Page 1

POMELO-P3 (G063)

SERVICE MANUAL

[Controller]

Page 2

17 January, 2001 INSTALLATION

1. INSTALLATION

Refer to the following materials.

• For the printer: Quick Installation Guide

• For options: Operating Instructions – Setup Guide

Installation

1-1

Page 3

17 January, 2001 PERIODIC MAINTENANCE

2. PERIODIC MAINTENANCE

Refer to Section 2. Periodic Maintenance in the G063 engine service manual.

Preventive

Maintenance

2-1

Page 4

17 January, 2001 REPLACEMENT AND ADJUSTMENT

3. REPLACEMENT AND ADJUSTMENT

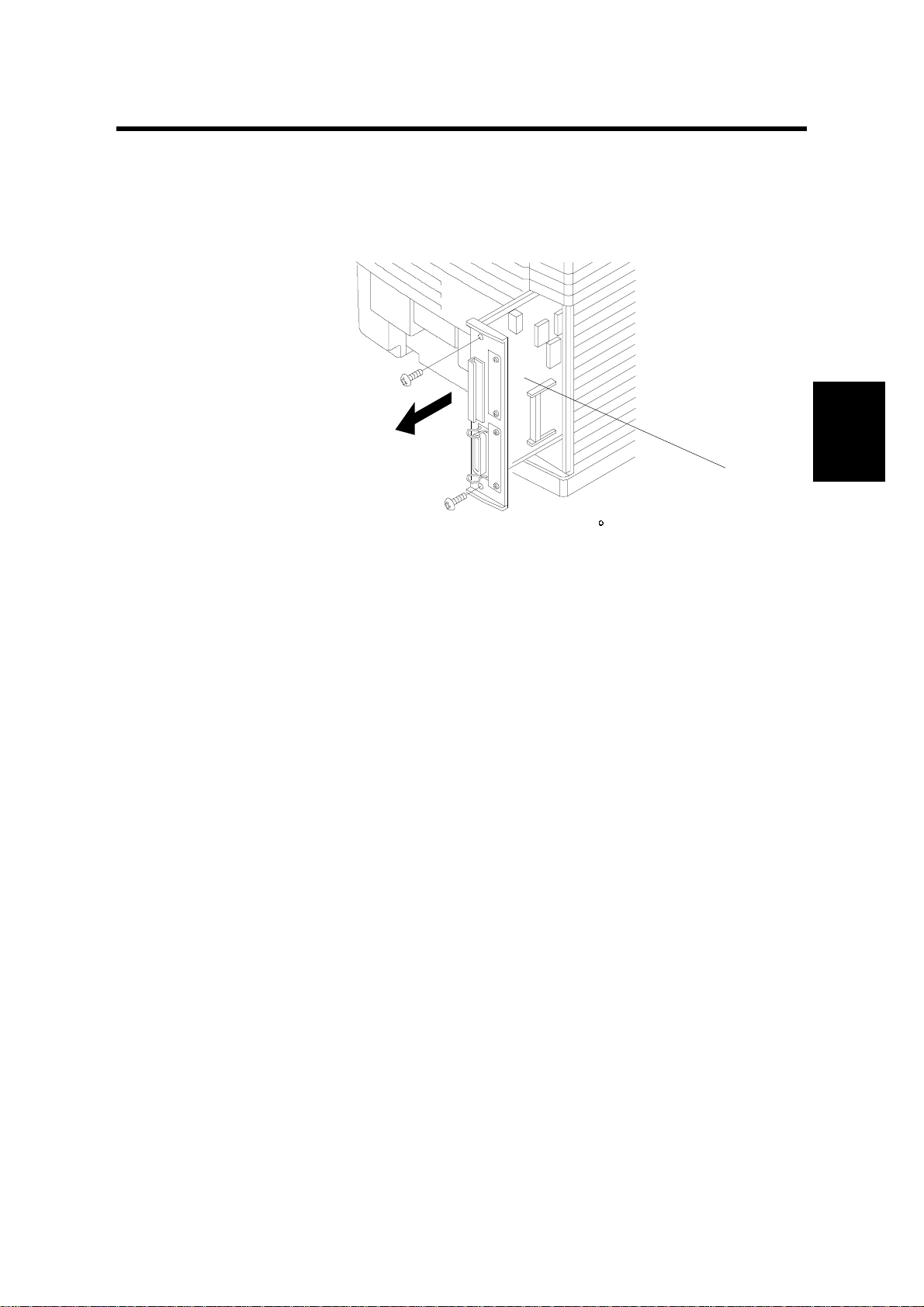

3.1 CONTROLLER BOARD REPLACEMENT

G063R092.WMF

1. Remove the printer controller board [A] (2 screws).

The following must be done after changing the board.

• Store the Printer ID (controller service mode S8)

• Store the network printer name (user mode)

• Do the gamma calibration (controller service mode S7)

3.2 REGISTRATION ADJUSTMENT

You can adjust the registration in the following three ways:

A. Controller’s user menu (Menu → Maintenance → 4. Registration);

refer to the operating instructions for more details

B. Controller’s SP mode (S5. Registration)

C. Engine SP mode (43 Margin Adjust)

[A]

Adjustment

Replacement

For tray 1, the leading edge and left side registrations can be adjusted either with

engine SP mode 43 or with controller SP mode S5 (Registration).

For tray 2, leading edge and left side registrations can be adjusted with engine SP

mode 43. The left side registration can also be adjusted with the controller user

mode, and the leading edge registration can be adjusted with controller SP mode 5

(Registration).

For how to adjust the registration, refer to ‘5. Service Tables – 5.5.1. Adjusting the

Leading Edge and Left Side Registrations’ in the engine service manual.

3-1

Page 5

REPLACEMENT AND ADJUSTMENT 17 January, 2001

3.3 IMAGE ADJUSTMENT

3.3.1 OVERVIEW

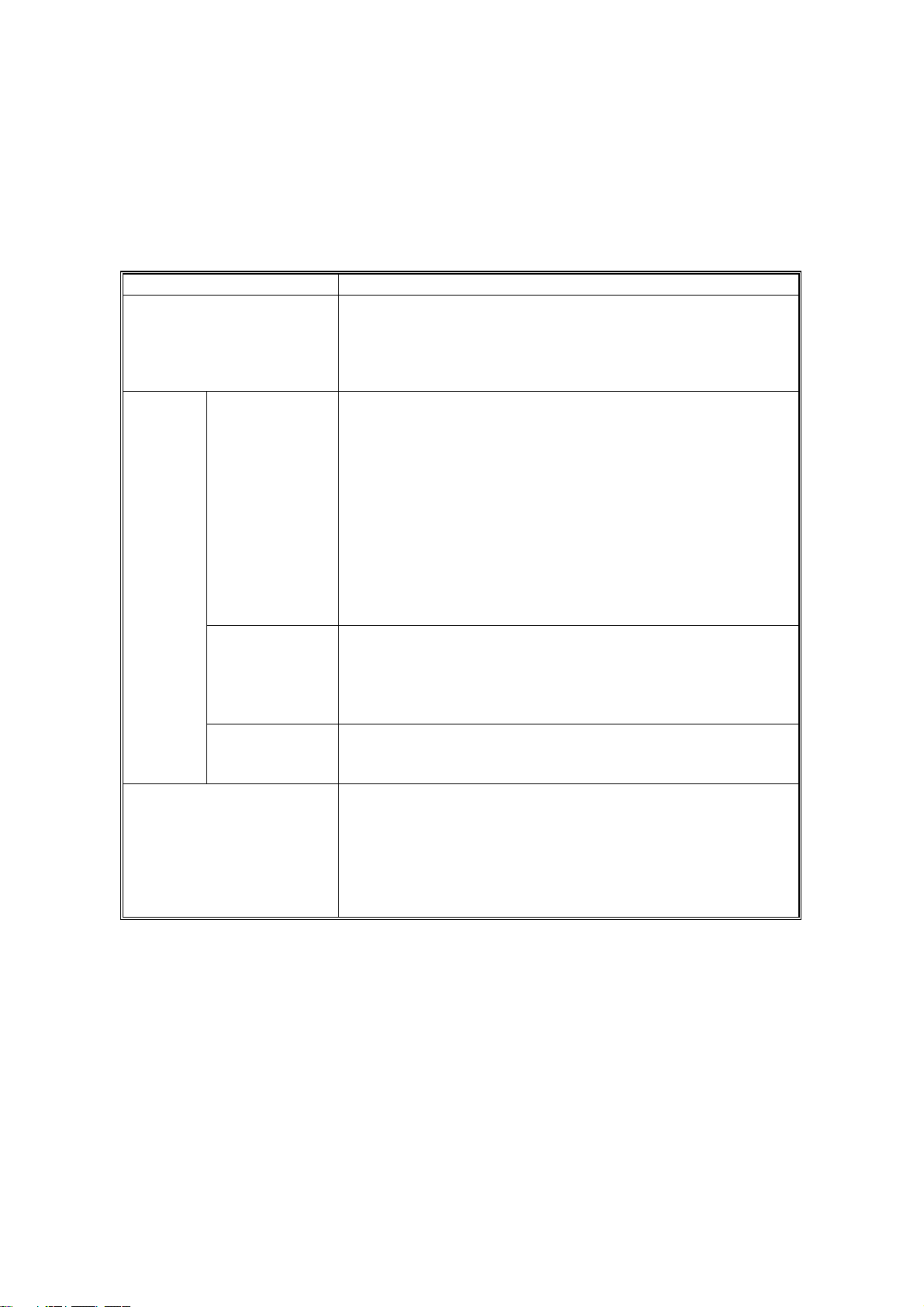

The table below lists the adjustable image parameters, with their corresponding

adjustment procedures.

Item Procedure

Brightness, Contrast,

Saturation, Color Balance

LD Power

Density

Development

Bias

Transfer Bias

Service Gamma

In the Print Quality tab of the Windows printer properties,

select the ‘Custom’ button and click ‘Setting’. A range of

adjustments is displayed. The results of the adjustments are

reflected in the image data processing by the driver and

controller.

Use either the user menu [Menu] →[Maintenance] →[Toner

Level] or engine SP mode 45-1 (LP Tune Up). You can

adjust the power for each CMYK color within a range of -1 to

+13 with the user menu and in ±4 steps in engine SP mode.

(For the actual procedures, refer to the operating instructions

and the engine service manual).

See ‘5.Service tables – 5.1.4 SP Mode Details’ in this manual

for the relationship between the settings in each of these

modes.

The settings made for this item are transferred to the engine

and stored in NVRAM on the MCTL board.

Note that the customer is able to adjust this.

Use engine SP mode 45-3 (DBV Tune Up); refer to the

engine service manual. You can adjust the bias for each

CMYK color in ±4 steps.

The settings made for this item are transferred to the engine

and stored in NVRAM on the MCTL board.

Use either controller SP mode S4 (Transfer Bias) or engine

SP mode 45-2 (THV Tune Up). You can adjust in ±4 steps for

plain paper, OHPs, and labels.

Use controller SP mode S7 (Gamma Calib.). You can adjust

each color for both text and photograph modes. The results

of the adjustment are reflected in the gamma correction done

by the controller (see ‘3. Replacement and Adjustment –

3.3.2 Service Gamma Adjustment’ and 6. Detailed

Descriptions – 6.1.2 Controller Gamma’ in this manual for

more information on how the controller does this).

3-2

Page 6

17 January, 2001 REPLACEMENT AND ADJUSTMENT

3.3.2 SERVICE GAMMA ADJUSTMENT

NOTE: For problems related to color quality and gradation, clean the engine and

replace supplies and other parts at first. Use this mode only when the

customer insists on further fine adjustments (e.g., matching colors between

machines).

Adjustment Menu (Controller SP, S7. Gamma Calibration)

The menu items under Gamma Calibration in controller SP mode are organized as

shown below. See “5. Service tables – 5.1.3 SP Mode Menu Hierarch,” in this

manual for instructions on how to access the “S7. Gamma Calib. Color Correction”

menu.

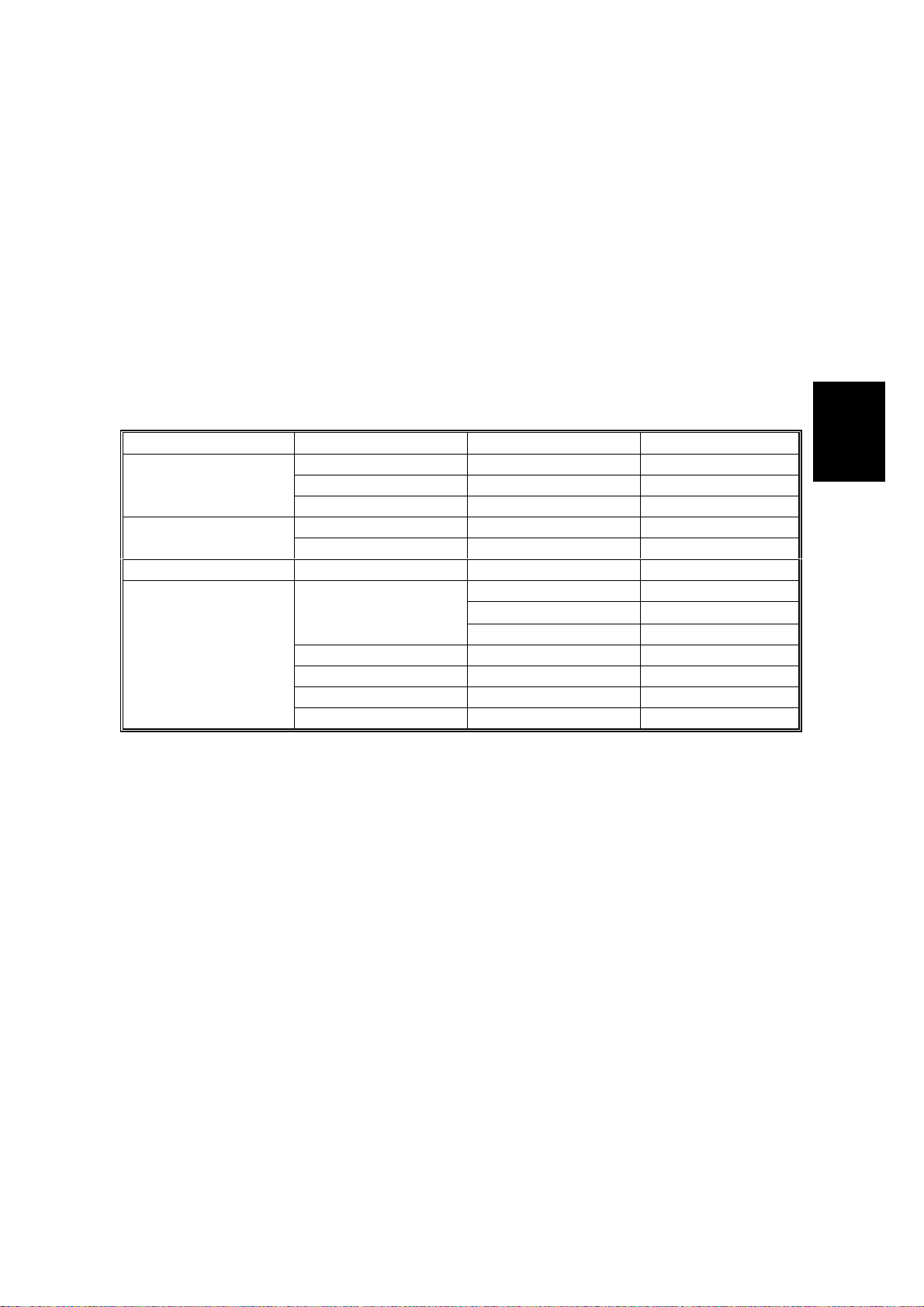

Layer 3 Layer 4 Layer 5 Layer 6

Load Setting

Print Setting

Gamma Setting

Default

Setting-Old

Setting-Current

1 bit/PhotoMode Setting

1 bit/Text

Black

Cyan Same as above Same as above

Magenta Same as above Same as above

Yellow Same as above Same as above

Save Settings

K/01th.[xxx] K/01th.=xxx/255

↓↓

K/15th.[xxx] K/15th.=xxx/255

(continued on the next page)

Adjustment

Replacement

3-3

Page 7

REPLACEMENT AND ADJUSTMENT 17 January, 2001

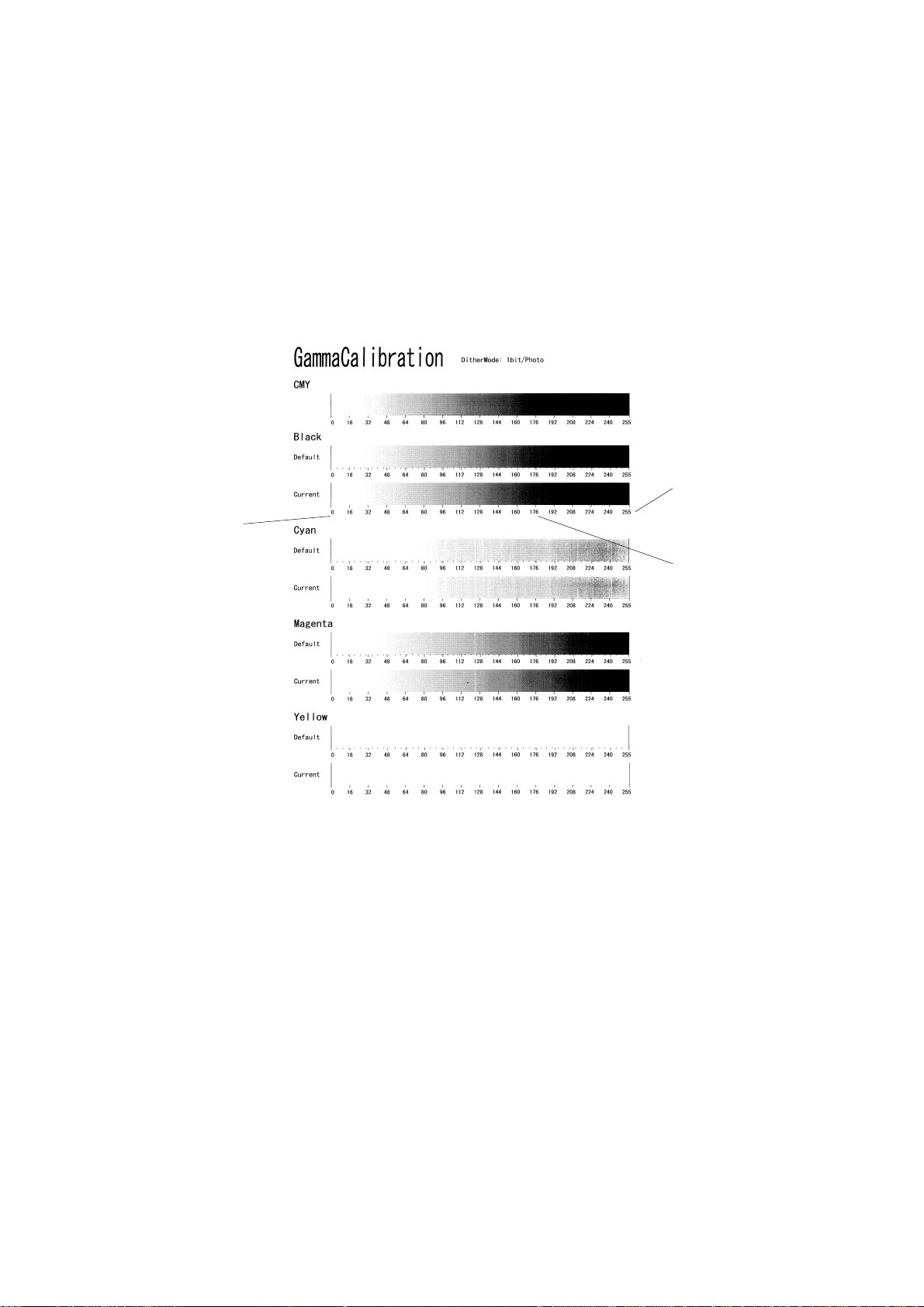

Adjustment Overview

To carry out this adjustment, select the print mode to adjust (text or photograph),

then print out a color adjustment sheet. Make the gradation scales on the printout

smooth from the lowest to the highest density. Adjust the CMY gradation scale at

the top of the chart by balancing the density of the C, M, and Y gradation scales –

the CMY gray scale should change smoothly from minimum to maximum, and

there should be no coloration.

The color adjustment sheet is as follows.

[C]

[B]

[A]

G063R503.BMP

For each color, you can adjust 15 points (example [A]) between 0 (lowest density)

[B] and 255 (highest density) [C]. For each point, you can adjust the density within

0 and 255.

The gradation scales marked ‘Default’ are printed according to the default gamma

settings in the flash ROM in the controller. The gamma adjustment changes the

densities at the adjustable points in the gradation scale. The gradation scale

marked “Current” sho ws th e current settings.

During the adjustment procedure, compare the “Current” gradation scale with the

‘Default’. Select the density for each of the 15 adjustable points, excluding points 0

and 255, from the ‘Default’ gradation scale.

3-4

Page 8

17 January, 2001 REPLACEMENT AND ADJUSTMENT

The NVRAM holds three controller gamma settings, those saved this time (SettingCurrent), those saved in the preceding adjustment (Setting-Old), and the factory

settings (Default).

Adjustment Procedure

1. Select “Load Setting” and load the settings that will serve as the base for the

adjustment.

2. Select “Mode Setting”, and select the print mode that you are going to adjust

(text or photograph).

3. To review the image quality for these settings, choose “Print Setting” to print

out a color adjustment sheet (Gamma Calibration at the top of the page).

4. Select “Gamma Setting”. Then select a color (K, C, Y, or M).

5. Adjust the color density at each of the 15 points.

NOTE: To decide what density value to input, do the following.

1. Look at the color adjustment sheet.

2. For the color you are adjusting, look at the gradation scale entitled

‘Default’.

3. Go along the scale until you reach the density that you wish to

input.

4. Read off the value on the scale and store it in the machine.

5. Do the same for all 15 points.

6. When the density setting is complete for all colors, print out a color adjustment

sheet again and make sure that the gradation scale for each printed color is

smooth and that the CMY gradation scale is gray. Repeat the adjustment if

there is an anomaly (normally, repeat this procedure 3 to 5 times).

7. If the adjustment results prove satisfactory, do the following:

1) Execute “Save Settings”.

2) Reset the controller (press the [Reset] key when the machine is off line”) to

use the new settings.

NOTE: The new settings will not be saved in the controller NVRAM unless you

reset the controller.

Adjustment

Replacement

3-5

Page 9

REPLACEMENT AND ADJUSTMENT 17 January, 2001

3.3.3 SOFTWARE UPGRADE PROCEDURE

Required Tool

- IC card Adapter (G0319350)

- IC card containing new firmware

The controller, RICOH-SCRIPT2 and network interface boards have a flash ROM

for storing control software. This allows version upgrades using an IC card.

NOTE: Before starting an upgrade procedure, make sure that the software in the

IC card is newer than the software in the controller, RICOH-SCRIPT2, or

network interface board.

To check, print out a configuration page (user mode).

Follow the procedure shown below to upgrade the software:

1. Turn off the machine, and then unplug all cables from the parallel interface

board(s) and network interface board, if connected.

2. Install IC card into IC card adapter.

3. Remove the controller board. Then install the IC card adapter in either optional

bus I/F slot 1 or slot 2.

4. Put the controller board back in the machine.

5. Turn on the machine. The machine automatically copies the firmware from the

IC card to the appropriate flash ROM (controller, RICOH-SCRIPT2, or network

interface board).

CAUTION: 1) Do not turn off the machine while the software is being updated.

Otherwise, the controller, NIB, or RICOH-SCRIPT2 module ma y be

damaged.

2) Do not turn off the machine until at least 30 seconds after the

message “OK!!OK!!” or “DOWNLOAD OK.” appears.

3-6

Page 10

17 January, 2001 REPLACEMENT AND ADJUSTMENT

For the controller or RICOH-SCRIPT2:

The LCD display on the operation panel changes as shown below as the

rewrite procedure proceeds. (‘MELT’ is displayed during the software upgrade

for RICOH-SCRIPT2 since it involves a decompression process.)

(MELT ->) ERASE -> WRITE -> VERIFY -> OK!!OK!!

The appearance of the message “OK!!OK!!” indicates that the controller has

received the data from the IC card. However, note that it takes about 30

seconds to rewrite the data in the controller or RICOH-SCRIPT2 after this

message is displayed.

The message NG!!NG!!” is displayed if an error occurs during the rewrite

process. If this condition occurs, reinstall the IC card and turn the power off and

on again.

For the network interface board:

The appearance of the message “DOWNLOAD OK.” indicates that the

controller has received the data from the IC card. However, note that it takes

about 30 seconds to rewrite the data in the network interface board after this

message is displayed.

Adjustment

Replacement

DOWNLOAD -> ############ -> DOWNLOAD OK.

The message “DOWNLOAD NG.” is displayed if an error occurs during the

rewrite process. If this condition occurs, reinstall the IC card and turn the power

off and on again.

4. When the rewrite ends, turn off the main unit, reset all DIP switches to OFF, and

remove the IC card.

5. Replace the IC card cover. Turn the power on again and print the user mode

configuration page.

6. Check the new software version and make sure that it matches the version on

the IC card.

3-7

Page 11

17 January, 2001 TROUBLESHOOTING

4. TROUBLESHOOTING

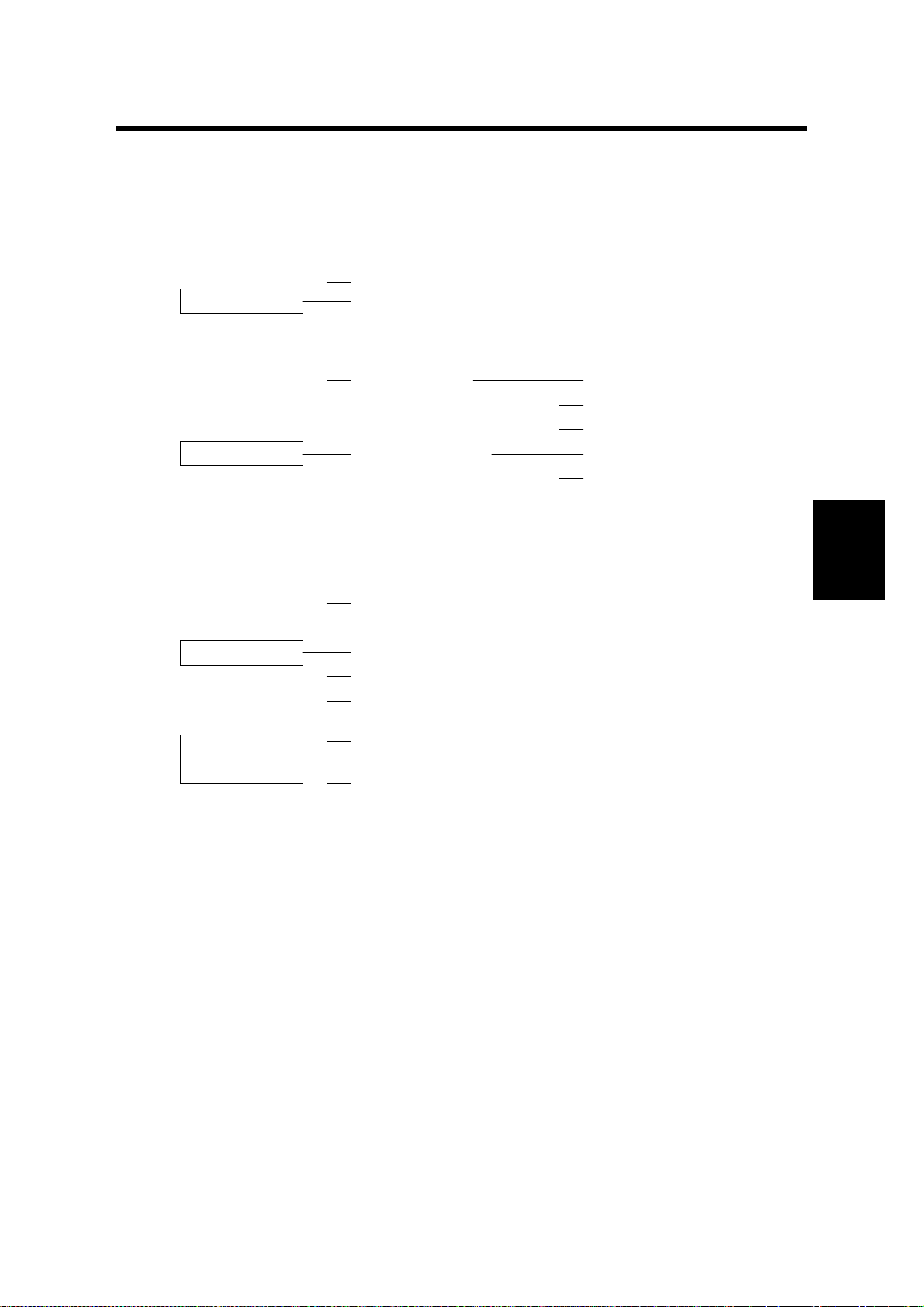

4.1 TYPES OF PROBLEMS

The problems can be classified as follows.

Printer-side Print Settings

•

Operation

Hardware

Printer-side Initial Settings

•

Host-side Application Settings

•

•

Faulty Engine

Faulty Controller

•

Hardware Limitations

•

•

Main Unit

•

Option

•

Consumables

Main Unit

•

•

Option

Software

Operating

conditions

•

Bug in Controller ROM

•

Bug in Emulation Module Software

Controller Limitations

•

•

Bug in Host-side Application

•

Host-side Application Limitations

•

Environment (power, temperature and humidity,

dust, noise, vibration)

•

Consumables

G063T500.WMF

Trouble-

shooting

4-1

Page 12

TROUBLESHOOTING 17 January, 2001

4.2 TROUBLESHOOTING PROCEDURE

4.2.1 HARDWARE TESTS

1. Power-up self-diagnostics

Turn on the power and check that an error code is not displayed.

After the system starts, check for error messages on the configuration page

that is automatically printed.

2. Detailed diagnostic test

See “4.Service Tables - Detailed Self-diagnostics Mode” in this manual for the

procedure.

3. Checking the configuration page output.

Print out from the user menu: [Menu] → [List Print] → [Config. Page]. If error

messages are included, check the relevant part of the machine and replace any

defective components.

4. Connectivity test

Make a test print from a computer.

• Check that the correct cable is used (and connected properly).

• Check the cable continuity.

• Check the cable length (is it too long?).

• Do not connect the printer to the computer through a printer selector switch

– connect the printer to the computer directly.

• If the optional parallel interface is installed, connect the computer to the

parallel interface board that is being tested.

4.2.2 OPERATION-RELATED TESTS

Check the print conditions and initial settings.

Check the printer settings against the application settings. Check whether the

current settings match the settings on the configuration page that the customer

keeps.

NOTE: Ask the customer to print a configuration page at some time when the

controller is working normally, and keep it for reference.

4-2

Page 13

17 January, 2001 TROUBLESHOOTING

4.2.3 SOFTWARE-RELATED TESTS

Obtain information about the following:

• PC model

• OS type and version

• Configuration page

• Application software used, and the version

• Data file being printed when the problem occurred (if obtainable)

• RICOH-SCRIPT2 data file when the problem occurred

• Sample printouts when the error occurred and when the printer is normal

• Detailed operating procedure

• Controller system and emulation module version

• Firmware versions (engine, controller, NIB)

Trouble-

shooting

4-3

Page 14

TROUBLESHOOTING 17 January, 2001

4.3 ERROR MESSAGES

4.3.1 OVERVIEW

The error messages that this unit can issue are classified as follows:

1. Controller Self -diagnostics Errors

Errors detected while the unit performs power-up self-diagnostics/detailed selfdiagnostics on the controller hardware.

2. Controller User Errors

Errors caused because the controller software cannot process the job because

of, for example, insufficient memory.

3. Internal Errors

Errors caused because the controller’s control function fails to function

normally.

4. Engine User Errors (Cautionary)

Errors that do not require user intervention to continue printing (the printer can

still communicate with the PC over the interface). However, for the best printing

quality, the user should correct the problem as soon as possible.

5. Engine User Errors

Severe errors that cause the unit to stop printing, requiring the user to fix the

problem before printing again.

6. Engine Service Codes (SCs)

Severe errors that cause the unit to stop printing, requiring a technician to fix

the problem before printing again.

Only one error message can be displayed at once. There is an order of priority for

displaying the errors. This is as follows, starting with the highest priority: Internal

Errors, Controller Se lf-diagnostics Errors, En gine Service Codes (SCs), Engine

User Errors, Engine User Errors (Cautionary), Controller User Errors.

4-4

Page 15

17 January, 2001 TROUBLESHOOTING

4.3.2 CONTROLLER SELF-DIAGNOSTICS ERRORS

When a contro ller self-diagnostics error occurs, the error code is displayed on the

first line of the operation panel LCD.

The second line contains an 8-digit code that gives details of the error for

designers to debug the error. For a memory error, the second line of the LCD

indicates the address in which the error occurred. For errors other than memory

errors, the second line always reads “FFFFFFFF”.

Code Description Location

00XX Exception processing error Controller

0101 Flash ROM sum check error Controller

0201 Standard memory read/write error Controller

0301/0401 Optional memory read/writ e error

Non-fatal error (printed as B0 in the error

log.)

060X CPU exception self-diagnostics error Controller

0D0X ASIC timer error Controller

0F0X ASIC engine interface error MCTL/Controller

11XX ASIC Centronics interface error

Non-fatal error (printed as B1 in the error

log.)

1401 NVRAM error Controller

1601 Font ROM error Controller

170X IC card error

1703 represents a non-fatal error (printe d as

B4 in the error log.)

1B0X Optional Interface 1 Error Controller

1C0X Optional Interface 2 Error Controller

1D0X Optional par allel interface board

Non-fatal error (printed as B6 in the error

log.)

250X Optional emulation module error

Non-fatal error (printed as B5 in the error

log.)

400X FPU error Controller

450X ASIC compression/decompression error Controller

Optional memory

Controller

IC card/Controller

Optional paralle l int e rface

board

Emulation module/Contr oller

Trouble-

shooting

4-5

Page 16

TROUBLESHOOTING 17 January, 2001

4.3.3 CONTROLLER USER ERRORS

Display Description Location/action

85: Error

86: Error

91: Error

94: Error

A3: Error

A6: Error Overflow during compression Install additional memory.

A7: Error

A8: Error

AB: Error Print overrun Install additional memory.

B0: Error

B1: Error Standard parallel interface err or Interface cable/controller

B3: Error

B4: Error IC card slot error Controller/IC card

B5: Error

B6: Error

B7: Error

Graphics environment i nit ialization

error

Invalid control code paramet er Incorrect printer driver or

Font/image environ me nt initialization

error

Download data error Incorrect ‘total memory size’

Receive buffer overflow Increase the I/O buffer size

Error during drawing processing

Error during library drawing Switch the machine off/on. If

Optional memory error Reinstall/replace optional

Invalid initial setup setting Reset the printer settings using

Optional emulation mo dule error Reset/replace emulat ion

Optional parallel int e rface board

error

Optional network interface board

error

Optional memory/Controller

incorrect cable installed

Install additional memory.

setting in the driver

using the system menu (user

mode)

Use a smaller font size or a

less complex font, or replace

the controller

that does not work, replace the

controller.

memory.

‘Menu reset’ in the

Maintenance menu (user

mode).

module.

Reset/replace optional parallel

interface board

Reinstall/replace net w ork

interface board

4-6

Page 17

17 January, 2001 TROUBLESHOOTING

4.3.4 INTERNAL ERRORS

When an internal error occurs, the message “Err Power Off/On” is displayed on the

first line of the operation panel LCD. The internal error code is on the second line in

the format “Error XXYY-ZZZZZZZZ” (“XX” denotes a classification code; “YY”

denotes a process number, and “ZZZZZZZZ” indicates the program address where

the error occurred).

The classification code portions (XX) and their descriptions are shown below. The

“YY” and “ZZZZZZZZ” portions are for designer use only (for debugging).

Code (XX) Description

00 Error in the TLB user area.

01 CPU TLB update exception

02 CPU mis match exception (load or fetch)

03 CPU mis match exception (store)

04 CPU addres s error exception (load or fetch)

05

06 CPU bus error exc ept i on (load or fetch)

07 CPU bus error exc ept i on (st ore)

08 CPU sy stem call exception

09 CPU break point exception

10 CPU reserv ed instruction exception

11 CPU coproc essor disabled exception

12 CPU operati on overflow exception

13 CPU trap exception

14 Coherency (instruction) error

15 CPU float ing-point operation exception

16 CPU timer interrupt

17 EAGLE level 4 interrupt (ART or Tim)

18 EAGLE level 3 interrupt (CP)

19 EAGLE level 2 interrupt (XINT1 or XINT0)

20 EAGLE level 1 interrupt (CBE, DBE, Dtc0, Verr, F in, Vdtc, Fout)

21 EAGLE level 0 interrupt (Debug)

22 Software interrupt

23 Software interrupt

24 Other CPU exceptions

25 Memory allocation error

26 Overflow error

27 Frame allocation error

28 Card eject error

29 Printer engine error

30 Option board error

31 Session-to-net w ork interface board communications error

CPU address error exception (store)

Trouble-

shooting

4-7

Page 18

TROUBLESHOOTING 17 January, 2001

4.3.5 ENGINE USER ERRORS (CAUTIONARY)

The unit can continue printing even when one of the messages listed below is

encountered.

Display Description

Low on: XXX Toner near end

XXX denotes the color name

(CMYK or their combination).

Chg. Cleaner Fusing cleaner replacement

time arrived

Fusing Oil Fusing oil near end 30

Change PCU Photoconductor unit

replacement time arrived

Change 120K 120k maintenan ce requested Information only

Change Fuser

Fusing unit replacement time

arrived.

Number of sheets until warning

500 at a 5% image ratio (300

sheets for Black).

1,000 at a 5% image ratio

Information only

Information only

state

4-8

Page 19

17 January, 2001 TROUBLESHOOTING

4.3.6 ENGINE USER ERRORS

The unit can no longer continue printing when one of the following messages is

displayed:

Display Description

Add Toner XXX Toner end (XXX: Cyan, magenta, yellow, or black)

Waste Toner is

Full

Fusing Oil Fusing oil end

Paper Size Error Paper size error

Change Fuser

Cleaner

Paper Type Error Media mismatch

Load YYY tray

XXX

Reset Paper Tray

Correctly

Close Top Cover Paper exit cover open

Close Front Cover Front cover open

Reset XXX Toner

Correctly

Close Rear Cover Rear cover open

Reset Fusing Unit

Correctly

Reset PCU

Correctly

Reset Cleaning

Roller Correc tly

Remove Misfeed

from Tray XXX

Waste toner bottle full

Fusing cleaner needs replacement.

Paper end (XXX denotes a tray name and YYY a paper size.)

No tray

No toner cartridge (XXX denotes a color name.)

No fusing unit

No photoconductor unit

No fusing cleaner

Paper jammed

Trouble-

shooting

4-9

Page 20

TROUBLESHOOTING 17 January, 2001

4.3.7 ENGINE SERVICE CODES

When an engine service call (SC) erro r occurs, an error me ssage is displayed on

the operation panel LCD in the format “Call Service SC: XX” where XX denotes an

error code. The engine SC error codes and their descriptions are shown below.

For the troubleshooting procedures, refer to the engine service manual.

Display Description

SC: EC

SC: 22

SC: 23

SC: 24

SC: 25

SC: 31

SC: 33

SC: 34

SC: 35

SC: 41

SC: 42

SC: 43

SC: 44

SC: 45

SC: 51

SC: 52

SC: 53

SC: 54

SC: 55

SC: 61

SC: 62

SC: 63

SC: 64

SC: 65

SC: 66

SC: 71

SC: 72

SC: 73

SC: 74

SC: 75

SC: 76

SC: 81

SC: 83

SC: 84

SC: 85

SC: 86

Engine communication error

Development motor error

Main motor error

Polygon mirror motor error

Charge corona voltage (CHV) error

Fusing thermistor error

Fusing temperature error (warming-up time error)

Fusing temperature error (temperature too low)

Fusing temperature error (temperature too high)

Beam sensor error

Laser power error

NVRAM error (MCTL)

Engine controller MCTL hardware error

Process timing clock error (main motor clock error)

Quenching lamp error

Toner end sensor error

Control fan error

Ozone fan error

Fusing fan error

Yellow development clutch error

Magenta development clutch error

Cyan development clutch error

Black development clutch error

HPSI signal error (retraction error for the black and yellow toner cartridges)

HPSI signal error (retraction error for the cyan and magenta toner cartridges)

Transfer drum rotational error

Transfer roller contact solenoid error

Cleaner contact solenoid error

Cleaner clutch error

Fusing unit clutch error

Belt sensor error

Duplex unit controller error

Duplex unit lower solenoid error

Duplex unit motor error

Duplex unit upper solenoid error

Duplex unit fan motor error

4-10

Page 21

17 January, 2001 SERVICE TABLES

5. SERVICE TABLES

5.1 SP MODES

5.1.1 OVERVIEW

The printer has two types of SP modes:

1. Engine SP modes

2. Controller SP modes

This section deals with controller SP modes.

5.1.2 ENGINE SP MODE

Refer to the service manual for the engine for how enter engine SP mode and use

the engine SP modes.

5.1.3 CONTROLLER SP MODE

Entering and Exiting Controller SP Mode

[A]

[B]

Power

Error

Media

G063S000

On Line

EscapeMenu

Enter

#

Data in

Reset

[A]

[B]

#

G063S001

To enter controller SP mode: Turn on the printer while holding down the [On

Line] [A] and [Reset] [B] keys on the operator panel. Hold the keys down until all

of the LEDs and the LCD turn on. Then after the printer completes its cycling, press

the [Menu] key.

Tables

Service

To exit controller SP mode: Turn the main switch off and, after a brief period,

back on.

NOTE: When accessing controller SP mode, “SP” is displayed in the upper right

corner of the display. Do not forget to exit SP mode after servicing. If

inadequately left in controller SP mode, users could change settings or

clear all settings by accident.

5-1

Page 22

SERVICE TABLES 17 January, 2001

SP Mode Menu Hierarchy

The table below shows the controller SP mode menu hierarchy. The individual

layers in the table below can be accessed in the controller SP mode by pressing

the [Enter] key. When in SP mode, S1 to Sa are added to the Maintenance menu.

Layer 1 Layer 2 Layer 3 Layer 4

Maintenance

1.Toner Level Cyan

Magenta

Yellow

Black

2.Reinstall Fuser Cleaner

Photoconductor Unit

3.Menu Reset

4. Registration L:Tray 2

5. Menu Protect Off

On

S1.Maint. Page

S2.Color Chart

S3.Maint. Clear Fusing Unit

120k

S4.Transfer Bias Plain paper

Thick paper

OHP paper

S5.Registration W:Tray 1/2

L:Tray 1

S6.Clear All Memo

S7.Gamma Calib. Load Setting Default

Mode Setting 1 bit/Photo

Print Setting

Gamma Setting Black

S8.Printer ID

S9 Toner Limiter Text

Photograph

Sa Meter Click Off

Print/Jam

Develop. Count

Print Count

It can also be accessed if

the [Enter], [Escape],

and [Menu] key s ar e

pressed in sequence

when the printer is on line.

Setting-Old

Setting-Current

1 bit/Text

Cyan

Magenta

Yellow

Save Settings

5-2

Page 23

17 January, 2001 SERVICE TABLES

5.1.4 SP MODE DETAILS

S1. Maintenance Page

The table below explains the contents of the engine maintenance list printout. The

controller obtains the data from the engine (MCTL).

Item Description

MCTL

firmware

Registration

setting

Toner density

setting

Total counter Indicates the total number of printouts and the total number of toner images

Maintenance

counter

The MCTL board firmware version number.

For tray 1, the leading edge and left side registrations can be adjusted either

with engine SP mode 43 (Margin Adjust) or with controller SP mode 5

(Registration).

For tray 2, the leading edge and left side registrations can be adjusted with

engine SP mode 43 (Margin Adjust). The left side registration can also be

adjusted with a controller user mode (Registration Adjustment), and the leading

edge registration can be adjusted with controller SP mode 5 (Registration).

For how to use this adjustment, see ‘5.Service Tables – 5.5.1 Adjusting the

Leading Edge and Left Side Registrations’ in the engine service manual.

The registration values can be adjusted in 0.5 mm increments in either the

controller or the engine SP mode. Whichever mode is used, the settings are

stored in the NVRAM on the MCTL.

Indicates the following:

LD power setting for each toner color (CMYK)

Transfer roller voltages for plain paper, thick paper, and OHPs

Development bias for each toner cartridge (CMYK)

These values can all be adjusted with engine SP mode. LD power can also be

changed with the user menu (Density Setup) and the transfer bias values can

be changed in controller SP mode (S4. Transfer Bias).

See the explanation after this table for more about this part of the printout.

made in each of the CMYK toners. The counter is incremented when the paper

exit sensor detects the completion of paper exit (regardless of paper size, type,

and mono/color mode).

Indicates the following for the fusing cleaning roller, fusing unit, and 120k

maintenance parts:

Next life limit counter (expected number of prints remaining)

Current value of the total counter

Lifetime of the part (fixed), divided by 100 to get a % value on the report

Amount of expected life time remaining

Indicates the following for the belt cartridge:

Next life limit counter (expected number of images remaining)

Sum of the current values of the CMYK image counters

Lifetime of the part (fixed), divided by 100

Amount of expected life time remaining

The formula used is as follows:

(Next Life Limit - Total Counter)/Life Period = Life remaining (%)

The values of the next life limit counters, except for 120k maintenance, vary

according to the image ratio or the job sizes during the life of the part. For

details, see ‘5.Service Tables – 5.5.3 Setting the Next Life Limit Value’ in the

engine service manual.

Tables

Service

Meter Click The selected Meter Click mode is shown.

SC Logging The latest 6 SC codes are shown.

The codes in square brackets are internal engine error codes.

5-3

Page 24

SERVICE TABLES 17 January, 2001

Item Description

Jam Logging The latest 6 jam codes are shown.

00: No Error (Initial stored data)

01: Entrance

02: Internal

03: Around the transfer drum

04: Exit

05: Duplex (Upper)

06: Duplex (Lower)

Toner density setting

The displayed value of the laser power when it is set in engine SP mode differs

from when it is set from the user menu. Both values are included in the printout, as

shown below. The following is an example for cyan (C).

C (Laser Power: SP [Usr]) +1 [08]

Value displayed in engine

SP mode

Value displayed in user

mode

The table below compares the density settings that are set from the user menu

(“Toner level”) with those set in engine SP mode.

As seen from the table, finer adjustments are possible with user mode.

User Mode

Display Value

-1 -4

0-3

1-3

2-2

3-2

4-1

5-1

60

70

8* 1*

91

10 2

11 2

12 3

13 4

Engine SP

Mode Display

Value

*: Default setting

5-4

Page 25

17 January, 2001 SERVICE TABLES

S2. Color Chart

This prints a color test chart, so that the image quality can be tested for all colors at

various densities. This chart can be printed on all paper sizes supported by the

machine (the layout of the print pattern varies from paper size to paper size).

S3. Maintenance Clear

This mode resets the maintenance counters for the fusing unit replacement or 120k

maintenance parts (these counters are in the NVRAM on the MCTL board). Use it

after doing the PM required for these units. See ‘4.Service Tables – Setting the

Next Life Limit Value’ in the engine service manual for information about how to

use this SP mode.

S4. Transfer Bias

This mode adjusts the transfer roller voltages used for the three paper types (plain

paper, thick paper and OHP transparency) supported by this unit. For each paper

type, you can set the value in 4 increments. The settings are stored in the NVRAM

on the MCTL board.

Default value: 0

S5. Registration

This mode adjusts the leading edge registration for trays 1 and 2 and the left side

registration for tray 1. You can set each value in ±7 increments (1 step = 0.5 mm).

The values are stored in the NVRAM on the MCTL board. See ‘4.Service Tables –

Adjusting the Leading Edge and Left Side Registrations’ in the engine service

manual for information about how to use this SP mode.

NOTE: Engine service mode 43 (Margin Adjust) can be used to adjust all of the

registrations, whereas controller SP mode S5 can only adjust a few of

them.

S6. Clear All Memory

Executing this function resets the following user settings, stored in the NVRAM on

the controller, to their initial values:

• Emulation/system initial setup items

• Printer ID

• Printer name on the network

• Gamma calibration

The “Menu Reset” clear function in the user menu only resets the emulation/system

initial setup items to their initial values.

Tables

Service

5-5

Page 26

SERVICE TABLES 17 January, 2001

S7. Gamma Calibration

This mode adjusts the gamma tables used in text and photograph modes.

NOTE: For problems with color quality and gradation, clean the engine and

replace consumables and other parts at first. Use this mode only when the

customer insists on further fine adjustments (e.g., matching colors between

machines)

See “3. Replacement and Adjustment – 3.3.2 Service Gamma Adjustment” in this

manual for the adjustment procedure.

S8. Printer ID

The printer ID allows the RICOH-SCRIPT2 emulation module to identify the printer

main unit. It is programmed in the NVRAM on the controller at the factory.

When replacing the controller, it is necessary to use this SP mode to re-input the

printer ID since the printer ID for the old controller is required.

Follow the procedure given below to input the printer ID:

1. Select the first digit using the [!!!!] and [""""] keys.

2. Input the number by pressing the [Enter] key (you can use the [Escape] key to

cancel the setting if you input an incorrect number).

3. Repeat these steps until the last digit is entered. Pressing the [Enter] key on

the last digit returns you to the “S8. Printer ID” menu.

4. Print a configuration page and verify that the correct printer ID is defined.

5. Turn the power off and on again to exit SP mode.

S9. Toner Limiter

The maximum toner values can be adjusted from 100 to 400% for both Text and

Photo Modes. The default value for both is 250%.

If this value is set high, the printed image appears more true to the original data.

However, since a greater amount of toner is used, it is easy to scatter the toner

around lines and text areas. If the value is set low, the color balance of low-density

areas varies, however toner does not scatter as easily.

5-6

Page 27

17 January, 2001 SERVICE TABLES

Sa Meter Click

In this mode, the counting method can be selected depending on the type of

service contract.

When meter click mode is activa ted, the machine is affected as follows:

1. A new user mode, “Show Counter” displays the counter values.

2. The printer will stop printing when toner has run out. In addition, “Toner Empty”

disappears from the Maintenance menu.

3. The configuration sheet includes the value for the counting method selected in

Meter Click mode, not the total counter value. Both counter values are included

in the engine maintenance sheet.

4. After selecting meter click mode, the counter value for the selected counting

method is automatically set to 0. However, it cannot be reset to 0 after the

machine begins counting.

5. All developments/prints are counted at paper exit.

6. Counting method:

1) By developments

B/W Image

Color Counter +1 +2 +3 +3

Black Counter +1 +1

1C image 2C image 3C image Full color

2) By prints

B/W Image

Color Counter +1 +1 +1 +1

Black Counter +1

1C image 2C image 3C image Full color

7. The following are not counted:

1) The final page when printing an odd number of pages in duplex mode.

2) The engine maintenance sheet, color chart and gamma calibration sheets in

controller SP mode.

3) All sheets printed out in engine SP mode.

4) The Low-Memory Error Sheet.

5) A list of settings (B/W) if a non-fatal error is detected during Self-Diagnostics.

Tables

Service

5-7

Page 28

SERVICE TABLES 17 January, 2001

5.2 DETAILED SELF-DIAGNOSTICS MODE

Overview

In this mode, the controller tests components that are not tested during the powerup self-diagnostics. These are the memory, standard parallel interface, and options

(optional interfaces, Memory slot and DIMM slot), if the devices are installed.

The following special tools are required to execute this mode:

Parallel Interface Loopback Connector

Part No. Type of Interface Remarks

G0219350 For the standard parallel

interface board

G0109350 For the optional parallel

interface board

NOTE: A decal with the part number is attached to each connector, to avoid

confusing the two types.

If not used, the controller continues t he test

to the end, but flags a non-fatal error.

If an interface board is inst alled but the

loopback connector is not, the cont roller

continues the test to the end, but fl ags a

non-fatal error.

Operating Procedure

[A]

Power

Error

On Line

EscapeMenu

[A]

Data in

Reset

[B]

[B]

#

Media

G063S000.WMF

Enter

#

G063S001.WMF

To enter the detailed self-diagnostics mode, make sure that the devices that you

wish to test are installed. Then do the following.

1. Switch off the power.

2. Connect the loopback connector to the parallel port. If the optional additional

parallel interface has been installed, connect the loopback connector for this

port also.

3. Turn on the power while simultaneously pressing and holding down the [On

Line] [A] and [Enter] [B] keys on the operation panel. Hold the keys down until

all of the LEDs and the LCD turn on.

5-8

Page 29

17 January, 2001 SERVICE TABLES

Operation Panel Behaviour during Detailed Self-diagnostics

Immediately after power is turned on

The controller turns on all LEDs and the LCD.

During detailed self-diagnostics

When the controller starts the self-diagnostics, it turns off all LEDs except the

Power LED and causes the Power LED to blink. It displays the message “Service

diag” on the LCD.

When the tests terminate normally

When an error does not occur during the self-diagnostic test, the controller causes

the blinking Power LED to stay on and turns off all the other LEDs and the LCD.

The controller starts the system immediately afterward and prints out a list of

settings in color mode.

When an error is detected

Errors are divided broadly into non-fatal errors and fatal errors. The controller takes

different actions and gives different status information for different types of errors.

• When a non-fatal error (user error) is detected

The controller turns the blinking Power LED on, turns off all of the other LEDs

and the LCD, and restores the standby display. Since non-fatal errors do not

adversely influence any print operation, the controller starts the system

immediately after it takes these actions.

The system turns on the Error LED and prints out a list of settings with error

descriptions in monochrome mode (see 4. Troubleshooting – 4.3.3 Controller

User Errors in this manual for the error codes).

After printing a list of settings, the system returns to the normal state and sets up

all devices except the failed device.

• When a fatal error is detected

Since there is no guarantee that the system can generate a list of settings after

detecting a fatal error, the system turns off the Power LED and turns on the Error

LED. At the same time, it displays an error message on the LCD until the power

turns off.

The first line of the LCD contains a 4-digit code that identifies the error and the

second line contains an 8-digit code that gives details of the error for designers

to debug the error (see 4. Troubleshooting – 4.3.2 Controller Self-diagnostics

Errors in this manual for a description of the error codes).

Tables

Service

5-9

Page 30

SERVICE TABLES 17 January, 2001

Detailed Self-diagnostics Flow

Chart

Turn On Power

Code ROM sum check

Tests the timer functions of

the EAGLE 2

Read/write test

Operation test

Tests the engine interface functions of the

EAGLE 2 and KOTO; makes a loopback

test on the standard Centronics interface

Read/write test

Code ROM sum check

IC card sum check (if

card is installed)

Test Code ROM

Test Timer

Test Memory

Test CPU

Test ASIC

Test NV-RAM

Test Font ROM

IC Card installed?

Yes

Test IC Card

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Fatal Error Detected

Display error on panel

No

DIMM (emulation module)

sum check

Optional parallel interface

board loopback test (if board

is installed)

Yes

Test DIMM

Optional Parallel

I/F installed?

Yes

Test Optional Parallel I/F

Start System

Generate list of

settings

No

G063M503.WMF

5-10

Page 31

17 January, 2001 SERVICE TABLES

Test Results Printout when No Fatal Errors Occur

If a non-fatal error occurred, the report is printed in black and white. The “Error

Log” section at the bottom of the printout explains the non-fatal errors that

occurred.

If no error occurred, the report is printed in color. The “Error Log” section contains

“None”.

The right side of the sample printout contains gradation patterns in the following

colors, from the top, C, M, Y, K, R, G, B, and CMY.

5.3 BRAND SETTING

Operating Procedure

Power

Error

On Line

Data in

Reset

[C]

[B]

EscapeMenu

[A]

#

Media

G063S000

Enter

#

G063S001

1. Press the [!!!!][A], [""""] [B], and [Menu] [C] keys sequentially.

2. Select “S1. Brand” in the Maintenance menu.

Layer 1 Layer 2 Layer 3 Layer 4

Maintenance S1.Brand RICOH JPN

RICOH EXP(Default)

SAVIN

Gestetner

NRG

[C]

[B]

[A]

Tables

Service

3. Press the [Reset] key to reboot the machine.

5-11

Page 32

17 January, 2001 FUNCTIONAL OVERVIEW

6. DETAILED DESCRIPTIONS

6.1 FUNCTIONAL OVERVIEW

6.1.1 PRINT DATA PROCESSING

The diagram below shows the print data processing path. The boxes in the

diagram represent function blocks and the text next to the arrows indicates the

data type. The diagram is followed by a brief description of color processing by the

printer driver.

IPDL-C Driver

BG/UCR

CMYK 8bit

Gamma

Correction

CMYK 8bit

Maximum

Toner Control

Dithering

CMYK 1/2bit

Amount

CMS

Controller

CMYK 8bit

Gamma

Correction

Table

Maximum

Amount Value

(for service)

1/2bit

Text/Photo

Dither

PS Driver

RGB 8bit CMYK 8bitRGB 8bit

RPS2 Module

(including CMS)

BG/UCR

Manual Gamma

Correction

Detailed

Descriptions

MCU

Printer Engine

Operation Panel

G063D500.WMF

NOTE: 1-bit color for 600 x 600 dpi printing and 2-bit color for 1200 x 600 dpi

mode printing

6-1

Page 33

FUNCTIONAL OVERVIEW 17 January, 2001

CMS (Color Management System)

CMS adjusts the RGB values of the colors in the application data in preparation for

RGB to CMYK conversion, which is done in the controller.

A file known as a ‘profile’ (filename extension ‘prf’) is automatically installed in the

\windows\system\ folder during printer driver installation. This file contains

instructions for CMS on how to convert the colors in the print data produced by the

application.

CMS is used whenever the color correction setting in the printer driver is set to any

value other than “Off”.

Color Adjustment by the Driver

The driver adjusts the following parameters in accordance with the driver settings

made by the user: Brightness, Contrast, Saturation, and Color Balance.

The driver does not perform RGB to CMYK color conversion.

Color Conversion, Gamma Conversion, and Dithering by the Controller

The controller performs gamma conversion (see Gamma Correction), RGB-toCMYK conversion, and dithering.

6.1.2 GAMMA CORRECTION

Gamma correction in this model has two components: controller gamma (nonadjustable) and service gamma (adjustable).

Controller gamma

This gamma is programmed into the flash ROM in the controller. If there has been

no service gamma adjustment in the machine so far since installation, the controller

gamma is the only gamma that is used (i.e., service gamma = 0).

Service gamma

This gamma is stored in the NVRAM in the controller. It can be adjusted using

controller SP mode (S7. Gamma Calibration). See “3. Replacement and

Adjustment – 3.3.2 Service Gamma Adjustment” in this manual for the adjustment

procedure.

The controller combines the service gamma (the default setting is zero) with the

controller gamma when doing gamma correction.

6-2

Page 34

17 January, 2001 FUNCTIONAL DESCRIPTION

6.2 FUNCTIONAL DESCRIPTION

6.2.1 CONTROLLER LAYOUT

VIDEO I/F

DIP SW

ASIC

KOTO

CPU

RM5261

Optional Memory I/F

Optional BUS I/F 1 Optional BUS I/F 2

ASIC

EAGLE 2

Flash

Font ROM

NVRAM

Detailed

Descriptions

IEEE 1284 I/F

6-3

G063D501.WMF

Page 35

FUNCTIONAL DESCRIPTION 17 January, 2001

6.2.2 FUNCTIONS OF COMPONENTS

Device Function

CPU RM5261-250

ASIC EAGLE 2 This ASIC controls the following:

• Memory mapping

• Reset

• DRAM

• Data received from the parallel

• Video DMA

• PvDMA

• Interrupt

• Serial communication with engine

• IEEE1284 interface

• Timer

•

I/O Port

ASIC KOTO Video da t a interface

FLASH ROM Stores program (2 MB) The flash ROM is programmable via an IC

card.

NVRAM

FONT ROM Stores internal printer fonts.

Program ROM RICOH-SCRIPT2 Emulat ion Modul e

DIP SW

Stores the initial settings and printer parameters.

(8 KB EEPROM)

(One 64-Mbit mask ROM)

The emulation module is progra mmable by IC card.

1234

5678

OFF

G063C004.WMF

SW No. Setting Content

1OFF

2ON

3-8 OFF

Set this switch ON when downloading

MCTL firmware.

Do not touch these switches in the field.

Video I/F Interface the controller with the pr int er engine.

IEEE1284 I/F Provides an interface that connects to a local host (IEEE1284

compliant).

Option Bus I/F

• Two slots; each can hold either an optional network interface or

a parallel interface board. You cannot install two boards of the

same type.

• IC card adapter for downloading the Controller and MCTM

firmware.

Option RAM I/F A slot for accommodating the memory.

6-4

Page 36

17 January, 2001 POWER-UP SELF-DIAGNOSTICS

6.3 POWER-UP SELF-DIAGNOSTICS

6.3.1 OPERATION PANEL DISPLAY DURING POWER-UP SELFDIAGNOSTICS

The controller starts power-up self-diagnostic tests when the printer power is

turned on. It shows the test status on the panel as the self-diagnostics proceed.

Immediately after turning the power on

The controller turns on all LEDs and the LCD.

During power-up self-diagnostics

When the controller starts the self-diagnostics, it turns off all LEDs except the

Power LED, which it causes to blink. It displays the message “Warming UP” on the

first line of the LCD.

If the test terminates normally

If an error is not detected during the self-diagnostic test, the controller turns the

blinking Power LED on and turns off all the other LEDs and the LCD. The

controller starts the system immediately afterwards.

If an error is detected

Errors are divided broadly into fatal and non-fatal (user) errors. The controller takes

different actions and gives different status information for different types of errors.

See section 4 (Troubleshooting) for tables o f the di ffer ent ty pes of err ors .

Detailed

Descriptions

6-5

Page 37

POWER-UP SELF-DIAGNOSTICS 17 January, 2001

Non-fatal error (user error) detected

The controller causes the blinking Power LED to stay on, turns off all of the other

LEDs and the LCD, and restores the standby display state. Since non-fatal errors

do not adversely affect any print operation, the controller starts the system

immediately after it takes these actions.

The system turns on the Error LED and prints out a list of settings with error

descriptions, in monochrome mode (see section 4 Troubleshooting – 4.3.3.

Controller User Errors in this manual for the error codes).

After printing the above list of settings, the system returns to the normal state and

enables all devices except the failed device.

Fatal error detected

Since there is no guarantee that the system can generate a list of settings when

the error detected is fatal, the system turns off the Power LED and turns on the

Error LED. At the same time, it displays and keeps an error message on the LCD

until the power is turned off.

The first line of the LCD contains a 4-digit code that identifies the error. (see

section 4 Troubleshooting – 4.3.2 Controller Self-diagnostics Errors in this manual

for a description of the error codes).

6-6

Page 38

17 January, 2001 POWER-UP SELF-DIAGNOSTICS FLOW CHART

6.4 POWER-UP SELF-DIAGNOSTICS FLOW CHART

Turn on power

Fatal Error

Code ROM sum check

Tests the timer functions

of the EAGLE 2

Operation check

Tests the engine interface functions

of the EAGLE 2 and KOTO

Font ROM sum check

Test Code ROM

Test Timer

Test CPU

Test ASIC

Test Font ROM

Detected

Fatal Error

Detected

Fatal Error

Detected

Fatal Error

Detected

Fatal Error

Detected

IC card sum check, if IC

card is installed

IC card installed?

YES

Test IC card

YES

Test DIMM

Non-fatal Error

(user error)?

YES

Start System

Generate List of

Settings

NO

NO

Display Error on

Panel

Detailed

Descriptions

Start System

6-7

G063M057.WMF

Loading...

Loading...