Ricoh AFICIO 200 Service Manual AD1

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main switch is turned off.

4. If any adjustment or operation check has to be made with exterior

covers off or open while the main switch is turned on, keep hands away

from electrified or mechanically driven components.

5. If the Start key is pressed before the copier completes the warm-up

period (the Start key starts blinking red and green alternatively), keep

hands away from the mechanical and the electrical components as the

copier starts making copies as soon as the warm-up period is

completed.

6. The inside and the metal parts of the fusing unit become extremely hot

while the copier is operating. Be careful to avoid touching those

components with your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your

eyes by accident, it may cause temporary eye discomfort. Try to remove

with eye drops or flush with water as first aid. If unsuccessful, get

medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course

on those models.

2. The RAM board on the system control board has a lithium battery which

can explode if replaced incorrectly. Replace the battery only with an

identical one. The manufacturer recommends replacing the entire RAM

board. Do not recharge or burn this battery. Used batteries must be

handled in accordance with local regulations.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite

suddenly when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later,

do not put more than 100 batteries per sealed box. Storing larger

numbers or not sealing them apart may lead to chemical reactions and

heat build-up.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair

of laser-based optical units in the field. The optical housing unit can only be

repaired in a factory or at a location with the requisite equipment. The laser

subsystem is replaceable in the field by a qualified Customer Engineer. The

laser chassis is not repairable in the field. Customer engineers are therefore

directed to return all chassis and laser subsystems to the factory or service

depot when replacement of the optical subsystem is required.

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

WARNING FOR LASER UNIT

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can

seriously damage your eyes.

CAUTION MARKING:

DANGER

>PS<

DANGER

INVISIBLE LASER RADIATION

WHEN OPEN.

!

AVOID DIRECT EXPOSURE TO

BEAM.

INVISIBLE LASER RADIATION

WHEN DISCONNECT OPTICAL

FIBER CABLE.

!

AVOID DIRECT EXPOSURE TO

BEAM.

>PS<

>PS<

SECTION 1

OVERALL MACHINE

INFORMATION

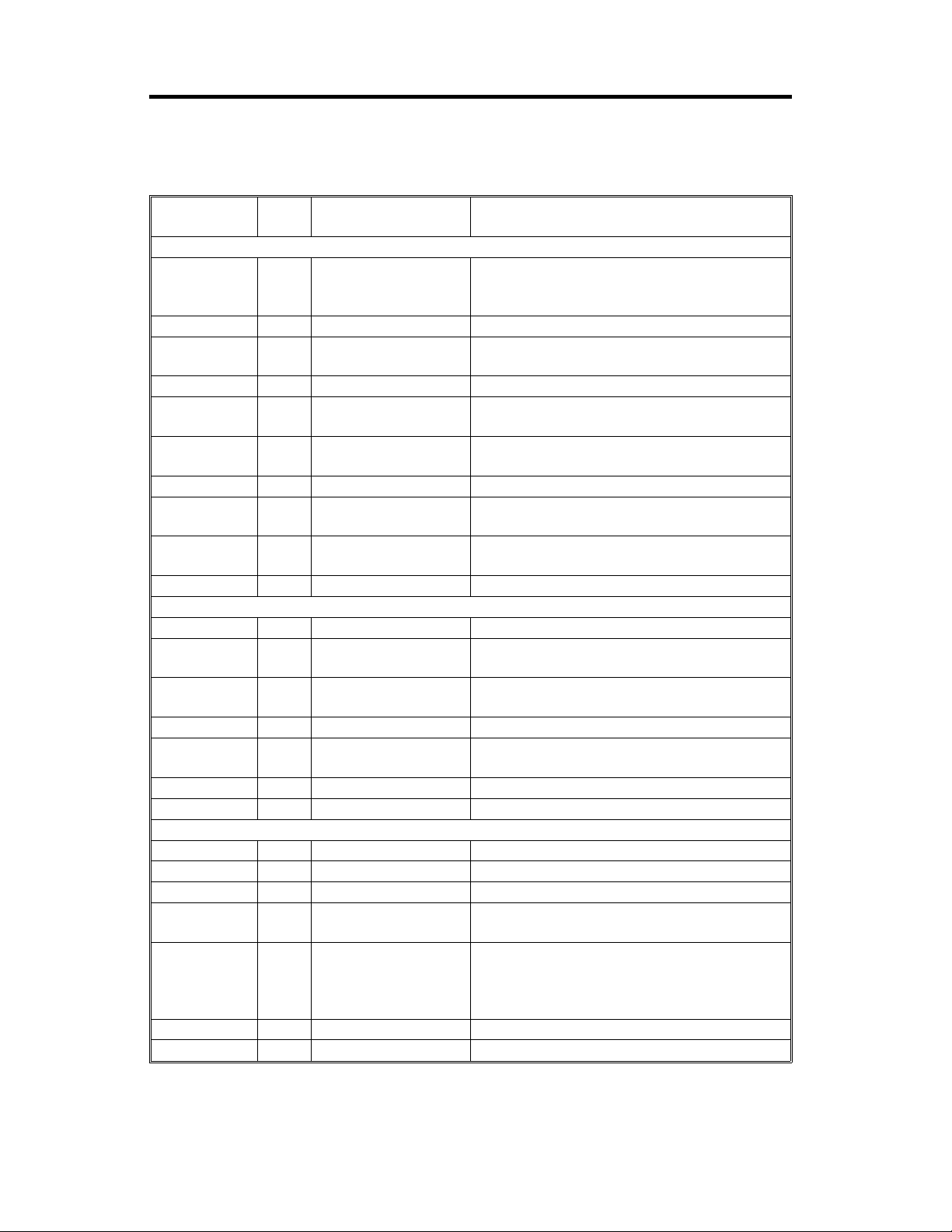

1 August 1996 SPECIFICATIONS

1. SPECIFICATIONS

Configuration: Desktop

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book

Original Size: Maximum A3/11" x 17"

Copy Paper Size: Maximum

A3/11" x 17"

Minimum

A5/8

A6/5

1/2

1/2

" x 5

" x 8

1/2

" sideways (Paper tray)

1/2

" lengthwise (By-pass)

Copy Paper Weight: Paper tray:

2

60 ~ 90 g/m

, 16 ~ 24 lb

By-pass:

2

60 ~ 157 g/m

, 16 ~ 42 lb

Reproduction Ratios: 5 Enlargement and 7 Reduction

A4/A3 Version LT/DLT Version

400%

200%

Enlargement

Full size 100% 100%

Reduction

141%

122%

115%

93%

87%

82%

71%

65%

50%

25%

400%

200%

155%

129%

121%

93%

85%

77%

74%

65%

50%

25%

Zoom: 25% to 400% in 1% steps

Power Source: 120V/60 Hz:

More than 12 A (for North America)

220V ~ 240V/50 Hz:

More than 7 A (for Europe)

220V ~ 240V/60 Hz:

More than 7 A (for Asia)

1-1

SPECIFICATIONS 1 August 1996

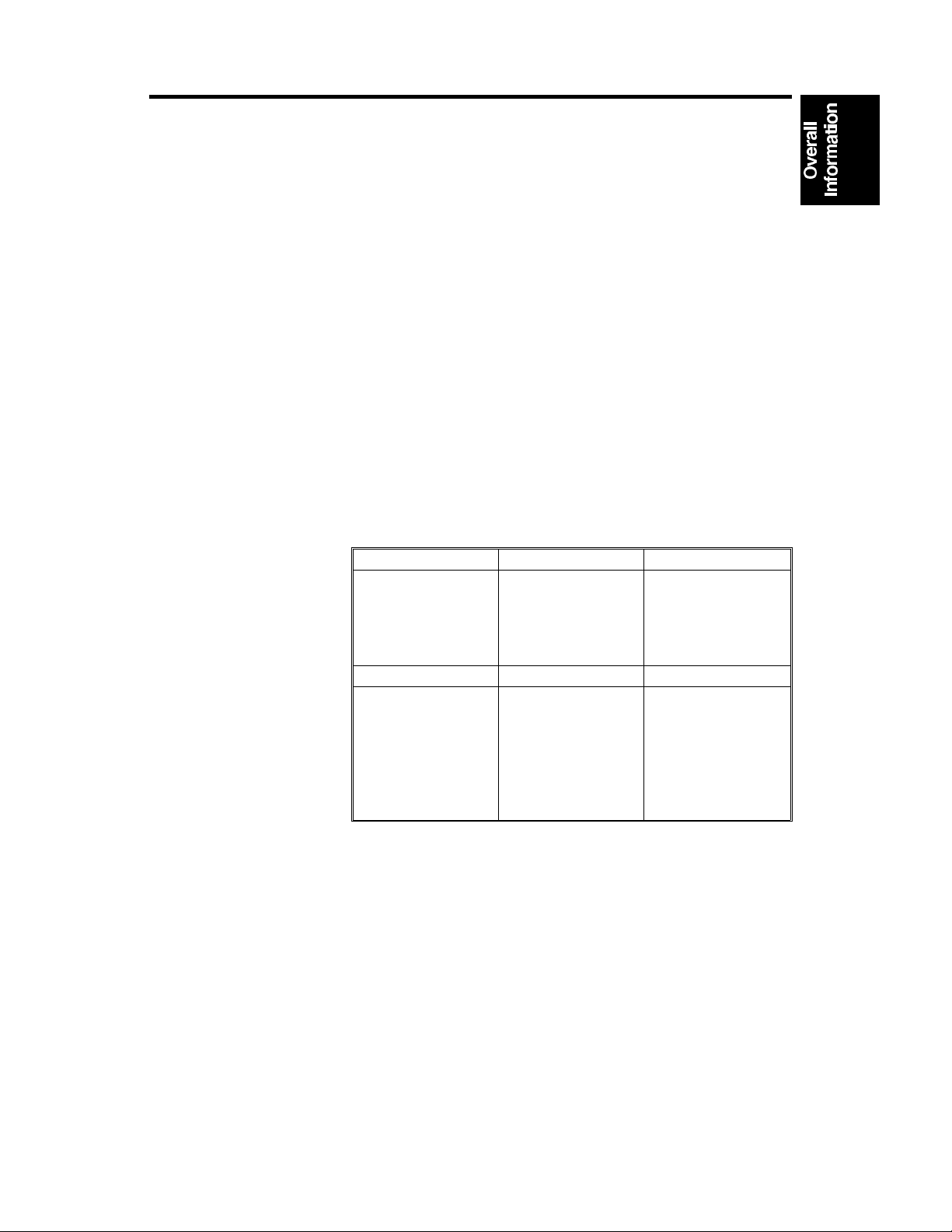

Power Consumption:

Mainframe Onl y Full System

120V 220V ~ 240V 120V 220V ~ 240V

Maximum Less than 1.1 kW Less than 850 W Less than 1.2 kW Less than 1 kW

Copying Approx. 470 W Approx. 500 W Approx. 500 W Approx. 530 W

Warm-up Approx. 1.0 kW Approx. 750 W Approx. 1.0 kW Approx. 750 W

Stand-by Approx. 130 W Approx. 130 W Approx. 140 W Approx. 140 W

Auto Shut Off Approx. 2.0 W Approx. 2.2 W Approx. 2.2 W Approx. 2.4 W

NOTE:

Full System: Mainframe + ADF + Paper Tray Unit + Duplex Tray +

1-bin Sorter

Noise Emission:

Mainframe Onl y Full System

1. Sound Power Level

Copyin g 61.5 dB(A) 64.5 dB(A)

Stand-by 30.0 dB(A) 30.0 dB(A)

2. Sound Pressure Level at the Operator Position

Copyin g 47.5 dB(A) 52.0 dB(A)

Stand-by 17.5 dB(A) 17.5 dB(A)

NOTE:

The above measurements were made in accordance with ISO 7779.

Full System: Mainframe + ADF + Paper Tray Unit + Duplex Tray +

1-bin Sorter

Dimensions (W x D x H): 550 x 580 x 652 mm (21.7" x 22.9" x 25.7")

Measurement Conditions

1) With by-pass feed table closed

2) Without the optional paper tray unit

3) Without the ADF

Weight: Less than 57 kg (126 lb)

Copying Speed in Multicopy mode (copies/minute):

A4 sideways/

11" x 8

No optional memory 15 9 10

With 4MB or 8MB

optional memory

Warm-up Time

"

1/2

20 11 12

Less than 30 seconds (20°C, 68°F): 115V

A3/11" x 17" B4/8

1/2

machine

Less then 35 seconds (20°C, 68°F): 230V

machine

1-2

" x 14"

1 August 1996 SPECIFICATIONS

First Copy Time: Less than 9.8 s (from 1st paper tray to face down

copy tray)

Less than 8.8 s (from 1st paper tray to face up

copy tray)

Copy Number Input: Ten-key pad, 1 to 99 (count up or count down)

Manual Image Density: 7 steps

Automatic Reset: 60 s is the standard setting; it can be changed

with a UP mode.

Auto Shut Off 15 min. is the standard setting; it can be

changed with a UP mode.

Copy Paper Capacity: Paper Tray: 250 sheets

Optional Paper Tray Unit: 500 sheets x 2

Bypass: 100 sheets (A4, B5, A5, B6, 8.5 x 11",

5.5 x 8.5")

10 sheets (A3, B4, 11 x 17", 8 x 13")

1 sheet (non-standard sizes)

Toner Replenishment: Cartridge exchange (216 g/cartridge)

Toner Yield: 8 k copies (A4 sideways, 6% full black, 1 to 1

copying, ADS mode)

•

Optional Equipment:

Platen cover

•

Auto document feeder

•

Paper tray unit with two paper trays

•

1-bin sorter

•

Duplex unit

•

Key counter

•

Tray heater

•

Optical anti-condensation heater

Copy Tray Capacity Face down mode: 500 sheets

Face up mode: 100 sheets

Memory Capacity:

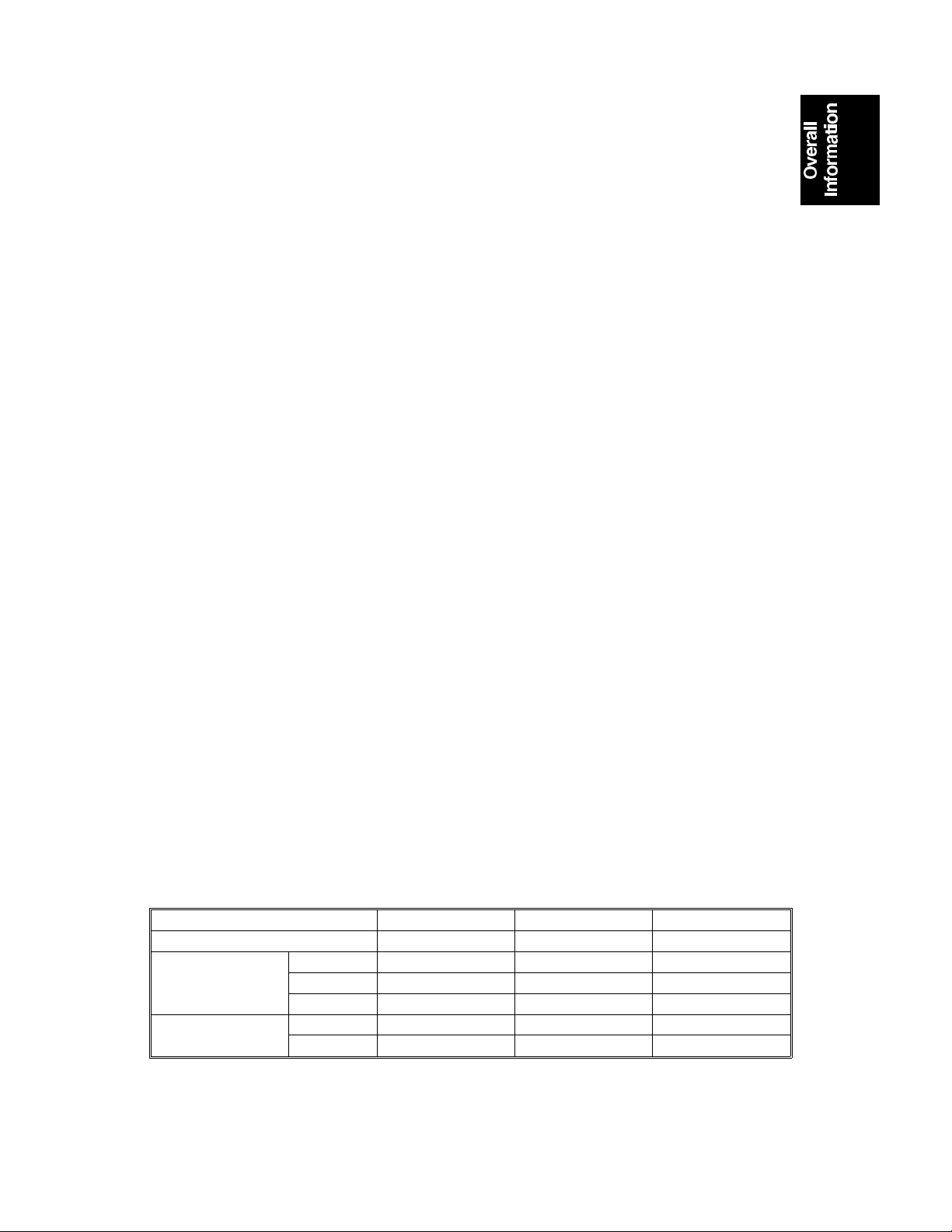

Standard (4 MB) Optional 4 MB Optional 8 MB

Multi duplex copy X O O

Sort, Rotate Sort A4, LT O O O

B4, LG X O O

A3, DLT X O O

Number of pages A4 6% 35 99 99

ITU-T#4154575

X: Not AvailableO: Available

1-3

MACHINE CONFIGURATION 1 August 1996

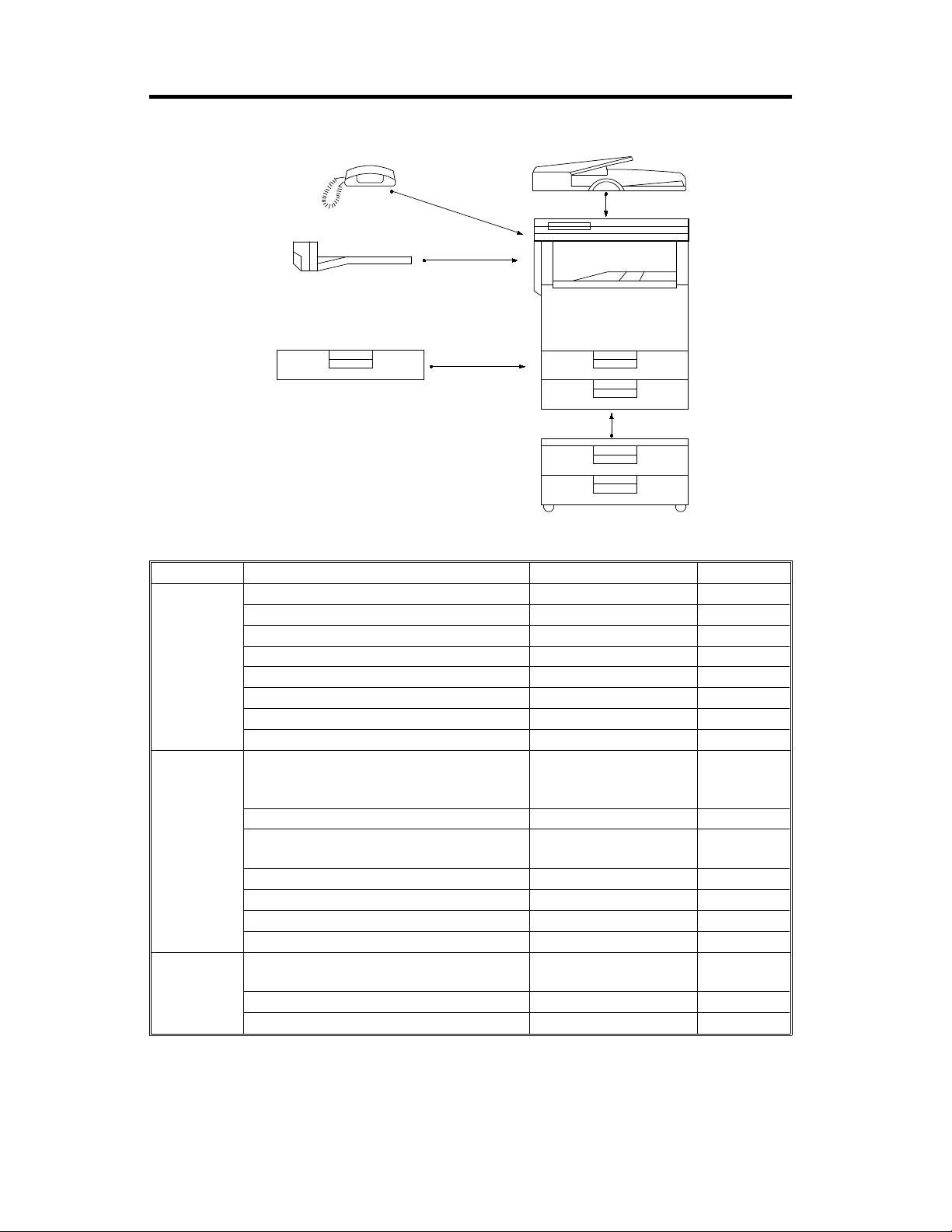

2. MACHINE CONFIGURATION

A

D

B

E

C

F

A193V501.wmf

Version Item Machine Code No.

Copier Copier A193 E

ADF (Option) A628 D

Paper Tray Unit (Opt ion) G697 F

Duplex Unit (Opt i on) G694 C

1-bin Sorter (Option) A629 B

Platen Cover (Option) A645

Memory 4MB (Opti on) A642-01

Memory 8MB (Opti on) A642-02

Fax Fax Controller (Option) A639-01 (115V),

-02(230V),

-03(F rance), -04 (TWN)

Telephone (Opt i on) H160 A

ISDN (Option) A644-01(115V),

-02(230V)

HDD (Option) A641

Memory Card (Option) H130-54

Function Card (Option) H130- 52

Page Memory (Option) A640

Printer Printer Controlle r (O pt i on) A643-00 (1 15V) ,

-01(230V)

PS Option (Option) A643-02

HDD (Option) A643-03

1-4

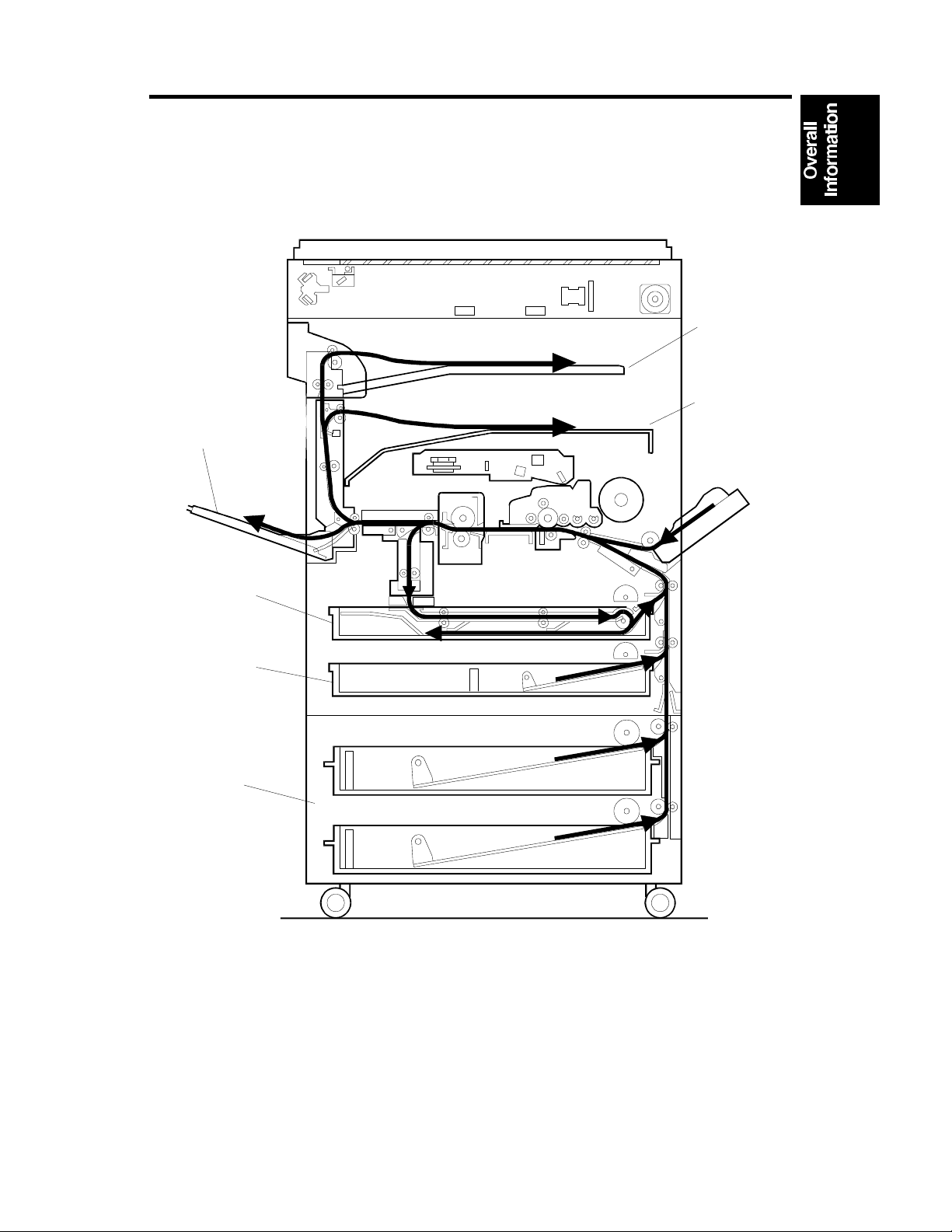

1 August 1996 PAPER PATH

3. PAPER PATH

Optional

1-bin

Sorter

Face

Face Up

Tray

Down Tray

Optional

Duplex

Tray

Paper

Tray

Optional

Paper

Tray Unit

A193V005.wmf

1-5

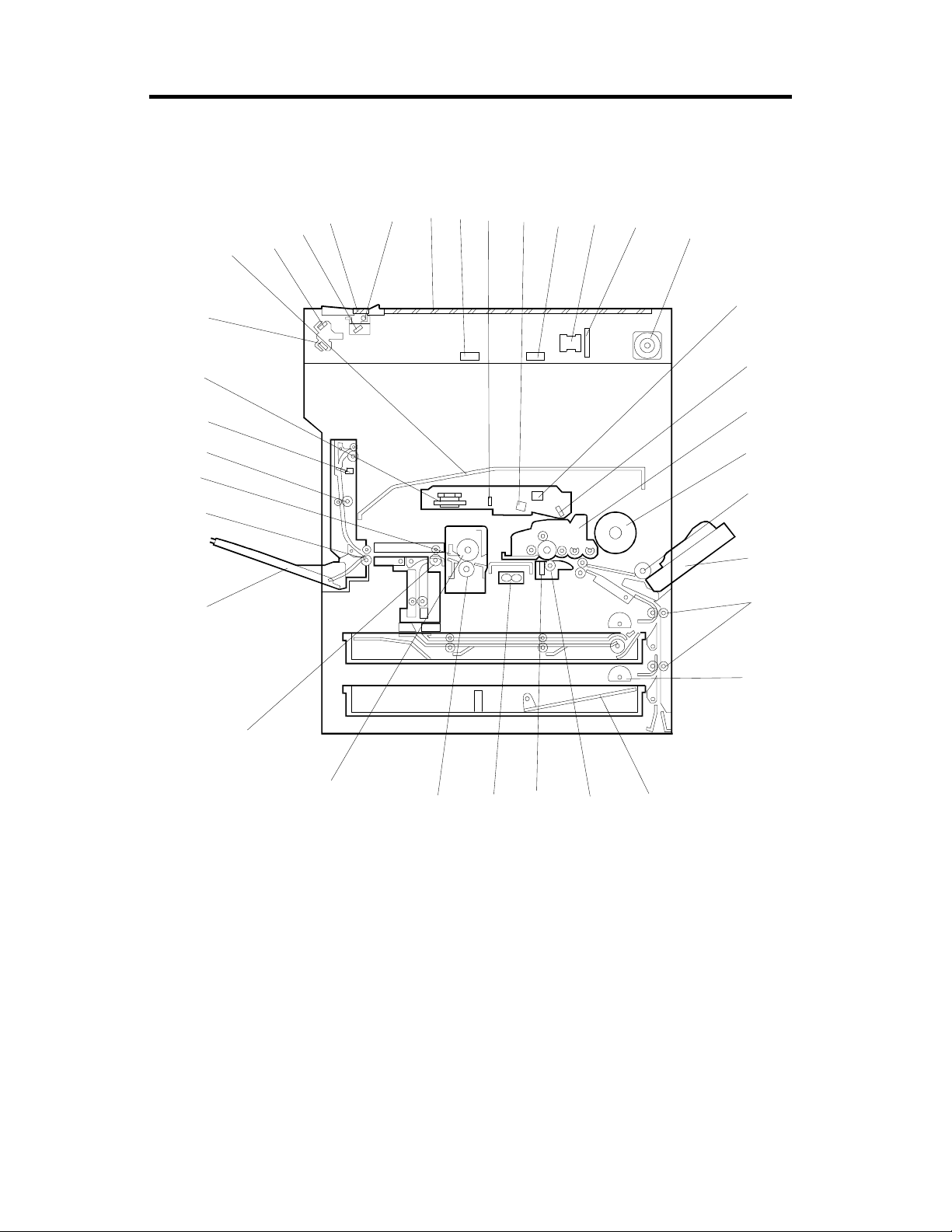

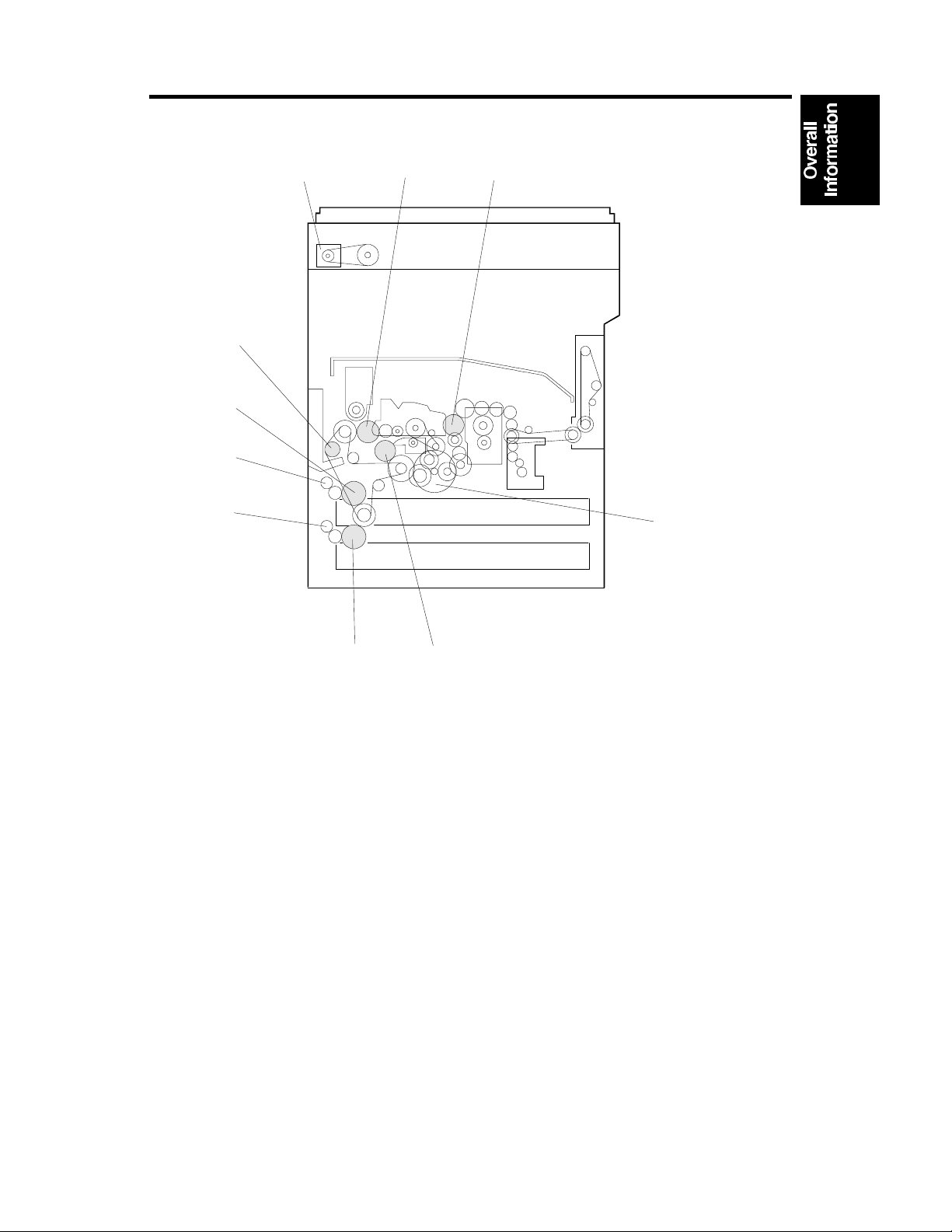

MECHANICAL COMPONENT LAYOUT 1 August 1996

4. MECHANICAL COMPONENT LAYOUT

6

7

8

10

9

11

12

13

34

35

5

3

2

4

1

33

32

31

30

29

28

27

26

25

24

23

22

14

15

16

17

18

19

20

A193V502.wmf

21

1-6

1 August 1996 MECHANICAL COMPONENT LAYOUT

1. 2nd Mirror

2. 1st Mirror

3. DF Exposure Glass

4. Xenon Lamp

5. Exposure Glass

6. Original Width Sensors

7. 1st Mirror

8. Barrel Toroidal Lens (BTL)

9. Original Length Sensors

10. Lens

11. SBU Board

12. Scanner Motor

13. F-theta Mirror

14. 2nd Mirror (Laser Unit)

15. PCU

22. Transfer Roller

23. Separation Brush

24. Transport Vacuum Fan

25. Pressure Roller

26. Hot Roller

27. Fusing Exit Roller

28. Left Vertical Door/Face Up

Tray

29. Junction Gate

30. Hot Roller Strippers

31. Left Vertical Roller

32. Lower Exit Sensor

33. Polygonal Mirror Motor

34. 3rd Mirror

35. Face Down Tray

16. Toner Bottle

17. By-pass Feed Roller

18. By-pass Table

19. Relay Rollers

20. Paper Feed Rollers

21. Bottom Plate

1-7

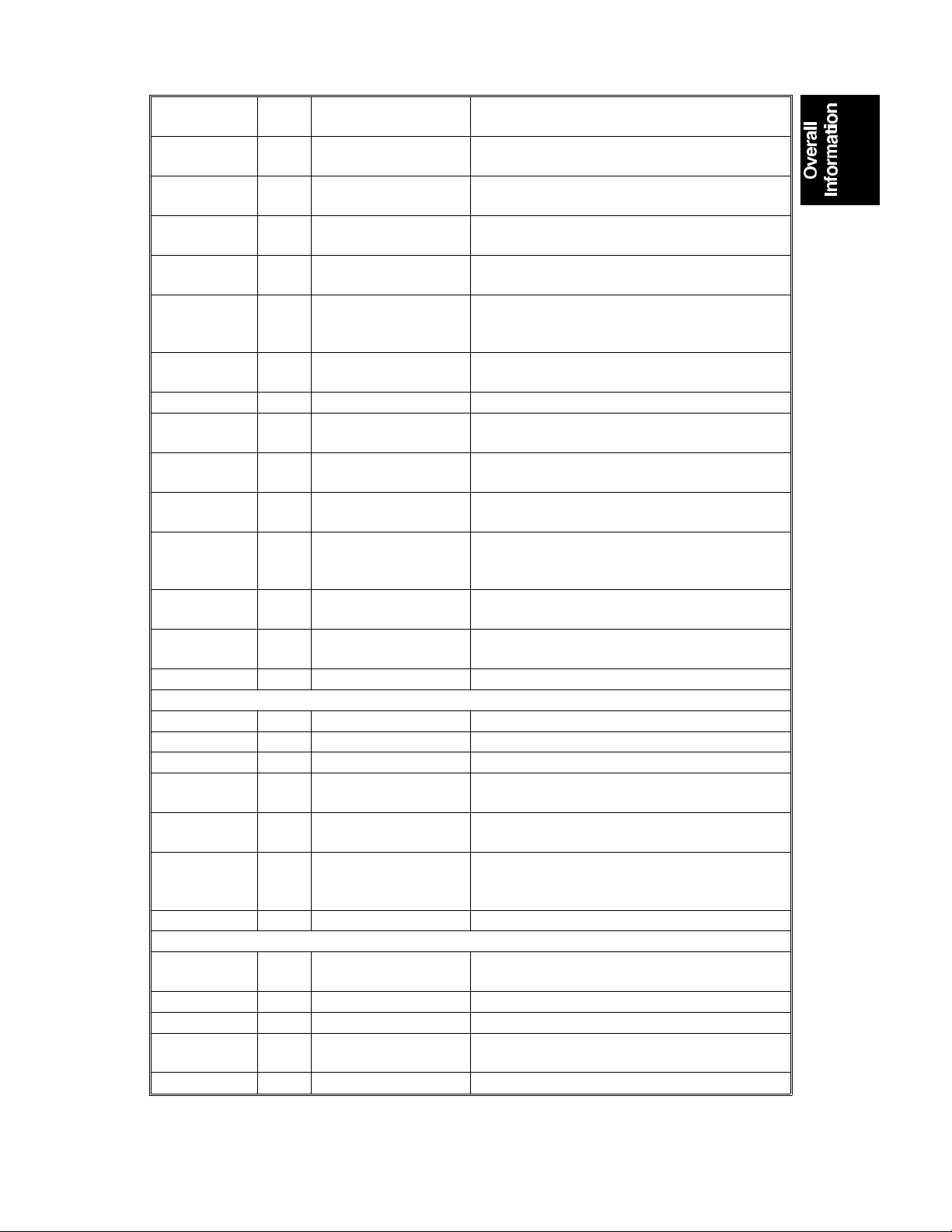

ELECTRICAL COMPONENT DESCRIPTIONS 1 August 1996

5. ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout and the point-to-point diagram on the

waterproof paper in the pocket for the locations of these components.

Symbol

Printed Circuit Boards

PCB1 54

PCB2 50 Lamp Stabilizer Provides dc power for the exposure lamp.

PCB3 58

PCB4 61 LD Unit Controls the laser diode.

PCB5 62

PCB6 51

PCB7 55 IOCSS Co nt rols the mechanical par t s of the p rinter.

PCB8 52

PCB9 53

Motors

M1 45 Main Drives the m ai n body components.

M2 36

M3 47

M4 49 Pol ygonal Mirror Turns the polygonal mirror.

M5 37

M6 35 Exhaust Fan Removes heat from around the fusing unit.

Index

No.

Description Note

High Voltage Supply

Board

PSU Provides dc powe r to the system and ac

Operation Pan e l Controls th e to uch panel displa y and LED

SBU Contains the CCD, and outputs a video

BICU Cont ro l s al l copier functions b ot h di r ect l y or

MSU Compressed the imag e dat a, stores the

Scanner Drive Drives the 1st and 2nd scanners (dc stepper

Transport Vac uum

Fan

Toner Supply Rotates the toner bottle to supply toner to

Supplies high voltage to the drum charge

roller, devel opment roller , tra n sf er roller, and

discharge br ush.

power to the fusing lamp.

matrix, and monitors the key matrix.

signal to the BICU b oar d.

through othe r co ntrol boards.

data, and appl i es the image editing.

motor).

Aids paper transportation from the transfer

roller to the fusing u n it.

the toner supply unit.

Sensors

S1 33 Up per Exi t Detects misf eeds.

S2 31 Low er Exi t Detects misfeeds.

S3 28 Left Vert i cal D oor Cuts the +5 and +24 Vdc power lines.

S4 27

S5 17

S6 10 PCU Detects when a new PCU is installed.

S7 29 Fusi ng Exit Detects misf eeds.

Left Door Detects whether the left door is open or

closed.

Relay Detects the leading edge of paper from the

paper tray and d upl ex unit to determ ine the

stop timing of the paper feed clutch and

duplex feed motor. Also detects misfeeds.

1-8

1 August 1996 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol

S8 9

S9 14

S10 15

S11 16

Index

No.

Description Note

Charge Roller H.P Informs the CPU when the dru m charge

roller is at home position.

Upper Tray Paper

End

Lower Tray Paper

End

By-pass Feed Paper

End

Informs the CPU w hen the upper paper tr ay

runs out of pape r.

Informs the CPU when the lower paper tray

runs out of pape r.

Informs the CPU w hen there is no paper in

the by-pass tray.

Registrati on Detect s th e l eading edge of the cop y paper

S12 12

to determin e th e stop timing of the pap er

feed clutch, and detects misfe eds.

S13 11

By-pass Feed Paper

Width

Detects the wi dt h of the paper in the by-pass

feed table.

S14 59 Humidity Monitors the humidity around the PCU.

S15 4

S16 5

S17 6

Original Width Detects the width of the original. This is one

of the APS (Auto Paper Select) sen sors.

Original Length-1 Detects the length of the or i gi nal. This is one

of the APS (Auto Paper Select) sen sors.

Original Length-2 Detects the length of the or i gi nal. This is one

of the APS (Auto Paper Select) sen sors.

Platen Cover Informs the CPU w het her the platen cover is

S18 3

up or down (related to APS/ARE functions).

ARE: Auto Reduce and Enlarge

S19 1

S20 23

Scanner H.P. Informs the CPU when the 1st and 2nd

scanners are at th e hom e position.

Toner Densi t y (TD) Detects the amount of toner inside the

development uni t .

Switches

SW1 21 AC Supplies power to the copier.

SW2 32 Ma i n Supplies powe r to operate the machine.

SW3 13 Right Vertical Guide Cuts the +5 and +24 Vdc power lines.

SW4 20

SW5 19

Upper Paper Size Determin es w hat size of paper is in t he

upper paper tray.

Lower Paper Size Determines what size of paper is in the lower

paper tray.

Front Door Safety Cuts the +5VLD and +24V dc power lines

SW6 26

and detects whet her the front cove r is open

or not.

Magnetic Clutches

MC1 46

Charge Roller Contact Controls the touch and release movem ent of

the drum ch arge rol l er.

MC2 42 Upper R el ay Drives the upper rel ay rollers.

MC3 43 Lower Relay Drives the lower relay rollers.

MC4 40

By-pass Feed Starts paper feed from the by -pass feed

table.

MC5 41 Upper Paper Feed Starts paper feed from the upper paper tray.

1-9

ELECTRICAL COMPONENT DESCRIPTIONS 1 August 1996

Symbol

MC6 44 Lower Paper Feed Starts paper feed from the lower paper tray.

MC7 39 Registration Drives the registration rollers.

MC8 38

Solenoids

SOL1 48

Lamps

L1 60

L2 2 Scanner Applies light to the origin al fo r exposure.

L3 8 Fusing Provides heat to the hot roller.

Heaters

H1 18

H2 34

Index

No.

Description Note

Development Dri ves the development roller.

Junction Gate Moves the junction gate to direct copies to

the face up or face down copy tray.

Quenching Neutralizes any charge remai ning on the

drum surfa ce af t er cl eaning.

Tray (option) Turns on when the main sw i tc h i s of f to keep

paper in the pa per tray dry. Tray heaters are

also available for the optional paper feed unit.

Anti-condensation

(option)

Turns on when t he main switch is of f to

prevent moisture from accumulating.

Thermistors

TH1 24

TH2 22 Fusi ng Monitors the temper at ur e of the hot roller.

Thermofuses

TF1 7

Counters

CO1 2 5

CO2 ---

Others

LSD1 30

NF 56

CB 57

Charge Roller Monitors the tem perature of the drum charge

roller.

Fusing Provides back-up overheat pr ot ection in the

fusing unit.

Total Keeps track of the total number of copies

made.

Key

(option)

Laser

Synchronization

Detector

Noise Filter

(230V machine only)

Circuit Breaker

(230V machine only)

Used for contro l of authorized use . Th e

copier will not operate until it is installed.

Detects the laser beam at the sta rt of the

main scan.

Removes electrical noise from the AC input

line.

Guards against voltage surg es i n t he AC

input line.

1-10

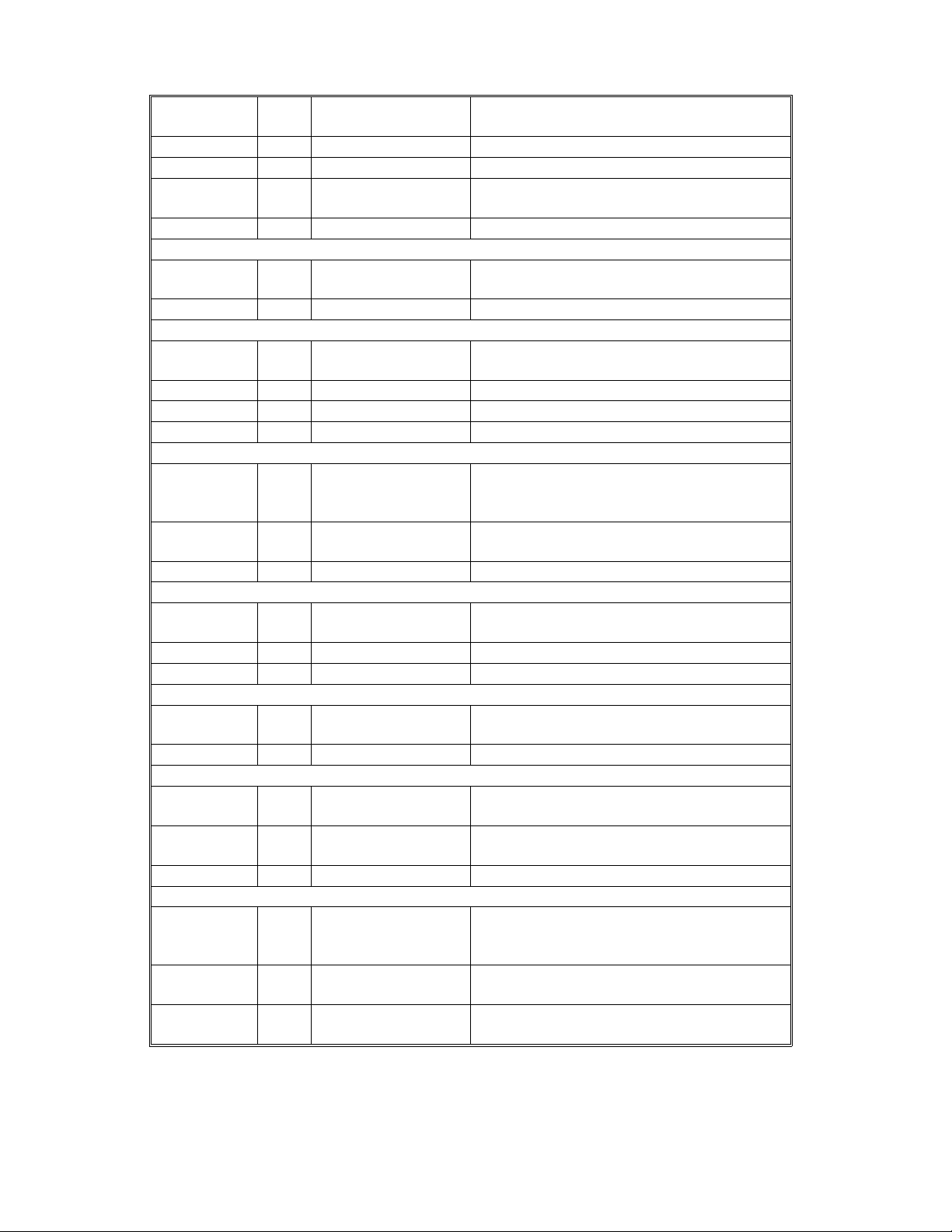

1 August 1996 DRIVE LAYOUT

6. DRIVE LAYOUT

1

2

3

10

9

8

7

4

A193V503.wmf

6

1. Scanner Drive Motor

2. Development Clutch

3. Charge Roller Contact

4. Main Motor

5. Registration Clutch

5

6. Lower Paper Feed Clutch

7. Lower Relay Clutch

8. Upper Relay Clutch

9. Upper Paper Feed Clutch

10. By-pass Feed Clutch

1-11

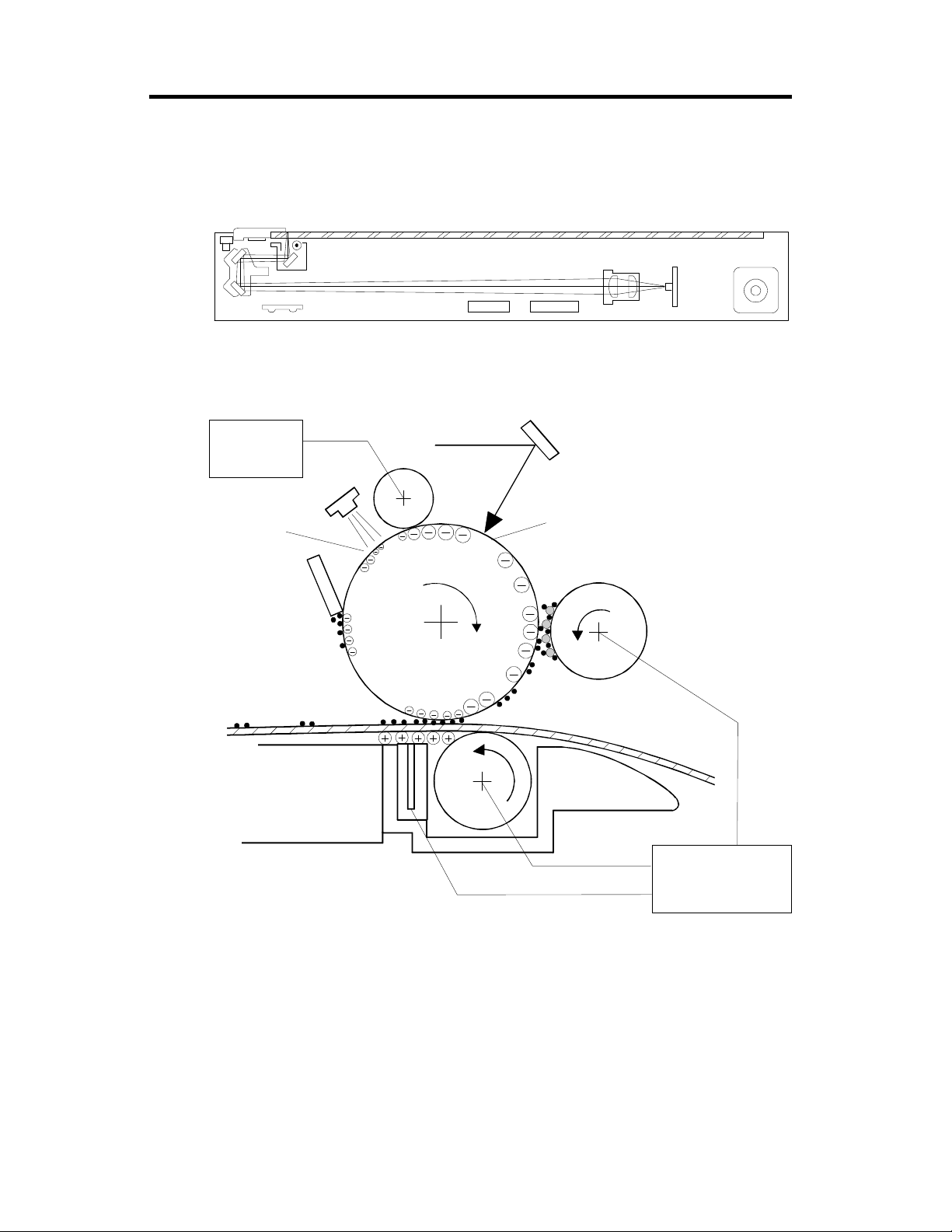

COPY PROCESS 1 August 1996

7. COPY PROCESS

7.1 OVERVIEW

Pow er

Pack

-90 V

-1750 V

8

7

1

2

3

-140 V

-900 V

4

-600 V

6

5

A193V505.wmf

+2 kV

1-12

+15 µA

Pow e r Pa ck

A193V506.wmf

1 August 1996 COPY PROCESS

1. EXPOSURE

A xenon lamp exposes the original. Light reflected from the original passes to

the CCD, where it is converted into an analog data signal. This data is

converted to a digital signal, processed, and stored in the memory. At the

time of printing, the data is retrieved and sent to the laser diode. For

multi-copy runs, the original is scanned once only and stored to the memory.

2. DRUM CHARGE

In the dark, the charge roller gives a negative charge to the organic

photo-conductive (OPC) drum. The charge remains on the surface of the

drum because the OPC layer has a high electrical resistance in the dark.

3. LASER EXPOSURE

The processed data scanned from the original is retrieved from the memory

and transferred to the drum by a laser beam, which forms an electrical latent

image on the drum surface. The amount of charge remaining as a latent

image on the drum depends on the laser beam intensity, which is controlled

by the BICU board.

4. DEVELOPMENT

The magnetic developer brush on the development rollers comes in contact

with the latent image on the drum surface. Toner particles are

electrostatically attracted to the areas of the drum surface where the laser

reduced the negative charge on the drum.

5. IMAGE TRANSFER

Paper is fed to the area between the drum surface and the transfer roller at

the proper time for aligning the copy paper and the developed image on the

drum surface. Then, the transfer roller applies a high positive charge to the

reverse side of paper. This positive charge produces an electrical force which

pulls the toner particles from the drum surface on to the paper. At the same

time, the paper is electrically attracted to the transfer roller.

6. PAPER SEPARATION

Paper separates from the drum as a result of the electrical attraction between

the paper and the transfer roller. The discharge brush helps separate the

paper from the drum.

7. CLEANING

The cleaning blade removes any toner remaining on the drum surface after

the image is transferred to the paper.

8. QUENCHING

The light from the quenching lamp electrically neutralizes the charge on the

drum surface.

1-13

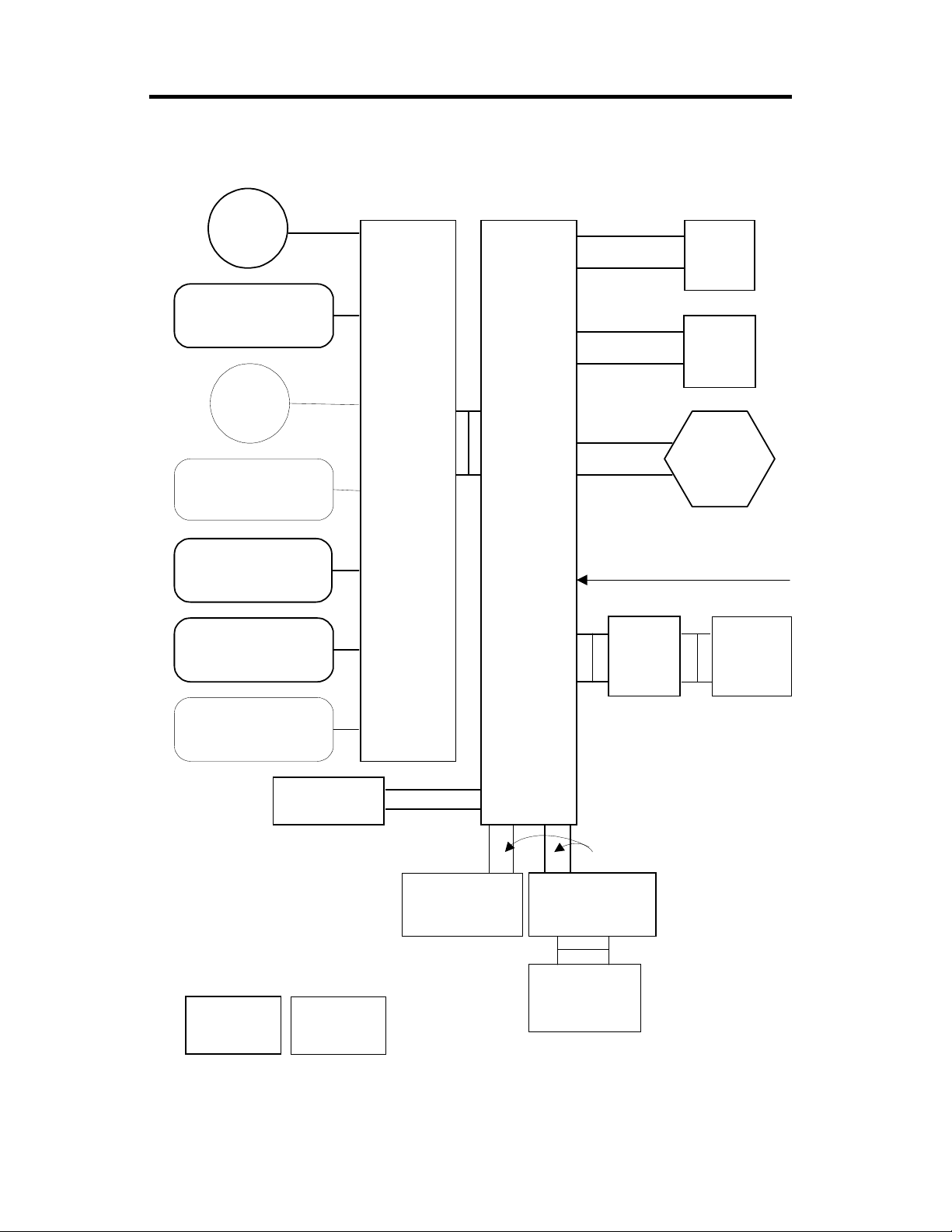

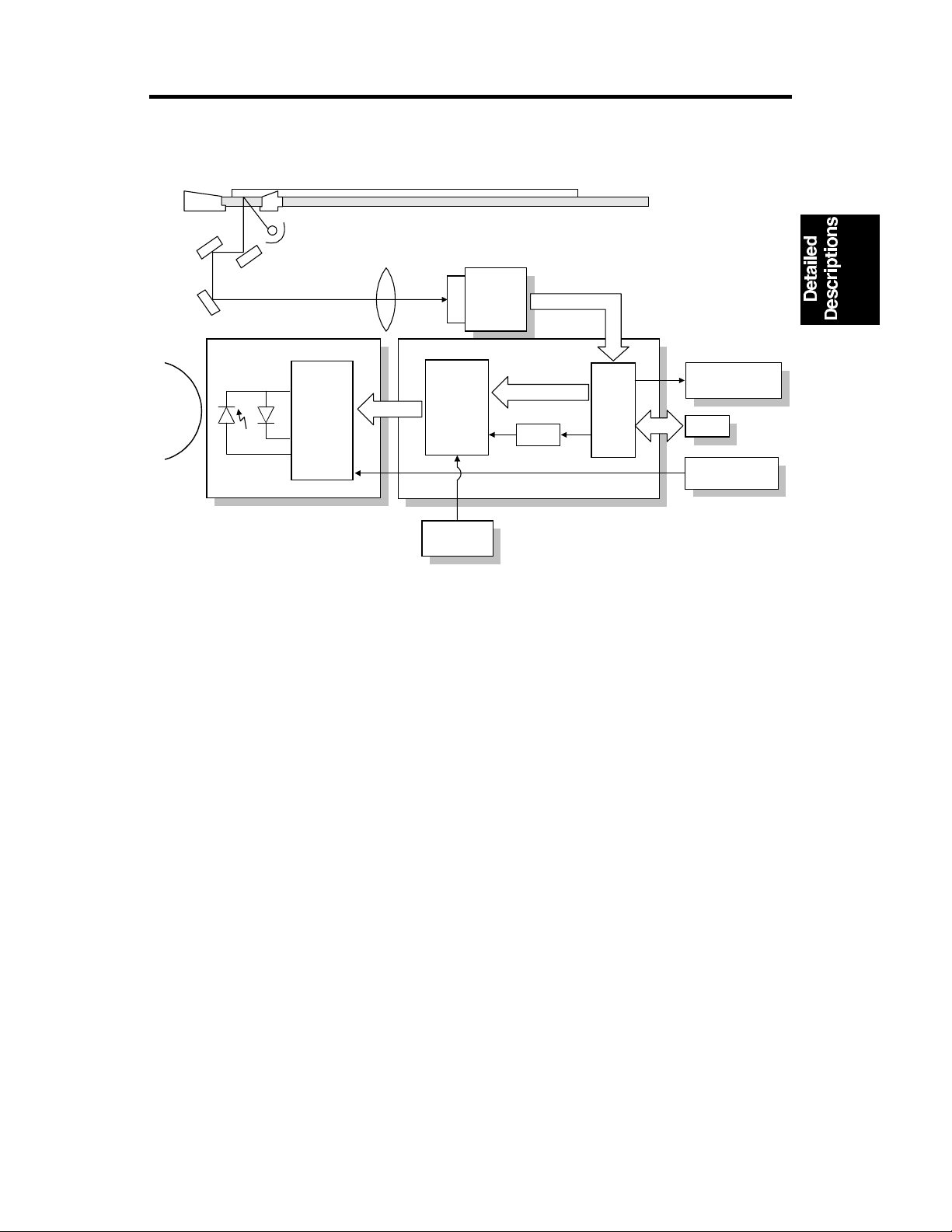

BOARD STRUCTURE 1 August 1996

8. BOARD STRUCTURE

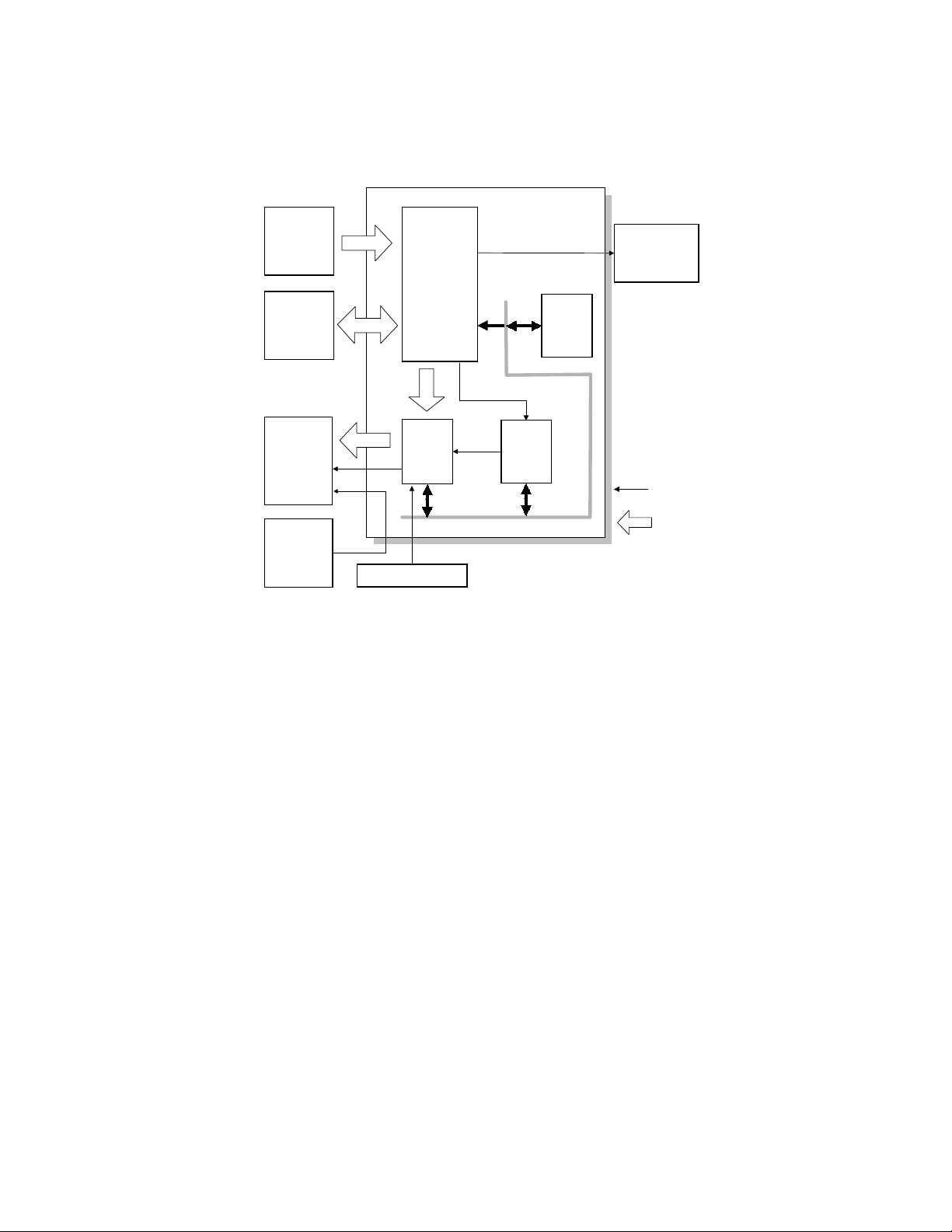

8.1 OVERVIEW

Scanner

Motor

Flat Cable

SBU

Scanner

Laser Printer

Sensors, Solenoids,

Motors, Clutches

High Voltage Supply

Peripheral

Motors, Solenoids,

Sensors

Motor

DF

Sensors,

DF

Solenoids

Sensors,

Clutches

Harness

BICUIOCSS

Harness

LD Unit

Polygon

Mirror

Motor

Laser Synchronization

Signal = Optical Cable

MSU

Additional

Memory

Operation

Panel

Standard Option

Harness

Flat Cable

Fax Controller Mother Board

Printer

Controller

A193V504.wmf

1-14

1 August 1996 BOARD STRUCTURE

8.2 DESCRIPTION

1. BICU (Base Engine and Image Control Unit)

This is the main board. It controls the following functions:

•

Engine sequence

•

Scanner, laser printer engine

•

Timing control for peripherals

•

Image processing, video control

•

Operation control

•

Corresponding application boards

•

Machine control, system control

2. IOCSS (I/O and Customer Support System Unit)

The IOCSS board handles the following functions:

•

Drive control for the sensors, motors, solenoids of the printer and scanner

•

PWM control for the high voltage control board

•

Serial interfaces with peripherals

•

Circuit for fusing control

3. SBU (Sensor Board Unit)

The SBU deals with the analog signals from the CCD and converts them into

digital signals.

4. MSU (Memory Super-charger Unit)

The MSU stores and compresses the image data. It also does image editing

on the data if requested by the user. An extra 4 MB or 8 MB of memory can

be added (see below).

5. Additional Memory (Option)

This is an additional image memory board for the MSU.

6. LD Unit

This is the laser diode drive circuit board.

7. Mother Board

This is the printer control board as well as the BICU interface board. It

receives the signals from the printer control board and sends signals to the

printer control board.

1-15

SECTION 2

DETAILED SECTION

DESCRIPTIONS

1 August 1996 SCANNING

1. SCANNING

1.1 OVERVIEW

[E]

[G]

[A]

A193D001.wmf

[D][F]

[C]

[B]

The original is illuminated by the exposure lamp (a xenon lamp in this model)

[A]. The image is reflected onto a CCD (charge coupled device) [B] via the

1st, 2nd, 3rd mirrors, and lens [C].

The 1st scanner [D] consists of the exposure lamp, a reflector [E], and the 1st

mirror [F].

The exposure lamp is energized by a dc supply to avoid uneven light

intensity as the 1st scanner moves in the sub scan direction. The entire

exposure lamp surface is frosted to ensure even exposure in the main scan

direction.

The light reflected by the reflector is of almost equal intensity, to reduce

shadows on pasted originals.

An optics anti-condensation heater [G] is available as an option. It can be

installed on the left side of the inner cover. It turns on whenever the power

cord is plugged in.

2-1

SCANNING 1 August 1996

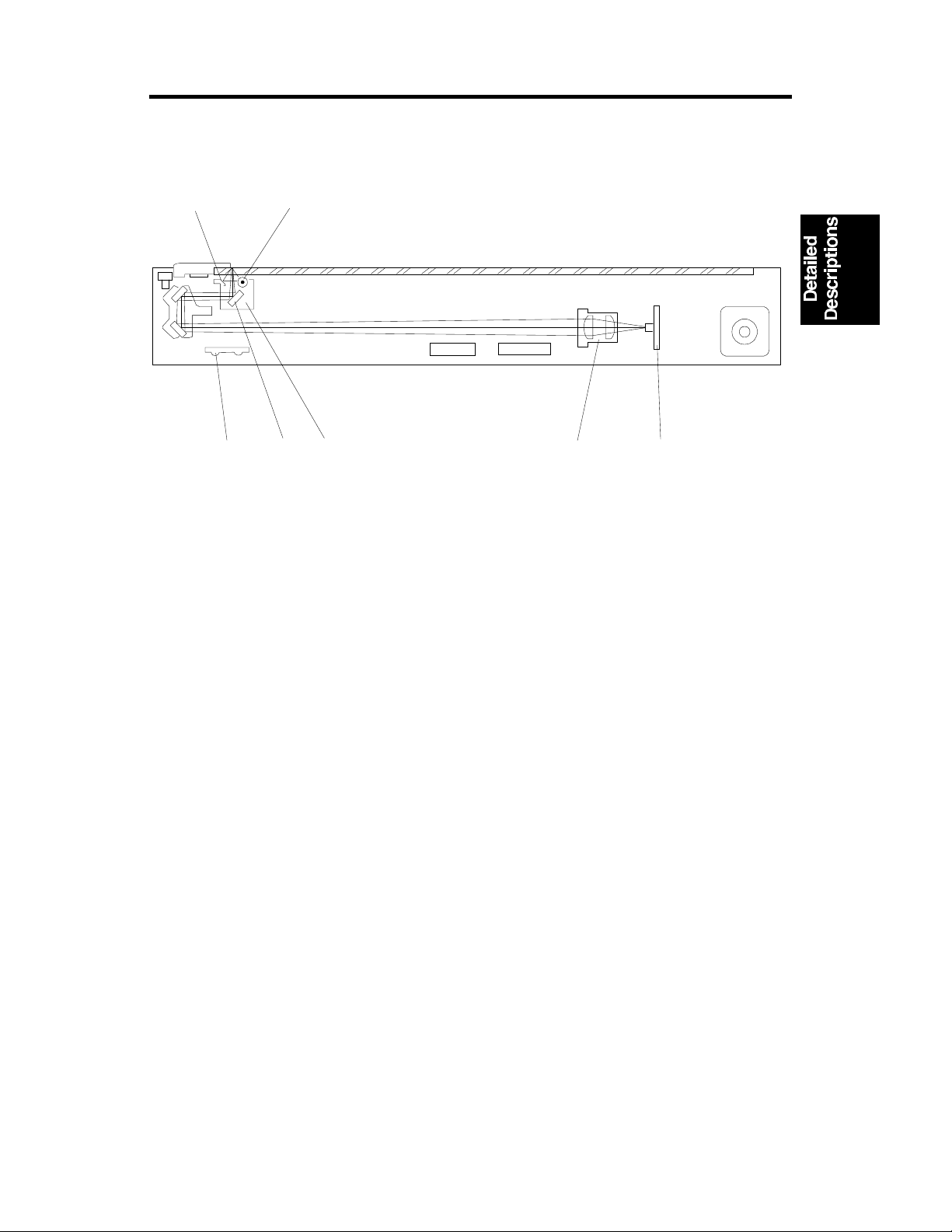

1.2 SCANNER DRIVE

[B]

[H]

[G]

[A]

[E]

[D]

[G]

[F]

[C]

[E]

A193D546.wmf

A stepper motor is used to drive the scanner. The 1st and 2nd scanners [A,B]

are driven by this scanner drive motor [C] through the timing belt [D], scanner

drive pulley [E], scanner drive shaft [F], and two scanner wires [G].

– Book mode –

The scanner drive board controls and operates the scanner drive motor. In

full size mode, the 1st scanner speed is 90 mm/s during scanning. The 2nd

scanner speed is half that of the 1st scanner.

In reduction or enlargement mode, the scanning speed depends on the

magnification ratio (M: 0.25 to 4.00). The returning speed is always the same,

whether in full size or magnification mode. The image length change in the

sub scan direction is done by changing the scanner drive motor speed, and

in the main scan direction it is done by image processing on the BICU board.

Magnification in the sub-scan direction can be adjusted by changing the

scanner drive motor speed using SP4-101. Magnification in the main scan

direction can be adjusted using SP4-008.

– ADF mode –

The scanners are always kept at their home position (the scanner H.P sensor

[H] detects the 1st scanner) to scan the original. The ADF motor feeds the

original through the ADF. In reduction/enlargement mode, the image length

change in the sub-scan direction is done by changing the ADF motor speed.

Magnification in the main scan direction is done in the BICU board, like for

book mode.

Magnification in the sub-scan direction can be adjusted by changing the ADF

motor speed using SP6-007. In the main scan direction, it can be adjusted

with SP4-008, like for book mode.

2-2

1 August 1996 SCANNING

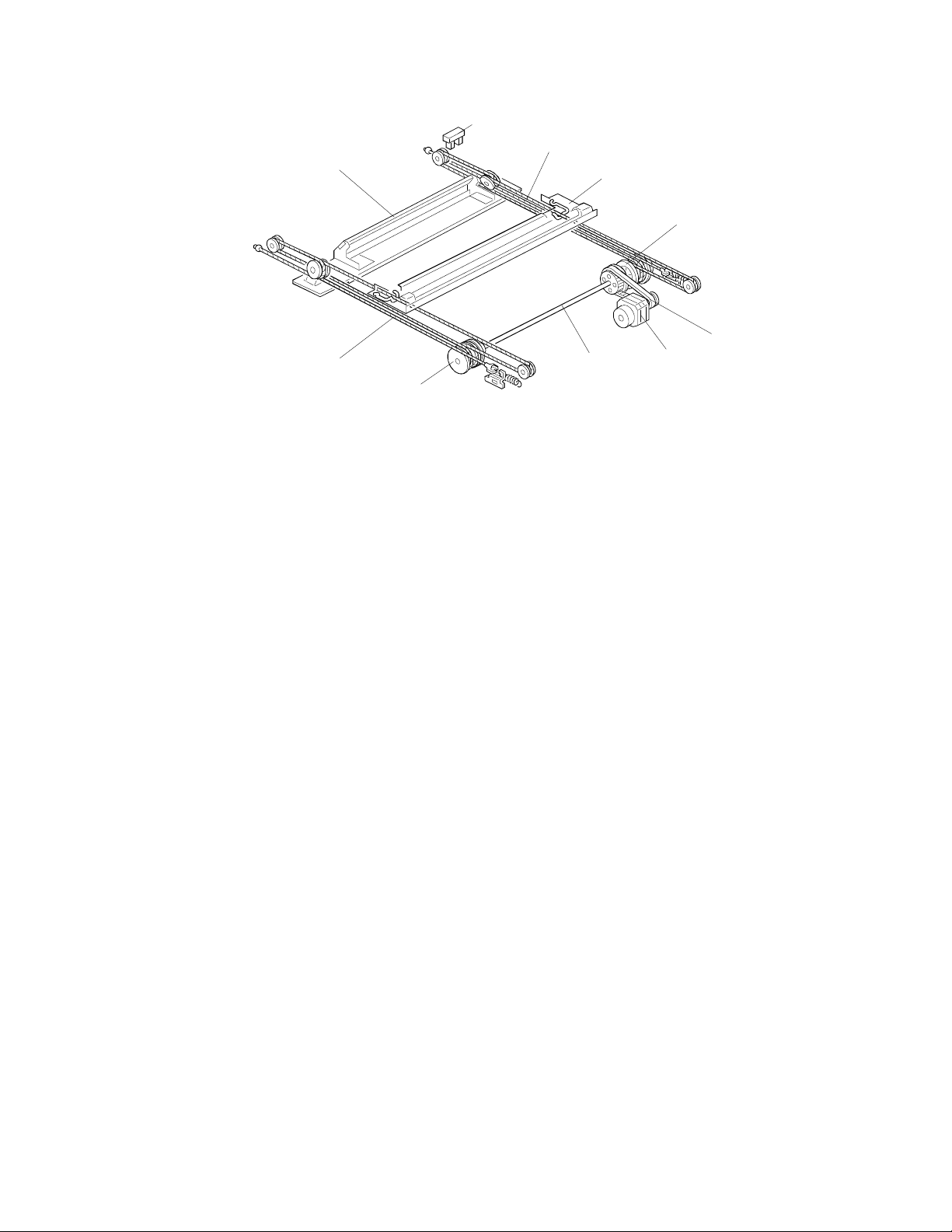

1.3 ORIGINAL SIZE DETECTION IN PLATEN MODE

[B]

[C]

A193D526.wmf

[A]

A193D003.wmf

In the optics cavity for original size detection, there are four reflective sensors

in the 115V machines, and six reflective sensors in the 230V machines. The

Original Width Sensors [A] detect the original width, and the Original Length

Sensors [B] detect the original length. These are the APS (Auto Paper

Select) sensors. Each APS sensor is a reflective photosensor.

While the main switch is on, these sensors are active and the original size

data is always sent to the CPU. However, the CPU checks the data only

when the platen cover is opened.

The original size data is taken by the main CPU when the platen cover

sensor [C] is activated. This is when the platen is positioned about 15 cm

above the exposure glass. At this time, only the sensor(s) located underneath

the original receive the reflected light and switch on. The other sensor(s) are

off. The main CPU can recognize the original size from the on/off signals

from the APS sensors.

If the copy is made with the platen fully open, the main CPU decides the

original size from the sensor outputs when the Start key is pressed.

2-3

SCANNING 1 August 1996

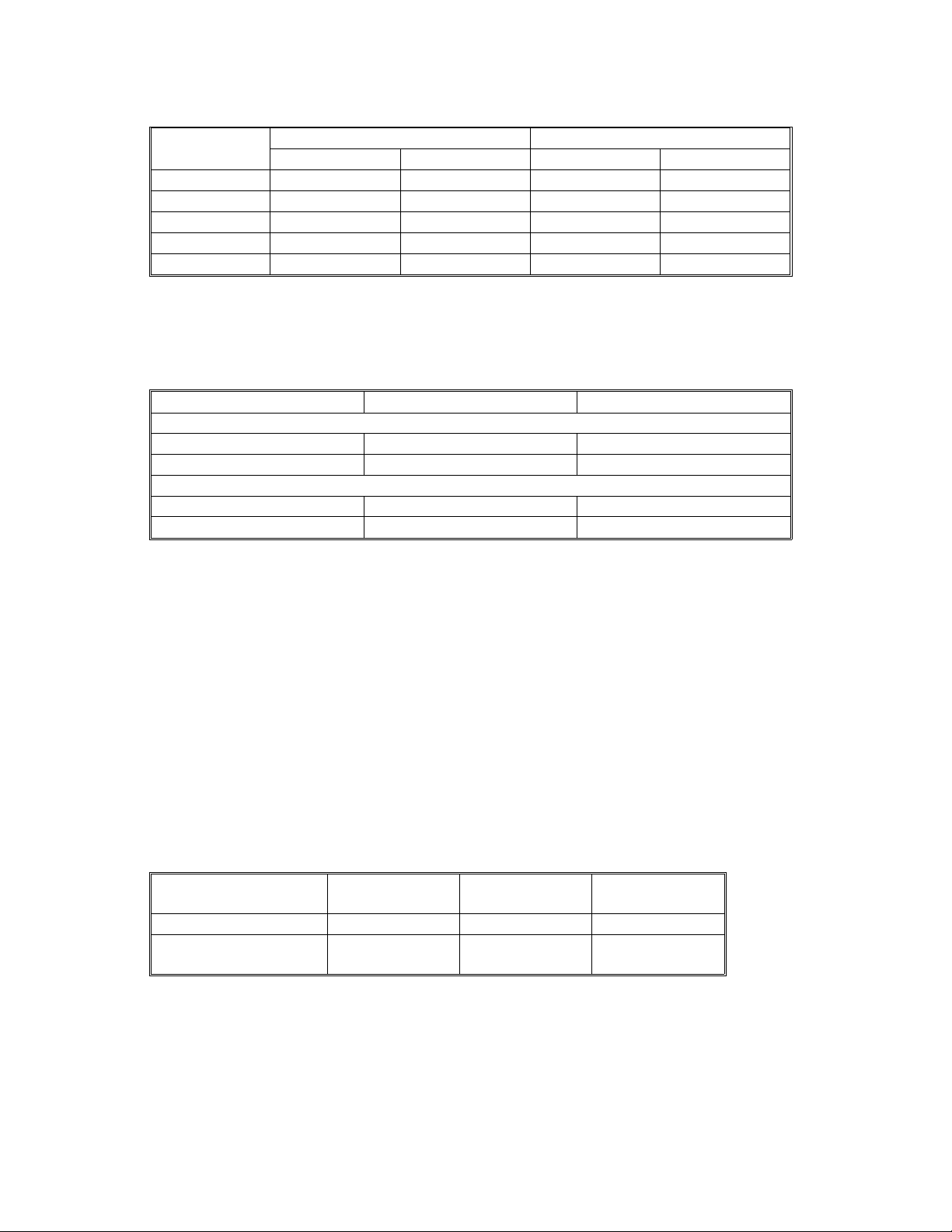

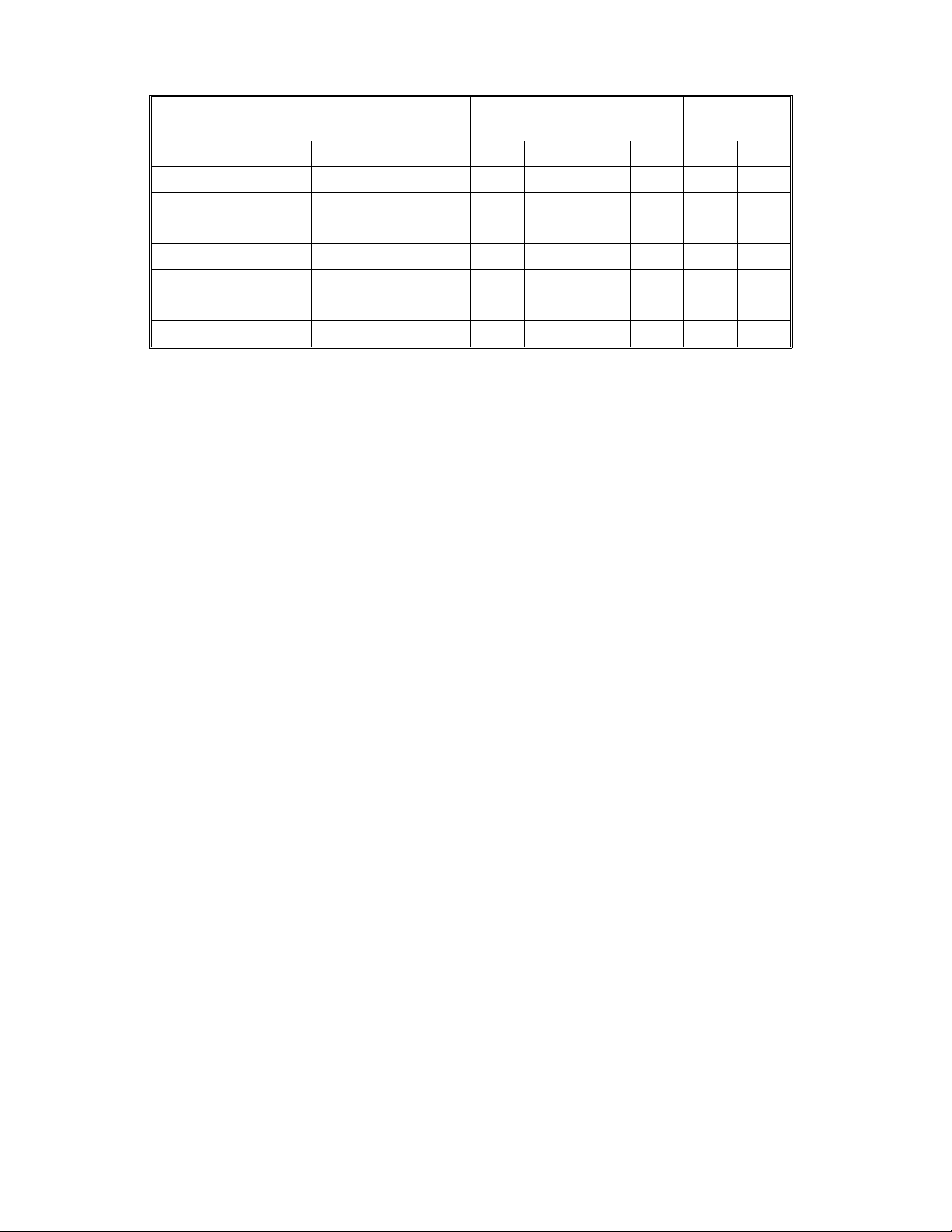

Original Size Length Sensors

A4/A3 version LT/DLT versi on

A3 11" x 17" OOOOOO

B4 10" x 14" OOOOOX

1/2

F4 8

A4–L 8

B5–L — OXXXXX

A4–S 11" x 8

B5–S — X X X X O X

" x 14" (8" x 13") O O O X X X

1/2

" x 11" OOXXXX

1/2

" XXXXOO

L1 L2 L3 L4 S1 S2

Width

Sensors

O: ON X: OFF

NOTE:

The length sensors L3 and L4 are used only for 230V machines.

For other combinations, "CANNOT DETECT ORIG. SIZE" will be indicated

on the operation panel display.

The above table shows the outputs of the sensors for each original size. This

original size detection method eliminates the necessity for a pre-scan and

increases the machine’s productivity.

However, if the by-pass feeder is used, note that the machine assumes that

the copy paper is lengthwise. For example, if A4 sideways paper is placed on

the by-pass tray, the machine assumes it is A3 paper and scans the full A3

area, disregarding the original size sensors. This can cause excess toner to

be transferred to the transfer roller, so users should be instructed to always

set the paper lengthwise on the by-pass tray. This problem occurs for the first

page only. The registration sensor detects the length of the first page, and

will assume that the following sheets of copy paper are the same length.

Original size detection using the ADF is described in the manual for the ADF.

2-4

1 August 1996 IMAGE PROCESSING

2. IMAGE PROCESSING

2.1 OVERVIEW

SBU

CCD

Fax Controller

X

T

IPU

MSU

Printer

Controller

Drum

LDDR

LD Driver

Controller

BICU

LD

(GAVD)

X

R

FCI

Fax

Controller

A193D501.wmf

The CCD generates an analog video signal. The SBU (Sensor Board Unit)

converts the analog signal to an 8-bit digital signal, then it sends the digital

signal to the BICU (Base-engine and Image Control Unit) board.

The BICU board can be divided into three image processing blocks; the IPU

(Image Processing Unit), FCI (Fine Character Image), and LD controller

(GAVD)

IPU: Auto shading, filtering, magnification, γ correction, and gradation

•

processing

FCI: Smoothing (binary picture processing mode only)

•

LD controller: LD print timing control and laser power PWM control

•

Finally, the BICU board sends the video data to the LD drive board at the

correct time.

2-5

IMAGE PROCESSING 1 August 1996

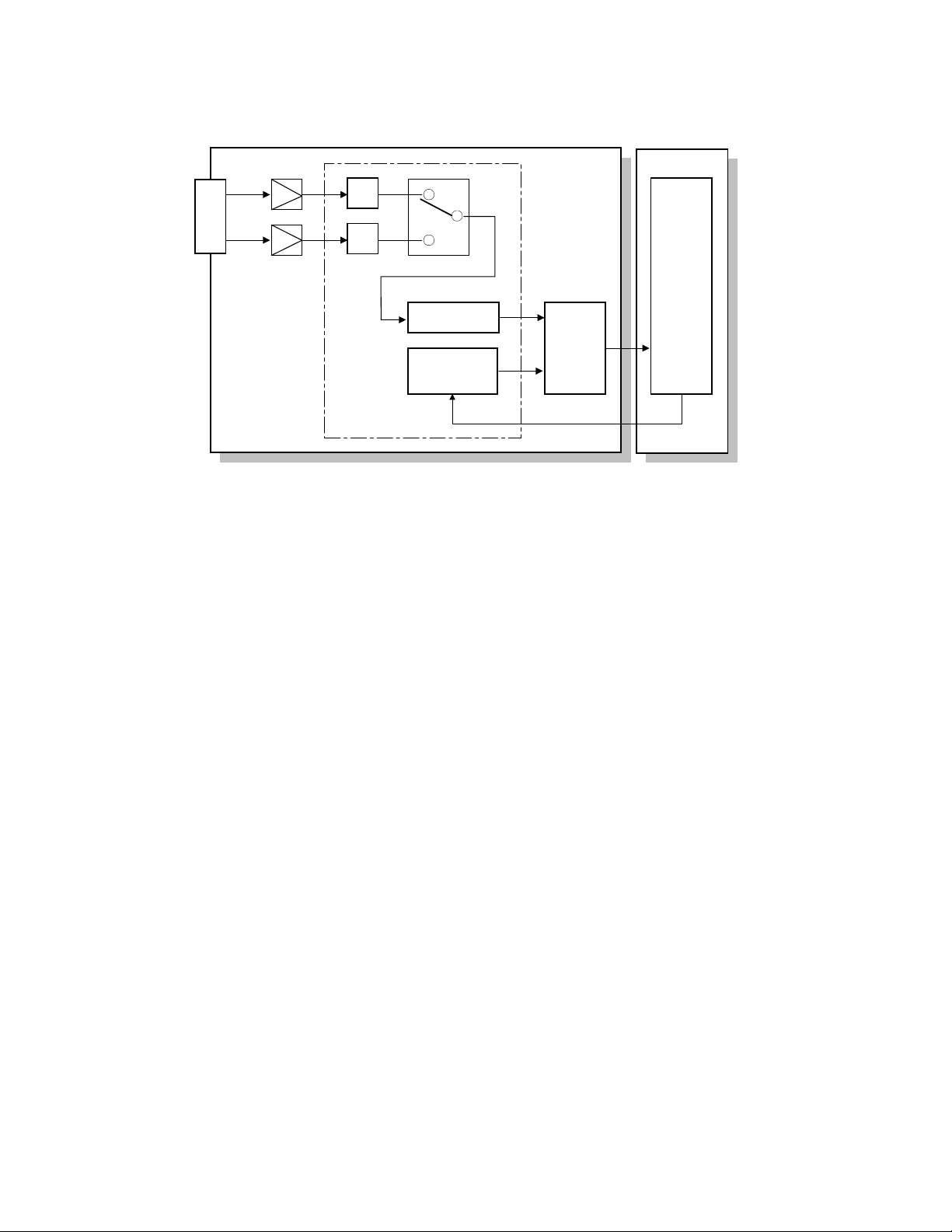

2.2 SBU (SENSOR BOARD UNIT)

ODD

CCD

EVEN

Amp.

SBU

Z/C

Z/C

BICU

IPU

AGC

Reference

Controller

A/D

Vin

ref

Analog

Processing IC

Z/C: Zero Clamp

AGC: Automatic Gain Control Circuit

A193D502.wmf

The CCD converts the light reflected from the original into an analog signal.

The CCD line has 5,000 pixels and the resolution is 400 dpi (15.7 lines/mm).

The CCD has two output lines, for odd and even pixels, to the analog

processing IC. The analog processing IC performs the following operations

on the signals from the CCD:

1) Z/C (Zero Clamp):

Adjusts the black level reference for even pixels to match the odd pixels.

2) Signal Composition:

Analog signals for odd and even pixels from the CCD are merged by a

switching device.

3) Signal Amplification

The analog signal is amplified by operational amplifiers in the AGC circuit.

The maximum gains of the operational amplifiers are controlled by the

CPU on the BICU board.

After the above processing, the analog signals are converted to 8-bit signals

by the A/D converter. This will give a value for each pixel on a scale of 256

grades. Then, the digitized image data goes to the BICU board.

2-6

1 August 1996 IMAGE PROCESSING

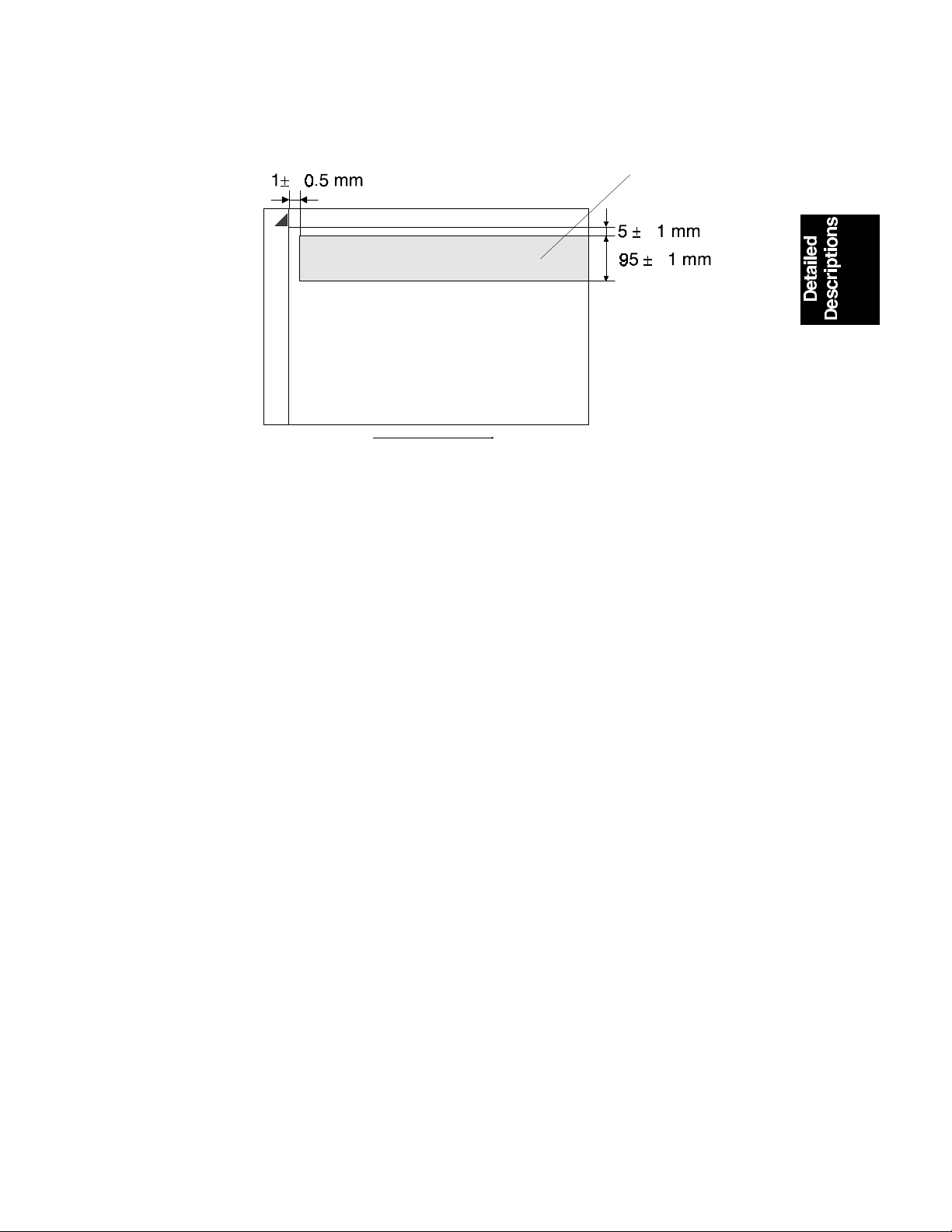

2.3 AUTO IMAGE DENSITY (ADS)

[A]

Sub scan di rection

A193D004 .w m f

This mode prevents the background of an original from appearing on copies.

The copier scans the auto image density detection area [A] as shown in the

diagram. This corresponds to a few mm at one end of the main scan line. As

the scanner scans down the page, the IPU on the BICU detects the peak

white level for each scan line. The IPU determines the reference value for the

A/D conversion for a particular scan line using the peak white level for that

scan line. Then, the IPU sends the reference value data to the reference

controller on the SBU.

When an original with a gray background is scanned, the density of the gray

area is the peak white level density. Therefore, the original background will

not appear on copies. Because peak level data is taken for each scan line,

ADS corrects for any changes in background density down the page.

As with previous digital copiers, the user can select manual image density

when selecting auto image density mode, and the machine will use both

settings when processing the original.

2-7

IMAGE PROCESSING 1 August 1996

2.4 IPU (IMAGE PROCESS ING UNIT )

2.4.1 Overview

BICU

SBU

MSU

LD

Unit

Printer

controller

+

IPU

+

+

GAVD FCI

+

R

x

Fax Controller

Tx

CPU BUS

+

CPU

Fax controller

1 bit

Data

8 bit

+

Data

A193D527.wmf

The image data from the SBU goes to the IPU (Image Processing Unit) IC on

the BICU board, which carries out the following processes on the image data:

1. Auto shading

2. Filtering (MTF and smoothing)

3. Magnification

4. γ correction

5. Grayscale processing

6. Binary picture processing

7. Error diffusion

8. Dithering

9. Video path control

10. Test pattern generation

The image data then goes to either the LD controller (GAVD) or the FCI

depending on the selected copy modes.

2-8

1 August 1996 IMAGE PROCESSING

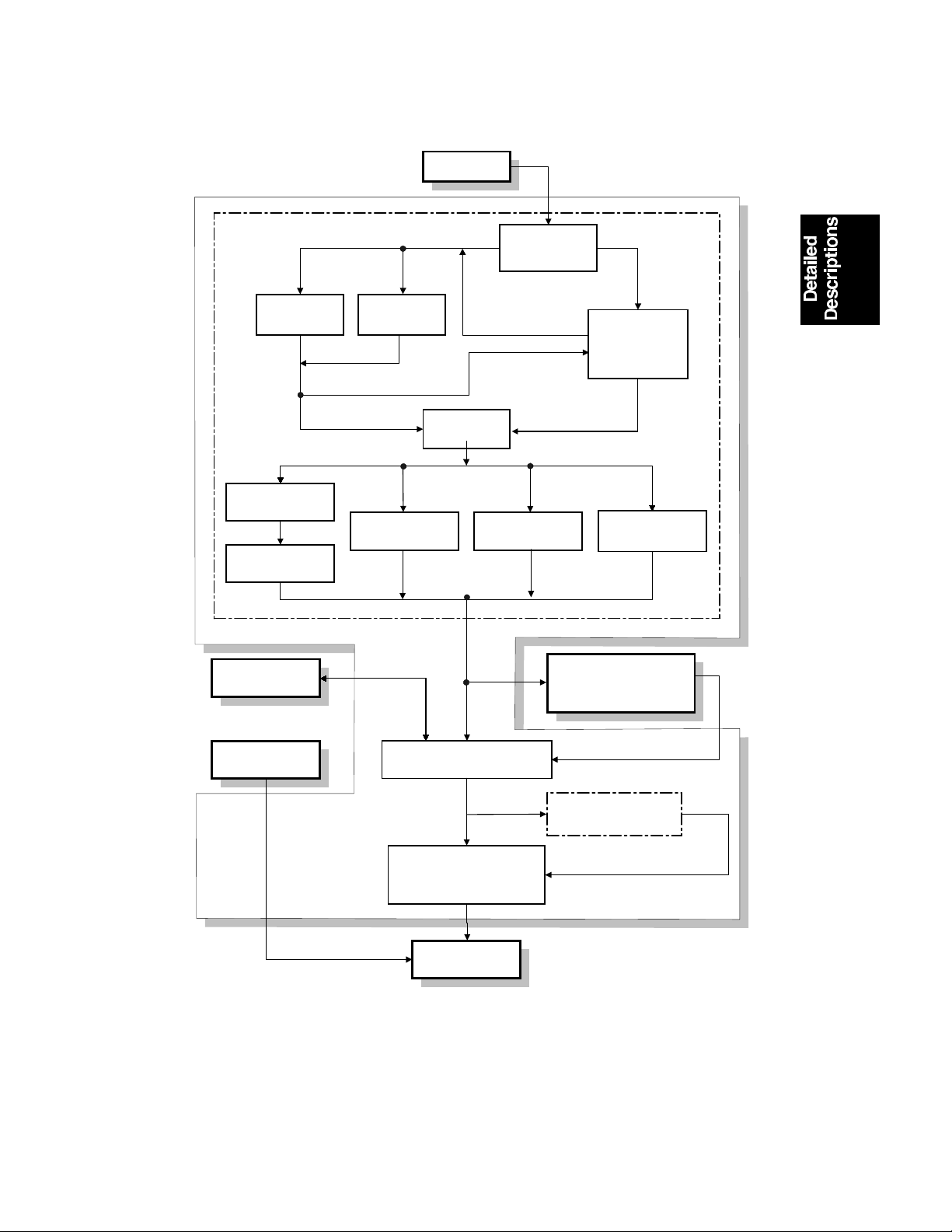

2.4.2 Image Processing Path

SBU

Text mode

Text/Photo

mode Photo mode

MTF

Correction

Grayscale

Processing

Line Width

Correction

Fax Controller

Smoothing

Dithering Error Diffusion

Correction

γ

(Scanner)

ADS and Auto

Shading

Main Scan

Magnification/

Reduction

Binary Picture

Image Compression/

Decompression, Image

Rotation/Adjust Image

IPU

Processing

MSU

Controller

BICU

Printer

Video Path Controller

Laser Diode Power

Modulation

Correction (Printer)

γ

LDDR

2-9

Edge Smoothing

Line Width Correction

FCI

A193D506.wmf

IMAGE PROCESSING 1 August 1996

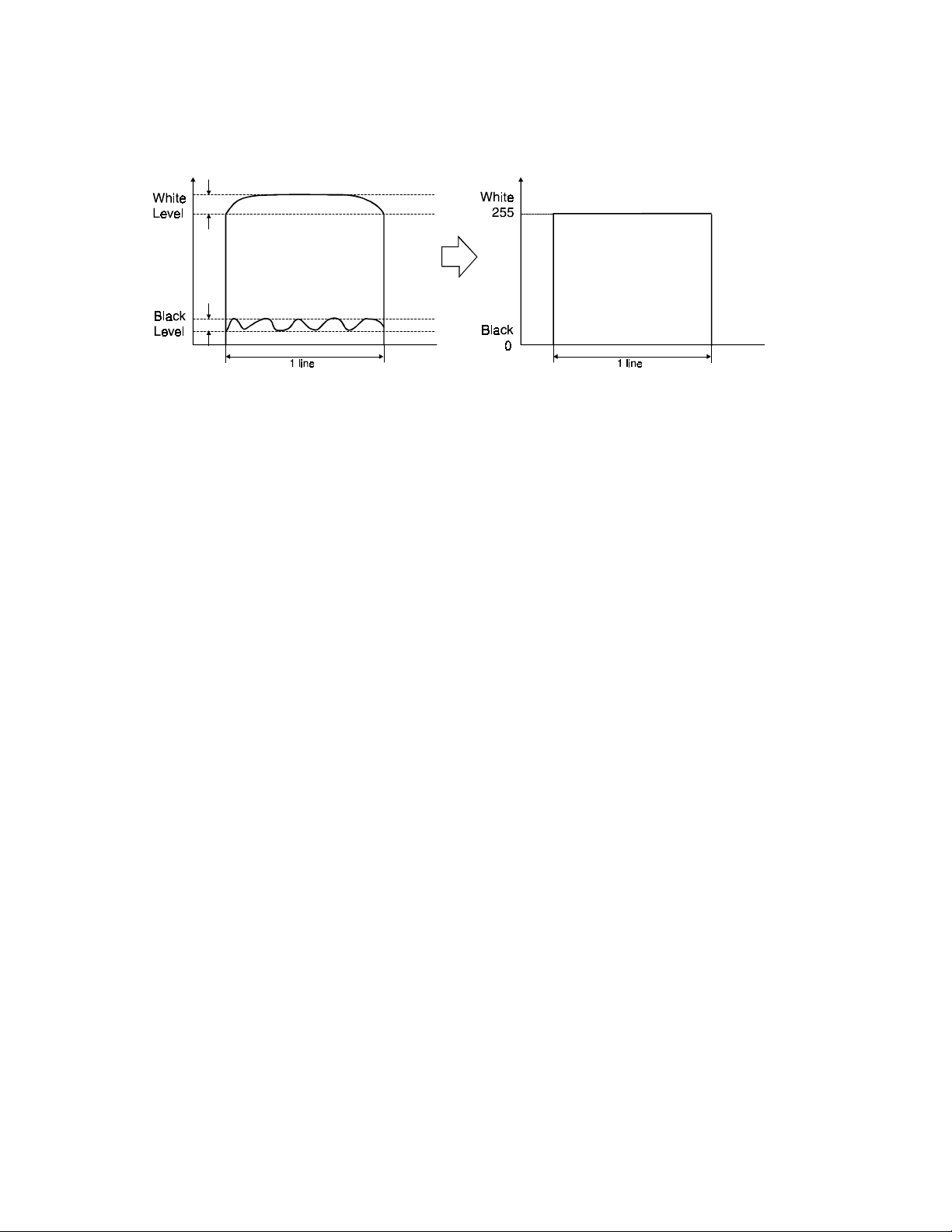

2.4.3 Auto Shading

A193D517.wmf

As with the previous digital copiers, there are two auto shading methods. One

is black level correction and the other is white level correction. Auto shading

corrects errors in the signal level for each pixel.

1) Black Level Correction

The CPU reads the black dummy data from one end of the CCD signal (64

pixels at the end are blacked off) and takes the average of the black dummy

data. Then, the CPU deletes the black level value from each image pixel.

2) White Level Correction

Before scanning the original, the machine reads a reference waveform from

the white plate. The average of the white video level for each pixel is stored

as the white shading data in the FIFO memory in the IPU chip.

The video signal information for each pixel obtained during image scanning is

corrected by the IPU chip.

In book mode, auto shading is done at the beginning of each scan.

In ADF mode, auto shading is done at a specific time interval. This interval

can be set with SP4-913 (the default setting is 30 seconds). The machine

waits until the end of the page before doing the auto shading.

2-10

1 August 1996 IMAGE PROCESSING

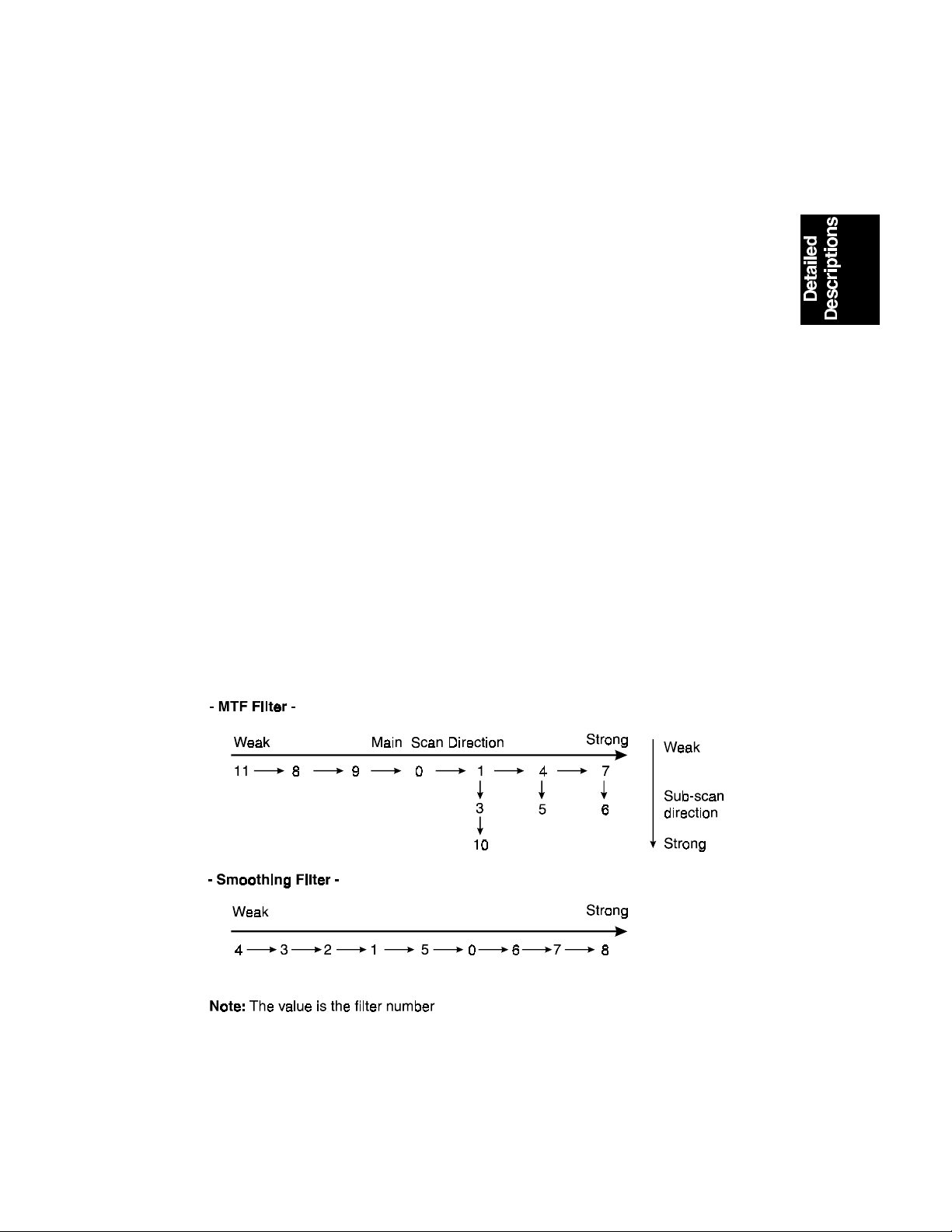

2.4.4 Filtering and Main Scan Magni fi cation/Reduction

1. Overview

After auto shading, the image data is processed by both filtering and main

scan magnification. However, to reduce the occurrence of moire in the image,

the processing order is different depending on the reproduction ratio, as

follows.

1) Reduction and Full size

Main Scan Reduction → Filtering

2) Enlargement

Filtering → Main Scan Magnification

2. Filtering

There are two software filters for enhancing the desired image qualities of the

selected original mode: the MTF filter and the smoothing filter.

The MTF filter emphasizes sharpness and is used in Text and Text/Photo

modes. The smoothing filter is used in Photo mode.

The relationships between the coefficient of the filter and the filter strengths

are as follows. Note that these relationships are for copier mode only. Fax

mode has its own unique table. (Refer to the fax section.)

The filter strengths for each mode can be adjusted with SP4-407.

NOTE:

Never select "1." Abnormal images may result.

2-11

A193D503.wmf

Loading...

Loading...