Page 1

!"#$% T

echnical Bulletin

PAGE: 1/1

Model

Subject:

From:

: Mojito

Software Update for Mail Box CS360

Technical Service Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

14-Apr-00

Prepared by:

No.:

RA293001

A. Sasaki

Action required

Service manual revision

Retrofit information

Background

The mail box (CS360) is currently an optional item for the SP5/SP5L (A229) and NAD

30S/30/40 (A230/A231/A232), and can also be installed on the Mojito (A292/A293).

The A292/A293 has a faster process speed than the A229 and A230/A231/A232. New

software (G909 0339 A) is necessary to allow the CS360 to work smoothly on the Mojito.

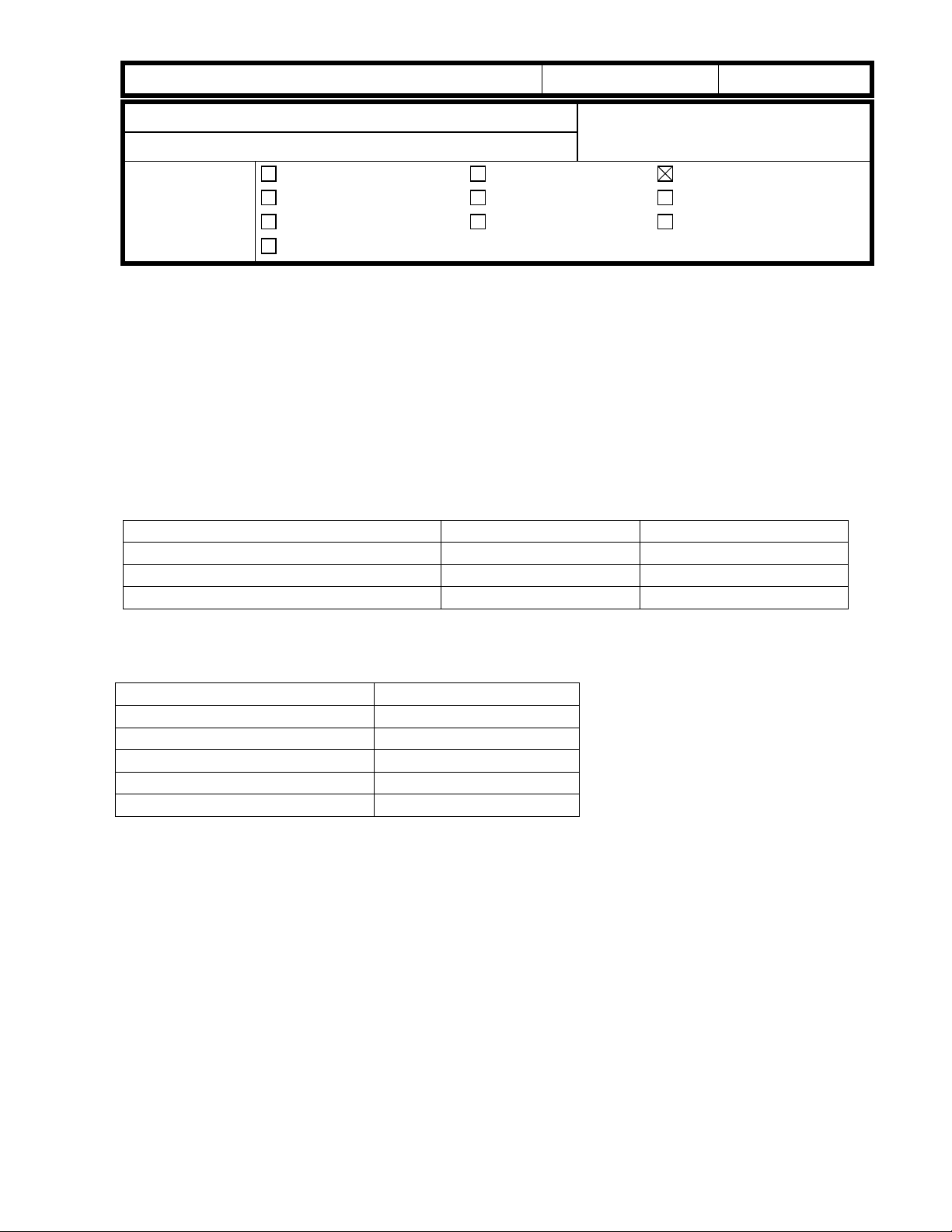

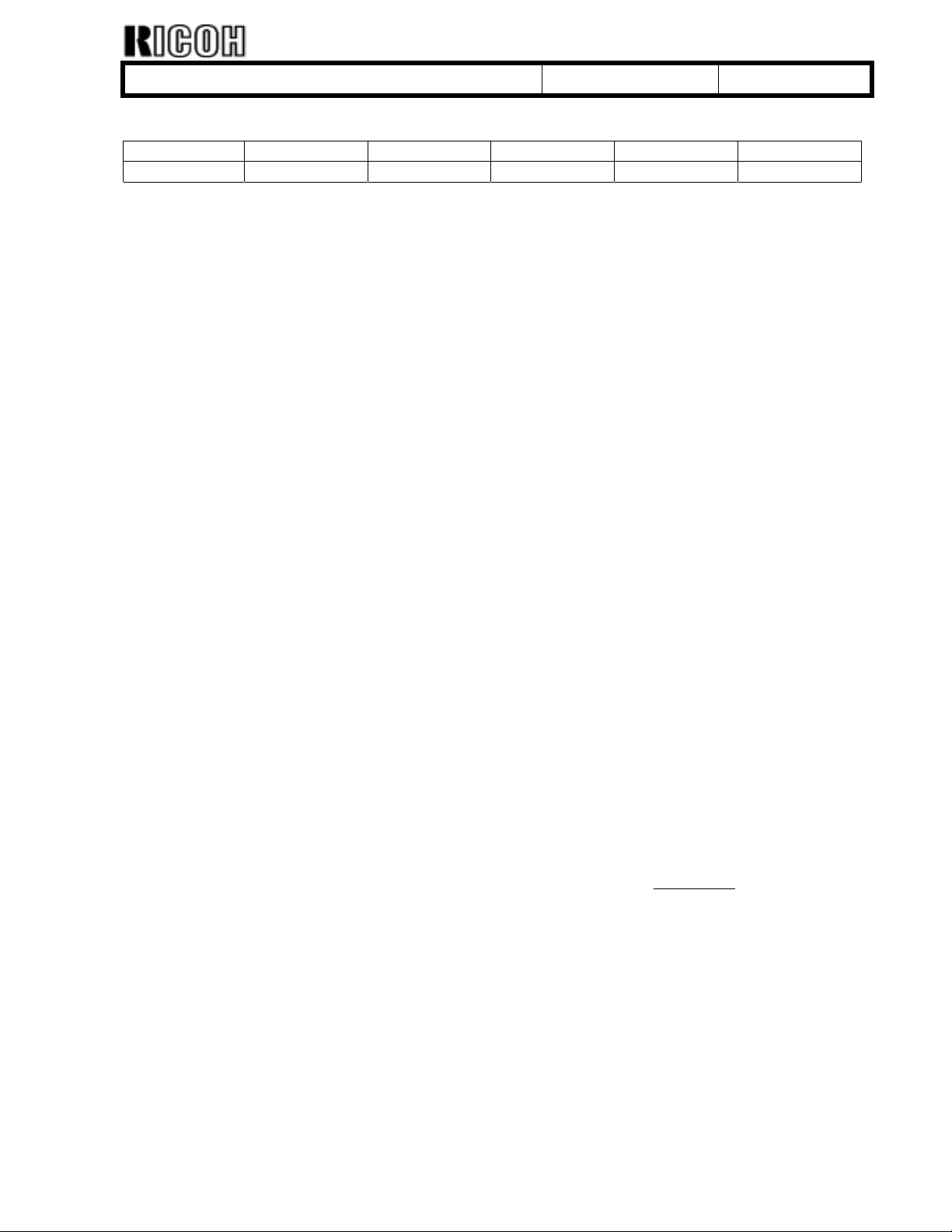

Interchangeability between Main Frame and CS360

The new software can also handle the A229 and A230/A231/A232 perfectly.

Old CS360 Software New CS360 Software

NAD 30S/30/40 (A230/A231/A232) Workable Workable

SP5/SP5L (A229) Workable Workable

Mojito (A292/A293) Not workable Workable

Cut-in Serial Numbers

Destination Cut-in Serial Number

G909-15 (Savin, Gestetner) 2B20030001

G909-17 (Ricoh) G8170020001

G909-22 (NRG) BO00020001

G909-26 (Infotec) From next production

G909-55 (Lanier) L0340020001

Page 2

!"#$% T

echnical Bulletin

PAGE: 1/12

Model:

Subject:

Installation procedure and parts catalog

From:

Classification:

Mojito

LG kit (81/2"x14"paper size tray

Technical Service Dept., GTS Division

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

19-May-00

Prepared by:

No.:

RA293002

F. Noguchi

Action required

Service manual revision

Retrofit information

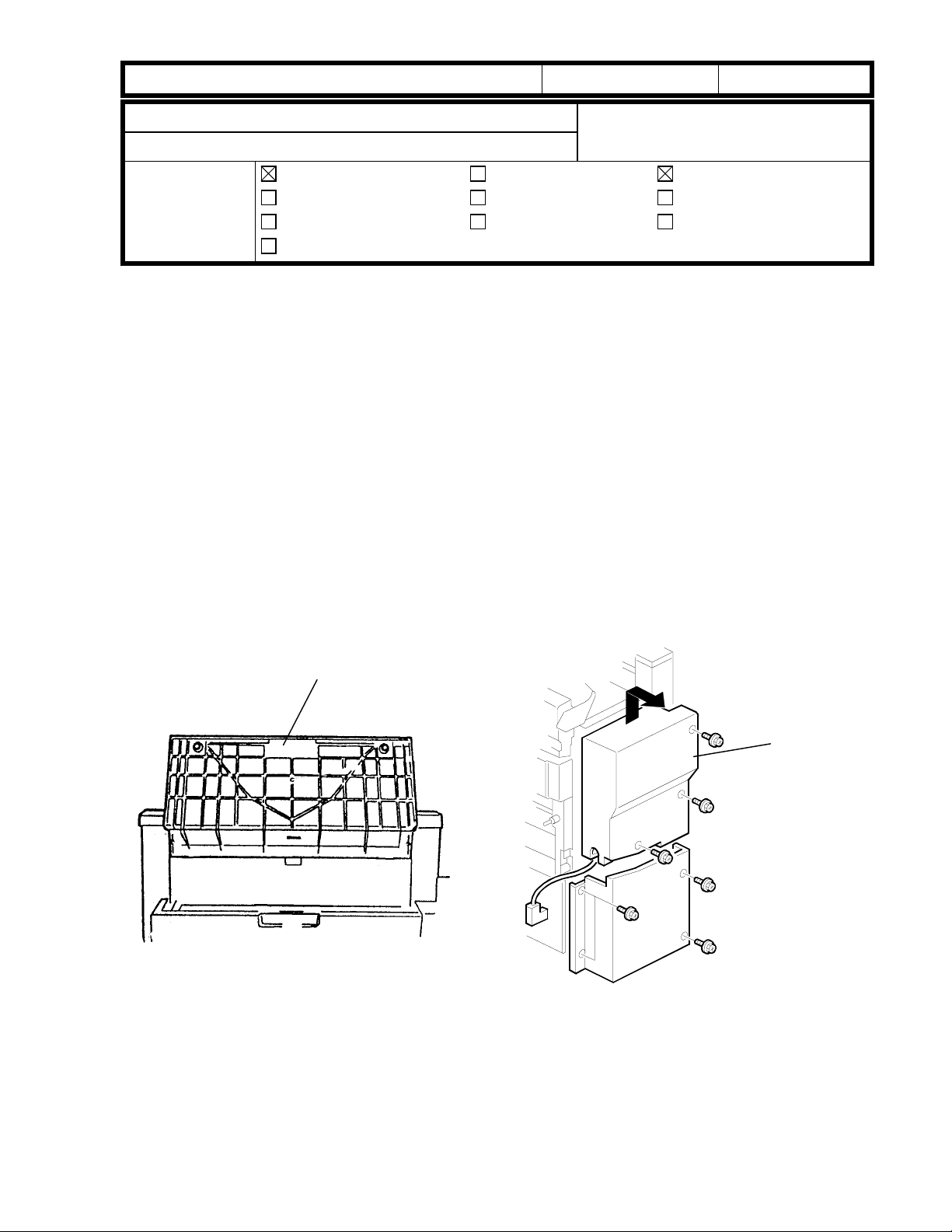

The LG Kit (paper tray for 8 1/2” x 14”) has been registered as an option. Please refer to

the relevant Service Manual and Parts Catalog information below.

The purpose of this kit is to make it possible to feed 8 1/2” x 14” sized paper from the LCT

(A698: RT37). Please note that when the kit is installed, 8 1/2” x 14” is the only size that

can be fed from the LCT.

Please add the following documents to your manuals:

1. Service Manual

1) Accessory check

2) Installation procedure

2. Parts Catalog

1) Parts catalog contents

2) B375 parts catalog and parts index

Page 3

!"#$% T

echnical Bulletin

PAGE: 1/3

Model:

Subject:

From:

Mojito

Service Manual

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

Please correct your manual as follows:

Page 2-18

Please replace this page with the following explanation.

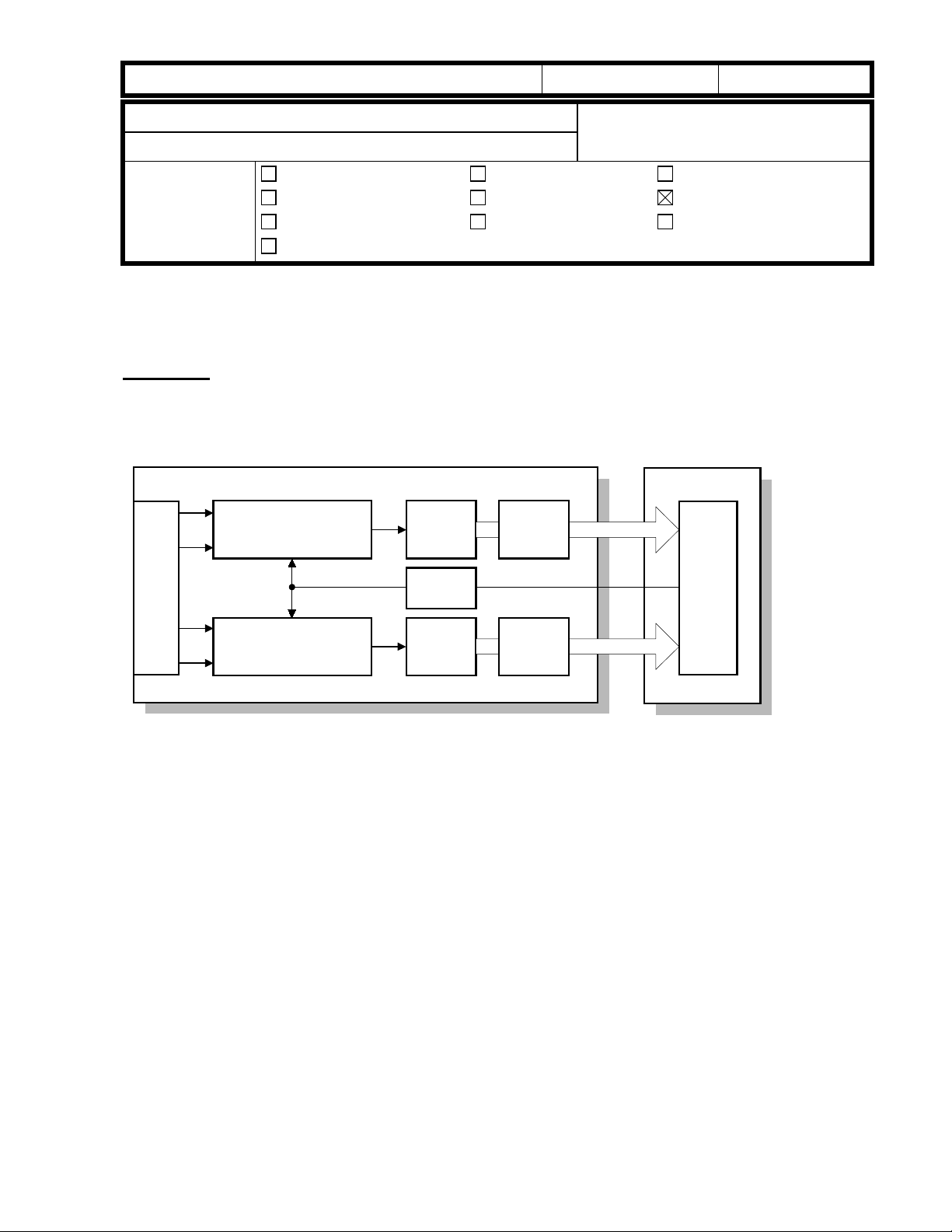

2.3.2 SBU

OS4

OS3

Analog

Processing (Last)

A/D 1

LVDS

06-Jun-00

Prepared by:

Action required

Service manual revision

Retrofit information

8-bit data

No.:

M. Tsuyuki

BICUSBU

RA293003

CCD

IPUGA

OS2

OS1

Analog

Processing (First)

A/D 2

LVDS

8-bit data

The CCD converts the light reflected from the original into an analog signal. The CCD line

has 7,500 pixels and the resolution is 600 dpi (23.6 lines/mm).

The CCD has four output lines: OS1, OS2, OS3, and OS4. OS1 and OS2 are for the first

half of the scan line (Non-operation side), and OS3 and OS4 are for the last half of the

scan line (Operation side). There are two analog processing ICs; one handles the first half

line (OS 1 and OS2) and the other handles the last half line (OS3 and OS4). The analog

processing IC performs the following operations:

1) Combines the odd and even signals into one line signal.

2) Adjust the black reference level of each CCD output channel.

3) Amplifies the analog signal from the CCD.

After the above processing, the analog signals are converted to 8-bit signals by the A/D

converter. This gives a value for each pixel on scale of 256 grades. Then, the two 8-bit

signals are sent to the BICU board through the LVDS (Low Voltage Differential Signaling).

The LVDS is a noise-resistant interface.

Page 4

!"#$% T

echnical Bulletin

PAGE: 2/3

Model:

Mojito

Date:

06-Jun-00

No.:

RA293003

Page 4-46

SP5-009: Language Selection

Please delete a sentence “After changing the setting for this SP mode, turn the main

power switch off and on”.

This SP mode is same function as “Language Priority” in UP mode.

Page 4-66

Please correct the pattern tables as follows.

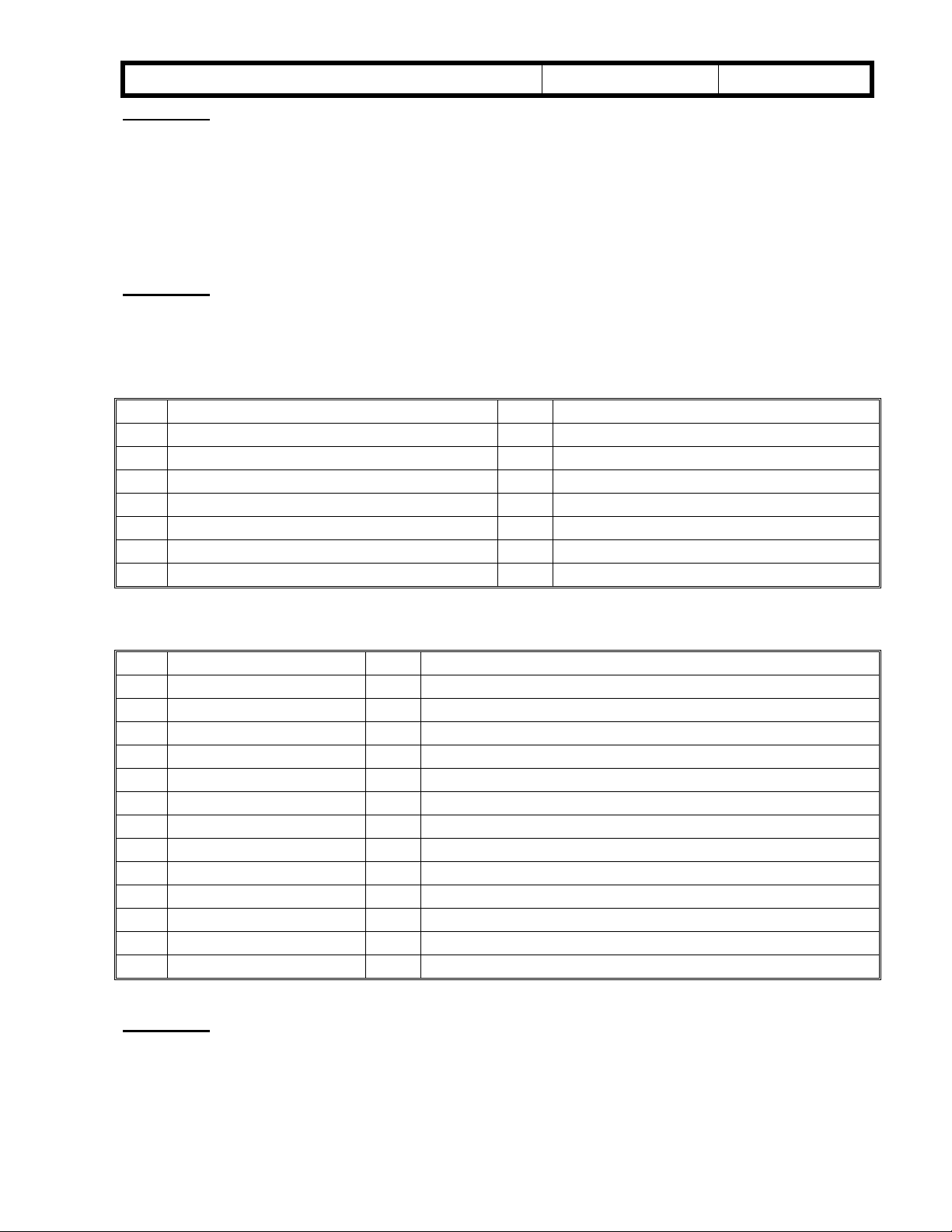

Test Pattern Table (SP2902-2: Test Pattern Printing – IPU)

No. Test Pattern No. Test Pattern

0 None 7 Vertical Stripes

1 Vertical Lines (1-dot) 8 Grayscale (Vertical)

2 Vertical Lines (2-dot) 9 Grayscale (Horizontal)

3 Horizontal Lines (1-dot) 10 Cross Pattern

4 Horizontal Lines (2-dot) 11 Argyle Pattern

5 Alternating Dot Pattern 12 Frequency (Horizontal)

6 Grid Pattern (1-dot) 13 Frequency (Vertical)

Test Pattern Table (SP2902-3: Test Pattern Printing – Printing)

No. Test Pattern No. Test Pattern

0 None 13 16 Grayscale (Vertical)

1 Vertical Lines (1-dot) 14 16 Grayscale (Vertical/Horizontal)

2 Horizontal Lines (1-dot) 15 16 Grayscale (Grid)

3 Vertical Lines (2-dot) 16 Hound’s Tooth Check (1-dot 600dpi) (Cross Stitch)

4 Horizontal Lines (2-dot) 17 Hound’s Tooth Check (1-dot 400dpi) (Cross Stitch)

5 Grid Pattern (1-dot) 18 Horizontal Line (1-dot) (Reverse Order of LD1 and LD2)

6 Grid Pattern (1-dot pair) 19 Grid Pattern (1-dot) (Reverse Order of LD1 and LD2)

7 Independent Pattern 20 Grid Pattern (1-dot pair) (Reverse Order of LD1 and LD2)

8 Full Dot Pattern 21 Independent Pattern (1-dot) (Reverse Order of LD1 and LD2)

9 Black Band 22 Blank Page

10 Trimming Area 23 Grid Pattern (1-dot) (Overlaying Outside Data)

11 Argyle Pattern 24 Trimming Area (Overlaying Outside Data)

12 16 Grayscale (Horizontal)

Page 4-78

“NOTE” after step 6:

Please delete SP7-007. SP7-007 is not used in this model.

Page 5

!"#$% T

echnical Bulletin

PAGE: 3/3

Model:

Page 7-18

Please delete SC388. This number is not used in this model.

Laser Beam Pitch Adjustment

The “Laser Beam Pitch Adjustment” procedure is same as SP5. However, SP mode

numbers are changed as follows.

SP2-902-2 no.12: IPU Test Pattern – Cross Stitch – 400dpi

SP2-902-3 no.17: Printing Test Pattern - Hound’s Tooth Check (1-dot 400dpi) (Cross

SP2-902-2 no.13: IPU Test Pattern – Cross Stitch – 600dpi

SP2-902-3 no.16: Printing Test Pattern - Hound’s Tooth Check (1-dot 600dpi) (Cross

Mojito

⇓

Stitch)

⇓

Stitch)

Date:

06-Jun-00

No.:

RA293003

Page 6

!"#$% T

echnical Bulletin

PAGE: 1/7

Model:

Subject:

From:

Mojito

Service Manual

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

08-Jun-00

Prepared by:

No.:

RA293004

M. Tsuyuki

Action required

Service manual revision

Retrofit information

Please add the following SC descriptions to your service manuals.

Page 7-34

SC740: 1000-sheet finisher error in finisher area

- Definition – [B]

Note: When this SC is displayed, check SP7-902 (SC details). The first 2 digits indicate

the type of error.

Example: 740 0100000000000000

01: Shutter movement error

1) The shutter position switch does not turn on within 1 second after the transport motor

starts to turn in reverse.

2) The shutter sensor does not deactivate within 1 second after the transport motor

starts to turn in reverse.

3) The shutter position switch is off when the shift tray safety switch is off.

- Possible causes -

• Transport motor defective

• Shutter position switch defective

• Shift tray safety switch defective

02: Exit motor error

1) After the exit motor turns on, the exit motor sensor does not send the proper signal to

the finisher board.

2) The exit motor sensor does not send the clock signal to the finisher board for a certain

period while the exit motor is on.

- Possible causes -

• Exit motor defective

• Exit motor sensor defective

Page 7

!"#$% T

echnical Bulletin

PAGE: 2/7

Model:

03: Upper exit plate movement error

1) The upper exit guide 2 switch does not turn on within 1 s after the guide plate motor

2) The upper exit guide sensor does not activate within 1 s after the guide plate motor

3) The upper exit guide 2 switch does not turn on when the shift tray safety switch is off.

- Possible causes -

04: Jogger motor error

1) After the jogger motor turns on to move the jogger fence from its home position, the

Mojito

turns on.

turns on.

• Guide plate motor defective

• Upper exit guide 2 switch defective

• Upper exit guide sensor defective

• Shift tray safety switch defective

jogger HP sensor does not deactivate within 2 s.

Date:

08-Jun-00

No.:

RA293004

2) After the jogger motor turns on to return the jogger fence to its home position, the

jogger HP sensor does not activate within 2 s.

- Possible causes -

• Jogger motor defective

• Jogger HP sensor defective

05: Stapler motor error

1) After the stapler motor turns on to move the stapler unit from its home position, the

stapler unit HP sensor does not deactivate within 4 s.

2) After the stapler motor turns on to return the stapler unit to its home position, the

stapler unit HP sensor does not activate within 4 s.

- Possible causes -

• Stapler motor defective

• Stapler unit HP sensor defective

Page 8

!"#$% T

echnical Bulletin

PAGE: 3/7

Model:

06: Staple hammer motor error

1) The staple hammer HP sensor does not deactivate within 0.5 s after the staple

2) The staple hammer HP sensor does not activate within 0.5 s after the staple hammer

- Possible causes -

07: Tray lift motor error

1) The tray lift motor does not stop within 15 s after being turned on.

2) The shift tray HP sensor does not activate within 15 s after the tray lift motor turns on.

3) The shift tray upper limit switch turns on while the shift tray is being raised.

4) Lift motor sensors 1 and 2 do not send the clock signals to the finisher board every

Mojito

hammer motor turns on.

motor turns on.

• Staple hammer motor defective

• Staple hammer HP sensor defective

200 ms while the tray lift motor is on.

Date:

08-Jun-00

No.:

RA293004

- Possible causes -

• Tray lift motor defective

• Lift motor sensor 1 defective

• Lift motor sensor 2 defective

• Shift tray HP sensor defective

• Shift tray upper limit switch defective

08: Shift tray height sensor error

1) Abnormal communication data between finisher board and shift tray height sensor.

2) No communication between finisher board and shift tray height sensor for a certain

period.

3) The finisher board detects a connection error with the connector for the shift tray

height sensor.

4) Adjustment error during shift tray height sensor adjustment.

- Possible causes -

• Shift tray height sensor defective

• Finisher board defective

Page 9

!"#$% T

echnical Bulletin

PAGE: 4/7

Model:

09: Back-up RAM error

- Possible causes -

0A: Communication error

Communication error between finisher board and booklet unit board.

- Possible causes -

SC741: 1000-sheet finisher error in saddle stitching area

Mojito

The check sum is abnormal when the main switch is turned on.

• Finisher board defective

• Finisher board defective

• Booklet unit board defective

• Poor cable connection

Date:

08-Jun-00

No.:

RA293004

- Definition – [B]

Note: When this SC is displayed, check SP7-902 (SC details. The first 2 digits indicate the

type of error.

Example: 741 0100000000000000

01: Positioning plate motor error

1) After the positioning plate motor turns on to move the positioning plate from its home

position, the positioning plate HP sensor does not deactivate within 1.25 s.

2) After the positioning plate motor turns on to return the positioning plate to its home

position, the positioning plate HP sensor does not activate within 1 s.

- Possible causes -

• Positioning plate motor defective

• Positioning plate HP sensor defective

Page 10

!"#$% T

echnical Bulletin

PAGE: 5/7

Model:

02: Folder roller motor error

1) The folder roller motor sensor doesn’t send a clock pulse to the booklet unit board

- Possible causes -

03: Shutter guide motor error

1) After the shutter guide motor turns on to move the shutter guide from its home

2) After the shutter guide motor turns on to return the shutter guide to its home position,

- Possible causes -

Mojito

within a certain period after the folder roller motor turns on.

• Folder roller motor defective

• Folder roller motor sensor defective

position, the shutter guide HP sensor does not deactivate within 0.4 s.

the shutter guide HP sensor does not activate within 1 s.

• Shutter guide motor defective

Date:

08-Jun-00

No.:

RA293004

• Shutter guide HP sensor defective

04: Booklet jogger motor error

1) After the booklet jogger motor turns on to move the booklet jogger plate from its home

position, the booklet jogger HP sensor does not deactivate within 0.5 s.

2) After the booklet jogger motor turns on to return the booklet jogger plate to its home

position, the booklet jogger HP sensor does not activate within 1 s.

- Possible causes -

• Booklet jogger motor defective

• Booklet jogger HP sensor defective

Page 11

!"#$% T

echnical Bulletin

PAGE: 6/7

Model:

05: Stapler motor error

1) The front staple hammer HP switch does not turn off within 0.5 s after the front stapler

2) The front staple hammer HP switch does not turn on within 0.5 s after the front stapler

3) The rear staple hammer HP switch does not turn off within 0.5 s after the rear stapler

4) The rear staple hammer HP switch does not turn on within 0.5 s after the rear stapler

- Possible causes -

Mojito

motor turns on.

motor turns on during jam recovery.

motor turns on.

motor turns on during jam recovery.

• Front stapler motor defective

• Front staple hammer HP switch defective

• Rear stapler motor defective

• Rear staple hammer HP switch defective

Date:

08-Jun-00

No.:

RA293004

06: Folder plate motor error

1) After the folder plate motor turns on to return the folder plate to its home position, the

folder plate HP sensor does not activate within 0.3 s.

2) After the folder plate motor turns on to move the folder plate from its home position,

the folder plate HP sensor does not deactivate within 0.3 s.

3) After the folder plate motor turns on to return the folder plate to its home position, the

folder plate return sensor does not deactivate within 0.3 s.

4) The folder plate return sensor does not activate within 0.3 s after the HP sensor

deactivates.

5) The pulse count from the folder plate motor sensor is lower than the target minimum.

- Possible causes -

• Folder plate motor defective

• Folder plate HP sensor defective

• Folder plate return sensor defective

• Folder plate motor sensor defective

Page 12

!"#$% T

echnical Bulletin

PAGE: 7/7

Model:

07: Connector error

1) The connector of the shutter guide HP sensor is not connected.

2) The connector of the folder plate HP sensor is not connected.

3) The connector of the folder plate return sensor is not connected.

- Possible causes -

08: Switch error

1) When the booklet entrance guide sensor, lower door sensor, and booklet exit cover

2) When the booklet entrance guide sensor, lower door sensor, and booklet exit cover

Mojito

• Poor connection or no connection of the shutter guide HP sensor connector

• Poor connection or no connection of the folder plate HP sensor connector

• Poor connection or no connection of the folder plate return sensor connector

sensor are all activated (doors closed), the booklet entrance guide safety switch does

not turn on within 1 s after a copy job or warm-up idling begins.

sensor are all activated (doors closed), the lower door safety switch does not turn on

within 1 s after a copy job or warm-up idling begins.

Date:

08-Jun-00

No.:

RA293004

3) When the booklet entrance guide sensor, lower door sensor, and booklet exit cover

sensor are all activated (doors closed), the booklet exit cover safety switch does not

turn on within 1 s after a copy job or warm-up idling begins.

- Possible causes -

• Booklet entrance guide safety switch defective

• Lower door safety switch defective

• Booklet exit cover safety switch defective

Page 13

echnical Bulletin

T

PAGE: 1/3

Model:

Subject:

From:

Mojito

BICU Firmware Modification History

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

09-Jun-00

Prepared by:

No.:

RA293005

F. Noguchi

Action required

Service manual revision

Retrofit information

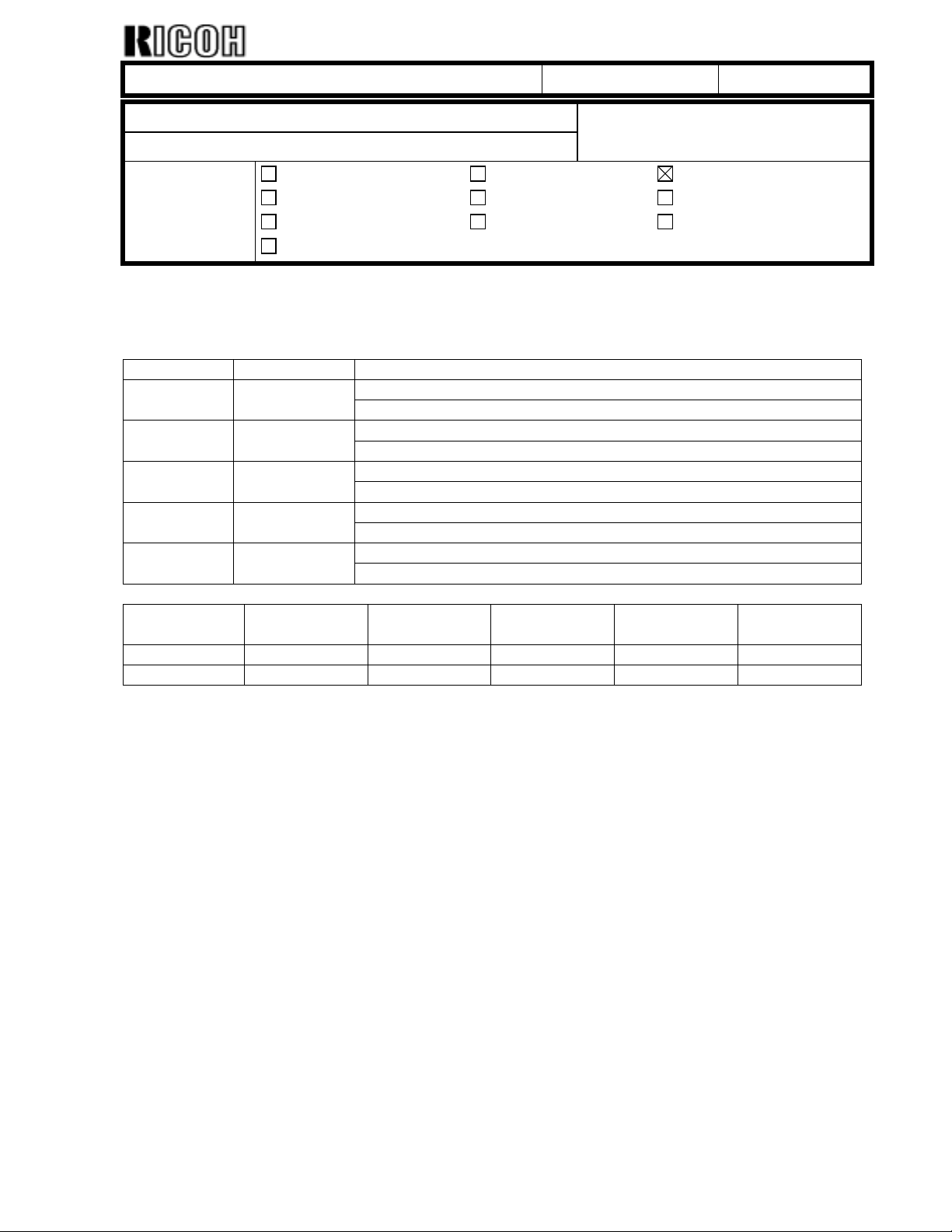

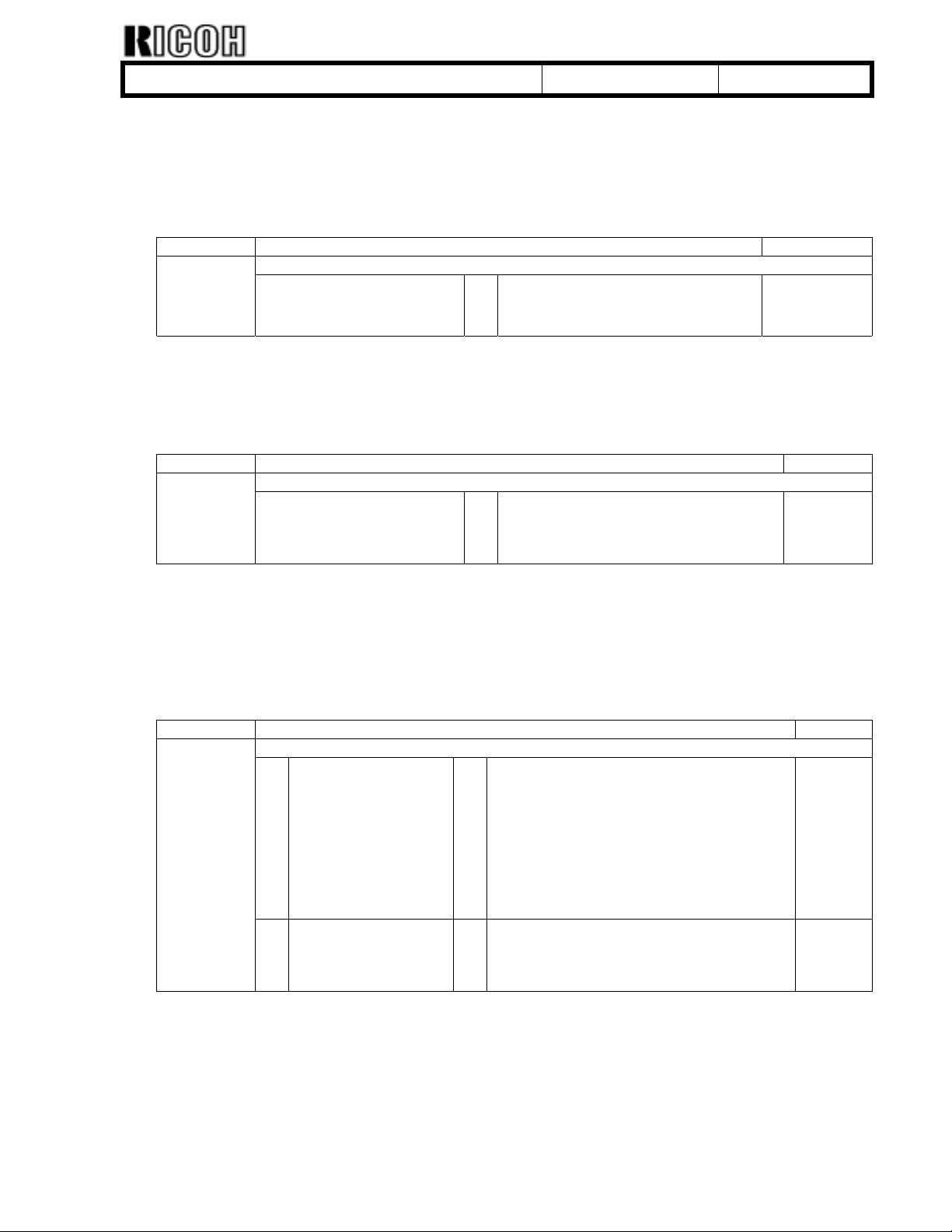

Modification history of the BICU firmware

As there are five types of the firmware, use the appropriate one for each customer.

Destination Part Number Model Codes/Languages

A292 -15, -17, A293 -15, -17America A293 7553C

US English, French, Spanish

A292 -19, -22, -26, -27, -29, A293 -22, -26, -27, -29Eu1_Asia A293 7653C

English, French, Spanish, German, Italian, Dutch

A292 -22, -26, -27, A293 -22, -26, -27Eu2 A293 7564

English, German, Swedish, Norwegian, Danish, Finnish

A292 -22, -26, -27, A293 -22, -26, -27Eu3 A293 7565

English, German, Portuguese, Polish, Hungarian, Czech

A292 -14, -24, A293 –14, -24Eu3 (Lanier) A293 7566

English, German, Portuguese, Polish, Czech

Destination/

Part Number

Version/Suffix

3.1 C C - - -

America

A293 7553

Eu1_Asia

A293 7653

Eu2

A293 7564

Eu3

A293 7565

Eu3(Lanier)

A293 7566

Page 14

echnical Bulletin

T

PAGE: 2/3

Model:

Mojito

Date:

09-Jun-00

No.:

RA293005

Version 3.1

Destination/ America Eu1_Asia Eu2 Eu3 Eu3 (Lanier)

Part Number A293 7553C A293 7653C A293 7564 A293 7565 A293 7566

Note:

1) The LCDC ROM A2935203C is required for BICU firmware version 3.1 (A293 7564,

A293 7565 and A293 7566).

2) Version 3.1 requires the printer controller.

1. Language

The following items have been changed from English to the language selected:

1) Stamp Setting

Note: For Portuguese and Polish, the Stamp setting is still displayed in English.

The correction for this will be included in the next software update.

2) Language Priority button

2. A3/DLT Double Count corrected for copy counter and printer counter

When making A3/DLT copies, the copy and printer counters do not count up by 2,

even if A3/DLT Double Count has been set.

Note: The total counter correctly counts up by 2.

3. Key counter in connect copy mode

When the key counter is removed from the machine during a copy job in connect copy mode,

both copiers will stop and display “paper jam”.

4. Slip-Sheet Mode

It is possible to select “Copy” or “Blank” from the operation panel in Slip-Sheet Mode.

5. Mailbox

The software has been modified so that the correct picture indicator is displayed when the

mailbox door is open.

Note: The incorrect indicator was displayed when the Mailbox was the only option installed.

6. Conditions for reverse drum rotation

To reduce the load on the units around the drum, the cycle for reverse drum rotation has been

changed as follows:

New: The drum is turned in reverse at the end of a copy job if the cumulative running time for

the drum has reached or exceeded 4 minutes.

Old: The drum turns in reverse at the end of every copy job.

Page 15

echnical Bulletin

T

PAGE: 3/3

Model:

Mojito

Date:

09-Jun-00

No.:

RA293005

7. New SP Mode for B302 Finisher: SP6119

SP6119 has been added to enable the punch function for Thick Paper Mode.

Note:

1. Before enabling SP6119, please be sure that the customer is aware of the specific range of

paper weights that can be used with this mode.

2. Do not enable this mode if the customer is using OHP transparencies.

Mode No. Function Setting

Punch Function Enabled (Thick Paper)6119

* Selects whether the punch function

is enabled or not in thick paper

mode.

No: Disable

Yes: Enable

8. 8K/16K Paper Size (China/Taiwan)

8K/16K paper size can be fed from Trays 2 and 3 by selecting 3:CH in SP5131 “Paper Size

Type Selection”.

Note: The factory default for SP5131 is 3:CH in models for China and Taiwan.

Mode No. Function Setting

Paper Size Type Selection5131

* Refer to the service manual. 0: JP

1: NA

2: EU

3: CH

9. Copy Settings preserved when entering Energy Saver Mode

The software has been modified so that the selected copy settings are not reset when the

machine enters Energy Saver Mode.

10. New SP Mode added to enable Margin Per Original function (SP5924)

The settings for this mode are as follows:

Mode No. Function Setting

5924

Margin Per Original

1 Margin Per Original * Selects whether or not Margin Per Original

is enabled.

No : Images are shifted with a binding

margin during image writing.

Yes: The margin is applied during

scanning.

NOTE: After Yes has been selected, the

“per original” key is displayed. This key

must be pressed to activate the mode.

2 Per Original Priority * Selects whether or not Margin Per Original

is enabled as the default.

This setting is given priority over

5924-1.

Note: 1) When this mode is enabled, the ADF feed interval is longer.

2) Although it is possible to “adjust” the margins at the operation panel for Sample

Copies, the adjustment itself is not applied to the samples.

3) The following modes cannot be used with Margin Per Original: Booklet, Magazine,

Combine, Double copy, Image repeat.

No

Yes

On

Off

Page 16

echnical Bulletin

T

PAGE: 1/2

Model:

Subject:

From:

Mojito

NV-RAM Minus Counter Replacement Procedure

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

27-Jun-00

Prepared by:

No.:

RA293006

F. Noguchi

Action required

Service manual revision

Retrofit information

NV-RAM replacement procedure

Case 1: NV-RAM is not defective.

1. Print out all SMC data lists (SP 5-990-1).

2. Upload the NVRAM data from the BICU to the flash memory card (SP 5-824).

3. Turn the main power switch off.

4. Replace the NV–RAM Minus Counter.

5. Perform memory all clear (SP 5-801).

5. Turn the main power switch off and on.

6. Calibrate the LCD touch panel.

7. Input the machine serial number (SP 5-811).

9. Download the NVRAM data from the flash memory card to the BICU (SP 5-825).

Or, referring to the SMC data lists, re-enter any value which has been changed from

its factory setting.

10. Download the stamp data from the flash memory card (SP5-829).

11. Check the copy quality and the paper path and do any necessary adjustments.

Page 17

echnical Bulletin

T

PAGE: 2/2

Model:

Case 2: NV-RAM is defective

1. If possible, print out all SMC data lists (SP 5-990-1).

2. Turn the main power switch off.

3. Replace the NV–RAM Minus Counter.

4. Replace the developer because the TD initial data is missing if the NV-RAM is

5. Perform memory all clear (SP 5-801).

6. Turn the main power switch off and on.

7. Calibrate the LCD touch panel.

8. Perform the TD initial setting (SP 2-963).

9. Input the machine serial number (SP 5-811).

10. Adjust the laser beam pitch (SP 2-109).

11. Perform the printer and scanner registration adjustments.

12. Referring to the SMC data lists, re-enter any value which has been changed from its

13. Download the stamp data from the flash memory card (SP5-829).

14. Perform SP 3-001-2 (ID Sensor Initial Setting) and SP 4-911-1 (HDD media test).

15. Check the copy quality and the paper path and do any necessary adjustments.

Mojito

defective.

Note: Do this step before the machine automatically starts the Auto Process Control

(within approximately 2 minutes after the main switch is turned on).

(See Replacement and Adjustment – Copy Image - Adjustments)

factory setting.

Note: Be sure that the customer is aware that the HDD media test will delete copy

server and stamp data on the hard drives.

Date:

27-Jun-00

No.:

RA293006

Page 18

Reissued: 06-Jul-00

echnical Bulletin

T

PAGE: 1/3

Model:

Mojito

Date:

09-Jun-00

No.:

RA293005a

RTB Correction

Version 3.5 and 3.5.1 has been added.

Subject:

From:

BICU Firmware Modification History

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

F. Noguchi

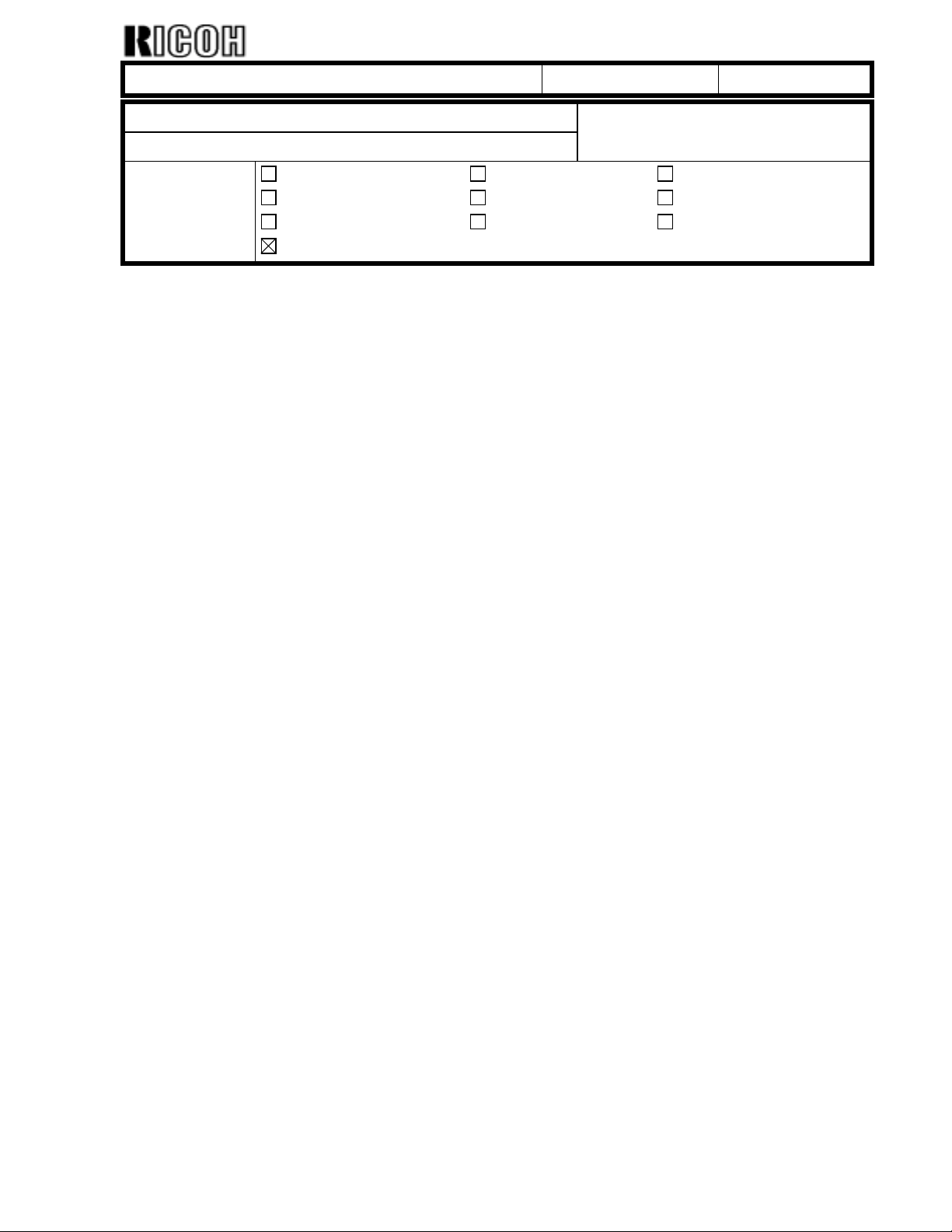

Modification history of the BICU firmware – versions 3.5 and 3.5.1 only (for earlier

versions, see previous RTBs).

As there are five types of the firmware, use an appropriate one for each customer.

Destination Part Number Model Codes/Languages

A292 -15, -17, A293 -15, -17America A293 7553

US English, French, Spanish

A292 -19, -22, -26, -27, -29, A293 -22, -26, -27, -29Eu1_Asia A293 7653

English, French, Spanish, German, Italian, Dutch

A292 -22, -26, -27, A293 -22, -26, -27Eu2 A293 7564

English, German, Swedish, Norwegian, Danish, Finnish

A292 -22, -26, -27, A293 -22, -26, -27Eu3 A293 7565

English, German, Portuguese, Polish, Hungarian, Czech

A292 -14, -24, A293 –14, -24Eu3(Lanier) A293 7566

English, German, Portuguese, Polish, Czech

Destination/

Part Number

Version/Suffix

3.1 C C - - - 09-Jun-00

3.5 D D A A A 06-Jul-00

3.5.1 E E B B B 06-Jul-00

America

A293 7553

Eu1_Asia

A293 7653

Eu2

A293 7564

Eu3

A293 7565

Eu3(Lanier)

A293 7566

RTB issue

date

Page 19

Reissued: 06-Jul-00

echnical Bulletin

T

PAGE: 2/3

Model:

Mojito

Date:

09-Jun-00

No.:

RA293005a

Version 3.5.1

Destination/ America Eu1_Asia Eu2 Eu3 Eu3(Lanier)

Part Number A293 7553E A293 7653E A293 7564B A293 7565B A293 7566B

1. New Copy Feature and SP Mode (SP5971) Added

1) New Copy Feature: Enhance Density Mode

This feature has been added to ensure that image density does not drop while making

multiple copies of originals with a high percentage of solid black areas.

To set thebeffective original density and number of copies for multi-copy mode, use SP5971

(see below).

To add the Enhance Density key to the display panel and to control the level, do the

following procedure:

(1) Press the User Tools/Counter key.

(2) Press the Copy/Document Server Features Key.

(3) Open General Features, screen 3/3.

(4) Select one of the Shortcut Keys from F1 – F5.

(5) Register the Enhance Density Key.

(6) Open General Features, screen 1/3.

(7) Select the setting for Enhance Density Level.

High: Vt+0.6

Medium: Vt+0.4 (default)

Low: Vt+0.2

2) New SP Mode: SP5971 (Enhance Copy Setting):

The following settings apply to Enhance Density Mode:

Mode No. Function Setting

5971

2. Paper jam in finisher (B302) + Printer Mode

Depending on the printer mode settings, jams can occur in the finisher when continuous print

jobs are shifted alternately between the proof and shift trays.

The machine cannot switch fast enough between the two paper paths in these cases. The

interval between jobs has been slightly increased to allow the machine enough time to make

the switch.

3. Fusing Unit Fan Motor Off-Timing Change

To ensure that hot air around the toner bottle is removed properly, the fusing unit fan motor

will be kept on whenever 24V is being supplied.

Therefore, it will turn off only when the main switch or operation switch is turned off or when

the machine is shut down by the Auto-Off function.

Enhance Copy Setting

2 Effective Original

Density

3 Effective Multiple

Copy

* Selects the effective original

density level for multi-copy mode.

* Selects the number of multiple

copies for multi-copy mode.

1 ∼ 60%

1% step

4%

1 ∼ 50sheets

1 sheet step

3 sheets

4. Wording Correction

Some display language words and phrases have been corrected/improved.

Page 20

Reissued: 06-Jul-00

echnical Bulletin

T

PAGE: 3/3

Model:

Version 3.5

Destination/ America Eu1_Asia Eu2 Eu3 Eu3(Lanier)

Part Number A293 7553D A293 7653D A293 7564A A293 7565A A293 7566A

Note: This is information only, as version3.5 was not released to the field and was not used in

Mojito

any product machine.

Date:

09-Jun-00

No.:

RA293005a

Page 21

!"#$% T

echnical Bulletin

PAGE: 1/5

Model:

Subject:

From:

Mojito

SC740 and Jam indicator turns on.

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

04-Jul-00

Prepared by:

No.:

RA293007

M. Tsuyuki

Action required

Service manual revision

Retrofit information

Some booklet finishers (A763) may exhibit the following problem. Please check the

machine at installation or at the next customer site visit.

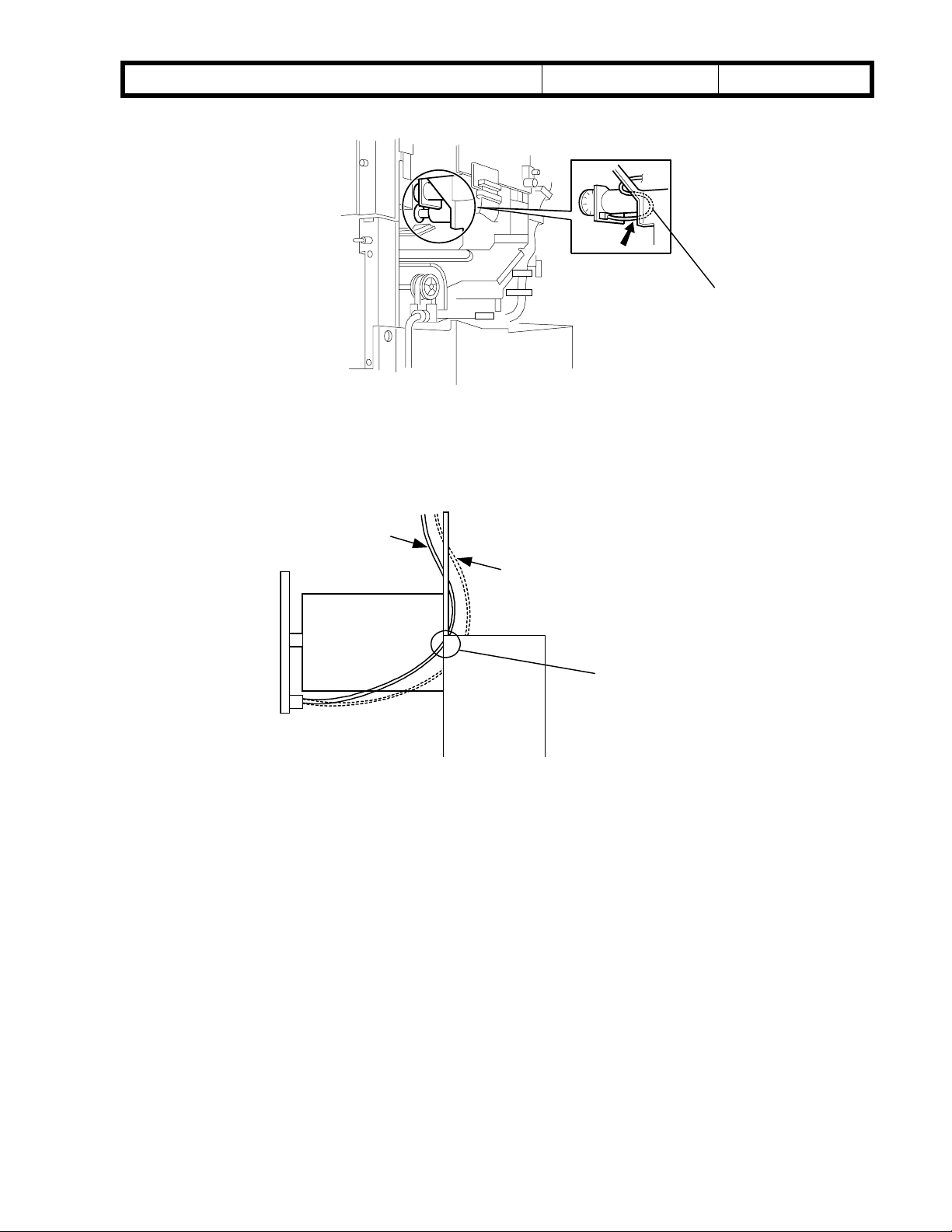

SYMPTOM

When making copies in staple mode, an IC on the finisher board shorts and SC740 is

displayed. After the main switch is turn off and on, a jam is indicated.

CAUSE

The cable of the guide plate motor is caught between the guide plate unit and frame. In the

worst case, the cable covering peels off and the +24V line is shorted to ground. These two

factors combine to cause the finisher board to be damaged.

ACTION

[A]

1. Hold up the proof tray and open the top cover [A].

[B]

2. Unhook the upper rear cover [B] and remove it (3 screws).

Page 22

!"#$% T

echnical Bulletin

PAGE: 2/5

Model:

3. Check to see if the cable [C] is caught.

4. If it is not caught, the finisher is Ok. If it is caught, go on to the next step.

Mojito

Date:

04-Jul-00

NG

No.:

[C]

RA293007

NG

OK

[D]

5. If the cable is caught at area [D], go on to the next step. If not, the finisher is OK.

Page 23

!"#$% T

echnical Bulletin

PAGE: 3/5

Model:

[E]

6. Remove the lower rear cover [E] (4 screws).

Mojito

[G]

[F]

Date:

04-Jul-00

No.:

RA293007

7. Disconnect the connector [F] and remove the grounding wire [G] (1 screw).

[H]

[I]

8. Unhook the two stoppers [H] and remove them.

[J]

9. Remove the slide guide [I] by pulling it up.

10. Remove the shift tray unit [J] by pulling it up.

Page 24

!"#$% T

echnical Bulletin

PAGE: 4/5

Model:

10. Remove the upper shift guide [K] (6 screws (5 x M4, 1 x M3).

11. Remove the lower shift guide [L] (2 connectors, 6 screws [3 x M4, 3 x M3]).

Mojito

[K]

[L]

Date:

04-Jul-00

No.:

RA293007

[M]

12. Loosen the rear side screws [M] of the exit unit.

13. Free the cable [N].

14. Check the surface of the cable.

15. If the cable wires are visible, wrap them with vinyl tape.

[N]

Page 25

!"#$% T

echnical Bulletin

PAGE: 5/5

Model:

16. Reassemble the machine.

Mojito

[O]

Note: When reinstalling the shift tray unit, release the clutch gear [O] of the tray lift

motor by carefully inserting a screwdriver.

Date:

04-Jul-00

No.:

RA293007

COUNTERMEASURE

The length of the cable has been decreased and the route of the cable has been modified.

Serial numbers of finishers which may have this problem:

Model Code Serial Number:

A763-14 : From first production to L0740030077

A763-17 : From first production to H5000400375

A763-22 : From first production to H5000300440

A763-26 : From first production to 4D80300090

A763-27 : From first production to H5000300571

Page 26

!"#$% T

echnical Bulletin

PAGE: 1/2

Model:

Subject:

From:

Mojito

Low ID

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

06-Jul-00

Prepared by:

No.:

RA293008

M. Tsuyuki

Action required

Service manual revision

Retrofit information

SYMPTOM

Low image density on copies made by low CV machines around 20 to 30K after

installation.

CAUSE

The fusing fan motor stops when the low power timer runs out (60 s) and the machine

enters Energy Saver Mode. Because the fusing lamp remains on in order to maintain hot

roller temperature, the temperature of the areas surrounding the unit rises. The resulting

heat can damage the toner that is stored in the bottle above the fusing unit, causing some

of the toner’s constituents to separate out. The altered toner is then sent to the

development unit and is mixed in with the developer, causing developer chargeability to

drop. This results in low image density on copies.

This heat damage occurs on low CV machines, as the toner remains in the bottle for

extended periods of time.

ACTION

Newly installed machines:

Please upgrade the BICU firmware to ver 3.5.1 at installation.

Field machines which have no low ID problem:

Please upgrade the BICU firmware to ver 3.5.1 at the next field visit.

Field machines which have a low ID problem:

1. Upgrade the BICU firmware to ver 3.5.1.

2. Replace the developer.

3. Replace the toner bottle.

4. Clean the toner from the toner hopper.

Page 27

!"#$% T

echnical Bulletin

PAGE: 2/2

Model:

Mojito

Date:

06-Jul-00

No.:

RA293008

COUNTERMEASURE

1. Firmware:

The off-timing of the fusing fan motor has been delayed, so that it will remove the hot air

around the toner bottle.

2. Hardware:

As an added measure, a heat insulator will be installed between the front frame of the

scanner unit and the toner bottle to ensure that the toner is not damaged, even if the

internal temperature should rise.

Page 28

Reissued: 13-Nov-00

echnical Bulletin

T

PAGE: 1/2

Model:

Mojito

Date:

17-Jul-00

No.:

RA293009a

RTB Correction

The items in bold italics have been corrected.

Subject:

From:

SC 124,501,502,503,362(220-240V version only)

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

F. Noguchi

SYMPTOM

One of the following SCs is activated when the power is turned on by the weekly timer or

by the operation switch (upper right of the panel):

SC124: Scanner motor encoder error SC501: 1st tray lift malfunction

SC335: Polygonal mirror motor error 1 SC502: 2nd tray lift malfunction

SC362: Hard disk detector error SC503: 3rd tray lift malfunction

SC493: Exhaust fan motor lock SC520: Duplex jogger motor error 1

SC494: Fusing exhaust fan motor lock

CAUSE

When the power is turned on, the supply of voltage through the 24V line is slow.

FIELD ACTION

The occurrence rate is predicted to be extremely low because the range of tolerance for

the start-up current in 220V machine PSUs is approximately +/- 20%. If you receive reports

of any of the SCs mentioned above, please do the following procedure:

1. Set the machine to turn off with the weekly timer.

2. After the machine has turned off, turn the operation switch on and off at least ten times.

3. When any of the SCs listed above is activated, please replace the PSU board.

If none are activated, please check other possible causes for the SCs reported.

Note: The PSU boards themselves cannot be modified in the field. Therefore, all PSUs

now in service parts stock are either modified units or previous units that were found

to have no problems (see below for details). The part number for the PSU has not

been changed.

Page 29

Reissued: 13-Nov-00

echnical Bulletin

T

PAGE: 2/2

Model:

COUNTERMEASURE

Temporary

The PSUs in service parts stock have been checked and the units with defective boards

have been sorted out using the IC301-9 output signatures.

Permanent

An 820 Ohm (1/4w) resistor has been added to the PSU board. In order to do this,

the board pattern was changed.

Mojito

Date:

17-Jul-00

No.:

RA293009a

Added

820 Ohms

Cut-in serial Numbers

The modified PSUs have been used in production machines from the following serial

numbers:

Temporary Permanent

A292

A293

-22 ----

-24

-26 ----

-27

-29

-22 ----

-24

L0710060126 ∼ L0710070132 ∼

H4700500599 ∼ H4700600371 ∼

H4700500616 ∼ H4700600001 ∼

L0720060126 ∼ L0720070105 ∼

H4700600123 ∼

4D60600001 ∼

H4800600001 ∼

-26 ----

-27

-29

H4800500101 ∼ H4800600173 ∼

H4800500559 ∼ H4800600426 ∼

4D50600001 ∼

Page 30

echnical Bulletin

T

PAGE: 1/3

Model:

0M

Subject:

From:

Mojito

Service manual

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

11-Aug-00

Prepared by:

No.:

RA293010

F. Noguchi

Action required

Service manual revision

Retrofit information

Please correct or add the following to your service manuals:

Page 3-27 Correction

3.5.2 PUNCH UNIT INSTALLATION

When attaching the punch unit (A812) to the SR740 finisher (B312), it is not necessary

to change the dip switch setting. From the B312 model, the dip switch is located on the

A812 unit's punch drive board and is set at the factory.

Incorrect:

10. When a three-punch-hole-unit is installed: Change switch 1 of DIP SW 100 on

the finisher control board to ON.

Correct:

10. When a three-punch-hole-unit is installed: Check to see that switch 1 of DIP SW

100 on the punch drive board has been set to ON.

Page 4-61 Addition

4.2.2 SERVICE PROGRAM MODE TABLES

The following SP modes have been added from the 1st production.

7-504 Copy Jam Counter by Jam Location

41 SR750

Booklet Exit

sensor

(On check)

42 SR750

Booklet Exit

sensor

(Off check)

43 SR750

Booklet staple

jam

*

*

*

Page 31

echnical Bulletin

T

PAGE: 2/3

Model:

0M

Page 4-76 Addition

4.3 PROGRAM AND DATA Downloading to the SBICU

The downloading procedure for the Mojito is the same as for the SP5.

Downloading to the SBICU

1. Turn off the main power switch.

2. Remove the flash memory card cover [A].

3. Insert the flash memory card [B] into the card slot.

4. Turn on the main power switch.

5. Press “Install”. The machine erases the current software, then writes the new

Mojito

NOTE: Make sure that the surface marked “A” faces upwards.

software to the SBICU. This takes about 200 seconds.

If downloading fails, an error message appears on the display. At this time, press the

“OK” key to attempt the download again.

Date:

11-Aug-00

No.:

RA293010

Page 32

echnical Bulletin

T

PAGE: 3/3

Model:

0M

Mojito

Page A763-1 Correction

1.1 SPECIFICATIONS

Incorrect

Paper Capacity (80 g/m2, 20 lb):

Tray Modes Paper size Capacity

Proof tray

Shift tray

No staple

Staple

One size

Mixed sizes

Date:

A4-S, LT-S or shorter 150 sheets

A4-L, LT-L or longer 75 sheets

A4-S, LT-S or shorter

A4-L, LT-L or longer

A4-S, LT-S or shorter

A4-L, LT-L or longer

1-5 sheets 25 sets

6-10 sheets 15 setsStaple tray

11-15 sheets 10 sets

(-L”: Lengthwise ,-S: Sideways)

11-Aug-00

1000 sheets

500 sheet

750 sheets

500 sheets

No.:

RA293010

Correct

Paper Capacity (80 g/m2, 20 lb):

Tray Modes Paper size Capacity

Proof tray

Shift tray

* The machine will inform the operator that the tray is full when any of the listed

conditions are met (whichever occurs first).

No staple

Staple

One size

Mixed sizes

A4-S, LT-S or shorter 150 sheets

A4-L, LT-L or longer 75 sheets

A4-S, LT-S or shorter

A4-L, LT-L or longer

A4-S, LT-S or shorter

A4-L, LT-L or longer

1-5 sheets 25 sets

6-10 sheets 15 setsStaple tray

11-15 sheets 10 sets

(-L”: Lengthwise ,-S: Sideways)

147mm stack height

or 1000 sheets (*)

74mm stack height

or 500 sheet (*)

110mm stack height

or 30 sets

or 750 sheets (*)

74mm stack height

or 30 sets

or 500 sheets (*)

Page 33

echnical Bulletin

T

PAGE: 1/2

Model:

Subject:

From:

Mojito

Installation Procedure for Copy Tray Tape 700

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

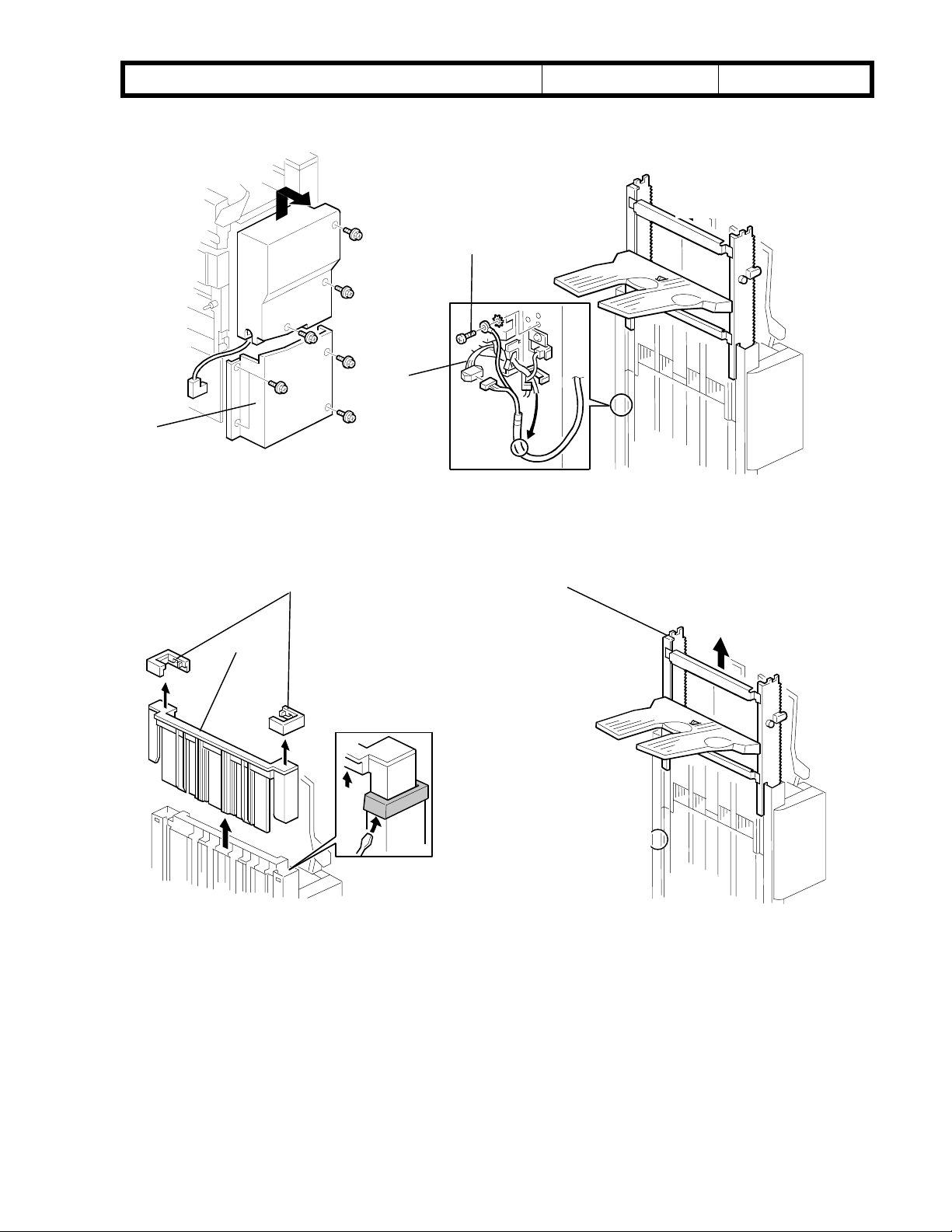

Installation procedure for the Copy Tray Type 700

1. Accessory check

Check the accessories in the box against the following list.

Description Q’ty

1) Copy Tray ……………………………………………. 1

2) Tray Paper Limit Sensor Assembly..…..………….. 1

3) Cap – φ22 …………………………………….……… 4

4) Connector Cap …………………..…………..……… 1

22-Aug-00

Prepared by:

Action required

Service manual revision

Retrofit information

No.:

F. Noguchi

RA293011

5) Philips Tapping Screw – M4x8………… ………… 2

2. Installation Procedure

1) Remove the left cover [A] (2 screws).

[A]

2) Slide the collars (black) [B] into the holes in the

rubber rollers [C] of the exit drive roller.

[C]

[B]

[C]

Page 34

echnical Bulletin

T

PAGE: 2/2

Model:

3) Remove the shorting connector [A].

4) Install the tray paper limit sensor

Mojito

assembly [B].

Date:

22-Aug-00

[A]

[B]

No.:

RA293011

5) Reinstall the left cover.

6) Install the four caps (φ22) [C] and

the connector cap [D].

7) Install the copy tray [E].

[E]

[D]

[C]

Page 35

Reissued: 30-Aug-00

echnical Bulletin

T

PAGE: 1/5

Model:

Mojito

Date:

09-Jun-00

No.:

RA293005b

RTB Correction

Version 3.6 has been added.

Subject:

From:

BICU firmware Modification History

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

F. Noguchi

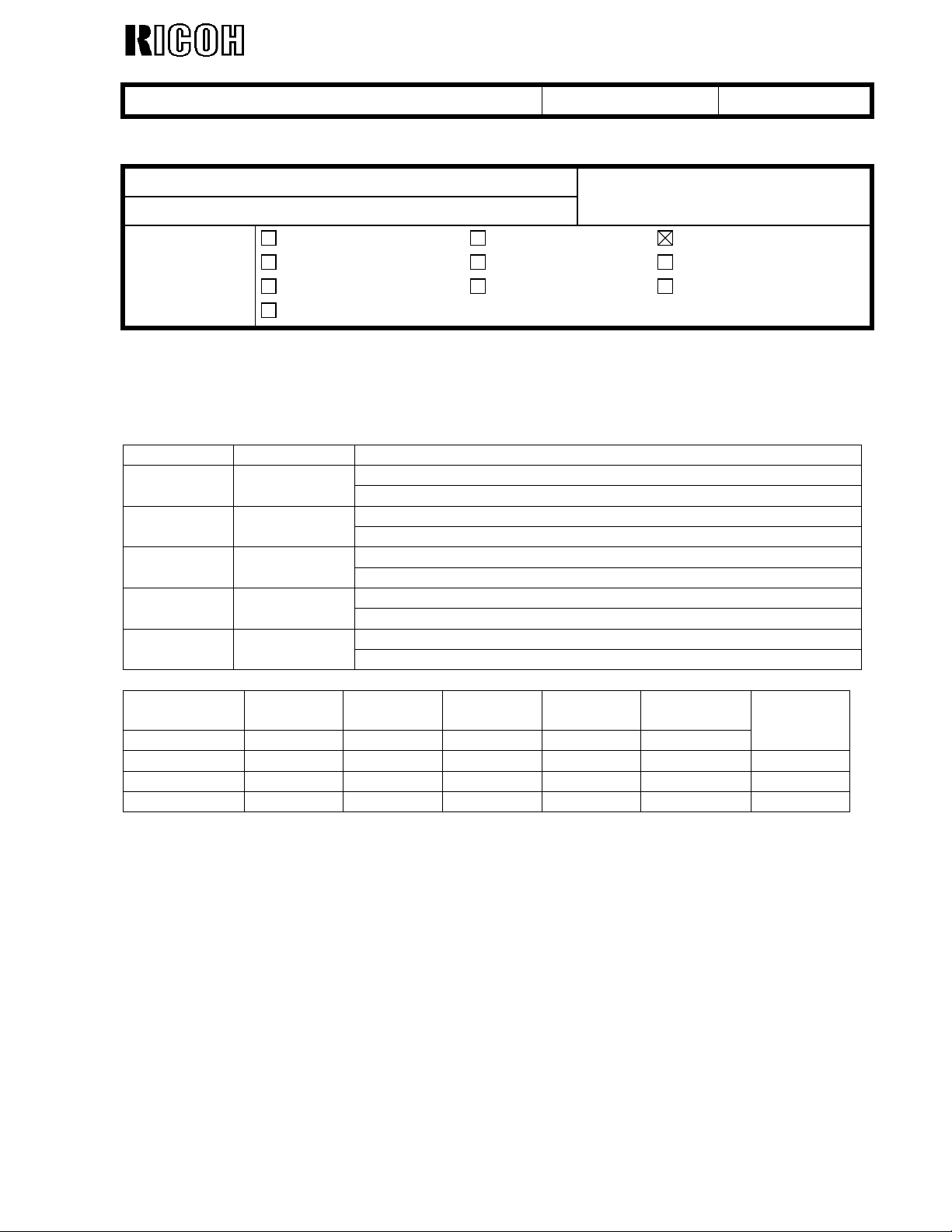

BICU firmware modification history (version 3.6 only – for earlier modifications, see earlier

RTBs)

As there five types of the firmware, use an appropriate one for each customer.

Destination Part Number Model Codes/Languages

A292 -15, -17, A293 -15, -17America A293 7553

US English, French, Spanish

A292 -19, -22, -26, -27, -29, A293 -22, -26, -27, -29Eu1_Asia A293 7653

English, French, Spanish, German, Italian, Dutch

A292 -22, -26, -27, A293 -22, -26, -27Eu2 A293 7564

English, German, Swedish, Norwegian, Danish, Finnish

A292 -22, -26, -27, A293 -22, -26, -27Eu3 A293 7565

English, German, Portuguese, Polish, Hungarian, Czech

A292 -14, -24, A293 –14, -24Eu3(Lanier) A293 7566

English, German, Portuguese, Polish, Czech

Destination/

Part Number

Version/Suffix

3.1 C C - - - 09-Jun-00

3.5 D D A A A 06-Jul-00

3.5.1 E E B B B 06-Jul-00

3.6 F F C C C 30-Aug-00

America

A293 7553

Eu1_Asia

A293 7653

Eu2

A293 7564

Eu3

A293 7565

Eu3(Lanier)

A293 7566

RTB issue

date

Page 36

Reissued: 30-Aug-00

echnical Bulletin

T

PAGE: 2/5

Model:

Mojito

Date:

09-Jun-00

No.:

RA293005b

Version 3.6

Destination/ America Eu1_Asia Eu2 Eu3 Eu3(Lanier)

Part Number A293 7553F A293 7653F A293 7564C A293 7565C A293 7566C

1. New SP Mode (SP5970) for EB-70 (Printer controller)

The following setting applies when the EB-70 printer controller is installed.

Mode No. Function Setting

Printer Installed5970

Selects whether the EB-70 printer

controller is installed or not.

2. Some of the Image Missing in Tab Stock when Printing from the Document Server

Symptom

0: No

1: Yes

When files in the Document Server are printed onto Tab Stock, the image is not

rotated even though tab stock can be set sideways only. This is because, in the

Document Server, the documents are saved lengthwise only.

Modification

The error has been corrected.

3. Malfunction with Printer Dot Edge Parameter Setting when Printing from the Document

Server

Symptom

When edge smoothing is off, the line thickness is not changed when the printer dot edge

parameter setting (SP2114) is changed.

Modification

The error has been corrected.

Page 37

!"#$% T

echnical Bulletin

PAGE: 1/3

Model:

Subject:

From:

Mojito

Service Manual

Technical Services Dept.,GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

Prepared by:

Please correct your service manual as follows.

SP Modes

SP1-008 : Duplex Fence Adjustment

SP1-008-1 → Delete

SP1-008-2 → SP1-008

SP2-210 : ID Sensor Interval

Change the maximum interval from 500 copies to 200 copies.

11-Sep-00

No.:

RA293012

M. Tsuyuki

Action required

Service manual revision

Retrofit information

New SP Modes

SP2-921 : Shading correction

Designer use only.

SP5-212: Page Numbering

SP5-212-003 : Page Print Position – Side to Side

Adjusts the position (sub scan direction) of "Page Numbering" on the 2nd side when

making a duplex copy.

Range: -10 to +10mm Default: 0mm Setting: 1mm/Step

SP5-212-004 : Page Print Position – Up and Down

Adjusts the position (main scan direction) of “Page Numbering” on the 2nd side when

making a duplex copy.

Range: -10 to +10mm Default: 0mm Setting: 1mm/Step

SP5-513: PM Alarm Setting Interval

SP5-513-001: Copy Paper Based

Japanese market only

Default: 300

SP5-513-002: Original Based

Japanese market only

Default: 300

Page 38

!"#$% T

echnical Bulletin

PAGE: 2/3

Model:

SP5-514: PM Alarm on/off Setting

SP5-514-001: Copy Paper Based

Japanese market only

Default: 1

SP5-514-001: Copy Paper Based

Japanese market only

Default: 0

SP6-016: ADF Motor Speed Auto Adjustment

Adjust the speed of the feed-in motor, transport motor and feed-out motor.

Use this SP mode after replacing the main board, feed-in motor, transport motor, or

feed-out motor.

SP6-120-***: Staple Jogger Adjustment

Adjusts the jogger fence position of the staple tray.

Range: 0.0 to 1.5 Default:0.0 Setting: 0.5/step

***

001: A3

002: B4

003: A4 lengthwise

004: A4 Sideways

005: B5 lengthwise

006: B5 Sideways

007: DLT

008: LG

009: LT lengthwise

010: LT Sideways

011: Others

Mojito

Date:

11-Sep-00

No.:

RA293012

SP-7-990-***: SC990 Information

Displays the detailed information for SC990.

When SC990 has occurred, ask the technician to check this information.

***

001: File name

002: Line number

003: Value

Page 39

!"#$% T

echnical Bulletin

PAGE: 3/3

Model:

Deleted SP modes

The follwing SP modes have been deleted from mass-production machines.

SP1-110: Paper Exit – Platen Mode

SP4-903-18: Filter Level – Pale Mode

SP4-903-19: Filter Level – Generation Copy

SP4-904-3: Graduation Processing Selection – Text/Photo

SP4-904-5: Phase Control – Text

SP4-904-8: Graduation Process in Photo Area

SP4-904-9: Image Data Pass

SP4-904-12: Binary Thresh Level

SP4-904-18: Binary Dither Pattern

SP4-905-2: Image Data Path – Generation

SP4-907: Text/Photo Auto Separation Method

Mojito

Date:

11-Sep-00

No.:

RA293012

SP4-908: Text/Photo Separation Method

SP4-912-1 – 18: Text/Photo Separation Setting (All SP Modes)

SP7-830: Copy Counter by paper size

SP7-928: Document Server: Clear Copy Number of Each Job

Page 5-4

Please correct the product code of the finisher as follows;

BRAZOS-B → B312

VICTORIA → B302

TONEGAWA-B → A763

Please remove “Punch Waste Hopper” from the table of Finisher (A673).

Page 40

echnical Bulletin

T

PAGE: 1/1

Model:

Subject:

From:

Mojito

Image Quality of Half Tone and Gray Scale

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other (Recommended action)

Part information

Electrical

Transmit/receive

Date:

12-Sep-00

Prepared by:

No.:

RA293013

A. Sasaki

Action required

Service manual revision

Retrofit information

SYMPTOM

The image quality of half tone or gray scale areas on printouts is not clear or sharp

enough.

ACTION

1. Recommend customers to set the Edge Smoothing function to the OFF position in

the printer driver.

The default setting of the Edge Smoothing function for each driver language and

printer controller type is as follows:

Driver Language Controller Type A Controller Type B

PCL5e ON OFF

PCL6 ON OFF

PostScript3 OFF OFF

2. Change the printer dot edge parameter in the printer SP mode (Printer SP – Settings –

Printer Dot Edge Parameter) from “Normal” (default) to “SP mode”.

Note: With this change, the print line width can be thickened. This change is valid only

when the Edge Smoothing function is set to “OFF”.

3. Change Copy SP2114 (Printer dot edge parameter setting) to the original settings.

SP Number Original Setting

SP2114-1 7

SP2114-2 7

SP2114-3 11

SP2114-4 7

4. If the customer wants an even thicker line width, change Copy SP2114 (Printer dot

edge parameter setting) from the original settings to the thicker settings.

SP Number Original Setting Thicker Setting

SP2114-1 7 10

SP2114-2 7 10

SP2114-3 11 15

SP2114-4 7 10

Note: Do not set any other combinations of the four settings other than in the above

table. Otherwise, an unexpected image appears on printouts.

This SP is valid only when the Edge Smoothing function is set to “OFF” and the

Printer Dot Edge Parameter in the printer SP mode is set to “SP mode”.

Page 41

echnical Bulletin

T

PAGE: 1/3

Model:

Subject:

From:

Mojito (Finisher)

SC729 (Punch Motor Failure)

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

06-Oct-00

Prepared by:

No.:

RA293014

S. Hizen

Action required

Service manual revision

Retrofit information

SYMPTOM

SC729 is displayed, or the mainframe does not detect the finisher.

CAUSE

1. Electrical noise generated by the drive motor affects the initial check routine of the

punch drive board firmware, such that the motor reset signal is constantly sent out. The

only units on which the symptom may occur are the USA two-punch-hole and European

four-punch-hole units.

2. The two screws securing the heat resistor to the IC on the punch drive board come

loose. As a result, the temperature of the IC becomes too high.

SOLUTION

1. The software has been changed so that the drive motor reset signal is deactivated at the

proper time, even if electrical noise occurs.

Production units:

The ROM on the finisher main board has been changed from the beginning of

September 2000 mass-production, and on some units from August mass-production.

Old ROM P/N: B302-5103F

New ROM P/N: B302-5103G

Listed below are the serial numbers for August production finishers that contain the new

modified ROM.

Note: These units are marked with yellow, circular labels next to the bar code on the

carton.

Page 42

echnical Bulletin

T

PAGE: 2/3

Model:

B302-14

L0670080009

L0670080016∼L0670080018

L0670080020∼L0670080023

L0670080025∼L0670080028

L0670080030∼L0670080035

L0670080037∼L0670080039

L0670080044∼L0670080047

L0670080049∼L0670080050

L0670080115∼L0670080151

L0670080153

L0670080155∼L0670080156

L0670080177∼L0670080178

L0670080181∼L0670080186

L0670080189∼L0670080191

L0670080193∼L0670080213

Total 99 units

B302-17

H3800800066

H3800800073∼H3800800074

H3800800082∼H3800800451

Total 373 units

Mojito (Finisher)

Date:

06-Oct-00

No.:

RA293014

B302-26: None

2 From September 2000 production of the punch units, the heat resistor securing screws

have been locked in place with an adhesive.

P/N change:

Old Punch Drive Board P/N: A812-5120

New Punch Drive Board (Heat resistor screw lock) P/N: A812-5150

Page 43

echnical Bulletin

T

PAGE: 3/3

Model:

3 Action required for field units:

3-1 Please check the two heat resistor screws when visiting the machine site and

tighten them if they are loose.

Mojito (Finisher)

Date:

Punch Motor

06-Oct-00

Make sure these

screws are tightened

securely

No.:

RA293014

Heat Sink Plate

3-2 Replace the finisher ROM only in the following finishers:

-USA: 2-punch hole unit

-Europe: 4-punch hole unit

Page 44

!"#$% T

echnical Bulletin

PAGE: 1/2

Model:

Subject:

From:

Mojito

Printer Controller (B337) System Firmware Histories

Technical Service Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other (Information)

Part information

Electrical

Transmit/receive

Date:

10-Nov-00

Prepared by:

No.:

RA293015

A. Sasaki

Action required

Service manual revision

Retrofit information

This is to inform about the modification histories of the system firmware of Printer

Controller Type 700 (B337).

As there are two types of the firmware, use the appropriate one for the product brand.

Destination Part Number Product Codes/Brands

Generic B337 5800

Lanier B337 5814

B337-01, -10, -15, -17

Ricoh, Savin, Gestetner, Nashuatec, Rexrotary, Infotec

B337-14

Lanier

- Firmware Version and Part Number Suffix for Each Destination -

Destination Generic Lanier

Part Number B337 5800 B337 5814

Version Suffix Suffix

0.40 None None

0.43 A A

0.46 B B

- Version 0.40 -

Destination Generic Lanier

Part Number B337 5800 B337 5814

This is the first version of the mass production.

- Version 0.43 -

Destination Generic Lanier

Part Number B337 5800 A B337 5814 A

1. Blank Sheet as the Last Page of a Duplex Job with Odd-numbered Pages

Symptom

When a duplex job with odd-numbered pages is printed using the sample print function, the

second side of the last sheet is stored as a blank page.

Modification

The blank page is deleted when the file for the job is stored as a document server document.

Note

This modification is valid only with the engine firmware version 3.51 onwards.

Page 45

!"#$% T

echnical Bulletin

PAGE: 2/2

Model:

2. Error when Deleted Files are Accessed

3. Unnecessary Characters when Downloading User Defined Symset of PCL5e

4. Wait State of Flash ROM

Mojito

Symptom

An error occurs when deleted files in the deletion list of the engine are accessed.

Note

This modification is valid only with the engine firmware version 3.51 onwards.

Symptom

Unnecessary characters are also included when Downloading User Defined Symset of PCL5e.

Symptom

The Wait State of the flash ROM is valid with not only 70-ns ROM but also 90-ns ROM.

Date:

10-Nov-00

No.:

RA293015

- Version 0.46 -

Destination Generic Lanier

Part Number B337 5800 B B337 5814 B

1. Measure for 10” x 14” Paper.

2. Symptom

A print job with more than 1000 pages stops printing.

3. Symptom

The user tools are not accessible and SC955 occurs if a print job is canceled after more than

1000 pages are stored in the document server.

4. Symptom

SC2002 occurs with Portuguese, Czech, Polish, Hungarian and Finnish.

5. The value of prtAlertTrainingLevel when an error occurs with MIB is changed from 5

(fieldService) to 2 (unknown).

6. Symptom

Job histories are not logged if a user code is not entered.

7. Symptom

PJL job end is not correctly returned.

8. ASI commands have been added.

9. Some errors are not logged in MinorErrorLog.

Page 46

Reissued: 08-Dec-00

echnical Bulletin

T

PAGE: 1/6

Model:

Mojito

Date:

09-Jun-00

No.:

RA293005c

RTB Correction

1.Version 3.6 has been added.

2.The following item in italics has been corrected.

Version 3.6 item No.1: New SP mode (SP5970) for EP-70 (Printer Controller).

Subject:

From:

BICU firmware Modification History

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

F. Noguchi

This is to inform about modification histories of the BICU firmware (versions 3.6 and 3.11

only – for earlier modification see earlier bulletins).

As there five types of the firmware, use an appropriate one for each customer.

Destination Part Number Model Codes/Languages

A292 -15, -17, A293 -15, -17America A293 7553

US English, French, Spanish

A292 -19, -22, -26, -27, -29, A293 -22, -26, -27, -29Eu1_Asia A293 7563

English, French, Spanish, German, Italian, Dutch

A292 -22, -26, -27, A293 -22, -26, -27Eu2 A293 7564

English, German, Swedish, Norwegian, Danish, Finnish

A292 -22, -26, -27, A293 -22, -26, -27Eu3 A293 7565

English, German, Portuguese, Polish, Hungarian, Czech

A292 -14, -24, A293 –14, -24Eu3(Lanier) A293 7566

English, German, Portuguese, Polish, Czech

Destination/

Part Number

Version/Suffix

3.1 C C - - - 09-Jun-00

3.5 D D A A A 06-Jul-00

3.5.1 E E B B B 06-Jul-00

3.6 F F C C C 30-Aug-00

3.11 G G D D D

America

A293 7553

Eu1_Asia

A293 7563

Eu2

A293 7564

Eu3

A293 7565

Eu3(Lanier)

A293 7566

RTB issue

date

Page 47

Reissued: 08-Dec-00

echnical Bulletin

T

PAGE: 2/6

Model:

Mojito

Date:

09-Jun-00

No.:

RA293005c

Version 3.11

Destination America Eu1_Asia Eu2 Eu3 Eu3 (Lanier)

Part Number A293 7553G A293 7563G A293 7564D A293 7565D A293 7566DC

1. SP5009 (Language Selection) Deleted

This SP mode is no longer necessary since the display language can be selected using

Language Priority inside User Tools.

2. SC990 Misdetection (Taiwan machines only)

Symptom Corrected

SC990 occurs when the document server key is pressed. The cause was determined to be a

bug in the software.

3. New Items Added to Output Checks (SP5804)

The following items have been added to the output check for the tandem tray:

No. Description

22 Right Tray Lock

23 Left Tray Lock

4. Incorrect Drum Unit Installation

Feature Changed

There is no response when the Start key is pressed, and the machine displays “copying”. This

was because the drum unit had not been set properly. The new software version allows the

machine to start the job even if the drum has not been set properly, however this will be

indicated by an image quality problem on the printout. Therefore if this occurs, check to see if

the drum has been set properly.

5. Page Numbering for Duplex Copying

Feature added

Even when Center has been selected for the page numbering position and fine adjustments

are made left/right, the actual printing positions on the front and rear sides will match.

6. Scanning Speed Increased

The Document Server scanning speed has been increased from 60 to 70 spm.

7. SC Display Error (SC740 instead of SC720)

Symptom Corrected

For a finisher motor failure, the machine displays SC740 when it should display SC720. In

addition, a SC740 occurrence is logged in the machine history.

Note: SC740 is an SC error code for the A763 Booklet Finisher.

8. Paper Exit Orientation Error

Symptom Corrected

Normally when switching from platen to DF mode, the copy paper exit orientation will be

changed so that the front side faces up. However, when switching over to Batch (SADF)

mode, the machine does not make the change (i.e. paper is still fed out with the rear side

facing up).

Page 48

Reissued: 08-Dec-00

echnical Bulletin

T

PAGE: 3/6

Model:

9. Error when fusing temperature has been set to 175°°°°C or lower.

10. Display Deletion

11. Word Correction

Mojito

Symptom Corrected

If the fusing temperature has been set to 175°C or lower and thick paper feed is set for the

bypass tray, the machine displays “copying” but the job does not start.

Symptom Corrected

“Tab Stock” was displayed in the Tray 2 Special Paper Indication menu (User Tools ! System

Settings) when the Mailbox was connected.

Some words and phrases have been corrected or improved.

For example: System Setting - Auto Tray Switching

Date:

09-Jun-00

No.:

RA293005c

Version 3.6

Destination/ America Eu1_Asia Eu2 Eu3 Eu3(Lanier)

Part Number A293 7553F A293 7563F A293 7564C A293 7565C A293 7566C

1. New SP Mode (SP5970) for EB-70 (Printer controller)

The EB-70 printer controller requires 3 minutes to warm up once the main switch has

been turned on. This is why it is necessary to have "Now loading.....Please wait"

displayed if the Printer key (operation panel, left side) is pressed during this warm-up

period.

Mode No. Function Setting

Printer Installed5970

Selects whether "Now

loading.....Please wait" is displayed

or not.

0: No

1: Yes

2. Some Part of Image Missing in Tab Stock when Printing from Document Server

Symptom

When files in the Document Server are printed onto Tab Stock, the image is not

rotated even though tab stock can be set sideways only. This is because the

documents are saved lengthwise only in the Document Server.

Modification

The error has been corrected.

3. Malfunction with Printer Dot Edge Parameter Setting when Printing from Document

Server

Symptom

When edge smoothing is off, the line thickness is not changed when the printer dot edge

parameter setting (SP2114) is changed.

Modification

The error has been corrected.

Page 49

Reissued: 22-Dec-00

echnical Bulletin

T

PAGE: 1/2

Model:

Mojito

Date:

09-Jun-00

No.:

RTB Correction

Version 3.11.1 has been added.

Subject:

From:

BICU firmware Modification History

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

F. Noguchi

Modification history of the BICU firmware.

As there five types of the firmware, use an appropriate one for each customer.

Destination Part Number Model Codes/Languages

A292 -15, -17, A293 -15, -17America A293 7553

US English, French, Spanish

A292 -19, -22, -26, -27, -29, A293 -22, -26, -27, -29Eu1_Asia A293 7563

English, French, Spanish, German, Italian, Dutch

A292 -22, -26, -27, A293 -22, -26, -27Eu2 A293 7564

English, German, Swedish, Norwegian, Danish, Finnish

A292 -22, -26, -27, A293 -22, -26, -27Eu3 A293 7565

English, German, Portuguese, Polish, Hungarian, Czech

A292 -14, -24, A293 –14, -24Eu3(Lanier) A293 7566

English, German, Portuguese, Polish, Czech

RA293005d

Destination/

Part Number

Version/Suffix

3.1 C C - - - 09-Jun-00

3.5 D D A A A 06-Jul-00

3.5.1 E E B B B 06-Jul-00

3.6 F F C C C 30-Aug-00

3.11 G G D D D 08-Dec-00

3.11.1 H H E E E 22-Dec-00

America

A293 7553

Eu1_Asia

A293 7563

Eu2

A293 7564

Eu3

A293 7565

Eu3(Lanier)

A293 7566

RTB issue

date

Page 50

Reissued: 22-Dec-00

echnical Bulletin

T

PAGE: 2/2

Model:

Mojito

Date:

09-Jun-00

No.:

RA293005d

Version 3.11.1

Destination/ America Eu1_Asia Eu2 Eu3 Eu3(Lanier)

Part Number A293 7553H A293 7563H A293 7564E A293 7565E A293 7566E

Note: The pre-paid card and key counter have not been fully tested with the Mojito by Ricoh,

because they are not official options for the Mojito. However, the following items (1 and 2)

have been improved as per a field request.

1. Error when connecting the pre-paid card connector to the mainframe 4-pin key counter

connector

Symptoms

1) The copier only counts up once for every 2 copies made.

2) When the key card has been set in the machine and the main switch turned on, the machine

does not detect the card unless the card is taken out and set again.

* Other symptoms are possible. The actual symptom can vary depending on the type of card

used.

2. Counter error after the key counter is removed and a jam occurs

Symptom

If a jam occurs after the key counter is removed during a copy job, the counter value is less than

the actual number by 1 when copying starts again.

3. SC337 Logged by Mistake

Symptom

SC337 is not displayed but is recorded in the logged data.

Cause

There are cases where the 24V line is cut before the 5V line when the main switch is turned off,

causing SC337 to occur. Since this occurs when the machine is being turned off, there is no

SC337 display, and an error is logged by mistake.

Solution

To prevent SC337 from occuring at power off, both the display and logging of the error will be

done at a fixed time after occurrence (200ms). This will allow time for all power lines to drop to

0V, thus preventing misdetection of SC337.

Page 51

Reissued: 26-Feb-01

echnical Bulletin

T

PAGE: 1/2

Model:

Mojito

Date:

09-Jun-00

No.:

RA293005e

RTB Correction

Version 3.13 has been added.

Subject:

From:

BICU firmware Modification History

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

F. Noguchi

Modification history of the BICU firmware.

As there are five types of the firmware, use an appropriate one for each customer.

Destination Part Number Model Codes/Languages

A292 -15, -17, A293 -15, -17America A293 7553

US English, French, Spanish

A292 -19, -22, -26, -27, -29, A293 -22, -26, -27, -29Eu1_Asia A293 7563

English, French, Spanish, German, Italian, Dutch

A292 -22, -26, -27, A293 -22, -26, -27Eu2 A293 7564

English, German, Swedish, Norwegian, Danish, Finnish

A292 -22, -26, -27, A293 -22, -26, -27Eu3 A293 7565

English, German, Portuguese, Polish, Hungarian, Czech

A292 -14, -24, A293 –14, -24Eu3(Lanier) A293 7566

English, German, Portuguese, Polish, Czech

Destination/

Part Number

Version/Suffix

3.1 C C - - - 09-Jun-00

3.5 D D A A A 06-Jul-00

3.5.1 E E B B B 06-Jul-00

3.6 F F C C C 30-Aug-00

3.11 G G D D D 08-Dec-00

3.11.1 H H E E E 22-Dec-00

3.13 J J F F F 22-Feb-01

America

A293 7553

Eu1_Asia

A293 7563

Eu2

A293 7564

Eu3

A293 7565

Eu3(Lanier)

A293 7566

RTB issue

date

Page 52

Reissued: 26-Feb-01

echnical Bulletin

T

PAGE: 2/2

Model:

Mojito

Date:

09-Jun-00

No.:

RA293005e

Version 3.13

Destination/ America Eu1_Asia Eu2 Eu3 Eu3(Lanier)

Part Number A293 7553J A293 7563J A293 7564F A293 7565F A293 7566F

1. SC990 when printing out the SMC sheet: Polish language only

Symptoms

When SP5590-1/-3 is used to print out the SMC sheet and Polish has been selected as the

display language, the wrench symbol lights up and an SC990 error is logged.

2. SC990 at copy start when ID sensor Vsg=0V

Symptom

SC990 occurs if copying is initiated when the ID sensor Vsg is at 0V. The condition is cleared

when process control initialization is performed. However, when the power is turned off and then

on again, it will always occur when copying is initiated.

3. Diagonal white lines/image shifting with SMC sheet printing

Symptom

When printing out the SMC sheet or counter data printout onto 81/2 x 11 lengthwise paper,

diagonal white lines appear on the copy or the image data is shifted.

4. PM alert display not displayed at PM timing

Symptom

The PM alert is not displayed when the PM counter reaches its set value.

5. Margin adjustment setting error - Interrupt key

Symptom

When the interrupt key is pressed and the margin adjustment settings are changed for a new

job, the machine returns to the original copy job modes/settings, but does not return to the

original margin settings.

6. Default setting error when performing Memory All Clear on models for China

Symptom

When SP5801 (Memory All Clear) is performed on models for China, the default for the third

paper was displayed as B4, instead of what it should have been (A3). The default value (A3) will

now be correctly set.

7. New SP Mode (SP5972: Document Server Counter Selection)

When copy/print files on the document server are printed out, this SP mode allows them to be

counted separately as copies and prints, or all together

Mode No. Function Setting

Document Server Counter Selection5972

Select the counter

as copies.

0: Copy

1: Copy or Printer

Page 53

echnical Bulletin

T

PAGE: 1/1

Model:

Subject:

From:

Mojito

Necessary precautions - NVRAM replacement

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

20-Feb-01

Prepared by:

No.:

RA293016

F. Noguchi

Action required

Service manual revision

Retrofit information

Important:

In addition to turning off the main switch, please be sure to take the following precautions

when replacing the NVRAM.

1. Loss of ALL data stored on the NVRAM.

The NVRAM contains an internal battery, so please observe the following two

guidelines when replacing the NVRAM:

1) Before replacement, the technician should touch a metal portion of the machine to

eliminate the possibility of a static electricity buildup.

2) Do not place the NVRAM on an object made of conductive material.

This will cause a short, resulting in the loss of all the data inside.

2. Physical damage to the NVRAM pins when removed.