Page 1

Reissued: 19-Mar-03

T

echnical Bulletin

PAGE: 1/4

Model:

General RTB

Date:

4-Feb-03

No.:

RGene013b

RTB Reissue

The items in bold italics have been corrected or updated.

Subject:

From:

Classification:

Service remarks at installation

Technical Service Sec. Service Planning Dept.

Troubleshooting

Mechanical

Paper path

Other (Specification change)

Prepared by:

Part information

Electrical

Transmit/receive

T. Itoh

Action required

Service manual revision

Retrofit information

Please note the following change in counter specification. Although a production line

modification will not be applied to some products, the action described in 4. Important

Notes for Installation below must be taken for

all products

at installation

.

Overview:

Electronic counters will now be set to 0 when released from the factory, instead of being

set to a negative value.

Background:

Previously, counters were set to a negative value when shipped from the factory, and later

set to “0” at installation, following installation test copies/prints. However this may cause

confusion among some customers as to why the counter value at the commencement of

the contract is “0”, even though some installation test copies have already been made.

Details:

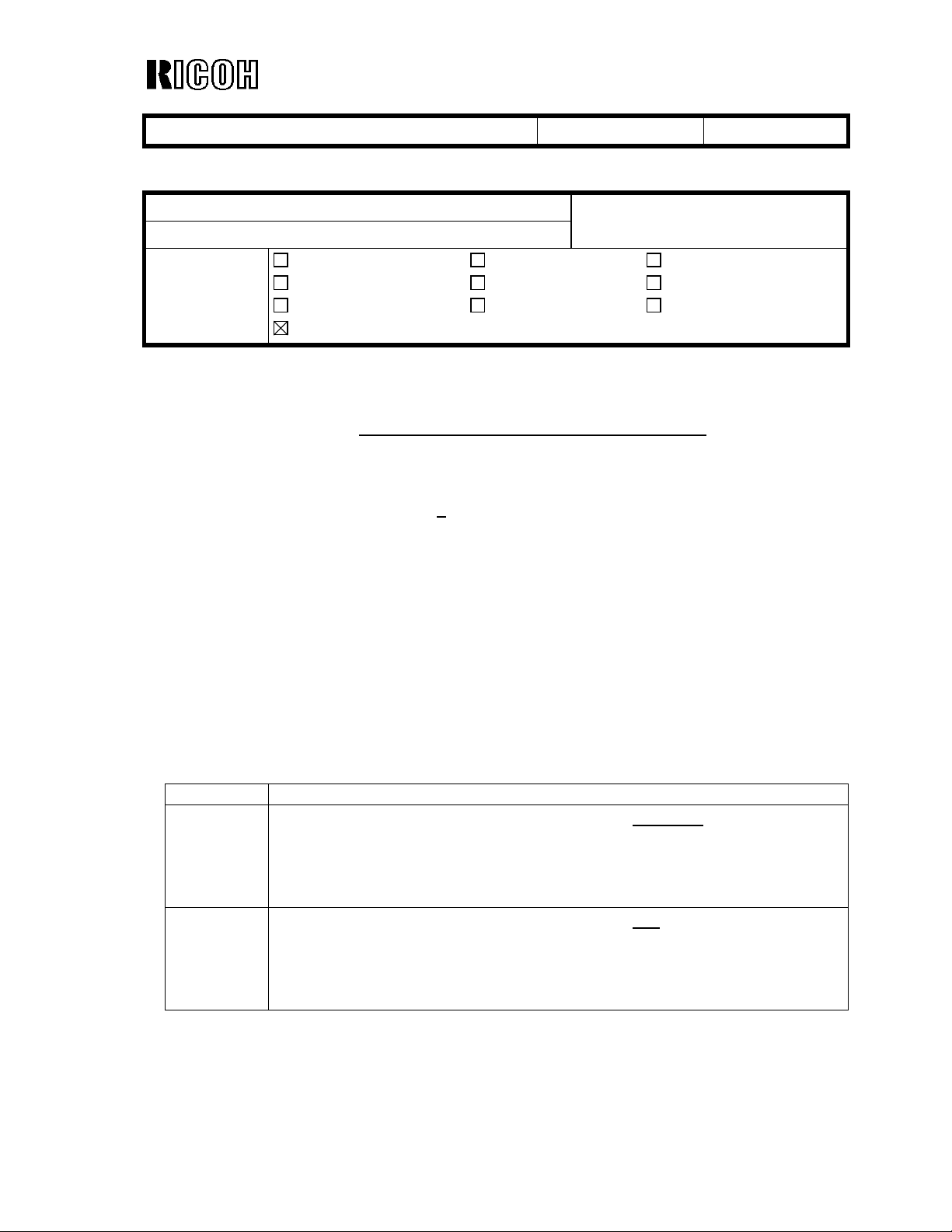

1. Specification Change

Specification

Current

New

• The initial value of the electrical counter is

are shipped from the factory.

Note:

After making test samples at installation, the negative counter

value can be set to “0” with SP mode.

• The initial value of the electrical counter is

shipped from the factory.

Note:

After making test samples at installation, the (positive) counter

value cannot be set back to “0” with SP mode.

negative

“0”

when products

when products are

Page 2

Reissued: 19-Mar-03

T

echnical Bulletin

PAGE: 2/4

Model:

General RTB

Date:

4-Feb-03

No.:

RGene013b

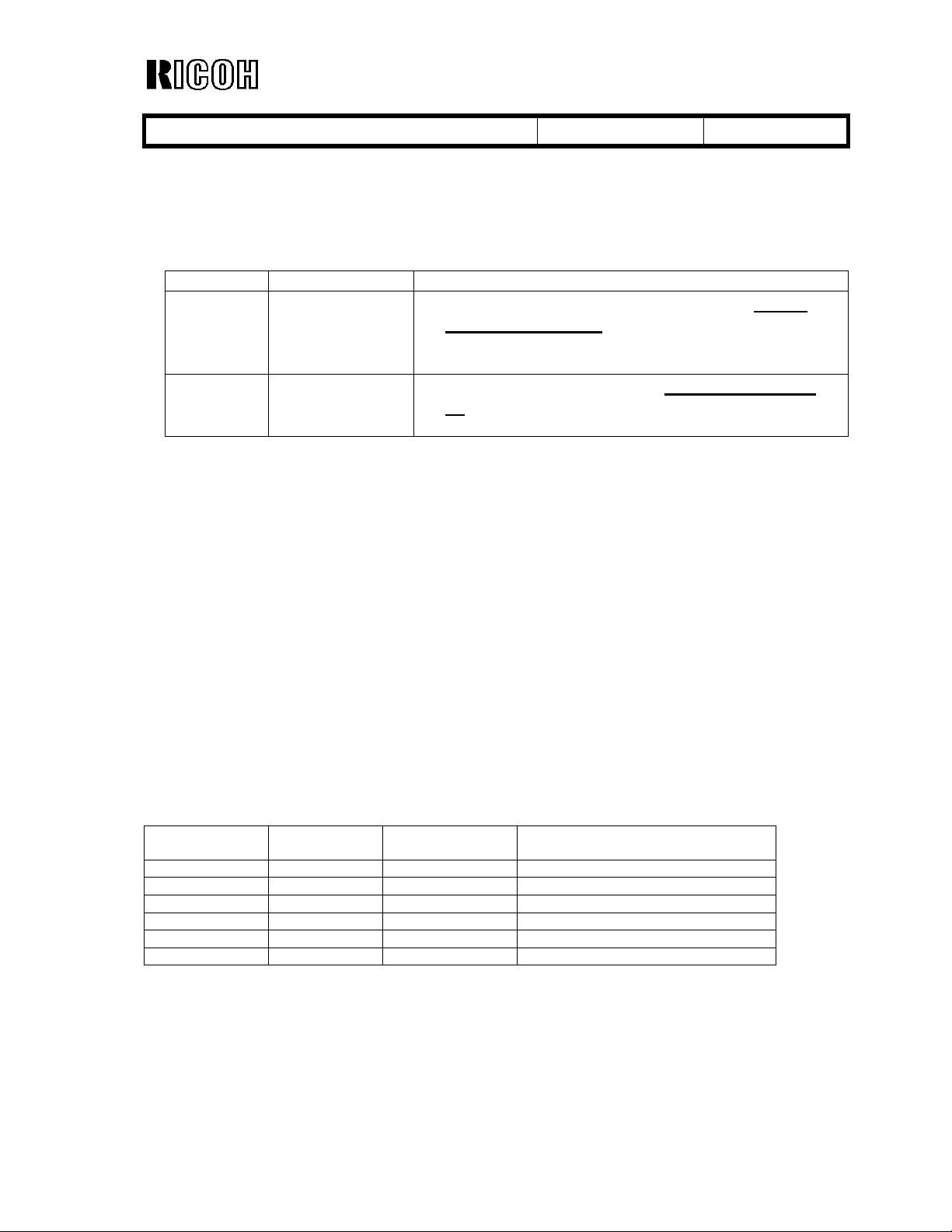

2. Firmware Modification

Due to the counter modification, SP5-849 has also been changed as follows for products

that have this SP mode (listed below).

SP mode name: Specification:

Current Counter Clear

Day

•

When the electrical counter is changed

negative value to 0

, the machine recognizes this

from a

as the counter clear day and stores this date in the

NVRAM.

New Installation Date

• When the electrical counter reaches a value of

20, the machine recognizes this as the installation

date and stores this date in the NVRAM.

NOTE: The following products have SP5-849. The new firmware for these products has

not yet been released. However the release notes for each will clearly mention the

new firmware version.

New products: Bellini-C2, Adonis C3

Current products: Martini C1, Model-U C1

3. Schedule for the Counter Modification

The following is the current schedule for when the counter modification will be applied.

Please note that there are some models to which the change will not be applied (marked

as “---“), due to production schedules, production lot quantities and sales figures.

NOTE: The actual cut-in months that have been confirmed appear in the “Cut-in

production month” column below. This RTB will be reissued when these dates

have been confirmed for the remaining products.

(1) New products

Product Name Product

Code

Bellini C2 B070 2003.03 April ’03 production

Adonis C3 B079/82 2003.03 First mass production lot

Model J-P2 G080 2003.03 March ’03 production

Model J-P2 CF G367 2003.03 March ’03 production

Model AR- P1 G081/92 2003.03 March ’03 production

Model K-C1a B120 2003.03 March ’03 production

Target cut-in

production month

Cut-in production month

Page 3

Reissued: 19-Mar-03

T

echnical Bulletin

PAGE: 3/4

Model:

General RTB

Date:

4-Feb-03

No.:

RGene013b

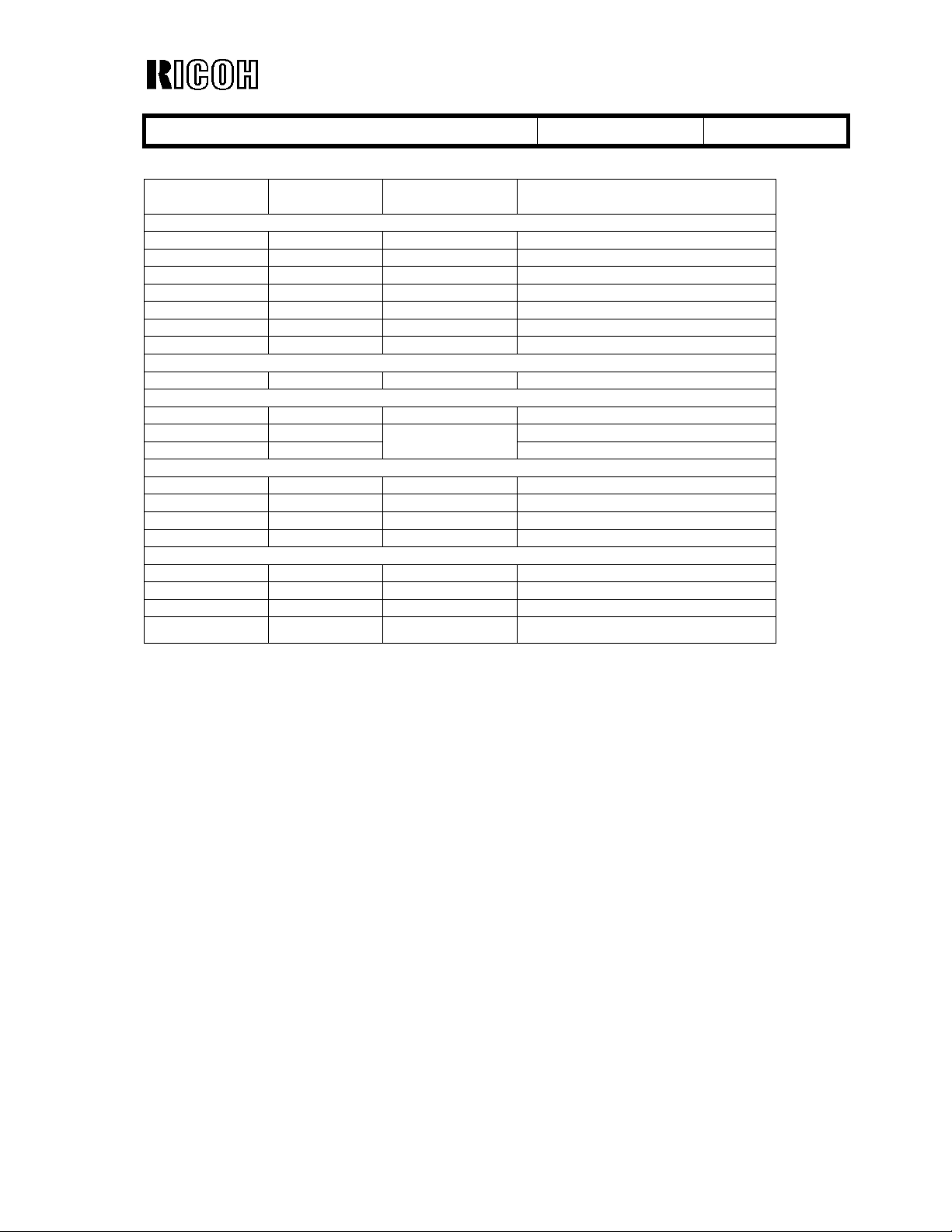

(2) Current products

Product Name Product

Code

Digital B&W Copiers

Bellini C1 A294 --- --Martini C1 B064/65 2003.03 April ’03 production (see Note)

Model M-C2b B098 2003.03 March ’03 production

Adonis C2 B003/04/06/07 --- --Russian C2 B022/27/31 2003.03 February

Model K-C1 B039/40/43 2003.03 March ’03 production

Stella C1 B044/45/46/49 2003.03 March ’03 production

Digital WF Copiers

Dolphin B010 2003.03 March ’03 production

Analog Copiers

All products - --- --J2SS-C3 B047/48 March ’03 production

Whale A174

Color Copiers

Model I2 B018 --- --Model L2 B017 --- --Model C2 B023 2003.02 February

Model U-C1 B051/52 2003.03 April ’03 production

Color Printers

Model J-P1 G060 --- --Model J-P1 CF G570 --- --Model U-P1 G071 2003.03 March ’03 production

Pomelo P3 G063 2003.03 March ’03 production

Target cut-in

production month

(See Note)

Cut-in production month

’03

production

March ’03 production

’03

production

NOTE: The counter change will be applied as a running change to production units only.

For machines already shipped out or in the field, please be sure to take the action

described below in Section 4.

NOTE: For Martini-C1 mainframes assembled in Japan, the counter change will be

applied from the first unit of April ’03 production. For mainframes assembled

at REI, the change will be applied midway through April production. These

cut-in serial numbers will be announced as soon as they have been

confirmed.

NOTE: The change will also be applied to analog models J2SS-C3 and Whale, as

production will continue for a while. However, as these models use only

mechanical counters, the initial value when shipped from the factory will be

1 or 2 (not 0), following the 1 or 2 factory test copies.

Page 4

Reissued: 19-Mar-03

T

echnical Bulletin

PAGE: 4/4

Model:

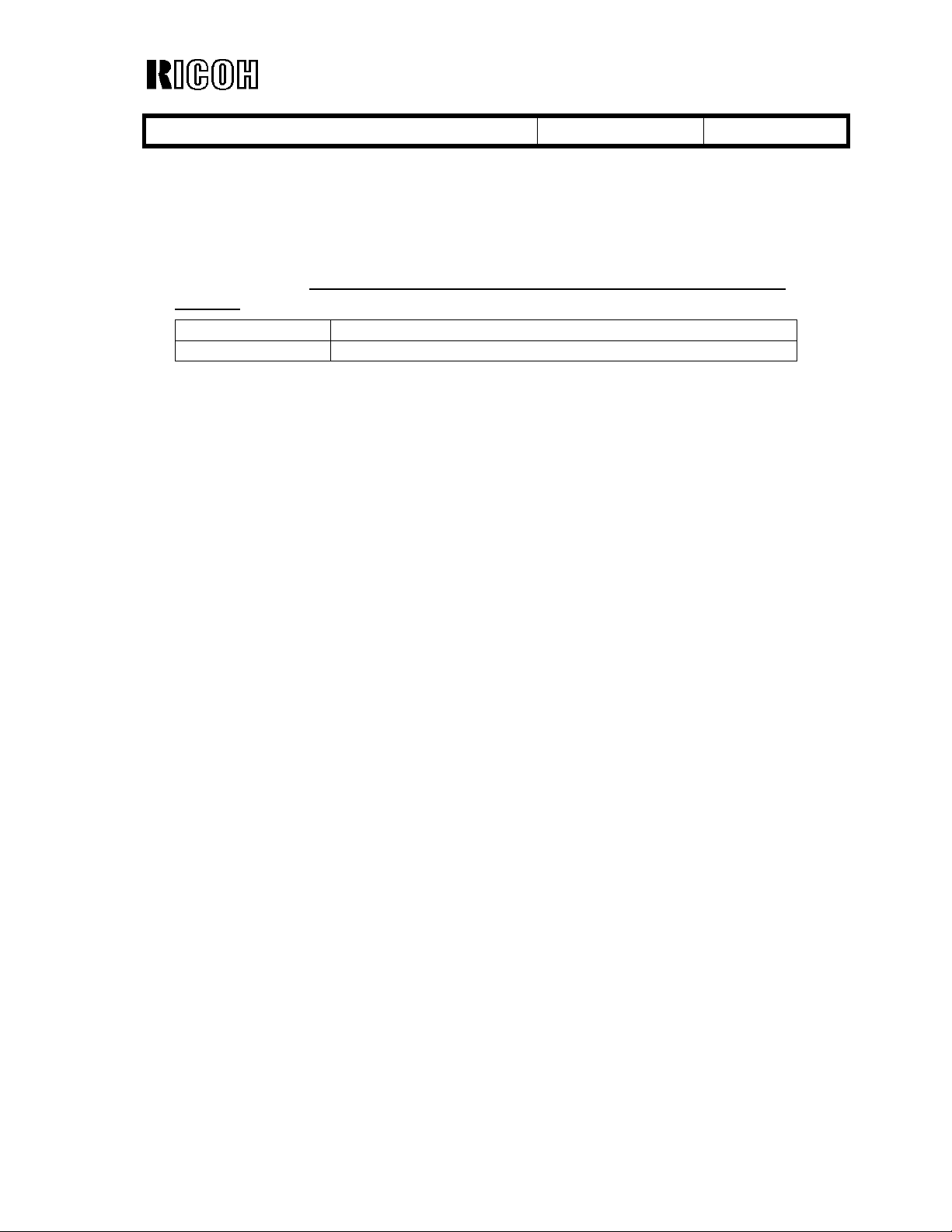

4. Important Notes for Machine Installation – All Products

Please be sure to perform the following at machine installation:

1. If the product is from before the counter modification, i.e. the counter is at a negative

2. If the product is modified, i.e. the counter is already at 0 (or above 0 following pre-

3. After completing the installation, make sure to record the counter value. This is very

General RTB

value, be sure to set the counter value to 0 first, then make the installation test

samples.

Digital products Set the electrical counter to 0 with SP mode.

Analog products Set the mechanical counter to 0 with a reset key (tool).

installation at a service depot), simply make the installation test samples.

important, as this value will be used for billing with Meter Click contracts. Also, inform

the customer of the value along with the reason why the counter does not start from

“0”.

Date:

4-Feb-03

No.:

RGene013b

Page 5

T

echnical Bulletin

PAGE: 1/20

Model:

Subject:

From:

Classification:

Model J-P2

Service Manual Revision

1st Tech. Support Sec. Service Support Dept.

Date:

Prepared by:

Troubleshooting

Mechanical

Paper path

Other ( )

Please apply the following revisions

Service Manuals.

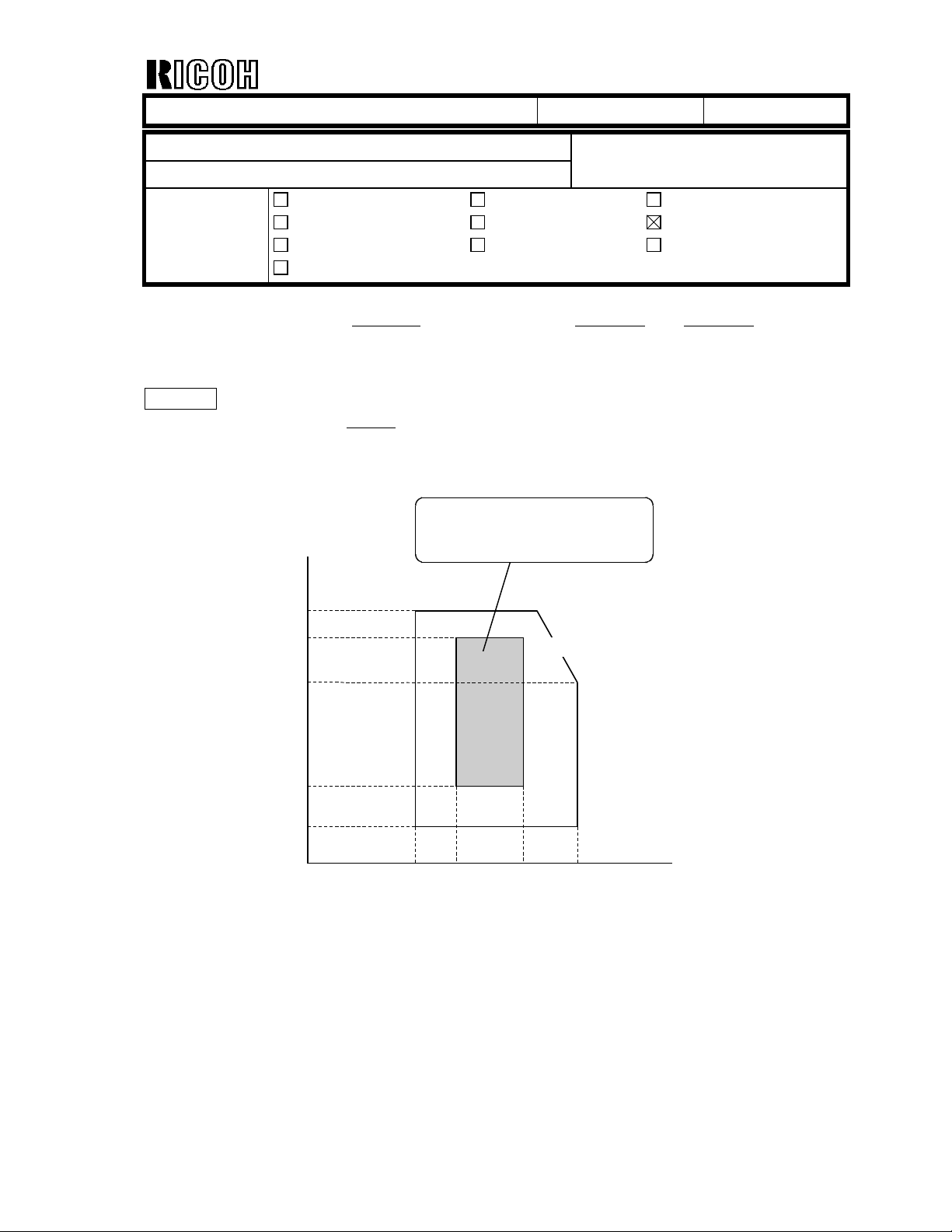

Page 1-1

The following has been added:

10°C 80%

Ambient Humidity (% RH)

15°C 30%

10°C 15%

2-Apr-03

Part information

Electrical

Transmit/receive

bold

in

Recommended Conditions:

, as well as additions and deletions to your

15 to 25 °C

30 to 70 %RH

27°C 80%

25°C 70%

32°C 54%

32°C 15%

No.:

H.Taguchi

Action required

Service manual revision

Retrofit information

RG080001

Ambient Temperature (°C)

Page 6

T

echnical Bulletin

PAGE: 2/20

Model:

Model J-P2

Date:

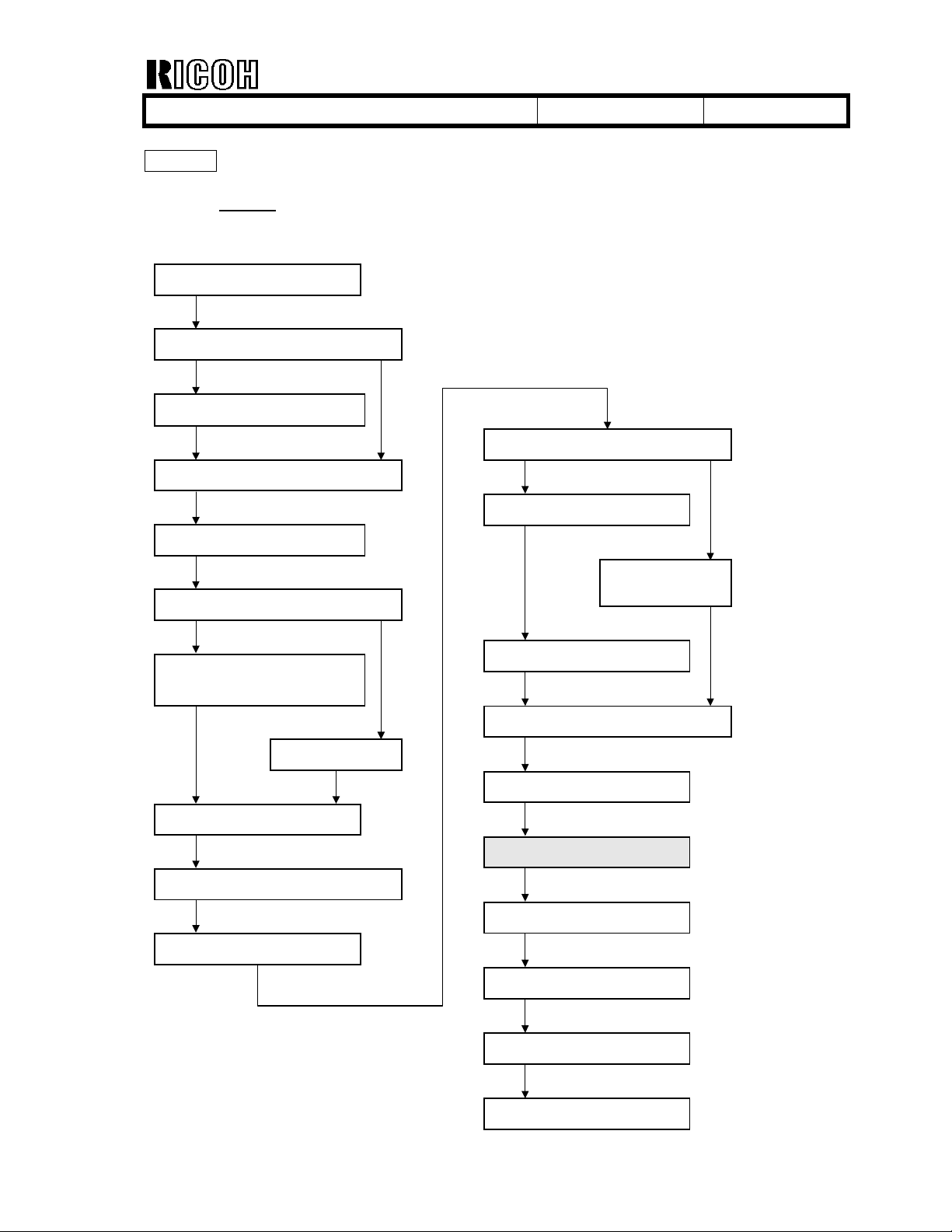

Page 1-7

Contents revised

: The following bold word was deleted from the flowchart illustration.

Clear the memory of IPU/Netfile/Scanner (SP-5-801-10,12) ].

1. Place the printer on the PFU or LCT.

2. Install the PFU or LCT.

Unpack the printer.

Will the paper feed unit (PFU) or LCT be

installed?

Install the controller options (if required).

Install the duplex unit (if required).

Will the two-tray finisher be installed?

Yes

Install the punch unit (if required).

2-Apr-03

No.:

RG080001

No

Will the rack be installed?

Yes

1. Install the printer.

2. Assemble the rack during printer

initialaization

Install the printer

Dock the printer and rack.

Install the CF expander.

Install the platen cover or ARDF.

Install the m ulti-bin

output tray (if required).

No

Install the two-tray finisher.

Select the language.

Set the date and time.

Clear the memory of IPU/Scanner.

(SP5-801-10, 12)

Perform ACC.

Check magnification and registration.

Adjust the operation panel display if

Set the meter charge mode depending

necessary.

on the service contract.

Page 7

T

echnical Bulletin

PAGE: 3/20

Model:

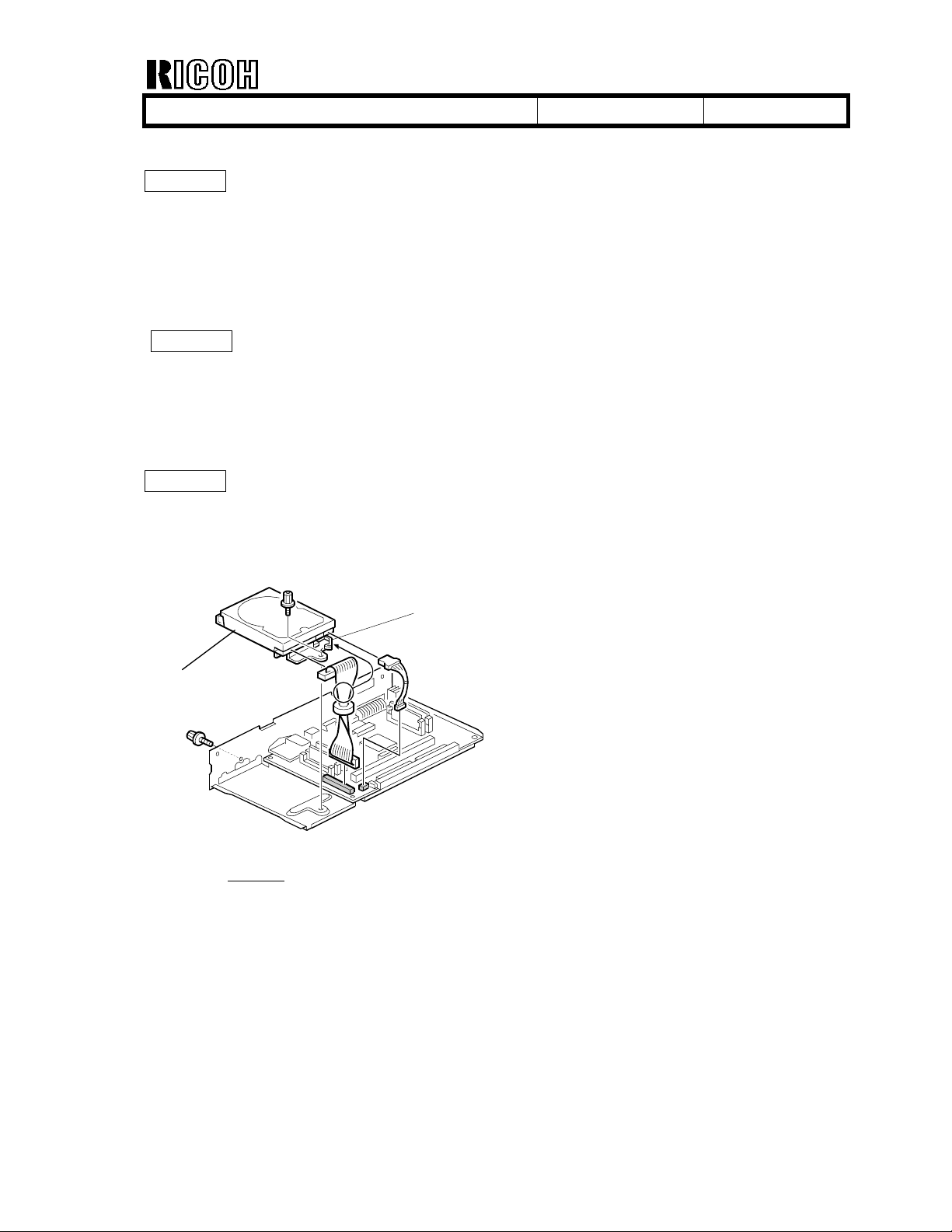

Page 1-24

Page 1-25

Page 1-32

Model J-P2

Accessories Check List

7. DIMM #1 (

8. DIMM #2 (

2. Replace the printer module [A] in the upper slot with DIMM #1 (

3. Insert DIMM #2 (

A harness clamp [C] and harness core have been added, and the harness attachment

has been revised as follows.

Date:

SYSTEM/PRT

SCN

) ......................................................... 1

SCN

) [C] into the center slot.

) .......................................... 1

2-Apr-03

No.:

SYSTEM/PRT

RG080001

) [B].

[C]

[B]

- Step 2 revised

2. Mount the 40GB HDD [B] on the controller (Harness x 2, Screw x 2,

as follows:

Clamp[C] x 1

)

Page 8

T

echnical Bulletin

PAGE: 4/20

Model:

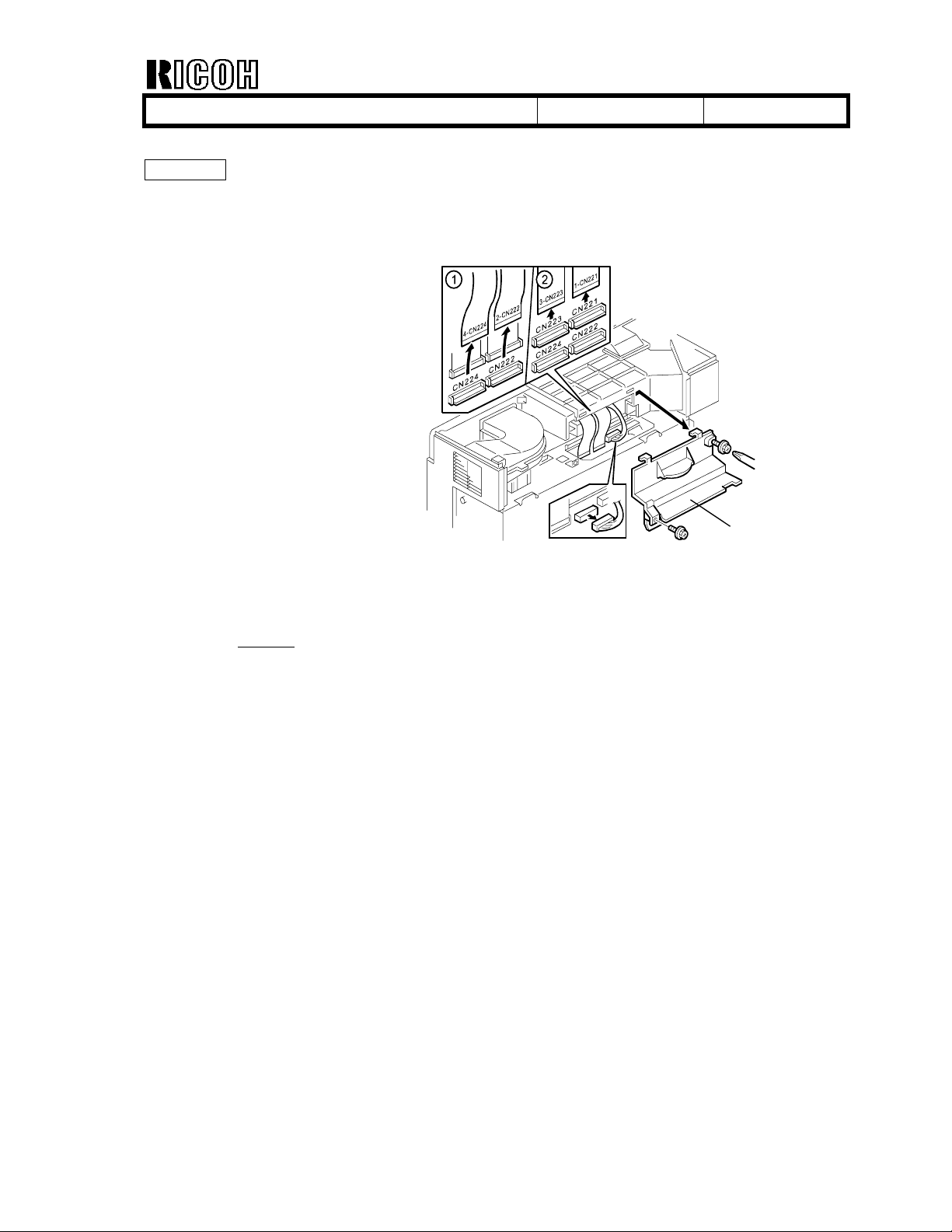

Page 3-10

- A screw has been added and the shape of the connector cover has been changed as

follows.

!!!!!!!!!!!!!!!

!

!

!!!

- Step 12 revised

12. Connector cover [E] (Screw x 2)

!

Model J-P2

Date:

as follows:

!

2-Apr-03

No.:

RG080001

[E]

!

Page 9

T

echnical Bulletin

PAGE: 5/20

Model:

Model J-P2

Date:

2-Apr-03

No.:

RG080001

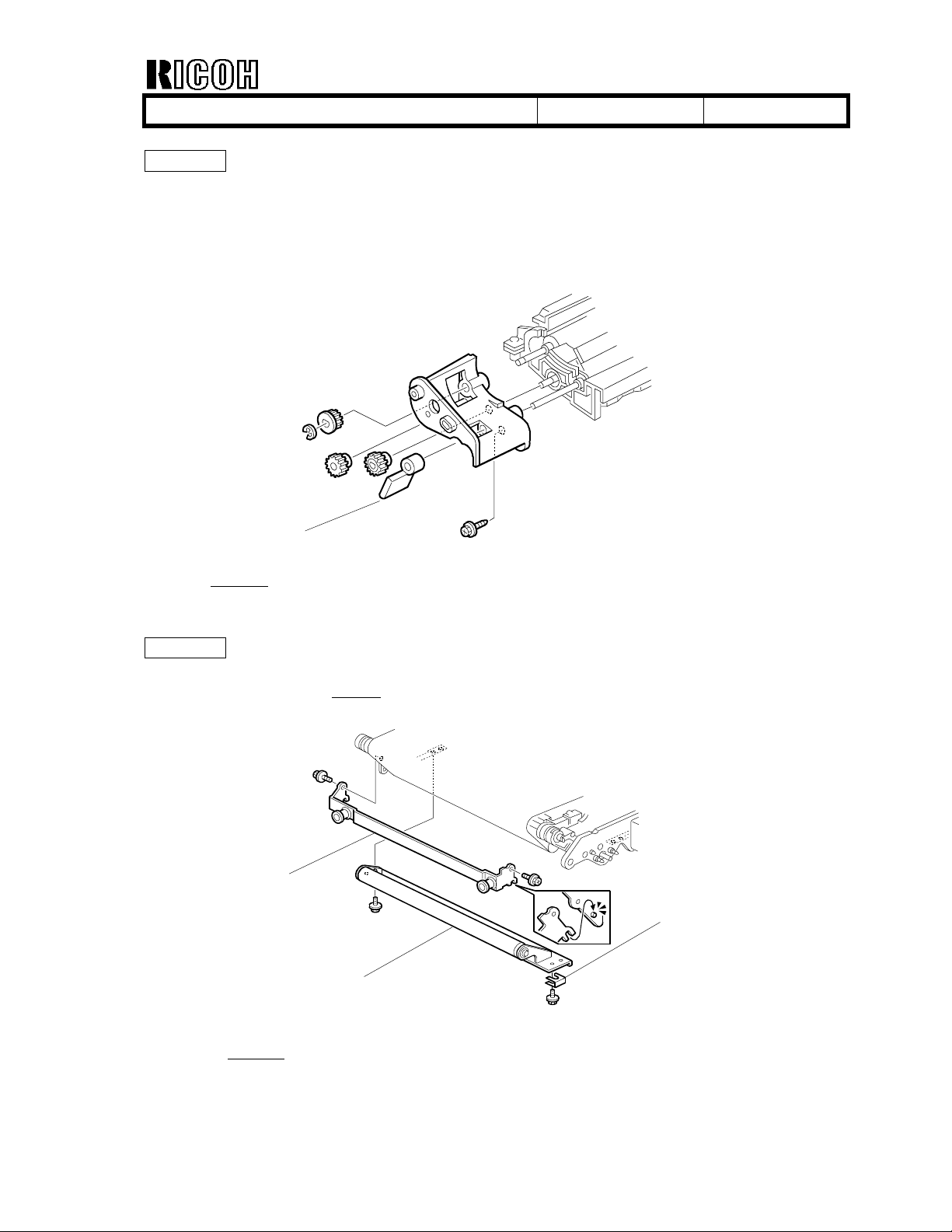

Page 3-23

- The screw which stops the lever has been deleted, and the shape of the lever has been

changed as follows.

Lever

G080R741.WMF

- Step 4 deleted

.

4. Lever [C] (Screw x 1)

Page 3-25

- A spacer [E] has been added

[C]

[D]

- Step 6 revised

as follows.

6. Tension roller [D] (

.

Spacer [E] x 1

[E]

G080R745.WMF

, Screw x 2)

Page 10

T

echnical Bulletin

PAGE: 6/20

Model:

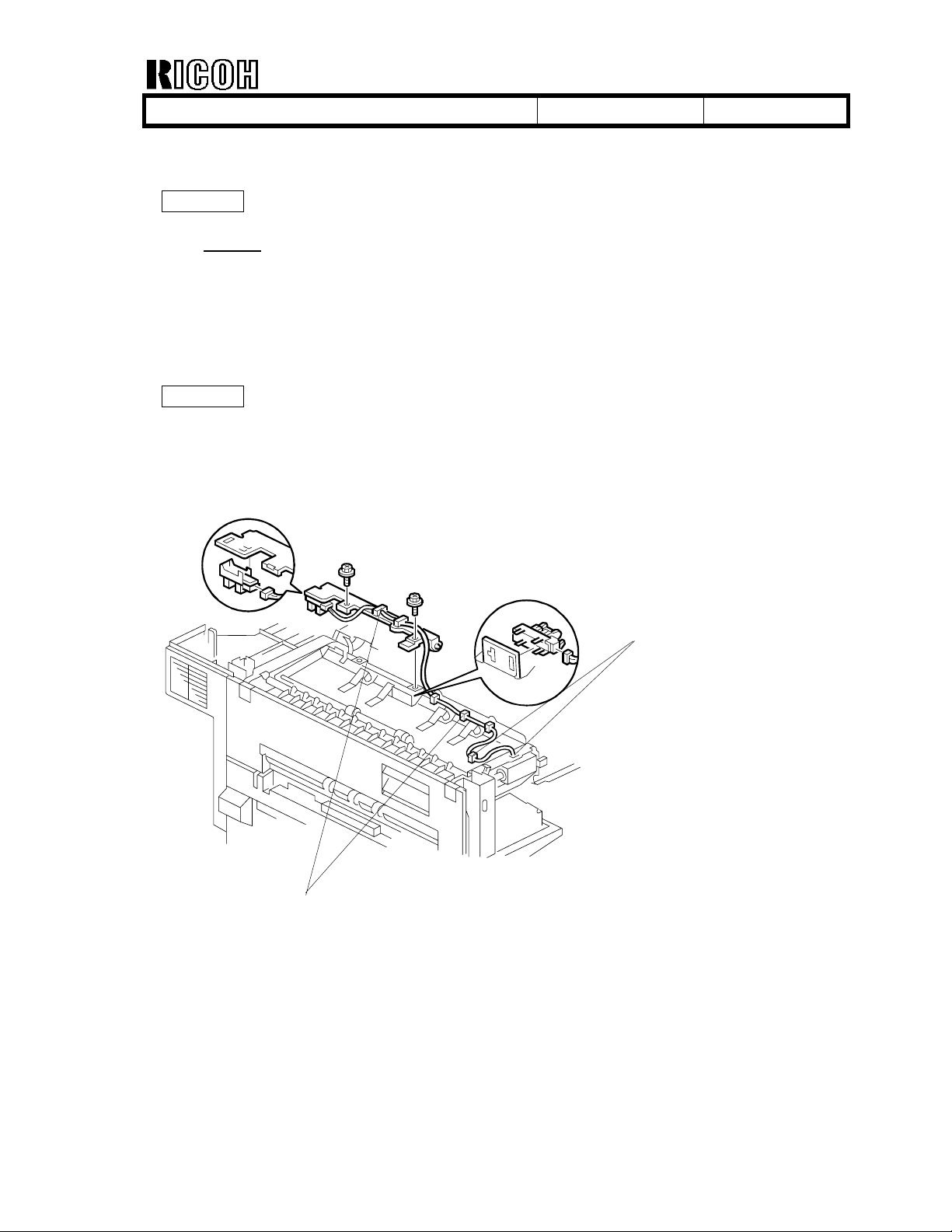

Page 3-26

Note deleted

Page 3-42

Model J-P2

NOTE: 1)

- Four clamps [D] have been added, and the attachment of the harness has been

changed as follows. The clamp at the right-hand end is not visible in the drawing.

Date:

:

If the transfer charge brushes are dirty, clean them with a vacuum

cleaner.

2-Apr-03

No.:

RG080001

[D]

[D]

Page 11

T

echnical Bulletin

PAGE: 7/20

Model:

Page 3-43

- A screw has been added, and the shape of the connector cover has been changed as

follows.

- Step 4 revised.

Model J-P2

Date:

4. Connector cover [E] (Screw x 2)

2-Apr-03

No.:

RG080001

Page 12

T

echnical Bulletin

PAGE: 8/20

Model:

Page 3-45

- A screw has been added and the shape of the connector cover has been changed as

follows.

Model J-P2

Date:

2-Apr-03

No.:

RG080001

- Step 6 revised.

6. Connector cover [E] (Screw x 2)

Page 13

T

echnical Bulletin

PAGE: 9/20

Model:

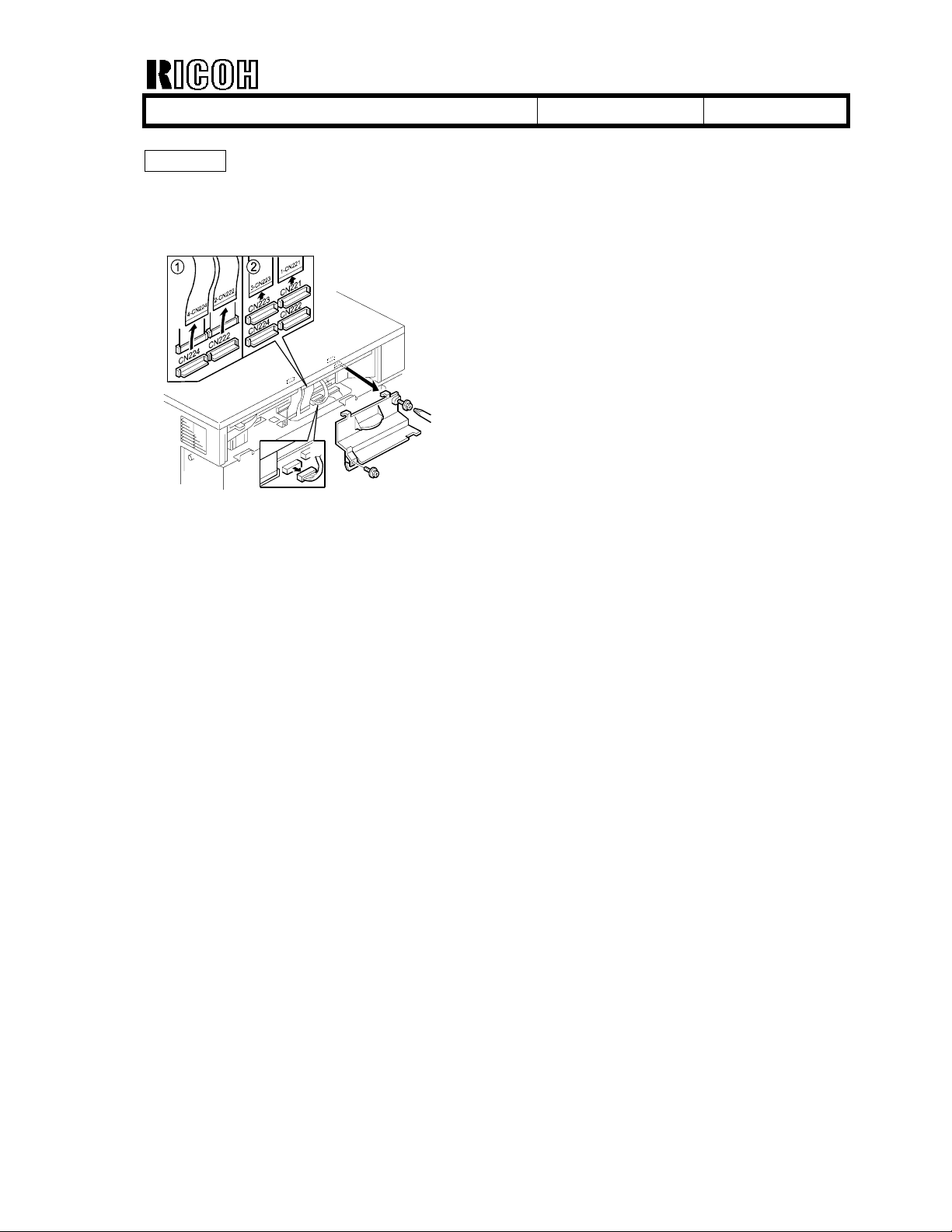

Page 3-50

- A retaining ring [B] has been inserted between the magnetic clutch and the bushing, as

follows.

- Step 3 revised.

Model J-P2

3. Development clutch [A] (Connector x 1, Screw x 1, Retaining ring [B] x 1)

Date:

[B]

2-Apr-03

No.:

RG080001

Page 14

T

echnical Bulletin

PAGE: 10/20

Model:

Model J-P2

Page 4-19

SC

No.

SC

392001

Item Definition

Air

pump

motor

error

392

001:

MY

392

002:

CK

Page 4-24

SC

543

Heating

roller

fusing

lamp

overheat

Page 4-25

SC

Heating

roller fusing

544

lamp high

temperature

error

SC

552

Pressure

roller

warm-up

error

SC

553

Pressure

roller

fusing

lamp

overheat

Date:

Three consecutive

errors are detected

in motor-driversignal samples.

The samples are

collected every

0.01 second.

The detected fusing

temperature stays at

210

°C or more for

five seconds.

During stand-by

mode or a print job,

the detected heating

roller temperature

stays at 210 °C or

more for

After the main switch

is turned on or the

door is closed, the

pressure roller

temperature does not

reach the ready

temperature within

180 seconds during

fusing unit warm-up.

The detected

pressure roller

temperature stays at

210

five seconds.

0.2

second.

°C or more for

Possible

Cause

•

Damaged

cable

•

Short circuit

•

Defective

motor

• Defective PSU

• Defective

BCU

•

• Defective

• Defective

• Pressure roller

fusing lamp

broken

•

Defective

pressure roller

thermistor

• Defective

BCU

•

Defective PSU

•

Defective

BCU

Defective

heating roller

thermistor

PSU

BCU

Related

SCs

1. Turn the main switch off and

2-Apr-03

Troubleshooting Procedure Type

on.

2. Replace the air pump.

3. Check the circuit.

1. Replace the PSU.

1. Replace the fusing unit.

1. Check if the pressure

1. Replace the fusing unit.

No.:

2. Replace the BCU.

2. Replace the PSU.

3. Replace the BCU.

roller thermistor is firmly

connected.

2. Replace the fusing unit.

3. Replace the BCU.

2. Replace the PSU.

3. Replace the BCU.

RG080001

A

A

A

A

Page 15

T

echnical Bulletin

PAGE: 11/20

Model:

Model J-P2

Date:

Page 4-26

SC Code deleted

:

SC

554

Pressure

roller fusing

lamp low

temperature

error

During stand-by

mode or printing, the

detected pressure

roller temperature

stays at 50°C or less

for five seconds.

Page 4-27

SC

BCU Controller

640

communication

error (check

sum error)

Page 4-30

SC description added

SC

GAPCI I2C

communication

692

error

The check sum of

the interface

between the BCU

and controller is not

the same.

:

• The I2C bus

device ID is not

identified during

initialization.

•

A device-status

error occurs

during I2C bus

communication.

• The I2C bus

communication is

not established

due to an error

other than a buffer

shortage.

•

Loose

connection

between the

fusing unit

and the

machine

• Defective

pressure roller

thermistor

• Defective

PSU

•

Defective

BCU

• Defective

controller

•

Defective

BCU

• Loose

connection

• Defective

BCU

• Defective LD

controller

board

2-Apr-03

1. Check the connection

1. Turn the main switch off

1. Turn the main switch off

No.:

between the fusing unit

and main frame.

2. Replace the fusing unit.

3. Replace the PSU.

4. Replace the BCU.

and on.

2. Replace the controller.

3. Replace the BCU.

and on.

2. Check the cable

connection.

3. Replace the BCU.

RG080001

A

CTL

A

Page 16

T

echnical Bulletin

PAGE: 12/20

Model:

Model J-P2

Date:

Page 4-34

SC descriptions added

SC

800

SC

801

SC

802

SC

803

Startup

without

video

output end

error (K)

Startup

without

video

output end

error (Y)

Startup

without

video

output end

error (M)

Startup

without

video

output end

error (C)

Video transfer to the

engine is started, but

the engine did not

issue a video

transmission end

command within the

specified time.

Video transfer to the

engine is started, but

the engine did not

issue a video

transmission end

command within the

specified time.

Video transfer to the

engine is started, but

the engine did not

issue a video

transmission end

command within the

specified time.

Video transfer to the

engine is started, but

the engine did not

issue a video

transmission end

command within the

specified time.

Page 4-37

Contents revised:

SC

827

[0201]

Verification

error

Self-diagnostic error: Standard

Error detected during

a write/verify check

for the standard RAM

SDRAM

(

:

DIMM).

•

Defective

BCU

•

Defective

BCU

• Defective

BCU

•

Defective

BCU

SDRAM

• Loose

connection

• Defective

SDRAM

DIMM

•

Defective

controller

2-Apr-03

1. Turn the main switch off

1. Turn the main switch off

1. Turn the main switch off

1. Turn the main switch off

DIMM [XXXX]: Detailed error code

1. Turn the main switch off

No.:

and on.

2. Check the cable

connection.

3. Replace the BCU.

and on.

2. Check the cable

connection.

3. Replace the BCU.

and on.

2. Check the cable

connection.

3. Replace the BCU.

and on.

2. Check the cable

connection.

3. Replace the BCU.

and on.

2. Replace the

DIMM.

3. Replace the controller.

RG080001

SDRAM

CTL

CTL

CTL

CTL

CTL

Page 17

T

echnical Bulletin

PAGE: 13/20

Model:

Model J-P2

Date:

Page 4-39

SC

857

USB

interface

error

The USB interface

cannot be used due

to a driver error.

Page 4-40

SC description added:

SC

991

Software

continuity

error

The software attempted to perform

an unexpected operation.

However, unlike SC990, the cause

of the error is continuity of the

software.

•

Defective USB

driver

• Loose

connection

2-Apr-03

1. Check the connection.

No.:

2. Replace the USB board.

RG080001

• Software error

• Internal

parameter

incorrect,

insufficient

working memory.

This SC is not

displayed on the

LCD (log only).

CTL

Page 18

T

echnical Bulletin

PAGE: 14/20

Model:

Model J-P2

Page 5-14

Contents revised:

1

[

Fusing Cont.] Fusing Control

104

1 Control Method *BCU Selects the fusing control method.

25 Process Speed *BCU Selects the power-on default target fusing

(Class 1, 2, and 3)

Date:

2-Apr-03

No.:

RG080001

Mode No.

[ 0 or 1 / 0

0: ON/OFF Control

1: Phase Control

NOTE: This mode can be used only for N.

America models.

operation temperature.

The target operating fusing temperature depends

on the process speed. When the machine is

switched on, it starts warming up for the process

speed specified in this SP mode.

[0 to 4 / 4

0: Color 62.5 mm/s (temperature specified by SP

1-105-8 and 19)

1: Color 125 mm/s (temperature specified by SP

1-105-9 and 20)

2: Thick / OHP (temperature specified by SP 1105-13 and 24)

3: K 125 mm/s (temperature specified by SP 1105-4 and 15)

4: K 185 mm/s (temperature specified by SP 1105-5 and 16)

Function / [ Setting ]

/ - ] Alphanumeric

/ 1/step] Alphanumeric

Page 19

T

echnical Bulletin

PAGE: 15/20

Model:

Model J-P2

Page 5-15

1

[Fusing Temp.] Fusing Temperature

105

(Heating or Pressure roller: Paper Type, [Color], Simplex/Duplex, Process Speed)

Paper Type -> N: Normal, OHP. TH: Thick, SP: Special

Some settings of fusing temperature depend on the destination (US or Europe/Asia).

US: Setting for US, EU: Setting for Europe/Asia

1 H: Ready *BCU Sets the heating roller temperature for the printing

2 P: Ready *BCU Sets the pressure roller temperature for the

The following SPs set the target operating temperatures of the heating and pressure

rollers in various modes. (The default settings are different for N. America and Eur./Asia)

4 H:N [K] S 125 *BCU

5 H:N [K] S 185 *BCU

6 H:N [K] D 125 *BCU

7 H:N [K] D 185 *BCU

8 H:N[FC] S 62.5 *BCU

9 H:N[FC] S 125 *BCU

10 H:N[FC] D 62.5 *BCU

11 H:N[FC] D 125 *BCU

1 3 H :O H P *BCU

15 P:N [K] S 125 *BCU

16 P:N [K] S 185 *BCU

17 P:N [K] D 125 *BCU

18 P:N [K] D 185 *BCU

19 P:N[FC] S 62.5 *BCU

20 P:N[FC] S 125 *BCU

21 P:N[FC] D 62.5 *BCU

22 P:N[FC] D 125 *BCU

2 4 P :O H P *BCU

2 6 H :T H *BCU

Date:

Mode No.

(Class 1, 2, and 3)

ready condition.

After the main switch has been turned on, the

machine enters the print ready condition when the

heating roller temperature reaches the

temperature specified in this SP mode.

When the machine is in the recovery mode from

the energy saver or auto off mode, the machine

becomes ready when both heating and pressure

roller temperatures reach the specified

temperature.

Ready temperature = (Target temperature

specified in SP1-104-25 or 105-3 to 28) –

Temperature specified in this SP mode.

[ 10 to 100 / 10

printing ready condition.

Ready temperature = (Target temperature

specified in SP1-104-25 or 105-3 to 28) –

Temperature specified in this SP mode

[ 10 to 100 / NA: 10

[ 100 to 190 / NA:

/

[ 100 to 190 /

[ 100 to 190 /

[ 100 to 190 /

[ 100 to 190 / NA: 150

[ 100 to 190 / 180

[ 100 to 190 / NA:

[ 100 to 190 / NA:

[ 100 to 190 / 165

[ 0 to 190 / NA: 160

[ 0 to 190 / NA:

[ 0 to 190 / NA: 135

[ 0 to 190 / NA: 145, EU: 155 / 5°C/step]

[ 0 to 190 / NA: 125

[ 0 to 190 / 160

[ 0 to 190 / NA: 120, EU: 125 / 5°C/step]

[ 0 to 190 / NA: 135

[ 0 to 190 / 150 / 5°C/step]

[ 0 to 190 / 175

NA: 165

NA: 175

2-Apr-03

Function / [ Setting ]

/ 1oC/step ]

, EU: 20 / 1oC/step ]

180

, EU: 175 / 5°C/step]

NA: 185, EU: 180

, EU: 165 / 5°C/step]

, EU: 175

, EU: 150 / 5°C/step]

/ 5°C/step]

145

, EU: 145/ 5°C/step]

165

, EU: 170 / 5°C/step]

/ 5°C/step]

, EU: 155 / 5°C/step]

155

, EU: 160 / 5°C/step]

, EU: 145 / 5°C/step]

, EU: 130 / 5°C/step]

/ 5°C/step]

, EU: 150 / 5°C/step]

/ 5°C/step]

No.:

/ 5°C/step]

RG080001

/ 5°C/step]

Page 20

T

echnical Bulletin

PAGE: 16/20

Model:

Model J-P2

Date:

2-Apr-03

No.:

Page 5-32

3

107 4 LED Current C *BCU Displays the ID sensor LED current adjusted

Mode No.

(Class 1, 2, and 3)

Function / [ Setting ]

during Vsg adjustment.

1023

[ 0 to

/ - / 1 ]

Page 5-33

3

6 LED Current R *BCU Displays the ID sensor LED current adjusted

107

7 Vsg avg bk *BCU Displays the average black Vsg value of the

Mode No.

(Class 1, 2, and 3)

Function / [ Setting ]

during Vsg adjustment.

1023

[ 0 to

center ID sensor.

[ 0.00 to 5.00 / - / 0.01V/step ]

/ - / 1 ]

Page 5-46

Contents revised

:

5

[

Simplex Back Sheet Setting]

118

1 Simple Back Sheet

Setting

Mode No.

(Class 1, 2, and 3)

Function / [ Setting ]

*CTL Enables or disables all machine functions.

[ 0 or 1 / 0

0: Enabled

1: Disabled

/ - ] DFU

RG080001

Page 21

T

echnical Bulletin

PAGE: 17/20

Model:

Model J-P2

Date:

2-Apr-03

No.:

RG080001

Page 5-97

Contents revised

:

Type of firmware Function

Printer Engine

Printer Controller

1. Main Printer engine control 1 card

2. MUSIC Line position adjustment 1 card

3. DSP Line position adjustment 1 card

4. System System firmware 1 card

5. Printer Printer Application

firmware

6. NIB

NIB firmware 1 card

Number of IC cards

required

1 card

Page 5-99

Contents revised

:

Type of firmware Function

* Engine - Main Printer engine control BCU Flash ROM Engine (1)

* Engine - Music Line position adjustment BCU MUSIC CPU Music (1)

* Engine - DSP Line position adjustment BCU DSP CPU DSP (1)

•

System

• Netfile Application

Copier Application Feature application DIMM 1 Rescue & Copy (1)

Printer Application Feature application DIMM 1 Onboard Printer (1)

Scanner Application Feature application DIMM 2 Onboard Scn (1)

Fax Application Feature application DIMM 2 Opt DIMM Fax (1)

NIB (see Notes)

Scanner IPU Scanner control IPU Flash ROM Scanner IPU (1)

Operation Panel Panel control Operation Panel Ope Panel. XX (1)

Fax FCU Fax control FCU Jupi FCU (XXX)-1 (1)

Language

(16 languages)

2 different firmware (system

and Netfile applications) is

combined.

Network Interface DIMM 2 Network Support (1)

Language firmware

Two languages can be

selected from 16

languages.

Location of

firmware

DIMM 1

Operation Panel

Message displayed

Onboard System (1)

Netfile DocBox (2)

LANG.1 (1)

LANG.2 (2)

Note: The NIB used in the CF is different from the one used in the printer.

Page 22

T

echnical Bulletin

PAGE: 18/20

Model:

Model J-P2

Page 6-42

- Illustration revised

1.Doctor blade

Date:

2-Apr-03

No.:

RG080001

to show correct parts:

1

2

3

6

Page 6-67

Contents revised

:

Mode Resolution (dpi)

Energy saver

level 1

Standby mode

Color

Black and white

OHP All

Thick All

1200 x 1200

1200 x 600

600 x 600

1200 x 1200

1200 x 600

600 x 600

Temperature of

Heating Roller

100°C 130°C

NA: 175

EU: 170

150°C

180°°°°C 160°°°°C

NA: 180°°°°C

EU: 175

NA: 185°°°°C

EU: 180°°°°C

165°C 150°C

175°C 155°C

5

°°°°

°°°°

°°°°

C

C

C

4

Temperature of

Pressure Roller

NA: 145

EU: 140

NA: 125°C

EU: 130°C

NA: 160°°°°C

EU: 155

NA: 155°°°°C

EU: 160°°°°C

C

°°°°

C

°°°°

C

°°°°

G080D953.WMF

Note

If SP1-104025 is set to 4

Page 23

T

echnical Bulletin

PAGE: 19/20

Model:

Color

(duplex)

Black and white

(duplex)

Model J-P2

Date:

1200 x 1200

1200 x 600

600 x 600

1200 x 1200

1200 x 600

600 x 600

145°C

NA: 165°C

EU: 170°C

165°C

175°C

2-Apr-03

NA: 120°C

EU: 125°C

NA: 135°C

EU: 150°C

NA: 135°C

EU: 145°C

NA: 145°C

EU: 155°C

No.:

RG080001

Page 6-68

Overheat Protection

If the heating or pressure roller temperature becomes higher than

210

°C, the CPU cuts

off the power to the fusing lamp. SC543 for the heating roller or SC553 for the pressure

roller is generated.

Page 6-89

Partition 40GB HDD 20GB HDD Function Comment

Image Local

Storage

File System 1 500 MB 500 MB

File System 2 1,000 MB 1,000 MB Job spooling area Erased after power off.

File System 3 2,000 MB 2,000 MB Work data area

Image TMP

Job Log 10 MB 10 MB Job log

17,700 MB --- Document server

Downloaded fonts,

forms.

7,486 MB 7,486 MB

7,200 MB --- Copier application Erased after power off.

3,440 MB 3,440 MB Printer application Erased after power off.

1,000 MB

1000MB

Commonly used area

for applications

Scanner application Erased after power off.

Remains stored even

after cycling power

off/on.

Remains stored even

after cycling power

off/on.

Remains stored even

after cycling power

off/on.

Erased after power off.

Remains stored even

after cycling power

off/on.

Page 6-103

Item in bold deleted:

Data rates: 480 Mbps (high speed), 12 Mbps (full speed), 1.5 Mbps (low speed);

High-speed mode is only supported by USB 2.0.

Page 24

T

echnical Bulletin

PAGE: 20/20

Model:

Model J-P2

Date:

SPEC-2

Contents revised:

Maximum 1200 W or less

Energy Saver

120V

1500 W or less

15 W or less 15 W or less

SPEC-7

Internal Options

IEEE802.11b

USB2.0 B525 L

G628 K

SPEC-12

Power source:

System:

120 V, 60 Hz: 12 A (for North America)

220 - 240 V, 50/60 Hz:

6A+1A

Scanner:

120 V, 60 Hz: 2 A (for North America)

220 - 240 V, 50/60 Hz: 1.1 A (for Europe/Asia)

Maximum power

System: 1,440 W or less

2-Apr-03

220~240V

(for Europe/Asia)

(NA)

No.:

RG080001

1,500W+120W or less (EU)

Page 25

T

echnical Bulletin

PAGE: 1/3

Model:

Subject:

From:

Classification:

Model J-P2

Wrong resolution printing with PS3 driver

1st Tech. Support Sec. Service Support Dept.

Date:

Troubleshooting

Mechanical

Paper path

Other ( )

24-Apr-03

Prepared by:

No.:

H. Someya

RG080002

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

SYMPTOM

Jobs specified in the PS driver as 600dpi Fast (600x600dpi, 1 bit), or 1200dpi

(1200x1200dpi, 1 bit) are printed out at the wrong resolution when:

1) Printing from a PS driver, except those for Win9x/Me, and

2) The mainframe PS menu resolution is set to "600dpi Std" (default).

The following are the test results with various combinations of resolution settings from the

PS driver and mainframe PS menu:

Resolution setting in PS

driver:

600dpi Fast

(600x600dpi 1 bit)

600dpi Fast: Default

(600x600dpi, 1 bit)

600dpi Std

(600x600dpi, 2 bit)

1200dpi

(1200x1200dpi, 1 bit)

None specified

(driver not used)

600x600dpi

1200x600dpi 1200x600dpi 1200x600dpi

1200x1200dpi 600x600dpi

600x600dpi 1200x600dpi 1200x1200dpi

Resolution setting in mainframe PS menu:

600dpi Std: Default

(600x600dpi 2 bit)

1200x600dpi

NG

NG

(1200x1200dpi 1 bit)

1200dpi

600x600dpi

1200x1200dpi

CAUSE

The commands for resolution and grayscale (number of bits) are sent by the PS driver and

received by the machine. However, when the machine is set for 2-bit grayscale, it is not

overwritten by the 1-bit grayscale setting from the driver (normally the driver is given

precedence).

Note:

This does not occur with Win9x/Me drivers since the grayscale bit setting is

specified with PJL commands.

Page 26

T

echnical Bulletin

PAGE: 2/3

Model:

Model J-P2

Date:

24-Apr-03

No.:

RG080002

Affected firmware versions:

J-P2: Printer 1.09 (used from 1st production)

J-P2CF: Printer 1.09 (used from 1st production)

Affected S/N:

See the S/N table below.

SOLUTION

Production

1) Modify the Printer firmware (scheduled to be applied from the end of March ‘03).

2) Modify all PS drivers except those for Win9x/Me (schedule TBA).

Note:

Although from a technical standpoint only one of the above is necessary to fix the

symptom, both will be applied in order to perform the action in the field described

below.

Action in the field

Please take the following action for all machines within the S/N range listed below.

1. For machines installed by service technicians, please do one of the following at

installation:

1) Change the PS Menu resolution setting (UP mode) to "

2) Update the printer firmware to v1.12 or later.

2. For user-installed machines, please advise any customers reporting the symptom to

do one of the following:

1) Change the PS menu resolution setting (UP mode) to "

2) Install one of the modified PS drivers accessible on the Web.

Web release schedule for modified PS drivers:

Without MS logo: Already released

With MS logo: May 2, 2003

600dpi Fast

600dpi Fast

", or

,” or

Page 27

T

echnical Bulletin

PAGE: 3/3

Model:

Model J-P2

Date:

24-Apr-03

No.:

RG080002

Affected serial number table:

Model Code Serial Number

G080-22 P9630201479 – 1537, 1539 – 1558, 1560 – 1688, 1690 – 1718, 1720 – 1745, 2473 –

2594,

P9630301111 – 1138, 1140 – 1174, 1176 – 1202, 1204 – 1268, 1270 – 1283, 1285

G080-24 L1403020002 – 0007, 0009 – 0032, 0034 – 0037, 0039 – 0100

G080-26 8Q40230001 – 0003, 0005 – 0048, 0050 – 0073, 0075 – 0078, 0080 - 0100

G080-27 P9630100042 – 000048, 0050 – 0054, 0056 – 0060, 0062 – 0080,

P9630201746 – 1755, 1757 – 1766, 1768 – 1793, 1795 – 1808, 1810 – 1867, 1870–

1940, 1942 – 2081, 2083 – 2105, 2107 – 2141, 2143 – 2187, 2189 – 2212, 2214 –

2216, 2218 – 2249, 2251 – 2262, 2264 - 2265, 2267 – 2285, 2287 – 2311, 2313 –

2365,

P9630301531, 1533 – 1534, 1536 – 1539, 1541, 1543 – 1546, 1549, 1551 – 1555,

1557 – 1563, 1566, 1569, 1572, 1575, 1577, 1581 – 1582, 1587, 1597 – 1598, 1601,

1606 – 1607, 1610, 1613, 1615, 1619 – 1636, 1638 – 1655, 1657 – 1674, 1676 – 1685,

1687 – 1691, 1693 – 1719, 1721 – 1739, 1741 – 1742, 1744 – 1751, 1754, 1756 –

1761, 1764, 1766 – 1769, 1771 – 1775, 1777, 1779 – 1782, 1784 – 1793, 1795 – 1801,

1804 – 1807, 1809 – 1820, 1823 – 1825, 1827, 1829, 1831 – 1832, 1834, 1836 – 1838,

1840, 1844 – 1845, 1847, 1852, 1855, 1861, 1872 – 1873, 1877, 1885, 1904, 1906,

1920, 1924

G080-29 P9630202366 – 2384, 2386 – 2412, 2414 – 2422, 2424, 2426 – 2427, 2429 – 2433,

2435 – 2445, 2447 – 2455, 2457 – 2467, 2469 - 2471

G367-26 8Q50230001 – 0040

8Q50330001 – 0050

G367-27 P9830100021, 0023 – 0040,

P9830200796 – 0903,0905 – 1230, 1280 – 1324,

P9830300881 – 0918, 0920 – 1045, 1047 - 1070

G367-29 P9830201231 – 1279,

P9830301470, 1473 - 1482

Page 28

T

echnical Bulletin

PAGE: 1/4

Model:

Subject:

From:

Classification:

Model J-P2

Firmware Modification

1st Tech. Support Sec. Service Support Dept.

Date:

Prepared by:

Troubleshooting

Mechanical

Paper path

Other ( )

25-Apr-03

Part information

Electrical

Transmit/receive

No.:

H.Someya

Action required

Service manual revision

Retrofit information

RG080003

Firmware modification history for the Model J-P2 (details begin on page 2).

Engine Controller

Firmware

Type

Remarks

Main MUSIC DSP Printer

System

Application

Printer

Printer NIB

Note:

The Engine Main, Music and DSP firmware are used for both the G080 printer and

the G080/G367 CF Expander.

RTB Revision List

Issue Date Control Symbol Revised contents

25-Apr-03 - First edition

Page 29

T

echnical Bulletin

PAGE: 2/4

Model:

Model J-P2 Date: 25-Apr-03 No.: RG080003

[ Modification History ]

1. Engine Main Firmware

P/N Version Check

Sum

G0805601D 1.03 --- Firmware installed from the first mass production run. January, 03

G0805601E 1.04 DEDF The following have been fixed.

• SC544. Fusing control changed so that the machine rotates the fusing belt if the fusing

temperature is 200°C or greater when the main power is turned on or the machine recovers

from Energy Saver Mode (stopping when the temperature cools to 190°C).

•

SC552 (detection time lengthened from 150s to 180s).

G0805601F 1.05 FA42

G0805601G 1.06 40B9 The following have been fixed.

• Key card interface supported as a customized request. To activate this function, it is necessary

to use CF system firmware

•

The following have been fixed.

! Default settings for transfer bias changed to fix fireflies in black solid image areas on

OHP sheets under high-temperature and humidity conditions.

! Main scan color shift caused by electromagnetic noise.

• "Copying" displayed for about 30 seconds before copying begins.

• Color drum lock at first color print following a 3-hour interval when energy saver is disabled.

• Paper jam following jam recovery if the duplex copy output tray is set to the Finisher.

• Copying is halted if the number of copies on the key card reaches 0 or the key card is pulled

out during duplex copying and finisher output selected with SP5-113 is set to 12 (Exp. Key

Card: Deduct). After a new key card is inserted, a jam occurs at the finisher.

Contents of Modification Cut-in Month

February, 03

April, 03

v1.12

or newer.

April 14, 03

NOTE: Machines containing v1.03 have been reworked locally.

Page 30

T

echnical Bulletin

PAGE: 3/4

Model:

Model J-P2 Date: 25-Apr-03 No.: RG080003

2. Engine MUSIC

P/N Version Check

Sum

G0805611B M1.01 4EBC Firmware installed from the first mass production run. January, 03

Contents of Modification Cut-in Month

3. Engine DSP

P/N Version Check

Sum

G0805621B 1.01 8DFE Firmware installed from the first mass production run. January, 03

Contents of Modification Cut-in Month

4. Printer System Firmware

P/N Version Check

Sum

G0805910B 1.09 --- Firmware installed from the first mass production run. January, 03

G0805910C 1.11 7B3D The Wireless LAN does not function if using 802.11adhoc mode when network traffic is low. February, 03

G0805910D 1.12 99B9 The Printer function is now displayed on the configuration page.

Contents of Modification Cut-in Month

April, 03

NOTE: Machines containing v1.09 have been reworked locally.

Page 31

T

echnical Bulletin

PAGE: 4/4

Model:

Model J-P2 Date: 25-Apr-03 No.: RG080003

5. Printer Application Firmware

P/N Version Check

Sum

G0805911B 1.09 --- Firmware installed from the first mass production run. January, 03

G0805911C 1.12 4754 The following have been fixed.

- Barcodes appear separated (shifted) when printed out (GFPR#RE03010016).

- Downloaded PCL Barcode fonts are not printed correctly on the PCL font list

(GFPR#RC03010004).

- PS error occurs when unknown media type is specified (GFPR# RE03010003).

- Selecting HDD font or DIMM font may reduce available memory.

- Supports SAP Barcode & OCR printing.

Other changes:

- The default for the mainframe PS Menu resolution setting has been changed to “600dpi Fast”,

because the resolution setting in the PS driver is not recognized when the mainframe setting is

600dpi Std.

NOTE:

When updating the Printer Application Firmware, please also update the Printer System Firmware to the same version.

Contents of Modification Cut-in Month

April, 03

4. NIB Firmware

P/N Version Check

Sum

G0805920C 3.0.1 1CC3 Firmware installed from the first mass production run. January, 03

Contents of Modification Cut-in Month

Page 32

Reissued: 9-May-03

T

echnical Bulletin

PAGE: 1/3

Model:

Model J-P2

Date:

2-May-03

No.:

RG080004a

RTB Reissue

The items in bold italics have been corrected.

Subject:

From:

Noise from paper transfer section

1st Tech. Support Sec. Service Support Dept.

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Prepared by:

H.Someya

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

SYMPTOM

Noise from the paper transfer-cleaning unit.

CAUSE

The edge of the cleaning unit [C] bends slightly during operation, causing the gap between

it and the left lower driver roller [B] (#G0803945, P/C 41-7) to narrow and the unit to

contact the roller.

[B]

[A]

[C]

SOLUTION

Action required in the field:

At installation or the next service visit, please check to see if noise can be heard from the

paper transfer cleaning unit. If there is noise, file down the edge of the cleaning unit case

as described in the

Troubleshooting Procedure

below.

Page 33

Reissued: 9-May-03

T

echnical Bulletin

PAGE: 2/3

Model:

Production line

! Temporary:

Cut-in S/N

G080-17: From P9630400341

G080-22: From P9630401761

G080-24: From L1403040001

G080-26: From 8Q40430001

G080-27: From P9630402580

G080-29: From P9630402955

! Permanent:

Model J-P2

The edge of the cleaning unit case has been filed down 1.5 mm using a special tool to

ensure enough of a gap between the cleaning unit case and the roller.

NOTE:

in S/N below), and has already been applied to all service parts (#G0803830 and

#G0803831).

The shape of the cleaning unit case will be modified to prevent contact with the roller.

This temporary solution was applied to the production line on April 4, 2003 (cut-

Date:

2-May-03

No.:

RG080004a

Troubleshooting Procedure

1. Turn off the main switch.

2. Open the front cover and pull out the paper transfer unit (1 screw).

3. Remove the cleaning unit, holding the cleaning blade release lever (1 screw).

4. Place the cleaning unit onto a sheet of paper, as shown below.

5. Using the blunt side of a box cutter or metal ruler, file down the edge [A] of the

cleaning unit case, from front to rear, by approximately 1.5 mm (0.06 in.).

[A]

Page 34

Reissued: 9-May-03

T

echnical Bulletin

PAGE: 3/3

Model:

NOTE: Make sure to prevent any plastic particles from getting inside the cleaning unit, e.g.

NOTE: If the rear side of the output already shows the dirty lines, and the roller, cleaning

Model J-P2

by covering the open space [A] with a sheet of paper. If any particles get into the

unit, it can cause damage to the cleaning blade, resulting in dirty lines on the rear

side of outputs.

blade or paper transfer belt show scratches, please replace the damaged

component(s).

Date:

[A]

2-May-03

No.:

RG080004a

Page 35

T

echnical Bulletin

PAGE: 1/1

Model:

Subject:

From:

Classification:

Model-JP2

Tear off the harness

1st Tech. Support Sec. Service Support Dept.

Date:

Prepared by:

Troubleshooting

Mechanical

Paper path

Other ( )

21-May-03

Part information

Electrical

Transmit/receive

No.:

H.Taguchi

Action required

Service manual revision

Retrofit information

RG080005

SYMPTOM

Power is not supplied when the main switch is turned ON after replacing the PSU [A],

Harness - AC Switch [B] or Bracket – PSU Fan [C].

Note: This may occur on all G060 and G080 series models.

CAUSE

When replacing the above mentioned parts, the harness may be damaged when it comes

in contact with the edge of the bracket or PSU bracket.

SOLUTION

When replacing the PSU, Harness or Bracket, wrap the area of the harness shown by the

arrow in electrical tape to protect it from the bracket edges.

[B]

[C]

[A]

Page 36

T

echnical Bulletin

PAGE: 1/3

Model:

Subject:

From:

Model J-P2

Service Manual Revision

1st Tech. Support Sec. Service Support Dept.

Classification:

Date:

Troubleshooting

Mechanical

Paper path

Other ( )

Please add the items in

bold

Page 1-24

Accessories Check List

13. Contact Glass Cleaning Cloth

14. Cloth Holder

Page 1-29

- Between Steps 16 and 17:

Attach the cloth holder [F] to the left face of the scanner unit.

!

Place the contact glass cleaning cloth [G] in the cloth holder [F].

!

Illustration added:

23-May-03

Prepared by:

No.:

H.Taguchi

RG080006

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

below to your Service Manuals.

[G]

[F]

Page 37

T

echnical Bulletin

PAGE: 2/3

Model:

Model J-P2

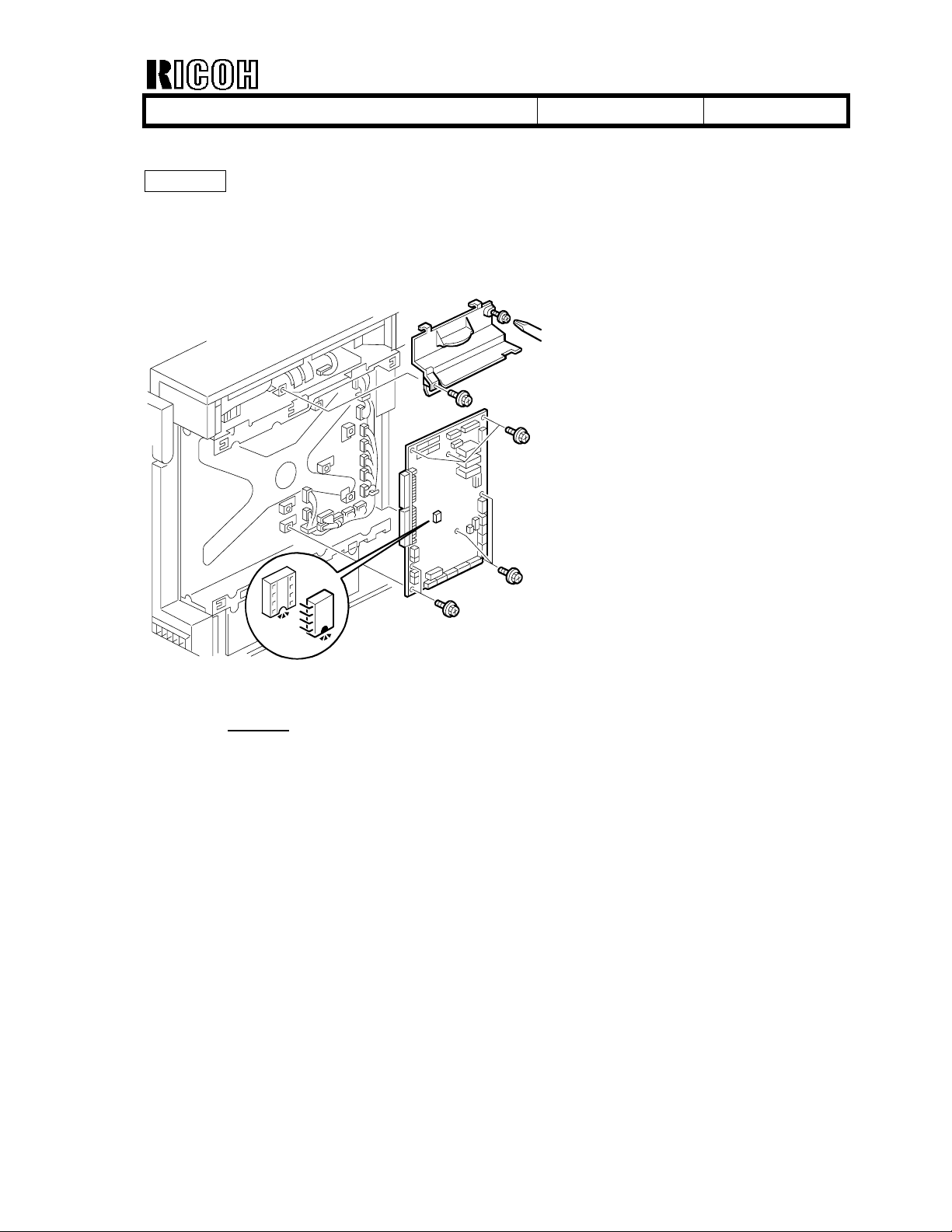

Page 3-24

Printer Application

Controller → IPU (through) → Controller

Page 3-32

Illustration revised to show the gear and collar:

Date:

[D]

[E]

[F]

23-May-03

(straight through) →

No.:

BCU

RG080006

- Steps 4, 5 revised as follows:

4. Gear [D] and Collar [E] (retaining ring x 1).

5. Cleaning unit [F] (screw x 2).

Note: When reattaching, make sure to set the cleaning unit [F] in place first,

and then attach the gear [D] and collar [E].

Page 38

T

echnical Bulletin

PAGE: 3/3

Model:

Page 5-50

5

828

Page 6-89

Model J-P2

52

ECP Switches the ECP setting for Centronics off/on.

53

Transmission Speed

Date:

Mode No.

(Class 1, 2, and 3)

*

CTL

[ 0 or 1 / 1

CF

0: Disabled, 1: Enabled

With “1” selected, SP5-828-050 must be enabled

for 1284 mode compatibility.

Selects the Ethernet transmission speed.

[ 0 to 3 / 0

0: Auto

1: 100 Base-TX

2: 10 Base-T

3: Auto

/ - ]

/ 1 /step]

23-May-03

Function / [ Setting ]

No.:

RG080006

A 20GB hard disk is used for printer

and scanner

functions. A 40GB hard disk is provided

as an option for the copier feature expander. The hard disks are partitioned as listed in the

table.

Page 39

T

echnical Bulletin

PAGE: 1/2

Model:

Subject:

From:

Classification:

Model J-P2

Factory assembly error on model-J P2 PCU

1st Tech. Support Sec. Service Support Dept.

Date:

Troubleshooting

Mechanical

Paper path

Other ( )

18-Jun-03

Prepared by:

No.:

H.Taguchi

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

RG080007

SYMPTOM

The PCU cannot be installed on the J-P2.

CAUSE

Eight drum silencers from before the J-P1 PCU modification (opening 5mm) were

mistakenly used in the J-P2 PCU from after the modification (opening 10mm), and as a

result the J-P2 shaft holder cannot fit into the 5mm opening in the silencer.

Note: The drum shaft was lengthened to maximize the smoothness of rotation and

minimize wobbling with the model change (J-P2). In accordance with this change,

the opening in the silencer was increased from 5mm to 10mm (for attachment to the

P2 holder).

Affected Units

A total of 8 out of the following 2,319 J-P2 PCUs may contain the older drum silencer.

However, it is not possible to determine how many are contained in J-P2 units.

The occurrence rate in the field cannot be determined, since it is not known how many are

packaged together with J-P2 kits, but there would be a maximum rate of 0.3%(8units).

G211-17 (EDP: 400879): Printer Maintenance Kit Type 7000A (Color)

G212-17 (EDP: 400880): Printer Maintenance Kit Type 7000F (Black)

:

Page 40

Reissued: 25-Jun-03

T

echnical Bulletin

PAGE: 1/1

Model:

Model J-P2

Date:

RTB Reissue

Subject:

From:

Classification:

Service Manual Revision

1st Tech. Support Sec. Service Support Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Prepared by:

Revision:

Note for pg. 3-24 has been deleted

23-May-03

No.:

H.Taguchi

RG080006a

Part information

Electrical

Transmit/receive

.

Action required

Service manual revision

Retrofit information

Loading...

Loading...