX Redirector program setup. ............................................... 37

Figure 2-7.4.1. Attach the digital duplicator printer driver to the desired IPX

port.......................................................................................38

Figure 2-7.4.2. An IPX LAN printer port ‘attached’ to the printer driver.....40

ix

Page 10

Figure 2-7.4.3. Finished IPX port installation..............................................41

Figure 2-7.6. Testing the LAN connection. .................................................43

Figure 2-8.3. Enable Auto-Cycle..................................................................49

Figure 2-8.4. Turn the collate feature off (Microsoft Word 97)....................50

Figure 2-10.2. Configuration Utility Desktop Icon......................................58

Figure 2-10.3. Configuration Utility screen..................................................59

Figure 3-2.1. Configuration Utility Screen ..................................................62

Figure 3-2.2.1. Selecting a digital duplicator to configure. ..........................63

Figure 3-2.3. Model and serial number label. ..............................................64

Figure 4-2.1.2. MAP Configuration.............................................................72

Figure 4-2.2.1. NIC discovery.....................................................................73

Figure 4-2.2.2. NIC Network Administration page......................................74

Figure 4-2.3.1. Sample NIC Test Page (PostScript).....................................78

Figure 4-2.3.2. Sample NIC Status Page (PostScript)..................................78

Figure 4-3.1. Custom IPX LAN printer port name.......................................82

Table 4-4.1.3. Windows Workstation Configurations..................................86

Figure 5-1.1. Push the ONLINE button on the digital duplicator to take it

OFFLINE. .......................................................................... 108

Figure 5-1.2. Place the document to be copied on or into the digital

duplicator. ..........................................................................109

Figure 5-1.3. Push the OVERLAY button on the digital duplicator...........110

Figure 5-1.4. Push the ONLINE button on the digital duplicator...............111

Figure 5-1.5. Print the computer page. ......................................................112

Figure A-1.1. Push the Diagnostic Test Page button..................................125

Figure A–1.2.1. Enabling ON LINE .......................................................... 126

Figure A–1.2.2. Enabling Auto-Cycle.......................................................127

Figure A–1.2.3. Sample Diagnostic Test Page...........................................128

Figure B-1.1. Normal Operation State Diagram.........................................130

Figure E-1.1. Controller Clearance Dimensions ........................................137

x

Page 11

List of Tables

Table 2-8.1. Common Page Size/Orientation Faults ....................................47

Table 4-2.3.1. Network Administration Options – System Area ..................76

Table 4-2.3.2. Network Administration Options – Protocols Area...............76

Table 4-2.3.3. Network Administration Options – Others Area ...................77

Table 4-4.1.1. Special NIC Configuration utilities ....................................... 84

Table 4-4.1.2. NetWare Workstation Configurations...................................86

Table 4-4.2. IP-P2P Setup Field Descriptions .............................................. 98

Table 7-1.1. Resolving Problems with Incorrect Digital Duplicator

Table 7-1.2. Resolving Error Messages.....................................................118

Table 7-2.1. Frequently Asked Questions Table #1....................................119

Table 7-2.2. Frequently Asked Questions Table #2 ................................... 120

Table 7-2.3. Frequently Asked Questions Table #3....................................121

Table 7-2.4. Frequently Asked Questions Table #4....................................122

Output ................................................................................ 116

Table 7-2.5. Frequently Asked Questions Table #5 ................................... 123

Table B-1.1. Normal Controller Status Light Conditions...........................131

Table B-1.2. Abnormal Controller Status Light Conditions.......................132

Table E-1.1. Physical Dimensions.............................................................138

Table E-1.2. Electrical Power....................................................................138

Table E-1.3. Environmental Specifications................................................138

xi

Page 12

xii

Page 13

1

Controller Features

Introduction This chapter provides an overview of the key features

of your controller.

1

Page 14

Key Features

Print Engine Performance

Features

Formatter/Language/Typeface

Features

User and Computer Interface

Features

q NEC Vr4300 MIPS RISC 100 MHz technology.

q Patented Adobe PostScript 3 compression and

printing technology.

q Printer drivers included for the Microsoft

Windows 95/98/NT4 and Apple MAC OS 7.6.1

(or higher) operating systems.

q Compatible with digital duplicators having a

print resolution of 300 dpi, 400 dpi, or 600 dpi.

q PostScript 3 printer language compatible - 136

Adobe PostScript fonts built-in.

q PCL-5e printer language compatible - 45

scalable typefaces built-in

q 32 Mbytes standard memory.

q Two SIMM slots for up to 256 MByte industry

standard memory.

q Configuration Utility software included for the

Microsoft Windows 95/98/NT4 and Apple MAC

OS 7.6.1 (or higher) operating systems.

q Three Types of Input Ports:

♦ Standard Bi-directional/ECP parallel port.

♦ LocalTalk port.

♦ 10BASE-T Ethernet LAN port

q Two computers and a LAN may be connected to

and use the controller simultaneously.

2

Page 15

System

Requirements

Note Early models of the digital duplicators that do not

q An IBM-compatible PC with:

« Microsoft Windows 95 w/IE4, Windows 98,

or Windows NT4 w/SP3 operating system,

« CDROM,

« 15 MB of free hard drive space,

« A parallel port (LPT1:) defined as ECP (bi-

directional).

q A controller-compatible digital duplicator (see

Note below) with the appropriate video interface

installed and working.

have an ONLINE button on their control panel, or

that have a printing resolution of 406 dpi, are not

compatible with this controller.

3

Page 16

Controller The following illustrations give the location and

names of key parts of the controller:

1 2 3 4 5

Figure 1-1.4. Controller (front and right side view)

1. Left status light 4. Front panel bezel

2. Right status light 5. Side/top cover

3. Brand nameplate

4

Page 17

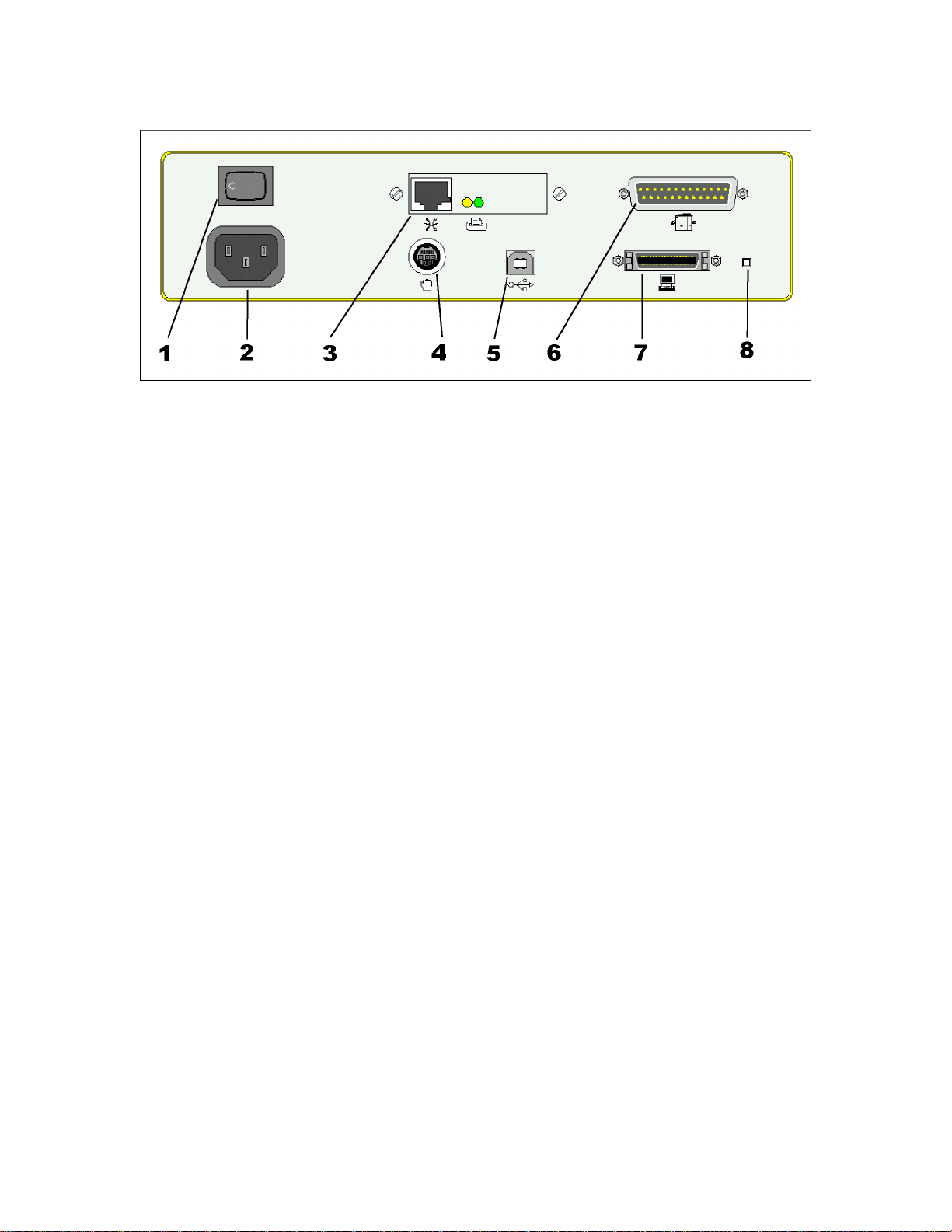

Figure 1-1.5. Controller (rear view)

1. ON/OFF power switch 5. Not supported

2. Power connector jack 6. Digital Duplicator port

3. 10BASE-T Ethernet LAN port 7. Bi-directional parallel (ECP) port

4. LocalTalk port (Apple Macintosh) 8. Diagnostic Test Page button

5

Page 18

6

Page 19

2

Using Your Controller

Introduction This chapter provides instructions on how to setup

and use your controller. It includes information

about:

q Connection Components.

q Setting Up Your Controller.

« A step-by-step process.

« Required memory.

« Print resolution.

q Installing a Printer Driver.

q Changing Printer Drivers.

q Automatic I/O switching.

q Connecting to a Peer-to-Peer Ethernet Local Area

Network.

q Managing Paper.

« Page size and orientation.

« Number of copies.

« Bleed-off printing.

q Shared Printer Environments.

« Using a switchbox.

« I/O port order.

« Optimizing multiple I/O port operation.

« Personality/language switching.

q Managing Print Jobs

« The Configuration Utility program.

« Starting the Utility.

« Canceling a print job.

« Optimizing operation in a shared printer

environment.

Caution Proper Grounding: Ensure that all interface cables

and host computer(s) or other equipment attached to

the controller follow proper grounding methods for

electronic equipment in accordance with local

electrical codes.

7

Page 20

Connection Components

Figure 2-2.1. Major Components

The three major components are:

1) Controller. Several models are available which

will work with your digital duplicator. Its

function is to make the digital duplicator appear

as a printer to a computer. As such, it provides

one or more physical connection ports for a

computer, formats the documents sent by a

computer for printing on the digital duplicator,

and houses built-in fonts.

2) Cable for the digital duplicator-to-controller

connection. This cable is shipped with the

controller and provides the communication path

between controller and digital duplicator.

3) Digital Duplicator. Various models exist, each

one unique in its characteristics and

specifications. The function of the digital

duplicator is to make the physical master and

copies.

8

Page 21

Setting Up Your

Controller The process of setting up your controller is extremely

easy and straightforward.

A step-by-step

Process Follow the simple steps below to have your product

printing documents in a very short time.

Network Note If you are in the process of installing the controller/

digital duplicator on your computer as a printer

accessible though a local area network (LAN), and

the controller and digital duplicator have been

previously set up using the procedure outlined by the

steps in this section, you may skip this section and

proceed to the section in this chapter entitled

Installing a Printer Driver.

If the controller/digital duplicator are to be used as a

network printer, but have not been previously setup

using the procedure outlined by the steps in this

section, you must follow the steps outlined in this

section first, then proceed with installation as a

network printer.

Caution Power OFF the digital duplicator before proceeding

with the setup steps that follow.

9

Page 22

Step 1

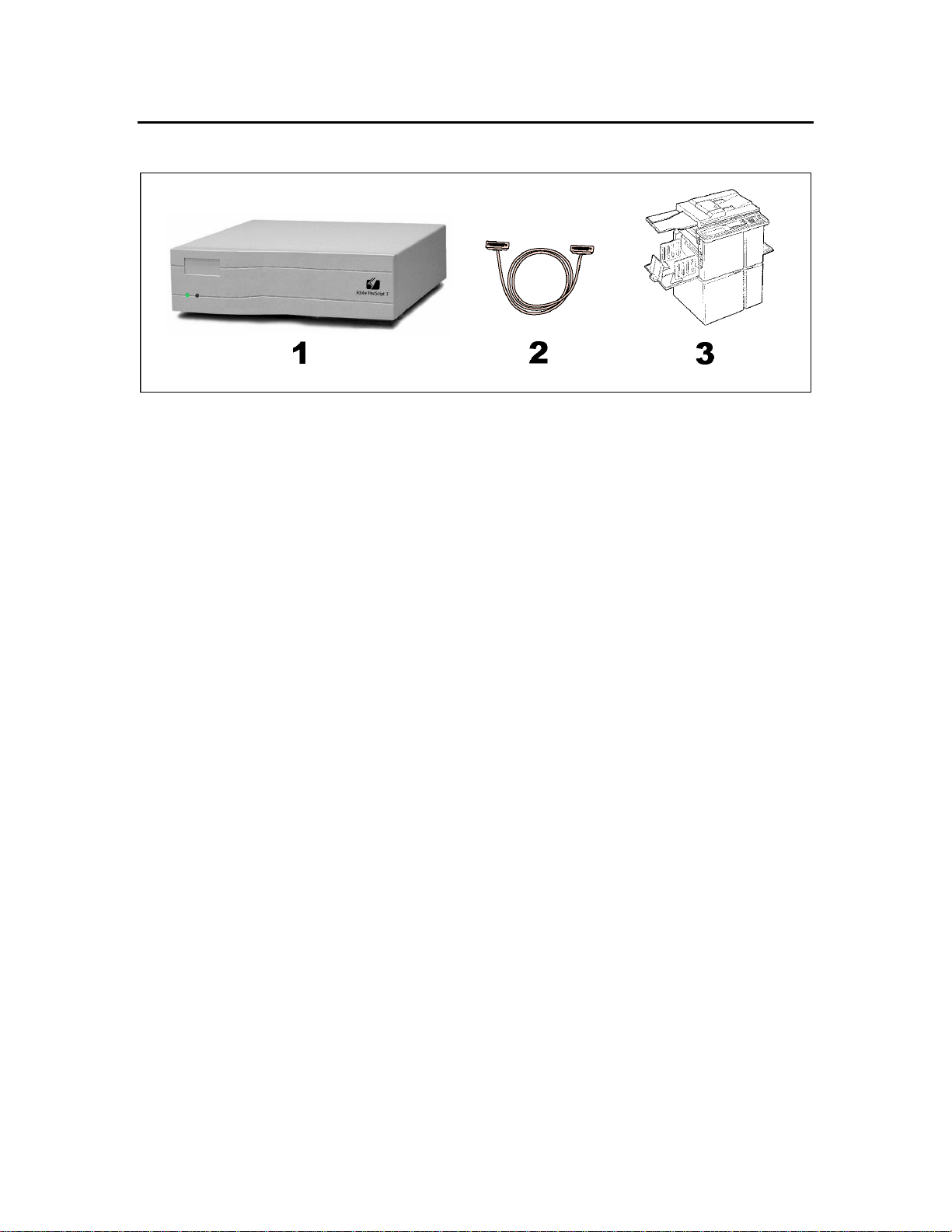

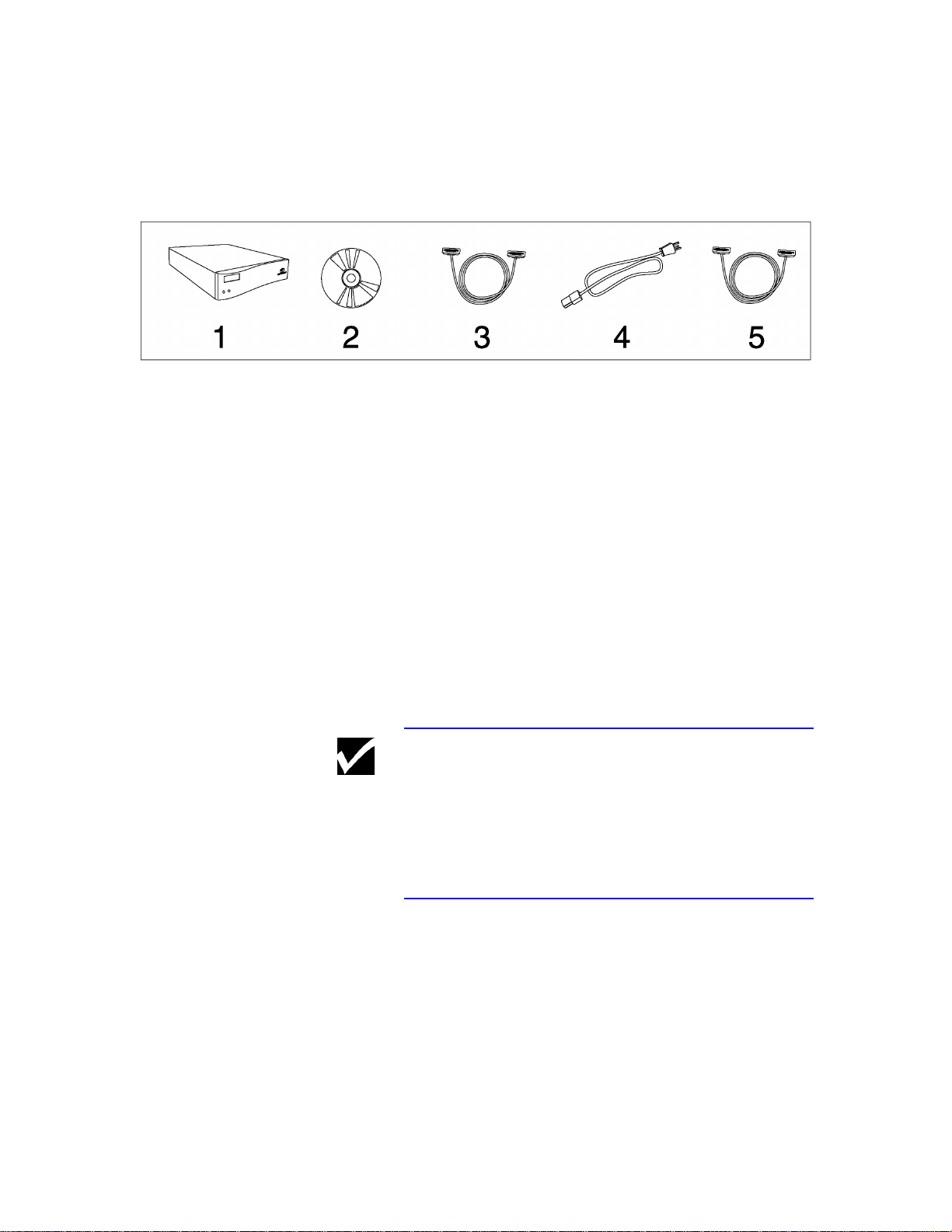

Unpack the Controller There are five items (shown in Figure 2-3.1)

contained in the controller shipping box.

Figure 2-3.1. Items contained in the shipping box.

1. Digital duplicator controller.

2. CDROM containing the Configuration Utility

software, drivers, and controller documentation.

3. Controller-to-digital duplicator communications

cable - DB25M connector to DB25F connector.

4. Power cord for the controller.

5. Computer-to-controller communications cable -

DB25M connector to IEEE 1284C MiniCentronics connector.

Unpack all items and set on a table near the digital

duplicator.

Note The shipping container for the controller is designed

specifically to protect the controller and other

components from being damaged during shipment.

We recommend that you store the box in a safe place,

from where it may be retrieved and used should you

need to return the controller for service.

10

Page 23

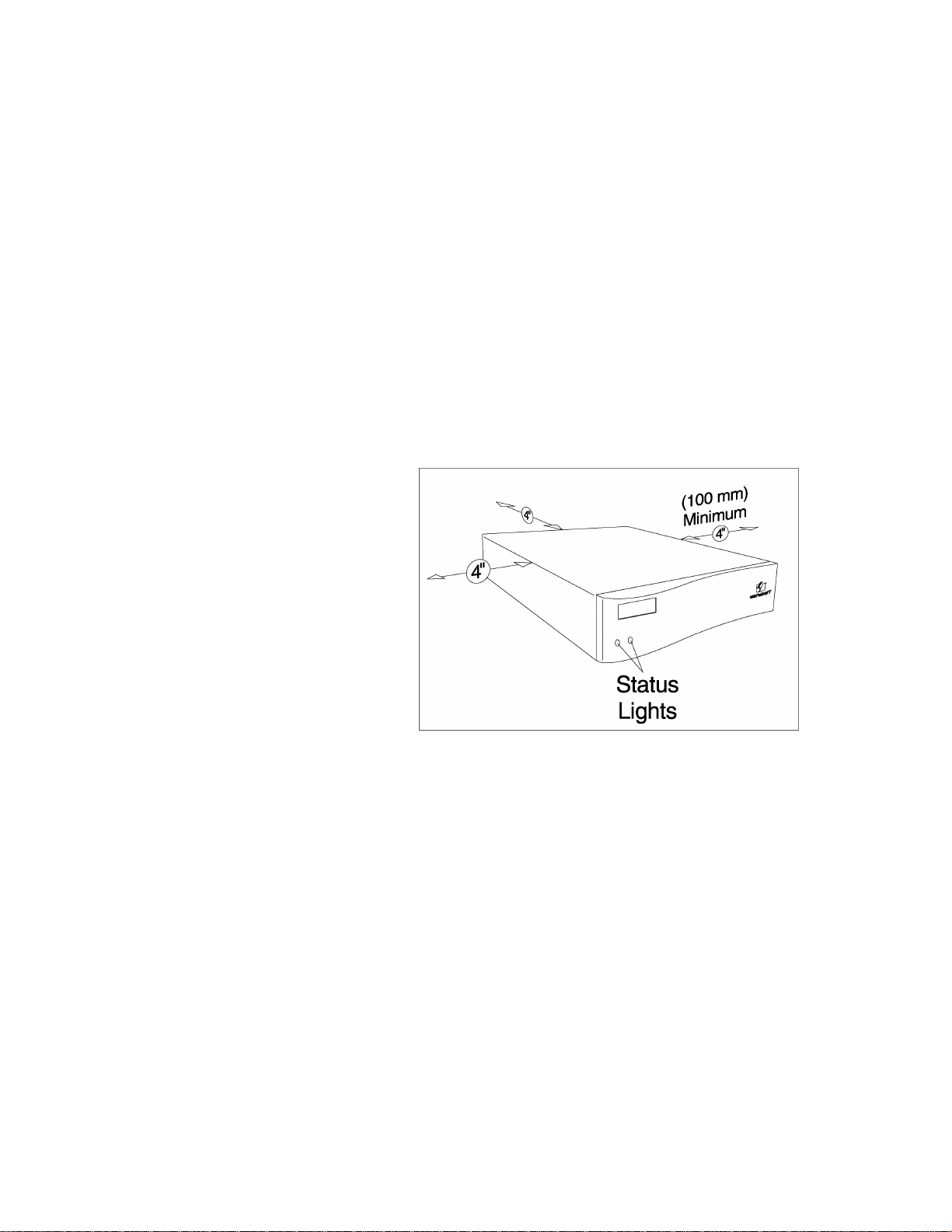

Step 2

Locate a Place to

Keep the Controller The controller must be set up within 6 feet (2 meters)

of the digital duplicator. This is the length of the

cable between the two units.

The controller may be mounted in any position or

direction. The only constraints are:

1) Leave a minimum or 4 inches (100 mm) between

the back panel, left and right side panels and any

other object for proper ventilation,

2) If possible, mount the controller in a position

where the computer operator may clearly see the

front panel status lights.

Figure 2-3.2.1. Controller Ventilation

Requirements

11

Page 24

Connect the Digital

Duplicator to the

Controller Use the cable supplied with the controller to connect

Step 3

the controller’s digital duplicator port to the controller

port on the digital duplicator.

.

Figure 2-3.2.2. Connecting the Controller to

the Controller-Digital Duplicator Cable

12

Page 25

Figure 2-3.2.3. Connecting the Digital

Duplicator to the Controller-Digital Duplicator

Cable

Your digital duplicator will have one or the other of

the following types of controller connections.

The vertical connection is typically located on the

side of the digital duplicator.

The horizontal connection is typically located on the

back of the digital duplicator.

13

Page 26

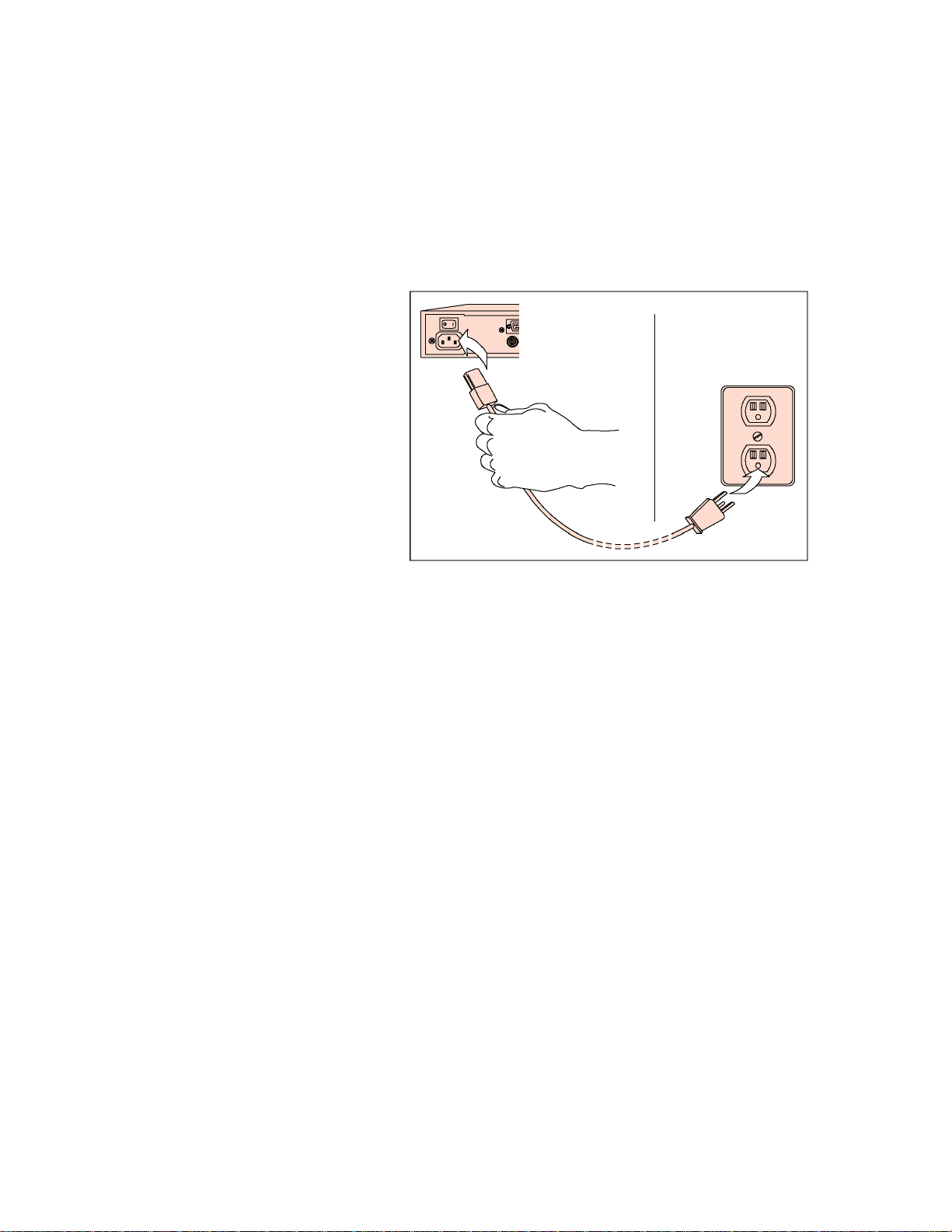

Step 4

Connect Power to

the Controller Locate the power cord which came with the

controller, and attach it to the controller’s power input

jack, and a local mains power socket (can be the same

supply as is used for the digital duplicator).

Figure 2-3.3.1. Connect Power to the

Controller

14

Page 27

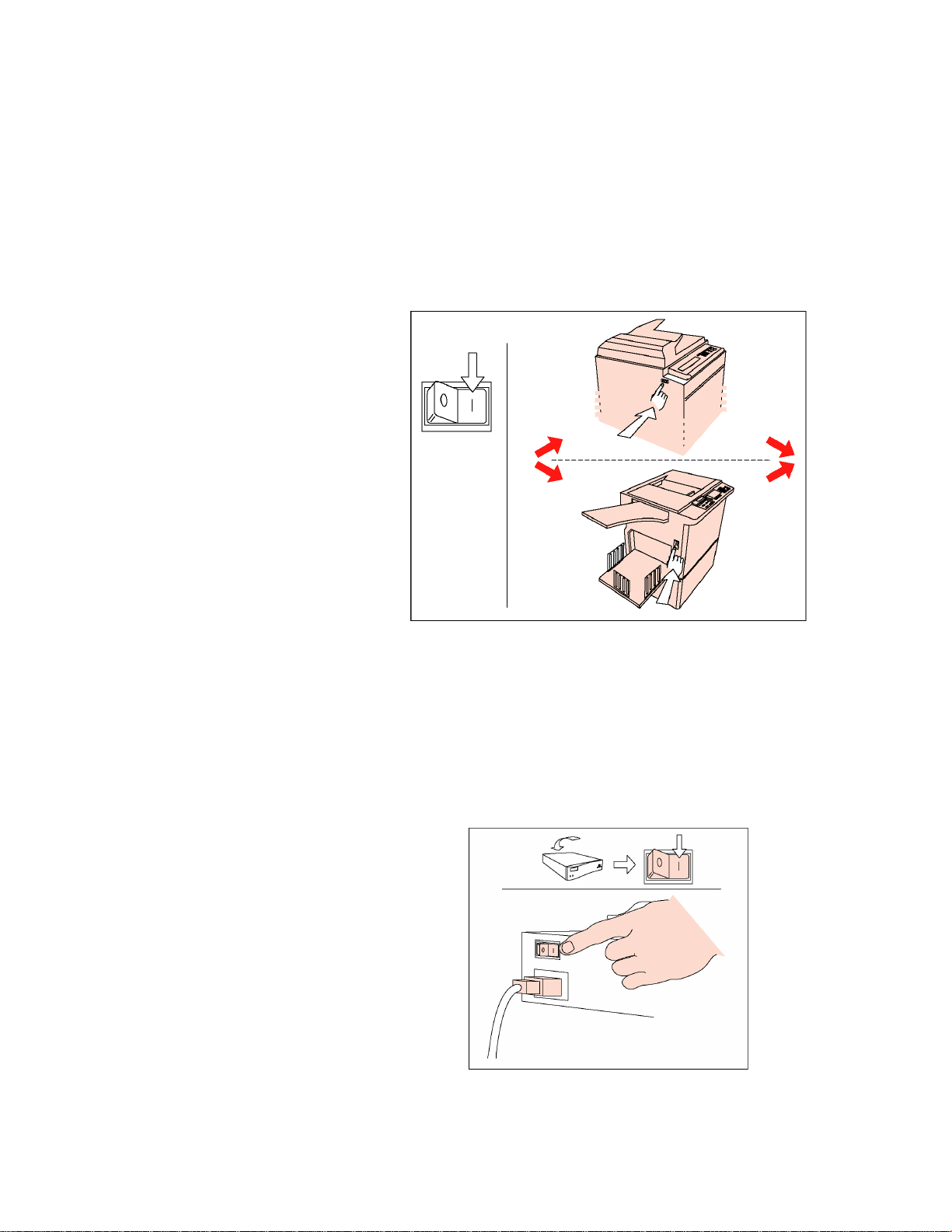

Step 5

Apply Power to the

Digital Duplicator Power ON the digital duplicator by locating the

power switch and pushing it to the ON (“1”) position.

The switch is usually located in one or the other of

the positions indicated by the drawings in Figure 2-

3.3.2.

Apply Power to the

Controller Power ON the controller by locating the power switch

Figure 2-3.3.2. Power On the Digital

Duplicator

Step 6

and pushing it to the ON (“1”) position.

Figure 2-3.3.3. Power On the Controller

15

Page 28

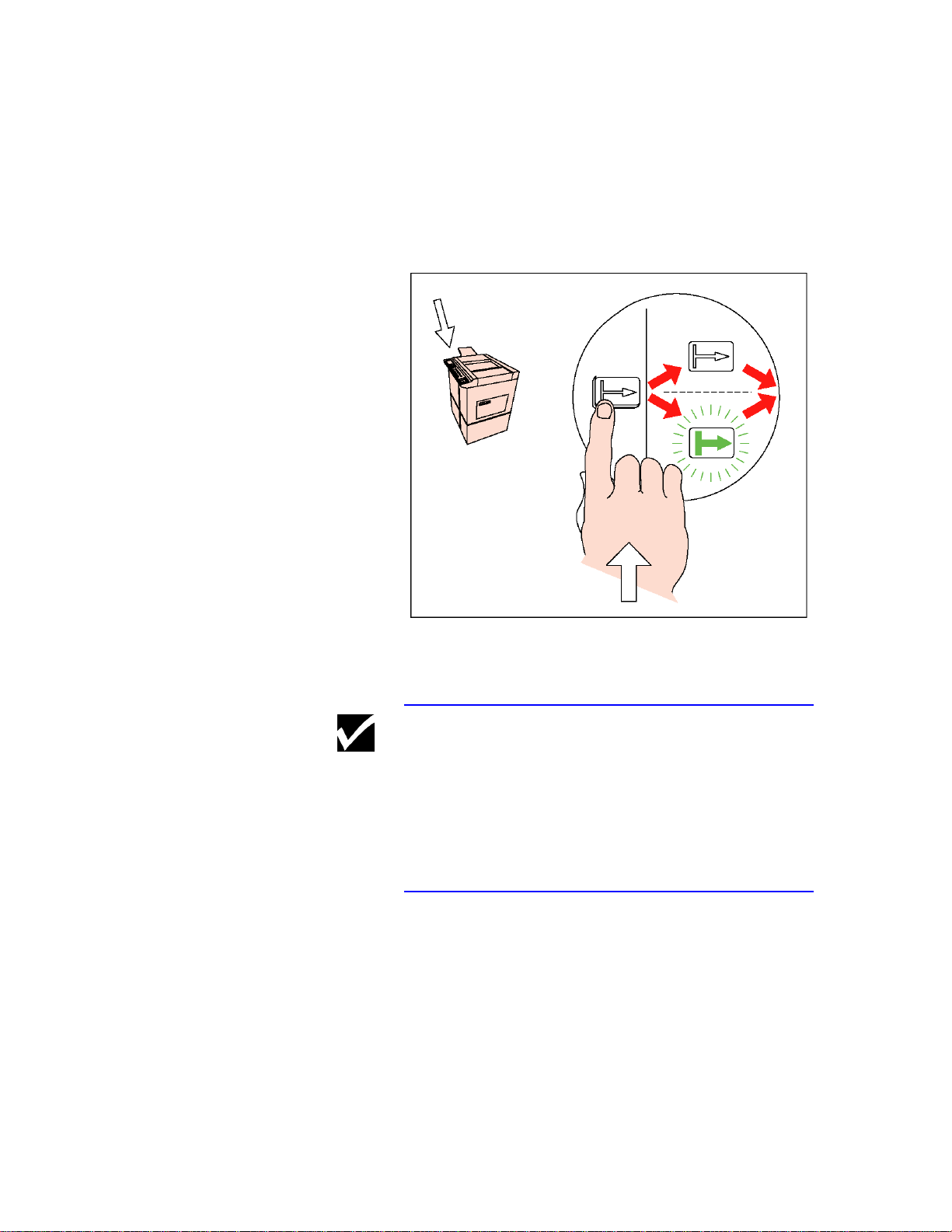

Step 7

Put the Digital

Duplicator ONLINE Locate and push the ONLINE button on the digital

duplicator.

Figure 2-3.3.4. Push the ONLINE button on

the Digital Duplicator

Note The ONLINE symbol or light may or may not

illuminate when the button is pressed. Even though

the action of pushing the ONLINE button enables

communication with the controller, some models of

digital duplicators will illuminate the lamp only after

a print job has been sent.

16

Page 29

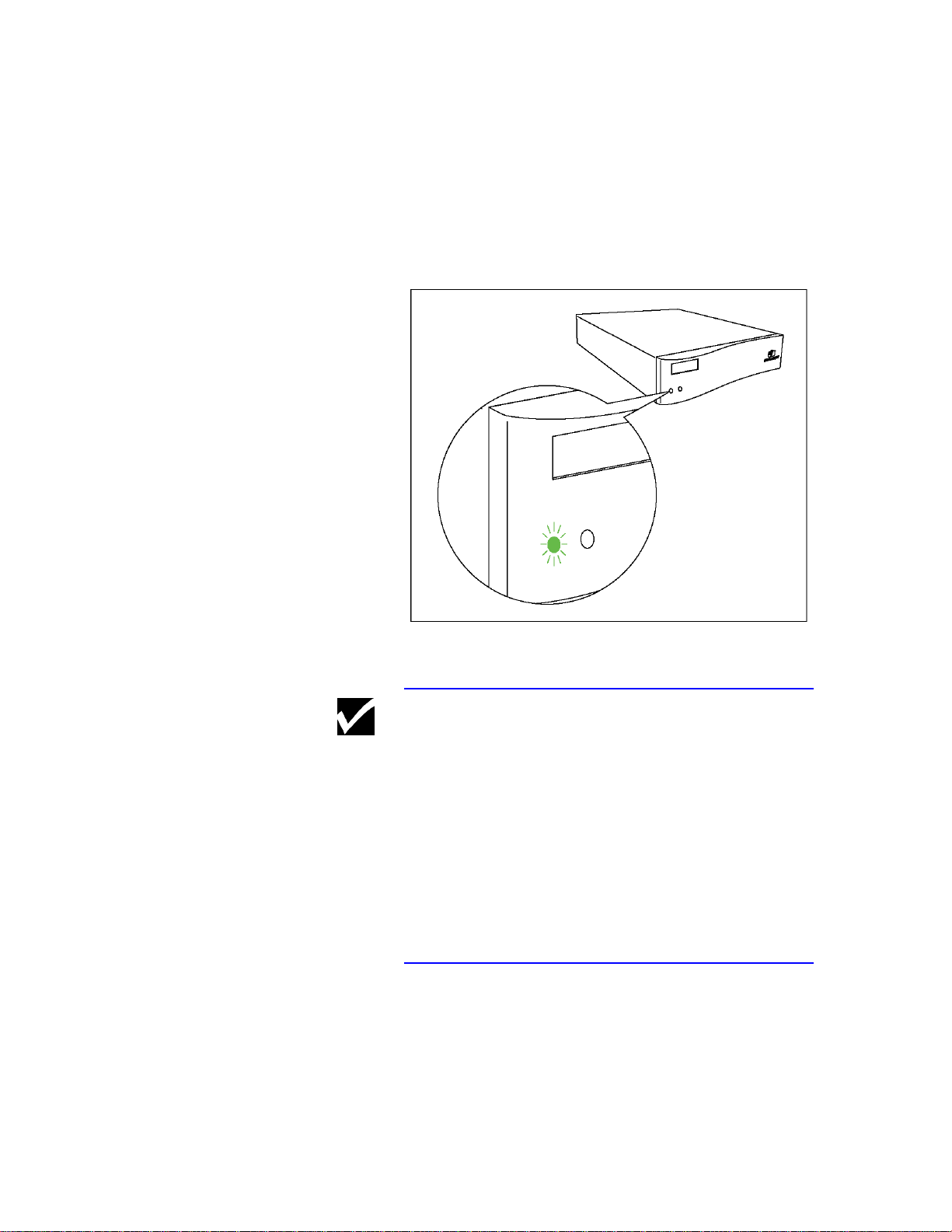

Check for Controller

Green Light Status

Step 8

Locate and observe the status lights on the front panel

of the controller. If the digital duplicator is ONLINE

and it and the controller are functioning properly, the

left status light should be green and on steady.

Figure 2-3.4.1. Controller Green Light Status

Note If the controller begins flashing error messages (red

or yellow lights), either the setup has not been done

correctly or there is a problem with the digital

duplicator or controller. DO NOT PROCEED with

the remainder of this setup procedure until the

problem has been resolved.

For assistance, look in Chapter 7, Troubleshooting, or

Appendix B, Controller Status Lights, for assistance.

If the problem persists, contact the supplier of your

digital duplicator.

17

Page 30

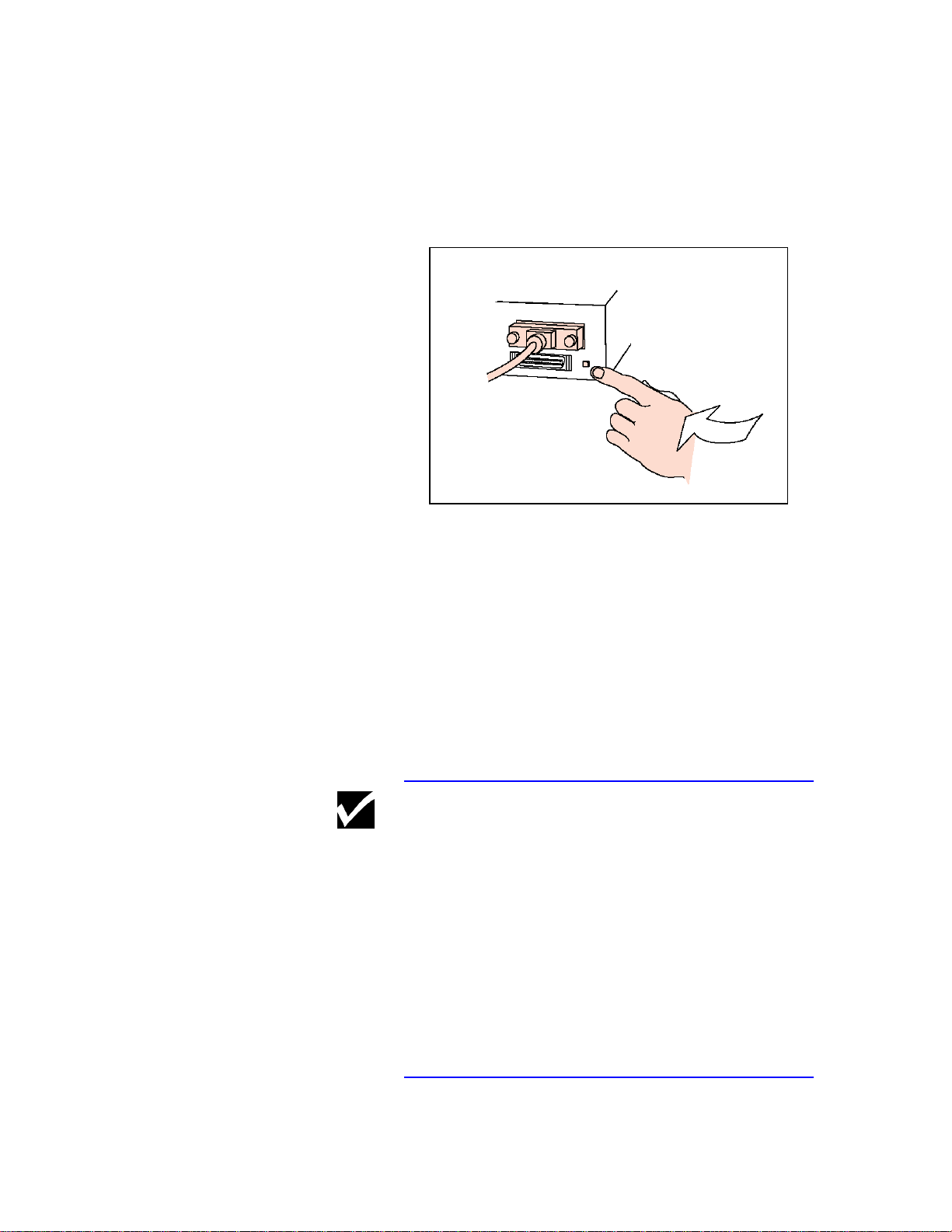

Print a Diagnostic

Test Page

Step 9

Locate and push the Diagnostic Test Page button on

the rear of the controller.

Figure 2-3.4.2. Push the Diagnostic Test

Page Button

The digital duplicator will make a master and print a

page similar to the one shown in Figure 2-3.4.3.

This process confirms that the controller and the

digital duplicator are communicating correctly. The

exact contents of the Diagnostic Test Page do not

matter at this point – we are only confirming that the

controller and digital duplicator are functioning

together.

Note If the controller or digital duplicator begin flashing

error messages, or you do not get a test page printed

from the digital duplicator, either the setup has not

been done correctly or there is a problem with the

digital duplicator or controller. DO NOT PROCEED

with the remainder of this setup procedure until the

problem has been resolved.

For assistance, look in Chapter 7, Troubleshooting, or

Appendix B, Controller Status Lights, for assistance.

If the problem persists, contact the supplier of your

digital duplicator.

18

Page 31

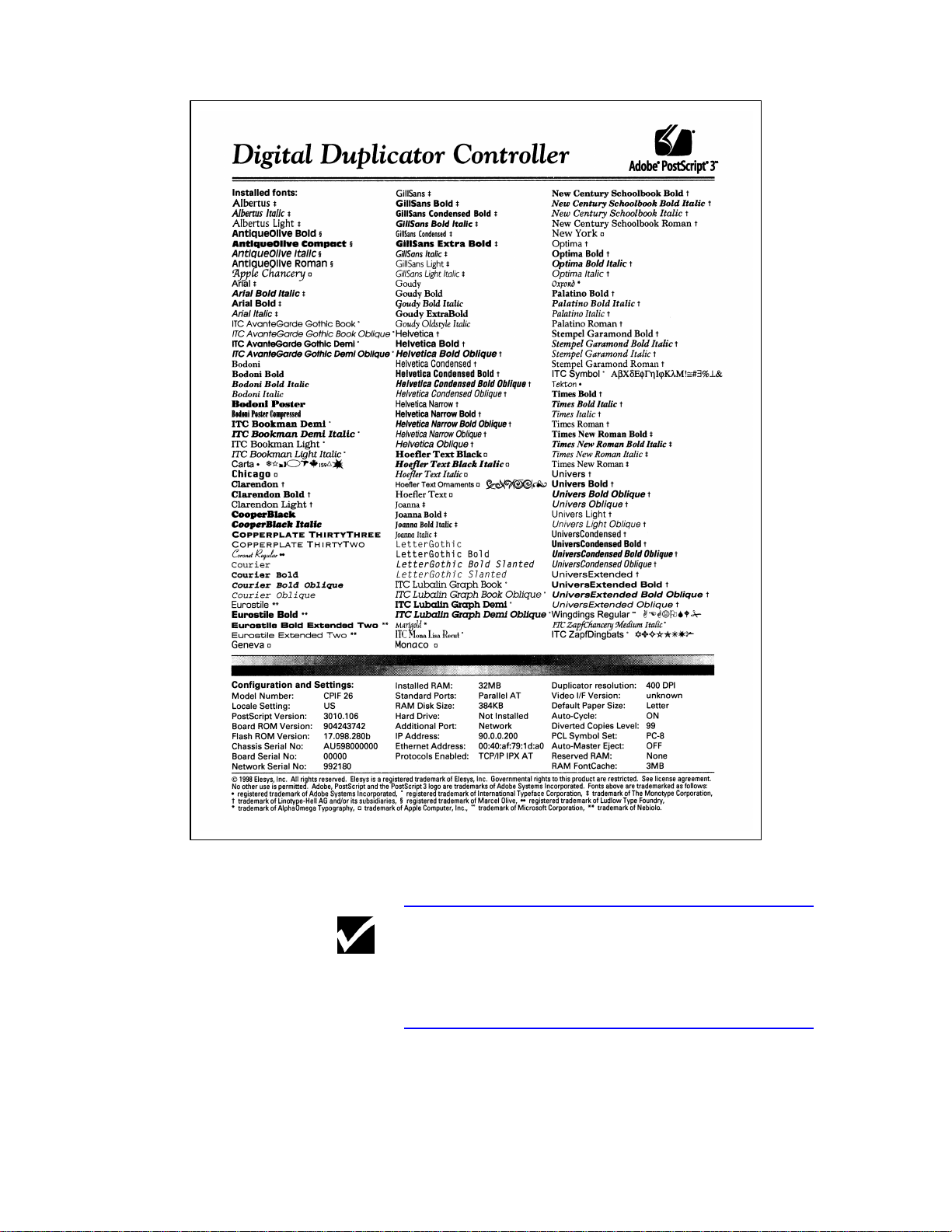

Figure 2-3.4.3. Diagnostic Test Page (sample)

Note The contents of the Configuration and Settings:

section of the page will depend upon your particular

controller and digital duplicator combination.

19

Page 32

Connect Your

Computer to the

Controller Locate the parallel port on the back of the controller

Step 10

and attach an appropriate parallel cable between it

and the parallel output port of your computer.

Figure 2-3.5.1. Connect your computer to the

controller’s parallel port

Note To facilitate the setup procedure, the initial

connection between the PC and the controller is done

at the parallel port. After the setup of your controller

is complete, connection of the computer to the

controller may be done at any of the other ports.

20

Page 33

Load the CDROM into

Your Computer Locate and install the CDROM that came with the

Step 11

controller into your computer’s CDROM drive.

Figure 2-3.6. Load the CDROM into your

computer.

21

Page 34

Step 12

Install the

Configuration

Utility software Once the CDROM has been loaded into your

computer, it will be necessary to locate and start the

Configuration Utility installation program:

a) Start Windows Explorer and open the CDROM

directory,

b) Locate and double-click on the SETUP.EXE

filename.

Screens will appear prompting you for answers to

questions regarding your digital duplicator in order to

install it as a printer for your computer.

22

Figure 2-3.7. Configuration Utility

installation.

Page 35

Required Memory The amount of memory required for printing with

your controller has been predetermined and installed

in the controller. No additional memory is required.

However, additional memory may be installed to

enhance your controller’s job loading and master

creation speeds, to increase its soft font download

capacity, or both. See Upgrading Controller Memory

in the appendix of the Controller Reference Manual,

for details.

Print Resolution The resolution of the printed output is the same as the

specification for your digital duplicator.

23

Page 36

Installing a Printer

Driver The Configuration Utility installation program on the

CDROM that came with your controller provides a

very intuitive, screen-by-screen installation process of

the:

• Configuration Utility program,

• Printer drivers for your model of digital duplicator

and controller,

• User’s Guide,

• Reference Manual, and

• LAN administration tools.

Note Correct installation of the Configuration Utility,

printer drivers, manuals and other software assumes

the controller/digital duplicator have been setup

previously following the procedure outlined in the

section entitled Setting Up Your Controller, in this

chapter. If this is not the case, you must first follow

the steps outlined in that section before proceeding.

24

Page 37

Network Note If controller/digital duplicator are being installed on

this computer as a printer accessible through an

Ethernet local area network (LAN), and the controller

is not currently connected to the computers parallel

port, do the following (assuming the controller/digital

duplicator are already setup and functioning on the

LAN):

1) Follow the steps outlined here, ignoring any

warning messages you receive regarding the

computer not being able to communicate with the

controller/digital duplicator.

2) Skip any steps relating to generating a test page.

3) After completion of the installation steps, proceed

to the section in this chapter entitled Connecting

to a Peer-to-Peer Ethernet Local Area Network.

25

Page 38

After inserting the installation CDROM,

c) Start Windows Explorer and open the CDROM

directory,

d) Locate and double-click on the SETUP.EXE

filename.

A screen similar to Figure 2-4.3 should appear.

Figure 2-4.3. Starting the CDROM installation

program.

As shown in Figure 2-4.3, the first screen asks you to

select your language. Select the desired language and

click on .

The installation program is user-friendly and will

guide you through a series of steps to complete the

installation.

When complete, the necessary components for using

the digital duplicator through the printer port of your

computer will be installed, along with the Controller

User’s Guide and the Controller Reference Manual.

26

Page 39

Note To determine the model number, look on the outside

bottom your controller chassis. There is a small label

containing a bar code affixed to the chassis near the

rear panel, similar that shown in Figure 2-4.4.

MODEL NO. CPIF 26

S/N: AU1234567891234567891

AU123456789

Figure 2-4.4. Model and serial number label.

27

Page 40

Changing a Printer

Driver Most of the time you will probably stay with one

printer driver for your digital duplicator. This is

because your software will use either PCL or

PostScript fonts. For example, if your desktop

publishing program uses primarily PostScript fonts,

you will want to use the PostScript printer driver for

your controller so you maintain WYSIWYG (‘whatyou-see-is-what-you-get’) compatibility between your

screen and the printed output. However, if you

switch to a different program, such as a spreadsheet

which uses PCL fonts, you will need to change printer

drivers to keep your screen and printed outputs

similar.

Changing to a different printer driver to match the

requirements of your software is very easy. The

following example is given for Microsoft Word 97,

but is similar for most programs that run under the

Microsoft Windows operating system. In this

example, we are changing from PostScript to PCL.

First, locate and activate the Print menu in your

software.

Figure 2-5.1.1. Locate your software’s Print

screen (example is Microsoft Word 97).

In the example shown in Figure 2-5.1.1, we are

currently using the PostScript 3 driver for a digital

duplicator. To change this to the PCL driver for the

same digital duplicator, click on the down arrow next

to the printer name field to bring up all of the choices.

28

Page 41

Figure 2-5.1.2. Selecting a different printer

driver.

Select/highlight the PCL version of the same digital

duplicator (as shown) by clicking on it once, then

select the OK tab on the bottom right of the screen.

In this example, the controller will automatically be

set to PCL mode to print the document, allowing the

screen and printed fonts to match.

29

Page 42

Automatic I/O

Switching Any your controller’s three I/O ports – LAN,

LocalTalk, and bi-directional/ECP parallel – may be

used at the same time. This allows you to attach

cables to all ports and communicate to all ports from

up to three host computer systems (see Figure 2-6.1).

Your controller will automatically switch between

ports to accommodate incoming data. This allows

you to think of each port as a separate controller.

Figure 2-6.1. Automatic I/O Switching Ports

A = LAN (hub), B = LocalTalk (Apple Macintosh), C

= ECP parallel (PC)

30

Page 43

Note Bi-directional/ECP parallel is backwards-compatible

with Centronics parallel standard. Although it uses

the same cable, hardware, and software as Centronics

parallel, to receive its enhanced capabilities – such as

bi-directional communication between computer and

controller, faster transmission of data, and autoconfiguration of printer drivers – you need software

that supports these features. Most Windows software

supports these features. However, if in doubt, check

with your software vendor to see if your software

supports bi-directional/ECP parallel features.

Automatic I/O switching can be adjusted for optimum

performance using the Controller Timeout value. If,

when using multiple ports, data from other ports

appears in the middle of your print job, increase the

value of this variable. For more information, see

Controller Timeout value under Managing Print Jobs,

Optimizing operation in a shared printer

environment, in this chapter.

Caution Proper Grounding: Ensure that all interface cables

and host computers attached to the controller follow

proper grounding methods for electronic equipment in

accordance with local electrical codes.

31

Page 44

Connecting to a Peerto-Peer Ethernet

Local Area Network Your controller can be attached directly to a peer-to-

peer, Ethernet-based Local Area Network, or LAN,

using the instructions outlined here. Any PC

connected to the network, once configured, may print

to the digital duplicator.

Network Note These instructions:

1) Assume the controller/digital duplicator have

already been set up though a computer’s parallel

port and function correctly so connected. If this is

not the case, you must return to the Setting Up

Your Controller section of this chapter and

complete the installation before proceeding.

2) Assume one or more printer drivers for the

controller/digital duplicator already exist on your

computer, set up to print through the parallel port

(LPT1:). If this is not the case, you must go to the

Installing a Printer Driver section of this chapter

and complete the procedure before continuing.

3) Apply to workstations only (not servers) on a

‘server-less’, peer-to-peer network. If your

network uses a server, if you do not know if your

network has a server, or if you are attempting to

setup a network server to use the controller,

contact your network administrator for assistance.

Instructions for network administration are found

in Chapter 4, User Administration, of the

Controller User’s Guide.

4) Assume that if you are on an NT4 workstation,

you have administrator privileges.

To enable printing to a controller/digital duplicator

from a network workstation on a server-less, peer-to-

peer LAN, follow the steps outlined in this section.

32

Page 45

Connect the Ethernet

LAN to the controller.

Step 1

Figure 2-7.1. Connecting to a LAN.

Locate the 10BASE-T LAN port on the back of the

controller, as shown in Figure 2-7.1. Using a

standard UTP (Unshielded Twisted Pair) Ethernet

cable, attach one end of the cable to this port on the

rear of the controller, and the other end to your

Ethernet network drop (LAN port jack on the wall or

floor, or to your LAN hub).

Network Note If you are unsure as to where the network drop/

connection is located for your office LAN, contact

your network administrator for assistance.

33

Page 46

Step 2

Configure your

computer to talk to

the controller over

the network. On your Windows desktop, locate the Network

Neighborhood icon, and click the right mouse

button. Click on Properties. Then click on the

Protocols tab. A screen similar to Figure 2-7.2 will

be displayed.

34

Figure 2-7.2. IPX/SPX protocol installation.

In order to communicate with the controller over the

network you must have the IPX/SPX protocol

installed on your computer. If this is not the case, it

must be installed before proceeding with IPX port

installation.

Page 47

Network Note If the IPX/SPX protocol is not installed on your

computer, you can install it using the instructions

contained in the Windows Help function (Start →

Help), clicking on the Index tab, and entering

protocols, installing into the field. Follow the

instructions for installing the IPX protocol.

If you are unsure as to whether the protocols are

installed on your computer, or do not wish to install

them, contact your network administrator for

assistance before proceeding further.

Step 3

Restart your

computer.

Step 4

Turn off all

applications running

on your computer. This includes word processing and spreadsheet

programs, and especially any programs that use the

network (web browsers, etc).

35

Page 48

Note You may skip Step 5 and Step 6 and proceed to Step

7 if the controller has been powered on for 2 minutes

or more.

Step 5

Power on the

digital duplicator,

then the controller.

Step 6

Wait until the

controller is ready to

receive data from the

LAN. Allow the controller to be powered on for at least 2

minutes before continuing.

Network Note It is necessary to wait for 2 minutes whenever power

is first applied to the controller, in order for it to

complete its internal power-up process. However,

once the controller has gone through its power-up

process, it will accept data from the network at any

time.

36

Page 49

Locate and install the

IPX Redirector

Program.

Step 7

This program installs an IPX ‘port’ for the controller

(similar in concept to your parallel or serial port, but

software only) into your computer. The program

actually searches for the controller through the

network, identifies it using the controller’s network

serial number, then creates and installs a port for it

into your Windows Printer Wizard.

The IPX redirector program is installed from the

CDROM supplied with your controller. To do this,

go to Start → Run. If the CDROM in your

computer is assigned drive letter e:, you would type

the following information into the ‘Open’ window:

e:\WIN\LAN Tools\IPXP2P\setup

followed by the Enter key. The setup installation

wizard will begin and you will be presented with a

screen similar to Figure 2-7.3.

Figure 2-7.3. IPX Redirector program setup.

Follow the instructions to completion.

37

Page 50

Step 8

Restart your

computer again.

Step 9

Attach the digital

duplicator printer

driver to the IPX port. Double-click on My Computer and open the

Printers folder. Right-click on the digital duplicator

printer driver (installed earlier) you wish to attach to

the network port, click on Properties, and select the

Ports tab. In a few seconds the ports screen will

open.

38

Figure 2-7.4.1. Attach the digital duplicator

printer driver to the desired IPX port.

Examine the Print to the following port: field. It

will be similar to what is shown in Figure 2-7.4.1.

Page 51

In our example, we have a PostScript 3 (PS3) printer

driver for our digital duplicator already installed on

our computer. It is currently attached to the LPT1:

printer/parallel port (performed during the initial

setup described under Installing a Printer Driver, in

this chapter).

In the list under the Port menu item appears the term

OTS_992180,

and under the Description menu item appears

(OTS Ethernet Option).

These two terms identify the IPX LAN printer port

assigned to the controller by the IPX Redirector

program. The 992180 number in the port name is

the network serial number of the controller, while the

(OTS Ethernet Option) character string identifies

it as being an active, IPX-protocol port. Note that,

since it is the only name of this type appearing in the

list, it is the only controller on the LAN visible by our

computer.

In order to print to the digital duplicator over the

LAN we must ‘attach’ our PS3 printer driver to this

IPX port. To do so, simply click on the box next to

the OTS_ port to make a check mark appear in it.

This action detaches the printer driver from the

computers parallel port and attaches it to the IPX

LAN port.

When finished, select the button. The

Ports screen should then appear similar to the

example in Figure 2-7.4.2.

39

Page 52

Figure 2-7.4.2. An IPX LAN printer port

‘attached’ to the printer driver.

If you exit and re-enter the Properties for this printer

driver, it should appear as shown on Figure 2-7.4.3,

with the printer driver name under the Printer

column.

40

Page 53

Figure 2-7.4.3. Finished IPX port installation.

41

Page 54

Network Note The IPX Redirector program installs an IPX port for

every controller/digital duplicator it finds attached to

the LAN. Thus, if more than one controller is

attached to the LAN, you will have multiple IPX

network names/ports from which to choose. You may

confirm you have selected the correct IPX network

name by verifying that the

1) controller’s network serial number matches the

number in the IPX LAN printer port name, and

that the

2) digital duplicator model to which the controller is

connected matches the printer driver with which

you are working.

The network serial number of the controller in

question may be identified using the Diagnostic Test

Page generated by it (see Appendix A, Diagnostic

Test Page, in the Controller User’s Guide). The

number is located in the lower left corner of the page.

The OTS_992180 character string of the IPX LAN

printer port name is also the NetWare Print Server

Name. A network administrator may change it to

another more readily identifiable name, such as Sales

Digital Duplicator, or the actual name/model of the

digital duplicator. See Assigning a custom name to

the controller under the section entitled Using a Web

Browser to Perform Common Network Management

Tasks in Chapter 4, User Administration, in the

Controller User’s Manual, for more details.

42

Page 55

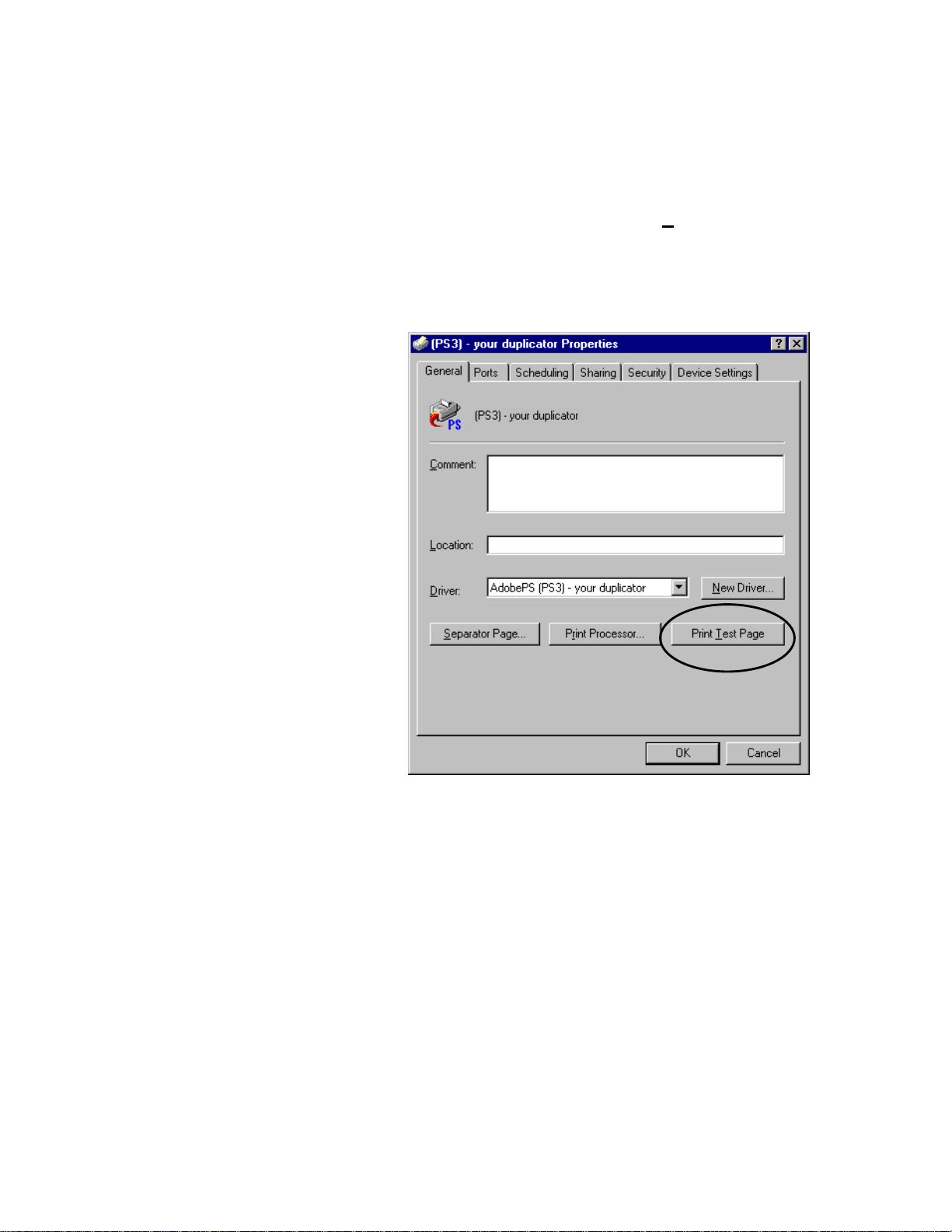

Print a Windows Test

Page. As shown in Figure 2-7.6, click on the General tab,

Step 10

then locate and click on the Print Test Page button.

In a few seconds to a few minutes (depending upon

how busy the LAN traffic is) the front status lights

should begin blinking, and the duplicator will print

the Windows Test Page.

Figure 2-7.6. Testing the LAN connection.

Correctly printing the Windows Test Page confirms

proper connection to the LAN and correct printer

driver installation.

43

Page 56

Troubleshooting The following suggestions may help if you run into

problems printing to the digital duplicator through the

LAN.

1) If there is more than one controller/digital

duplicator on the LAN, did you attach the printer

driver to the correct one? If not, go back and

repeat Step 8 and Step 9.

2) Is there a server on the LAN? Depending on the

type of server on the network, it may not allow

use of the IPX redirector program. In this case

you will need the help of your network

administrator to set up the workstation for

printing over the LAN to the controller/digital

duplicator.

3) Has any computer been able to print to the digital

duplicator correctly through the controller’s

parallel port? If so, the problem is probably with

the LAN installation, which will have to be redone - start by uninstalling the IPX Redirector

software (explained below), then go to Step 1. If

not, there may be a problem with the printer

driver you have installed. See the sections of the

Controller User’s Guide entitled Installing A

Printer Driver and Changing A Printer Driver in

Chapter 2, Using your Controller for assistance in

getting the correct printer driver installed on your

computer.

44

4) If the controller was off, or not powered on for 2

minutes or more, did you wait for the signal from

the LAN communications status lights before

installing the IPX Redirector program? The LAN

port on the controller is not active until the yellow

light begins blinking. If the IPX Redirector

program runs before this happens, it will most

likely not find the controller. Subsequently it will

not install an IPX port on your computer, and you

will not find it listed under ‘Print to the following

port:’ (see Step 9).

To correct this, re-do the IPX port installation.

Start by uninstalling the IPX Redirector software

(see below), then go to Step 1.

Page 57

Uninstalling the IPX

Redirector Software

5) Did you shut off all application software before

installing the IPX Redirector program? If not, it

may not have installed correctly, or a program

may be interfering with its operation. Try rebooting the computer. If that doesn’t work,

reinstall the IPX Redirector making sure to have

closed all application software (i.e., any program

except the Windows Operating System) before

installing again. Start by uninstalling the IPX

Redirector software (see below), then repeating

the installation from Step 1.

If you encounter problems installing or using the IPX

Redirector program, it may be uninstalled using a

utility provided for that purpose, found on the

CDROM.

To uninstall the IPX Redirector program, you must

insert the CDROM (e: in our example) do Start →

Run, and type the following into the ‘Open’ window:

e:\WIN\LAN Tools\IPXP2P\uninstall

followed by the Enter key .

Uninstalling will remove the IPX redirector program

as well as the port definition(s) from the Printer

Wizard’s list of available ports. Thus, you will no

longer be able to print to any digital duplicators on

the LAN using the IPX protocol of your computer.

45

Page 58

Managing Paper Take a few minutes to review the following sections

to understand how to effectively use the printing

capabilities of your controller.

Page size and

orientation For the most part, keeping track of the paper size and

orientation loaded into the digital duplicator paper

input tray is an automatic process for your controller.

If you remove, replace, or run out of paper, the digital

duplicator will go through a process to determine

what size paper is available and communicate that

information to the controller. Thus, your controller

automatically keeps track of what paper stock is

available for printing, and makes that information

available to the computer.

Be aware that anytime you remove paper from the

input tray, the digital duplicator will automatically go

OFFLINE. Then, when you send a print job to the

controller, the controller will set the digital duplicator

back ONLINE automatically1.

Note

1

You may have a model of digital duplicator that does

not allow the controller to automatically put it

ONLINE. If this is the case, you must manually push

the ON LINE and Auto-Cycle buttons to enable their

respective functions on the digital duplicator.

|→

46

Page 59

Table 2-8.1 lists common problems resulting from

page size mismatches, and their remedies.

Situation Probable Cause Remedy

The image on

the master is

truncated.

The image on

the master is

placed

incorrectly on

the page.

The software

you are using to

print never

reports a page

size mismatch.

A paper size too small

for the master has been

loaded into the input

paper tray.

The software is set up to

print on a smaller page

size than is currently

loaded in the input tray.

You are using one of the

standard printer drivers

that came with the

operating system.

Change the paper in the input tray of the

digital duplicator to match what the

software is calling for in order to print your

document. Then re-send the print job to

the controller.

You can print correctly-placed copies from

this master by doing the following:

1) Load the correct paper size into the

input tray.

2) Set the number of copies to be printed

manually using the keys on the digital

duplicator’s control panel

3) Push Print Start on the digital

duplicator.

Alternatively, you can load the correct

paper into the input tray and simply re-send

the print job from the computer.

Install the digital duplicator printer drivers

from the CDROM, then select the correct

one which matches your model of digital

duplicator.

Table 2-8.1. Common Page Size/Orientation Faults

47

Page 60

Number of copies The most effective way to make use of the digital

duplicator’s high-speed printing capabilities is to have

the controller manage the number of copies of each

page produced, rather than the word processing or

other computer software you may be using. This is

because the software will normally print multiple

copies of a document one at a time, a single page at a

time. This is referred to as collating the document

copies (the pages come out in numerical order, in

each document copy). This process causes the digital

duplicator to make a new master for each page.

Since the digital duplicator is designed to print many

copies of a page rapidly from one master, you will

need to turn the collate feature off in the software and

allow the controller to manage the copy creation

process.

The following two, simple steps will ensure that your

digital duplicator makes fast and efficient copies of

the documents you send to it from your computer.

48

Page 61

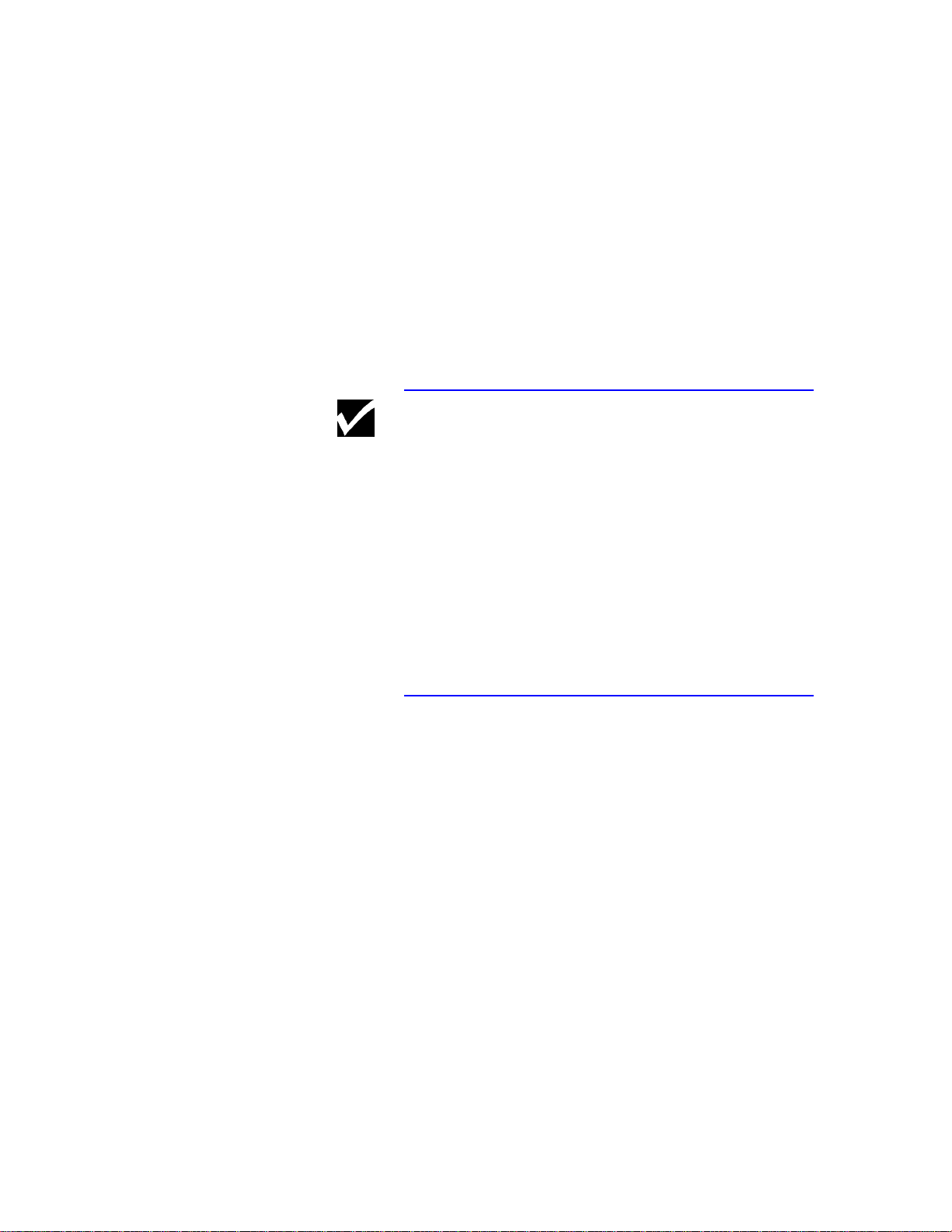

Step 1 – Make sure Auto-Cycle is ON

Normally the controller will turn this feature of the

digital duplicator ON1. Just to be safe, look at the

digital duplicator’s control panel and make sure

Auto-Cycle is ON.

The Configuration Utility program may be used to

have the controller enable the Auto-Cycle feature

automatically. Start the Configuration Utility and

locate the Settings section on the screen. Click on the

Enable Auto-Cycle circle, as shown in Figure 2-8.3.

The press the button.

Figure 2-8.3. Enable Auto-Cycle

1

See Note under the preceding section, Page size and

orientation.

49

Page 62

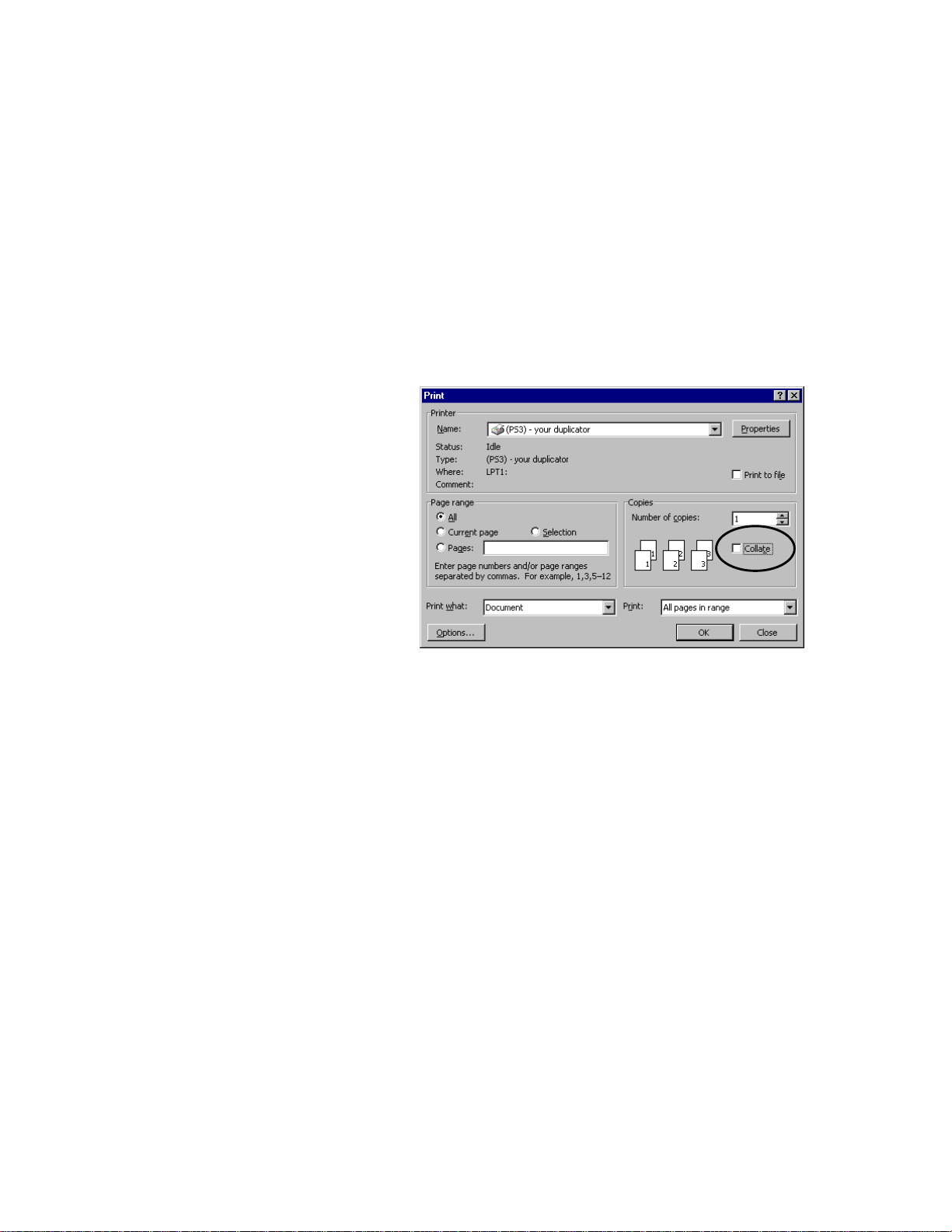

Step 2 – Turn the software collate

feature off

Most programs have an on/off switch for the collate

feature located on their print menu screen. In some

programs, this is referred to as ‘copies generated by

<software>’, versus ‘copies generated by printer’.

Turn the collate feature off. (For the Microsoft

Word 97 example in Figure 2-8.4 you would uncheck

the box, as shown.)

Figure 2-8.4. Turn the collate feature off

(Microsoft Word 97)

With the feature off, the digital duplicator will make

one master per page and produce the copies at a high

rate of speed, in a non-collated fashion, as it was

designed to do. In addition, the number of copies to

be printed will pass through from the software to the

digital duplicator, and be displayed on the digital

duplicator’s control panel screen.

50

Page 63

Note FOR DOS USERS:

Unless your DOS software application specifically

allows you to turn off the collating feature, passing

copy control (i.e., the number of copies) through to

the digital duplicator will not work properly. In this

case, you will have to send one page at a time from

the computer to the digital duplicator, and use the

control panel of the digital duplicator to manually

create the number of desired copies from each master.

51

Page 64

Bleed-off Printing Most desktop publishing programs allow printing to

the edges of the paper. You should be aware of the

following limitations as they apply to your controller

and digital duplicator regarding this function.

PostScript Printing

Due to the technology employed in the digital

duplicator for paper handling, there is a non-printing

area on the leading (first in) edge of the paper of

5mm.

PCL Printing

PCL printer driver technology does not allow bleedoff printing. Instead, you will have a border of

unprintable area of approximately .25 inches (6 mm)

on all four paper edges.

If you need to do the bleed-off function, use the

PostScript printer driver.

52

Page 65

Shared Printer

Environments You may wish to attach more than one computer to

your controller. Multiple ports have been provided

on the rear panel of the controller for this purpose see the section on Automatic I/O Switching above, in

this chapter.

This section lists several things to be aware of so that

operation between the computers and your controller

will run as smoothly as possible:

• Using a switchbox.

• I/O port order.

• Optimizing multiple I/O port operation.

Using a switchbox If you wish to share your digital duplicator through an

electronic or mechanical switchbox, you may

experience some difficulty under certain conditions,

particularly with mechanical switchboxes.

If you are using a mechanical switchbox:

• Do not switch when the controller is printing to

the digital duplicator, or receiving data (i.e., when

either of the controller status lights are blinking).

• Do not switch to a host computer that is OFF,

then switch that computer ON. The computer can

send unusable data to the controller, resulting in

unwanted output, or corruption of the next print

job.

Note Ensure that your switchbox is equipped with a surge

protector. Damage to the controller could occur from

use of unprotected mechanical switchboxes.

53

Page 66

I/O port order Print jobs arriving at the various ports are performed

(or Raster Image Processed – RIPped, for short) on a

first come, first served basis. Thus, the first computer

to begin sending data to the digital duplicator has the

controller’s full attention. Other computers must wait

until the first computer’s print job has completed.

Thus, even though the parallel port is the fastest one

to accept data, if the AppleTalk/LocalTalk port is the

first to be used, its job will complete before the one

coming from the parallel port.

Optimizing multiple

I/O port operation The Configuration Utility program may be used to

optimize the operation of your controller, so that

multiple computers may use the digital duplicator

efficiently. See the section in this chapter on

Managing the Print Jobs.

54

Page 67

Personality/

language switching You can select the print language – PCL or PostScript

– one of several ways, depending upon your operating

system software:

• For Microsoft Windows: select either a PCL or a

PostScript printer driver.

• For DOS: use context (automatic) language

switching, or PJL (Printer Job Language) software

switching (i.e., PJL commands embedded in

software).

Note When the controller’s personality is switched, its

memory is reconfigured, resulting in the loss of all

user-downloaded data (such as soft-font typefaces).

The result of this is that multiple print jobs with a

significant number of downloaded fonts can take

noticeably longer to process and print if the controller

keeps switching between PCL and PostScript, than if

it stays in one language.

Other than this longer processing time, changing print

languages is transparent to users because the software

simply re-downloads the fonts it needs.

Windows PCL and PostScript printer drivers

Both custom PCL and PostScript printer drivers are

available for your digital duplicator. Use the

installation program on the CDROM to install both of

the drivers. Then, in your Windows software, select

the printer driver on the Print menu screen you wish

to use. Personality switching will be accomplished

automatically when you send your print job to the

digital duplicator.

55

Page 68

Switching personalities in DOS programs

Context language switching is employed for PCL and

PostScript. In this mode, the controller analyzes the

stream of data being sent to determine which

language is being used by the print job. Then the

controller switches its personality to that language,

automatically.

As an example, if PostScript is made the current

language, the controller will be dedicated to that

language and will switch to another ‘personality’ only

when it encounters specific PJL commands embedded

in software to do so.

For more information about PJL commands, see the

PCL Printing chapter in the Controller Reference

Manual.

56

Page 69

Managing Print

Jobs Once a print job has been initiated by the software

you are using, it is offloaded to hardware or other

software set up to manage the printer. This process is

known as ‘spooling’. Programs that manage the

spooling process may exist in several places: 1) the

operating system of the computer you are using, 2) a

print server (such as on a network), or 3) the digital

duplicator’s controller.

Use the right tool to manage your print jobs.

If the job has been spooled by the operating system,

you should use a print management tool that came

with your computer’s operating system to manage

print jobs (e.g., Print Manager for Microsoft

Windows). Likewise for a network, there are a

number of tools your network administrator may use

to manage print jobs sent to printers attached to the

network.

57

Page 70

The Configuration

Utility Program The Configuration Utility program is used to setup

and manage specific aspects of the print jobs sent to

your digital duplicator. It has been designed to make

management of printing on your digital duplicator

very easy. By simply starting the program and using

your mouse, you may:

« Set operating parameters of your digital duplicator

specific to the needs of your environment.

« Manage printing to your digital duplicator in a

shared printer environment.

The Configuration Utility is very easy to start and

use. The steps below outline some of the

fundamental tasks associated with managing the use

of your digital duplicator and the print jobs sent to it.

Starting the Utility Activate the Configuration Utility program by

double-clicking on the Configuration Utility icon on

your computer’s desktop, as shown below.

58

Figure 2-10.2. Configuration Utility Desktop

Icon

Note If the icon shown in Figure 2-10.2 does not appear on

your computer’s desktop, look under Programs –

Configuration Utility. If it still does not appear, you

may need to run the CDROM installation program.

See the Setting Up Your Controller section of this

chapter, or contact your computer specialist for

assistance.

Page 71

Your computer will display the screen of the

Configuration Utility program, similar to what is

shown in Figure 2-10.3.

Figure 2-10.3. Configuration Utility screen

59

Page 72

The default value of the Controller Timeout is 45

seconds, which is adequate for the majority of

printing applications. However, some applications

may require a longer value. The reasons for this

could include (but are not limited to):

• An environment where most people are using

Windows-based, graphics intensive printouts that,

due to processing time, require the controller to

wait longer than 45 seconds to start receiving the

output.

In these cases it is recommended that the value of this

variable be set at 120 seconds or longer, to ensure

that the output from a second computer will not

disrupt the print job of the first.

For other tasks, see Chapter 3, Configuration Utility

Features.

60

Page 73

3

Configuration Utility Features

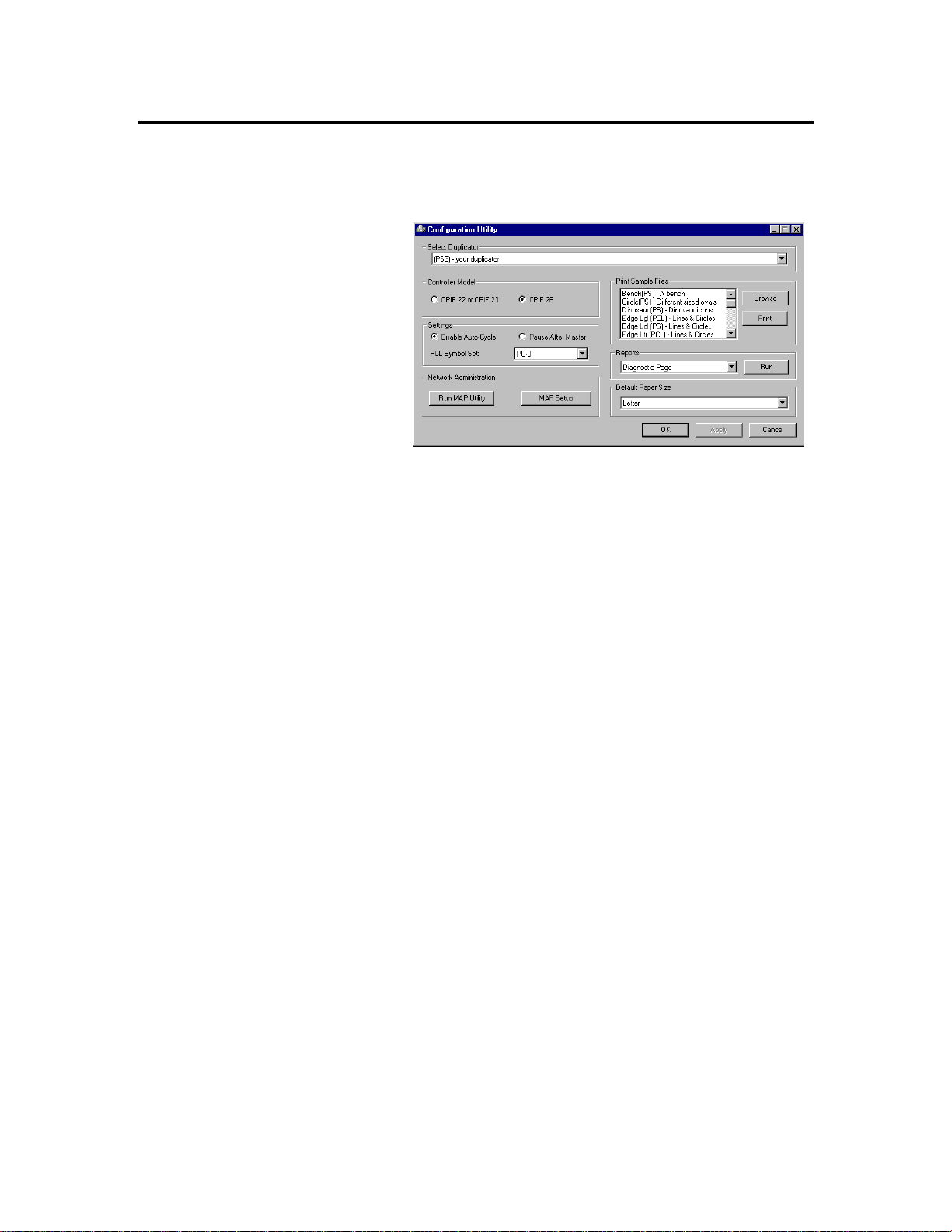

Introduction This chapter provides explanations for every function

available in the Configuration Utility program. It is

organized in order of the screen sections as they

appear from top to bottom, left to right.

Look in this chapter if you are interested in:

q Finding definitions of Configuration Utility terms.

q Understanding a Configuration Utility function or

feature.

To get an understanding of more general terms having

to do with printing and computers, see the Glossary at

the end of this book, located after the Appendices.

61

Page 74

Configuration Utility

Screen After clicking on the icon, the Configuration Utility

screen in Figure 3-2.1 will appear.

Figure 3-2.1. Configuration Utility Screen

The Configuration Utility screen is divided into seven

sections. These are:

• The Select Duplicator selection screen,

• The Controller Model selection panel,

• The Settings selection panel,

• The Network Administration control panel,

• The Print Sample Files selection screen,

• The Reports selection screen,

• The Default Paper Size selection screen.

62

Page 75

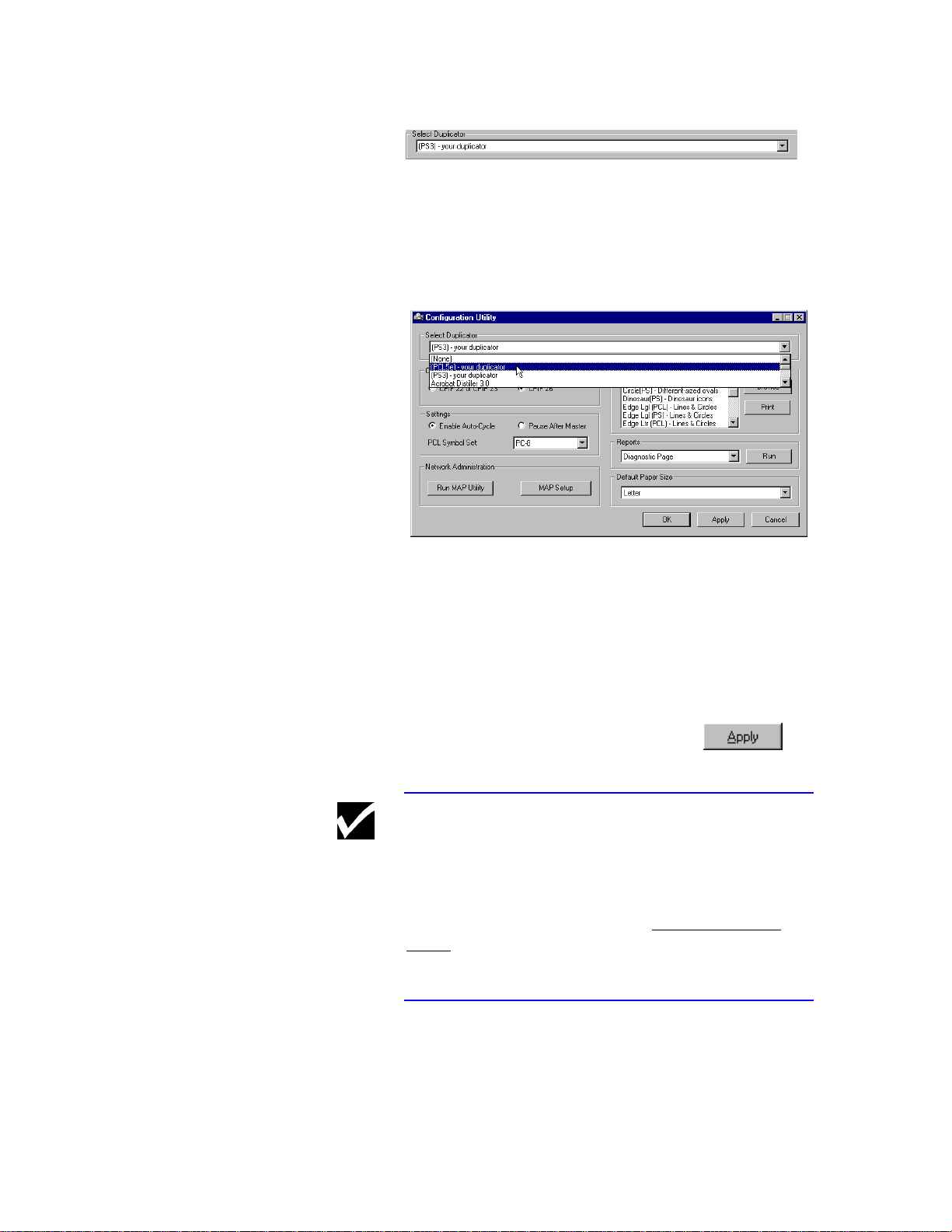

Select Duplicator

This feature is used to select the digital duplicator you

wish to configure.

To select a digital duplicator different from the one

that is being displayed, click on the down arrow at the

right of the display.

Figure 3-2.2.1. Selecting a digital duplicator

to configure.

A list of installed printer drivers will be shown.

Select the one corresponding to the digital duplicator

you desire to configure. After doing so, the selection

window will close, leaving the model of the digital

duplicator you selected in the window.

After making your choice, click on the

button to save the information

Note If the printer driver for your model of digital

duplicator does not appear as a choice on the screen,

it is likely that it has not been installed on your

computer. See Installing a Printer Driver in Chapter

2, Using your Controller, in this Controller User’s

Guide, for instructions regarding the installation of

printer drivers.

63

Page 76

Controller Model

This is where you inform the Configuration Utility as

to the model of controller connected to the digital

duplicator (see Select Duplicator above).

To determine the model number, look on the outside

bottom your controller chassis. There is a small label

containing a bar code affixed to the chassis near the

rear panel, similar that shown in Figure 3-2.3.

MODEL NO. CPIF 26

S/N: AU1234567891234567891

AU123456789

Figure 3-2.3. Model and serial number label.

After making your choice, click on the

button to save the information.

Settings

64

Enable Auto-Cycle or Pause After Master

This feature allows the controller to automatically

configure the digital duplicator for the mode of

master and subsequent copy making you wish to use.

If you enable Auto-Cycle, Pause After Master will be

disabled, and vice versa.

Page 77

PCL Symbol Set

Here you may select the symbol set to match the PCL

fonts your document is using. To select something

other than the default PC-8 symbol set shown, click

on the down arrow and select another from the

displayed list.

For a more complete discussion of which symbol set

to select, see Chapter 3, PCL Printing in the

Controller Reference Manual.

After making your choice, click on the

button to save the information.

65

Page 78

Network Administration

Discussion of the tools provided in the Network

Administration section (i.e., the Run MAP Utility and

MAP Setup functions), the resulting NIC HTML

screens and changing controller parameters is found

in Chapter 4, User Administration, and is oriented

toward the network administrator. Changing the

configuration of the controller’s LAN behavior to

optimize its operation in your LAN environment

requires particular knowledge and skills. In addition,

you need a password to access the LAN parameters,

which is set and kept by your network administrator.

Network Note If you are on a workstation operating in a server-less,

peer-to-peer LAN environment, it may possible to

setup and use the digital duplicator controller using a

relatively simple network installation. Read

Connecting to a Peer-to-Peer Ethernet Local Area

Network in Chapter 2, Using Your Controller, in this

Controller User’s Guide, to see if your situation

applies.

66

Page 79

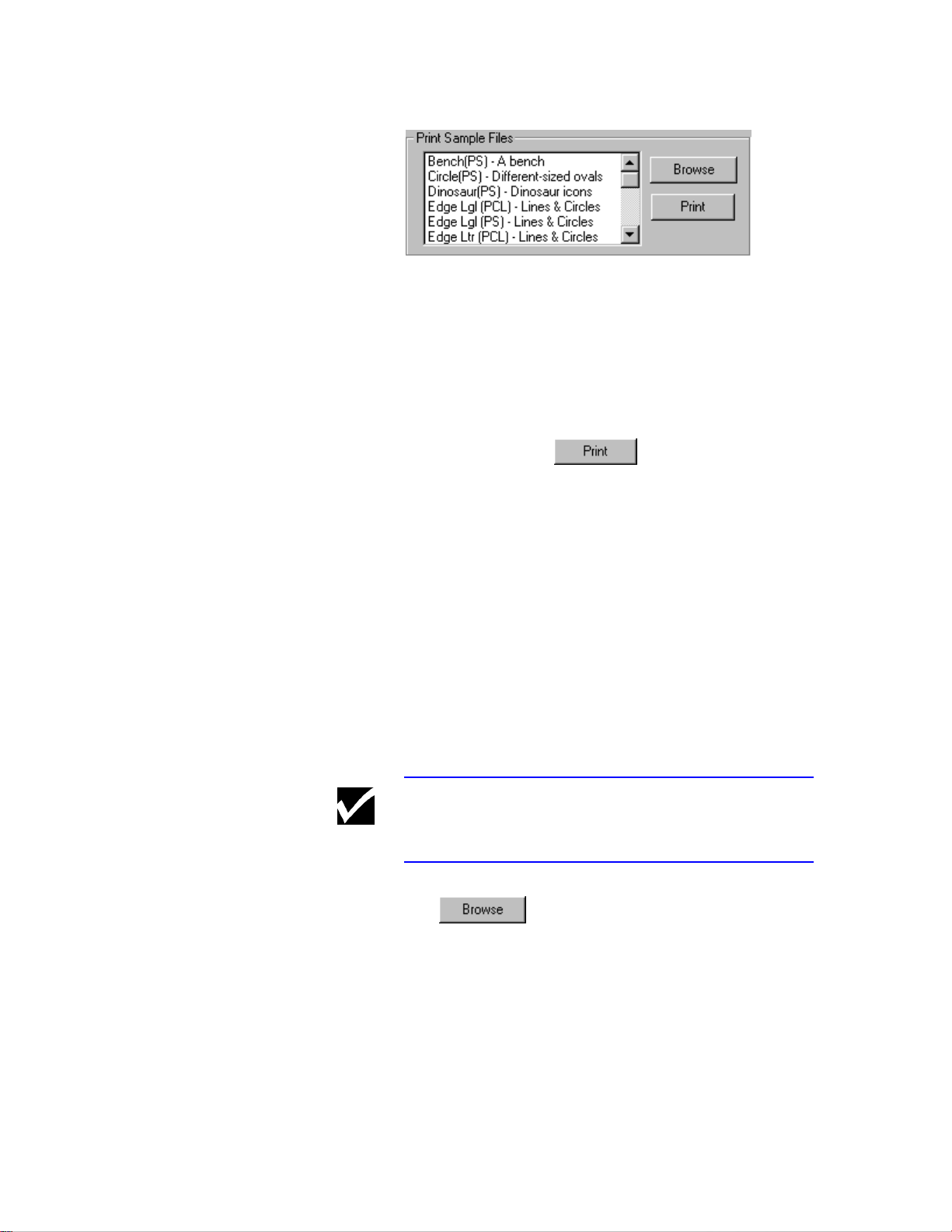

Print Sample Files

This feature allows you to print sample or raw test

files loaded on your computer. It is useful for

sending raw PCL or PostScript files to the digital

duplicator for printing, without having to use an

intermediate desktop publishing or word processing

software program.

Click on the file of interest in the window to highlight

it, then click on the button to immediately

send the file to the digital duplicator for printing.

You may also store your own custom files so they

appear in the directory shown above, by doing the

following:

1) Locate the PostScript file(s) you wish to have the

Configuration Utility add to the list above,

2) Store the files with a .PS extension into the

Samples folder inside the Configuration Utility

folder, on your hard drive.

The files will appear automatically in the Print

Sample Files directory Window.

Note The default location of the Configuration Utility

folder is the C: drive, inside the Program Files folder.

The button provides a convenient way to

access the files stored on your computer by opening a

simple file manager window. This window will allow

you to pick or find a printer file anywhere on your

computer, or (if installed) computer network, to send

to the digital duplicator for printing.

67

Page 80

Run Selected Report

The Reports section allows you to print a predesigned report selected from the pull-down menu,

appearing in the center. You may view the titles of

the available reports by clicking on the down arrow

on the right-hand portion of the menu.

The Diagnostic Page is the default report. Use this

report to print a Diagnostic Test Page on the digital

duplicator by clicking on the button .

This is the same page you would get if you were to

press the Diagnostic Test Page button on the rear

panel of the controller. For more information

regarding the Diagnostic Test Page, see Appendix A,

Diagnostic Test Page, in this Controller User’s

Guide.

Another report, the PCL Test Page, prints a list of

PCL fonts resident in the controller.

For more information regarding the PCL font list, see

Chapter 3, PCL Printing, in the Controller Reference

Manual.

68

Default Paper Size

Use this area to set the Default Paper setting.

Normally, the software you are using to print will

assign a paper size to a print job. Where this is not

the case, the controller must select a default size of

paper to associate with the print job. This is called

the Default Paper Size.

Select a default paper size by simply clicking on the

arrow on the right of the window and selecting the

desired size. After making your choice, click on the

button to save the information.

Page 81

User Administration

Introduction In this chapter we will discuss the aspects of

managing the controller and digital duplicator for

multiple users, where network print server functions

are being administered.

The subjects covered are:

q Using the Configuration Utility to Set Up Your

Network Controller.

« HTML setup screens.

« NIC Management Password.

« Setting NIC parameters.

q Using a Web Browser to Perform Common

Network Management Tasks

« Setting a custom NIC management password.

« Assigning a custom name to the controller.

4

q Network Environments and Special Utilities

« Common NOS environments.

« Special NIC management utilities.

« Preparing the controller.

« Common workstation configurations.

« NetWare notes.

« Windows notes.

« AppleTalk notes.

« NIC “Reset to Factory” procedure.

To get an understanding of more general terms having

to do with printing and computers, see the Glossary at

the end of this book, located after the Appendices.

69

Page 82

Network Note When working with the digital duplicator controller

from a network, you are actually communicating with

a Network Interface Controller, or NIC, card in the

controller. Keep in mind the following characteristics

of the card:

• Reset of the NIC and reset of the digital duplicator

controller are two different events: resetting the

controller also causes the NIC to reset (such as at

power up), while resetting the NIC from the LAN

only resets the card, and not the rest of the

controller hardware.

• Setting to factory defaults is only a NIC function,

and does not affect the rest of the hardware in the

digital duplicator controller.

• After reset or cycling power, the NIC enters a

warm-up state that lasts for approximately 2

minutes. Before the warm-up state of the NIC is

completed, you will not be able to communicate

with it.

The end of the warm-up state is signaled by the

digital duplicator printing a NIC Status Page, if

the Print Status Page on Startup parameter in the

NIC has been enabled. Otherwise, no status page

will print and the only way to tell if the warm-up

state has completed is by waiting 2 minutes or

more past a NIC reset or power up.

• Setting parameters on the NIC are only stored into

non-volatile memory after cycling power on the

controller.

70

Page 83

Using the

Configuration Utility

to Set Up Your

Network Controller The digital duplicator controller will operate in a

variety of network environments. In order to have it

do so efficiently, the Network Interface Controller

card, or NIC, in the digital duplicator controller must

be configured for the type of network on which it will

be used.

The easiest way to configure the NIC is to use the

Network section of the Configuration Utility screen.

The MAP utility, which is invoked by the buttons in

this section, automatically finds any controller in

most LAN environments. This provides the network

administrator a tool for rapidly configuring the NIC

parameters to suit the LAN environment.

The MAP utility uses two different protocols to

‘discover’ the controller: IPX and IP.

IPX/IP discovery

After the prescribed warm-up time, a NIC set to