Ricoh cattleya Service Manual catt2

CATTLEYA 2

SERVICE MANUAL

!

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

5. If the Start key is pressed before the copier completes the warm-up period

(the Start key starts blinking red and green alternatively), keep hands away

from the mechanical and the electrical components as the copier starts

making copies as soon as the warm-up period is completed.

6. The inside and the metal parts of the fusing unit become extremely hot while

the copier is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your eyes

by accident, it may cause temporary eye discomfort. Try to remove with eye

drops or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

those models.

2. The NVRAM on the system control board has a lithium battery which can

explode if replaced incorrectly. Replace the NVRAM only with an identical

one. The manufacturer recommends replacing the entire NVRAM. Do not

recharge or burn this battery. Used NVRAM must be handled in accordance

with local regulations.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly

when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

3. When keeping used lithium batteries in or der to dispose of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

!

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

!

WARNING

WARNING: Turn off the main switch before atte mpting any of the

procedures in the Laser Unit section. Laser beams can

seriously damage your eyes.

CAUTION MARKING:

Symbols

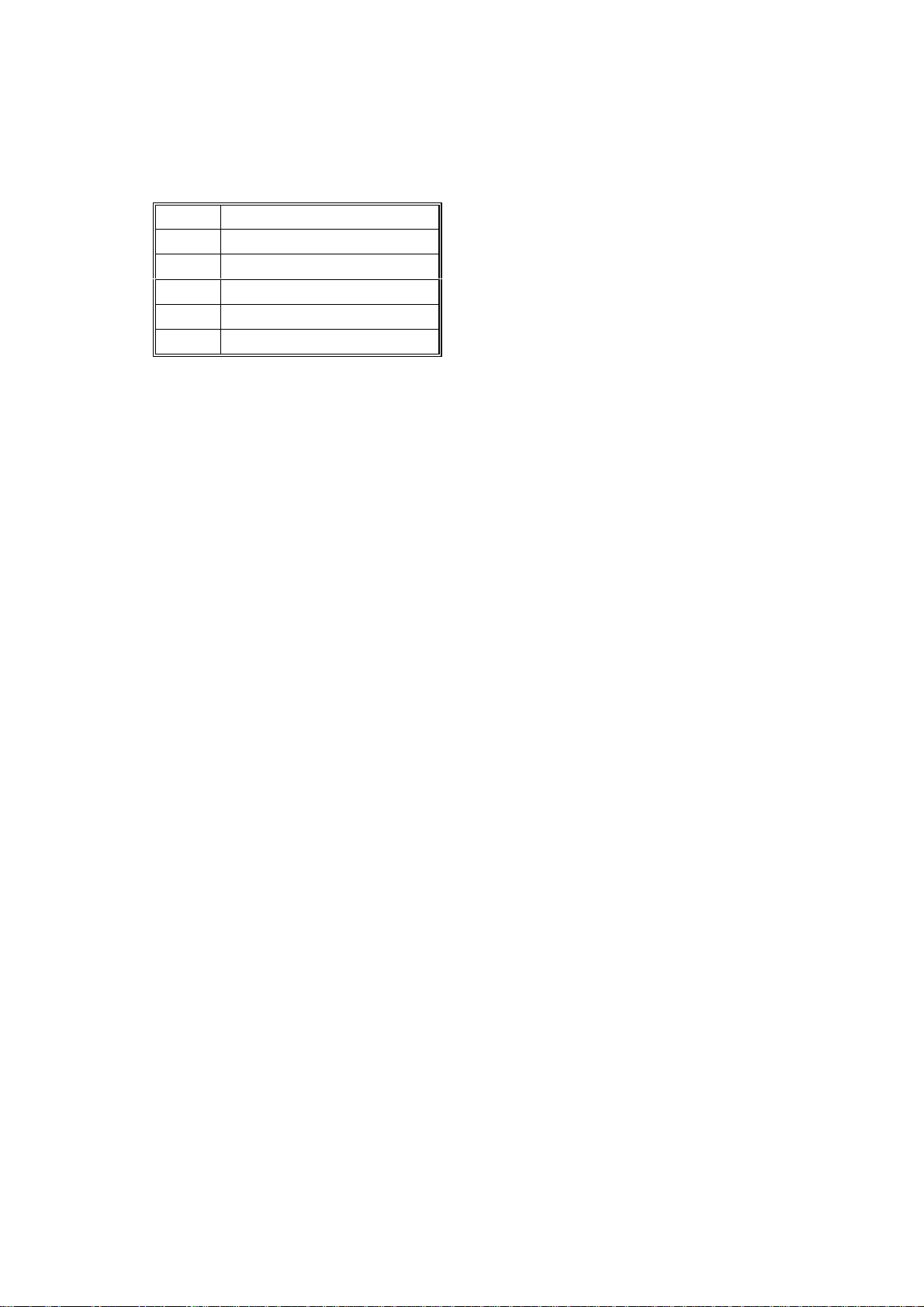

This manual uses several symbols. The meaning of those symbols are as follows:

☛

!

"

#

$

%

See or Refer to

Core tech manual

Clip ring

E-ring

Screw

Connector

TABLE OF CONTENTS

1 INSTALLATION PROCEDURES ................................................. 1-1

1.1 INSTALLATION REQUIREMENTS...........................................................1-1

1.1.1 DIMENSIONS...................................................................................1-1

1.1.2 ENVIRONMENT...............................................................................1-2

Environmental Requirements................................................................1-2

Minimum Space Requirements.............................................................1-3

Power Requirements............................................................................1-3

1.2 COPIER.....................................................................................................1-4

1.2.1 ACCESSORY CHECK......................................................................1-4

1.2.2 PREPARATION................................................................................1-5

1.2.3 DEVELOPER INSTALLATION.......................................................1-11

1.2.4 LOADING TONER CARTRIDGES..................................................1-16

1.2.5 FUSING UNIT.................................................................................1-18

1.2.6 DEFAULT SETTINGS AND OPERATION CHECKS......................1-19

1.2.7 HEIGHT ADJUSTMENT.................................................................1-21

1.2.8 COUNTER DISPLAY SETTING.....................................................1-21

1.2.9 RESETTING THE ELECTRONIC TOTAL COUNTER....................1-21

1.2.10 PREPARATION FOR TRANSPORT............................................1-22

1.3 PLATEN COVER (A749-01) ....................................................................1-23

1.3.1 INSTALLATION..............................................................................1-23

1.4 ARDF (A663)...........................................................................................1-24

1.4.1 ACCESSORY CHECK....................................................................1-24

1.4.2 INSTALLATION..............................................................................1-25

1.5 SORTER STAPLER (A831)....................................................................1-26

1.5.1 INSTALLATION..............................................................................1-26

1.6 LCT (A683)..............................................................................................1-31

1.6.1 INSTALLATION..............................................................................1-31

1.7 LCT ADAPTER (A840)............................................................................1-32

1.7.1 INSTALLATION..............................................................................1-32

1.8 EDIT OPTION (B370-01).........................................................................1-38

1.8.1 ACCESSORY CHECK....................................................................1-38

1.8.2 INSTALLATION PROCEDURE......................................................1-39

1.9 CONTROLLER INTERFACE (B371).......................................................1-41

1.9.1 ACCESSORY CHECK....................................................................1-41

1.9.2 INSTALLATION PROCEDURE......................................................1-42

1.10 KEY COUNTER HOLDER.....................................................................1-45

1.11 USER CODE SETTING.........................................................................1-46

2 PREVENTIVE MAINTENANCE.................................................... 2-1

2.1 REGULAR PM ITEMS...............................................................................2-1

2.1.1 REGULAR PM TABLE......................................................................2-1

Peripherals............................................................................................2-4

2.2 PM PROCEDURES...................................................................................2-6

2.2.1 PM-RELATED COUNTERS .............................................................2-6

SP7-803 (PM Counter Display).............................................................2-6

i

2.2.2 REGULAR PREVENTIVE MAINTENANCE FLOW DIAGRAM.........2-9

3 REPLACEMENT AND ADJUSTMENT......................................... 3-1

3.1 GENERAL CAUTION................................................................................3-1

3.2 COVERS AND FILTERS...........................................................................3-1

3.2.1 FRONT DOOR AND LOWER FRONT COVER................................3-1

3.2.2 RIGHT-SIDE FRONT COVER AND RIGHT EDGE COVER............3-2

3.2.3 INNER COVERS..............................................................................3-2

3.2.4 REAR COVERS ...............................................................................3-3

3.2.5 LEFT COVERS.................................................................................3-3

3.2.6 EXPOSURE GLASS.........................................................................3-4

3.2.7 UPPER COVERS.............................................................................3-4

3.2.8 OPERATION PANEL........................................................................3-4

3.2.9 USED TONER TANK........................................................................3-5

3.2.10 CHARGE CORONA FILTER..........................................................3-5

3.2.11 DUST AND OZONE FILTERS........................................................3-6

3.2.12 OPTICS DUST FILTERS................................................................3-7

3.2.13 REVOLVER FILTER.......................................................................3-7

3.2.14 INNER COVER FILTER .................................................................3-7

3.2.15 FUSING UNIT FILTER ...................................................................3-8

3.3 UNIT REMOVAL........................................................................................3-9

3.3.1 REVOLVER/DRUM DRAWER .........................................................3-9

3.3.2 DRUM UNIT REMOVAL.................................................................3-11

3.3.3 REINSTALLING THE REVOLVER/DRUM DRAWER ....................3-12

3.3.4 IMAGE TRANSFER BELT UNIT REMOVAL..................................3-14

Reinstalling the Image Transfer Belt Unit............................................3-15

3.3.5 PAPER TRANSFER UNIT REMOVAL...........................................3-17

3.3.6 REMOVING THE FUSING UNIT....................................................3-18

3.4 SCANNER UNIT......................................................................................3-19

3.4.1 EXPOSURE LAMP REPLACEMENT.............................................3-19

3.4.2 SBU REPLACEMENT....................................................................3-19

3.4.3 SCANNER IPU BOARD REPLACEMENT......................................3-21

3.4.4 SCANNER WIRE/SCANNER MOTOR REPLACEMENT...............3-22

3.4.5 APS SENSORS..............................................................................3-24

3.4.6 SCANNER HP SENSOR................................................................3-24

3.5 LASER OPTICS SECTION .....................................................................3-25

3.5.1 OPENING THE SCANNER UNIT...................................................3-25

3.5.2 POLYGON MIRROR MOTOR REPLACEMENT ............................3-26

3.5.3 LASER SYNCHRONIZING DETECTOR REPLACEMENT............3-27

3.5.4 LD UNIT REPLACEMENT..............................................................3-27

3.5.5 LD PITCH CHECK AND ADJUSTMENT].......................................3-28

3.5.6 LASER ANGLE ADJUSTMENT......................................................3-32

3.5.7 LD CONTROL BOARD REPLACEMENT.......................................3-34

3.6 DRUM UNIT ............................................................................................3-35

3.6.1 DRUM REPLACEMENT.................................................................3-35

Post-replacement Procedure..............................................................3-36

3.6.2 CLEANING BLADE REPLACEMENT.............................................3-37

3.6.3 CLEANING BRUSH REPLACEMENT............................................3-38

3.6.4 LUBRICANT BAR REPLACEMENT...............................................3-38

ii

3.6.5 BIAS ROLLER BLADE REPLACEMENT........................................3-38

3.6.6 CHARGE GRID AND CORONA WIRE AND CLEANER PAD

REPLACEMENT.............................................................................3-39

3.6.7 PCC WIRE REPLACEMENT..........................................................3-39

3.6.8 DRUM POTENTIAL SENSOR REPLACEMENT............................3-40

3.6.9 ID SENSOR REPLACEMENT........................................................3-41

3.7 IMAGE TRANSFER SECTION................................................................3-42

3.7.1 IMAGE TRANSFER BELT REPLACEMENT..................................3-42

3.7.2 TRANSFER BELT LUBRICANT BAR AND LUBRICANT BRUSH

REPLACEMENT.............................................................................3-44

3.7.3 IMAGE TRANSFER BELT BLADE REPLACEMENT .....................3-45

3.7.4 ENTRANCE SEAL GAP ADJUSTMENT........................................3-46

3.7.5 PAPER TRANSFER ROLLER........................................................3-47

PTR Discharge Plate Cleaning...........................................................3-47

PTR Coating Bar and Cleaning Blade Replacement ..........................3-47

Transfer Roller Replacement..............................................................3-47

3.8 DEVELOPMENT UNIT............................................................................3-48

3.8.1 DEVELOPER REPLACEMENT......................................................3-48

Collecting Old Developer....................................................................3-48

Loading New Developer......................................................................3-52

Initialization.........................................................................................3-55

3.8.2 SETTING THE DEVELOPMENT UNIT COLOR............................3-56

3.8.3 CLEANING THE TONER CATCH COVER.....................................3-56

3.8.4 REVOLVER MOTOR REPLACEMENT..........................................3-57

3.8.5 TONER DENSITY SENSOR REPLACEMENT ...............................3-57

3.8.6 TD SENSOR INTERFACE (I/F) BOARD REPLACEMENT ............3-58

3.9 PAPER FEED AND REGISTRATION SECTION.....................................3-59

3.9.1 BY-PASS FEED TABLE REMOVAL...............................................3-59

3.9.2 BY-PASS FEED PAPER WIDTH/PAPER LENGTH/

PAPER END SENSOR REPLACEMENT.......................................3-60

3.9.3 BY-PASS PICK-UP ROLLER REPLACEMENT .............................3-61

3.9.4 BY-PASS FEED ROLLER REPLACEMENT ..................................3-61

3.9.5 BY-PASS SEPARATION ROLLER/

BY-PASS TABLE LIFT MOTOR ASSEMBLY REPLACEMENT.....3-62

3.9.6 BY-PASS PAPER FEED UNIT REMOVAL.....................................3-62

3.9.7 BY-PASS PAPER FEED UNIT INSTALLATION.............................3-63

3.9.8 REGISTRATION SENSOR REPLACEMENT.................................3-65

3.9.9 PAPER DUST CATCHING MYLAR CLEANING ............................3-65

3.9.10 PAPER TRAY ROLLER REPLACEMENT....................................3-66

3.9.11 PAPER FEED UNIT AND PAPER FEED CLUTCH

REPLACEMENT...........................................................................3-67

3.9.12 COPY IMAGE AREA ADJUSTMENT...........................................3-69

3.10 PAPER TRANSPORT, FUSING, AND PAPER EXIT............................3-71

3.10.1 TRANSPORT UNIT REMOVAL....................................................3-71

3.10.2 FUSING UNIT TOP COVER REMOVAL......................................3-71

3.10.3 OIL SUPPLY UNIT REPLACEMENT AND CLEANING................3-72

3.10.4 HOT ROLLER BLADE REPLACEMENT......................................3-73

3.10.5 HOT ROLLER SEPARATION PAWL CLEANING ........................3-74

iii

3.10.6 CLEANING THE CLEANING ROLLER SCRAPER AND

PRE-CLEANING ROLLER REPLACEMENT................................3-74

3.10.7 FUSING THERMOFUSE AND THERMISTOR

REPLACEMENT...........................................................................3-75

3.10.8 OIL TANK REMOVAL...................................................................3-75

3.10.9 FUSING UNIT DISASSEMBLY.....................................................3-76

3.10.10 FUSING LAMP REPLACEMENT................................................3-77

3.10.11 HOT ROLLER REPLACEMENT.................................................3-77

3.10.12 CLEANING THE HOT ROLLER CLEANING ROLLER...............3-78

3.10.13 PRESSURE ROLLER LAMP/ROLLER REPLACEMENT...........3-78

3.10.14 PRESSURE THERMOFUSE AND THERMISTOR

REPLACEMENT.........................................................................3-79

3.10.15 CLEANING THE PRESSURE CLEANING ROLLER..................3-79

3.10.16 PRESSURE ROLLER BLADE CLEANING

(230 V MACHINES ONLY) .........................................................3-80

3.10.17 PRESSURE ROLLER OIL SUPPLY PAD REPLACEMENT

(230 V MACHINES ONLY) .........................................................3-80

3.10.18 NIP BAND WIDTH ADJUSTMENT.............................................3-82

3.10.19 CAUTIONS TO BE TAKEN WHEN USING A FUSING UNIT

THAT HAS BEEN IN STOCK FOR A LONG PERIOD................3-83

3.11 DUPLEX UNIT.......................................................................................3-84

3.11.1 DUPLEX UNIT REMOVAL ...........................................................3-84

3.11.2 SEPARATION ROLLER REPLACEMENT ...................................3-84

3.11.3 FEED ROLLER REPLACEMENT.................................................3-85

3.11.4 DUPLEX FEED MOTOR REPLACEMENT...................................3-86

3.12 SYSTEM AND ELECTRONICS.............................................................3-88

3.12.1 SOFTWARE UPDATE USING AN IC CARD................................3-88

Care of the IC Card.............................................................................3-88

Upgrading the Main Control Board Software ......................................3-88

Upgrading the Scanner IPU Software.................................................3-89

NV-RAM Uploading and Downloading................................................3-90

Upload/download procedur e...............................................................3-90

3.12.2 RAM CLEAR.................................................................................3-91

RAM Clear Procedure.........................................................................3-91

3.12.3 MAIN CONTROL BOARD ............................................................3-92

Main Control Board Replacement Procedure .....................................3-92

3.12.4 COUNTERS .................................................................................3-93

About the Total Counter......................................................................3-93

Mechanical Counter............................................................................3-93

NV-RAM Replacement Procedure......................................................3-93

3.12.5 TOUCH PANEL CALIBRATION...................................................3-94

3.12.6 DOOR SAFETY SWITCH LOCK TOOLS.....................................3-95

4 TROUBLESHOOTING ................................................................. 4-1

4.1 PROCESS CONTROL ERROR CONDITIONS.........................................4-1

4.1.1 PROCESS CONTROL SELF CHECK RESULTS (SP3-975-00)......4-1

4.1.2 DEVELOPER SETUP RESULTS (SP3-964-00)...............................4-2

“Developer Agitation (SP2-225)” Operation Flow..................................4-3

4.1.3 TD SENSOR INITIALIZATION RESULTS (SP3-005-006)................4-3

iv

How to Avoid the Abnormal TD Sensor Initialization.............................4-4

Countermeasure...................................................................................4-4

Action in the Field.................................................................................4-5

4.1.4 TONER SCATTERING.....................................................................4-6

4.1.5 SELF-CHECK PROCESS CONTROL RELATED SC’s....................4-7

SC385: VSG Adjustment Error..............................................................4-7

Other Self-check Process Control Related SC’s...................................4-7

4.2 DRUM LIGHT FATIGUE............................................................................4-8

4.3 ANTI-CONDENSATION HEATERS ..........................................................4-9

Condition...............................................................................................4-9

4.4 JITTER IN THICK OR EXTRA THICK PAPER MODE............................4-10

4.5 SC CODE TABLE....................................................................................4-11

4.5.1 SC TYPES AND RESETTING PROCEDURES..............................4-11

SC CODE TABLE...............................................................................4-12

5 SERVICE TABLES....................................................................... 5-1

5.1 SERVICE PROGRAM (SP) MODES.........................................................5-1

5.1.1 HOW TO ENTER AN SP MODE......................................................5-1

How to make copies from SP mode:.....................................................5-1

Pop-up Screen......................................................................................5-2

5.1.2 SP MODE TYPES............................................................................5-3

5.1.3 SERVICE PROGRAM MODE TABLES............................................5-3

SP1-XXX (Feed)...................................................................................5-4

SP2-XXX (Drum)...................................................................................5-7

SP3-XXX (Process Control)................................................................5-20

SP4-XXX (Scanner Unit).....................................................................5-24

SP5-XXX (Opera tio n Modes/System).................................................5-30

SP6-XXX (Peripherals).......................................................................5-34

SP7-XXX (Logging Data)....................................................................5-35

SP8-XXX (Special Mode)....................................................................5-37

5.1.4 POP-UP SCREEN..........................................................................5-42

SCREEN-A (1/2).................................................................................5-42

SCREEN-A (2/2).................................................................................5-42

SCREEN-B.........................................................................................5-43

SCREEN-C.........................................................................................5-43

SCREEN-D.........................................................................................5-44

SCREEN-E.........................................................................................5-44

SCREEN-F .........................................................................................5-45

SCREEN-G.........................................................................................5-45

SCREEN-H (1/2).................................................................................5-46

SCREEN-H (2/2).................................................................................5-46

SCREEN-I...........................................................................................5-47

SCREEN-J..........................................................................................5-47

SCREEN-K (1/6).................................................................................5-48

SCREEN-K (2/6).................................................................................5-48

SCREEN-K (3/6).................................................................................5-49

SCREEN-K (4/6).................................................................................5-49

SCREEN-K (5/6).................................................................................5-50

SCREEN-K (6/6).................................................................................5-50

v

5.1.5 SP4-301 APS OPERATION CHECK DETAILS.............................. 5-51

5.1.6 TEST PATTERN.............................................................................5-52

IPU Test Pattern (SP4-417)................................................................5-52

LD Control Board Test Pattern (SP4-907) ..........................................5-52

5.1.7 SP5-803 INPUT CHECK................................................................5-53

COPIER..............................................................................................5-53

LCT.....................................................................................................5-54

SORTER.............................................................................................5-55

ADF.....................................................................................................5-55

5.1.8 SP5-804 OUTPUT CHECK ............................................................5-56

COPIER..............................................................................................5-56

OPTIONS (SORTER, ADF)................................................................5-57

5.1.9 SP5-955 PRINTER INTERNAL PATTERN.....................................5-58

5-955-018: Internal Pattern Ty pes......................................................5-58

5.2 USER TOOLS.........................................................................................5-58

5.2.1 HOW TO ENTER USER TOOLS....................................................5-58

5.2.2 DETAILED DESCRIPTION OF USER TOOLS...............................5-58

5.3 TP/SW/LED/FUSE...................................................................................5-59

5.3.1 MAIN CONTROL BOARD TEST PINS...........................................5-59

5.3.2 LD MAIN CONTROL BOARD TEST PINS..................................... 5-60

5.3.3 I/O CONTROL BOARD TEST PINS...............................................5-60

5.3.4 FUSE SPECIFICATIONS...............................................................5-65

5.3.5 LED/SW SPECIFICATIONS OF SCANNER IPU BOARD..............5-66

LED Specifications..............................................................................5-66

SW Specifications...............................................................................5-66

6 DETAILED SECTION DESCRIPTIONS ....................................... 6-1

6.1 MECHANISM OVERVIEW........................................................................6-1

6.1.1 IMAGE GENERATION PROCESS...................................................6-1

6.1.2 MAJOR UNITS AND PAPER PATH.................................................6-3

6.2 PARTS LAYOUT.......................................................................................6-4

6.2.1 MAJOR UNIT LAYOUT DIAGRAM...................................................6-4

6.3 DRIVE LAYOUT........................................................................................6-5

6.4 AIR FLOW.................................................................................................6-6

6.4.1 AIR FLOW SYSTEM 1......................................................................6-6

6.4.2 AIR FLOW SYSTEM 2......................................................................6-7

6.5 PROCESS CONTROL ..............................................................................6-8

6.5.1 OVERVIEW......................................................................................6-8

6.5.2 POTENTIAL CONTROL.................................................................6-10

Overview............................................................................................. 6-10

Potential Control Timing......................................................................6-10

6.5.3 PROCESS CONTROL SELF-CHECK OPERATION FLOW...........6-12

Step 1: VSG Adjustment......................................................................6-13

Step 2: Generating ID Sensor Patch Patterns....................................6-13

Step 3: Sensor Pattern Potential Detection.........................................6-14

Step 4: Sensor Pattern Density Detection...........................................6-15

Step 5: Toner Amount Calculation......................................................6-17

Step 6: Development Potential Calculation.........................................6-17

Step 7: Selecting the Optimum VD, VB, VL.........................................6-18

vi

6.5.4 PROCESS CONTROL γ CORRECTION........................................6-19

What is process control γ?..................................................................6-19

How is it done?...................................................................................6-19

Process Control γ Correction Timing...................................................6-20

Relationship Between Process Control γ Correction, ACC, and

Other γ Corrections.............................................................................6-20

6.5.5 TONER SUPPLY CONTROL .........................................................6-21

Toner Supply Control Modes..............................................................6-21

TD Sensor Output...............................................................................6-22

Detecting VSP for Toner Supply Control .............................................6-22

Calculating the Amount of Toner on the Drum....................................6-23

Summery of Toner Supply Control......................................................6-23

6.6 DRUM UNIT ............................................................................................6-24

6.6.1 MAJOR COMPONENTS ................................................................6-24

6.6.2 DRUM UNIT DRIVE........................................................................6-25

Drum Drive..........................................................................................6-25

Cleaning Drive....................................................................................6-25

6.6.3 CHARGE CORONA UNIT..............................................................6-26

6.6.4 CHARGE CORONA UNIT CLEANER............................................ 6-27

Drive ...................................................................................................6-27

Cleaning Conditions............................................................................6-27

Related SP modes..............................................................................6-27

Home Position ....................................................................................6-27

Cleaning Path (front → rear → front)..................................................6-27

Position Detection...............................................................................6-27

6.6.5 CLEANING MECHANISM ..............................................................6-28

Cleaning.............................................................................................. 6-28

Lubricant.............................................................................................6-28

6.6.6 PRE-CLEANING CORONA (PCC).................................................6-28

6.6.7 QUENCHING..................................................................................6-29

6.6.8 CARRIER CATCHER.....................................................................6-29

6.7 SCANNER UNIT......................................................................................6-30

6.7.1 OVERVIEW....................................................................................6-30

6.7.2 SCANNER......................................................................................6-31

First Scanner ......................................................................................6-31

Exposure Lamp...................................................................................6-31

Mirrors.................................................................................................6-31

6.7.3 SCANNER DRIVE..........................................................................6-32

Full Size mode....................................................................................6-32

Reduction/Enlargement modes...........................................................6-32

6.7.4 COLOR CCD..................................................................................6-33

6.7.5 WHITE PLATE SCANNING............................................................6-34

6.7.6 SCANNER IPU...............................................................................6-34

6.7.7 ORIGINAL SIZE DETECTION........................................................6-35

6.7.8 OTHERS.........................................................................................6-37

Anti-condensation Heater ...................................................................6-37

Fans ....................................................................................................6-37

6.8 IMAGE PROCESSING............................................................................6-38

vii

6.8.1 OVERVIEW....................................................................................6-38

6.8.2 SCANNER SECTION BLOCK DIAGRAM......................................6-39

6.8.3 SCANNER FUNCTIONS................................................................6-40

Photoelectric Conversion....................................................................6-40

Signal Processing (Analog ASIC).......................................................6-40

A/D Conversion...................................................................................6-40

Shading Compensation Circuit ...........................................................6-41

D/A Conversion...................................................................................6-42

Scan Line Correction Circuit...............................................................6-42

6.8.4 IPU SECTION BLOCK DIAGRAM..................................................6-43

6.8.5 IPU FUNCTIONS............................................................................6-44

Scanner γ Conversion and Picture Element Correction......................6-44

ACS (Auto Color Selection)................................................................6-46

Automatic Original Type Selection......................................................6-47

Image Separation ...............................................................................6-48

Filtering and Color Conversion ...........................................................6-49

Image Creation...................................................................................6-54

Gradation Processing.........................................................................6-56

Area Manipulation Functions ..............................................................6-59

CPU....................................................................................................6-59

IPU Board Test...................................................................................6-59

6.9 LASER EXPOSURE................................................................................6-60

6.9.1 OVERVIEW....................................................................................6-60

6.9.2 LD UNIT..........................................................................................6-61

LD Safety Switch.................................................................................6-61

LD Unit Configuration..........................................................................6-62

Auto Power Control (APC)..................................................................6-63

6.9.3 LASER OPTICS SYSTEM..............................................................6-64

Cylindrical Lens ..................................................................................6-64

Polygon Mirror.....................................................................................6-64

fθ Lenses and the BTL........................................................................6-65

Laser Synchronization Mechanism.....................................................6-65

Laser Exposure Control......................................................................6-66

Multibeam Laser Exposure.................................................................6-67

Laser Diode Control Board Functions .................................................6-67

6.10 DEVELOPMENT UNIT..........................................................................6-68

6.10.1 OVERVIEW..................................................................................6-68

6.10.2 REVOLVER MECHANISM...........................................................6-69

Revolver Drive....................................................................................6-70

Revolver Home Position Detection .....................................................6-71

6.10.3 DEVELOPMENT MECHANISM....................................................6-72

Development.......................................................................................6-72

Magnetic Doctor Blade........................................................................6-72

Narrow Gap Development..................................................................6-72

6.10.4 DEVELOPMENT DRIVE...............................................................6-73

6.10.5 DEVELOPER AGITATION...........................................................6-73

6.10.6 TONER AGITATION.....................................................................6-74

6.10.7 DEVELOPMENT BIAS.................................................................6-74

6.10.8 TONER SUPPLY MECHANISM...................................................6-75

viii

6.10.9 TONER BLOCKING MECHANISM...............................................6-76

6.10.10 TONER CARTRIDGE DETECTION...........................................6-77

6.10.11 TONER CARTRIDGE SHUTTER LOCK PIN .............................6-77

6.10.12 INCORRECT TONER INSTALLATION PREVENTION..............6-77

6.10.13 TONER END SENSOR ..............................................................6-78

Sensor ................................................................................................6-78

Toner Near End/Toner End Detection ................................................6-78

6.10.14 TONER END RECOVERY .........................................................6-80

6.10.15 TONER LOOSENING.................................................................6-81

6.10.16 REVOLVER LOCK MECHANISM...............................................6-82

6.11 TRANSFER SYSTEM ...........................................................................6-83

6.11.1 OVERVIEW..................................................................................6-83

6.11.2 IMAGE TRANSFER BELT SECTION...........................................6-84

Image Transfer Belt Drive Mechanism................................................6-84

Belt Tension Release Mechanism ......................................................6-85

Image Transfer Belt Bias....................................................................6-86

Error Codes ........................................................................................6-87

Belt Mark Sensor................................................................................6-87

Belt Pressure Release Mechanism.....................................................6-87

Belt Cleaning Mechanism...................................................................6-88

Cleaning Vacuum ...............................................................................6-90

Toner Collection Mechanism ..............................................................6-90

6.11.3 PAPER TRANSFER MECHANISM..............................................6-91

Paper Transfer Roller Unit Contact/Release Mechanism....................6-91

Paper Transfer Roller Cleaning ..........................................................6-92

Paper Transfer Roller and Transport Belts Drive................................6-93

Paper Transfer Bias............................................................................6-94

6.11.4 PAPER SEPARATION MECHANISM...........................................6-96

6.12 PAPER FEED AND REGISTRATION SECTION...................................6-97

6.12.1 MAJOR COMPONENTS ..............................................................6-97

Diagram..............................................................................................6-97

6.12.2 PAPER TRAY SECTION..............................................................6-98

Paper Feed/Separation Mechanism ...................................................6-98

Reverse Roller Release Mechanism...................................................6-98

Paper Feed Operation........................................................................6-98

Paper Lift Mechanism.........................................................................6-99

Paper End Detection.........................................................................6-100

Paper Near End Detection................................................................6-100

6.12.3 BY-PASS PAPER FEED SECTION............................................6-101

By-pass Feed Table..........................................................................6-101

By-pass Feed Unit............................................................................6-101

By-pass Paper End Sensor...............................................................6-101

By-pass Feed Table Lift Mechanism.................................................6-102

By-pass Pick-up Roller Pressure......................................................6-102

6.12.4 PAPER FEED DRIVE.................................................................6-103

Tray Feed Unit Drive.........................................................................6-103

Registration Roller Drive...................................................................6-103

By-pass Feed Unit Drive................................................................... 6-104

6.12.5 PAPER DUST CATCHING.........................................................6-104

ix

6.12.6 PAPER FEEDING SPEED......................................................... 6-105

6.12.7 PAPER PATH.............................................................................6-105

Dipping Up-hill Paper Path................................................................ 6-105

6.13 TRANSPORT, FUSING, AND EXIT ....................................................6-106

6.13.1 MAJOR COMPONENTS ............................................................6-106

6.13.2 DRIVE MECHANISM..................................................................6-107

6.13.3 FUSING UNIT OVERVIEW ........................................................6-107

6.13.4 FUSING TEMPERATURE CONTROL........................................6-108

6.13.5 FUSING PRESSURE.................................................................6-108

6.13.6 OIL SUPPLY...............................................................................6-109

6.13.7 CLEANING MECHANISM ..........................................................6-110

6.13.8 FUSING OIL RECYCLING MECHANISM...................................6-111

6.13.9 HOT ROLLER SEPARATION PAWL..........................................6-111

6.13.10 PAPER EXIT AND PAPER INVERSION..................................6-112

Paper Exit Mechanism......................................................................6-112

Junction Gate Mechanism................................................................6-112

Paper Exit Cover...............................................................................6-112

6.14 DUPLEX TRAY....................................................................................6-113

6.14.1 OVERVIEW................................................................................6-113

6.14.2 DRIVE MECHANISM..................................................................6-114

6.14.3 PAPER FEED INTO THE DUPLEX TRAY .................................6-115

Duplex Stacking................................................................................6-115

Paper Feed from the Duplex Tray.....................................................6-116

Duplex Entrance to Duplex Tray.......................................................6-117

6.14.4 JOGGER MECHANISM..............................................................6-118

6.14.5 PAPER FEED FROM THE DUPLEX TRAY ...............................6-119

Bottom Plate Lift Mechanism............................................................6-119

6.14.6 PAPER FEED-OUT MECHANISM.............................................6-120

6.15 SYSTEM CONFIGURATION...............................................................6-121

6.15.1 CONFIGURATION......................................................................6-121

6.15.2 POWER STATES.......................................................................6-122

Energy Saver Mode..........................................................................6-122

Power-off (Sleep) State (AOF Mode)................................................6-122

Main Power Switch Off State............................................................6-122

Copier Modes ...................................................................................6-123

6.15.3 OPERATION PANEL..................................................................6-124

6.15.4 PRINTER CONTROLLER INTERFACE.....................................6-125

SPECIFICATIONS.....................................................................SPEC-1

1. MAJOR UNITS....................................................................................SPEC-1

B023 Copier:.................................................................................SPEC-1

2. BASIC SPECIFICATIONS...................................................................SPEC-2

3. PLATEN/ARDF ORIGINAL SIZE DETECTION...................................SPEC-7

4. COPY PAPER SIZES..........................................................................SPEC-8

5. NOISE EMISSION...............................................................................SPEC-9

6. POWER CONSUMPTION...................................................................SPEC-9

x

PERIPHERALS

ARDF (A663)

1 SPECIFICATIONS..................................................................A663-1

2 COMPONENT LAYOUT.........................................................A663-2

2.1 MECHANICAL COMPONENTS ......................................................... A663-2

2.2 ELECTRICAL COMPONENTS........................................................... A663-3

3 ELECTRICAL COMPONENT DESCRIPTION........................A663-4

4 DETAILED DESCRIPTIONS..................................................A663-5

4.1 ORIGINAL PICK-UP MECHANISM.................................................... A663-5

4.2 SEPARATION AND PAPER FEED MECHANISM ............................. A663-6

4.3 FRICTION BELT DRIVE MECHANISM.............................................. A663-7

4.4 ORIGINAL SIZE DETECTION............................................................ A663-8

4.5 PAPER TRANSPORT MECHANISM ................................................. A663-9

4.6 THICK/THIN ORIGINAL MODES..................................................... A663-10

4.7 ORIGINAL FEED-OUT MECHANISM.............................................. A663-11

4.8 TWO-SIDED ORIGINAL FEED MECHANISM..................................A663-12

5 TIMING CHARTS.................................................................A663-13

5.1 A4 SIDEWAYS: 1 SIDED ORIGINAL............................................... A663-13

5.2 COMBINE 2 ORIGINAL MODE........................................................ A663-14

5.3 A4 SIDEWAYS: DUPLEX................................................................. A663-15

6 SERVICE TABLES...............................................................A663-16

6.1 DIP SWITCHES................................................................................ A663-16

6.2 VARIABLE RESISTORS.................................................................. A663-17

6.3 LED .................................................................................................. A663-17

6.4 FUSE................................................................................................ A663-17

7 REPLACEMENT AND ADJUSTMENT.................................A663-18

7.1 TRANSPORT BELT REPLACEMENT.............................................. A663-18

7.2 FEED ROLLER REPLACEMENT..................................................... A663-19

7.3 FRICTION BELT REPLACEMENT................................................... A663-20

7.4 ORIGINAL SET AND WIDTH SENSOR REPLACEMENT ............... A663-21

7.5 VERTICAL REGISTRATION ADJUSTMENT...................................A663-22

7.5.1 ONE SIDED THIN ORIGINAL MODE...................................... A663-22

7.5.2 TWO SIDED ORIGINAL MODE .............................................. A663-23

7.6 SIDE-TO-SIDE REGISTRATION (DF POSITIONING)

ADJUSTMENT ................................................................................. A663-24

xi

SORTER STAPLER (A831)

1 OVERALL MAHCINE INFORMATION...................................A831-1

1.1 SPECIFICATIONS.............................................................................. A831-1

1.2 COMPONENT LAYOUT..................................................................... A831-3

1.2.1 MECHANICAL COMPONENT LAYOUT.................................... A831-3

1.2.2 DRIVE LAYOUT........................................................................ A831-4

2 DETAILED DESCRIPTION ....................................................A831-5

2.1 BASIC OPERATION........................................................................... A831-5

2.1.1 NORMAL (PROOF MODE) AND SORT/STACK MODE........... A831-5

Normal (Proof) Mode (From the Turn Gate Section to

the Proof Tray)............................................................................... A831-5

Sort Mode (From the Turn Gate Section to the Bins)..................... A831-6

Stack Mode (From the Turn Gate Section to the Bins).................. A831-7

Reverse Mode (From the Turn Gate Section to the Bins).............. A831-8

2.1.2 STAPLE MODE.........................................................................A831-9

2.2 TURN GATE SECTION.................................................................... A831-11

2.3 BIN DRIVE MECHANISM................................................................. A831-12

2.4 BIN HOME POSITION...................................................................... A831-13

2.5 JOGGER SECTION ......................................................................... A831-14

2.6 BIN REAR PLATE DRIVE SECTION ............................................... A831-15

2.7 GRIP ASSEMBLY............................................................................ A831-16

2.7.1 GRIP MOTOR ......................................................................... A831-17

2.7.2 GRIP SHIFT MOTOR.............................................................. A831-18

2.8 STAPLE UNIT.................................................................................. A831-19

2.8.1 STAPLE UNIT DRIVE MECHANISM....................................... A831-19

2.8.2 STAPLER................................................................................ A831-20

Staple Prohibit Conditions............................................................ A831-21

2.8.3 STAPLE UNIT PULLED-OUT MECHANISM........................... A831-22

3 REPLACEMENTS AND ADJUSTMENTS............................A831-23

3.1 EXTERIOR COVER REMOVAL....................................................... A831-23

3.2 STAPLER REMOVAL AND REINSTALLATION............................... A831-24

3.3 JOGGER PLATE REMOVAL AND INSTALLATION......................... A831-25

Removal....................................................................................... A831-25

Installation.................................................................................... A831-25

3.4 BINS REMOVAL............................................................................... A831-26

Removal....................................................................................... A831-26

Installation.................................................................................... A831-28

3.5 MAIN MOTOR REMOVAL................................................................ A831-30

3.6 GRIP ASSEMBLY REMOVAL.......................................................... A831-31

3.7 UPPER GRIP ASSEMBLY REMOVAL............................................. A831-32

3.8 GRIP SHIFT MOTOR REMOVAL.....................................................A831-33

3.9 HELICAL WHEELS REMOVAL........................................................ A831-34

Removal....................................................................................... A831-34

Front Helical Wheel...................................................................... A831-34

Rear Helical Wheel...................................................................... A831-35

xii

Installation.................................................................................... A831-36

Rear Helical Wheel...................................................................... A831-36

Front Helical Wheel...................................................................... A831-37

Alignment of the 2 Helical Wheels ............................................... A831-38

3.10 GRIP MOTOR AND SENSORS REMOVAL................................... A831-39

3.10.1 GRIP MOTOR/GRIP MOTOR HP SENSOR/GRIP SHIFT MOTOR

HP SENSOR REMOVAL................................................................... A831-39

3.11 MAIN CONTROL BOARD REPLACEMENT................................... A831-40

4 SP MODE AND STAPLE POSITION ADJUSTMENT ..........A831-41

4.1 SERVICE TABLES (MAIN CONTROL BOARD)...............................A831-41

4.1.1 DIP SWITCHES....................................................................... A831-41

DIP 1 (Mode) SP Mode................................................................ A831-41

DIP 2 (Staple) Staple Position Adjustment (A)............................. A831-41

DIP 3 (Chuck) Staple Position Adjustment (B)............................. A831-41

LCT (A683)

1 OVERALL MACHINE INFORMATION...................................A683-1

1.1 SPECIFICATIONS.............................................................................. A683-1

1.2 MECHANICAL COMPONENT LAYOUT ............................................ A683-2

1.3 ELECTRICAL COMPONENT LAYOUT.............................................. A683-3

1.4 ELECTRICAL COMPONENT DESCRIPTION.................................... A683-4

1.5 DRIVE LAYOUT................................................................................. A683-5

2 DETAILED DESCRIPTIONS..................................................A683-6

2.1 PAPER FEED MECHANISM.............................................................. A683-6

2.2 TRAY LIFT AND PAPER HEIGHT DETECTION MECHANISM.........A683-7

Tray lifting conditions.....................................................................A683-7

Tray lowering conditions................................................................ A683-7

2.3 TRAY UNIT SLIDE MECHANISM ...................................................... A683-8

3 SERVICE TABLES.................................................................A683-9

3.1 DIP SWITCHES.................................................................................. A683-9

3.2 TEST POINTS.................................................................................... A683-9

3.3 SWITCHES......................................................................................... A683-9

3.4 FUSES ............................................................................................... A683-9

4 REPLACEMENT AND ADJUSTMENT.................................A683-10

4.1 COVER REPLACEMENT................................................................. A683-10

Tray Cover................................................................................... A683-10

Front Cover.................................................................................. A683-10

Rear Cover .................................................................................. A683-10

Right Lower Cover....................................................................... A683-10

Upper Cover ................................................................................ A683-10

4.2 ROLLER REPLACEMENT............................................................... A683-11

xiii

4.2.1 PAPER FEED, SEPARATION, AND PICK-UP ROLLERS...... A683-11

Pick-up Roller .............................................................................. A683-11

Paper Feed Roller........................................................................ A683-11

Separation Roller......................................................................... A683-11

4.3 TRAY LIFT AND PAPER END SENSOR REPLACEMENT ............. A683-12

Tray Lift Sensor ........................................................................... A683-12

Paper End Sensor ....................................................................... A683-12

4.4 RELAY SENSOR REPLACEMENT.................................................. A683-13

4.5 SIDE FENCE POSITION CHANGE................................................... A683-14

xiv

26 January, 2001 INSTALLATION REQUIREMENTS

1. INSTALLATION PROCEDURES

1.1 INSTALLATION REQUIREMENTS

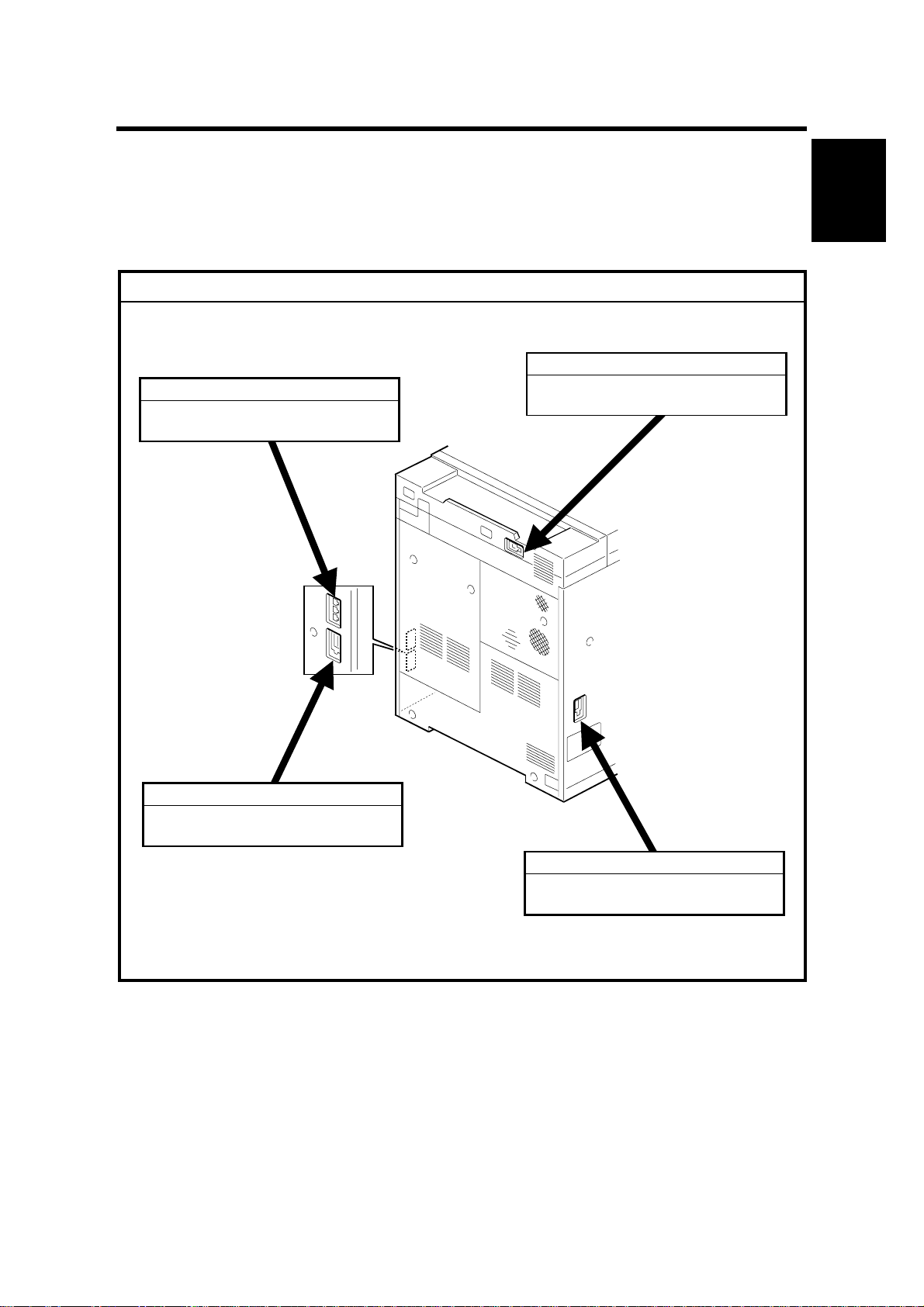

1.1.1 DIMENSIONS

!

CAUTION

Rating voltage for Peripherals

Remote Diagnostic System

Rating voltage output connector

for accessory Max. DC5 V

Installation

ARDF

Rating voltage output connector

for accessory Max. DC24 V

LCT

Rating voltage output connector

for accessory Max. DC24 V

SORTER

Rating voltage output connector

for accessory Max. DC24 V

B023I921.WMF

1-1

INSTALLATION REQUIREMENTS 26 January, 2001

1.1.2 ENVIRONMENT

To ensure the optimum copy quality, the following environmental requirements

need to be observed. When installing this copier at the customer site, make sure

that the location meets the followi ng req uir ements.

Environmental Requirements

1. Avoid an area which is exposed to direct sunlight or is excessively illuminated

(the illumination should not exceed 2,000 lux).

2. Avoid an area which is too hot and humid or too cold and dry.

Standard temperature range: 10°C to 32°C

Standard humidity range: 15% to 80%

Limit of high temperature and humidity: 32°C/54% or 27°C/80%

3. Avoid an area near fire or heat.

4. Avoid an area which is exposed to sudden temperature changes. This includes

areas where the machine will not be directly exposed to:

1) Cool air from an air conditioner

2) Heat from a heater.

5. Avoid a dusty area (maximum allowable amount of dust: 0.15 mg/m3).

6. Avoid a poor-ventilated area (required minimum ventilation: 30 m3/hr/man

7. Do not place the machine where it will be expos ed to corrosive gases.

8. Place the machine on a level floor (the inclination on any side should be no

more than 5 mm).

9. Do not place the machine where it may be subjected to strong vibrations.

10. Do not install the machine at any location over 2,000 m (6,500 feet) above sea

level.

11. If the machine is installed close to other electronic equipment, they may

interfere with each other. To avoid this problem:

1) Keep the machine as far away as possible from television sets or radios.

2) Reorient the receiving antenna of television sets and radios as needed.

3) Use a separate outlet for the machine.

!

CAUTION

1. Do not install the machine in a very humid or dusty area.

2. Do not install the machine on a shaky or inclined floor.

1-2

26 January, 2001 INSTALLATION REQUIREMENTS

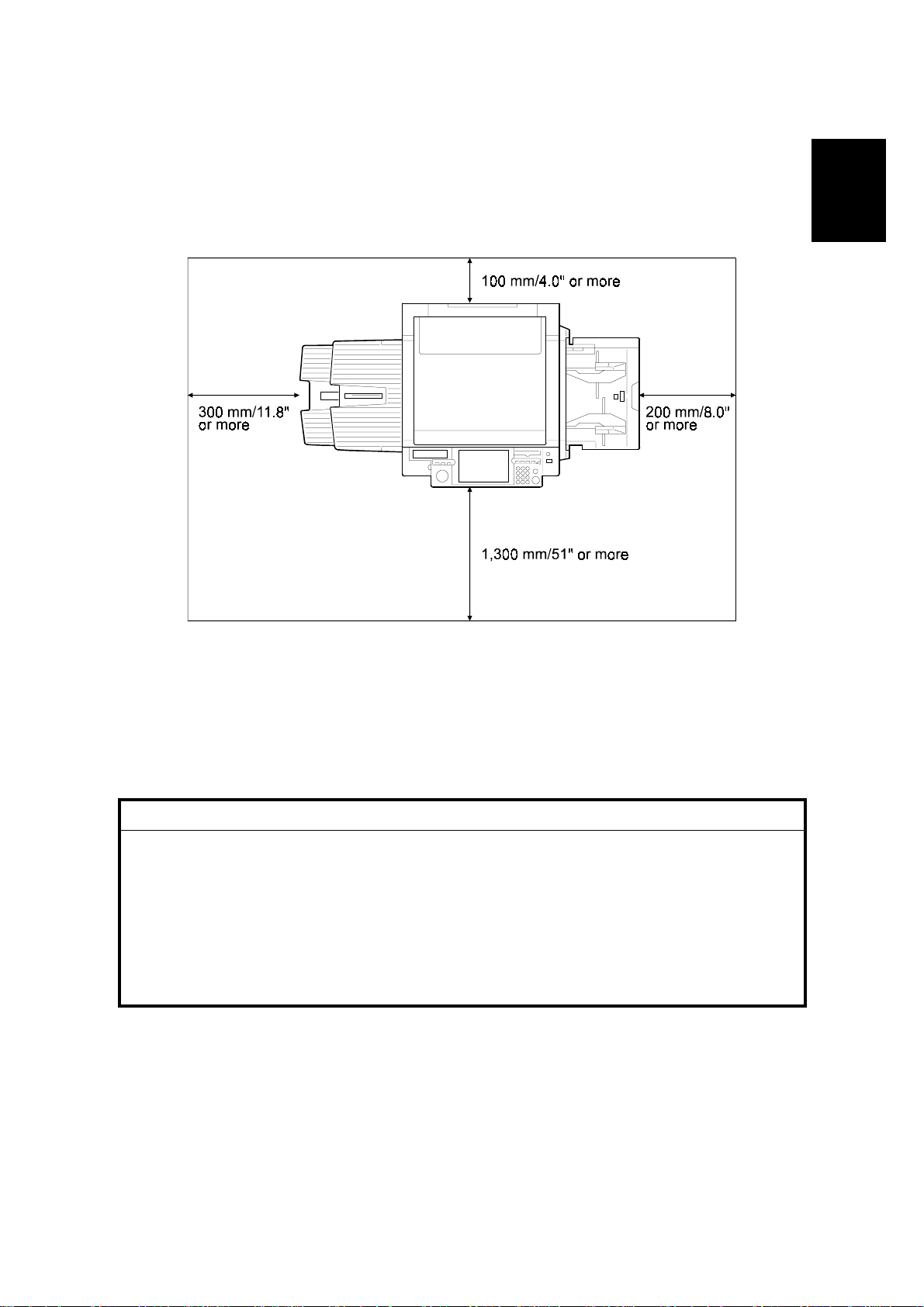

Minimum Space Requirements

Provide clearance for the copier, as shown below. If one or more options (such as

the ARDF or sorter stapler) are added to the copier, this clearance should be

provided around the entire system.

Installation

B023I157.WMF

NOTE: A space of at least 100 mm (4.0") at the rear of the machine is important

for machine ventilation.

Power Requireme nts

!

WARNING

1. Install the machine as close to the outlet as possible. Firmly plug in the

machine after installation.

2. Avoid multi-wiring.

3. The power cord should be placed where it cannot be stepped on or

flattened by the machine. When installing the machine, route the power

cord out of the way of general traffic.

4. Be sure to connect the power cord’s grounding wire.

1. Input voltage level:

120 V, 60 Hz: More than 16 A (North America)

220 V to 240 V, 50 Hz: More than 8 A (Europe, Middle Ease)

220 V to 240 V, 50/60 Hz: More than 8 A (Asia)

2. Permissible voltage fluctuation: ±10%

3. Do not set anything on the power cord.

1-3

COPIER 26 January, 2001

1.2 COPIER

1.2.1 ACCESSORY CHECK

Description Qty

1. Operating Instructions Quick Reference................................1

2. Operating Instructions Manual...............................................1

3. Copy Tray..............................................................................1

4. Tray Size Decal.....................................................................1

5. Image Samples .....................................................................1

6. Factory Data Sheet ...............................................................1

1-4

26 January, 2001 COPIER

1.2.2 PREPARATION

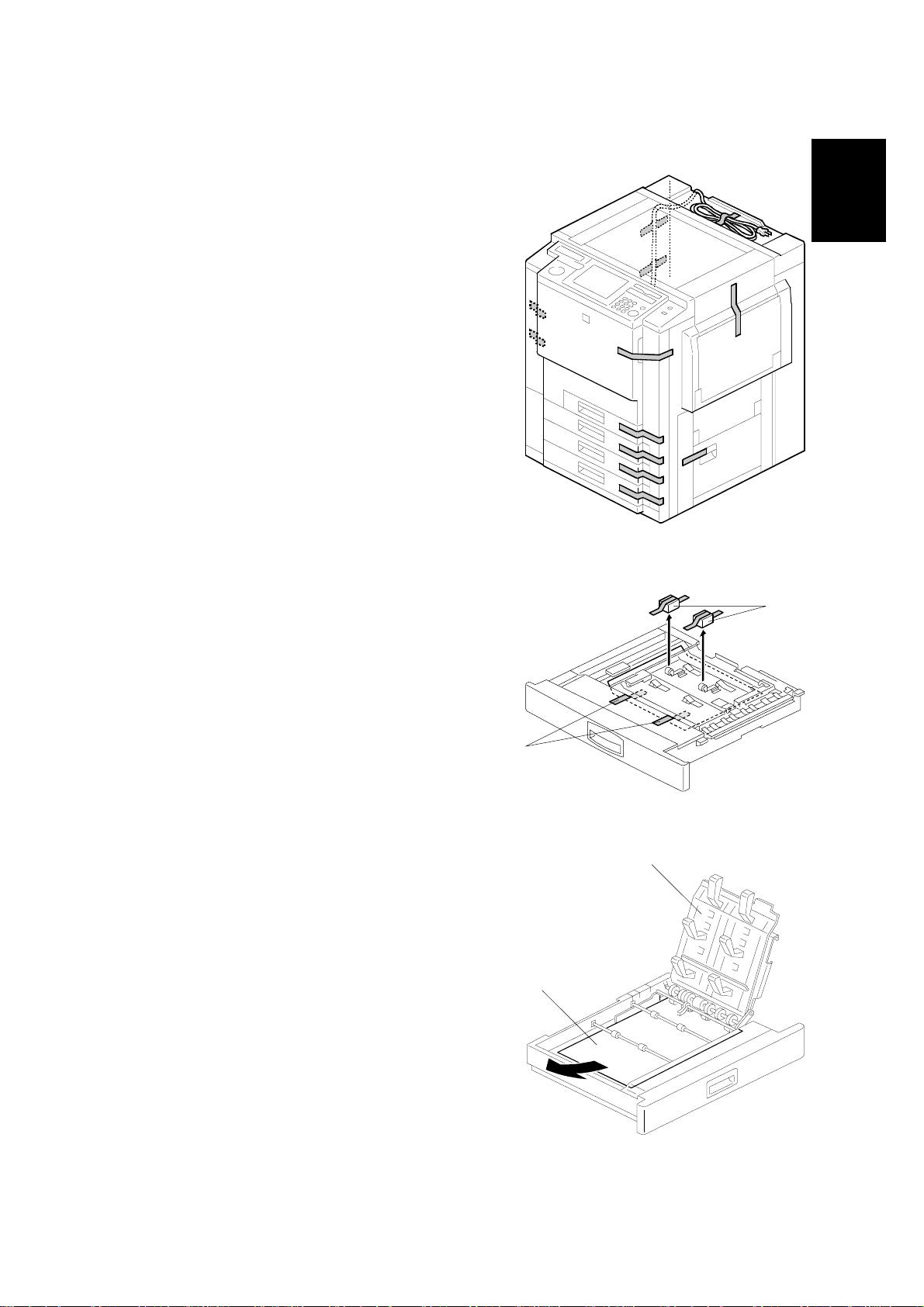

1. Remove the strips of filament tape shown

in the figures to the right.

B023I101.WMF

Installation

2. Pull out the duplex tray and remove the

protectors [A] from the metal rollers.

3. Peel off the two strips of filament tape [B]

and remove the protective sheet [C].

4. Lift the lower guide plate [D] and take out

the protective sheet.

[A]

[B]

B023I154.WMF

[D]

[C]

1-5

B023I152.WMF

COPIER 26 January, 2001

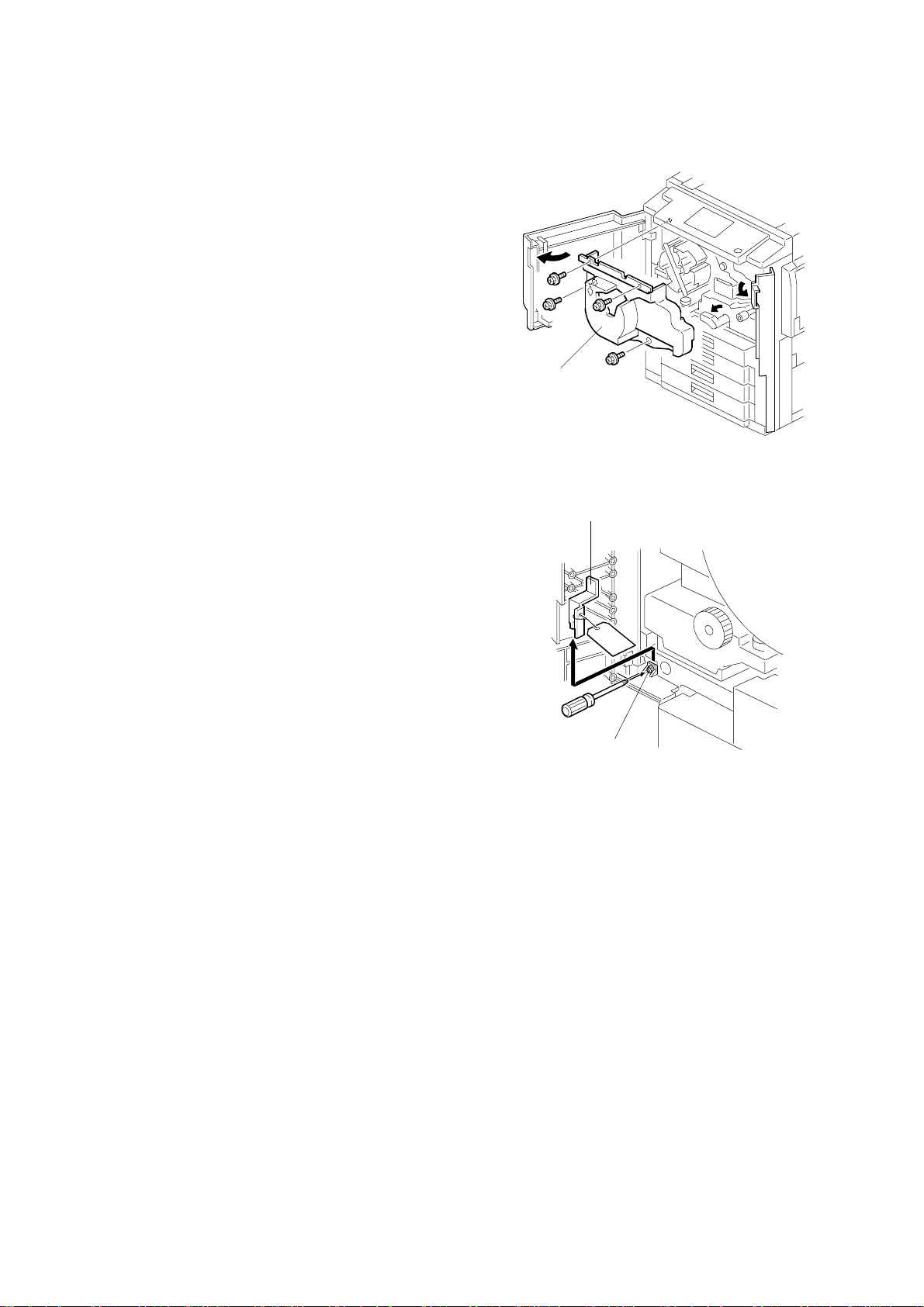

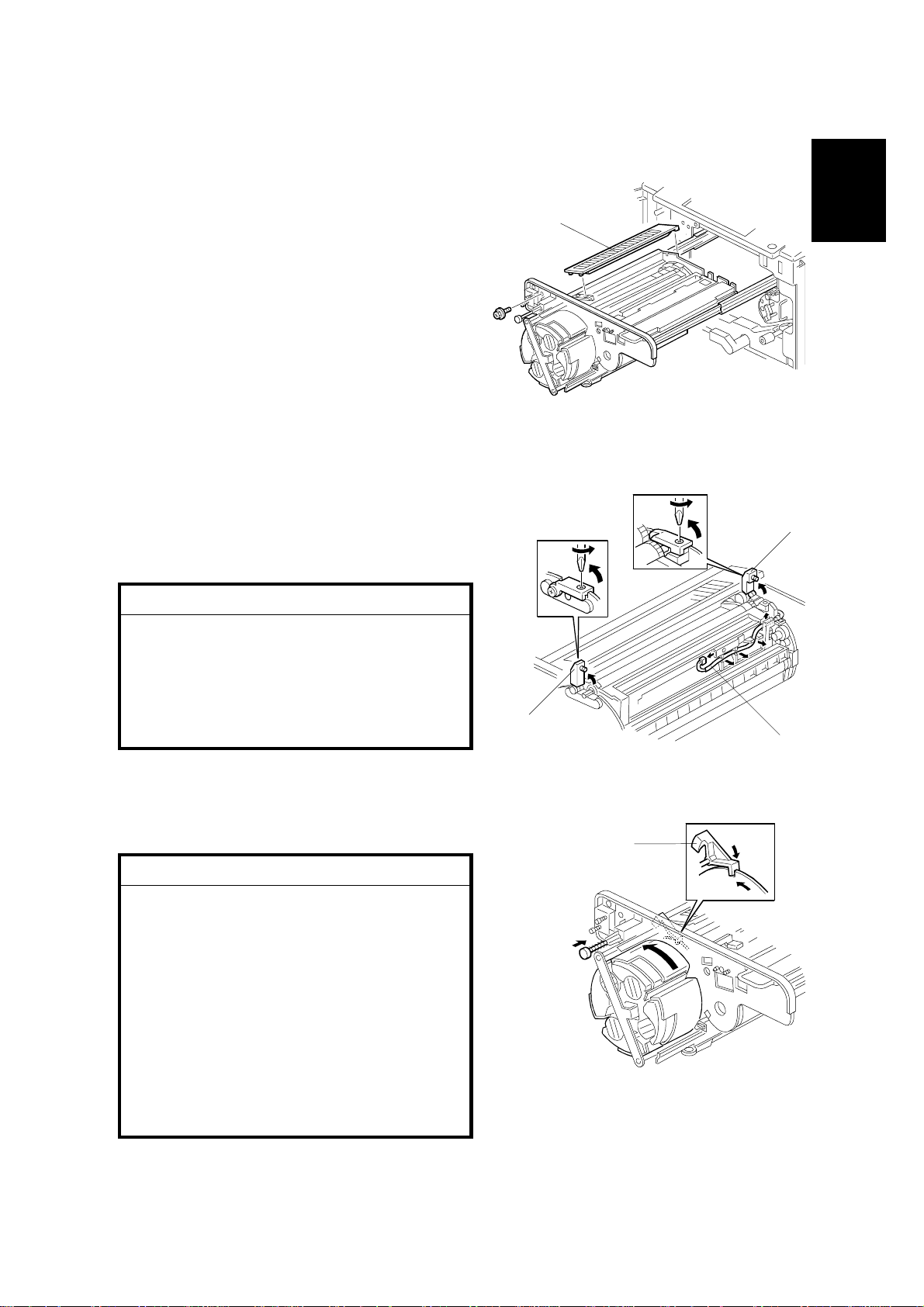

5. Open the front door and remove the

revolver cover [A] (4 screws).

[A]

B023I102.WMF

[C]

6. Loosen the screw [B] (don’t remove) then

remove the fusing/transfer drawer clamp

[C].

NOTE: Keep the fusing/transfer drawer

clamp in a safe location as it will

be reused when relocating the

copier.

Part No.: A2691115

7. Tighten screw [B] again.

[B]

B023I140.WMF

1-6

26 January, 2001 COPIER

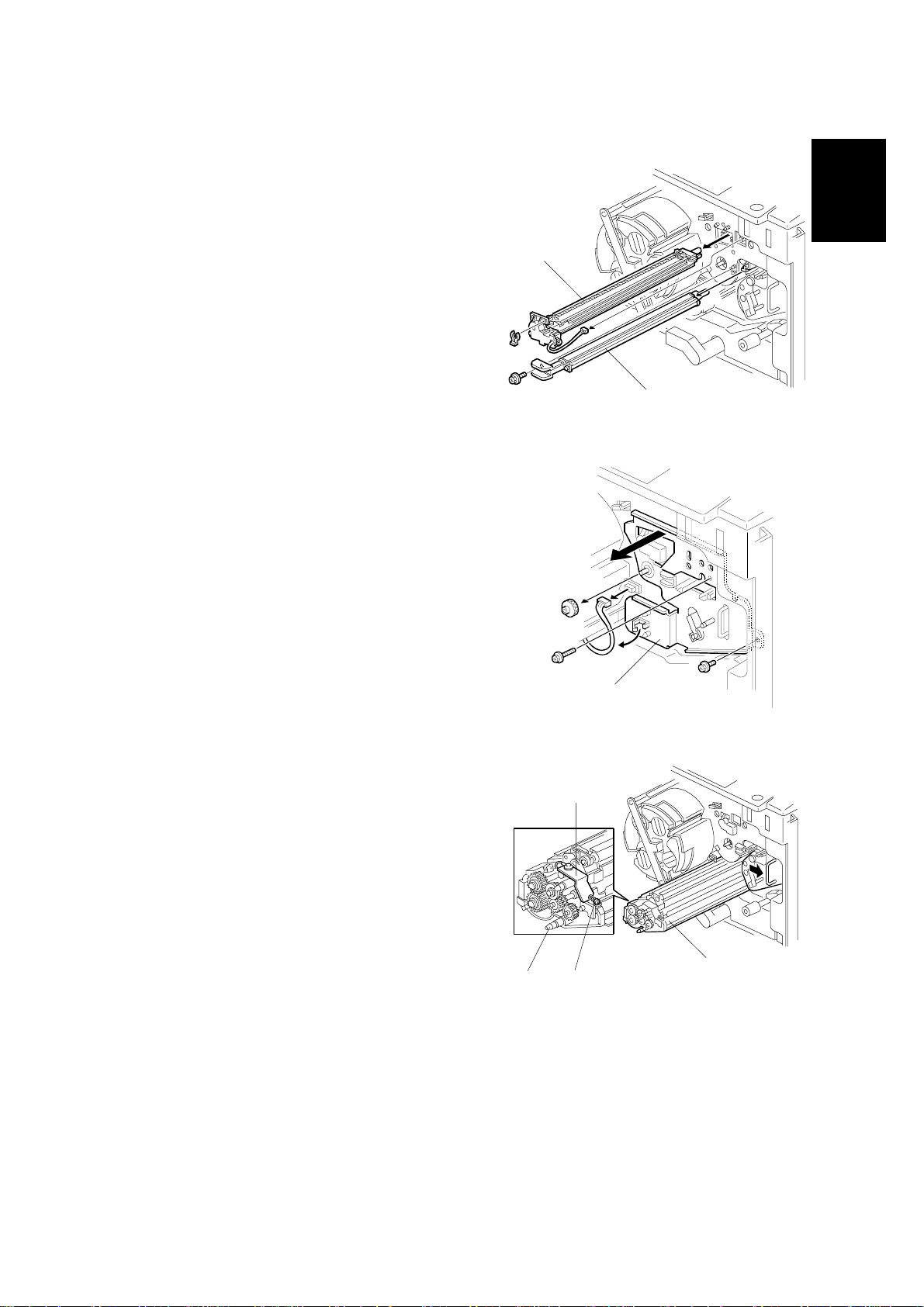

8. Remove the charge corona unit [A] (1

snap ring and 1 connector).

9. Remove the pre-cleaning corona unit

[B] (1 screw).

[A]

Installation

10. Remove the transfer faceplate [C] (3

long screws, 1 knob, 1 connector, and

2 clamps).

11. Remove the image transfer belt cleaning

unit [D].

NOTE: 1) When removin g and

reinstalling the image

transfer belt cleaning unit

during servicing, please do

so while holding the

positioning pin [E].

2) Do not hold the entrance

seal release lever [F]. If the

lever is held, it will move and

the gap will fall out of the

adjustment range. This will

cause the problems. (☛

3.7.4)

3) The screw [G] that fastens

the entrance seal release

lever should not be loosened

during servicing.

[E]

[F]

[G]

[C]

[B]

B023I327.WMF

B023I390.WMF

[D]

B023I973.WMF

1-7

COPIER 26 January, 2001

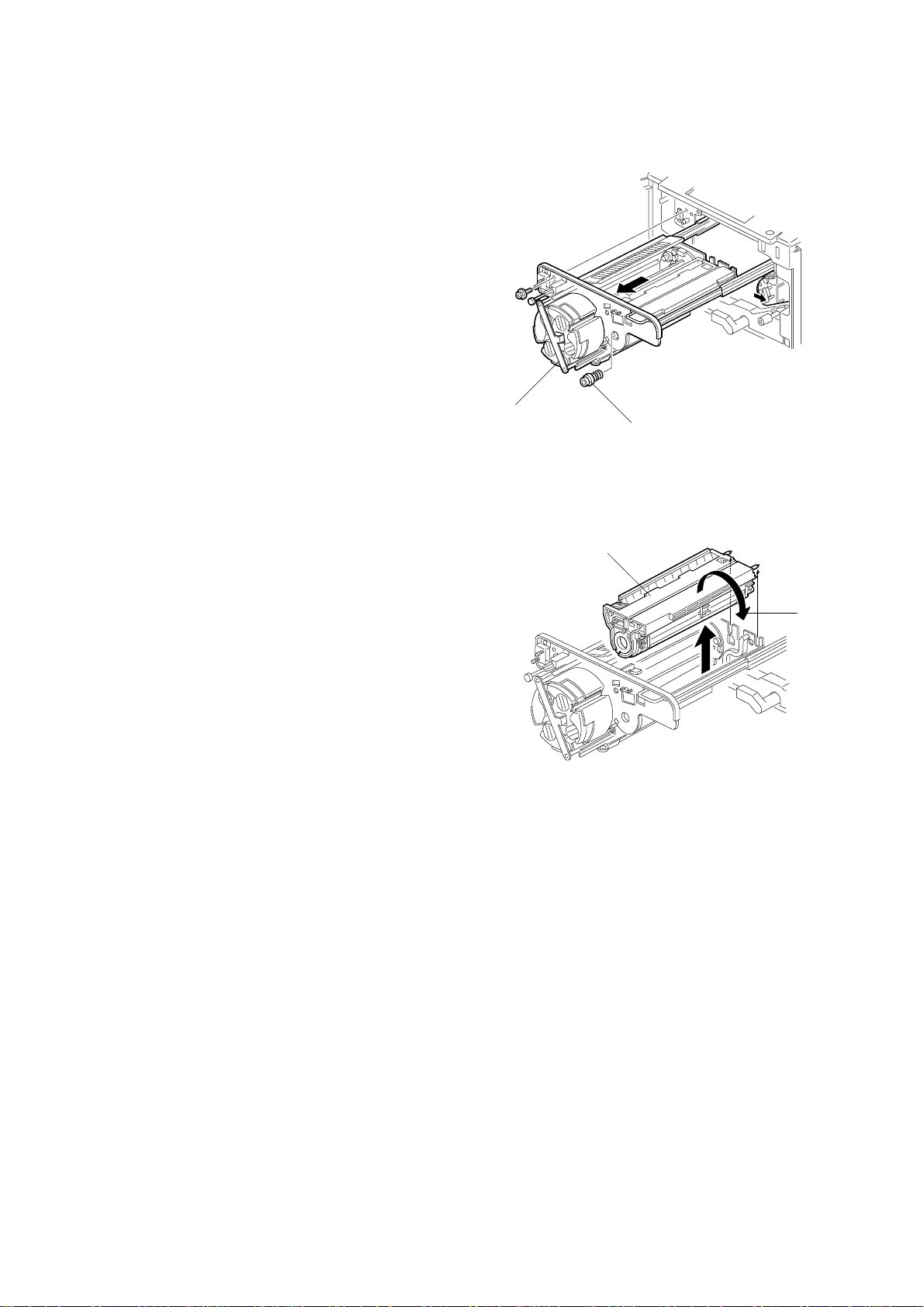

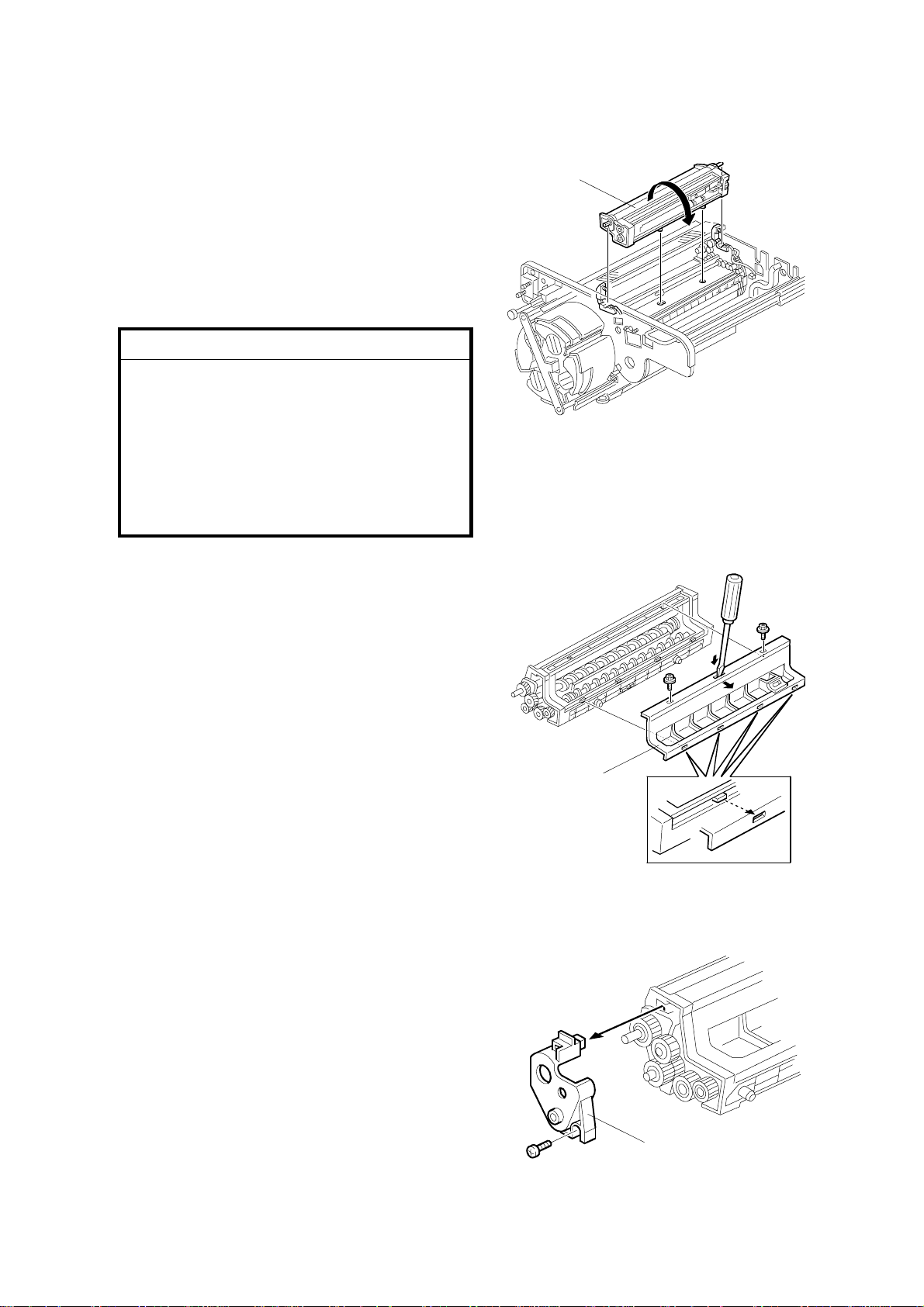

12. Pull out the revolver/drum drawer [A] (1

long screw and a pressure spring [B]).

NOTE: 1) Pulling out the drawer unit

exposes the drum to light.

Prolonged exposure can

cause optical fatigue,

resulting in poor image

quality. Be sure to shield the

drum unit with 5 or more

sheets of paper.

2) Make sure that the pressure

spring [B] is in place before

reinstalling the transfer

[A]

[B]

B023I905.WMF

faceplate.

13. Lift the drum unit [C] out of the

revolver/drum drawer.

14. Rotate the drum unit clockwise as

shown by the arrow [D] and set it

upside-down.

NOTE: If you do not rotate the drum

unit as shown, toner might

spill out.

[C]

[D]

B023I306.WMF

1-8

26 January, 2001 COPIER

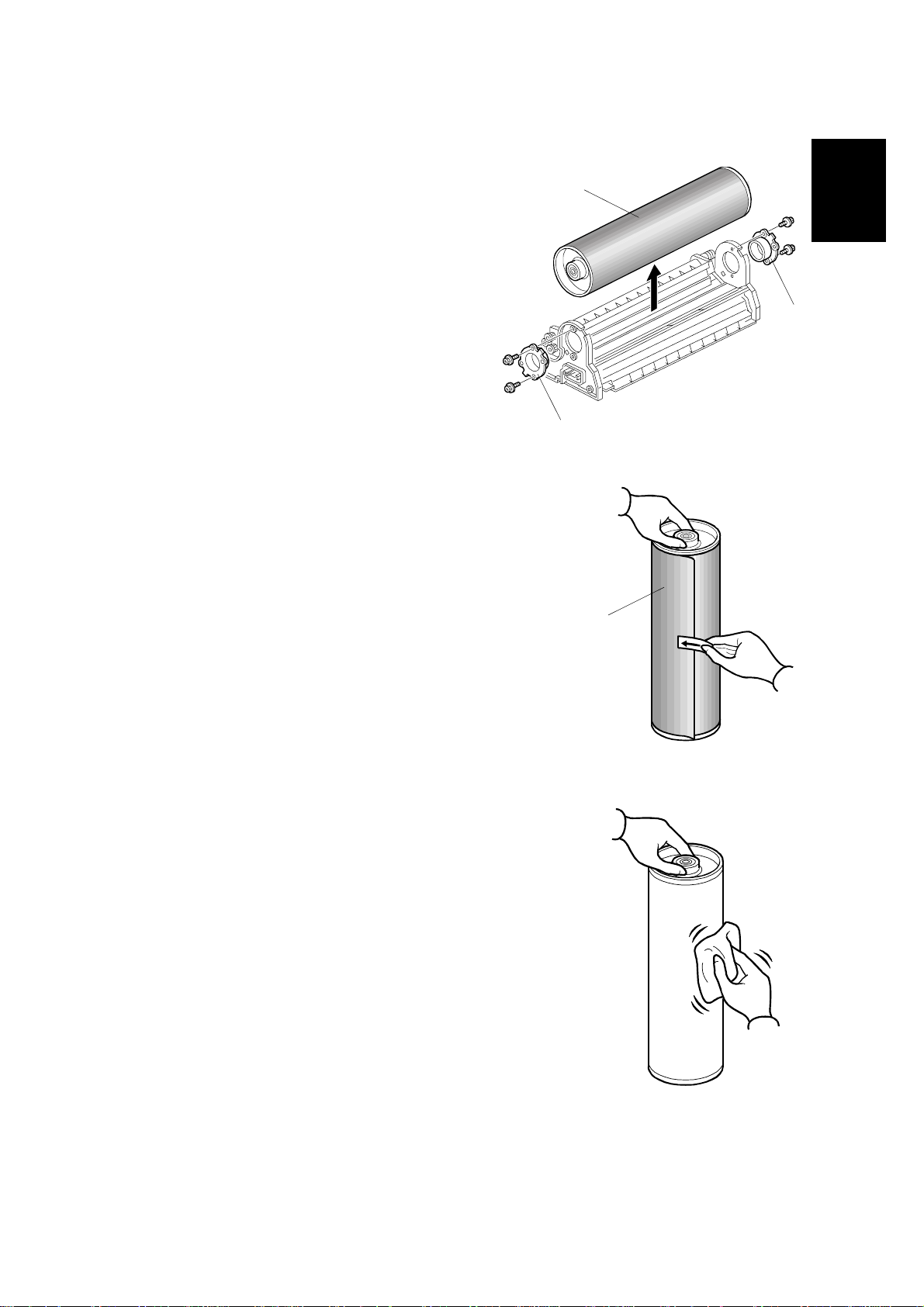

15. Remove the drum protective sheet

[A]: Drum support bushing (! x 2 each)

[B]: Drum with the drum protective

sheet.

[C]: Drum protective sheet

16. Apply setting powder to the entire drum

surface then re-install the drum to the

drum unit.

NOTE: 1) Be sure to apply the

setting powder over the

entire drum. This prevents

the cleaning blade from

catching on the drum

surface.

2) Be sure not to spill the

setting powder on the drum

potential sensor.

1) Turn the drum two or three rotations

to settle the setting powder to the

drum surface.

NOTE: 1) Never remove the drum

protective sheet while the

drum is still in the drum

unit. If you do, the drum

cleaning blade will catch

on the sheet. This can

damage the drum surface.

2) Only touch the edges of

the drum unit. Do not

touch any part further than

10 mm from the edge.

3) Shield the drum unit with

5 or more sheets of paper

after removing the drum

protective sheet.

Otherwise, exposure to

light will cause optical

fatigue, resulting in poor

image quality.

[A]

[B]

Installation

[B]

B023I201.WMF

[C]

B023I977.WMF

1-9

B023I960.WMF

COPIER 26 January, 2001

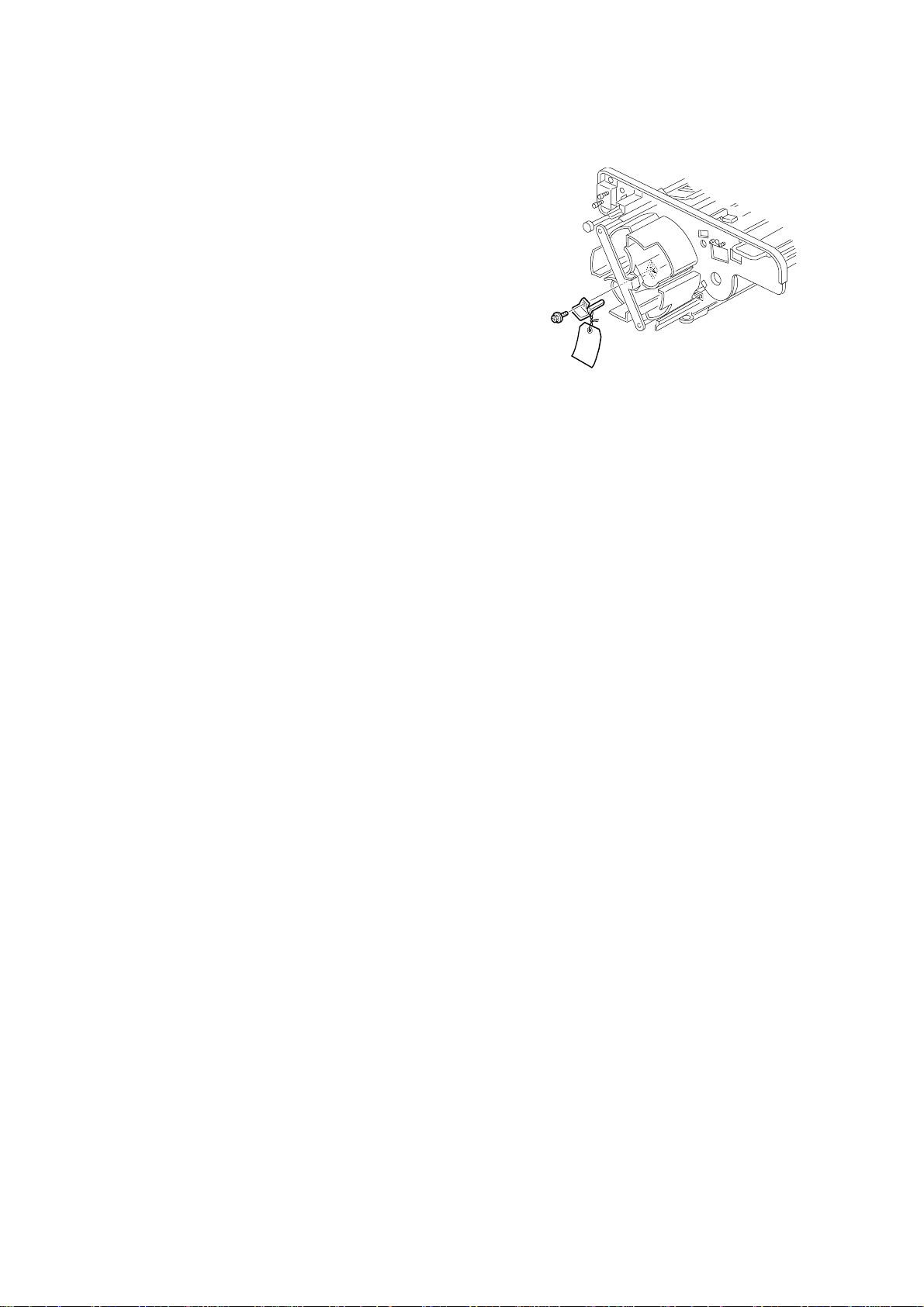

17. Remove the revolver clamp (! x 1).

NOTE: Keep the revolver clamp in a safe

location. If you ever need to relocated

the printer, you can use it to hold the

revolver in place.

Part No.: A2573256

B023I110.WMF

1-10

26 January, 2001 COPIER

1.2.3 DEVELOPER INSTALLATION

NOTE: Place a floor mat or other

protective sheet on the floor. Take

care not to contaminate the

customer’s floor.

1. Remove the revolver filter [A].

2. Disconnect the toner density sensor

connector [B] and open the

development unit locks [C] at both

ends of the revolver.

[A]

B023I325.WMF

Installation

[C]

!

CAUTION

Do not push the revolver/drum

drawer into the copier with

development locks left open.

Otherwise, the revolver locks may

strike the main unit frame, resulting

in permanent damage to the revolver.

3. Engage the revolver lock [D].

!

CAUTION

1. Be sure the pawl of the revolver

lock [D] is engaged before

removing a development unit.

Failure to observe this precaution

may allow the revolver to rotate,

causing permanent damage to the

development unit or its locks.

2. Always rotate the revolver

counter-clockwise (as shown in

the illustration). Otherwise, the

developer might spill out.

[C]

[B]

B023I308.WMF

[D]

B023I357.WMF

1-11

COPIER 26 January, 2001

4. Remove the development unit [A].

NOTE: When you remove a

development unit, be sure to

rotate in the direction shown in

the figure. Rotating a

development unit in the wrong

direction will spill developer.

!

CAUTION

Remove only one development unit at

a time. Removing two or more

development units at the same time

unbalances the revolver. This can

cause the revolver to turn rapidly,

possibly either catching your fingers,

or rotating clockwise and spilling

developer.

5. Remove the developer cover [B] (2

screws, 4 hooks). (Release the hooks

with a screwdriver.)

[A]

B023I309.WMF

6. Remove the development unit gear cover

[C] (1 screw).

1-12

[B]

B023I151.WMF

[C]

B023I908.WMF

Loading...

Loading...