Ricoh af500 Service Manual

A217 COPIER

7

Service Manual

– Insert Version –

The A217 machine is based on the A133 copier.

Only the differences from the base copier are described in the following

pages. Therefore, this documentation should be treated as an insert

version of the base copier's service manual. It should always be utilized

together with the base copier's service manual.

TS Dept. IPP Business Division

RICOH Co., LTD.

August 14th 199

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

5. If the Start key is pressed before the copier completes the warming-up

period (the Start key starts blinking red and green alternatively), keep hands

away from the mechanical and electrical components as the copier starts

making copies as soon as the warming-up period is completed.

6. The inside and the metal parts of the fusing unit become extremely hot while

the copier is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your eyes

by accident, use eye drops or flush with water as first aid. If unsuccessful,

get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

those models.

2. The NVRAM on the system control board has a lithium battery which can

explode if replaced incorrectly. Replace the NVRAM only with an identical

one. The manufacturer recommends replacing the entire NVRAM. Do not

recharge or burn the battery. Used batteries must be handled in accordance

with local regulations.

i

SAFETY AND ECOLOGICAL NOTICE FOR DISPOSAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly

when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors according to

local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer Engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

WARNING

Use of controls, or adjustment, or performance of procedures other than those

specified in this manual may result in hazardous radiation exposure.

WARNING FOR LASER UNIT

WARNING:

CAUTION MARKINGS:

Turn off the main switch before attempting any of the procedures in

the Laser Unit section. Laser beams can seriously damage your

eyes.

For the 115 V version

For the 230 V version

ii

14 August 1997 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

NOTE:

Only items marked with ✽ are different from the A133 copier.

Configuration: Desktop

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book

Original Size: Maximum A3/11" x 17"

Copy Paper Size: Maximum

A3/11" x 17" (Paper tray and By-pass tray)

A5/81/2” x 51/2” sideways Paper tray)

Minimum

A6/5

1/2

" x 8

1/2

" lengthwise (By-pass)

LCT

A4/11" x 8

1/2

" sideways only

Duplex Copying: Maximum A3/11" x 17"

Minimum A5/8

Copy Paper Weight: Paper tray:

60 ~ 105 g/m

By-pass:

60 ~ 157 g/m

LCT:

60 ~ 128 g/m

Duplex copying:

64 ~ 105 g/m

1/2

1/2

" x 5

2

, 16 ~ 24 lb

2

, 16 ~ 42 lb

2

, 16 ~ 34 lb

2

, 17 ~ 24 lb

" sideways

A217 Copier

✽

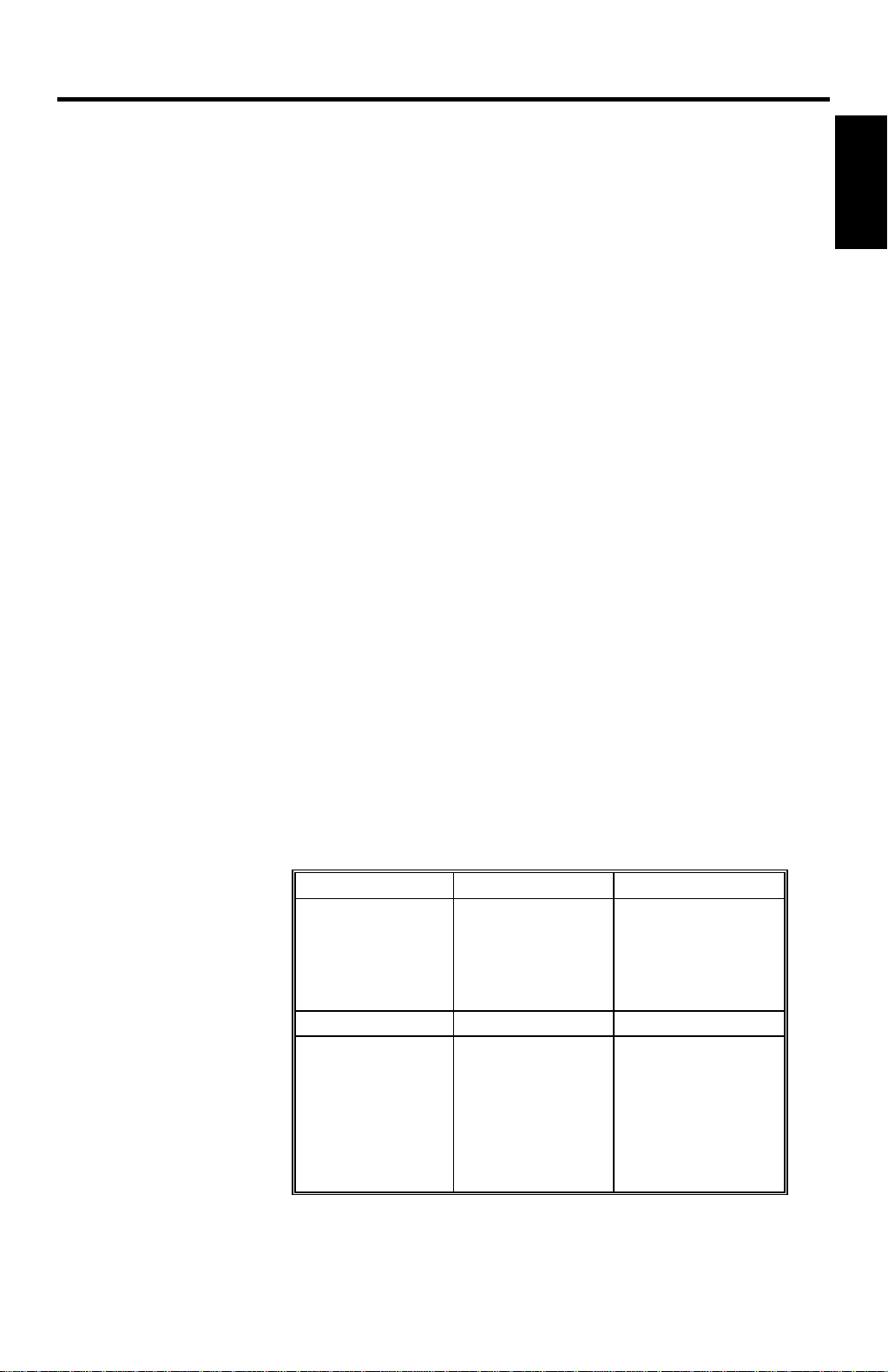

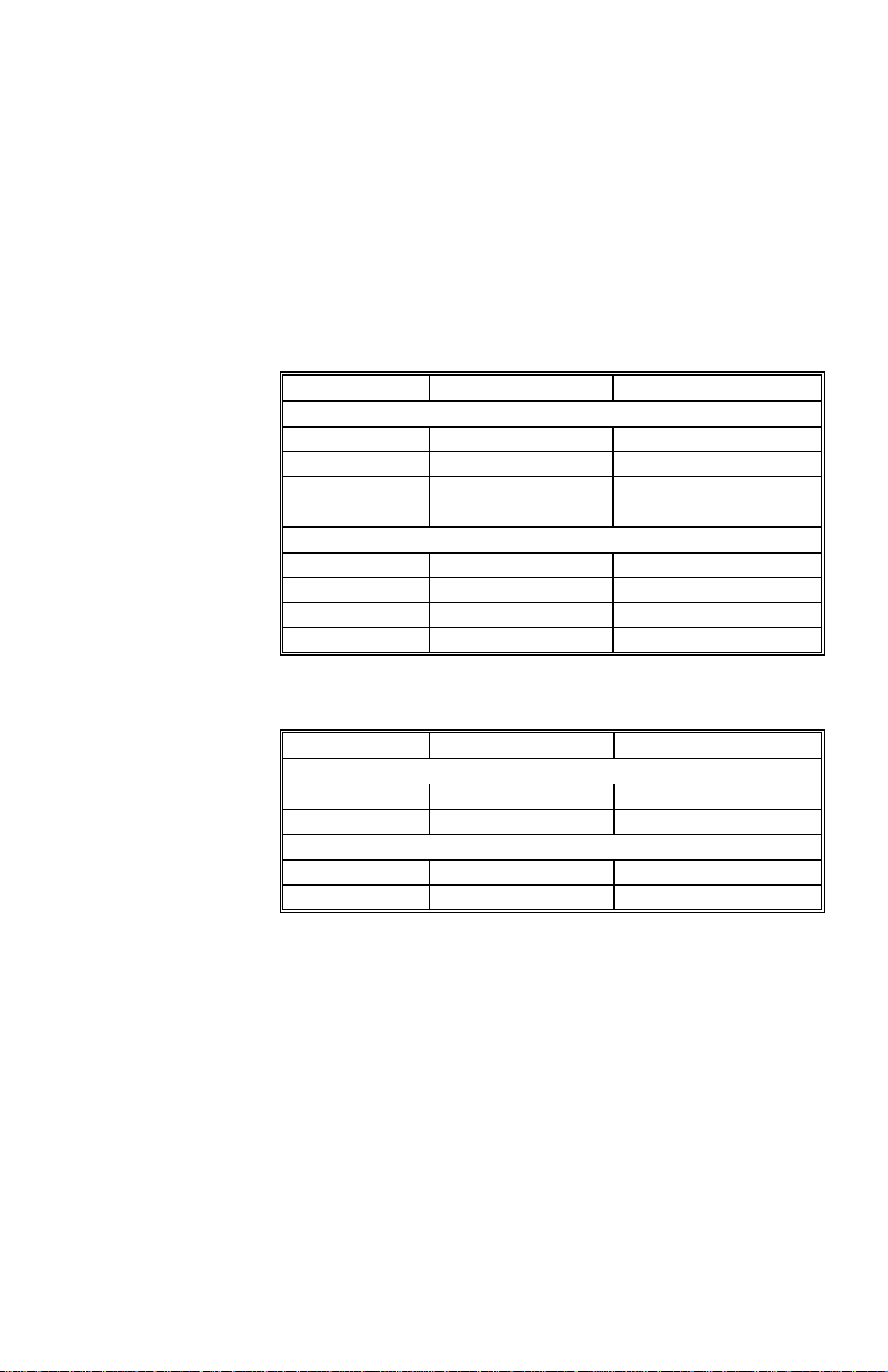

Reproduction Ratios:

5 Enlargement and 7 Reduction

A4/A3 Version LT/DLT Version

Enlargement 400%

200%

141%

122%

115%

Full size 100% 100%

Reduction 93%

87%

82%

71%

65%

50%

35%

1

400%

200%

155%

129%

121%

93%

85%

77%

74%

65%

50%

35%

SPECIFICATIONS 14 August 1997

✽

Zoom:

32% to 400% in 1% steps

Power Source: 120V/60Hz:

More than 12 A (for North America)

220V ~ 240V/50Hz:

More than 7 A (for Europe)

220V ~ 240V/60Hz:

More than 7 A (for Asia)

✽

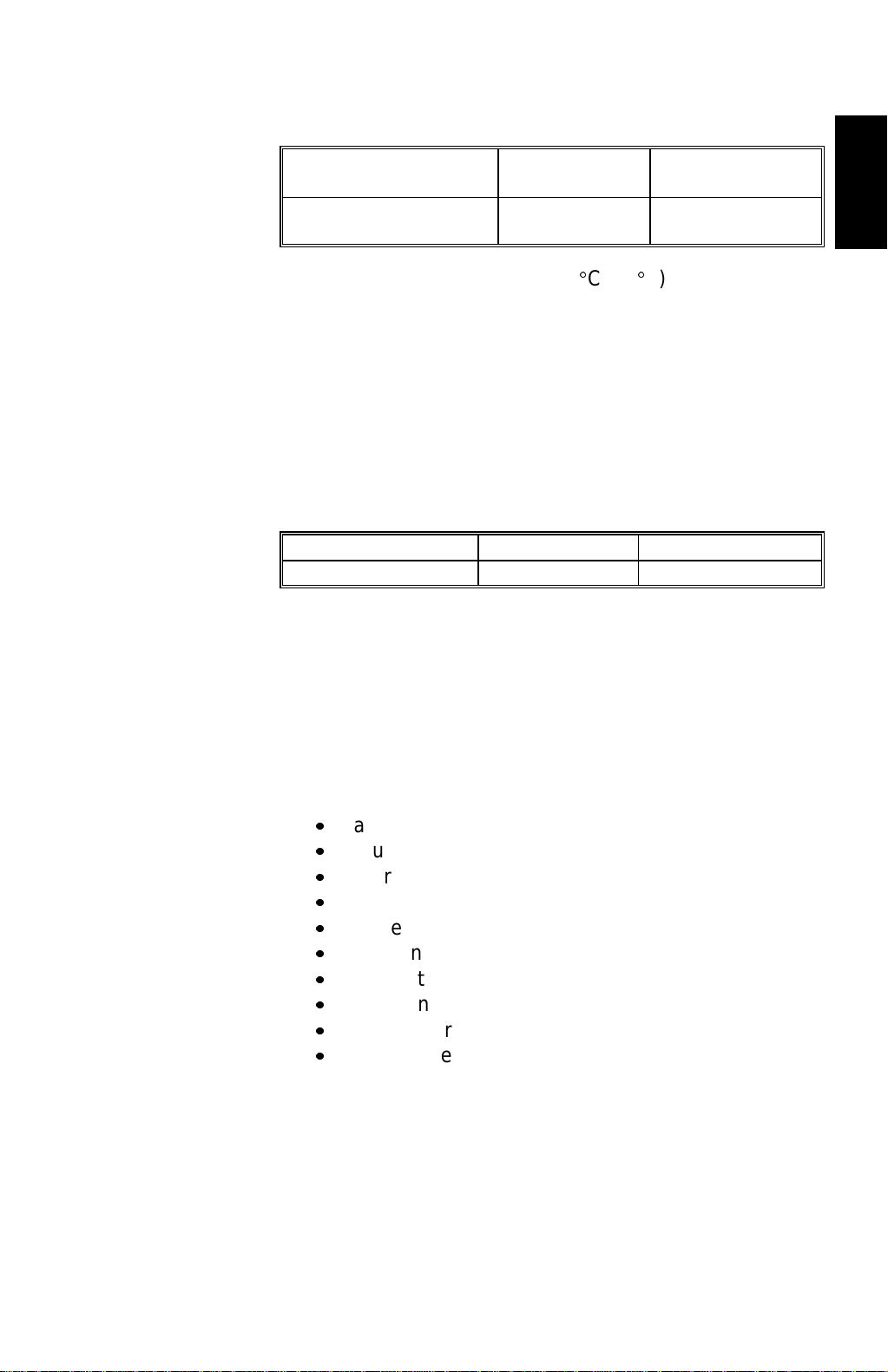

Power Consumption:

115 V Machine

Maximum Less than 1.44 kW Less than 1.44 kW

Copying Less than 1.30 kW Less than 1.35 kW

Warm-up Less than 1.05 kW Less than 1.07 kW

Stand-by Less than 0.22 kW Less than 0.24 kW

230 V Machine

Maximum Less than 1.50 kW Less than 1.50 kW

Copying Less than 1.30 kW Less than 1.35 kW

Warm-up Less than 1.10 kW Less than 1.12 kW

Stand-by Less than 0.27 kW Less than 0.29 kW

Copier Only Full System

NOTE:

✽

Noise Emission:

NOTE:

Full System: Copier + ADF + Paper Tray Unit + Finisher

Copier Only Full System

1. Sound Power Level

Copying 67 dB(A) 69 dB(A)

Stand-by 40 dB(A) 41 dB(A)

2. Sound Pressure Level at the Operator Position

Copying 53 dB(A) 59 dB(A)

Stand-by 28 dB(A) 28 dB(A)

The above measurements are to be made in accordance

with ISO 7779.

Full System: Copier + ADF + Paper Tray Unit + Finisher.

Dimensions (W x D x H): 880 x 655 x 602 mm (34.7" x 25.8" x 23.8")

Measurement Conditions

1) With by-pass feed table closed

2) With copy tray attached

3) With LCT cover closed

4) Without the 500-sheet copy tray

✽

Weight:

97 kg (214 lb)

2

14 August 1997 SPECIFICATIONS

✽

Copying Speed (copies/minute):

1/2

" x 14"

Warm-Up Time

✽First Copy Time:

A4 sideways/

1/2

11" x 8

50 (US, France)

51 (EU, ASIA)

"

Less than 140 seconds (20

Less than 4.5 s (from LCT)

A3/11" x 17" B4/8

22 32

q

C, 68qF)

Copy Number Input: Ten-key pad, 1 to 999 (count up or count down)

Manual Image Density

7 steps

Selection:

Automatic Reset: 30 s is the standard setting; it can be changed with

a UP mode.

Copy Paper Capacity:

Paper Tray By-pass Feed LCT

About 500 sheets x1 About 40 sheets About 1000 sheets

Hard Disk: More than 1.0 GB, Fast SCSI-2

1/2

Duplex Tray Capacity A4/11" x 8

A3/11" x 17": 50 sheets (80 g/m

30 sheets (81 ~ 105 g/m

": 50 sheets

2

, 20 lb paper)

2

,

21.5 ~ 27.9 lb paper)

A217 Copier

Toner Replenishment: Cartridge exchange (700 g/cartridge)

Toner Yield: 20K copies (A4, 6% full black, ID Level 4)

x

Optional Equipment:

Copy Tray Capacity B4/8

Platen cover

x

Document feeder

x

Paper tray unit with two paper trays

x

Paper tray unit with three paper trays

x

Finisher

x

Key counter

x

Tray heater

x

Optical anti-condensation heater

x

Drum heater

x

500-sheet receiving tray

1/2

" x 14" ~ A4/8

1/2

" x 11" 500 sheets

A3/11" x 17" 200 sheets

Less than B5/5

1/2

" x 8

1/2

": 200 sheets

3

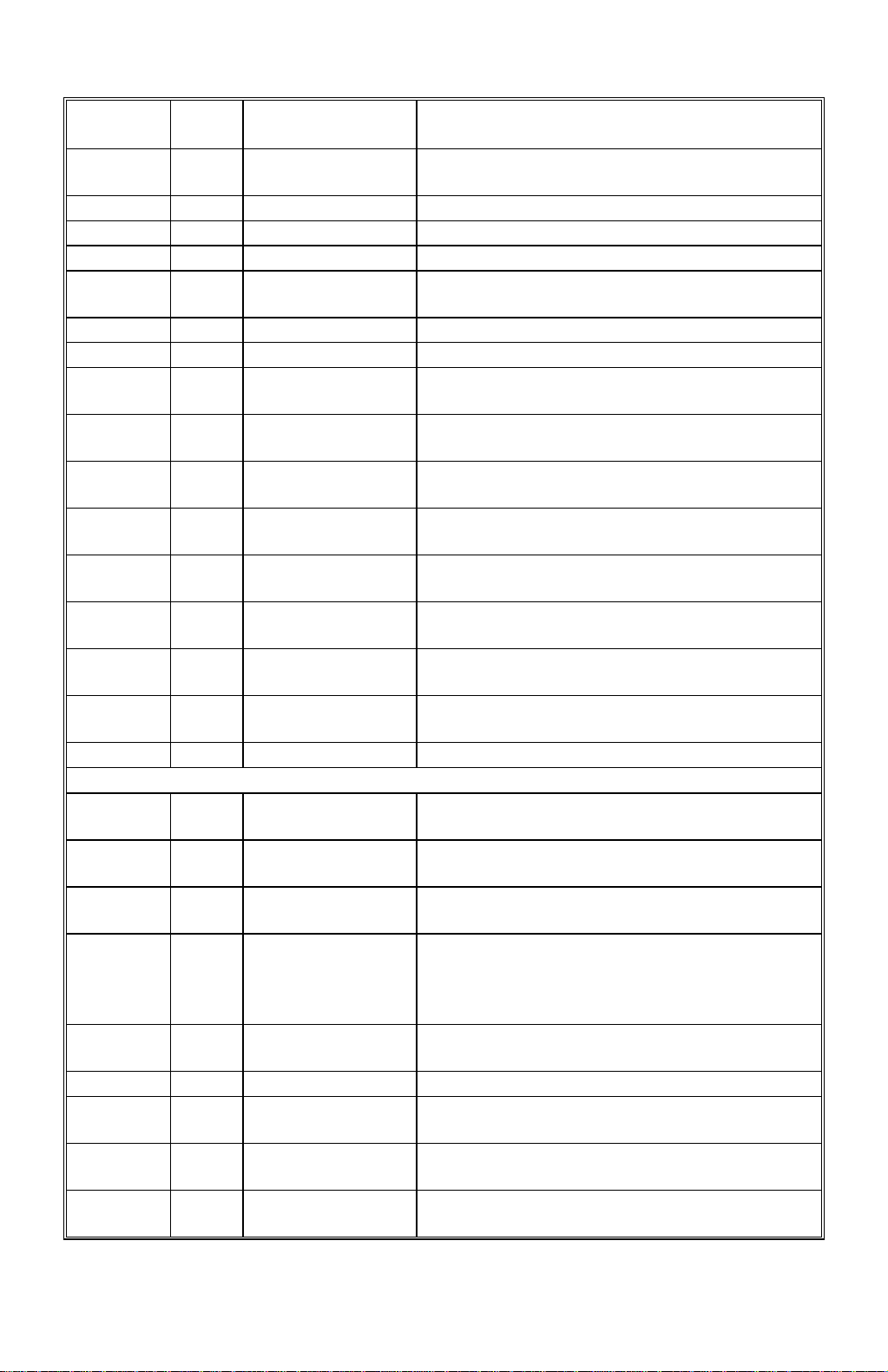

MACHINE CONFIGURATION 14 August 1997

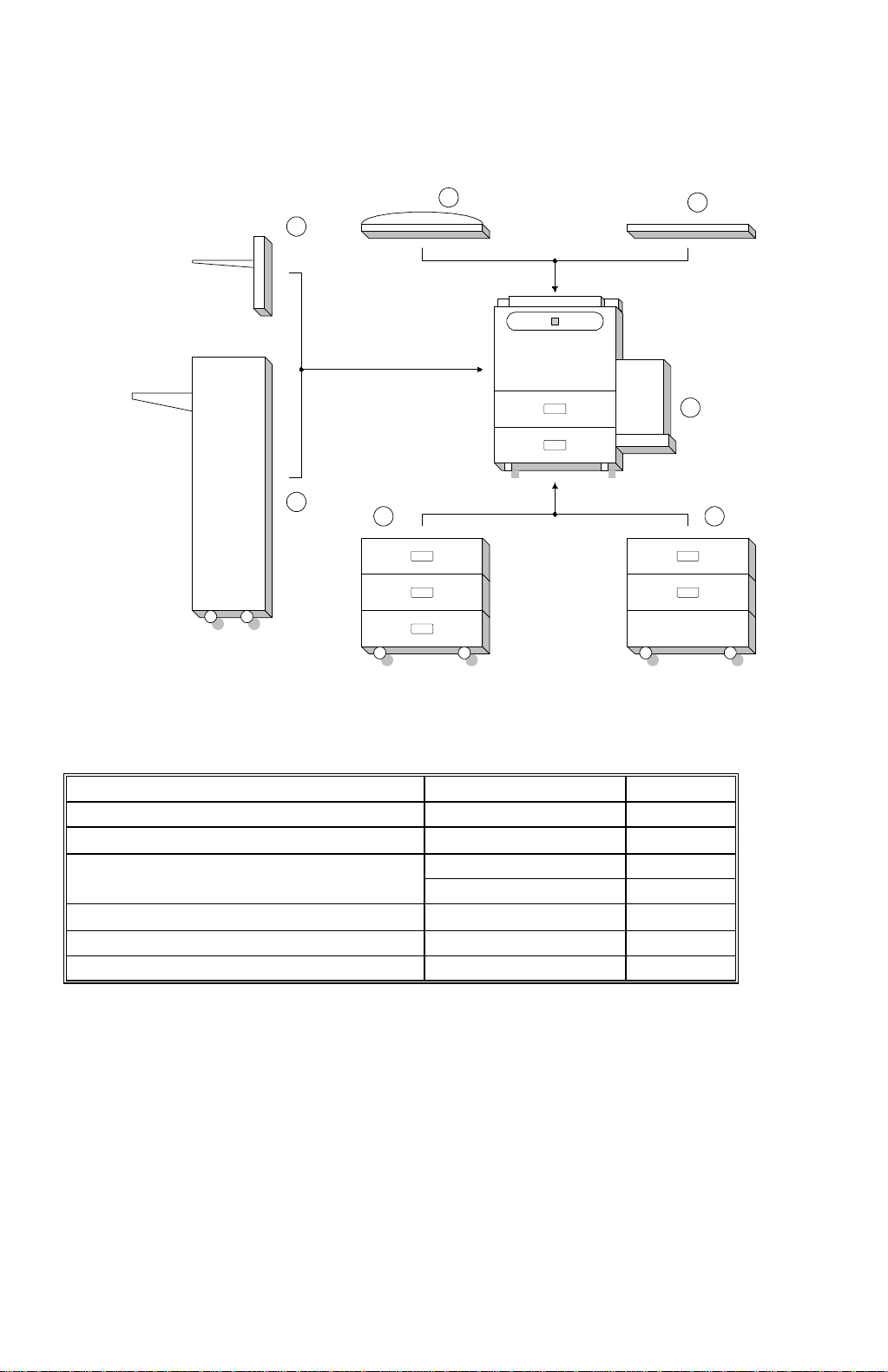

1.2 MACHINE CONFIGURATION

1

7

6

5 4

2

3

A217V500.vsd

NOTE:

Only items marked ✽ are new items.

Item Machine Code No.

Copier A217 3

✽ADF (Option)

A663 1

Paper Feed Unit (Option) A549 5

A550 4

✽Finisher (Option)

A612 6

500-sheet Receiving Tray (Option) A615 7

Platen Cover (Option) A381 2

4

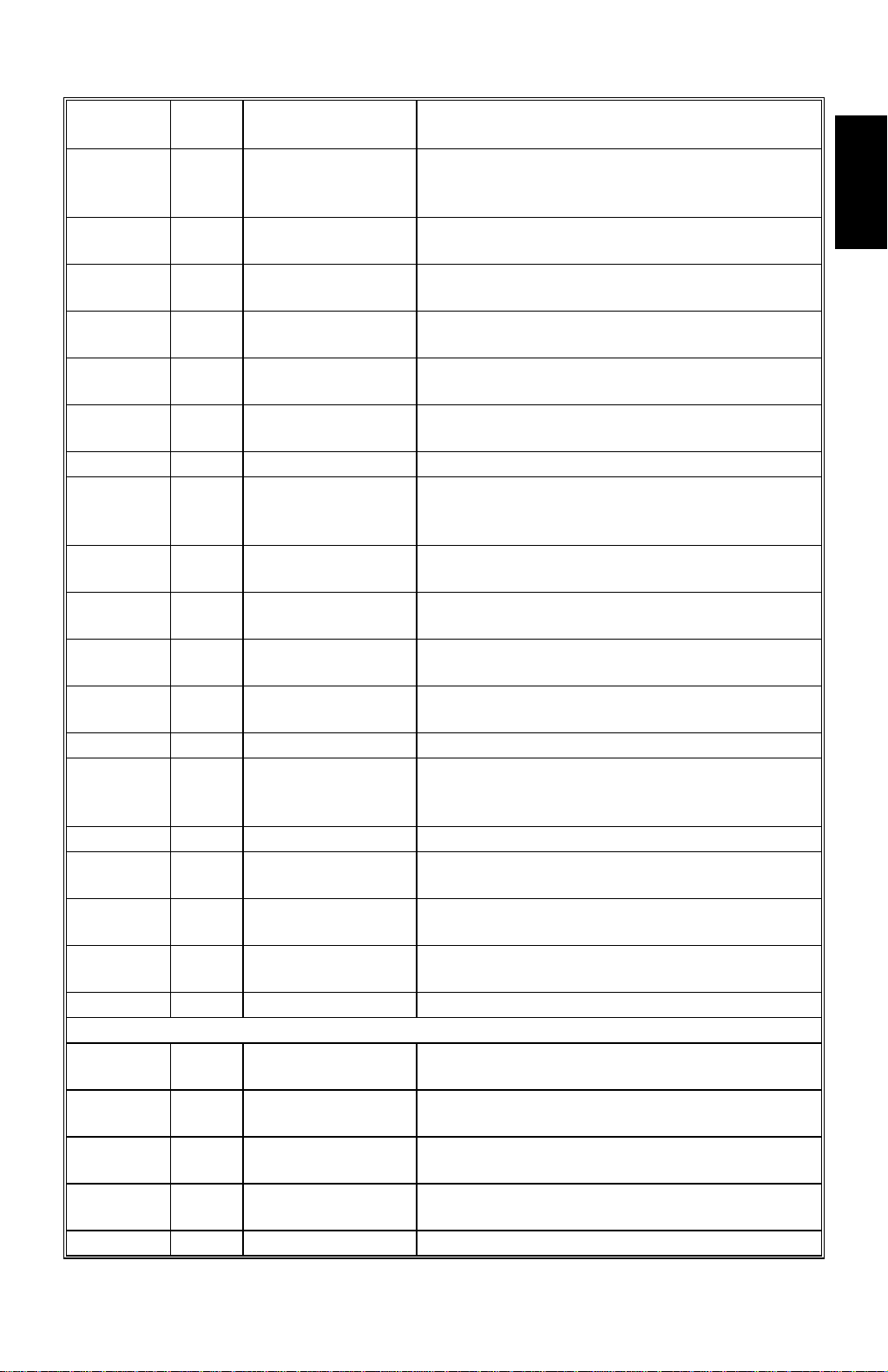

14 August 1997 ELECTRICAL COMPONENT DESCRIPTIONS

1.3 ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout and the point-to-point diagram on the

waterproof paper in the pocket for the locations of these components.

✽

: New or modified components.

Symbol Index

No.

Printed Circuit Boards

PCB1 90 SCU Controls all copier functions both directly or

PCB2 89 AC Drive Provides ac power to the exposure lamp and

PCB3 92 DC Power Supply Provides dc power.

PCB4 93 BCU Controls the mechanical parts of the printer.

PCB5 80 Charge High

PCB6 85 High Voltage

PCB7 87 Operation Panel Controls the touch panel display and LED

PCB8 95 Scanner Drive Drives the scanner motor.

PCB9 81 EX-IPU Processes the video signal from the SBU and

PCB10 84 SBU Contains the CCD, and outputs a video

PCB11 94 Lamp Stabilizer Provides dc power for the exposure lamp.

PCB12 86 Main Scan

PCB13 83 Main Scan

PCB14 31 Transfer High

PCB15 33 Development

PCB16 40 Duplex Control Controls the operation of the duplex tray.

PCB17 N/A Liquid Crystal

PCB18 51 LCT Interface Interfaces the LCT control signal between the

PCB19 91 Relay Board Switches ac power to either the dc drive

PCB20 7 Laser Diode Drive Controls the laser diode.

Description Note

through other control boards.

fusing lamps.

Supplies high voltage to the charge corona

Voltage Supply

Control

Synchronization

Detector - 1

Synchronization

Detector - 2

Voltage

Bias Power Pack

Display

unit.

Controls the high voltage boards and the

quenching lamp.

matrix, and monitors the key matrix.

sends the video signal to the LD unit.

signal to the EX-IPU board.

Detects the laser beam at the start of the

main scan.

Detects the laser beam at the end of the main

scan.

Supplies high voltage to the transfer belt.

Supplies high voltage to the development

roller.

Controls the guidance display and displays

guidance for machine operation.

main board and the LCT.

board (if the main switch is on) or to the

heaters (if the main switch is off).

A217 Copier

Motors

M1 57 Main Drives the main body components.

5

ELECTRICAL COMPONENT DESCRIPTIONS 14 August 1997

Symbol Index

No.

M2 66 Toner Bottle Drive Rotates the toner bottle to supply toner to the

M3 73 Tray Lift Raises the bottom plate in the paper tray.

M4 56 Polygonal Mirror Turns the polygonal mirror.

M5 48 LCT Lift Lifts up and lowers the LCT bottom plate.

M6 74 Optics Exhaust

M7 65 IPU Fan Removes heat from the IPU board.

M8 78 Exhaust Fan Removes heat from around the fusing unit.

M9 60 Ozone Fan Removes ozone-laden air from inside the

M10 55 Scanner Drive Drives the 1st and 2nd scanners (dc stepper

M11 36 Duplex Feed Drives the feed roller and moves the bottom

M12 39 End Fence

M13 38 Side Fence

M14 75 DC Drive Board

M15 68 Charge Inlet Fan Provides air flow around the charge corona

✽ M16

59 Development

Description Note

toner supply unit.

Removes heat from the optics unit.

Fan

machine.

motor).

plate up and down.

Drives the end fence jogger to square the

Jogger

Jogger

Fan

Drive

paper stack.

Drives the side fence jogger to square the

paper stack.

Removes heat from around the DC drive

board.

unit section.

Drives the development unit.

Sensors

S1 13 By-pass Feed

Paper Width

S2 15 By-pass Feed

Paper End

S3 18 Tray Paper End Informs the CPU when the paper tray runs

S4 46 Upper Relay Detects the leading edge of paper from the

S5 16 Tray Upper Limit Detects the height of the paper stack in the

S6 47 Lower Relay Detects misfeeds.

S7 49 LCT Lower Limit Sends a signal to the CPU to stop lowering

S8 50 LCT Paper End Informs the CPU when the LCT runs out of

S9 12 LCT Upper Limit Signals the CPU to stop lifting the LCT

Informs the CPU what width paper is in the

by-pass feed table.

Informs the CPU that there is no paper in the

by-pass tray.

out of paper.

paper tray and duplex unit to determine the

stop timing of the paper feed clutch and

duplex feed motor. Also detects misfeeds.

paper tray to stop the upper tray lift motor.

the LCT bottom plate.

paper.

bottom plate.

6

14 August 1997 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Index

No.

S10 19 Registration Detects the leading edge of the copy paper to

S11 29 Image Density

S12 30 Toner Density

S13 1 Scanner HP Informs the CPU when the 1st and 2nd

S14 8 Original Length-1 Detects the length of the original. This is one

S15 9 Original Length-2 Detects the length of the original. This is one

S16 24 Fusing Exit Detects misfeeds.

S17 6 Platen Cover Informs the CPU whether the platen cover is

S18 32 Toner End Instructs the CPU to add toner to the toner

S19 28 Auto Response Returns the operation panel display and exits

S20 10 Transfer Belt

S21 2 Original Width Detects the width of the original. This is one

S22 34 Duplex Paper End Detects paper in the duplex tray.

S23 35 Duplex Turn Detects the trailing edge of the copy paper to

S24 42 Duplex Entrance Detects misfeeds.

S25 37 Side Fence

S26 41 End Fence

S27 23 Toner Overflow Detects when the used toner collection bottle

S28 14 By-pass Relay Detects misfeeds.

Switches

SW1 11 By-pass Feed

SW2 53 Tray Down Sends a signal to the CPU to lower the LCT

SW3 20 Tray Paper Size Determines what size of paper is in the paper

SW4 54 LCT Cuts the dc power line and detects whether

SW5 52 LCT Cover Cuts the dc power line of the LCT lift motor.

Description Note

determine the stop timing of the paper feed

clutch, and detects misfeeds.

Detects the density of various patterns on the

(ID)

(TD)

Position

Jogger HP

Jogger HP

Table

drum during process control.

Detects the amount of toner inside the

development unit.

scanners are at the home position.

of the APS (Auto Paper Select) sensors.

of the APS (Auto Paper Select) sensors.

up or down (related to APS/ARE functions).

ARE: Auto Reduce and Enlarge

supply unit, and detects toner end conditions.

from the energy saver mode.

Informs the CPU of the current position of the

transfer belt unit.

of the APS (Auto Paper Select) sensors.

determine the jogging timing, and detects

misfeeds.

Detects the home position of the duplex side

fence jogger.

Detects the home position of the duplex end

fence jogger.

is full.

Detects whether the by-pass feed table is

open or closed.

bottom plate.

tray.

the LCT is open or not.

A217 Copier

7

ELECTRICAL COMPONENT DESCRIPTIONS 14 August 1997

Symbol Index

No.

SW6 27 Main Supplies power to the copier.

SW7 26 Front Cover

Magnetic Clutches

CL1 61 Toner Supply Turns the toner supply roller to supply toner

✽ CL2

CL3 76 Transfer Belt Lift Controls the touch and release movement of

CL4 58 Registration Drives the registration rollers.

CL5 63 By-pass Feed Starts paper feed from the by-pass feed table

CL6 71 Relay Drives the relay rollers.

CL7 72 Paper Feed Starts paper feed from the paper tray.

CL8 62 By-pass Relay Drives the by-pass relay rollers.

Solenoids

SOL1 67 By-pass Pick-up Drops the pick-up roller to the by-pass paper

SOL2 77 Junction Gate Moves the junction gate to direct copies to

SOL3 64 LCT Pick-up Drops the pick-up roller all the way down to

SOL4 69 Pick-up Controls the up/down movement of the pickSOL5 70 Separation Controls the up/down movement of the

Description Note

Cuts the dc power line and detects whether

Safety

Not used

the front cover is open or not.

to the development unit.

the transfer belt unit.

or LCT.

feed position. When paper is fed from the

LCT, this solenoid assists SOL3.

the duplex tray or to the paper exit.

the LCT paper feed position from the by-pass

paper feed position.

up roller in the paper tray.

separation roller at the paper tray feed

station.

Lamps

L1 3 Exposure Applies high intensity light to the original for

exposure.

L2 43 Fusing Provides heat to the hot roller.

L3 88 Quenching Neutralizes any charge remaining on the

drum surface after cleaning.

Heaters

H1 21 Drum (option) Turns on when the main switch is off to

prevent moisture from forming around the

drum.

H2 5 Optics Anti-

condensation

(option)

Turns on when the main switch is off to

prevent moisture from forming on the optics.

8

14 August 1997 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Index

No.

H3 22 Tray

Thermistors

TH1 45 Fusing Monitors the temperature at the central area

Thermofuses

TF1 44 Fusing Provides back-up overheat protection in the

Thermoswitch

TS1 4 Exposure Lamp Opens the exposure lamp circuit if the 1st

Counters

CO1 25 Total Keeps track of the total number of copies

CO2 N/A Key

Others

CB1 17 Circuit Breaker

HDD 82 Hard Disk Drive Scanned image data is compressed and held

Description Note

Turns on when the main switch is off to keep

(option)

(option)

(220 ~ 240V

machines only)

paper dry in the paper tray.

of the hot roller.

fusing unit.

scanner overheats.

made.

Used for control of authorized use. The

copier will not operate until it is installed.

Provides back-up high current protection for

electrical components.

here temporarily during copying; also holds

user stamp data.

A217 Copier

9

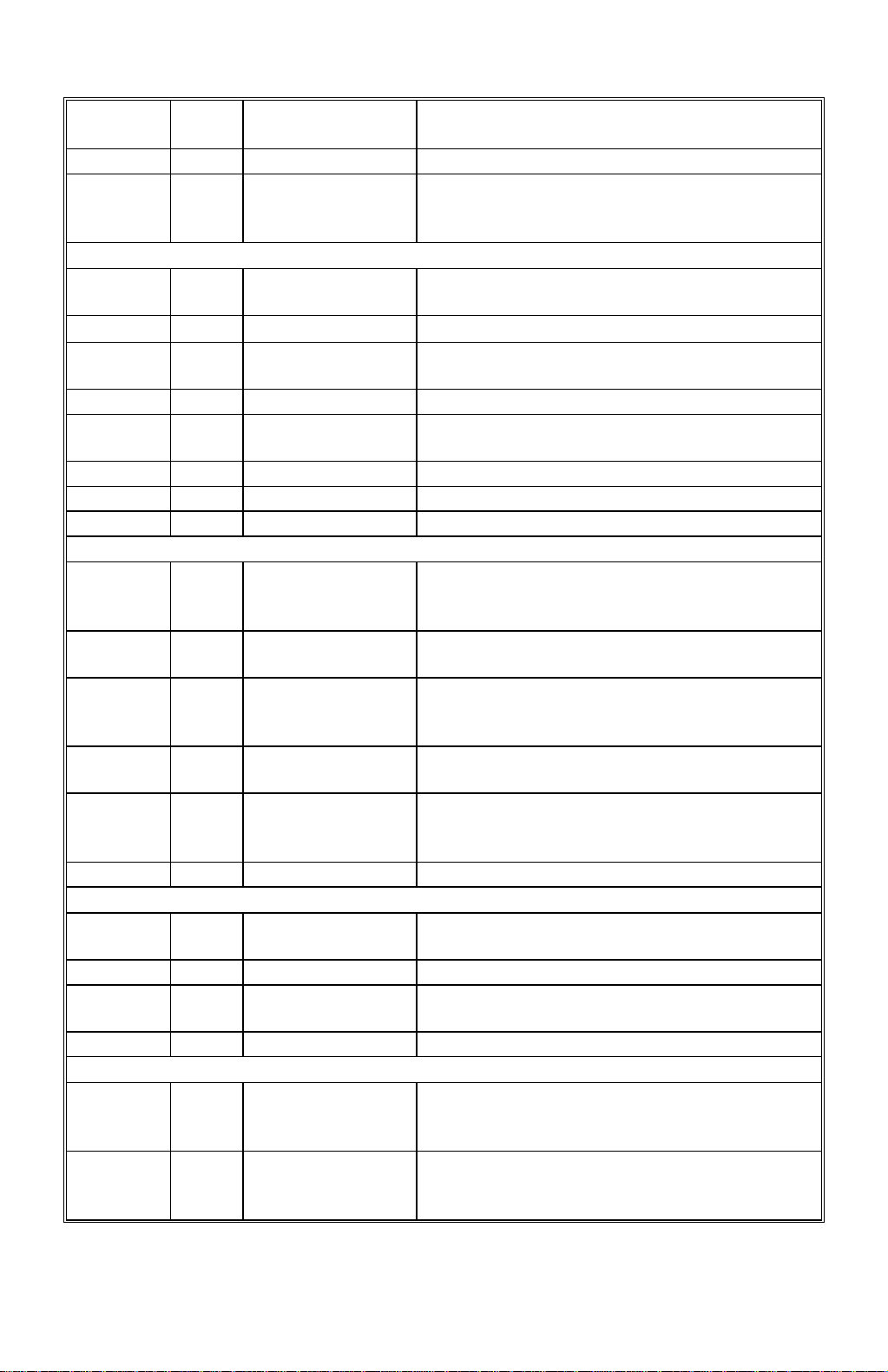

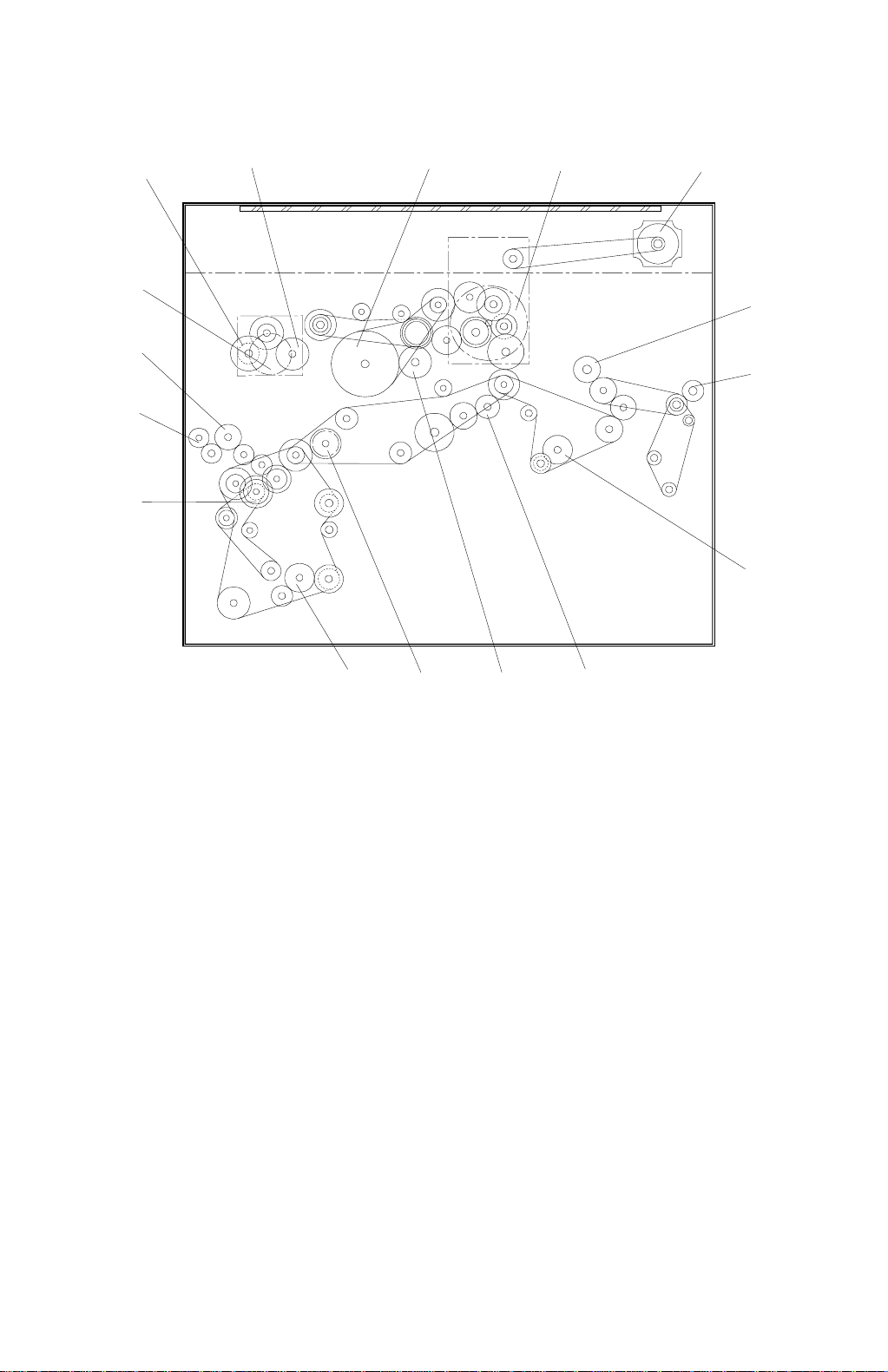

DRIVE LAYOUT 14 August 1997

1.4 DRIVE LAYOUT

16

15

14

13

1

2

3

4

5

6

7

8

A217v501.cdr

12

1011

9

The development drive mechanism has been changed. (See Drive Mechanism for

more information.)

✽

: New or modified components.

1. Toner Supply Clutch

2. Development Gear

3. Drum Drive Pulley

4. Main Motor

5. Scanner Drive Gear

6. Fusing Drive Gear

7. Exit Drive Gear

8. Toner Collection Bottle Drive Gear

9. Transfer Belt Drive Gear

10. Cleaning Blade Drive Gear

11. Registration Clutch

12. Paper Feed Clutch

13. Relay Clutch

14. By-pass Feed Clutch

15. By-pass Relay Relay Clutch

16. Development Drive Motor

10

14 August 1997 DRIVE LAYOUT

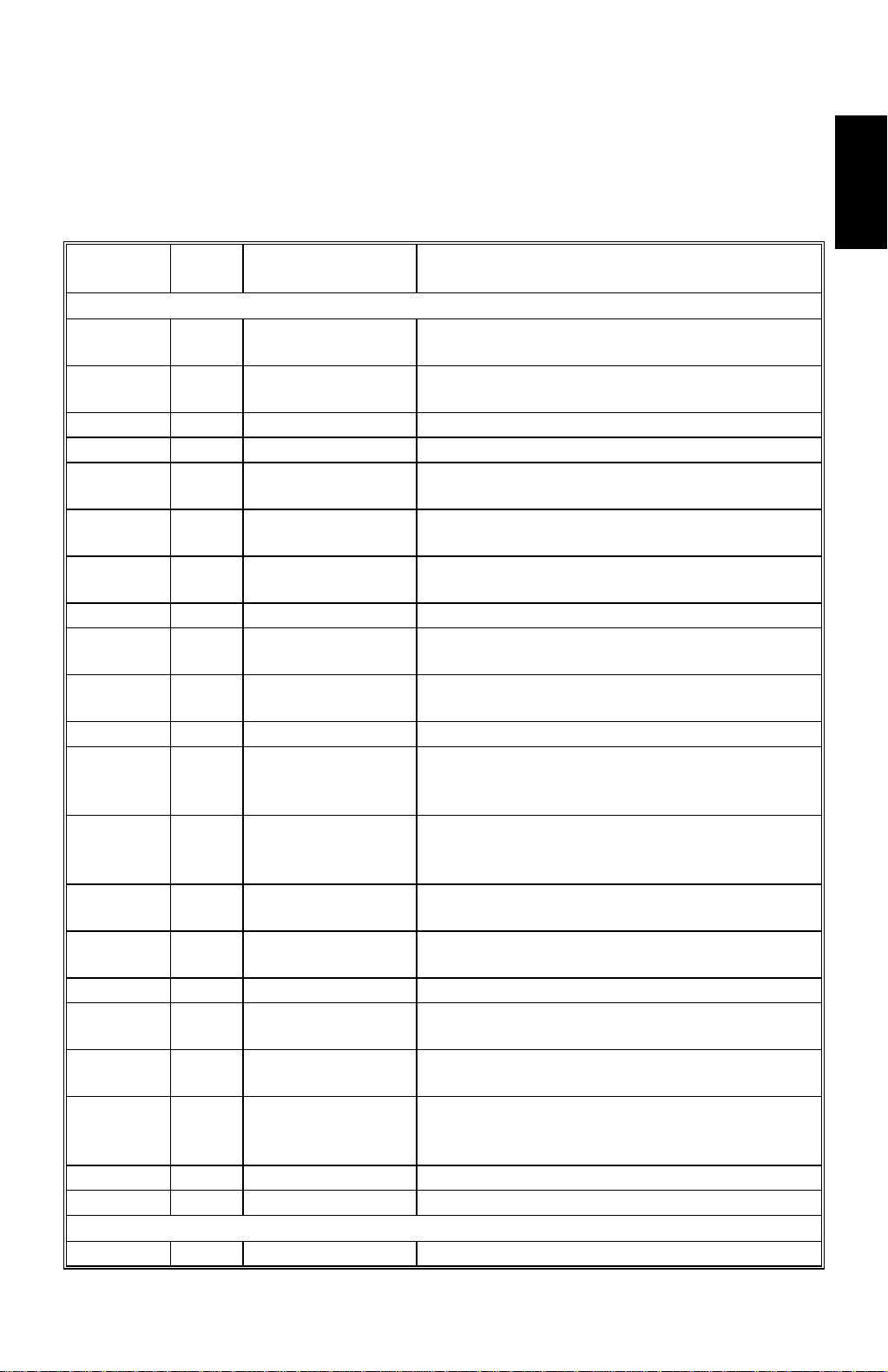

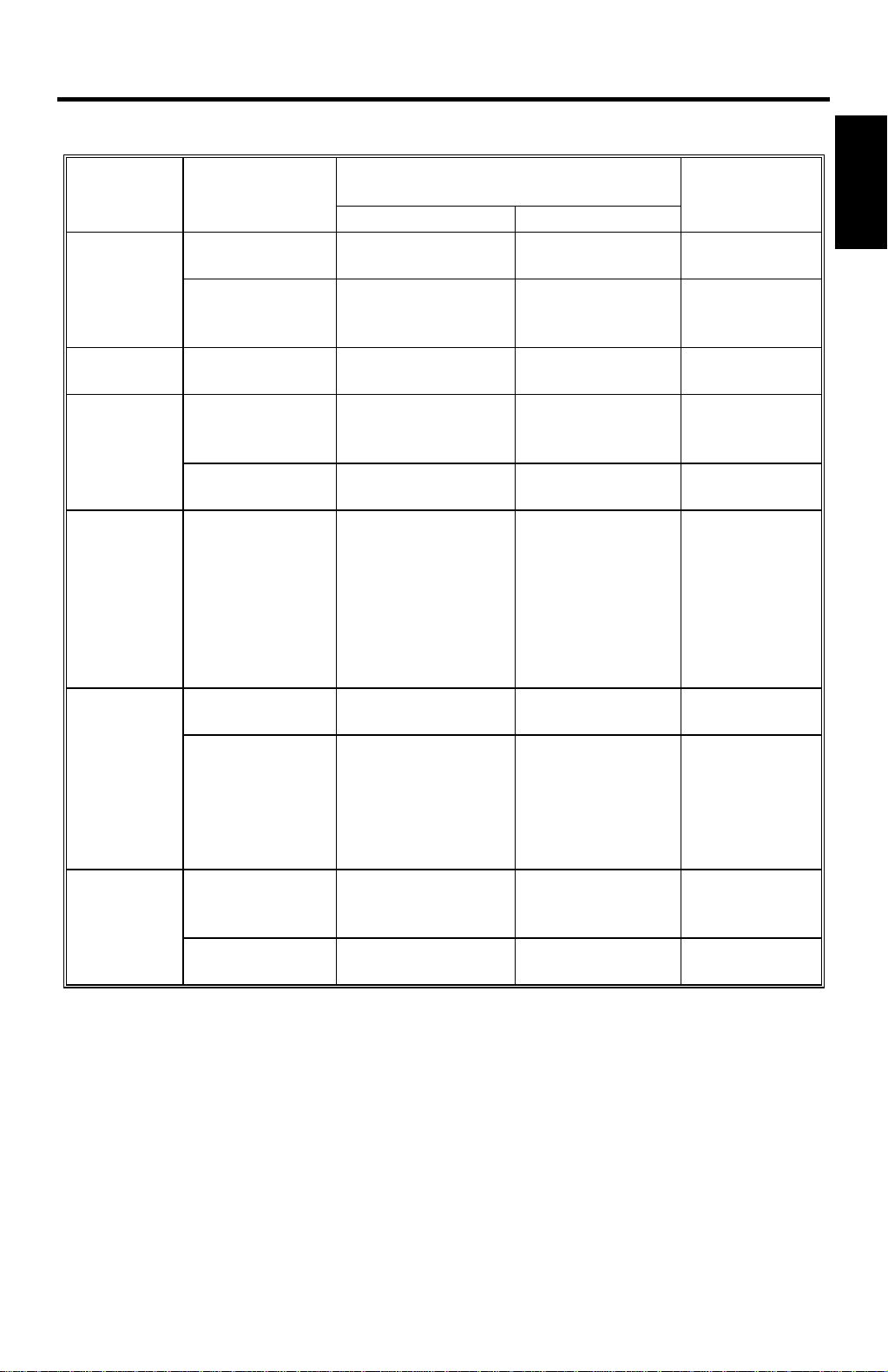

2. DIFFERENCES FROM THE A133 MACHINE

Unit Item Details Main

Reasons

A133 A217

Scanner Scanner speed 200 mm/s 250 mm/s Increased

CPM

Scanner lamp 75V 200W 75V 140W High

sensitivity

CCD

Image

Processing

Laser

Exposure

Toner

Supply

Paper Tray Side fence --- Secured with

Fusing Unit Material of the

Analog ProcessIC1 pc 2 pcs Faster image

processing

Laser power on

the OPC

surface

Polygon motor

rotation speed

Operation --- When opening

Housing --- A pawl has been

housing

Fusing lamp 790W 930W Increased

1.3 mW 1.66 mW Increased

CPM

31,496 rpm 39,370 rpm Increased

CPM

To facilitate

the toner supply

unit over 60

degrees, the

toner supply unit

automatically

opens out to 90

degrees.

screws

added

Plastic Metal Increased

toner bottle

replacement.

To prevent

image skew

To remove

jammed paper

in the

machine when

the tray is

drawn out.

fusing

pressure

CPM

A217 Copier

11

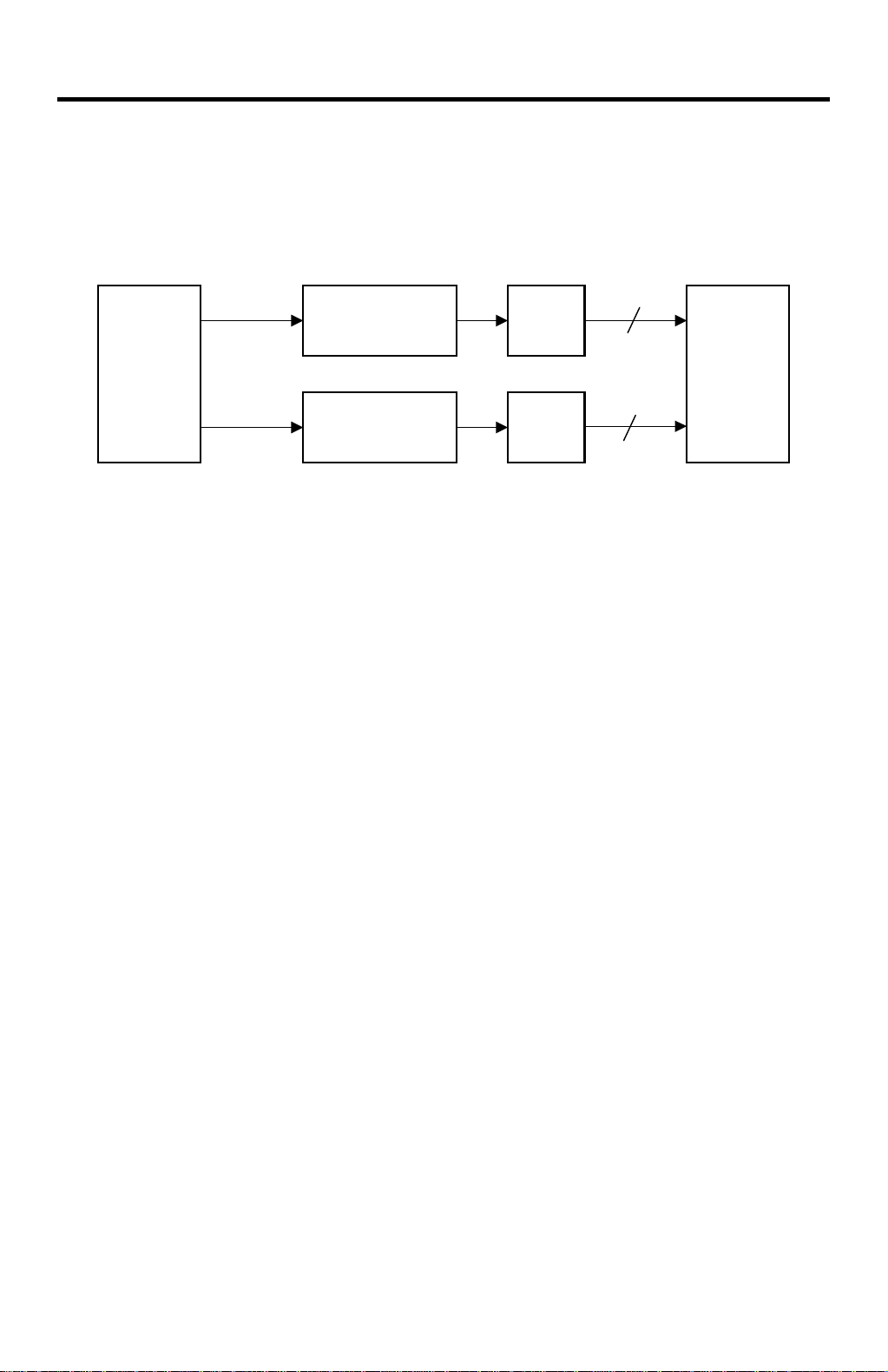

EX-IPU 14 August 1997

3. IMAGE PROCESSING

3.1 EX-IPU

3.1.1 OVERVIEW

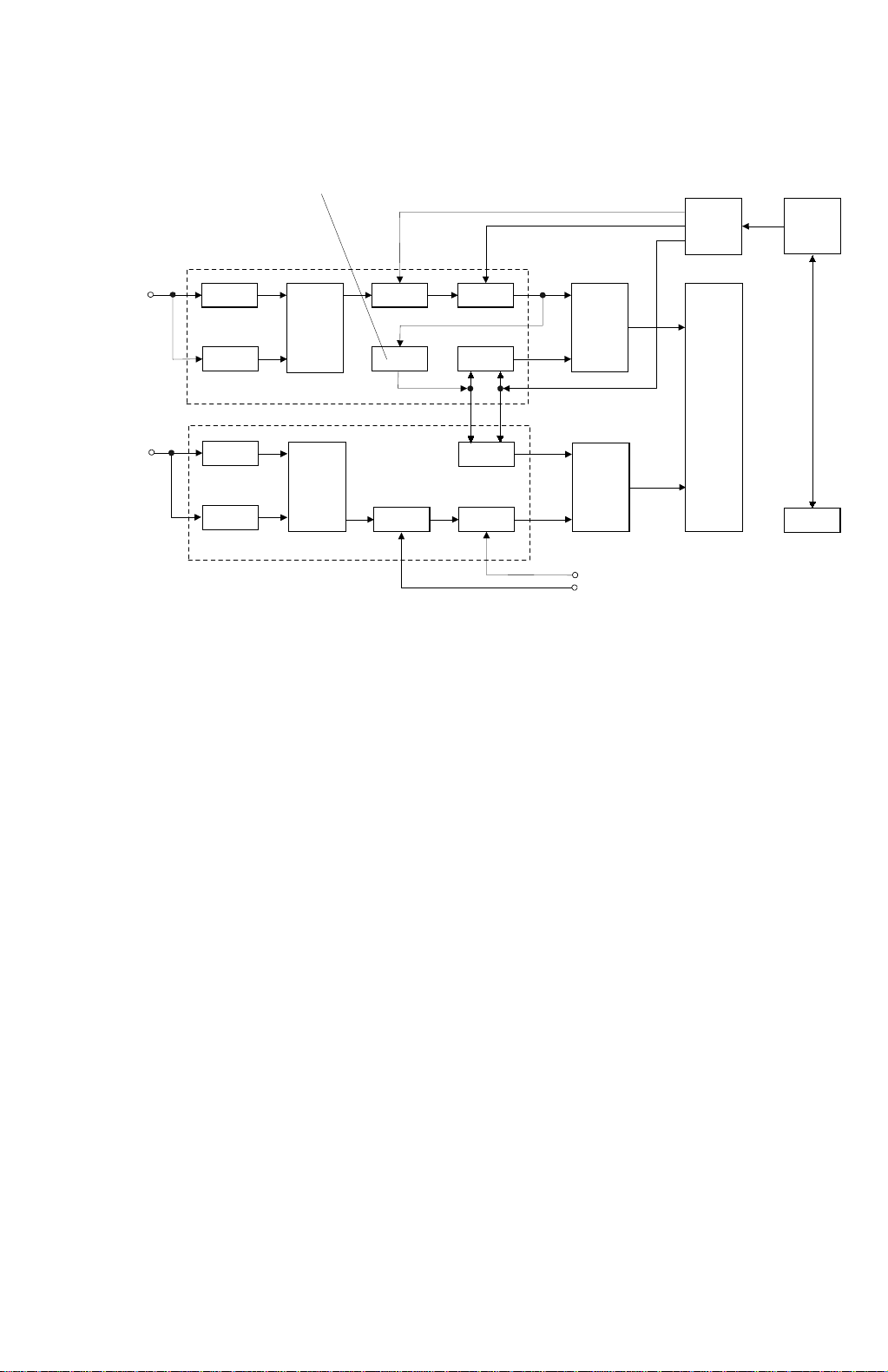

8

GA1

(GARD1S)

8

A217D505.vsd

SBU

Even

Odd

Analog

Process IC 1

Analog

Process IC 2

A/D

A/D

Analog signals for odd and even pixels from the SBU undergo analog processing

and A/D conversion individually, then these signals go to GA1. This is to speed up

the image processing.

12

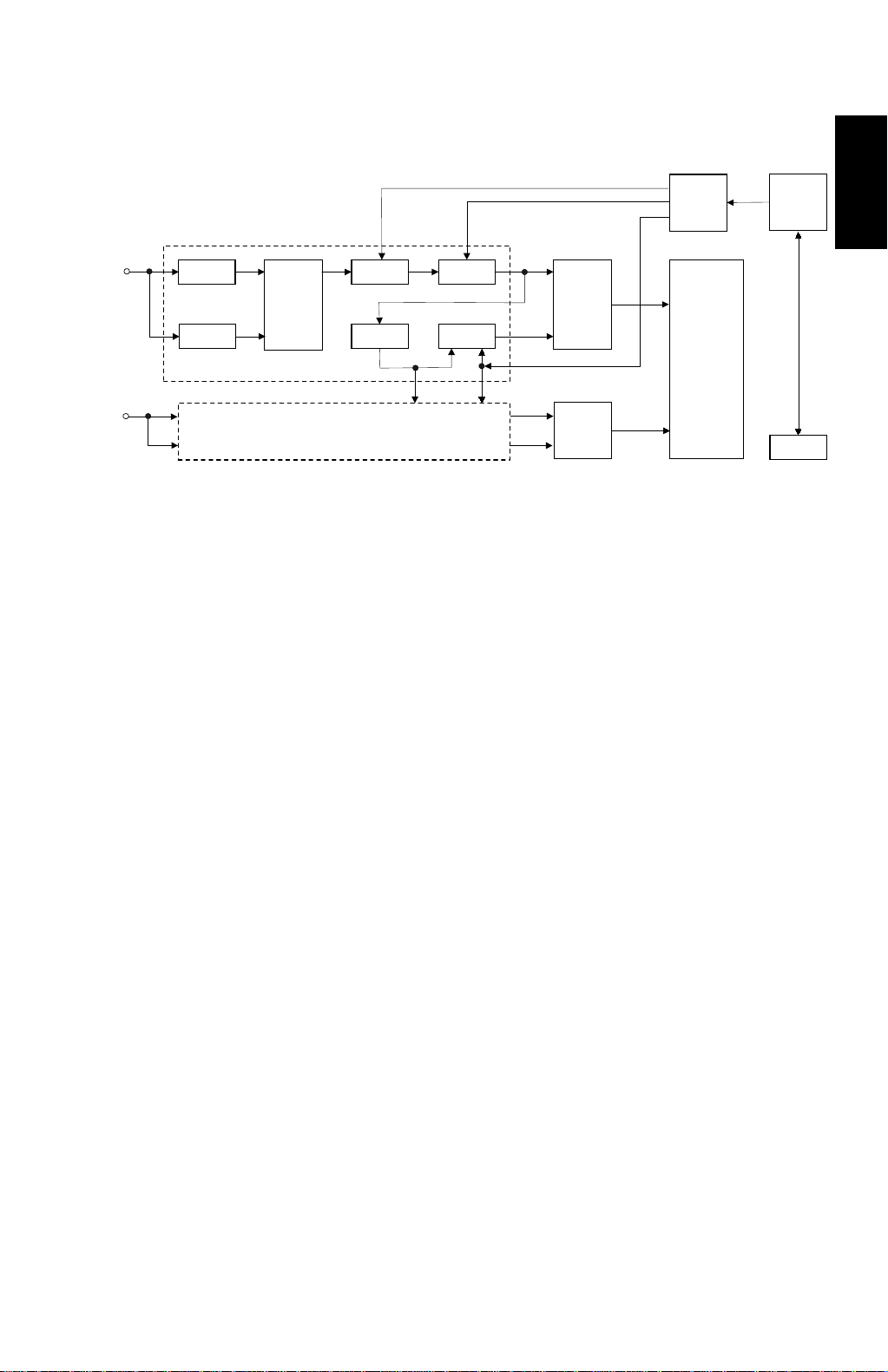

14 August 1997 EX-IPU

3.1.2 ANALOG PROCESSING

rom SBU

EVEN

rom SBU

ODD

Z/C

Z/C

Analog Process IC 1

1. Signal Composition

Analog signals for odd and even pixels are merged by a switching device in

the GA1, not in the Analog Process ICs.

2. Signal Amplification

This function is the same as in the A133 machine.

AGC

Multi-

plexer

P/H SEL

Analog Process IC 2

Z/C

Vin

A/D

8

Vref

Vin

A/D

Vref

D/A

GA1

(GARD1S)

CPU

A217 Copier

NVRAM

A217D504.vsd

3. A/D conversion

Converts individual pixels to 8-bit digital signals.

4. Feedback - D/A Conversion

There are no D/A converters in the Analog Process ICs. Instead of this,

there is a D/A converter outside the IC, and the CPU controls the feedback

signal for the Analog Process ICs via the D/A converter.

The CPU ignores the Z/C which is before the multiplexer.

13

EX-IPU 14 August 1997

3.1.3 AUTO IMAGE DENSITY (ADS)

[A]

D/A

from SBU

EVEN

from SBU

ODD

Z/C

Z/C

Analog Process IC 1

Z/C

Z/C

Analog Process IC 2

Multi-

plexer

Multi-

plexer

AGC

P/H SEL

AGC

Z/C

SEL

Z/C

Vin

A/D

8

Vref

Vref

A/D

8

Vin

from D/A

Converter

GA1

(GARD1S)

A217D506.vsd

This function is the same as in the A133 machine. However, in this machine, the

CPU detects the peak white level only for even pixels using the P/H (Peak Hold)

circuit [A]. This data will be used for the odd pixels.

CPU

NVRAM

14

14 August 1997 DEVELOPMENT DRIVE MECHANISM

4. DEVELOPMENT

4.1 DEVELOPMENT DRIVE MECHANISM

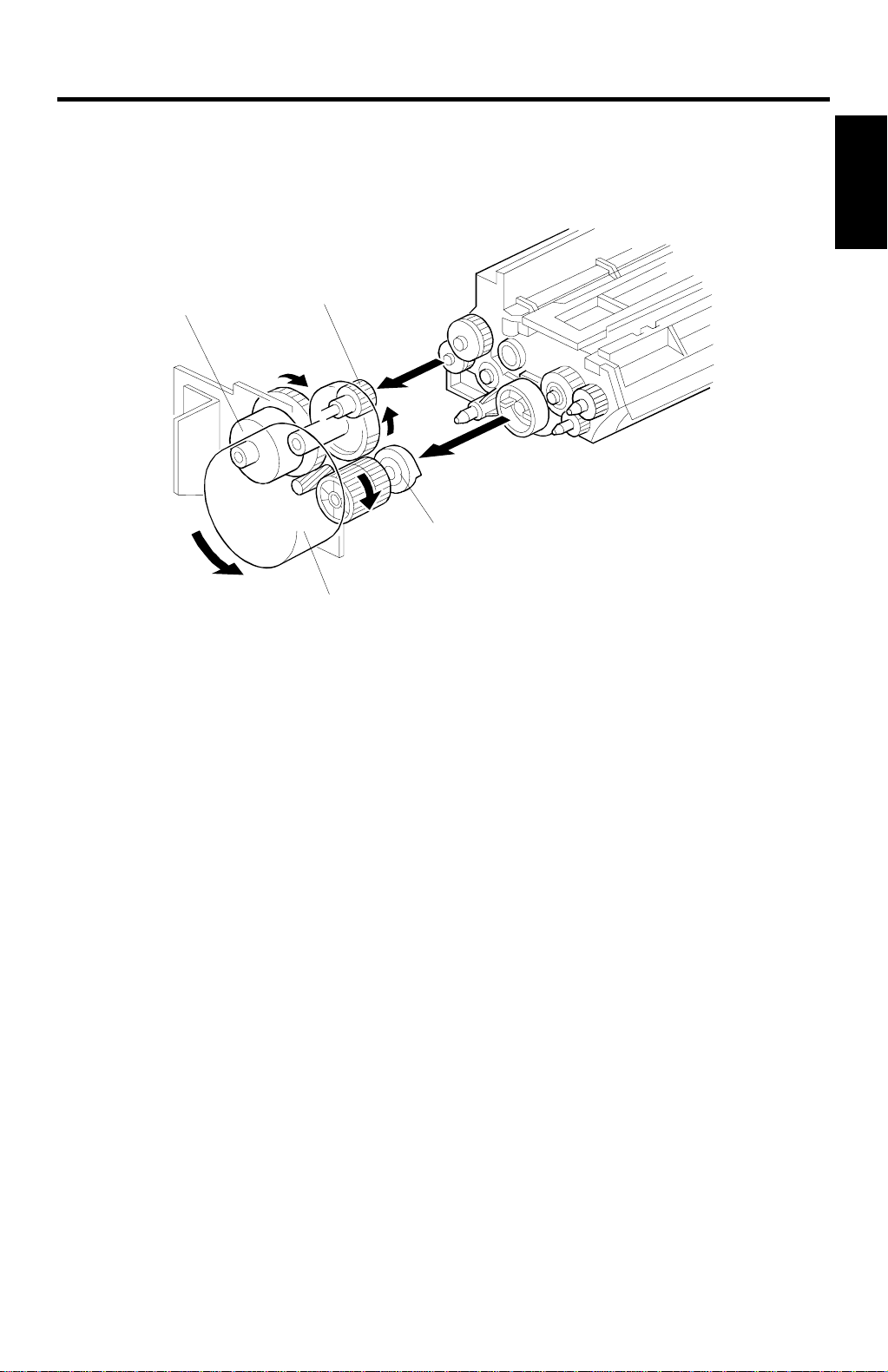

A217 Copier

[D]

In the A133 machine, the main motor drives the development roller and the toner

supply roller. However, in this machine, the development drive motor [A] drives the

development drive gear [B], which drives the gears in the development unit and the

toner supply roller, which is driven by the gear [C] when the toner supply clutch [D]

activates.

This reduces the main motor torque.

[C]

[A]

[B]

A217D508.cdr

15

FUSING TEMPERATURE CONTROL 14 August 1997

5. IMAGE FUSING

5.1 FUSING TEMPERATURE CONTROL

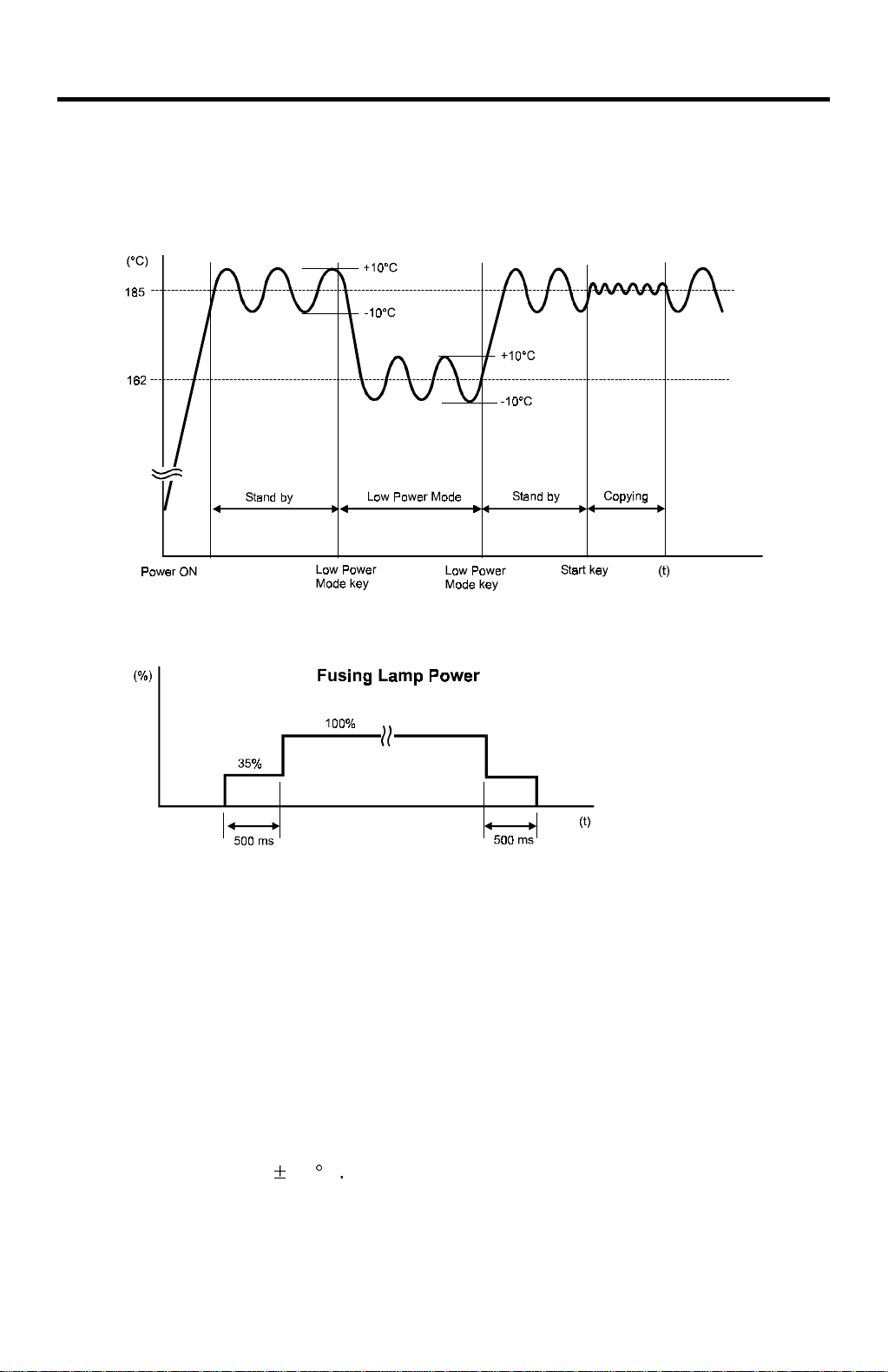

5.1.1 OVERVIEW

A217D507.cdr

5.1.2 ON/OFF CONTROL

NOTE:

To prevent the power supply from the inlet from fluctuating when the fusing lamp

turns on, this machine controls the fusing temperature as follows.

1. When the fusing lamp turns on, 35% of the ac power is applied to the lamp for

2. When not copying, the BCU keeps the fusing temperature at the appropriate

The following explanation is for the 230V machine only.

500 ms, then full ac power is applied. In the fusing lamp off condition, ac power

is reduced to 35% for 500 ms, then cut.

r

fusing temperature

This reduces the number of times the fusing lamp switches on/off.

10qC.

16

14 August 1997 FUSING TEMPERATURE CONTROL

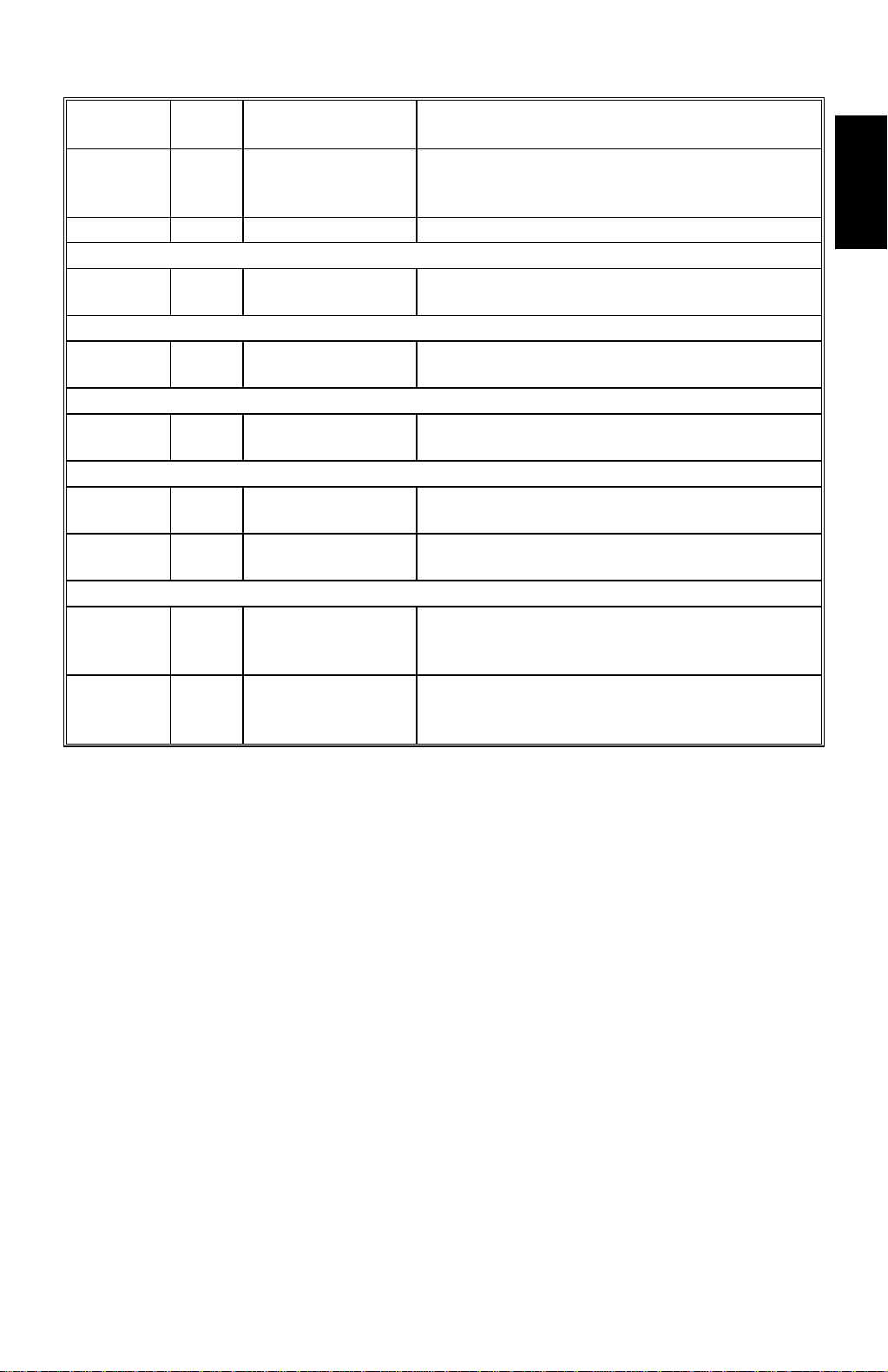

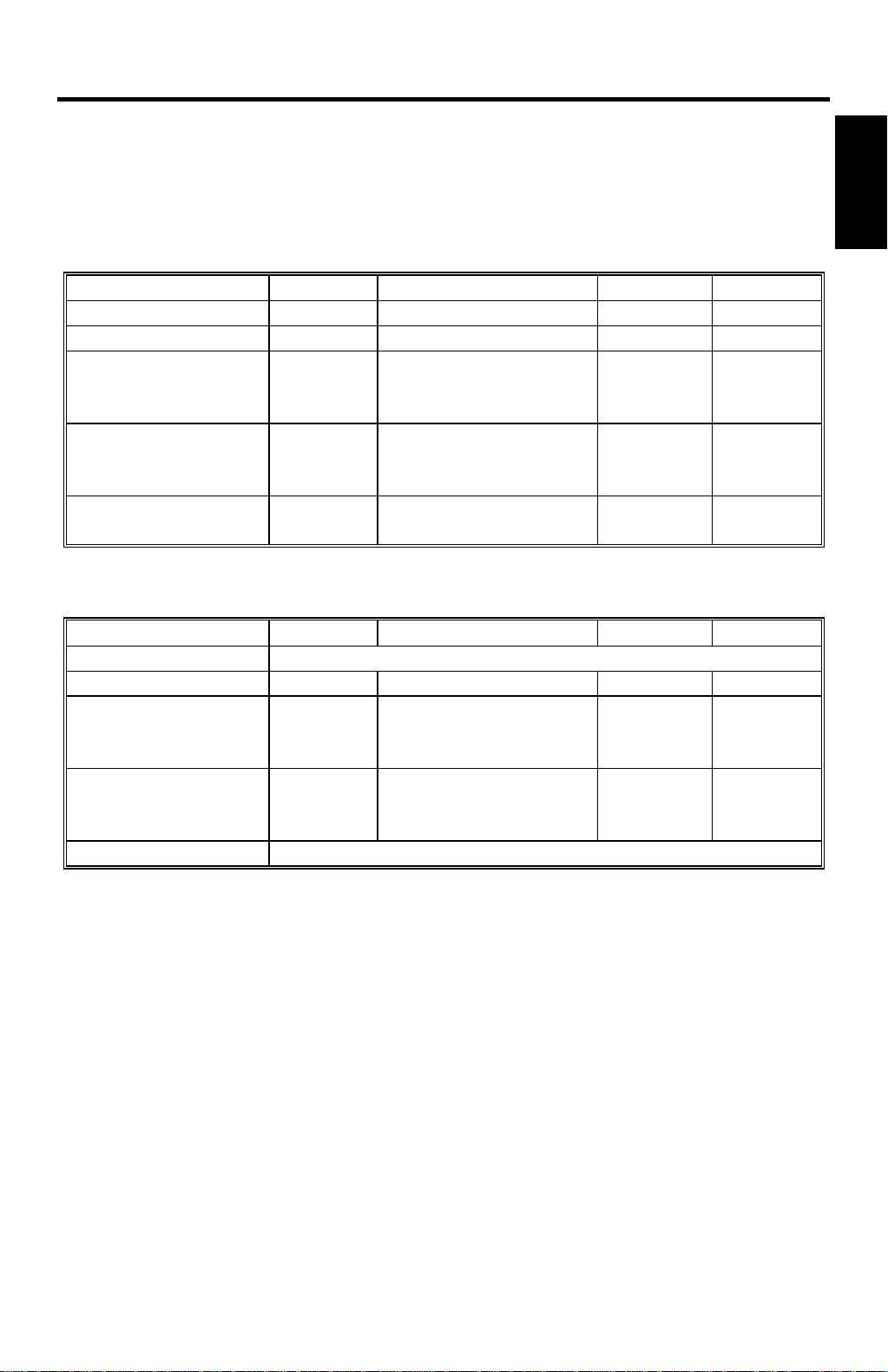

6. ENERGY SAVER AND ENERGY STAR

The energy star and energy saver functions are the same as for the A133

machine. The programming modes for these energy saver functions are as

follows.

- 115V machine -

Mode Method Selectable values Default Unit/Step

Auto off timer UP mode 10 ~ 240 min 60 min 10 min

Low power timer UP mode 1 ~ 240 min 15 min 1 min

Recovery time from

the low power mode

Duplex priority UP mode 1 sided to 1 sided

Auto off mode SP mode Enabled

SP mode 10 s (175ºC)

20 s (162ºC)

30 s (150ºC)

1 sided to 2 sided

2 sided to 2 sided

Disabled

20 s

(162ºC)

1 sided to

2 sided

Enabled

A217 Copier

- 230V machine -

Mode Method Selectable values Default Unit/Step

Auto off timer This function only works in 115V machines.

Low power timer UP mode 1 ~ 15 min 10 min 1 min

Recovery time from

the low power mode

Duplex priority UP mode 1 sided to 1 sided

Auto off mode This function only works in 115V machines.

SP mode 10 s (175ºC)

20 s (162ºC)

30 s (150ºC)

1 sided to 2 sided

2 sided to 2 sided

20 s

(162ºC)

1 sided to

1 sided

17

Loading...

Loading...