Ricoh cattleya Technical Bulletin cattle

T

echnical

B

ulletin

PAGE: 1/1

Model:

Subject:

From:

Classification:

For the Cattleya fusing unit, “Silicone Oil Type SS” P/No. A2579100 should be used.

Please correct your service manual as follows:

Page 3 -16

Page 5 - 9

Cattleya

Silicone Oil for the Fusing Unit

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

After “Step 3”, please add the following:

NOTE: “Silicone Oil Type SS” P/No. A2579100 should be used for this copier.

In the PM table for the fusing unit, please add the following remarks for the column

on silicone oil:

Part information

Electrical

Transmit/receive

Date:

15-Jun-99

Prepared by:

No.:

RA257001

H. Matsui

Action required

Service manual revision

Retrofit information

Remarks: “Silicone Oil Type SS” P/No. A2579100 should be used.

CAUSE

One of the features of the new silicone oil is its (small amount of) low molecular “siloxane”.

This has an effect on the volatility of the oil. At around 150 °C, the volatility of the new

silicone oil is about 1/3 that of the previous silicone oil. This feature prevents the charge

corona wire from getting soiled by the vaporized silicone oil. However, the lubrication

properties of this new silicone oil are the same as those of the old type.

For Cattleya, be sure to use the new type of silicone oil. The new silicone oil has been

used from the first step of the development of Cattleya and therefore the machine is not

designed to operate using the old type of oil. Consequently, it is impossible to predict the

performance under the old type of oil (there are no tests on this available).

NOTE:

1. ”Siloxane” is the name of a chemical compound, which consists of silicon and oxygen.

2. The lubrication properties of a mix between the old and new oils would remain

unaffected. However, the advantage of the new silicone oil over the older type is that

the low volatility will be lost.

RICOH Technical

Bulletin

PAGE: 1/4

Model:

Subject:

From:

Classification:

This RTB contains the necessary information related to the firmware of Cattleya.

Cattleya

Firmware-related Information

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

15-Aug-99

Prepared by:

Action required

Service manual revision

Retrofit information

No.:

H.Matsui

RA257002

Modification History of the Cattleya Firmware

The following table shows the modification history of the main control and scanner IPU

firmware for Cattleya. The major modifications of each version of firmware are listed at the

end of this RTB.

Version Production Cut in

Main

Control

Scanner

IPU

1.501 March ‘99 production (Start of the production)

1.502 April ‘99

1.514 May ‘99

1.542 June ‘99

1.561 July ‘99

1.15 March ‘99 production (Start of the production)

1.16 May ‘99

1.19 July ‘99

Approved Firmware for connection with the printer controller E-650

To enable the printer functions using the printer controller E-650, it is necessary to use the

following version or newer.

Main Control : version 1.561

Scanner IPU : version 1.19

Language

The main control firmware containing Spanish, Dutch, Swedish, and Danish has recently

been released. Since the version of this firmware is 1.561, it is necessary to update the

scanner IPU firmware to version 1.19 at the same time for machines produced before July.

RICOH Technical

Bulletin

PAGE: 2/4

Model:

Cattleya

Date:

15-Aug-99

No.:

RA257002

Interchangeability of the firmware

The main control firmware version 1.561 and scanner IPU firmware version 1.19 are not

interchangeable with the older versions unless used as a set. They should be updated at

the same time. When version 1.561 main firmware is used with the scanner firmware older

than version 1.19, or when scanner firmware version 1.19 is used with the main firmware

older than version 1.561, errors in machine operation may be expected.

Recommendation for machines produced before July

It is recommended that the firmware for machines manufactured before July 99 are

updated to main firmware version 1.561 and scanner firmware version 1.19 at installation.

This is because updating to these versions should be done at the same time. If this is not

done, trouble may occur if main or scanner firmware update become necessary in the

future.

Interchangeability of the main board and the scanner IPU board

The part numbers of the main board and the IPU board have been changed due to the

firmware update to ver.1.561 and ver.1.19. (Please refer to MB No. MA257002.) The only

difference between the new and old parts is the version of the firmware.

Because the new firmware is not interchangeable with the older versions, please check the

version of the firmware and update as necessary when replacing the main control board or

the scanner IPU board.

Description Old P/N Firmware Interchan

geability

Scanner IPU A2575135 ver. 1.16

or older

Main (120V) A2575107 ver. 1.542

or older

Main (230V) A2575108 ver. 1.542

or older

x/x A2575137 ver. 1.19

x/x A2575105 ver. 1.561

x/x A2575106 ver. 1.561

New P/N Firmware

RICOH Technical

Bulletin

PAGE: 3/4

Model:

Cattleya

Date:

15-Aug-99

No.:

RA257002

List of Major Modifications

Main Firmware Version 1.502

The following software bug has been corrected:

Some text in the Systems Setting screen on the operation panel display was misaligned.

Main Firmware Version 1.514

The following software bugs have been corrected:

1. When twin color (red and green), poster (2x2), and thick paper modes are selected in

combination, a solid image may appear on the leading edge of the copy.

2. Copy may become solid black when using ADF in ACS mode when making more than

two continuous copies.

3. In machines without an ADF, the operation panel may be locked when removing the

paper waiting for the second side to be copied in the duplex tray.

4. Abnormal image may appear when copying on 13x19 inches paper with an

enlargement ratio of 200%.

5. Erase margin may be abnormal when using A6 paper with European models.

6. Some items were not printed out by the SP data printing function.

Main Firmware Version 1.542

1. Drum motor stop timing has been optimized to prevent the possibility of the transfer

belt surface scratching the OPC drum.

2. On/off timing of the ITB cleaning brush and cleaning blade has been optimized to

prevent toner accumulated on the edge of the blade from falling on the image transfer

belt.

3. The following SP Modes have been added.

SP8-115 Fusing temperature s et t ing for Special Mode Progra m: Copy (for Special Mode 1)

SP8-215 Fusing temperature s et t ing for Special Mode Progra m: Copy (for Special Mode 2)

SP8-315 Fusing temperature s et t ing for Special Mode Progra m: Printer (for Special Mo de 3)

SP8- (130-138) Paper transfer current set ting for Special Mode Program: Copy (for Specia l Mode 1)

SP8- (230-238) Paper transfer curre nt setting for Special Mode Program: Copy (for Specia l Mode 2)

SP8- (330-338) Paper transfer curre nt setting for Special Mode Program: Printer (for Special Mode 3)

RICOH Technical

Bulletin

PAGE: 4/4

Model:

Main Firmware Version 1.561

The following SP Modes have been added

SP8-(140-148)-(01-08) Gamma setting for Special Mode Program: Copy (for Special Mode 1)

SP8-(240-248)-(01-08)Gamma setting for Special Mode Program: Copy (for Special Mode 2)

SP8-(340-343)-(01-08)Gamma setting for Special Mode Program: Printer (for Special Mode 3)

Scanner IPU Firmware Version 1.16

The following software bugs have been corrected.

1. Small no painted area may appear in the image after having painted inside a closed

2. SC326 may appear when making A3 copies in Auto Original Type Select and 400%

3. APS may not function properly immediately after ACC has failed.

Cattleya

loop area.

enlargement modes.

Date:

15-Aug-99

No.:

RA257002

Scanner IPU Firmware Version 1.19

1. The following SP Mode is added :

SP8-(140-148)-(01-08) Gamma setting for Special Mode Program: Copy (for Special Mode 1)

SP8-(240-248)-(01-08)Gamma setting for Special Mode Program: Copy (for Special Mode 2)

SP8-(340-343)-(01-08)Gamma setting for Special Mode Program: Printer (for Special Mode 3)

2. When th e setting is changed from the default (5) to 6, the ACC target density level for

the printer mode (SP mode 4-502-001 to 004) has been changed as follows:

If the setting of ACC target density level for the printer mode (SP mode 4-502-001 to 004,

adjustable range:0 to 10, default setting:5) is changed to 6, the level of ID max will become

greater (20% up for K, 15% up for Y, M, C).

NOTE:

1. The level of ID max will not change, even if the setting is changed to 7, 8, 9, or 10.

2. If ID max is increased, there is a greater tendency for toner scattering to occur in text

areas.

RICOH Technical

Bulletin

PAGE: 1/3

Model:

Subject:

From:

Classification:

This Technical Bulletin contains some important notes concerning the installation of the E650color controller for the Cattleya.

1. Approved Firmware of Cattleya for connection with the E-650printer controller.

To enable the printer functions using the E-650 controller, it is necessary to use the

following version of Cattleya firmware.

Main Control: Ver. 1.561 or new er

Scanner IPU: Ver. 1.19 or newer

Cattleya

Important notes at installation of E-650.

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

15-Aug-99

Prepared by:

Action required

Service manual revision

Retrofit information

No.:

RA257003

Chisato Tsuji

If the version is older, please make sure to update the firmware.

For details regarding the Cattleya firmware, please refer to RTB No.

on August 15th, 1999.)

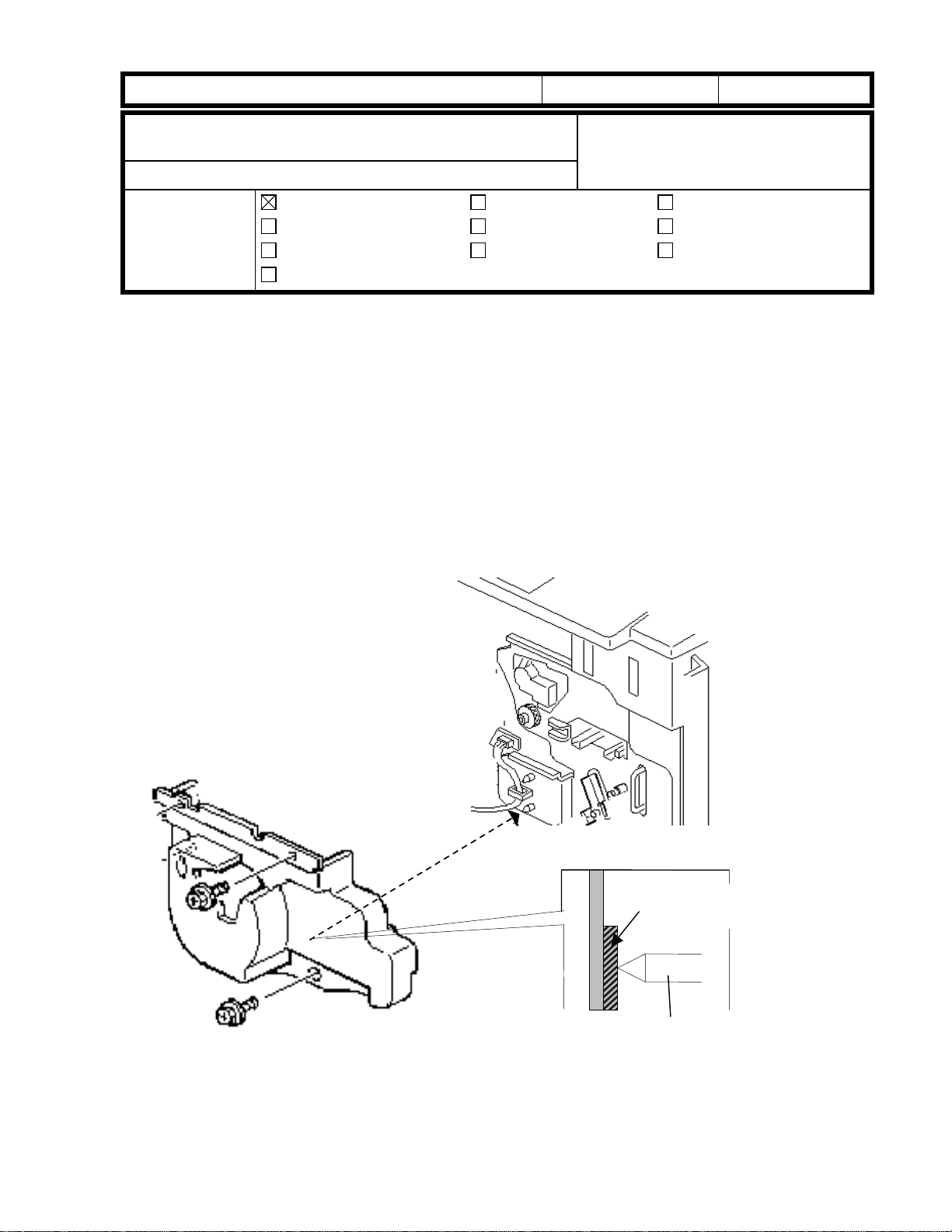

2. EMI Shield installation.

Make sure to intall the EMI shield on the interface unit (“I/F unit”) before installing the

controller interface Type F kit in the copier.

(The EMI shield and the installation procedure sheet are packed with the E-650.)

Tool required: #2 phillips h ea d screwdriver.

Note: Attach an ESD grounding wrist strap and follow standard ESD (electrostatic

discharge) precautions before doing this procedure.

RA257002

(issued

RICOH Technical

)

)

)

Bulletin

PAGE: 2/3

Model:

Cattleya

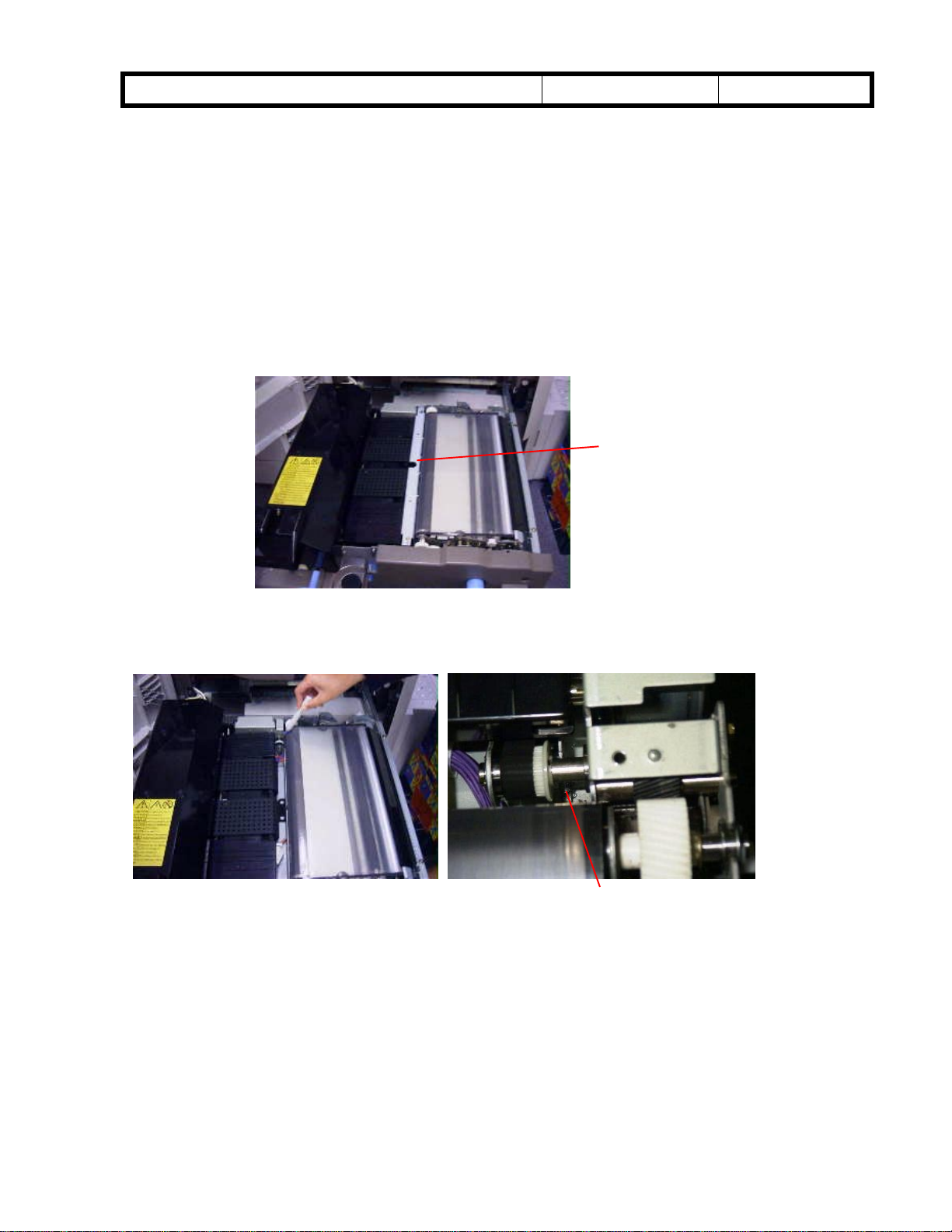

To install the EMI Shield on the I/F Unit.

2-1. Place the I/F unit on a stable static-free surface.

Note: If the I/F unit is already installed in the copier, you may skip this step.

I/F unit left shield cover

Date:

15-Aug-99

No.:

RA257003

Remove this screw

I/F unit bottom view

2-2. Remove and set aside the I/F unit screw indicated in the figure above.

2-3. Unpack the EMI shield and align the EMI shield on the bottom of the I/F unit where the

copier interface board is exposed. Make sure that the EMI shield’s:

Two tabs are outside of the I/F unit

Lip is inside the I/F unit

Other edges are outside the I/F unit’s left shield cover

Placement of EMI Shield

I/F unit (bottom view

Tab (outside

Lib (inside

Tab (outside)

RICOH Technical

Bulletin

PAGE: 3/3

Model:

2-4. Make sure the screw holes line up and replace the screw you removed earlier.

Now you are ready to install the Controller Interface Type F kit and the E-650 controller as

described in the

Cattleya

While replacing the screw, hold the shield against the I/F unit to ensure a tight fit.

E-650 Installation and Service Guide

Date:

.

15-Aug-99

Replace this screw

EMI shield installed

No.:

RA257003

RICOH Technical

C

Bulletin

PAGE: 1/2

Model:

Subject:

From:

Classification:

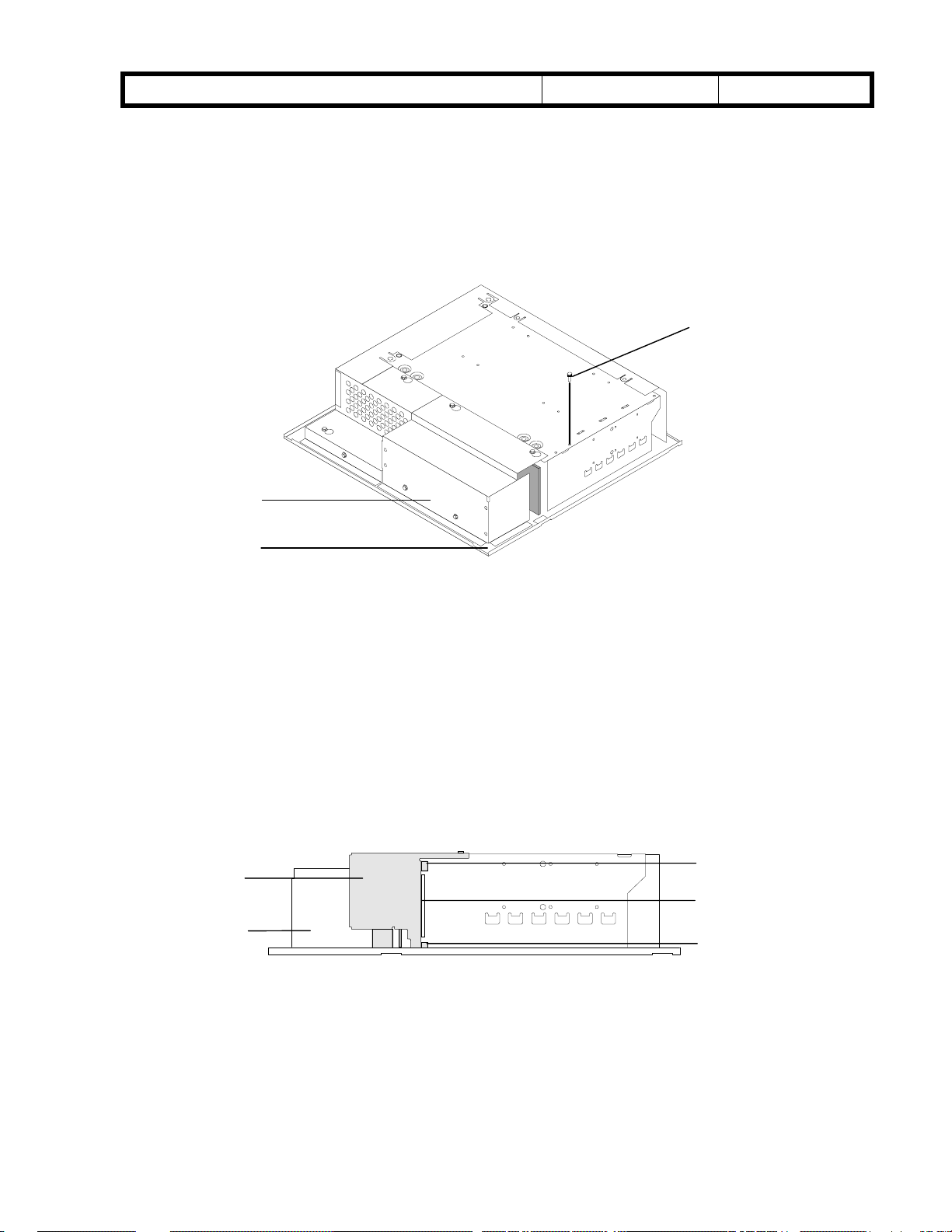

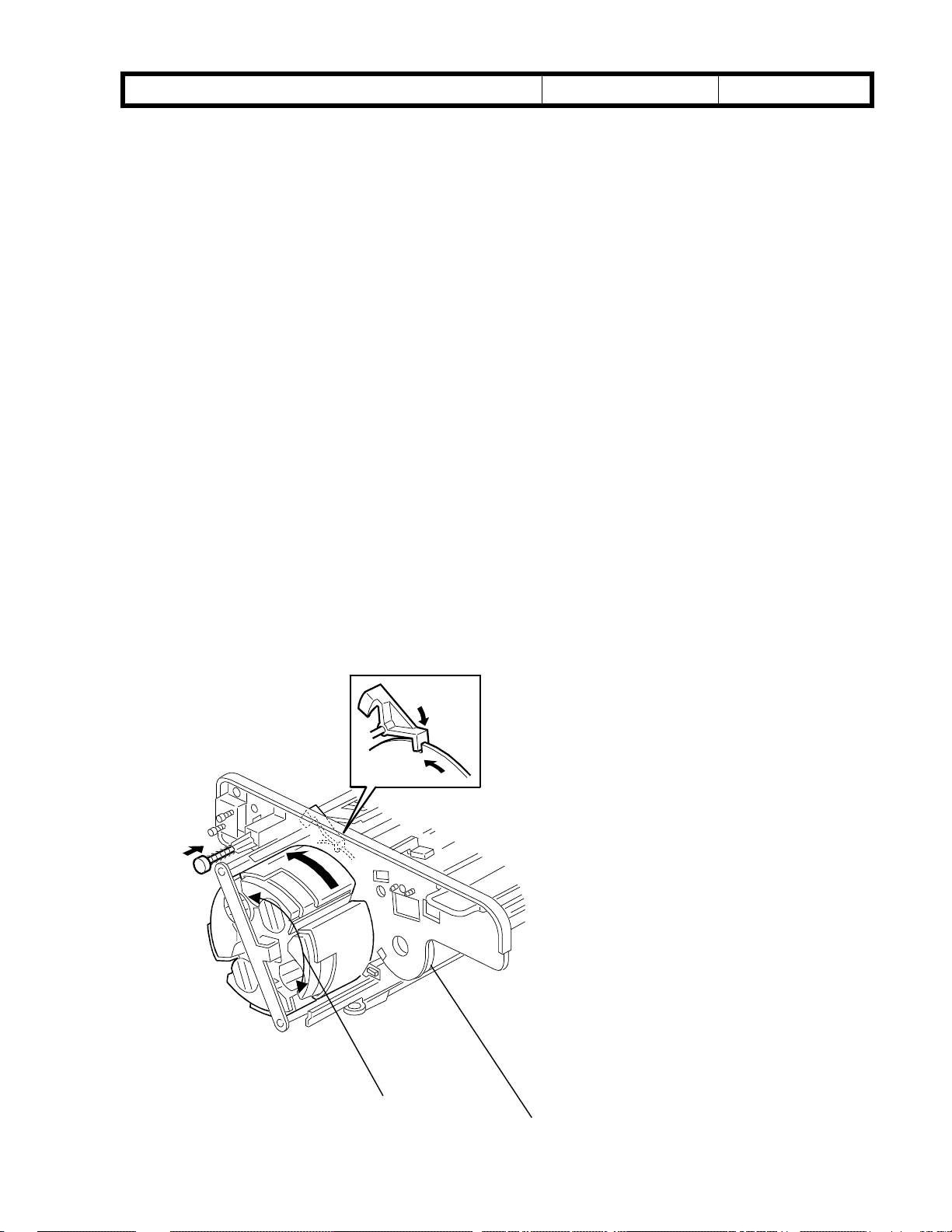

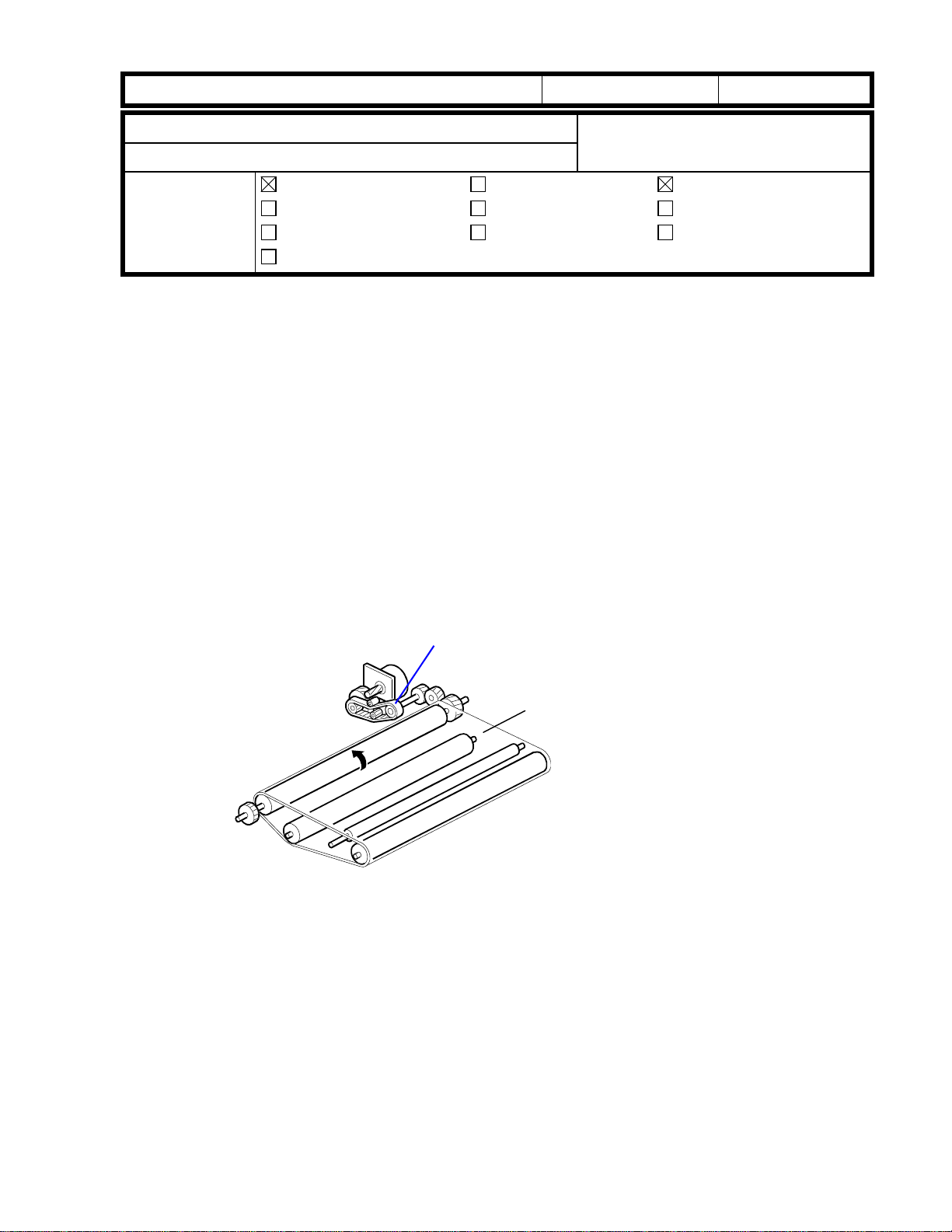

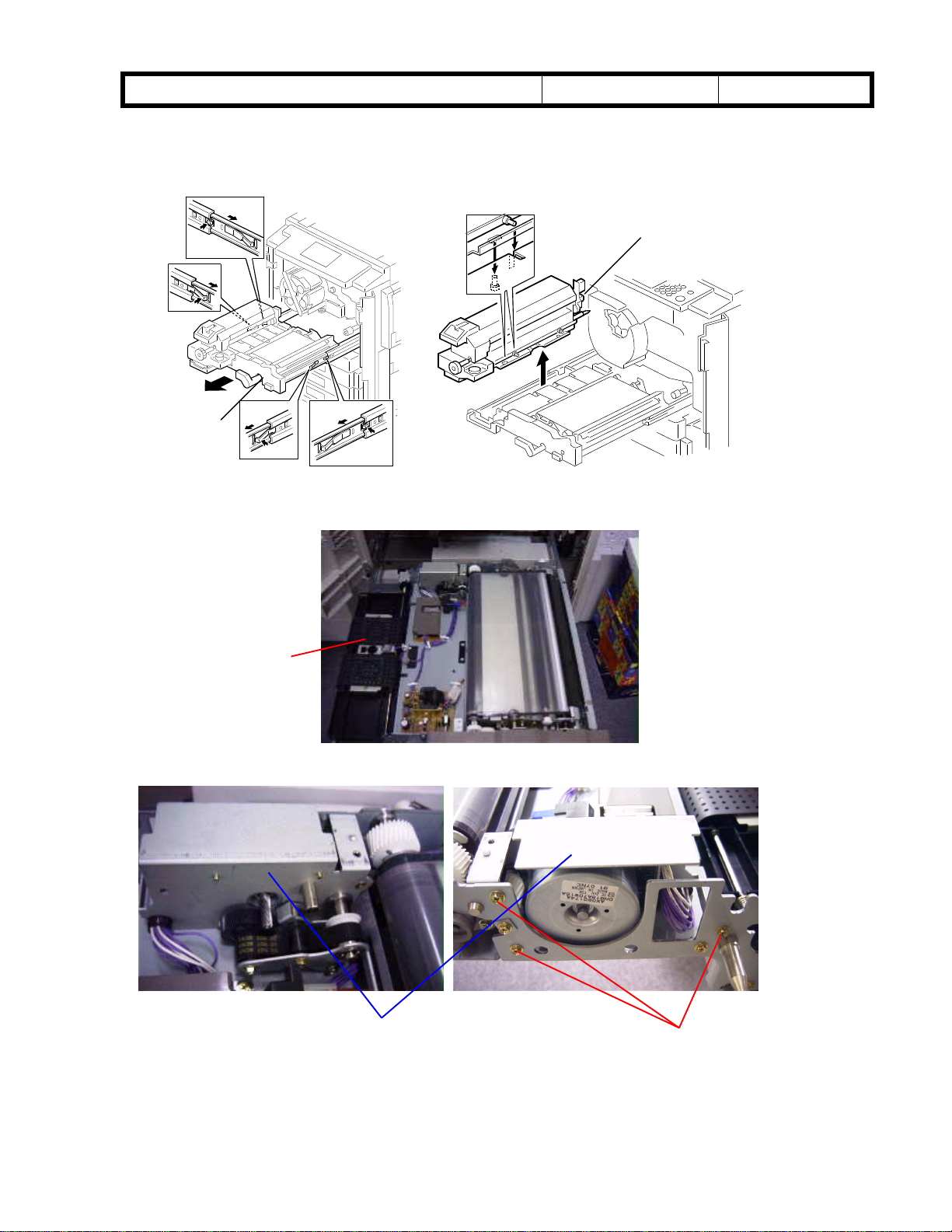

The positioning of the revolver unit is a critical check item when setting the drum unit in the

upper drawer unit. To prevent any problems similar to the symptom described below,

please release the following information to all technicians in your regions servicing this

machine.

Problem

When the drum unit was set in the upper drawer un it, the devel opment unit was placed at

90 degrees (vertical), which is the development unit removal position. Being in this

position, the drum came in direct contact with the ribs of the development unit upper cover,

causing the drum to be scratched or damaged.

Cattleya

Drum damage at installation

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

31-Aug-99

Prepared by:

Action required

Service manual revision

Retrofit information

No.:

H. Matsui

RA257004

Action required

The above problem would normally happen at the time of installation or developer

replacement. To prevent the drum from being damaged, the revolver unit must be set to

its home position before the drum unit is set in the upper drawer unit.

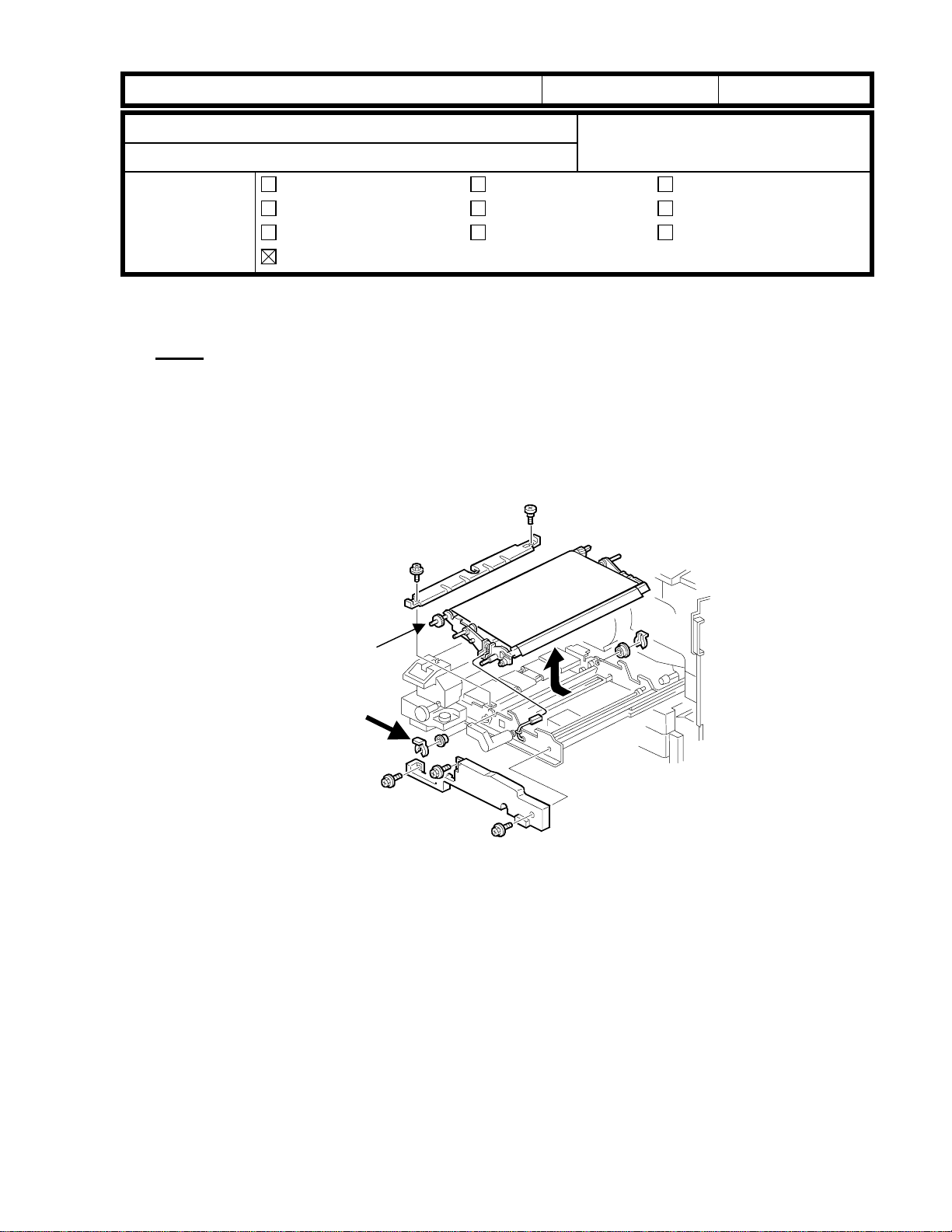

Revolver Home Position

As shown in the following illustration, the magenta development roller should be positioned

at an angle of 60 degrees (from horizontal). When rotating the revolver unit, you can see

the cut-out [A] in the wheel, which locks the revolver unit in the home position.

M

60 degrees

[A]

Y

Revolver home position

K

OPC drum

RICOH Technical

Bulletin

PAGE: 2/2

Model:

Additional Information

In addition to the above information, please note the following remarks for when the

revolver unit is set in the machine:

1. Revolver unit

If the gears on the mainframe and revolver unit are not engaged firmly, this may result in a

gap between the revolver unit frame and copier frame (thus the unit will not be properly

set). This also may cause the gears to be damaged when the revolver starts rotating. To

ensure that the gears are properly engaged, it is necessary to manually fit (i.e. lock) the

gears together by manipulating the revolver unit back and forth (slightly) as shown in the

illustration (arrow [A]). This should be done while holding the toner hoppers.

2. Drum unit

To ensure that the gears between the drum and drum shaft properly engage, the flange [B]

of the OPC drum must be pushed toward the back of the machine. (This is explained on

S/M page 6-11.)

Cattleya

Date:

31-Aug-99

No.:

RA257004

Since the vibration generated from the image transfer belt drive section is transmitted to

the drum section, this vibration may interfere with drum rotation if the gears are not

properly engaged. This causes banding on the image (at 1.7 mm intervals).

[A]

[B]

RICOH Technical

Model: Cattleya Date: 15-Oct-99 No.: RA257005

Bulletin

PAGE: 1/2

Subject:

near the leading edge

From:

Classification:

Dirty or colored background in the area

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Prepared by:

Part information

Electrical

Transmit/receive

M. Furusawa

Action required

Service manual revision

Retrofit information

SYMPTOM

Dirty or colored background appears in the area near the leading edge.

A slightly pale image or normal ima ge appears in the other areas towards the trailing edge.

(The width of the area with this dirty or colored background varies.)

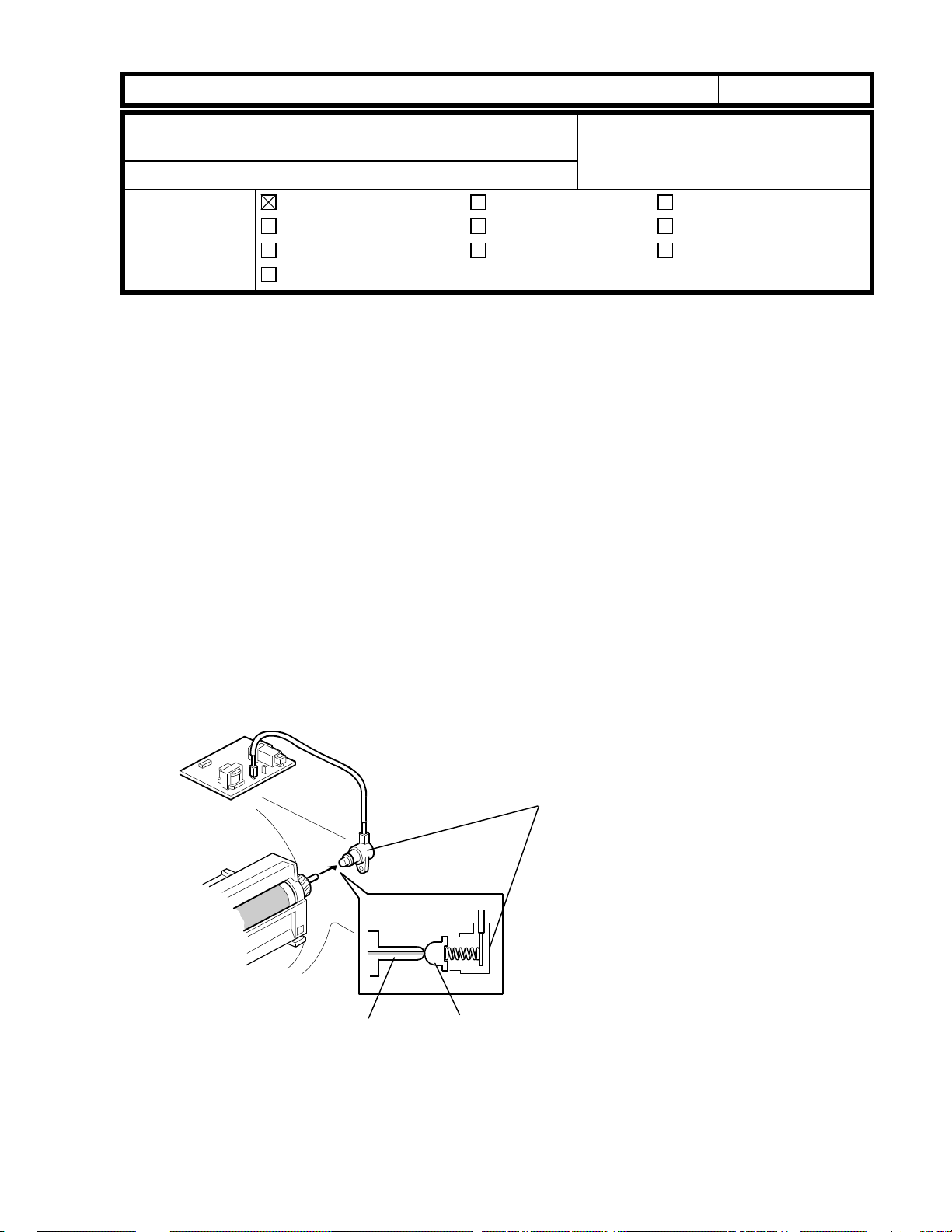

CAUSE

The development bias terminal is pushed against the development input shaft by a spring

to ensure proper terminal contact when the development unit reaches the copying position.

When the terminal does not move smoothly, poor contact of the development bias terminal

results at the beginning of development of the latent image (dirty background will occur

under these conditions).

When the contact between the terminal and the development input shaft is not as poor, the

image becomes slightly pale (or normal if contact is good).

Development Input Shaft

Development Bias Terminal

Terminal

RICOH Technical

Model: Cattleya Date: 15-Oct-99 No.: RA257005

Bulletin

PAGE: 2/2

ACTION

Pull out the revolver/drum drawer and clean the development bias terminal.

Turn the terminal counterclockwise then clockwise (more than ten turns each).

Push the terminal repeatedly more than ten times so that terminal movement is smooth.

Reassemble the machine and check the copy quality.

If the above action is not successful (this is a very rare case), replace the development

bias terminal with a new one (P/N A2573298).

If the new part is not available, loosen the upper screw that secures the development

bias terminal to the copier rear side frame.

- Objective Machines -

The development bias terminal was previously modified from a one-screw type to a

two-screw type, effective from around May, 1999.

If the two-screw type terminal is secured too tightly, a slight deformation of the

terminal casing can occur.

The machines in the field that could potentially exhibit this problem were produced

from May to July, 1999, because the bias terminal was not inspected in these

machines.

However, the occurrence rate is expected to be very low.

Countermeasure for machines in mass-production:

The bias terminals have been inspected at the factory since August, 1999.

To ensure proper contact between the bias terminal and the development input shaft

without the inspection, a modification of the development bias terminal has been applied to

the production line from October, 1999 (the inner diameter of the terminal casing has been

slightly increased).

The part number has been changed from A2573297 to A2573298.

RICOH Technical

Model: Cattleya Date: 15-Oct-99 No.: RA257006

Bulletin

PAGE: 1/2

Subject:

from the leading edge

From:

Classification:

Horizontal black or magenta line at 106 mm (4.17”)

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Prepared by:

Part information

Electrical

Transmit/receive

M. Furusawa

Action required

Service manual revision

Retrofit information

SYMPTOM

The following only occurs in thick paper mode and OHP mode.

A horizontal line appears at 106 mm from the leading edge.

The line is normally colored Black but the last one of the multiple copy run is colored

Magenta (in the Full Color mode).

CAUSE

When the drum speed is slowed in thick pape r/OHP mode, loose screws that fasten the

flywheel supporter to the drum shaft cause the drum to stop for a very short while.

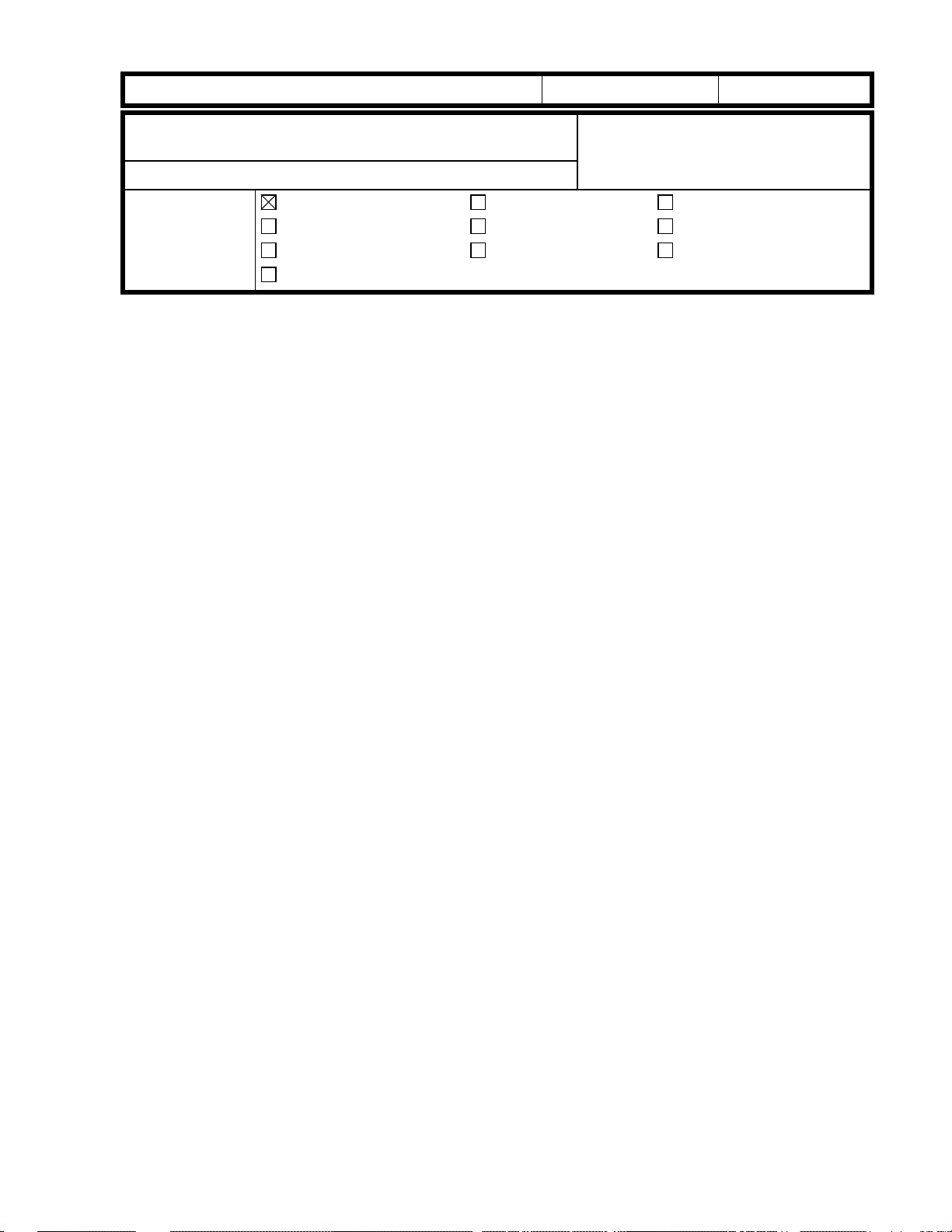

ACTION

Remove the large and small flywheels and tighten the screws for the flywheel supporter.

(Refer to the illustration on the next page.)

The flywheel supporter has four cut-outs for the screws. Two out of the four cut-outs have

a flat surface (from May production: the cut-in serial numbers were not controlled). Make

sure that the screws are positioned on these flat surfaces, especially after disassembling

these areas.

RICOH Technical

Model: Cattleya Date: 15-Oct-99 No.: RA257006

Bulletin

PAGE: 2/2

Flywheel Supporter

RICOH Technical

Model: Cattleya Date: 15-Oct-99 No.: RA257007

Bulletin

PAGE: 1/1

Subject:

From:

Classification:

SC450 (Paper transfer bias current error)

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

M. Furusawa

SYMPTOM

SC450 is displayed when the main switch is turned on or during a copy/print cycle.

CAUSE

Paper transfer belt shift clutch (P/N AX210067) failure.

Some of these shift clutches may overrun the stop position over time.

When the cl utch is energized, it rotates for 180 degrees and stops. If it overruns its stop

position, the paper transfer belt unit drops and SC450 is indicated.

ACTION

Replace the paper transfer belt shift clutch with a modified one (AX210076).

Clutch modification:

The clutch shaft has been modified to prevent the possibility of the overrun.

The electric power of the clutch has been increased from 8 W to 15 W to ensure that

the armature plate is properly pulled when the clutch is energized.

This modification has been applied to the production line from the end of July, 1999.

AX210067 à AX210076

RICOH Technical

Model: Cattleya Date: 15-Oct-99 No.: RA257008

Bulletin

PAGE: 1/1

Subject:

From:

Classification:

Magenta image

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

M. Furusawa

SYMPTOM

Only the Magenta image is transferred to the copy paper in the Full Color mode (only the

last color image is transferred in the 2C and 3C modes).

CAUSE

Image transfer belt cleaning shift clutch (P/N AX210067) failure.

When this clutch overruns, the image tran sfer belt cleaning blade remains in contact with

the image transfer belt.

With the exception of the last color toner, the cleaning blade wipes off the toner on the

image transfer belt before the toner image is transferred to the copy paper.

ACTION

Replace the image transfer belt shift clutch with a modified one (AX210076).

Note:

paper transfer belt shift clutch.

Clutch modification:

The image transfer belt cleaning shift clutch has the same part number as the

AX210067 à AX210076

The clutch shaft has been modified to prevent the possibility of the overrun.

The electric power of the clutch has been increased from 8 W to 15 W to ensure that

the armature plate is properly pulled when the clutch is energized.

This modification has been applied to the production line from the end of July, 1999.

RICOH Technical

Model: Cattleya Date: 15-Oct-99 No.: RA257009

Bulletin

PAGE: 1/2

Subject:

(Image transfer belt cleaning unit position error)

From:

Classification:

n

Symptom:

If operations are attempted on the machine after the revolver cover has been removed, the

SC457 indication lights up (error in the setting of the belt cleaner).

Procedure:

Setting the Revolver Cover:

In order to ensure the accurate setting of the image transfer belt cleaning unit, there

-

SC457

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

When checking machine operation without the revolver cover:

is a rubber plate on the rear side of the revolver cover to push the lower positioning

pin of the image transfer belt cleaning unit (refer to the illustration below).

Prepared by:

M. Furusawa

Action required

Service manual revision

Retrofit information

Rubber Plate

Lower Positioning Pin

If performing tests (e.g. on machine operation) after the revolver cover has been

-

removed, please do so after pushing the lower positioning pin and properly setting

the unit.

RICOH Technical

Model: Cattleya Date: 15-Oct-99 No.: RA257009

If the machine does not operate normally after the installation of the revolver

cover:

Check to see if the touch and release mechanism of the blade/brush of the image

transfer belt cleaning area is working properly.

If working properly, there is a problem with the belt cleaning HP sensor.

-

If not working properly, there is a problem with the belt cleaning shift clutch.

-

If such abnormalities occur with this sensor and/or clutch, check to see that the

sensors are clean and that the connectors are properly connected to the sensors.

Also be aware that it is possible for the belt mark detector to be malfunctioning as well.

Summary of Causes:

1. Faulty setting of the image transfer belt cleaning unit.

2. Problem with the touch and release mechanism of the blade/brush of the image

transfer belt cleaning unit.

3. Malfunction of the belt mark detector of the image transfer belt unit.

Bulletin

PAGE: 2/2

n

Loose knob for the transfer faceplate

Symptom:

When the knob of the transfer faceplate is loose, SC457 is displayed.

Cause:

Due to a mistake when setting the transfer faceplate, the drum knob loosens and the

setting position of the image transfer belt cleaning unit shifts.

Procedure:

Reinstalling the transfer faceplate:

1. Remove the transfer faceplate.

2. Reinstall the transfer faceplate and

tighten the knob [1].

3. Push ing the upper lef t part of the

faceplate against the revolver/drum

drawer, tighten the three screws in the

following order: [2], [3], [4].

4. Re-tighten the knob.

Note:

transfer belt tension lever as is (until

the drum rotates along with the

knob).

Re-tighten this knob with the

[ 2 ]

[ 1 ]

[ 4 ]

[ 3 ]

RICOH Technical

Model: Cattleya Date: 15-Oct-99 No.: RA257010

Bulletin

PAGE: 1/5

Subject:

From:

Classification:

Random Jitter

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

M. Furusawa

SYMPTOM

Jitter bands appear at random positions on copies.

For an A4 (LT) lengthwise or A3 (DLT) copy, one jitter band is observed (at first

occurrence). Later, two or three may be observed on A3 (DLT) copies.

Once it appears, this jitter is likely to occur continuously for certain copy jobs.

CAUSE

The timing belt that drives the paper transfer belt disengages from the cogs of the timing

pulley (jumping one cog over) when the movement of the tension roller bracket becomes a

little worse.

It has been found that the tension spring for the timing belt does not have enough strength

to prevent this random jitter.

Timing Belt that

drives the Paper

Transfer Belt

Paper Transf er Belt

SOLUTION

Replace the tension spring with a stronger one at installation or at the next visit to the

customer site.

The strength of the original spring (P/N A2573997) is 1.0 Newton and the new one (P/N

AA060836) is 2.3 Newtons.

The color of the new tension spring is also different (i.e. old: silver, new: black).

(The new springs will be provided free of charge.)

RICOH Technical

Model: Cattleya Date: 15-Oct-99 No.: RA257010

- Objective Machines -

The Cattleya produced from May to early August, 1999 are the objective machines.

The details are shown in the following table.

(About 20% of the objective production machines have been modified in Japan before

the shipment.)

Bulletin

PAGE: 2/5

Objective machines

A257-15 No Yes Yes No

A257-17 No Yes Yes Yes (first 53 units)

A257-22 No Yes Yes No

A257-26 Yes Yes Yes No

A257-27 Yes Yes Yes No

A257-29 Yes Yes Yes No

A257-55 --- --- No No

A269-15 No Yes Yes No

A269-17 No Yes Yes No

A269-22 No Yes Yes No

A269-26 Yes Yes Yes No

A269-27 Yes Yes Yes No

A269-29 Yes Yes Yes No

A269-55 --- --- No No

NOTE:

The material of timing belt that drives the paper transfer belt has been changed from

chloroprene rubber (P/N A2573993) to polyurethane rubber (P/N AA043285). This is

to increase its resistance to ozone, thereby increasing durability as well.

This modification has been applied to the production runs from May, 1999 (from June

for machines with destination code -15, -17, and -22).

The new spring has been applied to production from August 4, 1999.

:

May

Production

Yes = Objective machines, No = Non-objective machines

June

Production

July

Production

August

Production

The following table explains the possibility of the problem for each combination.

Tension Spring

Old (A2573997) New (AA060836)

Timing

Belt

Old (A2573993) No problem Lifetime of the timing belt

may be reduced.

New (AA043285) Random jitter may occur. No problem

RICOH Technical

Model: Cattleya Date: 15-Oct-99 No.: RA257010

Bulletin

PAGE: 3/5

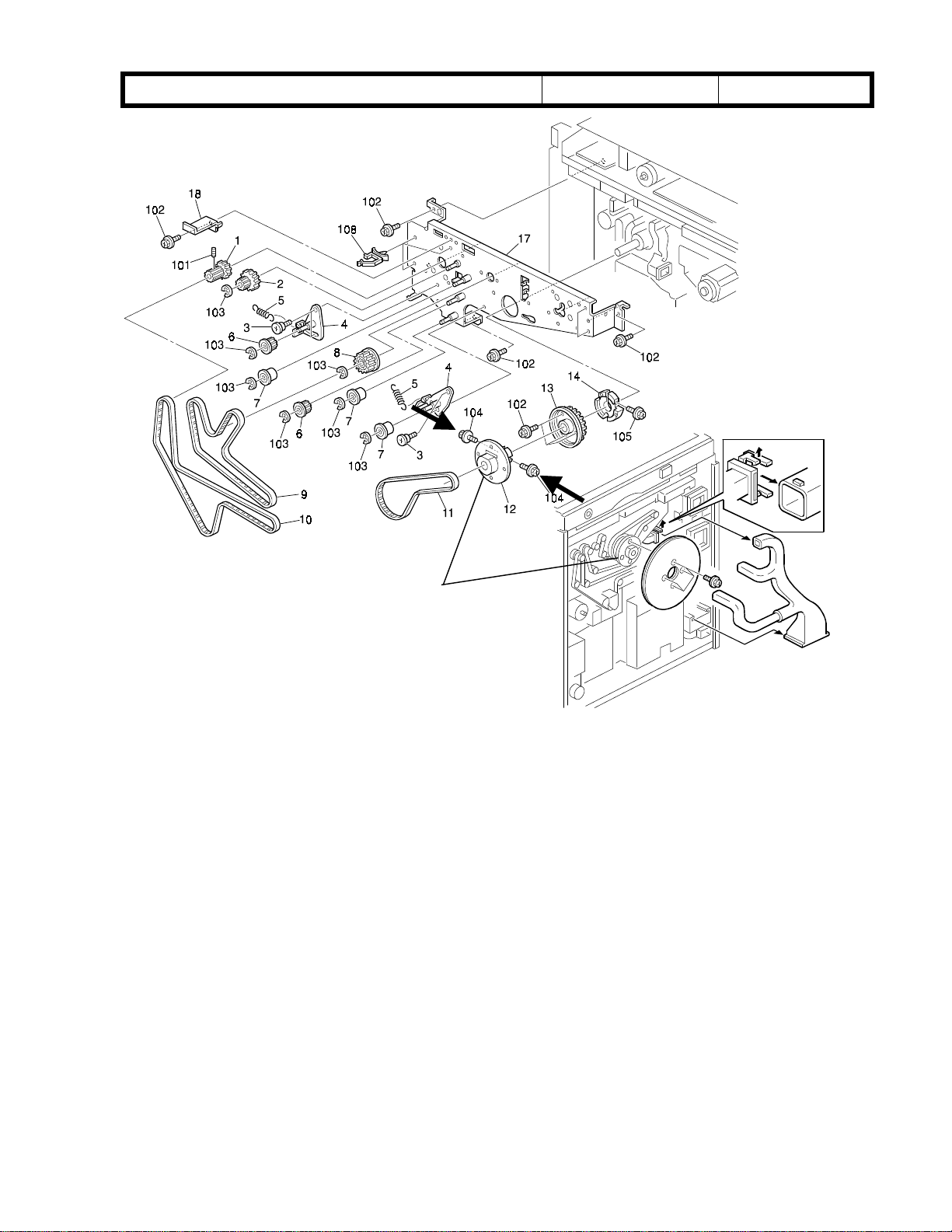

Checking and Replacement Procedure

Since about 20% of the objective production machines have been modified with the new

tension spring, the following 2 pages explain how to distinguish between the old and new

springs, then how to replace the old spring with the new one.

This procedure will take about 5 minutes.

Procedures to prevent random jitter

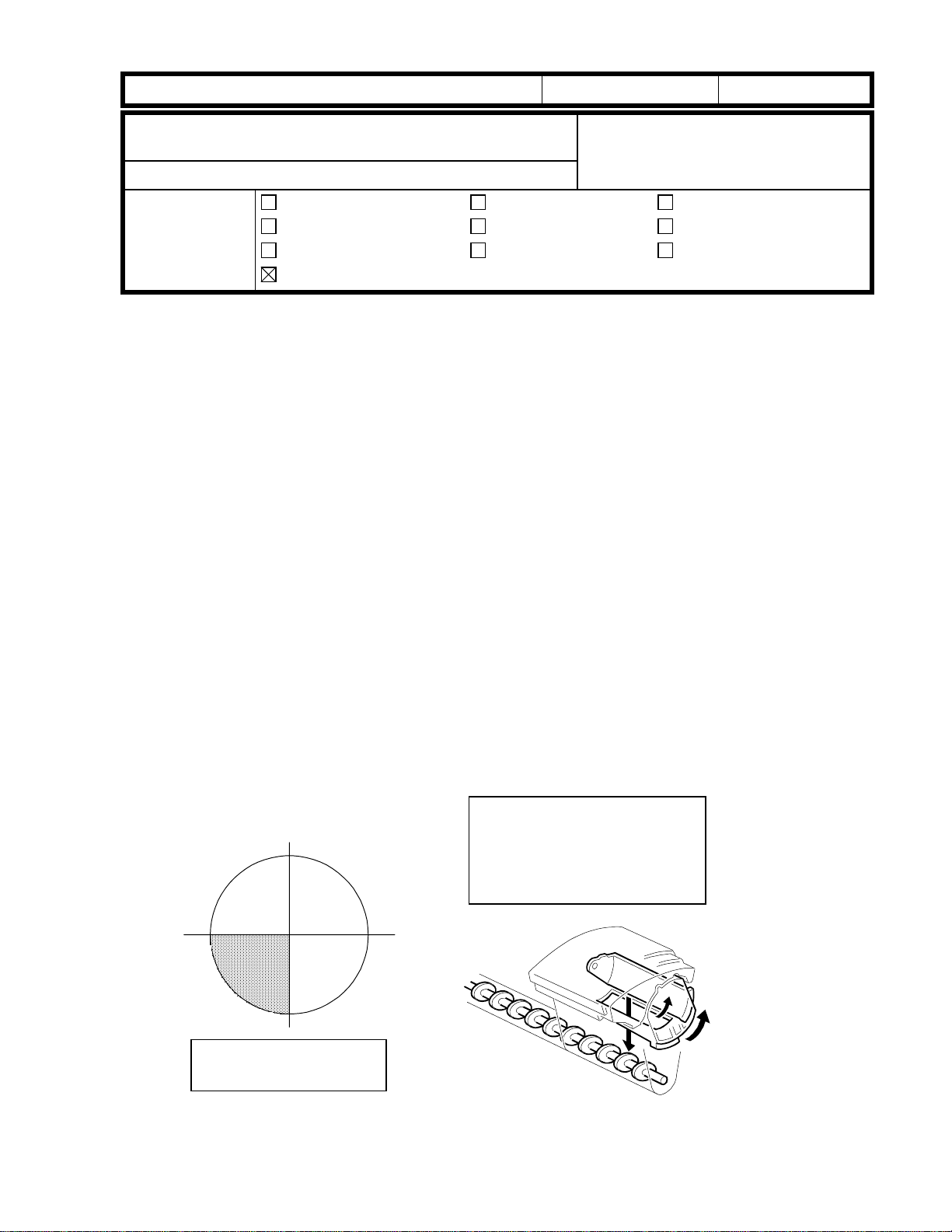

= Check Procedure =

1. Open the front covers and pull out the fusing/transfer drawer.

2. Remove the separation plate (1 shoulder screw and 1 screw).

Separation Plate

3. Check the color of the tension spring of the PTB (paper transfer belt) drive belt.

If the color is black, reassemble the machine sin c e this will indicate that the spring is a

new one.

If the color is silver, go onto the next procedure “Spring Replacement Procedure”.

Tension Spring

RICOH Technical

Model: Cattleya Date: 15-Oct-99 No.: RA257010

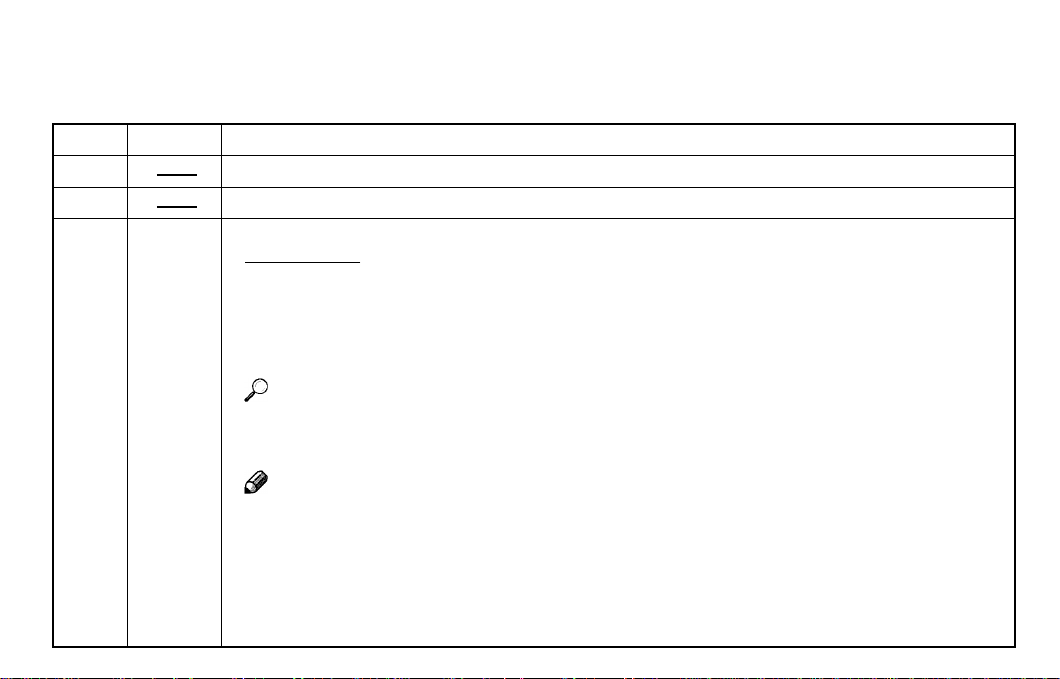

= Spring Replacement Procedure =

1. Press the stoppers on both sides of the fusing/transfer drawer rail and pull out the

drawer.

2. Lift and remove the fusing unit.

Fusing/Transfer

Drawer

3. Remove the transport unit (2 snap rings and 2 bushings, keep the connector coupled),

turn it around, and place it on the drawer as shown in the picture.

Bulletin

Fusing Unit

PAGE: 4/5

Transport Unit

4. Remove the paper transfer belt motor assembly (3 screws).

- Front view - - Rear View -

Transfer Belt Motor

Assembly

Screws

RICOH Technical

Model: Cattleya Date: 15-Oct-99 No.: RA257010

5. Remove the tension spring (silver) and install a new one (black).

6. Reassemble the machine.

Bulletin

Tension Spring

PAGE: 5/5

RICOH Technical

Bulletin

PAGE: 1/1

Model: Cattleya Date: 15-Oct-99 No.: RA257011

Subject:

without toner end indication

From:

Classification:

Notes for when removing the toner cartridge

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other (Technical Tips)

Prepared by:

Part information

Electrical

Transmit/receive

M. Furusawa

Action required

Service manual revision

Retrofit information

Notes for when removing the toner cartridge without toner end indication

If the toner cartridge (which is not empty) is removed from the toner cartridge

replacement position, the cartridge lever may not turn smoothly when reinstalling the

toner cartridge. If the cartridge lever is not completely turned to its lock position, toner

may scatter from the toner hopper.

To prevent the above possibility, follow the following procedure:

1. Remove the revolver cover.

2. Rotate the revolver unit until the cartridge you wish to remove is in the removal

position (lower left, looking from the front). See the illustration below.

Note:

If the Cyan cartridge is removed in this position, it is possible to reinstall the

revolver clamp for machine transportation.

3. Tap the toner cartridge near the cartridge lever (e.g. with a handle end of a

screwdriver) and empty the toner into the cartridge from the hopper.

4. (In this position), remove the toner cartridge after having closed the cartridge

shutter. (Make sure that the shutter is completely shut).

5. Clean the shutter area of the cartridge with a vacuum (as well as the silver tape on

the reverse side).

6. Rotate the revolver clockwise to set the toner cartridge to its proper position.

7. After cleaning the area around the shutter (of the hopper), make sure that the

shutter can be moved easily. After closing the shutter completely, set the cleaned

cartridge.

Press the lock pin and turn the

shutter completely.

Clean the sponge seal around

the opening of the cartridge as

well.

Toner Cartridge

Replacement Position

RICOH Technical

Model: Cattleya Date: 15-Oct-99 No.: RA257012

Bulletin

PAGE: 1/1

Subject:

From:

Classification:

Notes when installing the paper transfer unit

Notes when installing the paper transfer unit

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other (Technical Tips)

Note:

When installing the paper transfer unit, make sure that t he snap ring is set in the

groove of the paper transport belt drive roller shaft.

Otherwise, the following problems may occur:

* SC456 (Paper transfer unit position error)

* Damage to the paper transfer belt

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

M. Furusawa

Paper Transfer

Belt Drive Roller

Shaft

Snap Ring

RICOH Technical

Model: Cattleya Date: 15-Oct-99 No.: RA257013

Bulletin

PAGE: 1/2

Subject:

Double Transfer Image Mechanism

From:

Classification:

The following two items are additional information (detailed explanation of the

specifications/features).

1. Image rotation in combination with other functions:

Additional Information for the Image Rotation and

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other (Additional Information)

Image rotation is available under the following conditions.

(1) When “Image Rotation ON” is selected in the "General Features" section of the

User Tools.

(2) When "Auto Paper Select" is selected at the operation panel.

(3) When paper of the same size as the original on the exposure glass is set in the

paper tray perpendicular to the original.

(4) When the Color Mode selected at the operation panel is B&W or Single Color.

Part information

Electrical

Transmit/receive

Prepared by:

M. Furusawa

Action required

Service manual revision

Retrofit information

The "Image Rotation" cannot be performed in the following copy modes:

Area editing mode

Ø

Auto Reduce/Enlarge mode

Ø

(à Possible with Main firmware Ver. 1.572 or later)

Poster mode

Ø

Image Shift mode

Ø

Combine mode

Ø

Book mode

Ø

Image creation mode

Ø

Image overlay

Ø

Film projector

Ø

Staple mode

Ø

2. Conditions for the Double Transfer Image Mechanism

The conditions for the Double Transfer Image Mechanism are as follows:

(1) Copy paper size: A4 sideways (11” x 8

(2) Copy mode: Full Color mode or 1C mode

The copying speed with the Double Transfer Image Mechanism is 10 cpm for Full

Color and 40 cpm for 1C mode.

”) or smaller

1/2

RICOH Technical

Model: Cattleya Date: 15-Oct-99 No.: RA257013

The Double Transfer Image Mechanism in the Full Color mode is not available

with the following functions (even if the above conditions are satisfied):

Margin adjustment

Ø

Centering

Ø

Cornering

Ø

Series copy

Ø

Duplex (2 sided à 2 sided, Book à 2 sided)

Ø

Image overlay

Ø

Poster mode

Ø

Projector mode

Ø

Bulletin

PAGE: 2/2

Note:

sideways (11” x 8

The copying speed of the Full Color mode is 5 cpm. This also applies to A4

”) or smaller.

1/2

RICOH Technical

Model: Cattleya Date: 15-Oct-99 No.: RA257014

Bulletin

PAGE: 1/2

Subject: Main Firmware ver1.572 Information Prepared by:

From:

Classification:

This RTB contains the necessary information related to the main control board firmware

ver 1.572 NA/EU/EU2/EU3 for Cattleya.

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

H.Matsui

Action required

Service manual revision

Retrofit information

Language

The main control board firmware contains the following languages.

Ver1.572NA: US English, French, Spanish

Ver1.572EU: UK English, French, German, Italian

Ver1.572EU2: Spanish, Dutch, Swedish, Danish

Ver1.572EU3: Norwegian, Portuguese, Polish, Czech

NOTE:

Along with installing the above firmware, it is necessary to update the scanner IPU

firmware to version 1.19 or newer in machines produced before July. If main firmware

version 1.572 is used with the scanner firmware older than version 1.19, errors in machine

operation may occur.

RICOH Technical

Model: Cattleya Date: 15-Oct-99 No.: RA257014

Bulletin

PAGE: 2/2

Contents of the software change

1 “Copies” or “Developments” is displayed on the counter display (when the Counter Key

is pressed).

“Copies” is displayed for a machine with the copy counter set.

“Developments” is displayed for a machine with the development counter set.

NOTE: This change is available only when “English” has been selected as the

operating language.

2. The confirmation button on rhe operation panel is changed from “OK” to “Confirm”

3. The full color sorting setting button in “Duplex/ADF/Sorter” mode in “Copier Feature”

mode in the User Tools is changed from “On” / “Off” to “Off”/ “On”. This is because the

default setting of Full color sorting is “On”.

4. “Image rotation” and “Auto Reduce/Enlarge” can be used at the same time.

5. “Area editing” and “Auto Reduce/Enlarge” can be used at the same time.

NOTE:

Due to software modifications 3, 4, and 5 mentioned above, the operating instructions for

the Cattleya also need to be modified. This will be effective within the month of October.

Errata will be included in the operating instructions. We would like to recommend that

copies of the errata be provided to customers updating to ver 1.572 or newer (please refer

to the following page). The errata can also be printed out from the attached PDF file

CattleyaErrata2.pdf

(

).

Errata

This manual contains some misprints and should be corrected as follows:

P.158 Add You can also change the Auto Reduce/Enlarge setting during area editing.

P.165 The entry in the combination chart for Auto Reduce/Enlarge and “n” should read “✩” and not “×”.

P.198 Full Color Copy Sorting is turned on by default (not off as stated).

P. 56 Add

Auto Off Mode

This machine automatically turns itself off 60 minutes after the last copy or

print job has finished. If you wish to make copies when the machine is in

Auto Off mode, press the operation switch.

Reference

For how to change the default interval that the machine waits before entering

Auto Off mode, see “Auto Timer”on page 191.

Note

The Auto Off timer does not take effect in the following cases:

• When there are originals on the exposure glass or in the document feeder.

• When there are copies in the bins of the sorter stapler.

• While the machine is making copies.

• When a paper misfeed has occurred.

• When a cover is open.

• When a service call message is displayed.

Loading...

Loading...