Page 1

RICOH GROUP COMPANIES

G081/G092

SERVICE MANUAL

001481MIU

Page 2

Page 3

SERVICE MANUAL

G081/G092

®

®

RICOH GROUP COMPANIES

Page 4

Page 5

G081/G092

SERVICE MANUAL

001481MIU

Page 6

Page 7

A

f

r

It is the reader's responsibility when discussing the information contained

within this document to maintain a level of confidentiality that is in the best

interest of Ricoh Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH CORPORATION.

ll product names, domain names or product illustrations, including

desktop images, used in this document are trademarks, registered

trademarks or the property of their respective companies.

They are used throughout this book in an informational or editorial fashion

only and for the benefit of such companies. No such use, or the use o

any trade name, or web site is intended to convey endorsement or othe

affiliation with Ricoh products.

2003 RICOH Corporation. All rights reserved.

Page 8

Page 9

p

t

r

g

l

p

WARNING

The Service Manual contains information

regarding service techniques, procedures,

rocesses and spare parts of office equipmen

distributed by Ricoh Corporation. Users of this

manual should be either service trained o

certified by successfully completing a Ricoh

Technical Training Program.

Untrained and uncertified users utilizin

information contained in this service manual to

repair or modify Ricoh equipment risk persona

injury, damage to property or loss of warranty

rotection.

Ricoh Corporation

Page 10

Page 11

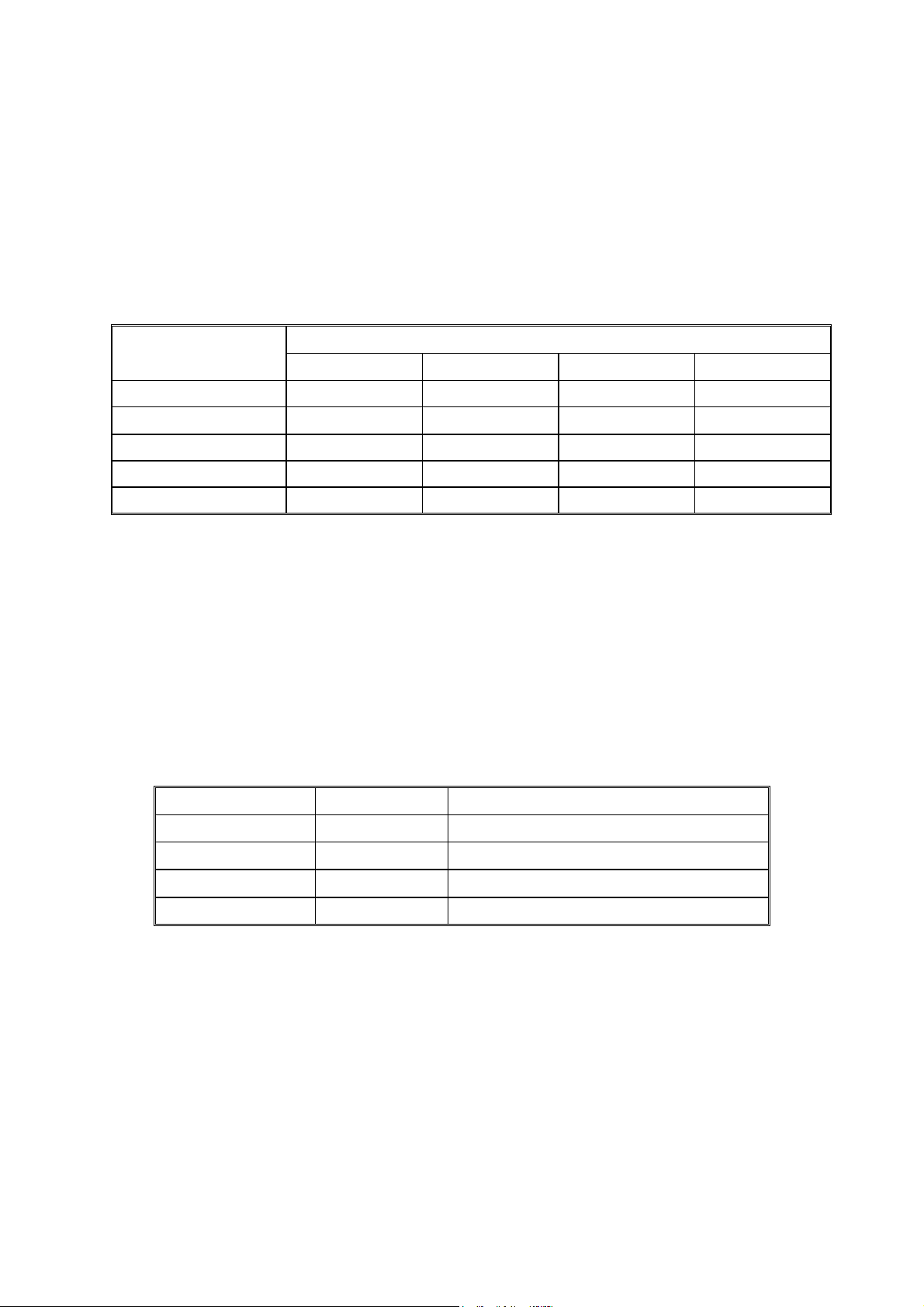

LEGEND

PRODUCT CODE COMPANY

G081 C7116 LP020c CL3000 CLP1620

G092

GESTETNER LANIER RICOH SAVIN

– – – –

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

*

2/2003 Original Printing

Page 12

Page 13

G081/G092

TABLE OF CONTENTS

INSTALLATION

1. INSTALLATION...............................................................................1-1

1.1 INSTALLATION RE QUIREMENTS...................................................................1-1

1.1.1 ENVIRONMENT.........................................................................................1-1

1.1.2 MACHINE LEVEL......................................................................................1-1

1.1.3 MACHINE SPACE REQUIREMENT.......................................................1-2

1.1.4 POWER REQUIRE MENTS ......................................................................1-3

1.2 MACHINE INSTALLATION ................................................................................1-3

1.2.1 INSTALL ING THE PHOTOCONDUCTOR UNIT ..................................1-3

1.2.2 INSTALLING THE TONER CARTRIDGE ..............................................1-6

1.2.3 LOADING PAPER......................................................................................1-8

1.2.4 CONNECTING TH E POWER CORD...................................................1-10

1.2.5 SELECTING THE PANEL DISPLAY LANGUAGE .............................1-11

1.2.6 PRINTING THE TEST PAGE.................................................................1-13

1.2.7 ADJUSTING THE IMAGE DENSITY....................................................1-14

1.2.8 CONNECTING TH E PRINTER TO A COMPUTER...........................1-16

Connecting the printer to a computer using a network interface cable1-16

Connecting the printer to a computer using a parallel cable .................1-17

1.2.9 CONFIGURING THE PRINTER FOR THE NETWORK ....................1-18

1.2.10 INSTALLING THE PRINTER DRIVERS AND UTILITIES...............1-21

1.2.11 METER CHARGE..................................................................................1-22

1.3 OPTIONAL UNIT INSTALLATION ..................................................................1-23

1.4 MACHINE INSTALLATION ..............................................................................1-24

PREVENTATIVE MAINTENANCE

2. PREVENTATIVE MAINTENANCE ..................................................2-1

2.1 USER REPLACEABLE ITEMS..........................................................................2-1

2.2 SERVICE MAINTEN ANCE.................................................................................2-2

2.2.1 PM TABLE...................................................................................................2-2

2.2.2 RECOMMENDED CLEANING PROCEDURE......................................2-2

REPLACEMENT AND ADJUSTMENT

3. REPLACEMENT AND ADJUSTMENT...........................................3-1

3.1 SPECIAL TOOLS AND LUBRICANTS.............................................................3-1

3.1.1 TOOLS.........................................................................................................3-1

3.1.2 LUBRICATION............................................................................................3-1

3.2 FUSING UNIT.......................................................................................................3-2

3.3 TRANSFER BELT UNIT .....................................................................................3-3

SM i G081/G092

Page 14

3.4 EXTERIOR COVERS..........................................................................................3-3

3.4.1 FRONT DOOR WI TH TRANSFER ROLLER UNIT..............................3-3

3.4.2 TRANSFER ROLLER ASSEMBLY.........................................................3-4

3.4.3 RIGHT COVER...........................................................................................3-4

3.4.4 REAR COVER............................................................................................3-5

3.4.5 LEFT COVER.............................................................................................3-5

3.4.6 TOP COVER AND LCD PANEL..............................................................3-6

3.5 ECB AND DRIVE U NITS....................................................................................3-7

3.5.1 ECB (ENGINE CONTROL BOARD) AND TEMPERATURE/

HUMIDITY SENSOR BOARDS..............................................................3-7

3.5.2 SUB FUSING-FAN AND SUB FUSING-FAN DUCT............................3-8

3.5.3 TONER CARTRIDGE HOLDER..............................................................3-9

3.5.4 TONER CARTRIDGE DRIVE UNIT ......................................................3-10

3.5.5 PAPER PICKUP MOTOR AND MOTOR BRACKET.........................3-10

3.5.6 MAIN DRIVE UNIT...................................................................................3-11

3.5.7 BIAS UNIT.................................................................................................3-17

3.5.8 POWER SUPPLY FAN MOTOR AND PSU FAN MOTOR DUCT...3-17

3.6 LASER SCANNING UNIT.................................................................................3-18

3.6.1 CAUTION DECAL LOCATIONS............................................................3-18

3.6.2 LASER SCANNING UNIT.......................................................................3-19

3.7 PAPER FEED.....................................................................................................3-19

3.7.1 PAPER EXIT.............................................................................................3-19

3.7.2 DISASSEMBLY OF PAPER EXIT SUB ASSEMBLY.........................3-22

3.8 PAPER FEED UNIT...........................................................................................3-22

3.8.2 PAPER FEED UNIT DISASSEMBLY...................................................3-24

3.9 IH (INDUCTIVE HEATER) UNIT .....................................................................3-27

3.10 ELECTRICAL COM PONENTS......................................................................3-28

3.10.1 POWER SUPPLY UNIT........................................................................3-28

3.10.2 POWER SUPPLY UNIT DISASSEMBLY..........................................3-29

3.10.3 MAIN CONTROL BOARD ....................................................................3-30

3.10.4 NVRAM/EEPROM REPLACEMENT PROCEDURES.....................3-30

EEPROM on the ECB..................................................................................3-30

NVRAM on the Controller............................................................................3-31

EEPROM on the ECB and the NVRAM on the Controller.....................3-31

3.10.5 MAIN CONTROL BOARD SHIELD COVERS...................................3-32

3.10.6 HIGH VOLTAGE BOARD AND REGISTRATION SENSOR

BOARD....................................................................................................3-33

3.11 TRANSFER BELT TENSION UNIT..............................................................3-34

3.11.1 TRANSFER BELT TENSION UNIT REMOV AL................................3-34

3.11.2 CHANGER SOLENOID AND CAM RATCHET SOLENOID ...........3-35

3.12 PCU HOLDER..................................................................................................3-37

3.13 FUSING FAN MOT OR....................................................................................3-39

3.14 SENSORS.........................................................................................................3-39

3.14.1 FRONT AND RI GHT COVER OPEN DETECTION SWITCHES...3-39

3.14.2 BY-PASS TRAY HOME POSITION SENSOR AND BY-PASS

TRAY PAPER DETECTION SENSOR BOARDS............................3-40

3.14.3 WASTE TONER CARTRIDGE FULL SENSO R...............................3-40

3.15 STANDARD PAPER CASSETTE.................................................................3-41

G081/G092 ii SM

Page 15

TROUBLESHOOTING

4. TROUBLESHOOTING.....................................................................4-1

4.1 SERVICE CALL CO NDITIONS .........................................................................4-1

4.1.1 SUMMARY..................................................................................................4-1

4.1.2 SC CODE DESCR IPTIONS.....................................................................4-2

4.2 CONTROLLER ERROR.....................................................................................4-6

4.3 TROUBLESHOOTING GUIDE........................................................................4-10

4.3.1 BLANK PRINT ..........................................................................................4-10

4.3.2 ALL-BLACK PRI NT..................................................................................4-10

4.3.3 MISSING CMY COLOR ..........................................................................4-11

4.3.4 LIGHT PRINT............................................................................................4-11

4.3.5 REPEATED SPOTS OR LINES ON PRINTS......................................4-12

4.3.6 DARK VERTICAL LINE IN PRINT........................................................4-12

4.3.7 WHITE HORIZONTAL LINES OR BANDS..........................................4-13

4.3.8 MISSING PARTS OF IMAGES..............................................................4-13

4.3.9 DIRTY BACKGROUND...........................................................................4-13

4.3.10 PARTIAL CMY COLOR DOTS............................................................4-13

4.3.11 DARK IRREGULAR STREAKS ON PRINTS....................................4-13

4.3.12 CMY COLOR IRREGULAR STREAKS..............................................4-14

4.3.13 GHOSTING.............................................................................................4-14

4.3.14 UNFUSED OR PARTIALLY FUSED PRINTS ...................................4-14

4.3.15 IMAGE SKEW ........................................................................................4-14

4.3.16 BACKGROUND STAIN.........................................................................4-15

4.3.17 NO PRINTING ON PAPER EDGE......................................................4-15

4.3.18 IMAGE NOT CENTERED WHEN IT SHOULD BE ..........................4-15

4.4 ELECTRICAL COMPONENT DEFECTS.......................................................4-16

4.4.1 SENSORS.................................................................................................4-16

4.5 BLOWN FUSE CONDITIONS..........................................................................4-18

Power supply unit..........................................................................................4-18

High voltage unit...........................................................................................4-18

4.6 LEDS....................................................................................................................4-18

SERVICE TABLES

5. SERVICE TABLES..........................................................................5-1

5.1 SERVICE PROGRAM MODE............................................................................5-1

5.1.1 SERVICE MODE OPERATION...............................................................5-1

Entering the Service Mode............................................................................5-1

Accessing the Required Program ................................................................5-2

Inputting a Value or Setting for a Service Program...................................5-2

Exiting Service Mode......................................................................................5-2

5.2 PRINTER CONTROLLER SERVICE MODE...................................................5-3

5.2.1 SERVICE (CONT ROLLER SERVICE MODES)...................................5-3

Bit Switch Settings..........................................................................................5-5

Gamma Adjustment........................................................................................5-7

5.3 PRINTER ENGINE SERVICE MODE.............................................................5-10

SM iii G081/G092

Page 16

5.3.1 SERVICE MODE TABLE (“2. ENGINE”)..............................................5-10

SP1-XXX (Feed)...........................................................................................5-10

SP2-XXX (Drum)...........................................................................................5-12

SP5-XXX (Mode)..........................................................................................5-14

SP7-XXX (Data Log)....................................................................................5-20

5.3.2 INPUT CHECK TABLE............................................................................5-24

Table 1: Paper Size Switch.........................................................................5-26

5.3.3 OUTPUT CHECK TABLE.......................................................................5-26

5.4 FIRMWARE UPDATE PROCEDURE.............................................................5-28

5.4.1 TYPE OF FIRMWARE ............................................................................5-28

5.4.2 ERROR RECOVERY..............................................................................5-28

Engine Firmware...........................................................................................5-28

Controller System Firmware:......................................................................5-28

5.4.3 CONTROLLER/ENGINE FIRMWARE UPGRADE.............................5-29

Engine Firmware...........................................................................................5-29

Controller System Firmware........................................................................5-30

5.5 POWER ON SELF-TEST .................................................................................5-32

5.5.1 CONTROLLER SELF-DIAGNOSTIC ....................................................5-32

Overview........................................................................................................5-32

Detailed self-diagnostics..............................................................................5-33

5.5.2 ENGINE SELF-D IAGNOSTIC ................................................................5-33

5.6 USER PROGRAM MODE................................................................................5-34

5.7 DIP SWITCHES .................................................................................................5-35

Controller Board............................................................................................5-35

DETAILED DESCRIPTIONS

6. DETAILED SECTION DESCRIPTIONS.........................................6-1

6.1 OVERVIEW...........................................................................................................6-1

6.1.1 COMPONENT LAYOUT ...........................................................................6-1

6.1.2 PAPER PATH.............................................................................................6-2

6.2 DRIVE MECHANISM...........................................................................................6-3

6.2.1 GENERAL DESCRIPTION.......................................................................6-3

6.2.2 BK MOTOR DRIVE....................................................................................6-4

6.2.3 CMY MOTOR DRIVE ................................................................................6-5

6.2.4 BOARD STRUCTURE ..............................................................................6-6

Overview..........................................................................................................6-6

Descriptions.....................................................................................................6-7

6.3 PRINT PROCESS................................................................................................6-8

6.3.1 OVERVIEW.................................................................................................6-8

6.3.2 CHARGE ...................................................................................................6-10

6.3.3 LASER EXPOSURE................................................................................6-11

Laser scanning..............................................................................................6-11

Polygon motor and laser exposure............................................................6-12

6.3.4 TONER SUPPLY......................................................................................6-13

Toner cartridge..............................................................................................6-13

Paddle shaft switching mechanism............................................................6-14

Toner cartridge and toner end detection...................................................6-15

G081/G092 iv SM

Page 17

6.3.5 DEVELOPMENT......................................................................................6-17

PCU and OPC drum.....................................................................................6-17

6.3.6 TRANSFER BELT UNIT DRIVE............................................................6-19

Belt tension unit.............................................................................................6-19

Four phases...................................................................................................6-20

Belt home position sensor...........................................................................6-20

Monochrome printing and color printing....................................................6-21

6.3.7 BELT TRANSFER AND CLEANING.....................................................6-23

Transfer from drum to belt...........................................................................6-23

Transfer from belt to paper..........................................................................6-24

Belt cleaning ..................................................................................................6-25

6.3.8 WASTE TONER CARTRIDGE ..............................................................6-26

Mechanism.....................................................................................................6-26

Sensor ............................................................................................................6-27

6.3.9 FUSING .....................................................................................................6-28

Fusing process..............................................................................................6-28

Circuit board ..................................................................................................6-29

6.3.10 PAPER FEED.........................................................................................6-34

Drive motors ..................................................................................................6-35

Sensors ..........................................................................................................6-35

Paper size detection switch combination..................................................6-35

Registration clutch........................................................................................6-36

Feeding envelopes.......................................................................................6-36

Paper feed speed..........................................................................................6-36

6.3.11 STANDARD TRAY LOCK MECHANISM...........................................6-37

6.3.12 PAPER EXIT AND PAPER SWITCHBACK.......................................6-38

Normal Printing Mode (Not Duplex Printing Mode).................................6-38

Duplex Printing Mode (Paper Switchback)...............................................6-39

6.3.13 COLOR POINT ADJUSTMENT...........................................................6-40

Adjustment types ..........................................................................................6-40

Adjustment timing .........................................................................................6-41

6.4 CONTROLLER...................................................................................................6-42

6.4.1 OVERVIEW...............................................................................................6-42

6.4.2 BOARD LAYOUT.....................................................................................6-44

6.4.3 PRINT DATA PROCESSING.................................................................6-45

RPCS Driver..................................................................................................6-45

PCL5c Driver.................................................................................................6-45

PS3 Driver......................................................................................................6-46

CMS (Color Management System)............................................................6-46

Gray Correction.............................................................................................6-46

BG/UCR (Black Generation/Under Color Removal)................................6-46

Gamma Correction.......................................................................................6-46

Toner Limitation............................................................................................6-47

Dither Processing and ROP/RIP ................................................................6-47

6.5 CONTROLLER FUNCTIONS...........................................................................6-48

6.5.1 SAMPLE PRINT.......................................................................................6-48

6.5.2 LOCKED PRINT.......................................................................................6-48

6.5.3 PAPER SOURCE SELECTION.............................................................6-49

Tray Priority (Auto Tray Select)..................................................................6-49

SM v G081/G092

Page 18

Tray Lock........................................................................................................6-49

Manual Tray Select.......................................................................................6-49

6.5.4 AUTO CONTINUE ...................................................................................6-50

Auto Tray Select............................................................................................6-50

Manual Tray Select.......................................................................................6-50

ACS (Auto Color Sensing) Mode................................................................6-51

Energy saver mode ......................................................................................6-52

6.6 IEEE1394 INTERF ACE.....................................................................................6-53

6.6.1 SPECIFICATIONS...................................................................................6-53

Hardware Specification................................................................................6-53

System Requirements..................................................................................6-53

6.6.2 IEEE1394 SCSI PRINT...........................................................................6-53

6.6.3 BLOCK DIAGRAM...................................................................................6-54

6.6.4 PIN ASSIGNMENT ..................................................................................6-54

6.6.5 REMARKS.................................................................................................6-55

6.6.6 TROUBLESHOOTING NOTES .............................................................6-55

6.6.7 IP OVER 1394..........................................................................................6-56

6.7 USB......................................................................................................................6-57

6.7.1 SPECIFICATIONS...................................................................................6-57

6.7.2 USB 1.1/2.0...............................................................................................6-57

6.7.3 USB CONNECTOR S...............................................................................6-58

6.7.4 PIN ASSIGNMENT ..................................................................................6-58

6.7.5 REMARKS.................................................................................................6-59

Related SP Mode..........................................................................................6-59

6.8 IEEE802.11B (WI RELESS LAN).....................................................................6-60

6.8.1 SPECIFICATIONS...................................................................................6-60

6.8.2 BLOCK DIAGRAM...................................................................................6-61

6.8.3 TRANSMISSION MODE.........................................................................6-62

Ad Hoc Mode.................................................................................................6-62

Infrastructure Mode ......................................................................................6-62

6.8.4 SECURITY FEAT URES..........................................................................6-63

Using the SSID in Ad hoc mode.................................................................6-63

6.8.5 TROUBLESHOOTING NOTES .............................................................6-64

Communication Status.................................................................................6-64

Channel Settings...........................................................................................6-64

Troubleshooting steps..................................................................................6-65

6.9 BLUETOOTH (WIRELESS).............................................................................6-66

6.9.1 SPECIFICATIONS...................................................................................6-66

6.9.2 BLOCK DIAGRAM...................................................................................6-66

6.9.3 COMMUNICATION USING BLUETOOTH..........................................6-67

Piconet............................................................................................................6-67

Frequency Hopping Spread Spectrum (FHSS) ........................................6-67

Profiles............................................................................................................6-68

6.9.4 SECURITY FEATURES..........................................................................6-68

Public and Private Mode..............................................................................6-68

PIN Code (Personal Identification Number) .............................................6-68

6.10 CONNECTOR PIN DESCRIPTIONS ...........................................................6-69

CN1 (on ECB)/CN1 (on LSU) .....................................................................6-69

CN2 (on ECB)/CN3 (on LSU) .....................................................................6-69

G081/G092 vi SM

Page 19

CN3 (on ECB)/CN2 (on LSU) .....................................................................6-69

CN5 (on ECB)/CN1 (on high voltage board)............................................6-70

CN6 PCU ........................................................................................................6-70

CN7 Front/Right Door Sensor.....................................................................6-70

CN8 Power Supply Unit Fan.......................................................................6-70

CN9 Fusing Fan............................................................................................6-70

CN10 (on ECB)/CN1503 (on Toner Empty Sensor Board)....................6-71

CN11 Toner Cartridge Cover Sensor........................................................6-71

CN12 (on ECB)/CN1 (on CMY Motor)/CN1 (BK Motor).........................6-71

CN13 (on ECB)/CN1509 (PCU Home Sensor)........................................6-72

CN14 (on ECB) / CN1510 (on TB Unit Cam Home Position Sensor)..6-72

CN15 (on ECB)/CN1601 (on Fusing Unit)................................................6-72

CN17 (on ECB)/CN1505 (on Paper Full/Jam Sensor)...........................6-72

CN18 (on ECB) / CN1506 (on Paper Empty/Registration Sensor).......6-73

CN19 Pickup Solenoid.................................................................................6-73

CN20 Registration Clutch............................................................................6-73

CN21 BK Solenoid........................................................................................6-73

CN22 Paper Pickup Motor...........................................................................6-73

CN23 (on ECB)/CN1507 (on By-pass Tray Paper Detection

Sensor)/CN1512 (on By-pass Tray Home Position Sensor)..............6-74

CN24 Mono/Color Changer Solenoid........................................................6-74

CN25 TB Unit Cam Switching Solenoid....................................................6-74

CN26 Switchback Solenoid.........................................................................6-74

CN27 (on ECB)/CN1501 (on Color Registration Sensor) ......................6-75

CN28 Paper Size Detector..........................................................................6-75

CN29 (on ECB)/CN1 (on Humidity/Temperature Sensor).....................6-75

CN30 Sub Fusing Fan..................................................................................6-76

CN31 (on ECB)/CN1 (on Option Paper Feeder Unit) .............................6-76

CN32 (on ECB)/CN2503 (on Power Supply Board)................................6-76

CN33 (on ECB)/CN2505 (on Power Supply Board)................................6-77

CN34 (on ECB)/CN2504 (on Power Supply Board)................................6-77

CN35 LSU Safety Interlock Switch............................................................6-77

CN38 Printer Control Board 1 of 3 .............................................................6-78

CN38 Main Control Board 2 of 3 ................................................................6-79

CN38 Main Control Board 3 of 3 ................................................................6-80

CN39 (on ECB)/CN1508 (on Duplex Unit Jam Sensor).........................6-80

CN43 Toner Supply Solenoid.....................................................................6-81

CN45, CN46 (on ECB)/CN3301 (on LCD Panel) ....................................6-81

CN1502 Waste Toner Full Sensor.............................................................6-82

CN2001 AC Line...........................................................................................6-82

CN2203 (on IH Power Board).....................................................................6-82

CN2204 IH Heater........................................................................................6-82

CN1502 Power Switch.................................................................................6-82

CN1502 (on Power Supply Board)/CN2207 (on IH Power

Supply Board) ............................................................................................6-83

CN2506 Side/Front Door Interlock Switch................................................6-83

SM vii G081/G092

Page 20

SPECIFICATIONS

SPECIFICATIONS............................................................................. 7-1

1. GENERAL SPECIFICATIONS.....................................................................7-1

1.1 SUPPORTED PAPER SIZES ..............................................................7-3

2. SOFTWARE ACCESSORIES .....................................................................7-4

2.1 PRINTER DRIVERS ............................................................................ 7-4

2.2 UTILITY SOFTWARE .......................................................................... 7-4

3. MACHINE CONFIGURATION .................................................................... 7-5

PAPER FEED UNIT TYPE 3000 G342

SEE SECTION G342 FOR DETAILED TABLE OF CONTENTS

G081/G092 viii SM

Page 21

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the printer power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. Note that some components of the printer and the paper tray unit are

supplied with electrical voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

5. The inside and the metal parts of the fusing unit become extremely hot while

the printer is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

Toner, including monocomponent toner, and developer are non-toxic, but if you

get either of them in your eyes by accident, it may cause temporary eye

discomfort. Try to remove with eye drops or flush with water as first aid. If

unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The printer and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

the appropriate models.

2. The NVRAM module (option) installed on the controller has a lithium battery

which can explode if replaced incorrectly. Replace the NVRAM only with an

identical one. The manufacturer recommends replacing the entire NVRAM.

Do not recharge or burn this battery. Used NVRAM must be handled in

accordance with local regulations.

Page 22

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite

suddenly when exposed to an open flame.

2. Dispose of or recycle as required, used toner, developer, and organic

photoconductors in accordance with local regulations. (These are non-toxic

supplies.)

3. Dispose of or recycle as required, replaced parts in accordance with local

regulations.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the

repair of laser-based optical units in the field. The optical housing unit

can only be repaired in a factory or at a location with the requisite

equipment. The laser subsystem is replaceable in the field by a qualified

Customer Engineer. The laser chassis is not repairable in the field.

Customer engineers are therefore directed to return all chassis and laser

subsystems to the factory or service depot when replacement of the

optical subsystem is required.

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

WARNING

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can seriously damage

your eyes.

CAUTION MARKING:

Page 23

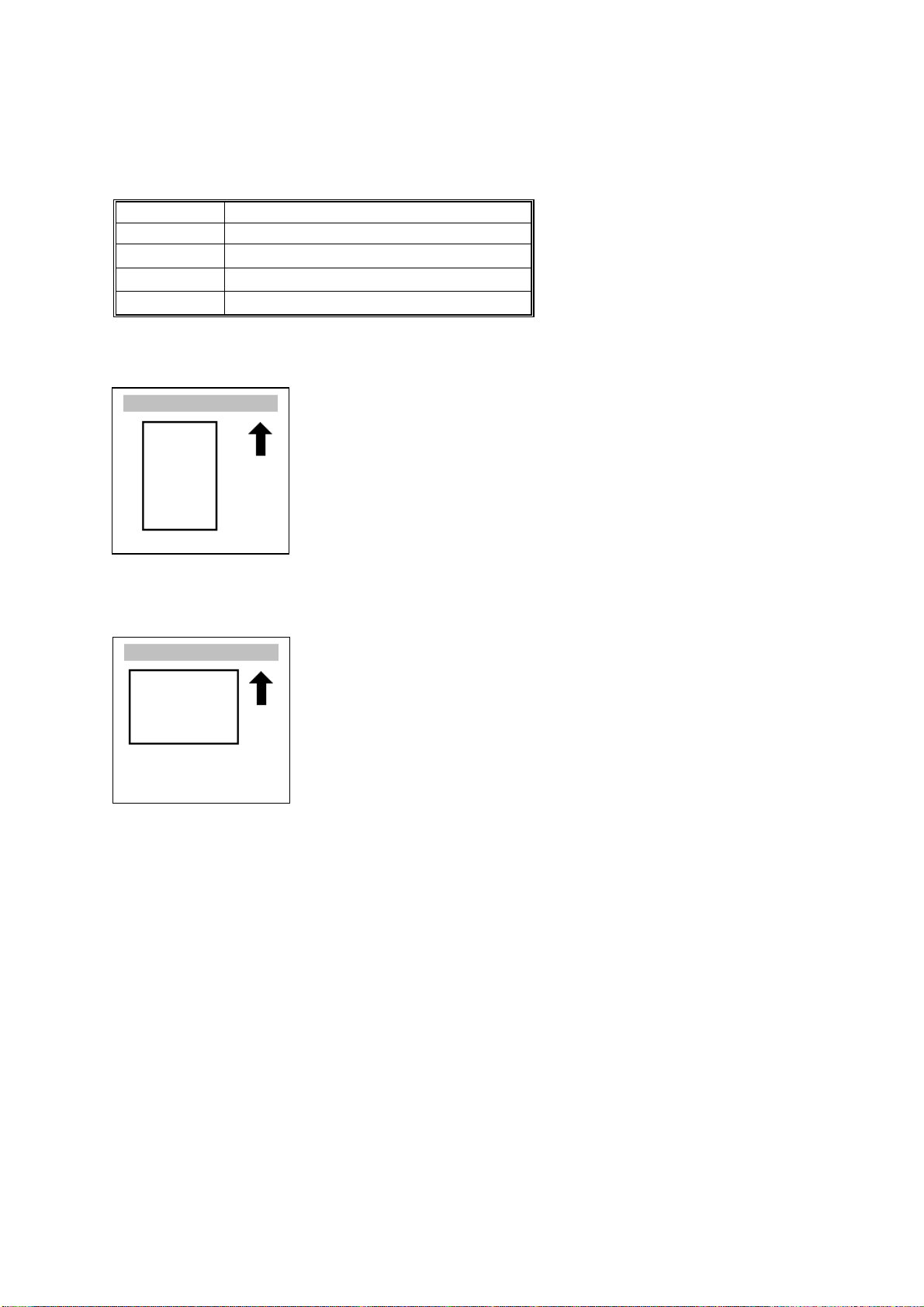

Conventions in this Manual

This manual uses several symbols.

Symbol What it means

!

Refer to section number

See Core Tech Manual for details

Screw

Connector

Lengthwise, SEF (Short Edge Feed)

Sideways, LEF (Long Edge Feed)

Page 24

Page 25

INSTALLATION

PREVENTIVE MAINTENANCE

REPLACEMENT AND ADJUSTMENT

TROUBLESHOOTING

TAB

POSITION 1

TAB

POSITION 2

TAB

POSITION 3

TAB

POSITION 4

SERVICE TABLES

DETAILED DESCRIPTIONS

SPECIFICATIONS

PAPER FEED UNIT TYPE 3000 G342

TAB

POSITION 5

TAB

POSITION 6

TAB

POSITION 7

TAB

POSITION 8

Page 26

Page 27

INSTALLATION

Page 28

Page 29

INSTALLATION REQUIREMENTS

1. INSTALLATION

1.1 INSTALLATION REQUIREMENTS

1.1.1 ENVIRONMENT

1. Temperature Range : 10 °C to 32 °C (50 °F to 89.6 °F)

2. Humidity Range : 15 % to 80 % RH

3. Ambient Illumination : Less than 2,000 lux (do not expose to direct sunlight)

4. Ventilation : 3 times/hr/person

5. Avoid areas that are exposed to sudden temperature changes. This includes:

1) Areas directly exposed to cool air from an air conditioner.

2) Areas directly exposed to heat from a heater.

6. Do not place the machine in an area where it will be exposed to any corrosive

gas (i.e. ammonia as used in a print shop).

7. Do not install the machine at any location over 2,500 m (8,125 ft.) above sea

level.

8. Place the machine on a strong, level base. (Inclination on any side should be

no more than 5 mm.)

9. Do not place the machine where it may be subjected to strong vibration.

Installation

1.1.2 MACHINE LEVEL

Front to back : Within 5 mm (0.2") of level

Right to left : Within 5 mm (0.2") of level

SM 1-1 G081/G092

Page 30

INSTALLATION REQUIREMENTS

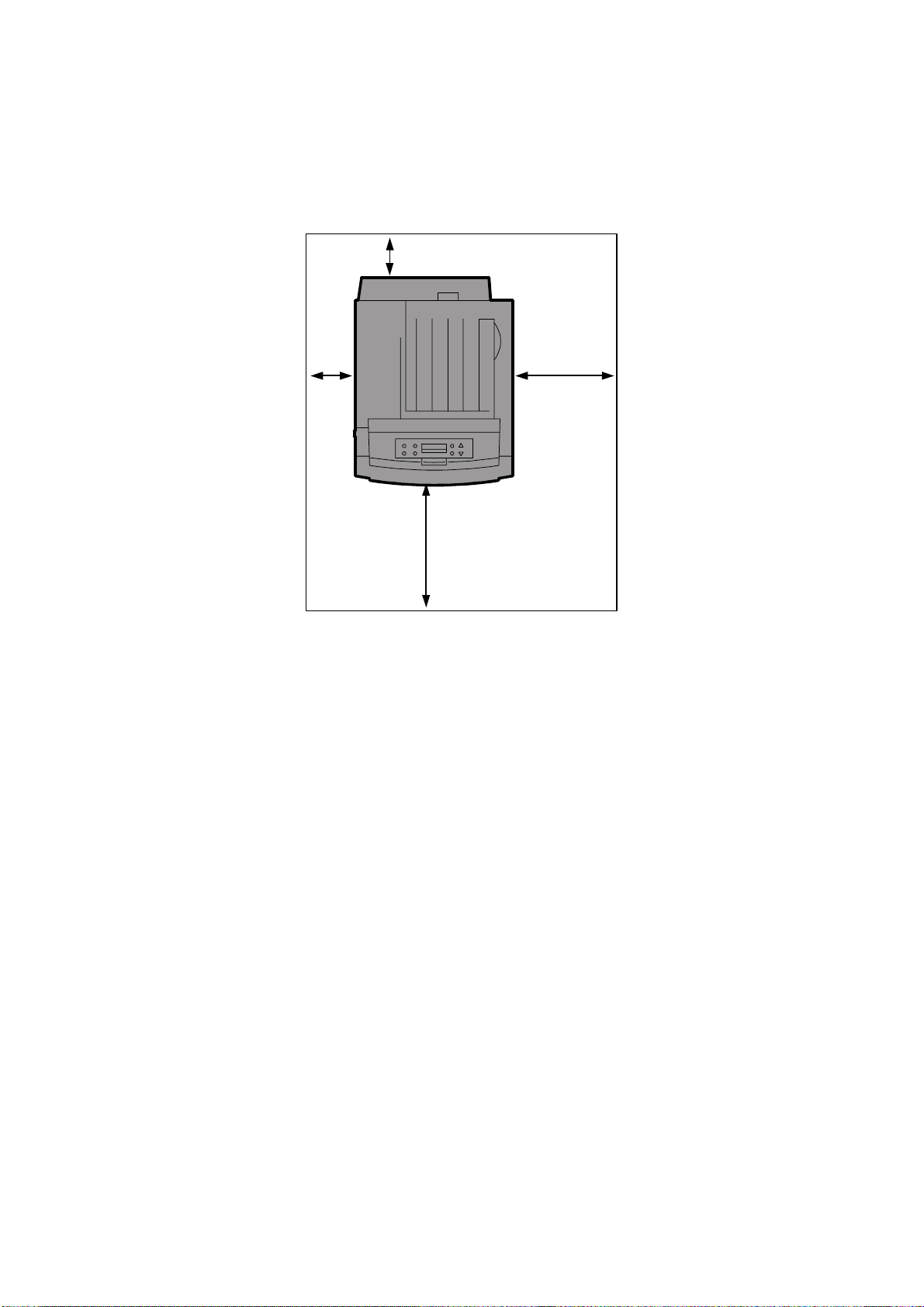

1.1.3 MACHINE SPACE REQUIREMENT

Place the machine near the power source, providing clearance as shown.

B

A

C

D

G081I710.WMF

A (left side) : Over 10 cm (4")

B (rear) : Over 10 cm (4")

C (right side) : Over 55 cm (22")

D (front) : Over 75 cm (30")

G081/G092 1-2 SM

Page 31

MACHINE INSTALLATION

1.1.4 POWER REQUIREMENTS

CAUTION

1. Make sure the plug is firmly inserted in the outlet.

2. Avoid multi-wiring.

3. Be sure to ground the machine.

1. Input voltage level: 120 V, 60 Hz: More than 10 A

220 V to 240 V, 50 Hz/60 Hz: More than 6 A

2. Permissible voltage fluctuation: ±10 %

3. Do not set anything on the power cord.

1.2 MACHINE INSTALLATION

1.2.1 INSTALLING THE PHOTOCONDUCTOR UNIT & WASTE

TONER BOTTLE

1. Open the right cover [A] of the printer.

NOTE: The machine should NOT be

plugged into the power outlet

during installation.

Installation

[A]

2. Pull out the green levers on the left

and right that are fastening the inner

cover [B].

[B]

G081I291.WMF

G081I301.WMF

SM 1-3 G081/G092

Page 32

MACHINE INSTALLATION

3. Lift the inner cover [A] until it stays up.

[A]

4. Remove the black photoconductor unit from its

packing materials.

5. Peel off the tape surrounding the

photoconductor unit, and remove the

top cover [B] on the unit.

NOTE: Do not remove the cover

attached to the bottom of the

photoconductor unit at this

time.

[B]

G081I311.WMF

NOTE: After taking the new

photoconductor unit out of the bag,

immediately install it. Do not expose it to

ambient light for prolonged periods.

NOTE: Before proceeding with the

actual installation of the

development units, observe

the locations for each

photoconductor unit as shown

in this illustration.

when ready, continue to step 6

on the following page.

! Photoconductor unit (black)

" Photoconductor unit (color)

G081I680.WMF

2 1

G081I720.WMF

G081/G092 1-4 SM

Page 33

MACHINE INSTALLATION

6. While holding the photoconductor unit

from the bottom cover in your left

hand, match the green arrow at the tip

of the photoconductor unit [A] to the

rail inside the printer.

NOTE: Make sure the green arrow fits

securely on the rail before

proceeding to the next step.

Do not touch the surface of

the OPC drum(s) with your

hands.

7. Slide the front of the photoconductor

carefully in. Slide the unit on the cover,

and then push the unit in until it stops.

NOTE: If you do not properly attach

the green arrow of the

photoconductor unit securely

to the rail, you may damage

the photoconductor unit.

[A]

G081I370.WMF

Installation

G081I390.WMF

8. Repeat steps 4 through 7 to install the color photoconductor unit.

9. Lower the inner cover [B] slowly,

applying even pressure.

[B]

G081I410.WMF

SM 1-5 G081/G092

Page 34

MACHINE INSTALLATION

10. Push the green lever to fasten the

inner cover [A].

[A]

11. Locate and remove the Waste Toner

Bottle from its shipping materials.

12. Install the Waste Toner Bottle in the

appropriate location below the

photoconductor units (label-side out).

13. Slide the green locking lever to the

locked position.

NOTE: Refer to the Operating

G081I420.WMF

Instructions Maintenance Guide, page 32, for added details.

14. Close the right cover [B] of the printer

slowly. The Waste Toner Bottle will

automatically be pushed upwards into

its proper position.

NOTE: You may wish to save the

lower photoconductor unit

covers and “light-proof”

photoconductor unit shipping

bags to use should removal of

these units become necessary

for servicing.

[B]

G081I430.WMF

1.2.2 INSTALLING THE TONER CARTRIDGE

1. Open the upper left cover [A] of the

printer.

2. Remove the packing tape and foam

strips, attached to the tape, located

inside.

[A]

G081I441.WMF

G081/G092 1-6 SM

Page 35

MACHINE INSTALLATION

3. Locate and remove from the packing

materials one of the toner cartridges.

Hold the cartridge [A] horizontally as

illustrated, and shake it back and forth

about 10 times.

[A]

Installation

NOTE: Be careful of any loose toner

that may be present in the

toner’s shipping bag. If a

large amount of toner is

present inside the bag, check

to ensure that the cartridge’s

G081I460.WMF

shutter is properly closed.

NOTE: Do not open the shutter [B] on

the bottom of the toner

cartridge. Toner may spill out.

4. Check that the toner color and location

are correct, and then insert the toner

cartridge vertically and slowly.

NOTE: Reading the labels on the

printer, you can check the

location for each cartridge.

[B]

G081I470.WMF

G081I481.WMF

SM 1-7 G081/G092

Page 36

MACHINE INSTALLATION

5. Push the toner cartridge [A] in the

direction of the arrow to fasten the

toner cartridge.

[A]

6. Repeat steps 2 through 5 to install the other cartridges.

[B]

7. Close the upper left cover [B] of the

printer.

NOTE: If the toner cartridges are not

set properly, you cannot close

the upper cover of the printer.

G081I491.WMF

G081I500.WMF

1.2.3 LOADING PAPER

CAUTION: When pulling the paper tray out, be careful not to pull it strongly. Doing

so may cause the tray to fall causing personal injury.

1. Pull the paper tray [A] out of the printer

until it stops. Then tilt it upwards

slightly, and remove it completely.

Place it on a flat surface.

NOTE: You cannot pull tray 1 out if

the by-pass tray is open.

[A]

G081I930.WMF

G081/G092 1-8 SM

Page 37

MACHINE INSTALLATION

2. Remove any and all shipping tape

and shipping materials.

3. Press the PUSH sign [A], and adjust

the rear guide to the paper size you

want to load.

4. Adjust the side guides to the paper

size you want to load.

[A]

G081I931.WMF

PUSH

G081I924.WMF

Installation

5. Load paper into the paper tray with the

paper manufacture’s indicated printside up.

NOTE:

1) Make sure that the top of

the stack does not exceed

the limit mark [B] inside the

tray.

2) To avoid paper misfeeds,

[B]

the front and side guides

should be set exactly to the

paper size.

3) Do not load different kinds

of paper in the tray.

6. Slide the paper tray completely into the printer.

NOTE: Be sure to insert the paper tray correctly. Otherwise, misfeeds may

occur, or the front cover may touch the paper tray.

Also remember to only use quality and “fresh” laser paper that is

suitable for color laser printing. Doing this will help ensure quality and

consistent color print results.

G081I932.WMF

G081I923.WMF

SM 1-9 G081/G092

Page 38

MACHINE INSTALLATION

1.2.4 CONNECTING THE POWER CORD

CAUTION

1. It is dangerous to handle the plug with wet hands. Doing this may result

in receiving an electric shock.

2. When you pull the plug out of the socket, grip the plug, not the cord, to

avoid damaging the cord and causing a fire or an electric shock.

NOTE:

1) Be sure to firmly connect the power plug to the socket outlet.

2) The printer must be off when you plug-in or unplug the power cord.

1. Confirm that the printer's power switch

[A] is off.

[A]

G081I730.WMF

2. Locate and remove the power cord from the machines packing materials.

3. Attach the power cord to the socket on the back of the printer.

4. Plug the other end securely into the socket outlet.

G081/G092 1-10 SM

Page 39

MACHINE INSTALLATION

1.2.5 SELECTING THE PANEL DISPLAY LANGUAGE

NOTE:

1) You can select one of the following languages (the default is English):

English, German, French, Italian, Dutch, Swedish, Norwegian, Danish,

Spanish, Finnish, Portuguese, Czech, Polish or Hungarian.

2) If you use the English panel display, it is not necessary to do the

following procedure.

1. Turn on the printer.

NOTE: After the machine warms up, “Ready”

appears on the panel display.

Ready

G081I740.WMF

G081I901.WMF

Installation

2. Press the Menu key [A].

NOTE: The message appears on the panel

display.

[A]

On Line Menu Escape

#

Powe r Er ror Dat a In

Enter

Menu:

Paper Input

G081I937.WMF

G081I902.WMF

SM 1-11 G081/G092

Page 40

MACHINE INSTALLATION

3. Press the “#” or “$” key to display

“Language.”

Menu:

Language

4. Press the Enter key. The message appears on

the panel display.

NOTE: English is the default

Language:

%

English

5. Press the “#” or “$” key to display the language you want to select.

6. Press the Enter key to select. An asterisk (*)

will be displayed next to the selected language.

Menu:

Language

G081I903.WMF

G081I904.WMF

G081I903.WMF

7. Press the On Line key or “Menu” key. “Ready”

(in the language you selected) appears on the

panel display.

Ready

G081I901.WMF

G081/G092 1-12 SM

Page 41

MACHINE INSTALLATION

1.2.6 PRINTING THE TEST PAGE

NOTE: You can check if the printer works properly by printing a test page such as

the configuration page. However, you cannot check the connection

between the printer and the computer by printing the test page.

1. Turn on the printer.

Installation

NOTE: After the machine warms up, “Ready”

appears on the panel display.

2. Press the Menu key.

3. Press the “#” or “$” key to display "List/Test

Print."

Ready

Menu:

Paper Input

Language:

List/Test Print

G081I740.WMF

G081I901.WMF

G081I902.WMF

G081I905.WMF

4. Press the Enter key. The message appears on

the panel display.

5. Confirm that “Config. Page” is on the display,

List/Test Print:

Config. Page

G081I906.WMF

and then press the Enter key.

SM 1-13 G081/G092

Page 42

MACHINE INSTALLATION

6. The test printing starts shortly after.

Printing...

NOTE: If you cannot complete the test print,

G081I907.WMF

check if an error message appears on the panel display. For more

information about error messages, see Section 5 "Troubleshooting" in

the Operating Instructions Maintenance Guide and Section 4 in this

support documentation.

7. Press the “On Line” key. “Ready” appears on

the panel display.

Ready

8. Turn off the printer's power switch.

G081I901.WMF

9. At this point in the installation, you may wish to check and ensure that the

firmware level is current. The firmware version is indicated on the top (third item

under “System Reference”) on the Configuration page.

Refer to the “Firmware Update Procedure” located in Section 5 of this manual.

Update the firmware if necessary. After completing the firmware update return

to this section and continue.

10. Next press the “#" or “$" key to display the “Color Demo Page.” Press the

Enter key. Check to ensure that this page appears as expected (all colors

present)

1.2.7 ADJUSTING THE IMAGE DENSITY

1. Press the “Menu” key. “Menu” appears on the

panel display.

2. Press the “#” or “$” key to display

"Maintenance," then press the Enter key.

3. Press the “#” or “$” key to display “Image

Density”, then press the Enter key.

NOTE: The message appears on the panel

display.

Menu:

Paper Input

G081I902.WMF

Menu:

Maintenance

G081I908.WMF

Maintenance:

Image Density

G081I909.WMF

Image Density:

Prt. Test Sheet

G081I910.WMF

G081/G092 1-14 SM

Page 43

MACHINE INSTALLATION

4. Press the Enter key. When the message

appears on the panel display, press the Enter

key.

Prt. Test Sheet

Press # to Start

G081I911.WMF

NOTE: The test printing will start shortly after.

Printing...

G081I907.WMF

5. Compare the colors on the printed image density test sheet with those on the

Image Density Adjusting Card.

6. Press the “#” or “$” key to select the color

you want to adjust, then press the Enter key.

Image Density:

Black

G081I912.WMF

7. Press the “#” or “$” key to set the image

density value, and press the Enter key. To

adjust another color, repeat steps 6 and 7.

Black:

(-10 +10) 0

G081I913.WMF

Installation

NOTE:

1) You can adjust the image density from -10 to +10. Increasing the

value darkens the printouts and decreasing the value lightens the

printouts.

2) Pressing the “#” or “$” key increases or decreases the value by

one.

8. Print another image density test sheet and check if the colors on the test sheet

now mach those on the Image Density Adjusting Card. If they still do not match,

adjust the image density again.

9. Press the On Line key. “Ready” appears on

Ready

the panel display.

10. At this point in the installation turn to section

1.3 “Optional Unit Installation” in this manual.

G081I901.WMF

Perform any option installation necessary then return to this section and

continue to section 1.2.8 “Connecting the Printer to a Computer” found on the

following page.

SM 1-15 G081/G092

Page 44

MACHINE INSTALLATION

1.2.8 CONNECTING THE PRINTER TO A COMPUTER

Connecting the printer to a computer using a network interface cable

1. Confirm that the printer's power switch

[A] is off.

G081I730.WMF

2. Connect the network interface cable

[B] to the Ethernet port on the back of

the printer.

[B]

G081I934.WMF

3. Connect the other end of the cable to the network (for example, to a hub).

4. Turn on the printer.

[A]

5. Check the LEDs on the Ethernet port.

! Lights when 100 BASE-TX is in use

and does not light when 10 BASE-T is

in use

" Lights when the printer is securely

connected to the network

6. Go to section 1.2.9.

G081I935.WMF

G081/G092 1-16 SM

Page 45

MACHINE INSTALLATION

Connecting the printer to a computer using a parallel cable

NOTE:

1) The parallel cable is not provided with the printer.

2) You must provide the appropriate parallel cable for the computer that

you are using.

3) The printer’s parallel connection is a standard bi-directional interface. It

requires a standard 36-pin parallel cable compliant with IEEE1284 and

the parallel port on the computer.

4) To avoid electrical interference, use a shielded cable.

5) Do not use a parallel cable longer than 2.5 meters (8.2 feet).

1. Confirm that the printer’s power switch

[A] is off.

2. Turn the computer off.

[A]

G081I730.WMF

Installation

3. Attach the parallel cable [B] to the port

of the printer. Secure the cable with

the metal fittings (bale-clips) as shown

in the illustration.

NOTE: The Voltage rating of the

parallel port for the computer

is: Max. DC 5 V.

[B]

G081I936.WMF

4. Attach the other end of the parallel cable to the parallel port of the computer.

Secure the cable. (2 screws)

5. Turn on the printer and the computer.

6. Proceed to 1.2.10.

SM 1-17 G081/G092

Page 46

MACHINE INSTALLATION

1.2.9 CONFIGURING THE PRINTER FOR THE NETWORK

When using the printer in a network environment, you must configure the printer

settings using the printer’s operation panel. The following list is the items you can

set and their default settings.

IP Address 011.022.033.044

Subnet Mask 000.000.000.000

Gateway Address 000.000.000.000

Network Boot None

Frame Type (NW) Auto

Active Protocol TCP/IP

Ethernet Auto

The procedure below shows an example to specify TCP/IP as the active protocol.

1. Press the Menu key. “Menu” appears on the

panel display.

2. Press the “#” or “$” key to display “Host

Interface,” and then press the Enter key. The

interface setting menu appears.

3. Start the protocol for use.

1) Press the “#” or “$” key to display “Network

Setup,” and then press the Enter key.

2) Press the “#” or “$” key to display “Active

Protocol,” and then press the Enter key.

Menu:

Paper Input

G081I902.WMF

Menu:

Host Interface

G081I914.WMF

Host Interface:

Network Setup

G081I915.WMF

Network Setup:

Active Protocol

G081I916.WMF

3) Press the “#” or “$” key to display “TCP/IP,”

and then press the Enter key.

G081/G092 1-18 SM

Active Protocol:

TCP/IP

G081I917.WMF

Page 47

MACHINE INSTALLATION

4) Press the “!” or “"” key to display “Active,”

and then press the Enter key. In about two

seconds, the display returns to the "Active

Protocol" setting screen.

NOTE: * shows the current setting.

5) Set the rest of the protocols for use.

6) When all settings for the protocol are done, press the Escape key. The “Network

Setup” setting screen appears.

NOTE:

1) The default settings for all of the protocols are “Active.”

TCP/IP:

#

Active

G081I918.WMF

Installation

2) It is recommended to set all the unused protocols to “Not Active.”

4. Set the IP address for the printer.

NOTE: Check the IP address with the network

administrator.

1) Press the “!” or “"” key to display “IP

Address,” and then press the Enter key. The

currently selected IP address appears.

NOTE:

1) When the Enter key is pressed, the cursor moves to the next field.

Network Setup:

IP Address

G081I919.WMF

2) When the “!” or “"” key is kept pressed for a few seconds, the value

changes by 10.

3) If DHCP is assigned the IP address can not be changed. Turn

DHCP off, then assign IP address.

2) Press the “!” or “"” key to set the value for

the field.

IP Address:

199.022.033.044

G081I920.WMF

3) Press the Enter key. The cursor moves to the next field.

4) Repeat 2) and 3) to set the value for the rest of the fields.

5. Set “Subnet Mask” and “Gateway Address” by following the same procedure as

for setting the IP address

1)

NOTE:

Check the subnet mask value with the network administrator.

.

2) The gateway address is the address of the host or router that acts as a

gateway when interacting with work stations in another network. Check the

value with the network administrator.

3) If you are not sure of the addresses, do not set them.

SM 1-19 G081/G092

Page 48

MACHINE INSTALLATION

6. When using DHCP with TCP/IP protocol, set network boot, as follows.

1) From within Network Setups press the “!”

or “"” key to display to display “DHCP,” and

then press the Enter key. In about two

Network Setup:

#

DHCP

seconds, the display returns to the "Network

Setup" setting screen.

G081I922.WMF

NOTE: * shows the current setting.

Depending upon the firmware this setting may be located under

“Network Boot.”

7. When all of the settings are done, press the

Ready

On Line key. “Ready” appears on the panel

display.

G081I901.WMF

8. Print the configuration page to confirm the settings made. See 1.2.6 for printing

the configuration page.

G081/G092 1-20 SM

Page 49

MACHINE INSTALLATION

1.2.10 INSTALLING THE PRINTER DRIVERS AND UTILITIES

Install the printer drivers and software using the CD-ROM labeled “Printer Drivers

and Utilities.” The supported operating systems are Windows 95/98/Me, Windows

2000, Windows XP and Windows NT 4.0. (The procedure below may vary slightly

from the procedure you experience based on software version.)

Click Quick Install to install PCL5c and RPCS printer drivers.

When the TCP/IP protocol is used, SmartNet-Monitor for Client will be installed as

well. When using with TCP/IP protocol, confirm the following:

• The printer is connected to a network with the network interface cable.

• TCP/IP protocol is set up.

• The IP address is set for the printer and the computer.

To install the PostScript3 printer driver, click the PostScript3 printer driver button.

For more information about the PostScript3 printer driver, see the Administrator

Reference or the Client Reference manual included on the CD-ROM labeled

“Operating Instructions”.

1.

Insert the CD-ROM labeled “Printer Drivers and Utilities” into the CD-ROM

drive. Auto Run will start the installer.

Installation

2. Select a language, then click [OK]. The following languages are available:

Cestina (Czech), Dansk (Danish), Deutsch (German), English (English),

Espanol (Spanish), Francais (French), Italiano (Italian), Magyar (Hungarian),

Nederlands (Dutch), Norsk (Norwegian), Polski (Polish), Portugues

(Portuguese), Suomi (Finnish), Svenska (Swedish). The default interface

language is English.

3. Select Quick Install. The software license agreement appears in the License

Agreement dialog box.

4. After reading the contents, click “I accept the agreement”, then click Next.

5. In the “Select Printer” dialog box, select the printer model you want to install.

For a network connection with TCP/IP, select the printer whose IP address

NOTE:

1)

is displayed in “Connect to”.

For parallel connection, select the printer whose printer port is displayed in

2)

“Connect to”.

6. Click [Install]. When finished, the Installation Completion dialog box appears.

NOTE:

1) Under Windows 2000, the Digital Signature Not Found dialog box may

appear when installing the printer driver. In this case, click Yes to continue

the installation.

2) Under Windows XP, the Hardware Installation dialog box may appear. In

this case, click Continue Anyway to continue the installation.

7. Click [Finish].

NOTE: A message telling you to restart the computer may appear. In this case,

restart your computer to complete the installation. If no message

appears, go to step 5.

8. Click Exit. The installation is now complete.

SM 1-21 G081/G092

Page 50

MACHINE INSTALLATION

1.2.11 METER CHARGE (MACHINE INSTALLATION)

If the customer has a service contract, change the settings of the following SP

modes depending on the contract type.

Item SP No. Function Default

Meter charge SP5-930-1

Counting method SP5-045-1

Fax No. setting SP5-812-2

Counter reset SP7-825-1 Resets the counters to 0.

Specifies whether the meter charge

mode is enabled or disabled.

Meter charge mode enabled:

• The Counter menu appears

immediately after the Menu key is

pressed.

• The counter type selected by the

counting method (SP5-045-1) can

be displayed with the Counter

menu.

• The counter values can also be

printed with the Counter menu.

• The selected counter starts from a

negative number.

• The PM warning is not displayed

when the replacement time

arrives.

Meter charge mode disabled:

• The Counter menu is not

displayed.

• The total counter starts from 0.

Specifies whether the counting

method used in meter charge mode is

based on developments or prints.

Important:

This SP can only be done before the

negative counters are reset with SP7825-001

Programs the service station fax

number.

The number is printed on the counter

list when the meter charge mode is

selected, so that the user can fax the

counter data to the service station.

Important: This must be done at

installation after all the above settings

have been finished. The negative

counters used in meter charge mode

will be reset to zero.

Off

Developments

NOTE:

1) The default setting for this machine is meter-charge mode off.

2) The meter-charge counter cannot be reset.

G081/G092 1-22 SM

Page 51

OPTIONAL UNIT INSTALLATION

1.3 OPTIONAL UNIT INSTALLATION

The following options are available for this machine. Refer to the appropriate unit’s

Operating Instructions (Option Setup Guide) for how to install these options.

• Paper Feed Unit Type 3000 Unit (G342)

• AD440 Duplex Unit (G343)

• Printer Hard Disk Type 3000 (G345)

• IEEE802.11b Interface Unit Type A (Wireless LAN: G628)

• IEEE1394 Interface Unit Type 4510 (G336)

• Bluetooth Interface Unit Type A (G350)

• 128 MB DIMM Memory Unit Type C (G331)

• 256 MB DIMM Memory Unit Type C (G332)

• NVRAM (User Account Enhancement Unit Type B G311)

• Ethernet LAN option for G092 (G355)

NOTE: The model G092 is not available in the U.S. market

Installation

SM 1-23 G081/G092

Page 52

Page 53

PREVENTIVE MAINTENANCE

Page 54

Page 55

USER REPLACEABLE ITEMS

2. PREVENTATIVE MAINTENANCE

2.1 USER REPLACEABLE ITEMS

If the service contract requires that the user performs some of the PM, the user will

replace the following items.

Item Remarks

Toner 5K (C,M,Y,K)

PCU 13K (CMY,K)

Transfer Belt Unit 83K

Waste Toner Cartridge 36K

Fusing Unit 100K

NOTE: The transfer roller is supplied with the fusing unit.

Chart: A4 (LT), 5%

Mode: Three pages per print job

Environment: Normal temperature and humidity

Yield may change depending on circumstances and print conditions.

Preventive

Maintenance

When the machine’s default settings are used, a message is displayed when a

maintenance counter reaches the value in the PM table shown on the next page.

Important: The customer must clear the maintenance counters for the above

items, except the PCUs (the machine automatically detects new

PCUs).

SM 2-1 G081/G092

Page 56

SERVICE MAINTENANCE

2.2 SERVICE MAINTENANCE

2.2.1 PM TABLE

The following table lists the PM items that must always be done by the technician.

NOTE: The technician may also have to do the PM listed on the previous page, if it

is specified by the service contract.

Symbol C: Clean

Item 50K EM Remarks

Main unit

Registration Roller C C Clean with water

Paper feed unit

Pickup Roller C C Clean with water

By-pass tray

Pickup Roller C C Clean with water

Separation pad C C Clean with water

NOTE: Cleaning the inside of the machine is recommended when replacing the

PCUs and transfer belt unit.

2.2.2 RECOMMENDED CLEANING PROCEDURE

1. Turn off the main switch.

2. Remove the waste toner bottle.

3. Remove the PCUs.

4. Remove the transfer belt unit. Do not touch the transfer belt surface.

5. Remove the fusing unit.

6. Slide out the standard paper cassette.

7. Clean the paper path.

8. Clean all printer rollers with a dampened cloth. Never apply alcohol to the

transfer roller.

9. Clean the laser unit windows with a blower brush.

10. Vacuum the interior of the printer.

11. Carefully clean the area surrounding the transfer roller.

G081/G092 2-2 SM

Page 57

REPLACEMENT AND ADJUSTMENT

Page 58

Page 59

SPECIAL TOOLS AND LUBRICANTS

3. REPLACEMENT AND ADJUSTMENT

CAUTION

Turn off the main power switch and unplug the machine before attempting

any of the procedures in this section.

Important: Before performing the following steps, layout several sheets of clean

paper and remove the 4 toner cartridges (cyan, magenta, yellow, and

black), waste toner bottle, and standard paper cassette from the

printer. Place the toner cartridge and waste toner bottle on the sheets

of paper.

NOTE: This manual uses the following symbols.

! : See or Refer to : Screws : Connector

Adjustment

Replacement &

3.1 SPECIAL TOOLS AND LUBRICANTS

3.1.1 TOOLS

Part Number Description

N8036701 PCMCIA "Flash" Memory Card - 4MB 5.4 1

G0219350 Loop-back connector - parallel 5.5 1

G0819310 Color PCU Skew Adjustment Knob 3.12 1

The following are also recommended.

• PCU shipping cover (for Black and Color); supplied with the PCU

3.1.2 LUBRICATION

Area Part

Main Drive Unit

Transfer Belt Drive

Unit

Paper Exit Roller Roller Supporting Portion 52039501 Grease G501

Gear and Gear Shafts

Grounding Spring Plate

Transfer Cam ( 4 pieces )

Planetary Gear Base – B

Lubricant Part

Number

52039501

G0049668

52039501 Grease G501

Described

Section

Q’ty

Type of Lubricant

Grease G501

Grease KS-660

SM 3-1 G081/G092

Page 60

FUSING UNIT

3.2 FUSING UNIT

CAUTION

1. The fusing unit is hot. To avoid personal injury, wait 1 hour for the

fusing unit to cool after turning the power off.

2. When replacing parts, use only the manufacturer’s specified

components.

3. After servicing, be sure to restore the insulators, shields, etc.

• Open the front door.

[A]: Fusing unit connector

[B]: Release the two fusing unit

levers.

[C]: Fusing unit.

[B]

NOTE: After removing the fusing unit,

use caution not to push the

thermostat [D][E]. The

thermostat is easily broken.

[A]

[D]

[E]

[C]

G081R900.WMF

G081R104.WMF

G081/G092 3-2 SM

Page 61

TRANSFER BELT UNIT

3.3 TRANSFER BELT UNIT

• Open the right cover.

• Waste toner cartridge

• Release the PCU holder.

• Remove the black

photoconductor unit then the

color photoconductor unit.

(Press the green locking tab

down on the color PCU to fully

remove.)

[A]: Transfer belt unit ( x 2)

NOTE: The two screws are

the green thumbscrews located at

either side of the

transfer unit [B].

When removing the

transfer belt unit, take care not to damage the transfer belt.

[B]

[A]

[B]

G081R901.WMF

Adjustment

Replacement &

3.4 EXTERIOR COVERS

3.4.1 FRONT DOOR WITH TRANSFER ROLLER UNIT

[A]: Front support lever

NOTE: Open the front door. Hold the

bottom end of the lever. Slowly

close the door, and the upper

end of the lever comes off the

door.

[B]: Lever spring

[C]: Left door-hinge (1 hook)

[D]: Right door-hinge (1 hook)

[E]: Plastic belt

[F]: Front door

[F]

[D]

[A]

[B]

[E]

[C]

G081R902.WMF

SM 3-3 G081/G092

Page 62

EXTERIOR COVERS

3.4.2 TRANSFER ROLLER ASSEMBLY

[B]

[J]

[K]

[H]

[G]

[A]

[A]: Transfer roller holder ( x 4)

[G]

[E]

G081R903.WMF

[B]: Front door cover

[C]: Transfer roller paper guide

[D]: Transfer roller

NOTE: Using the provided green levers the transfer roller can be easily

unclipped from the bushings.

It is not necessary to remove the front door to replace the transfer

roller. Avoid touching the transfer roller’s surface with your hands.

[E]: Transfer roller right bushing

[F]: Transfer roller left bushing

[G]: Transfer roller spring

[H]: Transfer roller plate

[I]: Lock lever spring

[J]: Front door lock lever

[K]: Plastic belt

[I]

[F]

[C]

[D]

3.4.3 RIGHT COVER

[A]

[A]: Cartridge lever (1 hook, x 1)

[B]: Plastic strap

[C]: Right cover (1 hook at the rear end)

NOTE: Release the three hinges [D].

[C]

[B]

G081R906.WMF

[D]

G081/G092 3-4 SM

Page 63

EXTERIOR COVERS

3.4.4 REAR COVER

• Unplug the optional paper feed unit’s harness connector (if present).

• Open the right cover

[A]: Rear cover ( x 2 (self-tapping),

5 hooks [B])

NOTE: Use a small flat blade screw

driver to assist unclipping the

hooks. Be careful not to

damage the hooks or the

cover.

[C]: Cassette cover

[D]: Harness cover

NOTE: Use a penlight or other

suitable light source to view

how each cover hook is

clipped to the mainframe

before prying the clip to

release.

[B]

[C]

[A]

[D]

G081R907.WMF

Adjustment

Replacement &

3.4.5 LEFT COVER

[A]: x 2

[B]: Release the two hooks.

[C]: Release the openings from the

two projections.

[D]: Left cover with the toner

cartridge cover [E]

[B]

[E]

[D]

[B]

[A]

[C]

SM 3-5 G081/G092

G081R904.WMF

Page 64

EXTERIOR COVERS

3.4.6 TOP COVER AND LCD PANEL

[B]

[C]

[A]

[D]

[D]

[E]

[A]: LCD panel (4 hooks [B], x 2)

[C]: Top cover (7 hooks [D])

NOTE: Use caution not to damage the paper exit sensor [E].

This cover is a very precise fit. Use extra caution and work alternately from

the right and left sides of the top cover to gradually release the cover from

the printer.

G081R905.WMF

G081/G092 3-6 SM

Page 65

ECB AND DRIVE UNITS

3.5 ECB AND DRIVE UNITS

3.5.1 ECB (ENGINE CONTROL BOARD) AND

TEMPERATURE/HUMIDITY SENSOR BOARDS

• Rear covers (! 3.4.4)

• Left cover (! 3.4.5)

• Top cover (! 3.4.4)

[A]: Engine board shield cover

( x 8)

[B]: Engine control board

(All , x 7)

[A]

Adjustment

Replacement &

[B]

G081R912.WMF

NOTE: After replacing the ECB, remove the EEPROM from the old board and

install it on the new board. (If the EEPROM on the old board is defective,

replace the EEPROM (! 3.10.4).)

[C]

[E]

[D]

G081R913.WMF

[C]: Engine board small bracket ( x 3, x 1)

[D]: Engine board large bracket ( x 6)

[E]: Temperature/humidity sensor board ( x 1)

SM 3-7 G081/G092

Page 66

ECB AND DRIVE UNITS

3.5.2 SUB FUSING-FAN AND SUB FUSING-FAN DUCT

[B]

[A]

[C]

• Rear covers (! 3.4.4)

• Left cover (! 3.4.5)

• Top cover (! 3.4.4)

[A]: Sub fusing-fan ( x 2, x 1)

[B]: Jam detection sensor board ( x 1)

[C]: Sub fusing-fan duct ( x 2, x 2)

G081R981.WMF

G081/G092 3-8 SM

Page 67

ECB AND DRIVE UNITS

3.5.3 TONER CARTRIDGE HOLDER

CAUTION: The toner cartridge

[B]

holder assembly

contains toner. Take

care not to spill toner

when handling the

toner cartridge holder

assembly.

[A]: Toner cartridge drive unit (

x 2, x 1)

A

A

[B]: PC guide ( x 1)

[C]: Toner cartridge holder

assembly ( x 2, x 1 [D])

[D]

Lubricating

Lubricate the following parts (Grease G501) when replacing them (values in

parentheses indicate the amount of lubricant):

[B]

G081R908.WMF

[C]

Adjustment

Replacement &

[A]

[C]

[A]: Shaft excluding both ends (0.1 cc)

[B]: Toner cartridge drive base (indicated with arrows) (0.05 cc x 4)

[C]: Gear (0.1 cc x 3)

[D]: Gear (0.1 cc)

[D]

G081R973.WMF

SM 3-9 G081/G092

Page 68

ECB AND DRIVE UNITS

3.5.4 TONER CARTRIDGE DRIVE UNIT

[A]: Toner cartridge drive unit ( x 2,

x 1)

[A]

G081R910.WMF

3.5.5 PAPER PICKUP MOTOR AND MOTOR BRACKET

[A]: Paper pickup motor ( x 1,

x 2)

NOTE: The connector is at