Page 1

C249/C264

SERVICE MANUAL

001780MIU

Page 2

Page 3

C249/C264

SERVICE MANUAL

Page 4

Page 5

C249/C264

SERVICE MANUAL

001780MIU

Page 6

Page 7

It is the reader's responsibility when discussing the information contained

within this document to maintain a level of confidentiality that is in the best

interest of Ricoh Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH CORPORATION.

All product names, domain names or product illustrations, including

desktop images, used in this document are trademarks, registered

trademarks or the property of their respective companies.

They are used throughout this book in an informational or editorial fashion

only and for the benefit of such companies. No such use, or the use of

any trade name, or web site is intended to convey endorsement or other

affiliation with Ricoh products.

© 2006 RICOH Corporation. All rights reserved.

Page 8

Page 9

The Service Manual contains information

regarding service techniques, procedures,

p

rocesses and spare parts of office equipmen

t

distributed by Ricoh Corporation. Users of this

manual should be either service trained o

r

certified by successfully completing a Ricoh

Technical Training Program.

Untrained and uncertified users utilizin

g

information contained in this service manual to

repair or modify Ricoh equipment risk persona

l

injury, damage to property or loss of warrant

y

p

rotection.

Ricoh Corporation

WARNING

Page 10

Page 11

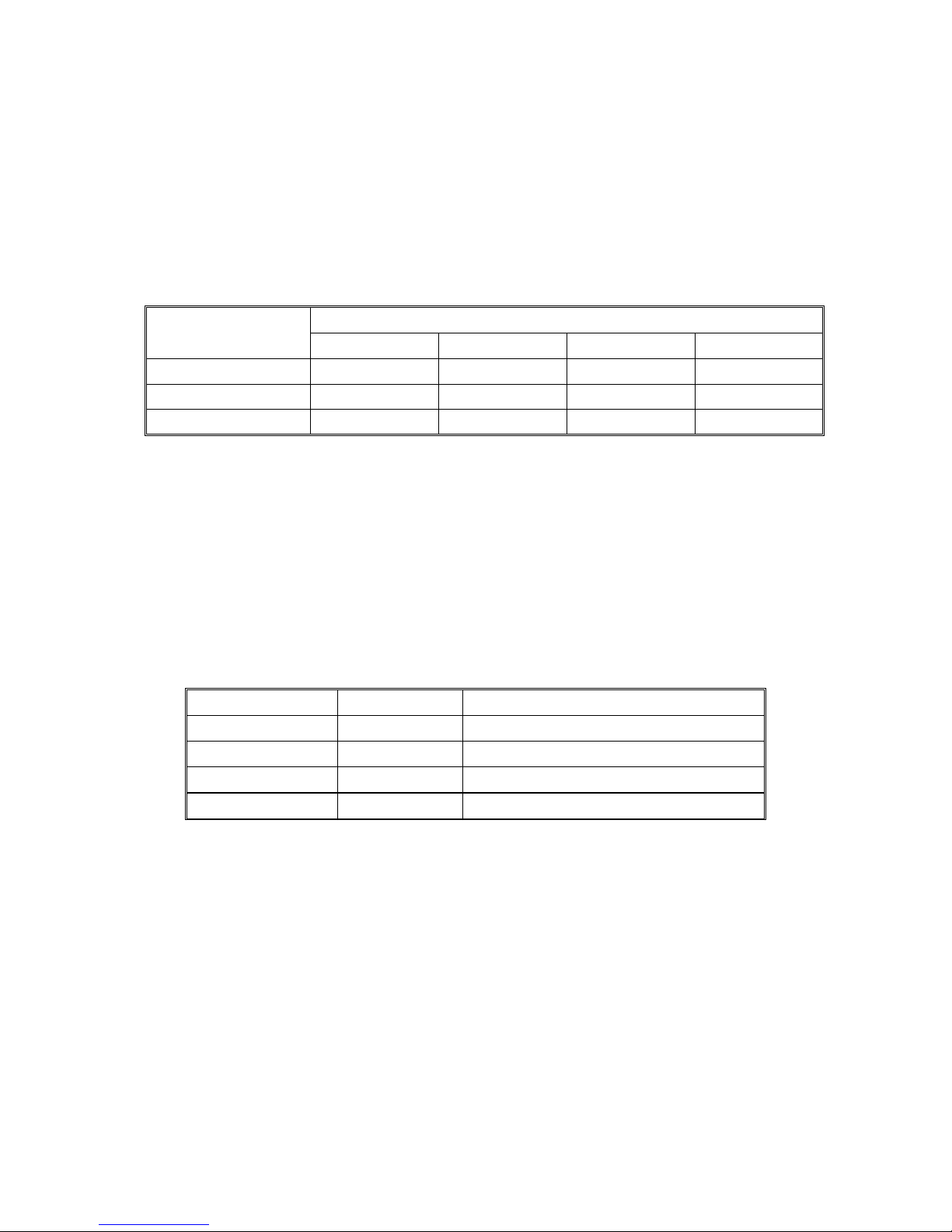

LEGEND

PRODUCT CODE COMPANY

GESTETNER LANIER RICOH SAVIN

C249 CP244 LDD145 JP4500 3560DNP

C264 CP6244 LDD245 DX4542 3270DNP

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

*

10/2003 Original Printing

1 09/2006 C264 Addition

Page 12

Page 13

SM i C249/C264

C249/C264

TABLE OF CONTENTS

INSTALLATION

1. INSTALLATION............................................................................ 1-1

1.1 INSTALLATION REQUIREMENTS ...........................................................1-1

1.1.1 OPTIMUM ENVIRONMENTAL CONDITION....................................1-1

1.1.2 ENVIRONMENTS TO AVOID...........................................................1-1

1.1.3 POWER CONNECTION ...................................................................1-1

1.1.4 MACHINE ACCESS .........................................................................1-2

1.2 INSTALLATION PROCEDURE .................................................................1-3

1.2.1 MAIN UNIT .......................................................................................1-3

1.2.2 BEFORE BEGINNING MACHINE OPERATION ..............................1-9

1.2.3 PLATEN COVER INSTALLATION (OPTION) ...................................... 1-10

1.2.4 ADF INSTALLATION (OPTION).....................................................1-11

1.2.5 TAPE MARKER (OPTION)..............................................................1-15

1.2.6 OPTIONAL DRUMS .......................................................................1-22

PREVENTIVE MAINTENANCE

2. PREVENTIVE MAINTENANCE.................................................... 2-1

2.1 MAINTENANCE TABLE ............................................................................2-1

REPLACEMENT AND ADJUSTMENT

3. REPLACEMENT AND ADJUSTMENT ........................................ 3-1

3.1 GENERAL CAUTION ................................................................................3-1

3.2 PRINT KEY / START KEY......................................................................... 3-1

3.3 COVERS / BOARDS .................................................................................3-2

3.3.1 FRONT COVER / PANEL.................................................................3-2

3.3.2 REAR COVERS................................................................................3-3

3.3.3 MPU..................................................................................................3-3

3.3.4 PSU ..................................................................................................3-4

3.4 SCANNER .................................................................................................3-5

3.4.1 EXPOSURE GLASS / SCALES........................................................3-5

3.4.2 SBU AND LAMP STABILIZER / SCANNER MOTOR....................... 3-5

3.4.3 SCANNER H.P. SENSOR / PLATEN COVER SENSOR .................3-6

3.4.4 EXPOSURE LAMP (XENON LAMP) ................................................3-7

3.4.5 SCANNER WIRES ...........................................................................3-8

3.4.6 IMAGE ADJUSTMENT ...................................................................3-10

3.5 MASTER EJECT ..................................................................................... 3-11

3.5.1 MASTER EJECT UNIT ................................................................... 3-11

3.6 MASTER FEED ....................................................................................... 3-12

3.6.1 MASTER MAKING UNIT ................................................................ 3-12

Rev. 04/2004

Page 14

C249/C264 ii SM

3.6.2 THERMAL HEAD............................................................................3-12

3.6.3 DUCT PLATE HP SENSOR / DUCT PLATE MOTOR.................... 3-16

3.6.4 CUTTER UNIT................................................................................ 3-17

3.6.5 THERMAL HEAD DRIVING UNIT ..................................................3-17

3.6.6 THERMAL HEAD VOLTAGE ADJUSTMENT................................. 3-18

3.6.7 DUCT JAM SENSOR ADJUSTMENT ............................................3-19

3.6.8 MASTER EDGE SENSOR ADJUSTMENT ....................................3-20

3.6.9 2ND DRUM MASTER SENSOR ADJUSTMENT............................ 3-21

3.6.10 MASTER END SENSOR ADJUSTMENT ..................................... 3-22

3.7 PAPER FEED..........................................................................................3-23

3.7.1 PICK-UP ROLLER / PAPER FEED ROLLER / FRICTION PAD..... 3-23

3.7.2 PAPER SEPARATION PRESSURE ADJUSTMENT......................3-24

3.7.3 PAPER WIDTH DETECTION BOARD ...........................................3-25

3.8 PRINTING ...............................................................................................3-26

3.8.1 PRESS ROLLER ............................................................................3-26

3.8.2 PRESS ROLLER RELEASE LEVER ADJUSTMENT ..................... 3-27

3.8.3 PRINTING PRESSURE ADJUSTMENT.........................................3-28

3.9 DRUM...................................................................................................... 3-29

3.9.1 PREPARATION..............................................................................3-29

3.9.2 CLOTH SCREEN............................................................................3-29

3.9.3 CLAMPER / METAL SCREEN .......................................................3-31

3.9.4 INK PUMP ADJUSTMENT .............................................................3-33

3.9.5 INK ROLLER UNIT / INK ROLLER ONE-WAY CLUTCH ............... 3-35

3.9.6 DOCTOR ROLLER GAP ADJUSTMENT ....................................... 3-36

3.9.7 INK DETECTION ADJUSTMENT...................................................3-37

3.9.8 MAIN MOTOR PULLEY POSITION................................................3-37

3.9.9 MAIN DRIVE TIMING BELT ADJUSTMENT ..................................3-37

3.9.10 INK IDLING MOTOR /INK IDLING ROLLER HP SENSOR .......... 3-38

3.9.11 EXIT PAWL ADJUSTMENT .........................................................3-39

3.10 PAPER DELIVERY................................................................................3-41

3.10.1 PAPER DELIVERY UNIT .............................................................3-41

3.10.2 DELIVERY BELT / PAPER EXIT SENSOR..................................3-41

3.10.3 EXIT PAWL ADJUSTMENT .........................................................3-42

3.10.4 AIR PUMP ADJUSTMENT ...........................................................3-44

3.11 SPECIAL TOOLS .................................................................................. 3-45

TROUBLESHOOTING

4. TROUBLESHOOTING ................................................................. 4-1

4.1 ERROR CODES........................................................................................4-1

4.2 ELECTRICAL COMPONENT DEFECTS ..................................................4-3

4.2.1 SENSORS ........................................................................................4-3

4.2.2 SWITCHES.......................................................................................4-5

4.2.3 LINES ...............................................................................................4-5

4.3 FUSE, LED, VR, DIP-SW, AND TP TABLES ............................................4-6

4.3.1 BLOWN FUSE CONDITIONS ..........................................................4-6

4.3.2 LED’S ...............................................................................................4-6

4.3.3 VR’S .................................................................................................4-6

4.3.4 DIP SWITCHES................................................................................ 4-7

Page 15

SM iii C249/C264

4.3.5 TEST POINTS ..................................................................................4-7

4.4 OTHERS ...................................................................................................4-8

4.4.1 PAPER FEED PROBLEMS ..............................................................4-8

4.4.2 PAPER EJECTION ERRORS ........................................................4-10

4.4.3 MASTER FEED ERRORS..............................................................4-10

4.4.4 MASTER DELIVERY ERRORS...................................................... 4-11

4.4.5 DRUM ERRORS.............................................................................4-11

4.4.6 POOR IMAGE ................................................................................4-12

4.4.7 OTHERS.........................................................................................4-13

4.4.8 USER INSTRUCTIONS..................................................................4-14

SERVICE TABLES

5. SERVICE TABLES....................................................................... 5-1

5.1 USING SERVICE PROGRAM MODES.....................................................5-1

5.1.1 ACCESSING SP MODES.................................................................5-1

5.1.2 HOW TO SELECT A PROGRAM NUMBER.....................................5-2

5.2 MAIN MENU NO.1: COPY DATA ..............................................................5-3

5.2.1 SP TABLE ........................................................................................5-3

5.2.2 SP1-70: MAIN FIRMWARE PARTS NUMBER.................................5-3

5.2.3 SP1-80: ERROR CODE HISTORY...................................................5-3

5.3 MAIN MENU NO.2: BASIC SETTINGS .....................................................5-4

5.3.1 SP TABLE ........................................................................................5-4

5.3.2 SP2-7: CHINESE DISPLAY SETTING (CHINA MODEL ONLY) ......5-5

5.3.3 SP2-32: INK SUPPLY AFTER TRIAL...............................................5-5

5.3.4 SP2-33: RE - FEEDING SETTING ...................................................5-5

5.3.5 SP2-34: SLOW STARTING MODE ..................................................5-5

5.3.6 SP2-35: PRINTING PRESSURE ADJUSTMENT.............................5-5

5.3.7 SP2-36: INK IDLING ROLLER SETTING .........................................5-6

5.3.8 SP2-38: IDLING AFTER PRINT (SP2-28, 29) ..................................5-6

5.3.9 SP2-41, 2-42: THERMAL HEAD ENERGY CONTROL....................5-6

5.3.10 SP2-60: BOLD MODE: LETTER MODE ONLY ..............................5-6

5.3.11 SP2-100: MAKE A MASTER WITHOUT PRINTING.......................5-6

5.4 MAIN MENU NO.3: SYSTEM SETTINGS .................................................5-7

5.4.1 SP TABLE ........................................................................................5-7

5.4.2 SP3-1: INPUT THE PRESENT TIME ...............................................5-7

5.4.3 SP3-4: INPUT INSTALLATION DATE..............................................5-8

5.5 MAIN MENU NO.4: INPUT MODE ............................................................ 5-9

5.5.1 SP TABLE ........................................................................................5-9

5.6 MAIN MENU NO.5: OUTPUT MODE ......................................................5-10

5.6.1 SP TABLE ......................................................................................5-10

5.7 MAIN MENU NO.6: ADJUSTMENT.........................................................5-11

5.7.1 SP TABLE ......................................................................................5-11

5.7.2 SP6-40: INK DETECTION ADJUSTMENT .....................................5-14

5.7.3 IMAGE ADJUSTMENT (SP6-10, -21, -5, -3, AND -1).....................5-14

5.7.4 SP6-31: SBU CALIBRATION .........................................................5-17

5.7.5 SP6-32 TO 37: MTF FILTER ..........................................................5-17

5.7.6 SP6-20: REGISTRATION BUCKLE (NOT USED).......................... 5-18

5.7.7 SP6-60: MASTER RETURNING VALUE........................................5-18

Rev. 10/2004

Page 16

C249/C264 iv SM

5.7.8 SP6-64: MASTER PUSHING VALUE (NOT USED).......................5-18

5.7.9 SP6-100 TO 107: PAPER REGISTRATION - EACH SPEED.........5-19

5.7.10 SP6-116 TO 123: PAPER MIDDLE BUCKLE (NOT USED) .........5-20

5.7.11 SP6-124 TO 131: PAPER FRONT BUCKLE (NOT USED) .......... 5-22

5.8 MAIN MENU NO.7: MEMORY CLEAR....................................................5-25

5.8.1 SP TABLE ......................................................................................5-25

5.8.2 SP7-1: FACTORY SETTINGS CLEAR...........................................5-25

5.9 MAIN MENU NO.8: SYSTEM TEST........................................................5-26

5.9.1 SP TABLE ......................................................................................5-26

5.9.2 SP8-1: DOWNLOAD MAIN FIRMWARE ........................................5-26

5.9.3 SP8-2: UPLOAD MAIN FIRMWARE...............................................5-27

5.9.4 SP8-10: TEST PATTERNS ............................................................5-27

5.9.5 SP8-21: PAPER FEED TEST (15 RPM).........................................5-27

5.9.6 SP8-22: FREE RUN PAPER FEED (15 RPM) ...............................5-27

5.9.7 SP8-18: TEMPORARY SECURITY................................................5-28

DETAILED DESCRIPTIONS

6. DETAILED SECTION DESCRIPTIONS ....................................... 6-1

6.1 MECHANISM OVERVIEW ........................................................................6-1

6.1.1 COMPONENT LAYOUT ...................................................................6-1

6.1.2 ELECTRICAL COMPONENT LAYOUT ............................................6-2

6.1.3 DRIVE LAYOUT ...............................................................................6-7

6.2 MASTER EJECT UNIT..............................................................................6-8

6.2.1 OVERVIEW ......................................................................................6-8

6.2.2 MASTER CLAMPER OPENING MECHANISM ................................6-9

6.2.3 MASTER EJECT ROLLER MECHANISM ...................................... 6-10

6.2.4 PRESSURE PALTE MECHANISM.................................................6-11

6.3 SCANNER UNIT......................................................................................6-12

6.3.1 OVERVIEW ....................................................................................6-12

6.3.2 BOARD LAYOUT............................................................................6-13

6.3.3 AUTO BACKGROUND CORRECTION ..........................................6-14

6.3.4 MTF FILTER...................................................................................6-14

6.3.5 SMOOTHING FILTER .................................................................... 6-14

6.3.6 MAIN SCAN ENLARGEMENT/REDUCTION .................................6-14

6.3.7 BINARY PROCESSING .................................................................6-15

6.3.8 FINE MODE....................................................................................6-15

6.3.9 THERMAL HEAD............................................................................6-16

6.4 MASTER FEED ....................................................................................... 6-18

6.4.1 OVERVIEW ....................................................................................6-18

6.4.2 AUTO ADJUSTABLE MASTER SET..............................................6-19

6.4.3 THERMAL HEAD DRIVING MECHANISM.....................................6-20

6.4.4 MASTER BUFFER MECHANISM...................................................6-21

6.4.5 DETECTION OF MASTER IN THE LOWER MASTER TRAY........6-22

6.4.6 DUCT PLATE MECHANISM ..........................................................6-23

6.4.7 MASTER FEED MECHANISM .......................................................6-25

6.4.8 CLAMPER AND TENSION ROLLER MECHANISM.......................6-26

6.4.9 MASTER PUSH MYLAR ................................................................6-27

6.4.10 2ND DRUM MASTER SENSOR................................................... 6-28

Rev. 10/2004

Page 17

SM v C249/C264

6.4.11 CUTTER MECHANISM ................................................................6-29

6.4.11 MASTER SET COVER SENSOR.................................................6-29

6.4.13 RE-CUTTING MECHANISM......................................................... 6-30

6.5 DRUM...................................................................................................... 6-31

6.5.1 OVERVIEW ....................................................................................6-31

6.5.2 DRUM DRIVE MECHANISM ..........................................................6-32

6.5.3 INK SUPPLY MECHANISM............................................................6-33

6.5.4 INK ROLLER MECHANISM ...........................................................6-34

6.5.5 INK SUPPLY CONTROL ................................................................6-35

6.5.6 DRUM IDLING MECHANISM .........................................................6-36

6.6 PAPER FEED..........................................................................................6-38

6.6.1 OVERVIEW ....................................................................................6-38

6.6.2 PAPER FEED MECHANISM ..........................................................6-39

6.6.3 PAPER FEED/SEPARATION PRESSURE MECHANISM .............6-40

6.6.4 REGISTRATION ROLLER MECHANISM.......................................6-41

6.6.5 PRINTING PRESSURE MECHANISM ........................................... 6-42

6.6.6 AUTO ADJUTABLE PRINTING PRESSURE MECHANISM .........6-43

6.6.7 PAPER TABLE MECHANISM .........................................................6-44

6.7 PAPER DELIVERY..................................................................................6-46

6.7.1 OVERVIEW ....................................................................................6-46

6.7.2 PAPER DELIVERY UNIT DRIVE MECHANISM............................. 6-46

6.7.3 PAPER SEPARATION FROM THE DRUM ....................................6-47

6.7.4 EXIT PAWL DRIVE MECHANISM..................................................6-48

6.8 TIMING CHART.......................................................................................6-49

6.8.1 MASTR EJECT/MASTER FEED ....................................................6-49

6.8.2 MASTER WRAPPING .................................................................... 6-51

6.8.3 PRINTING ......................................................................................6-53

6.9 JAM DETECTION....................................................................................6-55

6.9.1 MASTER EJECT JAM (B JAM LOCATION INDICATOR) ..............6-55

6.9.2 DF JAM (P JAM LOCATION INDICATOR).....................................6-56

6.9.3 MASTER FEED JAM (D JAM LOCATION INDICATOR)................6-57

6.9.4 DRUM JAM (B JAM LOCATION INDICATOR)...............................6-60

6.9.5 PAPER FEED JAM (A JAM LOCATION INDICATOR)................... 6-60

6.9.6 PAPER DELIVERY JAM (C JAM LOCATION INDICATOR)...........6-61

SPECIFICATIONS

SPECIFICATIONS............................................................................. 7-1

1. GENERAL SPECIFICATIONS.....................................................................7-1

C264

SEE SECTION C264 FOR DETAILED TABLE OF CONTENTS

DOCUMENT FEEDER C600

SEE SECTION C600 FOR DETAILED TABLE OF CONTENTS

Rev. 07/2004

Page 18

C249/C264 vi SM

PRINTER SCANNER C624

SEE SECTION C624 FOR DETAILED TABLE OF CONTENTS

Page 19

INSTALLATION C249

DOCUMENT FEEDER C600

PREVENTIVE MAINTENANCE C249

PRINTER/CONTROLLER C624

REPLACEMENT AND ADJUSTMENT C249

TROUBLESHOOTING C249

SERVICE TABLES C249

DETAILED DESCRIPTIONS C249

SPECIFICATIONS C249

C264

TAB

POSITION 2

TAB

POSITION 1

TAB

POSITION 3

TAB

POSITION 4

TAB

POSITION 6

TAB

POSITION 5

TAB

POSITION 8

TAB

POSITION 7

Page 20

Page 21

INSTALLATION

Page 22

Page 23

INSTALLATION REQUIREMENTS

SM 1-1 C249

Installation

1. INSTALLATION

1.1 INSTALLATION REQUIREMENTS

Carefully select the installation location. Environmental conditions greatly affect

machine performance.

1.1.1 OPTIMUM ENVIRONMENTAL CONDITION

1. Temperature 10 to 30 °C (50 to 86 °F)

2. Humidity 20 to 90 % RH

3. Install the machine on a strong and level base. The machine must be level

within 5 mm (0.2") both front to rear and left to right.

1.1.2 ENVIRONMENTS TO AVOID

1. Locations exposed to direct sunlight or strong light (more than 1,500 lux).

2. Dusty areas.

3. Areas containing corrosive gases.

4. Locations directly exposed to cool air from an air conditioner or reflected heat

from a space heater. (Sudden temperature changes from low to high or vice

versa may cause condensation within the machine.)

1.1.3 POWER CONNECTION

1. Securely connect the power cord to a power source.

2. Make sure that the wall outlet is near the machine and easily accessible.

3. Make sure the plug is firmly inserted in the outlet.

4. Avoid multi-wiring.

5. Do not pinch the power cord.

Page 24

INSTALLATION REQUIREMENTS

C249 1-2 SM

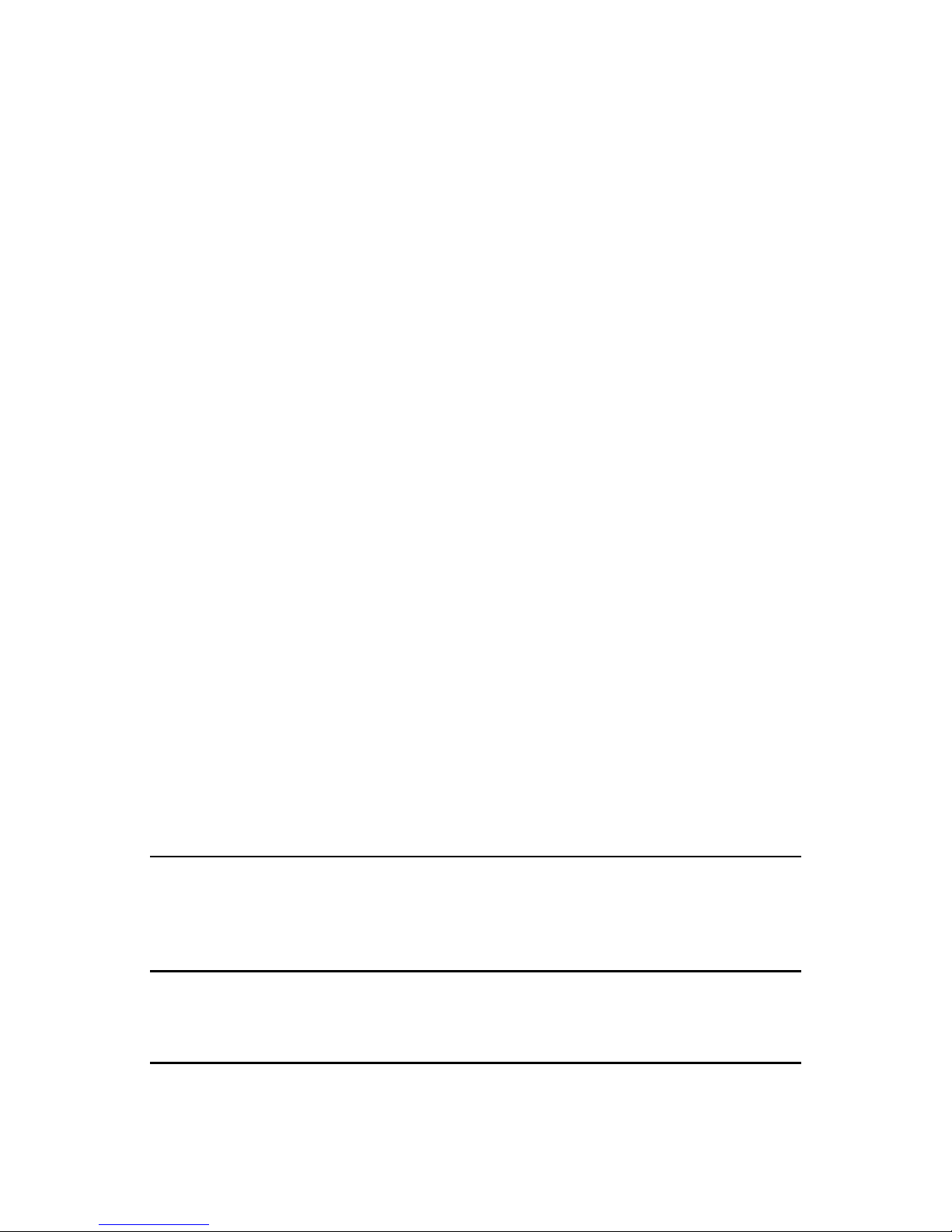

1.1.4 MACHINE ACCESS

Place the machine near a power source, providing clearance as shown below.

C249I000.WMF

Page 25

INSTALLATION PROCEDURE

SM 1-3 C249

Installation

1.2 INSTALLATION PROCEDURE

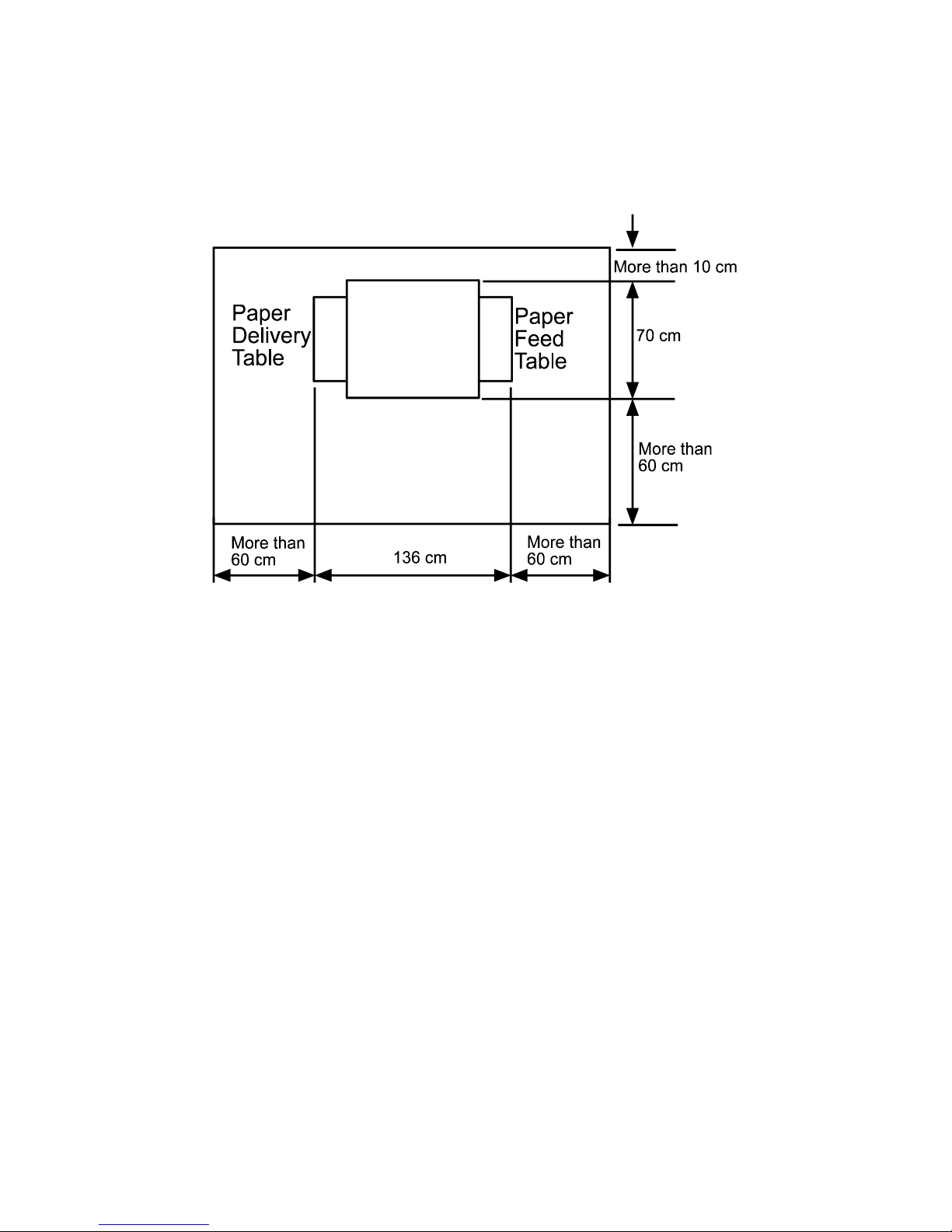

1.2.1 MAIN UNIT

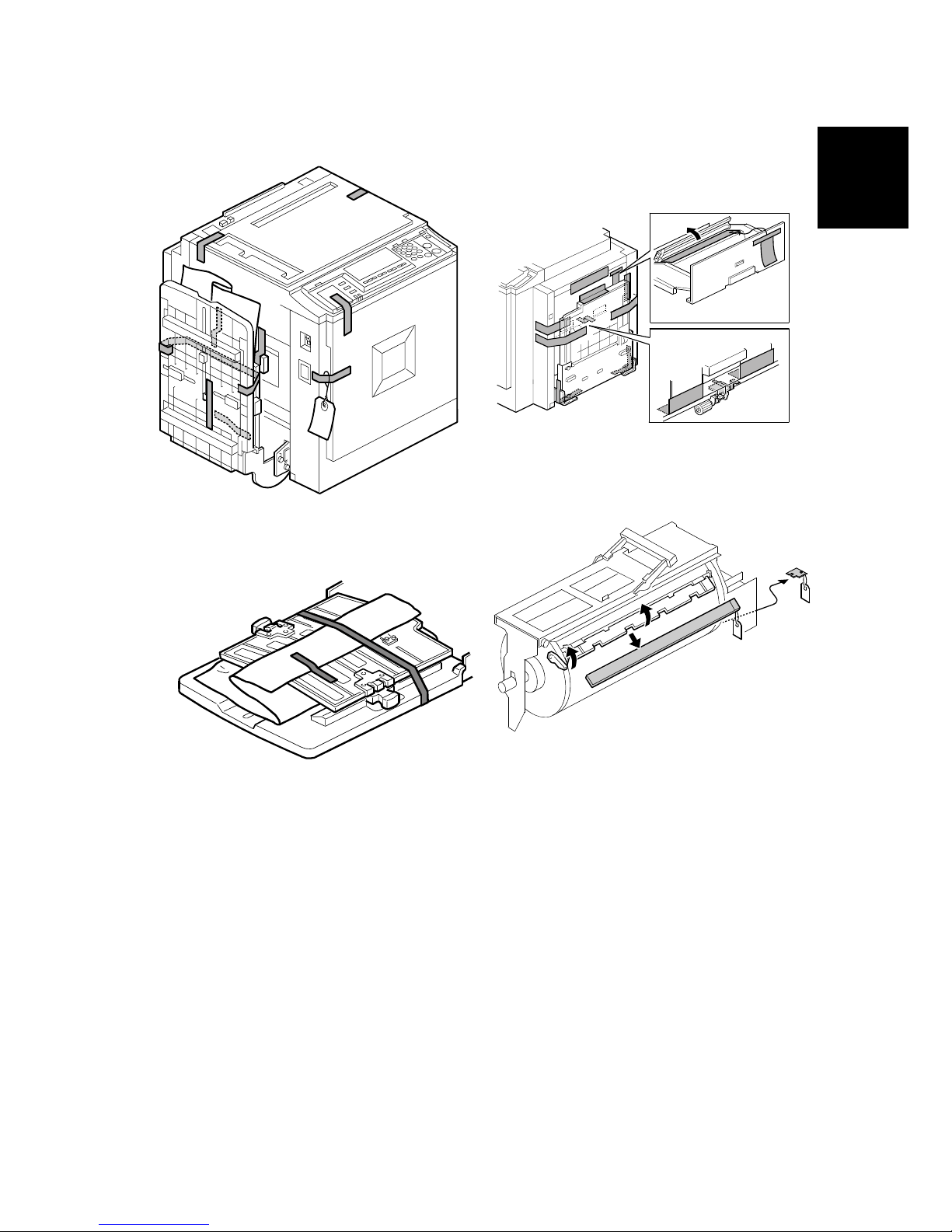

Accessory Check

Make sure that you have all the accessories listed below:

Description Q'ty

1. Master Spool.............................................................................. 2

2. Operating Instructions................................................................ 1

3. NECR (Ricoh version only)........................................................ 1

4. Model Name Plates (C249-22, and -52 only)............................. 1 set

C249I019.WMF

Page 26

INSTALLATION PROCEDURE

C249 1-4 SM

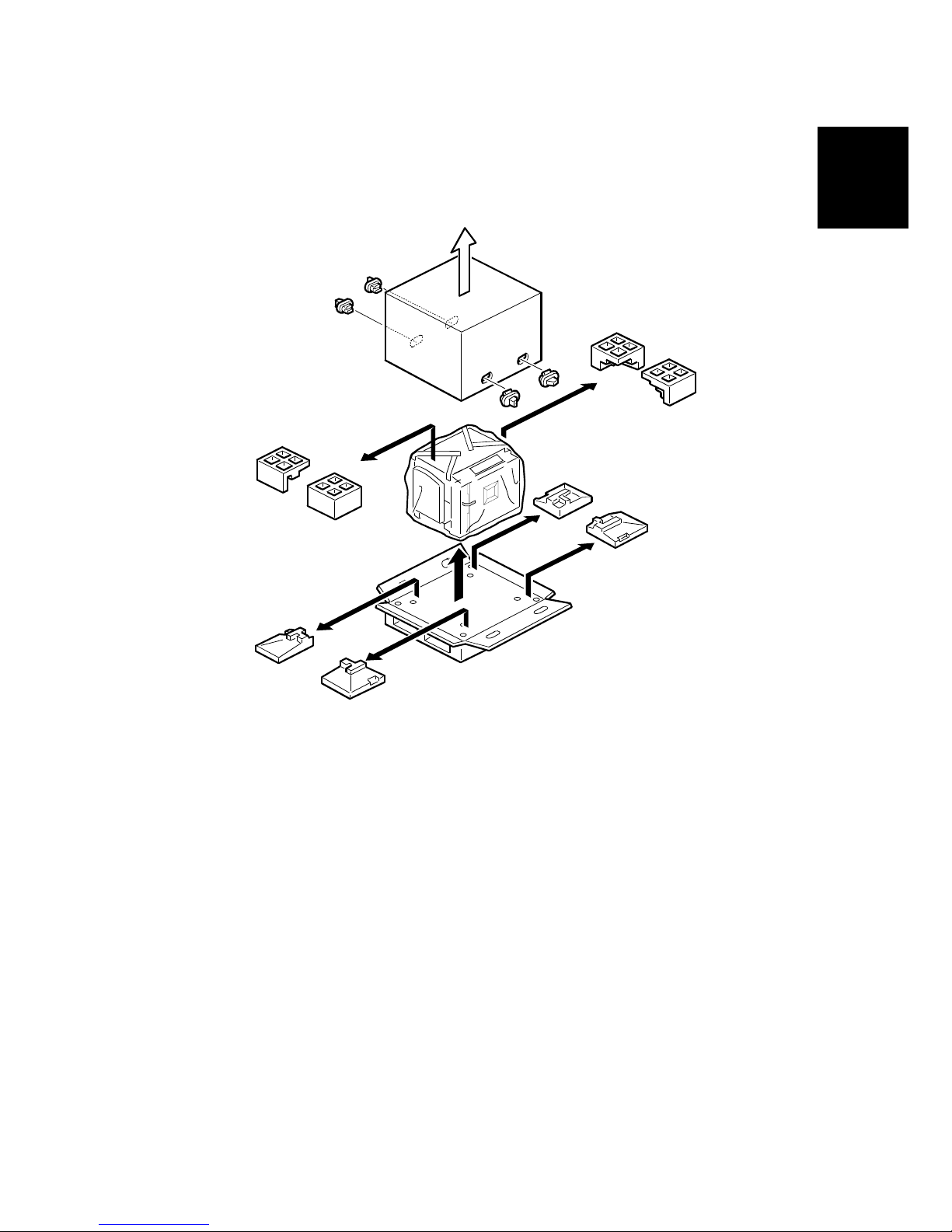

Installation Procedure

1. Unpack the box. When installing the optional table, mount the machine as

shown (there are 2 screws [A] packed with the table).

CAUTION

Only lift with the carrying handles on the bottom corners of the machine.

Secure the machine on the table with the 2 screws [A] provided. This

prevents the machine from falling from the table when the platen cover is

open.

Lock the casters of the table as shown [B], to prevent the machine from

moving (e.g. when the drum is set).

C249I014.WMF

[B]

[A]

Page 27

INSTALLATION PROCEDURE

SM 1-5 C249

Installation

2. Remove the filament tape and string securing the covers and units as shown

above.

C249I907.WMF

C249I020.WMF

C249I908.WMF

C249I909.WMF

Page 28

INSTALLATION PROCEDURE

C249 1-6 SM

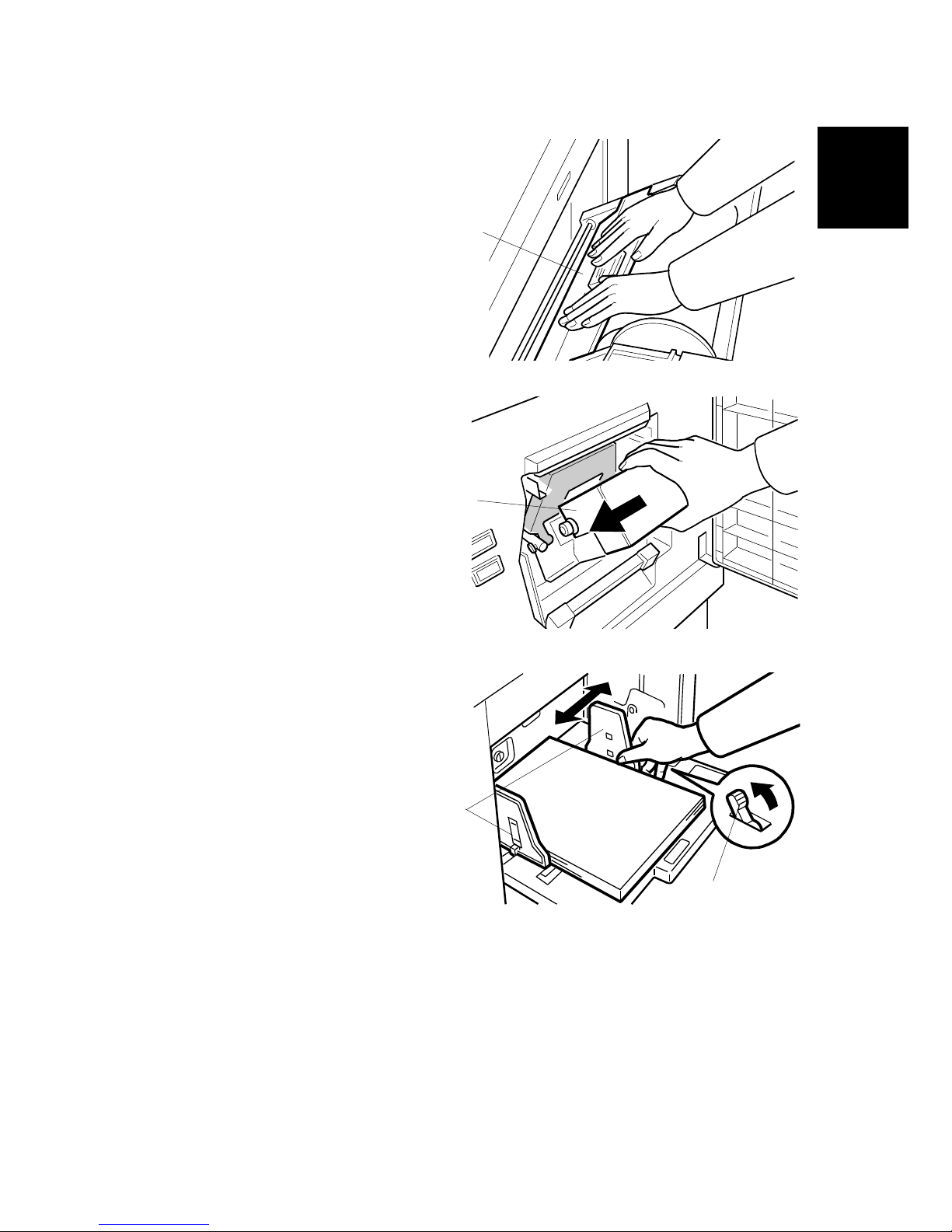

3. Pull out the master making unit, and

take out the accessory bag [A].

4. Insert both spools into a new master

roll.

5. Install the master roll as shown to the right.

6. Insert the leading edge of the master

roll under the platen roller. The arrows

[B] indicate the correct position of the

master leading edge.

C249I038.WMF

C249I030.WMF

C249I032.WMF

C249I910.WMF

[B]

[A]

Page 29

INSTALLATION PROCEDURE

SM 1-7 C249

Installation

7. Close the cover [C] using both hands.

8. Set the master-making unit.

9. Open the door, and insert a new ink

cartridge [D].

10. Open the paper table, and load a

stack of paper.

11. Make sure that the side plates [E]

touch the paper gently. Shift the lock

lever [F] in the direction of the arrow.

C249I031.WMF

C249I034.WMF

C249I028.WMF

[D]

[C]

[E]

[F]

Page 30

INSTALLATION PROCEDURE

C249 1-8 SM

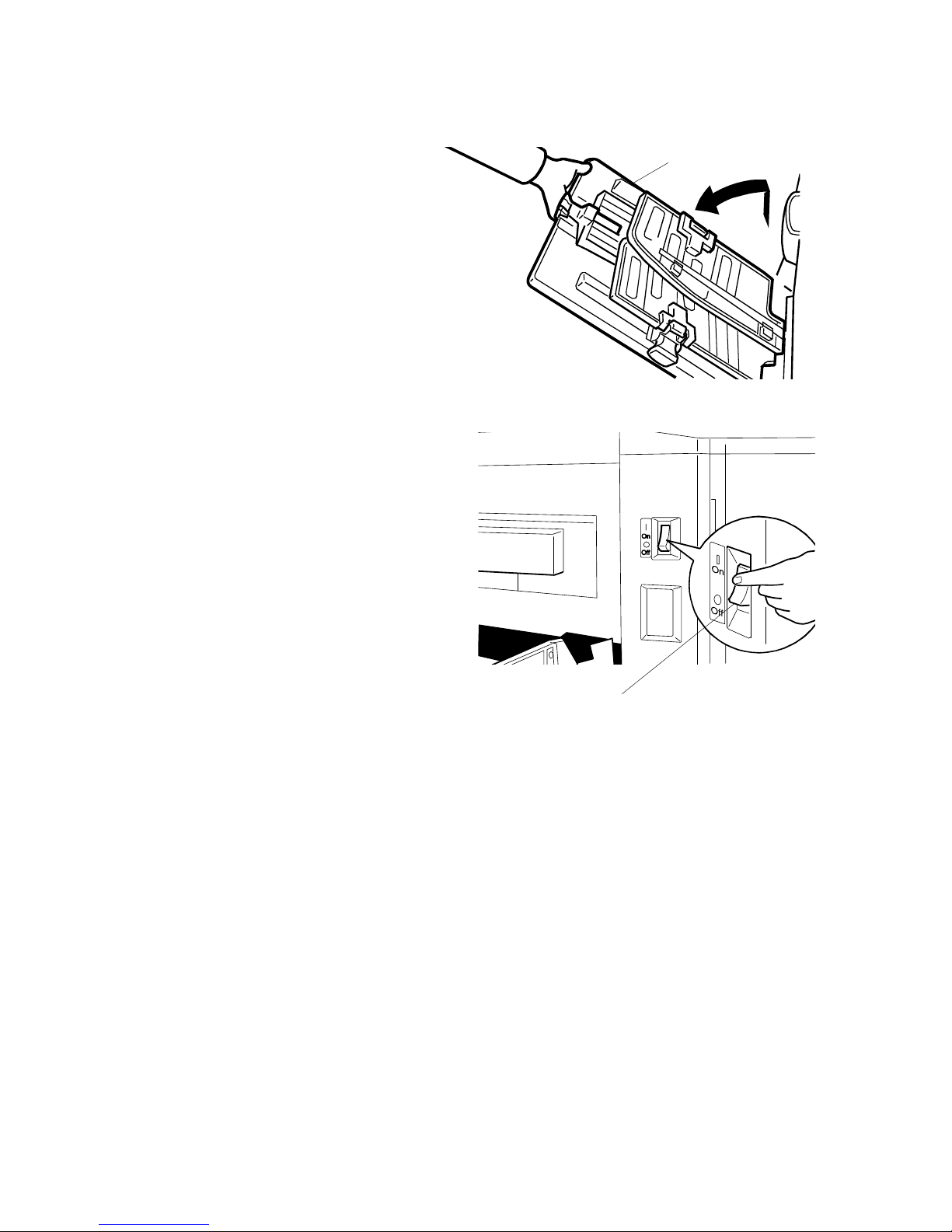

12. Raise the paper delivery table [G]

slightly, then gently lower it.

13. Lift the side plates and the end

plate, and adjust them to the

paper size.

14. Firmly insert the power plug in the

outlet.

15. Make sure that the wall outlet is near

the machine and easily accessible.

16. Turn on the main switch [H].

17. Press the “Economy mode” key while

holding down the “0” key, to supply

ink inside the drum.

18. Make some test copies.

C249I027.WMF

C249I026.WMF

[G]

[H]

Page 31

INSTALLATION PROCEDURE

SM 1-9 C249

Installation

1.2.2 BEFORE BEGINNING MACHINE OPERATION.

NOTE: Strips of tape and a styrene foam sponge have been added as shown

below to secure the Press Roller during transport. Please be sure to

remove the tape [A], sponge [B] and tag [C] by pulling the portion shown in

the illustration toward the front of the machine before beginning machine

operation.

NOTE: If they are not removed:

Paper jams or blank images may occur, due to the lack of pressure on the

Press Roller.

The tape may stick to the drum screen or Press Roller.

[A]

[B]

[C]

Rev.04/2004

⇒

Page 32

INSTALLATION PROCEDURE

C249 1-10 SM

1.2.3 PLATEN COVER INSTALLATION (OPTION)

Accessory Check

Check the quantity and condition of the accessories in the box against the following

list:

Description Q'ty

1. Stepped Screw............................................................................... 2

Installation Procedure

1. Install the platen cover [A] (2 screws).

C249I001.WMF

[A]

Rev.04/2004

Page 33

INSTALLATION PROCEDURE

SM 1-11 C249

Installation

1.2.4 ADF INSTALLATION (OPTION)

Accessory Check

Check the quantity and condition of the accessories in the box against the following

list:

Description Q'ty

1. Stepped Screw .......................................................................... 2

2. Screws....................................................................................... 3

3. Screwdriver................................................................................ 1

4. DF Exposure Glass.................................................................... 1

5. Decal - Exposure Glass............................................................. 1

6. Decal - Scale - mm .................................................................... 1

7. Decal - Scale - inch.................................................................... 1

8. Scale Guide ............................................................................... 1

9. Stabilizer Bracket....................................................................... 2

10. Thumbscrew .............................................................................. 4

11. Caution Label............................................................................. 1

Installation Procedure

1. Remove the strips of tape.

C249I002.WMF

Rev.04/2004

Page 34

INSTALLATION PROCEDURE

C249 1-12 SM

2. Remove the left scale [A] (2 screws).

3. Place the DF exposure glass [B] on the glass holder.

NOTE: When installing the DF exposure glass, make sure that the white point

[C] is positioned at the lower front side, as shown.

4. Peel off the backing [D] of the double-sided tape attached to the rear side of the

scale guide [E], then install the scale guide (2 screws removed in step 2).

5. Install the two stud screws [F].

6. Mount the DF by aligning the holes [G] in the DF with the stud screws, then

slide the DF to the front as shown.

7. Secure the DF unit with two screws [H].

C249I003.WMF

C249I004.WMF

[A]

[B]

[C]

[D]

[E]

[F]

[G]

[H]

Rev.04/2004

Page 35

INSTALLATION PROCEDURE

SM 1-13 C249

Installation

8. Connect the cables [I] and [J] to the main body.

9. Attach the scale decal [K] as shown.

10. Plug in the power cord, then turn the main switch on.

11. Make a full size copy using the ADF. Then check to make sure the side-to-side

and leading edge registrations are correct. If they are not, adjust their values

(do the adjustment procedures in section 5.7.3).

C249I018.WMF

C249I500.WMF

[I]

[J]

[K]

Rev.04/2004

Page 36

INSTALLATION PROCEDURE

C249 1-14 SM

ADF stabilizer installation

1. Attach the two stabilizer brackets [A] to the back of the table using the

thumbscrews (4 screws).

2. Attach the caution label [B], as shown.

CAUTION

This procedure must be done to prevent the machine from falling

backwards when the ADF is open.

C249I040.WMF

[A]

[B]

Rev.04/2004

Page 37

INSTALLATION PROCEDURE

SM 1-15 C249

Installation

1.2.5 TAPE MARKER (OPTION)

Accessory Check

Check the quantity and condition of the accessories in the box against the following

list:

Description Q'ty

1. Knob Screw (C210, C217, C218, C219, C222, C223, C225,

C228, C231, C237, C238, C247, C248 and C249 only) ...... 2

2. Screw M4 x 25 (C211, C212, C213, C214, C216, C224,

and C226 only) .................................................................... 2

3. Hexagon Nut M4 (C211, C212, C213, C214, C216, C224,

and C226 only) .................................................................... 2

4. Auxiliary Bracket (C226 only)............................................... 1

5. Auxiliary Bracket (C238, C247, and C249 only)................... 1

6. Screw M4 x 8 (C226, C238, C247 and C249 only).............. 2

7. Lock Washer (C226 only) .................................................... 1

8. Lock Washer........................................................................ 1

9. Tape .................................................................................... 1

Rev.04/2004

Page 38

INSTALLATION PROCEDURE

C249 1-16 SM

Installation Procedure

- For C238, C247 and C249 -

1. Turn off the main switch and unplug the power cord.

2. Remove the paper delivery plate (4 screws).

3. Cut the cap [A] off the rear cover of the main body with pliers, then connect the

tape marker cable to the main body.

4. Install the auxiliary bracket [B] (#C5326502) on the tape marker with M4 x 8

screws (accessories) [C].

NOTE: Install the lock washer [E] (accessories) with the lower of the two

screws.

5. Install the tape marker on the main body with two knob screws [D]

(accessories) in the two outer holes in the tape marker bracket.

6. Reinstall the paper delivery plate.

7. Refer to "Common Steps".

C249I994.WMF

C249I536.WMF

[B]

[C]

[D]

[E]

[A]

Rev.04/2004

Page 39

INSTALLATION PROCEDURE

SM 1-17 C249

Installation

- For C231 , C237, and C248 -

1. Turn off the main switch and unplug the power cord.

2. Remove the paper delivery table (2 screws).

3. Remove the paper delivery plate (4 screws).

4. Cut the cap [A] off the rear cover with pliers, then connect the tape marker

cable to the main body.

5. Install the tape marker on the main body with two knob screws [B]

(accessories) in the two outer holes in the tape marker bracket.

NOTE: 1) Tighten the knob screws with a screwdriver to prevent them from

coming loose.

2) Install the lock washer [C] (accessories) with the lower of the two

knob screws.

6. Reinstall the paper delivery plate and paper delivery table.

7. Refer to "Common Steps".

C249I536.WMF

C249I533.WMF

[A]

[B]

[C]

Rev.04/2004

Page 40

INSTALLATION PROCEDURE

C249 1-18 SM

- For C226 -

Main Body:

1. Turn off the main switch and unplug the power cord.

2. Remove the rear cover (6 screws).

3. Replace the screw [A], to secure the AC drive board with M4 x 25 screws

(accessories).

4. Reinstall the rear cover.

5. Install the auxiliary bracket [B] on the main body with the hexagon nut [D]

(accessories) as shown.

NOTE: Install the lock washer [C] (accessories) with the nut.

Tape Marker:

6. Install the tape marker on the auxiliary bracket with two M4 x 8 screws [E]

(accessories).

7. Install the lock washer [F] (accessories) with one of the two screws.

8. Refer to "Common Steps".

C238I516.PCX

C249I517.WMF

[A]

[B]

[C]

[D]

[F]

[E]

Rev.04/2004

Page 41

INSTALLATION PROCEDURE

SM 1-19 C249

Installation

- For C210, C218, C219, C222, and C223 -

1. Turn off the main switch and unplug the power cord.

2. Install the tape marker on the main body with two knob screws [A]

(accessories) in the two outer holes in the tape marker bracket.

NOTE: 1) Install the lock washer [B] (accessories) with the lower of the two

knob screws.

2) .Tighten the knob screws with a screwdriver to prevent them from

coming loose

3. Refer to “Common Steps”.

— For Model C228 and the models on which the new Paper Delivery Table is

installed —

Use the two holes in the tape marker bracket [C] as shown below.

C238I502.PCX

C238I504.PC

X

[A]

[B]

[C]

Rev.04/2004

Page 42

INSTALLATION PROCEDURE

C249 1-20 SM

- For C217 and C225 -

1. Turn off the main switch and unplug the power cord.

2. Install the tape marker on the main body with two knob screws [A]

(accessories) in the two inner holes of the tape marker bracket.

NOTE: 1) Install the lock washer [B] (accessory) with the lower of the two knob

screws..

2) Tighten the knob screws with a screwdriver to prevent them from

coming loose

3. Refer to “Common Steps”.

C238I503.PCX

[A]

[B]

Rev.04/2004

Page 43

INSTALLATION PROCEDURE

SM 1-21 C249

Installation

- Common Steps -

1. Remove the small cap in the rear cover of

the main body [A]. Then, connect the tape

marker cable [B] to the main body, and install

the connector cover [C] using one of the rear

cover securing screws. (For C238, C247 and

C249, this has already been done.)

2. Open the tape marker cover [D]. Then,

insert the leading edge of the tape into

the tape entrance until it stops as

shown in the illustration [E].

NOTE: Be sure that the tape is

installed in the proper direction.

If it is not, the tape marker will

not work correctly.

3. Turn on the main switch of the main

body and set the SP mode to activate

the tape marker. (Refer to the service

program table.)

4. Turn on the tape marker switch [F].

5. Press the tape cut button [G] to cut off

the leading edge of the tape.

6. Check the tape marker operation using

the Memory/Class modes of the main

body.

C238I518.PCX

C238I519.PCX

C238I520.PCX

C238I521.PCX

[A]

[B]

[C]

[D]

[E]

[F]

[G]

Rev.04/2004

Rev.04/2004

Page 44

INSTALLATION PROCEDURE

C249 1-22 SM

1.2.6 OPTIONAL DRUMS

There are two types of drum units:

A3 Size: Color drum

A4 Size: Black drum (Black ink only)

1. Remove the protective sheet [A] and the lock [B] from the drum unit.

2. Remove the tape securing the ink holder.

3. Attach a color indicator decal to the drum case. The decal must be the same

color as the ink in use.

4. Remove the drum unit.

5. Leave the master wrapped around the removed drum to protect the drum from

dust and from drying.

6. Keep the removed drum unit in the drum case.

7. Install the drum unit.

NOTE: The color drum indicator (or A4 drum indicator) on the operation panel

stays lit when a drum is mounted in the machine.

8. Remove the ink cartridge cap.

9. Insert the ink cartridge in the ink holder.

C249I534.WMF

C249I020.WMF

[A]

[B]

Rev.04/2004

Page 45

PREVENTIVE MAINTENANCE

Page 46

Page 47

MAINTENANCE TABLE

2. PREVENTIVE MAINTENANCE

2.1 MAINTENANCE TABLE

The following items should be maintained periodically. There are two sets of

intervals - one based on time and the other based on print count. For maintenance

items with entries in both of them, use whichever comes first.

Preventive

Maintenance

C: Clean, R: Replace, L: Lubricate, A: Adjust

Time Print Counter Interval

Item

6M 1Y 2Y 3Y

1M 1.2M

2M 2.4M 3M

EM NOTE

Scanner/Optics

Exposure Lamp C C C C Dry Cloth

Mirror/Reflector C C C C Soft Cloth

Scanner Guide Rail C C C C Dry Cloth

Platen Cover / White

Plate

C C C C

Damp

Cloth

Exposure Glass C C C C Dry Cloth

Master Feed

Thermal Head C Alcohol

Platen Roller

C C C C

Damp cloth

and water

Master Eject Rollers C C C C Alcohol

Drum Master

Sensor

C Dry Cloth

Paper Feed

Paper Pick-up Roller

C C R C R R

Damp

Cloth

Paper Feed Roller

C C R C R R

Damp

Cloth

Pick-up Roller/Feed

Roller Shafts [A]

L L L

Motor Oil

(SAE #20)

Friction Pad

C C R C R R

Damp

Cloth

Press Roller C C R C R R Alcohol

Table Fulcrum

Shafts [B]

L L L

Motor Oil

(SAE #20)

Table Racks [C]

L L L

Grease

(Alvania

#2)

Paper Delivery

Transport Belts

R R R

Paper End Sensor C C C C Dry Cloth

Registration/Exit

Sensors

C C C C Dry Cloth

Registration Roller C C C C Dry Cloth

SM 2-1 C249

Page 48

MAINTENANCE TABLE

C249 2-2 SM

Time Print Counter Interval

Item

6M 1Y 2Y 3Y

1M 1.2M

2M 2.4M 3M

EM NOTE

Drum and Ink Supply

Cloth Screen R R R

Ink Roller One-way

Clutch

R ! 3.8.5

Drum Drive Gears

and Cam [D] L L L

Grease

(Alvania

#2)

Ink Pump Gears [E]

L L L

Motor Oil

(SAE #20)

In/Outside of Drum C C C C Alcohol

Ink Nozzle C C C C Alcohol

Black Patch [G] C C C C Dry Cloth

Others

Main Drive Timing

Belt Tension

A

! 3.8.9

Printing Pressure

Spring Hooks [F] L L L

Grease

(Alvania

#2)

Press Roller

Release Lever

Position

A

ADF (Option)

DF Feed Rollers C C C C Dry Cloth

[C]

[D]

[B]

[A]

[F]

[E]

[G]

Page 49

REPLACEMENT AND ADJUSTMENT

Page 50

Page 51

GENERAL CAUTION

SM 3-1 C249

Replacement

&

Adjustment

3. REPLACEMENT AND ADJUSTMENT

Only items that were changed or newly added to the C249 model are described.

3.1 GENERAL CAUTION

CAUTION

Turn off the main power switch and unplug the machine before attempting

any of the procedures in this section.

NOTE: This manual uses several symbols. The meaning of those symbols are as

follows:

! : See or Refer to : screw : connector : E-ring : Clip

3.2 PRINT KEY / START KEY

[A]: Key Cover

[B]: Print start key

[C]: Master making key

C249R119.WMF

C249R120.WMF

C238A086.WMF

[A]

Page 52

COVERS / BOARDS

C249 3-2 SM

3.3 COVERS / BOARDS

3.3.1 FRONT COVER / PANEL

[A]: Front door ( x 4)

[B]: Front cover ( x 6)

[C]: Upper right cover ( x 2)

[D]: Operation panel ( x 4, x 1)

C238R006.WMF

[B]

[A]

[C]

[D]

Page 53

COVERS / BOARDS

SM 3-3 C249

Replacement

&

Adjustment

3.3.2 REAR COVERS

[A]: Rear left cover ( x 5)

[B]: Rear right cover ( x 3)

[C]: Upper left cover ( x 2)

[D]: Rear upper cover

3.3.3 MPU

• Rear left cover, Rear right cover (! 3.3.2)

[A]: MPU ( x 17, x 6, 9 clamps)

CAUTION: Move the RAM [B] from the old board to the new one, so that the SP

mode settings will be transferred to the new board. Adjust the master

end sensor (! 3.6.10) after installing the new MPU.

C238R007.WMF

C238R008.WMF

[A]

[B]

[C]

[D]

[A]

[B]

Page 54

COVERS / BOARDS

C249 3-4 SM

3.3.4 PSU

• Upper left cover (! 3.3.2)

• Master eject unit (! 3.5.1)

[A]: PSU ( x 5, x 2, 2 clamps)

CAUTION: When the PSU is replaced, the thermal head voltage returns to the

default. Adjust the thermal head voltage (! 3.6.6) after installing the

new board.

C238R009.WMF

[A]

Page 55

SCANNER

SM 3-5 C249

Replacement

&

Adjustment

3.4 SCANNER

3.4.1 EXPOSURE GLASS / SCALES

[A]: Left scale ( x 2)

[B]: Upper scale ( x 3)

[C]: Exposure glass

3.4.2 SBU AND LAMP STABILIZER / SCANNER MOTOR

• Left scale, Upper scale, Exposure glass

(! 3.4.1)

• Upper right cover (! 3.2.1)

[A]: SBU cover ( x 4)

[B]: SBU ( x 1, x 5)

C238R038.WMF

C238R039.WMF

[A]

[B]

[C]

[A]

[B]

Page 56

SCANNER

C249 3-6 SM

[C]: Lamp stabilizer ( x 2, 3 standoffs)

[D]: Scanner motor ( x 2, x 1, 1 spring)

3.4.3 SCANNER H.P. SENSOR / PLATEN COVER SENSOR

• Left scale, Upper scale, Exposure glass (! 3.4.1)

• Operation panel (! 3.3.1)

• Rear upper cover (! 3.3.2)

[A]: Platen cover sensor ( x 1)

[B]: Left stay ( x 1)

[C]: Scanner H.P. sensor ( x 1)

C238R041.WMF

C238R042.WMF

C238R043.WMF

[D]

[A]

[B]

[C]

[C]

Page 57

SCANNER

SM 3-7 C249

Replacement

&

Adjustment

3.4.4 EXPOSURE LAMP (XENON LAMP)

• Move the first scanner next to the opening in the frame.

• Exposure glass (! 3.4.1)

• [1]: Left stay (! 3.4.3)

[A]: Platen base ( x 1, x 5)

[B]: Rear frame ( x 1, x 2)

[C]: Front frame ( x 5)

[D]: Exposure lamp ( x 1)

NOTE: After installing the lamp, press the lamp holder [E] up to the original

position so that it can hold the lamp properly.

C238R044.WMF

C238R045.WMF

[A]

[B] [C]

[1]

[D]

[E]

Page 58

SCANNER

C249 3-8 SM

3.4.5 SCANNER WIRES

• Move the first scanner next to the opening in the frame.

• Exposure glass (! 3.4.1)

• SBU cover (! 3.4.2)

• Left stay (! 3.4.3)

• Rear and front frames (! 3.4.4)

1. First scanner ([1]: 2 pins)

NOTE: The drawings show only the front side. Repeat to remove components

on the other side.

[A]: Wire tension brackets (2 springs, x 2)

[B]: Scanner drive pulleys (2 Allen screws)

[C]: Scanner wires

Installation

1. Wrap the new scanner wire around the pulley as shown ", then temporarily

secure the pulley with tape.

2. Re-install the first scanner. Then secure the first and second scanner with the

scanner positioning pins (P/N A0069104), as shown in the illustration on the

next page.

3. Wind the new scanner wire around the scanner drive pulley in the correct way,

as shown.

4. Wind the end of the new wire with the ball as shown (

#).

5. Wind the end of the new wire with the ring as shown ($,%, and &).

6. Connect the tension spring to the wire tension bracket (&).

7. Wind the new scanner wire for the other side as well.

C238R046.WMF

C238R029.WMF

[B]

[C]

[D]

[A]

[1]

Page 59

SCANNER

SM 3-9 C249

Replacement

&

Adjustment

8. Secure the first scanner with the pins [E].

9. Tighten the screw securing the tension bracket [F].

10. Secure the scanner drive pulley [G] (1 Allen screw).

11. Remove the scanner positioning pins [I] (P/N: #A0069104).

12. Slide the scanner to the left and right several times, then set the scanner

positioning pins to check the clamp position and wire tension bracket position

again.

C238R047.WMF

C238R048.WMF

[E]

[F]

[G]

[I]

Page 60

SCANNER

C249 3-10 SM

3.4.6 IMAGE ADJUSTMENT

Purpose: To adjust the image position on prints by changing the SP settings.

Adjust the following in the order given below.

SP6-10: Master writing speed (! 5.7.3)

↓

SP6-21: Paper registration position (! 5.7.3)

↓

SP6-05: Scanning speed - platen (! 5.7.3)

SP6-06: Scanning speed - ADF

↓

SP6-03: Scanning start position - platen (! 5.7.3)

SP6-04: Scanning start position - ADF

↓

SP6-01: Main scan position - platen (! 5.7.3)

SP6-02: Main scan position - ADF

↓

SP6-31: SBU calibration (! 5.7.4)

Page 61

MASTER EJECT

SM 3-11 C249

Replacement

&

Adjustment

3.5 MASTER EJECT

3.5.1 MASTER EJECT UNIT

[A]: Master eject unit ( x 1, x 2, 1 clamp)

C249R001.WMF

[A]

Page 62

MASTER FEED

C249 3-12 SM

3.6 MASTER FEED

3.6.1 MASTER MAKING UNIT

[A]: Master making unit ( x 2)

3.6.2 THERMAL HEAD

1. Connect the power plug. Then turn on the main switch to access SP mode.

2. Select SP5-74 (T/H driving motor - up), then press the enter (#) key and turn off

the main switch.

NOTE:

1) The thermal head is released, after about 2 seconds. (There is almost

no sound of operation.)

2) The thermal head does not separate, unless it releases as mentioned

above.

C249R121.WMF

[A]

Page 63

MASTER FEED

SM 3-13 C249

Replacement

&

Adjustment

• Master making unit (! 3.6.1)

• Open the platen roller unit [1].

[A]: T/H upper cover ( x 2)

[B]: T/H side cover ( x 1)

• Close the platen roller unit [1].

[C]: Thermal head ( x 2)

C249R049.WMF

C249R122.WMF

[1]

[C]

[A]

[B]

[1]

Page 64

MASTER FEED

C249 3-14 SM

1. Turn the thermal head clockwise and remove a nail (").

2. Turn the thermal head counterclockwise, and remove a nail (#).

3. Remove the thermal head slowly.

NOTE: If you cannot access SP modes, open the master making unit and loosen

the 2 screws [D].

C249R116.WMF

C249R110.WMF

[D]

Page 65

MASTER FEED

SM 3-15 C249

Replacement

&

Adjustment

Installation

1. Insert in the nails (") to the operation side and middle.

2. Turn the thermal head counterclockwise and insert in the nail (

#) to in front.

3. Turn the thermal head clockwise and insert in the nail (

$) to the non-operation

side.

Make sure to follow the above procedure or the thermal head will not be installed

correctly.

1) Fit the base’s springs [A] over the protrusions [B] on the underside of the

thermal head (6 points).

2) While fitting the tops of the springs [A] over the protrusions on the underside

of the thermal head.

3) Make sure that all protrusions are properly fitted into the springs.

CAUTION: Adjust the thermal head voltage (! 3.6.6) after installing the new

thermal head.

C249R117.WMF

C249R030.WMF

[A]

[B]

Page 66

MASTER FEED

C249 3-16 SM

3.6.3 DUCT PLATE HP SENSOR / DUCT PLATE MOTOR

• Master making unit (! 3.6.1)

[A]: Rear cover ( x 2)

[B]: Duct plate HP sensor ( x 1, x 1)

[C]: Rear rail bracket ( x 2)

[D]: Duct plate motor ( x 1, x 2)

C249R101.WMF

C249R102.WMF

[A]

[B]

[C]

[D]

Page 67

MASTER FEED

SM 3-17 C249

Replacement

&

Adjustment

3.6.4 CUTTER UNIT

[A]: Cutter unit ( x 1, x 1)

3.6.5 THERMAL HEAD DRIVING UNIT

• Thermal head (! 3.6.2)

• Rear cover (! 3.3.2)

• Cutter unit (! 3.6.4)

[A]: Anti-Static roller ( x 2)

[B]: Thermal head driving unit ( x 2, x 2)

C249R103.WMF

C249R105.WMF

[A]

[B]

[A]

Page 68

MASTER FEED

C249 3-18 SM

3.6.6 THERMAL HEAD VOLTAGE ADJUSTMENT

CAUTION

This adjustment is always required when the thermal head or PSU has been

replaced.

Purpose: To maintain master making quality and extend the lifetime of the thermal

head.

Standard: Refer to the voltage value (X) printed on the thermal head. The value

varies from one thermal head to another.

The adjustment voltage should be between X and X - 0.1 V.

Tools: Circuit tester

• Upper left cover (! 3.3.2)

• Read the voltage value on the

decal on the thermal head.

1. Slide out the master making unit.

CAUTION: Never turn VR1

clockwise rapidly

while the master

making unit is

connected. The T/H

will be damaged if too

much voltage is

supplied suddenly.

2. Connect the positive terminal of a

circuit tester to TP701 and the

negative terminal to TP702 .

CAUTION: If the output and

ground terminals

touch each other, the board will be damaged.

3. Connect the power plug, and turn on the main switch to access SP mode.

4. Select SP5-12 (Thermal head signal output).

5. Press the Start key. Power is continuously supplied to the thermal head, so

press the Stop key if you cannot finish the adjustment quickly.

A beeper sounds while the power is being supplied.

6. Measure the voltage, and turn VR1 so that the value becomes between “+0”

and “-0.1” volts from the value on the thermal head decal.

C238R012.WMF

Page 69

MASTER FEED

SM 3-19 C249

Replacement

&

Adjustment

3.6.7 DUCT JAM SENSOR ADJUSTMENT

Ensures that the sensor detects when a master remains in the duct.

Standard: 0.5 volts (within “+0.1” and “-0.1”volts)

Tools: Circuit tester

• Rear cover (! 3.3.2)

1. If a master remains in the duct, remove the master from the duct.

2. Connect the terminals of a circuit tester to TP102 and a grounded place (e.g.

iron base)

3. Connect the power plug, and turn on the main switch to access SP mode.

4. Select SP6-52 (Duct jam sensor voltage).

5. Press the Print Start key.

6. Measure the voltage, and turn VR102 so that the value becomes between “-

0.1” and “+0.1” volts from the standard value (0.5 volts)

NOTE: When the value of the voltage does not become the standard value, adjust

the threshold level of the duct jam sensor. (SP6-52 : Duct jam sensor

voltage)

Standard Value

Master being

Threshold level (SP6-52)

Standard Value

Master nothing

Above 2.0V 2.0V

0.5 ±0.1V

C249R123.WMF

C249R124.WMF

C249R113.WMF

Page 70

MASTER FEED

C249 3-20 SM

3.6.8 MASTER EDGE SENSOR ADJUSTMENT

Ensures that the sensor detects the leading edge of the master.

Standard: 2.0 volts (within “+0.1” and “-0.1”volts)

Tools: Circuit tester

• Rear cover (! 3.3.2)

1. Connect the terminals of a circuit tester to TP103 and a grounded place (e.g.

iron base)

2. Connect the power plug, and turn on the main switch to access SP mode.

3. Select SP6-51 (Master edge sensor voltage).

4. Remove the lower master tray.

5. Pull out the master-making unit from the machine and open the master set

cover.

6. Insert the leading edge of the master under the master tension roller, then

close the master set cover and reinstall the master-making unit to the machine.

7. Measure the voltage, and turn VR103 so that the value becomes between “-

0.1” and “+0.1” volts from the standard value (2.0 volts).

NOTE: When the value of the voltage does not become the standard value, adjust

the threshold level of the master edge sensor. (SP6-51 : Master edge

sensor voltage)

Standard Value

Master being

Threshold level (SP6-51)

Standard Value

Master nothing

2.0 ±0.1V

2.8V Above 3.3V

C249R133.WMF

Page 71

MASTER FEED

SM 3-21 C249

Replacement

&

Adjustment

3.6.9 2ND DRUM MASTER SENSOR ADJUSTMENT

Ensures that the sensor detects if there is a master on the drum.

Standard: 2.0 volts (within “+0.1” and “-0.1”volts)

Tools: Circuit tester

• Rear cover (! 3.3.2)

1. Confirm that the master is wrapped on the drum.

2. Connect the terminals of a circuit tester to TP104 and a grounded place (e.g.

iron base)

3. Connect the power plug, and turn on the main switch to access SP mode.

4. Select SP6-53 (2nd drum master sensor voltage) and press the master-making

key.

5. Measure the voltage, and turn VR104 so that the value becomes between “-

0.1” and “+0.1” volts from the standard value (2.0 volts).

6. Turn off the main switch, then remove the master that is wrapped around the

drum and install the drum in the main body.

7. Turn on the main switch to access SP mode.

8. Select SP6-53 (2nd drum master sensor voltage) and press the master-making

key.

9. Check if the value of the voltage becomes below 0.8 volts.

10. If the voltage is not correct, clean the black patch [A] on the screen.

NOTE: When the value of the voltage does not become the standard value, adjust

the threshold level of the 2nd drum master sensor. (SP6-53 : 2nd drum

master sensor voltage)

Standard Value

Master being

Threshold level (SP6-53)

Standard Value

Master nothing

2.0 ±0.1V

1.0V Below 0.8V

C249R126.WMF

[A]

Page 72

MASTER FEED

C249 3-22 SM

3.6.10 MASTER END SENSOR ADJUSTMENT

Ensures that the sensor detects the end mark (a solid black area) on the master

roll.

Standard: 1.8 volts (within “+0.1” and “-0.1” volts)

Tools: Circuit tester, the core of a used master roll (the core has no master)

• Rear cover (! 3.3.2)

1. Connect the terminals of a circuit tester to TP101 and to a grounded place (e.g.

iron base).

2. Put a piece of master [A] on the used master roll.

3. Place the core of the used master roll inside the master-making unit, and close

the master-making unit.

NOTE: Detect a low fiber content paper side of a piece of paper to the master

end sensor.

4. Connect the power plug, and turn on the main switch.

5. Measure the voltage, and turn VR101 so that the value becomes between “-

0.1” and “+0.1” volts from the standard value (1.8 volts).

NOTE: When the value of the voltage does not become the standard value, adjust

the threshold level of the master end sensor. (SP6-50 : Master end sensor

voltage)

Standard Value

Master being

Threshold level (SP6-50)

Standard Value

Master nothing

Below 1.8V 1.9V

2.0 ±0.1V

TP101

VR101

C249R118.WMF

C249R114.WMF

[A]

Page 73

PAPER FEED

SM 3-23 C249

Replacement

&

Adjustment

3.7 PAPER FEED

3.7.1 PICK-UP ROLLER / PAPER FEED ROLLER / FRICTION PAD

• Lower the paper table.

[A]: Pick-up roller ( x 1)

[B]: Paper guide ( x 1)

[C]: Feed roller ( x 1)

[D]: Friction pad

[E]:

C249R115.WMF

[A]

[B]

[C]

[D]

Page 74

PAPER FEED

C249 3-24 SM

3.7.2 PAPER SEPARATION PRESSURE ADJUSTMENT

Purpose: To ensure that the friction pad

exerts sufficient pressure for smooth

printing paper separation.

Default: The next position to the top.

Adjust the paper separation pressure by

loosening and moving the adjusting screw

[A] up or down.

Moving up the screw ⇒ Increases the

paper separation pressure

Moving down the screw ⇒ Decreases the

paper separation pressure

Tighten the screw after the adjustment.

C238R031.WMF

[A]

Page 75

PAPER FEED

SM 3-25 C249

Replacement

&

Adjustment

3.7.3 PAPER WIDTH DETECTION BOARD

• Lower the paper table.

[A]: Paper table ( x 1, x 2)

[B]: Table cover ( x 5, 3 washers)

[C]: Sensor cover ( x 2)

[D]: Paper width detection board ( x 1, x 1)

C238R018.WMF

C238R019.WMF

C238R020.WMF

[A]

[B]

[C]

[D]

Page 76

PRINTING

C249 3-26 SM

3.8 PRINTING

3.8.1 PRESS ROLLER

CAUTION

Take care to avoid possible injury. If the printing pressure release arms

disengage, the press roller will be pulled upwards suddenly.

• Remove the drum.

[A]: Press roller ( x 1)

The bearings on the rear and front differ. During installation, ensure that the

bearing with the stopper [B] is positioned towards the rear of the machine.

C238R037.WMF

[A]

[B]

Page 77

PRINTING

SM 3-27 C249

Replacement

&

Adjustment

3.8.2 PRESS ROLLER RELEASE LEVER ADJUSTMENT

Purpose: To maintain the correct clearance between the press roller arms and

press roller lock levers. This ensures that the press roller is correctly released and

pressed against the drum when the press roller release solenoid is energized.

Standard: 0.7 to 1.2 mm

Tools: A thickness gauge

• Front cover (! 3.3.1)

• Rear covers (! 3.3.2)

1. Turn the drum manually until the drum master clamper on the drum moves into

the lowest position. (This is when the high points of the cams on the drum

flanges meet with the cam followers on both ends of the press roller.)

• To find out the correct position of the drum for the adjustment, look at the

rear end of the drum shaft. The recess on the drum drive gear meets the hole

[A] in the bracket when the drum is in the correct position.

2. Using a thickness gauge, measure the clearance [B] between the press roller

arm [C] and the press roller lock lever [D] (rear side). It should be between 0.7

and 1.2 mm.

3. If it is not correct, adjust the position of the press roller lock lever after

loosening the two screws [E].

4. Repeat steps 2 and 3 for the front side.

C238R001.WMF

C238R051.WMF

[A]

[B]

[C]

[D]

[E]

Page 78

PRINTING

C249 3-28 SM

3.8.3 PRINTING PRESSURE ADJUSTMENT

Improves print results without decreasing the run length.

Standard: Within 17 ± 0.2 mm

1. Adjust the distance [A] to 17 ± 0.2 mm by turning the adjusting bolt [B].

2. Repeat the same procedure for the printing pressure spring at the nonoperation side.

C249R127.WMF

[A]

[B]

Page 79

DRUM

SM 3-29 C249

Replacement

&

Adjustment

3.9 DRUM

3.9.1 PREPARATION

Before attempting any of the procedures in this section, wipe off the ink around the

ink roller. To do this, set SP2-10 (ink detection) to OFF, and feed paper until ink

ends.

After finishing the required procedures in this section, do not forget to return SP210 to the default (ink detection on).

3.9.2 CLOTH SCREEN

• Remove the drum

1. Remove the drum upper bracket ( x 4).

2. Release the stopper [A], then rotate the drum until the master clamper faces

top.

3. Remove the cloth screen [B] ( x 4).

C238R053.WMF

C238R054.WMF

[A]

[B]

Page 80

DRUM

C249 3-30 SM

Installation

• Do not scratch the cloth screen or metal screen.

• Properly insert the edge of the mylar [A] on the cloth screen under the mylar [B]

on the metal screen, as shown above.

Otherwise, ink will leak from the trailing edge of the master on the drum during a

long printing run.

• Make sure that the correct side of the screen is facing up. In addition, make sure

that the stays for securing the cloth screen are positioned correctly. (Refer to the

upper right illustration.)

• When replacing the cloth screen, spread the screen around the metal screen

while strongly pulling the stay [C]. Adjust the stay so that it is parallel to the

master clamper, then tighten the screws.

• Make sure that the cloth screen is not wrinkled while spreading it around the

drum.

C238R055.WMF

C238R056.WMF

C238R057.WMF

[A]

[B]

Inside

Outside

[C]

Page 81

DRUM

SM 3-31 C249

Replacement

&

Adjustment

3.9.3 CLAMPER / METAL SCREEN

• Remove the drum

• Cloth screen (! 3.9.2)

[A]: Clamper lever (1 hexagon screw)

[B]: Clamper - open the clamping plate [C], then remove the clamper.

NOTE:

1) Do not allow ink to get on the inside of the clamping plate [C]. If it is

dirty with ink, the master may slip off and the image position on the

prints will move toward the trailing edge of the prints during a

printing run.

2) Use a cloth dampened with water to clean the inside of the clamping

plate [C]. Never use alcohol or other solvents. The clamping force of

the magnet will be weakened.

[D]: Tape (do not lose it)

[E]: Metal screen ( x 12)

C238R058.WMF

C238R002.WMF

[A]

[B]

[C]

[D]

[E]

Page 82

DRUM

C249 3-32 SM

Installation

• Make sure that the correct end of the metal screen is overlapping. (The right side

overlaps, as viewed from the non-operation side, as shown above.)

• The 4 screws holding the drum master clamper are longer than the 12 screws

holding the metal screen, although they are similar in appearance. Be careful not

to mix them up or use the wrong screws.

• When installing the metal screen, secure the trailing edge first with the 2 screws.

Then, tighten the other screws while removing the slack from the screen. Make

sure that the gap between the drum flanges and the screen is 0.3 mm or less, as

shown above. (The two holes [A] on the trailing side are round holes and the

other holes are long holes, to allow for the removal of the slack.)

• Do not scratch the cloth screen or metal screen.

C238R059.WMF

[A]

Page 83

DRUM

SM 3-33 C249

Replacement

&

Adjustment

3.9.4 INK PUMP ADJUSTMENT

Purpose: To ensure the smooth operation of the ink pump plunger by properly

positioning its holder.

• Remove the drum

[A]: Lower pump cover ( x 2)

[B]: Upper pump cover ( x 3)

1. Remove the E-ring [C] to free the plunger from the pump drive slider [D].

2. Loosen the two screws securing the holder [E]. (Do not remove the holder.)

3. Push the plunger [F] until it reaches the bottom.

NOTE: The end of the plunger [F] must not stick out from the holder [E].

C238R014.WMF

C238R015.WMF

[A]

[B]

[C]

[D]

[E]

[F]

Page 84

DRUM

C249 3-34 SM

4. Check that the piston motion is smooth.

5. If the motion is stiff, loosen the pump screws [G] and adjust the pump position.

6. After tightening, repeat step 4 and step 3.

7. Re-tighten the two screws [H].

8. Check that the piston motion is smooth.

9. Reinstall the E-ring [C].

C238R016.WMF

C238R017.WMF

[C]

[G]

[H]

Page 85

DRUM

SM 3-35 C249

Replacement

&

Adjustment

3.9.5 INK ROLLER UNIT / INK ROLLER ONE-WAY CLUTCH

• Metal screen (! 3.9.3)

• Pump covers (! 3.9.4)

[A]: Board cover ( x 2)

[B]: Front stay ( x 2, x 3)

[C]: Front flange

[D]: Rear stay ( x 2)

[E]: Rear stoppers ( x 1)

[F]: Ring

[G]: Rear flange

[H]: Ink roller unit

[I]: Ink roller one-way clutch

C238R023.WMF

C238R060.WMF

C238R033.WMF

[D]

[E]

[F]

[G]

[E]

[I]

[H]

[A]

[B]

[C]

Page 86

DRUM

C249 3-36 SM

3.9.6 DOCTOR ROLLER GAP ADJUSTMENT

Purpose: To control the ink thickness around the ink roller.

Standard: 0.08 mm gauge passes, 0.10 mm gauge does not.

Tools: Thickness gauge

CAUTION: Normally the doctor roller gap is not adjusted or changed. It tends to be

difficult to change in the field. If the gap is too narrow, an uneven image

may appear on the prints. If it is too wide, too much ink will be applied

to the drum screens, resulting in ink leakage from the drum.

• Ink roller unit (! 3.9.5)

1. Make sure that a 0.08 mm gap gauge goes through the gap [A] between the ink

and doctor rollers, and that a 0.10 mm gap gauge does not.

NOTE:

1) The gap should be checked at both ends of the doctor roller. Insert a

gap gauge at each end of the roller. The gap tends to be larger for

the center.

2) While the gap gauge is inserted, hold the doctor and ink rollers with

your fingers in order to stop the rollers from rotating.

3) While the gap gauge is inserted, hold the end of the gap gauge.

2. If the gap is out of the standard, loosen the screw [B] and adjust the gap by

turning the cam bushing [C] for the front and for the rear.

NOTE: Make sure to repeat the adjustment for both ends of the rollers.

C238R004.WMF

[A]

[B]

[C]

Page 87

DRUM

SM 3-37 C249

Replacement

&

Adjustment

3.9.7 INK DETECTION ADJUSTMENT

Purpose: To ensure that the CPU detects a no-ink condition.

CAUTION: Before attempting this procedure, wipe off the ink around the ink roller.

To do this, set SP2-10 (ink detection) to OFF, and feed paper until ink

ends.

After finishing this procedure, do not forget to return SP2-10 to the

default (ink detection on).

• SP6-40 Ink detection adjustment (! 5.7.2)

3.9.8 MAIN MOTOR PULLEY POSITION

After putting the pulley back on

the main motor shaft, refer to

the above illustration for the

correct position of the pulley.

3.9.9 MAIN DRIVE TIMING BELT ADJUSTMENT

Purpose: After the timing belt is

replaced, correct belt

tension must be applied.

• Rear covers (! 3.3.2)

• MPU (! 3.3.3)

1. Loosen the screws [A], [B], and

[C].

2. Move the tension roller [D] to the

right with a screwdriver [E] as

shown.

3. Tighten the screws [A], [B], and

[C].

4. Remove the screwdriver.

C238R546.WMF

C238R032.WMF

[A]

[B]

[C]

[D]

[E]

[E]

38.8 ± 0.2 mm

Page 88

DRUM

C249 3-38 SM

3.9.10 INK IDLING MOTOR /INK IDLING ROLLER HP SENSOR

• Cloth Screen (! 3.9.2)

• Clamper / Metal Screen (! 3.9.3)

[A]: Ink idling roller HP sensor ( x 1, x 1)

[B]: Ink idling motor ( x 1, x 2)

C249R106.WMF

[A]

[B]

Page 89

DRUM

SM 3-39 C249

Replacement

&

Adjustment

3.9.11 EXIT PAWL ADJUSTMENT

Ensures that the exit pawls can move out of the way of the drum master clamper

while the drum is rotating.

Clearance adjustment

Standard: Within 0.80 ± 0.15 mm

• Front cover (! 3.3.1)

1. Loosen screw [A] then screw [B] in this order (do not remove them). Make sure

that the bracket [C] becomes free from engagement and the cam follower [D]

contacts the drum flange.

2. Using a gap gauge, measure the clearance [E] between the drum surface and

the exit pawls. It should be 0.80 ± 0.15 mm.

3. If the clearance is not correct, adjust the clearance by turning the bolt [F].

4. Reposition the bracket [C] and tighten the screws [A] and [B].

5. Do the timing adjustment (see the next page).

C249R129.WMF

C249R130.WMF

[A]

[B]

[C]

[D]

[E]

[F]

Page 90

DRUM

C249 3-40 SM

Timing adjustment

Standard: 0 or less than 0.5 mm

• Front cover (! 3.3.1)

• Rear covers (! 3.3.2)

• Do this after the clearance adjustment.

1. Turn the drum manually until the recess in the drum drive gear meets the

positioning hole [A] in the bracket, as shown.

2. Loosen screw [B] then screw [C] in that order (do not remove them). Make sure

that the bracket [D] becomes free from engagement and the cam follower [E]

contacts the drum flange.

3. Measure the gap [F] between the cam follower and cam face (front drum

flange). It should be 0 to 0.5 mm.

4. If the gap is not correct, loosen the two screws securing the cam follower

bracket [G].

5. Re-tighten the two screws while pushing the cam follower against the cam face.

Make sure that the gap [F] is 0 or less than 0.5 mm.

NOTE: Do not push the cam followers too strongly against the cam.

6. Re-position the bracket [D] and tighten the screws [B] and [C].

C249R131.WMF

C249R132.WMF

[A]

[B]

[C]

[D]

[E]

[F]

[G]

Page 91

PAPER DELIVERY

SM 3-41 C249

Replacement

&

Adjustment

3.10 PAPER DELIVERY

3.10.1 PAPER DELIVERY UNIT

[A]: Paper delivery cover ( x 4)

[B]: Paper delivery unit ( x 3, x

2)

3.10.2 DELIVERY BELT / PAPER EXIT SENSOR

• Paper delivery unit (! 3.10.1)

[A]: Paper guide ( x 2)

[B]: Delivery belts

[C]: Vacuum fan motor ( x 1, x 4)

[D]: Paper exit sensor ( x 1)

C238R027.WMF

C238R036.WMF

C238R035.WMF

[A]

[B]

[C]

[D]

[A]

[B]

Page 92

PAPER DELIVERY

C249 3-42 SM

3.10.3 EXIT PAWL ADJUSTMENT

Purpose: To ensure that the exit pawls can move out of the way of the drum master

clamper while the drum is rotating.

Clearance adjustment

Standard: Within 1.15 ± 0.15 mm

• Front cover (! 3.3.1)

6. Loosen screw [A] then screw [B] in this order (do not remove them). Make sure

that the bracket [C] becomes free from engagement and the cam follower [D]

contacts the drum flange.

7. Using a gap gauge, measure the clearance [E] between the drum surface and

the exit pawls. It should be 1.15 ± 0.15 mm.

8. If the clearance is not correct, adjust the clearance by turning the bolt [F].

9. Reposition the bracket [C] and tighten the screws [A] and [B].

10. Do the timing adjustment (see the next page).

C238R061.WMF

C238R034.WMF

[A]

[B]

[C]

[D]

[E]

[F]

Page 93

PAPER DELIVERY

SM 3-43 C249

Replacement

&

Adjustment

Timing adjustment

Standard: 0 or less than 0.5 mm

• Front cover (! 3.3.1)

• Rear covers (! 3.3.2)

• Do this after the clearance adjustment.

7. Turn the drum manually until the recess in the drum drive gear meets the

positioning hole [A] in the bracket, as shown.

8. Loosen screw [B] then screw [C] in that order (do not remove them). Make sure

that the bracket [D] becomes free from engagement and the cam follower [E]

contacts the drum flange.

9. Measure the gap [F] between the cam follower and cam face (front drum

flange). It should be 0 to 0.5 mm.

10. If the gap is not correct, loosen the two screws securing the cam follower

bracket [G].

11. Re-tighten the two screws while pushing the cam follower against the cam face.

Make sure that the gap [F] is 0 or less than 0.5 mm.

NOTE: Do not push the cam followers too strongly against the cam.

12. Re-position the bracket [D] and tighten the screws [B] and [C].

C238R022.WMF

C238R005.WMF

[A]

[B]

[C]

[D]

[E]

[F]

[G]

Page 94

PAPER DELIVERY

C249 3-44 SM

3.10.4 AIR PUMP ADJUSTMENT

Purpose: To ensure that the exit pawl produces a jet of air at the proper time.

• Rear covers (! 3.3.2)

1. Check the recess in the drum drive gear meets the positioning hole [A] in the

bracket, as shown.

2. Check whether the hole [B] in the pump drive gear is aligned with the hole [C]

in the air pump unit bracket.

3. If the alignment is incorrect, remove the air pump unit and re-position the gear.

C238R028.WMF

C238R026.WMF

[A]

[B]

[C]

Page 95

SPECIAL TOOLS

SM 3-45 C249

Replacement

&

Adjustment

3.11 SPECIAL TOOLS

The following are the special tools used for service.

Description Part number Note

Scanner positioning pins (4 pins as a set) A006 9104 ! 3.4.5

Flash memory card A230 9352 ! 5.9.2

! 5.9.3

Page 96

Page 97

TROUBLESHOOTING

Page 98

Page 99

ERROR CODES

SM 4-1 C249

Trouble-

shooting

4. TROUBLESHOOTING

4.1 ERROR CODES

No. Symptom Possible cause

E-00 Clamper error

The MPU cannot detect the clamper position sensor

signal (open or closed) within 3.0 seconds after the

clamper motor turns on.

Clamper drive

Clamper sensors

Clamper motor

E-01 Cutter error

The cutter HP sensor does not turn on within 3.0

seconds after the cutter motor turns on.

Cutter drive

Cutter switch

Cutter motor

E-02 Paper Table Drive error

The paper height sensor or the table lower limit sensor

does not turn on within 7.5 seconds after the table motor

turns on.

Table drive

Table motor

Table height sensor

Table lower sensor

E-04 Thermal Head Overheat

The temperature of the thermal head is greater than

54°C when the Start key is pressed.

Overheat (wait for the

thermal head to cool

down)

Thermal head

E-06 Main Motor error

The CPU cannot detect the master eject position sensor