Ricoh ap305 Technical Bulletin fresa

RICOH Technical

Bulletin

PAGE: 1/6

Model:

Subject:

From:

Classification:

Although the Fresa engine service manual is based on the Fresa Win model, it may also

be used for reference regarding the PS model as well. This is due to the fact that nearly all

parts for the engine are identical, with a few exceptions such as the operation panel, some

exterior parts and some decals.

The differences are described on the following pages.

Fresa

Service Manual

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

31-May-99

Prepared by:

No.:

RG024001

H. Someya

Action required

Service manual revision

Retrofit information

RICOH Technical

Bulletin

PAGE: 2/6

Model:

Fresa

Page 1-1 SPECIFICATIONS

Paper Size

(for NA model)

Standard tray

Short edge feed:

Long edge feed:

By-pass feed tray*

Short edge feed:

Long edge feed:

* Specify the paper size with the system menu (at the

operation panel by the user).

Paper Size

(for EU model)

Standard tray

Short edge feed:

Long edge feed:

Date:

12" x 18", 11" x 17", 8

8

1/4

A4, 8

" x 13", 8

" x 11", 7

1/2

" x 13", 13" x 18")

1/2

1/4

" x 14", Others* (A3, 8" x 13",

1/2

" x 10

1/2

A3, A6, B4 JIS, 11" x 17", 8

8

" x 13", 8

1/4

A4, A5, B5 JIS, 8

A3, A5, 12" x 18", 8

11" x 17", 8

A4, 8

5

1/2

" x 11", Others* (B5 JIS, 7

1/2

" x 8

1/2

" x 13", 12" x 18", 13" x 18"

1/2

" x 11", 5

1/2

" x 13", Others* (B4 JIS,

1/2

" x 14", 8" x 13", 8

1/2

")

31-May-99

", Others* (5

" x 14", 8" x 13",

1/2

1/2

" x 8

1/4

", 7

1/2

" x 13", 13" x 18")

" x 10

1/4

1/2

No.:

" x 8

1/4

1/2

RG024001

1/2

" x 10

",

")

1/2

"

By-pass feed tray*

Short edge feed:

A3, A6, B4 JIS, B6 JIS, 11" x 17", 8

" x 14", 8" x

1/2

13",

8

" x 13", 8

1/4

" x 13", 12" x 18", 13" x 18"

1/2

Long edge feed:

A4, A5, B5 JIS, 8

" x 11", 5

1/2

1/2

" x 8

1/2

", 7

1/4

" x 10

* Specify the paper size with the system menu (at the

operation panel by the user).

1/2

"

RICOH Technical

Bulletin

PAGE: 3/6

Model:

Fresa

Date:

31-May-99

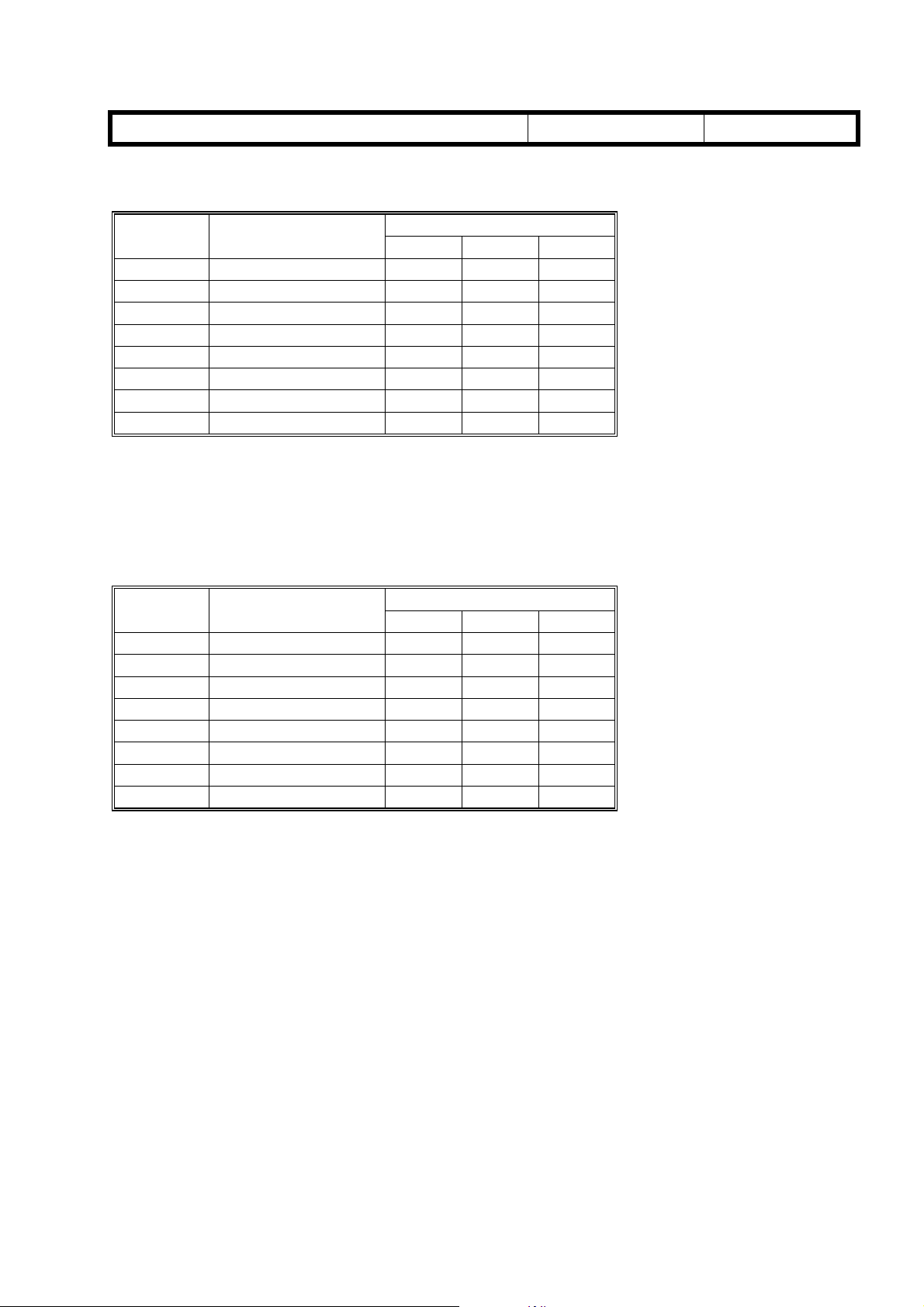

Page 2-49 Paper size detection

Paper size detection for tray 1 (for North America models)

Dial No. Paper Size

1 12" x 18" SEF 0 0 0

2 Others 0 1 1

37

48

58

6 A4 LEF 0 1 0

7 11" x 17" SEF 1 1 0

8 No Cassette 1 1 1

" x 10

1/4

x 14" SEF 1 0 0

1/2

"

" x 11” LEF 1 0 1

1/2

" LEF 0 0 1

1/2

XNOB2 XNOB1 XNOB0

Sensor Status

SEF: Short edge feed

LEF: Long edge feed

Others: SEF – A3, 8" x 13", 8

LEF - 5

1/2

" x 8

1/2

"

" x 13", 8

1/4

" x 13", 13" x 18"

1/2

Paper size detection for tray 1 (for Europe models)

No.:

RG024001

Dial No. Paper Size

1 12" x 18" SEF 0 0 0

2 Others 0 1 1

3 A5 SEF 0 0 1

48

58

6 A4 LEF 0 1 0

7 A3 SEF 1 1 0

8 No Cassette 1 1 1

x 13" SEF 1 0 0

1/2

"

" x 11” LEF 1 0 1

1/2

XNOB2 XNOB1 XNOB0

Sensor Status

SEF: Short edge feed

LEF: Long edge feed

Others: SEF – B4 JIS, 11" x 17", 8

LEF - (B5 JIS, 7

1/4

" x 10

" x 14", 8" x 13", 8

1/2

1/2

", 5

1/2

" x 8

1/2

" x 13", 13" x 18"

1/4

"

RICOH Technical

Bulletin

PAGE: 4/6

Model:

Fresa

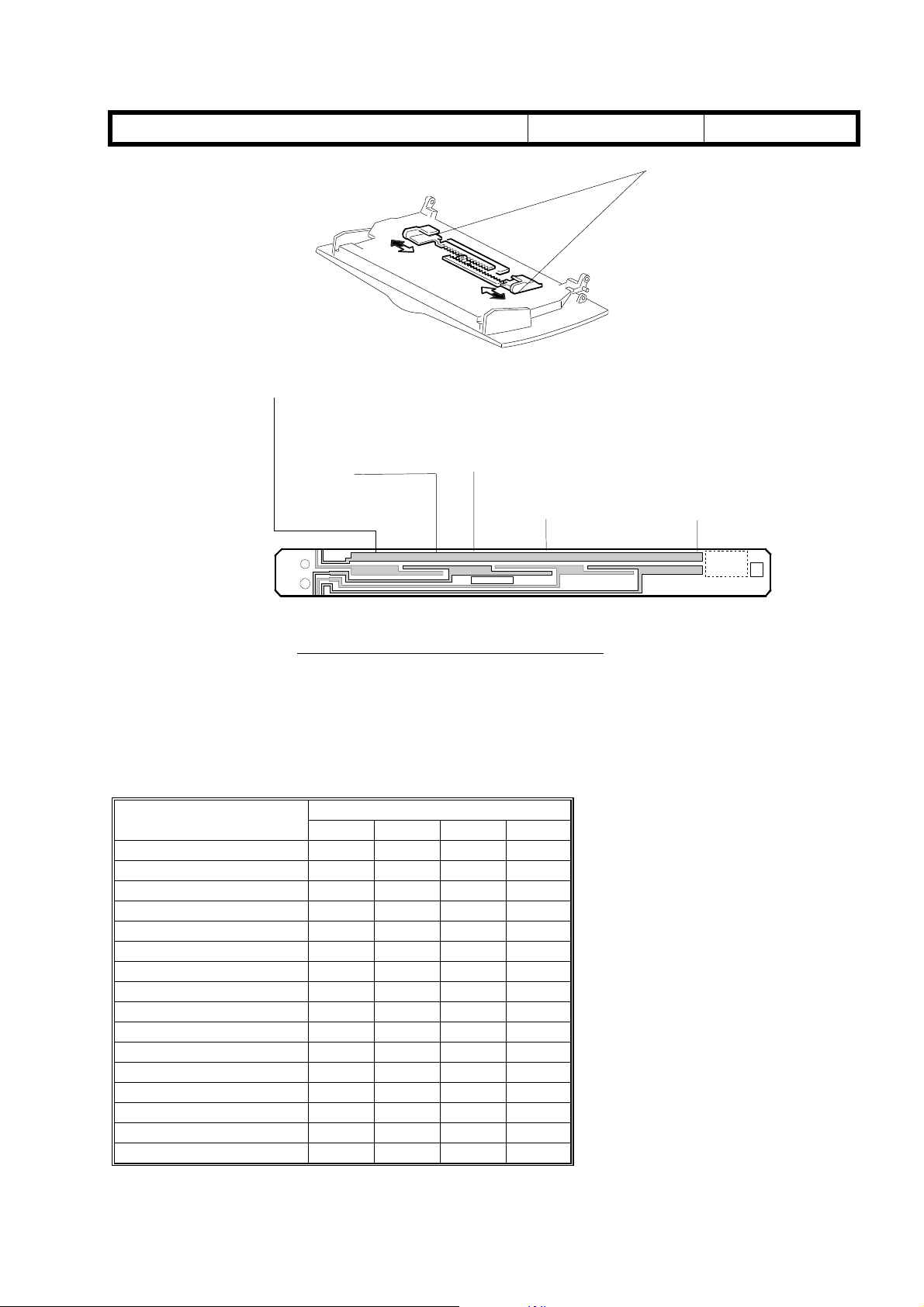

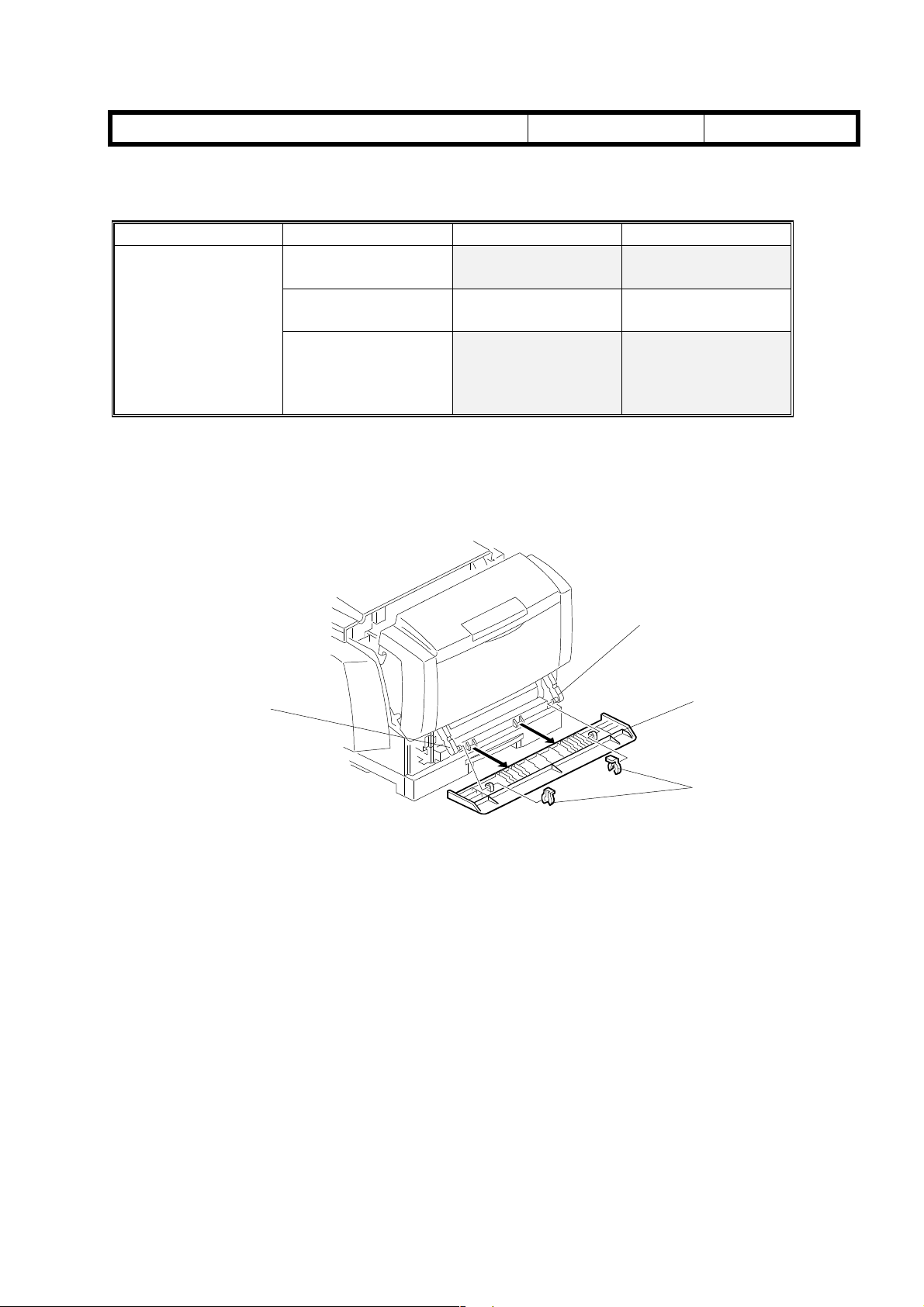

Page 2-52 Paper size detection

A3 WIDE SEF

A3 SEF

A4 LEF

DTL SEF

LT LEF

B4 SEF

B5 LEF

EXE LEF

Date:

G024D410.WMF

A5 LEF

HLT LEF

LG SEF

31-May-99

[A]

No.:

A6 SEF

B6 SEF

RG024001

G024D411. WMF

LEF: Long edge feed SEF: Short edge feed

An electrode plate is connected to each of the two side fences [A]. The electrode plates

short the patterns on the paper size detection board. Paper width is detected from the

locations of the shorting.

Paper size detection for the by-pass feed tray

Paper Size

A3 Wide LEF 1 1 1 0

A4 LEF 1100

A3 SEF 1 1 0 0

81/2" x 11" LEF 1 1 0 0

11" x 17" SEF 1 1 0 0

71/4" x 101/2" LEF 1 1 0 1

B5 JIS LEF 1 1 0 1

B4 JIS SEF 1 1 0 1

81/2" x 14" SEF 1 0 0 1

51/2" x 81/2" SEF 1 0 0 1

A5 LEF 1001

8" x 13" SEF 1001

81/4" x 13" SEF 1 0 0 1

81/2" x 13" SEF 1 0 0 1

B6 JIS SEF 0 1 1 1

A6 SEF 0 1 1 1

XBIT0 XBIT1 XBIT2 XBIT3

Sensor Status

RICOH Technical

Bulletin

PAGE: 5/6

Model:

Fresa

Date:

31-May-99

No.:

RG024001

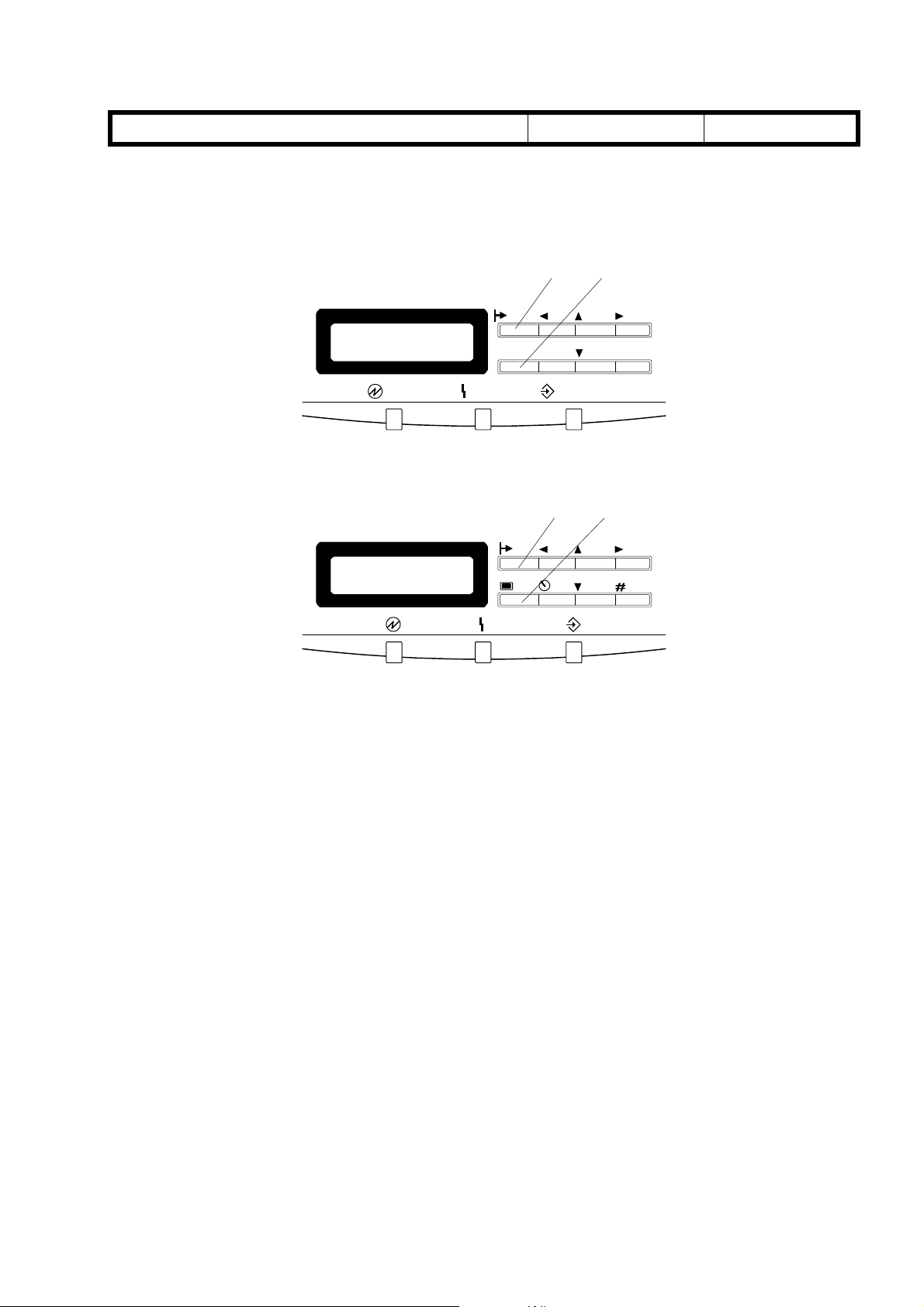

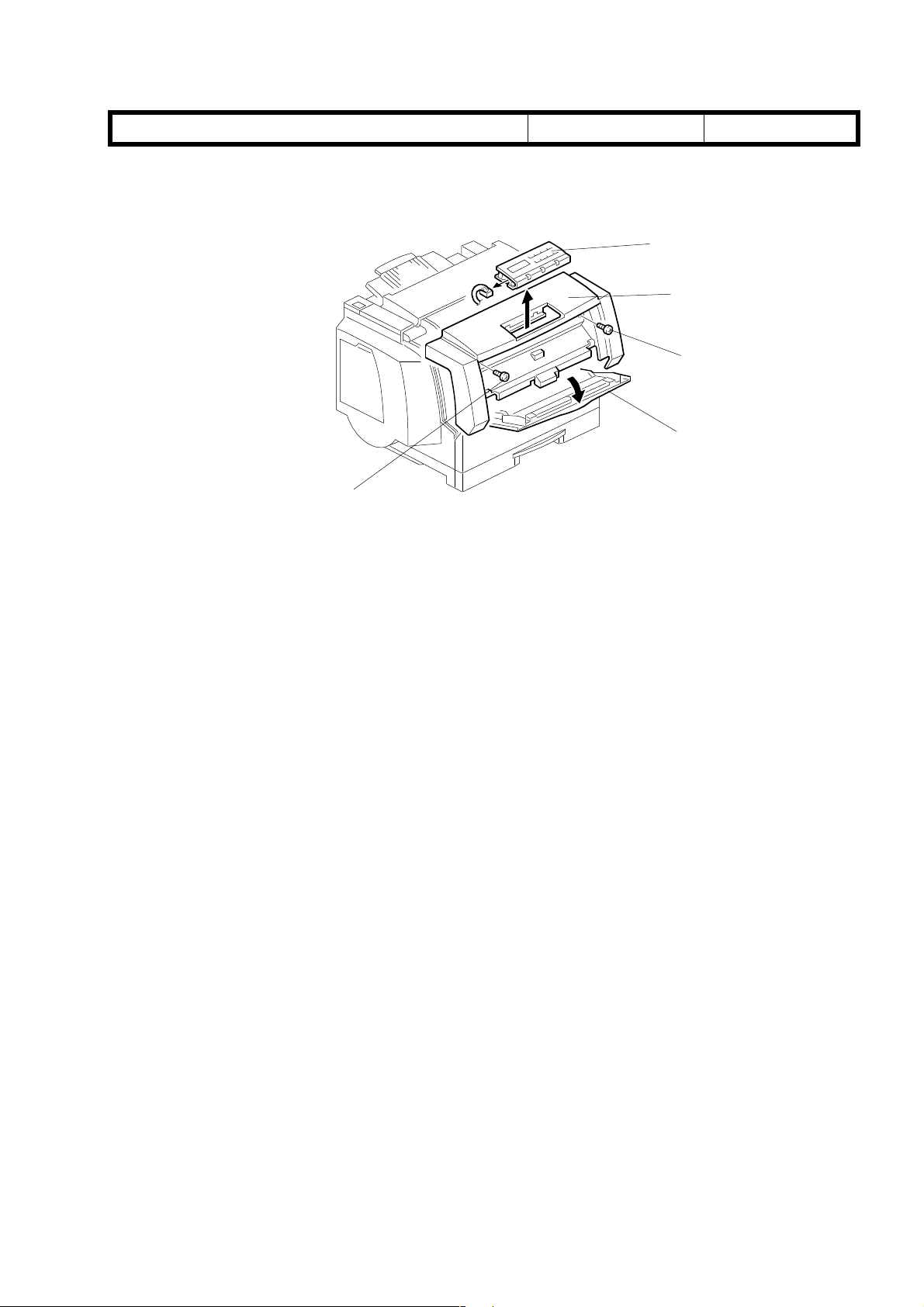

Page 4-1 Entering engine SP mode

To enter engine SP mode, hold down the [Online] [A] and [Menu] [B] keys on the operation

panel and turn on the power.

[A] [B]

On Line

Menu Cancel

ErrorPower Data in

#Enter

G024C500.WMF

[A] [B]

G024C501.WMF

Page 4-2 Key operation

[Cancel] key: Pressing this key moves you to a higher level in the current

menu. Before the specified value is confirmed by the [# Enter]

key, pressing this key keeps the existing setting.

RICOH Technical

Bulletin

PAGE: 6/6

Model:

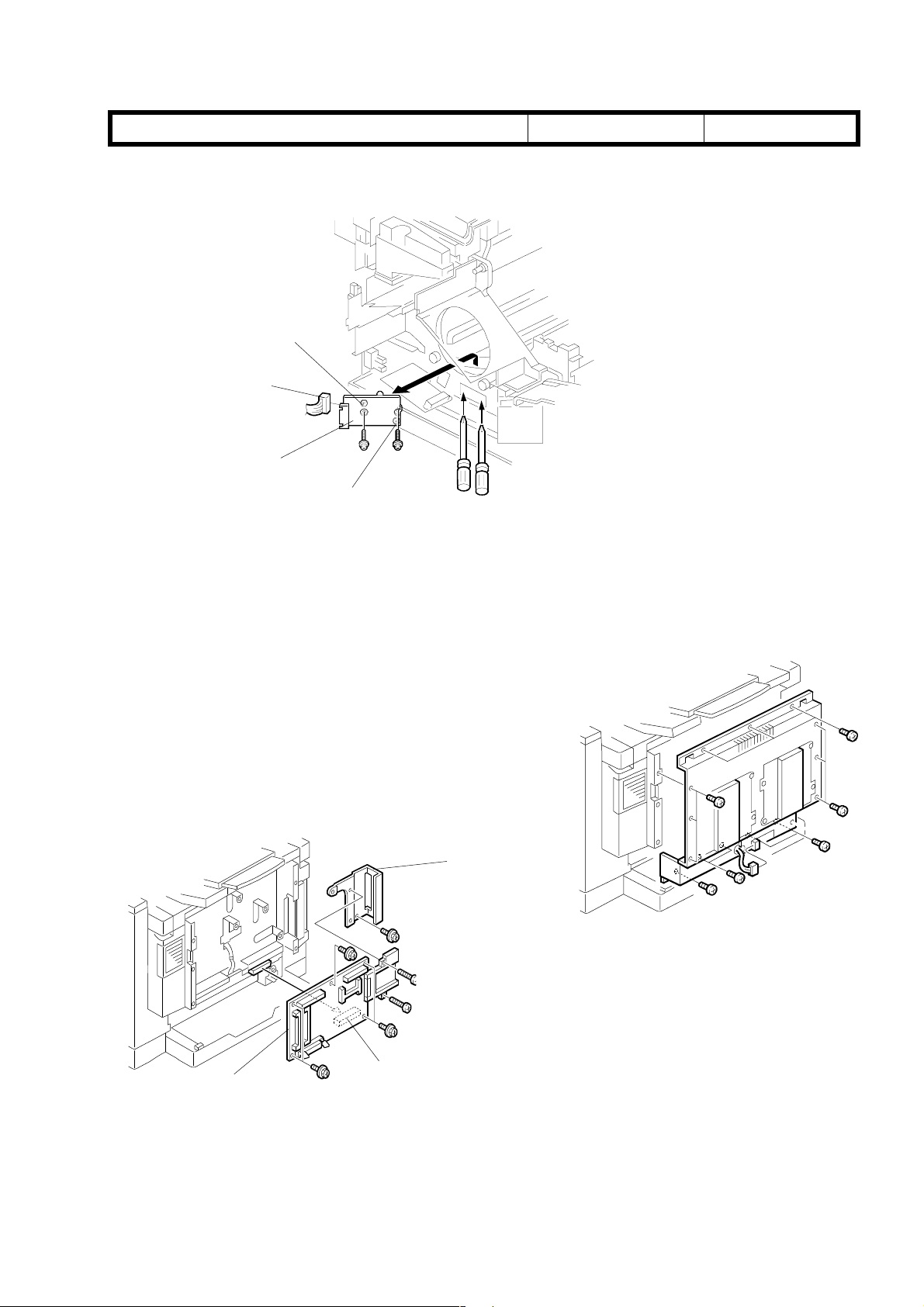

Page 6-35

CONTROLLER BOARD AND TEMPERATURE/HUMIDITY SENSOR REPLACEMENT

NOTE:

Fresa

Print the “Configuration sheet” prior to removing the controller board as the NVRAM cannot be exchanged.

G024R551.WMF

[A]

Date:

[C]

[D]

31-May-99

No.:

RG024001

[E]

[B]

G024R552.WMF

[F]

G024R553.WMF

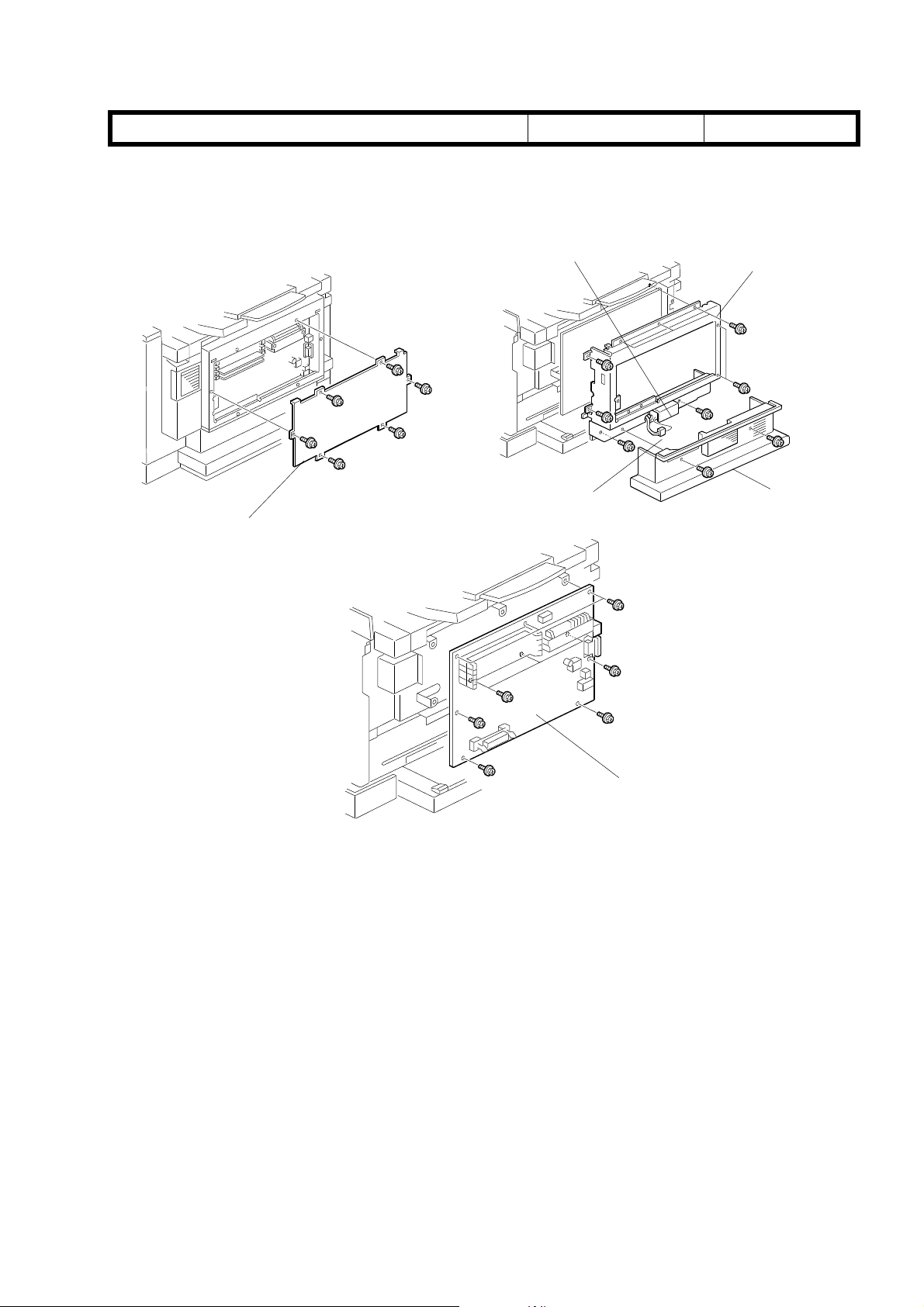

1. Remove the controller cover [A] (12 screws).

2. Remove the tray cover [B] (two screws).

3. Remove the temperature/humidity sensor cover (one screw) and sensor [C], (one

screw). Make sure to unplug the connector [D].

4. Remove the controller bracket [E] (5 screws).

5. Remove the controller board [F] (6 screws).

After replacing the controller board, make sure that the brand name (and MAC address if

required by the user) stored in the machine is correct.

Technical

Bulletin

PAGE: 1/7

Model: Fresa Date:

Subject:

From:

Classification:

Please correct your service manual as follows.

Engine

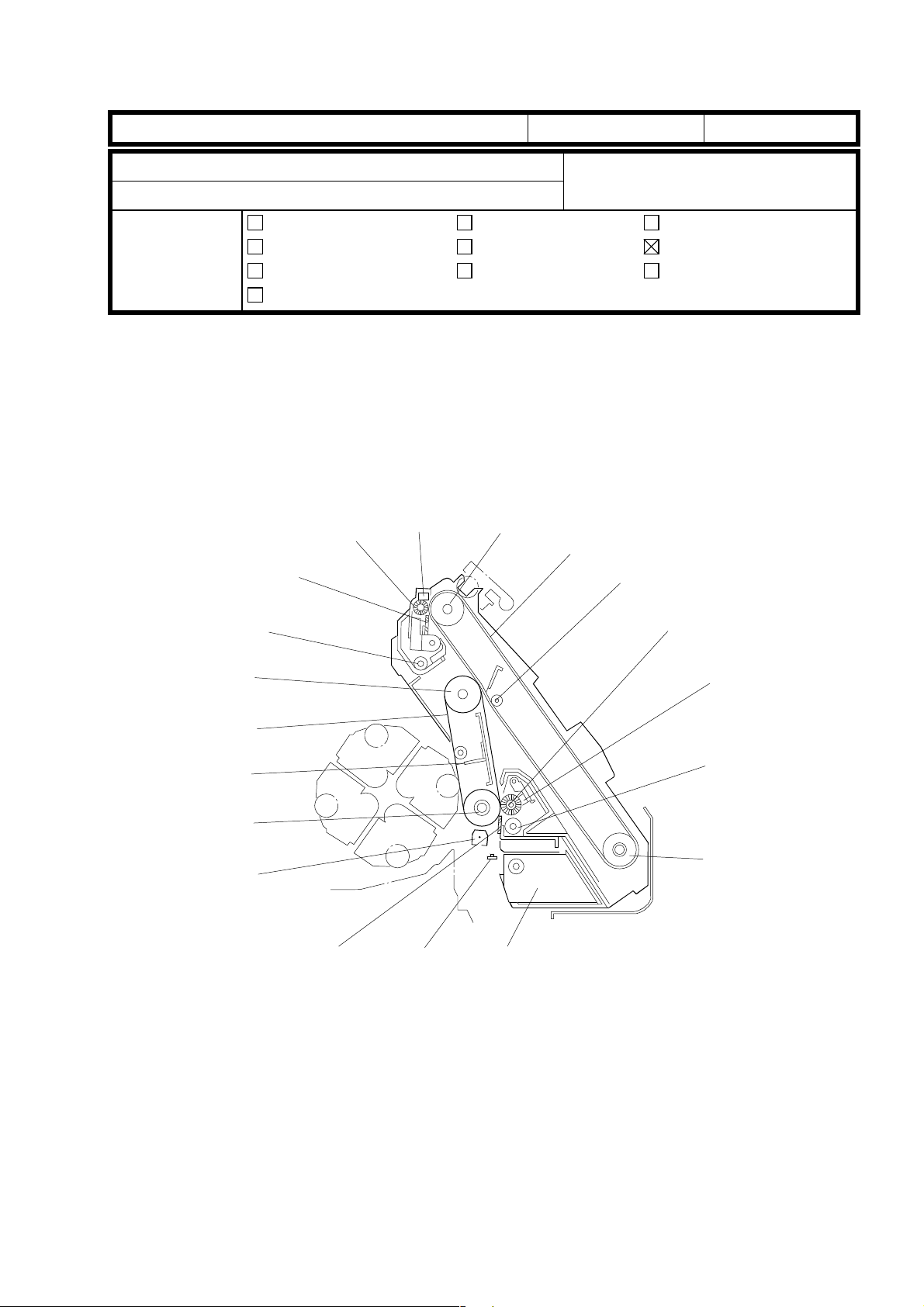

Page 2-6 PCU Overview

The callouts in the illustration below must be corre cted .

Service Manual

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

16 15

17

18

Part information

Electrical

Transmit/receive

30-Jun-99

Prepared by:

Action required

Service manual revision

Retrofit information

14

13

No.:

H. Someya

RG024002

19

1

2

3

4

5

12

11

10

9

G024D151.WMF

6

7

8

Technical

Bulletin

PAGE: 2/7

Model: Fresa Date:

Page 2-16 Used Toner Tank

Incorrect

The used toner sensor [D] detects when the tank becomes full. After detecting the toner

near-end condition, the printer can make 20 additional prints before the machine stops

printing.

Correct

The used toner sensor [D] detects when the tank becomes full. After detecting

condition, the printer can make 20 additional prints before the machine stops printing.

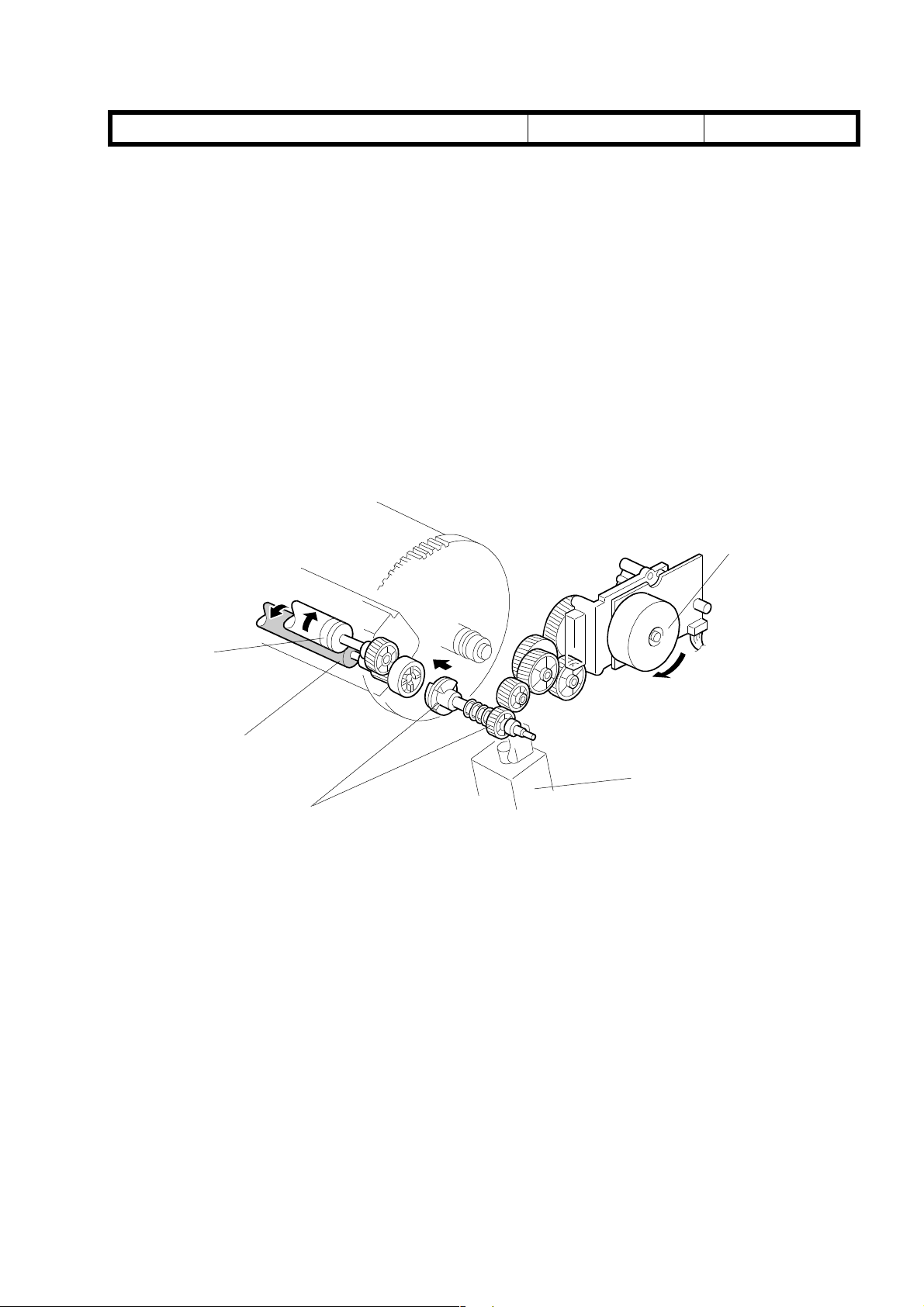

Page 2-32 Development Unit Drive

The callout [A] should be added to the gear.

30-Jun-99

No.:

[B]

RG024002

this

[D]

[C]

[E]

[A]

G024D162.WMF

Technical

Bulletin

PAGE: 3/7

Model: Fresa Date:

Page 2-36 DTM (Development Toner Magazine) Detection

[B]

30-Jun-99

G024D164.WMF

[A]

No.:

RG024002

Incorrect

Installing a toner bottle and closing the front cover [B] automatically initiates the recovery

procedure, clearing the error.

Correct

Installing a toner bottle and closing the

procedure, clearing the error.

The callout [B] should be added.

Page 4-5 Margin (Registration Adjustment)

Minor corrections should be added to step 3 of this procedure (below). Also, the note

below should be added.

3. Move to the Adjust menu to adjust the vertical and horizontal registrations. The

adjustment range for the horizontal

units with 0.4 mm increments. The adjustment rang e for the ver ti cal

is between –2.5 and +2.5 mm in units with increments of 0.5 mm.

NOTE:

The LCD panel displays the horizontal registration as “Left” and the vertical

registration as “Top”.

DTM cover

registration is between –2.0 and +2.0 mm in

(Left)

[B] automatically initiates the recovery

registration

(Top)

Technical

Bulletin

PAGE: 4/7

Model: Fresa Date:

Page 4-6 Clear Memory

The explanations in the shaded cells below must be corrected.

Layer 1 Layer 2 Layer 3 Layer 4

Clear Memory

SC

Clear Memory

Maintenance

3:Clear Memory

Page 6-3 Bottom Front Cover

A supplementary explanation should be added to the procedure below.

Jam

Clear Memory

All

NOTE:

only.

Factory use

Clear: SC

Press # to clear

Clear: Jam

Press # to clear

Clear: All

Press # to clear

30-Jun-99

Clearing

SC

Clearing

Jam

Clearing

All

No.:

RG024002

[B]

[B]

G024R268.WMF

1. Open the front cover half way, and remove the two snap rings [A].

2. Carefully slide the hinge levers [B] out from the bottom front cover [C].

The levers are spring loaded.

3. Remove the bottom front cover.

[C]

[A]

Technical

Bulletin

PAGE: 5/7

Model: Fresa Date:

Page 6-3 Front Cover and Operation Panel

A supplementary explanation should be added to the procedure below.

[B]

G024R153.WMF

1. Open the by-pass tray [A].

30-Jun-99

[D]

[C]

[A]

[B]

No.:

RG024002

2. Remove the two screws [B] and carefully lift the front cover [C] from the printer.

3. Remove the operation panel [D] from the front cover (two hooks). Be sure to unplug

the connector from the operatio n panel .

NOTE:

Page 6-7 Calibrating the ID Sensor

A supplementary procedure should be added to steps 2 and 3 below.

2. Select “9: ID Sensor PWM” in the engine SP menu. Specify 150 as the PWM value.

3. Select “7: Process Ctrl” in the engine SP menu. Execute “Color Bias” (this starts the

The surface of the operation panel circuit board is not insulated. When turning on

the printer while the operation panel is being removed from the front cover,

exercise extra caution in order to prevent a short circuit of the board.

Press the [Enter] key. An asterisk (*) is then displayed before the value. Press the

[Escape] or [Menu] key.

process control for the color development bias settings). Wait until “Finish OK” is

displayed. Then press the [Escape] or [Menu] key.

Technical

Bulletin

PAGE: 6/7

Model: Fresa Date:

Page 6-18 LD Unit

The callouts of the illustration below must be corrected.

[E]

[D]

[C]

[E]

G024R259A.WMF

30-Jun-99

No.:

RG024002

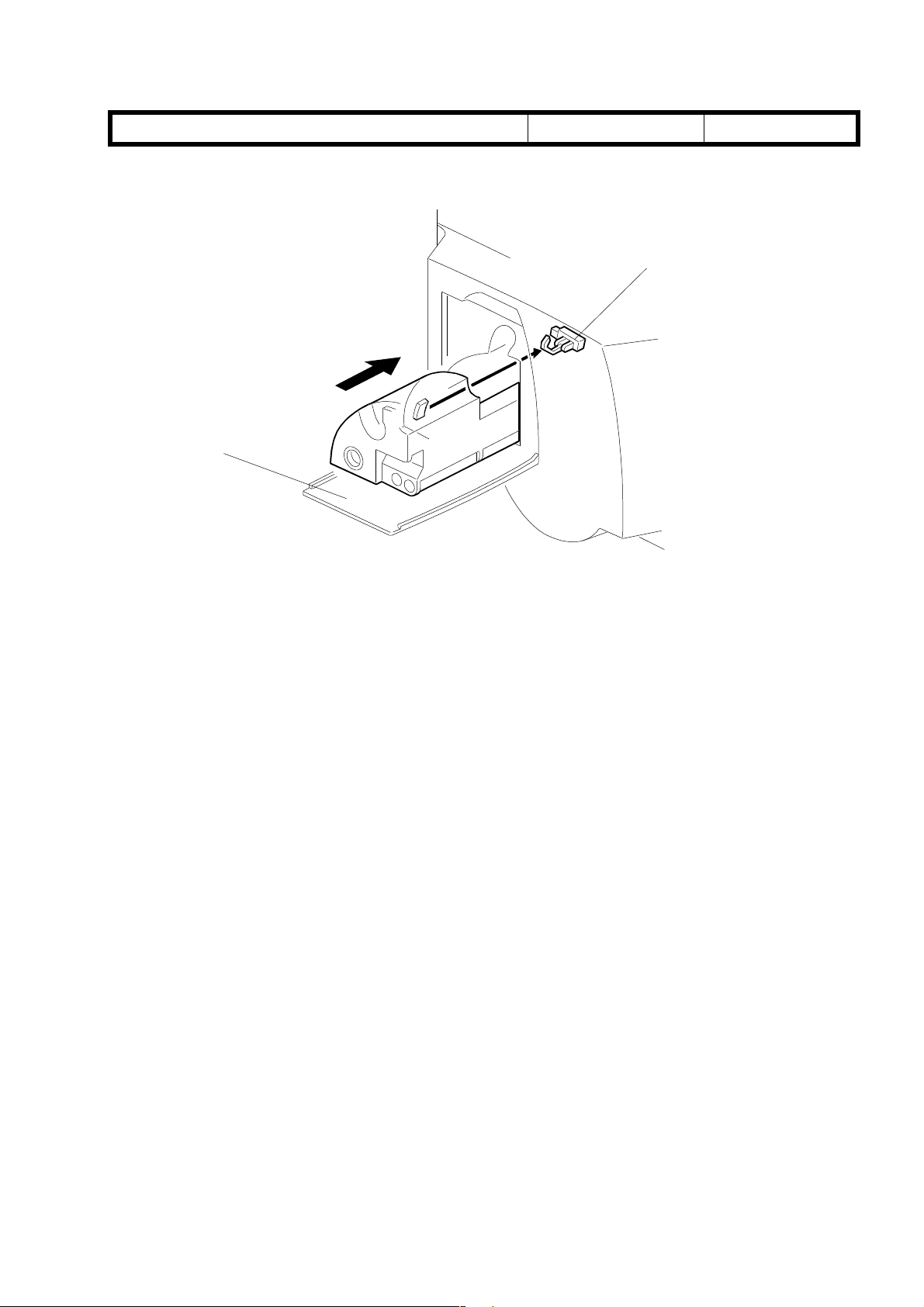

Page 6-35 Controller Board, Temperature/Humidity Sensor

The explanation in step 2 of the procedure and callout [H] should be corrected.

4. Remove the controller cover [E] (16 screws,

including 2 screws around the parallel port).

5. Remove the controller board [F] with the bracket

[G] attached to it (6 screws, 1 connector [H]).

6. Remove the bracket [G] and 2 screws from the

controller board.

[G]

NOTE:

[H]

[F]

G024R166.WMF

To replace the controller boards, remove the

NVRAM chip (IC23) on the old board, install it

on the new board and finally install the new

board itself. The NVRAM chip stores user

settings and service records. These settings

will be lost if the NVRAM chip is not

transferred to the new board.

G024R184.WMF

Loading...

Loading...