Page 1

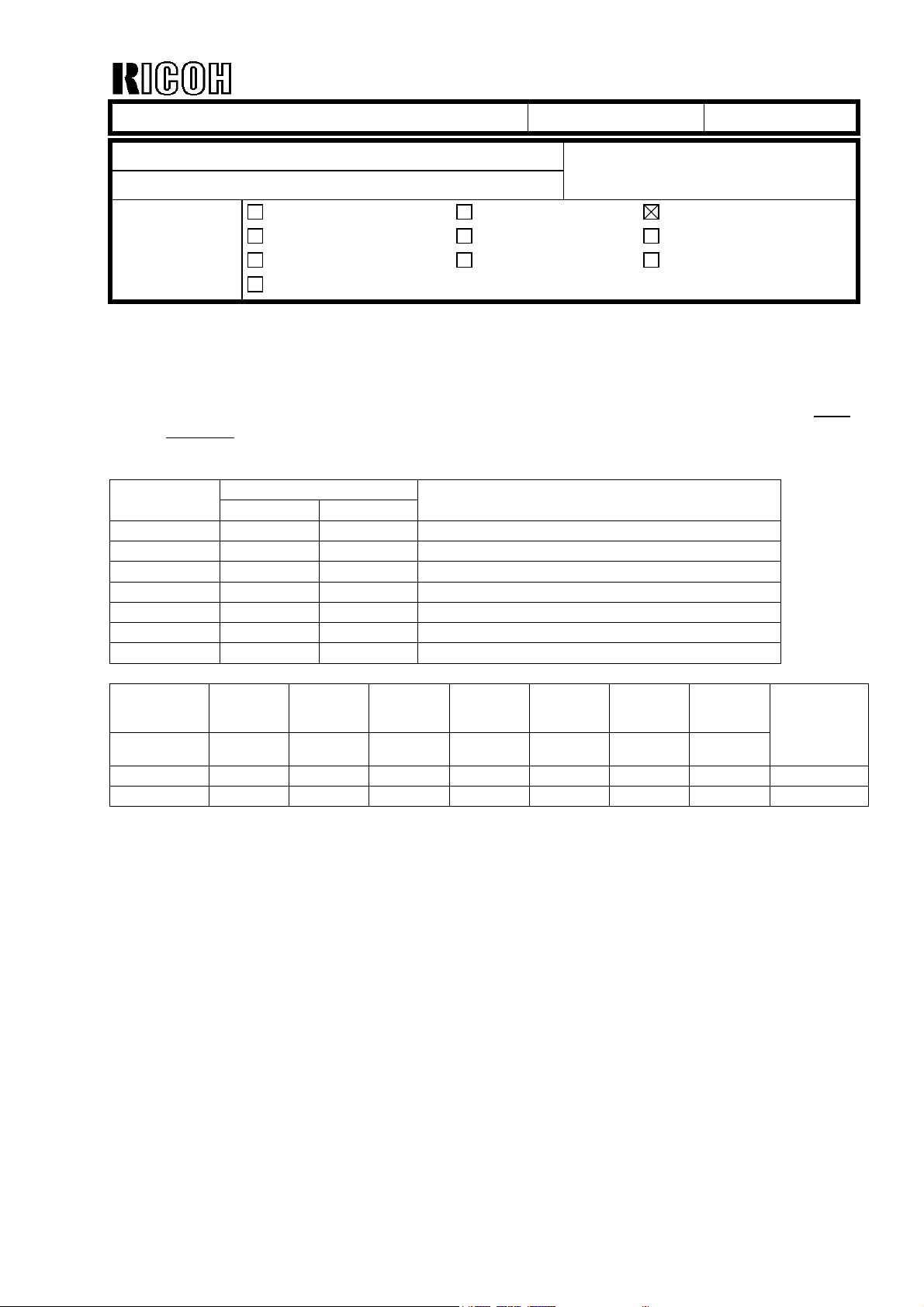

echnical Bulletin

T

PAGE: 1/3

Model:

Subject:

From:

Dolphin

Service Manual

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

23-Aug-01

Prepared by:

No.:

RB010001

F. Noguchi

Action required

Service manual revision

Retrofit information

The sentences in italics show recent corrections to the Service Manual. Please correct

your manuals accordingly.

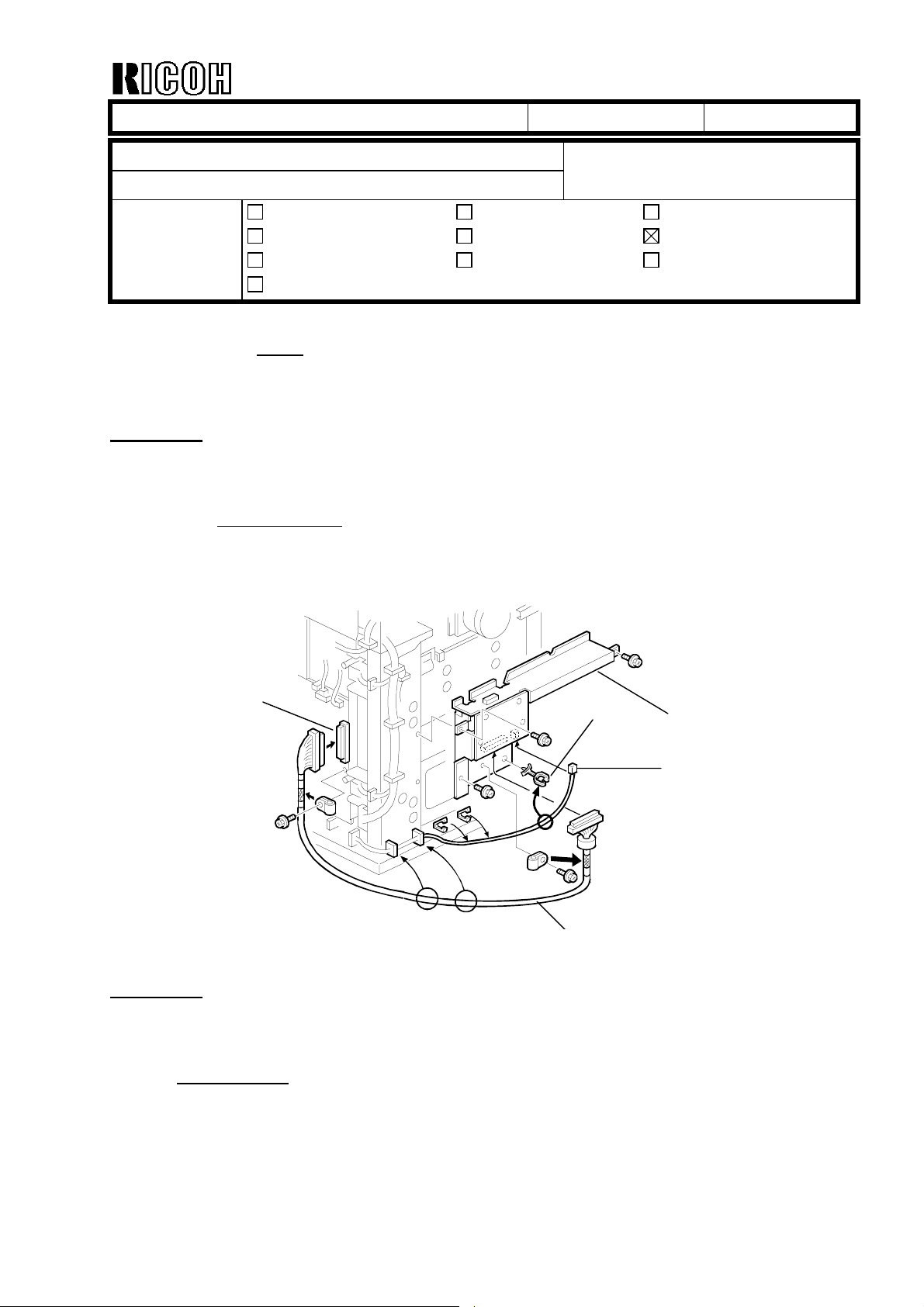

Page 1-25 1.7.2 INSTALLATION PROCEDURE

Corrected: Step 5 and illustration

5. Install the wire saddle [H] and connect the DC harness [I] from the main frame to the

I/F board.

[G]

Page 3-11 3.5.1 DRUM AND DEVELOPMENT UNIT

Corrected: Step [C]

[C]: Toner hopper cover (! x 2)

[F]

[H]

[E]

[I]

Page 2

echnical Bulletin

T

PAGE: 2/3

Model:

Dolphin

Date:

23-Aug-01

Page 5-21 5.9 SP (SERVICE PROGRAM) MODE TABLE

Deleted: The following SP modes.

5501: PM Alarm Level

5504: JAM Alarm Level

5505: Error Alarm Interval

5507: Paper Supply Call Level

5590: Auto Call Level

5816: CSS Function

5821: CSS PI Device Code

Corrected: SP mode descriptions.

Mode Number/Name Function / [Setting]

1103 Fusing Idling Selects the fusing idling time.

[0 ~ 3/ 0 / 1 min. step]

0: No idling

1: 1 minutes

2: 3 minutes

3: 5 minutes

5958 15 m Setting Enables or disables the optional special order firmware

designed for measuring 15 meter paper lengths.

[0 ~ 1 / 0 / 1 step]

0: Enable

1: Disable

No.:

RB010001

Page 6-30 6.6.3 DEVELOPMENT BIAS

Corrected: “Making ID Sensor Patterns” paragraph

Making ID Sensor Patterns

The machine makes two different ID sensor patterns, one for Low Duty Mode and one

for High Duty Mode. The mode is determined by SP 2201 004.

If the average copy volume is high (2.5 km/month or more), this SP should be

switched to High Duty Mode to prevent toner scattering.

However, if the machine is in High Duty Mode and the average copy volume becomes

low again, the image density may decrease. If this happens, switch back to Low Duty

Mode.

The ID sensor pattern development bias voltages for high and low duty modes can be

adjusted with SP 2201 002 and 003, as shown in the following table.

Page 3

echnical Bulletin

T

PAGE: 3/3

Model:

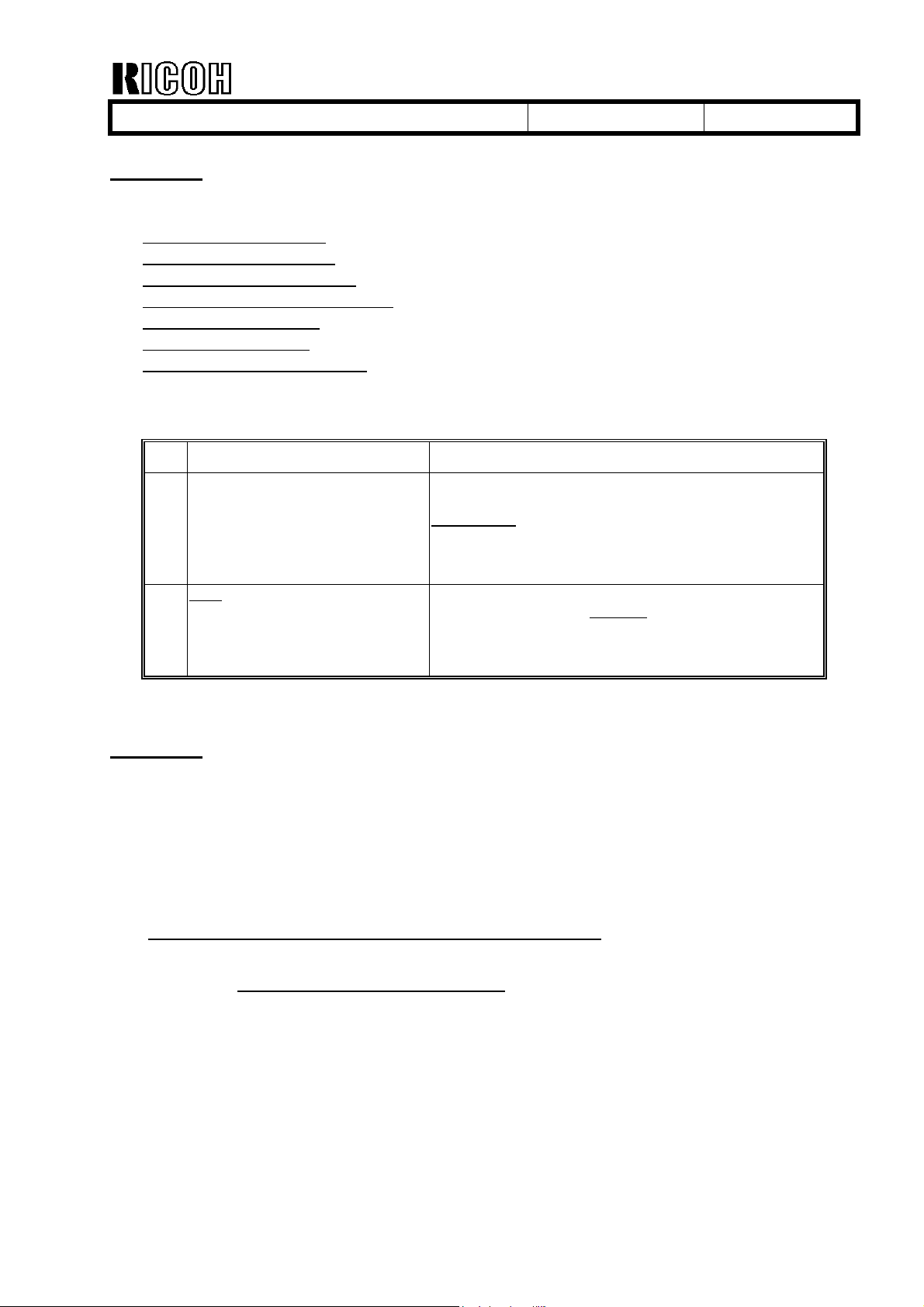

Page 6-53 6.10.6 HOT ROLLER THERMOFUSE

Corrected: Description and illustration.

Dolphin

Non-contact thermofuses (rated for 192°C [A] and 216°C [B]) near the hot roller [C]

prevent accidental overheating which may lead to a fire hazard.

[B]

Date:

23-Aug-01

No.:

RB010001

[A]

[C]

Page 4

echnical Bulletin

T

PAGE: 1/1

Model:

Subject:

From:

Dolphin

HDD Spindle Control Setting (SP4960 005,006)

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

23-Aug-01

Prepared by:

No.:

RB010002

F. Noguchi

Action required

Service manual revision

Retrofit information

SYMPTOM

When HDD Spindle Control is disabled (default), SC980 may occur just after the machine

recovers from Auto Off / Panel Off.

CAUSE

When the machine is brought out of these modes, it is able to warm up quicker than when

the main power is turned on, and therefore checks the HDD status at an earlier point.

However since the HDD must warm up from a stop, it does not reach the ready speed in

time and a mainframe/HDD communication error occurs.

SOLUTION

The default setting for HDD Spindle Control (SP4960-005, 006) has been changed from

Off ! On, which keeps the HDD rotating constantly.

Cut-in serial numbers:

B010-17: From 1st production

B010-22: From 1st production

B017-27: From J201070001

ACTION IN THE FIELD

When installing the HDD option in the following machines, please change the setting of

SP4960-005 and 006 from Off ! On:

B010-27: J201060001 – J201060040 (40 units)

Page 5

echnical Bulletin

T

PAGE: 1/3

Model:

Subject:

From:

Dolphin

BICU & SCU Firmware Modification History

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

07-Sep-01

Prepared by:

No.:

RB010003

F. Noguchi

Action required

Service manual revision

Retrofit information

This RTB contains the modification histories for the BICU and SCU firmware.

Note: When installing either the BiCU or SCU firmware in the field, be sure to update both

together.

Part NumberDestination

BICU SCU

USA B0105162 B0105172 B010-17: US English

EU1, Asia B0105163 B0105173 B010-22,-27: English

EU2 B0105180 B0105190 B010-22,-27: French

EU3 B0108182 B0105192 B010-22,-27: German

EU4 B0108184 B0105194 B010-22,-27: Italian

EU5 B0105186 B0105196 B010-22,-27: Spanish

EU6 B0105188 B0105198 B010-22,-27: Dutch

Model Codes/Languages

Destination/

Part Number

Version/

Suffix

USA

B0105162

B0105172

Eu1_Asia

B0105163

b0105173

Eu2

B0105180

B0105190

Eu3

B0105182

B0105192

Eu4

B0105184

B0105194

Eu5

B0105186

B0105196

Eu6

B0105188

B0108198

RTB

issue

date

6.00AAAAAAA ---

6.06 B B B B B B B 07-Sep-01

Page 6

echnical Bulletin

T

PAGE: 2/3

Model:

Dolphin

Date:

07-Sep-01

No.:

RB010003

Version 6.06

1. SP4960 005,006 (HDD Spindle Control) setting changed

Symptom

When HDD Spindle Control is disabled (default), SC980 may occur just after the machine

recovers from Auto Off / Panel Off.

Cause:

When the machine is brought out of these modes, it is able to warm up quicker than when the

main power is turned on, and therefore checks the HDD status at an earlier point. However since

the HDD must warm up from a stop, it does not reach ready speed in time and a

mainframe/HDD communication error occurs.

Solution:

The default setting for HDD Spindle Control (SP4960-005, 006) has been changed from

Off ! On, which keeps the HDD rotating constantly.

Cut-in serial numbers:

B010-17, -22: From 1

B010-27 : From J201070001

Note: When installing the HDD option in the following machines, please change the setting of

SP4960-005 and 006 from Off ! On:

B010-27: J201060001 – J201060040 (40 units).

st

production

2. New UP mode added (Weekly Output Volume)

To prevent toner scattering from the development unit (see the conditions below), the “Weekly

Output Volume” setting has been added to System Setting – General Features.

Symptom

When customers use low duty mode to make high-volume copy jobs (relative to the ACV), the

toner concentration in the development unit increases. This causes the oversupplied toner to

drop onto the copies, especially under low temperature conditions.

Solution

Change the “Weekly Output Volume” according to the customer’s average weekly copy volume

from inside System Setting – General Features:

Less than 750m (2,500 ft): Low duty mode (default).

More than 750m (2,500 ft): High duty mode

Action in the field

Please instruct customers on the following points at machine installation:

1) Method for how to enter UP Mode and change the Weekly Output Volume value.

2) For the first 1-2 months following installation, have the customers keep track of their copy

volumes at weekly intervals. The weekly changes in CV over this time will enable them to

decide which of the two settings is best for them.

Note: For customers installing the Dolphin as a replacement machine, please use the weekly

ACV on the previous machine for reference and set the Weekly Output Volume accordingly

(as a starting point).

3) During these first couple of months, if the average weekly copy volume exceeds 750m (2,500

ft), please have the customer change the setting of the Weekly Output Volume to “More than

750m (2,500 ft)”.

Note: Please also check the total counter value at PM visits, calculate the weekly CV, and if

necessary change the Weekly Output Volume setting.

Page 7

echnical Bulletin

T

PAGE: 3/3

Model:

3. 24-inch originals are recognized as 30-inch originals

When 30-inch paper is selected on the operation panel, 24-inch originals are automatically

detected as 30-inch originals.

4. “NRG A070” added to SP5907 (Plug & Display)

The model name NRG A070 has been added as follows:

Dolphin

1: Ricoh Imagio Wide 7040 (Japan)

2: Ricoh Aficio 470W

3: NRG A070

Date:

07-Sep-01

No.:

RB010003

Page 8

echnical Bulletin

T

PAGE: 1/3

Model:

Subject:

From:

Dolphin

Service Manual

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

22-Oct-01

Prepared by:

No.:

RB010004

F. Noguchi

Action required

Service manual revision

Retrofit information

Please apply the following corrections and additions to your Service Manual Installation

Procedures. In addition, please see the Note on the last page on how to read the factory

settings data sheet.

1. Corrections: Cushion - Rear Copy Tray Holder (B010-22, -27 only).

The “Cushion - Rear Copy Tray Holder (B010-22, -27 only)” was not packed as an

accessory from 1st production.

1) Pg. 1-4: Accessory Checklist.

Delete the “Cushion - Rear Copy Tray Holder (B010-22, -27 only)”.

2) Pg. 1-8: Installation Procedure and Illustration.

Delete Step 16: “Adhere the cushions [F] to the rear copy tray holders [G].”

Delete the cushion [F] (B010I206.WMF) from the illustration.

Illustration correction:

[H]

[I]

[F]

[G]

[F] [H]

[G]

Page 9

echnical Bulletin

T

PAGE: 2/3

Model:

2. Addition: Key Counter Installation Procedure

1) Remove the right front cover [A]

2) Remove the small cover [B] (1 screw)

3) Install the key counter holder [C] by

4) Reinstall the right rear cover.

5) Instruct the key operator on how to

Dolphin

[B]

(5 screws).

and plate nut (2 screws).

attaching it to the bracket (2 screws,

1 connector [D]).

enable the Key Counter from inside User Tools.

(User Tools → System Settings → Key Operator Tools → Key Counter Access)

Date:

[C]

22-Oct-01

No.:

RB010004

[A]

[D]

Note:

Please be sure to set the Key Operator Access code so that only the authorized key

operator is able to change the system settings.

6) Change the following SP Mode settings:

SP5997: Optional Counter Unit

Select “x 1/10” or “x1” for the Key Counter unit.

The machine counter units are as follows:

-17 version machine: Feet, Yards or Meters (depending on SP5980).

-27 version machine: Meters.

SP5120: Mode Clear Option Counter Removed

This SP determines what happens to the copy job settings (magnification, density,

etc.) when the Key Counter is removed or the paper supply runs out midway through

a job.

0: Yes (default): Job settings and job are cleared

1: Stand-by : Job settings are cleared after the job is completed

2: No : Job settings remain even after job is completed

Page 10

echnical Bulletin

T

PAGE: 3/3

Model:

3. Supplementary information: How to read the factory settings data sheet.

ROM Version: B0105173B B0105163B B0105085B A2325372C

2001/08/07 – 10:39

S/N : J2010800025

Counter : 9999935

Product No. : B0102700025

Dolphin

SCU BICU Operation Panel CSS

Product code

SP 1001-01 Value SP 1926-61 Value SP 7803-01 Value

Date:

22-Oct-01

No.:

RB010004

51010010100 5 05019206100 -12 13078030100 0

51010010200 5 05019206200 -23 15074010100 0

SP 1001-02 Value SP 1920-62 Value SP 7401-01 Value

Note: The following are User Program codes, not SP codes:

05051010300: Panel Off Timer

05051010400: Energy Saver Timer

Page 11

echnical Bulletin

T

PAGE: 1/1

Model:

Subject:

From:

Dolphin

Caution of the toner cartridge installation

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

06-Nov-01

Prepared by:

No.:

RB010005

F. Noguchi

Action required

Service manual revision

Retrofit information

The four symptoms listed below tend to occur if the toner cartridge is not shaken properly

before it is inserted into the toner hopper. This is because transport and storage conditions

can cause the toner to bunch together, which prevents the toner agitator from rotating

properly.

Please be sure to remind the customer at installation that it is very important to shake the

bottle 5 to 10 times before inserting it into the hopper. This is also mentioned on the decal

on the left side of the machine.

1) The toner supply drive gears (B0103126, AB017539) break.

2) The shaft for these drive gears break.

Note: In this case, it is necessary to replace the development unit.

3) The toner hopper cover opens during copying.

4) Add Toner is displayed again soon after replacing the cartridge.

Page 12

Reissued: 30-Nov-01

echnical Bulletin

T

PAGE: 1/4

Model:

Dolphin

Date:

07-Sep-01

No.:

RB010003a

Version 6.08 has been added.

Subject:

From:

BICU & SCU Firmware Modification History

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Prepared by:

Action required

Service manual revision

Retrofit information

F. Noguchi

This RTB contains the modification histories for the BICU and SCU firmware.

Note: When installing either the BICU or SCU firmware in the field, be sure to update both

together.

Part NumberDestination

BICU SCU

USA B0105162 B0105172 B010-17: US English

EU1, Asia B0105163 B0105173 B010-22,-27: English

EU2 B0105180 B0105190 B010-22,-27: French

EU3 B0108182 B0105192 B010-22,-27: German

EU4 B0108184 B0105194 B010-22,-27: Italian

EU5 B0105186 B0105196 B010-22,-27: Spanish

EU6 B0105188 B0105198 B010-22,-27: Dutch

Model Codes/Languages

Destination/

Part Number

Version/

Suffix

USA

B0105162

B0105172

Eu1_Asia

B0105163

b0105173

Eu2

B0105180

B0105190

Eu3

B0105182

B0105192

Eu4

B0105184

B0105194

Eu5

B0105186

B0105196

Eu6

B0105188

B0108198

RTB

issue

date

6.00AAAAAAA ---

6.06 B B B B B B B 07-Sep-01

6.08 C C C C C C C 30-Nov-01

Page 13

Reissued: 30-Nov-01

echnical Bulletin

T

PAGE: 2/4

Model:

Dolphin

Date:

07-Sep-01

No.:

RB010003a

Version 6.08

USA EU1 Asia EU2 EU3 EU4 EU5 EU6

BICU B0105162C B0105163C B0105180C B0105182C B0105184C B0105186C B0105188C

SCU B0105172C B0105173C B0105190C B0105192C B0105194C B0105196C B0105198C

Note: Version 6.08 requires the printer/scanner controller.

1. New SP Mode added to enable the Ready Temperature Setting function (SP1917)

This has been added in order to prevent insufficient fusing with translucent paper when making

copies just after the machine is turned on. The settings for this mode are as follows:

1 Mode Number/name Function/ [Setting]

1917 Ready Temp. Setting Select the ready fusing temperature.

[0 ~ 2/ 0 / 1 step]

0: Standard (143ûC)

1: 195°C (

2: 195°C (

2. Default change for Function Reset Timer (System Settings – General Features 2/3)

The default of this mode was changed from "3 seconds" to "instant" for use with the

Printer/Scanner controller.

All paper types/ thickness

)

Translucent thickness 3 & 4

)

3. Design-use SP Modes added

SP5959 and SP5957 have been newly added. However, these are strictly for design use only.

Please do not change the values in the field. The defaults are as follows:

SP5959:OFF

SP5957:Disabled

The following items (4 ~9) have been corrected in this version.

4. SMC printout onto undefined paper sizes

In response to a request from the field, the SMC printouts can now be printed onto any

paper size that can be loaded into the paper trays.

5. Occurrence conditions changed for SC353

SC353 will not be displayed during Toner End.

This was changed because sometimes when copying originals with a very high image area ratio,

SC353 would occur unnecessarily when the ID sensor pattern density dropped and the Near

End condition was detected.

6. Jam Recovery

The machine was sometimes unable to perform successful jam recovery if a jam occurred while

printing out a series of preset jobs.

7. Display error - number of jobs

Even after being cancelled, a preset job is not subtracted from the total job count.

Page 14

Reissued: 30-Nov-01

echnical Bulletin

T

PAGE: 3/4

Model:

8. Part of image missing when printing out "Additional Copies" with electronic sort, mixed

original mode

Following a mixed-original electronic sorting job, the machine is still set to use the paper roll it

did for the last copy.

Therefore when "Additional Copies" are initiated, instead of resetting the paper roll to the initial

one, the machine starts printing out onto the most recently used roll, cutting off some of the

image. The software was corrected so that copies of any additional sets are printed out onto

their correct sizes, i.e. as originally set in the initial job.

9. Unlimited scanning before beginning a copy job

The software was changed so that when the Print Start Trigger is set to "press start key",

originals can be scanned an unlimited number of times before initiating the copy job. Each time a

new scan is initiated, the previous scan data is overwritten.

Dolphin

Date:

07-Sep-01

No.:

RB010003a

Page 15

echnical Bulletin

T

PAGE: 1/1

Model:

Subject:

From:

Dolphin

Serial number sheet for printer/scanner controller

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

30-Nov-01

Prepared by:

No.:

RB010006

F. Noguchi

Action required

Service manual revision

Retrofit information

With the release of the Printer/Scanner Controller, this RTB has been issued to explain the

serial number sheet and the Controller Board Assembly service part.

1. Serial number sheet for the Printer/Scanner Controller Board

The following serial number sheet is packaged together with the Printer/Scanner

Controller and the Controller Board Assembly service part.

When installing the board, be sure to attach the decal to the outside of the server PC.

Note:

1) The serial number on this sheet is necessary to obtain the RSP files.

2) If the board needs to be replaced again, it will be necessary to replace the serial

number sheet together.

Serial number

P8219105005-C

2. Service parts

The following is the only service part registered for the Printer/Controller Board.

P/N Description Q’ty

G0675900 Controller Board Ass’y 1

Note:

A parts catalog for the Printer/Scanner Controller will not be issued, because the

controller board assembly is the only registered spare part for this item.

Page 16

echnical Bulletin

p

p

T

PAGE: 1/4

Model:

Subject:

From:

Dolphin

MCU breakage

Technical Services Dept., GTS Division

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Date:

06-Nov-01

Prepared by:

No.:

RB010007

F. Noguchi

Action required

Service manual revision

Retrofit information

SYMPTOM

The machine shuts down after the MCU breaks (only the operation switch LED is lit).

CAUSE

At power off, surge current damages the oscillator circuit IC on the MCU.

SOLUTION

Replace the MCU with the modified one (suffix C) at installation or the next customer visit.

See the attached MCU Replacement Procedure. See page 3 of this RTB.

Added

D105

5VE

C113

20

9

C115

20

VHC04

8

IC131

F

VHC04

11

IC131

R130 10M

F

GND

OSC105

HC-49/U-S:

19.660MHZ

10

GND

Page 17

echnical Bulletin

T

PAGE: 2/4

Model:

Machines for MCU replacement in the field:

B010-17: J2010700056 ~ 80 (25 units)

B010-22: J2010600044, 54, 58, 64, 66, 67, 70 (7 units)

B010-27: J2010600001, 9, 12, 31, 32, 34, 39 (7 units)

Dolphin

J2010800001 ~ 22 (22 units)

J2010900035, 38, 42, 43, 46 ~ 49, 51, 53, 55 ~ 58, 60 (15 units)

J2010700036 ~ 39, 46 ~ 50, 52 ~ 54 (12 units)

J2010800058, 62, 64 (3 units)

J2010900022, 26, 28 (3 units)

J2010700001, 4, 15 ~ 17, 21 ~ 23, 25, 27, 29, 30, 34 (13 units)

J2010800025, 42, 44, 51 (4 unit)

J2010900005 (1 unit)

Date:

06-Nov-01

No.:

RB010007

COUNTERMEASURE

A surge current protection diode has been added to the MCU at the factory from the

following cut-in serial numbers:

B010-17: J2010900032 ~ 34, 36, 37, 39 ~ 41, 44, 45, 50, 52, 54, 59, 61

and from J2011000001

B010-22: J2010600041 ~ 43, 45 ~ 53, 55 ~ 57, 59 ~ 63, 65, 68, 69

J2010700040 ~ 45, 51, 55

J2010800059 ~ 61, 63, 65,

J2010900023 ~ 25, 27 and from J2010900029

B010-27: J2010600002 ~ 8, 10, 11, 13 ~ 30, 33, 35 ~ 38, 40

J2010700002, 3, 5 ~ 14, 18 ~ 20, 24, 26, 28, 31 ~ 33, 35

J2010800023, 24, 26 ~41, 43, 45 ~50, 52 ~57

J2010900001 ~ 8, and from J2010900010

Note: The P/Ns for the MCU have not been changed (NA: B0105071, EU: B0105076).

The suffix has been changed for both from B to C.

Page 18

echnical Bulletin

T

PAGE: 3/4

Model:

Dolphin

Date:

06-Nov-01

No.:

RB010007

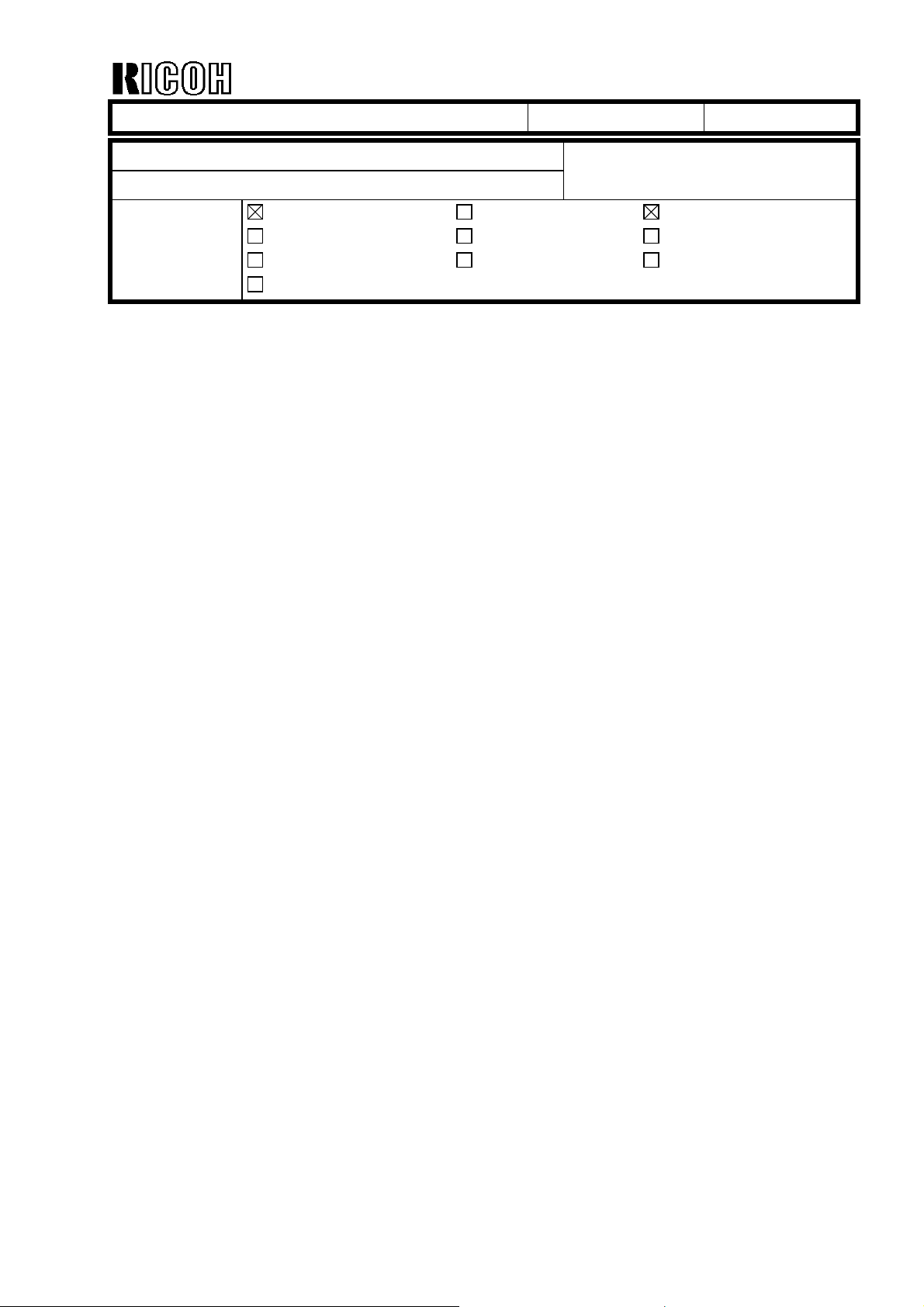

ACTION IN THE FIELD

At installation or the next customer visit, please use the following procedure to replace the

MCU with the modified one (suffix C).

After replacing the MCU, please send back the old MCU (suffix A or B) to the location that

sent you the new MCU.

MCU REPLACEMENT PROCEDURE

Caution: Be sure to unplug the power cord before starting the following procedure.

1. Remove the right rear cover [A]

(5 screws).

[A]

[C]

2. Release the lock of CN251 and

CN254, then pull out the flat cables [B]

from the MCU board [C].

3. Remove the MCU board (3 screws).

[D]

4. Remove the following NVRAMs

from the MCU board:

IC101 [D] (RAM - STK15C68 - P45)

IC108 [E] (SRAM - STK15C88 - W45)

IC109 [F] (RAM - STK15C88 - P45)

Note:

1) Before removal and insertion, the engineer should touch a metal portion of the

machine to eliminate the possibility of a static electricity buildup.

2) Do not place the NVRAM on an object made of conductive material. This will cause a

short, resulting in the loss of all the data inside.

[E]

[B]

[F]

Page 19

echnical Bulletin

T

PAGE: 4/4

Model:

3) When removing the NVRAM, inserting a small, flat-head (standard) screwdriver into

4) When inserting the NVRAM, it is important to first make sure that all of the pins on

5. Mount these 3 NVRAMs onto the new MCU board.

6. Install the new MCU board and connect the flat cables.

7. Plug in the power cord and turn on the main power switch.

8. Confirm the machine serial number using SP5811.

9. Make a copy and confirm that the machine functions normally.

10.Turn off the main power switch and unplug the power cord.

11. Reinstall the right rear cover (5 screws).

Dolphin

the space between the NVRAM casing and the RAM socket (at the ends where there

are no pins), lifting the RAM up on both ends with the screwdriver, and finally taking it

out by hand.

both sides have been properly set in their holes, and then to push the pins in all the

way (in this order).

Date:

06-Nov-01

No.:

RB010007

Loading...

Loading...