Page 1

Model AP-P3

Machine Code: M124/M125

Field Service Manual

14 September, 2012

Subject to change

Page 2

Page 3

Important Safety Notices

Prevention of Physical Injury

1. Before disassembling or assembling parts of the machine and peripherals, make sure that the

machine power cord is unplugged.

2. The wall outlet should be near the machine and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off or open while the

main switch is turned on, keep hands away from electrified or mechanically driven components.

4. The machine drives some of its components when it completes the warm-up period. Be careful to

keep hands away from the mechanical and electrical components as the machine starts operation.

5. The inside and the metal parts of the fusing unit become extremely hot while the machine is

operating. Be careful to avoid touching those components with your bare hands.

Health Safety Conditions

1. Toner and developer are non-toxic, but if you get either of them in your eyes by accident, it may

cause temporary eye discomfort. Immediately wash eyes with plenty of water. If unsuccessful, get

medical attention.

2. The machine, which use high voltage power source, can generate ozone gas. High ozone density

is harmful to human health. Therefore, the machine must be installed in a well-ventilated room.

Observance of Electrical Safety Standards

The machine and its peripherals must be serviced by a customer service representative who has

completed the training course on those models.

• Keep the machine away from flammable liquids, gases, and aerosols. A fire or an explosion

might occur.

• The Controller board on this machine contains a lithium battery. The danger of explosion exists if a

battery of this type is incorrectly replaced. Replace only with the same or an equivalent type

recommended by the manufacturer. Discard batteries in accordance with the manufacturer's

instructions and local regulations.

• The optional fax and memory expansion units contain lithium batteries, which can explode if

replaced incorrectly. Replace only with the same or an equivalent type recommended by the

1

Page 4

manufacturer. Do not recharge or burn the batteries. Used batteries must be handled in

accordance with local regulations.

Safety and Ecological Notes for Disposal

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly when exposed to an

open flame.

2. Dispose of used toner, the maintenance unit which includes developer or the organic

photoconductor in accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do not put more than 100

batteries per sealed box. Storing larger numbers or not sealing them apart may lead to chemical

reactions and heat build-up.

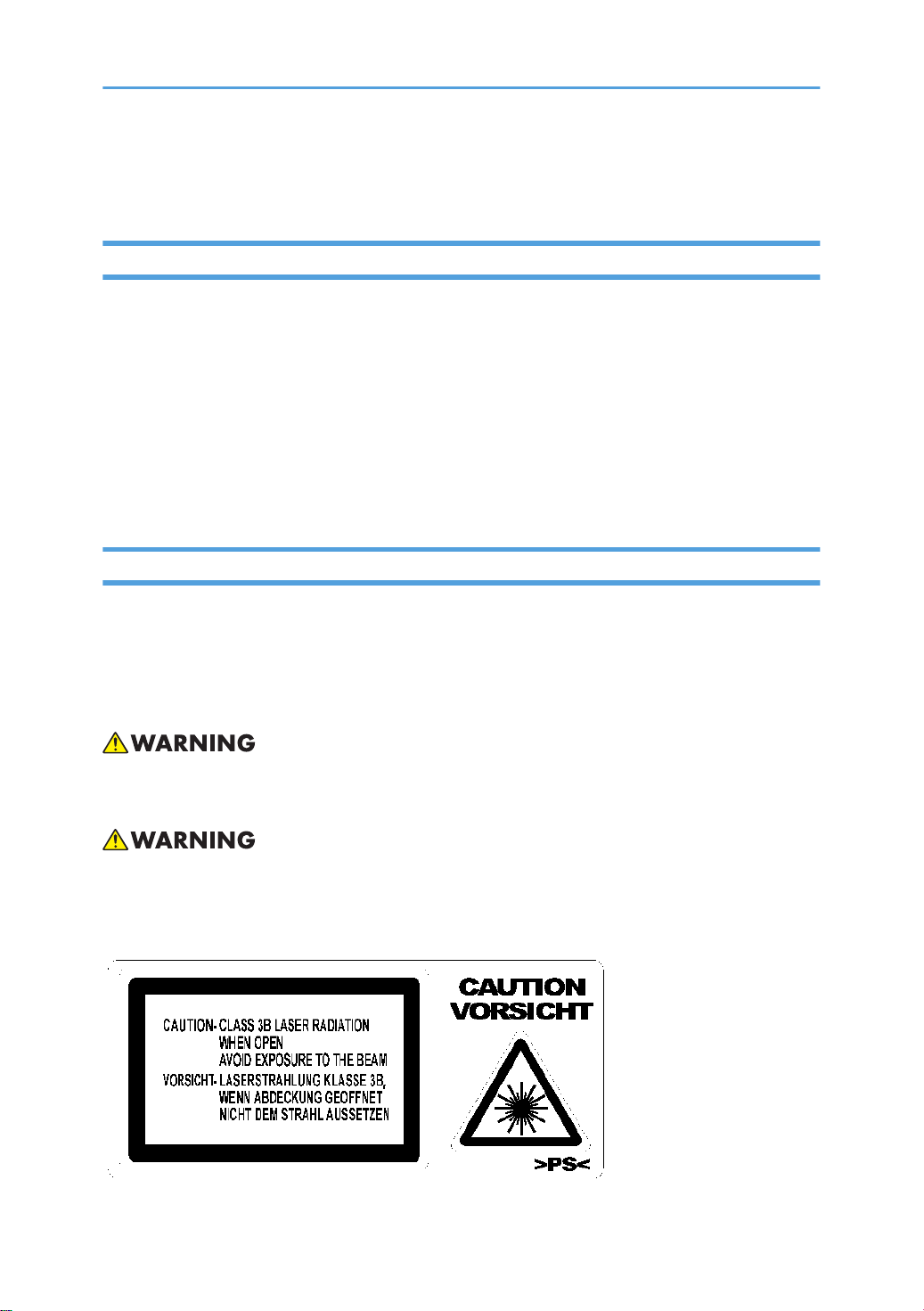

Laser Safety

The Center for Devices and Radiological Health (CDRH) prohibits the repair of laser-based optical units

in the field. The optical housing unit can only be repaired in a factory or at a location with the requisite

equipment. The laser subsystem is replaceable in the field by a qualified Customer Engineer. The laser

chassis is not repairable in the field. Customer engineers are therefore directed to return all chassis and

laser subsystems to the factory or service depot when replacement of the optical subsystem is required.

• Use of controls, or adjustment, or performance of procedures other than those specified in this

manual may result in hazardous radiation exposure.

• WARNING: Turn off the main switch before attempting any of the procedures in the Laser Optics

Housing Unit section. Laser beams can seriously damage your eyes.

• CAUTION MARKING:

2

Page 5

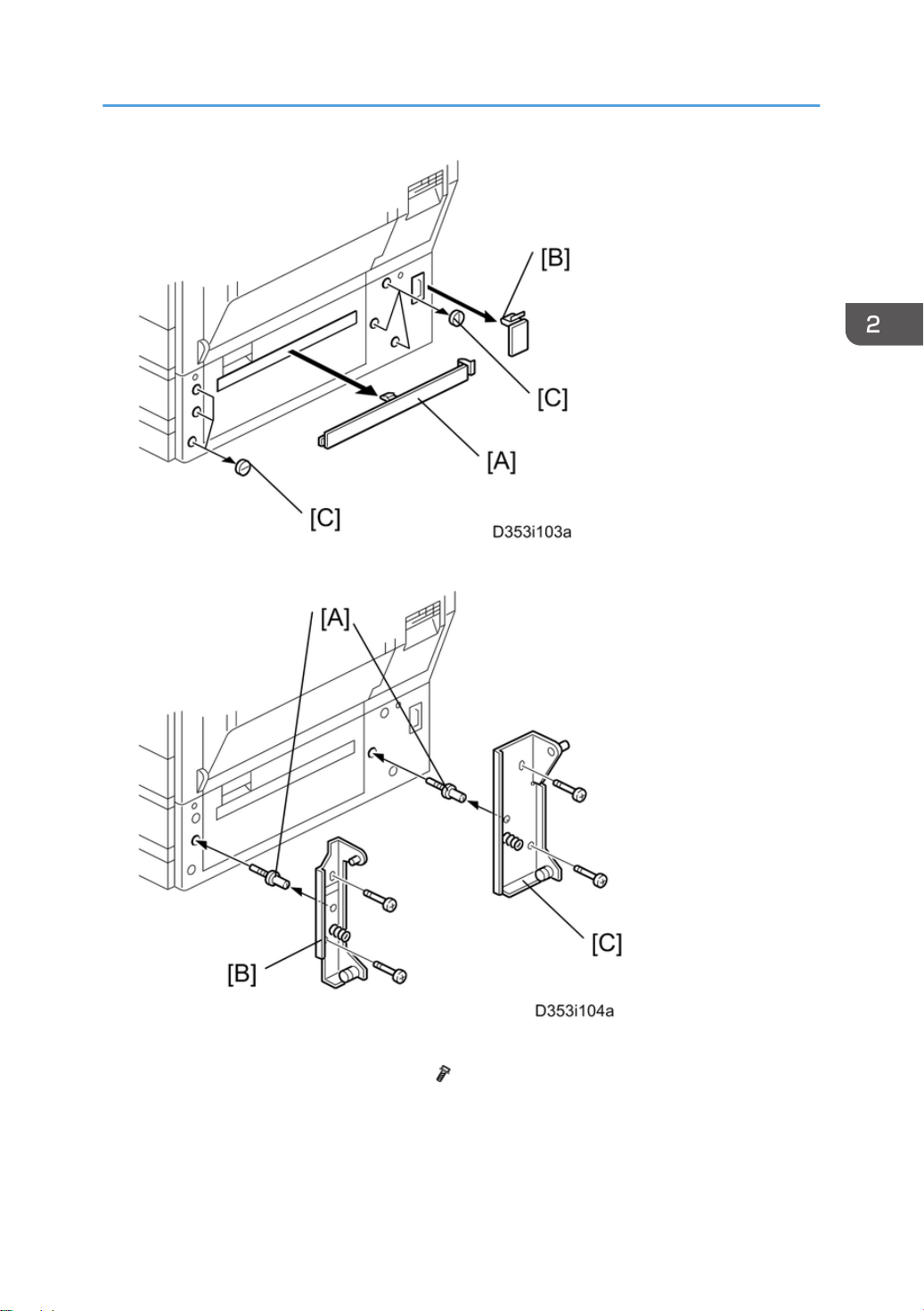

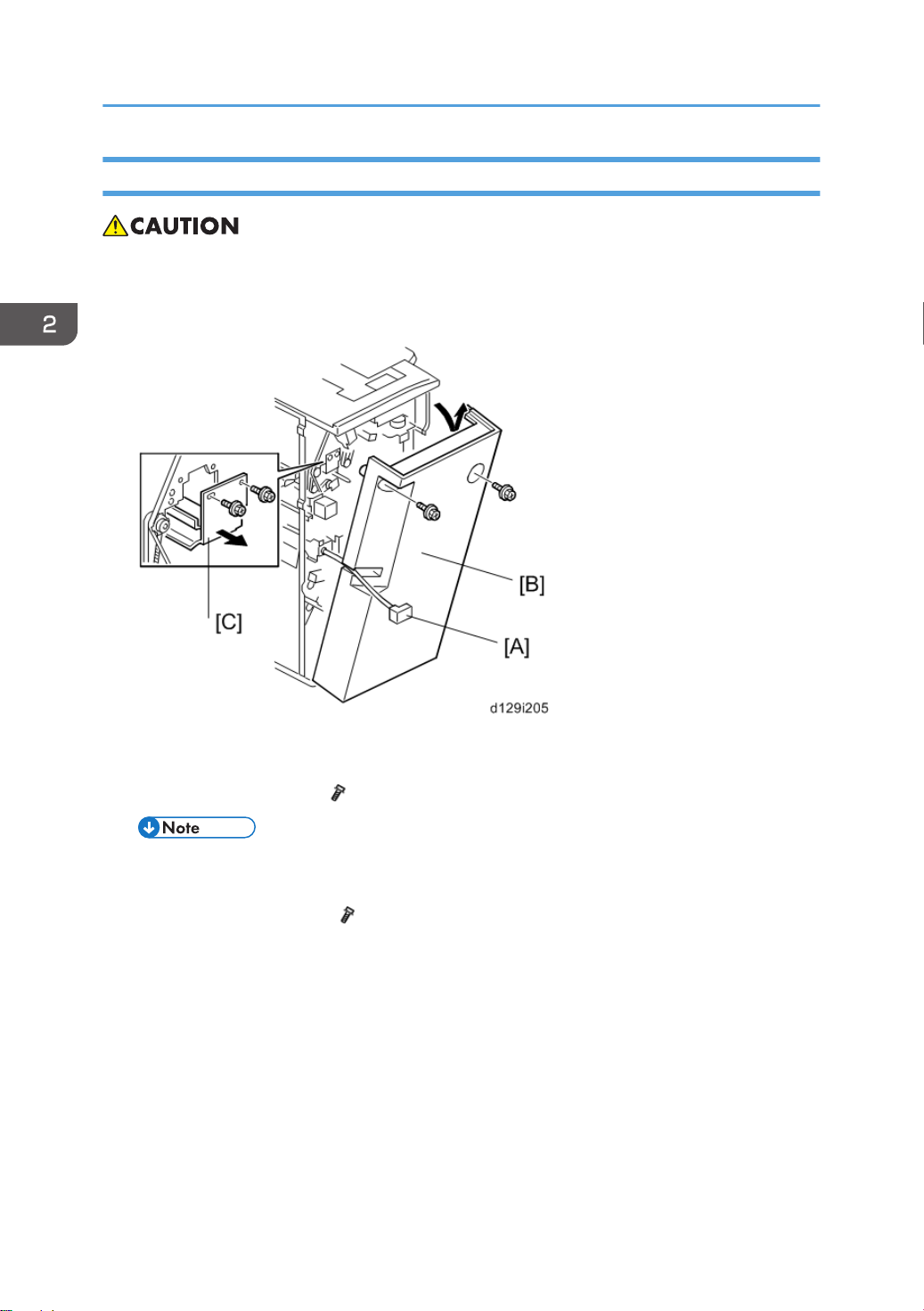

The Aim of Anti-tip Components and Precautions

The anti-tip components are necessary for meeting the requirements of IEC60950-1, the international

standard for safety.

The aim of these components is to prevent the products, which are heavy in weight, from toppling as a

result of people running into or leaning onto the products, which can lead to serious accidents such as

persons becoming trapped under the product. (U.S.: UL60950-1, Europe: EN60950-1)

Therefore, removal of such components must always be with the consent of the customer. Do not remove

them at your own judgment.

Warnings, Cautions, Notes

In this manual, the following important symbols and notations are used.

• A Warning indicates a potentially hazardous situation. Failure to obey a Warning could result in

death or serious injury.

• A Caution indicates a potentially hazardous situation. Failure to obey a Caution could result in

minor or moderate injury or damage to the machine or other property.

• Obey these guidelines to avoid problems such as misfeeds, damage to originals, loss of valuable

data and to prevent damage to the machine.

• This information provides tips and advice about how to best service the machine.

3

Page 6

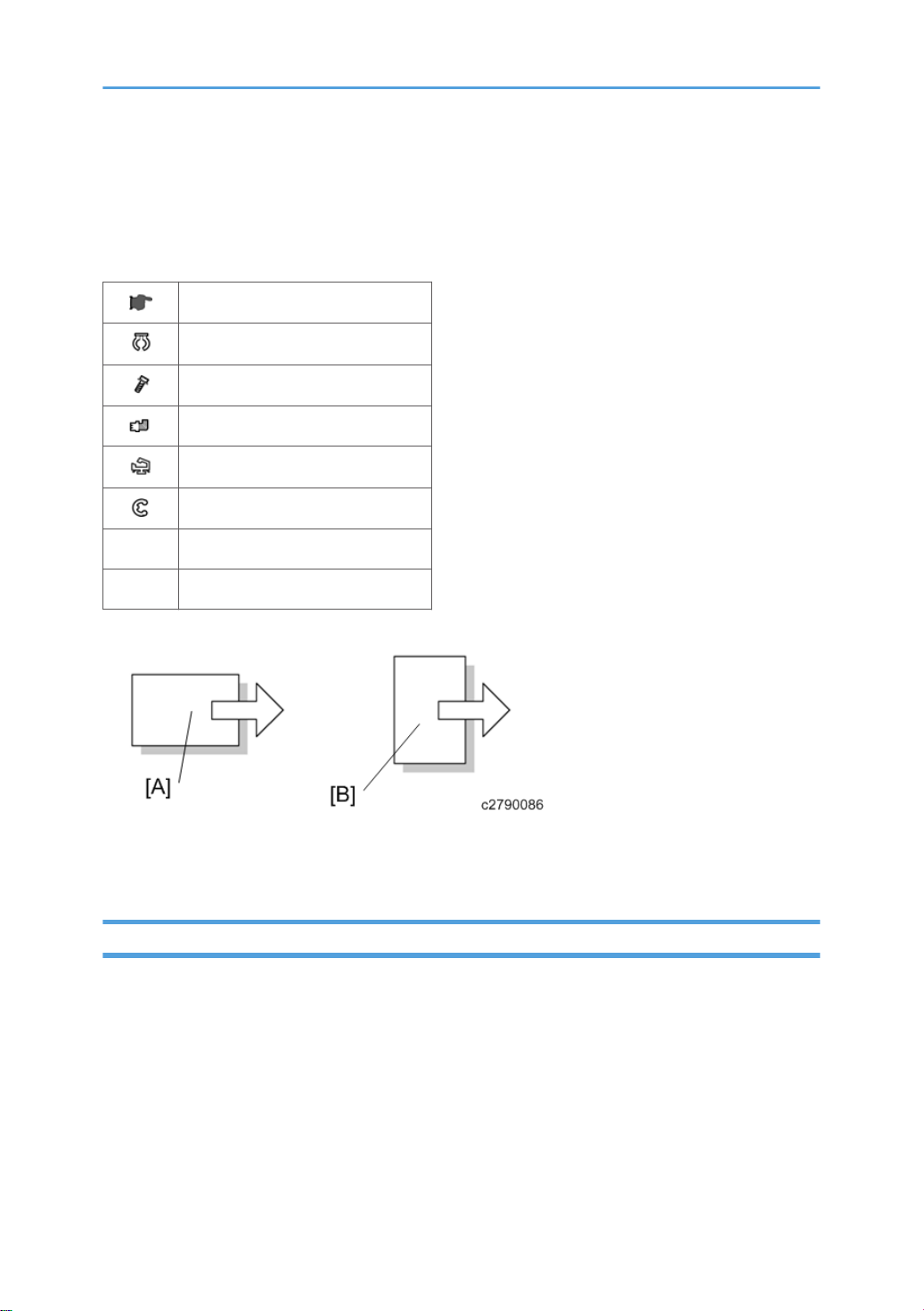

Symbols, Abbreviations and Trademarks

This manual uses several symbols and abbreviations. The meaning of those symbols and abbreviations

are as follows:

See or Refer to

Clip ring

Screw

Connector

Clamp

E-ring

SEF Short Edge Feed

LEF Long Edge Feed

[A] Short Edge Feed (SEF)

[B] Long Edge Feed (LEF)

Trademarks

Microsoft®, Windows®, and MS-DOS® are registered trademarks of Microsoft Corporation in the

United States and /or other countries.

PostScript® is a registered trademark of Adobe Systems, Incorporated.

PCL® is a registered trademark of Hewlett-Packard Company.

Ethernet® is a registered trademark of Xerox Corporation.

PowerPC® is a registered trademark of International Business Machines Corporation.

4

Page 7

Other product names used herein are for identification purposes only and may be trademarks of their

respective companies. We disclaim any and all rights involved with those marks.

5

Page 8

TABLE OF CONTENTS

Important Safety Notices...................................................................................................................................1

Prevention of Physical Injury..........................................................................................................................1

Health Safety Conditions...............................................................................................................................1

Observance of Electrical Safety Standards.................................................................................................1

Safety and Ecological Notes for Disposal...................................................................................................2

Laser Safety.....................................................................................................................................................2

The Aim of Anti-tip Components and Precautions.......................................................................................3

Warnings, Cautions, Notes...........................................................................................................................3

Symbols, Abbreviations and Trademarks.........................................................................................................4

Trademarks.....................................................................................................................................................4

1. Product Information

Specifications....................................................................................................................................................19

Product Overview.............................................................................................................................................20

Component Layout.......................................................................................................................................20

Paper Path....................................................................................................................................................21

Drive Layout..................................................................................................................................................22

Machine Codes and Peripherals Configuration............................................................................................24

Guidance for Those Who are Familiar with Predecessor Products..............................................................27

2. Installation

Installation Requirements.................................................................................................................................29

Environment..................................................................................................................................................29

Machine Level..............................................................................................................................................30

Machine Space Requirements....................................................................................................................30

Power Requirements....................................................................................................................................31

Printer Installation.............................................................................................................................................32

Power Socket for Peripherals......................................................................................................................32

Installation Flow Chart.................................................................................................................................32

Installation Procedure..................................................................................................................................34

Unpacking...........................................................................................................................................34

Installing the Toner..............................................................................................................................38

Loading Paper.....................................................................................................................................39

Turning Power On...............................................................................................................................41

Selecting the Panel Display Language..............................................................................................42

6

Page 9

Printing the Test Page..........................................................................................................................43

Settings Relevant to the Service Contract..........................................................................................43

Settings for @Remote Service (Embedded RC Gate).......................................................................44

Meter Click Charge.....................................................................................................................................47

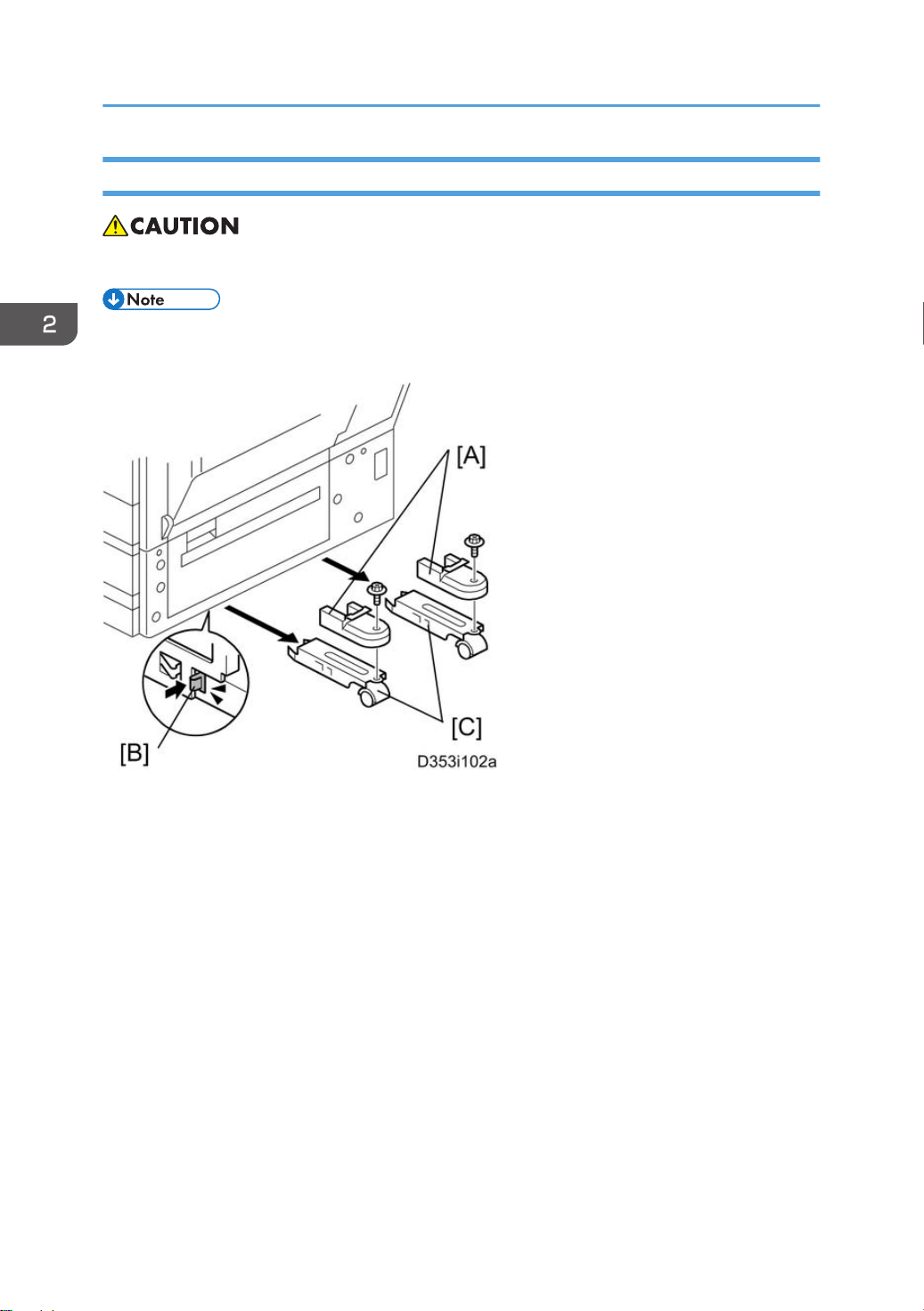

External USB Keyboard (External Option)................................................................................................50

Moving the Machine...................................................................................................................................51

Transporting the Machine...........................................................................................................................52

Optional Unit Combinations............................................................................................................................53

Machine Options.........................................................................................................................................53

Controller Options.......................................................................................................................................53

1200 LCT (D631)............................................................................................................................................55

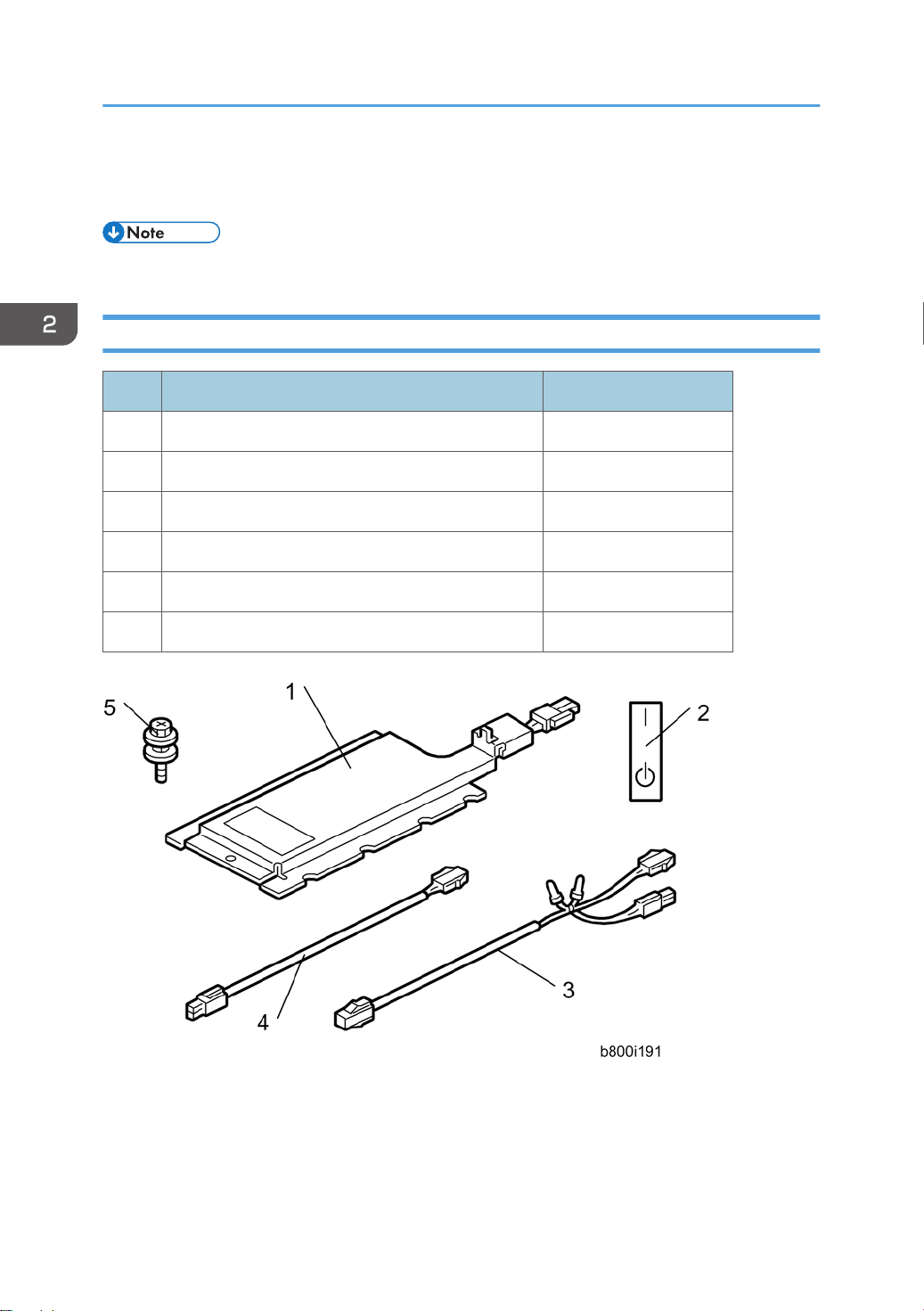

Component Check.......................................................................................................................................55

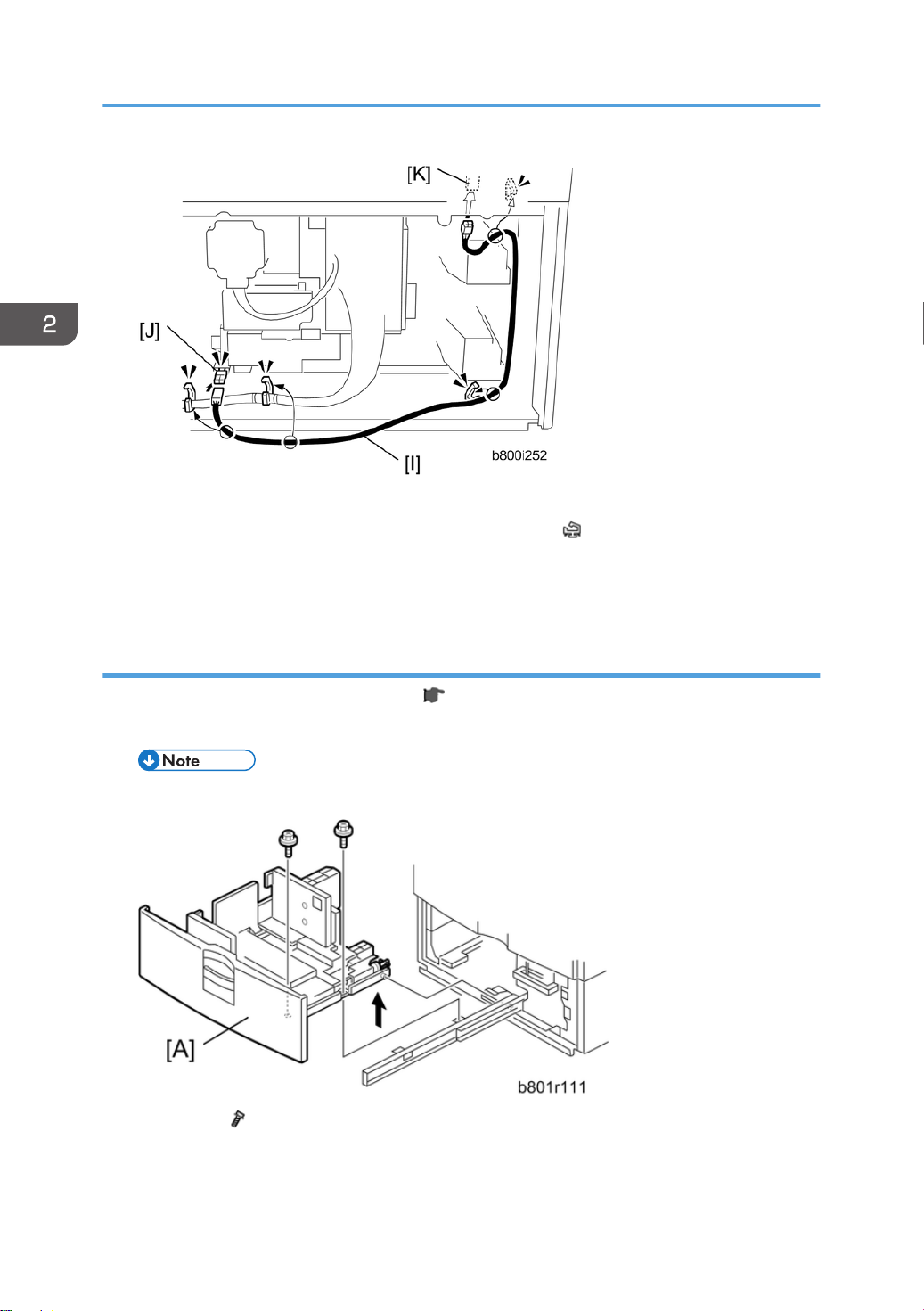

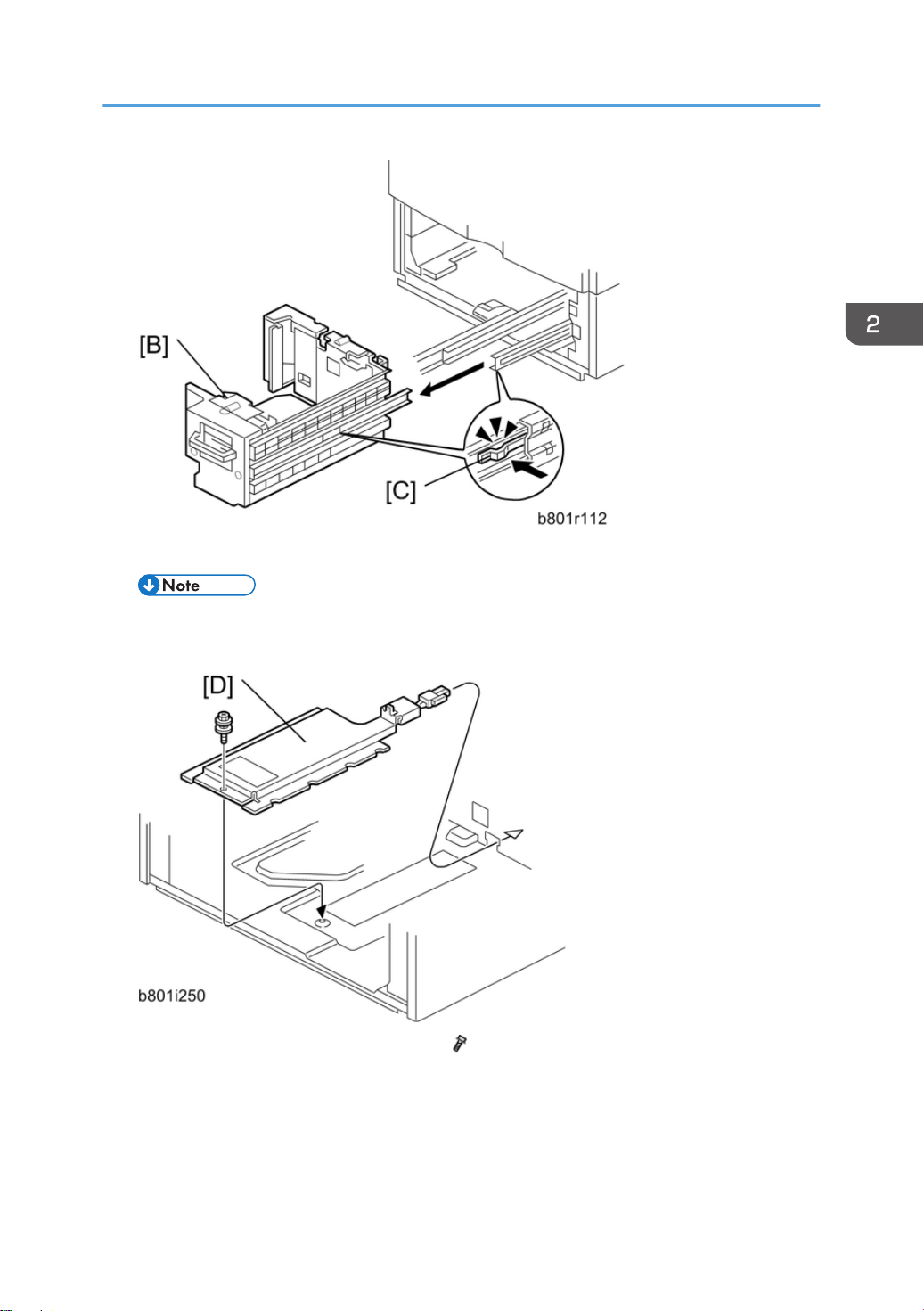

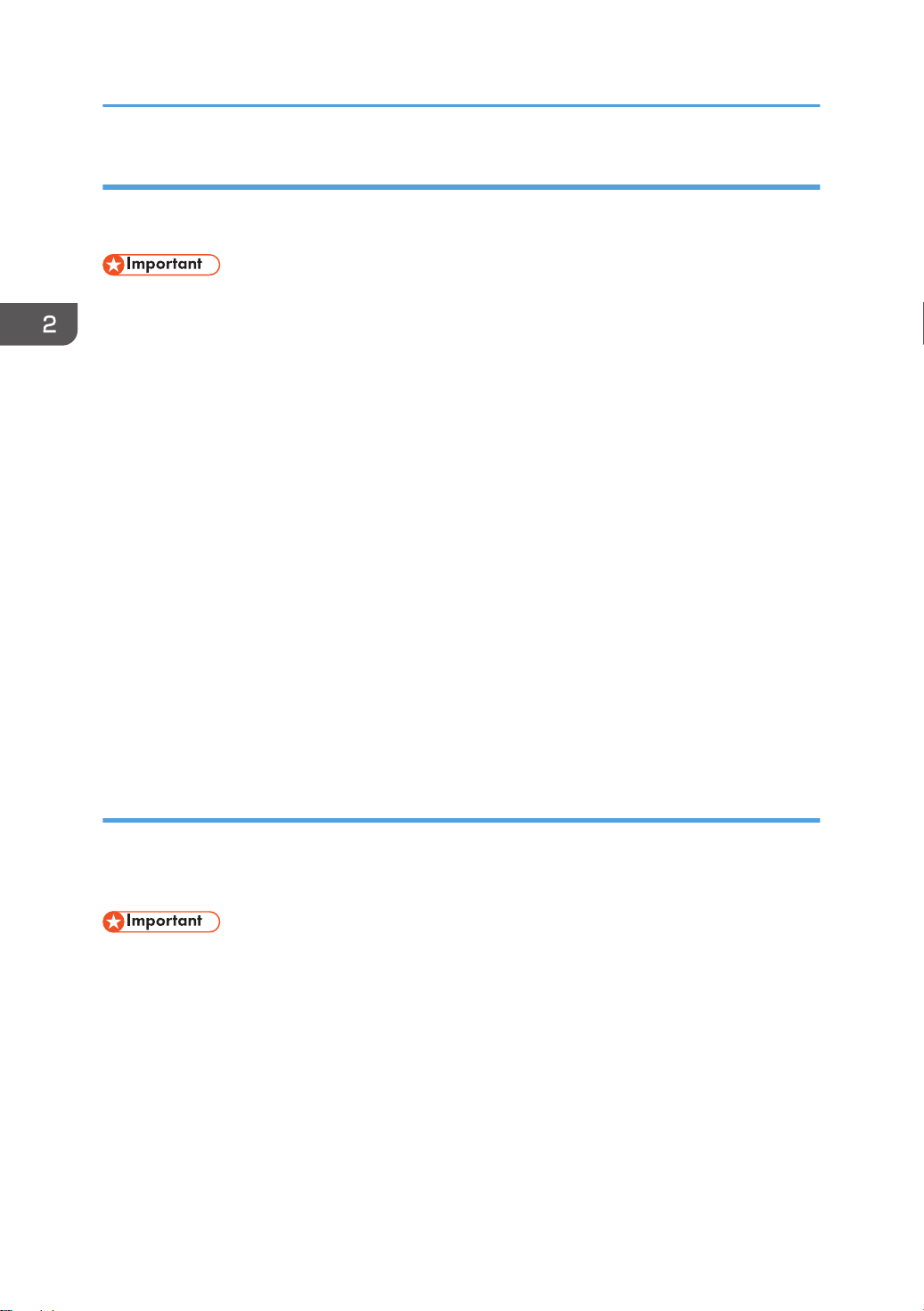

Installation Procedure..................................................................................................................................56

Side Fence Position Change.......................................................................................................................58

Bridge Unit (D634)..........................................................................................................................................60

Component Check.......................................................................................................................................60

Installation Procedure..................................................................................................................................60

2000-sheet booklet finisher (D637) /3000-sheet finisher (D636)............................................................64

Accessory Check..........................................................................................................................................64

Installation Procedure..................................................................................................................................65

Support Tray Installation.....................................................................................................................70

Punch Unit (D570)...........................................................................................................................................71

Component Check.......................................................................................................................................71

Installation Procedure..................................................................................................................................72

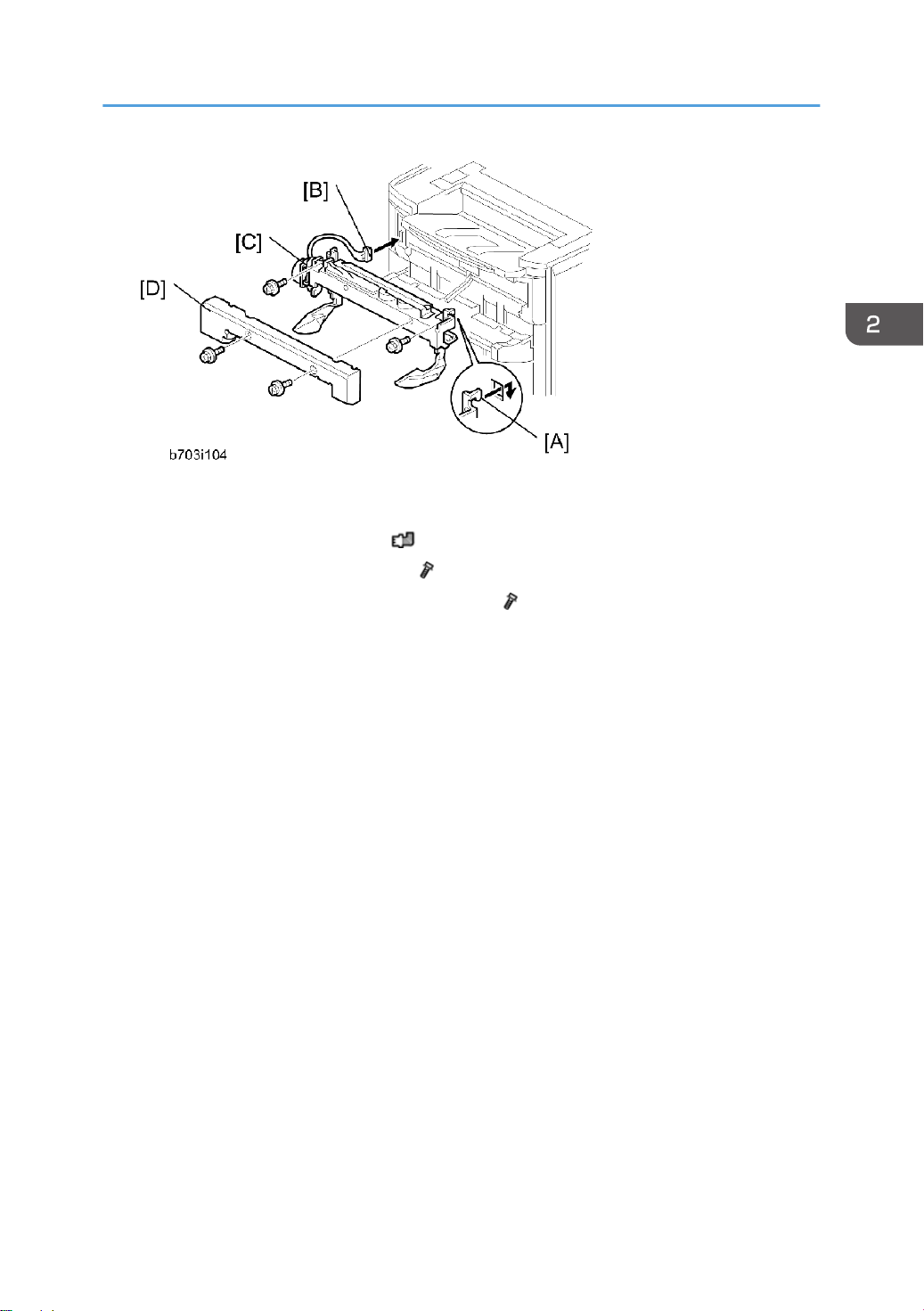

Output Jogger Unit (B703).............................................................................................................................77

Accessories...................................................................................................................................................77

Installation....................................................................................................................................................77

Mail Bin (M413)..............................................................................................................................................80

Component Check.......................................................................................................................................80

Installation Procedure..................................................................................................................................81

Anti-Condensation Heater...............................................................................................................................88

Component Check.......................................................................................................................................88

Installation Procedure..................................................................................................................................89

7

Page 10

For installing the tray heater in the main machine............................................................................89

For installing the tray heater in D580................................................................................................90

For Installing the tray heater in D581................................................................................................92

Controller Options............................................................................................................................................96

Overview......................................................................................................................................................96

I/F Card Slots......................................................................................................................................96

SD Card Slots......................................................................................................................................96

SD Card Appli Move...................................................................................................................................97

Overview.............................................................................................................................................97

Move Exec...........................................................................................................................................98

Undo Exec...........................................................................................................................................98

3. Preventive Maintenance

Maintenance Items........................................................................................................................................101

Touch Screen Calibration.............................................................................................................................102

4. Replacement and Adjustment

Beforehand.....................................................................................................................................................107

Special Tools..................................................................................................................................................108

Image Adjustment..........................................................................................................................................109

Registration................................................................................................................................................109

Image Area.......................................................................................................................................109

Leading Edge....................................................................................................................................109

Side to Side.......................................................................................................................................109

Adjustment Standard........................................................................................................................109

Paper Registration Standard............................................................................................................110

Adjustment Procedure.......................................................................................................................110

Erase Margin Adjustment..........................................................................................................................111

Color Registration......................................................................................................................................112

Line Position Adjustment...................................................................................................................112

Gamma Correction...................................................................................................................................113

Summary............................................................................................................................................113

Adjustment Procedure.......................................................................................................................115

Exterior Covers...............................................................................................................................................117

Front Door..................................................................................................................................................117

8

Page 11

Left Cover...................................................................................................................................................118

Rear Cover.................................................................................................................................................118

Top Right and Rear Cover........................................................................................................................119

Right Rear Cover.......................................................................................................................................119

Operation Panel........................................................................................................................................120

Paper Exit Cover........................................................................................................................................122

Output Tray................................................................................................................................................123

Ozone Filter...............................................................................................................................................124

Ozone filter for the charge unit.......................................................................................................124

Ozone filter for the AC Controller...................................................................................................125

Laser Optics....................................................................................................................................................126

Caution Decal Location............................................................................................................................126

LD Safety Switch........................................................................................................................................127

Error Messages.................................................................................................................................127

Laser Optics Housing Unit........................................................................................................................128

Preparing the new laser optics housing unit...................................................................................128

Before removing the old laser optics housing unit.........................................................................129

Recovery procedure for no replacement preparation of laser optics housing unit.....................129

Removing the old laser optics housing unit.....................................................................................130

Installing a new laser optics housing unit........................................................................................131

After installing the new laser optics housing unit............................................................................132

Polygon Mirror Motor and Drive Board..................................................................................................133

Airflow Fans...............................................................................................................................................135

Laser Optics Rear Right Thermistor...........................................................................................................135

Image Creation..............................................................................................................................................137

PCDU..........................................................................................................................................................137

Drum Unit and Development Unit............................................................................................................138

Developer..........................................................................................................................................141

Toner Collection Bottle..............................................................................................................................143

Second Duct Fans......................................................................................................................................144

When reinstalling the second duct fans..........................................................................................145

Third Duct Fan............................................................................................................................................145

When reinstalling the third duct fan................................................................................................146

9

Page 12

Toner Pump Unit........................................................................................................................................146

When installing the new toner pump unit.......................................................................................149

Toner End Sensor......................................................................................................................................152

Image Transfer...............................................................................................................................................153

Image Transfer Belt Cleaning Unit...........................................................................................................153

Image Transfer Belt Unit............................................................................................................................153

Image Transfer Belt....................................................................................................................................155

When reinstalling the image transfer belt.......................................................................................159

Paper Transfer................................................................................................................................................162

Paper Transfer Roller Unit.........................................................................................................................162

Paper Transfer Unit....................................................................................................................................162

ID Sensor Board........................................................................................................................................164

Cleaning for ID sensors....................................................................................................................165

After installing a new ID sensor unit/board ..................................................................................166

Temperature and Humidity Sensor..........................................................................................................166

Drive Unit........................................................................................................................................................167

Gear Unit...................................................................................................................................................167

When installing the drive unit...........................................................................................................174

Adjustment after replacing the gear unit.........................................................................................174

Registration Motor.....................................................................................................................................175

Paper Feed Motor.....................................................................................................................................176

Drum/Development Motors for M, C, and Y.........................................................................................177

Drum/Development Motor-K...................................................................................................................178

ITB Drive Motor.........................................................................................................................................179

Fusing/Paper Exit Motor..........................................................................................................................179

Image Transfer Belt Contact Motor..........................................................................................................180

Duplex Inverter Motor...............................................................................................................................180

Pressure Roller Contact Motor..................................................................................................................182

Duplex/By-pass Motor.............................................................................................................................183

Paper Transfer Contact Motor..................................................................................................................185

Toner Transport Motor..............................................................................................................................187

Toner Collection Unit.................................................................................................................................188

Paper Feed Clutches.................................................................................................................................188

10

Page 13

Development Clutch-Y..............................................................................................................................191

Development Clutches for M and C........................................................................................................192

Development Clutch-K..............................................................................................................................193

Fusing..............................................................................................................................................................195

Fusing Unit..................................................................................................................................................195

Fusing Exit Shutter Plate............................................................................................................................197

Fusing Entrance Guide Plate.....................................................................................................................197

Cleaning Requirement......................................................................................................................199

Fusing Exit Guide Plate Cleaning Procedure...........................................................................................199

Fusing Unit Upper Cover..........................................................................................................................200

Fusing Unit Lower Cover...........................................................................................................................201

Fusing Sleeve Belt Unit..............................................................................................................................202

Oil Absorber Felt..............................................................................................................................205

Pressure Roller............................................................................................................................................206

Stripper Plate.............................................................................................................................................208

Cleaning Requirement......................................................................................................................209

Pressure Roller Thermistors........................................................................................................................209

Pressure Roller Thermostats.......................................................................................................................210

NC Sensors................................................................................................................................................210

Fusing Fan..................................................................................................................................................211

When installing the fusing fan..........................................................................................................212

Paper Exit Fan............................................................................................................................................212

When installing the paper exit fan..................................................................................................213

AC Controller Board Fan..........................................................................................................................213

When installing the AC controller fan.............................................................................................214

Fusing Entrance Thermopiles....................................................................................................................214

When cleaning the lens of the thermopile......................................................................................215

Pressure Roller HP Sensor.........................................................................................................................215

QSU fan.....................................................................................................................................................216

Fusing Unit Shutter Plate Drive Motor......................................................................................................218

Fusing Unit Shutter Plate Home Position Sensor......................................................................................218

Fusing Unit Shutter Plate Drive Mechanism.............................................................................................219

Paper Feed.....................................................................................................................................................222

11

Page 14

Paper Feed Unit.........................................................................................................................................222

Pick-Up, Feed and Separation Rollers.....................................................................................................223

Tray 1 and Tray 2.............................................................................................................................223

Tray Lift Motor............................................................................................................................................224

Vertical Transport, Paper Overflow, Paper End and Paper Feed Sensor.............................................224

Registration Sensor....................................................................................................................................225

By-pass Paper Size Sensor and By-pass Paper Length Sensor.............................................................226

When reinstalling the by-pass paper size sensor..........................................................................227

By-pass Bottom Tray..................................................................................................................................228

By-pass Paper End Sensor........................................................................................................................231

By-pass Pick-up, Feed and Separation Roller, Torque Limiter...............................................................232

By-pass Feed Clutch..................................................................................................................................233

Paper Exit Unit...........................................................................................................................................234

Fusing Exit, Paper Overflow, Junction Paper Jam and Paper Exit Sensor............................................235

Duplex Unit.....................................................................................................................................................237

Duplex Unit................................................................................................................................................237

Duplex Door Sensor..................................................................................................................................238

Duplex Entrance Sensor............................................................................................................................239

Duplex Exit Sensor....................................................................................................................................240

Electrical Components...................................................................................................................................241

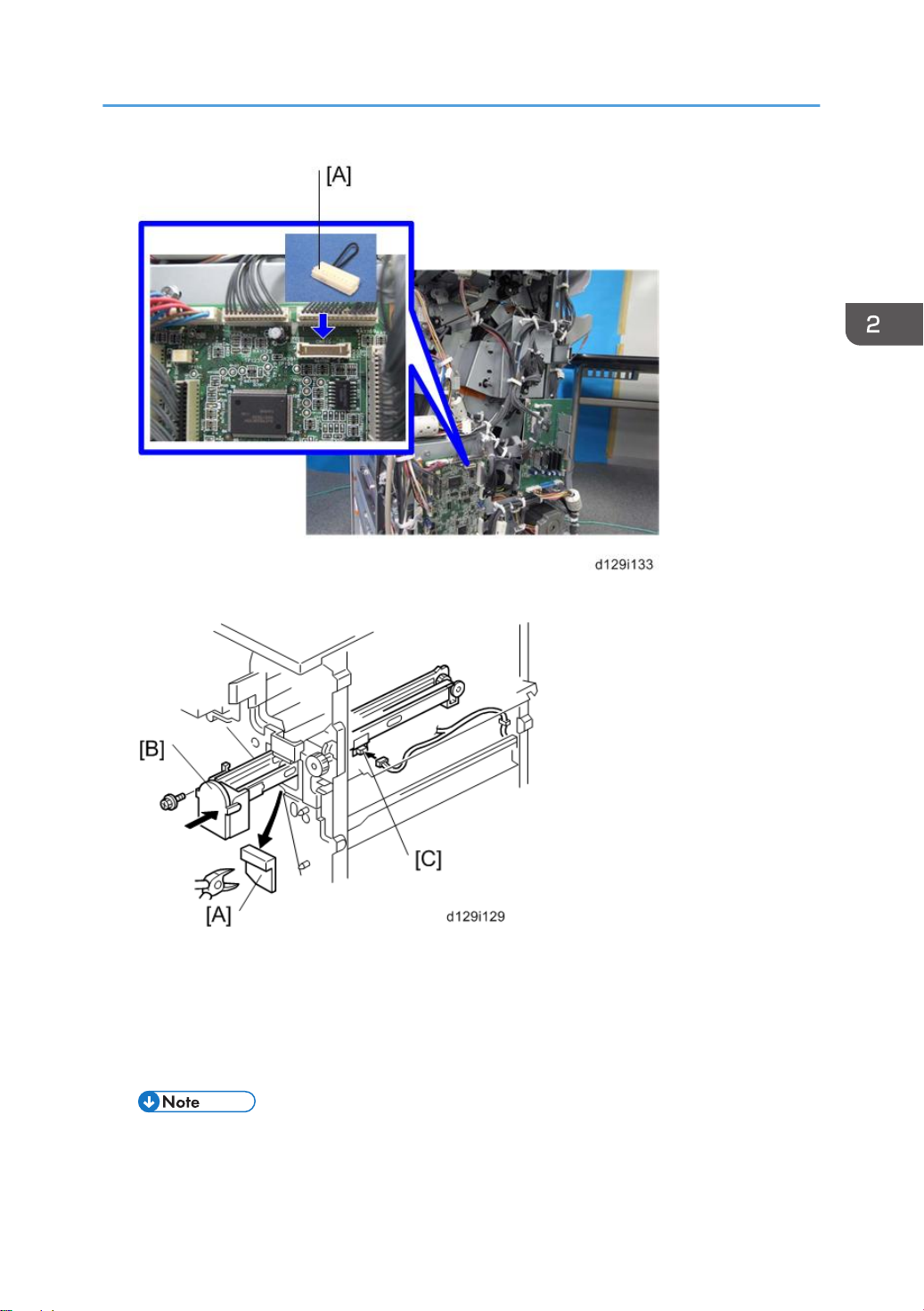

Boards........................................................................................................................................................241

Controller Box closed.......................................................................................................................241

Behind the IOB..................................................................................................................................242

Controller Box Open........................................................................................................................242

Controller Unit...........................................................................................................................................243

Controller Box Right Cover.......................................................................................................................243

Controller Box............................................................................................................................................243

When opening the controller box...................................................................................................243

When removing the controller box.................................................................................................244

IOB (In/Out Board)..................................................................................................................................247

BB (Bridge Board).....................................................................................................................................248

BCU............................................................................................................................................................248

When installing the new BCU..........................................................................................................249

12

Page 15

PSU.............................................................................................................................................................250

PSU bracket.......................................................................................................................................250

PSU board.........................................................................................................................................250

PSU fans............................................................................................................................................251

Shutdown Switch.......................................................................................................................................252

ITB Power Supply Board...........................................................................................................................253

High Voltage Supply Board.....................................................................................................................254

High Voltage Supply Board Bracket.......................................................................................................254

AC Controller Board.................................................................................................................................255

AC Controller Board Bracket...................................................................................................................255

Controller Board........................................................................................................................................256

When installing the new controller board......................................................................................258

HDD Fan....................................................................................................................................................258

When installing the HDD fan...........................................................................................................259

HDD............................................................................................................................................................259

When installing a new HDD unit.....................................................................................................260

Toner Bottle Detection Board...................................................................................................................260

NVRAM Replacement Procedure............................................................................................................261

NVRAM on the BCU........................................................................................................................261

NVRAM on the controller board.....................................................................................................262

Tube Cooling Fan (1st Duct Fan).............................................................................................................263

Using Dip Switches........................................................................................................................................264

Controller Board........................................................................................................................................264

BCU Board.................................................................................................................................................264

5. System Maintenance

Service Program Mode.................................................................................................................................265

SP Tables....................................................................................................................................................265

Enabling and Disabling Service Program Mode....................................................................................265

Entering SP Mode.............................................................................................................................265

Exiting SP Mode...............................................................................................................................265

Types of SP Modes....................................................................................................................................265

SP Mode Button Summary...............................................................................................................266

Selecting the Program Number.......................................................................................................267

13

Page 16

Exiting Service Mode.......................................................................................................................268

Service Mode Lock/Unlock............................................................................................................268

Remarks......................................................................................................................................................268

Display on the Control Panel Screen..............................................................................................268

Others................................................................................................................................................268

Service SP Table............................................................................................................................................270

SP1-XXX (Service Mode)..........................................................................................................................270

Engine SP Tables-1........................................................................................................................................285

SP1-XXX (Feed).........................................................................................................................................285

Engine SP Tables-2........................................................................................................................................299

SP2-XXX (Drum).........................................................................................................................................299

Engine SP Tables-3........................................................................................................................................307

SP3-XXX (Process).....................................................................................................................................307

Engine SP Tables-4........................................................................................................................................327

SP5-XXX (Mode).......................................................................................................................................327

Engine SP Tables-5........................................................................................................................................382

SP6-XXX (Peripherals)...............................................................................................................................382

Engine SP Tables-6........................................................................................................................................390

SP7-XXX (Data Log)..................................................................................................................................390

Input and Output Check................................................................................................................................440

Input Check Table.....................................................................................................................................440

Printer.................................................................................................................................................440

Table 1: Paper Height Sensor..........................................................................................................443

Table 2: Paper Size Switch (Tray 2)...............................................................................................443

Table 3: Paper Size (By-pass Table)...............................................................................................444

[FIN (EUP) INPUT Check] Finisher (D636/ D637).......................................................................445

[FIN (JAK) INPUT Check] 4bin Mail Box (M413)........................................................................447

Bridge Unit (D634)...........................................................................................................................448

Two-Tray Paper Feed Unit (D580)/ LCT 2000 (D581)/ LCT 1200 (D631)............................448

Output Check Table..................................................................................................................................449

Printer.................................................................................................................................................449

[FIN (EUP) OUTPUT Check] (Booklet) Finisher (D636/D637)....................................................455

FIN(JAK)OUTPUT Check 4bin Mail Box (M413).........................................................................457

14

Page 17

Bridge Unit (D634)...........................................................................................................................457

4bin Mail Box (M413)....................................................................................................................457

Two-Tray Paper Feed Unit (D580)/ LCT 2000 (D581)/ LCT 1200 (D631)............................457

Firmware Update...........................................................................................................................................459

Type of Firmware.......................................................................................................................................459

Before You Begin.......................................................................................................................................460

Updating Firmware...................................................................................................................................461

Preparation........................................................................................................................................461

Updating Procedure.........................................................................................................................461

Error Messages.................................................................................................................................462

Firmware Update Error.....................................................................................................................462

Recovery after Power Loss...............................................................................................................463

Updating the LCDC for the Operation Panel..........................................................................................463

Handling Firmware Update Errors...........................................................................................................464

Error Message Table........................................................................................................................464

NVRAM Data Upload/Download..............................................................................................................466

Uploading Content of NVRAM to an SD card.......................................................................................466

Downloading an SD Card to NVRAM....................................................................................................467

Address Book Upload/Download..............................................................................................................469

Information List...........................................................................................................................................469

Download..................................................................................................................................................469

Upload.......................................................................................................................................................470

Using the Debug Log.....................................................................................................................................471

Overview....................................................................................................................................................471

Switching ON and Setting UP Save Debug Log.....................................................................................471

Retrieving the Debug Log from the HDD.................................................................................................475

Debug Log Codes.....................................................................................................................................476

SP5857-015 Copy SD Card-to-SD Card: Any Desired Key.......................................................476

SP5857-016 Create a File on HDD to Store a Log......................................................................476

SP5857-017 Create a File on SD Card to Store a Log................................................................476

Card Save Function.......................................................................................................................................477

Overview....................................................................................................................................................477

Card Save:........................................................................................................................................477

15

Page 18

Procedure...................................................................................................................................................477

Error Messages..........................................................................................................................................481

SMC List Card Save Function.......................................................................................................................482

Overview....................................................................................................................................................482

SMC List Card Save.........................................................................................................................482

Procedure...................................................................................................................................................482

File Names of the Saved SMC Lists.........................................................................................................484

Error Messages..........................................................................................................................................485

6. Troubleshooting

Service Call....................................................................................................................................................487

Service Call Conditions.............................................................................................................................487

SC Code Classification....................................................................................................................488

SC Table.........................................................................................................................................................491

Service Call Tables - 1..............................................................................................................................491

SC1xx: Scanning..............................................................................................................................491

Service Call Tables - 2..............................................................................................................................491

SC 2xx: Exposure.............................................................................................................................491

Service Call Tables - 3..............................................................................................................................498

SC3xx: Image Processing – 1.........................................................................................................498

SC3xx: Image Processing – 2.........................................................................................................499

Service Call Tables - 4..............................................................................................................................503

SC4xx: Image Processing - 3..........................................................................................................503

Service Call Tables - 5..............................................................................................................................509

SC5xx: Paper Feed and Fusing.......................................................................................................509

Service Call Tables - 6..............................................................................................................................529

SC6xx: Device Communication.......................................................................................................529

Service Call Tables - 7..............................................................................................................................543

SC7xx: Peripherals...........................................................................................................................543

Service Call Tables - 8..............................................................................................................................553

SC8xx: Overall System....................................................................................................................553

Service Call Tables - 9..............................................................................................................................569

SC9xx: Miscellaneous.....................................................................................................................569

Process Control Error Conditions..................................................................................................................577

16

Page 19

Developer Initialization Result..................................................................................................................577

Process Control Self-Check Result............................................................................................................578

Vsg Adjustment Result.......................................................................................................................580

Line Position Adjustment Result.................................................................................................................580

Troubleshooting Guide..................................................................................................................................582

Image Quality............................................................................................................................................582

Line Position Adjustment............................................................................................................................584

Test.....................................................................................................................................................585

Countermeasure list for color registration errors............................................................................585

Stain on the Outputs..................................................................................................................................591

Problem at Regular Intervals.....................................................................................................................592

Toner End Recovery Error.........................................................................................................................592

Flow Chart for the Toner End Recovery Error.................................................................................593

Toner Bottle Detection Error......................................................................................................................594

Solid Image or Halftone Image Error......................................................................................................595

Recovery Procedure.........................................................................................................................595

Problem Prevention Procedure.........................................................................................................596

Faulty Cleaning..........................................................................................................................................596

Black or color lines (2-3mm)...........................................................................................................596

Band Image Between 20mm and 30mm.......................................................................................597

Encryption Key Restoration for NVRAM..................................................................................................597

How to restore the old encryption key to the machine..................................................................597

How to do a forced start up with no encryption key.....................................................................598

Other Symptoms........................................................................................................................................599

Flowchart for the error......................................................................................................................600

Countermeasure list for the error.....................................................................................................600

Jam Detection.................................................................................................................................................603

Paper Jam Display.....................................................................................................................................603

Jam Codes and Display Codes................................................................................................................603

Paper Size Code...............................................................................................................................608

Sensor Locations...............................................................................................................................610

Electrical Component Defects.......................................................................................................................611

Sensors.......................................................................................................................................................611

17

Page 20

Blown Fuse Conditions..............................................................................................................................616

Power Supply Unit............................................................................................................................616

AC Drive Board................................................................................................................................616

7. Energy Saving

Energy Save...................................................................................................................................................619

Energy Saver Modes................................................................................................................................619

Timer Settings....................................................................................................................................619

Return to Stand-by Mode.................................................................................................................620

Recommendation..............................................................................................................................620

Energy Save Effectiveness........................................................................................................................620

Paper Save.....................................................................................................................................................622

Effectiveness of Duplex/Combine Function............................................................................................622

1. Duplex:..........................................................................................................................................622

2. Combine mode:............................................................................................................................622

3. Duplex + Combine:......................................................................................................................623

How to calculate the paper reduction ratio ..................................................................................623

18

Page 21

1. Product Information

Specifications

See "Appendices" for the following information:

• General Specifications

• Supported Paper Sizes

• Software Accessories

• Optional Equipment

19

Page 22

1. Product Information

Product Overview

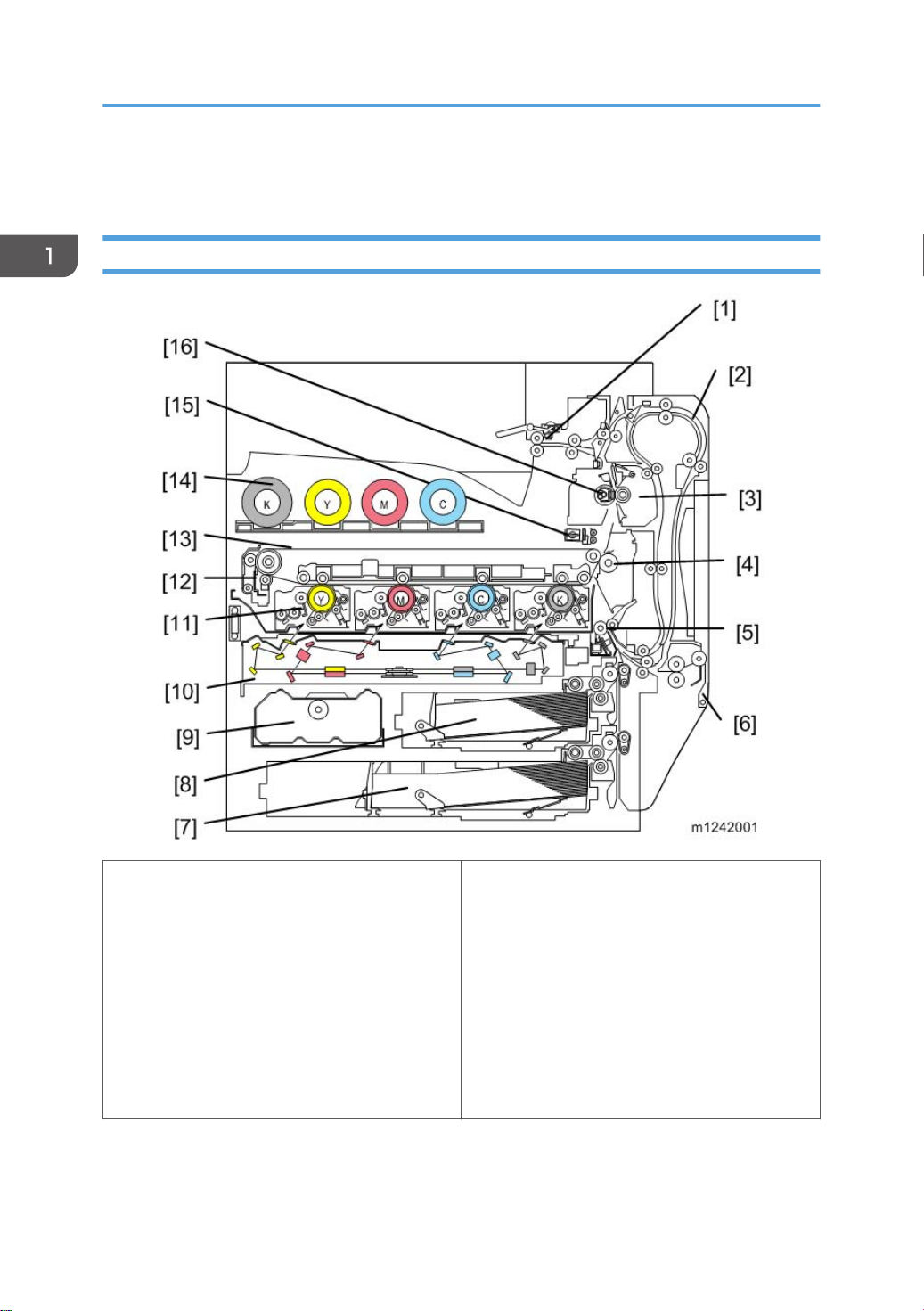

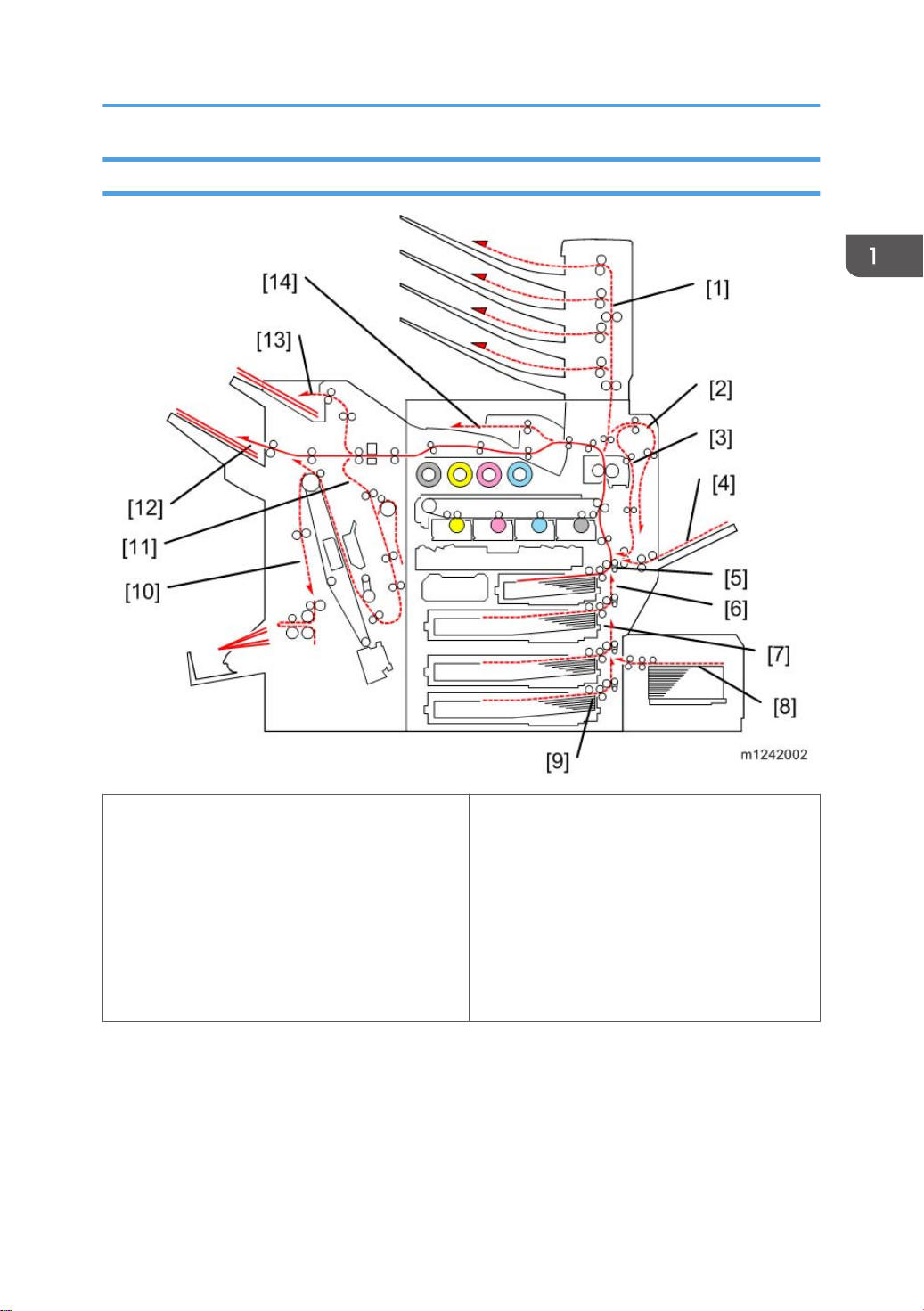

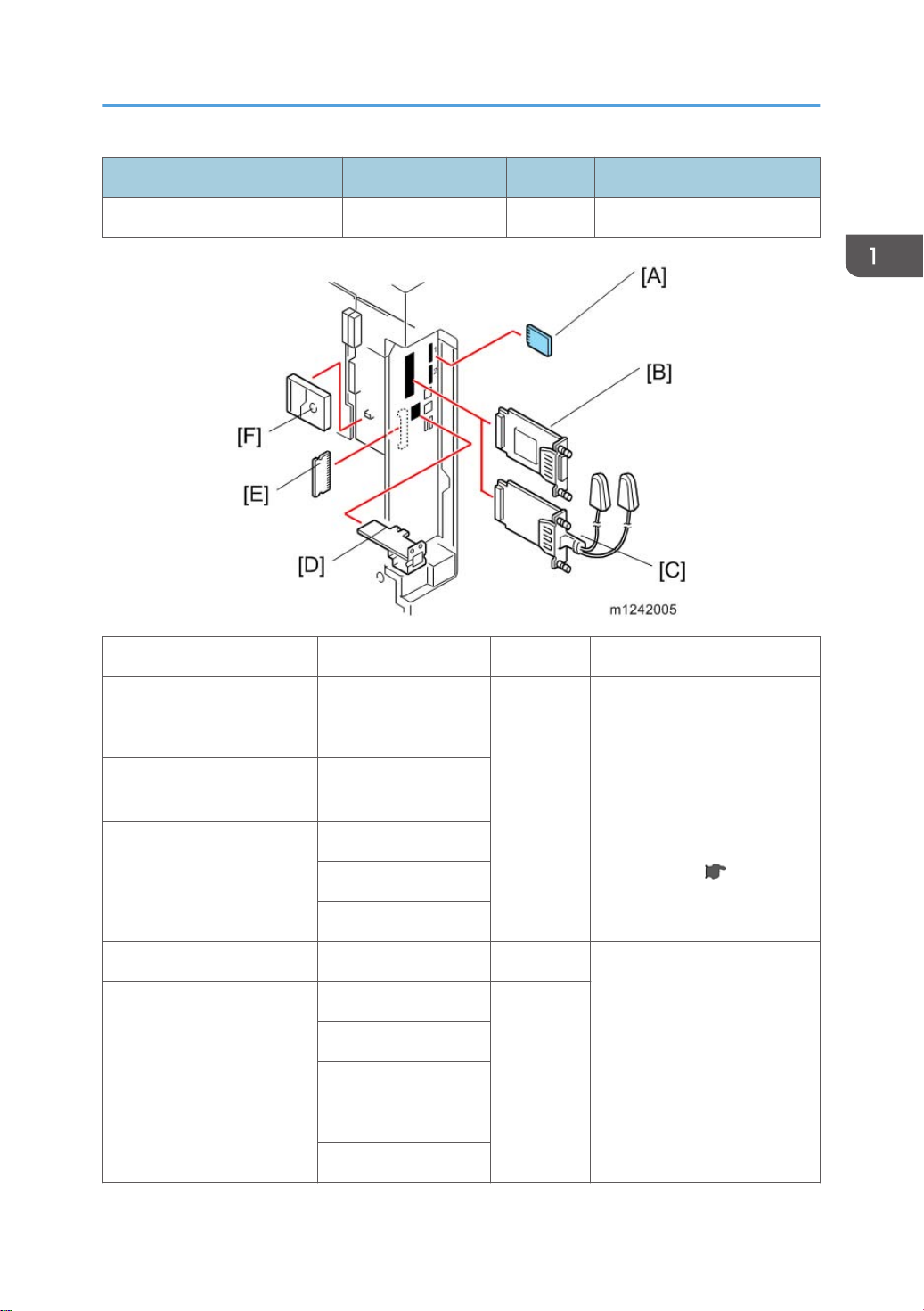

Component Layout

20

1. Paper exit rollers

2. Duplex unit

3. Fusing unit

4. Paper transfer roller

5. Registration roller

6. By-pass feed table

7. Tray 2

8. Tray 1

9. Toner collection bottle

10. Laser optics housing unit

11. PCDU (4 colors)

12. Image transfer belt cleaning unit

13. Image transfer belt unit

14. Toner bottle (4 colors)

15. ID sensor

16. Fusing sleeve belt unit

Page 23

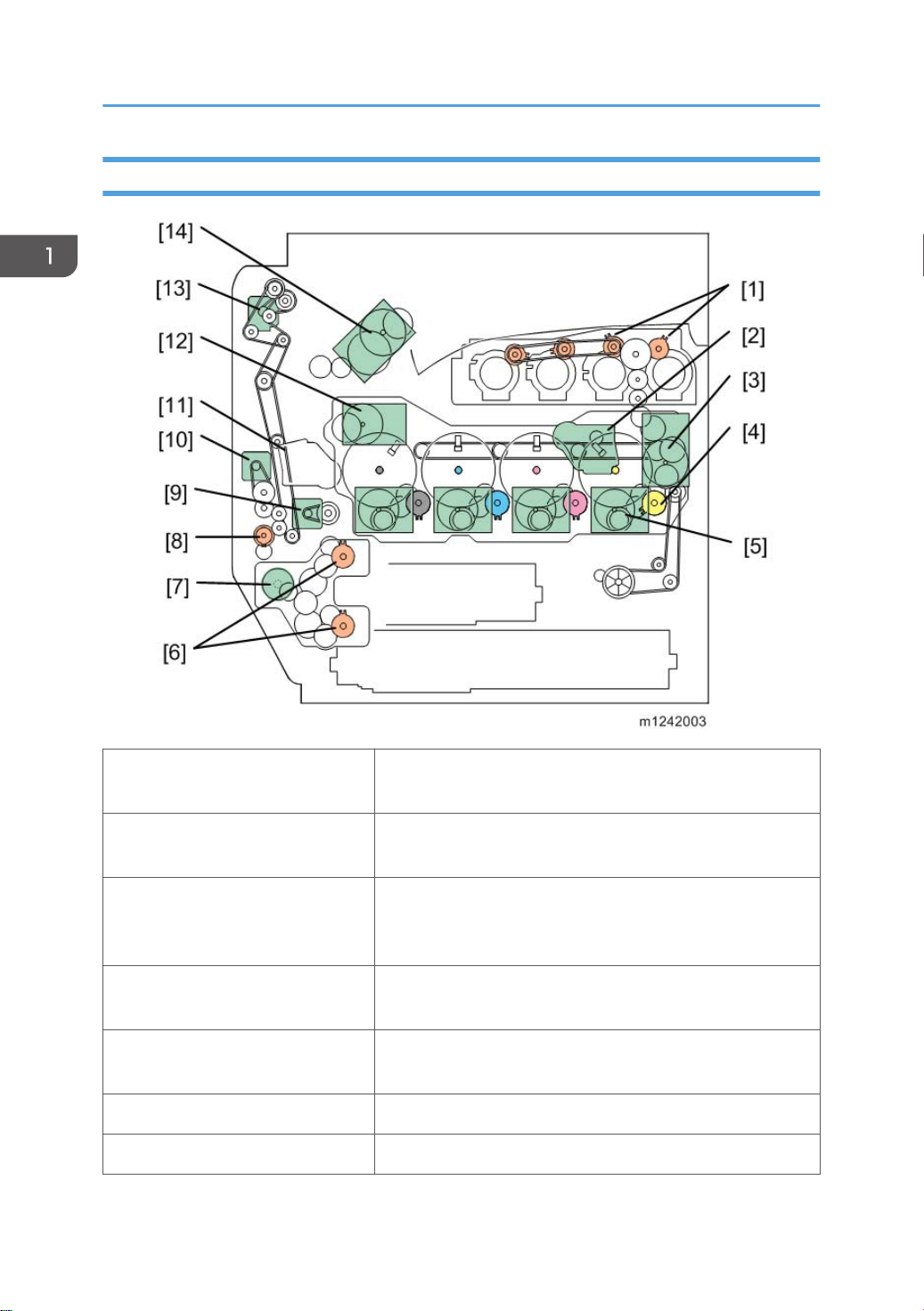

Paper Path

Product Overview

1. Mail bin

2. Duplex inverter

3. Duplex feed

4. By-pass tray feed

5. Tray 1 feed

6. Tray 2 feed

7. Tray 3: Optional paper feed unit/LCT

The 2000/3000-sheet (booklet) finisher requires the bridge unit and one from the two-tray paper feed

unit or the LCT.

8. Tray 5: Optional LCT 1200

9. Tray 4: Optional paper feed unit

10. Finisher booklet stapler (Optional)

11. Finisher stapler (Optional)

12. Finisher upper tray (Optional)

13. Finisher proof tray (Optional)

14. Output tray

21

Page 24

1. Product Information

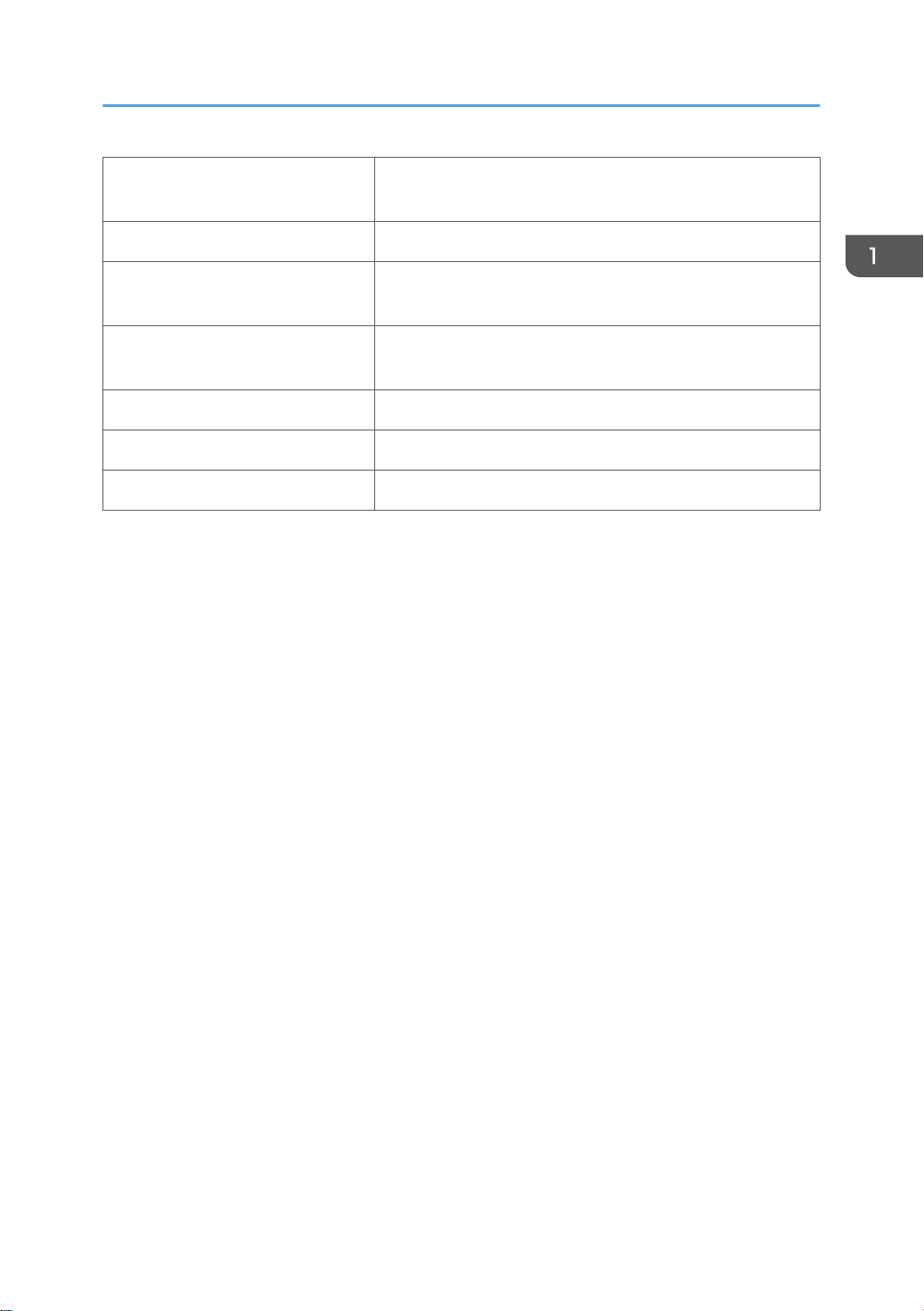

Drive Layout

22

1. Toner supply clutch-K and -CMY:

2. ITB (Image Transfer Belt) contact

motor:

3. Toner transport motor:

4. Development clutch (K, Y, M, C):

5. Drum/Development drive motor

(K, Y, M, C):

6. Paper feed clutch: Switches the drive power between tray 1 and tray 2.

7. Paper feed motor: Drives the paper feed mechanisms (tray 1/tray 2).

Turns on/off the drive power to the toner supply unit (K and CMY).

Moves the ITB into contact and away from the color PCDUs.

Drives the toner attraction pumps and the toner collection coils

from the PCDUs, from the transfer belt unit, and inside the

toner collection bottle. Also rotates the toner bottles.

Turns on/off the drive power to the development unit (K, Y,

M, C).

Drives the color drum unit and development unit (K, Y, M, C).

Page 25

Product Overview

8. By-pass feed clutch:

Turns on/off the drive power to the by-pass pick-up, feed and

separation rollers.

9. Registration motor: Drives the registration roller.

10. By-pass/duplex feed motor:

11. Paper transfer contact motor:

Drives the by-pass pick-up, feed and separation roller, and

duplex transport rollers.

Moves the paper transfer roller in contact with the image

transfer belt.

12. ITB drive motor: Drives the image transfer belt unit.

13. Duplex inverter motor: Drives the duplex inverter rollers and duplex transport rollers.

14. Fusing/paper exit motor: Drives the fusing unit and paper exit section.

23

Page 26

1. Product Information

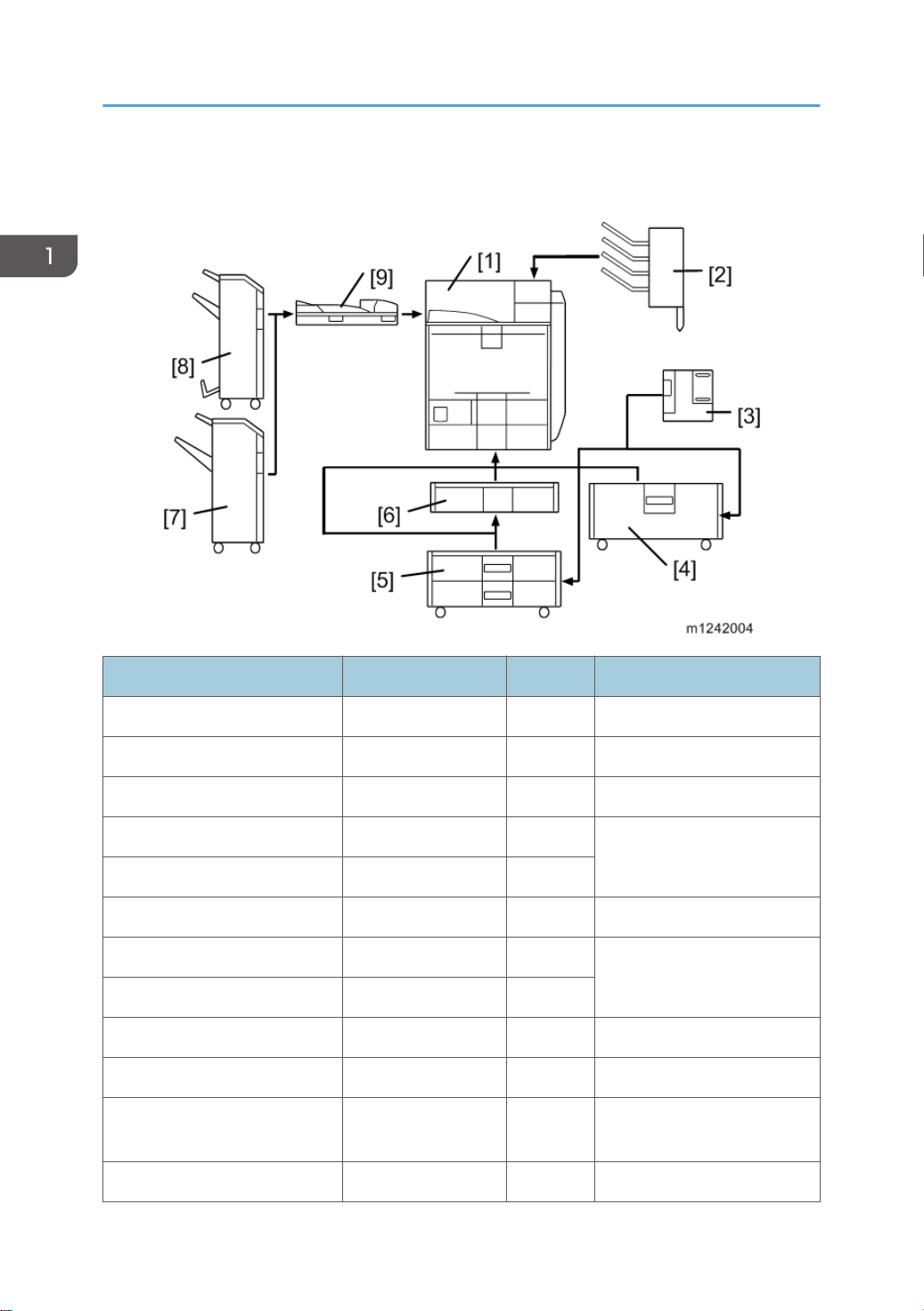

Machine Codes and Peripherals Configuration

Item Machine Code Call out Remarks

Mainframe M124/M125 [1] -

Mail bin M413 [2] -

1200-sheet LCT D631 [3] Requires [4] or [5]

2000-sheet LCT D581 [4]

One from the two

Two-tray paper feed unit D580 [5]

One-tray paper feed unit D579 [6] -

3000-sheet finisher D636 [7]

2000-sheet booklet finisher D637 [8]

Punch unit 2/3 holes D570-00 (NA) - Requires [7] or [8]

Punch unit 2/4 holes D570-01 (EU) - Requires [7] or [8]

Punch unit 4 holes

Bridge unit D634 [9] -

D570-02

(Scandinavia)

- Requires [7] or [8]

One from [7] and [8];

Requires one from [4] and [5]

24

Page 27

Machine Codes and Peripherals Configuration

Item Machine Code Call out Remarks

Output jogger unit B703 - Requires [7]

Item Machine code Call out Remark

PictBridge D645-15

IPDS Unit M416-24

SD Card for Netware

Printing

M416-29

[A]

D640-21 (NA)

VM Card

D640-22 (EU)

D640-23 (AA)

IEEE 1284 B679 [B]

M344-01 (NA)

Wireless LAN

[C]M344-02 (EU)

M344-08 (EU/AA)

M416-30

Gigabit Ethernet

[D] -

D377

Those cards should be

installed from SD slot 2

(lower).

If multiple applications are

required, merge all

applications in one SD card

with SP mode. ( p.97 "SD

Card Appli Move")

You can only install one of

these at a time.

25

Page 28

1. Product Information

512MB Memory Option M354-03

[E] -

1GB Memory Option M416-27

HDD*1 (250GB) M416-28 [F] -

Data Overwrite Security,

HDD Encryption

The hard disk (M416-28) is supplied with the M125 model as standard equipment.

*1

- - Included in the controller ROM

26

Page 29

Guidance for Those Who are Familiar with Predecessor Products

Guidance for Those Who are Familiar with

Predecessor Products

Machines M124/M125 are successor models to Machines G188/G189. If you have experience with

the predecessor products, the following information will be of help when you read this manual.

Different Points from Predecessor Products

Item M124/M125 G188/G189

Controller Type GW+ Controller GW Controller

New Fusing Unit without the

Decurler

Fusing Unit NEW QSU-DH fusing system IH roller fusing system

SMC data SD card download or printing Printing only

Operation Panel Tiltable Operation Panel

Includes USB/SD slot

USB2.0/SD Slot Standard Optional

Data Overwrite Security,

HDD Encryption

Included in the controller ROM SD card

Yes No

Stationary Operation Panel

27

Page 30

1. Product Information

28

Page 31

2. Installation

Installation Requirements

Environment

1. Temperature Range: 10°C to 32°C (50°F to 89.6°F)

2. Humidity Range: 15% to 80% RH

3. Ambient Illumination: Less than 1500 lux (do not expose to direct sunlight)

4. Ventilation: 3 times/hr/person or more

5. Do not let the machine get exposed to the following:

1) Cool air from an air conditioner

2) Heat from a heater

6. Do not install the machine in areas that are exposed to corrosive gas.

7. Install the machine at locations lower than 2,000 m (6,560 ft.) above sea level.

8. Install the machine on a strong, level base. (Inclination on any side must be no more than 5 mm.)

9. Do not install the machine in areas that get strong vibrations.

• Do not leave the toner bottle in a place directly exposed to sunlight.

29

Page 32

2. Installation

• The toner bottle must be kept at a temperature of 35°C (95°F) or less. Be careful not to leave the

toner bottle in a hot place when transporting or storing it.

Machine Level

Front to back: Within 5 mm (0.2")

Right to left: Within 5 mm (0.2")

Machine Space Requirements

• This machine, which uses high voltage power sources, can generate ozone gas. High ozone

density is harmful to human health. Therefore, the machine must be installed in a well-ventilated

room.

A: Over 100 mm (3.9")

B: Over 100 mm (3.9")

C: Over 100 mm (3.9")

D: Over 750 mm (29.5")

Put the machine near the power source with the clearance shown above.

30

Page 33

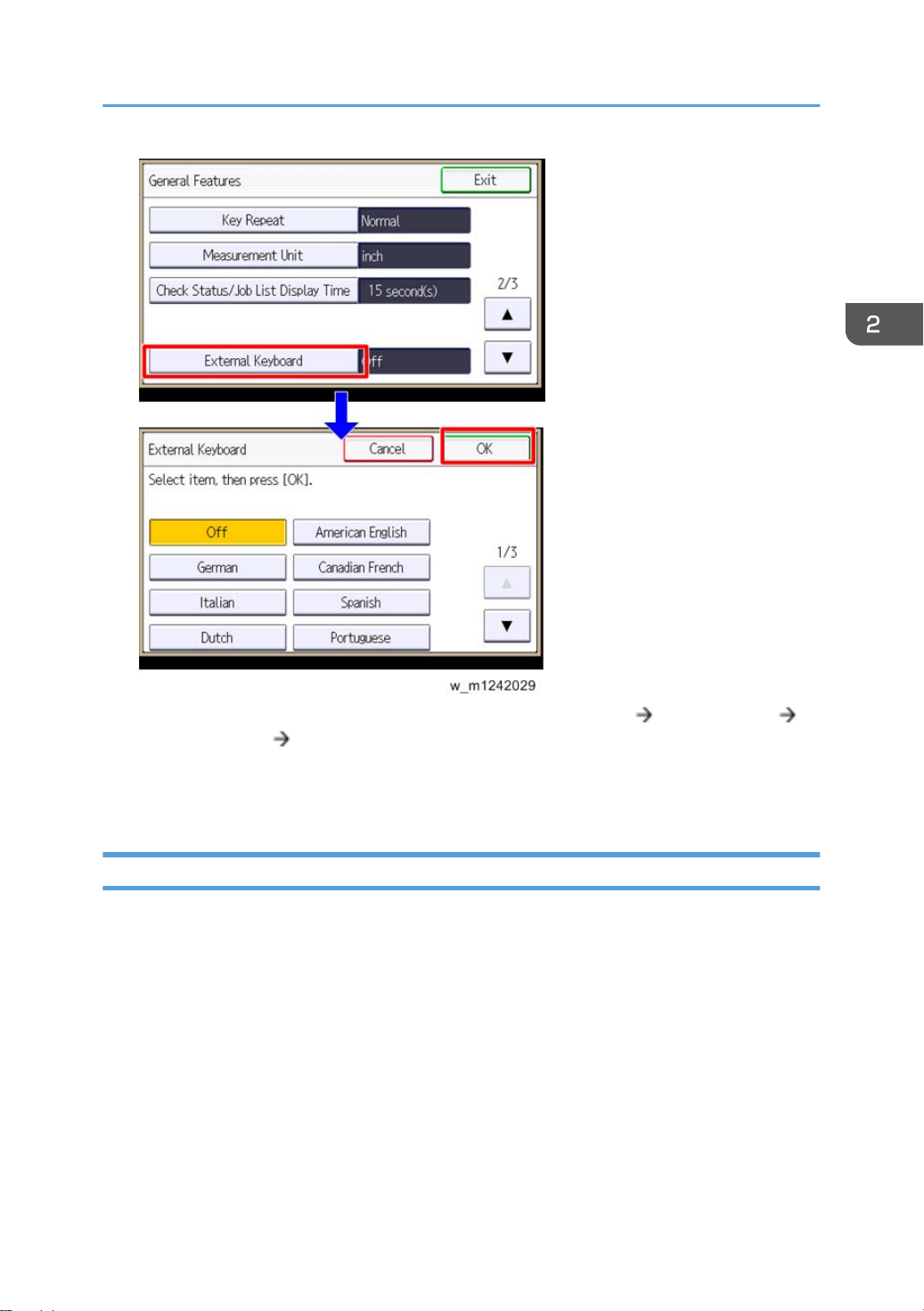

Power Requirements

• Insert the plug firmly in the outlet.

• Do not use an outlet extension plug or cord.

• Ground the machine.

1. Input voltage level:

120 to 127 V, 60 Hz: More than 12 A (NA)

220 V to 240 V, 50 Hz/60 Hz: 10 A (EU/AA/China)

2. Permissible voltage fluctuation: +8.66 %/ -10 % (NA)

Permissible voltage fluctuation: ± 10 % (Others)

3. Do not put things on the power cord.

Installation Requirements

31

Page 34

2. Installation

Printer Installation

• Make sure that the image transfer belt is in its correct position (away from the PCDUs) before you

move the machine. Otherwise, the image transfer belt and the black PCDU can be damaged.

Power Socket for Peripherals

• Rating voltage for peripherals.

• Make sure to plug the cables into the correct sockets.

Installation Flow Chart

This flow chart shows the best procedure for installation.

32

Page 35

Printer Installation

You need the optional paper tray unit or the LCT if you want to install the finisher (D636 or D637) or

1200-sheet LCT (D631).

The punch unit is for 2000-sheet booklet finisher (D637) and 3000-sheet finisher (D636).

33

Page 36

2. Installation

Installation Procedure

• Remove the tape from the development units before you turn the main switch on. The development

units can be severely damaged if you do not remove the tape.

Put the machine on the paper tray unit or the LCT first if you install an optional paper tray unit or the

optional LCT at the same time. Then install the machine and other options.

• Keep the shipping retainers after you install the machine. You may need them in the future if you

transport the machine to another location.

Unpacking

• When lifting the machine, use the handle and grips on both sides of the machine.

• If not, the machine could be dropped. This may cause an injury and may damage the machine.

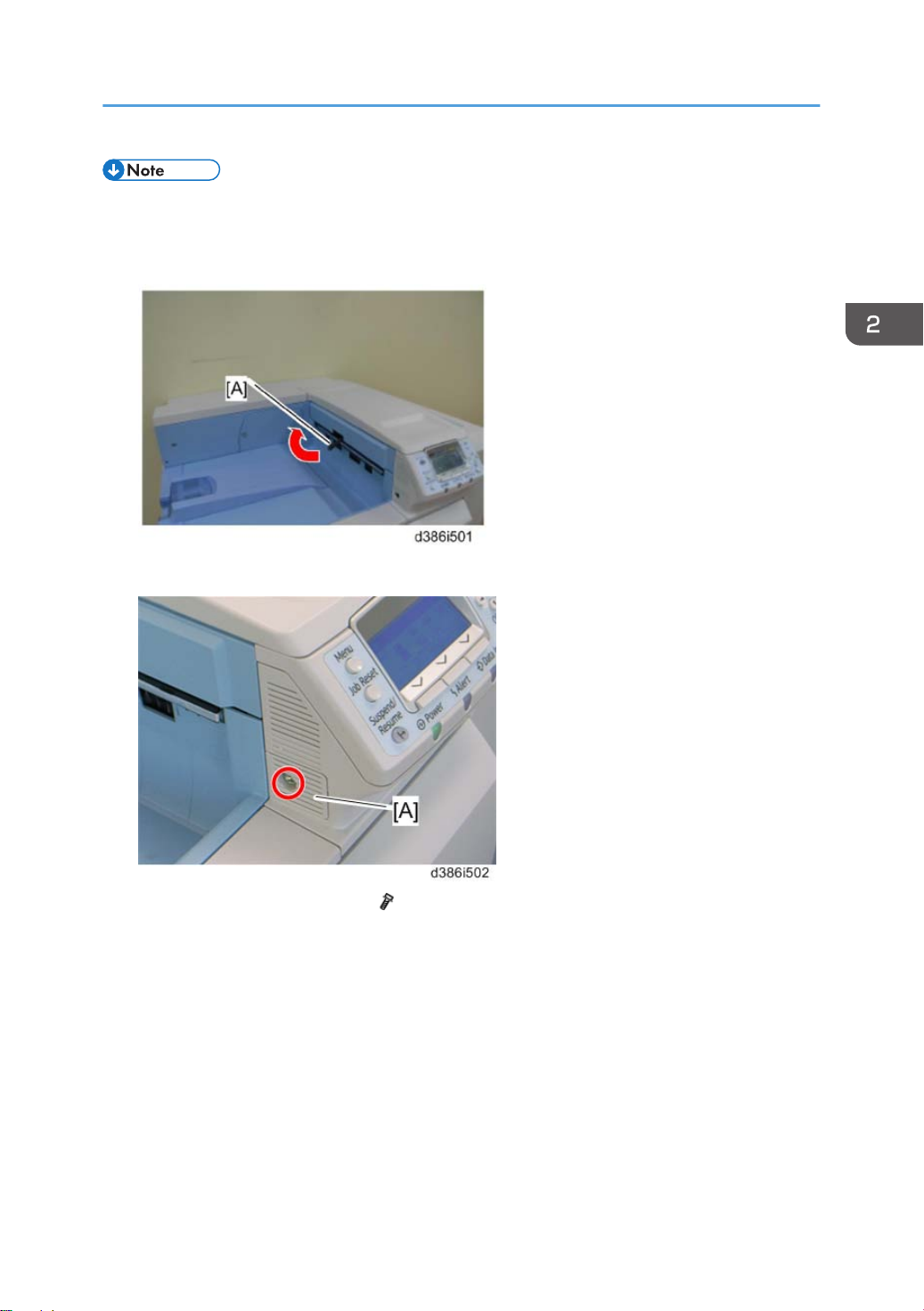

1. Pull out the handle [A].

34

Page 37

Printer Installation

2. Lift the machine with four people by using the handle and grips on both sides of the machine.

• Do not remove the tapes before placing the machine.

• Lower the machine slowly and carefully, so as not to pinch your hands.

3. Push back the handle [A] into the machine.

35

Page 38

2. Installation

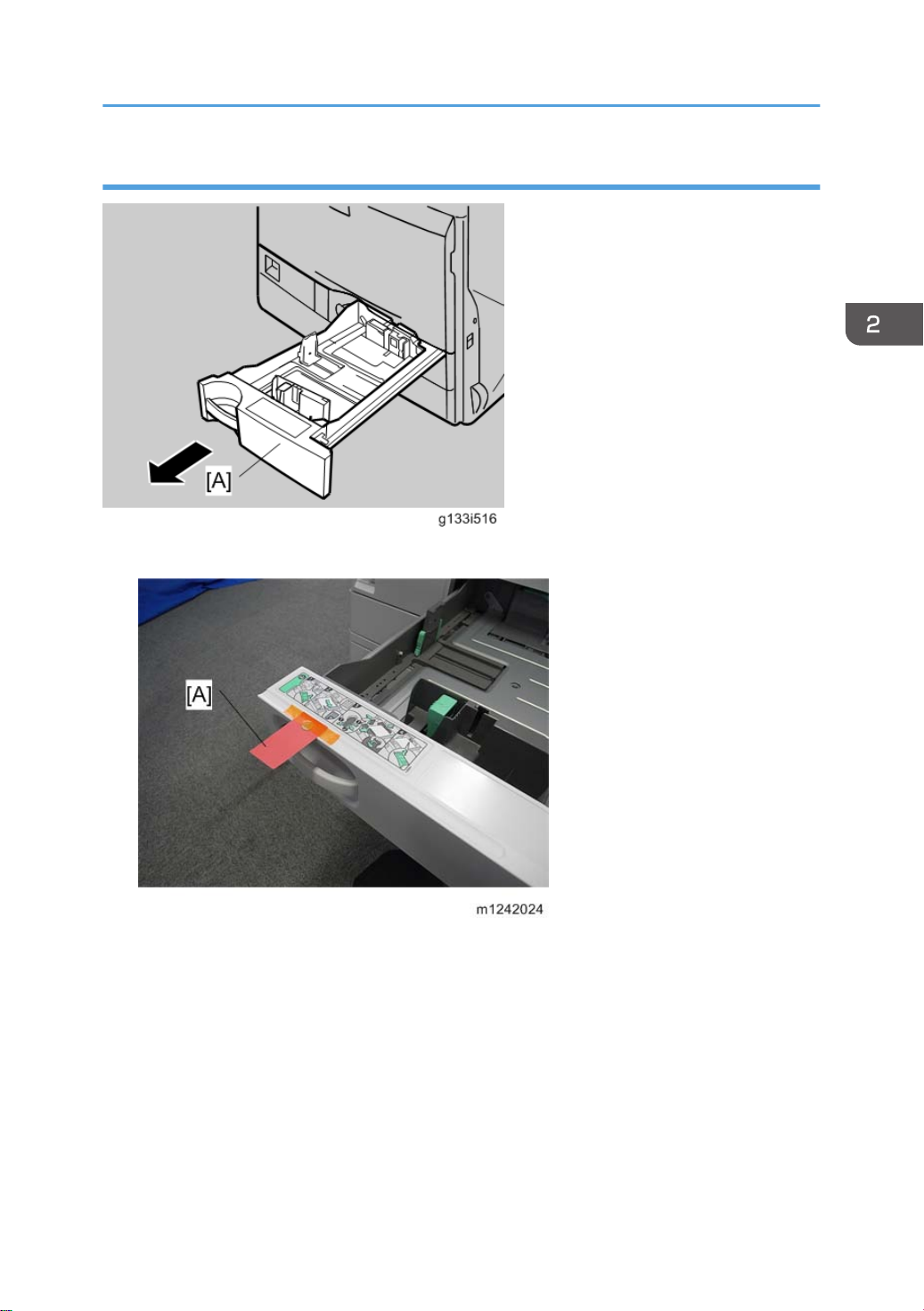

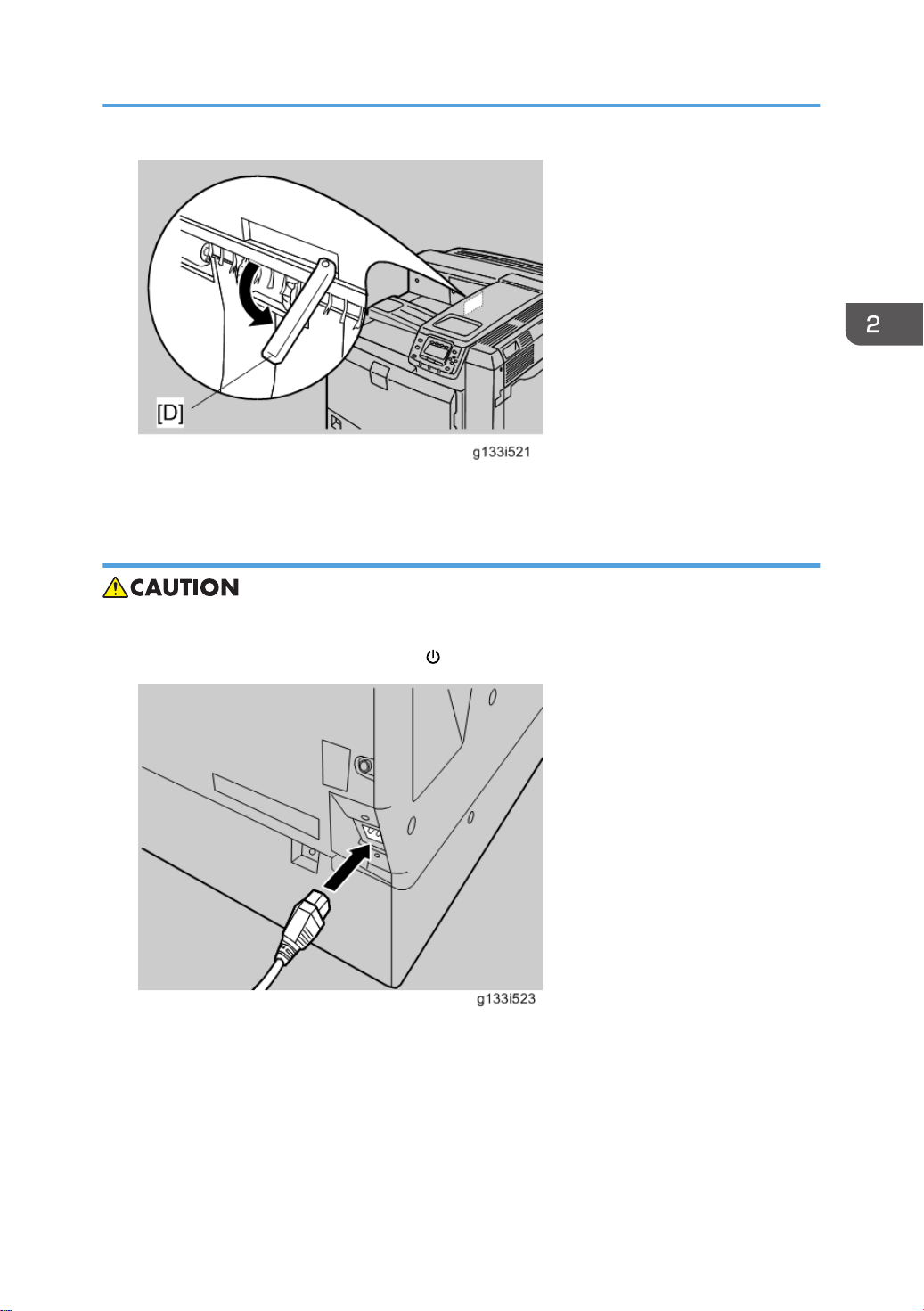

4. Push up the lever [C] on the right door, and then open the right door.

36

5. Remove the tape [A].

6. Close the right door.

Page 39

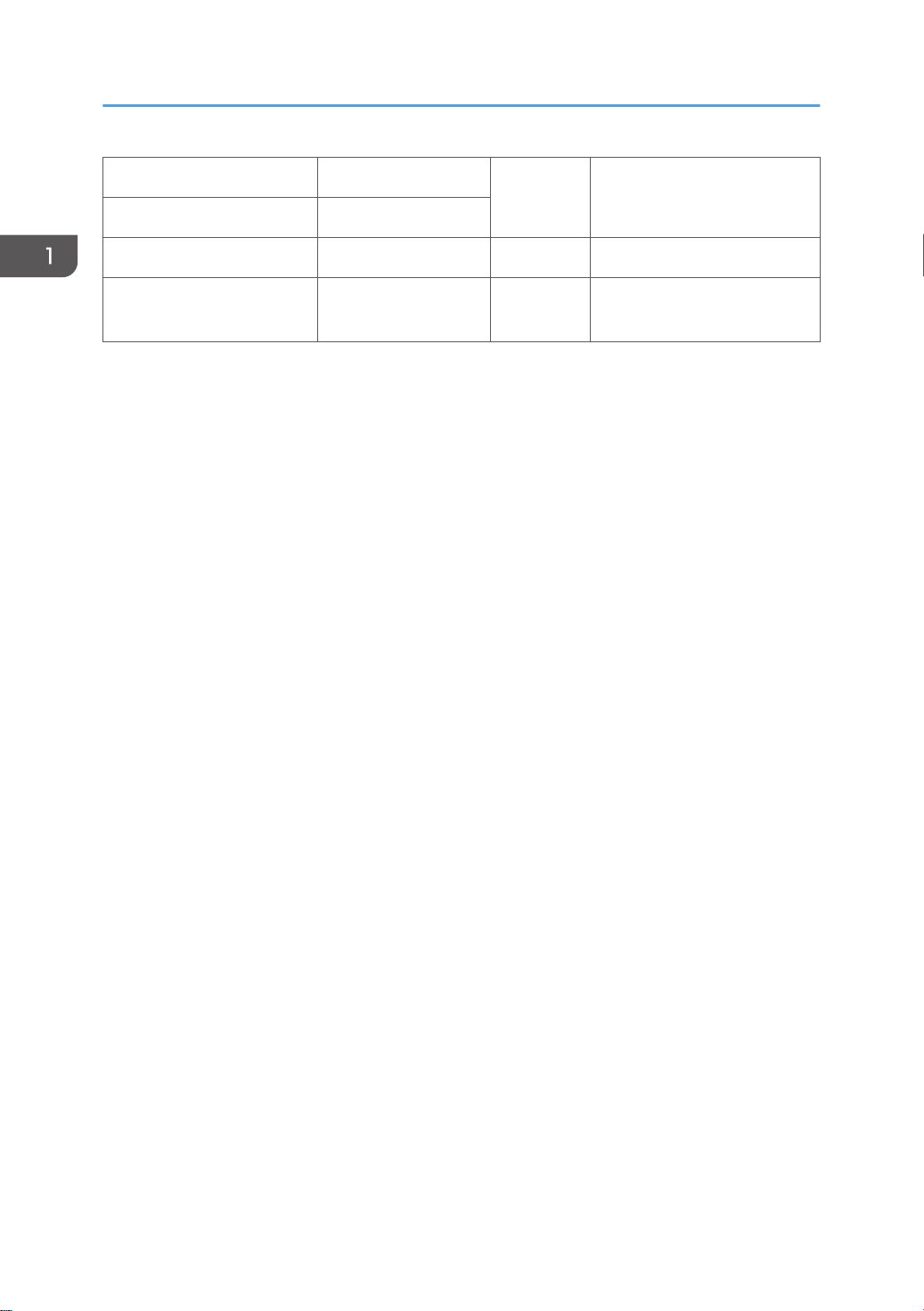

7. Open the front door [F].

8. Turn the two green levers [G] counterclockwise.

9. Open the drum positioning plate [H].

Printer Installation

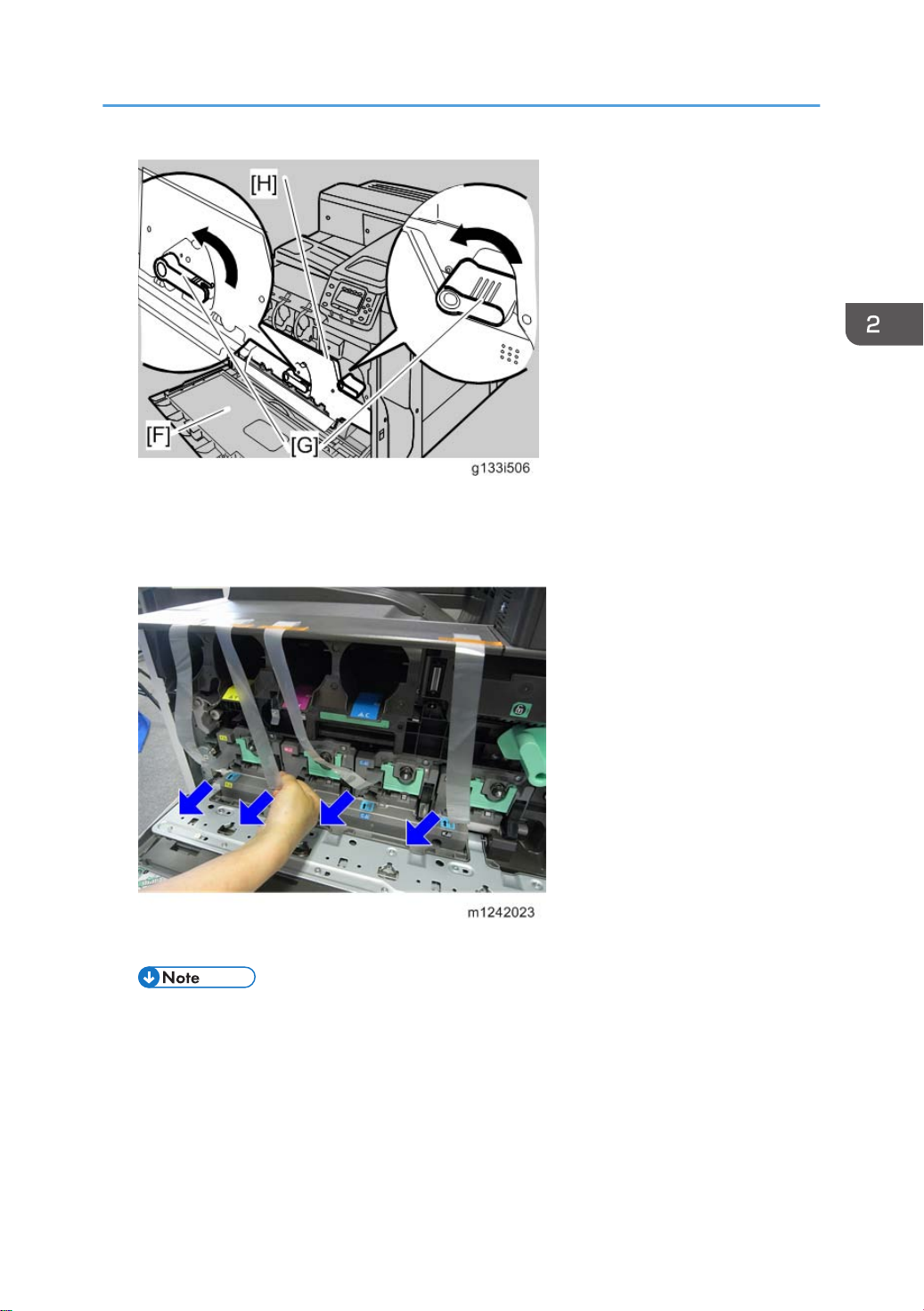

10. Remove and pull out the four tapes horizontally from all PCUs.

• Make sure that all tapes are removed.

11. Close the drum positioning plate.

12. Turn the green levers clockwise to lock the levers.

37

Page 40

2. Installation