Page 1

TABLE OF CONTENTS

1. OVERALL MACHINE INFORMATION........................................ 1-1

1.1 SPECIFICATIONS.....................................................................................1-1

1.1.1 COPIER ENGINE.............................................................................1-1

1.1.2 ADF ..................................................................................................1-4

1.2 MACHINE CONFIGURATION...................................................................1-5

1.3 COMPONENT LAYOUT............................................................................1-6

1.3.1 COPIER ENGINE.............................................................................1-6

1.3.2 ADF ..................................................................................................1-7

1.4 PAPER PATH............................................................................................1-8

1.5 COPY PROCESS......................................................................................1-9

1.6 DRIVE LAYOUT......................................................................................1-11

1.6.1 COPIER ENGINE...........................................................................1-11

1.6.2 ADF ................................................................................................1-12

1.7 ELECTRICAL COMPONENT DESCRIPTIONS......................................1-13

1.7.1 COPIER ENGINE...........................................................................1-13

1.7.2 ADF ................................................................................................1-19

2. DETAILED SECTION DESCRIPTIONS ...................................... 2-1

2.1 DOCUMENT FEEDER..............................................................................2-1

2.1.1 PICK-UP ROLLER RELEASE..........................................................2-1

2.1.2 BOTTOM PLATE LIFT......................................................................2-2

2.1.3 PICK-UP AND SEPARATION ..........................................................2-3

2.1.4 ORIGINAL FEED..............................................................................2-4

2.1.5 ORIGINAL SIZE DETECTION..........................................................2-5

2.1.6 ORIGINAL TRANSPORT.................................................................2-6

2.1.7 ORIGINAL SKEW CORRECTION....................................................2-7

2.1.8 ORIGINAL INVERSION AND FEED-OUT........................................2-8

2.1.9 JAM CONDITIONS.........................................................................2-12

2.2 SCANNING..............................................................................................2-13

2.2.1 OVERVIEW....................................................................................2-13

2.2.2 SCANNER DRIVE..........................................................................2-14

2.2.3 ORIGINAL SIZE DETECTION IN BOOK MODE............................2-15

2.3 IMAGE PROCESSING............................................................................2-17

2.3.1 OVERVIEW....................................................................................2-17

2.3.2 SBU................................................................................................2-18

2.3.3 AUTO IMAGE DENSITY (ADS)......................................................2-19

2.3.4 IMAGE PROCESSING STEPS AND RELATED SP MODE...........2-20

2.3.5 AUTO SHADING............................................................................2-26

2.3.6 BACKGROUND ERASE.................................................................2-27

2.3.7 INDEPENDENT DOT ERASE........................................................2-28

2.3.8 FILTERING, MAIN SCAN MAGNIFICATION/REDUCTION...........2-29

2.3.9 GAMMA (γ) CORRECTION............................................................2-31

2.3.10 GRADATION PROCESSING .......................................................2-31

2.3.11 LINE WIDTH CORRECTION........................................................2-32

A294 II-i

Page 2

2.4 LASER EXPOSURE................................................................................2-33

2.4.1 OVERVIEW....................................................................................2-33

2.4.2 OPTICAL PATH..............................................................................2-34

2.4.3 AUTO POWER CONTROL (APC)..................................................2-35

2.4.4 FOUR BEAM LASER WRITING.....................................................2-36

2.4.5 LD SAFETY SWITCHES................................................................2-37

2.5 DRUM UNIT ............................................................................................2-38

2.5.1 PROCESS CONTROL....................................................................2-38

2.5.2 TONER DENSITY CONTROL........................................................2-43

2.5.3 DRUM UNIT COMPONENTS.........................................................2-46

2.5.4 DRIVE.............................................................................................2-47

2.5.5 DRUM CHARGE.............................................................................2-48

2.5.6 DRUM CLEANING..........................................................................2-50

2.5.7 OTHERS.........................................................................................2-53

2.6 DEVELOPMENT.....................................................................................2-56

2.6.1 OVERVIEW....................................................................................2-56

2.6.2 DEVELOPMENT MECHANISM......................................................2-57

2.6.3 DRIVE.............................................................................................2-58

2.6.4 CROSSMIXING..............................................................................2-59

2.6.5 DEVELOPMENT BIAS...................................................................2-60

2.7 TONER SUPPLY AND RECYCLING ......................................................2-61

2.7.1 TONER BANK................................................................................2-61

2.7.2 SUPPLYING TONER TO THE DEVELOPMENT UNIT..................2-65

2.7.3 TONER HOPPER...........................................................................2-66

2.7.4 TONER RECYCLING AND WASTE TONER COLLECTION..........2-68

2.8 PAPER FEED..........................................................................................2-71

2.8.1 OVERVIEW....................................................................................2-71

2.8.2 DRIVE.............................................................................................2-72

2.8.3 PAPER LIFT – TRAYS 2 & 3..........................................................2-73

2.8.4 PICK-UP AND FEED – TRAYS 1 TO 3..........................................2-75

2.8.5 REMAINING PAPER/

PAPER END DETECTION – TRAYS 2 & 3....................................2-79

2.8.6 PAPER SIZE DETECTION – TRAYS 2 & 3....................................2-80

2.8.7 TRAY LOCK – TRAYS 2 & 3..........................................................2-81

2.8.8 TANDEM FEED – TRAY 1 .............................................................2-82

2.8.9 VERTICAL TRANSPORT...............................................................2-89

2.8.10 PAPER REGISTRATION..............................................................2-90

2.9 IMAGE TRANSFER AND PAPER SEPARATION...................................2-93

2.9.1 OVERVIEW....................................................................................2-93

2.9.2 IMAGE TRANSFER AND PAPER SEPARATION..........................2-94

2.9.3 TRANSFER BELT UNIT LIFT.........................................................2-96

2.9.4 PAPER TRANSPORTATION AND BELT DRIVE...........................2-97

2.9.5 TRANSFER BELT CLEANING.......................................................2-98

2.9.6 TONER COLLECTION...................................................................2-99

2.9.7 TRANSFER ANTI-CONDENSATION HEATER............................2-100

2.10 FUSING...............................................................................................2-101

2.10.1 OVERVIEW................................................................................2-101

2.10.2 FUSING ENTRANCE GUIDE.....................................................2-102

2.10.3 FUSING UNIT DRIVE.................................................................2-103

A294 II-ii

Page 3

2.10.4 FUSING LAMP CONTROL.........................................................2-104

2.10.5 OIL SUPPLY AND CLEANING...................................................2-105

2.10.6 PAPER COOLING......................................................................2-106

2.10.7 FUSING PRESSURE.................................................................2-107

2.10.8 HOT ROLLER STRIPPER RELEASE........................................2-108

2.11 PAPER EXIT/DUPLEX........................................................................2-109

2.11.1 OVERVIEW................................................................................2-109

2.11.2 PAPER EXIT MECHANISM........................................................2-110

2.11.3 DUPLEX DRIVE MECHANISM ..................................................2-111

2.11.4 INVERTER .................................................................................2-112

2.11.5 DUPLEX TRAY FEED MECHANISM.........................................2-114

2.11.6 BASIC DUPLEX FEED OPERATION.........................................2-115

2.12 ENERGY SAVER MODES..................................................................2-119

2.12.1 OVERVIEW................................................................................2-119

2.12.2 ENERGY SAVER (PANEL OFF) MODE ....................................2-120

2.12.3 LOW POWER MODE.................................................................2-121

2.12.4 OFF MODE.................................................................................2-122

2.12.5 SUMMARY.................................................................................2-124

2.13 OTHERS .............................................................................................2-125

2.13.1 OPERATION UNIT.....................................................................2-125

2.13.2 DOOR SAFETY SWITCH LOCK TOOLS...................................2-126

2.13.3 HDD CONTROL.........................................................................2-127

2.13.4 DATA PATH THROUGH THE INTERFACE BOARD.................2-129

3. INSTALLATION PROCEDURE................................................... 3-1

3.1 INSTALLATION REQUIREMENTS...........................................................3-1

3.1.1 ENVIRONMENT...............................................................................3-1

3.1.2 MACHINE LEVEL.............................................................................3-1

3.1.3 MINIMUM SPACE REQUIREMENTS...............................................3-2

3.1.4 POWER REQUIREMENTS..............................................................3-2

3.2 COPIER (A294).........................................................................................3-3

3.2.1 ACCESSORY CHECK......................................................................3-3

3.2.2 INSTALLATION PROCEDURE........................................................3-5

3.3 FINISHER INSTALLATION (B302)..........................................................3-12

3.3.1 ACCESSORY CHECK....................................................................3-12

3.3.2 INSTALLATION PROCEDURE......................................................3-13

3.4 LCT INSTALLATION (B303)....................................................................3-16

3.4.1 ACCESSORY CHECK....................................................................3-16

3.4.2 INSTALLATION PROCEDURE......................................................3-17

3.5 PUNCH UNIT INSTALLATION (A812)....................................................3-19

3.5.1 ACCESSORY CHECK....................................................................3-19

3.5.2 PUNCH UNIT INSTALLATION.......................................................3-20

3.6 A3/DLT TRAY (B331)..............................................................................3-23

3.6.1 ACCESSORY CHECK....................................................................3-23

3.6.2 INSTALLATION PROCEDURE......................................................3-24

3.7 KEY COUNTER INSTALLATION............................................................ 3-27

3.8 INTERFACE BOARD

(CD-RW/TANDEM COPY KIT/PRINTER CONTROLLER)......................3-30

3.8.1 INSTALLATION PROCEDURE......................................................3-30

A294 II-iii

Page 4

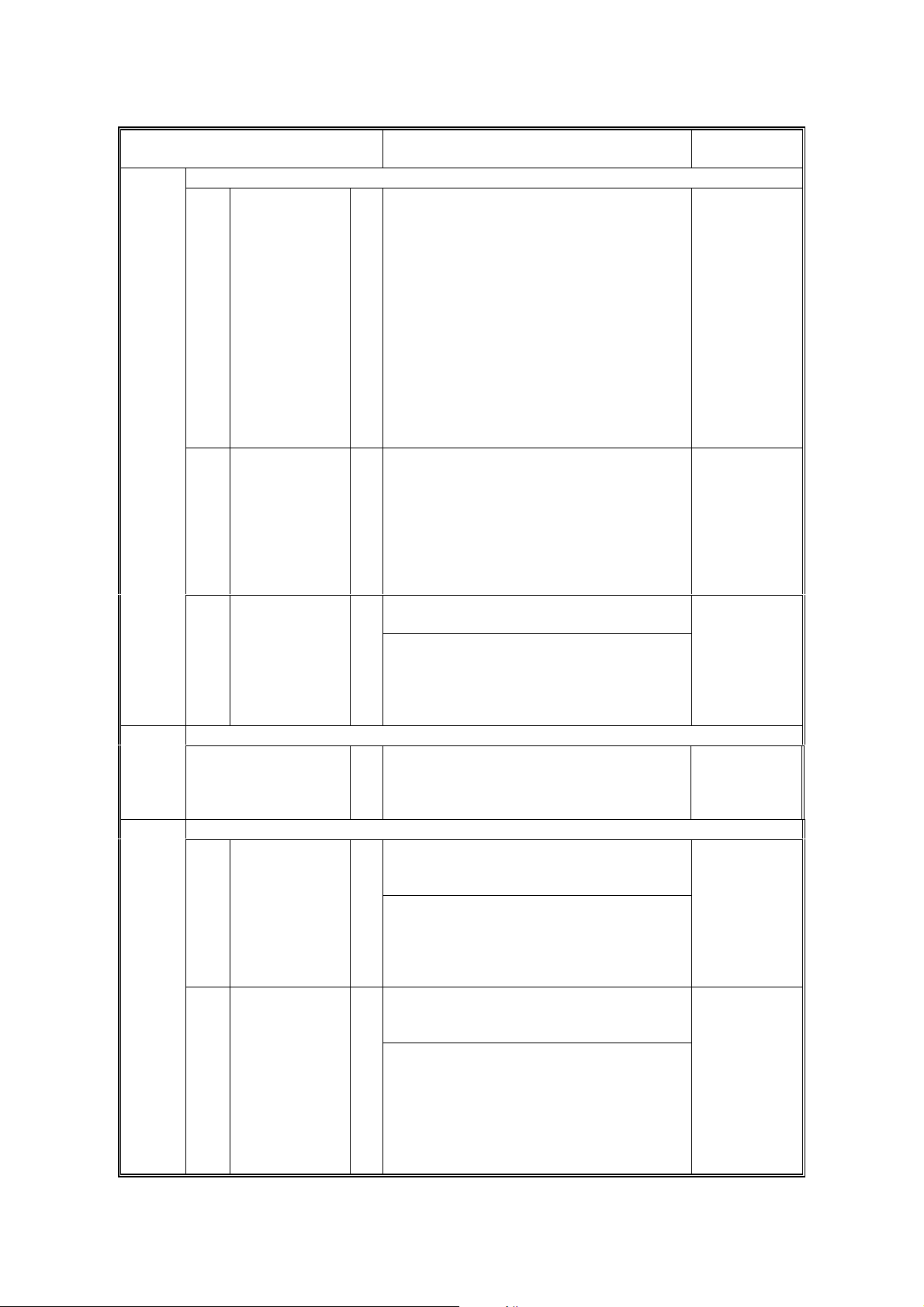

4 SERVICE TABLES....................................................................... 4-1

4.1 GENERAL CAUTIONS..............................................................................4-1

4.1.1 DRUM...............................................................................................4-1

4.1.2 DRUM UNIT .....................................................................................4-1

4.1.3 TRANSFER BELT UNIT...................................................................4-2

4.1.4 SCANNER UNIT...............................................................................4-2

4.1.5 LASER UNIT ....................................................................................4-2

4.1.6 CHARGE CORONA..........................................................................4-3

4.1.7 DEVELOPMENT ..............................................................................4-3

4.1.8 CLEANING.......................................................................................4-4

4.1.9 FUSING UNIT...................................................................................4-4

4.1.10 PAPER FEED.................................................................................4-4

4.1.11 USED TONER................................................................................4-4

4.2 SERVICE PROGRAM MODE....................................................................4-5

4.2.1 SERVICE PROGRAM MODE OPERATION.....................................4-5

4.2.2 SERVICE PROGRAM MODE TABLES..........................................4-10

4.2.3 TEST PATTERN PRINTING (SP2-902) .........................................4-59

4.2.4 INPUT CHECK...............................................................................4-60

4.2.5 OUTPUT CHECK...........................................................................4-68

4.2.6 SYSTEM PARAMETER AND DATA LISTS (SMC LISTS) .............4-70

4.2.7 MEMORY ALL CLEAR (SP5-801)..................................................4-70

4.2.8 SOFTWARE RESET......................................................................4-71

4.2.9 SYSTEM SETTING AND

COPY SETTING (UP MODE) RESET............................................4-71

4.3 PM COUNTER ........................................................................................4-72

4.3.1 PM COUNTER ACCESS PROCEDURE........................................4-72

4.4 PROGRAM DOWNLOAD........................................................................4-78

4.5 NVRAM DATA DOWNLOAD...................................................................4-80

4.6 LANGUAGE DATA DOWNLOAD............................................................4-81

4.7 STAMP DATA DOWNLOAD....................................................................4-81

4.8 USER PROGRAM MODE.......................................................................4-82

4.8.1 HOW TO ENTER AND EXIT UP MODE.........................................4-82

4.8.2 UP MODE TABLE ..........................................................................4-82

4.8.3 IMAGE QUALITY SETTING BY UP MODE....................................4-85

4.8.4 LEDS..............................................................................................4-91

4.9 TEST POINTS/DIP SWITCHES/LEDS....................................................4-92

4.9.1 DIP SWITCHES..............................................................................4-92

4.9.2 TEST POINTS................................................................................4-93

4.9.3 FUSES............................................................................................4-93

4.9.4 VARIABLE RESISTORS................................................................4-93

4.10 SPECIAL TOOLS AND LUBRICANTS..................................................4-94

4.10.1 SPECIAL TOOLS.........................................................................4-94

4.10.2 LUBRICANTS...............................................................................4-94

5 PREVENTIVE MAINTENANCE SCHEDULE............................... 5-1

5.1 PM PARTS................................................................................................5-1

A294 II-iv

Page 5

6. REPLACEMENT AND ADJUSTMENT........................................ 6-1

6.1 EXTERIOR................................................................................................6-1

6.1.1 FRONT.............................................................................................6-1

6.1.2 RIGHT ..............................................................................................6-2

6.1.3 LEFT.................................................................................................6-3

6.1.4 REAR................................................................................................6-4

6.2 DOCUMENT FEEDER..............................................................................6-5

6.2.1 COVER REMOVAL..........................................................................6-5

6.2.2 FEED UNIT REMOVAL AND

SEPARATION ROLLER REPLACEMENT .......................................6-7

6.2.3 FEED BELT REPLACEMENT..........................................................6-8

6.2.4 PICK-UP ROLLER REPLACEMENT................................................6-9

6.2.5 SENSOR REPLACEMENT.............................................................6-10

6.2.6 TRANSPORT BELT REPLACEMENT............................................6-14

6.2.7 MOTOR REPLACEMENT..............................................................6-15

6.2.8 FEED-IN CLUTCH REPLACEMENT..............................................6-17

6.3 SCANNER UNIT......................................................................................6-18

6.3.1 EXPOSURE GLASS.......................................................................6-18

6.3.2 LENS BLOCK.................................................................................6-19

6.3.3 ORIGINAL SIZE SENSORS...........................................................6-20

6.3.4 EXPOSURE LAMP.........................................................................6-21

6.3.5 LAMP REGULATOR.......................................................................6-22

6.3.6 OPTICS DUST FILTER..................................................................6-23

6.3.7 SCANNER H.P. SENSOR..............................................................6-24

6.3.8 SCANNER MOTOR........................................................................6-25

6.3.9 SCANNER DRIVE WIRES .............................................................6-26

6.4 LASER UNIT...........................................................................................6-29

6.4.1 CAUTION DECAL LOCATIONS.....................................................6-29

6.4.2 LDB AND LD FILTER REPLACEMENT .........................................6-30

6.4.3 POLYGON MIRROR MOTOR REPLACEMENT ............................6-31

6.4.4 LASER SYNCHRONIZATION DETECTOR REPLACEMENT........6-32

6.5 DRUM UNIT ............................................................................................6-33

6.5.1 DRUM UNIT REMOVAL AND DRUM REPLACEMENT.................6-33

6.5.2 QUENCHING LAMP REPLACEMENT...........................................6-34

6.5.3 GRID PLATE/CHARGE CORONA WIRE/

WIRE CLEANER REPLACEMENT ................................................6-35

6.5.4 DRUM POTENTIAL SENSOR REPLACEMENT............................6-37

6.5.5 CLEANING BLADE/ID SENSOR REPLACEMENT........................6-38

6.5.6 CLEANING BRUSH REPLACEMENT............................................6-39

6.5.7 PICK-OFF PAWL REPLACEMENT................................................6-40

6.5.8 DRUM FILTER REPLACEMENT....................................................6-41

6.6 DEVELOPMENT AND TONER SUPPLY................................................6-42

6.6.1 DEVELOPMENT UNIT REMOVAL.................................................6-42

6.6.2 DEVELOPER REPLACEMENT......................................................6-43

6.6.3 DEVELOPMENT AND AIR DUST FILTER REPLACEMENT.........6-45

6.6.4 DEVELOPMENT ENTRANCE, FRONT, AND

REAR SIDE SEALS........................................................................6-46

6.6.5 TONER DENSITY SENSOR REPLACEMENT...............................6-47

A294 II-v

Page 6

6.6.6 TONER HOPPER SENSOR REPLACEMENT...............................6-48

6.6.7 DEVELOPMENT MOTOR REPLACEMENT ..................................6-49

6.6.8 DEVELOPMENT ROLLER SHAFT CLEANING.............................6-50

6.7 TRANSFER BELT UNIT..........................................................................6-51

6.7.1 TRANSFER BELT UNIT REMOVAL/INSTALLATION....................6-51

6.7.2 TRANSFER BELT REPLACEMENT...............................................6-53

6.7.3 TRANSFER BELT CLEANING BLADE REPLACEMTNT...............6-55

6.7.4 TRANSFER BELT BIAS BRUSH REPLACEMENT........................6-56

6.8 PAPER FEED..........................................................................................6-57

6.8.1 PAPER TRAY REMOVAL..............................................................6-57

6.8.2 PAPER FEED ROLLER REPLACEMENT......................................6-60

6.8.3 PAPER FEED AND VERTICAL TRANSPORT CLUTCH, AND

TRAY LIFT, PAPER FEED, AND

PAPER END SENSOR REMOVAL...............................................6-61

6.8.4 REAR FENCE RETURN SENSOR REPLACEMENT.....................6-64

6.8.5 REAR FENCE HP SENSOR REPLACEMENT...............................6-65

6.8.6 RIGHT 1ST TRAY PAPER SENSOR REPLACMENT....................6-66

6.8.7 BOTTOM PLATE LIFT WIRE REPLACEMENT .............................6-67

6.8.8 PAPER DUST REMOVER CLEANING..........................................6-69

6.8.9 REGISTRATION SENSOR CLEANING.........................................6-70

6.8.10 UNIVERSAL TRAY SIZE SWITCH REPLACEMENT...................6-71

6.8.11 1ST TRAY LIFT MOTOR REMOVAL ...........................................6-72

6.8.12 LIFT MOTOR REMOVAL (2ND & 3RD TRAYS)...........................6-73

6.8.13 PAPER FEED MOTOR REMOVAL..............................................6-74

6.8.14 RELAY MOTOR, UPPER RELAY CLUTCH,

LCT RELAY CLUTCH REMOVAL................................................6-75

6.8.15 REGISTRATION MOTOR REMOVAL..........................................6-76

6.8.16 COPIER FEED UNIT/DEVELOPMENT FAN MOTOR

REMOVAL....................................................................................6-77

6.8.17 LCT RELAY AND RELAY SENSOR REMOVAL..........................6-78

6.8.18 TANDEM FEED TRAY PAPER SIZE CHANGE...........................6-79

6.8.19 MECHANICAL SIDE REGISTRATION ADJUSTMENT................6-82

6.9 FUSING UNIT..........................................................................................6-83

6.9.1 OIL SUPPLY & CLEANING WEB UNIT REMOVAL.......................6-83

6.9.2 HOT ROLLER UNIT REMOVAL AND

PRESSURE ROLLER REPLACEMENT.........................................6-84

6.9.3 HOT ROLLER REPLACEMENT.....................................................6-86

6.9.4 OIL SUPPLY & CLEANING WEB REPLACEMENT.......................6-88

6.9.5 WEB CLEANING ROLLER REPLACEMENT.................................6-90

6.9.6 HOT ROLLER STRIPPER REPLACEMENT..................................6-91

6.9.7 PRESSURE ROLLER STRIPPER REPLACEMENT......................6-92

6.9.8 PRESSURE ROLLER CLEANING ROLLER REPLACEMENT......6-93

6.9.9 FUSING AND EXIT UNIT REMOVAL.............................................6-94

6.9.10 FUSING PRESSURE ADJUSTMENT..........................................6-95

6.10 PAPER EXIT/DUPLEX UNIT.................................................................6-96

6.10.1 EXIT SENSOR REPLACEMENT..................................................6-96

6.10.2 DUPLEX UNIT REMOVAL ...........................................................6-97

6.10.3 DUPLEX UNIT INNER COVER REMOVAL..................................6-98

6.10.4 JOGGER MOTOR REPLACEMENT ............................................6-99

A294 II-vi

Page 7

6.10.5 DUPLEX UNIT CLUTCH REPLACEMENT.................................6-100

6.10.6 DUPLEX ENTRANCE SENSOR REPLACEMENT.....................6-101

6.10.7 DUPLEX TRANSPORT SENSORS 2 & 3 ..................................6-102

6.10.8 DUPLEX TRANSPORT SENSOR 1/

DUPLEX INVERTER SENSOR..................................................6-103

6.11 TONER BANK.....................................................................................6-104

6.11.1 WASTE TONER BOTTLE REMOVAL........................................6-104

6.11.2 TONER BANK UNIT REMOVAL ................................................6-105

6.11.3 TONER SUPPLY MOTOR AND

TONER SUPPLY MOTOR SENSOR REMOVAL.......................6-108

6.11.4 ACCESS TO INSIDE THE TONER BANK..................................6-109

6.12 BOARDS AND OTHER ITEMS...........................................................6-110

6.12.1 SICU BOARD.............................................................................6-110

6.12.2 HARD DISK DRIVE....................................................................6-111

6.12.3 BCU BOARD..............................................................................6-112

6.12.4 I/O BOARD.................................................................................6-113

6.12.5 PSU............................................................................................6-114

6.12.6 CHARGE/GRID/BIAS POWER PACK........................................6-115

6.12.7 FUSING/DUPLEX MOTOR REPLACEMENT.............................6-116

6.12.8 DRUM MOTOR REPLACEMENT...............................................6-117

6.13 COPY IMAGE ADJUSTMENT: PRINTING/SCANNING......................6-118

6.13.1 PRINTING ..................................................................................6-118

6.13.2 PARALLELOGRAM IMAGE ADJUSTMENT ..............................6-121

6.13.3 SCANNING.................................................................................6-123

6.13.4 ADF IMAGE ADJUSTMENT.......................................................6-124

6.14 TOUCH SCREEN CALIBRATION.......................................................6-125

7 TROUBLESHOOTING ................................................................. 7-1

7.1 SERVICE CALL CONDITIONS.................................................................7-1

7.1.1 SUMMARY.......................................................................................7-1

7.1.2 SC CODE DESCRIPTIONS .............................................................7-2

7.2 ELECTRICAL COMPONENT DEFECTS ................................................7-37

7.2.1 SENSORS......................................................................................7-37

7.2.2 SWITCHES.....................................................................................7-41

7.3 BLOWN FUSE CONDITIONS.................................................................7-42

A294 II-vii

Page 8

OPTION

3,000-SHEET FINISHER (B302)

1. OVERALL MACHINE INFORMAT ION..................................B302-1

1.1 SPECIFICATIONS.............................................................................. B302-1

1.2 MECHANICAL COMPONENT LAYOUT ............................................ B302-3

1.3 ELECTRICAL COMPONENT DESCRIPTION.................................... B302-4

1.4 DRIVE LAYOUT................................................................................. B302-6

2. DETAILED DESCRIPTIONS.................................................B302-7

2.1 TRAY AND STAPLER JUNCTION GATE.......................................... B302-7

2.2 PAPER PRE-STACKING ................................................................... B302-8

2.3 JOGGER UNIT PAPER POSITIONING ............................................. B302-9

2.4 STAPLER UNIT MOVEMENT.......................................................... B302-10

2.5 STAPLER......................................................................................... B302-12

2.6 FEED-OUT....................................................................................... B302-14

2.7 SHIFT TRAY UP/DOWN MOVEMENT............................................. B302-15

2.8 SHIFT TRAY SIDE-TO-SIDE MOVEMENT...................................... B302-16

2.9 PUNCH UNIT DRIVE ....................................................................... B302-17

2.10 PUNCH WASTE COLLECTION..................................................... B302-18

2.11 JAM CONDITIONS......................................................................... B302-19

3. SERVICE TABLES..............................................................B302-20

3.1 DIP SWITCHES................................................................................ B302-20

3.2 TEST POINTS.................................................................................. B302-20

3.3 FUSES ............................................................................................. B302-20

4. REPLACEMENT AND ADJUSTMENT................................B302-21

4.1 COVER REPLACEMENT................................................................. B302-21

4.2 POSITIONING ROLLER REPLACEMENT ....................................... B302-24

4.3 ALIGNMENT BRUSH ROLLER REPLACEMENT............................ B302-25

4.4 SENSOR REPLACEMENT .............................................................. B302-26

4.4.1 STACK HEIGHT 1, 2 AND EXIT GUIDE OPEN SENSOR...... B302-26

4.4.2 UPPER TRAY PAPER LIMIT AND EXIT SENSOR................. B302-27

4.4.3 SHIFT TRAY EXIT SENSOR................................................... B302-28

4.4.4 ENTRANCE AND

STAPLER TRAY ENTRANCE SENSORS .............................. B302-29

4.4.5 PRE-STACK STOPPER SENSOR .......................................... B302-30

4.4.6 STAPLE WASTE HOPPER SENSOR..................................... B302-31

4.4.7 STAPLER ROTATION HP AND

STAPLER RETURN SENSORS.............................................. B302-32

4.5 STAPLER REMOVAL....................................................................... B302-33

4.6 PUNCH POSITION ADJUSTMENT.................................................. B302-34

A294 II-viii

Page 9

LCT (B303)

1. OVERALL MACHINE INFORMAT ION..................................B303-1

1.1 SPECIFICATIONS.............................................................................. B303-1

1.2 MECHANICAL COMPONENT LAYOUT ............................................ B303-2

1.3 ELECTRICAL COMPONENT DESCRIPTIONS................................. B303-3

1.4 DRIVE LAYOUT................................................................................. B303-5

2. DETAILED DESCRIPTIONS.................................................B303-6

2.1 PAPER FEED..................................................................................... B303-6

2.2 PICK-UP AND FEED.......................................................................... B303-7

2.2.1 OVERVIEW............................................................................... B303-7

2.2.2 PICK-UP AND FEED................................................................. B303-8

2.2.3 SEPARATION ROLLER RELEASE........................................... B303-9

2.3 PAPER LIFT..................................................................................... B303-10

2.3.1 TRAY DETECTION................................................................. B303-10

2.3.2 LIFT MECHANISM.................................................................. B303-10

2.3.3 LIFT SENSOR......................................................................... B303-11

2.4 PAPER SIZE DETECTION............................................................... B303-12

2.5 PAPER END DETECTION............................................................... B303-13

3. REPLACEMENT AND ADJUSTMENT................................B303-14

3.1 EXTERIOR COVER REMOVAL....................................................... B303-14

3.2 INNER COVER REMOVAL.............................................................. B303-15

3.3 PAPER FEED ROLLER REPLACEMENT........................................ B303-16

3.4 LCT MOTOR REPLACEMENT.........................................................B303-17

3.5 RELAY SENSOR REPLACEMENT.................................................. B303-18

3.6 PAPER HEIGHT SENSOR AND

PAPER SIZE SWITCH REPLACEMENT ......................................... B303-19

3.7 MAIN DRIVE BELT REPLACEMENT............................................... B303-20

3.8 SIDE REGISTRATION ADJUSTMENT............................................ B303-21

A3/DLT TRAY KIT (B331)

1. OVERALL MACHINE INFORMAT ION..................................B331-1

1.1 SPECIFICATIONS.............................................................................. B331-1

2. DETAILED DESCRIPTIONS.................................................B331-2

2.1 SECTIONAL DESCRIPTION.............................................................. B331-2

3. REPLACEMENT AND ADJUSTMENT..................................B331-3

3.1 BOTTOM PLATE LIFT WIRE REPLACEMENT................................. B331-3

A294 II-ix

Page 10

CHANGES MADE FROM THE A294 I / A295 I MODELS

1 DETAILED SECTION DESCRIPTIONS ............................. A294 II-1

1.1 TONER AND DEVELOPER.............................................................A294 II-1

1.2 NEWLY ADDED: DEVELOPMENT S UCTION MOTOR AND

SUCKED TONER COLLECTION BOTTLE.....................................A294 II-1

1.3 DEVELOPMENT UNIT....................................................................A294 II-2

1.4 TONER BANK UNIT........................................................................A294 II-3

1.5 CLEANING UNIT.............................................................................A294 II-3

1.6 FUSING UNIT..................................................................................A294 II-4

1.7 NEW ADDITIONS TO TRANSFER CURRENT CONTROL ............A294 II-5

1.8 CHARGE CORONA UNIT...............................................................A294 II-6

1.9 ELECTRICAL COMPONENTS........................................................A294 II-6

2 SERVICE TABLES.............................................................A294 II-9

2.1 SERVICE PROGRAM MODE..........................................................A294 II-9

3 PREVENTIVE MAINTENANCE SCHEDULE................... A294 II-13

3.1 PM PARTS....................................................................................A294 II-13

4 TROUBLESHOOTING ..................................................... A294 II-14

4.1 SERVICE CALL CONDITIONS.....................................................A294 II-14

A294 II-x

Page 11

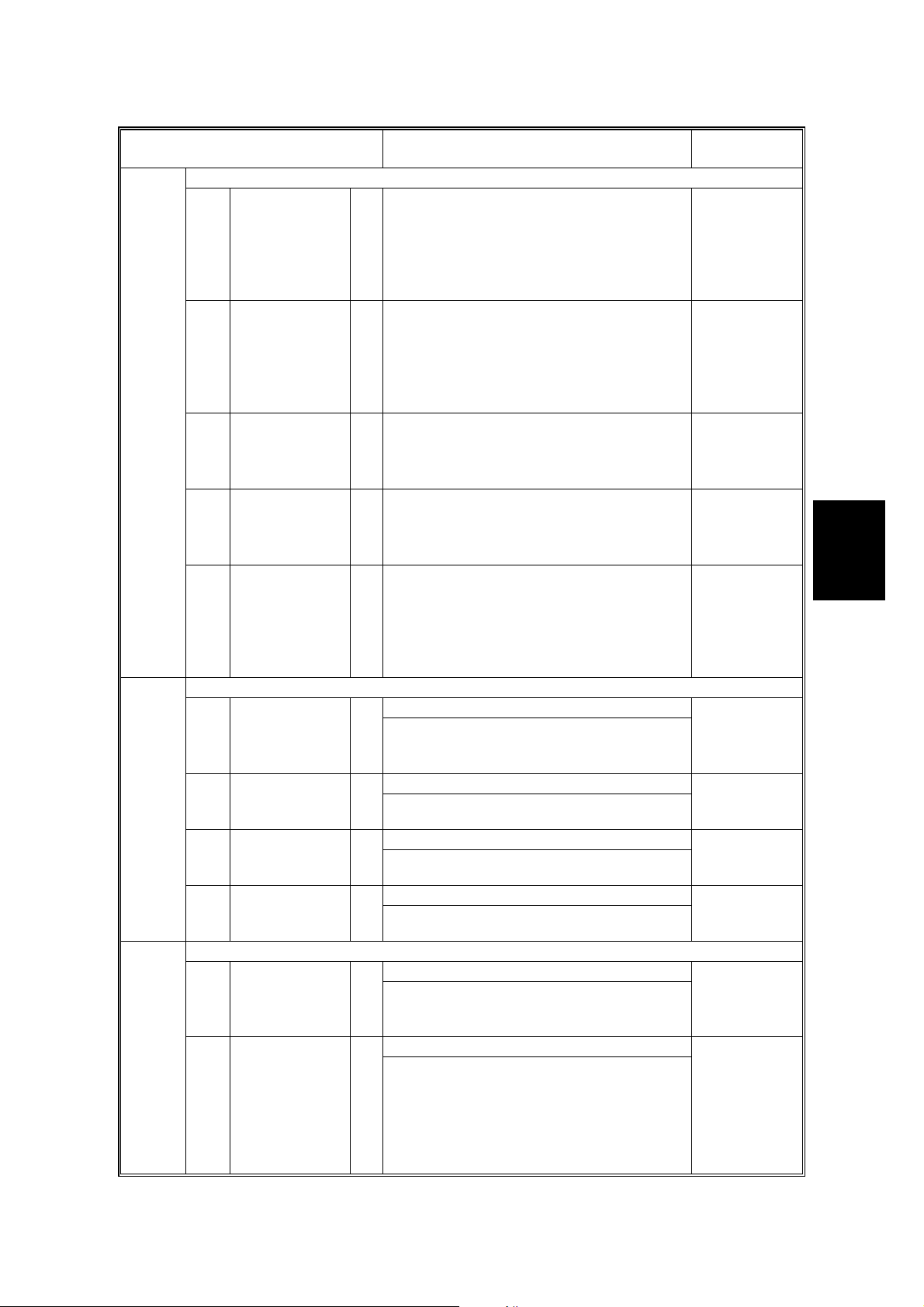

18 July, 2001 GENERAL CAUTIONS

4. SERVICE TABLES

4.1 GENERAL CAUTIONS

Do not turn off either of the power switches while any of the electrical components

are active. Doing so might cause damage to units such as the transfer belt, drum,

and development unit when they are pulled out of or put back into the copier.

4.1.1 DRUM

An organic photoconductor (OPC) drum is more sensitive to light and ammonia gas

than a selenium drum. Follow the cautions below when handling an OPC drum.

1. Never expose the drum to direct sunlight.

2. Never expose the drum to direct light of more than 1,000 Lux for more than a

minute.

3. Never touch the drum surface with bare hands. When the drum surface is

touched with a finger or becomes dirty, wipe it with a dry cloth or clean it with

wet cotton. Wipe with a dry cloth after cleaning with wet cotton.

4. Never use alcohol to clean the drum; alcohol dissolves the drum surface.

Tables

Service

5. Store the drum in a cool, dry place away from heat.

6. Take care not to scratch the drum as the drum layer is thin and is easily

damaged.

7. Never expose the drum to corrosive gases such as ammonia gas.

8. Always keep the drum in the protective sheet when keeping the drum unit, or

the drum itself, out of the copier. Doing so avoids exposing it to bright light or

direct sunlight, and will protect it from light fatigue.

9. Dispose of used drums in accordance with local regulations.

10. When installing a new drum, do the Auto Process Control Data Adjustment (SP

2-962).

4.1.2 DRUM UNIT

1. Before pulling out the drum unit, place a sheet of paper under the drum unit to

catch any spilt toner.

2. Make sure that the drum unit is set in position and the drum stay is secured

with a screw before the main switch is turned on. If the drum unit is loose, poor

contact of the drum connectors may cause electrical noise, resulting in

unexpected malfunctions (RAM data change is the worst case).

3. To prevent drum scratches, remove the development unit before removing the

drum unit.

4-1

Page 12

GENERAL CAUTIONS 18 July, 2001

4.1.3 TRANSFER BELT UNIT

1. Never touch the transfer belt surface with bare hands.

2. Take care not to scratch the transfer belt, as the surface is easily damaged.

3. Before installing the new transfer belt, clean all the rollers and the inner p art of

the transfer belt with a dry cloth to prevent the belt from slipping.

4.1.4 SCANNER UNIT

1. When installing the exposure glass, make sure that the white p aint is at the rear

left corner.

2. Clean the exposure glass with alcohol or glass cleaner to reduce the amount of

static electricity on the glass surface.

3. Use a cotton pad with water or a blower brush to clean the mirrors and lens.

4. Do not bend or crease the exposure lamp flat cable.

5. Do not disassemble the lens unit. Doing so will throw the lens and the copy

image out of focus.

6. Do not turn any of the CCD positioning screws. Doing so will throw the CCD out

of position.

4.1.5 LASER UNIT

1. Do not loosen the screws that secure the LD drive board to the laser diode

casing. Doing so would throw the LD unit out of adjustment.

2. Do not adjust the variable resistors on the LD unit, as they are adjusted in the

factory.

3. The polygon mirror and F-theta lenses are very sensitive to dust. Do not open

the optical housing unit.

4. Do not touch the glass surface of the polygon mirror motor unit with bare

hands.

4-2

Page 13

18 July, 2001 GENERAL CAUTIONS

4.1.6 CHARGE CORONA

1. Clean the corona wires with a dry cloth. Do not use sandpaper or solvent.

2. Clean the charge corona casing with water first to remove NOx based

compounds. Then clean it with alcohol if any toner still remains on the casing.

3. Clean the end block with a blower brush first to remove toner and paper dust.

Then clean with alcohol if any toner still remains.

4. Do not touch the corona wires with bare hands. Oil stains from fingers may

cause uneven image density on copies.

5. Make sure that the wires are correctly between the cleaner pads and that there

is no foreign material (iron filings, etc.) on the casing.

6. When installing new corona wires, do not bend or scratch the wire surface.

Doing so may cause uneven charge. Also be sure that the corona wires are

correctly positioned in the end blocks. (See Charge Corona Wire Replacement)

7. Clean the grid plate with a blower brush (not with a dry cloth).

8. Do not touch the charge grid plate with bare hands. Also, do not bend the

charge grid plate or make any dent in it. Doing so may cause uneven charge.

Tables

Service

4.1.7 DEVELOPMENT

1. Be careful not to nick or scratch the development roller.

2. Place the development unit on a sheet of paper after removing it from the

copier.

3. Never disassemble the development roller assembly. The position of the doctor

plate is set with special tools and instruments at the factory to ensure the

proper gap between the doctor blade and the development roller.

4. Clean the drive gears after removing used developer.

5. Dispose of used developer in accordance with local regulations.

6. Never load types of developer and toner into the development unit other than

specified for this model. Doing so will cause poor copy quality and toner

scattering.

7. Immediately after installing new developer, the TD sensor initial setting

procedure should be performed to avoid damage to the copier. Do not perform

the TD sensor initial setting with used developer. Do not make any copies

before doing the TD sensor initial setting.

8. When u sing a vacuum cleaner to clean the development unit casing, al ways

ground the casing with your fingers to avoid damaging the toner density sensor

with static electricity.

9. When replacing the TD sensor, the developer should be replaced and then the

TD sensor initial setting procedure (SP2-801) should be done, followed by

process control initialization (SP2-962).

4-3

Page 14

GENERAL CAUTIONS 18 July, 2001

4.1.8 CLEANING

1. When servicing the cleaning section, be careful not to damage the edge of the

cleaning blade.

2. Do not touch the cleaning blade with bare hands.

3. Before disassembling the cleaning section, place a sheet of paper under it to

catch any toner falling from it.

4.1.9 FUSING UNIT

1. After installing the fusing thermistor, make sure that it is in contact with the hot

roller and that it is movable.

2. Be careful not to damage the edges of the hot roller strippers or their tension

springs.

3. Do not touch the fusing lamp and rollers with bare hands.

4. Make sure that the fusing lamp is positioned correctly and that it does not touch

the inner surface of the hot roller.

4.1.10 PAPER FEED

1. Do not touch the surface of the pick-up, feed, and separation rollers.

2. To avoid paper misfeeds, the side fences and end fence of the paper tray must

be positioned correctly to align with the actual paper size.

4.1.11 USED TONER

1. We recommend checking the amount of used toner at every EM.

2. Dispose of used toner in accordance with local regulations. Never throw toner

into an open flame, for toner dust may ignite.

4-4

Page 15

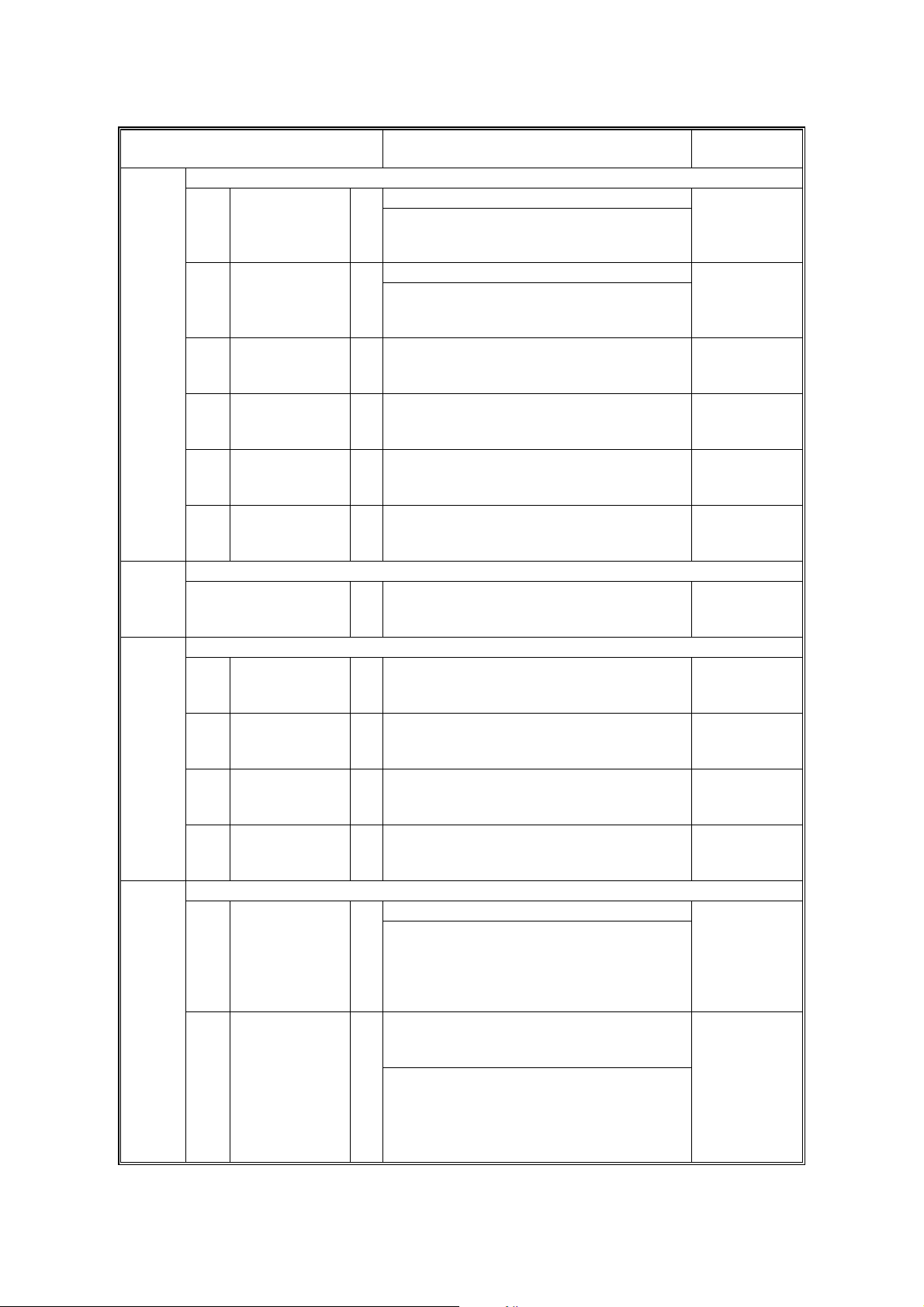

18 July, 2001 SERVICE PROGRAM MODE

4.2 SERVICE PROGRAM MODE

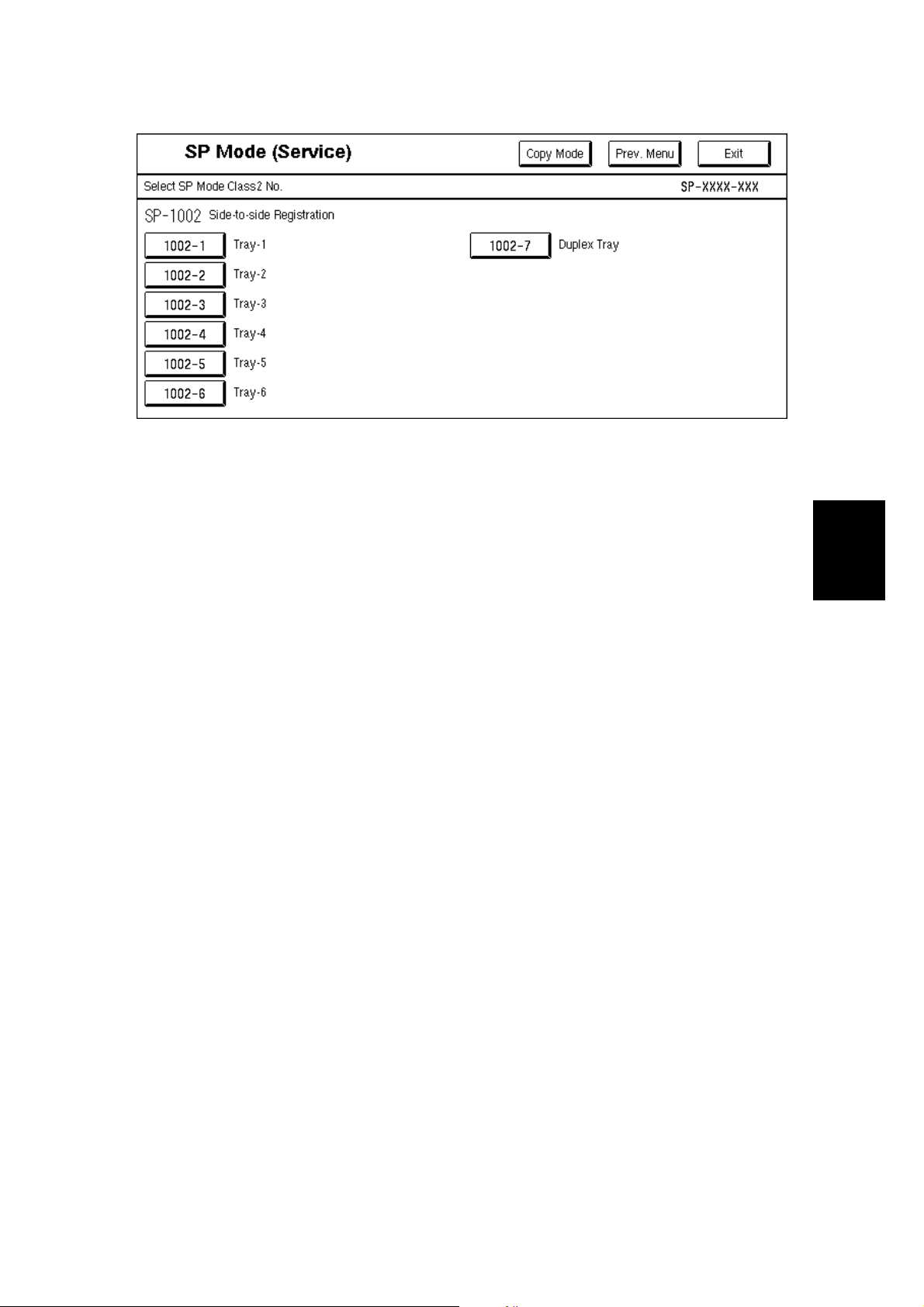

4.2.1 SERVICE PROGRAM MODE OPERATION

The service program (SP) mode is used to check electrical data, change modes,

and adjust values.

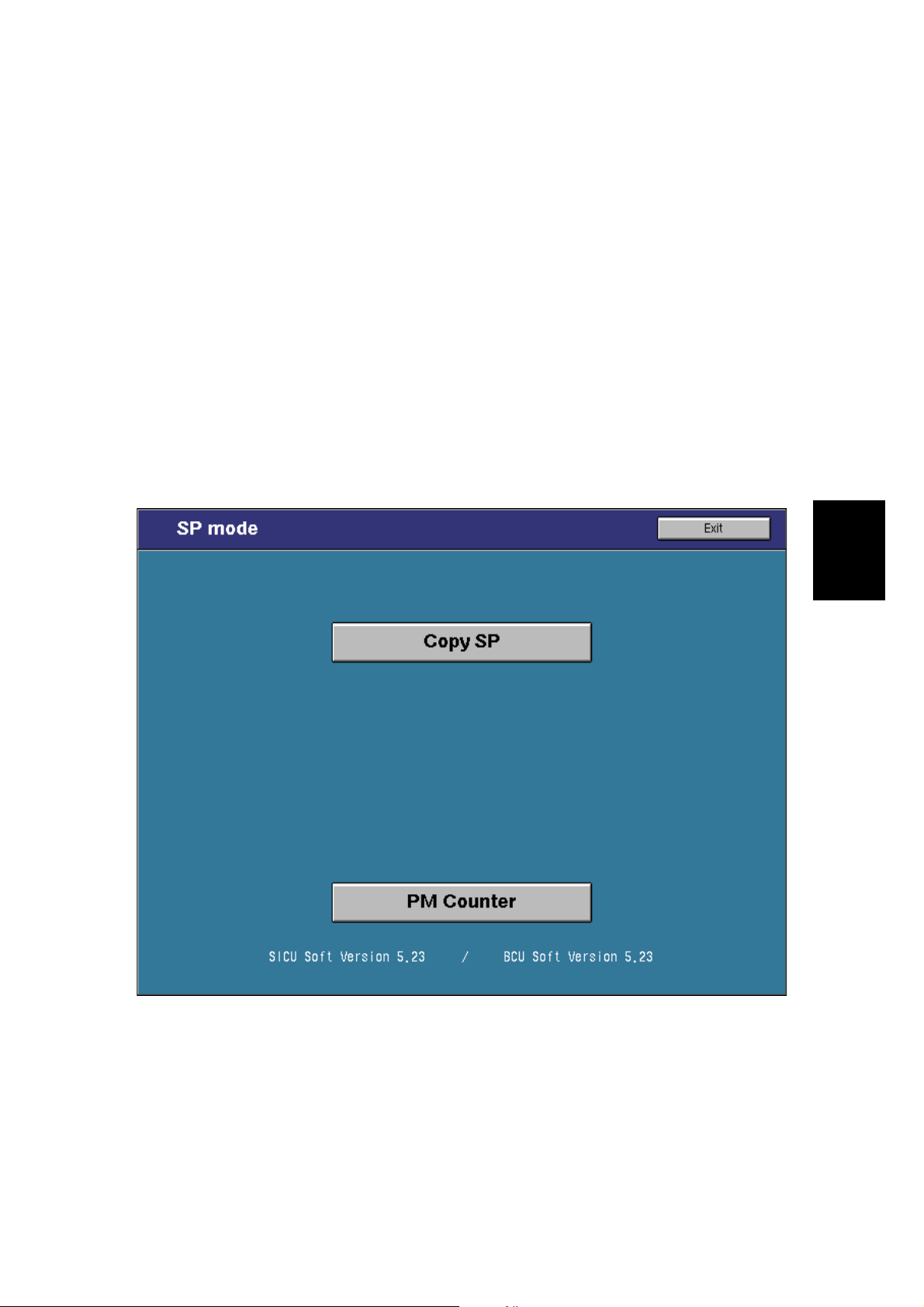

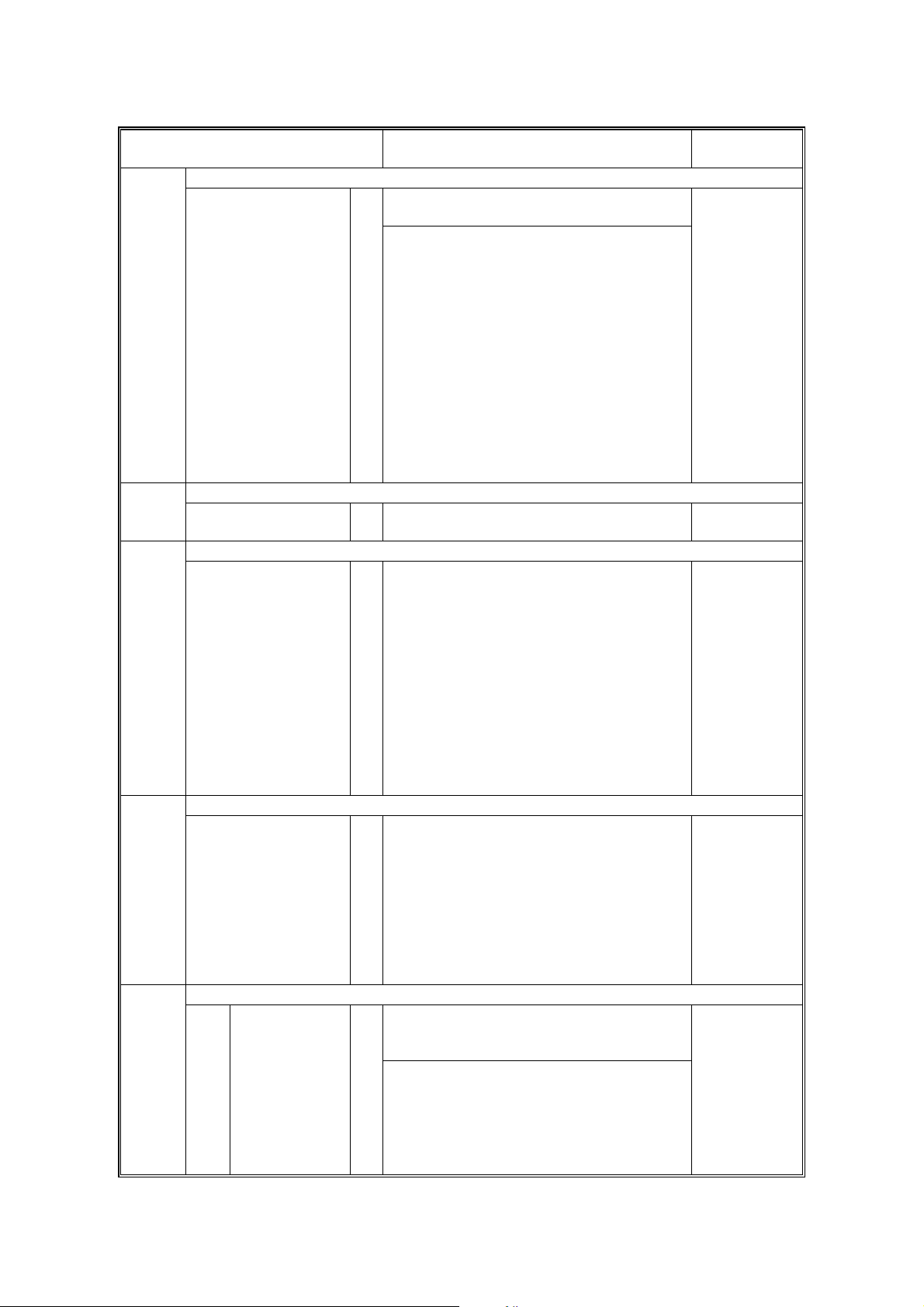

Service Program Access Procedure

Entering SP mode

1) Press the following keys in sequence.

!

Hold the " key for more than 3 seconds.

2) A menu of SP modes is displayed on the LCD.

→

!

"

→

→

#

→

"

Tables

Service

A294M001.PCX

NOTE: The installed applications appear as Copy SP and Printer SP. If the

printer application is not installed, its name does not appear.

4-5

Page 16

SERVICE PROGRAM MODE 18 July, 2001

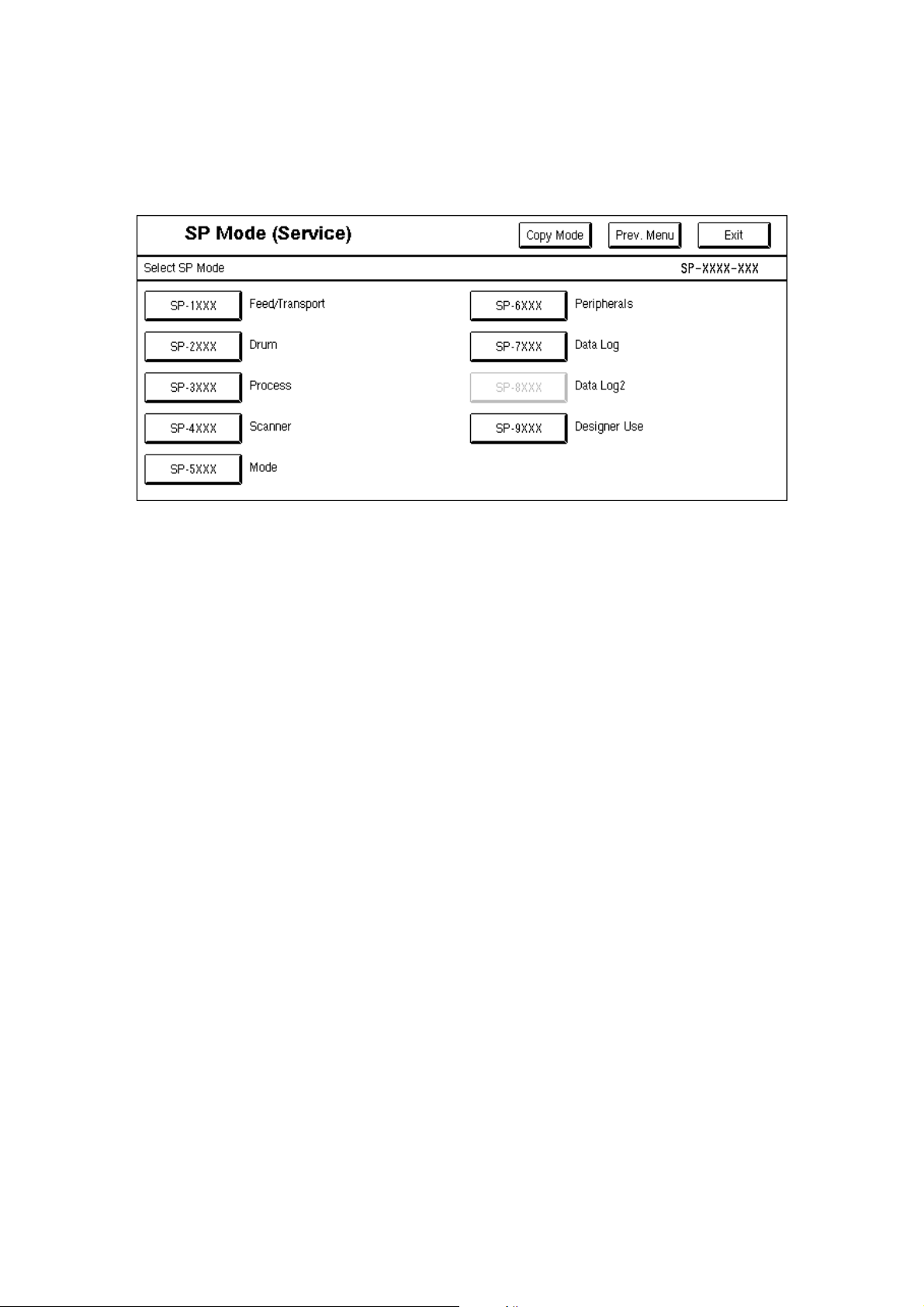

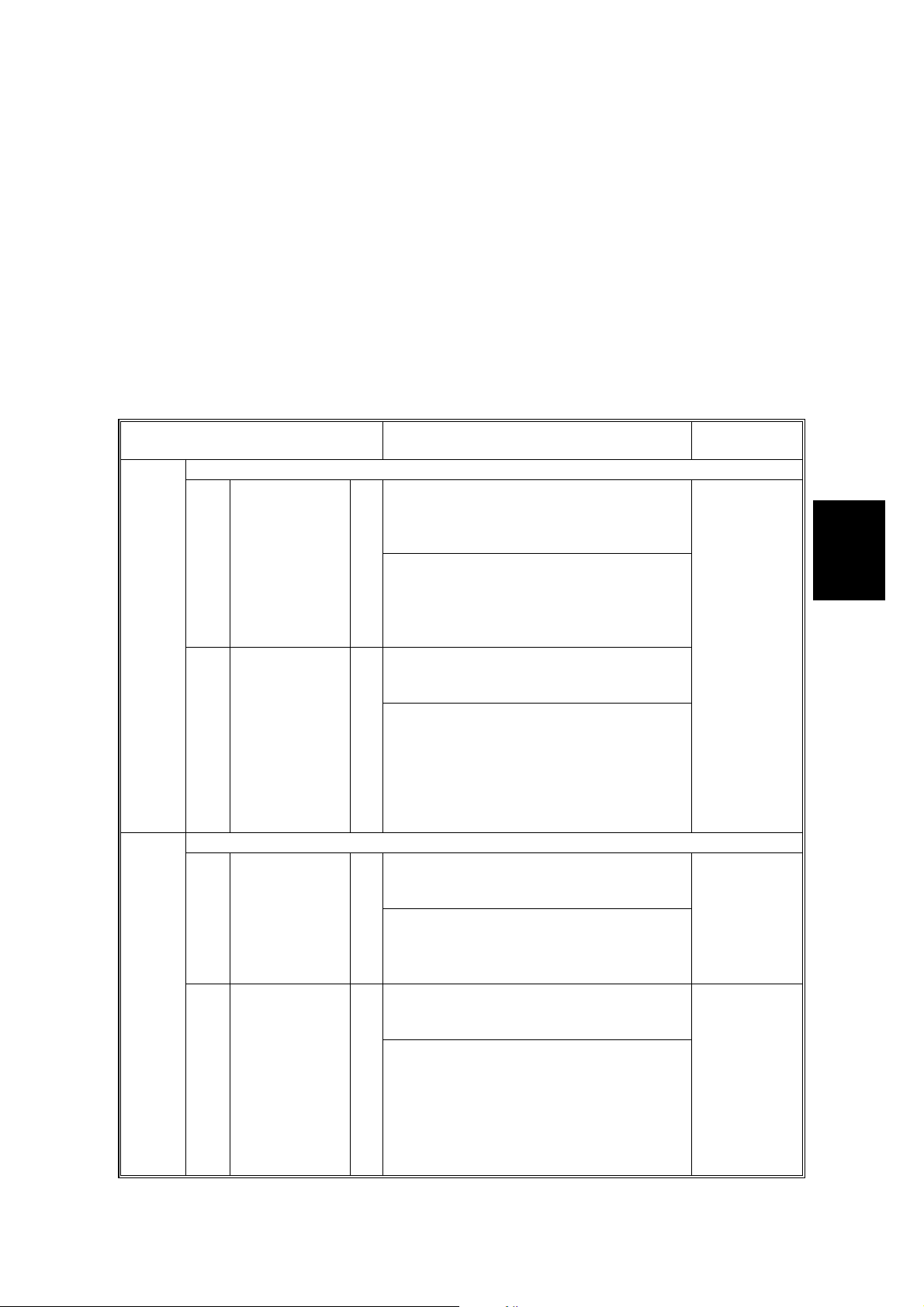

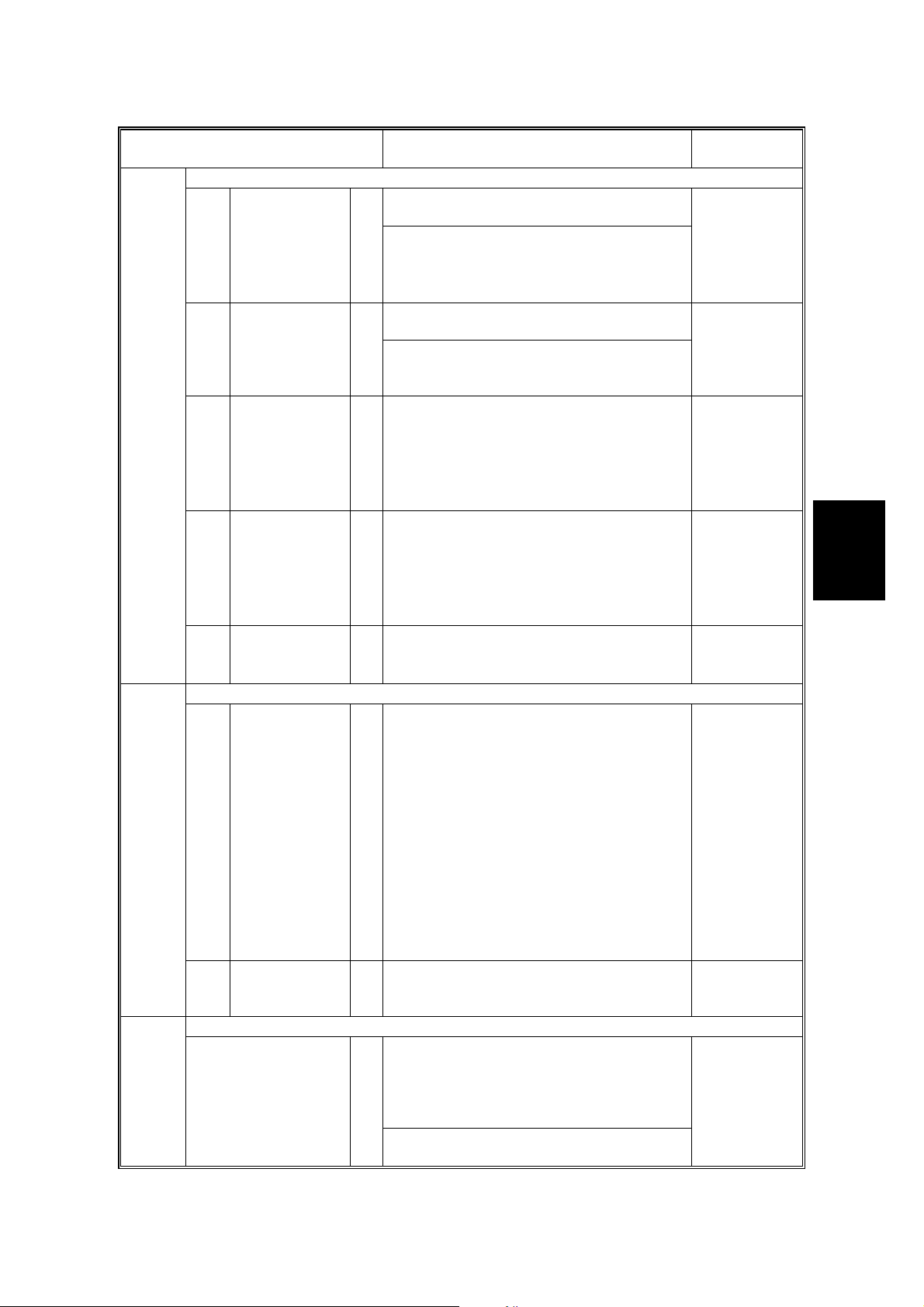

3) Touch the application which you need. Then, the application’s SP mode

display will appear, as shown.

A294M002.PCX

Exiting SP mode

1) Touch the “Exit” keys to return to the standby mode display.

4-6

Page 17

18 July, 2001 SERVICE PROGRAM MODE

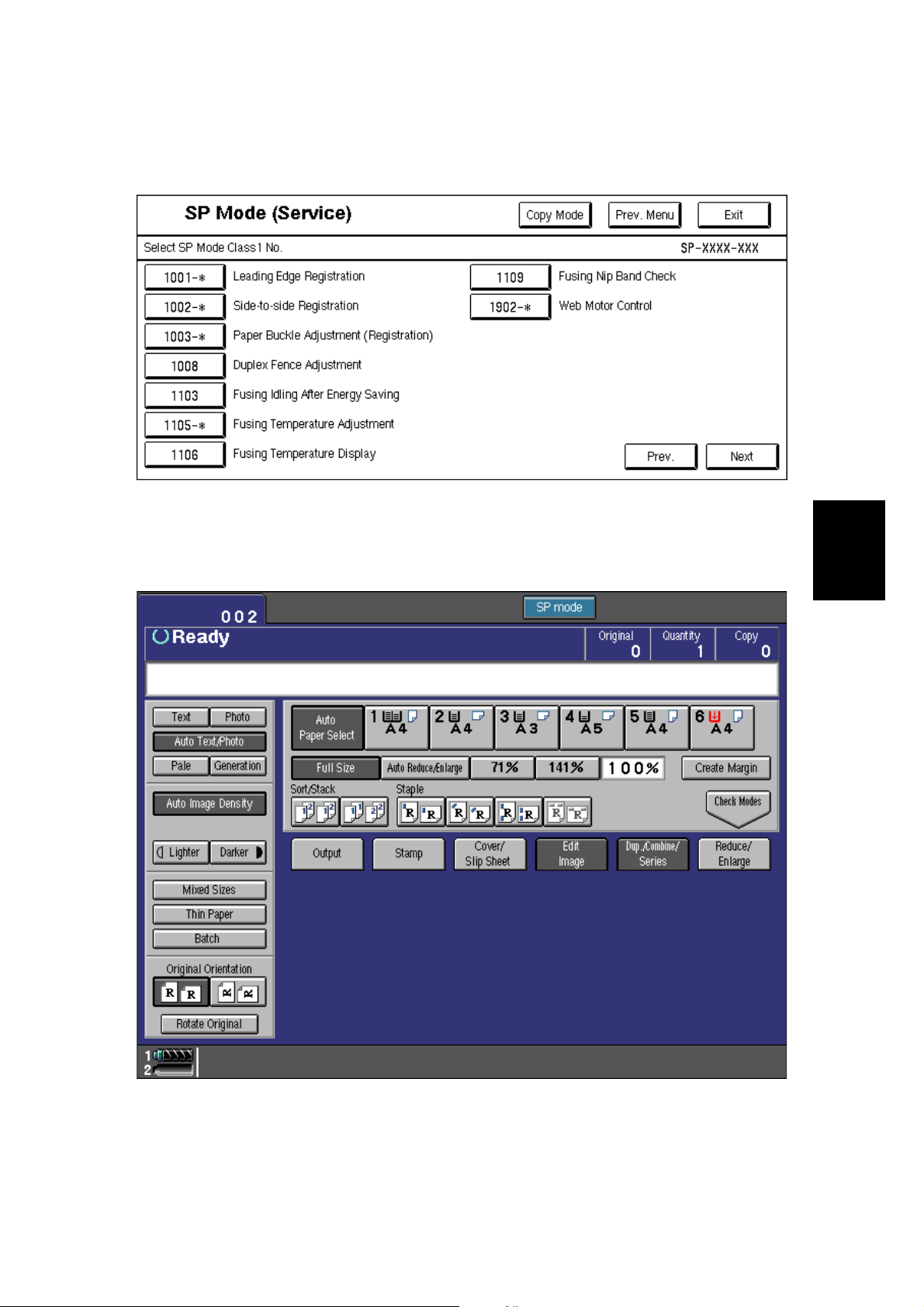

Accessing Copy Mode from within an SP Mode

1) Touch the “Copy Mode” key.

A294M003.PCX

2) Select the appropriate copy mode and make trial copies.

3) To return to the SP mode, touch the “SP mode” key.

Tables

Service

4-7

A294M004.PCX

Page 18

SERVICE PROGRAM MODE 18 July, 2001

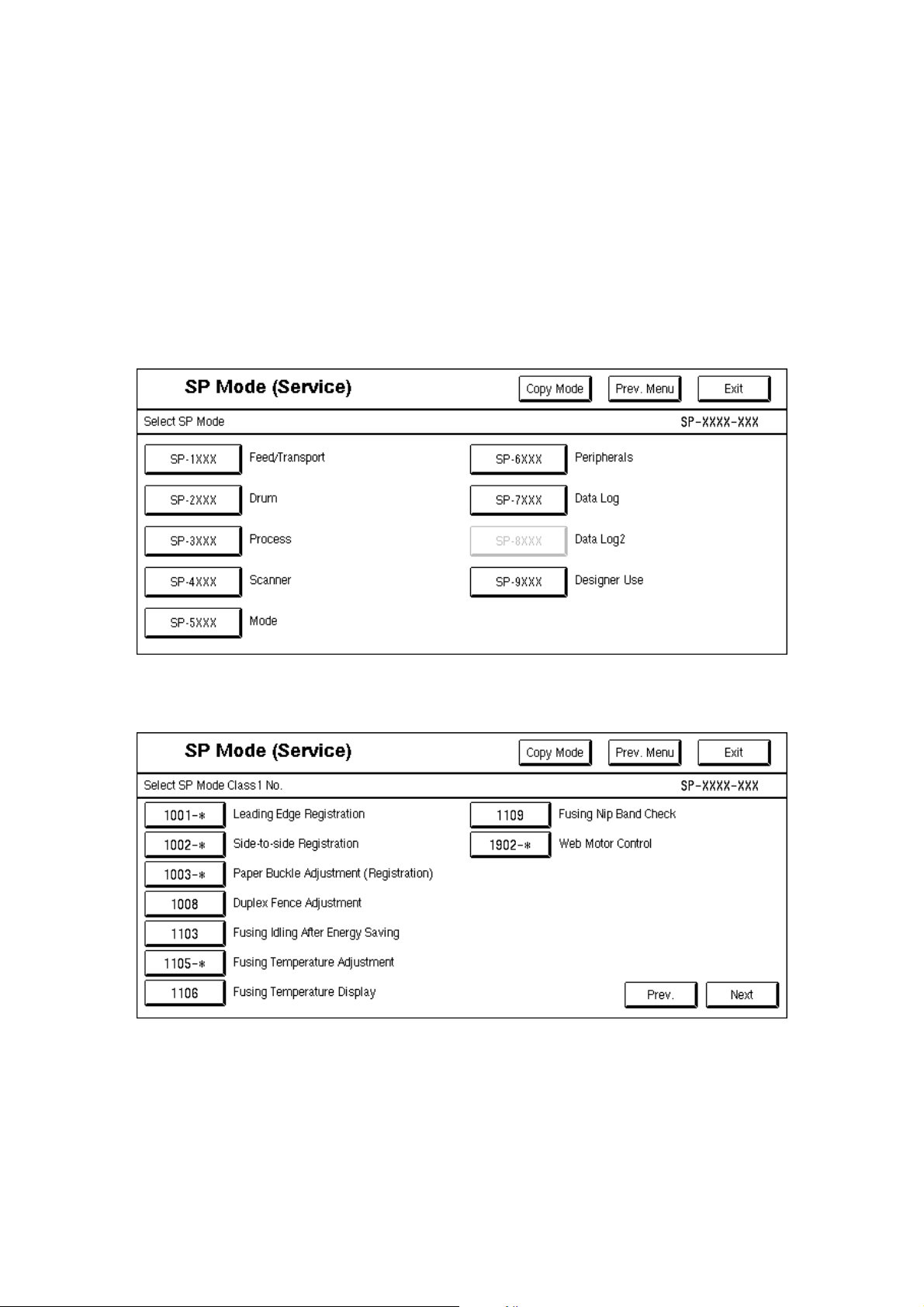

Selecting the Program Number

Program numbers are composed of two or three levels.

There are two ways to select the program number.

Ten-key Pad

Input the required program number.

Touch Panel

1) Touch the 1st level program.

2) Touch the 2nd level program.

NOTE: A “*” mark indicates that there are 3rd level programs.

3) Touch the 3rd level program.

A294M002.PCX

A294M003.PCX

4-8

Page 19

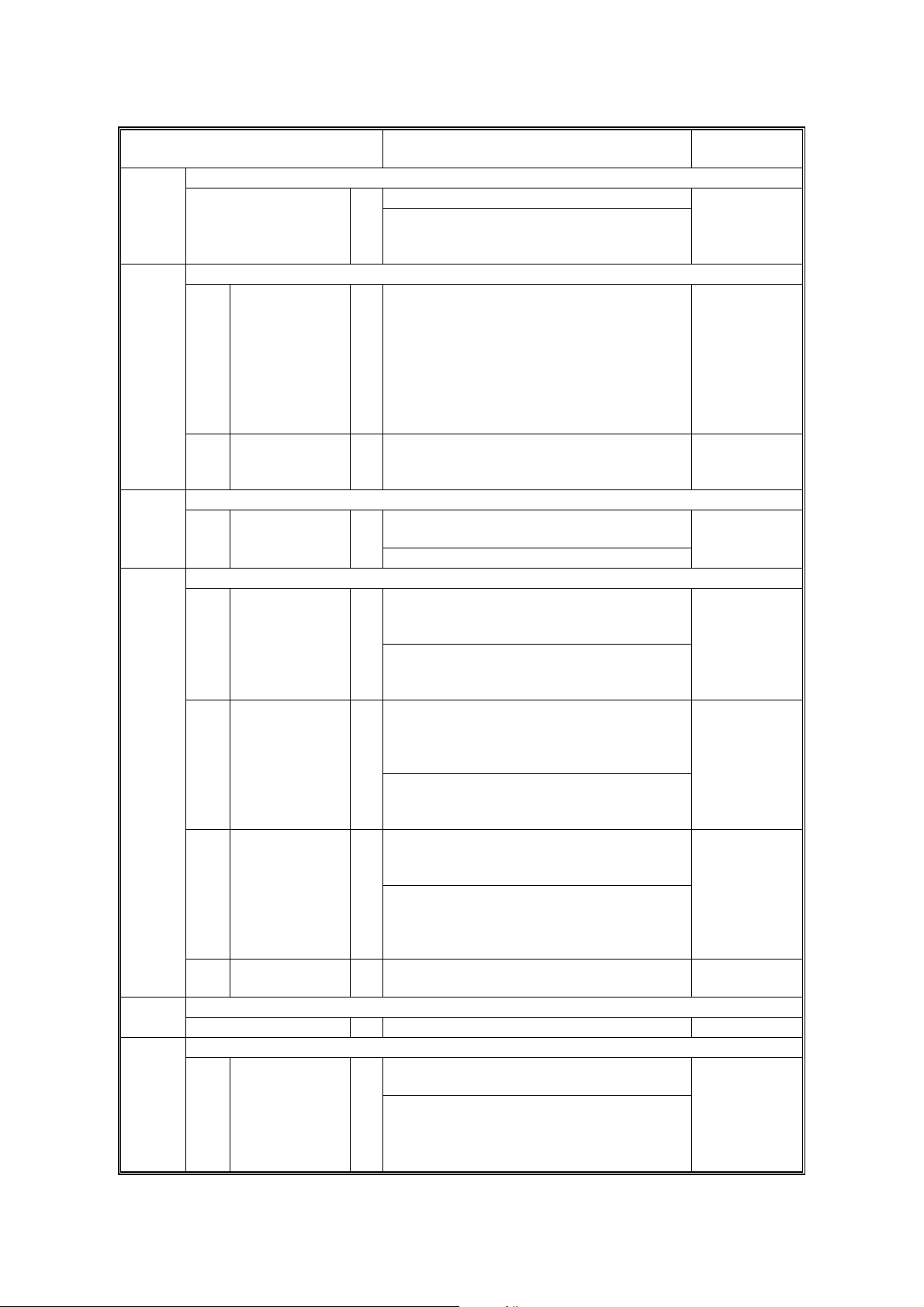

18 July, 2001 SERVICE PROGRAM MODE

A294M005.PCX

Tables

Service

4-9

Page 20

SERVICE PROGRAM MODE 18 July, 2001

Inputting a Value or Setting for an SP Mode

1. Select the required program mode as explained on the previous page.

2. Enter the required setting using the ten-key pad, then touch the “Start” key or

OK key or $ key.

NOTE: 1) If you forget to touch the “Start” key or OK key, the previous value

remains.

2) Change between “+” and “–” using the “•” key before entering the

required value.

3. Exit SP mode.

4-10

Page 21

18 July, 2001 SERVICE PROGRAM MODE

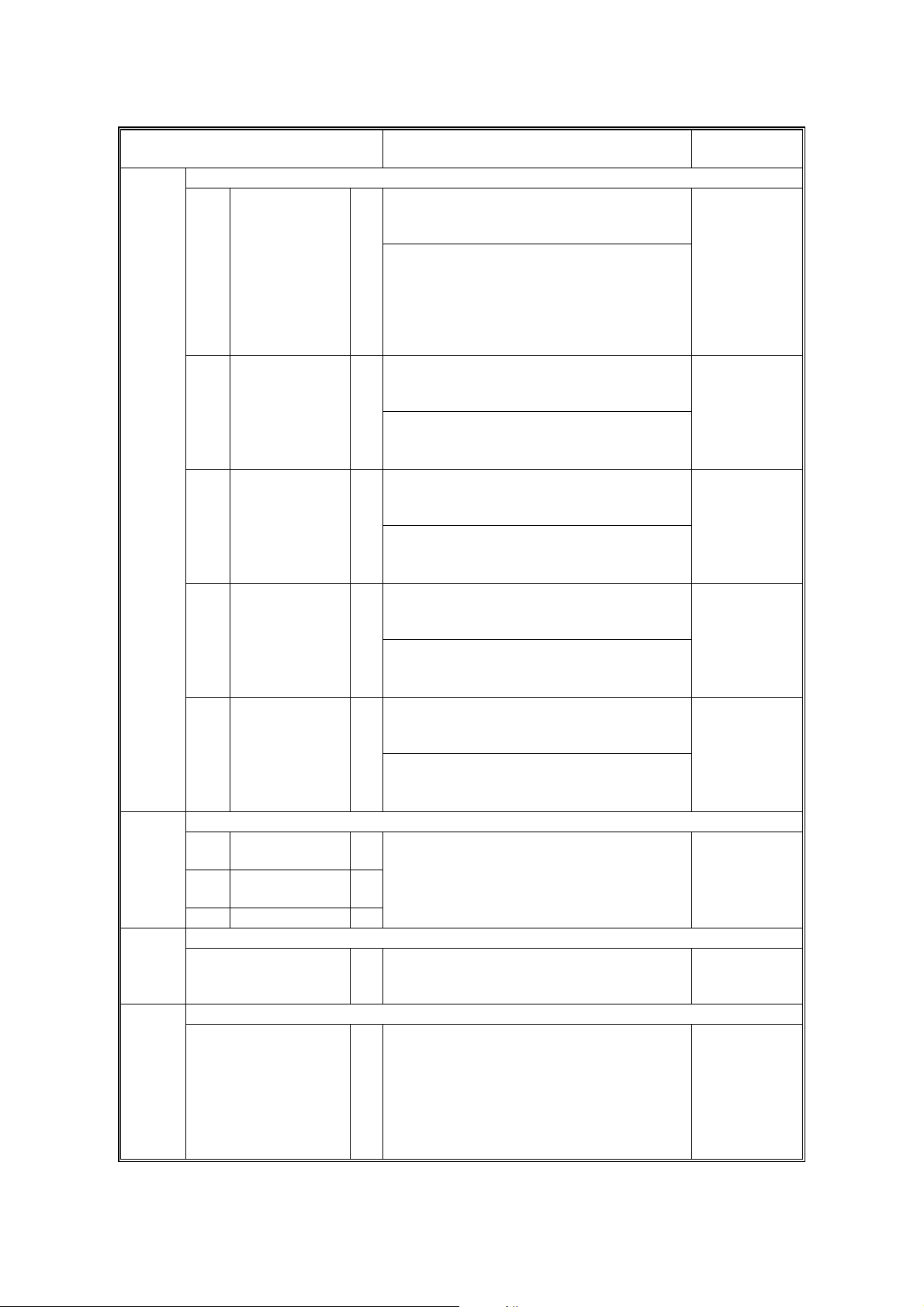

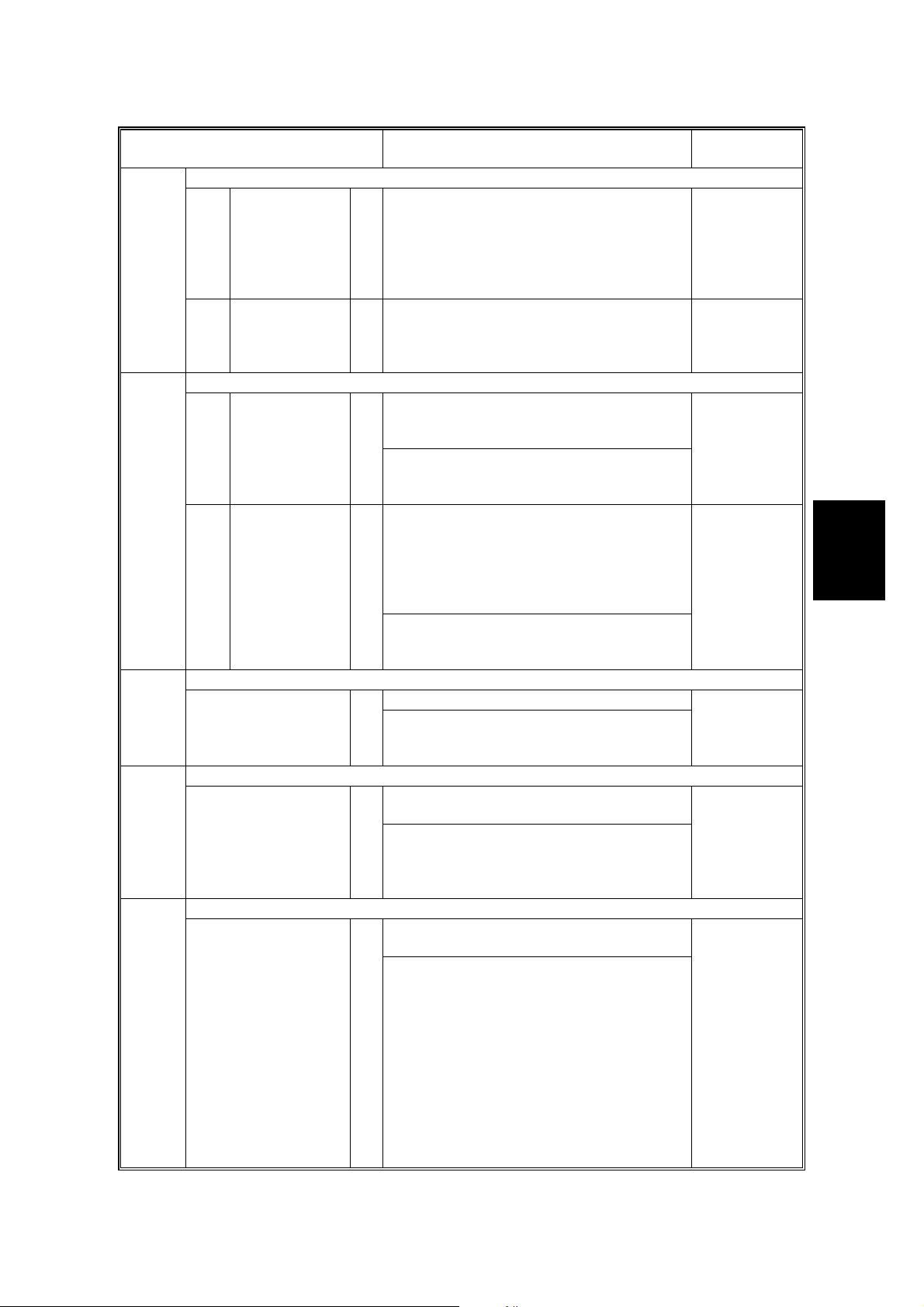

4.2.2 SERVICE PROGRAM MODE TABLES

NOTE: 1) In the Function column, comments are in italics.

2) In the Settings column, the default value is in bold letters.

3) S and B in the right hand side of the mode number column means that

this mode is stored in the NVRAM on the SICU (S) or BCU (B). If you do

a RAM reset, all these SP modes will be reset to their factory settings.

4) [A294 I], [A295 I], [A294 II] and [A295 II] in the Settings column mean

the following product types:

[A294 I]: Existing 85 cpm model. [A295 I]: Existing 105 cpm model.

[A294 II]: Enhanced 85 cpm model. [A295 II]: Enhanced 105 cpm

model.

1-001

1-002

Mode No.

(Class 1, 2 and 3)

Leading Edge Registration

Paper Tray

1

(Copier and

LCT)

2 Duplex Tray

Side-to-Side Registration

1Tray-1

2Tray-2

Function Settings

Adjusts the printing leading edge

registration for feeding from the trays using

the trimming area pattern (SP2-902-3,

No.15).

B

Use the “

before entering the value.

The specification is 3

See "Replacement and Adjust m ent – Copy

Image Adjustments" for details.

Adjusts the printing leading edge

registration for the duplex feeding using the

trimming area pattern (SP2-902-3, No.15).

Use the “

before entering the value.

B

The specification is 3

See "Replacement and Adjust m ent – Copy

Image Adjustments" for details.

Adjusts the printing side-to-side registration

from the 1st paper feed station using the

trimming area pattern (SP2-902-3, No.15).

B

Use the “

before entering the value.

See “Replacement and Adjustment – Copy

Image Adjustments” for details on SP1-002.

Adjusts the printing side-to-side registration

from the 2nd paper feed station using the

trimming area pattern (SP2-902-3, No.15).

Use the “

before entering the value.

B

The specification is 0

•

” key to toggle between + and –

±

2 mm.

•

” key to toggle between + and –

±

2 mm.

•

” key to toggle between + and –

•

” key to toggle between + and –

±

2.0 mm.

+9 ~ –9

0.1 mm/step

+3.0 mm

+9 ~ –9

0.1 mm/step

–1.5 mm

+9 ~ –9

0.1 mm/step

–1.5 mm

Tables

Service

4-11

Page 22

SERVICE PROGRAM MODE 18 July, 2001

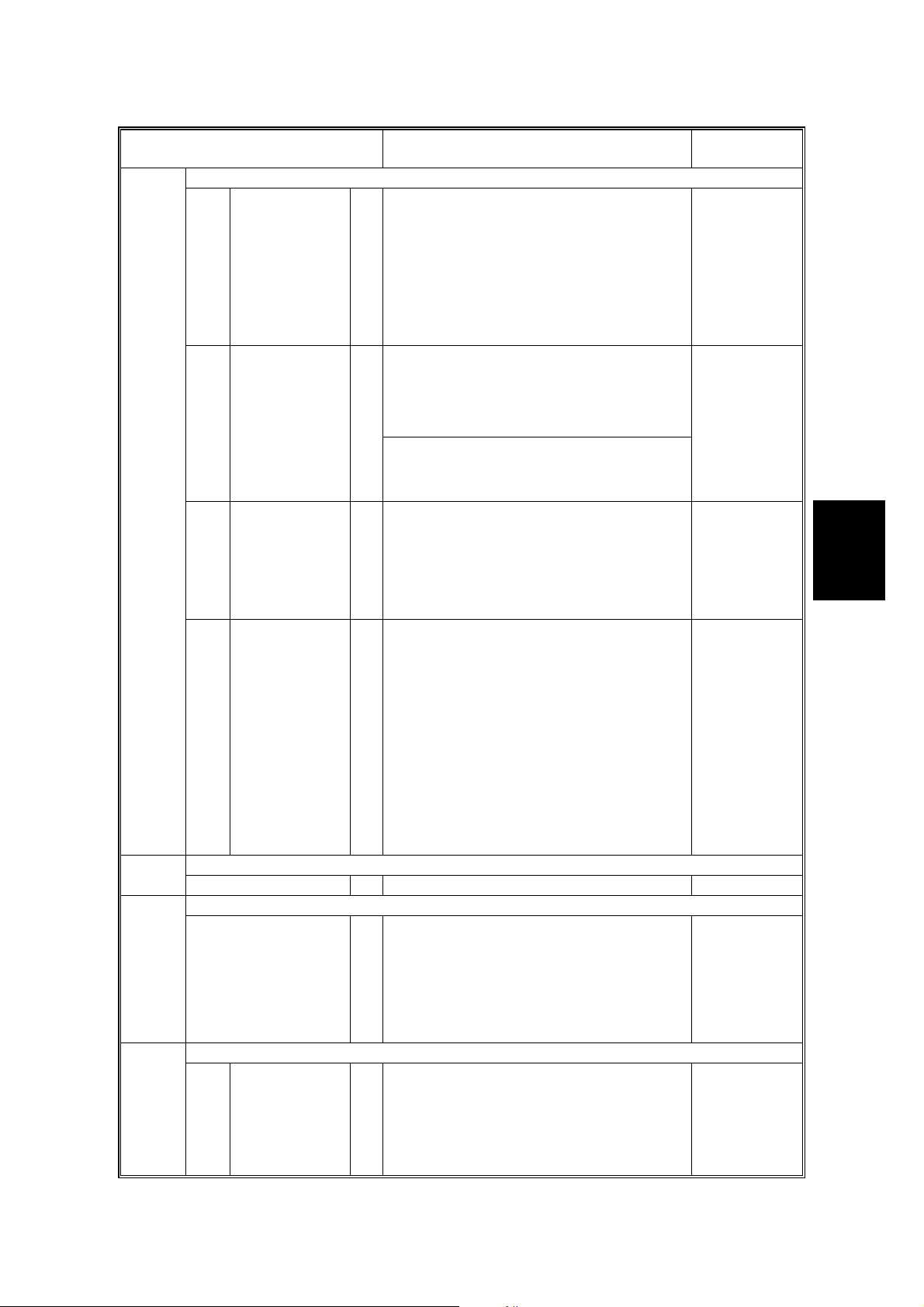

1-002

1-003

Mode No.

(Class 1, 2 and 3)

Side-to-Side Registration

3Tray-3

4 Tray-4 (LCT)

5 Tray-5 (LCT)

6 Tray-6 (LCT)

7 Duplex Tray

Paper Buckle Adjustment (Registration)

1 Copier Paper

Tray

2LCT Tray

3 Duplex Tray B

Duplex Fence Adjustment1-008

Fusing Idling After Low Power Mode1-103

Adjusts the printing side-to-side registration

from the 3rd paper feed station using the

trimming area pattern (SP2-902-3, No.15).

Use the “

B

before entering the value.

The specification is 0

Adjusts the printing side-to-side registration

from the 4th paper feed station using the

trimming area pattern (SP2-902-3, No.15).

B

Use the “

before entering the value.

The specification is 0

Adjusts the printing side-to-side registration

from the 5th paper station using the

trimming area pattern (SP2-902-3, No.15).

B

Use the “

before entering the value.

The specification is 0

Adjusts the printing side-to-side registration

from the 6th paper station using the

trimming area pattern (SP2-902-3, No.15).

B

Use the “

before entering the value.

The specification is 0

Adjusts the printing side-to-side registration

from the duplex tray using the trimming

area pattern (SP2-902-3, No.15).

B

Use the “

before entering the value.

The specification is 0

Adjusts the relay clutch timing at

B

registration. The relay clutch timing

determines the amount of paper buckle at

B

registration. (A +ve setting leads to more

buckling.)

Adjusts the distance between the front and

B

rear fences.

Selects whether fusing idling is done or not

when recovering from the low power mode.

Function Settings

•

” key to toggle between + and –

±

2.0 mm.

•

” key to toggle between + and –

±

2.0 mm.

•

” key to toggle between + and –

±

2.0 mm.

•

” key to toggle between + and –

±

2.0 mm.

•

” key to toggle between + and –

±

2.0 mm.

+9 ~ –9

0.1 mm/step

–1.5 mm

+9 ~ –9

0.1 mm/step

–2.5 mm

+9 ~ –9

0.1 mm/step

–2.5 mm

+9 ~ –9

0.1 mm/step

–2.5 mm

+9 ~ –9

0.1 mm/step

–3.0 mm

+9 ~ –9

1 mm/step

+4.0 mm

+4 ~ –4

0.5 mm/step

0.0 mm

0: Not done

1: Done

B

4-12

Page 23

18 July, 2001 SERVICE PROGRAM MODE

1-105

Mode No.

(Class 1, 2 and 3)

Fusing Temperature Adjustment

Fusing

1

Temperature in

Waiting

Condition

2Fusing

Temperature

Lower Limit

3Fusing

Temperature

Correction

(<A4/LT)

4Fusing

Temperature

Correction

(A4/LT)

Fusing Temperature Display1-106

Fusing Nip Band Check1-109

Web Motor Control1-902

1Web

Consumption

Adjusts the fusing temperature for standby.

B

Adjusts the fusing temperature lower limit.

When the fusing unit falls below this

temperature, the machine stops copying.

Copying automatically restarts when the

B

fusing temperature recovers.

This SP mode is for designer’s use only.

Specifies the amount to raise the fusing

temperature from standby mode to print on

A4/LT or smaller width paper.

B

Specifies the amount to raise the fusing

temperature from standby mode to print on

paper of A4/LT width.

B

Displays the fusing temperature.

Feeds a sheet from a paper tray and stops

the sheet when it is between the hot roller

and the pressure roller. Use an OHP sheet.

After keeping the sheet there for 30

seconds, the sheet is automatically fed out.

For details, see Replacement and

Adjustment – Fusing.

Displays the percentage of the web

consumption in 1% steps (0% ~ 107%).

The value can be manually input using

B

number keys.

Function Settings

[A294 I & II]

168 ~ 178

1°C/step

173°°°°C

[A295 I & II]

173 ~ 178

1°C/step

178°°°°C

[A294 I & II]

157 ~ 163

1°C/step

163°°°°C

[A295 I & II]

157 ~ 167

1°C/step

167°°°°C

+0 ~ +20

1°C/step

[A294 I & II]

+15°°°°C

[A295 I & II]

+20°°°°C

–5 ~ +20

1°C/step

[A294 I]

+10°°°°C

[A295 I]

+15°°°°C

[A294 II]

+5°°°°C (US)

+10°°°°C (EU)

[A295 II]

+5°°°°C (US)

+15°°°°C (EU)

Tables

Service

4-13

Page 24

SERVICE PROGRAM MODE 18 July, 2001

1-902

2-001

Mode No.

(Class 1, 2 and 3)

Web Motor Control

Web Motor

2

Drive Interval

Web Motor

3

Drive Time

Web Near End

4

Setting

Duplex Stop Position – Right1-906

Charge Corona Bias Adjustm ent

1 Image Area

(Auto Process

Control OFF)

2 ID Sensor

Pattern (Auto

Process Control

OFF)

Change the interval of copy operation time

after which the web motor is driven

B

Changes the time that the web motor is

driven.

B

Changes the web consumption ratio at

which web near end is displayed.

About 40k A4 copies can be made after the

B

web consumption reaches 100%.

Changes the paper stop position in the

duplex unit after passing duplex transport

B

sensor 2.

For designer use only.

Adjusts the voltage applied to the grid plate

during copying when auto process control

is off.

Normally, there is no need to adjust this.

B

If there is an ID or TD sensor problem, the

machine goes into fixed toner supply mode.

After replacing the drum or charge corona

wire, change this value to the default.

Adjusts the voltage applied to the grid plate

when making the ID sensor pattern, when

auto process control is switched off.

Normally, there is no need to adjust this.

If the user wants high density copies, the

B

sensor pattern must be lighter, so this

voltage must be a higher negative voltage.

Function Settings

[A294/A295 I]

15 ~ 130

1 s/step

[A294 I] 42 s

[A295 I] 34 s

[A294/A295 II]

3 ~ 130

1 s/step

[A294 II]

11 s (EU)

21 s (US)

[A295 II]

9 s (EU)

17 s (US)

[A294/A295 I]

0.1 ~ 3.0

0.1 s/step

0.8 s

[A294/A295 II]

0.3 ~ 3.5

0.1 s/step

2.8 s

0 ~ 105

1%/step

[A294/A295 I]

100%

[A294/A295 II]

86% (EU)

90% (US)

–10 ~ 10

2 mm/step

–8 mm

–600 ~ –1,300

10 V/step

–1,000 V

–600 ~ –1,300

10 V/step

–800 V

4-14

Page 25

18 July, 2001 SERVICE PROGRAM MODE

2-001

2-101

Mode No.

(Class 1, 2 and 3)

Charge Corona Bias Adjustm ent

Image Area

3

(Auto Process

Control ON)

Adjusts the voltage applied to the grid plate

during copying when auto process control

is switched on.

B

This voltage changes every time auto

process control starts up (every time the

machine is switched on)

4 Grid Voltage for

Transparent

Sheet

Adjusts the voltage applied to the grid plate

when translucent mode is selected.

Use this if there is a copy quality problem

B

when making copies on translucent paper.

Normally there is no need to adjust this.

See 2-001-1.

5 Total Corona

Current

Total Corona

6

Current (Photo

mode)

D

7V

(Auto

Process

Control)

Adjusts the current applied to the charge

corona wire except for Photo mode.

B

Adjusts the current applied to the charge

corona wire for Photo mode.

B

Adjusts the target V

Control Initial Setting.

B

Printing Erase Margin

Adjusts the leading edge erase margin.1 Leading Edge

See “Replacement and Adjustment – Copy

S

Image Adjustments” for more on SP2-101.

Function Settings

–600 ~ –1,300

10 V/step

[A294/A295 I]

–1,000 V

[A294/A295 II]

–950 V

–600 ~ –1,300

10 V/step

[A294/A295 I]

–1,070 V

[A294/A295 II]

–950 V

–1,400 ~

–2,800

100µA/step

–1,400 µµµµA

1,400 ~

–2,800

100µA/step

–1,600 µµµµA

D

voltage for Process

–800 ~ –1,000

10 V/step

[A294/A295 I]

–970 V

[A294/A295 II]

–850 V

0.0 ~ 9.0

0.1 mm/step

2.5 mm

Tables

Service

2-103

4Right

LD Power Adjustment

2 LD2 - 600dpi

Adjusts the trailing edge erase margin.2 Trailing Edge

S

Adjusts the left side erase margin.3 Left

S

Adjusts the right side erase margin.

S

Adjusts the power of LD1.1 LD1 - 600dpi

Do not change the value.

B

Adjusts the power of LD2.

Do not change the value.

B

4-15

0.0 ~ 9.0

0.1 mm/step

2.5 mm

0.0 ~ 9.0

0.1 mm/step

2.0 mm

0.0 ~ 9.0

0.1 mm/step

2.0 mm

–127 ~ +127

1/step

1 = 1.1 µW

+0

–127 ~ +127

1/step

1 = 1.1 µW

+0

Page 26

SERVICE PROGRAM MODE 18 July, 2001

2-103

2-114

2-201

Mode No.

(Class 1, 2 and 3)

LD Power Adjustment

Adjusts the power of LD3.3 LD3 - 600dpi

Do not change the value.

B

Adjusts the power of LD4.4 LD4 - 600dpi

Do not change the value.

B

LD1 Power

5

Adjustment

(Start/End)

LD2 Power

6

Adjustment

(Start/End)

LD3 Power

7

Adjustment

(Start/End)

LD4 Power

8

Adjustment

(Start/End)

LD Power Adjustment (for ID pattern)2-104

Printer Dot Edge Parameter Setti ng

1 Leading Dot

Level Setting

(Left Edge)

2 Trailing Dot

Level Setting

(Right Edge)

3 Multiple Dot

Level Setting S

4 Independent

Dot Level

Setting

Development Bias Adjustment

2 ID Sensor

Pattern

Factory use only. Do not use this SP

B

mode.

Factory use only. Do not use this SP

B

mode.

Factory use only. Do not use this SP

B

mode.

Factory use only. Do not use this SP

B

mode.

Selects the LD power for making the ID

pattern when auto process control is

B

switched on. Do not use unless advised.

Changes the LD power level for the left

S

edge pixel in printer mode, if FCI is off.

Changes the LD power level for the left

S

edge pixel in printer mode, if FCI is off.

Changes the LD power level for continuous

pixels in printer mode, if FCI is off.

Changes the LD power level for

S

independent dots in printer mode, if FCI is

off.

Adjusts the development bias for copying.1 Image Area

This can be adjusted as a temporary

measure if faint copies appear due to an

B

aging drum.

Adjusts the development bias for making

the ID sensor pattern for V

when the auto process control is set to off.

This should not be used in the field,

B

because it affects ID sensor pattern

density, which affects toner supply.

Function Settings

–127 ~ +127

1/step

1 = 1.1 µW

+0

–127 ~ +127

1/step

1 = 1.1 µW

+0

Start

Stop

Start

Stop

Start

Stop

Start

Stop

0 ~ 7

1/step

4

20 ~ 100%

1% step

50%

20 ~ 100%

1% step

50%

20 ~ 100%

1% step

100%

20 ~ 100%

1% step

50%

–200 ~ –700

10 V/step

[A294/A295 I]

–530 V

[A294/A295 II]

–650 V

–200 ~ –700

SP

measurement

10 V/step

–400 V

4-16

Page 27

18 July, 2001 SERVICE PROGRAM MODE

2-201

2-207

2-208

2-209

2-210

Mode No.

(Class 1, 2 and 3)

Development Bias Adjustment

Transparent

3

Sheet

B

4 ID Sensor

Development

Potential

B

Forced Toner Supply

1 Forced Toner

Supply

2 Toner Bank

Toner Setup

Toner Supply Mode

B

Toner Supply Rate

B

ID Sensor Pattern Interval

Function Settings

Adjusts the development bias for copying

onto translucent sheets.

Adjusts the development potential for

making the ID sensor pattern for V

SP

measurement when the auto process

control is set on.

Forces toner supply for 7 seconds from the

toner bank through the toner hopper to the

development unit.

This mode finishes automatically after the

toner is supplied 7 times (1 s for each

time).

Turns on the main motor, development

motor, development bias, toner supply

motor and charge corona. Then turns on

the toner supply coil clutch to supply toner

to the toner hopper, but not to the

development unit. It takes about 7 minutes.

This mode should be used to fill the toner

transport path with toner after cleaning the

toner supply unit, or at installation.

Selects the toner supply mode.

Use image pixel count mode only as a

temporary countermeasure if the ID or TD

sensor is defective.

Adjusts the toner supply rate from the

hopper.

Increasing this value reduces the toner

supply roller clutch on time. Use a lower

value if the user tends to make lots of

copies that have a high proportion of black.

Changes the interval for making the ID

sensor pattern (V

SP/VSG

detection).

If the user normally makes copies with a

high proportion of black, reduce the

interval.

–200 ~ –700

10 V/step

[A294/A295 I]

–530 V

[A294/A295 II]

–650 V

180 ~ 380

1 V/step

280 V

Start

Start

Sensor

Control

Pixel Count

Control

100 ~ 2,000

10 mg/s/step

[A294 I & II]

800 mg/s

[A295 I & II]

1000 mg/s

0 ~ 500

1 copy/step

10 copies

Tables

Service

B

4-17

Page 28

SERVICE PROGRAM MODE 18 July, 2001

2-220

2-301

Mode No.

(Class 1, 2 and 3)

REF

V

Manual Setting

B

VT Display2-223

B

Toner Bank Toner Discharge2-226

Toner Supply Mode Display2-227

Transfer Current Adjustment

11st Copy Side

B

Function Settings

Adjusts the TD sensor reference voltage

REF

(V

).

Change this value after replacing the

development unit with another one that

already contains toner.

For example, when using a development

unit from another machine for test

purposes, do the following:

1. Check the value of SP2-220 in both the

machine containing the test unit and the

machine that you are going to move it to.

2. Install the test development unit, then

input the V

for this unit into SP2-220.

REF

3. After the test, put back the old

development unit, and change SP2-220

back to the original value.

Displays the current TD sensor output

voltage.

This SP removes toner from the toner bank

to the toner hopper.

After turning the toner supply motor and the

toner bank motor on, the toner supply coil

clutch turns on and off at 2 second

intervals. The motors and clutch stop when

the toner near-end sensor (in the toner

bank unit) detects no toner.

Even if the sensor continues to detect

toner, this operation stops when the clutch

has been turned on and off 10 times, so

this SP may have to be repeated to clean

out the system completely.

Displays the toner supply mode used for

the last copy.

1: ID Sensor and TD Sensor (from the 11th

copy, using V

T

– V

REF

)

2: ID Sensor and TD Sensor (using

SP/VSG

V

) – before the 10th copy of a job

3: TD Sensor – temporary mode when ID

sensor output is abnormal

4: Image Pixel Count

Adjusts the current applied to the transfer

belt during copying on the 1st side of the

paper.

If the user uses thicker paper, the current

may have to be increased to ensure

sufficient transfer of toner.

0 ~ 5.0

0.01 V/step

2.5 V

Start

10 ~ 200

1 µA/step

[A294 I & II]

120 µµµµA

[A295 I & II]

140 µµµµA

4-18

Page 29

18 July, 2001 SERVICE PROGRAM MODE

2-301

2-506

2-801

Mode No.

(Class 1, 2 and 3)

Transfer Current Adjustment

2 Thick Paper

3 OHP Sheet

4 Transparent

Paper

5 2nd Copy

6 Between Pages

Cleaning Interval – Multiple Copy

1On/Off

2 Interval

TD Sensor Initial Setting

Adjusts the current applied to the transfer

belt during copying on thick paper.

See above.

B

Adjusts the current applied to the transfer

belt during copying on OHP sheet.

B

See above. If the user normally feeds

thicker paper from the bypass tray, use a

higher setting.

Adjusts the current applied to the transfer

belt during copying on translucent paper.

B

Adjusts the current applied to the transfer

belt during copying on the 2nd side of the

paper.

B

Adjusts the current applied to the transfer

belt between the pages.

B

Selects whether multiple copy jobs are

stopped at regular intervals for the following

purposes.

1. Stop and turn the drum motor in reverse

2. Make an ID sensor pattern to correct the

B

The interval depends on SP2-506-2.

Use if the drum gets dirty or images get too

pale or too dark during a long job.

Normally keep at ‘No’, because the ‘Yes’

setting causes the machine to stop copying

every 15 minutes, which may cause

problems for the customer.

Selects the interval at which multi copy jobs

are stopped.

B

Performs the TD sensor initial setting. This

SP mode controls the voltage applied to the

TD sensor to make the TD sensor output

about 2.5 V. After finishing this, the TD

B

sensor output voltage is disp layed.

Use this mode only after changing the TD

sensor or the developer.

Function Settings

to clean the cleaning blade edge

toner density control.

10 ~ 200

1 µA/step

[A294 I & II]

120 µµµµA

[A295 I & II]

140 µµµµA

10 ~ 200

1 µA/step

140 µµµµA

10 ~ 200

1 µA/step

[A294 I & II]

120 µµµµA

[A295 I & II]

140 µµµµA

10 ~ 200

1 µA/step

[A294 I & II]

120 µµµµA

[A295 I & II]

140 µµµµA

10 ~ 200

1 µA/step

20 µµµµA

1: No

2: Yes

1 ~ 100

1 minute/step

30 minutes

Start

Tables

Service

4-19

Page 30

SERVICE PROGRAM MODE 18 July, 2001

2-803

2-804

2-813

2-902

2-909

Mode No.

(Class 1, 2 and 3)

Corona Wire Cleaner On

Turns on the corona wire cleaner manually.

When copy density across the paper is

uneven at EM, clean the wire with this

mode.

Charge Corona Cleaner Setting

1 Corona Wire

Cleaner

Operation

Setting

2 Operation

Interval B

Printer Gamma Setting

Printing Test Pattern

2IPU Test

Pattern

Selection

(for Scanner)

3 Printing Test

Pattern

4 Outer I/F Block

Test Pattern

Frequency

5

Pattern Density

Vcont Manual Setting2-906

Main Scan Magnification

1 Copier

Selects when automatic corona wire

cleaning is done.

0: Corona wire cleaning is not done.

1: When process control initial setting is

B

2: At the period set in SP2-804-2.

Selects the interval for automatic corona

wire cleaning.

Select if printer gamma correction is

applied or not.

S

This SP mode is for designer use only.

Prints the test patterns for the IPU chip.

See section 4.2.3. for how to print test

patterns.

This SP mode is useful for finding whether

the SICU or the SBU is defective. If the

printout is not OK, the SICU is defective.

Prints the printer test patterns.

See section 4.2.3. for how to print test

patterns.

Example: 15. Trimming Area

This SP mode is useful for finding whether

the LDDR or the SICU is defective. If the

printout is not OK, the LDDR is defective.

Prints the test patterns for the IPU chip.

See section 4.2.3. for how to print test

patterns.

This SP mode is useful for finding whether

the SICU or the printer application is

defective. If the printout is not OK, the

SICU is defective.

Designer use only.

B Factory use only.

Adjusts the magnification in the main scan

direction for copy mode.

Use the “

S

See “Replacement and Adjustment – Copy

Image Adjustments” for details.

Function Settings

done, if the copy number after the last

cleaning operation is over the number

set in SP2-804-2.

•

” key to toggle between + and –.

Start

[A294/A295 I]

0: Not done

1: Done

2:Periodically

[A294/A295 II]

0: Not done

1: Done

2:Periodically

100 ~ 10,000

100 print/step

5,000

0: Applied

1: Not applied

9.7 V

–2.0 ~ +2.0

0.1%/step

+0.0%

4-20

Page 31

18 July, 2001 SERVICE PROGRAM MODE

2-909

2-910

2-911

2-913

2-920

2-940

Mode No.

(Class 1, 2 and 3)

Main Scan Magnification

2 Printer

Writing Sub Scan Magnification

Transfer Current On/Off Timing

1 La (ON)

2 Lb (On/Off

exchange

timing)

3 Lc (OFF)

Drum Reverse Rotation Interval2-912

Test Pattern ID Adjustment

LD Off Check

Transfer Pre-cleaning2-930

Leading Edge Transfer Current Adjustment

1Tray-1

2Tray-2

3Tray-3

4 Tray-4 (LCT)

5 Tray-5 (LCT)

6 Tray-6 (LCT)

7 Duplex Tray

Adjusts the magnification in the main scan

direction when printing from a personal

computer.

S

Use the “

See “Replacement and Adjustment – Copy

Image Adjustments” for details.

Adjusts the magnification in the sub scan

direction.

S

Use the “

See "Replacement and Adjust m ent – Copy

Image Adjustments" for details.

Adjusts the transfer current on timing at the

B

leading edge.

Adjusts the transfer current on/off

exchange timing.

B

(A294/A295 II models only)

Adjusts the transfer current off timing

B

(for example: –5 mm is 5 mm after the

trailing edge).

This SP mode is for designer use only.

Do not change the value.

B

Adjusts the image density for printing test

patterns (with SP2-902). Usually this SP

mode is only used by designers.

The value is cleared when the main power

switch is turned off and on.

Checks whether the LD turns off or on

when the front door is opened.

0: On 1: Off

Factory use only.

Designer use only

Adjusts the leading edge transfer current

for each paper feed station.

(A294/A295 II models only)

B

•

” key to toggle between + and –.

•

” key to toggle between + and –.

Function Settings

–2.0 ~ +2.0

0.1%/step

+0.0%

–1.0 ~ +1.0

0.1%/step

+0.0%

–30 ~ +30

1 mm/step

0 mm

[A294/A295 II]

0 ~ +60

1 mm/step

+45 mm

–30 ~ +30

1 mm/step

0 mm

0 ~ 10

1/step

2

0 ~ 15

1/step

15

0: ON

1: OFF

10 ~ 200

1 µA/step

[A294 II]

120 µµµµA

[A295 II]

140 µµµµA

Tables

Service

4-21

Page 32

SERVICE PROGRAM MODE 18 July, 2001

2-941

2-962

Mode No.

(Class 1, 2 and 3)

Transfer Current for Semi-thick Paper

Determines that the transfer current for

semi-thick paper is handled as Plain paper

or Thick paper

• Setting this mode to “Thick paper” is

effective when image at the leading edge

is not good.

• To use this mode, “Recycled paper”

B

should be selected in the User Tools for

semi-thick paper.

• Selecting “Thick paper” in the User Tools

is the same effect as this mode. But

selecting “Thick paper” in the User Tools

does not allow the duplex or punch

mode.

Developer Initialization (Factory)2-961

Factory use only.

Auto Process Control

Automatically adjusts the following process

control factors.

1. Drum potential sensor

2. ID sensor

3. Charge grid voltage (by changing V

4. LD power (by changing V

B

Before using this SP, auto process control

should be on (SP3-901).

After changing the drum, ID sensor, drum

potential sensor, LD unit, charge corona

wires, or toner density sensor, this SP

should be used.

Periodical Auto Process Control2-966

Selects whether auto process control is

done after the first job since 24 hours is

finished. This setting is required for a

B

customer who keeps the main switch on all

day.

Function Settings

0: Plain paper

1: Thick paper

Start

D

)

H

)

ON

OFF

2-967

Auto Image Density Adjustment

Selects whether auto image de nsity

adjustment is done during machine warm

up. This mode is to counter dirty

background that occurs when a machine is

used in an area that contains ammonia.

If Periodical Auto Process Control (SP2-

966) is used, this adjustment is done also

after the auto process control is finished.

B

OFF

ON

4-22

Page 33

18 July, 2001 SERVICE PROGRAM MODE

2-971

2-972

2-973

Mode No.

(Class 1, 2 and 3)

Function Settings

Toner Density Correction2-968

To prevent the image density dropping

during continuous copying after a long

interval (this is caused by a sudden

increase of Q/M), V

0.06 V every (100 X (SP2-974 value + 1))

B

REF

is changed by –

0 ~ 20 k

1 k prints/step

0

prints. This correction is applied from when

the auto process control is done, until “(the