Page 1

RICOH Technical

Model:

NAD 30S/30/40

Bulletin

Date:

31-May-98

No:

PAGE: 1/14

1

Subject:

From:

Classification:

The China and Taiwan versions are going to be produced from June 1998. This RTB

clarifies the differences between other Ricoh versions and China/Taiwan versions.

Please refer to the attached documents for more detail.

China/Taiwan Version Information

Technical Service Department.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

S. Tomoe

Page 2

RICOH Technical

Model:

For both versions

3. Installation

3.1 Chinese paper sizes

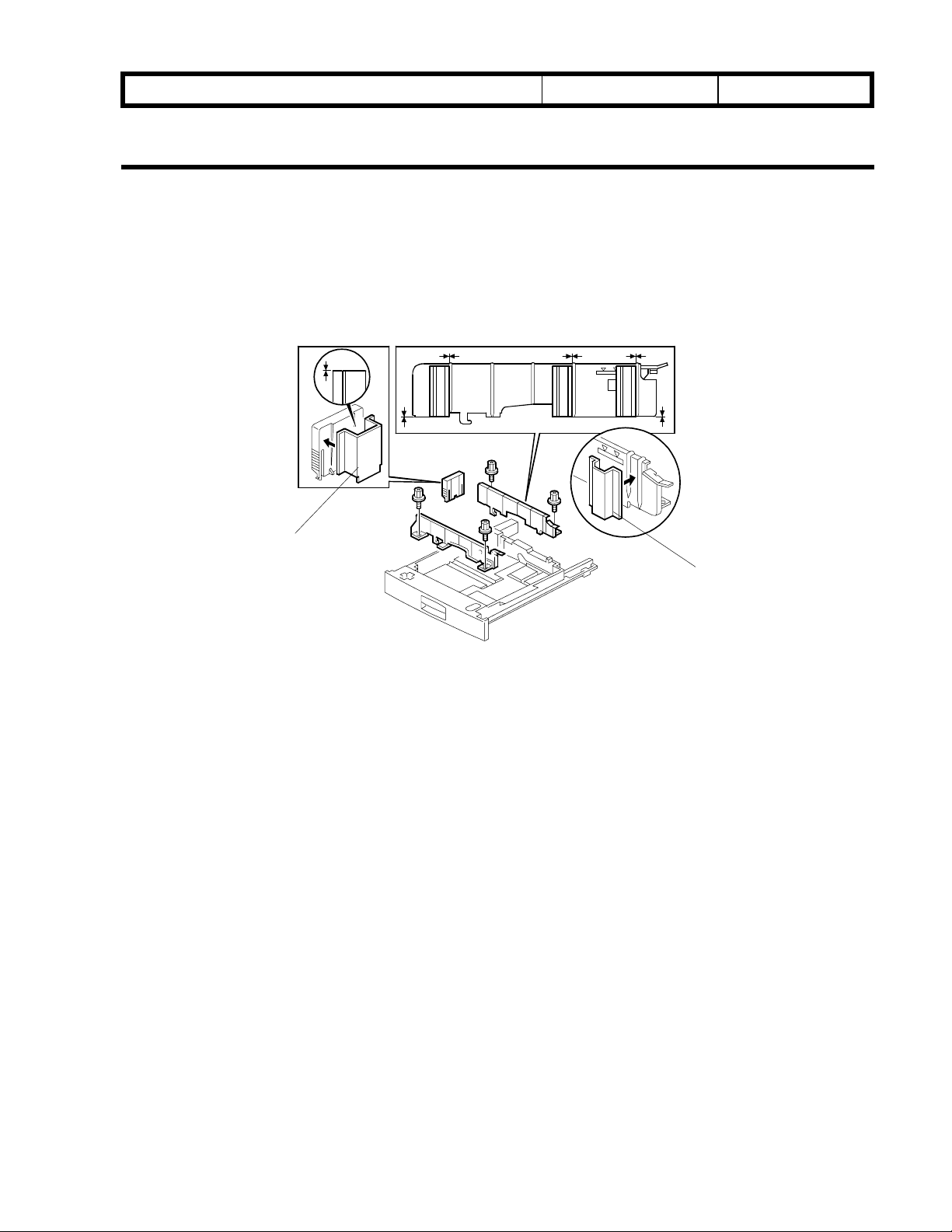

3.1.1 267 mm x 390 mm paper

NAD30/40

Bulletin

Date:

No:

PAGE: 2/14

[B]

[A]

A231I542.WMF

1. Remove the paper tray.

2. Remove the side fences (2 screws each) and the end fence.

3. Peel off the backing of the double-sided tape that is attached to the side fence spacer

(t=7.2 mm) [A].

4. Attach the side fence spacer to the side fence as shown (3 spacers for each side

fence).

NOTE:

5. Peel off the backing of the double-sided tape that is attached to the end fence spacer

(t=31 mm) [B].

6. Attach the end fence spacer to the end fence as shown.

Both edges of the spacer should be aligned with the bottom edge of the fence.

7. Install the side fences in the 11” position in the paper tray.

8. Install the end fence In the A3 position in the paper tray.

9. Install the paper tray in the machine and enter the UP mode.

10. Select the paper size as follows

267 x 390 mm paper = 16

·

Page 3

RICOH Technical

Bulletin

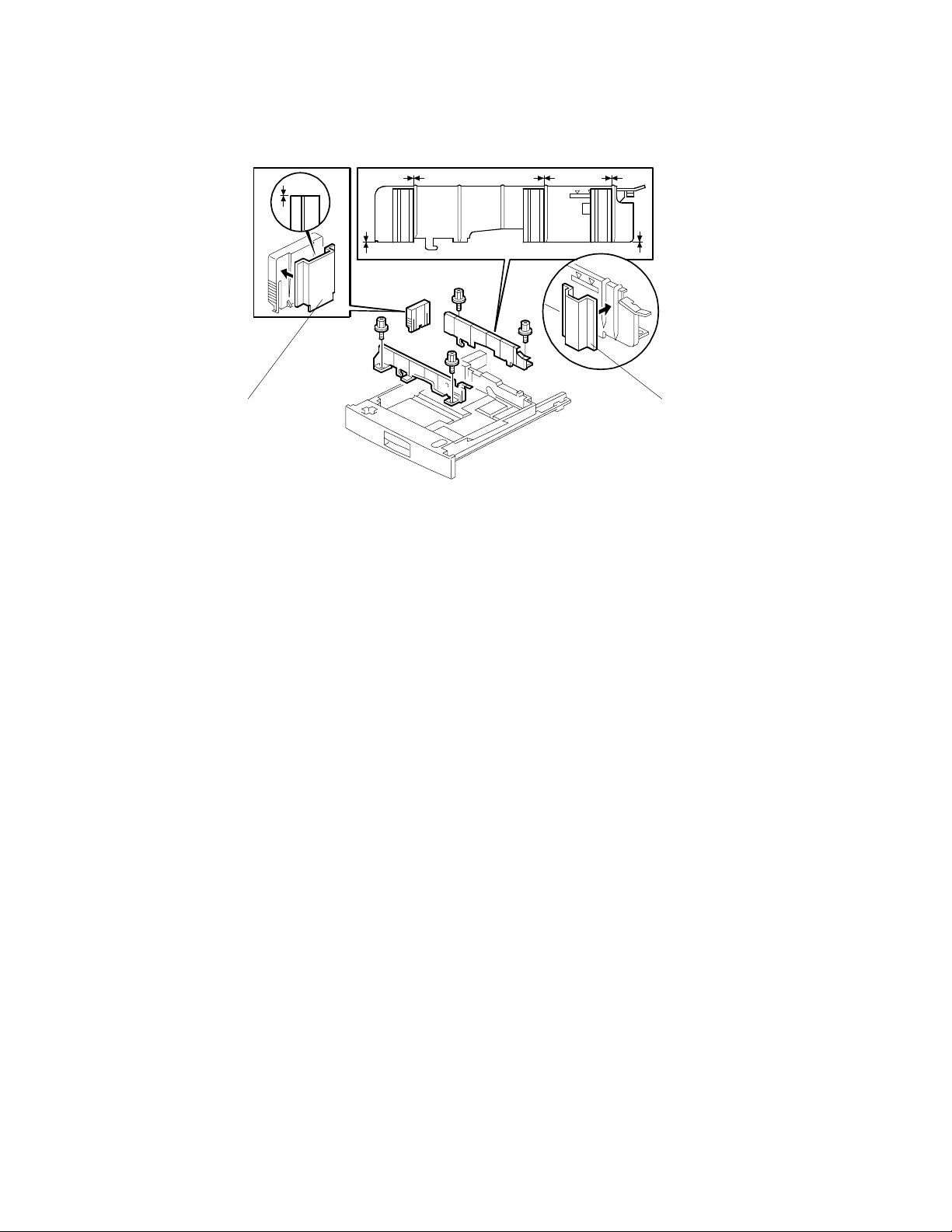

3.1.2 195 mm x 267 mm lengthwise paper

PAGE: 3/14

[A][B]

A231I541.WMF

1. Remove the paper tray.

2. Remove the side fences (2 screws each) and the end fence.

3. Peel off the backing of the double-sided tape that is attached to the side fence spacer

(t=7.2 mm) [A].

4. Attach the side fence spacer to the side fence as shown (3 spacers for each side

fence).

NOTE:

5. Peel off the backing of the double-sided tape that is attached to the end fence spacer

(t=16 mm) [B].

6. Attach the end fence spacer to the end fence as shown.

7. Install the side fences in the 11” position in the paper tray.

8. Install the end fence in the A4Y position in the paper tray.

9. Install the paper tray in the machine and enter the UP mode.

10. Select the paper size as follows

195 x 267 mm paper = 8

·

Both edges of the spacer should be aligned with the bottom edge of the fence.

M

Page 4

RICOH Technical

Bulletin

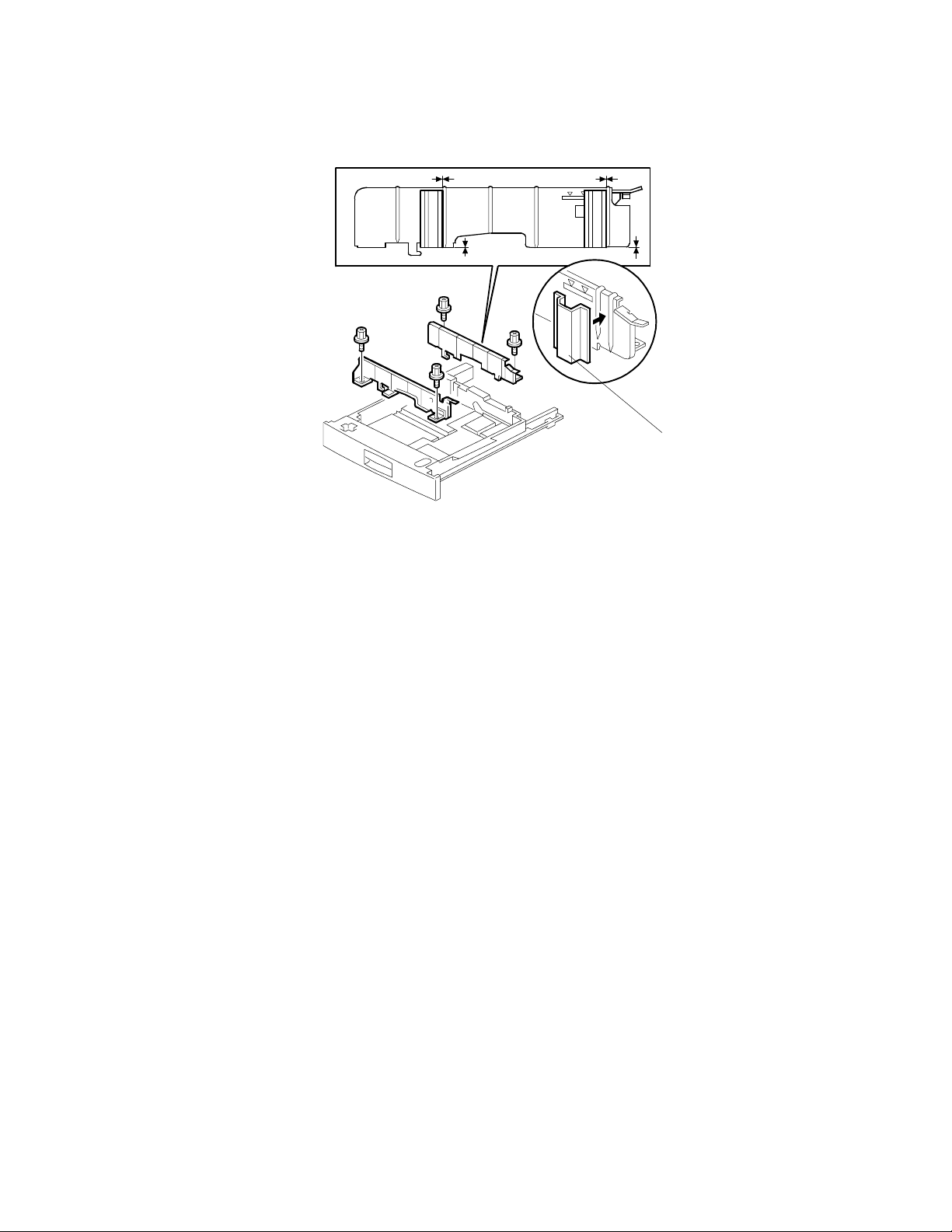

3.1.3 267 mm x 195 mm lengthwise paper

PAGE: 4/14

[A]

A231I540.WMF

1. Remove the paper tray.

2. Remove the side fences (2 screws each) and the end fence.

3. Peel off the backing of the double sided tape that is attached to the side fence spacer

(t=5.1 mm) [A].

4. Attach the side fence spacer to the side-fence as shown (2 spacers for each side

fence).

NOTE:

5. Install the side fences in the 8” position in the paper tray.

6. Install the end fence in the 10.5” position in the paper tray.

7. Install the paper tray in the machine and enter the UP mode.

8. Select the paper size as follows

267 x 195 mm paper = 8

·

Both edges of the spacer should be aligned with the bottom edge of the fence.

L

Page 5

RICOH Technical

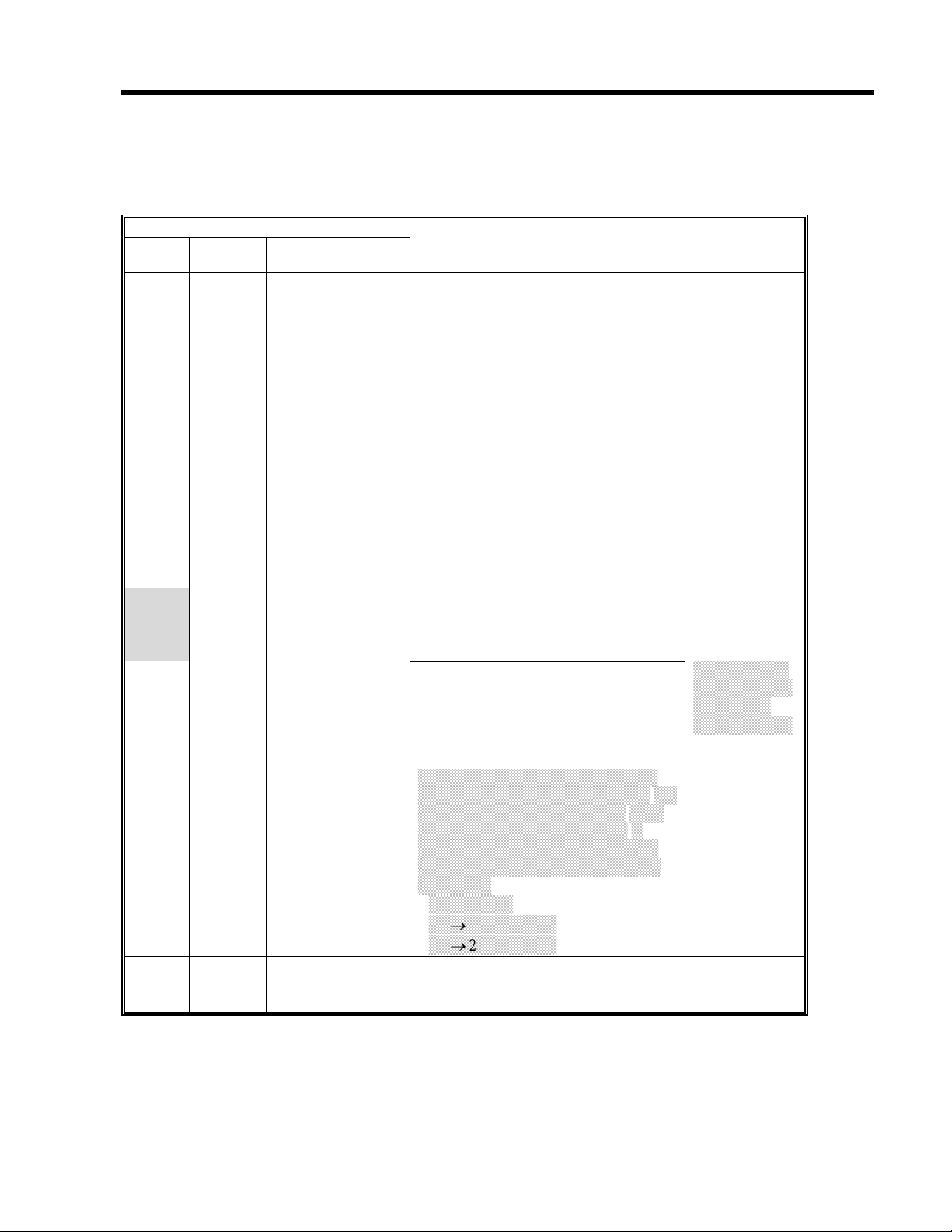

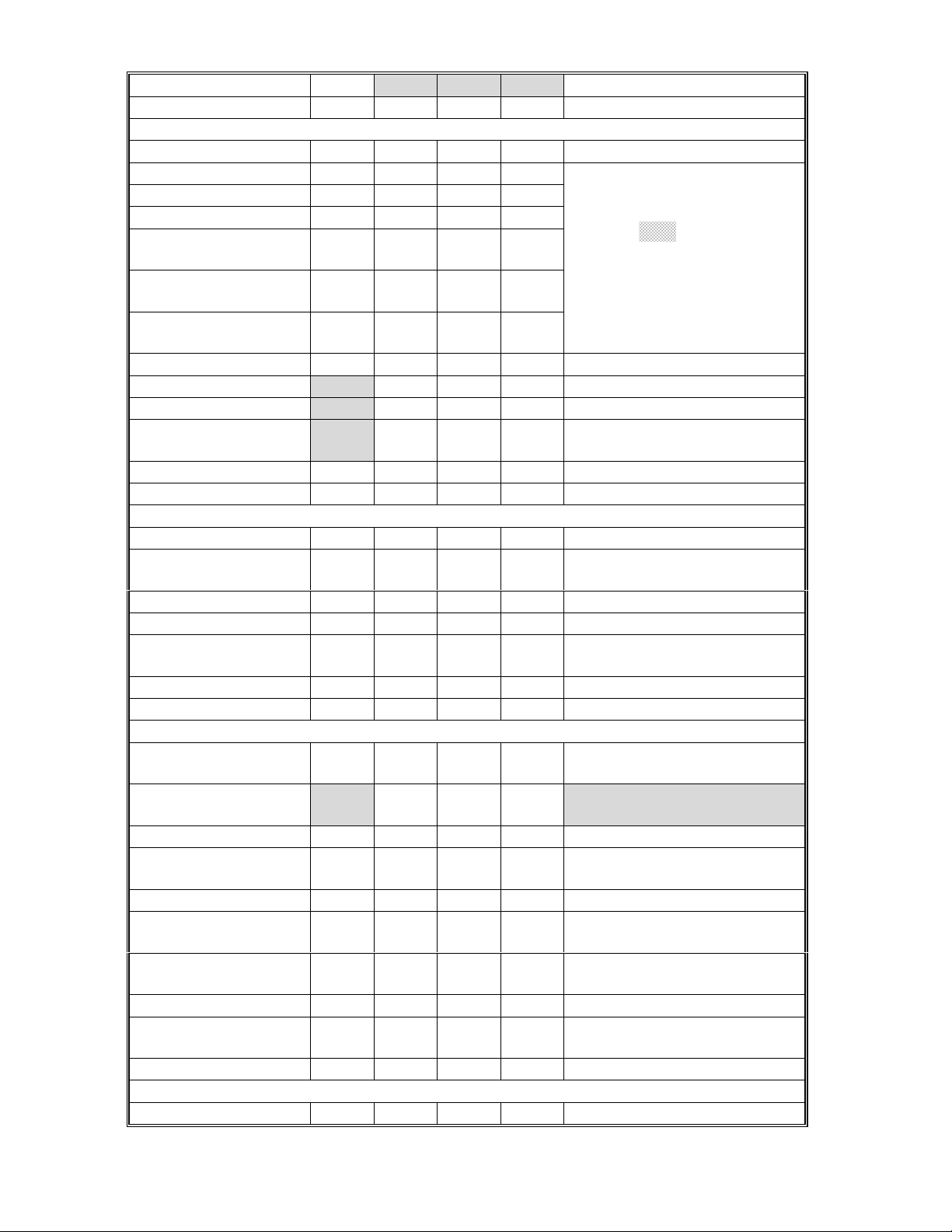

4. SERVICE TABLES

4.1 Service program mode

Mode No.

Class 1

and 2

4-301

Class 3

APS Sensor

Output Check

Displays the APS sensor output

signals when an original is placed on

the exposure glass.

Bit 0: Width sensor 1

Bit 1: Width sensor 2

Bit 2: Length sensor 1

Bit 3: Length sensor 2

Bit 4: Length sensor 3

See “Detailed Section Descriptions –

Original Size Detection in Platen

Mode” for more details.

Bulletin

Function Settings

00000000

0: Not

detected

1: Detected

PAGE: 5/14

4-303

*

4-428* 1* Standard White

APS Small Size

Original Detection

Chinese Paper

Size Detection

Level Adjustment

Flag

Selects whether or not the copier

determines that the original is

A5/HLT size when the APS sensor

does not detect the size.

If "A5 length/5.5" x 8.5" is selected,

paper sizes that cannot be detected

by the APS sensors are regarded as

A5 lengthwise or 5.5" x 8.5".

If "Not detected" is selected, "Cannot

detect original size" will be displayed.

Numbers 2 and 3 are used for Chinese

paper sizes (267 x 390 mm and 195 x 267

mm). The meanings of numbers 2 and 3

are the same as for number 1 and 2.

However, if the APS sensors detect the

original, the machine assumes Chinese

paper sizes.

For example:

A4 ® 195 x 267 mm

A3 ® 267 x 390 mm

Displays whether or not the standard

white level adjustment has been

done.

0: Not

detected

1: A5 length/

5.5" x 8.5"

2: Not detected

(Chinese pap er)

3: A5 length

(Chinese pap er)

0: Performed

1: Not

performed

Page 6

RICOH Technical

Bulletin

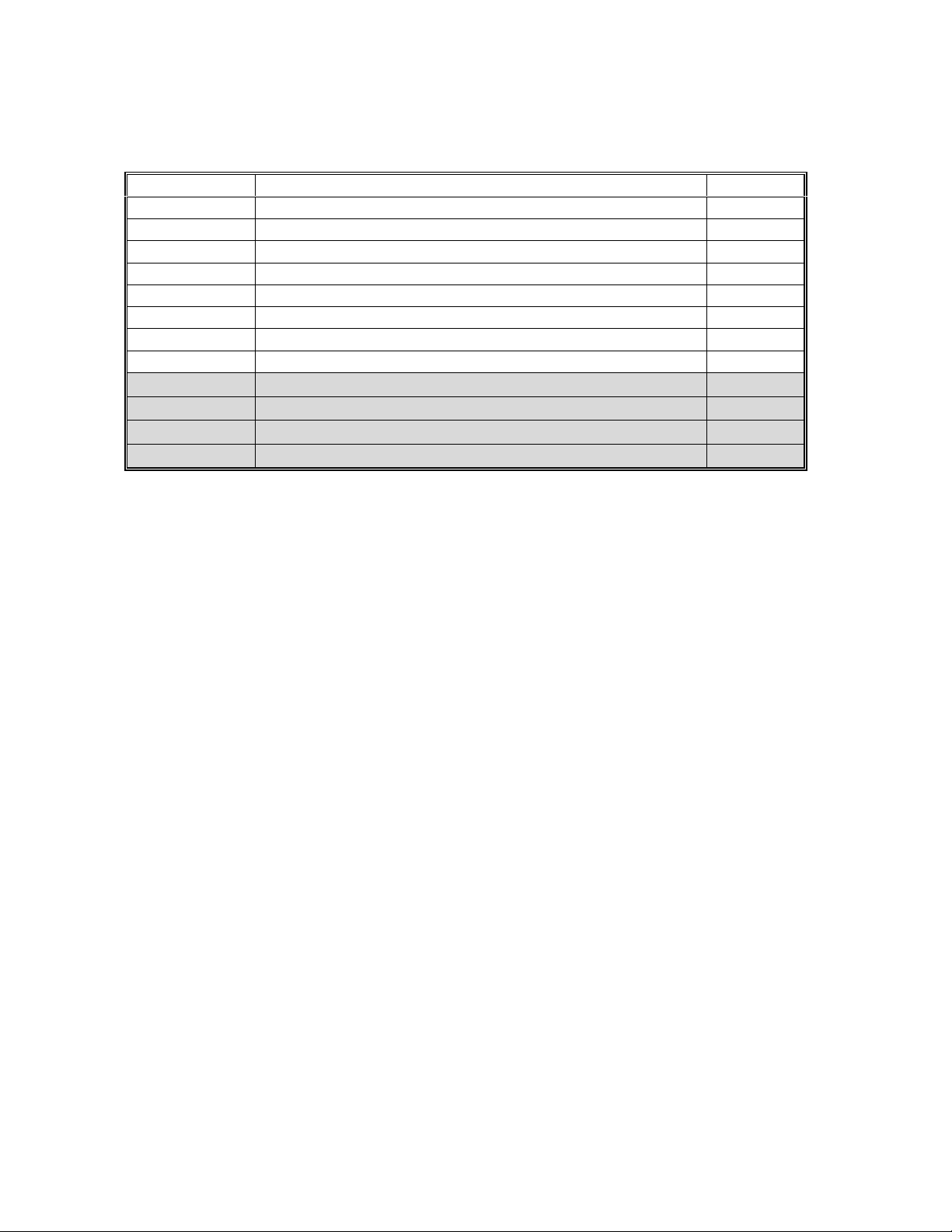

4.2 Special Tools and Lubricants

4.2.1 Special tools

Part Number Description Q’ty

A2309003 Adjustment Cam – Laser Unit 1

A2309004 Positioning Pin – Laser Unit 1

A2309352 Flash Memory Card – 4MB 1

A2309351 Case – Flash Memory Card 1

A0069104 Scanner Positioning Pin (4 pcs/set) 1

54209516 Test Chart – OS-A3 (10 pcs/Set) 1

A0299387 Digital Multimeter – FLUKE 87 1

A2309099 NVRAM – Minus Counter 1

A2309600 Side Fence Spacer – 7.2 mm (6 pcs) 1

A2309610 Side Fence Spacer – 5.1 mm (4 pcs) 1

A2309620 End Fence Spacer – 31 mm 1

A2309630 End Fence Spacer – 16 mm 1

PAGE: 6/14

Page 7

RICOH Technical

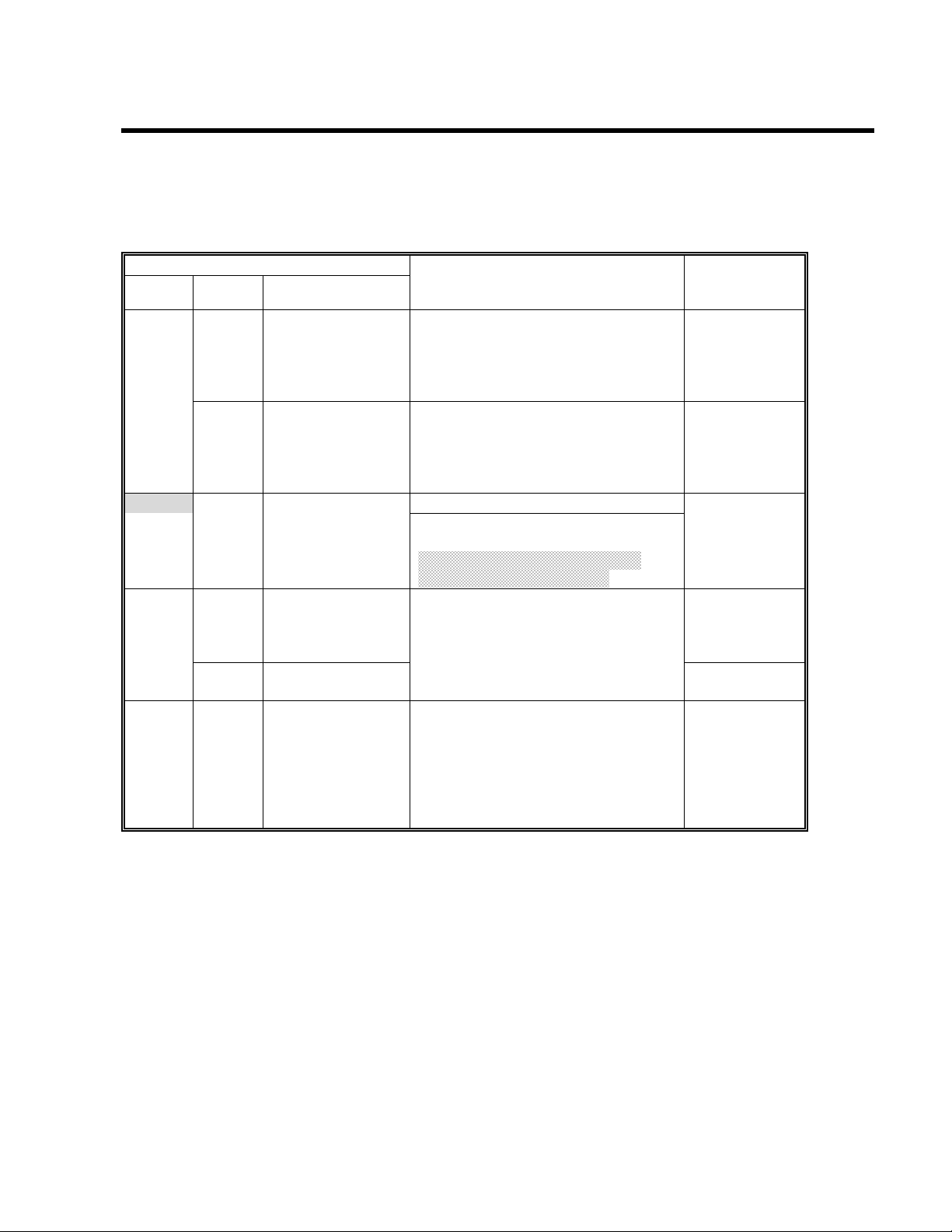

For the China version

4. SERVICE TABLES

4.1 Service Program Mode

Mode No.

Class 1

and 2

5-401* 82* Restricted Access

Class 3

Control for Key

Counter – Other

Enhanced Kit

Japanese version only.

Do not change the value.

Bulletin

Function Settings

0: No

1: Yes

PAGE: 7/14

83*

5-501 * PM Alarm Interval Sets the PM interval, with an alarm.

5-504* 1*

2*

5-505* Error Alarm Level

Restricted Access

Control for other

counters – Other

Enhanced Kit

Jam Alarm Level

(RSS function)

Jam Auto Call

(RSS function)

Japanese version only.

Do not change the value.

When the setting is "0", this function

is disabled.

For the China version, this value

should be changed to 100k.

Japanese version only.

Do not change the values.

Japanese version only.

Do not change the values.

0: No

1: Yes

0 ~ 255

1k copies/step

150 k copies

0: Z

1: L

2: M

3: H

0: Off

1: On

0 ~ 255

100

copies/step

2500 copies

(30)

5000 copies

(40)

Page 8

RICOH Technical

Bulletin

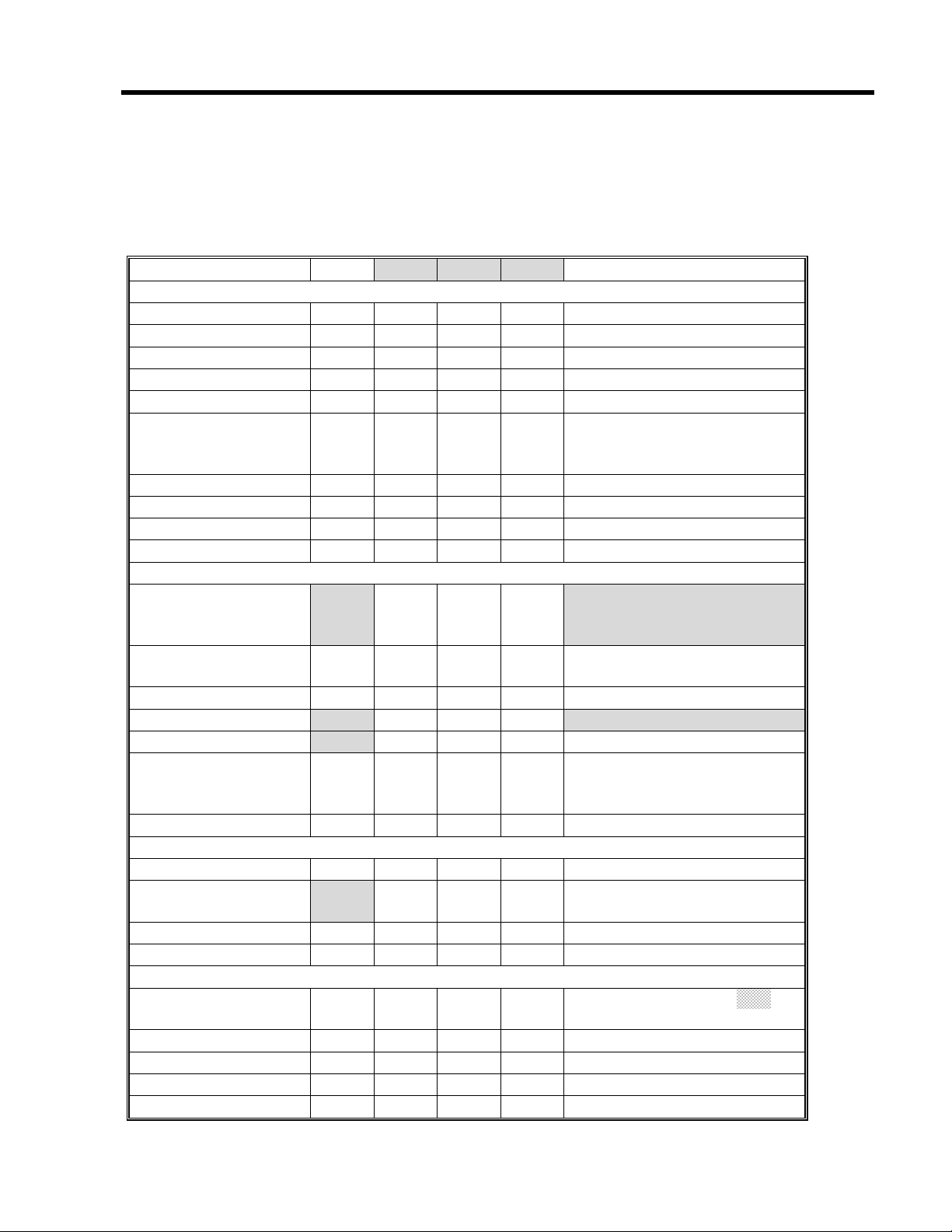

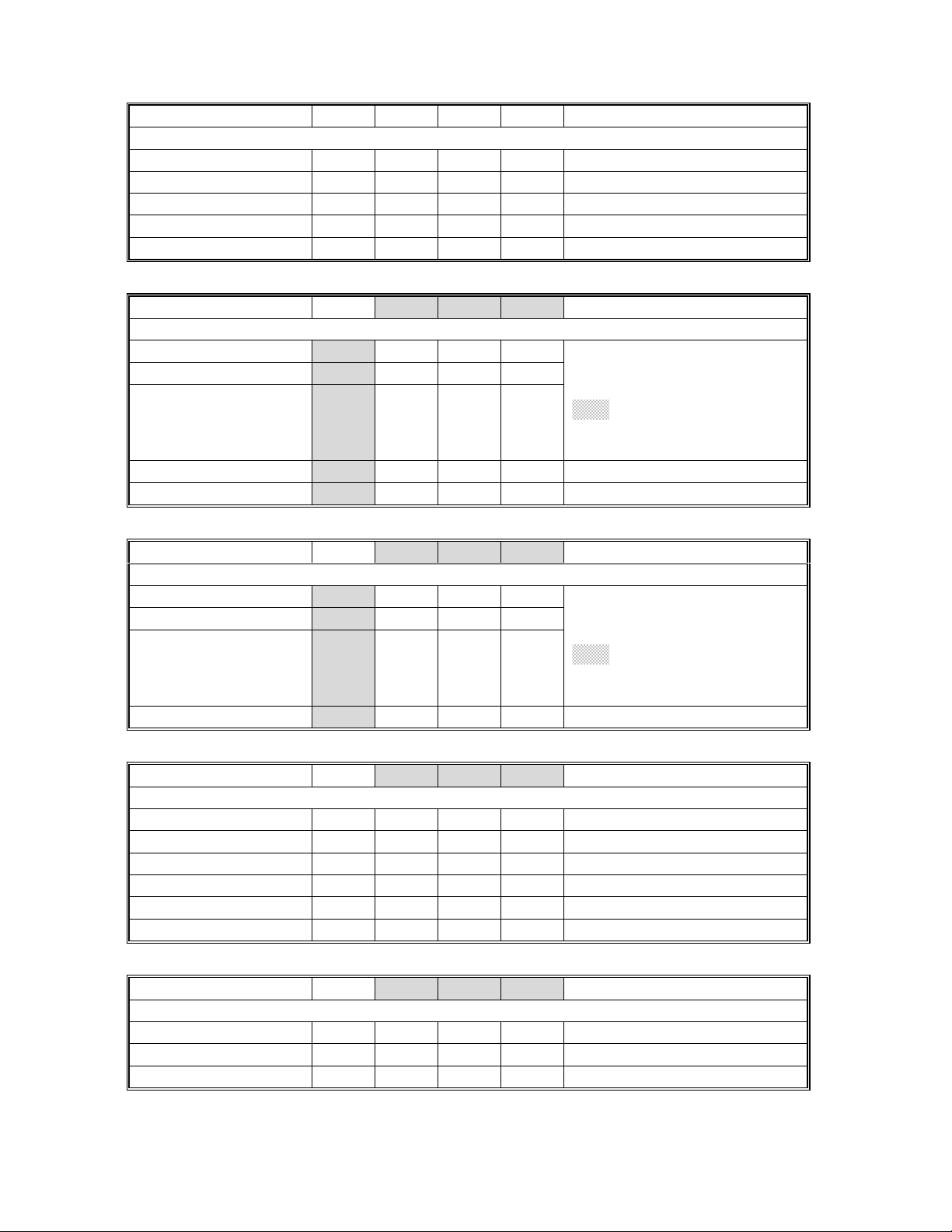

5. PREVENTIVE MAINTENANCE SCHEDULE

5.1 PM TABLE

NOTE:

Symbol key: C: Clean, R: Replace, L: Lubricate, I: Inspect

The amounts mentioned as the PM interval indicate the number of prints.

PAGE: 8/14

A230/A231/A232 EM

SCANNER/OPTICS

Reflector C C C Optics cloth

1st Mirror C C C Optics cloth

2nd Mirror C C C Optics cloth

3rd Mirror C C C Optics cloth

Scanner Guide Rails I I I Do not use alcohol.

Platen Sheet Cover C I I I

Exposure Glass C C C Dry cloth or alcohol

Toner Shield Glass C C C Optics cloth

APS Sensor C C C Dry cloth or alcohol

AROUND THE DRUM

Charge Roller

Charge Roller

Cleaning Pad

Quenching Lamp C Dry cloth

Pick-off Pawls

Spur

ID Sensor C C C

C

C

C

100K 200K 300K

Replace the platen sheet, if

necessary.

Dry cloth or alcohol

RRR

R R R Dry cloth

RRR

C C C Dry cloth or alcohol

Clean with alcohol. After

cleaning, dry the roller with a

dry cloth.

Dry cloth

Perform the ID sensor initial

setting (SP3-001-2) after

cleaning (blower brush)

NOTE

CLEANING UNIT

Drum Cleaning Blade R R R

Cleaning Entrance

Seal

Side Seal I I I

DEVELOPMENT UNIT

Development Drive

Gears

Development Filter R

Developer I R I

Entrance Seal I I I

Side Seal I I I

C

C C C Blower brush or dry cloth.

III

Replace if necessary.

Replace every 5 PM

(

500k)

Page 9

RICOH Technical

Bulletin

PAGE: 9/14

A230/A231/A232 EM

PAPER FEED

Registration Roller C C C C Clean with water or alcohol.

Paper Feed Roller I R R R

Separation Roller I R R R

Pick-up Roller I R R R

Paper Feed Roller

(By-pass feed table)

Separation Roller

(By-pass feed table)

Pick-up Roller

(By-pass feed table)

Paper Feed Guides C C C Clean with water or alcohol.

Relay Rollers

Bottom Plate Pad

Bottom Plate Pad

(By-pass feed)

Registration Sensor C C C Blower brush

TRANSFER BELT UNIT

Transfer Belt C R R R Dr y cloth

Transfer Belt

Cleaning Blade

Transfer Belt Rollers C C C Dry cloth

Entrance Seal C C C Dry cloth

Transfer Entrance

Guide

Used Toner Tank I C C C Empty the tank.

C

C

C

CCCCDry cloth

100K 200K 300K

Check the counter value for

each paper tray station (SP7-

204). If the value has

IRRR

IRRR

IRRR

C C C Clean with water or alcohol.

C C C Clean with water or alcohol.

C C C Clean with water or alcohol.

RRR

reached

roller. After replacing the

roller, reset the counter (SP7-

816).

NOTE

100k, replace the

FUSING UNIT AND PAPER EXIT

Fusing Entrance and

Exit Guide Plates

Hot Roller

Pressure Roller R R R

Fusing Thermistor I I I Clean if necessary (suitable

Cleaning Roller C C C Clean with water or alcohol.

Cleaning Roller

Bushings

Pressure Roller

Strippers

Hot Roller Strippers C R C Clean wit h water or alcohol.

Paper Exit Guide

Ribs

OTHERS

Drive Belts I Replace if necessary

C

C C C Clean with water or alcohol.

RRR

L L L Grease Barrierta JFE 55/2

C C C Clean with water or alcohol.

C C C Clean with water or alcohol.

Clean with alcohol (or a suitable

solvent)

solvent)

Page 10

RICOH Technical

EM 80K 160K 240K NOTE

ADF

(for origina ls)

Transport Belt C R R R Belt cleaner

Feed Belt C R R R Belt cleaner

Separation Roller C R R R Dry or damp cloth

Sensors C C C Blower brush

Drive Gears L L L Grease G501

Bulletin

PAGE: 10/14

EM

PAPER TRAY UNIT

Paper Feed Rollers

Pick-up Rollers

Separation Rollers

Relay Rollers C C C Dry or damp cloth

Bottom Plate Pad

LCT

Paper Feed Roller

Pick-up Roller

Separation Roller

Bottom Plate Pad

C

EM

C

100K 200K 300K

I

I

I

I

I

I

RRR

RRR

RRR

C C C Dry or damp cloth

100K 200K 300K

RRR

RRR

RRR

C C C Dry or damp cloth

Check the counter value for

each paper tray station (SP7-

204). If the value has reached

100k, replace the roller. After

replacing the roller, reset the

counter (SP7-816).

Check the counter value for

each paper tray station (SP7-

204). If the value has reached

100k, replace the roller. After

replacing the roller, reset the

counter (SP7-816).

NOTE

NOTE

EM

1,000-SHEET/3,000-SHEET FINISHERS

Rollers C Clean with water or alcohol.

Brush Roller I I I I Replace if necessary.

Discharge Brush C C C C Clean with a dry cloth

Sensors C Blower brush

Jogger Fences I I I I Replace if necessary.

Punch Waste Hopper I I I I Empty the hopper.

EM

1-BIN TRAY UNIT

Rollers C Dry or damp cloth

Copy Tray C Dry or damp cloth

Sensors C Blower brush

100K 200K 300K

100K 200K 300K

NOTE

NOTE

Page 11

RICOH Technical

Bulletin

PAGE: 11/14

5.2 Maintenance Items for the China Version

Using Chinese paper, paper dust may accumulate inside the machine during copying.

After the machine has been used for a long time, some copy quality or mechanical

problems may occur. So, do the following to maintain the machine’s quality.

1. PM interval

Every 100,000 copies

NOTE:

2. At the PM and EM period, change the PM parts and/or clean the parts in accordance

with the PM table. Especially, the following should be done.

Around the Drum

Charge Roller Replace Clean

Pick-off Pawls Replace Clean Clean with a dry cloth. B

Spurs Clean Clean Clean with a dry cloth. C

PCU Entrance

Seal

ID Sensor Clean Clean

Cleaning Unit

Cleaning

Entrance Seal

Paper Feed

Relay Rollers Clean Clean Clean with water or alcohol.

Registration

Roller

Bottom Plate

Pad

Fusing Unit

Hot roller Replace Clean Clean with alcohol ( or a

At the machine installation, change the value of SP5-501 (PM alarm interval)

to 100 k.

PM EM Action Problem Fig.

Clean with alcohol. After

cleaning, dry the roller with

a dry cloth.

Clean Clean Clean with a dry cloth

Clean with a dry cloth. After

cleaning perform, SP3001-

2.

Clean Clean Clean with dry cloth Toner falls onto

Clean Clean Clean with water or alcohol. G

Clean Clean Clean with water or alcohol.

suitable solvent).

Dirty background

on front and rear

of paper

Toner falls onto

the paper.

the paper.

Paper non feed or

paper double

feed

Offset image

A

F

E

D

Page 12

RICOH Technical

[A]

[B]

Bulletin

PAGE: 12/14

[C]

1. Pull out the PCU, then clean the following parts.

ID Sensor [E]

·

PCU Entrance Seal [F]

·

Registration Roller [G]

·

2. Remove the drum, then clean the following parts.

Charge Roller [A]

·

Pick-off Pawls [B]

·

Spurs [C]

·

Cleaning Entrance Seal [D]

·

[D]

A231P501.WMF

[E]

[F]

[G]

A231P500.WMF

Page 13

RICOH Technical

Model:

NAD30/40

Bulletin

Date:

Taiwan Version

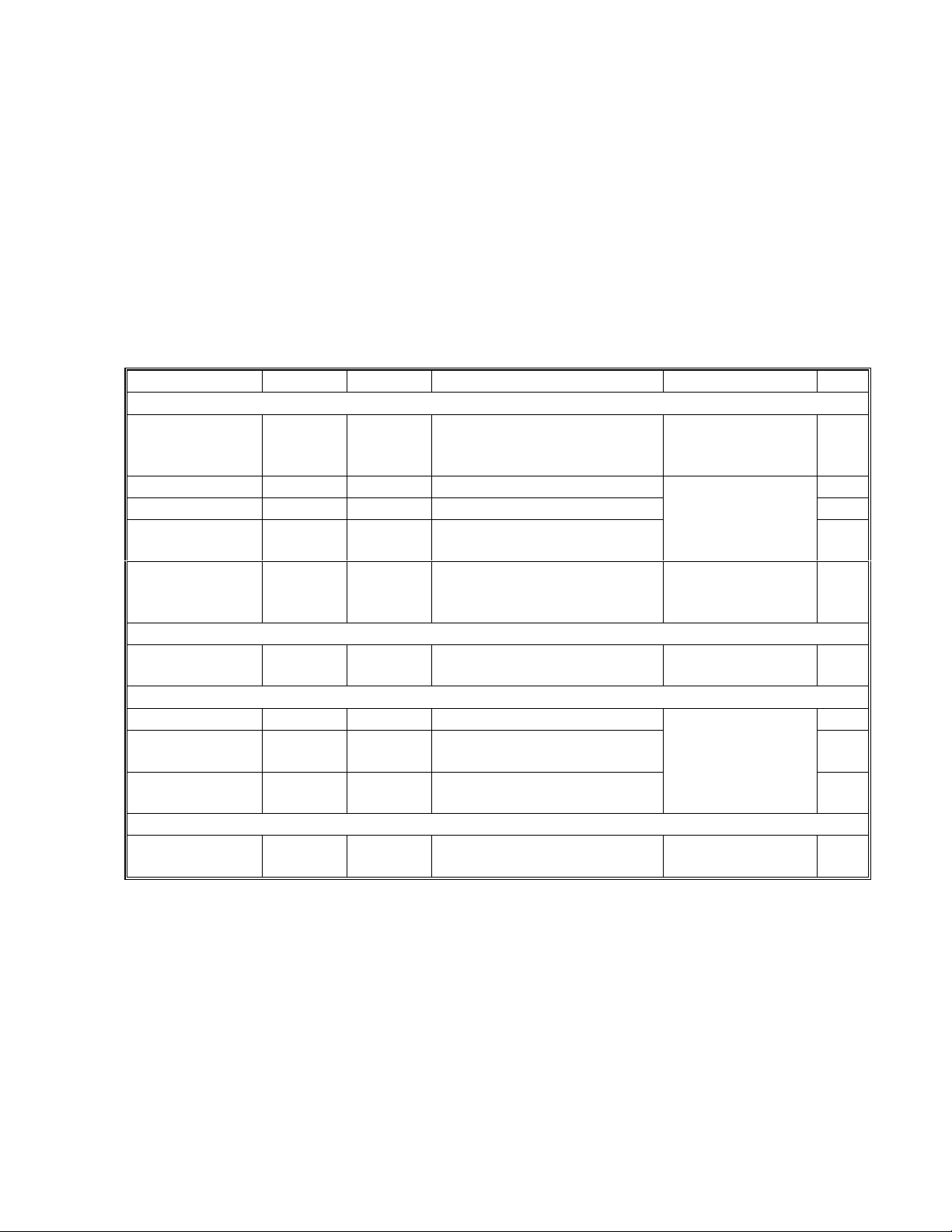

1. Overall Machine Information

5.3 Specifications

Power Consumption:

Mainframe only

(115 V Machine)

NAD30S/NAD30 NAD40 Note

Maximum

Copying Less than 1.15 kW

Warm-up Less than 1.05 kW Less than 1.15 kW

Stand-by Less than 200 W/h Less than 220 W/h

Energy Saver Level 1 Ave. 150 W/h Ave. 170 W/h

Energy Saver Level 2 Ave. 130 W/h Ave. 150 W/h

Auto Shut Off Ave. 12 W/h Ave. 12 W/h

Less than 1.44 kW Less than 1.44 kW

Less than 1.32 kW Less than 1.32 kW Taiwan version

Less than 1.3 kW

Less than 1.25 kW Taiwan version

PAGE: 13/14

No:

System: Without the optional heater s, fax unit, and printer controller.

(115 V machine)

NAD30S/NAD30 NAD40 Note

Maximum

Copying Less than 1.2 kW Less than 1.35 kW

Warm-up Less than 1.05 kW Less than 1.15 kW

Stand-by Less than 220 W/h Less than 260 W/h

Less than 1.44 kW Less than 1.44 kW

Less than 1.32 kW Less than 1.32 kW Taiwan version

Page 14

RICOH Technical

Bulletin

5.4 Machine configuration

Version Item Machine Code No.

Copier (NAD30-S) A230 8

Copier (NAD30) A231 8

Copier (NAD40) A232 8

ARDF (Option) A680 2

Platen Cover (Option) A381 1

Paper Tray Unit (Option) A682 9

LCT (Option) A683 7

By-pass Feed Unit (Option – NAD30S only) A689 5

Duplex Unit (Option – NAD30S only) A687 6

Interchange Unit (Option – NAD30S only) A690 4

Copy

Fax

1-bin Tray (Option) A684 3

Bridge Unit (Option) A688 13

1000-sheet Finisher (Option) A681 11

3000-sheet Finisher (Option – NAD40 only) A697 10

Punch Unit (Option for 3000-sheet Finisher) A812-17 (3 holes)

A812-27 (2 holes)

External Output Tray (Option) A825 12

Electrical Sort Kit – 8 MB Memory (Option –

NAD30S only)

Image Enhancement Kit – HDD (Option)

Key Counter Bracket (Option) A674 14

Expansion Box (Option) A692

Fax Unit (Option) A693

ISDN Unit (Option) A816

SAF Memory – HDD (Option) A818-10

Fax Feature Expander (Option) A818-11

400-dpi High Resolution (Option) A818-12

Handset (Option – North America only) A646

Stamp Unit (Option) A813

NOTE

*

A818

A691

PAGE: 14/14

*NOTE:

For the Taiwan version, this kit will be available when the optional printer unit

is installed.

Page 15

RICOH Technical

Model:

NAD 30S/30/40

Bulletin

Date:

31-May-98

No:

PAGE: 1/5

2

Subject:

From:

Service Manual Corrections

Technical Service Department.

Classification:

Troubleshooting

Mechanical

Paper path

Other (Manual Correction)

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

S. Tomoe

The following should be corrected. Please correct your service manual.

1. 2.2.5 MEMORY BLOCK page 2-19

- Incorrect -

Copy Mode

Multiple copy of

single page original

Gradation

Processing

Binary/Grayscale

DRAM

(4 MB)

O / O

DRAM + SIMM

(4 + 8 MB)

O / O X / O

DRAM + SIMM + HDD

- Correct -

Copy Mode

Gradation

Processing

DRAM

(4 MB)

DRAM + SIMM

(4 + 8 MB)

DRAM + SIMM + HDD

(12 MB + 1.6GB)

(12 MB + 1.6GB)

Multiple copy of

single page original

Binary/Grayscale

O / X

O / O X / O

2. 2.6.7 TONER NEAR END/END DETECTION Page 2-44

Second paragraph from the bottom

- Incorrect If Vsp is

However, If Vsp is

less

than 2.0V, the density of the ID sensor pattern is very light, so ……

bigger

than 2.0V but 90 copies have been made after toner near end

was detected,….

- Correct If Vsp is

However, If Vsp is

bigger

than 2.0V, the density of the ID sensor pattern is very light, so ……

less

than 2.0V but 90 copies have been ma de a fter toner near end

was detected,….

Page 16

RICOH Technical

Model:

3. 2.10.3 FUSING ENTRANCE GUIDE SHIFT MECHANISM page 2-66

Second and third paragraphs

NAD 30S/30/40

- Incorrect -

Bulletin

Date:

31-May-98

No:

PAGE: 2/5

2

For thin paper, move the entrance guide to the

For thick paper, move the entrance guide to the

- Correct For thin paper, move the entrance guide to the

For thick paper, move the entrance guide to the

4. 3.1.4 POWER REQUIRMENTS page 3-3

- Incorrect Input voltage level: 220V ~ 240V, 50 Hz/60 Hz: More than 6A

- Correct Input voltage level: 220V ~ 240V, 50 Hz/60 Hz: More than 8A

5. 3.3.1 ACCESSORY CHECK page 3-5

- Incorrect -

Operation Instructions – Fax Reference

12.

left

by securing it with screw holes [C].

right

(using screw holes [B]).

right

by securing it with screw holes [B].

left

(using screw holes [C]).

- Correct -

Copy Quick Guide

12.

6. 3.12 1000-SHEET FINISHER INSTALLATION page 3-46

Delete step 5 and modify illustration A230I704.wmf (see the attached illustration).

·

Add the following step after step 13 on page 3-47 and modify illustration

·

A230i706.wmf (see the attached illustration).

14. Attach the staple position decal [F] to the ARDF, as shown.

Page 17

RICOH Technical

Bulletin

7. 3.13 3000-SHEET FINISHER INSTALLATION page 3-48

Change the step from 5 to 8

·

- Incorrect -

PAGE: 3/5

5. Attach

Cut away a part of the main power switch cover [E].

6.

two

lower grounding plates …..

7. Attach the cushion [F] to the plate as shown.

8. Install the entrance guide plate [G] (2 screws).

- Correct -

5. Attach

one

lower grounding plate ……

6. Attach the cushion [E] to the plate as shown.

7. Install the entrance guide plate [F] (2 screws).

Change illustrations A230I754.wmf and A230I755.wmf.

·

8. 3.18 KEY COUNTER INSTALLATION page 3-62

Add step 11.

11. Change the value of SP5-401-2 to 1.

NOTE:

The key counter function is availabl e for fax and printer mod es by chang ing the

following SP modes.

SP5-401-52 (Fax mode)

SP5-401-62 (Printer mode)

9. 4.4.2 SERVICE PROGRAM MODE TABLE page 4-10

- Incorrect -

Mode No.

Class 1

and 2

2-101

Class 3

3 *

4 *

Left

Side

Edge Erase

Margin

(Printing)

Right

Side

Edge Erase

Margin

(Printing)

Adjusts the

The specification is 2

Adjusts the

The specification is 2 + 2.5/- 1.5 mm

Function Setting

left

side erase margin.

±

1.5 mm

±

right

side erase margin.

0.0 ~ 9.0

0.1 mm/step

2.0 mm

0.0 ~ 9.0

0.1 mm/step

2.0 mm

Page 18

RICOH Technical

- Correct -

Mode No.

Class 1

and 2

Class 3

Bulletin

Function Setting

PAGE: 4/5

2-101

3 *

4 *

Right

Side

Edge Erase

Margin

(Printing)

Left

Side

Edge Erase

Margin

(Printing)

Adjusts the

The specification is 2 + 2.5/- 1.5 mm

Adjusts the

The specification is 2

right

side erase margin.

left

side erase margin.

±

1.5 mm

±

0.0 ~ 9.0

0.1 mm/step

2.0 mm

0.0 ~ 9.0

0.1 mm/step

2.0 mm

10. Laser Beam Pitch Adjustment page 6-18

- Incorrect -

8. Adjust the laser beam pitch position …. Appear on the printout), doing steps

and 3 (in step 1, input a value which is estimated to be correct, then steps 2 and 3,

then if necessary go back to step 1 and try another value).

9. After adjusting the laser beam pitch ….. (….for 600 dpi).

The laser beam pitch for

600 dpi should be 24 ~ 48 more than for 400 dpi.

- Correct -

8. Adjust the laser beam pitch position …. Appear on the printout), doing steps

and 4 (in step 2, input a value which is estimated to be correct, then steps 3 and 4,

then if necessary go back to step 2 and try another value).

1, 2

2, 3

,

,

9. After adjusting the laser beam pitch ….. (….for 600 dpi).

adjustment for 600 dpi, input a value for SP2-109-1 that is between 24 and 48

higher than the final result for 400 dpi.

11. Blank Margin page 6-52

- Incorrect -

SP mode Specification

Right edge

Left edge

SP2-101SP2-101-

4

3

- Correct -

SP mode Specification

Right edge

Left edge

SP2-101SP2-101-

3

4

When starting the

2 +2.5/-1.5 mm

2 ± 1.5 mm

2 +2.5/-1.5 mm

2 ± 1.5 mm

Page 19

RICOH Technical

12. SC630 page 7-18

The SC condition level, [D], should be added.

Bulletin

PAGE: 5/5

SC630: CSS (RSS) communication error between line adapter and CSS center

13. Illustrations

[E]

[A]

[B]

[C]

[C]

A230i704.wmf A230i706.wmf

[D]

[A]

[D]

[F]

[C]

[A]

[E]

[F]

[D]

A230i754.wmf A230i755.wmf

Page 20

RICOH Technical

Model:

NAD 30S/30/40

Bulletin

Date:

31-May-98

No:

PAGE: 1/6

3

Subject:

From:

Classification:

This bulletin contains corrections for the Fax Option Type 450 service manual.

Service Manual Corrections

Technical Service Department.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

Y. Furuya

Chapter 3

Problem

1) The installation procedure was not suitable for the Taiwan version

2) A bracket must be removed before installing the expansion box; this was not

mentioned.

3) The procedure for attaching the PTT approval label was missing.

Correction

1) The installation procedure has been modified for all versions, including Taiwan.

2) Missing steps have been added. (Items 2 and 3 above; refer to pages 2 to 5.)

Page 21

RICOH Technical

Bulletin

PAGE: 2/6

NOTE:

[A]

To install the fax unit, the Expansion Box Type 450 is required in addition.

The following procedure is written on the premise that the expansion box

has not been installed.

[C]

[D]

[B]

A693I500.WMF

[I][J]

[I]

[F]

A693I501.WMF

[M]

[F]

[E]

[L]

[K]

[H]

A693I519.WMF

1. Remove the rear cover [A] (4 screws) and the left side cover [B] (4 screws), as shown.

2. Cut away the covers [C] and [D] (shaded parts), as shown.

NOTE:

3. Remove the cover [E] from the expansion box, then install the FCU cover bracket [F]

(1 screw) as shown.

NOTE:

4. Remove the bracket [G], and run the cable [H] through the clamps [I], then install a

metal core [J] as shown.

NOTE:

5. Connect the harness [K] to CN355 on the expansion box, then install the expansion

box (4 screws) so that the CN350 fits in CN304 [L] on the BiCU.

NOTE:

If installing the fax hard disk option at the same time, refer to the hard

disk installation procedure before going on to the next step.

The bracket [F] is included in the fax unit.

The metal core [J] is not installed the model for Taiwan.

Use a magnetic screwdriver so as not to drop any screws inside the

machine.

A693I503.WMF

6. Attach the modular jacks [M] to the bracket [F] as indicated on the bracket.

Page 22

RICOH Technical

[N]

[P]

Bulletin

PAGE: 3/6

[Q]

[O]

[U]

[S]

A693I504.WMF

[R]

A693I514.WMF

[R]

[O]

[T]

A693I505.WMF

[V]

A693I515.WMF

7. Set the locking support [N] and the edge saddle [O] as shown, then install the

NCU/Speaker assembly [P] (2 screws).

8. Connect the cable [Q] and the harness [R] as shown. The harness [R] must run

through the edge saddle [O] as shown.

9. Turn on the battery switch (SW1) on the FCU [S] then set it in the right-most slot of the

expansion box as shown. Connect the harness [R] to the FCU (CN328 and CN330),

then slide the FCU [S] all the way in (1 connector).

10. Install the brackets [T] (3 screws), [U] (2 screws) and [V] (1 screw) as shown.

NOTE:

The bracket [U] is installed only in the model for Taiwan.

Page 23

RICOH Technical

Bulletin

PAGE: 4/6

[X]

[Y]

[d]

[Z]

A693I507.WMF

[a]

[W]

[c]

[b]

A693I508.WMF

[e]

[g]

[i]

[W]

[f]

A693I509.WMF

11. Remove the operation panel [W], then remove parts [X], [Y],

and [Z].

12. Install part [a], then connect the harnesses [b] and [c] to the

operation panel as shown.

13. Replace the operation panel [W], then install the parts [d] and

[e], as shown.

14. Replace the left side cover (4 screws) and the rear cover (4

screws).

15. Affix the serial number label [f], the LINE/TEL label [g] and the

appropriate approval label [h] onto the rear cover. Then install

the bracket [i] (1 screw).

16. Attach the “Super G3” label [j] to the front cover.

[h]

A693I516.WMF

[j]

A693I511.WMF

Page 24

RICOH Technical

[k]

17. Wrap the phone line around the core [k] as shown, and connect it to the “LINE” jack at

the rear of the machine.

18. Plug in the machine and turn on the main power switch.

19. Press the ‘Facsimile’ key and check the facsimile LED lights.

At this time, the display reads: SC1201 - Functional problem with the fax. Data should

be initialized.

NOTE:

This is not a functional problem. The machine shows this message only

when the fax unit is first installed. If the same message appears at the

next power-on, check whether the battery switch (SW1) on the FCU

has been turned on.

Bulletin

A693I517.WMF

PAGE: 5/6

20. Press “Yes” to initialize the fax unit.

21. Set up and program the items required for fax communications as shown below. If the

user function keys (F1, F2, F3, F4, and F5) need to be programmed, attach the label.

The default settings of the user function keys are as follows:

F1: Start Manual Rx

·

F2: Tx Result Display

·

F3: TEL Mode

·

F4: Not programmed

·

F5: Not programmed

·

NOTE:

Program the serial number into the fax unit (service function 10). The serial number can be

found on the serial number label (attached to the machine in step 15).

Be sure to set the clock (date and time).

Page 25

RICOH Technical

Bulletin

PAGE: 6/6

Chapter 4

4.5 Service RAM Addresses

Two addresses are mentioned for the Rx counter, 4801C4 - 4801C6 (H) and 480A64 480A67 (H). This is not correct. 480A64 - 480A67 (H) is the correct address range.

Chapter 5

Section 5.4.1 (Page 5-7)

Problem

SW3 on the FCU MUST BE TURNED OFF

memory card, but the manual does not explain this.

If SW3 is kept on at power-up, the fax application will not start without a 'master' flash

memory card connected.

after downloading firmware from a flash

Correction

Insert the underlined step after step 8 on page 5-7 as shown below.

8. Turn off the main power switch then disconnect the flash memory card.

9. Turn OFF (lower position) SW3 below the card slot.

10. Turn the machine back on.

RC RE ASIA

Page 26

T

Model:

NAD 30S/30/40

echnical

B

ulletin

Date:

31-May-98

No:

PAGE: 1/3

4

Subject:

From:

Software Release Information

Technical Service Department.

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

This RTB shows the software release information for the BICU board.

April 1998

PCB Part Number: A2325051K (BICU board – 115V)

A2325052K (BICU board – 230V)

A2325053C (BICU board – Asia)

Software Version: 13.1.8

Program Number: A2325113E (NA)

A2325114E (EU)

A2325115B (Asia)

Effective date: From first production of April 1998

S.Tomoe

Spec.

No. Function Details

When doing initial SP settings such as

1

TD sensor initialization during

warming-up, SC542 will occur.

If entering the following SP mode

during warming-up, the beeper

sounds twice and the operation is

canceled.

Related SP mode:

SP2207

SP2801

SP2805

SP3001-2

Problems

No. Title Details

The machine may stall when making a

1

combined copy, after printing the

archive file list.

The “ Menu” key LED stays on even if

2.

copy job is finished.

When pr essing “ +” after i nputting

3.

400% with the Zoom key, “*

maximum” is displayed. If this

This happens when an archive file list

is printed with double sided copying,

but one side does not have any

archive files. Then, the machine

makes a combine mode copy with one

part blank.

This happens when selecting the

Original Mode in the Menu mode and

selecting the staple mode.

Page 27

T

No. Title Details

condition continues until the auto

reset time, SC990 may occur.

When the HDD is defective and the

4

main power switch is turned on, the

machine does not go to an SC

condition but it may stall.

The description of SP 5803-6 has

5.

been corrected.

Archive file malfunction When an original is stored as an

6

The memory is cleared automatically,

7

three seconds just after entering

SP5801.

The description of SP2213 does not fit

8

in the display.

-17 only

9.

The paper size determined when the

machine detects a non-standard

original size has been changed.

echnical

By-pass Paper Set Sensor

Unit Set Detection

archive file, two archive files will be

made.

The memory should be cleared as

follows.

1. Enter SP5801

2. Hold down the “1” for over 3 s.

B

ulletin

PAGE: 2/3

Æ

2. May 1998

PCB part number: A2325051M (BICU board – 115V)

A2325052M (BICU board – 230V)

A2325053E (BICU board – Asia)

Software Version: 13.6.3

Program Number: A2325113G (NA)

A2325114G (EU)

A2325115D (Asia)

Effective date: Form first production of May, 1998

Spec.

No. Function

1 When A3 or B4 paper size is selected in the rotate sort (or stack) mode, the

machine can now copy with normal sort (or stack) mode.

2 Theh electrical total counter value of brand new machines has been changed

from -2000 to –5000.

3 During multiple copying and with no HDD option installed, the machine can

scan an original for fax transmission.

4 The copy quality for light original mode has been improved. The gamma curve

value for the original mode has been changed.

5 SC900-01 will be generated when the mechanical counter is disconnected.

Page 28

T

Problem

No. Title Details

NAD40 only:

1

To improve the copy quality (Medaka

image), the default values of the

following SP modes have been

changed.

SP2001-1: 1650V Æ 1620V

SP2005-3: 1650V Æ 1620V

2. The machine sometimes does not

reach the stand-by mode condition

after the main switches are turned on

or after clearing a jam. This is

because the machine cannot detect

the zero cross signal.

3. When changing the value of SP6105

(staple position adjustment) and

SP6113 (punch hole position

adjustment) to a negative value, then

turning the main switch off and on, the

machine does not send the SP setting

to the finisher.

4 If the electrical counter value is a

negative value, the counters for the

fax option do not increment.

echnical

Countermeasure:

1. If the zero cross signal is not

detected after main power switch is

turned on, SC 547 will occur.

2. If the zero cross signal is not

detected after operation switch is

turned on, SC 542 will occur.

B

ulletin

PAGE: 3/3

NOTE:

The following software versions were released. However, soon after release, the next

version was released. So, the following software version has never been used.

PCB Part number: A2325051L (BICU board – 115V)

A2325052L (BICU board – 230V)

A2325053D (BICU board – Asia)

Software Version: 13.6.1

Program Number: A2325113F (NA)

A2325114F (EU)

A2325115C (Asia)

Page 29

T

Model:

NAD 30S/30/40

echnical

B

ulletin

Date:

15-Jun-98

No:

PAGE: 1/1

5

Subject:

From:

Classification:

The US government version NAD will be produced in Japan, and the standard version in

China. Accordingly, some parts used in the government version are different from the

standard version. This RTB will introduce the machine codes for the government version

and the different parts.

1. Machine Code and Model Name

Government Version Information

Technical Service Department

Troubleshooting

Mechanical

Paper path

Other ( )

Brand Ricoh Gestetner/Savin

Machine Code A230-37 A231-37 A232-37 A230-30 A231-30 A232-30

Model Name Aficio 340 Aficio 350 Aficio 450 G : 3235S

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

S: 9935D

S.Tomoe

G: 3235

S: 9935DP

G: 3245

S: 9945DP

2. Parts Information

The following are the unique parts for the government version.

Parts Number Description Index No. Page

AX400077 DC Motor – 3W 18 59

AZ230074 Power Suppl y Unit – 115V 14 61

A2321289 Lower Rear Cover 16 13

G0201964 Mirror 16 23

NOTE:

The above parts, except for the mirror, are interchangeable with those parts for the

standard US version of the machine. If the above mirror is replaced with the standard

version’s mirror (P/N: AC030115), the laser beam pitch adjustment must be

performed.

Page 30

T

Model:

NAD 30S/30/40 (1000-sheet Finisher)

echnical

B

ulletin

Date:

30-Jun-98

No:

PAGE: 1/2

6

Subject:

From:

Classification:

Paper rolled up on the shift tray

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

M.Mimura

SYMPTOM

When a large number of sheets, such as thirty, are stapled in the multiple copy mode, a

couple of the bottom sheets in the stapled stack may be rolled up on the shift tray.

CAUSE

If the paper facedown-curls excessively, the stapled set of paper will not slide back all the

way to the extreme right position on the shift tray. If this happens, the lower leading edge

of the next set may catch on the trailing edge of the set already on the tray, causing a

couple of the bottom sheets to roll up.

This symptom could occur with a thick stapled set when the copies have piled up high on

the tray. Heavy paper sets will generate stronger friction with the paper set underneath,

and as the copies pile up, the angle of the top copies will level off and make sliding back

more difficult.

Note

: 1. Non-staple mode copies will not exhibit this symptom because single sheets of

paper are delivered to the shift tray at a time.

2. Due to the nature of the copy job type in which this problem occurs, this symptom

would more likely occur with heavy volume users such as copy shops, rather

than with casual users.

SOLUTION

1 The copy paper has a characteristic that one side creates more curl than the other

side. Therefore, instruct the customer to flip over the paper in the paper tray to reduce

the amount of paper curl.

For those customers who have a wide selection of paper brands, recommending a

paper brand which creates less curl might be more beneficial for the customer. (See

page 23 of the Copy Reference manual for related remarks.)

2 This symptom may occur more with A4/11” x 8.5” sideways feed. This is because the

paper can slide up the tray further than other paper sizes. (Larger sizes of paper will

not go that far because of the friction with the lower set of copies.)

If that is the case, install the new version ROM (#A6815103E). The new version ROM

decreases the exit speed of A4/11” x 8.5” sideways paper to drop the paper close to

the right frame for easy switch back. (This happens for stapling more than 11 sheets.)

Page 31

T

Model:

Cut-in Serial Numbers

The new version ROM will be implemented into the production from July ’98. The cut-in

serial numbers are as follows:

Code Brand Cut-in Serial #s

-15 GES. US / SAVIN 1B48070001

-17 RICOH A7728070001

-22 NRG AR2807000

-26 INFOTEC 3R0780001

-55 LANIER From 1st Production

NAD 30S/30/40 (1000-sheet Finisher)

echnical

B

ulletin

Date:

30-Jun-98

No:

PAGE: 2/2

6

Page 32

T

Model:

NAD 30S/30/40 (3000-sheet Finisher)

echnical

B

ulletin

Date:

30-Jun-98

No:

PAGE: 1/2

7

Subject:

From:

Classification:

Paper rolled-up on the shift tray

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

M.Mimura

SYMPTOM

When a large number of sheets, such as fifty, are stapled in the multiple copy mod e, a

couple of the bottom sheets in the stapled stack may be rolled up on the shift tray.

CAUSE

The leading edge of the stapled set of paper tends to hang down when fed out onto the

shift tray. If there is an excessive facedown curl at the leading edge, it may catch on the

backside of the prior stack and become rolled up.

This is more evident with thick stapled sets because the curl of the upper paper will press

against the lower paper and this exaggerates the curl.

Note

: 1. Non-staple mode copies will not exhibit this symptom as single she ets of paper

are delivered to the shift tray one at a time.

2. Due to the nature of the copy job in which this problem occurs, this symptom

would more likely occur with heavy volume users, such as copy shops, rather

than with casual users.

SOLUTION

1 The copy paper has a characteristic that one side creates more curl than the other

side. Therefore, instruct the customer to flip over the paper in the paper tray to reduce

the amount of paper curl.

For those customers who have a wide selection of paper brands, recommending a

paper brand which creates less curl might be more beneficial for the customer. (See

page 23 of the Copy Reference manual for related remarks.)

2 Install the new version ROM (#A6975156B). The new version ROM is different from

the current ROM in the following ways:

2.1 After the shift tray has moved from its stand-by position to the upper position, it

will start moving down 50 ms after the paper stack has actuated the finisher exit

sensor. Thus, the paper stack makes a “soft landing” on the shift tray, reducing

the chances of the paper being rolled up.

2.2 The finisher exit roller speed has been increased from 600 to 700 mm/s which

matches that of the stack exit. This will prevent th e leading edge from receiving

the pressure which may encourage the face-down curl.

Note

: The statement in the Service Manual (page # A697-12) that “The speed of the

exit roller is higher than the stack feed-out belt speed.” is wrong.

Page 33

T

Model:

NAD 30S/30/40 (3000-sheet Finisher)

2.3 The mode in which the shift tray receives the stapled copies at its stand-by

position after the 1,500th copy has been suspended for stapled sets of more than

35 sheets because receiving at the stand-by position may lead to a steeper paper

landing angle, causing the rolling-up.

echnical

B

ulletin

Date:

30-Jun-98

No:

PAGE: 2/2

7

Cut-in Serial Numbers

The new version ROM will be implemented into the production from July ’98. The cut-in

serial numbers are as follows:

Code Brand Cut-in Serial #s

-15 GES. US / SAVIN 1B58070001

-17 RICOH A7778070001

-22 NRG AR3807000

-26 INFOTEC 3R1780001

-55 LANIER From 1st Production

Page 34

T

Model:

NAD 30S/30/40

echnical

B

ulletin

Date:

30-Jun-98

No:

PAGE: 1/1

8

Subject:

From:

Classification:

This bulletin clarifies the function of the jam location decal in the option decal sheet

(#A2327380 for LT and #A2327780 for A4).

The jam locations are indicated on the Jam Removal Sheet (#A2321380) located inside

the copier front cover. However, the jam location decal is available so that the customer

can determine the jam location without opening the front cover.

The position of the jam location decal is not pre-determined. You may place it wherever it

stands out after installing all peripherals.

Jam Location Decal

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

M.Mimura

Option Decal Sheet

Jam Location Decal

Page 35

T

Model:

NAD 30S/30/40

echnical

B

ulletin

Date:

30-Jun-98

No:

PAGE: 1/1

9

Subject:

From:

Classification:

Unify the name of the SP mode both on the machine display and in the service manual.

Incorrect

Class1

and 2

2-805 Pr ocess

Correct

Class1

and 2

Service Manual Correction

QAC Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Class 3 Function Setting

Performs the process initial setting.

Initial Setting

Class 3 Function Setting

Press 1 to start.

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

S.Tomoe

1. Start

2-805

Developer

Initialization

Performs the

Press 1 to start.

developer initialization

.

1. Start

Loading...

Loading...