Page 1

Model:

BRG-P1w

Machine Code:

J034

Field Service Manual

8 January, 2013

Page 2

Page 3

Safety Instructions, Conventions

For your safety, please read this manual carefully before you service the machine. Always keep this

manual handy for future reference.

Safety Information

Always obey these safety precautions when using this product.

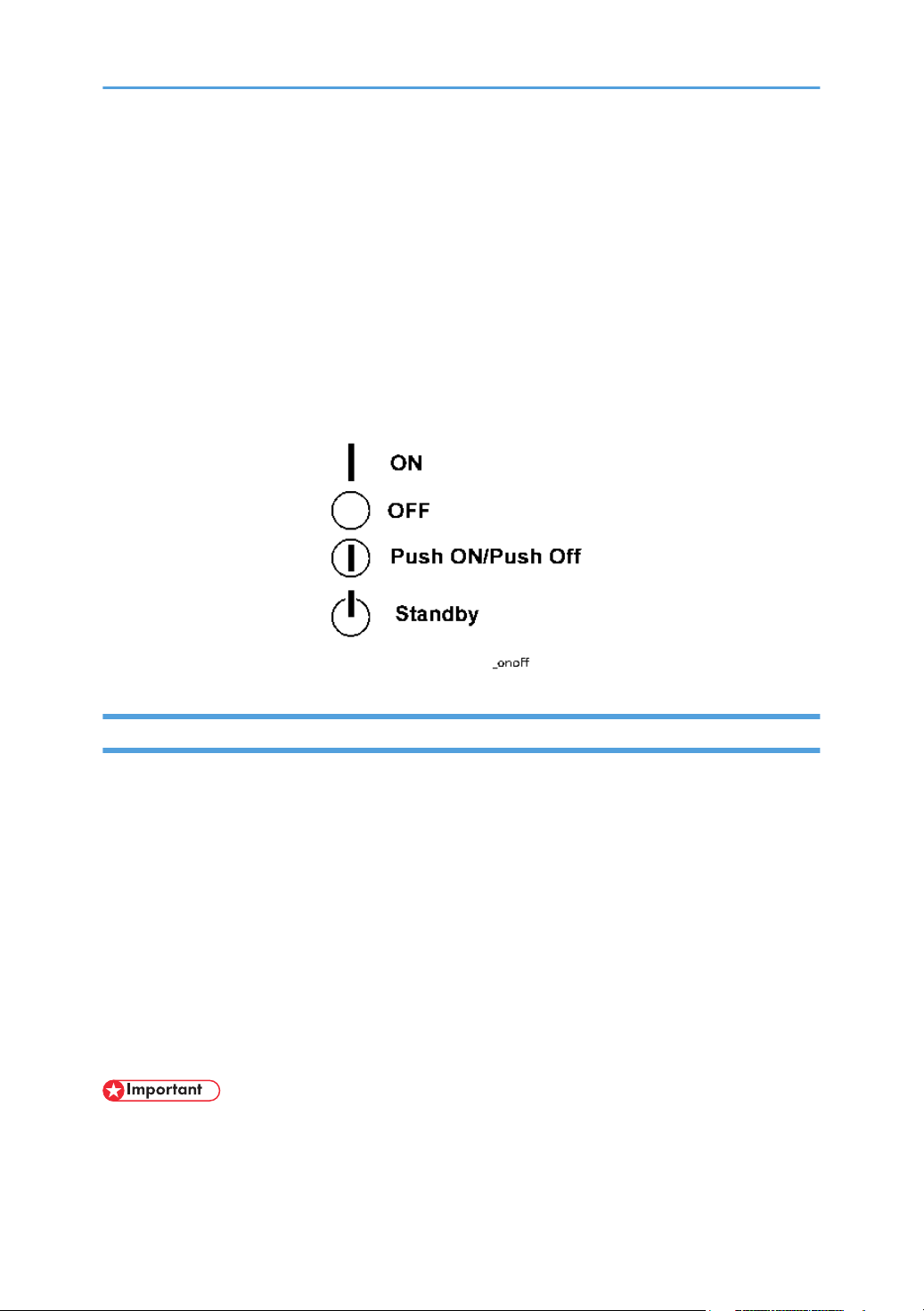

Switches and Symbols

Where symbols are used on or near switches on machines for Europe and other areas, the meaning of

each symbol conforms with IEC60417.

Responsibilities of the Customer Engineer

Maintenance

Maintenance shall be done only by trained customer engineers who have completed service training for

the machine and all optional devices designed for use with the machine.

Installation

The main machine and options can be installed by either the customer or customer engineer. The

customer or customer engineer must follow the installation instructions described in the operating

instructions.

Reference Material for Maintenance

Maintenance shall be done with the special tools and the procedures prescribed for maintenance of the

machine described in the reference materials (service manuals, technical bulletins, operating

instructions, and safety guidelines for customer engineers).

• Use only consumable supplies and replacement parts designed for use with the machine.

1

Page 4

Before Installation, Maintenance

Shipping and Moving the Machine

• Work carefully when lifting or moving the machine. If the machine is heavy, two or more customer

engineers may be required to move the machine without causing injury (muscle strains, spinal

injuries, etc.) or damage to the machine if it is dropped or tipped over.

• Personnel working around the machine should always wear proper clothing and footwear. Never

wear loose fitting clothing or accessories (neckties, loose sweaters, bracelets, etc.) or casual

footwear (slippers, sandals, etc.) when lifting or moving the machine.

• Always unplug the power cord from the power source before you move the machine. Before you

move the machine, arrange the power cord so it will not fall under the machine.

Power

• Always turn the machine off and disconnect the power plug before doing any maintenance

procedure.

• After turning the machine off, power is still supplied to the main machine and other devices. To

prevent electrical shock, switch the machine off, wait for a few seconds, then unplug the machine

from the power source.

• Before you do any checks or adjustments after turning the machine off, work carefully to avoid

injury.

• After removing covers or opening the machine to do checks or adjustments, avoid touching

electrical components or moving parts (gears, timing belts, etc.).

After turning the machine on with any cover removed, keep your hands away from electrical

•

components and moving parts.

• Never touch the cover of the fusing unit, gears, timing belts, etc.

Installation, Disassembly, and Adjustments

• After installation, maintenance, or adjustment, always check the operation of the machine to make

sure that it is operating normally. This ensures that all shipping materials, protective materials, wires

and tags, metal brackets, etc., (attached to protect the machine during shipping), have been

removed and that no tools remain inside the machine.

2

Page 5

• Never use your fingers to check moving parts that are causing spurious noise. Never use your

fingers to lubricate moving parts while the machine is operating.

Special Tools

• Use only standard tools approved for machine maintenance.

• For special adjustments, use only the special tools and lubricants described in the service manual.

Using tools incorrectly, or using tools that could damage parts, could damage the machine or

cause injuries.

During Maintenance

General

• Before you begin a maintenance procedure always switch the machine off.

• Disconnect the power plug from the power source.

• Allow the machine to cool for at least 10 minutes.

• Avoid touching the components inside the machine that are labeled as hot surfaces.

Safety Devices

• Never remove any safety device (a fuse, thermistor, etc.) unless it requires replacement. Always

replace a safety device immediately.

• Never do any procedure that defeats the function of any safety device. Modification or removal of

a safety device (fuse, thermistor, etc.) could cause a fire and personal injury. After removal and

replacement of any safety device, always test the operation of the machine to ensure that it is

operating normally and safely.

• For replacement parts use only the correct fuses, thermistors, circuit breakers, etc. rated for use with

the machine. Using replacement devices not designed for use with the machine could cause a fire

and personal injuries.

3

Page 6

Organic Cleaners

• During cleaning never use any organic cleaners (alcohol, etc.) other than those described in the

service manual.

• Make sure the room is well ventilated before using any organic cleaner. Always use organic

solvents in small amounts to avoid breathing the fumes and becoming nauseous.

• Switch the machine off, unplug it, and allow it to cool before doing preventive maintenance.

• To avoid fire or explosion, never use an organic cleaner near any component that generates heat.

Wash your hands thoroughly after cleaning parts with an organic cleaner to avoid contamination

•

of food, drinks, etc.

Power Plug and Power Cord

• Before servicing the machine (especially when responding to a service call), always make sure that

the power plug has been inserted completely into the power source. A partially inserted plug could

generate heat (due to a power surge caused by high resistance) and cause a fire or other

problems.

• Always check the power plug and make sure that it is free of dust and lint. Clean it if necessary. A

dirty plug can generate heat and cause a fire.

• Inspect the entire length of the power cord for cuts or other damage. Replace the power cord if

necessary. A frayed or otherwise damaged power cord can cause a short circuit which could lead

to a fire or personal injury from electrical shock.

• Check the length of the power cord between the machine and power supply. Make sure the power

cord is not coiled or wrapped around any object such as a table leg. Coiling the power cord can

cause excessive heat to build up and could cause a fire.

Make sure that the area around the power source is free of obstacles so the power cord can be

•

removed quickly in case of an emergency.

• Make sure that the power cord is grounded (earthed) at the power source with the ground wire on

the plug.

• Connect the power cord directly into the power source. Never use an extension cord.

• When you disconnect the power plug from the power source, always pull the plug, not the cable.

4

Page 7

After Installation Servicing

Disposal of Used Items

• Ink is flammable. Never attempt to incinerate empty ink cartridges.

• Always dispose of used items in accordance with the local laws and regulations regarding the

disposal of such items.

• To protect the environment, never dispose of this product or any kind of waste from consumables at

a household waste collection point. Dispose of these items at one of our dealers or at an

authorized collection site.

Points to Confirm with Operators

At the end of installation or a service call, instruct the user about use of the machine. Emphasize the

following points.

• Show operators how to remove jammed paper and troubleshoot other minor problems by

following the procedures described in the operating instructions.

• Point out the parts inside the machine that they should never touch or attempt to remove.

• Confirm that operators know how to store and dispose of consumables such as ink cartridges,

ammonia water, paper, etc.

Make sure that all operators have access to an operating instruction manual for the machine.

•

• Confirm that operators have read and understand all the safety instructions described in the

operating instructions.

• Demonstrate how to turn off the power and disconnect the power plug (by pulling the plug, not the

cord) if any of the following events occur:

1. Something has spilled into the product.

2. Service or repair of the product is necessary.

3. The product cover has been damaged.

• Caution operators about removing paper fasteners around the machine. They should never allow

paper clips, staples, or any other small metallic objects to fall into the product.

5

Page 8

Safety Instructions for Ink Cartridges

Accidental Exposure To Ink

• If ink gets on the skin, wash the affected area immediately with soap and cold running water.

• If ink gets into the eyes, immediately flush the eyes with cold running water. If there are signs of

irritation or other problems, seek medical attention.

• If ink is swallowed, drink a strong solution of cold water and table salt to induce vomiting. Seek

medical attention immediately.

• Ink is difficult to remove from fabric. Work carefully to avoid staining clothing when performing

routine maintenance or replacing cartridges.

Handling and Storing Ink Cartridges

• Ink is flammable. Never store ink cartridges in a location where they will be exposed to high

temperature or an open flame.

• Always store ink cartridges out of the reach of children.

• Always store ink cartridges in a cool, dry location that is not exposed to direct sunlight.

Ink Cartridge Disposal

• Attach the caps to empty ink containers for temporary storage to avoid accidental spillage.

• Return empty ink cartridges to a local dealer who can accept such items for collection and

recycling or disposal.

• If the customer decides to dispose of empty ink cartridges, make sure that they are disposed of in

accordance with local laws and regulations.

Safety Instructions for Batteries

• Always replace a lithium battery on a PCB with the same type of battery prescribed for use on that

board.

6

Page 9

• Replacing a lithium battery with any type other than the one prescribed for use on the board could

lead to an explosion or damage to the PCB.

• Never discard used batteries by mixing them with other trash.

• Remove used batteries from the work site and dispose of them in accordance with local laws and

regulations regarding the disposal of such items.

Conventions Used in this Manual

Symbols and Abbreviations

This manual uses several symbols.

Symbol What It Means

Clamp

Clip ring

Connector

E-ring

FFC (Flat Film Connector)

Hook

Pointer (cross-reference to another manual section)

Screw

Spring

Standoff

Timing Belt

This manual uses the following abbreviations.

7

Page 10

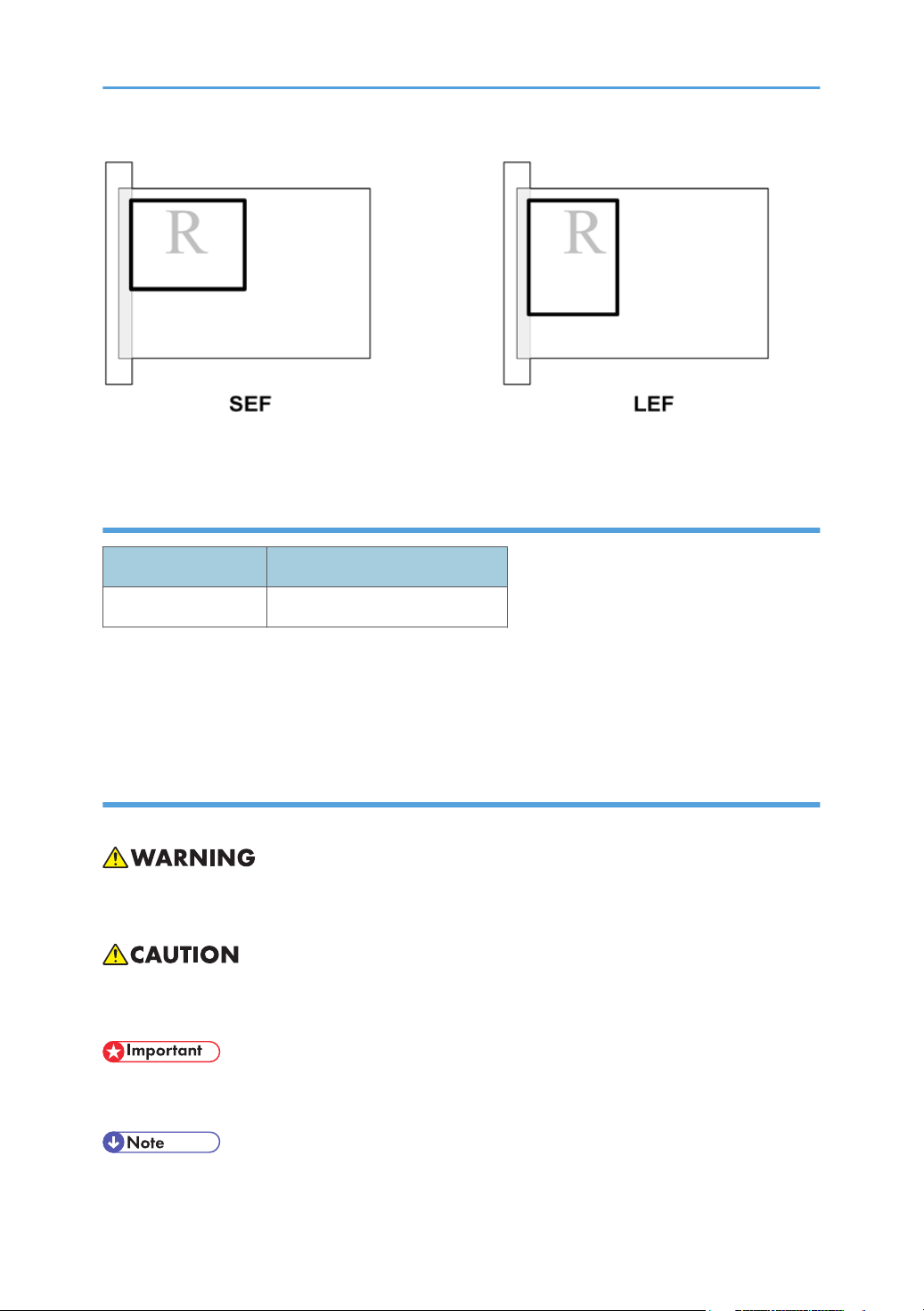

Throughout this service manual, "SEF" denotes "Short Edge Feed" and "LEF" denotes "Long Edge Feed".

Machine Name

Printer Name Model No.

BRG-P1w J034

• The J034 is equipped with the ZICO controller.

• The NIC is mounted on the CTL board.

• The J034 does not support PCL.

Warnings, Cautions, Notes

In this manual, the following important symbols and notations are used.

• A Warning indicates a potentially hazardous situation. Failure to obey a Warning could result in

death or serious injury.

• A Caution indicates a potentially hazardous situation. Failure to obey a Caution could result in

minor or moderate injury or damage to the machine or other property.

• Obey these guidelines to avoid problems such as mis-feeds, damage to originals, loss of valuable

data and to prevent damage to the machine

• This information provides tips and advice about how to best service the machine.

8

Page 11

Trademarks

• Microsoft®, Windows®, and MS-DOS® are registered trademarks of Microsoft Corporation in the

United States and /or other countries.

• PostScript® is a registered trademark of Adobe Systems, Incorporated.

• PCL® is a registered trademark of Hewlett-Packard Company.

• Ethernet® is a registered trademark of Xerox Corporation.

PowerPC® is a registered trademark of International Business Machines Corporation.

•

• Other product names used herein are for identification purposes only and may be trademarks of

their respective companies. We disclaim any and all rights involved with those marks.

9

Page 12

TABLE OF CONTENTS

Safety Instructions, Conventions........................................................................................................................1

Responsibilities of the Customer Engineer....................................................................................................1

Before Installation, Maintenance..................................................................................................................2

Shipping and Moving the Machine.....................................................................................................2

Power......................................................................................................................................................2

Installation, Disassembly, and Adjustments.........................................................................................2

Special Tools..........................................................................................................................................3

During Maintenance......................................................................................................................................3

General..................................................................................................................................................3

Safety Devices........................................................................................................................................3

Organic Cleaners..................................................................................................................................4

Power Plug and Power Cord................................................................................................................4

After Installation Servicing.............................................................................................................................5

Disposal of Used Items..........................................................................................................................5

Points to Confirm with Operators.........................................................................................................5

Safety Instructions for Ink Cartridges............................................................................................................6

Accidental Exposure To Ink..................................................................................................................6

Handling and Storing Ink Cartridges...................................................................................................6

Ink Cartridge Disposal...........................................................................................................................6

Safety Instructions for Batteries......................................................................................................................6

Conventions Used in this Manual.................................................................................................................7

Symbols and Abbreviations..................................................................................................................7

Machine Name......................................................................................................................................8

Warnings, Cautions, Notes..................................................................................................................8

Trademarks.............................................................................................................................................9

1. Product Information

Specifications....................................................................................................................................................17

Overview..........................................................................................................................................................18

Before You Begin.........................................................................................................................................18

What This Manual Contains...............................................................................................................18

Printer Models and Options...............................................................................................................19

Print Cartridges....................................................................................................................................20

10

Ink Collector Unit.................................................................................................................................20

Page 13

Main Machine.............................................................................................................................................21

Front View............................................................................................................................................21

Left View...............................................................................................................................................22

Rear View.............................................................................................................................................22

Options.........................................................................................................................................................23

External Options: J034.......................................................................................................................23

Guidance for Differences between J034 and that of the base machine

Ink Tube Stay................................................................................................................................................24

Paper Transport Belt Unit.............................................................................................................................24

Rollers...........................................................................................................................................................24

The Paper Feed Roller.........................................................................................................................25

The Connecting Roller.........................................................................................................................25

.....................................................24

2. Installation

Preparation.......................................................................................................................................................27

Environment..................................................................................................................................................27

Choosing a Location....................................................................................................................................27

Minimum Space Requirements...................................................................................................................29

Power Source...............................................................................................................................................29

Using the Operation Panel..............................................................................................................................30

Key Summary Table.....................................................................................................................................30

Printer Display Summary.............................................................................................................................32

Operation Panel: Cartridge replacement indicator.........................................................................32

Operation Panel: Waste Ink Full Indicator

........................................................................................33

Display Menu Summary..............................................................................................................................33

User Menu Mode................................................................................................................................34

Access to menus during an error........................................................................................................39

Installation.........................................................................................................................................................41

Important Information......................................................................................................................................42

Checklist Before Moving the Printer...........................................................................................................42

If the Printer Is Not Used Frequently…........................................................................................................42

3. Preventive Maintenance

PM Table...........................................................................................................................................................43

Service Call Procedures..............................................................................................................................43

11

Page 14

4. Replacement and Adjustment

Before Replacing Parts.....................................................................................................................................45

Removal Table.............................................................................................................................................45

Required Tools.............................................................................................................................................47

Common Procedures........................................................................................................................................48

Simple Removals..........................................................................................................................................48

Duplex Unit..........................................................................................................................................

Ink Collector Unit.................................................................................................................................49

Covers...........................................................................................................................................................50

Cover Names......................................................................................................................................50

Order of Removal Cover....................................................................................................................51

Rear Cover, Top Cover.......................................................................................................................51

Right Front Cover.................................................................................................................................53

Right Cover..........................................................................................................................................54

Port Cover............................................................................................................................................56

Left Cover.............................................................................................................................................56

Canopy Cover.....................................................................................................................................57

Front Cover, Operation Panel Board................................................................................................57

Re-assembly.........................................................................................................................................59

Unlocking, Moving the Carriage................................................................................................................64

Maintenance Unit, Right Ink Sump.................................................................................................................66

Maintenance Unit........................................................................................................................................66

Right Ink Sump..............................................................................................................................................69

48

Encoders...........................................................................................................................................................71

Vertical Encoder Wheel..............................................................................................................................71

Horizontal Encoder Strip.............................................................................................................................73

Reinstallation........................................................................................................................................75

Boards...............................................................................................................................................................78

PSU................................................................................................................................................................78

HVPS.............................................................................................................................................................79

Printer Engine CTL Board.............................................................................................................................80

Before Replacement............................................................................................................................80

CTL Board Replacement.....................................................................................................................81

12

Page 15

After Replacement...............................................................................................................................83

Motors...............................................................................................................................................................86

Horizontal Motor.........................................................................................................................................86

Vertical Motor..............................................................................................................................................88

Fan................................................................................................................................................................91

Clutches.............................................................................................................................................................93

Feed Clutch...................................................................................................................................................93

Transport Belt....................................................................................................................................................96

Transport Belt, Charge Roller, Pressure Plate, Pressure Rollers................................................................96

Sensors, Switches

Vertical Encoder Sensor............................................................................................................................101

Ink Level Sensor.........................................................................................................................................102

1st Registration Sensor..............................................................................................................................104

2nd Registration Sensor............................................................................................................................107

Air Purge Detection Switch.......................................................................................................................108

Top Cover Switch......................................................................................................................................110

Right Front Cover Switch...........................................................................................................................111

Temperature/Humidity Sensor.................................................................................................................113

Trailing Edge Sensor.................................................................................................................................114

Paper End Sensor......................................................................................................................................115

Duplex Unit Set/Cover Open Switch......................................................................................................116

Bypass Drawer Connector........................................................................................................................117

Drive Switching Module and Ink Supply Unit.............................................................................................120

Rollers.............................................................................................................................................................123

Paper Feed Roller......................................................................................................................................123

Connecting Rollers....................................................................................................................................126

..........................................................................................................................................101

Carriage Unit.................................................................................................................................................129

Replacing the Carriage Unit.....................................................................................................................129

Accessories........................................................................................................................................129

Preparation........................................................................................................................................129

Re-installation....................................................................................................................................133

After Replacing the Carriage...........................................................................................................136

Print Head Cleaning and Adjustment...........................................................................................................138

13

Page 16

Preparing for Test Printing.........................................................................................................................138

Nozzle Check............................................................................................................................................138

Nozzle Check Pattern......................................................................................................................138

Color Demo Print.......................................................................................................................................139

Print Head Cleaning..................................................................................................................................140

Print Head Flushing....................................................................................................................................141

Adjust Paper Feed.....................................................................................................................................141

Head Position.............................................................................................................................................143

Registration................................................................................................................................................144

Cleaning

Refurbishing....................................................................................................................................................156

.........................................................................................................................................................146

Maintenance Unit Cleaning.....................................................................................................................146

Connecting Rollers Cleaning....................................................................................................................147

Transport Belt Cleaning............................................................................................................................148

Friction Pad Cleaning................................................................................................................................150

Horizontal Encoder Strip Cleaning..........................................................................................................151

Cleaning procedure.........................................................................................................................151

Horizontal Encoder Sensor Cleaning (TBA)...........................................................................................153

Vertical Encoder Wheel Cleaning...........................................................................................................154

Swap and Repair Flow.............................................................................................................................156

Before Shipping from Customer Site to Repair Center..................................................................157

What You Need...............................................................................................................................157

Refurbishing Flow......................................................................................................................................158

Purging.......................................................................................................................................................158

Clean the Machine....................................................................................................................................160

5. System Maintenance Reference

Service Program Mode.................................................................................................................................161

SP Mode Service Tables...............................................................................................................................162

SP Table Key..............................................................................................................................................162

SP3-XXX......................................................................................................................................................163

Reset and Restoration Settings.........................................................................................................163

Maintenance, Replacement

SP5-XXX......................................................................................................................................................164

14

.............................................................................................................164

Page 17

Input Check: Sensors........................................................................................................................164

Input Check: Sensors........................................................................................................................165

Input Check: Temperature and Humidity........................................................................................165

Input Check: Air................................................................................................................................166

Input Check: Ink Cartridge Set Sensors..........................................................................................166

Input Check: Ink Cartridge Levels....................................................................................................167

Print an Engine Maintenance Summary..........................................................................................167

SP7-XXX......................................................................................................................................................167

Display Count: Machine Total.........................................................................................................167

Display Count: User Cleaning.........................................................................................................168

Display Count: User Flushing

Date Display SC Log........................................................................................................................168

Display Total Count: SC Log............................................................................................................169

Display Jam Log................................................................................................................................169

Display Total Count: Jam Log..........................................................................................................169

Status Reports.................................................................................................................................................171

1. Page Counter........................................................................................................................................173

2. Config. List.............................................................................................................................................174

3. Service Summary..................................................................................................................................175

4. Engine Summary Chart.........................................................................................................................175

Firmware Updates.........................................................................................................................................179

Operating Environment and Other Requirements..................................................................................179

Update Cautions.......................................................................................................................................179

Firmware Update Operating Instructions................................................................................................180

Bidirectional-Enabled................................................................................................................................181

Bidirectional-Disabled...............................................................................................................................183

...........................................................................................................168

6. Troubleshooting

Troubleshooting Guide..................................................................................................................................187

Image Problems.............................................................................................................................................188

Basic Check Points and Specifications....................................................................................................188

Problems and Solutions....................................................................................................................190

Error Codes....................................................................................................................................................198

Operation Panel Display..........................................................................................................................198

15

Page 18

Operation Panel Messages......................................................................................................................200

Service Call Conditions.............................................................................................................................206

SC code display patterns and how to clear them..........................................................................206

Service Call Code Tables.........................................................................................................................207

Jam Codes

Status Monitor Messages.........................................................................................................................234

.................................................................................................................................................224

Jam Codes.........................................................................................................................................224

Jammed paper location...................................................................................................................233

7. Energy Saving

Energy Save...................................................................................................................................................239

Energy Saver Modes................................................................................................................................239

Timer Settings....................................................................................................................................239

Return to Standby Mode..................................................................................................................239

Recommendation..............................................................................................................................240

Paper Save.....................................................................................................................................................241

Effectiveness of Duplex/Combine Function............................................................................................241

1. Duplex:..........................................................................................................................................241

2. Combine mode:............................................................................................................................241

3. Duplex + Combine:......................................................................................................................241

Recommendation..............................................................................................................................242

Duplex Mode Tables........................................................................................................................242

16

Page 19

1. Product Information

Specifications

See "Appendices" for the following information:

• Printer Engine

• Supported Paper Sizes

• Control Boards

17

Page 20

1. Product Information

Overview

Before You Begin...

What This Manual Contains

This Service Manual covers J034 model of this printer series. This is a brief summary of the differences

between J034 and that of base machine J028.

J028

The NIC is mounted on the CTL board.

This model is PCL compatible.

J034

The NIC is mounted on the CTL board.

This model is not PCL compatible.

This table below compares the J034 model with that of base machine J028. The size and number of

components differ in some cases but their basic design and function are almost the same. The removal

procedures described in the manual apply to this model.

J028 J034

Main Components

Print Heads x2

Maint. Unit Common

Ink Supply Unit Common

Ink Collector Unit Common

Ink Cartridges S size, M size

Horizontal Encoder Film Common

Duplex Std Std

Wireless LAN No No

PCBs

18

CTL Board*

1

FIGO ZICO

Page 21

J028 J034

PSU Common

This depends on the territory in which it will be used.

Europe and Asia: 200V board

North America: 100V board

Supply Unit Board Common

Carriage Unit Board Common

Operation Panel Black

Covers

Right Front Door Product Name Printed on Each

Other Covers The right, left, and duplex unit covers are black.

All other covers are white.

Overview

Options

Multi Bypass Yes (J313) Yes (J315)

PFU Yes (J312) Yes (J314)

*1 The NIC is mounted on the CTL board of the J028/J034.

Printer Models and Options

This manual describes the following printer model and options.

No. Name Ricoh Name

J034 BRG-P1w Aficio SG 7100DN(SG 7100DN)

J314 Paper Feed Unit Paper Feed Unit TK1190

J315 Multi Bypass Tray Multi Bypass Tray BY1050

The electrical components and mechanisms that drive this printer and that of base machine are nearly

identical. However, you should note these differences about options:

• The Paper Feed Unit TK1190 (J314) is an optional paper tray that holds 250 sheets. Only one

paper feed unit can be attached (comprising two drawers together with the standard Tray 1).

19

Page 22

1. Product Information

Print Cartridges

The following print cartridges can be used with the J034.

Name Comments

Starter Ink Cartridge (K)*

Starter Ink Cartridge (C) *

Starter Ink Cartridge (M) *

Starter Ink Cartridge (Y) *

1

1

1

1

These are the starter cartridges shipped with the

machine. These are used to initialize ink supply when

the machine is installed and then discarded.

Print Cartridge GC 41K

Print Cartridge GC 41C

These are medium-size cartridges.

Print Cartridge GC 41M

Print Cartridge GC 41Y

Print Cartridge GC 41KL*2

Print Cartridge GC 41CL*2

These are small-size cartridges.

Print Cartridge GC 41ML*2

Print Cartridge GC 41YL*2

*1: Always use the starter cartridges shipped with the machine to initialize ink supply at installation.

Never install used ink cartridges to initialize ink supply at installation.

*2: L = Low

• The large-size cartridges are supplied only for the Japan domestic models.

Ink Collector Unit

The ink collector unit is installed on the right side of the machine behind the right front door below the ink

supply unit.

Collector Comment

Ink Collector Unit IC 41 Ink Collector Unit for all models.

20

Page 23

Main Machine

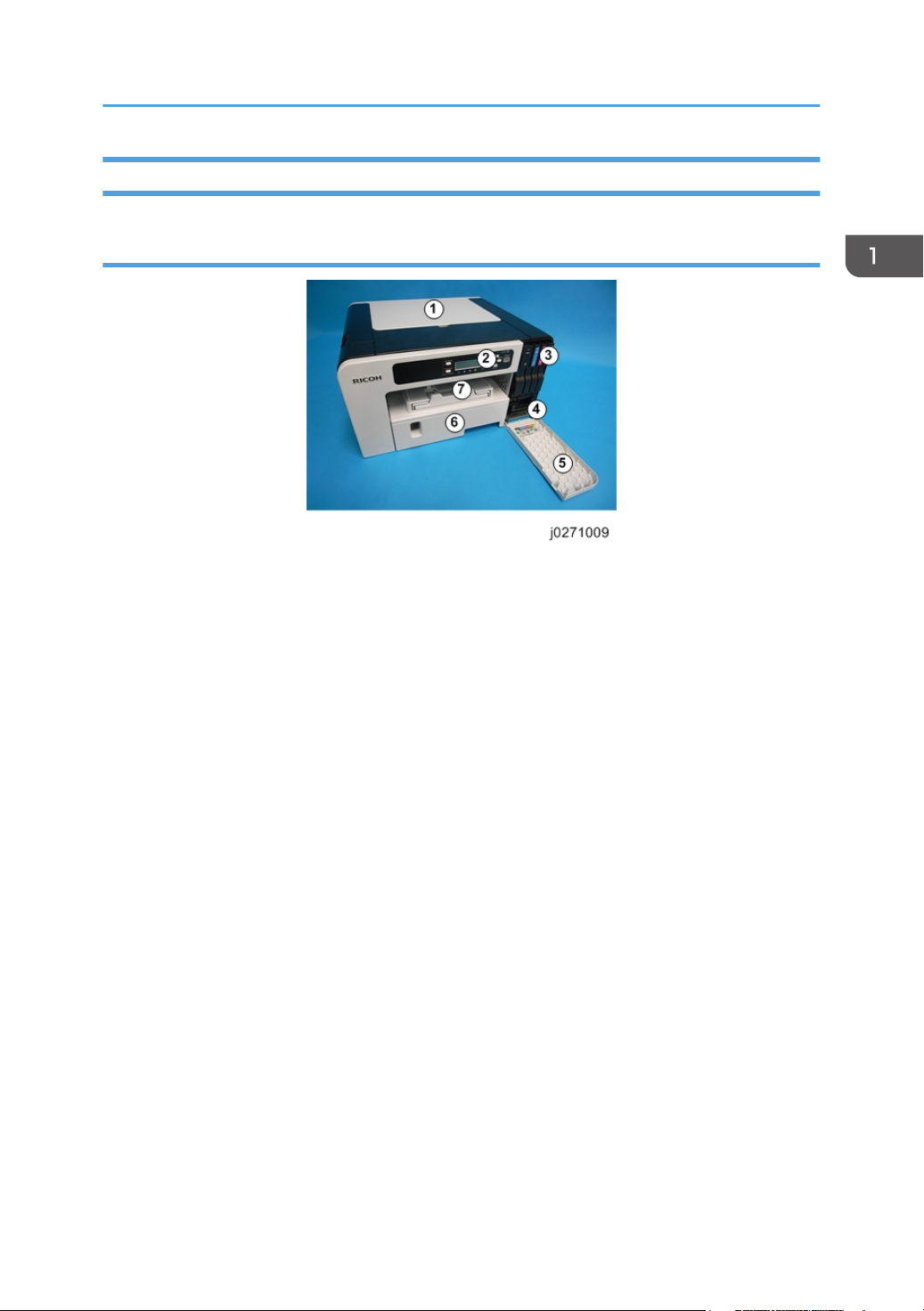

Front View

1. Top cover

Open to see inside the printer if a jam occurs.

Overview

2. Operation panel

Operation keys and the 2-line LCD. The operation panel can be raised and set in the upright

position if the printer is placed at a height where it is difficult to reach.

3. Ink cartridges (K), (C), (M), (Y)

Supply ink to the print heads.

4. Ink collector unit

Pull out the ink collector unit when it needs to be replaced, or before servicing the printer.

5. Right front cover

Covers the ink cartridges and the ink collector. Open only when installing or replacing Ink

cartridges, or when pulling out the ink collector unit. Otherwise, this door should remain closed. A

small switch detects when this cover is open and closed. The door must be closed for the printer to

operate.

6. Paper cassette (Standard Tray 1)

This is the standard tray that holds paper fed to the machine.

7. Paper output tray and extension

Holds paper that has exited the printer. Pull out the output tray extension when printing on paper

longer than A4 or LTR.

21

Page 24

1. Product Information

Left View

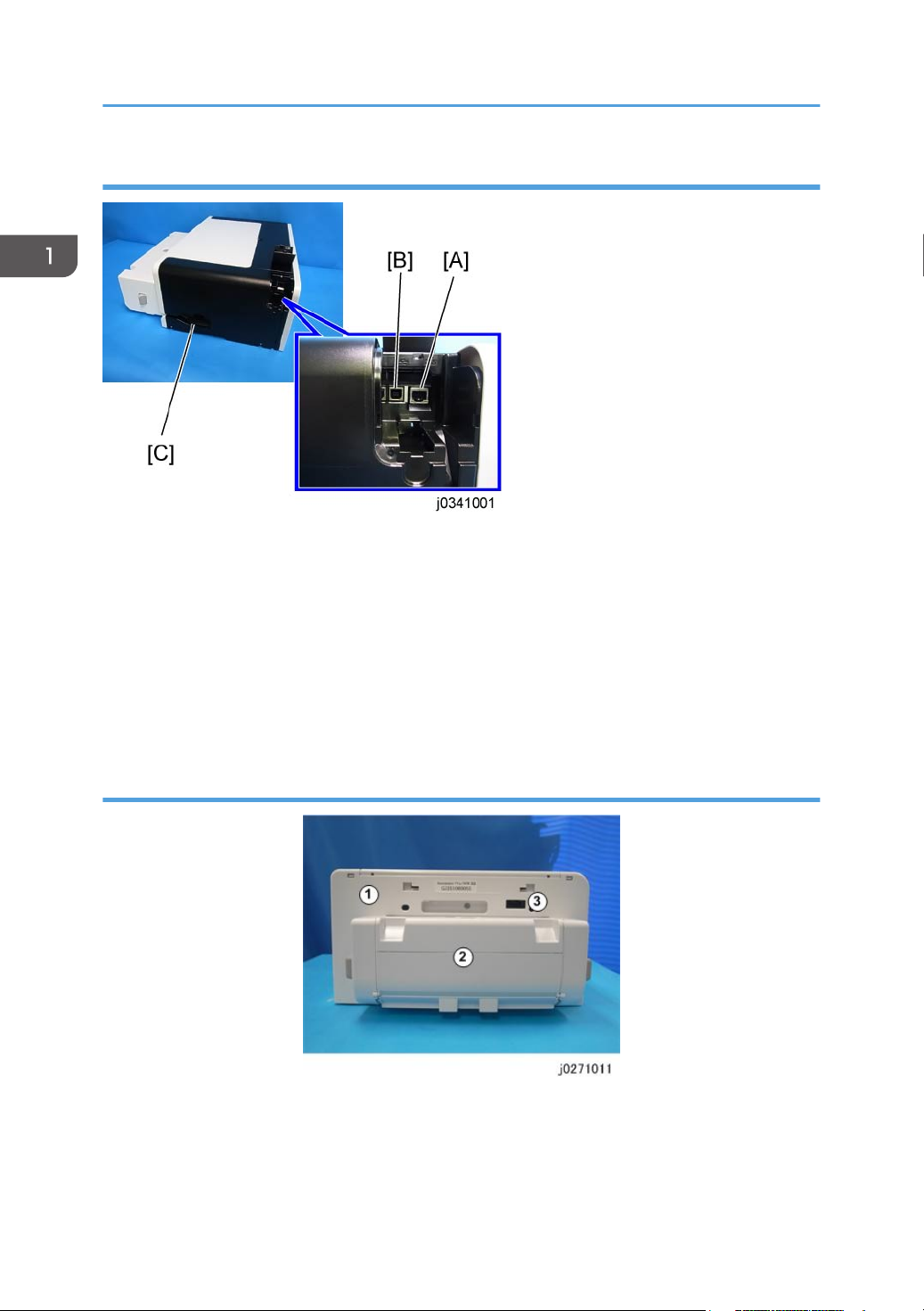

A: Ethernet port

The port for the ethernet cable. The NIC is mounted on the controller board.

B: USB port

This is the connection point for the USB cable from the PC.

C: Power inlet

The connection point for the power cord. Use only the detachable power cord provided with the printer.

Make sure you ground (earth) the head of the plug at the power source.

Rear View

1. Rear cover

2. Duplex unit

22

The duplex is standard for the J034 (it is not an option). It is easily detached and re-attached. A

small switch detects the presence or absence of the duplex unit.

Page 25

3. Bypass tray connection point

This is the connection point for an optional multi bypass tray.

Options

External Options: J034

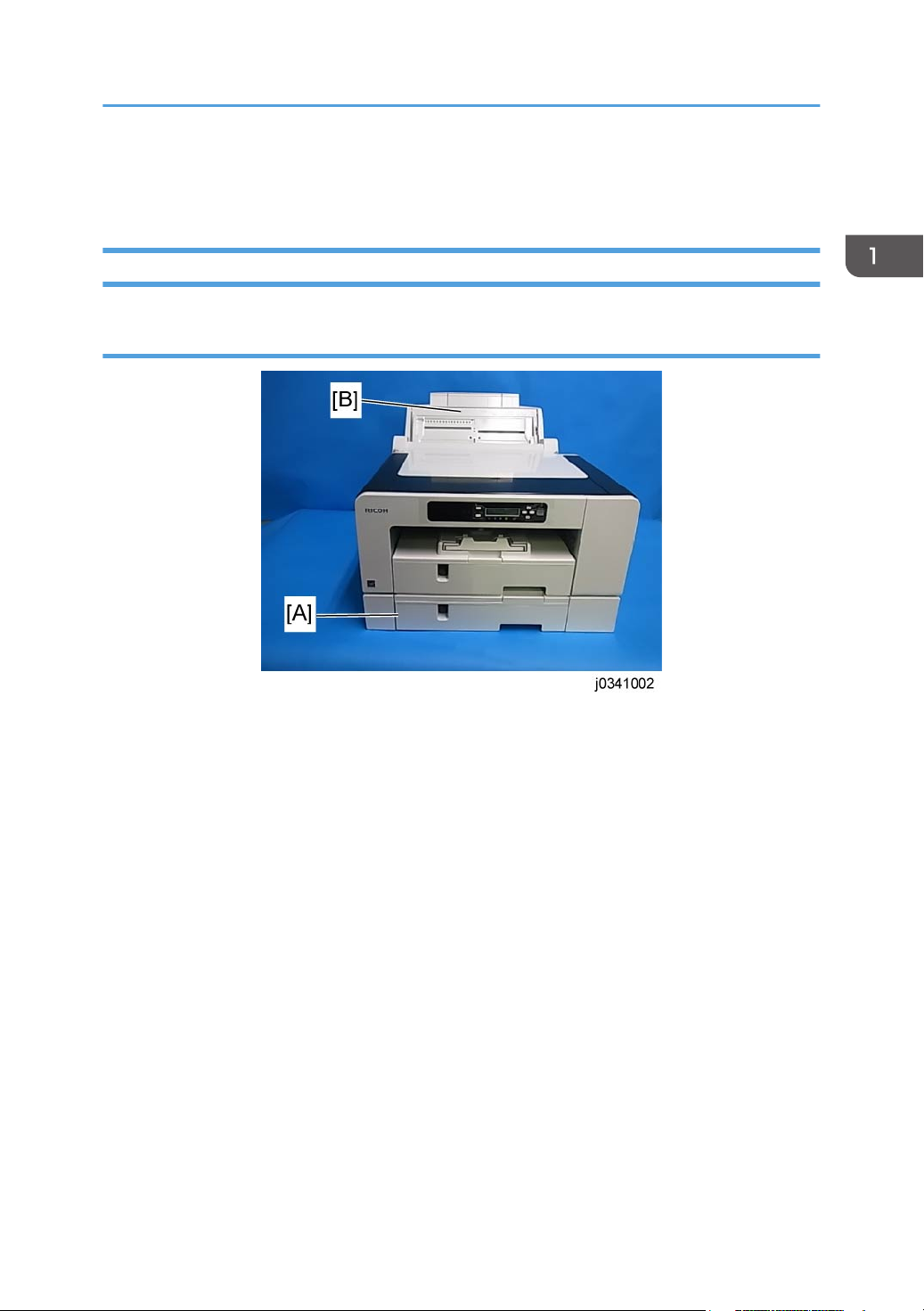

Overview

The Paper Feed Unit TK1190 (J314) [A] is used with the J034 only. Only one paper feed units can be

installed.

The Multi Bypass Tray BY1050 (J315) [B] can be used with the J034 only.

23

Page 26

1. Product Information

Guidance for Differences between J034 and that of the base machine

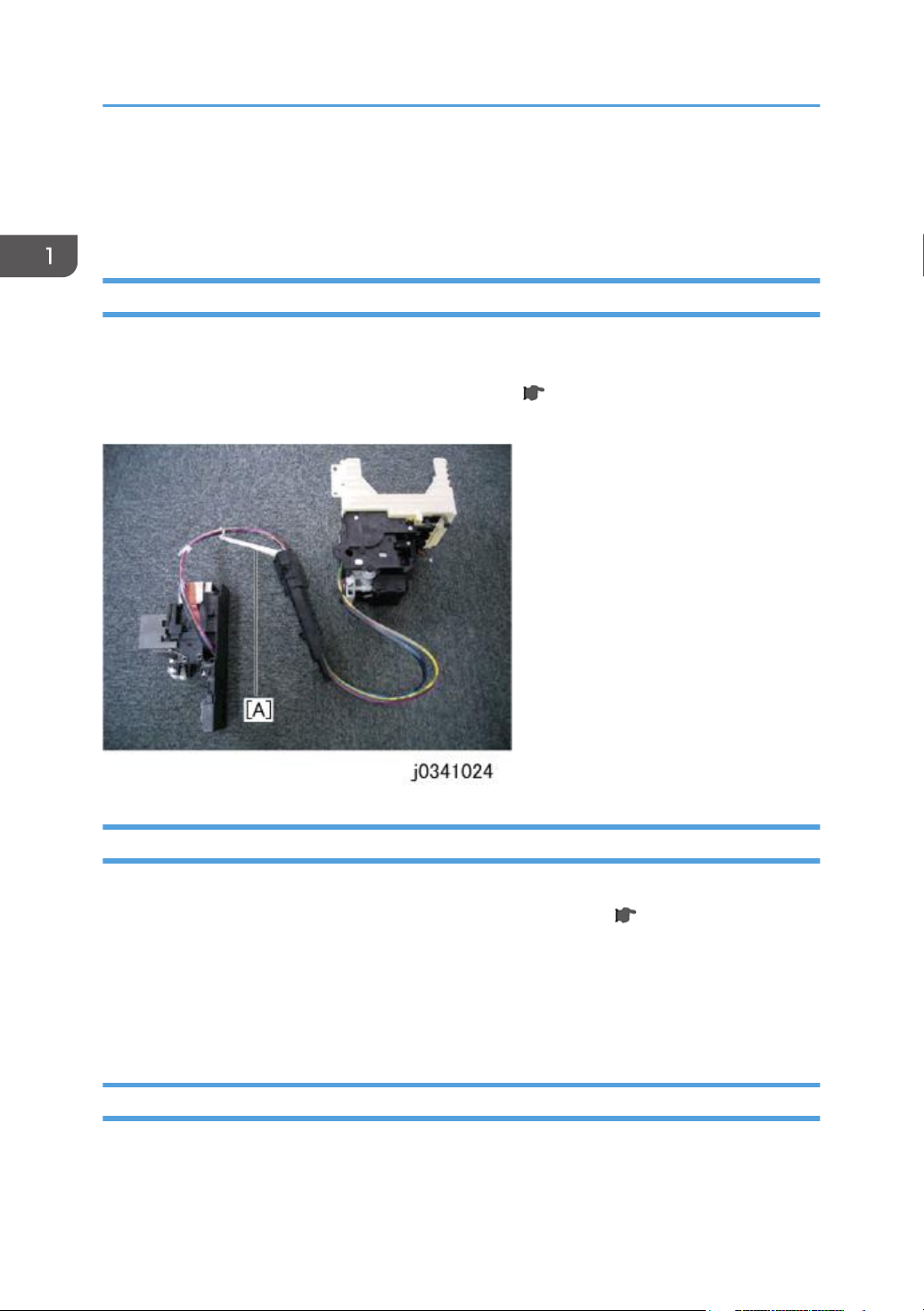

Ink Tube Stay

The J034 model adds the ink tube support stay [A] between the carriage and the ink supply unit so that

the large size papers can be printed smoothly. However, this stay requires no additional steps for the

replacement. Pay extra attention to remove the carriage unit ( p.129) from the main machine to

avoid damaging to this stay.

Paper Transport Belt Unit

For supporting the large size papers, The J034 machine’s width is increased consequently. This changes

some replacement procedures. Regarding as the paper transport belt unit ( p.96 "Transport Belt"),

the following procedures are changed.

• The carriage unit should be removed before removing the belt unit.

• The number of the pressure plate’s screws becomes 4.

• The number of the pressure plate’s springs becomes 6.

Rollers

The Pickup roller and the connecting roller removing procedures are also changed in some parts.

24

Page 27

Guidance for Differences between J034 and that of the base machine

The Paper Feed Roller

• The two e-rings should be released to remove the pressure rollers that pinch the paper feed roller

( p.123).

The Connecting Roller

• The ink level sensor should be removed to pull out the right side of the connecting roller shaft ( p.

126 "Connecting Rollers") from the main machine.

25

Page 28

1. Product Information

26

Page 29

2. Installation

Preparation

Environment

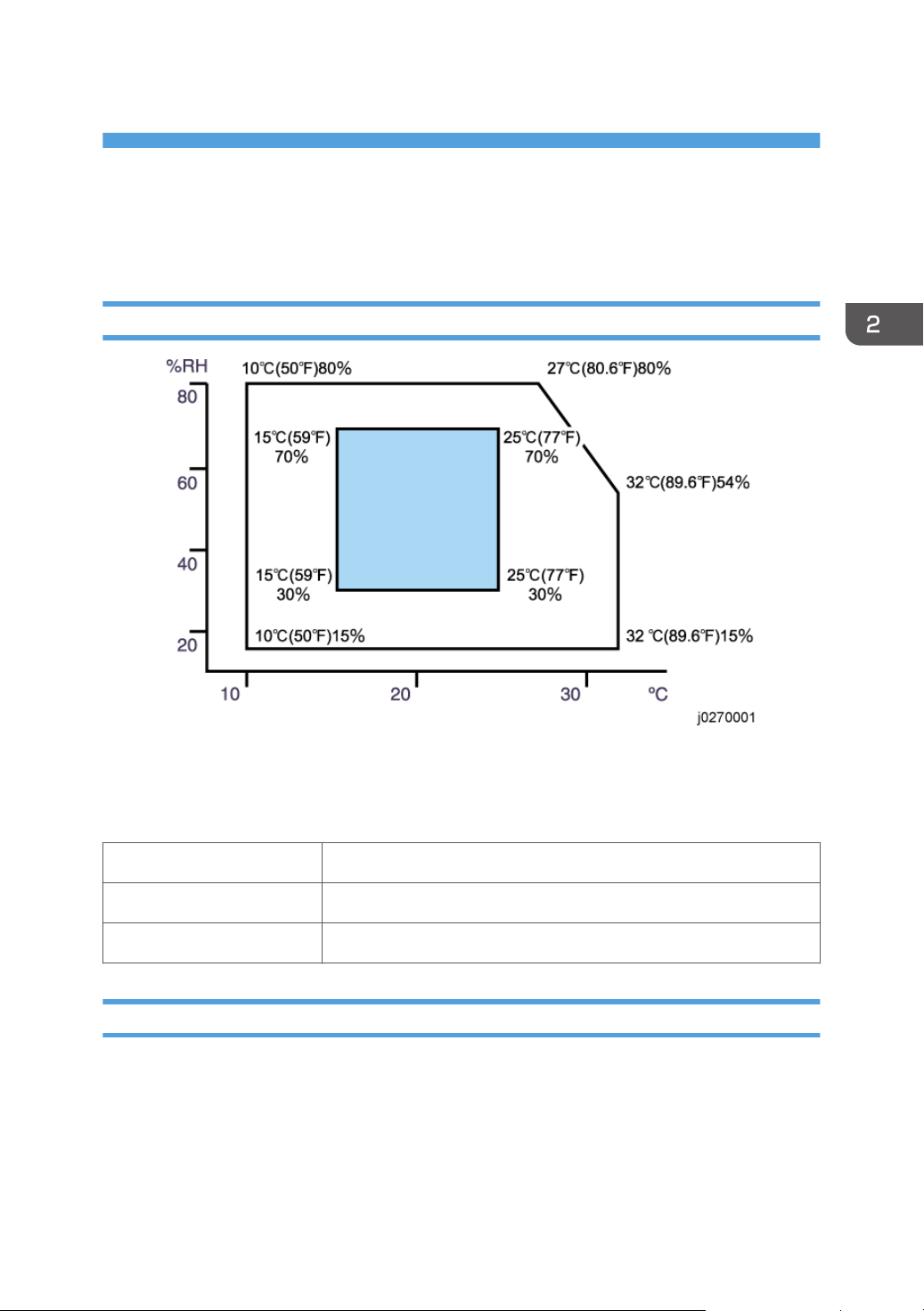

• White area: Permissible Range

• Blue area: Recommended Range

Set up the machine in a location that meets these minimum requirements:

Temperature Range: 10°

Humidity Range: 15% to 80% RH

Ambient Illumination: Less than 2,000 Lux (never expose to direct sunlight).

C to 32°C (50°F to 89.6°F)

Choosing a Location

1. Always install the machine:

• On a sturdy, level surface.

• Where it will not become damp.

2. Make sure the machine is never exposed to:

27

Page 30

2. Installation

• Extreme changes from low to high temperature or high to low temperature.

• Cold or cool air directly from an air conditioner.

• Heat from a space heater.

3. Never install the machine in areas near:

Dust, lint, or corrosive fumes.

•

• Strong vibration.

4. Do not use the machine at any location higher than 2,500 m (8,200 ft) above sea level.

5. Set up and use the machine on a sturdy, level surface.

• Place a carpenter's level on the machine front-to-back, and side-to-side and confirm that it is

level.

• Variations between the front/back and left/right level readings should be less than 2

degrees.

Required Software Environment

Software • Microsoft Windows XP/Vista/Windows 7

• Microsoft Windows Server 2003/2003 R2/2008/2008 R2

• Mac OS X 10.5 Leopard and later versions*1

• PC/AT-compatible computer with USB or network interface

• Macintoshes that are PowerPC G3 or higher with USB port or network port

Hardware

• Macintoshes that are Intel Core Duo or higher with USB port or network port

• 80-100 MB of HDD space available

*1: Mac driver included on CD-ROM (The supported languages are English, French, German and

Japanese.).

28

Page 31

Minimum Space Requirements

a. At least 26 cm (10.3 inches)

Preparation

b. At least 3 cm (1.2 inches)

c. At least 45 cm (17.8 inches)

d. At least 10 cm (4.0 inches)

e*1. At least 13 cm (5.2 inches)

*1 A clearance of 30 cm (11.9 inches) is necessary if the multi bypass tray is attached.

Power Source

J034

North America 100-120 V: 50/60 Hz 1.2 A (when fully equipped)

Europe 220-240 V: 50/60 Hz 0.6 A (when fully equipped)

29

Page 32

2. Installation

Using the Operation Panel

Here is a brief description of how to use the keys on the printer operation panel. This information is

provided as a quick summary of important information described in the Operating Instructions.

Key Summary Table

Key/Indicator What It Does

1 Power Press this key to turn the power on. To turn the power off, press and hold

2 Job Reset When the machine is online, press this key to cancel an ongoing print job.

3 Form Feed When the printer is offline, push to print all the data in the printer buffer.

4 Escape Push to restore the display to the previous condition.

30

down this key for one second.

Blinks when the printer is receiving data from a computer or if there is data

to be printed.

If there is a paper jam, press this key according to the displayed error

message and remove the jammed paper.

Page 33

Key/Indicator What It Does

Using the Operation Panel

5

/Menu

[ ], [ /Menu]: Increase or decrease values on the display when making

settings.

[ /Menu]: When the printer is in standby mode, press [ /Menu] key to

enter the user menu.

6 Cartridge

Show the ink levels of the print cartridges.

replacement

indicator

7 Waste ink full

Show the waste ink levels of the ink collector unit.

indicator

8 Display Shows the current printer status and error messages.

9 Alert indicator The symbol appears in the LCD when an error occurs.

Red indicator illuminating: Indicates an error that requires the

•

operator or service representative to deal with. Printing stops.

• Red indicator flashing: An alert message appears. Follow the

instruction that appears in the display.

10 #Enter Push to execute the menu item on the display.

11

No-Fuss Head

Cleaning

When the machine is in standby mode, press the [Job Reset] and [Form

Feed] keys at the same time to perform head cleaning for all colors.

31

Page 34

2. Installation

Printer Display Summary

Operation Panel: Cartridge replacement indicator

The printer shows a multi-level dynamic display that keeps the operator informed about the status of the

ink levels in the tanks. The example below for Black (K) shows the progression in the display from full on

the left to completely empty on the right.

A software count determines when the ink cartridge is has less than 20% ink remaining. The 0% and Ink

Out display begin flashing alternately at 3 sec. intervals. This is the near-end alert.

When the cartridge is empty the machine issues the ink-end alert and printing stops.

32

Page 35

Using the Operation Panel

The operator can continue printing by pressing [Form Feed] on the operation panel. The printer will

continue to print until the print head ink tank is empty. However, in this operation mode the machine

cannot perform print head maintenance.

Operation Panel: Waste Ink Full Indicator

The amount of waste ink in the ink collector unit is indicated on a six-step scale, namely 0, 20, 40, 60,

80, and 100%. It is reset to 0% if a new ink collector unit is installed. If it reaches 100%, printing cannot

be done. A message prompting the user to replace the unit appears on the panel display. A message

prompting the user to replace the ink collector unit appears also if it is not mounted.

The amount of waste ink can be displayed also on the Status Monitor and Web Image Monitor.

On the other hand, "Ink C.U. Space" in the machine's menu on the control panel displays the available

storage space left in the ink collector unit. (It is reset to 100% if a new ink collector unit is installed.)

Display Menu Summary

Here is a summary of the function menus. Items needed for printer maintenance or troubleshooting are

marked in the left column with an asterisk (*).

33

Page 36

2. Installation

User Menu Mode

Menu/Menu Item Function

Counter Displays or prints the number of pages printed in B&W, full color, and

Economy Color.

Note: Changing Bit SW 5 modifies the display:

• Setting Bit SW 5-6 to "0" switches the Economy Color display off.

• The default setting for Bit SW 5-6 is "1". Mono and Economy Color are

both displayed.

Show Counter Displays the counters on the LCD ("Black", "Color")

Prints the "Page Counter" report that lists: the machine serial number, Total

Print

Full Color, Total Mono Color, Total Economy Color, and Total Duplex. It

also lists Coverage information for full color, mono, and Economy Color.

Paper Input

Paper Type Specifies type of paper loaded in the paper tray.

Tray Paper Size Specifies size of paper to be loaded in the paper tray.

Note: The setting of Bit SW6-7 determines whether hidden functions (hidden

paper sizes A5 SEF, B6 SEF) are displayed:

• 0: No A5 SEF, B6 SEF display (default)

• 1: A5 SEF, B6 SEF displayed

Aut. Tray Select Specify that the paper tray be automatically selected. The paper tray will

automatically be selected according to the paper size and paper type. Tray

1 (the standard paper cassette) is the default. "Tray 2" and "Tray 3" appear

only if the paper feed unit(s) is attached. "Bypass Tray" appears only if the

bypass tray is attached.

Tray Priority

You can specify the prioritized paper tray. This setting appears only if the

paper feed unit or multi bypass tray is attached.

List/Test Print

34

Page 37

Using the Operation Panel

Menu/Menu Item Function

Config.Page(*) Prints information that tells you the current configuration of the printer.

• System Reference. Lists printer version, attached options, name of print

language, amount of ink remaining for each ink cartridge.

• Paper Input. Lists the specified Tray Priority setting and the Paper Input

menu settings.

• Host Interface, Interface Information. Lists the settings of the Host

Interface menu

Color Demo Page Prints a color sample.

Error Log Prints list of most recent errors.

PCL Config. Page Lists current PCL configuration

Maintenance

Nozzle Check(*) Prints the cross-hatch test pattern so you can visually confirm whether inks are

ejecting correctly from the print head.

Head-cleaning(*) Cleans the print head. Clean the print head when certain colors are missing

or printing faintly. Head cleaning consumes ink.

Head-flushing(*) Cleans the print head more thoroughly than "Head-cleaning". Flushing

consumes more ink. Use this function only after "Head-cleaning" fails to solve

the problem.

Head Position(*) Adjusts the alignment of the print head if the Nozzle Check test pattern

shows broken vertical lines, or if printed images are blurred.

Adj. Paper Feed(*) Adjusts the paper feed setting if the Nozzle Check test pattern shows

horizontal misalignment, or if printed images appear uneven.

Registration Adjusts the print starting point for each paper tray. Use the Nozzle Check

test pattern as reference.

Date/Time Allows setting current date/time.

Key Repeat Enables/disables repetition of a key pushed and held down on the

operation panel.

35

Page 38

2. Installation

Menu/Menu Item Function

Dry-delay (Exit) To prevent spoiling of printed copies, select a print delivery interval to allow

them to dry.

The interval must be long enough to allow a sheet to dry. You can specify an

interval between 1 and 20 seconds.

Default: [Off]

Dry-delay (Dup) Pauses printing to allow first side of duplex print to dry before printing

second side of same page.

Note: Supported by the J028/J029 only.

Paper Feed Test(*) Feeds and ejects 1 blank sheet of paper to remove moisture inside the

machine.

De-condensation(*) Feeds and ejects 3 blank sheets of paper to remove moisture inside the

machine.

System

Prt. Err Report Prints error report.

Auto Continue Determines how the printer handles a print job when the specified paper size

and type is not loaded in the tray.

Off: The job does not print if the specified paper size/type is not loaded in

the tray. The job will execute once the specified paper size/type is loaded.

On: The job prints even if the specified paper size/type is not loaded in the

tray.

Sub Paper Size Determines whether to print on A4 paper if LT size paper is specified in the

printer driver, and vice versa.

Default: Off

Energy Saver Switches the energy saving function on/off. When this function is on, the

printer will automatically shut down some of its functions automatically after it

remains idle for the prescribed amount of time.

The "E. Saver Timer" can be set for 5, 15, 30, 35, 60 min.

Once the printer enters the energy save mode, it will require some time to

recover full operation once it receives a print job.

Notify by Email Determines whether a notification is sent to a specified email address when a

printer error occurs. Be sure to cycle the printer off/on after doing this

setting.

36

Page 39

Menu/Menu Item Function

Memory Usage Frame Priority, Font Priority

Unit of Measure Determines the units of measure ("mm" or "in.")

Default: mm

Page Size Allows selection of page size.

Paper Type Plain Paper, IJ Plain Paper, Glossy Paper, Thick Paper, Postcard, Inkjet

Postcard, Envelope

Preprinted Ppr. Off, On

Copies Allows selection of number of copies: 1 to 999.

Blank Pg. Print On (Prints), Off (Does Not Print)

Tray Switching Off (Does Not Switch Trays), On (Switches Trays)

Uni-direct Prt. Env. Selector: On, Auto Detect, Always

Using the Operation Panel

Density Dark, Light, Standard

Color Mode Color, Economy Color, Black and White

Recycl. Ppr. Mode Off, On

Pg Recov. Error Specify whether or not [Page Recovery Error] is reported.

Default: [Display]

Ink C.U. Space Displays the current status of ink collector unit. The number means the

amount of space remaining. (100% means the unit is empty.)

Ppr. Size Error This function enables the printer to notify users if the paper in the tray does

not match the paper size specified in the [Paper Input] menu.

Default: [Display]

Host Interface

I/O Timeout Determines how long the printer waits for the interface to respond. After the

specified time elapses, the printer can receive data from another interface. If

the specified time is too short, a timeout might occur while a data transfer is

in progress. If this occurs, the print job will be interrupted by a new job from

another interface. Default: 15 sec.

37

Page 40

2. Installation

Menu/Menu Item Function

Network Setup Use to do the network settings.

Setting Default

Machine Name Display only

Host Name Display only

Domain Name Display only

IPv4 DNS ServerAddress 1 and 2

0.0.0.0

IPv4 DDNS On

DHCP Off

IPv4 Address 11.22.33.44

Pv4 Subnet M 0.0.0.0

Network Setup Pv4 Gatewy. Ad 0.0.0.0

IPv6 DDNS On

IPv6 DNS ServerAddress 1 and 2

::

DHCPv6 Off

IPv6 Statlss Ad On

IPv6 Address Manual Confg Ad

MnCfgAd PrfxLen

IPv6 Gatewy.Ad. 0:0:0:0:0:0:0:0

Active Protocol IPv4: Active

IPv6: Active

HTTP (IPv4): Active

HTTP (IPv6): Active

Web: Active

38

Page 41

Menu/Menu Item Function

Network Setup IPsec Off

MAC Address Display only

Ethernet Speed Auto Select

Prmt SNMPv3 Com Cleartext

Pmt SSL/TLS Com IPv4: Active

IPv6: Active

Restore Default ---

USB Setting Two settings are available:

USB Speed.

•

• Auto: 480 Mbps or 12 Mbps automatically adjusted

• Full Speed: 12 Mbps fixed

Using the Operation Panel

Default: Auto. Normally, this setting does not require changing.

•

Port Setting.

• Specifies communication settings for a USB connection.

• Default: Off

Language You can select which language the menu is displayed in.

The "Language" menu will be displayed in English.

• NA model

Japanese, English, French, German, Italian, Spanish, Dutch,

Norwegian, Danish, Swedish, Portuguese, Finnish (Default: English)

• EU/Asia model

Same as above plus: Czech, Polish, Hungarian

Access to menus during an error

In previous models, menus could not be accessed during an error. However, this model allows access to

user menus by pressing the [ /Menu] key.

However, functions that require printing, such as the printing of the counter, cannot be executed during

an error.

example:

• Counter. The counts can be displayed but not printed.

39

Page 42

2. Installation

• List/Test Print. No selections are available.

Even without computers, you can specify settings, such as the time and date, on the machine's control

panel.

• Menus could not be accessed while the printer is busy.

40

Page 43

Installation

Installation

These machines and all peripherals are installed by the customer.

The installation procedures are described in the operating instruction manuals issued to the customer

with purchase of the main machine or peripheral unit.

41

Page 44

2. Installation

Important Information

Make sure that the customers understand the following points about moving, storing, and using the

printer.

Checklist Before Moving the Printer

1. Turn the printer off. Disconnect the power cord.

• Never disconnect the power cord without first turning off the printer.

2. To lift the printer, grip it at the center of each side by the hand recesses provided.

3. Never grip the duplex unit on the back of the printer.

4. Make sure the covers and trays are closed. Secure them with tape. Attach the tape at the same

area you removed at the time of installation.

Disconnect the power cord. Tape the power cord to the back of the printer.

5.

6. Remove all paper in the feed trays.

7. Do a test print to confirm that the printer operates correctly after you move it to another location. Do

the cleaning procedures with the printer driver, if necessary.

8. The ink cartridges should remain in the printer. It is not necessary to remove the before transporting

the printer. However, ink must be purged from the print head tanks before the printer is transported.

(See procedure below.)

• To avoid ink spillage, always hold the printer level when you move it.

• Work carefully to avoid dropping it or colliding with other objects in the work area.

If the Printer Is Not Used Frequently…

1. Turn the power off, disconnect the USB cable, and unplug the power cord.

2. To prevent the print nozzles from drying out, periodically print something.

3. Turn the printer on for a few minutes once a month.

4. After storage or a long period of disuse, use the printer driver to print a nozzle check text pattern

and clean the print head nozzles if necessary.

42

Page 45

3. Preventive Maintenance

PM Table

There are no PM Parts in this machine.

Service Call Procedures

The procedures listed below should be done by the service technician. For more details about how to do

these procedures, please refer to "Cleaning Procedures".

Description At Service Call, or As Required

External Covers Damp cloth.

Connecting Rollers,

Paper Feed Roller

Friction Pad Damp cloth. This is the cork friction pad on the front edge of the standard

Maintenance Unit Damp cloth. Always use a tightly wrapped damp cloth to remove the ink

Printer Operation, Print

Quality

Transport Belt Slightly damp cloth. Then dry cloth.

Horizontal Encoder

Strip

Vertical Encoder Wheel Clean linen cloth, dampened with alcohol. Do not use cotton, tissue paper,

Damp cloth. Rotate the roller freely as you clean it.

paper cassette.

that has hardened around the suction cap and wiper blade when you

replace the ink collector unit.

Print a Nozzle Check Pattern and check the results. Clean the print heads if

necessary. For more, see "Print Head Cleaning and Adjustment" in section

"4. Replacement and Adjustment".

Important: To protect the surface of the transport belt, never use alcohol or

any other type of organic solvent.

Clean linen cloth, dampened with alcohol. Do not use cotton, tissue paper,

any material that could shred and leave fibers.

any material that could shred and leave fibers.

43

Page 46

3. Preventive Maintenance

44

Page 47

4. Replacement and Adjustment

Before Replacing Parts

Removal Table

The swap-and-repair system is used for this printer. The table below lists the level of difficulty for

replacement of each item.

Level 1: No Tools Required

Component Comments

1 Duplex Unit Standard. Back of machine

2 End Fence Inside paper cassette

3 Ink Cartridge Front

4 Ink Collector Unit Front

5 Paper Cassette Standard

6 Paper Output Tray On top of paper cassette

7 Right Front Cover Front

8 Port Cover Left side

Level 2: Replaced by Service Technician

Component Difficulty: Low, Medium, High

1 Canopy Cover Low

2 Top Cover Low

3 Rear Cover Low

4 Right Cover Low

5 Left Cover Low

6 Front Cover Low

7 Connecting Rollers Low

45

Page 48

4. Replacement and Adjustment

Component Difficulty: Low, Medium, High

8 Front Cover Low

9 High Voltage Power Supply (HVPS) Low

10 Maintenance Unit Low

11 OPU (Operation Panel Unit) Low

12 PSU Low

13 Vertical Encoder Sensor Low

14 Vertical Encoder Wheel Low

15 Vertical Motor Low

16 Controller Board Medium

17 Cooling Fan Medium

18 Right Ink Sump Medium

19 2nd Registration Sensor High

20 Carriage Unit High

21 Friction Pad High

22 Horizontal Motor High

23 Transport Belt High

24 Air Purge Detection Switch Low

25 Drive Switching Position Sensor High

26 Maintenance Unit Control Sensor High

27 Drive Switching Motor High

28 Drive Motor (DC Motor) High

29 Temperature/Humidity Sensor High

30 Paper End Sensor High

46

31 Paper Feed Roller High

32 Charge Roller Medium

Page 49

Before Replacing Parts

Level 3: Require precision adjustment at factory (Not Replaced in this Field)

Component Comments

--- None ---

Required Tools

This is a list of tools needed to service the machines. These tools are used to keep the print heads from

drying out during long periods of storage following machine repair. (The ink is purged and fresh

cleaning liquid is supplied.)

Item Description Qty Unique or Common

1 Ink Cartridge K Cleaning Assy 1 U

2 Ink Cartridge C Cleaning Assy 1 U

3 Ink Cartridge M Cleaning Assy 1 U

4 Ink Cartridge Y Cleaning Assy 1 U

5 Special Cloth 10 pcs/bag 1 C (PG-C1)

• Parts 1 to 4 are used at the Repair Center.

47

Page 50

4. Replacement and Adjustment

Common Procedures

Simple Removals

Duplex Unit

48

1. Push and hold the left and right release tabs [A] together to unlock the duplex unit [B].

2. Pull the duplex unit out of the machine.

Reinstallation

• The duplex unit must be installed in the machine at all times. The machine will not operate without

the duplex unit installed.

• The locks on either end of the duplex unit lock automatically when the unit is attached to the back

of the printer.

Page 51

Common Procedures

Ink Collector Unit

Before you begin:

Never remove the ink collector unit unless it requires replacement. A message will appear and tell you

that the ink collector unit needs to be replaced.

• You will need a self-sealing plastic bag to hold the ink collector unit.

• When you dispose of the used ink collector unit always obey the local laws and regulations

regarding the disposal of such items.

At any time you can determine if the ink collector unit needs to be replaced.

• Never attempt to clean and re-use an ink collector unit.

To remove the ink collector unit:

1. Gently touch the right front cover to release and open it.

2. Pull the ink collector unit [A] out.

3. The ink collector [A] is completely enclosed to prevent leakage.

4.

If you are replacing the ink collector unit, insert the new one.

49

Page 52

4. Replacement and Adjustment

5. Push in the ink collector [B] until you hear it snap and lock in place.

6. Close the right front cover.

• The ink collector unit has an internal ID chip that automatically resets the counter for the ink

collector unit. No SP adjustment is required.

7. Discard the used ink collector unit.

• Obey the local laws and regulations regarding disposal of items like the full ink collector unit.

• Never attempt to open and clean a full ink collector unit and use it again.

Covers

Cover Names

50

[A] Top Cover

[B] Canopy Cover

[C] Front Cover Brand Logo attached

[D] Operation Panel

[E] Right Front Cover Product Logo attached

[F] Output Tray

Page 53

[G] Paper Cassette

[H] Rear Cover

[I] Duplex Unit

[J] Right Cover

[K] Left Cover

Common Procedures

[L] Port Cover *

1

No screws, tabs only.

*1 This picture is a shot that is taken with the port cover opened because of the easily view.

Order of Removal Cover

It is very important that you understand how to remove and reinstall the covers before doing