Page 1

RICOH Technical

Bulletin

PAGE: 1/3

Model:

Subject:

From:

Classification:

While SP2-207-2 (Toner Bank Toner Supply) is performed at installation, the rotation of

the toner hopper gear (AB013748: Joint Gear -15Z) may cause an oversupply of toner

from the hopper to the development unit. This in turn causes relatively high image density

in copies/printouts made just following installation. To correct this, machines in massproduction have been modi fied as fol lows:

Bellini

Toner Hopper Gear Replcement at Installation

Technical Services Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

15-Dec-99

Prepared by:

Action required

Service manual revision

Retrofit information

H.K.

No.:

RA294001

Temporary Solution

The toner hopper contains a red idler gear (A2943255: Idler Gear - 15Z). This gear

reduces the drive supplied to the toner hopper and prevents the oversupply of toner that

occurs in the initial period following installation .

The toner hopper gear for normal operation (White gear:AB013748: Joint Gear -15Z) and

a spare C-ring (07200060B: Retaining Ring - M6) have been packed in the accessory

plastic bag.

The procedure for the Toner Hopper Drive Gear Replacement (Joint Gear - 15Z) has been

packed in the accessory plastic bag. The procedure is also included on page 2/3 of this

bulletin.

Action required

Replace the red idler gear with the white gear after carrying out SP2-207-2 (Toner Bank

Toner Supply) by referring to the procedure for the Toner Hopper Drive Gear Replacement

(Joint Gear - 15Z) packed in the accessory plastic bag. The red idler gear is not

necessary after machine installation.

Permanent Solution

The permanent solution is basically the same as the temporary solution. To facilitate gear

replacement, the gear has been mounted with screw (09513006B: Philips Screw With Flat

Washer - M3x6) instead of a C-ring. The procedure is included on page 3/3 of this bulletin.

Regarding the cut-in serial numbers for this modification, we will issue an MB as soon as

they are available.

Action required

Same as “Action required” described above.

Page 2

RICOH Technical

Bulletin

PAGE: 2/3

Model:

The part number of the toner hopper unit will be changed from #A2943200 to a new part

number due to the above modification. If the toner hopper unit is replaced in the field,

replace the red idler gear in the new toner hopper with the white gear in the original toner

hopper unit.

The toner hopper unit part number will be therefore changed because of the gear

replacement and C-ring substitution. As the spare part of #A2943200 contains the white

gear, the old unit part can be replaced in the machines installed in the field. It is not

necessary to change the red gear to a white gear.

The following is the procedure packed in the accessory plastic bag as the temporary

solution. After step #35, remove the development unit and follow the instruction marked

with an asterisk (

Bellini

. Then, put back the development unit.

*

)

Date:

15-Dec-99

No.:

RA294001

Toner Hopper Drive Gear (Joint Gear 15Z) Replacement

Please add the gear replacement procedure (*) after step #35 (Toner Bank Toner Supply).

#35. Supply toner from the toner bank to the toner hopper as follows:

1) Select SP2-207-2 (Toner Bank Toner Suppl y)

2) Press the “Start key” on the LCD.

# *

#36. Change the paper size for all paper trays to suit the customer’s request.

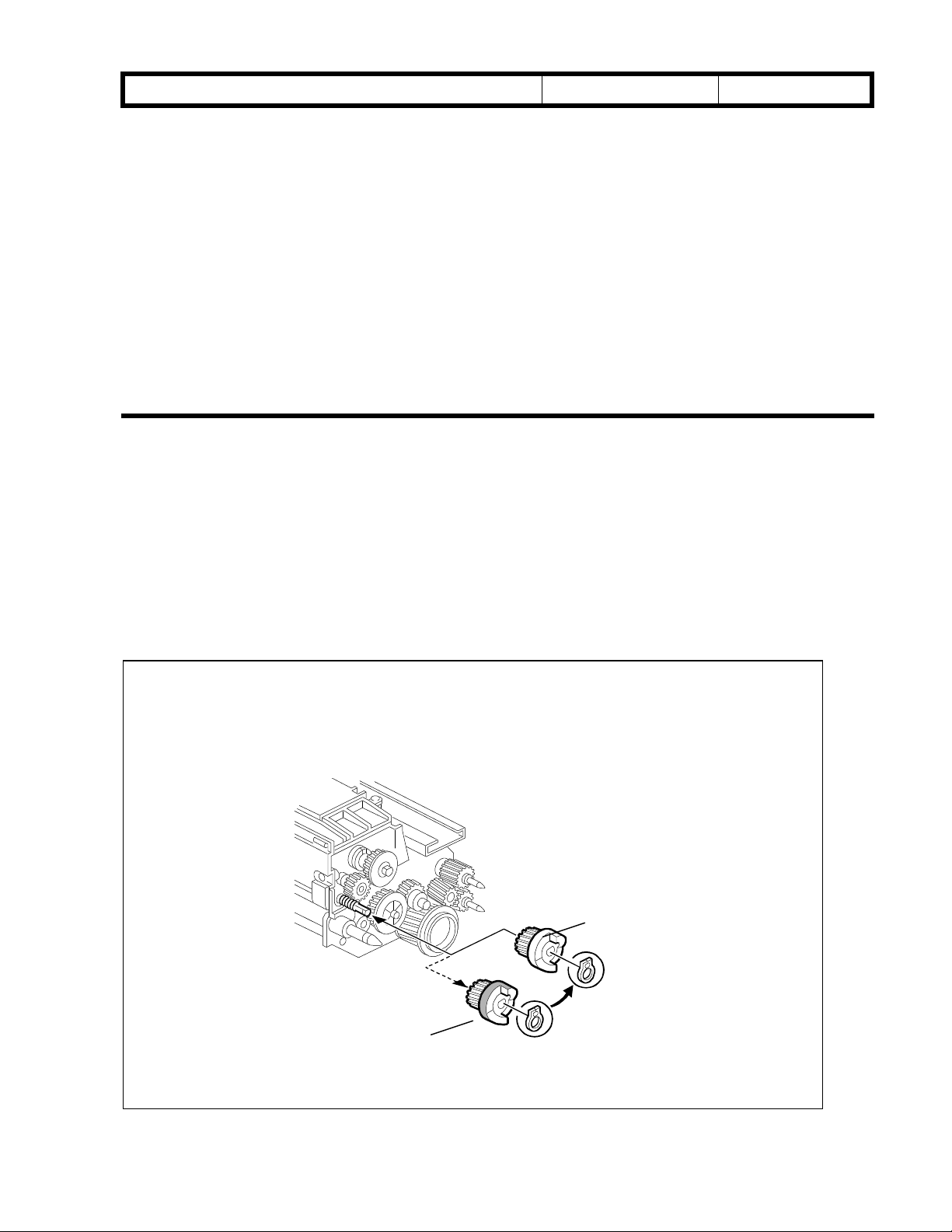

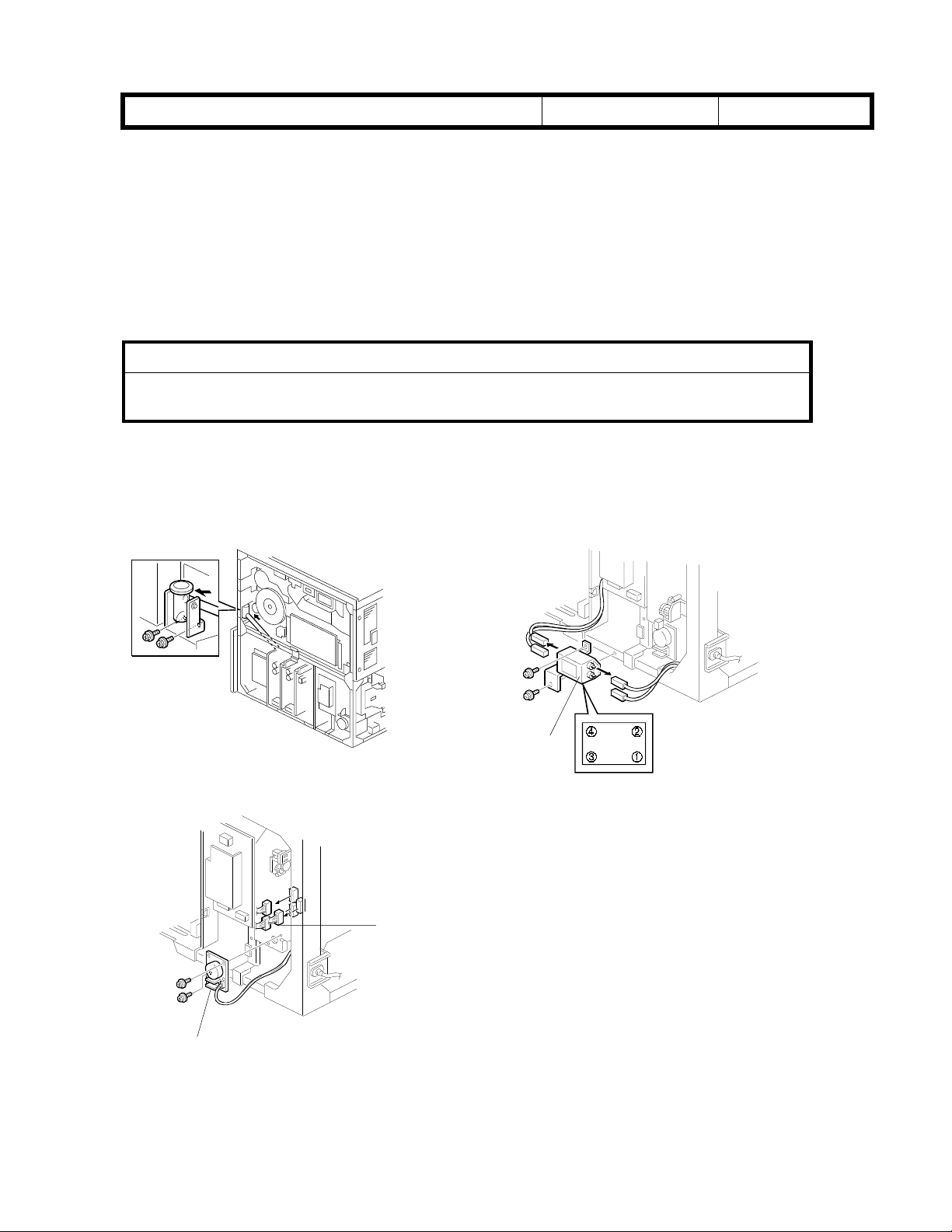

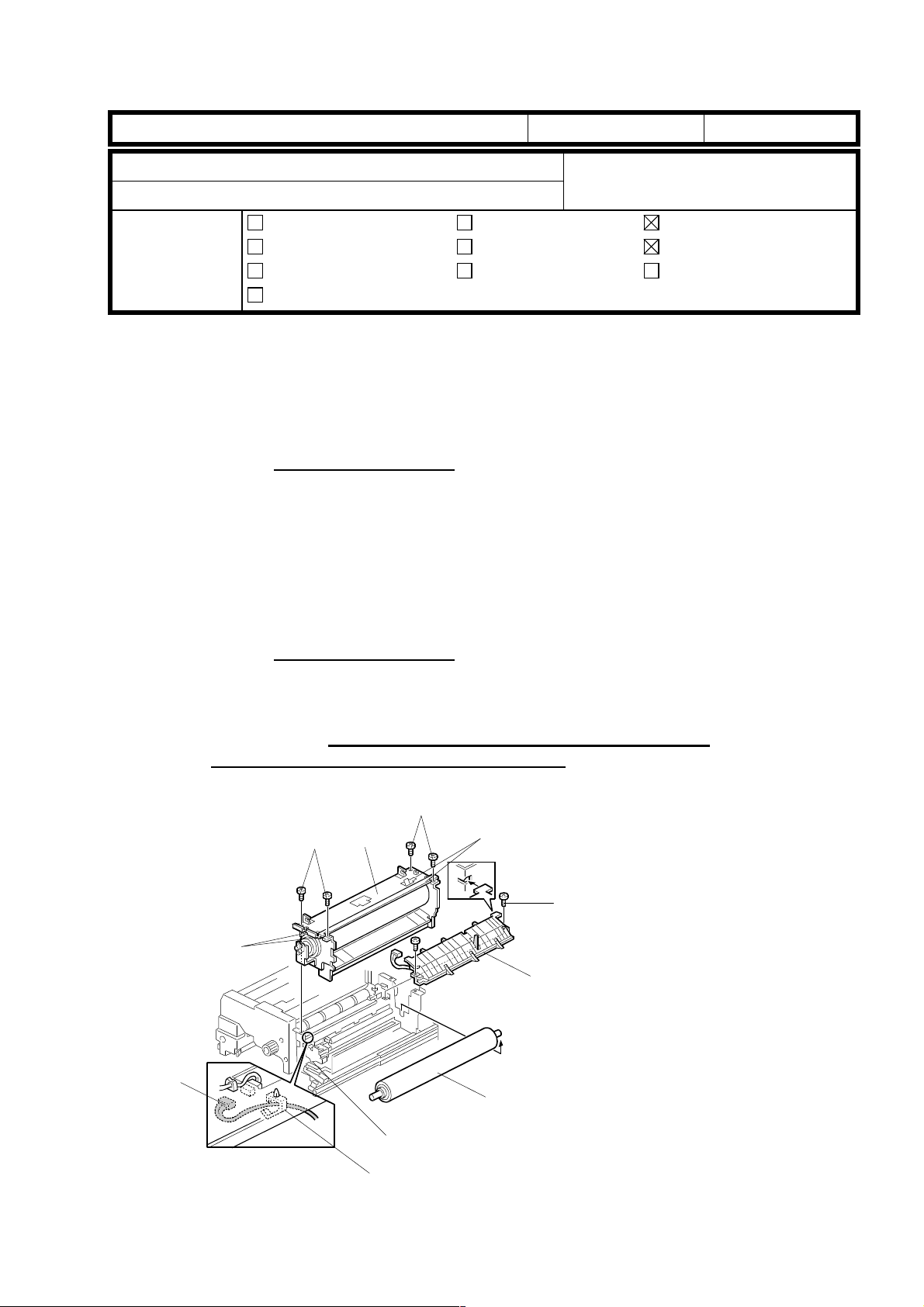

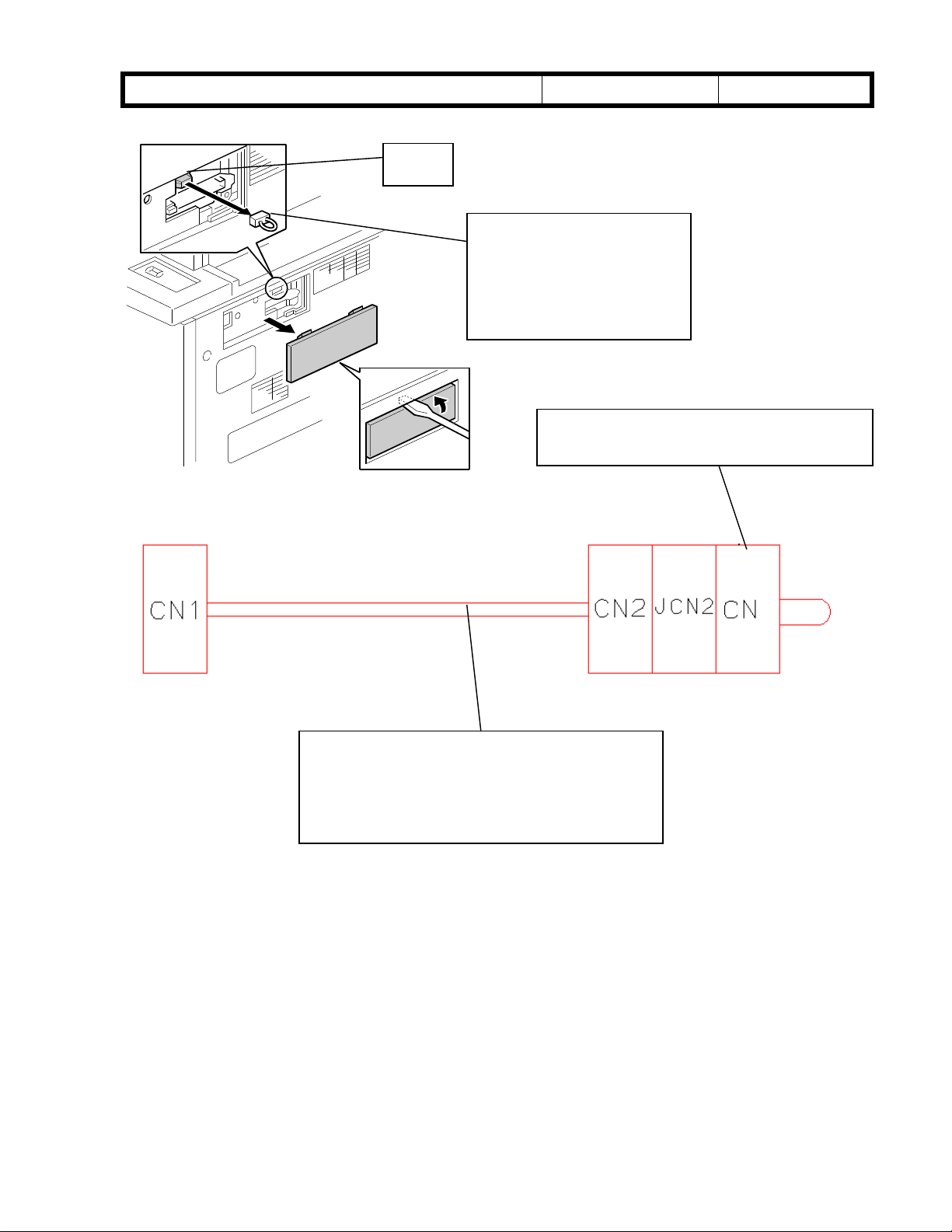

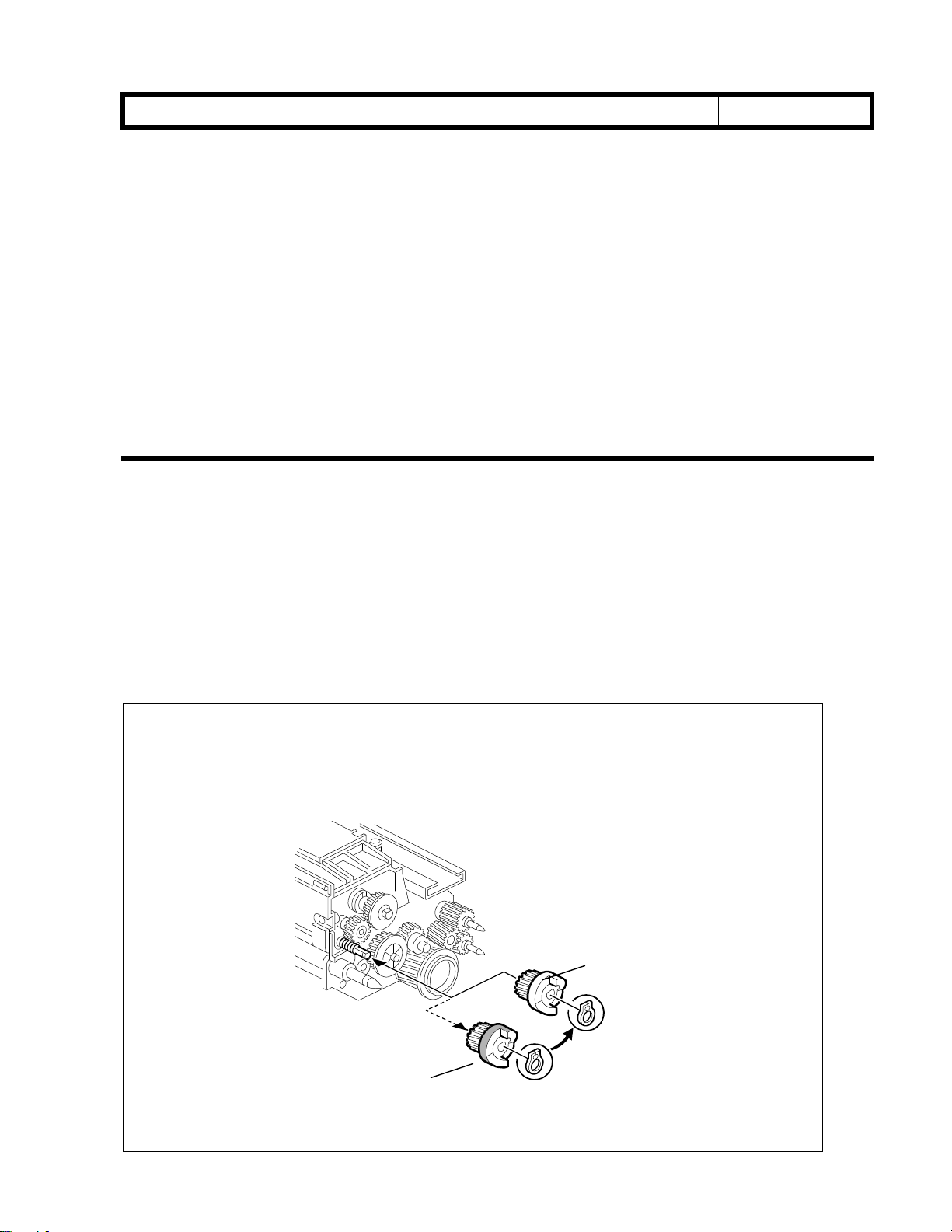

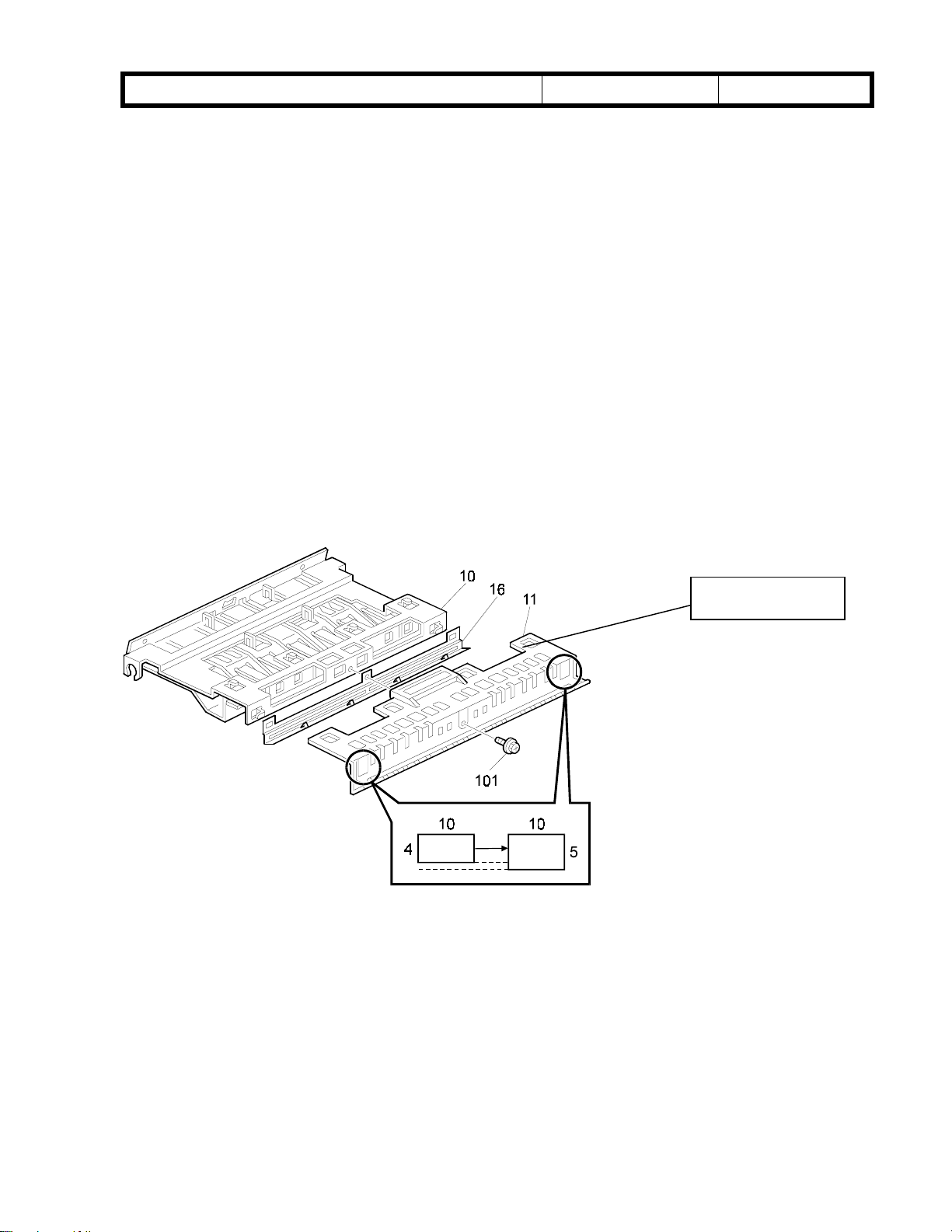

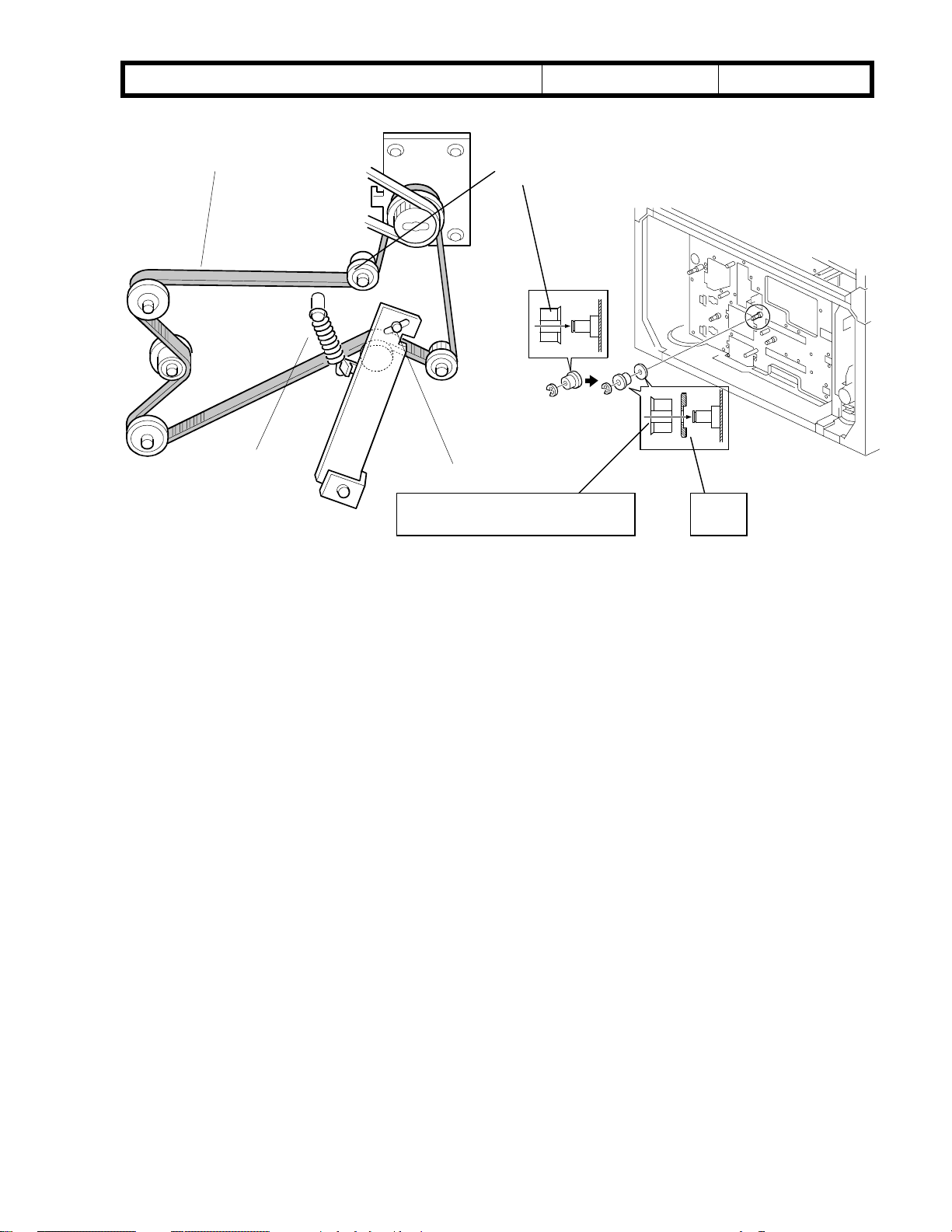

Remove the Joint Gear 15Z that has been marked red [A].

*

Replace it with the white gear [B] and a spare C-ring packed in the accessory

plastic bag.

B

A

Toner Hopper Unit Rear View

Page 3

RICOH Technical

Bulletin

PAGE: 3/3

Model:

The following is the procedure packed in the accessory plastic bag as the permanent

solution. After step #35, remove the development unit and follow the instruction marked

with an asterisk (

Bellini

. Then, put back the development unit.

*

)

Date:

15-Dec-99

No.:

RA294001

Toner Hopper Dr ive Gear (Joint Gear 15Z) Replacement

Please add the gear replacement procedure after step #35 (Toner Bank Toner Supply).

#35. Supply toner from the toner bank to the toner hopper as follows:

1) Select SP2-207-2 (Toner Bank Toner Suppl y)

2) Press the “Start key” on the LCD.

*:

#36. Change the paper size for all paper trays to suit the customer’s request.

*

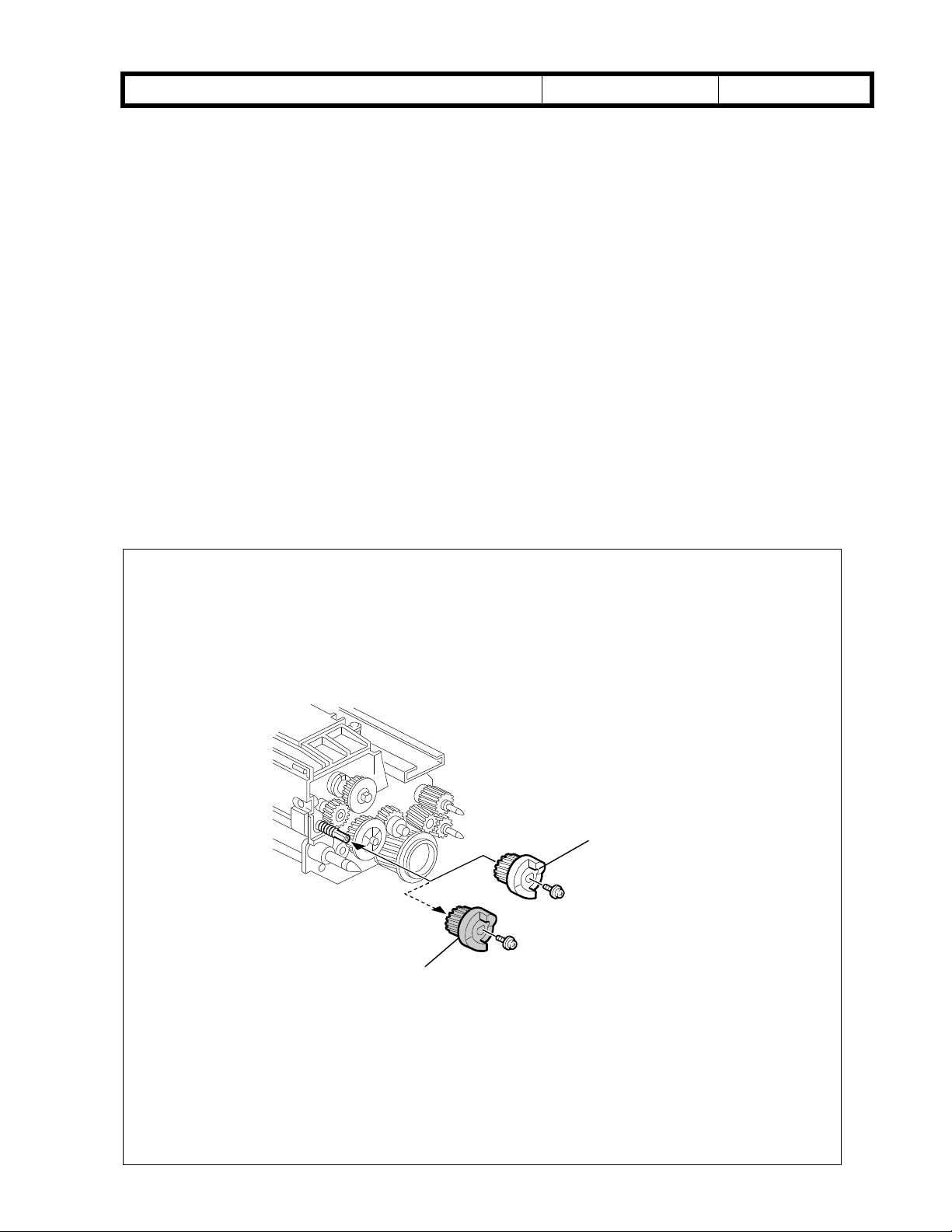

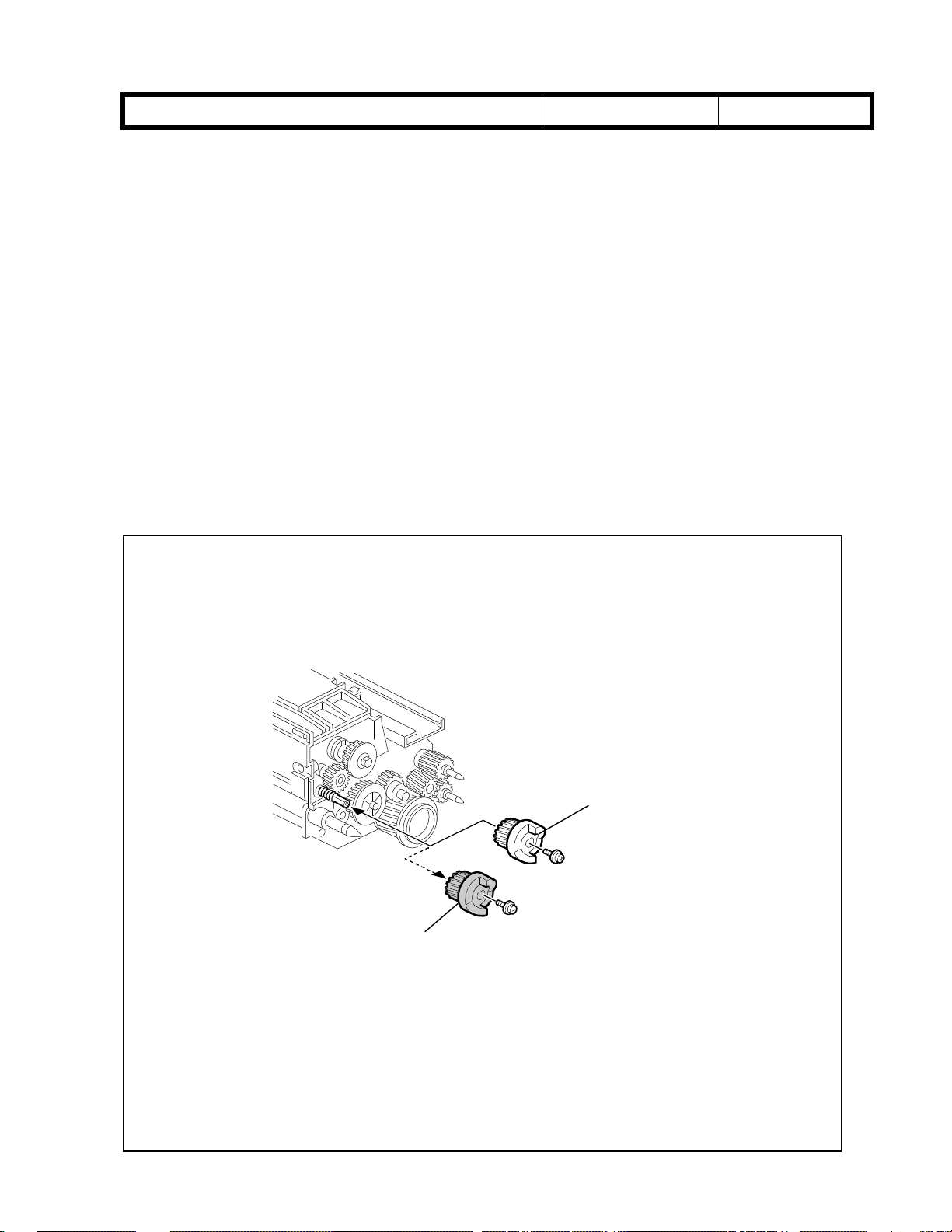

Remove the Joint Gear 15Z that has been marked red [A].

Replace it with the white gear [B] and a spare C-ring packed in the

accessory plastic bag.

B

A

Toner Hopper Unit Rear View

Page 4

RICOH Technical

Reissued: 03-Feb-00

Bulletin

PAGE: 1/5

Model:

RTB Correction

The following items in bold italics have been added.

Subject:

From:

Classification:

We have found that toner in the toner transport tube may be blocked due to vibrations during

machine transportation. Please note the following remarks and do the

machine is transported.

Bellini

Transportation Remarks

Technical Services Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

15-Dec-99

Prepared by:

Action required

Service manual revision

Retrofit information

procedure when the

H.K.

No.:

RA294002a

3.9 TRANSPORTATION REMARKS

3.9.1 TONER TRANSPORT TUBE CLEANING

NOTE:

1) When transporting the machine, do the following operations. Otherwise, the

toner system may be blocked.

2) Be careful not to drop the toner.

3) If this procedure is not carried out, SC592 (Toner Bank Motor Error) or SC495

(Toner Bottle Unit Error) could be displayed and the toner transport tube and

screw should be replaced.

I. Procedure before transportation (Removing toner from the toner transport tube):

1. Close the toner bottle cap using SP5-804-62 (upper bottle) or -63 (lower bottle). Then

remove the toner bottles from the bank.

2. Remove the upper rear and lower rear covers.

3. Remove the upper left cover, lower left cover, upper right cover .

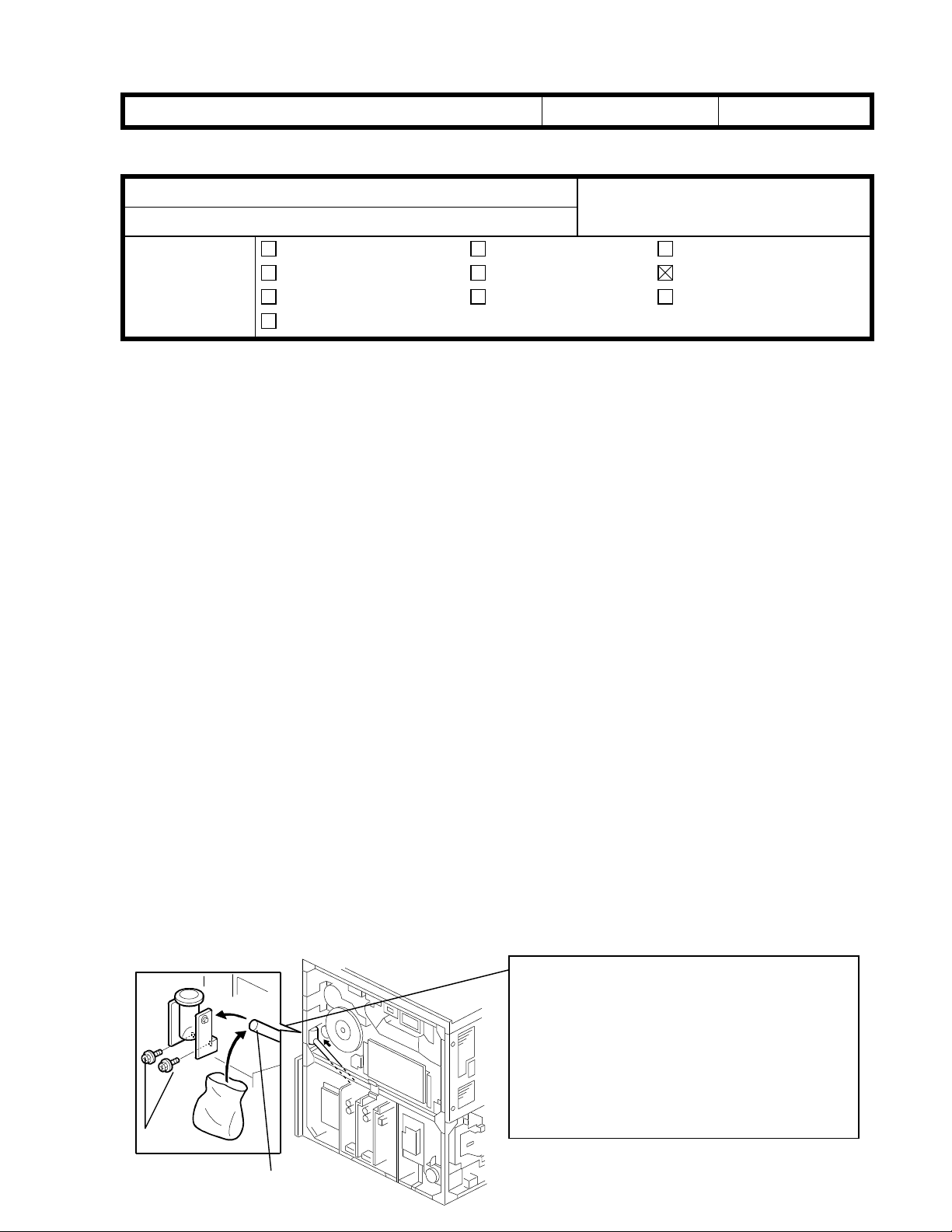

4. Remove the two screws [A] securing the toner supply cylinder.

5. Cover the end of the toner transport coil tube [B] with a plastic bag.

NOTE: See “Note for step 6”.

6. Energize the toner bank motor and toner supply coil clutch for 2 minutes using SP5804-61 and -64 to remove all of the toner in the supply tube.

7. Re-install all removed parts except for the toner bottles.

NOTE for step 6:

Take extra caution not to bend the

toner transport coil tube [B]. If it is

bent, this can cause the coil (screw)

inside to be overloaded, locked, or

damaged. SC592 will be displayed,

and the coil (screw) inside should

be replaced.

[B]

Page 5

RICOH Technical

Reissued: 03-Feb-00

Bulletin

PAGE: 2/5

Model:

NOTE: Make sure that three tubes are connected to the toner supply cylinder when

putting it back.

II. Procedure after transportation (loading toner into the toner transport tube):

1. Load the toner bottles into the toner bank.

2. Remove the upper right cover. Open the cylinder top cover and clean the inner surface

3. Energize the toner bank motor using SP5-804-61.

4. Energize the toner bottle motors for 5 to 6 seconds using SP5-804-59, -60.

5. Energize the toner supply coil clutch using SP5-804-64.

6. 50 to 60 seconds later, toner is supplied to the toner supply cylinder. Make sure that

7. Turn off the toner supply coil clutch and then the toner bank motor.

8. Return all removed parts.

Bellini

of the cylinder with a cloth to check the toner supply at step 6. Then, close the cylinder

top cover.

toner is properly supplied to the cylinder.

Date:

15-Dec-99

No.:

RA294002a

Note:

Do not energize the toner bottle motors for a long time, otherwise toner overflows in

the toner entrance tank.

Page 6

RICOH Technical

Reissued: 03-Feb-00

Bulletin

PAGE: 3/5

Model:

Upon reviewing the previous Toner Bank Unit Removal procedure in the Service Manual,

the above procedures on pp.1-2 have been added as step 1:

6.11.2 TONER BANK UNIT REMOVAL

1. Follow steps 1 to 6 of the procedure before transportation.

2. Turn off the main switch and unplug the power cord. Follow steps 1 and 2 of the waste

toner bottle removal procedure.

I

Make sure that the power cord is unplugged before removing the noise

filter in the next step.

3 Remove the noise filter [C] (2 screws and 4 connectors; upper: Ã, Á white lower: Â,

4 Disconnect the three connectors [E] from the toner bank unit.

Bellini

CAUTION

yellow) and toner bank motor [D] (2 screws, 1 connector).

Date:

15-Dec-99

No.:

RA294002a

À

A294R903.WMF

[D]

A294R905.WMF

[C]

A294R904.WMF

[E]

Page 7

RICOH Technical

Reissued: 03-Feb-00

Bulletin

PAGE: 4/5

Model:

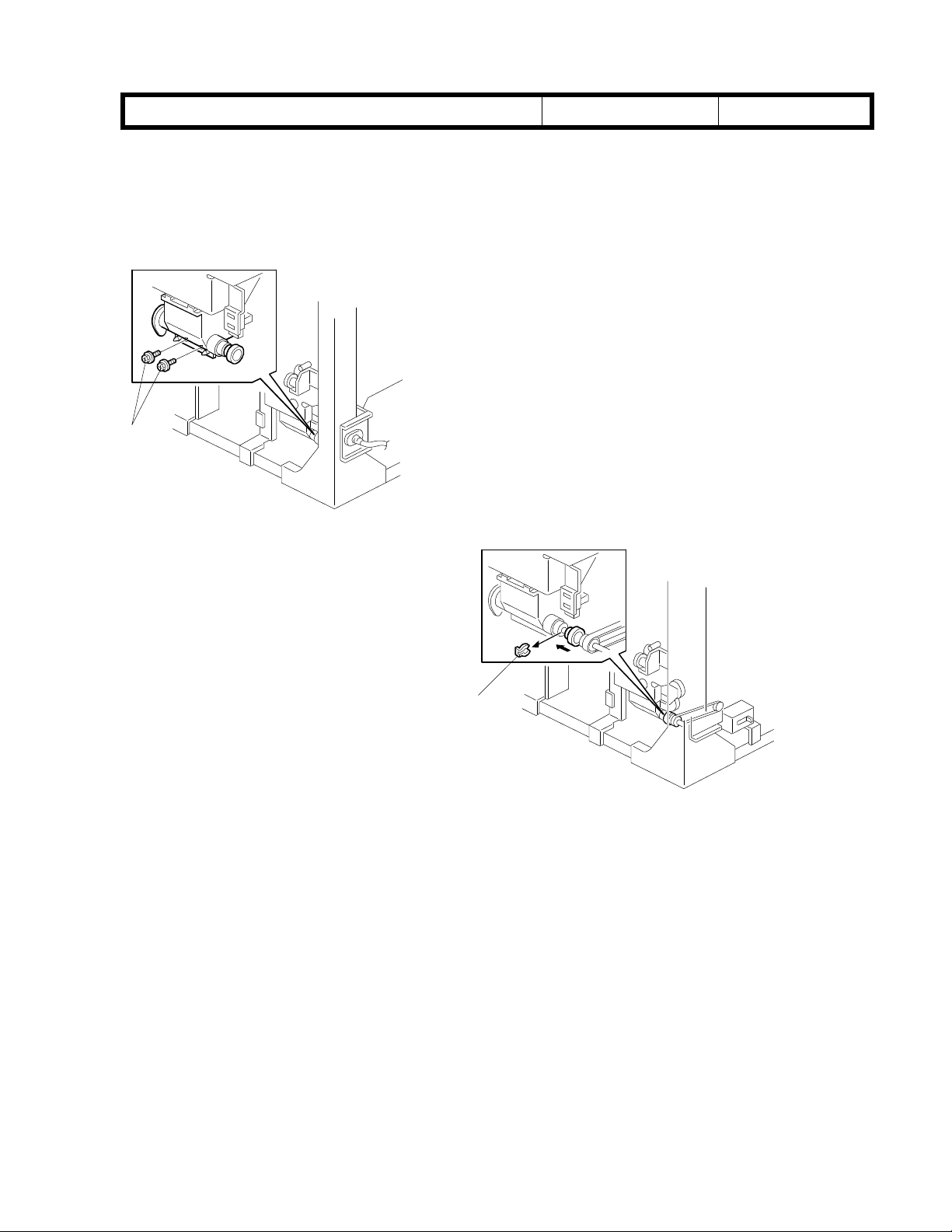

5 Remove the two screws [A] securing the toner transport coil tube.

6 While sliding the toner transport coil tube, remove the snap ring [B].

[A]

A294R907.WMF

Bellini

Date:

15-Dec-99

No.:

RA294002a

[B]

A294R906.WMF

Page 8

RICOH Technical

Reissued: 03-Feb-00

Bulletin

PAGE: 5/5

Model:

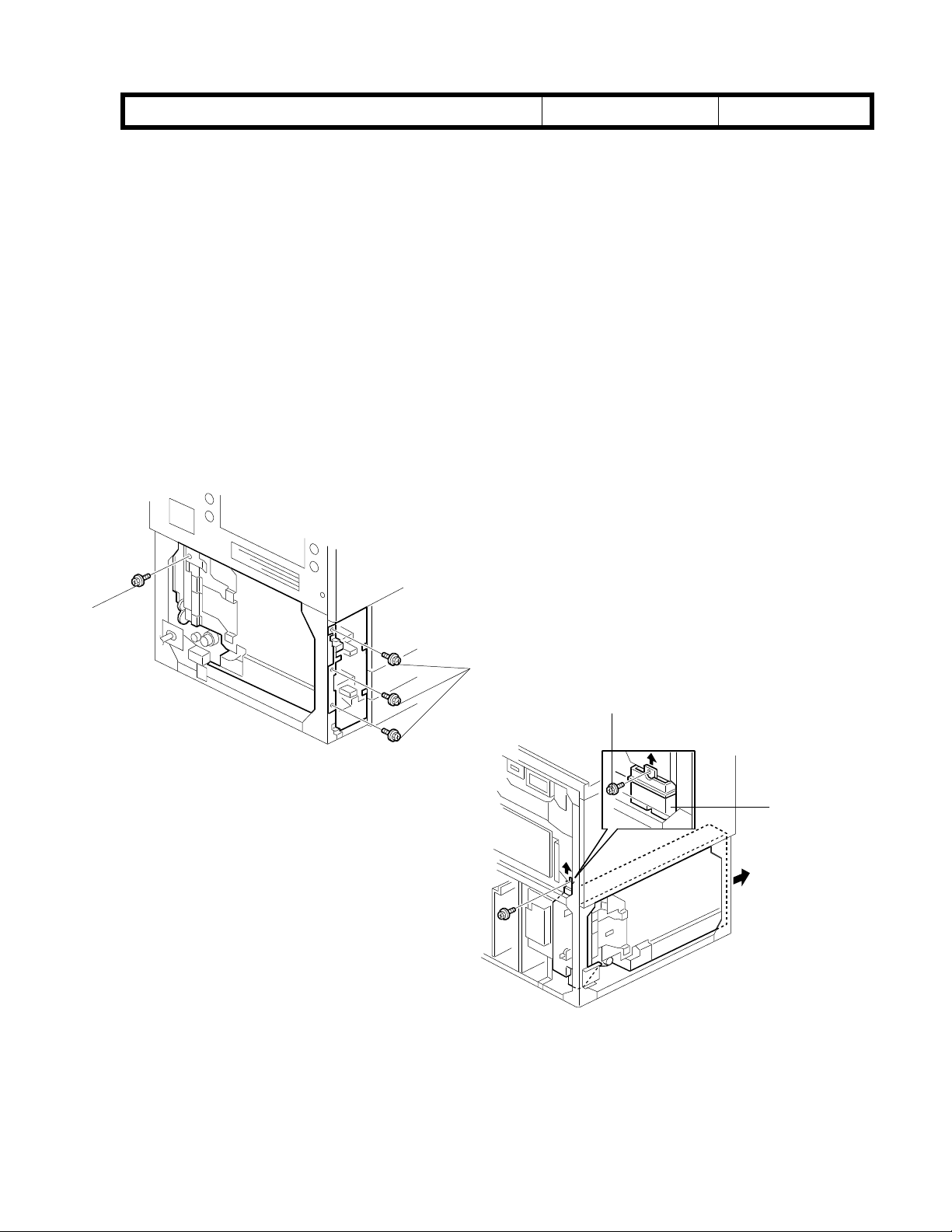

7 Remove the four screws [A] securing the toner bank unit.

8 Remove the screw [B] securing the toner recycling and collection cover [C].

9 While lifting the toner recycling and collection cover [C], pull out the toner bank unit.

10 Remove the plastic bag from the toner transport coil tube. Re-connect the toner supply

11 Perform Procedure II. described on pp.1-2 of this bulletin (“After Transportation”).

Bellini

NOTE:

NOTE:

cylinder to the toner transport coil tube (2 screws).

Try not to spill any toner from the toner bank.

When pullin g out the toner bank unit, toner may leak out of the junction

between the tube and toner bank. Place a cloth on the machine bottom plate

so that the plate does not become dirty.

Date:

15-Dec-99

No.:

RA294002a

[A]

[A]

[B]

A294R908.WMF

[C]

A294R909.WMF

Page 9

RICOH Technical

Bulletin

PAGE: 1/1

Model:

Subject:

From:

Classification:

Bellini

SC495 (After installation)

Technical Services Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Date:

Prepared by:

Part information

Electrical

Transmit/receive

31-Dec-99

Action required

Service manual revision

Retrofit information

No.:

RA294003

J. Mochizuki

SYMPTOM

SC495 is displayed while making copies. This symptom occurs soon after the machine

installation is completed.

CAUSE

When SP220 7 is performed at installation, the toner supply from the toner bank stops

before enough toner is supplied to the toner hopper.

This is because the toner hopper sensor tends to misdetect the toner amount before the

toner inside the toner hopper is stabilized.

SOLUTION

If this symptom occurs in the field, turn the main switch off and on. When enough toner is

supplied to the toner hopper, this problem will not reo ccur.

For a permanent countermeasure, the firmware has been changed to change the SP2207

operation. The firmware version was changed from Ver. 7.1 to Ver. 7.8.1.

The new firmware will be used from the January 2000 production.

Before modification:

While performing SP2207 (Forced toner supply), toner supply from the toner bank stops 4

minutes after the toner hopper sensor detects the toner.

After modification:

Toner supply stops 6 minutes after starting SP2207.

The part numbers (suffix) have been changed as follows:

Old (Ver 7.1) New (Ver 7.8.1)

P/N for the firmware (NA) A2945610B A2945610C

P/N for the firmware (EU) A2945660B A2945660C

It is recommended to install the new software (ver 7.8.1) before starting toner initial setting

with SP2207.

Page 10

T

echnical

B

ulletin

PAGE: 1/3

Model:

Subject:

From:

Classification:

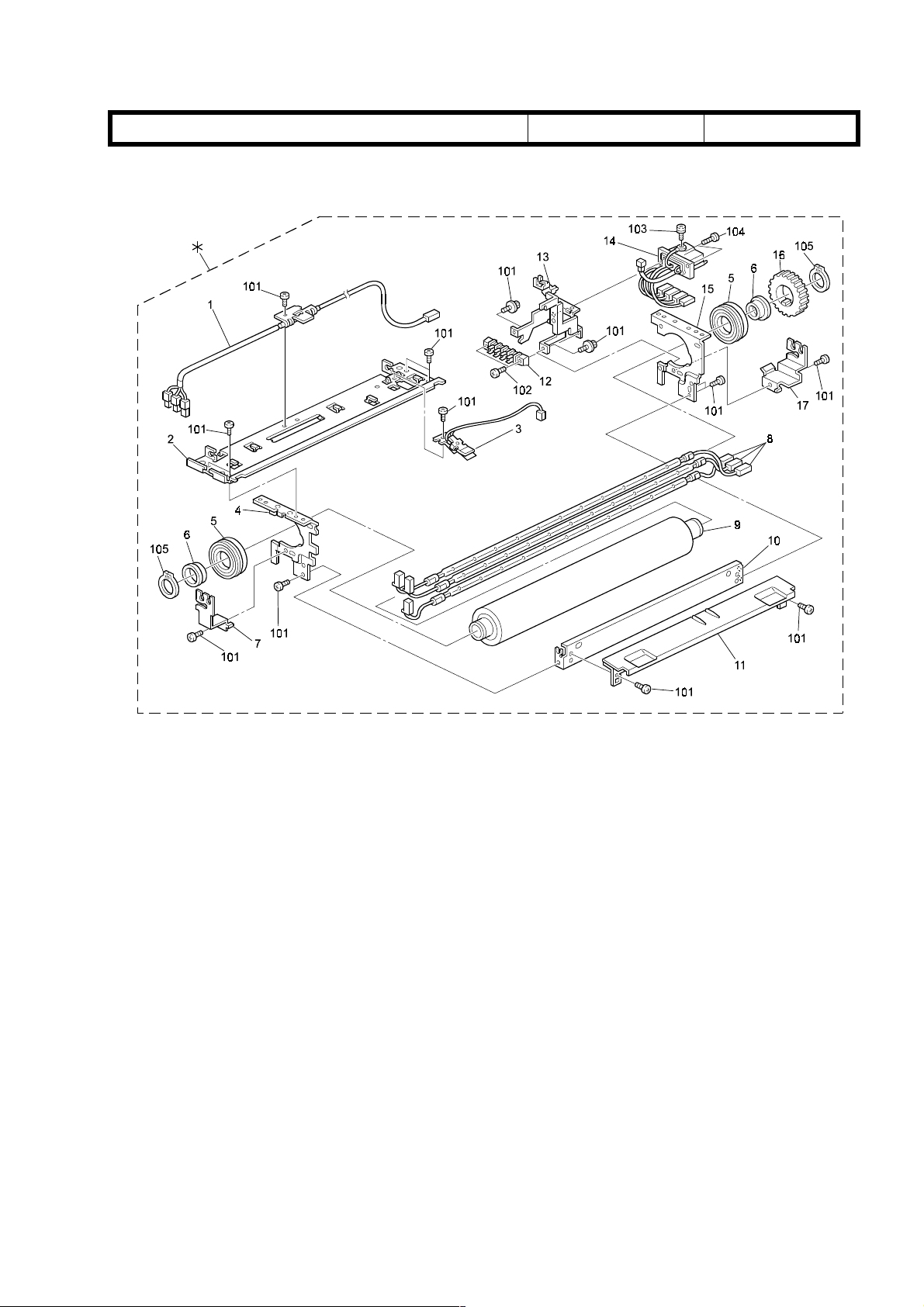

Note on reinstallation of the hot roller unit:

We have found that an audible resonance may occur inside the fusing unit while making

copies. To correct this, the method for reinstalling the hot rolle r unit has been changed.

Please correct the note on page 6-85 in the service manual as follows:

Old

5. Remove the four M5 pan head screws [B] and remove the hot roller unit [C].

New

Bellini

Noise from the fusing unit

Technical Services Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

NOTE: 1) When re -installing the hot roller unit, make sure that the flanges of

the ball bearings in the hot roller unit are set inside the fusing exit

side plate [D] and the gear in the hot roller unit is installed on the

rear side.

2) Secure the M5 pan head screws at the rear side first. Then, secure

the screws at the front side.

Part information

Electrical

Transmit/receive

Date:

31-Jan-00

Prepared by:

No.:

RA294004

H. K.

Action required

Service manual revision

Retrofit information

5. Remove the four M5 pan head screws [B] and remove the hot roller unit [C].

NOTE: 1) When re-installing the hot roller unit, make sure that the flanges of

the ball bearings in the hot roller unit are set inside the fusing exit side

plate [D] and the gear in the hot roller unit is installed on the rear side.

2) Secure the M5 pan head screws in the following order:

left-rear, right-front, right-rear, left-front.

[B]

[A]: Do not remove these screws.

[E]

[F]

[G]

[A]

[C][B]

[A]

[I]

A294R503.WMF

[D]

[H]

Page 11

T

echnical

B

ulletin

PAGE: 2/3

Model:

Bellini

Date:

31-Jan-00

No.:

RA294004

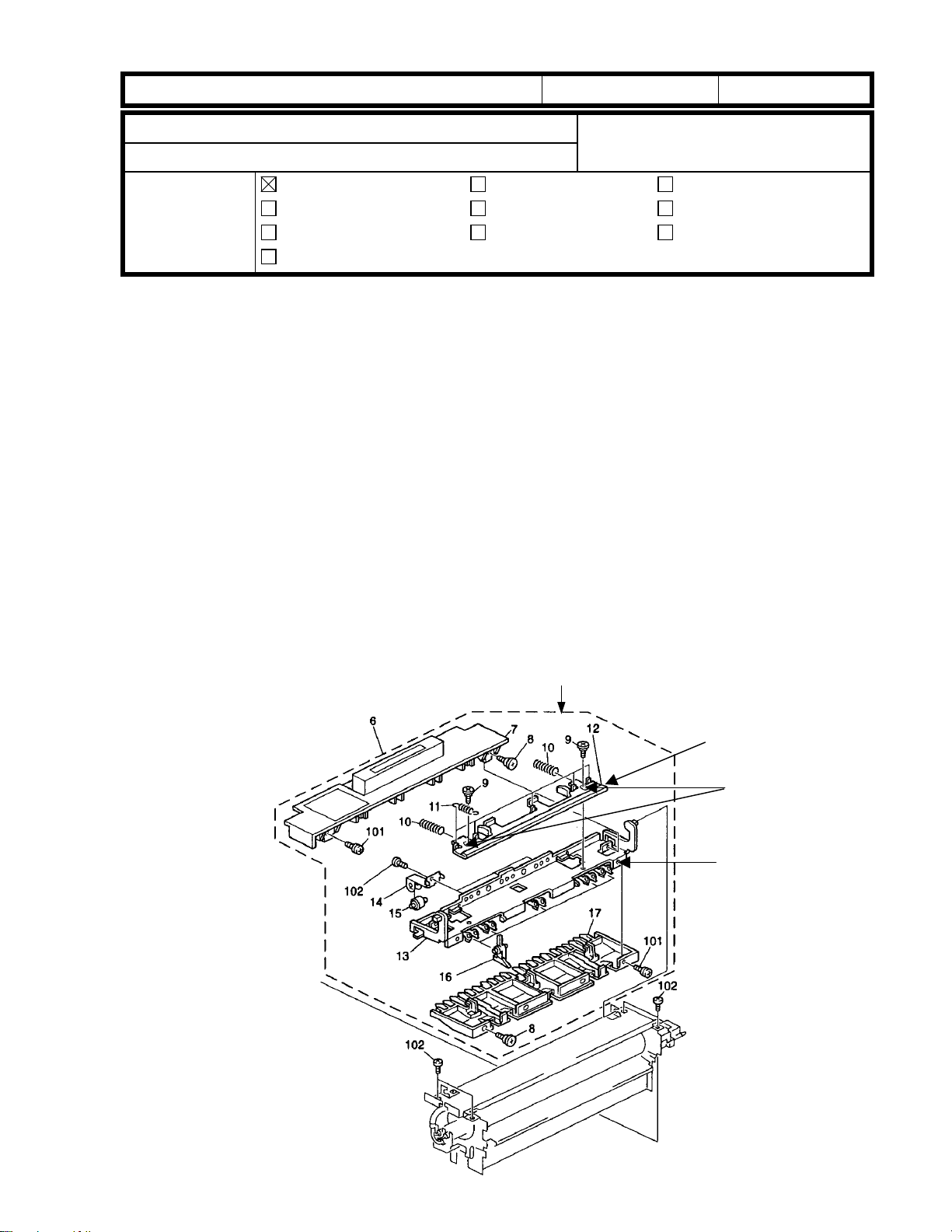

Noise (resonance) during copying

An audible resonance may occur during copying. To correct this, machines in production

have been modified as follow s:

Temporary countermeasure applied from December 1999 production:

The screws for attaching the right lower fusing stay (#10:A2944059) and the rear fusing

plate (#15: A2944057) have been inserted from the front side. They were previously

inserted from the rear side.

Permanent countermeasure for machines in production:

The screw holes in the rear fusing plate have been changed from 4.1 ± 0.1 mm and

4.1 ± 0.1 x 6 mm to 4 mm. The screw holes in the right lower fusing stay have been

changed from 4 mm to 4.1 ± 0.1 mm and 4.1 ± 0.1 x 6 mm. Please note that for the

permanent countermeasure, the insertion direction of the screws for the right lower fusing

stay and rear fusing plate is unchanged (i.e. from the rear side).

The right lower fusing stay and rear fusing plate will be given new part numbers (see

below). The interchangeability between old and new parts is O/O as a set. Detailed parts

Page 12

T

echnical

B

ulletin

PAGE: 3/3

Model:

information will be announced in an MB when the cut-in serial numbers are available.

P/N change:

-Right lower fusing stay: P/N changed from A2944059 to A2944099.

-Rear fusing plate: P/N changed from A2944057 to A2944094.

Action in the field for machines produced before December 1999:

If this symptom occurs on machines with the following serial numbers, please insert the

screws from the front instead of the rear side. Refer to the temporary countermeasure on

the previous page.

A29414,24; L0659110XXX, A29426: 4B11190XXX, A29415,17,22,27; H369110XXX

Bellini

Date:

31-Jan-00

No.:

RA294004

Page 13

RICOH Technical

Bulletin

PAGE: 1/3

Model:

Subject:

From:

Bellini

Key Counter Extension Kit & Relay Key Counter

Harness

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Date:

Prepared by:

Part information

Electrical

Transmit/receive

03-Feb-00

Action required

Service manual revision

Retrofit information

No.:

RA294005

Hiroki Kobayashi

Part Number of the Key Counter Extension Kit

The part number for the extension cable is not listed in the parts catalogue or service

manual. This cable is required when installing the key counter together with the LCT, and

can be ordered as a spare part. For the installation procedure, please refer to page 3-27 of

the service manual.

The part number is as follows:

Old part

number

New part

Description Q’ty

number

A2949501 Key Counter Extension Kit

1

Key Counter Relay Harness - (Lanier Version Only)

Per Lanier's request, the Key Counter Relay Harness has been connected to the copier

key counter harness in production machines. This harness will allow the Lanier key

counter to be installed in the copier. Regarding the cut-in serial numbers, we will issue an

MB as soon as they are available.

#: New index in the parts catalog

Old part

number

A0965464 Key Counter Connector

New part

number

A2945496

A2945497

Description Q’ty Int Page Index Note

Key Counter Relay Harness

- Lanier

Key Counter Short

Connector - 4P

0 - 1

0 - 1

1 - 0

47 #27

47 #28

47 23

Page 14

RICOH Technical

Bulletin

PAGE: 2/3

Model:

Bellini

[A]

Date:

#28: Key Counter Short

Connector.

Ricoh: A0965464

Lanier: A2945497

#28: Key Counter Short Connector.

Lanier: A2945497

03-Feb-00

No.:

RA294005

A2945496

#27: Key Counter Relay Harness.

This part includes the short connector

(A2945497).

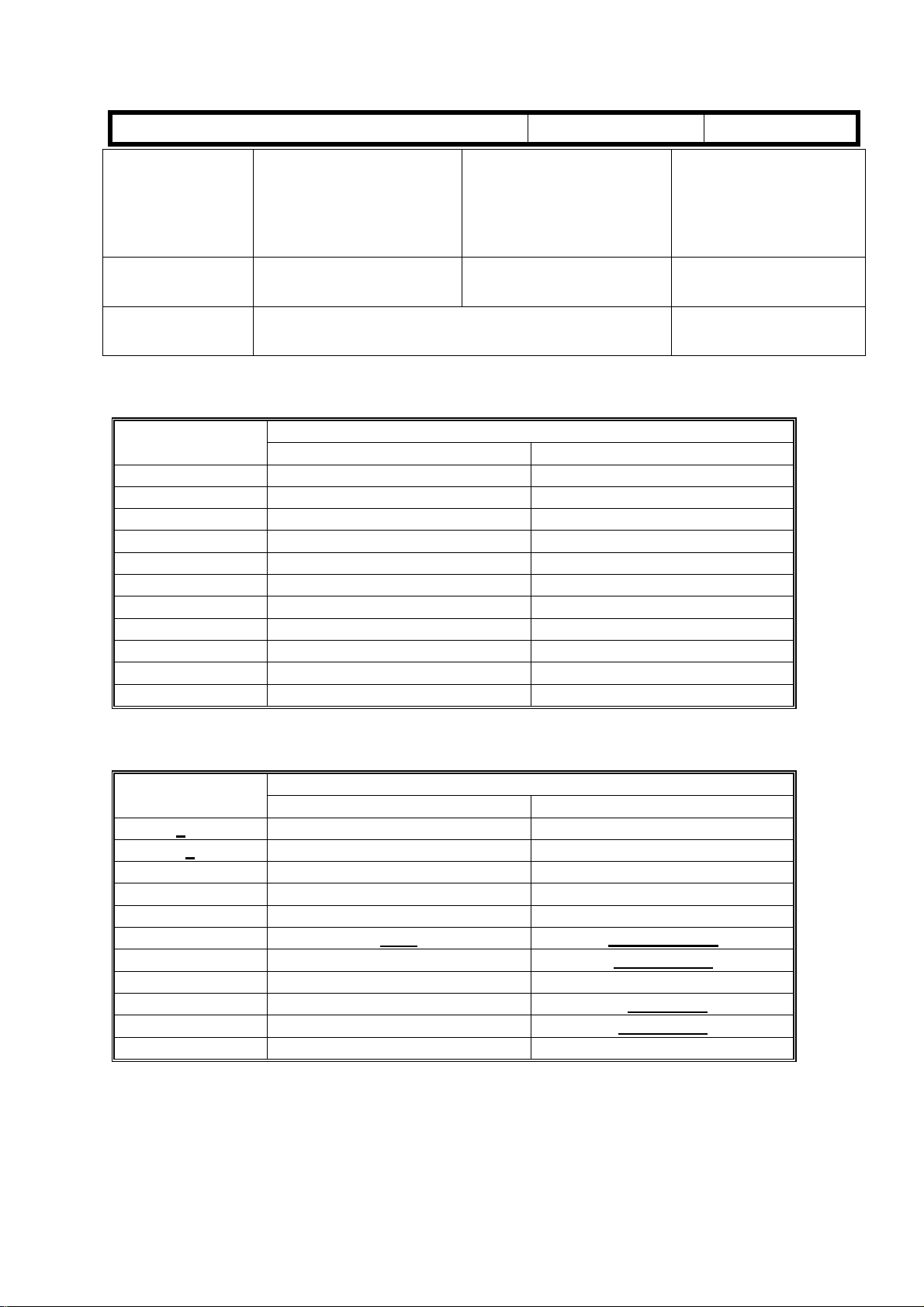

CN1 has been connected to connector [A] of the copier harness (A2945098: SICU

Connect Harness). The service manual procedure for key counter installation has not been

changed. Because the key counter relay harness reverses the orientation of the four

harness cables, it is not necessary to add additional key counter relay harnesses to the

LCT (even if the optional LCT is installed).

In addition, the service manual procedure for key counter installation with the LCT remains

unchanged. (Key counter extension kit <A2949501> on page 1/3 is required.)

Page 15

RICOH Technical

Bulletin

PAGE: 3/3

Model:

Note on attaching the new key counter relay harness in Lanier machines:

Do not install key counters for Ricoh copiers in Lanier copiers. This may damage the ICs

on the BICU board.

Do not connect the Ricoh short connector (A0965464: Key Counter Connector) to Lanier

copiers. This may also damage the ICs on the BICU board.

Bellini

Date:

03-Feb-00

No.:

RA294005

Page 16

T

echnical

B

ulletin

PAGE: 1/2

Model:

Subject:

From:

Bellini

Manual Correction

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

15-Feb-00

Prepared by:

J. Mochizuki

Action required

Service manual revision

Retrofit information

Please correct your Bellini service manuals as follows:

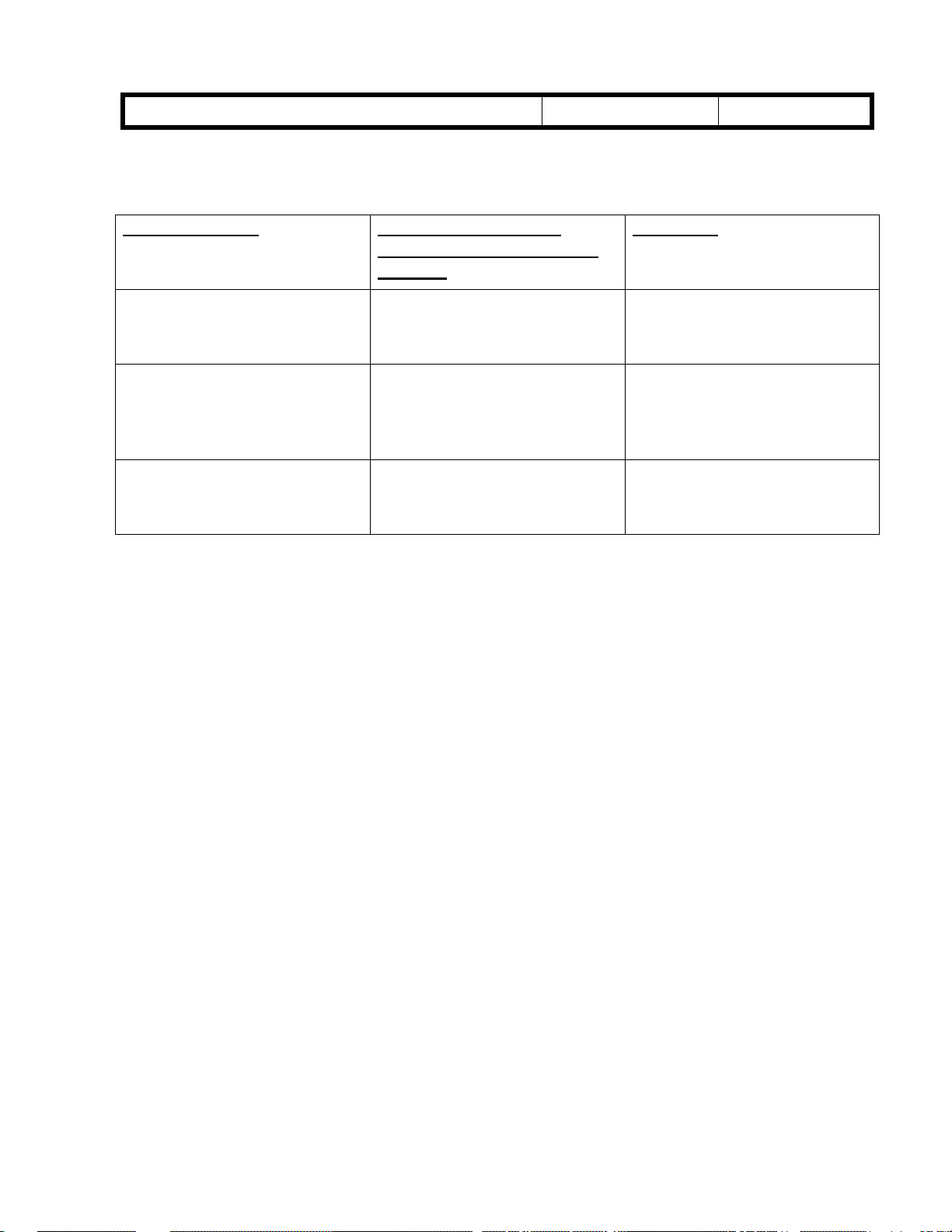

Location: Incorrect description: Correct description: Note:

Page 1-2

Toner Yield:

Page 1-8

Item 3

Page 1-8

55k copies 53k copies

3. Tray 3 (1,500-sheet

LCT)

4. Tray 2 (550-sheet) 4. Tray 2 (500-sheet)

3. Tray 3 (500-sheet)

No.:

RA294006

Item 4

Page 2-105

Last paragraph,

second sentence.

Page 3-11

Step 33-3

Page 3-11

Step 39 Note

Page 4-17

SP2-301-3

Page 4-37

SP4-903-84, 85

“Setting” Column

Page 4-38

SP4-904-5

400K 300K The yield of the oil

supply cleaning web is

300K.

Hold down the clear/stop

key

Perform SP6-009 (DF

Free Run)

If the user normally feeds

thicker paper from the

by-pass tray, use a

higher setting.

0 ∼ 5

1/step

2

Please delete this mode from the manual. This mode has been

Hold down the clear key

Perform SP6-008-3 (DF

Output Check)

If the user normally feeds

thicker paper, use a

higher setting.

0 ∼ 2

1/step

2

Using SP6-008-3

makes it easier to

remove dust.

removed from the first

production lot.

Page 4-42

SP5-038

“Setting” Column

0: No

1: Yes

The default setting was

missing.

Page 17

T

echnical

ulletin

B

PAGE: 2/2

Model:

Page 4-47

SP6-116

“Function”

Column

Page 7-31

Page 2-80

Bellini

Incorrect

Paper Size

Switch

00111 A3-L 11" x 17"-L

00011 8

10011 A4-L 8

01001 A4-S 8

00100 8

00010 — 8" x 10"-S

00001 A5-S 8" x 10"-L

10000 8 k-L (Taiwan version only) 8" x 13"-L

11000 16 k-L (Taiwan version only) 10" x 14"-L

11100 16 k-S (Taiwan version only) 11" x 15"-L

11110

Date:

Multiply

by this number to

determine the staple limit

number for thick paper

mode.

SC735: Finisher Exit

Guide Error

Paper size switch and paper size (see the tables

below)

the normal limit

A4/A3 Version LT/DLT Version

" x 13" 8

1/4

" x 13" 5

1/2

✻✻

Divide

by this number to

determine the staple limit

number for thick paper

mode.

SC736: Finisher Exit

Guide Error

the normal limit

Paper Size

15-Feb-00

1/2

1/2

1/2

1/2

" x 14"-L

" x 11"-L

" x 11"-S

" x 8

1/2

"-S

No.:

RA294006

Correct

Paper Size

Paper Size

Switch

01111

00111

10011 A4-L 8

01001 A4-S 8

00100 8

00010

00001 A5-S

10000 8 k-L (Taiwan version only)

11000 16 k-L (Taiwan version only)

11100 16 k-S (Taiwan version only)

11110

A4/A3 Version LT/DLT Version

A3-L 11" x 17"-L

8

" x 13" 8

1/4

" x 13" 5

1/2

A5-L

✻✻

" x 14"-L

1/2

" x 11"-L

1/2

" x 11"-S

1/2

" x 8

1/2

5

1/2

8" x 10

8" x 10"-L

8" x 13"-L

10" x 14"-L

" x 8

1/2

1/2

1/2

"-L

"-S

"-L

Page 18

RICOH Technical

Reissued: 16-Mar-00

Bulletin

PAGE: 1/

5

Model:

Bellini

Date:

15-Dec-99

No.:

RA294001a

RTB Correction

The items in bold italics have been corrected added.

Subject:

From:

Classification:

While SP2-207-2 (Toner Bank Toner Supply) is performed at installation, the rotation of

the toner hopper gear (AB013748: Joint Gear -15Z) may cause an oversupply of toner

from the hopper to the development unit. This in turn causes relatively high image density

in copies/printouts made just following installation. To correct this, machines in massproduction have been modi fied as fol lows:

Toner Hopper Gear Replcement at Installation

Technical Services Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

H.K.

Temporary Solution

The toner hopper contains red idler gear (A2943255: Idler Gear - 15Z). This gear reduces

the drive supplied to the toner hopper and prevents the oversupply of toner that occurs in

the initial period following installation.

The toner hopper gear for normal operation (White gear:AB013748: Joint Gear -15Z) and

a spare C-ring (07200060B: Retaining Ring - M6) have been packed in the accessory

plastic bag.

The procedure for the Toner Hopper Drive Gear Replacement (Joint Gear - 15Z) has been

packed in the accessory plastic bag. The procedure is also included on page 2/3 of this

bulletin.

Action required

Replace the red idler gear with the white gear after carrying out SP2-207-2 (Toner Bank

Toner Supply) by referring to the procedure for the Toner Hopper Drive Gear Replacement

(Joint Gear - 15Z) packed in the accessory plastic bag. The red idler gear is not necessary

after machine installation.

Permanent Solution

The permanent solution is basically the same as the temporary solution. To facilitate gear

replacement, the gear has been mounted with a screw (09513006B: Philips Screw With

Flat Washer - M3x6) instead of a C-ring. The procedure is included on page 3/3 of this

bulletin. Regarding the cut-in serial numbers for this modification, we will issue an MB as

soon as they are available.

Action required

Same as “Action required” described above.

Page 19

RICOH Technical

Reissued: 16-Mar-00

Bulletin

PAGE: 2/

5

Model:

The part number of the toner hopper unit will be changed from #A2943200 to a new part

number due to the above modificati o n.

field, perform SP2-207-2 using the red gear because the new toner hopper does not

contain any toner.

The toner hopper unit part number will therefore be changed because of the gear

replacement and C-ring substitution.

#A2943200 contains a white gear, this gear should be changed to the red gear when

installing A2943200 in machines already in the field. After performing SP2-207-2

with the red gear, it is necessary to reinstall the white gear.

The following is the procedure packed in the accessory plastic bag as the temporary

solution. After step #35, remove the development unit and follow the procedure labeled

(*)

Bellini

below.

When replacing the toner hopper unit in the

Please be aware that although the spare part

Then, put back the development unit.

Date:

15-Dec-99

No.:

RA294001a

Toner Hopper Drive Gear (Joint Gear 15Z) Replacement

Please add the gear replacement procedure (*) after step #35 (Toner Bank Toner Supply).

#35. Supply toner from the toner bank to the toner hopper as follows:

1) Select SP2-207-2(To ner Bank To ner Suppl y )

2) Press the “Start key” on the LCD.

# *

#36. Change the paper size for all paper trays to suit the customer’s request.

Remove the Joint Gear 15Z that has been marked red [A].

*

Replace it with the white gear [B] and a spare C-ring packed in the accessory

plastic bag.

B

A

Toner Hopper Unit Rear View

Page 20

RICOH Technical

Reissued: 16-Mar-00

Bulletin

PAGE: 3/

5

Model:

The following is the procedure packed in the accessory plastic bag as the permanent

solution. After step #35, remove the development unit and follow the instruction marked

with an asterisk (*). Then, put back the developme nt uni t.

Bellini

Date:

15-Dec-99

No.:

RA294001a

Toner Hopper Dr ive Gear (Joint Gear 15Z) Replacement

Please add the gear replacement procedure after step #35 (Toner Bank Toner Supply).

#35. Supply toner from the toner bank to the toner hopper as follows:

1) Select SP2-207-2 (Toner Bank Toner Supply)

2) Press the “Start” key on the LCD.

*:

#36. Change the paper size for all paper trays to suit the customer’s request.

*

Remove the Joint Gear 15Z that has been marked red [A].

Replace it with the white gear [B] packed in the accessory plastic bag.

B

A

Toner Hopper Unit Rear View

Page 21

RICOH Technical

Reissued: 16-Mar-00

Bulletin

PAGE: 4/

5

Model:

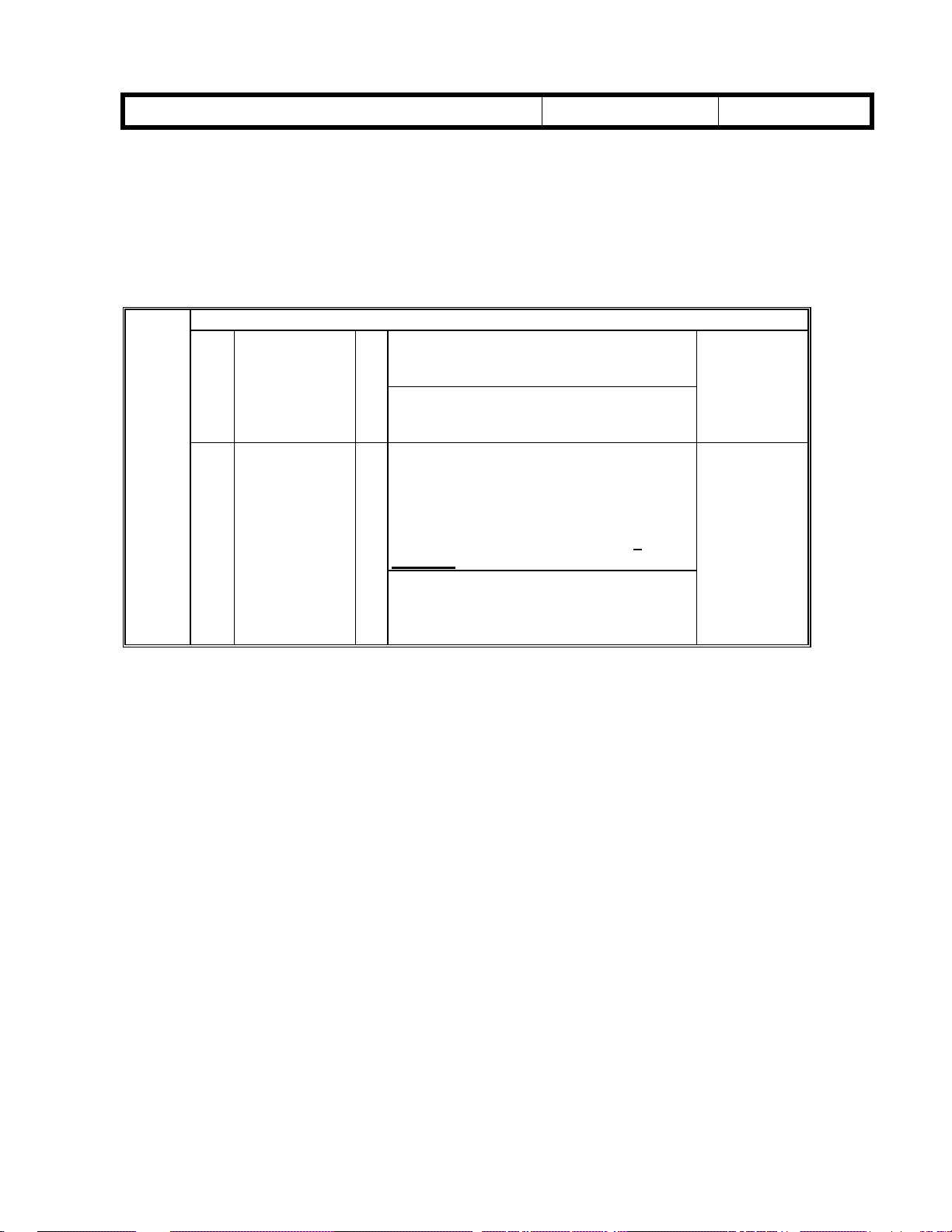

Please make note of the following necessary actions following each service activity

listed below:

Service activity Necessary action for

Developer replacement No further action is

Toner Hopper Unit

Replacement (empty toner

hopper installation).

Toner transport tube

cleaning (before and after

machine transportation).

Bellini

adding toner to the toner

hopper:

required. The white gear is

in the toner hopper unit.

* Refer to the procedures

described above in this

bulletin.

No further action is

required. The white gear is

in the toner hopper unit.

Date:

15-Dec-99

Remarks:

Toner can be supplied

from the toner hopper.

Toner is not in the toner

hopper. If the above action

is not carried out, SC495

will be displayed.

Toner is already inside the

development unit and

toner hopper.

No.:

RA294001a

Note for SP2-207-2

Occasionally, SP2-207-2 finishes within 2 seconds or so. If this happens, perform

SP2-207-2 again. Normally this mode will continue for about 5 minutes.

Reason

The mylar attached to the agitator in the toner hopper cleans the surface of the

toner hopper sensor. This is done so that the sensor will accurately detect the

amount of toner in the hopper. If the sensor detects toner in the hopper when SP2207-2 is initiated, the SP mode will not be carried out. This is to prevent toner from

being mistakenly supplied. However, when the mylar is rotated to clean the sensor

surface, the sensor may sometimes detect the mylar and judge that there is still

toner present. This may occur even if there is no toner in the hopper.

Page 22

RICOH Technical

Reissued: 16-Mar-00

Bulletin

PAGE: 5/

5

Model:

Bellini

Correction for service manual page 4-15

Please correct your service manual as follows:

Incorrect: 7 minutes

Correct : 5 minutes

2-207

Forced Toner Supply

1 Forced Toner

Supply

2 Toner Bank

Toner Setup

Forces toner supply for 7 seconds from

the toner bank through the toner hopper

to the development unit.

This mode finishes automatically after

the toner is supplied 7 times (1 s for

each time).

Turns on the main motor, development

motor, development bias, toner supply

motor and charge corona. Then turns on

the toner supply coil clutch to supply

toner to the toner hopper, but not to the

development unit. It takes about 5

minutes.

This mode should be used to fill the

toner transport path with toner after

cleaning the toner supply unit, or at

installation.

Date:

15-Dec-99

Start

Start

No.:

RA294001a

Page 23

RICOH Technical

g

g

Bulletin

PAGE: 1/2

Model:

Subject:

From:

Bellini

SP2506

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Date:

Prepared by:

Part information

Electrical

Transmit/receive

16-Mar-00

Action required

Service manual revision

Retrofit information

H.K.

No.:

RA294007

SYMPTOM

In the Japanese market, it has been reported that vertical black lines have a tendency to

appear in copy images after long continuous copy jobs (10 hours).

CAUSE

Toner is not completely removed by the cleaning blade due to paper dust that accumulates

on the cleaning blade after long continuous copying. During the continuous copying, the

drum motor does not stop and turn in reverse to clean the edge of the cleaning blade.

SOLUTION

On the production line (from March production: SICU&BCU version

The default settings of SP2506-1 and -2 will be changed from March production so that the

drum motor stops and turns in reverse every 30 minutes during continuous copying to

clean the blade edge.

Default setting: 2506-1 (changed from No to

minutes

).

Yes

), 2506-2 (changed from 15 to

Here is the revised SP Mode table:

2-506

Cleaning Interval – Multiple Copy

1On/Off

2 Interval

Selects whether multiple copy jobs are

stopped at re

purposes:

1. Stop and turn the drum motor in reverse

to clean the cleaning blade edge.

B

2. Make an ID sensor pattern to correct the

toner density control.

The interval is determined by SP2-506-2.

Use if the drum gets dirty or images get too

pale or too dark during long copy jobs.

Selects the interval at which m u lti copy jobs

B

are stopped for blade cleaning.

ular intervals for the followin

V.7.28.1)

30

1: No

2: Yes

1 ~ 100

1 minute/step

30 minutes

Page 24

RICOH Technical

Bulletin

PAGE: 2/2

Model:

Countermeasure in the field for machines produced up to February 2000:

Upgrade the SICU & BCU to V.7.28.1. Then, change the SP mode values as shown above

if the same symptom appears in the field.

Please note:

SP2-506-1 and –2

In order to activate the new default settings after you have installed the firmware, you must

enter the SP modes and manually change the settings to these new default values. After

this has been done, the machine will recognize these settings as the defaults.

If you change these two SP mode settings with versions older than 7.28.1, SC990 may

occur when printing out blank copies with the slip-sheet, cover sheet or chapter sheet

functions. Therefore, we recommend that you update the firmware to version V.7.28.1.

Continuous copy runs

Continuous copy runs are stopped for 5 or 6 seconds every 30 minutes to clean the edge

of the cleaning blade. However, the fusing unit maintains the ready temperature, as the

machine’s major internal mechanisms are not shut down during this interval.

Bellini

Date:

16-Mar-00

No.:

RA294007

Page 25

RICOH Technical

Bulletin

PAGE: 1/3

Model:

Subject:

From:

Bellini

Dog Ear

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Date:

Prepared by:

Part information

Electrical

Transmit/receive

21-Mar-00

Action required

Service manual revision

Retrofit information

H.K.

No.:

RA294008

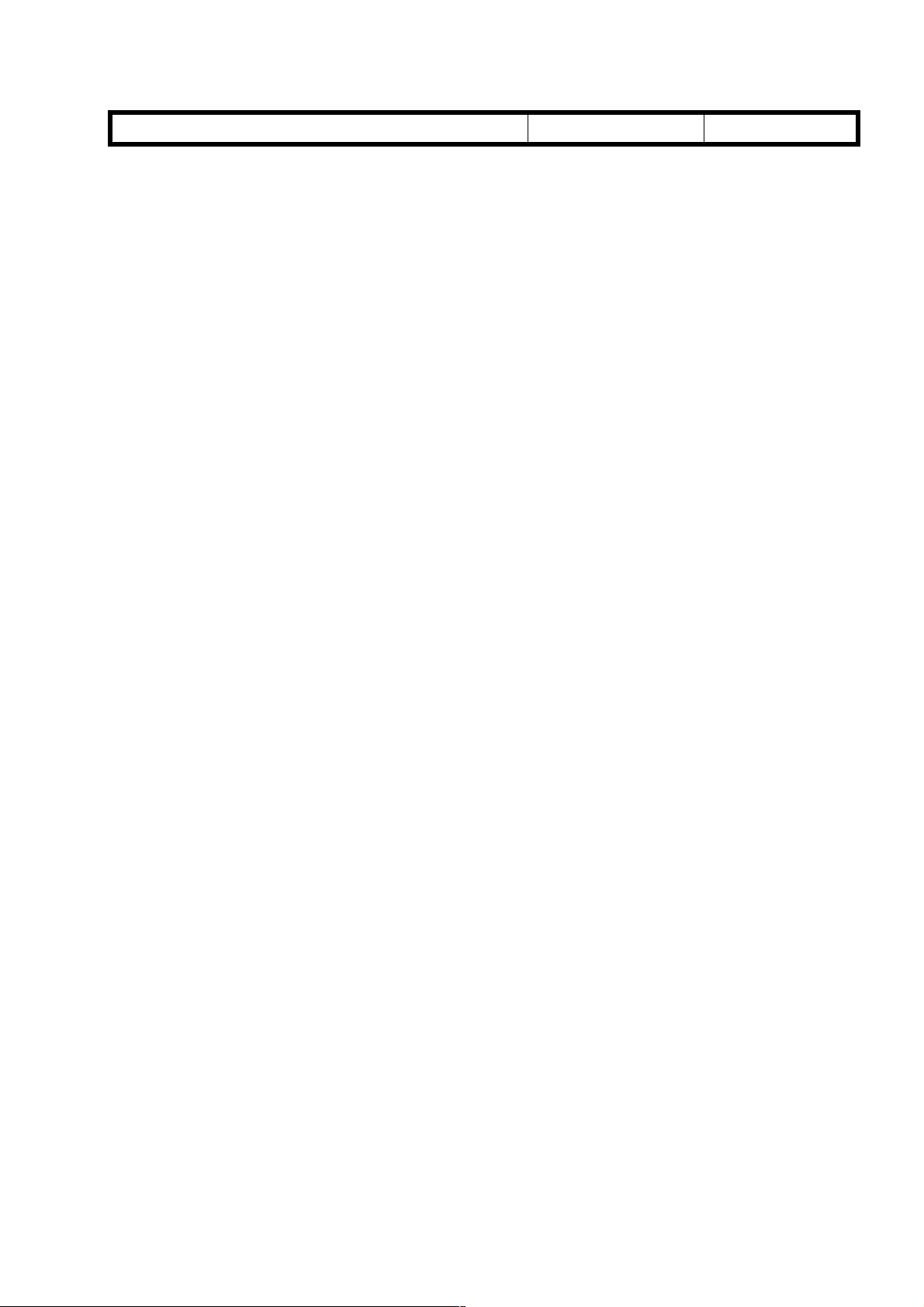

Symptom 1:

Dog ear at the rear side of the leading edge.

Cause:

The Fusing Exit Guide is not properly set. There is a small gap at the Rear Magnet Catch.

In addition, the hot roller strippers are not in the proper position when the exit guide is

closed due to the mechanical load of the stripper sliding mechanism.

Solution:

Temporary Solution: From December production.

In order to minimize the sliding mechanical load, apply grease to the Stripper Release

Slider in the following places:

- The 2 shoulder screw holes on the Guide Plate

- The 5 projections on the surface of the Exit Guide Bracket

Fusing Exit Guide

x

x

x

x

x

Guide Plate

Screw Holes

Exit Guide

Bracket

X: Projection

Page 26

RICOH Technical

Bulletin

PAGE: 2/3

Model:

Type of grease: Grease Barrierta –JFE5 5/2 (P/N: A028 9300)

Permanent Solution: From March production.

In addition to applying grease to the stripper release slider, the shape of the Exit Guide

Plate has been modified to smooth the stripper sliding mechanism as an "improvement".

The part number is still the same.

Bellini

Date:

21-Mar-00

No.:

RA294008

Symptom 2:

Dog-ears have a tendency to occur when using curled paper.

Solution:

Temporary Solution:

To minimize this, the following modification has been applied to machines in mass

production:

The height of the holes has been changed from 4 x 10 mm to 5 x 10 mm, so the position of

the entrance guide has been raised by 1 mm on the production line.

Cut-in serial numbers

A294-14 L065003XXXX

A294-15 H3600200180

A294-17 H3600200220

A294-22 H3600200001

Entrance Guide

A294-24 L065003XXXX

A294-26 4B10200001

A294-27 H3600200051

Page 27

RICOH Technical

Bulletin

PAGE: 3/3

Model:

Permanent Solution: From March production

Refer to Bellini MB No. 4 for details.

Bellini

Date:

21-Mar-00

No.:

RA294008

Page 28

!"#$% T

echnical Bulletin

PAGE: 1/2

Model:

Subject:

From:

Bellini

Timing Belt Slipping Off

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

24-Apr-00

Prepared by:

H.K.

Action required

Service manual revision

Retrofit information

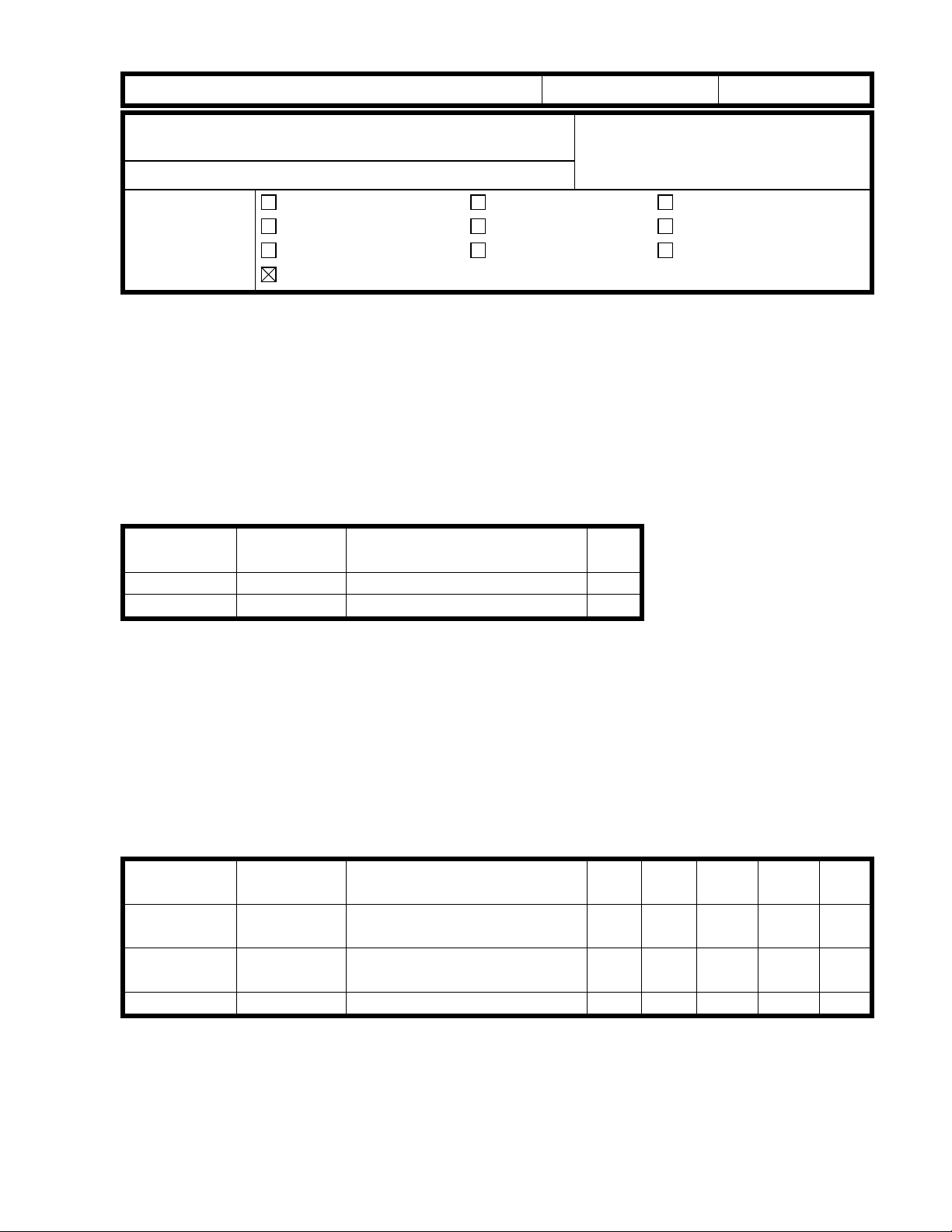

SYMPTOM

No paper feed from trays 2 and 3.

CAUSE

During rotation, the lower timing belt may tend to slip off the idler pulley.

SOLUTION

- Production line -

No.:

RA294009

A spacer (AA132212: Spacer – 8 x 22 x 1.5) will be added as a flange to prevent the belt

from slipping off the pulley. In addition, the orientation of the pulley (AB032716) will be

reversed.

This modification will be applied from May 2000 production.

- In the field -

If the problem occurs in the field, install the spacer as a flange and reverse the orientation

of the pulley.

Page 29

!"#$% T

echnical Bulletin

PAGE: 2/2

Model:

Bellini

[C]

[A]

[B]

[D]

Date:

24-Apr-00

[E]Reverse the pulley [D].

No.:

RA294009

A294R930.WMF

Spacer Installation for the Lower Timing Belt (2nd & 3rd Trays)

1. Turn off the main switch.

2. Remove the lower rear cover.

3. Remove the PSU (5 screws, all connectors) and IOB board (4 screws, all connectors).

See Boards and Other Items in the service manual.

4. Remove the tension spring [A].

5. Remove the screw [B].

6. Remove the lower timing belt [C].

7. Remove the pulley [D] (1 E-ring).

8. Attach the spacer [E].

9. Reverse the pulley [D] and attach it as shown (1 E-ring).

10. Put back all removed parts.

Page 30

!"#$% T

echnical Bulletin

PAGE: 1/3

Model:

Subject:

From:

Bellini

Toner bottle cap open/close mechanism faliure

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

01-May-00

Prepared by:

No.:

RA294010

H.K.

Action required

Service manual revision

Retrofit information

SYMPTOM

The open/close mechanism for the lower toner bottle cap does not work properly. In some

cases, the mechanism does not return the cap to the bottle, which causes the toner to spill

when the bottle is removed.

Note: This symptom occurs only with the lower toner bottle.

Occurrence conditions:

1. The lower toner bottle is not placed in the toner bank unit or the toner end

condition is detected for the lower toner bottle and:

2. The upper toner bottle is shaken several times before it is set.

CAUSE

If an operator shakes the bottle several times and then sets it in the machine, too much

toner will be supplied from the bottle. Normally, when the bottle cap is opened, about 30 to

40 g of toner is supplied. However, after the bottle has been shaken several times, this

amount can be up to 150 g.

In addition, if the upper bottle is installed first after having been shaken several times,

toner can get jammed in the lower bottle open/close mechanism, causing the mechanism

to lock.

SOLUTION

Production line (from April production: SICU&BCU version V.7.31.3)

-Software modification: If the upper toner bottle is set first, the machine LCD will instruct

the operator to install the lower toner bottle first.

-Decal: A caution decal [A] (A2941273) has been attached to the toner bank cover. Also,

step 3 of the existing toner bank decal [B] has been changed. This decal is attached to the

inner face of the toner bank cover.

The decal will read:

Do not shake toner bottle before setting.

Set lower toner bottle first.

Page 31

!"#$% T

echnical Bulletin

PAGE: 2/3

Model:

Bellini

Date:

01-May-00

No.:

RA294010

Countermeasure in the field for machines produced up to March 2000:

Update the SICU & BCU to V.7.31.3. Demonstrate to the customer the correct way to

install the toner bottles (according to the decal illustrations).

[A]

A2941273

CAUTION

DECAL - TONER

SUPPLY

2

1

1

2

Toner Bank Decal [B] (A2941272)

Page 32

!"#$% T

echnical Bulletin

PAGE: 3/3

Model:

NOTE:

Toner Bank Decal [B] (A2941272): The part number remains the same. The old decal has

never been supplied from SPC as a service part.

Bellini

Toner Bank Cover

Existing Toner Bank Decal [B] on the inner face

of the toner bank cover

Toner Bank Inner faceplate

Date:

01-May-00

No.:

RA294010

Page 33

!"#$% T

echnical Bulletin

PAGE: 1/7

Model:

Subject:

From:

Bellini

Used toner bottle full at an early stage

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

26-May-00

Prepared by:

No.:

RA294011

S. Hizen

Action required

Service manual revision

Retrofit information

SYMPTOM

Used toner bottle at an early stage.

Almost all of the toner that should be routed to the toner collection unit is sent to the used

toner bottle.

This is because the old-type toner collection pipe was installed in the following machines.

A294-17: H3691100001 to H3691100015 (15 machines)

A294-27: H3691100039 to H3691100053 (15 machines)

COUNTERMEASURE

Replace the toner collection pipe

Please refer to following toner collection unit removal and installation procedures.

Note: Before beginning the replacement procedure, please check whether the pipe in the

machine is the old type.

1. Toner Collection Unit Removal Procedure

Preparation:

1) Remove the upper rear cover.

2) Remove the drum inner cover and drum

stay. Slide the drum unit out 50 mm.

(Picture 1)

Picture 1

Page 34

!"#$% T

echnical Bulletin

PAGE: 2/7

Model:

Removing the Toner Collection Unit:

1) Remove the fly wheel (3 screws).

2) Remove the 4 BCU securing screws and

tilt out the BCU toward you.

(Picture 2)

3) Remove the BCU hinge brackets

(one on each side, one screw each).

The picture shows the right bracket

being removed.

(Picture 3)

Bellini

Date:

Picture 2

Picture 3

26-May-00

No.:

RA294011

4. Disconnect the three fusing unit

connectors and ground wire (1 screw).

These 3 harnesses run above the pipe.

(Picture 4)

Picture 4

Page 35

!"#$% T

echnical Bulletin

PAGE: 3/7

Model:

5. As shown in the picture to the right, remove the

support plate located near the main motor

(1 screw), loosen the 2 screws of the

tightener bracket and remove the tightener

tension spring.

Next, remove the three timing belts as shown

in the two pictures below.

(Pictures 5, 6)

Bellini

Date:

Picture 5

Picture 6

26-May-00

No.:

RA294011

6. Remove the exhaust fan duct, located to

the left of the main motor (no screws).

Note: It is easier to remove the duct

if you loosen the fan bracket securing screw

first. This screw is located to the left of the

duct.

(Picture 7)

Picture 7

Page 36

!"#$% T

echnical Bulletin

PAGE: 4/7

Model:

7. Remove the main motor (4 screws)

and remove the two connectors.

Note: Tilt the bottom face of the motor

toward you when removing it from

the machine.

(Picture 8)

8. Remove the 2 securing screws for the

collection case.

(Picture 9)

Bellini

Date:

Picture 8

Picture 9

26-May-00

No.:

RA294011

9. Remove the screw for the distribution case

(the only M4X10 screw).

(Picture 10)

Picture 10

Page 37

!"#$% T

echnical Bulletin

PAGE: 5/7

Model:

10. Slide the toner collection unit to the right,

disconnect the screw drive shaft from

the bushing and remove the unit.

(Picture 11)

11. The picture below is the toner collection

unit after it has been removed.

(Picture 12)

Bellini

Date:

Picture 11

Picture 12

26-May-00

No.:

RA294011

Page 38

!"#$% T

echnical Bulletin

PAGE: 6/7

Model:

Bellini

Date:

26-May-00

No.:

RA294011

2. Toner Collection Pipe Replacement Procedure

How to distinguish the old type from the current type:

The angles of the cut-outs are 60 degrees different.

1. Remove the two gears shown in the picture (2 e-rings).

2. Remove the 2 pipes from the distribution case.

3. Loosen the two screws of the collection case and remove the lower pipe only.

Note: Place a sheet of paper or newspaper underneath the case, as toner from the pipe

will tend to leak.

4. Replace the lower pipe with the current type.

Note: Make sure that the toner drop hole is facing downward. However, it does not need

to be completely vertical (90 degrees). In addition, make sure that the U-groove on

the left face of the pipe is properly lined up with the projection on the case.

5. Return all other parts to their original positions.

Note: Make sure that the toner drop hole is in a lower position.

(It would be hard to see the hole from the front when the hole is in the proper position)

NOTE: After installing the new pipe, please double check that the drop hole is facing

downward. You can check this by looking at the pipe from the front. If you can barely see

the hole, it is in the proper position.

Picture 13

Page 39

!"#$% T

echnical Bulletin

PAGE: 7/7

Model:

Bellini

Date:

26-May-00

No.:

RA294011

3. Toner Collection Unit Installation Procedure

Reinstall the parts in the reverse order in which they were removed (see the unit Removal

Procedure above).

Note: Please follow the procedure below when reinstalling the 3 Timing Belts (step 5):

1. Attach the support plate (see picture below).

2. Attach the belts.

3. Turn the belts several times in the motor rotation direction.

4. Tighten the 2 screws of the tightener bracket.

Picture 14

Page 40

echnical Bulletin

T

PAGE: 1/16

Model:

Subject:

From:

Bellini

105 CPM Version Information

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

26-May-00

Prepared by:

No.:

RA294012

H.K.

Action required

Service manual revision

Retrofit information

Introduction

To facilitate servicing the 105cpm (A295) model in the field, this RTB describes the

differences from the 85cpm (A294) model.

Major Parts

Fusing Lamps:

85 CPM AX430052 Fusing Lamp – 230V/530W

105 CPM AX430055 Fusing Lamp – 230V/630W

The wattage of the fusing lamps has been increased from 530 to 630W to improve fusing.

To distinguish these two lamps, the colors of the front harnesses [A] are as follows:

530W: Blue

630W: Red

The connectors for both the lamps have the same color. The following note for reassembly has not been changed:

[A]

Note on 6-87

At the front, connect the white fusing lamp connectors to the white connectors on the

cable. At the rear, connect the green fusing lamp connectors to the green connectors on

the cable.

Page 41

echnical Bulletin

T

PAGE: 2/16

Model:

Bellini

Date:

26-May-00

No.:

RA294012

Fusing Lamp Control:

The fusing temperature control for the 105cpm model is different from that of the 85cpm

model.

188°C (A4/LT width or less) (85cpm)

198°C (A4/LT width or less) (105cpm)

183°C (Larger than A4/LT width) (85cpm)

193°C (Larger than A4/LT width) (105cpm)

➀

: Main switch on

➁

: Process control data initialization

and idling begins.

➂

: Idling ends

➃

: Stand-by

➄

: Copying begins

155°C

177°C

173°C(85cpm)

178°C(105cpm)

➁➂ ➃➀➄

A294D627.WMF

The CPU turns on all three fusing lamps after the main switch is turned on, with a

one-second interval between each. This prevents the power from the AC line from

dropping too quickly.

When the fusing temperature reaches 155°C, the machine starts the process control data

initialization. However, this is not performed if the fusing temperature is already above

100°C at the time the main switch is turned on.

When the fusing temperature reaches 155°C, the copier starts fusing idling. However, the

idling is not performed if the fusing temperature is already above 100°C at the time the

main switch is turned on

When the temperature reaches 177°C, the warm-up period is completed and the “Ready”

indicator turns on. After this, the machine maintains a fusing temperature of 173°C (85

cpm model) and 178°°°°C (105cpm model).

In stand-by mode, one of the fusing lamps turns on intermittently in order to maintain ready

temperature. During the copy cycle, all three fusing lamps are used to maintain operating

temperature. The machine will turn the lamps on one at a time, with a one-second interval

between each.

Page 42

echnical Bulletin

T

PAGE: 3/16

Model:

The CPU changes the interval that the fusing lamp is on depending on the temperature

measured by the thermistor. This is to maintain the fusing temperature as close to the

target value as possible.

Even if one of the lamps fails during copying, the machine will continue to function.

However, if it detects a broken lamp just after being switched on, an SC error occurs and

copying is not possible.

The machine uses the fusing lamp on/off control mode to maintain the fusing temperature

as close to the target value as possible. Even if thick paper mode is selected, fusing

temperature control does not change.

SP1-902-2 Default setting (42 seconds: 85 cpm, 34 seconds: 105 cpm):

Page 2-105, second paragraph:

Every 42 seconds (85cpm) or 34 seconds (105cpm) during printing, the oil

supply/cleaning web motor turns for 0.8 seconds to move the oil supply and cleaning web

felt. This 42 or 34-second cycle starts when the first copy reaches the fusing exit sensor

and ends 2 seconds after the last copy has passed this sensor. Both the motor rotation

cycle and on-time are adjusted by SP1-902-2 / 3.

Bellini

Date:

26-May-00

No.:

RA294012

Hard Disk:

85 CPM A6915879 Hard Disk Drive

105 CPM A2955172 Hard Disk - Fireball Plus KX

For printing out with the 105 cpm model, it is necessary to use a hard disk with a faster

rotation speed in order to conform to the higher copy speed of the machine. The hard

disks used for both models are as follows:

Seek Time Rotation

Velocity

85cpm 9.5 ms 5400 rpm 4.3 GB

105cpm 8.5 ms 7200 rpm 6.8 GB

Capacity

Page 43

echnical Bulletin

T

PAGE: 4/16

Model:

Bellini

HDD Control (S/M 2-127):

UP Setting for

“Memory Allocation”

Copier Priority Copy Jobs: 0.82 GB

Copy Server Jobs:

3.08 GB (85 CPM)

5.00 GB (105 CPM)

Printer Jobs: 0.20 GB

Max. Memory for Document

Server

Copy Jobs: 1.23 GB

Copy Server Jobs:

2.57 GB (85 CPM)

5.00 GB (105 CPM)

Printer Jobs: 0.31 GB

HDD 1 (Front) HDD 2 (Rear)

Date:

26-May-00

Copy Jobs: 3.35 GB

Copy Server Jobs: Not used

Printer Jobs: 0.76 GB

Copy Jobs: 1.23 GB

Copy Server Jobs:

2.57 GB (85 CPM)

5.00 GB (105 CPM)

Printer Jobs: 0.31 GB

No.:

RA294012

Page 44

echnical Bulletin

T

PAGE: 5/16

Model:

Transfer Belt:

To achieve a higher copy speed than the 85cpm model, the transfer belt in the 105cpm

model is given a higher transfer current. With higher transfer current, black lines have a

greater tendency to appear in half-tone areas on the copy. To compensate for this, the

transfer belt used in the 105cpm model has a lower resistance.

To distinguish between the two transfer belt units, a seal is attached to the transfer belt

frame for the 105cpm model as shown. Note that the belt for the 105cpm model can also

be used for the 85cpm model.

Bellini

A229 3852 Transfer Belt85 CPM

A2943810 Transfer Belt Unit

A229 3899 Transfer Belt105 CPM

A2953810 Transfer Belt Unit

Date:

Seal

26-May-00

No.:

RA294012

Transfer Belt Frame

Page 45

echnical Bulletin

T

PAGE: 6/16

Model:

Bellini

Date:

26-May-00

No.:

RA294012

Specifications

The additional items added to the specifications of the 105cpm model are listed on page

7/16 of this bulletin.

SP Mode

The SP modes that have been revised or added for the 105cpm model are listed on page

11/16 of this bulletin. All information from Class 1 of the 85cpm model is also listed along

with these new additions/revisions.

Unique parts

An MB for information on the 105cpm model will be issued containing a list of the parts

that are unique to this model.

Input Voltage Level:

The input voltage for the 85cpm model listed on page 3-2 of the Service Manual is

incorrect. Please correct your manuals as follows:

North America:

240V, 60 Hz: More than 10A (85cpm)

240V, 60 Hz: More than 12A (105cpm)

Europe/Asia:

220 ~240V, 50/60 Hz: More than 10A (85cpm)

220 ~240V, 50/60 Hz: More than 12A (105cpm)

Finisher ROM interchangeability

Although the finisher itself is interchangeable between both the 85cpm and 105cpm

models, the EPROM firmware must be updated to version E or newer for fnishers

produced before April 2000. The cut-in serial numbers for April 2000 production are as

follows:

L0670040001 (B302-14)

H3800400001 (B302-17)

4B20400001 (B302-26)

Page 46

echnical Bulletin

T

PAGE: 7/16

Model:

Bellini

Date:

26-May-00

OVERALL MACHINE INFORMATION

SPECIFICATIONS

COPIER ENGINE

Configuration: Console

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book

Original Size: Maximum: A3/11" x 17"

Minimum: A5, 5

Original Alignment: Rear left corner

Paper Size/Weight:

Size: Mainframe, Tray 1 (Tandem Tray):

A4 sideways and LT sideways

Mainframe, Trays 2 and 3 (Universal Trays):

Europe/Asia:

N. America:

lengthwise

LCT, Trays 4 ~ 6:

A4 sideways, B5 sideways, LT sideways, A5,

HLT

Duplex Tray: A5/HLT (lengthwise or sideways)

1/2

"x 8

" (using ADF)

1/2

A5 - A3 lengthwise,

8-kai sideways, 16-kai

5

1/2

" x 8

" sideways - 11" x 17"

1/2

to A3/DLT. Tab paper cannot be used.

No.:

RA294012

Weight: Mainframe, Trays 1 to 3:

52 to 163 g/m

2

16 to 40 lbs Bond

50 to 60 lbs Cover

90 lbs Index (no Tab)

LCT, Trays 4 and 5:

52 to 216 g/m

2

16 to 40 lbs Bond

50 to 80 lbs Cover

90 to 110 lbs Index

LCT, Tray 6:

Same as Mainframe, Trays 1 to 3

Duplex Tray:

64 to 163 g/m

2

20 to 40 lbs Bond

50 to 60 lbs Cover

90 lbs Index (no Tab)

Page 47

echnical Bulletin

T

PAGE: 8/16

Model:

Bellini

Date:

26-May-00

Reproduction ratios: 7 reduction and 5 enlargement

Metric Version Inch Version

400%

200%

Enlargement

Full Size 100% 100%

Reduction

141%

122%

115%

93%

82%

75%

71%

65%

50%

25%

Zoom: 25 ~ 400%

Copy Speed: 85 cpm: Max. 85 cpm (A4/8

1/2

105 cpm: Max. 105 cpm (A4/8

No.:

400%

200%

155%

129%

121%

93%

85%

78%

73%

65%

50%

25%

" x 11" sideways)

" x 11" sideways)

1/2

RA294012

Resolution: Scanning: 600 dpi

Printing: 600 dpi

Gradation: 256 levels

Warm-up Time: Less than 360 s (from Off mode)

First Copy Time:

(1st Tray, A4 sideways)

Finisher upper tray: face down

85 cpm: Less than 5.4 s

105 cpm: Less than 4.9 s

Finisher upper tray: face up

85 cpm: Less than 4.1 s

105 cpm: Less than 3.8 s

Copier: face down

85 cpm: Less than 4.5 s

105 cpm: Less than 4.2 s

Copier: face up

85 cpm: Less than 3.2 s

105 cpm: Less than 2.9 s

Copy Number Input: Ten-key pad, 1 to 9999

Copy Paper Capacity: 1st Tray: 1,000 sheets (2,000 when used as a tandem

tray)

2nd/3rd Tray: 500 sheets each

4th/5th Tray (LCT): 1,000 sheets each

6th Tray (LCT): 2,550 sheets

Page 48

echnical Bulletin

T

PAGE: 9/16

Model:

Bellini

Date:

26-May-00

Memory Capacity: RAM: 48 MB x 2

HDD: 4.3 GB x 2 (85 CPM), 6.8 GB x2 (105 CPM)

Toner Replenishment: Cartridge exchange (1,450 g/cartridge)

Toner Yield: 53 k copies

(A4 sideways, 6% full black, 1 to 25 copying)

Power Source: North America: 240 V, 60 Hz, 20 A

Europe/Asia: 220 ~ 240 V, 50Hz/60 Hz, 16 A

Power Consumption:

N. America Version

Mainframe Only Full System *

Warm-up about 1.96 kW about 1.98 kW

Stand-by about 0.79 kW about 0.8 kW

Copying about 2.24 kW about 2.3 kW

Maximum less than 2.35 kW less than 2.38 kW

*1: Mainframe with Finisher, Large Capacity Tray

No.:

85 cpm

1

RA294012

Mainframe Only Full System *

Warm-up about 2.51 kW about 2.52 kW

Stand-by about 0.93 kW about 0.95 kW

Copying about 2.67 kW about 2.68 kW

Maximum less than 2.77 kW less than 2.84 kW

*1: Mainframe with Finisher, Large Capacity Tray

Mainframe Only Full System *

Warm-up about 1.89 kW about 1.9 kW

Stand-by about 0.75 kW about 0.77 kW

Copying about 2.14 kW about 2.18 kW

Maximum less than 2.24 kW less than 2.26 kW

*1: Mainframe with the finisher, large capacity tray

Mainframe Only Full System *

Warm-up about 2.38 kW about 2.39 kW

Stand-by about 0.89 kW about 0.9 kW

Copying about 2.52 kW about 2.54 kW

Maximum less than 2.64 kW less than 2.7 kW

*1: Mainframe with Finisher, Large Capacity Tray

105 cpm

1

Europe Version

85 cpm

1

105 cpm

1

Page 49

echnical Bulletin

T

PAGE: 10/16

Model:

Bellini

Date:

26-May-00

Noise Emission *1: 85 cpm

Mainframe Only Complete System *

Warm-up about 74 dB (A) 78 dB (A)

Stand-by about 59 dB (A) 58 dB (A)

Sound Pressure Level *

Mainframe Only Complete System *

During printing 59 dB (A) 68 dB (A)

*1: Actual values in accordance with ISO 7779 standards.

2

: Measured from the position of the bystander or operator during printing.

*

3

*

: Mainframe with all options installed.

Noise Emission *1: 105 cpm

Mainframe Only Complete System *

Warm-up 75 dB (A) 78 dB (A)

Stand-by 59 dB (A) 58 dB (A)

No.:

RA294012

Sound Power Level

3

3

Sound Power Level

3

2

Sound Pressure Level *

Mainframe Only Complete System *

During printing 61 dB (A) 67 dB (A)

*1: Actual values in accordance with ISO 7779 standards.

2

*

: Measured from the position of the bystander or operator during printing.

3

: Mainframe with all options installed.

*

Dimensions:

(W x D x H)

870 x 735 x 1,476 mm (34.3" x 28.9" x 58.1")

(without options)

Weight: 252 kg (without options)

Optional Equipment: Refer to Machine Configuration

2

3

Page 50

26 May 2000 PAGE:10 /16

SERVICE PROGRAM MODE TABLES

NOTE: 1) In the Function column, comments are in italics.

2) In the Settings column, the default value is in bold letters.

3) S and B in the right hand side of the mode number column means that

this mode is stored in the NVRAM on the SICU (S) or BCU (B). If you do

a RAM reset, all these SP modes will be reset to their factory settings.

1-002

Mode No.

(Class 1, 2 and 3)

Side-to-Side Registration

1Tray-1

2Tray-2

3Tray-3

4 Tray-4 (LCT)

5 Tray-5 (LCT)

6 Tray-6 (LCT)

Function Settings

Adjusts the printing side-to-side registration

from the 1st paper feed station using the

trimming area pattern (SP2-902-3, No.15).

B

Use the “

before entering the value.

See “Replacement and Adjustment – Copy

Image Adjustments” for details on SP1-002.

Adjusts the printing side-to-side registration

from the 2nd paper feed station using the

trimming area pattern (SP2-902-3, No.15).

B

Use the “

before entering the value.

The specification is 0

Adjusts the printing side-to-side registration

from the 3rd paper feed station using the

trimming area pattern (SP2-902-3, No.15).

B

Use the “

before entering the value.

The specification is 0

Adjusts the printing side-to-side registration

from the 4th paper feed station using the

trimming area pattern (SP2-902-3, No.15).

B

Use the “

before entering the value.

The specification is 0

Adjusts the printing side-to-side registration

from the 5th paper station using the

trimming area pattern (SP2-902-3, No.15).

B

Use the “

before entering the value.

The specification is 0

Adjusts the printing side-to-side registration

from the 6th paper station using the

trimming area pattern (SP2-902-3, No.15).

Use the “

before entering the value.

B

The specification is 0

•

” key to toggle between + and –

•

” key to toggle between + and –

±

2.0 mm.

•

” key to toggle between + and –

±

2.0 mm.

•

” key to toggle between + and –

±

2.0 mm.

•

” key to toggle between + and –

±

2.0 mm.

•

” key to toggle between + and –

±

2.0 mm.

+9 ~ –9

0.1 mm/step

–1.5 mm

+9 ~ –9

0.1 mm/step

–1.5 mm

+9 ~ –9

0.1 mm/step

–1.5 mm

+9 ~ –9

0.1 mm/step

–2.5 mm

+9 ~ –9

0.1 mm/step

–2.5 mm

+9 ~ –9

0.1 mm/step

–2.5 mm

Page 51

26 May 2000 PAGE:11 /16

1-002

1-003

1-105

Mode No.

(Class 1, 2 and 3)

Side-to-Side Registration

7 Duplex Tray

Paper Buckle Adjustment (Registration)

1 Copier Paper

Tray

LCT Tray

2

3 Duplex Tray B

Duplex Fence Adjustment1-008

Fusing Idling After Low Power Mode1-103

Fusing Temperature Adjustment

1Fusing

Temperature in

Waiting

Condition

2Fusing

Temperature

Lower Limit

Adjusts the printing side-to-side registration

from the duplex tray using the trimming

area pattern (SP2-902-3, No.15).

B

Use the “

before entering the value.

The specification is 0

Adjusts the relay clutch timing at

B

registration. The relay clutch timing

determines the amount of paper buckle at

B

registration. (A positive setting leads to

more buckling.)

Adjusts the distance between the front and

B

rear fences.

Selects whether fusing idling is done or not

B

when recovering from the low power mode.

Adjusts the fusing temperature for standby.

B

Adjusts the fusing temperature lower limit.

When the fusing unit falls below this

temperature, the machine stops copying.

Copying automatically restarts when the

B

fusing temperature recovers.

This SP mode is for designer’s use only.

Function Settings

•

” key to toggle between + and –

±

2.0 mm.

+9 ~ –9

0.1 mm/step

–3.0 mm

+9 ~ –9

1 mm/step

+4.0 mm

+4 ~ –4

0.5 mm/step

0 mm

0: Not done

1: Done

170 ~ 200

1°C/step

173°°°°C

(85 CPM)

178°°°°C

(105CPM)

157 ~ 167

1°C/step

163°°°°C

(85 CPM)

167°°°°C

(105 CPM)

1-902

3Fusing

Temperature

Correction

(<A4/LT)

4Fusing

Temperature

Correction

(A4/LT)

Web Motor Control

1Web

Consumption

2 Web Motor

Drive Interval

Specifies the amount to raise the fusing

temperature from standby mode to print on

B

A4/LT long edge or smaller width paper.

Specifies the amount to raise the fusing

temperature from standby mode to print on

B

paper of A4/LT long edge width.

Displays the percentage of the web

consumption in 1% steps (0% ~ 100%).

B

The value can be manually input using

number keys.

Change the interval of copy operation time

after which the web motor is driven

B

+0 ~ +20

1°C/step

+15°°°°C

+0 ~ +25

1°C/step

+10°°°°C

15 ~ 130

1 s/step

42 s

(85 CPM)

34 s

(105 CPM)

Page 52

26 May 2000 PAGE:12 /16

1-902

2-001

2-201

Mode No.

(Class 1, 2 and 3)

Web Motor Control

Web Motor

3

Drive Time

Web Near End

4

Setting

Changes the time that the web motor is

driven.

B

Changes the web consumption ratio at

which web near end is displayed.

B

About 40k A4 copies can be made after the

web consumption reaches 100%.

Charge Corona Bias Adjustment

1 Image Area

(Auto Process

Control OFF)

Adjusts the voltage applied to the grid plate

during copying when auto process control

is off.

Normally, there is no need to adjust this.

B

If there is an ID or TD sensor problem, the

machine goes into fixed toner supply mode.

After replacing the drum or charge corona

wire, change this value to the default.

2 ID Sensor

Pattern (Auto

Process Control

OFF)

Adjusts the voltage applied to the grid plate

when making the ID sensor pattern, when

auto process control is switched off.

B

Normally, there is no need to adjust this.

If the user wants high density copies, the

sensor pattern must be lighter, so this

voltage must be a higher negative voltage.

Image Area

3

(Auto Process

Control ON)

Adjusts the voltage applied to the grid plate

during copying when auto process control

is switched on.

B

This voltage changes every time auto

process control starts up (every time the

machine is switched on)

4 Grid Voltage for

Transparencies

(OHP)

Adjusts the voltage applied to the grid plate

when translucent mode is selected.

Use this if there is a copy quality problem

B

when making copies on transparencies.

Normally there is no need to adjust this.

See 2-001-1.

Total Corona

5

Current

6 Total Corona

Current (Photo

mode)

D

7V

(Auto Process

Control)

Adjusts the current applied to the charge

corona wire except for Photo mode.

B

Adjusts the current applied to the charge

corona wire for Photo mode.

B

Adjust the target V

Control Initial Setting.

B

Development Bias Adjustment

1 Image Area

Adjusts the development bias for copying.

This can be adjusted as a temporary

B

measure if faint copies appear due to an

aging drum.

Function Settings

0.1 ~ 3.0

0.1 s/step

0.8 s

0 ~ 100

1%/step

100%

–650 ~ –1,300

10 V/step

–1,000 V

–650 ~ –1,300

10 V/step

–800 V

–650 ~ –1,300

10 V/step

–1,000 V

–650 ~ –1,300

10 V/step

–1,070 V

–1,400 ~

–2,800

100 µA/step

–1,400 µµµµA

1,400 ~

–2,800

100 µA/step

–1,600 µµµµA

D

voltage for Process

–900 ~

–1,000

10 V/step

–970 V

–200 ~ –700

10 V/step

–530 V

Page 53

26 May 2000 PAGE:13 /16

2-201

2-209

2-301

2-301

Mode No.

(Class 1, 2 and 3)

Development Bias Adjustment

ID Sensor

2

Pattern

B

Transparencies

3

(OHP)

ID Sensor

4

Development

Potential

B

B

Toner Supply Rate

B

Transfer Current Adjustment

11st Copy Side

B

Transfer Current Adjustment

2 Thick Paper

B

Transparencies

3

(OHP)

B

4 Translucent

Sheet

B

5 2nd Copy

B

Function Settings

Adjusts the development bias for making

the ID sensor pattern for V

SP

measurement.

This should not be used in the field,

because it affects ID sensor pattern

density, which affects toner supply.

Adjusts the development bias for copying

onto transparencies.

Adjusts the development potential for

making the ID sensor pattern for V

SP

measurement.

Do not adjust.

Adjusts the toner supply rate from the

hopper.

Increasing this value reduces the toner

supply roller clutch on time. Use a lower

value if the user tends to make lots of

copies that have a high proportion of black.

Adjusts the current applied to the transfer

belt during copying on the 1st side of the

paper.

If the user uses thicker paper, the current

may have to be increased to ensure

sufficient transfer of toner.

Adjusts the current applied to the transfer

belt during copying on thick paper.

See above.

Adjusts the current applied to the transfer

belt during copying on transparencies.

See above. If the user normally feeds

thicker paper from the bypass tray, use a

higher setting.

Adjusts the current applied to the transfer

belt during copying on translucent sheet.

Adjusts the current applied to the transfer

belt during copying on the 2nd side of the

paper.

–200 ~ –700

10 V/step

–400 V

–200 ~ –700

10 V/step

–530 V

-180 ~ -380

1 V/step

-280 V

100 ~ 2,000

10 mg/s/step

800 mg/s

(85 CPM)

1,000 mg/s

(105 CPM)

15 ~ 200

1 µA/step

120 µµµµA

(85 CPM)

140 µµµµA

(105 CPM)

15 ~ 200

1 µA/step

120 µµµµA

(85 CPM)

140 µµµµA

(105 CPM)

15 ~ 200

1 µA/step

140 µµµµA

15 ~ 200

1 µA/step

120 µµµµA

(85 CPM)

140 µµµµA

(105 CPM)

15 ~ 200

1 µA/step

120 µµµµA

(85 CPM)

140 µµµµA

(105 CPM)

Page 54

21 June 2000 PAGE:14 /16

2-506

4-915

Mode No.

(Class 1, 2 and 3)

Transfer Current Adjustment2-301

6 Between Pages

Cleaning Interval – Multiple Copy

1On/Off

2 Interval

ID Sensor Pattern Interval – Multicopy2-969

CD-RW

1 CD-RW Model

Name Display

2 CD-RW F/W

Version Display

Border Erase Area Selection5-923

Adjusts the current applied to the transfer

belt between the pages.

B

Selects whether multiple copy jobs are

stopped at regular intervals for the following

purposes.

1. Stop and turn the drum motor in reverse

B

2. Make an ID sensor pattern to correct the

The interval depends on SP2-506-2.

Use if the drum gets dirty or images get too

pale or too dark during long jobs.

Selects the interval at which multi copy jobs

B

are stopped.

If this is enabled, an ID pattern is made

B

every minute if the machine is being used

during the first 20 minutes after process

control is done. This stabilizes image

density just after the machine has been

switched on. However, the printing

productivity will be decreased.

Displays the CD-R/RW model name and

firmware version.

Selects the standard for edge erase.

0: The margin is erased from the original

data.

1: The margin is erased from the data sent

Note that the output resulting from each of

the settings will be different when

reduction/enlargement is used.

Function Settings

15 ~ 200

1 µA/step

20 µµµµA

1: No

2: Yes

to clean the cleaning blade edge

toner density control.

1 ~ 100

1 minute/step

30 minutes

OFF

ON

0: Original

Standard

1: Copy

Standard

to the laser diode.

S

Page 55

26 May 2000 PAGE:15 /16

5-924

6-120

Mode No.

(Class 1, 2 and 3)

Margin Per Original

Margin Per

1

Original

Per Original

2

Priority

Staple Jogger Adjustment

1A3

2B4

3A4 L

4A4 S

5B5 L

6B5 S

7DLT L

8LG L

9LT L