Ricoh Aficio MP 161 Service Manual. Parts Catalog

Model SKS-C1

Machine Code: D108

Field Service Manual

6 August, 2010

Safety Notice

Important Safety Notices

Prevention of Physical Injury

1. Be sure that the power cord is unplugged before disassembling or assembling parts of the copier or

peripherals.

2. The wall outlet should be near the copier and easily accessible.

3. Note that electrical voltage is supplied to some components of the copier and the paper tray unit even

while the main power switch is off.

4. If you start a job before the copier completes the warm-up or initializing period, keep hands away

from the mechanical and electrical components until job execution has started. The copier will start

making copies as soon as warm-up or initialization is finished.

5. The inside and the metal parts of the fusing unit become extremely hot while the copier is operating.

Be careful to avoid touching those components with your bare hands.

Health Safety Conditions

Toner and developer are nontoxic, but getting either of these into your eyes may cause temporary eye

discomfort. Try to remove with eye drops or flush with water. If material remains in eye or if discomfort

continues, get medical attention.

Observance of Electrical Safety Standards

The copier and its peripherals must be installed and maintained by a customer service representative who

has completed the training course on those relevant models.

• Keep the machine away from flammable liquids, gases, and aerosols. A fire or an explosion might

occur if this precaution is not observed.

Safe and Ecological Disposal

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly if exposed to an open

flame.

2. Dispose

(These are nontoxic supplies.)

of used toner, developer, and organic photoconductors in accordance with local regulations.

1

3. Dispose of replaced parts in accordance with local regulations.

Laser Safety

The Center for Devices and Radiological Health (CDRH) prohibits the repair of laser-based optical units

in the field. The optical housing unit can only be repaired in a factory or at a location with the requisite

equipment. The laser subsystem is replaceable in the field by a qualified Customer Engineer. The laser

chassis is not repairable in the field. Customer engineers are therefore directed to return all chassis and

laser subsystems to the factory or service depot when replacement of the optical subsystem is required.

of controls not specified in this manual, or performance of adjustments or procedures not specified

• Use

in this manual, may result in hazardous radiation exposure.

WARNING FOR LASER UNIT

• Turn off the main switch before attempting any of the procedures in the Laser Unit section. Laser

beams can seriously damage your eyes.

CAUTION MARKING:

2

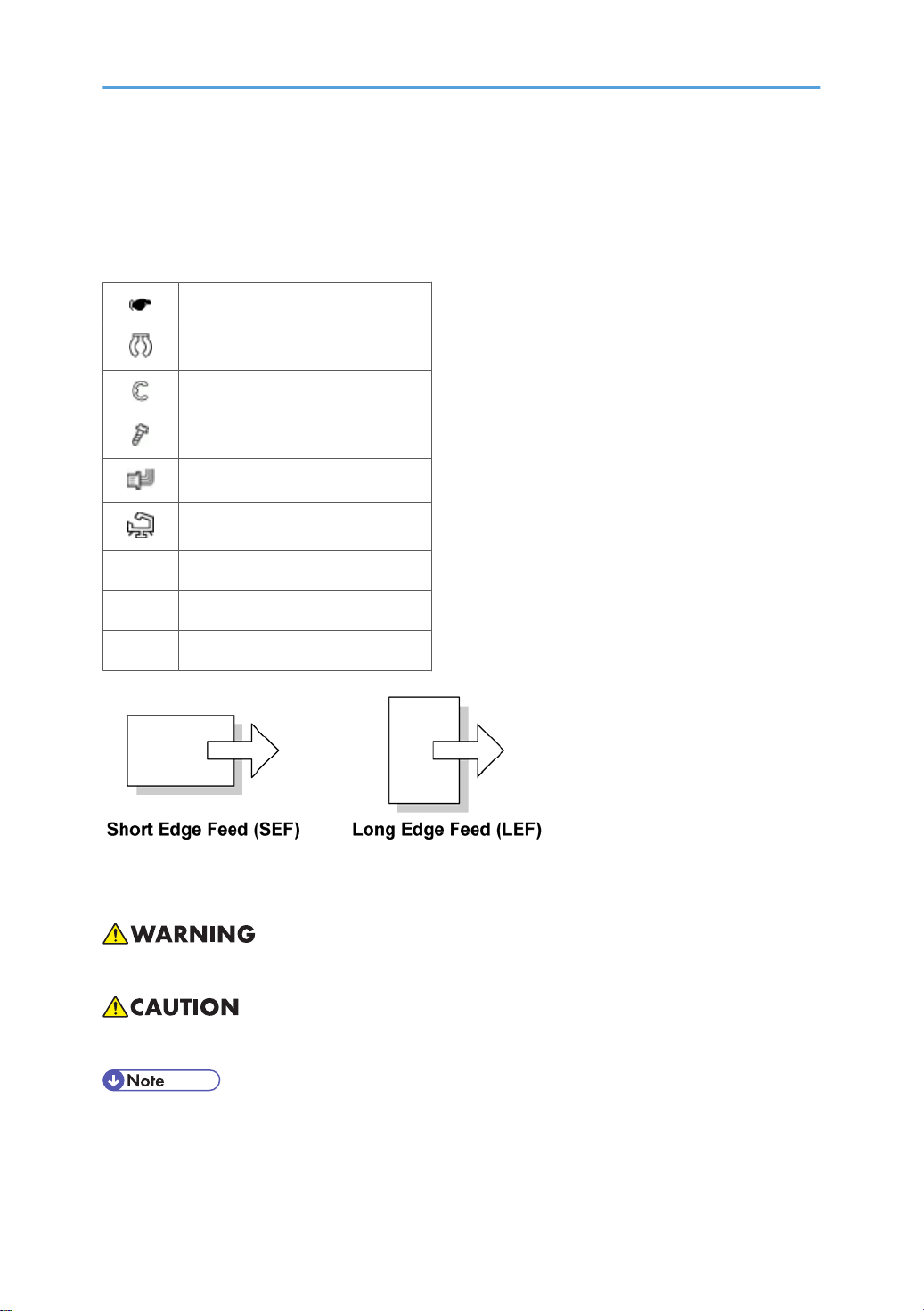

Symbols and Abbreviations

This manual uses several symbols and abbreviations. The meaning of those symbols and abbreviations is

as follows:

See or Refer to

Clip ring

E-ring

Screw

Connector

Clamp

SEF Short Edge Feed

LEF Long Edge Feed

- Core Technology manual

Cautions, Notes, etc.

The following headings provide special information:

• Failure to obey warning information could result in serious injury or death.

• Obey these guidelines to ensure safe operation and prevent minor injuries.

• This information provides tips and advice about how to best service the machine.

3

TABLE OF CONTENTS

Safety Notice......................................................................................................................................................1

Important Safety Notices...............................................................................................................................1

Laser Safety.....................................................................................................................................................

Symbols and Abbreviations...............................................................................................................................3

1. Product Information

Specifications......................................................................................................................................................9

Copier.............................................................................................................................................................9

Printer............................................................................................................................................................11

Scanner.........................................................................................................................................................12

Option Specifications..................................................................................................................................13

Supported Paper Sizes................................................................................................................................14

Machine Configuration....................................................................................................................................

Mainframe (D108)......................................................................................................................................18

Overview..........................................................................................................................................................19

Component Layout.......................................................................................................................................19

Electrical Components.................................................................................................................................21

Paper Path....................................................................................................................................................24

Drive Layout..................................................................................................................................................25

Guidance for Those Who are Familiar with Predecessor Products..............................................................27

18

2

2. Installation

Installation Cautions.........................................................................................................................................29

Installation Requirements.................................................................................................................................30

Environment..................................................................................................................................................30

Machine Level..............................................................................................................................................30

Minimum Operational Space Requirements.............................................................................................31

Power Requirements....................................................................................................................................32

Copier...............................................................................................................................................................33

Accessory Check..........................................................................................................................................

Installation Procedure..................................................................................................................................33

Paper Tray Unit.................................................................................................................................................38

Accessory Check..........................................................................................................................................38

Installation Procedure..................................................................................................................................38

Paper Tray Unit Heater....................................................................................................................................41

4

33

Accessory Check..........................................................................................................................................41

Installation Procedure..................................................................................................................................42

ARDF (B872)....................................................................................................................................................49

Accessory Check..........................................................................................................................................49

Installation Procedure..................................................................................................................................49

Optional Paper Tray Grip Handle..................................................................................................................56

Accessories...................................................................................................................................................56

Installation Procedure..................................................................................................................................57

3. Preventive Maintenance

PM Tables.........................................................................................................................................................59

How to Clear the PM Counter.........................................................................................................................61

4. Replacement and Adjustment

Precautions........................................................................................................................................................63

General.........................................................................................................................................................63

Halogen-free Cable....................................................................................................................................63

Special Tools and Lubricants...........................................................................................................................64

Exterior Covers and Operation Panel............................................................................................................65

Rear Cover...................................................................................................................................................65

Copy Tray.....................................................................................................................................................65

Scale Plate....................................................................................................................................................66

Operation Panel and Upper Covers..........................................................................................................67

Right Door.....................................................................................................................................................68

Bypass Tray..................................................................................................................................................68

Platen Cover Sensor....................................................................................................................................69

Scanner Unit.....................................................................................................................................................70

Exposure Glass............................................................................................................................................70

Lens Block.....................................................................................................................................................71

Exposure Lamp, Lamp Stabilizer Board.....................................................................................................71

Scanner Motor.............................................................................................................................................72

Scanner HP Sensor......................................................................................................................................74

Scanner Alignment Adjustment...................................................................................................................74

Fusing................................................................................................................................................................76

Fusing Unit....................................................................................................................................................76

5

Exit Sensor....................................................................................................................................................77

Hot Roller Stripper Pawls.............................................................................................................................77

Hot Roller and Fusing Lamp........................................................................................................................78

Thermoswitches and Thermistor..................................................................................................................80

Pressure Roller..............................................................................................................................................81

Checking the NIP band...............................................................................................................................82

PCU and Quenching Lamp.............................................................................................................................83

PCU...............................................................................................................................................................83

Quenching Lamp..........................................................................................................................................84

Exhaust Fan and Main Motor.........................................................................................................................85

Exhaust Fan..................................................................................................................................................85

Main Motor..................................................................................................................................................86

Paper Feed........................................................................................................................................................87

Paper Feed Roller and Friction Pad............................................................................................................87

Paper End Sensor.........................................................................................................................................88

Registration Sensor......................................................................................................................................88

Bypass Paper End Sensor...........................................................................................................................89

Bypass Feed Roller......................................................................................................................................90

Bypass Feed Clutch and Friction Pad.........................................................................................................91

Paper Feed and Registration Clutches.......................................................................................................92

Image Transfer..................................................................................................................................................94

Transfer Roller..............................................................................................................................................94

ID Sensor and Duplex Roller.......................................................................................................................95

Discharge Plate............................................................................................................................................96

BICU and Controller Board.............................................................................................................................97

BICU..............................................................................................................................................................97

Controller Board..........................................................................................................................................98

Other Replacements......................................................................................................................................101

Duplex Motor............................................................................................................................................101

High-Voltage Power Supply Board.........................................................................................................102

PSU.............................................................................................................................................................103

Contact-Release Solenoid........................................................................................................................104

Toner Supply Clutch..................................................................................................................................104

6

Laser Unit........................................................................................................................................................106

Location of the Caution Decal..................................................................................................................106

Laser Unit....................................................................................................................................................106

LD Unit and Polygon Mirror Motor..........................................................................................................107

ARDF...............................................................................................................................................................108

ARDF...........................................................................................................................................................108

DF Rear Cover...........................................................................................................................................109

Original Feed Unit.....................................................................................................................................109

Separation Roller.......................................................................................................................................110

DF Drive Board..........................................................................................................................................110

Original Set and DF Inverter Sensor........................................................................................................111

DF Registration and DF Exit Sensor..........................................................................................................112

DF Feed Motor..........................................................................................................................................113

DF Transport Motor...................................................................................................................................114

DF Feed Clutch..........................................................................................................................................115

Adjusting Copy Image Area.........................................................................................................................116

Printing........................................................................................................................................................116

Scanning....................................................................................................................................................118

DF Image Adjustment................................................................................................................................121

5. Troubleshooting

Service Call Conditions.................................................................................................................................123

Summary....................................................................................................................................................123

SC Code Descriptions...............................................................................................................................124

Electrical Component Defects.......................................................................................................................133

Sensor/Switch Open Errors.....................................................................................................................133

Blown Fuse Conditions..............................................................................................................................134

BICU LED Display......................................................................................................................................135

6. System Maintenance Reference

Service Program.............................................................................................................................................137

Using SP and SSP Modes.........................................................................................................................137

SP1-XXX (Feed).........................................................................................................................................138

SP2-XXX (Drum).........................................................................................................................................141

SP4-XXX (Scanner)....................................................................................................................................145

7

SP5-XXX (Mode).......................................................................................................................................153

SP6-XXX (Peripherals)...............................................................................................................................157

SP7-XXX (Data Log)..................................................................................................................................158

SP8-XXX (History)......................................................................................................................................163

Using SP Mode..............................................................................................................................................166

ID Sensor Error Analysis (SP2-221)........................................................................................................166

Memory Clear...........................................................................................................................................166

Input Check (SP5-803).............................................................................................................................168

Output Check (SP5-804).........................................................................................................................169

Serial Number Input (SP5-811-001)......................................................................................................171

NVRAM Data Upload/Download (SP5-824/825).............................................................................171

Firmware Update Procedure....................................................................................................................173

Test Pattern Print (SP5-902-001).............................................................................................................175

SMC Print (SP5-990)................................................................................................................................178

Printer Service Program Mode Table.......................................................................................................178

Scanner Service Program Mode Table...................................................................................................178

INDEX...........................................................................................................................................................179

8

1. Product Information

1

Specifications

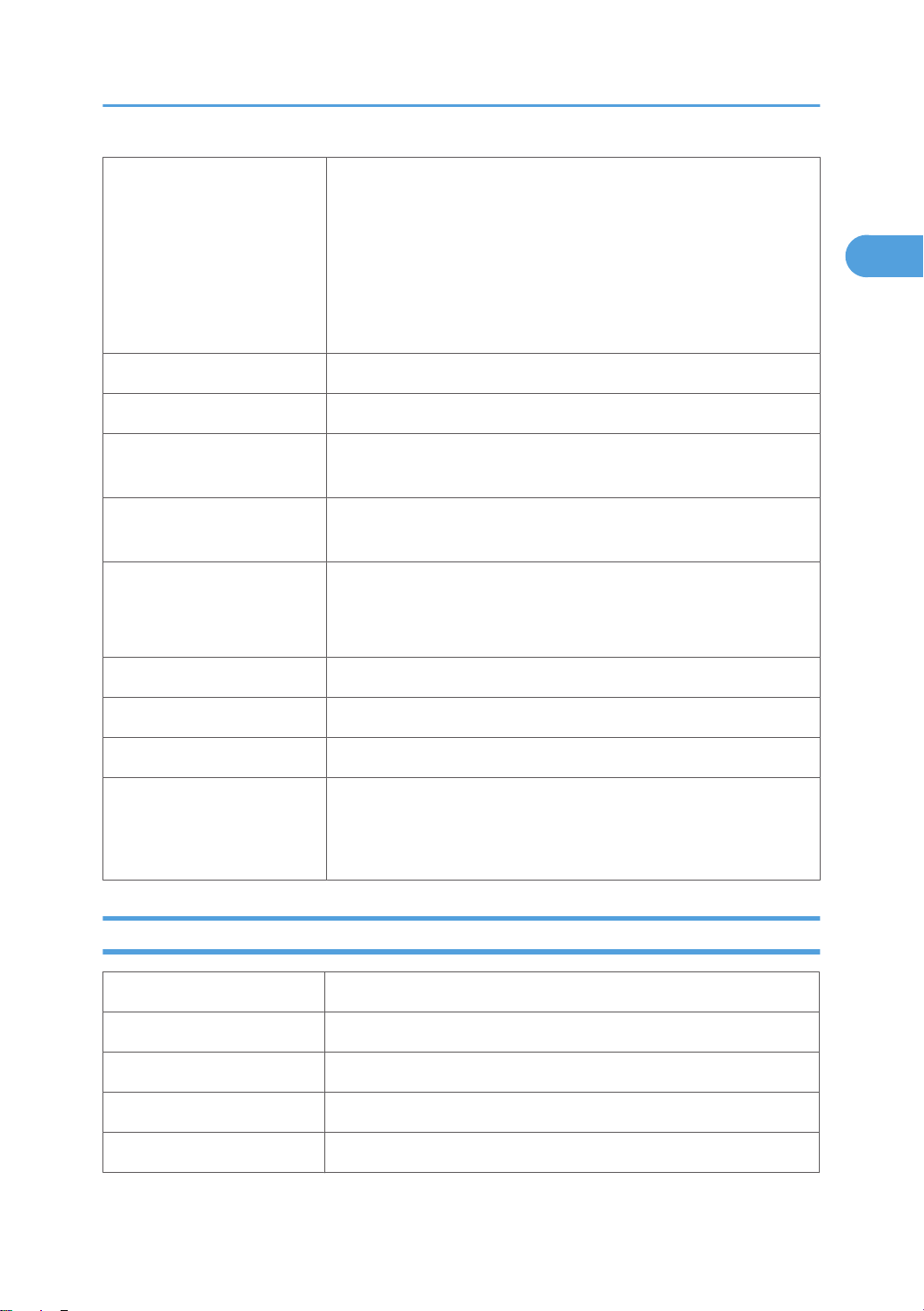

Copier

Configuration: Desktop

Copy Process: Laser beam scanning and electro photographic printing

Originals: Sheet/Book/Object

Maximum

Original Size:

A4 / 81/2" x 14"

A4 / 81/2" x 14" (ARDF)

Maximum

A4 SEF / 81/2" x 11" SEF (Copier's paper tray)

A4 SEF / 81/2" x 14" SEF (Bypass)

A4 SEF / 81/2" x 14" SEF (Optional paper tray)

A4 SEF / 81/2" x 14" SEF (Duplex)

Copy Paper Size:

Copy Paper Weight:

Minimum

A5 LEF / 81/2" x 51/2" LEF (Copier's paper tray)

A6 SEF/ 81/2" x 51/2" (Bypass)

A4 SEF / 81/2" x 11” SEF (Optional paper tray unit)

A4 SEF / 81/2" x 11” SEF (Duplex)

Custom sizes in the bypass tray:

Width: 90 – 216 mm (3.5" – 8.5")

Length: 139 – 600mm (5.48" – 23.62")

Standard paper tray; optional paper tray:

60 – 90 g/m2, 16 – 24 lb.

Bypass:

60 – 157 g/m2, 16 – 42 lb.

Duplex:

64 – 90 g/m2, 20 – 24 lb.

9

1. Product Information

1

A4 Version LT Version

Enlargement

Reproduction Ratios:

Zoom: 50% to 200%, in 1% steps

Power Source: 110 – 120 V, 60 Hz or 220 – 240 V, 50/60 Hz

Power Consumption:

Noise Emission:

Full Size 100% 100%

Reduction

Maximum: 900 W or less

Energy Saver: 25 W or less

Off Mode: 1 W or less

Sound Power Level

Standby 40 dB(A) or less

Operating (copier only) 62 dB(A) or less

Operating (full-system) 66 dB(A) or less

200%

141%

93%

71%

50%

155%

129%

93%

78%

65%

10

Copier: 485 x 450 x 371 mm (19.4" x 18" x 14.8")

Dimensions (W x D x H)

Weight:

Resolution: 600 dpi

Copying Speed in Multicopy

Mode (copies/minute):

Warm-up Time:

With

optional paper tray unit: 485 x 454 x 511 mm (18.4" x 17.7"

x 20.1")

Basic: 22 kg (48.5 lb.) or less

Basic with ARDF: 27 kg (59.4 lb.) or less

GDI model: 24 kg (52.8 lb.) or less

17 (A4 / 81/2" x 11"; 100%)

Basic: 10 seconds or less (at 20°C [68°F])

Other: Approximately 35 seconds (at 20°C [68°F])

7.5 seconds or less

1

Note: Measurement conditions

Specifications

First Copy Time:

Copy Number Input: Numeric keypad, 1 to 99 (increment, decrement)

Manual Image Density: 5 steps

Auto Off Timer

Energy Saver Timer:

Copy Paper Capacity:

Copy-Tray Capacity 250 sheets

Toner Replenishment: Cartridge replacement (230 g/cartridge)

• From the ready state, with the polygonal mirror motor spinning.

• A4/LT copying

• From copier's paper tray

• 100% size

Default: 1 minute

Range: 1 to 240 minutes

Default: 1 minute

Rage: 1 to 240 minutes

Paper Tray: 250 sheets

Optional Paper Tray Unit: 500 sheets x 1

Bypass Tray: 100 sheets

Toner Yield 7k copies /toner bottle (A4, 6% full black)

Auto reverse document feeder

Optional Equipment:

Paper tray unit

Anti-condensation heater for paper tray unit

Printer

Resolution 600 dpi

Printing speed 16 ppm (A4L, 8½" × 11"L plain paper)

Interface USB 2.0 interface

Printer language Host-Based Printing

Memory 64 MB

11

1. Product Information

1

Windows 98SE / Me

Operating systems supported

by this machine

Required network cable

Windows 2000

Windows XP

Windows Server 2003

100BASE-TX/10BASE-T shielded twisted-pair (STP, Category/

Type5)

cable.

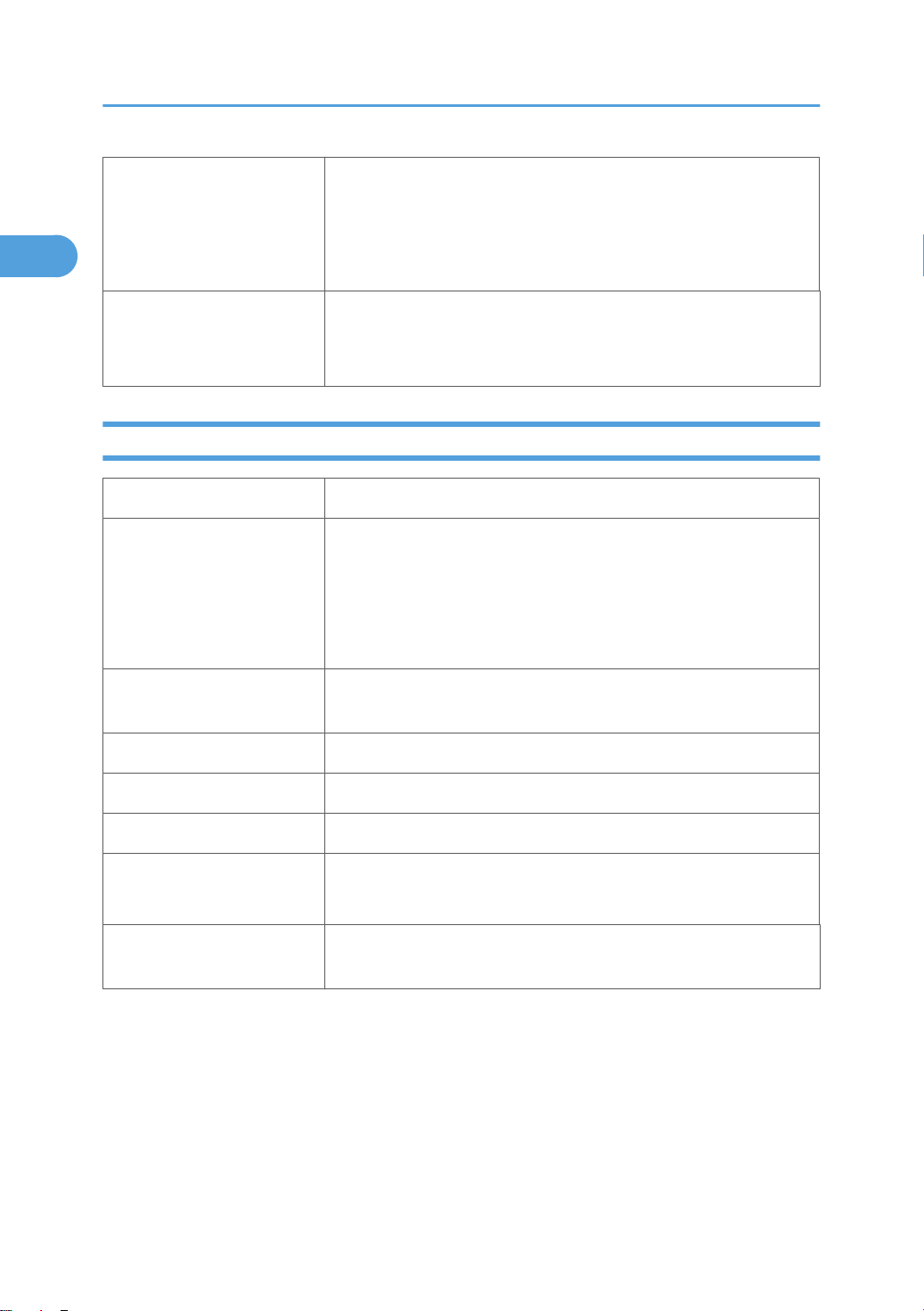

Scanner

Scan method Flatbed scanning

Approx. 18 pages/minute [Scan size: A4SEF, Colors/Gradations:

Binary, Resolution: 200dpi,

Scan speed *

Maximum power

consumption

1

device data compression (Binary/Halftone): Data compression

Select

(MMR),

Document feeder: ARDF, ITU-T No.1 Chart]

Less than 900 W

Image sensor type CCD Image Sensor

Scan types Sheet, book

Interface USB interface

Resolution

Variable range of scan

resolution

*1 Scanning speeds vary according to machine operating conditions, computer (specifications, network

traffic, software, etc.), and original types.

12

B/W: 600 dpi

Full color: 300 dpi (600 dpi with the optional DIMM)

Setting range: 100 dpi - 600 dpi

Option Specifications

1

ARDF

Original Size:

Specifications

Standard:

A4 to A5; 81/2" x 14" to 81/2" x 51/2"

Custom (Simplex):

Width: 139 mm to 216 mm

Length: 139 mm to 1260 mm

Custom (Duplex):

Width: 139 mm to 216 mm

Length: 160 mm to 356*1 mm

*1: When you use 310 mm or more originals, originals weighing

55k (17 lb./ 64 g/m2) or less cannot be used in duplex scanning

mode.

Original Weight: 52–105 g/m2 (14–28 lb.)

Table Capacity: 50 sheets (80 g/m2, 21 lb.)

Original Standard Position: Center

Separation: FRR

Transport: Roller transport

Feed Order: Top first

Reproduction Range: 50–200%

Power Source: 24 and 5 Vdc from the copier

Power Consumption:

Dimensions (W x D x H): 485 x 360 x 120 mm (19.1" x 14.2" x 4.72")

Weight: 4.9 kg (10.8 lb) (excluding the original table and platen cover)

Operating: 50 W or less

On standby: 1.2 W or less

13

1. Product Information

1

Paper Tray Unit

Paper Sizes:

Paper Weight: 60 – 90 g/m2, 16 – 24 lb.

Tray Capacity: 500 sheets (80 g/m2, 21 lb. ) x 1 tray

Paper Feed System: Feed roller and friction pad

Power Source:

Power Consumption: Maximum: 15 W (excluding optional tray heater)

Average: 14 W (excluding optional tray heater)

Weight: Not above 6 kg (13.2. lb.)

Size (W x D x H): 430 x 414 x 140 mm (16.9" x 16.3" x 5.5")

A4 SEF, 8½" x 11" SEF, 8½" x 13" SEF,

8½" x 14" SEF

24 Vdc and 5 Vdc, from copier. If optional tray heater is installed,

the copier also supplies Vac (120 Vac or

220 – 240 Vac).

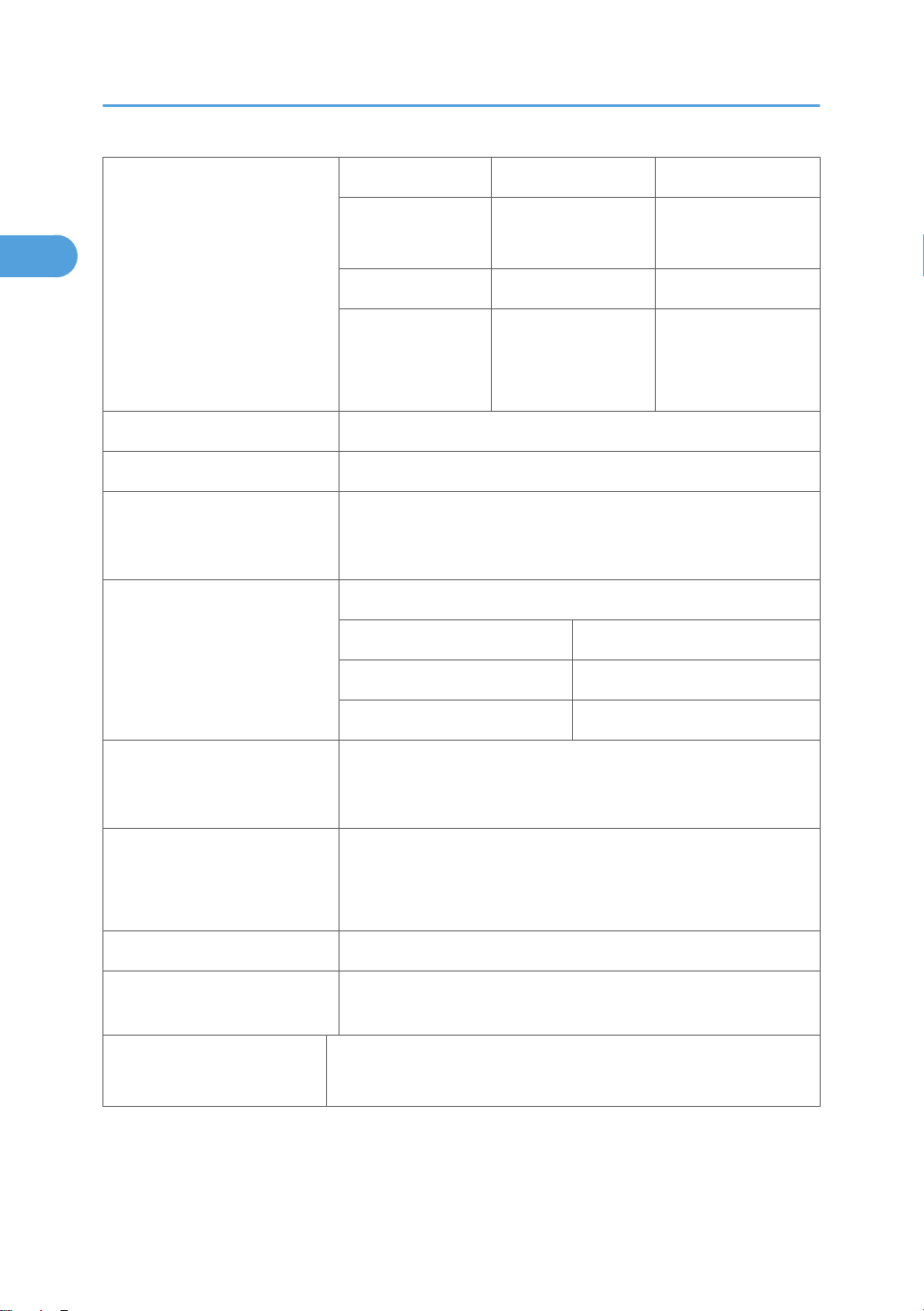

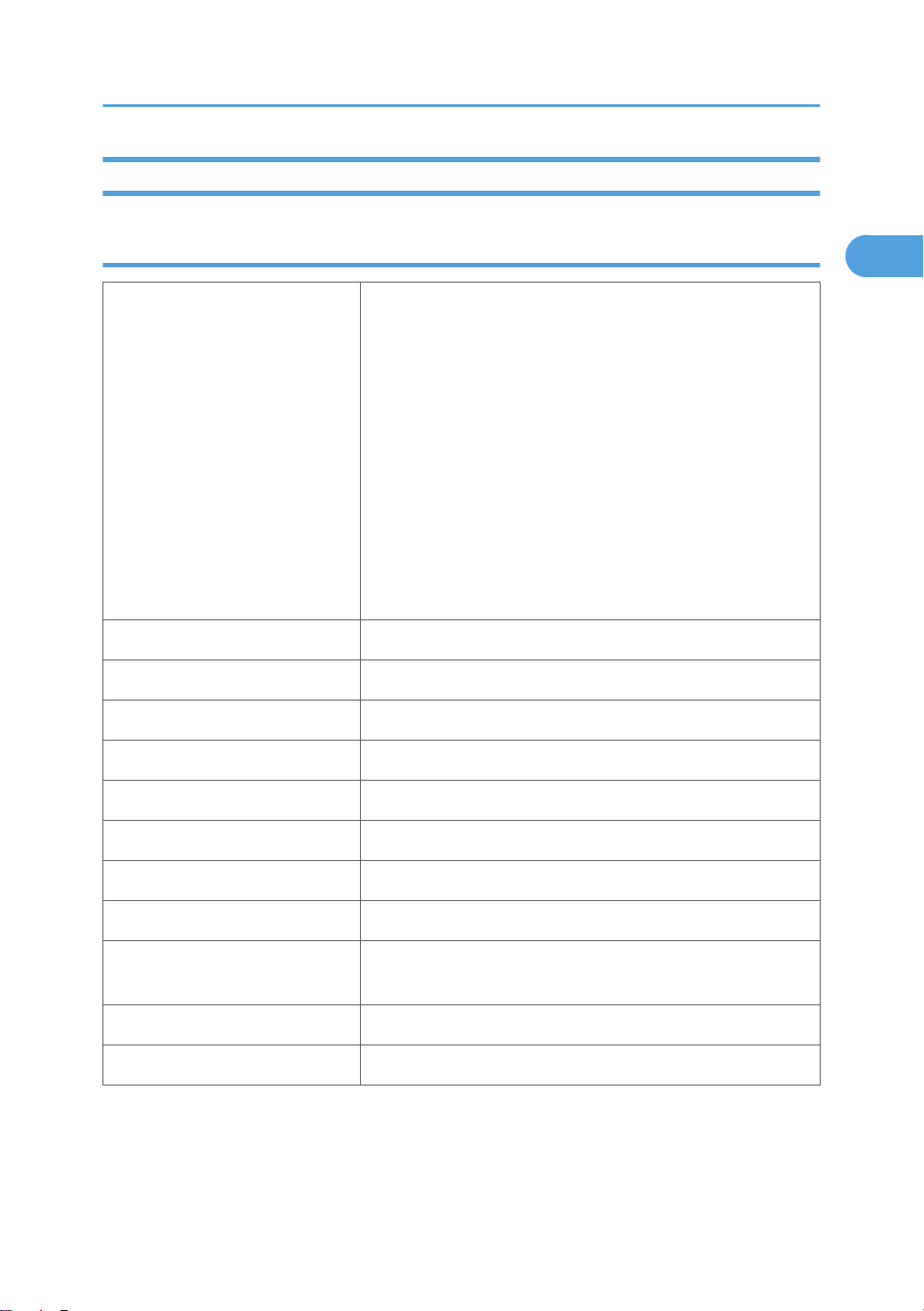

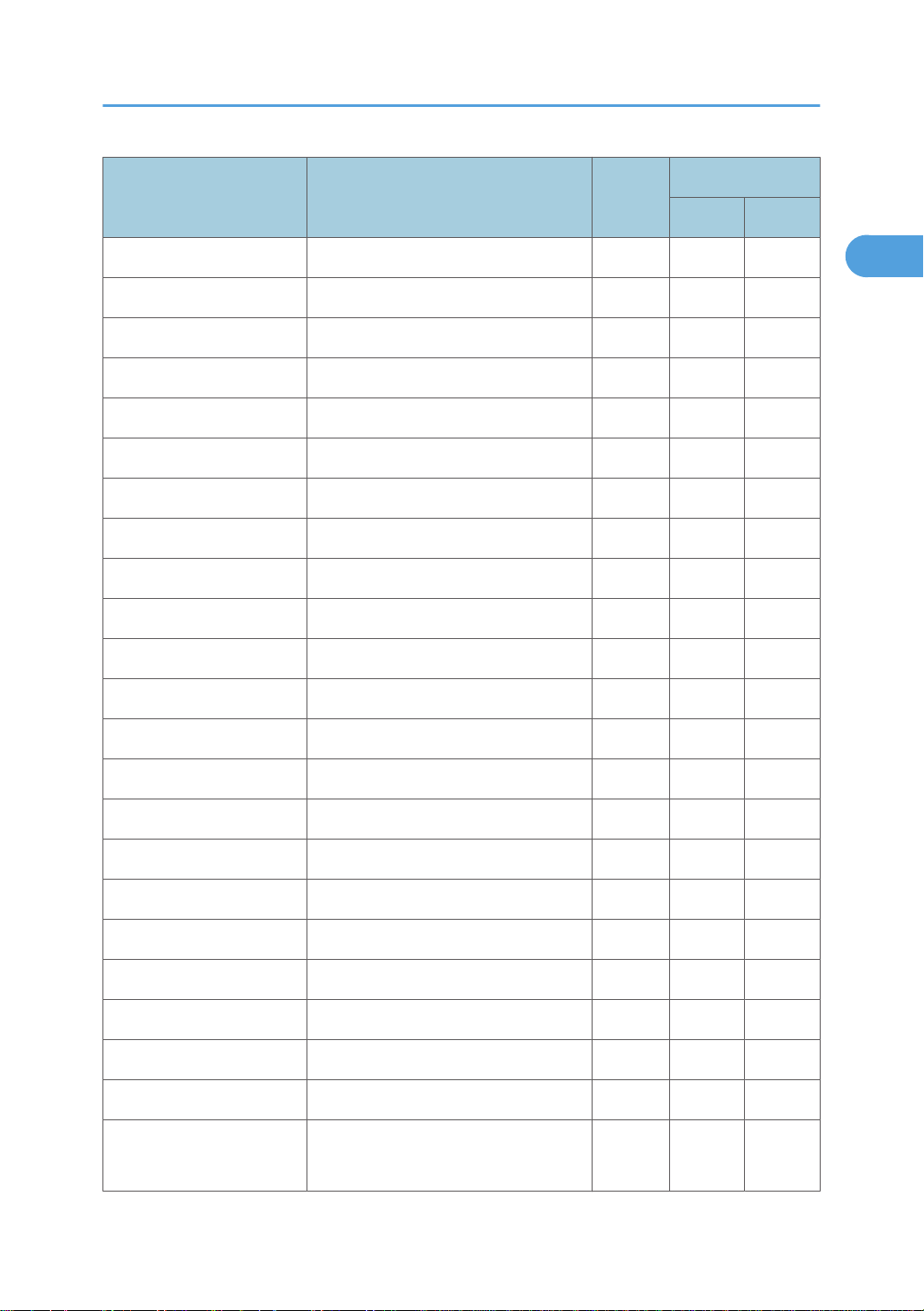

Supported Paper Sizes

Original Paper Sizes

The copier and ARDF do not detect original paper sizes. The following table lists the paper sizes that the

ARDF can transport.

Paper Size (W x L) Book

Simpl. Dupl.

A3 SEF 297 x 420 mm – – –

B4 SEF 257 x 364 mm – – –

A4 SEF 210 x 297 mm X X X

A4 LEF 297 x 210 mm –

B5 SEF 182 x 257 mm X X X

B5 LEF 257 x 182 mm –

14

ARDF

Specifications

1

ARDF

Paper Size (W x L) Book

Simpl. Dupl.

A5 SEF 148 x 210 mm X X X

A5 LEF 210 x 148 mm X X

B6 SEF 128 x 182 mm –

B6 LEF 182 x 128 mm –

A6 SEF 105 x 148 mm –

8K SEF 267 x 390 mm –

16K SEF 195 x 267 mm X X X

16K LEF 267 x 195 mm –

DLT SEF 11.0" x 17.0" –

LG SEF 8.5" x 14.0" X*

1

X X*

LT SEF 8.5" x 11.0" X X X

LT LEF 11.0" x 8.5" –

Executive SEF 7.25" x 10.5" – X X

HLT SEF 5.5" x 8.5" X X X

HLT LEF 8.5" x 5.5" X X

F/GL (F4) SEF 8.0" x 13.0" X*

Foolscap SEF 8.5" x 13.0" X*

Folio SEF 8.25" x 13.0" X*

Government 8.25" x 14" X*

1

1

1

1

X X*

X X*

X X*

X X*

USB4 SEF 10.0" x 14.0" –

Eng Quarto SEF 8.0" x 10.0" – X X*

Eng Quarto LEF 10.0" x 8.0" –

2

2

2

2

2

2

Custom:

Width 139-216 mm

Length 139-356 mm

– X*

3

X*

2, 4

15

1. Product Information

1

Symbol meanings:

X: Can use

–: Cannot use

*1: Can be used when the ARDF is installed

*2: 55k (17 lb./ 64 g/m2) or less original cannot be used.

*3: Width: 139-216 mm, Length: 139-1260 mm

*4: Width 139-216 mm, Length: 160-356 mm

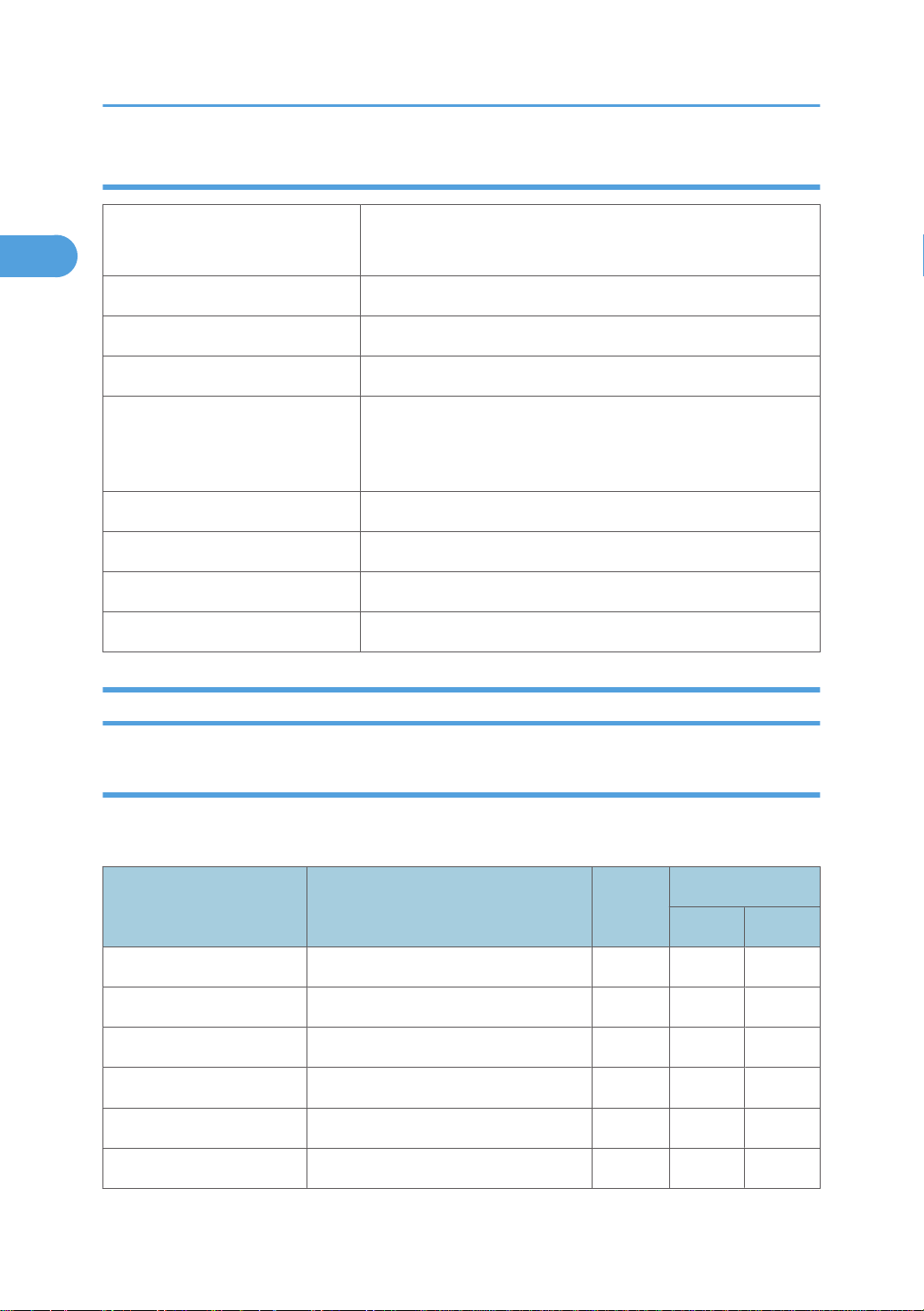

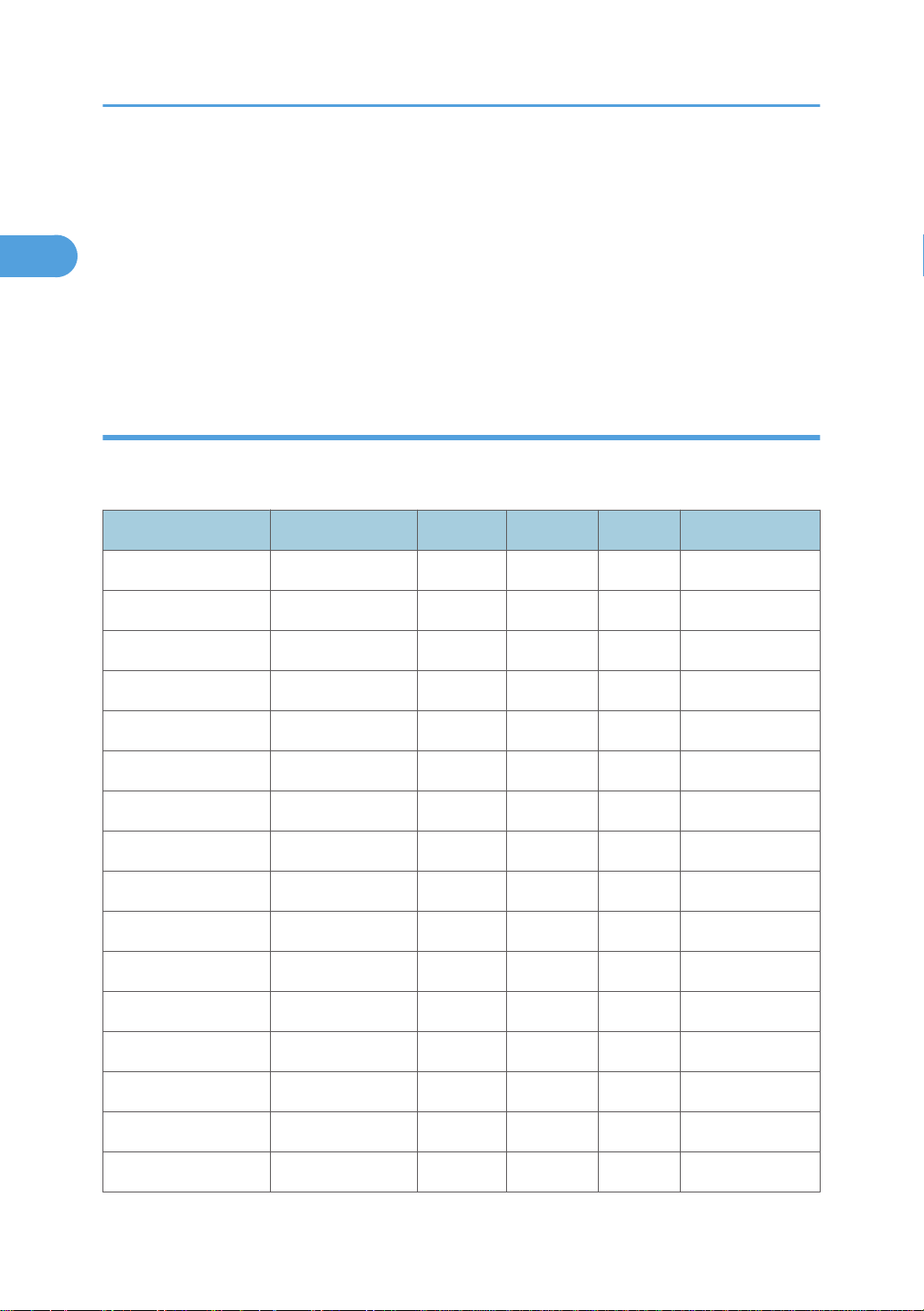

Paper Feed

The copier and optional paper feed unit do not detect paper sizes. The following table lists the paper sizes

that the copier and optional paper feed unit can transport.

Paper Size (W x L) Regular By-pass Duplex Optional PFU

A3 SEF 297 x 420 mm – – – –

B4 SEF 257 x 364 mm – – – –

A4 SEF 210 x 297 mm X X X X

A4 LEF 297 x 210 mm – – – –

B5 SEF 182 x 257 mm X X X –

B5 LEF 257 x 182 mm – – – –

A5 SEF 148 x 210 mm – X – –

A5 LEF 210 x 148 mm X X – –

B6 SEF 128 x 182 mm – – – –

B6 LEF 182 x 128 mm – – – –

A6 SEF 105 x 148 mm – – – –

8K SEF 267 x 390 mm – – – –

16K SEF 195 x 267 mm X X X –

16K LEF 267 x 195 mm – – – –

DLT SEF 11.0" x 17.0" – – – –

LG SEF 8.5" x 14.0" – X X X

16

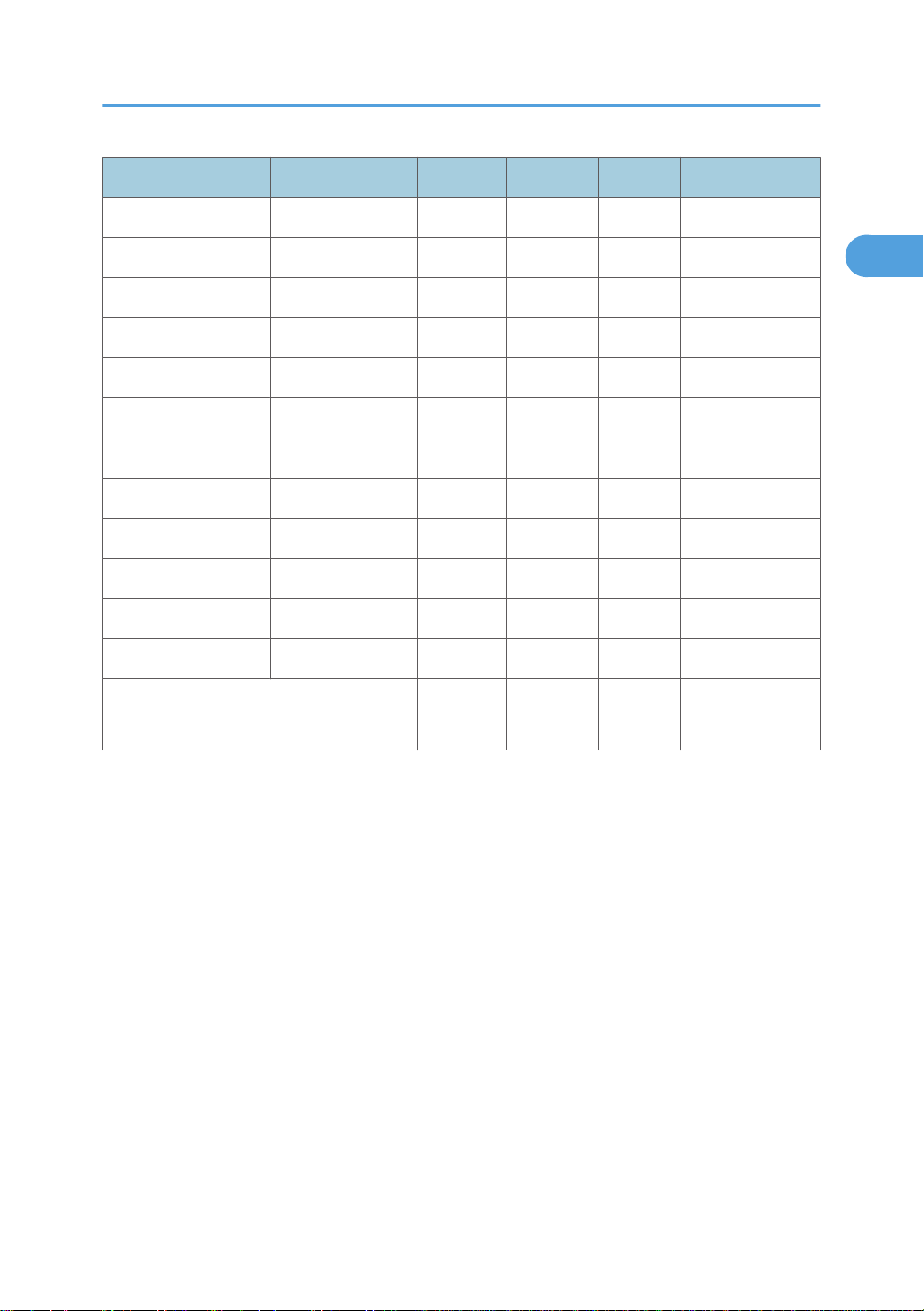

Paper Size (W x L) Regular By-pass Duplex Optional PFU

1

LT SEF 8.5" x 11.0" X X X X

LT LEF 11.0" x 8.5" – – – –

Executive SEF 7.25" x 10.5" – X – –

HLT SEF 5.5" x 8.5" – X – –

HLT LEF 8.5" x 5.5" X X – –

F/GL (F4) SEF 8.0" x 13.0" – X – –

Foolscap SEF 8.5" x 13.0" – X X X

Folio SEF 8.25" x 13.0" – X X X

Government 8.25" x 14" – X X X

USB4 SEF 10.0" x 14.0" – – – –

Specifications

Eng Quarto SEF 8.0" x 10.0" – – – –

Eng Quarto LEF 10.0" x 8.0" – – – –

Custom: Leading edge 90–216 mm

Side edge 139–356 mm

Symbol meanings:

X: Can transport

–: Cannot transport

– X – –

17

1. Product Information

1

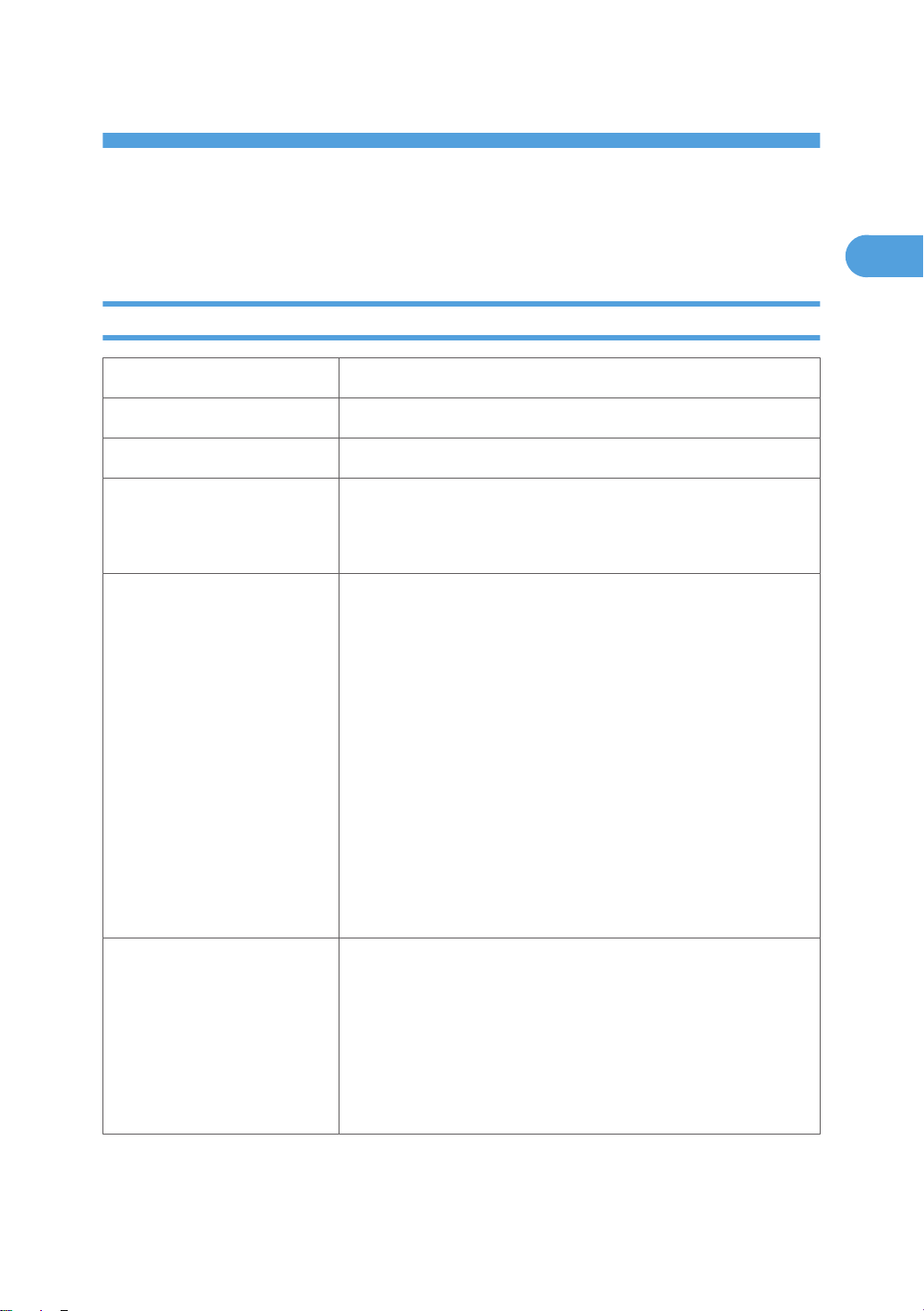

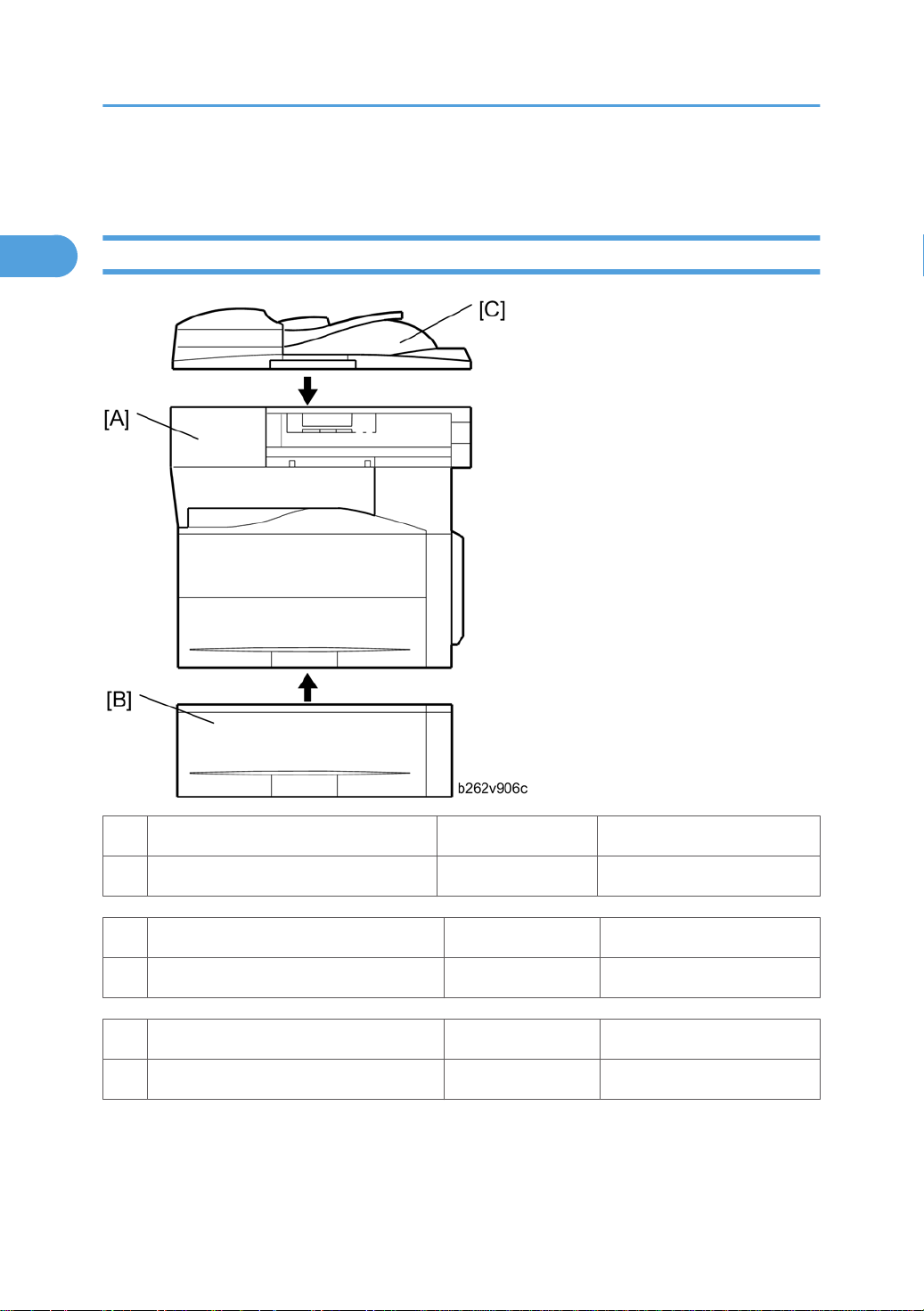

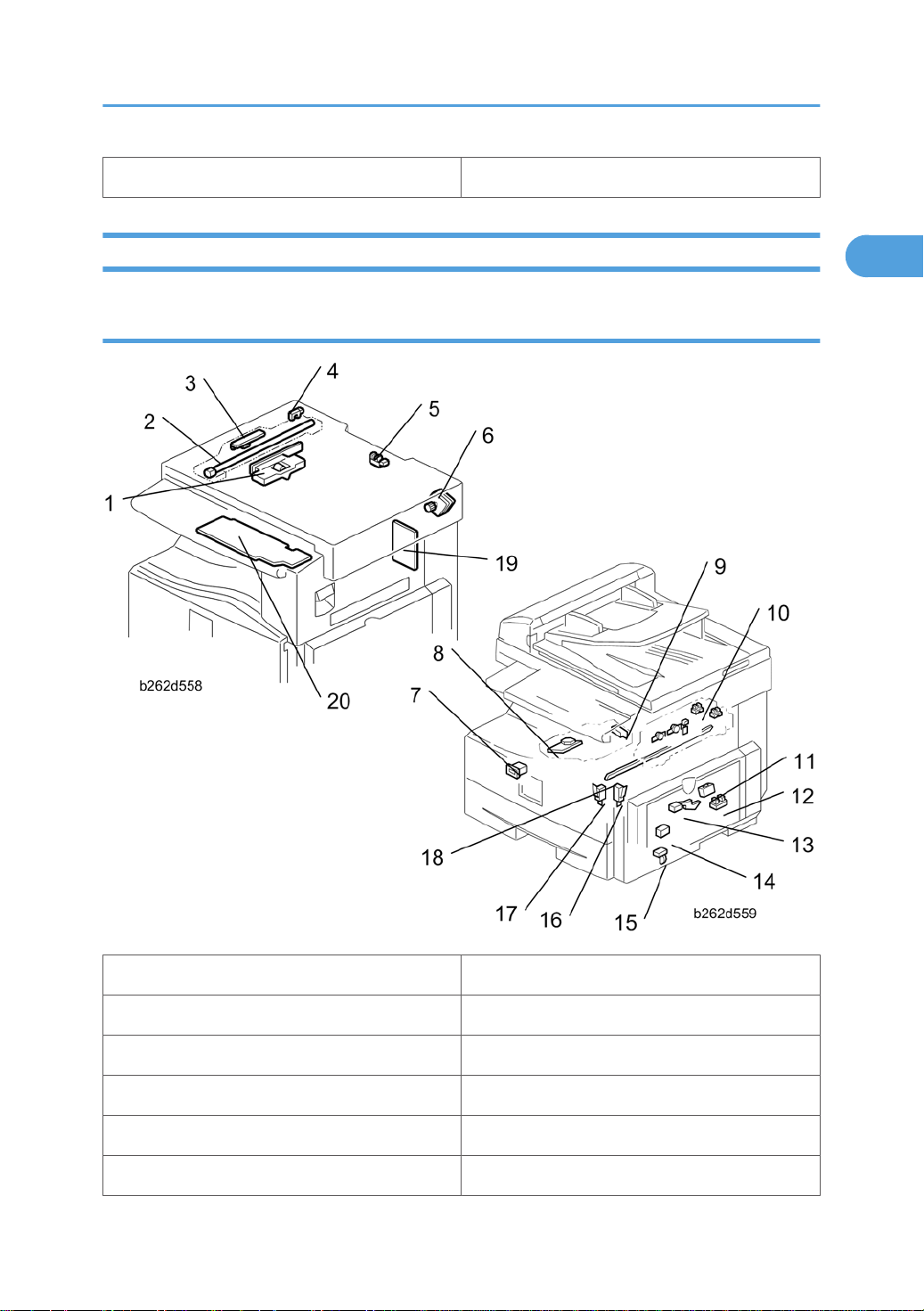

Machine Configuration

Mainframe (D108)

Standard Component Machine Code Remarks

1 Copier [A] D108 -

Optional Components Machine Code Remarks

2 500-Sheet Paper Feed Unit [B] B421 -

Standard/Optional Component Machine Code Remarks

3 ARDF [C] B872 -

18

Overview

1

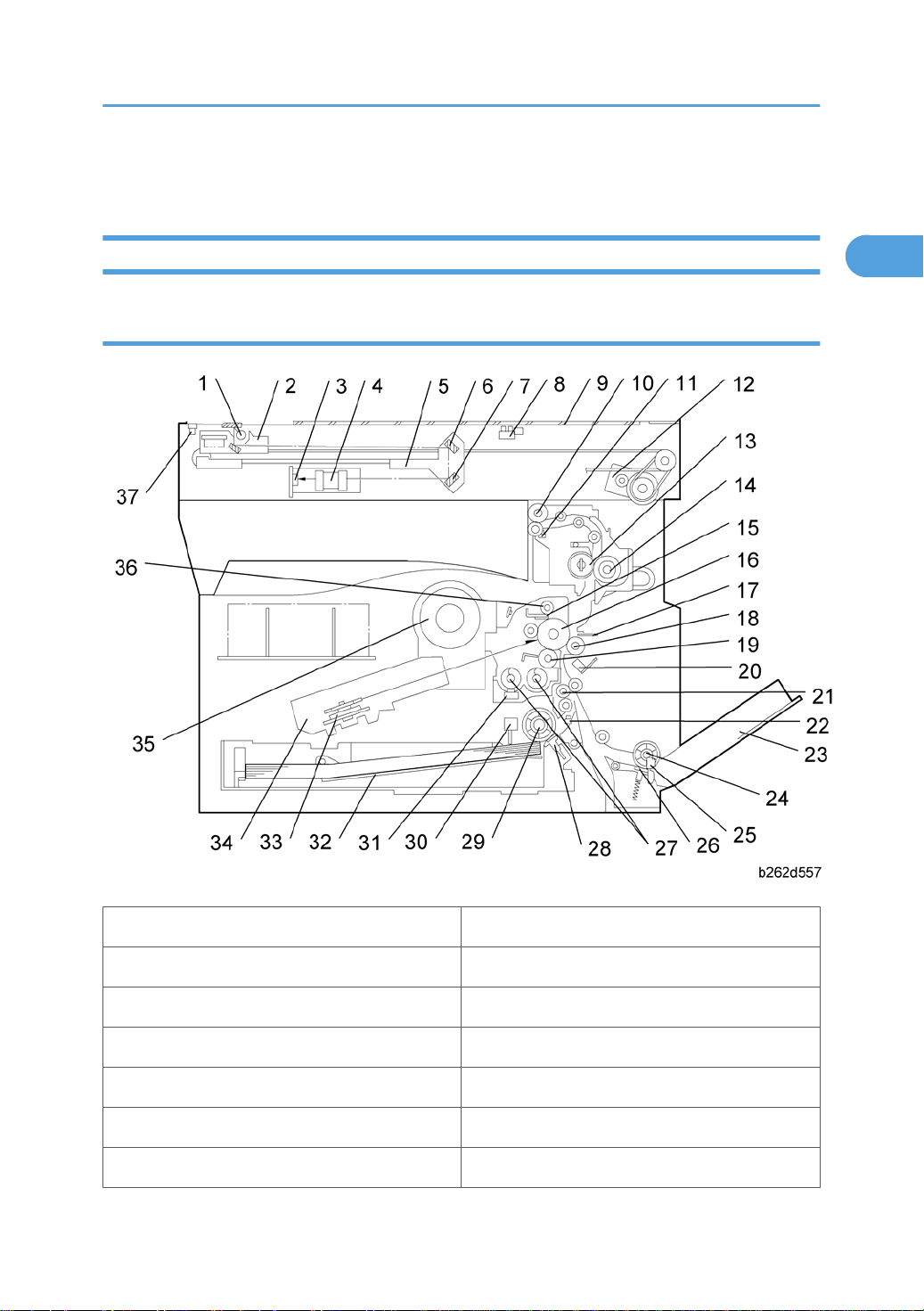

Component Layout

Mainframe

Overview

1. Exposure Lamp 20. ID (Image Density) Sensor

2. 1st Scanner 21. Registration Roller

3. CCD (on SBU) 22. Registration Sensor

4. Lens Block 23. Bypass Tray

5. 2nd Scanner 24. Bypass Paper Feed Roller

6. 2nd Mirror 25. Bypass Paper End Sensor

7. 3rd Mirror 26. Bypass Friction Pad

19

1. Product Information

1

8. Platen Cover Sensor 27. Mixing Augers

9. Exposure Glass 28. (Main) Friction Pad

10. Exit Roller 29. Paper Feed Roller

11. Exit Sensor 30. Paper End Sensor

12. Scanner Motor 31. TD (Toner Density) Sensor

13. Hot Roller 32. Bottom Plate

14. Pressure Roller 33. Polygon Mirror Motor

15. Cleaning Blade 34. Laser Unit

16. OPC Drum 35. Toner Supply Bottle (or THM)

17. Discharge Plate 36. Toner Collection Coil

18. Transfer Roller 37. Scanner HP Sensor

19. Development Roller

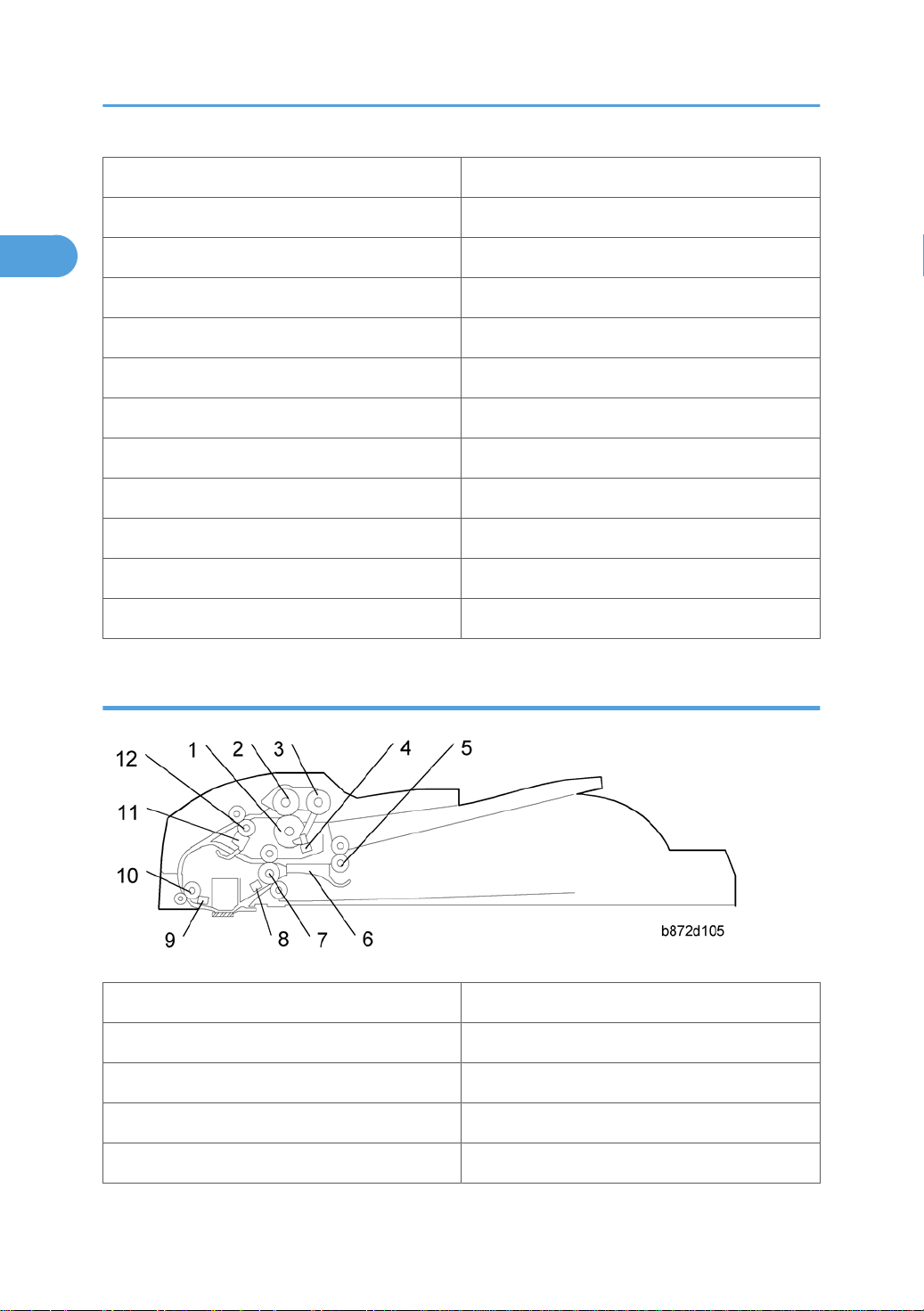

ARDF

1. Separation Roller 7. Exit Roller

2. Paper Feed Roller 8. Exit Sensor

3. Pick-up Roller 9. Registration Sensor

4. Original Set Sensor 10. Registration Roller

5. Inverter Roller 11. Inverter Sensor

20

6. Junction Gate 12. Transport Roller

1

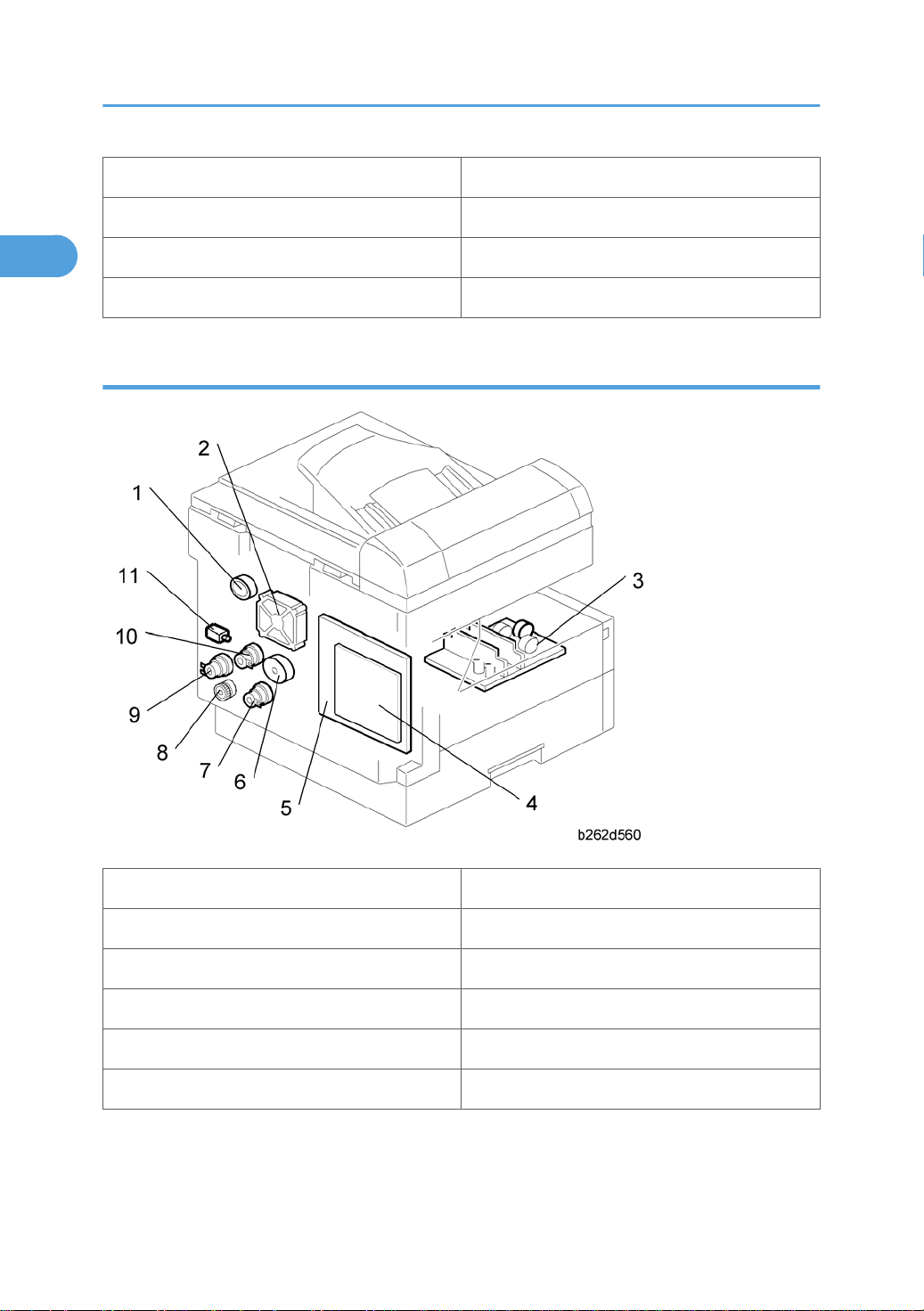

Electrical Components

Electrical Components 1

Overview

1. Lens Block 11. ID (Image Density) Sensor

2. Exposure Lamp 12. Registration Sensor

3. Lamp Stabilizer Board 13. Paper End Sensor

4. Scanner HP Sensor 14. Toner Density Sensor

5. Platen Cover Sensor 15. Bypass Paper End Sensor

6. Scanner Motor 16. Right Door Safety Switch

21

1. Product Information

1

7. Mechanical Counter 17. Front Door Safety Switch

8. Polygon Mirror Motor 18. Quenching Lamp

9. LD Unit 19. High-Voltage Power Supply Board

10. Exit Sensor 20. Operation Panel Board

Electrical Components 2

1. Duplex Motor 7. Paper Feed Clutch

2. Exhaust Fan 8. Toner Supply Clutch

3. PSU 9. Bypass Feed Clutch

4. Controller Board 10. Registration Clutch

5. BICU 11. Fusing Solenoid

6. Main Motor

22

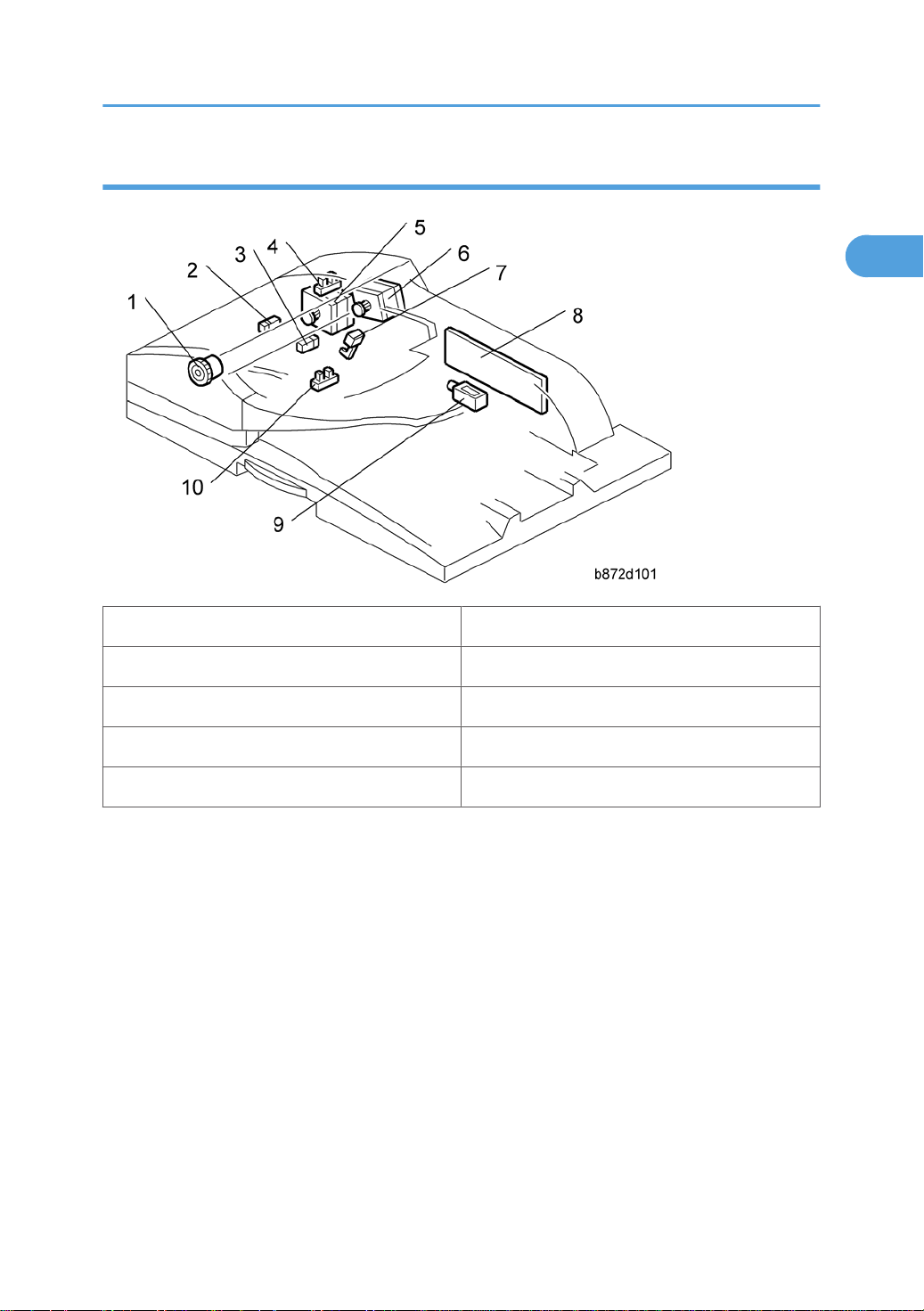

ARDF

1

Overview

1. DF Feed Clutch 6. DF Feed Motor

2. Registration Sensor 7. Inverter Sensor

3. Exit Sensor 8. DF Drive Board

4. Left Cover Sensor 9. Junction Gate Solenoid

5. DF Transport Motor 10. Original Set Sensor

23

1. Product Information

1

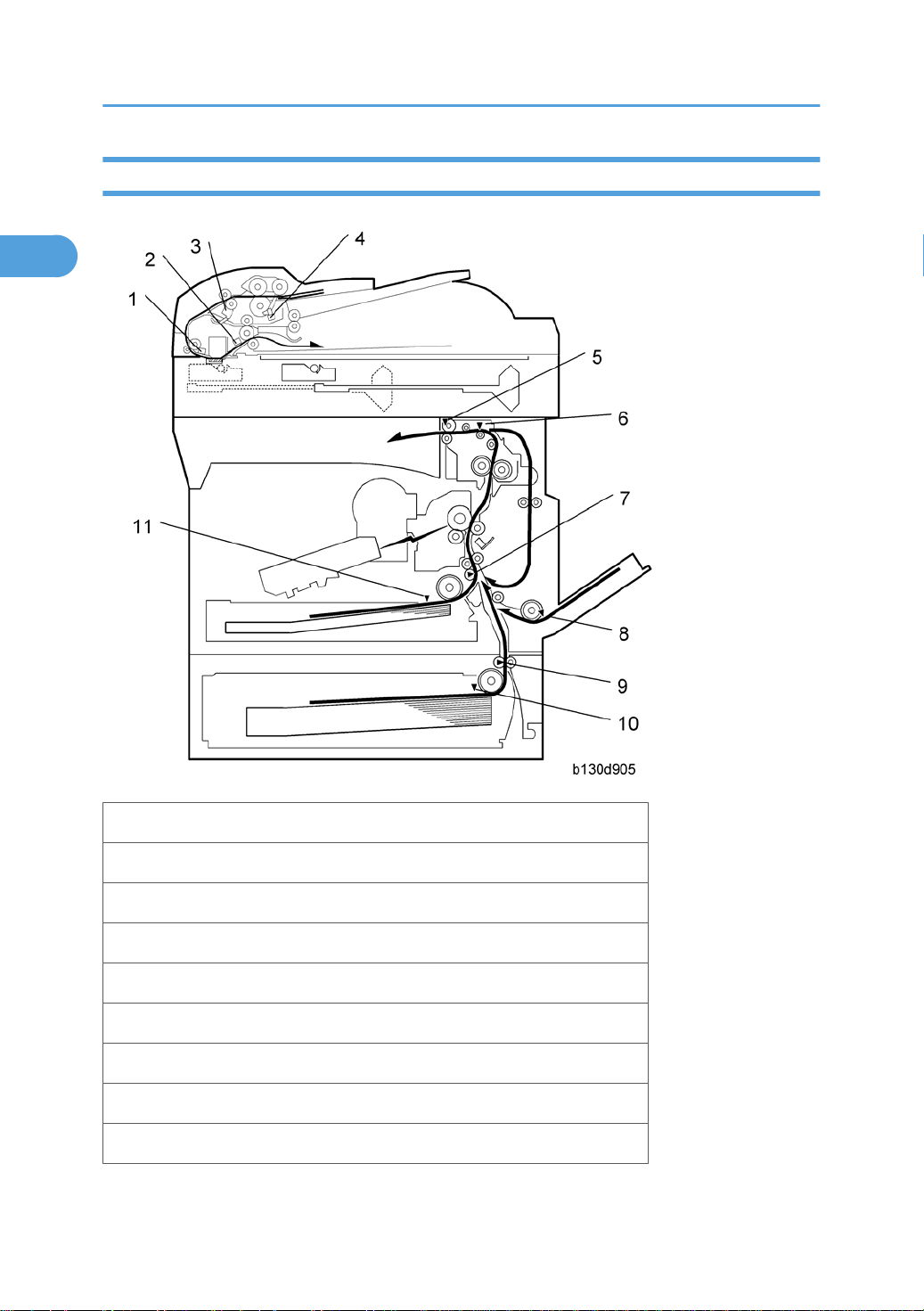

Paper Path

1. Original Registration Sensor (Document Feeder)

2. Exit Senor (Document Feeder)

3. Inverter Sensor (Document Feeder)

4. Original Set Sensor (Document Feeder)

5. Exit Sensor

6. Paper Path Sensor

7. Registration Sensor

8. By-pass Paper End Sensor

9. Paper Feed Sensor (Optional Tray)

24

10. Paper End Sensor (Optional Tray)

1

11. Paper End Sensor

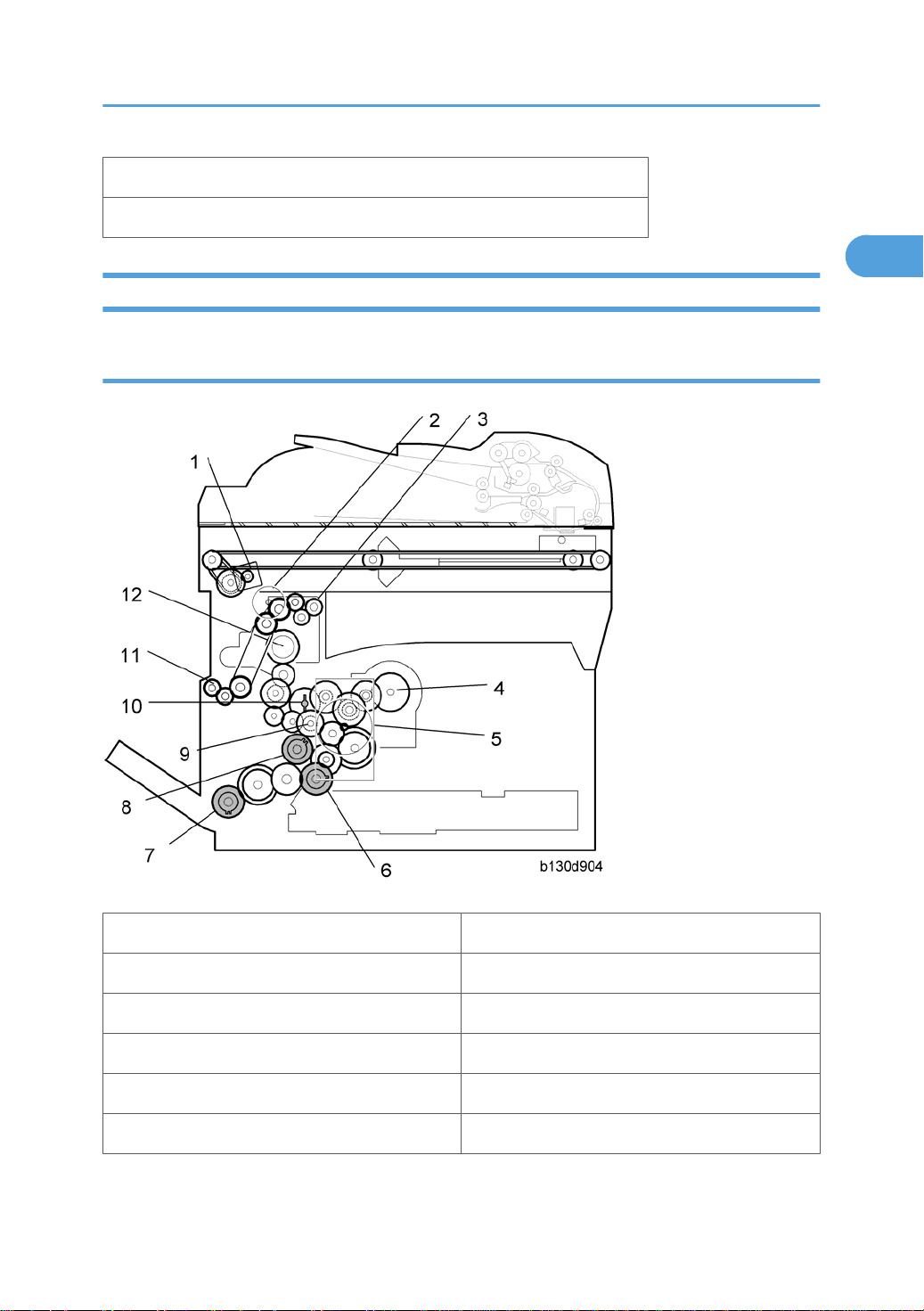

Drive Layout

Mainframe

Overview

1. Scanner Motor 7. Bypass Feed Clutch (By-pass Tray)

2. Duplex motor 8. Registration Clutch

3. Exit Roller 9. Developer Driver Gear

4. Toner Bottle Clutch 10. Drum Drive Gear

5. Main Motor 11. One-way Gear (Duplex Unit)

6. Paper Feed Clutch 12. Fusing Drive Gear

25

1. Product Information

1

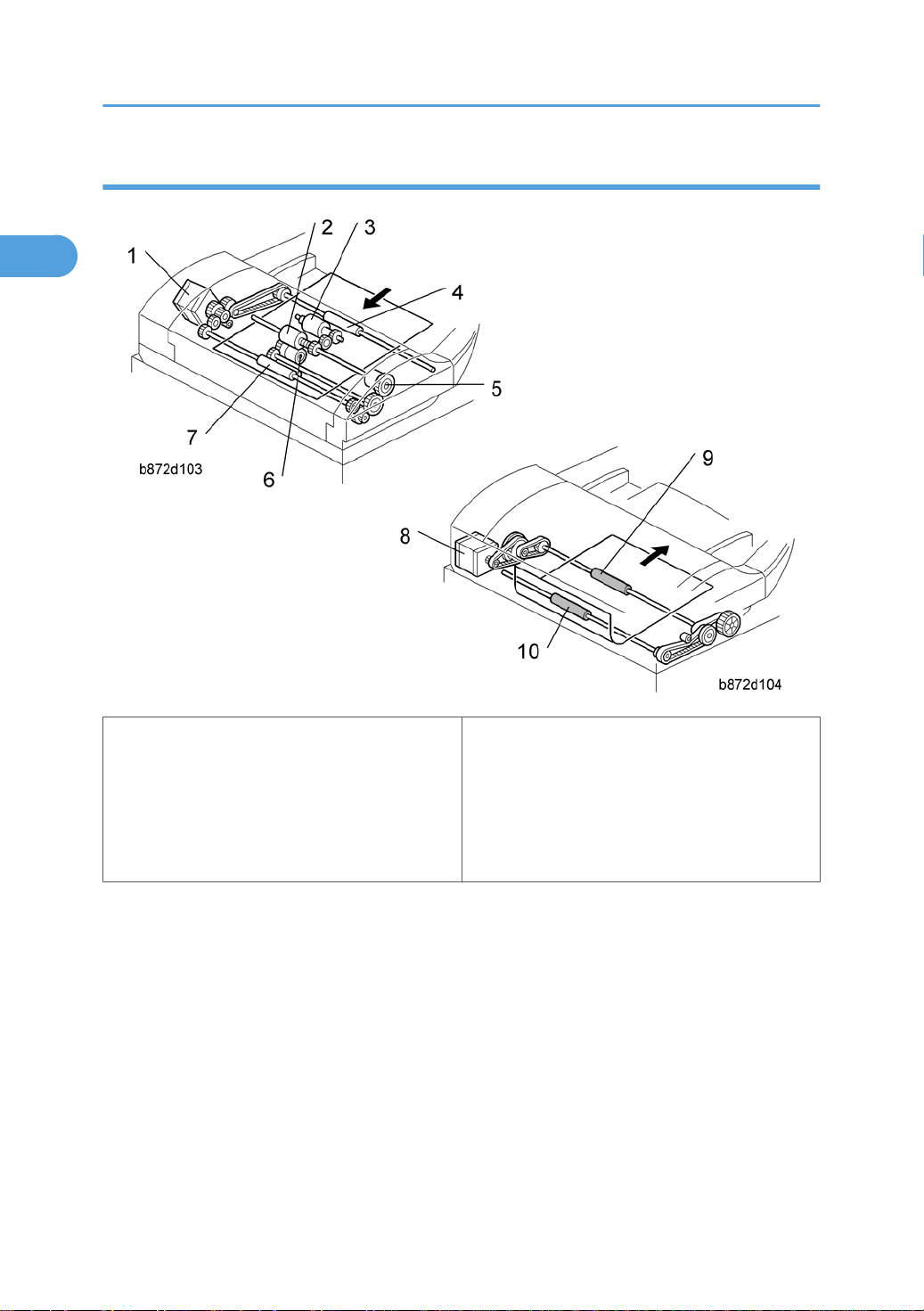

ARDF

26

1. DF Feed Motor

2. Feed Roller

3. Pick-up Roller

4. Inverter Roller

5. DF Feed Clutch

• DF Feed Motor: Drives the feed, separation, pick-up, and transport and inverter rollers.

•

DF Transport Motor: Drives the registration and exit rollers.

6. Separation Roller

7. Transport Roller

8. DF Transport Motor

9. Exit Roller

10. Registration Roller

Guidance for Those Who are Familiar with Predecessor Products

1

Guidance for Those Who are Familiar with

Predecessor Products

The

D108 range of machines is the successor model to the B129/B130/B168/B169 range of machines.

If you have experience with the predecessor line, the following information may be of help when you read

this manual.

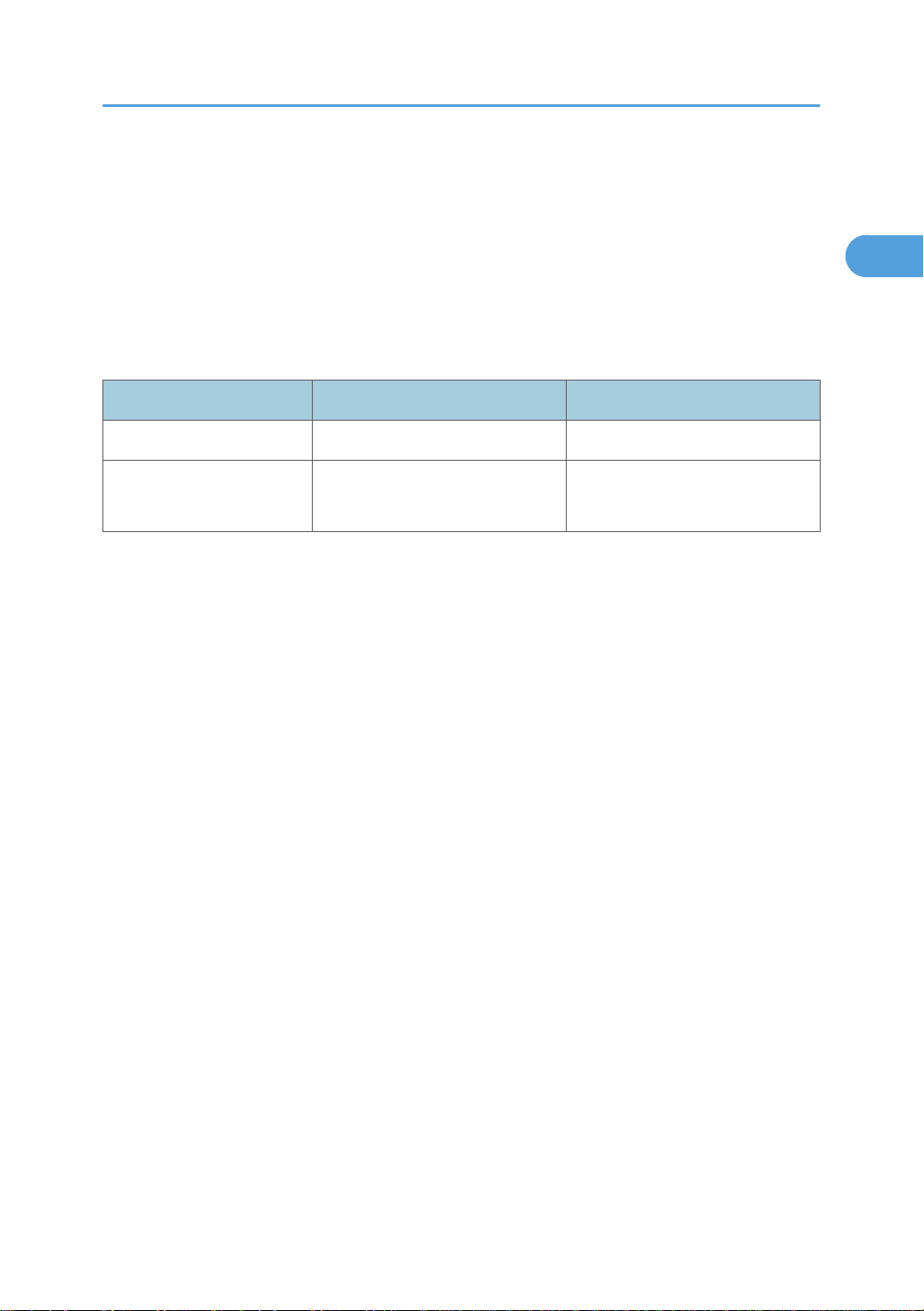

Differences from Predecessor Products

D108 B129/B130/B168/B169

Controller GDI Controller -

Copying Speed

17ppm: Memory copy

15ppm

16ppm: ADF 1 to 1

27

1. Product Information

1

28

Loading...

Loading...