Page 1

DOLPHIN

(Machine Code: B010)

SERVICE MANUAL

Page 2

!

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

5. If the Start key is pressed before the copier completes the warm-up period

(the Start key starts blinking red and green alternatively), keep hands away

from the mechanical and the electrical components as the copier starts

making copies as soon as the warm-up period is completed.

6. The inside and the metal parts of the fusing unit become extremely hot while

the copier is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your eyes

by accident, it may cause temporary eye discomfort. Try to remove with eye

drops or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

those models.

1

Page 3

1. SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

Do not incinerate toner bottles or used toner. Toner dust may ignite

suddenly when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lith iu m batteries in order to dispose of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

Lithium Batteries (Memory Back-up)

!

CAUTION

The danger of explosion exists if a battery of this type is incorrectly

replaced.

Replace only with the same or an equivalent type recommended by the

manufacturer. Discard used batteries in accordance with the

manufacturer’s instructions.

Warning concerning copyright

Many documents are copyrighted. Such documents may not be reproduced by

scanning or in any other form without the express permission of the copyright

holder.

2

Page 4

Conventions in this Manual

This manual uses several symbols.

Symbol What it means

☛

!

"

#

$

%

Refer to section number

See Core Tech Manual for

details

Screw

Connector

E-ring

Clip ring

Lengthwise, SEF

(Short Edge Feed)

Sideways, LEF

(Long Edge Feed)

3

Page 5

TABLE OF CONTENTS

1 INSTALLATION PROCEDURE.................................................... 1-1

1.1 PREPARATION.........................................................................................1-1

1.1.1 ENVIRONMENT...............................................................................1-1

1.1.2 MINIMUM SPACE REQUIREMENTS...............................................1-2

1.1.3 MACHINE LEVEL.............................................................................1-2

1.1.4 POWER SOURCE............................................................................1-3

1.2 COPIER INSTALLATION PROCEDURE ..................................................1-4

1.2.1 ACCESSORY CHECK......................................................................1-4

1.2.2 INSTALLATION PROCEDURE........................................................1-5

1.3 ROLL TRAY INSTALLATION PROCEDURE..........................................1-11

1.3.1 ACCESSORY CHECK....................................................................1-11

1.3.2 INSTALLATION PROCEDURE......................................................1-12

1.4 HDD INSTALLATION PROCEDURE ......................................................1-17

1.4.1 ACCESSORY CHECK....................................................................1-17

1.4.2 INSTALLATION PROCEDURE......................................................1-18

1.5 STAMP BOARD INSTALLATION PROCEDURE....................................1-20

1.5.1 ACCESSORY CHECK....................................................................1-20

1.5.2 INSTALLATION PROCEDURE......................................................1-20

1.6 ORIGINAL TRAY INSTALLATION PROCEDURE...................................1-21

1.6.1 ACCESSORY CHECK....................................................................1-21

1.6.2 INSTALLATION PROCEDURE......................................................1-22

1.7 I/F BOARD INSTALLATION PROCEDURE............................................1-24

1.7.1 ACCESSORY CHECK....................................................................1-24

1.7.2 INSTALLATION PROCEDURE......................................................1-25

2 PREVENTIVE MAINTENANCE.................................................... 2-1

2.1 PM TABLE.................................................................................................2-1

2.2 LUBRICATION POINTS............................................................................2-3

2.2.1 FUSING SECTION...........................................................................2-3

2.2.2 DEVELOPMENT SECTION..............................................................2-3

3 REPLACEMENT AND ADJUSTMENT......................................... 3-1

3.1 OPENING AND CLOSING THE MACHINE...............................................3-1

3.2 EXTERNAL COVERS ...............................................................................3-2

3.2.1 FRONT VIEW...................................................................................3-2

3.2.2 REAR VIEW .....................................................................................3-2

3.3 SCANNER.................................................................................................3-3

3.3.1 OPERATION PANEL........................................................................3-3

3.3.2 ORIGINAL SIZE SENSORS, ORIGINAL SET SENSOR,

ORIGINAL REGISTRATION SENSOR ...........................................3-5

3.3.3 WHITE PLATEN ROLLER................................................................3-6

3.3.4 ORIGINAL UPPER TRANSPORT UNIT AND EXIT SENSOR.........3-7

3.3.5 ORIGINAL TRANSPORT ROLLER..................................................3-8

3.3.6 CIS (CONTACT IMAGE SENSOR)..................................................3-8

i

Page 6

3.4 AROUND THE DRUM............................................................................... 3-9

3.4.1 VDB (VIDEO DRIVE BOARD)..........................................................3-9

3.4.2 LPH (LED PRINT HEAD).................................................................. 3-9

3.4.3 CHARGE CORONA WIRE, GRID WIRE, WIRE CLEANER...........3-10

3.4.4. QUENCHING LAMPS.....................................................................3-11

3.5 DRUM AND DEVELOPMENT UNIT........................................................3-11

3.5.1 DEVELOPMENT UNIT...................................................................3-11

3.5.2 DEVELOPER..................................................................................3-12

3.5.3 BY-PASS FEED SENSOR, REGISTRATION SENSOR.................3-13

3.5.4 TONER SUPPLY CLUTCH ............................................................3-14

3.5.5 DRUM DRIVE MOTOR...................................................................3-14

3.5.6 DRUM UNIT, ID SENSOR, AND CLEANING BLADE....................3-15

3.6 PAPER FEED..........................................................................................3-17

3.6.1 CUTTER UNIT................................................................................3-17

3.6.2 CUTTING SENSOR AND FEED EXIT ROLLER............................3-18

3.6.3 ROLL TRAY....................................................................................3-19

3.6.4 PAPER FEED DRIVE MOTOR.......................................................3-21

3.6.5 FIRST FEED ROLLER AND CLUTCH...........................................3-21

3.6.6 SECOND FEED ROLLER AND CLUTCH ......................................3-22

3.6.7 REGISTRATION MOTOR ..............................................................3-22

3.6.8 REGISTRATION CLUTCH.............................................................3-23

3.6.9 REGISTRATION ROLLER .............................................................3-23

3.7 TRANSFER UNIT ....................................................................................3-24

3.7.1 TRANSFER AND SEPARATION CORONA WIRES ......................3-24

3.7.2 TRANSPORT UNIT........................................................................3-25

3.7.3 TRANSPORT BELTS.....................................................................3-26

3.8 FUSING SECTION..................................................................................3-27

3.8.1 FUSING UNIT.................................................................................3-27

3.8.2 PAPER JUNCTION GATE SOLENOID/EXIT SENSOR.................3-29

3.8.3 FPDB (FUSING PRESSURE DRIVE BOARD)...............................3-29

3.8.4 HOT ROLLER STRIPPERS/PRESSURE MOTORS......................3-29

3.8.5 PRESSURE ROLLER THERMISTOR............................................3-30

3.8.6 THERMOFUSE/HOT ROLLER THERMISTOR..............................3-30

3.8.7 FUSING CLEANING ROLLER .......................................................3-30

3.8.8 FUSING LAMPS.............................................................................3-31

3.8.9 HOT ROLLER AND PRESSURE ROLLER....................................3-32

3.8.10 FUSING DRIVE MOTOR..............................................................3-34

3.9 BOARDS.................................................................................................3-35

3.9.1 PSU (POWER SUPPLY UNIT).......................................................3-35

3.9.2 IOB (INPUT OUTPUT BOARD), MCU (MAIN CONTROL UNIT)....3-35

3.9.3 IPU (IMAGE PROCESSING UNIT).................................................3-36

3.9.4 HDD REPLACEMENT....................................................................3-36

3.10 ADJUSTMENTS....................................................................................3-37

3.10.1 CIS AND WHITE PLATEN ROLLER ADJUSTMENT ...................3-37

3.10.2 LPH ADJUSTMENT ........................................................................... 3-38

3.10.3 IMAGE POSITION, MAGNIFICATION, MARGIN ADJUSTMENTS....3-41

ii

Page 7

4 TROUBLESHOOTING ................................................................. 4-1

4.1 SERVICE CALL CONDITIONS.................................................................4-1

4.1.1 SUMMARY.......................................................................................4-1

4.2 SC CODE DESCRIPTIONS......................................................................4-2

4.3 JAM CODE TABLE..................................................................................4-18

4.4 COVER OPEN.........................................................................................4-19

4.5 IMAGE DATA PROCESSING FLOW CHART.........................................4-20

4.5.1 DATA FLOW IN 1-TO-1 COPY MODE...........................................4-20

4.5.2 DATA FLOW IN REPEAT COPY MODE........................................4-20

4.5.3 DATA FLOW IN SCANNING MODE...............................................4-21

4.5.4 DATA FLOW IN PRINTING MODE (A0 OR SMALLER).................4-21

4.5.5 DATA FLOW IN PRINTING MODE (LARGER THAN A0)..............4-22

4.5.6 DATA FLOW IN TEST PATTERN PRINTING................................4-22

4.6 IMAGE PROBLEM TROUBLESHOOTING .............................................4-23

4.6.1 FLOW CHART................................................................................4-23

4.6.2 SCANNING.....................................................................................4-24

4.6.3 PRINTING ......................................................................................4-26

5 SERVICE TABLES....................................................................... 5-1

5.1 SOFTWARE UPGRADING .......................................................................5-1

5.1.1 OVERVIEW......................................................................................5-1

5.1.2 UPGRADING THE SCU FIRMWARE...............................................5-2

5.1.3 UPGRADING THE BICU FIRMWARE..............................................5-4

5.1.4 UPGRADING THE SCU AND BICU TOGETHER............................5-5

5.1.5 UPGRADING THE AMDP FIRMWARE............................................5-6

5.2 UP (USER PROGRAM) MODE.................................................................5-7

5.2.1 INITIAL SYSTEM SETTINGS...........................................................5-7

5.2.2 INITIAL COPIER SETTINGS............................................................5-8

5.3 SERVICE PROGRAM (SP) MODES.......................................................5-10

5.3.1 ENTERING SP MODE....................................................................5-10

5.3.2 HOW TO USE THE SP MODE .......................................................5-12

5.4 TOUCH PANEL CALIBRATION..............................................................5-14

5.5 SOFTWARE RESET...............................................................................5-14

5.6 PRINTING TEST PATTERNS.................................................................5-15

5.6.1 IMAGE PROCESSING TEST PATTERNS.....................................5-15

5.6.2 IMAGE DATA PATH TEST PATTERNS.........................................5-16

5.7 INPUT CHECK........................................................................................5-17

5.8 OUTPUT CHECK....................................................................................5-20

5.9 SP (SERVICE PROGRAM) MODE TABLES...........................................5-21

6 DETAILED DESCRIPTIONS......................................................... 6-1

6.1 OVERVIEW...............................................................................................6-1

6.1.1 MACHINE LAYOUT..........................................................................6-1

6.1.2 MECHANICAL COMPONENT LAYOUT...........................................6-2

6.1.3 DRIVE LAYOUT...............................................................................6-4

6.1.4 ORIGINAL/COPY PAPER PATHS ...................................................6-5

iii

Page 8

6.2 SCANNER.................................................................................................6-6

6.2.1 OVERVIEW......................................................................................6-6

6.2.2 ORIGINAL SIZE DETECTION..........................................................6-7

6.2.3 ORIGINAL FEED MECHANISM.......................................................6-7

6.2.4 ORIGINAL FEED SPEED.................................................................6-7

6.2.5 ORIGINAL TEMPORARY DELAY....................................................6-8

6.2.6 SCANNING MECHANISM................................................................6-8

6.2.7 AUTO IMAGE DENSITY CORRECTION..........................................6-9

6.2.8 ORIGINAL EXIT SWITCHING MECHANISM ...................................6-9

6.3 IMAGE PROCESSING............................................................................6-10

6.3.1 GENERAL IMAGE PROCESSING FLOW CHART ........................6-10

6.3.2 ORIGINAL MODES........................................................................6-11

Overview............................................................................................. 6-11

Text Mode...........................................................................................6-12

Photo Mode ........................................................................................ 6-13

Text/Photo Mode ................................................................................6-14

Pale Mode...........................................................................................6-15

Generation..........................................................................................6-16

Patched Original Mode.......................................................................6-17

Blue Line Mode...................................................................................6-18

Photo (Hard Tone) Mode....................................................................6-19

6.3.3 INDEPENDENT DOT ERASURE...................................................6-20

6.3.4 FOUR-VALUE ERROR DIFFUSION..............................................6-21

6.3.5 MTF SETTINGS.............................................................................6-21

6.4 AROUND THE DRUM.............................................................................6-22

6.4.1 OVERVIEW....................................................................................6-22

6.4.2 DRUM DRIVE.................................................................................6-23

6.4.3 CHARGE CORONA UNIT..............................................................6-23

6.4.4 CORONA WIRE CLEANING..........................................................6-23

6.4.5 CLEANING THE DRUM .................................................................6-24

6.4.6 COLLECTING USED TONER........................................................6-25

6.4.7 QUENCHING..................................................................................6-26

6.4.8 ANTI-CONDENSATION HEATERS................................................6-26

6.5 IMAGE WRITING....................................................................................6-27

6.5.1 LED HEADS...................................................................................6-27

6.6 DEVELOPMENT.....................................................................................6-28

6.6.1 OVERVIEW....................................................................................6-28

6.6.2 DEVELOPER CROSS-MIXING......................................................6-29

6.6.3 DEVELOPMENT BIAS...................................................................6-30

Copying...............................................................................................6-30

Making ID Sensor Patterns.................................................................6-30

6.6.4 DEVELOPMENT DRIVE MECHANISM..........................................6-31

6.6.5 TONER SUPPLY MECHANISM.....................................................6-31

6.6.6 ID SENSOR....................................................................................6-31

6.6.7 TONER END/NEAR-END CONTROL ............................................6-32

6.6.8 TONER END RECOVERY ............................................................. 6-33

6.6.9 TONER DENSITY CONTROL........................................................6-34

6.6.10 DEVELOPMENT TIMING CHART................................................6-35

iv

Page 9

6.7 PAPER FEED AND REGISTRATION .....................................................6-36

6.7.1 OVERVIEW....................................................................................6-36

6.7.2 PAPER HOLDER............................................................................6-37

6.7.3 PAPER WIDTH AND MEDIA TYPE SETTINGS.............................6-38

6.7.4 ROLL TRAY FEED MECHANISM..................................................6-38

6.7.5 BY-PASS FEED MECHANISM....................................................... 6-39

6.7.6 REGISTRATION.............................................................................6-39

6.7.7 CUTTING MECHANISM.................................................................6-40

6.7.8 ROLL END DETECTION................................................................6-41

6.7.9 CONDENSATION PREVENTION...................................................6-41

6.7.10 PAPER FEED TIMING CHART....................................................6-42

6.8 IMAGE TRANSFER AND PAPER SEPARATION...................................6-43

6.8.1 OVERVIEW....................................................................................6-43

6.8.2 TRANSFER AND SEPARATION TIMING CONTROL....................6-43

6.8.3 PICK-OFF PAWL OPERATION......................................................6-44

6.9 PAPER TRANSPORT.............................................................................6-45

6.9.1 OVERVIEW....................................................................................6-45

6.10 FUSING UNIT........................................................................................6-46

6.10.1 OVERVIEW..................................................................................6-46

6.10.2 FUSING PRESSURE CONTROL MECHANISM...........................6-48

6.10.3 TEMPERATURE AND PRESSURE CONTROL...........................6-49

6.10.4 FUSING CONTROL SETTING TABEL.........................................6-52

6.10.5 HOT ROLLER CLEANING ...........................................................6-53

6.10.6 HOT ROLLER THERMOFUSE.....................................................6-53

6.10.7 FUSING UNIT DRIVE MECHANISM............................................6-53

6.10.8 WRINKLE PREVENTION.............................................................6-54

6.11 PAPER EXIT.........................................................................................6-55

6.11.1 OVERVIEW..................................................................................6-55

6.11.2 PAPER EXIT DRIVE.....................................................................6-55

6.11.3 PAPER EXIT ACCESS.................................................................6-55

6.11.4 SWITCHING EXITS......................................................................6-56

6.11.5 EXIT JAM DETECTION................................................................6-56

6.12 ELECTRICAL COMPONENTS..............................................................6-57

6.12.1 MCU .............................................................................................6-57

6.12.2 IPU................................................................................................6-59

6.12.3 IOB ...............................................................................................6-60

6.12.4 VDB..............................................................................................6-60

6.12.5 RFDB............................................................................................6-60

6.12.6 FPDB............................................................................................6-60

6.12.7 PSU..............................................................................................6-61

SPECIFICATIONS

1 COPIER ENGINE.................................................................................SPEC-1

2 2ND ROLL TRAY (OPTION)................................................................SPEC-4

3 MACHINE CONFIGURATION..............................................................SPEC-5

v

Page 10

25 May, 2001 PREPARATION

1. INSTALLATION PROCEDURE

1.1 PREPARATION

1.1.1 ENVIRONMENT

1. Temperature Range:

2. Humidity Range: 15% to 80% RH

3. Ambient Illumination: Less than 1,500 Lux (do not expose to direct

4. Ventilation: Minimum space 20 m3 (approx. 700 cubic ft.)

5. Ambient Dust: Less than 0.075 mg/m

6. If the installation place is air-conditioned or heated, place the machine as

follows:

a) Where it will not be subjected to sudden temperature changes from low to

high, or vice versa.

b) Where it will not be directly exposed to cool air from an air conditioner in

the summer.

c) Where it will not be directly expo s ed to reflected heat from a spa ce heater

in the winter.

7. Avoid placing the machine in an area filled with corrosive gases.

10°C to 32°C (59°F to 86°F)

sunlight).

Room air should turn over at least 3 times per hour.

3

Installation

8. Avoid any area higher than 2,000 m (6,500 ft) above sea level.

9. Place the machine on a strong and level base.

10. Avoid any area where the machine may be subjected to frequent strong

vibration.

1-1

Page 11

PREPARATION 25 May, 2001

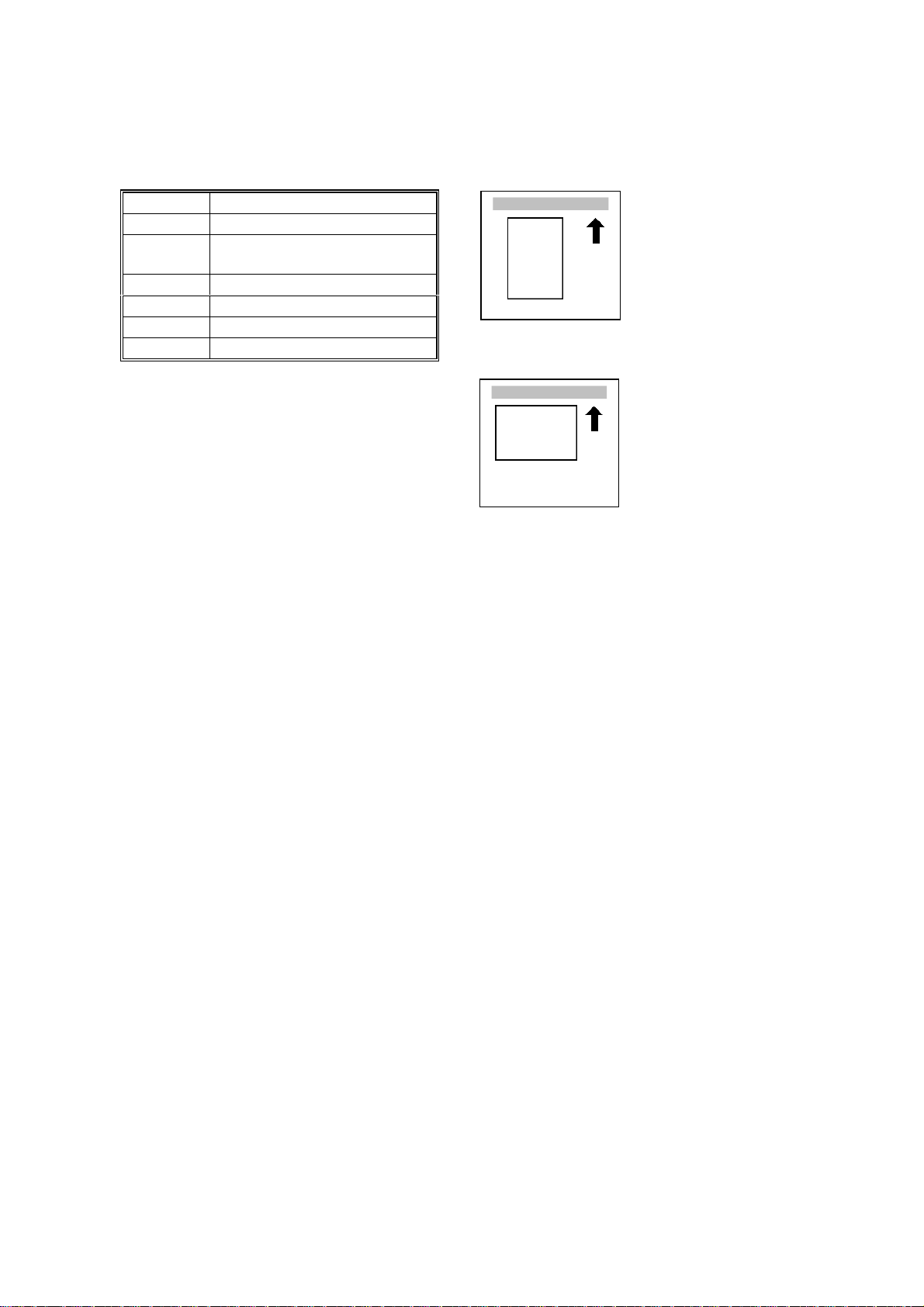

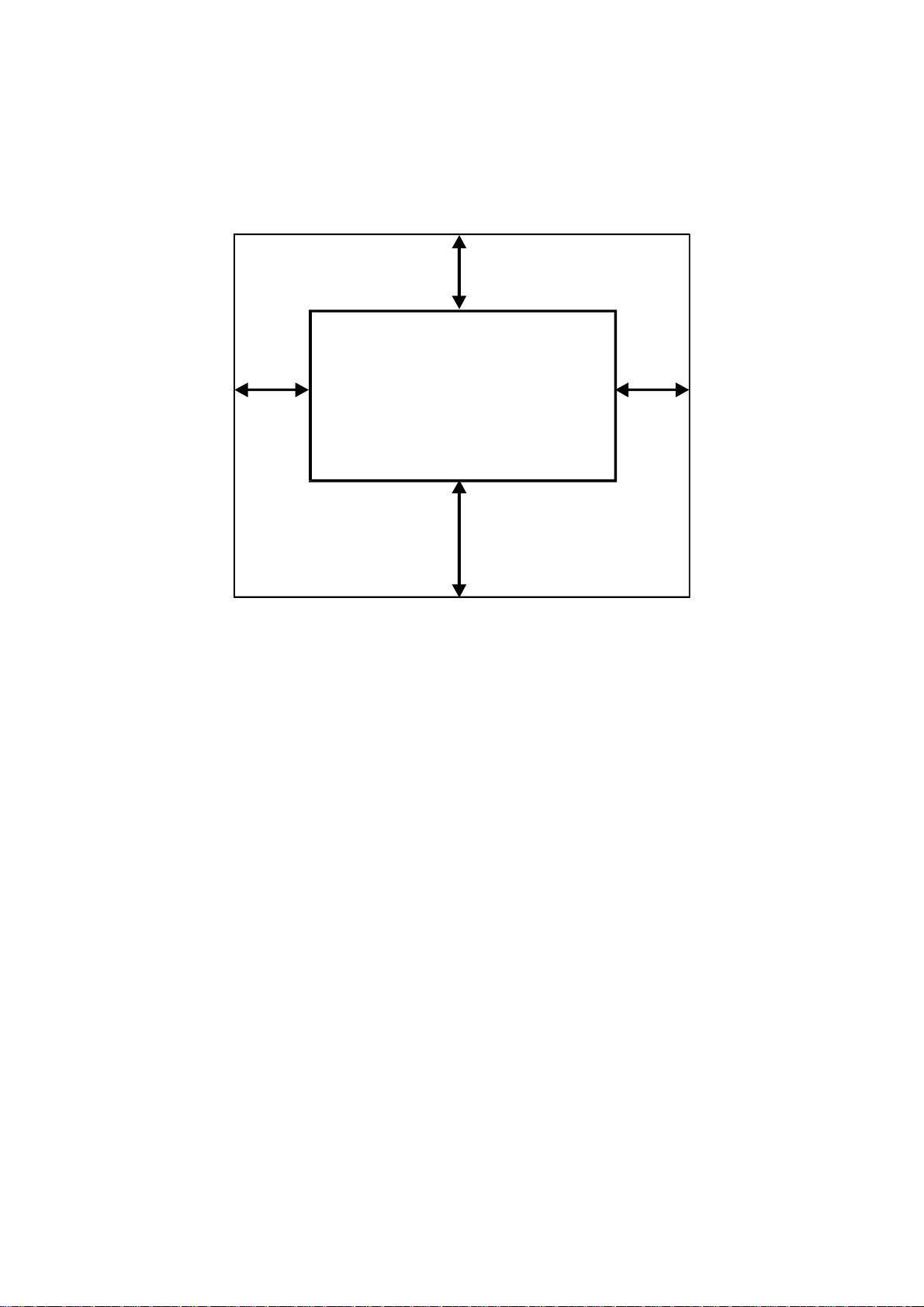

1.1.2 MINIMUM SPACE REQUIREMENTS

Back 450 mm

Left

400 mm

1. Front: 1,000 mm (39")

2. Back: 450 mm (18")

3. Right: 450 mm (18")

4. Left: 400 mm (16")

1.1.3 MACHINE LEVEL

Right

450 mm

Front 1,000 mm

B010I520.WMF

1. Front to back: Within 0.15 mm/1000 mm (0.006”/39.4”) of level

2. Right to left: Within 0.15 mm/1000 mm (0.006”/39.4”) of level

Make sure that the machine is level using a carpente r’s level.

1-2

Page 12

25 May, 2001 PREPARATION

1.1.4 POWER SOURCE

The machine must be installed in a building /facility equipped with a protective

device such as a circuit breaker, as the machine relies on such devices for

protection against over-current and short circuits

1. Input Voltage Level: 120V, 60Hz

More than 20 A (for the U.S.A. version)

220 ~ 240V, 50/60Hz

More than 10 A (for the European version)

Installation

2. Permissible Voltage

± 10%

Fluctuation:

3. Do not set anything on the power cord.

NOTE: 1) Make sure the plug is firmly inserted in the outlet.

2) Avoid multi-wiring.

1-3

Page 13

COPIER INSTALLATION PROCEDURE 25 May, 2001

1.2 COPIER INSTALLATION PROCEDURE

1.2.1 ACCESSORY CHECK

Check the accessories and their quantities against the following list:

Description Q’ty

Paper Holder ........................................................................... 4

Original Guide Tray.................................................................. 1

Original Guide Tray Hinge – Right........................................... 1

Original Guide Tray Hinge – Left............................................. 1

Upper Original Exit Guide........................................................ 3

Upper Original Exit Guide Joint (B010-22, -27 only)................ 2

Rear Original Tray................................................................... 3

Rear Copy Tray Guide - Large ................................................ 1

Rear Copy Tray Guide - Small................................................. 1

Rear Copy Tray....................................................................... 3

Rear Copy Tray Holder............................................................ 3

Cushion - Rear Copy Tray Holder (B010-22, -27 only)............ 3

Guide Mylar - Small................................................................ 3

Guide Mylar - Large................................................................. 1

Front Copy Tray....................................................................... 1

Leveling Shoes........................................................................ 4

Tapping Screw – M4 x 8.......................................................... 6

Screw with Washer – M4 x 10................................................. 2

NECR (B010-17, -27 only).......................................................1

Decal - Operation (B010-22, -27 only).....................................1

Decal - Paper Tray (B010-22, -27 only)...................................1

Decal - Toner Supply (B010-22, -27 only)...............................1

Copy Instructions Guide (B010-17 only)..................................1

System Instructions (B010-17 only).........................................1

1-4

Page 14

25 May, 2001 COPIER INSTALLATION PROCEDURE

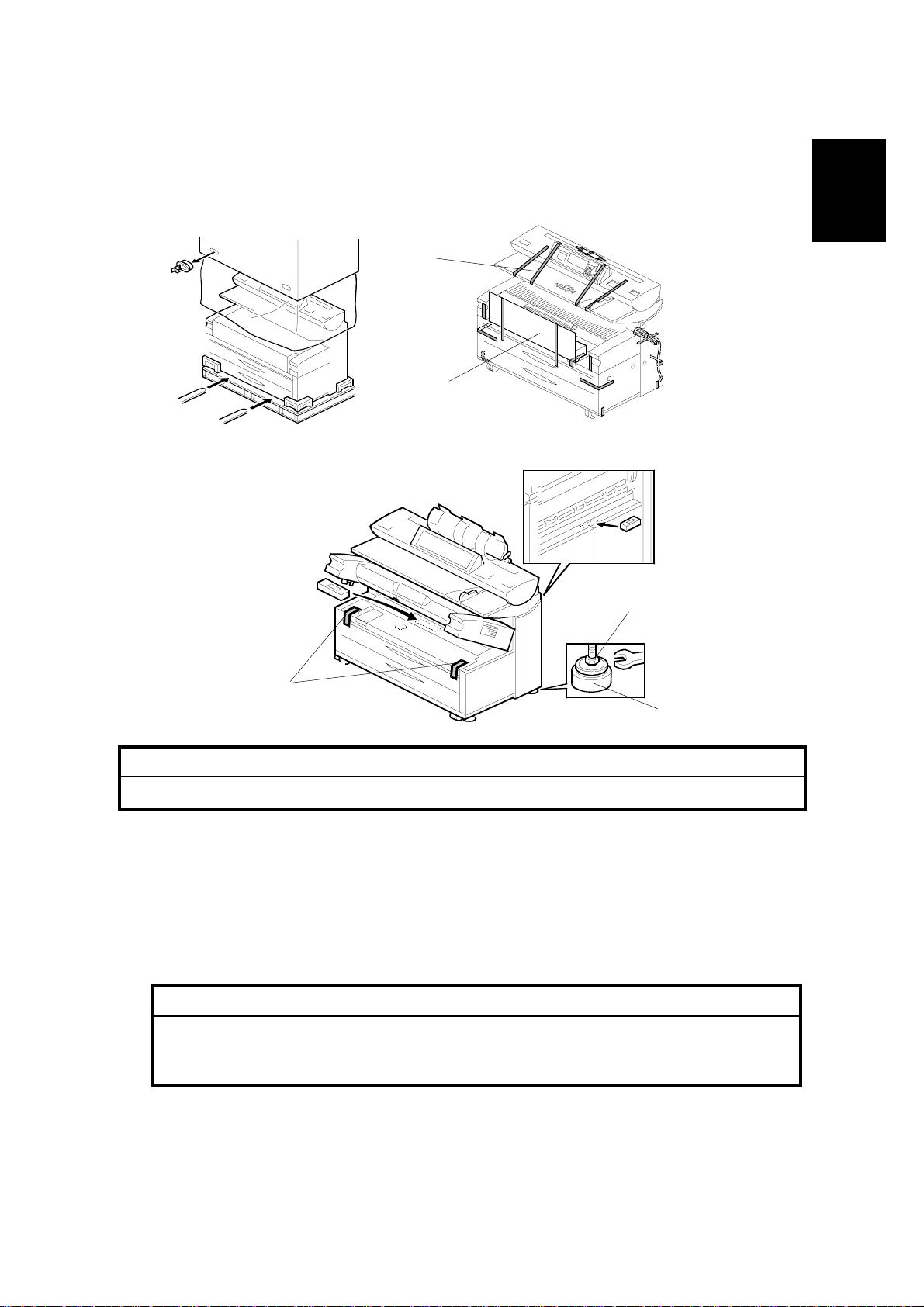

1.2.2 INSTALLATION PROCEDURE

NOTE: Since the installation procedure is not packed with the copier as an

accessory, always bring this manual with you.

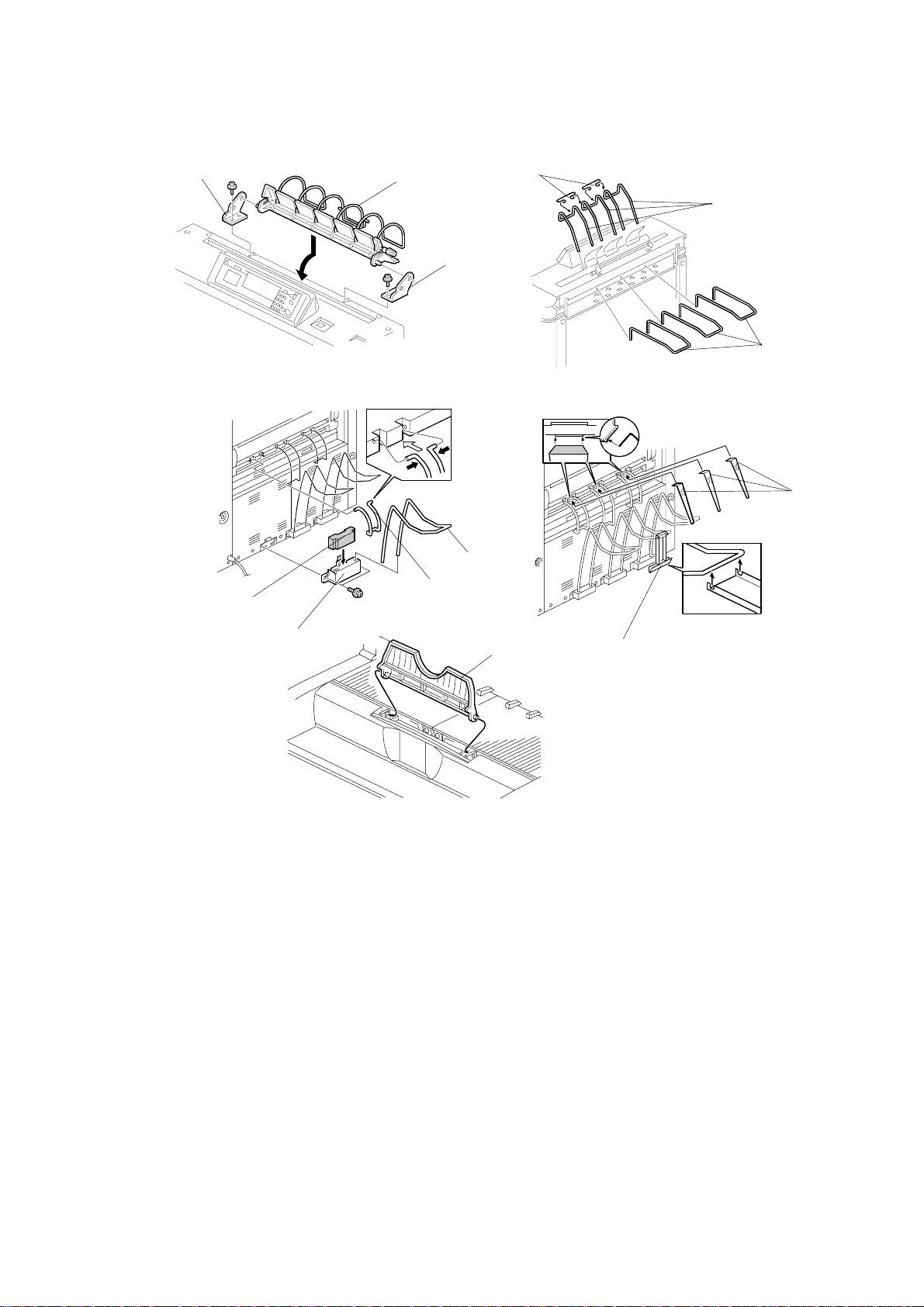

[A]

[B]

Installation

B010I103.WMF

B010I101.WMF

[E]

[C]

[D]

B010I107.WMF

!

CAUTION

Keep the power cord unplugged when starting the following procedure.

NOTE: 1) Keep the shipping retainers after installin g the machine. They will be

reused if the machine is moved to another location in the future.

2) Insert the leveling shoes [D] under the leveling feet [E], and level the

machine before starting the installation.

1. Unpack the machine box and place the copier onto a flat floor using lifting

equipment (a fork lift).

!

CAUTION

The machine weighs approximately 225 kg (496 LB). If a fork lift is not

available, at least 4 people, one on each corner of the machine, are

needed to lift it from the pallet.

2. Remove the upper original tray pack [B] from inside the upper unit.

3. Remove all strips of tape [A], [C] as shown above.

1-5

Page 15

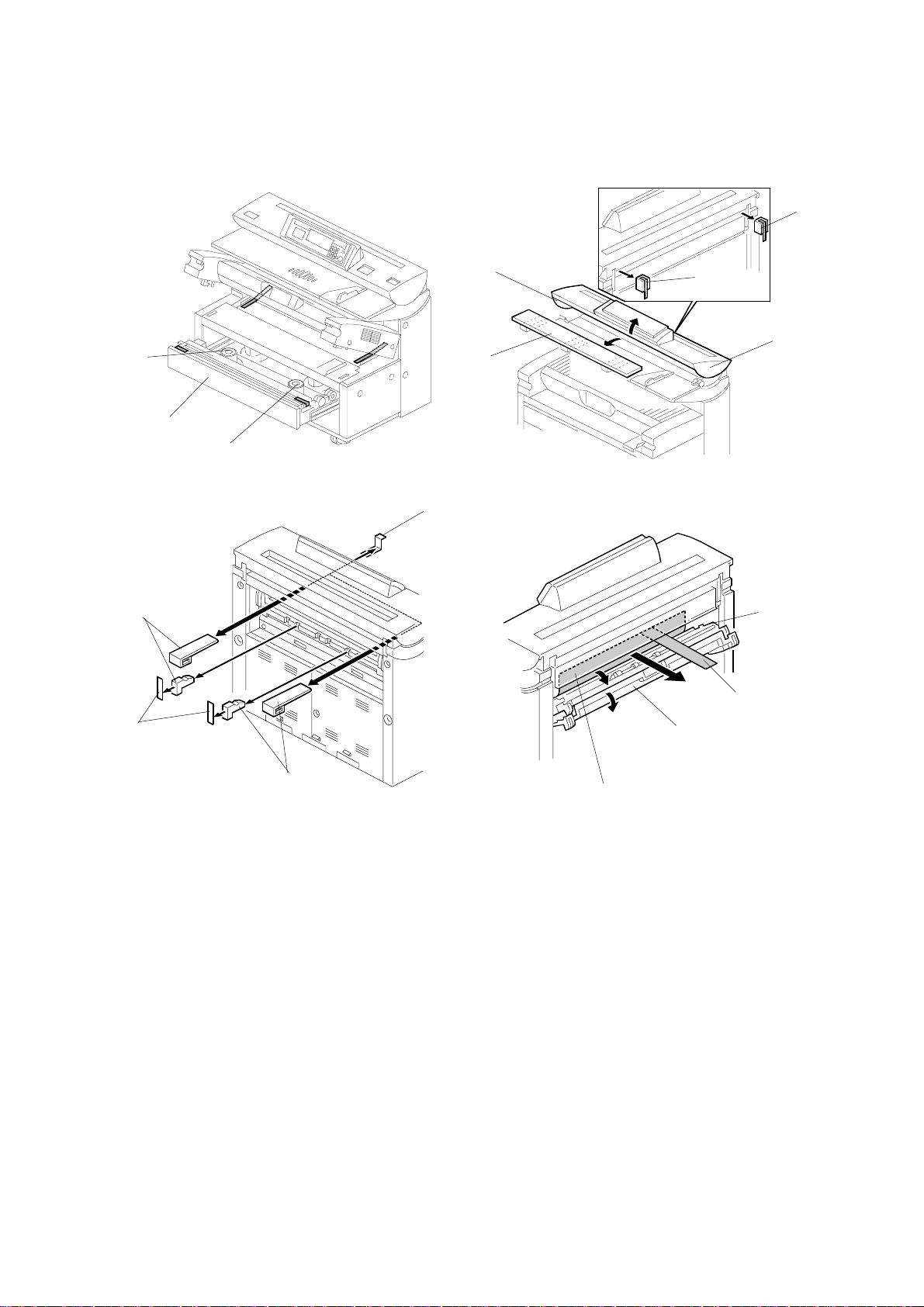

COPIER INSTALLATION PROCEDURE 25 May, 2001

Rear View

[C]

[B]

[H]

[A]

[B]

B010I102.WMF

[G]

[D]

[F]

[C]

[E]

B010I104.WMF

[K]

[L]

[I]

[H]

[M]

B010I212.WMF

[J]

B010I111.WMF

4. Pull out the upper tray [A] and remove strips of tape.

5. Take out the four paper holders [B]. Remove the tapes (x2 each).

6. At the rear, remove two shipping blocks [C] from the original junction gate.

7. Release the lock lever [D]. Open the original feed unit [E] and remove the

cushions and bubble pack [F].

8. At the front, remove the tapes [G], and then from the rear remove the shipping

blocks [H] and tape [I].

9. Open the exit cover [J] and junction gate unit [K], then pull the red ribbon [L] to

remove the protection sheet [M].

1-6

Page 16

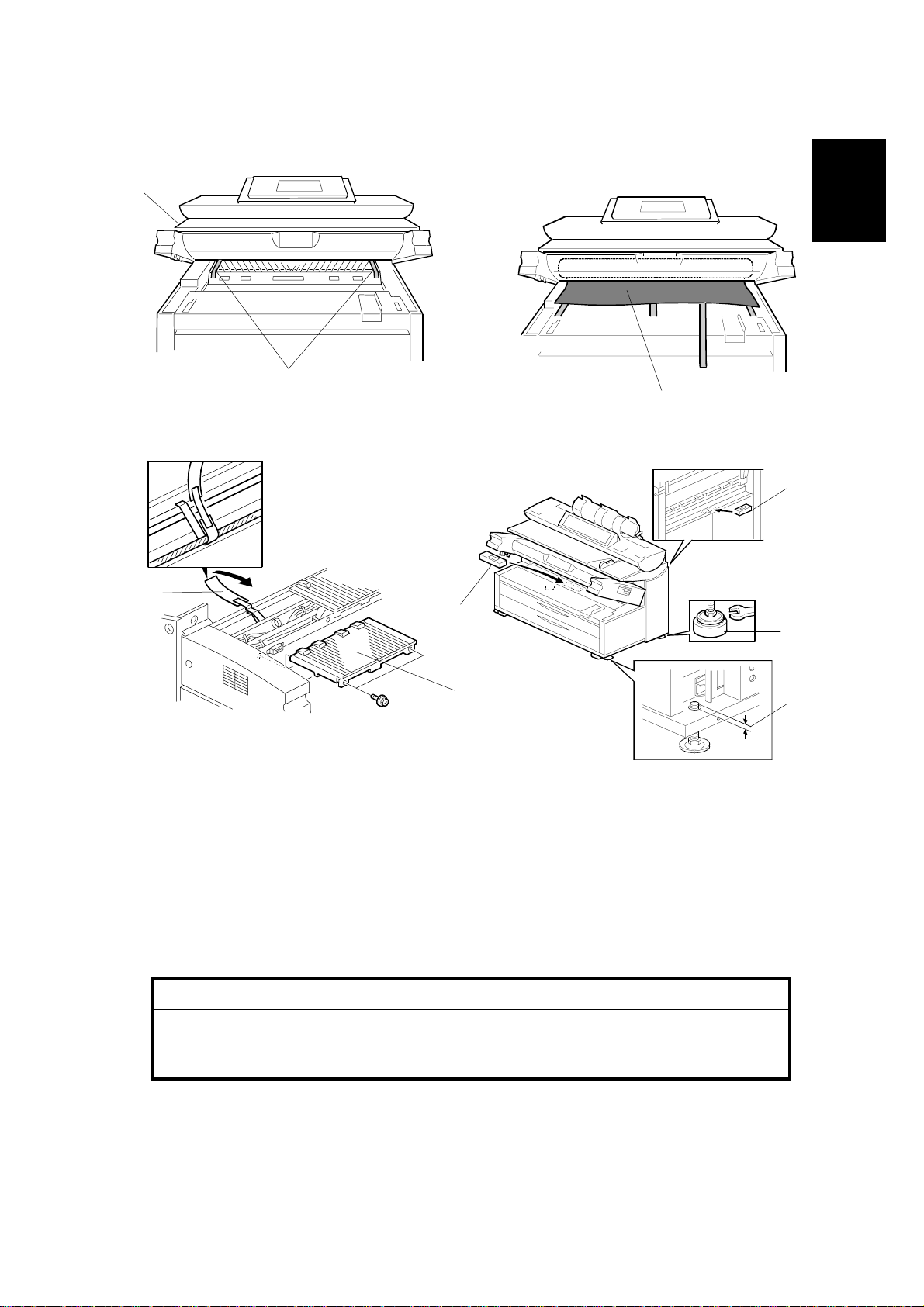

25 May, 2001 COPIER INSTALLATION PROCEDURE

[A]

Installation

[E]

[B]

B010I108.WMF

B010I203.WMF

[F]

[D]

[C]

B010I109.WMF

[F]

[G]

[H]

B010I107.WMF

10. Open the upper unit [A] and remove two strips of tape [B] from the transfer

corona unit.

11. At the front, peel off three strips of tape, and take out the drum protection sheet

[C] by pulling out the red tape.

12. Open the toner hopper cover, remove the left exit tray [D], remove the strip of

tape [E] from the corona wire cleaner, then reinstall the exit tray (! x 2).

!

CAUTION

The tape is looped around the corona wire drive screw. To avoid

damaging the drive screw, gently peel the tape from the mylar or cut it

with scissors.

13. Place a level [F] in the middle of the guide pla te as shown in the illustration.

Make the machine level by turning the bolts [G] on the machine’s four feet.

NOTE: The gap [H] must be less than 2 mm for the bolt to clear the 3rd roll

feeder (option) when the feeder is opened and closed.

1-7

Page 17

COPIER INSTALLATION PROCEDURE 25 May, 2001

[B]

[F]

[G]

[A]

B010I105.WMF

B010I206.WMF

[I]

[B]

[H]

[L]

[D]

[K]

[C]

[E]

B010I106.WMF

[J]

B010I207.WMF

B010I208.WMF

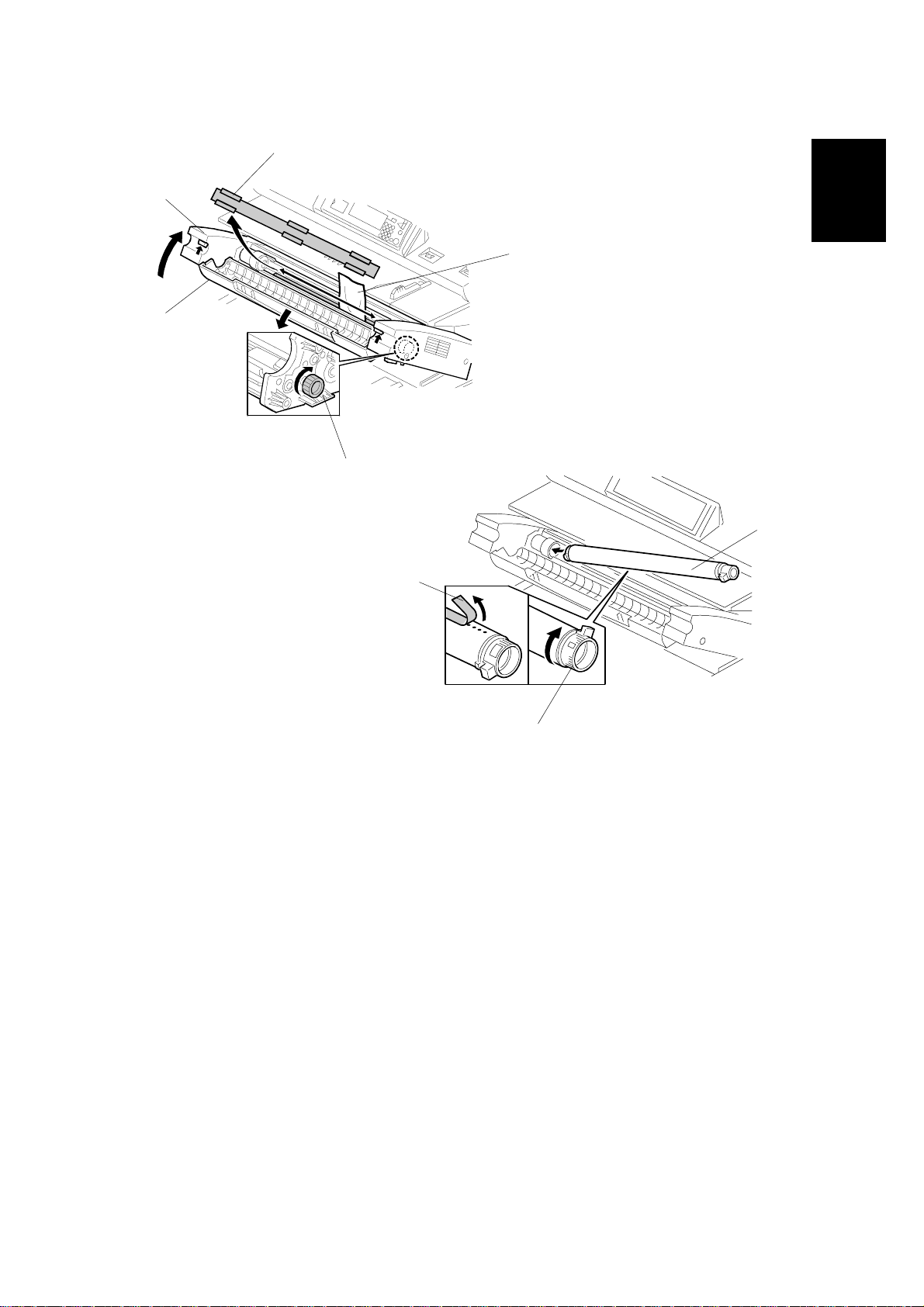

14. Install the upper original tray [A] by using the original guide tray hinges [B] (! x

1 each).

15. Install the upper original exit guides [C], joints [D] and the rear original trays [E].

16. Adhere the cushions [F] to the rear copy tray holders [G].

17. Install the rear copy tray holders (! x 2 each) and insert the rear copy trays [H].

NOTE: The rear copy tray holders must be installed to cover the holes and the

bare section of the frame.

18. Attach the large rear copy tray guide [I] in the center, then attach the two small

rear copy tray guides on either side of the large guide.

19. Attach the small guide mylars [J]. The guide mylars should be on the rear copy

tray guide.

20. Hook the large guide mylar [K] on the rear center copy tray.

21. Attach the front copy tray [L].

1-8

Page 18

25 May, 2001 COPIER INSTALLATION PROCEDURE

[C]

[A]

[D]

[B]

B010I100.WMF

[E]

[F]

Installation

[G]

B010I110.WMF

[H]

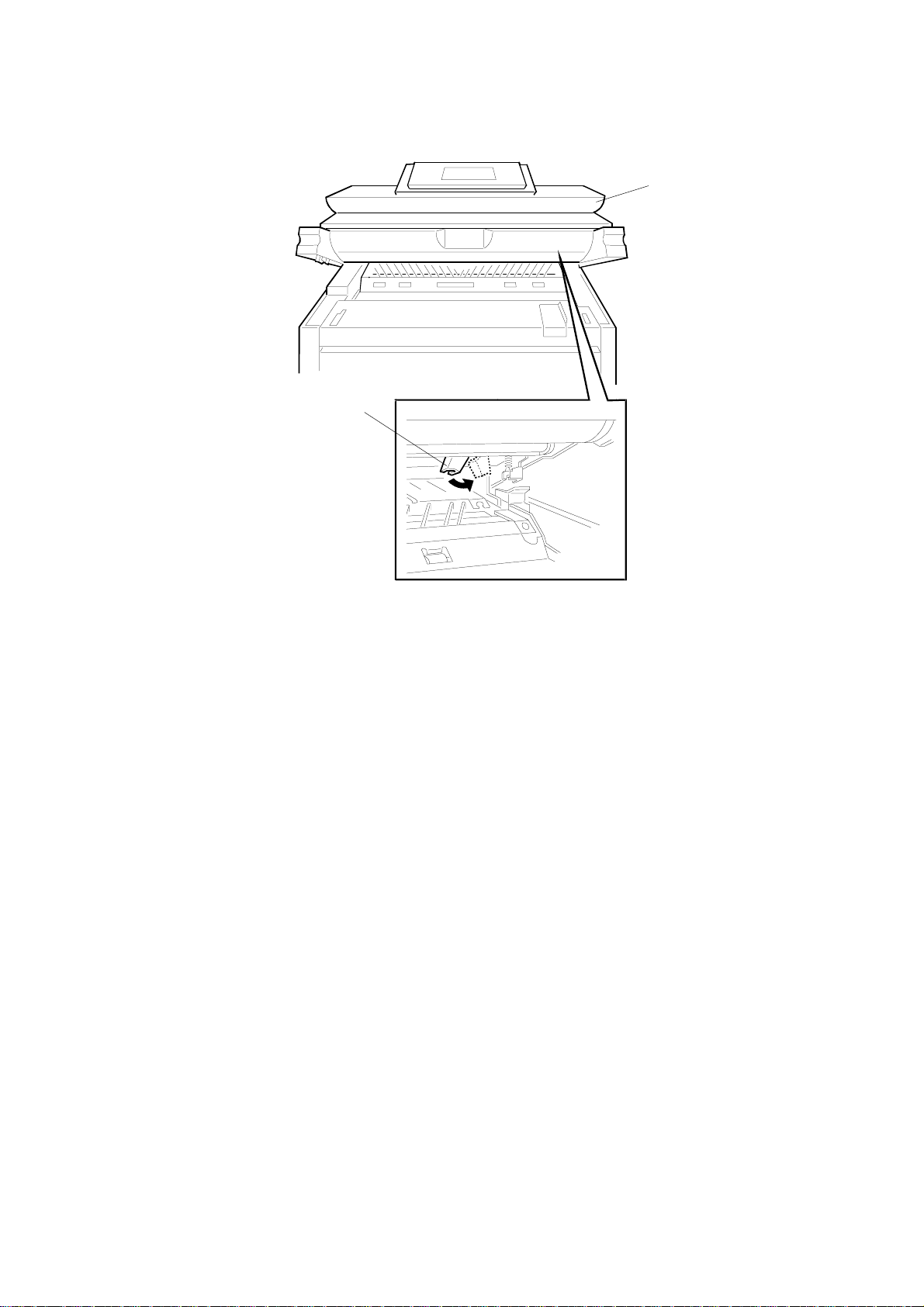

22. Raise the upper unit [A] and open the toner hopper cover [B].

23. Remove the sheet [C] covering the developer entrance.

24. Pour 2.4 kg (1.2 kg x 2) of developer [D] into the development unit evenly

across its width, while rotating the knob [E] clockwise as shown.

25. Install the toner cartridge [F]. Refer to the decal attached on the left side of the

machine.

1) Shake the cartridge 5 to 10 times and insert it into the toner hopper.

2) Peel off the green tape [G] from right to left to expose the clear tape and

toner supply holes.

3) Rotate the knob [H] of the cartridge clockwise until it stops.

26. Close the toner hopper cover and upper unit.

1-9

Page 19

COPIER INSTALLATION PROCEDURE 25 May, 2001

[A]

[B]

B010I521.WMF

27. Plug in the power supply cord and turn on the main switch.

28. Enter SP mode as follows:

1) Press the Clear Modes key

"

.

2) Enter #$%

3) Hold down Clear/Stop & for more than 3 seconds .

4) On the touch panel, press Copy SP.

NOTE: Do not attempt to make copies until after SP3-001-02 has finished in

step 31.

29. To initialize the developer, execute SP2801 (Developer Initial Setting). This

takes two minutes.

30. To initialize the drum, execute SP2923 002 (Drum Set Mode). This takes a few

seconds.

31. Open the upper unit [A], turn the pressure lever [B] to the right to push the

cleaning blade against the drum, then close the upper unit.

32. To initialize the ID sensor, execute SP3001 002. This takes a few seconds.

33. Set SP2924 (Developer Mixing) to “YES”.

34. Exit the SP mode and make copy samples.

1-10

Page 20

25 May, 2001 ROLL TRAY INSTALLATION PROCEDURE

1.3 ROLL TRAY INSTALLATION PROCEDURE

1.3.1 ACCESSORY CHECK

Check the accessories and their quantities against the following list:

Description Q’ty

1. Positioning Pin.....................................................................2

2. Screw – M4x6......................................................................4

3. Flat Harness (taped to right side of machine)......................1

4. Hexagonal Tapping Screw with Flat Washer – M4 x 8 ........4

5. Screw with Spring Washer – M4 x 6....................................1

6. Right Slide Rail....................................................................1

7. Left Slide Rail ......................................................................1

8. Stepped Screw – M4...........................................................4

9. Screw – M4 x 6....................................................................16

10. Positioning Pins – (M4 x 4)................................................2

11. Harness Clamp – FCW52..................................................2

12. Harness Clamp – LWS-0511Z...........................................2

13. Harness Clamp – LWS-2111Z...........................................1

Installation

14. Tapping Bind Screw M3x6................................................. 4

15. Edging ...............................................................................1

16. Screw – M4x6....................................................................6

17. Decal – Tray 3................................................................... 1

18. Paper Holder ....................................................................2

19. Installation Procedure........................................................1

20. Decal – Operation (B340-27 only) ....................................1

21. Decal – Roll Feeder (B340-27 only)...................................1

1-11

Page 21

ROLL TRAY INSTALLATION PROCEDURE 25 May, 2001

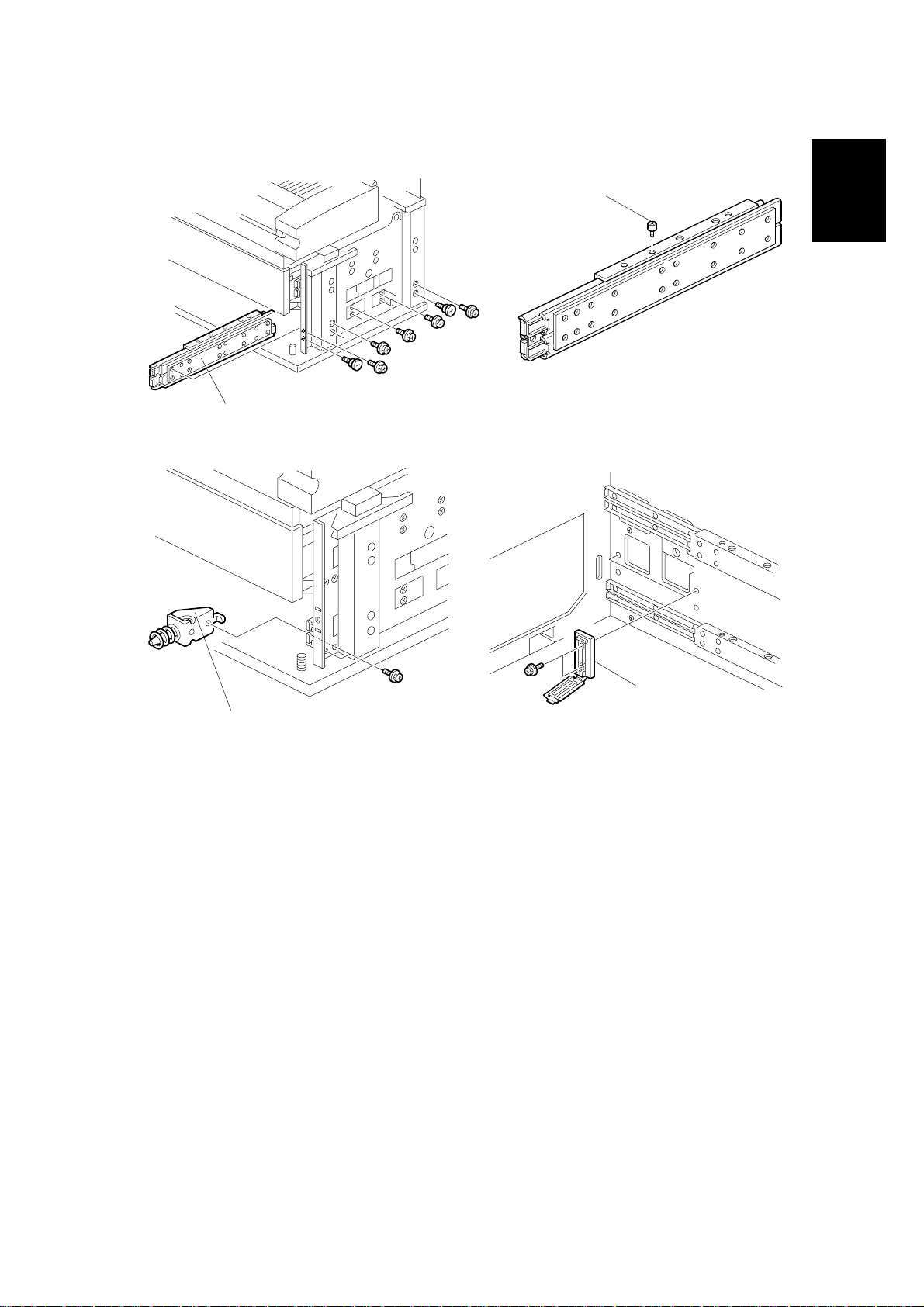

1.3.2 INSTALLATION PROCEDURE

[D]

[C]

[G]

[A]

[E]

[J]

[E]

[B]

B010I501.WMF

[F]

B010I502.WMF

[G]

[I]

[H]

!

CAUTION

1. Unplug the main machine power cord before starting the following procedure.

2. Before starting the installation, insert the leveling shoes under the leveling feet, and

level the machine.

3. The machine is very heavy. To avoid serious injury, make sure that you have a

sufficient number of people to assist, and use proper lifting equipment for lifting or

moving.

4. The feed tray is weighs 32 kg (14.5lbs) and requires at least two people to lift and

install.

B010I503.WMF

NOTE: Keep the shipping retainers after installing the machine. They will be

reused if the machine is moved to another location in the future.

1. Turn off the copier main switch.

2. Remove the following covers:

1) Right front [A] and rear [B] covers (4 screws, 6 screws).

2) Left front [C] and rear [D] covers (4 screws, 6 screws).

3) Rear covers [E] (9 screws).

3. Remove the lower cover [F] and two brackets [G] (2 screws each).

4. Remove the power supply unit [H] (4 screws, 16 connectors).

NOTE: Before removing the Line and Neutral bayonet connectors [I] from the

PSU, mark them “L” and “N” to prevent reversing their positions when they are

re-attached. “L” (Line) is on the right, and “N” (Neutral) is on the left.

5. Remove the toner collection bottle [J]

1-12

Page 22

25 May, 2001 ROLL TRAY INSTALLATION PROCEDURE

[C]

B010I505.WMF

[A, B]

B010I504.WMF

Installation

[E]

[D]

B010I506.WMF

B010I507.WMF

6. Install the right and left slide rails [A] ,[B] (2 stepped screws, 5 screws ea.

M4x6).

7. Install the positioning pins [C] in the center hole on each slide rail.

8. Install the positioning pins [D] (2 screws ea. M4x6).

9. Install two harness clamps [E] (2 tapping bind screws ea. M3x6).

1-13

Page 23

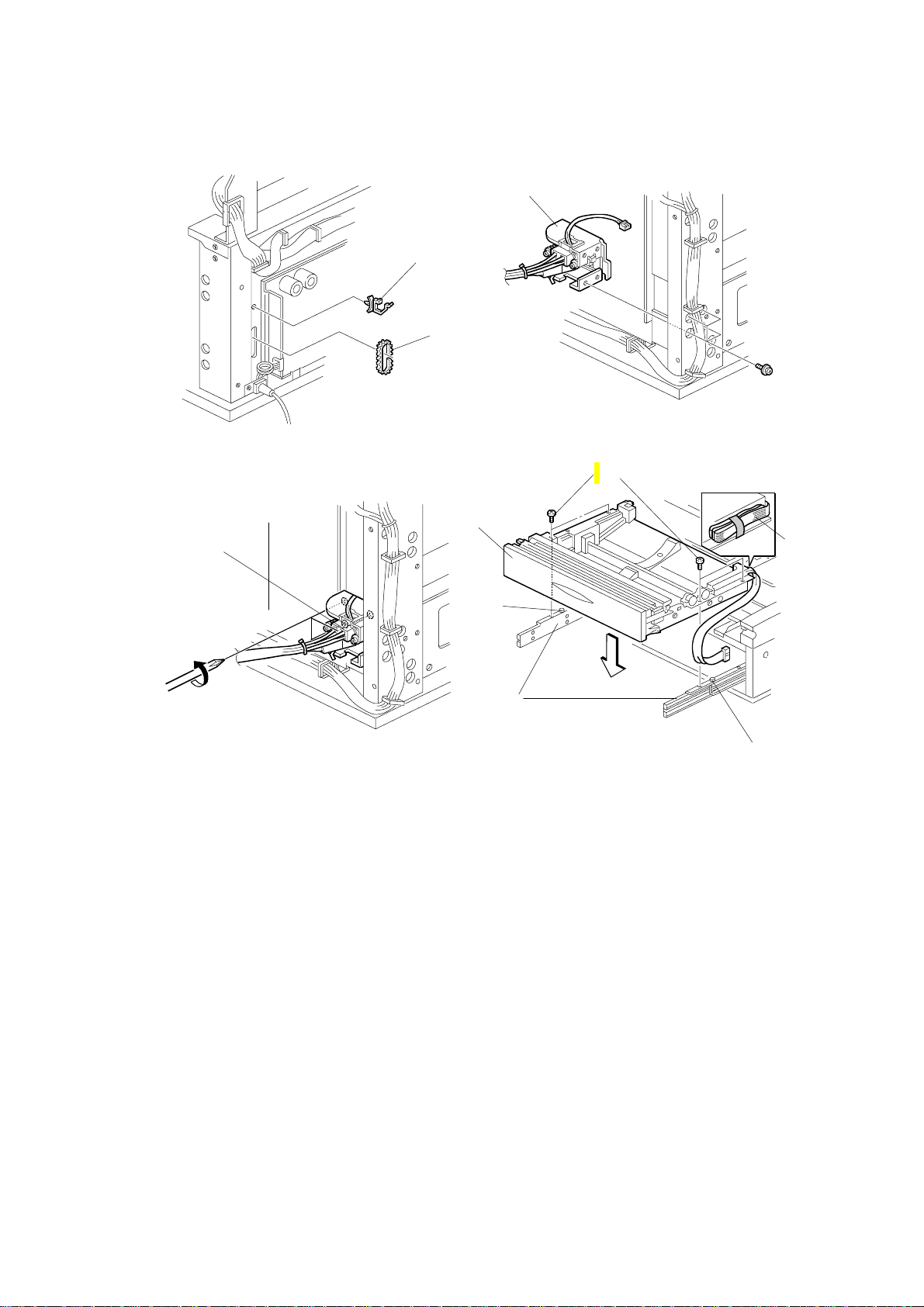

ROLL TRAY INSTALLATION PROCEDURE 25 May, 2001

[C]

[A]

[B]

B010I509.WMF

B010I508.WMF

[H]

[F]

[D]

[G]

[I]

B010I510.WMF

B010I511.WMF

[G]

10. Install the harness clamp [A] and edging [B].

11. Install the connector [C] (4 hex. tapping screws M4 x 8 with flat washers).

12. Loosen the three screws that secure the drawer connector [D].

13. Remove the shipping material from the flat cable [E].

14. Install the 3rd roll feeder [F] on the slide rails, and fit it over the positioning pins

[G].

[E]

15. Use the four screws [H] (2 screws ea. M4 x 6) to attach the tray to the side rails

[I].

1-14

Page 24

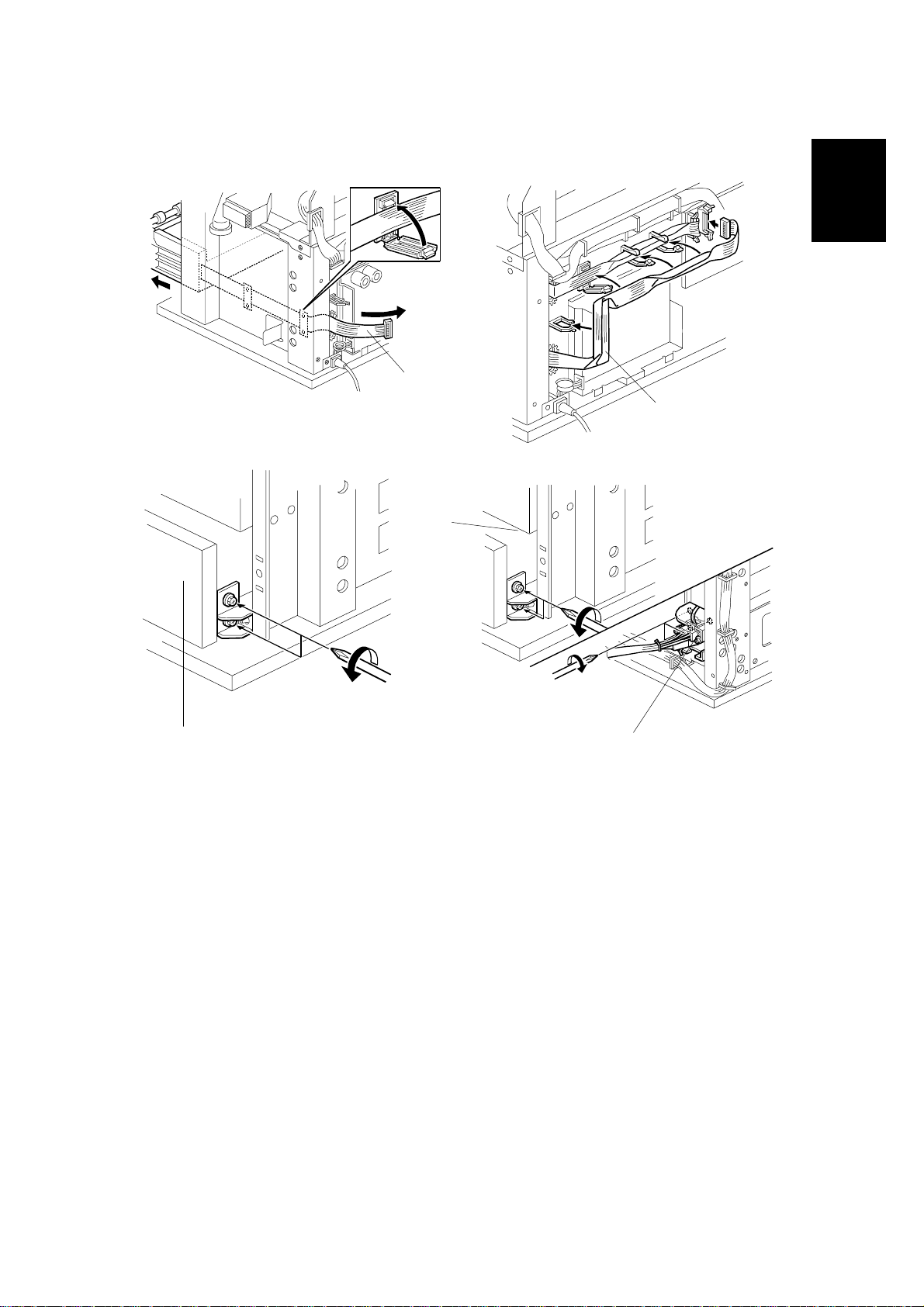

25 May, 2001 ROLL TRAY INSTALLATION PROCEDURE

[A]

Installation

B010I513.WMF

Tray 1

[A]

B010I514.WMF

[B]

Tray 2

B010I552.WMF

[B]

[C]

B010I551.WMF

16. Draw out the 3rd roll feeder and route the flat cable [A] as shown.

17. Loosen the positioning brackets [B] of the 3rd roll feeder (2 screws each).

18. Remove the plastic bags from the lock levers and push in the 3rd roll feeder

slowly.

19. Align the positioning bracket and the drawer connector [C] then secure them (2

screws each, 3 screws).

1-15

Page 25

ROLL TRAY INSTALLATION PROCEDURE 25 May, 2001

[B]

[E]

[A]

[G]

[F]

[A]

[D]

[C]

[A]

B010I553.WMF

[I]

[H]

B010I517.WMF

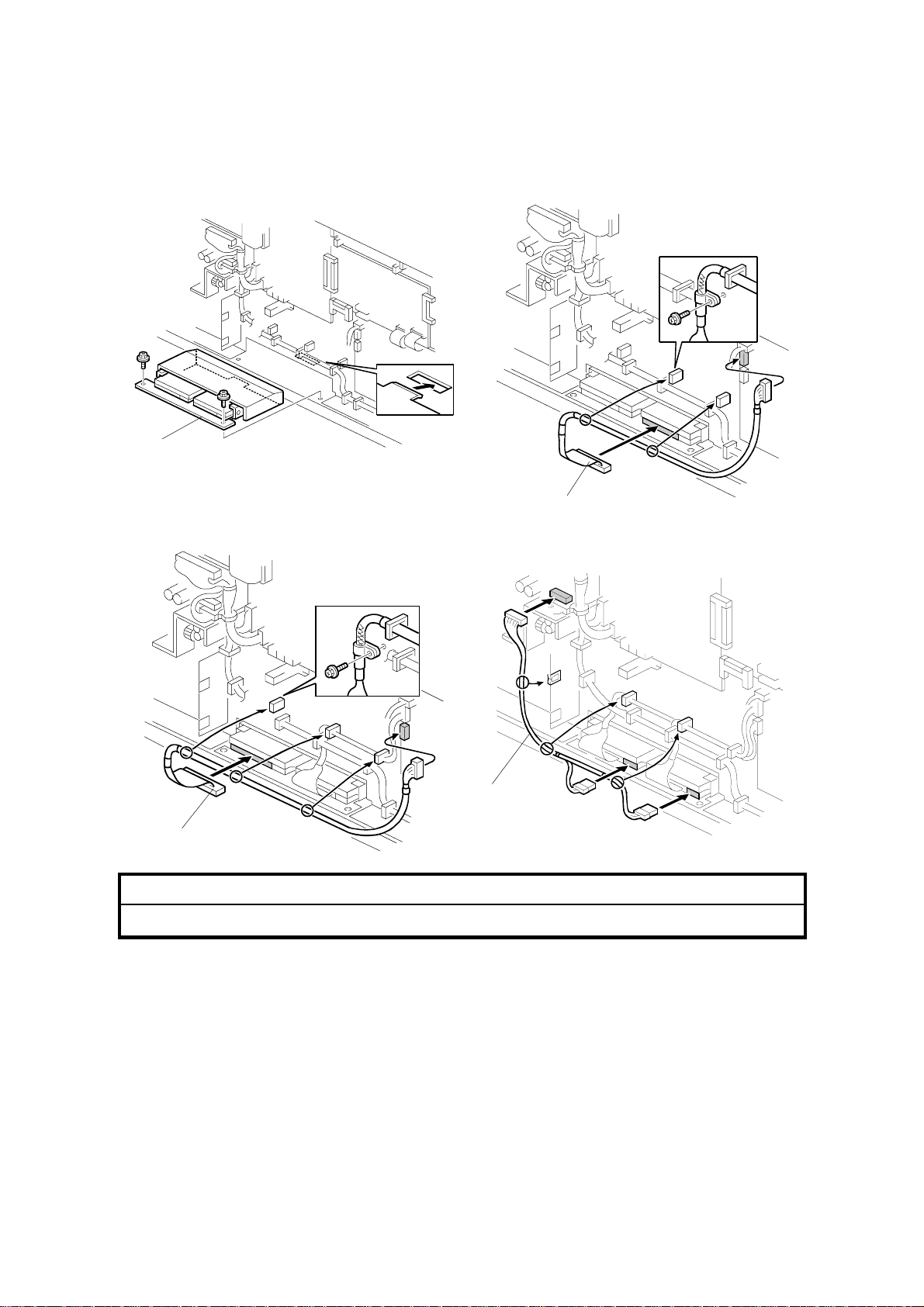

20. Install the two harness clamps [A] and connect the cables [B], [C], [D], and [E].

NOTE: Be sure to clamp cable [C, E] as shown with the pre-installed clamp [F].

21. Secure the ground (earth) wire [G] (1 screw M4x6 with spring washer).

22. Reinstall the lower front cover [H] and attach the decal [I] (2 hex. tapping

screws M4x8 with flat washer).

23. Reinstall the power supply unit, toner collection bottle, and covers.

NOTE: Connect the “N” (Neutral) connector on the left and connect the “L”

(Line) connector on the right.

!

CAUTION

When you position the power supply unit for re-installation, make sure that

the flat ribbon cable is not pinched at the top right.

1-16

Page 26

25 May, 2001 HDD INSTALLATION PROCEDURE

1.4 HDD INSTALLATION PROCEDURE

1.4.1 ACCESSORY CHECK

Check the accessories and their quantities against the following list:

Description Q’ty

1. HDD.....................................................................................1

2. DC Harness – Power Source...............................................1

3. DC Harness.........................................................................2

4. Harness Clamp....................................................................2

5. Philips Tapping Screw – M4 x 8...........................................2

6. Philips Tapping Screw – M3 x 8...........................................2

Installation

1-17

Page 27

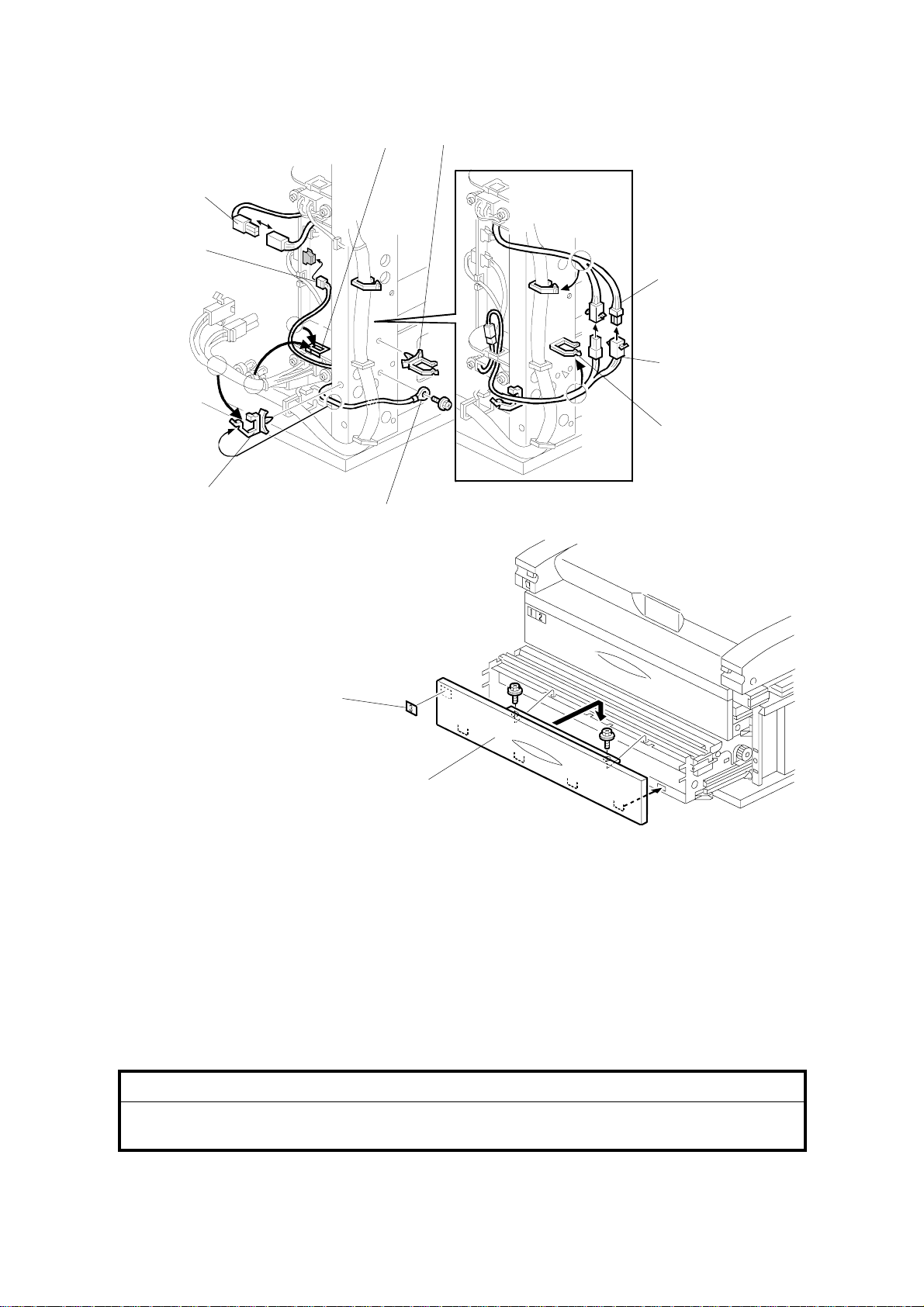

HDD INSTALLATION PROCEDURE 25 May, 2001

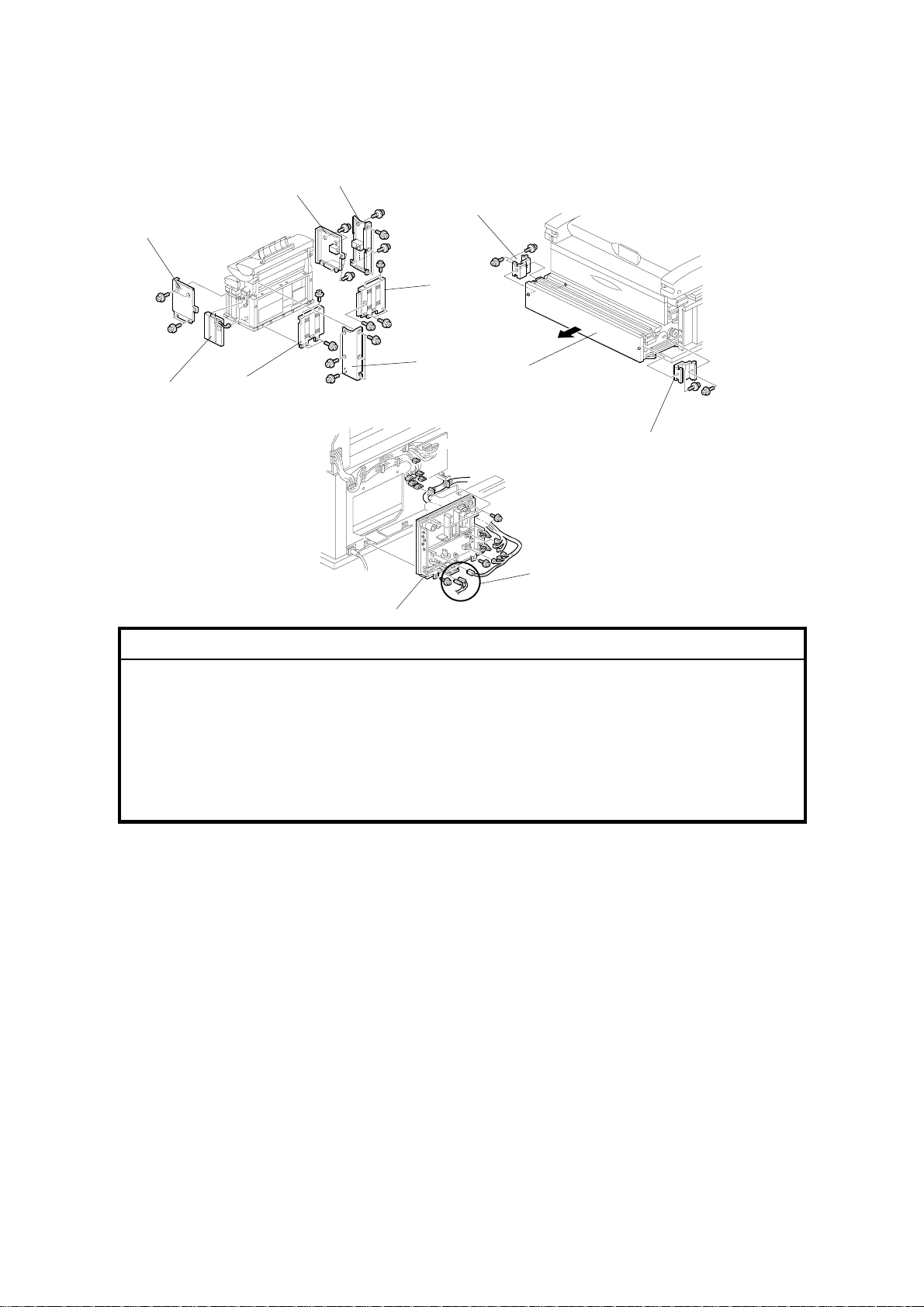

1.4.2 INSTALLATION PROCEDURE

[A]

B010I521A.WMF

[B]

B010I522.WMF

[C]

[B]

B010I524.WMF

B010I523.WMF

!

CAUTION

Unplug the power cord before starting the following procedure.

1. Remove the copier right and left rear covers (! x 9).

2. Remove the serial number decal from the HDD unit and attach it on the rear

frame, next to the machine’s serial number decal.

3. Remove 2 cushions from the HDD unit.

4. Install the HDD unit [A] onto the base plate (! x 2).

5. Connect the DC harnesses [B] (! x 1, " x 2 ea.).

6. Connect the power source DC harnesses [C] (" x 3).

1-18

Page 28

25 May, 2001 HDD INSTALLATION PROCEDURE

7. Enter SP mode as follows:

1) Press ".

2) Enter #$%

3) Hold down & for more than 3 seconds.

4) On the touch panel, press Copy SP.

8. Enter 4960 015 (HDD Connection On/Off) and then press On.

9. Turn off the main switch and reassemble the machine.

Installation

1-19

Page 29

STAMP BOARD INSTALLATION PROCEDURE 25 May, 2001

1.5 STAMP BOARD INSTALLATION PROCEDURE

1.5.1 ACCESSORY CHECK

Check the accessories and their quantities against the following list:

Description Q’ty

1. Stamp Board........................................................................1

1.5.2 INSTALLATION PROCEDURE

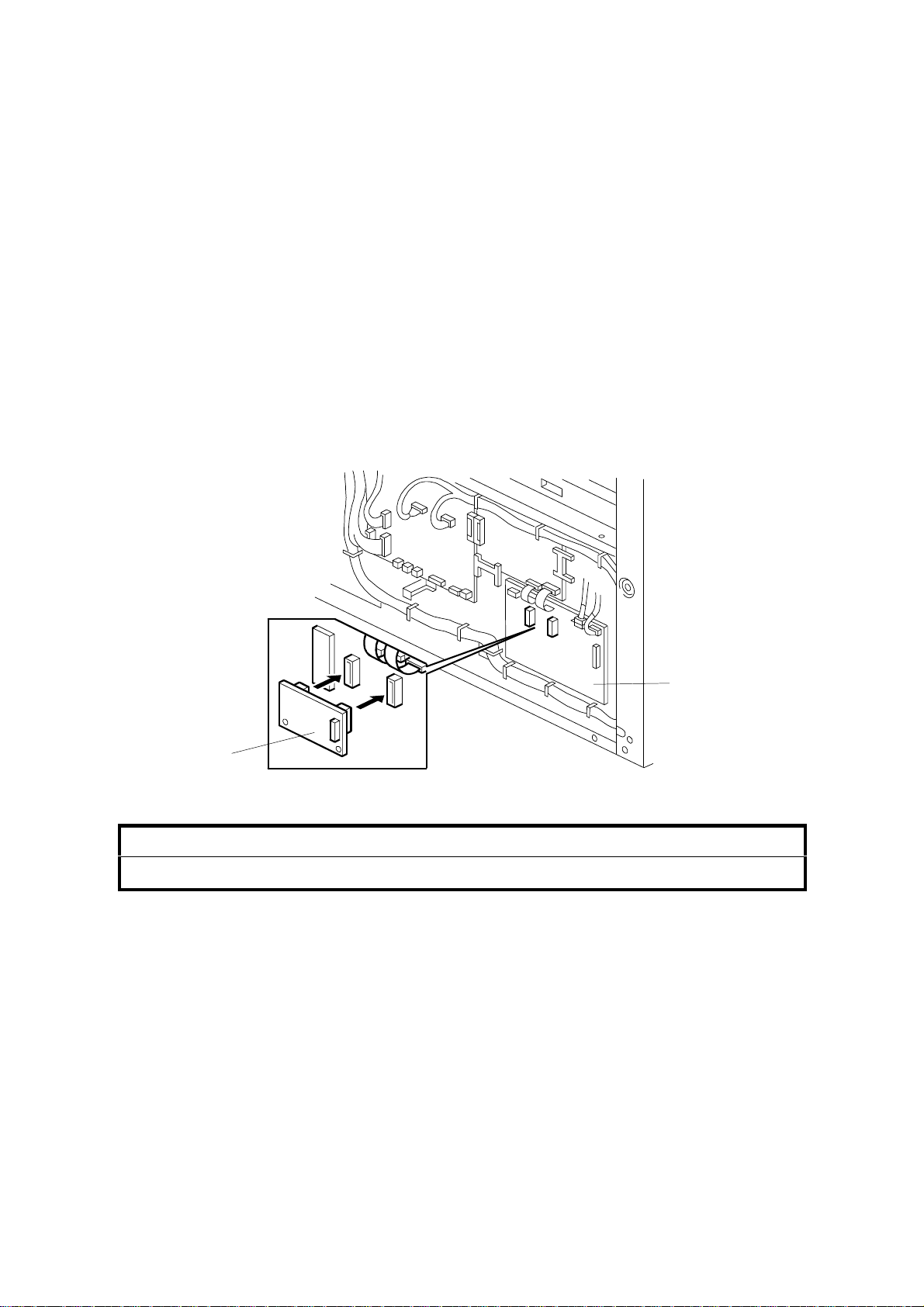

[B]

[A]

B010I204.WMF

!

CAUTION

Keep the power cord unplugged when doing the following procedure.

1. Remove the copier rear left cover (! x 5).

2. Install the stamp board [A] on the IPU board [B].

3. Plug in the power cord and turn on the main switch.

4. Enter SP mode as follows:

1) Press ".

2) Enter #$%

3) Hold down & for more than 3 seconds.

4) On the touch panel, press Copy SP.

5. Enter 5137 (Stamp Function On/Off), and then press Enabled.

6. Reassemble the machine.

1-20

Page 30

25 May, 2001 ORIGINAL TRAY INSTALLATION PROCEDURE

1.6 ORIGINAL TRAY INST ALLATION PROCEDURE

1.6.1 ACCESSORY CHECK

Check the accessories and their quantities against the following list:

Description Q’ty

1. Base Frame.........................................................................2

2. Base Stay............................................................................2

3. Middle Frame.......................................................................2

4. Original Tray Stay................................................................2

5. Original Tray........................................................................1

6. Size Decal Sheet ................................................................1

7. Original Stopper...................................................................2

8. Original Guide......................................................................2

9. Cap – Base Frame...............................................................2

10. Cap – Original Tray Stay ..................................................2

11. Hexagonal Bolt – M8 x 40..................................................12

12. Washer – 8 mm ................................................................20

Installation

13. Tapping Screw – M4 x 8 ...................................................6

14. Hex Nut – M8 ....................................................................8

15. Caster – φ40......................................................................2

16. Caster – φ40 Stopper.........................................................2

1-21

Page 31

ORIGINAL TRAY INSTALLATION PROCEDURE 25 May, 2001

1.6.2 INSTALLATION PROCEDURE

[E]

[B]

[D]

[E]

[C]

B010I301.WMF

[B]

[A]

[C]

[A]

[H]

[G]

[H]

[F]

B010I302.WMF

1. Snap the casters [A, B] onto the base frames [C].

[A]: Caster – φ40 Stopper

[B]: Caster – φ40

2. Install the base stays [D] on the base frames (4 bolts, 4 washers).

3. Install the caps [E] on the base frame.

4. Install the middle frames [F] (4 bolts, 8 washers, 4 nuts).

5. Install the original tray stays [G] (4 bolts, 8 washers, 4 nuts).

6. Install the caps [H] on the original tray stays.

1-22

Page 32

25 May, 2001 ORIGINAL TRAY INSTALLATION PROCEDURE

A1

A0

[A]

48"

[C]

Installation

34"

36"

44"

B010I305.WMF

[B]

B010I303.WMF

7. Install the original tray [A] on the original tray stays (! x 6).

8. Attach the size decals (A1', A0', 34"', 36"', 44"', 48"').

9. Attach the original stoppers [B] and original guides [C].

B010I304.WMF

1-23

Page 33

I/F BOARD INSTALLATION PROCEDURE 25 May, 2001

1.7 I/F BOARD INSTALLATION PROCEDURE

1.7.1 ACCESSORY CHECK

Check the accessories and their quantities against the following list:

Description Q'ty

I/F Board Kit.............................................................................1

I/F Video Cable........................................................................1

I/F Control Cable .....................................................................1

Tapping screw - M4 x 8...........................................................3

Tapping Screw - M3 x 8...........................................................1

Harness Clamp........................................................................2

Harness Clamp - Small............................................................1

1-24

Page 34

25 May, 2001 I/F BOARD INSTALLATION PROCEDURE

1.7.2 INSTALLATION PROCEDURE

!

CAUTION

Unplug the power cord before starting the following procedure.

1. Remove the following covers.

• Left Rear Cover [A] (6 screws).

• Left Front Cover [B] (4 screws).

• Rear Left Cover [C] (5 screws).

2. Remove the cover bracket [D]

(1 screw).

[C]

[D]

Installation

3. Install the I/F board unit [E] on

the left frame (3 screws).

4. Connect the I/F Video cable [F] to

the I/F board and IPU board [G]

(1 screw each).

NOTE: Make sure the connector

is inserted completely.

5. Install the wire saddle [H] and

connect the DC harness [I] from

the main frame to the I/F board.

G068I101.WMF

[G]

G068I103.WMF

[B]

[A]

[E]

[H]

[I]

[F]

1-25

Page 35

I/F BOARD INSTALLATION PROCEDURE 25 May, 2001

6. Remove the small covers [A, B] from

the left rear and left front covers [C, D]

(2 screws each).

7. Install the following covers.

• Left Front Cover

• Left Rear Cover

• Rear Left Cover

8. Connect the I/F Ctl Cable [E] between I/F board

and printer controller.

[C]

[A]

[D]

G068I102.WMF

[E]

G068I104.WMF

[B]

1-26

Page 36

25 May, 2001 PM TABLE

2. PREVENTIVE MAINTENANCE

2.1 PM TABLE

NOTE: Amounts (K) in the PM Interval column indicate kilometers (1,000 meters).

Symbol key : I: Inspect, R: Replace, C: Clean, L: Lubricate, A: Adjust

Part Number Description Q’ty

Original Feed

Original Feed / Exit Rollers 10K

Original Sensors 60K

Original Table 10K

Optics

White Platen Roller 10K

Exposure Glass 10K

Development

Developer 2 40K

Development Filter 1 20K

Development Roller Gear

Cartridge Holder 10K

Registration Upper Guide Plate 10K

Side Seals 10K

Development Unit Gears

Development Lower Casing 10K

Used Toner Bottle 10K

Cleaning

Cleaning Blade 1 30K

Cleaning Entrance Seal 20K

Side Seals 20K

Pick-off Pawl 20K

Around the Drum

Charge Corona Wire 1 10K

Corona Wire Cleaner Pad 1 10K

Charge Corona Casing 10K

Grid Wire 10K

Transfer Corona Wire 1 10K

Separation Corona Wire 1 10K

T&S Corona Casing / Guide 10K

Quenching Lamp 20K

ID Sensor 20K

LPH (LED Print Heads) 10K

*1

: See 2.2 Lubrication points.

*1

*1

1 200K

PM

Interval

10K

PM Comments

C

Alcohol or water, dr y cloth

C

Blower brush

C

Water, dry cloth

C

Alcohol or water, dr y cloth

C

Water, glass cleaner

R

Replace if necessary.

R

Replace if necessary.

R

Replace if necessary

C

Blower brush, dry cloth.

C

Damp cloth, then dry cloth.

I/C

Dry cloth

L

Silicone Grease G501.

C

Damp cloth, then dry cloth.

I

Empty used toner.

R

Replace if necessary.

C

Dry cloth.

C

Dry cloth.

C

Dry cloth.

C/R

Replace if necessary.

R

Replace.

C

Damp cloth, then dry cloth.

C

Damp cloth, then dry cloth.

C/R Clean with dry cloth. Replace if

necessary.

C/R

Clean with dry cloth. Replace if

necessary.

C

Damp cloth, then dry cloth.

C

Dry cloth

C

Blower brush.

C

Dry cloth. No chemical cleaners.

After wiping, touch to discharge

static.

Preventive

Maintenance

2-1

Page 37

PM TABLE 25 May, 2001

Part Number Description Q’ty

Paper Feed

Cutter Unit 1 10K

Paper Feed / Exit Rollers 10K

Cutting Sensor 20K

Registration Rollers 10K

Registration Sensor 20K

Transport Belt 10K

Timing Belt 10K

Fusing Unit

Hot Roller 1 30K

Fusing Cleaning Roller 1 30K

Bushing – Hot Roller 2 30K

Pressure Roller 1 30K

Hot Roller Stripper 10K

Pressure Roller Stripper 10K

Thermistor 30K

Fusing Exit Guide Plate 10K

Fusing Unit Gears*

Fusing Pressure Screw Shaf t*

2

2

Fusing Drive Gears 10K

Exit Turn Guide 10K

Paper Exit Sensor 10K

Exit Rollers 20K

Others

Ozone Filter 1 10K

*2

: See 2.2 Lubrication points.

PM

Interval

120K

40K

PM Comment

C

Replace if necessary (approx.

service life: 12K cuts)

C

Alcohol, dry cloth

C

Blower brush

C

Alcohol, dry cloth

C

Blower brush

C

Alcohol, dry cloth

I

Adjust tension if necessary.

R

Replace if necessary.

R

Always replace these parts

together.

R

R

Replace if necessary.

C

Dry cloth.

C

Dry cloth.

C

Dry cloth.

C

Alcohol, dry cloth.

L

Barrieta JFE 55/2

L

Barrieta JFE 55/2

L

Silicone Grease G501

C

Damp cloth, then dry cloth.

C

Blower brush

C

Alcohol, dry cloth

R

Replace.

2-2

Page 38

25 May, 2001 LUBRICATION POINTS

2.2 LUBRICATION POINTS

2.2.1 FUSING SECTION

[A]

[C]

B010P506.WMF

[B]

Preventive

Maintenance

[A]: Fusing Gears (Barrieta JFE 55/2)

[B]: Fusing Drive Gears (Silicone Grease G501)

[C]: Fusing Pressure Screw Shaft (Barrieta JFE 55/2)

2.2.2 DEVELOPMENT SECTION

[A, B] Development Unit Gears

(Silicone Grease G501)

NOTE: Development Ro ller Gear [A]

should be checked every 200

km and replaced if necessary.

[A]

[C]

B010P507.WMF

[B]

2-3

B010P303.WMF

Page 39

25 May, 2001 OPENING AND CLOSING THE MACHINE

3. REPLACEMENT AND ADJUSTMENT

!

WARNING

Before you attempt any procedure described in this section, always switch

off the main power switch on the machine and disconnect the machine

from the power source.

3.1 OPENING AND CLOSING THE MACHINE

[A]

[B]

[F]

Adjustment

Replacement

[C]

[B]

[D]

B010R912.WMF

[A]: Operation panel release

CAUTION: To close the operation panel, always press down evenly on both

sides.

[B]: Upper unit releases

CAUTION: To avoid bending the catch and release mechanisms, always

release and raise the right and left sides together.

[C]: Hopper cover

[D]: Roll tray release

[E]: Paper exit cover

[F]: Paper exit guide plate

[E]

3-1

Page 40

EXTERNAL COVERS 25 May, 2001

3.2 EXTERNAL COVERS

3.2.1 FRONT VIEW

[C]

[H]

[D]

[E]

[G]

[A]: Right rear cover (! x 6)

[B]: Right front cover (! x 4)

[C]: Left rear cover (! x 6)

[D]: Left front cover (! x 4)

[E]: Left inner cover (! x 1)

[I]

[F]

[B]

B010R701.WMF

[F]: Right inner cover (! x 2)

[G]: By-pass feed table (! x 4)

[H]: Left upper unit cover (! x 2)

[I]: Right upper unit cover (! x 2)

[A]

NOTE: Always remove the left and right covers together, the rear cover first and

then the front cover. To avoid scratching the paint on the covers, always

re-attach the front cover first and then the back cover.

3.2.2 REAR VIEW

[A]: Rear right cover (! x 5)

[B]: Rear left cover (! x 5)

[A]

B010R906.WMF

3-2

[B]

Page 41

25 May, 2001 SCANNER

3.3 SCANNER

3.3.1 OPERATION PANEL

[A]: Original roll take-up (! x 2, bracket x

2)

[A]: Left original guide plate (! x 1)

[B]: Right original guide plate (! x 1)

[C]: Operation panel front plate (! x 4)

[A]

[A]

B010R006.WMF

[C]

Adjustment

Replacement

[B]

B010R911.WMF

3-3

Page 42

SCANNER 25 May, 2001

[B]

Open the operation panel unit.

[A]: Lower sensor cover (! x 4)

[B]: Operation panel (! x 4, " x 2)

[C]: Upper scanner cover (! x 6)

[A]

B010R007.WMF

[A]: Scanner stop switch (! x 2, " x 1)

[B]: Operation switch (! x 2, " x 1)

[C]

[B]

[A]

B010R008.WMF

3-4

Page 43

25 May, 2001 SCANNER

3.3.2 ORIGINAL SIZE SENSORS, ORIGINAL SET SENSOR, ORIGINAL REGISTRATION SENSOR

Raise the operation panel unit.

Left, right original guide plates (! x 2) (☛ 3.3.1)

[A]: Operation panel lower cover (! x 4)

[B]: Original path upper bracket (! x 2)

[B]

[A]

B010R001.WMF

➁

[A]: Clamp

➀

Adjustment

Replacement

Original registration sensor

➀

Original set sensor

➁

(A4 Lengthwise)

Original size sensor

➂

(A3 Lengthwise)

Original size sensor

➃

(A2 Lengthwise)

Original size sensor

➄

(A1 Lengthwise)

Original size sensor

➅

(A0 Lengthwise)

*1

US paper sizes.

A*

B

C

D

E

1

➂

➃

➄

➅

B010R002.WMF

[A]

3-5

Page 44

SCANNER 25 May, 2001

3.3.3 WHITE PLATEN ROLLER

[A]: Raise the operation panel unit

[B]: Left operation panel unit cover (! x 2)

[C]: Right operation panel unit cover (! x

2)

[D]: Original table (! x 4)

[A]: Door switch bracket (! x 1)

[B]: Original transport guide (! x 4)

[A]

[B]

[D]

B010R003.WMF

[C]

[A]

[A]: Remove.

[B]: Loosen but do not remove.

[C]: White platen roller.

• Press the white platen roller out to

the left to remove it.

• Lift straight out to prevent the

stopper or gear from dropping off

either end.

• Before re-inst allation, make sure

the stopper on the left end of the

white platen roller is snug, inside

the roller.

SP Adjustment Required After Replacement

SP4428 002

Scanner Adjustment (see

section 3.10.1)

[B]

B010R004.WMF

[A]

[B]

[C]

B010R005.WMF

NOTE: When re-installing, set the right end of the white platen roller first.

3-6

Page 45

25 May, 2001 SCANNER

3.3.4 ORIGINAL UPPER TRANSPORT UNIT AND EXIT SENSOR

Original roll take-up, operation panel,

upper scanner cover, lower sensor cover

(see section 3.3.1)

Lower the operation panel frame.

[A]: Upper original transport unit (! x 2,

" x 1)

[B]: CIS cover (! x 7)

[A]: Original exit unit cover (! x 2)

[B]: Original exit sensor (! x 1)

[B]

[B]

[A]

B010R009.WMF

[A]

Adjustment

Replacement

NOTE: When you re-install the upp er

original transport unit, make sure

that the paper turn guide is below

the pin of the unit below [A].

B010R010.WMF

[A]

B010R567.WMF

3-7

Page 46

SCANNER 25 May, 2001

3.3.5 ORIGINAL TRANSPORT ROLLER

Upper original transport unit (☛ 3.3.4)

[A]: Original transport roller (# x 4)

3.3.6 CIS (CONTACT IMAGE SENSOR)

Upper original transport unit (☛ 3.3.4)

CIS cover (! x 2)

[A]

B010R011.WMF

[A]

[A]: CIS unit (! x 2, " x 3)

SP Adjustment Required After Replacement

SP4428 002

Scanner Adjustment (see

section 3.10.1)

B010R012.WMF

3-8

Page 47

25 May, 2001 AROUND THE DRUM

3.4 AROUND THE DRUM

3.4.1 VDB (VIDEO DRIVE BOARD)

Open the upper unit, and remove the exit tray if

it is attached.

[A]: Left copy tray (! x 2)

[B]: Right copy tray (! x 2)

CAUTION: To avoid damaging the pawls on

the bottom of the covers, hold the cover level

as you pull it straight out.

[C]: VDB (! x 7, " x 7)

3.4.2 LPH (LED PRINT HEAD)

Remove the exit tray if it is attached.

Open the upper unit.

Remove the left and right copy trays

(☛.3.4.1)

Remove the left and right upper unit covers.

( ☛ 3.2)

[A]: LPH connectors on VDB (" x 4)

[B]: Grounding wire (! x1)

[C]: Grounding wire (loosen ! x1)

[D]: LPH

[E]: Three ROMs.

[A]

[E]

[C]

((((

))))

[A]

[B]

****

B010R101.WMF

[B]

B010R555.WMF

++++

[D]

Adjustment

Replacement

• If you intend to replace the LPH, you

must replace the ROMS on the VDB with

the three ROMs provided with the new

LPH kit.

• Reading top to bottom on the board, the

[C]

ROMs are marked LPH-L (left), LPH-C

(center), and LPH-R (right).

• To confirm that each new ROM is

installed in the correct position, match

the numbers of the new ROMs with the

numbers printed on the labels of the LPH

unit.

• Perform an IPU Test Pattern print to

confirm that the joints of the LPH are

aligned correctly and then adjust if necessary. (☛ 3.10.2)

3-9

B010R102.WMF

Page 48

AROUND THE DRUM 25 May, 2001

3.4.3 CHARGE CORONA WIRE, GRID WIRE, WIRE CLE ANER

LPH (☛ 3.4.2)

[A]: Wire cleaner drive motor

bracket (! x 2)

[B]: Remove the white plastic

coupling from the drive screw.

CAUTION: To avoid losing this

coupling, always remove it before

removing the charge corona unit.

[C]: Left, right grounding plate

springs (! x 2)

[D]: Charge corona unit

SP Adjustment Required After

Replacement

SP2803

Charge Corona Wire Cleaning

[B]

➁

[D]

[A]

[C]

➀

B010R550.WMF

NOTE: 1) When removing this unit, shift the unit to the right and lift the left part of

the unit up.

2) Confirm that the grounding plate edge is securely set in the holes.

[D]

[A]: Grid wire

[B]: Right cover

[C]

[B]

[C]: Left cover

[D]: Charge corona wire

[E]: Shock absorbers

[A]: Charge corona wire cleaner

SP Adjustment Required After Replacement

SP2803

Charge Corona Wire Cleaning

[E]

B010R104.WMF

[A]

When replacing wires:

• Make sure the grid wires are correctly

positioned in the correct slots and not

crossed.

• If replacing wires, hold them by the

ends. Oil from hands could cause

B010R105.WMF

uneven charge on the drum.

• Handle wires carefully. Never bend or stretch them.

[A]

3-10

Page 49

25 May, 2001 DRUM AND DEVELOPMENT UNIT

3.4.4 QUENCHING LAMPS

Charge corona unit (☛ 3.4.3)

[A]

[A]: Lamp bracket, left (! x 2, " x 1)

[B]: Lamp bracket, right (! x 2, " x 1)

[C]: Quenching lamp arrays x 2

[C]

3.5 DRUM AND DEVELOPMENT UNIT

3.5.1 DEVELOPMENT UNIT

[A]: Left upper unit cover (! x 2)

[B]: Right upper unit cover (! x 2)

[C]: Right inner cover (! x 2)

[D]: Lower toner cartridge cover.

(Slides out, no screws need to

be removed.)

[A]

[B]

B010R106.WMF

Replacement

[B]

Adjustment

CAUTION: The development unit weighs

10.4 kg (22.9 lb.) with the toner cartridge

installed, or 8 kg (17.6 lb.) without the

toner cartridge.

Raise the upper unit.

[A]: Development bias connector (" x 1)

Make sure the upper unit is open. Do not

attempt to remove the development unit

with the unit closed.

[B]: Development unit (! x 6, " x 1)

CAUTION: To avoid damaging the fragile

wings on either end of the development

unit, never attempt to remove or install the

development unit in the machine with the

upper unit closed.

[D]

[B]

[C]

B010R301X.WMF

[A]

B010R302.WMF

3-11

Page 50

DRUM AND DEVELOPMENT UNIT 25 May, 2001

3.5.2 DEVELOPER

Remove the toner cartridge (follow the

instructions on the decal on the front left

side of the machine.

NOTE: To avoid damaging the bias terminal on

the left end of the development unit,

handle it carefully.

[A]: Toner supply casing (! x 2)

[B]: Development filter and bracket.

NOTE: Make sure that the filter is re-installed

with the holes facing down.

[B]

[A]

[A]: Raise the clutch-end up about 45o to

remove the developer, and then lay to

flat.

[A]: Rotate the unit to remove more developer.

[B]: Rotate the knob to remove the remaining

developer.

[A]

[A]

B010R918.WMF

B010R919.WMF

SP Adjustment Required After Replacement

SP2801 Developer Initial Setting

SP3001 002 ID Sensor Initial Setting

[B]

B010R920.WMF

3-12

Page 51

25 May, 2001 DRUM AND DEVELOPMENT UNIT

3.5.3 BY-PASS FEED SENSOR, REGISTRATION SENSOR

[A]: Development unit (☛ 3.5.1)

[B]: Registration bracket (! x 2)

[C]: Registration guide (! x 2)

[D]: By-pass feed sensor

[E]: Registration sensor

[D]

[A]

[C]

[E]

B010R304.WMF

[B]

Adjustment

Replacement

3-13

Page 52

DRUM AND DEVELOPMENT UNIT 25 May, 2001

3.5.4 TONER SUPPLY CLUTCH

[C]

[A]: Development unit (☛ 3.5.1)

[B]: Toner supply clutch (! x 1, # x 1,

bushing x1, bracket x 1)

[C]: Impeller

NOTE: After re-installing the ton er supply

clutch, make sure that the clutch pin is

inserted correctly in the slot [D] of the

hopper. If not inserted correctly, the

rotating clutch could damage the clutch

cable.

[B]

[D]

[A]

B010R305.WMF

3.5.5 DRUM DRIVE MOTOR

Left covers. (☛ 3.2.1)

[A]: Drum drive motor (! x 4, " x 1)

[A]

B010R303.WMF

3-14

Page 53

25 May, 2001 DRUM AND DEVELOPMENT UNIT

3.5.6 DRUM UNIT, ID SENSOR, AND CLEANING BLADE

Development unit (☛ 3.5.1)

To the right of the drum drive gear, loosen

the screw to relieve the tension on the

drive belt.

[A]: Drum drive gear and belt (! x1, use

a hex wrench)

[B]: ID sensor connector (" x 1)

[C]: Left drum bracket (! x 2)

[D]: Right drum bracket (! x 2)

[E]: OPC drum assembly

NOTE: Cover the OPC with a sheet

of paper to protect it from

light.

[A]: Drum unit left side (! x 1, spring x 1,

bushing x 1)

[B]: Drum unit right side (! x 1, spring x

1, bushing x 1)

[C]: OPC drum

[D]: Rubber plates

When installing a new drum, remove

both rubber plates inside the old

drum and install them in the new

drum. (These plates reduce the

noise caused by inertia when the

drum starts and stops.)

[E]: ID Sensor (! x 1, " x 1)

[F]: Pick-off pawl solenoid (! x 1, " x 1)

[B]

[A]

B010R202.WMF

[A]

[E]

[C]

[E]

[C]

[D]

[B]

B010R201.WMF

[D]

[F]

Adjustment

Replacement

SP Adjustment Required After Drum Replacement

SP2923

SP3001 002

Drum Set Mode (see the next

page)

ID Sensor Setting – Initial

Setting

3-15

Page 54

DRUM AND DEVELOPMENT UNIT 25 May, 2001

[A]: Cleaning blade (! x 2)

SP Adjustment Required After Cleaning Blade

Replacement

SP2923 002 Drum Set Mode – Execute

Drum Set Mode

Make sure that the drum protection sheet

is removed.

1. Set the pressure lever [A] to the left.

[A]

B010R203.WMF

2. Plug in the power cable and switch the

main power switch on.

3. Press ".

[A]

4. Enter #$%

5. Hold down & for more than 3

seconds.

6. On the touch panel, press Copy SP.

7. Enter 2923, press ' , then press Start

to execute Drum Set Mode.

B010R570.WMF

8. After it has finished, set the pressure lever [A] to the right.

9. If you have replaced the OPC drum, enter 3001 002, press ', then press Start

to initialize the ID sensor.

3-16

Page 55

25 May, 2001 PAPER FEED

3.6 PAPER FEED

3.6.1 CUTTER UNIT

[A]: Roll tray cover (! x 2)

[B]: Loosen side plate (! x 2).

[C]: Guide plate (pressure release).

[A]: Left cutter HP switch connector

(" x 1)

[B]: Left spring, hook (! x 1)

[C]: Side plate (! x 2)

[D]: Right cutter HP switch connector

(" x 1)

[E]: Cutter motor connector (" x 1,

clamps x 2)

[F]: Cutter unit (! x 2). (Slide out to

the left.)

[A]

[C]

[B]

[C]

[B]

[E]

B010R708.WMF

[A]

[F]

[D]

Adjustment

Replacement

3-17

B010R709.WMF

Page 56

PAPER FEED 25 May, 2001

3.6.2 CUTTING SENSOR AND FEED EXIT ROLLER

[A]: Lock plate (! x 2)

[B]: Sensor bracket

[C]: Cutting sensor (" x 1, ! x 1)

[B]

[E]

[C]

B010R715.WMF

[A]

Left inner cover. (☛3.6.3)

Right inner cover. (Raise out of position

without disconnecting cable.) (☛3.6.3)

[D]: Bushings (# x 2)

[E]: Guide plate (! x 4)

[F]: Feed exit roller

NOTE: Re-install the left end first

(viewed from the front.)

[F]

[D]

B010R714.WMF

3-18

Page 57

25 May, 2001 PAPER FEED

3.6.3 ROLL TRAY

!

CAUTION

The roll tray weighs 36 kg (80 lb.) At least two technicians are needed to

remove it and re-install lit.

Before removing the roll tray, prepare a clean flat surface to set the unit on after

removal. As the paper feed motor is mounted under the roll tray, a strong table, or

four blocks, to raise the roll tray slightly, is ideal and will make it easier to service.

[B]

[C]

Right covers (☛ 3.2.1)

[A]: Rear right cover (! x 5)

[B]: Open the harness clamps x 3

[C]: Connectors (" x 2)

[D]: PSU (☛ 3.9.1)

[A]: Left inner cover (! x 3)

[B]: Right inner cover (! x 2)

[C]: Harness clamp at the corner of the

right inner cover.

[A]

[A]

[D]

B010R551.WMF

[B]

Adjustment

Replacement

3-19

[C]

B010R707.WMF

Page 58

PAPER FEED 25 May, 2001

[A]: Harness clamps inside the machine (x

2)

B010I513.WMF

[A]

[A]: Roll tray (! x 4 with washers)

Do not remove the stainless steel

spotting screws on either side of the roll

tray.

[B]: Pull the connector from the back to the

front of the machine. Coil it and then

[A]

place it inside the roll tray.

With a technician on either side of the

roll tray, lift it off the rail and set it down

on a clean flat surface. The roll tray

B010R711.WMF

weighs about 32 kg (70.5 lb.)

[B]

3-20

Page 59

25 May, 2001 PAPER FEED

3.6.4 PAPER FEED DRIVE MOTOR

The paper feed drive motor is located under the front left corner of the roll tray.

Roll tray

Left inner cover (! x 3)

[A]: Paper feed drive cover, left rear

corner (! x 1)

[B]: Loosen adjustment screw.

[C]: Remove pressure spring

[D]: Motor assembly (" x 1, ! x 2

top, ! x 2 side)

[E]: Paper feed motor (! x 2)

[C]

3.6.5 FIRST FEED ROLLER AND CLUTCH

Roll tray

[A]: Bushings (# x 2)

[B]: First feed roller ($ x 1)

[C]: Paper feed clutch (" x 1, clamps x

2)

[B]

[E]

[B]

[A]

[D]

B010R712.WMF

[C]

Adjustment

Replacement

Adjustment Required After

Replacement

Adjust the cut length.

SP1920-001 ~

081

SP1921-001 ~

025

Cut Length Adjustment

Cut Length Adjustment

[A]

[A]

B010R716.WMF

3-21

Page 60

PAPER FEED 25 May, 2001

3.6.6 SECOND FEED ROLLER AND CLUTCH

[C]

Roll tray

[A]: Bushings (# x 2)

[B]: Second feed roller ($ x 1)

[C]: Paper feed clutch (" x 1, clamps x

2)

Adjustment Required After

Replacement

Adjust the cut length.

[A]

[B]

[A]

SP1920-001 ~

081

SP1921-001 ~

025

Cut Length Adjustment

Cut Length Adjustment

3.6.7 REGISTRATION MOTOR

Main machine left covers (☛ 3.2.1)

Top cover plate (! x 1)

[A]: Open clamps

[B]: Registration motor bracket (" x 3, !

x 3)

[C]: Registration motor (! x 4)

B010R713.WMF

[B]

[C]

3-22

[A]

B010R915.WMF

Page 61

25 May, 2001 PAPER FEED

3.6.8 REGISTRATION CLUTCH

Registration motor (☛ 3.6.7)

[A]: Stopper bracket (! x 1)

[B]: Registration clutch

NOTE: Use the flat head of a small

screwdriver to release the lock on

the clutch.

[A]

3.6.9 REGISTRATION ROLLER

Left and right covers, By-pass feed table (☛ 3.2.1)

Registration motor (☛ 3.6.7)

Registration clutch (☛ 3.6.8)

[A]: Cover plate (! x 2)

[B]: T&S power pack (! x 2, " x 1)

[C]: Torque limiter bracket (! x 2)

[D]: Torque limiter (! x 1)

[A]: Guide plate (! x 4)

[B]: Aluminum guide plate (! x 4)

NOTE: Hold the plate level as you pull it

out so the plastic flaps do not fall

from either end.

[C]: Registration roller (# x 2, bushings x

2)

[B]

[C]

B010R904.WMF

[C]

B010R910.WMF

[B]

[D]

[A]

Adjustment

Replacement

3-23

[A]

[B]

B010R905.WMF

Page 62

TRANSFER UNIT 25 May, 2001

3.7 TRANSFER UNIT

3.7.1 TRANSFER AND SEPARATION CORONA WIRES

Left, right upper unit covers (☛ 3.2.1)

Left inner cover plate (☛ 3.2.1)

Right inner cover plate (☛ 3.2.1)

[A]

[A]: Loosen (do not remove) (! x 2)

[B]: T&S corona unit connectors ("

x2)

[C]: T&S corona unit. (Press down on

the covers on both ends to prevent

them from falling.)

CAUTION: Remove the T&S corona unit

carefully to avoid touching or scratching

the OPC drum above.

[D]: Paper Guide

[A]: End block covers

[B]: Insulator plates (x 4)

[C]: Transfer and separation wires

NOTE: The single wire at the front and

double wire at the back are both

spring loaded on the left.

[A]

[C]

[D]

[C]

[A]

[B]

B010R702.WMF

[B]

[C]

When replacing wires:

• Make sure the wires are correctly

B010R703.WMF

positioned in the correct slots and not crossed.

• If replacing wires, hold them by the ends. Oil from hands could cause uneven

charge on the drum.

• Handle wires carefully. Never bend or stretch them.

3-24

Page 63

25 May, 2001 TRANSFER UNIT

3.7.2 TRANSPORT UNIT

Drum drive motor (☛ 3.5.5)

Fusing drive motor (☛ 3.8.10)

Fusing unit (☛ 3.8.1)

[A]: Duct vent (! x 2)

[B]: Internal duct. Push left and then right

to disconnect.

[C]: Transport unit (! x 4, " x 2)

[A]

!

CAUTION

When disconnecting the connectors

from the transport unit, avoid

touching or hitting the sharp

stripping pawls above the transport

unit.

[B]

[C]

B010R704.WMF

Adjustment

Replacement

3-25

Page 64

TRANSFER UNIT 25 May, 2001

3.7.3 TRANSPORT BELTS

[A]: Guide plate (! x 2)

[B]: Left transport fan motor (! x 2)

[C]: Right transport fan motor (! x 2)

[A]: Arm bushings (! x 3)

[B]: Bracket (! x 1)

[C]: Bushings x 2

[D]: Drive gear

[E]: Drive shaft

[F]: Transport belts

[B]

[E]

[C]

[D]

[A]

B010R705.WMF

[C]

[B]

[C]

[F]

B010R706.WMF

[A]

3-26

Page 65

25 May, 2001 FUSING SECTION

3.8 FUSING SECTION

3.8.1 FUSING UNIT

!

CAUTION

To avoid serious personal injury, before removing the fusing unit, switch