Page 1

C275

SERVICE MANUAL

005648MIU

Page 2

Page 3

C275

SERVICE MANUAL

Page 4

Page 5

C275

SERVICE MANUAL

005648MIU

Page 6

Page 7

It is the reader's responsibility when discussing the information contained

within this document to maintain a level of confidentiality that is in the best

interest of Ricoh Americas Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

F ASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH AMERICAS CORPORATION.

All product names, domain names or product illustrations, including

desktop images, used in this document are trademarks, registered

trademarks or the property of their respective companies.

They are used throughout this book in an informational or editorial fashion

only and for the benefit of such companies. No such use, or the use of

any trade name, or web site is intended to convey endorsement or other

affiliation with Ricoh products.

© 2010 RICOH Americas Corporation. All rights reserved.

Page 8

Page 9

The Service Manual contains information

regarding service techniques, procedures,

processes and spare parts of office equipment

distributed by Ricoh Americas Corporation.

Users of this manual should be either service

trained or certified by successfully completing a

Ricoh Technical Training Program.

Untrained and uncertified users utilizing

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property or loss of warranty

protection.

Ricoh Americas Corporation

WARNING

Page 10

Page 11

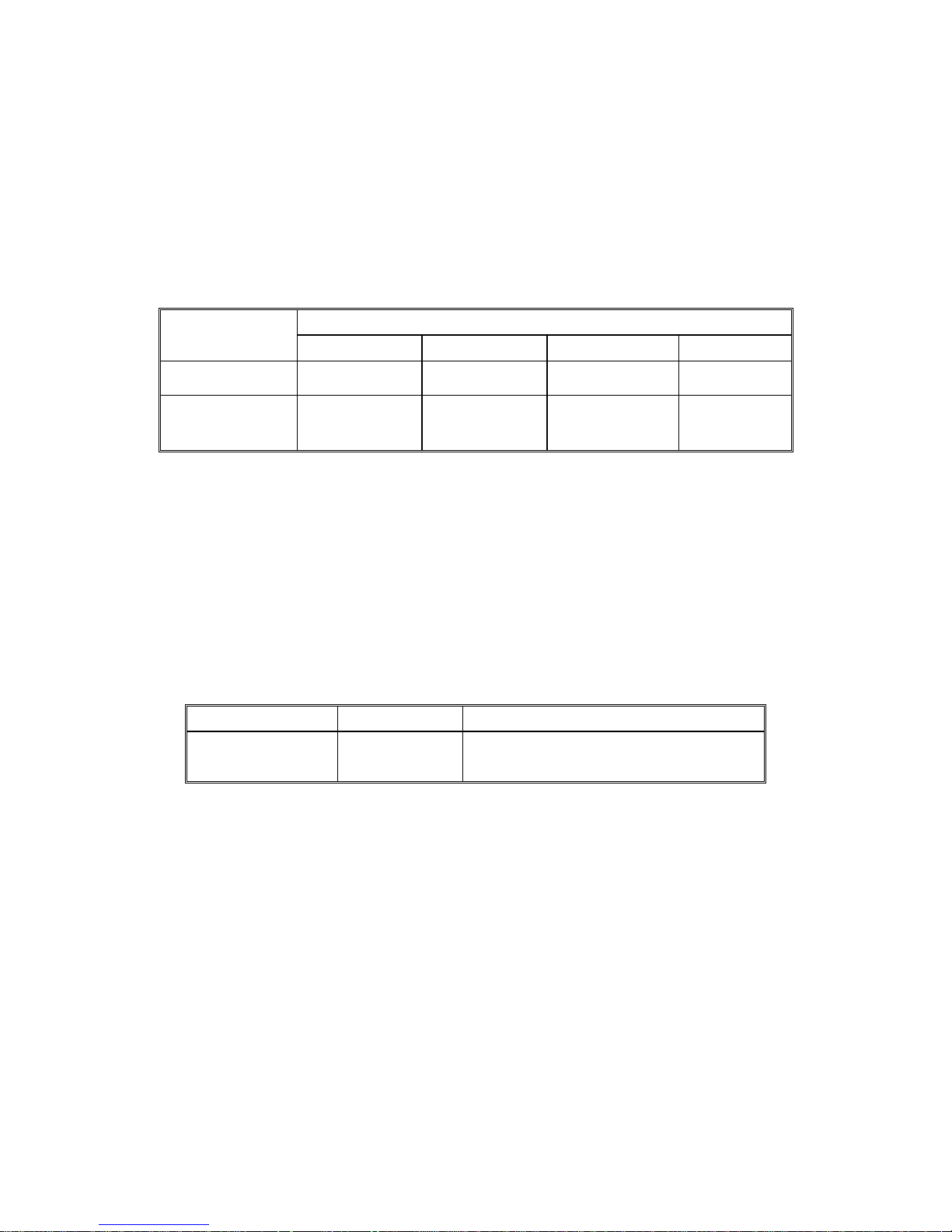

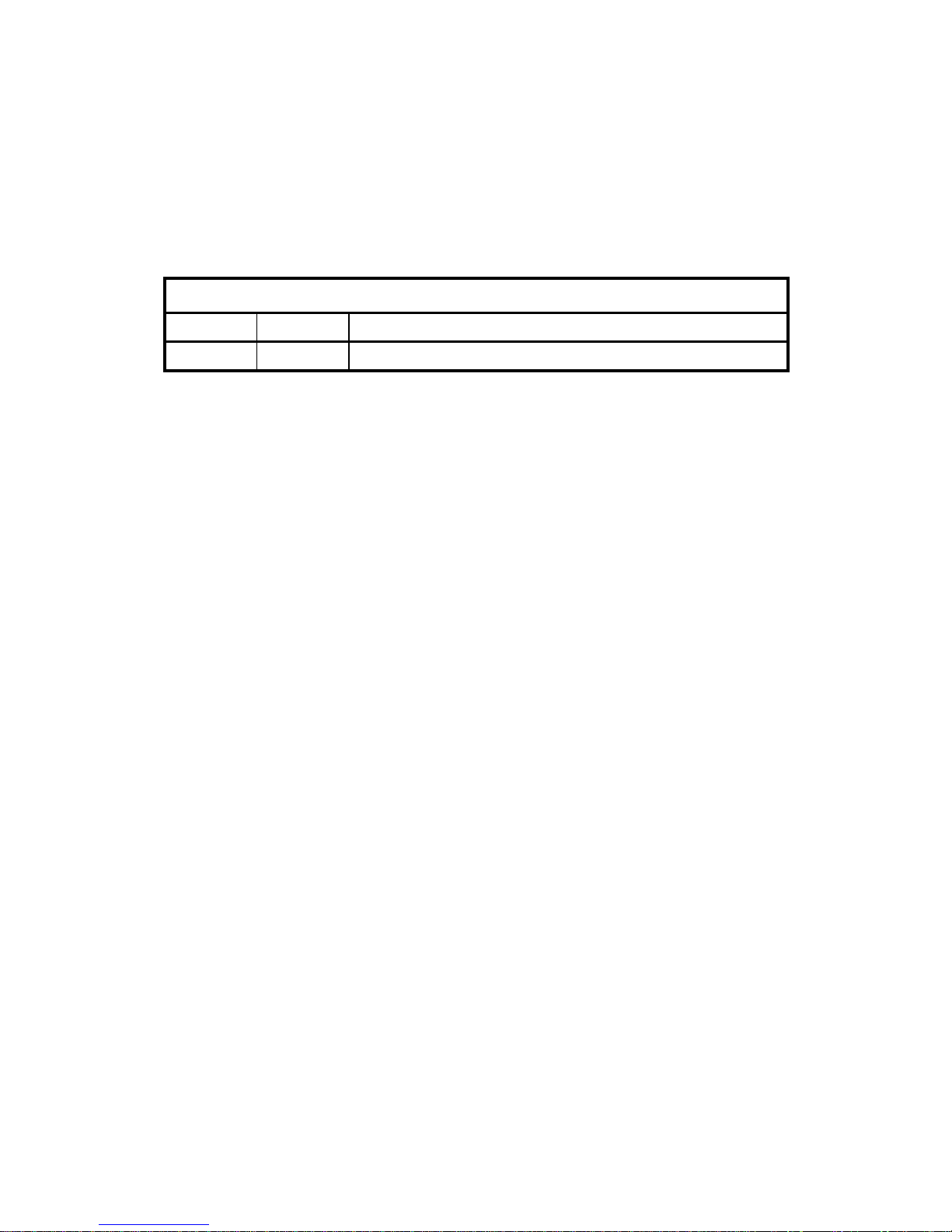

LEGEND

PRODUCT

CODE

COMPANY

GESTETNER LANIER RICOH SAVIN

C275 (USA) --- LDD130 DX 3343 3183DNP

C275 (LAD)

DX 3343/

DX 3443

--- DX 3443 ---

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

*

02/2010 Original Printing

Page 12

Page 13

SM i C275 cC

C275

TABLE OF CONTENTS

PRODUCT INFORMATION

1. PRODUCT INFORMATION ...........................................................1-1

1.1SPECIFICATIONS ..................................................................................... 1-1

1.2GUIDANCE FOR THOSE WHO ARE FAMILIAR WITH PREDECESSOR

PRODUCTS ..................................................................................................... 1-2

1.3OVERVIEW ................................................................................................ 1-4

1.3.1 MECHANICAL COMPONENT LAYOUT ........................................... 1-4

1.3.2 ELECTRICAL COMPONENT LAYOUT ............................................ 1-5

Boards .................................................................................................. 1-6

Motors .................................................................................................. 1-6

Solenoids.............................................................................................. 1-7

Switches ............................................................................................... 1-8

Sensors ................................................................................................ 1-8

Others ................................................................................................ 1-10

1.3.3 DRIVE LAYOUT .............................................................................. 1-11

INSTALLATION

2. INSTALLATION ............................................................................2-1

2.1INSTALLATION REQUIREMENTS ............................................................ 2-1

2.1.1 OPTIMUM ENVIRONMENTAL CONDITION .................................... 2-1

2.1.2 ENVIRONMENTS TO AVOID ........................................................... 2-1

2.1.3 POWER CONNECTION ................................................................... 2-1

2.1.4 MINIMUM SPACE REQUIREMENTS ............................................... 2-1

2.1.5 DIMENSIONS ................................................................................... 2-2

2.1.6 MAIN BODY AND PERIPHERALS ................................................... 2-3

2.1.7 POWER SOCKETS FOR PERIPHERALS ........................................ 2-4

Page 14

C275 ii SM

2.2INSTALLATION PROCEDURE .................................................................. 2-5

2.2.1 MAIN BODY ...................................................................................... 2-5

Accessory Check .................................................................................. 2-5

Installation Procedure ........................................................................... 2-6

Changing the operation panel language ............................................. 2-13

Date/Time Setting ............................................................................... 2-13

SP Codes Setting ............................................................................... 2-13

2.2.2 COLOR DRUM (OPTION) .............................................................. 2-14

Accessory Check ................................................................................ 2-14

Installation Procedure ......................................................................... 2-14

2.2.3 ADF (OPTION) ................................................................................ 2-15

Accessory Check ................................................................................ 2-15

Installation Procedure ......................................................................... 2-16

2.2.4 PLATEN COVER (OPTION) ........................................................... 2-18

Accessory Check ................................................................................ 2-18

Installation Procedure ......................................................................... 2-18

2.2.5 TAPE DISPENSER (OPTION) ........................................................ 2-19

Accessory Check ................................................................................ 2-19

Installation Procedure ......................................................................... 2-20

2.2.6 PRINTER UNIT VC-20 (OPTION) ................................................... 2-23

Accessory Check ................................................................................ 2-23

Installation Procedure ......................................................................... 2-24

2.2.7 PRINTER UNIT TYPE 4545A (OPTION) ........................................ 2-25

Components Check ............................................................................ 2-25

Installation Procedure ......................................................................... 2-26

PREVENTIVE MAINTENANCE

3. PREVENTIVE MAINTENANCE ....................................................3-1

3.1MAINTENANCE TABLES .......................................................................... 3-1

Page 15

SM iii C275

REPLACEMENT AND ADJUSTMENT

4. REPLACEMENT AND ADJUSTMENT .........................................4-1

4.1GENERAL CAUTION ................................................................................. 4-1

4.2SPECIAL TOOLS ....................................................................................... 4-2

4.3IMAGE ADJUSTMENT .............................................................................. 4-3

4.3.1 OVERVIEW ....................................................................................... 4-3

4.3.2 SP6-10: MASTER WRITING SPEED ............................................... 4-3

4.3.3 SP6-21: PAPER REGIST POSITION ............................................... 4-4

4.3.4 SP6-5: SCANNING SPEED – PLATEN AND SP6-6: SCANNING

SPEED – ADF MODE ................................................................................ 4-4

4.3.5 SP6-3: SCANNING START POSITION – PLATEN AND SP6-4:

SCANNING START POSITION - ADF ....................................................... 4-4

4.3.6 SP6-1: MAIN SCAN POSITION – PLATEN AND SP6-2: MAIN SCAN

POSITION - ADF ........................................................................................ 4-5

4.4COVERS .................................................................................................... 4-6

4.4.1 FRONT COVER AND FRONT DOOR .............................................. 4-6

4.4.2 OPERATION PANEL ........................................................................ 4-7

4.4.3 REAR COVER .................................................................................. 4-7

4.4.4 UPPER COVERS ............................................................................. 4-8

4.5BOARDS .................................................................................................... 4-9

4.5.1 MPU .................................................................................................. 4-9

4.5.2 PSU ................................................................................................ 4-10

PSU Board ......................................................................................... 4-10

PSU Board with Bracket ..................................................................... 4-10

4.6SCANNER ............................................................................................... 4-11

4.6.1 EXPOSURE GLASS, DF EXPOSURE GLASS AND SCALES ....... 4-11

Exposure Glass .................................................................................. 4-11

DF Exposure Glass ............................................................................ 4-11

4.6.2 LENS BLOCK ................................................................................. 4-12

4.6.3 EXPOSURE LAMP AND LAMP STABILIZER BOARD ................... 4-13

4.6.4 SCANNER MOTOR ........................................................................ 4-14

4.6.5 SCANNER HOME POSITION SENSOR......................................... 4-15

4.6.6 PLATEN COVER SENSOR ............................................................ 4-16

Page 16

C275 iv SM

4.6.7 ADJUSTING THE SCANNER POSITION ....................................... 4-17

Overview ............................................................................................ 4-17

Adjusting the Belt Contact Points for the First Scanner ...................... 4-18

Adjusting the Belt Contact Points for the Second Scanner ................. 4-19

4.7MASTER FEED ........................................................................................ 4-21

4.7.1 MASTER MAKING UNIT ................................................................. 4-21

4.7.2 MASTER MAKING UNIT SET SWITCHES ..................................... 4-22

4.7.3 THERMAL HEAD ............................................................................ 4-23

Installation .......................................................................................... 4-24

4.7.4 MASTER SET COVER SENSOR ................................................... 4-25

4.7.5 MASTER END SENSOR ................................................................ 4-25

4.7.6 CUTTER UNIT ................................................................................ 4-26

4.7.7 THERMAL HEAD VOLTAGE ADJUSTMENT ................................. 4-27

4.7.8 MASTER END SENSOR ADJUSTMENT ....................................... 4-29

4.8MASTER EJECT ...................................................................................... 4-31

4.8.1 MASTER EJECT UNIT ................................................................... 4-31

4.8.2 MASTER EJECT ROLLERS ........................................................... 4-32

4.8.3 MASTER EJECT MOTOR AND PRESSURE PLATE MOTOR ....... 4-32

4.8.4 DRUM MASTER SENSOR, MASTER EJECT SENSOR AND EJECT

BOX SET SENSOR ................................................................................. 4-33

4.8.5 PRESSURE PLATE HP SENSOR AND PRESSURE PLATE LIMIT

SENSOR .................................................................................................. 4-34

4.8.6 AIR KNIFE FAN MOTOR ................................................................ 4-35

4.8.7 MASTER EJECT POSITION SENSOR........................................... 4-35

4.8.8 MASTER CLAMPER OPENING UNIT ............................................ 4-36

4.9PAPER FEED .......................................................................................... 4-37

4.9.1 PICK-UP ROLLER, PAPER FEED ROLLER AND FRICTION PAD 4-37

4.9.2 PAPER TABLE LOWER LIMIT SENSOR ....................................... 4-38

4.9.3 PAPER HEIGHT SENSOR 1 AND 2 ............................................... 4-39

4.9.4 PAPER END SENSOR ................................................................... 4-40

4.9.5 PAPER TABLE MOTOR ................................................................. 4-41

4.9.6 PAPER FEED CLUTCH .................................................................. 4-41

4.9.7 PAPER SEPARATION PRESSURE ADJUSTMENT ...................... 4-42

Page 17

SM v C275

4.10 PRINTING .......................................................................................... 4-43

4.10.1 PRESS ROLLER ........................................................................ 4-43

4.10.2 REGISTRATION SENSOR ......................................................... 4-44

4.10.3 FEED START TIMING SENSOR ................................................ 4-44

4.10.4 2ND FEED TIMING SENSOR..................................................... 4-45

4.10.5 REGISTRATION MOTOR ........................................................... 4-46

4.10.6 REGISTRATION ROLLER .......................................................... 4-47

4.10.7 PRESS ROLLER RELEASE SOLENOIDS ................................. 4-49

4.10.8 PRESS ROLLER RELEASE LEVER ADJUSTMENT ................. 4-50

4.10.9 PRINTING PRESSURE ADJUSTMENT ..................................... 4-52

4.11 DRUM ................................................................................................ 4-53

4.11.1 PREPARATION .......................................................................... 4-53

4.11.2 CLOTH SCREEN ........................................................................ 4-53

Installation .......................................................................................... 4-54

4.11.3 CLAMPER AND METAL SCREEN ............................................. 4-56

Installation .......................................................................................... 4-57

4.11.4 INK PUMP UNIT ......................................................................... 4-58

4.11.5 INK ROLLER UNIT AND INK ROLLER ONE-WAY CLUTCH ..... 4-59

4.11.6 DOCTOR ROLLER GAP ADJUSTMENT ................................... 4-61

4.11.7 INK DETECTION ADJUSTMENT ............................................... 4-63

Using an Oscilloscope ........................................................................ 4-63

Simple Method ................................................................................... 4-64

4.12 PAPER DELIVERY ............................................................................ 4-65

4.12.1 PAPER DELIVERY UNIT ............................................................ 4-65

4.12.2 DELIVERY BELT, PAPER EXIT SENSOR, VACUUM FAN

MOTOR AND PAPER DELIVERY UNIT BUSHINGS .............................. 4-67

4.12.3 PAPER DELIVERY MOTOR ....................................................... 4-68

4.12.4 EXIT PAWL ADJUSTMENT ........................................................ 4-69

Clearance adjustment ........................................................................ 4-69

Timing adjustment .............................................................................. 4-70

4.13 MAIN DRIVE ...................................................................................... 4-72

4.13.1 REGISTRATION MOTOR ........................................................... 4-72

4.13.2 MAIN MOTOR............................................................................. 4-74

4.13.3 MAIN DRIVE TIMING BELT ADJUSTMENT .............................. 4-75

4.13.4 MAIN MOTOR PULLEY POSITION ............................................ 4-76

4.14 MODIFICATION OF COLOR DRUM INTO BLACK DRUM ................ 4-77

Rev. 12/15/2010

Page 18

C275 vi SM

SYSTEM MAINTENANCE

5. SYSTEM MAINTENANCE ............................................................. 79

5.1SERVICE PROGRAM MODE ..................................................................... 79

TROUBLESHOOTING

6. TROUBLESHOOTING ..................................................................6-1

6.1TROUBLESHOOTING GUIDE ................................................................... 6-1

ENERGY SAVING

7. ENERGY SAVING .........................................................................7-1

7.1ENERGY SAVE ......................................................................................... 7-1

7.1.1 ENERGY SAVER MODES ................................................................ 7-1

Timer Settings ...................................................................................... 7-2

Recommendation ................................................................................. 7-2

7.2PAPER SAVE ............................................................................................ 7-3

7.2.1 EFFECTIVENESS OF THE COMBINE FUNCTION ......................... 7-3

Combine mode: .................................................................................... 7-3

Recommendation ................................................................................. 7-3

275 ....................................................................................................... 7-3

C275 SERVICE MANUAL APPENDICES

SEE C275 SERVICE MANUAL APPENDICES SECTION FOR DETAILED TABLE OF

CONTENTS

Page 19

PRODUCT INFORMATION

APPENDIX: SPECIFICATIONS

INSTALLATION

APPENDIX: PREVENTIVE MAINTENANCE

PREVENTIVE MAINTENANCE

APPENDIX: SERVICE CALL CONDITIONS

REPLACEMENT AND ADJUSTMENT

APPENDIX: ELECTRICAL COMPONENT DEFECTS

SYSTEM MAINTENANCE REFERENCE

APPENDIX: DIP SW, LED, VR, TP AND FUSE TABLES

TROUBLESHOOTING

APPENDIX: SERVICE PROGRAM MODE TABLES

ENERGY SAVING

TAB

POSITION 2

TAB

POSITION 1

TAB

POSITION 3

TAB

POSITION 4

TAB

POSITION 6

TAB

POSITION 5

TAB

POSITION 7

Page 20

Page 21

Read This First

Important Safety Notices

Responsibilities of the Customer Engineer

Customer Engineer

Maintenance shall be done only by trained customer engineers who have completed service

training for the machine and all optional devices designed for use with the machine.

Reference Material for Maintenance

Maintenance shall be done using the special tools and procedures prescribed for

maintenance of the machine described in the reference materials (service manuals,

technical bulletins, operating instructions, and safety guidelines for customer engineers).

In regard to other safety issues not described in this document, all customer engineers

shall strictly obey procedures and recommendations described the "CE Safety Guide".

Use only consumable supplies and replacement parts designed for use of the machine.

Before Installation, Maintenance

Shipping and Moving the Machine

Work carefully when lifting or moving the machine. If the machine is heavy, two or

more customer engineers may be required to prevent injuries (muscle strains, spinal

injuries, etc.) or damage to the machine if it is dropped or tipped over.

Personnel moving or working around the machine should always wear proper

clothing and footwear. Never wear loose fitting clothing or accessories (neckties,

loose sweaters, bracelets, etc.) or casual footwear (slippers, sandals, etc.) when

lifting or moving the machine.

Always unplug the power cord from the power source before you move the product.

Before you move the product, arrange the power cord so it will not fall under the

product.

Page 22

Power

Always disconnect the power plug before doing any maintenance procedure. After

switching off the machine, power is still supplied to the main machine and other

devices. To prevent electrical shock, switch the machine off, wait for a few seconds,

then unplug the machine from the power source.

Before you do any checks or adjustments after turning the machine off, work

carefully to avoid injury. After removing covers or opening the machine to do checks

or adjustments, never touch electrical components or moving parts (gears, timing

belts, etc.).

After turning the machine on with any cover removed, keep your hands away from

electrical components and moving parts. Never touch the cover of the fusing unit,

gears, timing belts, etc.

Installation, Disassembly and Adjustments

After installation, maintenance, or adjustment, always check the operation of the

machine to make sure that it is operating normally. This ensures that all shipping

materials, protective materials, wires and tags, metal brackets, etc., removed for

installation, have been removed and that no tools remain inside the machine. This

also ensures that all release interlock switches have been restored to normal

operation.

Never use your fingers to check moving parts causing spurious noise. Never use

your fingers to lubricate moving parts while the machine is operating.

Special Tools

Use only standard tools approved for machine maintenance.

For special adjustments, use only the special tools and lubricants described in the

service manual. Using tools incorrectly , or using tools that could damage part s, could

damage the machine or cause injuries.

Page 23

During Maintenance

General

Before you begin a maintenance procedure:

1) Switch the machine off

2) Disconnect the power plug from the power source.

Safety Devices

Never remove any safety device unless it requires replacement. Always replace

safety devices immediately.

Never do any procedure that defeats the function of any safety device. Modification

or removal of a safety device (fuse, switch, etc.) could lead to a fire and personal

injury . Always test the operation of the machine to ensure that it is operating normally

and safely after removal and replacement of any safety device.

For replacements use only the correct fuses or circuit breakers rated for use with the

machine. Using replacement devices not designed for use with the machine could

lead to a fire and personal injuries.

Organic Cleaners

During preventive maintenance, never use any organic cleaners (alcohol, etc.) other

than those described in the service manual.

Make sure the room is well ventilated before using any organic cleaner. Use organic

solvents in small amounts to avoid breathing the fumes and becoming nauseous.

Switch the machine off, unplug it, and allow it to cool before doing preventive

maintenance. To avoid fire or explosion, never use an organic cleaner near any part

that generates heat.

Wash your hands thoroughly after cleaning parts with an organic cleaner to

contamination of food, drinks, etc. which could cause illness.

Clean the floor completely after accidental spillage of silicone oil or other materials to

prevent slippery surfaces that could cause accidents leading to hand or leg injuries.

Use dry rags to soak up spills.

Page 24

Power Plug and Power Cord

Before serving the machine (especially when responding to a service call), always

make sure that the power plug has been inserted completely into the power source.

A partially inserted plug could lead to heat generation (due to a power surge caused

by high resistance) and cause a fire or other problems.

Always check the power plug and make sure that it is free of dust and lint. Clean it if

necessary. A dirty plug can generate heat which could cause a fire.

Inspect the length of the power cord for cuts or other damage. Replace the power

cord if necessary. A frayed or otherwise damaged power cord can cause a short

circuit which could lead to a fire or personal injury from electrical shock.

Check the length of the power cord between the machine and power supply. Make

sure the power cord is not coiled or wrapped around any object such as a table leg.

Coiling the power cord can cause excessive heat to build up and could cause a fire.

Make sure that the area around the power source is free of obstacles so the power

cord can be removed quickly in case of an emergency.

Make sure that the power cord is grounded (earthed) at the power source with the

ground wire on the plug.

Connect the power cord directly into the power source. Never use an extension cord.

When you disconnect the power plug from the power source, always pull on the plug,

not the cable.

Page 25

After Installation, Servicing

Points to Confirm with Operators

At the end of installation or a service call, instruct the user about use of the machine.

Emphasize the following points.

Show operators how to remove jammed paper and troubleshoot other minor problems by

following the procedures described in the operating instructions.

Point out the parts inside the machine that they should never touch or attempt to remove.

Confirm that operators know how to store and dispose of consumables.

Make sure that all operators have access to an operating instruction manual for the

machine.

Confirm that operators have read and understand all the safety instructions described in

the operating instructions.

Demonstrate how to turn off the power and disconnect the power plug (by pulling the plug,

not the cord) if any of the following events occur: 1) something has spilled into the

product, 2) service or repair of the product is necessary, 3) the product cover has been

damaged.

Caution operators about removing paper fasteners around the machine. They should

never allow paper clips, staples, or any other small metallic objects to fall into the

machine.

Safety Instructions for this Machine

Prevention of Physical Injury

1. Before disassembling or assembling parts of the machine and peripherals, make sure

that the machine and peripheral power cords are unplugged.

2. The plug should be near the machine and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off or open

while the main switch is turned on, keep hands away from electrified or mechanically

driven components.

4. The inside and the metal parts of the fusing unit become extremely hot while the machine

is operating. Be careful to avoid touching those components with your bare hands.

5. To prevent a fire or explosion, keep the machine away from flammable liquids, gases,

and aerosols.

Page 26

Health Safety Conditions

1. If you get ink in your eyes by accident, try to remove it with eye drops or flush with water

as first aid. If unsuccessful, get medical attention.

2. If you ingest ink by accident, induce vomiting by sticking a finger down your throat or by

giving soapy or strong salty water to drink.

Observance of Electrical Safety Standards

1. The machine and its peripherals must be installed and maintained by a customer service

representative who has completed the training course on those models.

Safety and Ecological Notes for Disposal

1. Dispose of replaced parts in accordance with local regulations.

2. Used ink and masters should be disposed of in an environmentally safe manner and in

accordance with local regulations.

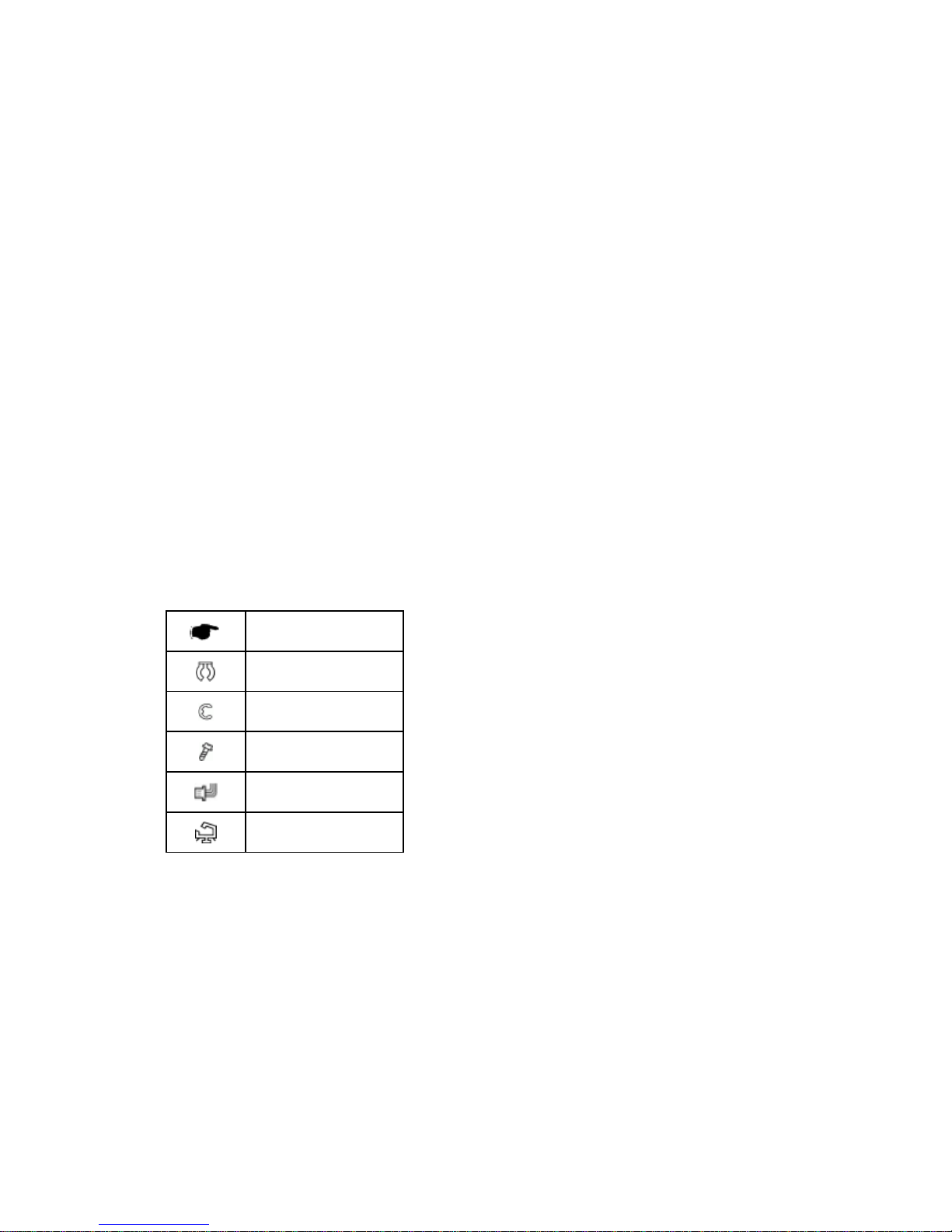

Symbols

This manual uses several symbols. The meanings of those symbols are as follows:

See or Refer to

Clip ring

E-ring

Screw

Connector

Clamp

Page 27

PRODUCT INFORMATION

REVISION HISTORY

Page Date Added/Updated/New

None

Page 28

Page 29

Specifications

SM 1-1 C275

Product

Information

1. PRODUCT INFORMATION

1.1 SPECIFICATIONS

See "Appendices" for the "General Specifications":

Page 30

Guidance for Those Who are Familiar with Predecessor Products

C275 1-2 SM

1.2 GUIDANCE FOR THOSE WHO ARE FAMILIAR WITH

PREDECESSOR PRODUCTS

Machine C275 is a successor model to Machine C267/C271. If you have experience with the

predecessor products, the following information will be of help when you read this manual.

Different Points from Predecessor Products

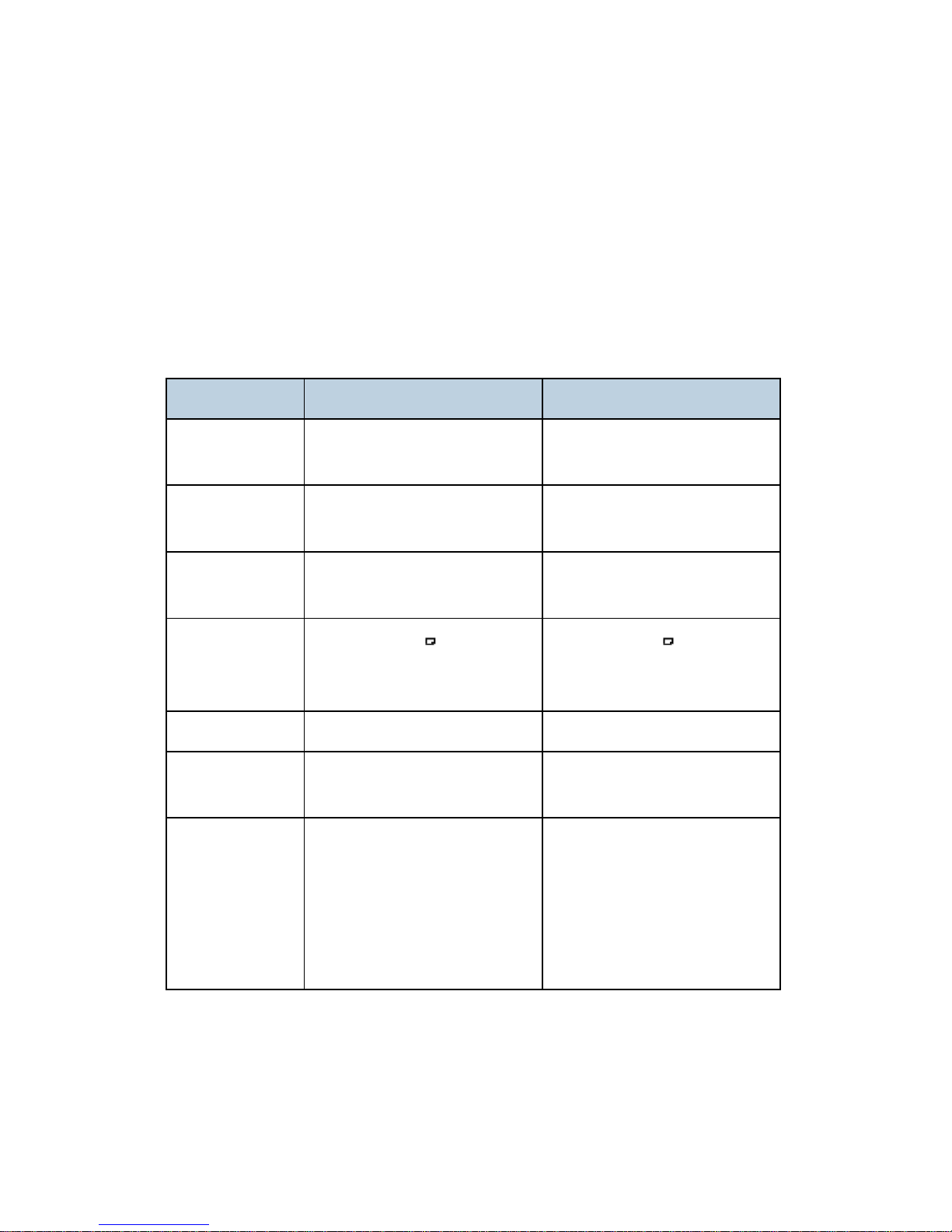

Item C267/C271 C275

Paper Delivery

Motor

No Yes

Drum HP Lock

Mechanism

No Yes

Optional Printer

Unit Type 4545A

No Yes

First Print Time

33 seconds (A4

)

When setting an original on the

exposure glass

34 seconds (A4 )

When setting an original on the

exposure glass

Depth 676 mm 681 mm

Power Source

120 V, 60 Hz, 1.7 A

220 V – 240 V, 50 – 60 Hz, 1.1 A

120 V, 60 Hz, 2.2 A

220 V – 240 V, 50 – 60 Hz, 1.2 A

Power

Consumption

120V, 60Hz:

Less than 150W (Printing)

Less than 150W (Master making)

220V-240V, 50-60Hz:

Less than 160W (Printing)

Less than 160W (Master making)

120V, 60Hz:

Less than 185W (Printing)

Less than 210W (Master making)

220V-240V, 50-60Hz:

Less than 185W (Printing)

Less than 210W (Master making)

Page 31

Guidance for Those Who are Familiar with Predecessor Products

SM 1-3 C275

Product

Information

Item C267/C271 C275

Noise Emission

Sound Power Level

Standby: 36 dB

Copying 80 cpm: 78 dB

Copying 100 cpm: 80 dB

Copying 130 cpm: 84 dB

Operating Position Sound

Power Level

Standby: 20 dB

Copying 80 cpm: 63 dB

Copying 100 cpm: 70 dB

Copying 130 cpm: 72 dB

Sound Power Level

Standby: 34 dB

Copying 80 cpm: 78 dB

Copying 100 cpm: 80 dB

Copying 130 cpm: 84 dB

Operating Position Sound

Power Level

Standby: 20 dB

Copying 80 cpm: 63 dB

Copying 100 cpm: 66 dB

Copying 130 cpm: 70 dB

Page 32

Overview

C275 1-4 SM

1.3 OVERVIEW

1.3.1 MECHANICAL COMPONENT LAYOUT

1. Tension Roller

2. Master Feed Roller

3. Platen Roller

4. Thermal Head

5. Master Roll

6. Paper Feed Roller

7. Paper Pick-up Roller

8. Paper Table

9. Registration Rollers

10. Doctor Roller

11. Press Roller

12. Ink Roller

13. Vacuum Fan Motor

14. Exit Pawl

15. Transport Belts

16. Paper Delivery Table

17. Air Knife Fan Motor

18. Master Eject Box

19. Master Eject Rollers

20. 3rd Mirror

21. 2nd Mirror

22. 1st Mirror

23. DF Exposure Glass

24. 1st Transport Roller

25. Separation Roller

26. Original Feed Belt

27. Pick-up Roller

28. 2nd Transport Roller

29. Original Exit Roller

Page 33

Overview

SM 1-5 C275

Product

Information

1.3.2 ELECTRICAL COMPONENT LAYOUT

Page 34

Overview

C275 1-6 SM

Boards

Index No. Name Function

18 LCD Displays messages for the operator

19 Operation Panel

Boards

These boards control the operation panel.

21 Lamp Stabilizer This supplies power to the xenon lamp.

25 SBU Makes a video signal from the scanned original.

44 Main Processing

Unit (MPU)

Controls all machine functions both directly and

through other boards.

49 Power Supply Unit Provides dc power to the system.

Motors

Index No. Name Function

1 Scanner Motor Stepper motor drives the book scanner.

4 Master Feed

Motor

Feeds the master to the drum.

11 Paper Table Motor Raises and lowers the paper table.

15 Cutter Motor Cuts the master.

29 Master Eject Motor Sends used masters into the master eject box.

30 Air Knife Fan

Motor

Rotates the fan to provide air to separate the leading

edge of the paper from the drum.

32 Vacuum Fan

Motor

Provides suction so that paper is held firmly on the

transport belt.

Page 35

Overview

SM 1-7 C275

Product

Information

Index No. Name Function

33 Paper Delivery

Motor

Drives the paper delivery unit.

35 Pressure Plate

Motor

Raises and lowers the pressure plate.

37 Clamper Motor Opens or closes the drum master clamper.

41 Main Motor Drives paper feed mechanisms and the drum.

42 Registration Motor Feeds the paper to align it with the master on the

drum.

46 Original Feed

Motor

Stepper motor drives the book scanner.

Solenoids

Index No. Name Function

13 Front Pressure

Release Solenoid

Releases the press roller to apply printing pressure.

39 Rear Pressure

Release Solenoid

Releases the press roller to apply printing pressure.

Page 36

Overview

C275 1-8 SM

Switches

Index No. Name Function

9, 14 Master making

unit set switches

The machine does not work until the two set switches

turn on.

12 Paper Table

Lowering Switch

Lowers the paper table.

16 Master eject unit

safety switch

Checks whether the master eject unit is properly

closed.

17 Door Safety

Switches

Checks whether the front door is properly closed.

24 Cutter HP Switch Detects when the cutter is at the home position

28 Main Switch Turns the power on or off.

Sensors

Index No. Name Function

3 Master End

Sensor

Informs the CPU when the master making unit runs out

of master roll.

6 Paper Height

Sensor 1

Detects when the paper table reaches the paper feed

position.

7 Paper Height

Sensor 2

Detects when the paper table reaches the paper feed

position.

8 Paper End Sensor Informs the CPU when the paper table runs out of

paper .

10 Paper Registration

Sensor

Detects paper approaching the registration roller.

Page 37

Overview

SM 1-9 C275

Product

Information

Index No. Name Function

24 Scanner Home

Position Sensor

Detects when the image sensor is at home position.

25 Platen Cover

Sensor

Detects whether the platen cover is open or closed.

26 Master Eject

Sensor

Detects used master misfeeds.

27 Drum Master

Sensor

Detects if there is a master on the drum

31 Paper Exit Sensor Detects paper misfeeds at the exit.

34 Pressure Plate

Limit Sensor

Detects if the pressure plate is in the lowest position.

36 2nd Feed start

Timing Sensor

Determines the paper misfeed check timing at the

paper registration area.

38 Clamper Open

Sensor

Detects if the clamper is in the open position.

40 Clamper Close

Sensor

Detects if the clamper is in the closed position.

43 Paper Table Lower

Limit Sensor

Detects when the paper table is at its lower limit

position.

47 Feed Start Timing

Sensor

Determines the paper feed start timing.

48 Master Eject

Position Sensor

Detects when the drum is at the master eject position

(this is the home position)

50 Pressure Plate

Home Position

Sensor

Detects if the pressure plate is at the home position.

Page 38

Overview

C275 1-10 SM

Index No. Name Function

51 Eject Box Set

Sensor

Checks if the master eject box is set.

Others

Index No. Name Function

5 Thermal Head Burns the image onto the master.

20 Xenon Lamp Applies light to the original for exposure.

45 Paper Feed Clutch

Transmits main motor drive to the paper feed roller at

the appropriate time.

Page 39

Overview

SM 1-11 C275

Product

Information

1.3.3 DRIVE LAYOUT

1. Master Eject Motor

2. Pressure Plate Motor

3. Clamper Motor

4. Paper Delivery Motor

5. Main Motor

6. Registration Motor

7. Paper Feed Clutch

8. Master Feed Motor

9. Scanner Motor

10. Original Feed Motor

Page 40

Page 41

INSTALLATION

REVISION HISTORY

Page Date Added/Updated/New

None

Page 42

Page 43

Installation Requirements

SM 2-1 C275

Installation

2. INSTALLATION

2.1 INSTALLATION REQUIREMENTS

Carefully select the installation location because environmental conditions greatly affect

machine performance.

2.1.1 OPTIMUM ENVIRONMENTAL CONDITION

1. Temperature: 10 to 30°C (50 to 86 F)

2. Humidity: 20 to 90 %RH

3. Install the machine on a strong and level base. The machine must be level within 5mm

(0.2") both front to rear left to right.

2.1.2 ENVIRONMENTS TO AVOID

1. Locations exposed to direct sunlight or strong light (more than 1,500 lux).

2. Dusty areas

3. Areas containing corrosive gases.

4. Locations directly exposed to cool air from an air conditioner or reflected heat from a

space heater. (Sudden temperature changes from low to high or vice versa may cause

condensation within the machine.)

2.1.3 POWER CONNECTION

1. Securely connect the power cord to a power source.

2. Make sure that the wall outlet is near the machine and easily accessible.

3. Make sure the plug is firmly inserted in the outlet.

4. Avoid multi-wiring

5. Do not pinch the power cord.

2.1.4 MINIMUM SPACE REQUIREMENTS

Place the machine near a power source, providing minimum clearance as shown below.

Page 44

Installation Requirements

C275 2-2 SM

2.1.5 DIMENSIONS

Page 45

Installation Requirements

SM 2-3 C275

Installation

2.1.6 MAIN BODY AND PERIPHERALS

This is a list of the peripheral devices that can be installed with the digital duplicator.

No. Model Name Comments

1 C275 Digital duplicator Main Machine

2 C642 ADF Auto document feeder

3 B406 Platen cover

4 C643/C647/C648 Color drum Optional drum – A4/LG/B4

5 C651 Tape Dispenser

6 C646 Printer unit VC-20 Printer controller unit

7 C654 Printer Unit Type 4545A

Page 46

Installation Requirements

C275 2-4 SM

2.1.7 POWER SOCKETS FOR PERIPHERALS

CAUTION

Rating Voltage for Peripherals

Make sure to plug the cables into the correct sockets.

Page 47

Installation Procedure

SM 2-5 C275

Installation

2.2 INSTALLATION PROCEDURE

2.2.1 MAIN BODY

Accessory Check

Make sure that you have all the accessories listed below.

No. Description Quantity

1 Master Spool 2

2 Paper Delivery Table Side Plate Guide 2

3 Paper Feed Side Pad 2

4 Emblem Cover (C275-80, -83, -92, -93) 1

5 Emblem – Ricoh DX 3440 (C275-80) 1

6 Emblem – Gestetner DX 3440 (C275-80) 1

7 Warranty Letter on carton box (C275-76, -78) 1

8 Leaflet (C275-76, -78) 1

9 Operating Instructions (C275-61, -76, -78, -80, -92) 1

10 Easy Operation Guide (C275-61, -76, -78, -80, -92) 1

Page 48

Installation Procedure

C275 2-6 SM

No. Description Quantity

11 German Acoustic Statement – Ricoh (C275-83, -93) 1

12 German Acoustic Statement – Gestetner (C275-83, -93) 1

13 Bundled Items List (C275-76, -78) 1

14 NECR (C275-80, -92) 1

Installation Procedure

To avoid serious injury, do not connect the power plug to the machine until you are

instructed to do so.

1. Unpack the machine and remove all the wrapping.

Page 49

Installation Procedure

SM 2-7 C275

Installation

2. When you install the optional table:

Mount the machine on the table. There are two screws [A] packed with the table.

Lock the caster [B]

Fix the caster lock stays [C] and tighten the screws [D] (NON-USA MODEL)

Attach the stabilizing brackets [E] (these help to prevent the machine from falling

over). (NON-USA MODEL)

Page 50

Installation Procedure

C275 2-8 SM

3. Remove the filament tape as shown above.

Page 51

Installation Procedure

SM 2-9 C275

Installation

4. Remove the string securing the covers and units as shown above.

5. Open the paper table.

6. Pull out the master making unit, and take out the accessory bag [A].

7. Remove the filament tape and string securing the covers and units.

8. Insert both spools into a new master roll.

Page 52

Installation Procedure

C275 2-10 SM

9. Install the master roll, and open the master making unit cover.

10. Insert the leading edge of the master roll under the platen roller. The arrows [B] indicate

the correct position of the master leading edge.

Page 53

Installation Procedure

SM 2-11 C275

Installation

11. Close the master making unit cover [C] using both hands until it clicks into place.

12. Close the master making unit [D].

13. Open the front door.

14. Release the ink holder lock lever [E] and pull out the ink holder [F].

15. Remove the cap of the new ink cartridge, and insert a new ink cartridge into the ink

holder.

16. Set the ink holder [F].

Page 54

Installation Procedure

C275 2-12 SM

17. Load a stack of paper on the paper table.

18. Shift the lock lever [G] in the direction of the arrow. Make sure that the side plates [H]

touch the paper gently.

19. Shift the lock lever [G] to its original position.

Two side fence friction pads [I] are included as accessories. They are not used

normally, but if paper multi-feed frequently occurs or thin paper is used, the side

fence friction pads [I] can be installed to apply stopping pressure to the paper.

20. Raise the paper delivery table slightly, then gently lower it.

21. Lift the side plates and the end plate, and attach the side plate guides [J] for both side

plates.

Page 55

Installation Procedure

SM 2-13 C275

Installation

When printing on A4 SEF, 81/2" SEF, B5 JIS LEF and SEF size paper and thin

paper, you should attach the side plate guides to the side plates of the paper

delivery tray. Users can also attach these guides.

22. Adjust the side and end fences of the paper delivery table to match the paper size.

23. Firmly insert the power plug in the outlet.

24. Turn on the main switch.

25. Make a master and make 30 prints with this master. Do this at least three times, until the

image quality is acceptable.

This is a new drum. Because of this, before the first print is made, ink is supplied

automatically. This takes 2 minutes.

Changing the operation panel language

There are ten languages in the machine. If you need to change the language, use the User

Tools menu to set the language.

On the operation panel, press the User Tools key.

Select "2. System".

Select "5. Language on LCD".

Select the language.

Date/Time Setting

Use the User Tools menu to set the current date and time.

On the operation panel, press the User Tools key.

Select "2. System".

Select "6. Date/Time".

Enter the date and the time.

SP Codes Setting

SP No. Menu Function

SP3-2 Input TEL number Do this SP and input the contact numbers of the

customer engineer. These numbers are shown when

a service call is issued.

Page 56

Installation Procedure

C275 2-14 SM

2.2.2 COLOR DRUM (OPTION)

Accessory Check

Check the quantity and condition of the accessories in the box against this list:

No. Description Quantity

1 Color Indicator Decal 5

Installation Procedure

To avoid serious injury, do not connect the power plug to the machine until you are

instructed to do so.

1. Remove the protective sheets [A] from the drum.

2. Attach a color indicator decal to the drum case. The decal must be the same color as the

ink in use.

3. Remove the drum from the machine.

4. Leave the master wrapped around the removed drum to protect the drum from dust and

from drying.

5. Keep the removed drum in the drum case.

6. Install the color drum in the machine.

The color drum indicator on the operation panel stays lit when a drum is

mounted in the machine.

7. Remove the ink cartridge cap.

Page 57

Installation Procedure

SM 2-15 C275

Installation

8. Insert the ink cartridge in the ink holder.

9. After main body installation, firmly insert the power plug in the outlet.

10. Turn on the main switch.

11. Make a master and make 30 prints with this master. Do this at least three times, until the

image quality is acceptable.

This is a new drum. Because of this, before the first print is made, ink is supplied

automatically. This takes 2 minutes.

2.2.3 ADF (OPTION)

Accessory Check

Check the quantity and condition of the accessories in the box against this list:

No. Description Quantity

1 Stepped Screw 2

2 Screws 2

3 Screwdriver Tool 1

4 DF Exposure Glass 1

5 Decal - Scale - mm 1

6 Decal - Scale - inch 1

7 Scale Guide 1

8 Attention Label 1

Page 58

Installation Procedure

C275 2-16 SM

Installation Procedure

To avoid serious injury, do not connect the power plug to the machine until you are

instructed to do so.

1. Remove the strips of tape.

2. Remove the left scale [A] (

x 2).

3. Place the DF exposure glass [B] on the glass holder.

When installing the DF exposure glass, make sure that the white dot [C] is

positioned at the front side facing down, as shown.

4. Peel off the backing [D] of the double-sided tape attached to the rear side of the scale

Page 59

Installation Procedure

SM 2-17 C275

Installation

guide [E], then install the scale guide (2 screws removed in step 2).

5. Install the two stepped screws [F].

6. Mount the DF by aligning the holes [G] in the DF with the stepped screws, then slide the

DF to the front as shown.

7. Secure the DF unit with two screws [H].

8. Connect the cables [I] to the main body.

9. Attach the scale decal [J] as shown.

10. Connect the power cord, then turn the main switch on.

Page 60

Installation Procedure

C275 2-18 SM

2.2.4 PLATEN COVER (OPTION)

Accessory Check

Check the quantity and condition of the accessories in the box against this list:

No. Description Quantity

1 Stepped Screw 2

Installation Procedure

To avoid serious injury, do not connect the power plug to the machine until you are

instructed to do so.

1. Install the platen cover [A] (

x 2).

Page 61

Installation Procedure

SM 2-19 C275

Installation

2.2.5 TAPE DISPENSER (OPTION)

Accessory Check

Check the quantity and condition of the accessories in the box against this list:

No. Description Quantity

1

Knob Screw (For C210, C217, C218, C219, C222, C223, C225, C228,

C238, C237, C238, C248, C249, C264 and C267, C271)

2

2 Screw M4 x 25 (For C211, C212, C213, C214, C216, C224 and C226) 2

3

Hexagon Nut M4 (For C211, C212, C213, C214, C216, C224 and

C226)

2

4 Auxiliary Bracket (For C226 and C267, C271) 1

5 Auxiliary Bracket (For C238, C247 and C249) 1

6 Auxiliary Bracket (For C264) 1

7 Screw M4 x 8 (For C226, C238, C247, C249 and C267, C271) 4

8 Lock Washer (For C226 only) 1

9 Lock Washer (Without C267, C271) 1

10 Tape 1

Page 62

Installation Procedure

C275 2-20 SM

Installation Procedure

1. Turn off the main switch and unplug the power cord.

2. Remove the paper delivery cover ( x 5).

3. Remove the cutout [A] from the rear cover, as shown.

4. Connect the harness from the tape dispenser to the connector [B].

5. Remove the screw [C] that is beside the connector [B]. Reuse the screw to secure the

bracket [D], as shown.

Page 63

Installation Procedure

SM 2-21 C275

Installation

6. Open the master eject unit.

7. Install the auxiliary bracket [E] on the tape dispenser with M4x8 screws (accessories) [F].

8. Install the tape dispenser on the main body with two M4x8 screws [G] (accessories) in

the two outer holes in the tape dispenser bracket.

9. Close the master eject unit. Reinstall the paper delivery cover.

10. Open the tape dispenser cover [H]. Then, insert the leading edge of the tape into the tape

entrance until it stops as shown in the illustration [I].

Be sure that the tape is installed in the proper direction. If it is not, the tape

dispenser will not work correctly.

Page 64

Installation Procedure

C275 2-22 SM

11. Firmly insert the power plug in the outlet.

12. Turn on the main switch of the main body.

13. Turn on the tape dispenser switch [J].

14. Press the tape cut button [K] to cut off the leading edge of the tape.

15. Check the tape dispenser operation using the Memory/Class modes of the main body.

Page 65

Installation Procedure

SM 2-23 C275

Installation

2.2.6 PRINTER UNIT VC-20 (OPTION)

Accessory Check

Make sure that you have all the accessories listed below.

No. Description Quantity

1 VC-20 Interface Board 1

2 Screws 3

3 Installation CD 1

4 Quick Install Guide 1

5 Safety Information 1

Page 66

Installation Procedure

C275 2-24 SM

Installation Procedure

To avoid serious injury, do not connect the power plug to the machine until you are

instructed to do so.

1. Remove the small rear cover [A] in the rear cover. (

x 2)

2. Cut out the USB port cover [B] in the small rear cover.

3. Connect the VC-20 interface board [C] to CN114 of the MPU board and secure it using

three screws.

4. Reinstall the small rear cover.

Page 67

Installation Procedure

SM 2-25 C275

Installation

2.2.7 PRINTER UNIT TYPE 4545A (OPTION)

Components Check

No. Description Quantity

1 ACU Board (with Case) 1

2 Top Right Bracket 1

3 Bottom Bracket 1

4 Top Left Bracket 1

5 Short Harness 1

6 Long Harness 1

7 Ground Cable 1

8 Cover 1

9 Ferrite Core 1

Page 68

Installation Procedure

C275 2-26 SM

No. Description Quantity

10 Screw: M3x4 5

11 Screw: M3x6 4

12 Clamp 1

13 Attachment Kit for HP4R2.5*1 1

*

1

: This item is not used for this machine.

Installation Procedure

Preparation for Installing

1. Attach the top left bracket [A], top right bracket [B] and bottom bracket [C] to the case

(

(silver) x 1 each)

2. Install the clamp [D].

3. Attach the long harness [E] to the left side of the case (

x 1).

4. Attach the ferrite core [F] to the long harness.

5. Attach the short harness [G] to the front side of the case.

6. Attach the cover [H] to the case (

(silver) x 2).

7. Check whether the "mm/inch" setting in the User Tools (System - mm/inch) is set to the

correct value. If necessary, change it to the correct "mm/inch" setting.

8. Check whether "SP2-7" (Vendor Selection) is set to the correct value. If necessary,

change it to the correct vendor setting.

Page 69

Installation Procedure

SM 2-27 C275

Installation

Installing the Controller in the Main Machine

1. Remove the controller cover [A] (

x 2).

2. Remove the rear cover [B] (

x 9).

3. Connect the 2 harnesses [D] to the main board.

4. Attach the controller [C] to the main machine (

(blue) x 3).

5. Attach the ground cable [E] (

x 2).

6. Reinstall the rear cover.

After installing the printer unit, make sure that the board and cable are securely

connected.

CAUTION:

Be careful not to

p

inch the wire

harness here.

Page 70

Page 71

PREVENTIVE MAINTENANCE

REVISION HISTORY

Page Date Added/Updated/New

None

Page 72

Page 73

Maintenance Tables

SM 3-1 C275

Preventive

Maintenance

3. PREVENTIVE MAINTENANCE

3.1 MAINTENANCE TABLES

See "Appendices" for the "Maintenance Tables".

Page 74

Page 75

REPLACEMENT AND ADJUSTMENT

REVISION HISTORY

Page Date Added/Updated/New

77 ~ 79 12/15/2010 Added Modification of Color Drum into Black Drum

Page 76

Page 77

General Caution

SM 4-1 C275

Replacement

and

Adjustment

4. REPLACEMENT AND ADJUSTMENT

4.1 GENERAL CAUTION

Turn off the main power switch and unplug the machine before attempting any of the

procedures in this section.

Page 78

Special Tools

C275 4-2 SM

4.2 SPECIAL TOOLS

The followings are the special tools used for service.

Description Part number Note

Scanner positioning pins

(4 pins as a set)

A0069104

p.4-17

Flash memory card – 4MB N8036701

"8. System Test" in the

Appendices

Alvamoa 2 (Alvania) Grease A0699502 -

Page 79

Image Adjustment

SM 4-3 C275

Replacement

and

Adjustment

4.3 IMAGE ADJUSTMENT

4.3.1 OVERVIEW

"Image Adjustment" adjust s the image position on prints by changing the SP settings.

Adjust the settings in the order:

SP6-10

6-21 6-5 6-6 6-3 6-4 6-1 6-2

When correcting errors made when printing with the controller, use only the first two

procedures. When correcting errors made when printing with scanned originals, do all six

adjustments in the given order.

This adjustment is required every time the RAM on the MPU has been replaced.

4.3.2 SP6-10: MASTER WRITING SPEED

1. Input SP8-10 (Test patterns) and enter "6", then press the Start key.

2. Exit the SP mode, print 10 copies at 100 rpm (speed 2). Use the 10th print for the

adjustment.

3. The length of the 6 squares in the feed direction should be 130 mm, as shown above.

4. If it is not, calculate the reproduction ratio using the following formula.

{(130 - Value) / 130} x 100 = ± X.X % (Round off to one decimal place)

5. Example: If the value is 133, {(130 - 133) / 130} x 100 = - 2.3 %

6. Access SP6-10, input the calculated ratio, and press the Enter key.

7. Repeat the procedure to make sure that the ratio is correct.

Page 80

Image Adjustment

C275 4-4 SM

4.3.3 SP6-21: PAPER REGIST POSITION

1. Input SP8-10 (Test patterns) and enter "6", then press the Start key.

2. Exit the SP mode, print 10 copies at 100 rpm (speed 2). Use the 10th print for the

adjustment.

3. The space between the leading edge and the next line should be 8 mm, as shown above.

4. If it is not, access SP6-21, input the difference and press the Enter key.

Example: If the value is 7 mm, 7 - 8 = -1.0

5. Repeat the procedure to make sure that the gap is correct.

4.3.4 SP6-5: SCANNING SPEED – PLATEN AND SP6-6:

SCANNING SPEED – ADF MODE

1. Make copies of the test pattern printed during the previous adjustments ( previous

page), in platen mode at speed 2. Use the 10th print for the adjustment.

2. The length of the 6 squares in the feed direction should be 130 mm.

3. If it is not, calculate the reproduction ratio using the following formula.

{(130 - Value) / 130} x 100 = ± X.X % (Round off to one decimal place)

Example: If the value is 133, {(130 - 133) / 130} x 100 = - 2.3 %

4. Access SP6-05, input the calculated ratio, and press the Enter key.

5. Check again to make sure that the ratio is correct.

6. Make copies of the test pattern in ADF mode and repeat the process using SP6-06.

4.3.5 SP6-3: SCANNING START POSITION – PLATEN AND

SP6-4: SCANNING START POSITION - ADF

1. Make copies of the test pattern printed during the previous adjustments ( previous

page), in platen mode at speed 2. Use the 10th print for the adjustment.

2. The space between the leading edge and the next line should be 8 mm.

3. If it is not, access SP6-03, input the gap value and press the Enter key.

Example: If the value is 7 mm, 7 - 8 = -1.0

4. Repeat the procedure to make sure that the gap is correct.

5. Make copies of the test pattern in ADF mode and repeat the process using SP6-04.

Page 81

Image Adjustment

SM 4-5 C275

Replacement

and

Adjustment

4.3.6 SP6-1: MAIN SCAN POSITION – PLATEN AND SP6-2: MAIN

SCAN POSITION - ADF

1. Make a copy in platen mode at speed 2.

2. Measure the difference between the center of the main-scan on the original and on the

print.

3. Access SP6-01, input the gap value and press the Enter key. (If you input a positive

value, the image moves towards the operation side.)

4. Repeat the procedure to make sure that there is no difference.

5. Make a copy in ADF mode and repeat the process using SP6-02.

Page 82

Covers

C275 4-6 SM

4.4 COVERS

4.4.1 FRONT COVER AND FRONT DOOR

[A]: Front cover (

x 9)

[B] Front door (

x 4)

Page 83

Covers

SM 4-7 C275

Replacement

and

Adjustment

4.4.2 OPERATION PANEL

Front cover (

p.4-6 "Front Cover and Front Door")

[A]: Operation panel (

x 5, x 2, x 3)

4.4.3 REAR COVER

[A]: Rear cover ( x 9)

Page 84

Covers

C275 4-8 SM

4.4.4 UPPER COVERS

[A]: Left upper cover ( x 2)

[B]: Top rear cover (

x 1)

[C]: Right upper cover (

x 1)

Page 85

Boards

SM 4-9 C275

Replacement

and

Adjustment

4.5 BOARDS

4.5.1 MPU

Rear cover (

p.4-7)

[A]: MPU (

x 10, x 18, 2 ribbon cables)

Take the NVRAM [B] from the old board and put it in the socket on the new board.

Adjust the master end sensor (

p.4-25) after installing the new MPU.

Adjust the ink detection (

p.4-61) after installing the new MPU.

If you must replace the MPU RAM, you must then do the image adjustments after

you install the new RAM (

p.4-3).

Page 86

Boards

C275 4-10 SM

4.5.2 PSU

When the PSU is replaced, the thermal head voltage returns to the default. Adjust

the thermal head voltage (

p.4-27) after installing the new board.

PSU Board

Rear cover ( p.4-7)

PSU (

x 6, x 7)

The split washer screw [B] is used for grounding. Do not use another type of screw

here.

PSU Board with Bracket

Rear cover ( p.4-7)

[A]: PSU (

x 5, x 7)

Page 87

Scanner

SM 4-11 C275

Replacement

and

Adjustment

4.6 SCANNER

4.6.1 EXPOSURE GLASS, DF EXPOSURE GLASS AND SCALES

Exposure Glass

[A]: Left scale ( x 2)

[B]: Rear scale (

x 3)

[C]: Exposure glass

When reinstalling, make sure that the mark [E] is at the rear left corner, and that the

left edge is aligned with the support on the frame.

DF Exposure Glass

[A]: Left scale ( x 2)

[D]: DF exposure glass

When reinstalling, make sure that the mark [F] is on the bottom.

Page 88

Scanner

C275 4-12 SM

4.6.2 LENS BLOCK

Do not touch the paint-locked screws on the lens block. The position of the lens

assembly (black part) is adjusted before shipment.

Do not grasp the PCB or the lens assembly when handling the lens block. The lens

assembly may slide out of position.

Exposure glass (

p.4-11)

[A]: Lens cover (

x 5)

[B]: Ribbon cable

[C]: Lens block (

x 4).

Page 89

Scanner

SM 4-13 C275

Replacement

and

Adjustment

4.6.3 EXPOSURE LAMP AND LAMP STABILIZER BOARD

Exposure glass (

p.4-11)

1. Slide the first scanner to a position where the front end of the lamp is visible.

2. Place one hand under the lamp stabilizer board [A] and release the hook [B].

3. Remove the lamp stabilizer board [A] (

x 2).

4. Press the plastic latch [C] and push the front end of the lamp toward the rear.

5. Remove the lamp [D] (with the cable).

Page 90

Scanner

C275 4-14 SM

4.6.4 SCANNER MOTOR

Rear cover (

p.4-7)

Exposure glass (

p.4-11)

[A]: Scanner motor (

x 3, x 1, x 1, 1 spring, 1 belt)

When reassembling, install the belt first, and set the spring next. Fasten the leftmost

screw (viewed from the rear), then fasten the other two screws.

Page 91

Scanner

SM 4-15 C275

Replacement

and

Adjustment

4.6.5 SCANNER HOME POSITION SENSOR

Left upper cover ( p.4-8 "Upper Covers")

Top rear cover (

p.4-8 "Upper Covers")

Front cover (

p.4-6 "Front Cover and Front Door")

Operation panel (

p.4-7)

Exposure glass, DF exposure glass (if installed) (

p.4-11)

[A]: Scanner left lid (

x 7, x 1).

[B]: Sensor tape

[C]: Scanner home position sensor

Page 92

Scanner

C275 4-16 SM

4.6.6 PLATEN COVER SENSOR

Top rear cover ( p.4-8 "Upper Covers")

[A]: Platen cover sensor (

x 1).

Page 93

Scanner

SM 4-17 C275

Replacement

and

Adjustment

4.6.7 ADJUSTING THE SCANNER POSITION

Grasp the front and rear ends (not the middle) of the first scanner when you

manually move it. The first scanner may be damaged if you press, push, or pull the

middle part of the scanner.

Overview

Adjust the scanner positions at these times:

When the first scanner [C] and second scanner [B] are not parallel with the side frames

[A]

When you have replaced one or more of the scanner belts.

To adjust the scanner positions, do either of the following:

To adjust the belt contact points on the first scanner (

Adjusting the Belt Contact

Points for the First Scanner)

To adjust the belt contact points on the scanner bracket (

Adjusting the Belt Contact

Points for the Second Scanner)

Page 94

Scanner

C275 4-18 SM

The two actions above have the same objectives: to align the following holes.

1st scanner [D], frame [E], arm of second scanner [F], and frame [G]

The scanner positions are correct when these holes are all aligned.

Adjusting the Belt Contact Points for the First Scanner

ADF or platen cover

Front cover (

p.4-6 "Front Cover and Front Door")

Operation panel (

p.4-7)

Rear cover (

p.4-7)

Top rear cover (

p.4-8 "Upper Covers")

Left upper cover (

p.4-8 "Upper Covers")

Exposure glass (

p.4-11)

1. Loosen the 2 screws [A] [F].

2. Slide the 1st and 2nd scanners to align the following holes and marks (

p.1-4

"Overview"):

Align all four holes: 1st scanner, frame, arm of second scanner and frame

3. Insert the positioning tools [D] [E] through the holes.

4. Check that the scanner belts [B] [C] [G] [H] are properly set between the bracket and the

1st scanner.

5. Tighten the screws [A] [F].

Page 95

Scanner

SM 4-19 C275

Replacement

and

Adjustment

6. Remove the positioning tools.

7. Reassemble the machine and check the operation.

Adjusting the Belt Contact Points for the Second Scanner

ADF or platen cover

Front cover ( p.4-6 "Front Cover and Front Door")

Operation panel (

p.4-7)

Rear cover (

p.4-7)

Top rear cover (

p.4-8 "Upper Covers")

Left upper cover (

p.4-8 "Upper Covers")

Exposure glass (

p.4-11)

1. Disconnect the platen cover sensor connector [A].

2. Scale bracket [B] (

x 2)

1). Take off the scale bracket, otherwise the screws [D] cannot be loosened.

2). Take off the bracket [C] in order to take off the scale bracket.

Page 96

Scanner

C275 4-20 SM

3. Loosen the 2 screws [D].

4. Slide the 2nd scanner to align the following holes and marks (

p.1-4 "Overview"):

Align all four holes: 1st scanner, frame, arm of second scanner and frame

5. Insert the positioning tools [E] [F] through the holes.

6. Check that the scanner belts are properly set in the brackets.

7. Remove the positioning tools.

8. Reassemble the machine and check the operation.

Page 97

Master Feed

SM 4-21 C275

Replacement

and

Adjustment

4.7 MASTER FEED

4.7.1 MASTER MAKING UNIT

[A]: Master making unit cover ( x 3)

[B]: Master making unit (

x 2, x 4, x 1, x 1)

Page 98

Master Feed

C275 4-22 SM

4.7.2 MASTER MAKING UNIT SET SWITCHES

Master making unit (

p.4-21)

[A]: Master making unit set switch (

x 1, x 1)

Front cover (

p.4-6 "Front Cover and Front Door")

[B]: Master making unit set switch (

x 1, x 1)

There are two master making unit set switches for safety. Both sensors must be on

or the machine will not start.

Page 99

Master Feed

SM 4-23 C275

Replacement

and

Adjustment

4.7.3 THERMAL HEAD

Master making unit (

p.4-21)

[A]: Open the platen roller unit.

[B]: Thermal head upper cover (

x 2)

[C]: Thermal head side cover (

x 1)

Close the platen roller unit.

[D]: Thermal head (

x 2)

Page 100

Master Feed

C275 4-24 SM

Installation

If the following remarks are not followed, the thermal head will be installed incorrectly.

1. Fit the base's springs [A] over the protrusions [B] on the underside of the thermal head (5

points).

2. While fitting the tops of the springs [A] over the protrusions on the underside of the

thermal head, hook the lock pawls [C] of the thermal head onto the base (3 lock pawls).

Make sure to set the front side [D] (the paper table side) first.

3. Make sure that all protrusions are properly fitted into the springs.

Adjust the thermal head voltage (

p.4-27) after installing the new thermal head.

Do not touch the surface with bare hands. (If you touch it, clean the surface with

alcohol.)

Do not touch the terminals of the connectors with bare hands.

Loading...

Loading...