Page 1

®

®

®

RICOH GROUP COMPANIES

C217/C225

SERVICE MANUAL

PN: RCSM1730

Page 2

Page 3

®

®

®

SERVICE MANUAL

C217/C225

RICOH GROUP COMPANIES

Page 4

Page 5

C217/C225

SERVICE MANUAL

PN: RCSM1730

Page 6

Page 7

WARNING

The Service Manual contains information regarding

service techniques, procedures, processes and

spare parts of office equipment distributed by

Ricoh Corporation. Users of this manual should be

either service trained or certified by successfully

completing a Ricoh T echnical Training Program.

Untrained and uncertified users utilizing

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property or loss of warranty

protection.

Ricoh Corporation

Page 8

Page 9

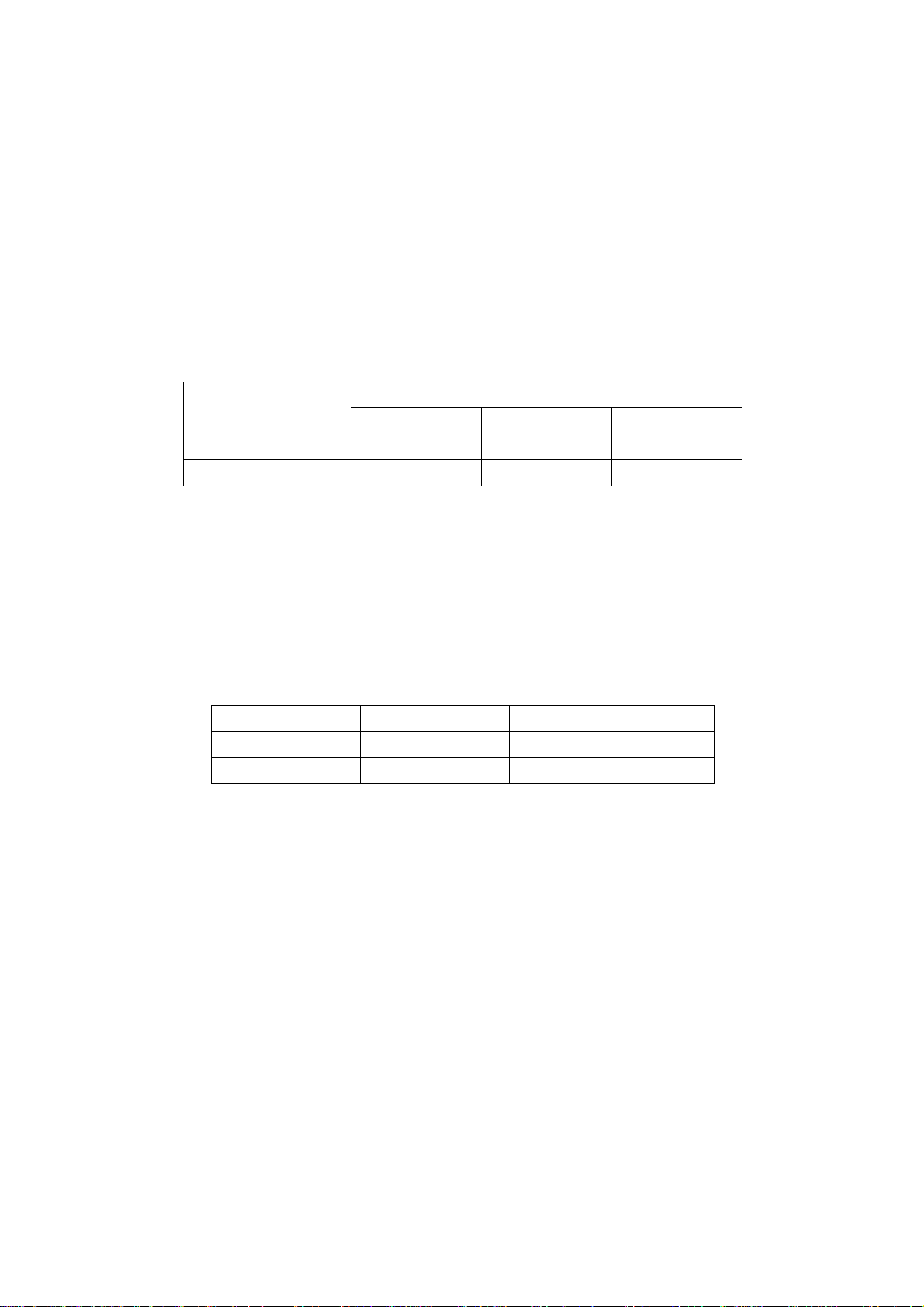

LEGEND

PRODUCT CODE COMPANY

GESTETNER RICOH SAVIN

C217 5303 VT1730 —

C225 5304 VT1800 3100DNP

DOCUMENTATION HISTORY

REV. NO. DATE COMMENT

* 5/93 Original Printing

1 10/95 VT1800 Addition

Page 10

Page 11

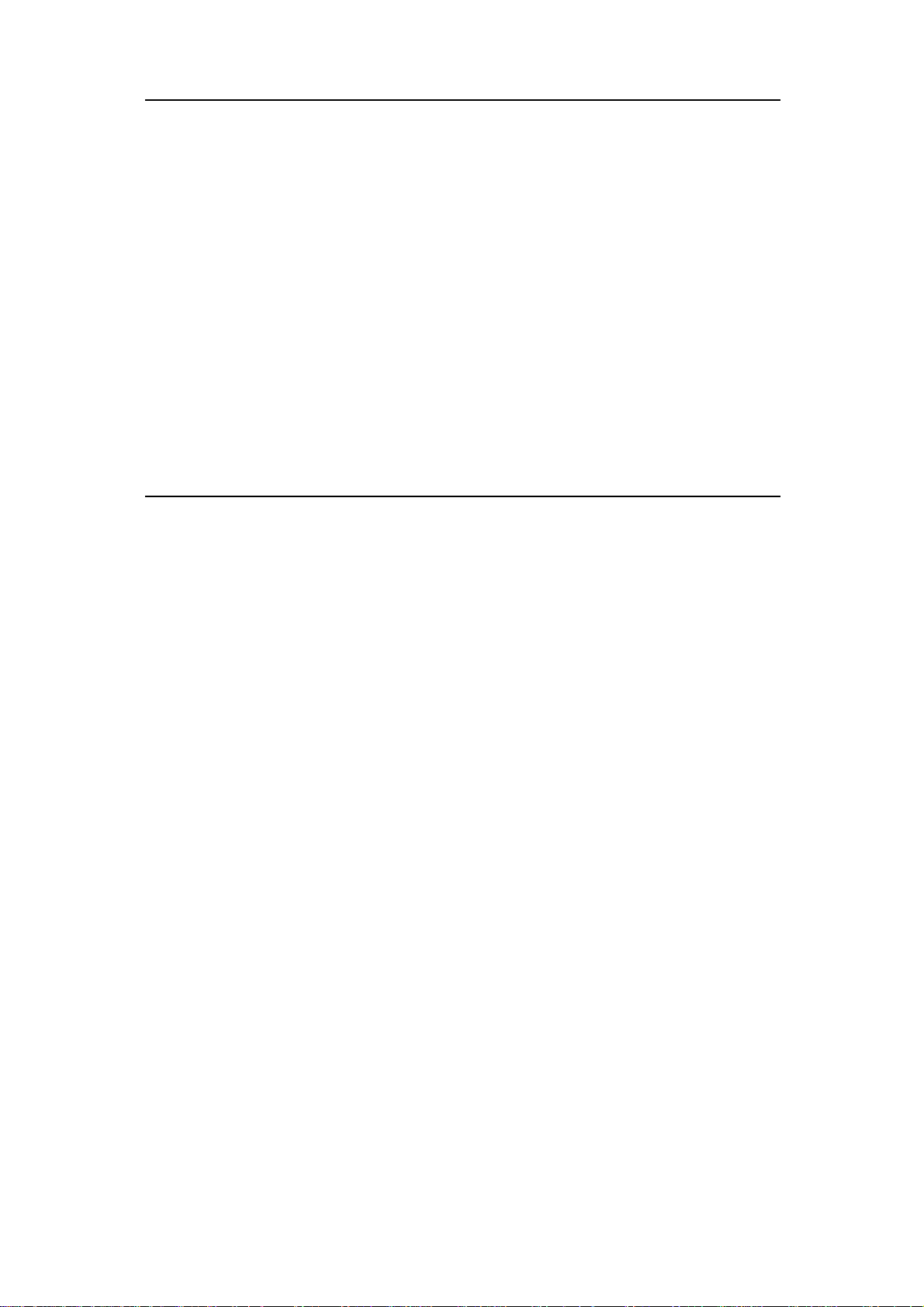

Table of Contents

OVERALL MACHINE INFORMATION

1. SPECIFICA TIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. PRINTING PROCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

3. MECHANICAL COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . 1-4

4. DRIVE LAYOUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

5. ELECTRICAL COMPONENT DESCRIPTION. . . . . . . . . . . . . . . . . . 1-6

6. OVERALL MACHINE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

DETAILED SECTION DESCRIPTIONS

1. MASTER EJECT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.1 OVERALL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

1.2 MASTER CLAMPER OPEN MECHANISM . . . . . . . . . . . . . . . . . 2-2

1.3 MASTER EJECT ROLLER MECHANISM . . . . . . . . . . . . . . . . . . 2-3

1.4 PRESSURE PLATE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . 2-4

2. SCANNER AND OPTICS SECTION . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.1 OVERALL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

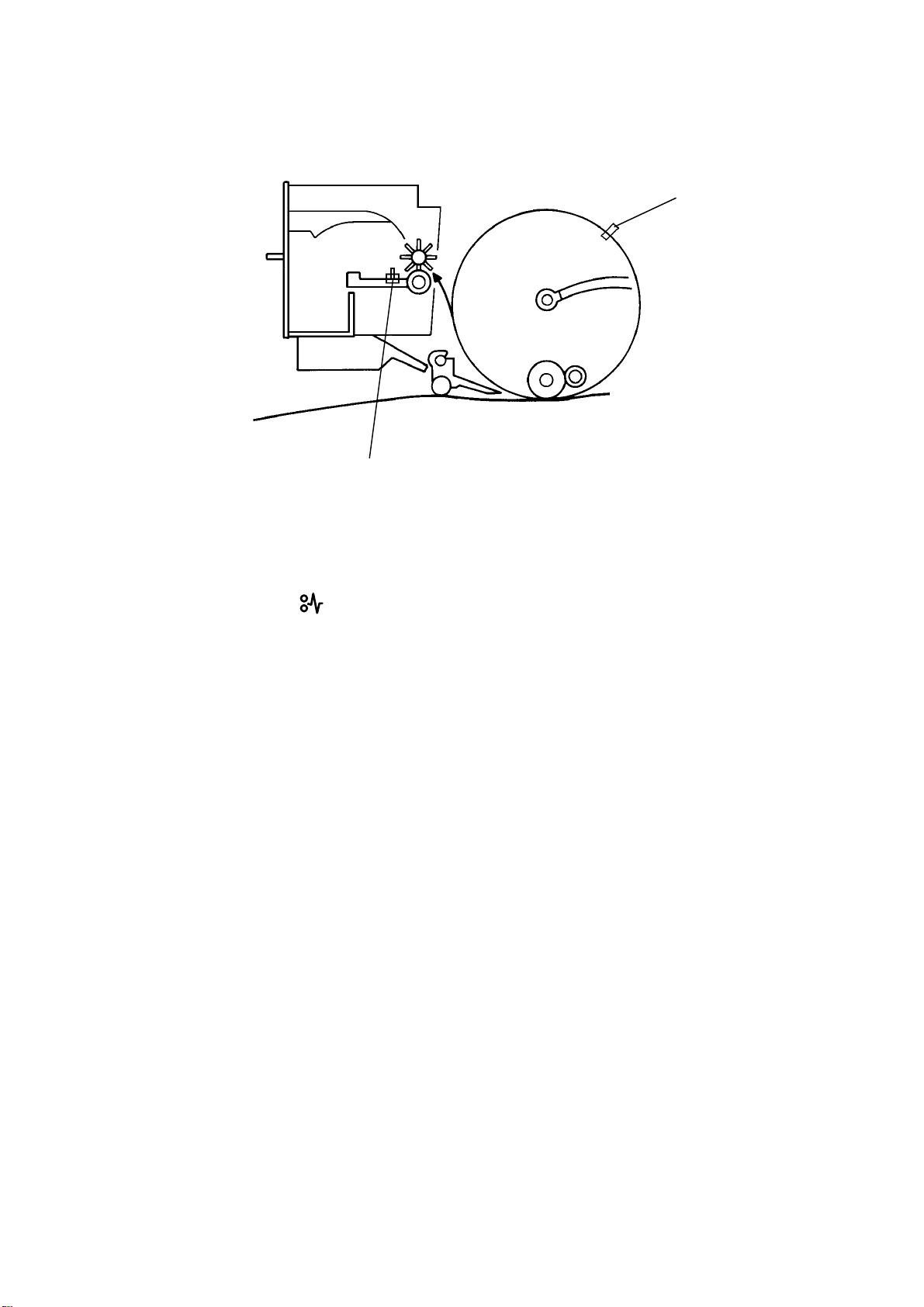

2.2 ORIGINAL FEED MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3 ORIGINAL FEED DRIVE MECHANISM. . . . . . . . . . . . . . . . . . . . 2-7

3. MASTER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

3.1 OVERALL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

3.2 MASTER FEED MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

3.3 MASTER CLAMPER OPERATION AND TENSION ROLLER

RELEASE MECHANISM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

3.4 CUTTER MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

4. PAPER FEED SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

4.1 OVERALL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

4.2 PAPER FEED ROLLER MECHANISM . . . . . . . . . . . . . . . . . . . 2-13

4.3 2ND FEED ROLLER MECHANISM . . . . . . . . . . . . . . . . . . . . . . 2-14

4.4 UPPER 2ND FEED ROLLER RELEASE MECHANISM . . . . . . 2-15

SM i C217

Page 12

4.5 PRINTING PRESSURE MECHANISM. . . . . . . . . . . . . . . . . . . . 2-16

4.6 PAPER TABLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

4.7 SIDE FENCE SLIDE MECHANISM . . . . . . . . . . . . . . . . . . . . . . 2-20

5. DRUM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

5.1 OVERALL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

5.2 DRUM DRIVE MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

5.3 MAIN MOTOR CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

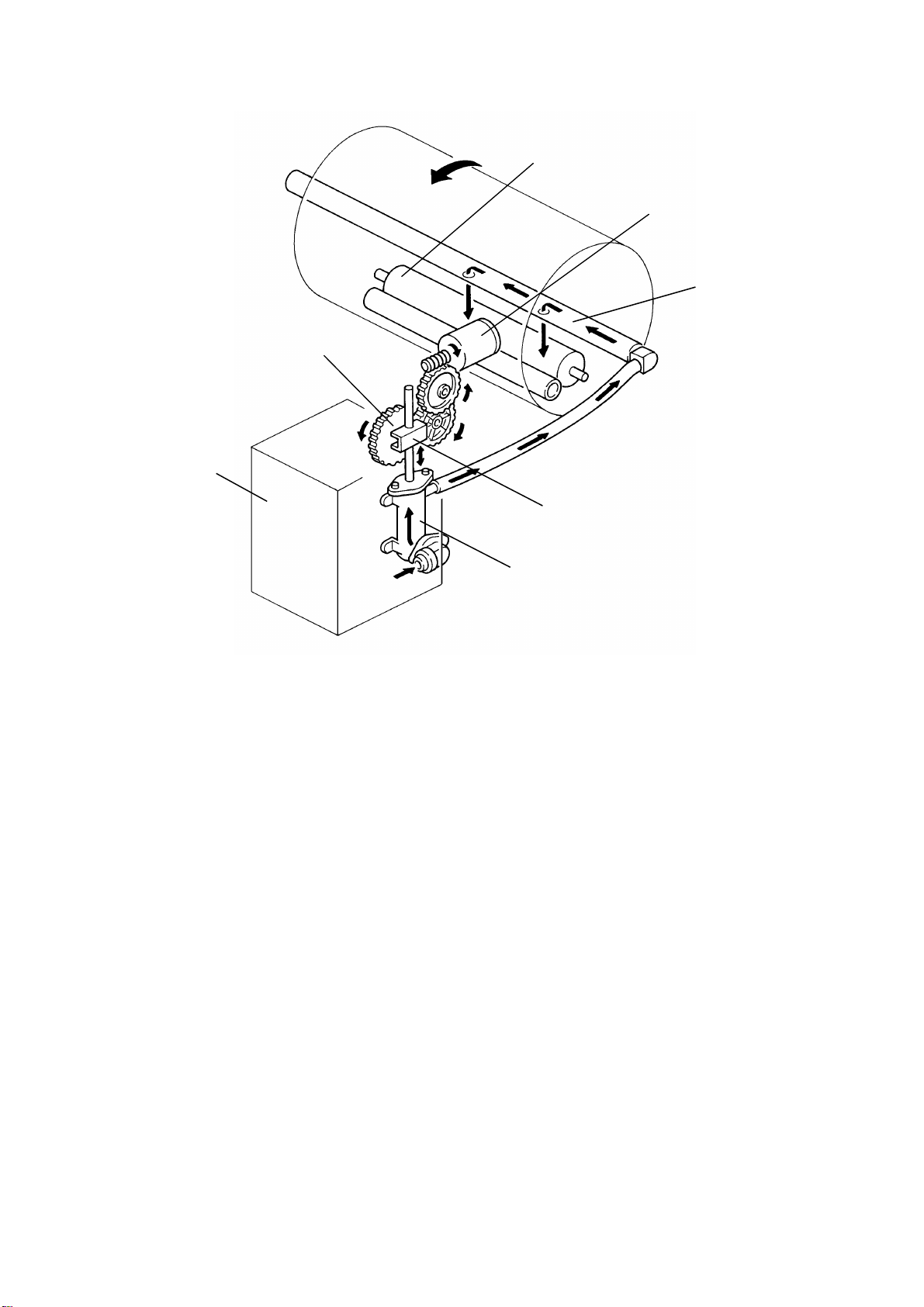

5.4 INK SUPPLY MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

5.5 INK ROLLER MECHANISM . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

5.6 INK SUPPLY CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

6. PAPER DELIVERY SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

6.1 OVERALL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

6.2 PAPER DELIVERY ROLLER . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

6.3 EXIT PAWL/AIR KNIFE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

6.4 EXIT PAWL RELEASE MECHANISM . . . . . . . . . . . . . . . . . . . . 2-32

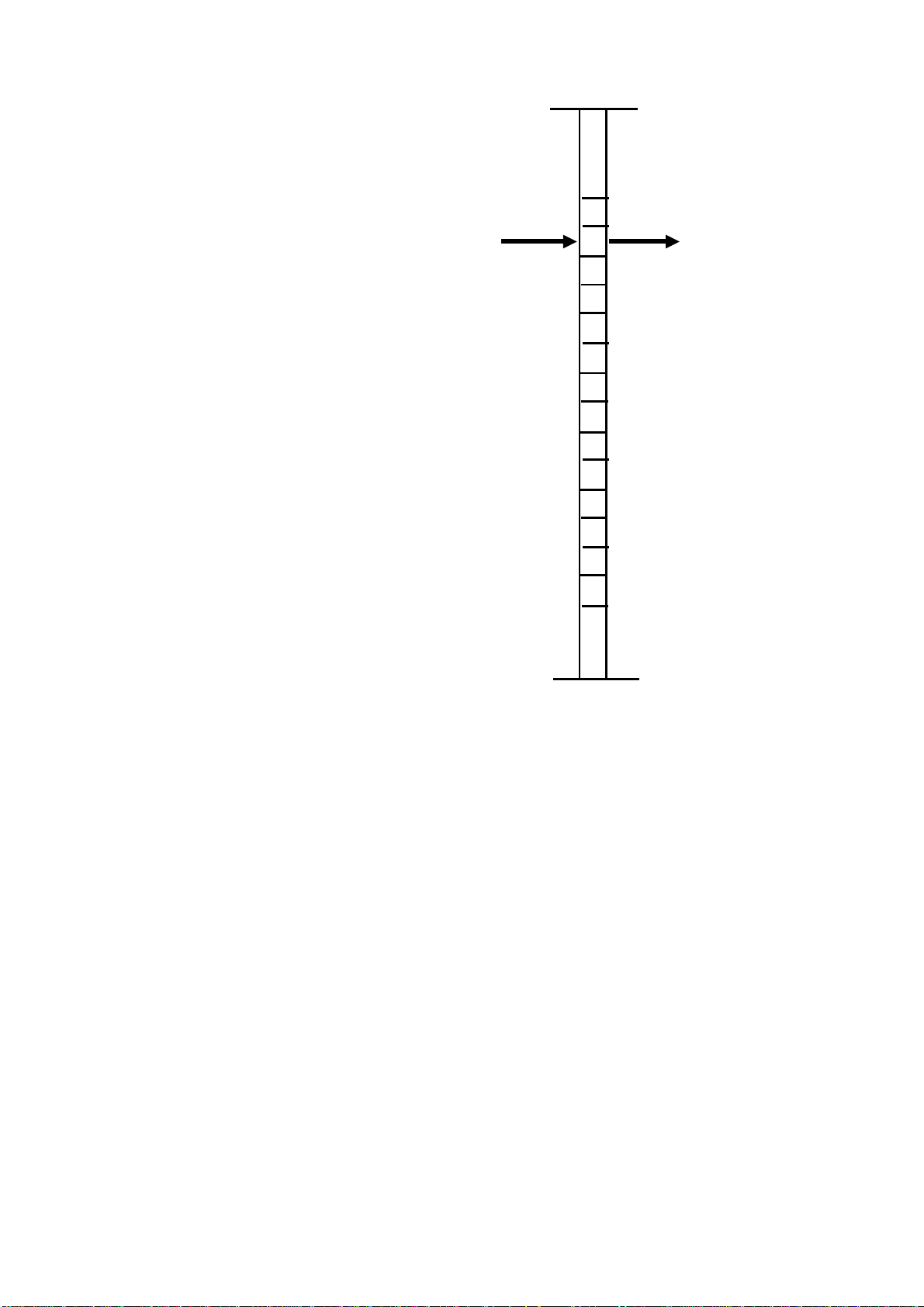

7. JAM DETECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

7.1 ORIGINAL JAM DETECTION . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

7.2 MASTER EJECT JAM DETECTION . . . . . . . . . . . . . . . . . . . . . 2-34

7.3 MASTER FEED JAM DETECTION . . . . . . . . . . . . . . . . . . . . . . 2-35

7.4 PAPER FEED JAM DETECTION. . . . . . . . . . . . . . . . . . . . . . . . 2-36

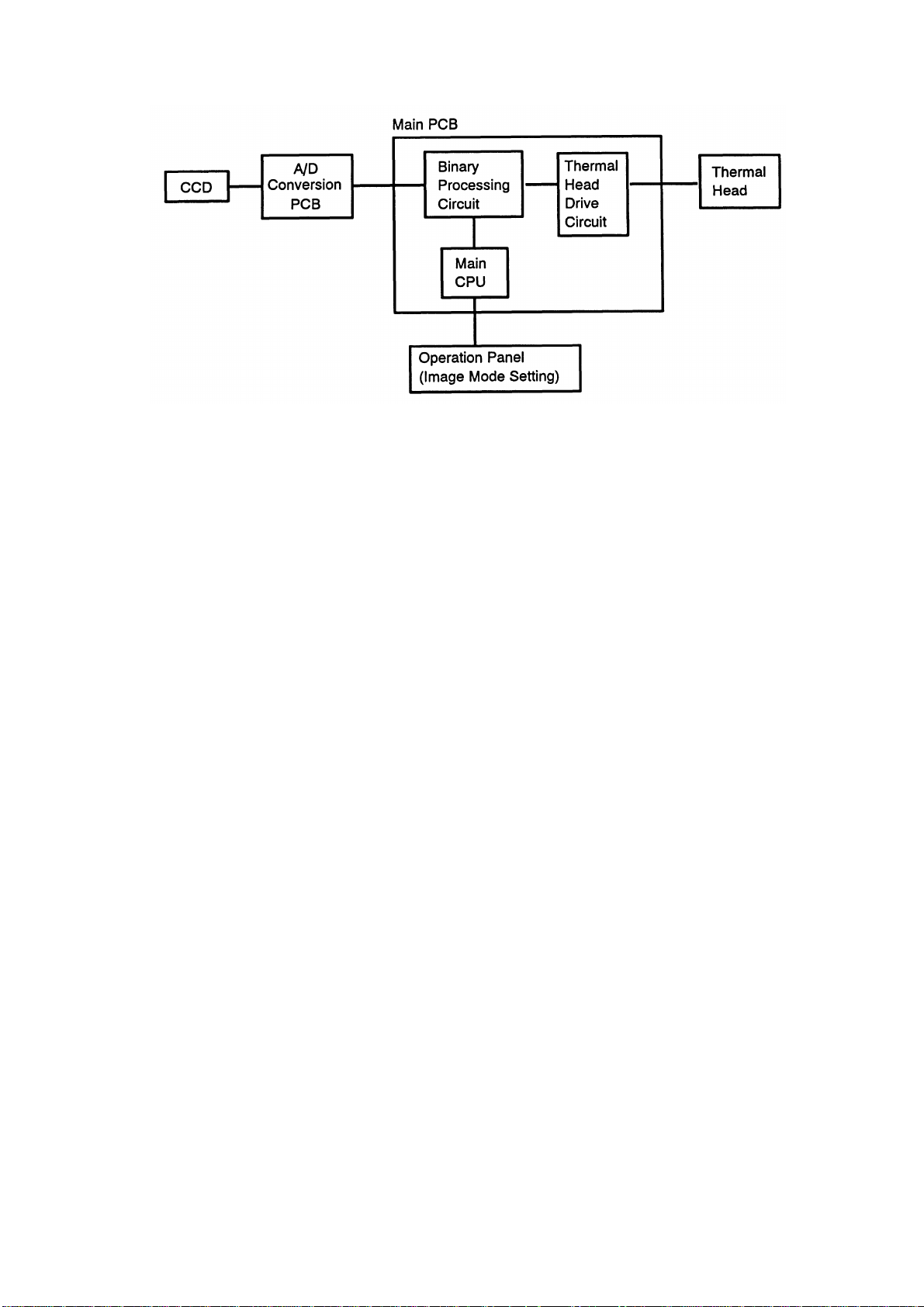

8. IMAGE PROCESSING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38

8.1 A/D CONVERSION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

8.2 BINARY PROCESSING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

8.2.1 MTF Correction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47

8.2.2 Dither Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

8.2.3 Edge Emphasis Processing in the Photo Mode . . . . . . . . . . . . . . . . . . . . . 2-48

8.3 THERMAL HEAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

8.3.1 Thermal Head Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

8.3.2 Thermal Head Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

9. MASTER PLOTTING AND PRINTING AREA. . . . . . . . . . . . . . . . . 2-51

C217 ii SM

Page 13

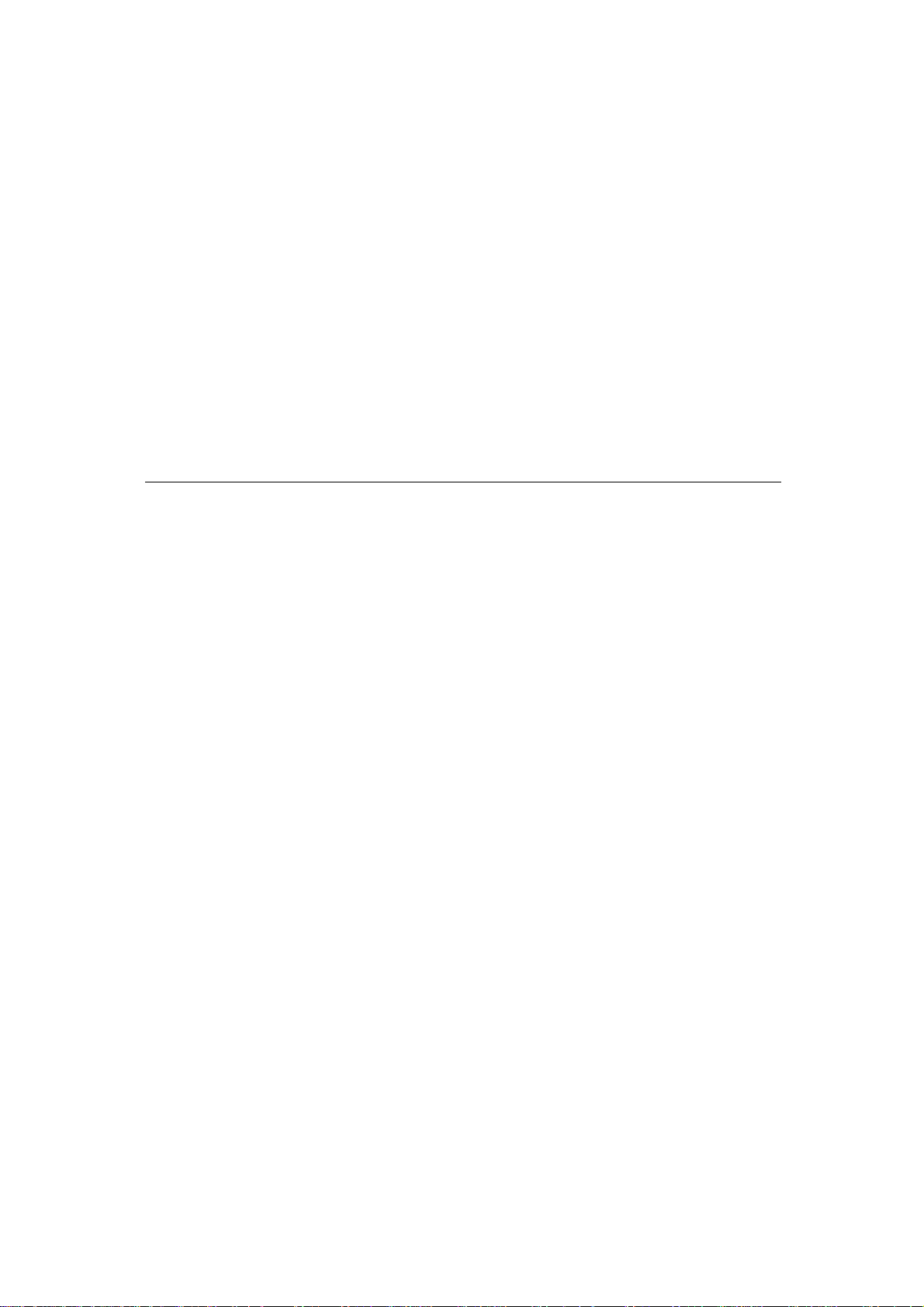

INSTALLATION

1. INSTALLATION REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.1 OPTIMUM ENVIRONMENTAL CONDITION: . . . . . . . . . . . . . . . 3-1

1.2 ENVIRONMENTS TO AVOID: . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

1.3 POWER CONNECTION: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

1.4 ACCESS TO MACHINE: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

2. INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3. TAPE MARKER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.2 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

SERVICE TABLES

1. SERVICE REMARKS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.1 SCANNER SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.2 MASTER FEED SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.3 PAPER FEED SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.4 DRUM AND DRUM DRIVE SECTION. . . . . . . . . . . . . . . . . . . . . 4-2

1.5 INK SUPPLY SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

1.6 PAPER DELIVERY SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

1.7 ELECTRICAL COMPONENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

2. MAINTENANCE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

3. LUBRICATION POINTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

3.1 FEED ROLLER BUSHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

3.2 EXIT ROLLER BUSHINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

3.3 FEED ROLLER DRIVE GEARS. . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

3.4 DRUM DRIVE GEARS AND CAM . . . . . . . . . . . . . . . . . . . . . . . . 4-6

3.5 DRUM FLANGE BUSHING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4. INPUT/OU TPUT CHECK MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.1 ACCESS PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.2 DRUM FREE RUN MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

SM iii C217

Page 14

4.3 INPUT CHECK MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.4 OUTPUT CHECK MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

5. THERMAL HEAD TEST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

6. SERVICE TABLES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

5.1 TEST POINT TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

5.2 VARIABLE RESISTOR TABLE . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

5.3 DIP SW TABLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

5.4 LED TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

5.5 FUSE TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

7. SERVICE CALL INDICATIONS TABLE . . . . . . . . . . . . . . . . . . . . . 4-16

REPLACEMENT AND ADJUSTMENT

1. SCANNER SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1.1 ORIGINAL REGISTRATION SENSOR ADJUSTMENT. . . . . . . . 5-1

1.2 ORIGINAL FRICTION PAD REMOVAL . . . . . . . . . . . . . . . . . . . . 5-3

1.3 EXPOSURE LAMP REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

1.4 ORIGINAL SET AND REGISTRATION SENSOR REMOVAL. . . 5-7

1.5 ORIGINAL PICK-UP AND FEED ROLLER REMOVAL . . . . . . . . 5-8

1.6 EXPOSURE GLASS REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

2. COPY IMAGE A DJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

2.1 LEADING EDGE REGISTRATION ADJUSTMENT . . . . . . . . . . 5-10

2.2 VERTICAL MAGNIFICATION ADJUSTMENT. . . . . . . . . . . . . . 5-11

2.3 TRAILING EDGE ERASE MARGIN ADJUSTMENT . . . . . . . . . 5-12

3. MASTER FEED SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

3.1 THERMAL HEAD VOLTAGE ADJUSTMENT . . . . . . . . . . . . . . 5-13

3.2 THERMAL HEAD REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

3.3 PLOTTER UNIT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

4. MASTER EJECT SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

4.1 MASTER EJECT UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . 5-19

5. PAPER FEED SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

C217 iv SM

Page 15

5.1 PAPER FEED ROLLER AND FRICTION PAD REMOVAL . . . . 5-21

6. PRINTING SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

6.1 PRESS ROLLER LOCK LEVER ADJUSTMENT. . . . . . . . . . . . 5-22

6.2 PRESS ROLLER REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

7. DRUM, DRUM DRIVE, AND INK SUPPLY SECTION. . . . . . . . . . . 5-25

7.1 DRIVE BELT TENSION ADJUSTMENT . . . . . . . . . . . . . . . . . . 5-25

7.2 DOCTOR ROLLER GAP ADJUSTMENT. . . . . . . . . . . . . . . . . . 5-26

7.3 INK DETECTION ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . 5-28

7.4 MAIN MOTOR REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . 5-29

7.5 INK PUMP PLUNGER POSITION ADJUSTMENT . . . . . . . . . . 5-30

7.6 DRUM UNIT REMOVAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-31

7.7 DRUM SCREEN REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-35

7.8 INK ROLLER UNIT REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . 5-36

8. PAPER DELIVERY SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-38

8.1 EXIT PAWL CLEARANCE ADJUSTMENT . . . . . . . . . . . . . . . . 5-38

8.2 EXIT PAWL DRIVE TIMING ADJUSTMENT . . . . . . . . . . . . . . . 5-40

8.3 EXIT ROLLER AND EXIT PAWL REMOVAL . . . . . . . . . . . . . . 5-42

9. OPTICS SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

9.1 OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-43

9.1.1 Preparation For Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

9.1.2 Scanning Start And Line Position Adjustment . . . . . . . . . . . . . . . . . . . . . . 5-49

9.1.3 Focus (Modulation Transfer Function) Adjustment. . . . . . . . . . . . . . . . . . . 5-51

9.1.4 Magnification Ratio Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-53

9.1.5 White Level Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-55

TROUBLESHOOTING

1. ELECTRICAL COMPONENT TROUBLE . . . . . . . . . . . . . . . . . . . . . 6-1

2. TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

2.1 IMAGE TROUBLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

2.2 PAPER FEED TROUBLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

SM v C217

Page 16

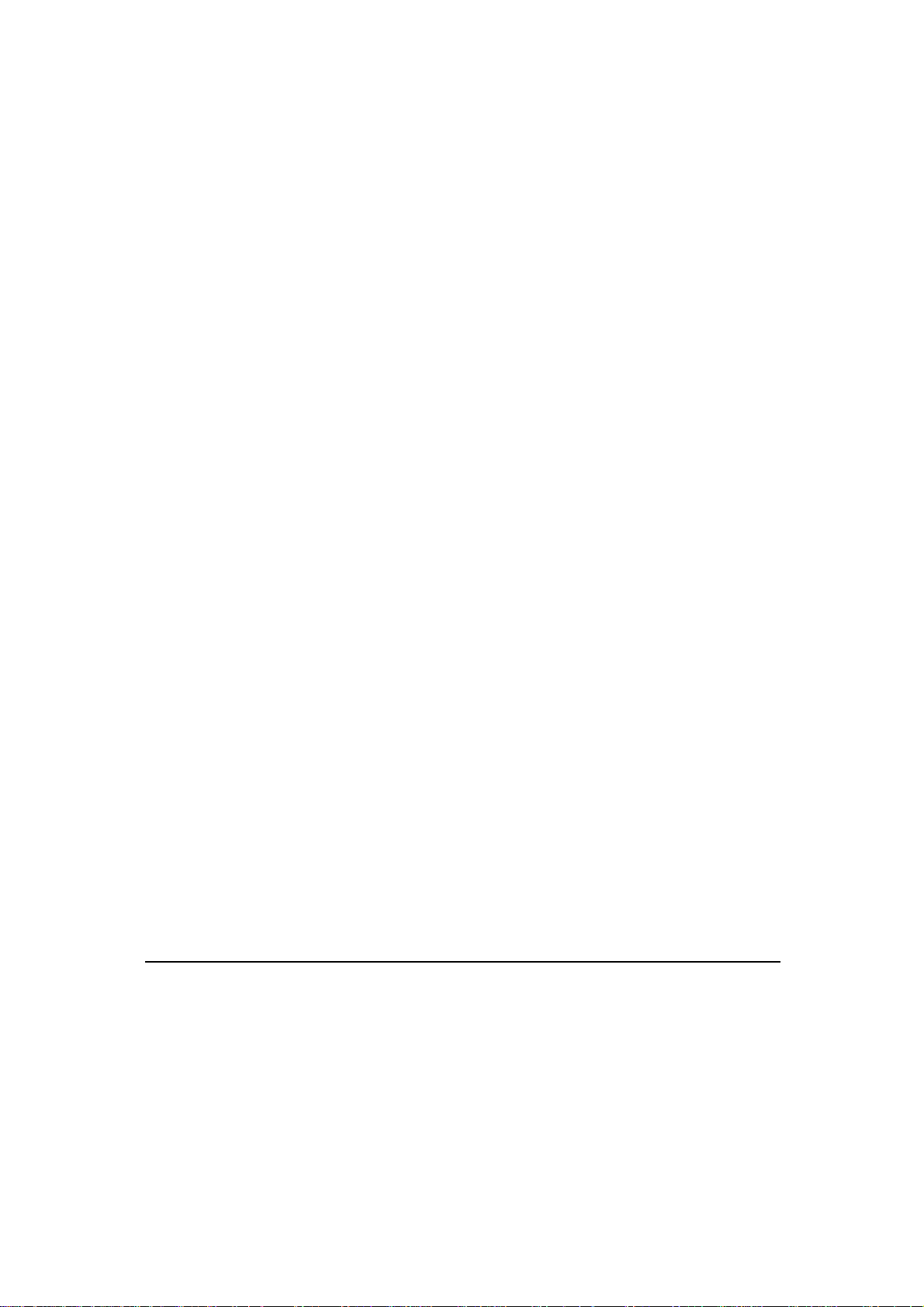

PRIPORT CONTROLLER INSTALLATION GUIDE

7.1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.2 SYSTEM REQUIREMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7.3 INSTALLATION PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

7.4 PARTS LISTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7.5 CABLING BETWEEN PCRIP-10 AND COMPUTER . . . . . . . . . 7-8

A. IBM AND COMPATIBLES - PARALLEL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

B. IBM AND COMPATIBLES - SERIAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

C. MACINTOSH COMPUTERS - APPLETALK STANDARD . . . . . . . . . . . . . . . . 7-9

7.6 SYSTEM VERIFICATION AND DEFAULT

CONFIGURATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

7.7 CABLE PIN-OUT DIAGRAMS. . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

A. PARALLEL INTERFACE, PIN-OUT CONNECTIONS. . . . . . . . . . . . . . . . . . 7-12

B. PARALLEL INTERFACE CABLE, PIN ASSIGNMENTS . . . . . . . . . . . . . . . . 7-12

C. SERIAL INTERFACE CABLE, PIN-OUT CORRECTIONS . . . . . . . . . . . . . . 7-13

D. SERIAL INTERFACE CABLE, PIN ASSIGNMENTS. . . . . . . . . . . . . . . . . . . 7-13

7.8 RAM UPGRADE PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . 7-14

PRIPORT CONTROLLER USER’S GUIDE

7.9 REGULATORY NOTICES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

7.10 TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

7.11 HARDWARE INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . 7-23

7.12 PRIPORT CONTROLLER CONFIGURATION . . . . . . . . . . . . 7-24

7.13 CONFIGURATION OF IBM PC AND COMPATIBLES . . . . . . 7-24

7.14 CONFIGUTATION OF MACINTOSH COMPUTERS . . . . . . . 7-28

7.15 APPLICATION SOFTWARE SET-UP . . . . . . . . . . . . . . . . . . . 7-29

7.16 PRIPORT CONTROLLER OPERATION. . . . . . . . . . . . . . . . . 7-30

7.17 COMMONLY ASKED QUESTIONS . . . . . . . . . . . . . . . . . . . . 7-31

7.18 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-34

7.19 APPENDIX A - DIAGNOSTIC STATUS PAGE. . . . . . . . . . . . 7-37

7.20 PARTS CATALOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-39

C217 vi SM

Page 17

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the machine, make sure

that the power cor d is un plu gged.

2. The wall outlet should be near the machine and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers

off or open while the main switch is turned on, keep hands away from

electrified or mech anically driven components.

HEALTH SAFETY CONDITIONS

1. If you get ink in your eyes by accident, try to remove with eye drops or

flush with water as fir st aid. If unsuccessful, get medical at te nt i on .

2. If you ingest ink by accident, indu ce vom i t ing by sticki ng fing er do w n

throat or by giving soapy or strong salty water to drink.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The printer and its peripherals must be installed and maintained by a

customer service representative who has completed the training course

on those models.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Dispose of replaced parts in accordance with local regulations.

2. Used ink and master should be disposed of in an environmentally safe

manner and in accorda nce wit h l oca l re gu lat i on s.

SM a C217

Page 18

Page 19

OVERALL MACHINE INFORMATION (C217)

OVERALL MACHINE INFORMATION (C225)

DETAILED SECTION DESCRIPTION (C217)

DETAILED SECTION DESCRIPTION (C225)

INSTALLATION (C217)

INSTALLATION (C225)

TAB POSITION 1

TAB POSITION 2TAB POSITION 3TAB POSITION 4

SERVICE TABLES (C217)

SERVICE TABLES (C225)

REPLACEMENT AND ADJUSTMENT (C217)/(C225)

TROUBLESHOOTING (C217)/(C225)

PCRIP-10 PRIPORT CONTROLLER

TAB POSITION 5TAB POSITION 6

TAB POSITION 7TAB POSITION 8

Page 20

Page 21

OVERALL MACHINE

INFORMATION

Page 22

Page 23

1. SPECIFICATION

Configuration: Desk top

Master Making Process: Digital

Printing Process: Full automatic one drum stencil system

Image Mode: Line/Photo

Original Type: Sheet

Original Weight: (17.0 lb~90 lb)

Original Size: Max: 216 mm x 356 mm (8

Min: 90 mm x 140 mm (3

Paper Size: Max: 216 mm x 356 mm (8

Min: 90 mm x 140 mm (3

Paper Weight: (18 lb~110 lb)

Printing Area: 210 mm x 349.6 mm (8.3" x 13.8") or less

Printing Speed: 70/100/130 cpm (3 settings)

First Print Time:

28 seconds ± 2 seconds

Leading Edge Margin:

5 mm ± 2 mm (0.2" ± 0.08")

Trailing Edge Margin:

1 mm ± 1 mm

Left Side Margin: 5 mm~10 mm (0.2"~0.4")

Right Side Mar gi n : 5 mm~10 mm (0.2" ~ 0. 4" )

Paper Feed Table Capacity: 500 sheets (80 g/m2, 20.0 lb)

Paper Delivery Table Capacity: 500 sheets (80 g/m2, 20.0 lb)

Master Eject Box Capacity: More than 15 masters

ADF Original Capacity: 6 sheets or a 0.6 mm height

1/2

1/2

1/2

1/2

" x 14")

" x 5

1/2

" x 14")

" x 5

1/2

")

")

Overall

Machine

Information

SM 1-1 C217

Page 24

Weight: 51 kg (112 lb)

Power Source: 120 V 60 HZ more than 2.4 A

Power Consumption : Mast er M akin g: Less than 160 W

Printing: Less than 160 W

Dimensions:

(W x D x H)

[Stored]692 mm x 612 mm x 440 mm

(26.2" x 24.1" x 17.3")

[Set up] 1050 mm x 612 mm x 440 mm

(41.3" x 24.1" x 17.3")

Pixel Density: 300 dpi

Print Counter: 7 digits

Master Counter: 6 digits

Noise Emission:

(Sound Pressure level*)

*= The measurements are to be

made according to ISO7779,

respectively.

Less than 70 dB

Master Making: 54 dB

Printing: 70 cpm: 62 dB

100 cpm: 64 dB

130 cpm: 68 dB

Optional Equip m en t: Key Counter, Tape Dispenser

Consumables:

Name Size Remarks

Thermal master Length: 125 m (410 ft)/roll

Width: 240 mm (9.5")

Ink 500 cc/pack Storage Conditions:

Tape for tape maker 35 m (114.8 ft)/roll

Thermal head cleaner Cleaner pen – 1pc

Replacement felt – 10 pcs

Cleaner bottle – 1 pc

255 masters can be made per roll.

Storage Conditions:

–10~40°C, 14°~104°F, 10~90% RH

–5~40°C, 23°~140°F, 10~90% RH

Clean the thermal head using the

cleaner after 2 master rolls have

been used.

C217 1-2 SM

Page 25

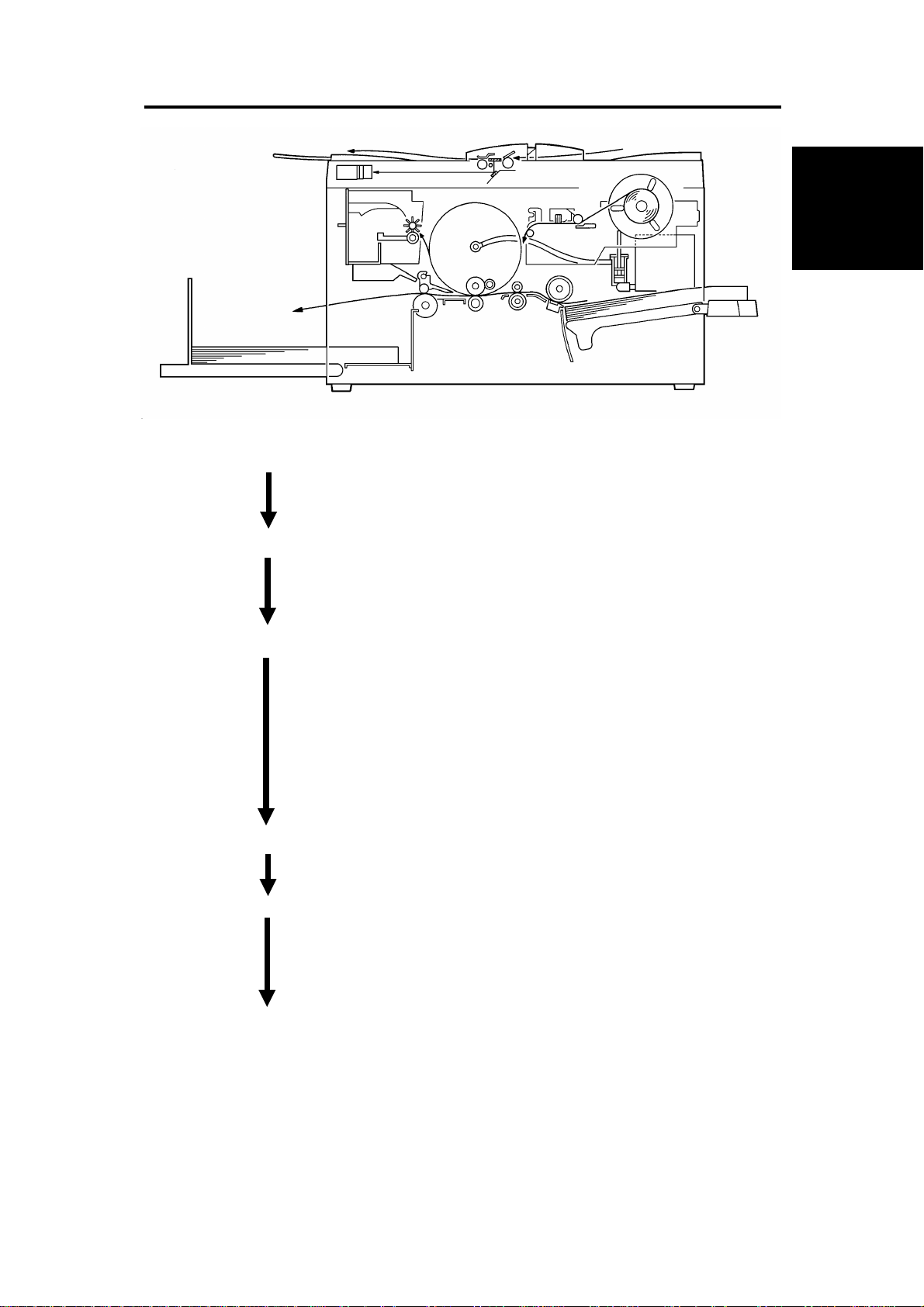

2. PRINTING PROCESS

1

6

1. Master Ejection: Removes the master from the drum and

ejects the used master into the master

eject box.

2. Scanning: Scans the original image through the

mirror and the lens to the CCD while

feeding the original.

3. Master Feeding: Converts the scanned CCD image signals

into digital signals which are used by the

thermal head to develop the master. The

generated heat de vel o ps th e m ast er by

atomizing the pla s tic coa ti n g It i s the n

clamped and wrapped around the drum

surface. The master is cut to cover the

entire drum surface.

4. Paper Feeding: Sends paper to the drum section.

2

3

Overall

Machine

Information

5

4

5. Printing: Presses th e paper fed from the paper

feed section onto the drum. This transfers

the ink to the paper through the drum

screen and the master.

6. Paper Delivering: The air knife and exit pawls removes the

printed paper from the drum, and ejects

the paper onto the pa pe r deli very table.

SM 1-3 C217

Page 26

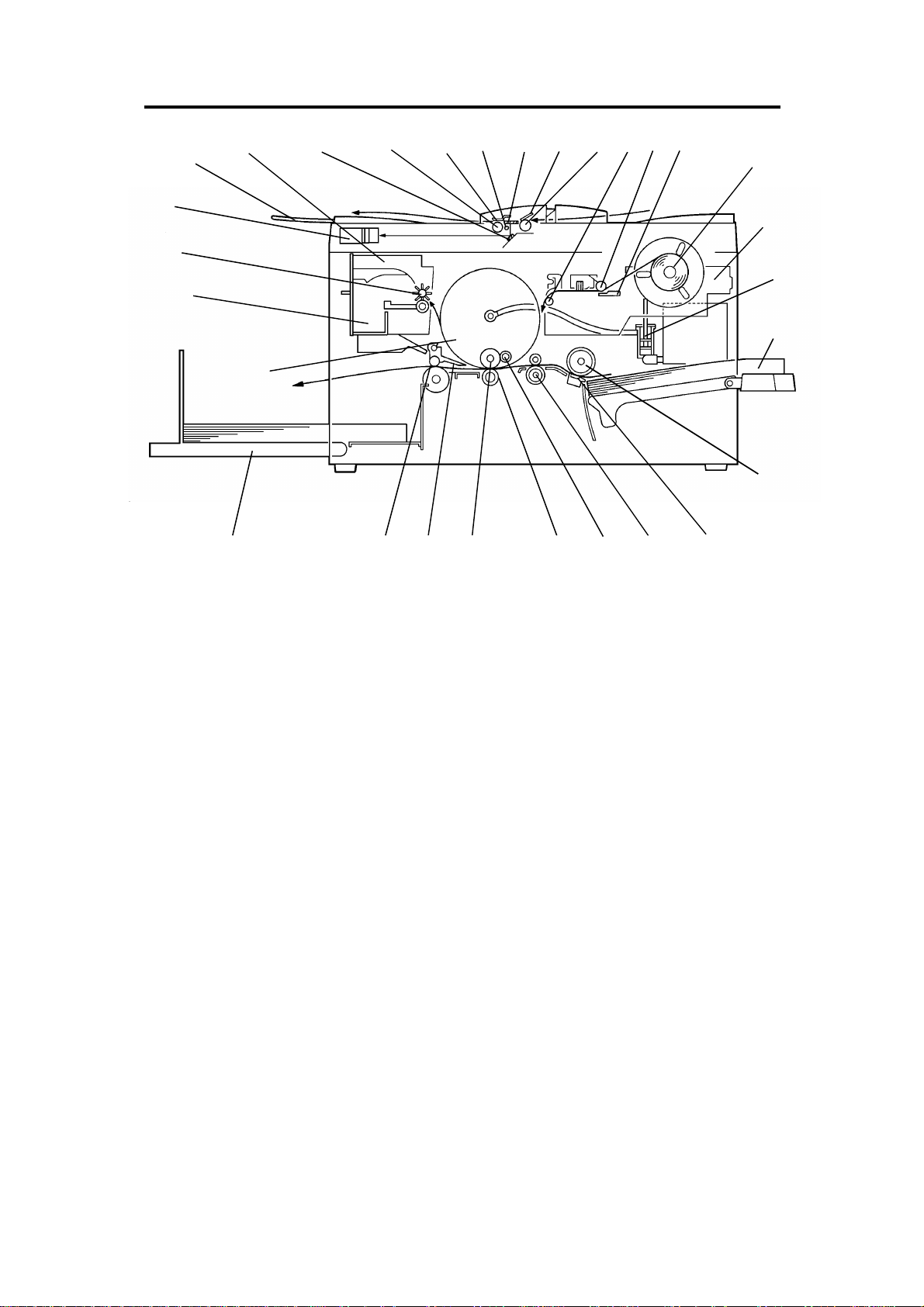

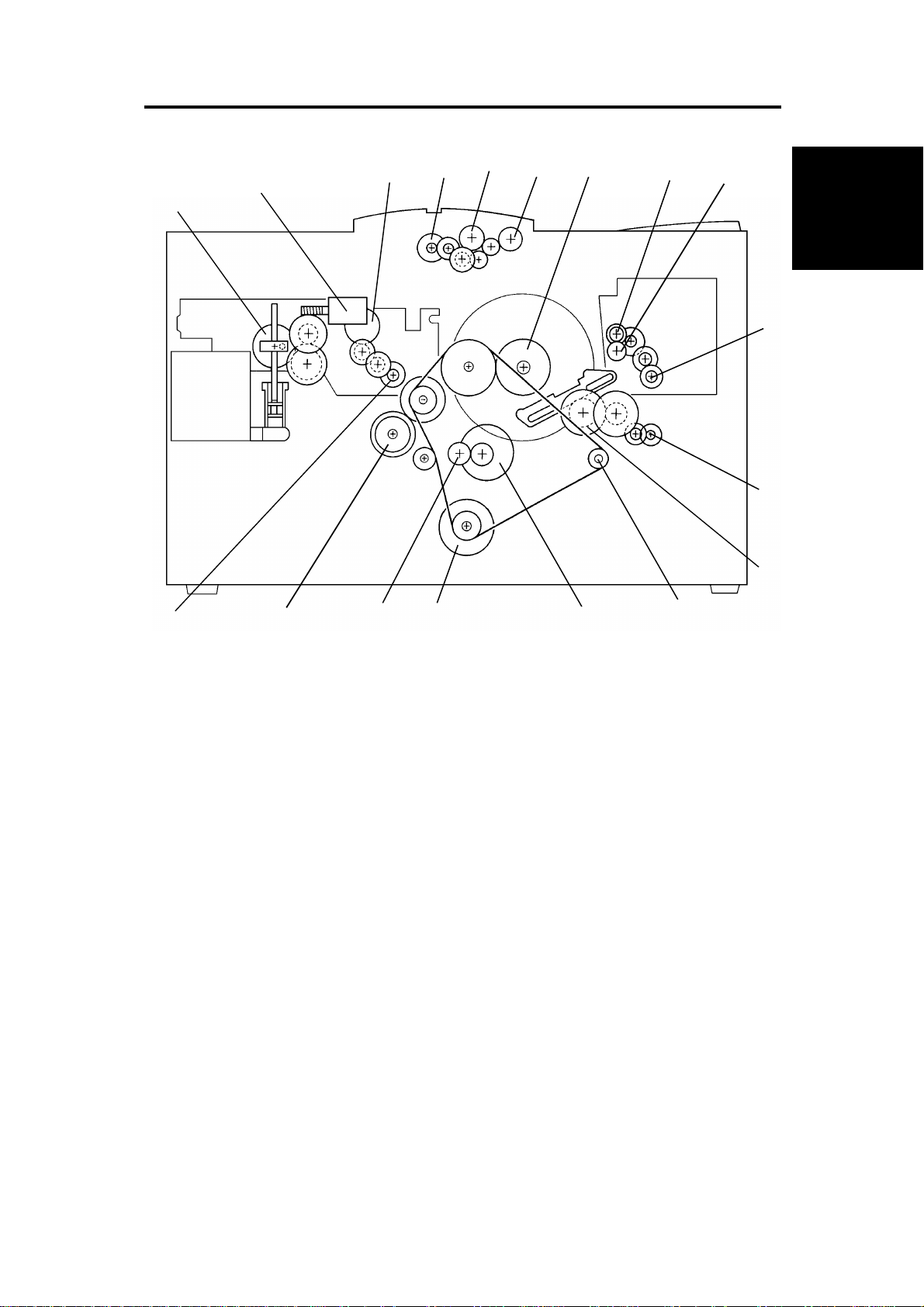

3. MECHANICAL COMPONENT LAYOUT

28

27

26

25

29

24

1234

5

6789

10

11

12

13

14

15

1617181920212223

1. Mirror

2. Original Feed Roller

3. Original Pressur e Pl at e

4. Exposure Lamp

5. Exposure Glass

6. Original Friction Pad

7. Original Pick-up Roller

8 . Master Tens ion Roller

9 . Plo tter Roller

10. Thermal Head

11. Master Roll

12. Plotter Unit

13. Ink Pump

14. Paper Table

15. Paper Feed Roller

16. Friction Pad

17. 2nd Feed Roller

18. Doctor Roller

19. Press Roller

20. Ink Roller

21. Exit Pawl

22. Exit Rollers

23. Paper Delivery Table

24. Drum

25. Master Eject Box

26. Master Eject Roller

27. CCD Unit

28. Original Exit Tray

29. Master Eject Unit

C217 1-4 SM

Page 27

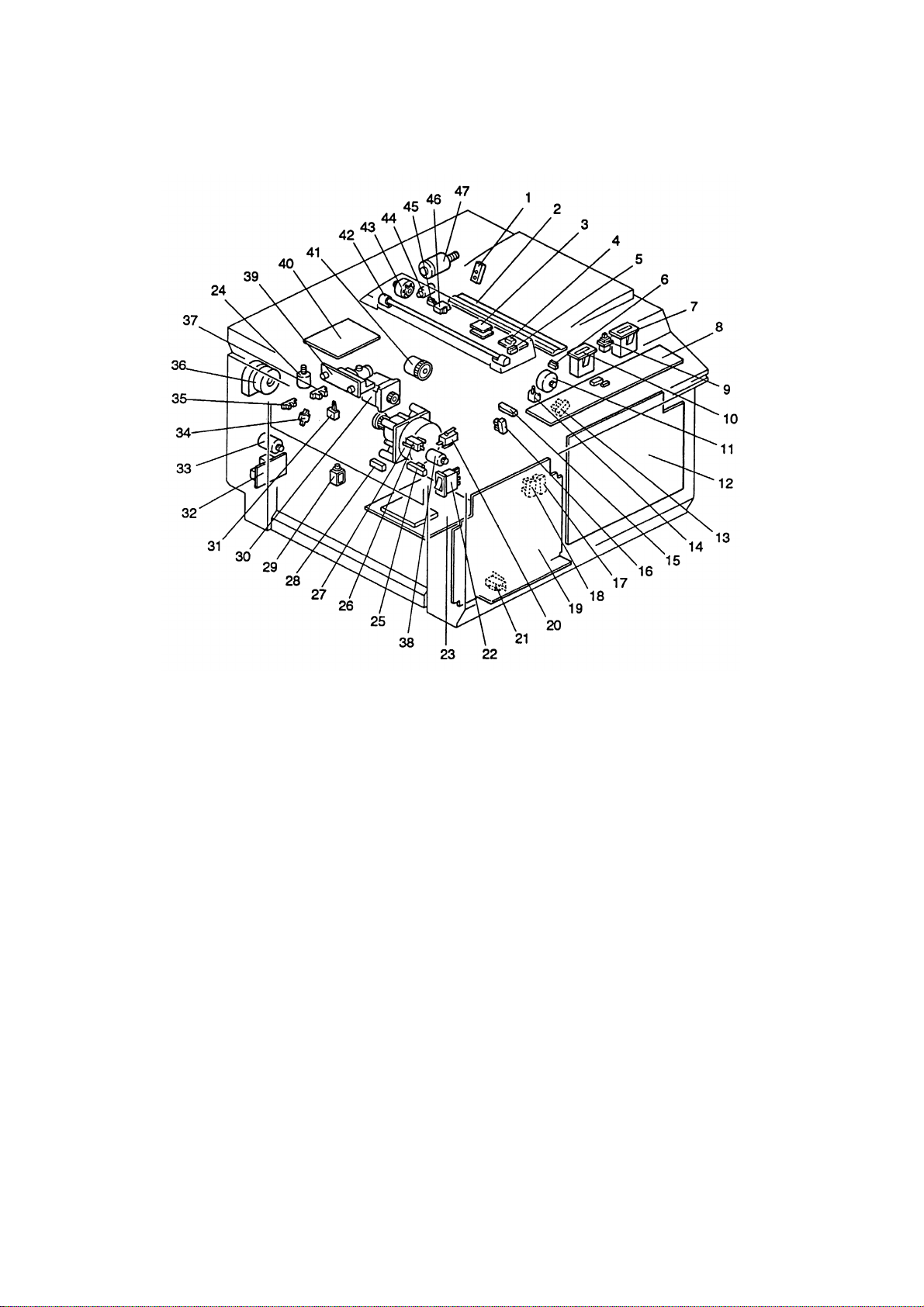

4. DRIVE LAYOUT

2

1

5

3

4

6

7

8

9

Overall

Machine

Information

10

11

18

1 . Pump Drive Gear

2. Ink Supply Motor

3. Platen Roller Gear

4. Original Feed Motor

5. Original Pick-up Roller

6. Original Feed Roller

7 . Drum Drive Gear

8. Upper Master Eject Roller Gear

17

16

15

10. Master Eject Motor

11. Master Clamper Motor

12. Master Clamper Drive Gear

13. Exit Roller Pulley

14. 2nd Feed Motor

15. Main Motor

16. 2nd Feed Roller Gear

17. Paper Feed Roller Gear

14

12

13

9 . Lo wer Master Eject Roller Gear

SM 1-5 C217

18. Master Feed Motor

Page 28

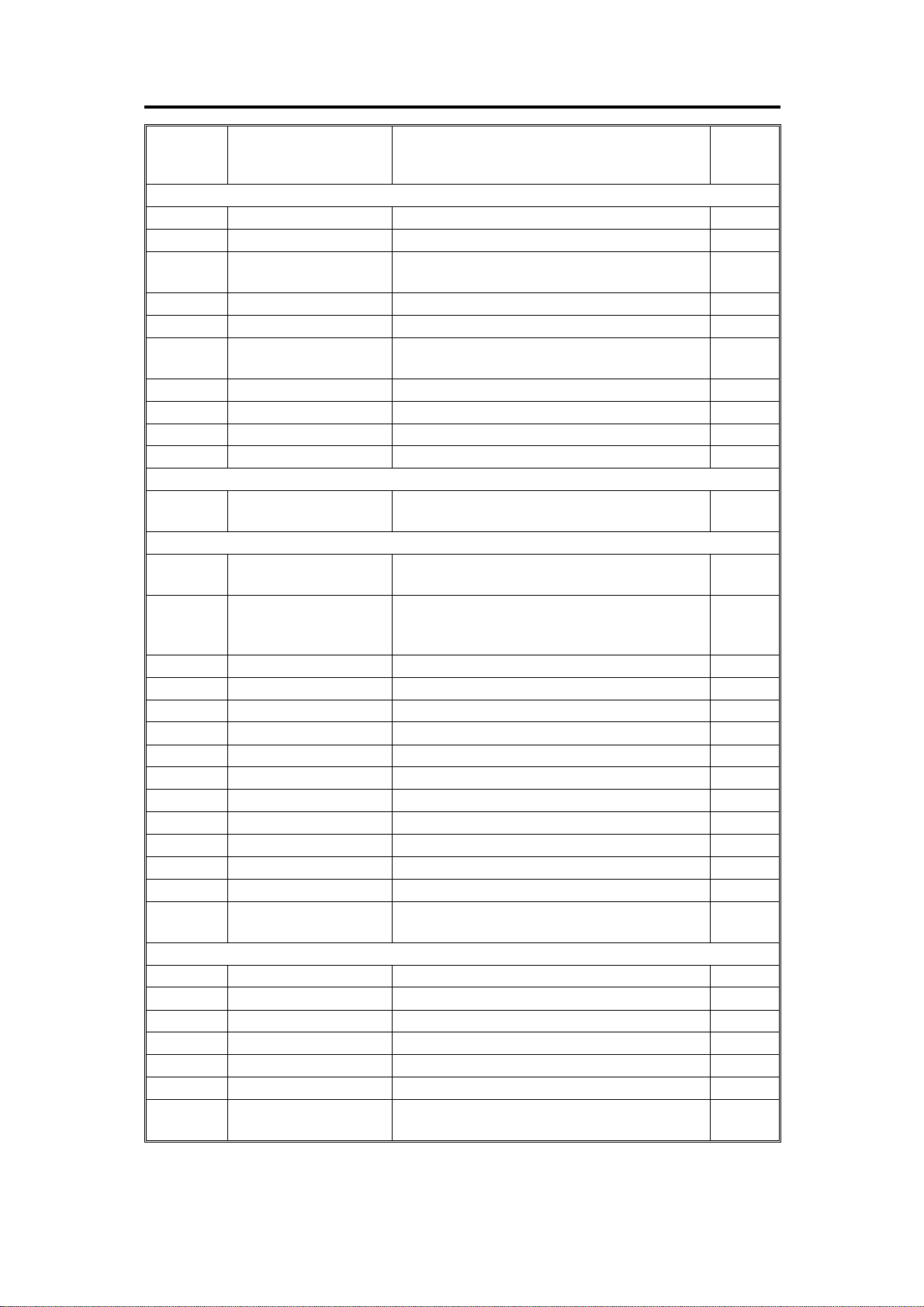

5. ELECTRICAL COMPONENT DESCRIPTION

P to P

Index No. Name Function

Motors

11

24

27

30

33

36

38

43

44

47

Solenoid

29

Sensors

1

3

13

14

15

16

17

18

25

28

31

35

37

46

Switches

5

6

9

20

21

22

26

Master Feed Feeds the master to the drum.

Pressure Plate Drives the pressure plate.

Main Drives paper feed, drum, printing and paper

delivery unit components.

2nd Feed Drives the 2nd feed roller.

Master Clamper Open and closes the master clamper.

Air Knife Rotates the fan to separate the paper from

the drum.

Master Eject Sends used master into the master eject box.

Original Feed Transports the original for scanning.

Master Cutter Cuts the master.

Ink Supply Drives ink pump to supply ink.

Pressure Release

Solenoid

Master End Detects if the plotter unit runs out of master

Original Registration

(Upper: light receiver,

Lower: light emitter)

Feed Jam Timing Determines the paper misfeed check timing.

Paper End Detects if the paper is set on the paper table.

Registration Detects misfeeds. In 2nd feed roller area .

Feed Start Timing Determines the paper feed start timing.

Exit Jam Timing Determines the paper misfeed check timing.

Master Eject Position Detects master eject position of the drum.

Drum Master Detects if the master is on the drum.

Exit Detects paper misfeeds.

Master Eject Detects used master misfeeds.

Full Master Detects if the master eject box is full.

Pressure Plate H.P. Detects the pressure plate home position.

Original Set Detects if the original is set on the original

ADF Open Check if the ADF is open.

Left Cutter Determines the left limit position of the cutter.

Master Cut Starts the cutter motor to cut the master.

Scanner Unit Open Checks if the scanner unit is open.

Delivery Cover Open Checks if the delivery cover is open.

Main Turns the power on or off.

Master Eject Box Checks if the master eject box is set

Releases the press roller to apply printing

pressure.

roll.

Informs the CPU of the original position.

Also, detects original misfeed.

table.

correctly.

Location

F-5

F-6

F-2

B-7

B-7

B-7

F-6

A-3

F-4

B-6

B-6

F-4

A-2

A-3

F-7

F-7

F-7

F-7

F-8

F-7

F-8

F-8

F-6

F-6

F-6

A-3

A-3

F-5

F-5

F-1

F-1

B-1

F-1

C217 1-6 SM

Page 29

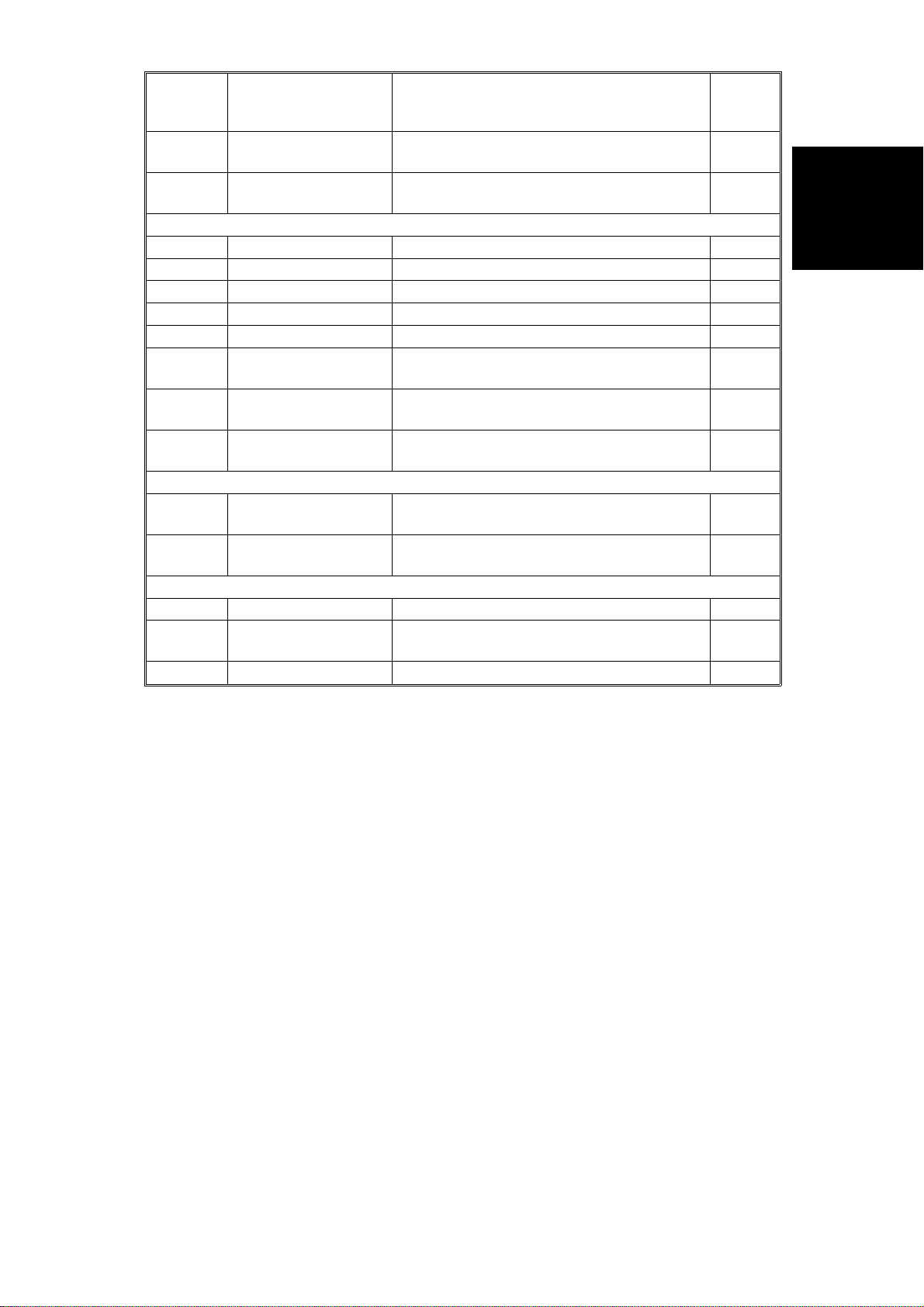

Index No. Name Function

P to P

Location

34

45

Printed Circuit Board

4

8

12

19

23

32

39

40

Counters

7

10

Others

2

41

42

Master Clamper Detects the master clamper open/close

Right Cutter Determines the right limit position of the

Lamp Control Controls the power to the exposure lamp.

Operation Panel Interfaces the CPU and the operator.

Main Controls all machine functions.

Power Supply Provides power for all DC components.

Main Motor Control Controls the main motor speed.

Noise Filter Filters electrical noise on the AC power input

CCD Converts light intensity into an electrical

A/D Conversion Converts the analog signals into digital

Print Keeps track of the total number of prints

Master Keeps track of the total number of masters

Thermal Head Plots the master using heat.

Paper Feed Clutch Transmits the main motor drive to the paper

Exposure Lamp Applies light to the original for exposure.

position.

cutter.

lines.

signal.

signals.

made.

made.

feed roller at an appropriate timing.

F-8

F-5

A-2

B-5

C-5

D-1

F-2

A-1

A-5

A-4

F-5

F-5

E-2

B-6

A-2

Overall

Machine

Information

SM 1-7 C217

Page 30

ELECTRICAL COMPONENT LAYOUT

C217 1-8 SM

Page 31

SM 1-9 C217

CCD PCB A/D Conversion PCB

A/D

Convert

Gate

Array

Exposure

Lamp

Lamp Control

PCB

Operation

Panel

Main PCB

Binary Processing Circuit

EPROM

Feed Control

RAM RAM

Gate

Array

Panel

Controller

EPROM

Main Control

I/O I/O

CPU

Thermal Head Drive

EPROM

I/O

Programable

Counter

Programable

Counter

RAM

RAM RAM

Gate

Array

Thermal Head

+20V

+5V, +/-12V, +24V,

+38V

+5V, +12V,

+38V

AC POWER

(120V or 220V)

Noise Filter

PCB

Main Switch

Power

Supply

PCB

6. OVERALL MACHINE CONTROL

Sensors

Switches

This diagram shows the control system

of the machine.

EPROM

Programable

Counter

Motor

Controller

2nd Feed Motor

CPU

Driver

Solenoid

Clutch

M M

Motors

Counters

EPROM

Motor

Controller

Main Motor

Control PCB

Main Motor

CPU

Driver

Overall

Machine

Information

Page 32

Page 33

DETAILED SECTION

DESCRIPTIONS

Page 34

Page 35

1. MASTER EJECT

1.1 OVERALL

[B]

[A]

[C]

At the end of the printing cycle, th e use d mast er rema ins wrap pe d aro und

the drum to prevent the ink on the drum surface from drying. When the

Master Making key is pressed to make a new master, the used master is

removed from the dr u m.

The machine checks if the drum is at the master eject position and if the

master is on the drum by the drum master sensor. The master clamper [A]

then opens to eject th e m ast er. If there is no master on the drum, th e

machine skips the master ej e ct op er a tio n and starts the master making

process.

The master eject rolle r s [B] turn for 0.5 seconds to pick up the leading edg e

of the used master. Aft er closi n g th e m ast er cl am p er, the dr um sta r ts r ot at ing

in the slowest speed (30 rpm). At the same time the master eject rolle rs turn

and feed the used master i nt o th e m ast er ej e ct bo x [C ].

Detailed

Section

Descriptions

When the drum stops at the master feed position after one and a half turns,

the pressure plate drive motor starts turning to compress th e used master in

the master eject box.

SM 2-1 C217

Page 36

1.2 MASTER CLAMPER OPEN MECHANISM

[B]

[J]

[E]

[J]

[K]

[G]

When the Master Making key is pressed the master eject position sensor [A]

is used to confirm that the drum is positioned at the master eject position

Normally, the drum is stop pe d at thi s po si tio n after every print job. If the

drum is not at this position, the machine first moves the drum to the master

eject position befor e ope nin g th e m ast er cl am p er.

[F]

[K]

[E]

[H]

[A]

[D]

[C]

The drum is moved to the eject position and locked usin g a "V" shaped notch

on the rear of the drum positioning guide [J] to locate and lock the drum

positioning stud [K] . A second stud, 180 degrees from the fir st, is use d to

position the drum du r ing ma ste r fee di n g op er a tions.

The master clamper ha s two spr in gs [B ] an d a m ag net pla te [C ] to secure

the master’s leading edge in the clamper. The clamper is fixed on the

clamper shaft [D] which has a lever [E] at the rear side.

The clamper motor [F] dri ves th e movi n g li nk [G ] an d pu she s up th e clam p er

lever [E].

The master clamper th en lif ts th e m ast er ej e ct ar m [H ] to r ele ase the

master’s leading edge from the clamper.

C217 2-2 SM

Page 37

1.3 MASTER EJECT ROLLER MECHANISM

[B]

[C]

Detailed

Section

Descriptions

[A]

The master eject roll e rs are dr iv e n by th e master eject motor [A] through id le

gears. The upper eject roller [B] has paddles to assure that the master is

picked up.

When the master clamper is ope ned and the master’s leading edge is

released from the master clamper, the master eject motor turns on for 0.5

seconds to pick up the leading edge of the used master.

When the master eject motor is turned off, the master clamper motor turns in

reverse direction to close the master clamper.

The drum then starts tur nin g at the slow est spee d (30 rp m) . At the same

time, the master eject rollers turn again to feed the master into the master

eject box.

After one turn of the drum, the master eject motor stops. The drum continues

turning for a half tu r n an d sto ps at the maste r fee d po siti o n.

The master eject sensor [C] is used to detect master eject jams.

SM 2-3 C217

Page 38

1.4 PRESSURE PLATE MECHANISM

[A]

[B]

[C]

[D]

[D]

[F]

[E]

[E]

[B]

[E]

The pressure plate m ot or [A ] dr ives the pressure plate [E] thro ug h th e dri ve

arm [B] and the pressure springs [C].

When the master has bee n ejected into the master eject box, the pressure

plate motor turns on and remains on until the full master detection sensor [D]

is actuated by the actua to r tab on th e pressure plate [E]. When the full

master sensor is actuated, the motor stops. When master making and

cutting are completed, the motor turns in the reverse direction to return the

pressure plate to the home position. When the pressure plate home position

sensor [F] is actuated, the motor stops.

If the full master senso r is not actuated within 2.4 seconds after the pressure

plate motor is activated, the machine stops the motor. The Empty Master

Eject Box indicator blinks after the master making procedure has finished

and the drum is positi on ed at th e mast er exi t posit i on (d rum ho m e posi ti o n).

C217 2-4 SM

Page 39

2. SCANNER AND OPTICS SECTION

2.1 OVERALL

[B]

[C]

[E]

[F]

[A]

[G]

A/D Conversion

PCB

Main PCB

Operation Panel

PCB

[H]

Thermal

Head

[D]

[J]

The first original at the bottom of the stack on the original table is separated

from the other originals by the original pick-up roller [A] and the original

friction pad [B], and is fed across the exposure glass [C]. The scanning starts

when the original is transported 5mm from the scan line. The master plotting

is synchronized with the original feeding.

Detailed

Section

Descriptions

The light of the exposure lamp [D] is reflected from the original and reflects

off the mirror through the lens [F] to the CCD [E]. The reflector [G]

compensates for shadows from the edge s of cut - and-p ast e orig ina ls. A

shading plate [H] installed between the mirror and the lens cuts some of the

light to correct for uneven light intensity between the center and both ends of

the lamp.

The light is changed to an electrical signal in each element of the CCD. The

analog signals from the CCD are converted into 4-bit digital data signals in

the A/D (analog\digital) conversion PCB and sent to the main PCB in which

each 4-bit digital data is converted into 1-bit data. The main PCB holds the

1-bit data for each pixel. The PCB uses the 1-bit data to turn on the thermal

head which will burn each pixel onto the master.

SM 2-5 C217

Page 40

2.2 ORIGINAL FEED MECHANISM

[D]

34 mm

[B]

13 mm

[C]

[A]

The originals on the original table are detected by the original set sensor [A].

A photo-transistor [B] in the upper position and an LED [C] in the lower

position make-up the original registration sensor.

After the master on the drum i s ejected to the master eject box, the or ig i na l

feed motor (stepper motor) starts rotating to feed the original to the exposure

glass [D]. When the original is transported 13 mm past the original

registration senso r , th e or ig i na l fee d mot or sto ps. At th i s tim e th e or ig i nal

leading edge is aligned with the CCD scan line on the exposure glass. Then

the original feed motor starts again synchronizing with the master feed.

The original pick-up roller keeps turning after the original trailing edge

passes the roller, so if a 2nd original is present, it will be fed directly after the

trailing edge of the 1st original.

After the 1st originals trailing edge is detected and transported 12 mm past

the original registration sensor, the original set sensor checks whether the

next original is present. If no original is detected, after the original trailing

edge passes the original registration sensor, the original is transported

further 35 mm (34+1) and fed out. If the next original is detected, the

originals are transported 1 mm further to ali g n th e 2nd original leading edge

with the scan line (the 2nd original has been transported a total of 13 mm

from the original registration sensor), then the original feed motor stops.

After printing of the 1st original is completed, the original transport motor

starts again for the nex t original.

C217 2-6 SM

Page 41

2.3 ORIGINAL FEED DRIVE MECHANISM

[D]

[A]

[B]

[C]

Detailed

Section

Descriptions

The pick-up roller [C] and the original feed roller [B] are driven through gears

by the original feed motor [A] (stepper motor).

The original feed roller [B] diameter is a little bit larger than the original

pick-up roller [C], so that a small gap is made between the continuous

originals while being transported. A one-way clutch is installed in the pick-up

roller gear [D] to ab sor b the spee d di f fe r en ce be tw e en the pick- up ro l ler an d

the original transport roller.

SM 2-7 C217

Page 42

3. MASTER FEED

3.1 OVERALL

[C]

[A]

[B]

[E]

[D]

The master materia l is fe d by th e pl a te n rol le r [A] acr oss th e th er ma l head

[B]. When the dru m is at the ma ste r fee d posi ti o n an d th e mast er cl amper is

opened, the tension roller [C] is released by the master clamper so that the

master’s leading edge is fed into the master clamper [D]. The leading edge

of the master is clampe d by th e m ast er clam p er , and the maste r is wr ap pe d

completely around the drum surface and then is cut by the cutter [E].

The drum is moved to the eject position and locked usin g a "V" shaped notch

on the rear of the drum positioning guide [J] to locate and lock the drum

positioning stud [K] . A second stud, 180 degrees from the fir st, is use d to

position the drum du r ing ma ste r fee di n g op er a tions.

C217 2-8 SM

Page 43

3.2 MASTER FEED MECHANISM

[B]

[D]

[C]

Detailed

Section

Descriptions

[F]

[E]

[A]

A stepper motor is used for the master feed motor [A] to drive the platen

roller [B]. The thermal head is pressed against the platen roller by the

pressure springs. The pressure can be released by the pressure release

lever [C] for master roll replenishment.

After the master eject procedure is finished, the dr um i s stopped at the

master feed position and the master clamper is opened for the new master.

The master’s leadin g ed ge is sto pp ed on th e gu ide pl at e [D ] aft er th e l ast

master cutting proce du re or af te r the maste r is cut manu al . The m ast er i s fed

for 23 mm and stopped once to synchronize with the original feed. The

master is fed for a further 67.5 mm before the master clamper is closed.

Since the clamper closin g timing is later than when the master’s leading

edge reaches the clampe r , a master buckle [E] is made on the master fe ed

guide. This master buckle absorbs the shock wave from the master clamping

operation.

The drum then turns intermittently in the slowest mode (30 rpm) to wrap the

master around the drum. The intermittent rotation keeps the master buckle

on the master feed guide to absorb the shock wave from the wrapping

operation. The tension roller [F] is pressed to the guide plate which gives the

tension to the master during the master wrapping operation.

SM 2-9 C217

Page 44

3.3 MASTER CLAMPER OPERATION AND TENSION ROLLER

RELEASE MECHANISM

[B]

[C]

[A]

[D]

[C]

[E]

When the master eject is completed, the drum is stopped at the master feed

position. At this time, the clamper motor [A] drive s the moving link [B] to

open the master clamp er [C ] .

The friction roller [D] is normally pressed against the master feed guide plate

to give tension to the master during the master wrapping operation. When

the clamper is opened, the clamper pushes the friction roller arms [E] and

releases the friction roller from the guide plate to allow the master to be fed

into the master clamper.

To close the master clamper, the clamper motor turns in the reverse

direction.

C217 2-10 SM

Page 45

3.4 CUTTER MECHANISM

[A]

[D]

[H][G]

[E]

[I]

Detailed

Section

Descriptions

[B]

[C]

[F]

After the master maki n g pro cess i s fi nish ed , th e m ast er fe ed moto r turn s off

and the cutter motor [A] starts turning.

The cutter motor drives the pulley [B] and the timing belt [C]. The cutter

holder [D] is mounted on the timing belt and has a switch actuator [E] at

each end.

The cutter mechanism is bi-directional. As the cutter travels in one direction

the master will be cut. During the next cutting operation, the cutter will travel

in the opposite direction.

There are two cutter position switches one at the front [F] and one at the rear

[G] of the cutter rail. When the cutter holder actuates one of these switches

at the end of cutter holder drive operation, the cutt er m ot or is turned off.

The inner roller [H] on the shaft of the rotary cutter blade [I] is touching the

cutter rail, so that the cutter blade is rotating while the cutter holder is moving.

After the master cut operation, the drum starts turning again to wrap the

remaining part of the master around the drum. At the same time, the mas ter

is fed another 32. 6 mm read y f or th e ne xt m ast er maki n g.

SM 2-11 C217

Page 46

4. PAPER FEED SECTION

4.1 OVERALL

[C]

[B]

[A]

The sheet of paper on th e pa pe r fee d ta bl e is sep ara ted by the paper feed

roller [A] and th e fr ic t i on pad [B] , an d tr a nsp or t ed to th e 2nd feed rollers [C].

The upper and lower 2nd feed rollers transport the sheet to the drum.

The paper feed roll e r is dri ven by the main motor, and an inde pe nd en t

stepper motor is used to control the 2nd feed rollers. The 2nd feed rollers

synchronize the paper feed timing with the image on the drum.

After the paper has come into contact with the 2nd feed rollers and the paper

is corrected for skew, the rollers will start rotating.

C217 2-12 SM

Page 47

4.2 PAPER FEED ROLLER MECHANISM

[C]

Detailed

Section

Descriptions

[D]

[A]

[E]

[B]

The paper feed roll e r [ A] is dri ven by the main motor [B] throug h ge ar s an d a

timing belt.

During the printing cycle, when the feed start timing sensor [C] is actuated by

the actuator on the drum, the electromagnetic clutch [D] is energized to

transmit the main motor rotation to the paper feed roller shaft. The top sheet

of paper is separated from the paper stack by the friction between the feed

roller [A] and th e fr ic t i on pad [E] , an d i s tr an spo r te d to t he 2nd f ee d rol le r .

A one-way clutch is installed in the paper feed roller so that after the

electromagnet ic clu tch is de- en erg i zed , i t do es no t di st ur b paper

transportation.

SM 2-13 C217

Page 48

4.3 2ND FEED ROLLER MECHANISM

[A]

[B]

The lower 2nd feed roller [A] is driven by a stepper motor [B]. The main PCB

controls the 2nd feed roller start timing to synchronize the image on the drum

master and the printing paper.

The stepper motor rot at i on spee d is chan ge d acco rdi n g to the pri nt i ng

speed. Also, by pressing the image position keys on the operation panel, the

2nd feed timing is chan ge d. If the paper feed timing is delayed , the image is

shifted forward (smaller lead edge margin). If the paper feed timing is

advanced, the image is shifted backward (large lead edge margin).

After the prin tin g pa pe r is cau gh t be tw e en the dr um an d th e pr e ss rol l er, the

feed roller stepper motor stops.

C217 2-14 SM

Page 49

4.4 UPPER 2ND FEED ROLLER RELEASE MECHANISM

[D]

[A]

Detailed

Section

Descriptions

[C]

[B]

When the feed rolle r step pe r motor stops, the upper 2nd feed rolle r is

released from the lower 2nd feed roller. This is to prevent interference of the

2nd feed roller s wh il e th e pa pe r is transported by the drum and the pr e ss

roller.

When the cam follower [A] reaches the top of the cam [B] which is installed

on the drum drive gear, the shaft [C] rotates clockwise (as seen from the

operation side) to release the upper 2nd feed roller [D] from the lower 2nd

feed roller.

If no image shifti ng mode is use d ( th e i mag e po si ti o n ind i cat or is at th e "0 "

position), the up pe r 2nd fee d r oll e r is rel e ase d whe n th e pa pe r is tr a nsp orted

30mm after reaching the press roller. Even if the paper feed timing is fully

delayed (Max. 15 mm), the paper leading edge reaches to the press roller

before the upper 2nd feed roller is released.

SM 2-15 C217

Page 50

4.5 PRINTING PRESSURE MECHANISM

[I]

[E]

[D]

[H]

[F]

[G]

[B]

[C]

[A]

While the machine is not in the printing cycle, the solen oid [A] stays of f an d

the stoppers [B] lock the brackets [C] to keep the press roller [D] away from

the drum.

When the 1st sheet of paper is fed, the solenoid is energized but the

brackets are still locked by the stoppers due to strong tension of the springs

[E]. When the cam fol low e r s [F], mounted on both sides of the press roll er

shaft, reach the top of the cams [G] on the front and rear drum flanges, a

small clearance is made between the stoppers an d the brackets. They are

then released from the brackets. Printing pressure is applied by tension of

the springs when the cam foll o wer s r eac h th e bo tt om of the cams .

During the printing cycle, the solenoid stays on. However, if paper does not

reach the registrat i on senso r [H] at the proper timing (at this time, the cam

follower is on the top of the cam), the solenoid is de-energized to lock the

brackets.

The printing pressur e is rel e ase d whe n th e cam s pu sh do w n th e cam

followers so that the press roller does not contact the master clamper [I].

C217 2-16 SM

Page 51

After printin g i s fi nish ed , the solenoid is de-energized an d th e stoppers

return by tension of the springs. Before the drum returns to the home

position, the bra cket is locke d by th e sto pp er ag ai n when the cams push

down the cam followers.

Detailed

Section

Descriptions

SM 2-17 C217

Page 52

4.6 PAPER TABLE

[H]

[A]

[G]

[F]

[E]

[C]

[D]

Paper on the paper table is lifted up to contact with the paper feed roller by

two springs [A]. When the lever [B] is lowered, the bearing [C] lifts up the

arm [D] to rotate the shaft [E] counterclockwise. The bracket [F] pushes

down the stay [G] and the paper table is lowered. The arm [D] hooks the

bearing [C] to stop the table in the lower position to allow easy paper setting.

A photo-interr u pter [H] is installed under the pap er table to detect paper on

the table.

[B]

[D]

[C]

[B]

C217 2-18 SM

Page 53

Section

Detailed

Descriptions

[A]

[B]

The paper feed roller pressure can be channeled by changing the position of

the pressure adjustment levers [A]. Normally the levers should be in the

upper position. If paper pick-up jams occurs frequently, the levers should be

lowered to increase the pressure.

If paper multif ee d occu r s f req ue ntly, the side pads [B] should be insta l l ed t o

apply stopping pre ssure to th e pa pe r .

SM 2-19 C217

Page 54

4.7 SIDE FENCE SLIDE MECHANISM

[D]

[A]

[E]

[B]

[C]

The paper table side fen c es [A ] are installed on the shaft [B]. When th e leve r

[C] is pinched, the stopper [D] is released from the shaft and either fence can

be moved independently. By turning the dial [E], the shaft and the side

fences move together side to side changing the paper position on the paper

table. If the dial is turned clockwise, the fences move to the left.

C217 2-20 SM

Page 55

5. DRUM

5.1 OVERALL

[B]

[C]

[D]

[A]

[F]

Detailed

Section

Descriptions

[E]

The drum consists of a met al scr ee n [A ] an d a cl ot h scr ee n [B ].

The ink pump supplies ink fr om th e i nk cartridge into the drum through the

drum shaft [C]. Ink is then spread evenly to the screens by the ink roller [D]

and doctor [E] roller. The developed master [F] with the plastic coatin g

removed from the image area allows the ink to flow through the exposed

porous material.

The drum is driven by the main motor and turns only clockwise (from the

operator side). The motor speed and the drum stop positions are controlled

by monitoring the main motor encoder.

SM 2-21 C217

Page 56

5.2 DRUM DRIVE MECHANISM

[D]

[A]

[C]

[B]

The drum is driven by the main motor (DC motor) through a timing belt [A]

and gears [B]. The main motor has an encoder which sends pulses to the

main PCB. The main PC B mo nitors the pulses and controls the dr um spe ed

and stop positions.

The drum has two stop positions as follows:

1) Master eject position/ Home position

2) Master feed position

These stop positions are determined by checking the feed start timing

sensor [C]. The main PCB sta r ts cou nt i ng the mai n mot or en cod er pu l ses

when the feed start timing sensor is actuated. The followin g pulse count

numbers are assigned for drum stop timing.

1) 440 pulses for the maste r ej ect position

2) 64 pulses for the master feed position

When the drum is stopped at the master eject position, the master eject

position sensor [D] is actuated. When the master eject operation is started,

the main PCB confir ms if the dr um i s at th e m ast er ej e ct po si tio n by th i s

sensor [D].

C217 2-22 SM

Page 57

5.3 MAIN MOTOR CONTROL

Detailed

Section

Descriptions

The main motor is driven by the main motor control PCB. The main PCB

sends the speed signals ( 0 an d 1), the main motor ON trigger, an d th e m ot or

brake trigger to the main motor control PCB. According to the combination of

two speed signals, the main motor control PCB can select on to of four

possible main motor speeds.

The main motor speed is converted in half for the drum rotation by the gears

and timing belt. The drum rotate s at 30rpm while the main motor rotates at

60rpm. This lowest possible speed also is used for the master eject and feed

operations. For th e m ast er w r ap pin g pr o cess, the ma in PC B send s the mai n

motor ON trigger as a pulse signal. As a result, the drum turns intermittently

at 30rpm.

The main motor speed is maintained by the main motor control PCB which is

monitoring th e en cod er pulses from the main motor.

CN108-4 (Speed 1) L L H H

CN108-5 (Speed 0) L H L H

Motor Speed 60 rpm 140 rpm 200 rpm 260 rpm

Drum Speed 30 rpm 70 rpm 100 rpm 130 rpm

SM 2-23 C217

Page 58

5.4 INK SUPPLY MECHANISM

[E]

[A]

[B]

[D]

[G]

[F]

[C]

Ink is supplied from th e ink car t r idg e [A ] to the ink ro ll er [B] by a pump [C].

The ink pump is driven by the ink supply motor (DC motor) [D] through

gears. There is a pin on the pump drive gear [E] which is coupled with the

pin holder [F] on the pump piston shaft. This mechanism converts the gear

rotating motion into the piston vertical alternatin g motion.

Two holes on the drum shaft [G] drop ink on to the ink roller [H].

C217 2-24 SM

Page 59

5.5 INK ROLLER MECHANISM

[C]

[B]

[A]

[D]

Detailed

Section

Descriptions

[E]

[F]

The ink roller [A] and the doctor roller [B] are driven by the gear [C] on the

drum shaft. Ink supplied on the ink roller is squeezed by the doctor roller and

an even thickness ink layer is applied to the ink roller. The ink drive gear [D]

has a one-way clutch to pre ven t th e ink r oll e r f rom tu r nin g in th e r eve rs e

direction when the drum is turne d in the reverse direction manually.

The ink roller only touches the screen [E] during printing. During the printing

process, the ink on the ink ro ll er i s app li ed to th e pa pe r thro ug h ho l es in th e

screens and master. This happens while the drum screen and the master

are held against th e i nk roll e r by the pressure roller [F] located under neath

the drum.

SM 2-25 C217

Page 60

5.6 INK SUPPLY CONTROL

[B]

[A]

[C]

[D]

The ink detection pins [A] work like the electrode of a capacitor and detect

the capacitan ce between the detection pins and the ink [B] and doctor [C]

rollers. This capaci ta nce is dif fe r en t whe n th e i nk leve l is hi g h and the pins

touch ink, compared to whe n th e ink l eve l is low an d th e pin s do not to uch

ink. By detecting the capacitance, the ink supply moto r is controlled to keep

the ink level.

The ink roller blade [D] is inst al le d on bot h en ds of the ink ro ll er to scra pe off

the built-up ink on the ink roller edges.

C217 2-26 SM

Page 61

[B]

Timer IC

1

OUT 1

TP102

5

2

[A]

TH1

VR101

12

TH2

OUT 2

+

+

TP102

TP103

(Sufficient Ink)

To

T1 T2

TP103

9

LED101

+

_

P

To

CPU

Main PCB

(Less Ink)

P

LED101 ON OFF

A timer IC is used to dete ct th e i nk leve l. The IC produces two pulse signals.

TP102 outputs the st an da r d pul se si gn al , the stan da r d pu l se l en gt h T0 is

determined by the VR101. TP103 outputs the detection pulse. This pulse

length is determined by the capacitance between the detection pins and ink

and doctor rollers.

M

Detailed

Section

Descriptions

(Sufficient ink condition)

When the ink level is high and the pins [A] are touching the ink, the

capacitance becomes large and increases the detection pulse length (T1).

When the detection pu lse length is longer than the standard pulse length

(T0<T1), "P" becomes low and turns on the LED101. While the CPU is

receiving the low si gn al at

, the CPU recognizes that ink level is sufficient

"P"

and does not turn on the ink supply motor [B].

(Less ink condition)

When the ink level is low, the capacitance is lowered and decreases the

pulse length (T2). When the detection pulse length is shorter than the

standard pulse len gt h ( T0> T2 ) , "P" becomes high and turns off the LED101.

While the CPU is re ceiv in g the high signal at "P", the CPU recognizes that

the ink level is low and turns on the ink supply motor to supply ink until the

signal at "P" becomes low.

SM 2-27 C217

Page 62

Rev. 10/20/93

(Ink End Condition)

If the less ink condition is detected contin uo usly fo r more then 25 second s

during the print cycle, the CPU stops the printing process and turns on the

Ink End indicator.

When printing starts in the less ink condition, the main motor keeps turning,

and turns on the ink supply motor turns on until the ink level returns to a

sufficient level. If the ink returns to a sufficient level within 25 seconds, the

machine starts the printing operation. If not, the machine lights the Ink End

indicator.

A beeper sounds intermittently while the machine is idling during the ink

supply.

The machine has a forced ink supply mode. When the Reset key is pressed

while holding down the "0" key, the machine starts the ink supply operation.

This operation continues for 50 seconds and stops automatically when ink

reaches a sufficient le vel. If ink is not neede d an d th e pr o cess w as

commenced it will proceed normally but the ink supply motor will not operate.

(To Disable Ink Detection Circuit)

The ink detection circuit can be disabled if the main switch is turned on while

both the Auto Cycle key and the Reset key are pressed. If this mode is

accessed, prints can be made even though the ink detection pin is not in

contact with the ink on the ink roller (see page 2-26 Ink Supply Control).

When the main switch is turned off, this condition is reset to normal

operation.

This function serves to remove the ink inside the drum.

C217 2-28 SM

Page 63

6. PAPER DELIVERY SECTION

6.1 OVERALL

[C]

[B]

[E]

[A]

[D]

Detailed

Section

Descriptions

The exit pawls [A] and the air knife [B] separate the paper from the drum.

The paper is deliver e d to the pap er delivery table [C] by the upper and lo w er

exit rollers [D].

There is a photore flector type photosensor mounted between exit roller

assemblies [E] to detect paper jams.

SM 2-29 C217

Page 64

6.2 PAPER DELIVERY ROLLER

[C]

[E]

[A]

[B]

The lower exit rolle r s [A] are driven by the main motor [B] thr o ug h th e ti m in g

belt. The upper exit rollers [C] and the lower exit rollers catch the paper and

transport it to the delivery table.

[A]

[D]

The lower exit roller are controlled by green plastic guide plates [D] which

are mounted to the exit pawl. This allows the upper and lower exit rollers to

move together.

Each roller position should be adjusted according to the paper position on

the paper table, so that the upper and lower exit rollers catch 5 mm inside of

the paper edge to transport it. The paper size indicator [E] shows the

standard deliver y rol le r posit i on for ea ch paper size.

C217 2-30 SM

Page 65

6.3 EXIT PAWL/AIR KNIFE

[F]

[D]

[E]

[C]

[B]

Detailed

Section

Descriptions

[A]

The air from the air knife nozzle [A] and the exit pawls [B] separate paper

from the drum.

The air knife motor starts blowing air when the print start key is pressed or

master cutting is completed. The paper passes under the exit pawls and is

caught by the exit rollers. The motor stops when the last sheet of paper is

fed out.

The upper exit rolle rs [ D] ar e insta l led on th e exit paw ls. They are pushed

against the lower exit rollers [E] by tension of the springs [F].

SM 2-31 C217

Page 66

6.4 EXIT PAWL RELEASE MECHANISM

[B]

[A]

[C]

[D]

[E]

The exit pawls [A] move away from the drum when the master clamper [B]

approaches the pawls. This is controlled by the cam [C] installed on the front

drum flange and the two cam followers [D and E] installed on the exit pawl

shaft. The two cams allow enough time to move the pawls away from the

drum.

While the cam followers are not on the top of the cam, the distance be tween

the pawls and the drum is very small to prevent paper wrap jams. At this

time, the distance is determined by the stopper, and the cam followers are

not in contact with the cam. However, when the master clamper approaches

the exit pawls, the pawls must be mov ed away from the drum to avoid

contact and damage against the master clamper. As the master clamper

approaches the exit pawls, the cam moves into contact with the cam follower

pushing them down. This rotates the cam follower arm, and the pawl shaft

clockwise, to move the pawl s awa y from th e dr u m. W he n bo th cam fol lo w ers

are out of contact with the cam, the pawls move back towards the drum to

their normal position.

C217 2-32 SM

Page 67

7. JAM DETECTION

7.1 ORIGINAL JAM DETECTION

[B]

13 mm

34 mm

[A]

Original jams are detected by the original set sensor [A] and the original

registration sensor [B]. The misfeed indicator ( + A) lights with the

following conditions:

1) When the main switch is turned on, if the original registration sensor

is interrupted.

Detailed

Section

Descriptions

2) When the original set sensor is actuated, if the original registration

sensor does not detect th e or i g ina l leading edge within 3 seconds

after the Master Making key is pressed.

3) If the original registration sensor does not detect the trailing edge of

the original within 4 seconds after the original leading edge is

transported 355.6 mm from the original registration sensor.

4) If the original stops interrupting the original registration sensor after

the stop key is pressed while scanning.

SM 2-33 C217

Page 68

7.2 MASTER EJECT JAM DETECTION

[A]

[B]

The master eject jams are detected by the master eject sensor [A]. The

misfeed indicator ( +F) lights in the following conditions:

1) If the master eject sensor is actuated when the main switch is turned

on.

2) If the master eject sensor is not actuated withi n 0.3 seconds after the

drum started turning to feed the master into the master eject box.

3) If the master eject sensor is not actuated when the drum makes a

half turn and passes the fe ed jam tim ing senso r [B] . Thi s is the case

when the picked up master leading edge is pulled back to the drum

and the master rema ins on the dr um. (The jam indicator lights afte r

the drum returns to the home position.)

4) If the master eject sensor is actuated when the pressure plate is

returned to the home po si tio n. Thi s is th e case when the maste r

trailing edge sticks on the pressure plate and is pulled back to the

master eject rolle rs .

C217 2-34 SM

Page 69

7.3 MASTER FEED JAM DETECTION

[B]

[C]

[A]

Detailed

Section

Descriptions

There is no master feed se nsor on the master paper feed path to detect

master feed jams. The mast er fe ed jam is de te cte d by th e dru m maste r

sensor [A] which detects the presence of a master on the drum.

When the drum is stopped at the master exit position prior to the start of

printing. After master making, if the master sensor [B] does not detect the

master on the drum, the master misfeed indication ( + C) will be displayed

on the operation panel. (The master eject position sensor [C] is used to

confirm that the drum is positioned at the master eject position.)

SM 2-35 C217

Page 70

7.4 PAPER FEED JAM DETECTION

[C]

[B]

[D]

Paper jams are detected by the registration sensor [A] and the exit sensor

[B]. Jam detection timing is determined by the drum position sensors and the

main motor encoder. The timing chart on the next page shows the jam

detection timing.

[E]

[A]

C217 2-36 SM

Page 71

NN

Feed Start

Timing Sensor

Feed Jam

Timing Sensor

t

Exit Jam

Timing Sensor

Registration

Sensor

a) ON Check

Exit Sensor

b) OFF Check

c) ON Check

c) B or E Jam Identification

a) When the CPU counts a determined number of pulses (N) from the

main motor after the feed start timing sensor [C] is actuated, if the

registration sens or do es no t de tect the paper, B + light.

Detailed

Section

Descriptions

b) When the exit jam timing sensor [D] is actuated, if the exit sensor

remains activated, G + light.

c) When the determined time (t) (th is time depends on the drum speed)

is counted after the exit jam timing sensor is actuated, if the exit

sensor is not activated, the machine detects a paper jam. If this jam

condition is detected, the main PCB stops the next paper from being

fed. When the feed jam timing sensor [E] is actuated:

1. If the registration senso r is act i vat ed , a 2n d fe ed fail u r e is

detected. (B + )

2. If the registration senso r is no t act i vat ed , a pa pe r wra p jam is

detected. (E + ).

SM 2-37 C217

Page 72

8. IMAGE PROCESSING

Image processing r eso l ves ho w to tra nsf or m an opt i cal i mage of a

continuous line, made up of an infinite number of color shades, into 2592

lined-up dots (pixels), each of which is black or white.

There are two basic sub-processes: first A/D conversion, i.e. con verting an

analog image to

binary processing, i.e. transforming that digital data into black or white pixels.

8.1 A/D CONVERSION

4-bit digital data

representing 16 shades of gray; second

CCD

(1) (2)

OS

DOS

Inversion &

Amplification

A/D Conversion

Parameter

(6)

Setting

Shading

Distortin

Correction

(3)

VB

VS

VH

M1

M2

M3

VL

Image mode/Image density

Setting

A/D

Converter

(7)

(4)

Peak

Hold

(5)

Black

Level

VPH

(8)

Shading

Distortion

Memory

4-bit Digital Data

Binary processing

Circuit

to

This block diagram shows the A/D conversion process (A/D= Analog to

Digital). The analog signal generated from the CCD is inverted and

amplified. Then the analog signal is converted into a 4-bit digital signal and is

sent to the binary pro cessi n g cir cui t .

The following sections (8.1.1 - 8.1.8) will give a brief explanation of the

various steps in the A/D conversion process.

C217 2-38 SM

Page 73

(1) CCD

The light reflected from the

original exposes the CCD

(Charge Coupled Device) which

OS

can read one complete scan line

at a time. The circuit of each

element in the CCD is shown at

the right. The CCD has 2592

effective elemen ts. The l igh t

reflected from the original is

sensed by a photodiod e. A

capacitor stores the electrical

charge corresponding to the

light’s intensity.

The electrical charges from the CCD elements are sent to the A/D

conversion PCB one after the other (OS signal).

The CCD always outputs a compensation data signal (DOS signal) with the

OS signal. This DOS signal is used for the inversion and amplification

described below.

Detailed

Section

Descriptions

(2) Inversion and Amplification

The CCD output is inverted and amplified.

To remove electrical no is e, the

difference

between the OS signal

and the DOS signal is amplified.

Even if electri cal no i se i nt r ud es

into the power source of the

CCD, it does not effect the

amplified signal, because the

noise affects both signals

identically. Ther ef or e ,

substracting the DO S sign al fr o m

Inverted &

Amplified

CCD Output

the OS signal will cancel the noise out.

The amplification ratio can be changed by turning VR201.

SM 2-39 C217

Page 74

(3) Shading Distortion Correction

The image data of one main scan line sent from the CCD does not exactly

represent the line of the original image, because of the followin g reasons:

1) Loss of brightness towards the ends of the fluores cent lamp and the

edge of the lens,

2) Variations in sensitivity among elements of the CCD,

3) Distortions of the light path.

These distortions are corre cted by applying individual amplification ratios (α)

to the output of each CCD element. The amplification ratio of each element

is determined so that all the CCD outputs are amplified to match the highest

voltage from the platen cover data when the white platen cover is scanned,.

When the main switch is tu rne d on , th e scan ne r scans th e w hit e pl a te n cove r

5 times. The white platen covers data which corresponds to each CCD

element is stored as 4-bit digital data in the shading distortion memory circuit

and used for the shadin g distortion correction.

Actual CCD output

when the white

Corrected output

A

platen cover is read

B

VB

Amplification ratio: α

A+B

α ≈

B

(4) Peak Hold (VPH)

Before the analog signal can be converted to digital data, the machine must

know the high and low bounds that match white and black. These bounds

are voltage values.

The low bound is called the bl ack leve l (VB, see pg. 2-41). The high bound is

called the peak hold value, or VPH.

When the analog signal is digitized, VB and VPH will serve as references to

determine how the CCD output will be distributed over the sixteen different

4-bit values.

C217 2-40 SM

Page 75

a) Peak Hold for the Shading Distortion Memory

When the main switch is tu rne d on , th e exp osu re l amp tur n s on and th e

white platen cover is scanned 5 times. The white peak value from the platen

cover scan is held in the peak ho l d cir cui t and used to de te r mi ne the

amplification ratio (α) of the shading distort i on memory.

b) Original Backgr o un d Pe ak H old

The peak hold from the platen cover scans is erased before original

scanning starts. After original scanning starts, this circuit holds the whitest

image voltage of the 43 mm (512 pixels) width in the middle of the scan line.

The highest value sens ed duri n g an or igi n al scan is cal le d the original

background peak hold. It does NOT always correspond to a pure white

original, but it will serve to establish the whitest part of the print image. In

other words it will turn a dark background white.

Once a peak hold is record ed, it does not change un til a higher (whiter)

value is scanned, or until the next original is scanned.

(5) Black level (VB)

This circuit always outputs 1.4V. This black level voltage is used as a

reference for A/D conversion and as the lower limit of the amplified CCD

output.

Detailed

Section

Descriptions

SM 2-41 C217

Page 76

(6) A/D Converter

The analog data VS (am p li fi e d

CCD outputs) is changed into

4-bit digital data. The 4 bits of

data represent a number between

0 and 15, for a total of 16 steps.

In the A/D conversion circuit, the

difference bet ween VH and VL

(see pg. 2-43) is di vi de d into 16

steps. Each step corresponds to

a VS voltage level.

VPH

VS

(Analog Data)

15

14

13

12

11

10

13

(Digital Data)

The digital data from the analog

image data (VS signal) is based

on these 16 steps.

For example, the amplified CCD

output (VS), whose level is as

shown at right, is changed into

"13" (digital data) to be sent to the

binary processing circuit.

VB (1.4 V)

PB (1.4 V)

9

8

7

6

5

4

3

2

1

0

A/D Converter

C217 2-42 SM

Page 77

(7) A/D Conversion Parameter Setting

Process

Shading Distortion Memory 100 86.5 73.0 59.5 46.0

Line Mode

Image

Setting

Photo

Mode

Parameter

Lighter 74.0 57.0 40.0 23.0 6.0

Normal 100 76.5 53.0 29.5 6.0

Darker 1 100 79.8 59.5 39.3 19.0

Darker 2 100 84.5 69.0 53.5 38.0

Lighter 70.0 36.6 19.6 11.4 7.0

Normal 80.0 43.4 24.8 15.8 11.0

Darker 1 85.0 47.9 29.0 19.9 15.0

Darker 2 92.0 52.3 32.0 22.3 17.0

The A/D conversion paramet er s

(VH, M1, M2, M3 and VL)

decide how the the VS signal is

distributed over 16 steps. The

parameters are determined

according to VPH, VB, the

image mode setting, and the

image density setting.

VH and VL are the upper and

lower image density bounds. If

a darker image setting is

selected, VH and VL incr ea se

(as shown at right). M1, M2 and

M3 are set to impro v e im ag e

quality in the phot o m od e.

The above table shows the

ratio of VPH (100 %) an d ea ch

parameter at various image

VH (%) M1 (%) M2 (%) M3 (%) VL (%)

VP = VH

M1

M2

M3

VL

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0

VP

VH

M1

M2

M3

mode settings (deciding the VB

at 0%). The voltage between

each parameter is divided into

further 4 steps, thus th e vol t ag e

between VH and VL is divi d ed

into 16.

VB (1.4 V)

Image Mode,

Darker 2

VL

VB (1.4 V)

Image Mode,

Lighter

15

14

13

12

11

10

Section

Detailed

Descriptions

9

8

7

6

5

4

3

2

1

0

SM 2-43 C217

Page 78

Line Mode

Normal

Photo Mode

Normal

100%

VS

50%

F

100

76.5

53.0

29.5

6.0

VH

M1

M2

M3

VL

80

43.4

24.8

15.8

11.0

Graph 1

VH

M1

M2

M3

VL

0

0.5

1.0 1.5

Original Density

Graph 2

Line Mode, Normal

0

0.5

F

1.0

1.5

Original Density

Graph 3

Photo Mode, Normal

0

0.5 1.0 1.5

Original Density

As shown in Graph 1, the relationship between the original density and VS

(amplified CCD output) is not linear due to CCD characteristic.

C217 2-44 SM

Page 79

In the line mode, M1, M2 , an d M 3 are set so th at the di sta nce bet wee n ea ch

of them is equal, and the relationship between the original density and the

output digital data are as shown in graph 2.

In the photo mode, M1, M 2, and M3 are set so tha t th er e ar e mor e step s in

the darker area (low sensitivit y area). This improves the quality of the

gradation. (Refer to (3) Shading Distortion Correction.)

(8) Shading Distortion Memory

The amplificatio n r at i os ( α) which corresponds to each CCD elements are

stored as 4-bit dig ita l dat a i n the shading distortion memory ci r cuit and used

for the shading dist ortion correction.

Detailed

Section

Descriptions

SM 2-45 C217

Page 80

8.2 BINARY PROCESSING

Binary processing resolves how to transform a line of "gray" pixels (the 4-bit

digital data from A/D conversion) into a line of black and white pixels in such

a way as to preserve th e quality of the image.

The binary processin g cir cuit produces 1-bit data (white or bl a ck pixel s) fr o m

the 4-bit output of the A/D converter, and sends it, as a serial signal to the

thermal head dri ve ci r cui t . The binary process is different betwe en the lin e

mode and the photo mod e.

1) Line Mode: MTF (Modulation Transfer Function) Correction