Page 1

BY-PASS

(Machine Code: A899/B415)

Page 2

10 August, 2001 SPECIFICATIONS

1 OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Paper Size:

Paper Weight: 52 g/m2 ~ 157 g/m2, 16 lb ~ 42 lb

Tray Capacity: 50 sheets (80 g/m2, 20 lb)

Paper Feed System: Friction Pad Paper Feed

Standard sizes

A6 lengthwise to A3

HLT lengthwise to DLT

Non-standard sizes

Width: 90 to 305 mm

Length: 148 to 432 mm

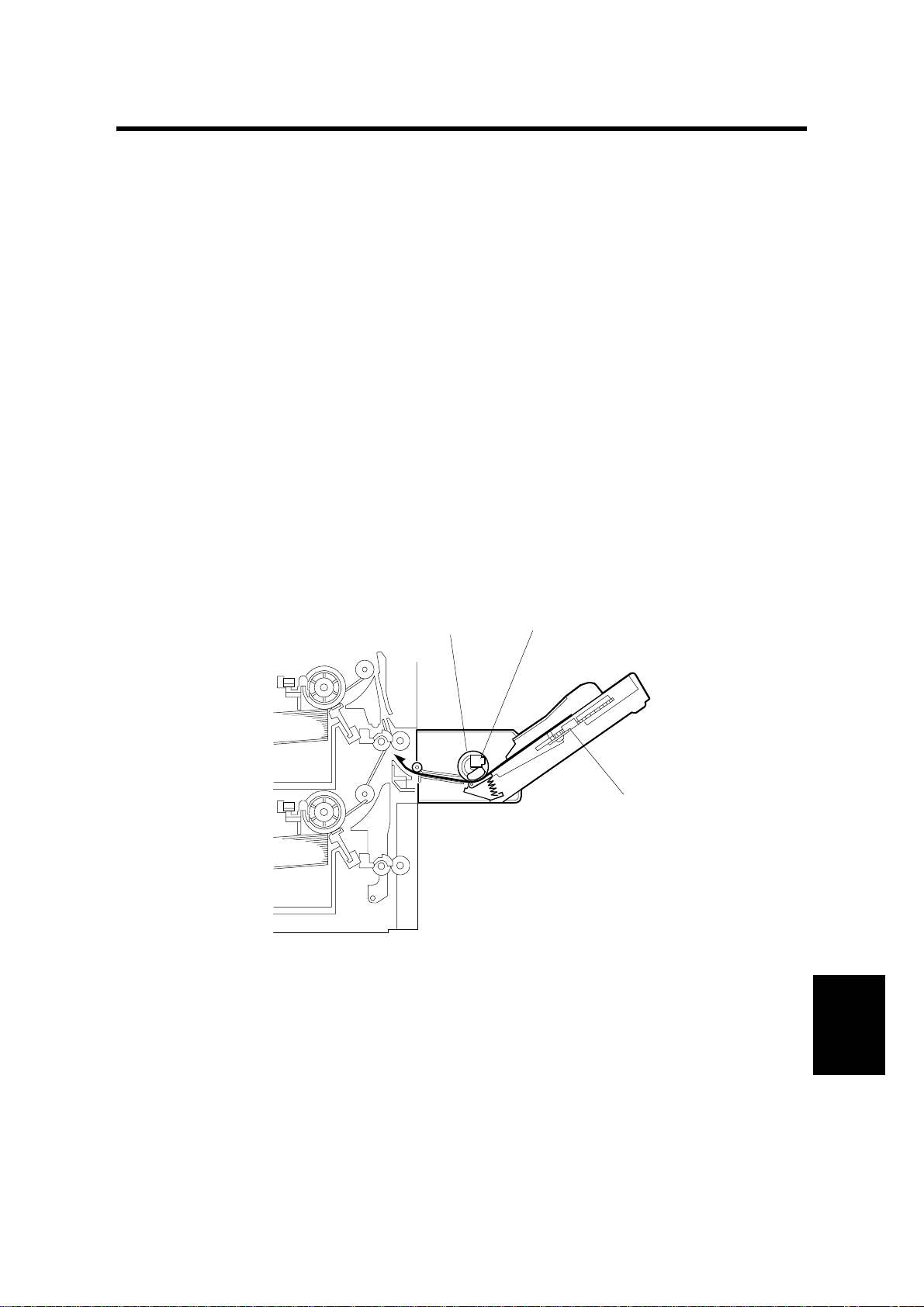

1.2 MECHANICAL COMPONENT LAYOUT

1

2

1. Paper Feed Roller

2. Paper End Sensor

3. Paper Size Sensor Board

3

B415V500.WMF

Options

B415-1

Page 3

ELECTRICAL COMPONENT LAYOUT 10 August, 2001

1.3 ELECTRICAL COMPONENT LAYOUT

2

1

3

B415V501.WMF

1. Paper End Sensor

2. Paper Feed Clutch

3. Paper Size Sensor Board

1.4 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function Index No.

Sensors

S1

S2

Magnetic Clutches

MC1 Paper Feed Starts paper feed from the by-pass tray. 2

Paper End Informs the copier/printer when the by-pass

tray runs out of paper.

Paper Size

Sensor Board

Detects the paper width.

1

3

B415-2

Page 4

10 August, 2001 BASIC OPERATION

2 DETAILED DESCRIPTIONS

2.1 BASIC OPERATION

[A]

[B]

[C]

B415D503.WMF

The by-pass unit uses a friction pad paper feed mecha ni sm. The transport roller

gear in the main copier/printer drives the gear on the paper feed clutch [B] through

a series of gears.

When paper is placed in the tray, the paper end sensor [C] switches off. When the

Start button is pressed, the paper feed clutch [B] is activated and the paper feed

roller [A] feeds the paper one sheet at a time.

B415-3

Options

Page 5

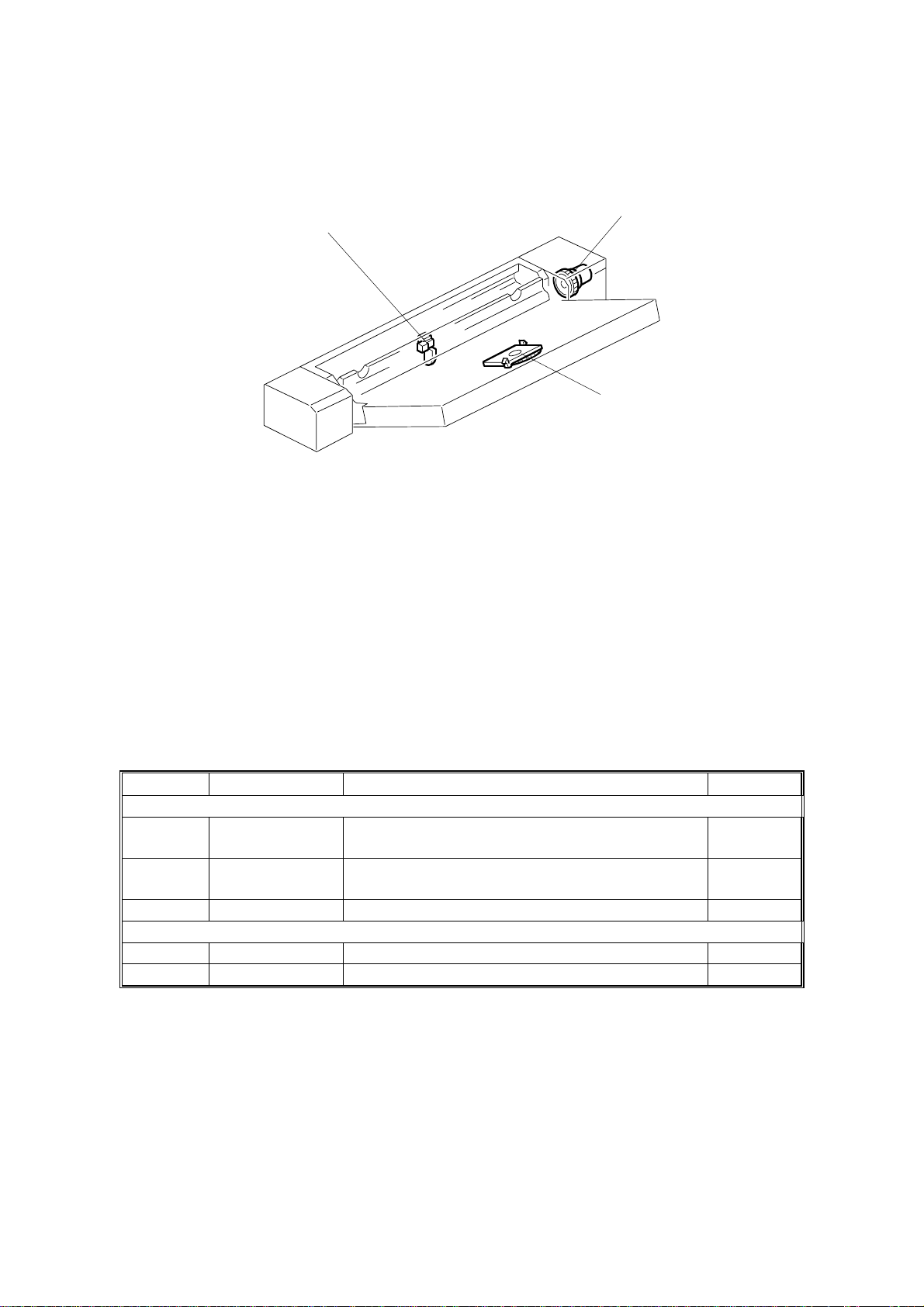

PAPER SIZE DETECTION 10 August, 2001

2.2 PAPER SIZE DETECTION

[A]

[B]

B415D504.WMF

The paper size sensor board [B] monitors the paper width. The rear side fence [A]

is connected to the terminal plate. The pattern for each paper width is unique.

Therefore, the copier/printer determines which paper has been placed in the bypass tray by the signal output from the board. However, the copier will not

determine the paper length from the by-pass tray hardware (refer to Original Size

Detection in the manual for the base copier for details on how paper length is

determined).

B415-4

Page 6

10 August, 2001 PAPER FEED ROLLER/FRICTION PAD/PAPER END SENSOR

3 REPLACEMENT AND ADJUSTMENT

3.1 PAPER FEED ROLLER/FRICTION PAD/PAPER END SENSOR

[A]

B415R501.WMF

[C]

[B]

1. Remove the upper cover [A] (2 screws).

2. Remove the paper end sensor bracket [B] (1 screw).

[D]

B415R505.WMF

Options

3. Remove the paper feed roller [C] (snap-fit).

4. If removing the friction pad [D], do so at this time.

B415-5

Page 7

PAPER SIZE SENSOR BOARD 10 August, 2001

3.2 PAPER SIZE SENSOR BOARD

[B]

[A]

[C]

B415R502.WMF

[H]

[G]

[D]

B415R503.WMF

1. Remove the rear cover [A] (2 screws).

2. Remove the by-pass tray [B] (1 connector, 2 release levers [C]).

3. Remove the lever [D] (1 snap ring, 1 pin).

4. While pushing the release lever [E], remove the paper tray [F].

5. Remove the by-pass width sensor [G].

[F]

[E]

NOTE: When installing th e by-pass width sensor [G], move the side fence inward

all the way so that the seal on the side face gear faces the surface with the

seal [H] on the by-pass width sensor.

B415-6

Page 8

10 August, 2001 PAPER FEED CLUTCH

3.3 PAPER FEED CLUTCH

[A]

[C]

1. Remove the rear cover [A] (2 screws).

[D]

[B]

B415R504.WMF

2. Remove the spring.

3. Remove the drive gear and drive gear bracket [B] (1 E-ring, 1 spring).

4. Remove the paper feed clutch bracket [C] (2 screws).

5. Remove the paper feed clutch [D] (1 connector).

Options

B415-7

Loading...

Loading...