Ricoh C249, C264 Service Manual

C249/C264

SERVICE MANUAL

001780MIU

C249/C264

SERVICE MANUAL

C249/C264

SERVICE MANUAL

001780MIU

It is the reader's responsibility when discussing the information contained

within this document to maintain a level of confidentiality that is in the best

interest of Ricoh Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH CORPORATION.

All product names, domain names or product illustrations, including

desktop images, used in this document are trademarks, registered

trademarks or the property of their respective companies.

They are used throughout this book in an informational or editorial fashion

only and for the benefit of such companies. No such use, or the use of

any trade name, or web site is intended to convey endorsement or other

affiliation with Ricoh products.

© 2006 RICOH Corporation. All rights reserved.

The Service Manual contains information

regarding service techniques, procedures,

p

rocesses and spare parts of office equipmen

t

distributed by Ricoh Corporation. Users of this

manual should be either service trained o

r

certified by successfully completing a Ricoh

Technical Training Program.

Untrained and uncertified users utilizin

g

information contained in this service manual to

repair or modify Ricoh equipment risk persona

l

injury, damage to property or loss of warrant

y

p

rotection.

Ricoh Corporation

WARNING

LEGEND

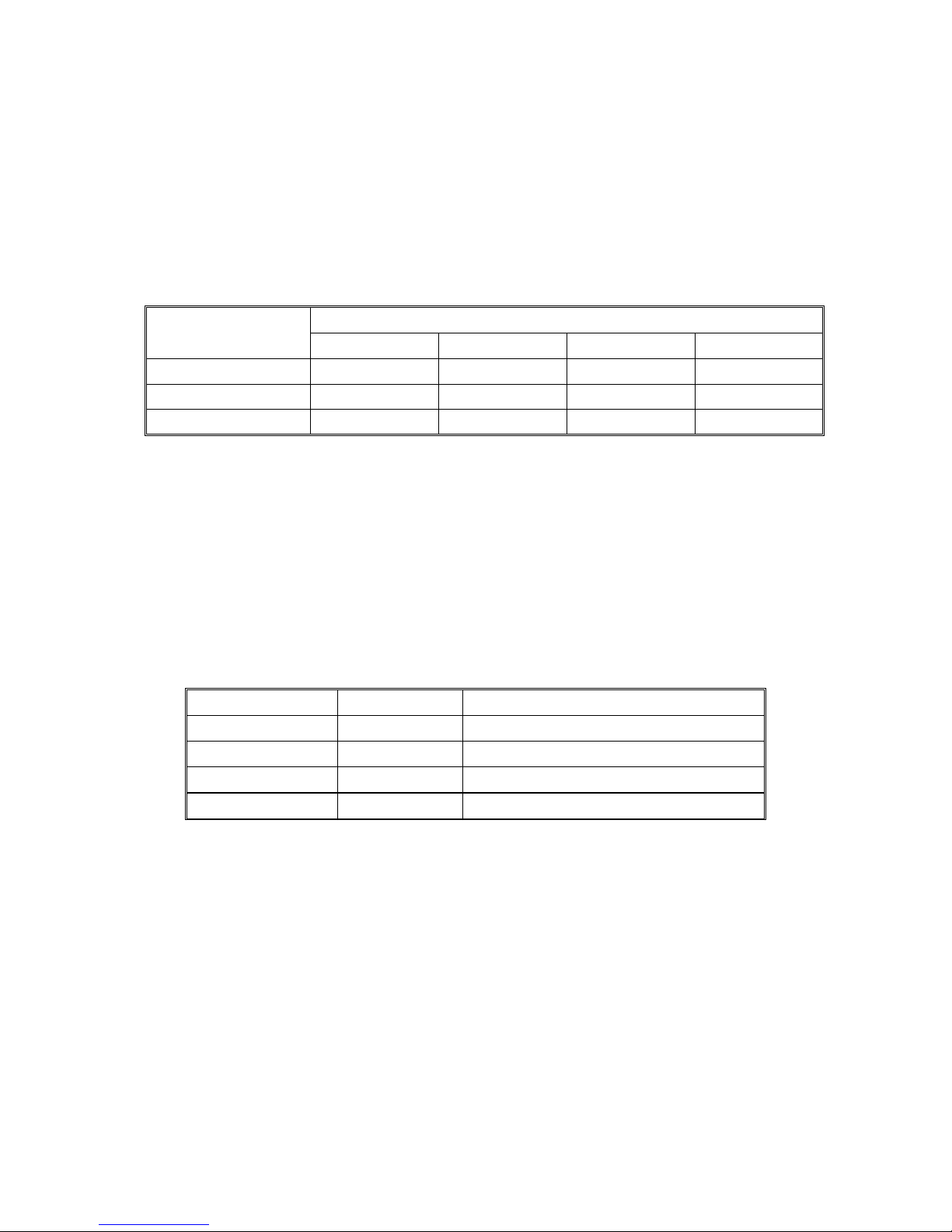

PRODUCT CODE COMPANY

GESTETNER LANIER RICOH SAVIN

C249 CP244 LDD145 JP4500 3560DNP

C264 CP6244 LDD245 DX4542 3270DNP

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

*

10/2003 Original Printing

1 09/2006 C264 Addition

SM i C249/C264

C249/C264

TABLE OF CONTENTS

INSTALLATION

1. INSTALLATION............................................................................ 1-1

1.1 INSTALLATION REQUIREMENTS ...........................................................1-1

1.1.1 OPTIMUM ENVIRONMENTAL CONDITION....................................1-1

1.1.2 ENVIRONMENTS TO AVOID...........................................................1-1

1.1.3 POWER CONNECTION ...................................................................1-1

1.1.4 MACHINE ACCESS .........................................................................1-2

1.2 INSTALLATION PROCEDURE .................................................................1-3

1.2.1 MAIN UNIT .......................................................................................1-3

1.2.2 BEFORE BEGINNING MACHINE OPERATION ..............................1-9

1.2.3 PLATEN COVER INSTALLATION (OPTION) ...................................... 1-10

1.2.4 ADF INSTALLATION (OPTION).....................................................1-11

1.2.5 TAPE MARKER (OPTION)..............................................................1-15

1.2.6 OPTIONAL DRUMS .......................................................................1-22

PREVENTIVE MAINTENANCE

2. PREVENTIVE MAINTENANCE.................................................... 2-1

2.1 MAINTENANCE TABLE ............................................................................2-1

REPLACEMENT AND ADJUSTMENT

3. REPLACEMENT AND ADJUSTMENT ........................................ 3-1

3.1 GENERAL CAUTION ................................................................................3-1

3.2 PRINT KEY / START KEY......................................................................... 3-1

3.3 COVERS / BOARDS .................................................................................3-2

3.3.1 FRONT COVER / PANEL.................................................................3-2

3.3.2 REAR COVERS................................................................................3-3

3.3.3 MPU..................................................................................................3-3

3.3.4 PSU ..................................................................................................3-4

3.4 SCANNER .................................................................................................3-5

3.4.1 EXPOSURE GLASS / SCALES........................................................3-5

3.4.2 SBU AND LAMP STABILIZER / SCANNER MOTOR....................... 3-5

3.4.3 SCANNER H.P. SENSOR / PLATEN COVER SENSOR .................3-6

3.4.4 EXPOSURE LAMP (XENON LAMP) ................................................3-7

3.4.5 SCANNER WIRES ...........................................................................3-8

3.4.6 IMAGE ADJUSTMENT ...................................................................3-10

3.5 MASTER EJECT ..................................................................................... 3-11

3.5.1 MASTER EJECT UNIT ................................................................... 3-11

3.6 MASTER FEED ....................................................................................... 3-12

3.6.1 MASTER MAKING UNIT ................................................................ 3-12

Rev. 04/2004

C249/C264 ii SM

3.6.2 THERMAL HEAD............................................................................3-12

3.6.3 DUCT PLATE HP SENSOR / DUCT PLATE MOTOR.................... 3-16

3.6.4 CUTTER UNIT................................................................................ 3-17

3.6.5 THERMAL HEAD DRIVING UNIT ..................................................3-17

3.6.6 THERMAL HEAD VOLTAGE ADJUSTMENT................................. 3-18

3.6.7 DUCT JAM SENSOR ADJUSTMENT ............................................3-19

3.6.8 MASTER EDGE SENSOR ADJUSTMENT ....................................3-20

3.6.9 2ND DRUM MASTER SENSOR ADJUSTMENT............................ 3-21

3.6.10 MASTER END SENSOR ADJUSTMENT ..................................... 3-22

3.7 PAPER FEED..........................................................................................3-23

3.7.1 PICK-UP ROLLER / PAPER FEED ROLLER / FRICTION PAD..... 3-23

3.7.2 PAPER SEPARATION PRESSURE ADJUSTMENT......................3-24

3.7.3 PAPER WIDTH DETECTION BOARD ...........................................3-25

3.8 PRINTING ...............................................................................................3-26

3.8.1 PRESS ROLLER ............................................................................3-26

3.8.2 PRESS ROLLER RELEASE LEVER ADJUSTMENT ..................... 3-27

3.8.3 PRINTING PRESSURE ADJUSTMENT.........................................3-28

3.9 DRUM...................................................................................................... 3-29

3.9.1 PREPARATION..............................................................................3-29

3.9.2 CLOTH SCREEN............................................................................3-29

3.9.3 CLAMPER / METAL SCREEN .......................................................3-31

3.9.4 INK PUMP ADJUSTMENT .............................................................3-33

3.9.5 INK ROLLER UNIT / INK ROLLER ONE-WAY CLUTCH ............... 3-35

3.9.6 DOCTOR ROLLER GAP ADJUSTMENT ....................................... 3-36

3.9.7 INK DETECTION ADJUSTMENT...................................................3-37

3.9.8 MAIN MOTOR PULLEY POSITION................................................3-37

3.9.9 MAIN DRIVE TIMING BELT ADJUSTMENT ..................................3-37

3.9.10 INK IDLING MOTOR /INK IDLING ROLLER HP SENSOR .......... 3-38

3.9.11 EXIT PAWL ADJUSTMENT .........................................................3-39

3.10 PAPER DELIVERY................................................................................3-41

3.10.1 PAPER DELIVERY UNIT .............................................................3-41

3.10.2 DELIVERY BELT / PAPER EXIT SENSOR..................................3-41

3.10.3 EXIT PAWL ADJUSTMENT .........................................................3-42

3.10.4 AIR PUMP ADJUSTMENT ...........................................................3-44

3.11 SPECIAL TOOLS .................................................................................. 3-45

TROUBLESHOOTING

4. TROUBLESHOOTING ................................................................. 4-1

4.1 ERROR CODES........................................................................................4-1

4.2 ELECTRICAL COMPONENT DEFECTS ..................................................4-3

4.2.1 SENSORS ........................................................................................4-3

4.2.2 SWITCHES.......................................................................................4-5

4.2.3 LINES ...............................................................................................4-5

4.3 FUSE, LED, VR, DIP-SW, AND TP TABLES ............................................4-6

4.3.1 BLOWN FUSE CONDITIONS ..........................................................4-6

4.3.2 LED’S ...............................................................................................4-6

4.3.3 VR’S .................................................................................................4-6

4.3.4 DIP SWITCHES................................................................................ 4-7

SM iii C249/C264

4.3.5 TEST POINTS ..................................................................................4-7

4.4 OTHERS ...................................................................................................4-8

4.4.1 PAPER FEED PROBLEMS ..............................................................4-8

4.4.2 PAPER EJECTION ERRORS ........................................................4-10

4.4.3 MASTER FEED ERRORS..............................................................4-10

4.4.4 MASTER DELIVERY ERRORS...................................................... 4-11

4.4.5 DRUM ERRORS.............................................................................4-11

4.4.6 POOR IMAGE ................................................................................4-12

4.4.7 OTHERS.........................................................................................4-13

4.4.8 USER INSTRUCTIONS..................................................................4-14

SERVICE TABLES

5. SERVICE TABLES....................................................................... 5-1

5.1 USING SERVICE PROGRAM MODES.....................................................5-1

5.1.1 ACCESSING SP MODES.................................................................5-1

5.1.2 HOW TO SELECT A PROGRAM NUMBER.....................................5-2

5.2 MAIN MENU NO.1: COPY DATA ..............................................................5-3

5.2.1 SP TABLE ........................................................................................5-3

5.2.2 SP1-70: MAIN FIRMWARE PARTS NUMBER.................................5-3

5.2.3 SP1-80: ERROR CODE HISTORY...................................................5-3

5.3 MAIN MENU NO.2: BASIC SETTINGS .....................................................5-4

5.3.1 SP TABLE ........................................................................................5-4

5.3.2 SP2-7: CHINESE DISPLAY SETTING (CHINA MODEL ONLY) ......5-5

5.3.3 SP2-32: INK SUPPLY AFTER TRIAL...............................................5-5

5.3.4 SP2-33: RE - FEEDING SETTING ...................................................5-5

5.3.5 SP2-34: SLOW STARTING MODE ..................................................5-5

5.3.6 SP2-35: PRINTING PRESSURE ADJUSTMENT.............................5-5

5.3.7 SP2-36: INK IDLING ROLLER SETTING .........................................5-6

5.3.8 SP2-38: IDLING AFTER PRINT (SP2-28, 29) ..................................5-6

5.3.9 SP2-41, 2-42: THERMAL HEAD ENERGY CONTROL....................5-6

5.3.10 SP2-60: BOLD MODE: LETTER MODE ONLY ..............................5-6

5.3.11 SP2-100: MAKE A MASTER WITHOUT PRINTING.......................5-6

5.4 MAIN MENU NO.3: SYSTEM SETTINGS .................................................5-7

5.4.1 SP TABLE ........................................................................................5-7

5.4.2 SP3-1: INPUT THE PRESENT TIME ...............................................5-7

5.4.3 SP3-4: INPUT INSTALLATION DATE..............................................5-8

5.5 MAIN MENU NO.4: INPUT MODE ............................................................ 5-9

5.5.1 SP TABLE ........................................................................................5-9

5.6 MAIN MENU NO.5: OUTPUT MODE ......................................................5-10

5.6.1 SP TABLE ......................................................................................5-10

5.7 MAIN MENU NO.6: ADJUSTMENT.........................................................5-11

5.7.1 SP TABLE ......................................................................................5-11

5.7.2 SP6-40: INK DETECTION ADJUSTMENT .....................................5-14

5.7.3 IMAGE ADJUSTMENT (SP6-10, -21, -5, -3, AND -1).....................5-14

5.7.4 SP6-31: SBU CALIBRATION .........................................................5-17

5.7.5 SP6-32 TO 37: MTF FILTER ..........................................................5-17

5.7.6 SP6-20: REGISTRATION BUCKLE (NOT USED).......................... 5-18

5.7.7 SP6-60: MASTER RETURNING VALUE........................................5-18

Rev. 10/2004

C249/C264 iv SM

5.7.8 SP6-64: MASTER PUSHING VALUE (NOT USED).......................5-18

5.7.9 SP6-100 TO 107: PAPER REGISTRATION - EACH SPEED.........5-19

5.7.10 SP6-116 TO 123: PAPER MIDDLE BUCKLE (NOT USED) .........5-20

5.7.11 SP6-124 TO 131: PAPER FRONT BUCKLE (NOT USED) .......... 5-22

5.8 MAIN MENU NO.7: MEMORY CLEAR....................................................5-25

5.8.1 SP TABLE ......................................................................................5-25

5.8.2 SP7-1: FACTORY SETTINGS CLEAR...........................................5-25

5.9 MAIN MENU NO.8: SYSTEM TEST........................................................5-26

5.9.1 SP TABLE ......................................................................................5-26

5.9.2 SP8-1: DOWNLOAD MAIN FIRMWARE ........................................5-26

5.9.3 SP8-2: UPLOAD MAIN FIRMWARE...............................................5-27

5.9.4 SP8-10: TEST PATTERNS ............................................................5-27

5.9.5 SP8-21: PAPER FEED TEST (15 RPM).........................................5-27

5.9.6 SP8-22: FREE RUN PAPER FEED (15 RPM) ...............................5-27

5.9.7 SP8-18: TEMPORARY SECURITY................................................5-28

DETAILED DESCRIPTIONS

6. DETAILED SECTION DESCRIPTIONS ....................................... 6-1

6.1 MECHANISM OVERVIEW ........................................................................6-1

6.1.1 COMPONENT LAYOUT ...................................................................6-1

6.1.2 ELECTRICAL COMPONENT LAYOUT ............................................6-2

6.1.3 DRIVE LAYOUT ...............................................................................6-7

6.2 MASTER EJECT UNIT..............................................................................6-8

6.2.1 OVERVIEW ......................................................................................6-8

6.2.2 MASTER CLAMPER OPENING MECHANISM ................................6-9

6.2.3 MASTER EJECT ROLLER MECHANISM ...................................... 6-10

6.2.4 PRESSURE PALTE MECHANISM.................................................6-11

6.3 SCANNER UNIT......................................................................................6-12

6.3.1 OVERVIEW ....................................................................................6-12

6.3.2 BOARD LAYOUT............................................................................6-13

6.3.3 AUTO BACKGROUND CORRECTION ..........................................6-14

6.3.4 MTF FILTER...................................................................................6-14

6.3.5 SMOOTHING FILTER .................................................................... 6-14

6.3.6 MAIN SCAN ENLARGEMENT/REDUCTION .................................6-14

6.3.7 BINARY PROCESSING .................................................................6-15

6.3.8 FINE MODE....................................................................................6-15

6.3.9 THERMAL HEAD............................................................................6-16

6.4 MASTER FEED ....................................................................................... 6-18

6.4.1 OVERVIEW ....................................................................................6-18

6.4.2 AUTO ADJUSTABLE MASTER SET..............................................6-19

6.4.3 THERMAL HEAD DRIVING MECHANISM.....................................6-20

6.4.4 MASTER BUFFER MECHANISM...................................................6-21

6.4.5 DETECTION OF MASTER IN THE LOWER MASTER TRAY........6-22

6.4.6 DUCT PLATE MECHANISM ..........................................................6-23

6.4.7 MASTER FEED MECHANISM .......................................................6-25

6.4.8 CLAMPER AND TENSION ROLLER MECHANISM.......................6-26

6.4.9 MASTER PUSH MYLAR ................................................................6-27

6.4.10 2ND DRUM MASTER SENSOR................................................... 6-28

Rev. 10/2004

SM v C249/C264

6.4.11 CUTTER MECHANISM ................................................................6-29

6.4.11 MASTER SET COVER SENSOR.................................................6-29

6.4.13 RE-CUTTING MECHANISM......................................................... 6-30

6.5 DRUM...................................................................................................... 6-31

6.5.1 OVERVIEW ....................................................................................6-31

6.5.2 DRUM DRIVE MECHANISM ..........................................................6-32

6.5.3 INK SUPPLY MECHANISM............................................................6-33

6.5.4 INK ROLLER MECHANISM ...........................................................6-34

6.5.5 INK SUPPLY CONTROL ................................................................6-35

6.5.6 DRUM IDLING MECHANISM .........................................................6-36

6.6 PAPER FEED..........................................................................................6-38

6.6.1 OVERVIEW ....................................................................................6-38

6.6.2 PAPER FEED MECHANISM ..........................................................6-39

6.6.3 PAPER FEED/SEPARATION PRESSURE MECHANISM .............6-40

6.6.4 REGISTRATION ROLLER MECHANISM.......................................6-41

6.6.5 PRINTING PRESSURE MECHANISM ........................................... 6-42

6.6.6 AUTO ADJUTABLE PRINTING PRESSURE MECHANISM .........6-43

6.6.7 PAPER TABLE MECHANISM .........................................................6-44

6.7 PAPER DELIVERY..................................................................................6-46

6.7.1 OVERVIEW ....................................................................................6-46

6.7.2 PAPER DELIVERY UNIT DRIVE MECHANISM............................. 6-46

6.7.3 PAPER SEPARATION FROM THE DRUM ....................................6-47

6.7.4 EXIT PAWL DRIVE MECHANISM..................................................6-48

6.8 TIMING CHART.......................................................................................6-49

6.8.1 MASTR EJECT/MASTER FEED ....................................................6-49

6.8.2 MASTER WRAPPING .................................................................... 6-51

6.8.3 PRINTING ......................................................................................6-53

6.9 JAM DETECTION....................................................................................6-55

6.9.1 MASTER EJECT JAM (B JAM LOCATION INDICATOR) ..............6-55

6.9.2 DF JAM (P JAM LOCATION INDICATOR).....................................6-56

6.9.3 MASTER FEED JAM (D JAM LOCATION INDICATOR)................6-57

6.9.4 DRUM JAM (B JAM LOCATION INDICATOR)...............................6-60

6.9.5 PAPER FEED JAM (A JAM LOCATION INDICATOR)................... 6-60

6.9.6 PAPER DELIVERY JAM (C JAM LOCATION INDICATOR)...........6-61

SPECIFICATIONS

SPECIFICATIONS............................................................................. 7-1

1. GENERAL SPECIFICATIONS.....................................................................7-1

C264

SEE SECTION C264 FOR DETAILED TABLE OF CONTENTS

DOCUMENT FEEDER C600

SEE SECTION C600 FOR DETAILED TABLE OF CONTENTS

Rev. 07/2004

C249/C264 vi SM

PRINTER SCANNER C624

SEE SECTION C624 FOR DETAILED TABLE OF CONTENTS

INSTALLATION C249

DOCUMENT FEEDER C600

PREVENTIVE MAINTENANCE C249

PRINTER/CONTROLLER C624

REPLACEMENT AND ADJUSTMENT C249

TROUBLESHOOTING C249

SERVICE TABLES C249

DETAILED DESCRIPTIONS C249

SPECIFICATIONS C249

C264

TAB

POSITION 2

TAB

POSITION 1

TAB

POSITION 3

TAB

POSITION 4

TAB

POSITION 6

TAB

POSITION 5

TAB

POSITION 8

TAB

POSITION 7

INSTALLATION

INSTALLATION REQUIREMENTS

SM 1-1 C249

Installation

1. INSTALLATION

1.1 INSTALLATION REQUIREMENTS

Carefully select the installation location. Environmental conditions greatly affect

machine performance.

1.1.1 OPTIMUM ENVIRONMENTAL CONDITION

1. Temperature 10 to 30 °C (50 to 86 °F)

2. Humidity 20 to 90 % RH

3. Install the machine on a strong and level base. The machine must be level

within 5 mm (0.2") both front to rear and left to right.

1.1.2 ENVIRONMENTS TO AVOID

1. Locations exposed to direct sunlight or strong light (more than 1,500 lux).

2. Dusty areas.

3. Areas containing corrosive gases.

4. Locations directly exposed to cool air from an air conditioner or reflected heat

from a space heater. (Sudden temperature changes from low to high or vice

versa may cause condensation within the machine.)

1.1.3 POWER CONNECTION

1. Securely connect the power cord to a power source.

2. Make sure that the wall outlet is near the machine and easily accessible.

3. Make sure the plug is firmly inserted in the outlet.

4. Avoid multi-wiring.

5. Do not pinch the power cord.

INSTALLATION REQUIREMENTS

C249 1-2 SM

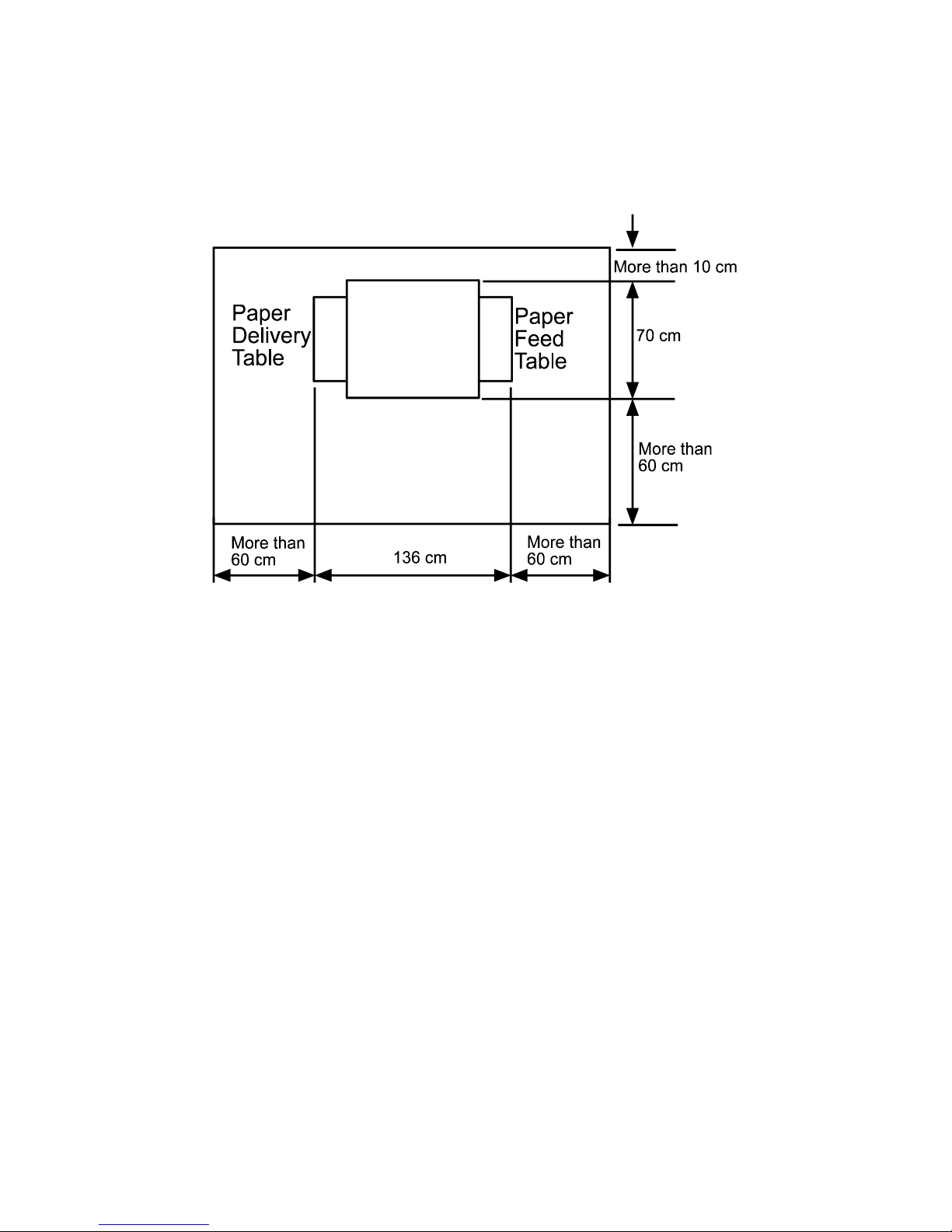

1.1.4 MACHINE ACCESS

Place the machine near a power source, providing clearance as shown below.

C249I000.WMF

INSTALLATION PROCEDURE

SM 1-3 C249

Installation

1.2 INSTALLATION PROCEDURE

1.2.1 MAIN UNIT

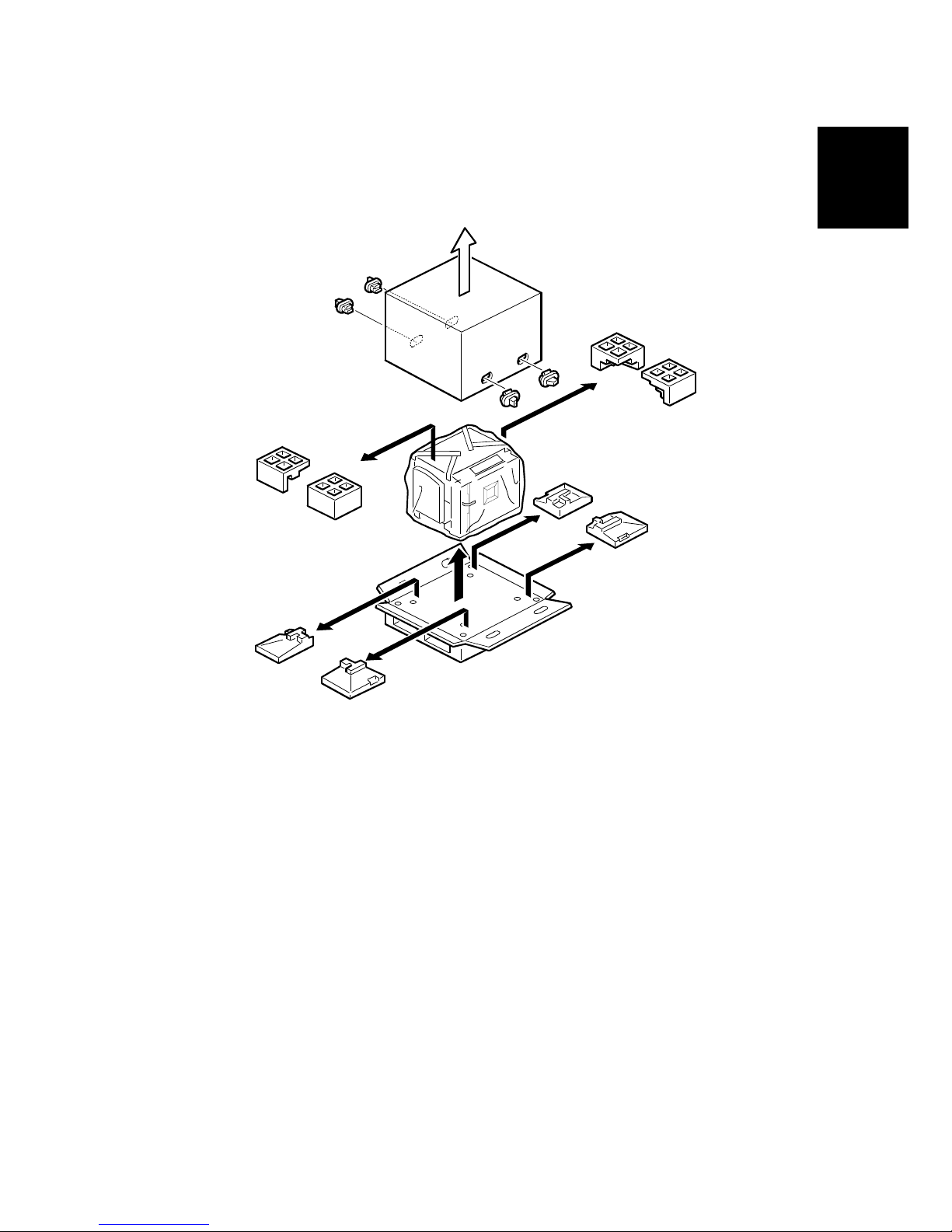

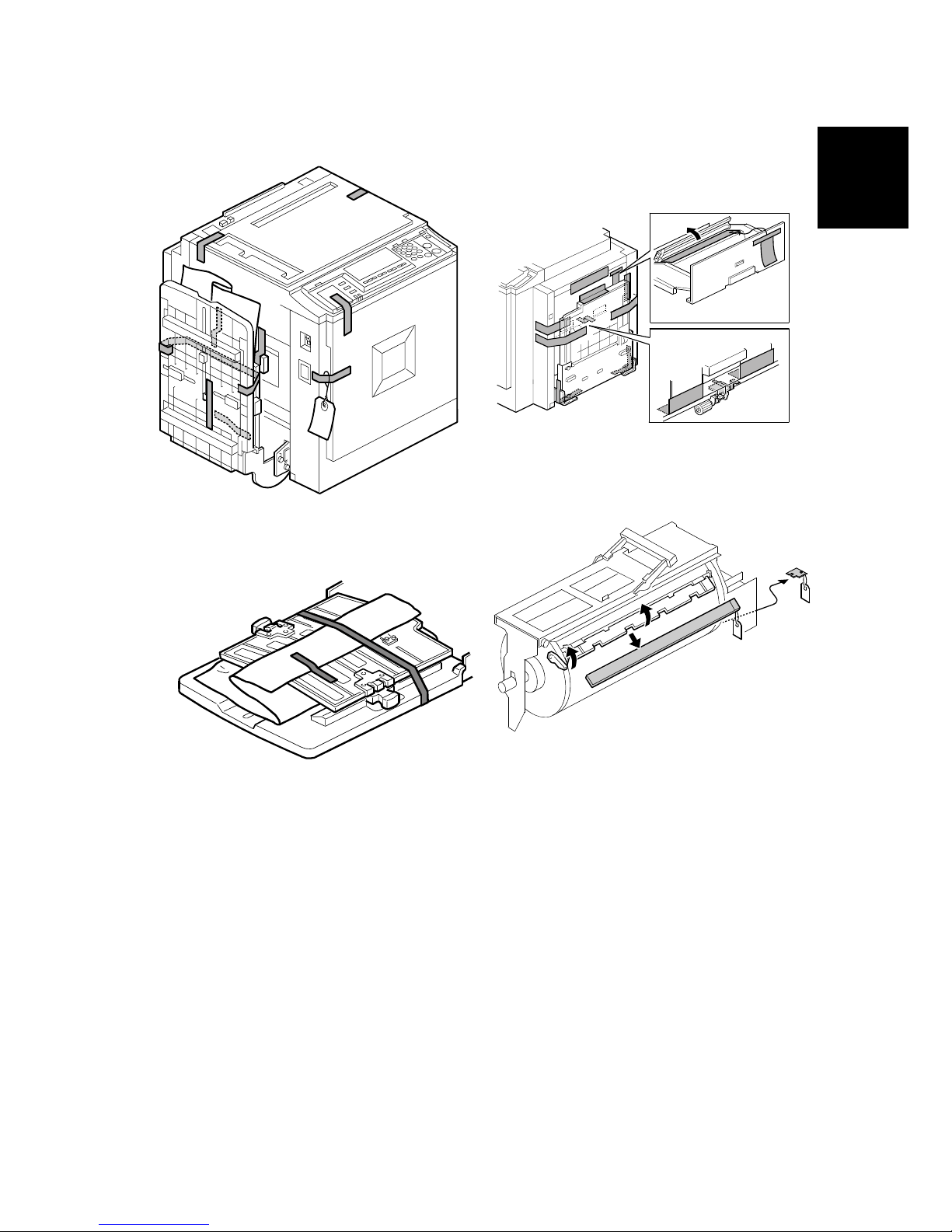

Accessory Check

Make sure that you have all the accessories listed below:

Description Q'ty

1. Master Spool.............................................................................. 2

2. Operating Instructions................................................................ 1

3. NECR (Ricoh version only)........................................................ 1

4. Model Name Plates (C249-22, and -52 only)............................. 1 set

C249I019.WMF

INSTALLATION PROCEDURE

C249 1-4 SM

Installation Procedure

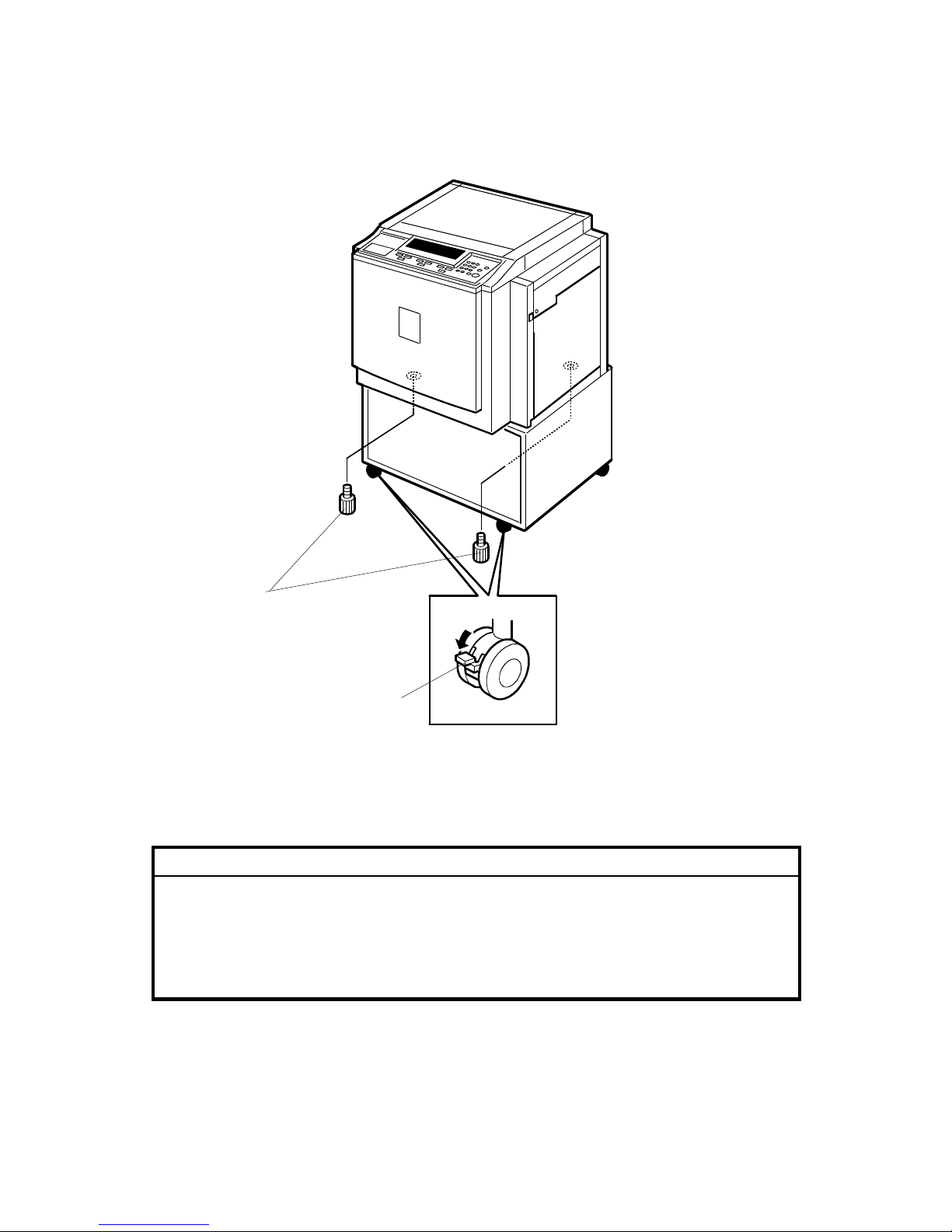

1. Unpack the box. When installing the optional table, mount the machine as

shown (there are 2 screws [A] packed with the table).

CAUTION

Only lift with the carrying handles on the bottom corners of the machine.

Secure the machine on the table with the 2 screws [A] provided. This

prevents the machine from falling from the table when the platen cover is

open.

Lock the casters of the table as shown [B], to prevent the machine from

moving (e.g. when the drum is set).

C249I014.WMF

[B]

[A]

INSTALLATION PROCEDURE

SM 1-5 C249

Installation

2. Remove the filament tape and string securing the covers and units as shown

above.

C249I907.WMF

C249I020.WMF

C249I908.WMF

C249I909.WMF

INSTALLATION PROCEDURE

C249 1-6 SM

3. Pull out the master making unit, and

take out the accessory bag [A].

4. Insert both spools into a new master

roll.

5. Install the master roll as shown to the right.

6. Insert the leading edge of the master

roll under the platen roller. The arrows

[B] indicate the correct position of the

master leading edge.

C249I038.WMF

C249I030.WMF

C249I032.WMF

C249I910.WMF

[B]

[A]

INSTALLATION PROCEDURE

SM 1-7 C249

Installation

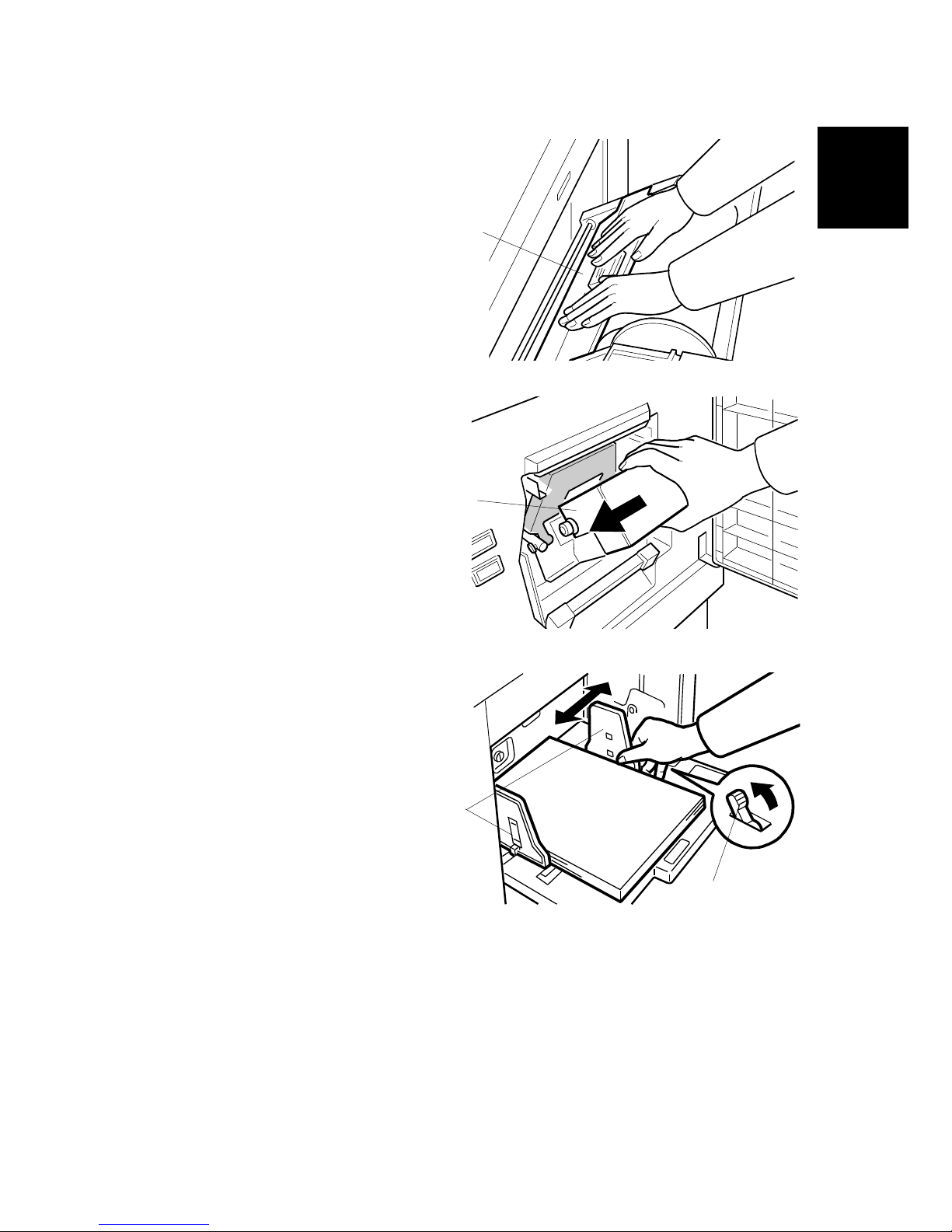

7. Close the cover [C] using both hands.

8. Set the master-making unit.

9. Open the door, and insert a new ink

cartridge [D].

10. Open the paper table, and load a

stack of paper.

11. Make sure that the side plates [E]

touch the paper gently. Shift the lock

lever [F] in the direction of the arrow.

C249I031.WMF

C249I034.WMF

C249I028.WMF

[D]

[C]

[E]

[F]

INSTALLATION PROCEDURE

C249 1-8 SM

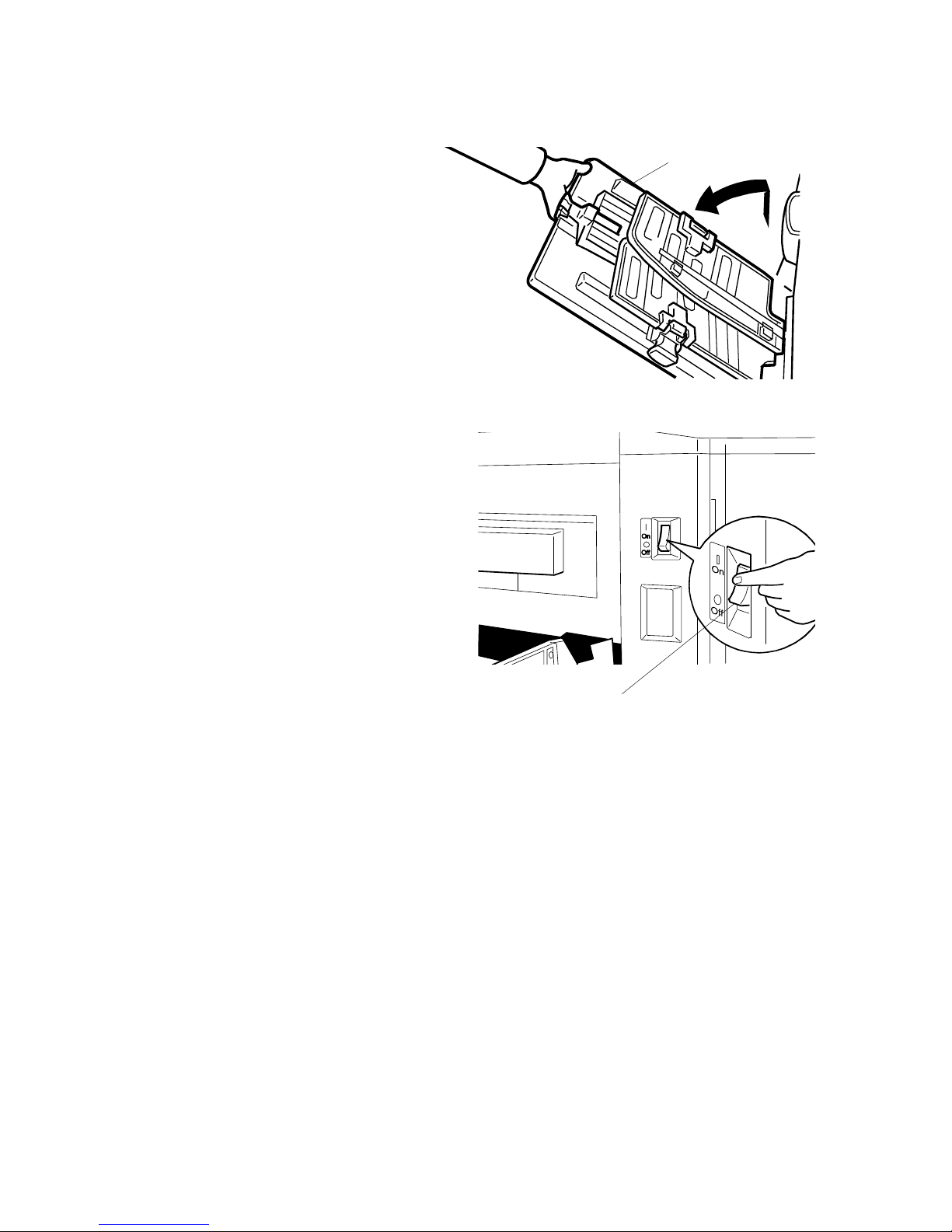

12. Raise the paper delivery table [G]

slightly, then gently lower it.

13. Lift the side plates and the end

plate, and adjust them to the

paper size.

14. Firmly insert the power plug in the

outlet.

15. Make sure that the wall outlet is near

the machine and easily accessible.

16. Turn on the main switch [H].

17. Press the “Economy mode” key while

holding down the “0” key, to supply

ink inside the drum.

18. Make some test copies.

C249I027.WMF

C249I026.WMF

[G]

[H]

Loading...

Loading...