echnical Bulletin

T

PAGE: 1/3

Model:

Subject:

From:

Cattleya 2

Main ROM upgrade for Cattleya2

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

26-Feb-01

Prepared by:

No.:

RB023001

H. Matsui

Action required

Service manual revision

Retrofit information

Symptom

Paper jams with the sorter stapler jogging function can occur under the following

conditions:

1. When ST33 (20 bin S/S) is used with Cattleya 2 (B023).

NOTE: If it is used for Cattleya 1(A257/A269), this will not occur.

2. When LT (11"X8 1/2") sideways is used when making 2 or more copies of an original.

Cause

The S/S main ROM software cannot compensate for the higher copy speed of Cattleya 2.

The timing of the jogger function and paper feeding does not match that of Cattleya 2.

Solution

When installing the ST33 on Cattleya 2, replace the S/S main ROM with ver "G" or newer.

The ROM version of the S/S main board can be viewed with copier SP7-801-005. The last

digit (for example G) indicates the ROM version. Version G can also be used for Cattleya1.

The part number of this new main ROM is A8315111.

echnical Bulletin

T

PAGE: 2/3

Model:

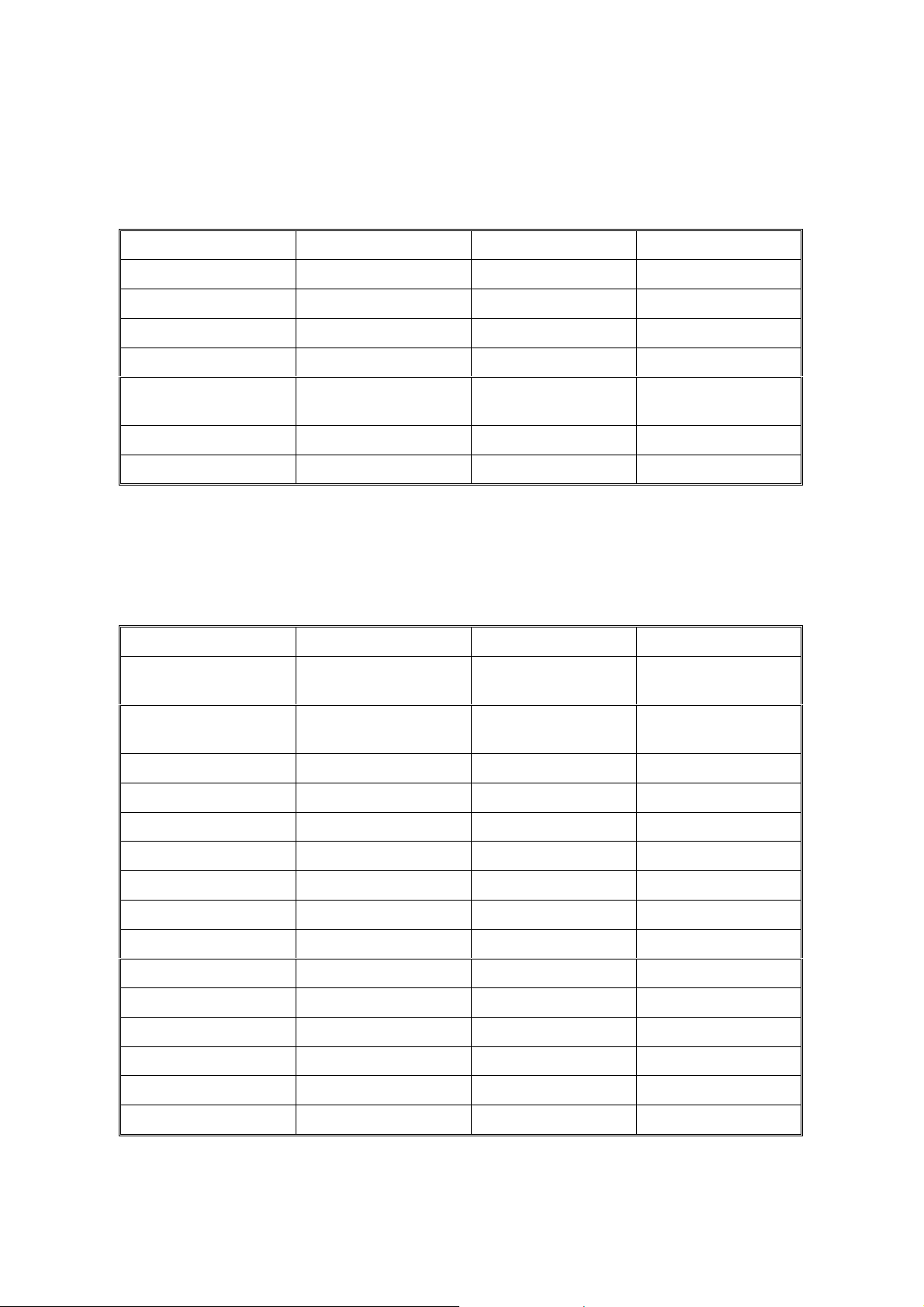

Program upgrade in mass production

The main ROM upgrade (ver G) has been applied from the first January 2001 production

run for each S/S. The cut-in serial numbers are as follows:

A831-17: H141130001 (see NOTE-1).

A831-26: 3T60110001 (see NOTE-2).

A831-55: L0551XXXXXX (see NOTE-3).

NOTE

1. "H14" is the prefix number. The 4th digit refers to the production year (1 = 2001). The

5th and 6th digits refer to the production month (13=January, 14=February, ........,

23=November, 24=December).

2. "3T6" is the prefix number. The 4th and 5th digits refer to the production month

(01=January, 02=February,........,11=November, 12=December). The 6th digit refers to the

production year (1 = 2001).

3. "L055" is the prefix number, The 5th digit refers to the production year (1 = 2001) and

the 6th and 7th digits refer to the production month (01=January,

02=February,........,11=November, 12=December). Because there are currently no A831-

55 models in production, there is no cut-in S/N at the moment. Please note that although

the Cattleya 2 has no Lanier model at present, there are cases in which A831-55 is used

with models other than Lanier.

Cattleya 2

Date:

26-Feb-01

No.:

RB023001

For the A831-17 model, machines with the following S/N have already been upgraded at

the factory:

H1402400031

H1402400050

H1402400054 to 57

H1402400059 to 63

H1402400068 to 69

H1402400076

H1402400090

H1402400117 to 154

<<Service parts>>

Service parts will be changed as follows:

S/S main board: A8315100 to A8315110 interchangeability: X/O

EPROM: A8315103 to A8135111 interchangeability: X/O

NOTE: The new main board and EPROM can also be used for the S/S which is installed

on the Cattleya 1.

echnical Bulletin

T

PAGE: 3/3

Model:

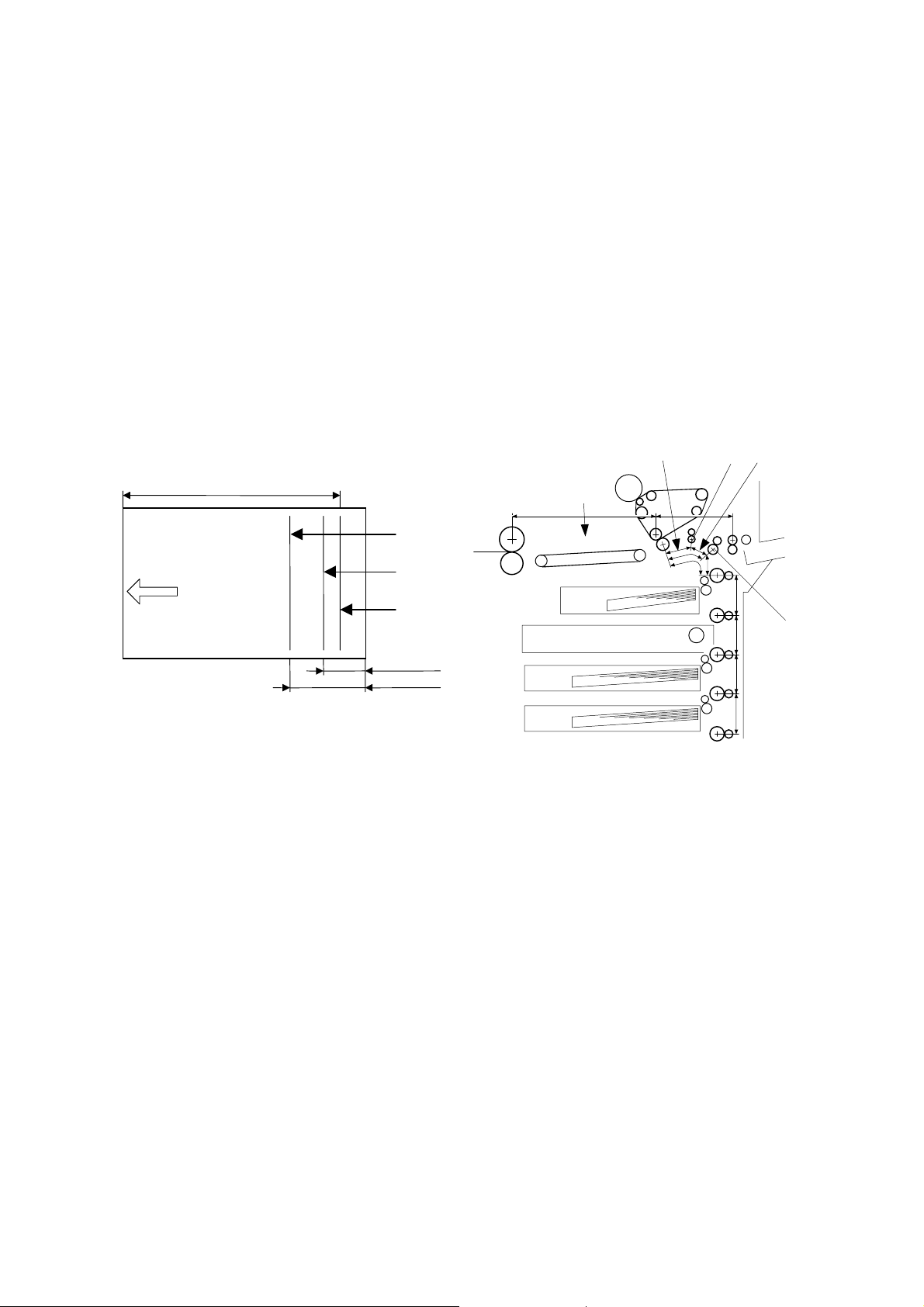

S/S main ROM replacement procedure

1. Remove the rear cover [A] (4 screws).

2. Replace the main ROM [B] with ver "G" or newer. The part number of this new main

ROM is A8315111.

3. Confirm the ROM version with copier SP7-801-005. The last digit (for example G)

indicates the ROM version.

Cattleya 2

Date:

26-Feb-01

[A]

No.:

RB023001

[B]

echnical Bulletin

T

PAGE: 1/2

Model:

Subject:

From:

Cattleya2

Anti-static Brush & Transport Belt

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

18-May-01

Prepared by:

No.:

RB023002

H.K.

Action required

Service manual revision

Retrofit information

SYMPTOM

It was found during production line tests that in duplex copy mode, the reverse side of the

copy paper may sometimes stick to the upper plate when the paper passes through the

transport belt unit.

CAUSE

A charged static electricity buildup on the transport belt surface repels the reverse side of

the copy paper.

SOLUTION

Temporary solution on the production line

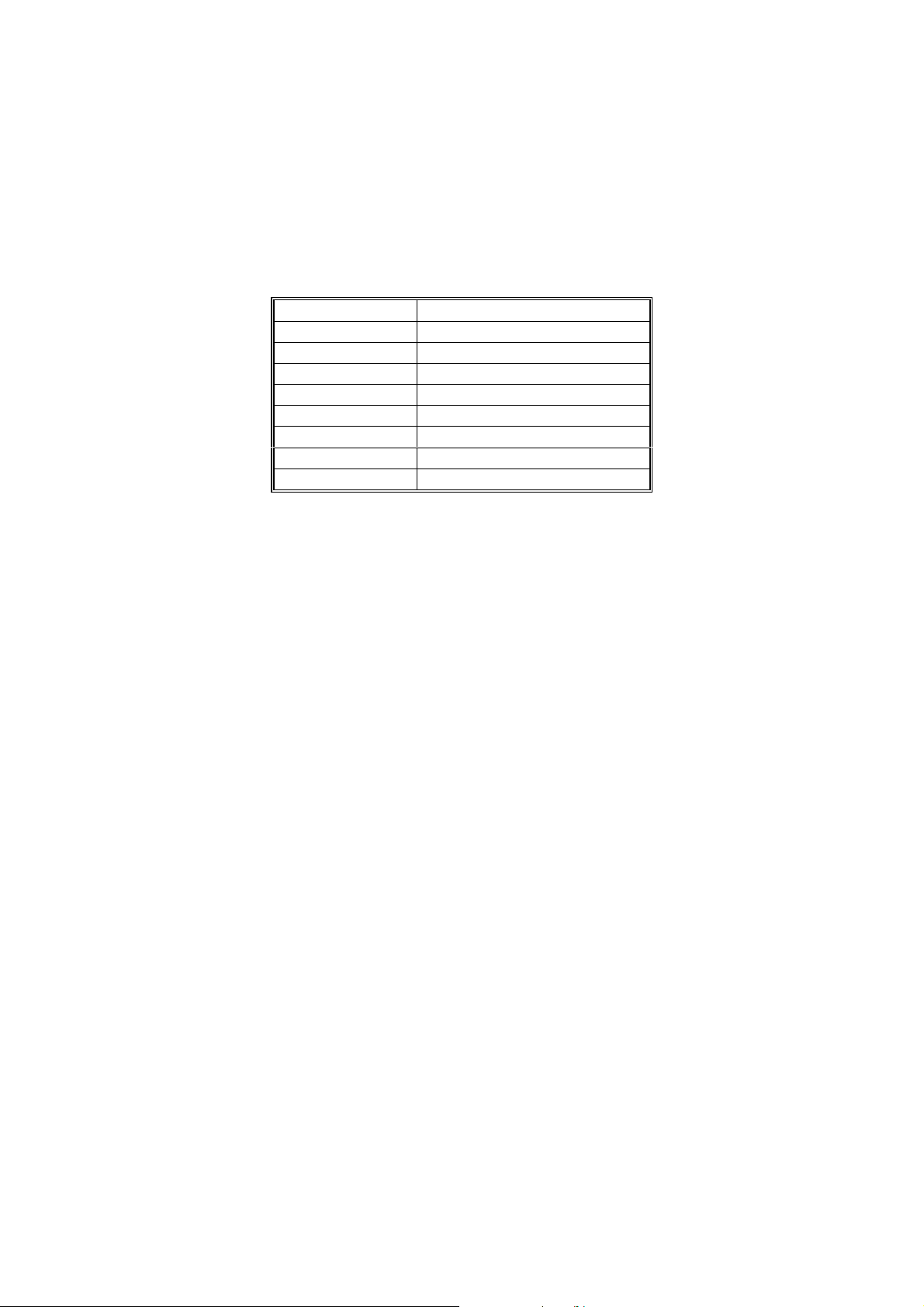

Two anti-static brushes have been attached to the transport left stay from the first

production lot (B0233880, Parts Catalogue page. 77, index 1).

Final solution on the production line

The material of the transport belt has been changed from a non-conductive to a conductive

one. The part number has been changed as follows:

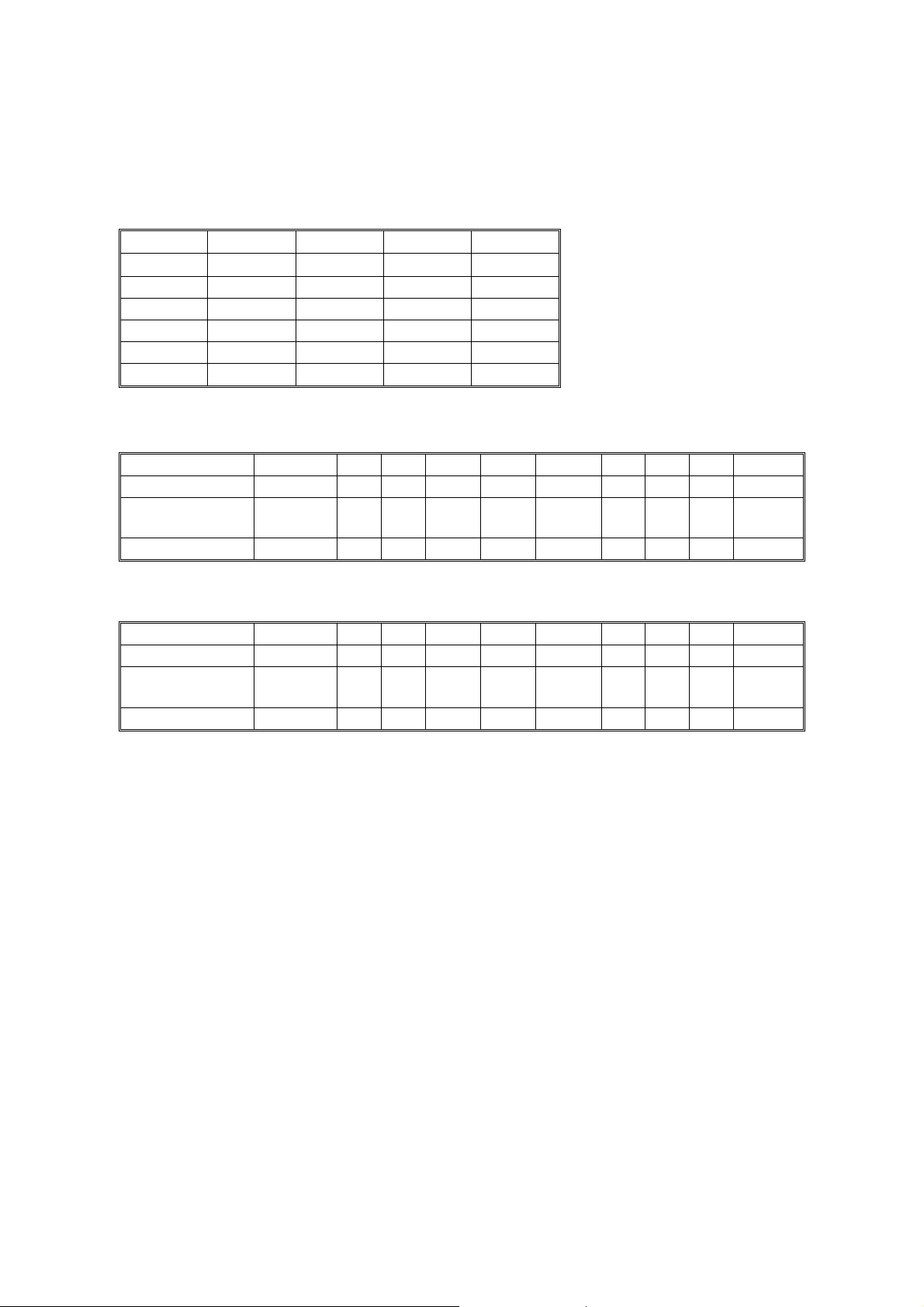

Old part

number

AA040023 AA040031 TRANSPORT BELT

Cut-in serial numbers

B02315 H6310200001

B02317 H6310200051

New part

number

Description Q’ty Int Page Index Note

2X/O

71 8

B02319 H63103xxxxx

B02322 H6310200181

B02326 4G40210001

B02327 H6310200264

B02329 H6310300570

echnical Bulletin

T

PAGE: 2/2

Model:

Remarks for machines produced before the above serial numbers:

If the old transport belt (AA040023) is replaced with the new part (AA040031) in machines

before the modification, remove the two anti-static brushes from the machine. This is

because the extra anti-static brushes can adversely affect copy quality in these older

machines.

Cattleya2

Date:

18-May-01

No.:

RB023002

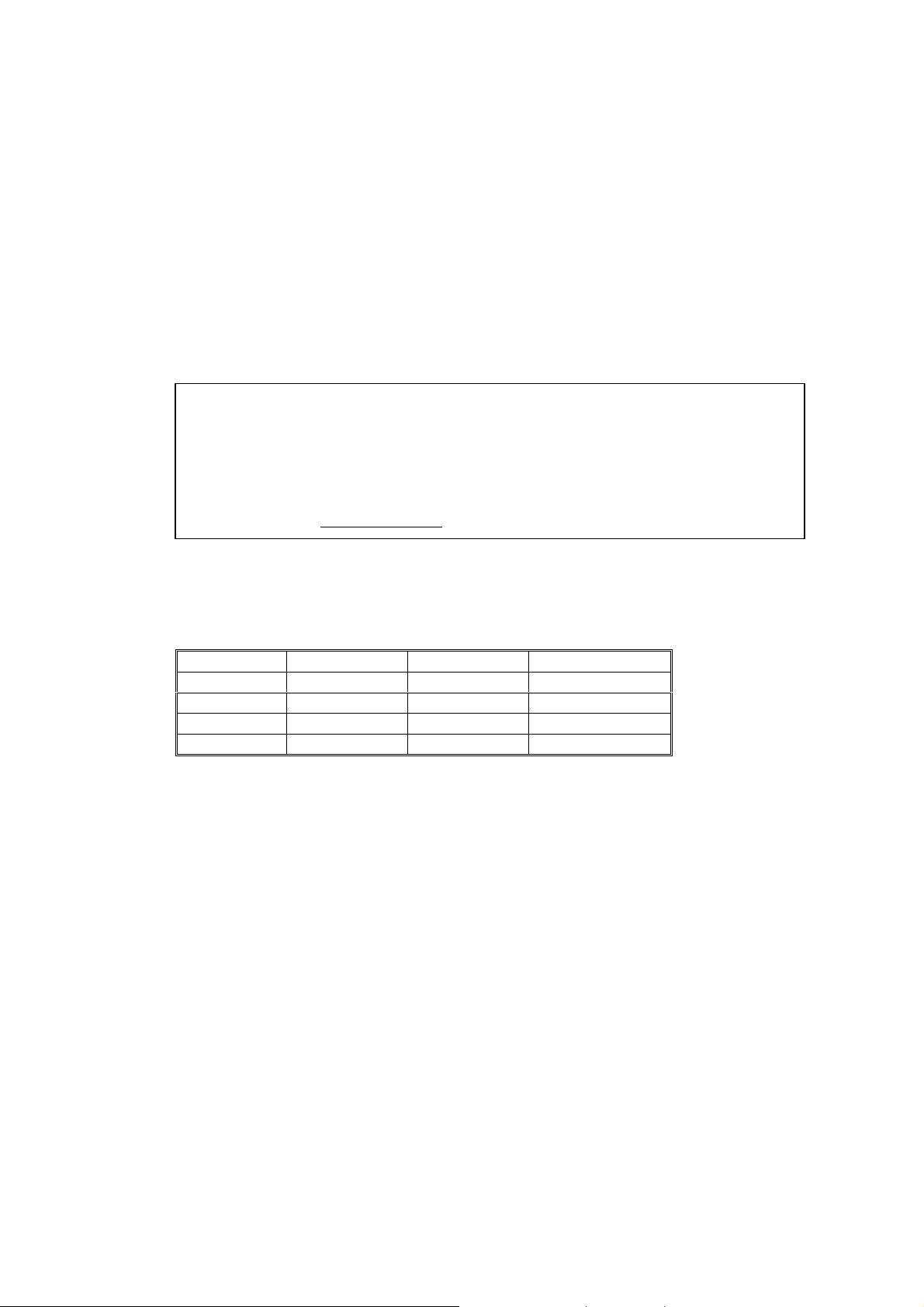

118±1mm

Transport Left Stay

126±1mm

Anti-static Brushes

echnical Bulletin

T

PAGE: 1/1

Model:

Subject:

From:

Classification:

Cattleya 2 Date: 24-May-01 No.: RB023003

Cattleya 2 Basic Tips

Technical Services Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

Tim. Okajima

Overview

This document is designed to allow field service representatives to do the following:

1. Easily access necessary troubleshooting and information very quickly

2. Customize maintenance programs for customers according to their needs and the

machine performance levels / capabilities.

Please keep this document accessible whenever you are servicing the Cattleya 2 in the

field. Later, this document will be updated based on your comments and other field

information.

Note:

As the customize maintenance program is a new concept and this document is a trial

version, we will not provide you with this kind of document for other models. If this will be

accepted and useful in the field, we will consider developing it for other models.

15 May, 2001 Basic Tips for Cattleya 2

Basic Tips for Cattleya 2

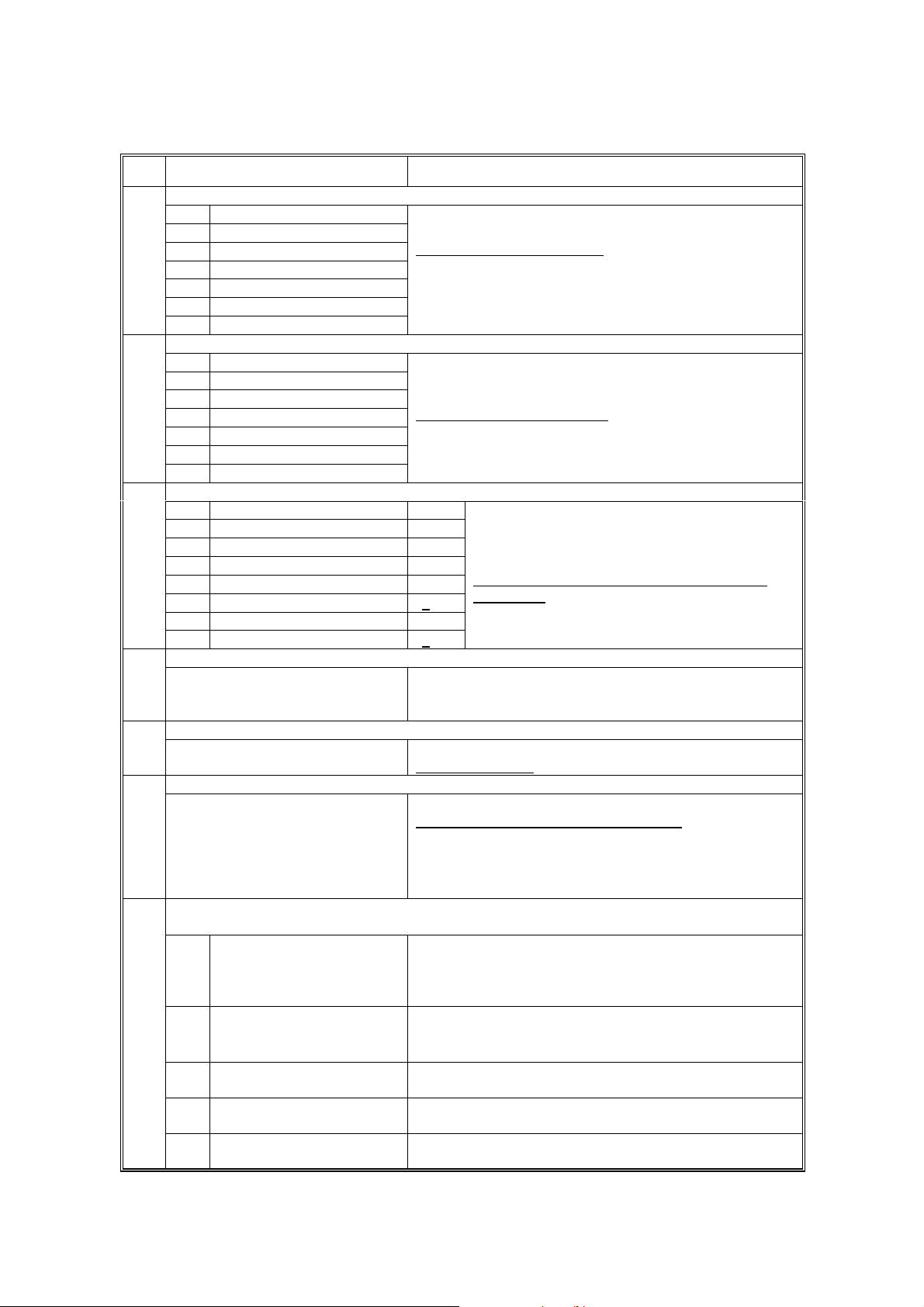

Contents

1. Specifications & Adjustments

1-1. Blank Margin

1-2. Registration

1-3. Magnification

1-4. Banding

1-5. Jitter

1-6. Hue / Density Consistency

1-7. Thick Paper Handling

2. Customized Maintenance Program (CMP)

2-1. Overview

2-2. Know the ma chine capability

2-3. How the CM P works

2-4. Procedure

Appendix A: Test patt er ns

Appendix B: SP mo des

Appendix C: SC Cod es

Appendix D: CMP Check Sheet

1st Issued on May 15, 2001

Issued by GTS, Ricoh Co. Ltd.

1

15 May, 2001 Basic Tips for Cattleya 2

Summary

This document is design ed t o al low field service representat ives to do the following:

1. Easily access necessary troubleshooting and information very quickly.

2. Customize maintenance programs for custo m ers according to their needs and the

machine performance lev els / capabilities.

Please keep this document accessible whenever you are servicing the Cattleya 2 in t he field.

Later, this document will be updated based on your comments a nd ot her field information. So

please feel free to contact us about this document.

2

15 May, 2001 Basic Tips for Cattleya 2

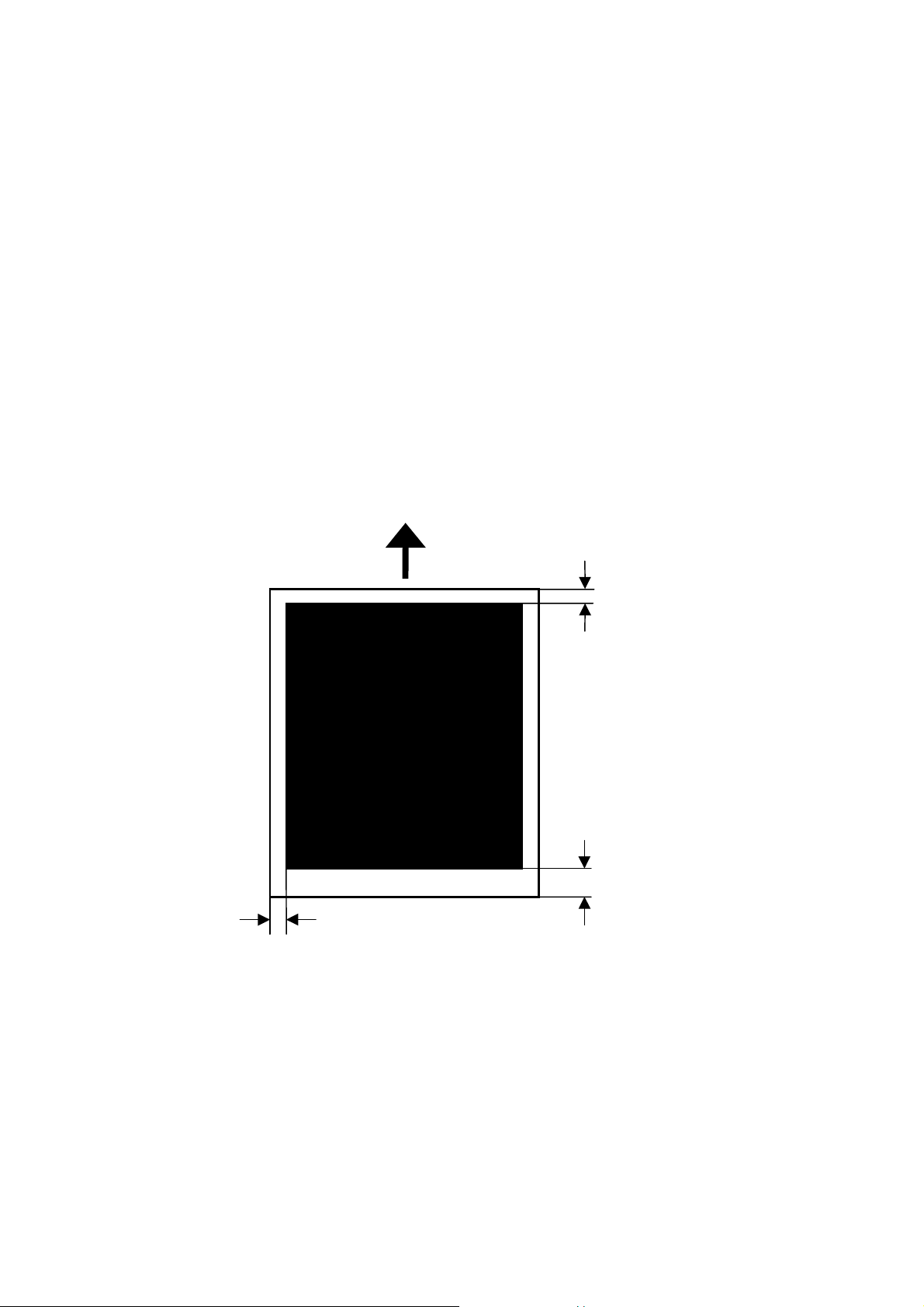

1. Specifications & Adjustments 1-1. Blank Margin

Definition

The blank margin at the leading edge is needed to help paper separate in the fusing unit and

also assists the margin in trimming the effective image area. With the current laser copier

technology, the leading edge margin must be created to prev ent paper jams (not adjustable

in the field).

Specification

Leading edge: 4mm ± 2mm

Trailing edge: 2mm ± 2mm (4mm ± 2mm in case of Thick 1 a nd 2 modes)*

Side edge: 2mm ± 2mm (maximum 4mm when sum both left and right side).

*Note: In both the Thick Mode 1 a nd 2, t here is 4mm blank margin at the lead ing edge

(predecessor model was 2mm). This is to eliminate blurred images which may

occur at the trailing edge due t o pot ential paper holding problems with the new

paper transfer roller system.

Side edge

Paper feed direction

Leading edge

Trailing edge

Competitor Information

Cattleya 1: Trailing edge in think mode: 2 mm+-2mm; the others are same as

those of the Cattleya 2.

Canon CLC1150: Leading edge: 8mm

Xerox DC1250: Trailing edge: 4mm, but smear ed image can be seen at the trai li ng

edge

3

15 May, 2001 Basic Tips for Cattleya 2

Related SP modes

SP2XXX (Drum)

2

Sub-scan/Main-scan margin adjustment

101

1 Sub-scan: Leading edge:

2

3 Sub-scan: Leading edge:

4 Sub-scan: Leading edge:

5 Sub-scan: Trailing edge:

6 Sub-scan: Trailing edge:

7

8 Sub-scan: Trailing edge:

9 Main-scan: Leading edge Adjust the leading margin (operator side). (Screen C,

10 Main-scan: Trailing edge Adjusts the trailing margin. (Screen C, SP9-703)

11

Mode Number Function / [Setting]

Normal

Sub-scan: Leading edge:

Thick 1

Thick 2

OHP

Normal

Thick 1

Sub-scan: Trailing edge :

Thick 2

OHP

Sub-scan: Auto 2nd side:

Trailing edge of 1st side

Adjusts the margin perpendicular to the front edge.

(Screen C, SP9-703)

[–4.0 to 4.0 mm / 0 / 0.1 mm/step]

Adjusts the margin perpendicular to the back edge.

(Screen C, SP9-703)

[–3.0 to 10.0 mm / 0 / 0.1 mm/step]

SP9-703)

[–2.0 to 5.0 mm / 0 / 0.1 mm/step]

[–2.0 to 5.0 mm / 0 / 0.1 mm/step]

Adjusts the trailing margin for the first side of duplex

copies. (Screen C, SP9-703)

[–3.0 to 10 mm / 0 / 0.1 mm/step]

4

15 May, 2001 Basic Tips for Cattleya 2

1-2. Registration

Definition

The registration is determined by t he paper start timing at the registration roller an d t he laser

start timing, both of which can b e adjusted by SP mode.

If you make the paper start timing earlier, t he i ma ge is moved toward the trailing edge.

Conversely, if you make it l at er, the image is moved toward the leading edge.

Note: If the timing is ma de t oo early or too late, this can c ause a paper jam.

Specification

Leading edge registration

Margin of error with recommended paper:

0 ± 1.5mm (full size or reduction mode)

0 ± 1.5mm x M (Enlargement ratio: M)

Margin of error with

0 ± 2.0mm (full size or reduction mode)

0 ± 2.0mm x M (Enlargement ratio: M)

Margin of error in Duplex mode with suggested paper weights:

(17g/m2-105g/m2)

0 ± 2.0mm (full size copy)

0 ± 2.0mm x M (Enlargement ratio: M)

Side to side registration

Margin of error with recommended paper and suggested paper weights:

1.5 ± 0.5 mm. < 4 mm total

Competitor Information

NA

* Suggested paper weights: Pa per included in the original pool of design target pap er weights,

i.e. is expected to work wel l w it h t he machine.

64g/m2 – 256g/m2 for Tray 2, 3, or LCT, 64g/m2 - 105g/m2 for Tray 1.

suggested paper weights *:

5

15 May, 2001 Basic Tips for Cattleya 2

Related SP modes

SP1-XXX (Feed)

1

001

002

Troubleshooting

The crop mark positions on the 1

Mode Number/Name Function / [Setting]

Leading Edge Registration

1 Normal paper

2OHP

3 Thick paper 1

4 Thick paper 2

5 Duplex

6 Second sheet, Half speed

7 Second sheet, 1/3rd speed

Side-to-Side Registration

1 By-pass

2Tray 1

3Tray 2

4Tray 3

5Tray 4

6 2nd side

7LCT

st

and 2nd faces do not match with duplex printing from the

Adjusts the leading edge registration by changing the

timing of the registration clutch. (Screen A, SP7-903)

[+7 to –7 / 0.0 / 0.1 mm/step] IAJ

Specification: 4 ± 1 mm

Thick paper 1 is listed as Thk on the screen.

Thick paper 2 is listed as Super Thk.

Adjusts the side-to-side registration by changing the laser

start position (main scan). (Screen A, SP1-236)

[+9 to –9 / 0.0 / 0.1 mm/step] IAJ

Specification: 1.5 ± 0.5 mm. < 4 mm total

controller.

1. Make sure that both the leading edge and side to side registrations of the 1st side in

Duplex printing are within specification. I f they are not, adjust them using the SP modes

described above.

2. Make duplex prints with crop marks and adjust the regist ration of the 2

nd

face using SP1-

001-005 (Duplex) and SP 1-002-006.

6

15 May, 2001 Basic Tips for Cattleya 2

1-3. Magnification

Definition

The margin of error for sub-scan magnification is twice as large as that of main scan

magnification. This is because sub-scan magnification is affect ed by the variations in p aper

feed speed (paper feed motor), in contrast to the relatively high accuracy of the image

processing unit (main scan mag.).

Specification

Margin of error:

Main Scan Direction: ± 0.5% or less

Sub Scan Direction: ± 1.0% or less

Competitor Information

NA

Related SP modes

SP2-XXX (Drum)

Mode Number Function / [Setting]

2

Main scan magnification adjustment

1 Copy mode DFU [0] (Screen D, SP9-703)

112

2 Print mode

Sub-scan magnification adjustment

1 Copy mode

113

2 Print mode

Troubleshooting

NA

Adjusts the magnification along the main scan direction

for printer mode (Screen D, SP9-703)

[–1.0% to +1.0% / 0 / 0.1/step]

Adjusts the magnification along the sub-scan direction for

copy mode (Screen D, SP9-703)

[–1.0% to +1.0% / 0 / 0.1/step]

Adjusts the magnification along the sub-scan direction for

printer mode (Screen D, SP9-703)

[–1.0% to +1.0% / 0 / 0.1/step]

The screen displays “FsynchMagAdj PRINTER”.

7

15 May, 2001 Basic Tips for Cattleya 2

1-4. Banding

Definition

Lighter or darker bands appear perpe ndicular to the paper feed direction at a fixed interval.

The possible causes are:

! Curves develop in the trans f er belt (areas wrapped around rollers)

! Drum with areas already exposed t o l ig ht

! Un-even development roller rotation speed

Specification

No specification is available for banding. I n addition, it is not possib le t o completely elimin at e

banding with current laser printing t echnology. Please refer to the i mag e sample section for

the banding level.

Competitor Information

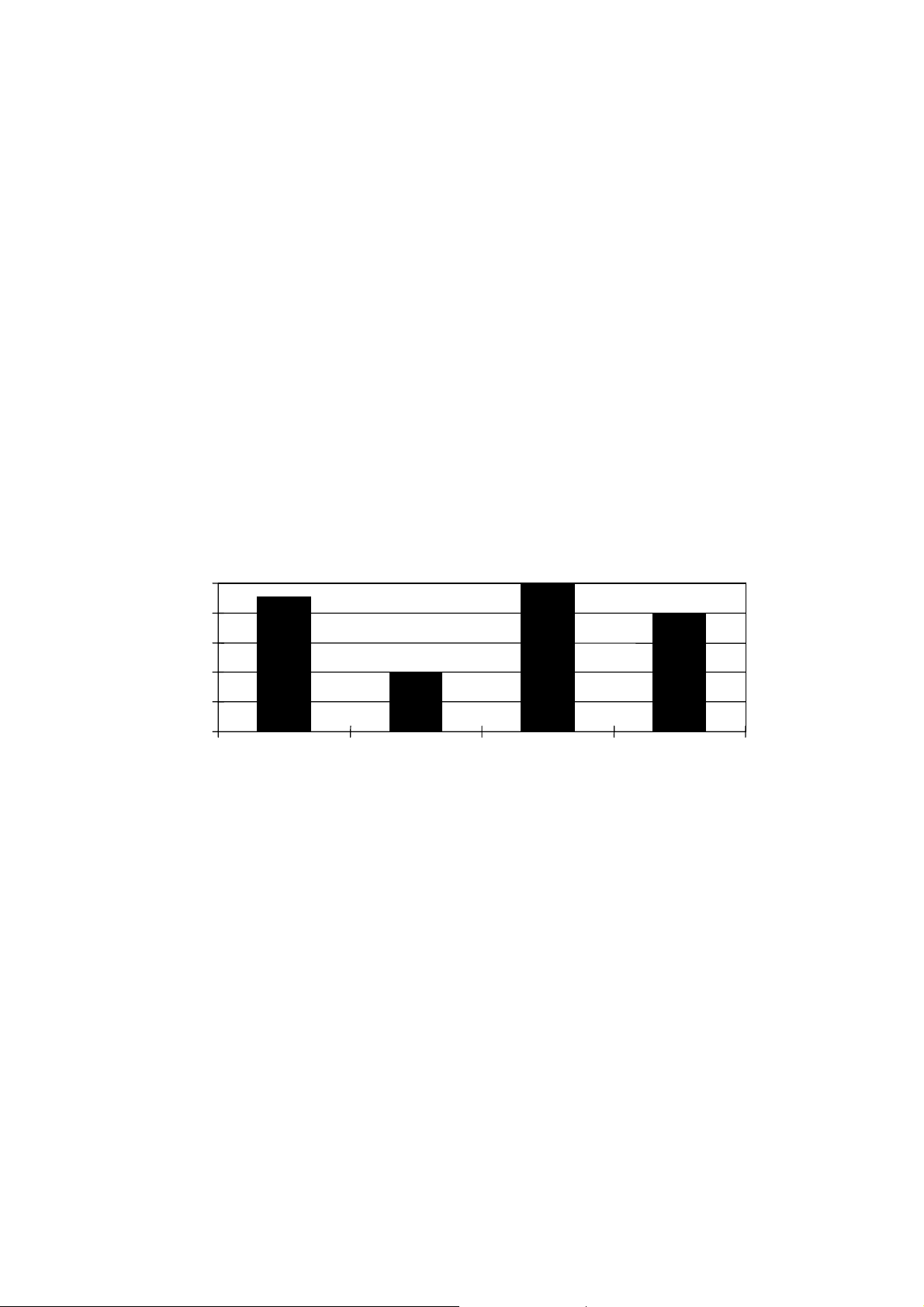

According to our research, the lev el of the banding on this ma chine in comparison with

competitor models is as follows:

Related SP modes

Banding Level

5

4

3

2

1

Banding Level

0

(5: Best, 1: Worst)

AC6513 AC6010 CLC1150 X 1250

Laser copier

NA

Related Information

Size of Rollers

Hot roller/Pressure roller: 60mm diameter, 187 mm circumference

Drum: 90mm diameter, 283mm circumference

Troubleshooting

NA

8

15 May, 2001 Basic Tips for Cattleya 2

1-5. Jitter

Definition

Dark or light bands perpendicu lar t o the paper feed direction, as vibration in the machine is

transmitted to the laser writ ing area. The Interval between bands varies, however the

general location is usually fixed (e. g. 130mm from the trailing edge).

Specification

There is no specification available for jitter. It is extremely difficult to completely elim inat e

this symptom with current laser printing technology. Please refer to the image sample

section for the jit t e r level.

Jitter in Thick or Extra Thick paper modes

If jitter appears in Thick or Ext r a Thick paper modes at the posit ion shown in figure [A], [B]

and [C], please confirm the following:

75mm

360mm

A3/DLT

Approx. 360mm

[C]

[D]

Feed direction

[B]

[A]

Approx. 75mm

Approx. 135mm

1) Jitter [A]: Approx. 360 mm from the leading edge

• Possible cause: The leading edge does not enter the fusing nip [D] smoothly, and the

paper impacts on some surrounding area, causing it to feel shock.

• Check to see if the fusing entranc e area components are properly alligned, and if the

area is dirty at all.

2) Jitter [B]: Approx. 75 mm from the trailing edge

• Possible cause: The shock felt by the paper when the tra il in g edge leaves the

registration rollers [E].

• Try adjusting the following SP modes:

SP1-801-011 (Registrati on motor speed for thick paper)

SP1-801-012 (Registrati on motor speed for extra thick pap er)

*Default: – 0.2, value range: –5.0 to +5.0, step 0.1

3) Jitter [C]: Approx. 135 mm from the trailing edge

• Cause: The shock felt by the paper w hen t he t r ailing edge leaves the paper feed

rollers [F].

• Try adjusting the following SP modes:

SP1-801-005 (Paper feeding motor speed for thick paper)

SP1-801-008 (Paper feeding motor speed for extra thick paper)

*Default: –2.0, value range: –5.0 to +5.0, step 0.1

[E]

135mm

[F]

B023T023.WMF

9

15 May, 2001 Basic Tips for Cattleya 2

Competitor Information

N/A

References – Paper siz e

Paper inch mm Paper mm

Half Letter 5.5x8.5 134x208 A5 148x210

Letter 8.5x11 208x269 A4 210x297

Legal 8.5x14 208x343 B4 257x364

Ledger 11x17 269x416 A3 297x420

12x18 12x18 294x441 — —

13x19 13x19 318x465 A3 Wide 318x465

Length from leading edge for po ssible jitter S: Sideways, L: Lengthwise

HLT/LT S LT L DLT 12x18 13x19 A5/A4S B4 A4 L A3 S3 Wide

Fusing entrance — — 360 360 360 — 360 — 360 360

Registration

Roller 138 227 350 371 395 140 294 227 350 395

Relay Roller 73 162 295 306 330 75 229 162 285 330

Length from trailing edge for possible jitter S: Sideways, L: Lengthwise

HLT/LT S LT L DLT 12x18 13x19 A5/A4S B4 A4 L A3 S3 Wide

Fusing entrance — — 56 81 105 — 4 — 60 105

Registration

Roller 70 70 70 70 70 70 70 70 70 70

Relay Roller 135 135 135 135 135 135 135 135 135 135

10

15 May, 2001 Basic Tips for Cattleya 2

1-6. Hue / Density Consistency

Definition

Different hue bands appear in solid image areas perpendicular to the paper feed direction.

The possible cause is a shi ft in t he dot alignment or an unev en development roller speed.

Specification

No

specification

is available for hue change. In addition, this cannot be completely

eliminated with current laser printing technology. Please refer to the image

sample section for the hue change level.

Competitor Information

NA

Related SP modes

NA

Troubleshooting

NA

11

15 May, 2001 Basic Tips for Cattleya 2

1-7. Thick Paper Handling 1-7-1. Overview

Thick paper handling is one of the sales points of the Cattleya series. Thick Mode (carried

over from Cattleya1) has been enhanced, and Very Thick Mode has been newly added.

These modes are able to handle the vast majority of thick paper types, however in some

cases fine tuning of the fusing temperature may be required. Therefore, please read the

following carefully and t ake the appropriate act io ns as listed at each occasion.

1-7-2. At Installation

1. Refer to the below box and follow t he instructions if the customer in w hich the machine

is about to be installed uses t he l isted t ype of paper in the most frequ ent manner.

! The following papers hav e already been tested in Jap an and it was confirmed th at

the fine tuning is NOT neede d for the 3 types of paper:

- Neusiedler Colour Copy White 250g/m2

- Neusiedler Colour Copy White 200g/m2

- Hammermille Color Copy Cover 80lb (216g/m2)

! Regarding the Fedrigo ni 200g/m2, we strongly recommend to perform the “3-4.

Fine tuning #2” at the installation.

2. If not listed, a clear exp lanation to the customer is required on the different kind of

paper modes available for t hi s machine, and that they follow t his setting sequence

properly.

Paper Modes

Mode: G/m2: Lb. (Bond): Feeding Speed:

Normal 64 to 105 17 to 28 245 mm/sec

OHP — — 122.5mm/sec

Thick 105 to 157 28 to 42 122.5mm/sec

Very Thick 157 to 256 42 to 68 70mm/sec

1-7-3. At First Visit After Installation (Approx. 40kD)

1. When making a first visit to the customer’s site since instal lation (It is probably 40kD

since the installation for cleaning the fusing blade), check the condition of the parts

listed in the following table. If their condition i s similar to the pictures shown b elow , take

a necessary action that is mentione d in t he t able.

12

15 May, 2001 Basic Tips for Cattleya 2

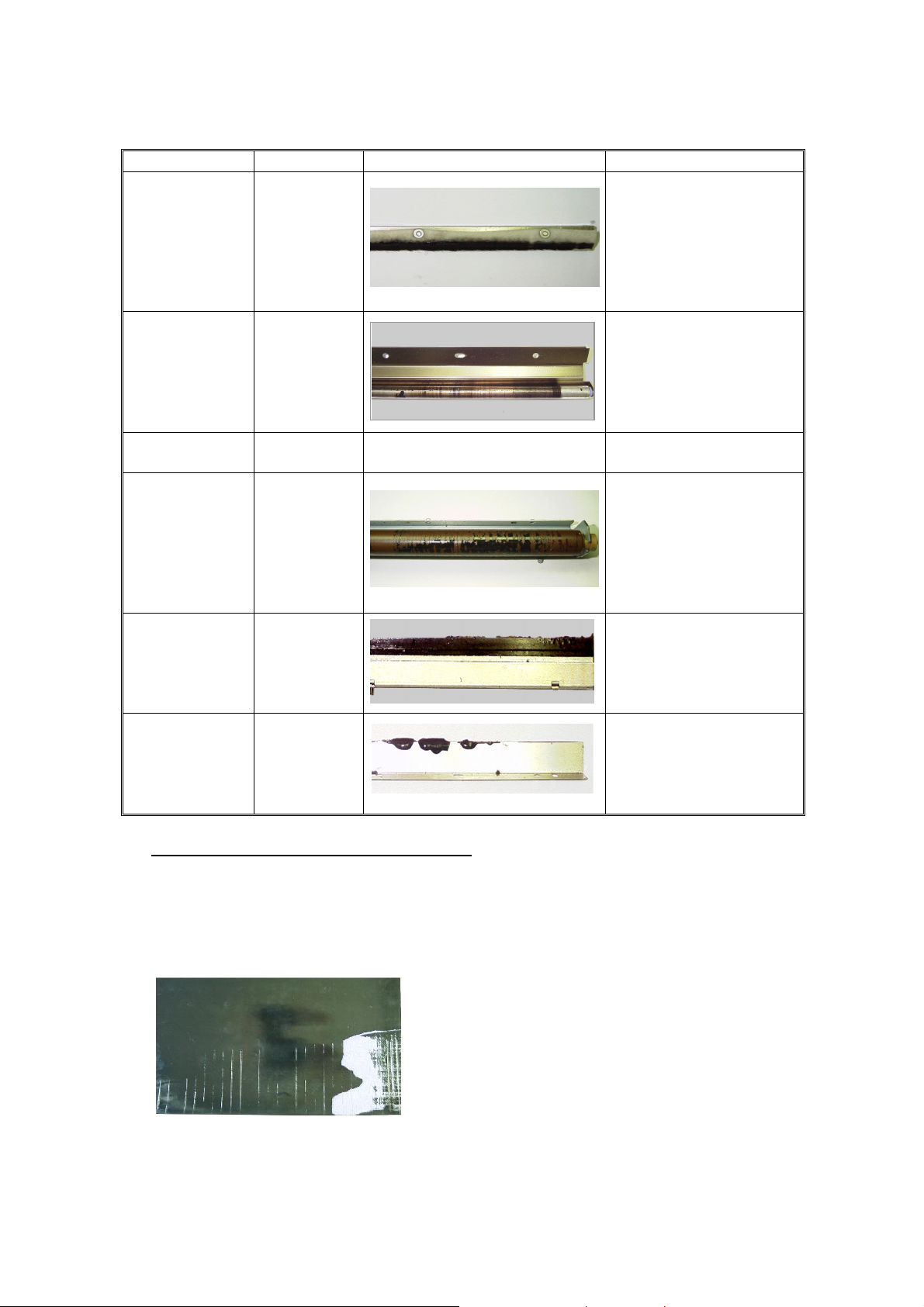

Part Name Part Number Conditions Action

Oil Supply Felt A2574171 If the condition is same

or comparable to the

picture on the left,

replace this part.

Pre-cleaning

Roller

Hot Roller AE010034 (no picture). Replace if damaged.

Cleaning Roller AE042044 Clean the part.

Hot roller blade AE 043031 Clean the part.

Scraper A2574213 Clean the part.

AE042049 Replace the roller if it is

noticeably dirtier than

the one shown in the

picture on the left.

3-2. With the exception of the pre-cleaning roller*, if you have the condit ion as shown in the

table above (even if one of the part s in t he t able gets dirty), reduce the fusi ng t emperature

according to the followin g procedure described as “FINE TU NIG #1”. This is because in

most of these cases are caused by t he over-fusing, also known as “hot offset”.

*As the pre-cleaning roller becomes dirty under the normal operating, this should not be

used to judge whether or not the fine-tu ned adjustment is needed.

Figure: Example of the Hot offset image

13

15 May, 2001 Basic Tips for Cattleya 2

3-3. Procedure – Fine Tuning #1

Set the fusing temperat ure as f ollows:

The Main firmware ver 1.082 or earlier:

SP1-105 - 002. Single side H ot Idling 195 " 190

005. Single side Hot OHP/Thick FC 180 " 168

006. Single side Hot OHP/Thick 1C 180 " 168

007. Single side Pressure Idl ing 160 " 155

010. Single side Press. OH P/ Thick FC 155 " 143

011. Single side Press. OH P/ Thick 1C 155 " 143

012. 2nd side Hot Idling 195 " 190

015. 2nd side Hot OHP/Thic k F C 180 " 168

016. 2nd side Hot OHP/Thic k 1 C 180 " 168

017. 2nd side Pressure Idling 160 " 155

020. 2nd side pressure OHP/Thick FC 155 " 143

021. 2nd side pressure OHP/Thick 1C 155 " 143

The Main firmware ver 1.09 or later:

SP1-105 - 002. Single side Hot I dling 195 " 190

022* Single side Hot Thick2 : FC 180 " 168

023* Single side Hot Thick2 : 1C 180 " 168

007. Single side Pressure Idl ing 160 " 155

024* Single side Pressure.Thick2: FC 155 " 143

025* Single side Pressure. Th ick2: 1C 155 " 143

012. 2nd side Hot Idling 195 " 190

026* 2nd side Hot Thick2.: FC 180 " 168

027* 2nd side Hot Thick2 : 1C 180 " 168

017 2nd side Pressure Idling 160 " 155

028* 2nd side pressure Thick2: FC 155 " 143

029* 2nd side pressure Thick2: 1C 155 " 143

*: Newly added SP modes from Ma in f irmware v1.09.

Note:

• Decreasing the fusing t emp erat ure will not damage the machi ne, t he only effect on copy

quality will be unev en image density and/or uneven glossiness.

• When using main firmware ver 1.082 or earlier, the above temperature adjustment will

affect not only Extra Thick Paper Mode (Thick 2) but also Thick Paper Mode (Thick 1) as

well.

• As this is only a guideline t o reducing hot offset, depending on the kind of paper, you may

need to reduce the temperature more tha n t he above figures. In which case, we sug gest

you do this by adjusting

SP 1-105-2, 5, 6, 12, 15, 16. (main ver 1.082 or earlier)

SP 1-105-2, 22, 23, 12, 26, 27 (main ver1.09 or later)

14

15 May, 2001 Basic Tips for Cattleya 2

3-4. Procedure – Fine Tuning #2

Hot/Pressure Rol l er Temperature Sett i ng for the Fedrigo ni 200g/m2 paper commonly

used in Italian market: Set the fusi ng temperature as follows :

The Main firmware ver 1.082 or earlier:

SP 1-105 - 002. Single side Hot I dling 195 " 180

005. Single side Hot OHP/Thick FC 180 " 165

006. Single side Hot OHP/Thick 1C 180 " 165

007. Single side Pressure Idl ing 160 " 155

010. Single side Press. OH P/ Thick FC 155 " 143

011. Single side Press. OH P/ Thick 1C 155 " 143

012. 2nd side Hot Idling 195 " 180

015. 2nd side Hot OHP/Thic k F C 180 " 165

016. 2nd side Hot OHP/Thic k 1 C 180 " 165

017. 2nd side Pressure Idling 160 " 155

020. 2nd side pressure OHP/Thick FC 155 " 143

021. 2nd side pressure OHP/Thick 1C 155 " 143

The Main firmware ver 1.09 or later:

SP 1-105 - 002. Single side Hot I dling 195 " 180

022. Single side Hot Th ick2: FC 180 " 165

023. Single side Hot Th ick2: 1C 180 " 165

007. Single side Pressure Idl ing 160 " 155

024. Single side Pressure.Thick2: FC 155 " 143

025. Single side Pressure. Thick2: 1C 155 " 143

012. 2nd side Hot Idling 195 " 180

026. 2nd side Hot Thick2.: FC 180 " 165

027. 2nd side Hot Thick2 : 1C 180 " 165

017. 2nd side Pressure Idling 160 " 155

028. 2nd side pressure Thick2: FC 155 " 143

029. 2nd side pressure Thick2: 1C 155 " 143

15

15 May, 2001 Basic Tips for Cattleya 2

2. Customized Maintenance Program (CMP) 2-1. Overview

The Standard Maintenance Program PM table in the Service M anual is designed to support a

wide spectrum of customers, including copy shops (Print for Pay ) , graphic design firms,

publishing companies a s well as general office environ me nt s . Alt hough this program is abl e t o

satisfy the needs of most of these customers, there are some high-demand prof essionals (e.g.

copy shops) who constantly require t he image quality to be t op level with the high-coverage

prints they make. This tends to increase the number of service calls.

To accommodate this, we wou ld li ke to o f fer the Customized Maintenance Program, which is

designed to consistently provide the high-demand customer with an image qualit y of Level B*

or higher (see the table below for definiti ons). The CMP basically reduces t he maintenance

interval in order to keep the mach ine in a better condition than it would be under the Standard

Maintenance Program. We have carefully chosen only those parts t hat have a major effect on

image quality and whose PM intervals could be reduced. This will allow for a reduction i n t he

rising service costs.

Although we have specified reduced intervals for certain parts, the CMP is a guideline for field

technicians. The actual time o f rep lac ement we leave to the technician's discretion.

Table: Definition of the Image quality lev e ls:

Rating Definition

Level A (Ideal) The image quality is equivalent to that at installation.

Level B (Excellent) Although not the same as at installation, still a very high level of image quality.

Level C (Good) Some high-demand professionals (copy shops) may not be 100% satisfied.

Level D (Fair) Most users would not be satisfied.

Level F (Poor) Servicing required.

Note: The CMP was created based on the results of a 1.5 PM running test using 3 production

units.

16

15 May, 2001 Basic Tips for Cattleya 2

2-2. Know the machine capability

We made the print samples by using 3 production units. These samples show how the mage

quality will be deteriorated during 1.5PM (120kD). Please see them carefully and know the

machine capability.

Note: You can see the big color shift on the print samples in the binders. These were caused

by the proto-type controller and its utility. So, please do not pay attention to the color

shift.

You can find three binders as a set. They were made under the following c onditions:

Binder Number

Thick paper

usage ratio

Maintenance

Cleaned the hot roller blade at 40kD only

#1 25%

during 120kD run, no other maintenance

was performed.

Cleaned the hot roller blade at 40kD only

#2 25%

during 120kD run, no other maintenance

was performed.

Cleaned the hot roller blade at 20kD only

#3 100%

during 60kD run, no other maintenance was

performed.

The following two items are the key to maintain the print quality in high level:

1.

Glossiness

(e.g. less streaks in paper feed direction and adequate glossiness)

2. Solid/halftone fill (e.g. less white streaks in paper feed direction, even and

smooth solid/halftone fill))

We used the five ranking (see the section 1) to evaluate the glossiness and

solid/halftone fill of the print samples:

The print samples:

Woman with black

background, TIF

EFI Sample Many

Images, JPG

Graphic Test Image,

PDF

17

15 May, 2001 Basic Tips for Cattleya 2

Blue Solid, PPT

Side to Side,

Illustrator

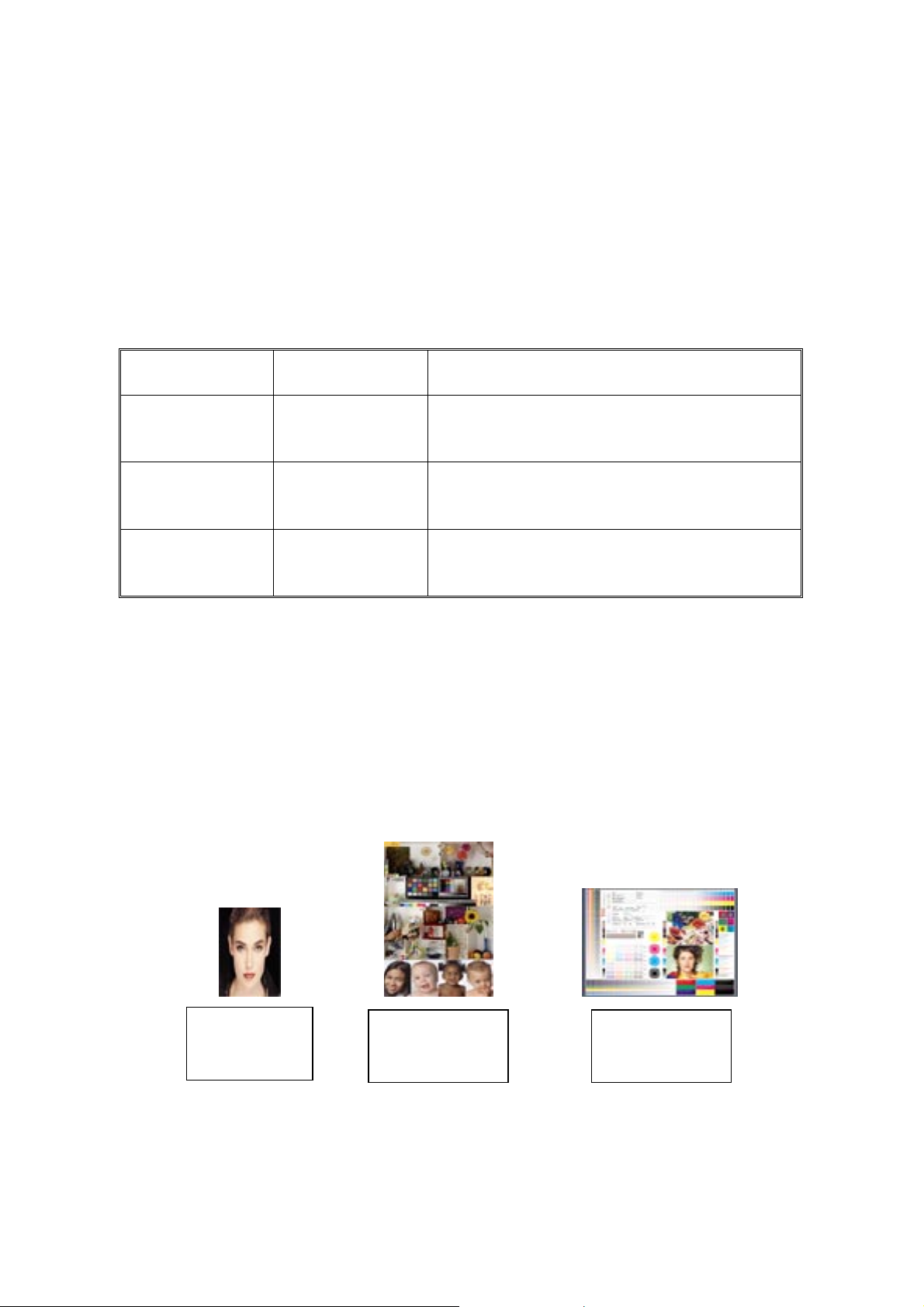

Glossiness for the #1 & #2 (25% Thic k paper usage)

Paper File / Original Installation 25kD 50kD 73kD 94kD 117kD

Woman with black back ground, TIF A C B C-D C-D D

EFI sample many images, JPG A A A A-B B B

Normal

Paper

Thick Paper

Graphic test image, PDF A A A B B C

Blue solid, PPT A B B C C-D D

C-4, COPY A A A C C-D D

EFI sample many images, JPG A B A-B C-D C-D D

Graphic test image, PDF A A A C C C

Blue solid, PPT A C B C C D

C-4, COPY

At 40kD, the hot roller

blade was cleaned.

C-4, COPY A B A-B B C C-D

At 20kD, the hot roller

Glossiness for the Machine #3 (100% Thick paper usage)

Paper File / Original Installation 13kD 23kD 33kD 42kD 52kD

EFI sample many images, JPG A A A B B B

Graphic test image, PDF A A A A-B A-B A-B

Thick Paper

Blue solid, PPT A A B B-C B B

C-4, COPY A A A B B B

blade was cleaned.

18

15 May, 2001 Basic Tips for Cattleya 2

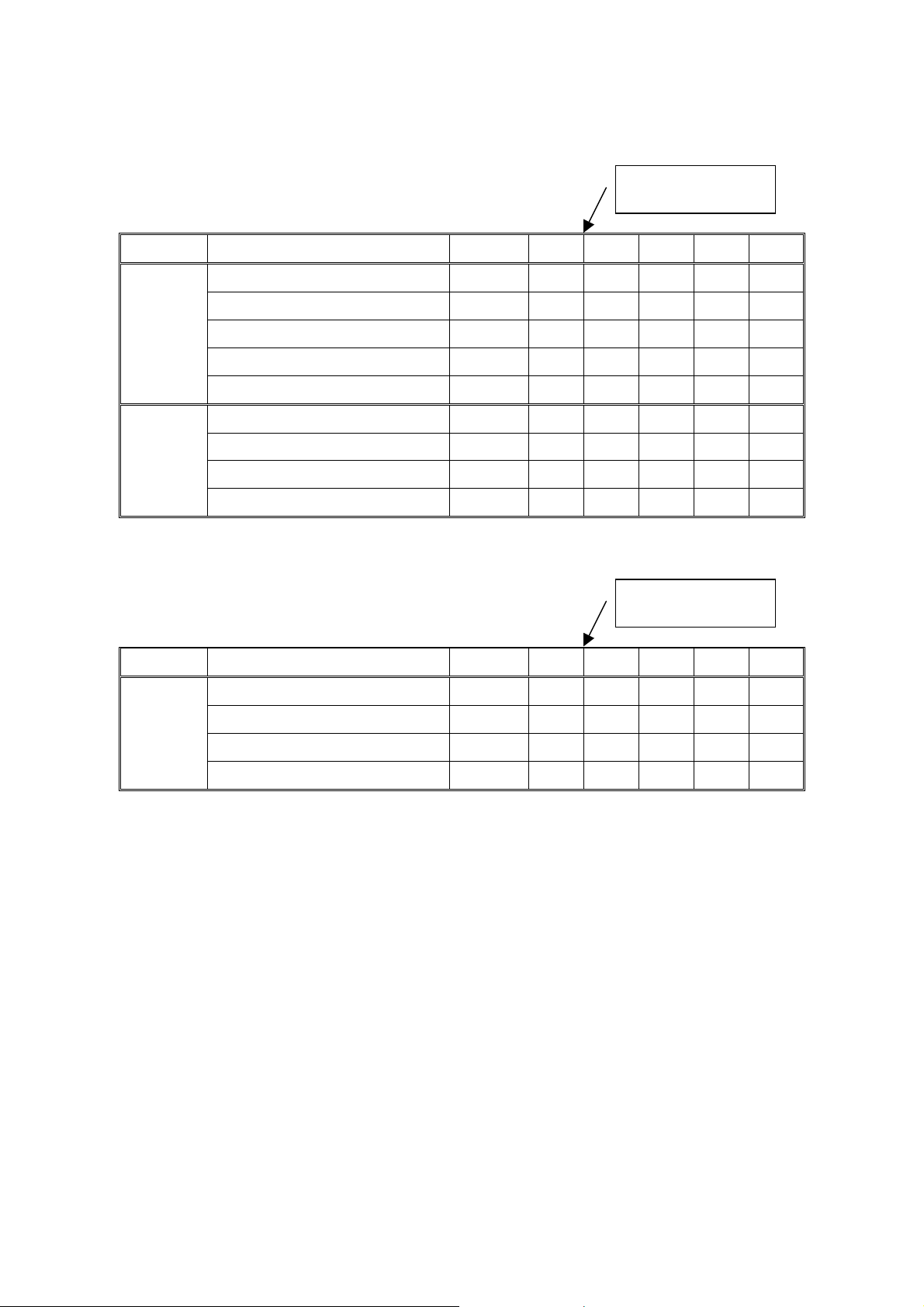

At 40kD, the hot roller

Solid/Halftone fill for #1 and #2 (25% Thick paper usage)

Paper File / Original Installation 25kD 50kD 73kD 94kD 117kD

Woman with black back ground, TIF A A A A B B

EFI sample many images, JPG A A A C-D C C

Normal

Paper

Graphic test image, PDF A A A A B B

Blue solid, PPT A B B D D-E D-E

C-4, COPY A A A C C C

EFI sample many images, JPG A A A A B B

blade was cleaned.

Thick Paper

Solid/Halftone fill for #3 (100% Thick paper usag e)

Paper File / Original Installation 13kD 23kD 33kD 42kD 52kD

Thick Paper

Graphic test image, PDF A A A A B B

Blue solid, PPT A A A C C D

C-4, COPY A A A A B B

At 20kD, the hot roller

blade was cleaned.

EFI sample many images, JPG A A B B C C

Graphic test image, PDF A A B B C C

Blue solid, PPT A A-B B B-C C D

C-4, COPY A A B B C C

19

15 May, 2001 Basic Tips for Cattleya 2

2-3. How the CMP works

Glossiness

To maintain the image qual it y Level B or higher, we recommend the following maintenance

program:

Description Part # SMP CMP

Hot Roller AE010034 80kD Replacement 40kD Replacement

Oil Supply Pad A25 741 71 80kD Replacement 40kD Replacement

Cleaning Roller AE042044 80kD Cleaning 40kD Cleaning

Scraper 80kD Cleaning 40kD Cleaning

Hot Roller Blade AE043012 40kD Cleaning

80kD Replacement

Pressure Roller Blade A2574187 (220V only) 320kD Replacement 160kD Replacement

Pre-cleaning Roller AE042049 80kD Replacement 40kD Replacement

20kD Cleaning

40kD Replacement

SMP: Standard Maintenance Program

CMP: Customized Maintenance Program

Solid / Halftone Fill

To maintain the image q uality Level B or higher for the pot ion of the Solid / Halftone fill, we

recommend the following maintenance program:

Description Part # SMP CMP

Developer -K — 60kD Replacement by

PM counter

Developer- C, M, Y — 48kD Replacement for

each color

PCC Wire AD020084 160kD Replacement 80kD Replacement

Drum Cleaning Blade AD041050 100kD Replacement 40kD Replacement

Drum Lubricant Bar A2573607 80kD Replacement 40kD Replacement

34kD replacement by

PM counter

27kD replacement

for each color

Drum Cleaning Brush AD042043 100kD Replacement 40kD Replacement

Drum B0239510 80kD Replacement 40kD Replacemen t

Drum Unit — 80kD Cleaning 40kD Cleaning

Charge Corona Wire AD020086 80kD Replacement 40kD Replacement

Charge Corona Grid AD020085 100kD Replacement 40kD Replacement

Belt Cleaning Unit — 80kD Cleaning 40kD Cleanin g

ITB Cleaning Blade A2576350 200kD Replacement 100kD Replacement

ITB Lubricant Bar B0236350 200kD Replacement 100kD Replacement

ITB Lubricant Brush B0236358 200kD Replacement 100kD Replacement

Transfer Belt B0236050 80kD Replacement 40kD Repla cement

20

15 May, 2001 Basic Tips for Cattleya 2

2-4. Procedure

1. Get the following information:

- How the print-out w ill be used at the custo mer site

(for sell, for internal distribution, for graphic d esi gn check).

- Customer’s dema nd

- Thick paper usage ratio

2. Discuss with the customer about the machine capabil it y and suggest the CMP if you think

that this program is needed the cust omer based on the information above.

3. Find the SMP / CMP ta ble in the Appendix D.

You can use this table whether the S M P or t he CMP will be performed.

Note: The CMP in the Appendix D is a guide line for the customer whose application is approx.

75% or higher thick paper usage ratio and h igh d emand on the image quality with the

high-coverage prints they make.

Although we have specified reduced intervals f or cert ain parts, the CMP is a guide line for

field technicians. The actua l ti me of rep lacement we leave to the technician's discretion.

21

15 May, 2001 Basic Tips for Cattleya 2

Appendix A: Test patterns

Max ID: ACC Pattern

Banding: SP5-955-6 Solid 55 (K, C, M, Y, R, G, B, P)

Jitter: SP5-955- 7, 1 dot 2x2, 180

Unevenness in Half tone: SP5-955-7, 1 dot 2x2, 128

Hue change (mail scan): SP5-955-6, Solid 110 (Purple, Green)

Color shift (sub scan): SP4-417-8 (YMCK 16 gradation)

Line alignment: SP5-955-14 Grid

Note: The test patterns for the banding, the jitter, the unevenness in the half tone,

and the color shift, enhance those symptom to make the troubleshooting

easily. And, the level of the symptom is way wroth compare to the symptom

on the printing under the normal operation. This is because the dither of the

test images are different from the dither on the usual copy./print mode.

1

15 May, 2001 Basic Tips for Cattleya 2

Appendix B: SP Modes

SP Mode Types

The SP modes of this copier are divided into the following eight groups:

Screen Name Group

Feed Paper feed/transport/fusing

Drum Drum unit

Process Process control

Scanner Scanner unit

Mode Operating mode/system

Periphs Peripherals

Log Logged data

Special Mode Others (special mode s)

Service Program Mode tables

NOTE:

1) In the Function/[Setting] column:

• The related pop-up screen and SP7 function (if any) are in parenthesis

after the function description,

• Comments are in italics.

• The “Setting” range is in brackets and the default “Setting” value is in

bold.

2) Clearing the RAM resets SP and UP values to their defaults. It does not

affect the serial number and main counter value, however.

3) DFU Designer or Factory Use only. Do not change these values.

4) USM This SP is ignored unless the user selects ‘Service Mode’ in UP

mode.

5) IAJ See “Replacement and Adjustment - Copy Image Area

Adjustments” for details.

6) RA See “Replacement and Adjustment” for details.

1

15 May, 2001 Basic Tips for Cattleya 2

SP1-XXX (Feed)

1

001

002

003

105

Mode Number/Name Function / [Setting]

Leading Edge Registration

1 Normal paper

2OHP

3 Thick paper 1

4 Thick paper 2

5 Duplex

6 Second sheet, Half speed

7 Second sheet, 1/3rd speed

Side-to-Side Registration

1 By-pass

2Tray 1

3Tray 2

4Tray 3

5Tray 4

6 2nd side

7LCT

Paper Feed Timing

1 Normal paper, by-pass

2 Tray paper feed

3 By-pass OHP

4 By-pass: Thick paper 1

5 2nd side

6 By-pass: Thick paper 2

7 Tray: Thick paper 1

8 Tray: Thick paper 2

By-pass Up Time010

Oil End Sensor101

Fusing Control104

Hot/Pressure Roller Temperature Setting (Screen B)

This SP sets the temperature of the hot and pressure rollers in various modes.

1 Single side: Hot: Reload

2 Single side: Hot: Idling

Single side: Hot: Normal

3

paper: FC

4 Single side: Hot: Normal

paper : 1C

5 Single side: Hot:

OHP/Thick paper: FC

Adjusts the leading edge registration by changing the

timing of the registration clutch. (Screen A, SP7-903)

[+7 to –7 / 0.0 / 0.1 mm/step] IAJ

Specification: 4 ± 1 mm

Thick paper 1 is listed as Thk on the screen.

Thick paper 2 is listed as Super Thk.

Adjusts the side-to-side registration by changing the

starting position for the laser’s main scan. (Screen A,

SP1-236)

[+9 to –9 / 0.0 / 0.1 mm/step] IAJ

Specification: 1.5 ± 0.5 mm. < 4 mm total

[ 5.0]

[ 5.0]

[ 3.0]

[ 1.5]

[ 5.0]

[–3.0]

[ 1.5]

[–3.0]

Not used.

NOTE: This SP is displayed and data can be input.

Turns the oil end sensor ON or OFF. (SP9-703)

[1 = ON, 0 = OFF]

Selects the fusing temperature control mode.

[1 = ON/OFF control, 0 = Phase control]

Phase control should be selected only if the user has a

problem with the fluorescent lamps flickering. The main

switch must be turned off and on when this setting is

changed.

[100 to 200 / 185 / 1°C/step]

Once the copier reaches this temperature, the ready light

comes on and copies can be made. The temperature

continues to increase until the ready state is reached.

[100 to 200 / 195 / 1°C/step]

Idling starts at 170

50

[100 to 200 / 180 / 1°C/step]

[100 to 200 / 170 / 1°C/step]

[100 to 200 / 180 / 1°C/step]

Adjusts the amount of paper buckle by changing

the timing of the relay clutch. A positive setting

creates more buckling.

(Screen A, SP7-903)

[+9 to –9 / 0.1 mm/step] +7 to –5 for by-pass:

thick paper

However, this function is not available.

C. If the temperature is higher than

°

C when the power is turned on, idling is not executed

°

2

15 May, 2001 Basic Tips for Cattleya 2

1

105

Mode Number/Name Function / [Setting]

6 Single side: Hot:

[100 to 200 / 180 / 1°C/step]

OHP/Thick paper: 1C

7 Single side: Pressure:

[100 to 200 / 160 / 1°C/step]

Idling

Single side: Pressure:

8

[100 to 200 / 155 / 1°C/step]

Normal paper: FC

9 Single side: Pressure:

[100 to 200 / 145 / 1°C/step]

Normal paper: 1C

10 Single side: Pressure:

[100 to 200 / 155 / 1°C/step]

OHP/Thick paper: FC

11 Single side: Pressure:

OHP/Thick paper: 1C

12 2nd side: Hot: Idling

2nd side: Hot: Normal

13

[100 to 200 / 195 / 1°C/step]

[100 to 200 / 180 / 1°C/step]

paper: FC

14 2nd side: Hot: Normal

[100 to 200 / 170 / 1°C/step]

paper: 1C

15 2nd side: Hot: OHP/Thick

[100 to 200 / 180 / 1°C/step]

paper: FC

16 2nd side: Hot: OHP/Thick

paper: 1C

17 2nd side: Pressure: Idling

2nd side: Pressure: Normal

18

[100 to 200 / 160 / 1°C/step]

[100 to 200 / 155 / 1°C/step]

paper: FC

19 2nd side: Pressure: Normal

[100 to 200 / 145 / 1°C/step]

paper: 1C

20 2nd side: Pressure:

[100 to 200 / 155 / 1°C/step]

OHP/Thick paper: FC

21 2nd side: Pressure:

OHP/Thick paper: 1C

22

Single side Hot Thick 2: FC

23

Single side Hot Thick 2: 1C

24

Single side Pressure: Thick

[100 to 200 / 180 / 1°C/step]

[100 to 200 / 180 / 1°C/step]

[100 to 200 / 155 / 1°C/step]

2: FC

25

Single side Pressure, Thick

2: 1C

26

27

28

29 2

nd

2

side Hot Idling

nd

2

side Hot Thick 2: FC

nd

2

side Hot Thick 2: 1C

nd

side Pressure Thick 2:

[100 to 200 / 155 / 1°C/step]

[100 to 200 / 180 / 1°C/step]

[100 to 200 / 180 / 1°C/step]

[100 to 200 / 155 / 1°C/step]

[100 to 200 / 155 / 1°C/step]

1C

Fusing Temperature Display

106

1 Pressure roller Displays the temperature of the pressure roller.

2 Hot roller Displays the temperature of the hot roller.

108 Fusing Unit Set Disables fusing unit set detection. Keep at 0 for normal

operation.

[0 = Detect, 1 = Do not detect]

- Procedure Turn off the main switch.

Remove the fusing unit.

Keep the front door open and turn on the main switch.

Access the SP mode and set the data to 1.

Close the front cover.

Fusing Nip Band Check109

Use to check the width of the fusing nip band. RA

3

15 May, 2001 Basic Tips for Cattleya 2

1

112

801

901

Mode Number/Name Function / [Setting]

Fusing Temperature Correction for Environment Temperature

1 High temperature

2 Low temperature

Motor Speed Adjustment

1 Fusing motor: Normal

speed

Paper feed motor: Normal

2

speed

3 Drum motor: Normal speed

4 Fusing motor: Half speed

5 Paper feed motor: Half

speed

6 Drum motor: Half speed

7 Fusing motor: 1/3rd speed

8 Paper feed motor: 1/3rd

speed

9 Drum motor: 1/3rd speed

10 Registration motor: Normal

speed

11 Registration motor: Half

speed

12 Registration motor: 1/3rd

speed

20 New motor/Old motor

Duplex Unit Side/End Fence Adjustment

1 Side fence Adjusts the duplex side fence stop position.

2 End fence Adjusts the duplex end fence stop position.

DFU [0°°°°C]

DFU [5°°°°C]

DFU [–5.0% to 5.0% / 0.0% / 0.1%/step]

DFU [–5.0% to 5.0% / 0.1% / 0.1%/step]

DFU [–3.0% to 3.0% / 0.0% / 0.1%/step]

DFU [–5.0% to 5.0% / 0.2% / 0.1%/step]

DFU [–5.0% to 5.0% / –2.0% / 0.1%/step]

DFU [–3.0% to 3.0% / 0.2% / 0.1%/step]

DFU [–5.0% to 5.0% / 0.2% / 0.1%/step]

DFU [–5.0% to 5.0% / –0.2% / 0.1%/step]

DFU [–3.0% to 3.0% / 0.2% / 0.1%/step]

DFU [–5.0% to 5.0% / 0.0% / 0.1%/step]

DFU [–5.0% to 5.0% / –0.2% / 0.1%/step]

DFU [0 to 1 / 0 / ]

1: New motor

0: Old motor

[–5.0 to 5.0 mm / 0 / 0.1 mm/step]

[–5.0 to 5.0 mm / 0 / 0.1 mm/step]

4

15 May, 2001 Basic Tips for Cattleya 2

SP2-XXX (Drum)

2

MChgCrrnt

10

1 MChgCrrnt EnvLmt [g/m3]

2

3

5

6

MchgFanONTime

11

1 Mchg FanONTime EnvLmt

2 MchgFanONTime [min]

3 MChgFanONTime [min]:

Sub-scan/Main-scan margin adjustment

101

1

2 Sub-scan: Leading edge:

3 Sub-scan: Leading edge:

4 Sub-scan: Leading edge:

5 Sub-scan: Trailing edge:

6

7 Sub-scan: Trailing edge :

8 Sub-scan: Trailing edge:

9 Main-scan: Leading edge Adjust leading margin. (operator side). (Screen C, SP9-

10 Main-scan: Trailing edge Adjusts the trailing margin. (Screen C, SP9-703)

11 Sub-scan: Auto 2nd side:

Fax Print Gamma Parameter111

000 Fax Print Gamma

Main scan magnification adjustment

112

1 Copy mode DFU [0] (Screen D, SP9-703)

2 Print mode Adjusts the magnification in the main scan direction for

Sub-scan magnification adjustment

113

1 Copy mode Adjusts the magnification in the sub-scan direction for

2 Print mode

Mode Number Function / [Setting]

MChgCrrnt [µA]: EnvHigh

MChgCrrnt [µA]

MChgCrrnt [µA]: Half

MChgCrrnt [µA]: 1/3rd

3

]

[g/m

EnvLow

Sub-scan: Leading edge:

Normal

Thick 1

Thick 2

OHP

Normal

Sub-scan: Trailing edge:

Thick 1

Thick 2

OHP

Trailing edge of 1st side

Parameter

DFU [0.6 to 50.0 / 11.0 / 0.1]

DFU [400 to 850 / 700 / 1.0]

DFU [400 to 850 / 560 / 1.0]

DFU [400 to 850 / 0 / 1.0]

DFU [0.6 to 50.0 / 4.3 / 0.1]

DFU [0.0 to 900.0 / 0.5 / 0.1]

DFU [0.0 to 900.0 / 20.0 / 0.1]

Adjusts the margin along the front edge. (Screen C, SP9-

703)

[–4.0 to 4.0 mm / 0 / 0.1 mm/step]

Adjusts the margin along the back edge. (Screen C, SP9-

703)

[–3.0 to 10.0 mm / 0 / 0.1 mm/step]

703)

[–2.0 to 5.0 mm / 0 / 0.1 mm/step]

[–2.0 to 5.0 mm / 0 / 0.1 mm/step]

Adjusts the trailing margin for the first side of duplex

copies. (Screen C, SP9-703)

[–3.0 to 10 mm / 0 / 0.1 mm/step]

Japan Only [0 to 255 / 192 / 1 per step]

printer mode. (Screen D, SP9-703)

[–1.0% to +1.0% / 0 / 0.1/step]

copy mode. (Screen D, SP9-703)

[–1.0% to +1.0% / 0 / 0.1/step]

Adjusts the magnification in the sub-scan direction for

printer mode. (Screen D, SP9-703)

[–1.0% to +1.0% / 0 / 0.1/step]

The screen displays “FsynchMagAdj PRINTER”.

5

15 May, 2001 Basic Tips for Cattleya 2

2

Forced toner supply positioning

207

1K

2C

3M

4Y

Forced toner supply cycle count

208

1K

2C

3M

4Y

5 Toner supply ratio: Fixed

6 Toner supply ratio: Fixed

7 Toner supply ratio: Fixed

8 Toner supply ratio: Fixed

9 Toner supply method Selects the toner supply method.

Developer initialization

225

1Exe: K

2Exe: C

3Exe: M

4Exe: Y

5Exe: All

6Exe: CMY

ITB bias adjustment

301

1 4C: 1st color

2 4C: 2nd color

3 4C: 3rd color

4 4C: 4th color

5 2C: 1st color

6 2C: 2nd color

7 3C: 1st color

8 3C: 2nd color

9 3C: 3rd color

10 1C : 1st color

11 Non-image areas

Mode Number Function / [Setting]

mode: K

mode: C

mode: M

mode: Y

Moves the selected development unit to the development

position and forces toner to be supplied in according to

the setting in SP2-208.

Press ON key to start after selecting the color.

Sets the number of forced toner supply cycles.

[1 to 50 / 10 / cycles]

The toner supply clutch turns on and off for 1 second.

This cycle repeats a number of times equal to the value

selected. (Approximately 0.5g of toner is supplied each

cycle. Therefor, about 5g of toner is supplied using the

default setting. This increases the toner density by about

0.7wt%.)

Sets the toner supply ratio for each color in fixed mode.

[0% to 100% / 5% / 1%/step]

0 = Fixed supply

1 = Proportional control supply (with TD sensor output)

2 = Fuzzy control supply

Initializes the developer and performs a forced self check

on the selected colors. Press the Execution key to start.

The results are displayed on the operation panel.

(Screen E)

0 = failure, 1 = success

Initial Vref check

The execution sequence is: Aging

Forced process control self-check.

DFU Adjusts the image transfer belt bias in standard

speed mode for each transfer process (1C - 4C) and color

mode selected.

[5 to 50 µA / 22 µµµµA / 1 µA/step]

[5 to 50 µA / 25 µµµµA / 1 µA/step]

[5 to 50 µA / 27 µµµµA / 1 µA/step]

[5 to 50 µA / 29 µµµµA / 1 µA/step]

[5 to 50 µA / 22 µµµµA / 1 µA/step]

[5 to 50 µA / 25 µµµµA / 1 µA/step]

[5 to 50 µA / 22 µµµµA / 1 µA/step]

[5 to 50 µA / 25 µµµµA / 1 µA/step]

[5 to 50 µA / 27 µµµµA / 1 µA/step]

[5 to 50 µA / 22 µµµµA / 1 µA/step]

DFU Adjusts the image transfer belt bias for the non-

image areas.

[5 to 50 µA / 6 µµµµA / 1 µA/step]

→

→

6

15 May, 2001 Basic Tips for Cattleya 2

2

301

Mode Number Function / [Setting]

12 Half-speed

24 VD Bias correction ON/OFF

25 4C : 2nd side : 1st color

26 4C : 2nd side : 2nd color

27 4C : 2nd side : 3rd color

28 4C : 2nd side : 4th color

29 2C : 2nd side : 1st color

30 2C : 2nd side : 2nd color

31 3C : 2nd side : 1st color

32 3C : 2nd side : 2nd color

33 3C : 2nd side : 3rd color

34 1C : 2nd side : 1st color

DFU Adjusts the image transfer belt bias for OHP/Thick

paper modes (Half speed). Before transferring to the

paper in these modes, the developed image on the

transfer belt passes the drum to synchronize the

registration.

[5 to 50 µA / 6 µµµµA / 1 µA /step]

DFU Sets the correction mode to ON or OFF. If ON, the

transfer belt bias for image area is corrected by V

(process control potential table).

[0 = ON, 1 = OFF]

DFU Adjusts the image transfer belt bias for the second

side copy in duplex mode for each transfer process (1C 4C) and color mode selected.

[5 to 50 µA / 22 µµµµA / 1 µA/step]

[5 to 50 µA / 25 µµµµA / 1 µA/step]

[5 to 50 µA / 27 µµµµA / 1 µA/step]

[5 to 50 µA / 29 µµµµA / 1 µA/step]

[5 to 50 µA / 22 µµµµA / 1 µA/step]

[5 to 50 µA / 25 µµµµA / 1 µA/step]

[5 to 50 µA / 22 µµµµA / 1 µA/step]

[5 to 50 µA / 25 µµµµA / 1 µA/step]

[5 to 50 µA / 27 µµµµA / 1 µA/step]

[5 to 50 µA / 22 µµµµA / 1 µA/step]

D

35 Lubricant brush 1

36 Lubricant brush 2

37 1/3rd Speed

40 V

PTR bias - Humidity range threshold

302

D

correction coefficient

1 Threshold 1

2 Threshold 2

3 Threshold 3

4 Threshold 4

These appear on the operation panel in the following

format, “1st 4C-mode NrmlBack”.

DFU Adjusts the image transfer belt bias during lubricant

brush cleaning mode.

[5 to 50 µA / 6 µA / 1 µA/step]

These appear as “Q1_Brush CLN1” and “Q1_Brush

CLN2”

DFU [5.0 to 50.0 µA / 5.0 µA / 1 µA/step ]

DFU [0 to 2.5 / 1.0 / 0.01/step]

DFU

Changes the thresholds for absolute humidity adjustment.

TH1 TH2 TH3 TH4

||||

Environment: LL L Normal H

HH

LL: Very low humidity [0.6 to 50 g/m

L : Low humidity [0.6 to 50 g/m3 / 11.3 g/m3/ 0.1]

H : High humidity [0.6 to 50 g/m3 / 18.0 g/m3/ 0.1]

HH: Very high humidity [0.6 to 50 g/m3 / 24.0 g/m3/ 0.1]

These appear as “EnvLmt [0]” through “EnvLmt [3].”

3

/ 4.3 g/m3 / 0.1]

7

15 May, 2001 Basic Tips for Cattleya 2

2

PTR bias adjustment

310

1 Humidity range set-up Specifies which humidity range is used for paper transfer

SP2-310-2 to SP2-310-29 adjust the PTR bias for the type of paper and the copy mode.

(Screen F, SP9-703)

2 Image area: Normal: 1C

3 Image area: Normal: 2C

4 Image area: Normal: 3C

5 Image area: Normal: 4C

6 Image area: Thick 1: 1C

7 Image area: Thick 1: 2C

8 Image area: Thick 1: 3C

9 Image area: Thick 1: 4C

10 Image area: OHP:1C

11 Image area: OHP:2C

12 Image area: OHP:3C

13 Image area: OHP:4C

14 Image area: Thick 2: 1C

15 Image area: Thick 2: 2C

16 Image area: Thick 2: 3C

17 Image area: Thick 2: 4C

18 Image area: Normal: 2nd

19 Image area: Normal: 2nd

20 Image area: Normal: 2nd

21 Image area: Normal: 2nd

22 Image area: Thick 1: 2nd

23 Image area: Thick 1: 2nd

24 Image area: Thick 1: 2nd

25 Image area: Thick 1: 2nd

26 Image area: Thick 2: 2nd

27 Image area: Thick 2: 2nd

28 Image area: Thick 2: 2nd

29 Image area: Thick 2: 2nd

Mode Number Function / [Setting]

bias. Change the value only if the humidity sensor fails.

0 = fixed humidity range (normal condition)

1 = changed by humidity sensor

2 = fixed humidity range (LL)

3 = fixed humidity range (L)

4 = fixed humidity range (H)

5 = fixed humidity range (HH)

The screen displays “EnvChoise”.

DFU [5 to 100 µA / 40 µµµµA / 1 µA /step]

DFU [5 to 100 µA / 47 µµµµA / 1 µA /step]

DFU [5 to 100 µA / 55 µµµµA / 1 µA /step]

DFU [5 to 100 µA / 16 µµµµA / 1 µA /step]

DFU [5 to 100 µA / 18 µµµµA / 1 µA /step]

DFU [5 to 100 µA / 24 µµµµA / 1 µA /step]

DFU [5 to 100 µA / 30 µµµµA / 1 µA /step]

DFU [5 to 100 µA / 36 µµµµA / 1 µA /step]

DFU [5 to 100 µA / 12 µµµµA / 1 µA /step]

DFU [5 to 100 µA / 14 µµµµA / 1 µA /step]

DFU [5 to 100 µA / 16 µµµµA / 1 µA /step]

DFU [5 to 100 µA / 40 µµµµA / 1 µA /step]

side: 1C

DFU [5 to 100 µA / 42 µµµµA / 1 µA /step]

side: 2C

DFU [5 to 100 µA / 45 µµµµA / 1 µA /step]

side: 3C

side: 4C

DFU [5 to 100 µA / 16 µµµµA / 1 µA /step]

side: 1C

DFU [5 to 100 µA / 19 µµµµA / 1 µA /step]

side: 2C

DFU [5 to 100 µA / 22 µµµµA / 1 µA /step]

side: 3C

side: 4C

DFU [5 to 100 µA / 12 µµµµA / 1 µA /step]

side: 1C

DFU [5 to 100 µA / 14 µµµµA / 1 µA /step]

side: 2C

DFU [5 to 100 µA / 16 µµµµA / 1 µA /step]

side: 3C

side: 4C

8

15 May, 2001 Basic Tips for Cattleya 2

2

SP2-310-30 to SP2-310-37 adjust the PTR bias used for the ID sensor pattern. (Screen F,

310

SP9-703)

30 ID pattern: Normal: 1C

31 ID pattern: Normal: 2C

32 ID pattern: Normal: 3C

33 ID pattern: Normal: 4C

34 ID pattern: All others: 1C

35 ID pattern: All others: 2C

36 ID pattern: All others: 3C

37 ID pattern: All others: 4C

38 Lubricant brush (Belt

311 1 Forced belt cleaning Lubricates the image transfer roller. Press the ON key to

PTR bias: Paper size correction

313

1 Normal: LT (S) or larger

2 Normal: B4 or larger

3 Normal: A5 (L) or larger

4 Normal: Less than A5 (L)

5 Thick 1: LT (S) or larger

6 Thick 1: B4 or larger

7 Thick 1: A5 (L) or larger

8 Thick 1: Less than A5 (L)

9 OHP:LT (S) or larger

10 OHP:B4 or larger

11 OHP:A5 (L) or larger

12 OHP: Less than A5 (L)

13 Thick 2: LT (S) or larger

14 Thick 2: B4 or larger

15 Thick 2: A5 (L) or larger

16 Thick 2: Less than A5 (L)

PTR bias: Leading edge correction

314

DFU Corrects the PTR bias for the paper leading edge area for the type of paper and copy

mode. The paper transfer belt bias times the percentage selected in this SP mode is applied to

the bias roller. (SP9-703)

1 Normal: 1C

2 Normal: 2C

3 Normal: 3C

4 Normal: 4C

5 Thick 1: 1C

6 Thick 1: 2C

7 Thick 1: 3C

8 Thick 1: 4C

9OHP: 1C

10 OHP: 2C

11 OHP: 3C

12 OHP: 4C

13 Thick 2: 1C

14 Thick 2: 2C

15 Thick 2: 3C

16 Thick 2: 4C

Mode Number Function / [Setting]

DFU [5 to 100 µA / 20 µµµµA / 1 µA /step]

DFU [5 to 100 µA / 50 µµµµA / 1 µA /step]

30 – 33 labeled as “P:Nrml”

DFU [5 to 100 µA / 12 µµµµA / 1 µA /step]

DFU [5 to 100 µA / 14 µµµµA / 1 µA /step]

34 – 37 labeled as “P:ElseNrml”

DFU Adjusts the paper transfer roller bias during lubricant

cleaning mode)

brush cleaning. (Screen F, SP9-703)

[5 to 100 µA / 35 µµµµA / 1 µA /step]

start.

This mode may help alleviate partial blank areas or

insufficient roller cleaning.

DFU Corrects the PTR bias for the paper type and size.

The paper transfer roller bias times the percentage

selected in this SP mode is applied to the bias roller.

(S = sideways, L = lengthwise)

[50 to 500% / 100% / 1%/step] (except for SP2-313-008)

[50 to 500% / 200% / 1%/step] (SP2-313-008)

[50 to 200% / 110% / 1%/step]

[50 to 200% / 79% / 1%/step]

[50 to 200% / 100% / 1%/step]

9

15 May, 2001 Basic Tips for Cattleya 2

2

314

315

316

17 Normal: 2nd side: 1C

18 Normal: 2nd side: 2C

19 Normal: 2nd side: 3C

20 Normal: 2nd side: 4C

21 Thick 1: 2nd side: 1C

22 Thick 1: 2nd side: 2C

23 Thick 1: 2nd side: 3C

24 Thick 1: 2nd side: 4C

25 Thick 2: 2nd side: 1C

26 Thick 2: 2nd side: 2C

27 Thick 2: 2nd side: 3C

28 Thick 2: 2nd side: 4C

PTR bias: Trailing edge correction

DFU Corrects the PTR bias for the paper trailing edge based on the type of paper and copy

mode. The paper transfer roller bias times the percentage selected in this SP mode is applied

to the bias roller. (SP9-703)

1 Normal: 1C

2 Normal: 2C

3 Normal: 3C

4 Normal: 4C

5 Thick 1: 1C

6 Thick 1: 2C

7 Thick 1: 3C

8 Thick 1: 4C

9OHP: 1C

10 OHP: 2C

11 OHP: 3C

12 OHP: 4C

13 Thick 2: 1C

14 Thick 2: 2C

15 Thick 2: 3C

16 Thick 2: 4C

17 Normal: 2nd side: 1C

18 Normal: 2nd side: 2C

19 Normal: 2nd side: 3C

20 Normal: 2nd side: 4C

21 Thick 1: 2nd side: 1C

22 Thick 1: 2nd side: 2C

23 Thick 1: 2nd side: 3C

24 Thick 1: 2nd side: 4C

25 Thick 2: 2nd side: 1C

26 Thick 2: 2nd side: 2C

27 Thick 2: 2nd side: 3C

28 Thick 2: 2nd side: 4C

PTR bias: Humidity correction

DFU Corrects the PTR bias for the humidity condition based on the type of paper and copy

mode. The paper transfer belt bias times the percentage selected in this SP mode is applied.

LL = Very low humidity, L = Low humidity, H = High humidity, HH = Very high humidity

1 LL: Normal : 1C

2 LL: Normal: 4C

3 L: Normal: 1C

4 L: Normal: 4C

5 H: Normal: 1C

6 H: Normal: 4C

Mode Number Function / [Setting]

[50 to 200% / 100% / 1%/step]

[50 to 200% / 68% / 1%/step]

[50 to 200% / 100% / 1%/step]

[50 to 200% / 100% / 1%/step]

[50 to 200% / 79% / 1%/step]

[50 to 200% / 100% / 1%/step]

[50 to 200% / 68% / 1%/step]

[50 to 200% / 100% / 1%/step]

[50 to 200% / 100% / 1%/step]

[50 to 200% / 120% / 1%/step]

[50 to 200% / 100% / 1%/step]

10

15 May, 2001 Basic Tips for Cattleya 2

2

316

Mode Number Function / [Setting]

7 HH: Normal: 1C

8 HH: Normal: 4C

9 LL: Thick 1: 1C

10 LL: Thick 1: 4C

11 L: Thick 1: 1C

12 L: Thick 1: 4C

13 H: Thick 1: 1C

14 H: Thick 1: 4C

15 HH: Thick 1: 1C

16 HH: Thick 1: 4C

17 LL: OHP: 1C

18 LL: OHP: 4C

19 L: OHP: 1C

20 L: OHP: 4C

21 H: OHP: 1C

22 H: OHP: 4C

23 HH: OHP: 1C

24 HH: OHP: 4C

25 LL: Thick 2: 1C

26 LL: Thick 2: 4C

27 L: Thick 2: 1C

28 L: Thick 2: 4C

29 H: Thick 2: 1C

30 H: Thick 2: 4C

31 HH: Thick 2: 1C

32 HH: Thick 2: 4C

33 LL: Normal: 2nd side:1C

34 LL: Normal: 2nd side: 4C

35 L: Normal: 2nd side:1C

36 L: Normal: 4C

37 H: Normal: 2nd side:1C

38 H: Normal: 2nd side:4C

39 HH: Normal: 2nd side: 1C

40 HH: Normal : 2nd side: 4C

41 LL: Thick 1: 2nd side: 1C

42 LL: Thick 1: 2nd side: 4C

43 L: Thick 1: 2nd side: 1C

44 L: Thick 1: 2nd side: 4C

45 H: Thick 1: 2nd side: 1C

46 H: Thick 1: 2nd side: 4C

47 HH: Thick 1: 2nd side: 1C

48 HH: Thick 1: 2nd side: 4C

49 LL: Thick 2: 2nd-side: 1C

50 LL: Thick 2: 2nd-side: 4C

51 L: Thick 2: 2nd-side: 1C

52 L: Thick 2: 2nd-side: 4C

53 H: Thick 2: 2nd-side: 1C

54 H: Thick 2: 2nd-side: 4C

55 HH: Thick 2: 2nd-side: 1C

56 HH: Thick 2: 2nd-side: 4C

[50 to 200% / 100% / 1%/step]

[50 to 200% / 125% / 1%/step]

[50 to 200% / 108% / 1%/step]

[50 to 200% / 100% / 1%/step]

[50 to 200% / 125% / 1%/step]

[50 to 200% / 89% / 1%/step]

[50 to 200% / 100% / 1%/step]

[50 to 200% / 67% / 1%/step]

[50 to 200% / 117% / 1%/step]

50 to 200% / 113% / 1%/step]

50 to 200% / 100% / 1%/step]

[50 to 200% / 88% / 1%/step]

[50 to 200% / 100% / 1%/step]

[50 to 200% / 130% / 1%/step]

[50 to 200% / 100% / 1%/step]

[50 to 200% / 75% / 1%/step]

[50 to 200% / 89% / 1%/step]

[50 to 200% / 125% / 1%/step]

[50 to 200% / 155% / 1%/step]

[50 to 200% / 100% / 1%/step]

[50 to 200% / 167% / 1%/step]

[50 to 200% / 127% / 1%/step]

[50 to 200% / 100% / 1%/step]

[50 to 200% / 83% / 1%/step]

[50 to 200% / 88% / 1%/step]

11

15 May, 2001 Basic Tips for Cattleya 2

2

Paper separation voltage adjustment: Image area

402

DFU Adjusts the separation voltage for the different copy modes.

1 Normal: 1C

2 Normal: 4C

3 Thick 1: 1C

4 Thick 1: 4C

5OHP: 1C

6OHP: 4C

7 Thick 2: 1C

8 Thick 2: 4C

9 Normal: 2nd side: 1C

10 Normal: 2nd side: 4C

11 Thick 1: 2nd side: 1C

12 Thick 1: 2nd side: 4C

13 Thick 2: 2nd side: 1C

14 Thick 2: 2nd side: 4C

Paper separation voltage adjustment: Leading edge

403

1Normal

2 Thick 1

3OHP

4 Thick 2

5 2nd side: Normal

6 2nd side: Thick 1

7 2nd side: Thick 2

Paper Separation Voltage: Humidity correction

404

1 LL: Normal: 1C

2 LL: Normal: 4C

3 L: Normal: 1C

4 L: Normal: 4C

5 H: Normal: 1C

6 H: Normal: 4C

7 HH: Normal: 1C

8 HH: Normal: 4C

9 LL: Thick 1: 1C

10 LL: Thick 1: 4C

11 L: Thick 1: 1C

12 L: Thick 1: 4C

13 H: Thick 1: 1C

14 H: Thick 1: 4C

15 HH: Thick 1: 1C

16 HH: Thick 1: 4C

17 LL: OHP: 1C

18 LL: OHP: 4C

19 L: OHP: 1C

20 L: OHP: 4C

21 H: OHP: 1C

22 H: OHP: 4C

23 HH: OHP: 1C

24 HH: OHP: 4C

25 LL: Thick 2: 1C

26 LL: Thick 2: 4C

27 L: Thick 2: 1C

28 L: Thick 2: 4C

29 H: Thick 2: 1C

Mode Number Function / [Setting]

[500 to 3000 V / 3000 V / 1 V/step]

[500 to 3000 V / 1000 V / 1 V/step]

[500 to 3000 V / 3000 V / 1 V/step]

[500 to 3000 V / 1000 V / 1 V/step]

DFU Adjusts the paper separation voltage for the paper

leading edge. The voltage of the image area times the

percentage selected in this mode is applied.

[50 to 200% / 100% / 1%/step]

DFU Corrects the paper separation voltage based on the

humidity and copy mode.

LL: Very low humidity

L : Low humidity

H : High humidity

HH: Very high humidity

[50 to 200% / 100% / 1%/step]

12

15 May, 2001 Basic Tips for Cattleya 2

2

404

405

30 H: Thick 2: 4C

31 HH: Thick 2: 1C

32 HH: Thick 2: 4C

33 LL: Normal: 2nd side: 1C

34 LL: Normal: 2nd side: 4C

35 L: Normal: 2nd side: 1C

36 L: Normal: 2nd side: 4C

37 H: Normal: 2nd side: 1C

38 H: Normal: 2nd side: 4C

39 HH: Normal: 2nd side: 1C

40 HH: Normal: 2nd side: 4C

41 LL: Thick 1: 2nd side: 1C

42 LL: Thick 1 : 2nd side: 4C

43 L: Thick 1: 2nd side: 1C

44 L: Thick 1: 2nd side: 4C

45 H: Thick 1: 2nd side: 1C

46 H: Thick 1: 2nd side: 4C

47 HH: Thick 1: 2nd side: 1C

48 HH: Thick 1: 2nd side: 4C

49 LL: Thick 2: 2nd side: 1C

50 LL: Thick 2: 2nd side: 4C

51 L: Thick 2: 2nd side: 1C

52 L: Thick 2: 2nd side: 4C

53 H: Thick 2: 2nd side: 1C

54 H: Thick 2: 2nd side: 4C

55 HH: Thick 2: 2nd side: 1C

56 HH: Thick 2: 2nd side: 4C

Paper separation voltage: AC Component ON/OFF

1 Normal - Normal: 1C

2 Normal - Normal: 4C

3 Normal - Thick 1: 1C

4 Normal - Thick 1: 4C

5 Normal - OHP: 1C

6 Normal - OHP: 4C

7 Normal - Thick 2: 1C

8 Normal - Thick2: 4C

9 Normal - Normal: 2nd side:

10 Normal - Normal: 2nd side:

11 Normal - Thick 1: 2nd side:

12 Normal - Thick 1: 2nd side:

13 Normal - Thick 2: 2nd side:

14 Normal - Thick 2: 2nd side:

15 LL: Normal: 1C

16 LL: Normal: 4C

17 LL: Thick 1: 1C

18 LL: Thick 1: 4C

19 LL: OHP: 1C

20 LL: OHP: 4C

21 LL: Thick 2: 1C

Mode Number Function / [Setting]

1C

4C

1C

4C

1C

4C

DFU Corrects the paper separation voltage based on the

humidity and copy mode.

LL: Very low humidity

L : Low humidity

H : High humidity

HH: Very high humidity

[50 to 200% / 100% / 1%/step]

DFU Turns the paper separation ON or OFF for each

mode.

0 = OFF

1 = ON

Defaults:

2-405-001 to 042 = 1

2-405-043 to 050 = 0

2-405-051 to 052 = 1

2-405-053 to 064 = 0

2-405-065 to 066 = 1

2-405-067 to 070 = 0

LL: Very low humidity

L : Low humidity

H : High humidity

HH: Very high humidity

For the second side, the operation panel uses the

following format: “NRML B_NRML”

13

15 May, 2001 Basic Tips for Cattleya 2

2

405

22 LL: Thick 2: 4C

23 LL: Normal: 2nd side: 1C

24 LL: Normal: 2nd side: 4C

25 LL: Thick 1: 2nd side: 1C

26 LL: Thick 1: 2nd side: 4C

27 LL: Thick 2: 2nd side: 1C

28 LL: Thick 2: 2nd side: 4C

29 L: Normal: 1C

30 L: Normal: 4C

31 L: Thick 1: 1C

32 L: Thick 1: 4C

33 L: OHP: 1C

34 L: OHP: 4C

35 L: Thick 2: 1C

36 L: Thick 2: 4C

37 L: Normal: 2nd side: 1C

38 L: Normal: 2nd side: 4C

39 L: Thick 1: 2nd side: 1C

40 L: Thick 1: 2nd side: 4C

41 L: Thick 2: 2nd side: 1C

42 L: Thick 2: 2nd side: 4C

43 H: Normal: 1C

44 H: Normal: 4C

45 H: Thick 1: 1C

46 H: Thick 1: 4C

47 H: OHP: 1C

48 H: OHP: 4C

49 H: Thick 2: 1C

50 H: Thick 2: 4C

51 H: Normal: 2nd side: 1C

52 H: Normal: 2nd side: 4C

53 H: Thick 1: 2nd side: 1C

54 H: Thick 1: 2nd side: 4C

55 H: Thick 2: 2nd side: 1C

56 H: Thick 2: 2nd side: 4C

57 H-H: Normal: 1C

58 H-H: Normal: 4C

59 H-H: Thick 1: 1C

60 H-H: Thick 1: 4C

61 H-H: OHP: 1C

62 H-H: OHP: 4C

63 H-H: Thick 2: 1C

64 H-H: Thick 2: 4C

65 H-H: Normal: 2nd side: 1C

66 H-H: Normal: 2nd side: 4C

67 H-H: Thick 1: 2nd side: 1C

68 H-H: Thick 1: 2nd side: 4C

69 H-H: Thick 2: 2nd side: 1C

70 H-H: Thick 2: 2nd side: 4C

101 Sep On Timing: Normal

102 Sep On Timing: Half

103 Sep On Timing: 1/3rd

104 Sep Off Timing: Normal

105 Sep Off Timing: Half

106 Sep Off timing: 1/3rd

Mode Number Function / [Setting]

DFU Turns the paper separation ON or OFF for each

mode.

0 = OFF

1 = ON

Defaults:

2-405-001 to 042 = 1

2-405-043 to 050 = 0

2-405-051 to 052 = 1

2-405-053 to 064 = 0

2-405-065 to 066 = 1

2-405-067 to 070 = 0

LL: Very low humidity

L : Low humidity

H : High humidity

HH: Very high humidity

For the second side, the operation panel uses the

following format: “NRML B_NRML”

[–50 to 50 / 0 / 1/step]

[–50 to 50 / 7 / 1/step]

[–50 to 50 / 0 / 1/step]

14

15 May, 2001 Basic Tips for Cattleya 2

2

ITB lubricant brush bias adjustment

601

SP2-601-001 to -008 adjust the bias for the image transfer belt’s lubricant brush. The bias is

applied after the image development is completed for each speed in 1C, 2C, and 4C modes.

1 Normal speed: 1C

2 Normal speed: 2C

3 Normal speed: 4C

4 Half speed: 1C

5 Half speed: 2C

6 Half speed: 4C

7 Normal speed: Others

8 Half speed: Others

SP2-601-009 to -025 shift the image transfer belt lubricant brush bias set by SP2-601-001 to

008 for each environment condition.

LL = Low temp./low humidity conditions, HH = High temp./high humidity conditions

Listed on the operator panel using the following format "ENV_LL SPEED_STD 1C"

9 Normal speed: LL: 1C

10 Normal speed: LL: 2C

11 Normal speed: LL: 4C

12 Half speed: LL: 1C

13 Half speed: LL: 2C

14 Half speed: LL: 4C

15 Normal speed: LL: Others

16 Half speed: LL: Others

17 Normal speed: HH: 1C

18 Normal speed: HH: 2C

19 Normal speed: HH: 4C

20 Half speed: HH: 1C

21 Half speed: HH: 2C

22 Half speed: HH: 4C

23 Normal speed: HH: Others

24 Half speed: HH: Others

25 Lubricant brush (Belt

26 1/3rd speed: 1C

27 1/3rd speed: 2C

28 1/3rd speed: 4C

29 1/3rd speed: Others

30 1/3rd speed: LL: 1C

31 1/3rd speed: LL: 2C

32 1/3rd speed: LL: 4C

33 1/3rd speed: LL: Others

34 1/3rd speed: HH: 1C

35 1/3rd speed: HH: 2C

36 1/3rd speed: HH: 4C

37 1/3rd speed: HH: Others

100 Image belt clean reset

Voltage adjustment for the PTR discharge corona

603

DFU Adjusts the voltage for the paper separation belt discharge corona based on the type of

paper and copy mode.

Non transfer area = The voltage which is applied to the discharge corona after the trailing edge

of paper passes it until next sheet of paper arrives

1 Normal: 1C

2 Normal: 2C

Mode Number Function / [Setting]

DFU [0 to 1000 V / 450 V / 1 V/step]

DFU [0 to 1000 V / 50 V / 1 V/step]

DFU [0 to 1000 V / 250 V / 1 V/step]

DFU [0 to 1000 V / 50 V / 1 V/step]

DFU [0 to 1000 V / 250 V / 1 V/step]

DFU [0 to 1000 V / 100 V / 1 V/step]

[–500 to 500 V / –250 V / 1 V/step]

[–500 to 500 V / 0 V / 1 V/step]

[–500 to 500 V / 50 V / 1 V/step]

[–500 to 500 V / 0 V / 1 V/step]

[–500 to 500 V / 50 V / 1 V/step]

[–500 to 500 V / 0 V / 1 V/step]

[–500 to 500 V / 100 V / 1 V/step]

cleaning mode)

Listed as “Q1_Brush CLN”

[–500 to 500 V / 50 V / 1 V/step]

[–500 to 500 V / 250 V / 1 V/step]

[–500 to 500 V / 50 V / 1 V/step]

[–500 to 500 V / 250 V / 1 V/step]

[–500 to 500 V / 50 V / 1 V/step]

[–500 to 500 V / 250 V / 1 V/step]

[–500 to 500 V / 0 V / 1 V/step]

[–50 to 5 / 0 / 1 ]

.

[100 to 1500 V / 900 V / 1 V/step]

[100 to 1500 V / 1100 V / 1 V/step]

15

15 May, 2001 Basic Tips for Cattleya 2

2

603

604

3 Normal: 3C

4 Normal: 4C

5 Normal: Non transfer area

6 Thick 1: 1C

7 Thick 1: 2C

8 Thick 1: 3C

9 Thick 1: 4C

10 Thick 1: Non transfer area

11 OHP: 1C

12 OHP: 2C

13 OHP: 3C

14 OHP: 4C

15 OHP: Non transfer area

16 Thick 2: 1C

17 Thick 2: 2C

18 Thick 2: 3C

19 Thick 2: 4C

20 Thick 2: Non transfer area

21 Lubricant brush (Belt

PTR discharge corona voltage: Humidity correction

1 LL: Normal: 1C

2 LL: Normal: 4C

3 L: Normal: 1C

4 L: Normal: 4C

5 H: Normal: 1C

6 H: Normal: 4C

7 HH: Normal: 1C

8 HH: Normal: 4C

9 LL: Thick 1: 1C

10 LL: Thick 1: 4C

11 L: Thick 1: 1C

12 L: Thick 1: 4C

13 H: Thick 1: 1C

14 H: Thick 1: 4C

15 HH: Thick 1: 1C

16 HH: Thick 1: 4C

17 LL: OHP: 1C

18 LL: OHP: 4C

19 L: OHP: 1C

20 L: OHP: 4C

21 H: OHP: 1C

22 H: OHP: 4C

23 HH: OHP: 1C

24 HH: OHP: 4C

25 LL: Thick 2: 1C

26 LL: Thick 2: 4C

27 L: Thick 2: 1C

28 L: Thick 2: 4C

29 H: Thick 2: 1C

30 H: Thick 2: 4C

31 HH: Thick 2: 1C

32 HH: Thick 2: 4C

Mode Number Function / [Setting]

cleaning mode)

100 to 1500 V / 1100 V / 1 V/step]

[100 to 1500 V / 800 V / 1 V/step]

[100 to 1500 V / 900 V / 1 V/step]

[100 to 1500 V / 1100 V / 1 V/step]

[100 to 1500 V / 800 V / 1 V/step]

[100 to 1500 V / 900 V / 1 V/step]

[100 to 1500 V / 1100 V / 1 V/step]

[100 to 1500 V / 800 V / 1 V/step]

[100 to 1500 V / 900 V / 1 V/step]

[100 to 1500 V / 1100 V / 1 V/step]

[100 to 1500 V / 800 V / 1 V/step]

[100 to 1500 V / 1100 V / 1 V/step]

Labeled as “Q1_Brush CLN.”

DFU Adjusts the paper transfer belt discharge corona

voltage based on the humidity and copy mode.

[50 to 200% / 100% / 1%/step]

LL: Very low humidity

L : Low humidity

H : High humidity

HH: Very high humidity

16

15 May, 2001 Basic Tips for Cattleya 2

2

802 Forced corona wire/grid cleaning Starts charge wire/grid cleaning.

Corona wire/grid auto-cleaning

803

1 Power ON cleaning Starts charge wire/grid cleaning after the main switch or

2 Counter setting

3 Time setting

4 FagingCHCln

Environment display

912

1 Temperature Displays temperature detected.

2 Relative humidity Displays relative humidity detected.

3 Absolute humidity Displays absolute humidity calculated using the

4 Humidity sensor selection Selects the manufacture of the humidity sensor.

913 Toner overflow detection setting Turns the toner overflow sensor detection on or off.

951 Toner end detection setting Turns the toner end sensors for all colors on or off.

Maximum toner supply ratio adjustment

953

1K

2CMY

Mode Number Function / [Setting]

Press the ON key to perform the wire cleaning.

operation switch is turned on and if the hot roller

temperature is less than 100ºC.

0 = OFF

1 = ON

2 = Cleaning takes place based on the interval set using

SP2-803-002

Tracks development cycles. Automatic wire/grid cleaning

Listed as “cintvCHCln

[kdev]”

Listed as “tintvCHCln

[hour]”

starts after a number of cycles equal to the value set in

this SP. If there is a copy job in progress, cleaning starts

after the job is completed.

0 = Disable the function

[0 to 80 K / 0 K / 1 K /step]

Automatic wire/grid cleaning starts after a time period set

by this SP. If there is a copy job in progress, cleaning

starts after the job is completed.

0 = Disable the function

[0 to 999 H / 0 H / 1 H/step]

DFU Corona wire/grid cleaning performed before the

developer initialization (SP2-222).

0 = ON

1 = OFF

temperature and relative humidity.

0: Shinei, 1: TDK

0 = OFF

1 = ON

1 = OFF

0 = ON

NOTE: Make sure to reset the data to ON if it is set to

OFF temporarily for servicing.

Adjusts the maximum toner supply ration (upper limit) in

the continuous supply mode.

[0 to 100% / 100% / 1%/step]

955 Counting method for the toner end

detection

Listed using the following format “MaxRtoBKTnAdd.”

Selects the method for counting the number of copies that