Ricoh af 650 Service Manual s af700

Mojito-C1b/C1c

(Machine Code: A292 and A293)

SERVICE MANUAL

ø

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

5. If the Start key is pressed before the copier completes the warm-up period

(the Start key starts blinking red and green alternatively), keep hands away

from the mechanical and the electrical components as the copier starts

making copies as soon as the warm-up period is completed.

6. The inside and the metal parts of the fusing unit become extremely hot while

the copier is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your eyes

by accident, it may cause temporary eye discomfort. Try to remove with eye

drops or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

those models.

2. The NVRAM on the system control board has a lithium battery which can

explode if replaced incorrectly. Replace the NVRAM only with an identical

one. The manufacturer recommends replacing the entire NVRAM. Do not

recharge or burn this battery. Used NVRAM must be handled in accordance

with local regulations.

1

1.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

Do not incinerate toner bottles or used toner. Toner dust may ignite

suddenly when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in or der to dispos e of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

ø

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

ø

WARNING

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can seriously damage

your eyes.

CAUTION MARKING:

2

TABLE OF CONTENTS

1. OVERALL MACHINE INFORMATION........................................1-1

1.1 SPECIFICATIONS.................................................................................... 1-1

1.1.1 COPIER ENGINE ............................................................................ 1-1

1.1.2 ADF.................................................................................................. 1-4

1.2 MACHINE CONFIGURATION.................................................................. 1-5

1.3 MECHANICAL COMPONENT LAYOUT................................................... 1-6

1.3.1 COPIER ENGINE ............................................................................ 1-6

1.3.2 ADF.................................................................................................. 1-8

1.4 PAPER PATH........................................................................................... 1-9

1.5 COPY PROCESS................................................................................... 1-10

1.6 DRIVE LAYOUT ..................................................................................... 1-12

1.6.1 COPIER ENGINE .......................................................................... 1-12

1.6.2 ADF................................................................................................ 1-13

1.7 ELECTRICAL COMPONENT DESCRIPTION........................................ 1-14

1.7.1 COPIER ENGINE .......................................................................... 1-14

1.7.2 ADF................................................................................................ 1-20

2. DETAILED DESCRIPTIONS .......................................................2-1

2.1 DOCUMENT FEEDER.............................................................................. 2-1

2.1.1 PICK-UP ROLLER RELEASE.......................................................... 2-1

2.1.2 BOTTOM PLATE LIFT..................................................................... 2-2

2.1.3 PICK-UP AND SEPARATION.......................................................... 2-3

2.1.4 ORIGINAL FEED............................................................................. 2-4

2.1.5 ORIGINAL SIZE DETECTION......................................................... 2-5

Original Length..................................................................................... 2-5

Original Width....................................................................................... 2-5

2.1.6 ORIGINAL TRANSPORT................................................................. 2-6

2.1.7 ORIGINAL SKEW CORRECTION................................................... 2-7

2.1.8 ORIGINAL INVERSION AND FEED-OUT....................................... 2-8

General Operation................................................................................ 2-8

Original Inversion................................................................................. 2-9

Original Exit (Single-Sided Original Mode)......................................... 2-10

Original Exit (Double-Sided Original Mode) ....................................... 2-11

2.1.9 JAM CONDITIONS........................................................................ 2-12

Feed-in............................................................................................... 2-12

Feed-out............................................................................................. 2-12

Inversion ............................................................................................ 2-12

2.2 SCANNING............................................................................................. 2-13

2.2.1 OVERVIEW ................................................................................... 2-13

2.2.2 SCANNER DRIVE ......................................................................... 2-14

2.2.3 ORIGINAL SIZE DETECTION IN BOOK MODE............................ 2-15

i

2.3 IMAGE PROCESSING ...........................................................................2-16

2.3.1 OVERVIEW ................................................................................... 2-16

2.3.2 SBU ............................................................................................... 2-17

2.3.3 AUTO IMAGE DENSITY (ADS)..................................................... 2-18

2.3.4 IPU (IMAGE PROCESSING UNIT)................................................ 2-19

2.3.5 IMAGE PROCESSING STEPS AND RELATED SP MODES........ 2-20

2.3.6 AUTO SHADING............................................................................ 2-25

Black Level Correction....................................................................... 2-25

White Level Correction....................................................................... 2-25

2.3.7 BACKGROUND ERASE................................................................ 2-26

2.3.8 INDEPENDENT DOT ERASE........................................................ 2-27

2.3.9 FILTERING, MAIN SCAN MAGNIFICATION/REDUCTION........... 2-28

Overview............................................................................................ 2-28

Filtering .............................................................................................. 2-28

Main Scan Magnification/Reduction................................................... 2-29

Sub Scan Magnification ..................................................................... 2-29

2.3.10 GAMMA (γ) CORRECTION ......................................................... 2-30

2.3.11 GRADATION PROCESSING....................................................... 2-30

Three-graduation Processing ............................................................. 2-30

Four-graduation Processing............................................................... 2-31

Error Diffusion and Dithering.............................................................. 2-31

2.3.12 LINE WIDTH CORRECTION....................................................... 2-31

2.4 LASER EXPOSURE............................................................................... 2-32

2.4.1 AUTO POWER CONTROL............................................................ 2-32

2.4.2 DUAL BEAM WRITING.................................................................. 2-33

2.4.3 LASER BEAM PITCH CHANGE MECHANISM............................. 2-34

2.4.4 LD SAFETY SWITCHES ............................................................... 2-35

2.5 DRUM UNIT............................................................................................ 2-36

2.5.1 PROCESS CONTROL................................................................... 2-36

Overview............................................................................................ 2-36

Drum potential sensor calibration....................................................... 2-37

VSG adjustment................................................................................. 2-37

VG Adjustment................................................................................... 2-38

LD power adjustment......................................................................... 2-39

Toner Density Adjustment.................................................................. 2-39

VREF Update..................................................................................... 2-40

2.5.2 DRUM UNIT COMPONENTS........................................................ 2-41

2.5.3 DRUM CHARGE............................................................................ 2-42

Overview............................................................................................ 2-42

Charge Corona Wire Cleaning Mechanism........................................ 2-43

2.5.4 DRUM CLEANING AND TONER RECYCLING............................. 2-44

Overview............................................................................................ 2-44

Drive Mechanism............................................................................... 2-45

Cleaning Blade Pressure Mechanism and Side-to-Side Movement... 2-46

ii

2.5.5 OTHERS........................................................................................ 2-47

Air Flow Around the Drum.................................................................. 2-47

Pick-off Mechanism............................................................................ 2-48

2.6 DEVELOPMENT AND TONER SUPPLY................................................ 2-49

2.6.1 OVERVIEW ................................................................................... 2-49

2.6.2 DEVELOPMENT MECHANISM..................................................... 2-50

2.6.3 DEVELOPMENT BIAS................................................................... 2-51

2.6.4 TONER DENSITY CONTROL....................................................... 2-52

Overview............................................................................................ 2-52

Sensor control mode.......................................................................... 2-52

Image pixel count control................................................................... 2-53

2.6.5 TONER END DETECTION............................................................ 2-54

Toner Near End.................................................................................. 2-54

Toner End.......................................................................................... 2-54

2.6.6 TONER END RECOVERY............................................................. 2-54

2.6.7 ABNORMAL TD AND ID SENSOR CONDITIONS ........................ 2-55

2.7 IMAGE TRANSFER AND PAPER SEPARATION.................................. 2-56

2.7.1 IMAGE TRANSFER AND PAPER SEPARATION MECHANISM... 2-56

2.7.2 TRANSFER BELT UNIT LIFT MECHANISM................................. 2-57

2.7.3 TRANSFER BELT CLEANING MECHANISM................................ 2-58

2.8 PAPER FEED.........................................................................................2-59

2.8.1 OVERVIEW ................................................................................... 2-59

2.8.2 DRIVE MECHANISM..................................................................... 2-60

2.8.3 TANDEM LCT – TRAY 1 ............................................................... 2-61

Overview............................................................................................ 2-61

Connecting the Left and Right Sides of the Tray................................ 2-62

Paper Lift/Remaining Paper Detection............................................... 2-63

Fence Drive........................................................................................ 2-65

Rear Fence Drive............................................................................... 2-66

Tray Positioning................................................................................. 2-67

2.8.4 TRAY POSITIONING MECHANISM – TRAYS 1 TO 3.................. 2-68

2.8.5 PAPER LIFT MECHANISM - TRAYS 2 AND 3.............................. 2-69

2.8.6 VERTICAL TRANSPORT MECHANISM ....................................... 2-70

2.8.7 PAPER REGISTRATION............................................................... 2-71

2.8.8 PAPER SIZE DETECTION – TRAY 2............................................ 2-72

2.9 IMAGE FUSING...................................................................................... 2-73

2.9.1 OVERVIEW ................................................................................... 2-73

2.9.2 FUSING ENTRANCE GUIDE........................................................ 2-74

2.9.3 FUSING DRIVE MECHANISM....................................................... 2-75

2.10 PAPER EXIT/DUPLEX......................................................................... 2-76

2.10.1 OVERVIEW ................................................................................. 2-76

2.10.2 INVERTER................................................................................... 2-77

Feed-in and Jogging .......................................................................... 2-77

Feed-out............................................................................................. 2-78

2.10.3 DUPLEX TRAY FEED MECHANISM........................................... 2-79

2.10.4 BASIC DUPLEX FEED OPERATION.......................................... 2-80

Longer than A4 / Letter lengthwise..................................................... 2-80

iii

2.11 ENERGY SAVER MODES ................................................................... 2-83

2.11.1 LOW POWER MODE .................................................................. 2-83

Entering low power mode................................................................... 2-83

What happens in low power mode..................................................... 2-83

Return to stand-by mode.................................................................... 2-83

3. INSTALLATION PROCEDURE...................................................3-1

3.1 INSTALLATION REQUIREMENTS .......................................................... 3-1

3.1.1 ENVIRONMENT .............................................................................. 3-1

3.1.2 MACHINE LEVEL............................................................................ 3-1

3.1.3 MINIMUM SPACE REQUIREMENTS.............................................. 3-2

3.1.4 POWER REQUIREMENTS.............................................................. 3-2

3.2 COPIER (A229/A293)............................................................................... 3-3

3.1.1 ACCESSORY CHECK..................................................................... 3-3

3.1.2 INSTALLATION PROCEDURE........................................................ 3-4

3.3 LCT (A698)............................................................................................. 3-14

3.3.1 ACCESSORY CHECK................................................................... 3-14

3.3.2 INSTALLATION PROCEDURE...................................................... 3-15

3.4 3,000-SHEET FINISHER (B312)............................................................ 3-20

3.4.1 ACCESSORY CHECK................................................................... 3-20

3.4.2 INSTALLATION PROCEDURE...................................................... 3-21

3.5 PUNCH UNIT INSTALLATION (A812) FOR B312 FINISHER................ 3-24

3.5.1 ACCESSORY CHECK................................................................... 3-24

3.5.2 PUNCH UNIT INSTALLATION...................................................... 3-25

3.6 FINISHER (B302)................................................................................... 3-28

3.6.1 INSTALLATION PROCEDURE...................................................... 3-28

3.7 PUNCH UNIT INSTALLATION (A812) FOR B302 FINISHER................ 3-31

3.7.1 ACCESSORY CHECK................................................................... 3-31

3.1.2 PUNCH UNIT INSTALLATION...................................................... 3-32

3.8 KEY COUNTER INSTALLATION ........................................................... 3-35

3.9 COPY CONNECTOR KIT INSTALLATION............................................. 3-36

4. SERVICE TABLES......................................................................4-1

4.1 GENERAL CAUTIONS............................................................................. 4-1

4.1.1 DRUM.............................................................................................. 4-1

4.1.2 DRUM UNIT ..................................................................................... 4-1

4.1.3 TRANSFER BELT UNIT .................................................................. 4-2

4.1.4 SCANNER UNIT..............................................................................4-2

4.1.5 LASER UNIT.................................................................................... 4-2

4.1.6 CHARGE CORONA......................................................................... 4-3

4.1.7 DEVELOPMENT.............................................................................. 4-3

4.1.8 CLEANING....................................................................................... 4-4

4.1.9 FUSING UNIT.................................................................................. 4-4

4.1.10 PAPER FEED................................................................................ 4-4

4.1.11 USED TONER ............................................................................... 4-4

iv

4.2 SERVICE PROGRAM MODE................................................................... 4-5

4.2.1 SERVICE PROGRAM MODE OPERATION.................................... 4-5

Service Program Access Procedure.................................................... 4-5

Accessing Copy Mode from within an SP Mode .................................. 4-7

Selecting the Program Number............................................................ 4-8

Inputting a Value or Setting for an SP Mode........................................ 4-9

4.2.2 SERVICE PROGRAM MODE TABLES......................................... 4-10

4.2.3 TEST PATTERN PRINTING (SP2-902)......................................... 4-66

Test Pattern Table (SP2-902-2: Test Pattern Printing – IPU)............. 4-66

Test Pattern Table (SP2-902-3: Test Pattern Printing – Printing)....... 4-66

4.2.4 INPUT CHECK............................................................................... 4-67

Main Machine Input Check (SP5-803)............................................... 4-67

ADF Input Check (SP6-007) .............................................................. 4-71

4.2.5 OUTPUT CHECK........................................................................... 4-72

Main Machine Output Check (SP5-804)............................................. 4-72

ADF Output Check (SP6-008)............................................................ 4-73

4.2.6 SYSTEM PARAMETER AND DATA LISTS (SMC LISTS)............. 4-73

4.2.7 MEMORY ALL CLEAR (SP5-801)................................................. 4-74

4.2.8 SOFTWARE RESET...................................................................... 4-75

4.2.9 SYSTEM SETTING AND COPY SETTING (UP MODE) RESET... 4-75

System Setting Reset......................................................................... 4-75

Copy Features Reset......................................................................... 4-75

4.3 PROGRAM AND DATA DOWNLOAD.................................................... 4-76

4.3.1 OVERVIEW ................................................................................... 4-76

4.3.2 DOWNLOAD THE BICU SOFTWARE FROM BICU TO FLASH

MEMORY CARD...................................................................................... 4-77

4.3.3 DOWNLOAD NVRAM DATA TO THE BICU.................................. 4-78

4.3.4 DOWNLOAD NVRAM DATA FROM BICU TO FLASH MEMORY

CARD....................................................................................................... 4-79

4.3.5 DOWNLOAD STAMP DATA TO THE BICU .................................. 4-80

4.4 USER PROGRAM MODE....................................................................... 4-81

4.4.1 HOW TO ENTER AND EXIT UP MODE........................................ 4-81

4.4.2 UP MODE TABLE.......................................................................... 4-81

System Setting Table......................................................................... 4-81

Copy Features Table.......................................................................... 4-82

4.4.3 IMAGE QUALITY SETTING BY UP MODE................................... 4-86

Text Mode.......................................................................................... 4-86

Text/Photo Mode................................................................................ 4-90

Photo Mode........................................................................................ 4-91

Pale Mode.......................................................................................... 4-92

Generation Mode............................................................................... 4-92

4.5 TEST POINTS/DIP SWITCHES/LEDS................................................... 4-93

4.5.1 DIP SWITCHES............................................................................. 4-93

4.5.2 TEST POINTS............................................................................... 4-93

4.5.3 FUSES........................................................................................... 4-94

4.5.4 VARIABLE RESISTORS................................................................ 4-95

4.5.5 LEDS ............................................................................................. 4-95

4.6 SPECIAL TOOLS AND LUBRICANTS ................................................... 4-95

4.6.1 SPECIAL TOOLS........................................................................... 4-95

v

4.6.2 LUBRICANTS................................................................................ 4-95

5. PREVENTIVE MAINTENANCE SCHEDULE...............................5-1

5.1 PM TABLE................................................................................................ 5-1

6. REPLACEMENT AND ADJUSTMENT ........................................ 6-1

6.1 EXTERIOR ............................................................................................... 6-1

6.1.1 FILTERS.......................................................................................... 6-1

Ozone Filter: Duct................................................................................ 6-1

Filter Vacuum....................................................................................... 6-1

6.2 DOCUMENT FEEDER.............................................................................. 6-2

6.2.1 COVER REMOVAL.......................................................................... 6-2

6.2.2 FEED UNIT REMOVAL AND SEPARATION ROLLER

REPLACEMENT............................................................................... 6-4

6.2.3 FEED BELT REPLACEMENT.......................................................... 6-5

6.2.4 PICK-UP ROLLER REPLACEMENT............................................... 6-6

6.2.5 SENSOR REPLACEMENT.............................................................. 6-7

Entrance and Registration Sensors...................................................... 6-7

Width Sensor........................................................................................ 6-8

Exit Sensor and Inverter Sensor.......................................................... 6-9

6.2.6 TRANSPORT BELT REPLACEMENT........................................... 6-10

6.3 SCANNER UNIT..................................................................................... 6-11

6.3.1 EXPOSURE GLASS...................................................................... 6-11

6.3.2 LENS BLOCK................................................................................ 6-12

6.3.3 ORIGINAL SIZE SENSORS.......................................................... 6-13

6.3.4 EXPOSURE LAMP........................................................................ 6-14

6.3.5 SCANNER MOTOR / MCU............................................................ 6-15

Scanner Motor.................................................................................... 6-15

MCU................................................................................................... 6-15

6.3.6 SCANNER WIRES......................................................................... 6-16

Rear Scanner Drive Wire................................................................... 6-19

Front Scanner Drive Wire................................................................... 6-20

Reinstallation...................................................................................... 6-21

6.4 LASER UNIT........................................................................................... 6-23

6.4.1 CAUTION DECAL LOCATIONS.................................................... 6-23

6.4.2 LD UNIT REPLACEMENT............................................................. 6-24

6.4.3 POLYGON MIRROR MOTOR REPLACEMENT............................ 6-25

6.5 DRUM UNIT............................................................................................ 6-26

6.5.1 DRUM ENTRANCE SEAL AND DRUM POTENTIAL SENSOR

REPLACEMENT...................................................................................... 6-26

6.5.2 DRUM MOTOR REPLACEMENT.................................................. 6-27

6.5.3 TONER OUTPUT AND RECYCLING PUMP UNIT

REPLACEMEN T............................................................................. 6-28

vi

6.6 DEVELOPMENT AND TONER SUPPLY................................................ 6-30

6.6.1 DEVELOPMENT AND AIR DUST FILTER REPLACEMENT ........ 6-30

6.6.2 DEVELOPER REPLACEMENT..................................................... 6-31

6.6.3 TONER END SENSOR REPLACEMENT...................................... 6-33

6.6.4 DEVELOPMENT MOTOR REPLACEMENT.................................. 6-33

6.7 TRANSFER BELT UNIT......................................................................... 6-34

6.7.1 TRANSFER BELT UNIT REMOVAL/INSTALLATION ................... 6-34

- Removal -......................................................................................... 6-34

- Installation -...................................................................................... 6-34

6.8 PAPER FEED.........................................................................................6-36

6.8.1 PAPER TRAY REMOVAL.............................................................. 6-36

Tandem Tray Removal....................................................................... 6-36

6.8.2 REAR FENCE RETURN SENSOR REPLACEMENT.................... 6-38

6.8.3 REAR FENCE HP SENSOR REPLACEMENT.............................. 6-39

6.8.4 BOTTOM PAPER SENSOR REPLACEMENT............................... 6-40

6.8.5 BOTTOM PLATE LIFT WIRE REPLACEMENT............................. 6-41

6.8.6 TANDEM LCT PAPER SIZE CHANGE.......................................... 6-43

6.8.7 BY-PASS PAPER SIZE BOARD REPLACEMENT........................ 6-46

6.8.8 PAPER FEED CLUTCH/RELAY CLUTCH REMOVAL.................. 6-48

6.8.9 BY-PASS FEED MOTOR/CLUTCH REMOVAL............................. 6-51

6.8.10 REGISTRATION MOTOR REMOVAL......................................... 6-52

6.8.11 PAPER TRAY UNIT REMOVAL.................................................. 6-53

6.9 FUSING UNIT......................................................................................... 6-54

6.9.1 FUSING UNIT REMOVAL ............................................................. 6-54

6.9.2 FUSING THERMISTOR AND FUSING THERMOFUSE

REPLACEMEN T............................................................................. 6-55

Fusing Thermistor Replacement........................................................ 6-55

Fusing Thermofuse Replacement...................................................... 6-55

6.9.3 FUSING LAMP REPLACEMENT................................................... 6-56

6.9.4 HOT ROLLER REPLACEMENT.................................................... 6-57

6.9.5 OIL SUPPLY/CLEANING ROLLER REPLACEMENT.................... 6-59

6.9.6 PRESSURE ROLLER CLEANING ROLLER REPLACEMENT...... 6-60

6.9.7 MAGNET POSITION ADJUSTMENT ............................................ 6-61

6.10 PAPER EXIT/DUPLEX UNIT................................................................ 6-62

6.10.1 1ST AND 2ND EXIT SENSOR..................................................... 6-62

6.10.2 JOGGER MOTOR ....................................................................... 6-63

6.10.3 DUPLEX ENTRANCE SENSOR.................................................. 6-63

6.10.4 DUPLEX TRANSPORT/DUPLEX FEED CLUTCHES................. 6-64

6.10.5 DUPLEX TRANSPORT SENSOR 1............................................ 6-64

6.10.6 DUPLEX TRANSPORT SENSORS 2 & 3.................................... 6-65

6.10.7 INVERTER EXIT CLIUTCH......................................................... 6-66

6.10.8 DUPLEX INVERTER SENSOR................................................... 6-66

6.11 BOARDS AND OTHER ITEMS............................................................. 6-67

6.11.1 BICU BOARD............................................................................... 6-67

6.11.2 I/O BOARD .................................................................................. 6-68

6.11.3 PSU ............................................................................................. 6-69

6.11.4 PAPER FEED CONTROL BOARD (PFC).................................... 6-69

vii

6.12 COPY IMAGE ADJUSTMENTS: PRINTING/SCANNING..................... 6-70

6.12.1 PRINTING.................................................................................... 6-70

Registration - Leading Edge............................................................... 6-70

Registration – Side-to-Side................................................................ 6-70

Tray 1................................................................................................. 6-71

Tray 2................................................................................................. 6-71

Tray 3................................................................................................. 6-72

By-pass Tray...................................................................................... 6-72

7. TROUBLESHOOTING.................................................................7-1

7.1 SERVICE CALL CONDITIONS................................................................. 7-1

7.1.1 SUMMARY....................................................................................... 7-1

7.1.2 SC CODE DESCRIPTIONS............................................................. 7-2

7.2 ELECTRICAL COMPONENT DEFECTS................................................ 7-40

7.2.1 SENSORS..................................................................................... 7-40

7.2.2 SWITCHES.................................................................................... 7-44

7.3 BLOWN FUSE CONDITIONS................................................................. 7-45

OPTIONS

3,000-SHEET FINISHER (B302)

1. OVERALL MACH INE INFORMATION..................................B302-1

1.1 SPECIFICATIONS..............................................................................B302-1

1.2 MECHANICAL COMPONENT LAYOUT.............................................B302-3

1.3 ELECTRICAL COMPONENT DESCRIPTION....................................B302-4

1.4 DRIVE LAYOUT .................................................................................B302-6

2. DETAILED DESCRIPTIONS .................................................B302-7

2.1 TRAY AND STAPLER JUNCTION GATE...........................................B302-7

Upper Tray Mode...........................................................................B302-7

Sort/Stack Mode.............................................................................B302-7

Staple Mode...................................................................................B302-7

2.2 PAPER PRE-STACKING....................................................................B302-8

2.3 JOGGER UNIT PAPER POSITIONING..............................................B302-9

Vertical Paper Alignment................................................................B302-9

Horizontal Paper Alignment ...........................................................B302-9

Paper Stack Correction..................................................................B302- 9

2.4 STAPLER UNIT MOVEMENT..........................................................B302-10

Side-to-Side.................................................................................B302-10

Rotation (1)..................................................................................B302-11

Rotation (2)..................................................................................B302-11

2.5 STAPLER .........................................................................................B302-12

2.6 FEED-OUT .......................................................................................B302-14

2.7 SHIFT TRAY UP/DOWN MOVEMENT.............................................B302-15

2.8 SHIFT TRAY SIDE-TO-SIDE MOVEMENT......................................B302-16

viii

2.9 PUNCH UNIT DRIVE........................................................................B302-17

2.10 PUNCH WASTE COLLECTION .....................................................B302-18

2.11 JAM CONDITIONS.........................................................................B302-19

3. SERVICE TABLES..............................................................B302-20

3.1 DIP SWITCHES................................................................................B302-20

3.2 TEST POINTS..................................................................................B302-20

3.3 FUSES.............................................................................................. B302-20

4. REPLACEMENT AND ADJUSTMENT................................B302-21

4.1 COVER REPLACEMENT.................................................................B302-21

Front Door....................................................................................B302-21

Left Inner Cover ...........................................................................B302-21

Inner Cover..................................................................................B302-21

Table............................................................................................B302-22

Upper Tray...................................................................................B302-22

Left Upper Cover..........................................................................B302-22

Left Lower Cover..........................................................................B302-22

Upper Cover.................................................................................B302-22

Rear Cover...................................................................................B302-22

Shift Tray......................................................................................B302-23

Front Shift Tray Cover..................................................................B302-23

Rear Shift Tray Cover ..................................................................B302-23

4.2 POSITIONING ROLLER REPLACEMENT.......................................B302-24

4.3 ALIGNMENT BRUSH ROLLER REPLACEMENT............................B302-25

4.4 SENSOR REPLACEMENT...............................................................B302-26

4.4.1 STACK HEIGHT 1, 2 AND EXIT GUIDE OPEN SENSOR ......B302-26

Stack Height Sensors 1 and 2......................................................B302-26

Exit Guide Open Sensor ..............................................................B302-26

4.4.2 UPPER TRAY PAPER LIMIT AND EXIT SENSOR.................B302-27

Upper Tray Paper Limit Sensor....................................................B302-27

Upper Tray Exit Sensor................................................................B302-27

4.4.3 SHIFT TRAY EXIT SENSOR...................................................B302-28

4.4.4 ENTRANCE AND STAPLER TRAY ENTRANCE SENSORS..B302-29

Entrance Sensor..........................................................................B302-29

Stapler Tray Entrance Sensor......................................................B302-29

4.4.5 PRE-STACK STOPPER SENSOR..........................................B302-30

4.4.6 STAPLE WASTE HOPPER SENSOR.....................................B302-31

4.4.7 STAPLER ROTATION HP AND STAPLER RETURN

SENSORS................................................................................ B302-32

Stapler Rotation HP Sensor.........................................................B302-32

Stapler Return Sensor..................................................................B302-32

4.5 STAPLER REMOVAL.......................................................................B302-33

4.6 PUNCH POSITION ADJUSTMENT..................................................B302-34

Right to Left..................................................................................B302-34

Front to Rear................................................................................B302-34

ix

3,000-SHEET FINISHER (B312)

1. OVERALL MACH INE INFORMATION..................................B312-1

1.1 SPECIFICATIONS..............................................................................B312-1

1.2 ELECTRICAL COMPONENT LAYOUT..............................................B312-4

1.3 ELECTRICAL COMPONENT DESCRIPTION....................................B312-6

1.4 MECHANICAL COMPONENT LAYOUT.............................................B312-8

1.5 DRIVE LAYOUT .................................................................................B312-9

2. DETAILED DESCRIPTIONS...............................................B312-10

2.1 TRAY AND STAPLER JUNCTION GATE MECHANISM..................B312-10

Upper tray mode..........................................................................B312-10

Sort/stack mode...........................................................................B312-10

Staple mode.................................................................................B312-10

2.2 PRE-STACK MECHANISM ..............................................................B312-11

2.3 JOGGER UNIT PAPER POSITIONING MECHANISM.....................B312-12

Vertical Paper Alignment..............................................................B312-12

Horizontal Paper Alignment .........................................................B312-12

2.4 STAPLER UNIT MOVEMENT MECHANISM....................................B312-13

Side-to-side:.................................................................................B312-13

Rotation:.......................................................................................B312-13

2.5 STAPLER .........................................................................................B312-14

2.6 FEED-OUT MECHANISM.................................................................B312-15

2.7 SHIFT TRAY UP/DOWN MECHANISM............................................B312-16

2.8 SHIFT TRAY SIDE-TO-SIDE MECHANISM.....................................B312-17

2.9 PUNCH UNIT DRIVE MECHANISM.................................................B312-18

2.10 PUNCH WASTE COLLECTION MECHNISM.................................B312-19

2.11 JAM CONDITIONS.........................................................................B312-20

3. SERVICE TABLES..............................................................B312-21

3.1 DIP SWITCHES................................................................................B312-21

3.2 TEST POINTS..................................................................................B312-21

3.3 FUSES.............................................................................................. B312-21

4. REPLACEMENT AND ADJUSTMENT................................B312-22

4.1 COVER REPLACEMENT.................................................................B312-22

Rear Cover...................................................................................B312-22

Upper Left Cover..........................................................................B312-22

Upper Cover.................................................................................B312-22

Front Door....................................................................................B312-22

Left Front Cover...........................................................................B312-22

Shift Tray......................................................................................B312-23

Lower Left Cover..........................................................................B312-23

Right Cover..................................................................................B312-23

Front Shift Tray Cover..................................................................B312-23

Rear Shift Tray Cover ..................................................................B312-23

4.2 POSITIONING ROLLER REPLACEMENT.......................................B312-24

4.3 ALIGNMENT BRUSH ROLLER REPLACEMENT............................B312-25

x

4.4 SENSOR REPLACEMNT.................................................................B312-26

4.4.1 STACK HEIGHT SENSOR 1 AND 2........................................B312-26

4.4.2 UPPER TRAY PAPER LIMIT AND EXIT SENSOR.................B312-27

Upper Tray Paper Limit Sensor....................................................B312-27

Upper Tray Exit Sensor................................................................B312-27

4.4.3 SHIFT TRAY EXIT SENSOR...................................................B312-28

4.4.4 ENTRANCE AND STAPLER TRAY ENTRANCE SENSOR....B312-29

Entrance Sensor..........................................................................B312-29

Stapler Tray Entrance Sensor......................................................B312-29

4.4.5 STAPLER ROTATION HP SENSOR.......................................B312-30

4.5 STAPLER REMOVAL.......................................................................B312-31

4.6 PUNCH POSITION ADJUSTMENT..................................................B312-32

Right to left...................................................................................B312-32

Front to rear.................................................................................B312-32

COPIER CONNECTION KIT (B322)

1. SPECIFICAT ION S.................................................................B322-1

2. DETAILED DESCRIPTIONS .................................................B322-2

2.1 OVERVIEW ........................................................................................B322-2

2.2 BASIC OPERATION...........................................................................B322-3

2.2.1 NO SORT AND NO STAPLE MODE.........................................B322-3

2.2.2 SORT, STAPLE MODE .............................................................B322-4

2.2.3 OPERATION IN IRREGULAR CONDITIONS............................B322-5

Paper end during copying ..............................................................B322-5

Copy tray full..................................................................................B322-5

Paper jam.......................................................................................B322-5

xi

January 8, 2000 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

1.1.1 COPIER ENGINE

Configuration: Console

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book

Original Size: Maximum A3/11" x 17"

Minimum B6, 5

Original Alignment: Rear left corner

Copy Paper Size: Maximum

A3/11" x 17" (2nd/3rd Tray, By-pass)

Minimum

A5/5

A6/5

1/2

1/2

" x 8

" x 8

1/2

1/2

Tandem LCT (1st Tray)

A4/8

" x 11" sideways only

1/2

Duplex Copying: Maximum A3/11" x 17"

Minimum A5/5

1/2

"x 8

" (using ADF)

1/2

" (2nd/3rd Tray)

" lengthwise (By-pass)

1/2

" x 8

" lengthwise

1/2

Overall

Information

Copy Paper Weight: Paper tray: 52.3 ~ 127.9 g/m2, 14 ~ 34 lb

Bypass feed table: 52.3 ~ 157 g/m2, 14 ~ 41.7 lb

Duplex copying: 64 ~ 104.7 g/m2, 17 ~ 28 lb

Reproduction Ratios: 6 reduction and 5 enlargement

Metric Version Inch Version

Enlargement 400%

200%

141%

122%

115%

Full Size 100% 100%

Reduction 93%

82%

75%

71%

65%

50%

400%

200%

155%

129%

121%

93%

85%

78%

73%

65%

50%

1-1

SPECIFICATIONS January 8, 2000

Zoom: 25 ~ 400%

Copy Speed: A292: Max. 55 cpm (A4 / 8

A293: Max. 70 cpm (A4 / 8

" x 11" sideways)

1/2

" x 11" sideways)

1/2

Resolution: Scanning: 600 dpi

Printing: 400/600 dpi

Gradation: 256 levels

Warm-up Time: Less than 330 s (from Off-mode)

Less than 30 s (from Low Power Mode)

First Copy Time:

(1st Tray)

Less than 3.5 s (A4/LT, Face up mode)

Less than 5.3 s (A4/LT, Face down mode)

Copy Number Input: Ten-key pad, 1 to 999

Copy Paper Capacity: Tray 1: 3100 sheets (when used as a tandem tray)

Tray 2: 550 sheets

Tray 3 : 550 sheets

By-pass Tray: 50 sheets

Copy Tray Capacity:

(Output Tray)

A4/8

" x 11" : 500 sheets (100 µm thickness paper)

1/2

A3/11" x 17" : 250 sheets

Memory Capacity: RAM: 48 MB

HDD: 4.3 GB

Toner Replenishment: Cartridge exchange (1220g/ cartridge)

Toner Yield: 42k copies/cartridge

(A4 sideways, 6% full black, 1 to 5 copying, including

toner recycling ratio 20%)

Power Source: North America:

120V, 60Hz, 20A

Europe/Asia:

220 ~ 240 V, 50Hz/60Hz, 10A

1-2

January 8, 2000 SPECIFICATIONS

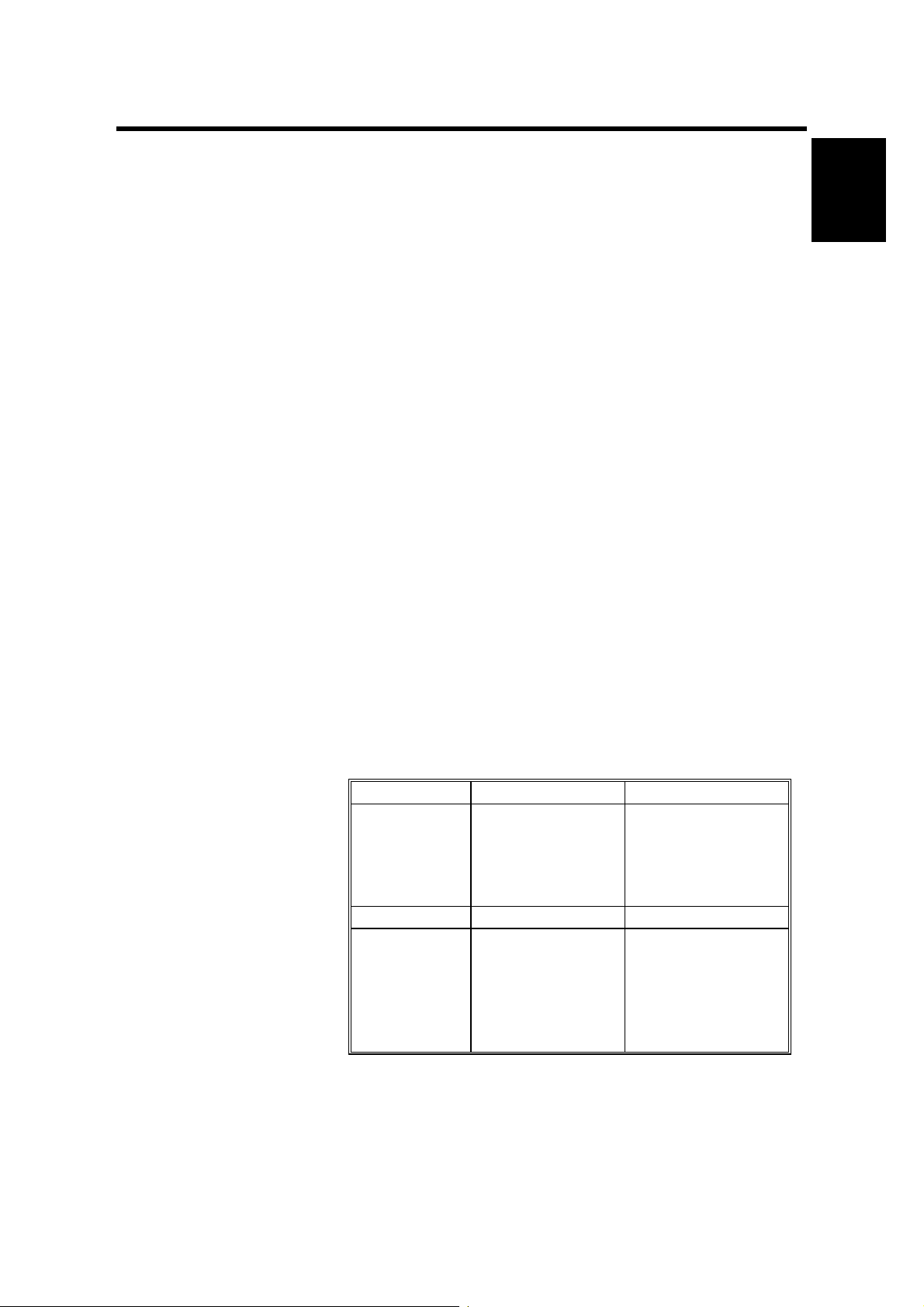

Power Consumption: A292/A293 copier (120 V Model)

Copier only Full system*

Warm-up About 1.290 kW About 1.300 kW

Stand-by About 0.255 kW About 0.270 kW

Copying About 1.630 kW About 1.650 kW

Maximum Less than 1.75 kW Less than 1.75 kW

Energy Saver About 0.230 kW About 0.240 kW

Low Power About 0.225 kW About 0.235 kW

Off Mode About 0.009 kW About 0.009 kW

A292/A293 copier (220 to 240 V Model)

Copier only Full system*

Warm-up About 1.255 kW About 1.300 kW

Stand-by About 0.270 kW About 0.285 kW

Copying About 1.610 kW About 1.590 kW

Maximum Less than 1.75 kW Less than 1.75 kW

Energy Saver About 0.245 kW About 0.255 kW

Low Power About 0.240 kW About 0.250 kW

Off Model About 0.012 kW About 0.012 kW

Overall

Information

Noise Emission:

Sound Power Level:

Stand-by Less than 49 dB(A) Less than 49 dB(A)

Copying (ADF 1 to 1) Less than 75 dB(A) Less than 75 dB(A)

Copying (From Memory) Less than 71 dB(A) Less than 71 dB(A)

Sound Pressure Level:

Stand-by Less than 35 dB(A) Less than 35 dB(A)

Copying (ADF 1 to 1) Less than 65 dB(A) Less than 65 dB(A)

*Full System:

Mainframe with LCT and Finisher (B302)

The measurements were made in accordance with ISO 7779 at

the operator position.

Copier only Full system

The measurements were made in accordance with ISO 7779.

Copier only Full system

Copying (From Memory) Less than 58 dB(A) Less than 58 dB(A)

1-3

SPECIFICATIONS January 8, 2000

Dimensions:

(W x D x H)

Weight: 188 kg (without options)

Optional Equipment:

690 x 750 x 1138 mm (27.2" x 29.5" x 44.8")

(without ADF right exit tray, and options)

•

Output tray (B333-17)

•

Finisher (A763)

•

Finisher (B302)

•

Finisher (B312)

•

Punch unit (A812-30, -31, -32, -57, 67)

•

Large capacity tray (A698)

•

Copy connector kit (B322)

•

LG kit (A375)

•

Tab sheet holder (B373)

1.1.2 ADF

Original Size: Normal Original Mode:

A3 to B6, DLT to HLT

Thin Original Mode:

A3 to B6 sideways, DLT to HLT

Duplex Original Mode:

A3 to B5, DLT to HLT

Original Weight: Normal Original Mode: 52 ~ 156 g/m2, 14 ~ 42 lb

Thin Original Mode: 40 ~ 156 g/m2, 11 ~ 42 lb

Duplex Original Mode: 52 ~ 128 g/m2, 14 ~ 34 lb

Table Capacity: 100 sheets (80 g/m2, 20 lb)

Original Standard Position: Rear left corner

Separation: FRR

Original Transport: One flat belt

Original Feed Order: From the top original

Power Source: DC 24 V and DC 38 V from the copier

Power Consumption: 130 W

Dimensions (W x D x H): 680 x 560 x 150 mm

1-4

January 8, 2000 MACHINE CONFIGURATION

1.2 MACHINE CONFIGURATION

2

34

1

Overall

Information

A293V551.WMF

Item Machine Code No.

Mainframe A292/A293 3

Output Tray B333 2

Finisher A763, B302, B312 1

Large Capacity Tray A698 4

A812-30 (4 holes)

A812-31 (4 holes)

Punch Unit (Option for Finisher)

Copy Connector Kit (for the

tandem copy feature)

LG Kit (Option for large capacity

tray)

Tab Sheet Holder B373

A812-32 (2 holes)

A812-57 (3 holes)

A812-67 (2 holes)

B322

A375

Inside the

Finisher

1-5

MECHANICAL COMPONENT LAYOUT January 8, 2000

1.3 MECHANICAL COMPONENT LAYOUT

1.3.1 COPIER ENGINE

45

44

43

42

41

40

39

38

37

8

41014 15

3

2

1

7

65

9

13

1211

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

36

31

32

A293V115.WMF

333435

1-6

January 8, 2000 MECHANICAL COMPONENT LAYOUT

1. 3rd Mirror

2. 2nd Mirror

3. 1st Mirror

4. Exposure Lamps

5. LD Unit

6. Cylindrical Lens

7. Polygonal Mirror

8. Cleaning Brush

9. Quenching Lamp

10. Barrel Toroidal Lends (BTL)

11. F-theta Mirror

12. SBU

13. Charge Corona Unit

14. Shield Glass

15. Laser Synchronization Detector

31. Separation Roller

32. Tray 1 (Tandem LCT)

33. Tray 2 (550-sheet Tray)

34. Tray 3 (550-sheet Tray)

35. Pick-up Roller

36. Duplex Feed Roller

37. Duplex Transport Rollers

38. Reverse Trigger Roller

39. Inverter Unit Paper Exit Roller

40. Inverter Feed Roller

41. Pressure Roller

42. Transport Rollers

43. Paper Exit Rollers

44. Curl Correction Roller

45. Hot Roller

Overall

Information

16. Optics Cooling Fan Motor

17. Drum Cleaning Blade

18. Drum Potential Sensor

19. Drum

20. Pick-off Pawl

21. Development Unit

22. TD Sensor

23. Pick-up Roller

24. Feed Roller (By-pass Tray)

25. Separation Roller

26. Registration Rollers

27. Transfer Belt Unit

28. Relay Roller

29. Vertical Transport Rollers

30. Feed Roller

1-7

MECHANICAL COMPONENT LAYOUT January 8, 2000

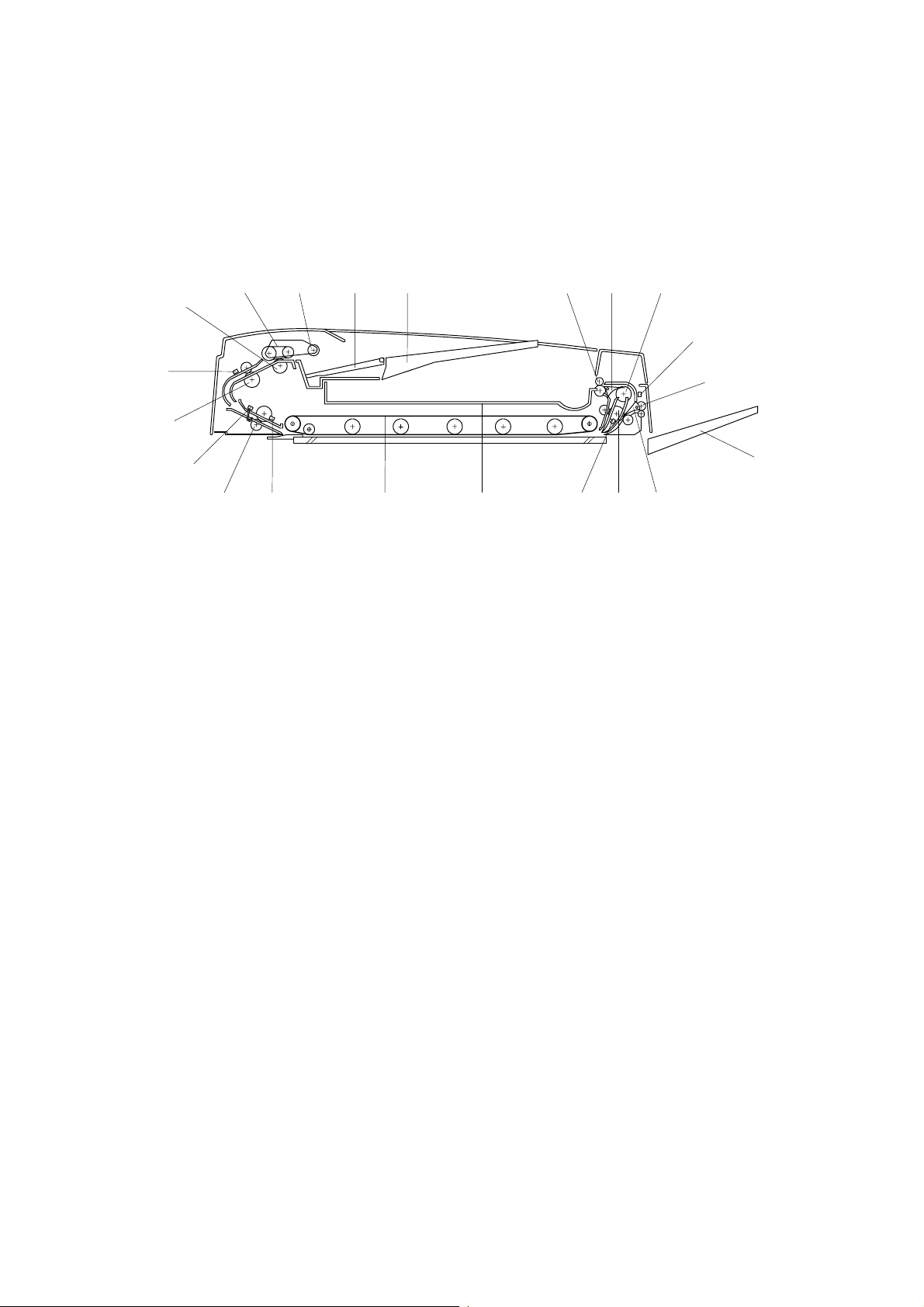

1.3.2 ADF

1

21

20

19

18 17 1213141516

1. Separation Roller

2. Feed Belt

3. Pick-up Roller

4. Bottom Plate

5. Original Tray

6. Upper Tray Exit Roller

7. Inverter Gate

8. Inverter Guide Roller

9. Inverter Sensor

10. Right Tray Exit Roller

11. Right Exit Tray

7

12. Exit Gate

13. Inverter Roller

14. Exit Sensor

15. Upper Exit Tray

16. Transport Belt

17. Registration Sensor

18. Lower Transport Roller

19. Width Sensor

20. Upper T ransport Roller

21. Entrance Sensor

863425

A293V554.WMF

9

10

11

1-8

January 8, 2000 PAPER PATH

1.4 PAPER PATH

11

10

9

8

7

1

2

Overall

Information

6

5

1. ADF

2. By-pass Tray

3. Optional LCT

4. Tray 3 (550-sheet Tray)

5. Tray 2 (550-sheet Tray)

6. Tray 1 (Tandem LCT)

3

A293V107.WMF

4

7. Duplex Unit

8. Finisher

9. Inverter Unit

10. Shift Tray

11. Upper Tray

1-9

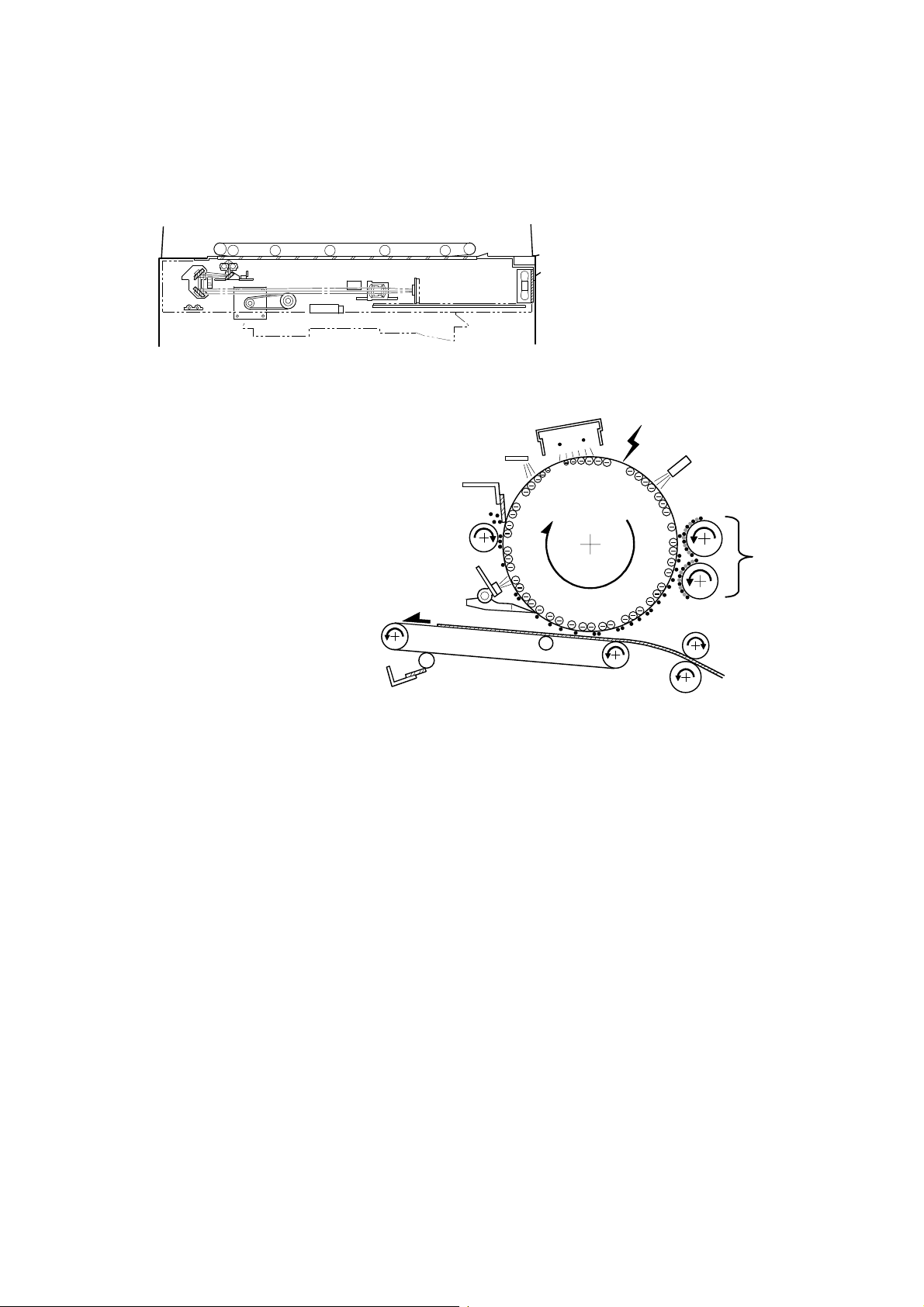

COPY PROCESS January 8, 2000

1.5 COPY PROCESS

1

A293V553.WMF

2

3

10

4

9

8

5

7

6

A293V501.WMF

1. EXPOSURE

A xenon lamp exposes the original. Light reflected from the original passes to the

CCD, where it is converted into an analog data signal. This data is converted to a

digital signal, processed, and stored in the memory. At the time of printing ,the data

is retrieved and sent to the laser diode. For multi-copy runs, the original is scanned

once only and stored to the hard disk.

2. DRUM CHARGE

An OPC (organic photoconductor) drum is used in this machine. In the dark, the

charge corona unit gives a negative charge to the drum. The grid plate ensures

that corona charge is applied uniformly. The charge remains on the surface of the

drum because the OPC layer has a high electrical resistance in the dark.

3. LASER EXPOSURE

The processed data from the scanned original is retrieved from the hard disk and

transferred to the drum by two laser beams, which form an electrostatic latent

image on the drum surface. The amount of charge remaining as a latent image on

the drum depends on the laser beam intensity, which is controlled by the BICU

board.

1-10

January 8, 2000 COPY PROCESS

4. DRUM POTENTIAL SENSOR

The drum potential sensor detects the electric potential on the drum to correct

various process control elements.

5. DEVELOPMENT

The magnetic developer br ush on the development rollers comes in contac t w i th

the latent image on the drum surface. Toner particles are electrostatically attracted

to the areas of the drum surface where the laser reduced the negative charge on

the drum.

6. IMAGE TRANSFER

Paper is fed to the area between the drum surface and the transfer belt at the

proper time to align the copy paper and the developed image on the drum. Then,

the transfer bias roller applies a high positive charge to the reverse side of the

paper through the transfer belt. This positive charge pulls the toner particles from

the drum to the paper. At the same time, the paper is electrically attracted to the

transfer belt.

7. PAPER SEPARATION

Overall

Information

Paper separates from the drum as a result of the electrical attraction between the

paper and the transfer belt. The pick-off pawls also help separate the paper from

the drum.

8. ID SENSOR

The laser forms a sensor pattern on the drum surface. The ID sensor measures the

reflectivity of the pattern. The output signal is one of the factors used for toner

supply control.

9. CLEANING

The cleaning brush removes toner remaining on the drum after image transfer and

the cleaning blade scrapes off all remaining toner.

10. QUENCHING

The light from the quenching lamp electrically neutralizes the charge on the drum

surface.

1-11

DRIVE LAYOUT January 8, 2000

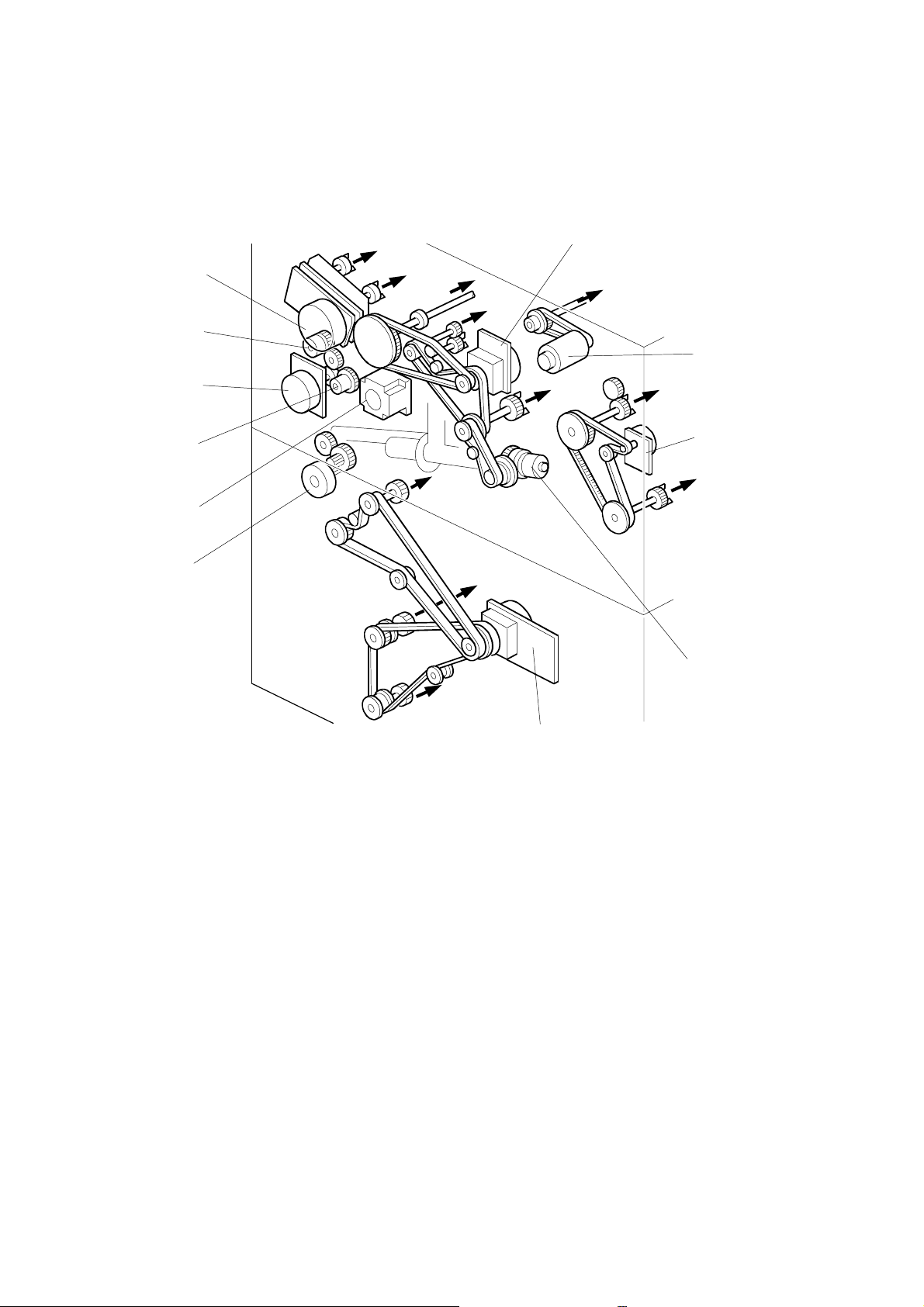

1.6 DRIVE LAYOUT

1.6.1 COPIER ENGINE

11

10

Ÿ

1

¡

š

™

2

9

8

›

ž

7

6

œ

3

•

ž

4

1. Drum Motor

2. Scanner Motor

3. Fusing/Duplex Motor

4. Toner Recycling Clutch

5. Paper Feed Motor

6. Toner Collection Motor

7. Registration Motor

8. Relay Clutch

9. By-pass Feed Motor

10. By-pass Feed Clutch

11. Development Motor

ž

5

™

Cleaning Unit

š

Scanner Unit

›

Transfer Belt Unit

œ

Fusing Unit

•

Duplex Unit

ž

Paper Feed Units

Ÿ

Toner Hopper

Development Unit

¡

Drum

A293V108.WMF

1-12

January 8, 2000 DRIVE LAYOUT

1.6.2 ADF

14

13

12

11

1

2

Overall

Information

3

4

10

5

6

9

8

7

A293V552.WMF

1. Pick-up Motor

2. Bottom Plate Motor

3. Feed-in Motor

4. Transport Motor

5. Upper Exit Roller

6. Feed-out Motor

7. Right Exit Roller

8. Transport Belt

9. Lower Transport Roller

10. Upper Transport Roller

11. Separation Roller

12. Feed Belt

13. Pick-up Roller

14. Feed-in Clutch

1-13

ELECTRICAL COMPONENT DESCRIPTION January 8, 2000

1.7 ELECTRICAL COMPONENT DESCRIPTION

Refer to the electrical component layout on the reverse side of the point-to-point

diagram for the location of the components using the symbols and index numbers.

1.7.1 COPIER ENGINE

Symbol Name Function

Motors

M1 Scanner Drives the 1st and 2nd scanners. 15

M2 Polygonal Mirror Turns the polygonal mirror. 22

LD Positioning

M3

M4 Drum Drives the drum and cleaning unit. 36

M5 Development Drives the development unit. 37

M6

M7

M8

M9

M10

M11

M12

M13

M14

M15 By-pass Feed Drives the by-pass feed rollers. 41

M16 Registration Drives the registration rollers. 40

M17

M18

M19 Optics Cooling Fan Removes heat from the optics unit. 21

M20 Drum Cooling Fan Sends the air to the drum inside. 38

M21

M22

Toner Supply Rotates the toner bottle to supply

Charge Corona Wire

Cleaner

Fusing/Duplex Drives the fusing unit, duplex unit,

Toner Collection Transports the collected toner to the

Toner Recycling

Paper Feed Drives all feed and transport rollers in

1st Tray Lift Raises and lowers the bottom plate in

2nd Tray Lift Raises the bottom plate in the 2nd

3rd Tray Lift Raises the bottom plate in the 3rd

Rear Fence Moves the paper stack in the left

Jogger Drives the jogger fences to square the

Exhaust Fan Removes heat from around the fusing

Fusing Fan

Rotates the LD unit to adjust the LD

beam pitch when a different resolution

is selected.

toner to the development unit.

Drives the charge corona wire

cleaner.

inverter unit, and paper exit rollers.

toner collection bottle.

Drives the air pump to send recycled

toner to the development unit.

the paper tray unit.

the 1st paper tray.

paper tray.

paper tray.

tandem tray to the right tandem tray.

paper stack in the duplex unit.

unit.

Removes heat from around the fusing

unit.

Index

No.

25

43

68

44

3

6

124

125

126

127

136

94

37

34

1-14

January 8, 2000 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function

M23

Duplex Cooling Fan Removes heat from around the duplex

unit.

M24 Exit Cooling Fan Removes heat from the exit unit. 45

M25 PSU Cooling Fan Removes heat from around the PSU. 54

M26 SBU Cooling Removes the heat from around CCD. 19

Magnetic Clutches

MC1

Toner Supply Turns the toner supply roller to supply

toner to the development unit.

MC2 Toner Recycling Drives the t oner recycling unit. 1

MC3 1st Paper Feed Starts paper feed from tray 1. 100

MC4 2nd Paper Feed Starts paper feed from tray 2. 104

MC5 3rd Paper Feed Starts paper feed from tray 3. 109

MC6

By-pass Feed Starts paper feed from the by-pass

table.

MC7 Inverter Exit Clutch Drives the inverter exit roller. 88

Duplex Transport Drives the duplex transport rollers to

MC8

transport the paper to the duplex feed

rollers.

Duplex Feed

MC9

Starts paper feed out of the duplex

tray back into the machine via to the

relay rollers.

MC10

MC11

MC12

1st Vertical Relay

2nd Vertical Relay

3rd Vertical Relay Drives the 3rd vertical transport

Drives the 1st vertical transport

rollers.

Drives the 2nd vertical transport

rollers.

rollers.

MC13 Bank Relay Drives the bank relay roller. 103

MC14 Relay Drives the relay rollers. 81

Index

No.

42

Overall

Information

39

78

89

91

101

105

108

Switches

SW1

SW2

SW3

SW4

SW5

SW6

Main Power Provides power to the machine. If this

is off, there is no power supplied to

the machine.

Operation

Provides power for machine

operation. The machine still has

power if this switch is off.

Front Door Safety

Cuts the +5 V LD dc power line.

Switch 1

Front Door Safety

Switch 2

Front Door Safety

Detects if the front door is open or not,

and cuts the +24 V dc power line.

Cuts the +5 V LD dc power line.

Switch 3

Lower Front Door

Cuts the +24 V dc power line.

Safety

1-15

9

27

10

11

12

8

ELECTRICAL COMPONENT DESCRIPTION January 8, 2000

Symbol Name Function

SW7

SW8

Toner Collection

Bottle Set

Toner Overflow Detects when the toner collection

Detects if the toner collection bottle is

set or not.

bottle is full.

SW9 Paper Size Determines the size of paper in tray 2. 3

Solenoids

SOL1

SOL2

SOL3

SOL4

SOL5

SOL6

SOL7

SOL8

SOL9

Transfer Belt Lift Controls the up-down movement of

the transfer belt unit.

1st Pick-up

Controls the up-down movement of

the pick-up roller in tray 1.

2nd Pick-up Cont rols the up-down movement of

the pick-up roller in tray 2.

3rd Pick-up Controls the up-down movement of

the pick-up roller in tray 3.

By-pass Pick-up

Controls the up-down movement of

the pick-up roller for by-pass feed.

1st Separation Roller Controls the up-down movement of

the separation roller in tray 1.

2nd Separation Roller Controls the up-down movement of

the separation roller in tray 2.

3rd Separation Roller

Controls the up-down movement of

the separation roller in tray 3.

Right Tray Lock Locks the right tandem tray during

paper feed from tandem tray.

Left Tray Lock Locks the left tandem tray during

SOL10

more the paper from left tray to right

tray.

SOL11

SOL12

SOL13

Front Side Fence Opens the front side fence of right

tandem tray.

Rear Side Fence Opens the rear side fence of right

tandem tray.

Duplex Inverter Gate

Moves the junction gate to direct

copies to the duplex tray or to the

paper exit.

SOL14

SOL15

SOL16

Reverse Roller Controls the up-down movement of

the reverse trig ger roller.

Guide Plate

Opens the guide plate when a paper

misfeed occurs around this area.

Inverter Gate Opens the inverter gate during a

duplex job.

Index

No.

5

4

70

99

106

110

76

102

107

111

126

123

134

130

96

95

80

74

Sensors

S1

S2

Scanner HP Informs the CPU when the 1st and

2nd scanners are at home position.

Original Width Detects original width. This is one of

APS (Auto Page Select) sensors.

1-16

32

33

Loading...

Loading...