Page 1

C231/C237

SERVICE MANUAL

RICOH GROUP COMPANIES

PN: RCSMC231

Page 2

Page 3

®

®

SERVICE MANUAL

C231/C237

RICOH GROUP COMPANIES

Page 4

Page 5

C231/C237

SERVICE MANUAL

PN:RCSMC231

Page 6

Page 7

It is the reader's responsibility when discussing the information contained within this

document to maintain a level of confidentiality that is in the best interest of Ricoh

Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH CORPORATION.

All product names, domain names or product illustrations, including desktop images,

used in this document are trademarks, registered trademarks or the property of their

respective companies.

They are used throughout this book in an informational or editorial fashion only and for

the benefit of such companies. No such use, or the use of any trade name, or web

site is intended to convey endorsement or other affiliation with Ricoh products.

2000 RICOH Corporation. All rights reserved.

Page 8

Page 9

n

t

s

r

h

g

o

l

y

WARNING

The Service Manual contains informatio

regarding service techniques, procedures,

processes and spare parts of office equipmen

distributed by Ricoh Corporation. Users of thi

manual should be either service trained o

certified by successfully completing a Rico

Technical Training Program.

Untrained and uncertified users utilizin

information contained in this service manual t

repair or modify Ricoh equipment risk persona

injury, damage to property. or loss of warrant

protection.

Ricoh Corporation

Page 10

Page 11

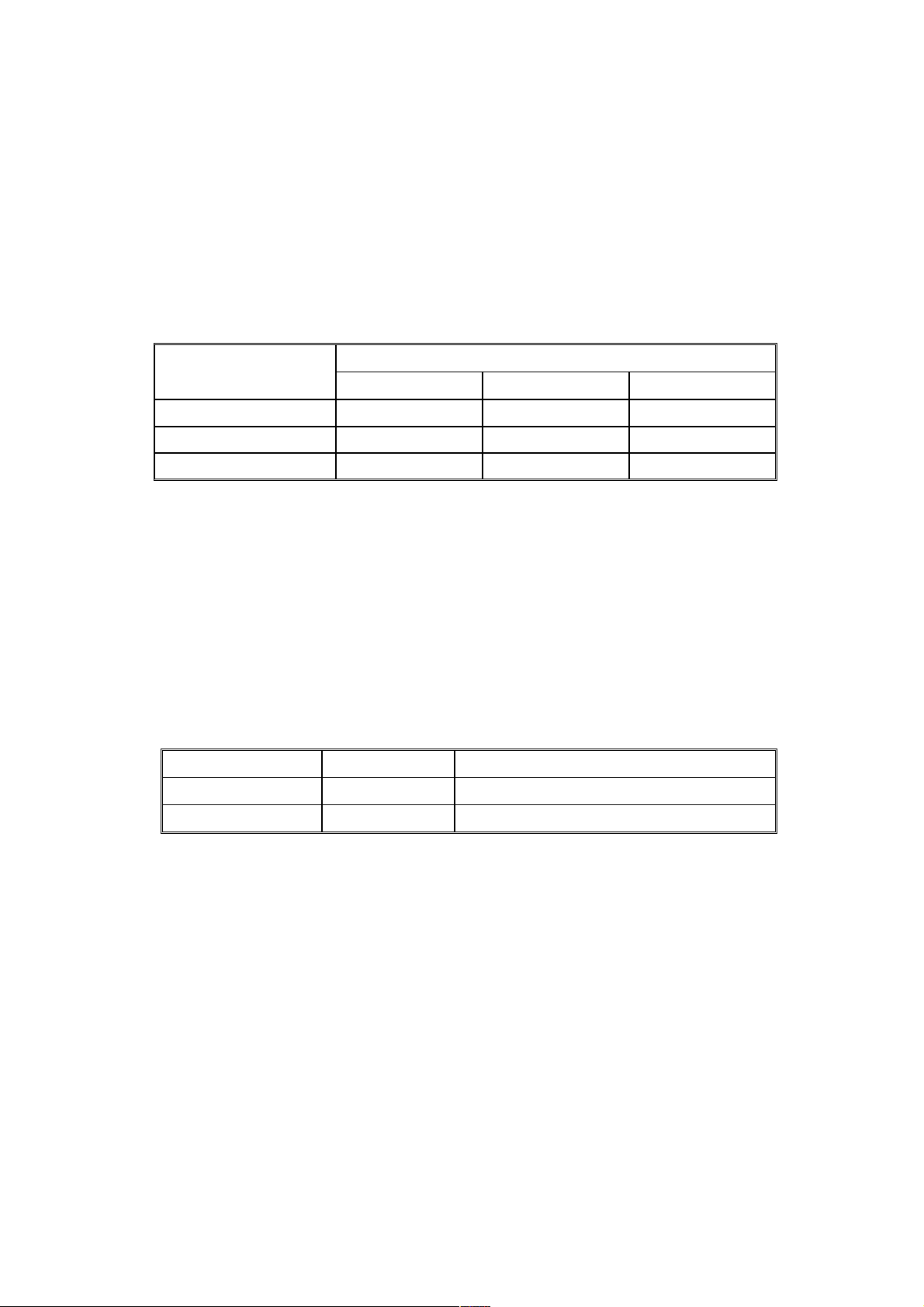

LEGEND

PRODUCT CODE COMPANY

GESTETNER RICOH SAVIN

C231 5306L JP1030 3150DNP

C237 5308L JP1230 3150eDNP

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

* 7/98 Original Printing

1 8/2000 C237 Addition

Page 12

Page 13

C231/C237

TABLE OF CONTENTS

OVERALL INFORMATION............................................................... 1-1

1.1 SPECIFICATION....................................................................................... 1-1

1.2 GUIDE TO COMPONENTS AND THEIR FUNCTION............................... 1-5

1.2.1 MACHINE EXTERIOR......................................................................1-5

1.2.2 MACHINE INTERIOR....................................................................... 1-6

1.2.3 OPERATION PANEL........................................................................1-7

Keys......................................................................................................1-7

Indicators ..............................................................................................1-9

1.3 PRINTING PROCESS............................................................................. 1-10

1.4 MECHANICAL COMPONENT LAYOUT ................................................. 1-11

1.5 ELECTRICAL COMPONENT LAYOUT...................................................1-12

1.5.1 ADF ................................................................................................ 1-12

1.5.2 MAIN BODY ................................................................................... 1-13

Boards ................................................................................................ 1-14

Motors................................................................................................. 1-14

Solenoids............................................................................................ 1-15

Switches ............................................................................................. 1-15

Sensors ..............................................................................................1-15

Counters .............................................................................................1-16

Others................................................................................................. 1-16

1.6 DRIVE LAYOUT...................................................................................... 1-17

DETAILED SECTION DESCRIPTIONS............................................ 2-1

2.1 SCANNER AND OPTICS.......................................................................... 2-1

2.1.1 BOOK SCANNER OVERVIEW ........................................................ 2-1

2.1.2 ADF OVERVIEW.............................................................................. 2-2

2.1.3 CONTACT IMAGE SENSOR ........................................................... 2-4

2.1.4 DRIVE MECHANISM........................................................................2-5

Book Scanner .......................................................................................2-5

ADF ......................................................................................................2-6

2.1.5 PICK-UP AND FEED (ADF) ............................................................. 2-7

2.1.6 SEPARATION MECHANISM (ADF)................................................. 2-8

2.1.7 ERROR CONDITIONS..................................................................... 2-9

Book Scanner .......................................................................................2-9

ADF ......................................................................................................2-9

2.2 IMAGE-PROCESSING............................................................................ 2-10

2.2.1 OVERVIEW....................................................................................2-10

2.2.2 A/D CONVERSION PROCESSING................................................2-11

Shading Distortion Correction............................................................. 2-11

Original Background Correction.......................................................... 2-12

Peak Hold ...........................................................................................2-12

SM C231/C237

i

Page 14

2.2.3 BINARY PROCESSING ................................................................. 2-13

Data Compensation Processing ......................................................... 2-13

MTF Correction................................................................................... 2-14

Binary Processing in Letter/Photo Mode............................................. 2-14

Error Diffusion..................................................................................... 2-15

2.2.4 MAIN SCAN MAGNIFICATION ......................................................2-16

2.2.5 IMAGE POSITION ADJUSTMENT IN THE MAIN

SCAN DIRECTION......................................................................... 2-17

2.2.6 PASTE SHADOW ERASE MODE.................................................. 2-17

2.2.7 THERMAL HEAD ...........................................................................2-18

Specifications .....................................................................................2-18

Thermal Head Control ........................................................................ 2-18

Thermal Head Protection.................................................................... 2-18

Remarks for Handling the Thermal Head ...........................................2-19

2.3 MASTER EJECT..................................................................................... 2-20

2.3.1 OVERALL....................................................................................... 2-20

2.3.2 MASTER CLAMPER OPEN MECHANISM .................................... 2-21

Drum Position Lock Mechanism ......................................................... 2-21

2.3.3 MASTER EJECT ROLLER MECHANISM...................................... 2-22

2.3.4 PRESSURE PLATE MECHANISM.................................................2-23

2.4 MASTER FEED....................................................................................... 2-24

2.4.1 OVERALL....................................................................................... 2-24

2.4.2 MASTER FEED MECHANISM .......................................................2-25

2.4.3 MASTER CLAMPER OPERATION AND TENSION ROLLER

RELEASE MECHANISM................................................................ 2-26

2.4.4 CUTTER MECHANISM..................................................................2-27

2.5 DRUM .....................................................................................................2-28

2.5.1 OVERALL....................................................................................... 2-28

2.5.2 DRUM DRIVE MECHANISM.......................................................... 2-29

2.5.3 INK SUPPLY MECHANISM ........................................................... 2-30

2.5.4 INK ROLLER MECHANISM ........................................................... 2-31

2.5.5 INK SUPPLY CONTROL................................................................ 2-32

2.5.6 DETECTION OF MASTERS ON THE DRUM ................................ 2-33

2.6 PAPER FEED..........................................................................................2-34

2.6.1 OVERALL....................................................................................... 2-34

2.6.2 PAPER FEED MECHANISM.......................................................... 2-35

2.6.3 PAPER FEED/SEPARATION PRESSURE ADJUSTMENT

MECHANISM ................................................................................. 2-36

2.6.4 REGISTRATION ROLLER MECHANISM ......................................2-37

Registration Roller Drive..................................................................... 2-37

Registration Roller Up/Down Mechanism ........................................... 2-38

2.6.5 PRINTING PRESSURE MECHANISM........................................... 2-39

2.6.6 PAPER TABLE MECHANISM........................................................ 2-40

Table Up and Down Mechanism.........................................................2-40

Paper End Detection Mechanism .......................................................2-40

Paper Table Side Fence Mechanism.................................................. 2-41

Paper Table Side-to-Side Shift Mechanism........................................ 2-41

Side Fence Friction Pads....................................................................2-42

C231/C237 SM

ii

Page 15

2.7 PAPER DELIVERY ................................................................................. 2-43

2.7.1 OVERALL....................................................................................... 2-43

2.7.2 PAPER DELIVERY UNIT DRIVE MECHANISM ............................ 2-44

2.7.3 PAPER SEPARATION FROM DRUM............................................ 2-45

2.7.4 EXIT PAWL DRIVE MECHANISM .................................................2-46

2.8 ERROR DETECTION.............................................................................. 2-47

2.8.1 ORIGINAL JAM DETECTION ........................................................2-47

2.8.2 MASTER EJECT JAM DETECTION .............................................. 2-47

2.8.3 MASTER FEED JAM DETECTION ................................................2-48

2.8.4 PAPER FEED JAM DETECTION...................................................2-49

INSTALLATION................................................................................ 3-1

3.1 INSTALLATION REQUIREMENTS........................................................... 3-1

3.1.1 OPTIMUM ENVIRONMENTAL CONDITION.................................... 3-1

3.1.2 ENVIRONMENTS TO AVOID ..........................................................3-1

3.1.3 POWER CONNECTION................................................................... 3-1

3.1.4 ACCESS TO MACHINE ................................................................... 3-2

3.2 INSTALLATION PROCEDURE................................................................. 3-3

3.2.1 MAIN BODY ..................................................................................... 3-3

Accessory Check.................................................................................. 3-3

Installation Procedure........................................................................... 3-4

3.2.2 AUTO DOCUMENT FEEDER (OPTION) ......................................... 3-9

Accessory Check.................................................................................. 3-9

Installation Procedure......................................................................... 3-10

3.2.3 TAPE MARKER (OPTION).............................................................3-14

Accessory Check................................................................................ 3-14

Installation Procedure - For C231 -.....................................................3-15

3.2.4 COLOR DRUM (OPTION).............................................................. 3-17

3.2.5 INTERFACE BOARD (OPTION) .................................................... 3-18

Accessory Check................................................................................ 3-18

Installation Procedure......................................................................... 3-18

SERVICE TABLES ........................................................................... 4-1

4.1 SERVICE REMARKS................................................................................ 4-1

4.1.1 MASTER FEED SECTION............................................................... 4-1

1. Thermal Head Installation................................................................. 4-1

2. Thermal Head Voltage Adjustment................................................... 4-1

4.1.2 PAPER FEED SECTION.................................................................. 4-1

1. Friction Pad ......................................................................................4-1

2. Paper Feed Roller and Paper Separation Roller ..............................4-1

3. Paper Guide Plate Position for Registration Roller ........................... 4-1

4.1.3 DRUM AND DRUM DRIVE SECTION..............................................4-2

1. Main Motor........................................................................................ 4-2

2. Doctor Roller..................................................................................... 4-2

3. Drum Master Clamper ...................................................................... 4-2

SM C231/C237

iii

Page 16

Rev. 11/2000

4.1.2 PAPER FEED SECTION..................................................................4-1

1. Friction Pad.......................................................................................4-1

2. Paper Feed Roller and Paper Separation Roller 1............................4-1

3. Paper Feed Roller and Paper Separation Roller 2............................4-1

4. Paper Guide Plate Position for Registration Roller ...........................4-1

4.1.3 DRUM AND DRUM DRIVE SECTION..............................................4-2

1. Main Motor........................................................................................4-2

2. Doctor Roller.....................................................................................4-2

3. Drum Master Clamper.......................................................................4-2

4. Ink Roller Unit ...................................................................................4-2

5. Ink Pump 1........................................................................................4-2

6. Ink Pump 2........................................................................................4-2

4.1.4 PAPER DELIVERY SECTION..........................................................4-3

1. Exit Pawl ...........................................................................................4-3

4.1.5 ELECTRICAL COMPONENTS.........................................................4-3

1. Main Processing Unit (MPU) 1..........................................................4-3

2. Main Processing Unit (MPU) 2..........................................................4-3

3. Power Supply Unit ............................................................................4-3

4. Sensor Adjustments..........................................................................4-3

4.2 DIP SW, LED, VR, TP, AND FUSE TABLES ............................................4-4

4.2.1 TEST POINTS ..................................................................................4-4

MPU......................................................................................................4-4

4.2.2 POTENTIOMETERS ........................................................................4-4

MPU......................................................................................................4-4

Power Supply Unit ................................................................................4-4

4.2.3 LED'S ...............................................................................................4-4

4.2.4 FUSES..............................................................................................4-5

MPU......................................................................................................4-5

PSU ......................................................................................................4-5

4.3 SERVICE CALL CODES ...........................................................................4-6

4.4 SERVICE PROGRAM MODE....................................................................4-8

4.4.1 ACCESS PROCEDURE...................................................................4-8

Service Program Mode Access Procedure (For Engineers) .................4-8

Service Program Mode Access Procedure (For Users) ........................4-9

Change Adjustment Values or Modes ................................................4-10

4.4.2 SERVICE PROGRAM TABLE........................................................4-11

Remarks .............................................................................................4-20

4.4.3 INPUT/OUTPUT CHECK MODE....................................................4-23

Input/Output Check Mode Access Procedure .....................................4-23

Input Check Table...............................................................................4-24

Output Check Table............................................................................4-26

4.5 TEST PATTERN IMAGE MODE .............................................................4-28

4.6 USER CODE MODE ...............................................................................4-29

4.7 ROM HISTORY .......................................................................................4-31

4.7.1 C231 FIRMWARE MODIFICATION HISTORY................................4-31

5. PREVENTIVE MAINTENANCE................................................... 5-1

5.1 MAINTENANCE TABLE ............................................................................5-1

iv

Page 17

6.2 COPY IMAGE ADJUSTMENT...................................................................6-6

6.2.1 LEADING EDGE REGISTRATION ADJUSTMENT.......................... 6-6

6.2.2 SIDE-TO-SIDE REGISTRAION ADJUSTMENT............................... 6-7

6.2.3 VERTICAL MAGNIFICATION ADJUSTMENT .................................6-8

6.2.4 LEADING EDGE BLANK MARGIN ADJUSTMENT .........................6-9

6.3 MPU REPLACEMENT ............................................................................6-10

6.4 ORIGINAL FEED SECTION.................................................................... 6-11

6.4.1 ADF ROLLER ASSSEMBLY .......................................................... 6-11

6.4.2 PICK-UP ROLLER .........................................................................6-11

6.4.3 FEED ROLLER ..............................................................................6-12

6.4.4 SEPARATION ROLLER................................................................. 6-12

6.4.5 ADF MOTOR AND COVERS ......................................................... 6-13

6.4.6 R0 AND R1 ROLLERS................................................................... 6-13

6.4.7 R2 ROLLER ...................................................................................6-14

6.4.8 DOCUMENT SENSOR...................................................................6-15

6.4.9 SCAN LINE SENSOR ....................................................................6-15

6.4.10 COVER SENSORS ...................................................................... 6-16

6.5 MASTER FEED SECTION...................................................................... 6-17

6.5.1 MASTER MAKING UNIT REMOVAL..............................................6-17

6.5.2 THERMAL HEAD REMOVAL......................................................... 6-19

Remarks for thermal head installation ................................................ 6-20

6.5.3 THERMAL HEAD VOLTAGE ADJUSTMENT ................................ 6-21

6.5.4 MASTER END SENSOR ADJUSTMENT....................................... 6-23

6.6 MASTER EJECT SECTION ....................................................................6-24

6.6.1 MASTER EJECT UNIT REMOVAL ................................................ 6-24

6.7 PAPER FEED SECTION......................................................................... 6-25

6.7.1 PAPER FEED ROLLER, PICK-UP ROLLER,

AND FRICTION PAD ....................................................................6-25

6.7.2 PAPER SEPARATION PRESSURE ADJUSTMENT...................... 6-26

6.7.3 PAPER FEED PRESSURE ADJUSTMENT................................... 6-27

6.7.4 REGISTRATION ROLLER CLEARANCE ADJUSTMENT .............6-28

6.8 PRINTING SECTION .............................................................................. 6-29

6.8.1 PRESS ROLLER REMOVAL ......................................................... 6-29

6.8.2 PRESS ROLLER LOCK LEVER ADJUSTMENT ...........................6-30

6.8.3 PRINTING PRESSURE ADJUSTMENT.........................................6-32

6.9 DRUM AND DRIVE SECTION ................................................................ 6-33

6.9.1 DRUM CLOTH SCREEN REMOVAL ............................................. 6-33

Remarks for the cloth screen installation............................................ 6-34

6.9.2 DRUM MASTER CLAMPER AND METAL SCREEN REMOVAL... 6-36

Remarks for drum screen installation ................................................. 6-38

6.9.3 INK ROLLER UNIT REMOVAL ...................................................... 6-39

6.9.4 DOCTOR ROLLER GAP ADJUSTMENT....................................... 6-41

6.9.5 INK DETECTION ADJUSTMENT................................................... 6-43

6.9.6 INK PUMP REMOVAL AND PLUNGER

POSITION ADJUSTMENT .............................................................6-44

6.9.7 MAIN DRIVE TIMING BELT TENSION ADJUSTMENT .................6-46

6.9.8 MAIN MOTOR PULLEY POSITION ADJUSTMENT ......................6-48

SM C231/C237

v

Page 18

6.10 PAPER DELIVERY SECTION...............................................................6-49

6.10.1 VACUUM UNIT REMOVAL ..........................................................6-49

6.10.2 DELIVERY BELT/PAPER EXIT SENSOR REMOVAL ................. 6-50

6.10.3 VACUUM MOTOR REMOVAL .....................................................6-51

6.10.4 EXIT PAWL CLEARANCE ADJUSTMENT ..................................6-52

6.10.5 EXIT PAWL DRIVE TIMING ADJUSTMENT................................ 6-53

TAPE MARKER C532

SPECIFICATIONS ............................................................................ 7-1

BASIC OPERATION......................................................................... 7-2

2.1 OVERVIEW............................................................................................... 7-2

2.2 DRIVE AND CUTTING MECHANISM .......................................................7-3

2.3 MANUAL CUT........................................................................................... 7-4

REPLACEMENT AND ADJUSTMENT ............................................. 7-5

3.1 CUTTER REPLACEMENT........................................................................ 7-5

3.2 CUTTER HOME POSITION SENSOR REPLACEMENT.......................... 7-6

3.3 TAPE CUT LENGTH ADJUSTMENT........................................................ 7-7

PRIPORT CONTROLLER USER’S GUIDE ...................................... 8-1

POINT TO POINT DIAGRAM

C231/C237 SM

vi

Page 19

Rev. 08/2000

C237

1. OVERALL INFORMATION.......................................................... 1-1

1.1 ESSENTIAL DIFFERENCES BETWEEN THE C237 AND C231

MODELS ................................................................................................... 1-1

1.2 SPECIFICATIONS .................................................................................... 1-4

1.3 NEW ELECTRICAL COMPONENTS ........................................................ 1-5

1.3.1 MAIN BODY ..................................................................................... 1-5

1.3.2 TABLES OF ELECTRICAL COMPONENTS.................................... 1-5

Boards .................................................................................................. 1-5

Switches ............................................................................................... 1-5

2. DETAILED SECTION DESCRIPTIONS....................................... 2-1

2.1 PAPER FEED............................................................................................2-1

2.1.1 PAPER FEED/SEPARATION PRESSURE ADJUSTMENT

MECHANISM ................................................................................... 2-1

2.2 PAPER DELIVERY ...................................................................................2-2

2.2.1 EXIT PAWL AIR PUMP MECHANISM (CHINESE MODEL ONLY) . 2-2

3. INSTALLATION........................................................................... 3-1

4. SERVICE TABLES ...................................................................... 4-1

4.1 SERVICE CALL CODES........................................................................... 4-1

4.2 SERVICE PROGRAM TABLE................................................................... 4-3

4.3 INPUT/OUTPUT CHECK MODE............................................................. 4-12

Input Check Table ..............................................................................4-12

Output Check Table............................................................................ 4-14

5. PREVENTIVE MAINTENANCE ................................................... 5-1

6. REPLACEMENT AND ADJUSTMENT ........................................ 6-1

6.1 MASTER FEED SECTION........................................................................ 6-1

6.1.1 MASTER END SENSOR ADJUSTMENT......................................... 6-1

6.2 MASTER EJECT SECTION ......................................................................6-2

6.2.1 MASTER EJECT UNIT REMOVAL .................................................. 6-2

6.3 PAPER FEED SECTION........................................................................... 6-2

6.3.1 PAPER SEPARATION PRESSURE ADJUSTMENT........................ 6-2

6.4 PAPER DELIVERY SECTION................................................................... 6-3

6.4.1 AIR PUMP ADJUSTMENT (CHINESE MODEL ONLY) ...................6-3

C237 POINT TO POINT DIAGRAM

SM C231/C237

vii

Page 20

Page 21

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the printer and peripherals, make

sure that the power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off or

open while the main switch is turned on, keep hands away from electrified or

mechanically driven components.

HEALTH SAFETY CONDITIONS

1. If you get ink in your eyes by accident, try to remove it with eye drops or flush

with water as first aid. If unsuccessful, get medical attention.

2. If you ingest ink by accident, induce vomiting by sticking a finger down your

throat or by giving soapy or strong salty water to drink.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The printer and its peripherals must be installed and maintained by a customer

service representative who has completed the training course on those models.

CAUTION

The RAM has a lithium battery which can explode if handled incorrectly.

Replace only with the same type of RAM. Do not recharge or burn this

battery. Used RAM's must be handled in accordance with local regulations.

ATTENTION

La carte RAM comporte une pile au lithium qui présente un risque

d'explosion en cas de mauvaise manipulation. Remplacer la pile

uniquement par une carte RAM identique. Ne pas recharger ni brûler cette

pile. Les cartes RAM usagées doivent être éliminées conformément aux

réglementations locales.

Page 22

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Dispose of replaced parts in accordance with local regulations.

2. Used ink and masters should be disposed of in an environmentally safe

manner and in accordance with local regulations.

3. When keeping used lithium batte ries (from the main proce ssing units) in orde r

to dispose of them later, do not store more than 100 batteries (from the main

processing units) per sealed box. Storing larger numbers or not sealing them

apart may lead to chemical reactions and heat build-up.

Page 23

OVERALL INFORMATION

Rev. 08/2000

C237 OVERALL INFORMATION

DETAILED SECTION DESCRIPTIONS

C237 DETAILED SECTION DESCRIPTIONS

INSTALLATION

C237 INSTALLATION

SERVICE TABLES

C237 SERVICE TABLES

TAB

POSITION 1

TAB

POSITION 2

TAB

POSITION 3

TAB

POSITION 4

PREVENTIVE MAINTENANCE

C237 PREVENTIVE MAINTENANCE

REPLACEMENT AND ADJUSTMENT

C237 REPLACEMENT AND ADJUSTMENT

TAPE MARKER C532

PRIPORT CONTROLLER USER'S GUIDE

TAB

POSITION 5

TAB

POSITION 6

TAB

POSITION 7

TAB

POSITION 8

Page 24

Page 25

OVERALL

INFORMATION

Page 26

Page 27

1

1. OVERALL INFORMATION

SPECIFICATION

1.1 SPECIFICATION

Configuration: Desktop

Master Processing: Digital with 300 dpi thermal head

Scanning (Pixel Density): Contact image sensor (300 dpi), with xenon lamp

* In Fine mode, 400 dpi in the sub-scanning

resolution

Printing Process: Fully automatic one-drum stencil system

Original Type: Sheet/Book

In Platen Mode: Document size:

Maximum 257 x 364 mm [10.2" x 14.4"]

Thickness: Less than 30 mm

Weight: Less than 5 kg

In ADF Mode: Document size:

Maximum 257 x 364 mm [10.2" x 14.4"]

Minimum 148 x 105 mm [5.8" x 4.1"]

Overall

Information

Document weight:

50 - 90 g/m2 [13.3 - 23.9 lb]

(40 - 120 g/m2 [10.6 - 31.9 lb]

in single sheet feed)

ADF capacity:

30 sheets (using 20 lb or 80 g/m2 paper)

Reproduction Ratios: Inch version Others

Full Size: 100% 100%

Reduction: 65% 71%

74% 82%

77% 87%

93% 93%

Enlargement: 121% 115%

129% 122%

155% 141%

Image Modes: Letter, Photo, Letter/Photo, Fine, Tint

SM C231/C237

-1

Page 28

SPECIFICATION

1

Printing Area:

(At 20 °C/ 65 % RH)

B4 size drum models:

250 mm x 355 mm

Legal size drum models:

210 mm x 355 mm [8.2" x 13.9"]

A4 size drum models:

210 mm x 288 mm [8.2" x 11.3"]

Edge Margins: Leading edge:

5 ± 3 mm (At the "0" position of Image Shift mode)

Trailing edge:

2 mm

Print Paper Size: Minimum: 90 mm x 148 mm [3.6" x 5.9"]

Maximum: 267 mm x 390 mm [10.5" x 15.3"]

Print Paper Weight: 47.1 g/m2 to 157.0 g/m2 [12.5 lb to 41.7 lb]

Printing Speed: 80, 100, 120 sheets/minute (3 steps)

Master Process Time: Platen mode:

Less than 28 seconds (A4 paper)

ADF mode:

Less than 30 seconds (A4 paper)

Master Eject Box Capacity: 40 masters (Normal conditions)

(30 masters at low temperatures)

Side Registration Adjustable

±

10 mm

Range:

Vertical Registration Adjustable

±

10 mm

Range:

Paper Feed Table Capacity: 1000 sheets (80 g/m2 / 20 lb)

2

Paper Delivery Table Capacity: 1000 sheets (80 g/m

/ 20 lb)

Power Source: 110/120 V, 50/60 Hz: 2.5 A

220 - 240 V, 50/60 Hz: 1.5 A

Maximum Power Consumption: 250 W

Noise Emission:

(At operation position)

At 80 rpm printing speed: 71 dB

At 100 rpm printing speed:72 dB

At 120 rpm printing speed:72 dB

C231/C237 SM

-2

Page 29

1

Weight: 65 kg [143.3 lb]

68 kg [149.9 lb] with ADF

Dimensions:

(Width x Depth x Height)

Trays closed: 594 mm x 601 mm x 567 mm

With ADF:

594 mm x 601 mm x 617 mm

Trays open: 1187 mm x 601 mm x 567 mm

With ADF:

1187 mm x 601 mm x 617 mm

Master Type: Master for B4 drum

Thermal master roll type:

280 mm width, 125 m/roll

Yield:

260 masters/roll

Max run length per master:

2,000 prints

SPECIFICATION

Overall

Information

Master for A4/Legal drum

Thermal master roll type:

240 mm width, 125 m/roll

Yield:

300 masters/roll (A4 drum)

260 masters/roll (Legal drum)

Max run length per master:

2,000 prints

Master Storage Conditions: Temperature:

0 °C to 40 °C

Humidity:

10% to 95% RH

Recommended maximum storage period:

One year after production date

* Avoid locations exposed to direct sunlight.

SM C231/C237

-3

Page 30

SPECIFICATION

1

Ink Type 600 ml cartridge type

Available colors:

Black, Red, Blue, Green, Brown

Ink Storage Conditions: Temperature:

-5 °C to 40 °C

(Optimum conditions: 15 °C to 25 °C)

Humidity:

10% to 95% RH

(Optimum conditions: 20% to 70% RH)

Recommended maximum storage period:

One year after production date

* Avoid locations exposed to direct sunlight.

•

Available Options

Color Drum

•

Document Feeder

•

Key Counter

•

Tape Marker

•

PC Controller

C231/C237 SM

-4

Page 31

GUIDE TO COMPONENTS AND THEIR FUNCTION

1

1.2 GUIDE TO COMPONENTS AND THEIR FUNCTION

1.2.1 MACHINE EXTERIOR

Overall

Information

1. Front Door

2. Operation Panel

3. Platen Cover

4. Original Table Release

Lever

5. Feed Roller Pressure

Lever

6. Paper Feed Side Plates

7. Paper Feed Table

8. Side Table Fine Adjusting

Dial

9. Paper Feed Table Down

key

10. Behind Cover

C231V504.WMF

Open for access to the inside of t he machine.

Operator controls and indicators are locat ed her e.

Lower this cover over an original before printing .

Use to open the original table unit when installing t he

master.

Use to adjust the contact pressure of the paper feed

roller according to paper thickness.

Use to prevent paper skew.

Set paper on this table for print ing.

Use to shift the paper f eed t able sideways.

Press to lower the paper feed table.

Flip up when you wish to use the keys underneath.

SM C231/C237

-5

Page 32

GUIDE TO COMPONENTS AND THEIR FUNCTION

1

1.2.2 MACHINE INTERIOR

1. Document Feeder (Option)

2. Paper Delivery Side Plates

3. Paper Delivery End Plate

4. Paper Delivery Table

5. Main Switch

6. Drum Unit

7. Drum Unit Lock Lever

8. Ink Holder

C231V505.WMF

Originals inserted into the document feeder are

individually and automatically fed onto and

removed from the exposure glass.

Use to align the prints on the paper delivery table.

Use to align the leading edge of prints.

Completed prints are delivered here.

Use to turn the power on or off.

The master is wrapped around this unit.

Lift to unlock and pull out the drum unit.

Set the ink cartridge in t his holder .

C231/C237 SM

-6

Page 33

1

1.2.3 OPERATION PANEL

1

4

5

98101

1

131

2

GUIDE TO COMPONENTS AND THEIR FUNCTION

Keys

6

C231V511.WMF

2

7

1. Security key

Press to make prints of

confidential documents.

2. Paste Shadow Erase key

Press to erase the shadows on

images of pasted originals.

3. Tint key

Press to make prints in grey.

(This is the Tint/Economy key for

the China version.)

3

1

2

4

15

21

0

Overall

Information

7. Center/Edge Erase key

Press to print book originals that

have a solid image on the center

or edges.

8. Scroll keys

Press to select size and direction

of paper or original for

Center/Edge Erase.

9. Reduce key

Press to reduce the image.

4. Image Density key

Press to make prints darker or

lighter.

5. Check Indicator

This indicator lights when you

have selected one or more of the

functions accessed by lifting the

behind cover and pressing the

keys underneath (e. g. Security

key, Paste Shadow Erase key

etc.). This lets you know whether

one or more of these functions is

selected, even if the cover is

lowered.

6. Skip Feed key

Press to select skip feed printing.

10. Full Size key

Press to make full size prints.

11. Enlarge key

Press to enlarge the image.

12. Economy key

Press to save ink. (This is the

Combine 2 Originals key for the

China version.)

13. Type of Original key

Press to select Letter, Photo, or

Letter/Photo mode.

14. Fine key

Press to select fine image mode.

15. Image Position key

Press to shift the image forwards

or backwards.

SM C231/C237

-7

Page 34

GUIDE TO COMPONENTS AND THEIR FUNCTION

1

2

2

2

2

1

1

1

1

2

6

7

9

8

16. Program key

Press to input or recall user

programs.

17. Clear Modes key

Press to clear the previously

entered job settings.

18. Auto Cycle key

Use to process the master and

make prints automatically.

19. Proof key

Press to make proof prints.

20. Speed keys

Press to adjust the printing

speed.

21. Memory/Class key

Press to select Memory or Class

mode.

4

3

1

C231V511.WMF

5

22. Number keys

Press to enter the desired

number of prints and data for

selected modes.

23. # key

Use to enter data in selected

modes.

24. Clear/Stop key

While entering numbers, press to

cancel a number you have

entered. While copying, press to

stop copying.

25. Start key

Press to make a master.

26. Print key

Press to start printing.

6

C231/C237 SM

-8

Page 35

1

Indicators

1

2

3

4

5

GUIDE TO COMPONENTS AND THEIR FUNCTION

Overall

Information

1. Error indicators

These indicators are lit when a

non-standard condition occurs

within the machine.

2. Memory/Class Indicator

Shows the number entered in

Memory or Class mode.

3. Speed indicator

These indicators show the

printing speed that is selected.

4. Counter

Displays the number of prints

entered. While printing, it shows

the number of prints remaining.

5. Guidance Display

Display the machine's condition.

SM C231/C237

-9

Page 36

PRINTING PROCESS

1

5

4

1

1.3 PRINTING PROCESS

2

3

C231V500.WMF

6

1. Master Eject: Ejects the used master wrapped around the drum

into the master eject box.

2. Scanning: The scanner, which is composed of the contact

image sensor (CIS) and xenon lamp, scans the

original image.

3. Master Feeding: Converts the image signal read by the CIS into digital

signals and sends them to the thermal head to

develop the image on the master. The master is then

wrapped around the drum.

4. Paper Feeding: Sends paper to the drum section.

5. Printing: Presses the paper fed from the paper feed section to

the drum. This transfers the ink onto the paper

through the drum screen and the master.

6. Paper Delivering: Peels the printed paper with the exit pawl and air

knife, and ejects the paper onto the paper delivery

table.

C231/C237 SM

-10

Page 37

MECHANICAL COMPONENT LAYOUT

1

123

252

10111

1

1.4 MECHANICAL COMPONENT LAYOUT

4232221

20

19

18

17

Overall

Information

4

5

6

7

8

9

16

1. Tension Roller

2. Master Feed Roller

3. Platen Roller

4. Scanner

5. Master Roll

6. Thermal Head

7. Paper Feed Roller

8. Paper Pick-up Roller

9. Paper Table

10. Registration Roller

11. Doctor Roller

C231V500.WMF

3

21415

14. Vacuum Fan Motor

15. Transport Belts

16. Paper Delivery Table

17. Air Knife Fan Motor

18. Master Eject Roller

19. Master Eject Box

20. DF R1 Roller

21. DF R0 Roller

22. DF Separation Roller

23. DF Document Feed Roller

24. DF Pick-up Roller

12. Ink Roller

25. DF R2 Roller

13. Press Roller

SM C231/C237

-11

Page 38

ELECTRICAL COMPONENT LAYOUT

1

2

3

1.5 ELECTRICAL COMPONENT LAYOUT

1.5.1 ADF

1

Motors

Index No. Name Function

4 ADF Motor Drives the original.

4

5

6

C231V508.WMF

Switches

Index No. Name Function

3 ADF Cover Switch Detects whether the ADF cover is open or

closed.

5 ADF Switch Detects whether the ADF unit is open or closed.

Sensors

Index No. Name Function

2 Scan Line Sensor Detects when a page is approaching the auto

shading position.

1 Document Sensor Detects the presence of a document in the

feeder.

6 Not Used

C231/C237 SM

-12

Page 39

1

1.5.2 MAIN BODY

C

2

2

3

3

3

3839404

4

5

1236547

1

1

1

5

25

24

ELECTRICAL COMPONENT LAYOUT

Overall

Information

8

9

23

22

21

48

47

20

9

49

18

50

17

10

11

12

13

14

5

6

1

2

C231V501.WMF

6

7

28

29

30

46

31

32

45

33

34

44

3

42

231V503.WMF

SM C231/C237

1

-13

7

5

6

Page 40

ELECTRICAL COMPONENT LAYOUT

1

Boards

Index No. Name Function

2 Main Processing Unit

(MPU)

3 Lamp Stabilizer This supplies power to the xenon lamp.

17 Power Supply Unit Provides dc power to the system.

25 Operation Panel Boards These boards control the operation panel.

4 Contact Image Sensor

and Xenon Lamp

40 Noise Filter Board Filters out electrical noise on the ac power input

42 Mai n Moto r Con trol

Board

Controls all machine functions both direct ly and

through other boards.

This sensor reads and converts the light

reflected from t he docum ent into an analog

video signal. It uses an RMLA (Roof Mirror Lens

Array) sensor unit.

The xenon lamp that illuminates the document is

contained in this unit.

lines.

Controls the main motor speed.

Motors

Index No. Name Function

7 Master Feed Motor Feeds the master to the drum.

18 Cutter Motor Cuts the master.

19 Registration Motor Feeds the paper to align it with the master on

the drum.

1 Scanner Motor Stepper mot or dr ives the book scanner.

30 Master Eject Motor Sends used mast ers into the master eject box.

31 Air Knife Fan Motor Rotates the fan to provide air t o separate the

leading edge of the paper from the drum.

34 Pressure Plate Motor Raises and lowers the pressure plate.

35 Vacuum Fan Motor Provides suction so that paper is held firmly on

the transport belt.

36 Paper Transport Motor Transports the printed paper.

39 Clamper Motor Opens or closes the drum master clamper.

44 Main Motor Drives paper feed mechanisms and the drum.

46 Paper Table Motor Raises and lowers the paper table.

52 Ink Pump Motor Drives the ink pump.

C231/C237 SM

-14

Page 41

ELECTRICAL COMPONENT LAYOUT

1

Solenoids

Index No. Name Function

43 Rear Pressure Release

Solenoid

20 Front Pressure Release

Solenoid

Releases the press roller to apply printing

pressure.

Releases the press roller to apply printing

pressure.

Switches

Index No. Name Function

49 Scanner Unit Safety

Switch

9 Master Making Unit

Cover Safety Switch

16 Table Lowering Switch Lowers the paper table.

21 Test Switch Releases the cover safety functions. (See the

23 Door Safety Switch Check s whether the front door is properly

24 Main Switch Turns the power on or off.

Checks whether the scanner unit is properly set.

Checks whether the cover on the master making

unit is properly closed.

notes below this table.)

closed.

Overall

Information

NOTE:

When you use this test switch, be sure to return it to the default position

after servicing.

Sensors

Index No. Name Function

50 Master Eject Position

Sensor

51 Paper Exit Timing

Sensor

48 Feed Start Timing

Sensor

26 Master Eject Sensor Detect s used master misfeeds.

28 Pressure Plate Limit

Sensor

27 Pressure Plate Home

Position Sensor

29 Drum Master Sensor Detects if there is a master on t he dr um .

32 Eject Box Set Sensor Checks if the master eject box is set.

33 Paper Exit Sensor Detects paper misfeeds at the exit.

37 2nd Feed Timing

Sensor

38 Clamper Open Sensor Detects if the clamper is in the open position.

41 Clamper Close Sensor Detects if the clamper is in the closed position.

45 Table Lower Limit

Sensor

Detects when the drum is at the master eject

position.

Determines the paper exit misfeed check t im ing .

Determines the paper feed start t im ing .

Detects if the pressure plate is in t he lowest

position.

Detects if the pressure plate is at t he hom e

position.

Determines the paper misfeed check t im ing at

the paper registration area.

Detects when the paper table is at its lower limit

position.

SM C231/C237

-15

Page 42

ELECTRICAL COMPONENT LAYOUT

1

Index No. Name Function

5 Platen Cover Sensor Detects whether the platen cover is open or

closed.

6 Scanner Home Position

Sensor

8 Master Set Cover

Detects when the image sensor is at home

position.

Checks if the master set cover is set.

Sensor

10 Master End Sensor I nforms the CPU when the master mak ing unit

runs out of master roll.

11 Paper Height Sensor Detects when the paper table reaches the paper

feed position.

13 Paper Registration

Sensor

Detects paper approaching the registr ation

roller.

15 Paper End Sensor Informs the CPU when the paper table runs out

of paper.

14 Cutter Home Position

Detects when the cutter is at the home position.

Sensor (Switch)

Counters

Index No. Name Function

22 Paper and Master

Counters

Keep track of the tot al num ber of copies and

masters made.

Others

Index No. Name Function

47 Paper Feed Clutch Transmits main motor drive to the paper feed

roller at the appropriate time.

12 Thermal Head Burns the image onto the master.

C231/C237 SM

-16

Page 43

1

1.6 DRIVE LAYOUT

3

4

8

7

DRIVE LAYOUT

Overall

Information

1

2

1. Pressure Plate Motor

2. Clamper Motor

3. Paper Transport Motor

4. Main Motor

C231V501.WMF

56

5. Registration Motor

6. Paper Table Motor

7. Paper Feed Clutch

8. Master Feed Motor

SM C231/C237

-17

Page 44

Page 45

DETAILED SECTION

DESCRIPTIONS

Page 46

Page 47

SCANNER AND OPTICS

[

2. DETAILED SECTION DESCRIPTIONS

2.1 SCANNER AND OPTICS

2.1.1 BOOK SCANNER OVERVIEW

[D]

[E]

I]

[C]

[H]

[A]

[B]

C231D500.WMF

The scanner motor [A] drives the scanner [B] through the timing belt [C] and drive

wire [D]. The shaft [E] guides the scanner movement in the sub-scan direction.

The scanner [B] consists of a contact image sensor and a xenon lamp driver.

Detailed

Section

Descriptions

The scanner home position sensor [H] detects when the scanner returns to the

home position after scanning.

The platen cover switch [I] detects the cover status.

SM C231/C237

2-1

Page 48

SCANNER AND OPTICS

2.1.2 ADF OVERVIEW

[D]

[E]

[C]

[F]

[B]

[G]

[A]

C231D501.WMF

[I]

[H]

C231D572.WMF

The sheet through-type ADF feeds the document from the top of the document

stack.

The pick-up roller [A] and feed roller [B] feed the original into the scanner, and the

separation roller [C] helps to feed one sheet at a time. Then, the R0 [D], R1 [E],

and R2 [H] rollers feed the document through the scanner.

During scanning, the scanner [I] moves to the scanning position under the

exposure glass [G]. The shading plate [F] secures the document at the scan line,

ensuring that the document is within the image sensor's range of focus.

After scanning, the ADF feeds the document onto the platen cover, and the

scanner moves back to its home position.

C231/C237 SM

2-2

Page 49

[A]

[B]

SCANNER AND OPTICS

C231D502.WMF

Detailed

Section

Descriptions

The document sensor [A] detects when an original is placed in the ADF. The

sensor [B] is not used in this unit. The ADF is a common part which is used in other

models.

SM C231/C237

2-3

Page 50

SCANNER AND OPTICS

2.1.3 CONTACT IMAGE SENSOR

[D]

[A]

[C]

[B]

[F]

[E]

C231D503.WMF

The contact image sensor (CIS) assembly [A] consists of the exposure glass [B],

roof mirror lens array [C], xenon lamp [D], and the image sensor [E].

The CIS moves under the exposure glass when scanning a book original, and

remains stationary at the ADF scan line when scanning a sheet original using the

ADF.

The image sensor is a row of 4096 photosensitive elements (B4 width x 16

dots/mm). The roof mirror lens array focuses the light reflected from the document

onto the image sensor.

Due to the short optical path of a CIS unit, the focal depth is much shorter than in a

CCD type scanner. Because of this, two springs are used to push the CIS against

the exposure glass [F], to keep the distance between the CIS and the original

constant. In book scanning mode, if the original is out of the CIS focal range,

however, the scanned image may be darkened.

NOTE:

Due to the characteristics of the CIS, shadows of a paste-up original tend

to appear on copies. To counter this, press the paste shadow erase key on

the operation panel to use the paste shadow erase mode.

The strength of the paste shadow erase level can be changed with SP no.

28.

C231/C237 SM

2-4

Page 51

2.1.4 DRIVE MECHANISM

Book Scanner

[D]

[C]

[A]

[G]

SCANNER AND OPTICS

[E]

[B]

Detailed

Section

Descriptions

[F]

C231D504.WMF

The book scanner motor [A] drives the scanner [B] via a timing belt [C] and drive

wire [D]. The scanner moves along the guide shaft [E].

The springs [F] apply pressure to the contact image sensor [G] to ensure that the

distance from the image sensor to the exposure glass surface remains constant

during scanning.

SM C231/C237

2-5

Page 52

SCANNER AND OPTICS

ADF

[D]

[A]

[C]

[B]

[E]

C231D505.WMF

The ADF motor [A] drives the pick-up roller [B], the feed roller [C], the R0 roller [D],

the R1 roller (not shown), and the R2 roller [E].

C231/C237 SM

2-6

Page 53

2.1.5 PI CK-UP AND FEED (ADF)

[A]

C231D507.WMF

[B]

SCANNER AND OPTICS

Detailed

Section

Descriptions

C231D506.WMF

When the ADF m otor starts, the mechanical clutch [A ] engages and lowers t he

pick-up roller [B] into contact with the document. Then the machine begins feeding

the original stack, beginning with the top page. After the last page is scanned, the

ADF motor reverses briefly to raise the pick-up roller back to the standby position.

SM C231/C237

2-7

Page 54

SCANNER AND OPTICS

2.1.6 SEPARATION MECHANISM (ADF)

[A]

[B]

C231D508.WMF

The feed roller [A] and the separation roller [B] prevent more than one sheet of

paper from feeding into the scanner at the same time.

When the feed roller feeds a sheet of paper, both the feed and the separation

rollers rotate in the feed-in direction. However, if two or more sheets are between

these rollers, the separation roller rotates in the feed-out direction to prevent the

lower sheet from being fed into the scanner.

C231/C237 SM

2-8

Page 55

SCANNER AND OPTICS

2.1.7 ERROR CONDITIONS

Book Scanner

The main CPU detects an error (error code E-13 is displayed) if either of the

following conditions occurs.

Condition Description Error Code

The scanner home position sensor does not

turn on within 7 seconds after the motor

engages.

Home position sensor

error condition

ADF

The scanner home position sensor does not

turn off within 4 seconds after power on.

Otherwise, when the scanner could not

return to the home position within 2

seconds of leaving.

E-13

Detailed

Section

Descriptions

"Paper feed jam" is displayed if any of the following conditions occurs.

Jam Condition Description

Non-feed

Misfeed 1

Misfeed 2

The scan line sensor does not switch on within 5 seconds after the

ADF motor starts.

The scan line sensor does not turn off even when the paper (a trial

print) reaches the registration area.

The ADF motor reverses after the last document feeds out of the

scanner or after a jam is cleared. At this time, the misfeed 2 error

condition occurs if the document sensor stays on.

SM C231/C237

2-9

Page 56

IMAGE-PROCESSING

2.2 IMAGE-PROCESSING

2.2.1 OVERVIEW

Main Processing Unit (MPU)

Contact Image

Sensor

Power Supply

PCB

Thermal

Head

Amplification

GA2

Thermal

Head

Drive

A/D

Conversion

Data

Compensation

Clock

Overlay

Letter/Photo

Image Area

Detection

MTF

Correction

Main-scan Direction

Image Position

Adjustment

Data Selection

Selection

GA1

Centering

Thresholding

Data

Diffusion

Control

Half Tone Processor

Error

Main

Data

Selection

Image

Enlargement/

Reduction

C231D509.WMF

This model uses a contact image sensor (CIS) instead of a CCD. It removes the

necessity for the complicated adjustments that are needed for a CCD scanner.

There are three main chips on the main processing unit (MPU) as shown. The

halftone processor chip enables the use of Letter/Photo mode in addition to Letter

and Photo modes. In Letter/Photo and Phot o mod es, error di ffusio n proc essi ng

produces better copy quality halftone images.

The halftone processor also includes the A/D conversion function, as well as the

image processing functions. The thermal head drive function is built into a chip

(GA2) on the MPU.

C231/C237 SM

2-10

Page 57

IMAGE-PROCESSING

2.2.2 A/D CONVERSION PROCESSING

The analog signal from the contact image sensor is converted into a digital signal

that represents 64 grayscale steps. This process is carried out in the halftone

processing chip in the MPU.

Shading Distortion Correction

The image data from one main scan line does not exactly represent the line from

the original image, because of the following reasons:

1) Loss of brightness towards the ends of the exposure lamp.

2) Variations in sensitivity among elements of the contact image sensor

3) Distortions of the light path

Detailed

Section

Descriptions

CIS

CIS

C231D510.WMF

Such distortions in the image data are corrected when they are converted into

digital data.

Before scanning the document, the scanner reads the white plate on the back of

the original scale. The output of each contact image sensor element is changed to

a 6-bit digital value and is stored in the shading distortion memory.

To change the analog shading distortion signals to digital data, a scale of 64 steps

is made between the whitest level when the white plate is scanned and 50% of the

whitest level. Using this scale, the analog signal is changed to 6-bit digital data.

While an original is scanned, the 6-bit shading distortion value for each pixel is

sent, in series, from memory to the D/A converter, synchronizing with the image

signal being sent to the A/D converter. The D/A converter changes the distortion

value to an electrical current. The current is converted to the voltage to be used as

high reference data for A/D conversion. In this way, the high reference voltage for

A/D conversion is changed sequentially for each pixel depending on the shading

distortion data for that pixel.

SM C231/C237

2-11

Page 58

IMAGE-PROCESSING

Original Background Correction

When an origin al is scanned, the whitest level of the original background is stored,

and that level is used as the white peak level for A/D conversion. The grayscale is

made based on the white peak level of the original. As a result, dark background

does not appear on the printout.

If the original background correction is disabled, the whitest level when the white

plate is scanned is used for the high reference voltage.

C231D512.WMF

Peak Hold

The peak hold circuit holds the voltage for the white peak level. Before scanning an

original, it holds the white peak voltage from the white plate to make shading

distortion data. When the original is scanned, it stores the white peak level of the

original for the original background correction.

NOTE:

The white peak level is checked 5 mm from the leading edge of the original

set on the exposure glass (and from the central 147-mm width). If the

original leading edge is not flush with the original scale and the platen

cover stays open, insufficient voltage will be input as the white peak level.

If insufficient voltage is detected, a fixed voltage is used as the white peak

level to avoid a faint image copy.

C231/C237 SM

2-12

Page 59

IMAGE-PROCESSING

2.2.3 BINARY PROCESSING

In the halftone-processing chip, the 6-bit digital signal data is generated in the A/D

conversion circuit and is sent to the binary processing circuit. At that time the data

is inverted to match the binary processing circuit. Therefore, the white peak level

becomes 0, and the black level becomes 63.

In the binary processing circuit, the 6-bit data is converted into 1-bit data for black

or white pixels. The binary processing for the letter and photo is different, as

follows:

Letter Mode, Letter areas in Letter/Photo Mode: MTF (Modulation Transfer

Function) Correction

Photo Mode, Photo areas in Letter/Photo Mode: Error Diffusion Processing

Data Compensation Processing

In this process, the 6-bit data are converted based on a compensation curve

(gamma curve) which corresponds to selected image settings. For example, if a

darker image is selected, a compensation curve, which converts each pixel value

to a higher number, is selected. The output data is still 6-bit.

Detailed

Section

Descriptions

Input

6-bit data from

the A/D conversion

PCB

Gamma curve

selection signal

Data

Compensation

Circuit

Output

6-bit data

C231D514.WMF

C231D515.WMF

SM C231/C237

2-13

Page 60

IMAGE-PROCESSING

MTF Correction

When the original image is converted to electrical signals by the c ontact image

sensor, the contrast is reduced. This is because neighboring black and white parts

of the image influence each other. This symptom is typical when the width and

spacing between black and white areas are narrow. MTF correction counters this

symptom and emphasizes image detail. The value of a target pixel is modified

depending on the value of surrounding pixels. The modified data is compared with

a threshold level. This determines if the pixel is to be black or white.

After the MTF correction is done, the corrected data is compared with the black or

white threshold level. If a pixel value is above the threshold level, it is set to black.

If the pixel value is equal or below the threshold level, it is set to white. The

threshold level depends on the selected density setting.

Image Density

Setting

Lighter 28 35

Normal 35 40

Darker 1 38 42

Darker 2 42 44

Threshold Level for Line

Mode

Threshold Level for Line

Areas in Line/Photo Mode

Binary Processing in Letter/Photo Mode

In the Letter/Photo mode, the machine checks each pixel of the original to see if

the pixel is in a letter area or in a photo area. To distinguish letter and photo areas,

the CPU does the calculation on the 6-bit pixel data.

If the CPU recognizes that the pixel is in a letter area of the image, it uses the MTF

process to convert the 6-bit value to 1-bit.

If the CPU recognizes that the pixel is in a photo area of the image, the pixel is

converted to 1-bit using error diffusion.

To emphasize characters in a photo original when using Letter/Photo mode, a data

compensation curve (γ curve) is used to make a darker image.

C231/C237 SM

2-14

Page 61

IMAGE-PROCESSING

Error Diffusion

Error diffusion is used to reproduce halftone images in photo mode.

Before a 6-bit image signal is converted into a single-bit signal based on the

threshold level, there is a difference between the image signal value and the

complete black value (63 for a 6-bit signal) or white value (0). With the error

diffusion process, the difference is distributed among the surrounding pixels. (The

MTF process simply erases these differences.)

When consid ering error diffusion in one dimension only (acros s the page), the 6-bit

data shown in the example below produces white and black data output as shown

below. In practice, this one-dimensional error diffusion is done in all directions on

each pixel (across the page, down the page, etc.).

Image data from one scan line

711132130384144

Detailed

Section

Descriptions

C231D518.WMF

In each dimension, the difference between the pixel value and the nearest extreme

(0 or 63) is transferred to the next pixel. The 1st pixel in the row becomes either

black or white, whichever is closest. Then, in the example above, the difference

between 7 and 0 is added to the 2nd pixel. The value of the 2nd pixel, which is now

18, is then added to the 3rd pixel. The 4th pixel becomes 52, which is closer to 63

than 0. In such cases, the difference is subtracted (not added) to get the next pixel

value. In this example, the difference is 63-52=11, and the next pixel value (30-11)

becomes 19.

SM C231/C237

2-15

Page 62

IMAGE-PROCESSING

2.2.4 MAIN SCAN MAGNIFICATION

Scanned Data

Points

Calculated Data

Points

Reduced Image

Data Points

Scanned Data

Points

Calculated Data

Points

Reduced Image

Data Points

Changing the original transport speed performs the reduction and enlargement in

the sub-scanning direction. Reduction and enlargement in the main scanning

direction is handled by the magnification and image shift processing circui ts.

C231D520.WMF

Pixels for scanning and master making are generated at fixed intervals (the contact

image sensor and thermal head element intervals). The image is scanned at the

contact image sensor element interval. If pixels on the master are made at the

same interval (by the thermal head elements) then the master image is the same

size as the original.

When actual pixels are divided in accordance with a magnification ratio, the

magnification processor calculates the imaginary point values that would

correspond to new pixels. The proper value for each imaginary point is calculated

based on the image data of the surrounding pixel values.

- 80 % Reduction For example, the contact image sensor scans data for 10 pixels in a main scan

line. Those data are compressed into data for 8 pixels by the magnification

processor. As a result, the image is reduced to 80 %.

- 140 % Enlargement Data for 10 pixels of a main scan line are expanded into data for 14 pixels. As a

result the image is enlarged with a 140 % magnification ratio.

C231/C237 SM

2-16

Page 63

IMAGE-PROCESSING

2.2.5 IMAGE POSITION ADJUSTMENT IN THE MAIN SCAN

DIRECTION

To adjust the image position of the original across the printout, the image can be

shifted ± 1.9 mm in the main scan direction using SP mode No. 31 (platen mode)

or No. 37 (ADF mode).

The image shift in the main scan direction is done by changing the relationship

between the position of the image data on the CIS and on the thermal head. Data

for one main scan line is stored in a line memory. When the data is output from

memory, the output timing is changed to shift the image.

CIS Center

3072

3072

3072

Data from CIS

After A/D Conversion

Data from

Thermal Head Driver,

No Image Shift

Data from

Thermal Head Driver,

Image Shift x mm

(SP 31 or 37)

0

Thermal Head

Center

0

x mm

0

Thermal Head

Center

Detailed

Section

Descriptions

C231D521.WMF

2.2.6 PASTE SHADOW ERASE MODE

Due to the characteristics of the contact image sensor, shadows of a paste-up

original tend to appear on copies. To counter this, the paste shadow erase mode

can be used by pressing the paste shadow erase key on the operation panel.

When this mode is selected, the black or white threshold level is slightly lowered.

At the same time, the emphasis in the sub-scan direction in the MTF correction

process is weakened to make the shadows inconspicuous.

The strength of the paste shadow erase level can be changed with SP No. 28.

SM C231/C237

2-17

Page 64

IMAGE-PROCESSING

2.2.7 THERMAL HEAD

Specifications

•

Length 260.2 mm

•

Number of thermal head elements 3072 dots

•

Density of thermal head elements 300 DPI

•

Applied voltage Approximately 21 volts

Thermal Head Control

The thermal head has heating elements at a density of 300 dpi. The thermal

heating elements melt the over-coating and polyester film layers of the master,

according to the image signal for each pixel.

The power supply unit applies power (VHD) to the thermal heating elements. The

power source varies from one head to another since the average resistance of

each element varies. Therefore, when the thermal head or power supply unit is

replaced, it is necessary to readjust the applied voltage with particular values for

each thermal head.

Thermal Head Protection

The thermistor on the thermal head provides thermal head protection, preventing

the thermal head from overheating when processing a solid image. The CPU

detects any abnormal condition when the Start key is pressed, and displays an SC

code on the operation panel as follows:

SC Code Conditions

E - 04

E - 09

E - 10 When the pulse width that controls the

Over 54°C

Under - 20°C (Normally, this indicates that

the thermistor has become open, or a

related connector is disconnected.)

thermal head energy becomes abnormal,

master making stops and this SC lights.

Detecting

Component

Thermistor

Thermistor

MPU

C231/C237 SM

2-18

Page 65

Remarks for Handling the Thermal Head

The following remarks must be noted when servicing:

Remove any foreign materials on

Do not touch the surface

•

with bare hands. If you

touch it, clean the surface

with alcohol.

Do not damage the

•

heating elements.

Platen

Master

•

the platen roller.

Remove foreign materials.

•

Do not touch the surface of the

•

IMAGE-PROCESSING

master film with bare hands.

Do not touch the terminals of

•

the connectors with bare

hands to prevent damage from

static electricity.

Detailed

Section

Descriptions

MPU

Thermal Head

Connect and disconnect the connectors

•

carefully. Keep them horizontal. Also,

make sure that they are reconnected

firmly.

Adjust the applied voltage to the

•

particular value for the thermal head.

Connector

PSU

- Other Remarks Avoid using the machine under humid conditions. Moisture tends to condense on

the thermal head, causing heating element damage.

SM C231/C237

2-19

Page 66

MASTER EJECT

[

2.3 MASTER EJECT

2.3.1 OVERALL

[C]

[B]

C231D531.WMF

[A]

B]

[C]

C231D530.WMF

At the end of the printing cycle, the used master remains wrapped around the drum

to prevent the ink on the drum surface from drying. When the Master Making key is

pressed to make a new master, the used master is removed from the drum.

The machine ensures that the drum is at the master eject position and a master is

on the drum by checking the drum master sensor. The master clamper [A] then

opens to eject the master. If there is no master on the drum, the machine skips the

master eject operation and proceeds to the master making process.

The master eject rollers [B] turn for 0.6 seconds and pick up the master's leading

edge. After closing the master clamper, the drum starts rotating at the slowest

speed (30 rpm). At the same time the master eject rollers turn to feed the used

master into the master eject box [C].

When the drum stops at the master feed position after one and a half turns, the

pressure plate drive motor starts turning to compress the used master into the

master eject box.

C231/C237 SM

2-20

Page 67

2.3.2 MASTER CLAMPER OPEN MECHANISM

[B]

MASTER EJECT

[A]

[H]

[D]

[I]

[G]

[C]

[F]

[E]

[J]

C231D557.WMF

The master eject position sensor [A] ensures that the drum is positioned at the

master eject position when the Start key is pressed.

The master clamper has a magnetic plate [C] to secure the master's leading edge

in the clamper. The clamper is fixed to the clamper shaft [D], which has a lever [E]

at the rear side.

Detailed

Section

Descriptions

The clamper motor [F] drives the moving link [G] and pushes the clamper lever

open [E]. (The link position, the clamper open and close positions, are detected by

the clamper open sensor [H] and clamper close sensor [I].)

The master clamper then lifts the master eject arm [J] to release the master's

leading edge from the clamper.

Drum Position Lock Mechanism

When the c lamper motor [ F] opens the clamper at the master eject position, th e

drum guide [B] moves and engages the pin on the rear flange of the drum.

The drum guide is moved by the same mechanism that drives the moving link [G].

This means that the drum guide captures the drum at the master eject position

when the master clamper is being opened.

When the c lamper motor turns on again to close the master clamper, the drum

guide also disengages the pin and the drum can now turn.

SM C231/C237

2-21

Page 68

MASTER EJECT

2.3.3 MASTER EJECT ROLLER MECHANISM

[B]

[C]

[A]

C231D532.WMF

The master eject rollers are driven by the master eject motor [A] through idle gears.

The upper eject roller [B] has paddles to assure the master pick-up.

When the master clamper is opened and the master's leading edge is released

from the master clamper, the master eject motor turns on for 0.6 seconds to pick

up the leading edge of the master.

When the master eject motor is turned off, the clampe r motor reverses to close the

master clamper.

The drum then starts turning at the slowest speed (30 rpm). At the same time, the

master eject rollers turn again to feed the master into the master eject box.

After one turn of the drum, the master eject motor stops. The drum turns for an

additional half turn, stopping 109 encoder pulses after the feed start timing sensor

is actuated (this means that the drum is at the master feed position).

The master eject sensor [C] is used to detect master eject jams.

C231/C237 SM

2-22

Page 69

2.3.4 PRESSURE PLATE MECHANISM

MASTER EJECT

[A]

[E]

[D]

[B]

[C]

C231D533.WMF

[C]

[B]

[F]

Detailed

Section

Descriptions

The pressure plate motor [A] drives the pressure plate through the drive arm [B]

and the pressure springs [C].