Ricoh biz406 Service Manual

G026/G036

SERVICE MANUAL

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the machine and peripherals,

make sure that the machine power cord is unplugged.

2. The wall outlet should be near the machine and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers

off or open while the main switch is turned on, keep hands away from

electrified or mechanically driven components.

4. If the print job process is started (the PC Interface LED lit) before the

machine completes the warm-up or initialising period, keep hands away

from the mechanical and electrical components because the machine

starts making prints as soon as the warm-up period is completed.

5. The inside and the metal parts of the fusing unit become extremely hot

while the printer is operating. Be careful to avoid touching those

components with your bare hands.

HEALTH SAFETY CONDITIONS

1. Toner is non-toxic, but if you get it in your eyes by accident, it may cause

temporary eye discomfort. Try to remove with eye drops or flush with

water as first aid. If unsuccessful, get medical attention.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate toner cassette. Toner dust may ignite suddenly when

exposed to an open flame.

2. Dispose of used toner cassette in accordance with local regulations. (It is

non-toxic supply.)

3. Dispose of replaced parts in accordance with local regulations.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair

of laser-based optical units in the field. The optical housing unit can only be

repaired in a factory or at a location with the requisite equipment. The laser

subsystem is replaceable in the field by a qualified Customer Engineer. The

laser chassis is not repairable in the field. Customer engineers are therefore

directed to return all chassis and laser subsystems to the factory or service

depot when replacement of the optical subsystem is required.

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation

exposure.

WARNING FOR LASER UNIT

This machine contains a laser beam generator. Laser beams can cause

permanent eye damage. Do not open the laser unit or look along the

laser beam path while the main power is on.

CAUTION MARKINGS:

G025C501.WMF

CAUTION FOR LITHIUM BATTERY (MEMORY BACK-UP)

The danger of explosion exists if a battery of this type is incorrectly

replaced. Replace only with the same or an equivalent type

recommended by the manufacturer. Discard used batteries in

accordance with the manufacture’s instructions.

G025C503.WMF

G025C502.WMF

Trademarks

Microsoft, Windows, and MS-DOS are registered trademarks of Microsoft

Corporation.

General Notice:

Other product names used herein are for identification purpose only and may

be trademarks of their respective companies. We disclaim any and all rights

in those marks.

TABLE OF CONTENTS

1. OVERALL MACHINE INFORMATION..........................................1-1

1.1 SPECIFICATIONS.................................................................................... 1-1

1.2 FEATURES............................................................................................... 1-3

1.3 COMPONENT LAYOUT ........................................................................... 1-5

1.3.1 MECHANICAL COMPONENTS.......................................................1-5

1.3.2 ELECTRICAL COMPONENTS ........................................................ 1-7

1.3.3 OPTIONAL PAPER FEED UNIT...................................................... 1-9

1.4 OVERALL MACHINE CONTROL ........................................................... 1-10

1.4.1 CONTROL BOARD........................................................................ 1-11

Overall................................................................................................ 1-11

Functions............................................................................................ 1-11

Components....................................................................................... 1-12

1.4.2 MCB (MECHANICAL CONTROL BOARD).................................... 1-13

Overall................................................................................................ 1-13

Functions............................................................................................ 1-13

Contents............................................................................................. 1-13

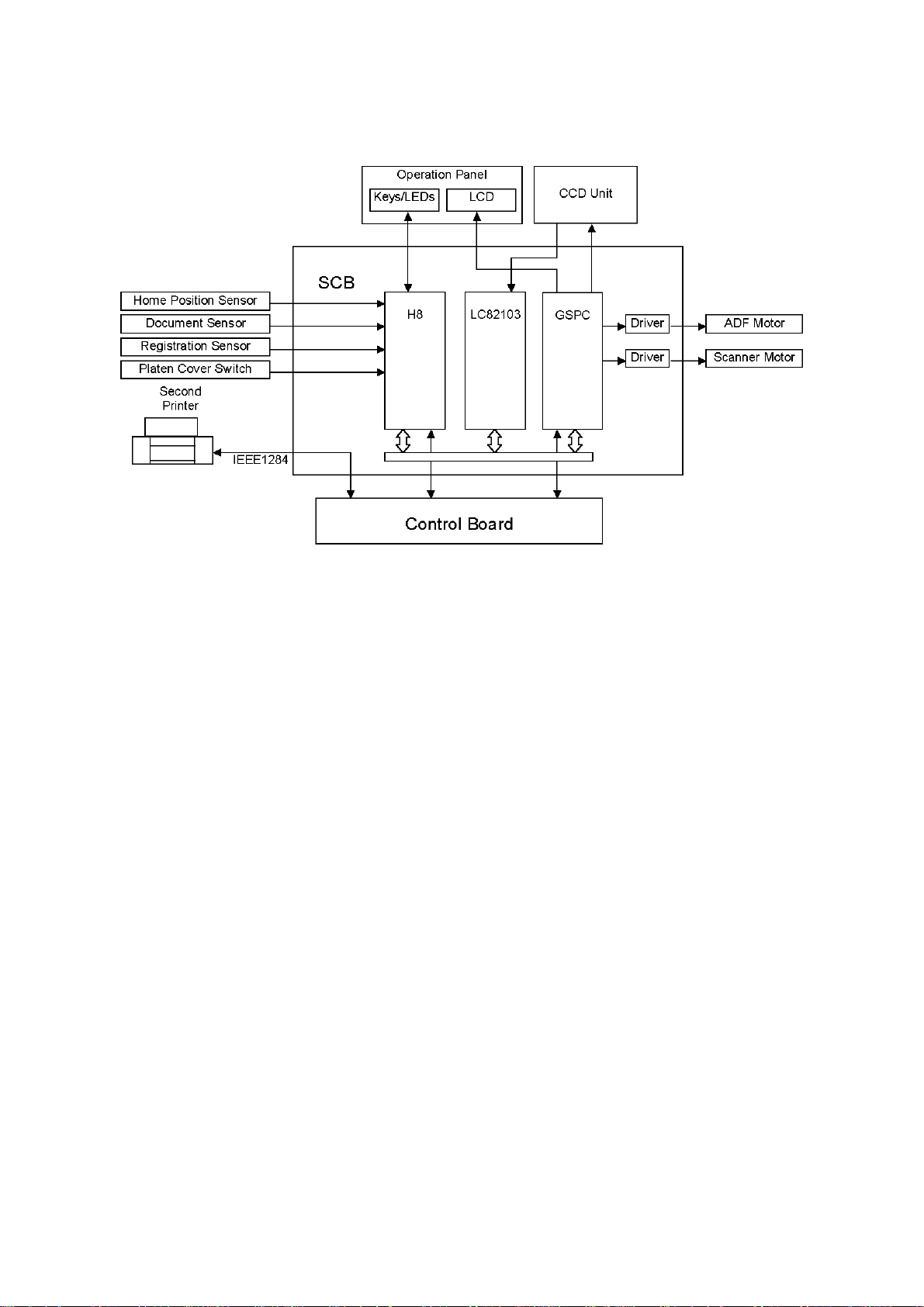

1.4.3 SCB (SCANNER CONTROL BOARD)........................................... 1-14

Overall................................................................................................ 1-14

Functions............................................................................................ 1-14

Contents............................................................................................. 1-14

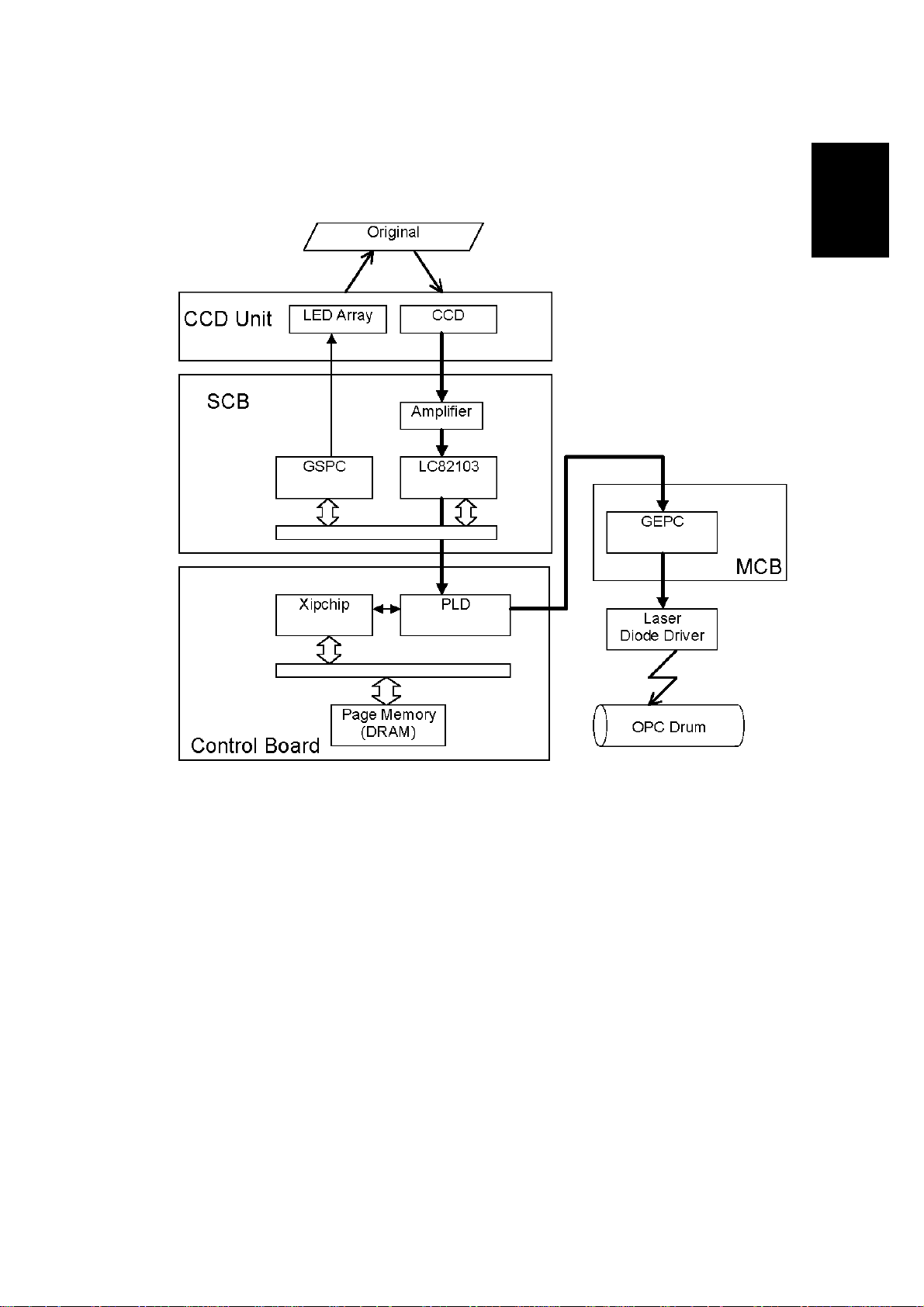

1.5 VIDEO DATA PATH................................................................................ 1-15

1.5.1 COPYING ...................................................................................... 1-15

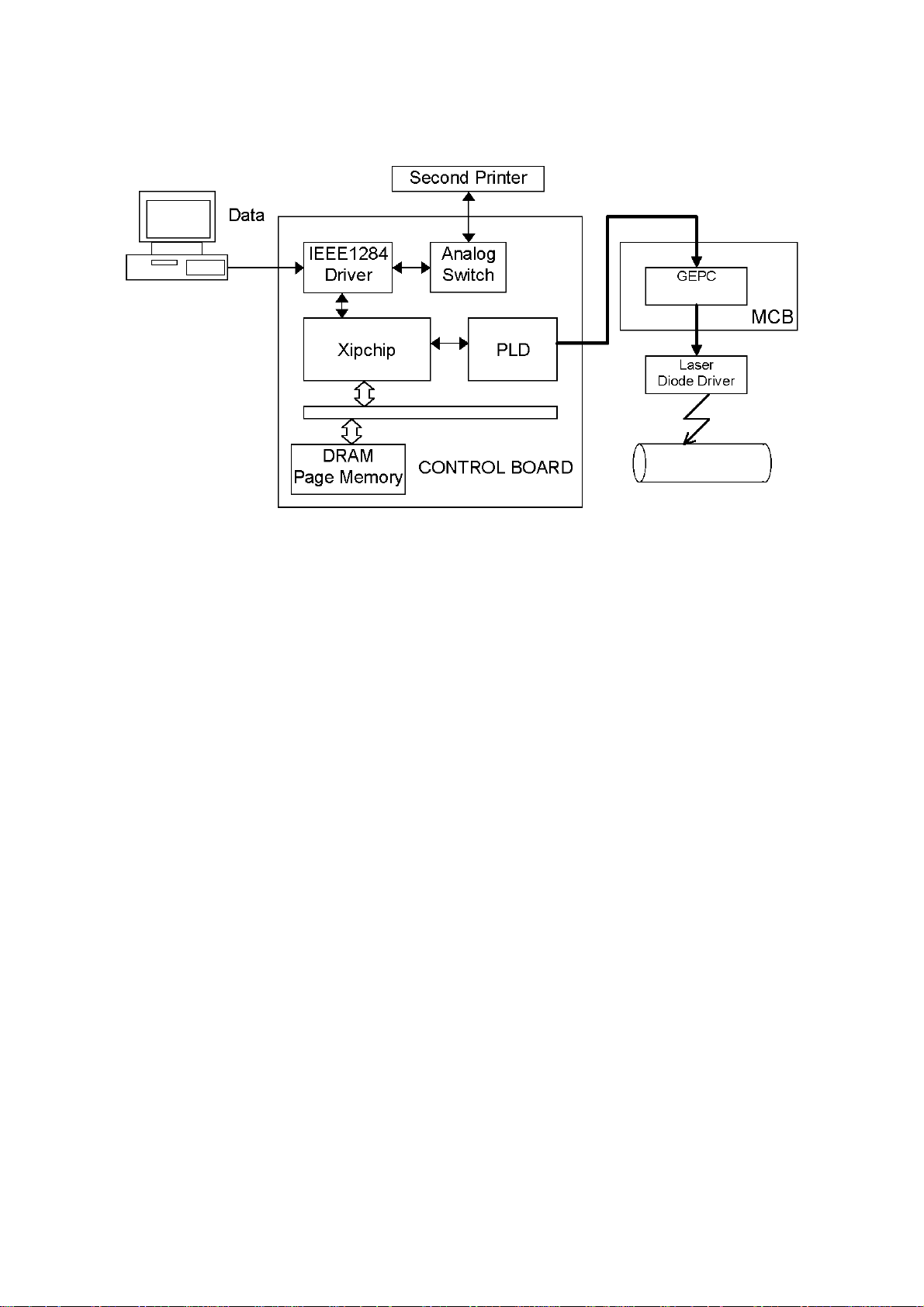

1.5.2 PC PRINTING................................................................................ 1-16

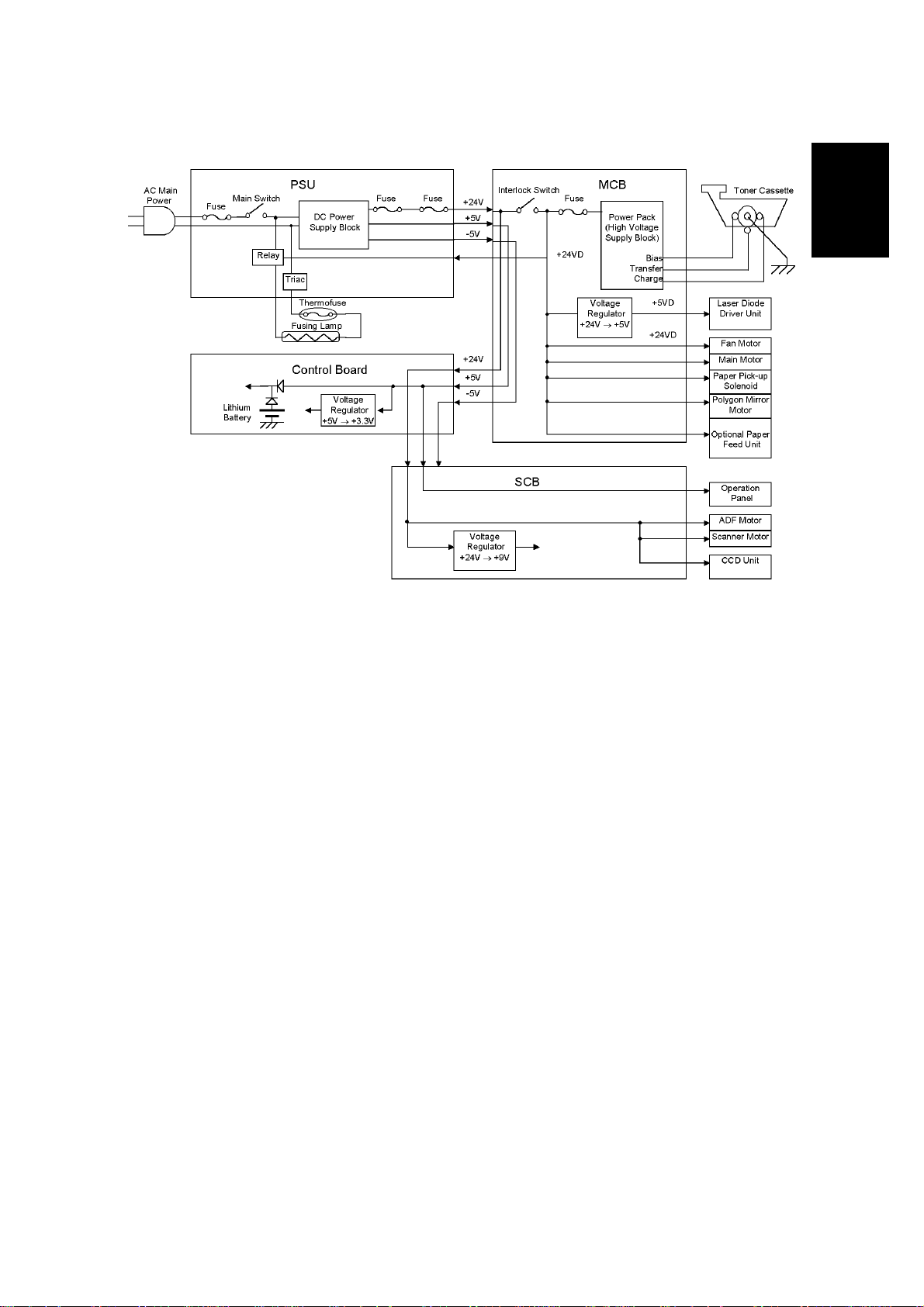

1.6 POWER DISTRIBUTION........................................................................ 1-17

2. DETAILED SECTION DESCRIPTIONS .........................................2-1

2.1 SCANNING...............................................................................................2-1

2.1.1 OVERVIEW...................................................................................... 2-1

2.1.2 CCD UNIT DRIVE............................................................................ 2-2

Book Scanning..................................................................................... 2-3

ADF Scanning...................................................................................... 2-3

2.1.3 ADF (G036 ONLY)........................................................................... 2-4

OVERVIEW.......................................................................................... 2-4

JAM CONDITION.................................................................................2-5

2.2 PRINTING................................................................................................. 2-6

2.2.1 PRINTING PROCESSES AROUND THE DRUM ............................ 2-6

2.2.2 CHARGE.......................................................................................... 2-7

2.2.3 LASER EXPOSURE ........................................................................ 2-8

OVERVIEW.......................................................................................... 2-8

BLOCK DIAGRAM ............................................................................... 2-9

ERROR CONDITIONS......................................................................... 2-9

2.2.4 DEVELOPMENT............................................................................2-10

OVERVIEW........................................................................................ 2-10

TONER END DETECTION ................................................................ 2-12

i

2.2.5 TRANSFER AND SEPARATION................................................... 2-14

OVERVIEW........................................................................................ 2-14

CLEANING MODE............................................................................. 2-14

2.2.6 DRUM CLEANING.........................................................................2-15

2.2.7 PAPER FEED AND REGESTRATION........................................... 2-16

OVERVIEW........................................................................................ 2-16

PAPER FEED MECHANISM.............................................................. 2-17

REGISTRATION ................................................................................ 2-20

PAPER WIDTH AND PAPER END DETECTION............................... 2-21

JAM DETECTION .............................................................................. 2-22

2.2.8 FUSING ......................................................................................... 2-23

OVERVIEW........................................................................................ 2-23

POWER SAVE CONTROL................................................................. 2-24

2.2.9 COVER SWITCH........................................................................... 2-26

2.2.10 PAPER FEED DRIVE RELEASE AND

FUSING DRIVE RELEASE.......................................................... 2-27

2.2.11 OPTIONAL PAPER FEED UNIT..................................................2-28

Overview............................................................................................ 2-28

Paper Feed Mechanism..................................................................... 2-29

Optional Paper Feed Unit Detection................................................... 2-30

Paper Tray, Paper Size and Paper End Detection.............................2-30

Paper Feed Selection......................................................................... 2-30

Jam Detection.................................................................................... 2-30

3. INSTALLATION..............................................................................3-1

3.1 INSTALLING THE MACHINE ................................................................... 3-1

3.2 INSTALLING OPTIONAL UNITS.............................................................. 3-1

3.3 MINIMUM SPACE REQUIREMENTS.......................................................3-2

4. SERVICE TABLES AND PROCEDURES.....................................4-1

4.1 SERVICE FUNCTIONS ............................................................................ 4-1

4.1.1 ENTERING AND EXITING USER AND SERVICE MODES............. 4-1

USER MODE........................................................................................ 4-1

SERVICE MODE.................................................................................. 4-1

4.1.2 SELECTING A SERVICE MODE.....................................................4-2

4.1.3 PAPER SIZE REGISTRATION........................................................ 4-2

UPPER TRAY PAPER SIZE REGISTRATION..................................... 4-2

LOWER TRAY (OPTION) PAPER SIZE REGISTRATION................... 4-3

4.1.4 LANGUAGE SELECTION................................................................ 4-3

4.1.5 USER PARAMETER (BIT SWITCH) PROGRAMMING................... 4-4

4.1.6 RAM CLEAR [FUNCTION 74].......................................................... 4-5

4.1.7 SYSTEM PARAMER LIST [FUNCTION 81]..................................... 4-5

Details of the system parameter list..................................................... 4-6

4.1.8 RAM DISPLAY/REWRITE [FUNCTION 82].....................................4-7

HEXADECIMAL MODE........................................................................ 4-7

BINARY MODE.................................................................................... 4-8

4.1.9 RAM DUMP [FUNCTION 83]........................................................... 4-9

4.1.10 RAM TEST [FUNCTION 91] ........................................................ 4-10

4.1.11 KEY TEST [FUNCTION 92]......................................................... 4-11

ii

LED TEST [FUNCTION 93]................................................................ 4-12

4.1.13 LCD TEST [FUNCTION 94]......................................................... 4-13

4.2 BIT SWITCHES ...................................................................................... 4-14

4.2.1 FUNCTION SWITCH PARAMETERS (SWFUNC)......................... 4-14

4.2.2 USER SWITCH PARAMETERS (SWUSER)................................. 4-14

4.2.3 COUNTRY CODE.......................................................................... 4-15

4.2.4 SERVICE SWITCH PARAMETERS (SWSERV)............................ 4-16

4.2.5 COUNTRY SWITCH PARAMETERS (SWCNTRY)....................... 4-17

5. PREVENTIVE MAINTENANCE.....................................................5-1

5.1 MAINTENANCE ITEMS AND METHODS................................................. 5-1

6. REPLACEMENT AND ADJUSTMENT ...........................................6-1

6.1 EXTERIOR................................................................................................ 6-1

6.1.1 UPPER COVER REMOVAL............................................................. 6-1

6.1.2 RIGHT COVER REMOVAL.............................................................. 6-6

6.1.3 UPPER UNIT REMOVAL................................................................. 6-7

6.2 OPTICS .................................................................................................... 6-9

6.2.1 ADF UNIT REMOVAL (G036 MODEL)............................................ 6-9

6.2.2 CCD UNIT REMOVAL ................................................................... 6-10

6.2.3 LASER UNIT REMOVAL ............................................................... 6-11

6.1.4 CCD DRIVE MOTOR REMOVAL................................................... 6-15

6.3 PAPER FEED......................................................................................... 6-16

6.3.1 PAPER FEED ROLLER REMOVAL............................................... 6-16

6.3.2 PAPER PICK-UP SOLENOID REMOVAL ..................................... 6-21

6.4 OPTIONAL PAPER FEED UNIT............................................................. 6-22

6.4.1 PAPER FEED TRAY MOTOR AND SOLENOID REMOVAL......... 6-22

6.4.2 PAPER PICK-UP ROLLER REMOVAL.......................................... 6-25

6.5 FUSING.................................................................................................. 6-26

6.5.1 FUSING UNIT REMOVAL.............................................................. 6-26

6.5.2 FUSING PRESSURE ROLLER REMOVAL................................... 6-28

6.5.3 FUSING HOT ROLLER AND LAMP REMOVAL............................6-29

6.5.4 HOT ROLLER STRIPPER PAWL REMOVAL................................ 6-30

6.5.5 FUSING THERMOFUSE REMOVAL............................................. 6-31

6.5.6 FUSING THERMISTOR REMOVAL .............................................. 6-32

6.6 OTHERS................................................................................................. 6-33

6.6.1 MAIN MOTOR REMOVAL ............................................................. 6-33

6.6.2 TRANSFER ROLLER REMOVAL..................................................6-37

6.6.3 LOWER UNIT SHELL REMOVAL.................................................. 6-38

6.6.4 CONTROL BOARD AND

SCANER CONTOROL BOARD REMOVAL................................... 6-42

6.6.5 MECHANICAL CONTROL BOARD REMOVAL.............................6-45

6.6.6 POWER SUPPLY UNIT REMOVAL............................................... 6-46

6.6.7 POLYGON MIRROR MOTOR AND

LASER DIODE UNIT REMOVAL................................................... 6-47

6.7 ADJUSTMENT........................................................................................ 6-48

6.7.1 REGISTRATION ADJUSTMENT................................................... 6-48

Adjustment Standard:......................................................................... 6-48

Adjustment Tool:................................................................................ 6-48

iii

Procedure:.......................................................................................... 6-48

6.7.2 READ START TIMING (FLATBED) AND

CARRIAGE STOP POSITION (ADF) ADJUSTMENT....................6-50

Adjustment Standard:......................................................................... 6-50

Adjustment Tool:................................................................................ 6-50

Procedure:.......................................................................................... 6-50

6.7.3 READ START POINT OF HORIZONTAL

SCANNING ADJUSTMENT (FLATBED AND ADF).......................6-52

Adjustment Standard:......................................................................... 6-52

Adjustment Tool:................................................................................ 6-52

Procedure:.......................................................................................... 6-52

6.7.4 FIRMWARE UPDATING................................................................6-54

Tool:................................................................................................... 6-54

Procedure:.......................................................................................... 6-54

6.8 CONNECTOR LAYOUT ......................................................................... 6-56

6.8.1 MECHANICAL CONTROL BOARD ............................................... 6-56

CONTROL BOARD............................................................................6-56

6.8.3 SCANNER CONTROL BOARD (G036 MODEL) ........................... 6-57

POWER SUPPLY UNIT..................................................................... 6-57

7. TROUBLESHOOTING...................................................................7-1

7.1 COPY QUALITY TROUBLESHOOTING .................................................. 7-1

7.1.1 BLANK COPIES............................................................................... 7-2

7.1.2 BLACK COPIES............................................................................... 7-4

7.1.3 DIRTY BACKGROUND.................................................................... 7-5

7.1.4 UNEVEN IMAGE DENSITY............................................................. 7-6

7.1.5 VERTICAL BLACK LINES ............................................................... 7-7

7.1.6 HORIZONTAL BLACK LINES.......................................................... 7-8

7.1.7 VERTICAL WHITE LINES................................................................ 7-9

7.1.8 HORIZONTAL WHITE LINES........................................................ 7-10

7.1.9 BLACK DOTS/SPOTS................................................................... 7-11

7.1.10 WHITE SPOTS IN BLACK IMAGE AREAS.................................. 7-12

7.1.11 FAINT COPIES............................................................................ 7-13

7.1.12 VERTICAL BLACK STREAKS..................................................... 7-14

7.1.13 UNFUSED COPIES..................................................................... 7-15

7.1.14 GHOST IMAGE............................................................................ 7-15

7.1.15 TONER ON THE BACK OF THE PRINT PAPER ........................ 7-16

7.1.16 MISALIGNED OUTPUT

(IMAGE SHIFTED TO THE RIGHT OR LEFT) ............................ 7-17

7.1.17 MISALIGNED OUTPUT

(IMAGE SHIFTED VERTICALLY)/SHRUNKEN IMAGE .............. 7-17

7.2 MECHANICAL PROBLEMS.................................................................... 7-18

7.2.1 ADF NON FEED (G036 ONLY) ..................................................... 7-18

7.2.2 ADF JAM (G036 ONLY)................................................................. 7-19

7.2.3 ADF SKEW (G036 ONLY) ............................................................. 7-20

7.2.4 ADF MULTI-FEED (G036 ONLY) .................................................. 7-20

7.2.5 SCANNER HOME POSITION ERROR (ERROR CODE 90)......... 7-21

7.2.6 PAPER NON-FEED (PRINTER).................................................... 7-21

7.2.7 PAPER JAM (REGISTRATION AREA).......................................... 7-22

iv

7.2.8 PAPER JAM (FUSING EXIT AREA).............................................. 7-23

7.2.9 PAPER SKEW (PRINTER)............................................................ 7-24

7.2.10 PAPER MULTI-FEED (PRINTER) ............................................... 7-24

7.3 ERROR CODES..................................................................................... 7-25

Fatal error........................................................................................... 7-25

Semi fatal error................................................................................... 7-25

v

26 August 1998 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Type Copier/Printer

G026: Flatbed scanner, Copier, PC Printer

G036: Flatbed scanner, ADF, Copier, PC

Printer

Document Size Flatbed Scanner

Width: Within 216 mm [8.5"]

Length: Within 355.6 mm [14"]

ADF (G036 only)

Width: 91 mm - 216 mm [3.6" - 8.5"]

Length: 140 mm - 355.6 mm [5.5" - 14"]

Document Weight: Equivalent to 60 g/m² - 90 g/m²

(0.05 mm to 0.2 mm [2 mils to 8 mils])

Document Feed Face down

ADF Capacity 10 sheets

Scanning Method CCD unit (including LED array)

Overall

Information

Scan Resolution Main scan: 300 dpi

Sub scan: 150 - 600 dpi

(Depends on reduction/enlargement ratio)

Printing System Laser printing, plain paper, dry toner

Print Speed Copier: 6 cpm

Printer: 6 ppm

Paper Size Upper Paper Tray

Width: 91 mm - 216 mm [3.6" - 8.5"]

Length: 140 mm - 355.6 mm [5.5" - 14"]

Lower Paper Tray (Option)

A4, 8½" x 11"

Paper Capacity Upper Paper Tray: 100 sheets (Plain paper)

Lower Paper Tray (Option): 250 sheets (Plain paper)

Printer Resolution 600 dpi x 600 dpi

(Enhanced 1200 dpi x 600 dpi with smoothing in the

PC print mode)

1-1

SPECIFICATIONS 26 August 1998

PC Connection PC: PC/AT Compatible

Interface: IEEE-1284

PDL: PCL5e Compatible

Power Supply AC 120 V 60 Hz

AC 220 V - 240 V 50 Hz/60 Hz

Power Consumption

(without optional paper

feed unit)

Standby (Pre heating mode):

120 V: 75 W (Normal) 300 W (Maximum)

220 V: 75 W (Normal) 255 W (Maximum)

240 V: 75 W (Normal) 280 W (Maximum)

Standby (Sleep mode):

120 V: 14.0 W (Normal) 15.0 W (Maximum)

220 V: 14.5 W (Normal) 15.0 W (Maximum)

240 V: 14.7 W (Normal) 15.0 W (Maximum)

Copying:

120 V: 240 W (Normal) 540 W (Maximum)

220 V: 240 W (Normal) 480 W (Maximum)

240 V: 240 W (Normal) 540 W (Maximum)

Printing:

120 V: 210 W (Normal) 530 W (Maximum)

220 V: 215 W (Normal) 470 W (Maximum)

240 V: 215 W (Normal) 530 W (Maximum)

Operating Environment Temperature: 10ºC - 35ºC [50ºF - 95ºF]

Humidity: 15% - 80%

Recommended

Environment

Temperature: 15ºC - 25ºC [59ºF - 77ºF]

Humidity: 30% - 70%

Dimensions

(W x D x H)

Main Unit:

G026: 352 mm x 576 mm x 249 mm

(13.9" x 22.7" x 9.8")

G036: 352 mm x 576 mm x 297 mm

(13.9" x 22.7" x 11.7")

(Excluding trays and optional unit)

Optional Paper Feed Unit

332 mm x 523 mm x 79 mm

(13.1" x 20.6" x 3.1")

Weight G026: 15.0 kg [33.0 lb]

G036: 15.5 kg [34.1 lb]

(Including toner cassette)

Optional Paper Feed Unit

2.8 kg [6.2 lb]

1-2

26 August 1998 FEATURES

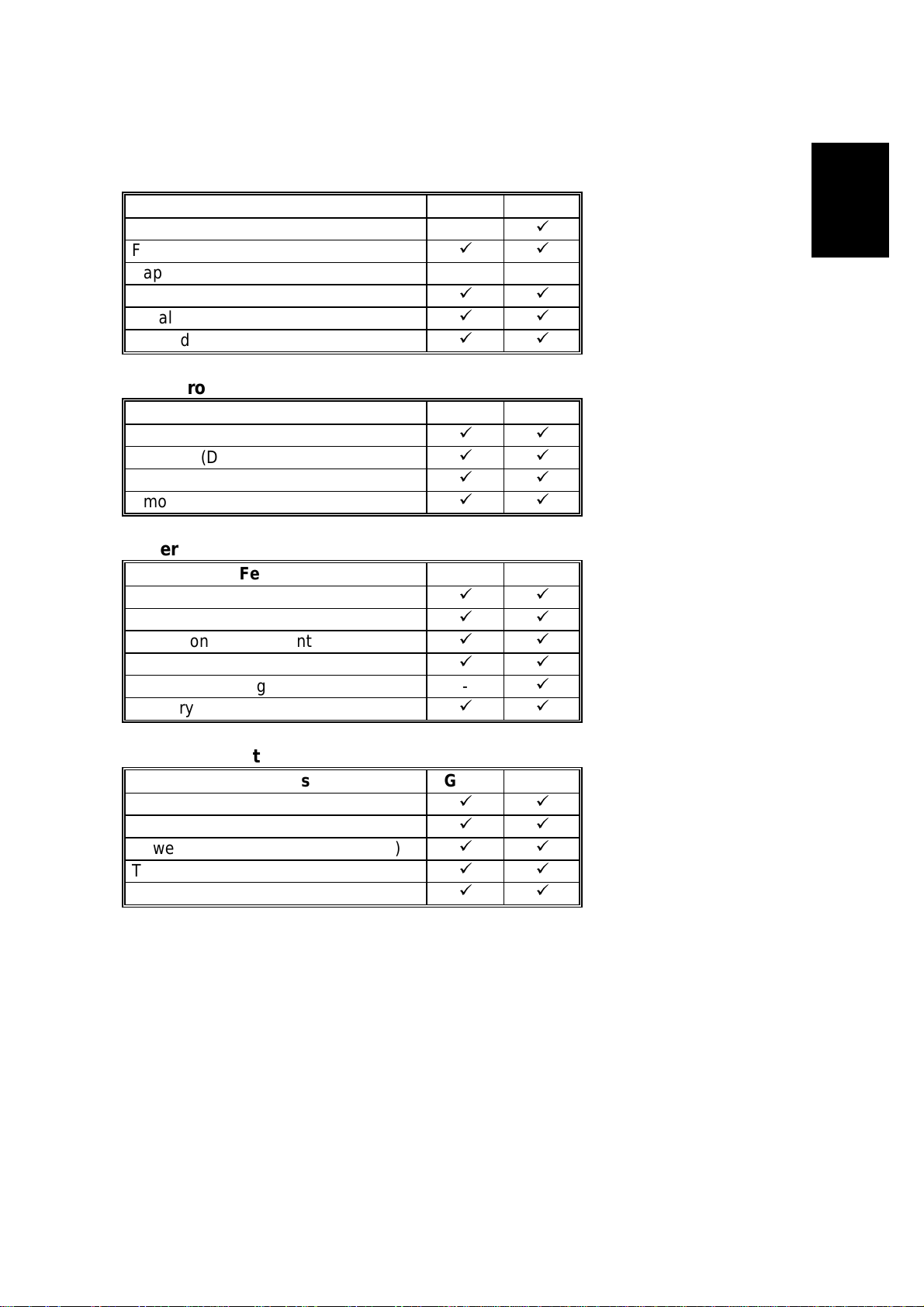

1.2 FEATURES

Equipment

Features G026 G036

ADF Flatbed Scanner

Paper Feed Unit option option

Software Counter

Parallel Interface

Second Printer Interface

Video Processing Features

Features G026 G036

Auto Image Density Control

Halftone (Dithering & Error diffusion)

Resolution

Smoothing

Overall

Information

Copier Features

Features G026 G036

Auto Image Density

Photo Mode

Reduction/Enlargement

Zoom

Electronic Sorting Memory Copy

Other User Features

Features G026 G036

Language Selection

Multi-copy Mode (up to 99)

Power Saver Mode (standby mode)

Toner Saving Mode

User Parameters

1-3

FEATURES 26 August 1998

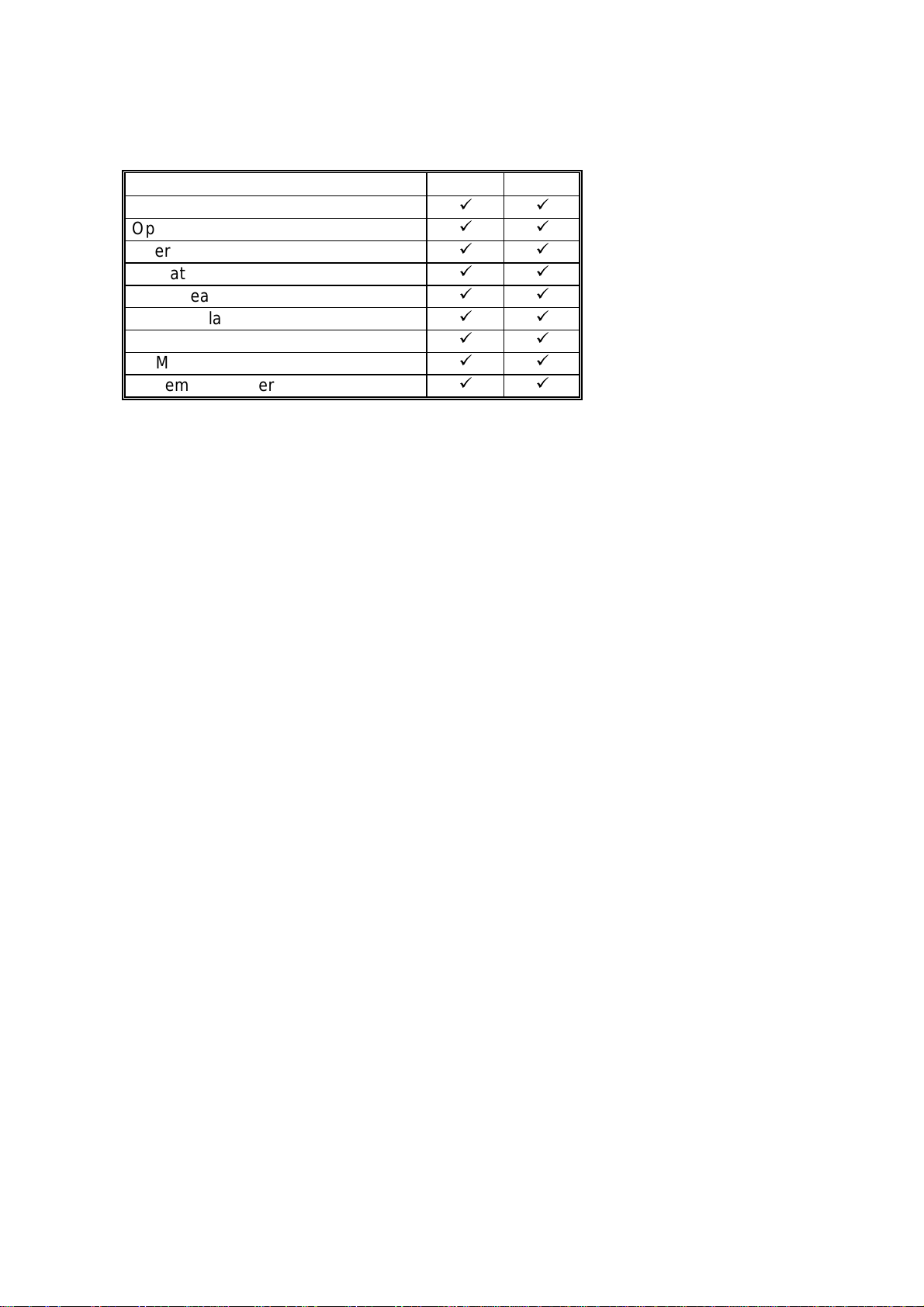

Service Mode Features

Features G026 G036

Country Code

Operation Panel Test (Key)

Operation Panel Test (LED)

Operation Panel Test (LCD)

RAM Clear

RAM Display/Rewrite

RAM Dump

RAM Test

System Parameter List

1-4

26 August 1998 COMPONENT LAYOUT

1.3 COMPONENT LAYOUT

1.3.1 MECHANICAL COMPONENTS

1 2 3 4 5

6

7

Overall

Information

G025D001.WMF

1415

No. Name Description

1 Exposure Glass Original is placed here for scanning.

2 Pick-up Roller (G036 only) Picks up pages of the document from the document

table one at a time.

3 Separation Tab (G036

only)

4 Document Feed Roller

(G036 only)

5 Document Feed-in Roller

(G036 only)

6 Document Feed-out Roller

(G036 only)

7 CCD Unit Contains the CCD and LED array.

8 Laser Unit Consists of the laser diode unit, cylindrical lens, f-

9 Upper Tray Bottom Plate Presses paper stacked in the upper paper tray

10 Paper Feed Roller Picks up the top sheet of paper fr om t he stack in

11 Toner Cassette Consists of the OPC drum, t oner , toner application

Prevents more than one sheet from feeding into the

scanner.

Feeds the document to the document f eed- in r oller .

Feeds the document through the scanning ar ea.

Feeds the document out from the scanning area.

theta lens, polygon mirror motor , and ot her laser

optical components.

against the paper feed roller.

the upper paper tray and feeds it into the transfer

area.

roller, development roller, charg e br ush roller,

cleaning blade, and other development components.

1089111213

1-5

COMPONENT LAYOUT 26 August 1998

No. Name Description

12 Transfer Roller Applies a charge to the paper to pull the toner off the

drum and onto the copy paper.

13 Pressure Roller Applies pressure to the paper during fusing.

14 Hot Roller Fuses the toner to the copy paper.

15 Paper Exit Roller Feeds the paper out of the printer .

1-6

26 August 1998 COMPONENT LAYOUT

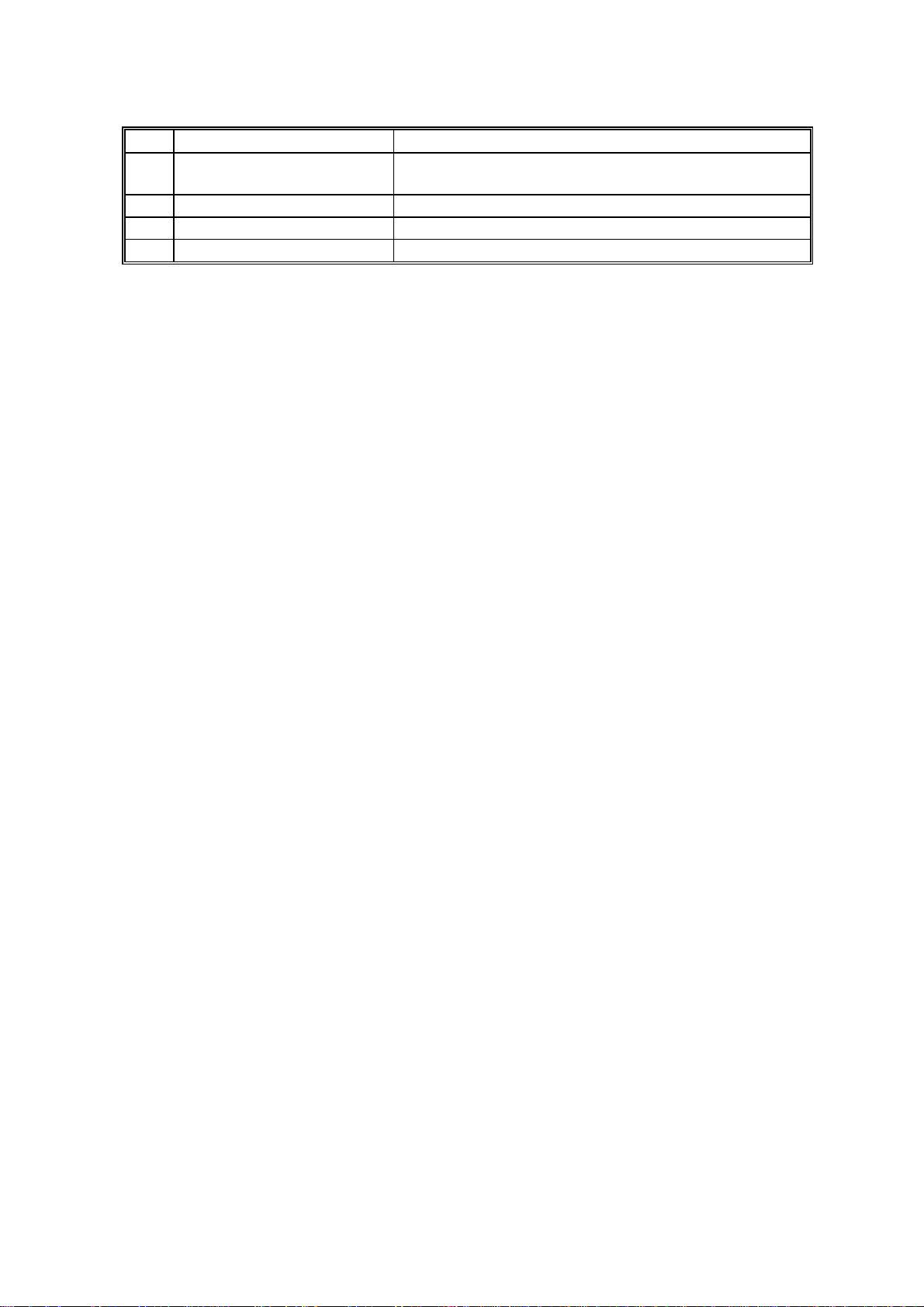

1.3.2 ELECTRICAL COMPONENTS

6 7 8 9 10

5

11

17

18 19 20 21 22

4

3

16

2

15

1

12

No. Name Description

1 Toner End Sensor This detects when the toner has run out.

2 Paper Width Sensor This detects whether the paper in the upper paper

3 Platen Cover Switch

(G036 only)

4 Paper End Sensor This detects when the paper in the upper paper tray

5 Main Motor This dc motor drives the toner cassette, paper feed

6 Home Position Sensor This detects when the CCD unit is at the home

7 Document Sensor (G036

only)

8 ADF Registration Sensor

(G036 only)

9 ADF Motor (G036 only) This stepper motor drives the ADF mechanism .

10 Paper Pick-up Solenoid This releases the cam stopper to pick up a sheet of

11 Operation Panel This board controls the operation panel.

12 Scanner Motor This stepper motor drives the book scanner.

13 Fan Motor This blows hot air out of the machine.

14 Control Board This board controls the m achine.

15 Scanner Control Board

(SCB)

16 Mechanical Control

Board (MCB)

G025V502.WMF

14 24

13

tray is wider than 203 millimeters or not.

This detects when the platen cover is opened.

has run out.

mechanism, and fusing unit.

position.

This detects the presence of a document in the

feeder.

This detects when the document has reached the

registration sensor.

paper.

This board controls the scanner components.

This board controls the printer component s.

G025V503.WMF

Overall

Information

23

1-7

COMPONENT LAYOUT 26 August 1998

No. Name Description

17 CCD Unit This includes the CCD and LED array. The CCD

reads and converts the light reflect ed from the

document into an analog video signal. The LED

array illuminates the document.

18 Power Supply Unit (PSU) This board supplies power to the machine.

19 Paper Registration

Sensor

20 Paper Exit Sensor This detects when the paper has been fed out of the

21 Interlock Switch If the upper cover is open, this interlock switch cuts

22 Thermofuse This interrupts the ac power supply to the fusing

23 Fusing Lamp This fuses the toner to the paper.

24 Thermistor This monitors the temperat ur e inside the fusing unit.

This detects when the paper has reached the

registration sensor.

fusing unit

the +5VLD power supply for the laser diode and the

+24V power supply for the fan motor, polygonal

mirror motor, main motor , and other components.

lamp if the temperature of the thermostat surface

exceeds 250°C.

1-8

26 August 1998 COMPONENT LAYOUT

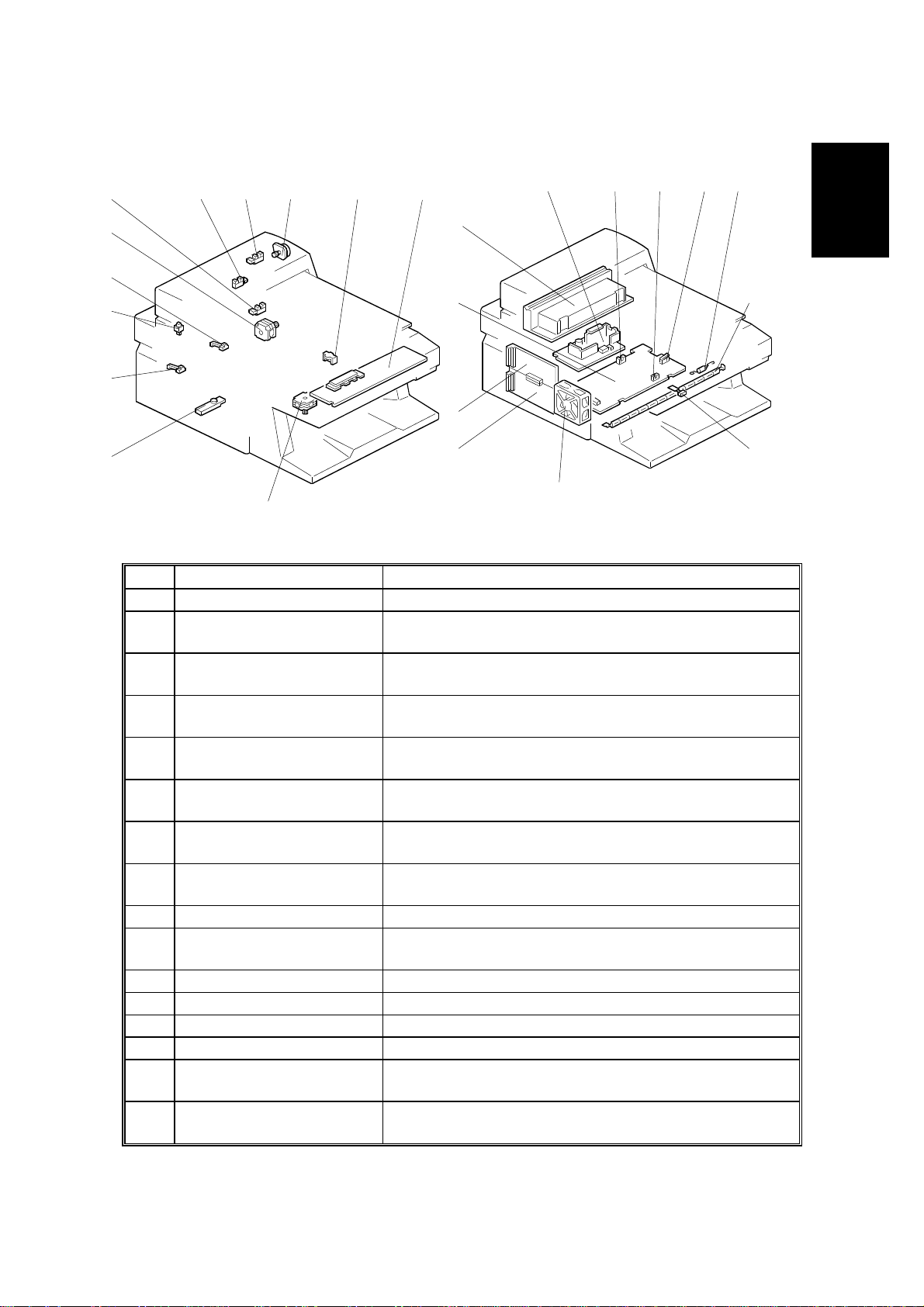

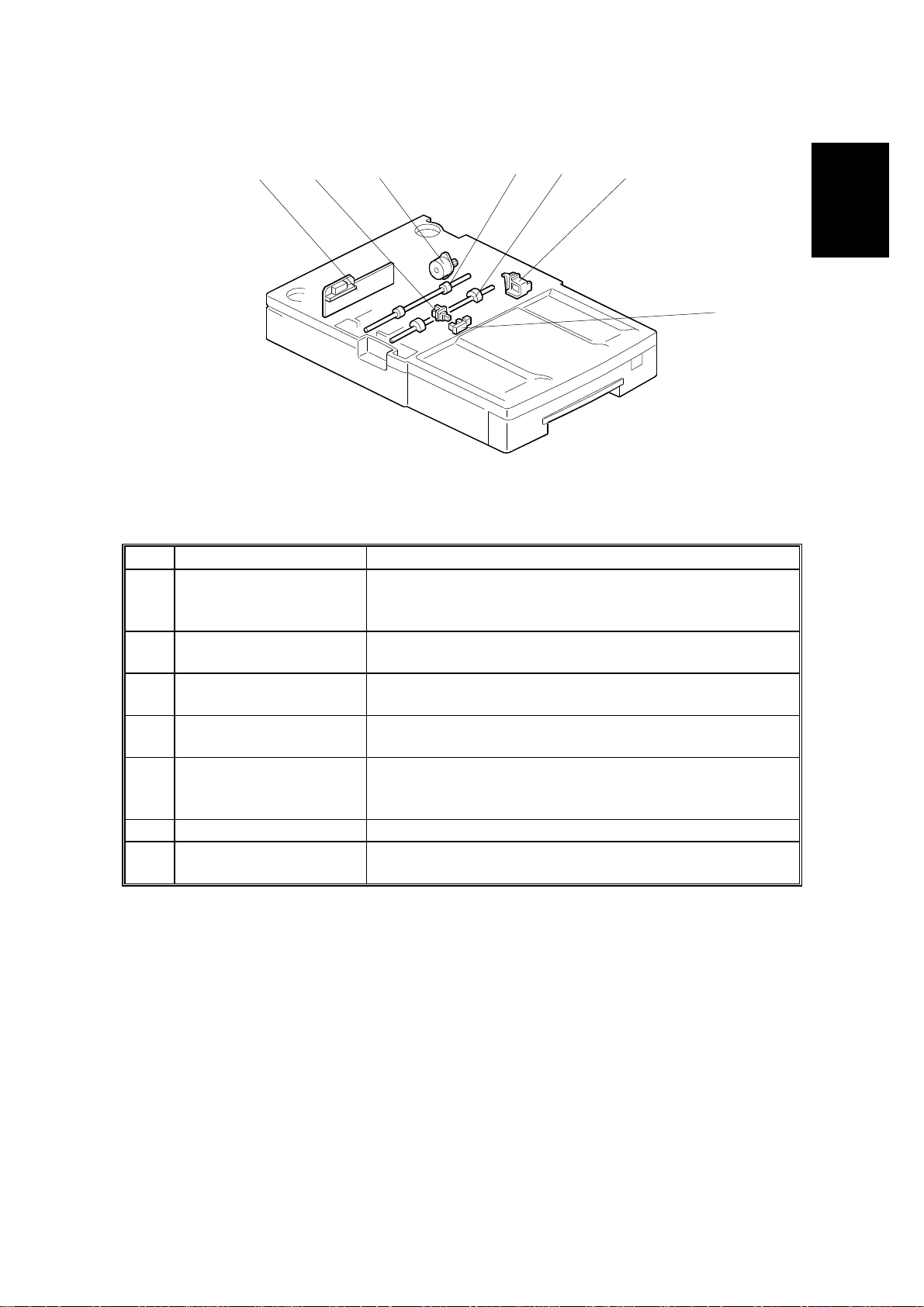

1.3.3 OPTIONAL PAPER FEED UNIT

1

2

3

54

6

7

G025V504.WMF

No. Name Description

1 Paper Feed Unit

Control Board

2 Paper Tray Sensor This detects whether the lower paper tray is set

3 Paper Feed Motor This motor drives the paper pick-up roller and paper

4 Paper Feed Roller This feeds paper from the lower paper tray into the

5 Paper Pick-up Roller This picks up t he t op sheet of paper from the stack in

6 Paper Feed Solenoid This controls the paper feed clutch.

7 Paper End Sensor This detects when paper in the opt ional paper feed unit

This board receives power and control signals from t he

mechanical control board. This board drives the motor

and solenoid in the optional paper feed unit.

correctly.

feed roller.

machine.

the lower paper tray and feeds it to the paper feed

roller.

has run out.

Overall

Information

1-9

OVERALL MACHINE CONTROL 26 August 1998

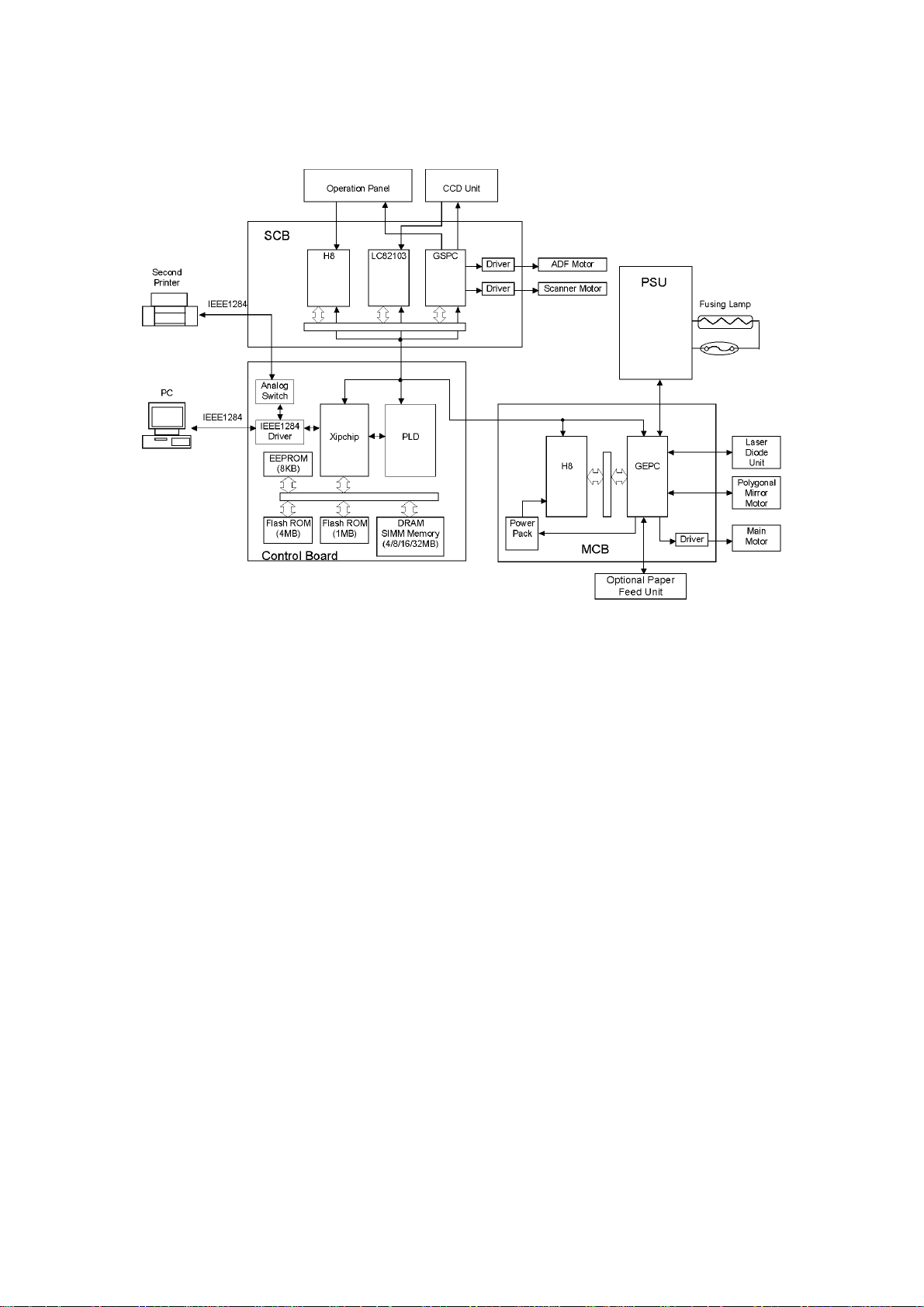

1.4 OVERALL MACHINE CONTROL

G025V705.WMF

This machine contains a control board, mechanical control board (MCB), scanner

control board (SCB), and power supply unit (PSU).

The control board controls the system and interfaces with the SCB, MCB, and PC.

The MCB controls devices related to the printer port, and the optional paper feed

unit. It also has an onboard power pack which generates high voltage supplies

necessary for the printing process.

The SCB controls devices related to the scanner.

The PSU generates dc +24 volts, +5 volts and -5 volts and supplies them to the

boards. It also supplies ac power to the fusing lamp.

1-10

26 August 1998 OVERALL MACHINE CONTROL

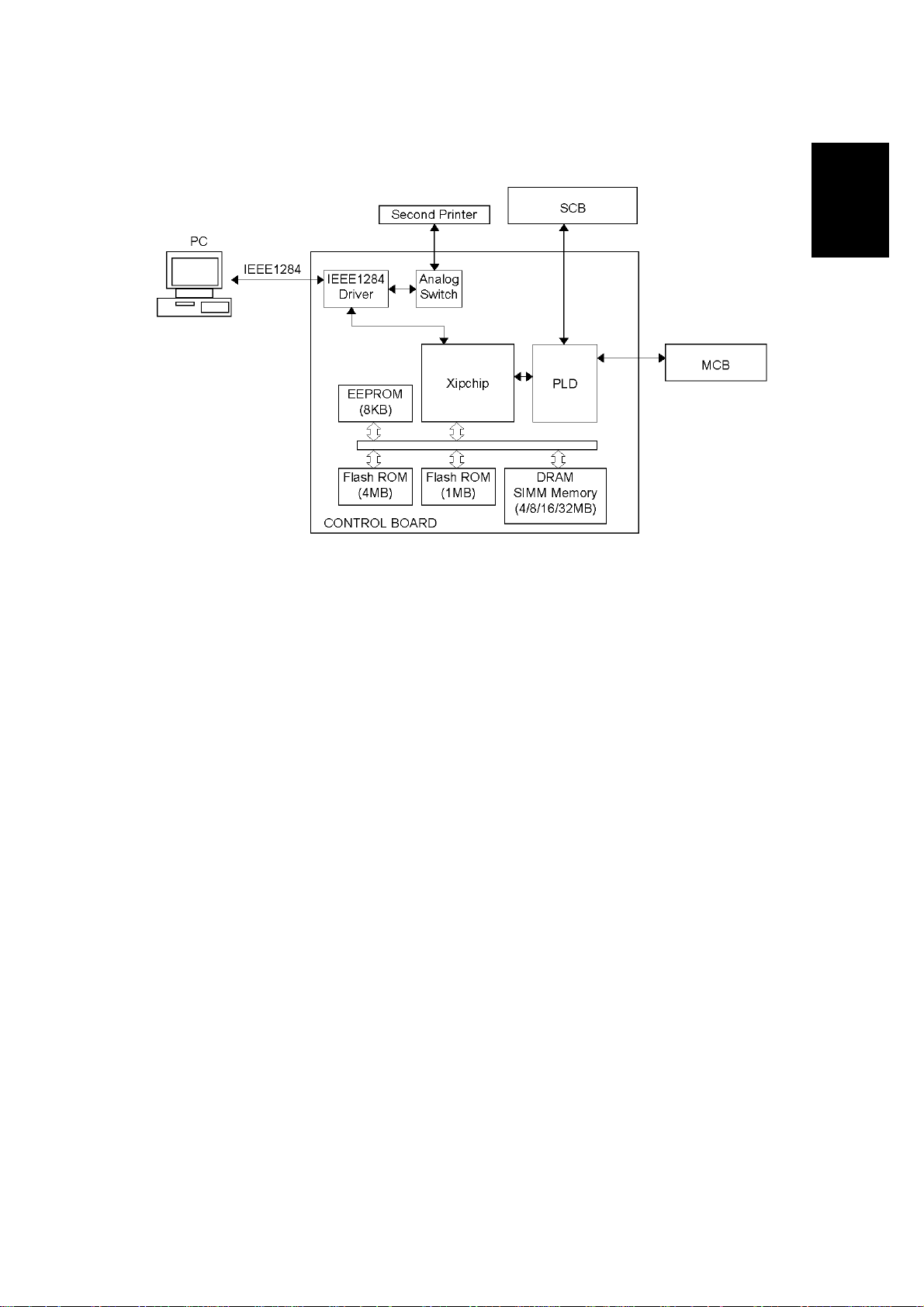

1.4.1 CONTROL BOARD

G025V706.WMF

Overall

Information

Overall

The control board controls the machine with the assistance of the mechanical

control board (MCB) and scanner control board (SCB). It contains a Xipchip, PLD,

flash ROM, EEPROM, DRAM, IEEE1284 connector, driver and analog switch. The

DRAM is plugged into a SIMM socket so that it can be changed easily by a user.

Functions

1. Scanning process control

2. Printing process control

3. Halftone image process (photo1: dithering, photo2: error diffusion)

4. Smoothing control

5. JBIG/ABIC control

6. IEEE1284 I/O port control

7. Second printer control

1-11

OVERALL MACHINE CONTROL 26 August 1998

Components

1. Xipchip

This is a multi-function peripheral controller. It functions as a CPU and an image

processor.

2. Memory

•

Flash ROM (4 MB/1 MB): For the firmware

•

EEPROM (8 KB): For individual data such as country code, factory

adjustments and so on.

•

DRAM (4 MB as standard): Working area for the Xipchip, image data,

and so on.

3. PLD

This chip functions as the interface for the SCB and MCB.

4. IEEE1284 driver

This chip is the IEEE1284 parallel interface driver.

Analog switch

This switch makes this machine function as a printer exchanger. Data for printing

passes through this switch to the second printer.

1-12

26 August 1998 OVERALL MACHINE CONTROL

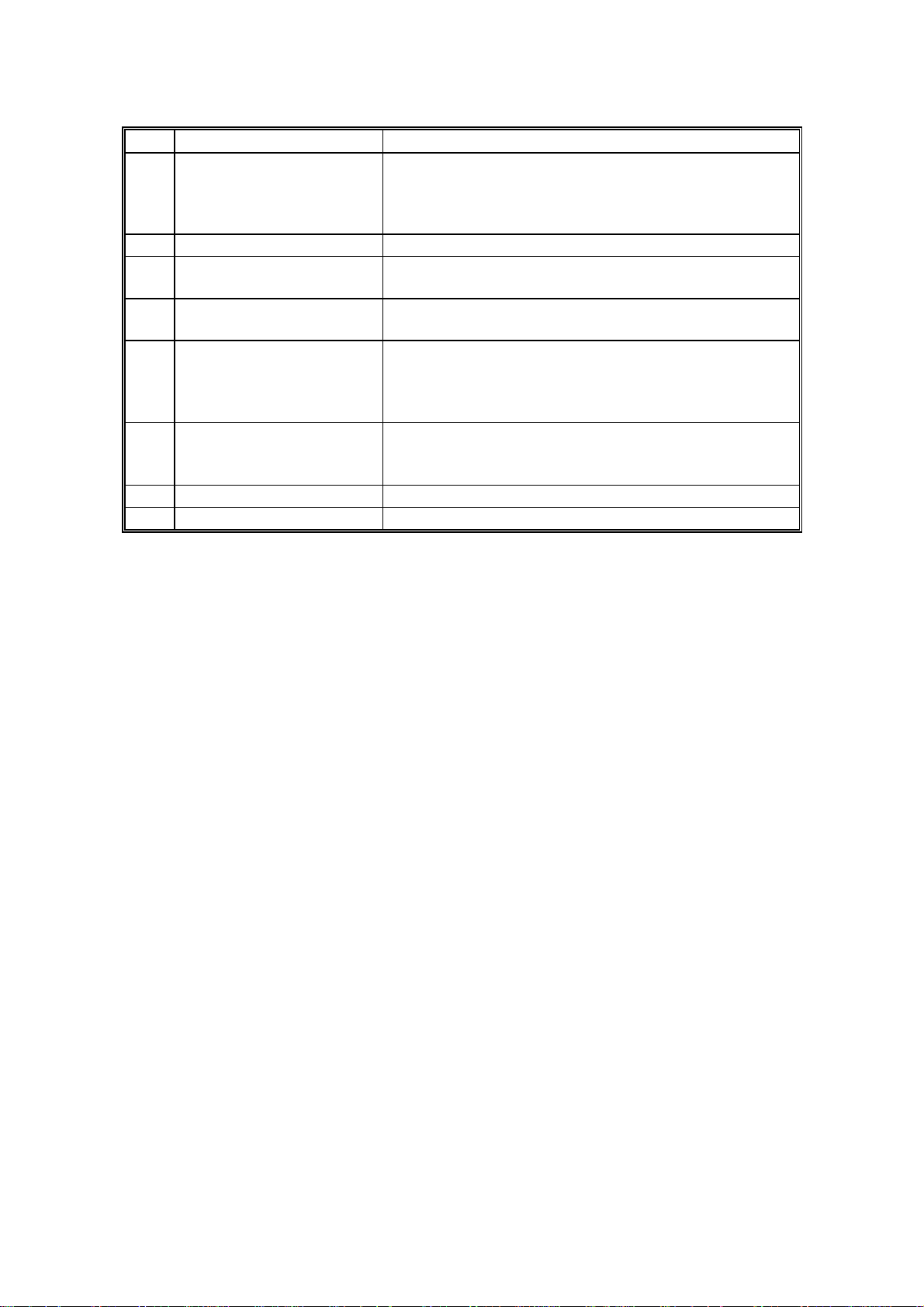

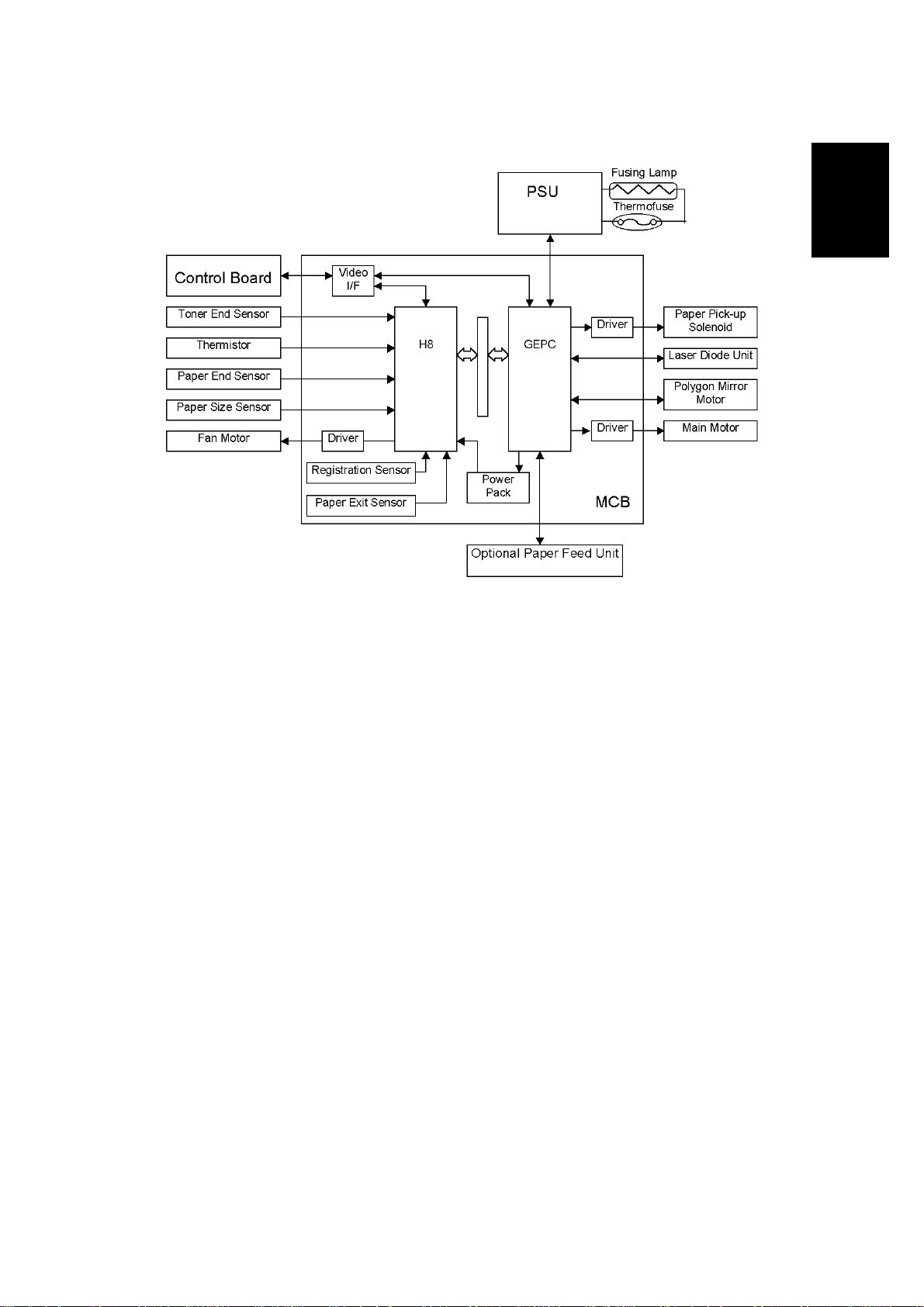

1.4.2 MCB (MECHANICAL CONTROL BOARD)

Overall

Information

G025V507.WMF

Overall

The mechanical control board (MCB) controls devices related to the printer and

optional paper feed unit.

The MCB contains a CPU (H8), peripheral control gate array (GEPC), video I/F

chips, motor drivers, power pack, and on-board sensors.

Functions

1. To control the main motor, laser diode driver, polygon mirror motor, sensors,

and so on.

2. To control fusing temperature through the power supply unit (PSU).

3. To generate high voltages for development bias, charge voltage, and transfer

voltage.

4. To control the optional paper feed unit.

Contents

1. H8

This eight-bit CPU controls the MCB. It receives outputs from sensors and the

thermistor.

2. GEPC

This chip contains an I/O port and controls the main motor, laser diode driver,

polygon mirror motor, optional paper feed unit, and so on. This chip generates

the pulse width modulation signal to control the power pack.

3. Video I/F

This chip is the interface for the control board.

4. Sensors

The registration sensor and paper exit sensor are built into this board.

1-13

OVERALL MACHINE CONTROL 26 August 1998

1.4.3 SCB (SCANNER CONTROL BOARD)

G025V508.WMF

Overall

The scanner control board (SCB) controls devices related to the scanner unit and

operation panel. The SCB contains a CPU (H8), peripheral control gate array

(GSPC), image processing LSI (LC82103), motor drivers, and an IEEE1284

connector for the second printer.

Functions

1. Flatbed scanner mechanism control

2. ADF mechanism (G036 only) control

3. CCD unit control

4. Operation panel control

5. Second printer interface

Contents

1. H8

This eight-bit CPU controls the SCB. It receives output from sensors.

2. GEPC

This chip contains an I/O port and it controls scanner motor, ADF motor (G036

only), CCD unit, and LCD display.

3. LC82103

This chip is an image processing LSI. It converts the analog signal from the

CCD unit to a digital signal.

1-14

26 August 1998 VIDEO DATA PATH

1.5 VIDEO DATA PATH

1.5.1 COPYING

Overall

Information

G025V510.WMF

The CCD generates an analog video signal from the light reflected from the

original.

The scanned data passes to the scanner control board (SCB). The SCB converts

scanned video data from the analog signal to a digital signal. Then the data passes

to the control board. The control board does digital video data processing, such as

halftone (dither/error diffusion), reduction/enlargement, and smoothing. Then it

stores the processed data in the page memory. The processed data passes to the

mechanical control board (MCB). The MCB drives the laser diode based on the

processed data signal. Then, the laser beam writes a latent image on the drum.

1-15

VIDEO DATA PATH 26 August 1998

1.5.2 PC PRINTING

G025V511.WMF

Data from the PC passes to the control board through the IEEE1284 driver. If the

analog switch is changed over the second printer by pressing the second printer

key on the operation panel, the video data passes to the second printer.

The control board does digital video data processing such as halftone (dither/error

diffusion), reduction/enlargement, and smoothing. Then it stores the processed

data in the page memory. The processed data passes to the mechanical control

board (MCB).

The MCB drives laser diode based on the processed data signal. Then, the laser

beam writes a latent image on the drum.

1-16

26 August 1998 POWER DI STRIBUTION

1.6 POWER DISTRIBUTION

Overall

Information

G025V709.WMF

The power supply unit (PSU) supplies +24 volts, +5 volts, and -5 volts dc power to

the mechanical control board (MCB). The MCB generates +5 volts from the +24

volts for the laser diode driver, and it also generates high voltage power for

development bias, charge voltage, and transfer voltage. The control board

generates +3.3 volts from the +5 volts supply, which is used internally. The

scanner control board (SCB) generates +9 volts from the +24 volts supply, which is

used internally.

The MCB contains an interlock switch, which is opened by opening the upper

cover. If this switch is opened, the +24 volt dc power is cut and the power to the

following devices is shut off.

•

Power pack

•

Main motor, fan motor, polygon mirror motor

•

Laser diode driver

•

Fusing lamp

•

Paper pick-up solenoid

•

Optional paper feed unit

1-17

26 August 1998 SCANNING

2. DETAILED SECTION DESCRIPTIONS

2.1 SCANNING

2.1.1 OVERVIEW

[A]

[D]

The CCD unit [A] consists of an LED array [B], 3 mirrors, a lens [C], and a CCD [D].

During a copy cycle, the light from the LED array is reflected off the original, and

then is transferred onto the CCD via 3 mirrors and a lens.

[B][C]

G025D501.WMF

Detailed

Descriptions

The CCD unit moves under the exposure glass to scan a book original. When

scanning a sheet original using the ADF, it remains at the ADF scan line.

2-1

SCANNING 26 August 1998

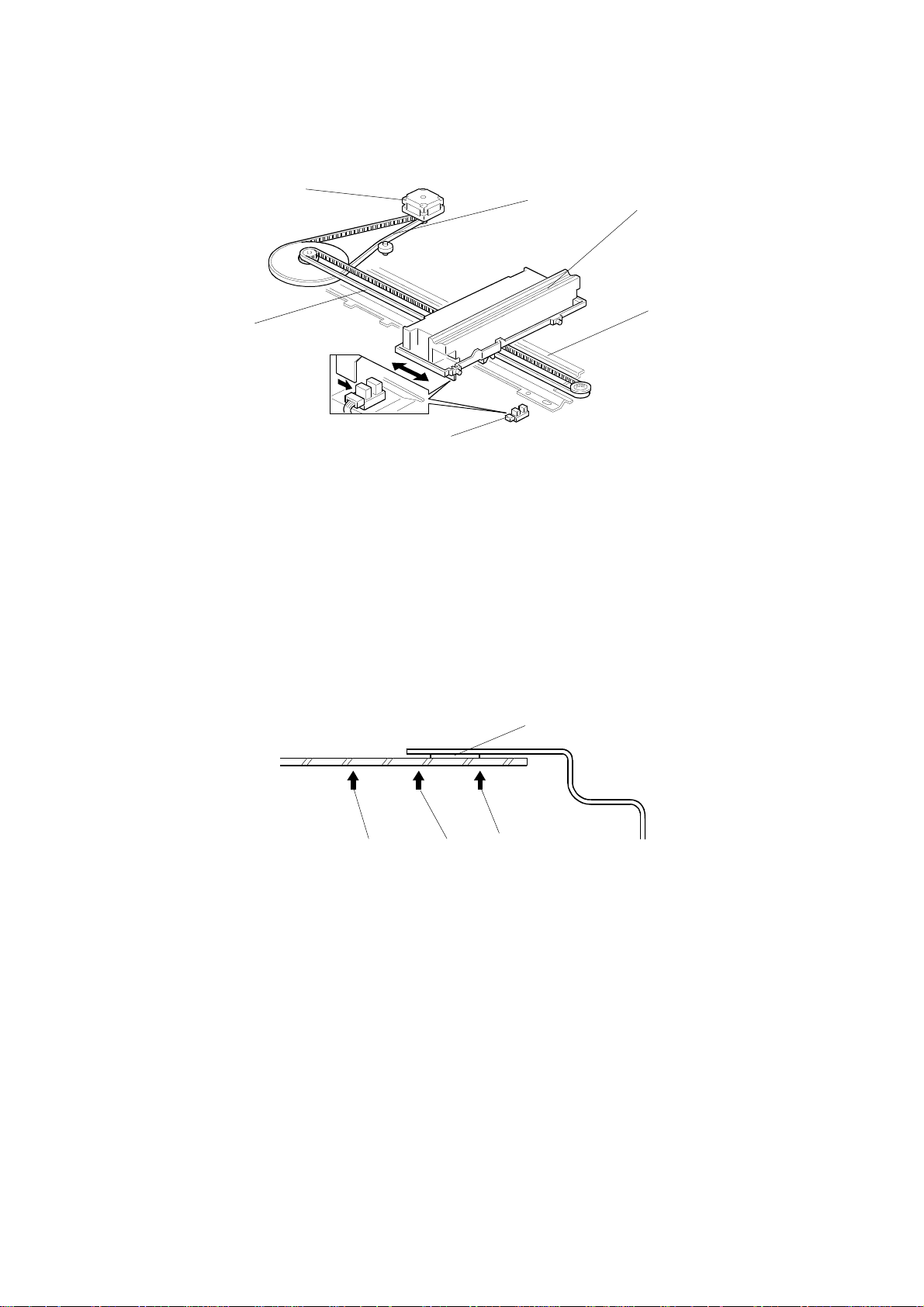

2.1.2 CCD UNIT DRIVE

[A]

[C]

[B]

[E]

[D]

[F]

G025D502.WMF

A stepper motor [A] is used to drive the CCD unit [B]. The motor drives the CCD

unit through the timing belt [C] and the drive belt [D]. The CCD unit moves along

the guide rail [E].

The home position sensor [F] detects when the CCD unit is at the home position.

The motor speed depends on the selected reduction or enlargement ratio.

When the machine is turned on, it checks the home position sensor. If home

position sensor is on, the CCD unit is at the home position. If home position sensor

is off, the machine moves the CCD unit until the home position sensor turns on.

[H]

[J][K]

[G]

G025D503.WMF

At the start of scanning, the CCD unit moves from the home position sensor [G] to

the left until the scanner position sensor turns off and then moves in the opposite

direction until the home position sensor turns back on. After that, the CCD unit

moves from the home position to a position under the white shading strip [H] to

adjust shading. At that time, the LED array is turned on.

2-2

26 August 1998 SCANNING

Book Scanning

After shading, the CCD unit stops temporarily at the reading standby position [J]

while the scan parameters (X/Y coordinates) are initialized. Then, it scans across

the original. Scanning speed depends on the reproduction ratio. Full size (100%)

scanning speed is 38 mm/s. Shading is done before scanning each page.

ADF Scanning

After shading, the scanner moves to the ADF scanning position [K] and stays there

while documents are fed through the ADF. Shading is done only once before

scanning.

Detailed

Descriptions

2-3

SCANNING 26 August 1998

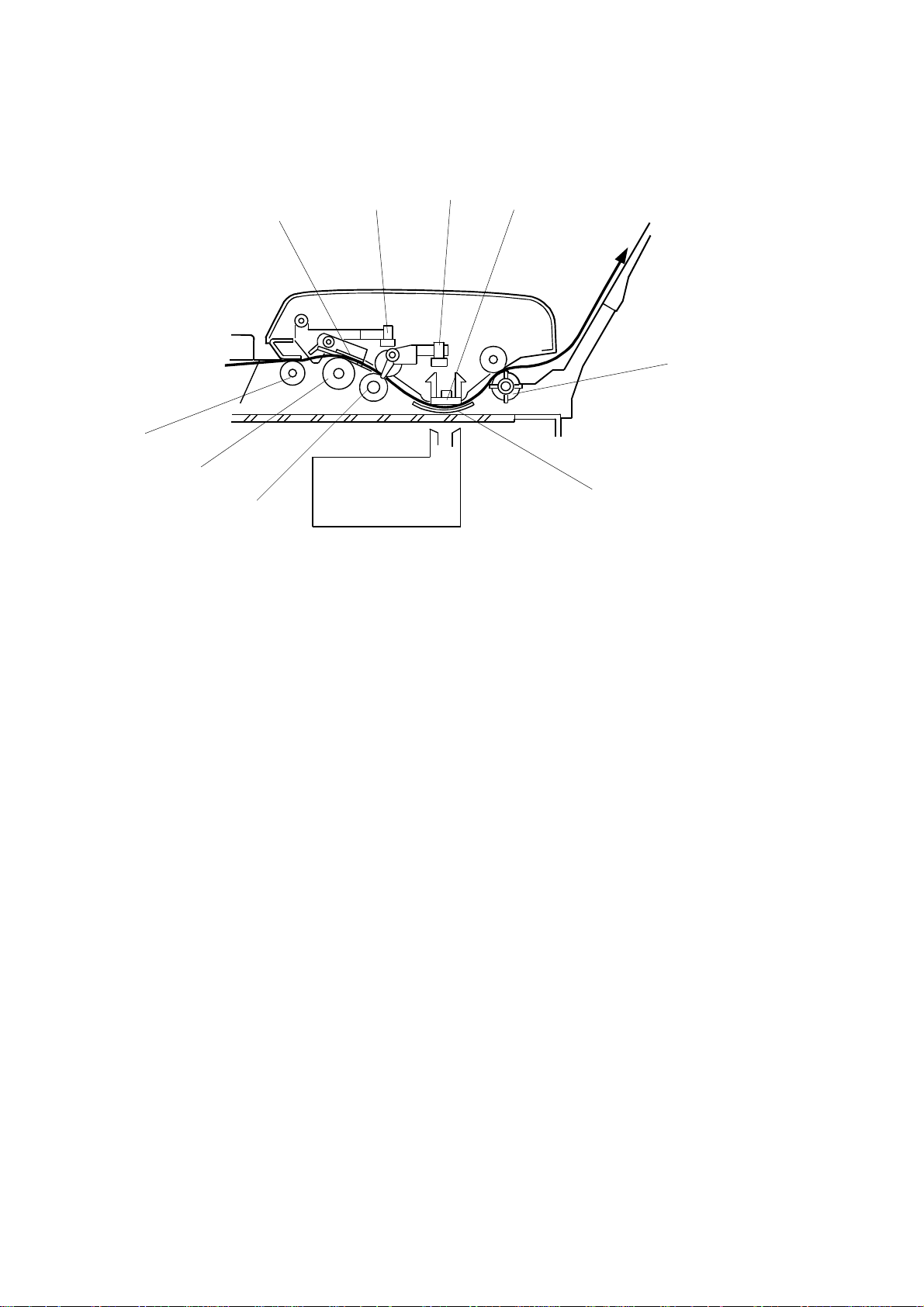

2.1.3 ADF (G036 ONLY)

OVERVIEW

[J]

[F]

[H]

[G]

G025D504.WMF

[B]

[C]

[E]

[D]

[A]

The sheet-through type ADF feeds documents from the bottom page of the

document stack on the ADF table. During scanning the document moves past the

CCD unit, which is locked in position.

The document sensor [A] detects documents set on the table.

Before the start of scanning, the CCD unit moves to the ADF scanning position.

The pick-up roller [B] and feed roller [C] feed the document into the ADF unit. Only

the bottom sheet is fed because the separation tab [D] prevents any other sheets

from feeding. The document feed-in roller [E] feeds the document through the ADF

unit. The document feed speed depends on the reproduction ratio. For 100%

copies, the feeding speed is 38 mm/s.

The pressure plate [F] presses the document to the exposure glass through the

mylar guide [G] at the scan line, so that the document is within the CCD unit’s

range of focus.

After the document passes the scanning position, the feed-out roller [H] feeds it

onto the document exit tray. When scanning is finished, the CCD unit moves back

to the home position.

The registration sensor [J] detects the lead ing edge and the trailing edge of the

document, and it is also used to detect document jam.

2-4

Loading...

Loading...