Ricoh af400 Service Manual

AD3

(Machine Code: A133)

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the cop ier po w er cord is un pl u gg ed .

2. The wall outlet should be ne ar th e cop i er an d easily accessible.

3. Note that some compone nt s of th e cop i er an d the paper tray unit ar e

supplied with electrical voltage even if the main switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers

off or open while the main switch is turned on, keep hands away from

electrified or mech anically driven components.

5. If the start key is pressed before the copier completes the warm-up period

(Start key starts blinking red and green alternatively), keep hands away

from the mechani cal an d th e el e ctr i ca l com po ne nt s as t he copie r star t s

making copies as soon as the warm-up period is completed.

6. The inside and the metal parts of the fusing uni t be com e extr e m el y ho t

while the copier is operating. Be careful to avoid touching those

components with your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get eithe r of them in your

eyes by accident, it may cause temporary eye discomfort. Try to remove

with eye drops or flush wit h w at er as fir st aid. If unsuccessful, get m ed ical

attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course

on those models.

CATION

2. The RAM board on the system control board has a lithium battery

which can explode if replaced incorrectly. Replace the battery only

with an identical one. The manufacturer recommends replacing

the entire RAM board. Do not recharge or burn this battery. Used

batteries must be handled in accordance with local regulations.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate the toner bottle or the used toner. Toner dust may ignite

suddenly when exposed to open flame.

2. Dispose of used toner, de vel o pe r , an d or g an i c pho to con ductor according

to local regulations. (These are non-to xic supp lies. )

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lith ium batteries in order to dispose of them later, do

not put more than 100 batteries per sealed box. Storing larger numbers or

not sealing them ap ar t ma y lead to chemical reacti o ns an d he at bui ld - up .

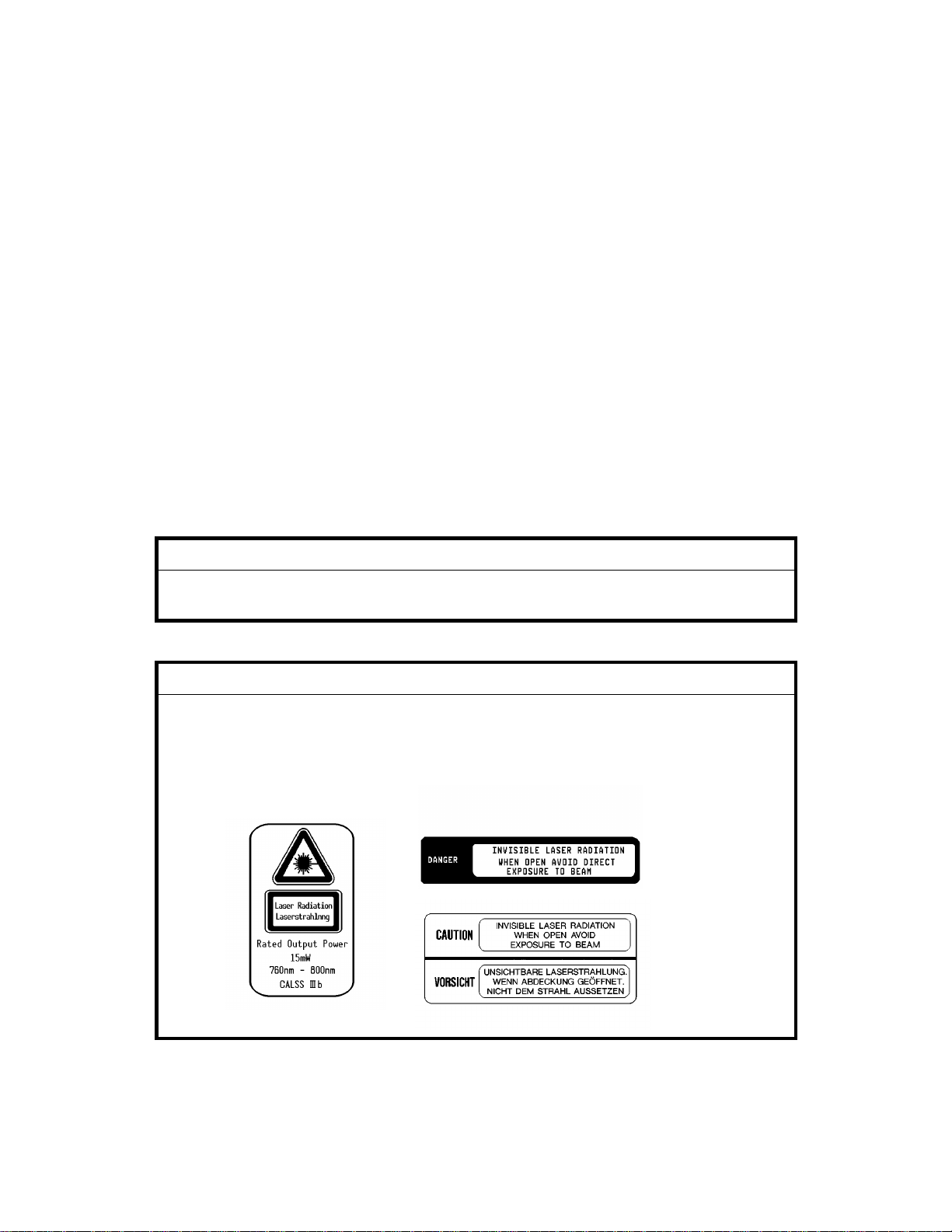

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair

of laser-based optical units in the field . The optical housing unit can only be

repaired in a factory or at a location with the requisite equipment. The laser

subsystem is replaceable in the field by a qualified Customer Engineer. The

laser chassis is not repairable in the field. Customer engineers are therefore

directed to return all chassis and laser subsystems to the factory or service

depot when replacement of the optical subsystem is required.

WARNING

Use of controls, or adju stm e nt, or performan ce of pr oce du r es ot he r tha n

those specified in th is manual may result in hazardous radiation exposure.

WARNING FOR LASER UNIT

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams

can seriously damage your eyes.

CAUTION MARKING:

For 115V version

For 230V version

SECTION 1

OVERALL MACHINE

INFORMATION

22 March 1996 SPECIFICATIONS

1. SPECIFICATIONS

Configuration: Desktop

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book

Original Size: Maximum A3/11" x 17"

Copy Paper Size: Maximum

A3/11" x 17" (Paper tray)

Minimum

A5/8

A6/5

1/2

1/2

" x 5

" x 8

" sideways (Paper tray)

1/2

" lengthwise (By-pass)

1/2

LCT

A4/11" x 8

" sideways only

1/2

Duplex Copying: Maximum

A3/11" x 17"

Minimum

A5/8

1/2

" x 5

" sideways

1/2

Copy Paper Weigh t: Paper tray:

60 ~ 105 g/m2, 16 ~ 24 lb

By-pass:

60 ~ 157 g/m2, 16 ~ 42 lb

LCT:

60 ~ 128 g/m2, 16 ~ 34 lb

Duplex copying:

64 ~ 105 g/m2, 17 ~ 24 lb

Overall

Information

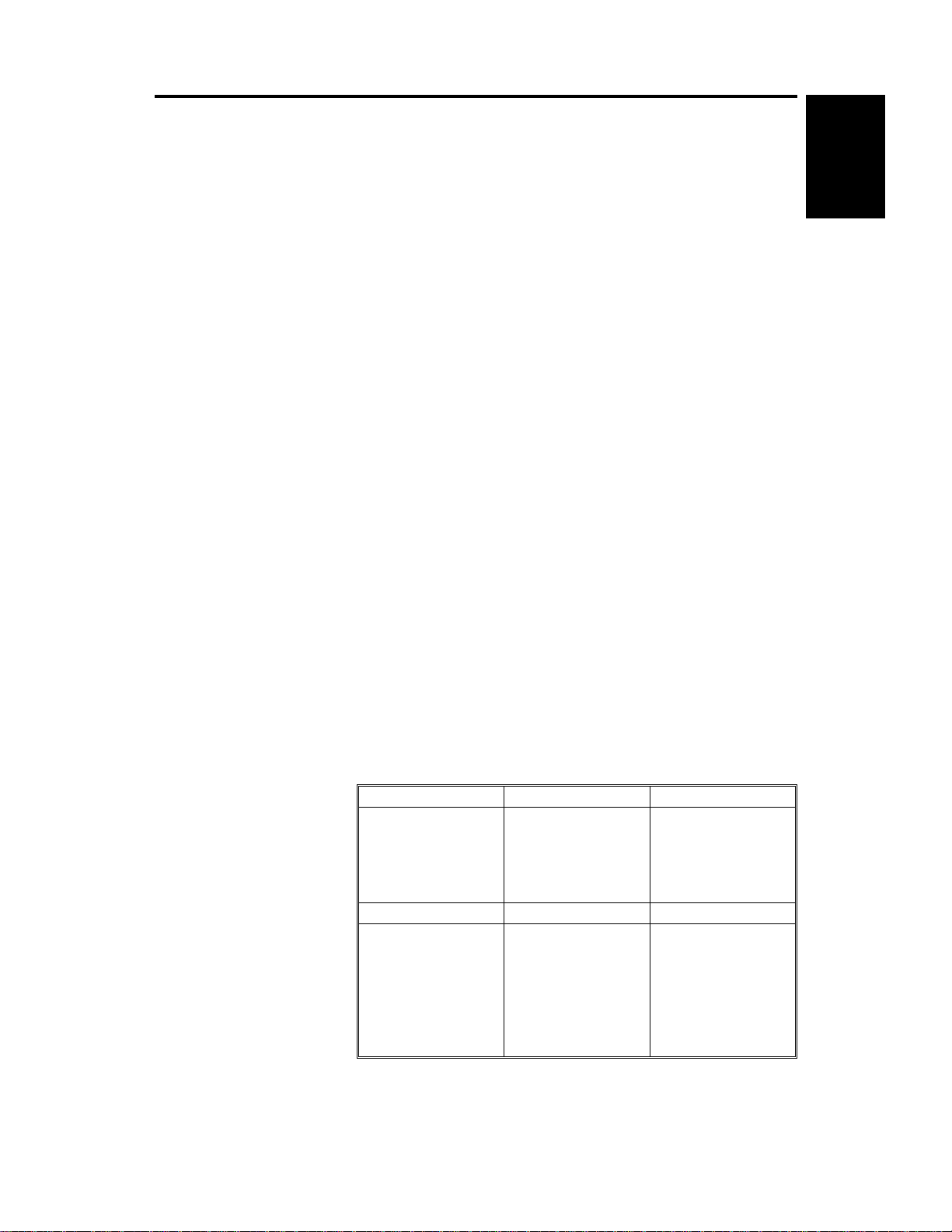

Reproduction R at i os: 5 Enlargement an d 7 R ed uct i on

A4/A3 Version LT/DLT Version

400%

200%

Enlargement

Full size 100% 100%

Reduction

1-1

141%

122%

115%

93%

87%

82%

71%

65%

50%

25%

400%

200%

155%

129%

121%

93%

85%

77%

74%

65%

50%

25%

SPECIFICATIONS 22 March 1996

Zoom: 25% to 400% in 1% steps

Power Source: 120V/60Hz:

More than 12 A (for North America)

220V ~ 240V/50Hz:

More than 7 A (for Europe)

220V ~ 240V/60Hz:

More than 7 A (for Asia)

Power Consumption:

Copier Only Full System

Maximum Less than 1.44 kW Less than 1.44 kW

Copying Less than 1.20 kW Less than 1.20 kW

Warm-up Less than 0.88 kW Less than 0.90 kW

Stand-by Less than 0.20 kW Less than 0.22 kW

NOTE:

1) Full System: Copier + ADF + Pap er Tr ay U nit + Fini sh er

Noise Emission:

Copier Only Full System

1. Sound Power Level

Copying 66.0 dB(A) 69.0 dB(A)

Stand-by 40.0 dB(A) 40.0 dB(A)

2. Sound Pressure Level at the Operator Position

Copying 54 dB(A) 59 dB(A)

Stand-by 25 dB(A) 25 dB(A)

NOTE:

The above measurements are to be made in accordance with ISO

7779.

Full System: Copier + ADF + Paper Tray U nit + Fini sh er .

Dimensions (W x D x H): 880 x 655 x 602 mm (34.7" x 25.8" x 23.8")

Measurement Conditions

1) With by-pass feed tab le cl ose d

2) With copy tray attached

3) With LCT cover closed

4) Without the 500-sheet copy tray

Weight: 95 kg (210 lb)

1-2

22 March 1996 SPECIFICATIONS

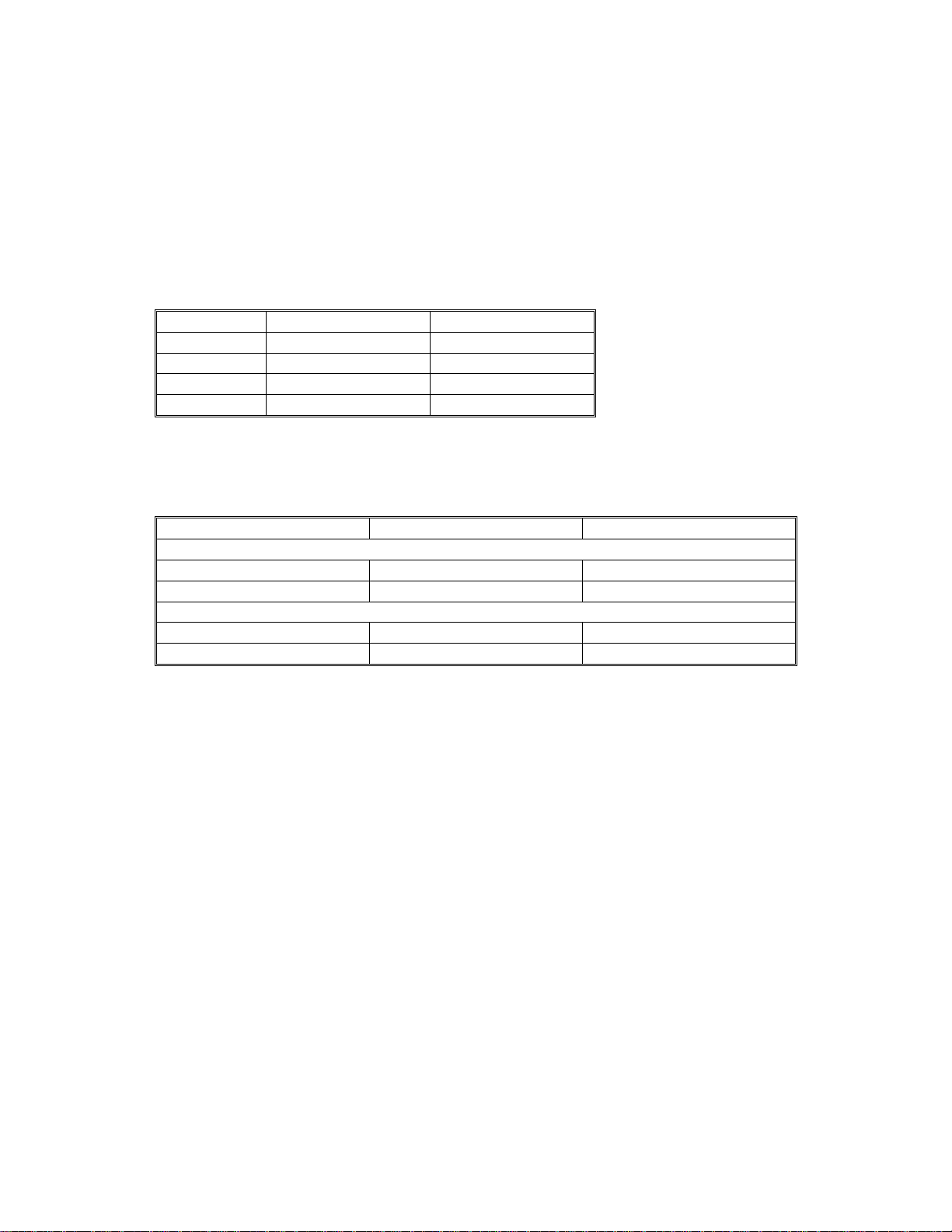

Copying Speed (copies/minute) :

A4 sideways/

11" x 8

"

1/2

40 18 26

Warm-Up Time

A3/11" x 17" B4/8

Less than 140 seconds (20°C, 68°F)

" x 14"

1/2

First Copy Time: Less than 5.2 s (from LCT)

Copy Number Input: Ten-key pad, 1 to 999 (count up or count down)

Manual Image Density

7 steps

Selection:

Automatic Reset: 30 s is the standard setting; it can be changed

with a UP mode.

Copy Paper Capacity:

Paper Tray By-pass Feed LCT

About 500 sheets x1 About 40 sheets About 1000 sheets

Hard Disk: 1 GB, Fast SCSI-2

Duplex Tray Capacity A4/11" x 8

": 50 sheets

1/2

A3/11" x 17": 50 sheets (80 g/m2, 20 lb paper)

30 sheets (81 ~ 105 g/m2,

21.5 ~ 27.9 lb paper)

Overall

Information

Toner Replenishment: Cartridge exchange (700 g/cartridge)

Toner Yield: 20K copies (A4, 6% full black , ID Level 4)

Optional Eq uipment:

Copy Tray Capacity B4/8

•

Platen cover

•

Document feeder

•

Paper tray unit wi th tw o pa pe r trays

•

Paper tray unit wi th thr e e pa pe r tr ays

•

Finisher

•

Key counter

•

Tray heater

•

Optical anti-condensation heater

•

Drum heater

•

500-sheet receivi ng tr ay

" x 14" ~ A4/8

1/2

" x 11" 500 sheets

1/2

A3\11" x 17" 200 sheets

Less than B5/5

1/2

" x 8

": 200 sheets

1/2

1-3

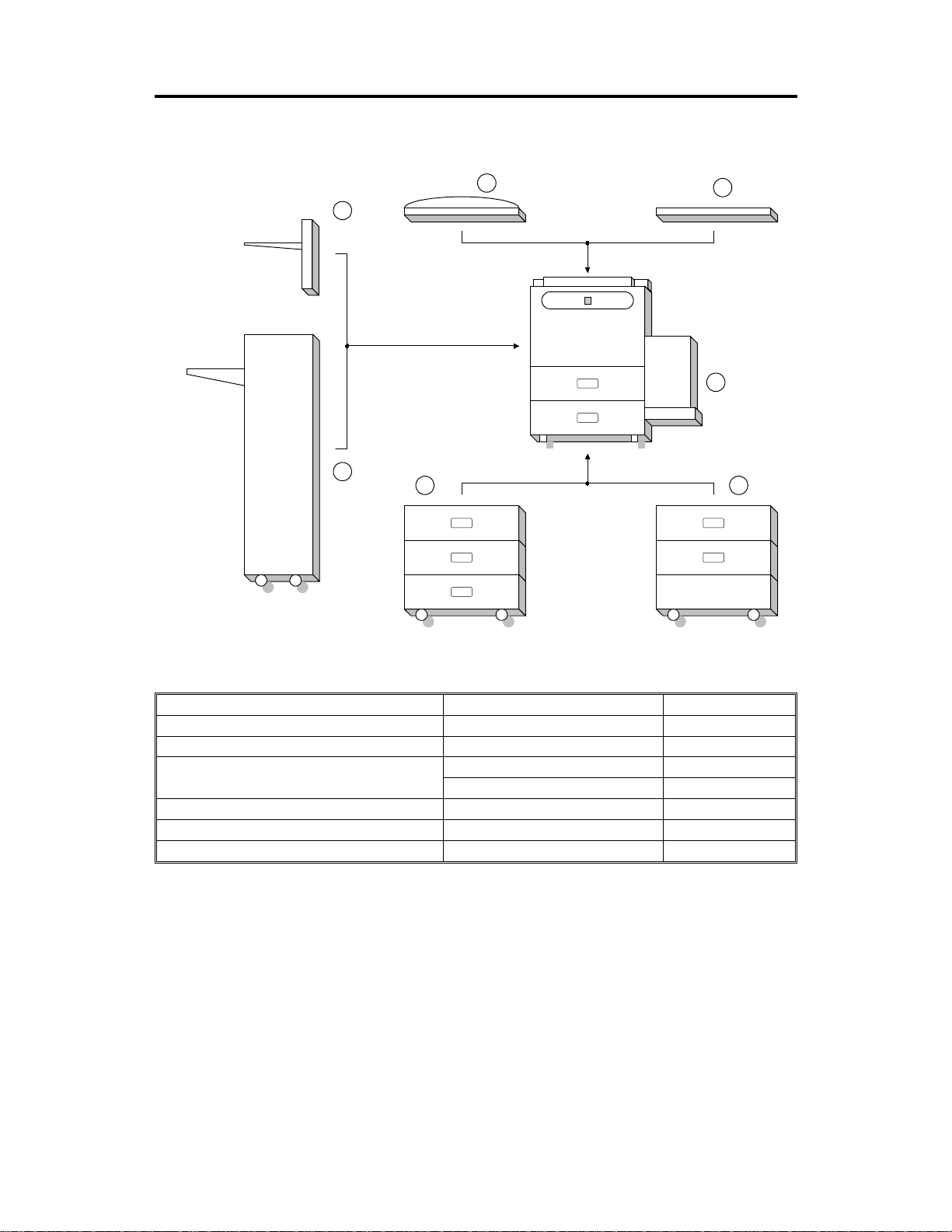

MACHINE CONFIGURATION 22 March 1996

2. MACHINE CONFIGURATION

1

7

6

5 4

2

3

A133V500.wmf

Item Machine Code No.

Copier A133 3

ADF (Option) A548 1

Paper Feed Unit (Option) A549 5

A550 4

Finisher (Option) A612 6

500-sheet Receiving Tray (Option) A615 7

Platen Cover (Option) A381 2

1-4

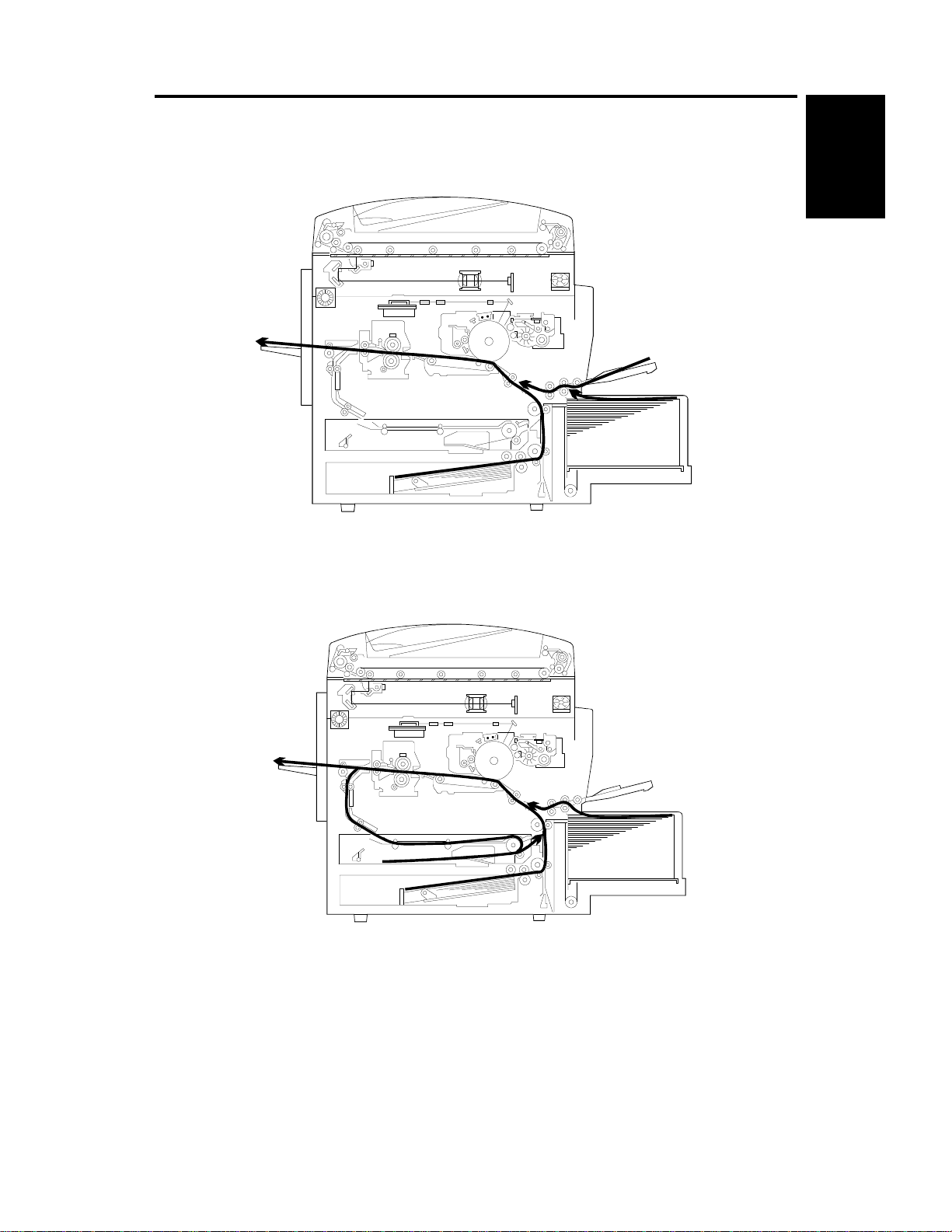

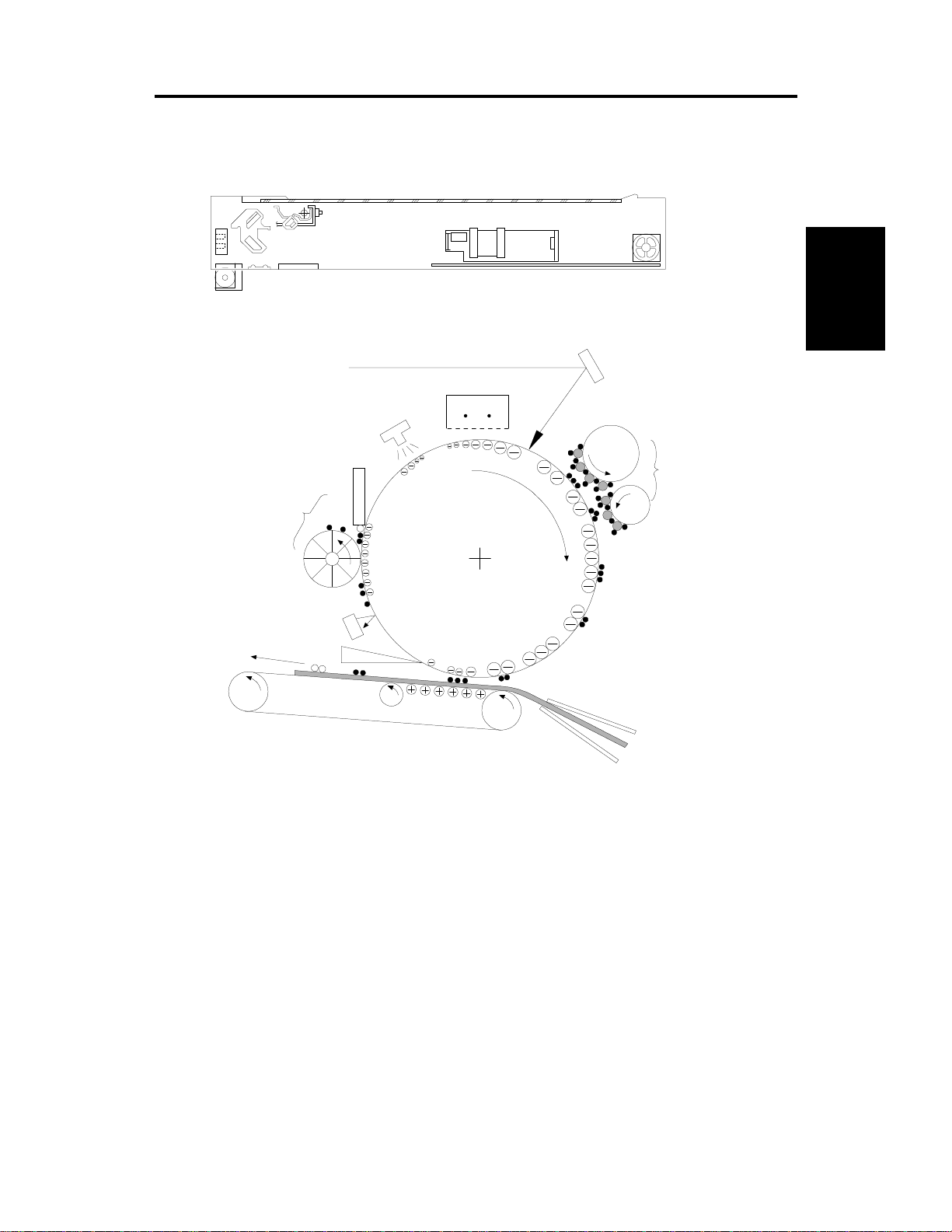

22 March 1996 PAPER PATH

3. PAPER PATH

3.1 NORMAL COPYING

Overall

Information

3.2 DUPLEX COPYING

A133V501.wmf

A133V502.wmf

1-5

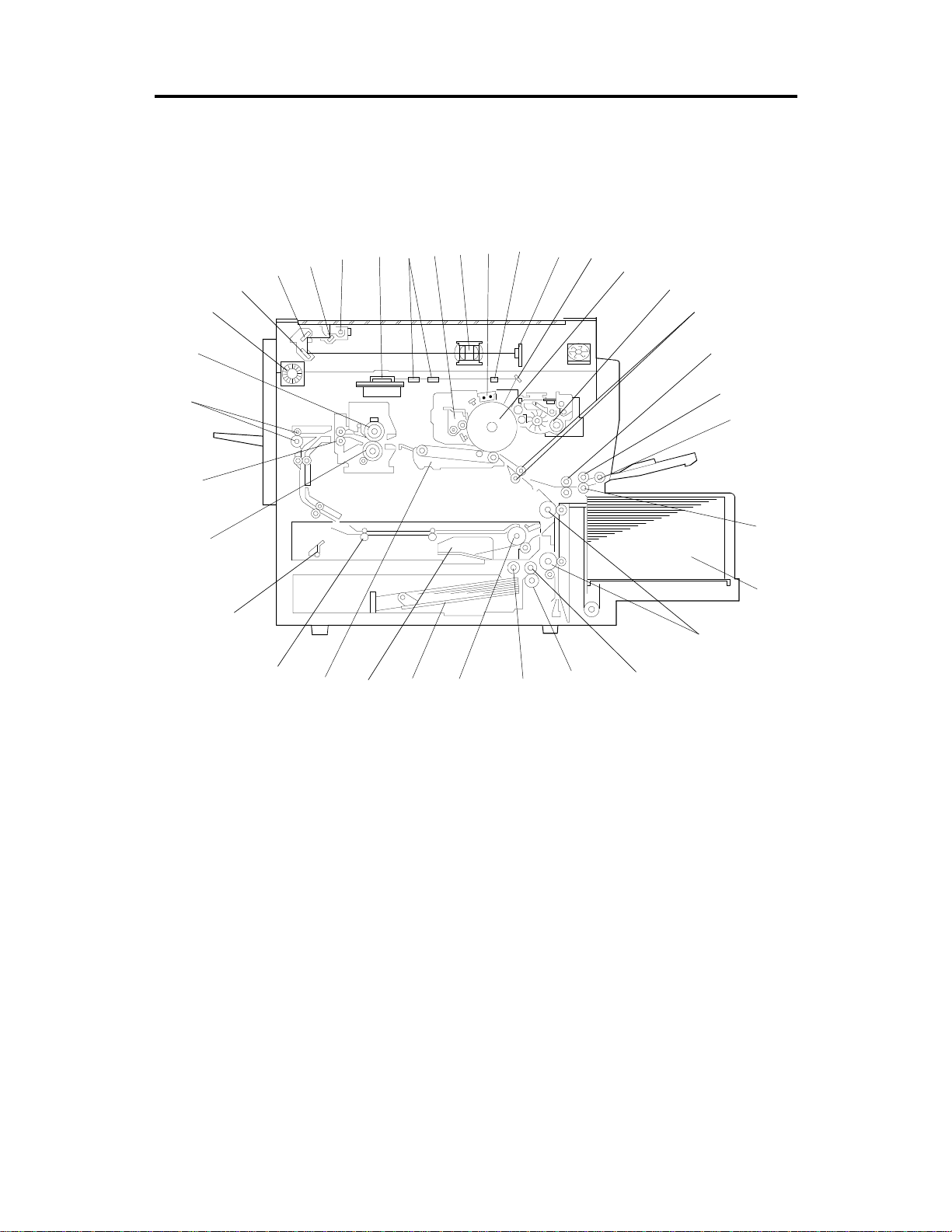

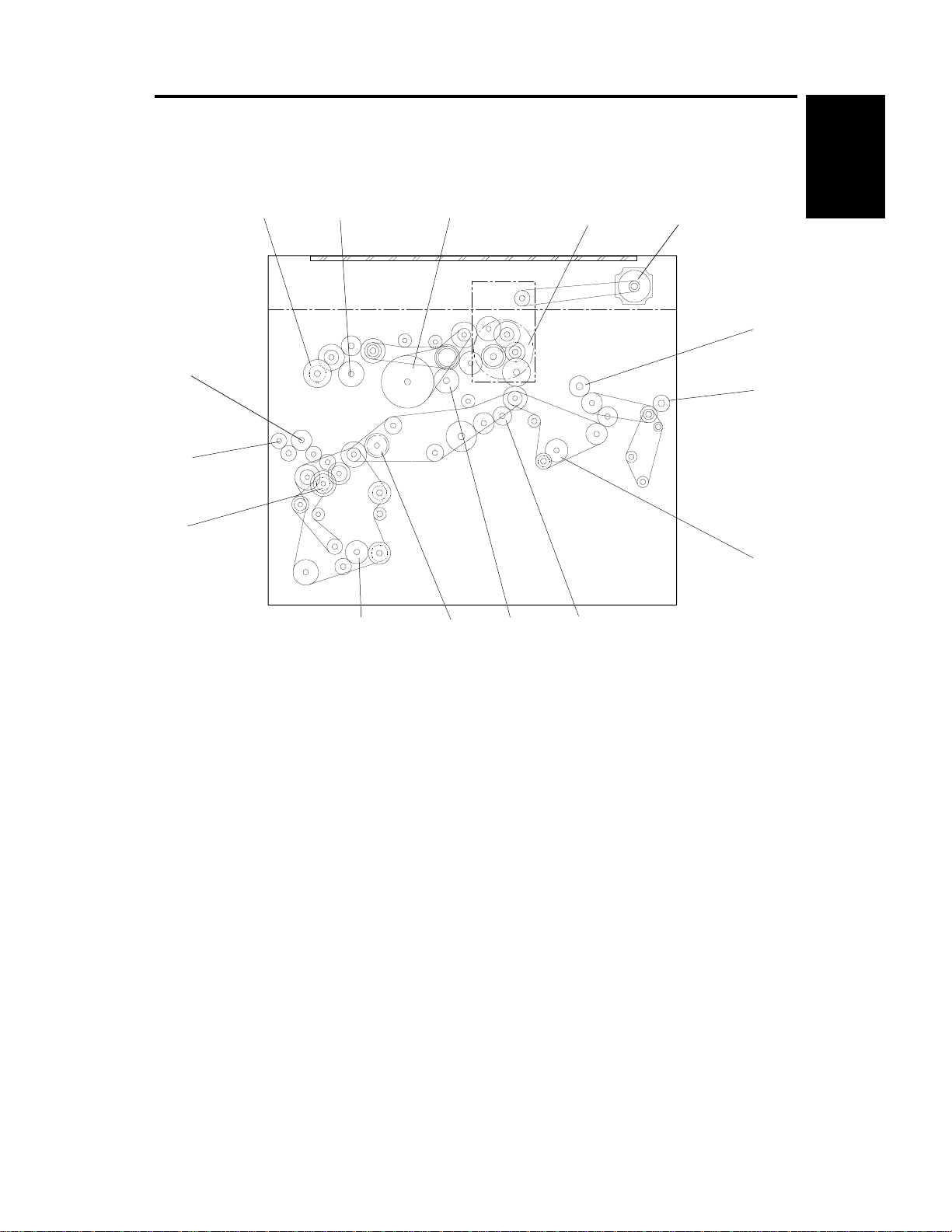

MECHANICAL COMPONENT LAYOUT 22 March 1996

4. MECHANICAL COMPONENT LAYOUT

9

8

7

10

11

12

13

14

15

35

6

5

4

3

2

1

34

33

32

31

30

29

28

16

17

18

19

20

21

23

24252627

22

A133V503.wmf

1-6

22 March 1996 MECHANICAL COMPONENT LAYOUT

1. 3rd. Mirror

2. 2nd. Mirror

3. 1st. Mirror

4. Exposure Lamp

5. Polygonal Mirror Motor

6. Fθ Lenses

7. Cleaning Unit

8. Lens

9. Charge Corona Unit

10. Barrel Toroidal Lens (BTL)

11. CCD

12. Mirror

13. Drum

22. Feed Roller

23. Separation Roller

24. Pick-up Roller

25. Duplex Feed Roller

26. Bottom Plate

27. Side Jogger Fen ce

28. Transfer Belt Unit

29. Entrance Rollers

30. End Jogger Fence

31. Pressure Roller

32. Fusing Exit Roller

33. Exit Rollers

34. Hot Roller

Overall

Information

14. Development Unit

15. Registration Rollers

16. By-pass Feed Relay Roller

17. By-pass Feed Roller

18. By-pass Pick-up Roller

19. By-pass Separation Roller

20. LCT

21. Relay Rollers

35. Optics Exhaust Fan Motor

1-7

ELECTRICAL COMPONENT DESCRIPTIONS 22 March 1996

5. ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout and the point-to-point diagram on the

waterproof paper in the pocket for the locations of these components.

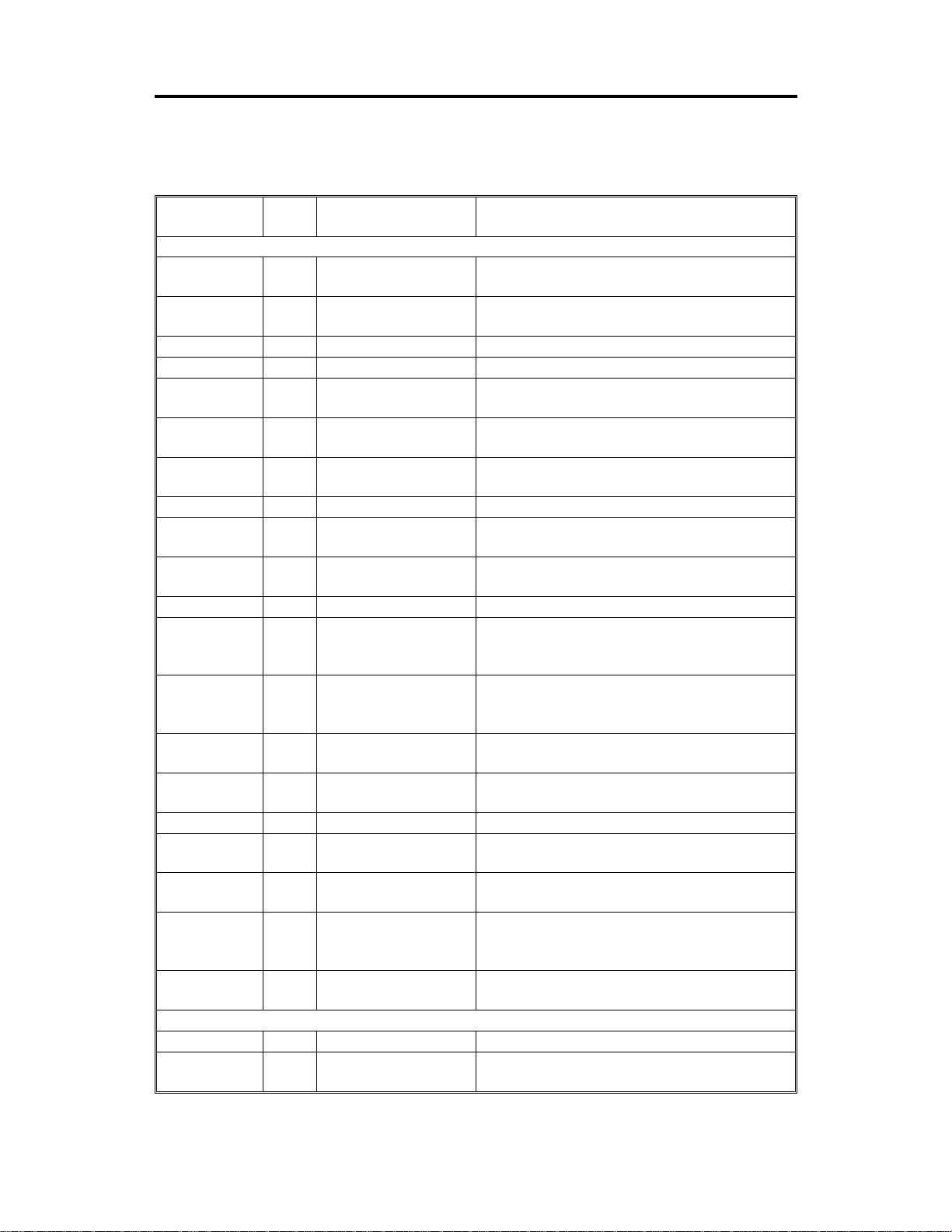

Symbol Index

No.

Printed Circuit Boards

PCB1 90

PCB2 89

PCB3 92 DC Power Supply Provides dc power.

PCB4 93 BCU Controls the mechanical parts of the printer.

PCB5 80

PCB6 85

PCB7 87

PCB8 79 Scanner Drive Drives the scanner motor.

PCB9 81

PCB10 84

PCB11 94 Lamp Stabilizer Provides dc power for the exposure lamp.

PCB12 86

PCB13 83

PCB14 31

PCB15 33

PCB16 40 Duplex Control Controls the operation of the duplex tray.

PCB17 N/A

PCB18 51

PCB19 91

PCB20 7

Description Note

SCU Controls all copier functions both directly or

through other control boards.

AC Drive Provides ac power to the exposure lamp and

fusing lamps.

Charge High Voltage

Supply

High Voltage Control Controls the high voltage boards and the

Operation Panel Controls the touch panel display and LED

EX-IPU Processes the video signal from the SBU

SBU Contains the CCD, and outputs a video

Main Scan

Synchronization

Detector - 1

Main Scan

Synchronization

Detector - 2

Transfer High

Voltage

Development Bias

Power Pack

Liquid Crystal Display Controls the guidance display and displays

LCT Interface Interfaces the LCT control signal between

Relay Board Switches ac power to either the dc drive

Laser Diode Drive Controls the laser diode.

Supplies high voltage to the charge corona

unit.

quenching lamp.

matrix, and monitors the key matrix.

and sends the video signal to the LD unit.

signal to the EX-IPU board.

Detects the laser beam at the start of the

main scan.

Detects the laser beam at the end of the

main scan.

Supplies high voltage to the transfer belt.

Supplies high voltage to the development

roller.

guidance for machine operation.

the main board and the LCT.

board (if the main switch is on) or to the

heaters (if the main switch is off).

Motors

M1 57 Main Drives the main body components.

M2 66

Toner Bottle Drive Rotates the toner bottle to supply toner to

the toner supply unit.

1-8

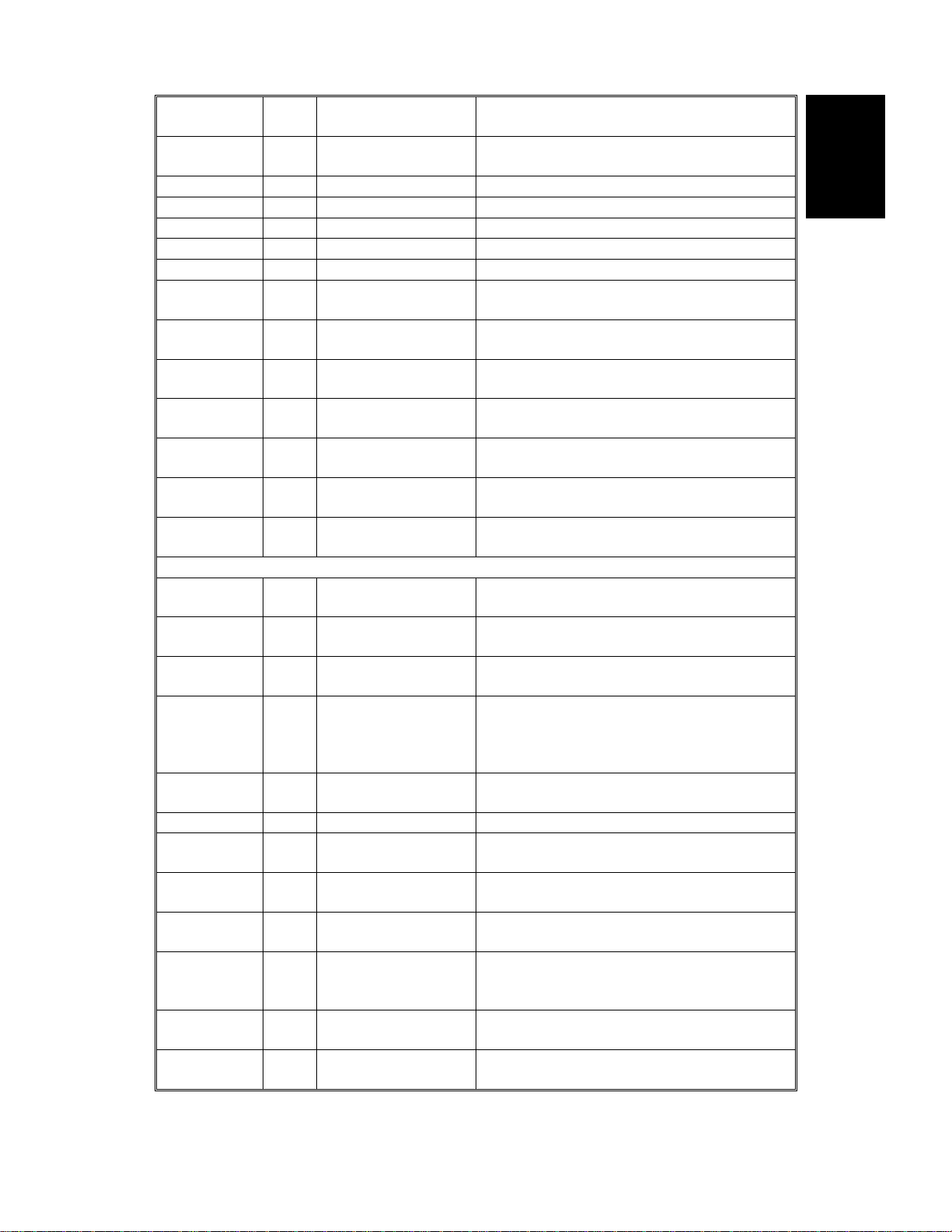

22 March 1996 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Index

No.

M3 73

M4 56 Polygonal Mirror Turns the polygonal mirror.

M5 48 LCT Lift Lifts up and lowers the LCT bottom plate.

M6 74 Optics Exhaust Fan Removes heat from the optics unit.

M7 65 IPU Fan Removes heat from the IPU board.

M8 78 Exhaust Fan Removes heat from around the fusing unit.

M9 60

M10 55

M11 36

M12 39

M13 38

M14 75

M15 68

Sensors

S1 13

S2 15

S3 18

S4 46

S5 16

S6 47 Lower Relay Detects misfeeds.

S7 49

S8 50

S9 12

S10 19

S11 29

S12 30

Description Note

Tray Lift Raises the bottom plate in the paper tray.

Ozone Fan Removes ozone-laden air from inside the

machine.

Scanner Drive Drives the 1st and 2nd scanners (dc stepper

motor).

Duplex Feed Drives the feed roller and moves the bottom

plate up and down.

End Fence Jogger Drives the end fence jogger to square the

paper stack.

Side Fence Jogger Drives the side fence jogger to square the

paper stack.

DC Drive Board Fan Removes heat from around the DC drive

board.

Charge Inlet Fan Provides air flow around the charge corona

unit section.

By-pass Feed Paper

Width

By-pass Feed Paper

End

Tray Paper End Informs the CPU when the paper tray runs

Upper Relay Detects the leading edge of paper from the

Tray Upper Limit Detects the height of the paper stack in the

LCT Lower Limit Sends a signal to the CPU to stop lowering

LCT Paper End Informs the CPU when the LCT runs out of

LCT Upper Limit Signals the CPU to stop lifting the LCT

Registration Detects the leading edge of the copy paper

Image Density

(ID)

Toner Density

(TD)

Informs the CPU what width paper is in the

by-pass feed table.

Informs the CPU that there is no paper in the

by-pass tray.

out of paper.

paper tray and duplex unit to determine the

stop timing of the paper feed clutch and

duplex feed motor. Also detects misfeeds.

paper tray to stop the upper tray lift motor.

the LCT bottom plate.

paper.

bottom plate.

to determine the stop timing of the paper

feed clutch, and detects misfeeds.

Detects the density of various patterns on

the drum during process control.

Detects the amount of toner inside the

development unit.

Overall

Information

1-9

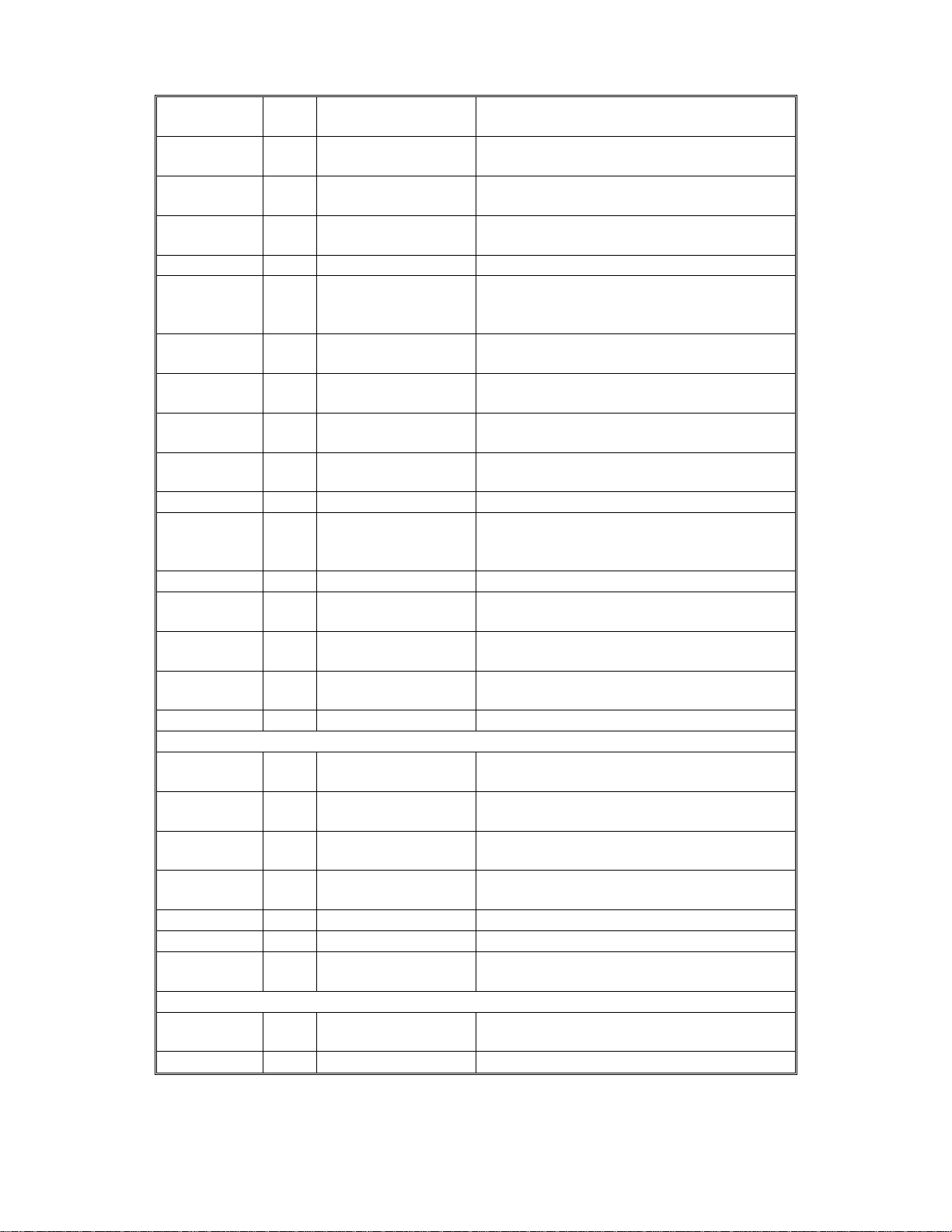

ELECTRICAL COMPONENT DESCRIPTIONS 22 March 1996

Symbol Index

No.

S13 1

S14 8

S15 9

S16 24 Fusing Exit Detects misfeeds.

S17 6

S18 32

S19 28

S20 10

S21 2

S22 34 Duplex Paper End Detects paper in the duplex tray.

S23 35

S24 42 Duplex Entrance Detects misfeeds.

S25 37

S26 41

S27 23

S28 14 By-pass Relay Detects misfeeds.

Switches

SW1 11

SW2 53

SW3 20

SW4 54

SW5 52 LCT Cover Cuts the dc power line of the LCT lift motor.

SW6 27 Main Supplies power to the copier.

SW7 26

Magnetic Clutches

CL1 61

CL2 59 Development Drives the development roller.

Description Note

Scanner HP Informs the CPU when the 1st and 2nd

scanners are at the home position.

Original Length-1 Detects the length of the original. This is one

of the APS (Auto Paper Select) sensors.

Original Length-2 Detects the length of the original. This is one

of the APS (Auto Paper Select) sensors.

Platen Cover Informs the CPU whether the platen cover is

up or down (related to APS/ARE functions).

ARE: Auto Reduce and Enlarge

Toner End Instructs the CPU to add toner to the toner

supply unit, and detects toner end conditions.

Auto Response Returns the operation panel display and exits

from the energy saver mode.

Transfer Belt

Position

Original Width Detects the width of the original. This is one

Duplex Turn Detects the trailing edge of the copy paper to

Side Fence Jogger

HP

End Fence Jogger

HP

Toner Overflow Detects when the used toner collection bottle

By-pass Feed Table Detects whether the by-pass feed table is

Tray Down Sends a signal to the CPU to lower the LCT

Tray Paper Size Determines what size of paper is in the

LCT Cuts the dc power line and detects whether

Front Cover Safety Cuts the dc power line and detects whether

Toner Supply Turns the toner supply roller to supply toner

Informs the CPU of the current position of

the transfer belt unit.

of the APS (Auto Paper Select) sensors.

determine the jogging timing, and detects

misfeeds.

Detects the home position of the duplex side

fence jogger.

Detects the home position of the duplex end

fence jogger.

is full.

open or closed.

bottom plate.

paper tray.

the LCT is open or not.

the front cover is open or not.

to the development unit.

1-10

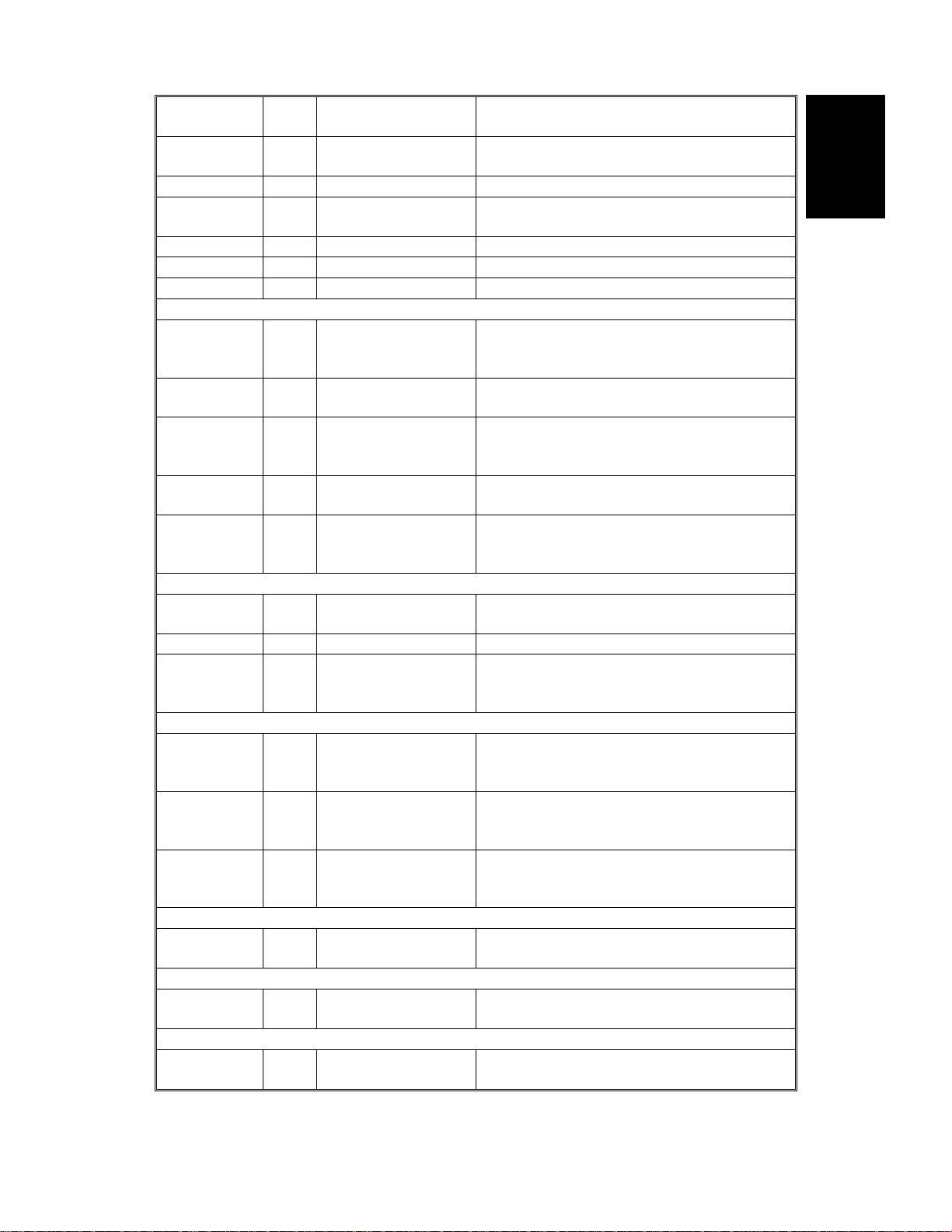

22 March 1996 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Index

No.

CL3 76

CL4 58 Registration Drives the registration rollers.

CL5 63

CL6 71 Relay Drives the relay rollers.

CL7 72 Paper Feed Starts paper feed from the paper tray.

CL8 62 By-pass Relay Drives the by-pass relay rollers.

Solenoids

SOL1 67

SOL2 77

SOL3 64

SOL4 69

SOL5 70

Lamps

L1 3

L2 43 Fusing Provides heat to the hot roller.

L3 88

Description Note

Transfer Belt Lift Controls the touch and release movement of

the transfer belt unit.

By-pass Feed Starts paper feed from the by-pass feed

table or LCT.

By-pass Pick-up Drops the pick-up roller to the by-pass paper

feed position. When paper is fed from the

LCT, this solenoid assists SOL3.

Junction Gate Moves the junction gate to direct copies to

the duplex tray or to the paper exit.

LCT Pick-up Drops the pick-up roller all the way down to

the LCT paper feed position from the

by-pass paper feed position.

Pick-up Controls the up/down movement of the

pick-up roller in the paper tray.

Separation Controls the up/down movement of the

separation roller at the paper tray feed

station.

Exposure Applies high intensity light to the original for

exposure.

Quenching Neutralizes any charge remaining on the

drum surface after cleaning.

Overall

Information

Heaters

H1 21

H2 5

H3 22

Thermistors

TH1 45

Thermofuses

TF1 44

Thermoswitch

TS1 4

Drum (option) Turns on when the main switch is off to

prevent moisture from forming around the

drum.

Optics

Anti-condensation

(option)

Tray

(option)

Fusing Monitors the temperature at the central area

Fusing Provides back-up overheat protection in the

Exposure Lamp Opens the exposure lamp circuit if the 1st

Turns on when the main switch is off to

prevent moisture from forming on the optics.

Turns on when the main switch is off to keep

paper dry in the paper tray.

of the hot roller.

fusing unit.

scanner overheats.

1-11

ELECTRICAL COMPONENT DESCRIPTIONS 22 March 1996

Symbol Index

Counters

CO1 25

CO2 N/A

Others

CB1 17

HDD 82

Description Note

No.

Total Keeps track of the total number of copies

made.

Key

(option)

Circuit Breaker

(220 ~ 240V

machines only)

Hard Disk Drive Scanned image data is compressed and

Used for control of authorized use. The

copier will not operate until it is installed.

Provides back-up high current protection for

electrical components.

held here temporarily during copying; also

holds user stamp data.

1-12

22 March 1996 DRIVE LAYOUT

6. DRIVE LAYOUT

3

4

5

6

7

15

14

1

2

Overall

Information

13

12

11

1. Toner Supply Clutch

2. Development Clutch

3. Drum Drive Pulley

4. Main Motor

5. Scanner Drive Motor

6. Fusing Drive Gear

7. Exit Drive Gear

8. Toner Collection Bottle Drive Gear

A133V504.wmf

10

9

9. Transfer Belt Drive Gear

10. Cleaning Blade Drive Gear

11. Registration Clutch

12. Paper Feed Clutch

13. Relay Clutch

14. By-pass Feed Clutch

15. By-pass Relay Clutch

8

1-13

SECTION 2

DETAILED

SECTION DESCRIPTIONS

22 March 1996 COPY PROCESS

1. COPY PROCESS

1.1 OVERVIEW

1

A133D591.wmf

2

9

3

4

Detailed

Descriptions

8

7

6

5

A133D593.wmf

1. EXPOSURE

A halogen lamp exposes the original. Light reflected from the original passes

to the CCD, where it is converted into an analog data signal. This data is

converted to a digital signal, processed, and stored on the hard disk. At the

time of printi ng , th e da ta is r et r ieve d an d sent to the laser diode . For

multi-copy runs, the original is scanned once only and stored to the disk.

2. DRUM CHARGE

In the dark, the char ge cor on a un i t give s a neg at i ve cha r ge to th e or g an i c

photo-conductive (OPC) drum. The grid plate ensures that corona charge is

applied uniformly. The charge remains on the surface of the drum because

the OPC layer has a high electrical resistance in the dark.

2-1

COPY PROCESS 22 March 1996

3. LASER EXPOSURE

The processed data scanned from the original is retrieved from the disk and

transferred to the drum by a laser beam, which forms an electrical latent

image on the drum surfa c e. The am o un t of char g e r emaining as a latent

image on the drum depends on the laser beam intensity, which is controlled

by the EX-IPU board.

4. DEVELOPMENT

The magnetic develope r brush on the de vel o pm e nt roll ers come s in cont act

with the latent i m ag e on the dr um sur face. Toner particl e s ar e

electrostati call y attracted to the ar ea s of th e dr u m surfa c e whe r e th e l ase r

reduced the negative charge on the drum.

5. IMAGE TRANSFER

Paper is fed to the area between the drum surface and the transfer belt at the

proper time so as to align the copy paper and the developed image on the

drum surface. Then, the transfer bias roller applies a high positive charge to

the reverse side of paper through the transfer belt. This positive charge

produces an electr ic a l f orc e whi ch pu l l s the ton er pa r tic les from the drum

surface on to the paper. At the same time , th e pa pe r is ele c tri cally attracted

to the transfer be l t.

6. PAPER SEPARATION

Paper separates from the drum as a result of the electrical attraction between

the paper and the transfer belt. The pick-off pawls help separate the paper

from the drum .

7. ID SENSOR

On every 200th copy cycle, the laser forms a sensor pattern on the drum

surface. The ID sensor measures the reflectivity of the pattern. The output

signal is one of the factors used for toner supply control.

8. CLEANING

The cleaning brush an d cl ea ni n g blade remove any toner re m ain i ng on th e

drum surface aft er the image is transfe r red t o th e pa pe r .

9. QUENCHING

The light from the quenching lamp electrically neutralizes the charge on the

drum surface.

2-2

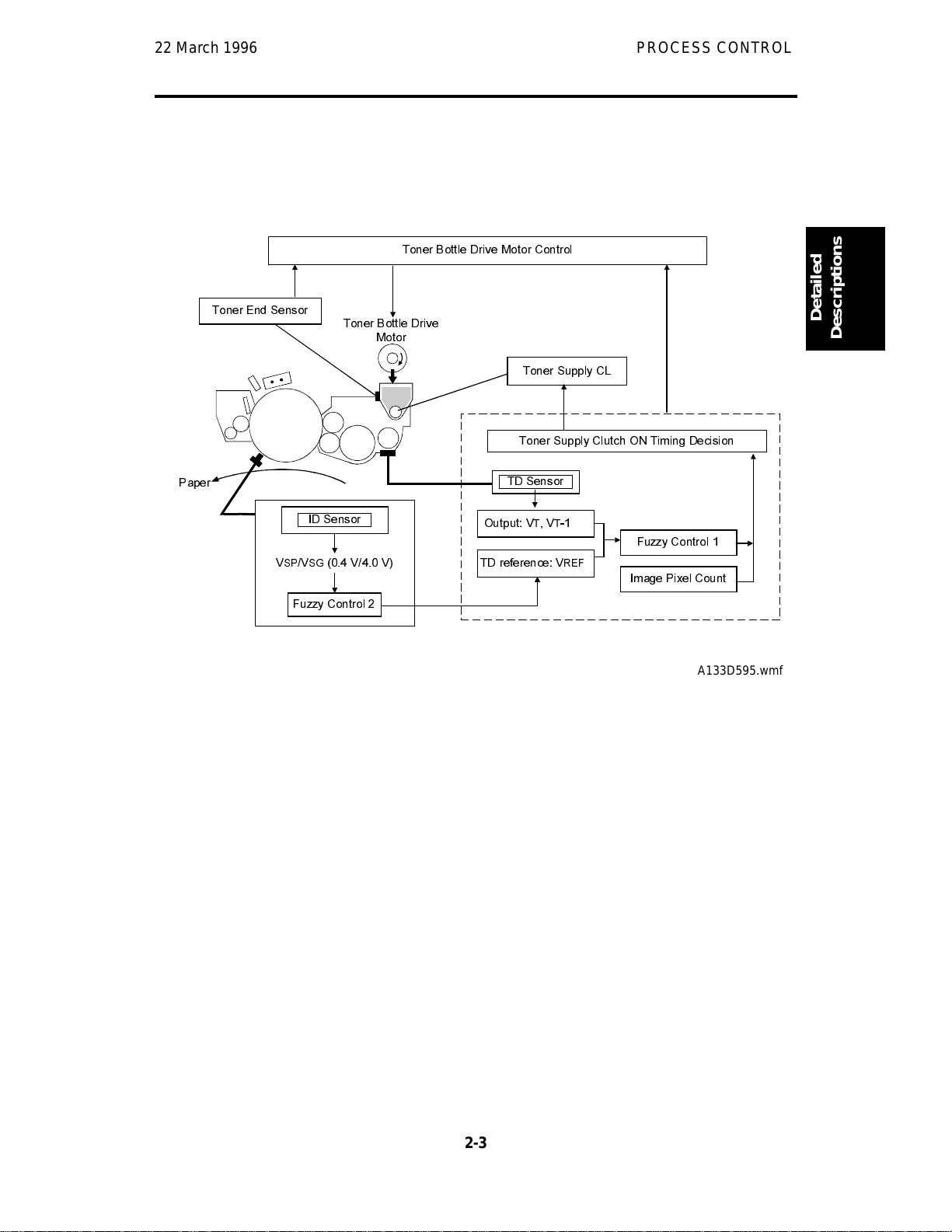

22 March 1996 PROCESS CONTROL

2. PROCESS CONTROL

2.1 OVERVIEW

7RQHU%RWWOH'ULYH0RWRU&RQWURO

7RQHU(QG6HQVRU

3DSHU

9

6396*

)X]]\&RQWURO

7RQHU%RWWOH'ULYH

,'6HQVRU

99

0RWRU

7RQHU6XSSO\&/

7RQHU6XSSO\&OXWFK217LPLQJ'HFLVLRQ

7'6HQVRU

2XWSXW9797

)X]]\&RQWURO

7'UHIHUHQFH9

5()

,PDJH3L[HO&RXQW

A133D595.wmf

In this model, pro c ess con tr o l consi sts only of monitori n g th e to ne r den si ty

(with a correction from the ID sensor) in order to control the toner

concentration and toner supply amount.

Detailed

Descriptions

The machine controls the toner supply mechanism using readings from the

toner density sensor (TD sen s or) an d im ag e de nsity sensor (ID sensor).

Readings from the TD sensor are used to keep the toner concentration in the

developer at a constant level. However, the toner concentration on the image

on the drum varies due to variations in toner chargeability, which is

influenced by the environment and the status of the carrier, even if the toner

concentration is con sta nt. Because of this, read i ng s f rom th e ID sen sor ar e

used to change the toner concentration to kee p th e i m ag e de nsity of the

reference pattern on the drum constant.

2-3

PROCESS CONTROL 22 March 1996

2.2 TONER DENSITY CONTROL

2.2.1 Overview

There are two modes for controlling toner supply: detect supply mode and

fixed supply mode.

The mode can be changed with SP2208-1. The factory settin g is detect

supply mode.

2.2.2 Detect Supply Mode Overview

&RS\LQJ

,PDJH3L[HO&RXQW

'HWHFWVWKHDPRXQWRIWRQHU

WREHXVHG

97GHWHFWLRQ

)X]]\&RQWURO

)DFWRUV

9

9

75()

75()

7

9

7

↓

9

*$,1'HWHUPLQDWLRQ

97&XUUHQW9

9

3UHYLRXV9

7

7

7

7RQHU6XSSO\&/RQWLPH

FDOFXODWLRQ

1R

+DYHFRSLHVEHHQ

PDGHVLQFHWKHODVW

9

75()FKDQJH

96396*'HWHFWLRQ

,'6HQVRU

)X]]\&RQWURO

)DFWRUV

9

75()

9639

'HWHUPLQHVWKHUHTXLUHG

FKDQJHWR9

ZKLFKLV∆9

1HZ9

&XUUHQW9

75()

∆9

75()

<HV

9

6*

↓

75()

75()

"

7

75()

2-4

A133D538.wmf

22 March 1996 PROCESS CONTROL

In detect supply mode, the machine varies toner sup ply for each copy based

on the amount of toner required to print the page (based on a black pixel

count for the page) and readings from the TD and ID sensors to maintain the

correct proportion of toner in the developer and to account for changes in

drum reflectivity over time.

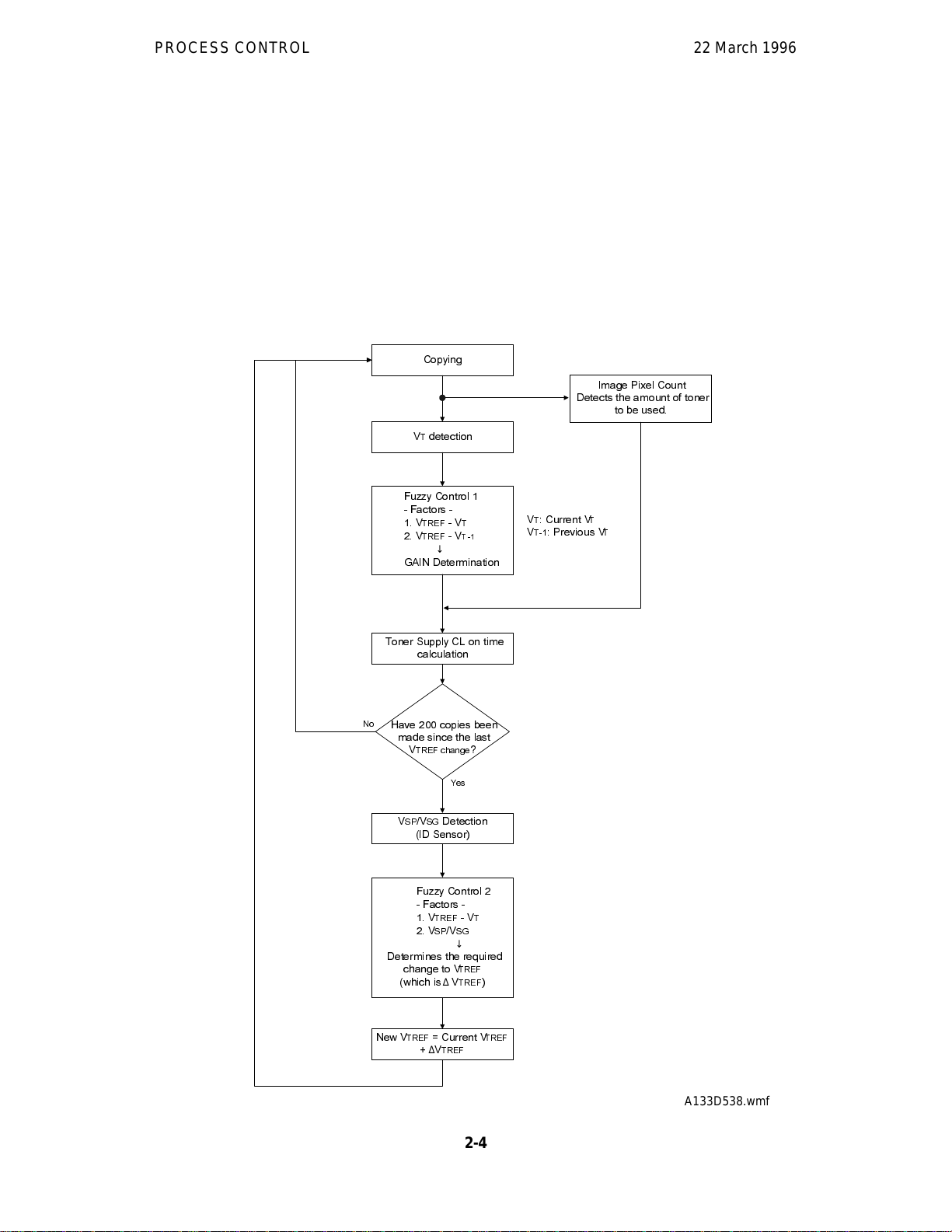

The flow chart on the prev iou s pag e outl in es th e de te ct sup pl y mod e. Each

step is explained in more detail on the following pages.

Toner Density Sensor

7&9

7

Detailed

Descriptions

6HQVRURXWSXW>9@

7RQHUZHLJKW>ZW@

A133D594.wmf

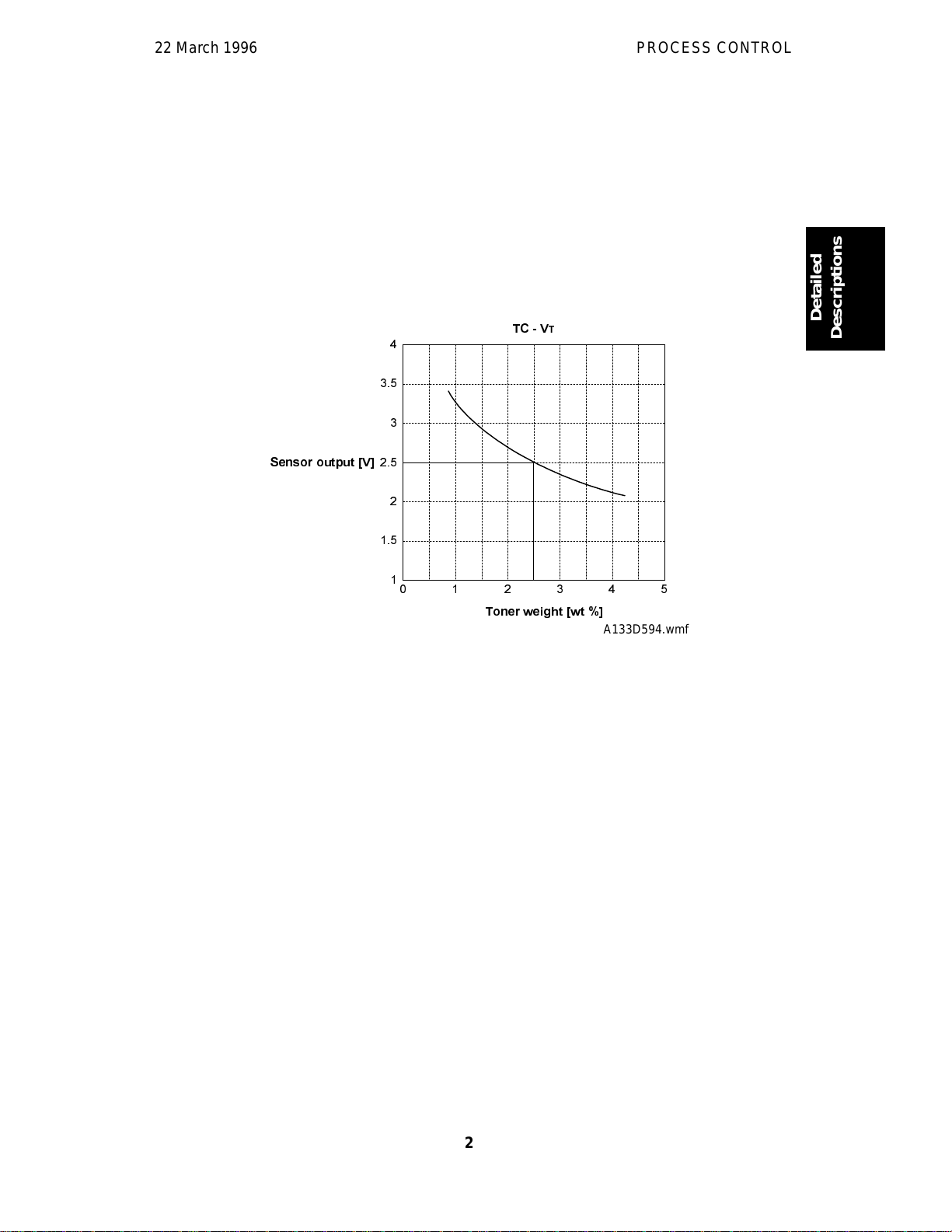

Developer consists of carrier particles (ferrite) and toner particles (resin and

pigment). Inside the de velopment unit, developer passes through a magnetic

field created by coils ins i de the toner density sen sor. When the toner

concentration changes, the voltage output by the sensor changes accordingly.

The output from th e sen s or ( VT) is checked every copy. The machine tries to

keep VT constant by varying the toner supply using a fuzzy logic process, as

shown in the flow cha rt on t he previ o us pa ge .

Toner Density Sensor Initial Setting

When new developer with the standard toner concentration (2.5% by weight,

21.25 g of toner in 850 g of developer) is installed, the TD sensor initial

setting must be done using SP mode 2801. This sets the sensor output to 2.5

± 0.1 V. This value will be used as the toner supply reference voltage (V

TREF)

of the TD sensor.

2-5

PROCESS CONTROL 22 March 1996

Toner Density Measurement

Toner density in the developer is detected on ce eve ry copy cycle. The sen sor

output voltage (VT) during the detection cycle is compared with the tone r

supply reference voltage (V

TREF).

Toner Supply Clutch On Time Calculation

7

9

7'6HQVRU

75()97

9

75()97

9

)X]]\&RQWURO

,PDJH3L[HO&RXQW

*$,1

7RQHU6XSSO\&/RQ

7LPH

A133D540.wmf

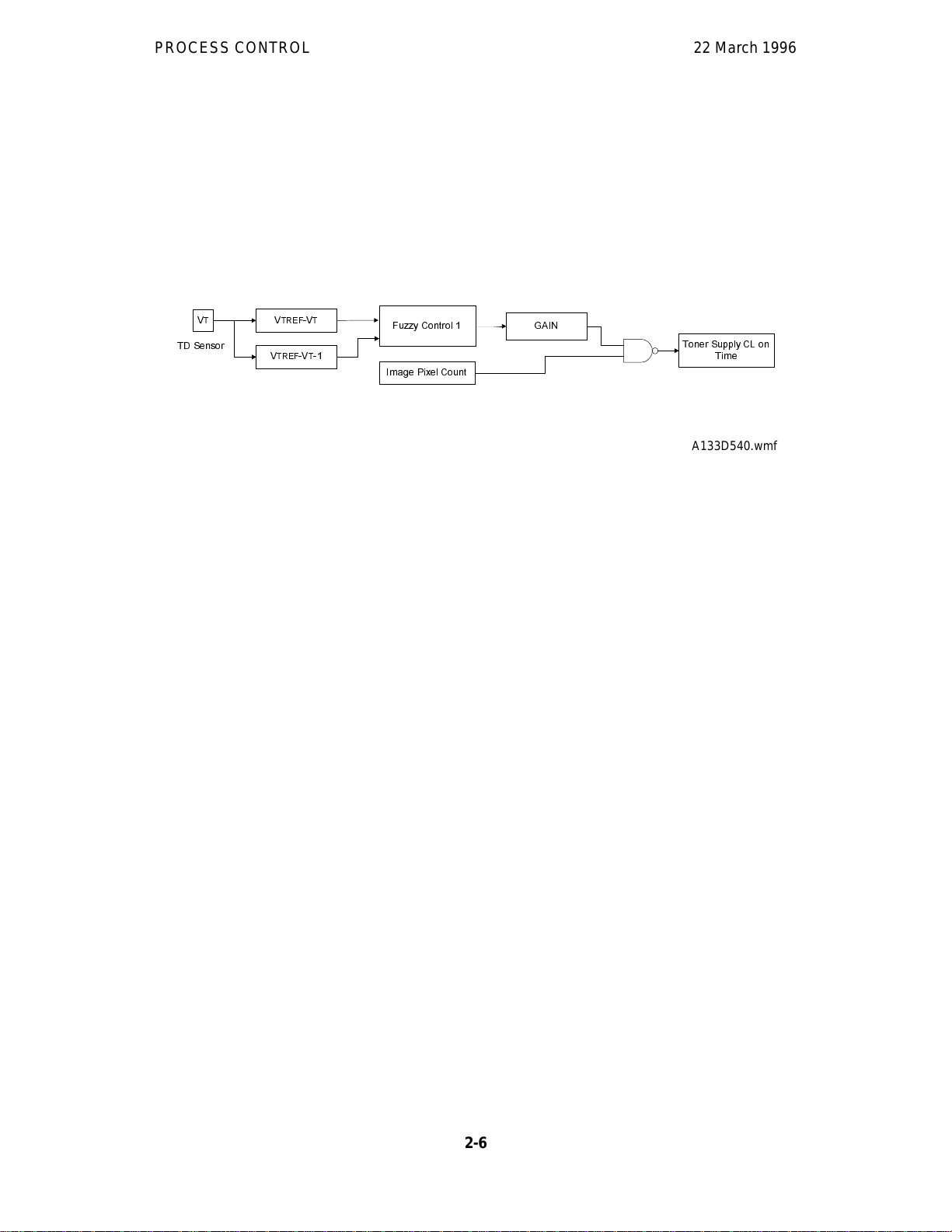

- Fuzzy Control Process 1 -

To stabilize toner concentration, the toner supply amount (controlled by the

toner supply clutch on time) is determined by referring to V

TREF

and VT.

The toner supply amount is calculated every copy using the following factors.

Factor 1: V

Factor 2: V

V

•

TREF

: TD sensor output at th e latest VSP detection corrected for ID

TREF

TREF

- V

- V

T

T-1

sensor output (VSP/VSG); this is calculated every 200 copies (see

V

calibration for more details). For new developer, the TD sensor

TREF

initial setting is used.

• V

: Current TD sensor output data

T

• V

: Previous TD sensor output da ta

T-1

By referring to these factors, the machine recognizes the difference between

the current toner concentration and the target toner concentration. It then

determines the GAIN value for calculating the toner supply clutch on time.

- Image Pixel Count -

The CPU refers to the solid area ratio for the whole page informed from the

EX-IPU to improve the precision of the toner density change prediction.

The CPU converts the image data value of each pixel to the toner supply

amount. Theref or e , th e m ach i ne und ers t an ds by ho w much th e to ner supply

amount will probably change.

2-6

22 March 1996 PROCESS CONTROL

- Toner Supply Clutch On Time Calculation -

The toner supply clutch on time is decided using value of the gain which was

calculated by the fuzzy control 1 procedure , th e imag e pixel coun t valu e, the

possible amount of toner on the drum, and the toner supply rate. The

calculation is done using the following formula:

mg

2

⁄

cm

⁄

)

s

Toner supply CL on time =

GAIN x Image pixel count x 0.7

Toner supply

rate

(116

mg

NOTE: The toner supply rate can be changed with SP2209. For example, if

the user commonly makes copies with a lot of black areas, reduce

the value stored in SP2209.

V

Calibration

TREF

- VSP and VSG Detection -

The ID sensor (below the drum cleaning section) detects the following

voltages.

• V

• V

: The ID sensor output when checking the drum surface.

SG

: The ID sensor output when checking the VSP pattern.

SP

In this way, the ref lectivity of both the dru m surface and the pattern on th e

drum are checked. This compensates for any variations in the reflectivity of

the pattern on the dr um or the reflectivity of the dr um sur face.

The VSP pattern is made on t he drum by th e cha r ge cor on a un it and the laser

diode.

Detailed

Descriptions

A133D541.wmf

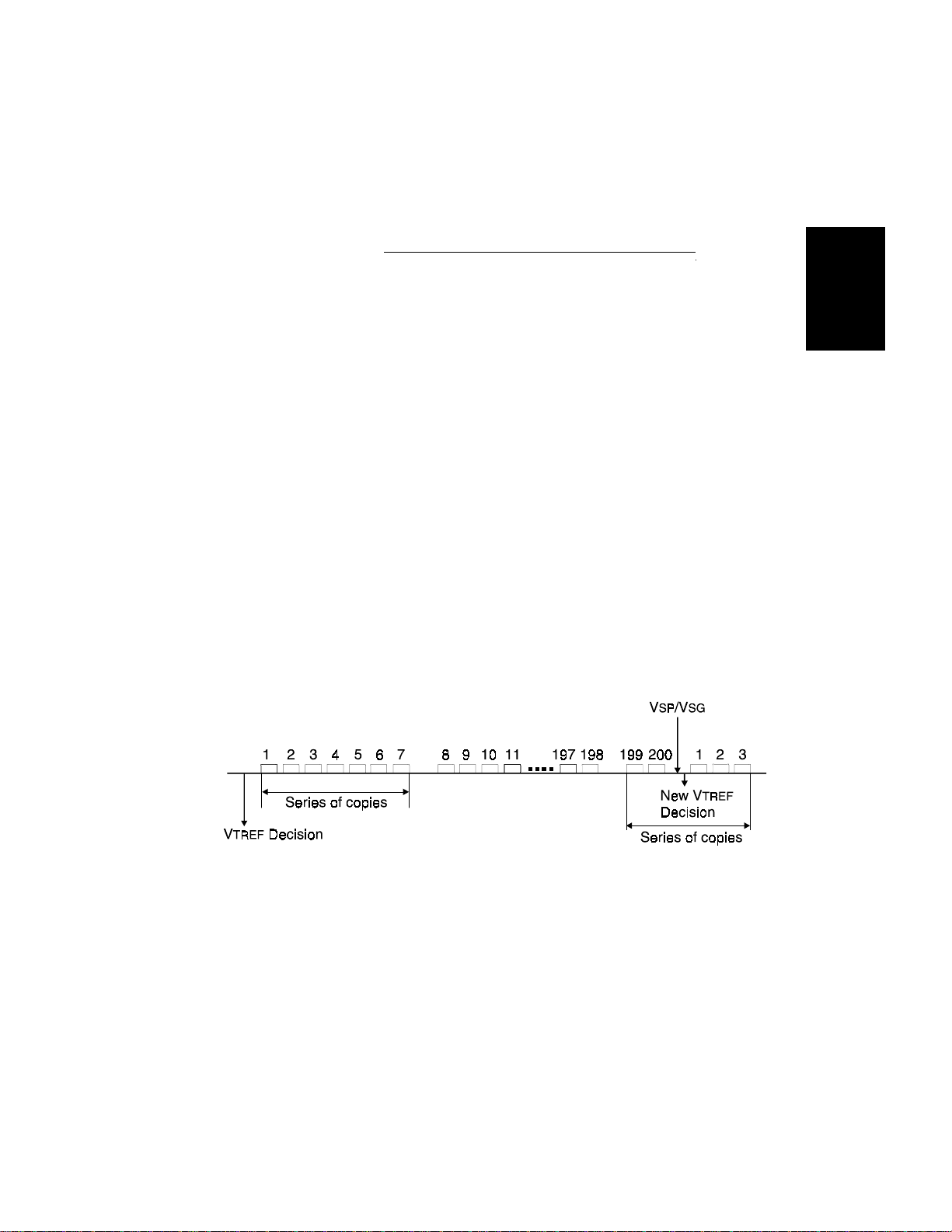

VSP/VSG detection is performed every 200 copies to decide the new V

TREF

.

The value of the copy counter fo r the VSP/VSG detection is stored in the

NVRAM (Non-volatile RAM) on the SCU board. So, even if the machine is

switched off, the copy cou nt start s from th e nu m ber whi ch was sto r ed in the

NVRAM. In addit i on , as th e di a gr a m show s, the new V

will take effect

TREF

even if the 200th copy occurs in the middle of a copy run; however, the

overall cpm for this copy run will be lower because of the copy cycle required

to make the ID sensor pattern.

2-7

PROCESS CONTROL 22 March 1996

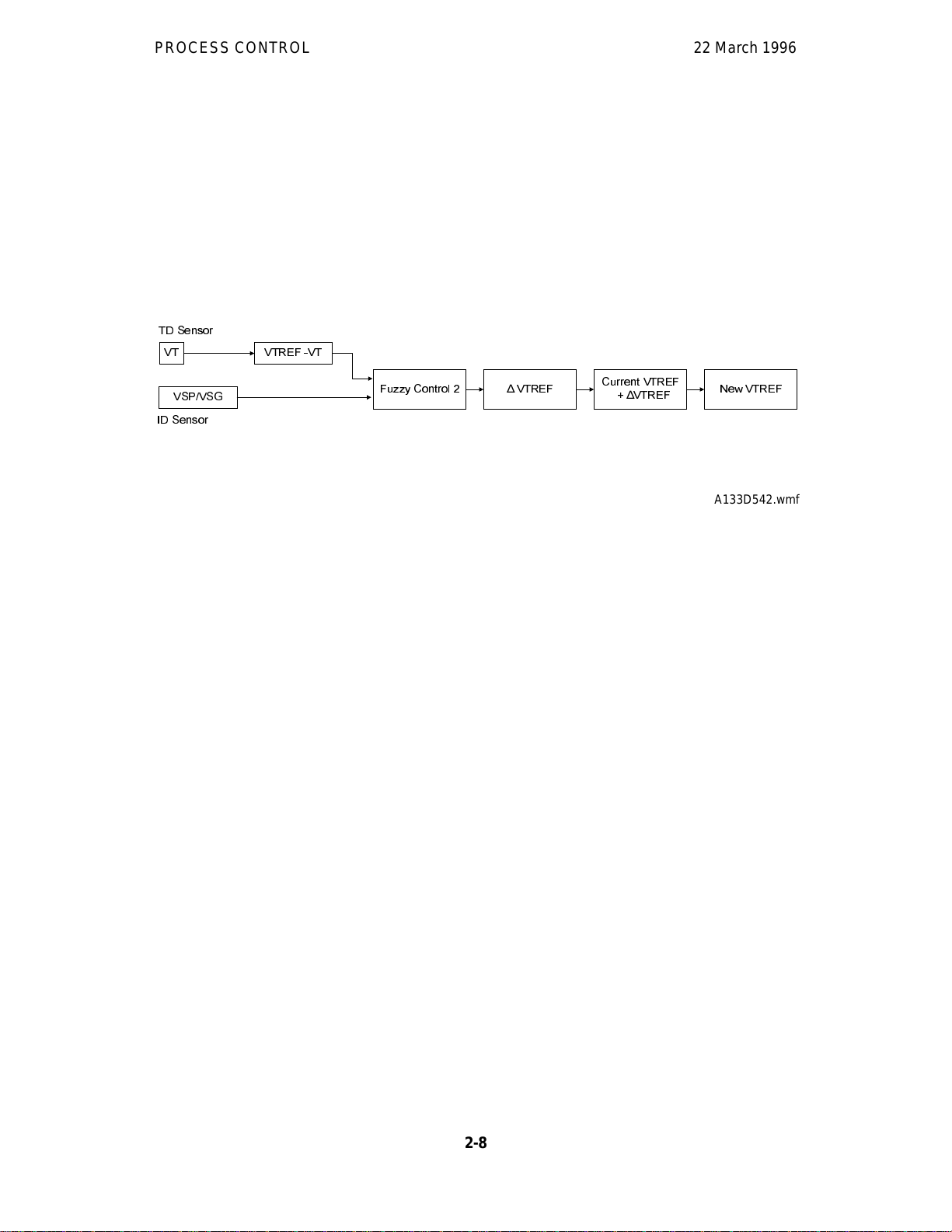

- New V

Determination -

TREF

Even if the toner concentration in the developer is kept constant by checking

the TD sensor, the toner potential (chargeability) and the image density

change with humidity and the amount of toner on the carrier.

Therefore, the ID sensor output is also used as one of the factors for deciding

the new V

7'6HQVRU

97

96396*

,'6HQVRU

which will be used for toner density control.

TREF

975()97

)X]]\&RQWURO

975()

∆

&XUUHQW975()

975()

∆

1HZ975()

A133D542.wmf

First of all, the CPU decides the adjustment that is required to the current

V

TREF

•

•

(∆V

V

TREF

VSP/V

) with the fuzzy control 2 procedure using the following factors.

TREF

- V

T

SG

Then, the CPU determines the new V

New V

TREF

= V

TREF

+ ∆V

TREF

From this point, toner density control is done using the new V

If V

is either higher than 4.0 V or less than 0.5 V on more than 10

TREF

using the following formula.

TREF

TREF

.

consecutive occasion s, the GAIN value is fixed at 0. 7 ( see t he equation at

the end of the "Toner Supply Clutch On Time Calculation" section). Then,

after finishing the copy job, SC390 will be generated.

2.2.3 Fixed Supply Mode

The machine supplies a fixed am o un t of ton er eve r y copy. The amo un t

depends on the settin g of SP2208-2 (for users who normally make copies

with a lot of black areas, use a higher settin g) . Re ad ing s fr om th e TD and ID

sensors are ignored.

Fixed supply mode should only be used as a temporary meas ure while

waiting for replacement parts, such as a TD sensor. The machine does not

fall back to fixed supply mode when there are sensor errors.

2-8

22 March 1996 PROCESS CONTROL

2.2.4 Toner Supply in Abnormal Sensor Conditions Overview

Under normal conditions, the machine uses detect supply mode, in which

toner supply is varied based on readings from the TD and ID sensors.

The TD sensor is checked every copy. If the readings from the TD sensor

become abnormal dur ing a copy job , th e m achi ne hold s the GAIN factor

constant (GAIN is normally calculated from TD sensor readings) to allow

toner supply to vary with only pixel count for the rest of the copy job. Then at

the end of the copy job, an SC code is generated and the machine must be

repaired. There is no fallback to fixed supply mode in this model.

The ID sensor is checked every 200 copies. If readings become abnormal,

an SC code is generate d an d th e m ach i ne must be re pa i red. If this happens

during a copy job, V

is not changed, the copy job is allowed to finish,

TREF

and then the SC code is generated.

Details of abnormal sensor detection follow below.

Abnormal TD Sensor Output (during normal operation and V

TREF

determination)

Detailed

Descriptions

When VT has been more than 4.0 V or less than 0.5 V on ten consecutive

occasions, the CPU fixes the value of the GAIN factor in th e to ne r supp ly

clutch on time formula to 0.7. Then the toner is supplied in accordance with

the value of the image pixel count data. After finishing the copy job, SC390

will be generated.

Also, SC390 is gener a te d w he n th e di f fe r en ce be tw e en VT and V

TREF

has

been more than 0.6 V ten times.

Abnormal ID Sensor Output (during VSP/V

measurement)

SG

When VSP≥2.5V or VSG≤2.5V twice consecutively, SC350 will be generated.

At this time, V

remains at the previous valu e.

TREF

Also, SC350 is gener a te d i f VSG cannot be adjusted to 4 ± 0.2V during ID

sensor initialization (SP3001: this is done after installing a new drum or a new

ID sensor, or after cleaning the ID sensor).

2-9

DRUM UNIT 22 March 1996

3. DRUM UNIT

3.1 OVERVIEW

76

1

5

4

32

The drum unit consists of the components shown in the above illustration. An

organic photoconductor (OPC) drum (diameter: 100 mm) is used in this

model.

1. OPC Drum

2. Pick-off Pawls

3. ID Sensor

4. Cleaning Brush

5. Cleaning Blade

6. Quenching Lam p

7. Charge Corona Unit

A133D500.wmf

2-10

22 March 1996 DRUM UNIT

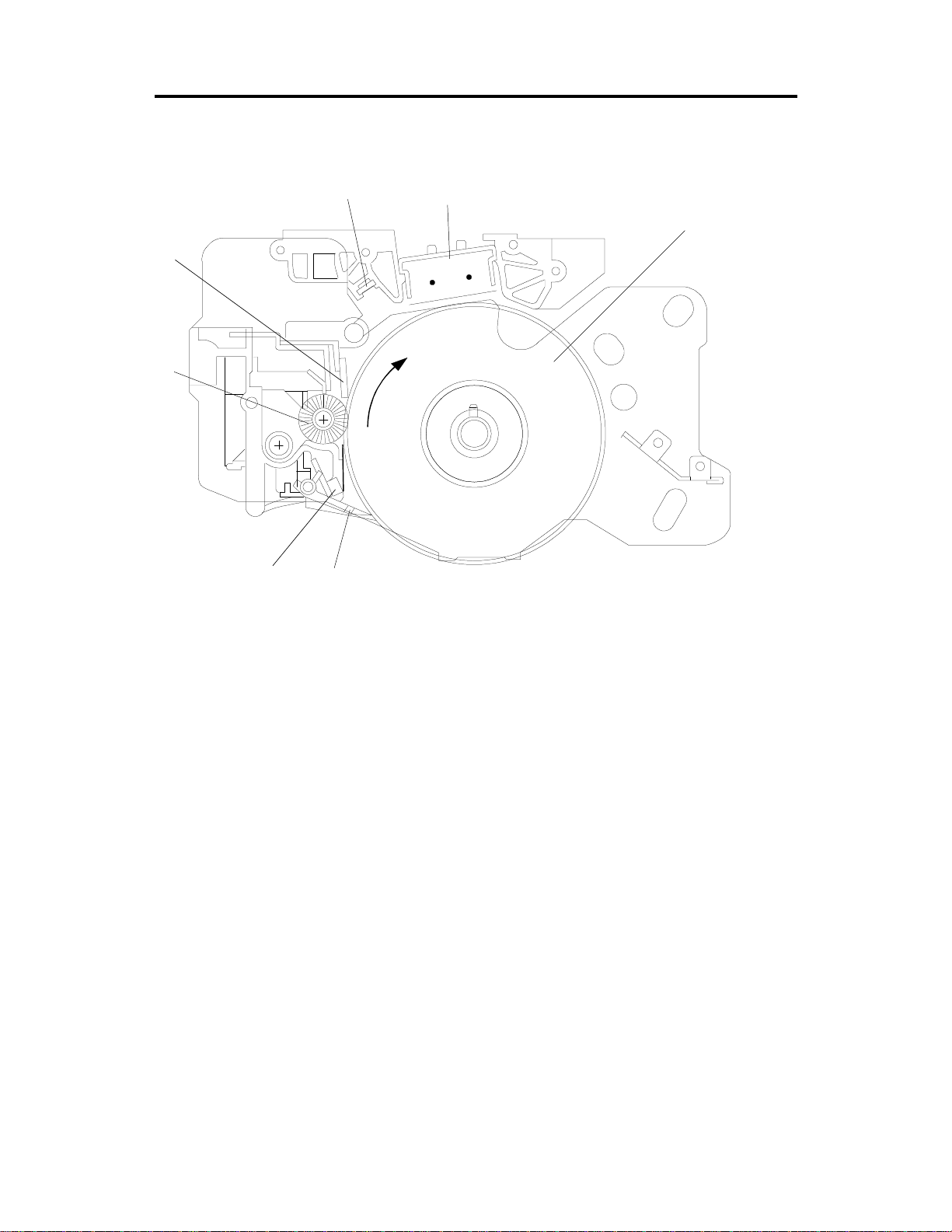

3.2 DRIVE MECHANISM

[A]

[D]

[C]

Detailed

Descriptions

[B]

A133D501.wmf

The drive from the main motor [A] is transmitted to the drum through a series

of gears, a timing belt, the drum drive pulley [B], and the drum shaft [C] . The

main motor has a drive controller, which outputs a motor lock signal when the

rotation speed is out of the specified range.

The fly-wheel [D] on the end of the drum shaft stabilizes the rotation speed

(this prevents ba nd i ng from ap pe ar i n g an d j itter on copies).

The drum rotation speed is 150 mm/s.

2-11

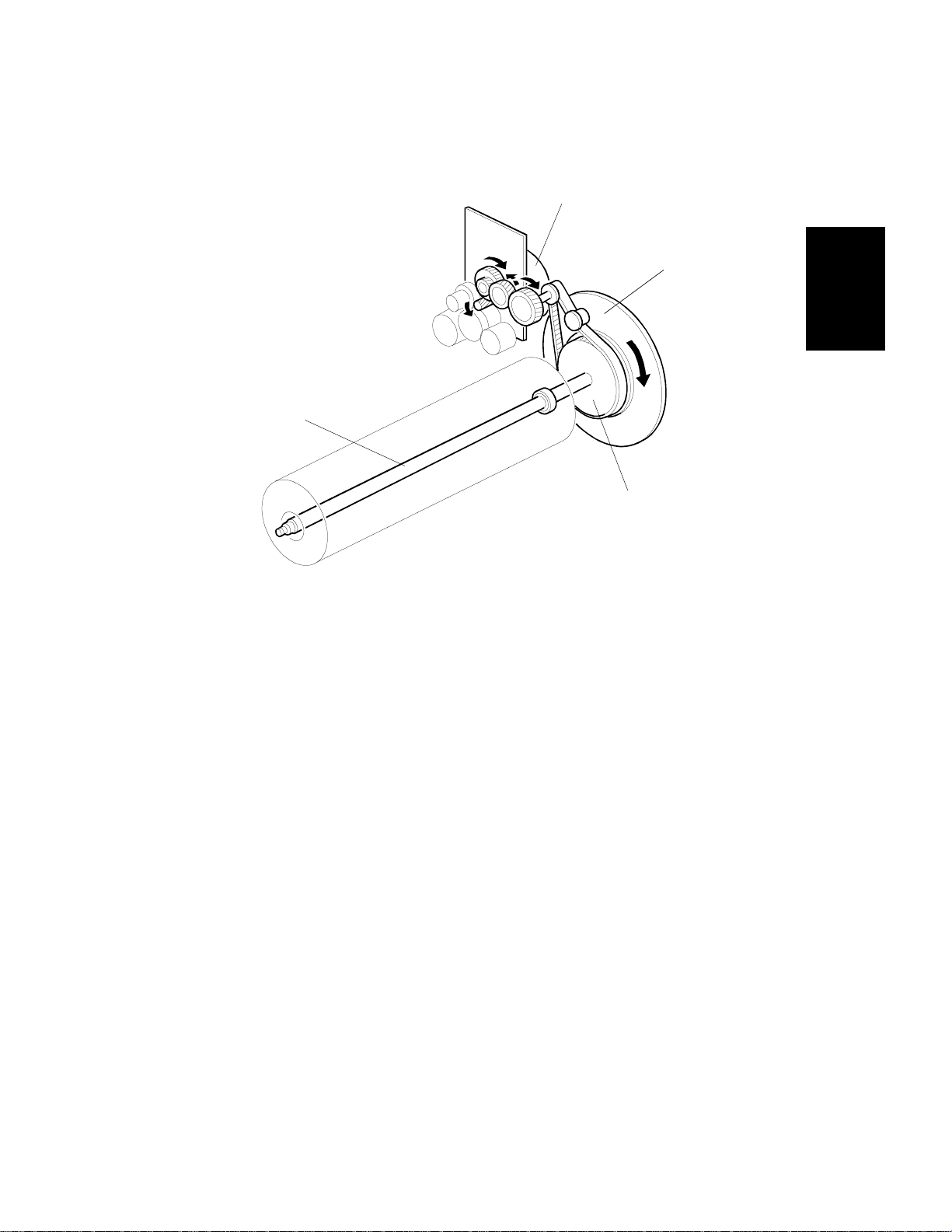

DRUM UNIT 22 March 1996

3.3 DRUM CHARGE

[B]

[A]

[C]

[D]

A133D502.wmf

This copier uses a double corona wire (single loop type) scorotron system for

charging the drum.

The two corona wires apply ne ga ti ve charg e to the dr um sur f ace . The

stainless steel grid plate [A] makes the corona charge uniform. The negative

voltage on this grid controls the amount of negative char ge on the drum.

The charge high voltage supply board [B] gives a constant corona current to

the corona wires, and applies –890V to the grid plate. The grid plate voltage

maintains a constant char ge on th e dru m surfa ce eve n w hen th e w ir e curr e nt

varies.

The ozone fan [C] provides a flow of air through the corona unit [D] in order to

prevent an uneven build up of ne ga tive io ns. This help s ma int ai n an even

image density.

A replacement charge corona unit with wire cleaner and motor is available as

an optional service part for machines which produce a high copy volume.

2-12

Loading...

Loading...