Page 1

OPCs

(Organic Photoconductors)

RICOH CO., LTD.

October, 1995

Page 2

Table of Contents

1. OUTLINE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. COMPOSITION AND FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1. Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2. Function and Material of Each Layer . . . . . . . . . . . . . . . . . . 2-1

3. STYLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1. Drum and Belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

4. COPY CYCLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1. Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2. The Steps of the Copy Cycle . . . . . . . . . . . . . . . . . . . . . . . . 4-2

5. OPC CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1. General Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2. Special Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2.1. Deterioration in OPC Thickness . . . . . . . . . . . . . . . . . 5-2

5.2.2. Wavelength of Light. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.3. Differences between Analog and Digital OPCs . . . . . . . . . . 5-4

6. EFFECTS OF ENVIRONMENTAL FACTORS . . . . . . . . . . . . . . 6-1

6.1. Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2. Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.3. Gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.4. Dust and Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Page 3

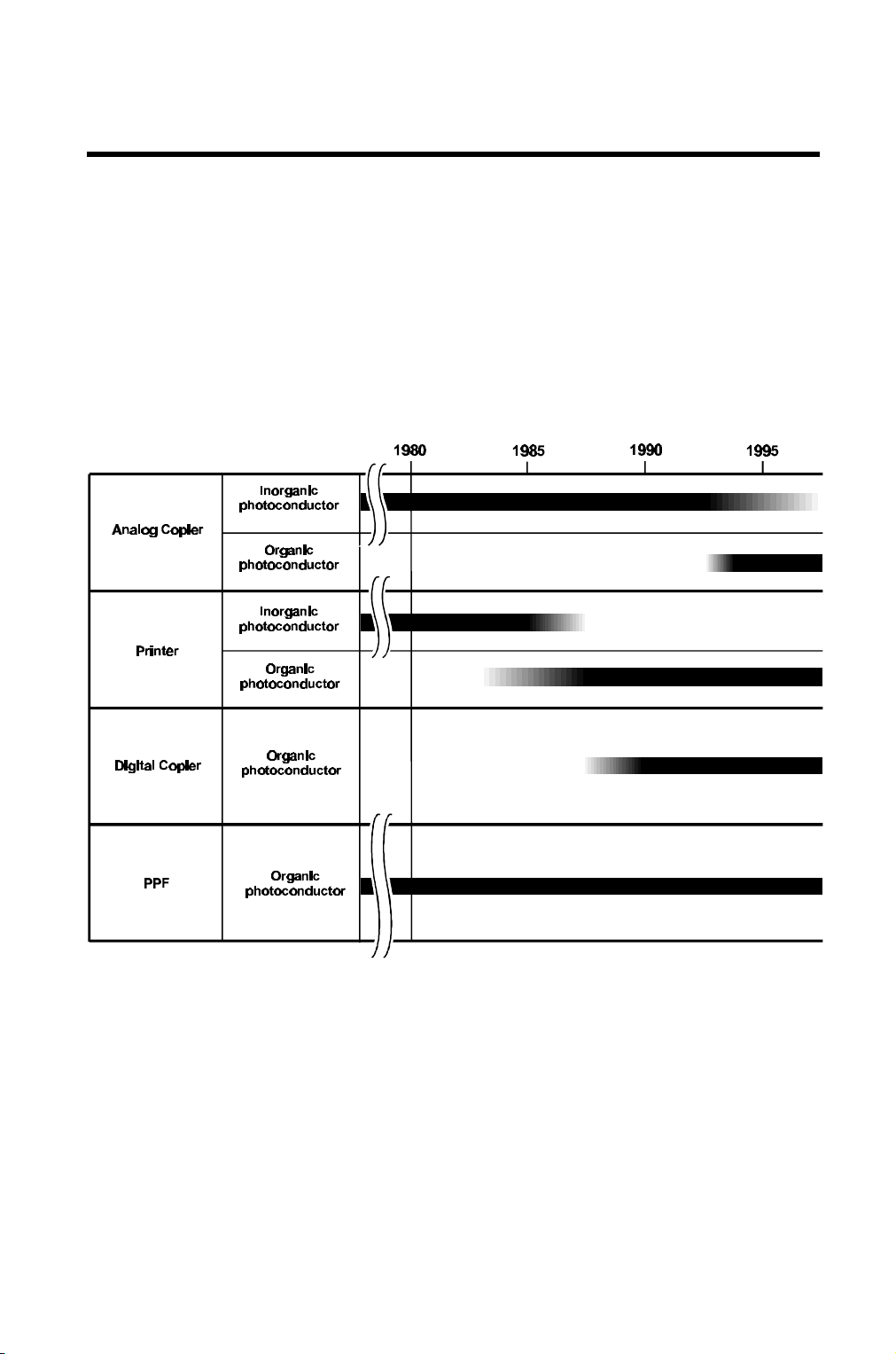

October 1st, 1995 OUTLINE

1. OUTLINE

In most copiers or plain paper facsimile machines, a photoconductor transfers

an image of the original to the output of a printer.

Generally, our products use two types of photoconductors. One type is an inorganic photoconductor, made of selenium, that was used in the past for

analog copiers. The other type is an organic photoconductor (OPC) that is

used for analog and digital copiers, plain paper facsimiles, and laser printers.

Recently, all such products use OPCs instead of inorganic photoconductors.

1-1

OPC507.wmf

Page 4

October 1st, 1995 COMPOSITION AND FUNCTIONS

Composition

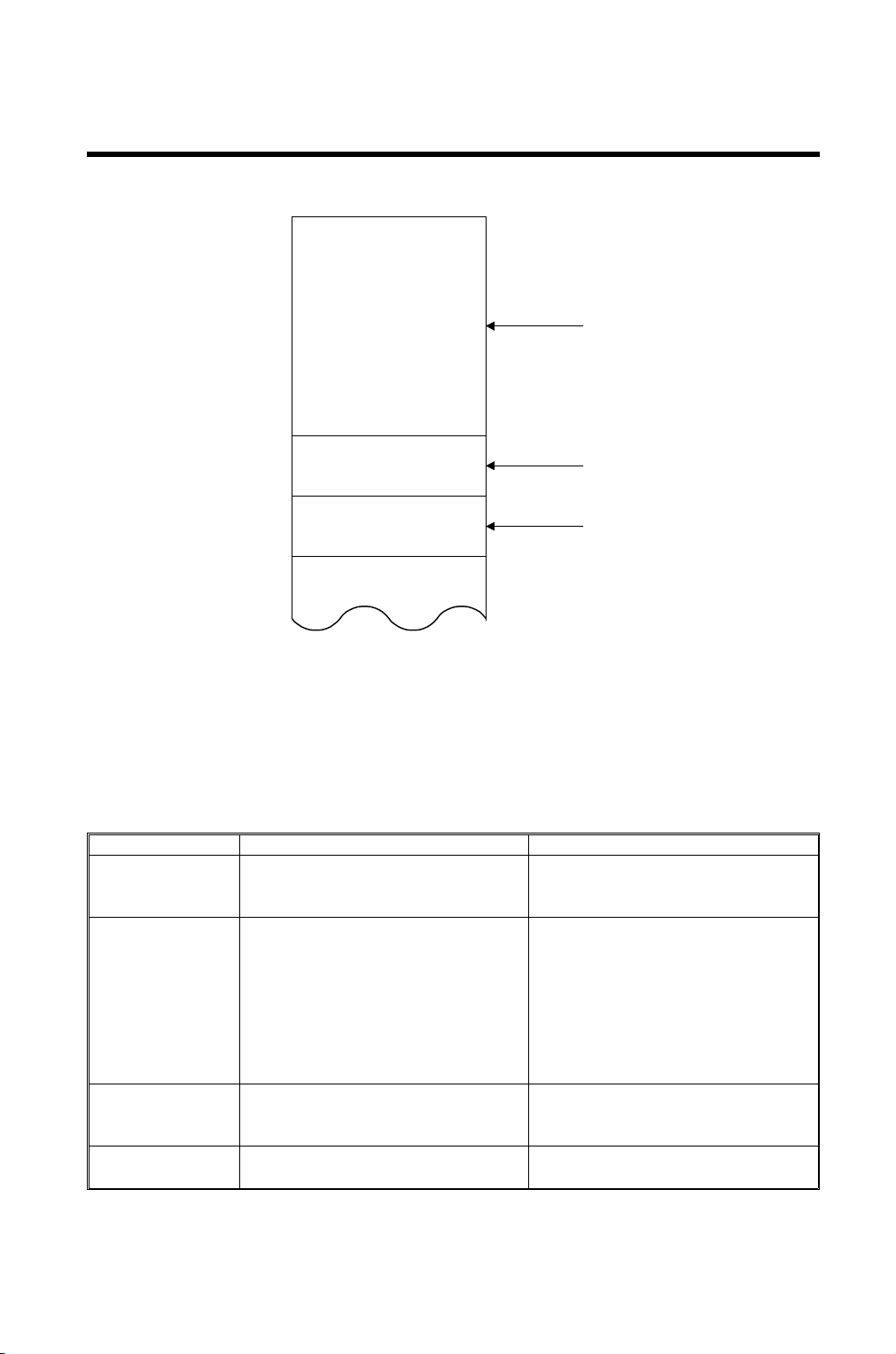

2. COMPOSITION AND FUNCTIONS

2.1. Composition

CTL

(Charge Transfer Layer)

(Charge Generation Layer)

CGL

UL

(Under Layer)

10 ~ 30µm

0.1 ~ 1µm

0.2 ~ 10µm

Base Board

OPC500.WMF

An OPC consists of a CTL (Charge Transfer Layer), CGL (Charge Generation

Layer), UL (Under Layer), and a base board.

2.2. Function and Material of Each Layer

Layer Main Function Material

CTL The charge generated in the CGL

is transmitted through this layer to

the surface of the photoconductor.

CGL Generates the charge from the

absorption of light.

UL Prevents positive charges

generated in the CGL from going to

ground.

Base board Develops the counter charge to the

charge developed on the CTL.

2-1

Organic additive

Plastic binder

Azo pigment

Plastic binder

(Analog OPCs have a different

pigment from digital OPCs; see

page 5-3 for more details. In analog

OPCs, The pigment gives analog

OPCs a dark blue color, and digital

OPCs a green color.)

Organic or inorganic additive

Plastic binder

Aluminum drum or nickel belt

Page 5

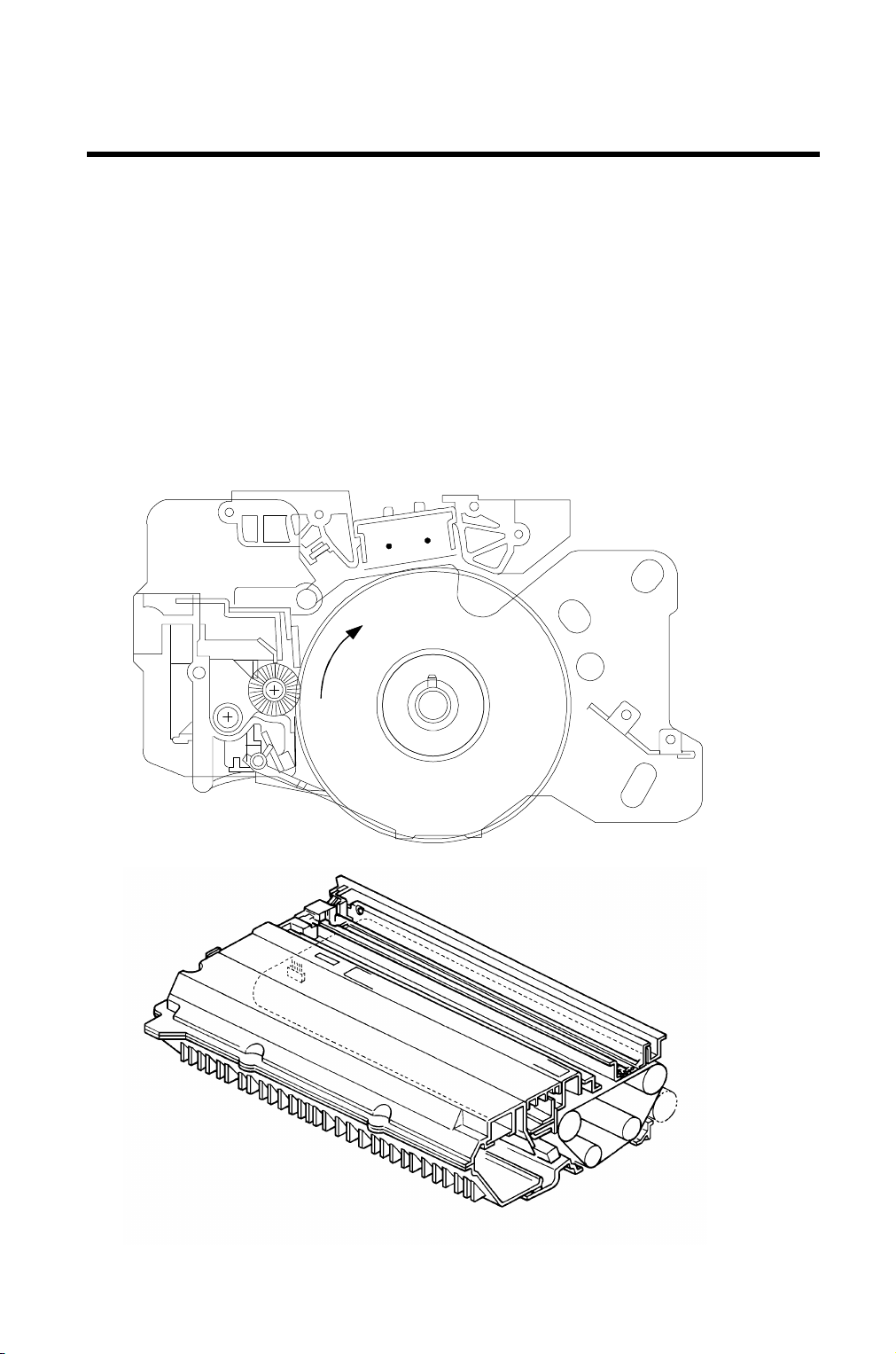

October 1st, 1995 STYLES

Drum and Belt

3. STYLES

3.1. Drum and Belt

There are two types of OPCs used today: the drum type [A] and the belt type

[B].

The drum type has a base of aluminum or nickel. It is usually used in copiers,

as well as laser facsimile machines and laser printers.

The belt type has either a film of polyester or a nickel belt. The nickel belt has

a bond seam, while the polyester film is seamless. The belt type is used in laser facsimile machines and laser printers. It is not normally used in copiers.

[A]

[B]

OPC506.wmf

OPC505.img

3-1

Page 6

October 1st, 1995 COPY CYCLE

Overview

4. COPY CYCLE

4.1. Overview

The OPC transfers an image of the original to the output paper (copy or fax).

It does this during the copy cycle.

Charge

Corona

Wire

1

-750V

2

Voltage

-100V

Light

- ------CTL

+ +

CGL

- -

+ ++++ +++

CTL

CGL

Quenching

Light

- ----

+ + +++

+ + +++

Charge

Corona Unit

- ------CTL

CGL

+ ++++ +++

Base

6

---- -+-

Cleaning

Assembly

Base

+

+

- ---CTL

CGL

+ + +++

+

+

5

Transfer

Corona Unit

Paper

- -

++ ++

- ---CTL

CGL

+ + +++

Transfer

Corona

Wire

Development

Roller

+

+

- ---CTL

CGL

+ + +++

4

+

+

+

+

P/P N/P

3

Development

Roller

-

-

- ----

-

-

CTL

CGL

+ + +++

Base

-

-

-

-

4-1

Page 7

COPY CYCLE October 1st, 1995

The Steps of the Copy Cycle

4.2. The Steps of the Copy Cycle

The following is a step-by-step description of how the OPC functions during

the copy cycle.

1. Charge

The transfer corona wire applies a negative charge to the surface of the

CTL (about -750 V). Due to a capacitor-like effect, a positive charge is produced on the base.

2. Exposure

Light (either reflected fluorescent light or laser light) strikes the OPC. This

light causes the CGL to generate positive and negative charges. The positive charges are attracted to the CTL’s surface negative charge. The negative charges are attracted to the CGL’s surface positive charge.

As a result, where light has struck the CTL, the CTL’s surface voltage drops

to about -100V.

Note: When exposure is done with a fluorescent lamp, the reflected light

corresponds to the white areas of the original. When exposure is

done with a laser diode, the light corresponds to the black areas of the

original, in most machines.

Exposure, therefore, creates a charged latent image of the original on

the surface of the OPC.

3. Development

The development roller applies charged toner to the OPC that will adhere

to the latent image.

In Positive/Positive (P/P) development, the development roller applies positively charged toner to the OPC. The toner is attracted to the negative areas where light has not contacted the OPC.

In Negative/Positive (N/P) development, the development roller applies negatively charged toner to the OPC. The toner is attracted to the relatively positive

areas where light has contacted the OPC.

P/P development is used when the light reaching the OPC corresponds to

white areas of the original. P/P development is used when exposure is done

with a fluorescent lamp, and in some earlier laser engines that used the "writeto-white" system.

N/P development is used when the light reaching the OPC corresponds to

black areas of the original, as in most laser-based print engines.

4-2

Page 8

October 1st, 1995 COPY CYCLE

The Steps of the Copy Cycle

4. Transfer

The transfer corona wire develops a charge of opposite polarity to the

toner (negative in P/P development, positive in N/P development). The

wire applies this charge to the back of the output paper. This charge,

therefore, will attract the toner (attached to the OPC in the latent image

of the original) to the paper. The paper then goes on to the fusing unit

where the toner is fused to the paper.

5. Cleaning

The cleaning assembly removes any residual toner on the OPC after

transfer.

6. Quenching

When the quenching light is applied to the OPC, it causes the CGL to

generate positive and negative charges (as in the exposure step).

These charges similarly cause the voltage on the surface of the CTL to

drop to about -100 V, except that in quenching, the entire surface of

the OPC is exposed. Therefore, the quenching lamp removes the high

negative potential remaining from the previous stages of the copy cycle. This readies the OPC for the next copy cycle.

4-3

Page 9

October 1st, 1995 OPC CHARACTERISTICS

General Characteristics

5. OPC CHARACTERISTICS

5.1. General Characteristics

These characteristics include:

1. The ability to accept a high negative electrical charge in the dark. (The

electrical resistance of a photoconductor is high in the absence of light.)

2. The ability to dissipate the electrical charge when exposed to light.

(Exposure to light greatly increases the conductivity of a photoconductor.)

3. The ability to dissipate an amount of charge in direct proportion to the

intensity of the light applied. Therefore, the greater the intensity of light

applied to the photoconductor, the smaller the voltage remaining on the

OPC.

4. An OPC is less sensitive to changes in temperature than selenium-

based drums (also known as F type drums).

5. An OPC is less sensitive to changes in rest time (in other words, it is

not so sensitive to light fatigue as F type drums). It is therefore

unnecessary to compensate development bias voltage for variations in

rest time.

6. Lower cost than an F type drum.

7. No need for special disposal considerations.

5-1

Page 10

OPC CHARACTERISTICS October 1st, 1995

Special Characteristics

5.2. Special Characteristics

5.2.1. Deterioration in OPC Thickness

Some abrasive actions in the copy cycle gradually reduce the thickness of the

CTL over time. These actions include cleaning, development (application of

the ferrite carrier by the development roller), and separation (the pick-off pawl

separating the page from the OPC).

This reduced thickness results in a decrease in the capacitor effect on the

OPC (resulting in reduced chargability). This will affect the chargeability of

analog OPCs and digital OPCs at different rates. (See the chart below.)

The chargeability of the analog OPC decreases much more rapidly than that

of the digital OPC. For the same amount of reduction in CTL thickness, therefore, the copy quality of the analog OPC decreases much more rapidly than

for digital OPCs.

3000

Analog OPC at

560nm

Chargeability

(V cm2/µJ)

2000

1000

302515 2010

CTL Thickness (µm)

OPC

Digital

OPC

OPC502.wmf

Analog OPCs use positive/positive development. Since positively charged

toner is applied to the OPC, the amount of negative voltage the OPC can accept is very important to copy quality.

Digital OPCs use negative/positive development. Since negatively charged

toner is applied to the OPC, a decrease in the OPCs negative voltage will not

have such a drastic effect on copy quality. (It will, however, cause a "dirty"

background appearance.)

Note: In the past, positive/positive development has sometimes been used

with digital OPCs. In this case, the laser exposure corresponds to

the white areas of the original. However, in most printouts, there are

many more white areas than black areas, so positive/positive development leads to a reduced OPC lifetime.

5-2

Page 11

October 1st, 1995 OPC CHARACTERISTICS

Special Characteristics

5.2.2. Wavelength of Light

The wavelength of fluorescent light is 450 nm ~ 650 nm. The wavelength of laser light is 780 nm. The charge generation material (CGM) for analog and

digital OPCs is designed differently due to these different wavelengths. The

difference is most easily observed in the colour of pigmentation

The CGM in an analog OPC is designed for maximum power output (chargeability) at 450 nm ~ 650 nm (depending on the machine). This will allow the

OPC to work optimally with reflected fluorescent light.

The CGM in a digital OPC is designed for maximum power output (chargeability) at 780 nm. This will allow the OPC to work optimally with laser light.

650nm

3000

2000

780nm

2000

Chargeability

(V cm2/µJ)

1000

500

600 800700

Wavelength of Light ( nm)

OPC503.wmf

Analog OPCs

Chargeability in relation to the

wavelength of light applied.

Chargeability

(V cm2/µJ)

1000

500

600 800700

Wavelength of Light (nm)

Digital OPCs

Chargeability in relation to the

wavelength of light applied.

OPC504.wmf

5-3

Page 12

OPC CHARACTERISTICS October 1st, 1995

Differences between Analog and Digital OPCs

5.3. Differences between Analog and Digital OPCs

Item Analog OPCs Digital OPCs

CGL Contains a material that

responds to the wavelength of

white light, such as light from a

fluorescent lamp.

CTL The CTLs are also different, to match the CGL that is used.

CTL Thickness vs

Chargeability

Development

Method

Image Transfer The image transfer charge has

If the CTL thickness is reduced,

the chargeability is also reduced.

Positive/positive only. Negative/positive or

the same polarity as the charge

corona unit.

Contains a material that

responds to the appropriate

laser wavelength.

The same as for Analog OPCs.

The chargeability does not,

however, decrease as rapidly as

in analog OPCs.

positive/positive can be used.

Negative/positive is mainly used.

The image transfer charge has

the opposite polarity as the

charge corona unit.

5-4

Page 13

October 1st, 1995 EFFECTS OF ENVIRONMENTAL FACTORS

Light

6. EFFECTS OF ENVIRONMENTAL FACTORS

6.1. Light

The CGL generates positive and negative charges when the OPC is exposed to

light. These charges flow normally (see page 4-1) when the OPC is in the machine. However, exposing the OPC to light after it has been removed from the

machine also causes the CGL to generate charges. Since there is no path for current flow, these charges may remain in the CGL. When the OPC is put back in

the machine, these stray charges will result in decreased chargeability and reduced copy quality.

OPC exposure to normal fluorescent lighting for 5~20 minutes will generate

stray charges. It is important, therefore, to cover the OPC with paper when removing it from the machine. If the OPC has been inadvertently exposed to

light, it is very important to shield it from any additional light for 10~15 minutes before making a copy. This will allow the charges to dissipate naturally. If

a copy is made before doing this, the stray charges will remain in the OPC. It

will take 1~2 months for the OPC to return to a normal condition. During this

time the residual voltage will be high and copy quality will be reduced.

6.2. Temperature

The melting temperature of the CTL is 60 °C ~ 70 °C. Take care (especially

during warehouse storage) not to exceed this temperature. Packing materials

may stick to the melting CTL. This will destroy the OPC.

6-1

Page 14

EFFECTS OF ENVIRONMENTAL FACTORS October 1st, 1995

Gases

6.3. Gases

Certain gases will affect the OPC.

Ozone

Ozone (O3) is produced in most machines by the charge corona unit and the

transfer corona unit. Usually, a machine which uses these units is equipped

with an ozone fan and ozone filter. This equipment removes the ozone from

the machine.

O3 will reduce the chargability of the OPC. O3 can affect both analog and digital OPCs.

Ammonia and Nitrogen Oxides

Ammonia (NH3) and nitrogen oxides (NOx) may reach the OPC from the outside environment.

NH3 can affect analog OPCs by removing negative charges from the CTL (as

the analog CTL material easily releases negative charges). This will reduce

chargeability and copy quality.

NOx can affect digital OPCs by adding negative charges to the CTL (as the

digital CTL material easily accepts negative charges). This will reduce chargeability and copy quality.

6.4. Dust and Oil

Dust and oil should be removed from the OPC. Dust and oil prevent toner from adhering to the OPC. This reduces copy quality.

Remove oil with a dry or slightly dampened cloth. Be sure to wipe the OPC

dry after applying a dampened cloth (use a clean dry cloth). It is important

that no water remains on the OPC.

Remove dust with a dry cloth.

Note: Never apply alcohol to the OPC.

6-2

Loading...

Loading...