Page 1

Container Stacker

Unpacking & Setup

Instructions

© 2007 Ricoh Corporation

5 Dedrick Place

West Caldwell, NJ 07006

January 2007

337641-006B

Page 2

© 2007 Ricoh Corporation. All rights reserved.

No part of this document may be reproduced without the expressed permission of Ricoh

Corporation.

The material in this document is for informational purposes and is subject to change

without notice. Ricoh Corporation assumes no responsibility for errors or omissions in

this document. No liability is assumed for any damages resulting from the use of the

information it contains.

TRADEMARK

Adobe and Postscript are registered trademarks of Adobe Systems Incorporated. PCL

is the trademark of Hewlett Packard. Ethernet is a trademark of Xerox Corporation.

Windows XP is a trademark of Microsoft Corporation. Digital Document Publisher and

DDP and its associated logo mark are the trademarks of Ricoh Corporation. Ricoh and

the Ricoh trademark are registered trademarks of Ricoh, Ltd. All rights reserved.

All other terms and product names may be trademarks or reg istered trade marks of the ir

respective owners and are hereby acknowledged.

NOTICE TO USER

In an effort to meet the demands of a rapidly changing technology, the manufacturer is

continually developing new features and functions to meet changing printing or printer

needs. Please be sure to consult all manual updates or addenda when using this

product’s documentation.

This document contains TrueType fonts from Monotype Imaging Inc. Reproduction of

these fonts is prohibited.

The software embedded in this product is based in part on the work of Independent

JPEG Group.

The software embedded in this product uses software by CMU. Copyright 1988, 1989

by Carnegie Mellon University. All rights reserved.

Permission to use, copy, modify, distribute and sell this software and its documentation

for any purpose and without fee is hereby granted, provided that the avove copyright

notice appears in all copies and that both the copyright notice and permission notice

appear in supporting documentation, and the name of CMU not be used in advertising

or publicity pertaining to distribution of the software without specific written prior

permission.

The software embedded in this product uses the software by Sam Leffler and Silicon

Graphics.

Copyright (c) 1988-1997 Sam Leffler

Copyright (c) 1991-1997 Silicon Graphics, Inc

Permission to use, copy, modify, distribute and sell this software and its documentation

for any purpose and without fee is hereby granted, provided that the above copyright

notice appear in all copies of the software and related documentation, and (ii) the names

of Sam Leffler and Silicon Graphics may not be used in advertising or publicity pertaining

to distribution of the software without specific, written prior permission of Sam Leffler and

Silicon Graphics.

Page 3

i

Revisions

Revision Page No. (Contents) Date

A Original Release - ECO-1554 October 2004

B Generic Version; Add rev history page, copyright page updated January 2007

Page 4

Table of Contents i

Table of Contents

Chapter 1. Container Stacker Installation Instructions

Installation Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Location of Leveling Bolts and Casters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Unpacking of Container Stacker 1 or 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Components in the Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Preparation for Installation of Container Stacker 1 or 2 . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Installation Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Prepare the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Install Container Stacker 1 or 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Installation of Container Stacker 2 and Container

Stacker 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-21

Installation of Container Stacker 2 and Standard Finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Standard Finisher (70 ppm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

Standard Finisher (92/184 ppm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-29

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

Appendix A. Installation/Maintenance Area

70/92 ppm Printer and Container Stacker 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

70/92 ppm Printer, High Capacity Hopper, Container Stacker 1 and Container Stacker 2 . . .A-2

70/92 ppm Printer, High Capacity Hopper, Container Stacker 2 and Standard Finisher . . . . .A-3

184 ppm Printer and Container Stacker 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

184 ppm Printer, High Capacity Hopper, and Container Stacker 1 . . . . . . . . . . . . . . . . . . . . .A-5

184 ppm Printer, Container Stacker 1, and Container Stacker 2 . . . . . . . . . . . . . . . . . . . . . . .A-6

184 ppm Printer, HIgh Capacity Hopper, and Container Stacker 1 and 2 . . . . . . . . . . . . . . . .A-7

184 ppm Printer, Container Stacker 2, and Standard Finisher . . . . . . . . . . . . . . . . . . . . . . . . . A-8

184 ppm Printer, High Capacity Hopper, Container Stacker 2, and Standard Finisher . . . . . .A-9

Page 5

ii Table of Contents

Page 6

Container Stacker Installation Instructions 1-1

Chapter 1

Container Stacker Installation Instructions

Installation Area

Refer to Appendix 1.

Environmental Conditions

The location where the Container Stacker is installed must meet the following

environmental conditions:

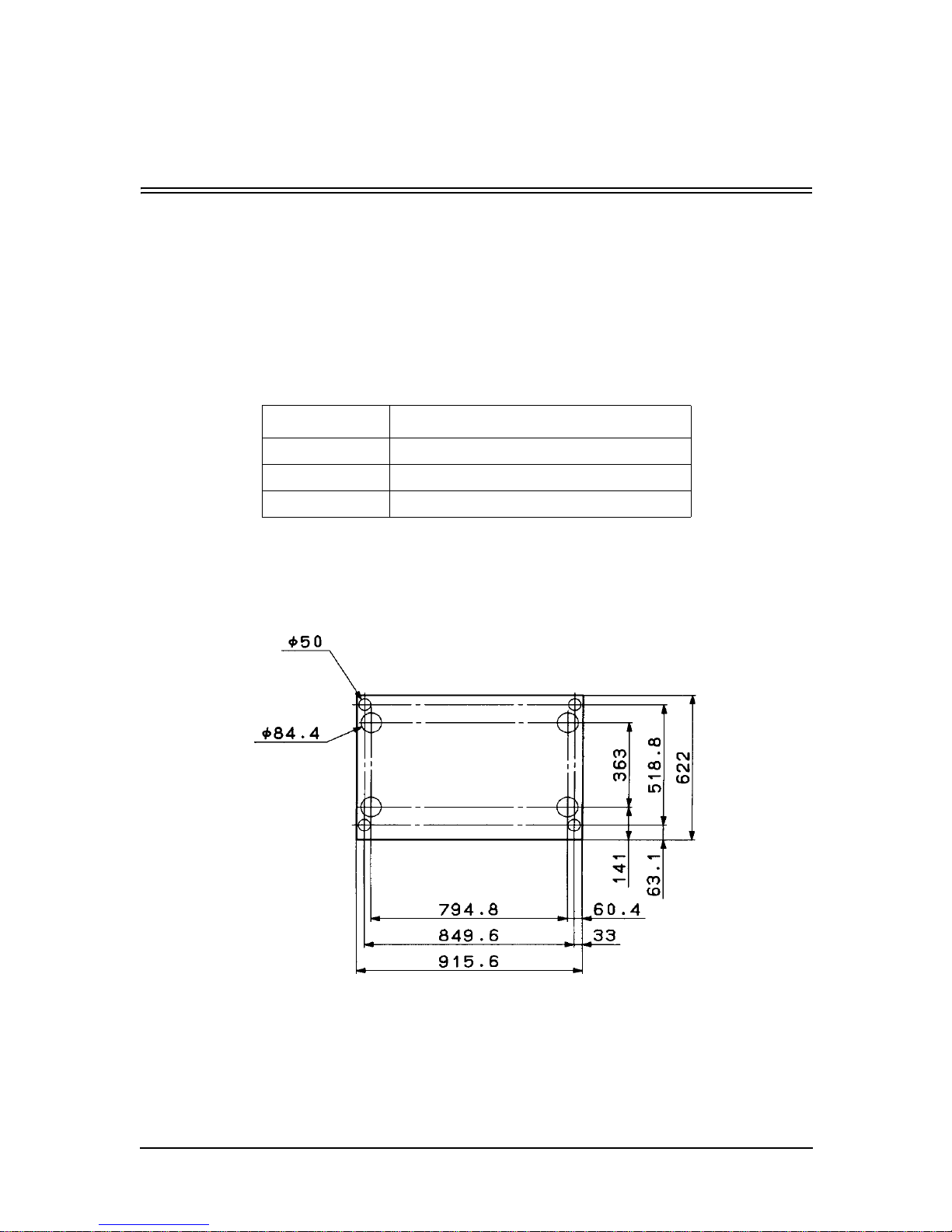

Location of Leveling Bolts and Casters

Install the leveling bolts and the casters to the Container Stackers 1 and 2 as follows.

ITEM CONDITION

Temperature 10 to 32 °C

Humidity 20 to 80%RH (non-condensing)

Altitude 0 to 2,100 m

Page 7

1-2 Container Stacker Installation Instructions

Tools Required

The following tools are required:

Important Safety Instructions

Observe the following safety instructions for safe unpacking and installation.

1. Keep the work area clean and free of loose parts.

2. Wear suitable clothing. Pay attention to ties, sleeves, and shirts so that they are

not caught in the equipment.

3. Work in a stable position. Working in a strained position may cause injury.

4. If you must move the equipment, be sure the path is clear of obstacles and high

voltage areas or wires.

5. Unplug the equipment before cleaning. Unplug the Printer from the outlet before

cleaning the inside of the Printer and label the power cord plug to prevent other

persons from plugging it in while you are cleaning.

6. Be sure to use the proper tools that are in good condition. Use of worn or

improper tools can cause injury.

TOOL APPLICATION

Cutter For unpacking

Phillips Screwdriver

No. 2 shaft length: approx. 100 mm

For installing the Printer and Containter Stacker

Adjustable open end wrench (Span; 30mm) For adjustment of leveling bolts

IC Gripper For replacement of nv-RAM

Level For installation of the Printer and Container

Stacker

Page 8

Container Stacker Installation Instructions 1-3

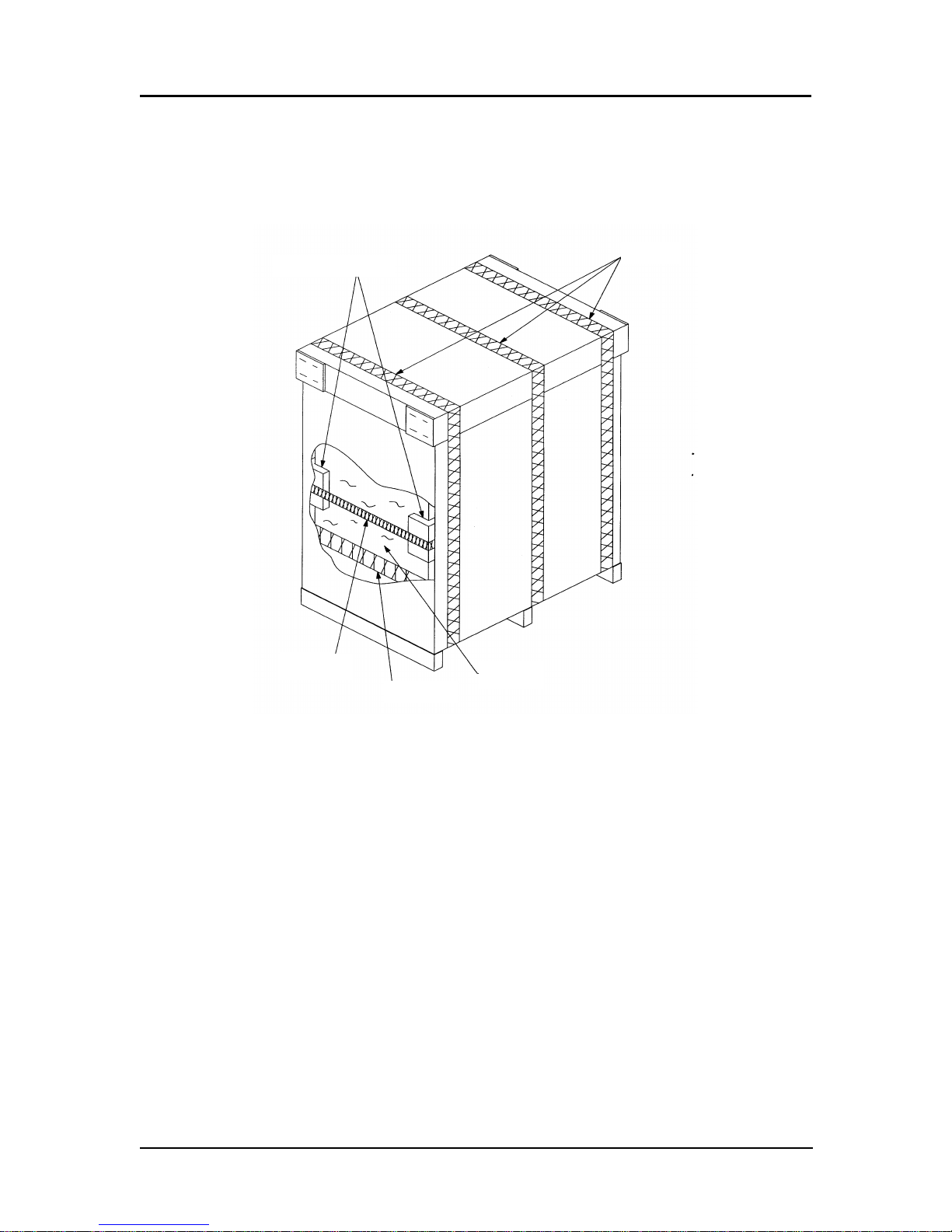

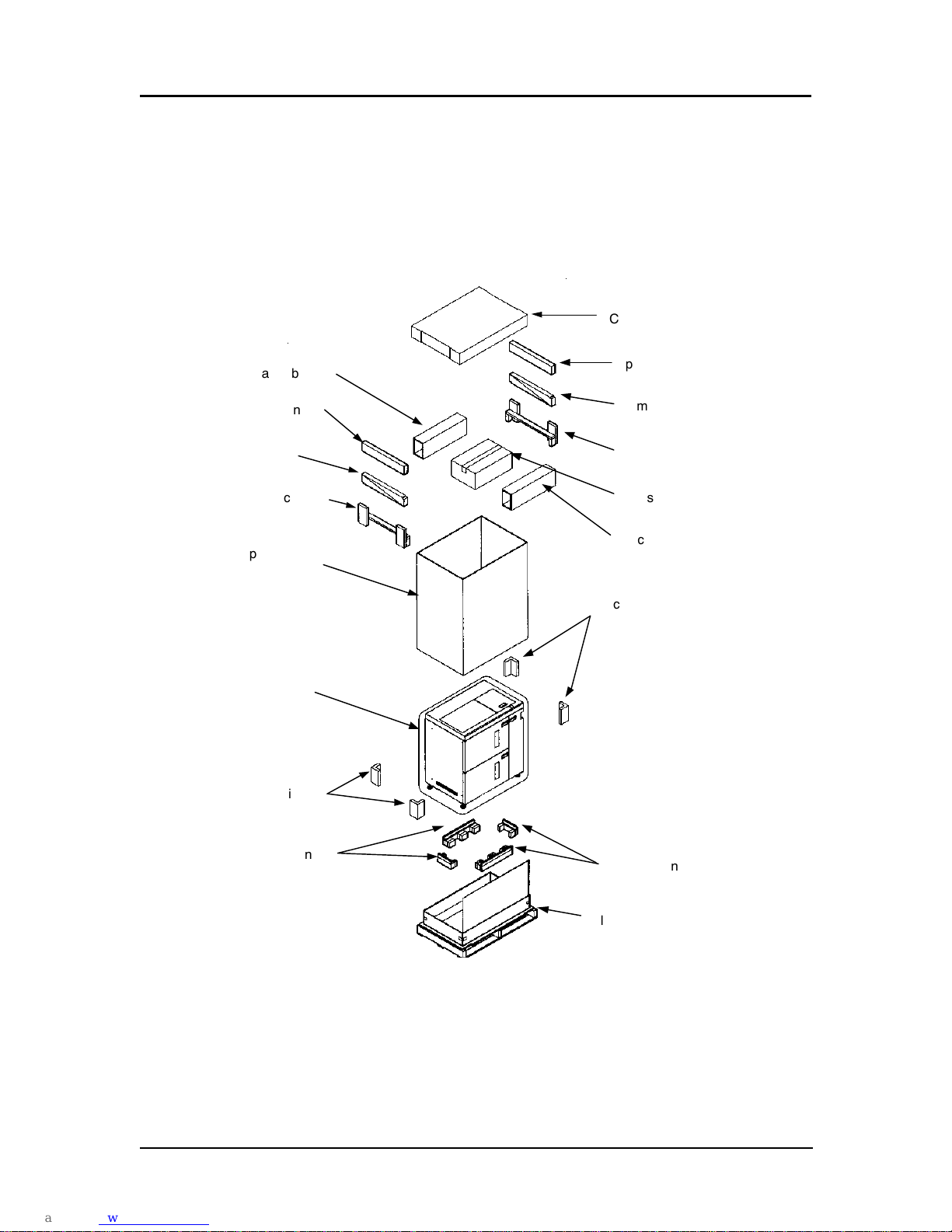

Unpacking of Container Stacker 1 or 2

Components in the Package

CAUTION!

When using a crane or forklift, handle the equipment with care. Do not drop, bump

or turn sideways.

Perform the unpacking procedure in a clean, dry location.

Do not place heavy objects (5 kg or more) on top of the equipment.

Keep the equipment balanced when lifting with a forklift. Use cushion materials to

avoid damage.

Move the equipment at a speed of 300 mm/sec (1.08 km/h) or slower. Do not tilt the

equipment more than 15

°. Slope on the path can be no more than 15°.

Do not allow condensation to form on the equipment.

Component Quantity

Container Stacker 1 or

Container Stacker 2

1

Accessory box 1

Page 9

1-4 Container Stacker Installation Instructions

Unpacking

1. Using a cutter, remove the V bandS from the shipping box and remove the cap.

V band

Corner packing

Plastic bag

Tape

V band

P.P band

Page 10

Container Stacker Installation Instructions 1-5

2. Remove the accessory box, spacer box, spacer packing, ramps and upper packing.

3. Remove the shipping box, band, and four corner pieces.

4. Peel off the adhesive tape and remove the plastic bag.

5. Cut the tape from the 4 corners of the base packing and push down the side of the

pallet to become an incline board.

Cap

Spacer packing

Pallet

Shipping box

Accessory box

Upper packing

Ramp

Spacer box

Upper packing

Corner packing

Base packing

Corner packing

Spacer packing

Plastic bag

Ramp

Base packing

Spacer box

Page 11

1-6 Container Stacker Installation Instructions

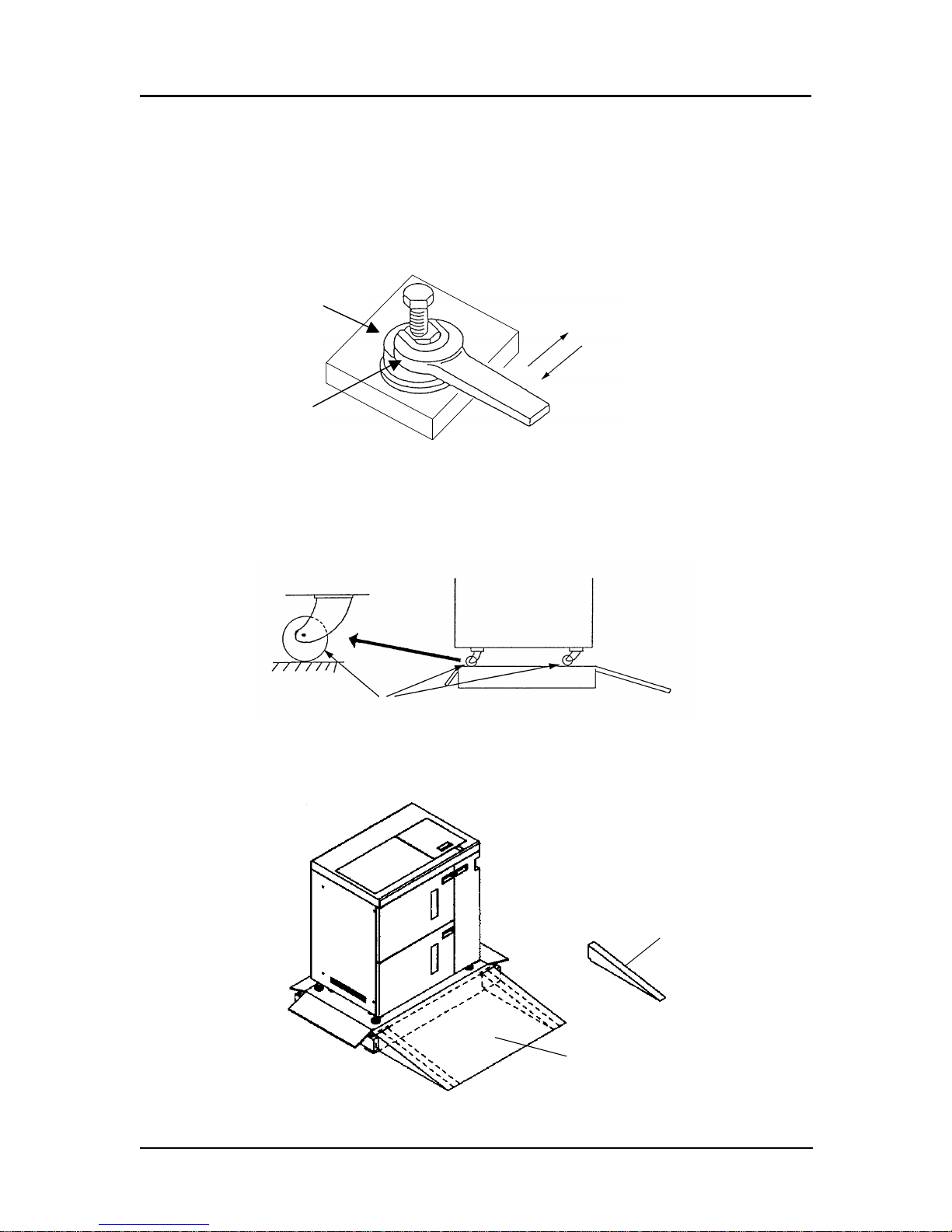

6. Romove the tape from the leveling bolts, take out the four wooden spacers from

the accessory box, and place them at the bottom of the bolts (under the plastic

bag).

7. Using an open-end wrench, raise the container stacker by rotating the leveling

bolts.

8. Remove the 4 pieces of base packing.

9. Turn all the casters in the same direction.

10. Install the ramps (two on each side) under the incline board.

Wood spacer

Leveling bolt

Down

Up

Ramp

Incline Board

Page 12

Container Stacker Installation Instructions 1-7

11. Raise the leveling bolts and remove the wood spacers.

12. Carefully slide the container stacker onto the floor.

WARNING!

Do not attempt the following step without another person to help guide the

stacker down the ramp.

Page 13

1-8 Container Stacker Installation Instructions

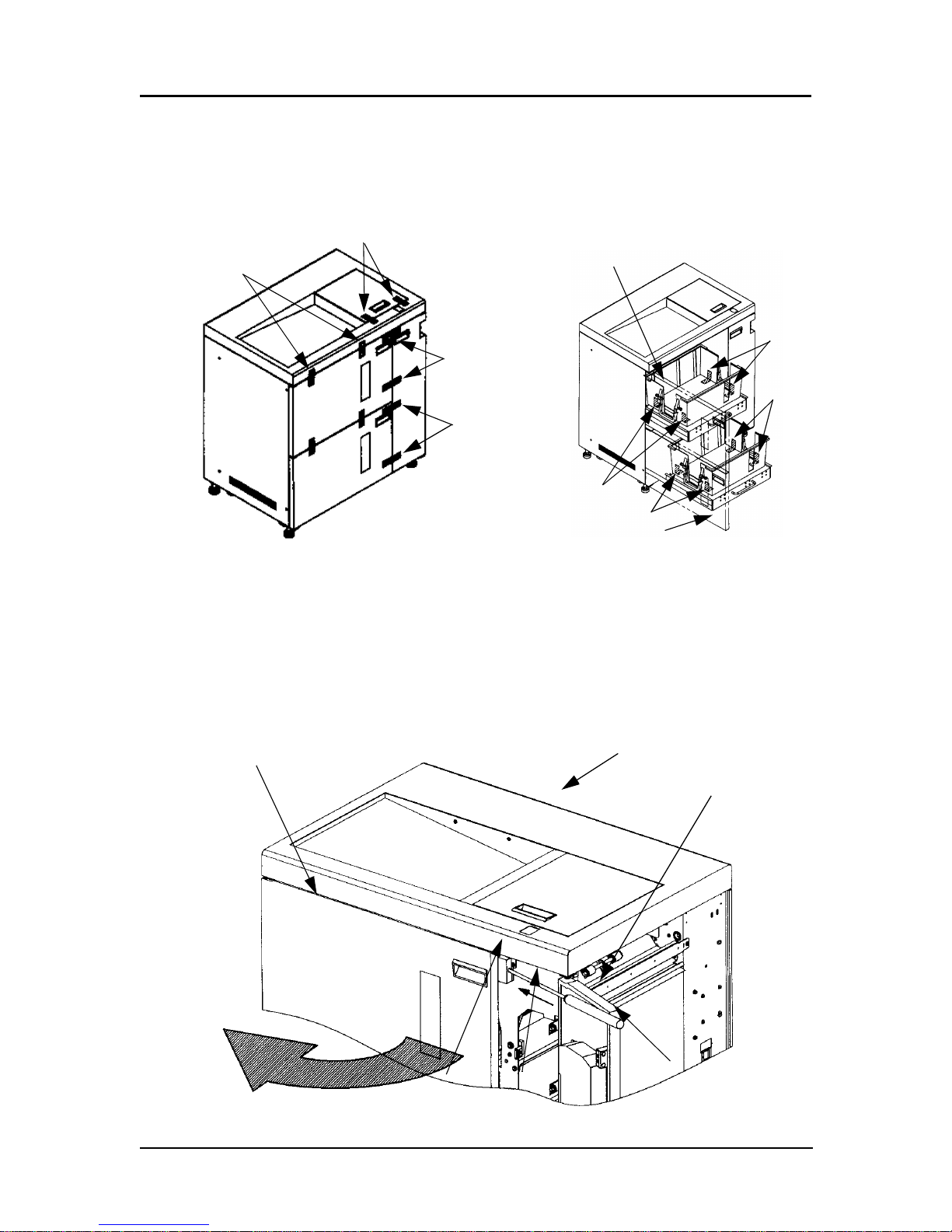

Preparation for Installation of Container Stacker 1 or 2

1. Peel off adhesive tape from the Container Stacker 1 or 2.

2. Open Front Cover L and peel off the adhesive tape

Opening procedure for Front Cover L

1. Open Front Cover R.

2. Using a Phillips screwdriver, push cover release A in the direction of the arrow

and open Front Cover L.

Ta pe

Tape

Ta pe

Ta pe

Ta pe

Tape

Tape

Tape

Front Cover L

Front Cover L

Front Cover L

Container Stacker 1 or 2

Phillips Screwdriver

Front Cover R

Arrow

A

Page 14

Container Stacker Installation Instructions 1-9

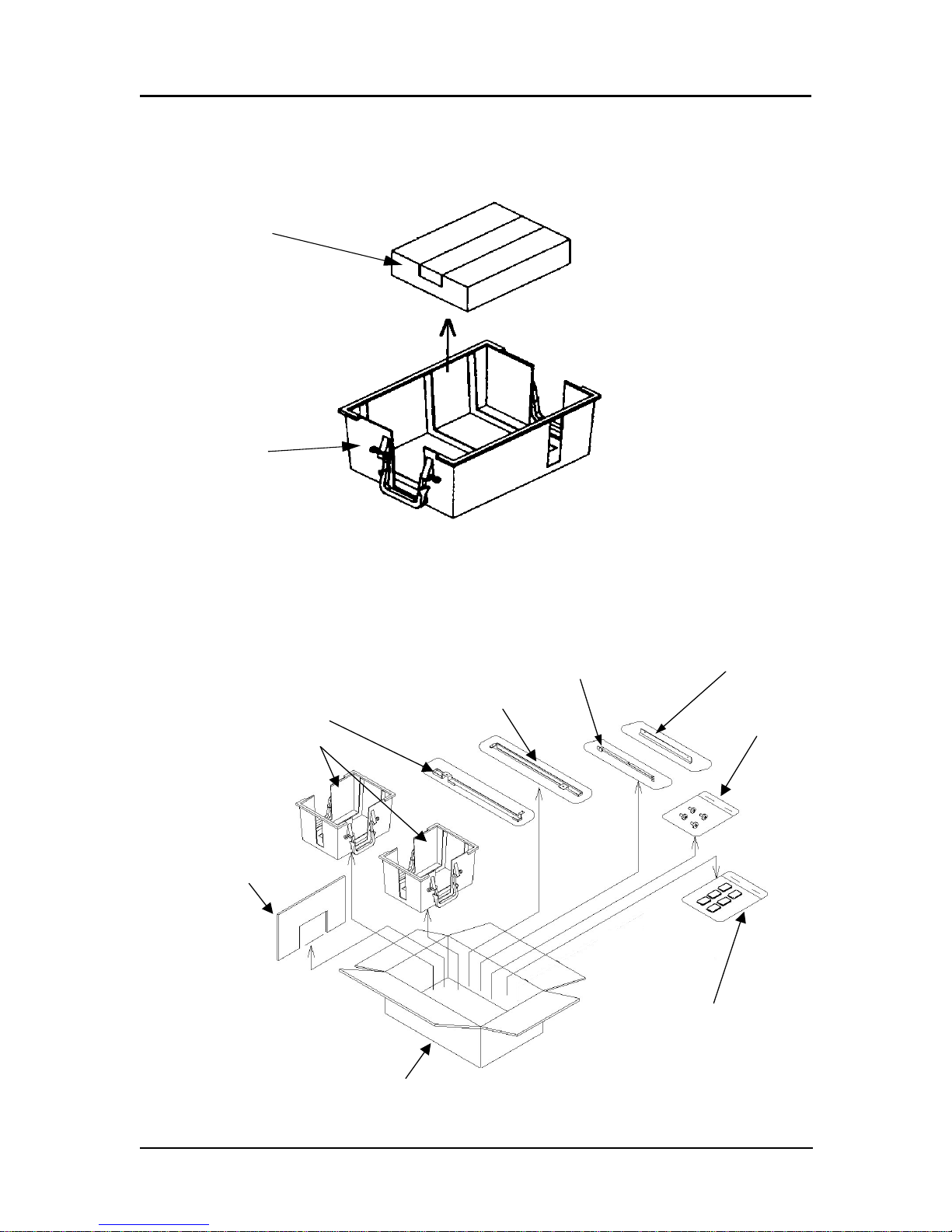

3. Take the box containing the CP417 assembly out of the lower basket. |

(70 ppm only)

4. Take the components out of the accessory box.

CP417 Assy

Basket

Screw

Joint bracket (L)

Basket (small)

Joint bracket (U)

Guide Plate(L)

Guide Plate(U)

Partition

Hopper spacer ass’y

Details of screw

(1) M3 x 8 2 pieces

(2) M4 x 8 4 pieces

(3) M4 x 12 6 pieces

A

ccessory box

Page 15

1-10 Container Stacker Installation Instructions

Installation Configuration

The table below shows the configuration of Printer and Post devices. Installation of

each configuration should be done according to the reference page shown the in table

below.

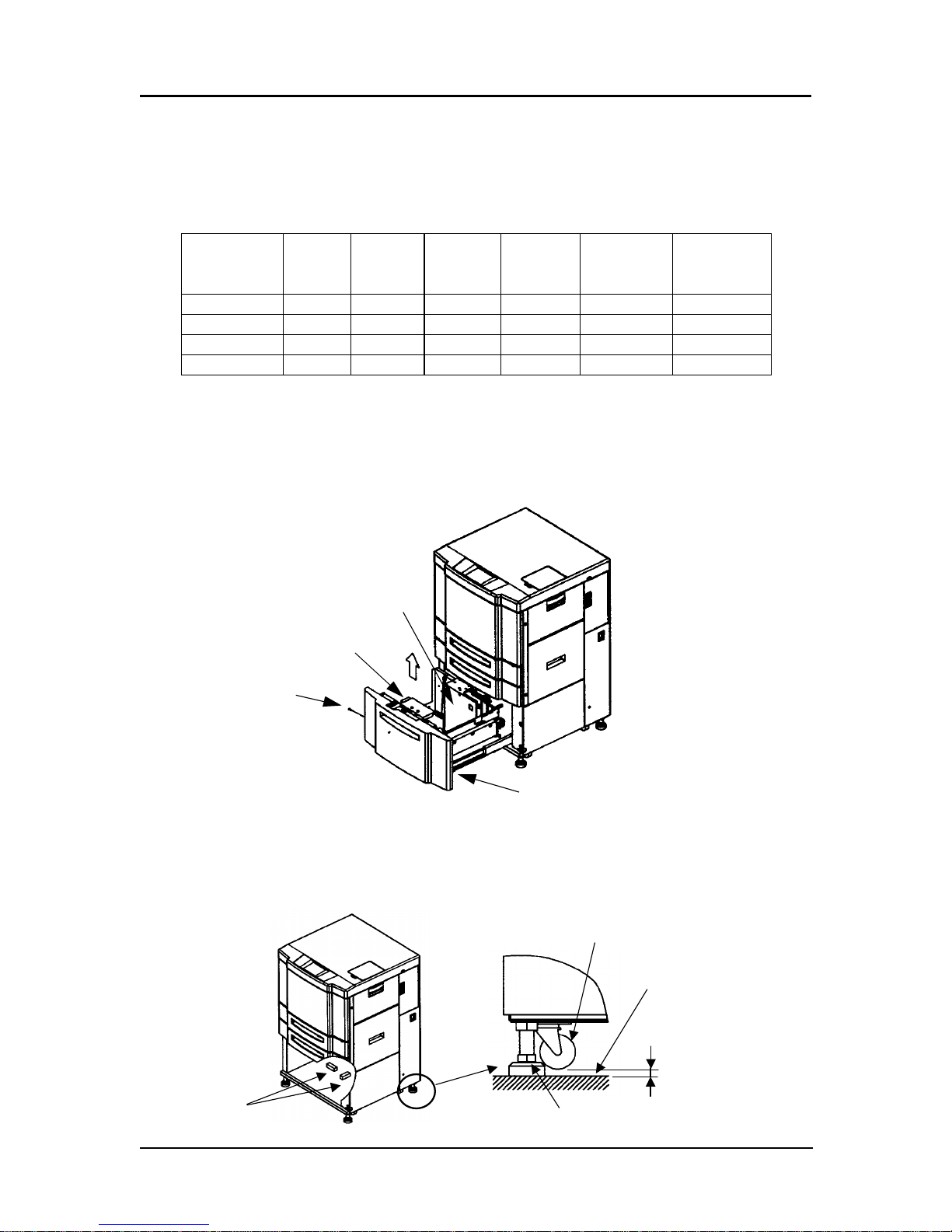

Prepare the Printer

70/92 ppm

1. Remove the 2000 sheet hopper.

2. Turn the four leveling bolts until the casters do not touch the ground.

3. Place a level on the Printer frame and adjust the leveling bolts until horizontal

level is achieved.

Configuration Printer

Container

Stacker 1

Container

Stacker 2

Standard

Finisher

DDP70e

Standard

Finisher

DDP92/184

Reference

Page

1xx 8

2 x x x 8, 16

3 x x x 8, 21

4 x x x 8, 24

Paper Guide

Lever

M4 Screw

2000 Sheet Hopper

Gap

Caster

Leveling Bolt

Floor

Level

(Max 1mm)

Page 16

Container Stacker Installation Instructions 1-11

4. Reinstall the 2000 Sheet Hopper.

184 ppm

1. Open the Front Cover of the printer and loosen the two M4 screws. (184 ppm

only)

2. Pull the upper part of the Front Lower Cover forward and unhook it by lifting and

pulling forward.

M4 Screw

2000 Sheet Hopper

Rear Engine

Hook

Front Cover

M4 Screw

Front Lower Cover

Page 17

1-12 Container Stacker Installation Instructions

3. Turn the four leveling bolts until the casters no longer touch the floor.

4. Using a Level, adust the horizontal level of the rear engine.

Install Container Stacker 1 or 2

1. Remove the two M3x8 screws and Static Electricity eliminator from the Printer.

2. Install the Guide Plate (U) with the Static Electricity eliminator using the two

M3x8 screws.(the front is lettered on the surface).

3. Install the Guide Plate (L) using the two M3x8 screws with washers.

4. Install Joint Bracket (U) and Joint Bracket (L) using the two M4x8 screws.

NOTE:

These installation instructions apply to the 70, 92 and 184 ppm

printers.When installing a Container Stacker on a 184 ppm printer, the

word printer always refers to the Rear Engine unless otherwise specified.

NOTE:

Take care that nothing interferes with the static eliminator.

(Max 1mm)

Gap

Leveling Bolt

Caster

Floor

Rear Engine

Level

Page 18

Container Stacker Installation Instructions 1-13

5. Install Joint Bracket (U) and Joint Bracket (L) using the two M4x8 screws.

6. Remove the six M4 screws. Unhook the lower hook of the Rear Cover and

remove the Rear Cover by lifting and pulling it forward.

M4x8 Screw

M4x8 Screw

Joint Bracket (L)

Joint Bracket (U)

M3x8 Screw with Washer

Guide Plate (U)

Guide Plate (L)

Static Electricity Eliminator

M3x8 Screw

Rear Cover

M4 Screws

Page 19

1-14 Container Stacker Installation Instructions

7. Remove the six M4 Screws and the Rear Cover.

8. Attach Container Stacker 1 or 2 to the Printer and loosely install the screws.

NOTE:

Refer to page 5 for instructions on opening Front Cover L.

Rear Cover

M4 Screws

Container Stacker 1 or 2

M4x12 Screws

Frame Projection Part

M4x12 Screws

Page 20

Container Stacker Installation Instructions 1-15

9. Close Front Cover R to allow you to see the gap between the Printer and

Container Stacker. Using the leveling bolts, adjust the height of the Container

Stacker until the Container Stacker frame projection is level with the Printer

Paper Guide projection. Adjust the horizontal level of the Container Stacker by

placing a level on the stacker frame in the three locations shown below. Tighten

the screws completely.

10. Verify the gap at A, B, C, and D is nearly equal.

Stacker Frame

Printer Paper Guide

Level

Front Cover L

Projection

Projection

Same Height

Leveling Bolts

Connection Part Details

A

B

C

D

Adjust the parallel gap

Page 21

1-16 Container Stacker Installation Instructions

11. Open the L Paper Guide A of the Container Stacker and make sure that the SB

Cover can be opened. If the cover cannot be opened, repeat steps 8 and 9 to

readjust the Container Stacker.

L Paper Guide A

SB Cover

Page 22

Container Stacker Installation Instructions 1-17

12. Remove the OC P/K ass’y from the Printer. Remove the CP411 P/K and CP P/K

holder (70 ppm only).

13. Remove the OC P/K ass’y and CP P/K holder from the Printer (92/184 ppm only).

14. Remove the nv-RAM from the CP411 P/K using an IC gripper. Install the

removed nv-RAM into the CP417 P/K (70 ppm only)

15. Connect the CST AC cable coming from the Container Stacker to J236 on the

power supply of the Printer (Connection 1 on the figure below). At this time,

connect the CE AC cable that was disconnected from J236 to the connector of the

CST AC cable (Connection 2 on the figure below).

16. Mount the CST FG cable coming from Container Stacker side on the Printer

frame using an M4 screw (Connection 3 on the following illustration).

17. Install the CP417 P/K on the CP P/K holder, and then install it and the board in

the Printer. (70 ppm only)

18. Install the CP P/K holder and OC P/K ass’y in the Printer (92/184 ppm only)

19. Connect the FNS IF cable of the 20 pin black connector coming from the Printer

to the J680 connector of ST09X board in Container Stacker (Connection 4 on the

figure below). Do not use the 4 pin white connector (Disconnection 2 on the

following illustration).

CPXXX P/K

CP P/K holder

OC P/K ass’y

nv-RAM

M4 Screw

M4 Screw

CST AC Cable

CST FG Cable

M4 Screw

Dent side

Page 23

1-18 Container Stacker Installation Instructions

20. Disconnect the 4 pin white connector of the DC IF cable of the Printer from the

FNS IF cable (Disconnection 1 on the figure below), then connect it to the RB

cable of the 4 pin white connector coming from Container Stacker (Connection 5

on the following illustration) (70/92 ppm only).

21. Connect the CS relay cable of accessory box of the printer to the 4 pin white

connector of the FNS IF cable and the RB cable of the 4 pin white translucent

connector of the Container Stacker (Connection 5 on the following illustration.)

(184ppm only)

NOTE:

Put the cable through opening “A” of the Printer.

On SW1 mounted on the CPXXX P/K, set switch No. 5 to ON and set switch No. 2

and No. 8 to OFF. (Front Engine of 184 ppm printer)

CE AC Cable

Connector : 2 pin white

Connector : 2 pin

PS

Connection 1 and 2 Details

70/92 ppm

CTS AC Cable

M4 Screw

(Connection 3)

Opening A

RB Cable

Connection 5

(4 pin white)

Disconnection 3

(2 pin white)

Connection 4

(20 pin black)

CST FG Cable

CE AC Cable

Connection 2

Connection 1

FNS IF Cable

Disconnection 2

(4 pin white)

Disconnection 1

(4 pin white)

DC IF Cable

Page 24

Container Stacker Installation Instructions 1-19

CTS AC Cable

M4 Screw

(Connection 3)

Opening A RB Cable

Connection 5

(4 pin white

CS Relay Cable

Connection 5

(4 pin white)

Disconnection 3

(2 pin white)

Connection 4

(20 pin black)

FNS IF Cable

(coming from Front Engine)

CST FG Cable

CE AC Cable

Connection 2

Connection 1

translucent)

184 ppm

CE AC Cable

Connector : 2 pin white

Connector : 2 pin

PS

Connection 1 and 2 Details

Page 25

1-20 Container Stacker Installation Instructions

22. Install the Rear Cover of the Printer and the Rear Cover of the Container Stacker.

M4 Screw

Page 26

Container Stacker Installation Instructions 1-21

Installation of Container Stacker 2 and Container

Stacker 1

1. Remove the two M3x8 Screws and Static Electricity eliminator from the Printer.

2. Attach the Guide Plate (U) with the Static Electricity eliminator using the two

M3x8 Screws.

3. Install Joint Bracket (U) and Joint Bracket (L) using the two M4x8 Screws.

NOTE:

Refer to page 9 for installation of the Printer and the Container Stacker 2.

M4x8 Screw

Guide Plate

Container Stacker 2

Static Electricity Eliminator

Joint Bracket U

M3 Screw

Joint Bracket L

Page 27

1-22 Container Stacker Installation Instructions

4. Remove the six M4 Screws and remove the Rear Cover from Container Stacker 1.

5. Attach Container Stacker 1 to Container Stacker 2 and loosely install the screws

M4 Screws

Rear Cover

Container Stacker 1

Container Stacker 1

M4x12 Screws

Frame Projection Part

Container Stacker 2

M4x12 Screws

M4x12 Screws

Page 28

Container Stacker Installation Instructions 1-23

6. Close Front Cover R to allow you to see the gap between the Printer and

Container Stacker. Using the leveling bolts, adjust the height of the Container

Stacker until the Container Stacker frame projection is level with the Paper Guide

projection. Adjust the horizontal level of the Container Stacker by placing a level

on the stacker frame in the three locations shown. Tighten the screws completely.

7. Verify the gap at A, B, C, and D are nearly equal.

NOTE:

Refer to page 5 for instructions on opening Front Cover L.

Stacker Frame

Stacker Paper Guide

Level

Front Cover L

Projection

Projection

Same Height

Leveling Bolts

Connection Part Details

A

BCD

Adjust the gap in parallel

Page 29

1-24 Container Stacker Installation Instructions

8. Connect the AF cable of 4 pin white connector coming from the Container

Stacker 2 to the J680 on the ST09X P/K of the Container Stacker 1. (Connection 1

on the following illustration)

9. Take out the CST AC cable of 2 pin white connector from the Container Stacker 1

and connect it to the CST AC cable of 2 pin white connector of the Container

Stacker 2. (Connection 2 on the following illustration)

10. Take out the RB cable from the Container Stacker 1 and connect it to the RB

cable of Container Stacker 2. (Connection 3 on the following illustration)

11. Mount the CST FG cable coming from Container Stacker 1 on the frame of

Container Stacker 2 using M4 Screw (Connection 4 on the following illustration).

NOTE:

Put the cable through opening “A” of the Printer.

On SW1 mounted on the CPXXX P/K, set switch No. 4 and No. 5 to ON

and set No. 2 and No. 8 to OFF. (Front Engine of 184 ppm)

Connection 2

(2 pin white)

Connection 1

(20 pin black)

AF cable

RB cable

(For Container Stacker 2)

RB cable

(For Container Stacker 1)

Connection 3

(4 pin white)

CST AC cable

CST FG cable

M4 screw

Printer

Container Stacker 2

(W/ Sample tray)

(W/ Through path)

Opening “A”

Container Stacker 1

Disconnection 1

(4 pin white)

Disconnection 2

(2 pin white)

70/92 ppm

184 ppm: Connect the CS Relay Cable (see Page 19 Step 21.

Page 30

Container Stacker Installation Instructions 1-25

12. Install the Rear Covers of the Printer, Container Stacker 1 and Container

Stacker 2.

Printer Rear Cover

M4 Screws

Container Stacker 2 Rear Cover

M4 Screws

Container Stacker 1 Rear Cover

Page 31

1-26 Container Stacker Installation Instructions

Installation of Container Stacker 2 and Standard Finisher

Refer to “Standard Finisher Installation Instruction” for unpacking and preparation for

installation of the Standard Finisher.

Standard Finisher (70 ppm)

1. Remove the two M3 Screws and the Discharging Brush from Container Stacker 2.

2. Install the Guide Plate (G) together with the Discharging Brush and secure them

with two M3 Screws.

3. Install the Guide Plate (H), Connecting Stay and Main MT Plate.

4. Remove the Rear Covers from the Printer, Container Stacker 2 and standard

Finisher.

NOTE:

Refer to the “Standard Finisher Installation Instruction” regarding

unpacking and installation of the Finisher.

Connecting Stay

Container Stacker 2

M4 Screws

M3 Screws

M3 Screws

M4 Screws

Main MT Plate

Guide Plate (G)

Static Electricity Eliminator

Guide Plate (H)

w/Washer

Page 32

Container Stacker Installation Instructions 1-27

5. Attach the Standard Finisher to the Container Stacker 2.

6. Adjust the difference between the Stacker Paper Guide and the Printer Paper

Guide to 0 - 3 mm.

7. Verify the gap of A, B, C, and D are nearly equal. If not, adjust the leveling bolts.

Standard Finisher

M4 Screws

M4 Screws

Container Stacker

Finisher Paper Guide

Container Stacker 2 Paper Guide

Adjust the Parallel Gap

Adjustment Bolt

Loosen

0 to 3 mm

A

B

C

D

Page 33

1-28 Container Stacker Installation Instructions

8. Connect the AF cable of 4 pin white and 20 pin black connectors and coming

from the Container Stacker 2 to the connectors CN9 and CN10 of the Finisher.

(Connection 1 and 2 on the illustration below)

9. Install the Rear Covers of the Printer, Container Stacker 2 and Standard Finisher.

Install the connecting cover between the Container Stacker and the Standard

Finisher.

NOTE:

Put the cable through opening “A” of Container Stacker 2.

On SW1 mounted on the CPXXX P/K of the Printer, set switch No. 5 and

No. 8 to ON and set switch No. 2 to OFF.

70/92 ppm

184 ppm: Connect the CS Relay Cable

(see Page 19 Step 21).

Opening A

AF Cable Connection 2

(20 pin black)

Disconnection 1

(4 pin white)

Disconnection 2

(2 pin white)

Connection 1

(4 pin white)

Printer

Container Stacker 2

(with Throughpath)

Standard

Finisher

Page 34

Container Stacker Installation Instructions 1-29

Standard Finisher (92/184 ppm)

1. Install the Joint Cover/U, Joint Cover/F, the Joint Cover/R, and the Main Fixed

Plate/1.

2. Remove the Rear Covers from Printer, Container Stacker 2 and Finisher

NOTE:

Refer to the “Standard Finisher Installation Instruction regarding

unpacking and installation of the Finisher.

Container Stacker

2

Joint cover / U

6-M4x6 TP screws

M4x6 Truss scre

w

Main Fixed Plate/ 1

Joint cover / R

Joint cover / F

Main Fixed Plate/ 1

Page 35

1-30 Container Stacker Installation Instructions

Attach the Finisher to the Container Stacker

3. Fit the hooks on the Container Stacker installation plates (upper and lower) into

the upper and lower holes on the Finisher as illustrated below, then lock them by

pushing the Finisher to the back.

CAUTION!

When installing the Finisher take care not to hit the part “A” against the

Printer.

Upper view

Lower view

Finisher

Container Stacker 2

Finisher

Container Stacker 2

Holes

Hooks

M4x6 Screws

Page 36

Container Stacker Installation Instructions 1-31

NOTE:

If the gap between the Finisher and the Printer is not equal from top to

bottom, adjust the height of the front and rear casters on the paper exit

side of the Finisher.

A

B

A=B

Page 37

1-32 Container Stacker Installation Instructions

4. Connect the connector of the AF cable of the 4-pin white and 20-pin black

connectors coming from the Container Stacker 2 to connector CN7 (4 pin) in the

Finisher.

5. Pull the cable through the opening in Container Stacker 2 marked “A” (shown

below).

6. On SW1, set the No. 5 and No. 8 switch to On and set the No. 2 switch to Off.

7. Install the Rear Covers of the Printer, Container Stacker 2 and the Finisher.

Printer

Container Stacker 2

(W/ Through path)

Standard Finisher

AF cable

Connection 2

(20 pin black)

Connection 1

(4 pin white)

Disconnection 1

(4 pin white)

Disconnection 2

(2 pin white)

Opening “A”

Page 38

Container Stacker Installation Instructions 1-33

Adjustment

Adjust paper feed position of Hopper 1

1. Print the same size paper from Hopper 1 and Hopper 2 and check the paper feeding position.

2. If the configuration includes Container Stacker 1, check the paper feeding

position on the sample tray.

3. If the configuration includes Container Stacker 2, open the top cover of Container

Stacker 2, insert the cheater found in the Printer accessory box) in the interlock

switch, and check the paper feeding position on the slit between Paper Guides.

4. Set a standard point in the sample tray and the frame of the Container Stacker and

check the gap of the paper feeding position between Hopper 1 and Hopper 2 and

whether the paper is closer to the front side or the rear side.

a. When the paper from Hopper 1 is closer to the front side compared with the

paper from Hopper 2, there is no need to add a Hopper spacer.

b. If the paper from Hopper 1 is closer to the rear side by 1-2 mm compared with

the paper from Hopper 2, add 1 piece of Hopper spacer at each location as

shown in below.

Page 39

1-34 Container Stacker Installation Instructions

c. If the paper from Hopper 1 is closer to the rear side by 2 mm or more com-

pared with the paper from Hopper 2, add 2 pieces of Hopper spacer at each

location as shown below.

(20)

(20)

100

100

Hopper Spacer

15

(20)

Hopper Spacer

Page 40

Installation/Maintenance Area A-1

Appendix A

Installation/Maintenance Area

70/92 ppm Printer and Container Stacker 1

700

(665) 1,200

700 (622) (671)

(2,565)

Page 41

A-2 Installation/Maintenance Area

70/92 ppm Printer, High Capacity Hopper, Container

Stacker 1 and Container Stacker 2

700

(655)

1,200

Page 42

Installation/Maintenance Area A-3

70/92 ppm Printer, High Capacity Hopper, Container

Stacker 2 and Standard Finisher

700

(655) 1,200

700

(1293)

(572)

2,565

Page 43

A-4 Installation/Maintenance Area

184 ppm Printer and Container Stacker 1

(??: mm)

Operator’s Side

Container Stacker 1

Printer (LB184A)

700

(665)

1200

2565

Server

Maintenance Area

Page 44

Installation/Maintenance Area A-5

184 ppm Printer, High Capacity Hopper, and Container

Stacker 1

High capacity

hopper

Operator’s Side

Container Stacker 1

Printer (LB184A)

Server

Maintenance Area

700

(665)

1200

2565

Page 45

A-6 Installation/Maintenance Area

184 ppm Printer, Container Stacker 1, and Container

Stacker 2

Operator’s Side

Container Stacker 1

Printer (LB184A)

Server

Maintenance Area

700

(665)

1200

2565

Container Stacker 2

Page 46

Installation/Maintenance Area A-7

184 ppm Printer, HIgh Capacity Hopper, and Container

Stacker 1 and 2

Operator’s Side

Container Stacker 1

Printer (LB184A)

Server

Maintenance Area

700

(665)

1200

2565

Container Stacker 2

High capacity

hopper

Page 47

A-8 Installation/Maintenance Area

184 ppm Printer, Container Stacker 2, and Standard

Finisher

Operator’s Side

Printer (LB184A)

Server

Maintenance Area

700

(665)

1200

2565

Container Stacker 2

Standard

Finisher

Page 48

Installation/Maintenance Area A-9

184 ppm Printer, High Capacity Hopper, Container

Stacker 2, and Standard Finisher

Operator’s Side

Printer (LB184A)

Server

Maintenance Area

700

(665)

1200

2565

Container Stacker 2

Standard

Finisher

High capacity

hopper

Page 49

A-10 Installation/Maintenance Area

Loading...

Loading...