Page 1

Adonis-C1b/C1c

(Machine Code: A283 and A284)

SERVICE MANUAL

Page 2

I

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

5. If the Start key is pressed before the copier completes the warm-up period

(the Start key starts blinking red and green alternatively), keep hands away

from the mechanical and the electrical components as the copier starts

making copies as soon as the warm-up period is completed.

6. The inside and the metal parts of the fusing unit become extremely hot while

the copier is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your eyes

by accident, it may cause temporary eye discomfort. Try to remove with eye

drops or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

those models.

2. The NVRAM on the system control board has a lithium battery which can

explode if replaced incorrectly. Replace the NVRAM only with an identical

one. The manufacturer recommends replacing the entire NVRAM. Do not

recharge or burn this battery. Used NVRAM must be handled in accordance

with local regulations.

Page 3

SAFETY AND ECOLOGICAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly

when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in or der to dispos e of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

NOTES

FOR DISPOSAL

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

WARNING

I

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

WARNING

I

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can

seriously damage your eyes.

CAUTION MARKING:

Page 4

TABLE OF CONTENTS

1. OVERALL MACHINE INFORMAT ION........................................1-1

1.1 SPECIFICATIONS.................................................................................... 1-1

1.2 PAPER EXIT TRAY SELECTION............................................................. 1-4

1.3 MACHINE CONFIGURATION.................................................................. 1-5

1.3.1 SYSTEM COMPONENTS ............................................................... 1-5

1.3.2 INSTALLABLE OPTION TABLE...................................................... 1-7

1.4 MECHANICAL COMPONENT LAYOUT................................................... 1-8

1.5 PAPER PATH........................................................................................... 1-9

1.6 DRIVE LAYOUT ....................................................................................... 1-9

1.7 ELECTRICAL COMPONENT DESCRIPTIONS...................................... 1-10

1.8 BOARD STRUCTURE............................................................................ 1-14

1.8.1 BLOCK DIAGRAM......................................................................... 1-14

1.8.2 DESCRIPTIONS............................................................................ 1-15

2. DETAILED DESCRIPTIONS .......................................................2-1

2.1 SCANNING............................................................................................... 2-1

2.1.1 OVERVIEW ..................................................................................... 2-1

2.2 IMAGE PROCESSING .............................................................................2-2

2.2.1 OVERVIEW ..................................................................................... 2-2

2.2.2 SBU ................................................................................................. 2 -3

2.2.3 IMAGE PROCESSING .................................................................... 2-4

3. INSTALLATION PROCEDURE...................................................3-1

3.1 INSTALLATION REQUIREMENTS .......................................................... 3-1

3.1.1 ENVIRONMENT ..............................................................................3-1

3.1.2 MACHINE LEVEL............................................................................ 3-1

3.1.3 MINIMUM SPACE REQUIREMENTS.............................................. 3-2

3.1.4 POWER REQUIREMENTS.............................................................. 3-3

3.2 INSTALLATION FLOW CHART................................................................ 3-4

3.3 COPIER INSTALLATION.......................................................................... 3-5

3.3.1 ACCESSORY CHECK..................................................................... 3-5

3.3.2 INSTALLATION PROCEDURE........................................................ 3-6

3.4 PAPER TRAY UNIT INSTALLATION..................................................... 3-11

3.4.1 ACCESSORY CHECK................................................................... 3-11

3.4.2 INSTALLATION PROCEDURE...................................................... 3-12

3.5 1-BIN TRAY UNIT INSTALLATION ........................................................ 3-16

3.5.1 ACCESSORY CHECK................................................................... 3-16

3.5.2 INSTALLATION PROCEDURE...................................................... 3-17

3.6 BRIDGE UNIT INSTALLATION.............................................................. 3-22

3.6.1 ACCESSORY CHECK................................................................... 3-22

3.6.2 INSTALLATION PROCEDURE...................................................... 3-23

3.7 AUTO REVERSE DOCUMENT FEEDER INSTALLATION.................... 3-25

3.7.1 ACCESSORY CHECK................................................................... 3-25

3.7.2 INSTALLATION PROCEDURE...................................................... 3-26

i

Page 5

3.8 LCT INSTALLATION .............................................................................. 3-28

3.8.1 ACCESSORY CHECK................................................................... 3-28

3.8.2 INSTALLATION PROCEDURE...................................................... 3-29

3.9 1,000-SHEET FINISHER INSTALLATION.............................................. 3-31

3.9.1 ACCESSORY CHECK................................................................... 3-31

3.9.2 INSTALLATION PROCEDURE...................................................... 3-32

3.10 3,000-SHEET FINISHER INSTALLATION............................................ 3-35

3.10.1 ACCESSORY CHECK................................................................. 3-35

3.10.2 INSTALLATION PROCEDURE.................................................... 3-36

3.11 PUNCH UNIT INSTALLATION............................................................. 3-39

3.11.1 ACCESSORY CHECK................................................................. 3-39

3.11.2 INSTALLATION PROCEDURE.................................................... 3-40

3.12 PLATEN COVER INSTALLATION........................................................ 3-43

3.13 KEY COUNTER INSTALLATION .........................................................3-44

3.14 ANTI-CONDENSATION HEATER........................................................ 3-46

3.15 TRAY HEATER..................................................................................... 3-48

3.16 TRAY HEATER (OPTIONAL PAPER TRAY UNIT).............................. 3-49

4. SERVICE TABLES......................................................................4-1

4.1 SERVICE PROGRAM MODE TABLES.................................................... 4-1

4.1.1 TEST PATTERN PRINTING (SP2-902)......................................... 4-42

4.1.2 INPUT CHECK............................................................................... 4-43

4.1.3 OUTPUT CHECK........................................................................... 4-47

4.1.4 SYSTEM PARAMETER AND DATA LISTS (SMC LISTS)............. 4-48

4.1.5 NIP BAND WIDTH ADJUSTMENT (SP1-109)............................... 4-49

4.1.6 MEMORY ALL CLEAR (SP5-801)................................................. 4-50

4.1.7 SOFTWARE RESET...................................................................... 4-51

4.1.8 SYSTEM SETTING AND COPY SETTING (UP MODE) RESET... 4-51

4.1.9 NVRAM DATA DOWNLOAD......................................................... 4-52

4.2 PROGRAM DOWNLOAD....................................................................... 4-54

4.3 USER PROGRAM MODE....................................................................... 4-58

4.3.1 HOW TO ENTER AND EXIT UP MODE........................................ 4-58

4.3.2 UP MODE TABLE.......................................................................... 4-58

4.4 TEST POINTS/DIP SWITCHES/LEDS................................................... 4-60

4.4.1 DIP SWITCHES............................................................................. 4-60

4.4.2 TEST POINTS............................................................................... 4-60

4.4.3 LEDS ............................................................................................. 4-61

4.5 SPECIAL TOOLS AND LUBRICANTS ................................................... 4-61

4.5.1 SPECIAL TOOLS........................................................................... 4-61

4.5.2 LUBRICANTS................................................................................ 4-61

5. PREVENTIVE MAINTENANCE SCHEDULE...............................5-1

5.1 PM TABLE................................................................................................ 5-1

ii

Page 6

6. REPLACEMENT AND ADJUSTMENT ........................................ 6-1

6.1 SCANNER UNIT....................................................................................... 6-1

6.1.1 EXPOSURE GLASS........................................................................ 6-1

6.1.2 SCANNER EXTERIOR/OPERATION PANEL................................. 6-2

6.1.3 LENS BLOCK/SBU ASSEMBLY...................................................... 6-3

6.1.4 SCANNER MOTOR......................................................................... 6-4

6.1.5 SIB/LAMP STABILIZER................................................................... 6-5

6.2 LASER UNIT............................................................................................. 6-6

6.2.1 CAUTION DECAL LOCATIONS...................................................... 6-6

6.2.2 LASER UNIT.................................................................................... 6-7

6.2.3 LASER BEAM PITCH ADJUSTMENT............................................. 6-8

6.3 COPY ADJUSTMENTS: PRINTING/SCANNING..................................... 6-9

6.3.1 PRINTING........................................................................................ 6-9

6.3.2 SCANNING.................................................................................... 6-12

6.3.3 ADF IMAGE ADJUSTMENT.......................................................... 6-14

7. TROUBLESHOOTING.................................................................7-1

7.1 SERVICE CALL CONDITIONS................................................................. 7-1

7.1.1 SUMMARY....................................................................................... 7-1

7.1.2 SC CODE DESCRIPTIONS............................................................. 7-2

7.2 ELECTRICAL COMPONENT DEFECTS................................................ 7-24

7.2.1 SENSORS..................................................................................... 7-24

7.2.2 SWITCHES.................................................................................... 7-25

7.3 BLOWN FUSE CONDITIONS................................................................. 7-26

iii

Page 7

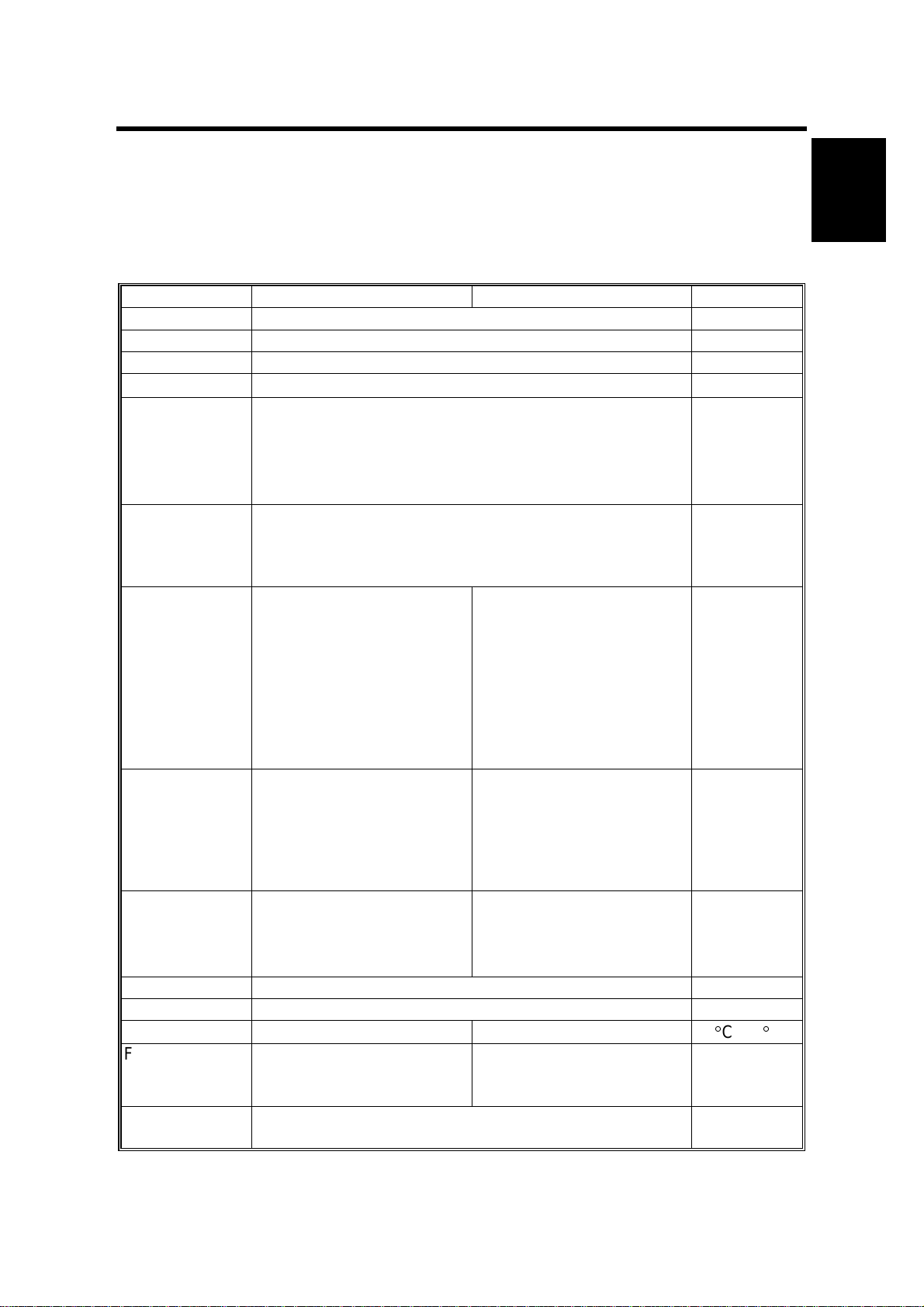

14 January, 2000 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

The “*” mark indicates differences between these machines and the NAD

machines.

Adonis-C1b (35 cpm) Adonis-C1c (45 cpm) Note

Configuration: Desktop

Copy Process: Dry electrostatic transfer system

Original: Sheet/Book

Original Size

Copy Paper

Size:

Copy Paper

Weight:

Reproduction

Ratios:

Zoom: Both versions:

Copying Speed 35 cpm

Resolution*: Scanning and Printing: 600 dpi

Gradation: Scanning and Printing: 256 levels

Warm-up Time: Less than 85 s Less than 100 s

First Copy Time

(1st Tray):

Copy Number

Input:

Maximum A3/11

Maximum:

A3/11

Minimum:

A5/5.5

A6/5.5" x 8.5" lengthwise (By-pass)

Paper Tray/Duplex:

64 - 105 g/m

By-pass:

52 - 157 g/m

7R5E

Metric version (%):

400, 200, 141, 122, 115,

100, 93, 87, 82, 71, 65,

50, 25

Inch version (%):

400, 200, 155, 129, 121,

100, 93, 85, 78, 73, 65,

50, 25

25% to 400% in 1%

steps

(A4/11

19 cpm

(A3/11

Less than 3.9 s Less than 3.2 s

Ten-key pad, 1 to 999 Count up or

x 17

"

x 8.5" lengthwise (Paper tray / Duplex)

"

x 8.5" sideways)

"

x 17")

"

x 17

"

"

"

2

, 20 – 28 lb

2

, 16 – 42 lb

7R5E

Metric version (%):

400, 200, 141, 122, 115,

100, 93, 87, 82, 71, 65,

50, 35

Inch version (%):

400, 200, 155, 129, 121,

100, 93, 85, 78, 73, 65,

50, 32

Metric version:

35% to 400% in 1%

steps

Inch version:

32% to 400% in 1%

steps

45 cpm

(A4/11

22 cpm

(A3/11

x 8.5" sideways)

"

x 17")

"

Full size

Repeat copy

mode

23°C, 73°F

A4/11

sideways (1st

paper tray)

count down

x 8.5

"

Overall

Information

"

1-1

Page 8

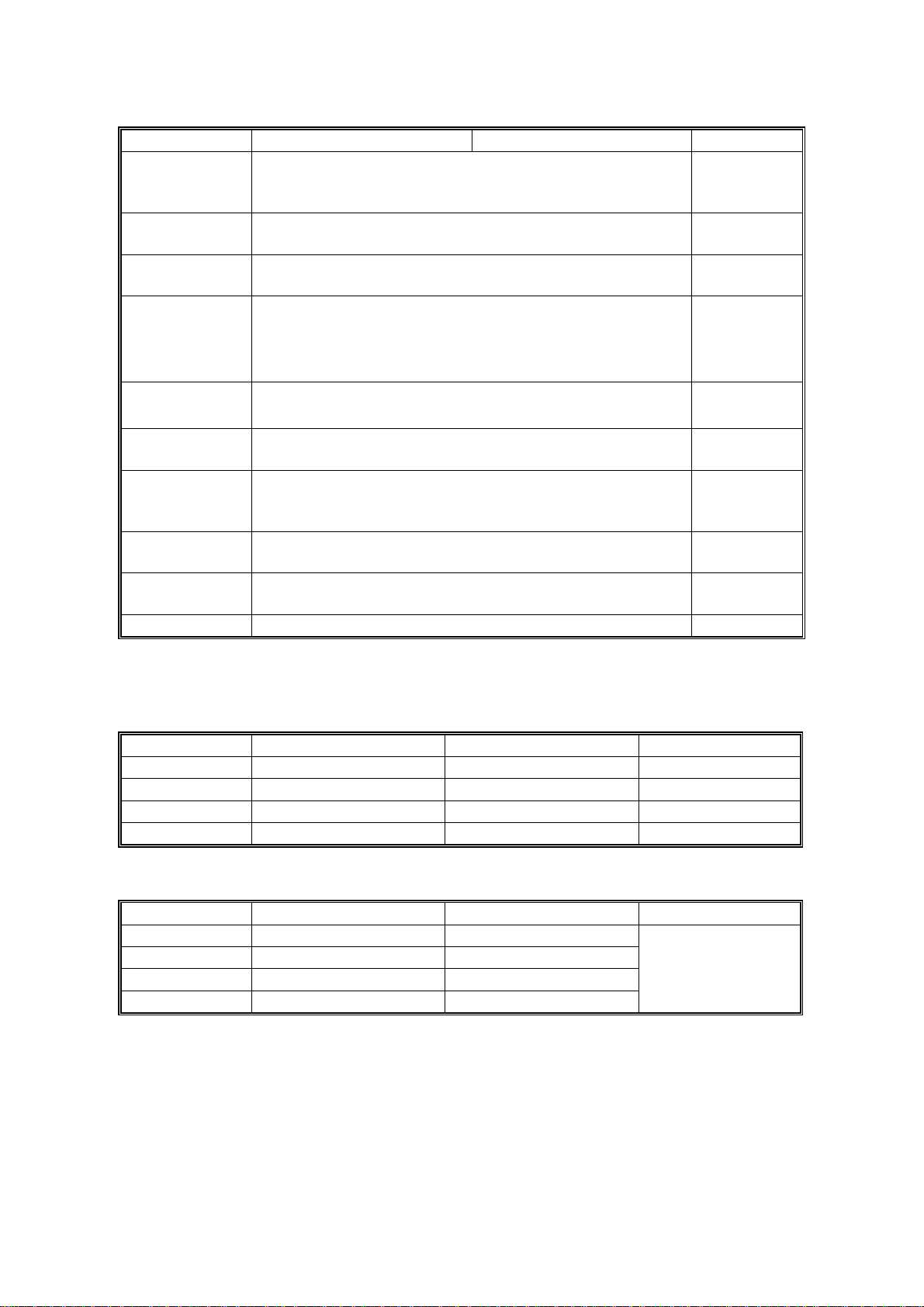

SPECIFICATIONS 14 January, 2000

Adonis-C1b (35 cpm) Adonis-C1c (45 cpm) Note

Manual Image

Density

Selection:

Automatic

Reset:

Auto Shut Off:

Copy Paper

Capacity:

Copy Tray

Capacity:

Toner

Replenishment:

Toner Yield:

Power Source: North America

Dimensions

(W x D x H)

Weight: 75 kg (166 lb)

5 steps

60 s is the standard setting; it can be changed with a UP

mode.

60 min. is the standard setting; it can be changed with a

UP mode.

Paper Tray:

500 sheets (stack thickness up to 56 mm, 2.2

By-pass Feed:

50 sheets (stack thickness up to 5.5 mm, 0.2

A4/11

A3/B4/8.5

Cartridge exchange (700 g/cartridge)

27k copies

670 x 640 x 720 mm (26.4

x 8.5": 500 sheets

"

x 14"/11" x 17": 250 sheets

"

(A4 sideways, 6% full black, 1 to 1 copying, ADS

mode)

120V/60Hz, More than 12 A

x 25.2" x 28.3")

"

"

)

"

) x 2

Standard

copy tray

Without

options

Power Consumption:

Mainframe only

Adonis-C1b Adonis-C1c Note

Maximum Less than 1.44 kW Less than 1.44 kW

Copying Less than 1.05 kW Less than 1.05 kW

Warm-up Less than 1.00 kW Less than 1.05 kW

Stand-by Less than 200 Wh Less than 220 Wh

System

Adonis-C1b Adonis-C1c Note

Maximum Less than 1.44 kW Less than 1.44 kW

Copying Less than 1.15 kW Less than 1.15 kW

Warm-up Less than 1.00 kW Less than 1.05 kW

Stand-by Less than 200 Wh Less than 230 Wh

Without the optional

heaters, fax unit,

and printer

controller.

1-2

Page 9

14 January, 2000 SPECIFICATIONS

Noise Emission:

Mainframe Only Full System

Copying

Adonis-C1b

Adonis-C1c

Stand-by

Adonis-C1b

Adonis-C1c

52 dB(A) or less

56 dB(A) or less

27 dB(A) or less

27 dB(A) or less

60 dB(A) or less

62 dB(A) or less

28 dB(A) or less

28 dB(A) or less

Overall

Information

NOTE:

1) The above measurements were made in accordance with ISO 7779.

2) Full system measurements do not include the optional fax unit and the

printer controller.

3) In the above stand-by condition, the polygon motor is not rotating.

1-3

Page 10

PAPER EXIT TRAY SELECTION 14 January, 2000

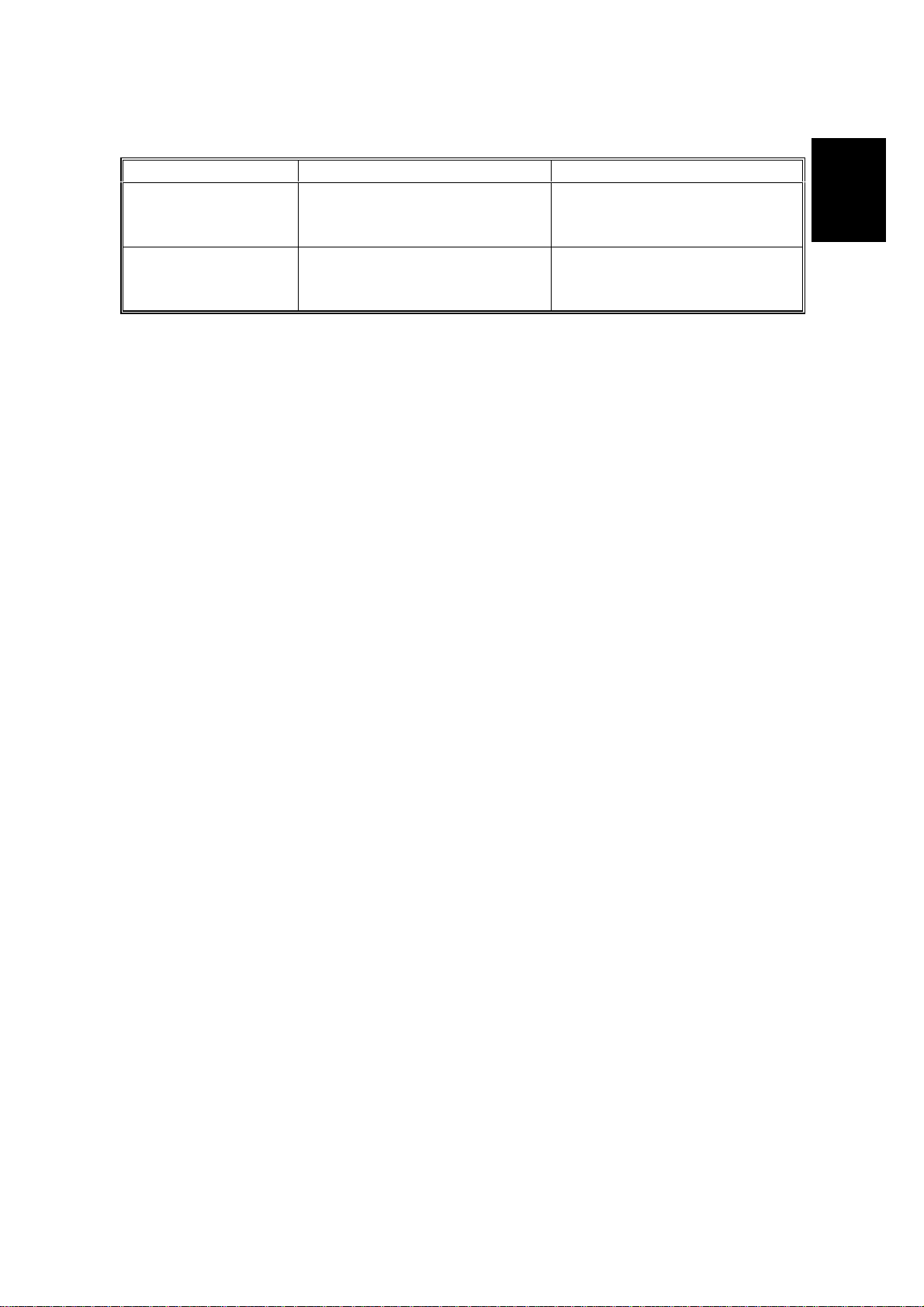

1.2 PAPER EXIT TRAY SELECTION

[A] A4, LT [B] A3, LT

[C] Longer than A3, DLT

A284V508.WMF

The machine allows selection between the paper tray exit trays: Int. Tray [A]

(standard output tray), Int. Tray 2 [B] (optional one-bin tray), and Ext. Tray [C]

(finisher or optional external output tray). If the sub-scan length is more than 330

mm, the exit tray is as shown below, if the relevant options have been installed.

Installed options Exit tray for paper longer than 330 mm

Bridge unit & Finisher (1,000-sheet) Int. Tray [A]

Bridge unit & Finisher (3,000-sheet) Ext. Tray [C]: The finisher upper tray

Bridge unit & optional ext. output tray Ext. Tray [C]: Ext. output tray

1-4

Page 11

14 January, 2000 MACHINE CONFIGURATION

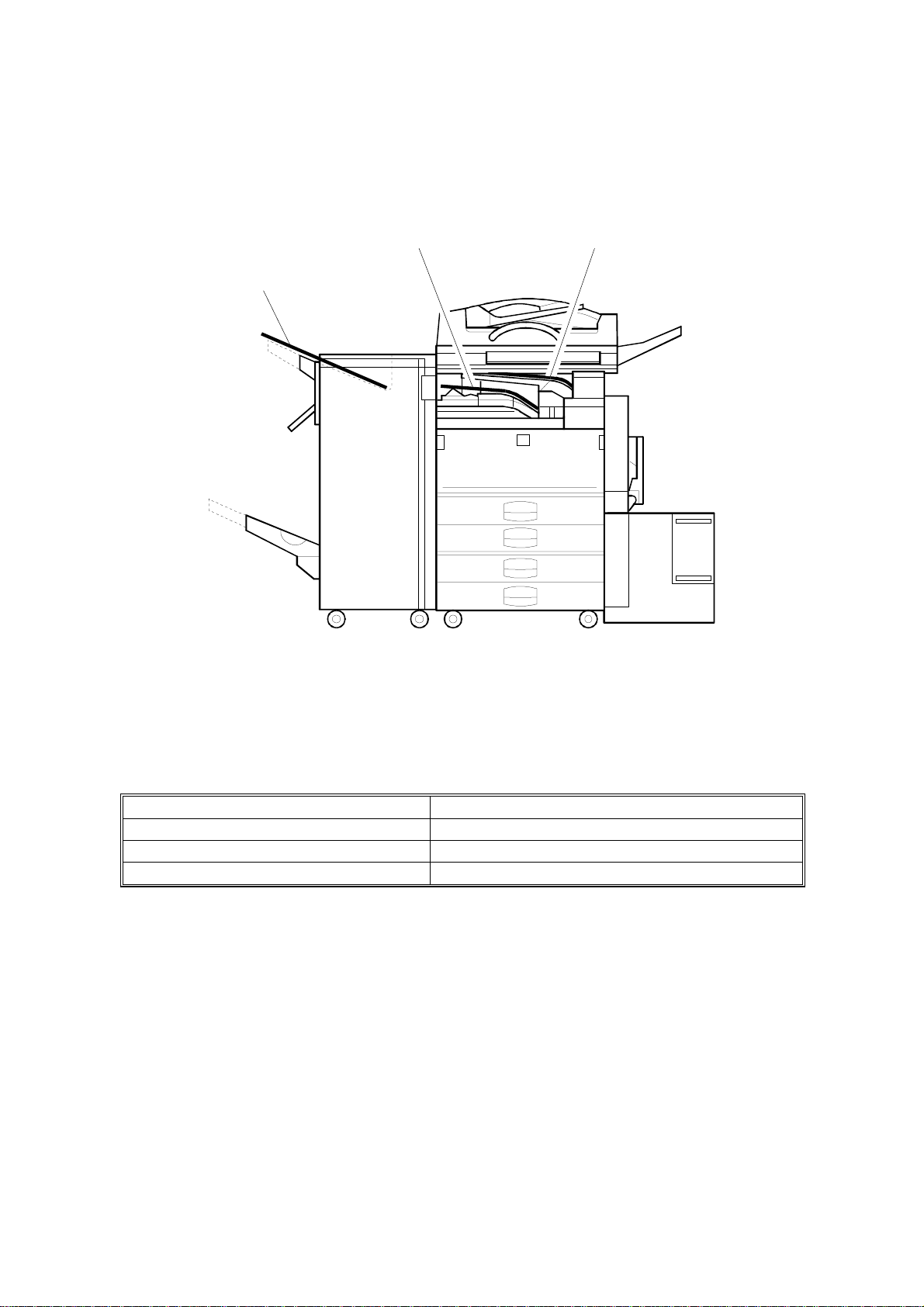

1.3 MACHINE CONFIGURATION

1.3.1 SYSTEM COMPONENTS

Overall

Information

11 1

9

10

2

3

8

5

7

4

6

A284V502.WMF

1-5

Page 12

MACHINE CONFIGURATION 14 January, 2000

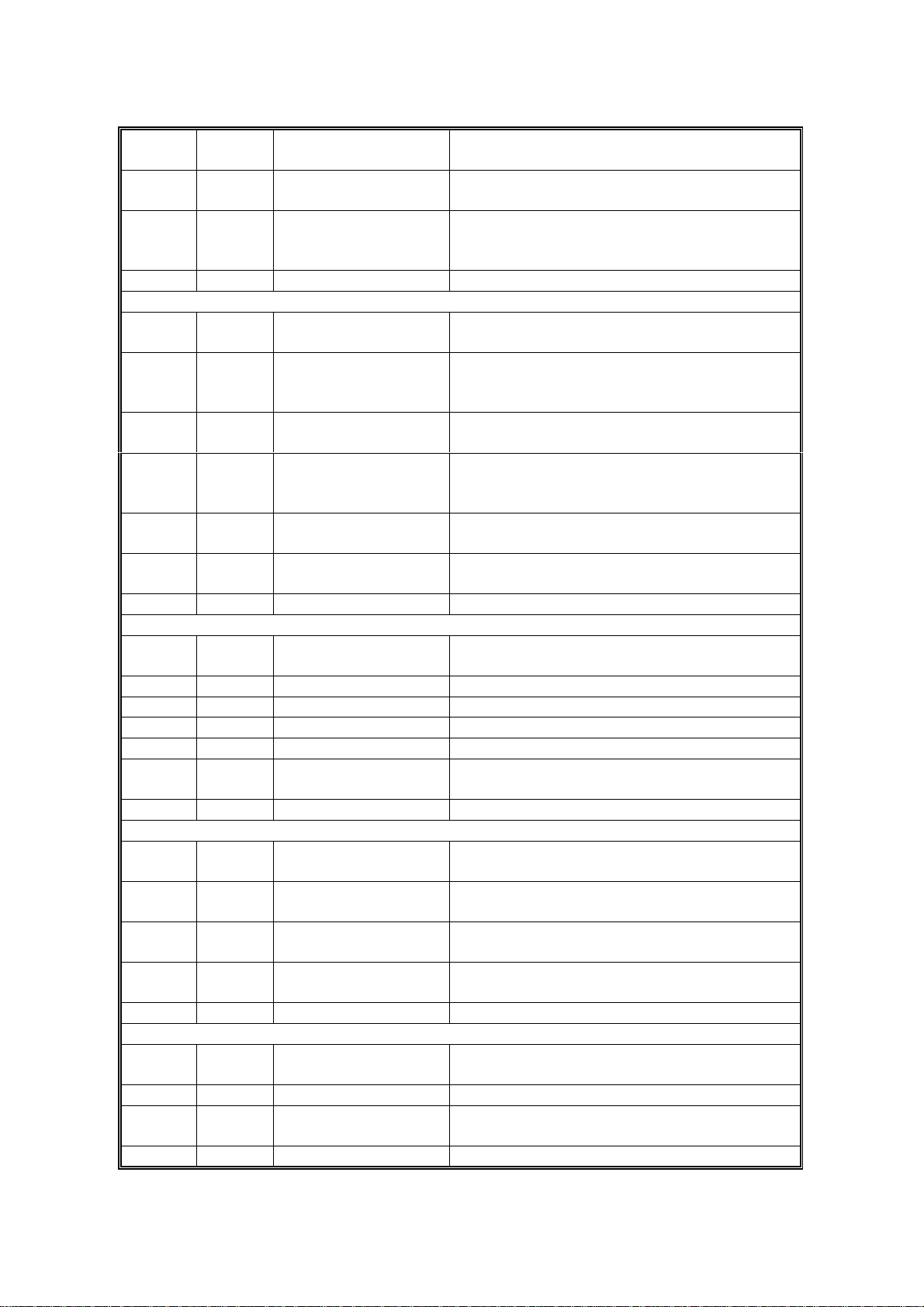

Symbol: U: Unique option, C: Option also used with other products

Version Item Machine Code No. Note

Copier (Adonis-C1b) A283 5

Copier (Adonis-C1c) A284 5

ARDF (Option) A680 2 C: (NAD)

Platen Cover (Option) A381 1 C: (NAD)

Paper Tray Unit (Option) A682 6 C: (NAD)

LCT (Option) A683 4 C: (NAD)

1-bin Tray (Option) A684 3 C: (NAD)

Copy

Fax

Printer

Scanner

Bridge Unit (Option) A688 10 C: (NAD)

1000-sheet Finisher (Option) A681 8 C: (NAD)

3000-sheet Finisher

(Option – Adonis-C1c only)

Punch Unit

(Option for 3000-sheet Finisher)

External Output Tray (Option) A825 9 C: (NAD)

Key Counter Bracket (Option) A674 11 C: (NAD)

Expansion Box (Option) A872 --- U

Fax Unit (Option) A874 --- U

ISDN Unit (Option) A816 --- C: (NAD)

RAM SIMM (Option) --- --400-dpi High Resolution (Option) A892 --- C: (Russian)

PC-Fax Expander B368 --- U

Handset (Option) A646 --- C: (NAD)

Stamp Unit (Option) A813 --- C: (NAD)

Printer Controller B358 --- U

PostScript Kit A854 --- C: (NAD)

Hard Disk A853 --- C: (NAD)

Network Interface Board A855 --- C: (NAD)

Mailbox G909 --- C: (NAD)

Mailbox Bridge Unit G912 --- C: (NAD)

RAM SIMM --- --Scanner Kit B359 --- U

RAM SIMM --- ---

A812-17 (3 holes)

A812-27 (2 holes)

A697 7 C: (NAD)

--- C: (NAD)

Symbol: U: Unique options C: Option also used with other products

1-6

Page 13

14 January, 2000 MACHINE CONFIGURATION

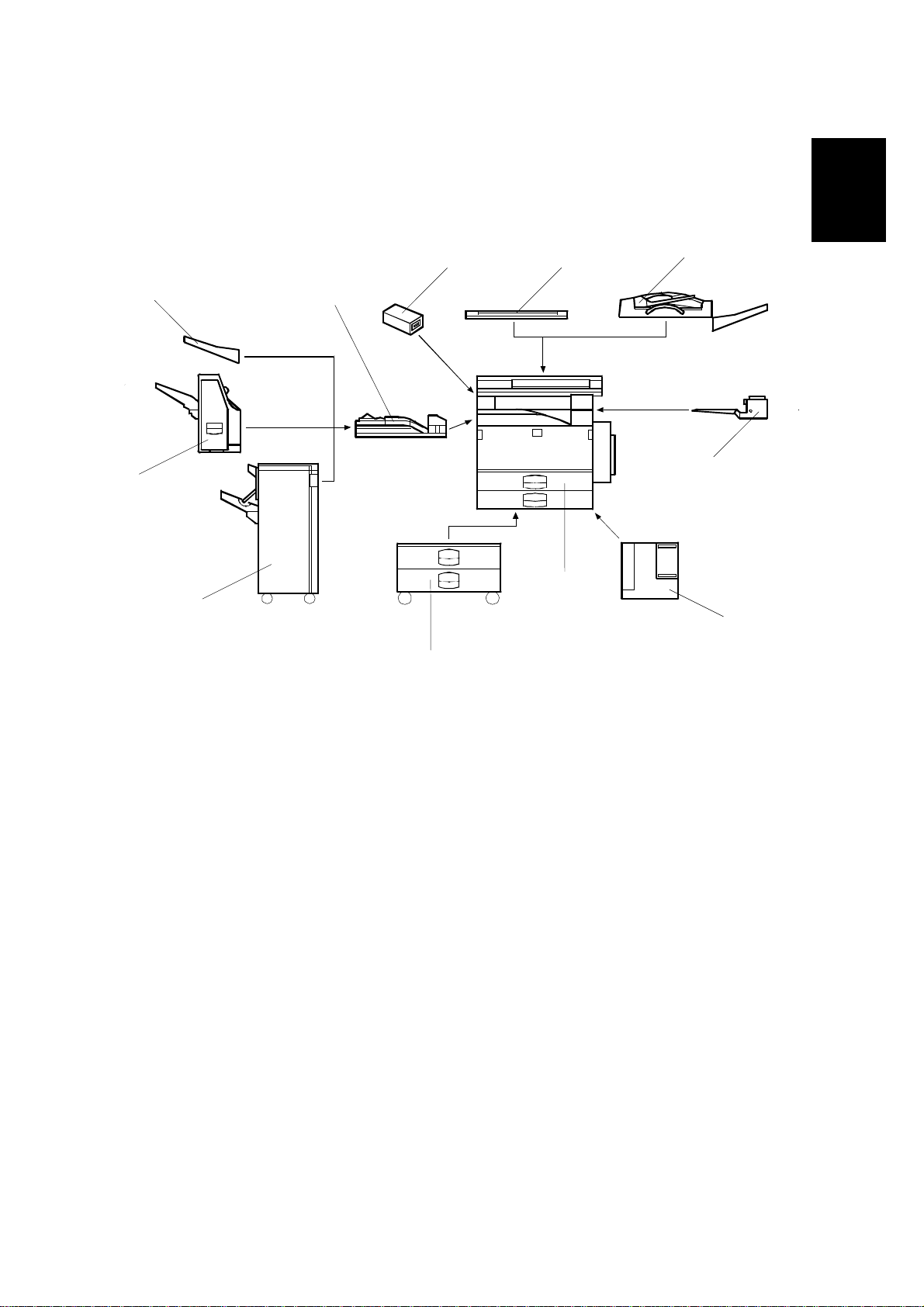

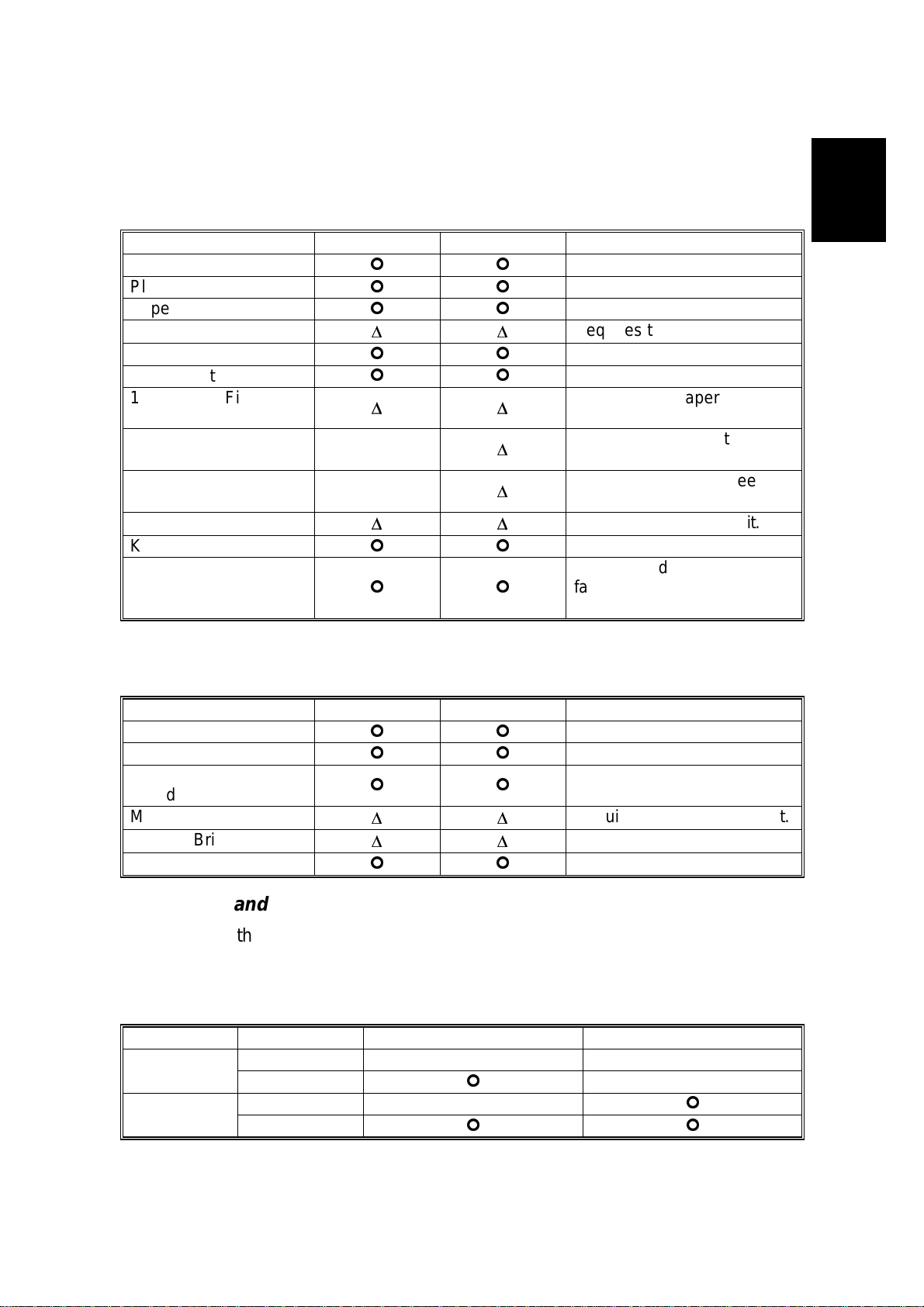

1.3.2 INSTALLABLE OPTION TABLE

Copier options

Option Adonis-C1b Adonis-C1c Note

ARDF

Platen Cover

Paper Tray Unit

LCT

1-bin Tray

Bridge Unit

1,000-sheet Finisher

3,000-sheet Finisher

Punch Unit

External Output Tray

Key Counter Bracket

Expansion Box

Printer options

¢

= Available,

¢¢

¢¢

¢¢

D

D

¢¢

¢¢

D

D

X

X

D

D

¢¢

¢¢

D

= Requires another option, X = Not available

D

D

D

D

D

D

D

D

D

D

Requires the paper tray unit.

Requires the paper tray unit

and bridge unit.

Requires the paper tray unit

and bridge unit.

Requires the 3000-sheet

finisher.

Requires the bridge unit.

It is required only when the

fax option and/or printer

option is installed.

Overall

Information

Option Adonis-C1b Adonis-C1c Note

PostScript Kit

Hard Disk

Network Interface

Board

Mailbox

Mailbox Bridge Unit

RAM SIMM

¢

= Available,

¢¢

¢¢

¢¢

D

D

D

D

¢¢

D

D

D

D

D

= Requires another option

Requires the paper tray unit.

Requires the mailbox.

Fax options and scanner kits

All options for the fax unit are available when the fax unit has been installed.

Relationship between main machine, mailbox, and finisher

¢

= Available, X = Not available

Model Mailbox 1000- sheet Finisher 3000-sheet Finisher

Adonis-C1b

Adonis-C1c

Installed

Not Installed

Installed

Not Installed

XX

¢

X

¢¢

X

¢

1-7

Page 14

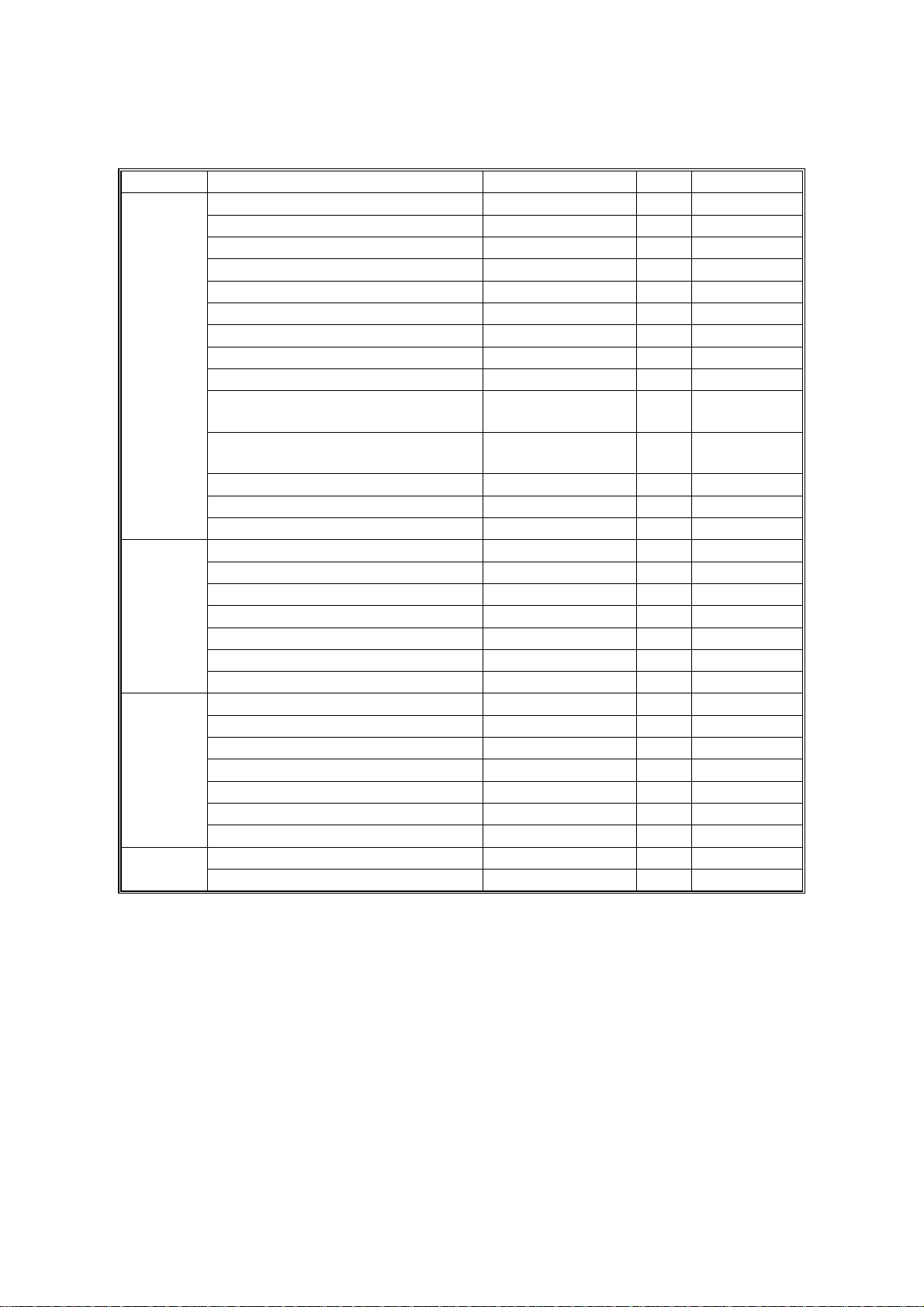

MECHANICAL COMPONENT LAYOUT 14 January, 2000

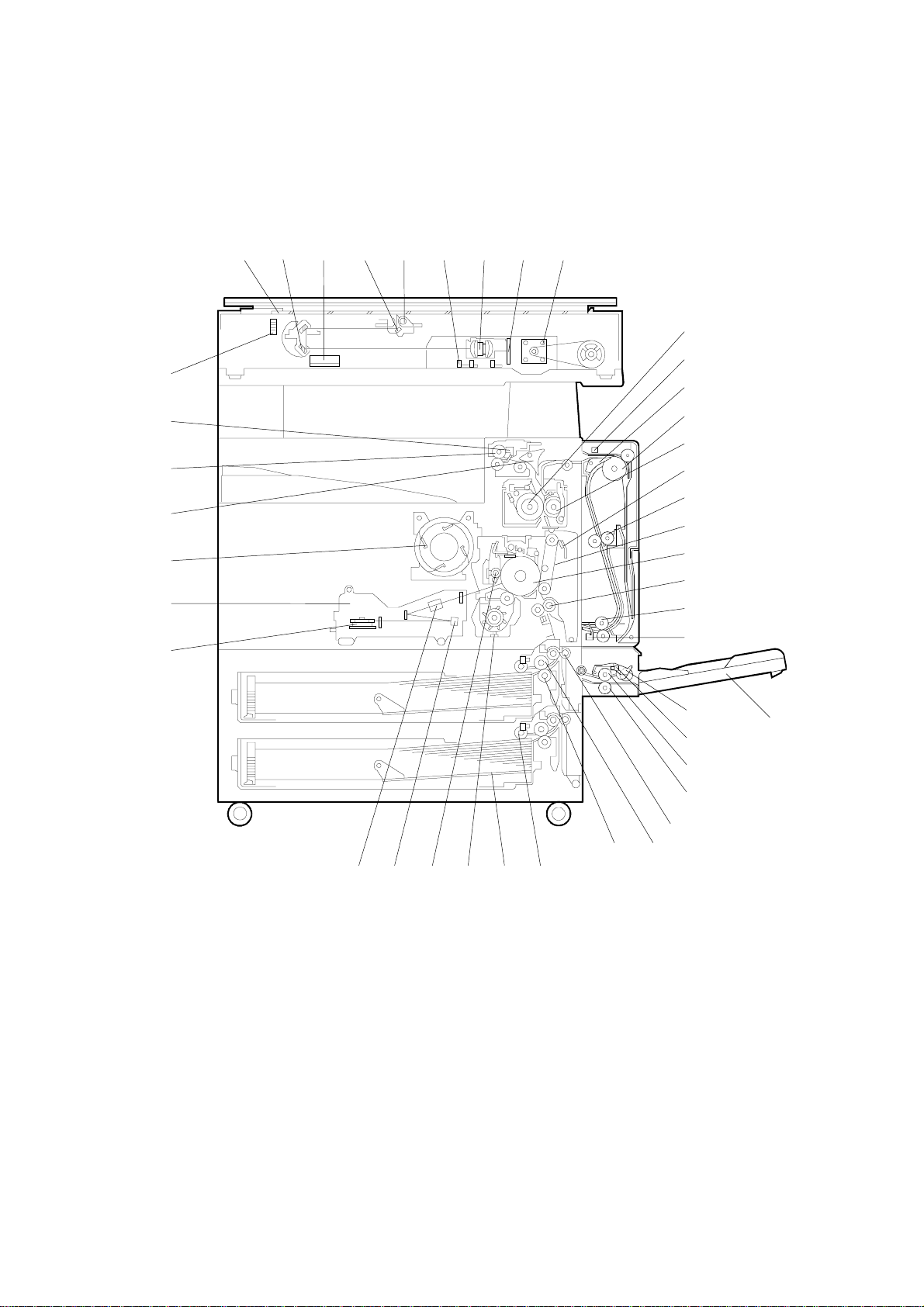

1.4 MECHANICAL COMPONENT LAYOUT

321 654 987

10

42

41

40

39

38

37

36

11

12

13

14

15

16

17

18

19

20

21

23

24

25

26

22

1-8

27

29 28

31 3033 3235 34

A284V503.WMF

Page 15

14 January, 2000 PAPER PATH

1. Exposure Glass

2. 2nd Mirror

3. Original Width Sensors

4. 1st Mirror

5. Exposure Lamp

6. Original Length Sensors

7. Lens

8. SBU

9. Scanner Motor

10. Hot Roller

11. Entrance Sensor

12. Inverter Gate

13. Inverter Roller

14. Pressure Roller

15. Transfer Belt Cleaning Blade

22. By-pass Tray

23. Pick-up Roller

24. Paper End Sensor

25. Paper Feed Roller

26. Separation Roller

27. Upper Relay Roller

28. Feed Roller

29. Separation Roller

30. Pick-up Roller

31. Bottom Plate

32. Development Unit

33. Charge Roller

34. Fq Mirror

35. Barrel Toroidal Lens (BTL)

36. Polygonal Mirror Motor

Overall

Information

16. Upper Transport Roller

17. Transfer Belt

18. OPC Drum

19. Registration Roller

20. Lower Transport Roller

21. Exit Sensor

37. Laser Unit

38. Toner Supply Bottle Holder

39. Exit Junction Gate

40. Exit Roller

41. Paper Exit Sensor

42. 3rd Mirror

1.5 PAPER PATH

The paper path is the same as for NAD machines.

1.6 DRIVE LAYOUT

The drive layout is the same as for NAD machines.

1-9

Page 16

ELECTRICAL COMPONENT DESCRIPTIONS 14 January, 2000

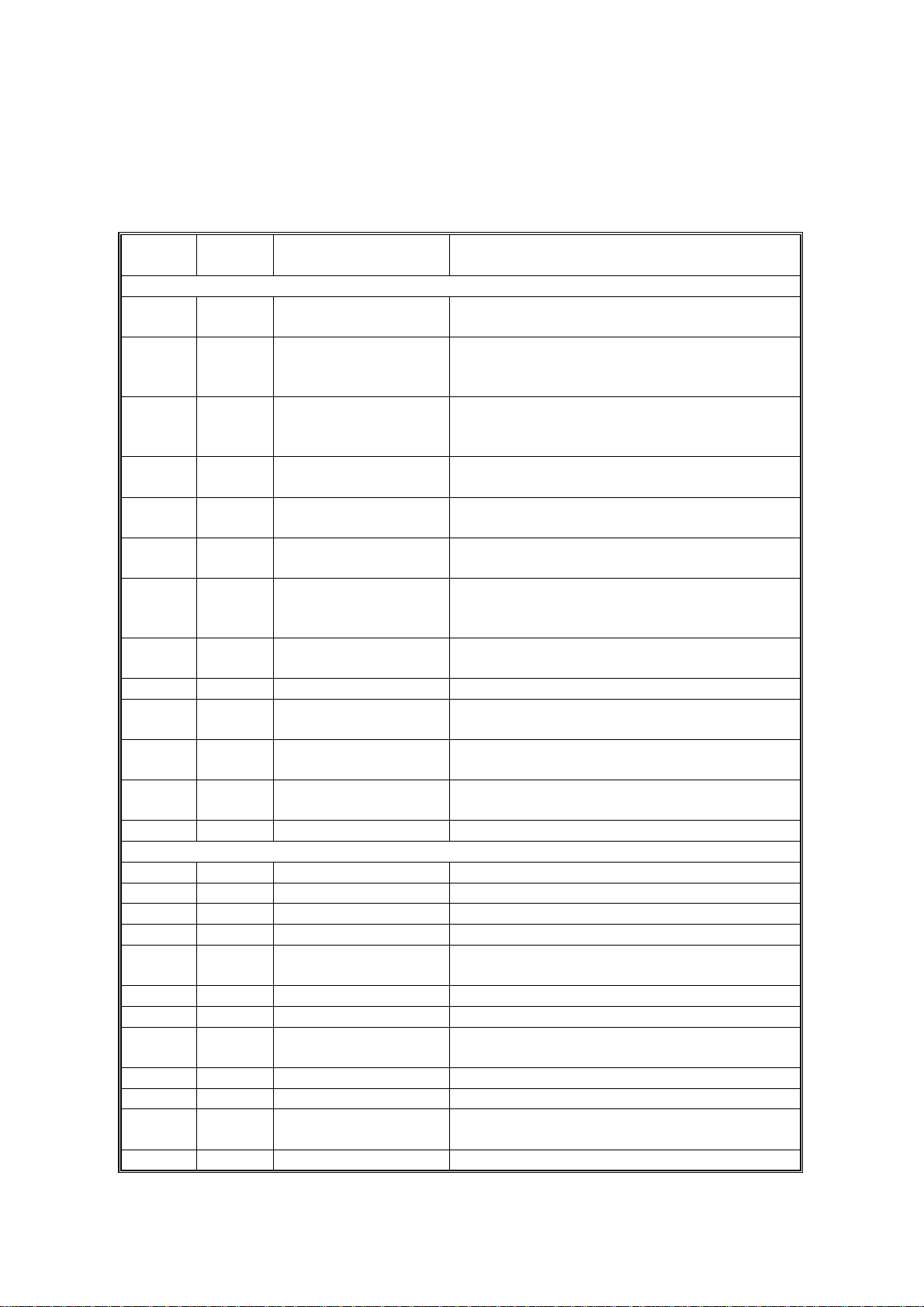

1.7 ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout and the point-to-point diagram on the

waterproof paper in the pocket for the locations of these components.

Symbol

Printed Circuit Boards

PCB1 58

PCB2 55

PCB3 61

PCB4 62

PCB5 63

PCB6 9

PCB7 7

PCB8 11

PCB9 4 Lamp Stabilizer Provides dc power to the exposure lamp.

PCB10 19

PCB11 54

PCB12 65

Index

No.

Description Note

BICU (Base Engine &

Image Control Unit)

PSU

(Power Supply Unit)

IOB

(Input/Output Board)

Paper Feed Control

(PFB)

High Voltage Supply Supplies high voltage to the drum charge

SBU

(Sensor Board Unit)

SIB

(Scanner Interface

Board)

Operation Panel Controls the LCD and LED matrix and

LDDR

(Laser Diode Driver)

SIFB (Scanner

Interface Board)

Main (Duplex)

Controls all copier functions both directly and

through other control boards.

Provides dc power to the system and ac

power to the fusing lamp and optional

heaters.

Controls the mechanical parts of the printer

(excluding the paper feed section), and the

fusing lamp power.

Controls the mechanical parts of all paper

feed sections.

roller, development roller, and transfer belt.

Contains the CCD, and outputs a video

signal to the BICU board.

Controls the scanner carriages and passes

signals from the scanner unit to the BICU

board.

monitors the key matrix.

Controls the laser diode.

Passes signals between the SBU and BICU

boards.

Controls the duplex unit and communicates

with the copier.

Motors

M1 35 Main Drives the main body components.

M2 8 Scanner Drive Drives the 1st and 2nd scanners.

M3 45 Tray Lift Raises the bottom plate in the paper tray.

M4 22 Polygonal Mirror Turns the polygonal mirror.

M5 20

M6 36 Cooling Fan Removes heat from the main PCBs.

M7 37 Exhaust Fan Removes heat from around the fusing unit.

M8 34

M9 56 PSU Cooling Fan Removes heat from the PSU.

M10 64 Inverter (Duplex) Drives the duplex inverter roller.

M11 66

LD Positioning

Toner Supply Rotates the toner bottle to supply toner to the

Transport (Duplex) Drives the duplex upper and lower transport

Rotates the LD unit to adjust the LD beam

pitch when a different resolution is selected.

development unit.

rollers.

1-10

Page 17

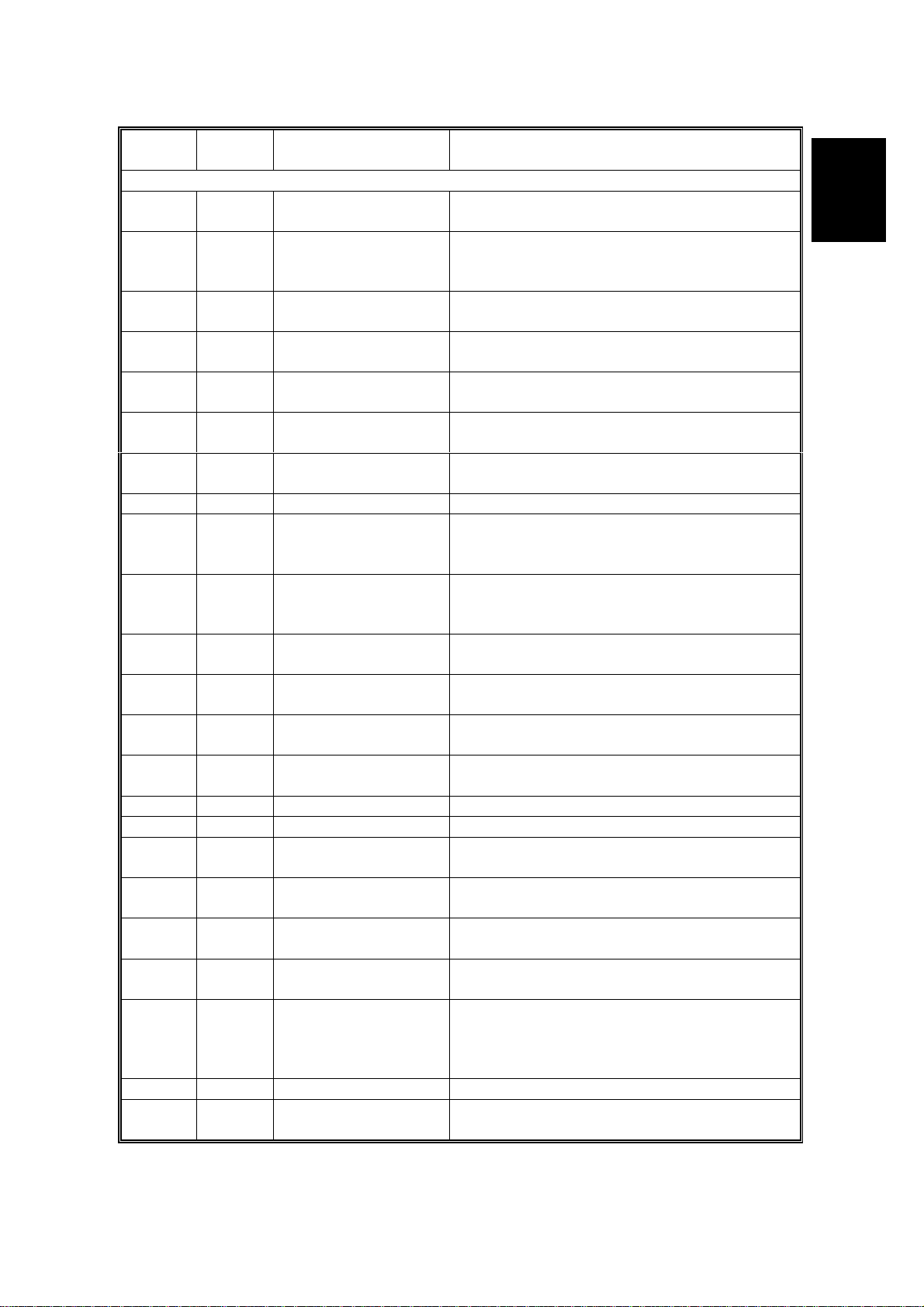

14 January, 2000 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol

Index

No.

Description Note

Sensors

S1 2

Scanner Home

Position

Informs the CPU when the 1st and 2nd

scanners are at the home position.

Platen Cover Informs the CPU whether the platen cover is

S2 3

up or down (related to APS/ARE functions).

ARE: Auto Reduce and Enlarge

S3 12

S4 5

S5 6

S6 21

S7 17

Original Width Detects the width of the original. This is one

of the APS (Auto Paper Select) sensors.

Original Length-1 Detects the length of the original. This is one

of the APS (Auto Paper Select) sensors.

Original Length-2 Detects the length of the original. This is one

of the APS (Auto Paper Select) sensors.

LD Unit Home

Position

Informs the CPU when the LD unit is at the

home positon.

Toner Density (TD) Detects the amount of toner inside the

development unit.

S8 24 Paper Exit Detects misfeeds.

Registration Detects the leading edge of the copy paper

S9 27

to determine the stop timing of the paper

feed clutch, and detects misfeeds.

Image Density (ID) Detect s the density of various patterns and

S10 26

the reflectivity of the drum for process

control.

S11 28

S12 30

S13 29

S14 31

Upper Paper Height Detects when the paper in the upper paper

tray is at the feed height.

Lower Paper Height Detects when the paper in the lower paper

tray is at the feed height.

Upper Paper End Informs the CPU when the upper paper tray

runs out of paper.

Lower Paper End Informs the CPU when the lower paper tray

runs out of paper.

S15 33 Upper Relay Detects misfeeds.

S16 32 Lower Relay Detects misfeeds.

S17 48

S18 46

S19 38

S20 18

S21 61

Upper Tray Informs the CPU whether the upper paper

tray is set into the machine or not.

Lower Tray Informs the CPU whether the lower paper

tray is set into the machine or not.

Transfer Belt Position Informs the CPU of the current position of the

transfer belt unit.

Toner Overflow Detects toner overflow in the toner collection

tank.

Duplex Entrance

Detects the trailing edge of the copy paper to

turn on the inverter gate solenoid and turn on

the inverter motor in reverse. Checks for

misfeeds.

S22 67 Exit (Duplex) Checks for misfeeds.

S23 68

Cover Guide (Duplex) Det ects whether the cover guide is opened

or not.

Overall

Information

1-11

Page 18

ELECTRICAL COMPONENT DESCRIPTIONS 14 January, 2000

Symbol

S24 69

S25 72

Switches

SW1 43

SW2 49

SW3 51

SW4 52

SW5 10

SW6 62

Index

No.

Description Note

Paper End

(By-pass)

Paper Size Sensor

Board

Informs the copier when the by-pass tray

runs out of paper.

Detects the paper width for the by-pass tray

unit.

(By-pass)

Right Lower Cover Detects whether the right lower cover is open

or closed.

Right Upper Cover Cut the +5VLD and +24V dc power line and

detects whether the right upper cover is open

or closed.

Main Power Switch Supplies power to the copier. If this is off,

there is no power supplied to the copier.

Front Cover Safety Cuts the +5VLD and +24V dc power line and

detects whether the front cover is open or

not.

Operation Switch Provides power for machine operation. The

machine still has power if this switch is off.

Duplex Unit

Detects whether the duplex unit is opened or

not.

Magnetic Clutches

CL1 3 9

Transfer Belt Controls the touch and release movement of

the transfer belt unit.

CL2 40 Registration Drives the registration rollers.

CL3 4 4 Relay Drives the relay rollers.

CL4 41 Upper Paper Feed Starts paper feed from the upper paper tray.

CL5 42 Lower Paper Feed Starts paper feed from the lower paper tray.

CL6 7 1

Paper Feed

(By-pass)

Starts paper feed from the by-pass tray unit.

Solenoids

SOL1 63

SOL2 70

SOL3 73

SOL4 74

Inverter Gate

(Duplex)

Pick-up

(By-pass)

Exit Junction Gate

(Interchange unit)

Duplex Junction Gate

(Interchange unit)

Controls the duplex inverter gate.

Moves the pick-up roller for the by-pass feed

tray to contact the paper.

Controls the exit junction gate.

Controls the duplex junction gate.

Lamps

L1 13

Exposure

Applies high intensity light to the original for

exposure.

L2 16 Fusing Provides heat to the hot roller.

L3 25

Quenching Neutralizes any charge remaining on the

drum surface after cleaning.

1-12

Page 19

14 January, 2000 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol

Index

Heaters

H1 1

H2 47

Thermistors

TH1 14

Thermofuses

TF1 15

Counters

CO1 50

CO2 N/A

No.

Description Note

Optics Anticondensation

(option)

Tray

(option)

Turns on when the main power switch is off

to prevent moisture from forming on the

optics.

Turns on when the main power switch is off

to keep paper dry in the paper tray.

Fusing Monitors the temperature at the central area

of the hot roller.

Fusing Provides back up overheat protection in the

fusing unit.

Total Keeps track of the total number of prints

made.

Key

(option)

Used for control of authorized use. If this

feature is enabled for copying, copying will

be impossible until it is installed. It can also

be enabled for fax and printer modes

separately.

Overall

Information

Others

LSD 23

Laser

Synchronization

Detector

Detects the laser beam at the start of the

main scan.

1-13

Page 20

BOARD STRUCTURE 14 January, 2000

1.8 BOARD STRUCTURE

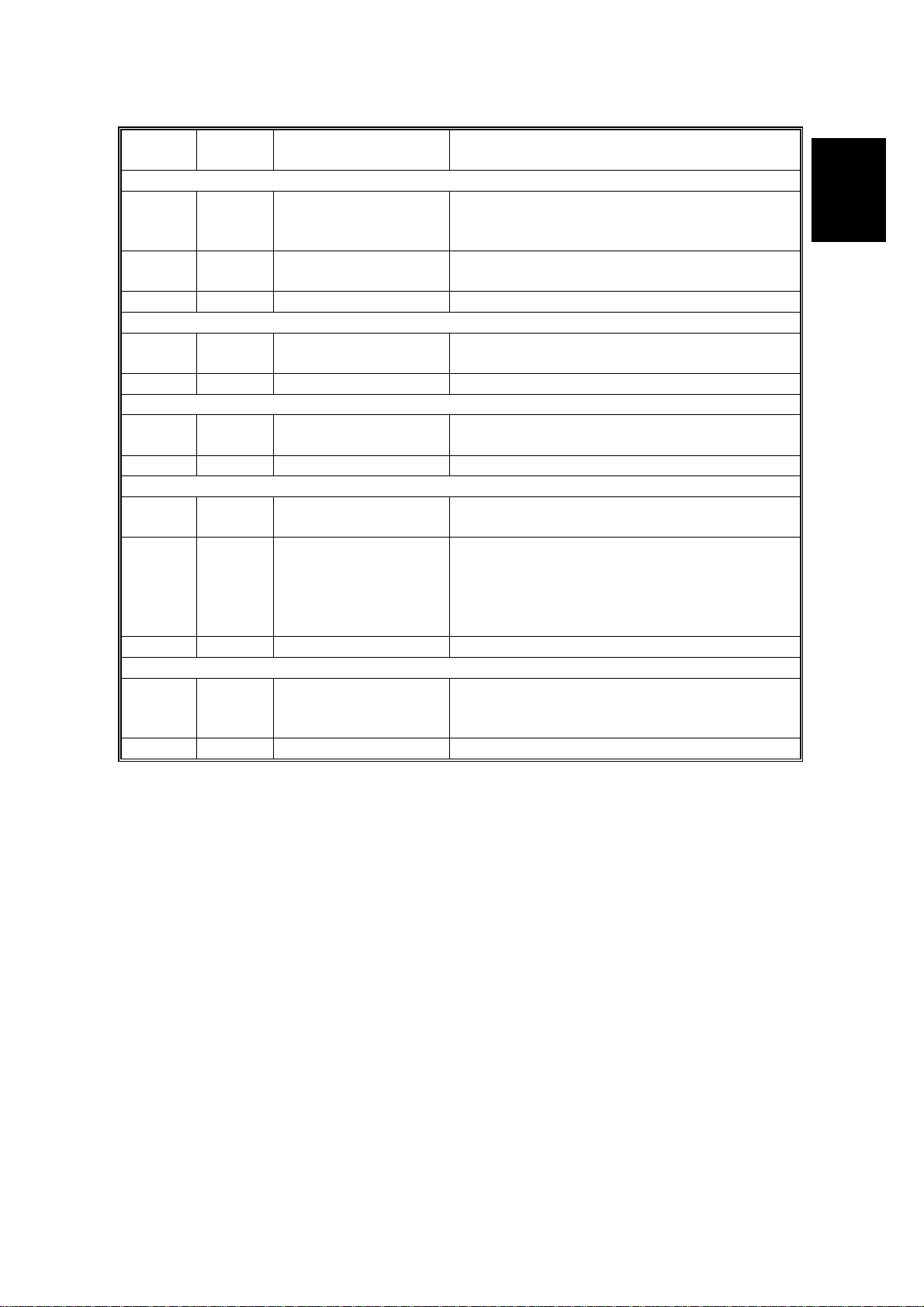

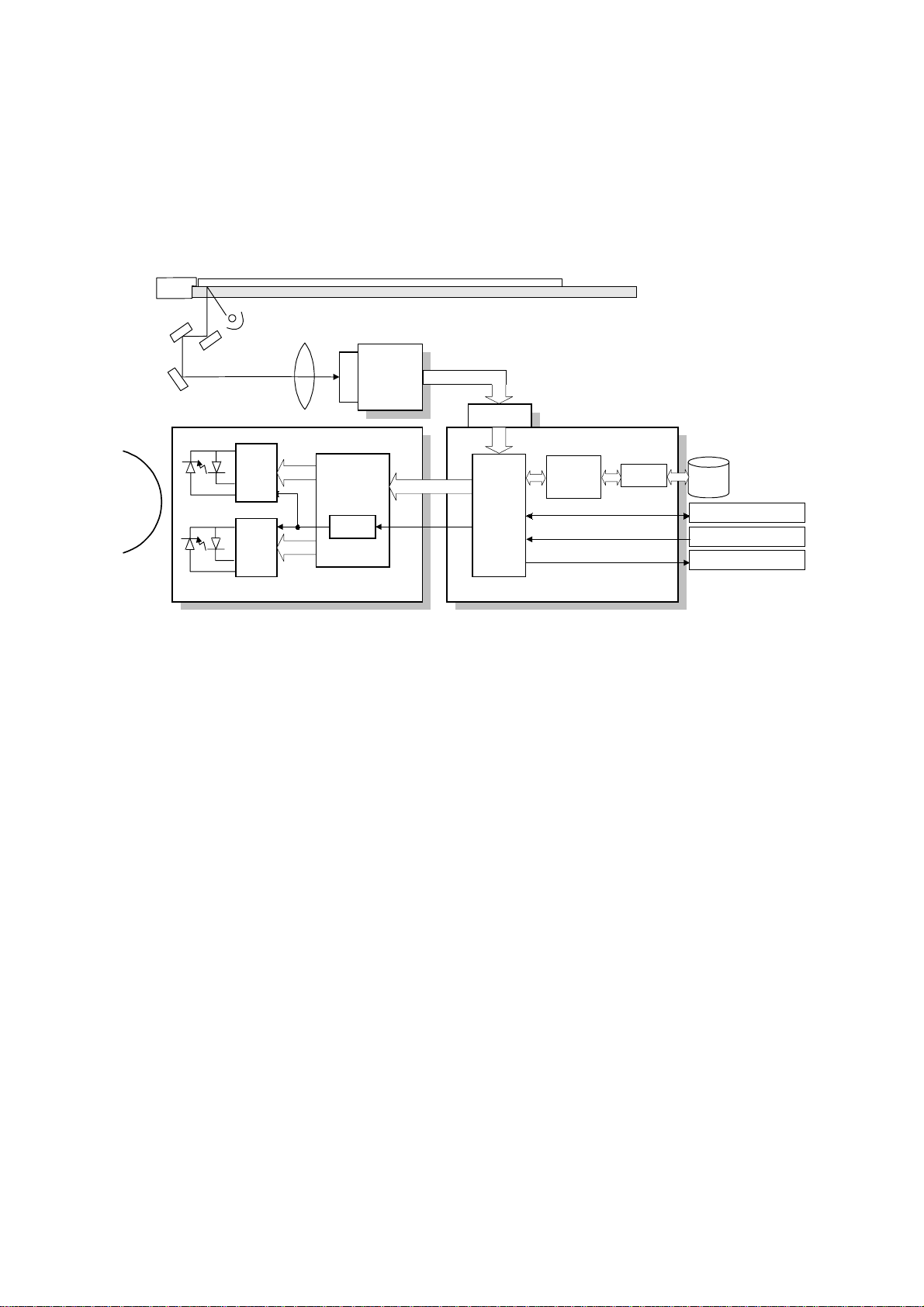

1.8.1 BLOCK DIAGRAM

SBU

Exposure

Lamp

Image data

Signal data

Lamp

Stabilizer

Scanner

Motor

APS

Sensors

Op.

Panel

ARDF

SIFB

SIB

BICU

Driver

Polygon

Motor

Mother

Board

LD

PSU

HDD

LSD

Fax Controller

Printer Controller

Scanner Controller

Duplex

Unit

1-bin Tray

Finisher

Main

Bridge Unit

IOB

Counter Clutches

: Standard : Option

Fans Sensors

Motor

High

Voltage

Supply

Paper Feed

Controller

(PFB)

Paper

Tray Unit

LD

Position

Motor

LCT

A284V501.WMF

LD H.P

Sensor

Sensors

Clutches

1-14

Page 21

14 January, 2000 BOARD STRUCTURE

1.8.2 DESCRIPTIONS

1. BICU (Base Engine and Image Control Unit)

This is the main board. It controls the following functions.

·

Engine sequence

·

Timing control for peripherals

·

Image processing, video control

·

Operation control

·

Application boards (fax, printer, scanner)

2. IOB (Input/Output Board)

The IOB handles the following functions.

·

Drive control for the sensors, motors, and solenoids in the printer engine

·

PWM control for the high voltage supply board

·

Serial interface with peripherals

·

Fusing control

Overall

Information

3. SBU (Sensor Board Unit)

The SBU receives analog signals from the CCD and converts them into digital

signals.

4. SIB (Scanner Interface Board)

This board controls the scanner motor and passes signals between the BICU

board and the component parts of the scanner unit.

5. SIFB (Scanner Interface Board)

This board interfaces the SBU with the BICU.

6. Mother Board (Option)

This board interfaces the BICU with the fax controller, printer controller and/or

the scanner kit. The mother board is part o f the ex pansi on box option.

1-15

Page 22

14 January, 2000 SCANNING

2. DETAILED DESCRIPTIONS

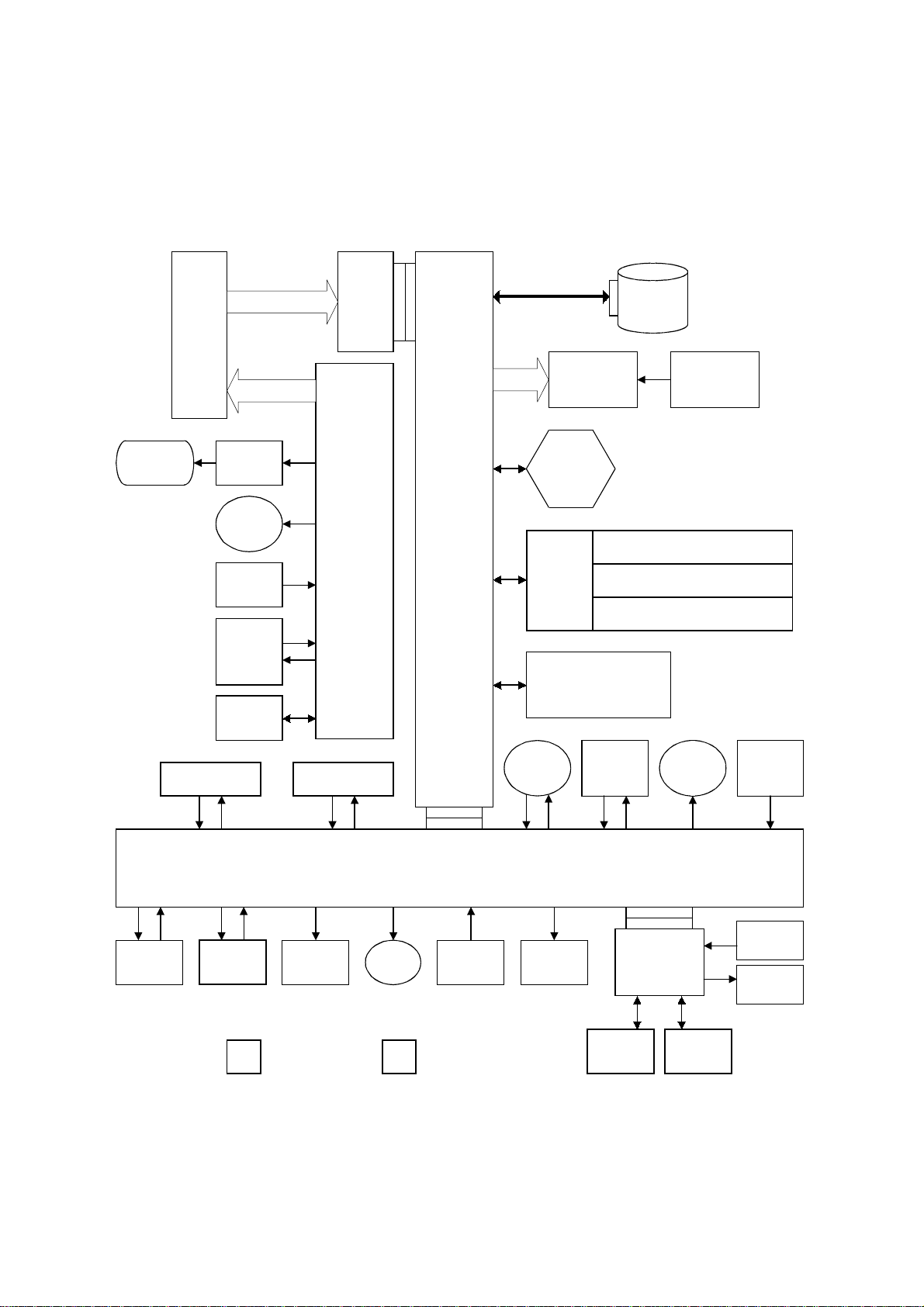

2.1 SCANNING

2.1.1 OVERVIEW

For NAD

A284D501.WMF A284D502.WMF

For Adonis-C1

The mechanical components of the scanner unit are the same as for the NAD.

However, the following items have been changed because this machine scans at

600 dpi.

·

The lens is larger

·

Because the lens size has been changed, the drive layout has been changed as

shown in the above illustration (note the position of the scanner drive motor).

·

Image processing is slightly different

·

To reduce the electrical noise generated by the high frequency image data

signal, a shield plate has been added to the lens block unit.

Detailed

Descriptions

2-1

Page 23

IMAGE PROCESSING 14 January, 2000

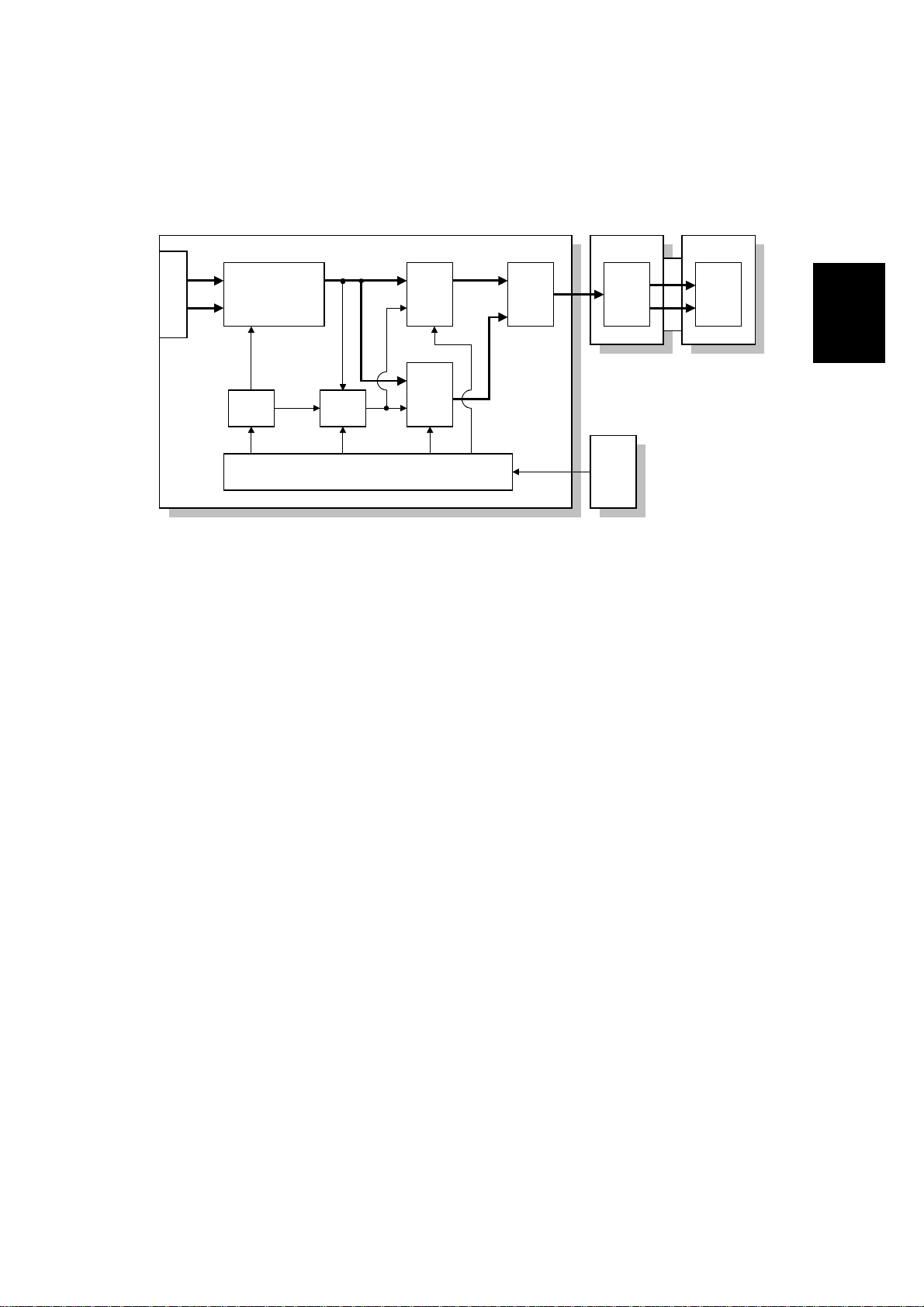

2.2 IMAGE PROCESSING

2.2.1 OVERVIEW

SBU

CCD

SIFB

Memory

Control

IC

MSU

BICU

HDD

Fax Controller

Printer Controller

Scanner Controller

A284D531.WMF

Drum

LDDR

LD

Driver

LD

Driver

LD

Controller

(GAVD)

FCI

IPU

The image data flows similarly to the NAD machine. The differences are the

following.

·

The video data go to the IPU chip through only the SIFB.

·

The MSU circuit is on the BICU board.

·

The image processing is changed.

2-2

Page 24

14 January, 2000 IMAGE PROCESSING

g

2.2.2 SBU

E

O

CCD

Analo

Processing IC

D/A

P/H

SBU

GA

A/D

A/D

Driver

SIFB

Driver

SIB

BICU

IPU

A283D500.WMF

The CCD has two output lines, one each for odd and even pixels, to the analog

processing IC. The analog processing IC performs the zero clamp and signal

amplification. The analog signals are then converted to 8-bit signals by the A/D

converter. The digital signals go to the driver, where they are converted to serial

data. Then, these go to the SIFB. In the SIFB, the data is converted to parallel

signals (8-bit x 2) by the driver, and these go to the IPU chip.

Detailed

Descriptions

The SIB controls the circuits on the SBU (such as those for shading).

2-3

Page 25

IMAGE PROCESSING 14 January, 2000

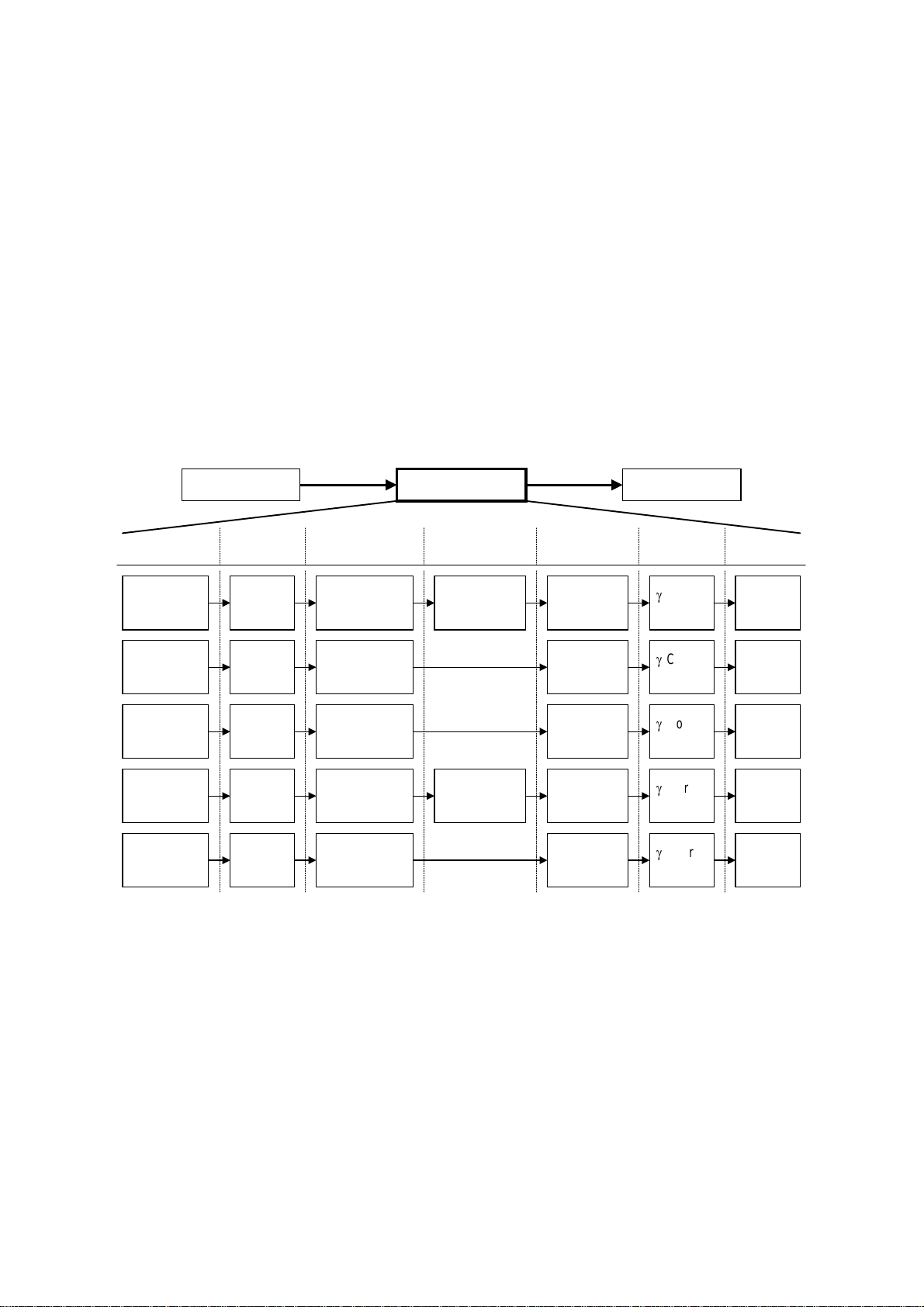

2.2.3 IMAGE PROCESSING

Overview

The differences in the image processing from the NAD are as follows.

·

600 dpi scanning and printing

·

Only grayscale processing mode is available.

·

The copy quality for the low contrast image is improved (the filters and the g table

have been modified).

·

To consist with gradation and resolution in the text mode, using the error

diffusion processing.

Image Processing Path

Scanning Image Processing Printing

Copy Mode

Letter Magnification

Letter/Photo Magnification

Generation Magnification

Low Density

Original

Input

Correction

Auto

Shading

Auto

Shading

Auto

Shading

Auto

Shading

Auto

Shading

Magnification

Magnification

Background

Erase

Background/

Independent

Dot Erase

Background/

Independent

Dot Erase

Filtering

MTF

(Strong)

MTF

(Weak)

Smoothing

MTF/

Line width

correction

MTF

(Strong)

Photo mode: MTF can be used instead of smoothing (SP4-904-3).

ID

Control

Corre-

g

ction

Corre-

g

ction

Corre-

g

ction

Corre-

g

ction

Corre-

g

ction

Gradation

Error

Diffusion

Error

Diffusion

DitheringPhoto Magnification

Error

Diffusion

Error

Diffusion

A284D533.WMF

2-4

Page 26

14 January, 2000 IMAGE PROCESSING

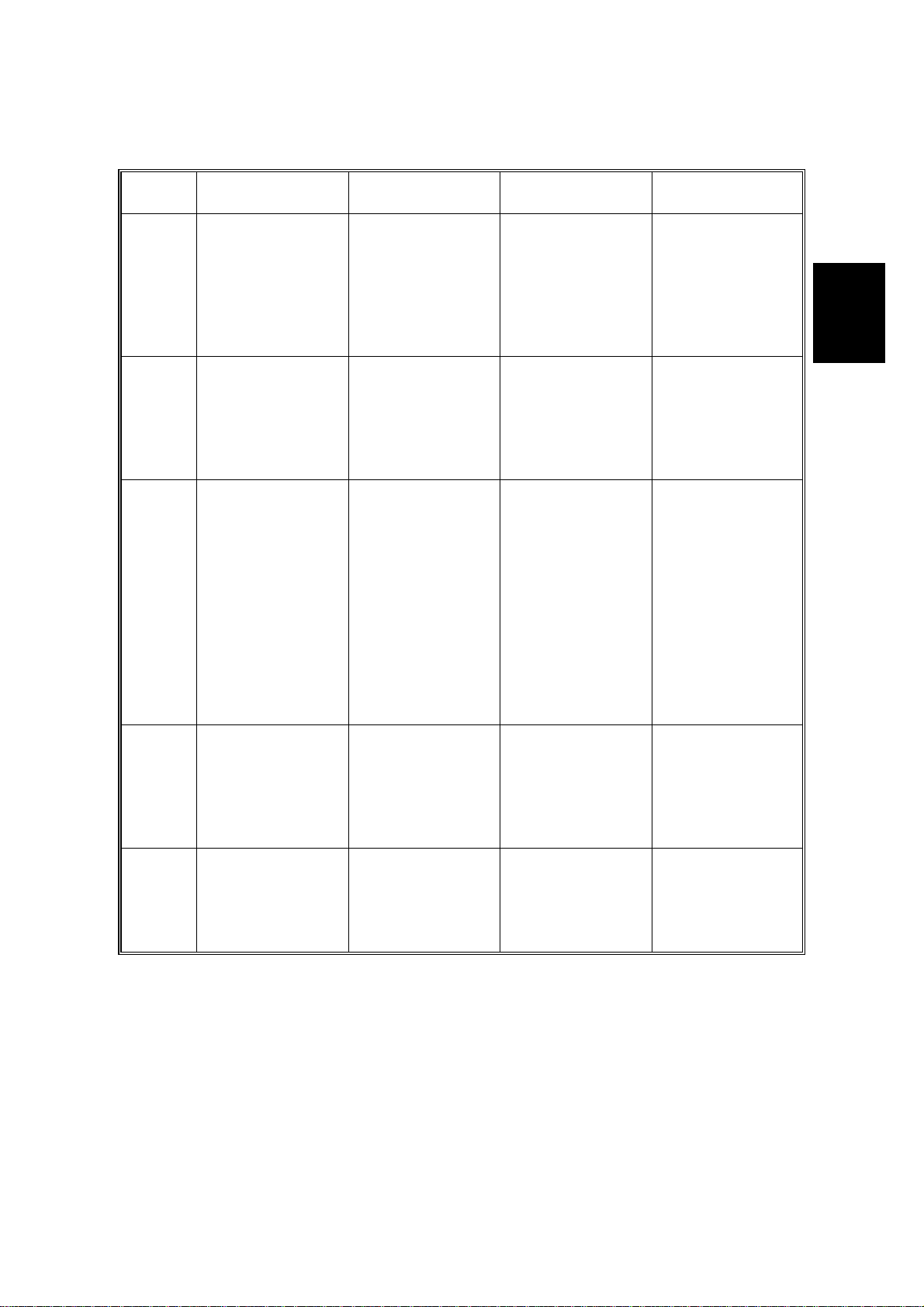

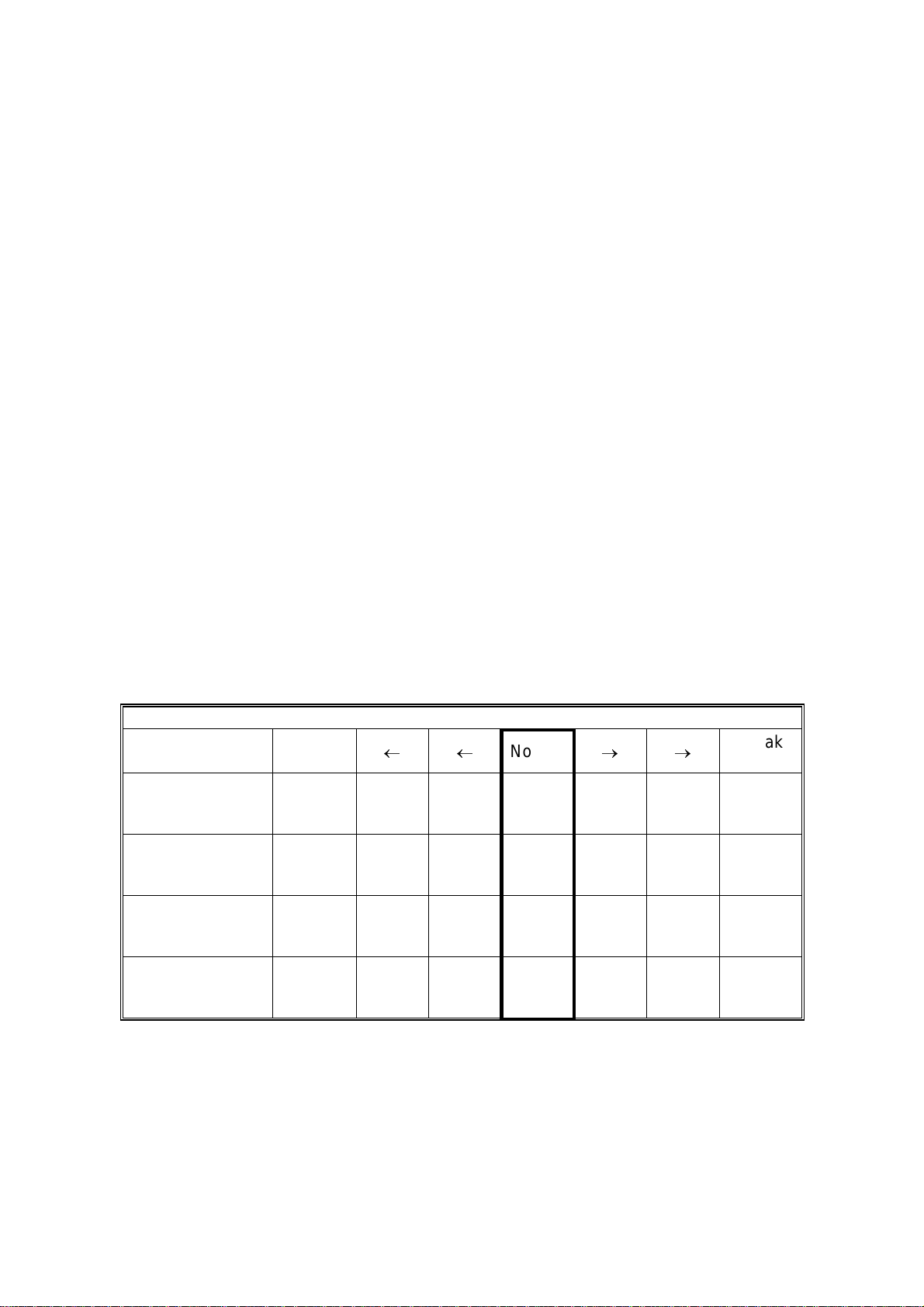

SP modes for each image processing mode

Copy

mode

Letter

Letter/

Photo

Photo

Copied

Original

Low

Density

Original

Background

erase

SP4903-34

Background erase

level

SP4903-28

Independent dot

erase level

SP4903-35

Background erase

level

SP4903-30

Independent dot

erase level

SP4903-36

Background erase

level

SP4903-37

Background erase

level

SP4903-32

Independent dot

erase level

SP4903-31

Independent dot

erase level

Filtering Magnification Gradation

SP4903-11~14,

41~44

SP2909-1

Main scan mag.

MTF filter

coefficient

SP4903-20~23,

50~53

MTF filter strength

SP4903-17, 47

MTF filter

SP2909-1

Main scan mag.

coefficient

SP4903-25, 55

MTF filter strength

SP4904-3

Filter type

SP2909-1

Main scan mag.

SP4904-2

Dither matrix type

(smoothing or

MTF)

SP4903-16

Smoothing filter

coefficient

SP4903-15, 48

MTF filter

coefficient

SP4903-24, 54

MTF filter strength

SP4903-19, 46

MTF filter

coefficient

SP2909-1

Main scan mag.

SP4904-6

Line width

correction type

SP4903-27, 57

MTF filter strength

SP4903-18, 45

MTF filter

SP2909-1

Main scan mag.

coefficient

SP4903-26, 56

MTF filter strength

Detailed

Descriptions

2-5

Page 27

IMAGE PROCESSING 14 January, 2000

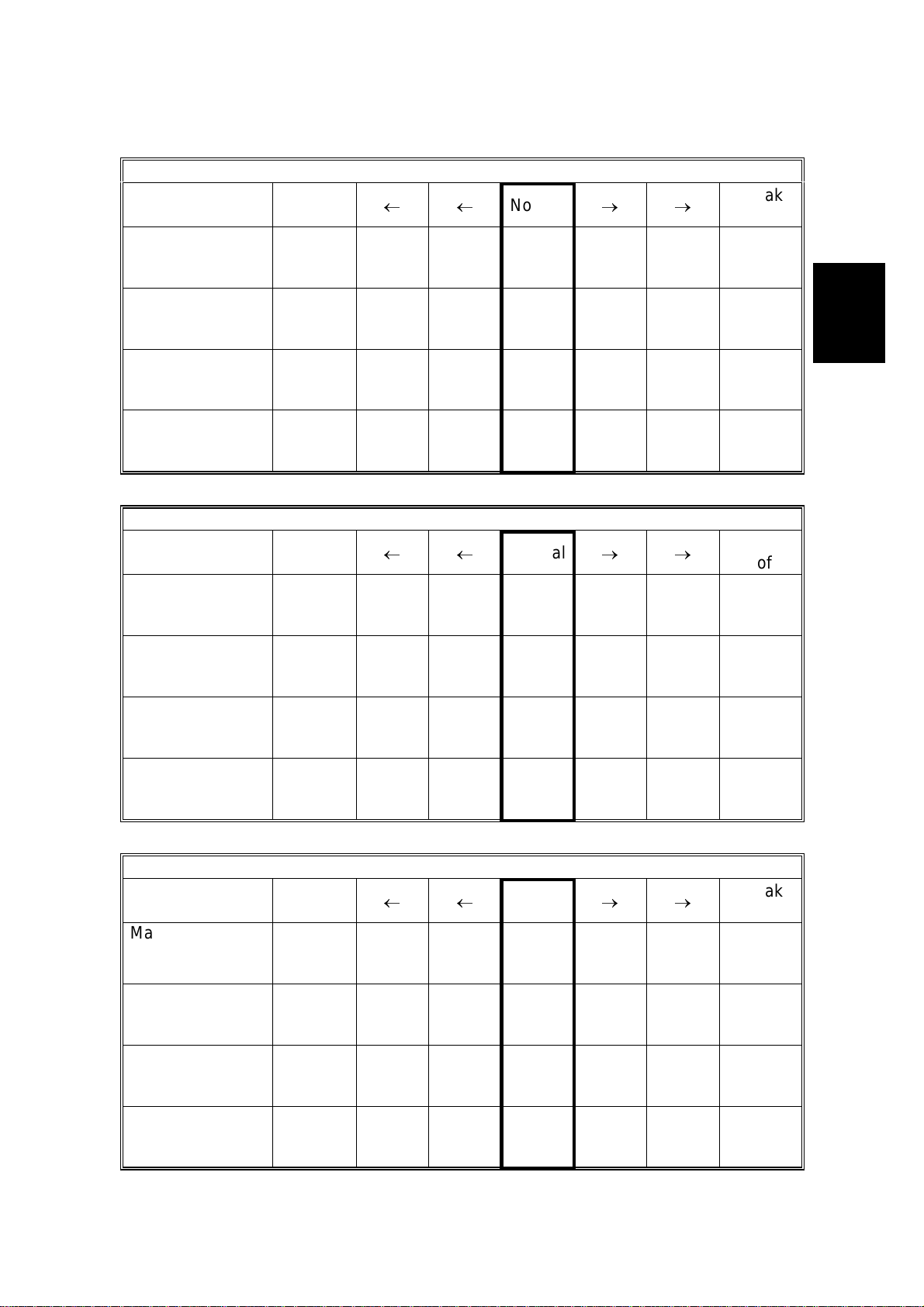

Filtering

There are two software filters: MTF and smoothing, as in the NAD. There are four

MTF filter types: filter strength for main scan direction, filter strength for sub scan

direction, filter coefficient for main scan direction, and filter coefficient for sub scan

direction. These filters can be adjusted with SP mode.

When the filter is stronger in the main scan direction, lines parallel to the feed

direction are emphasized. When the filter is stronger in the sub scan direction, lines

at right angles to the feed direction are emphasized.

The relationship between the filter coefficient and the filter strength is as follows.

MTF filter coefficient

(Weak) (Strong)

0 ® 1 ® 2 ® 3 ® 4 ® 5 ® 6 ® 7 ® 8 ® 9 ® 10 ® 11 ® 12 ® 13 ® 14 ® 15

MTF filter strength

(Weak) 0 ® 1 ® 2 ® 3 ® 4 ® 5 ® 6 ® 7 (Strong)

Smoothing filter coefficient

(Weak) 0 ® 1 ® 2 ® 3 ® 4 ® 5 ® 6 ® 7 (Strong)

It is difficult to explain how to use the filter coefficient and filter strengths to control

MTF and smoothing. Refer to the following charts to determine how to make the

filters weaker or stronger. The values in the bold columns are the default settings.

Text mode: 25 ~ 64 %

MTF strength Strong

(Sharp)

Main scan:

Filter coefficient

(SP4903-11)

Sub scan:

Filter coefficient

(SP4903-41)

Main scan:

Filter Strength

(SP4903-20)

Sub scan:

Filter Strength

(SP4903-50)

9 15141210 9 9

11 13 13 12 12 12 10

3 22222 2

3 22222 2

¬¬

Normal

®®

Weak

(Soft)

2-6

Page 28

14 January, 2000 IMAGE PROCESSING

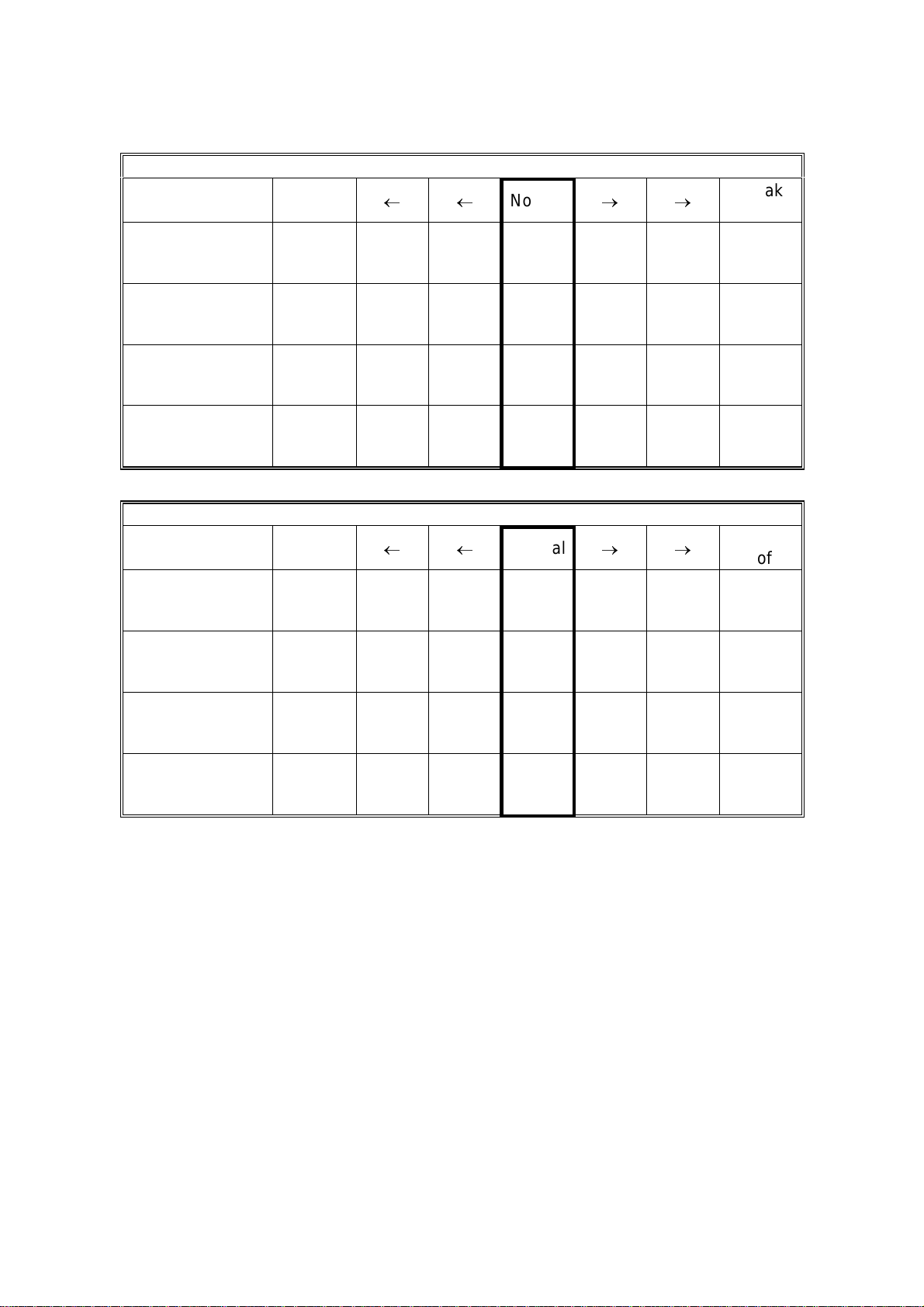

Text mode: 65 ~ 154 %

MTF strength

Strong

(Sharp)

¬¬

Normal

®®

Weak

(Soft)

Main scan:

Filter coefficient

9 9 15 14 12 10 9

(SP4903-12)

Sub scan:

Filter coefficient

13 11 13 13 13 13 13

(SP4903-42)

Main scan:

Filter Strength

3 32222 2

(SP4903-21)

Sub scan:

Filter Strength

3 32222 2

(SP4903-51)

Text mode: 155 ~ 400 %

MTF strength

Strong

(Sharp)

¬¬

Normal

®®

Weak

(Soft)

Main scan:

Filter coefficient

10 9 9 15 14 12 10

(SP4903-13)

Sub scan:

Filter coefficient

13 13 11 13 13 13 13

(SP4903-43)

Main scan:

Filter Strength

3 33222 2

(SP4903-22)

Sub scan:

Filter Strength

3 33222 2

(SP4903-52)

Detailed

Descriptions

Text mode: Notch 1 (lightest image density setting), 65 ~ 154 %

MTF strength

Strong

(Sharp)

¬¬

Normal

Main scan:

Filter coefficient

9 9 15 14 12 10 9

(SP4903-14)

Sub scan:

Filter coefficient

13 11 13 13 13 13 13

(SP4903-44)

Main scan:

Filter Strength

4 43333 3

(SP4903-23)

Sub scan:

Filter Strength

4 43333 3

(SP4903-53)

2-7

®®

Weak

(Soft)

Page 29

IMAGE PROCESSING 14 January, 2000

Photo mode: (when MTF filtering is selected with SP4903-3)

MTF strength

Strong

(Sharp)

¬¬

Normal

®®

Weak

(Soft)

Main scan:

Filter coefficient

9 9 15 14 12 10 9

(SP4903-15)

Sub scan:

Filter coefficient

13 11 13 13 13 13 13

(SP4903-48)

Main scan:

Filter Strength

2 21111 1

(SP4903-24)

Sub scan:

Filter Strength

2 21111 1

(SP4903-54)

Text/Photo mo de

MTF strength

Strong

(Sharp)

¬¬

Normal

®®

Weak

(Soft)

Main scan:

Filter coefficient

9141098109

(SP4903-17)

Sub scan:

Filter coefficient

10 13 13 10 9 13 10

(SP4903-47)

Main scan:

Filter Strength

2 11110 0

(SP4903-25)

Sub scan:

Filter Strength

2 11110 0

(SP4903-55)

2-8

Page 30

14 January, 2000 IMAGE PROCESSING

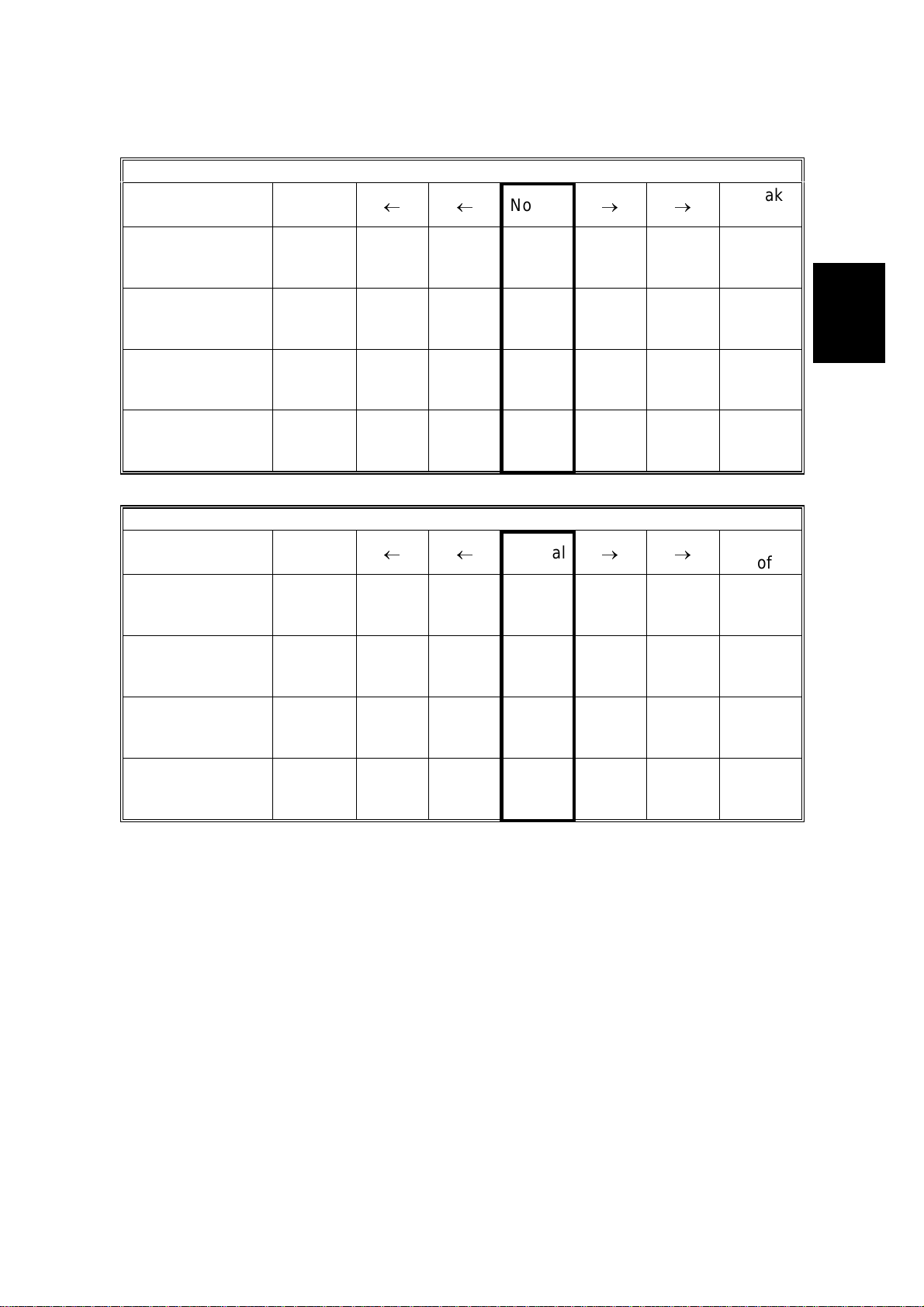

Low density mode

MTF strength

Strong

(Sharp)

¬¬

Normal

®®

Weak

(Soft)

Main scan:

Filter coefficient

14 12 10 9 9 14 10

(SP4903-18)

Sub scan:

Filter coefficient

13 13 13 13 10 13 13

(SP4903-45)

Main scan:

Filter Strength

3 33332 2

(SP4903-26)

Sub scan:

Filter Strength

3 33332 2

(SP4903-56)

Copied original mode

MTF strength

Strong

(Sharp)

¬¬

Normal

®®

Weak

(Soft)

Main scan:

Filter coefficient

9 9 12 10 9 9 14

(SP4903-19)

Sub scan:

Filter coefficient

13 10 13 13 13 10 13

(SP4903-46)

Main scan:

Filter Strength

3 32222 1

(SP4903-27)

Sub scan:

Filter Strength

3 32222 1

(SP4903-57)

Detailed

Descriptions

2-9

Page 31

14 January, 2000 INSTALLATION REQUIREMENTS

3. INSTALLATION PROCEDURE

3.1 INSTALLATION REQUIREMENTS

3.1.1 ENVIRONMENT

1. Temperature Range:

2. Humidity Range:

3. Ambient Illumination:

4. Ventilation:

5. Ambient Dust:

6. Avoid an area which is exposed to sudden temperature changes. This includes:

1) Areas directly exposed to cool air from an air conditioner.

2) Areas directly exposed to heat from a heater.

7. Do not place the machine in an area where it will be exposed to corrosive

gases.

8. Do not install the machine at any location over 2,000 m (6,500 ft.) above sea

level.

9. Place the copier on a strong and level base. (Inclination on any side should be

no more than 5 mm.)

10. Do not place the machine where it may be subjected to strong vibrations.

10°C to 30°C (50°F to 86°F)

15% to 80% RH

Less than 1,500 lux (do not expose to direct

sunlight.)

Room air should turn over at least 30

m3/hr/person

Less than 0.10 mg/m3 (2.7 x 10 -6 oz/yd3)

Installation

3.1.2 MACHINE LEVEL

Front to back: Within 5 mm (0.2") of level

Right to left: With in 5 mm (0.2") of level

3-1

Page 32

INSTALLATION REQUIREMENTS 14 January, 2000

3.1.3 MINIMUM SPACE REQUIREMENTS

Place the copier near the power source, providing clearance as shown:

C

A: In Front: Over 75 cm (29.6")

B: Left: Over 10 cm (4")

C: To Rear: Over 10 cm (4")

D: Right: Over 10 cm (4")

B

A

A284I501.WMF

D

560 mm (22")

A284I504.WMF

NOTE:

985 mm (38.8")

865 mm (34.1")

600 mm (23.6")

540 mm

(21.3")

360 mm

(14.2")

530 mm

(20.9")

760 mm (26.4")

610 mm (24")

180 mm

(7")

A284I502.WMF

A284I503.WMF

The 75 cm recommended for the space at the front is for pulling out the

paper tray only. If an operator stands at the front of the copier, more space

is required.

3-2

Page 33

14 January, 2000 INSTALLATION REQUIREMENTS

3.1.4 POWER REQUIREMENTS

I

CAUTION

1. Make sure that the wall outlet is near the copier and easily accessible.

Make sure the plug is firmly inserted in the outlet.

2. Avoid multi-wiring.

3. Be sure to ground the machine.

1. Input voltage level: 120 V, 60 Hz: More than 10 A

2. Permissible voltage fluctuation: ±10 %

3. Do not set anything on the power cord.

Installation

3-3

Page 34

INSTALLATION FLOW CHART 14 January, 2000

3.2 INSTALLATION FLOW CHART

The following flow chart shows how to install the optional units more efficiently.

Unpack the copier

Does the user require the Paper Tray Unit, LCT, or Finisher?

Yes No

Place the copier on the paper tray unit

Install the paper tray unit

Install the copier

Install the bridge unit (if required)

If the user requires the one-bin tray:

Remove the scanner unit

Install the one-bin tray

Replace the scanner unit

Install the remaining options in any order

A284I515.WMF

Bridge Unit: Needed for the finishers and the external output tray

Paper Tray Unit: Needed for the LCT and finishers

Other requirements: See Overall Machine Information – Installation Option Table

3-4

Page 35

14 January, 2000 COPIER INSTALLATION

3.3 COPIER INSTALLATION

3.3.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Operation Panel Decal.......................................................... 1

2. Paper Size Decal.................................................................. 1

3. Model Name Decal (-10 machines)....................................... 1

4. Operation Panel Brand Sticker (-10 machines)..................... 1

5. NECR – English (-17 machine)............................................. 1

6. Cushion................................................................................. 1

7. Operation Instructions – System Setting............................... 1

8. Operation Instructions – Copy Reference............................. 1

9. Operation Instructions – Quick Reference............................ 1

Installation

3-5

Page 36

COPIER INSTALLATION 14 January, 2000

3.3.2 INSTALLATION PROCEDURE

[B]

[A]

A284I505.WMF

[C]

[D]

A284I506.WMF

!

CAUTION

A284I507.WMF

Unplug the machine power cord before starting the following procedure.

If the optional paper tray unit is going to be installed now, put the copier on the

paper tray unit first, then install the paper tray unit, then install the copier.

NOTE: Keep the shipping retainers after installing the machine. They will be

reused if the machine is moved to another location in the future.

1. Remove the tapes on the exterior of the copier.

2. Open the duplex unit and open the upper right cover [A].

3. Remove the pin [B].

4. Pull out the paper trays and remove the bottom plate stoppers [C].

5. Install the middle front cover [D] which is in the second paper tray.

NOTE: If the optional paper tray unit is installed, this step is done while

installing the paper tray unit.

3-6

Page 37

14 January, 2000 COPIER INSTALLATION

[B]

[A]

[E]

[C]

A284I508.WMF

A284I516.WMF

Installation

[D]

A284I500.WMF

[F]

6. Open the front cover.

7. Push down the lever (1). Then pull the PCU [A] out a small distance (2), and

move the development unit [B] to the left (3) so that the development unit is

away from the drum, then slide out the PCU completely.

8. Remove three clamps [C].

9. Loosen the screw [D] and rotate the bracket [E] as shown.

10. Slide out the development unit [F].

3-7

Page 38

COPIER INSTALLATION 14 January, 2000

[A]

[B]

[C]

[B]

A284I509.WMF

[D]

A284I511.WMF

11. Remove the entrance seal plate [A] (2 clamps).

12. Remove two screws [B] and take out the development roller unit [C].

13. Pour all developer [D] into the development unit uniformly.

A284I510.WMF

3-8

Page 39

14 January, 2000 COPIER INSTALLATION

[A]

[A]

A284I512.WMF

[F]

[E]

[D]

[C]

14. Reassemble the development unit.

NOTE:

Make sure that the development side seals [A] are set inside the

development unit case.

15. Reassemble the machine.

NOTE:

When reinstallin g the PCU, make sure it is installed properly.

Otherwise, black copies may be printed.

Installation

[B]

A284I513.WMF

16. Push lever [B] to the side, raise the toner bottle holder lever [C], and pull the

toner bottle holder [D] out.

17. Shake the toner bottle well.

NOTE:

Do not remove the toner bottle cap [E] until after shaking.

18. Unscrew the bottle cap and insert the bottle into the holder.

NOTE:

Do not touch the inner bottle cap [F].

19. Reposition the holder and press down the holder lever to secure the bottle.

3-9

Page 40

COPIER INSTALLATION 14 January, 2000

[C]

[C]

[A]

A284I517.WMF

[B]

A284I514.WMF

20. Turn on the main power switch.

21. After the fusing warm-up period, enter the SP mode.

1) Press the “Clear Mode” key.

2) Enter “107” using the numeric keys.

3) Hold down the “Clear/Stop” key for more than 3 seconds.

4) Select “1” (copier).

NOTE:

Do not enter SP mode during the fusing warm-up period (the LED of

the start key is red during this period)

22. Perform the TD sensor initial setting as follows:

1) Enter “2-801” and press the “Enter” key.

2) Press “1” to start the TD sensor initial setting.

NOTE:

The machine will automatically stop when TD sensor initial setting is

completed, and the TD sensor output voltage will appear on the LCD.

23. Perform the process control initial setting using SP2-805.

24. When loading paper bigger than A4 (11" x 8.5") in the 1st paper tray, attach the

cushion [A] to the paper tray as shown.

NOTE:

1) This procedure is required only for the 1st paper tray.

2) Make sure that the pad is not attached over the ribs [B].

25. Change the side fences and end fence to match the paper size that will be

used. Then pull the paper tray out and load paper into it.

26. Enter the proper paper size for each paper tray using UP mode.

27. Attach the appropriate paper size decal [C] to the paper tray.

NOTE:

Paper size decals are also used for the optional paper tray unit. Keep

any remaining decals for use with the paper tray unit.

28. Check the copy quality and machine operation (refer to the “Replacement and

Adjustment - Copy Adjustment” section of the service manual).

3-10

Page 41

14 January, 2000 PAPER TRAY UNIT INSTALLATION

3.4 PAPER TRAY UNIT INSTALLATION

3.4.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Joint Bracket......................................................................... 1

2. Front Stand........................................................................... 1

3. Rear Stand............................................................................ 1

4. Stand Bracket ....................................................................... 1

5. Knob Screw – M3.................................................................. 1

6. Knob Screw – M4x10............................................................ 1

7. NECR – Multi-language (-17, -27 machines)........................ 1

8. Installation Procedure........................................................... 1

Installation

3-11

Page 42

PAPER TRAY UNIT INSTALLATION 14 January, 2000

3.4.2 INSTALLATION PROCEDURE

A682I557.WMF

[A]

A682I504.WMF

I

CAUTION

Unplug the main machine power cord before starting the following

procedure.

1. Unpack the paper tray unit. Then remove the tapes.

2. Remove the paper trays [A] from the base copier.

3-12

Page 43

14 January, 2000 PAPER TRAY UNIT INSTALLATION

[D]

[B]

[C]

[A]

[B]

Installation

A682I505.WMF

[F]

[E]

[G]

A682I514.WMF

3. Place the main machine on the paper tray unit [A] with the pegs [B] fitting into

main machine’s peg holes.

NOTE:

1) The machine must be held is as shown in the above illustration.

2) Do not hold the scanner unit.

4. Attach the spring washer [C] to the short knob screw [D]. Then, secure the

paper tray unit.

5. Open the right cover of the paper tray unit [E].

[H]

6. Secure the joint bracket [F] (1 long knob screw).

7. Remove the connector cover [G] of the main machine.

8. Connect the paper tray unit harness [H] to the main machine and reinstall the

connector cover.

3-13

Page 44

PAPER TRAY UNIT INSTALLATION 14 January, 2000

[B]

[A]

A682I516.WMF

[B]

[C]

A682I511.WMF

9. Install the middle front cover [A] which in the 2 nd paper tra y.

10. Install the front and rear stands [B] as shown above.

11. Install the stand bracket [C].

A682I509.WMF

3-14

Page 45

14 January, 2000 PAPER TRAY UNIT INSTALLATION

[A]

[A]

Installation

A682I500.WMF

12. Load paper into the paper tray and install the paper trays.

NOTE:

The side and rear fences should be properly positioned using the green

screw driver tool.

13. Attach the appropriate tray decals [A] which are included in the accessory box

for the main machine.

14. Turn on the ac switch.

15. Enter the paper size for each paper tray using a UP mode.

16. Check the machine’s operation and copy quality.

3-15

Page 46

1-BIN TRAY UNIT INSTALLATION 14 January, 2000

3.5 1-BIN TRAY UNIT INSTALLATION

3.5.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Grounding Bracket................................................................ 1

2. Connector Cover................................................................... 1

3. Base Cover........................................................................... 1

4. Copy Tray ............................................................................. 1

5. Copy Tray Bracket................................................................ 1

6. Snap Ring............................................................................. 1

7. Mylar Strip............................................................................. 2

8. Stepped Screw – M3x8......................................................... 5

9. Screw – M3x8....................................................................... 1

10. Tapping Screw – M3x6 ......................................................... 2

11. Tapping Screw – M3x14 ....................................................... 1

12. Tapping Screw – M3x8 ......................................................... 1

13. NECR.................................................................................... 1

14. Installation Procedure ........................................................... 1

3-16

Page 47

14 January, 2000 1-BIN TRAY UNIT INSTALLATION

3.5.2 INSTALLATION PROCEDURE

[A]

[B]

[E]

[C]

[D]

Installation

A684I001.WMF

NOTE:

The Interchange Unit (A690) must be installed before installing the 1-bin

tray unit.

I

CAUTION

Unplug the main machine power cord before starting the following

procedure.

1. Remove the scanner unit.

NOTE:

If the ARDF is installed, remove the ARDF before removing the

scanner unit.

1) Remove the stand rear cover [A] (2 screws).

2) Disconnect the scanner I/F board [B] and the power connector [C].

3) Disconnect the harness [D].

4) Disconnect the scanner I/F harness [E].

3-17

Page 48

1-BIN TRAY UNIT INSTALLATION 14 January, 2000

[A]

[C]

[C]

[B]

A684I302.WMF

A684I504.WMF

5) Remove the scanner unit [A] (2 knob screws).

NOTE:

1) Hold the scanner unit as shown in the above illustration. Otherwise,

scanner unit may be damaged.

2) Make sure the harnesses are not damaged by the edges of the

opening [B].

3) After removing the scanner, keep it in a flat level place.

6) Remove four plates [C] (1 screw each).

7) Remove the scanner unit plate [D] (1 screw).

[D]

[E]

A684I505.WMF

2. Unpack the 1-bin tray unit and remove the tapes.

3. Remove the paper exit cover [E] (4 screws).

3-18

Page 49

14 January, 2000 1-BIN TRAY UNIT INSTALLATION

[C]

[B]

A684I491.WMF

[A]

[H]

[F]

4. Cut away two covers [A] from the base cover [B].

NOTE:

Trim off any remaining unevenness from the edges.

5. Install the base cover (3 stepped screws).

[E]

A684I492.WMF

[D]

Installation

[G]

6. Place the 1-bin tray unit [C] on the base cover.

NOTE:

Make sure to hold the 1-bin tray unit at the both sides but never hold

the unit at the center.

7. Secure the 1-bin tray unit (1 screw [D] - M3x10).

8. Remove the cover [E].

9. Install the grounding bracket [F] (2 screws - M3x6).

10. Connect the harness [G].

11. Install the connector cover [H] (1 screw - M3x8).

3-19

Page 50

1-BIN TRAY UNIT INSTALLATION 14 January, 2000

[B]

[C]

[A]

A684I493.WMF

[D]

12. Install the copy tray.

- When the Bridge Unit (A688) is not installed -

1) Attach the decal [A], as shown.

2) Install two stepped screws [B], then attach the copy tray [C].

[E]

[F]

A684I494.WMF

- When the Bridge Unit (A688) is installed -

1) Open the right cover of the bridge unit.

2) Install the copy tray bracket [D] (1 screw).

3) Install the copy tray [E] (1 snap ring).

4) Attach the decal [F], as shown.

3-20

Page 51

14 January, 2000 1-BIN TRAY UNIT INSTALLATION

[C]

[B]

[A]

[A]

[D]

[B]

[E]

[G]

[A]

A684I515.WMF

[F]

13. Attach two mylar strips [A] to the scanner stand [B], as shown.

A684I303.WMF

A684I495.WMF

Installation

[G]

14. Change the height of the scanner stand.

1) Remove the stand cover [C] (1 screw).

2) Remove two screws [D] which are securing the scanner stand [B].

3) Raise the scanner stand position.

4) Secure the stand.

5) Reinstall the stand cover.

15. Reinstall the scanner unit plate [E] (1 screw).

NOTE:

The scanner unit plate should be positioned at the rear, as shown [F].

16. Reinstall four plates [G] (1 screw each).

17. Reinstall the scanner unit (2 knob screws).

18. Turn on the ac switch and check the 1-bin tray unit operation.

3-21

Page 52

BRIDGE UNIT INSTALLATION 14 January, 2000

3.6 BRIDGE UNIT INSTALLATION

3.6.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Stepped Screw...................................................................... 2

2. Connector Cover................................................................... 1

3. Entrance Mylar...................................................................... 2

4. Exit Mylar.............................................................................. 2

5. NECR.................................................................................... 1

6. Installation Procedure........................................................... 1

3-22

Page 53

14 January, 2000 BRIDGE UNIT INSTALLATION

3.6.2 INSTALLATION PROCEDURE

A688I401.WMF

A688I500.WMF

[C]

[A]

[D]

Installation

[E]

[B]

A688I407.WMF

I

CAUTION

Unplug the main machine power cord before starting the following

procedure.

1. Unpack the bridge unit. Then remove the tapes.

2. Remove the inner tray [A].

3. Remove three covers [B].

If the optional external output tray (A825) will be installed instead of a

finisher, do step 4.

4. Remove the two covers [C].

5. Remove the cover [D] (1 screw).

6. Remove the cap [E].

3-23

Page 54

BRIDGE UNIT INSTALLATION 14 January, 2000

[A]

[B]

A688I406.WMF

[F]

[C]

[E]

A688I402.WMF

[D]

A688I404.WMF

7. Attach two mylars [A] to the paper entrance area of the bridge unit as shown.

8.

If the optional finisher is installed:

Attach two mylars [B] to the bridge unit as shown.

9. Remove the cover [C].

10. Install the bridge unit (2 screws) [D].

11. Connect the bridge unit I/F harnesses [E].

12. Install the connector cover [F].

13. Turn on the ac switch and check the bridge unit operation.

3-24

Page 55

14 January, 2000 AUT O REVERSE DO CUMENT FEEDER INSTALLATION

3.7 AUTO REVERSE DOCUMENT FEEDER INSTALLATION

3.7.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Stepped Screw...................................................................... 2

2. Knob Screw........................................................................... 2

3. Original Tray ......................................................................... 1

4. Screw – M4x17..................................................................... 2

5. NECR.................................................................................... 1

6. Installation Procedure........................................................... 1

Installation

3-25

Page 56

AUTO REVERSE DOCUMENT FEEDER INSTALLATION 14 January, 2000

3.7.2 INSTALLATION PROCEDURE

A680I500.WMF

I

CAUTION

[B]

[A]

A680I501.WMF

Unplug the main machine power cord before starting the following

procedure.

[C]

[A]

1. Unpack the ARDF. Then remove the tapes on the exterior of the ARDF.

2. Tighten the two stud screws [A].

3. Mount the ARDF by aligning the screw holes [B] in the ARDF over the stud

screws, and slide the ARDF to front as shown.

NOTE:

When mounting the ARDF, hold it by hand as shown in the illustration.

Holding it in another way may damage the ARDF.

4. Secure the ARDF (2 knob screws [C]).

3-26

Page 57

14 January, 2000 AUT O REVERSE DO CUMENT FEEDER INSTALLATION

[D][C]

[B]

[A]

A680I502.WMF

5. Remove the two seals [A].

6. Install the original tray [B] (2 screws).

7. Attach the original direction decal [C] to the DF table as shown.

8. Connect the I/F harness [D] to the main machine.

9. Turn on the ac switch.

10. Check the ARDF operation and copy quality.

Installation

3-27

Page 58

LCT INSTALLATION 14 January, 2000

3.8 LCT INSTALLATION

3.8.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Joint Pin................................................................................ 2

2. Stepped Screw M3x18.......................................................... 4

3. Magnet Cover ....................................................................... 1

4. NECR (-17, -27 machines).................................................... 1

5. Installation Procedure........................................................... 1

3-28

Page 59

14 January, 2000 LCT INSTALLATION

3.8.2 INSTALLATION PROCEDURE

A683I501.WMF

Installation

A683I500.WMF

I

CAUTION

[D]

A683I502.WMF

[A]

Unplug the main machine power cord before starting the following

procedure.

NOTE:

The Paper Tray Unit (A682) must be installed before installing the LCT.

1. Unpack the LCT and remove the tapes.

2. Open the right cover of the paper tray unit [A].

[E]

[D]

[C]

[B]

3. Open the lower right cover [B] and cut the holding band [C].

NOTE:

When cutting the holding band, the upper part of the band should be

cut as shown. Otherwise, paper jams may occur.

4. Remove the lower right cover.

5. Remove two caps [D] and a cover [E].

3-29

Page 60

LCT INSTALLATION 14 January, 2000

[A]

[F]

[E]

[B]

[D]

[C]

A683I503.WMF

6. Install the joint pins [A].

7. Push the release lever [B] and slide the LCT to the right (front view).

8. Hang the LCT [C] on the joint pins, then secure the brackets [D] (4 screws).

9. Return the LCT to the previous position and connect the LCT cable [F].

10. Open the LCT cover and load the paper.

11. Turn on the ac switch and check the LCT operation.

3-30

Page 61

14 January, 2000 1,000-SHEET FINISHER INSTALLATION

3.9 1,000-SHEET FINISHER INSTALLATION

3.9.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Front Stand........................................................................... 1

2. Rear Stand............................................................................ 1

3. Knob Screw........................................................................... 1

4. Screw – M4x12..................................................................... 6

5. NECR (-17 machine)............................................................. 1

6. Installation Procedure........................................................... 1

Installation

3-31

Page 62

1,000-SHEET FINISHER INSTALLATION 14 January, 2000

3.9.2 INSTALLATION PROCEDURE

A681I503.WMF

A681I504.WMF

I

CAUTION

Unplug the main machine power cord before starting the following

procedure.

NOTE:

The bridge unit (A688) and paper tray unit (A682) must be installed before

installing this finisher.

1. Unpack the finisher and remove the tapes.

3-32

Page 63

14 January, 2000 1,000-SHEET FINISHER INSTALLATION

[A]

[C]

A681I505.WMF

[B]

Installation

[D]

[E]

A681I506.WMF

1. Install two screws [A] loosely.

2. Hang the front stand [B] and rear stand [C] on the screws which were installed

in step 2.

3. Secure the front and rear stands (6 screws, including the two screws [A]).

4. Pull out the stapler unit [D].

5. Draw out the locking lever [E] (1 screw).

6. Align the finisher on the stands, and lock it in place by pushing the locking

lever.

7. Secure the locking lever (1 screw) and push the stapler unit into the finisher.

3-33

Page 64

1,000-SHEET FINISHER INSTALLATION 14 January, 2000

[E]

[F]

[B]

[C]

[A][D]

A681I500.WMF

8. Secure the finisher (1 screw).

9. Adjust the securing knobs [A] under the front and rear stand until the finisher is

perpendicular to the floor.

10. Install the shift tray [B] (1 snap ring).

NOTE:

Make sure that the three pegs [C] fit into the slots [D] properly.

11. Connect the finisher cable [E] to the main machine.

12. Attach the staple position decal [F] to the ARDF as shown.

13. Turn on the main power switch and check the finisher operation.

3-34

Page 65

14 January, 2000 3,000-SHEET FINISHER INSTALLATION

3.10 3,000-SHEET FINISHER INSTALLATION

3.10.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Front Joint Bracket................................................................ 1

2. Rear Joint Bracket ................................................................ 1

3. Entrance Guide Plate............................................................ 1

4. Shift Tray............................................................................... 1

5. Exit Guide Mylar (A229 copier only)...................................... 1

6. Shift Tray Guide.................................................................... 1

7. Staple Position Decal............................................................ 1

8. Screw – M3x6....................................................................... 2

9. Screw – M4x14..................................................................... 4

10. Screw – M3x8 ....................................................................... 4

11. Cushion................................................................................. 1

12. Upper Grounding Plate ......................................................... 1

13. Lower Grounding Plate ......................................................... 2

14. NECR (-17 machine)............................................................. 1

15. Installation Procedure ........................................................... 1

Installation

3-35

Page 66

3,000-SHEET FINISHER INSTALLATION 14 January, 2000

3.10.2 INSTALLATION PROCEDURE

A697I506.WMF

I

CAUTION

Unplug the main machine power cord before starting the following

procedure.

NOTE:

The bridge unit (A688) and paper tray unit (A682) must be installed before

installing this finisher.

1. Unpack the finisher and remove the tapes.

A697I507.WMF

3-36

Page 67

14 January, 2000 3,000-SHEET FINISHER INSTALLATION

[C]

[B]

[A]

[D]

A697I508.WMF

Installation

[E]

[F]

A697I755.WMF

2. Install the front joint bracket [A] and rear joint bracket [B] (2 screws each).

3. Attach the upper grounding plate [C] (1 screw).

4. Peel off the backing of the double sided tape that is attached to the lower

grounding plate [D].

5. Attach one lower grounding plate to the center position of the paper tray unit as

shown.

6. Attach the cushion [E] to the plate as shown.

7. Install the entrance guide plate [F] (2 screws).

3-37

Page 68

3,000-SHEET FINISHER INSTALLATION 14 January, 2000

[C]

[H]

[G]

A697I534.WMF

[D]

[B]

[A]

[F]

A697I756.WMF

[E]

8. If the customer requires the punch unit, install it now, before attaching the

finisher to the machine. See Punch Unit Installation.

9. Open the front door of the finisher, and remove the screw [A] which secures the

locking lever [B]. Then pull the locking lever.

10. Align the finisher on the joint brackets, and lock it in place by pushing the

locking lever.

NOTE:

Before securing the locking lever, make sure that the top edges of the

finisher and the copier are parallel from front to rear as shown [C].

11. Secure the locking lever (1 screw) and close the front door.

12. Install the sub shift tray [D] on the shift tray. If the customer does not wish to

install it on the shift tray, store it at location [E].

NOTE:

The shift tray guide is required to assist in proper paper stacking.