Page 1

RICOH GROUP COMPANIES

G071

SERVICE MANUAL

001479MIU

Page 2

Page 3

®

SERVICE MANUAL

®

G071

RICOH GROUP COMPANIES

Page 4

Page 5

G071

SERVICE MANUAL

001479MIU

Page 6

Page 7

A

f

r

It is the reader's responsibility when discussing the information contained

within this document to maintain a level of confidentiality that is in the best

interest of Ricoh Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH CORPORATION.

ll product names, domain names or product illustrations, including

desktop images, used in this document are trademarks, registered

trademarks or the property of their respective companies.

They are used throughout this book in an informational or editorial fashion

only and for the benefit of such companies. No such use, or the use o

any trade name, or web site is intended to convey endorsement or othe

affiliation with Ricoh products.

2001 RICOH Corporation. All rights reserved.

Page 8

Page 9

p

t

r

g

l

y

p

WARNING

The Service Manual contains information

regarding service techniques, procedures,

rocesses and spare parts of office equipmen

distributed by Ricoh Corporation. Users of this

manual should be either service trained o

certified by successfully completing a Ricoh

Technical Training Program.

Untrained and uncertified users utilizin

information contained in this service manual to

repair or modify Ricoh equipment risk persona

injury, damage to property or loss of warrant

rotection.

Ricoh Corporation

Page 10

Page 11

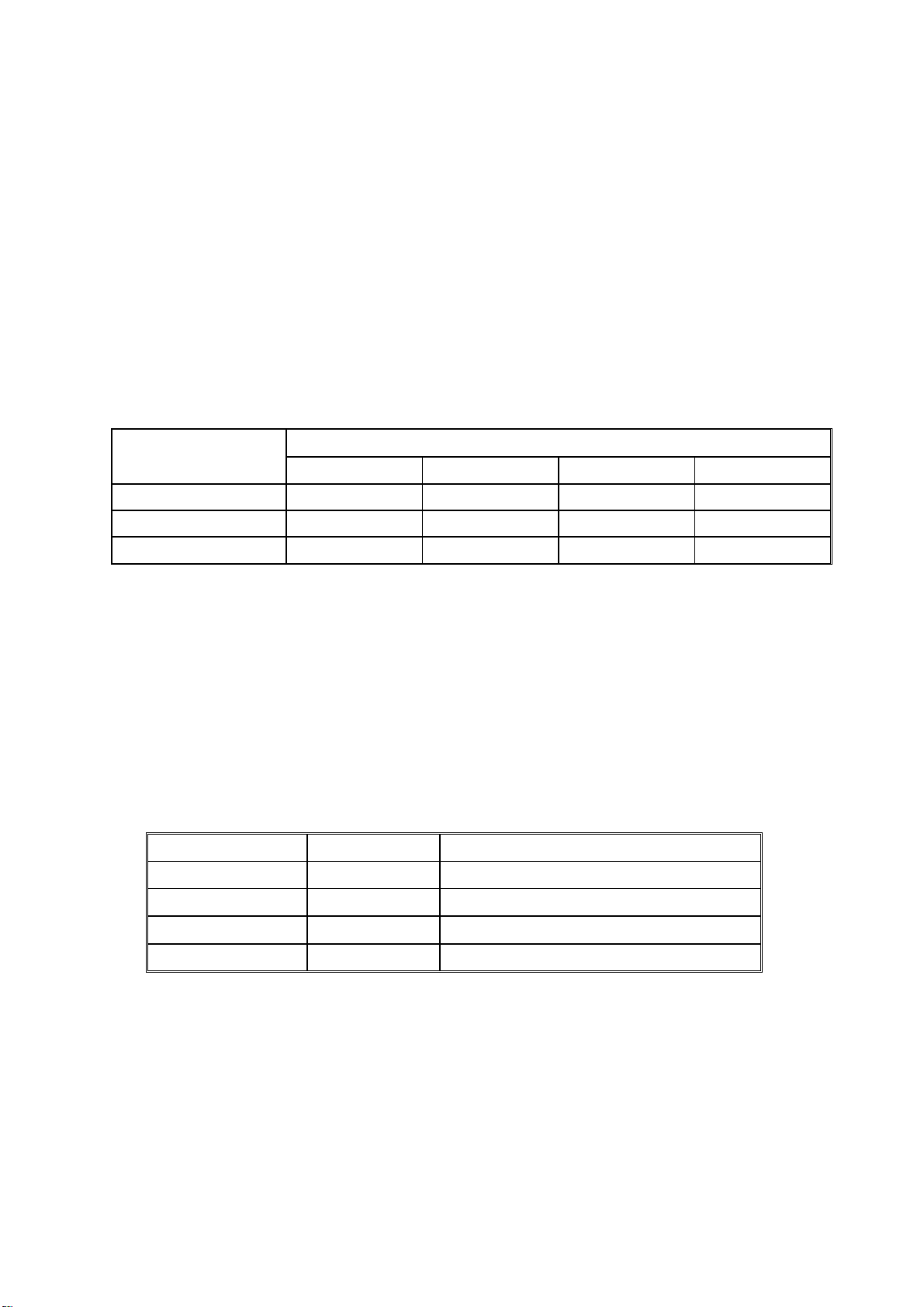

LEGEND

PRODUCT CODE COMPANY

G071 C7010 LP 036c Aficio CL5000 CLP1036

GESTETNER LANIER RICOH SAVIN

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

* 12/2002 Original Printing

Page 12

Page 13

G071

TABLE OF CONTENTS

INSTALLATION

1. INSTALLATION............................................................................ 1-1

1.1 INSTALLATION REQUIREMENTS ........................................................... 1-1

1.1.1 ENVIRONMENT ...............................................................................1-1

1.1.2 MACHINE LEVEL.............................................................................1-1

1.1.3 SPACE REQUIREMENTS................................................................1-2

1.1.4 POWER REQUIREMENTS .............................................................. 1-2

1.2 MACHINE INSTALLATION........................................................................1-3

1.3 OPTIONS ..................................................................................................1-4

1.4 REMARKS FOR INSTALLATION..............................................................1-5

PREVENTIVE MAINTENANCE

2. PREVENTIVE MAINTENANCE.................................................... 2-1

2.1 OVERVIEW ...............................................................................................2-1

Users Do the User PM Procedures....................................................... 2-1

All PM Done by Technicians .................................................................2-1

Counters ............................................................................................... 2-1

2.2 USER MAINTENANCE .............................................................................2-1

Main Unit...............................................................................................2-1

Optional Paper Tray Unit ......................................................................2-2

2.3 SERVICE MAINTENANCE........................................................................2-2

Main Unit...............................................................................................2-2

Optional Units ....................................................................................... 2-3

REPLACEMENT AND ADJUSTMENT

3. REPLACEMENT AND ADJUSTMENT ........................................ 3-1

3.1 SPECIAL TOOLS ................................................................................3-1

3.2 EXTERIOR COVERS ................................................................................3-2

3.2.1 REAR COVER..................................................................................3-2

3.2.2 LOWER LEFT COVER .....................................................................3-3

3.2.3 UPPER COVER, OPERATION PANEL............................................3-3

3.3 ELECTRICAL COMPONENTS..................................................................3-4

3.3.1 PRINTER CONTROLLER ................................................................3-4

3.3.2 CONTROLLER BOX.........................................................................3-4

3.3.3 BCU BOARD ....................................................................................3-4

3.3.4 I/O BOARD .......................................................................................3-5

3.3.5 PSU ..................................................................................................3-5

3.3.6 HIGH VOLTAGE SUPPLY BOARD.................................................. 3-6

SM i G071

Page 14

3.4 DRIVE UNITS............................................................................................3-7

3.4.1 DEVELOPMENT CLUTCHES .......................................................... 3-7

K/Y Development Units.........................................................................3-7

C/M Development Units ........................................................................3-7

3.4.2 DEVELOPMENT MOTOR ................................................................3-8

3.4.3 MAIN MOTOR .................................................................................. 3-8

3.4.4 PCU GEAR BOX AND OPC BELT CLEANING CLUTCH ................3-9

3.4.5 FUSING UNIT MOTOR ....................................................................3-9

3.4.6 PAPER FEED MOTOR...................................................................3-10

3.4.7 PAPER FEED CLUTCH .................................................................3-10

3.4.8 REGISTRATION CLUTCH .............................................................3-10

3.5 LASER OPTICS SECTION......................................................................3-11

3.5.1 CAUTION DECAL LOCATION ....................................................... 3-11

3.5.2 LASER OPTICS HOUSING UNIT ..................................................3-12

Adjusting for Image Skew ...................................................................3-14

Laser Beam Pitch Adjustment.............................................................3-15

3.5.3 POLYGONAL MIRROR MOTOR AND LSD ................................... 3-16

3.6 DEVELOPMENT UNIT ............................................................................3-17

3.7 PHOTOCONDUCTOR UNIT (PCU) ........................................................ 3-19

3.7.1 MAIN UNIT ..................................................................................... 3-19

3.7.2 WASTE TONER BOTTLES ............................................................3-20

3.7.3 CHARGE CORONA WIRE .............................................................3-21

3.7.4 CHARGE CORONA WIRE CLEANER MOTOR .............................3-22

3.7.5 OPC BELT CLEANING UNIT ......................................................... 3-22

3.7.6 IMAGE TRANSFER BELT CLEANING UNIT ................................. 3-22

3.8 PAPER TRANSFER UNIT.......................................................................3-23

3.8.1 VERTICAL TRANSPORT UNIT......................................................3-23

3.8.2 TRANSFER ROLLER .....................................................................3-23

Cleaning the Paper Dust Mylar ...........................................................3-24

3.9 FUSING/PAPER EXIT.............................................................................3-25

3.9.1 FUSING UNIT................................................................................. 3-25

3.9.2 OIL SUPPLY UNIT .........................................................................3-25

3.9.3 LAMPS ...........................................................................................3-26

3.9.4 FUSING INNER UNIT.....................................................................3-27

3.9.5 PRESSURE ROLLER THERMOFUSE...........................................3-27

3.9.6 FUSING BELT UNIT AND PRESSURE ROLLER UNIT .................3-27

3.9.7 PRESSURE ROLLER THERMISTOR ............................................3-28

3.9.8 HOT ROLLER STRIPPERS ...........................................................3-28

3.9.9 PRESSURE ROLLER.....................................................................3-29

3.9.10 OIL ABSORBERS.........................................................................3-30

3.9.11 PAPER EXIT UNIT AND PAPER EXIT/

OVERFLOW SENSOR .................................................................3-31

3.10 PAPER FEED AND TRANSPORT ........................................................ 3-32

3.10.1 FEED ROLLER AND FRICTION PAD ..........................................3-32

3.10.2 REGISTRATION SENSOR...........................................................3-33

3.10.3 PAPER FEED SENSOR...............................................................3-35

3.10.4 PAPER NEAR-END SENSOR......................................................3-35

3.10.5 PAPER END SENSOR.................................................................3-35

3.11 BYPASS TRAY......................................................................................3-36

G071 ii SM

Page 15

3.11.1 PICKUP/FEED ROLLER ..............................................................3-36

3.11.2 PAPER FEED CLUTCH ...............................................................3-37

3.11.3 REVERSE ROLLER .....................................................................3-37

Rev. 04/2003

TROUBLESHOOTING

4. TROUBLESHOOTING ................................................................. 4-1

4.1 SERVICE CALL.........................................................................................4-1

4.1.1 SERVICE CALL CONDITIONS ........................................................4-1

4.1.2 SC TABLE ........................................................................................ 4-2

4.2 CONTROLLER ERROR TABLE................................................................4-9

4.3 BLOWN FUSE CONDITIONS .................................................................4-12

4.4 CHECK POINTS FOR IMAGE PROBLEMS AT REGULAR

INTERVALS.............................................................................................4-12

SERVICE TABLES

5. SERVICE TABLES....................................................................... 5-1

5.1 SERVICE PROGRAM MODE....................................................................5-1

5.1.1 OPERATION PANEL KEYS .............................................................5-1

5.1.2 STARTING SERVICE PROGRAM MODE........................................5-2

Procedure 1 ..........................................................................................5-2

Procedure 2 ..........................................................................................5-2

5.1.3 MAIN MENU .....................................................................................5-2

5.1.4 SPECIFYING A VALUE OR SETTING .............................................5-3

5.1.5 LEAVING SERVICE MODE..............................................................5-3

5.2 SP MODE TABLES ................................................................................... 5-4

5.2.1 SERVICE (CONTROLLER SERVICE MODES) ...............................5-4

Bit Switch Settings ................................................................................5-6

Gamma Adjustment ..............................................................................5-8

5.2.2 ENGINE SERVICE MODES ...........................................................5-11

SP1-XXX: (Feed) ................................................................................5-11

SP2-XXX: (Drum)................................................................................5-15

SP3-XXX: (Process) ...........................................................................5-29

SP5-XXX: (Mode) ...............................................................................5-32

SP7-XXX: (Data Log)..........................................................................5-39

Input Check Table............................................................................... 5-47

Table 1: Tray 1 Paper Size ................................................................. 5-50

Table 2: 1st/2nd Bank Paper Size ......................................................5-50

Table 3: 1st/2nd Bank Near End.........................................................5-50

Output Check Table............................................................................5-51

5.3 CONTROLLER SELF-DIAGNOSTICS ....................................................5-53

5.3.1 OVERVIEW .................................................................................... 5-53

5.3.2 DETAILED SELF-DIAGNOSTICS ..................................................5-54

5.4 USER PROGRAM MODE .......................................................................5-55

5.5 UPGRADING SOFTWARE......................................................................5-56

5.5.1 OVERVIEW .................................................................................... 5-56

SM iii G071

Page 16

5.5.2 UPGRADING..................................................................................5-57

Procedure ........................................................................................... 5-57

Error Recovery....................................................................................5-58

5.6 DIP SWITCHES.......................................................................................5-59

Controller Board.................................................................................. 5-59

BCU Board..........................................................................................5-59

5.7 PRINTING A TEST PATTERN ................................................................5-60

Rev. 04/2003

DETAILED SECTION DESCRIPTIONS

6. DETAILED SECTION DESCRIPTIONS ....................................... 6-1

6.1 OVERVIEW ...............................................................................................6-1

6.1.1 MAJOR COMPONENTS ..................................................................6-1

6.1.2 PAPER PATH...................................................................................6-2

6.1.3 DRIVE COMPONENTS ....................................................................6-3

6.1.4 ELECTRICAL COMPONENTS.........................................................6-4

Image Transfer .....................................................................................6-4

Development Units................................................................................6-5

Paper Path............................................................................................6-6

Drive Components ................................................................................6-7

Circuit Boards .......................................................................................6-8

6.2 PRINTING PROCESS OVERVIEW...........................................................6-9

6.3 PROCESS CONTROL ............................................................................6-11

6.3.1 OVERVIEW .................................................................................... 6-11

6.3.2 PROCESS CONTROL STEPS....................................................... 6-12

Six Steps.............................................................................................6-12

When is Process Control Done?......................................................... 6-12

6.4 PHOTOCONDUCTOR UNIT (PCU) ........................................................ 6-13

6.4.1 OVERVIEW .................................................................................... 6-13

6.4.2 NEW PHOTOCONDUCTOR UNIT DETECTION ...........................6-14

New PCU Sensor................................................................................6-14

Mechanism .........................................................................................6-14

PCU Counter ......................................................................................6-14

6.4.3 CHARGE CORONA UNIT ..............................................................6-15

Power Supply......................................................................................6-15

Wire Cleaning .....................................................................................6-15

Cleaning Interval.................................................................................6-15

Quenching ..........................................................................................6-16

6.4.4 OPC BELT DRIVE..........................................................................6-16

6.4.5 OPC BELT CLEANING UNIT ......................................................... 6-17

Toner Collection Augers .....................................................................6-17

Counter Blade + Brush .......................................................................6-17

Waste Toner Bottle Sensors ...............................................................6-17

Drive ...................................................................................................6-18

6.4.6 IMAGE TRANSFER BELT UNIT ....................................................6-19

Drive ...................................................................................................6-19

Belt Mark Sensor ................................................................................6-19

Bias Roller ..........................................................................................6-20

G071 iv SM

Page 17

6.4.7 TRANSFER BELT CLEANING UNIT..............................................6-21

Bias Brush ..........................................................................................6-21

Bias Roller and Cleaning Blade ..........................................................6-21

Collecting Coil.....................................................................................6-21

Waste Toner Bottle Sensors ...............................................................6-21

Contact Mechanism ............................................................................6-22

Power Supply......................................................................................6-23

Drive ...................................................................................................6-23

6.5 LASER EXPOSURE................................................................................6-24

6.5.1 OVERVIEW .................................................................................... 6-24

Dust Shield Glass Cleaning ................................................................ 6-25

LD Unit Adjustment.............................................................................6-25

Polygonal Mirror..................................................................................6-25

Laser Diode Power Control.................................................................6-25

Maintenance Adjustment ....................................................................6-25

6.5.2 LD SAFETY SWITCH .....................................................................6-26

Operation Panel Message and Switch Mechanism............................. 6-27

6.6 DEVELOPMENT .....................................................................................6-28

6.6.1 OVERVIEW .................................................................................... 6-28

6.6.2 DEVELOPMENT UNIT ...................................................................6-29

Rollers and Agitators...........................................................................6-29

Replacing Units................................................................................... 6-29

Memory Chip ......................................................................................6-29

6.6.3 TONER SUPPLY MECHANISM .....................................................6-30

Toner Cartridge Agitators....................................................................6-30

Drive Power Path................................................................................ 6-30

Development Unit Agitator ..................................................................6-30

Toner Supply Roller and Doctor Roller ...............................................6-30

Shutter ................................................................................................6-30

6.6.4 TONER END DETECTION.............................................................6-31

Mechanism .........................................................................................6-31

Toner Near-End Detection ..................................................................6-31

Toner End Detection........................................................................... 6-32

Toner End Recovery ...........................................................................6-32

6.6.5 DEVELOPMENT UNIT CONTACT MECHANISM ..........................6-33

Mechanism .........................................................................................6-33

Reverse Rotation ................................................................................6-33

6.6.6 POWER SOURCE..........................................................................6-34

Development, Toner Supply, and Doctor Rollers................................6-34

Doctor Roller.......................................................................................6-34

6.7 PAPER FEED..........................................................................................6-35

6.7.1 OVERVIEW .................................................................................... 6-35

Transport Speed .................................................................................6-36

Friction Pad.........................................................................................6-36

6.7.2 STANDARD TRAY DRIVE .............................................................6-36

Feed and Vertical Transport Rollers ...................................................6-36

Registration Roller ..............................................................................6-36

6.7.3 STANDARD TRAY – BOTTOM PLATE LIFT .................................6-37

Lift Mechanism.................................................................................... 6-37

SM v G071

Page 18

Paper Near End Detection ..................................................................6-37

Paper End Detection...........................................................................6-37

6.7.4 STANDARD TRAY - PAPER SIZE DETECTION ...........................6-38

Mechanism .........................................................................................6-38

Switch Pattern.....................................................................................6-38

6.7.5 BYPASS TRAY............................................................................... 6-39

Paper Feed Mechanism......................................................................6-39

Bypass Tray Drive Power Path ...........................................................6-39

Pick-up Solenoid................................................................................. 6-39

Paper End Sensor ..............................................................................6-39

6.8 PAPER TRANSFER AND SEPARATION ...............................................6-40

6.8.1 OVERVIEW .................................................................................... 6-40

Jammed Paper Release .....................................................................6-40

Image Transfer and Paper Separation................................................6-40

6.8.2 MECHANISM..................................................................................6-41

Timing .................................................................................................6-41

Mechanism .........................................................................................6-41

6.8.3 POWER SUPPLY...........................................................................6-42

Electric Power Path.............................................................................6-42

Transfer Roller Bias ............................................................................6-42

Discharge Plate ..................................................................................6-42

Temperature/Humidity Control............................................................6-42

Roller Cleaning ...................................................................................6-43

6.9 FUSING UNIT AND OIL SUPPLY UNIT.................................................. 6-44

6.9.1 OVERVIEW .................................................................................... 6-44

6.9.2 FUSING UNIT CONFIGURATION.................................................. 6-45

Fusing Belt..........................................................................................6-45

Oil Supply ...........................................................................................6-45

Heating Roller Lamp ...........................................................................6-45

Pressure Roller Lamp .........................................................................6-45

Pressure Roller Pawls.........................................................................6-45

Fusing Bias .........................................................................................6-46

Fusing Unit SCs.................................................................................. 6-46

6.9.3 TEMPERATURE CONTROL ..........................................................6-47

6.9.4 OIL SUPPLY AND CLEANING.......................................................6-48

Oil Supply ...........................................................................................6-48

Oil Path ...............................................................................................6-48

Oil Recycling.......................................................................................6-48

Belt Cleaning ......................................................................................6-48

Oil End Detection................................................................................ 6-49

Fusing unit switch ...............................................................................6-49

6.9.5 DRIVE.............................................................................................6-49

Drive Power Path (Fusing Unit and Oil Supply Roller) ........................6-49

Drive Power Path (Pressure Roller).................................................... 6-49

6.9.6 ENERGY SAVER MODE................................................................6-50

Level 1 Energy Saver Mode (default: off)............................................6-50

Level 2 Energy Saver Mode................................................................6-50

Ready Mode .......................................................................................6-50

6.9.7 PAPER EXIT ..................................................................................6-51

G071 vi SM

Page 19

Drive Power Path................................................................................ 6-51

Paper Jam Detection ..........................................................................6-51

6.9.8 OVERFLOW DETECTION .............................................................6-51

6.10 PRINTED CIRCUIT BOARDS ............................................................... 6-52

6.10.1 PRINTER CONTROLLER ............................................................6-52

Function ..............................................................................................6-52

Memory...............................................................................................6-52

Interfaces ............................................................................................6-52

Slots....................................................................................................6-53

Options ...............................................................................................6-53

DIP Switch ..........................................................................................6-53

LED Indicators ....................................................................................6-53

6.10.2 BASE ENGINE CONTROL UNIT (BCU).......................................6-54

Function ..............................................................................................6-54

Upgrading ........................................................................................... 6-54

Nonvolatile Random Access Memory (NVRAM).................................6-54

DIP Switch ..........................................................................................6-54

6.10.3 INPUT/OUTPUT (I/O) BOARD .....................................................6-55

6.10.4 POWER SUPPLY UNIT (PSU)..................................................... 6-55

6.10.5 HIGH VOLTAGE SUPPLY............................................................6-55

6.11 CONTROLLER ......................................................................................6-56

6.11.1 OVERVIEW ..................................................................................6-56

6.11.2 BOARD LAYOUT..........................................................................6-58

6.11.3 PRINT DATA PROCESSING .......................................................6-59

RPCS Driver .......................................................................................6-59

PCL5c Driver ......................................................................................6-59

PS3 Driver ..........................................................................................6-60

CMS (Color Management System) .....................................................6-60

Gray Correction ..................................................................................6-60

BG/UCR (Black Generation/Under Color Removal)............................6-60

Gamma Correction..............................................................................6-60

Toner Limitation ..................................................................................6-61

Dither Processing and ROP/RIP......................................................... 6-61

6.11.4 CONTROLLER FUNCTIONS .......................................................6-62

Sample Print ....................................................................................... 6-62

Locked Print........................................................................................6-62

Paper Source Selection ......................................................................6-63

Auto Continue .....................................................................................6-64

Paper Output Tray ..............................................................................6-65

Stapling...............................................................................................6-66

6.12 IEEE1394 INTERFACE .........................................................................6-67

6.12.1 SPECIFICATIONS........................................................................6-67

Hardware Specification .......................................................................6-67

System Requirements.........................................................................6-67

6.12.2 IEEE1394 .....................................................................................6-67

6.12.3 BLOCK DIAGRAM........................................................................6-68

6.12.4 PIN ASSIGNMENT .......................................................................6-68

6.12.5 REMARKS ABOUT THIS INTERFACE KIT..................................6-69

6.12.6 TROUBLESHOOTING NOTES ....................................................6-69

SM vii G071

Page 20

6.12.7 IP OVER IEEE 1394 .....................................................................6-70

6.13 IEEE 802.11B (WIRELESS LAN) .......................................................... 6-71

6.13.1 SPECIFICATIONS........................................................................6-71

6.13.2 BLOCK DIAGRAM........................................................................6-71

6.13.3 TRANSMISSION MODE...............................................................6-72

Ad hoc Mode.......................................................................................6-72

Infrastructure Mode............................................................................. 6-72

6.13.4 SECURITY FEATURES ...............................................................6-73

Using the SSID in Ad hoc mode .........................................................6-73

6.13.5 TROUBLESHOOTING NOTES ....................................................6-74

Communication Status........................................................................6-74

Channel Settings ................................................................................6-74

Troubleshooting Steps ........................................................................6-75

6.14 USB .......................................................................................................6-76

6.14.1 SPECIFICATIONS........................................................................6-76

6.14.2 USB 1.1/2.0 .................................................................................. 6-76

6.14.3 USB CONNECTORS....................................................................6-77

6.14.4 PIN ASSIGNMENT .......................................................................6-77

6.14.5 REMARKS....................................................................................6-78

Related SP Mode................................................................................ 6-78

SPECIFICATIONS

SPECIFICATIONS............................................................................. 7-1

1. GENERAL SPECIFICATIONS.....................................................................7-1

1.1 MAIN UNIT ..........................................................................................7-1

2. SUPPORTED PAPER SIZES...................................................................... 7-4

2.1 MAIN TRAY, BYPASS TRAY, AND DUPLEX UNIT ............................7-4

2.2 FINISHER, MAIL BOX, AND PAPER TRAY UNIT...............................7-5

3. SOFTWARE ACCESSORIES .....................................................................7-6

3.1 PRINTER DRIVERS............................................................................ 7-6

3.2 UTILITY SOFTWARE ..........................................................................7-6

4. MACHINE CONFIGURATION..................................................................... 7-7

4.1 SYSTEM COMPONENTS ...................................................................7-7

Exterior .................................................................................................7-7

Interior...................................................................................................7-8

Maintenance Kits ..................................................................................7-8

4.2 OPTIONAL EQUIPMENT ..............................................................7-9

Finisher .................................................................................................7-9

Mail Box ..............................................................................................7-10

Duplex Unit ......................................................................................... 7-10

Interchange Unit .................................................................................7-10

G071 viii SM

Page 21

PAPER TRAY UNIT (G313)

SEE SECTION G313 FOR DETAILED TABLE OF CONTENTS

INTERCHANGE UNIT (G305)

SEE SECTION G305 FOR DETAILED TABLE OF CONTENTS

DUPLEX UNIT (G303)

SEE SECTION G303 FOR DETAILED TABLE OF CONTENTS

500-SHEET FINISHER (G314)

SEE SECTION G314 FOR DETAILED TABLE OF CONTENTS

FOUR-BIN MAILBOX (G312)

SEE SECTION G312 FOR DETAILED TABLE OF CONTENTS

SM ix G071

Page 22

Page 23

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the printer and peripherals,

make sure that the printer power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

4. The printer drives some of its components when it completes the warm-up

period. Be careful to keep hands away from the mechanical and electrical

components as the printer starts operation.

5. The inside and the metal parts of the fusing unit become extremely hot while

the printer is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

Toner and developer are non-toxic, but if you get either of them in your eyes by

accident, it may cause temporary eye discomfort. Try to remove with eye drops

or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The printer and its peripherals must be serviced by a customer service

representative who has completed the training course on those models.

2. The NVRAM module (option) installed on the controller has a lithium battery

which can explode if replaced incorrectly. Replace the NVRAM only with an

identical one. The manufacturer recommends replacing the entire NVRAM.

Do not recharge or burn this battery. Used NVRAM must be handled in

accordance with local regulations.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly

when exposed to an open flame.

2. Dispose of used toner, the maintenance unit which includes developer or the

organic photoconductor in accordance with local regulations. (These are

non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

When keeping used lithium batteries in order to dispose of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

4. When keeping used lithium batteries in order to dispose of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

Page 24

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

WARNING

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Optics Housing Unit section. Laser

beams can seriously damage your eyes.

CAUTION MARKING:

Trademarks

Microsoft

®

, Windows®, and MS-DOS® are registered trademarks of Microsoft

Corporation in the United States and /or other countries.

PostScript

®

PCL

Ethernet

PowerPC

®

is a registered trademark of Adobe Systems, Incorporated.

is a registered trademark of Hewlett-Packard Company.

®

is a registered trademark of Xerox Corporation.

®

is a registered trademark of International Business Machines

Corporation.

Other product names used herein are for identification purposes only and may be

trademarks of their respective companies. We disclaim any and all rights involved

with those marks.

Page 25

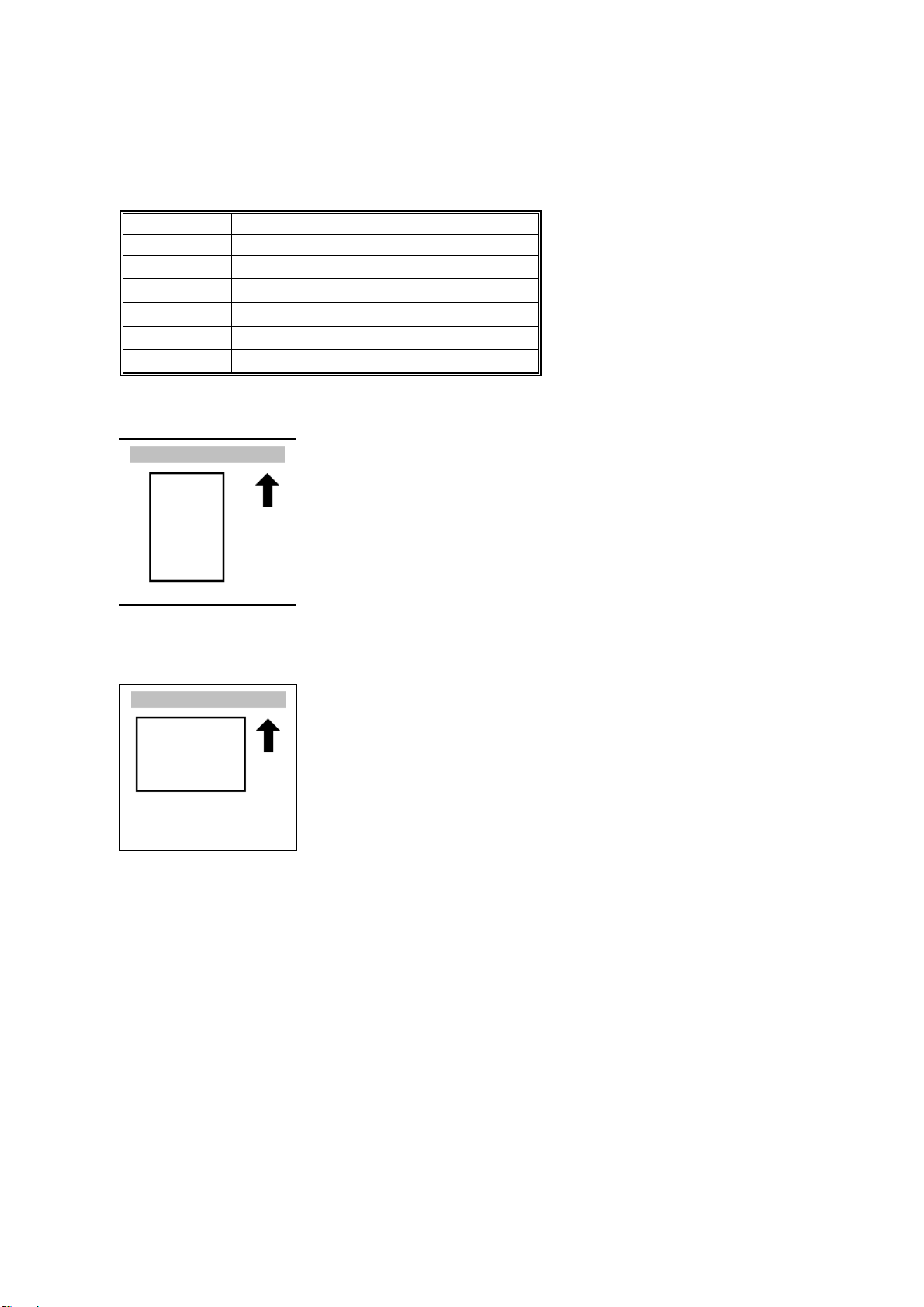

Conventions in this Manual

This manual uses several symbols.

Symbol What it means

!

Refer to section number

See Core Tech Manual for details

Screw

Connector

Clip ring

E-ring

Lengthwise, SEF (Short Edge Feed)

Sideways, LEF (Long Edge Feed)

Page 26

Page 27

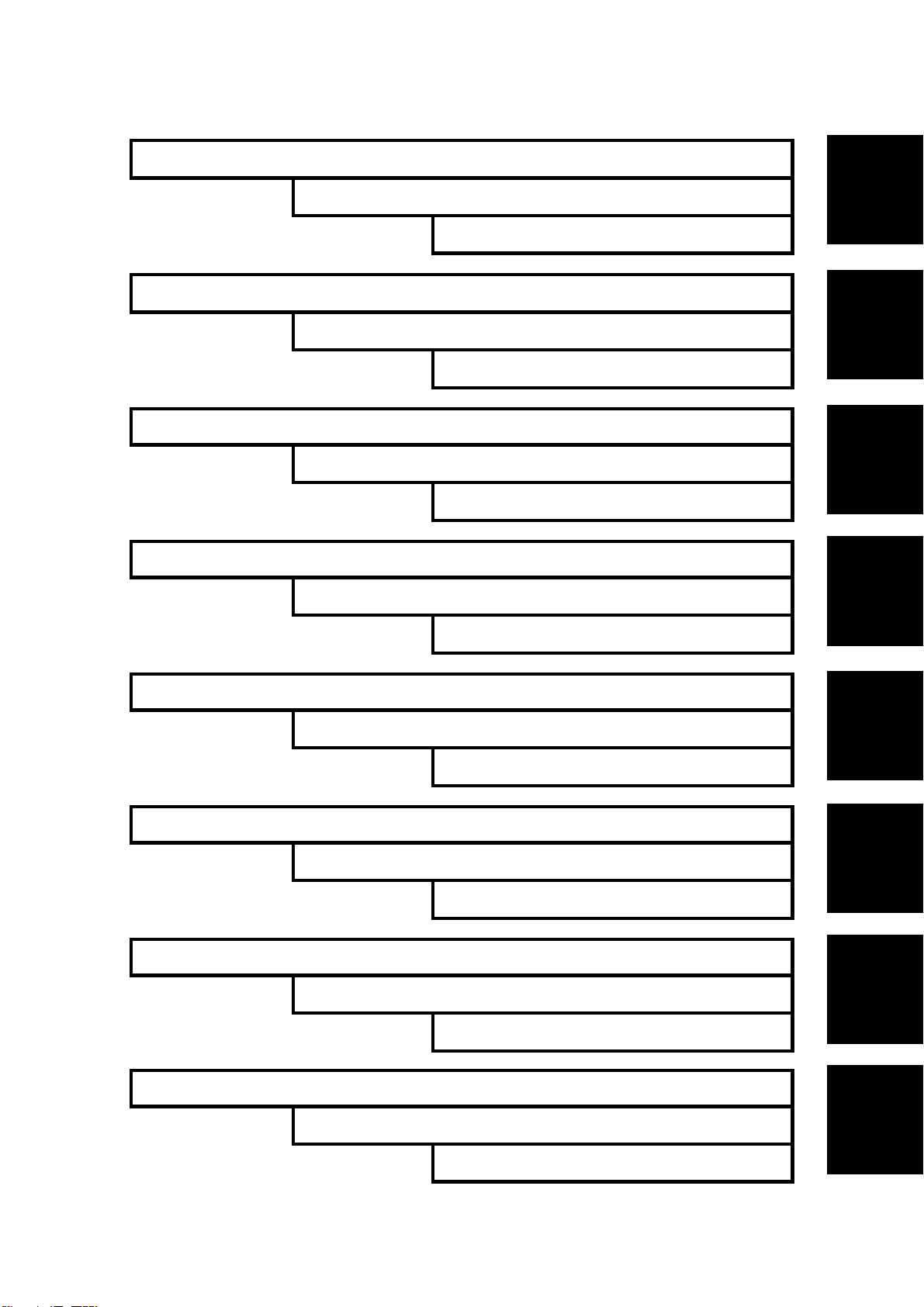

INSTALLATION

TAB

POSITION 1

PREVENTIVE MAINTENANCE

TAB

POSITION 2

REPLACEMENT AND ADJUSTMENT

TAB

POSITION 3

TROUBLESHOOTING

500-SHEET FINISHER G314

FOUR-BIN MAILBOX G312

TAB

POSITION 4

SERVICE TABLES

INTERCHANGE UNIT G305

DUPLEX UNIT G303

DETAILED DESCRIPTIONS

SPECIFICATIONS

PAPER TRAY UNIT G313

TAB

POSITION 5

TAB

POSITION 6

TAB

POSITION 7

TAB

POSITION 8

Page 28

Page 29

INSTALLATION

Page 30

Page 31

INSTALLATION REQUIREMENTS

1. INSTALLATION

1.1 INSTALLATION REQUIREMENTS

1.1.1 ENVIRONMENT

1. Temperature Range:

2. Humidity Range: 20% to 80% RH

3. Ambient Illumination: Less than 2,000 lux (keep the machine out of direct

4. Ventilation: 3 times/hr/person or more

5. Avoid exposing the machine to sudden temperature changes, which include:

1) Direct cool air from an air conditioner

2) Direct heat from a heater

6. Avoid installing the machine in areas that may be exposed to corrosive gas.

7. Install the machine at a location lower than 2,500 m (8,200 ft.) above sea level.

8. Install the machine on a strong, level base. (! 1.1.2)

9. Avoid installing the machine in areas that may be subjected to strong vibration.

10°C to 32°C (50°F to 89°F)

sunlight.)

Installation

1.1.2 MACHINE LEVEL

Front to back: Within 5 mm (0.2") of level

Right to left: Within 5 mm (0.2") of level

SM 1-1 G071

Page 32

INSTALLATION REQUIREMENTS

1.1.3 SPACE REQUIREMENTS

B

A: Over 100 mm (4")

B: Over 100 mm (4")

A

C

C: Over 550 mm (22")

D: Over 750 mm (30")

D

G070I001.WMF

1.1.4 POWER REQUIREMENTS

CAUTION

1. Insert the plug firmly in the outlet.

2. Avoid using an outlet extension plug or cord.

3. Ground the machine.

1. Input voltage level:

120 V, 60 Hz, More than 11 A

220 to 240 V, 50/60 Hz, More than 7 A

2. Permissible voltage fluctuation: ±10%

3. Do not put or place anything on the power cord.

G071 1-2 SM

Page 33

MACHINE INSTALLATION

1.2 MACHINE INSTALLATION

Refer to the Operating Instructions for details.

If the customer has a service contract, change the settings of the following SP

modes depending on the contract type.

Item SP No. Function Default

Meter charge

Counting method

A3/11" x 17"

double counting

PM warning

display 1

PM warning

display 2

SP5-930-1

(Meter_

Charge)

SP5-045-1

(Counter

Method)

SP5-104-1

(Double

Count)

SP5-931-1

(PM_Display

– Charger)

SP5-931-2

(PM_Display

– PCU)

Specifies whether the meter charge

mode is enabled or disabled.

If the user is doing the user PM

procedures, set meter charge to ‘Off’.

If the technician is doing all the PM,

set meter charge to ‘On’.

Meter charge mode enabled:

• The Counter menu appears

immediately after the Menu key is

pressed.

• The counter type selected by the

counting method (SP5-045-1,

Counter Method) can be displayed

with the Counter menu.

• The counter values can also be

printed with the Counter menu.

• The selected counter starts from a

negative number.

Meter charge mode disabled:

• The Counter menu is not

displayed.

• The total counter starts from 0.

Specifies whether the counting

method used in meter charge mode is

based on developments or prints.

Important:

This SP can only be done before the

negative counters are reset with SP7825-001 (Counter Reset)

Specifies whether the counter is

doubled for A3/11" x 17" paper.

Specifies whether the PM warning for

the charge corona unit is displayed

when the replacement time arrives.

1: Displayed

0: Not displayed

Specifies whether the PM warning for

the PCU is displayed.

1: Displayed

0: Not displayed

Off

Developments

No: Single

counting

1

1

Installation

SM 1-3 G071

Page 34

OPTIONS

Item SP No. Function Default

PM warning

display 3

Fax No. setting

Counter reset

SP5-931-3

(PM_Display

- Bank_

Feed)

SP5-812-2

(FAX TEL

No.)

SP7-825-1

(Counter

Reset)

Specifies whether the PM warning for

the feed rollers in the optional paper

feed unit is displayed.

1: Displayed

0: Not displayed

Programs the service station fax

number.

The number is printed on the counter

list when the meter charge mode is

selected, so that the user can fax the

counter data to the service station.

Resets the counters to 0.

Important: This must be done at

installation after all the above settings

have been finished. The negative

counters used in meter charge mode

will be reset to zero.

0

NOTE:

1) The default setting for this machine is meter-charge mode off.

2) The meter-charge counter cannot be reset.

1.3 OPTIONS

Refer to the Option Setup Guide for details.

No. Optional Unit Alternative Requirements

500-sheet finisher

1

2 4-bin mailbox No. 1

3 Interchange unit

Duplex unit

4

5 Paper tray unit

6 Printer hard disk

DIMM memory (64, 128, or 256

7

MB modules available)

IEEE1394 interface unit

8

9 User account enhancement unit

10 IEEE802.11b (Wireless LAN)

No. 2

• No. 3

• Hard disk or memory (extra 64

MB or more) for sort mode

• No. 3

• No. 3

• Extra 64 MB (or more) optional

SDRAM module

NOTE:

1) You cannot install the finisher and mailbox on the same machine.

2) You can install either 1 or 2 paper tray units.

G071 1-4 SM

Page 35

REMARKS FOR INSTALLATION

1.4 REMARKS FOR INSTALLATION

In case you install this printer or you instruct customers to install, please note the

following remark for development unit installation and replacement:

After installation or replacement of the development unit, print out the development

unit check sheet by user mode (User Mode – Maintenance – Development Unit

Check).

NOTE: For details please refer to the Quick Installation Guide.

Installation

SM 1-5 G071

Page 36

Page 37

PREVENTIVE MAINTENANCE

Page 38

Page 39

OVERVIEW

2. PREVENTIVE MAINTENANCE

2.1 OVERVIEW

Users Do the User PM Procedures

The user does PM for the items in section 2.2. The technician does PM for the

items in section 2.3. Meter-charge mode must be set to “off” (SP5-930

[Meter_Charge], ! 5.2).

All PM Done by Technicians

The technician does PM for the items in sections 2.2 and 2.3. Meter-charge mode

must be set to “on” (SP5-930, [Meter_Charge], ! 5.2).

Counters

When a maintenance counter for a unit has reached the limit, the corresponding

message is displayed on the operation panel. After completing the maintenance

procedure for that item, reset the counter (SP7-804, [PM_Clear ], ! 5.2).

2.2 USER MAINTENANCE

Abbreviations:

lean, Inspect, Lubricate, Replace, KiloPrints, KiloDevelopments, WheneverNecessary

C

Preventive

Maintenance

Main Unit

Item

T/B waste toner bottle

O/B waste toner bottle

Oil supply unit

Fusing unit with paper

feed roller

* : Replacement period calculated for a 50% color ratio (the actual waste toner bottle condition

is detected with the sensors)

** : Standard replacement period (the actual oil amount is detected with the sensor)

KD KP

50 120 30 120

R*

R*

R**

R

Detection Reset

Waste toner

sensors

Waste toner

sensors

Oil end

sensor/Oil

supply unit

counter

Exit sheet

counter

Auto-reset

(sensor)

Auto-reset

(sensor)

Manual reset

Manual reset

Machine

stops

Yes

Yes

Yes

Yes

SM 2-1 G071

Page 40

SERVICE MAINTENANCE

Item

Black development unit

Color development unit

PCU (includes charge

corona unit & dust

filters)

*Displayed with SP7-906 (PMCounter-PREV)

60 120 240

KD

R

R

R

Item WN Detection Reset

Registration roller

Dust shield glass

(LD unit)

Bottom plate pad

C None None No

C None None No

C None None No

Optional Paper Tray Unit

Item 150KP Detection Reset

Feed, pick-up, and

separation rollers

R None None No

Detection Reset

Dev. Bk

counter*

Dev. color

counter*

PCU counter*

Auto-reset

(memory chip)

Auto-reset

(memory chip)

Auto-reset (new

PCU sensor) No

Machine

stops

" damp cloth and

# dry cloth

Built-in cleaning

brush

" damp cloth and

# dry cloth

Machine

stops

" damp cloth and

# dry cloth

Machine

stops

Yes

Yes

Remarks

Remarks

2.3 SERVICE MAINTENANCE

Abbreviations:

lean, Inspect, Lubricate, Replace, KiloPrints, KiloDevelopments, WheneverNecessary

C

Main Unit

Bypass Tray

Item WN Remarks

Feed Roller

Pick-up Roller

Separation Roller

C

C

C

" damp cloth and

# dry cloth

" damp cloth and

# dry cloth

" damp cloth and

# dry cloth

G071 2-2 SM

Page 41

SERVICE MAINTENANCE

Optional Units

Paper Tray Unit

Item WN Remarks

Relay Roller

Bottom Plate Pad

C

C

" damp cloth and

# dry cloth

" damp cloth and

# dry cloth

Finisher

Item WN Remarks

Rollers

C

" damp cloth and

# dry cloth

Sensors C Blower blush or dry cloth

Anti-Static Brush C Blower blush or dry cloth

Bushings

Stapler

L

R

Launa oil when abnormal

noise occurs

Every 200K staples

(estimated replacement

period)

Mail Box

Item WN Remarks

Rollers

C

" damp cloth and

# dry cloth

Tray Paper Sensors C Blower blush or dry cloth

Duplex Unit

Item WN Remarks

Rollers

C

" damp cloth and

# dry cloth

Feed/exit sensors C Blower blush or dry cloth

Interchange Unit

Preventive

Maintenance

Item WN Remarks

Paper Exit Sensor C Blower blush or dry cloth

SM 2-3 G071

Page 42

Page 43

REPLACEMENT AND ADJUSTMENT

Page 44

Page 45

SPECIAL TOOLS

3. REPLACEMENT AND ADJUSTMENT

CAUTION

Turn off the main power switch and unplug the machine before beginning

any of the procedures in this section.

NOTE: This manual uses the following symbols.

! : See or Refer to : Screws : Connector : Clip ring

: E-ring

3.1 SPECIAL TOOLS

Part Number Part Name

N8036701 Flash Memory Card - 4MB

G0219350 Loop-back connector - Parallel

Adjustment

Replacement

SM 3-1 G071

Page 46

EXTERIOR COVERS

3.2 EXTERIOR COVERS

3.2.1 REAR COVER

1. Duct cover [A] (4 hooks)

2. Ozone filter [B]

3. Printer controller [C] ( x 2)

[A]

4. Rear cover [D] ( x 2)

[C]

G070R702.WMF

G070R703.WMF

[B]

Adjustment

Replacement

[D]

G071 3-2 SM

Page 47

EXTERIOR COVERS

3.2.2 LOWER LEFT COVER

1. Lower left cover [A] ( x 3)

[A]

3.2.3 UPPER COVER, OPERATION PANEL

1. Open the right cover [A].

2. Upper right cover [B]

3. Paper exit cover [C] ( x 1)

4. Open the front cover [D].

[F]

[E]

G070R704.WMF

Adjustment

Replacement

[C]

[B]

5. Upper cover [E] ( x 4)

6. Operation panel [F] (4 hooks,

x 2, x 1)

NOTE: Insert a screwdriver between

the upper cover and the main

unit and unhook the panel.

[D]

G070R701.WMF

[A]

SM 3-3 G071

Page 48

ELECTRICAL COMPONENTS

3.3 ELECTRICAL COMPONENTS

3.3.1 PRINTER CONTROLLER

! 3.2.1

NOTE: Remove the NVRAM from the old controller board, and install it on the new

one.

If the controller NVRAM is defective, reset the total counter to 0 after

changing the NVRAM, if meter charge mode is enabled.

3.3.2 CONTROLLER BOX

1. Rear cover (! 3.2.1)

2. Cooling fan [A] ( x 2)

NOTE: When reassembling,

install the fan with the

label facing the inside.

3. Controller box [B] ( x 11)

NOTE:

1) Do not remove the

BCU board base with

the controller box.

2) When putting back

the controller box,

take care not to

pinch the cable from

the I/O board.

3.3.3 BCU BOARD

[B]

[A]

G070R705.WMF

Adjustment

Replacement

1. Controller box (! 3.3.2)

[A]

2. All (12)

3. 1 flat cable

4. BCU board base [A] ( x 5)

5. BCU board [B] ( x 5)

NOTE: Remove the NVRAM from the old

BCU board, and install it on the

new one.

[B]

G071 3-4 SM

G070R706.WMF

Page 49

ELECTRICAL COMPONENTS

3.3.4 I/O BOARD

1. Controller box (! 3.3.2)

2. All (33)

3. I/O board [A] ( x 4)

3.3.5 PSU

1. Controller box (! 3.3.2)

2. Flywheel ( x 3) (! 3.4.1)

[A]

G070R707.WMF

[B]

Adjustment

Replacement

[C]

3. Duct [A] ( x 1, x 1)

NOTE: When removing and

reassembling the fan,

install it with the label

facing the outside.

4. PSU protector [B] ( x 1)

5. Unlink the main switch [C].

6. PSU base ( x 8, x 4)

NOTE:

1) Remove the PSU [D]

with the PSU base.

2) When reassembling,

check that the main

switch is linked to the

PSU.

[A]

[D]

G070R717.WMF

SM 3-5 G071

Page 50

ELECTRICAL COMPONENTS

3.3.6 HIGH VOLTAGE SUPPLY BOARD

1. Photoconductor unit (! 3.7)

2. Right inner cover (! 3.10.2)

3. Photoconductor unit rail [A] ( x 2)

4. [B] x 1

5. Bushing [C] x 1

[B]

[A]

G070R719.WMF

[C]

Adjustment

Replacement

6. High voltage supply board [D] ( x 17,

x 6)

[D]

G070R720.WMF

G071 3-6 SM

Page 51

DRIVE UNITS

3.4 DRIVE UNITS

3.4.1 DEVELOPMENT CLUTCHES

1. Controller box (! 3.3.2)

K/Y Development Units

1. Unhook the lock [A] and pull out

the clutch [B] ( x 1).

C/M Development Units

1. Flywheel [A] ( x 3)

2. Unhook the lock [B] and pull out

the clutch [C] ( x 1).

[A]

[B]

G070R708.WMF

Adjustment

Replacement

[C]

[A]

SM 3-7 G071

G070R709.WMF

[B]

Page 52

DRIVE UNITS

3.4.2 DEVELOPMENT MOTOR

1. Controller box (! 3.3.2)

2. Development motor [A] ( x 1,

x 3)

[A]

3.4.3 MAIN MOTOR

1. Controller box (! 3.3.2)

2. Flywheel [A] ( x 3)

3. Main motor [B] ( x 1, x 3)

G070R710.WMF

Adjustment

Replacement

[B]

[A]

G070R711.WMF

G071 3-8 SM

Page 53

DRIVE UNITS

3.4.4 PCU GEAR BOX AND OPC BELT CLEANING CLUTCH

1. I/O board (!3.3.4 )

2. Main motor (! 3.4.3)

3. C/M development unit clutch

(! 3.4.1)

4. Bracket [A] ( x 2)

5. Tension spring [B]

6. x 1 [C]

7. Gear box and clutch assembly

[D] ( x 5)

[A]

3.4.5 FUSING UNIT MOTOR

[C]

[B]

G070R712.WMF

[D]

Adjustment

Replacement

1. Rear cover (! 3.2.1)

2. Fusing unit motor ( x 1, x 3)

[A]

G070R713.WMF

[A]

SM 3-9 G071

Page 54

DRIVE UNITS

3.4.6 PAPER FEED MOTOR

1. Rear cover (! 3.2.1)

2. Pull out the handle [A].

3. Paper feed motor [B] ( x 1,

x 3)

[A]

3.4.7 PAPER FEED CLUTCH

1. Rear cover (! 3.2.1)

2. Pull out the handle [A].

3. Connector bracket [B] ( x 6,

x 2)

[A]

4. Paper feed clutch [C] ( x 1,

x 2)

3.4.8 REGISTRATION CLUTCH

[B]

G070R714.WMF

G070R716.WMF

[B]

[C]

Adjustment

Replacement

1. Rear cover (! 3.2.1)

2. Unhook the lock [A] and pull the

clutch out [B] ( x 1).

[B]

[A]

G070R715.WMF

G071 3-10 SM

Page 55

LASER OPTICS SECTION

3.5 LASER OPTICS SECTION

WARNING

Turn off the main switch and unplug the machine before beginning any of

the procedures in this section. Laser beams can cause serious eye injury.

3.5.1 CAUTION DECAL LOCATION

LD_CAUTION.TIF

G070R208.WMF

DANGER

Turn off the main switch and disconnect the power plug from the power

outlet before beginning any disassembly or adjustment of the laser unit.

This printer uses a class-1 laser beam with a wavelength of 650 nm and an

output of 7 mW. The laser can cause serious eye injury.

Adjustment

Replacement

SM 3-11 G071

Page 56

LASER OPTICS SECTION

3.5.2 LASER OPTICS HOUSING UNIT

1. Open the left cover [A].

2. ID chip connectors [B] ( x 4)

3. Development units [C] x 4

4. Rear cover (

! 3.2.1)

5. Left cover [D]

6. Lower left cover [E] ( x 3)

[B]

[E]

[C]

[A]

G070R301.WMF

Adjustment

Replacement

7. Controller box (

! 3.3.2)

8. Flat cable [F]

NOTE: When reassembling,

connect the flat cable with

the blue side up.

9. x 4 [G]

10. Harness clamps [H]

[G]

[D]

G070R201.WMF

[F]

[H]

G070R202.WMF

3-12 SM

G071

Page 57

LASER OPTICS SECTION

11. Open the front cover.

12. Remove the dust shield glass

cleaner lever [A] from the dust

shield glass cleaner.

NOTE: The dust shield glass

cleaner lever is the blue

lever at the right side of the

main switch.

13. LD cover [B] ( x 2)

14. Laser optics housing unit [C]

( x 4)

[A]

[B]

G070R209.WMF

Adjustment

Replacement

[C]

G070R203.WMF

SM 3-13 G071

Page 58

LASER OPTICS SECTION

Adjusting for Image Skew

1. Positioning pin [A] ( x 1)

2. Loosen (x 4) [B].

3. Adjust the position of the laser

optics housing unit [! NOTE].

4. Fasten (x 4) [B].

NOTE: After changing the position

of the laser optics housing

unit, do not reinstall the

positioning pin. Keep the

pin in a safe place.

NOTE: When the image skews as

shown, move the unit 1 mm

in the direction of the black

arrow as shown in the upper

diagram.

1mm

[B]

[A]

G070R207.WMF

[! NOTE]

Adjustment

Replacement

Paper feed

(A3 SEF)

G070R001.WMF

G071 3-14 SM

Page 59

LASER OPTICS SECTION

Laser Beam Pitch Adjustment

1. Select test pattern 15 with

SP5-955-1 (Test Pattern –

Pattern).

2. Check if vertical black stripes

can be seen.

a) If stripes cannot be seen

(Figure 2), laser beam

pitch adjustment is not

required.

b) If stripes can be seen

(Figure 1), laser beam

pitch adjustment is

required. Go on to the

next step.

3. To adjust the laser beam pitch,

tighten or loosen the screw [A]

on the LD unit holder.

Feed direction

Figure 1 Figure 2

G070R952.WMF

[A]

Adjustment

Replacement

4. Set SP 2-917 (Test Pattern) to

‘On’. Then send a one-page

job to the printer, or print an

SMC list (SP 5-990-6, SP Print

mode – Non default).

5. Repeat steps 2 through 4 until

the black stripes disappear

(Figure 2).

G070R820.WMF

SM 3-15 G071

Page 60

LASER OPTICS SECTION

3.5.3 POLYGONAL MIRROR MOTOR AND LSD

WARNING

Do not touch any edges of the polygon mirror, spring, or bracket. These

edges can cause serious injury.

1. Development units, LD cover (! 3.5.2)

2. Cover [A] ( x 1)

NOTE: Before removing the cover, clean

the cover to prevent toner from

entering into the unit.

3. Polygonal mirror motor [B]

( x 1, x 4)

NOTE: Do not touch the surface.

of the polygonal motor.

4. Synch. detection board (LSD) [C]

( x 1, x 1)

[C]

[B]

[A]

G070R204.WMF

Adjustment

Replacement

G070R205.WMF

G071 3-16 SM

Page 61

DEVELOPMENT UNIT

3.6 DEVELOPMENT UNIT

CAUTION

Do not touch the development unit sleeves or ID chip terminals.

1. Open the left cover [A].

2. ID chip connector [B]

3. Lift up the development unit [C]

slightly, and pull it out of the

machine.

NOTE: Remove the units in the

order K, Y, C, M. For

example, before removing

the M unit, remove the K, Y,

and C units first.

[B]

[C]

[A]

G070R301.WMF

Adjustment

Replacement

4. Peel off the toner cartridge seal [D].

5. Reinstall the toner cartridge in the

development unit.

6. Keep the development unit level and

shake the development unit about 10

times from side to side.

NOTE:

1) Do not touch the

development roller or the

development roller gear.

2) Use caution not to drop the

cartridge or to damage it.

3) If the cartridge has not been

shaken well, the machine

takes a longer time to

initialize the development

unit, or an error message or

SC350 is displayed. When

either of them is displayed,

turn the main switch off and

on.

[D]

G070R901.WMF

G070R902.WMF

SM 3-17 G071

Page 62

DEVELOPMENT UNIT

7. Install the development unit in the

machine.

8. After installing the development

unit, print out the "development unit

check" sheet to confirm the correct

installation of the development unit

(Menu — Maintenance —

Devp.UnitCheck).

NOTE: A white line or band may

appear on one end of the

paper if a development is

incorrectly installed. To

correct this, pull out the

development unit partially

(about 30 mm) [E] and

slowly reinstall it.

[E]

G070R457.WMF

Adjustment

Replacement

G071 3-18 SM

Page 63

PHOTOCONDUCTOR UNIT (PCU)

3.7 PHOTOCONDUCTOR UNIT (PCU)

3.7.1 MAIN UNIT

NOTE:

1) Before replacing any of the parts or consumables in this section, cover

the floor with cloth or some sheets of paper.

2) Never tilt the unit. The toner may come out of the unit.

3) When handling the unit, grasp the brown (front) and green (top) grips.

Never touch the OPC (left) or transfer (right) belts.

4) After removing the photoconductor unit, cover it with a light-proof sheet.

Keep it in a dark place.

[C]

Adjustment

Replacement

1. Open the front cover [A].

2. Open the right cover [B].

3. x 4

4. Pull the OPC unit [C] out of the machine.

5. Grasp the brown and green grips.

6. Lift the unit and remove it.

[B]

[A]

G070R308.WMF

SM 3-19 G071

Page 64

PHOTOCONDUCTOR UNIT (PCU)

3.7.2 WASTE TONER BOTTLES

1. O/B waste toner bottle [A]

2. T/B waste toner bottle [B]

[A]

[B]

G070R302.WMF

G070R303.WMF

Adjustment

Replacement

G071 3-20 SM

Page 65

PHOTOCONDUCTOR UNIT (PCU)

3.7.3 CHARGE CORONA WIRE

1. Modular cable [A]

2. Loosen (x 1) [B]

3. Charge corona unit [C]

4. Front bracket ( x 1) [D]

5. Grid [E]

6. Rear bracket [F]

[B]

[D]

[A]

[E]

[C]

G070R304.WMF

Adjustment

Replacement

[F]

[H]

G070R305.WMF

7. Front wire cover [G]

8. Rear wire cover [H]

9. Wire cleaner [I]

[G]

[J]

10. Unhook the corona wire [J].

G070R259.WMF

SM 3-21 G071

[I]

Page 66

PHOTOCONDUCTOR UNIT (PCU)

3.7.4 CHARGE CORONA WIRE CLEANER MOTOR

1. Charge corona unit (! 3.7.3)

2. Front motor cover [A] ( x 3)

3. Motor [B]

[A]

3.7.5 OPC BELT CLEANING UNIT

1. Photoconductor unit (! 3.7.1)

2. Charge corona unit (! 3.7.3)

3. Drive gear [A] ( x 1)

4. Rear brace [B] ( x 1)

5. Front brace [C] ( x 1)

6. OPC belt cleaning unit [D]

( x 2)

NOTE: Hold up the

photoconductor unit

while removing the OPC

belt cleaning unit.

[A]

[B]

[B]

G070R306.WMF

[C]

G070R315.WMF

Adjustment

Replacement

3.7.6 IMAGE TRANSFER BELT CLEANING UNIT

1. Photoconductor unit (! 3.7.1)

2. Bracket [A] ( x 2)

3. Image transfer belt cleaning unit

[B]

G071 3-22 SM

[B]

G070R309.WMF

[A]

Page 67

PAPER TRANSFER UNIT

Rev. 03/2003

3.8 PAPER TRANSFER UNIT

3.8.1 VERTICAL TRANSPORT UNIT

1. Open the right lower cover [A].

2. Right cover [B] ( x 1)

[B]

3.8.2 TRANSFER ROLLER

⇒

1. Brace [A] ( x 1)

2. Guide [B]

NOTE: To remove the screws,

turn the roller unit on its

pivot.

3. Transfer roller [C]

( x 2, Bushing x 2, Bearing x 2)

[A]

[C]

G070R451.WMF

[B]

Adjustment

Replacement

[A]

SM 3-23 G071

G070R453.WMF

Page 68

PAPER TRANSFER UNIT

Cleaning the Paper Dust Mylar

–Quick Method–

1. Cover [A]

2. Sweep away paper dust with a

blower brush [B].

–When the paper dust has to be removed completely–

[D]

1. Bracket [C] ( x 2)

[E]

[C]

[B]

[A]

G070R562.WMF

Adjustment

Replacement

2. Plate spring [D]

3. Metal roller [E]

[G]

4. Bearing [F][G]

5. Spring [H][I]

6. Clean the mylar [J] with a dry cloth.

[I]

[F]

[H]

[J]

G070R561.WMF

G071 3-24 SM

Page 69

FUSING/PAPER EXIT

3.9 FUSING/PAPER EXIT

CAUTION

Turn off the main switch and wait until the fusing unit cools down before

beginning any of the procedures in this section. The fusing unit can cause

serious burns.

3.9.1 FUSING UNIT

[C]

1. Loosen the knob screw [A].

2. Pull the unit out of the machine.

3. Unhook the bottom stopper [B].

4. Grasp the rear end (marked with a

green label) [C].

5. Release the unit [D] from the base

plate [E].

[A]

[D]

Adjustment

Replacement

3.9.2 OIL SUPPLY UNIT

NOTE: When removing either of the

lamps (! 3.9.3), remove the

knob screw (! 3.9.1) before

removing the oil supply unit.

1. Fusing unit (! 3.9.1)

2. Put the fusing unit on a level place.

3. Oil supply unit [A]

NOTE:

1) Do not touch the oiling felt.

2) When reassembling, push the top of the oil supply unit so that the front

and rear hinges are correctly set.

[B]

[A]

[E]

G070R501.WMF

G070R502.WMF

SM 3-25 G071

Page 70

FUSING/PAPER EXIT

3.9.3 LAMPS

1. Oil supply unit (! 0)

2. Gear bracket [A] ( x 2)

3. Upper cover [B] ( x 2, shoulder

screw x 1)

4. Terminals [C], [D] ( x 5)

NOTE:

[C]: Pressure roller lamp

terminals

[D]: Heating roller lamp

terminals

[D]

[B]

[C]

G070R503.WMF

[A]

[D]

Adjustment

Replacement

5. Pull out the lamp (350 W) [E].

6. Pull out the lamp (770 W) [F].

NOTE: “350 W” and “770 W” are etched

on the respective terminals.

[H]

[F]

350W

G070R504.WMF

[E]

770W

G070R510.WMF

G071 3-26 SM

Page 71

FUSING/PAPER EXIT

3.9.4 FUSING INNER UNIT

1. Lamps (! 3.9.3)

2. Drive gear [A]

3. Knob screw [B] ( x 1)

4. Heating roller lamp harness terminal

[C] ( x 1)

5. Fusing inner unit [D] ( x 2,

x 3)

[B]

3.9.5 PRESSURE ROLLER THERMOFUSE

1. Fusing inner unit (! 3.9.4)

2. Pressure roller thermofuse [A] ( x 2)

[D]

[A]

G070R506.WMF

[C]

[A]

Adjustment

Replacement

G070R508.WMF

3.9.6 FUSING BELT UNIT AND PRESSURE ROLLER UNIT

1. Fusing inner unit (! 3.9.4)

2. Springs [A] [B]

3. Separate the fusing belt unit [C] and

pressure roller unit [D].

[A]

[C]

[D]

G070R507.WMF

[B]

SM 3-27 G071

Page 72

FUSING/PAPER EXIT

3.9.7 PRESSURE ROLLER THERMISTOR

1. Pressure roller unit (! 3.9.6)

2. Pressure roller lower stay [A]

( x 2)

3. Pressure roller thermistor

holder [B] ( x 1)

4. Pressure roller thermistor [C]

[C]

[B]

3.9.8 HOT ROLLER STRIPPERS

1. Oil supply unit (! 3.9.2)

2. Fusing lamps (! 3.9.3)

3. Fusing inner unit (! 3.9.4)

4. Gear [A]

NOTE: Remove the gear before

removing the stripper pawl

assembly; otherwise, the

gear may be damaged.

5. Hot roller stripper pawl assembly [B]

(Spring x 1, x 2)

[F]

[D]

[E]

G070R509.WMF

[C] [B]

[A]

[A]

Adjustment

Replacement

6. Hot roller stripper pawl [C]

G070R552.WMF

Reassembling

1. Put the spring [D] on the pawl.

2. Put the left end of the pawl in the square opening [E].

3. Put the front and rear ends of the pawl in the holder [F].

4. Confirm that the pawl moves correctly.

G071 3-28 SM

Page 73

FUSING/PAPER EXIT

3.9.9 PRESSURE ROLLER

[B]

[C]

[D]

1. Pressure roller unit (! 3.9.6)

2. Gear [A]

[E]

G070R900.WMF

[A]

Adjustment

Replacement

3. Hot roller stripper assembly [B] ( x 2)

4. Front bracket [C] ( x 1)

5. Bearing [D]

6. Pressure roller [E]

SM 3-29 G071

Page 74

FUSING/PAPER EXIT

3.9.10 OIL ABSORBERS

[A]

[C]

G070R516.WMF

[G]

[L]

[K]

[J]

[I]

1. Fusing inner unit (! 3.9.4)

2. Absorber 1 [A]

3. Pressure roller unit (! 3.9.6)

4. Absorber holder [B] ( x 1)

[H]

[F]

[D]

[B]

Adjustment

Replacement

[E]

G070R825.WMF

5. Absorber 2 [C]

6. Spring [D]

7. Absorber holder [E] ( x 1)

8. Absorber 3 [F]

9. Spring [G]

10. Base bracket [H] ( x 2)

11. Absorber holder [I] ( x 1)

12. Absorber 4 [J]

13. Absorber 5 [K]

14. Absorber 6 [L]

G071 3-30 SM

Page 75

FUSING/PAPER EXIT

3.9.11 PAPER EXIT UNIT AND PAPER EXIT/OVERFLOW SENSOR

CAUTION

Turn off the main switch and wait until the paper exit unit cools down

before beginning any of the procedures in this section. The paper exit unit

can cause serious burns.

1. Paper exit cover (! 3.2.3)

2. Paper exit unit [A] ( x 3,

x 1)

NOTE: Remove 2 connectors

before removing the unit.

To remove the last

connector, remove the

unit and turn it. The

connector is on the

bottom side.

3. Paper exit sensor [B]

4. Paper overflow sensor [C]

[C]

[B]

[A]

G070R601.WMF

Adjustment

Replacement

SM 3-31 G071

Page 76

PAPER FEED AND TRANSPORT

3.10 PAPER FEED AND TRANSPORT

3.10.1 FEED ROLLER AND FRICTION PAD

1. Paper tray [A]

[A]

2. x 1 [B]

3. Slide the shaft [C].

4. Feed roller [D] (1 hook)

5. Friction pad [E]

[B]

[D]

[E]

G070R101.WMF

Adjustment

Replacement

[C]

G070R102.WMF

G071 3-32 SM

Page 77

PAPER FEED AND TRANSPORT

3.10.2 REGISTRATION SENSOR

1. Front cover [A] (L-shaped-pin x 2)

2. Rear cover (! 3.2.1)

3. Upper cover (! 3.2.3)

4. Lower left cover (! 3.5.2)

5. Dust shield glass cleaning lever [B]

(! 3.5.2)

6. Charge corona unit (! 3.7.3)

7. Right cover (! 3.8.1)

8. Left inner cover door [C]

9. Left inner cover [D] ( x 2)

10. Right inner cover [E] ( x 3)

[C]

[B]

[D]

[A]

[E]

G070R103.WMF

G070R653.WMF

Adjustment

Replacement

SM 3-33 G071

Page 78

PAPER FEED AND TRANSPORT

11. Terminal [A] ( x 1)

NOTE: You have to remove the

terminal to lift the

transport stay (! step

14).

12. Transport guide [B] ( x 1)

[B]

G070R104.WMF

[A]

13. Drive gear [C] (1 hook)

14. Lift the transport stay [D] ( x 2)

and release the wire [E].

NOTE: You can see the wire clip

from the rear of the

machine.

15. Registration sensor [F] ( x 1,

x 1)

[E]

[D]

[F]

G070R105.WMF

Adjustment

Replacement

[C]

G071 3-34 SM

Page 79

PAPER FEED AND TRANSPORT

3.10.3 PAPER FEED SENSOR

1. Lift the transport stay [A]

(! 3.10.2)

2. Paper feed sensor [B] ( x 1)

NOTE: Unhook the rear two pawls

first, move the feeler, and

unhook the front pawl.

3.10.4 PAPER NEAR-END SENSOR